Complex turbine device with variable section

A turbine and cross-section technology, applied in the direction of blade support components, stators, engine components, etc., can solve the difficulty of reliability and life of the rotary vane variable cross-section supercharger, and limit the market application and circulation of the variable cross-section supercharger The problem of severe cross-section changes and other problems can be easily controlled, the structure is simple, and the inheritance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

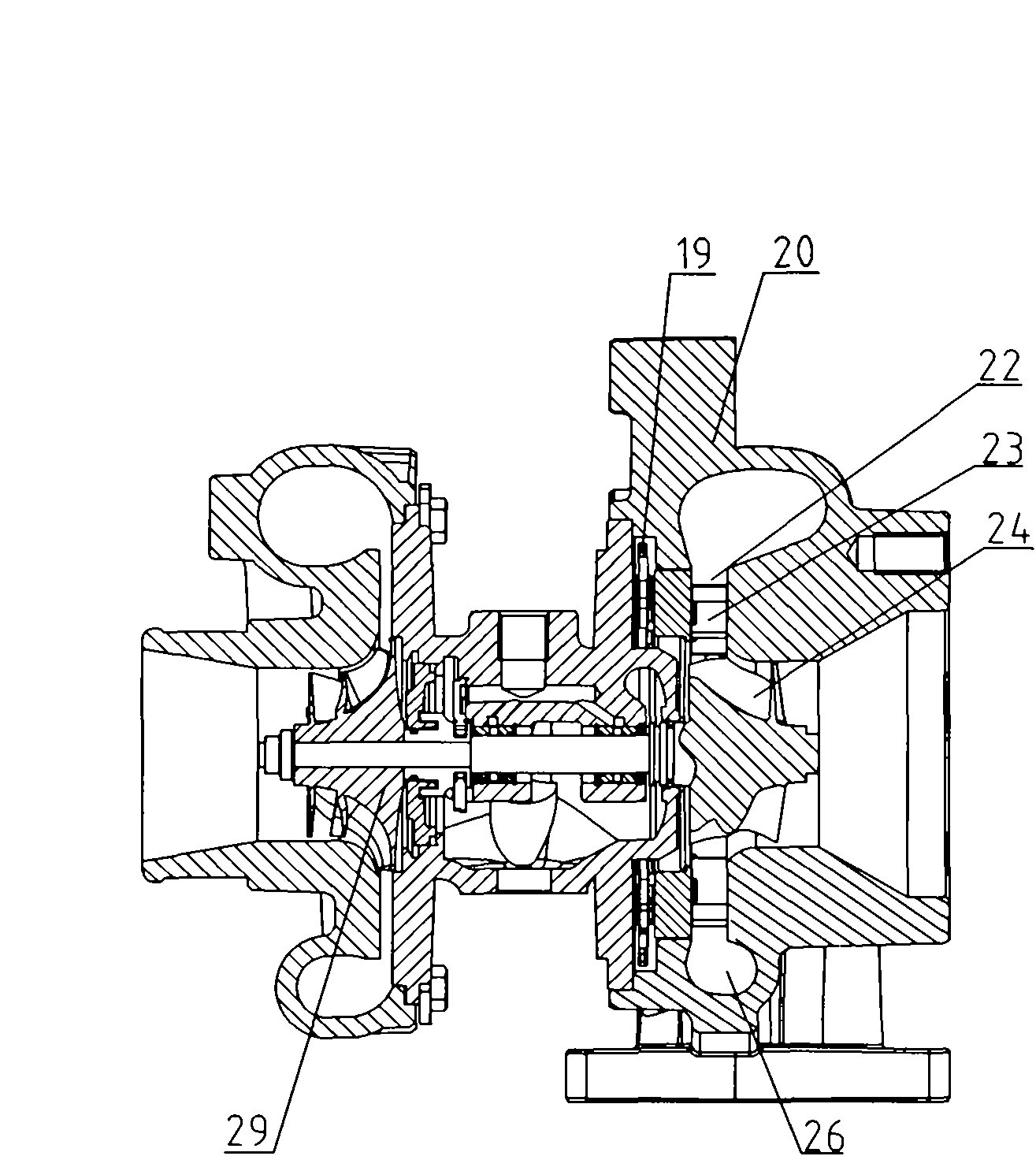

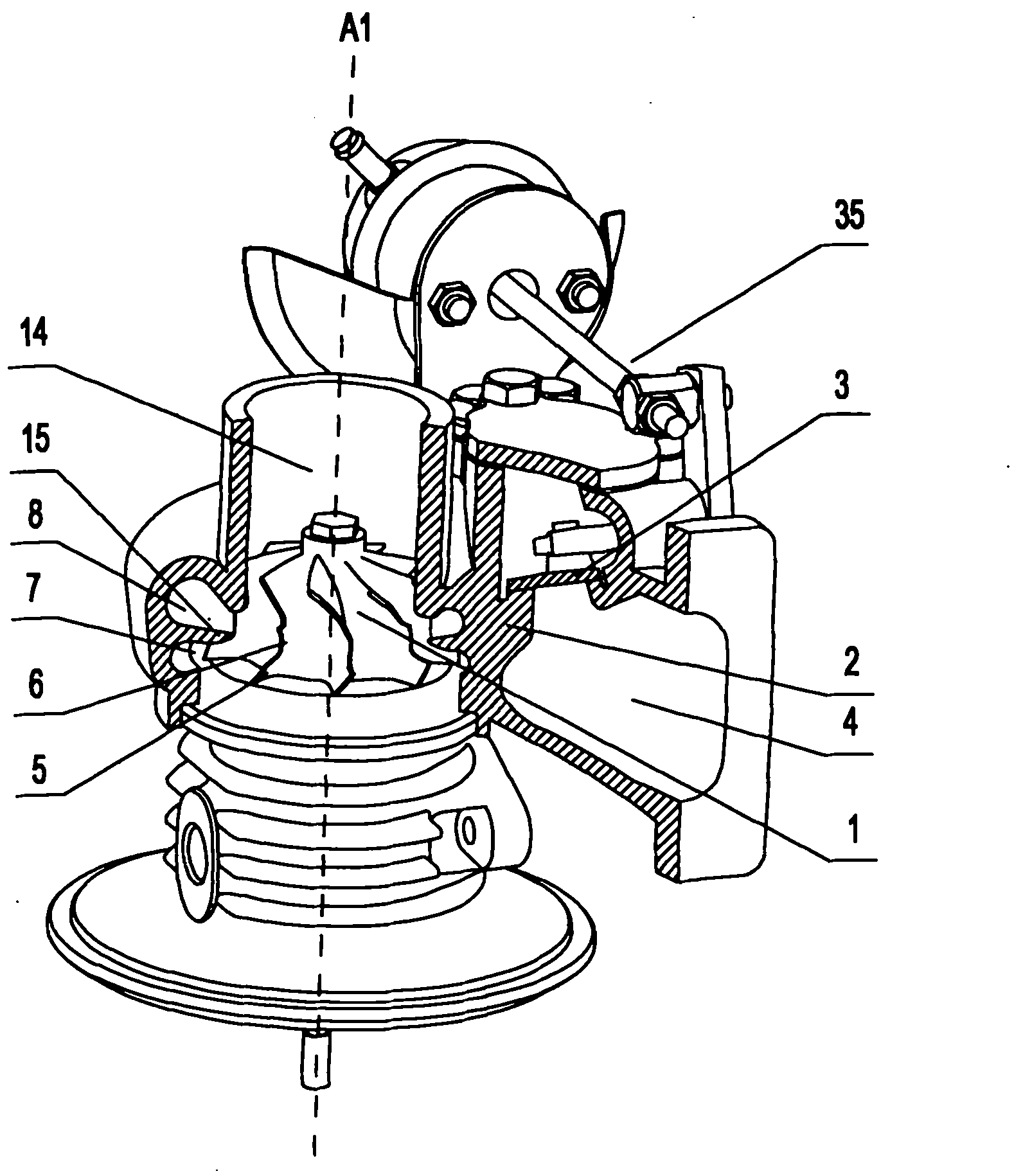

[0057] Embodiment 1, as attached figure 2 As shown, a variable cross-section compound turbine device includes a double-channel turbine volute 2, and the double-channel turbine volute 2 is provided with two airflow passages, and the airflow passage includes a small flow passage 7 and a large flow passage 8 The double-channel turbine volute 2 is provided with a volute air outlet 14 and a volute air inlet 4 communicating with the air flow channel, and a compound turbine wheel 1 is arranged in the double-channel turbine volute 2, and the compound turbine wheel 1 is composed of Two turbine impellers are combined, and the two turbine impellers are matched with two airflow passages one by one. The inlet of the double-channel turbine volute is provided with an airflow regulating valve 3 and a valve control mechanism 35 .

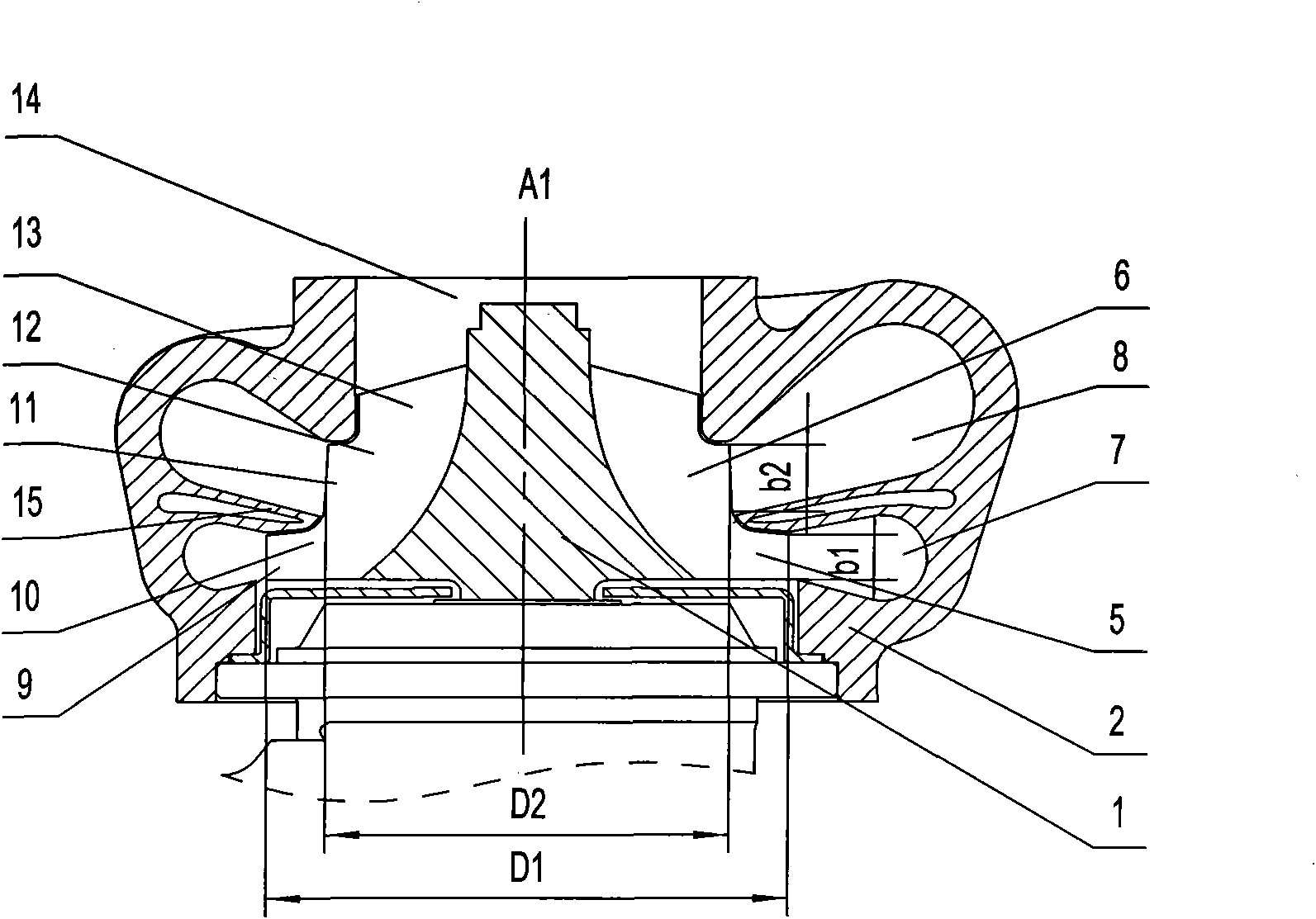

[0058] as attached image 3 As shown, the turbine impeller includes a primary turbine impeller 5 and a secondary turbine impeller 6 , and the primary turbine impe...

Embodiment 2

[0069] Embodiment 2, as attached Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the positions of the large flow passage 8 and the small flow passage 7 of the double-channel volute 2 are exchanged, and the first-stage turbine impeller 5 and the second-stage turbine wheel 5 of the compound turbine impeller 1 are The 6 positions of the impellers are exchanged. At this time, the large flow channel 8 is located on the side away from the volute air outlet 14, the small flow channel 7 is located on the side close to the volute air outlet 14, the first-stage turbine impeller 5 is located on the side of the wheel rim, and the second-stage turbine wheel 6 is located on the side of the wheel rim. plate side.

[0070] This configuration eliminates flow losses due to disc back clearance, further improving the efficiency of the first stage turbine at low engine speeds. Due to the relatively large diameter D1 of the primary turbine inlet, the double-cha...

Embodiment 3

[0072] Example 3, such as Figure 7 As shown, in the above-mentioned embodiment 1, an airflow guide vane 16 can also be provided at the nozzle of the large flow channel 8 , and the airflow guide vane 16 is obliquely installed at the nozzle of the large flow channel 8 . The airflow guide vane 16 is inclined to the direction of rotation of the turbine to ensure that the airflow enters the turbine at a prescribed angle. Adopting this technical solution can improve the energy utilization efficiency of the exhaust gas at medium and high speeds of the engine, and effectively prevent the backflow generated at the inlet of the secondary turbine from entering the large flow channel 8 at low speeds of the engine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com