Patents

Literature

2384results about How to "Prevent air leakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

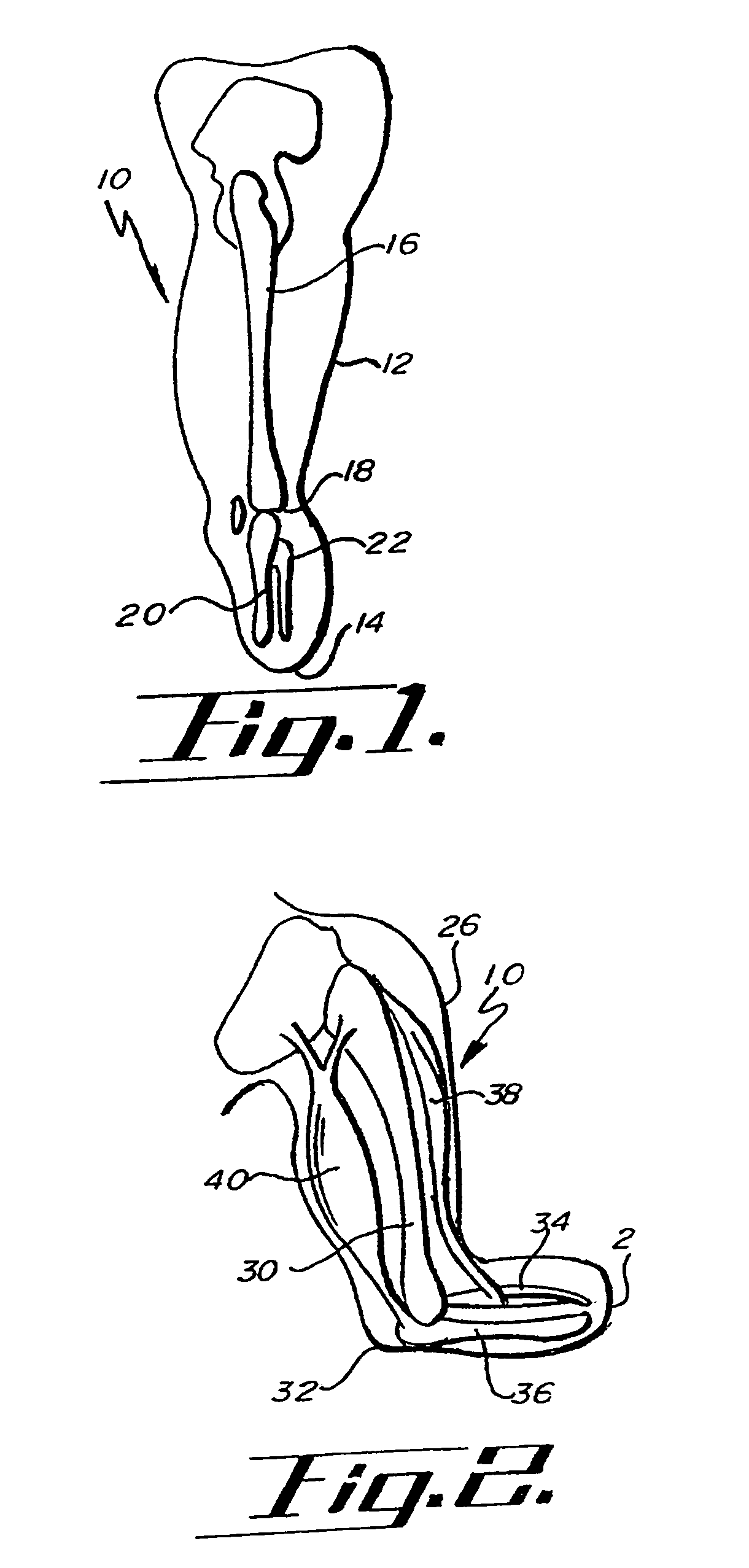

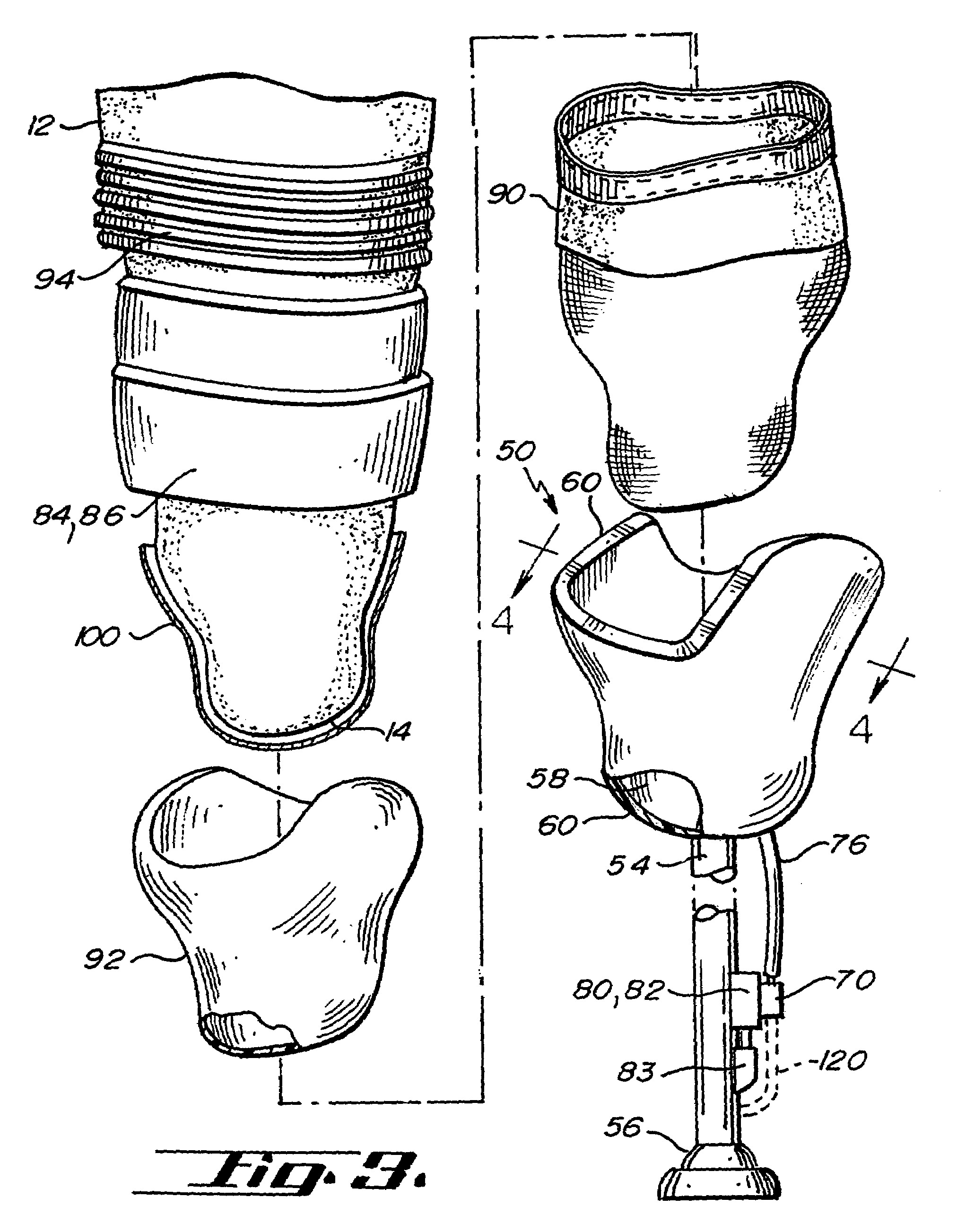

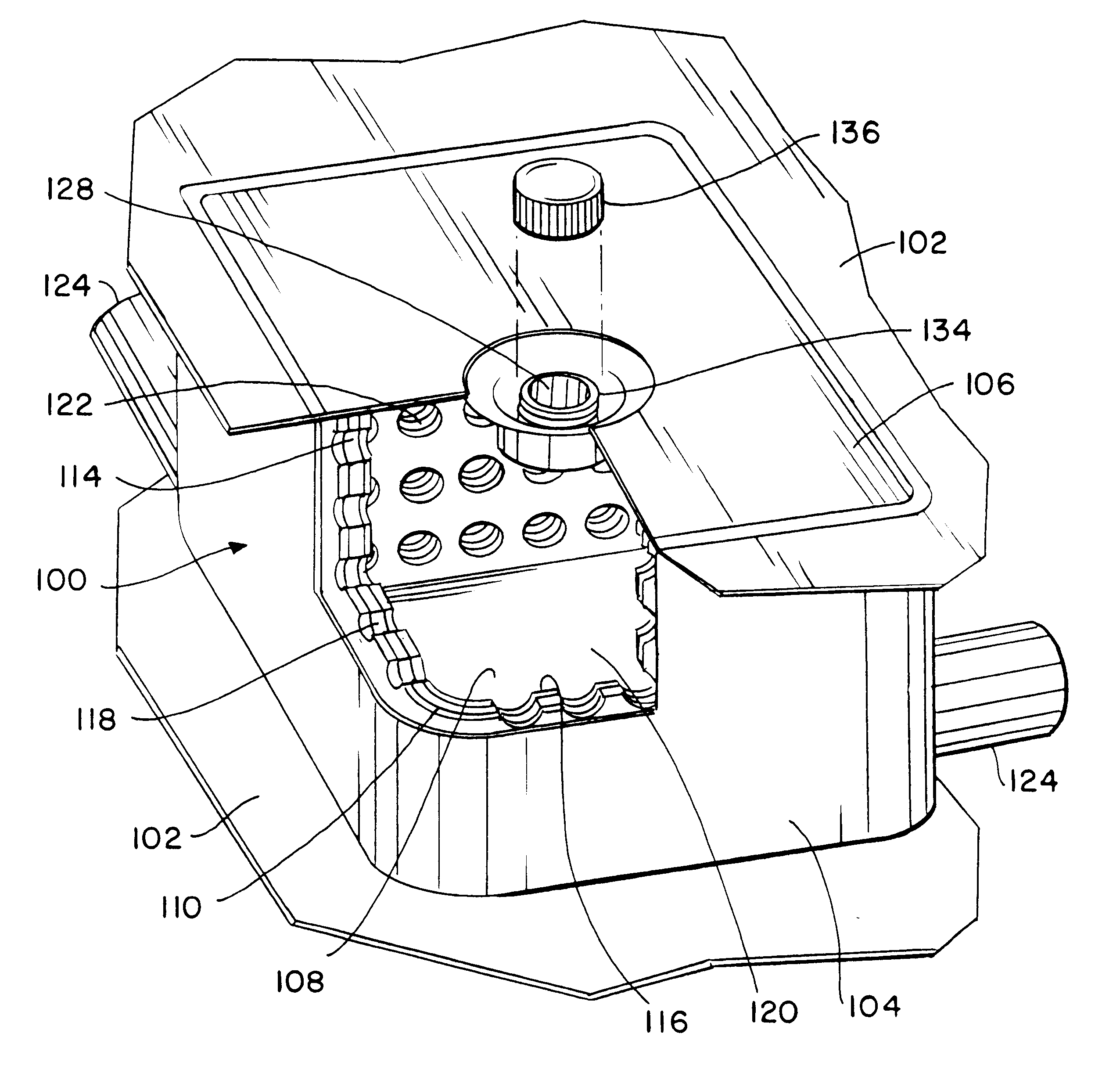

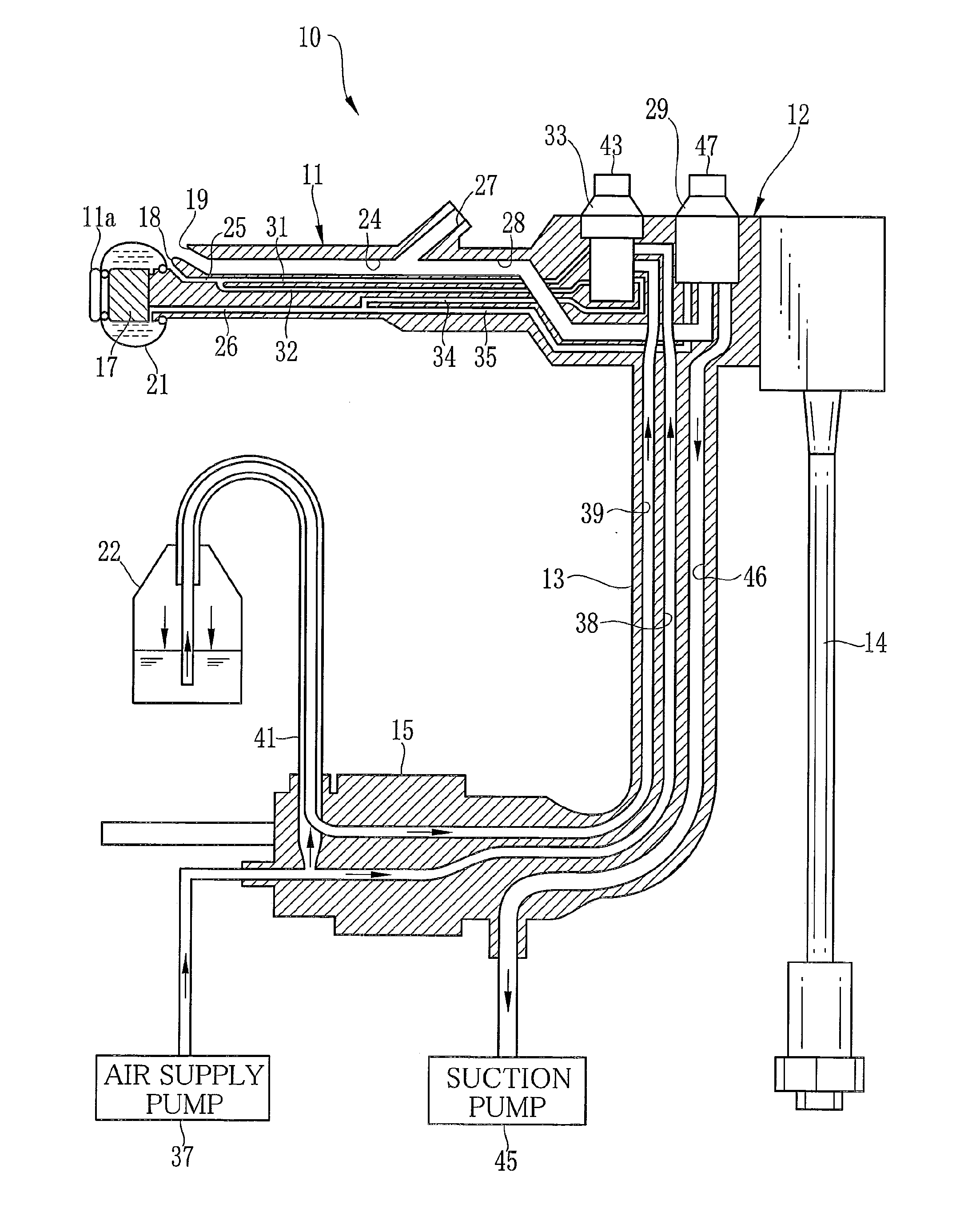

Surgical drape and suction head for wound treatment

InactiveUS7117869B2Improve featuresPrevent air leakageDiagnosticsSurgical drapesEngineeringWound therapy

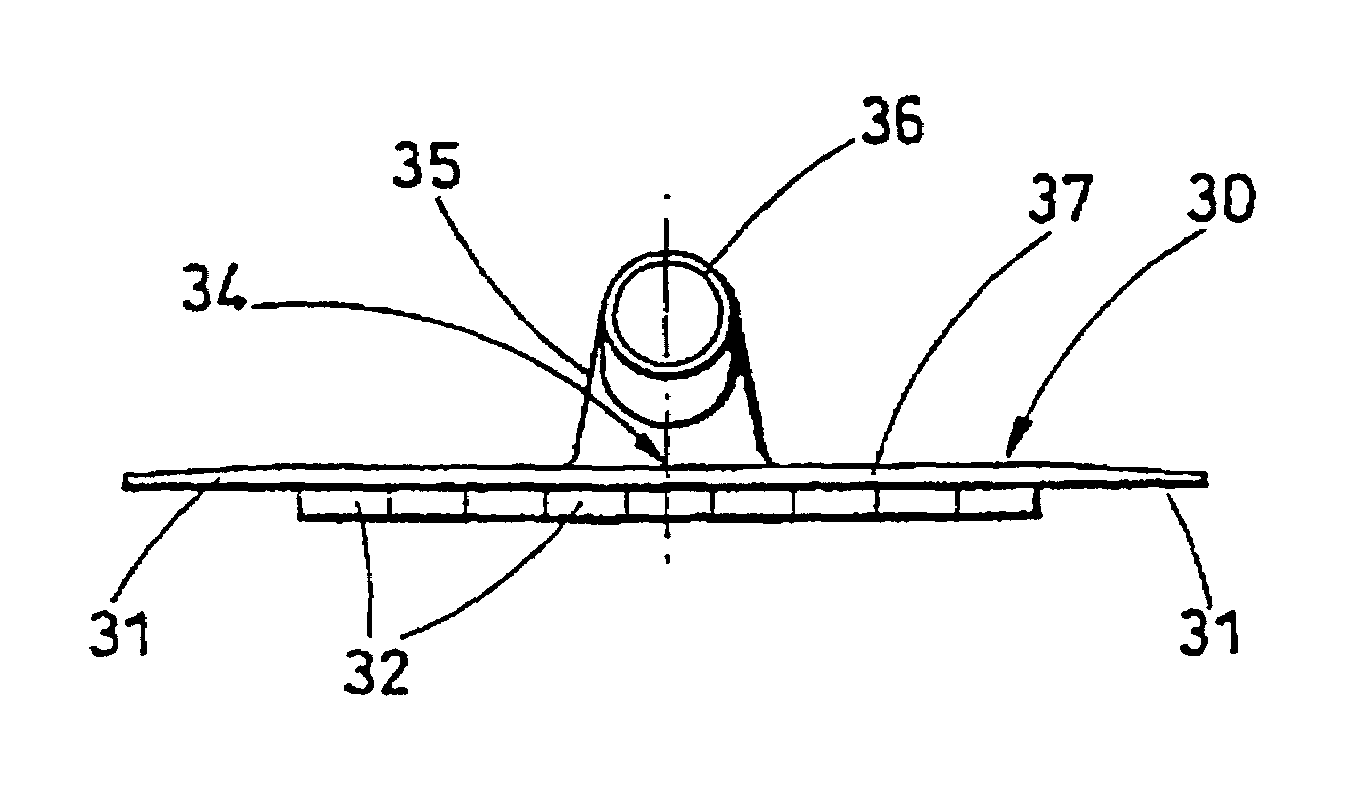

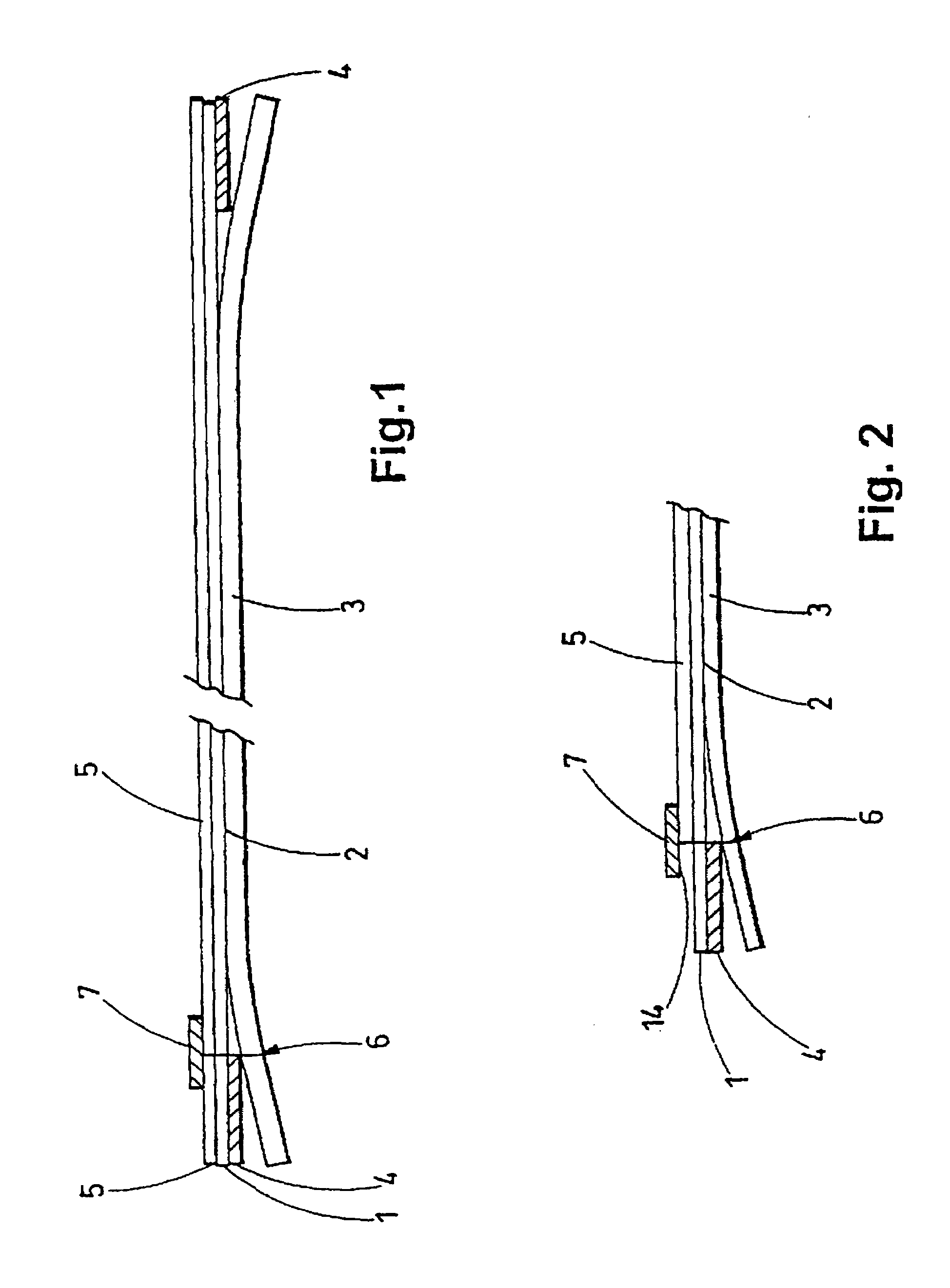

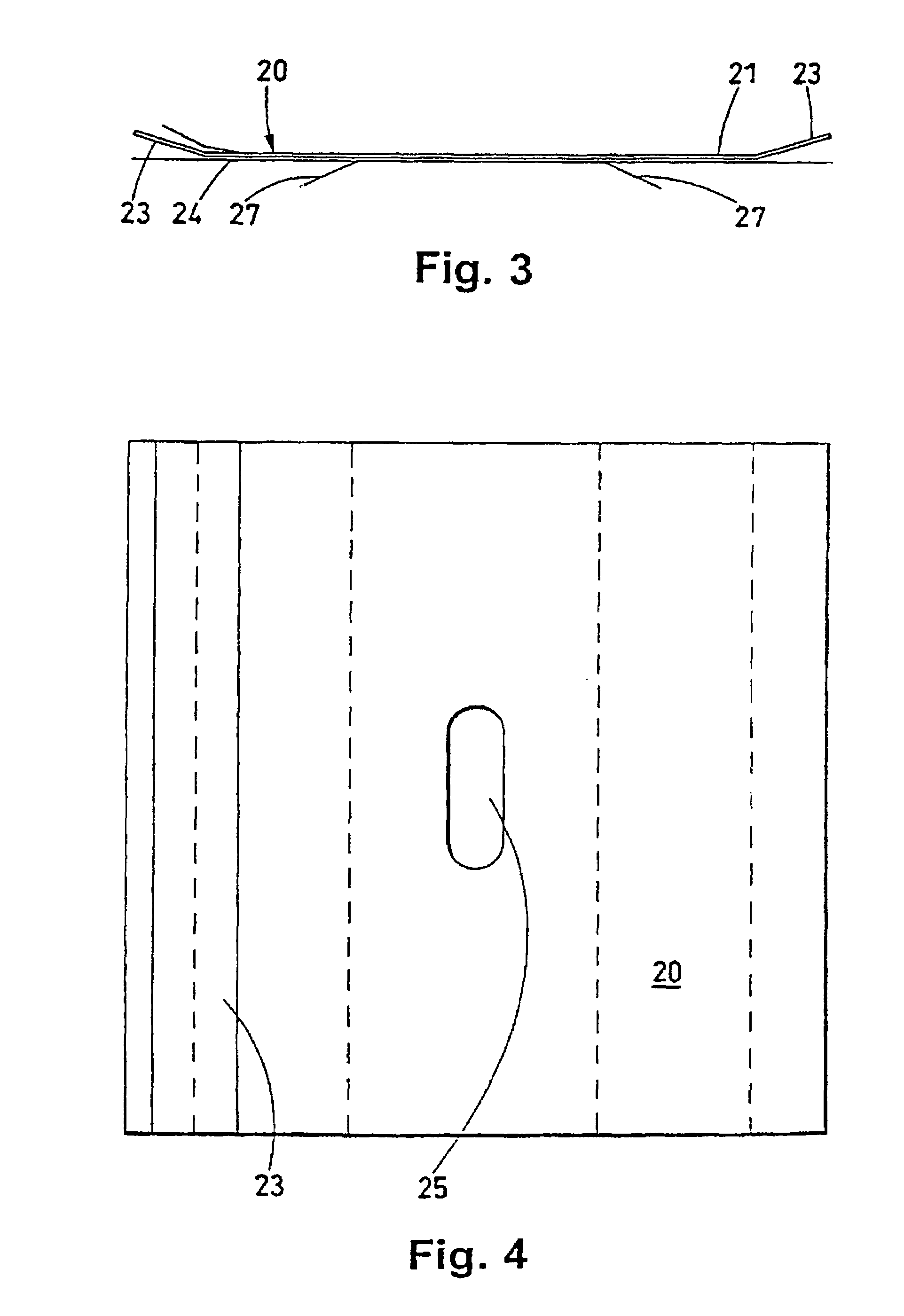

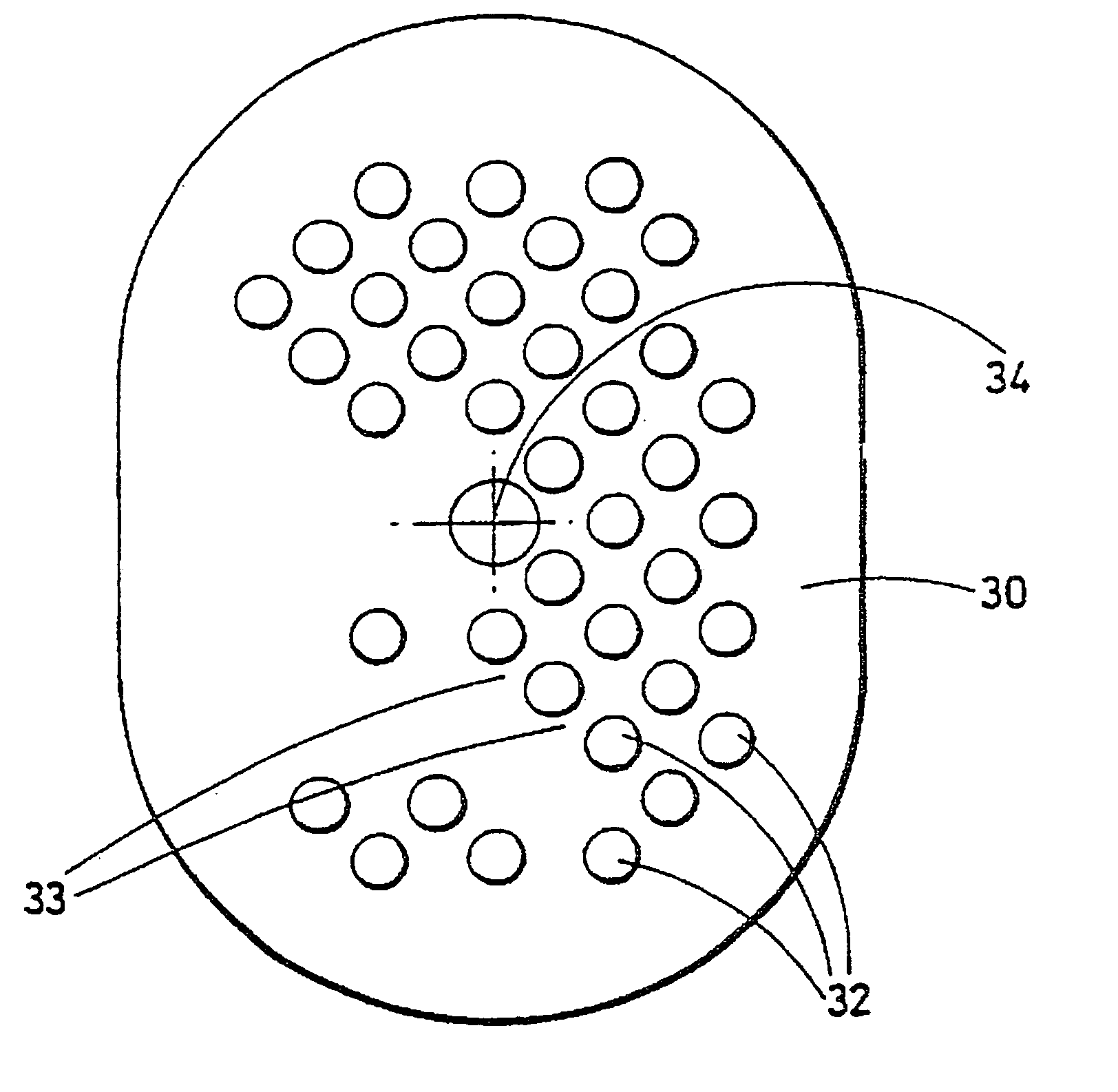

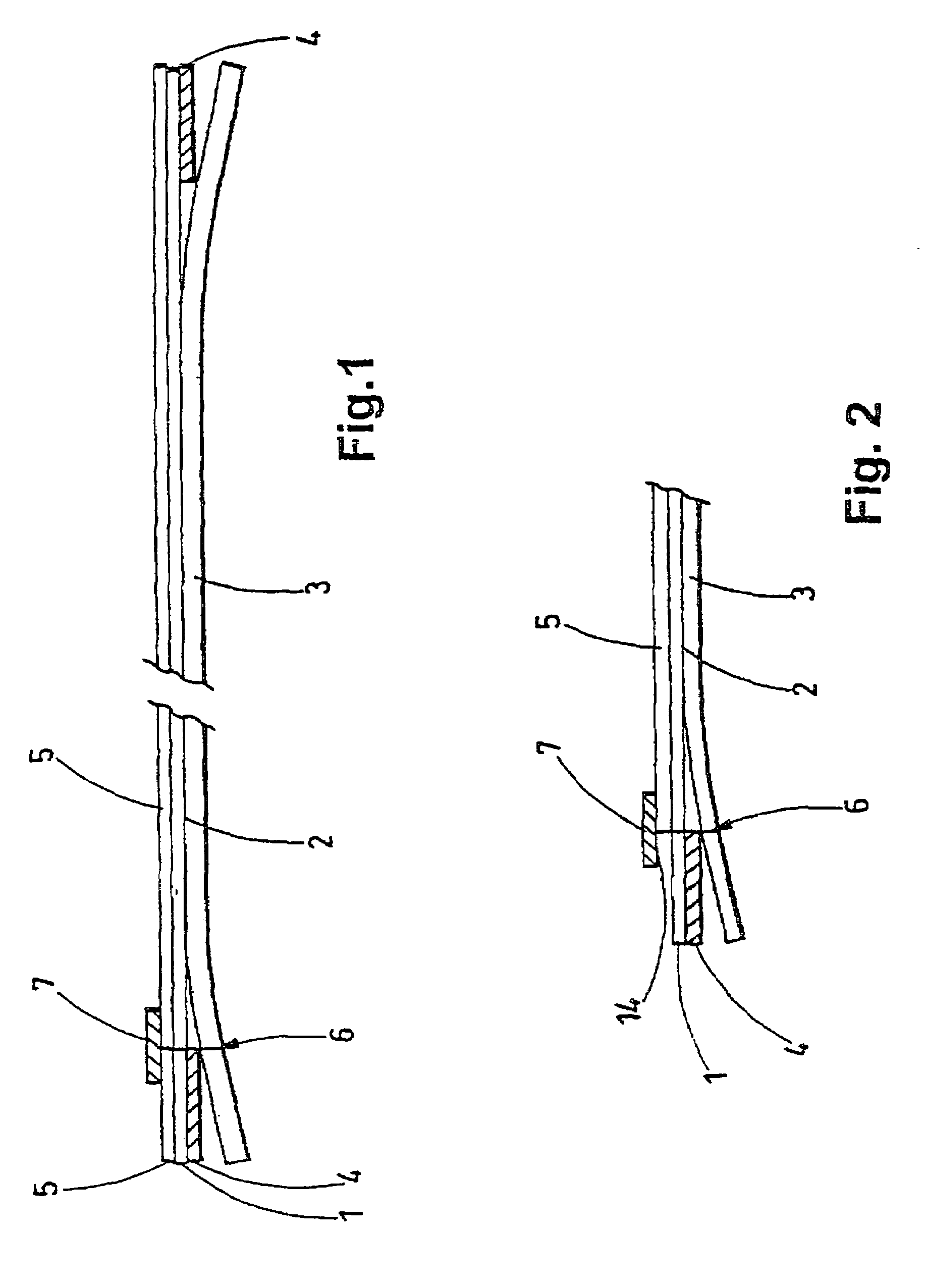

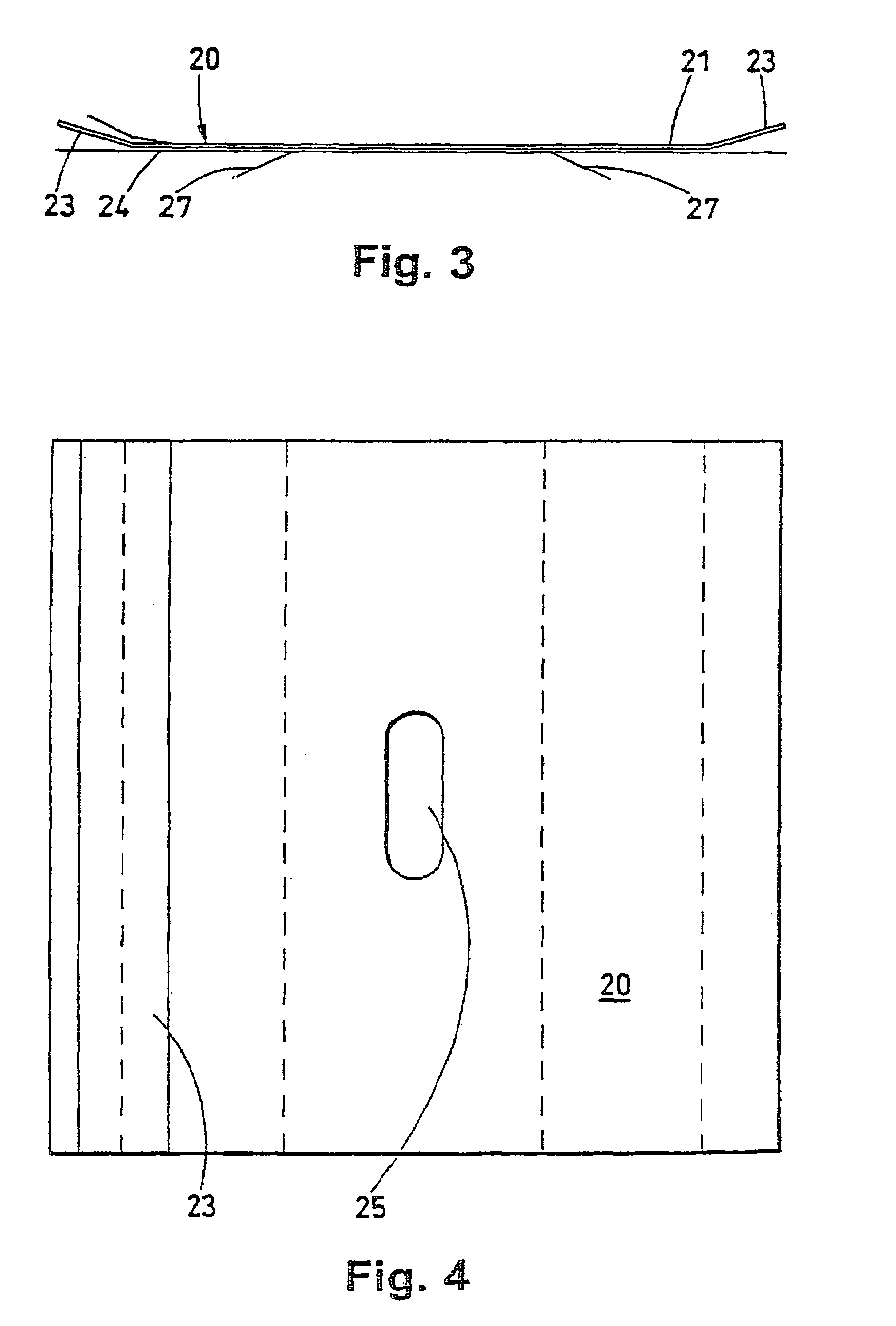

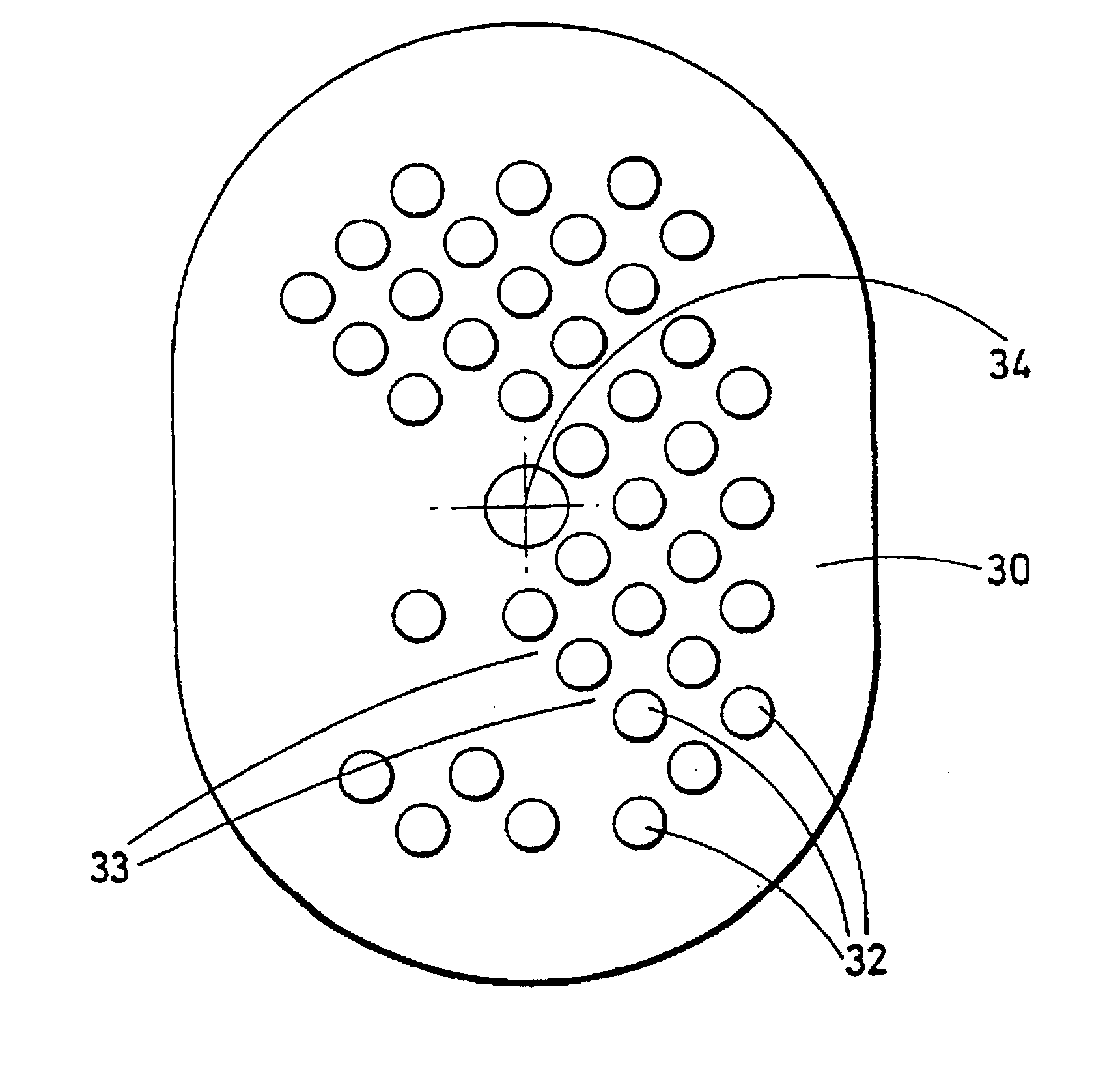

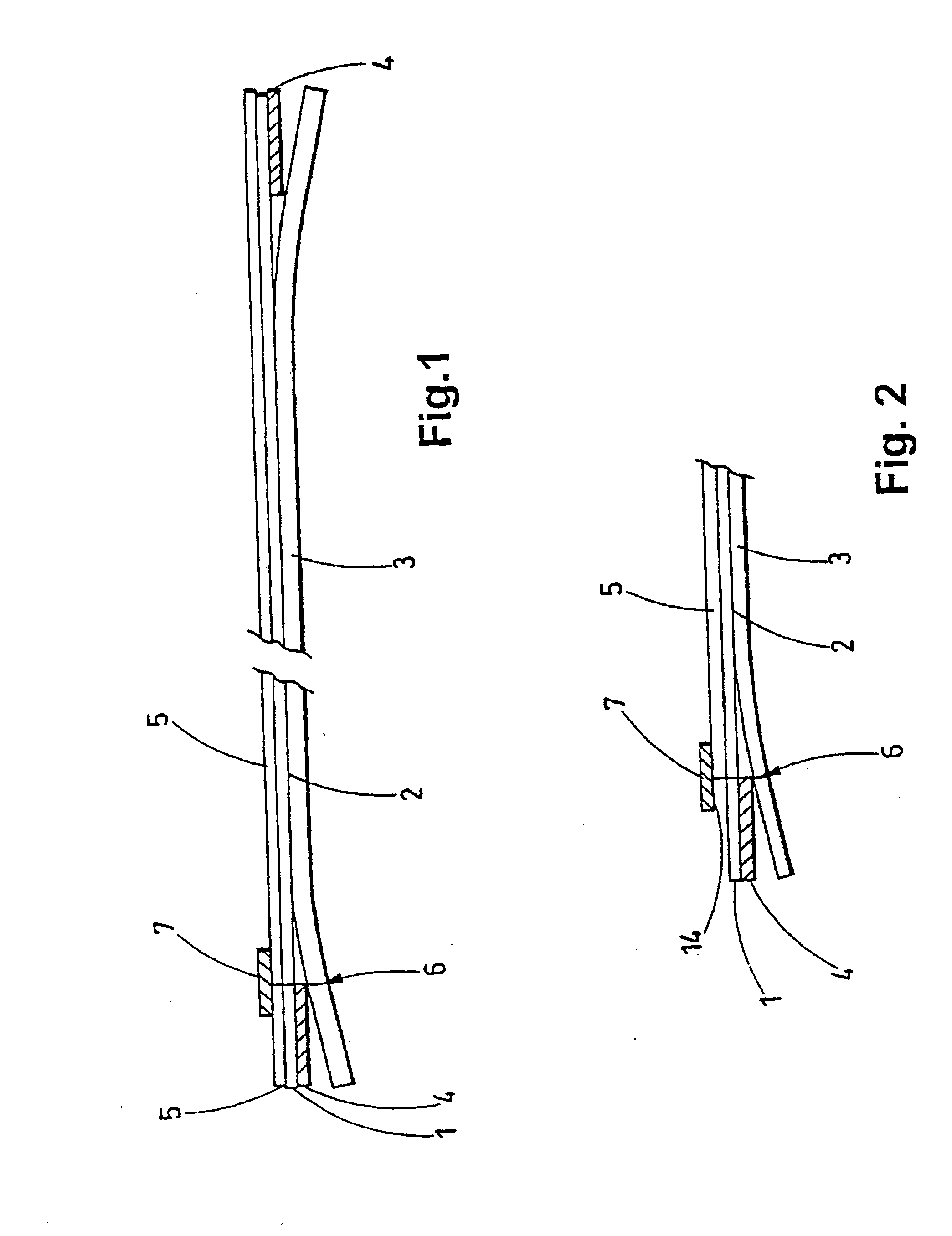

A wound therapy combination comprising a suction head and a surgical drape. The suction head comprises a planar flange portion and a tubular connector piece on a first face that communicates with an aperture extending to a second face. The second face is formed with projections that define flow channels for facilitating flow of liquids to the aperture.

Owner:KCI LICENSING INC

Surgical drape and head for wound treatment

InactiveUS7273054B2Improve featuresPrevent air leakageDiagnosticsSurgical drapesWound.exudateEngineering

A wound therapy device comprising a head and a surgical drape. The head comprises a planar flange portion and a tubular connector piece on a first face that communicates with an aperture extending to a second face. The second face is formed with projections that define flow channels for facilitating flow of liquids to and from the aperture. The device may provide medicated fluid to the wound evenly while withdrawing wound exudates.

Owner:KCI LICENSING INC

Surgical drape and suction head for wound treatment

InactiveUS20050028828A1Good handling characteristicsImprove featuresDiagnosticsSurgical drapesEngineeringWound therapy

A wound therapy combination comprising a suction head and a surgical drape. The suction head comprises a planar flange portion and a tubular connector piece on a first face that communicates with an aperture extending to a second face. The second face is formed with projections that define flow channels for facilitating flow of liquids to the aperture.

Owner:KCI LICENSING INC

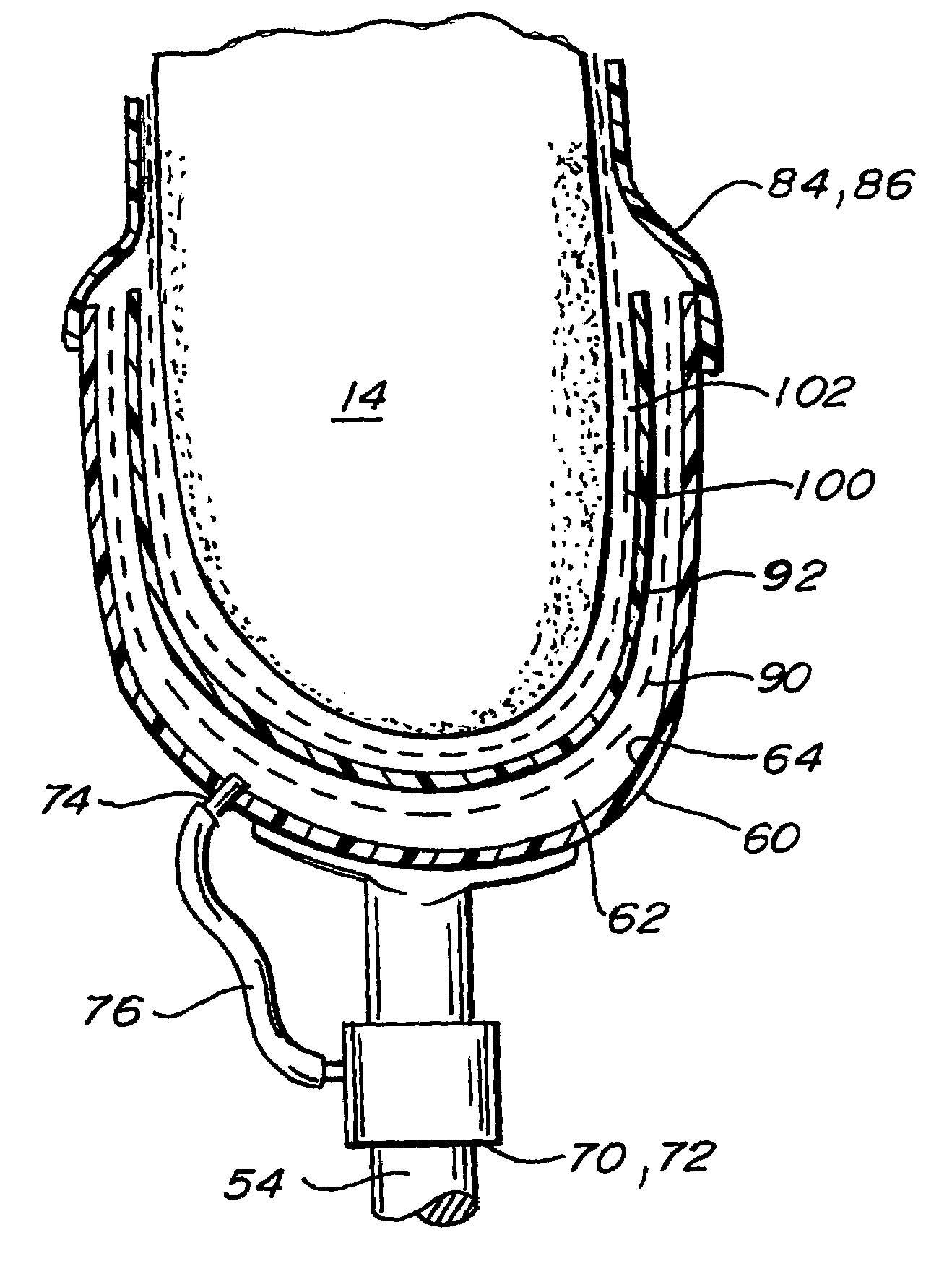

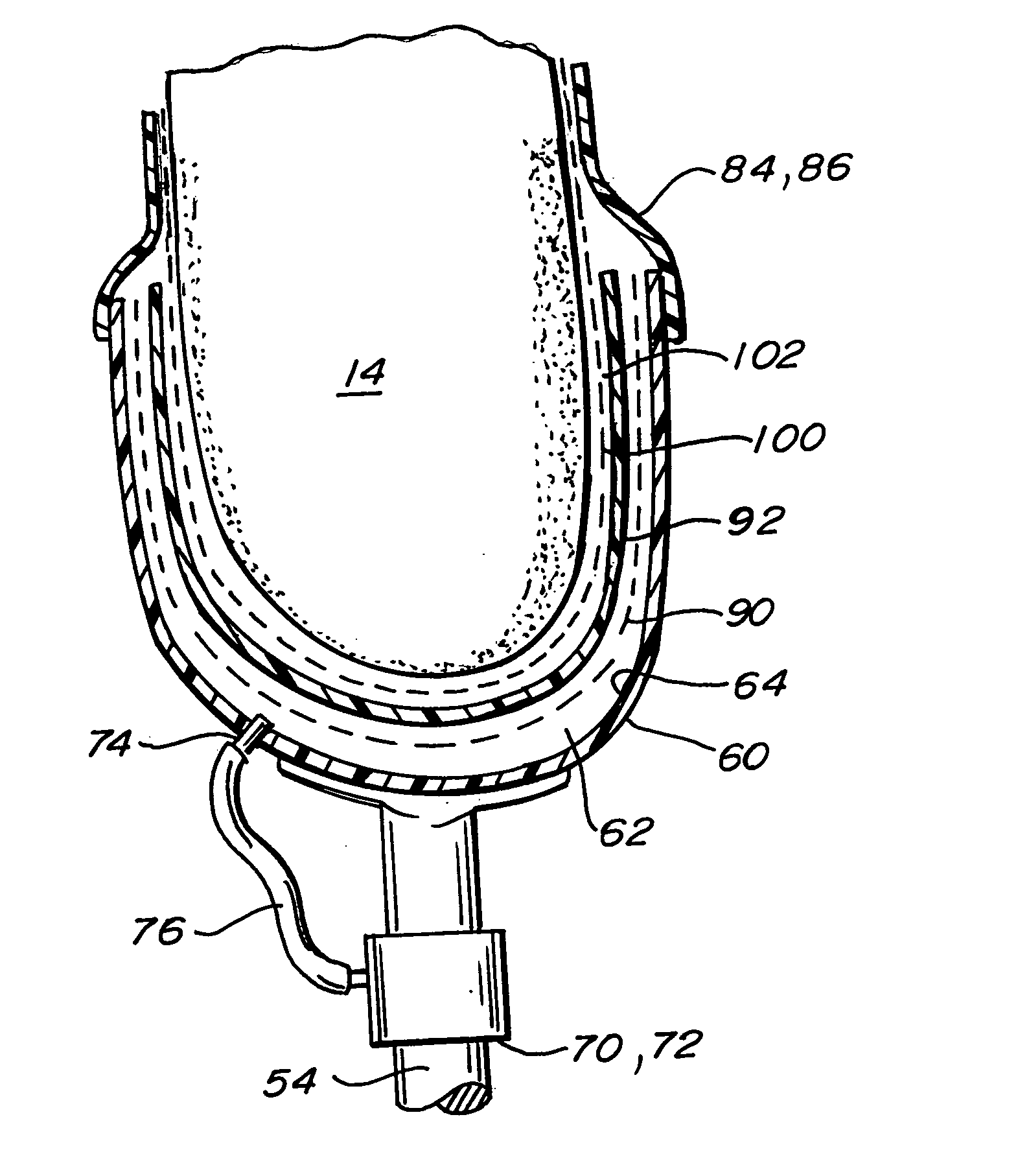

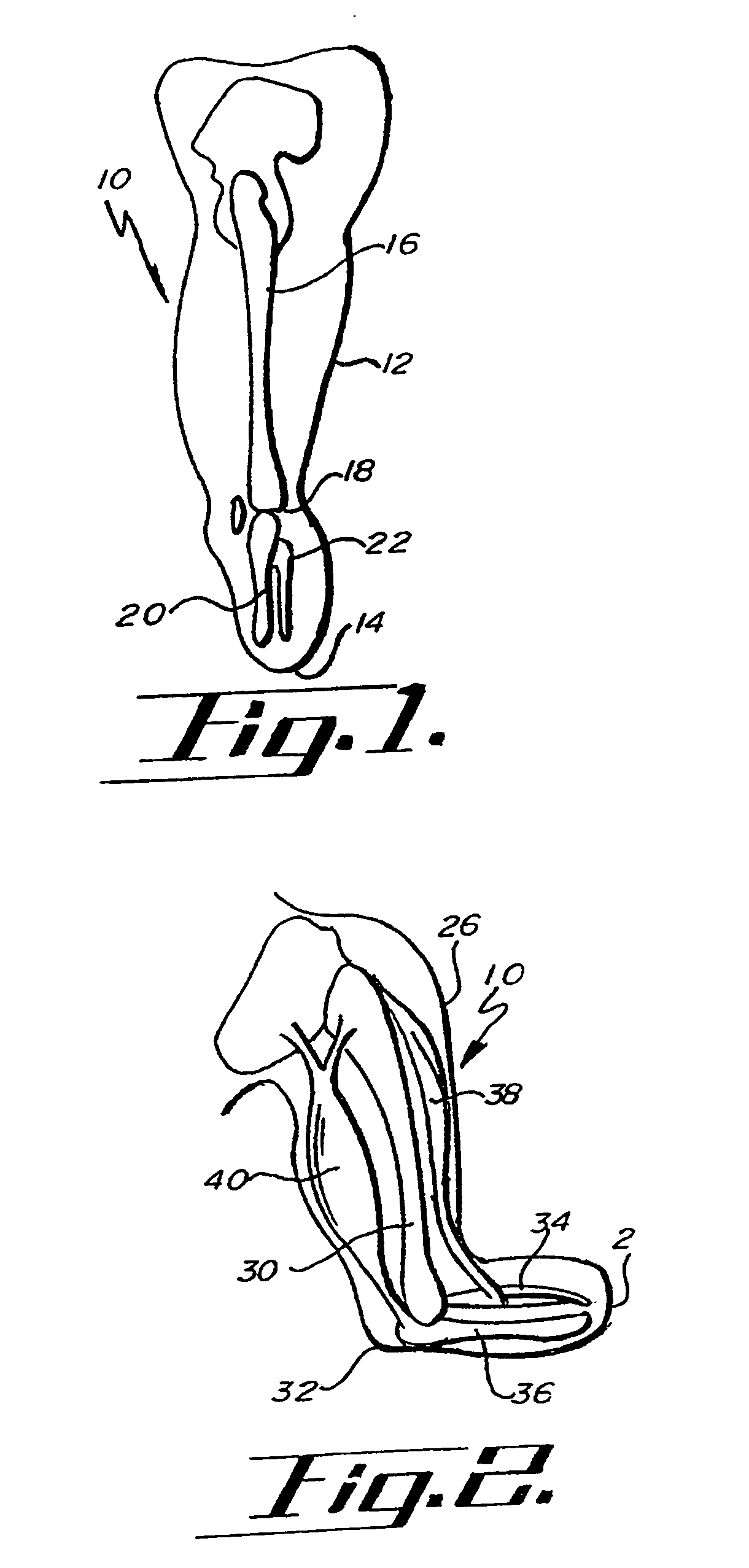

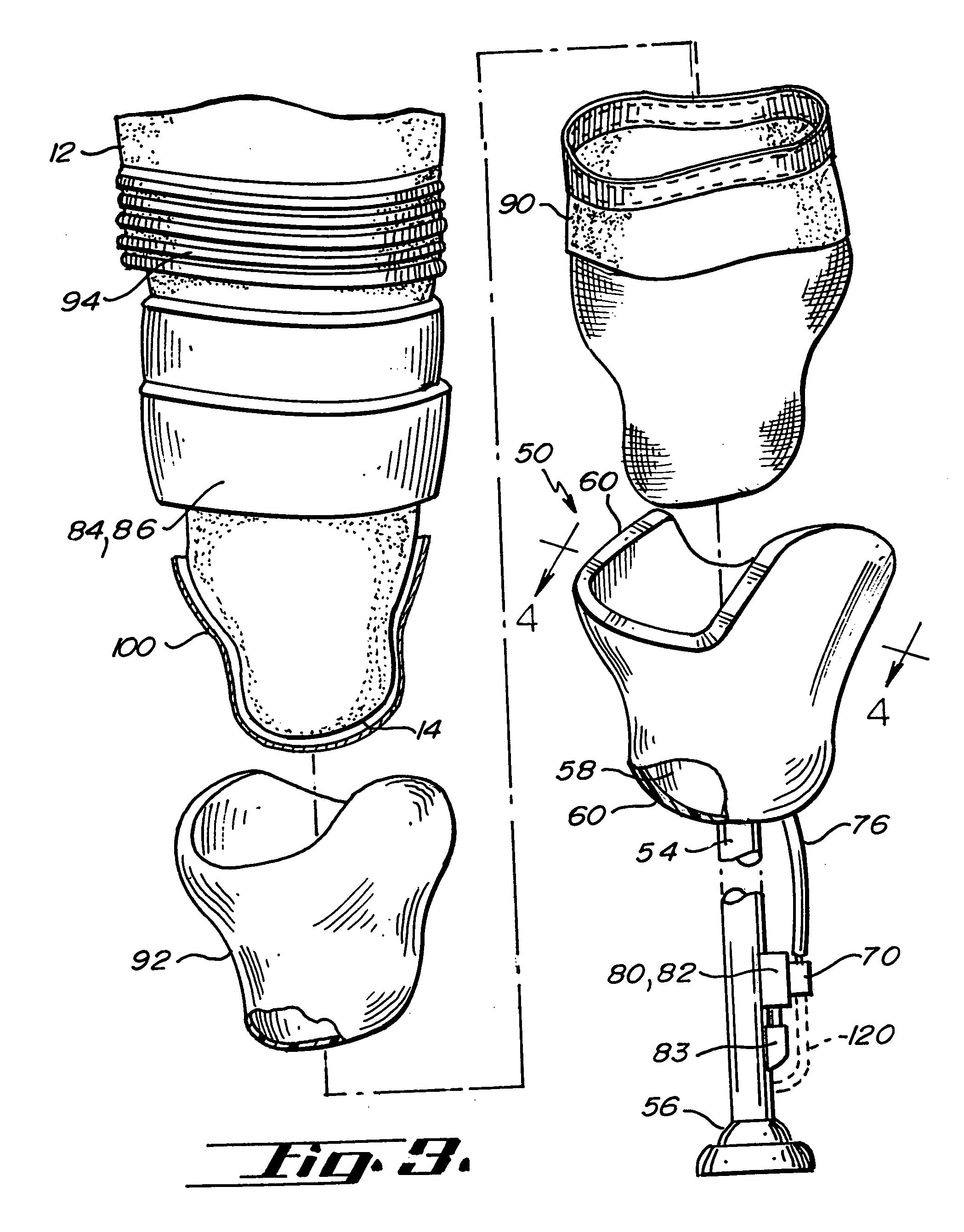

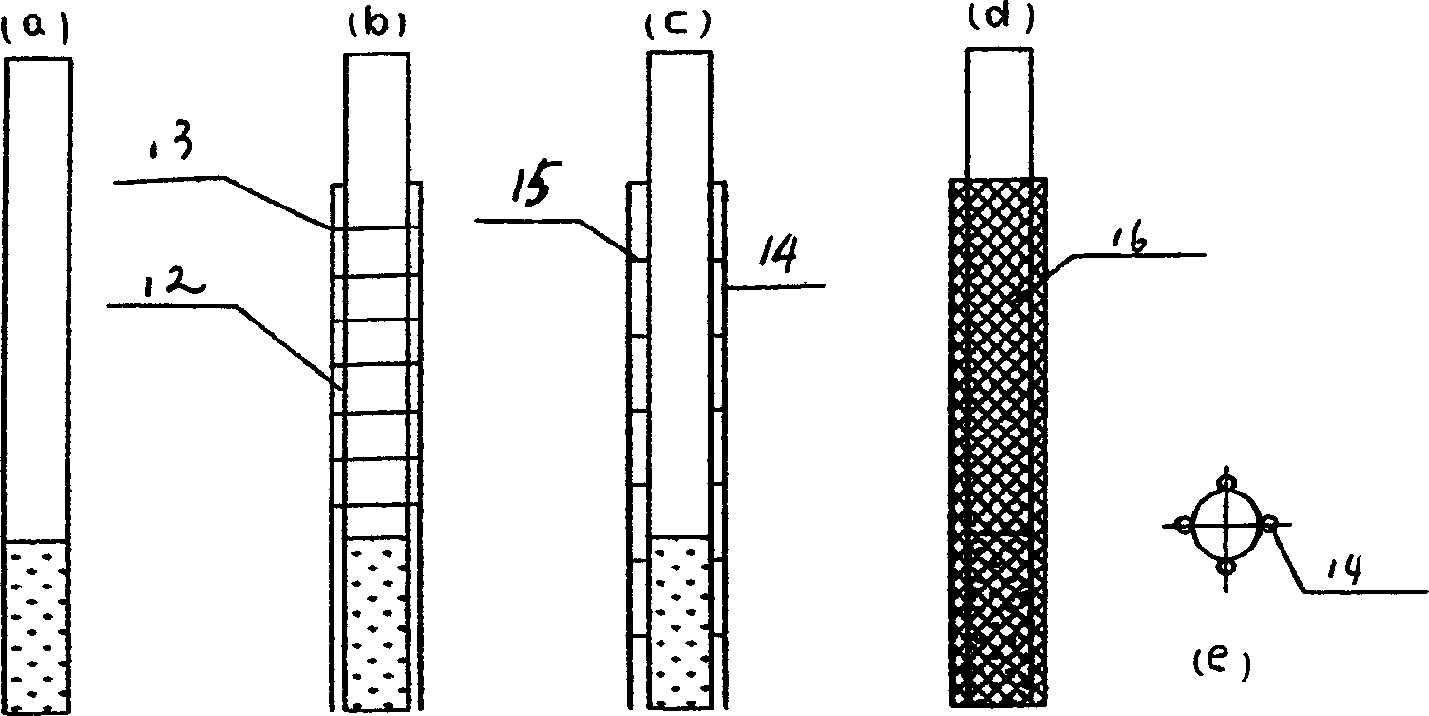

Osmotic membrane and vacuum system for artificial limb

InactiveUS6974484B2Prevent air leakageReduce pressureAbsorbent padsBaby linensWater vaporPerspiration

A system for removing perspiration from a residual limb inserted in a prosthesis comprising an nonporous prosthesis socket, a porous thin sheath adjacent the socket, a nonporous liner adjacent the sheath, an osmotic membrane adjacent the liner allowing water vapor to pass from the limb but preventing liquid from passing to the limb, a nonporous seal that prevents air leakage between the residual limb and the socket; and, a vacuum source to reduce the pressure in a space between the limb and socket. A method of removing perspiration from a residual limb in a prosthesis.

Owner:SANYO ELECTRIC CO LTD

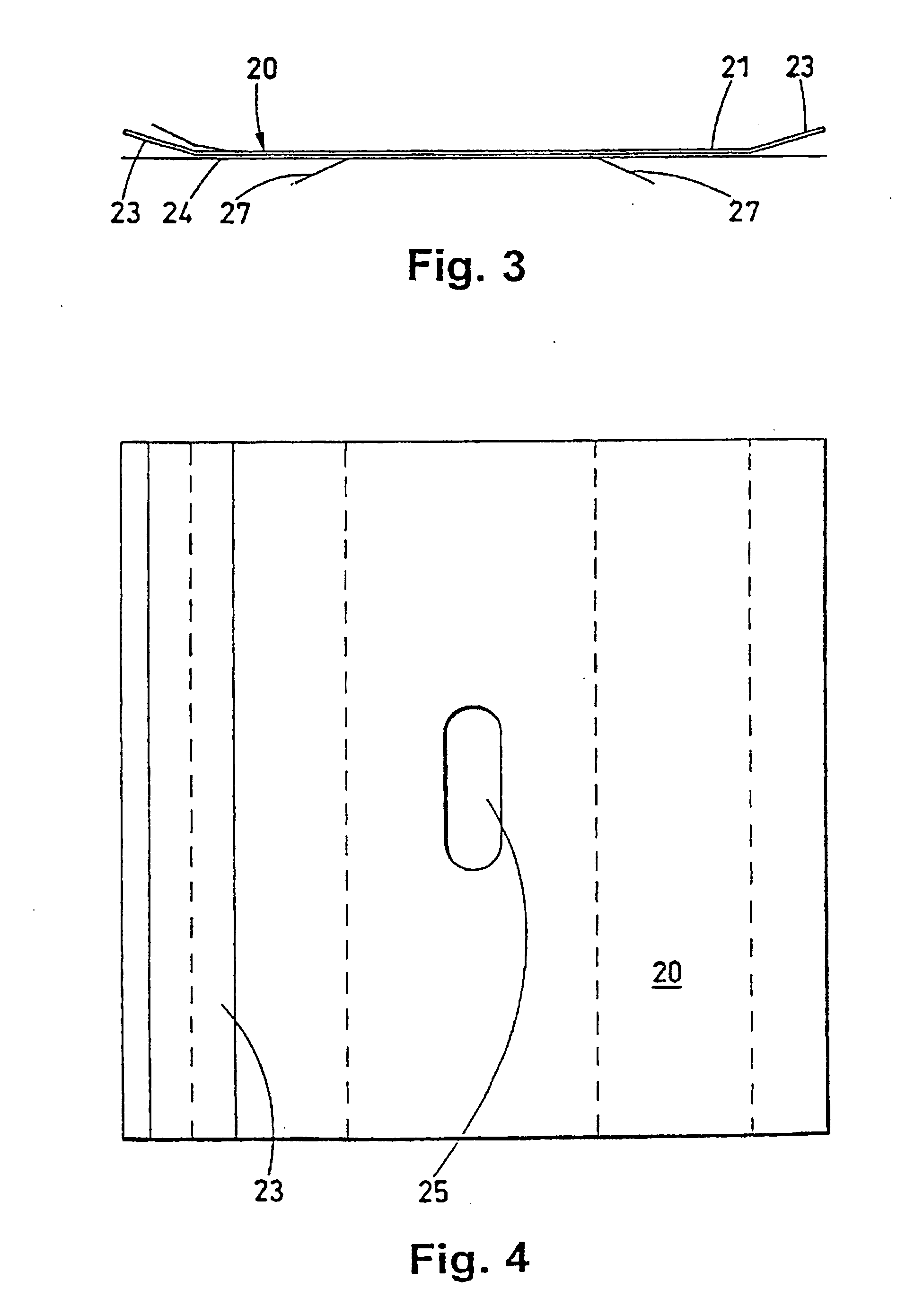

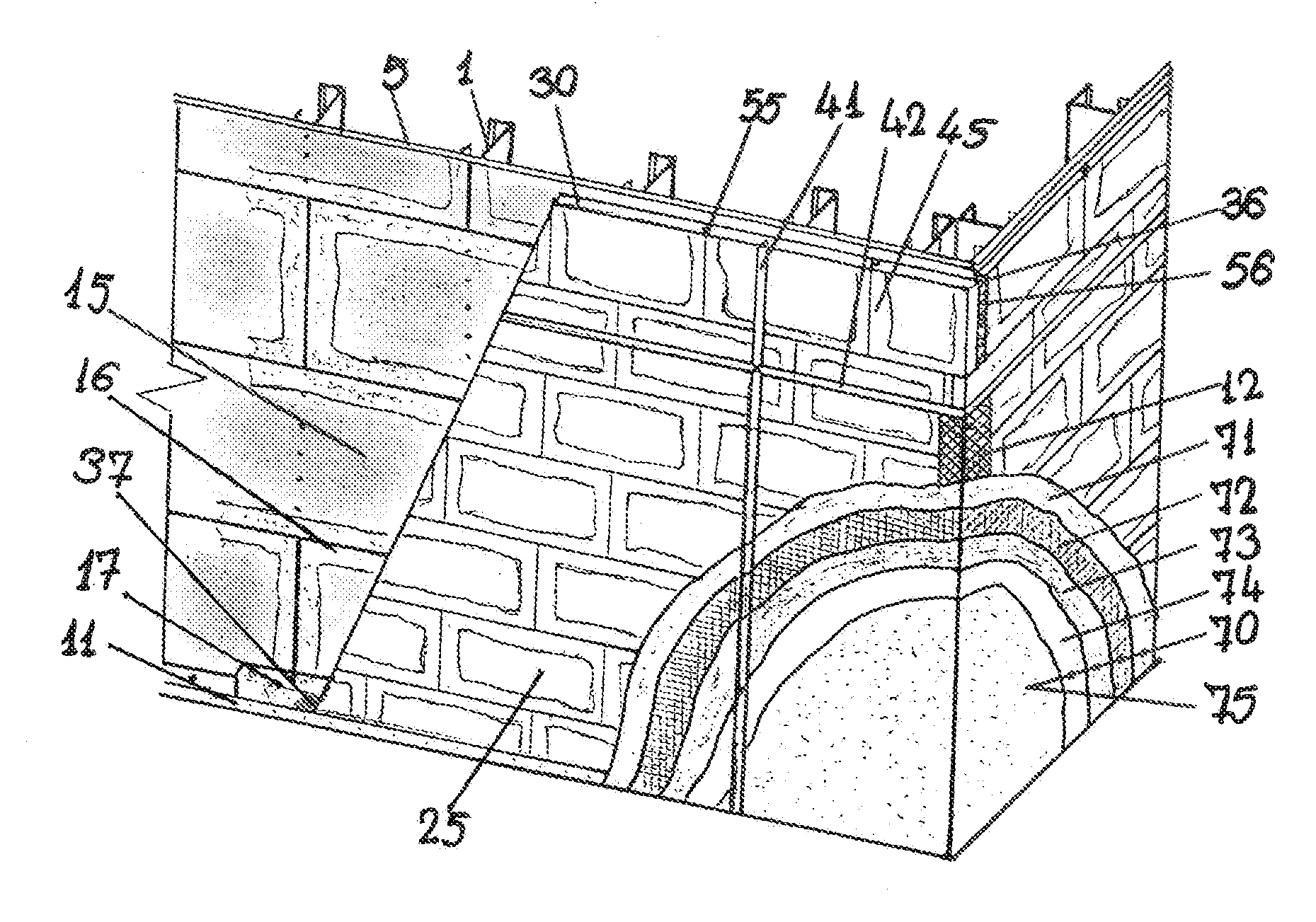

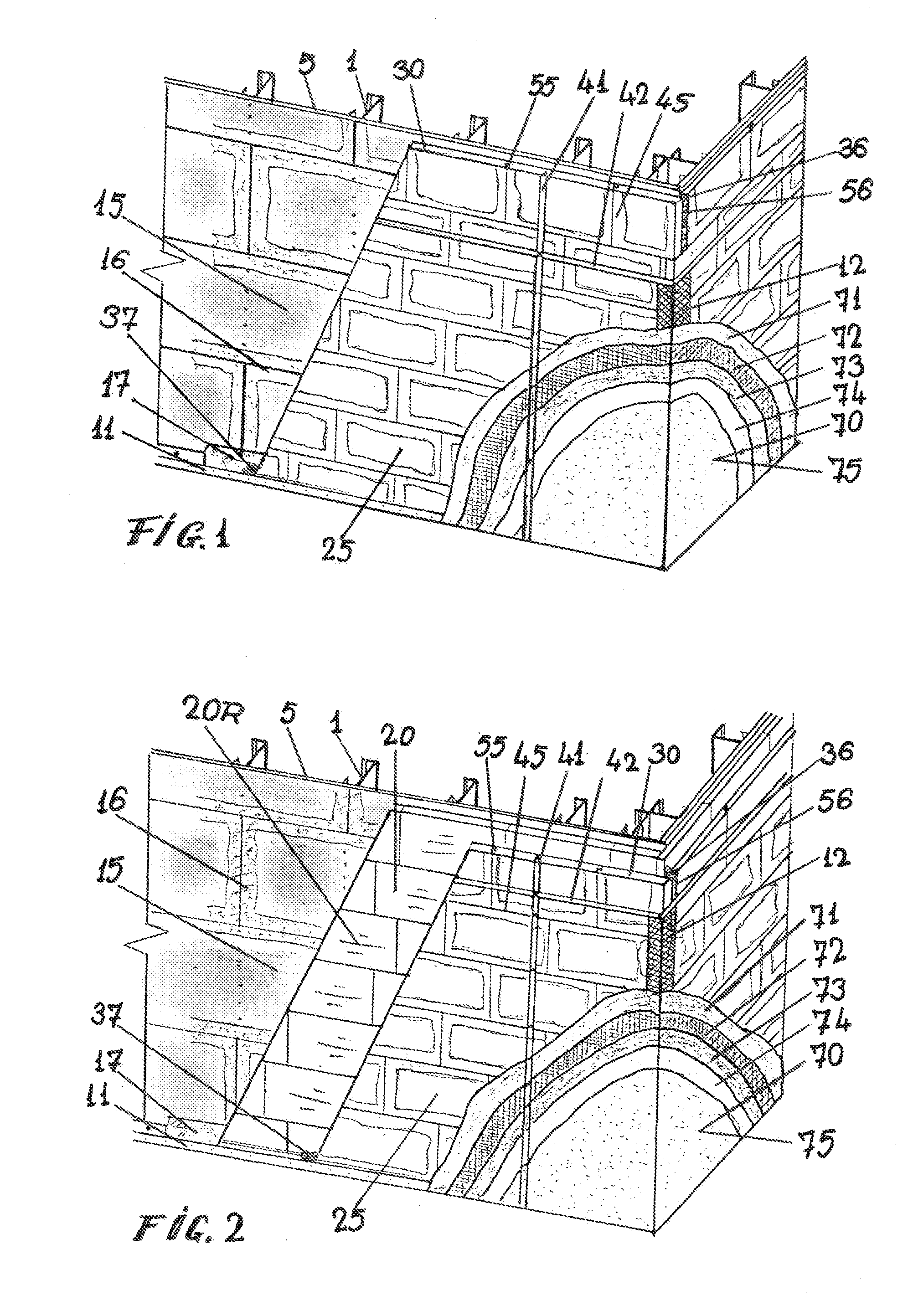

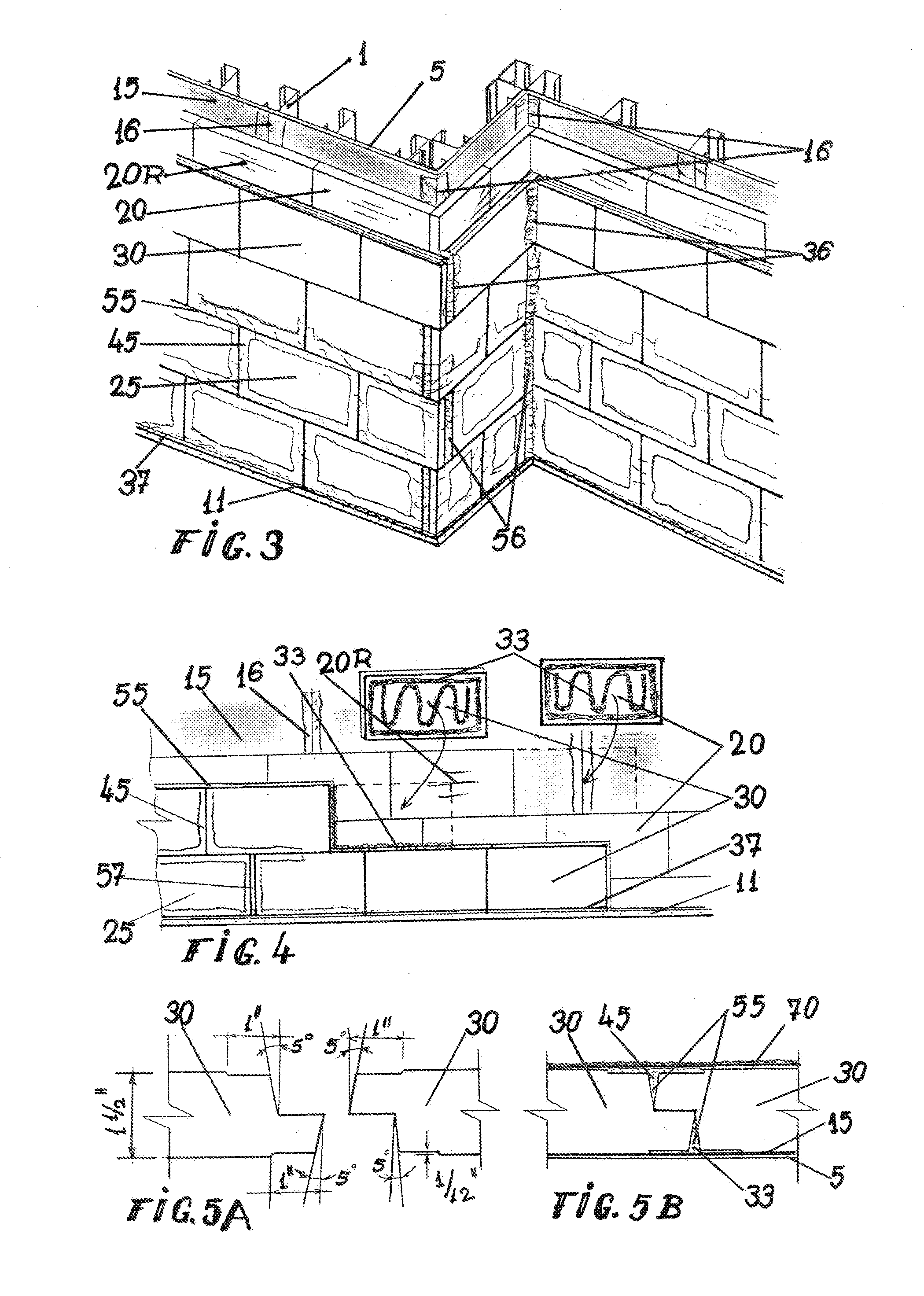

NP-EIFS Non-Permissive Exterior Insulation and Finish Systems concept technology and details

A new concept wall system is provided, wherein the Exterior Insulation and Finish System cladding is created using components with no water absorption, a very low vapor permeability and sealing properties, accommodated with an installation technology which extend the materials properties to the assembly, together with bonding and sealing the intersections and terminations, creating a Non-Permissive to water and vapor diffusion, Exterior Insulation and Finish System (NP-EIFS). The present invention relates to an EIFS cladding having two air and vapor barriers, one applied to the substrate, a continuous liquid membrane with sheathing joints sealed to be moisture barrier for inside vapors, and an exterior weather and vapor barrier which is created using closed cell extruded polystyrene insulation boards, special assembled with joints sealed, to create a non-permissive insulation envelope of the enclosure. Another object of the invention is to provide waterproof and air / vapor-proof details, a new concept of flashing and sealant application around windows / doors and other constructive elements to avoid thermal bridges and air leakage inside thermal envelope and wall assembly. Methods of installation are included.

Owner:RADOANE MARIUS

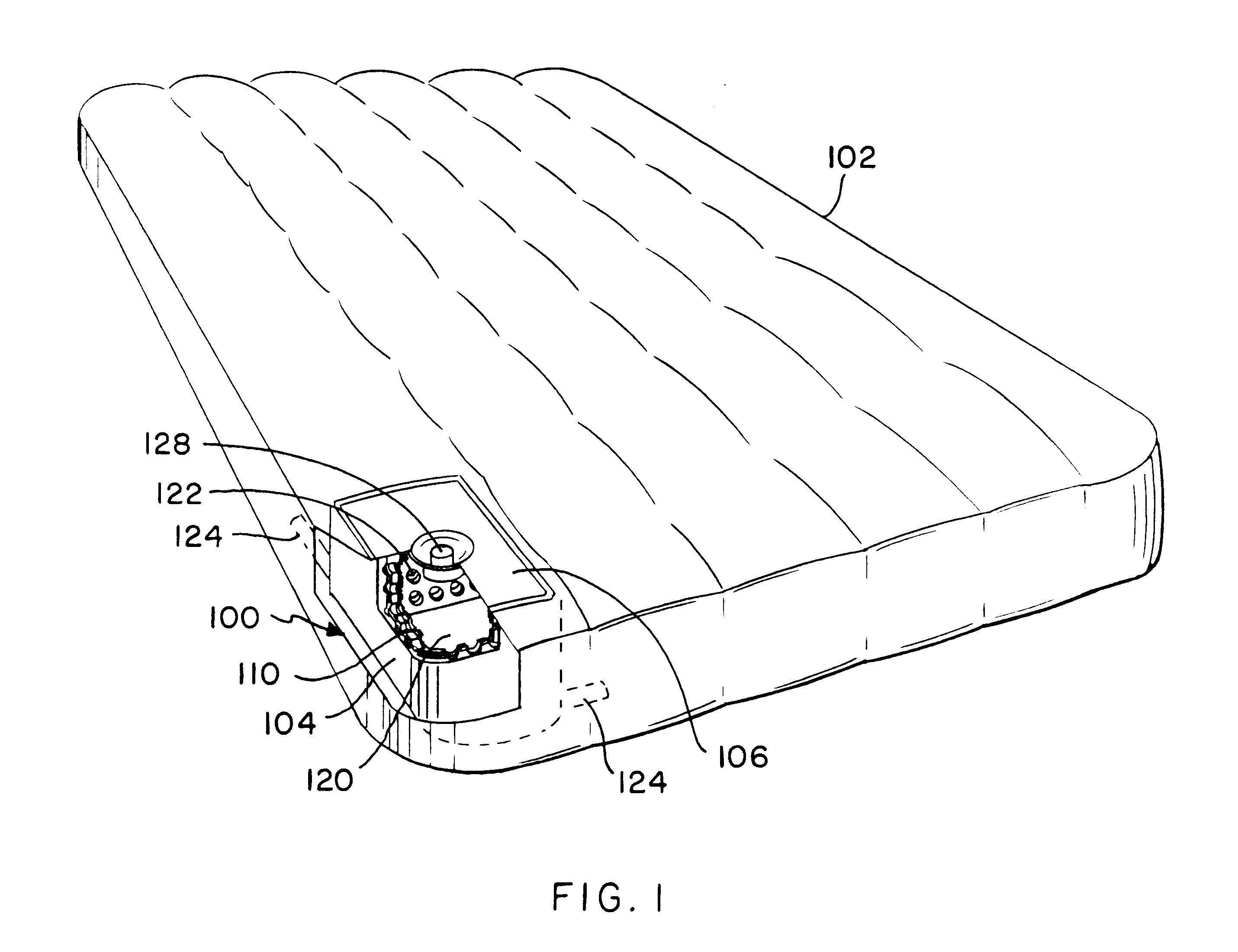

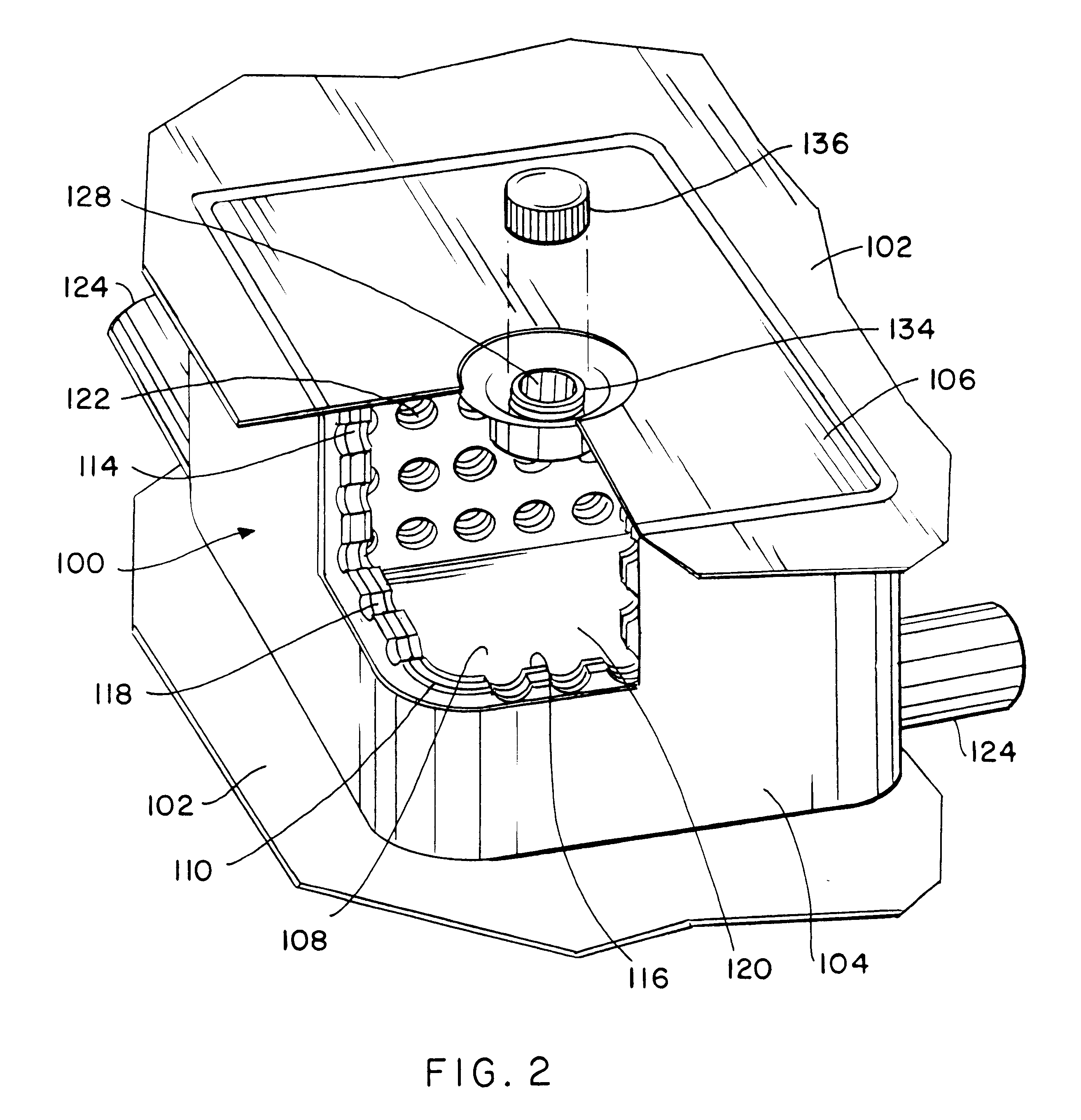

Internal air pump for inflatables

InactiveUS6287095B1Easy to packImprove efficiencyStuffed mattressesFlexible member pumpsPump chamberAir pump

An internal air pump for charging inflatables with air and method therefore is disclosed which is directed to an air pump mounted internal to an inflatable device for injecting air therein. The inventive air pump is a thin-walled, lightweight, highly elastic, flexible plastic construction which is easily packaged within the inflatable device and can be used to inflate the device to a desired air pressure. In its most fundamental embodiment, the internal air pump comprises a construction including an outer shell layer having a continuous sidewall, a roof layer and a floor layer for defining an enclosed inner pump chamber. An inner sandwich layer is positioned adjacent to the outer shell layer and includes a resilient component. At least one air intake valve is mounted within the roof layer for admitting air into the inner pump chamber. One or more exhaust ducts are mounted in the outer shell layer for discharging air from the inner pump chamber to an inflatable device. An external force applied to the air pump forces air from the inner pump chamber to the exhaust ducts. The resilient component enables the air pump to self-adjust after the external force is removed.

Owner:INTEX RECREATION

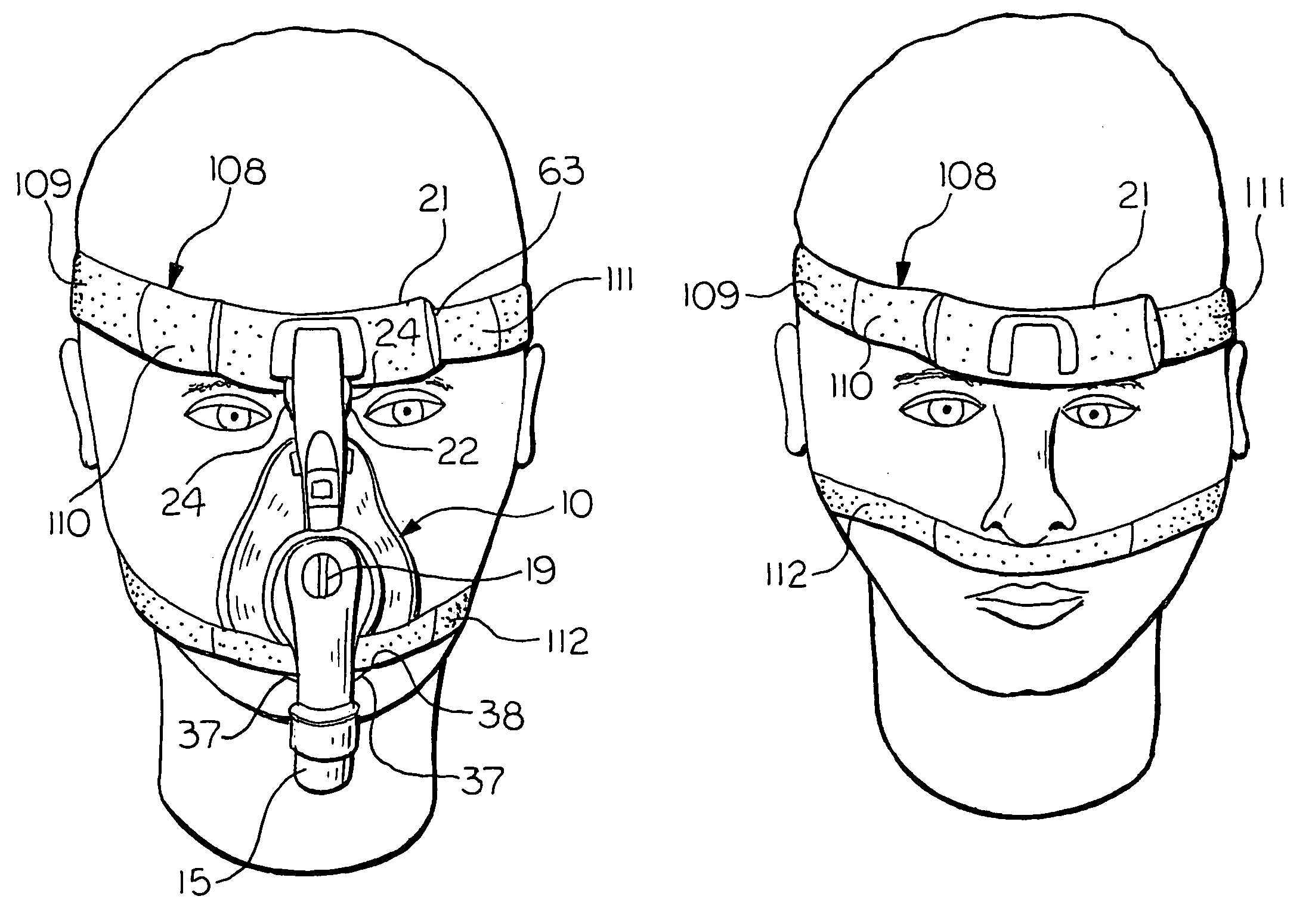

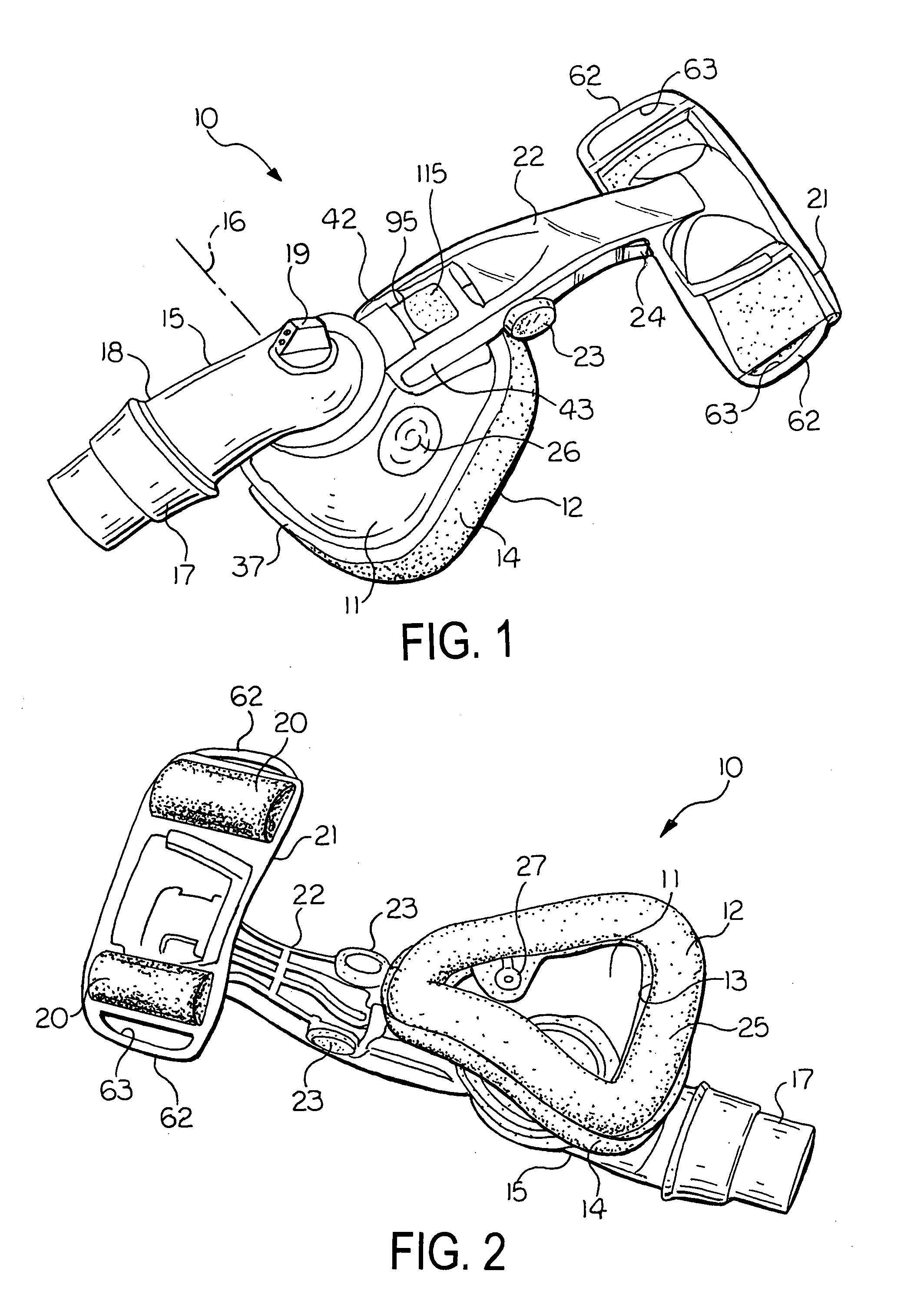

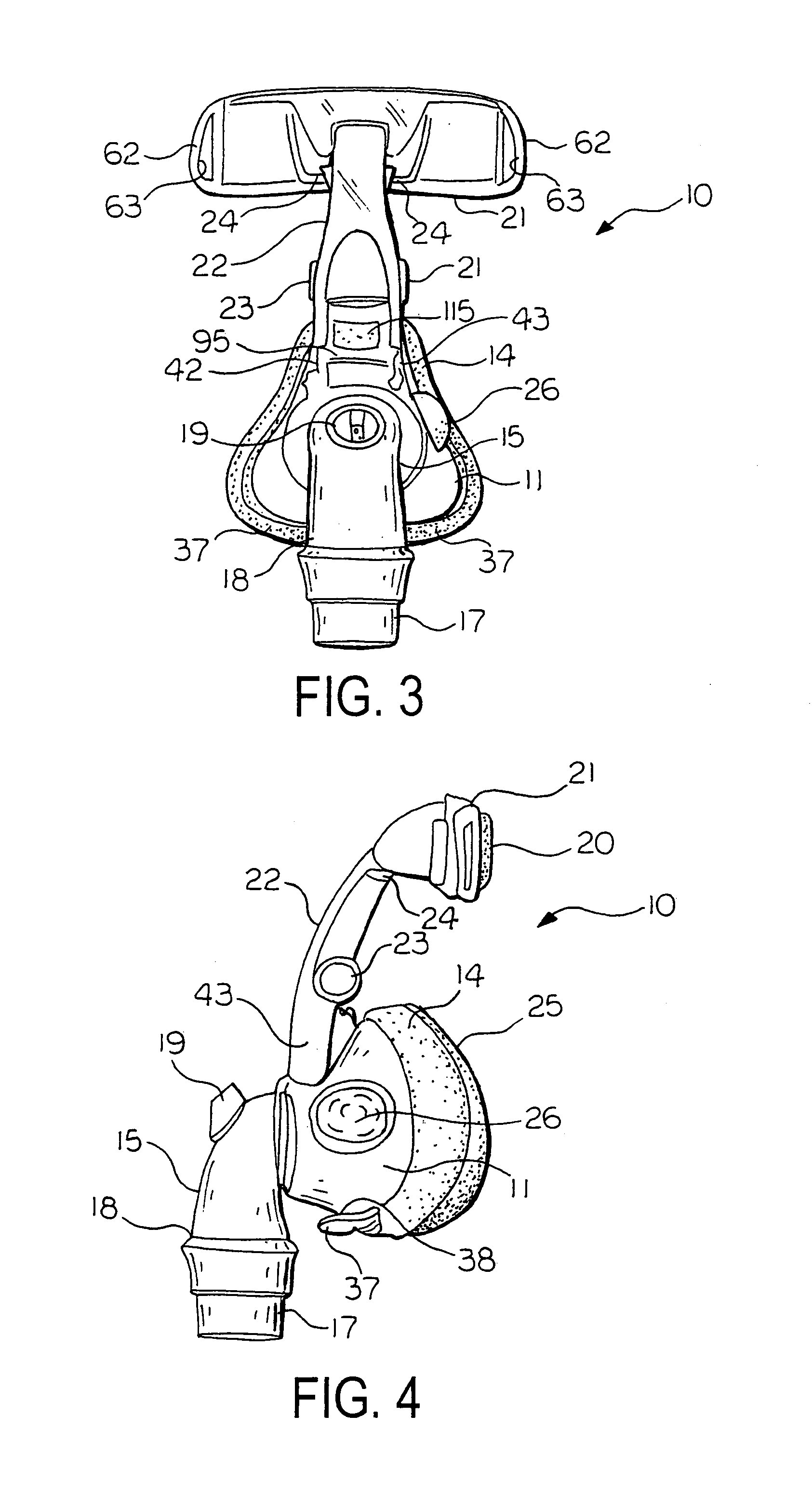

Method for securing a nasal mask

InactiveUS7219670B2Easy to customizeControl pressureRespiratory masksBreathing masksEngineeringForehead

A nasal mask for applying pressurized gas to a user's respiratory system. The mask includes an inflatable seal which is at least partially filled with a soft open cell foam. The seal includes a manual pump and a pressure release valve for inflating and deflating the seal. The mask includes an brow bar which is connected through a bridge to the mask body. The bridge can be adjusted to position the brow bar against the user's forehead for supporting an upper portion of the mask. Headgear for attaching the mask to the user is attached to the brow bar and is looped over a prong at a lower portion of the mask for securing the lower portion of the mask to the user. The mask can be easily removed from the patient while leaving the headgear and brow bar attached to the user.

Owner:DEVILBISS HEALTHCARE

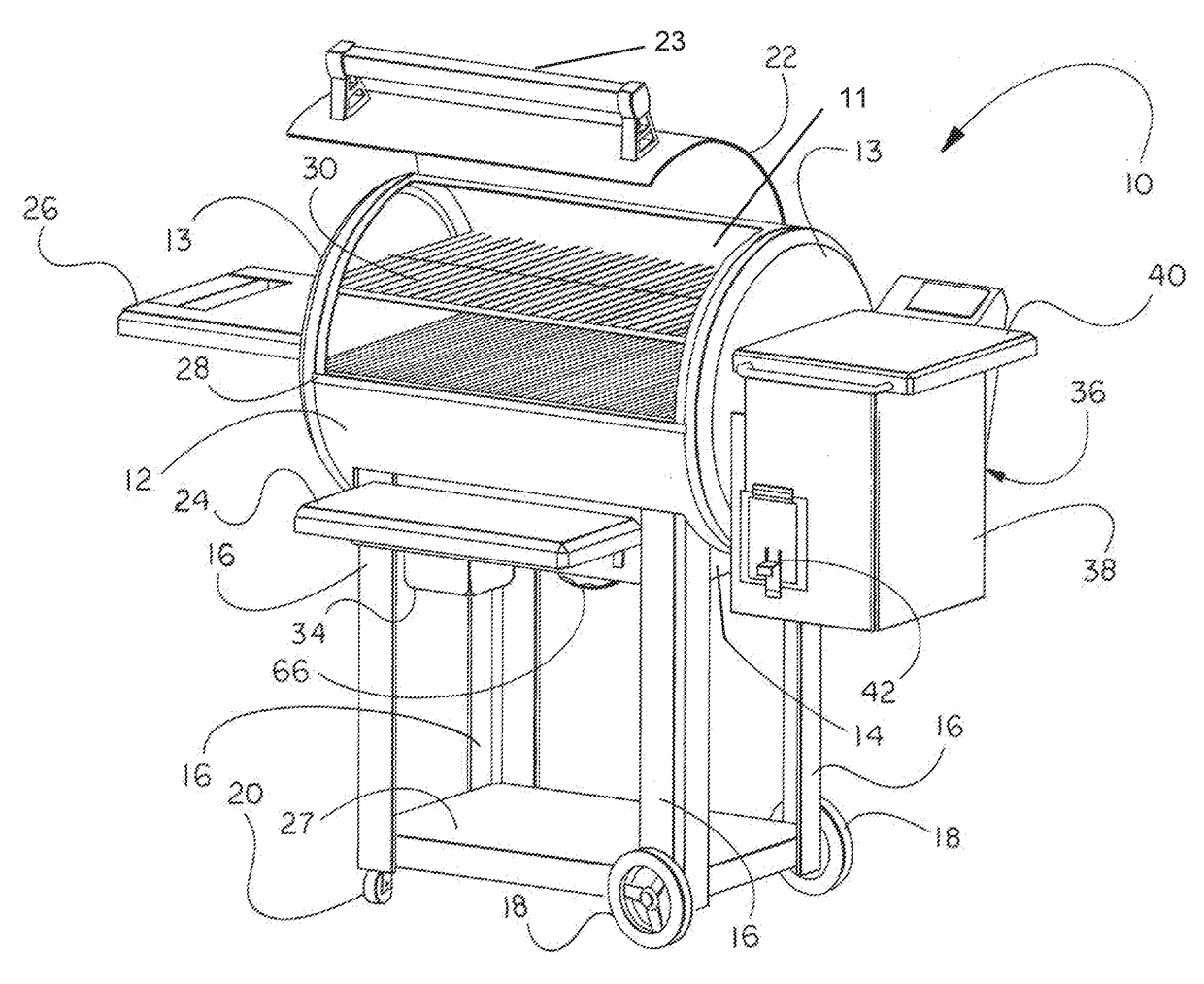

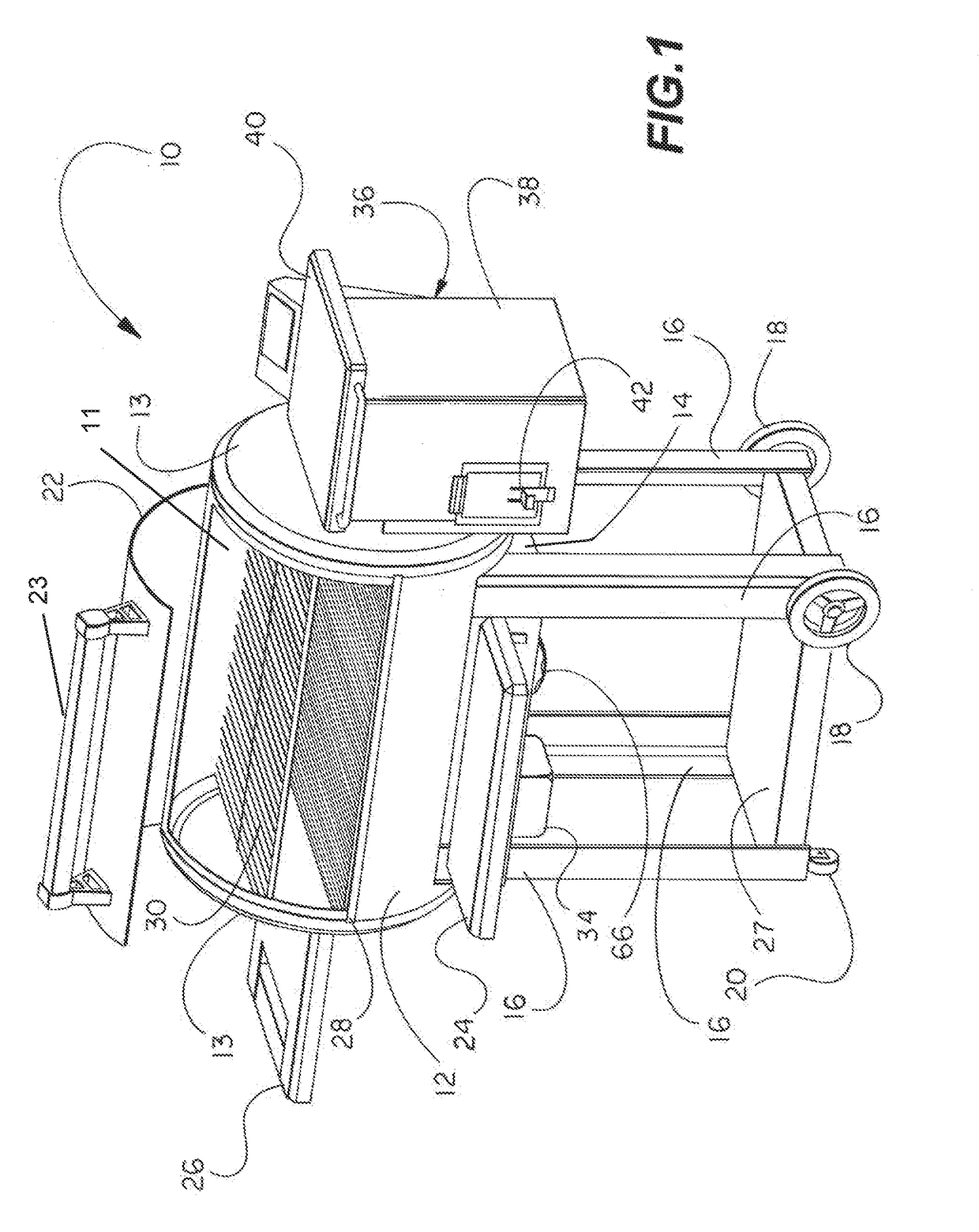

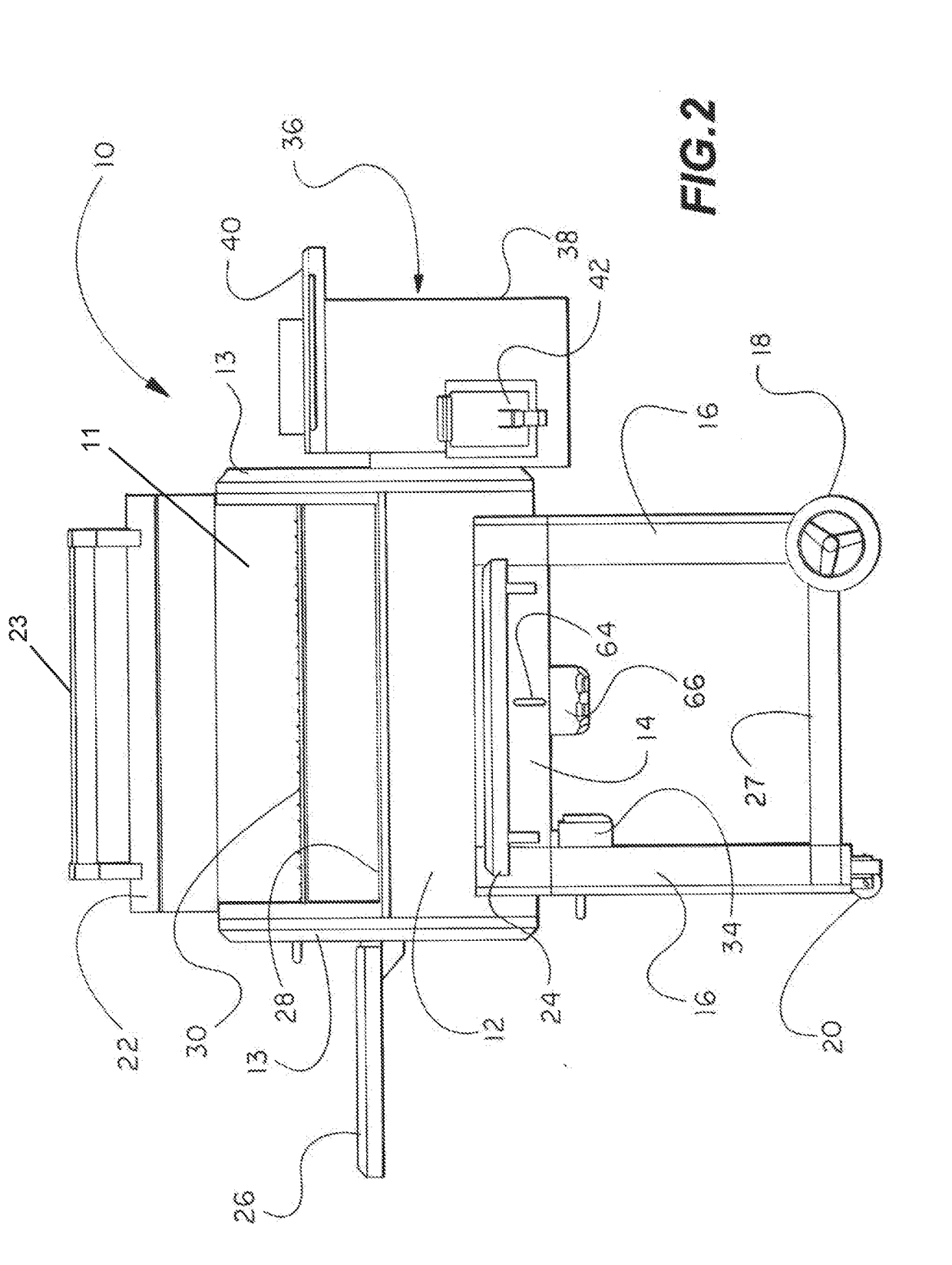

Smoker or Grill Ash Management System

InactiveUS20180296031A1Overcome problemsAvoid loopsClimate change adaptationCombustionManagement system

Owner:MASTERBUILT MFG LLC

Osmotic membrane and vacuum system for artificial limb

A system for removing perspiration from a residual limb inserted in a prosthesis comprising an nonporous prosthesis socket, a porous thin sheath adjacent the socket, a nonporous liner adjacent the sheath, an osmotic membrane adjacent the liner allowing water vapor to pass from the limb but preventing liquid from passing to the limb, a nonporous seal that prevents air leakage between the residual limb and the socket; and, a vacuum source to reduce the pressure in a space between the limb and socket. A method of removing perspiration from a residual limb in a prosthesis.

Owner:SANYO ELECTRIC CO LTD

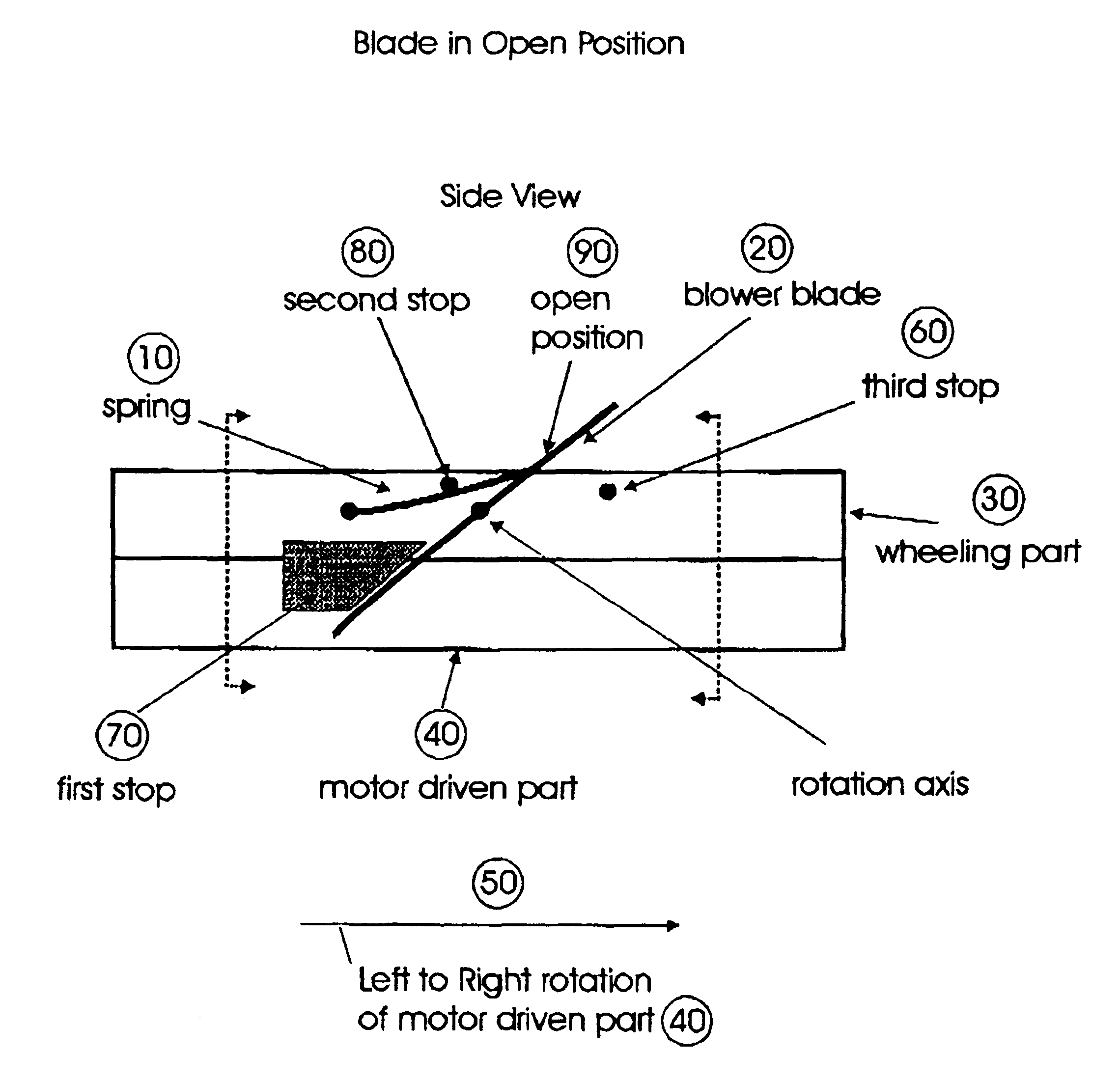

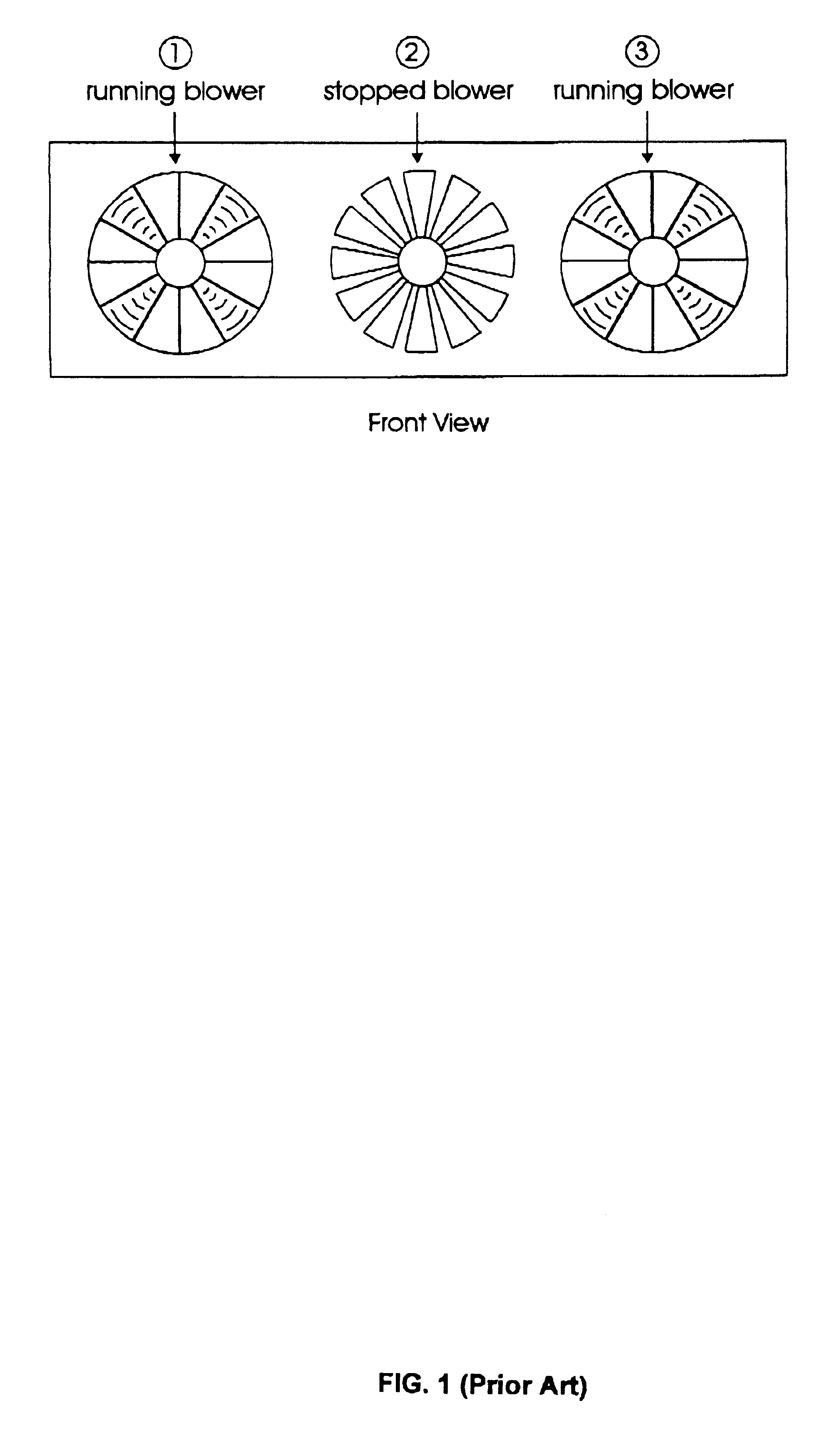

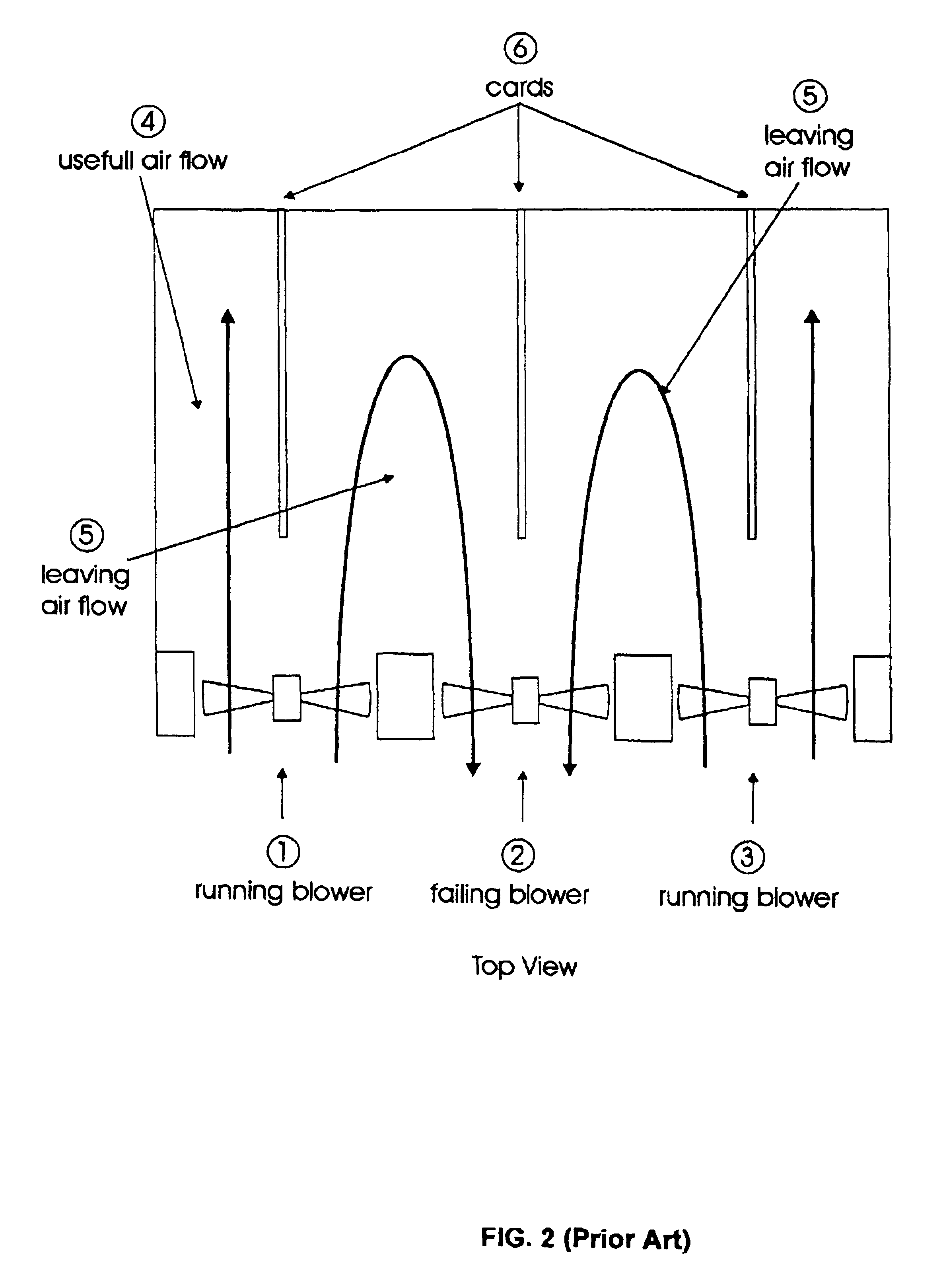

Fan with self closing blades

InactiveUS6386826B1Increased blowing capacityIncrease capacityPump componentsBlade accessoriesMotor driveKnife blades

A fan system to be mounted over an opening including a plurality of pivoting blades fixed on a free wheeling element and a motor driven element wherein, in operation, when the fan is operating the motor driven element pivots the blades to a blowing position allowing air flow through the opening, and when the fan is not operating a resilient member pivots the blades to a closed position preventing air flow through the opening.

Owner:TWITTER INC

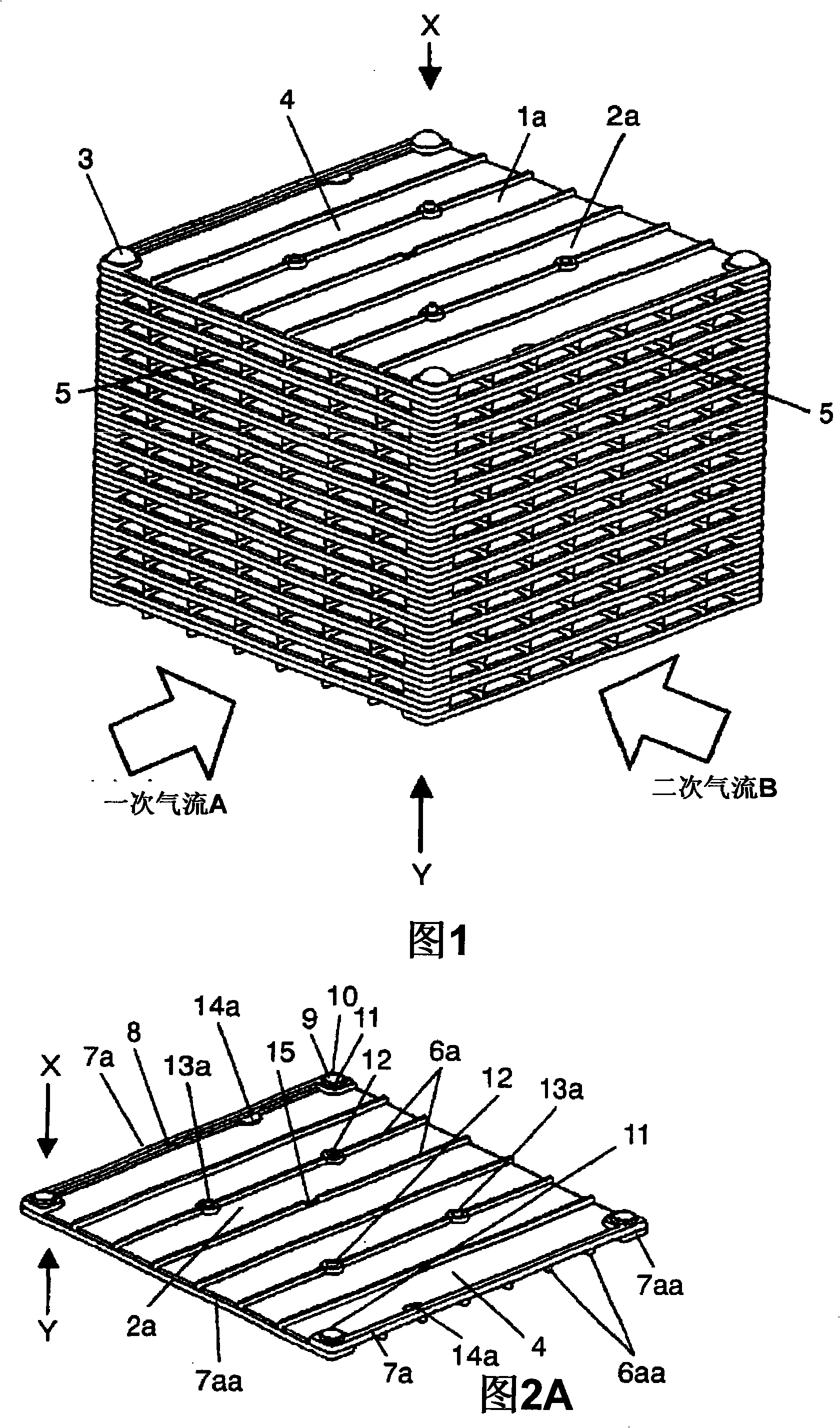

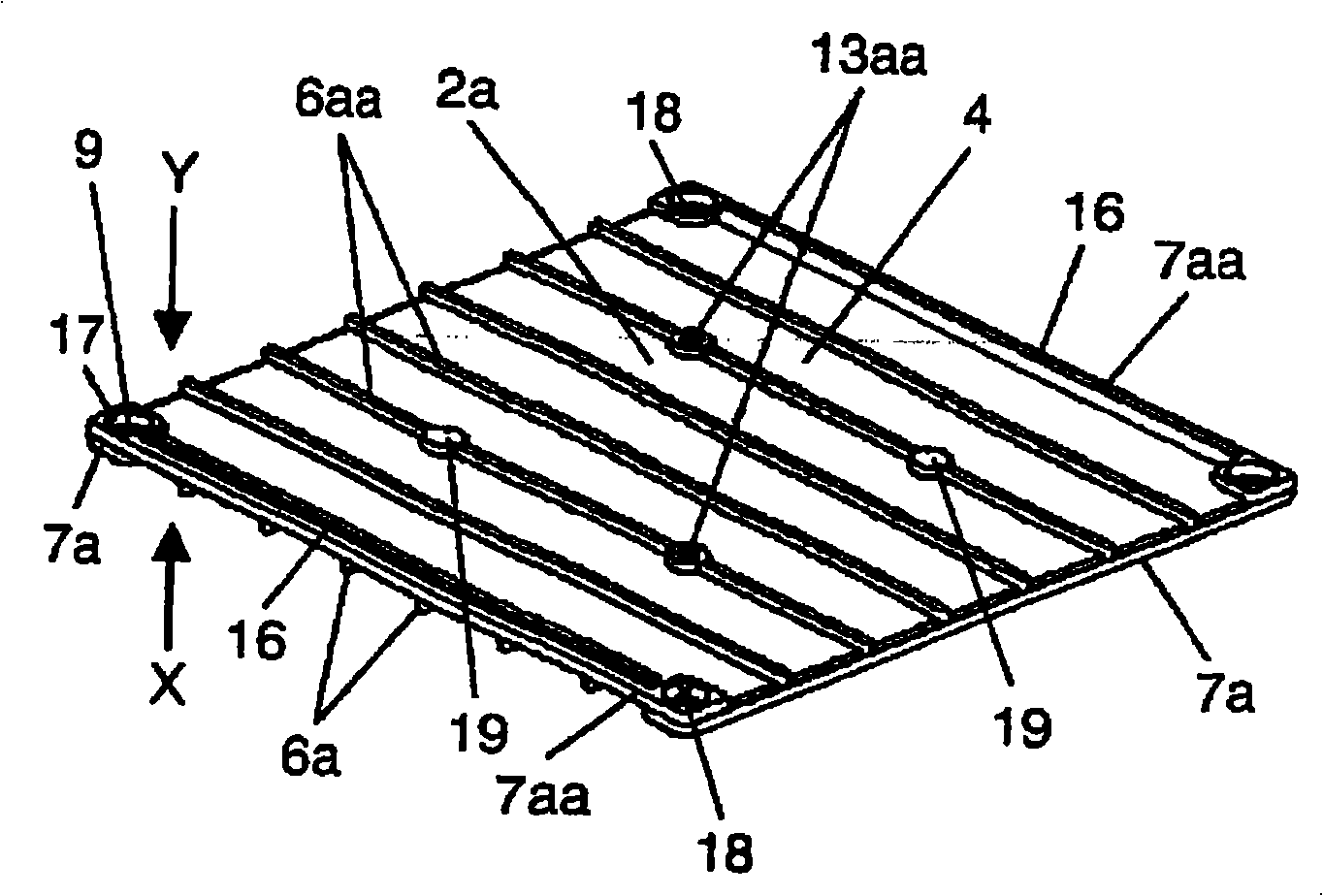

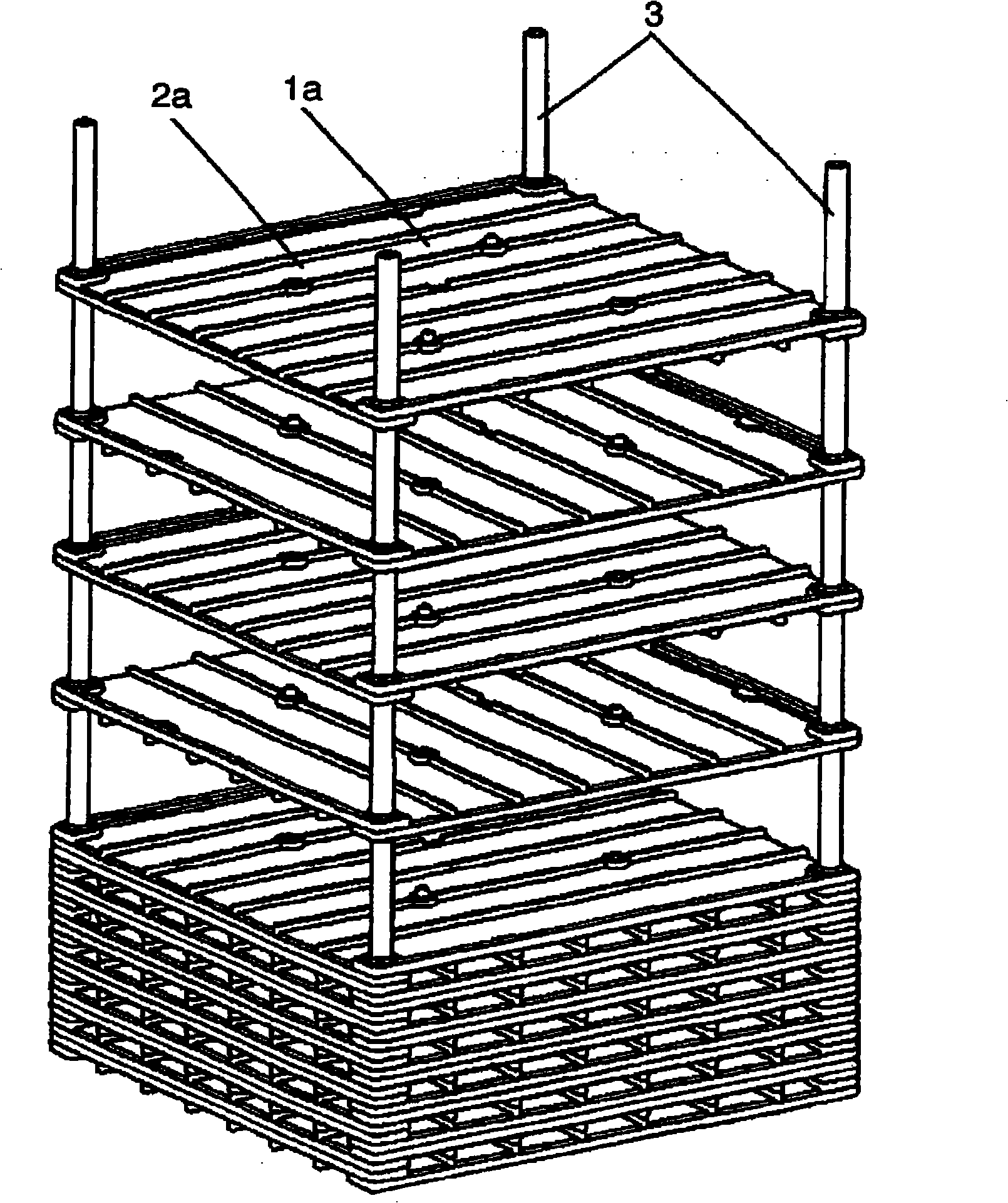

Heat exchanger and its manufacturing method

The present invention provides a heat exchanger for exchanging heat through heat transfer plates by flowing a primary airflow and a secondary airflow in air passages. The heat exchanger comprises a unit element having a heat transfer plate and an air passage formed between the heat transfer plates by stacking the unit elements. Each of the unit elements is structured by molding a space rib for holding the space between the heat transfer plates integrally with a shield rib for shielding the leak of the airflows by use of a resin. The unit element includes an error detection part which can easily detect an error in stacking when the unit elements are stacked.

Owner:PANASONIC CORP

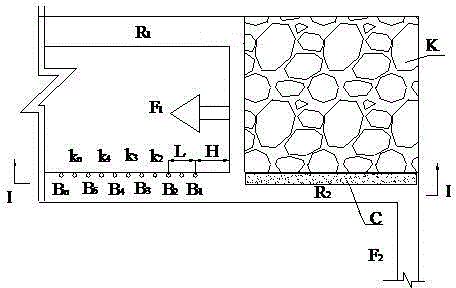

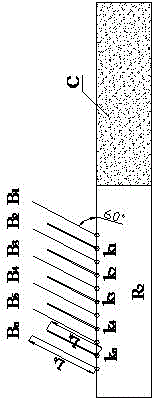

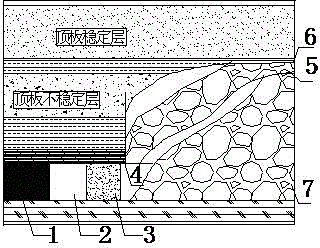

Method for fully mechanized continuously-filling coal mining of steeply pitching coal seam

InactiveCN102493838AIncrease the level of mechanizationReduce labor intensityUnderground miningSurface miningStopped workEngineering

The invention provides a method for fully mechanized continuously-filling coal mining of steeply pitching coal seams, which comprises the following steps: a stoping face is arranged as per the method of long-wall mining along the strike, and fully mechanized mining equipment for the steeply pitching coal seam is adopted; an air cushion and a working face filling pipeline are arranged on a base on the side of a mined out space of rear pillars of a fully mechanized mining support; whenever the working face advances for every 1.4 to 1.8 meters and after the support is moved, the working face filling pipeline is connected with an upper gateway filling main pipeline; the air cushion is filled with air, and auxiliary separation is arranged; paste is conveyed to a filling pipe branch sequentially from low to high so as to ensure filling and compacting, and finally the paste is conveyed to a supplementary filling pipe of the upper gateway; after the paste is coagulated, a portion of air in the air cushion is released, and the working face advances forward continuously; the steps are repeated until the stopping work for the whole working face and the filling work for the mined out space are finished. The method provided by the invention is convenient to operate and simple to carry out, can improve the mechanization level for mining the steeply pitching coal seams under buildings, railways and water bodies, improves the output of the working face, efficiently reduces the roof subsidence and the ground deformation, and realizes coal mining without the pillars and achieves Y type ventilation.

Owner:HUNAN UNIV OF SCI & TECH

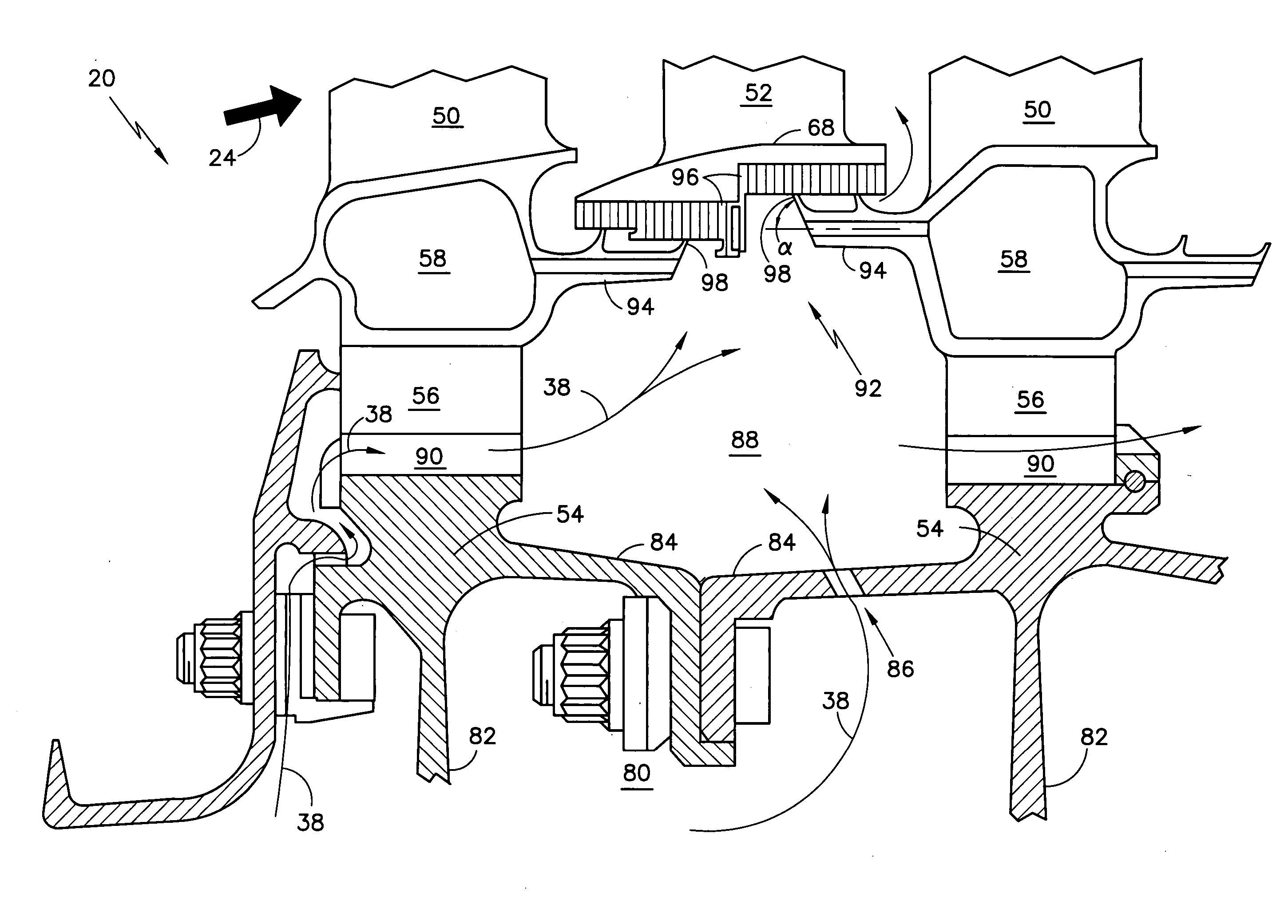

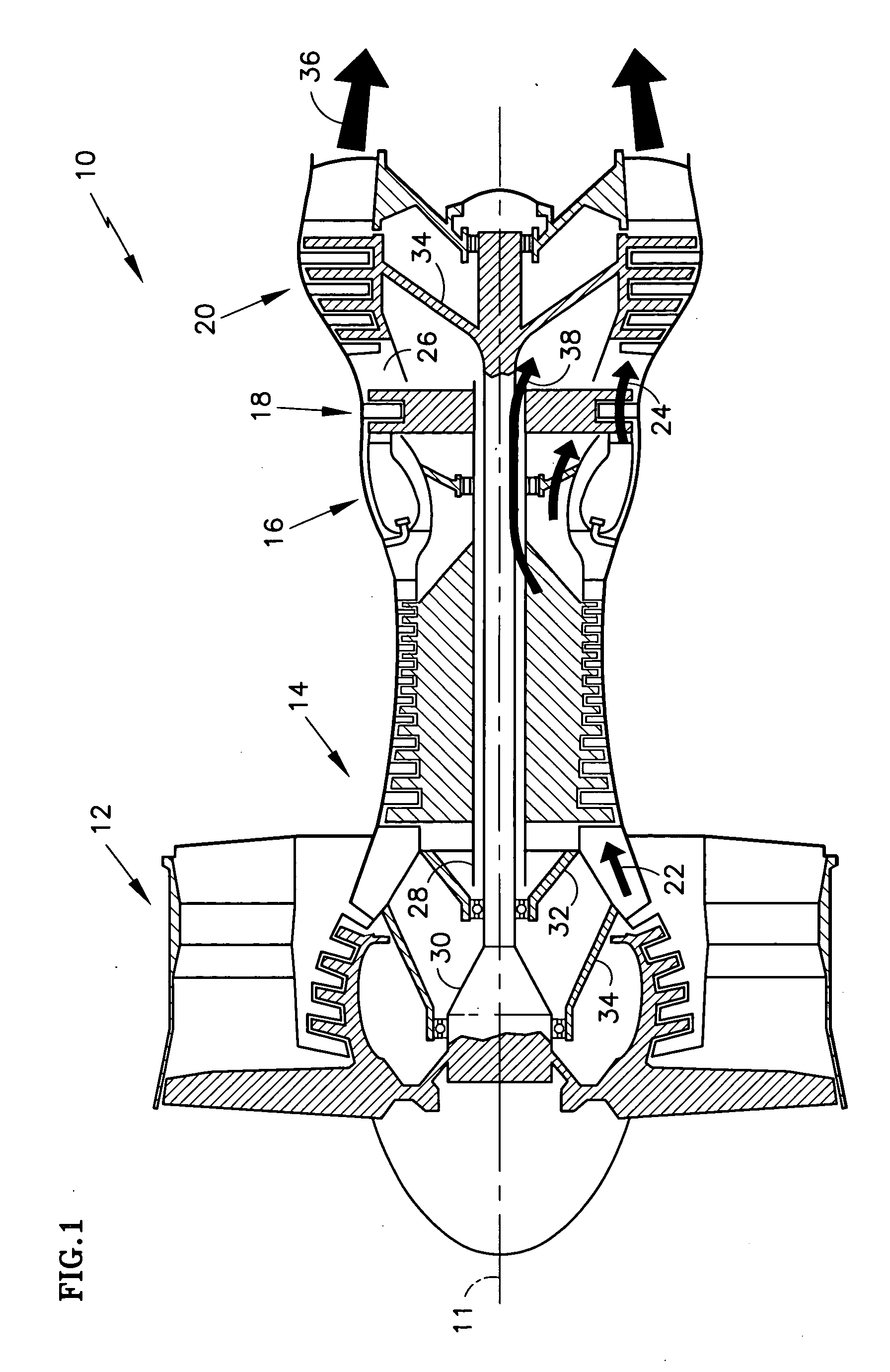

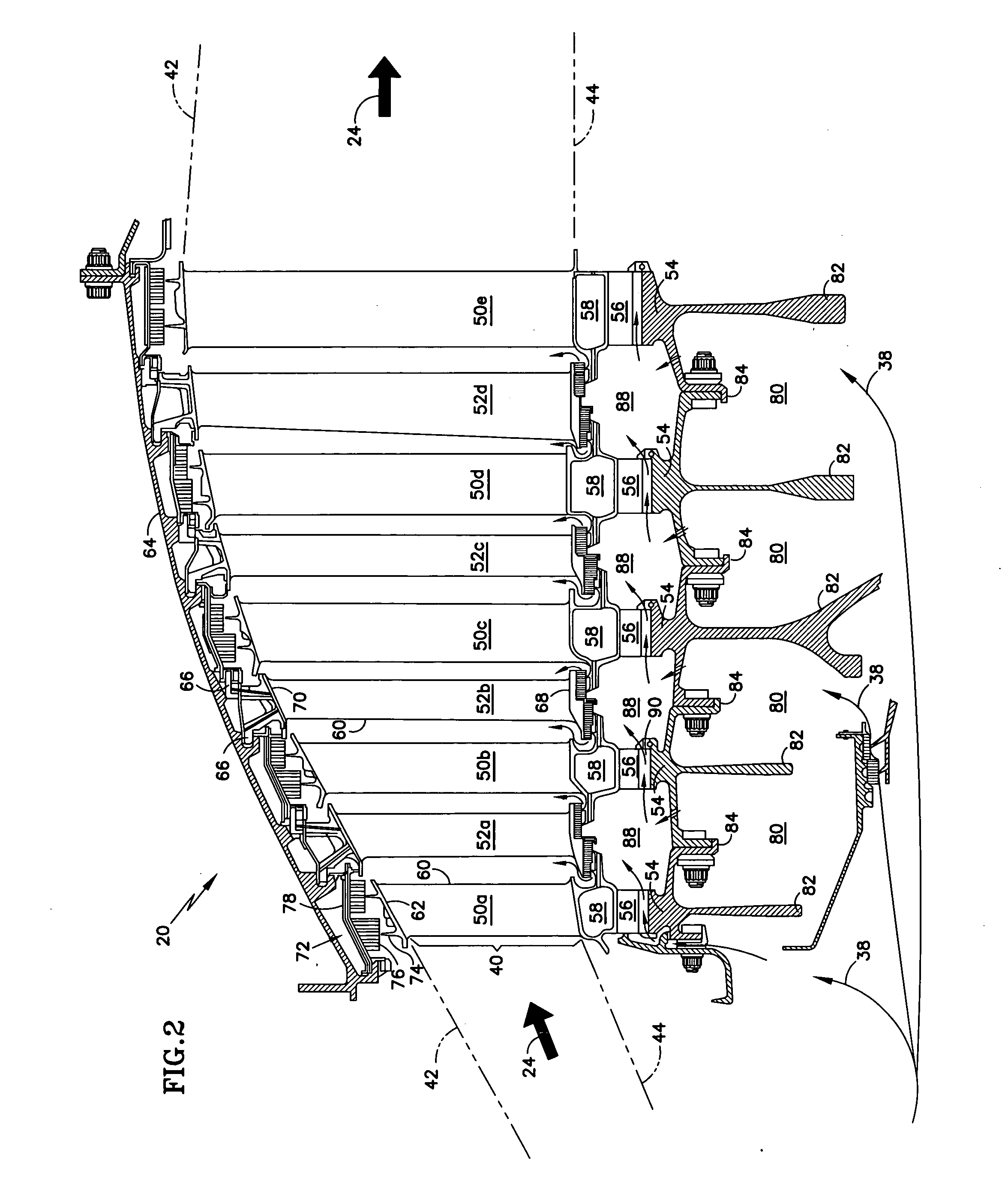

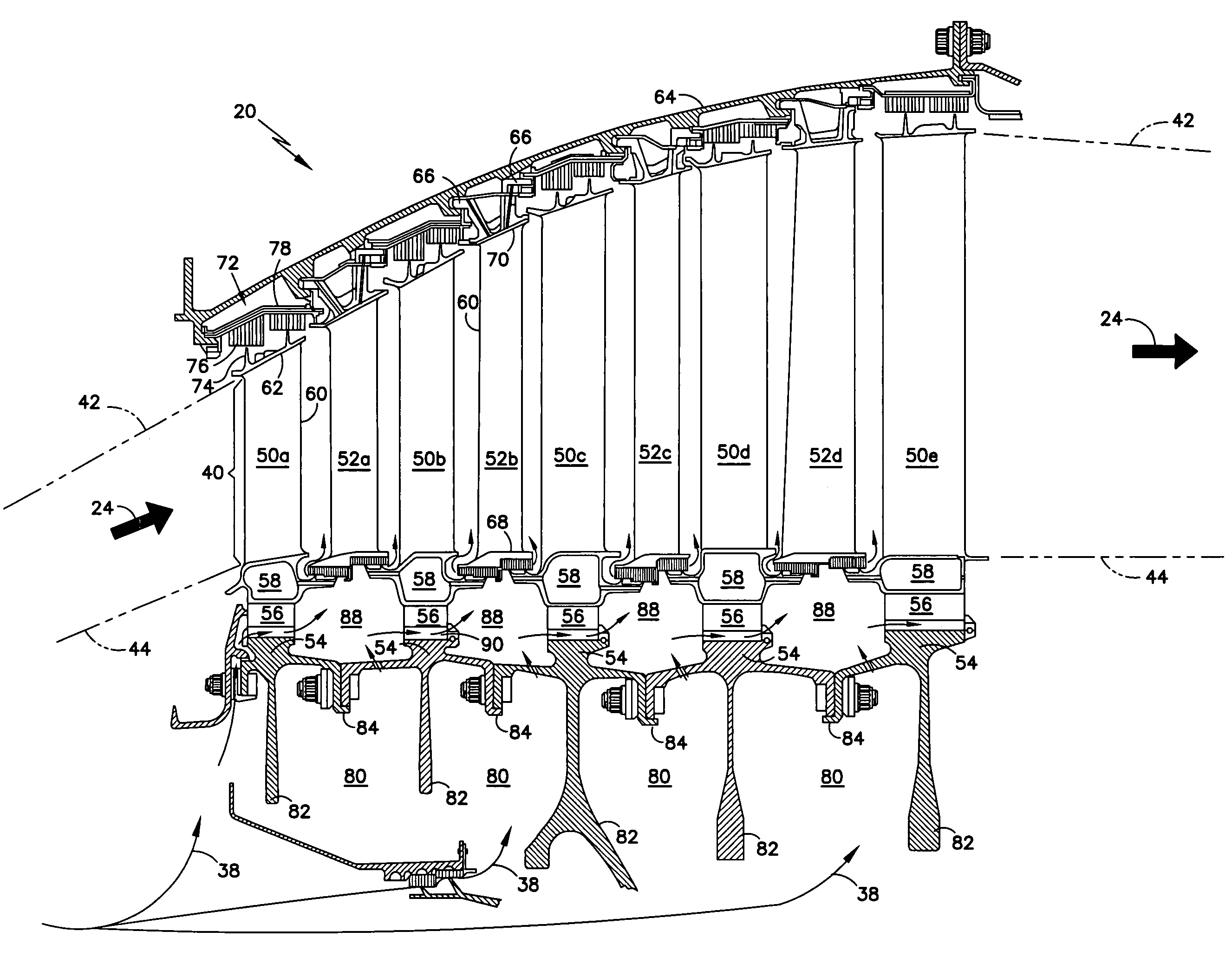

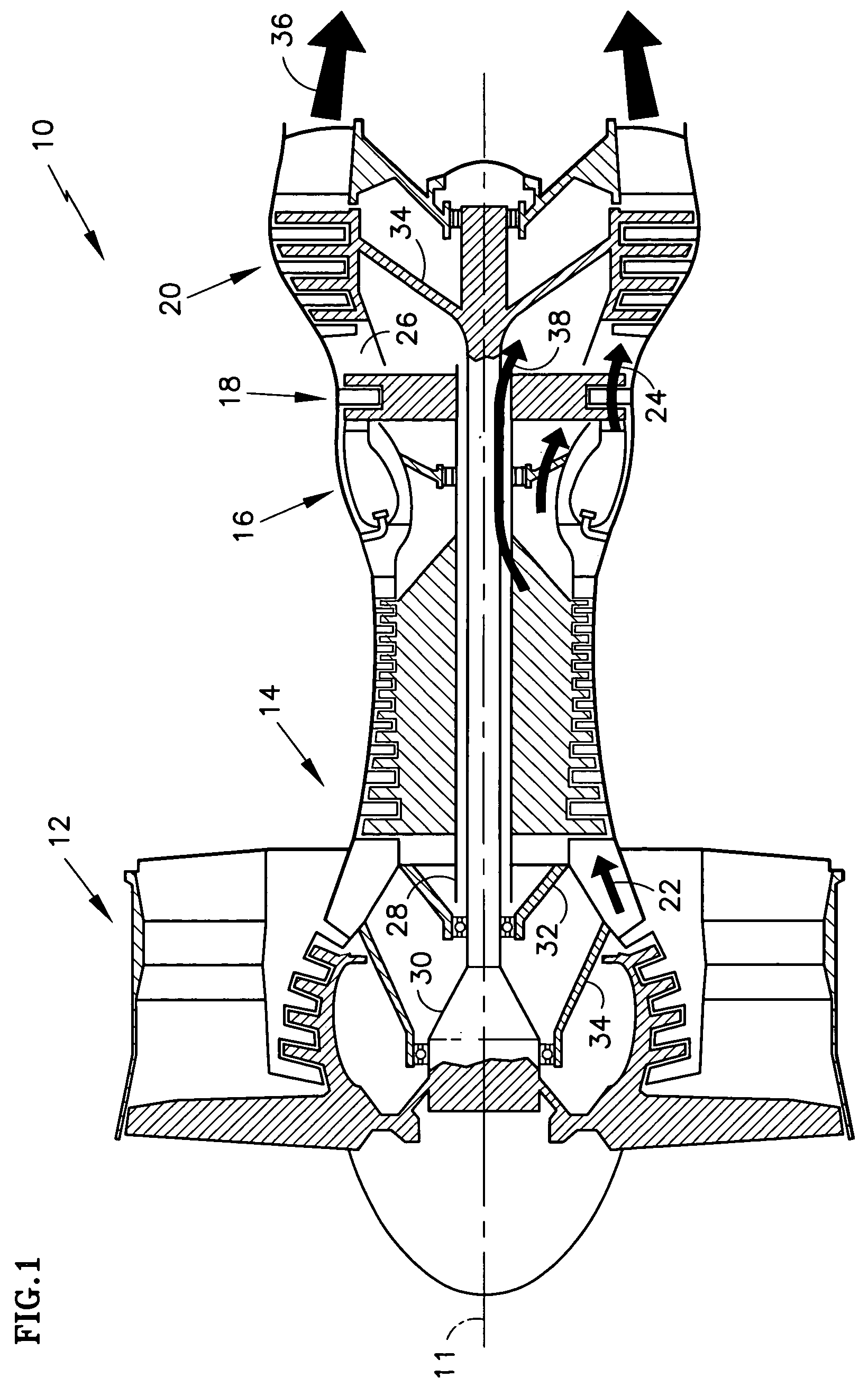

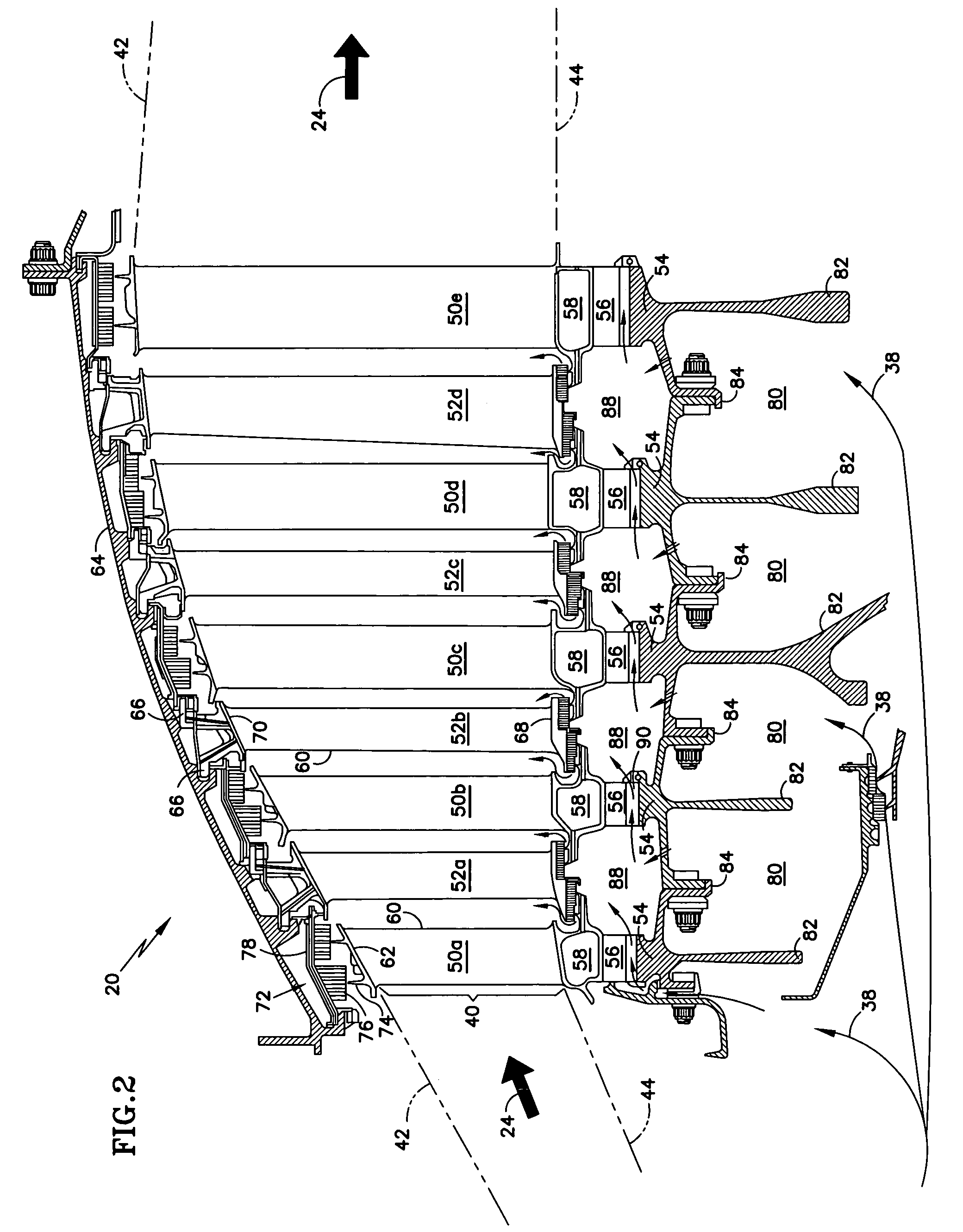

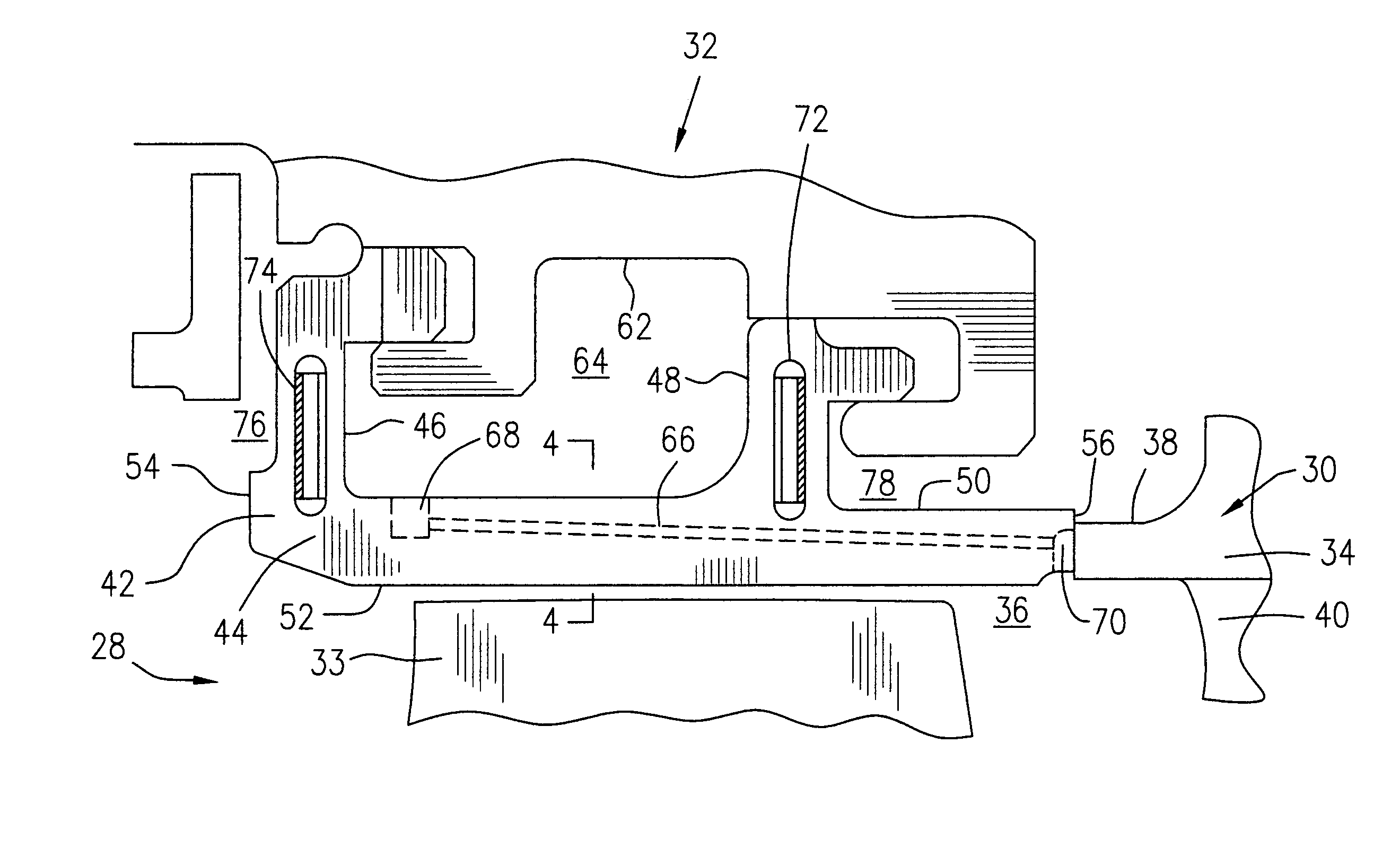

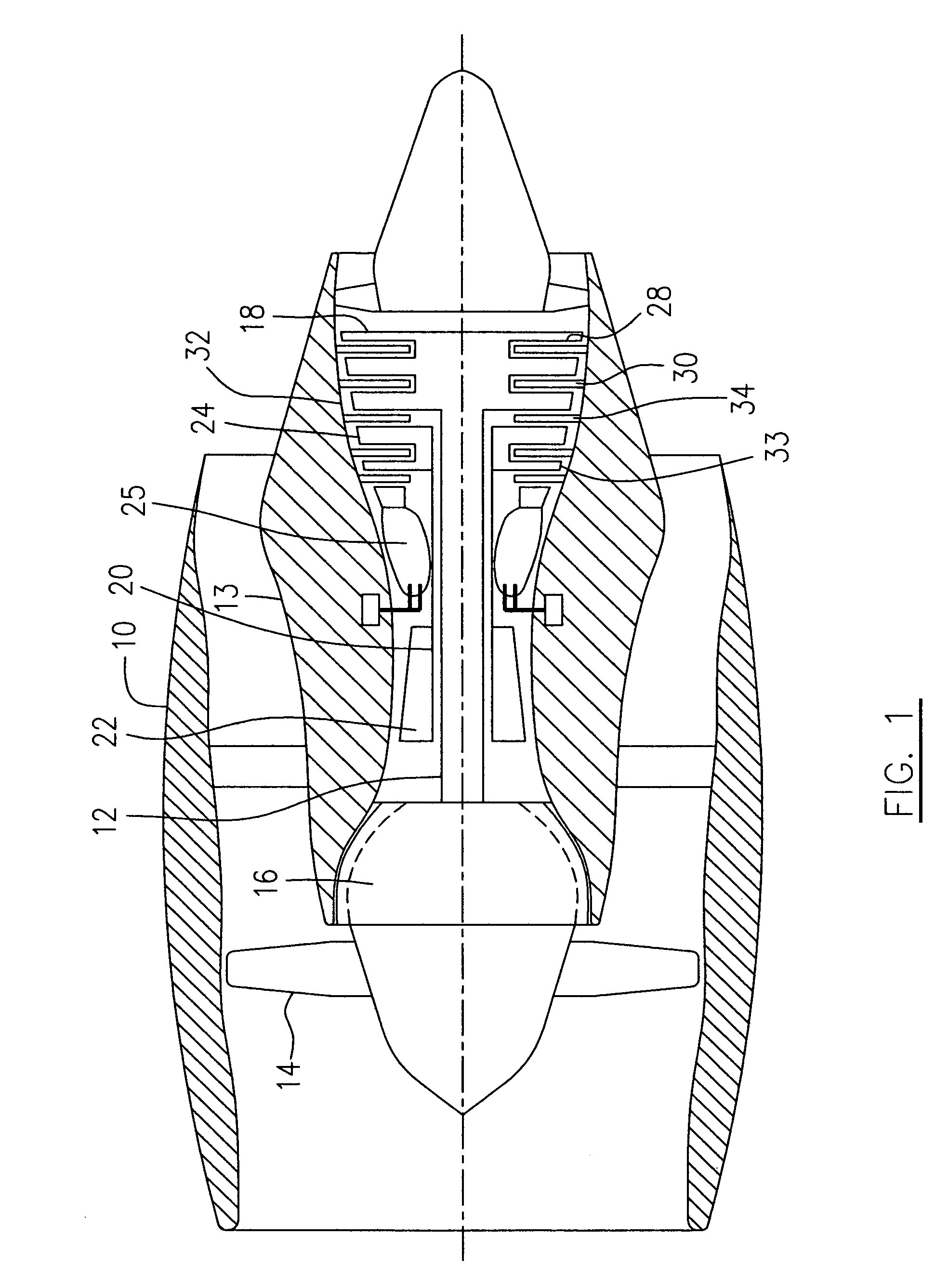

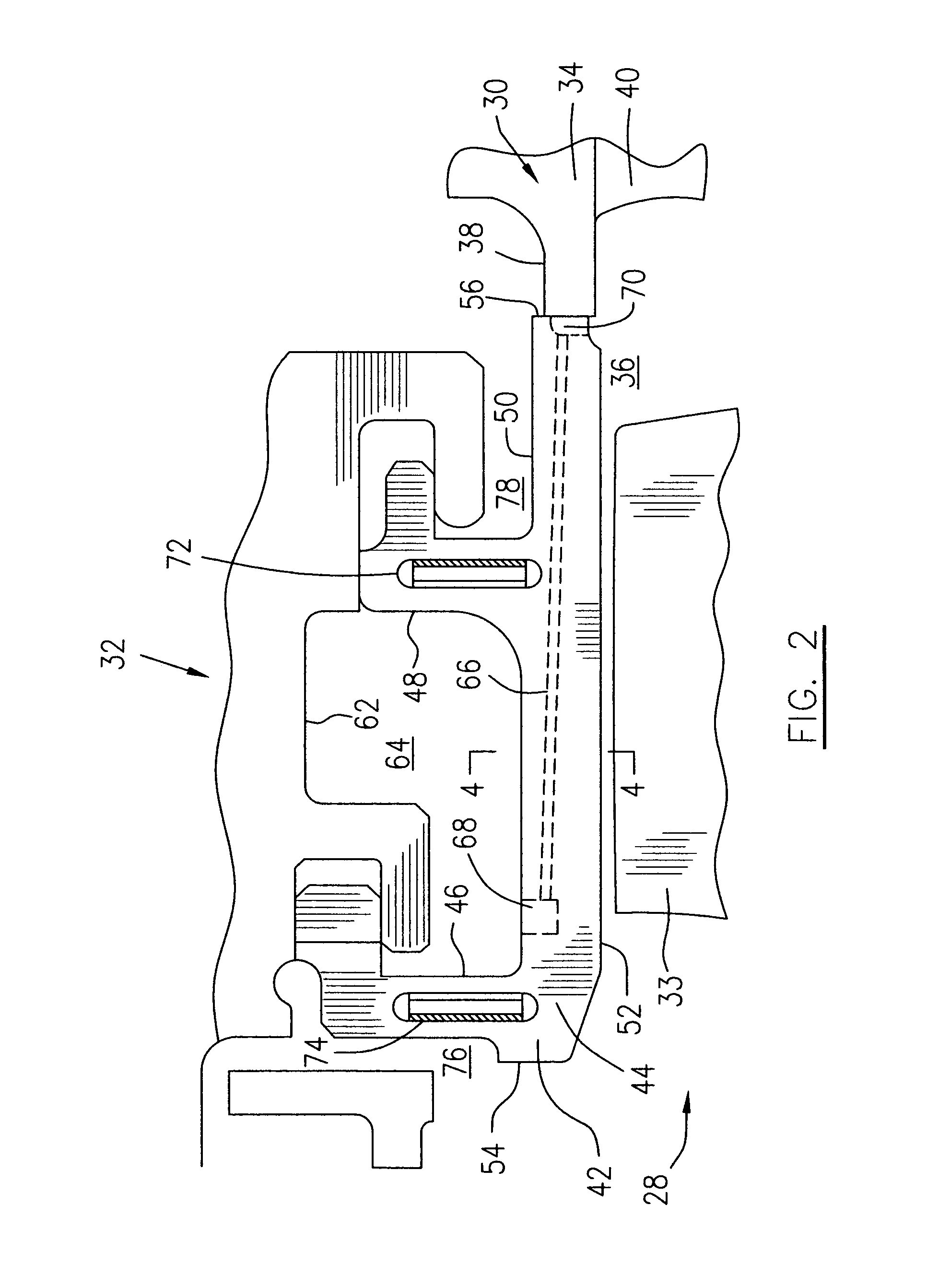

Integrated bladed fluid seal

ActiveUS20070098545A1Control leakageImproving apportioningPump componentsGas turbine plantsCouplingCooling fluid

Disclosed are various embodiments of a gas turbine blade to vane interface seal for restricting leakage of cooling air and improving the apportioning of the cooling air to the seal. Accordingly, a turbine rotor contains a first and a second stage of radially extending and circumferentially distributed blades. The stages are separated axially from one another by an annular coupling located radially inboard of the blades, forming a chamber therebetween. Interposed between the blade stages is a vane stage. The vane stage contains a land, facing radially inwardly. A ring projects axially from each of the first and second blade stages towards the vane stage. A ring may also project radially from the coupling towards the vane stage. The rings radially cooperate with the land and together form the blade to vane interface seal. The coupling contains an aperture for radially introducing a cooled fluid to the chamber for use in cooling the seal.

Owner:RAYTHEON TECH CORP

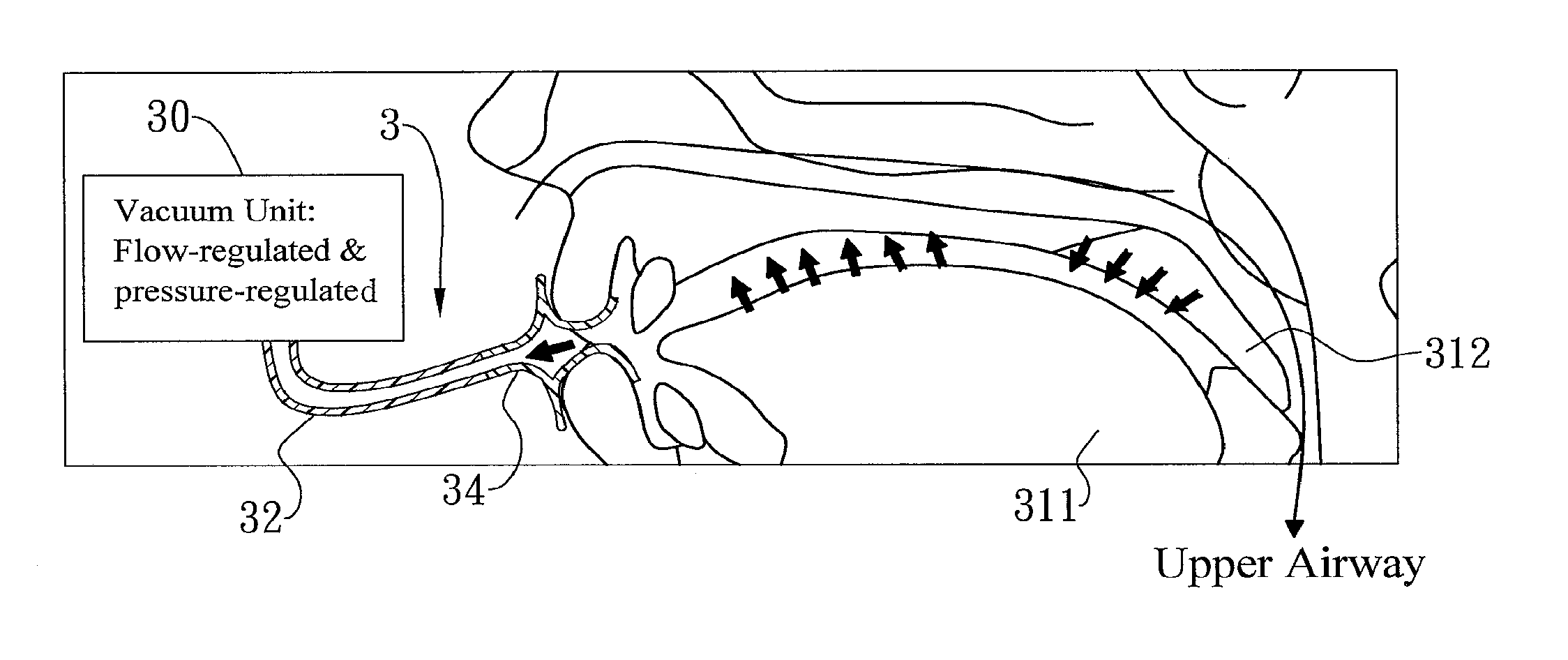

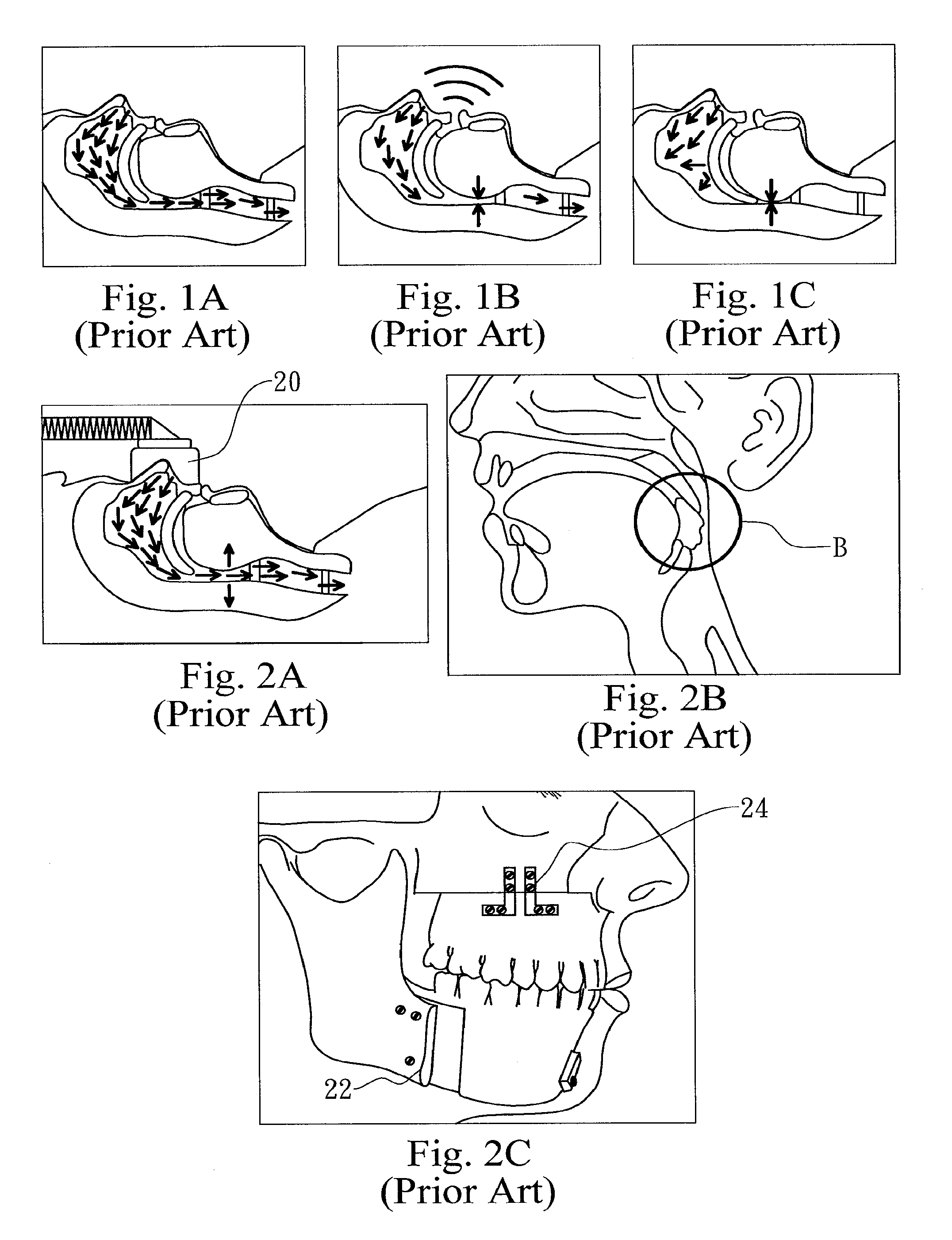

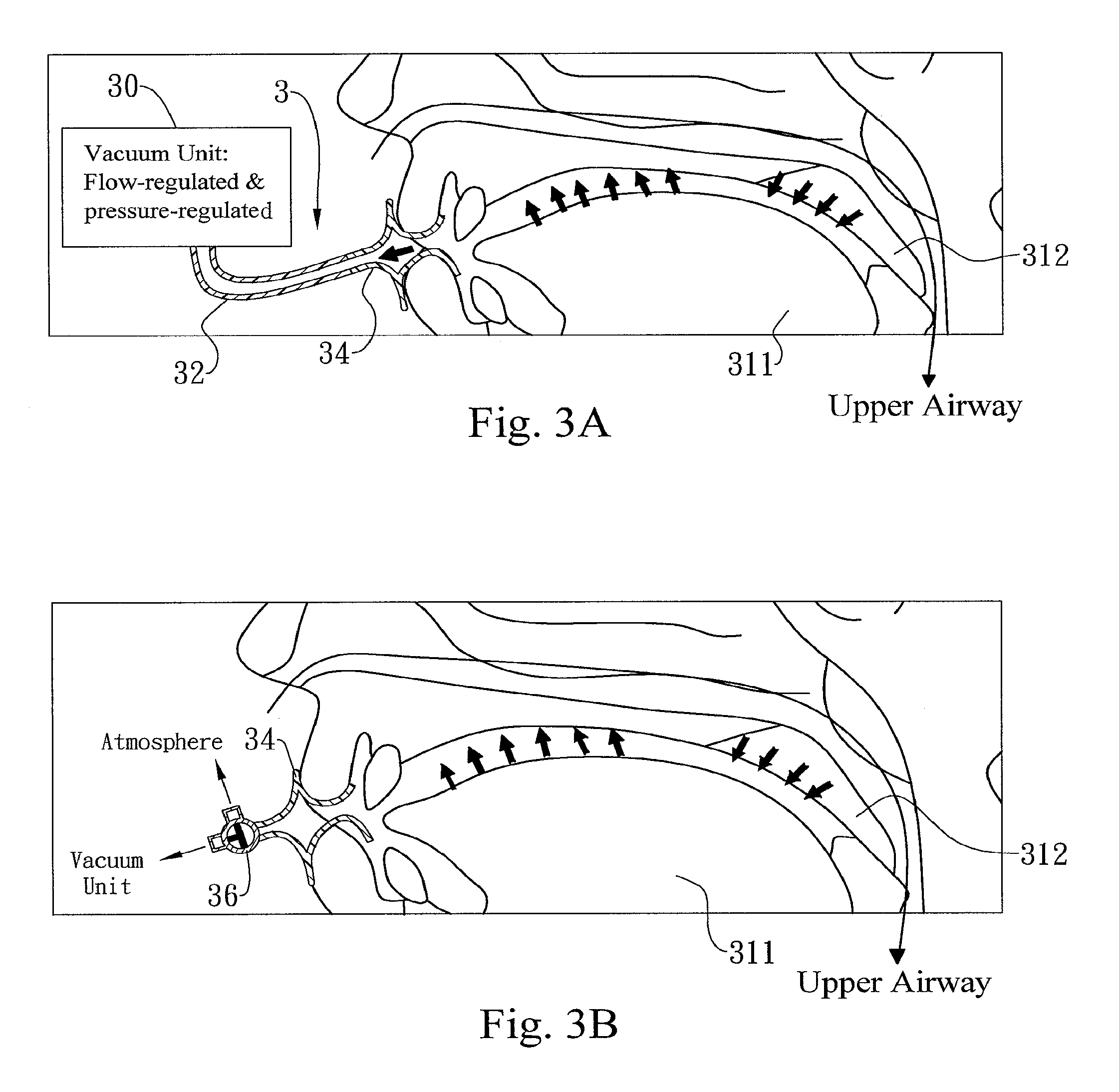

Method and apparatus for treating obstructive sleep apnea by using negative oral pressure to a patient

ActiveUS7918222B2Improve efficacyImprove complianceRespiratorsBreathing masksNasal cavitySoft palate

Owner:SOMNICS INC

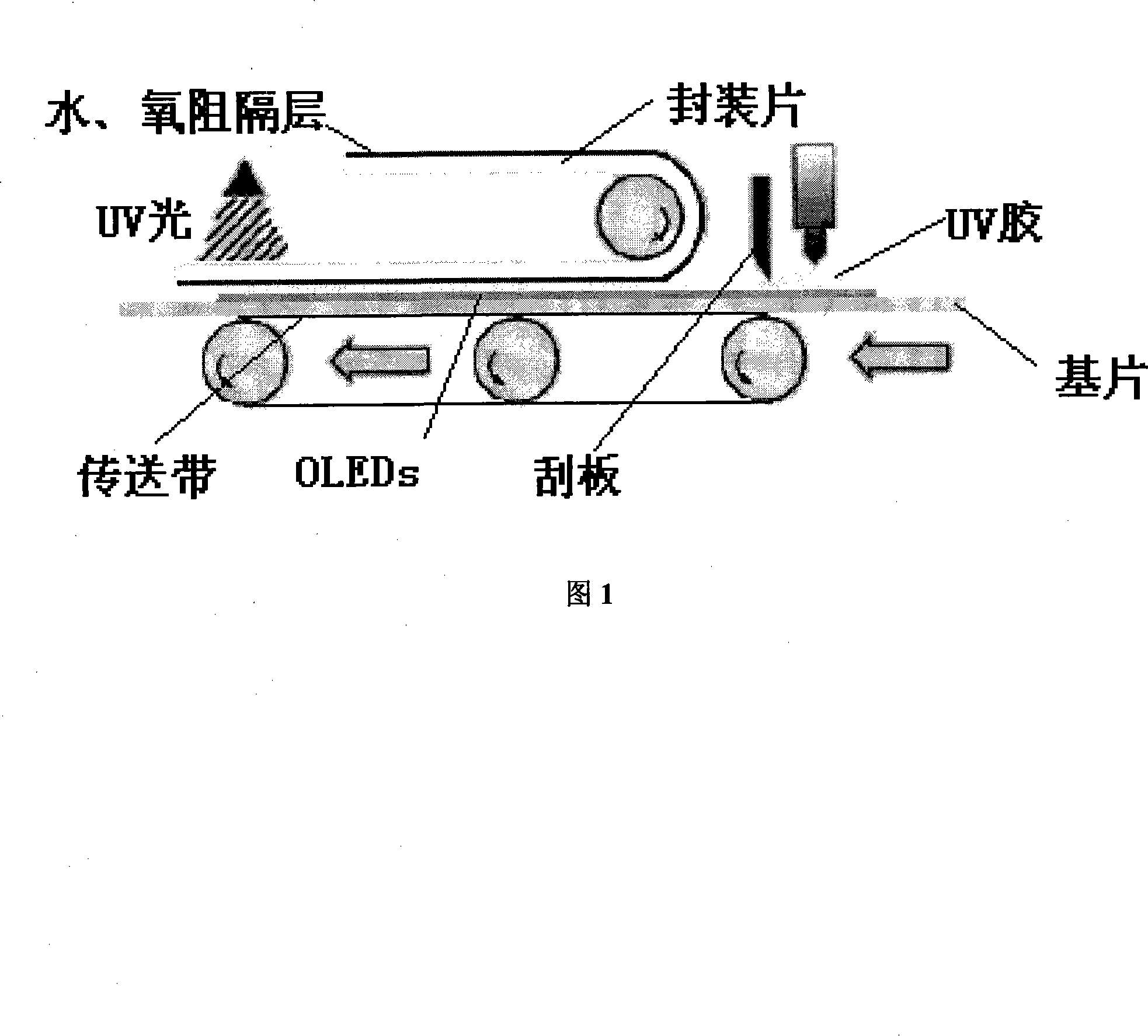

An organic EL part and its making method

InactiveCN101080121AContinuous production rhythmAvoid deformationElectrical apparatusElectroluminescent light sourcesDistortionOrganic electroluminescence

This invention relates to a package structure of an organic electroluminescent device and its manufacturing method, in which, the organic electroluminescent device includes a package structure with a flat packaged cover made of glass, polymer, metal or alloy material and its composite film material, and the flat package cover can be prepared by a roller extrusion method. The package structure is especially suitable for large size or soft OLED, since no gas space exists during the packaging process, the device can be made thinner and distortion of the cover can be avoided.

Owner:TSINGHUA UNIV +2

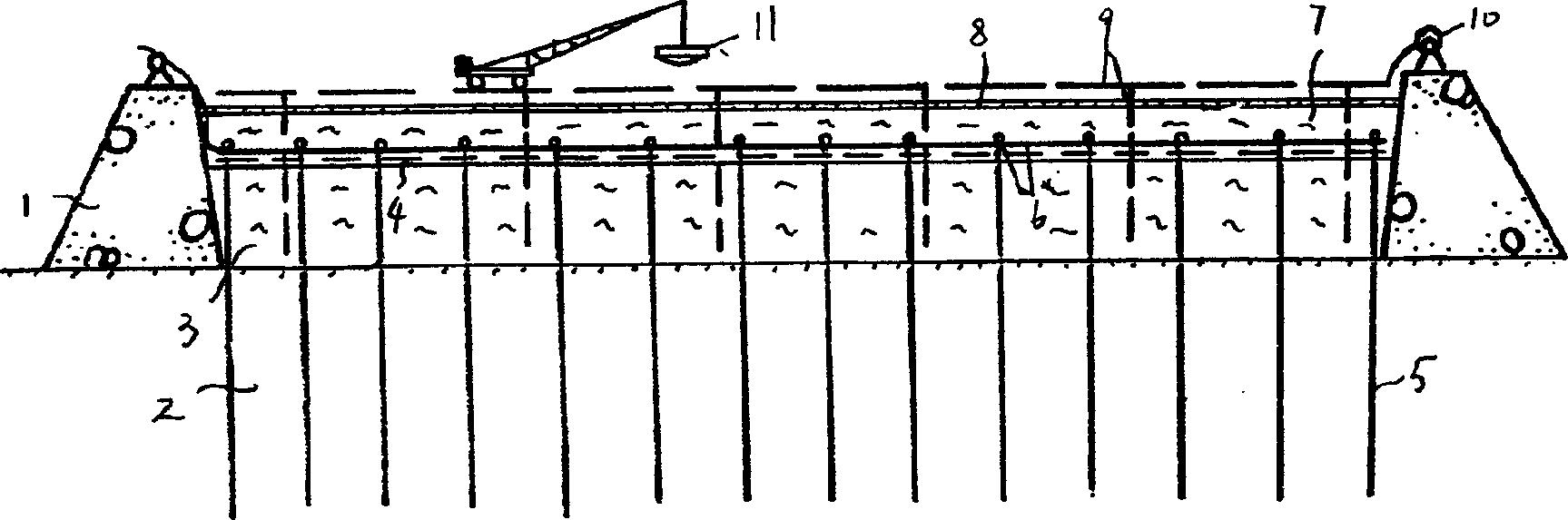

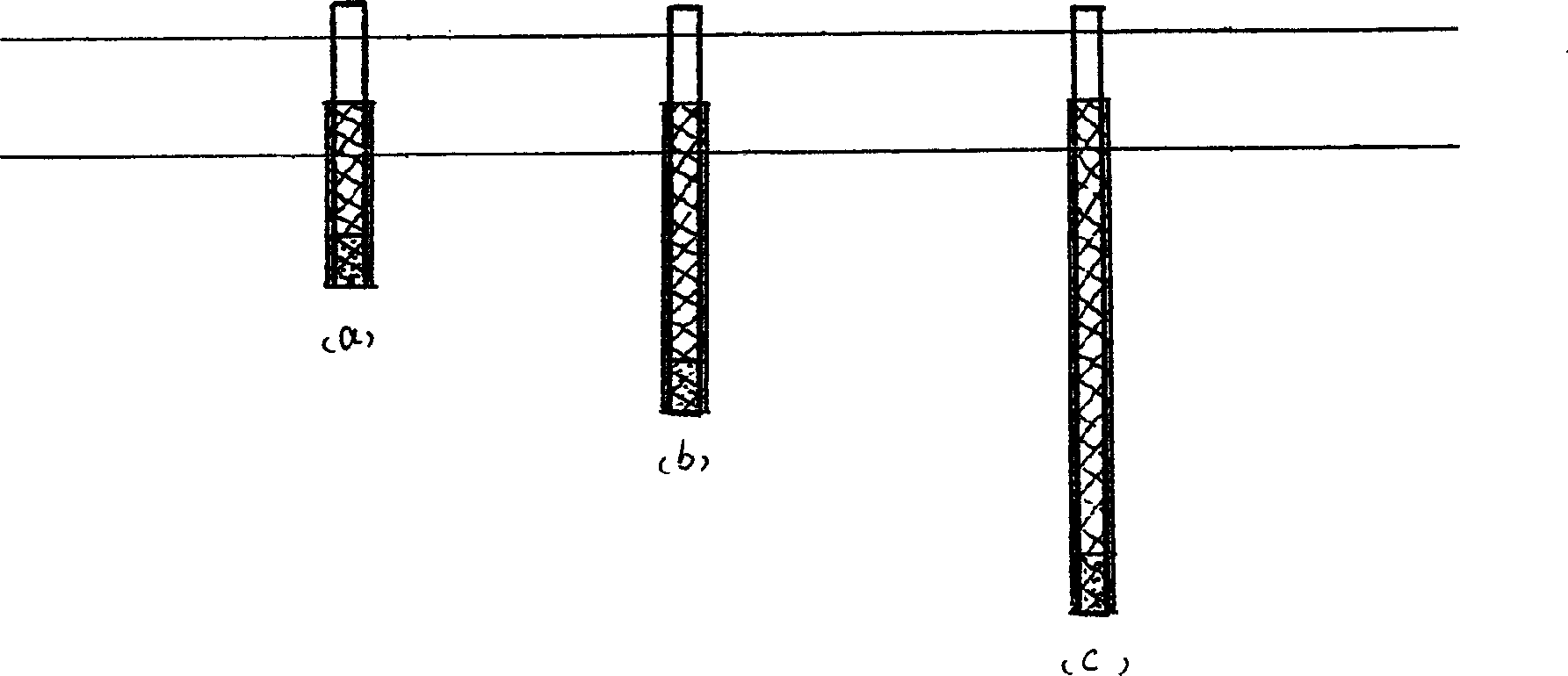

Combined method for fastening soft soil ground by dual vacuum prepressing and dynamic extruding method

InactiveCN1818227AEffective secondary reinforcementImprove consolidation indexSoil preservationFilling materialsReduction procedure

A method for reinforcement of yielding soil of large area or hollow land includes the following procedures in order: 1. low position vacuum pre-press procedure as building cofferdam, filling in sludge to certain height, paving cloth and bamboo fence on the top, vertically inserting in water emission plastic boards, laying horizontal vacuum pipe net, installing vacuum pre-press system and sealing with mud layer of 0.8-1.5 m thick then vacuum bumping for pre-press; 2. high vacuum rate well point water reduction procedure as applying a high vacuum rate well point water reduction system on the mud sealing layer, removing well point pipe after the first round of water reduction; 3. low power strong tamping procedure as paving a layer of filling material on the mud sealing layer then tamping. Roller compact the surface after 2-3 rounds of procedure 2 and 3.

Owner:张志铁 +1

Method and apparatus for eliminating register boxes, improving penetration sealing, improving airflow and reducing the labor costs to install ceiling registers

InactiveUS20080014860A1Reducing labor and material costImprove permeabilityLighting and heating apparatusAir conditioning systemsProcessor registerShaft collar

A method and apparatus for eliminating register boxes, improving penetration sealing, improving airflow and reducing the labor costs to install ceiling registers is disclosed. A collar plate assembly that interfaces with flexible or metal air ducts is provided with at least one spring indentation ring in the collar portion of the assembly to accept two or more locking springs. These locking springs are used to attach the ceiling register to the collar plate assembly. The collar plate assembly uses mounting rails that attach the assembly to either ceiling or wall supports. After the ceiling or wall material is applied, the circular area inside the collar is cut-out to provide access. A trim ring is inserted in the cut-out that attaches between the collar and the ceiling or wall to eliminate air leakage and provide an essentially smooth flow of air from the supply duct into the inside of the structure. After ceiling or wall installation and surface preparation is completed, the ceiling register is simply positioned over the register cut-out and firmly inserted until it seals against the ceiling or wall surface. The ceiling register is locked into place by the action of its locking springs expanding into the collar indentation ring. No ceiling register mounting hardware is required.

Owner:HEITMAN LYNN BYRON +1

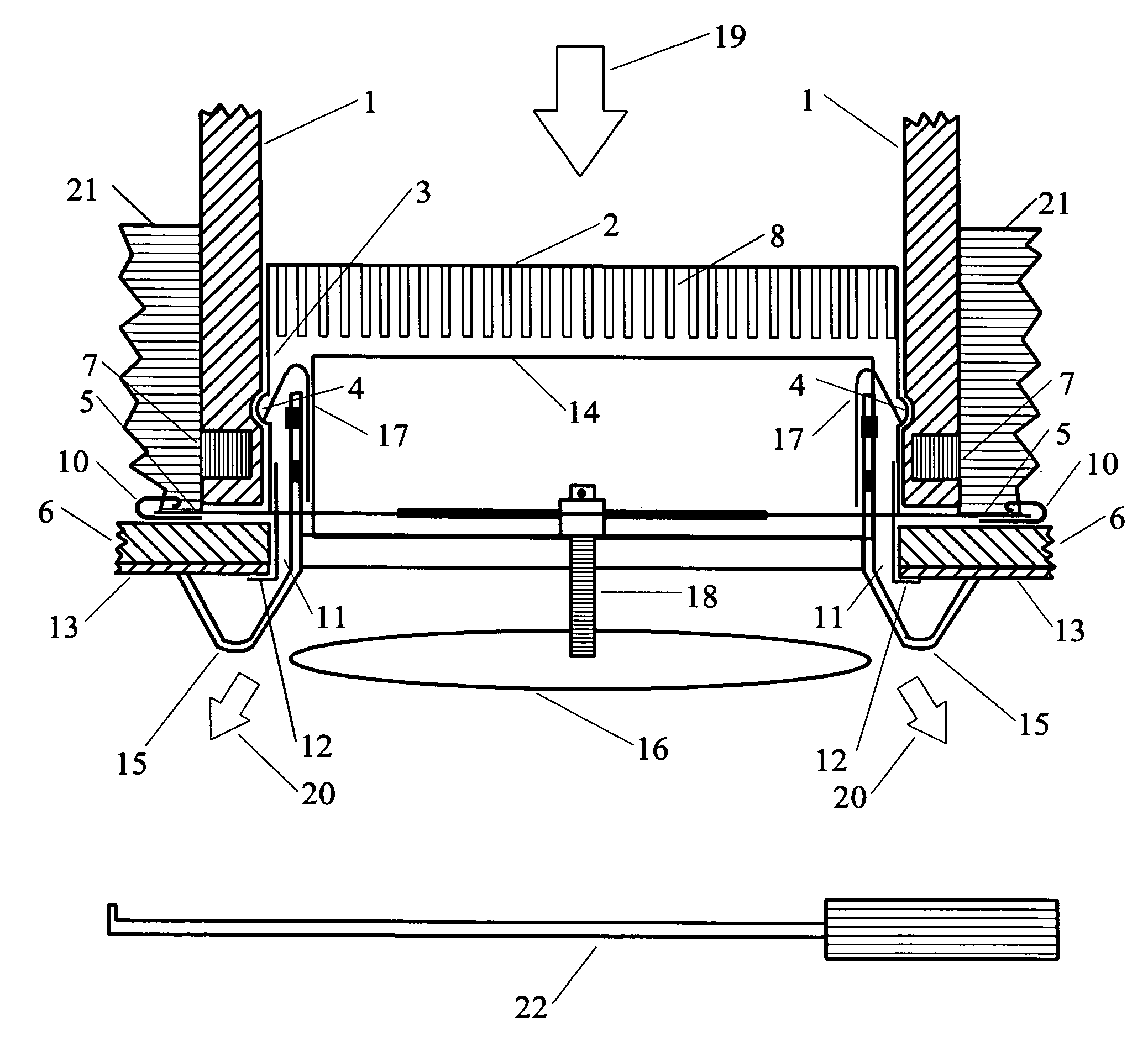

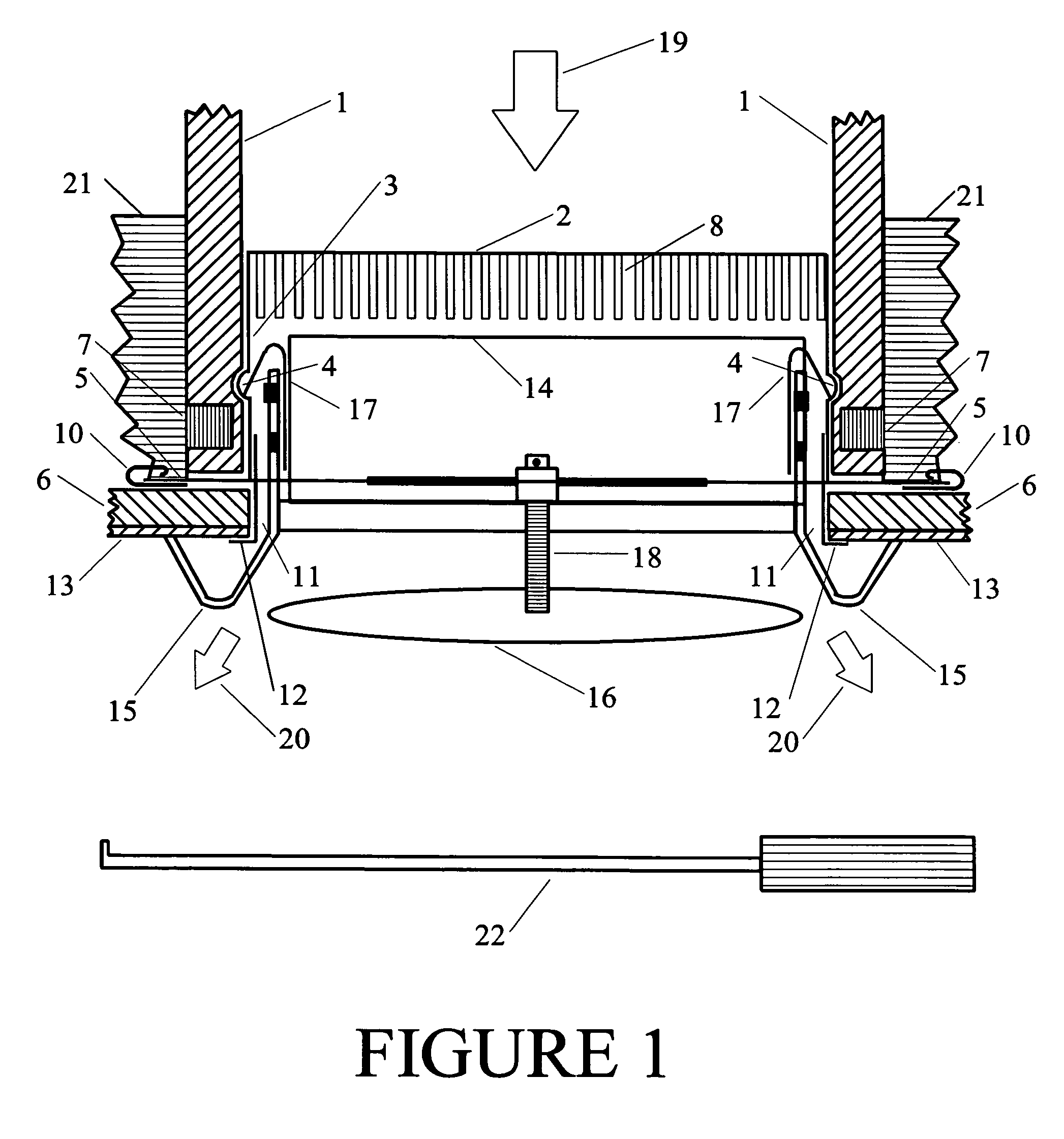

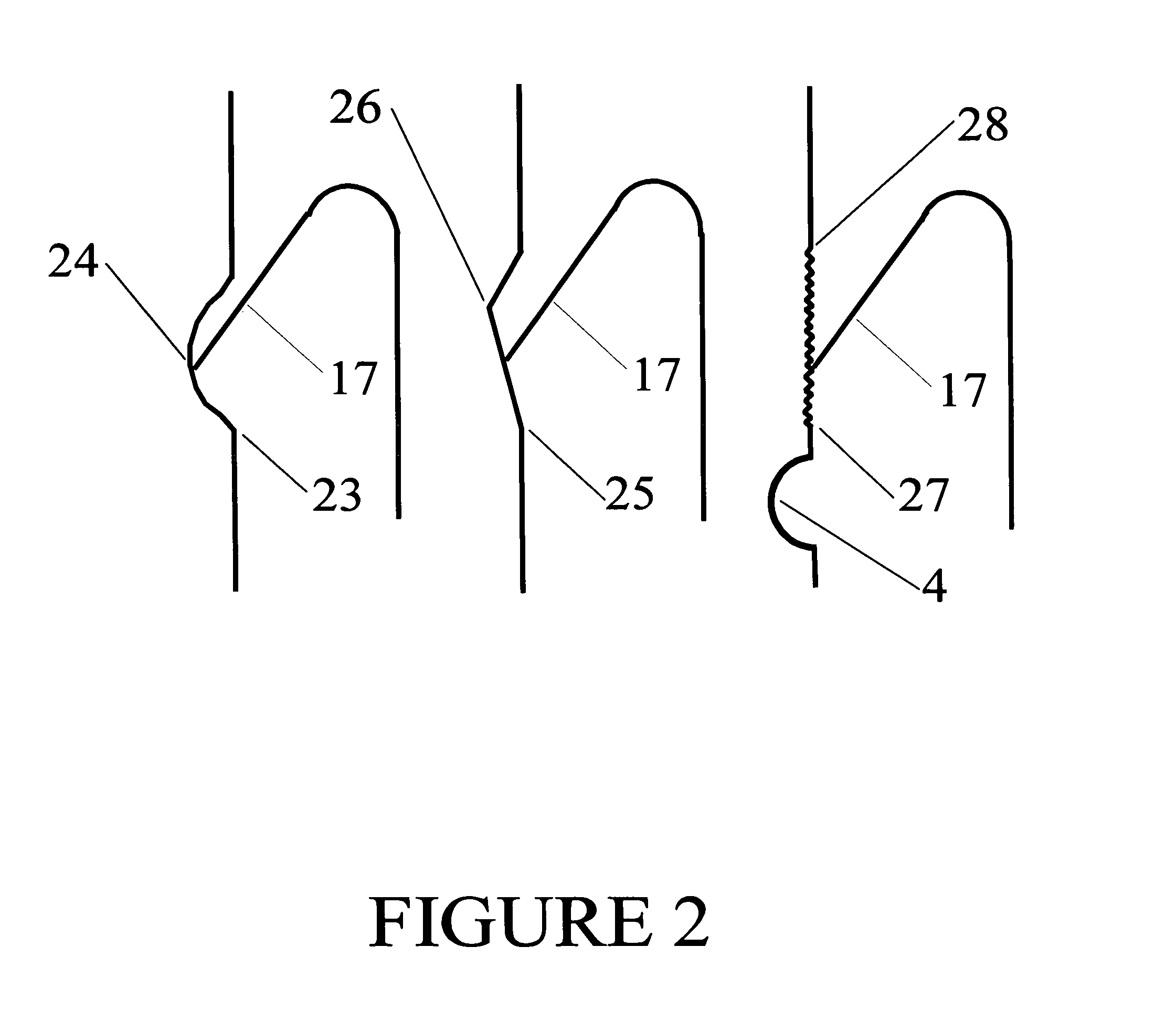

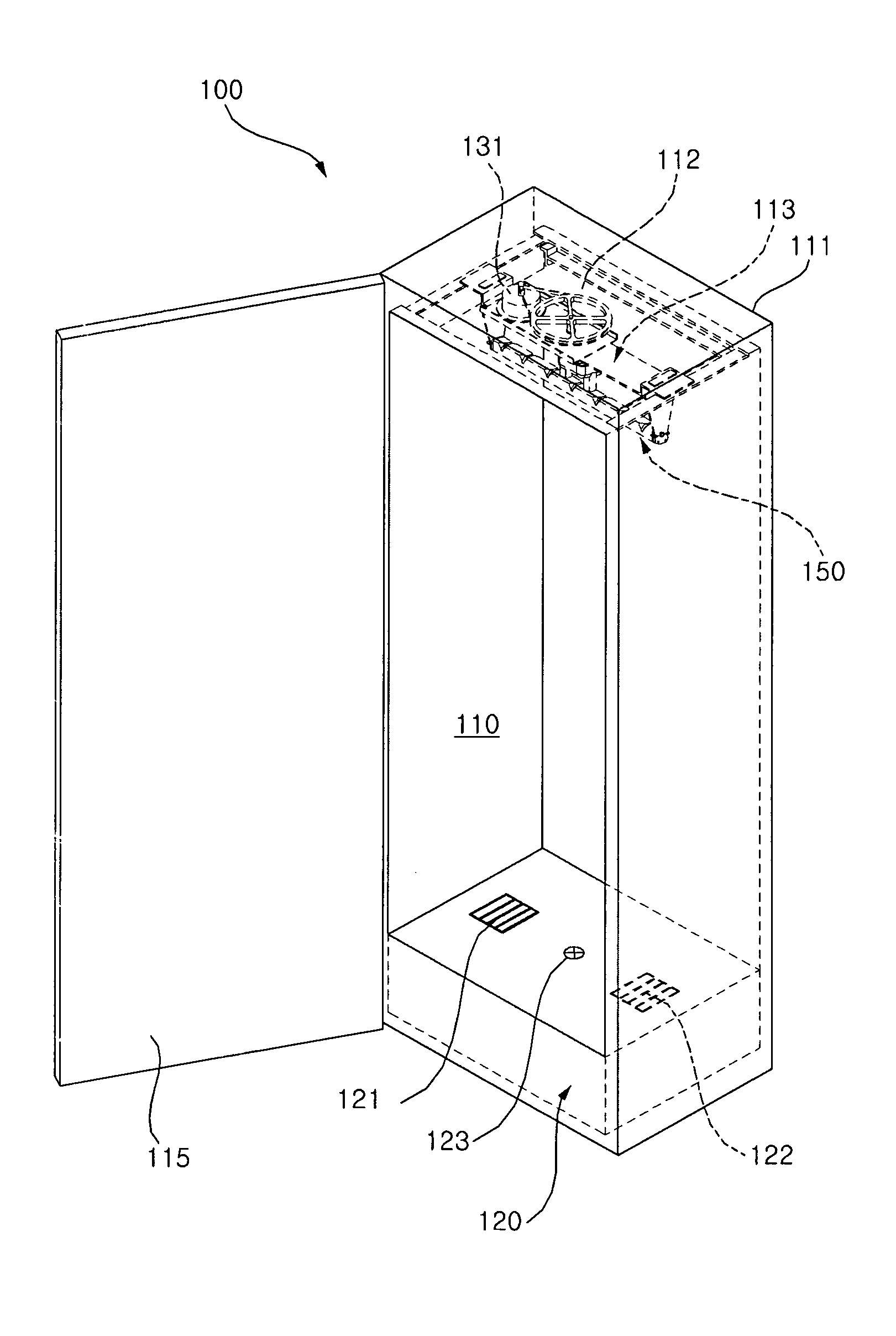

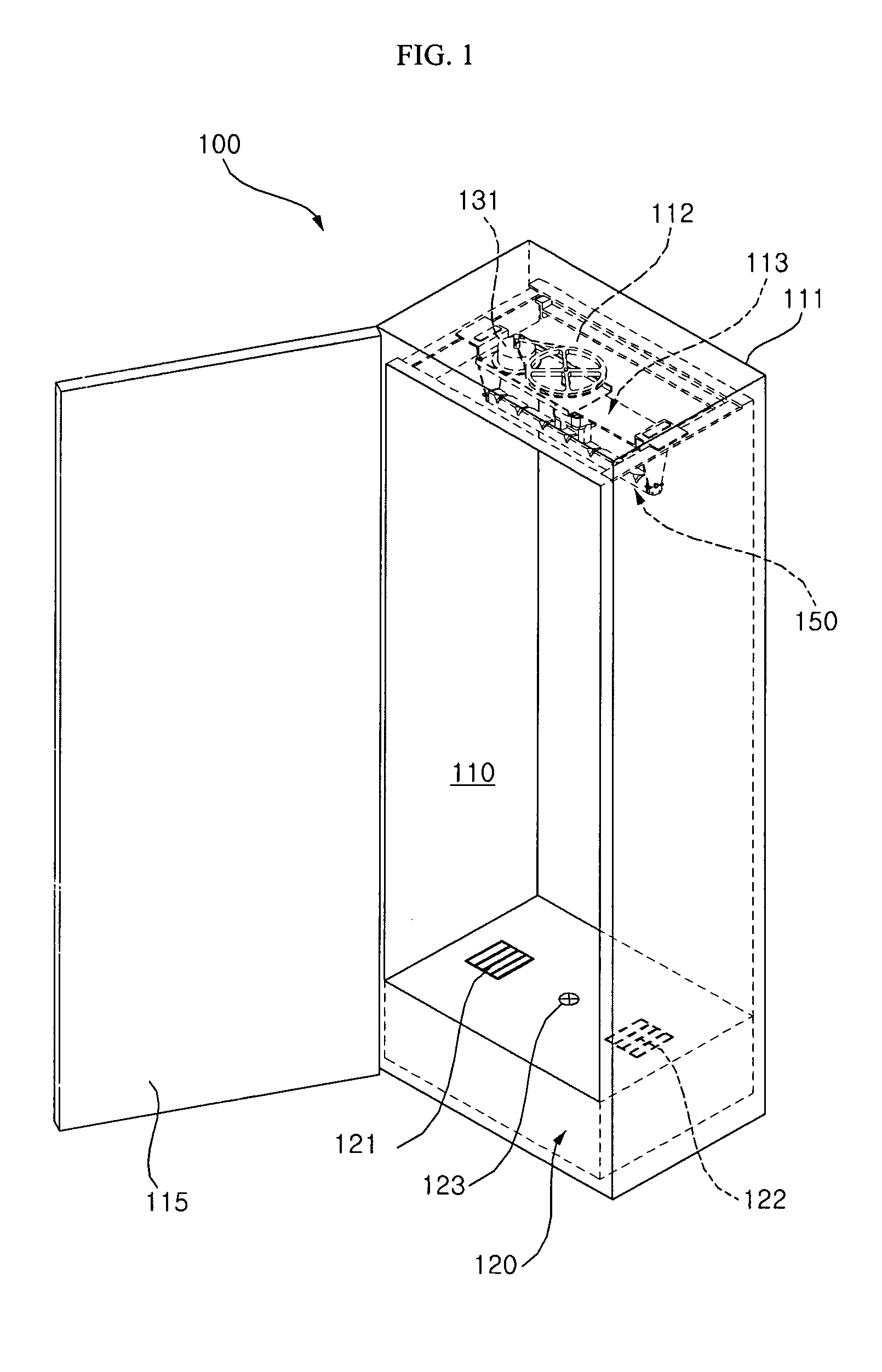

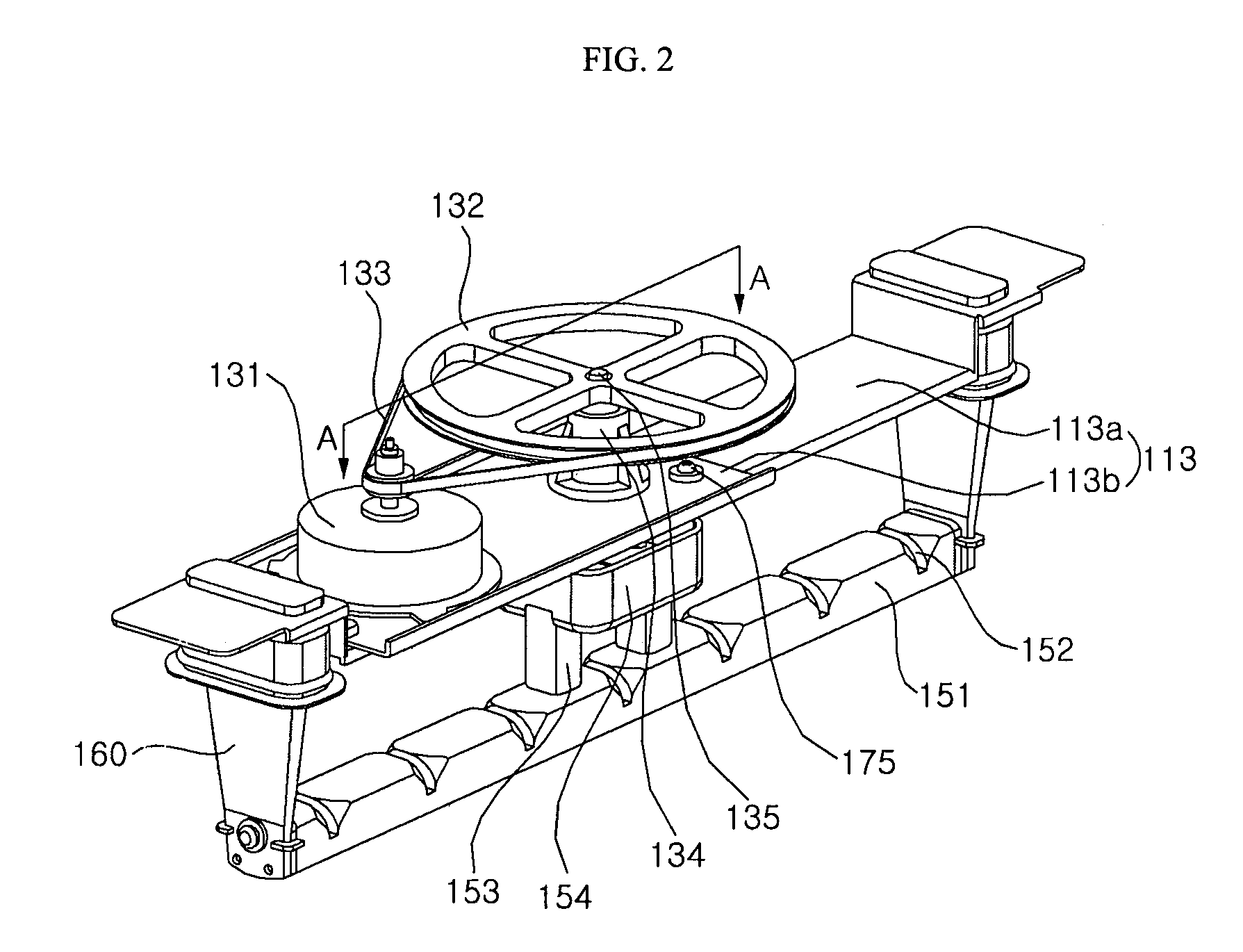

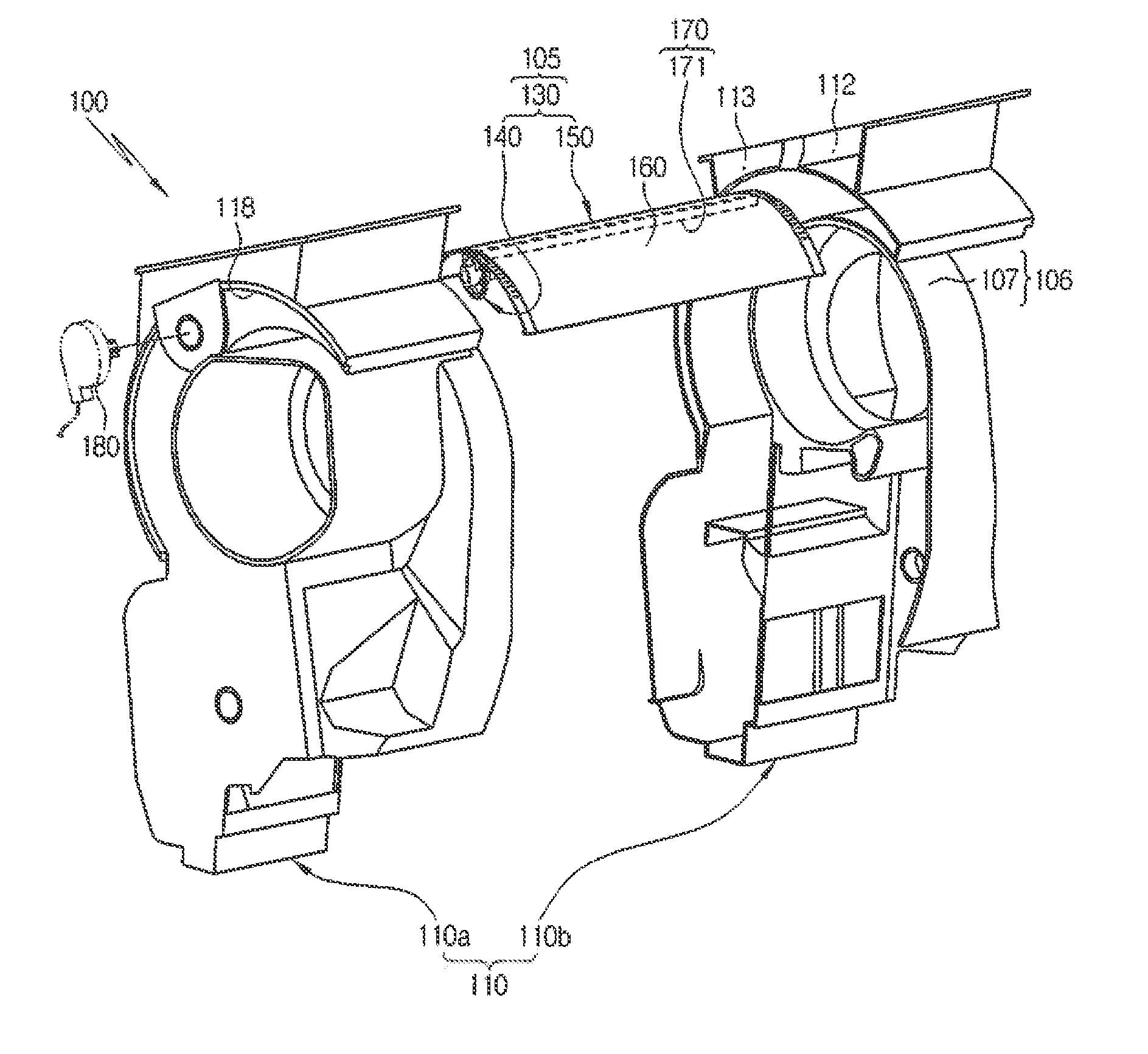

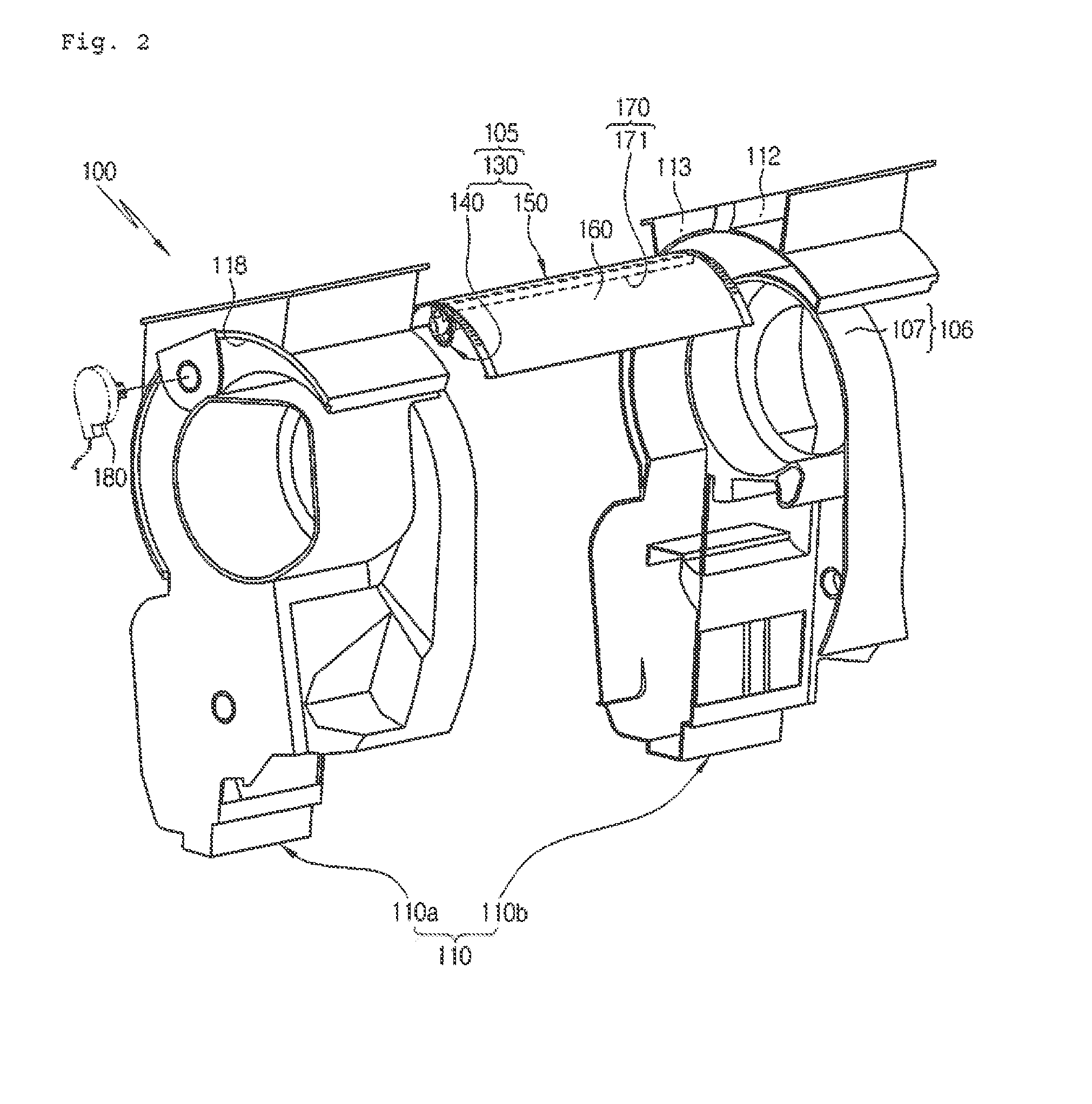

Fabric treating apparatus

ActiveUS8505340B2Prevent air leakageTextile treatment machine partsOther washing machinesEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

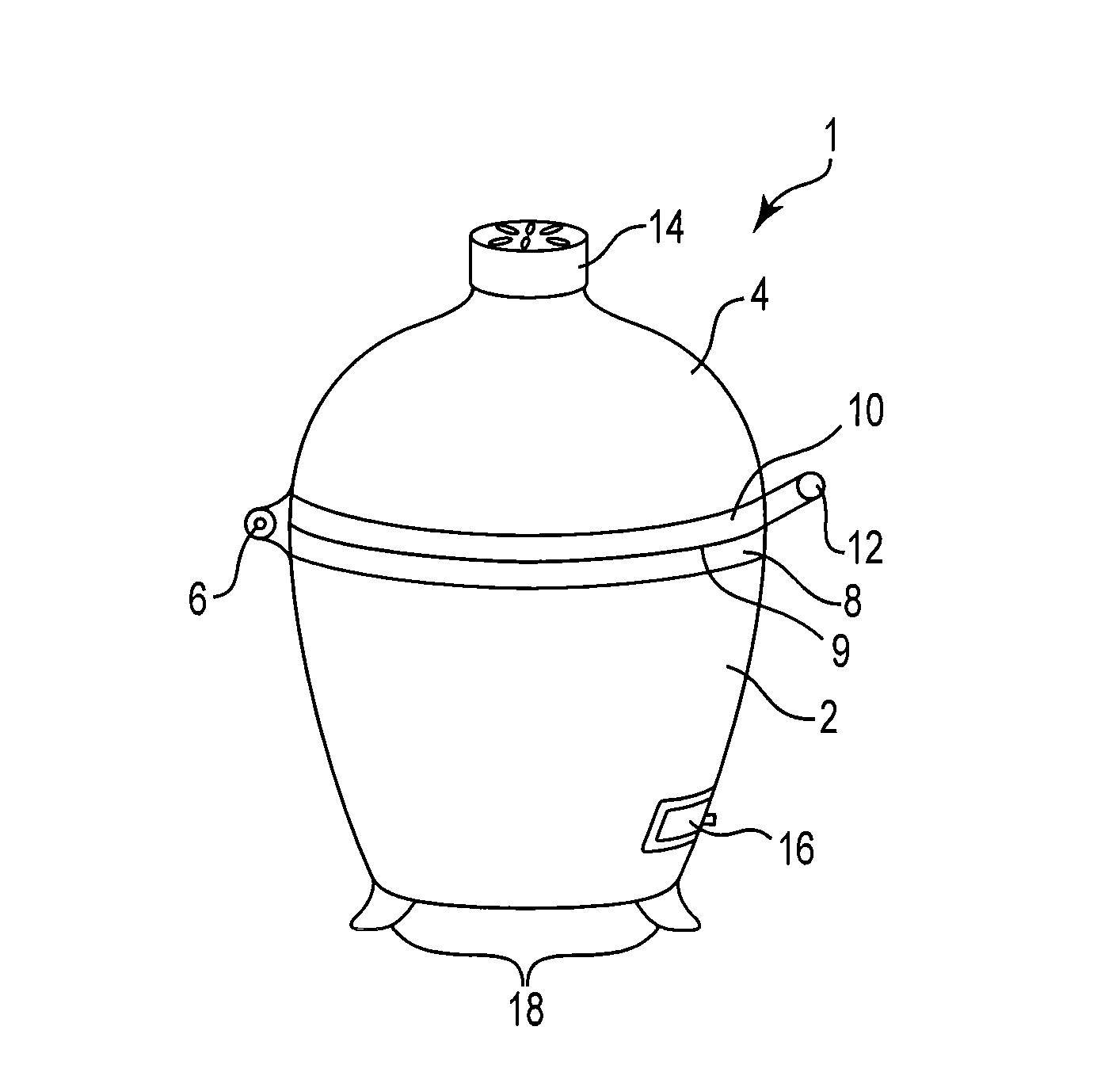

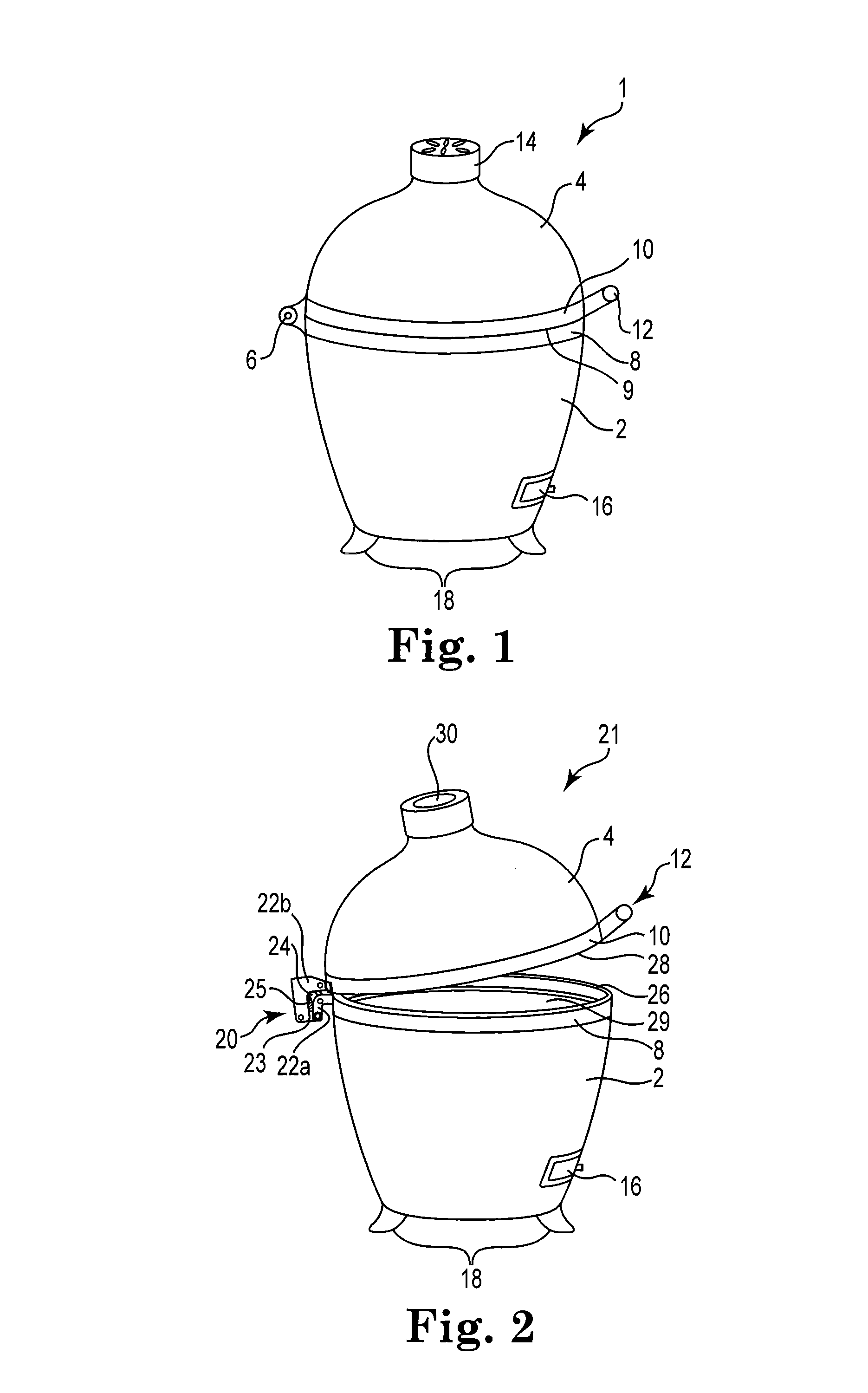

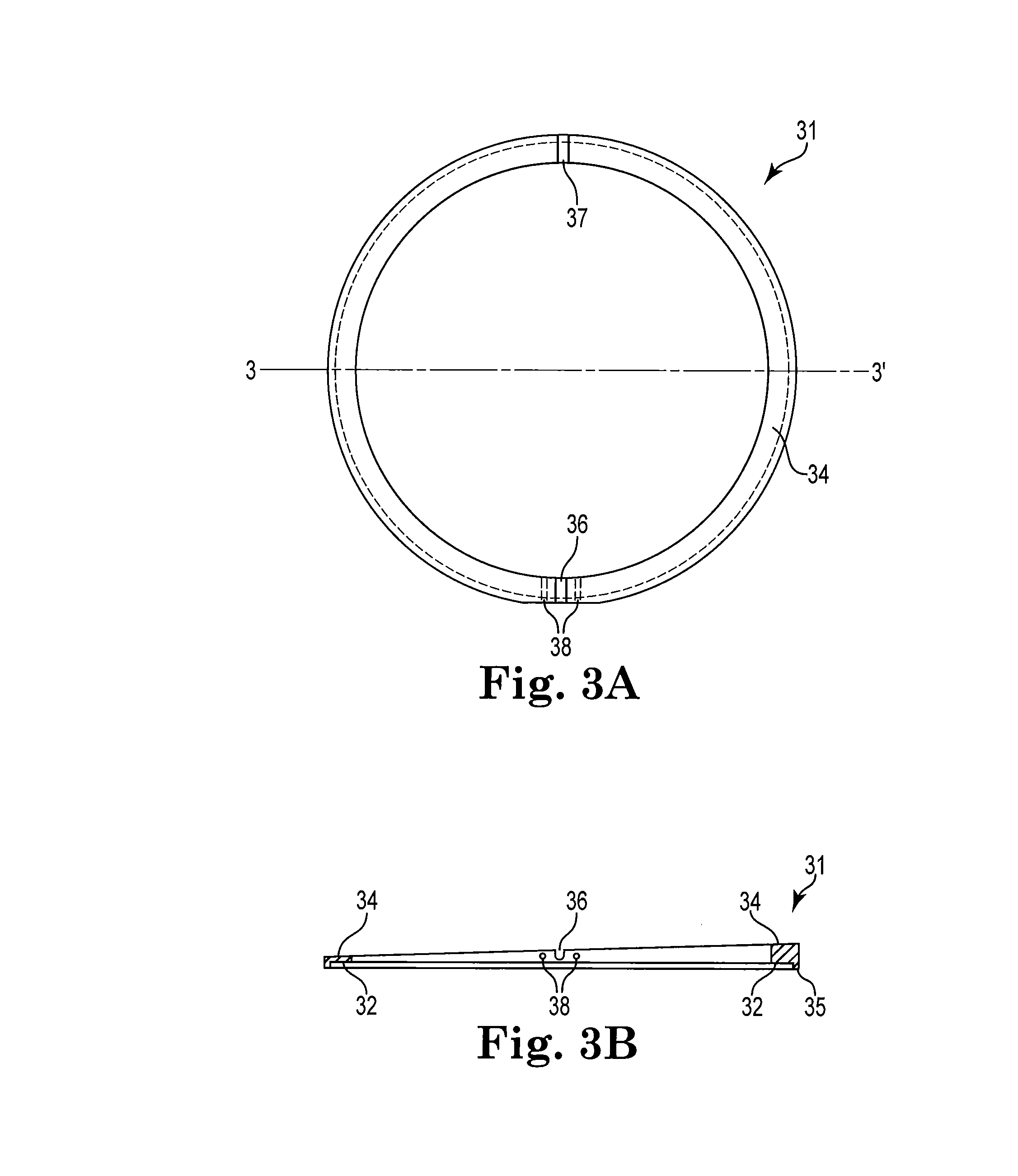

Ceramic cooker rotisserie

ActiveUS20130319258A1Speed up cookingPrevent air leakageRoasting apparatusRoasters/grillsCookerAirflow

A rotisserie device useful in a partially opened, hinged, covered grill includes a support ring that is shaped and configured to inhibit airflow into and out of the grill when the cover is partially opened. The support ring includes one or more cover supporting portions or chocks that hold the cover and base apart when the cover is partially opened, and one or more apertures through the ring that can receive a rotatable spindle which serves as or which drives a removable, rotatable rotisserie spit.

Owner:LINWOOD RESOURCES

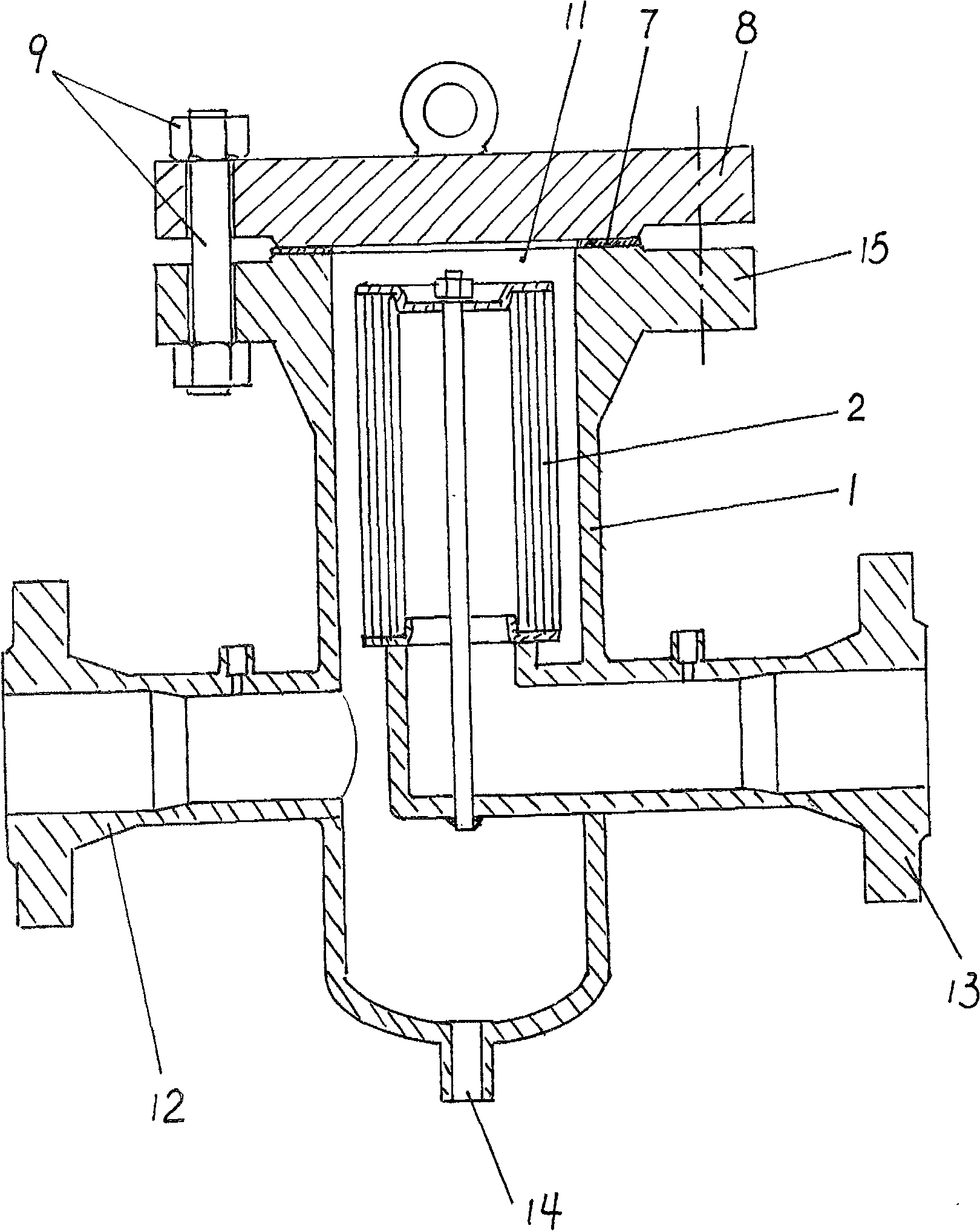

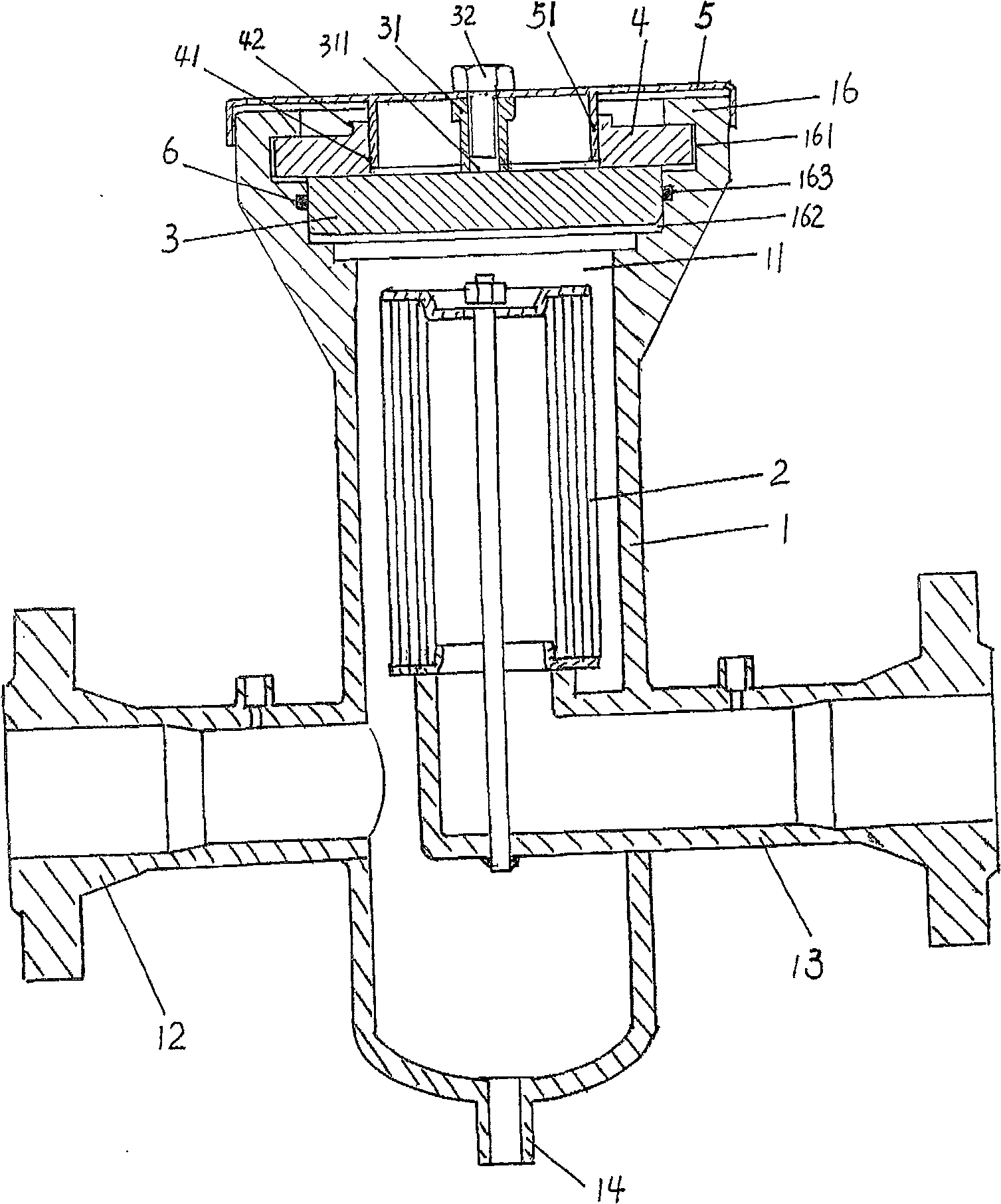

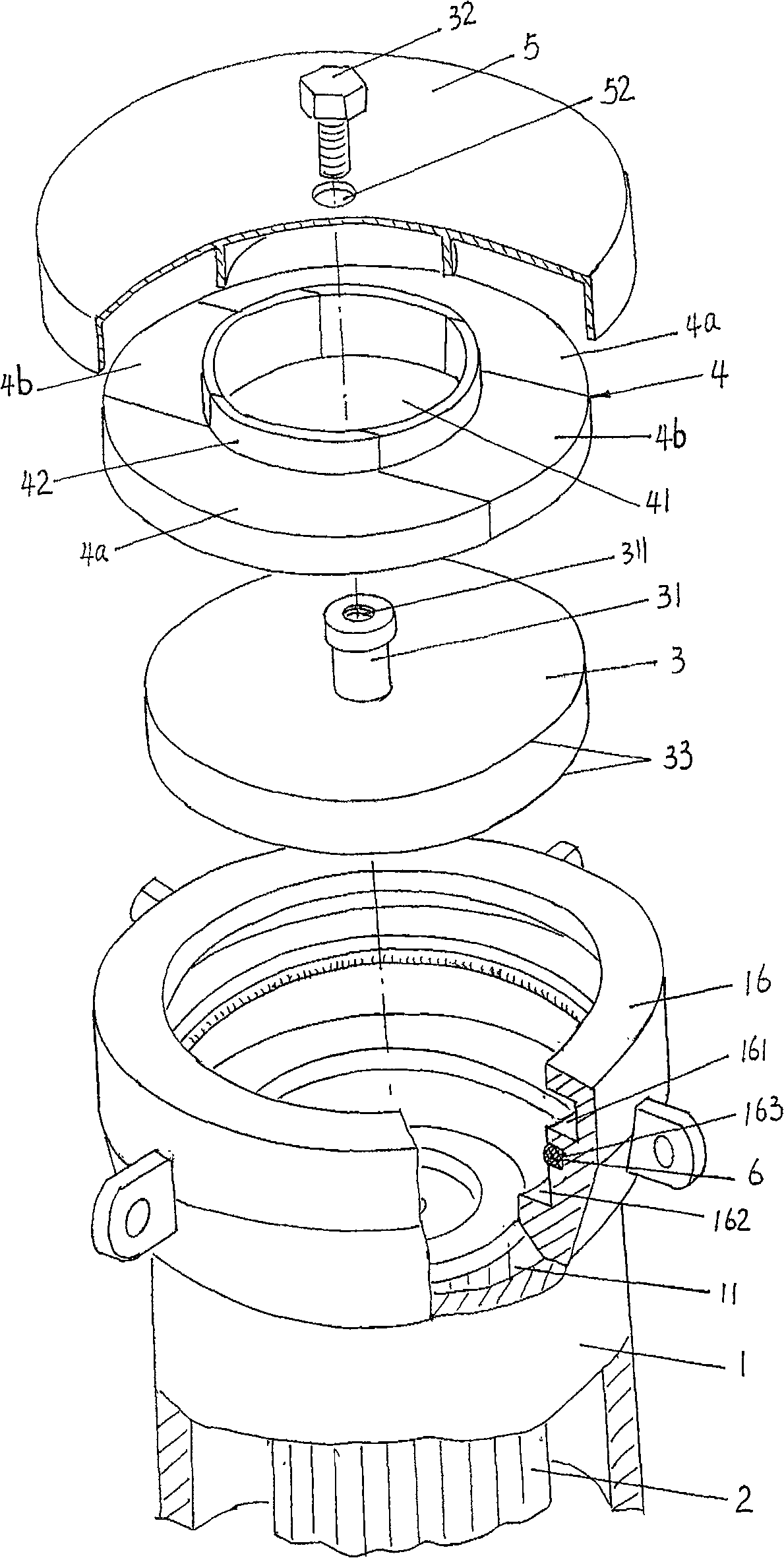

Natural gas filter

InactiveCN100535501CPrevent air leakageReduce incidenceDispersed particle filtrationPipe elementsFiltrationOutfall

The utility model relates to a natural gas filter, which belongs to a filtering device for natural gas pipelines in petroleum gathering and transportation projects such as natural gas fields, gas transmission and distribution pressure regulation systems, and city gate stations. It includes a cylinder with an opening on the top, a filter element placed in the cylinder, and a sealing mechanism for sealing the opening. The cylinder is provided with a raw material gas inlet, a purified gas outlet, and a sewage outlet. The filter element is The upper end is close to the opening, and the lower end of the filter element is connected to the outlet of the purified gas. The characteristic is that the sealing mechanism includes a high neck extending on the top of the cylinder, a sealing cover, a quarter ring, a protective cover, and fixing screws. Advantages: opening and closing the container becomes fast, convenient, time-saving, labor-saving and cost-saving; the sealing mechanism has a self-locking structure, which uses the pressure of its own natural gas in the container to lift the sealing cover, and the sealing cover and the high neck The space is sealed by an O-ring, and the four-part ring lifts the cover to meet the requirements of self-locking sealing. The sealing performance is good, which can prevent the container from leaking and reduce the incidence of accidents.

Owner:CHANGSHU NO 2 CHEM ENG EQUIP PLANT

Macromolecular synthesized memory sizing material

The invention discloses a macromolecular synthesized memory sizing material which comprises the following raw materials by weight percentage: 41-48% of elastomer, 38-41% of tackifier, 4-6% of softener, 1.5-3.2% of anti-aging agent and 4.5-9% of filler. A pricked part of a tyre sprayed with the macromolecular synthesized memory sizing material under various daily environments can heal automatically; accidents such as air leakage or tyre burst caused by prick of a sharp object can be effectively avoided; especially, the driving safety in a high speed driving state can be ensured to the greatest extent; the service life of the tyre is prolonged under the condition that the original performance of the tyre is not influenced; and various unnecessary troubles such as tyre repairing are reduced.

Owner:WUXI I REACH TECH

Integrated bladed fluid seal

ActiveUS7334983B2Improving apportioningControl leakagePump componentsGas turbine plantsCouplingCooling fluid

Disclosed are various embodiments of a gas turbine blade to vane interface seal for restricting leakage of cooling air and improving the apportioning of the cooling air to the seal. Accordingly, a turbine rotor contains a first and a second stage of radially extending and circumferentially distributed blades. The stages are separated axially from one another by an annular coupling located radially inboard of the blades, forming a chamber therebetween. Interposed between the blade stages is a vane stage. The vane stage contains a land, facing radially inwardly. A ring projects axially from each of the first and second blade stages towards the vane stage. A ring may also project radially from the coupling towards the vane stage. The rings radially cooperate with the land and together form the blade to vane interface seal. The coupling contains an aperture for radially introducing a cooled fluid to the chamber for use in cooling the seal.

Owner:RTX CORP

Air conditioner for vehicle

ActiveUS20150038067A1Avoid vibrationPrevent air leakageDucting arrangementsAir-treating devicesAir conditioningFace seal

Owner:HANON SYST

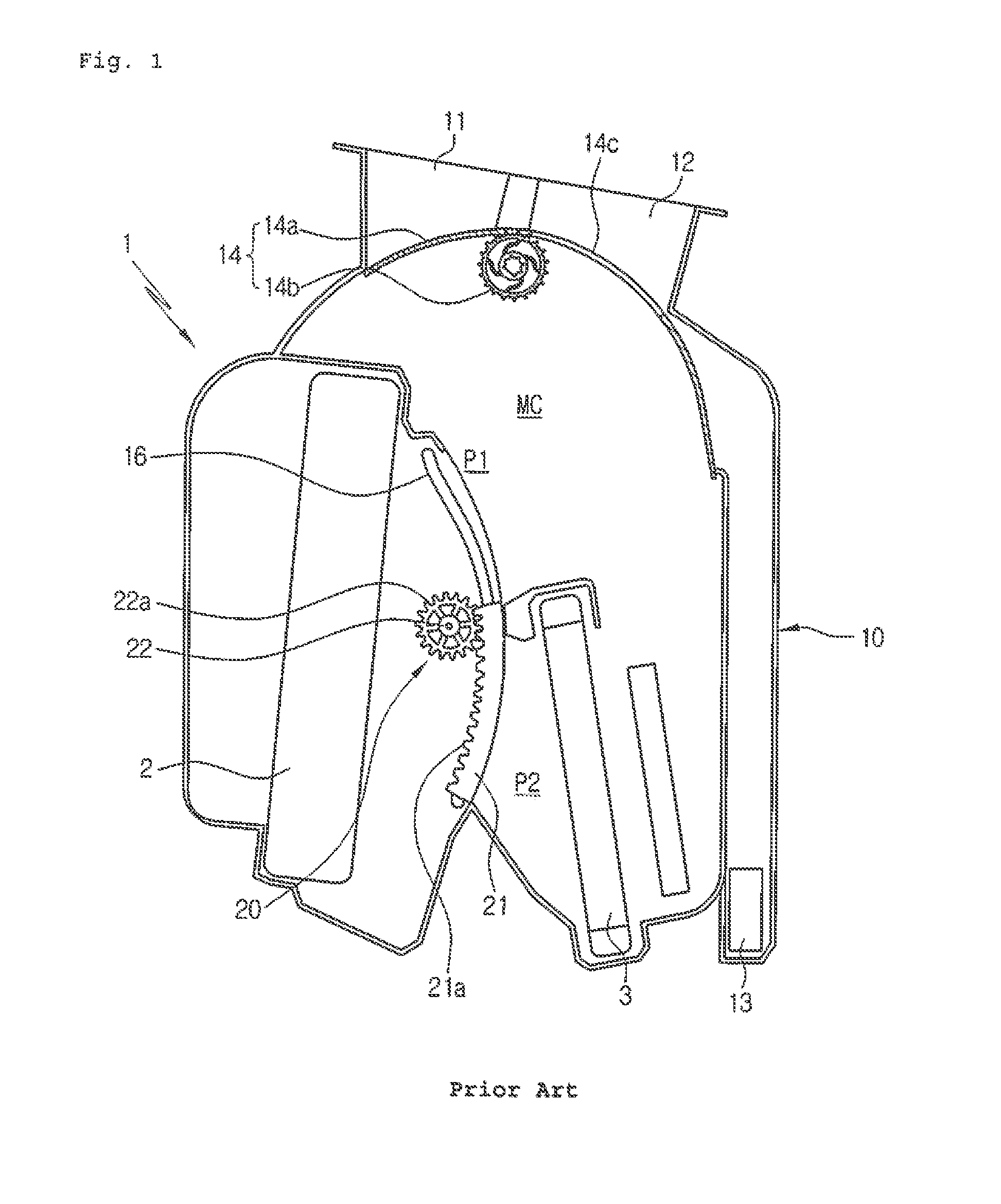

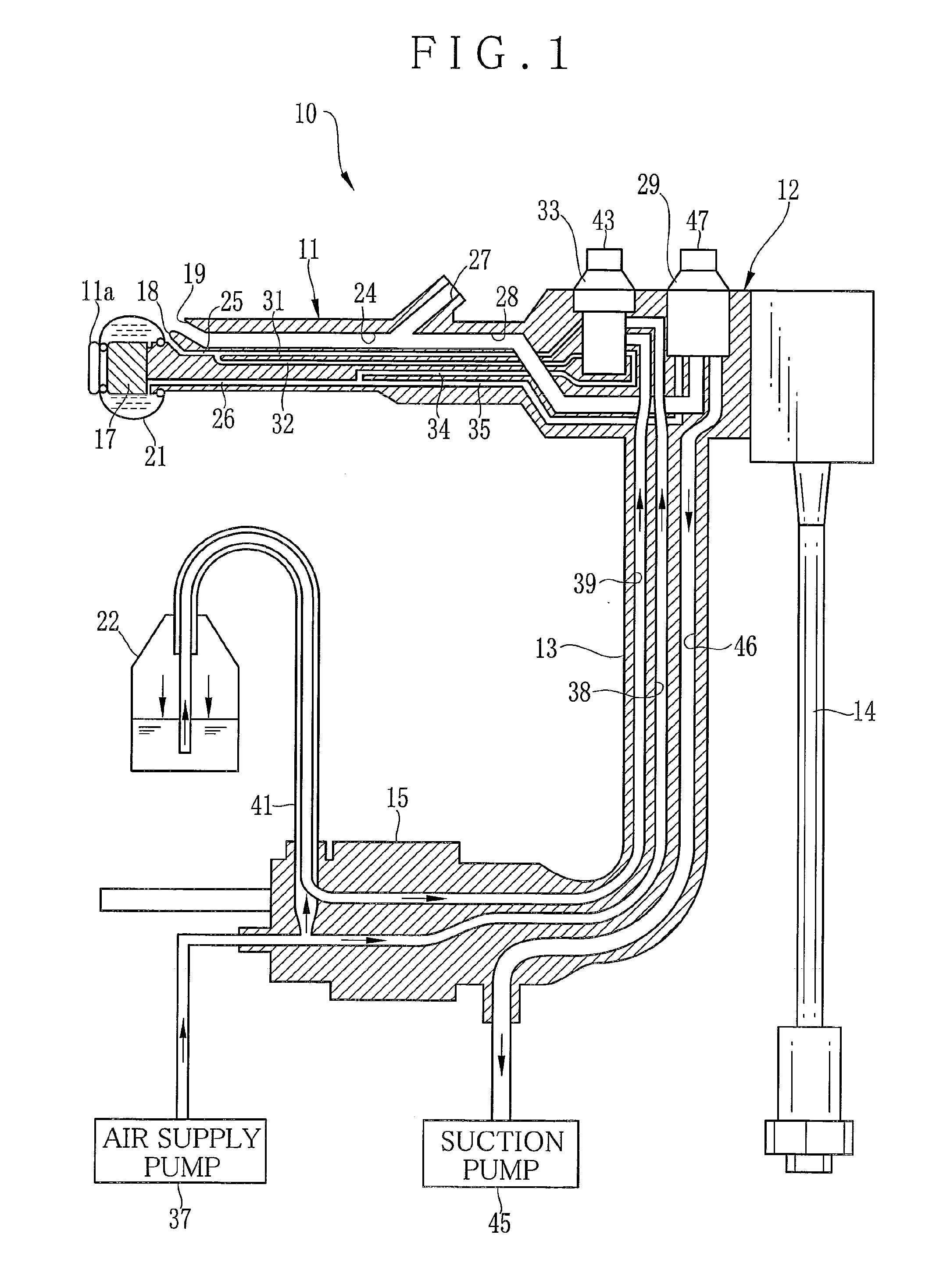

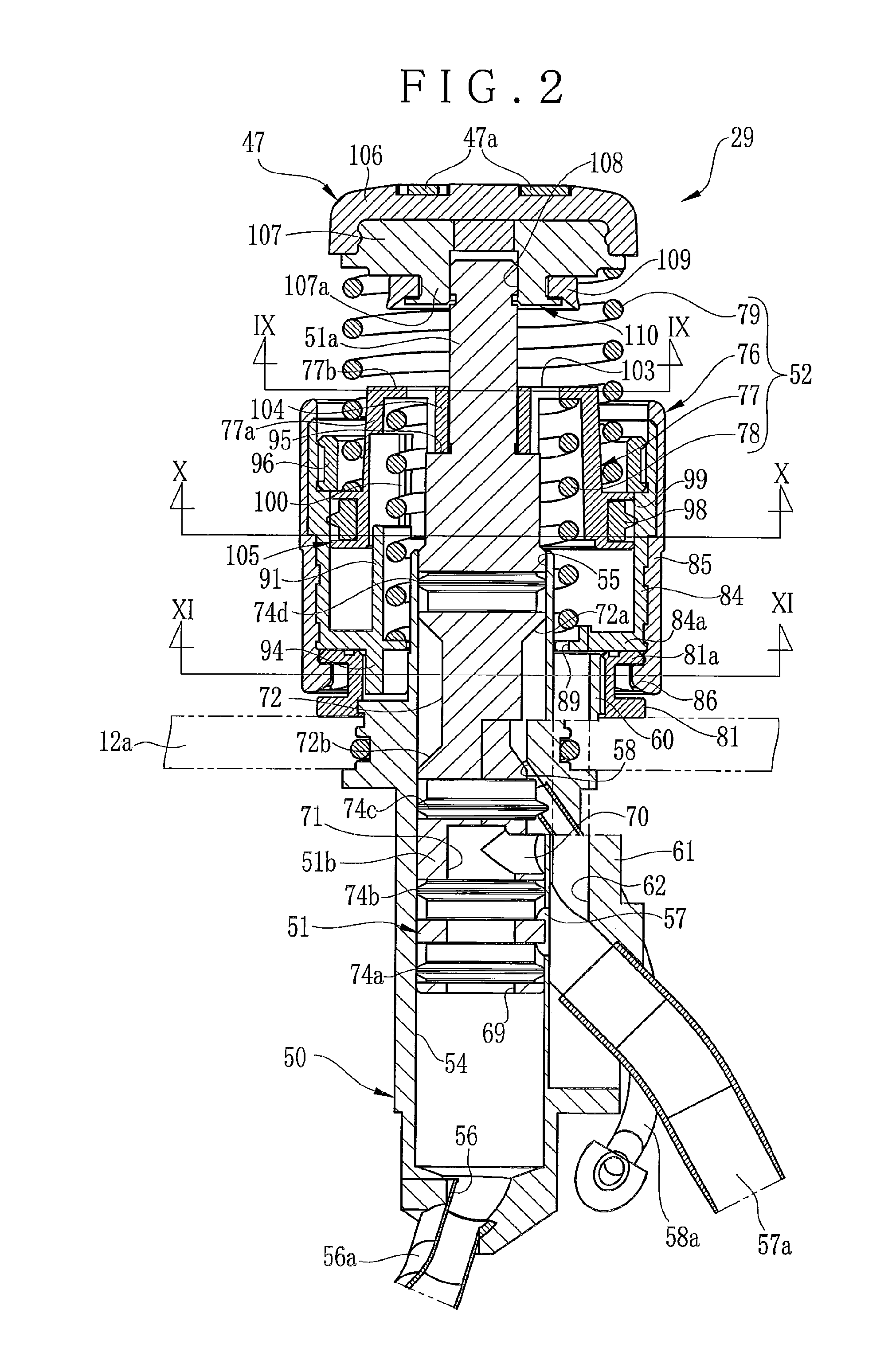

Switching valve assembly for endoscope

InactiveUS20120088975A1Prevent air leakageReliable preventionSurgeryEndoscopesCylinder headCoil spring

A switching valve assembly for an endoscope includes a cylinder, a piston unit, a button device, a flow channel in the piston unit, and plural flow openings. The piston unit changes over plural flow lines between communication and interruption by changing a combination of the flow openings with the flow channel for communication. The switching valve assembly includes a cylinder cap device and a slide device of a cup shape. An end ring keeps the slide device contained in the cylinder cap device. A first coil spring is disposed between the slide device and cylinder cap device, for biasing the slide device in an upward direction from the cylinder. A second coil spring is disposed between the button device and slide device, for biasing the button device in the upward direction with smaller force of bias than the first coil spring. The slide device includes an inner guide sleeve.

Owner:FUJIFILM CORP

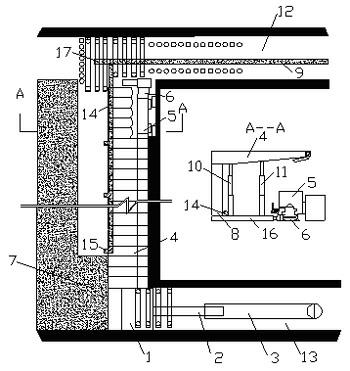

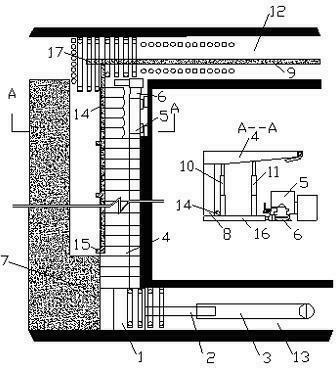

Roadside packing gob-side entry retaining top-cutting explosion pressure relief method

InactiveCN104790954ARelieve pressureEliminate problems such as support difficultiesUnderground miningSurface miningStructural engineeringDeep hole

The invention discloses a roadside packing gob-side entry retaining top-cutting explosion pressure relief method which comprises the following four steps: I, confirming a top-cutting method, the drilling construction time and a drilling construction site; II, confirming top-cutting pressure relief explosion drilling parameters; III, drilling deep-hole explosion holes and explosive filling and sealing holes; IV, performing explosion top-cutting pressure relief. The roadside packing gob-side entry retaining top-cutting explosion pressure relief method is applied to roadside packing gob-side entry retaining top-cutting explosion pressure relief.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Turbine shroud segment feather seal located in radial shroud legs

ActiveUS7374395B2Preventing cooling airPrevent air leakagePropellersPump componentsTurbineStructural engineering

A turbine shroud assembly is configured to adequately adjust a distribution of cooling air flow such that air leakage between radial shroud legs of adjacent shroud segments is minimized, while permitting cooling air to leak between platforms of adjacent shroud segments in order to cool sides of the platforms thereof.

Owner:PRATT & WHITNEY CANADA CORP

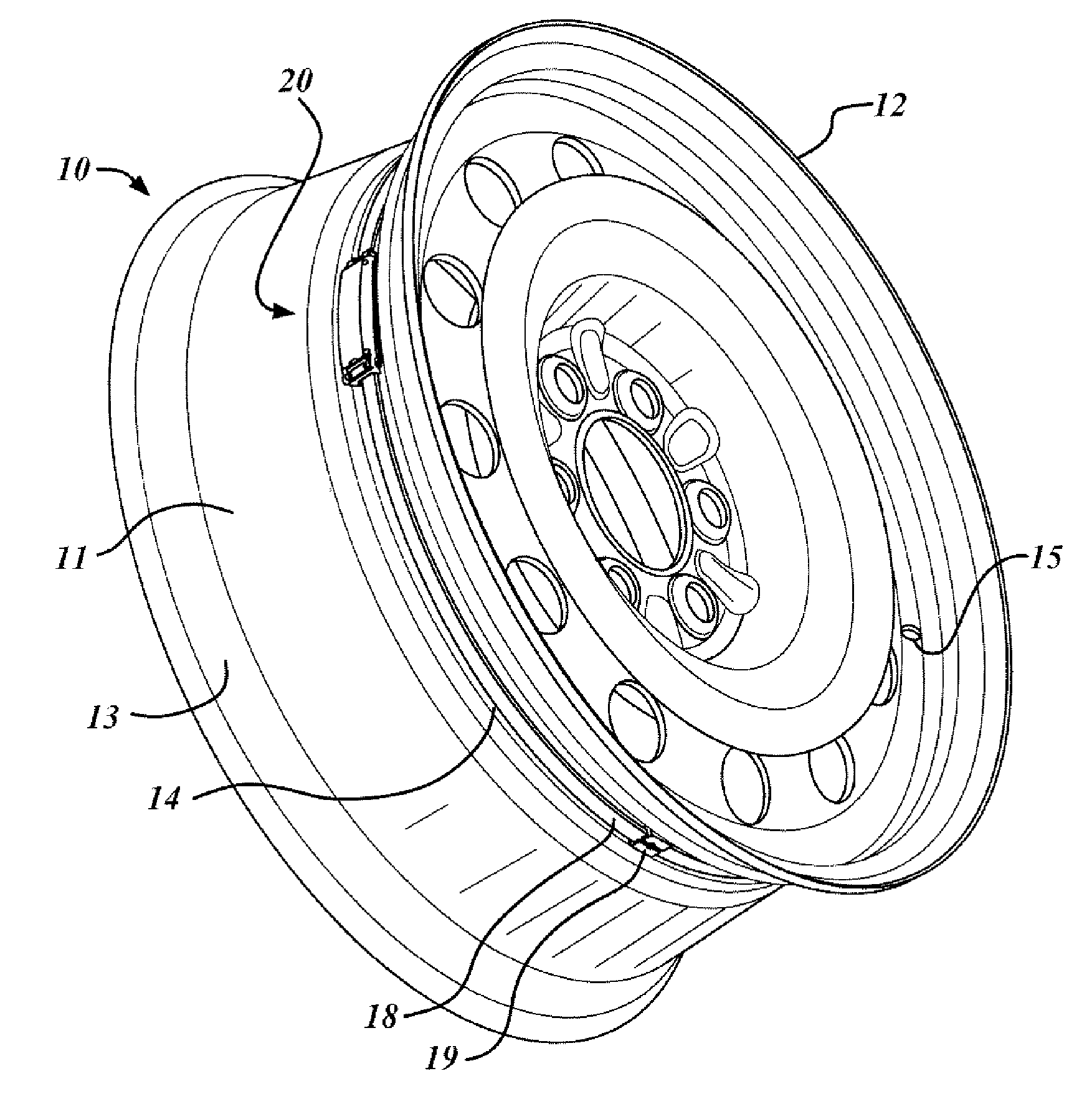

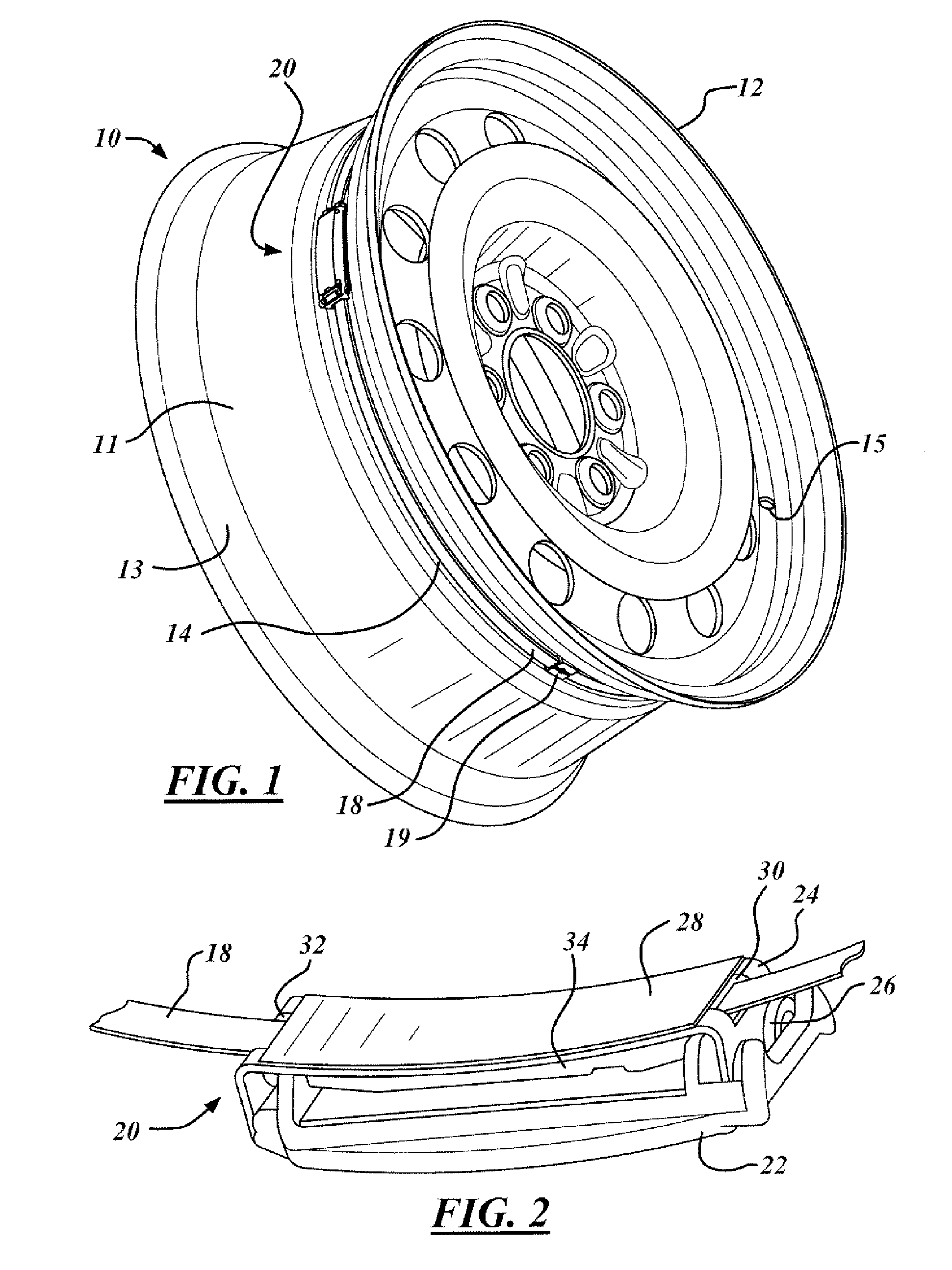

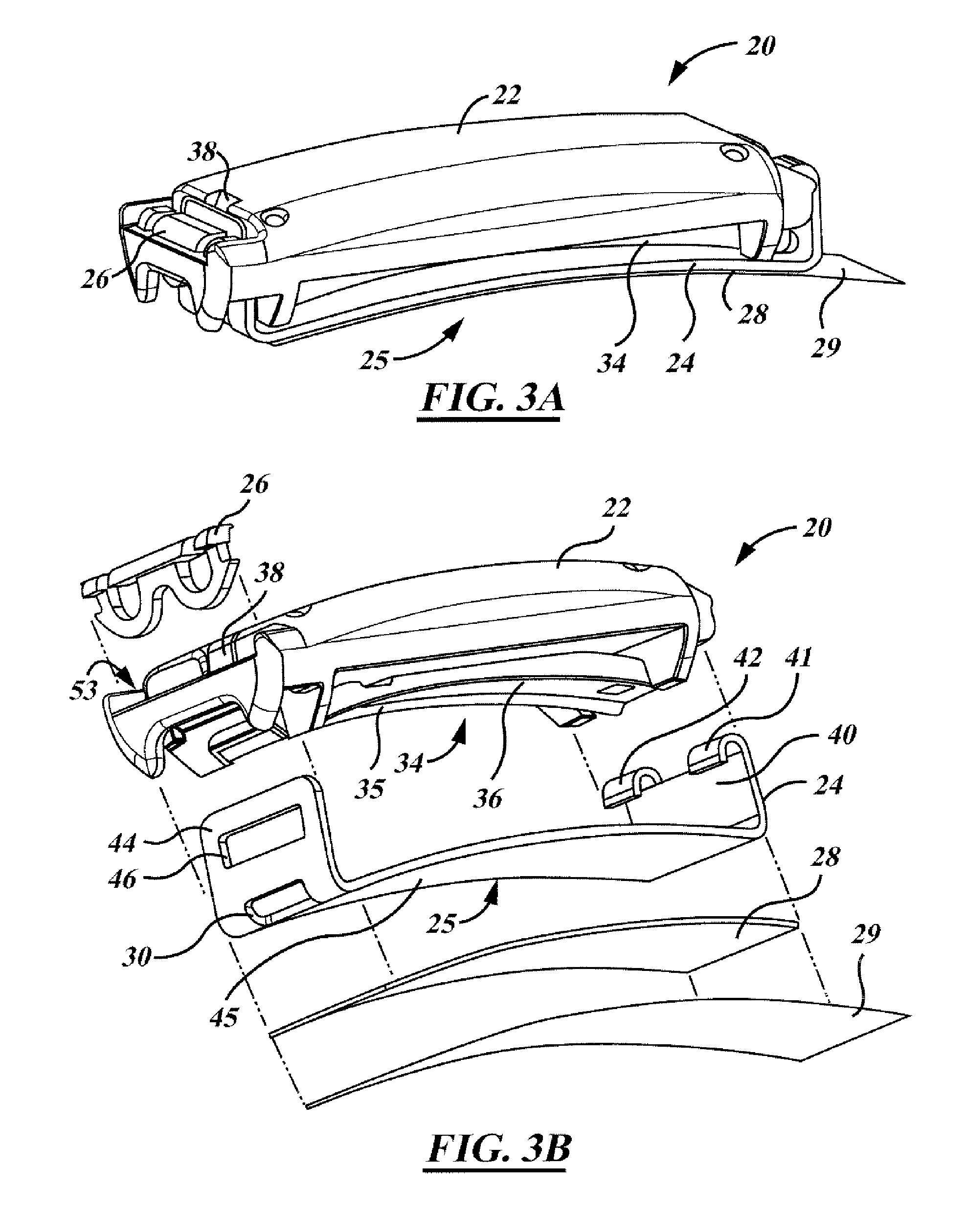

Tpms sensor assembly and method therefore

InactiveUS20060248947A1Preventing accidental air leakagePrevent air leakageInflated body pressure measurementTyre measurementsEngineeringElectrical and Electronics engineering

Owner:FORD GLOBAL TECH LLC

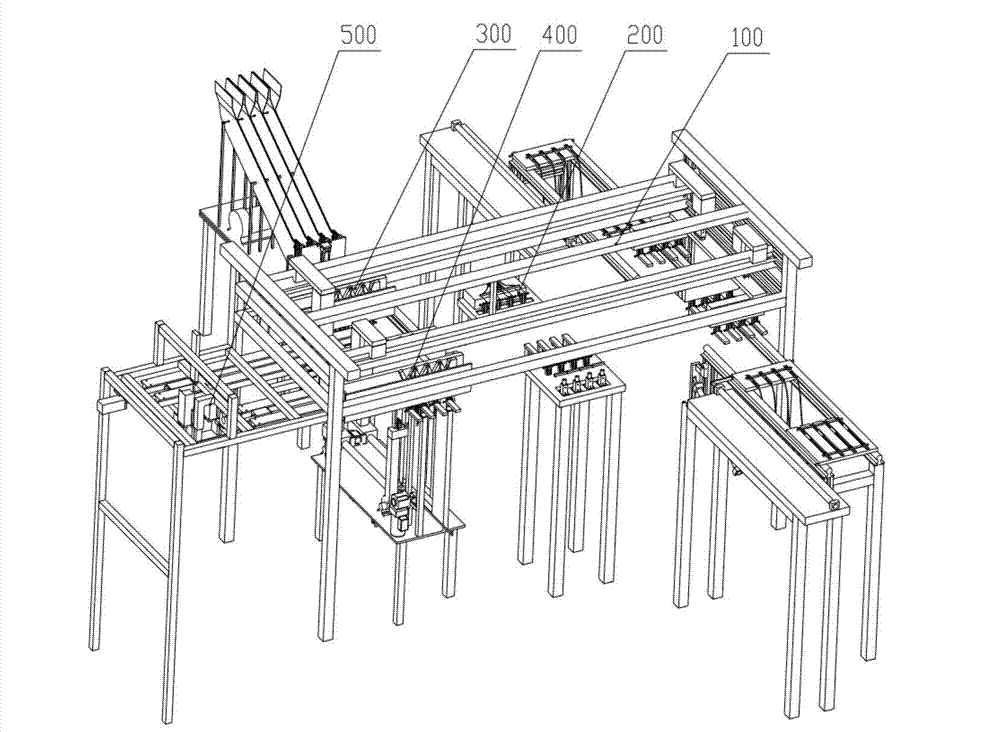

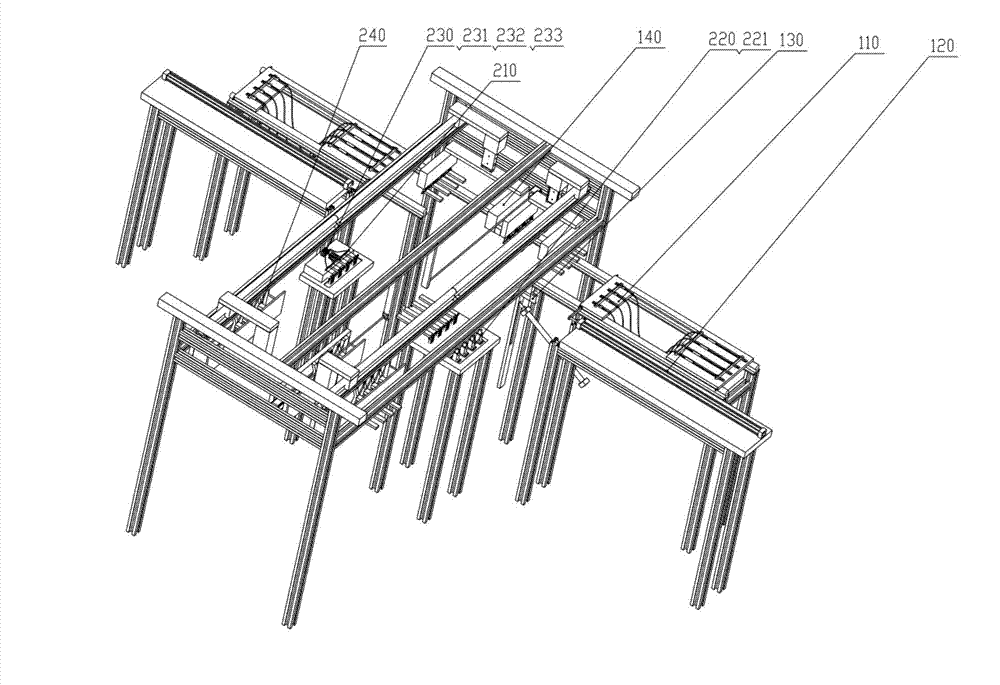

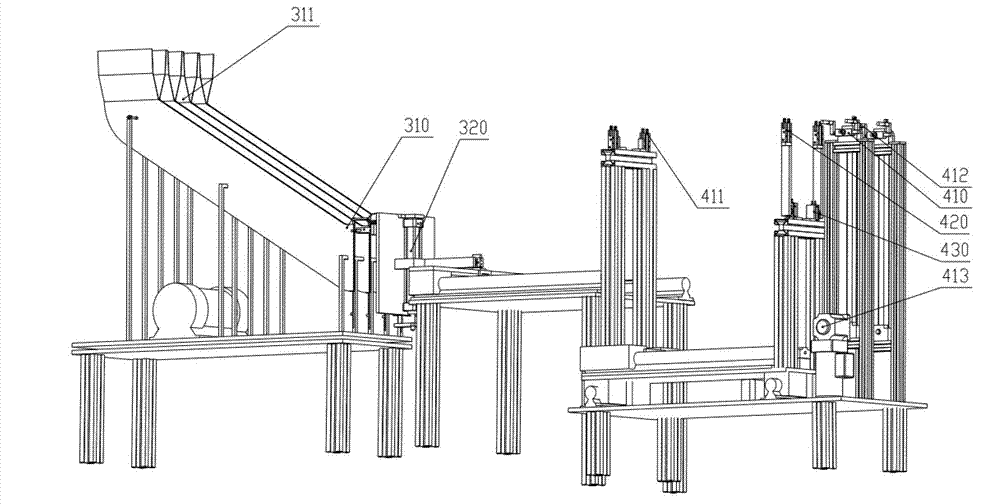

Infusion tube automatic production line

ActiveCN103083788APrevent air leakageEliminate uncertain operationsMeasurement of fluid loss/gain rateInfusion devicesProduction lineCircle bundle

The invention discloses an infusion tube automatic production line. The infusion tube automatic production line is used for achieving automatic detecting, assembling and packaging of infusion tubes, and comprises a feed mechanism, an air leakage detection mechanism, a needle head component assembly mechanism, a winding mechanism and a packaging and sealing mechanism, wherein the feed mechanism, the air leakage detection mechanism, the needle head component assembly mechanism, the winding mechanism and the packaging and sealing mechanism are sequentially arranged along working procedures. The feed mechanism is used for loading raw material tube bodies of the infusion tubes and transporting the raw material tube bodies to an air leakage detection station. The air leakage detection mechanism is used for carrying out air leakage detection on the infusion tube bodies on the air leakage detection station, and the qualified infusion tube bodies after detection can be sent to a needle head installation station. The needle head component assembly mechanism is used for installing needle head components on the infusion tube bodies to form the infusion tubes. The winding mechanism is used for winding the infusion tubes so that the infusion tubes are manufactured into circle bundles. The packaging and sealing mechanism places wound infusion tube circle bundles to packaging bags and carries out packaging and sealing on the packaging bags. According to the infusion tube automatic production line, automatic operation of detecting and packaging procedures of the infusion tubes can be achieved, production efficiency of the infusion tubes can be improved, and labor intensity of workers can be lowered at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

Hot-seal functional stretch film

InactiveCN102190824ANo heat sealabilityAvoid warpingFlexible coversWrappersBlow moldingOptical property

The invention provides a functional stretch film with hot seal property, and in particular relates to a hot-seal unidirectional or bidirectional stretch film, which has the hot seal strength of more than or equal to 3N / 15mm and the thickness of more than or equal to 0.010mm and less than or equal to 0.150mm and which is formed by a single layer, two layers or more than two layers of polyolefine resin by an auxiliary co-mixing process and a blow molding, flow casting extrusion stretching or co-extrusion stretching process. The functional stretch film solves the technical problem that the effective hot seal cannot be achieved on an occasion with higher hot-seal requirements due to difficult obtaining of hot seal or serious hot-seal performance reduction when the polyolefin film is stretched. The product has the advantages of high mechanical strength, excellent optical property, obviously high water vapor resistance, anti-puncturing property and extremely good seal grease resistance and anti-pollution hot seal property, and can be widely applied to bags and automatic filling type sealed packages of foods, articles of daily use, cosmetics, chemicals, pesticides, military products and medical products as well as intaglio printing films and flexographic printing films, particularly various hot-seal materials under the dry-type lamination, wet-type lamination and extrusion lamination processing conditions.

Owner:江苏彩华包装集团公司 +1

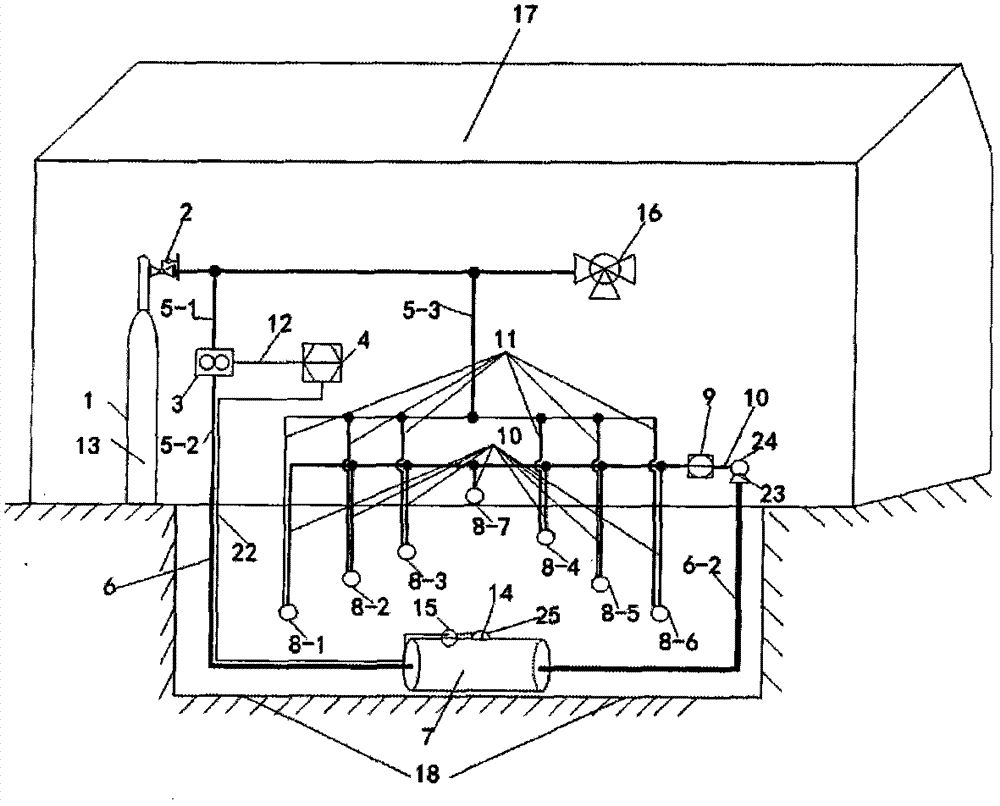

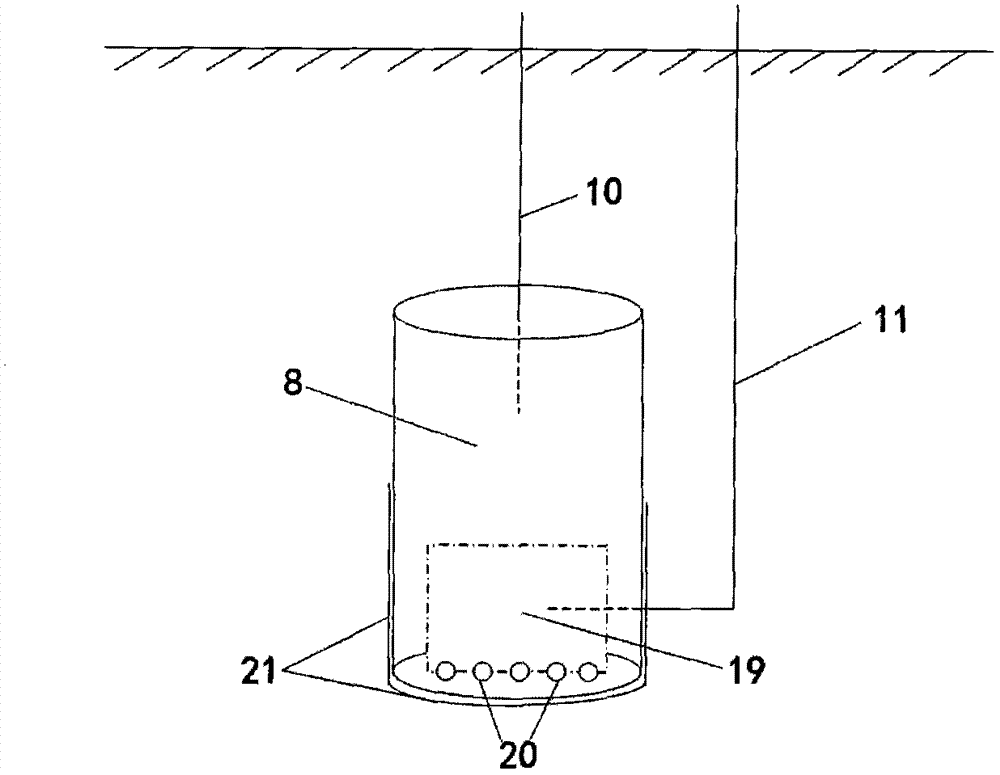

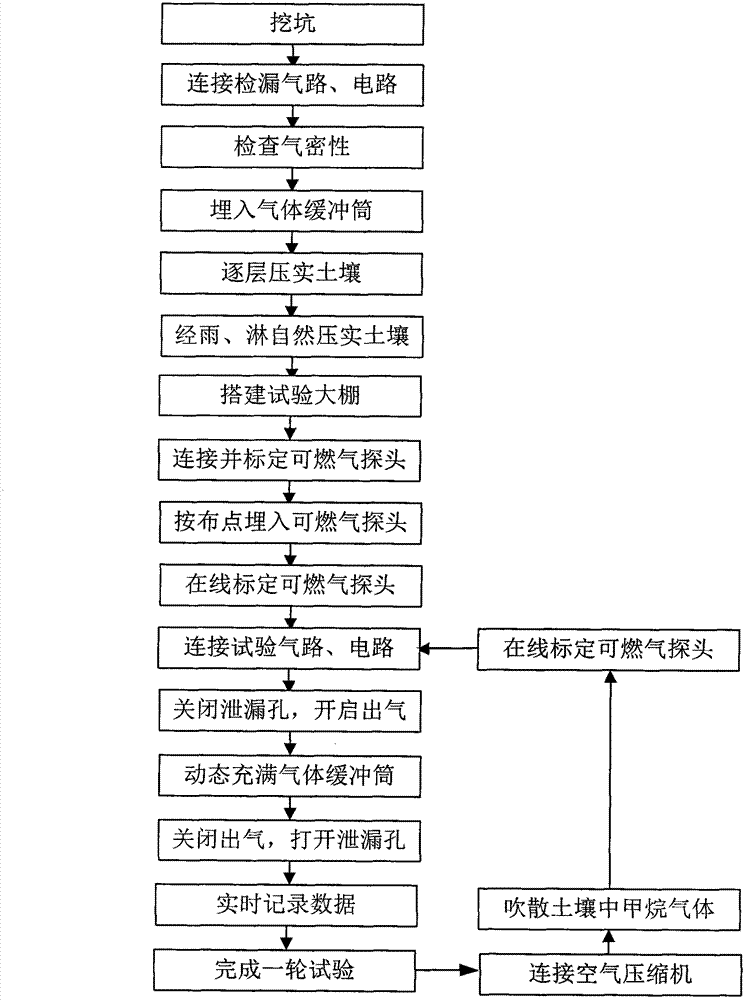

Test device and method for simulating natural gas leakage in soil

ActiveCN103712755APrevent air leakageSource Strength ControlMeasurement of fluid loss/gain rateShielded cableCombustible gas

The invention provides a test device and method for simulating natural gas leakage in soil. The test device comprises a compressed gas steel cylinder, a pressure reducing valve, a gas flow meter, a PC computer, a pressure-tolerant hose, a rigid pipe, a gas buffer cylinder, a combustible gas probe, a multichannel combustible gas probe controller, a waterproof shield cable, a rigid hose and the like. The gas buffer cylinder and the combustible gas probe are embedded in outdoor soil. Through the rigid hose, zero calibration can be carried out on the combustible gas probe buried in the ground. The test method comprises the steps that the pressure reducing valve of the compressed gas steel cylinder of natural gas is opened; the gas buffer cylinder is filled with the natural gas successively through the gas flow meter, the pressure-tolerant hose and the rigid pipe; the combustible gas probe buried in the ground is used to collect the concentration of the gas leaking out from the gas buffer cylinder; the diffusion law of the natural gas in soil after natural gas pipe leakage is researched; and a technical support is provided for the prevention and the disposition of a natural gas pipe leakage accident.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com