Patents

Literature

254results about How to "Increased torque output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

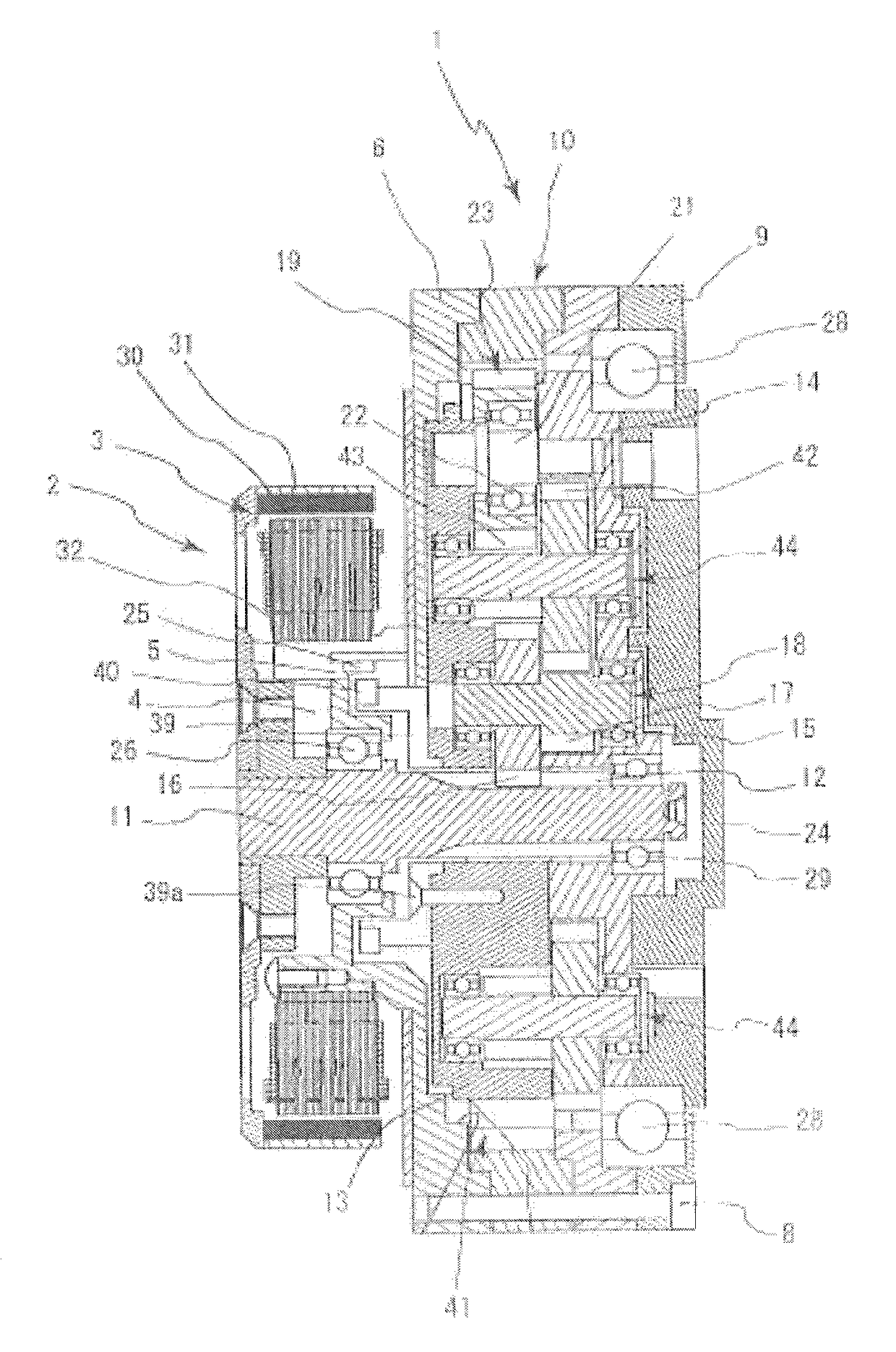

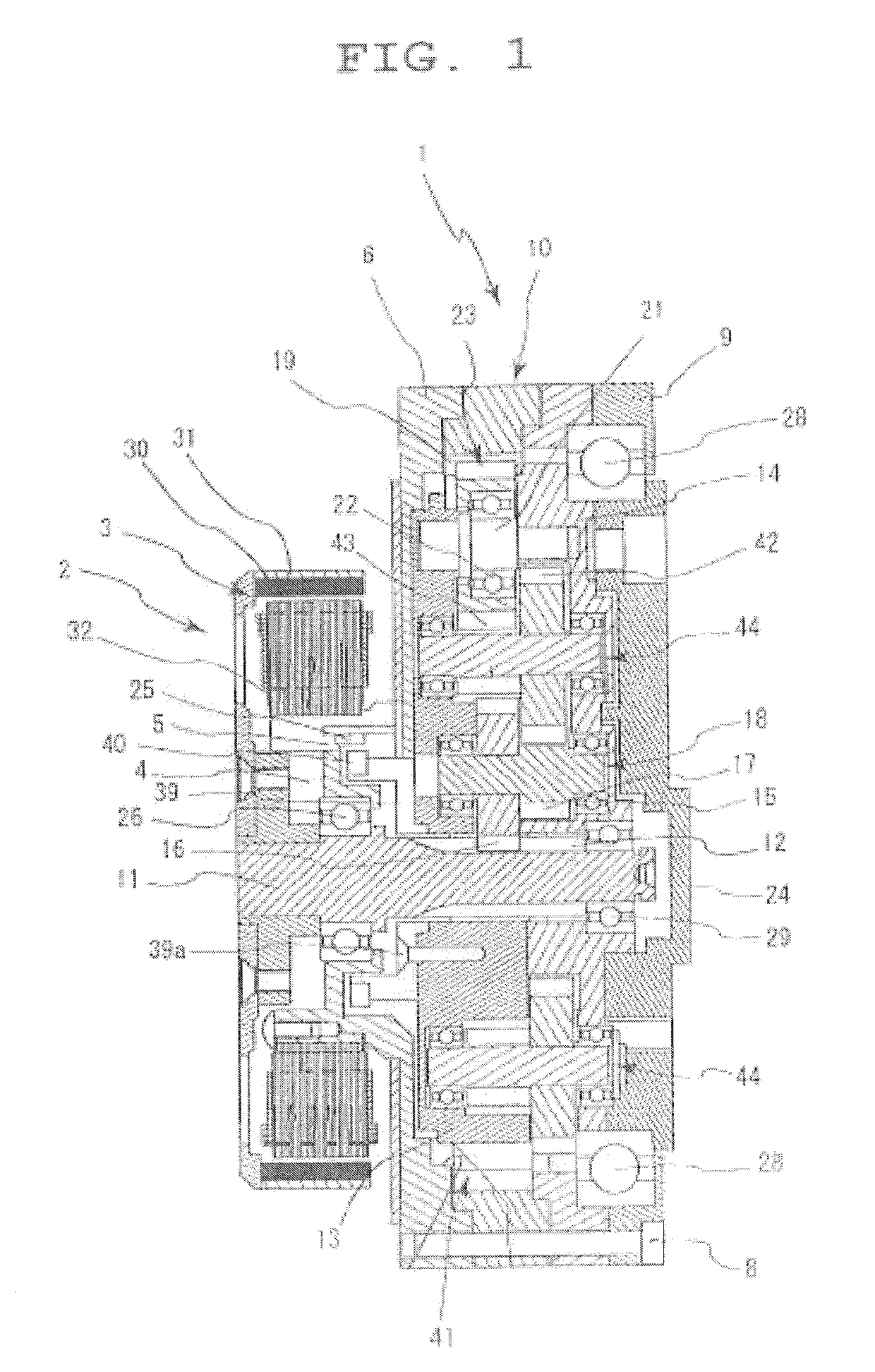

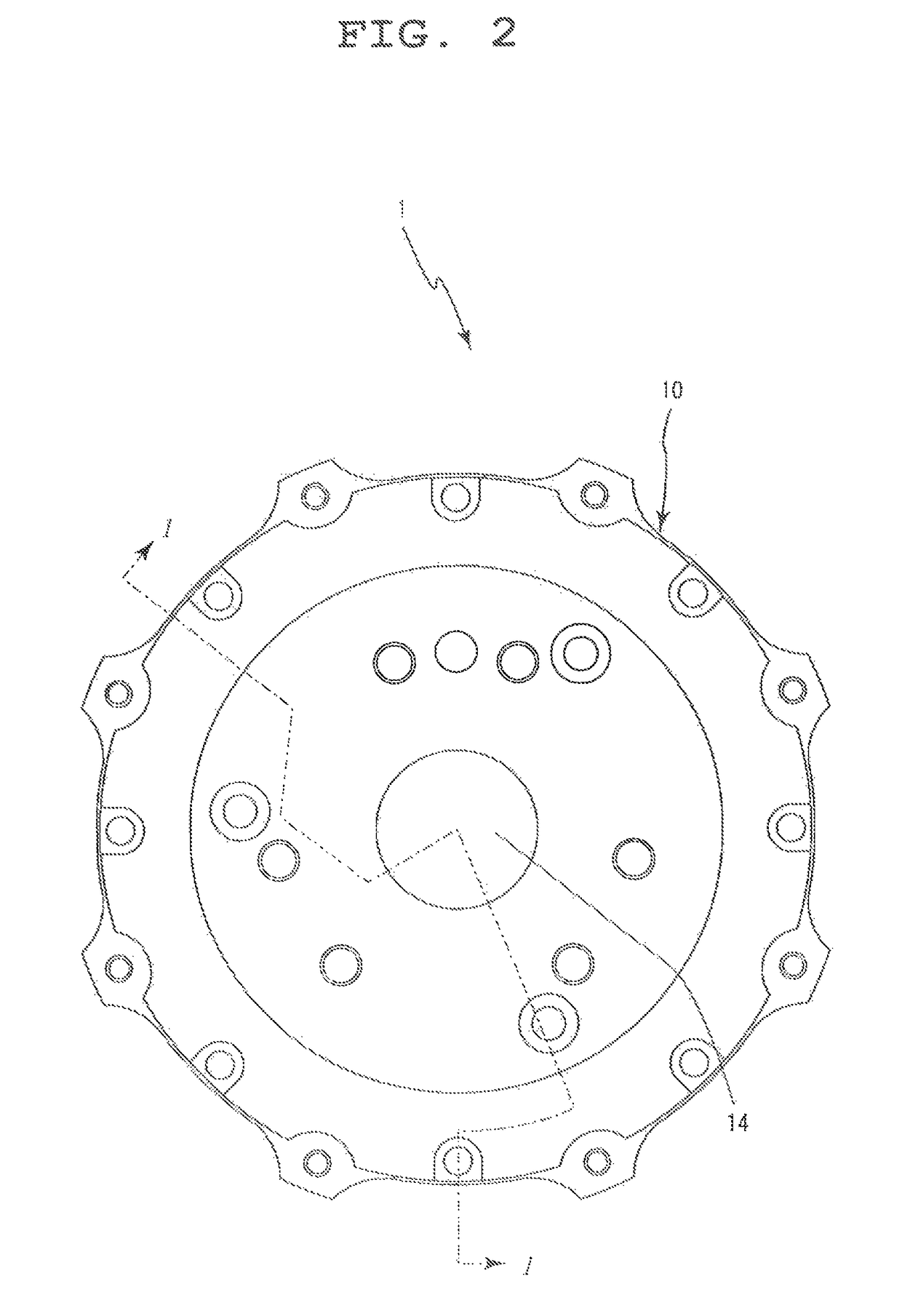

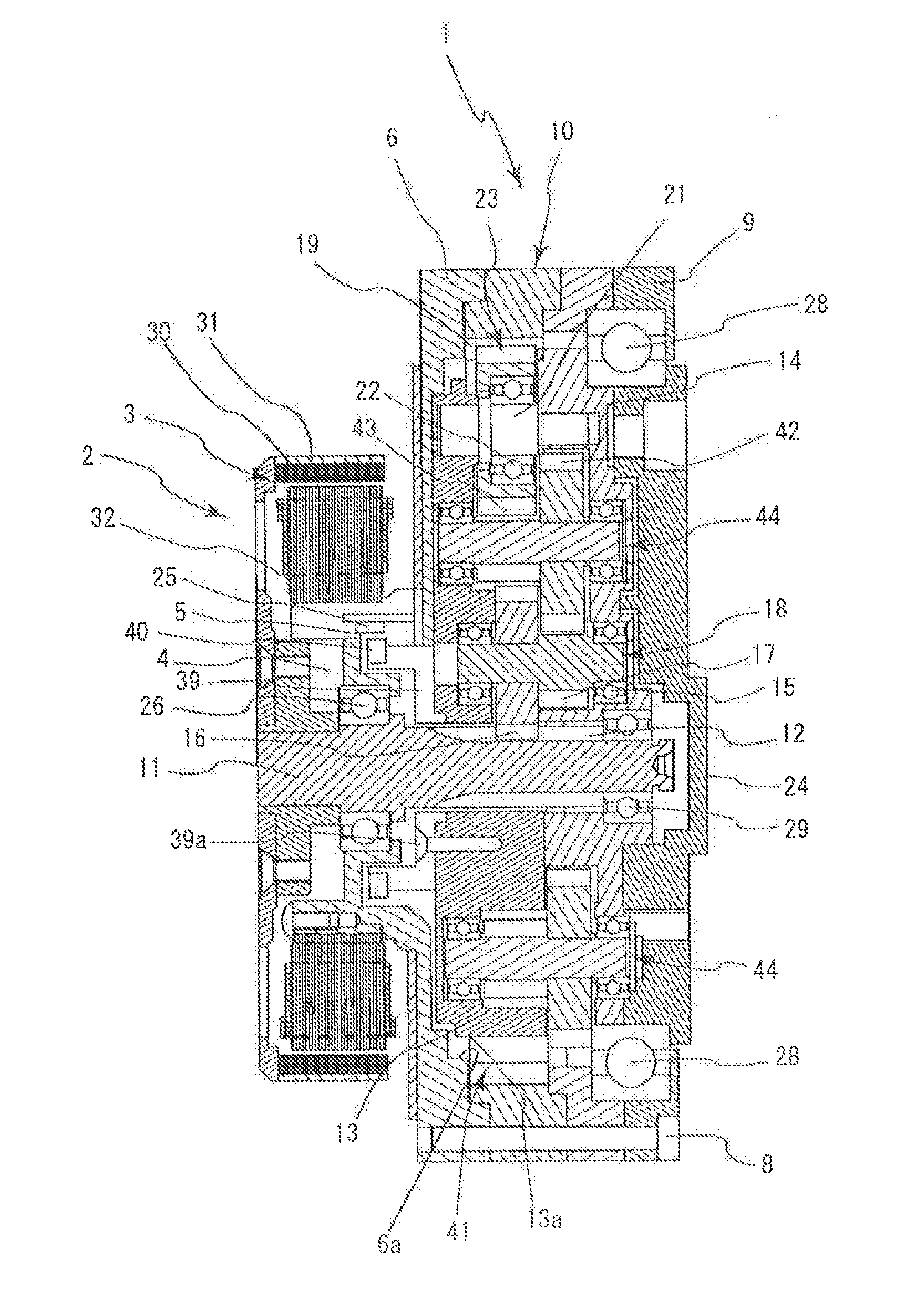

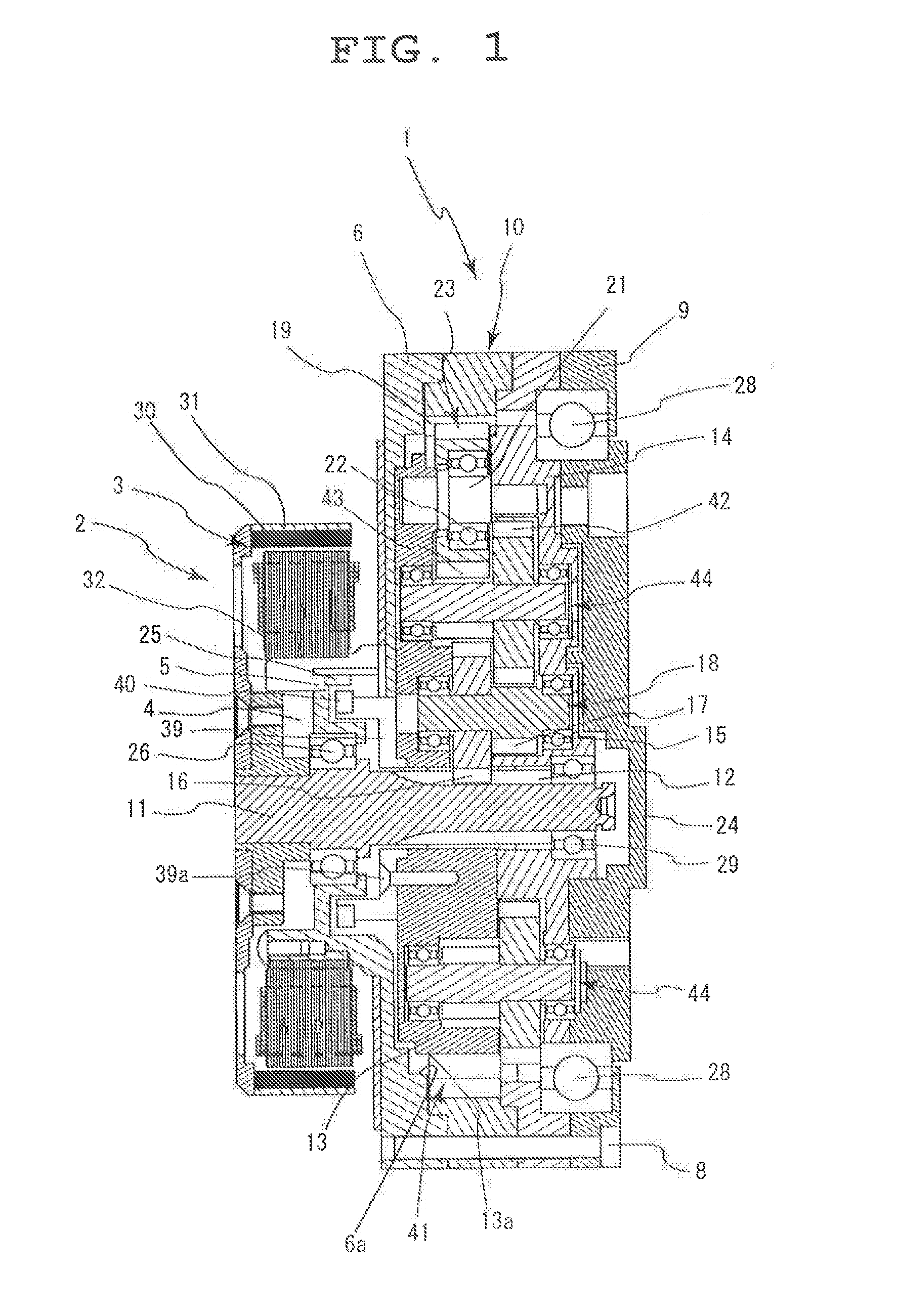

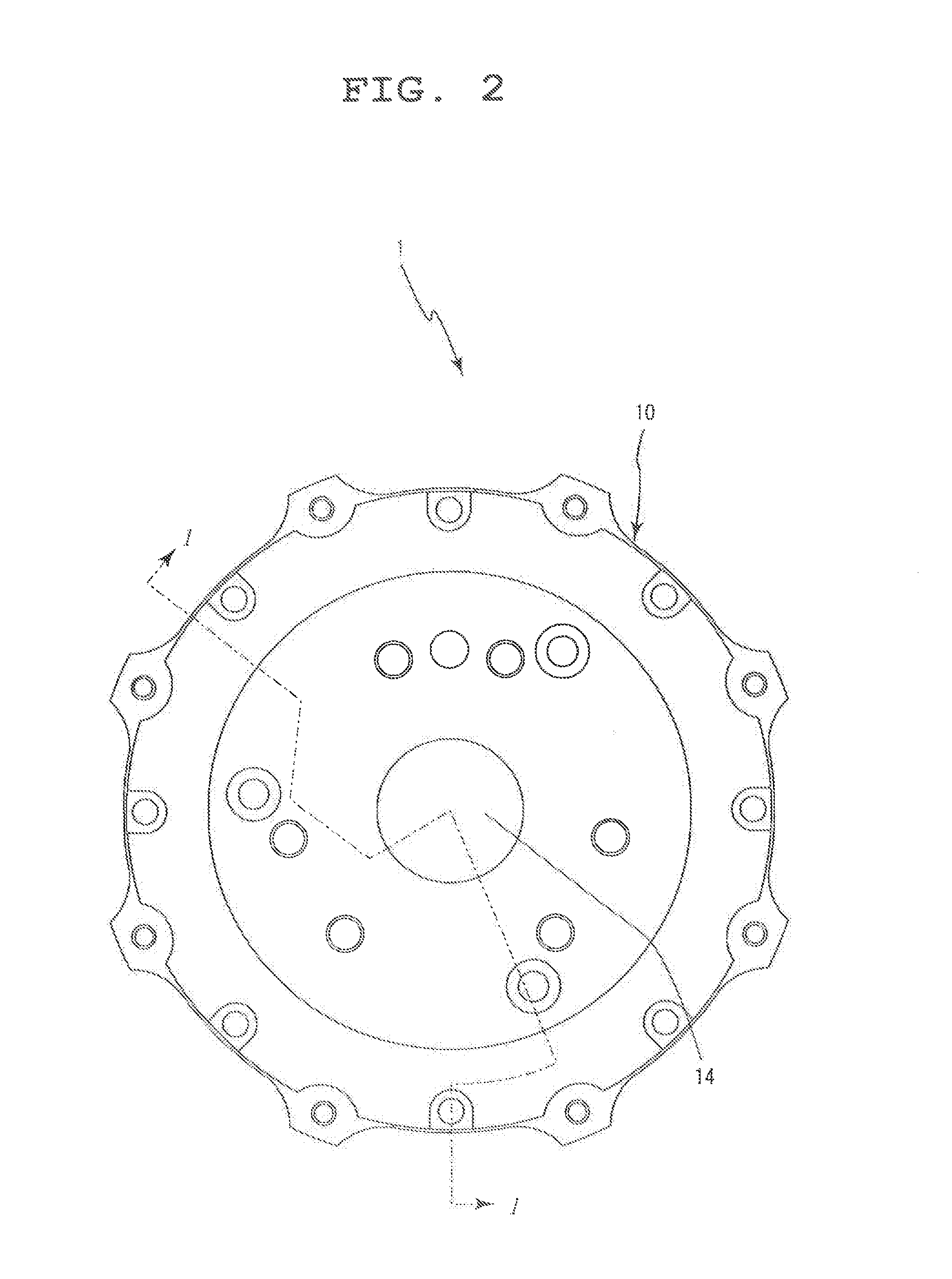

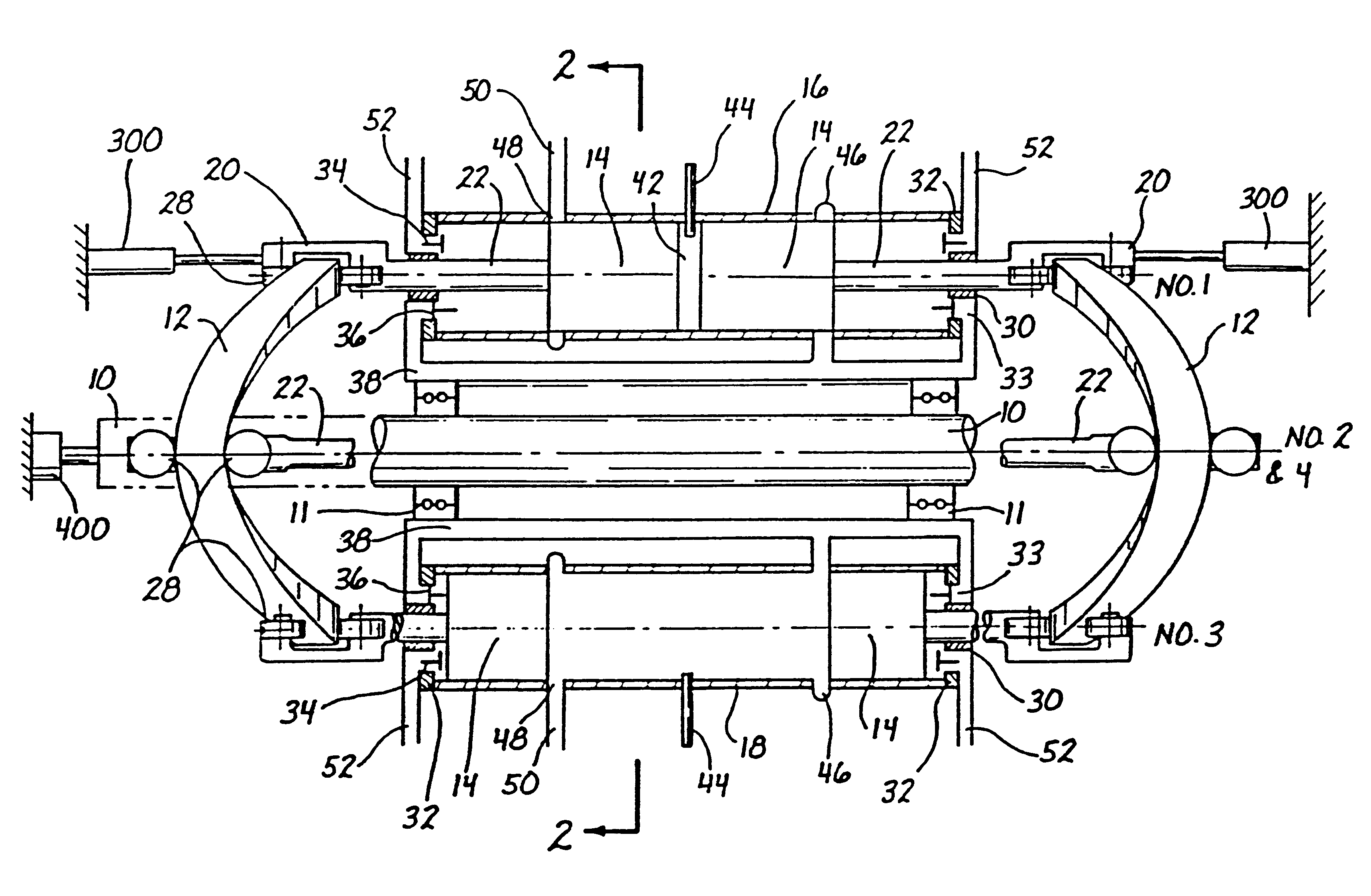

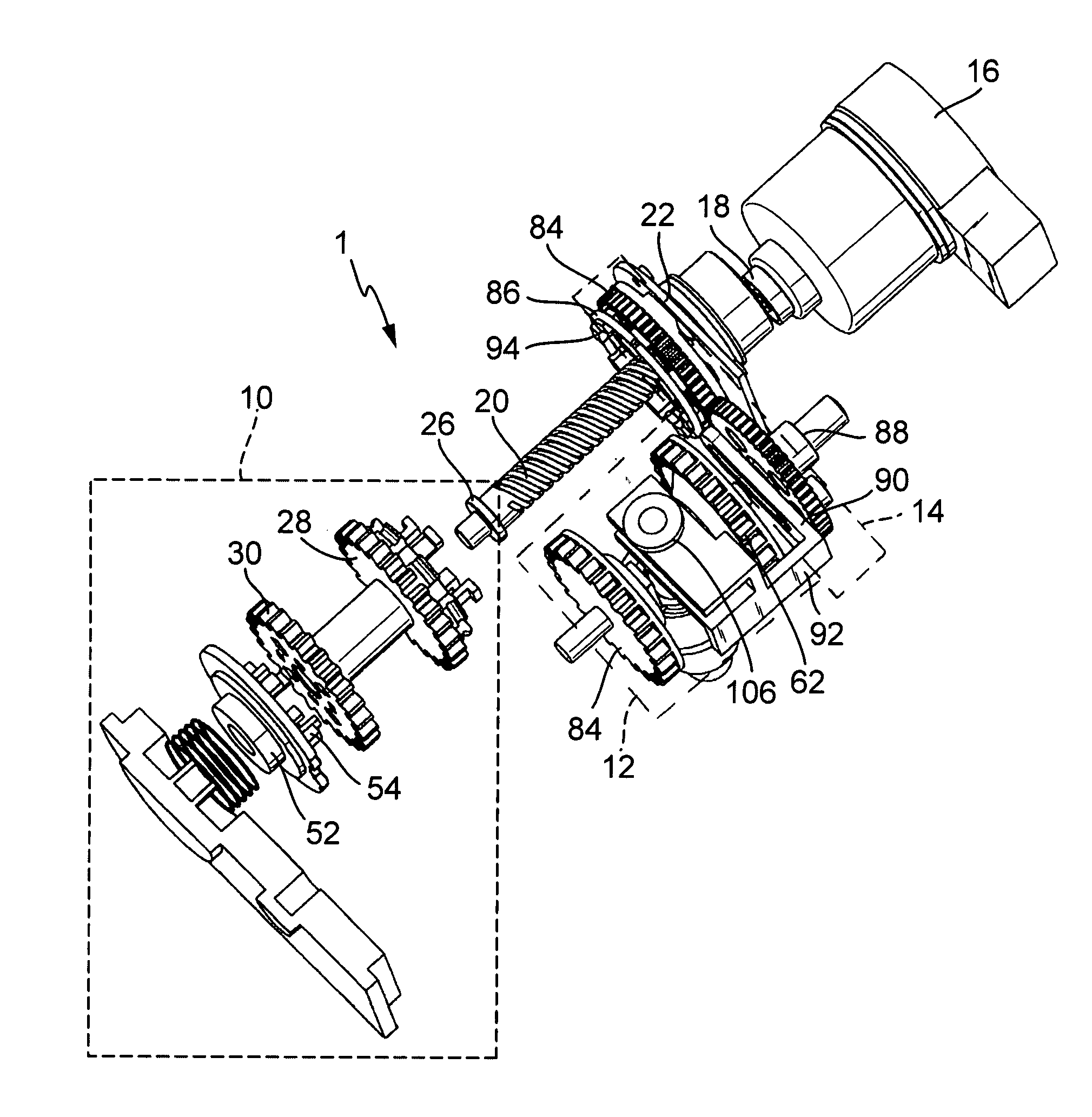

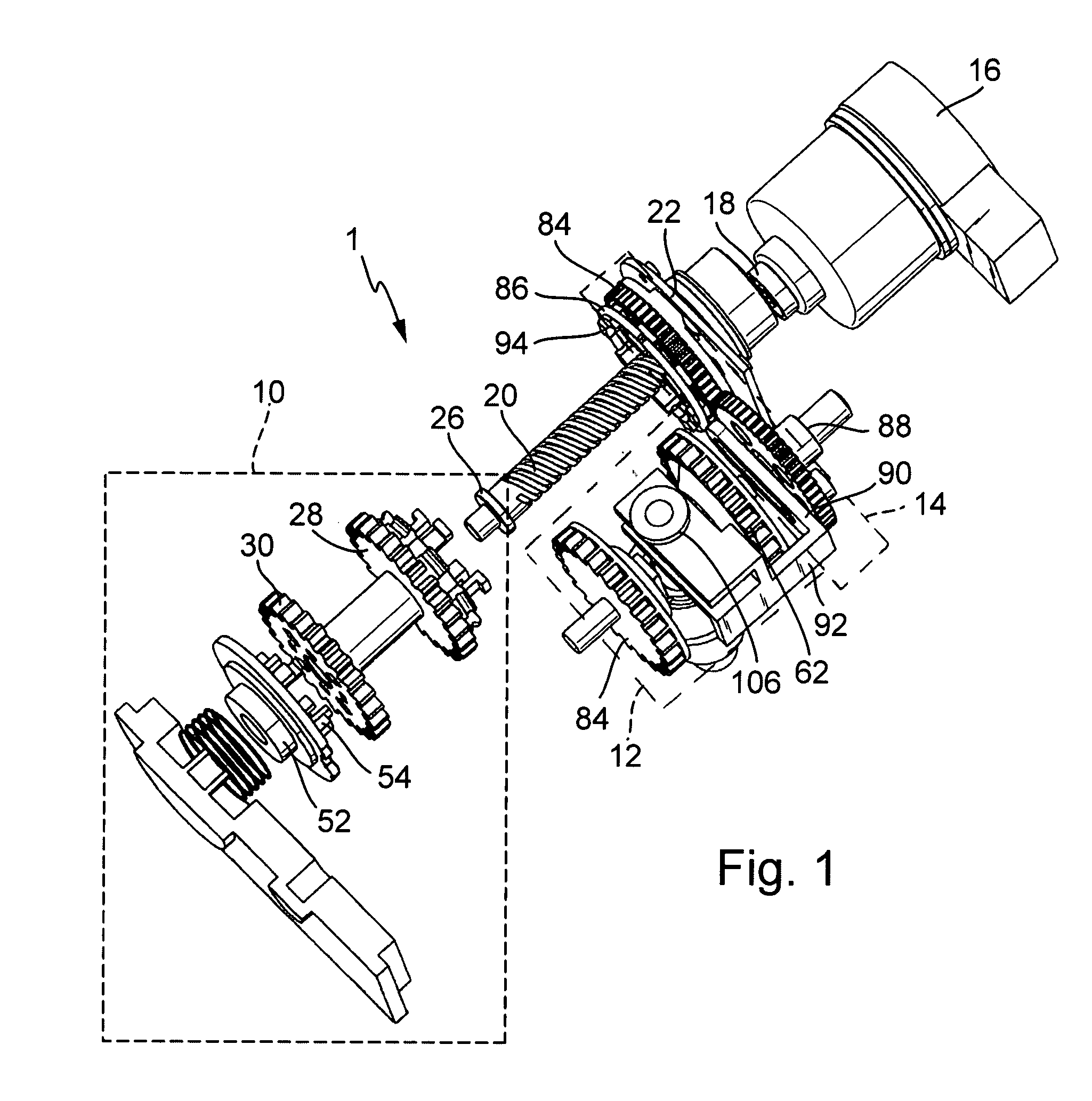

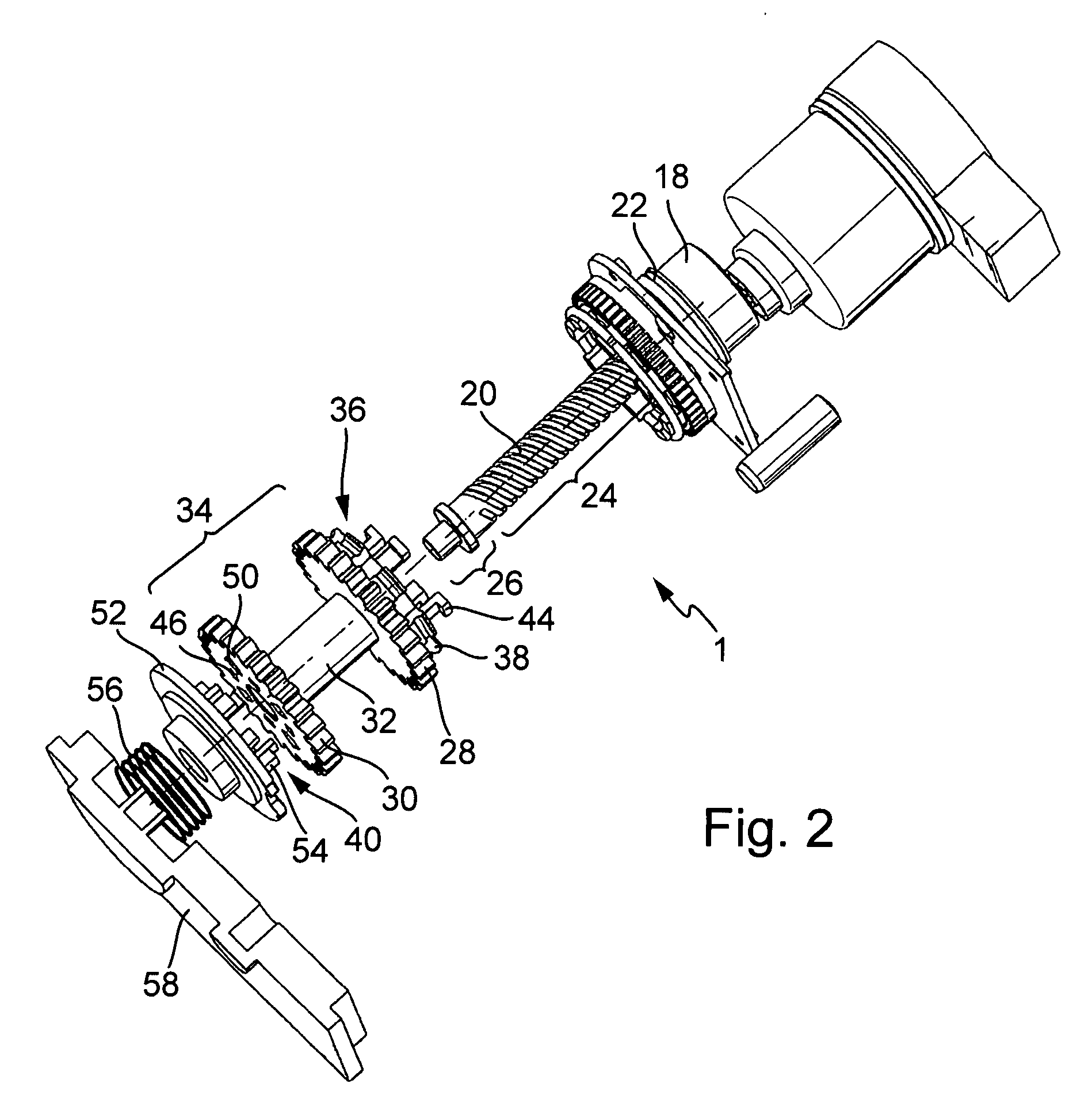

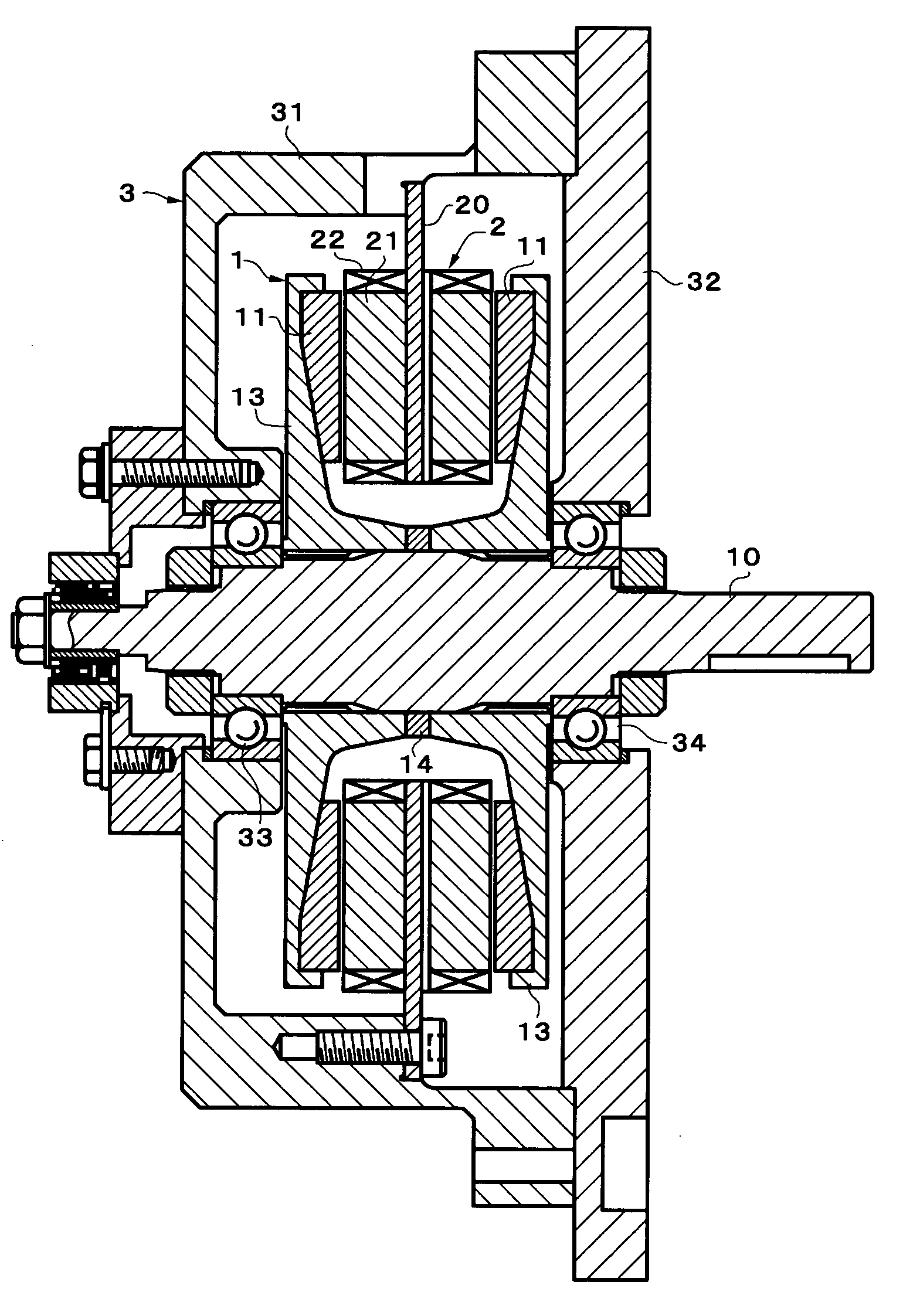

Gear motor including reduction mechanism

ActiveUS9689466B2Thinness and size and weight reductionAvoid instabilityToothed gearingsMechanical energy handlingBall bearingReduction ratio

The present invention provides a reduction mechanism in which high torque output can he achieved, thinness and size and weight reduction can be achieved, and the number of teeth of a gear and reduction ratio can be freely set. In a gear motor that includes a reduction mechanism in which a planetary two-stage gear is arrayed between a sun gear of a planetary gear mechanism and an internal gear of a planetary gear mechanism, the reduction mechanism has at least a single planetary two-stage gear arrayed such as to be positioned between the sun gear and the internal gear and including a small gear or a large gear that meshes together with a large gear or a small gear of the planetary two-stage gear, and both end portions of the at least a single planetary two-stage gear are supported by ball bearings.

Owner:COPAL ELECTRON CO LTD

Gear motor including reduction mechanism

ActiveUS20160238108A1Thinness and size and weight reduction of reductionAvoid instabilityToothed gearingsMechanical energy handlingBall bearingReduction ratio

The present invention provides a reduction mechanism in which high torque output can be achieved, thinness and size and weight reduction can be achieved, and the number of teeth of a gear and reduction ratio can be freely set. In a gear motor that includes a reduction mechanism in which a planetary two-stage gear is arrayed between a sun gear of a planetary gear mechanism and an internal gear of a planetary gear mechanism, the reduction mechanism has at least a single planetary two-stage gear arrayed such as to be positioned between the sun gear and the internal gear and including a small gear or a large gear that meshes together with a large gear or a small gear of the planetary two-stage gear, and both end portions of the at least a single planetary two-stage gear are supported by ball bearings.

Owner:COPAL ELECTRON CO LTD

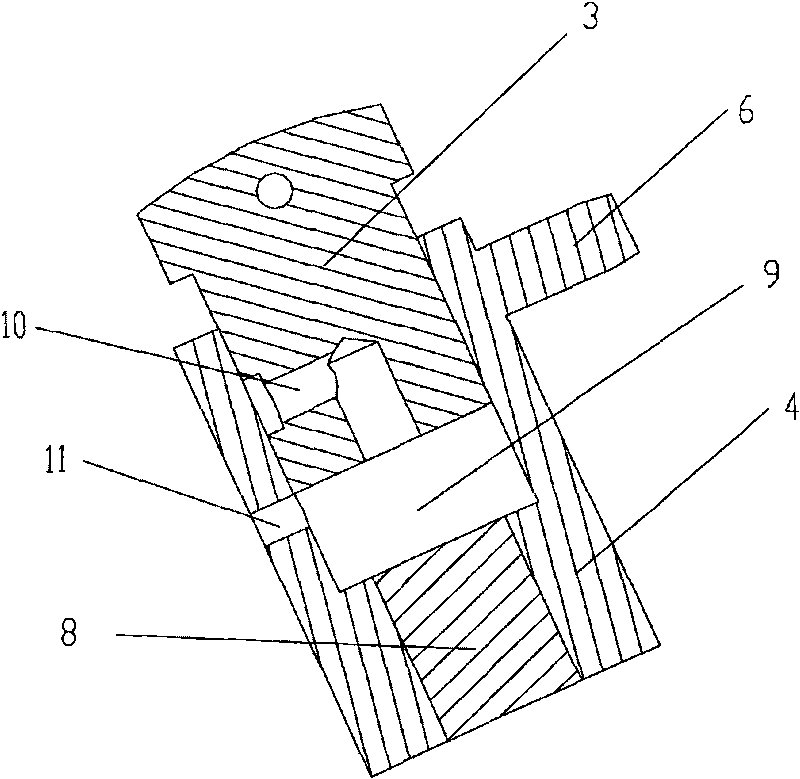

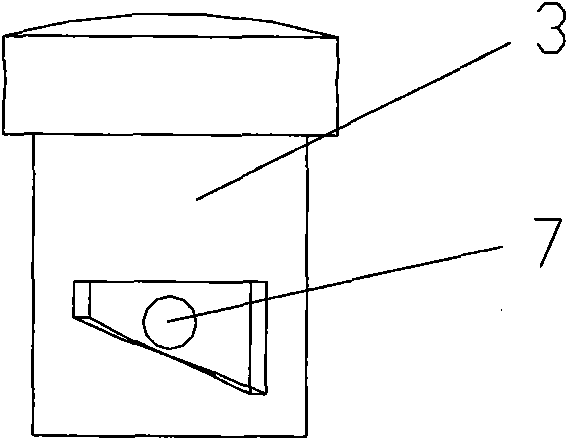

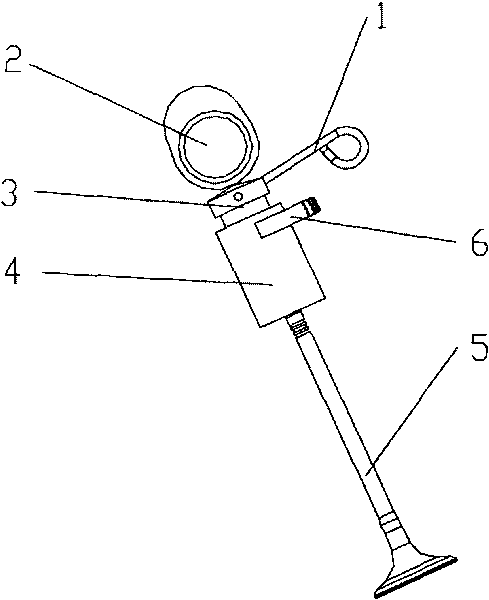

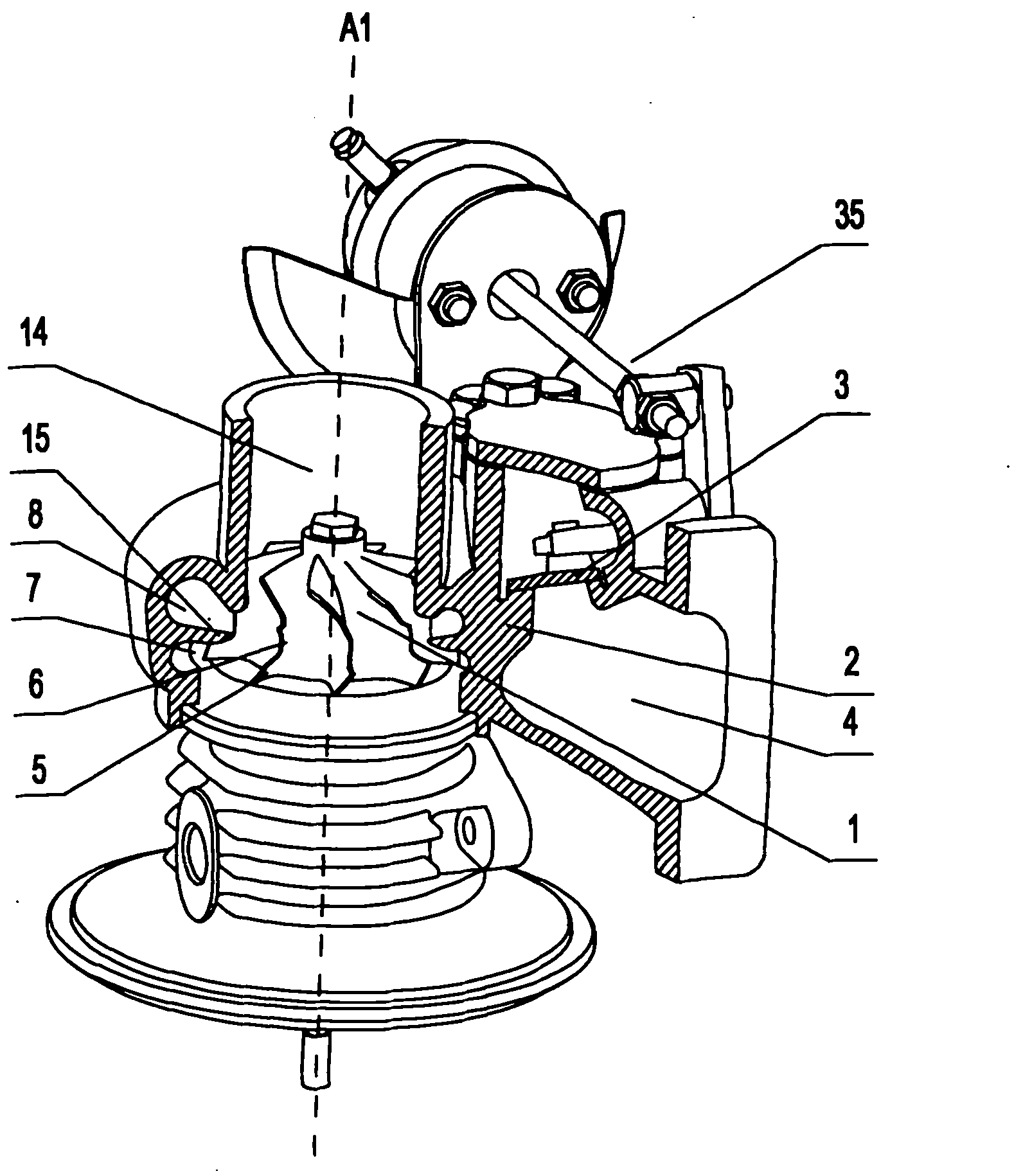

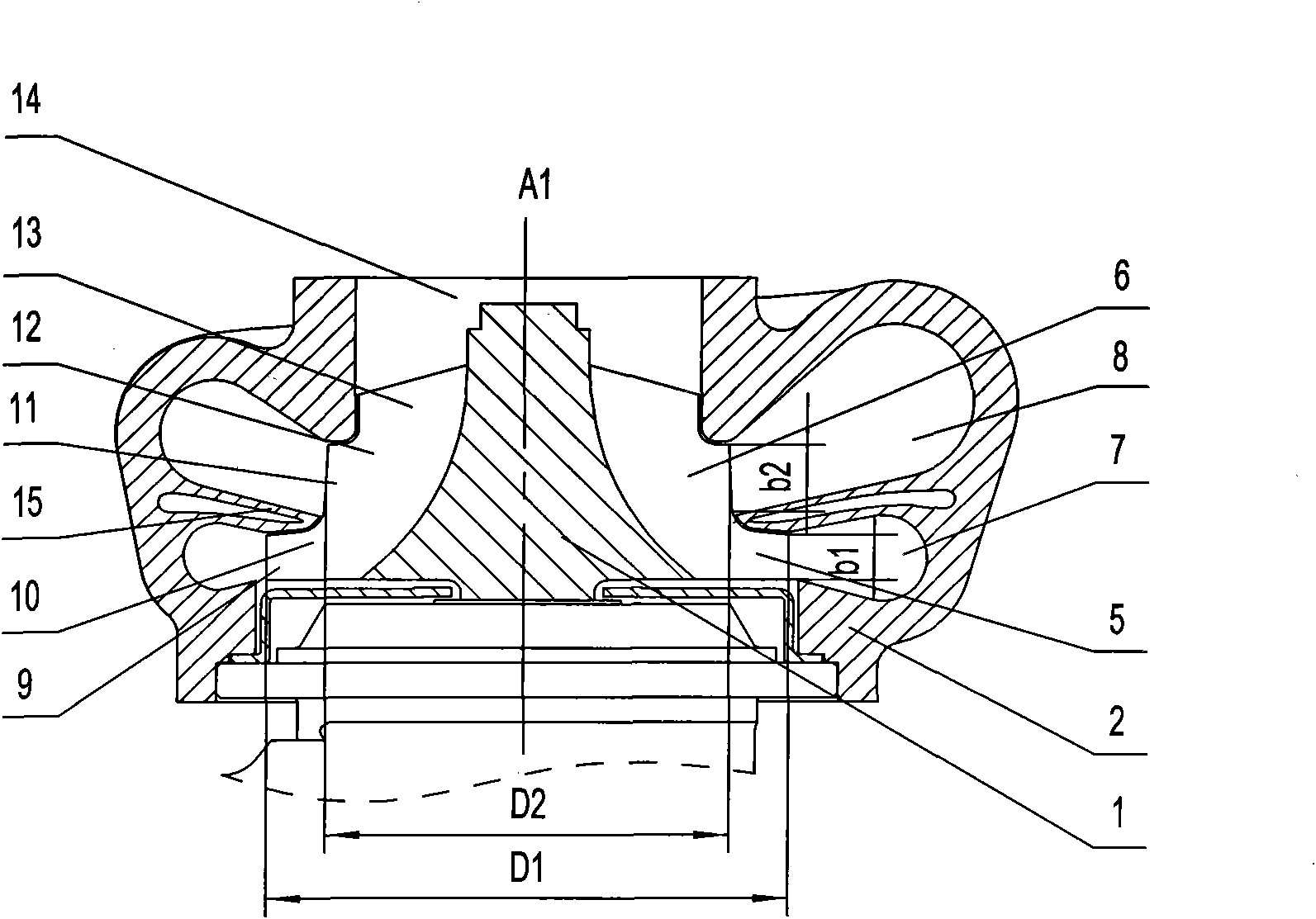

Hydraulic valve mechanism of variable valve lift

ActiveCN101713308AImprove performanceNo significant change in volumeMachines/enginesNon-mechanical valveGear wheelEngineering

The invention discloses a hydraulic valve mechanism of a variable valve lift. The hydraulic valve mechanism of the variable valve lift comprises a valve spool of a puller cam, a sleeve capable of rotating relative to the valve spool and a seal gland connected with a valve. The top end of the sleeve is adapted to the valve spool; the bottom of the sleeve is adapted to the seal gland and an oil chamber is formed in the middle part of the sleeve. The hydraulic valve mechanism of the variable valve lift is characterized in that a valve spool oil duct is formed in the valve spool; an inlet of the valve spool oil duct is movably adapted to a sleeve oil duct; the outlet of the valve spool oil duct is communicated with the oil chamber; and the inlet of the valve spool oil duct is in shape of a helical notch. Part of gears are arranged outside the sleeve so as to drive the sleeve to rotate by racks or other similar mechanisms. A return spring is further arranged on the valve spool. The problems of complicated structure, high cost and low reliability existing in prior art are solved. The hydraulic valve mechanism of the variable valve lift is a hydraulic valve mechanism which is capable of realizing quick response.

Owner:CHERY AUTOMOBILE CO LTD

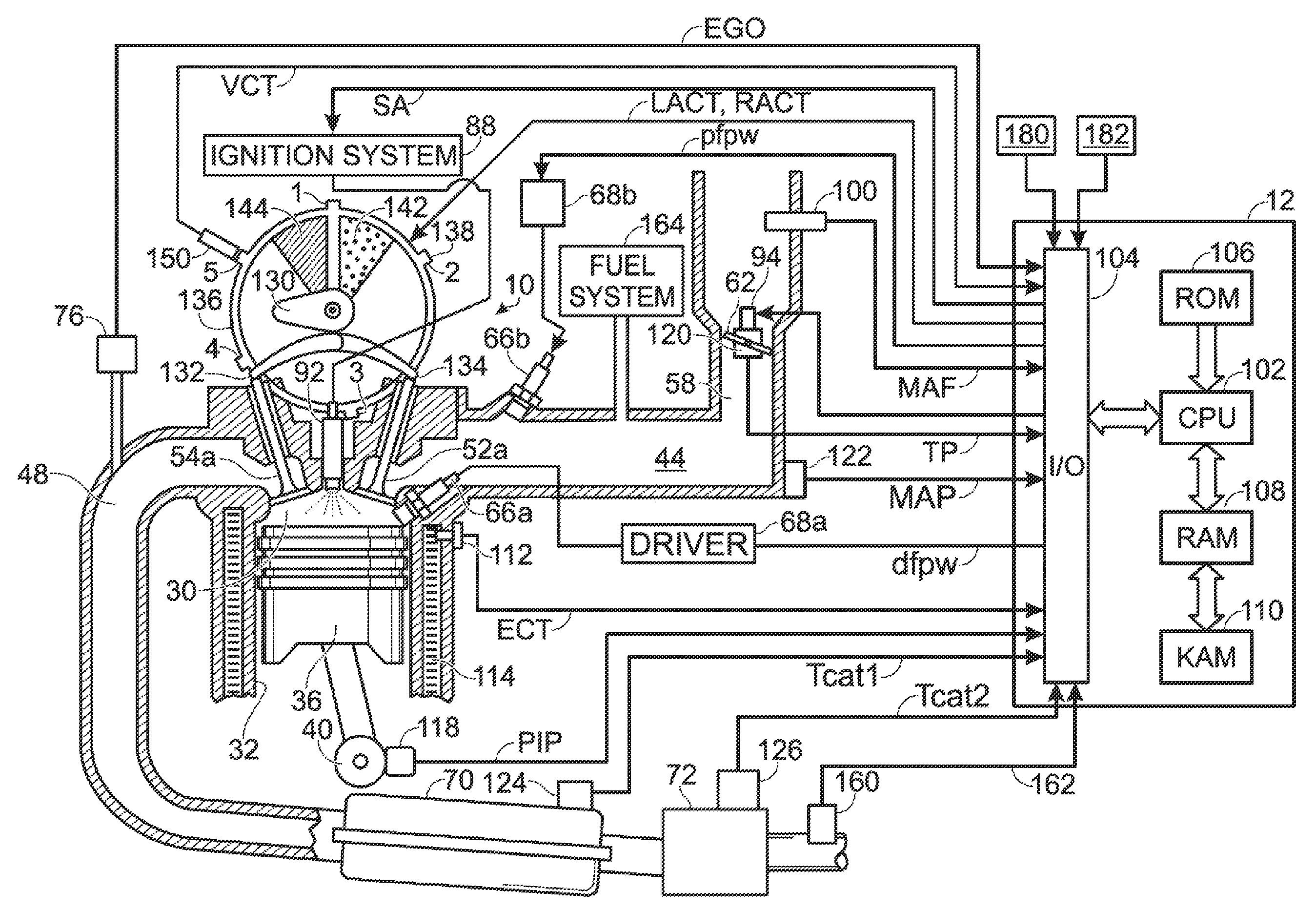

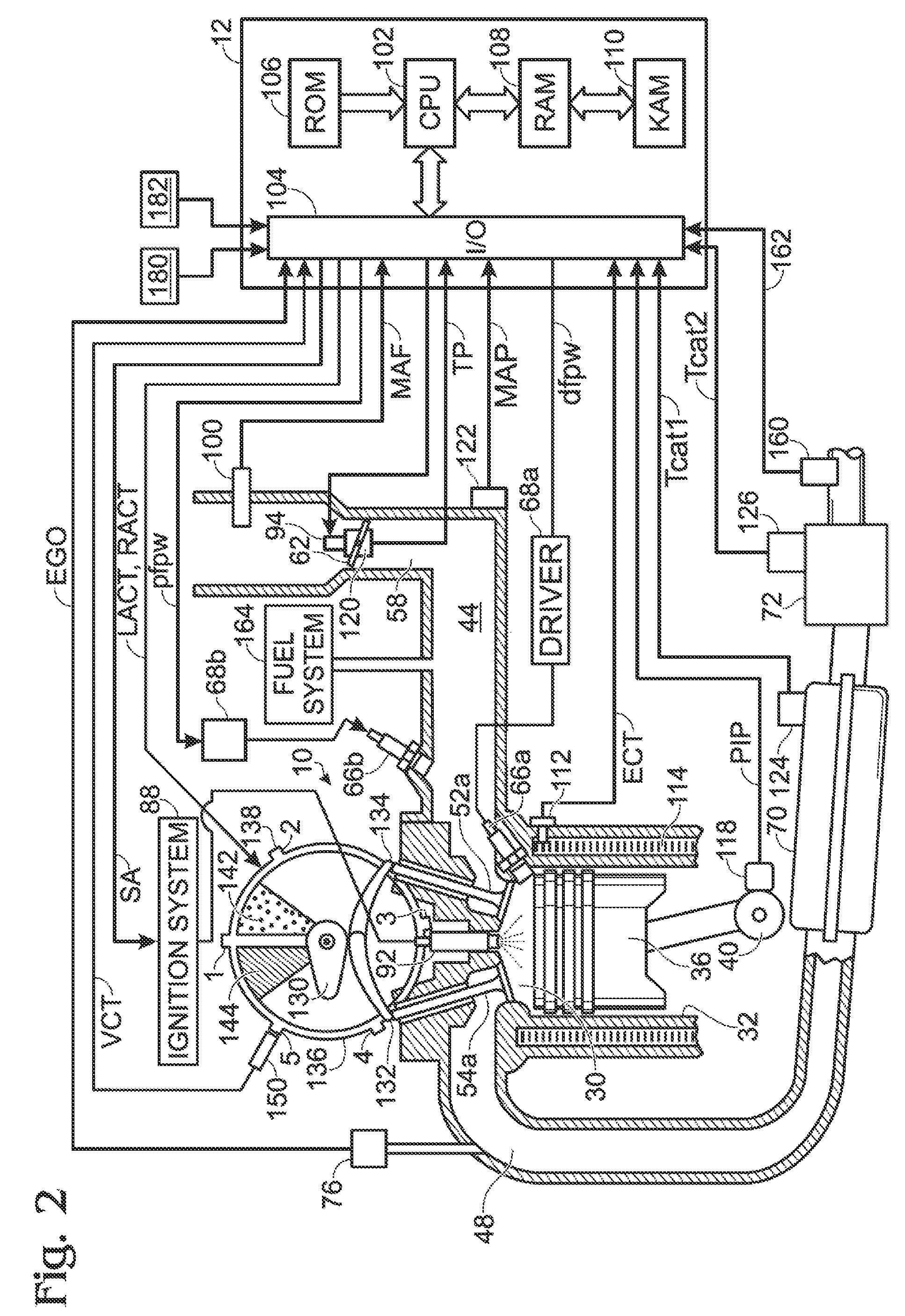

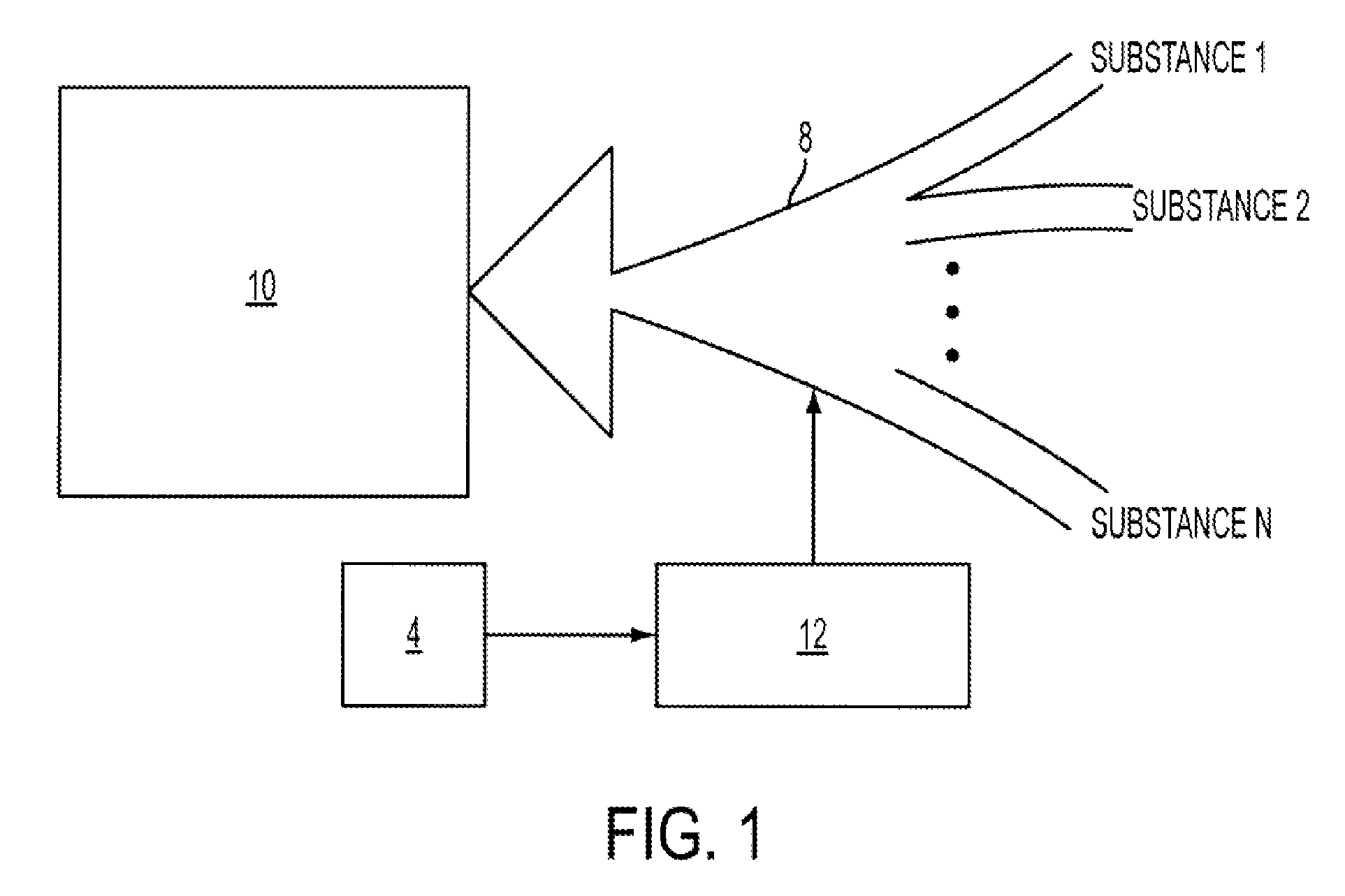

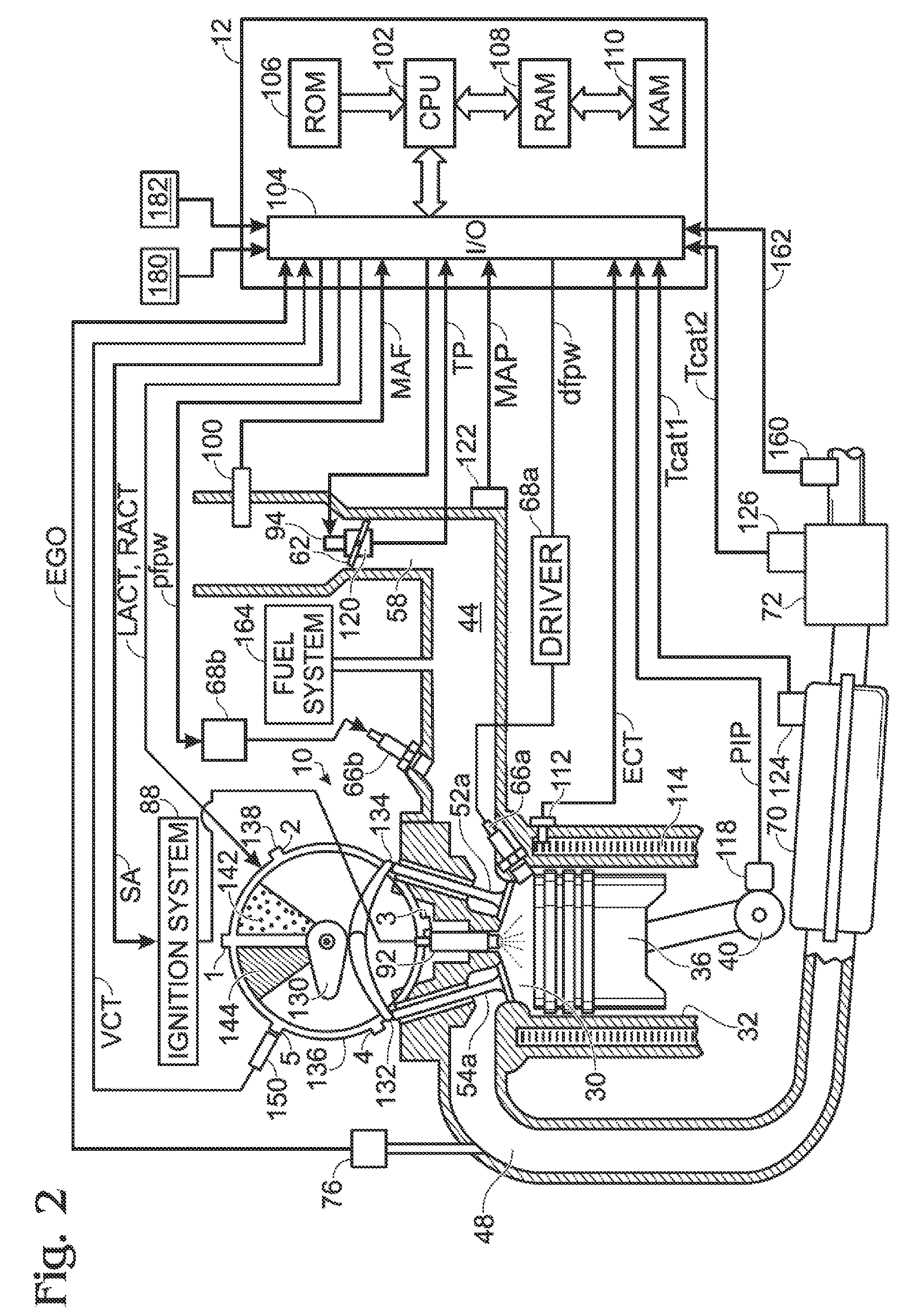

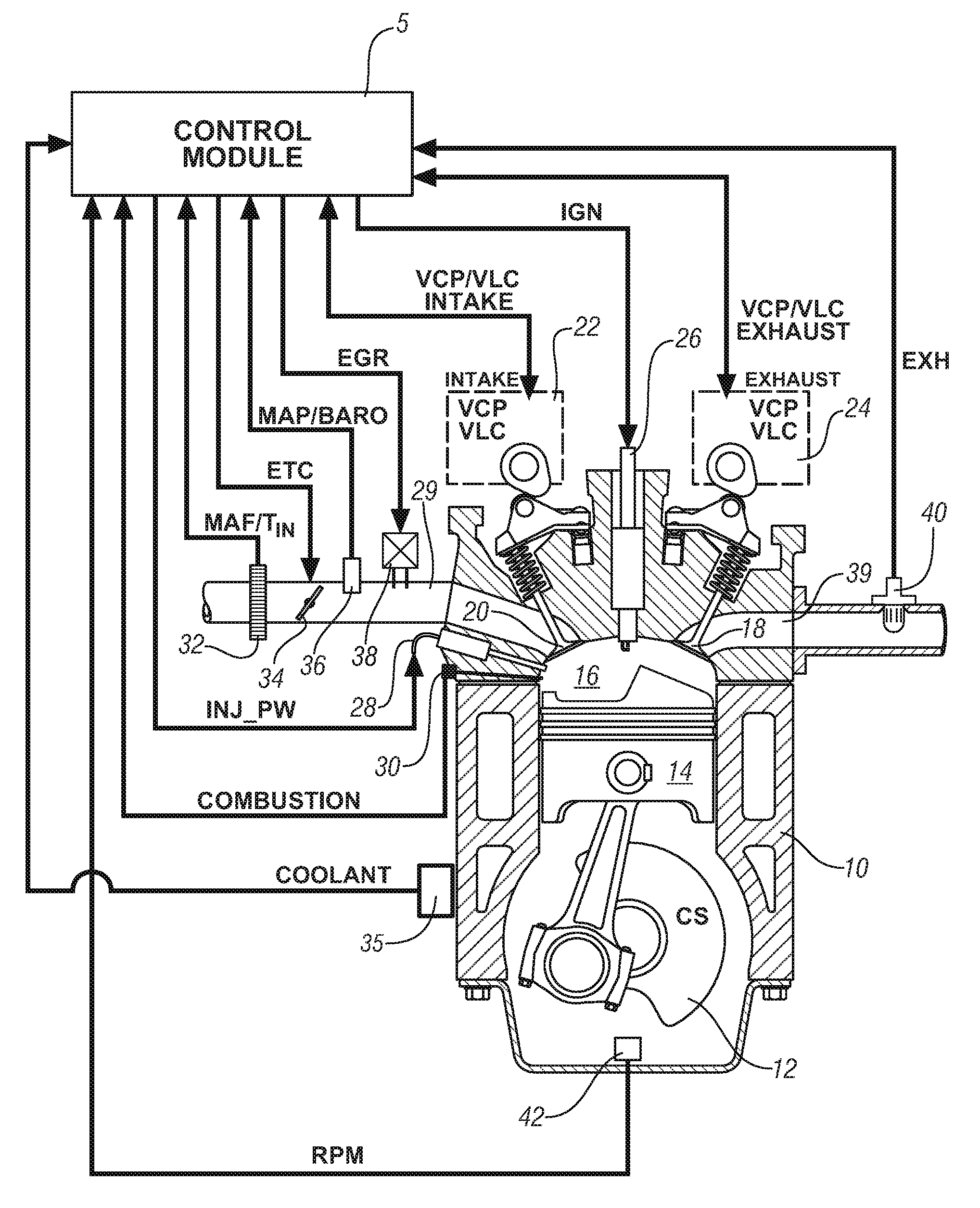

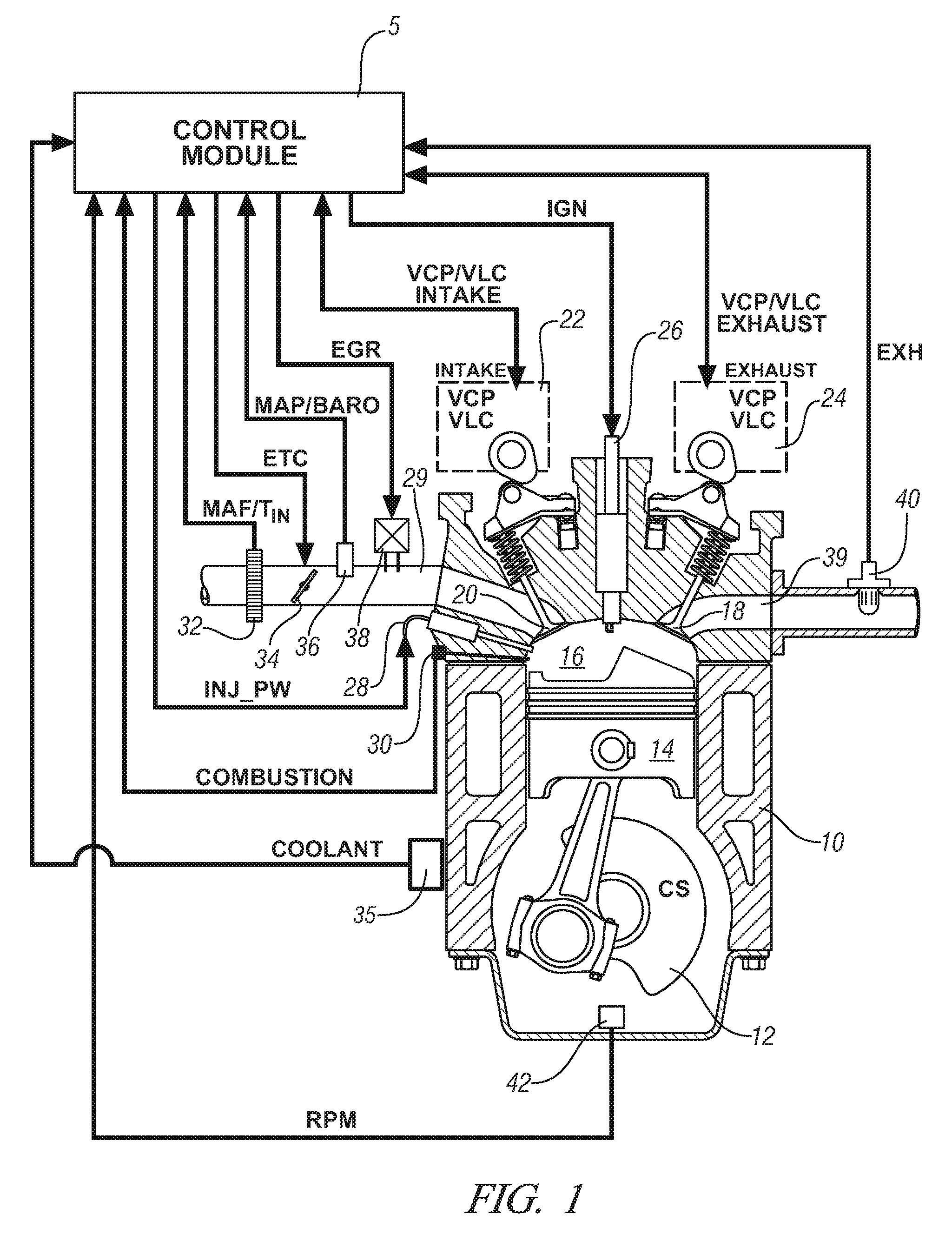

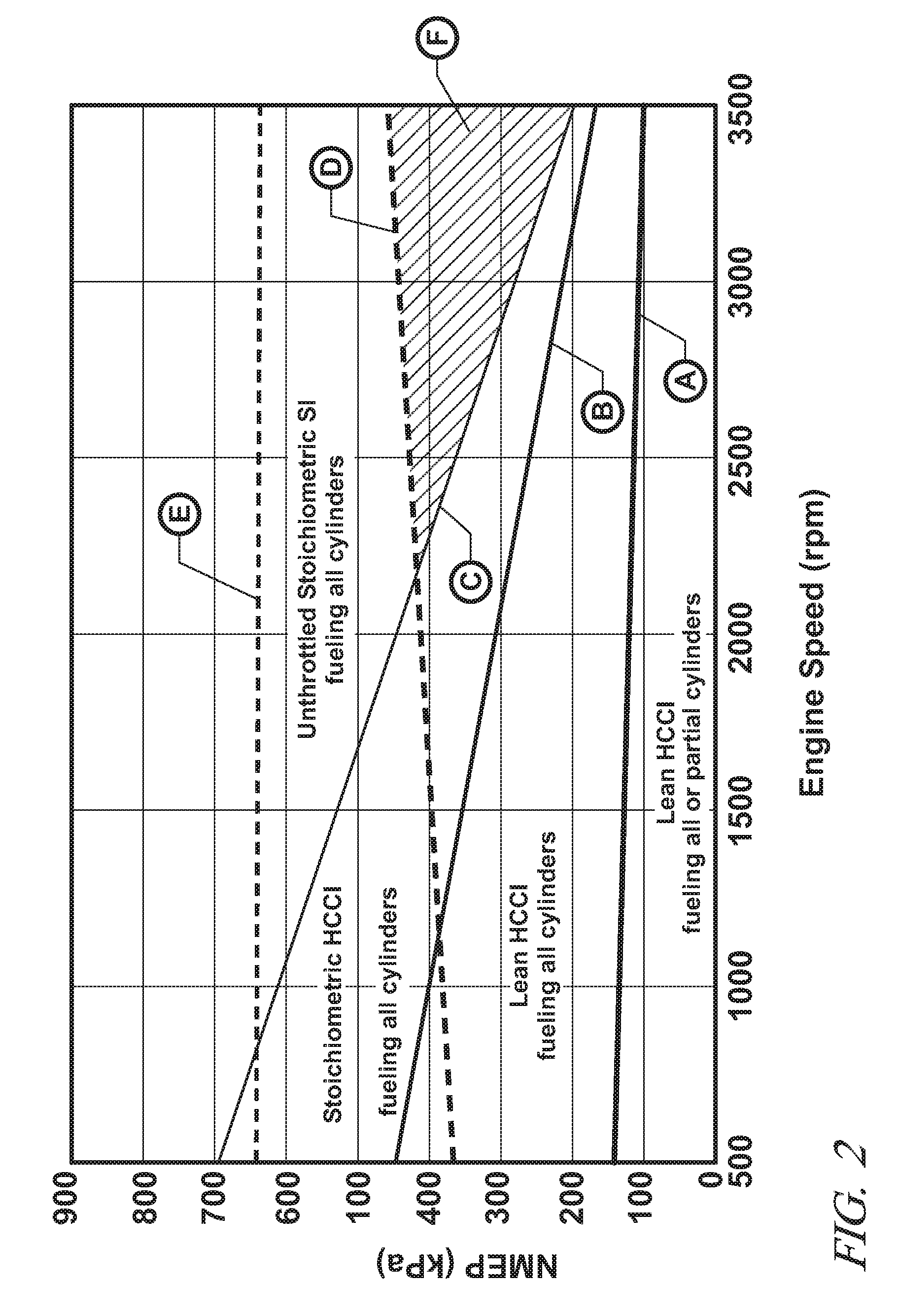

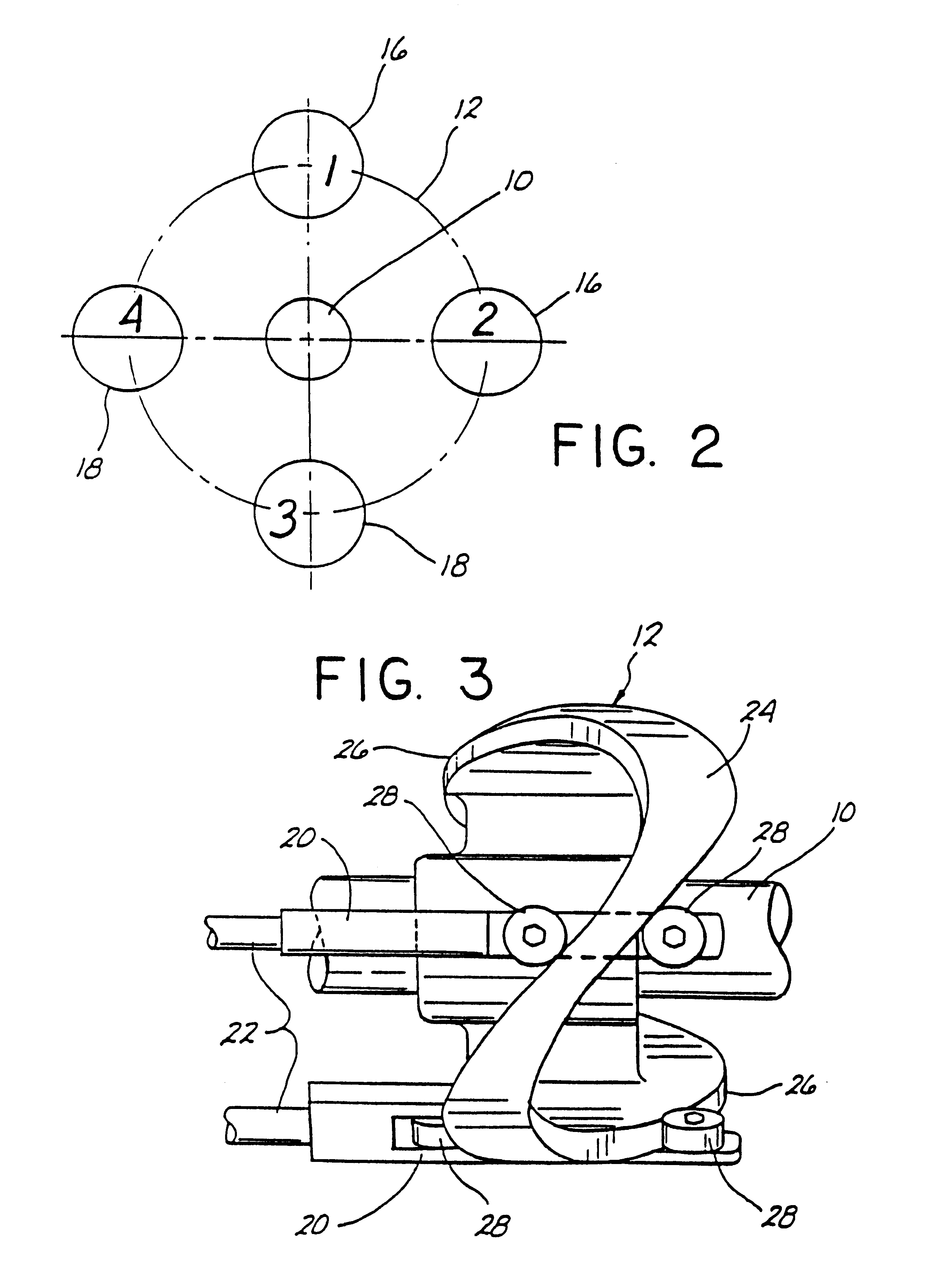

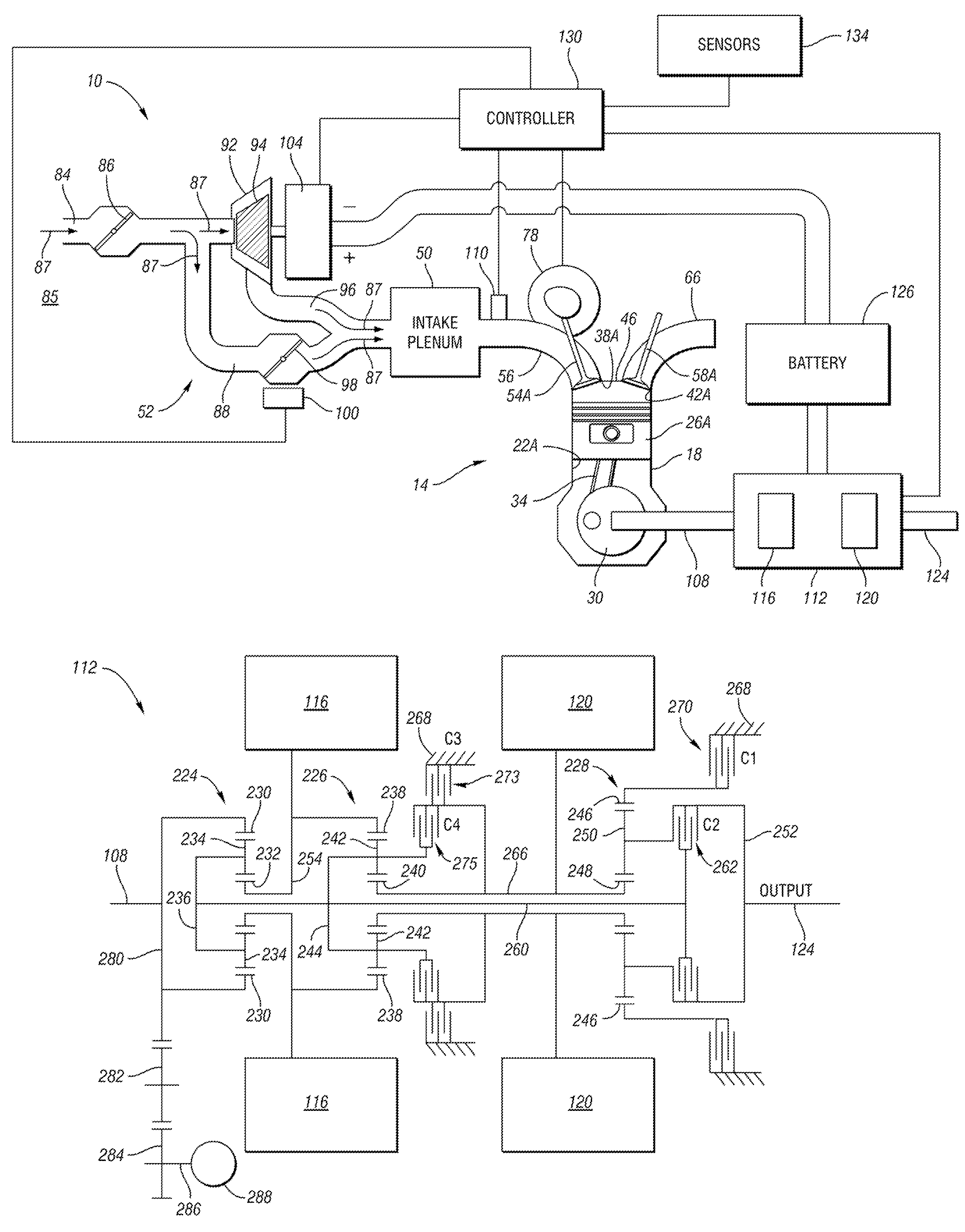

Multiple Combustion Mode Engine Using Direct Alcohol Injection

ActiveUS20080127933A1Improve operation and transient performanceDesign range be expandAnalogue computers for vehiclesElectrical controlAutomotive engineeringSpark-ignition engine

A method of operating an engine, comprising of performing homogeneous charge compression ignition combustion during a first operating condition, and performing spark ignition combustion during a second operating condition, where an amount of directly injected alcohol in at least one of said homogeneous charge compression ignition combustion and said spark ignition combustion is varied in response to at least an operating parameter.

Owner:FORD GLOBAL TECH LLC +1

Multiple combustion mode engine using direct alcohol injection

ActiveUS7461628B2Improve efficiencyReduce the production of nitrogen oxidesAnalogue computers for vehiclesElectrical controlHomogeneous charge compression ignitionAlcohol

A method of operating an engine, comprising of performing homogeneous charge compression ignition combustion during a first operating condition, and performing spark ignition combustion during a second operating condition, where an amount of directly injected alcohol in at least one of said homogeneous charge compression ignition combustion and said spark ignition combustion is varied in response to at least an operating parameter.

Owner:FORD GLOBAL TECH LLC +1

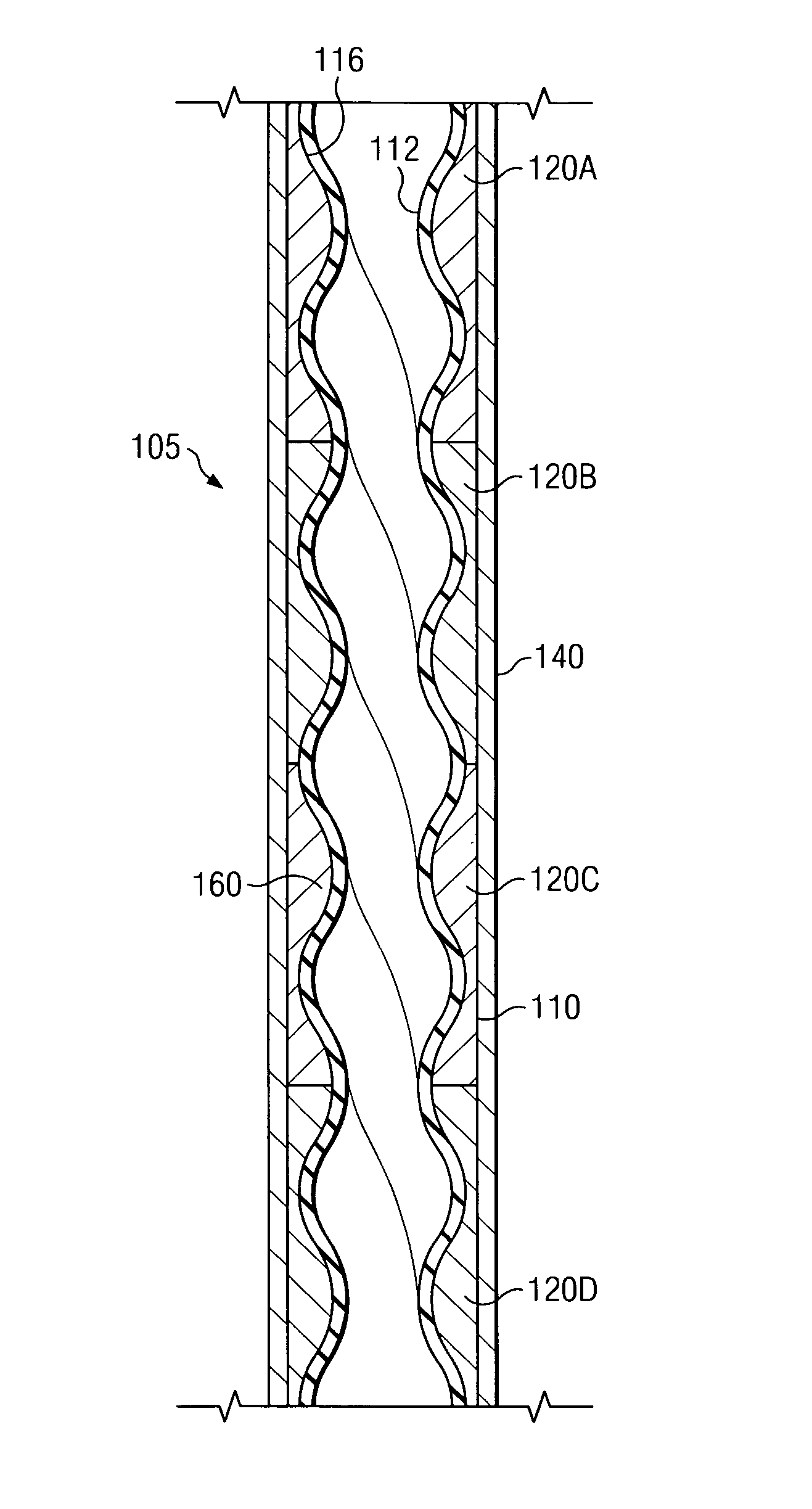

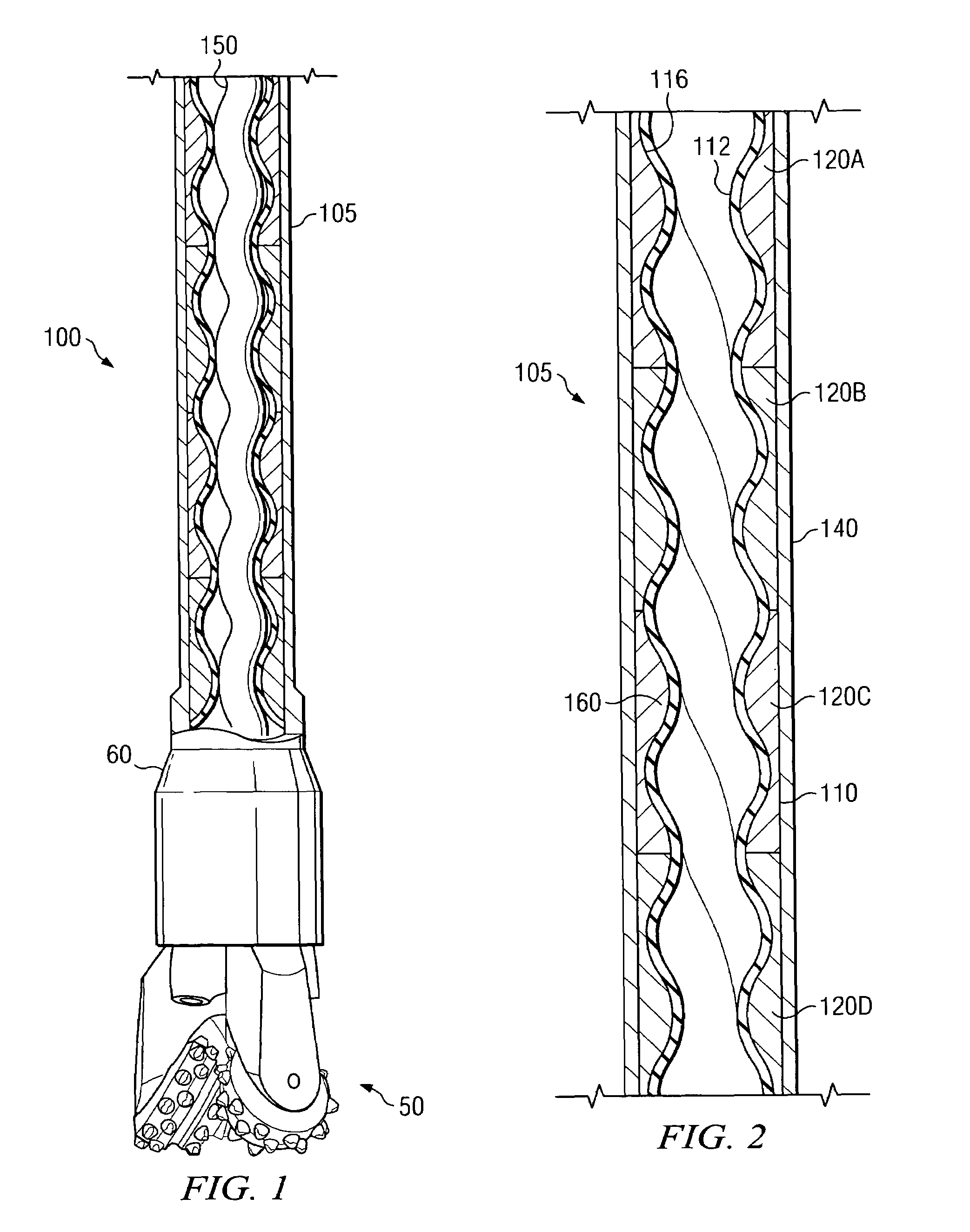

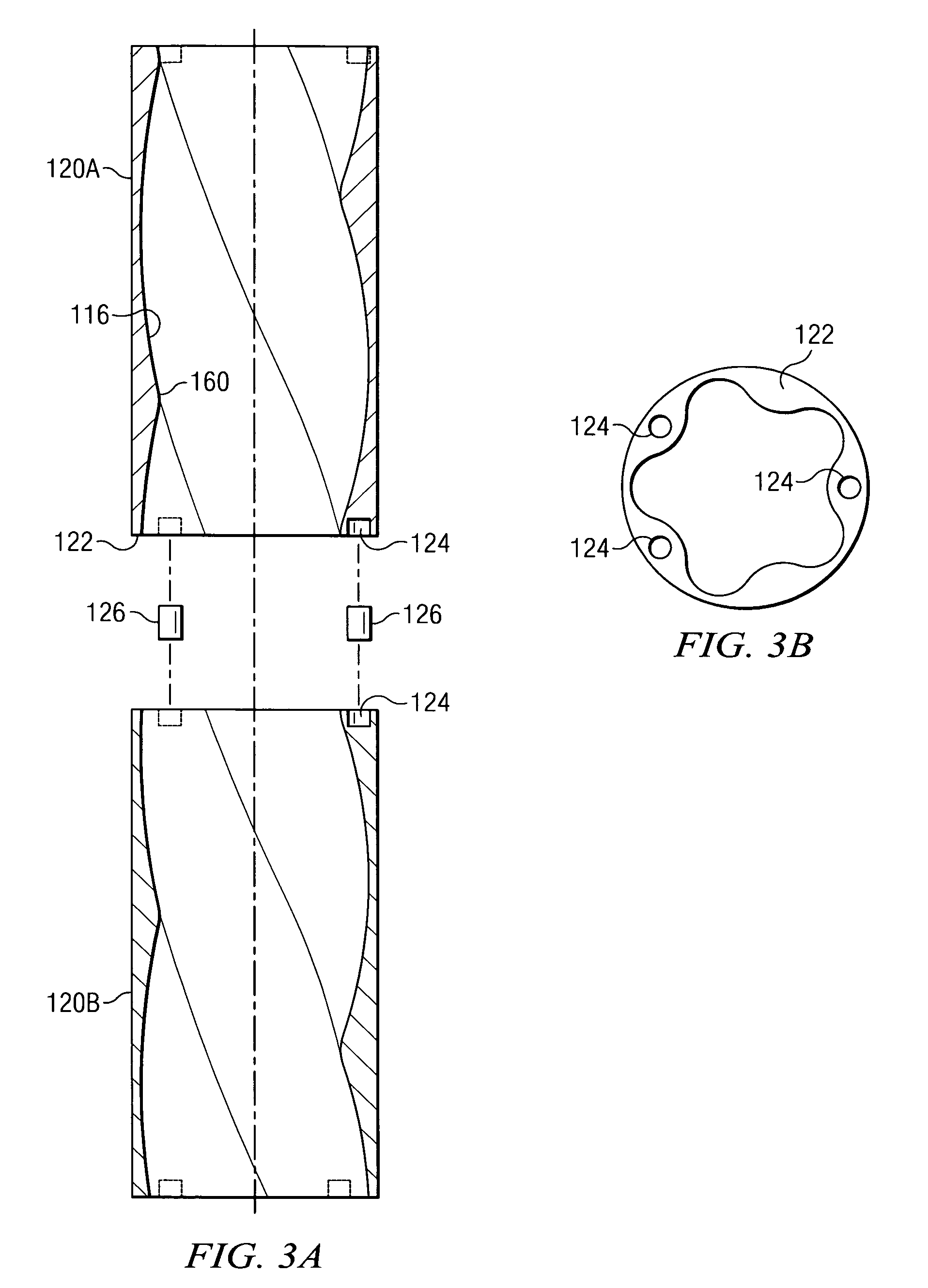

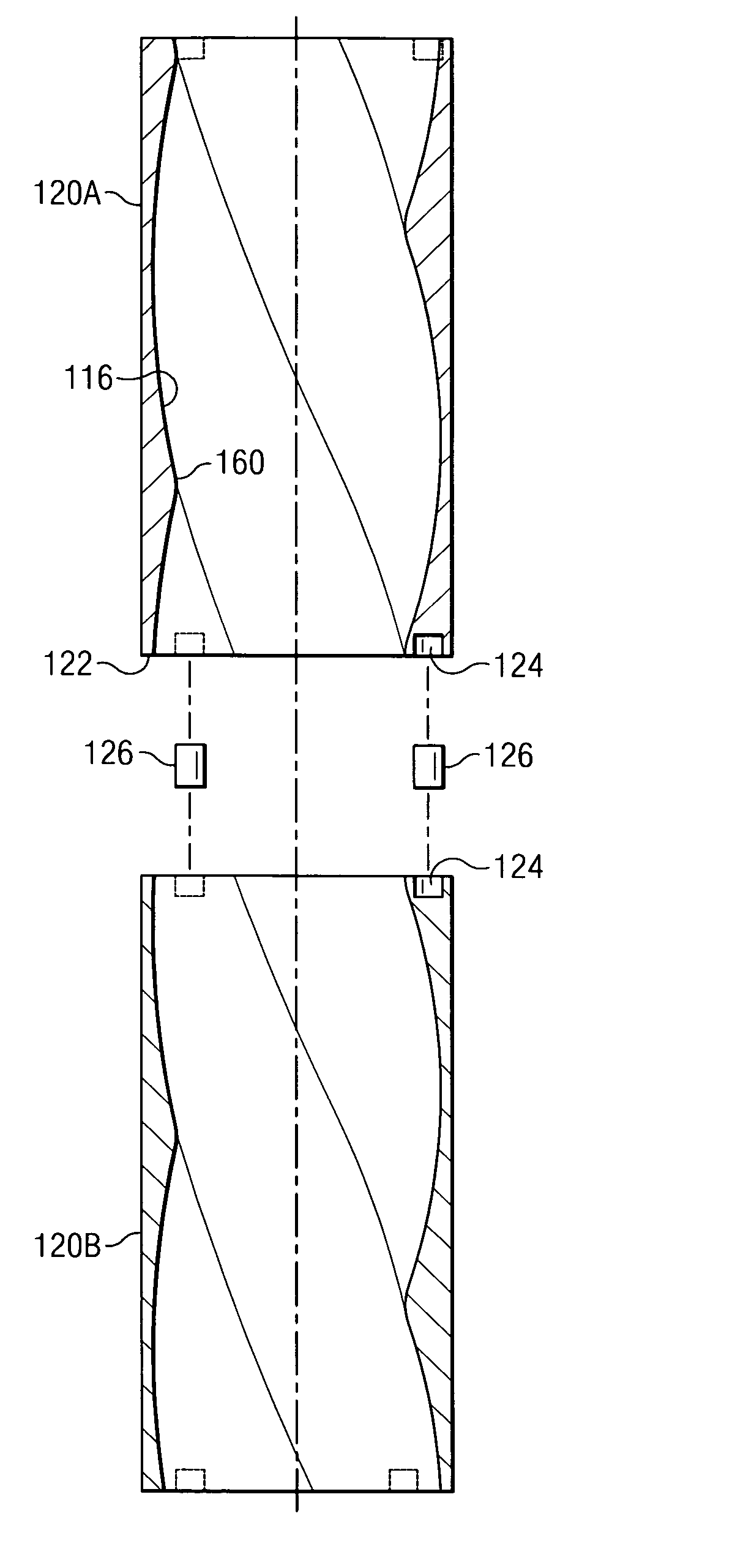

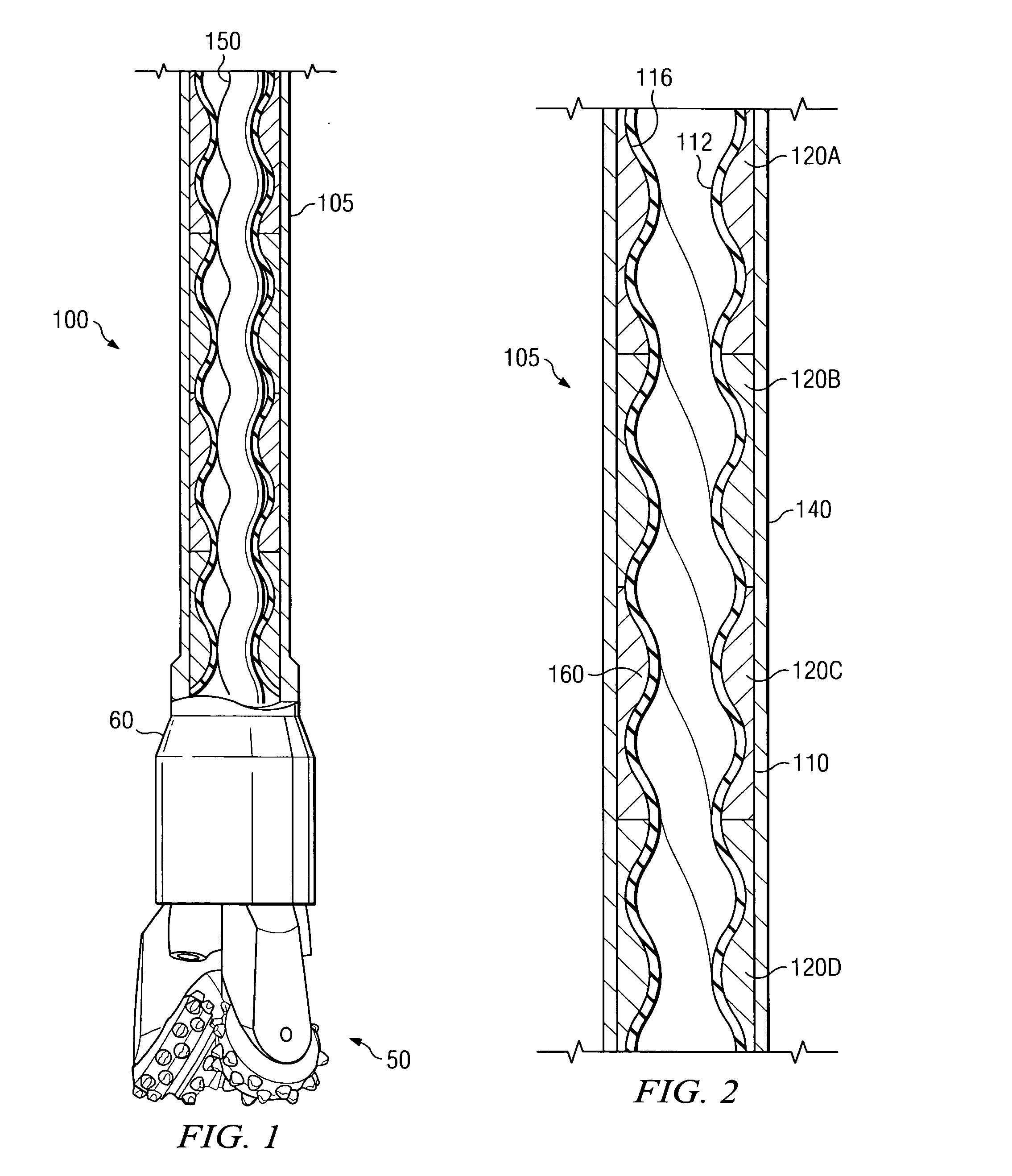

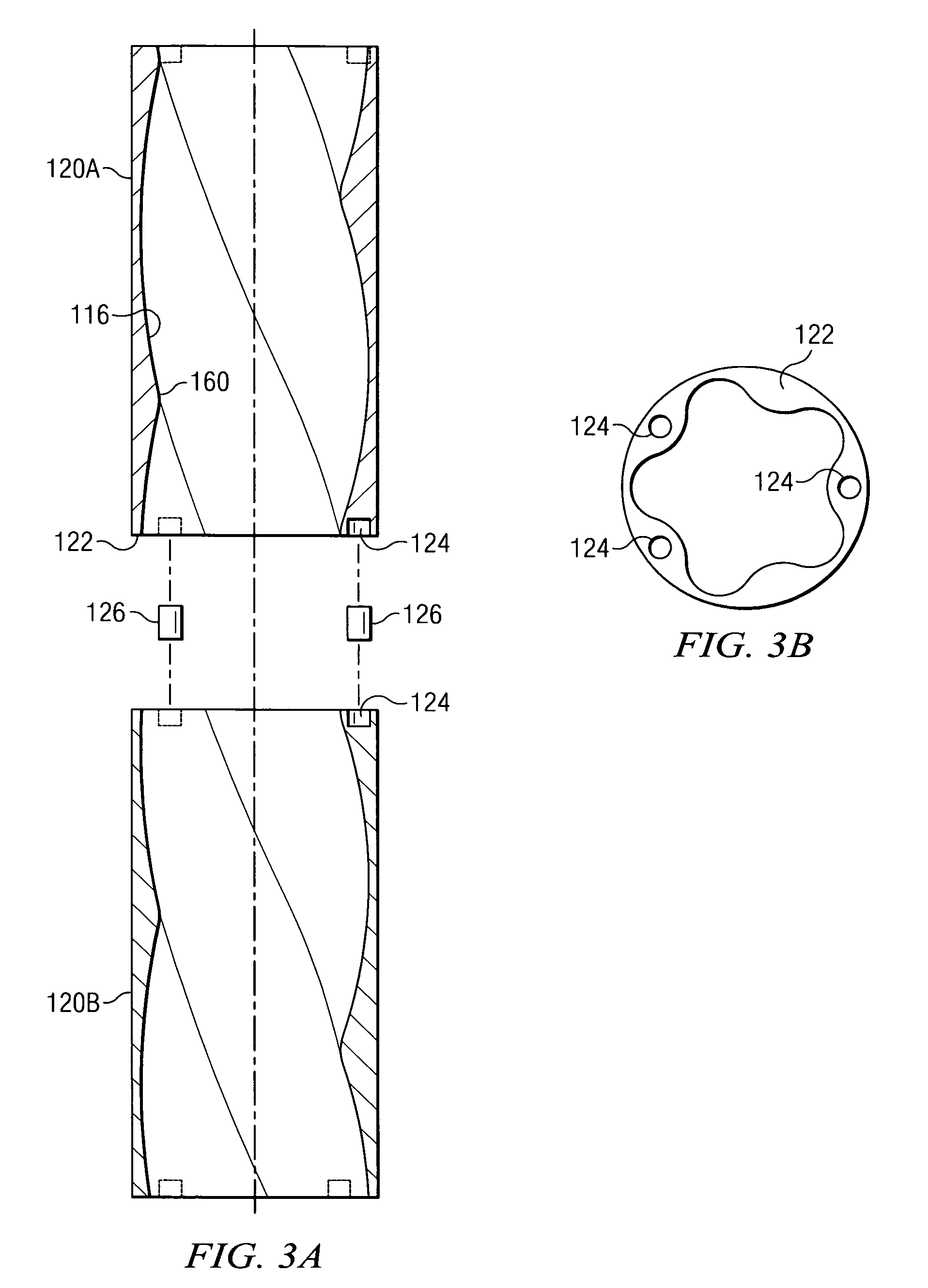

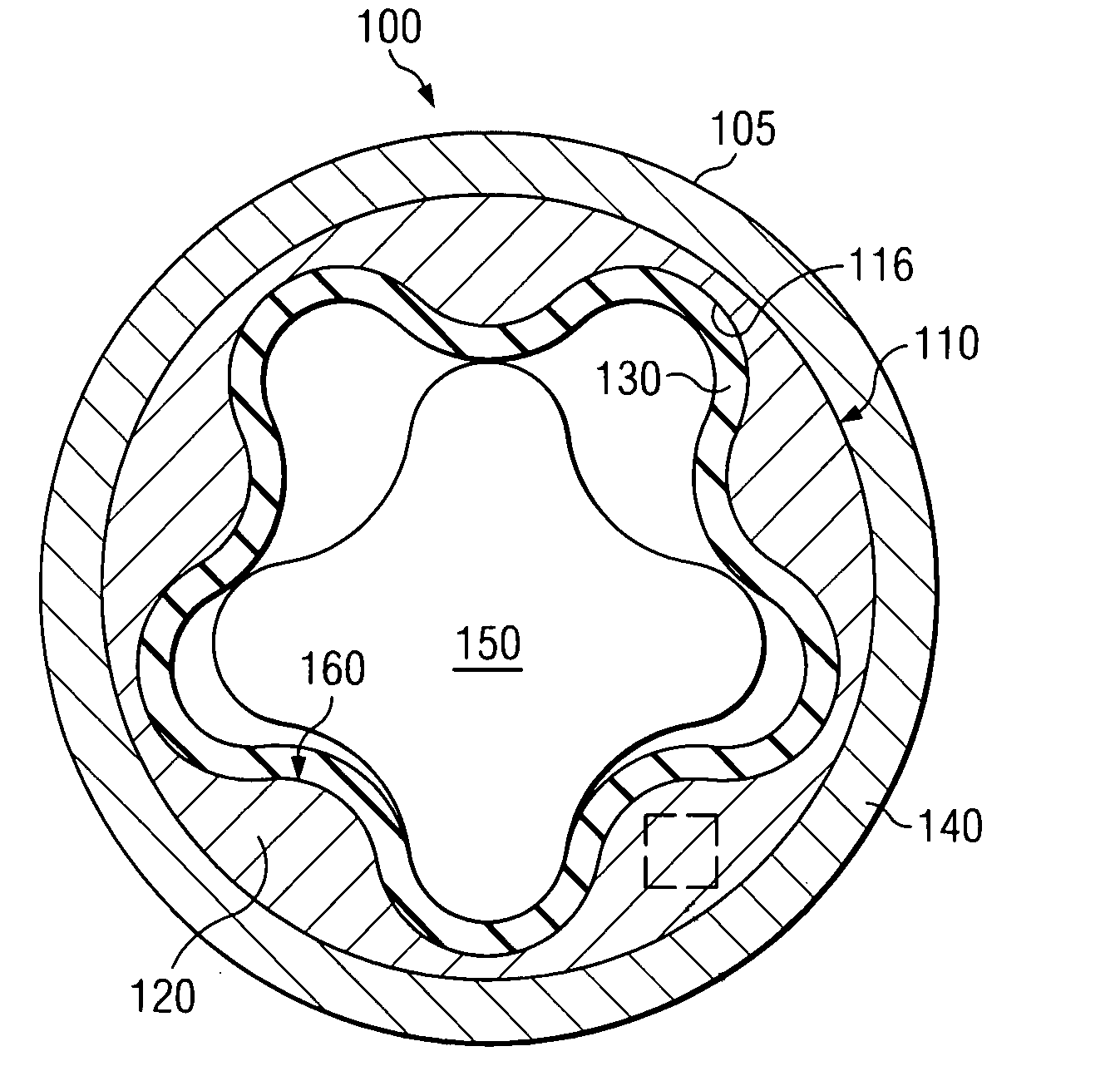

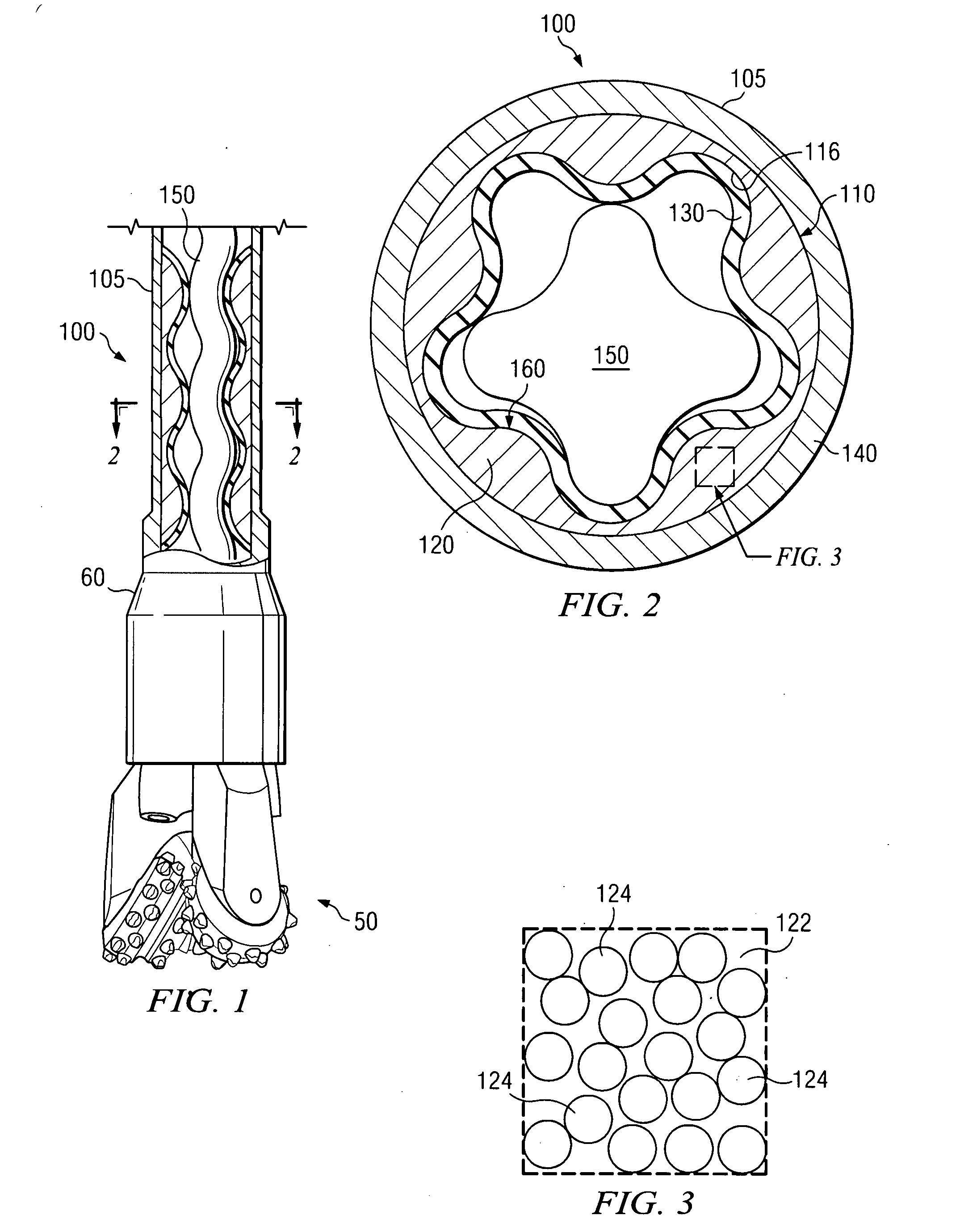

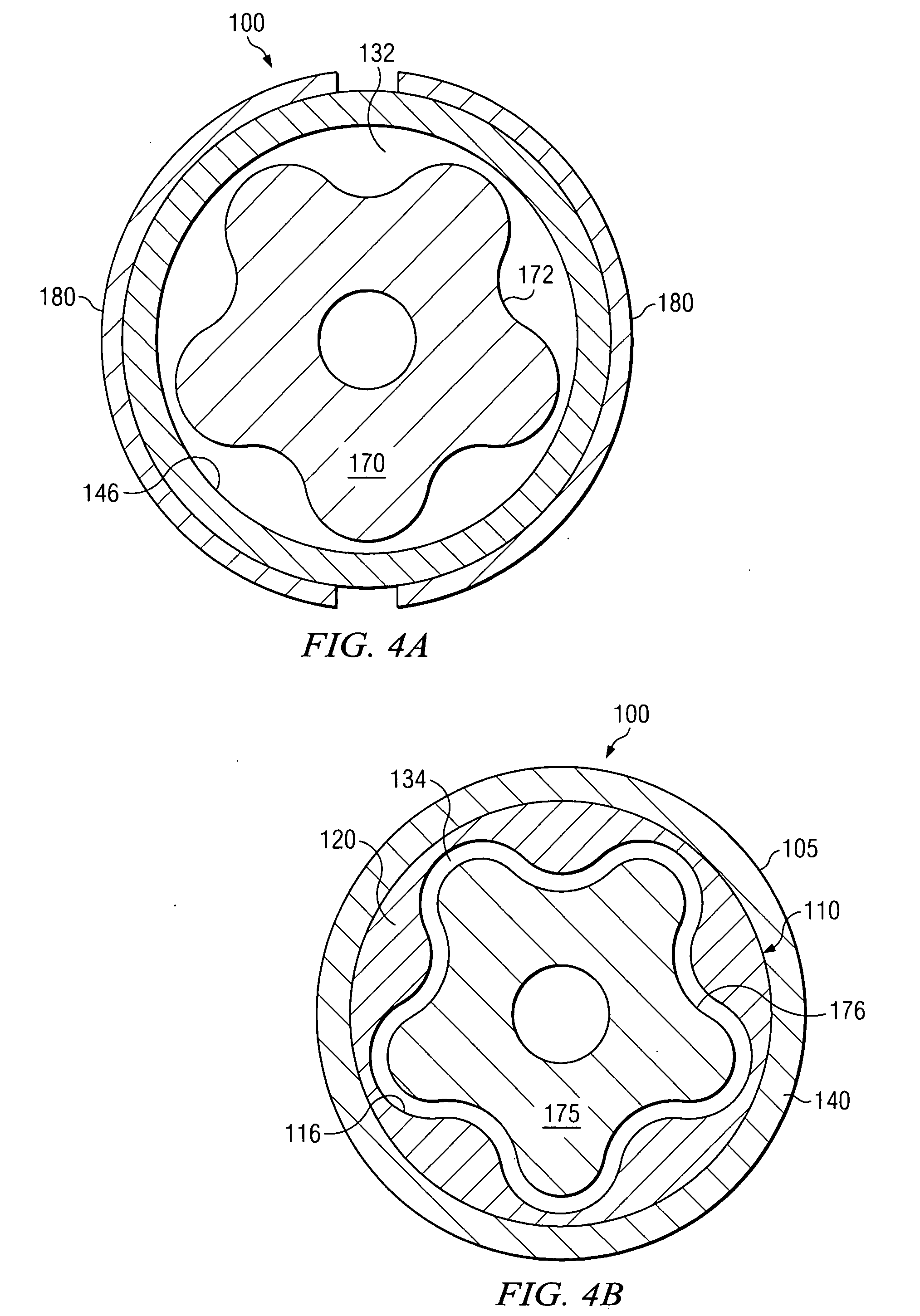

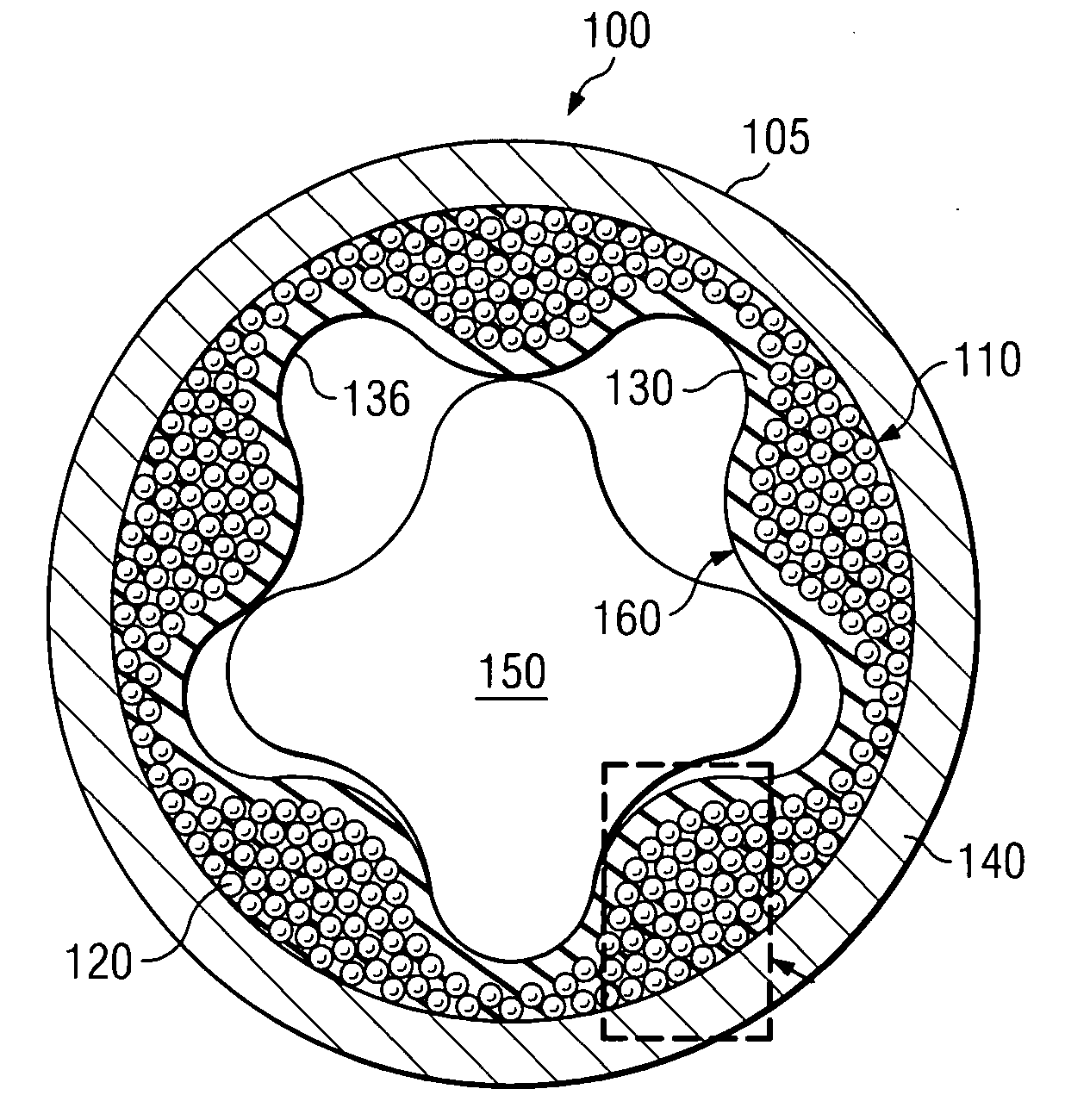

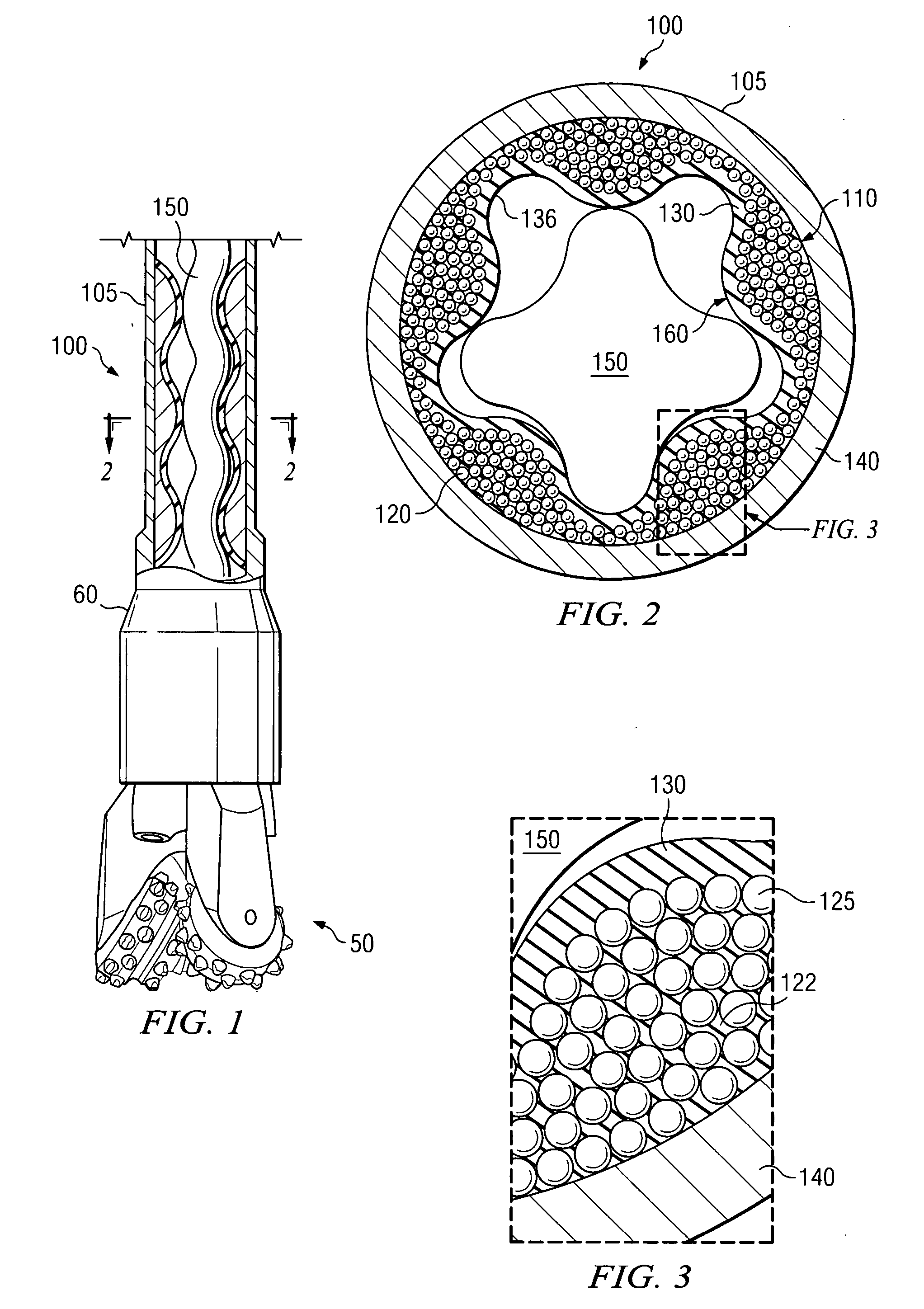

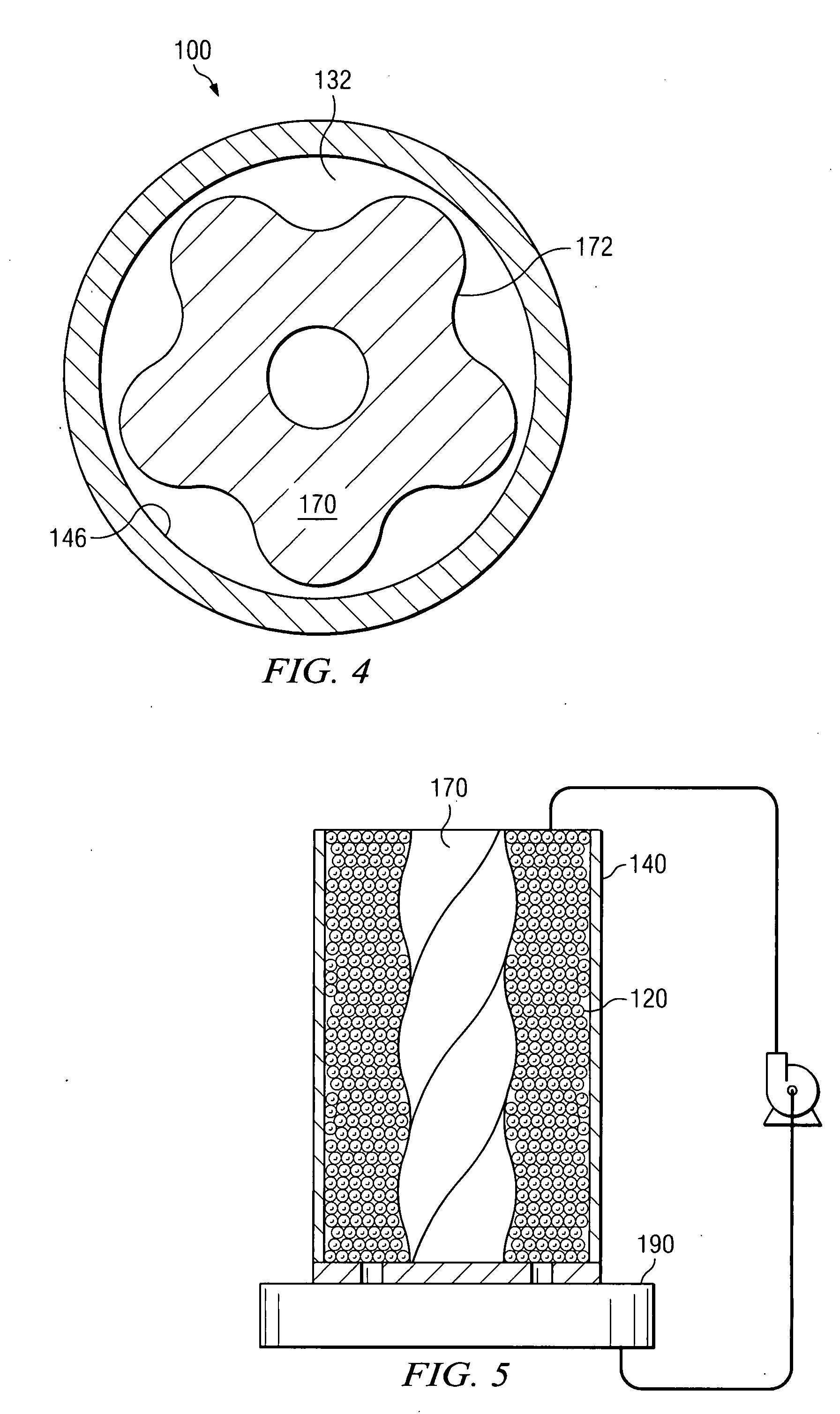

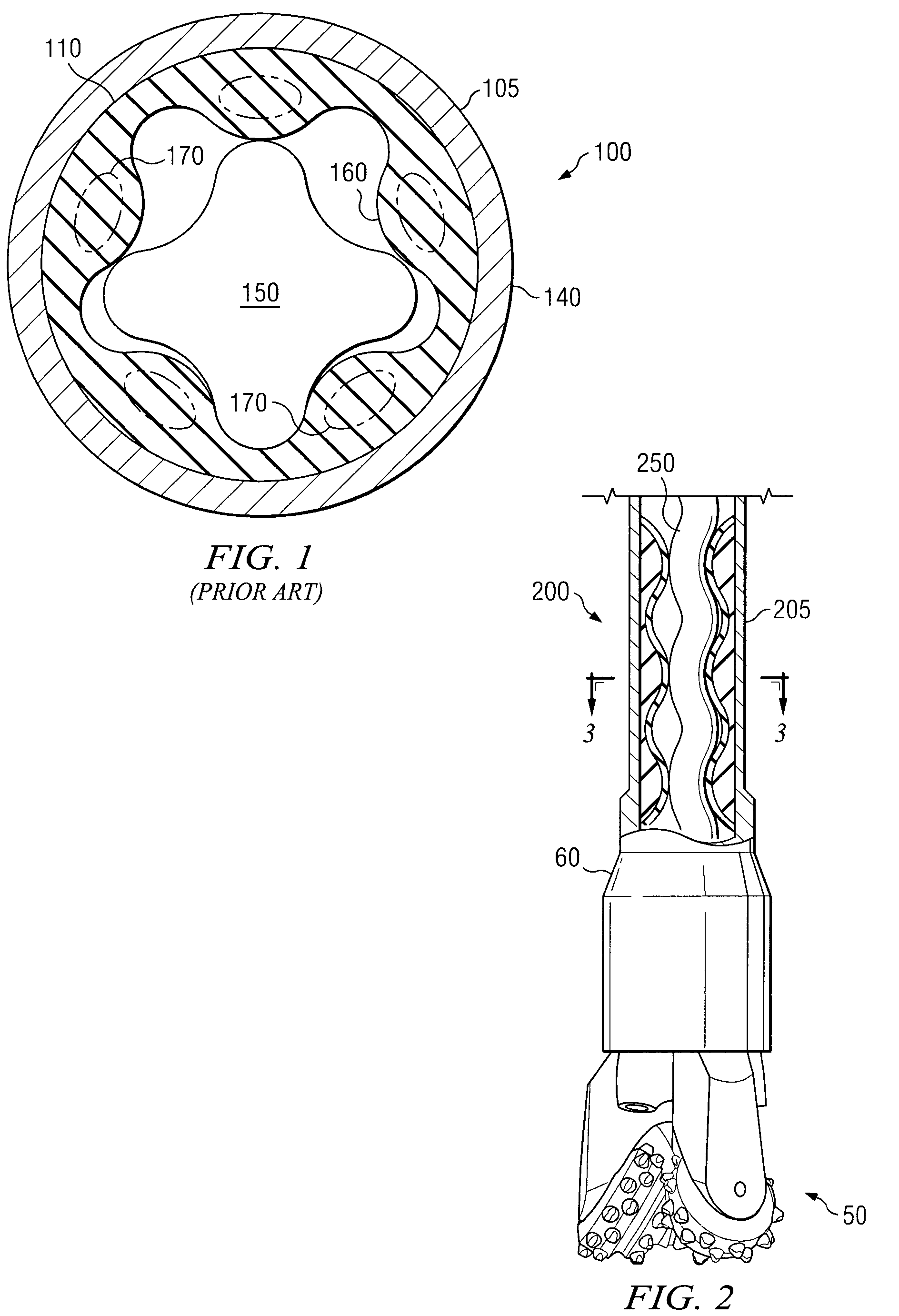

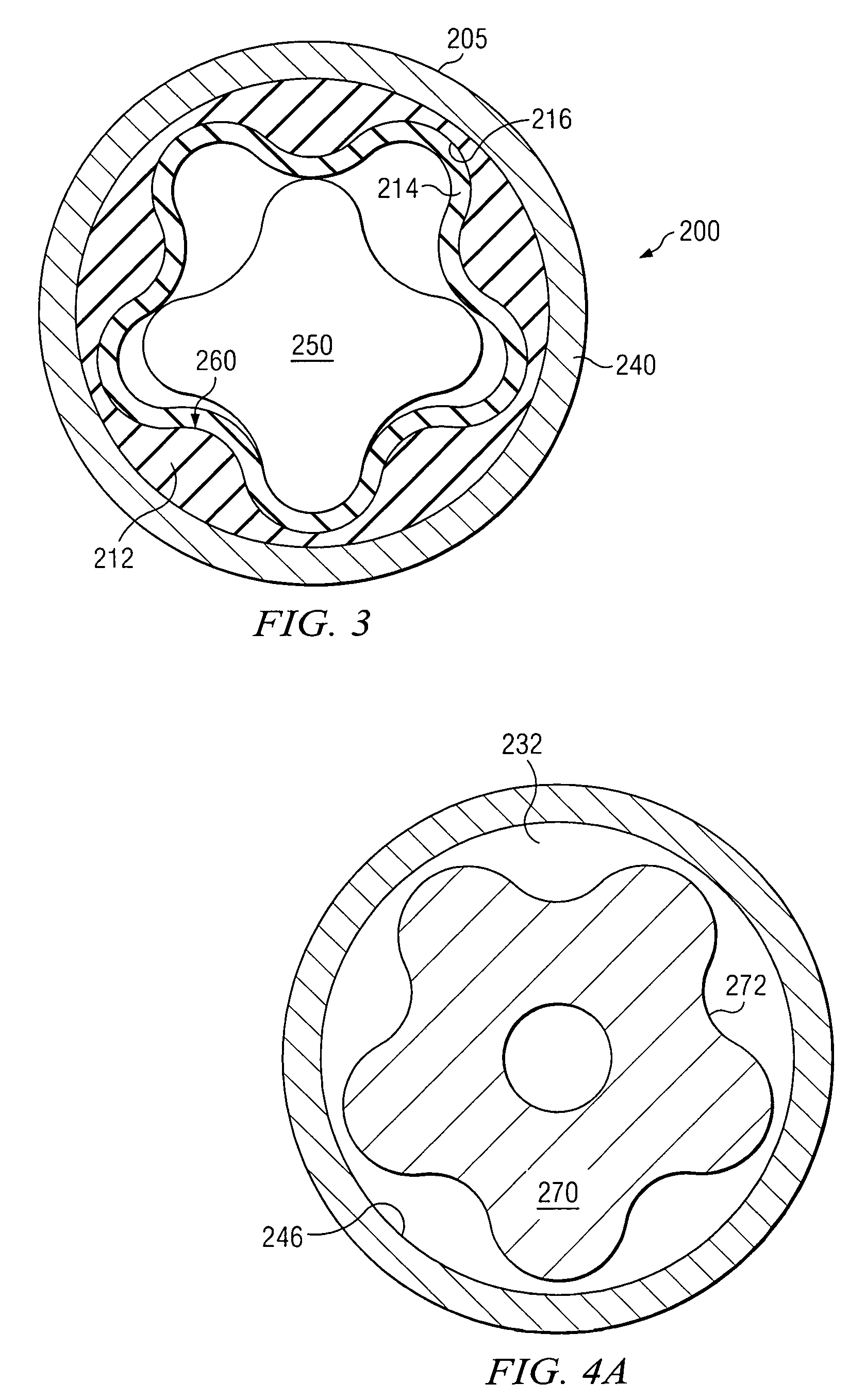

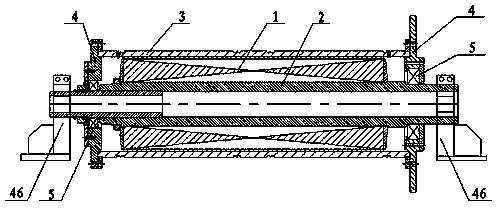

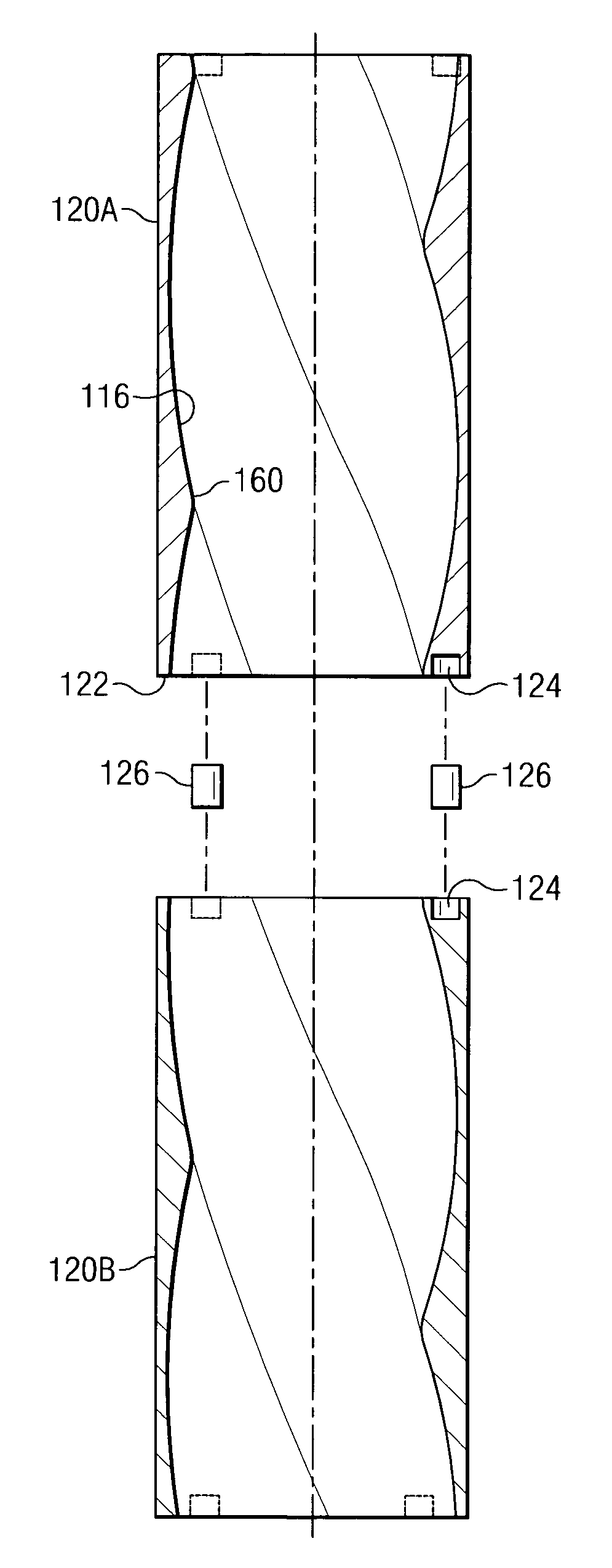

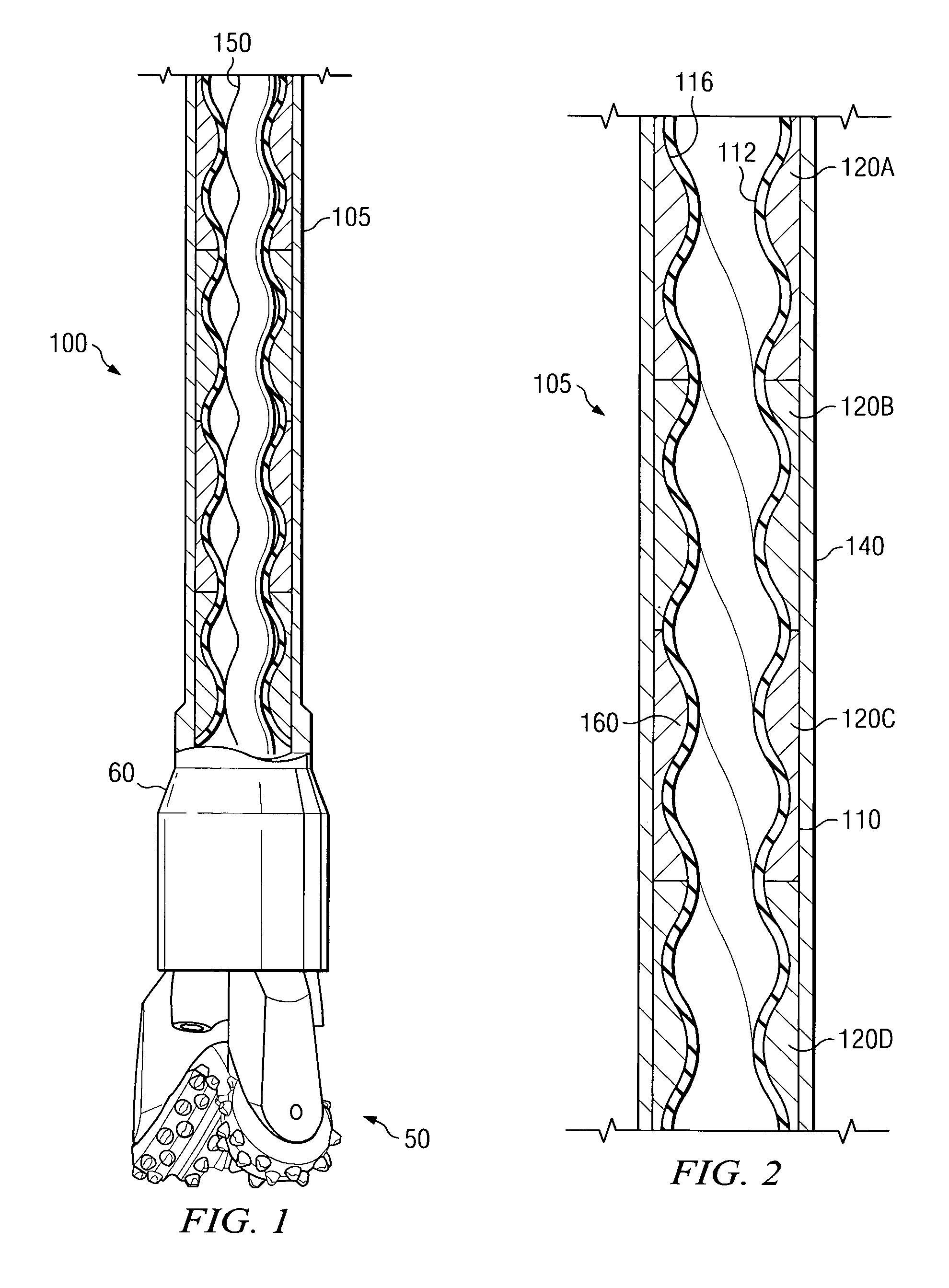

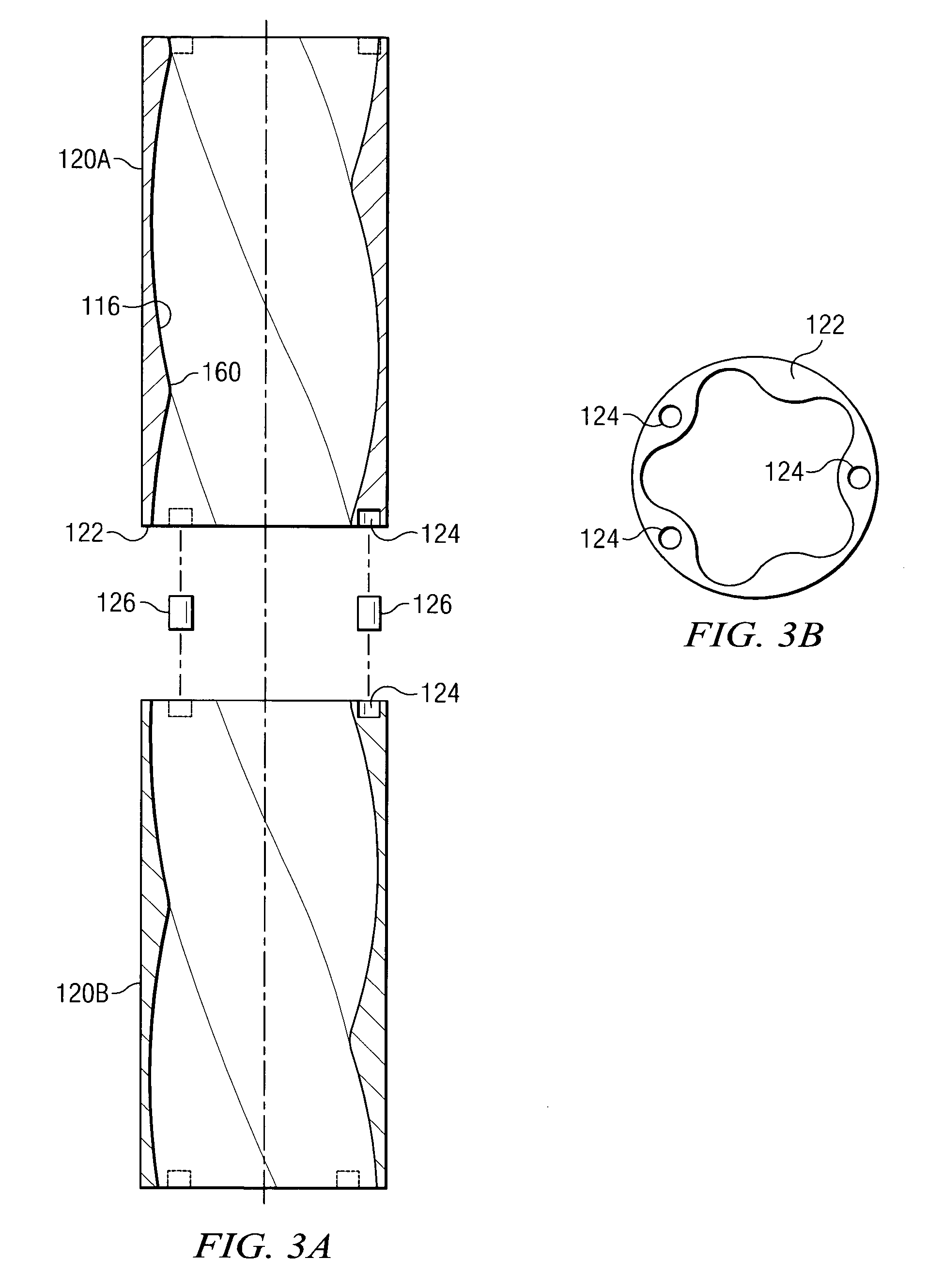

Progressing cavity stator including at least one cast longitudinal section

InactiveUS7396220B2Increased torque outputSimple and inexpensive to manufactureOscillating piston enginesEngine of intermeshing engagement typeElastomerHigh torque

A progressing cavity stator and a method for fabricating such a stator are disclosed. Exemplary embodiments of the progressing cavity stator include a plurality of rigid longitudinal stator sections concatenated end-to-end in a stator tube. The stator sections are rotationally aligned so that each of the internal lobes extends in a substantially continuous helix from one end of the stator to the other. The stator further includes an elastomer liner deployed on an inner surface of the concatenated stator sections. Exemplary embodiments of this invention include a comparatively rigid stator having high torque output and are relatively simple and inexpensive to manufacture as compared to prior art rigid stators.

Owner:SMITH INT INC

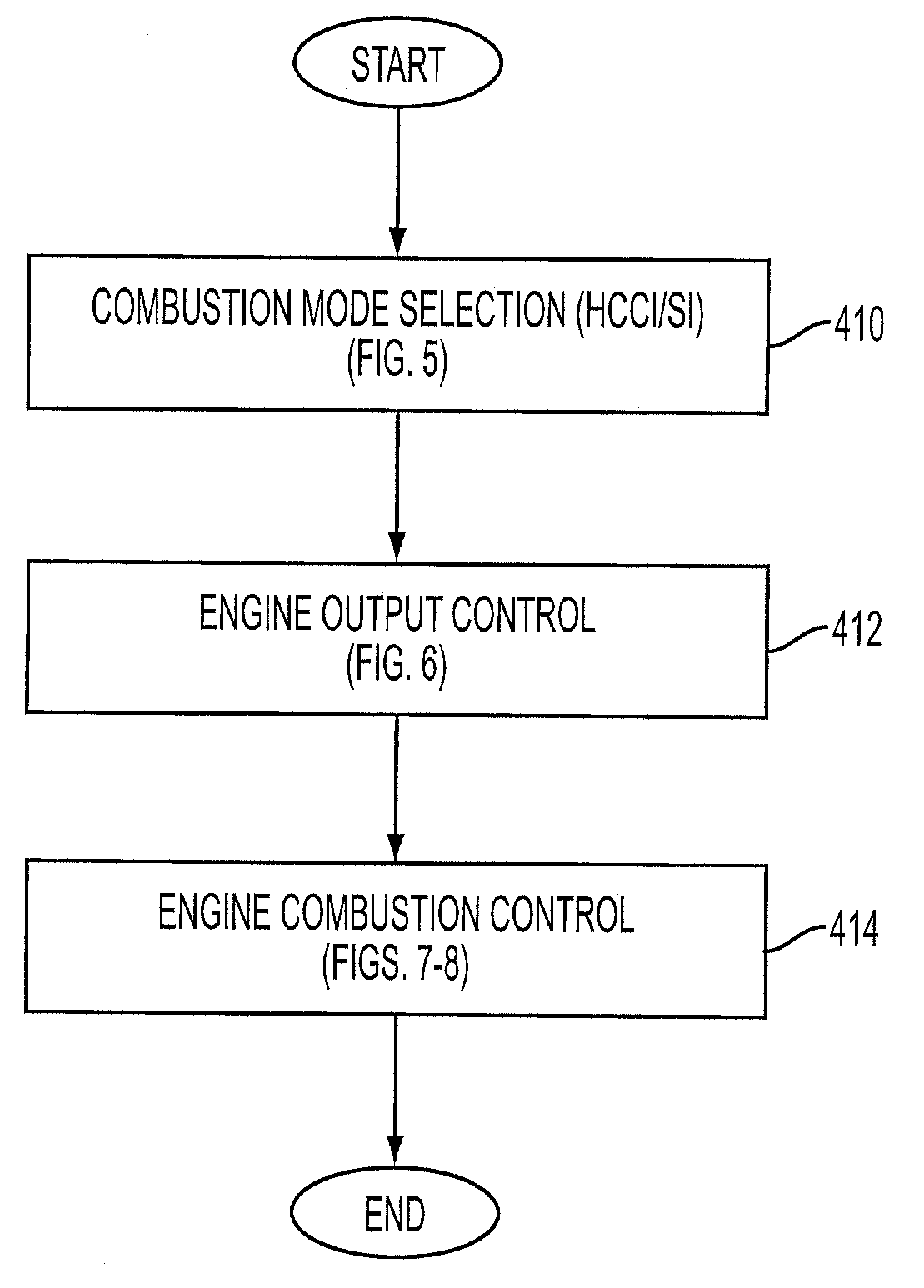

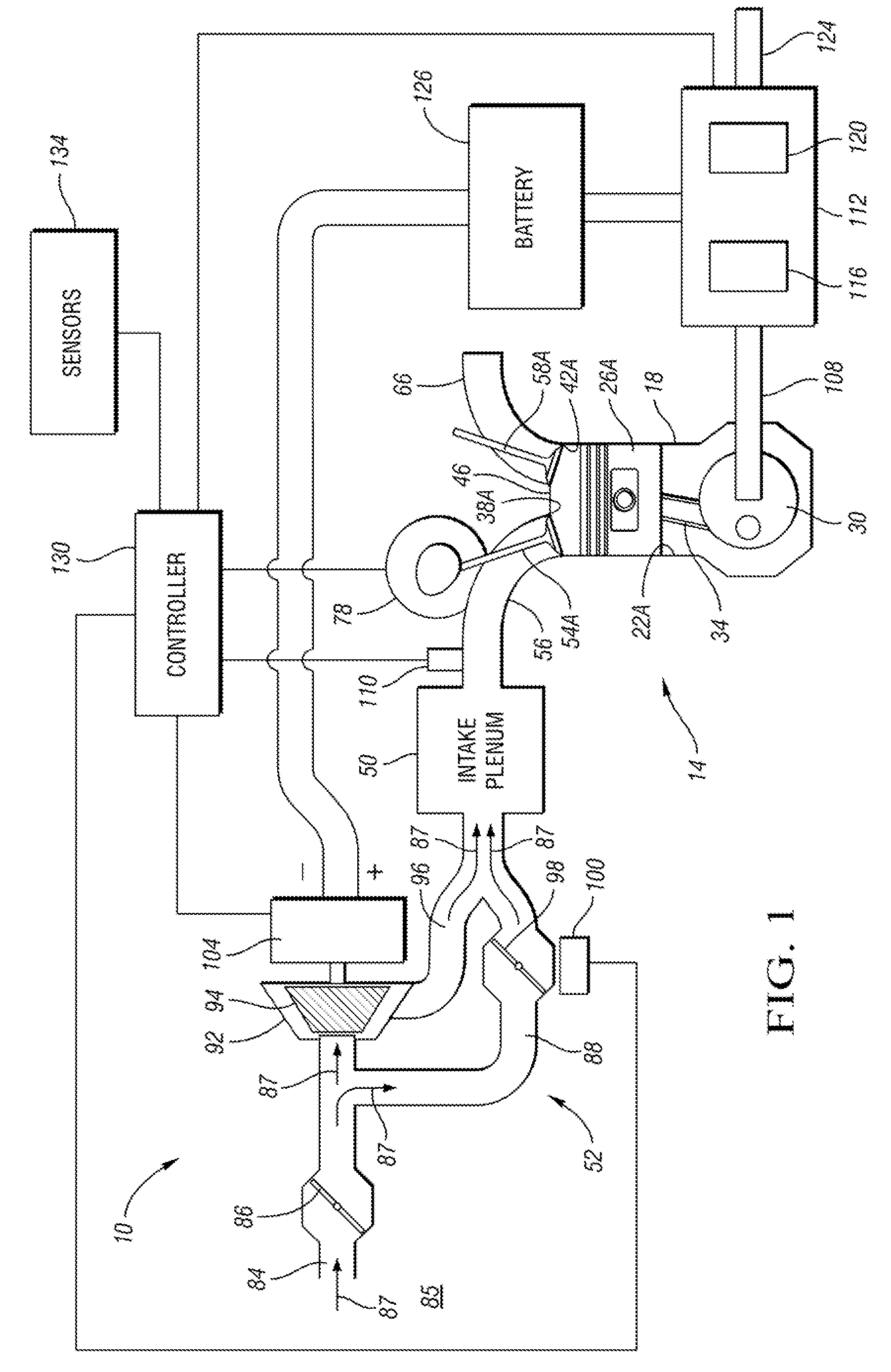

Method and apparatus to control a transition between HCCI and SI combustion in a direct-injection gasoline engine

InactiveUS20070272202A1Increased torque outputValve arrangementsElectrical controlOperating pointGasoline

A method to operate a multi-cylinder direct-injection engine in one of a controlled auto-ignition and a spark-ignition combustion mode is described. Engine operation and an operator torque request are monitored. Fuel delivery to a portion of the cylinders is selectively deactivated and torque output from non-deactivated cylinders is selectively increased to achieve the operator torque request when the monitored engine operation is above a predetermined threshold. An engine operating point at which an engine load demand exceeds an operating capability of the engine in a stoichiometric HCCI mode is identified. The engine is selectively operated in an unthrottled spark-ignition mode with at least one cylinder unfueled and torque output from the remaining cylinders is selectively increased.

Owner:GM GLOBAL TECH OPERATIONS LLC

Progressing cavity stator including at least one cast longitudinal section

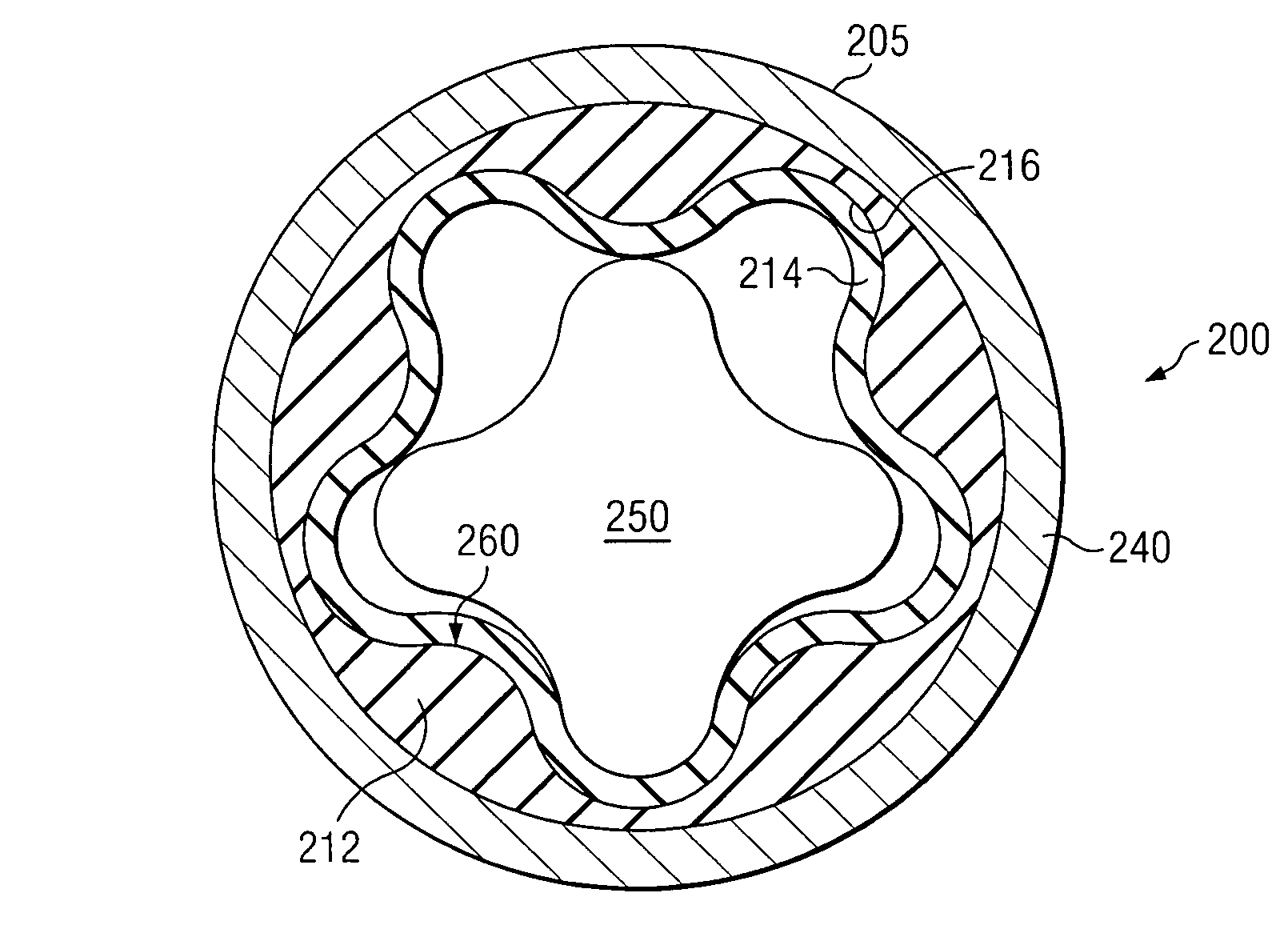

InactiveUS20060182644A1Prevent rotationIncreased torque outputOscillating piston enginesEngine of intermeshing engagement typeElastomerHigh torque

A progressing cavity stator and a method for fabricating such a stator are disclosed. Exemplary embodiments of the progressing cavity stator include a plurality of rigid longitudinal stator sections concatenated end-to-end in a stator tube. The stator sections are rotationally aligned so that each of the internal lobes extends in a substantially continuous helix from one end of the stator to the other. The stator further includes an elastomer liner deployed on an inner surface of the concatenated stator sections. Exemplary embodiments of this invention include a comparatively rigid stator having high torque output and are relatively simple and inexpensive to manufacture as compared to prior art rigid stators.

Owner:SMITH INT INC

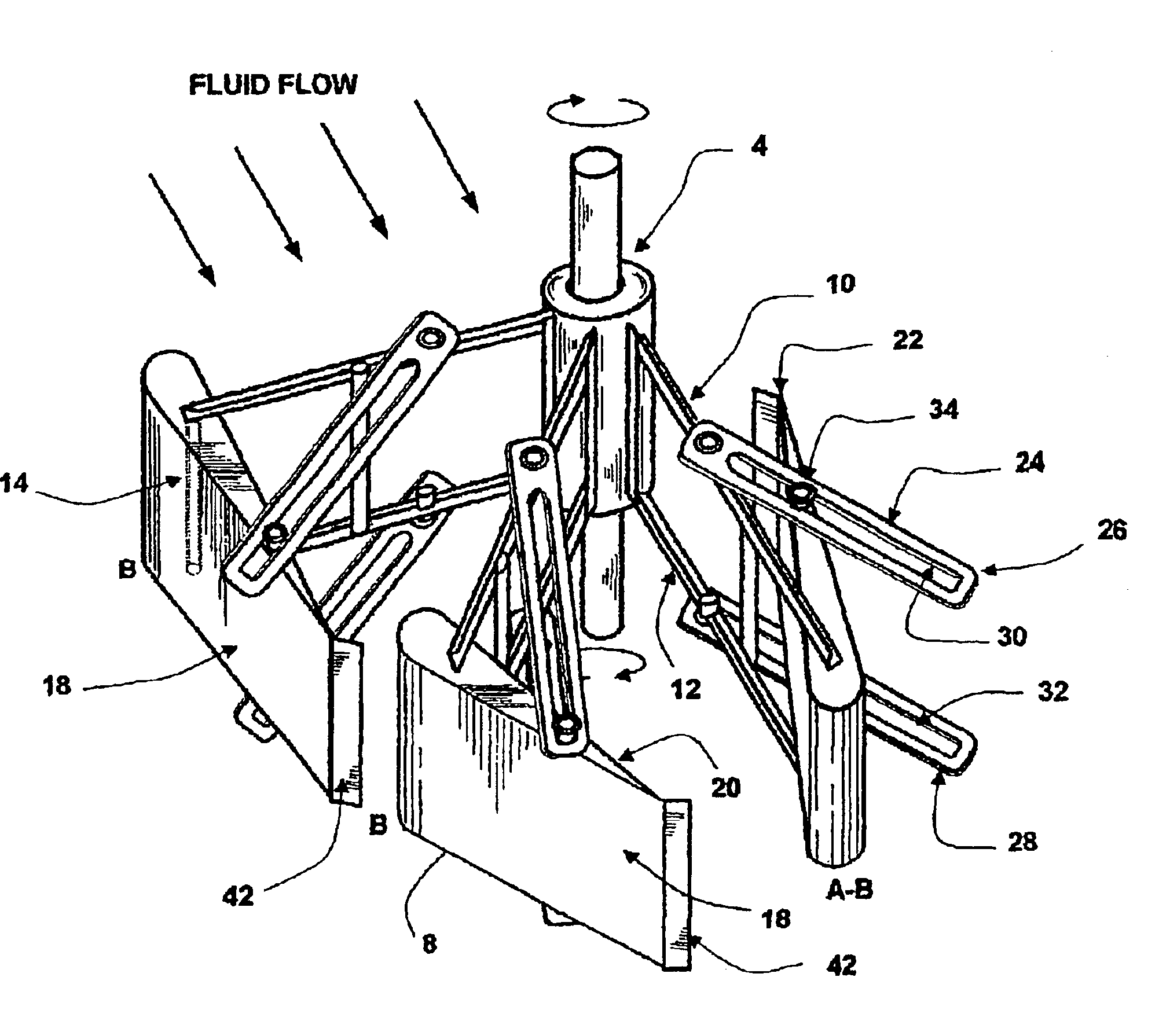

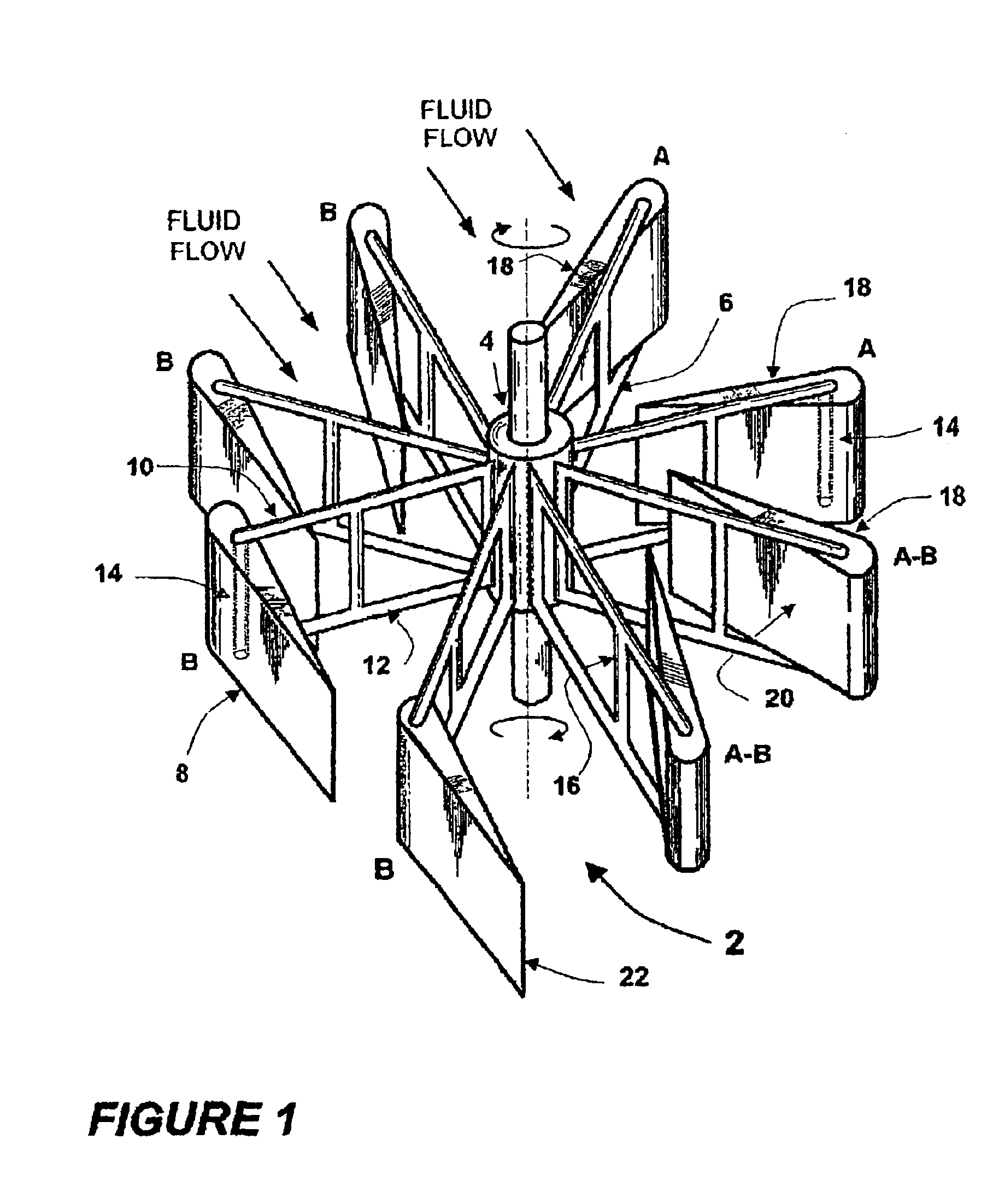

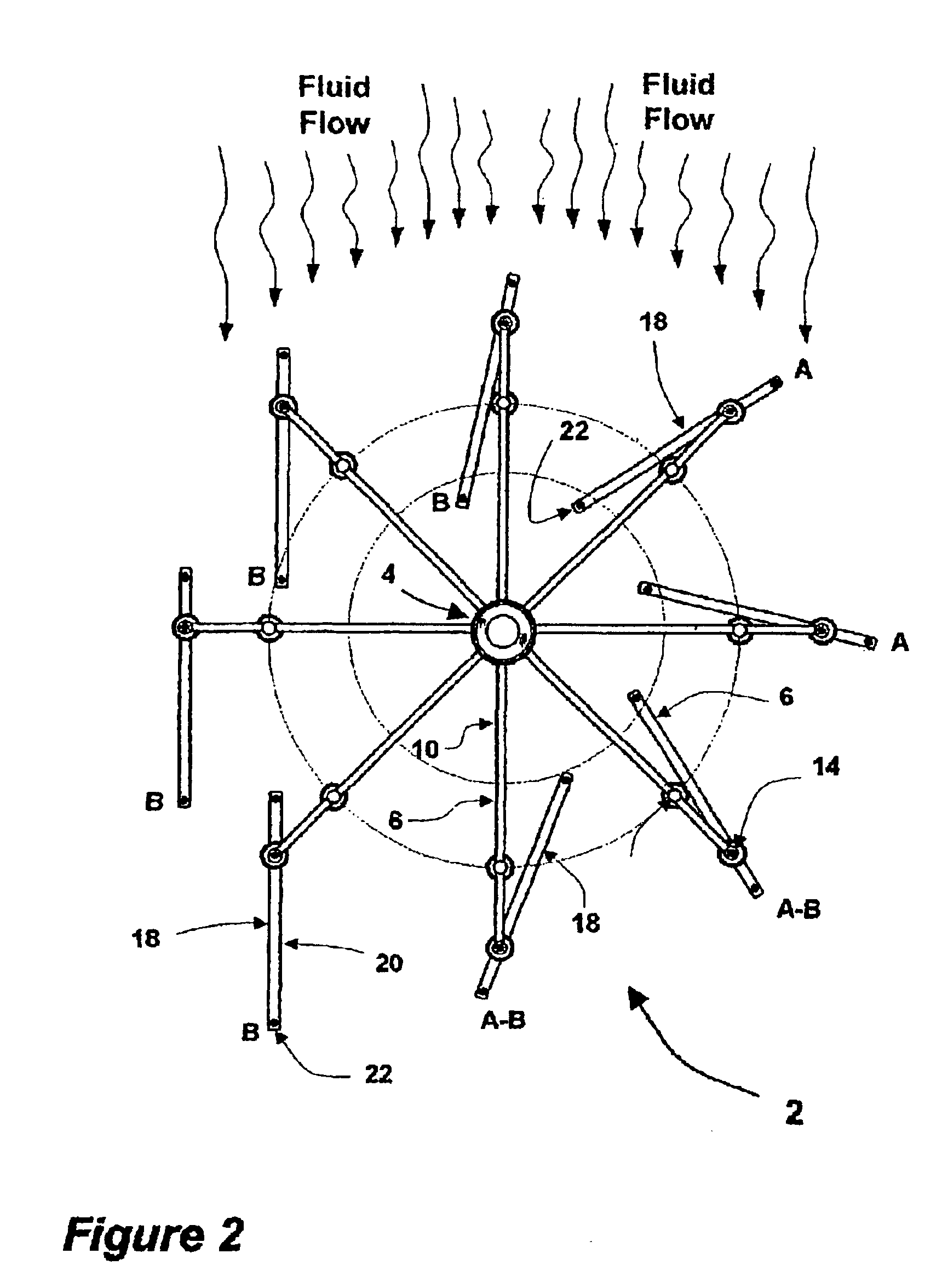

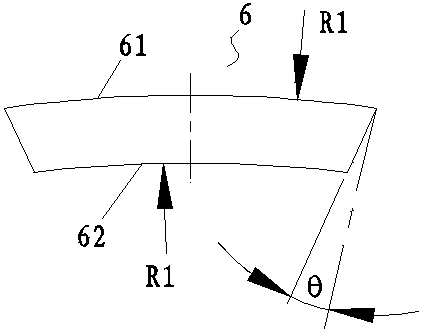

Vertical axis wind turbine

InactiveUS7083382B2Reduce resistanceReduces the drag on the prime moverPropellersPump componentsRotational axisVertical axis wind turbine

The present invention provides a prime mover (2) for harnessing energy from a flow of fluid, the prime mover (2) comprising a shaft (4) having a rotational axis, arranged to be rotatably mounted to a substructure, the shaft (4) comprising at leas one arm (6) extending radially from the shaft (4), the or each arm (6) comprising at least one blade (8) wherein the or each blade (8) is oriented such that flow action on the blade (8) effects rotation of the shaft (4), characterized in that the or each blade (8) is movably mounted on an arm (6) and wherein each blade (8) is movable from a first position, having a first drag, to a second position, having a second drag, wherein the first drag is higher than the second drag. The prime mover (2) of the invention provides substantially reduced drag in a flow of fluid, and an increased torque output, compared to prior art prime movers.

Owner:US ISIDRO U

Braze or solder reinforced moineu stator

InactiveUS20080304992A1Extended service lifeImprove efficiencyOscillating piston enginesEngine of intermeshing engagement typeElastomerState of art

A Moineau style stator includes a helical reinforcement component that provides an internal helical cavity. A resilient liner is deployed on an inner surface of the helical reinforcement component. The helical reinforcement component includes a solder or braze material and is typically metallurgically bonded to an inner wall of a stator tube. In exemplary embodiments, the helical reinforcement component includes a composite mixture of solder and aggregate. Exemplary embodiments of this invention address the heat build up and subsequent elastomer breakdown in the lobes of prior arts stators by providing a helical reinforcement component. Solder reinforced stators tend to be less expensive to fabricate than reinforced stators of the prior art.

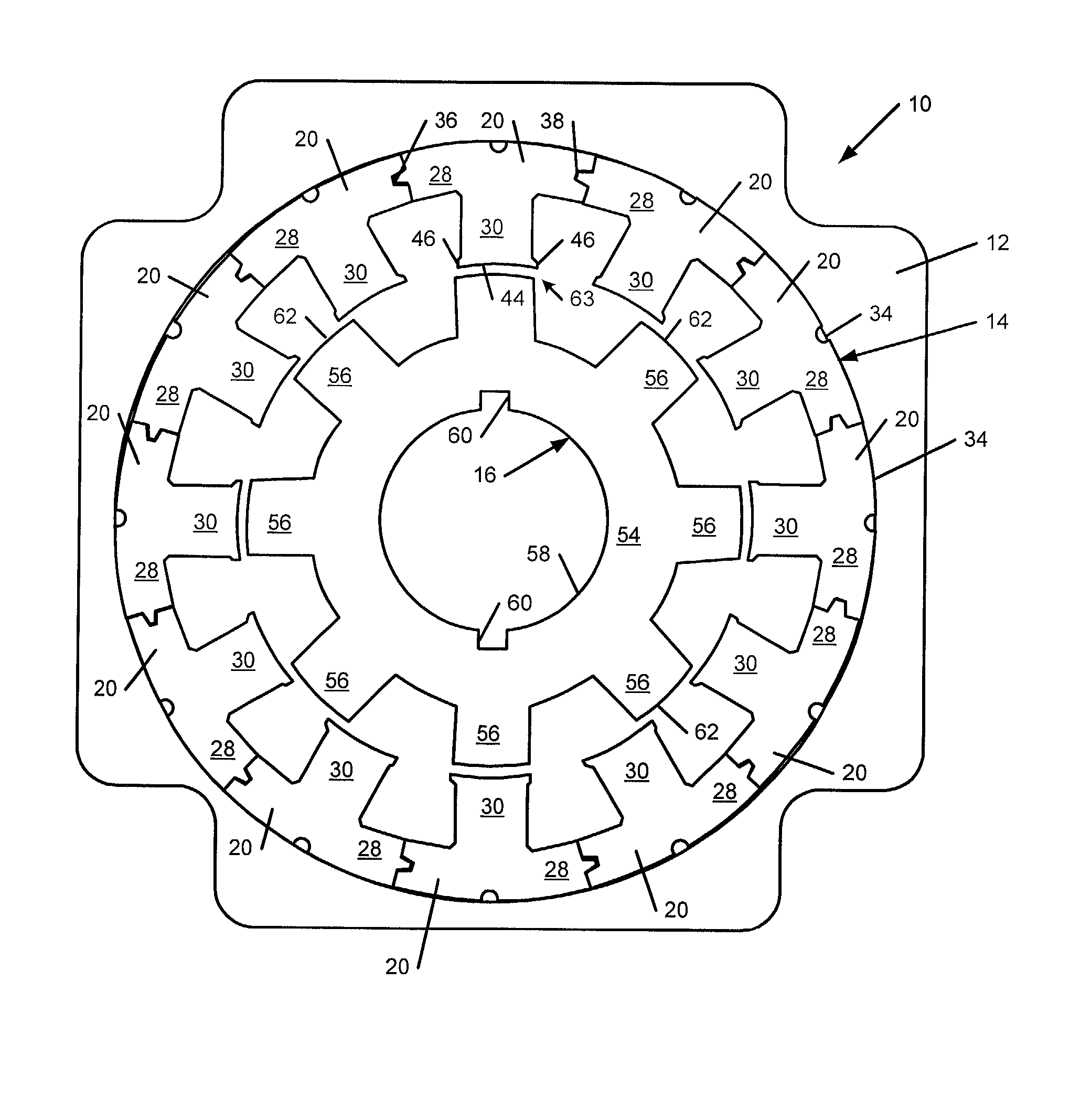

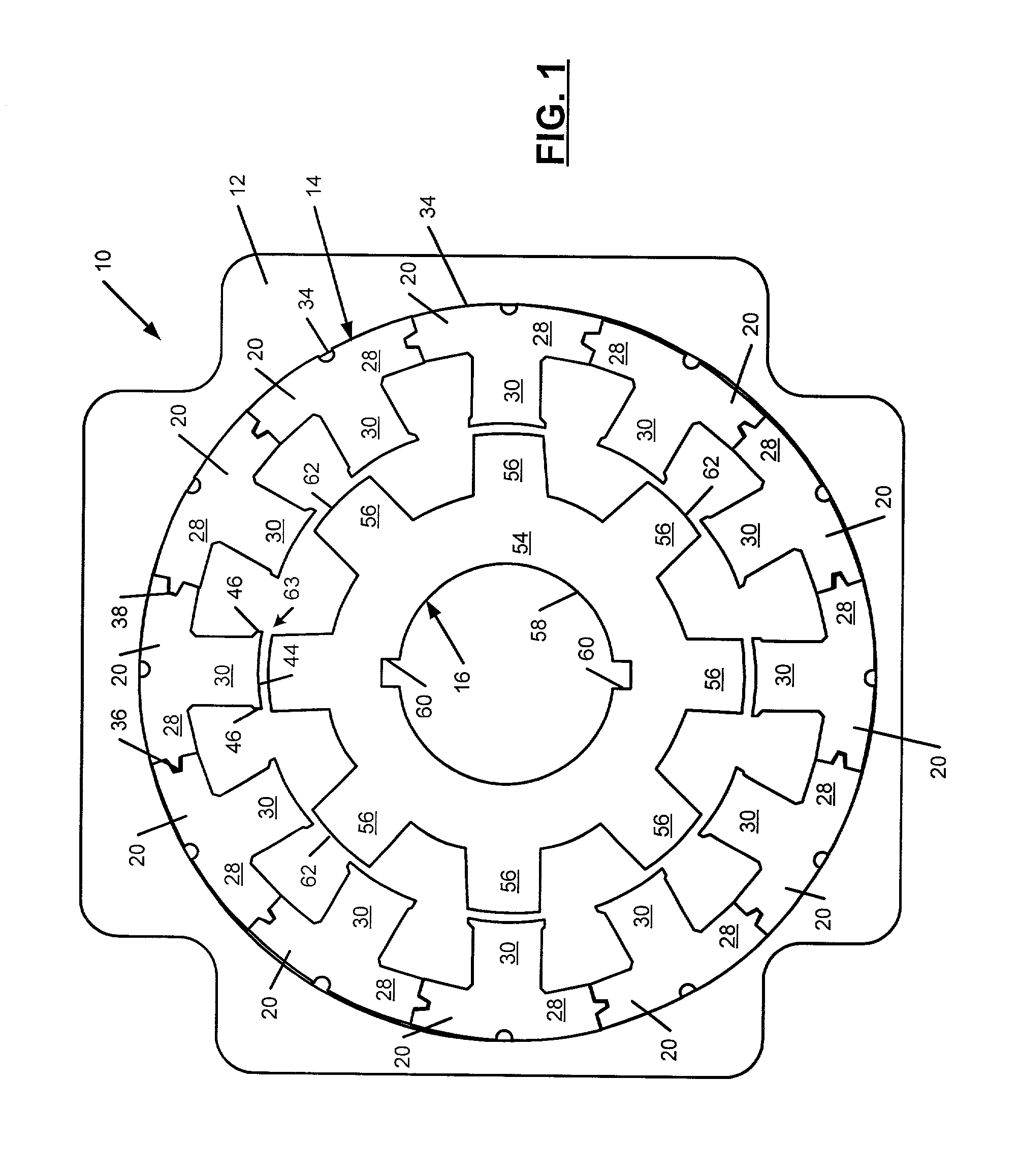

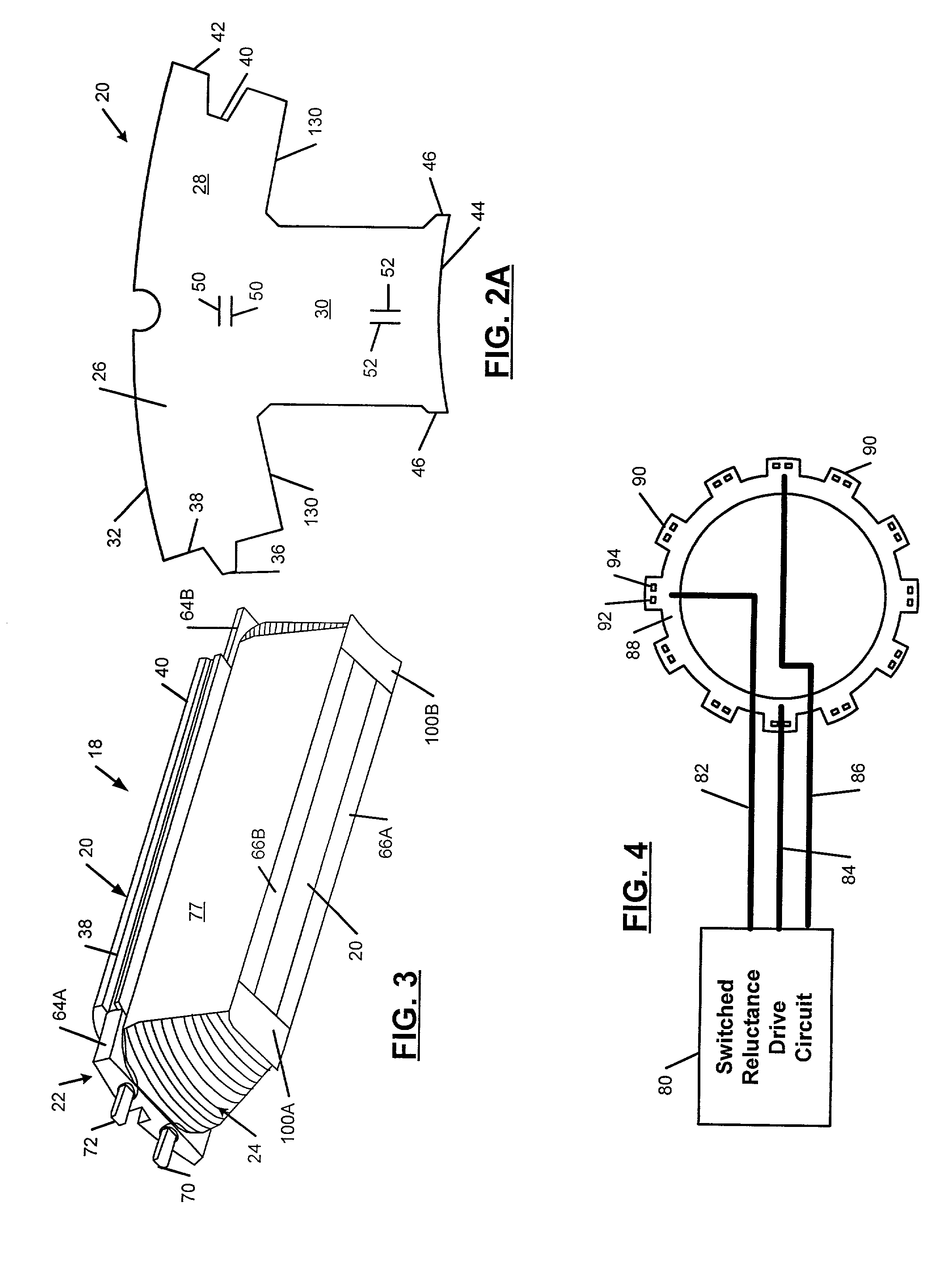

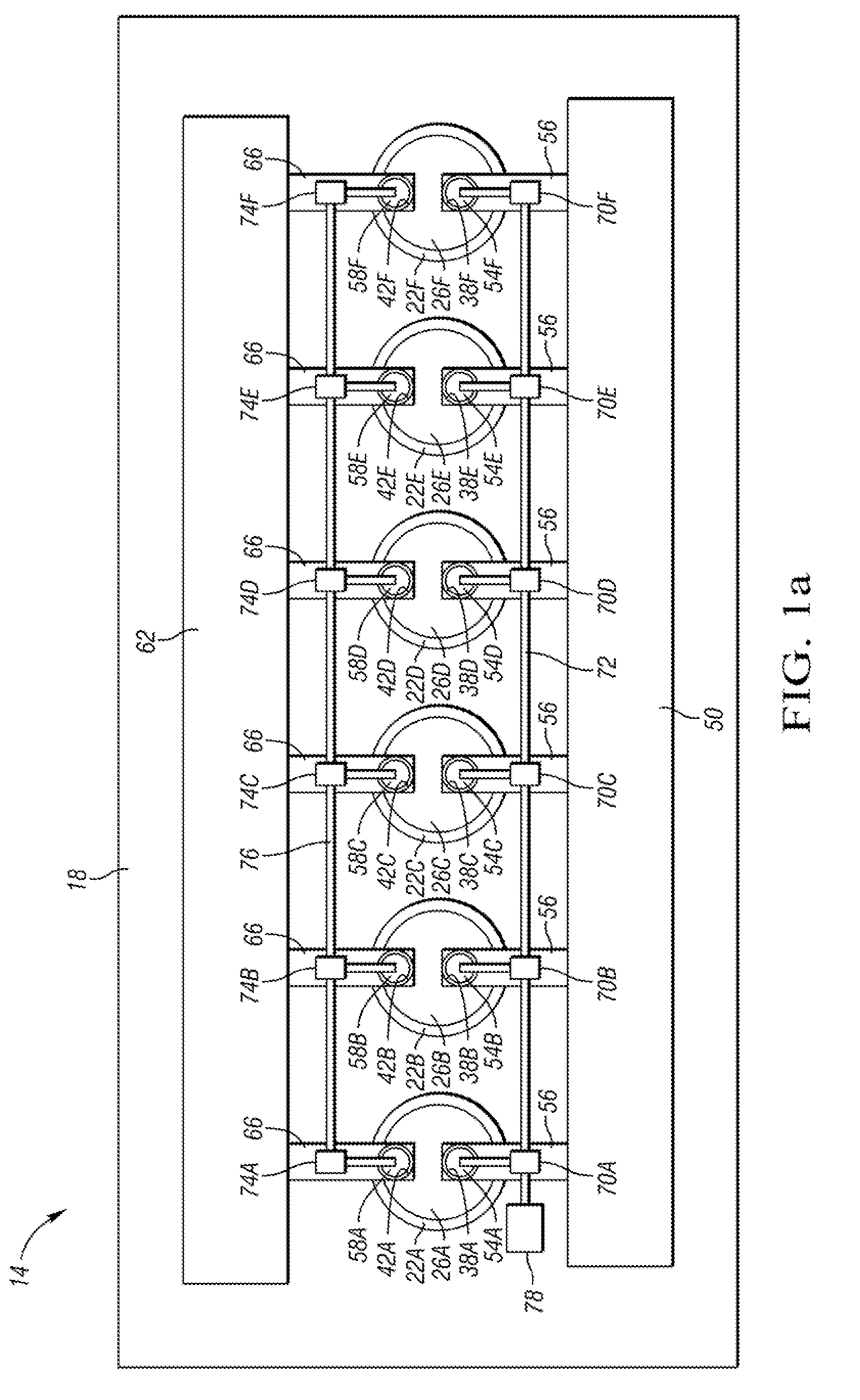

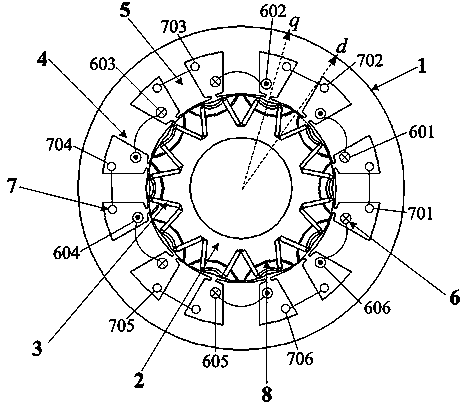

Segmented stator switched reluctance machine

InactiveUS20020125782A1Facilitate the improvement of precisionReduce usageElectronic commutation motor controlMotor/generator/converter stoppersConductor CoilMechanical engineering

A switched reluctance machine includes a stator with a plurality of circumferentially-spaced stator segment assemblies that include salient stator poles and inter-polar stator slots. Each of the stator segment assemblies includes a stack of stator plates forming a stator segment core, an end cap assembly, and winding wire wound around the stator segment core and the end cap assembly. The rotor defines a plurality of rotor poles. The rotor tends to rotate relative to the stator to maximize the inductance of an energized winding. A drive circuit energizes the winding wire around the stator segment assemblies based on a rotational position of the rotor. Each stator plate includes a first radially outer rim section and a tooth section that extends radially inwardly from a first center portion of the first radially outer rim section.

Owner:NIDEC MOTOR CORP

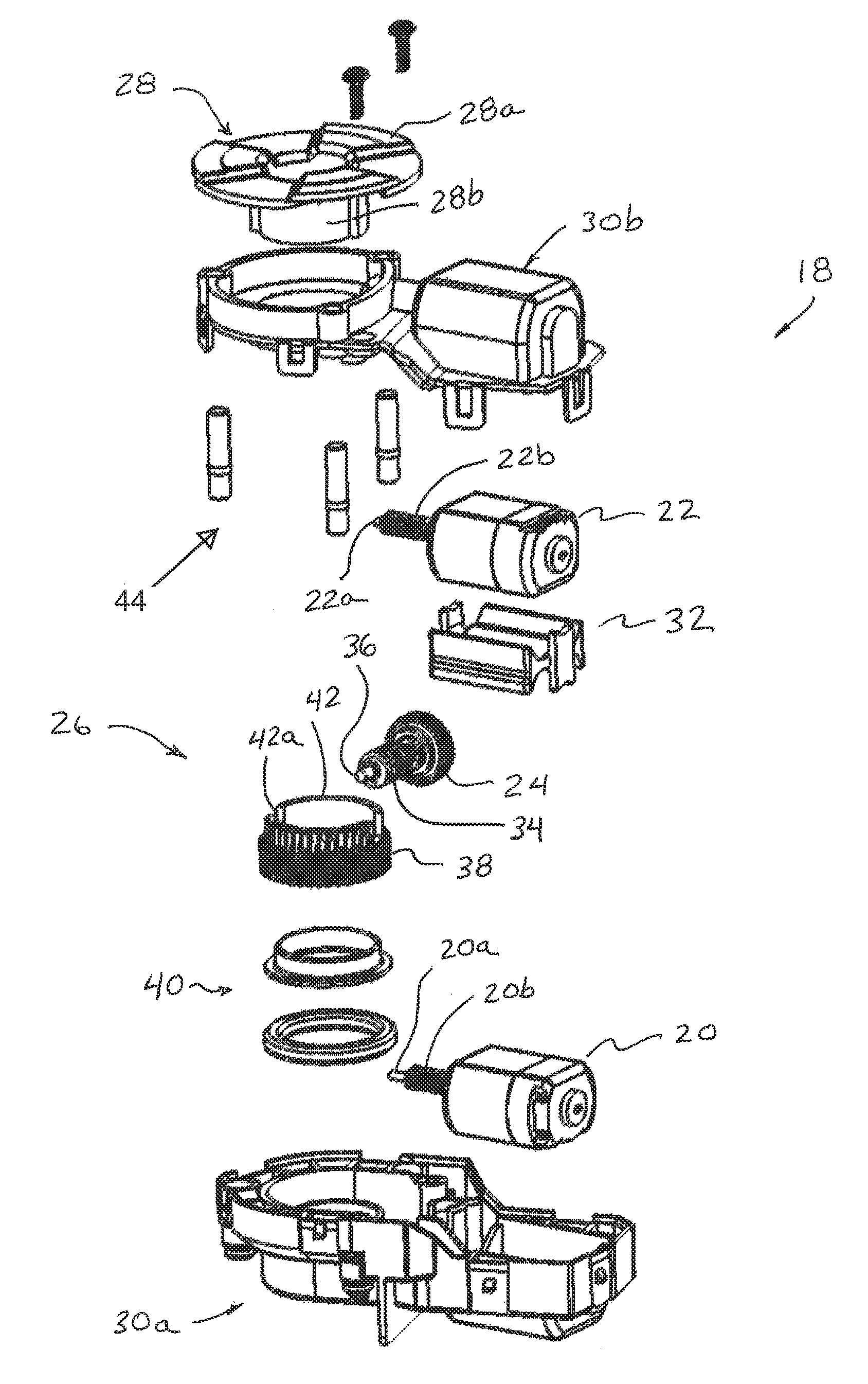

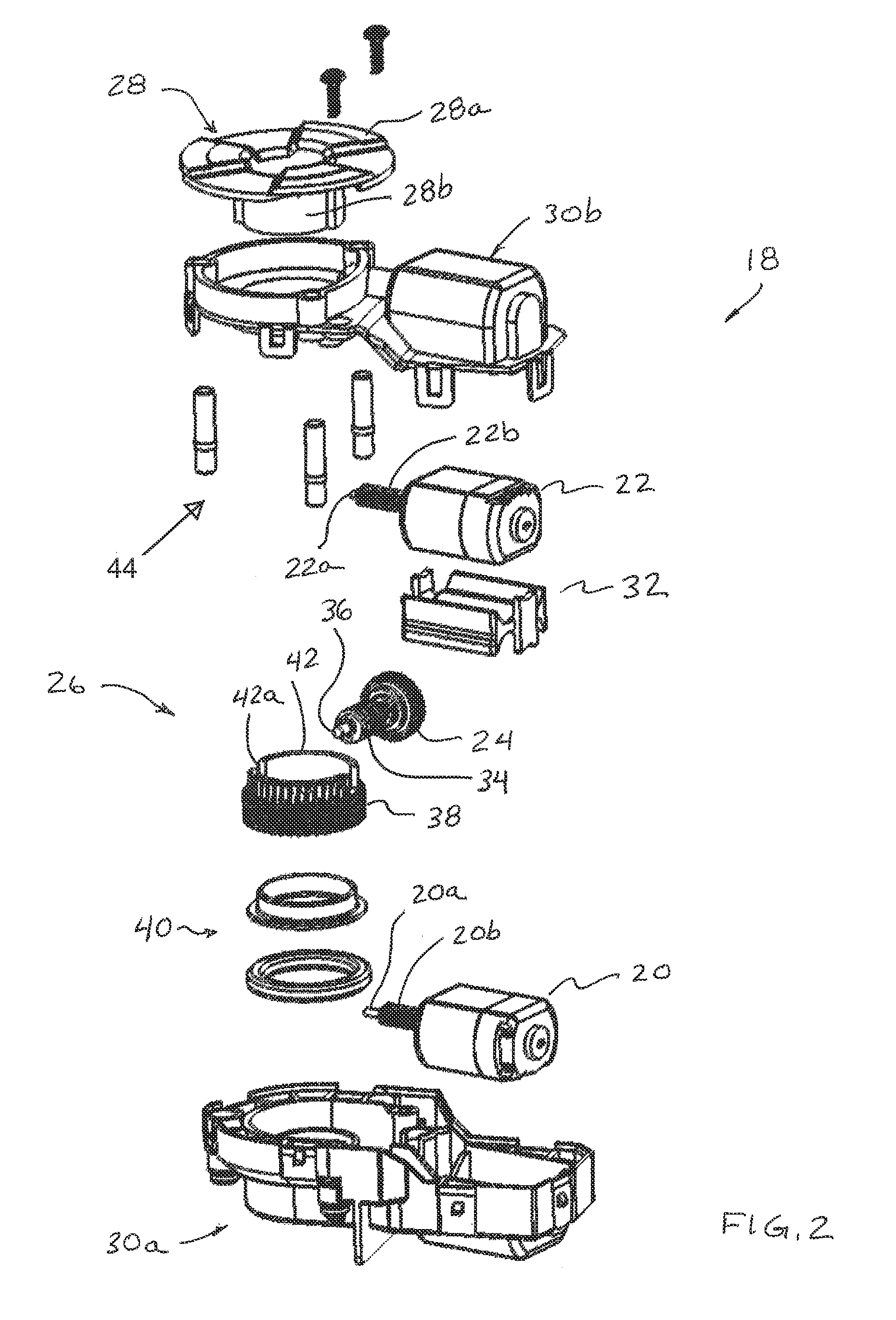

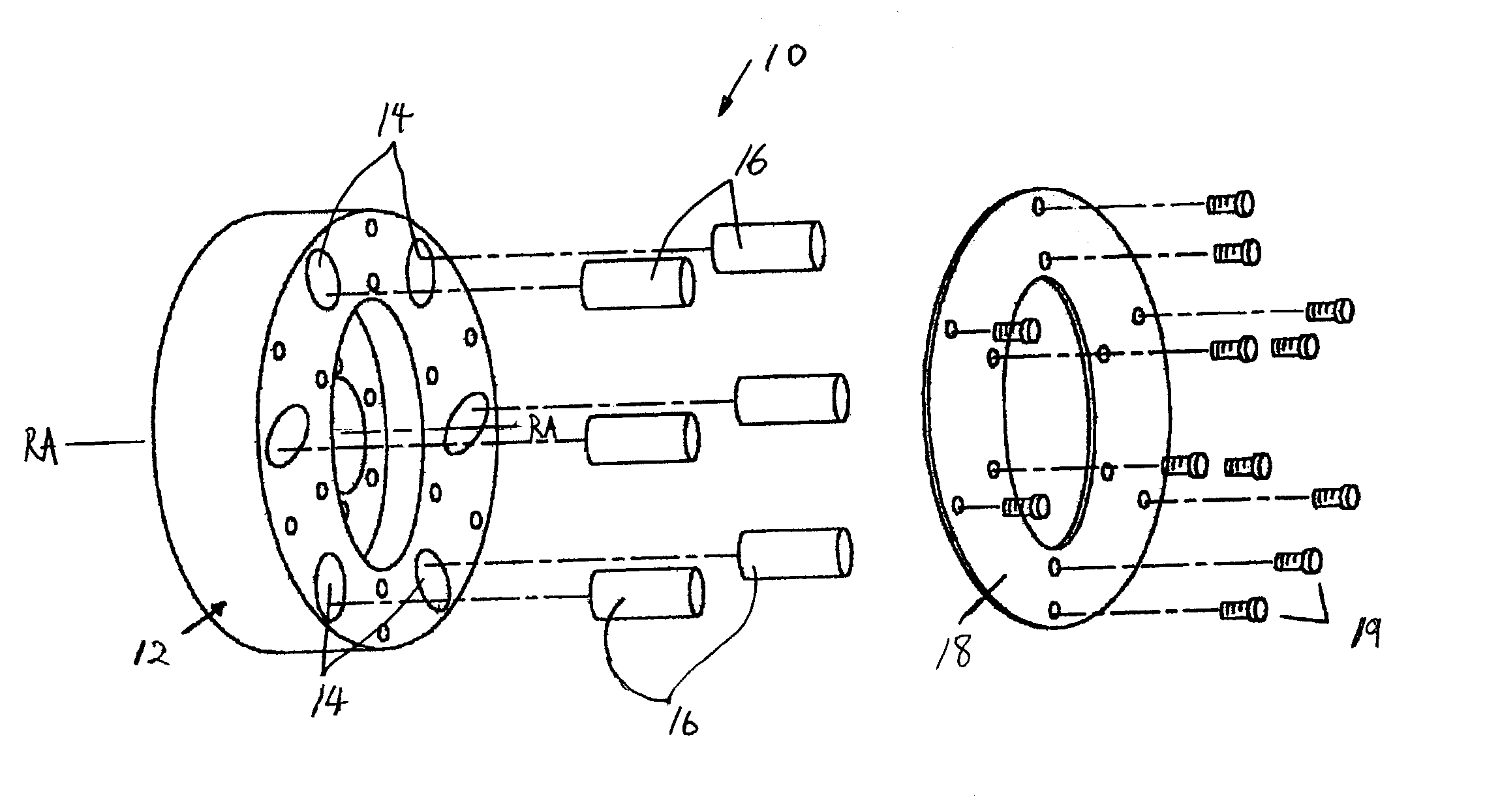

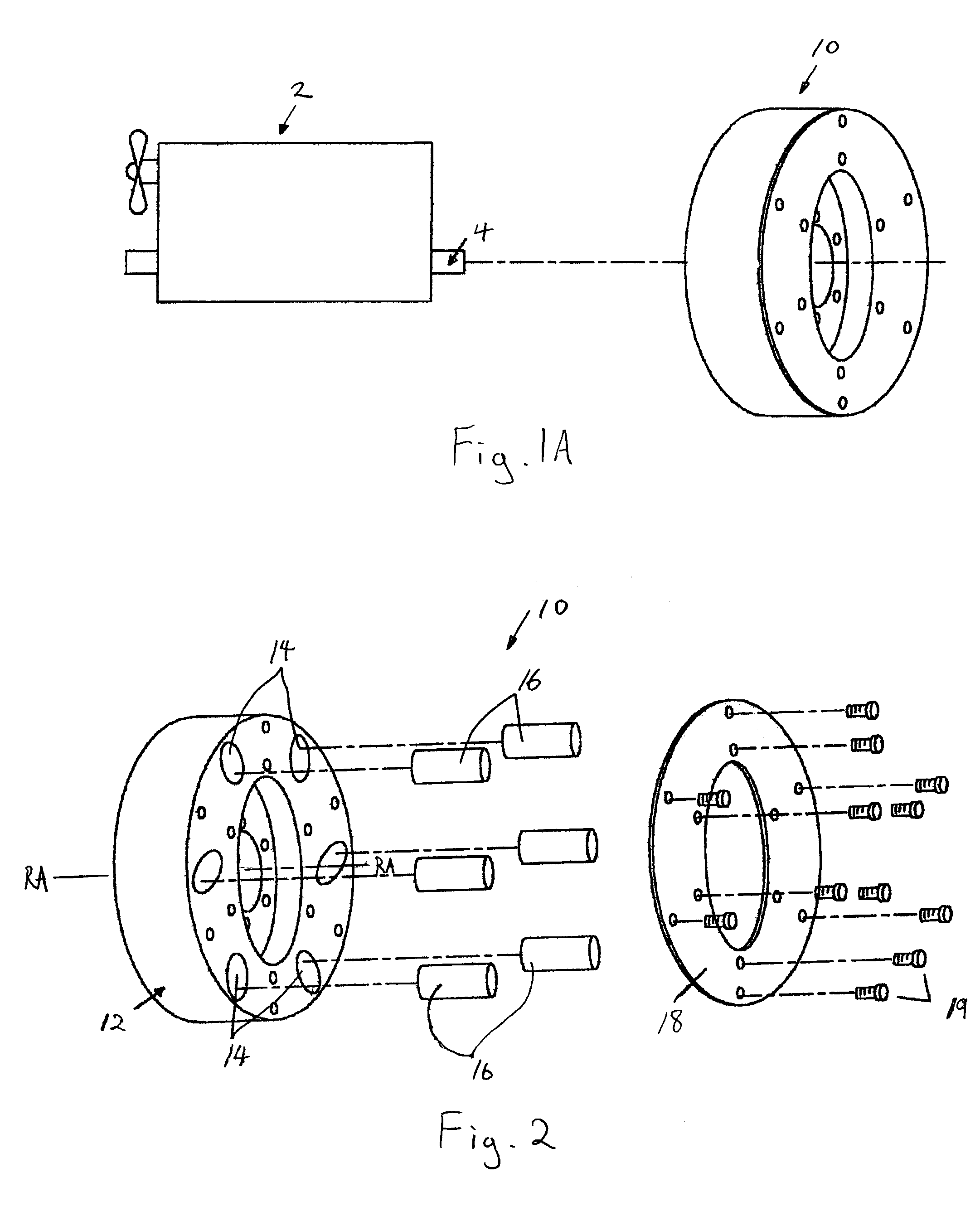

Exterior mirror assembly with actuator

ActiveUS9067541B2Increase output torqueIncreased torque outputMountingsOptical viewingGear systemActuator

An exterior rearview mirror assembly for a vehicle includes a mounting portion mountable at a side of a vehicle, a mirror head portion adjustably mounted at the mounting portion, and a reflective element at the mirror head portion. An actuator is operable to impart pivotal movement of the mirror head portion relative to the mounting portion and about a generally vertical pivot axis to pivotally adjust the mirror head portion relative to the side of the vehicle at which the mounting portion is mounted. The actuator comprises at least two motors and the motors are operable in tandem to cooperatively rotatably drive a common gear of a gear system to pivot the mirror head portion relative to the mounting portion.

Owner:MAGNA MIRRORS OF AMERICA INC

Moineu stator including a skeletal reinforcement

ActiveUS20080304991A1Extended service lifeNot easy to layerOscillating piston enginesEngine of intermeshing engagement typeElastomerInterference fit

A Moineau style stator includes a helical cavity component having reinforced helical lobes. The lobes are reinforced with a three-dimensional network of physically bonded aggregate particles. The network of bonded aggregate provides a porous skeletal-like structural reinforcement. Pore volume between the bonded aggregate particles may optionally be partially or substantially filled with an elastomer. An elastomer liner is typically deployed on an inner surface of the helical lobes to promote a rotational interference fit with a rotor.

Owner:SMITH INT INC

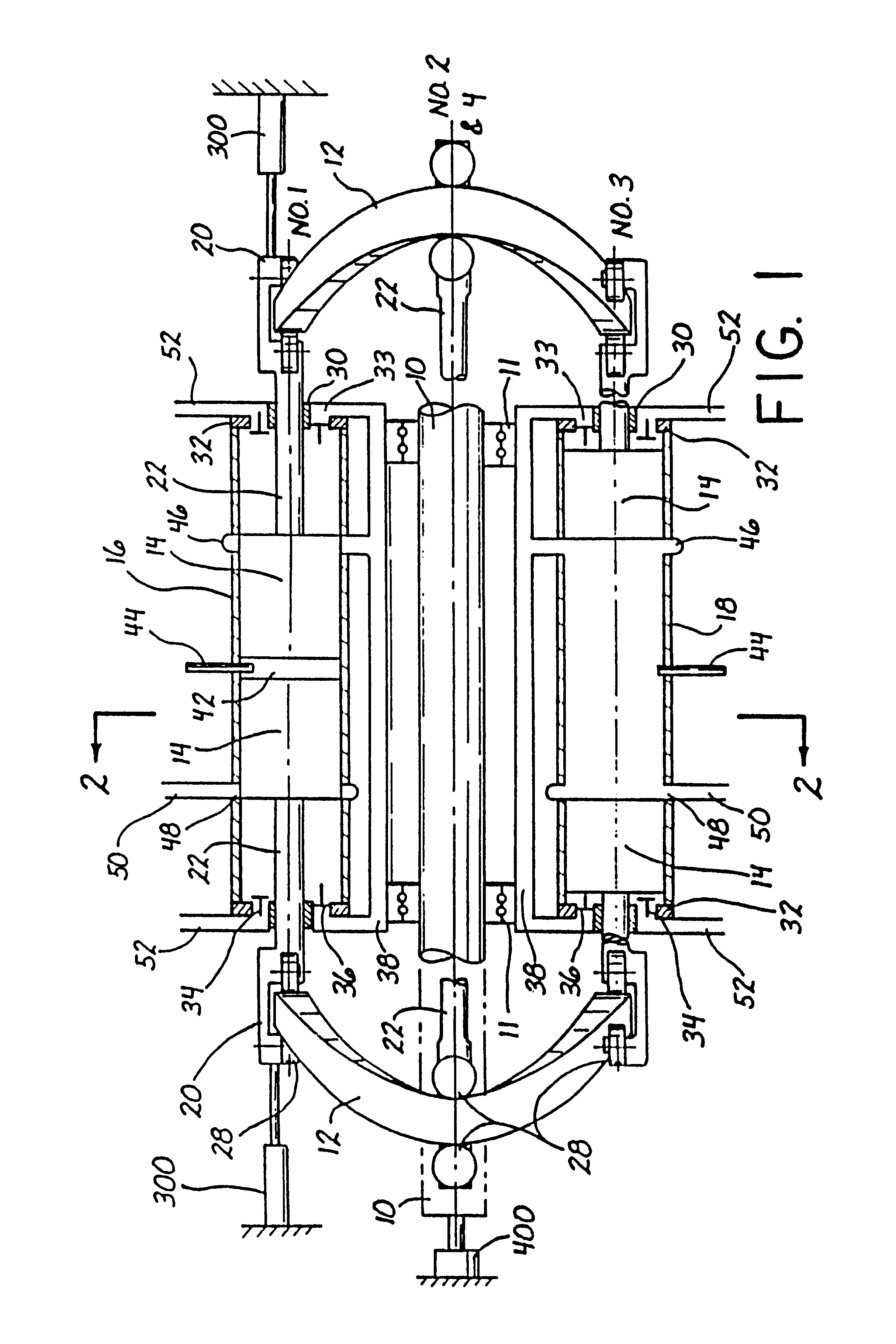

Adiabatic, two-stroke cycle engine having novel scavenge compressor arrangement

InactiveUS6279520B1Improve thermal efficiencyReduce heat lossReciprocating piston enginesAir compressionExhaust valve

An engine structure and mechanism that operates on various combustion processes in a two-stroke-cycle without supplemental cooling or lubrication comprises an axial assembly of cylindrical modules and twin, double-harmonic cams that operate with opposed pistons in each cylinder through fully captured rolling contact bearings. The opposed pistons are double-acting, performing a two-stroke engine power cycle on facing ends and induction and scavenge air compression on their outside ends, all within the same cylinder bore. The engine includes a novel compressor arrangement having an intake valve comprising a V-shaped double reed valve with an apex pointing toward the intake port and an exhaust valve having a V-shaped double reed valve with an apex pointing away from the exhaust port. The compressor arrangement may further include rectangular intake and exhaust ports, a rectangular piston rod and rectangular crosshead bearings.

Owner:LOWI JR ALVIN

Atkinson cycle powertrain

ActiveUS7765806B2Increased torque outputReduce power densityValve arrangementsInternal combustion piston enginesAtmospheric airAtkinson cycle

A powertrain includes an Atkinson cycle engine having at least one cylinder, a crankshaft, and an air intake system that provides selective fluid communication between the at least one cylinder and the atmosphere. A motor is in hybrid combination with the engine, and a compressor is configured to selectively pressurize air in the air intake system. The powertrain provides the fuel efficiency of an Atkinson cycle engine while compensating for the reduced torque output of an Atkinson cycle engine.

Owner:GM GLOBAL TECH OPERATIONS LLC

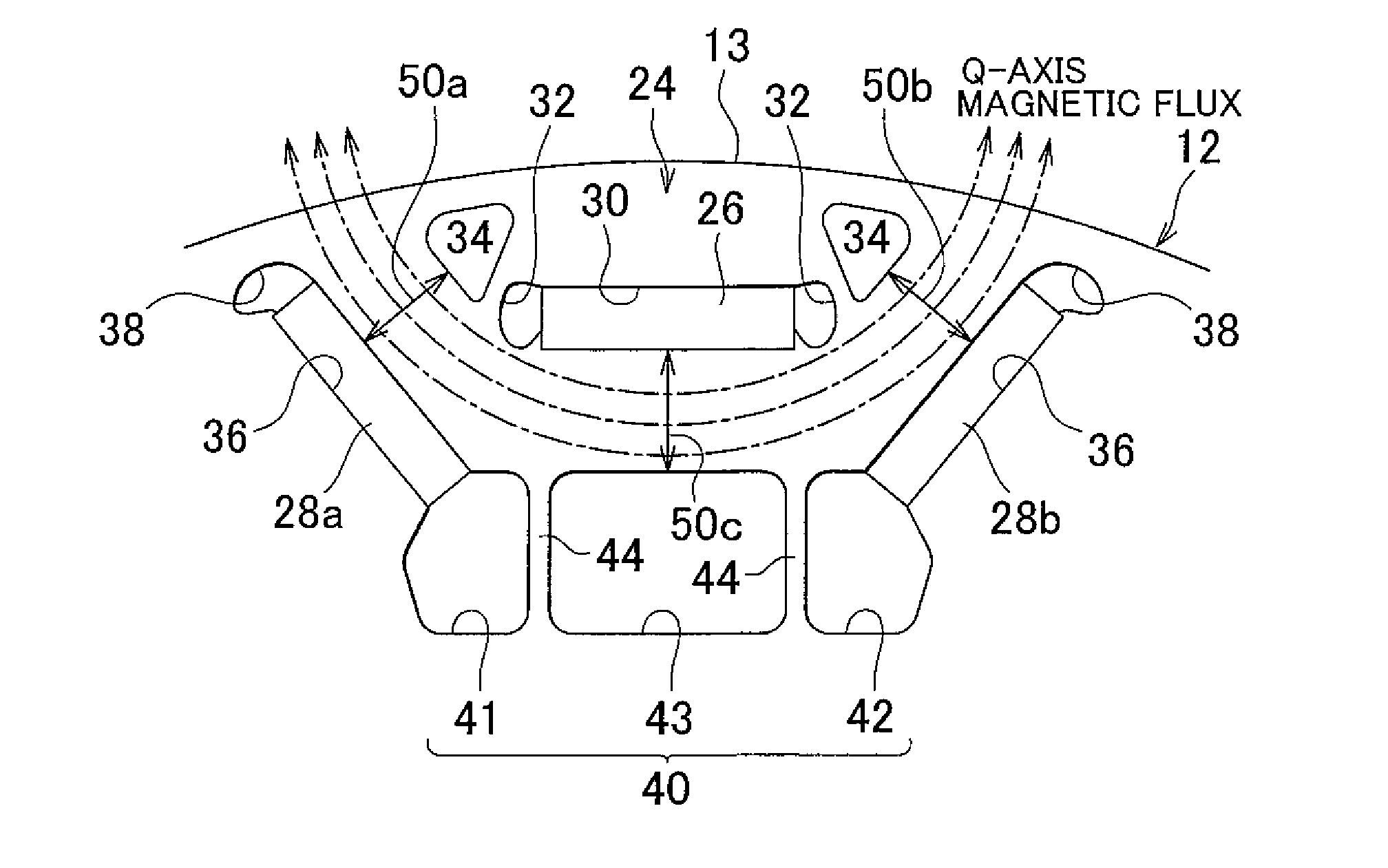

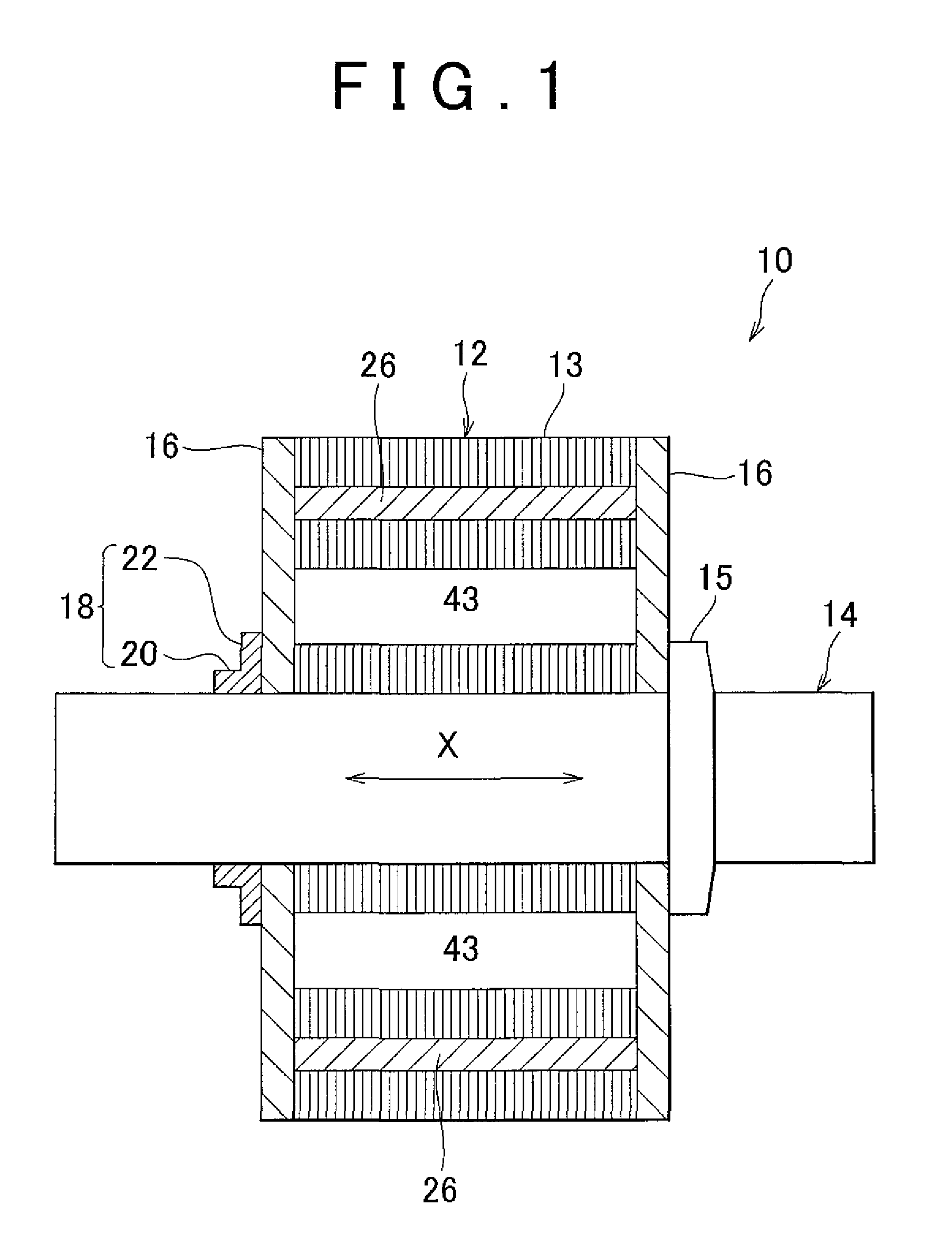

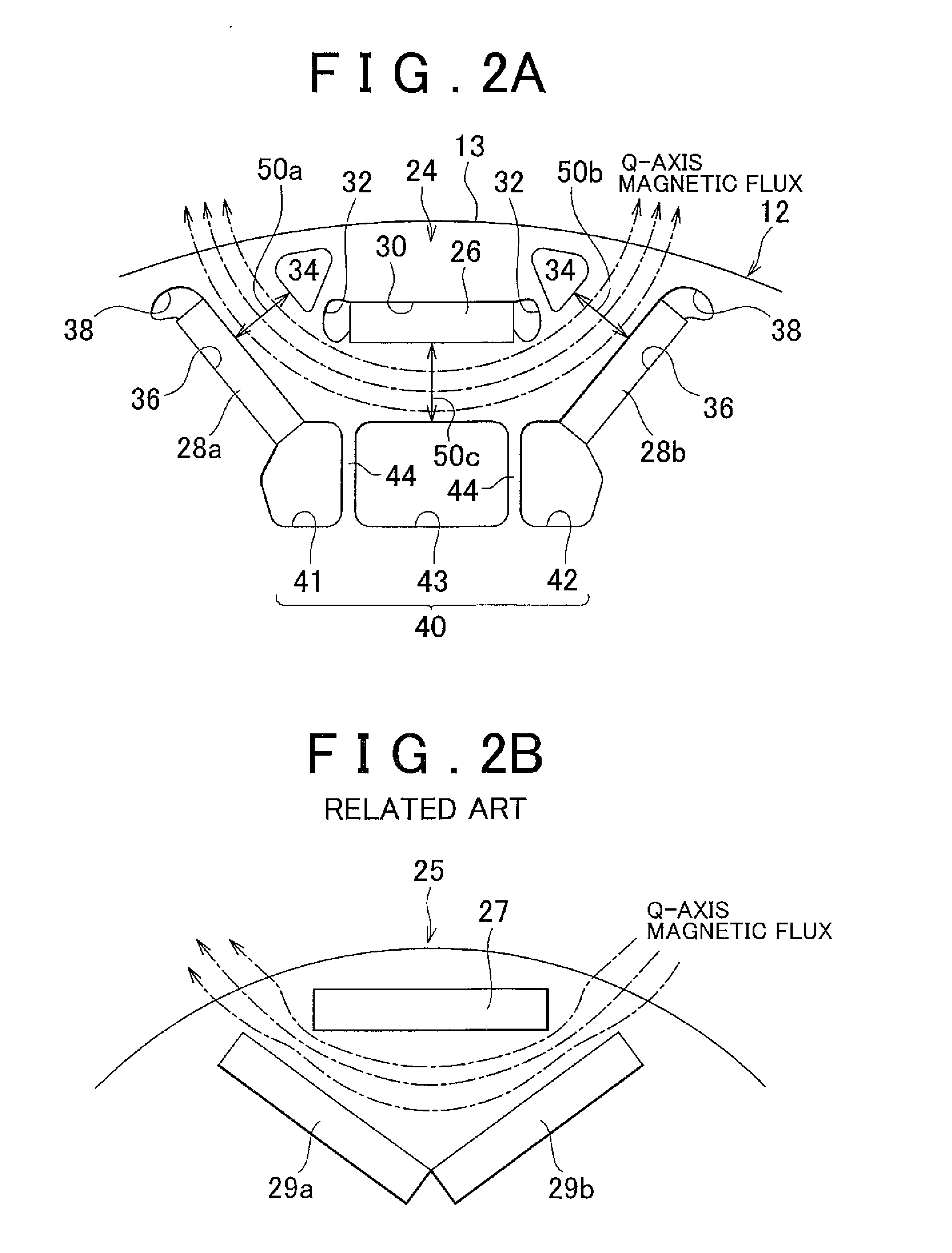

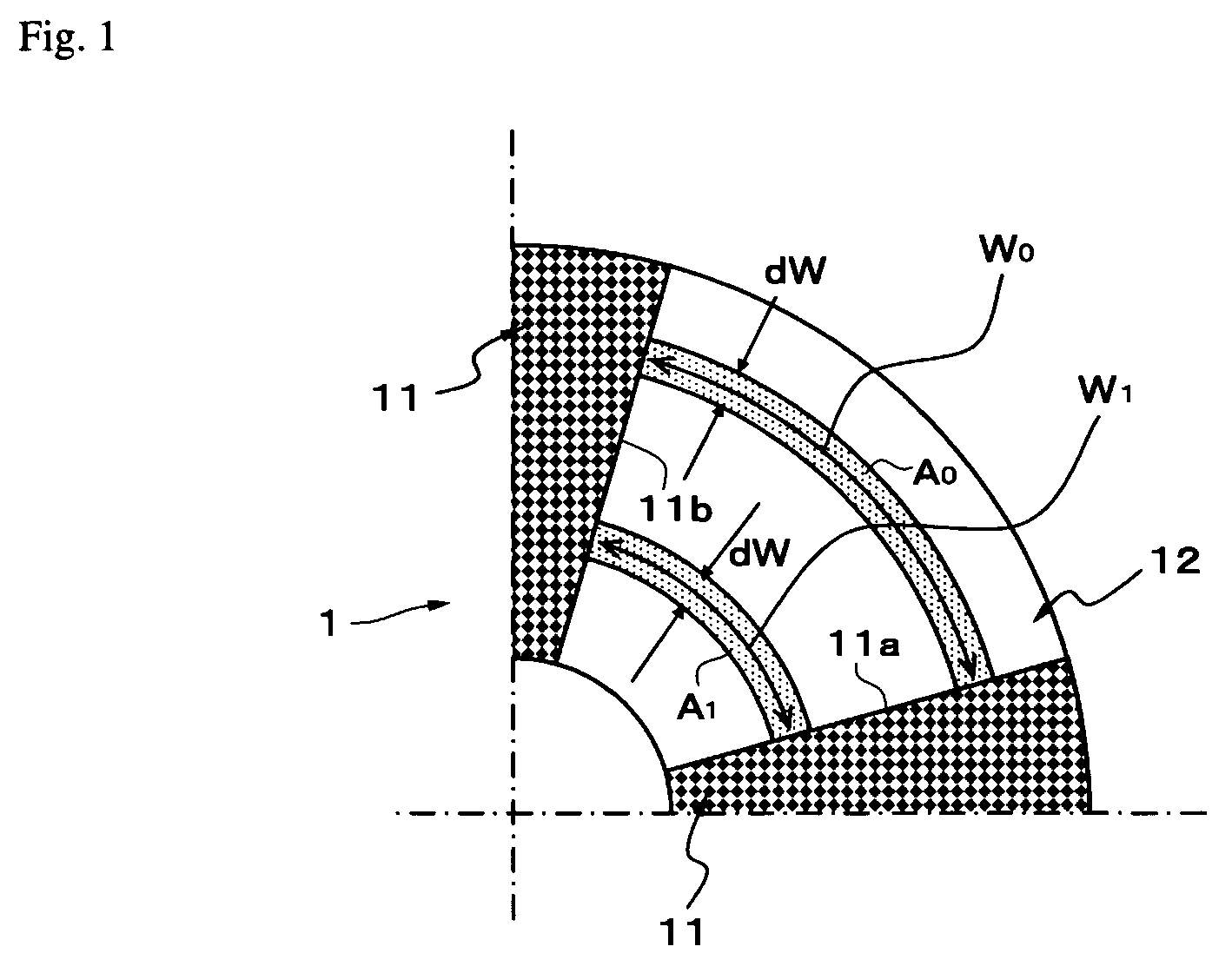

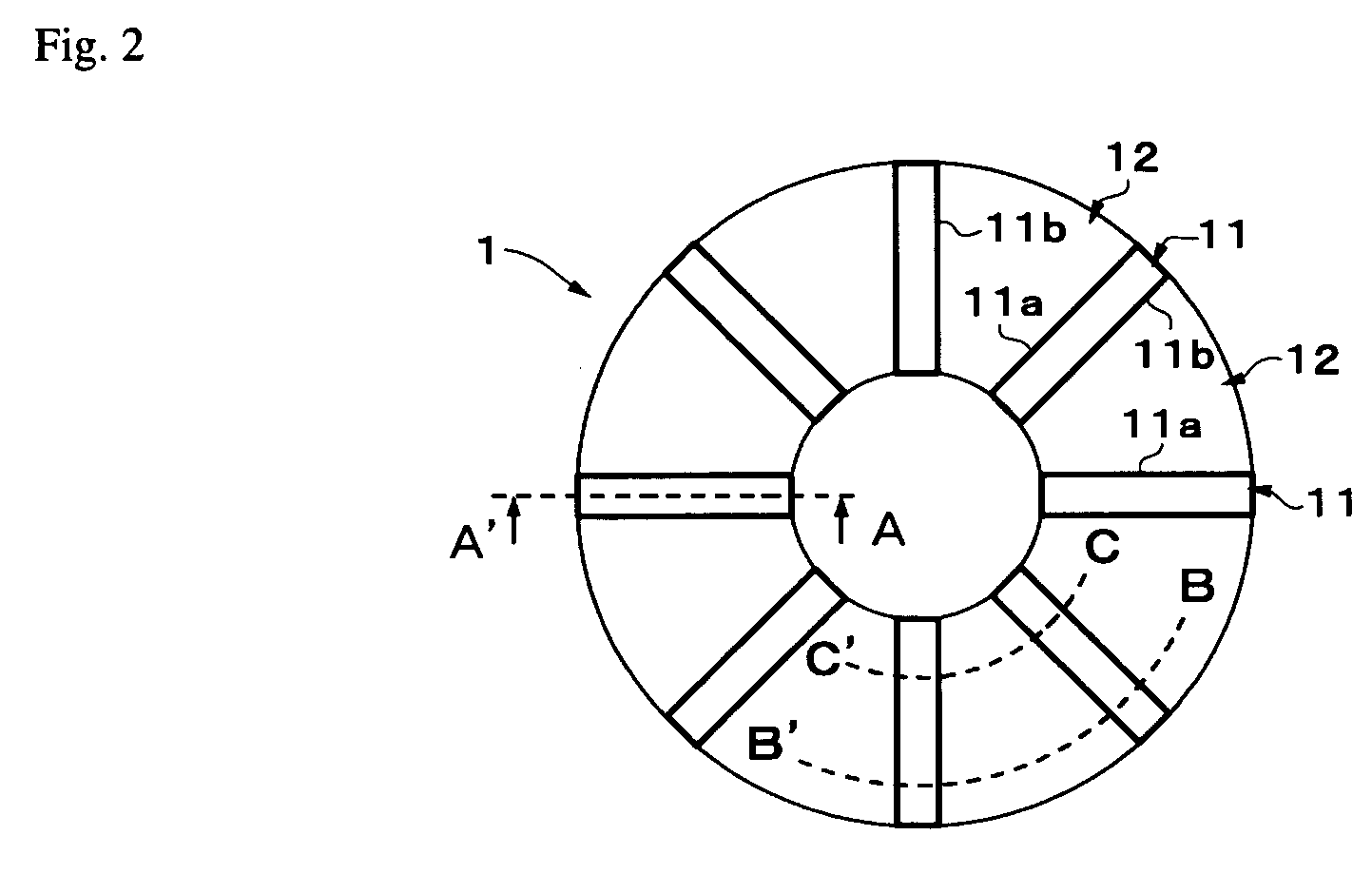

Rotor for electric rotating machine

InactiveUS20120200186A1Efficient implementationEasy to useMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic fluxMagnet

An iron rotor core includes a first permanent magnet in an outer peripheral portion of the iron rotor core, second permanent magnets on both circumferential sides of the first permanent magnet and arranged in a generally V-shaped configuration opening radially outward, and a first region provided opposite to the first permanent magnet radially inside the region between the second permanent magnets and having a low magnetic permeability. A q-axis magnetic flux path is formed in an iron core region among the first permanent magnet, the second permanent magnets and the first region, and a central portion thereof is formed between the first permanent magnet and the first region, and entrance / exit portions of the q-axis magnetic flux path formed between the second permanent magnets and second regions provided on both circumferential sides of the first permanent magnet and having a low magnetic permeability with generally the same width.

Owner:TOYOTA JIDOSHA KK +2

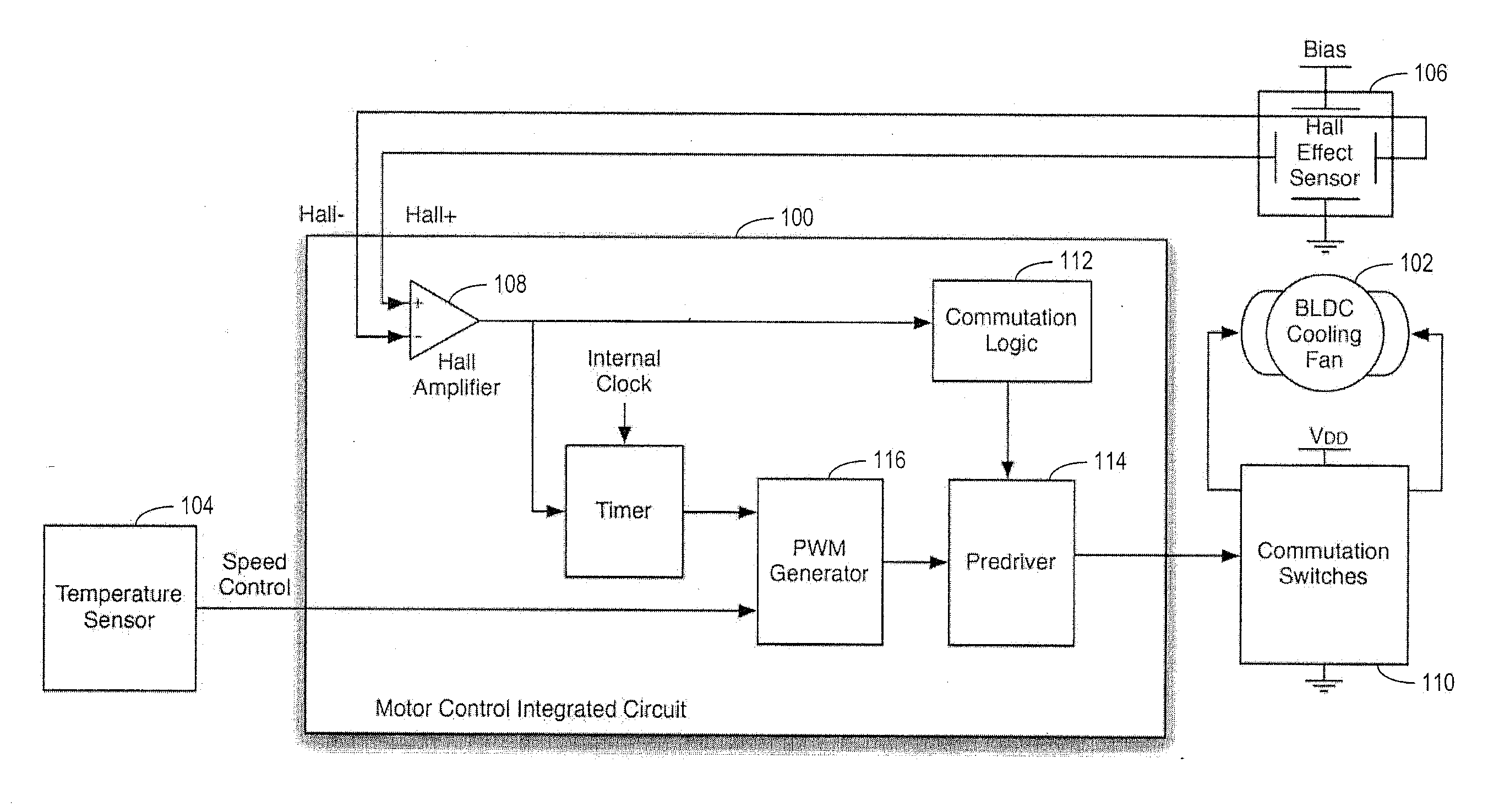

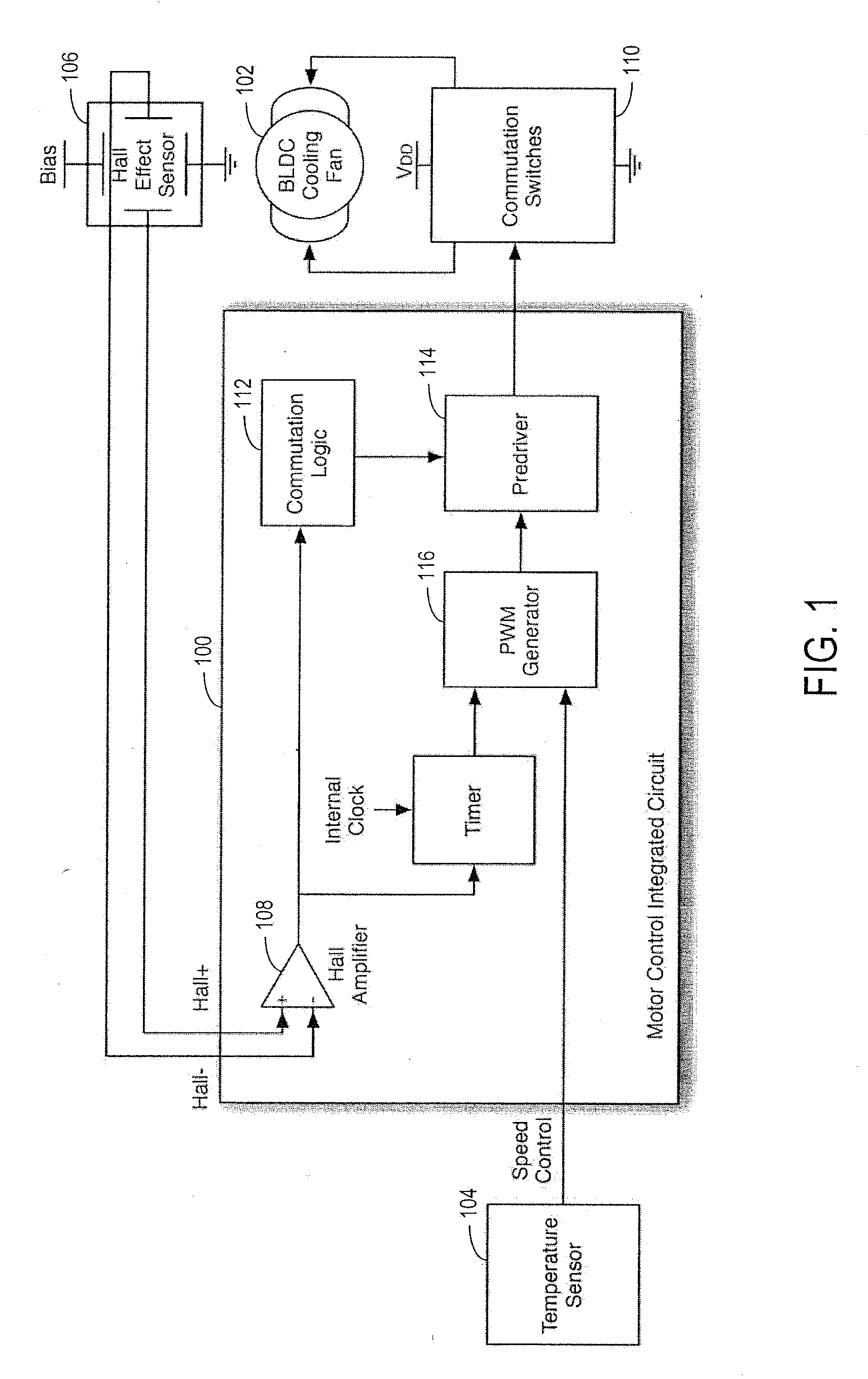

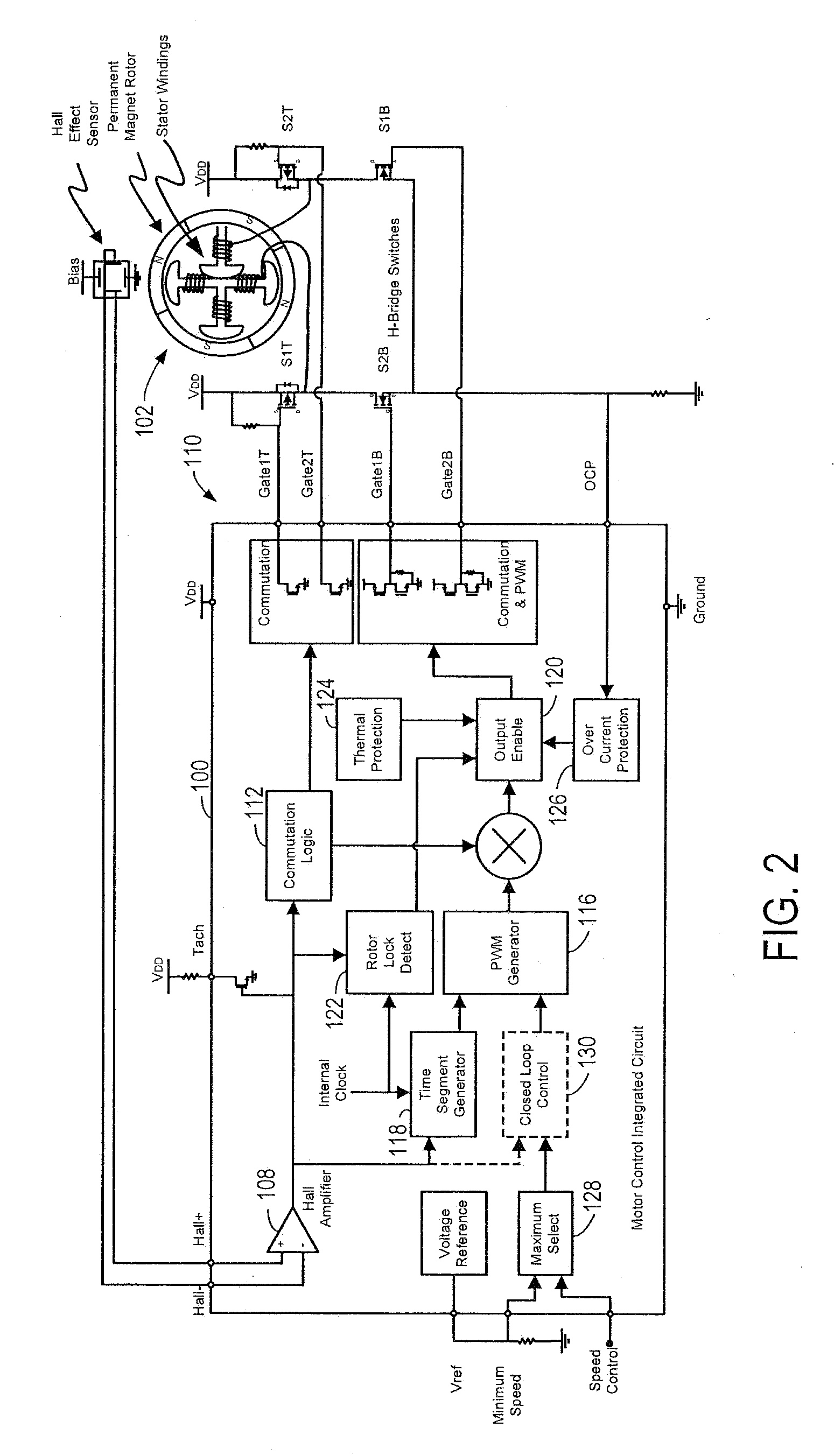

Position Corrected Pulse Width Modulation for Brushless Direct Current Motors

ActiveUS20120326643A1Increased torque outputReduce motor noiseTorque ripple controlMotor/generator/converter stoppersPosition dependentDirect current

A method of operating a brushless direct current motor is provided that generates a rotor position dependent pulse width modulation waveform. The waveform can improve motor efficiency and reduce torque variation.

Owner:AGAVE SEMICON

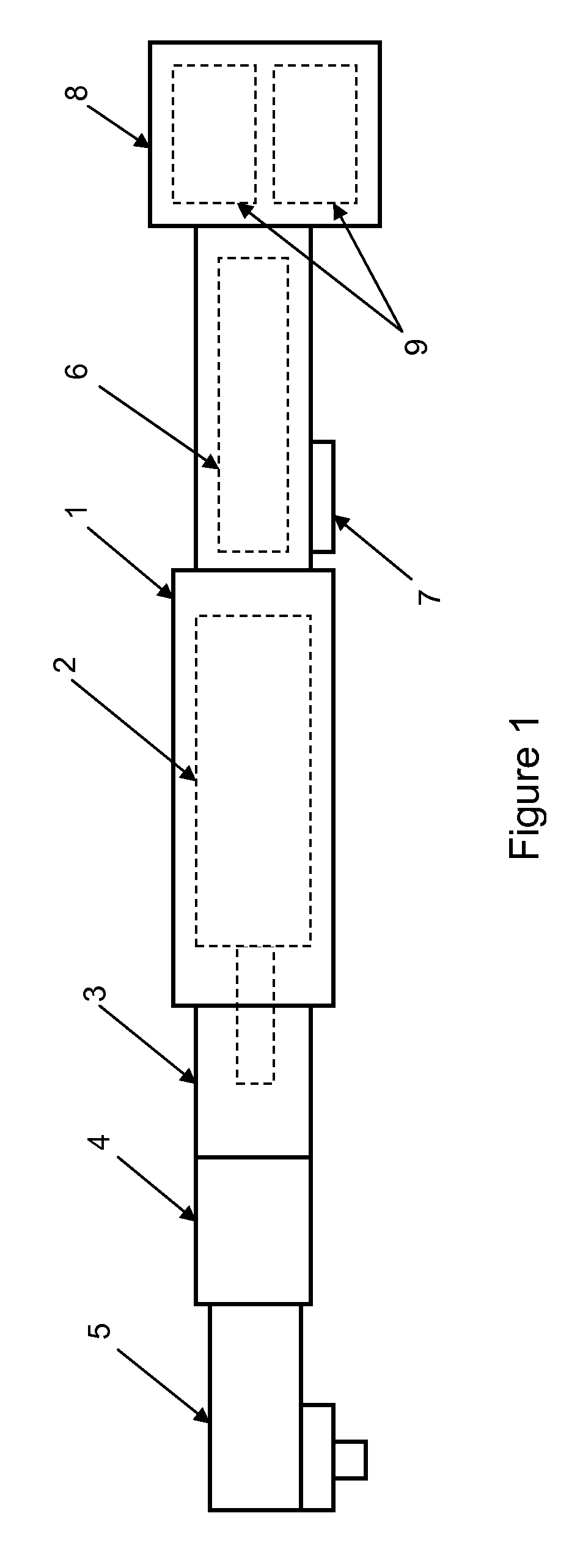

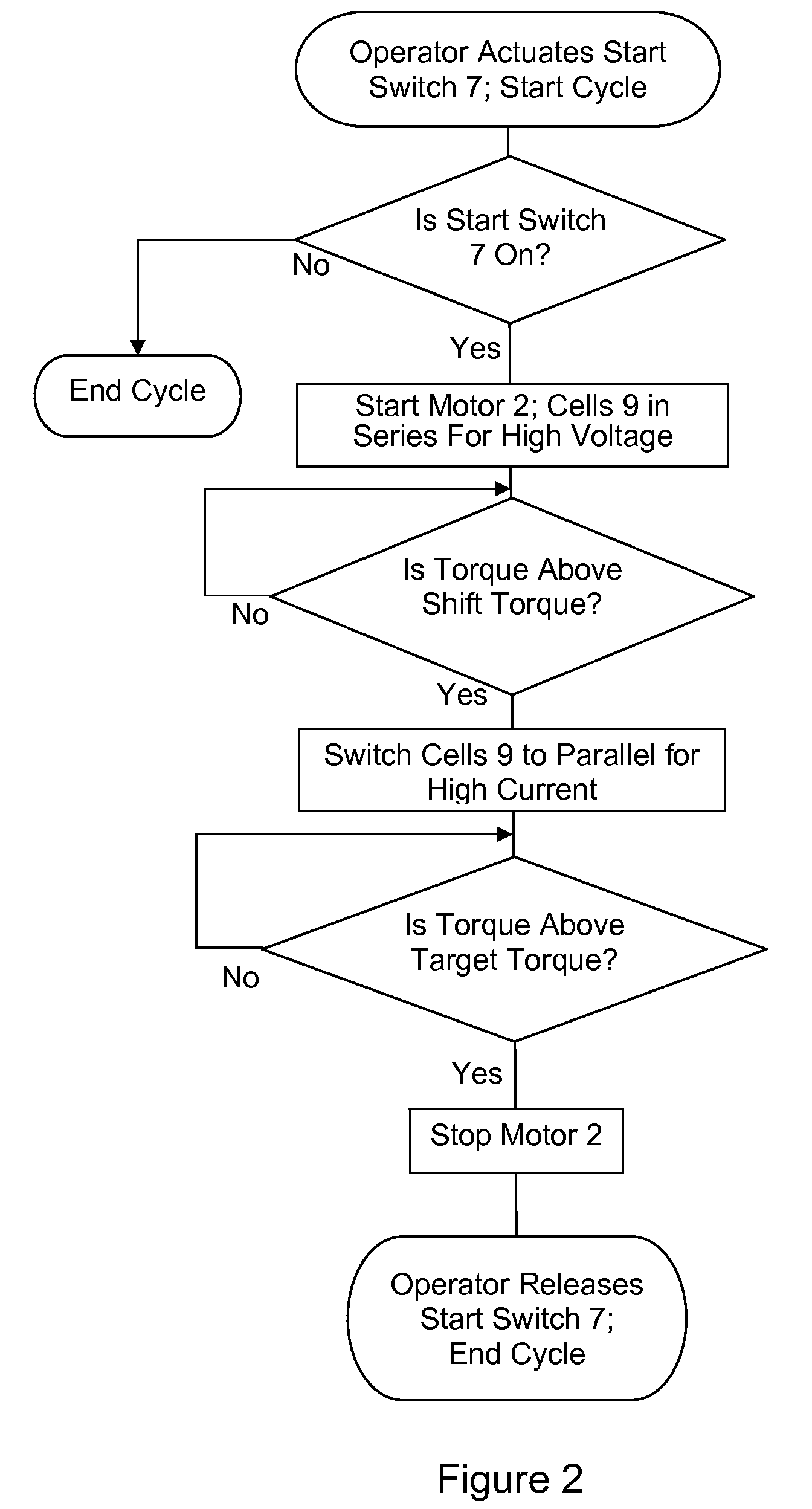

Battery management system for a cordless tool

ActiveUS8310177B2High voltageIncreases the motor's torque/forceAC motor controlSynchronous motors startersElectrical resistance and conductanceHand held

Owner:STANLEY WORKS THE

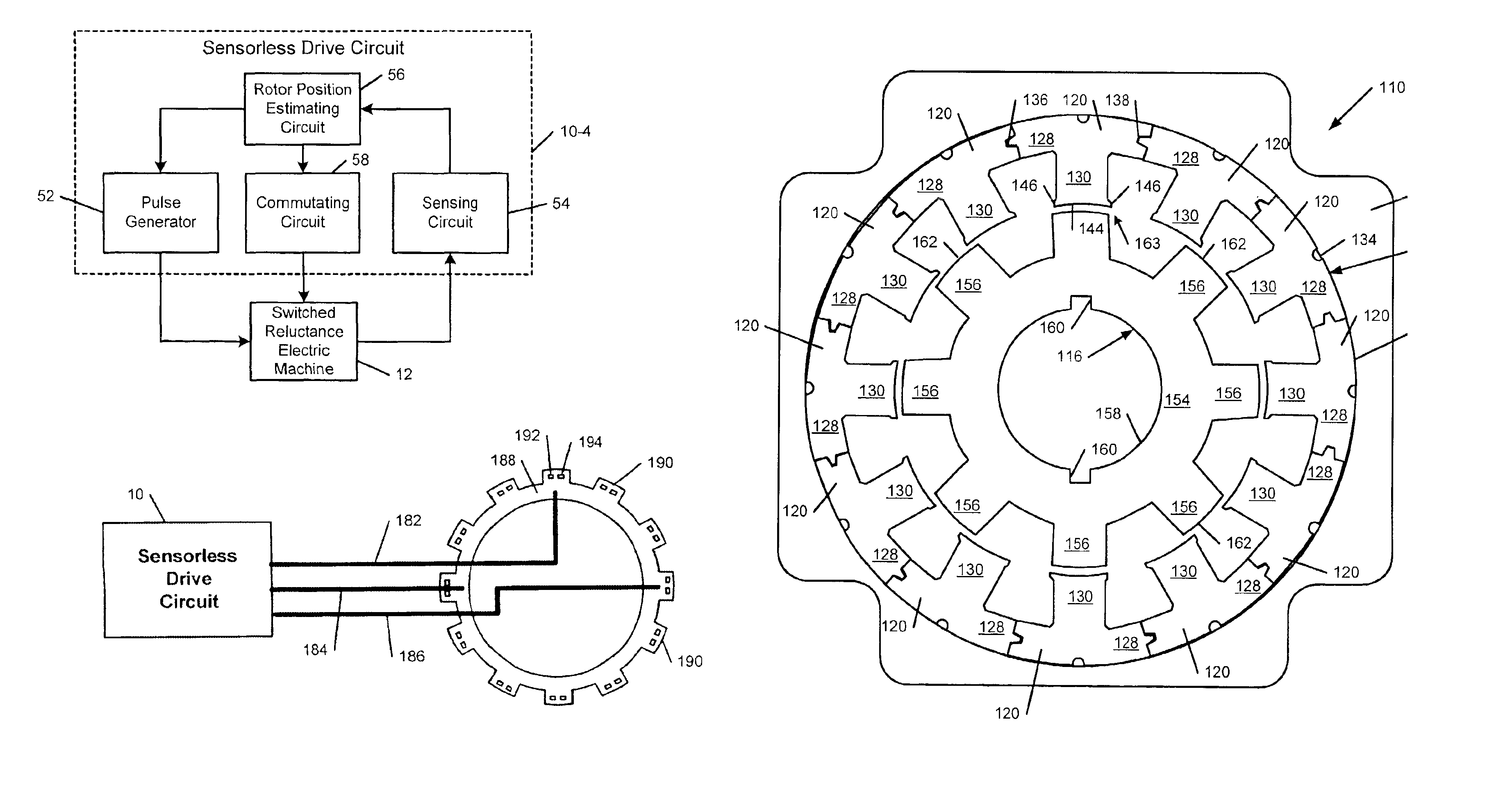

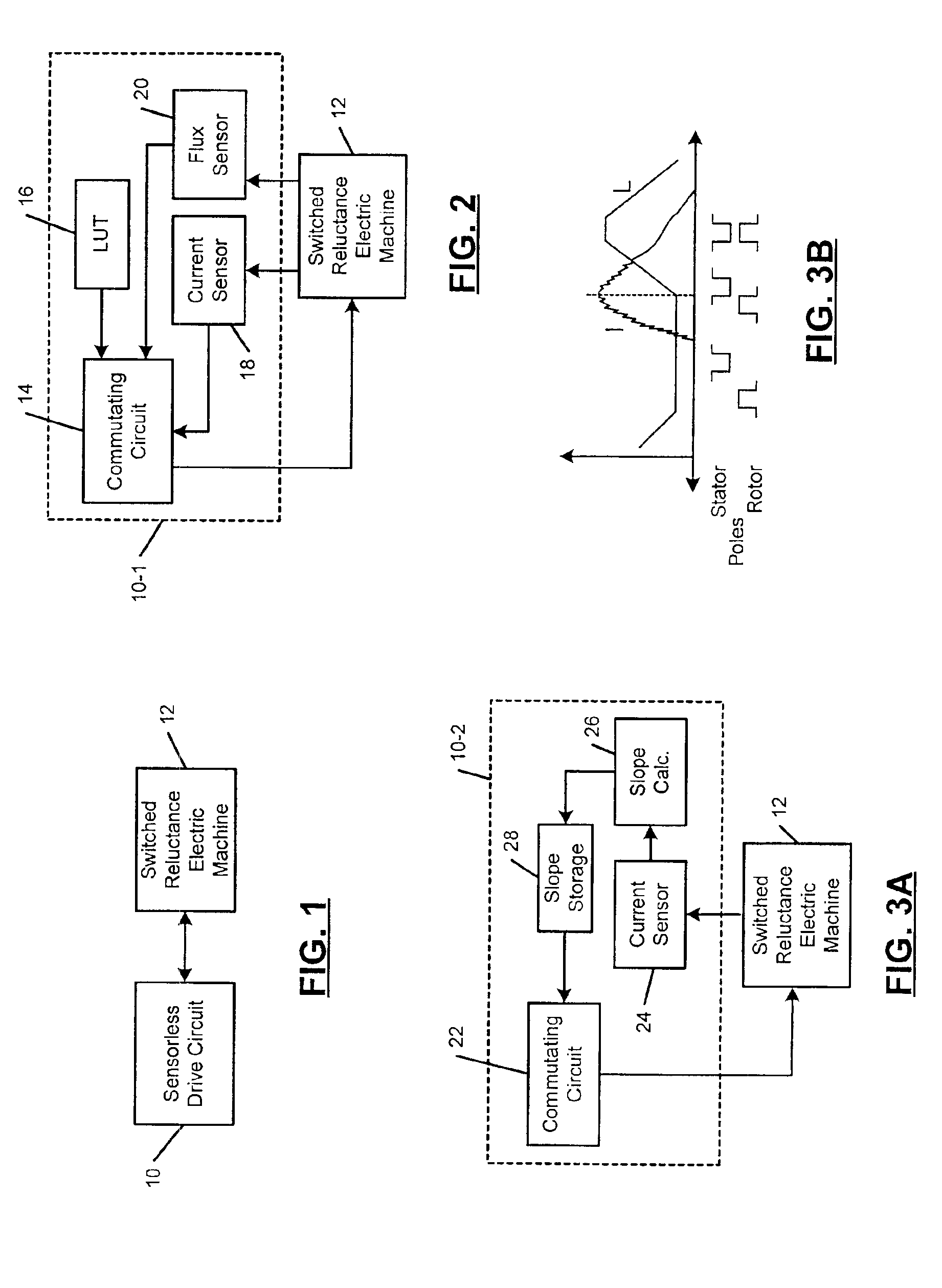

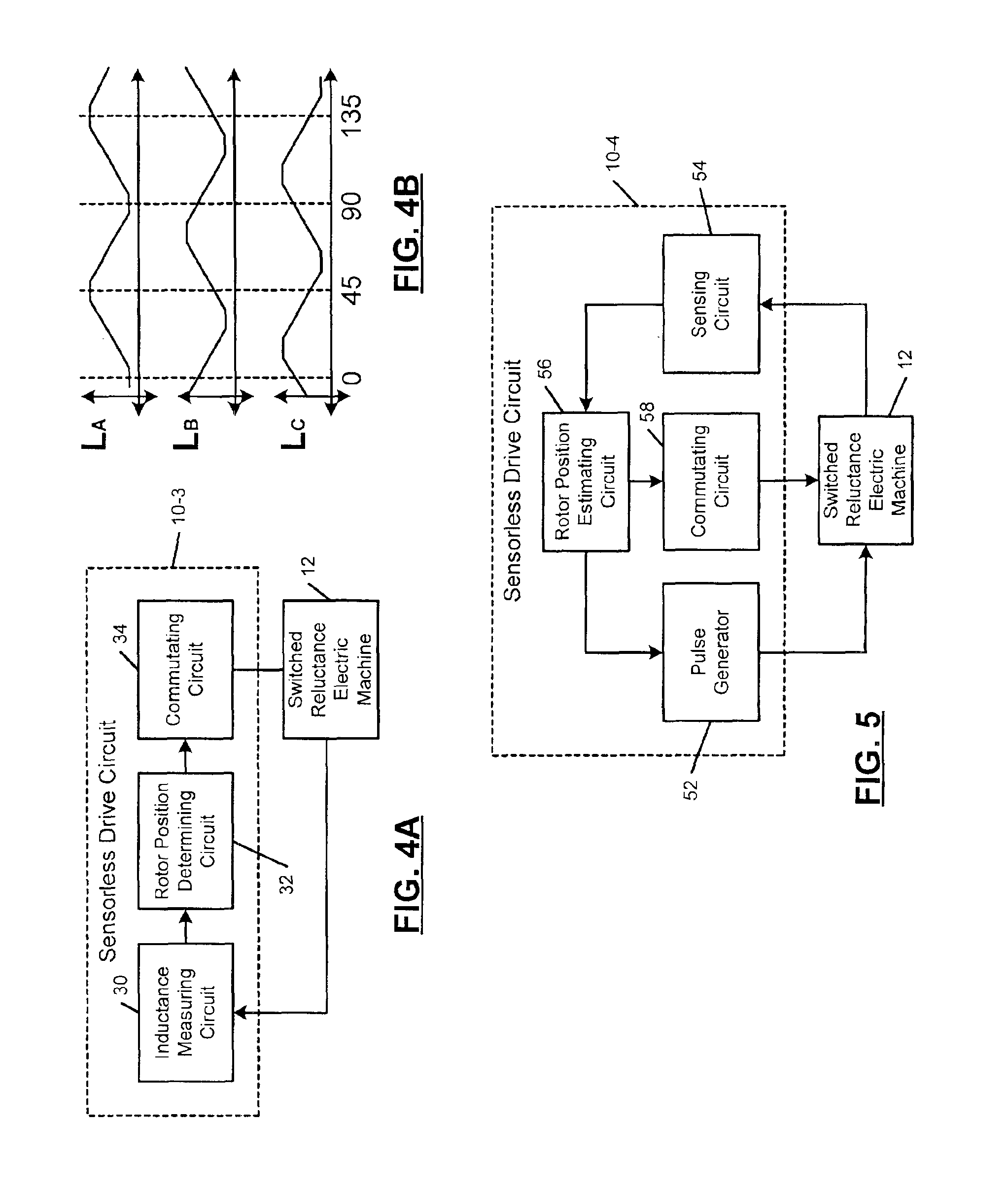

Sensorless switched reluctance electric machine with segmented stator

InactiveUS6897591B2Facilitate the improvement of precisionReduce usageElectronic commutation motor controlMotor/generator/converter stoppersElectric machineEngineering

A sensorless switched reluctance machine includes a stator with a plurality of circumferentially-spaced stator segment assemblies that include salient stator poles and inter-polar stator slots. Each of the stator segment assemblies includes a stack of stator plates forming a stator segment core, an end cap assembly, and winding wire wound around the stator segment core and the end cap assembly. The rotor defines a plurality of rotor poles. The rotor tends to rotate relative to the stator to a rotational position that maximizes the inductance of an energized winding. A sensorless drive circuit derives rotor position and energizes the winding wire around the stator segment assemblies based on the derived rotor position. Each stator plate includes a first radially outer rim section and a tooth section that extends radially inwardly from a first center portion of the first radially outer rim section.

Owner:NIDEC MOTOR CORP

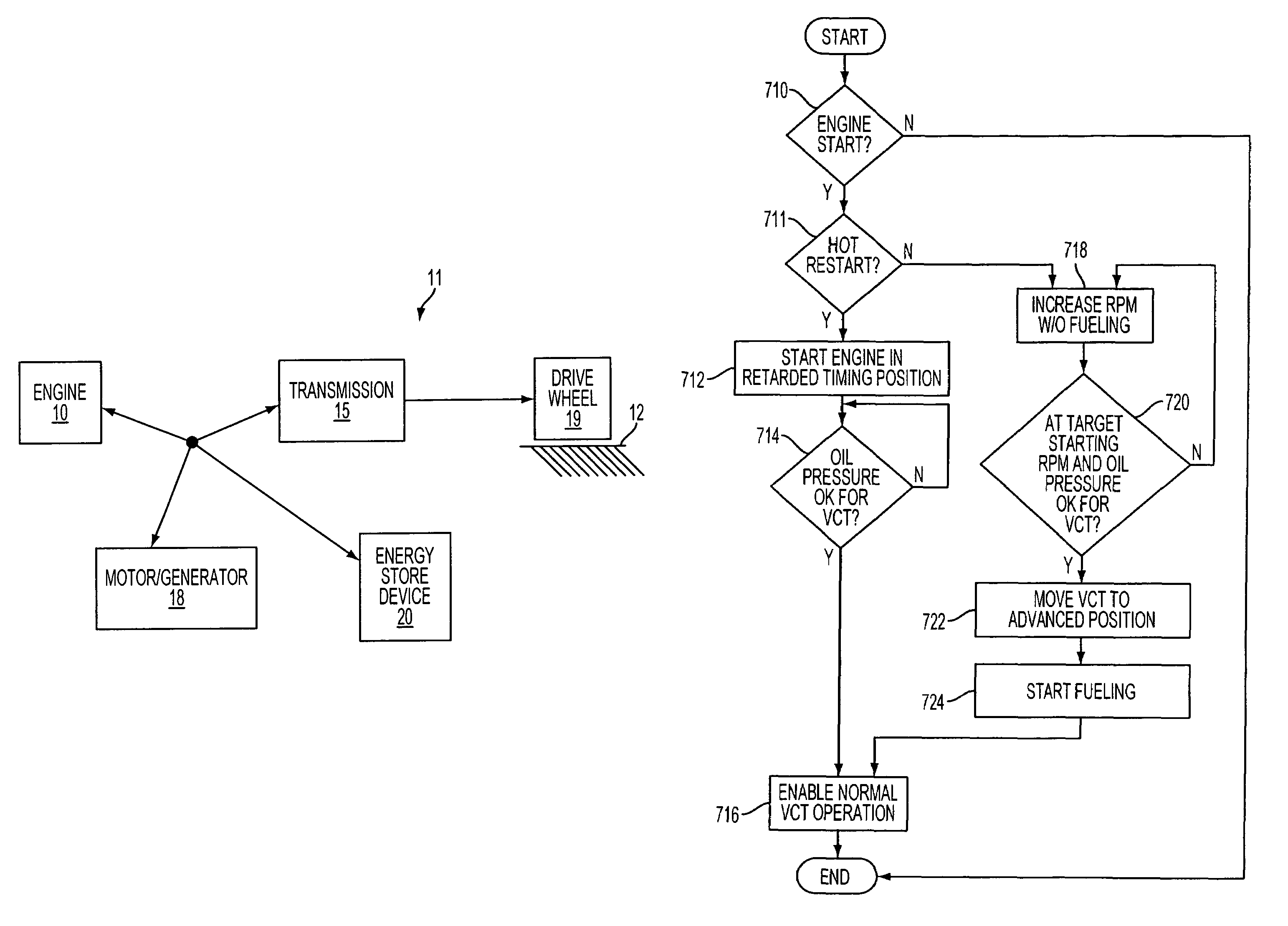

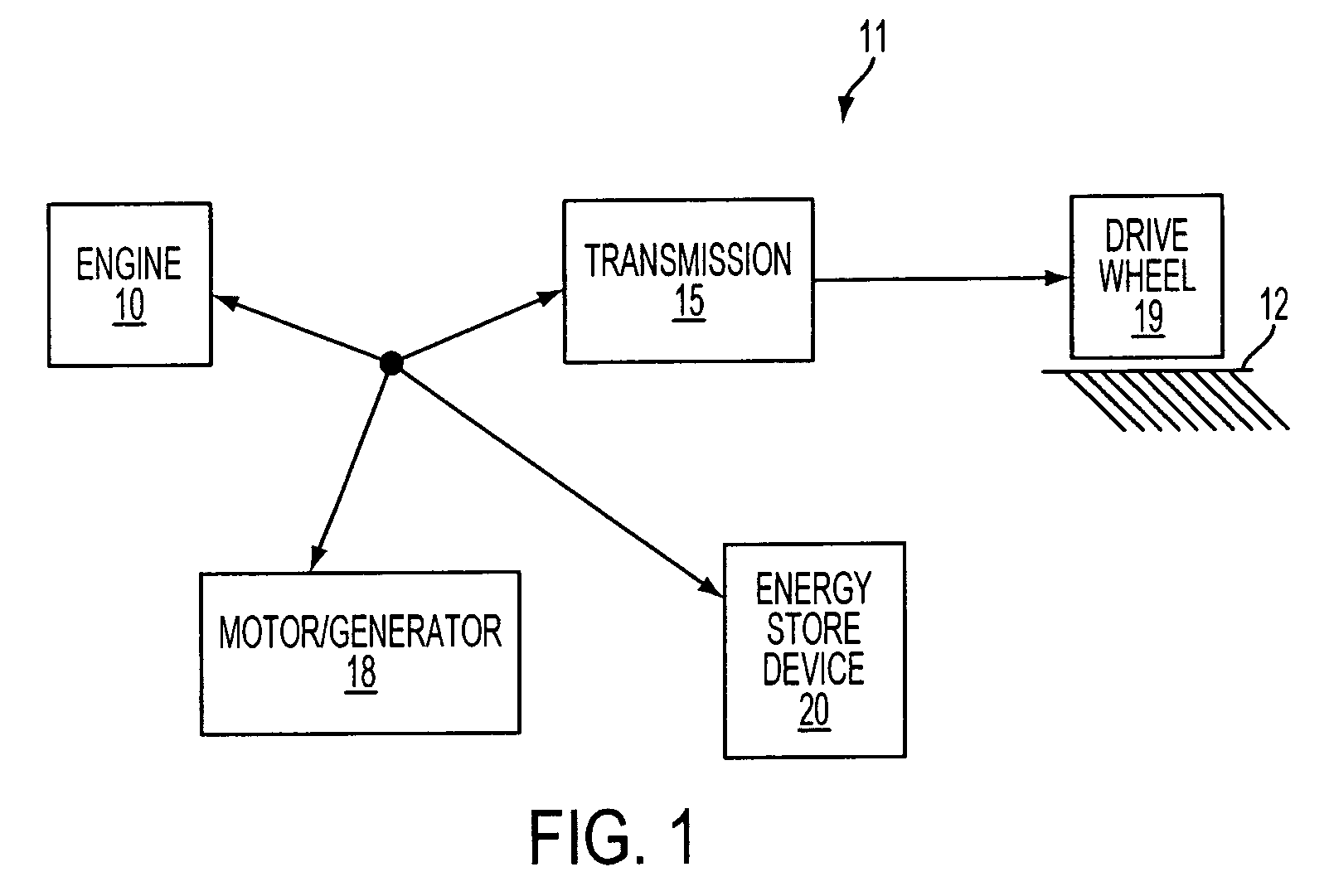

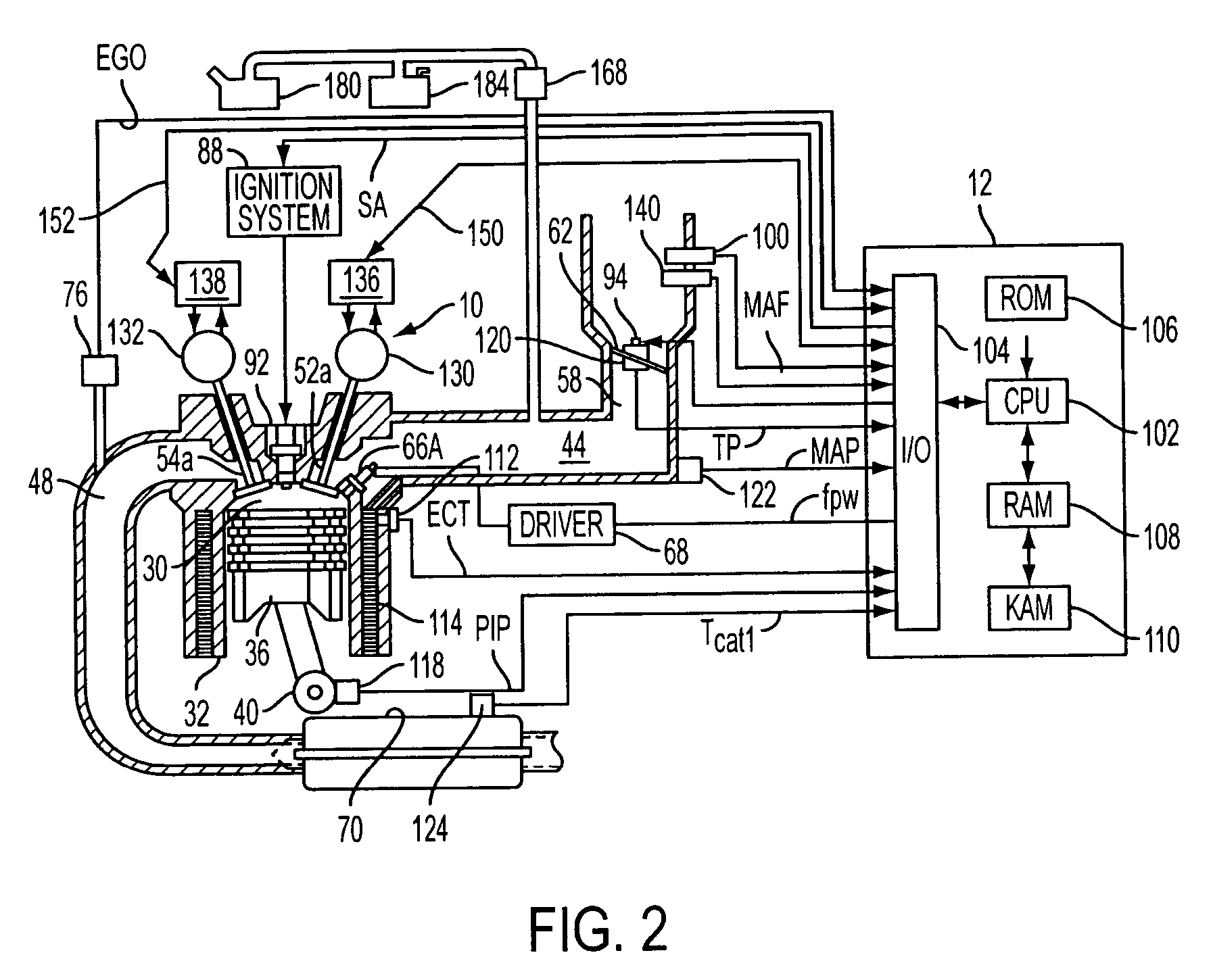

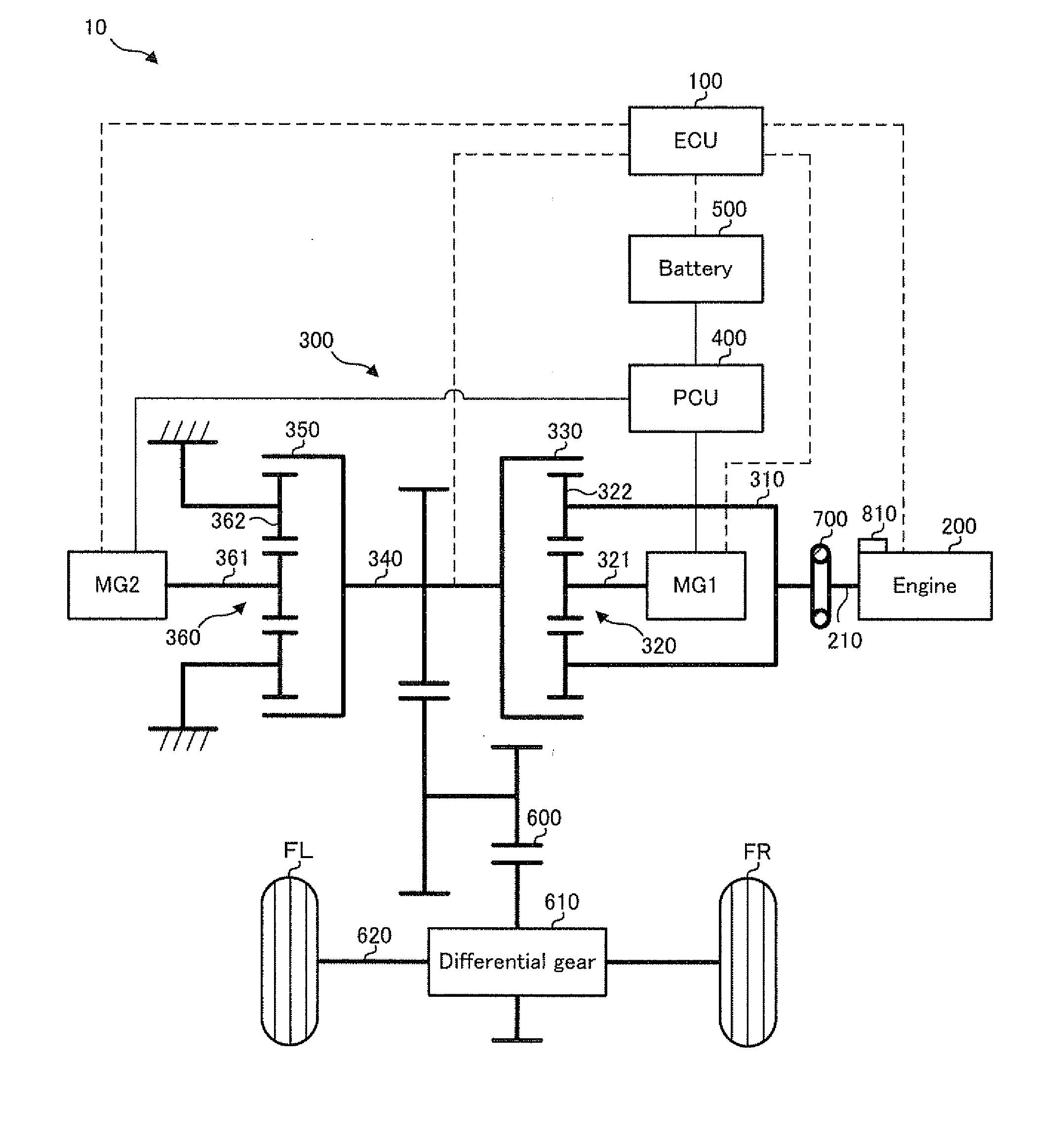

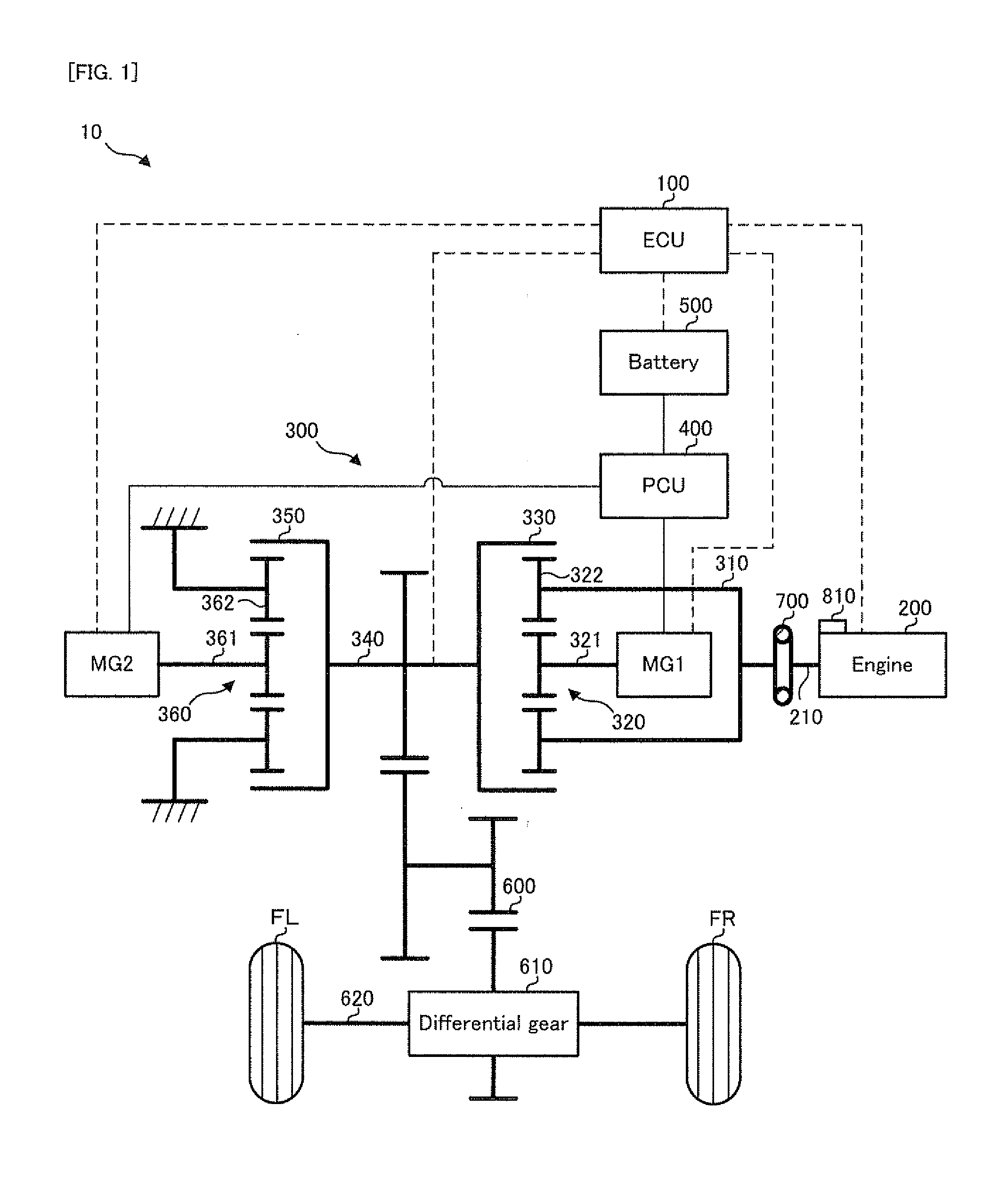

Hybrid vehicle system having engine with variable valve operation

ActiveUS7527028B2Improve operationReduce vibrationHybrid vehiclesYielding couplingExhaust valveVariable valve timing

Owner:FORD GLOBAL TECH LLC

Multiple elastomer layer progressing cavity stators

InactiveUS7517202B2Improve performanceReducing tradeoffs associatedOscillating piston enginesEngine of intermeshing engagement typeElastomerPolymer science

A progressing cavity stator and a method for fabricating such a stator are disclosed. The progressing cavity stator includes first and second elastomer layers fabricated from corresponding first and second elastomer materials. The first and second elastomer materials are selected to have at least one distinct material property. Exemplary embodiments of this invention may reduce tradeoffs associated with elastomer material selection and may further address the heat build up and subsequent elastomer breakdown in the lobes of prior art stators.

Owner:SMITH INT INC

Single motor transmission shifting mechanism for a motor vehicle transmission

InactiveUS20080060462A1Reliable in operationSimple to manufactureToothed gearingsGearing controlVariatorMode switching

A single motor transmission shifting mechanism with exactly one electric motor for generating drive motions for selecting, and for generating drive motions for shifting gears of a motor vehicle transmission device, and with a threaded spindle for switching from a mode, in which selection motions can be effectuated, into a mode, in which shifting motions can be effectuated, and with a shifting shaft, which can be moved in axial direction for selecting, and which can be rotated around its longitudinal axis for shifting, wherein all components, transferring the drive load for shifting from the electric motor to the shifting shaft during shifting operation, maintain their axial position relative to the longitudinal axis of the threaded spindle during this shifting operation.

Owner:SCHAEFFLER TECH AG & CO KG

Vibration absorber assembly

InactiveUS7004294B2Effective absorptionHigh outputRotating vibration suppressionControlling membersRotational axisEngineering

A vibration absorber assembly including a disc shaped housing having a central rotational axis and a plurality of radially elongated cavities, and a plurality of movable masses, each movable mass being housed in, and movable within, one of the plurality of radially elongated cavities. The plurality of movable masses are movable in the plurality of radially elongated cavities to absorb torsional vibration, and / or alter moment of inertia of the vibration absorber assembly.

Owner:WILLIAMS KENNETH A

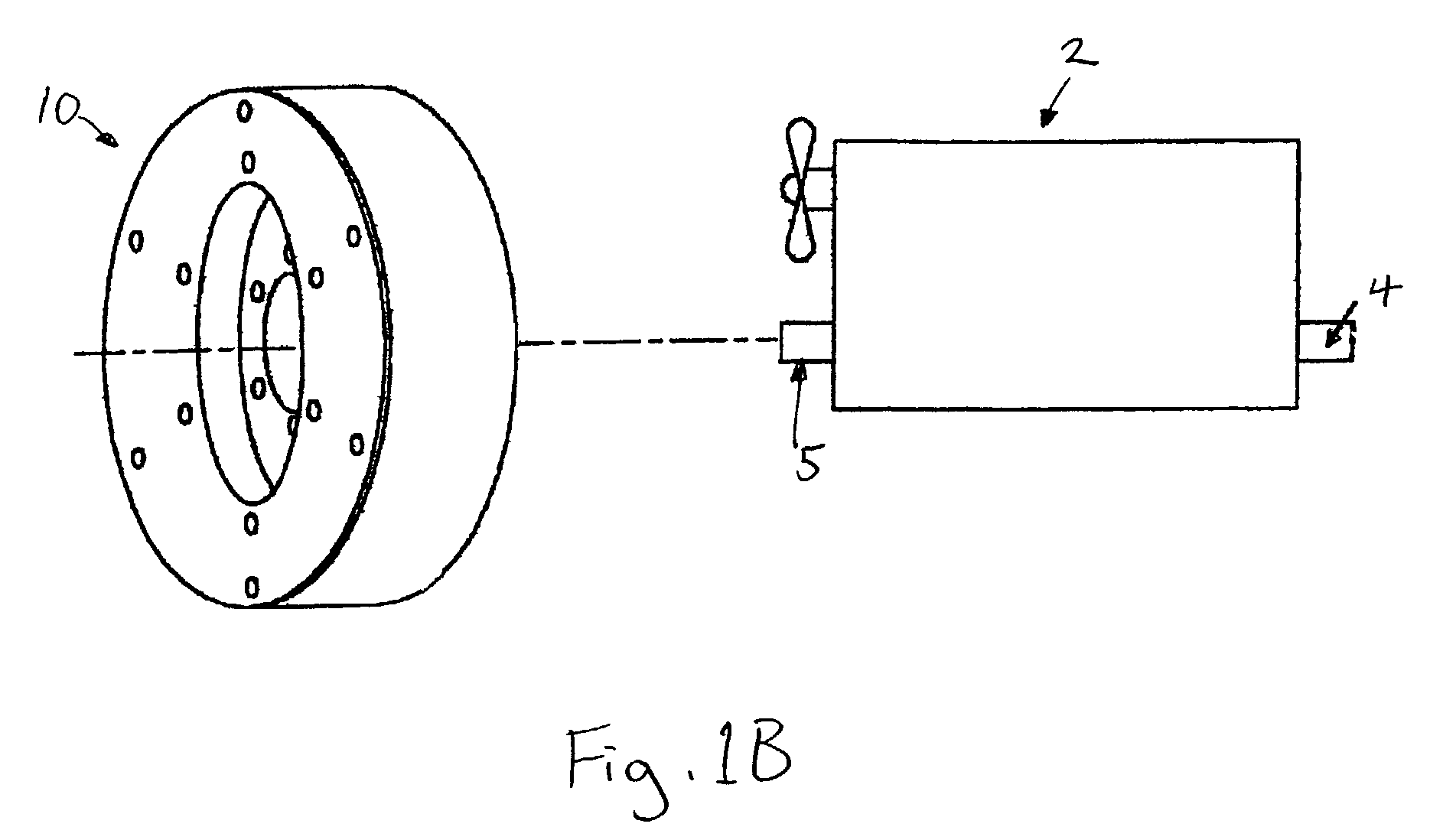

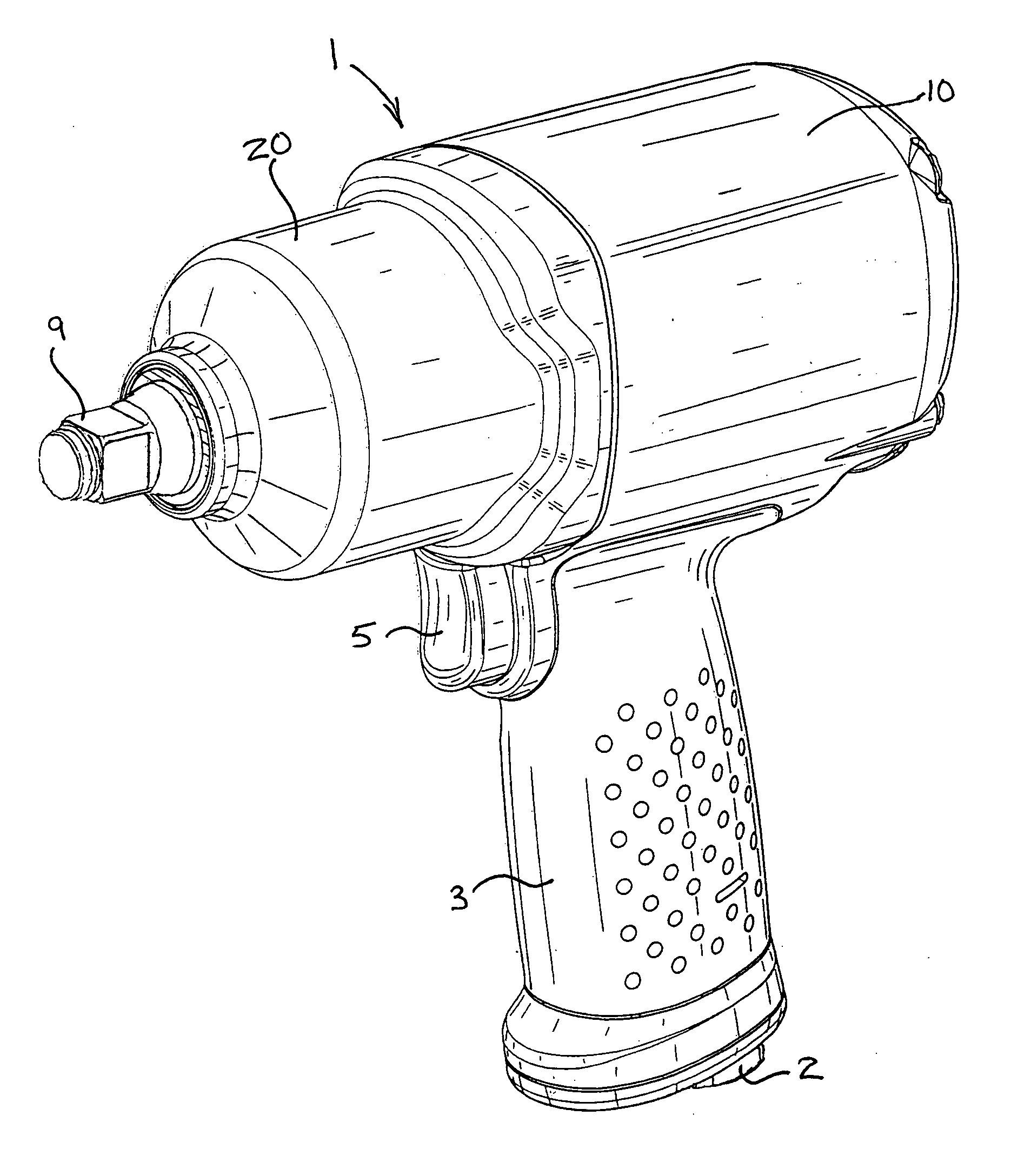

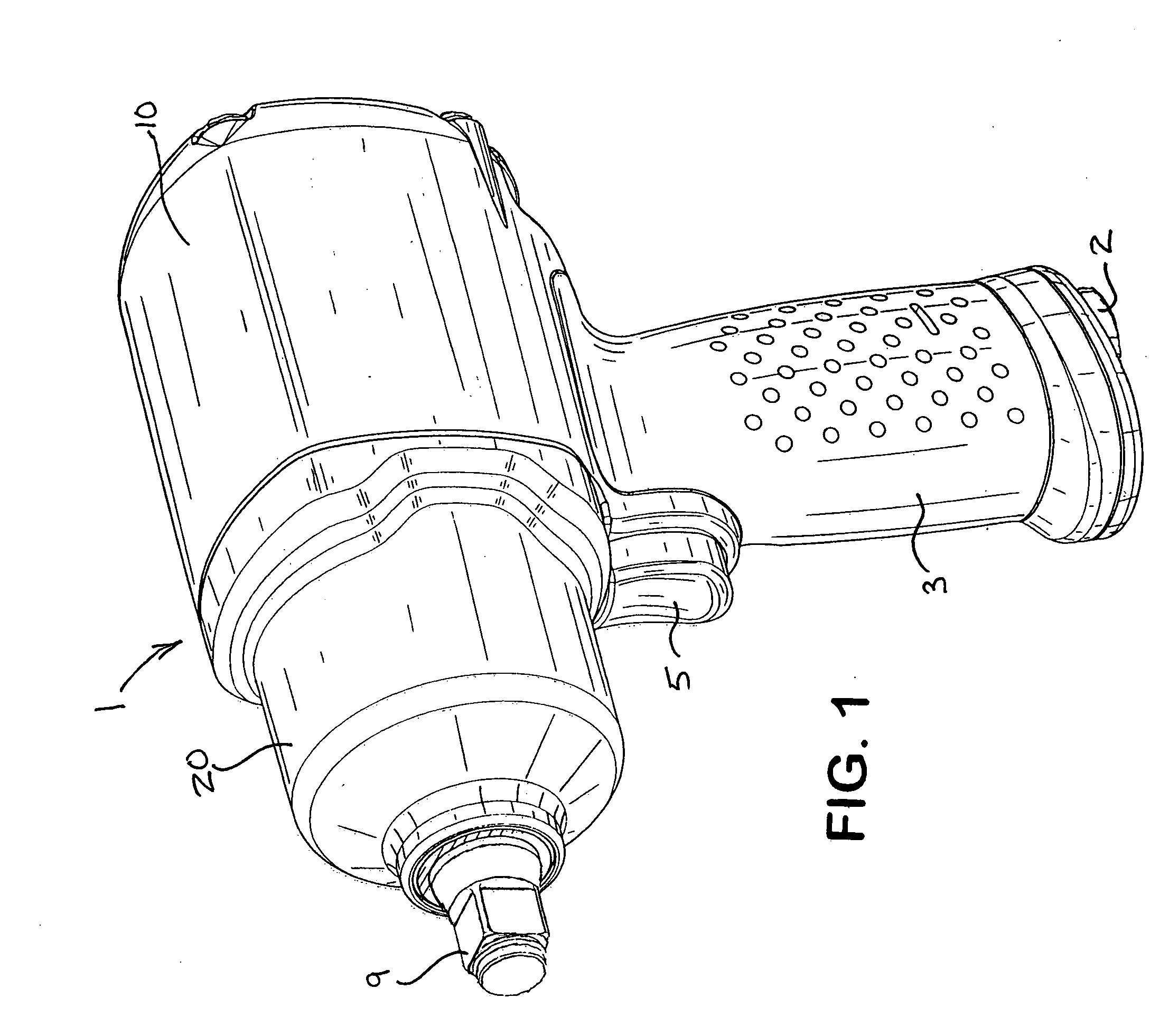

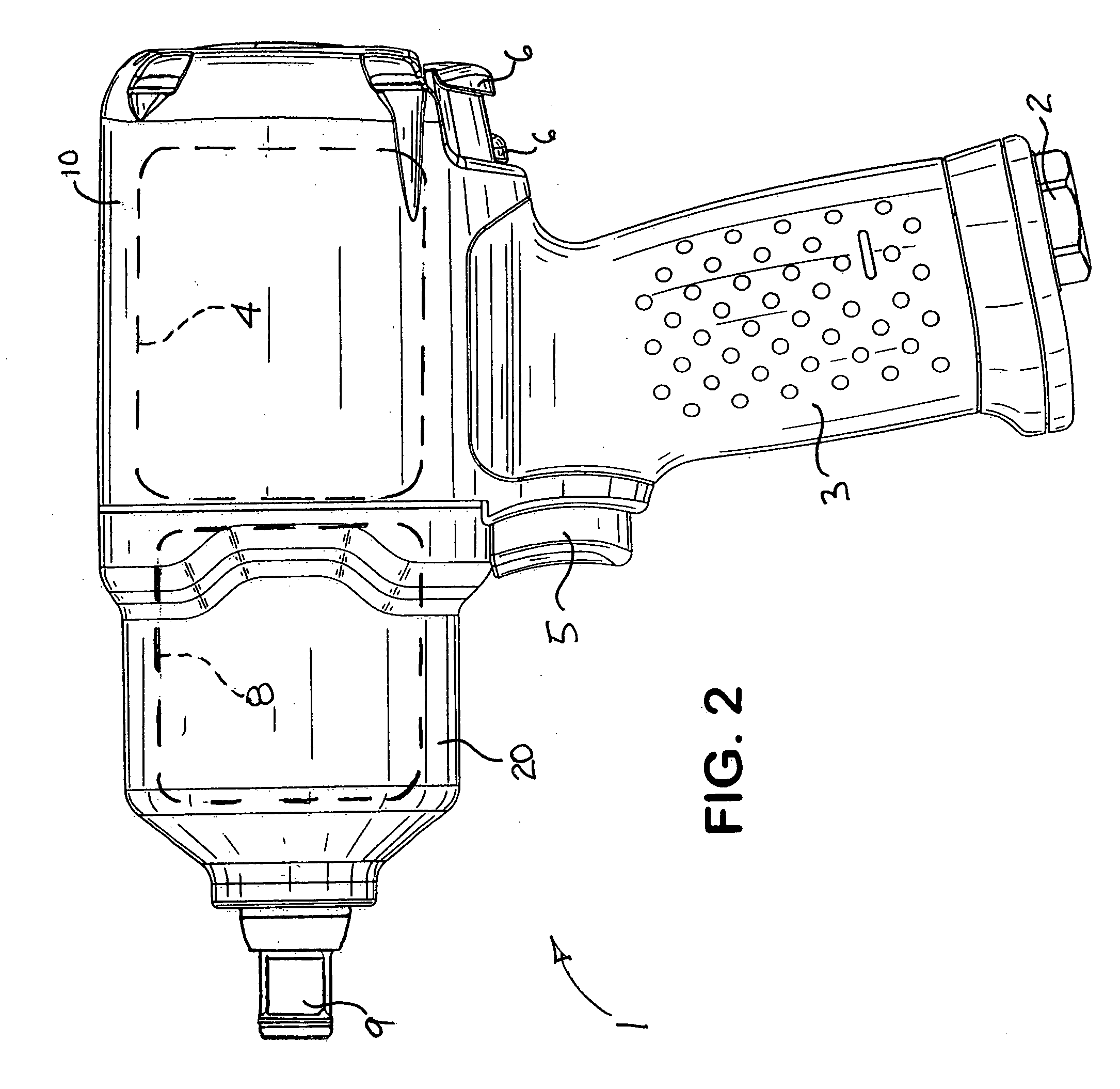

Titanium based containment structures for handheld impact tools

InactiveUS20050161243A1Increased torque outputIncrease speedOperator-supported drilling machinesPortable percussive toolsHand heldStructural engineering

Owner:INGERSOLL RAND CO

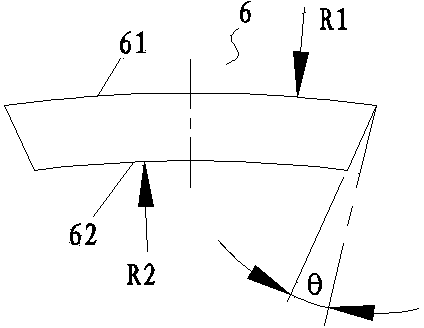

Axial gap rotating electrical machine

ActiveUS7187098B2Increased torque outputIncrease torqueMagnetic circuit rotating partsMechanical energy handlingMagnetizationMagnetic flux

An axial gap rotating electrical machine is provided with permanent magnets and cores in a rotor. The permanent magnets are oriented such that magnetization surfaces face in the circumferential direction of the rotor. The cores are arranged alternately with the permanent magnets in the circumferential direction of the rotor. The amount of magnetic flux on the outside in the radial direction of the rotor is made greater than the amount of magnetic flux on the inside in the radial direction of the rotor. As a result, the magnetic flux density at the rotor cores can be made substantially constant in the radial direction of the rotor and torque output with respect to the size of the permanent magnets is improved by preventing magnetic saturation of the cores.

Owner:EQUOS RES

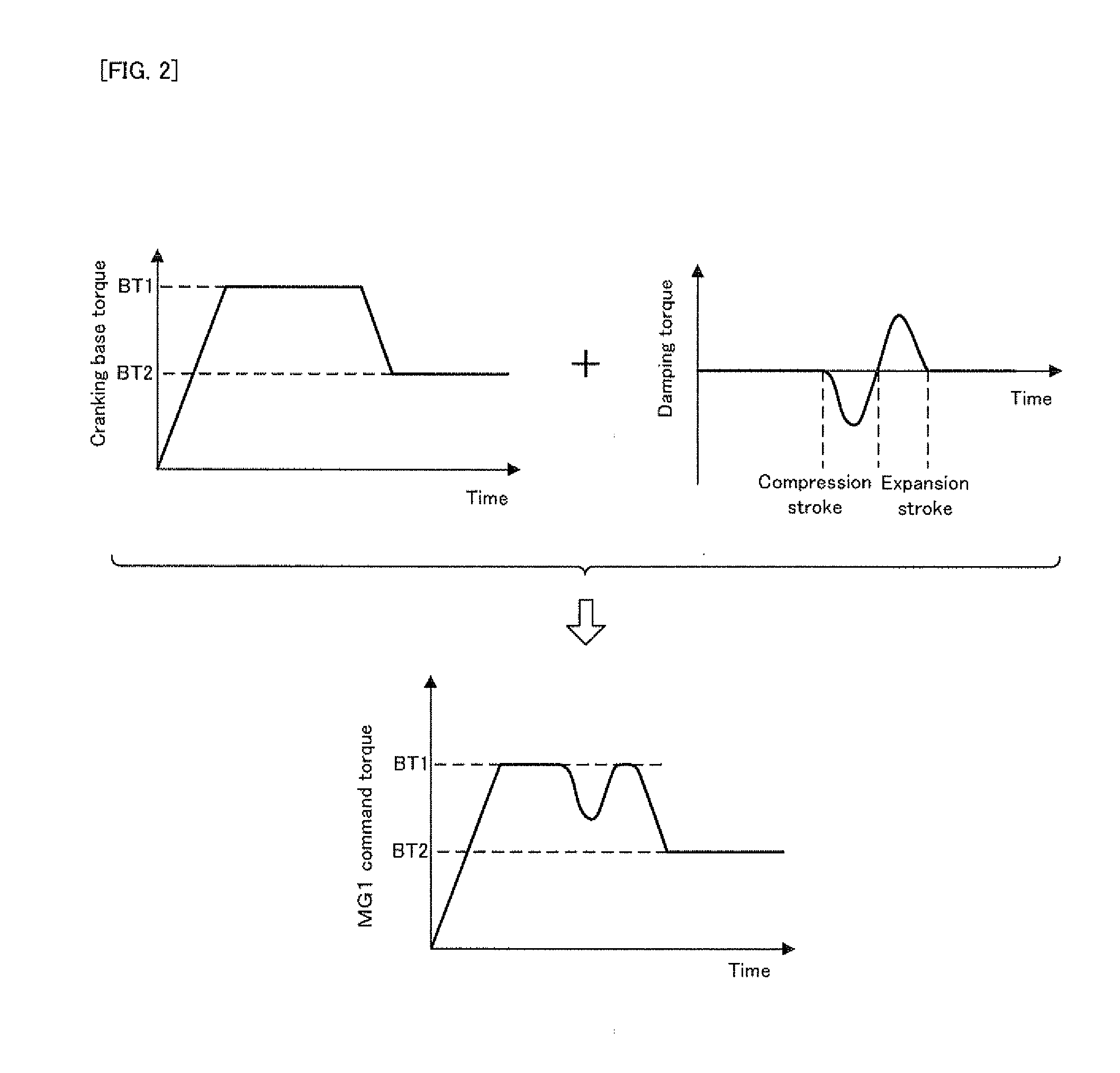

Engine starting apparatus

InactiveUS20130233268A1Reduce power consumptionMiniaturize batteryPower operated startersPropulsion using engine-driven generatorsVibration controlResonance

An engine starting apparatus is provided with: a target torque setting device for setting a sum of a cranking base torque for cranking an engine and a vibration controlling torque for suppressing vibration of a power transmission system due to resonance of a damper, as a target torque to be outputted by a motor in cranking the engine; and a motor controlling device for controlling the motor to output the set target torque. The target torque setting device has a base torque controlling device for setting the cranking base torque to a first torque value if the number of revolutions of the engine is less than or equal to predetermined number of revolutions of the engine and for controlling the cranking base torque.

Owner:TOYOTA JIDOSHA KK

Hybrid excitation fault tolerant motor system based on automatic position detection

InactiveCN104201808AHigh outputImprove power densityElectronic commutation motor controlMagnetic circuit rotating partsElectric machinePermanent magnet synchronous motor

The invention discloses a hybrid excitation fault tolerant motor system based on the automatic position detection. The system comprises a stator, a rotor, permanent magnets, armature teeth, fault tolerant teeth, armature coils and excitation coils. The armature coils are winded on the armature teeth, the excitation coils sleeve the fault tolerant teeth of the stator, the permanent magnets are embedded in the rotor and form the permanent magnetic field, and all the excitation coils form an electric excitation magnetic field; each permanent magnet comprises two magnetic stripes which are symmetrical about the rotor radially and which are assembled at one end adjacent to the axis of the rotor, and a pair of permanent magnetic poles in the rotor are provided with one or multiple grooves along the q-axis magnetic circuit direction to form one or multiple magnetic isolation layers. Compared with a traditional permanent magnet synchronous motor, the system has the advantages that the magnetic isolation layers are increased along the q-axis magnetic circuit direction in the rotor, the zero low-speed operation without the position sensor control can be implemented, the reliability and fault tolerance capability of the motor drive system are further improved, and the torque output of the motor can be further increased.

Owner:SOUTHEAST UNIV

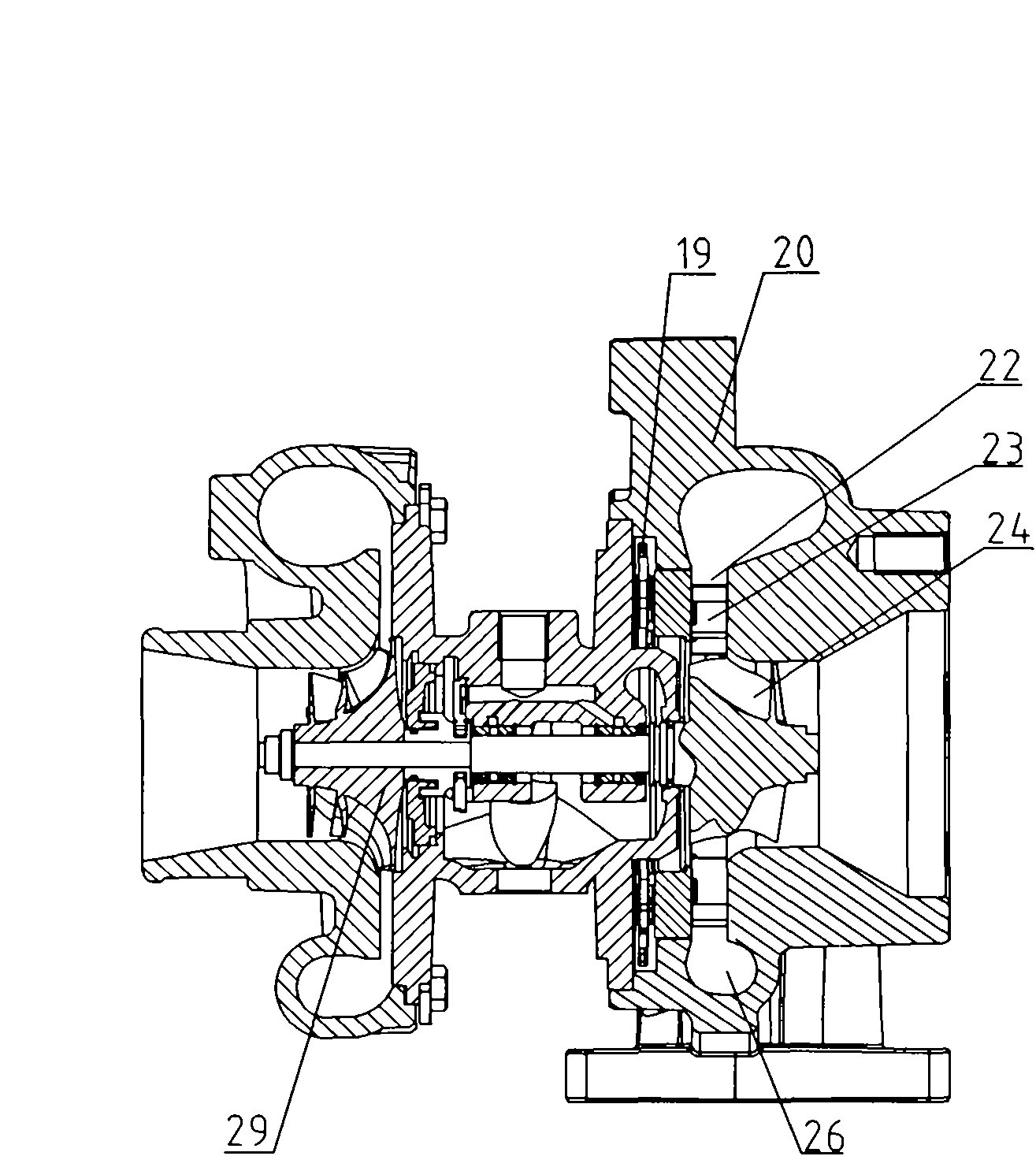

Complex turbine device with variable section

InactiveCN101985897AGuaranteed inflowAvoid enteringInternal combustion piston enginesBlade accessoriesImpellerLow speed

The invention discloses a complex turbine device with a variable section, comprising a double flow channel turbine volute, wherein the double flow channel turbine volute is provided with two air flow passageways; the double flow channel turbine volute is provided with a volute air outlet and a volute air inlet which are communicated with the air flow passageways; a complex turbine impeller is arranged in the double flow channel turbine volute; and the complex turbine impeller is formed by compounding two turbine impellers which correspond to the two air flow passageways one by one. In the invention, the variable section function can be achieved by design and development of the turbine of a turbocharger and by using the complex turbine device, thereby effectively solving the defects of poor reliability and high cost of a vane type turbocharger with the variable section, effectively improving the efficiency of the turbine of an engine in low speed and increasing the torque output of the turbine.

Owner:KANGYUE TECH

Super-low-speed high-torque motor and crane with motor

ActiveCN104158375AReflect the impactGood for high torque outputMagnetic circuit rotating partsMagnetic circuit stationary partsWinding machineLow speed

The invention discloses a super-low-speed high-torque motor and a crane with the motor. The motor comprises an outer rotor and a stator. The stator is provided with a stator temperature sensor for collecting a temperature signal within the stator. The outer cylinder inner side of the outer rotor is fixedly equipped with a plurality of permanent magnets which are the same tile-shaped hexahedral structures and are regularly arranged along a circumferential direction and an axial direction. A plurality of permanent magnets are arranged in any circumferential and any axial direction. Two circumferential side faces of the permanent magnets are inclined plane shapes with inside cutting angle shapes, and the angle of a cutting angle is 5 degrees to 35 degrees. According to the crane with the motor, the outer cylinder of the motor is used as the winding drum of a lifting mechanism. The motor can normally run in the condition of low speed (super low speed) and large torque, the operation is stable, the vibration is small, the noise is small, the temperature rise is small, and the motor is mainly used for a crane, a port machine, a tower crane, an elevator, a winding machine and other similar occasion.

Owner:JIANGXI GONGBU MACHINERY

Progressing cavity stator having a plurality of cast longitudinal sections

InactiveUS20060182643A1Prevent rotationIncreased torque outputPump componentsOscillating piston enginesElastomerHelical line

A progressing cavity stator and a method for fabricating such a stator are disclosed. Exemplary embodiments of the progressing cavity stator include a plurality of rigid longitudinal stator sections concatenated end-to-end in a stator tube. The stator sections are rotationally aligned so that each of the internal lobes extends in a substantially continuous helix from one end of the stator to the other. The stator further includes an elastomer liner deployed on an inner surface of the concatenated stator sections. Exemplary embodiments of this invention include a comparatively rigid stator having high torque output and are relatively simple and inexpensive to manufacture as compared to prior art rigid stators.

Owner:DYNA DRILL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com