Centrifugal pump with impeller rotation boosting structure

A power-assisted structure and impeller rotation technology, which is applied to the components, pumps, pump elements, etc. of the pumping device used for elastic fluid, can solve the problem that energy is not effectively used, and achieve the effect of reducing torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

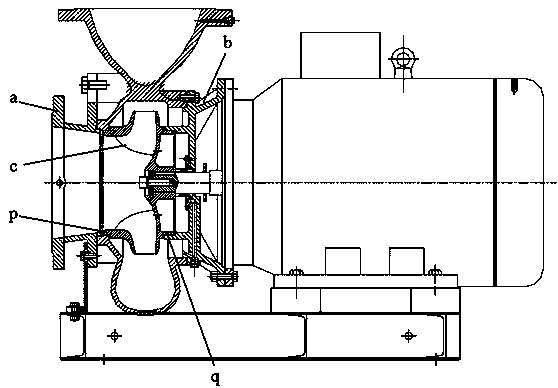

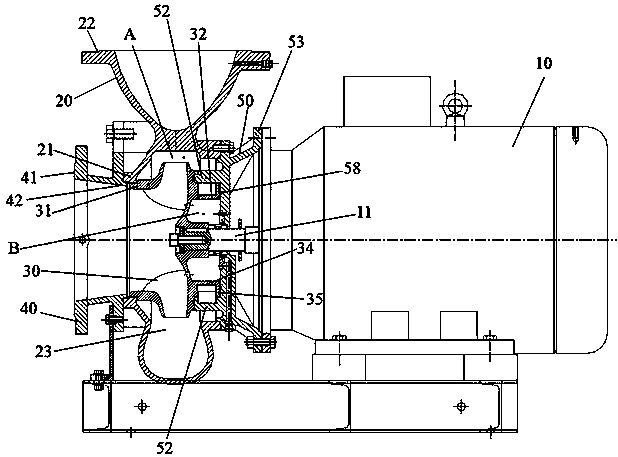

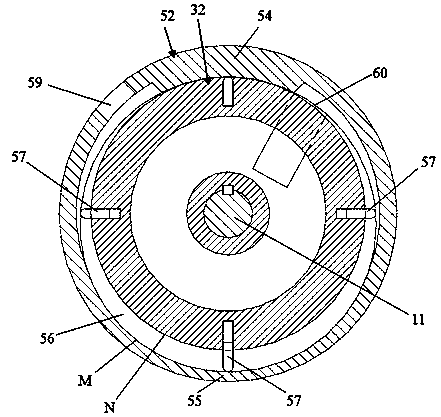

[0019] see Figure 2 to Figure 5 As shown, the present invention provides a centrifugal pump 100, including a motor 10, a pump body 20 located at one end of the motor 10 and connected to the motor 10, an impeller 30 located in the pump body 20, a front end cover 40 and a rear cover located on the front and rear sides of the impeller 30. End cap 50.

[0020] see figure 2 As shown, the pump body 20 includes a front port 21 and an upper port 22, which are respectively located at the front end and the upper end of the impeller 30, for providing an input and output path for fluid. The pump body 20 is provided with an accommodating cavity 23 for accommodating the impeller 30 . The front port 21 of the pump body 20 is mated with the front end cover 40 .

[0021] The impeller 30 is located in the accommodating chamber 23 of the pump body 20 and below the upper port 22. The center of the impeller 30 is connected with the rotating shaft 11 of the motor 10 and can follow the directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com