Heat exchanger and its manufacturing method

A technology for heat exchangers and manufacturing methods, which is applied in the field of heat exchangers with a laminated structure, can solve problems such as reduced heat exchange efficiency, reduced mass production, and poor production, so as to reduce processing steps, prevent airflow leakage, and reduce parts Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

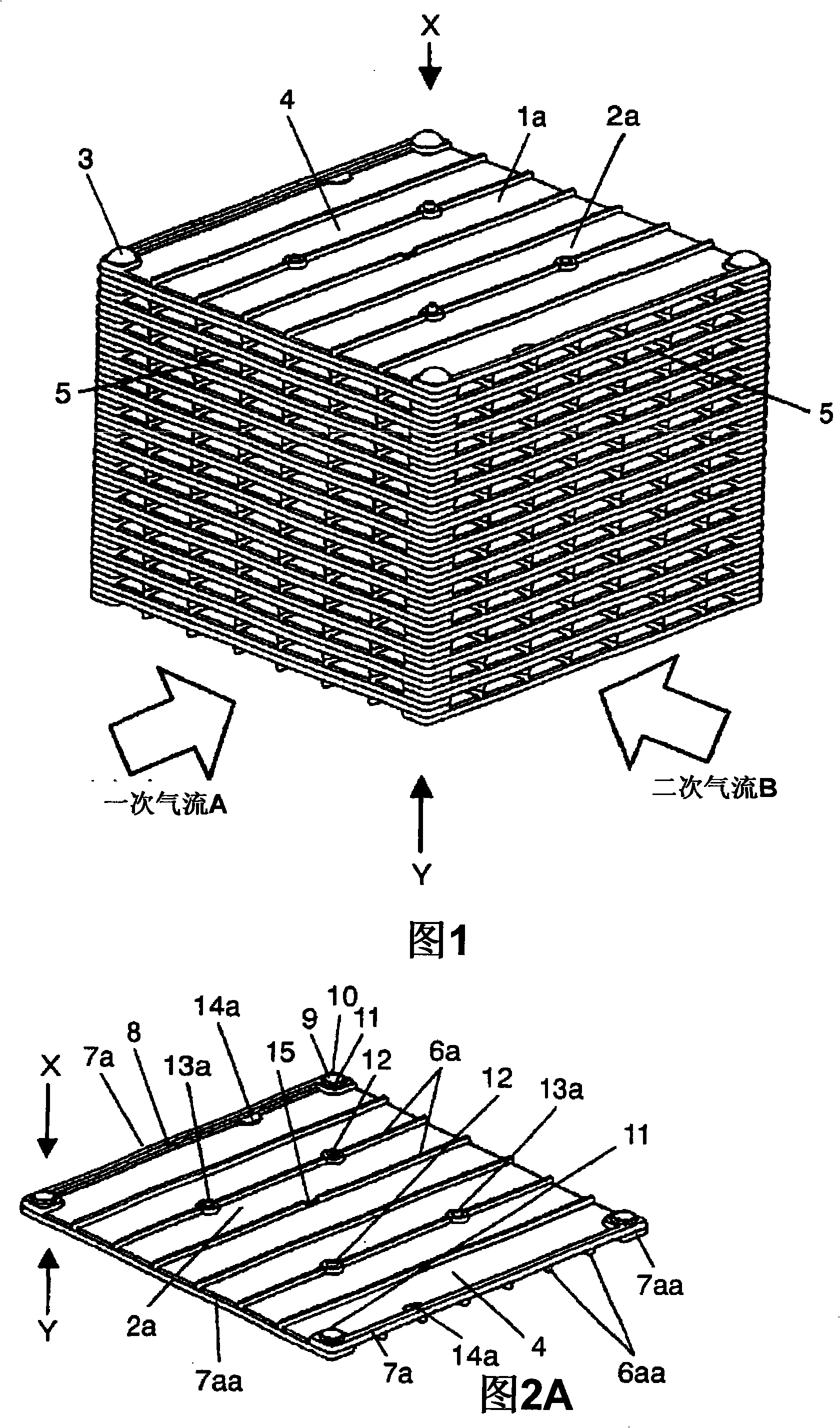

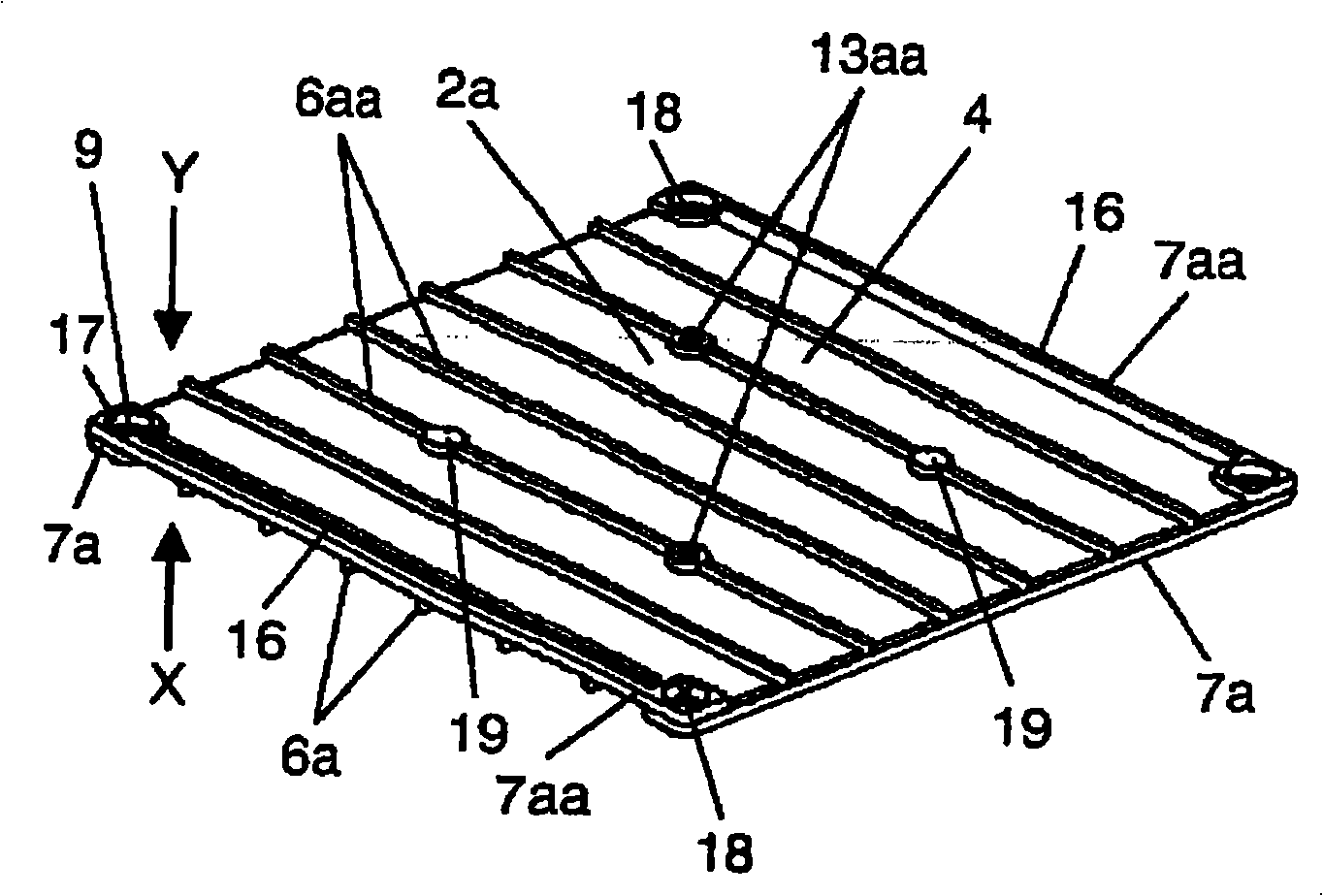

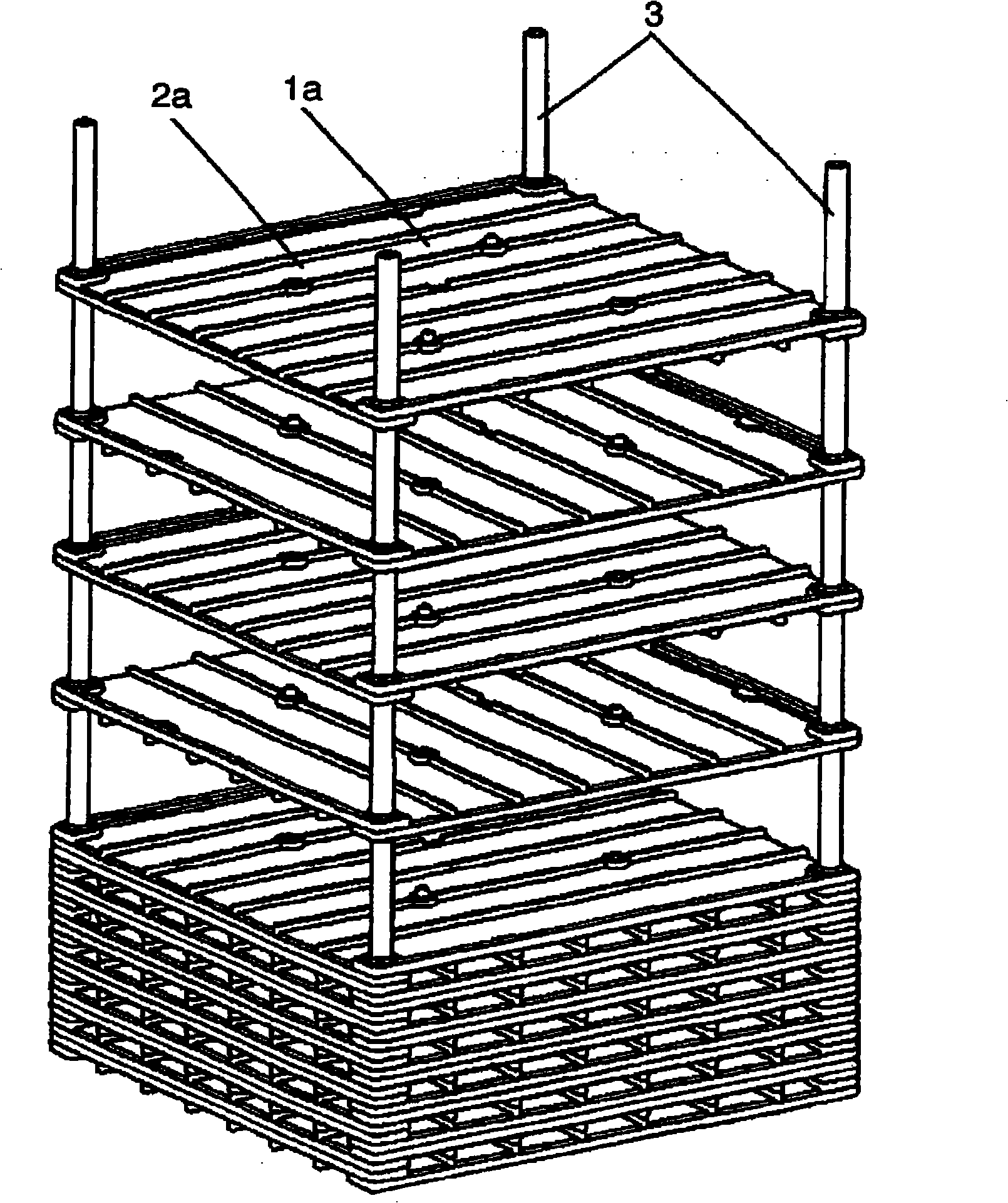

[0097] Fig. 1 is a schematic perspective view of a heat exchanger in Embodiment 1, and Fig. 2A is a schematic perspective view of a unit element viewed from the X direction shown in Fig. 1 , Figure 2B It is a schematic perspective view of the unit cell seen from the Y direction shown in FIG. 1 . image 3 It is a schematic exploded perspective view of the heat exchanger shown in FIG. 1 . Figure 4A It is a schematic perspective view of a heat exchanger showing unit elements of the heat exchanger shown in FIG. 1 stacked correctly, Figure 4B yes Figure 4A A schematic perspective view of the heat exchanger shown in section 4B-4B, Figure 4C yes Figure 4B A schematic enlarged perspective view of the circled portion in . Figure 5A It is a schematic perspective view of a heat exchanger in which the unit elements of the heat exchanger shown in FIG. 1 are erroneously stacked, Figure 5B yes Figure 5A A schematic enlarged perspective view of the circled portion in .

[0098...

Embodiment approach 2

[0167] FIG. 14 is a schematic perspective view of a heat exchanger in Embodiment 2. FIG. Fig. 15A is a schematic perspective view of the unit element seen from the X direction shown in Fig. 14, Figure 15B It is a schematic perspective view of the unit cell seen from the Y direction shown in FIG. 14 . Figure 16A It is a schematic perspective view of a heat exchanger in which the unit elements of the heat exchanger shown in FIG. 14 are correctly stacked, Figure 16B yes Figure 16A A schematic perspective view of the heat exchanger shown in section 16B-16B, Figure 16C yes Figure 16B A schematic enlarged perspective view of the circled portion in .

[0168] Figure 17A It is a schematic perspective view of a heat exchanger in which unit elements of the heat exchanger shown in FIG. 14 are mistakenly stacked, Figure 17B yes Figure 17A A schematic perspective view of the heat exchanger shown in section 17B-17B, Figure 17C is Figure 17B A schematic enlarged perspective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com