Patents

Literature

1034results about How to "Reduced parts count" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

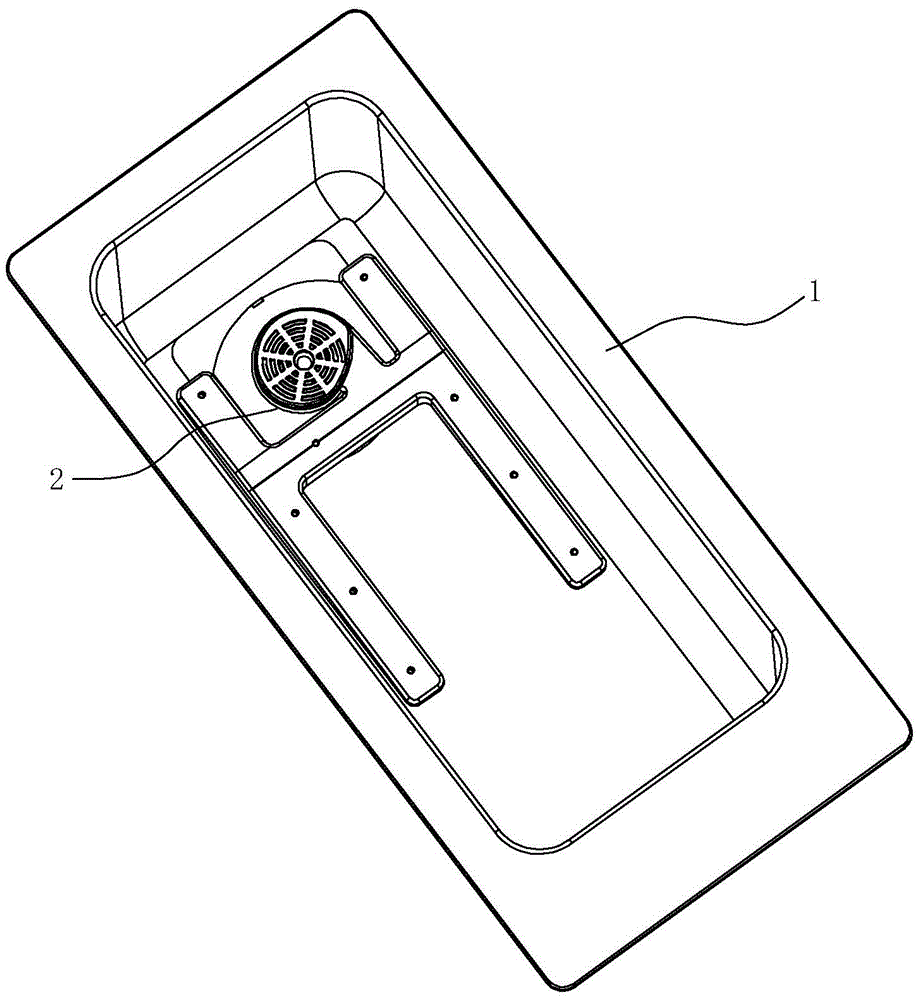

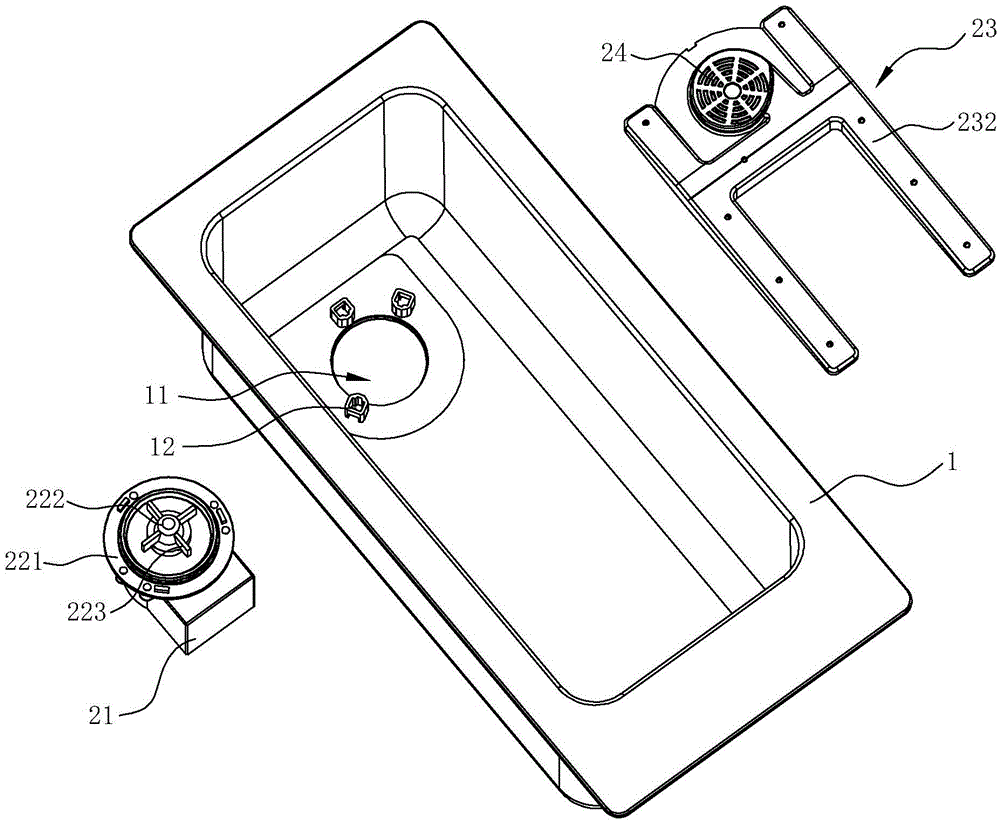

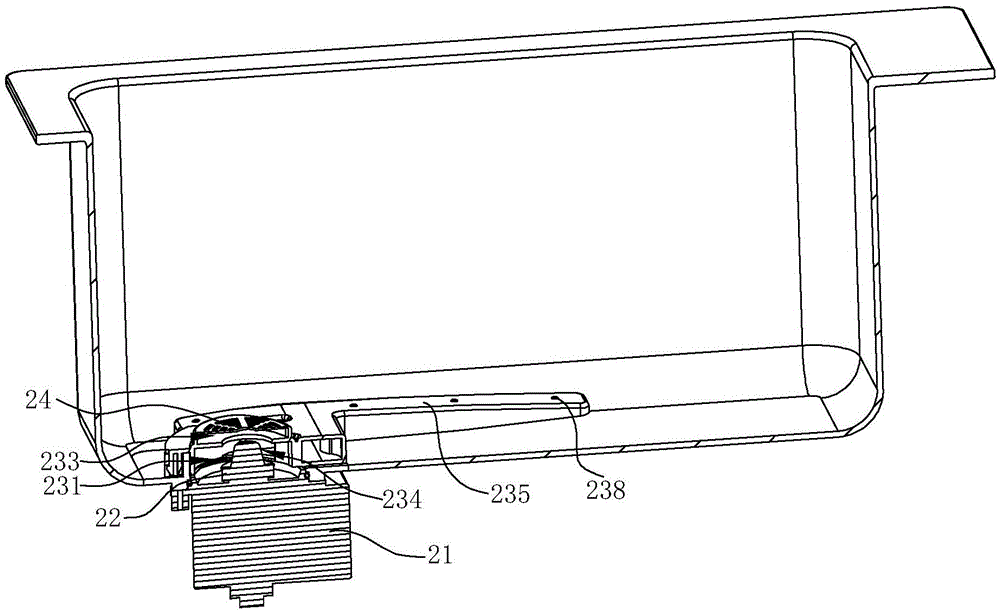

Open water pump and water tank groove cleaning machine with same

The invention discloses an open water pump which comprises an impeller, a containing cavity and a water outflow part. The impeller comprises a center shaft and a plurality of blades which are evenly arranged on the peripheral face of the center shaft in the peripheral direction. A plurality of water spraying holes are formed in the top face of the water outflow part, and the impeller is placed in the containing cavity. The open water pump is characterized in that a water inlet is formed in a top end opening of the containing cavity, a water outlet is formed in the side face of the containing cavity, the water outflow part is communicated with the water outlet, and a filtering plate is arranged on the water inlet. The invention further discloses a water tank groove cleaning machine with the open water pump.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Optical sensing key, touch screen, fingerprint collecting device and electronic device

ActiveCN104035620AEasy to integrateProtect Surface IntegrityDigital data protectionDigital data authenticationLight guideTouchscreen

The invention discloses an optical sensing key, a touch screen, a fingerprint collecting device and an electronic device. The optical sensing key comprises at least one light guide plate, the light guide plates are provided with transmission areas, a pair of light emitter and a light receiver is correspondingly arranged in each transmission area, the light emitters can transmit light rays at least capable of transmitting in the transmission areas, and the light receiver receives the light rays transmitted by the transmission areas. The optical sensing key is ultrathin in structure, convenient to implement and power saving.

Owner:渭南印象认知技术有限公司

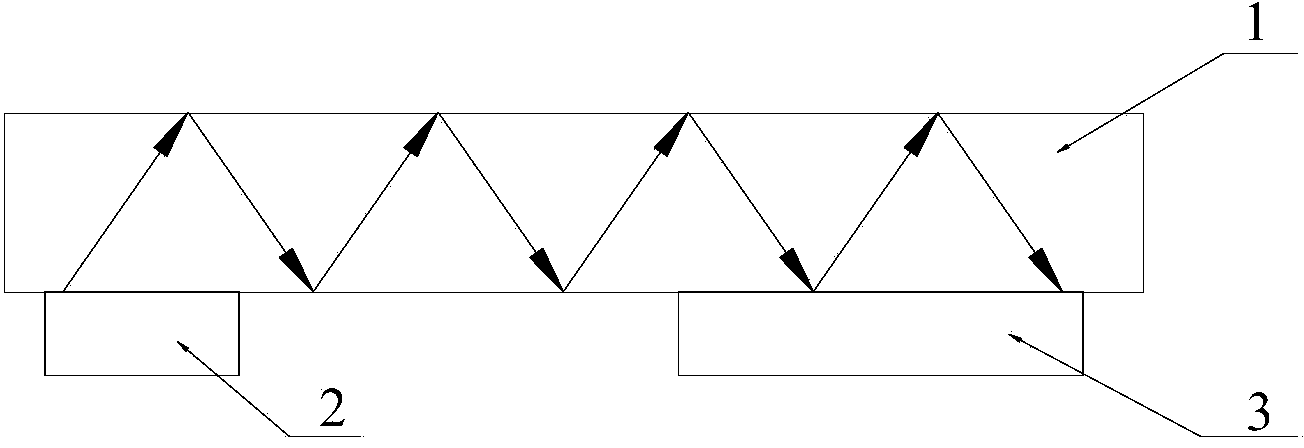

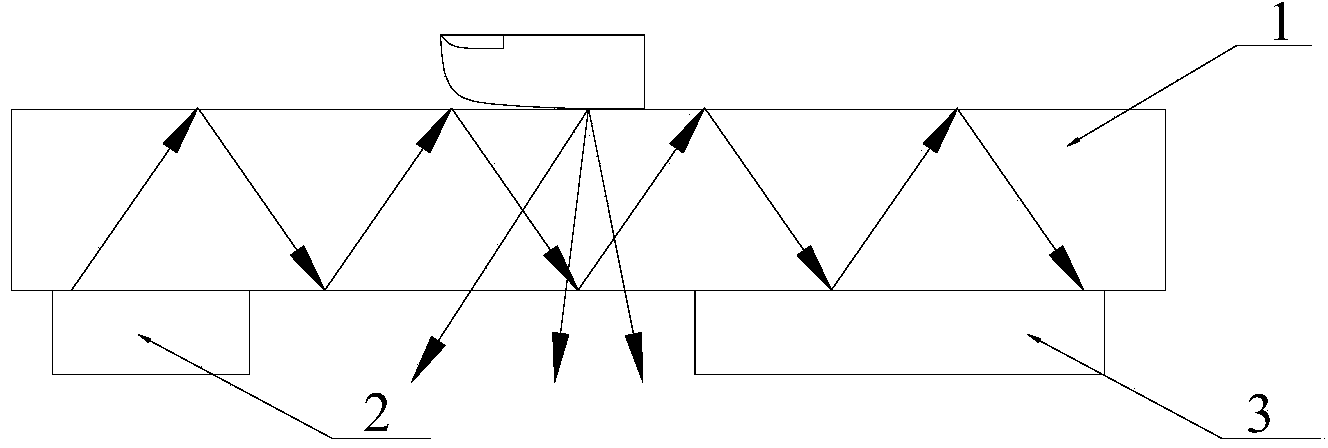

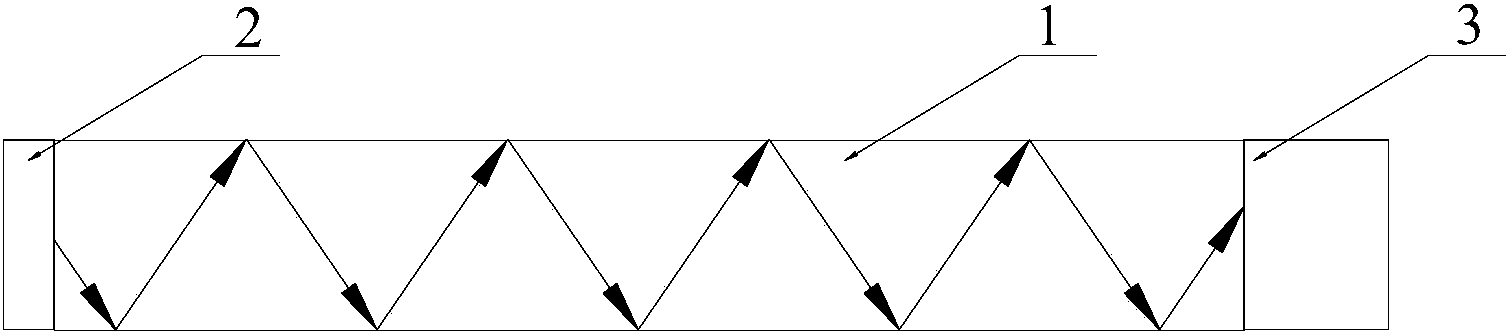

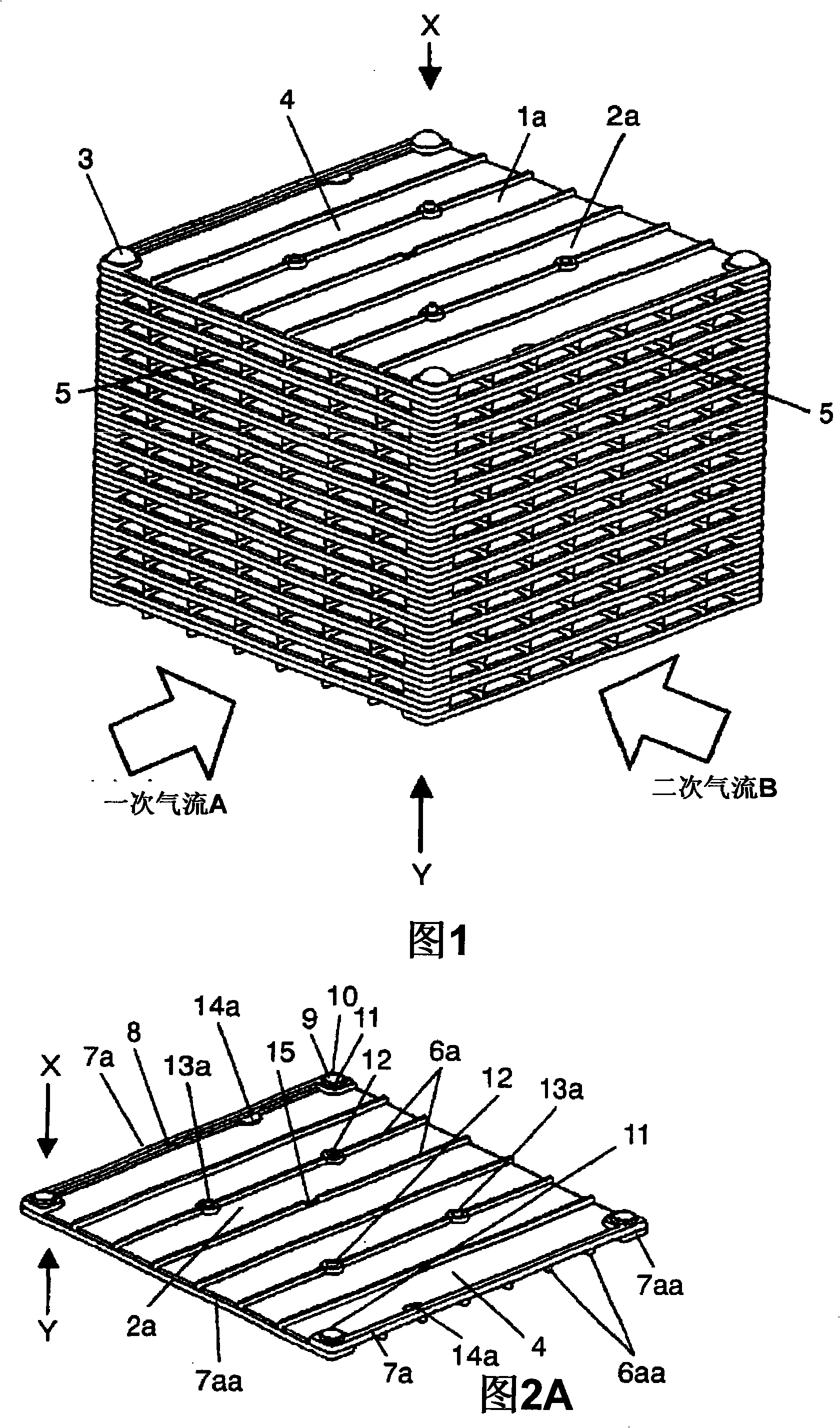

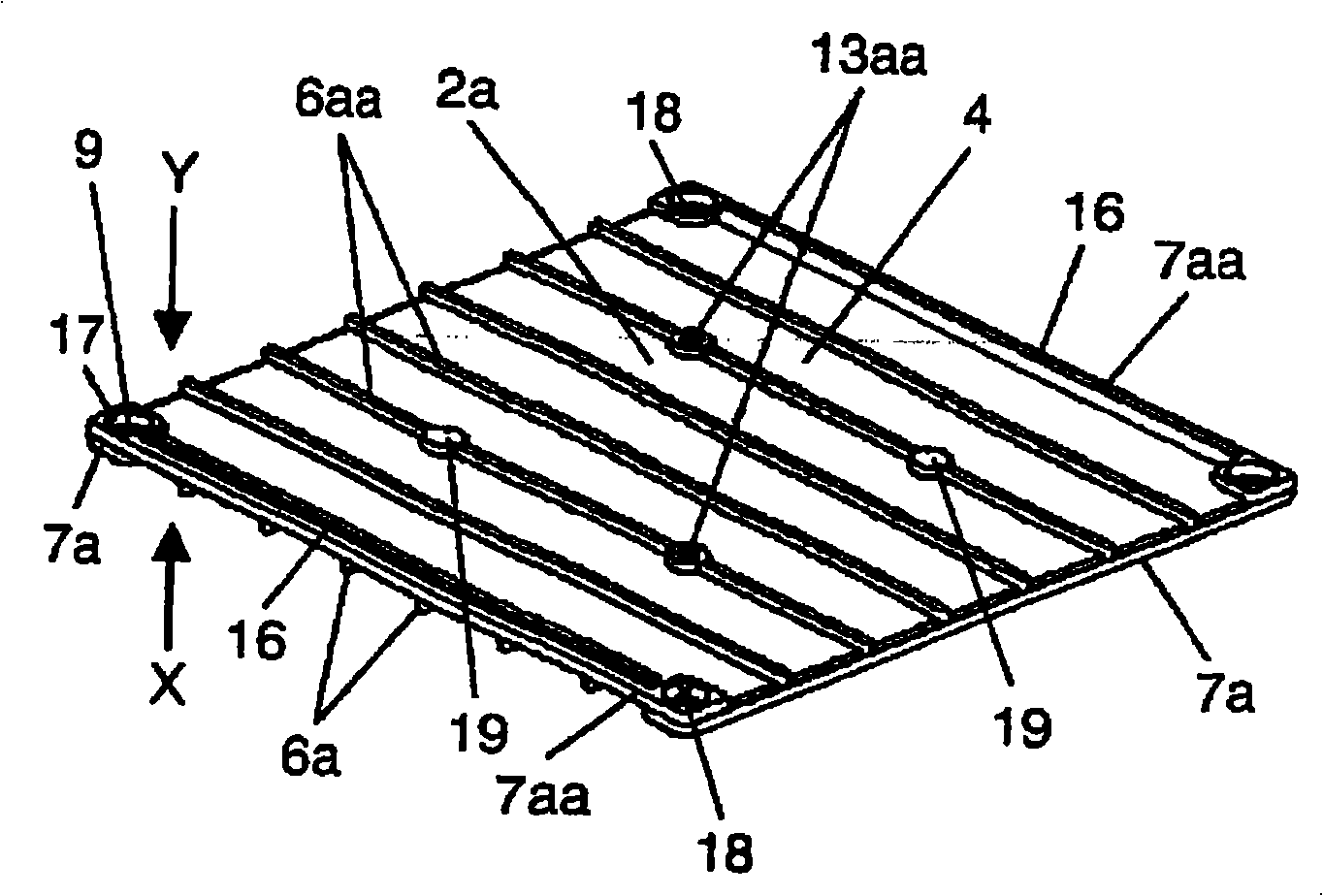

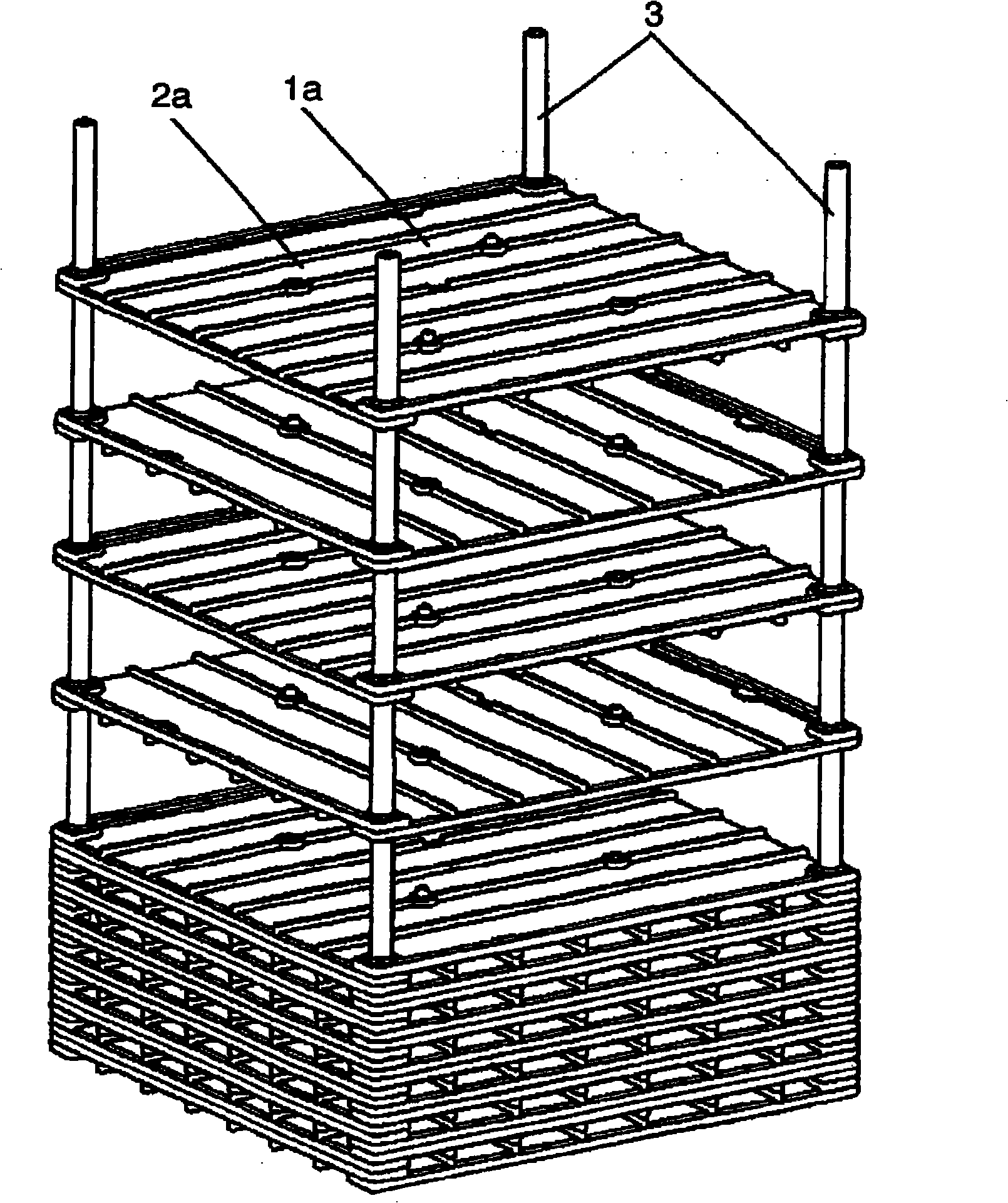

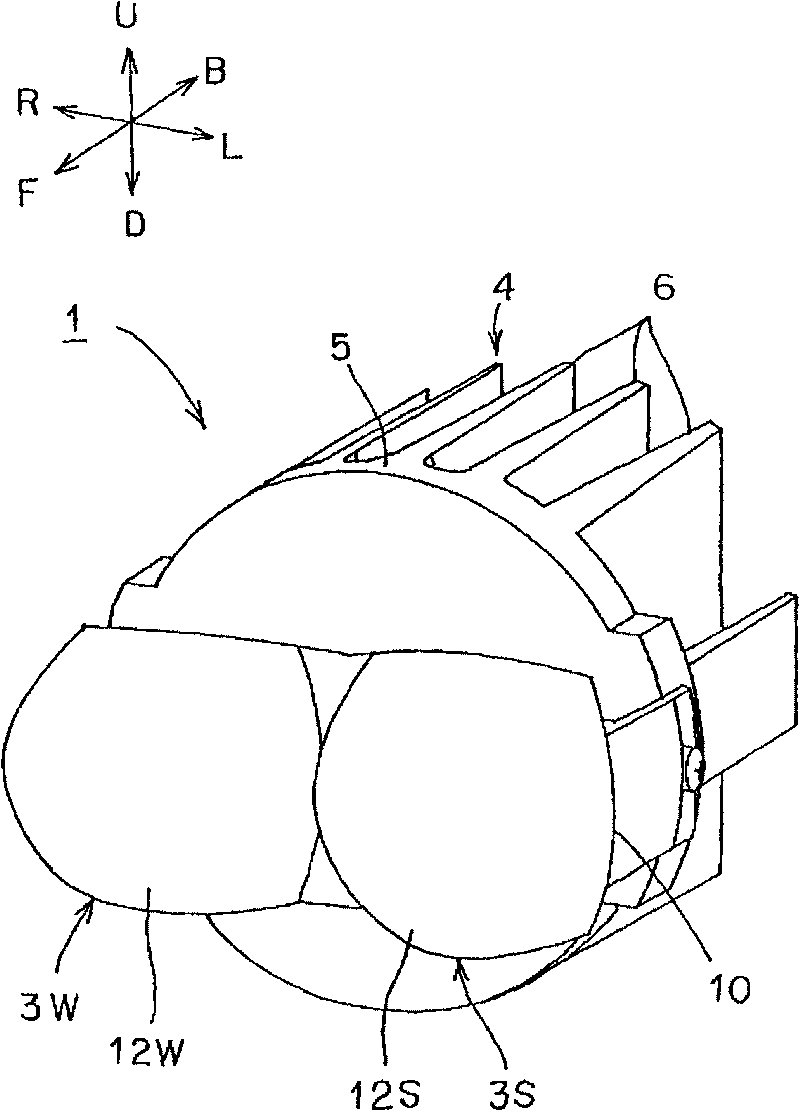

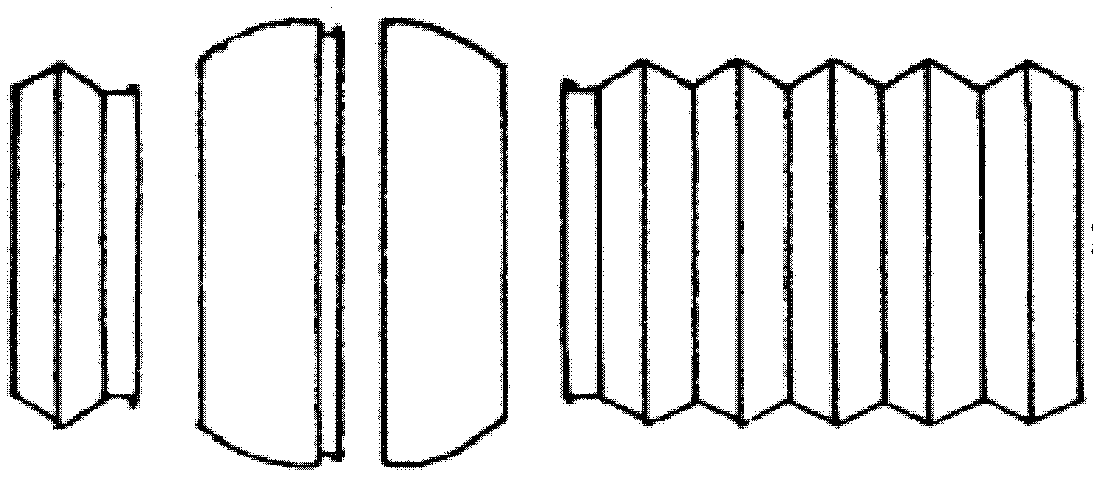

Heat exchanger and its manufacturing method

The present invention provides a heat exchanger for exchanging heat through heat transfer plates by flowing a primary airflow and a secondary airflow in air passages. The heat exchanger comprises a unit element having a heat transfer plate and an air passage formed between the heat transfer plates by stacking the unit elements. Each of the unit elements is structured by molding a space rib for holding the space between the heat transfer plates integrally with a shield rib for shielding the leak of the airflows by use of a resin. The unit element includes an error detection part which can easily detect an error in stacking when the unit elements are stacked.

Owner:PANASONIC CORP

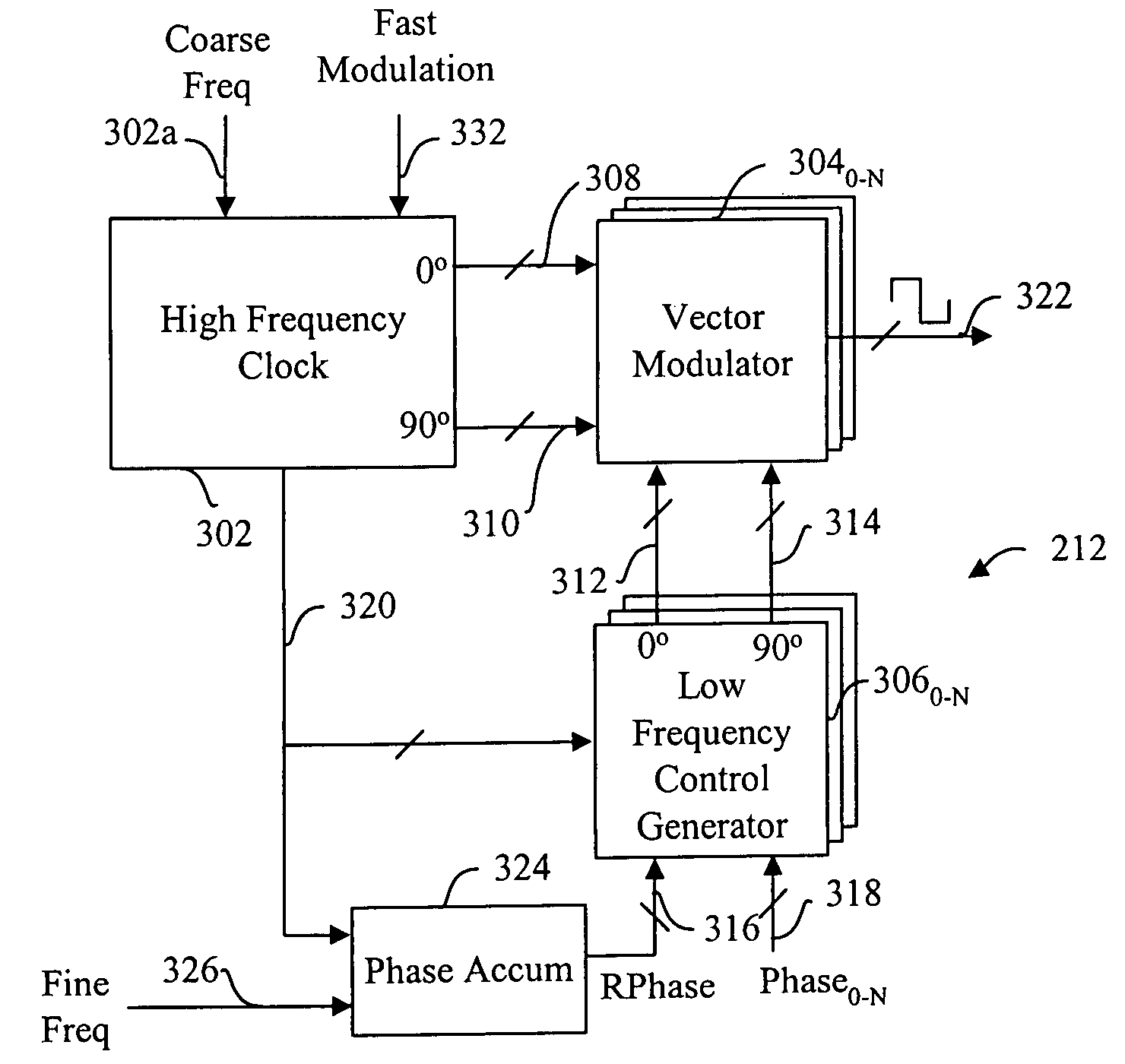

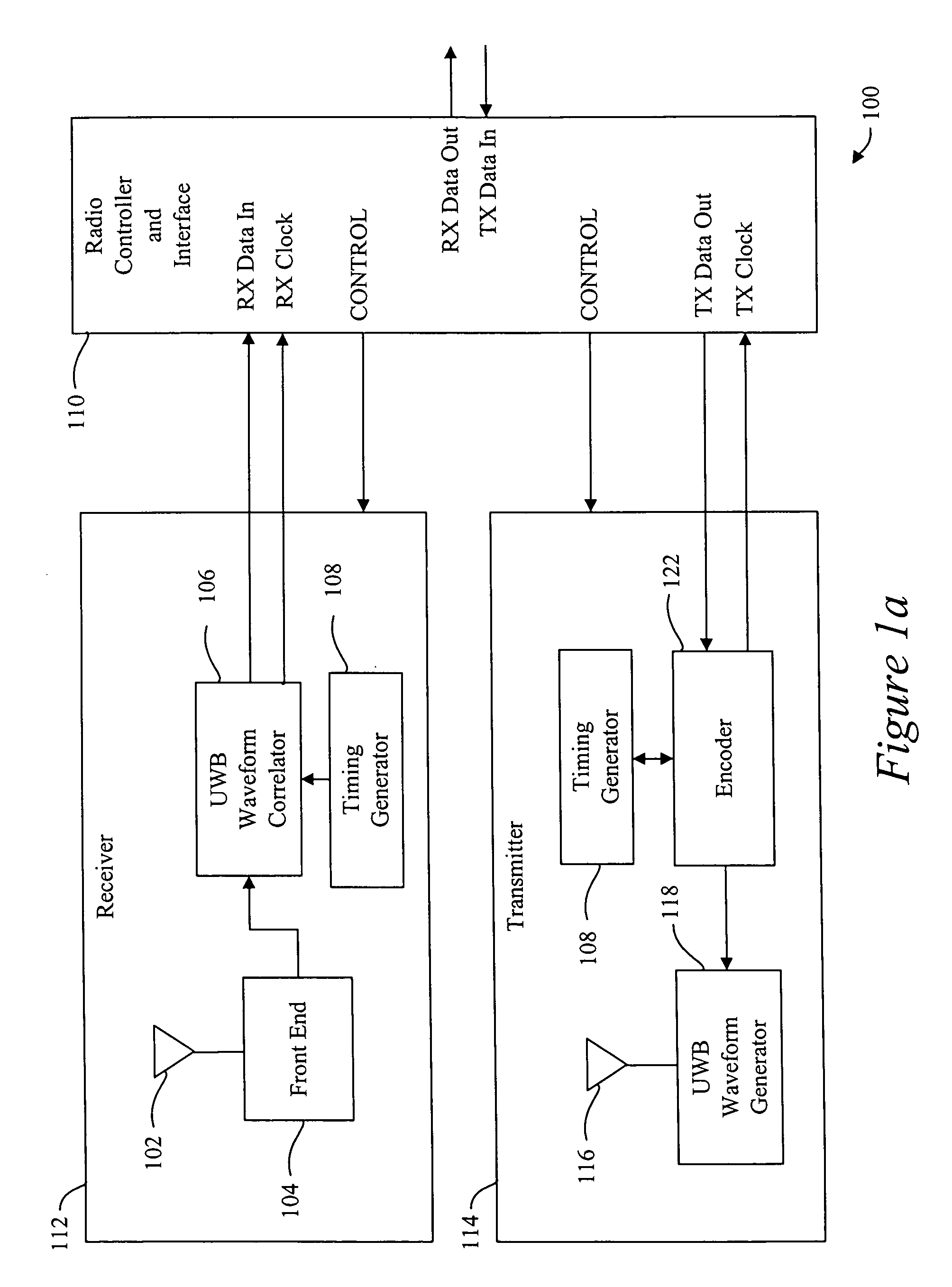

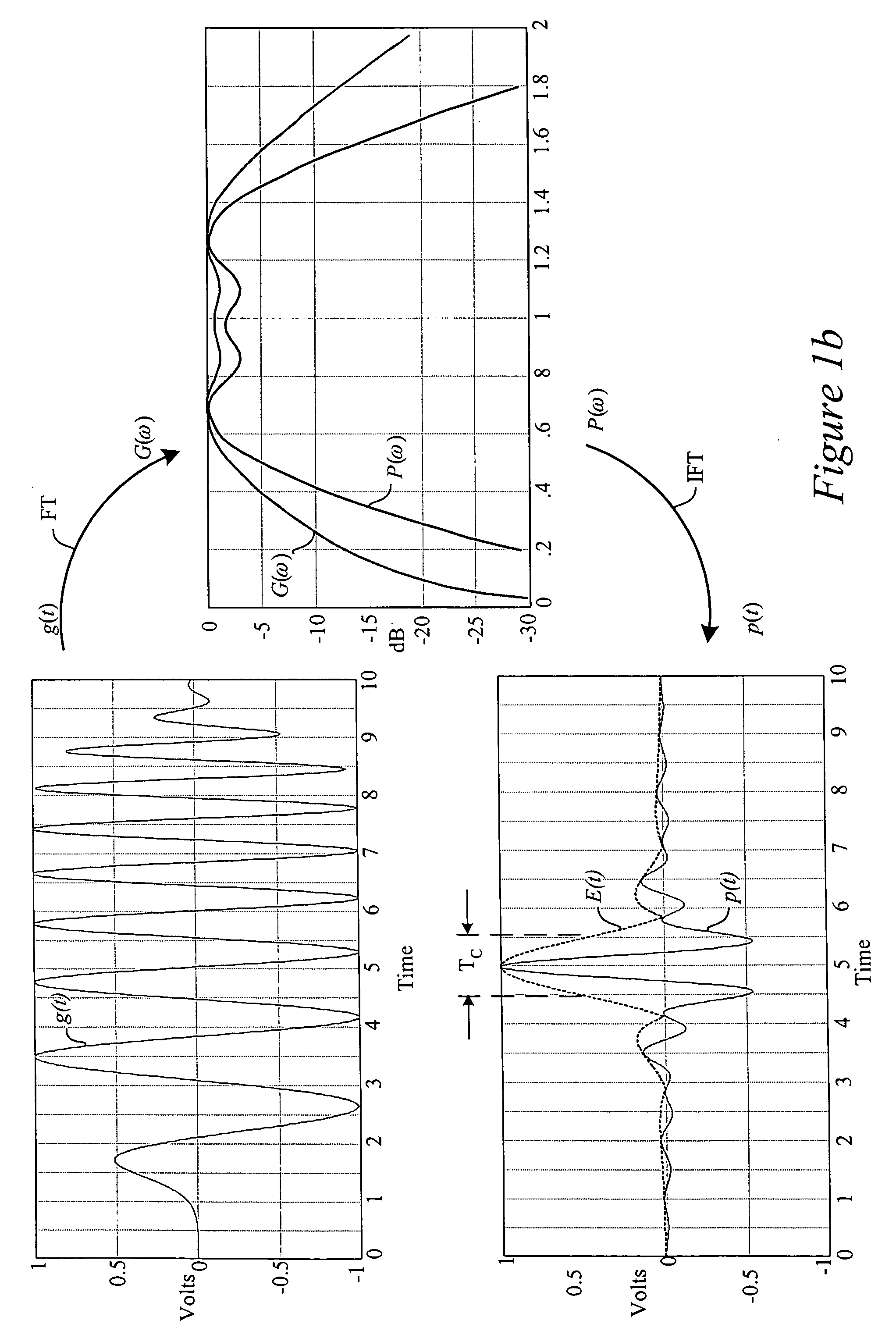

Low power, high resolution timing generator for ultra-wide bandwidth communication systems

An ultra wide bandwidth communications system, method and computer program product including an ultra wide bandwidth timing generator. The timing generator includes a high frequency clock generation circuit having low phase noise; a low frequency control generation circuit; and a modulation circuit coupled between the high frequency clock generation circuit and the low frequency control generation circuit. The high frequency clock generation circuit generates a plurality of high frequency clock signals. The low frequency control generation circuit generates a plurality of low frequency control signals. The modulation circuit modulates the high frequency clock signals with the low frequency control signals to produce an agile timing signal at a predetermined frequency and phase. The agile timing signal is generated at the predetermined frequency and phase by adjustments to at least one of frequency of the low frequency control signals, phase of the low frequency control signals, frequency of the high frequency clock signals, and phase of the high frequency clock signals.

Owner:NORTH STAR INNOVATIONS

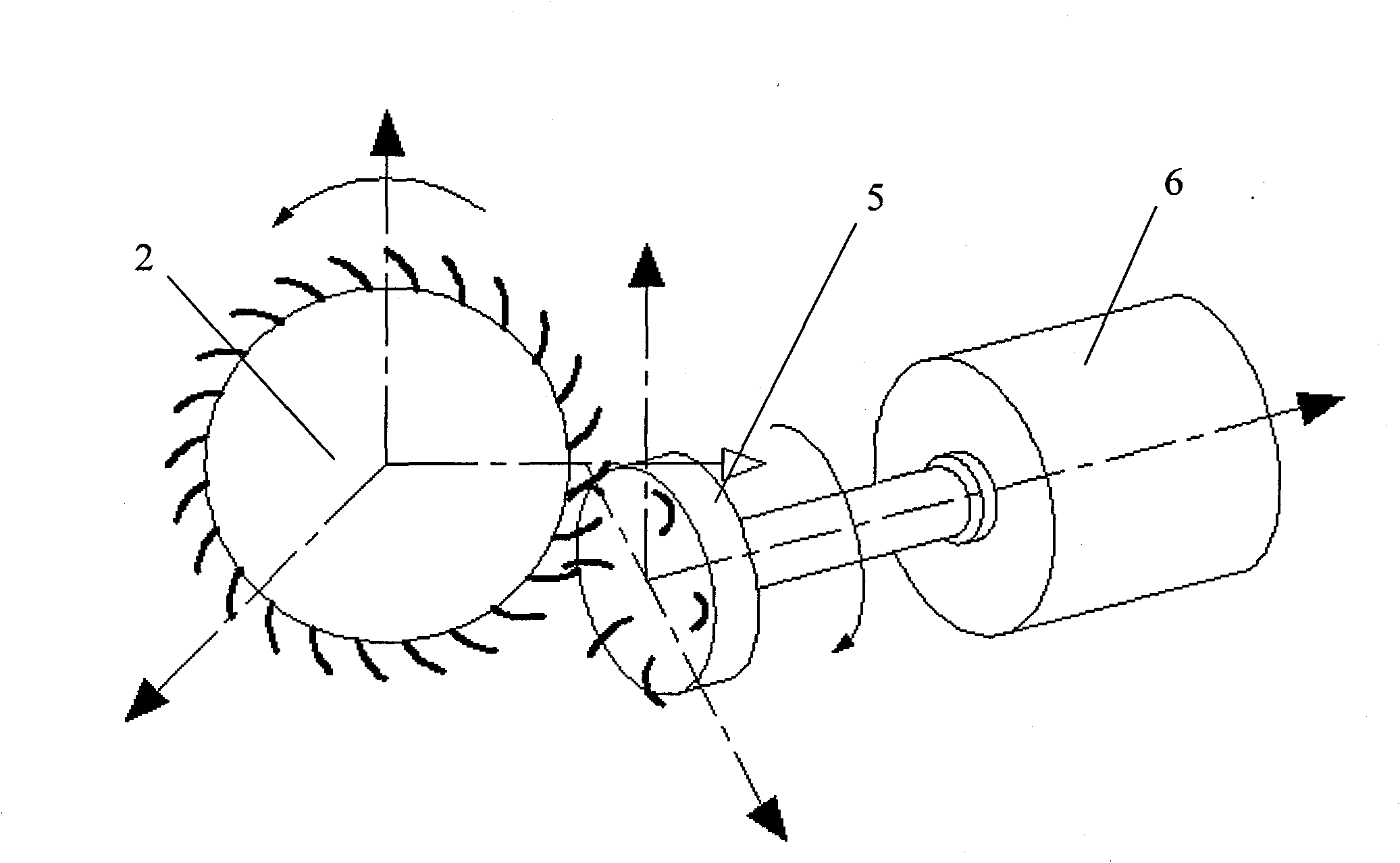

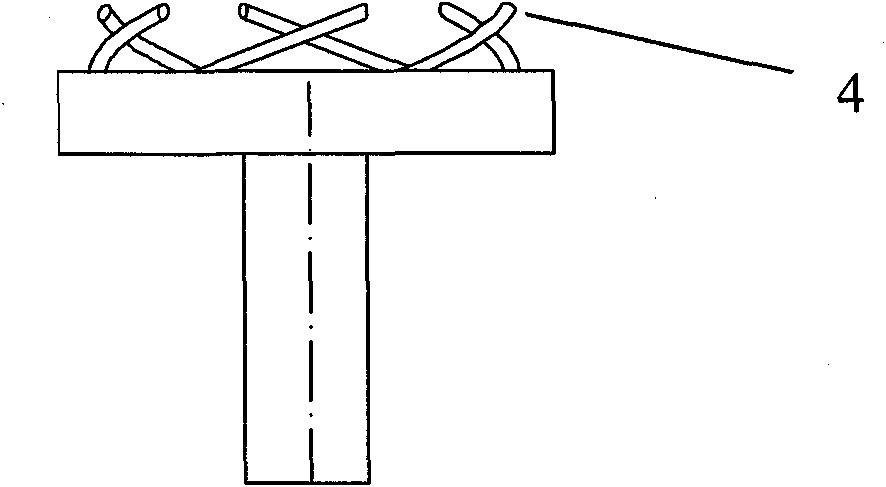

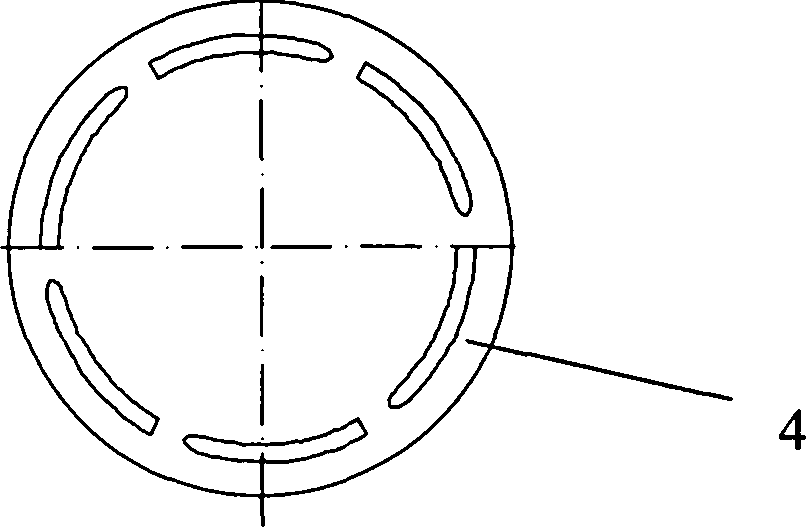

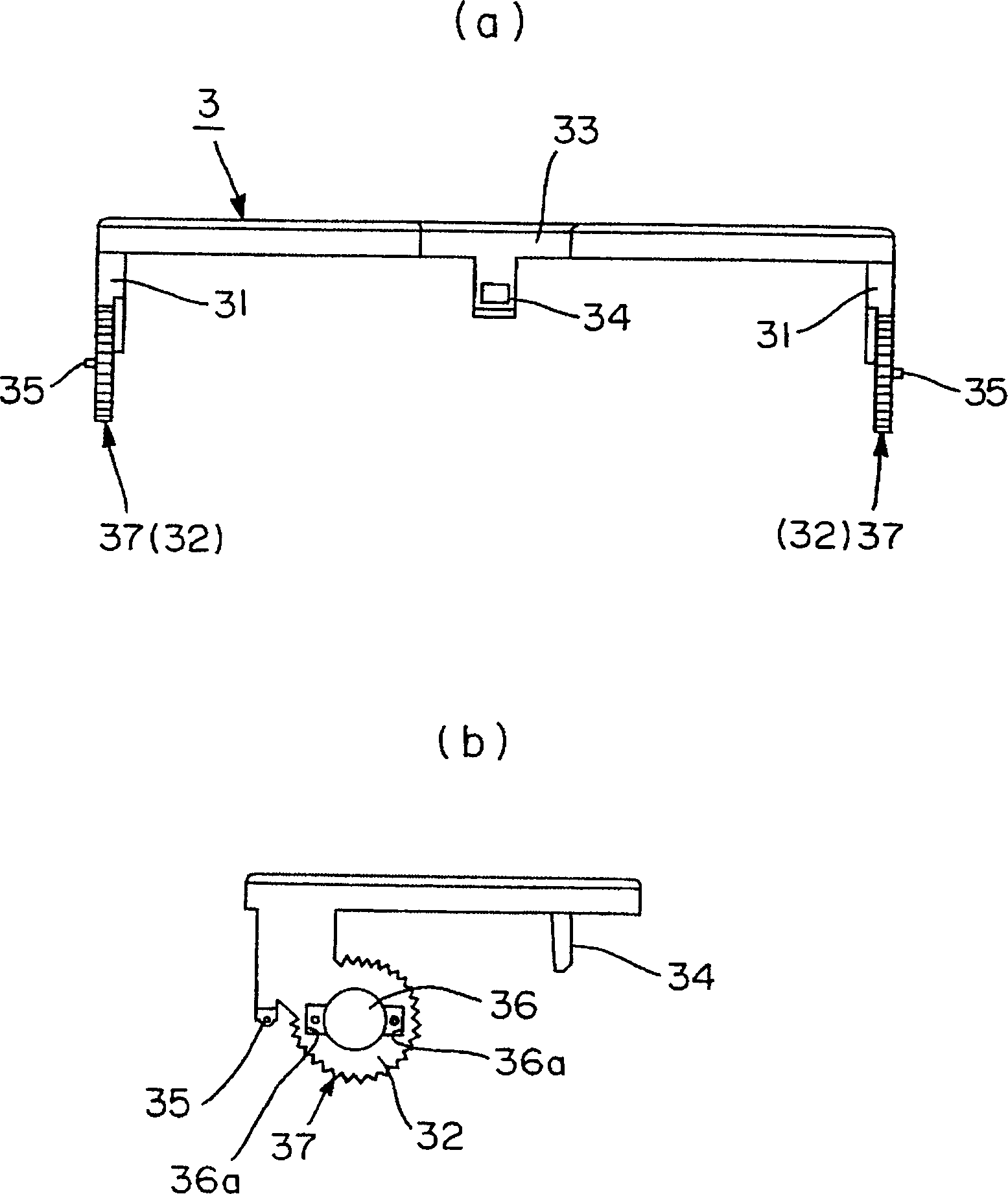

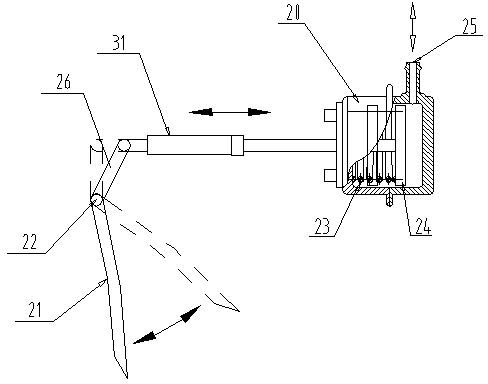

Angular bevel gear mechanism

ActiveCN101782129AReduced structureSmall geometryPortable liftingToothed gearingsDrive wheelElectric machine

Owner:SOUTH CHINA UNIV OF TECH

Sound absorption structure body

ActiveCN101151417AStrong physical adsorption capacityLow resonance frequencyNoise reduction constructionAxle-box lubricationMiniaturizationEngineering

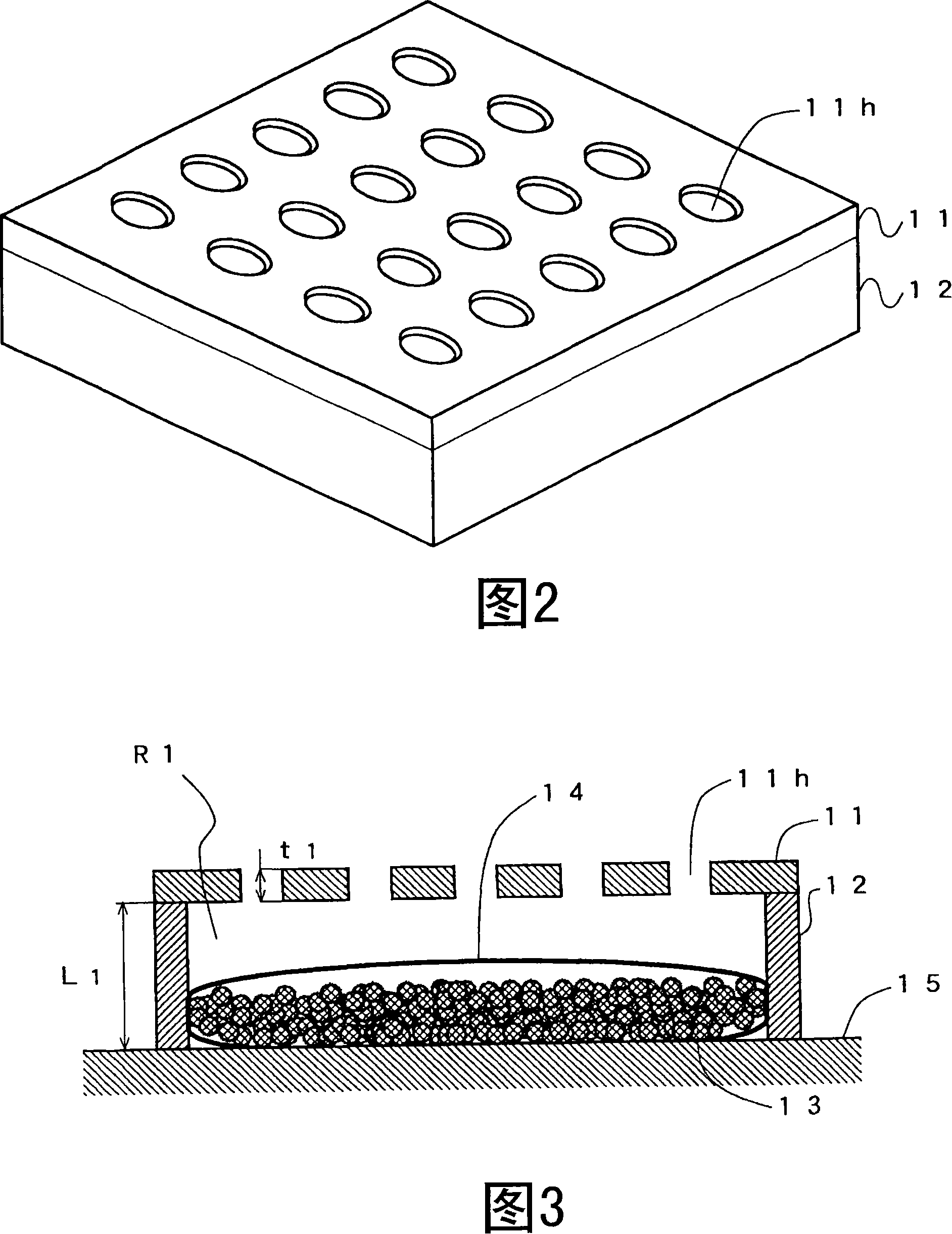

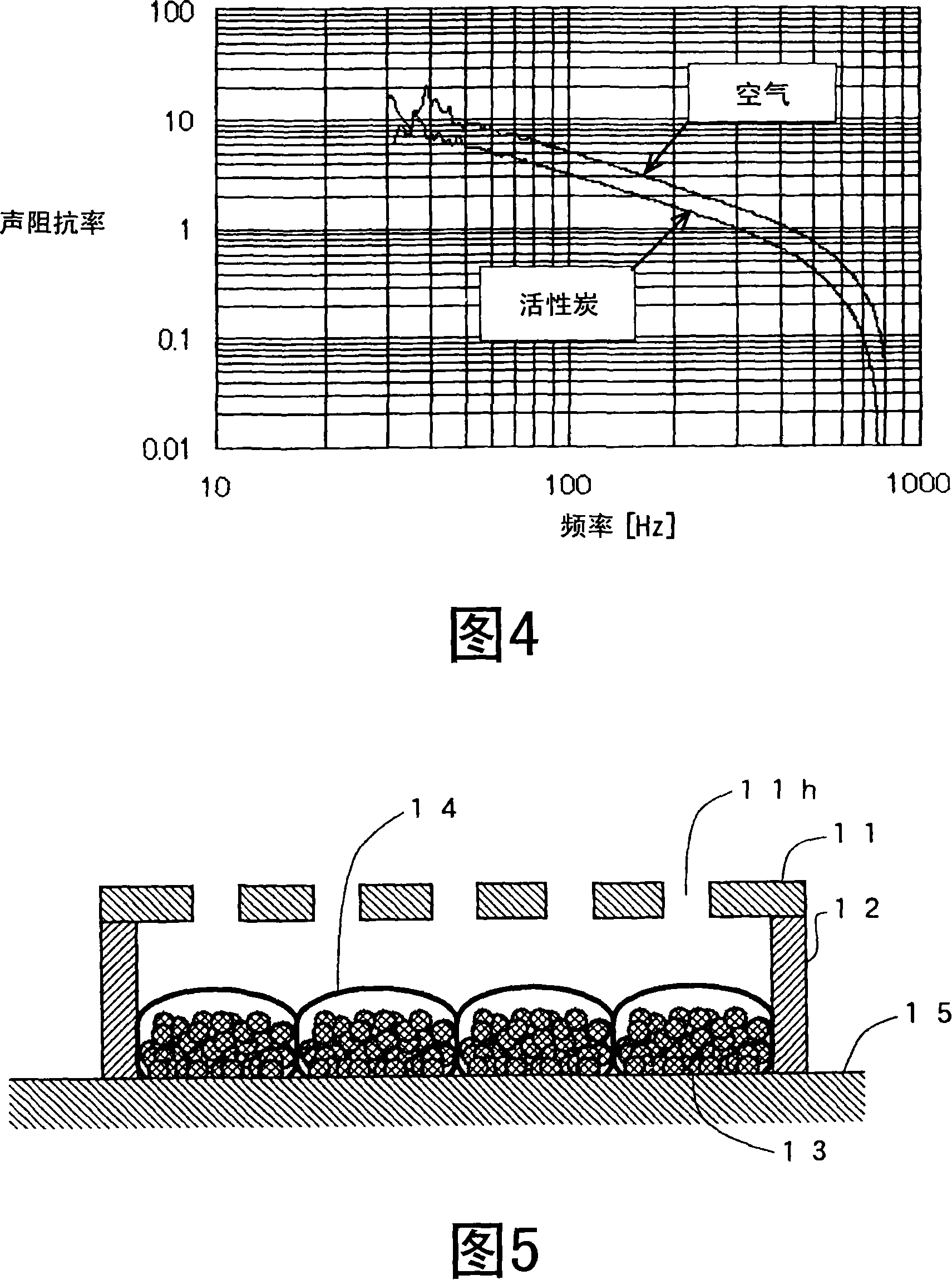

A sound absorption structure body has a housing has a front side and a side face raised at at least a part of an outer edge section of the front face, a gas adsorption body placed in the internal space, surrounded by the front face and the side face, of the housing and physically adsorbing gas in the internal space, a sealing means for sealing the gas adsorption body from the outside, and an acoustic connection section provided at at least either the front face or the side face and functioning as an acoustic mass for acoustically connecting the internal space of the housing and the space outside the housing. The sound absorption structure body achieves both sound absorption in a low -pitched sound range and downsizing of the sound absorption structure body itself.

Owner:GOERTEK INC

Door shutter mechanism and door shutter with the mechanism

Owner:NIFCO INC

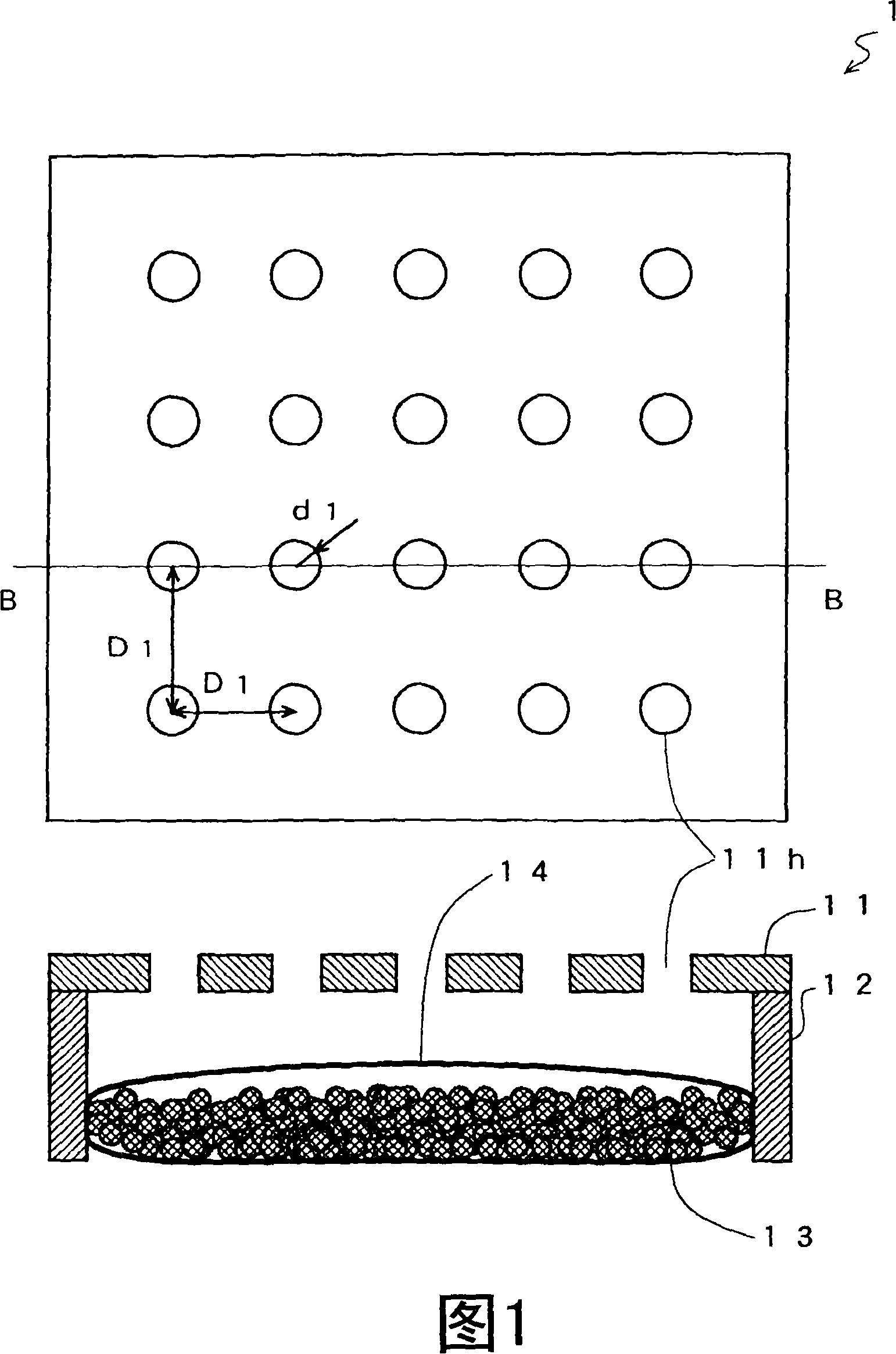

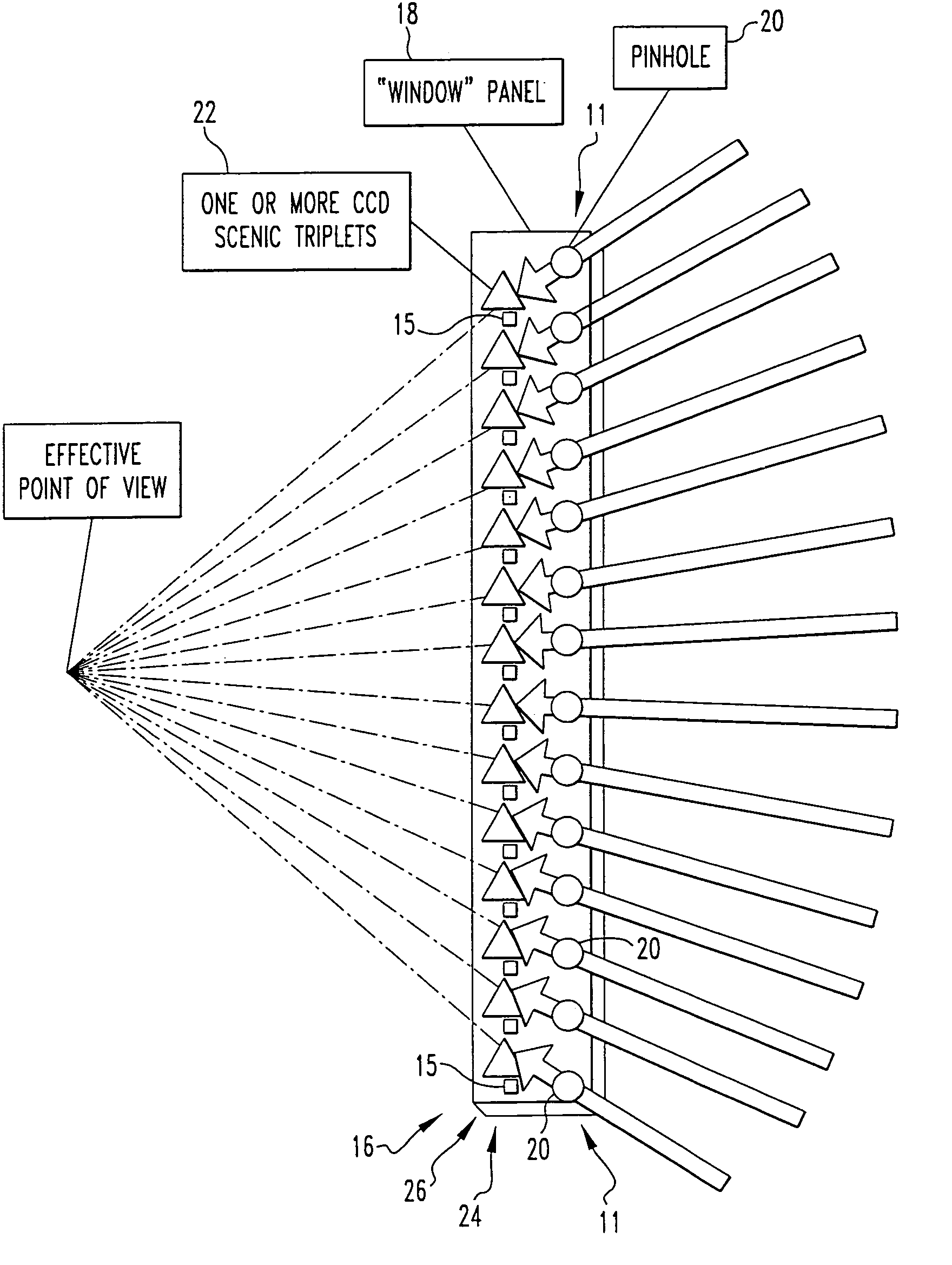

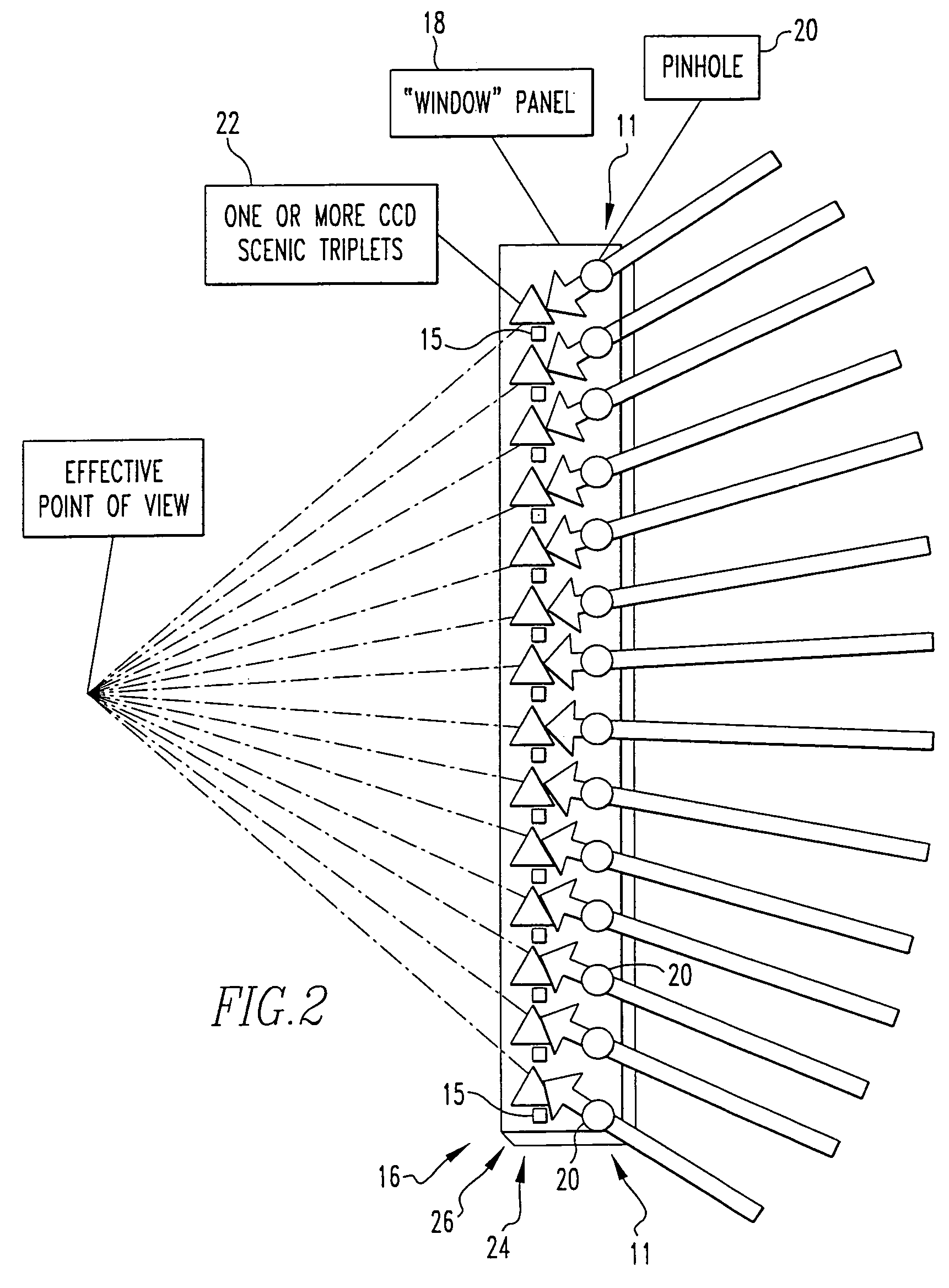

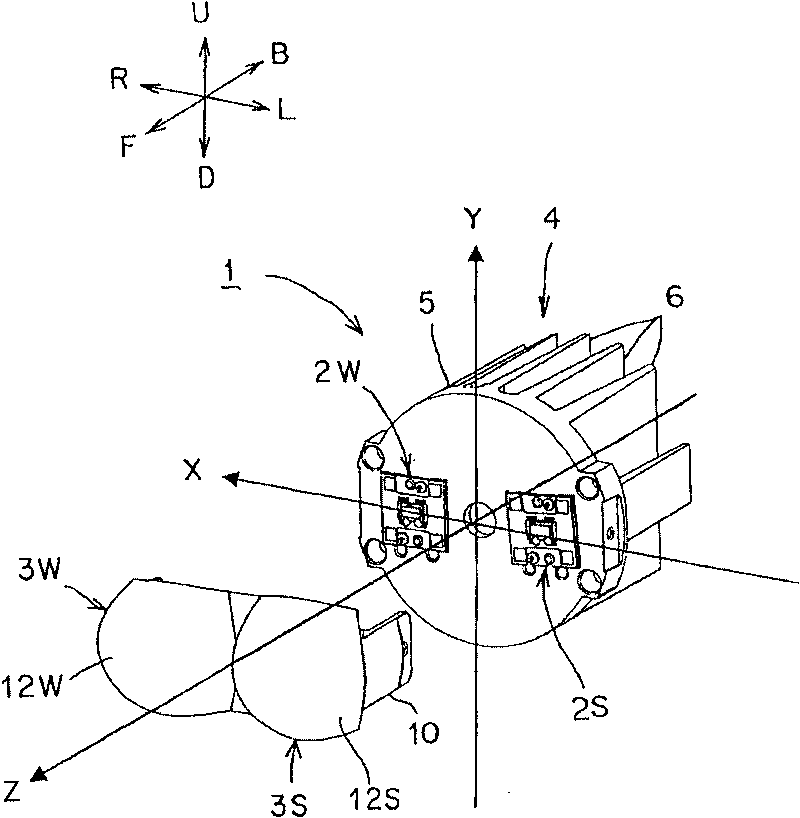

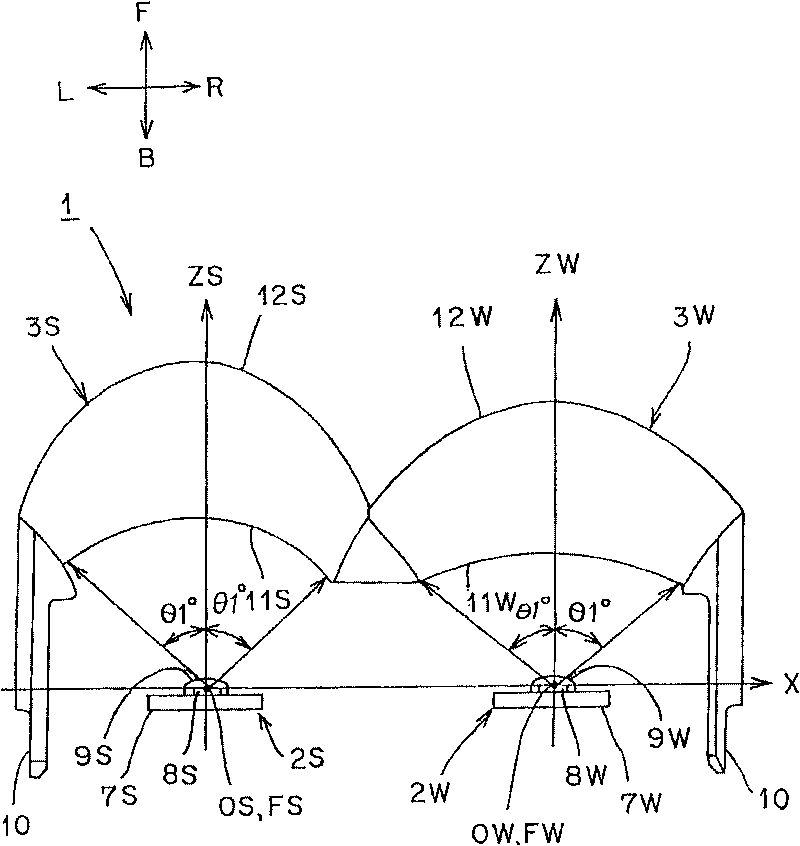

Method and apparatus for displaying images in combination with taking images

ActiveUS7196728B2Reduced parts countLow costTelevision system detailsStatic indicating devicesComputer graphics (images)Display device

An imaging apparatus. The apparatus includes a display mechanism for displaying an image. The apparatus includes a camera mechanism distributed throughout the display mechanism to take images of objects in view of the display mechanism. A screen. The screen includes a display for displaying an image. The screen includes a plurality of pinholes distributed in the display. The screen includes a plurality of sensors with at least one sensor of the plurality of sensors in alignment with and corresponding with one pinhole of the plurality of pinholes to receive light passing through the pinhole to image a ray of a specific size and a specific direction out from the display. A method for imaging.

Owner:TELEFON AB LM ERICSSON (PUBL)

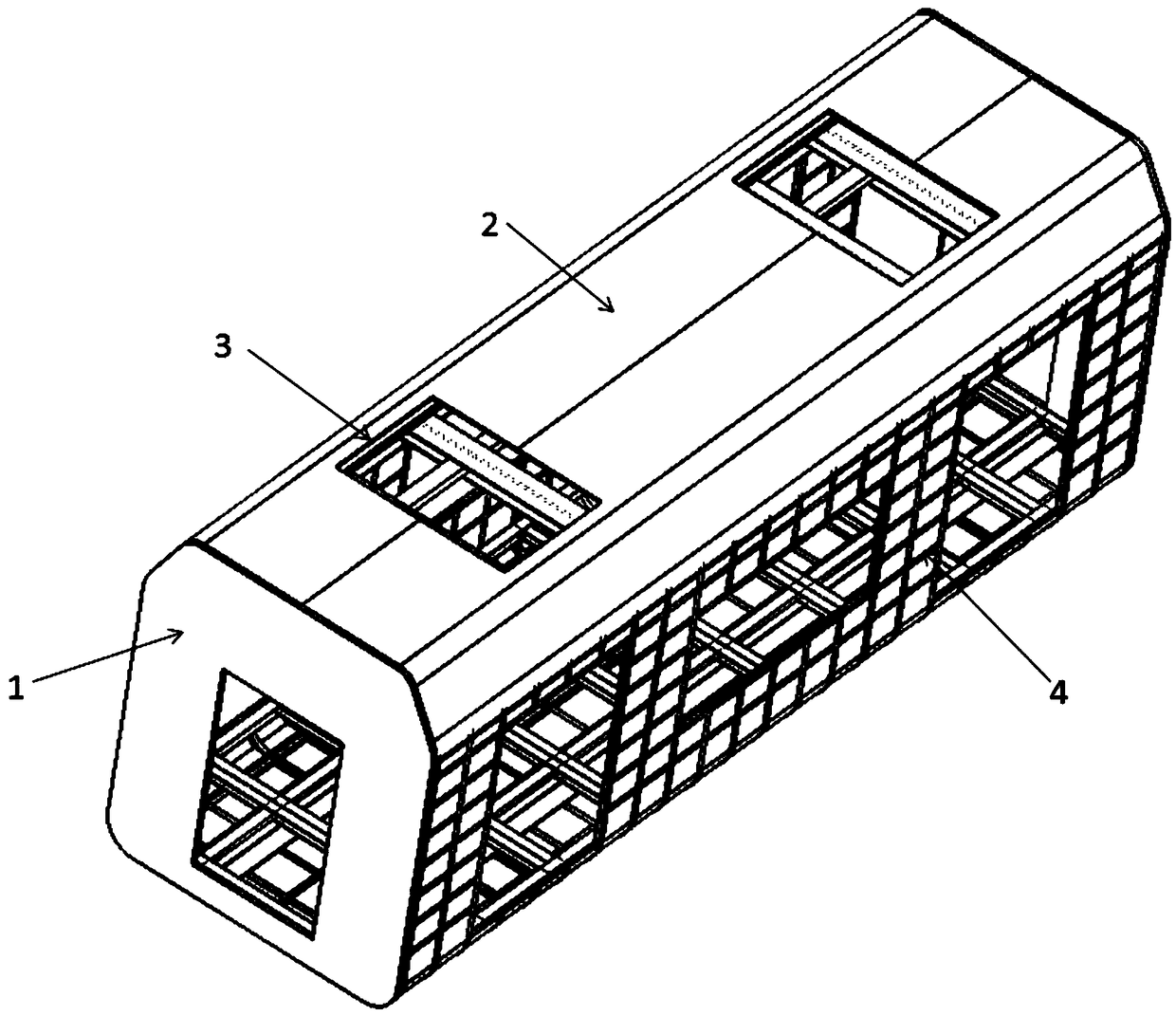

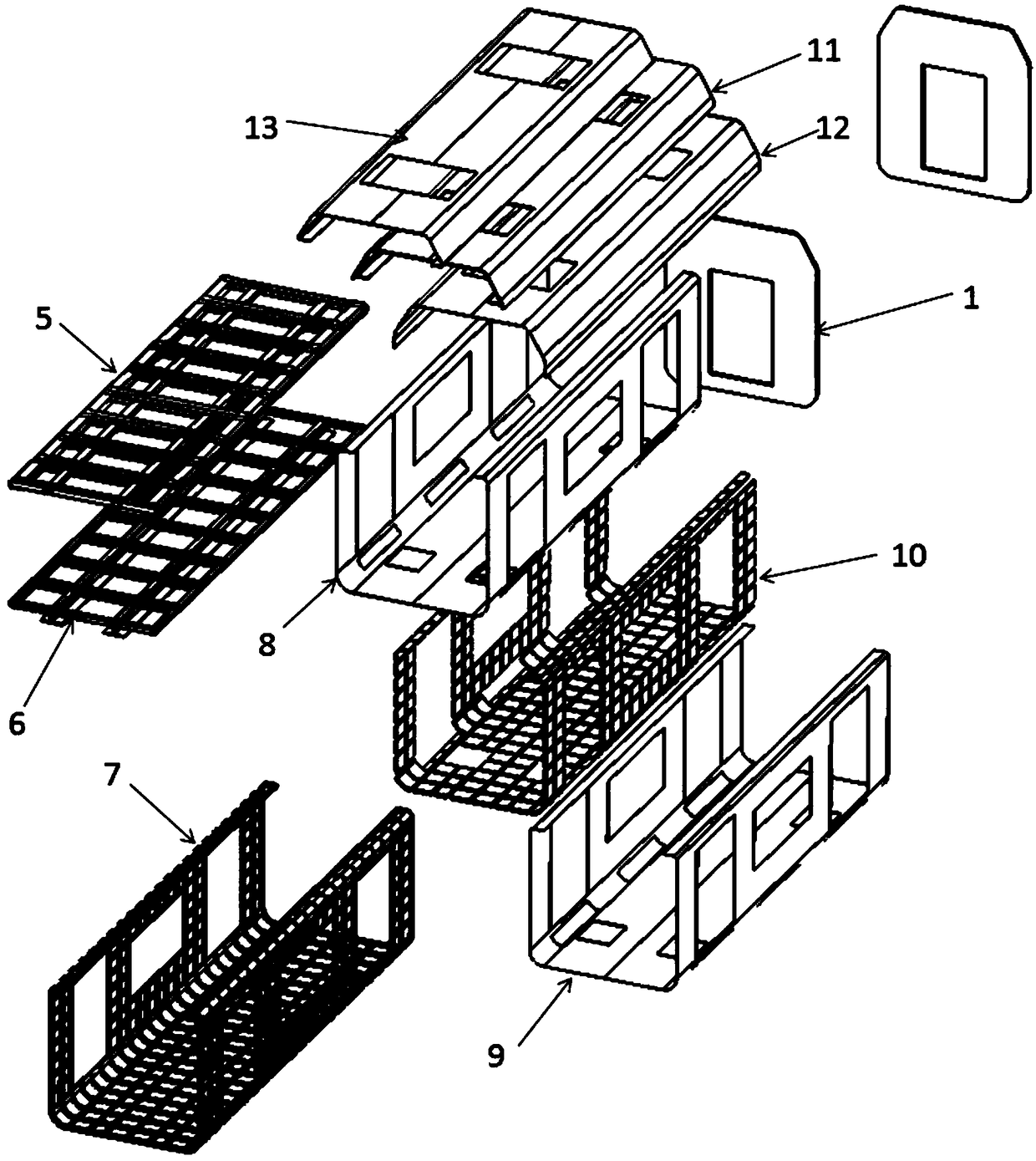

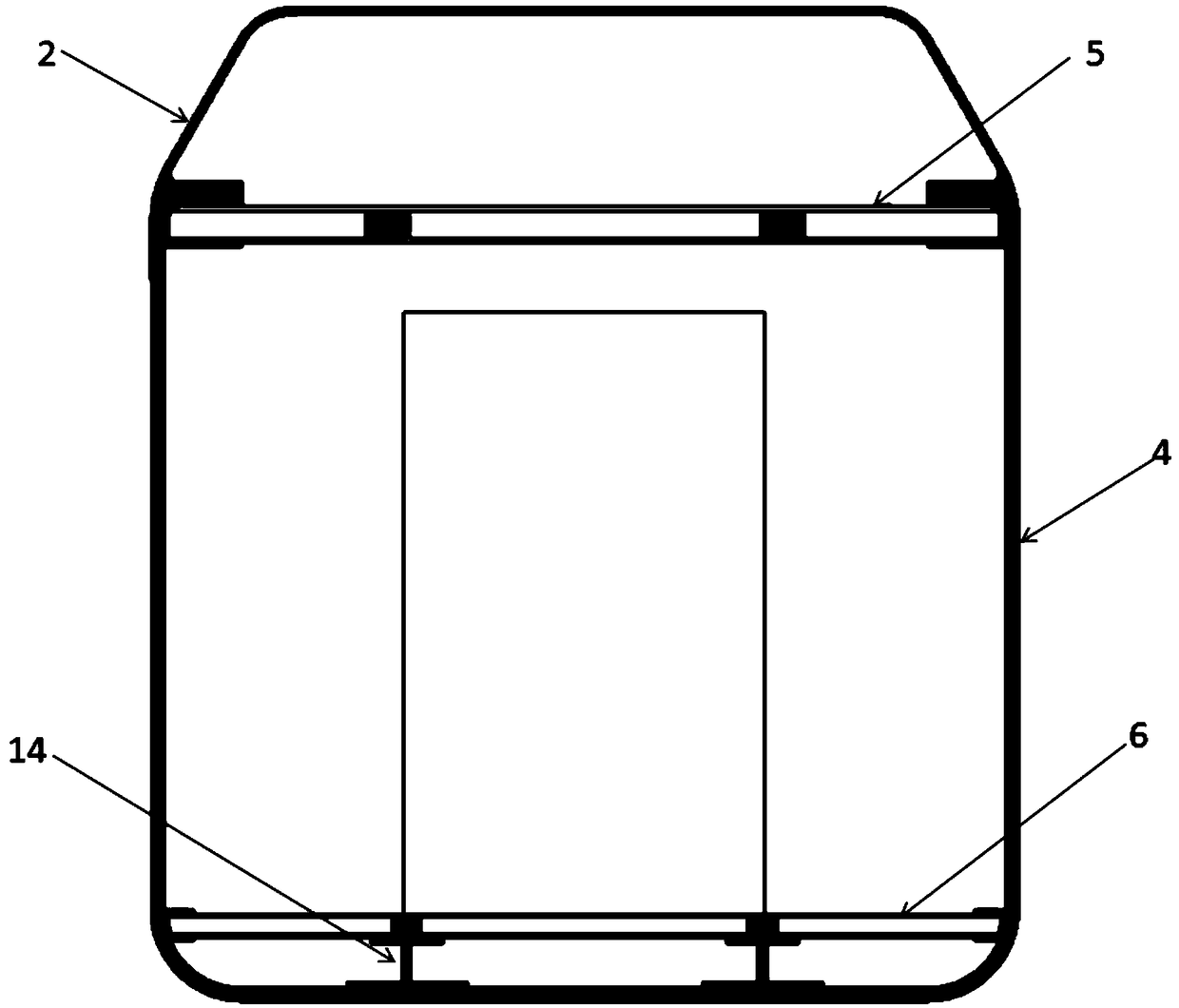

Structure and manufacturing process of low-cost carbon fiber composite material sky railway train body

ActiveCN108622123AAchieve lightweightIncrease stiffnessRailway roofsAxle-box lubricationBogieEngineering

The invention discloses a structure and a manufacturing process of a low-cost carbon fiber composite material sky railway train body, and belongs to the technical field of application of composite materials on rail vehicles. The structure comprises a train body side wall, wherein end walls are assembled and connected to the both ends of the train body side wall; a top frame and a bottom frame arecorrespondingly assembled and connected to the inner top surface and the inner bottom surface of the train body side wall, a ceiling is assembled and connected to the outer top surface of the train body side wall, and a bogie mounting hole is formed in the ceiling; the train body side wall and the end walls both comprise reinforced rib frames, inner skins and outer skins, and grids of the reinforcing rib frames are filled with sandwich foam blocks; the ceiling comprises a sandwich panel, an upper skin and a lower skin, and the top frame, the bottom frame, the reinforcing rib frame, the inner skins, the outer skins, the upper skin and the lower skin are all integrally molded from carbon fiber composite materials; and the inner portions of the reinforcing rib frames are filled with sandwichfoam, and the purpose of satisfying the function and structure of the load bearing mode of a suspension-type train body on the premise of light weight of the train body is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

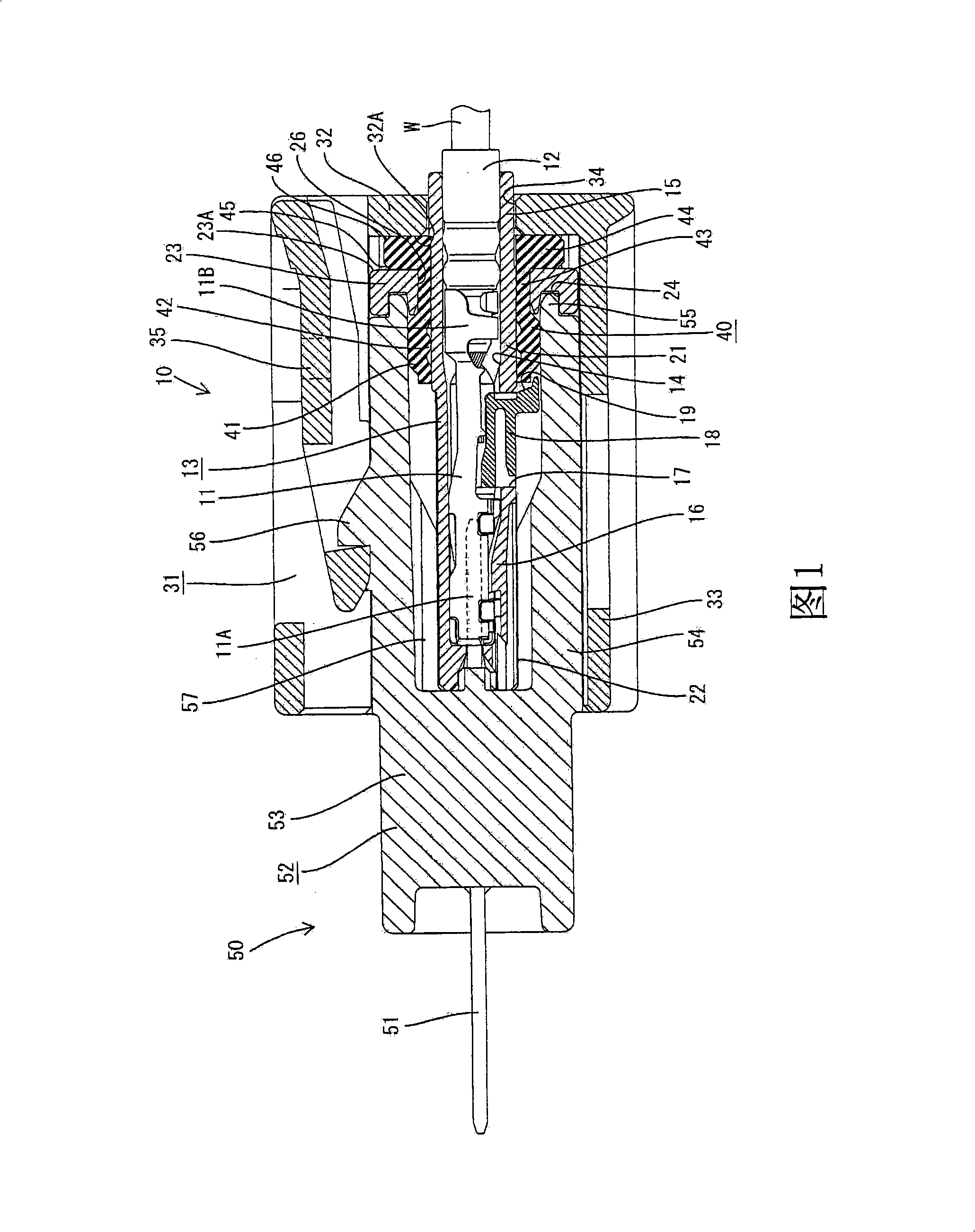

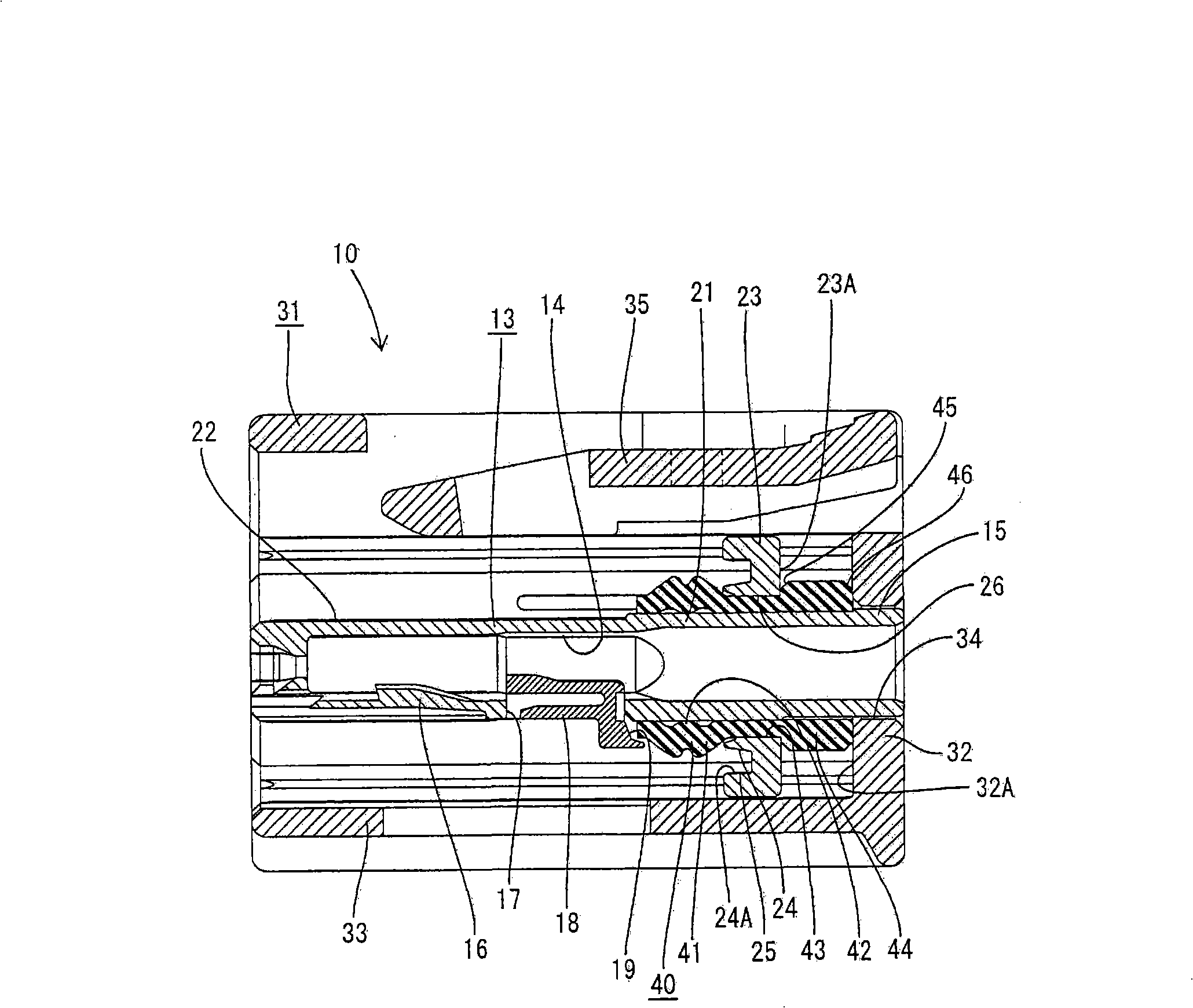

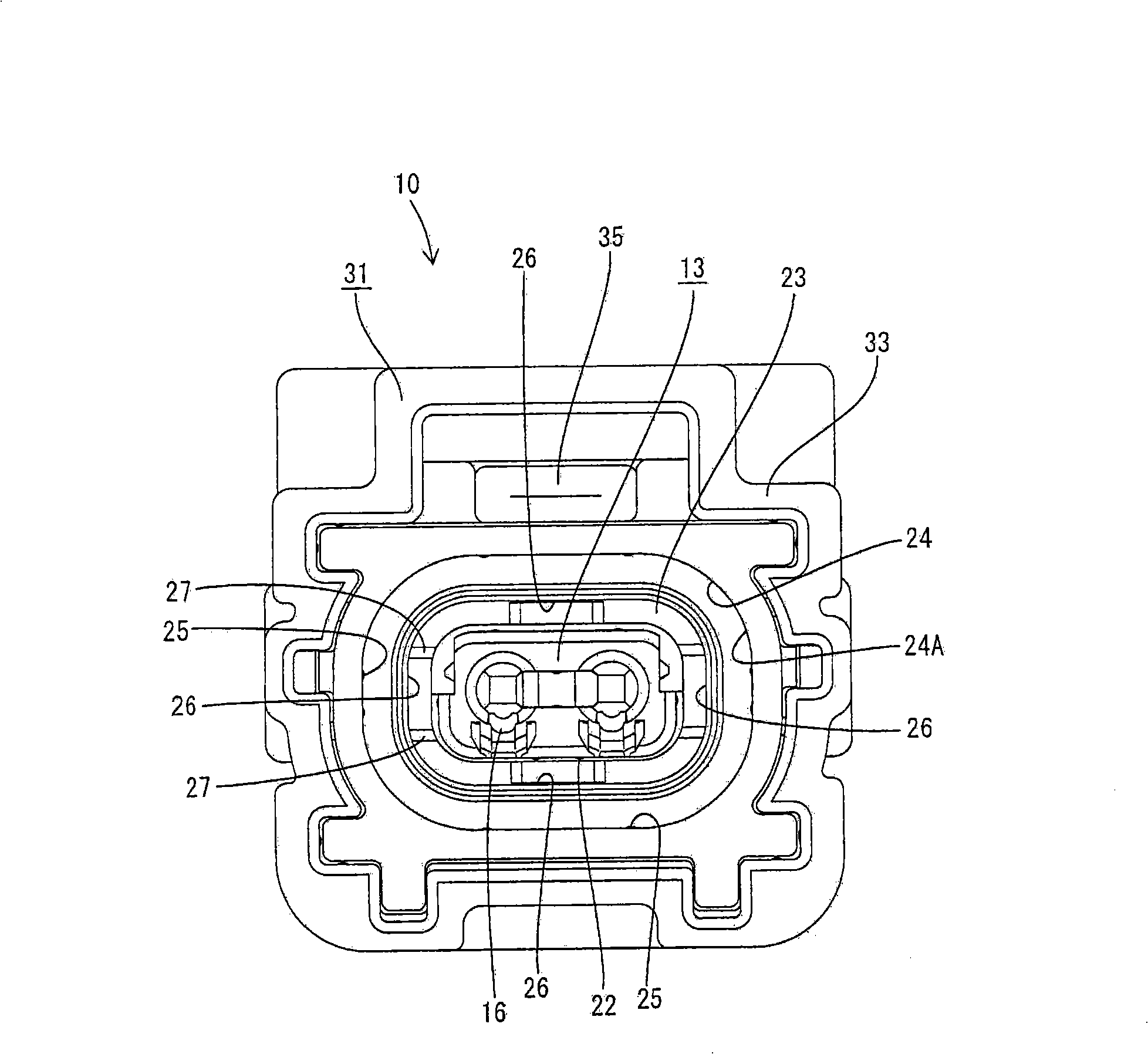

Fluidtight connector and connector assembly

The object of the present invention is to provides a watertight connector which can prevent the recoil between the connectors and reduce the number of components. A rubber member (40) is mounted on an inner housing (13) and includes a sealing portion (41) substantially in the form of a tube fittable on the outer circumferential surface of the inner housing (13) before a flange (23), legs (43) integral to the sealing portion (41) and shaped to be insertable backward through pass-through openings (26), and backlash preventing portions (44) integral to the legs (43), shaped to be engageable with the peripheral edges of the pass-through openings (26) from behind and arranged between the flange (23) and a facing wall (32).

Owner:SUMITOMO WIRING SYST LTD

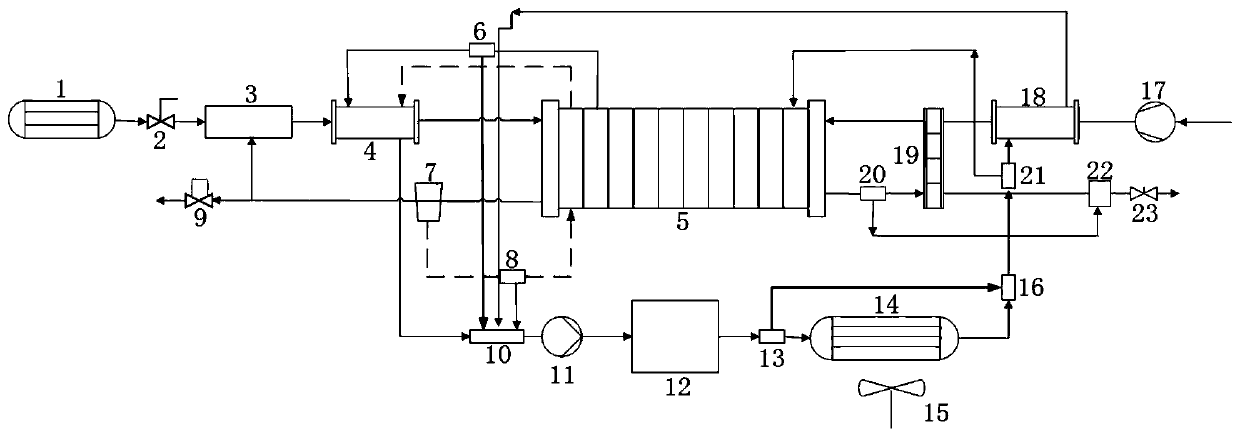

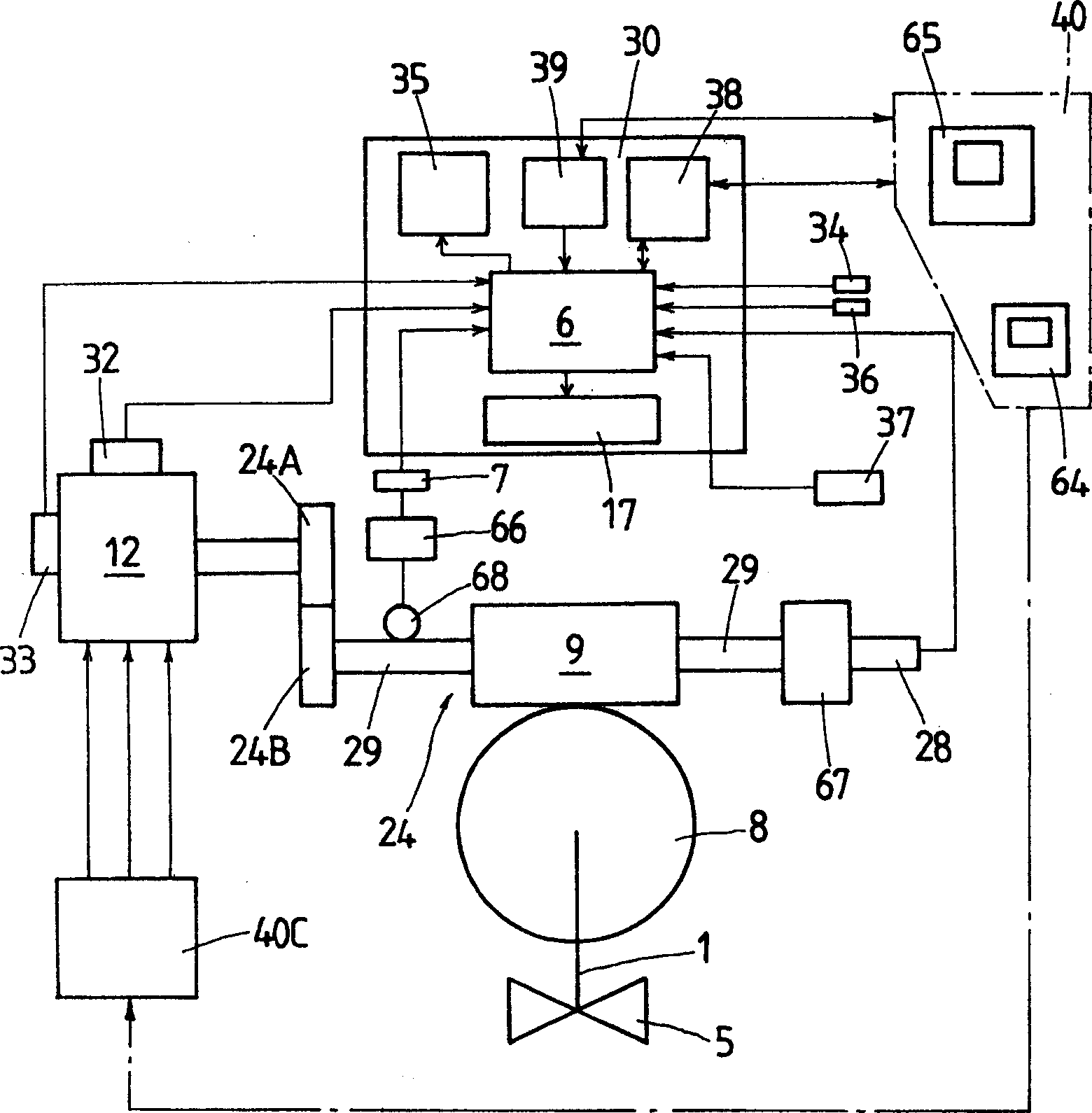

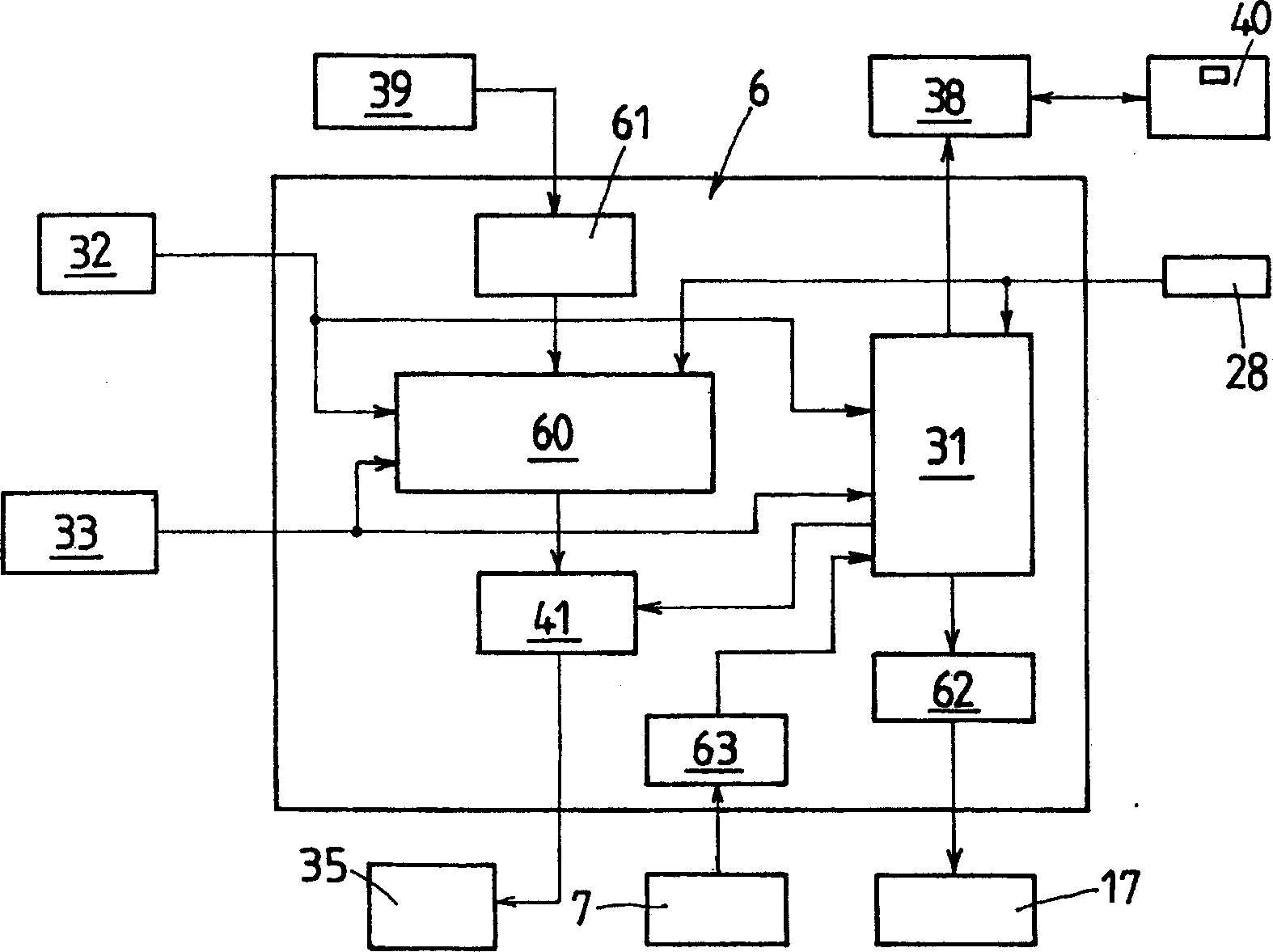

Hydrothermal management system for fuel cell engine system

InactiveCN109818012AReduce power consumptionReduced parts countFuel cell heat exchangeWater vaporEngineering

The invention provides a hydrothermal management system of a fuel cell engine system, which comprises a hydrogen supply system, an air supply system and a heat dissipation system, wherein the hydrogensupply system is configured to recycle hydrogen through an ejector, to conduct hydrogen humidification through water vapor generated by a fuel cell stack, and to conduct hydrogen heating through cooling water at an outlet of the fuel cell stack, so that after the temperature and humidity of hydrogen meet the water balance adjusting requirement, the hydrogen enters the fuel cell stack to participate in a reaction; the air supply system is configured to compress air and humidify dry air entering the fuel cell stack through wet air at the outlet of the fuel cell stack, so that the air enters thefuel cell stack to participate in the reaction after the temperature and the humidity of the air reach set requirements; and the heat dissipation system is configured to perform heat dissipation on part of cooling water at the outlet of the fuel cell stack, mix the cooling water which is subjected to heat dissipation with the other part of cooling water which is not subjected to heat dissipationand feed the mixture into the fuel cell stack again.

Owner:SHANDONG UNIV

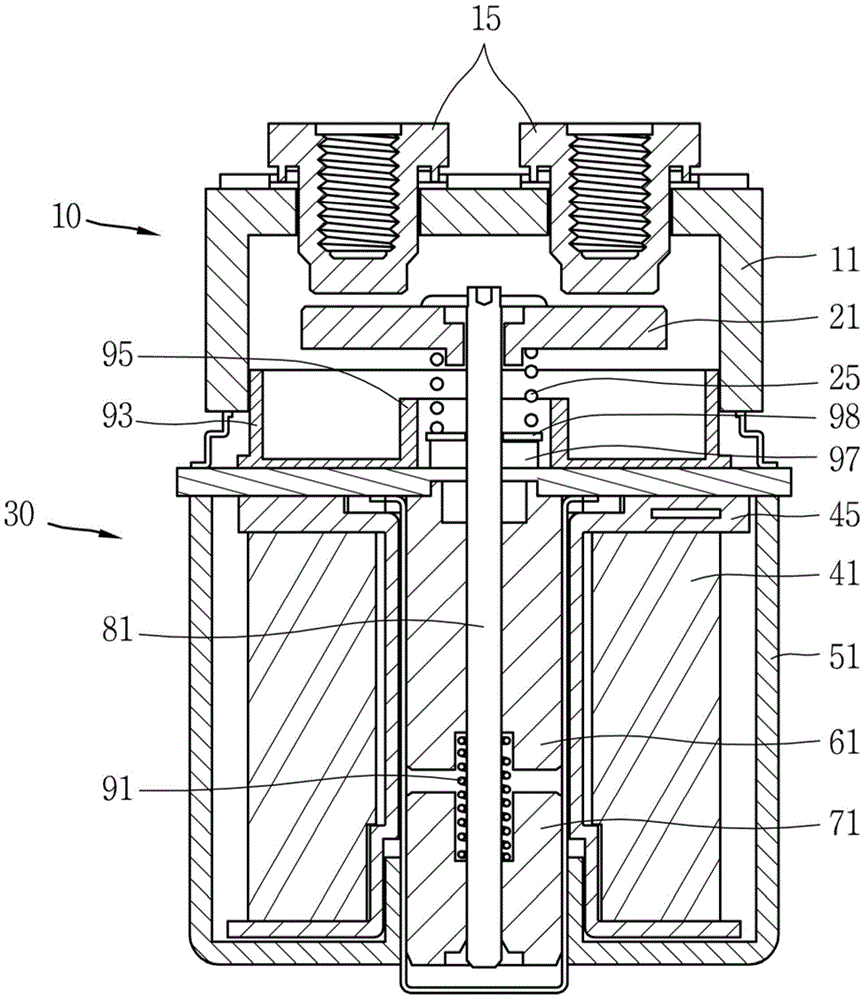

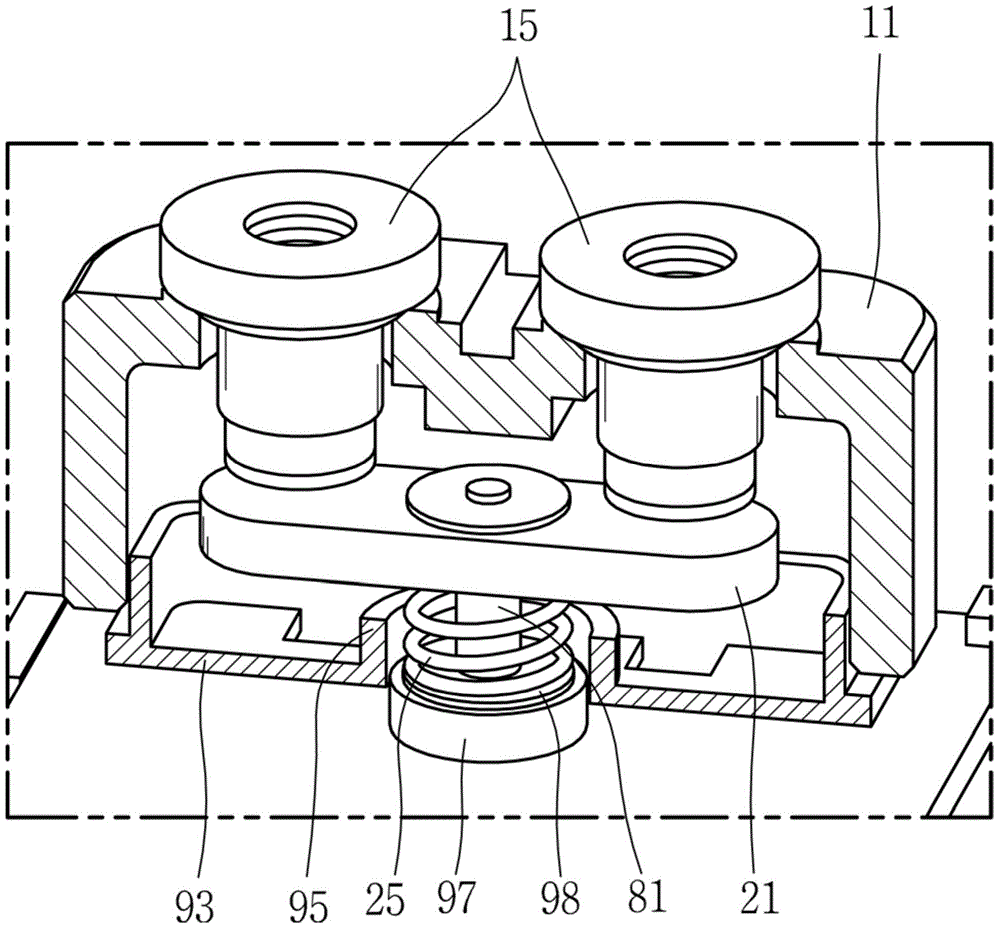

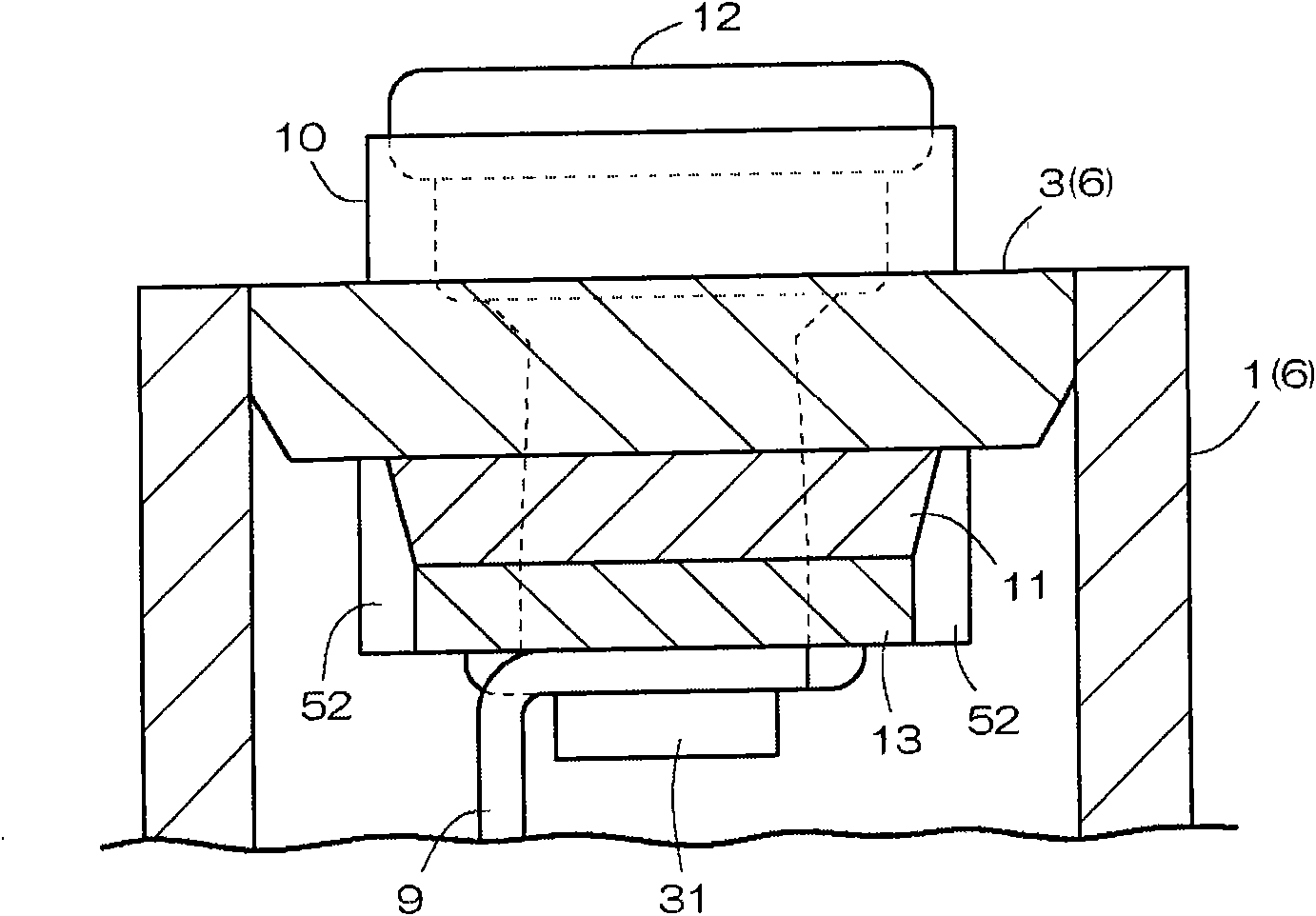

Electromagnetic relay

ActiveCN104810207AReduced parts countReduce working hoursElectric switchesElectromagnetic relay detailsMechanical engineeringRelay

An electromagnetic relay includes a housing; a fixed contact provided within the housing; a movable contact disposed within the housing so as to be contactable to and separable from the fixed contact; a driving unit configured to drive the movable contact, and including a shaft having one end connected to the movable contact and a compression spring for applying an elastic force to the movable contact so as to be in contact with the fixed contact; and an arc protector including an arc shielding portion for shielding an arc, and a compression spring support portion formed to protrude from the arc shielding portion to support the compression spring, the compression spring support portion comprising a shaft accommodating portion for accommodating the shaft therein. Under such configuration, the number of required components can be reduced and generation of a gap can be prevented.

Owner:LSIS CO LTD

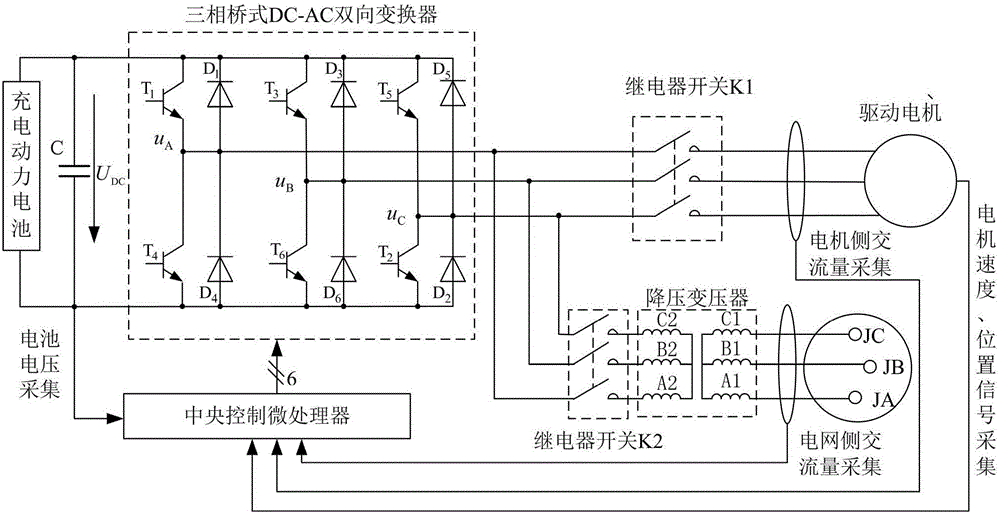

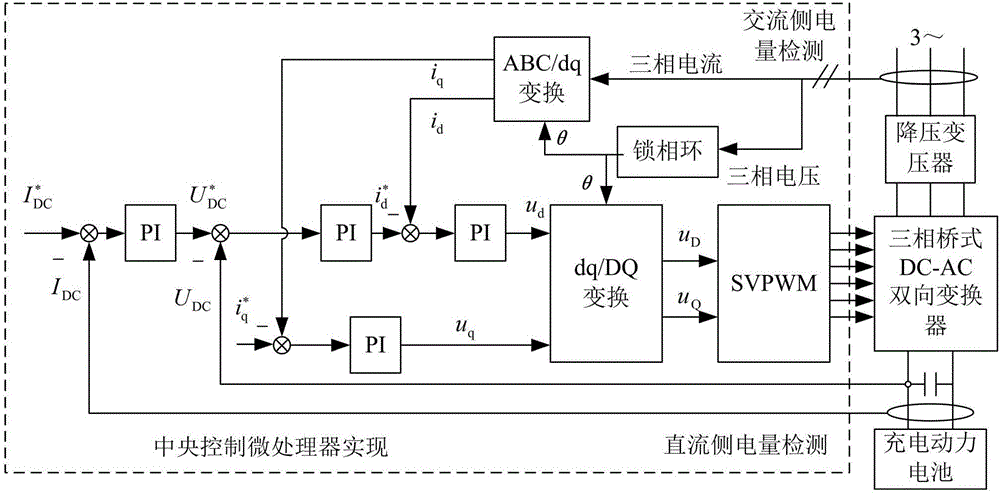

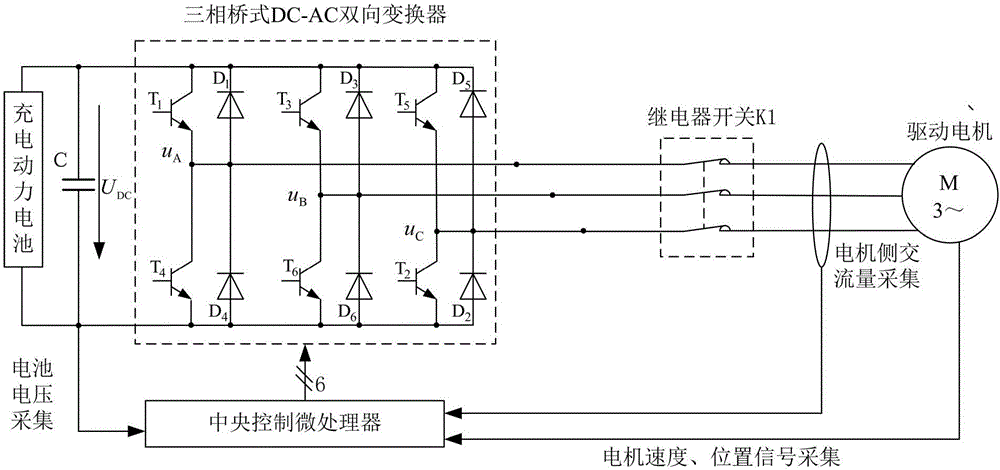

Electric vehicle driving motor controller with charging function and control method thereof

InactiveCN106452279ASimple structureWork reliablyBatteries circuit arrangementsAC motor controlElectrical batteryTransformer

An electric vehicle driving motor controller with a charging function is characterized by comprising a three-phase bridge-type DC-AC bidirectional converter, a first relay switch, a second relay switch, an AC power supply input interface device, a driving motor, a voltage reduction transformer, a charging power battery and a central control microprocessor. The electric vehicle driving motor controller and the control method thereof have advantages of concise circuit structure, effective number reduction of electrical elements, higher operation reliability, low cost, small weight, small size and high power factor.

Owner:BOHAI UNIV

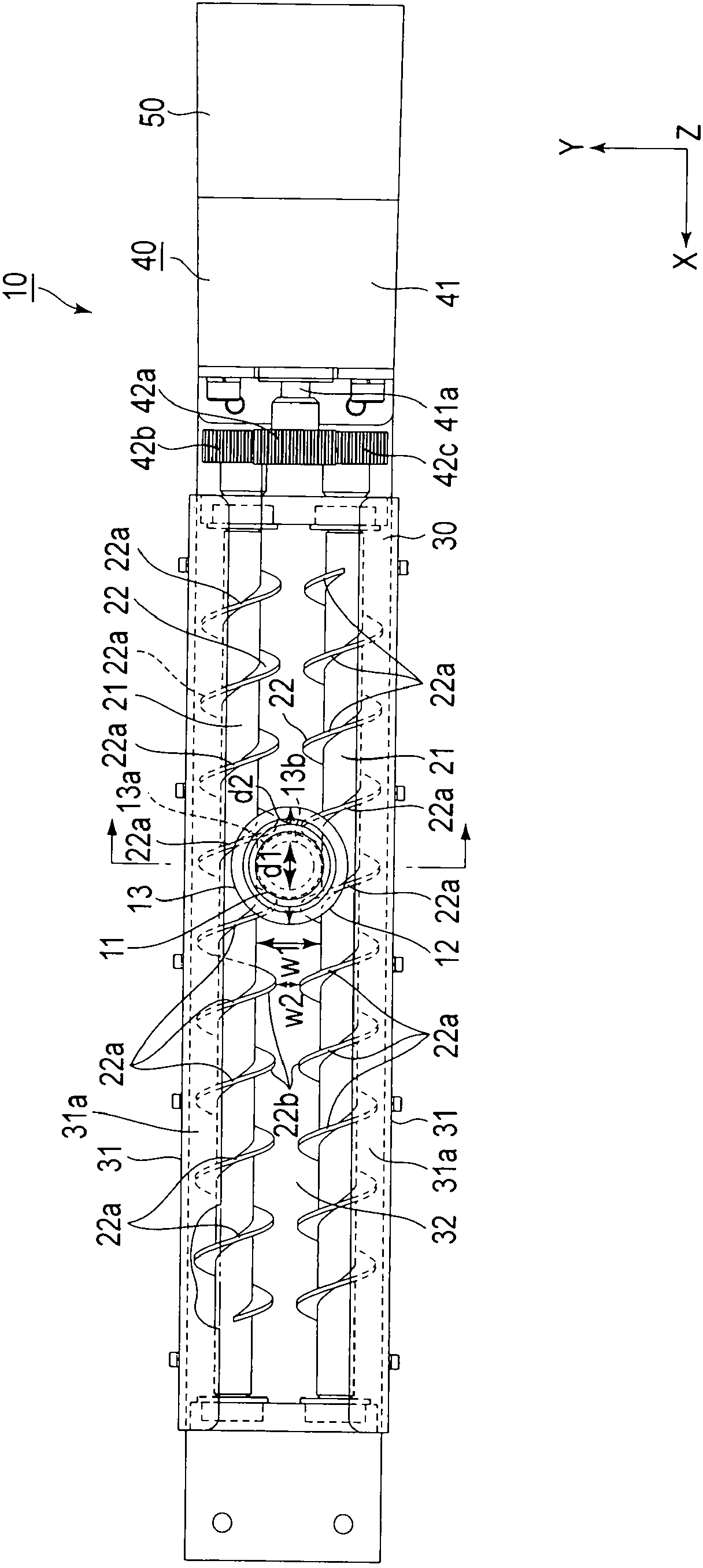

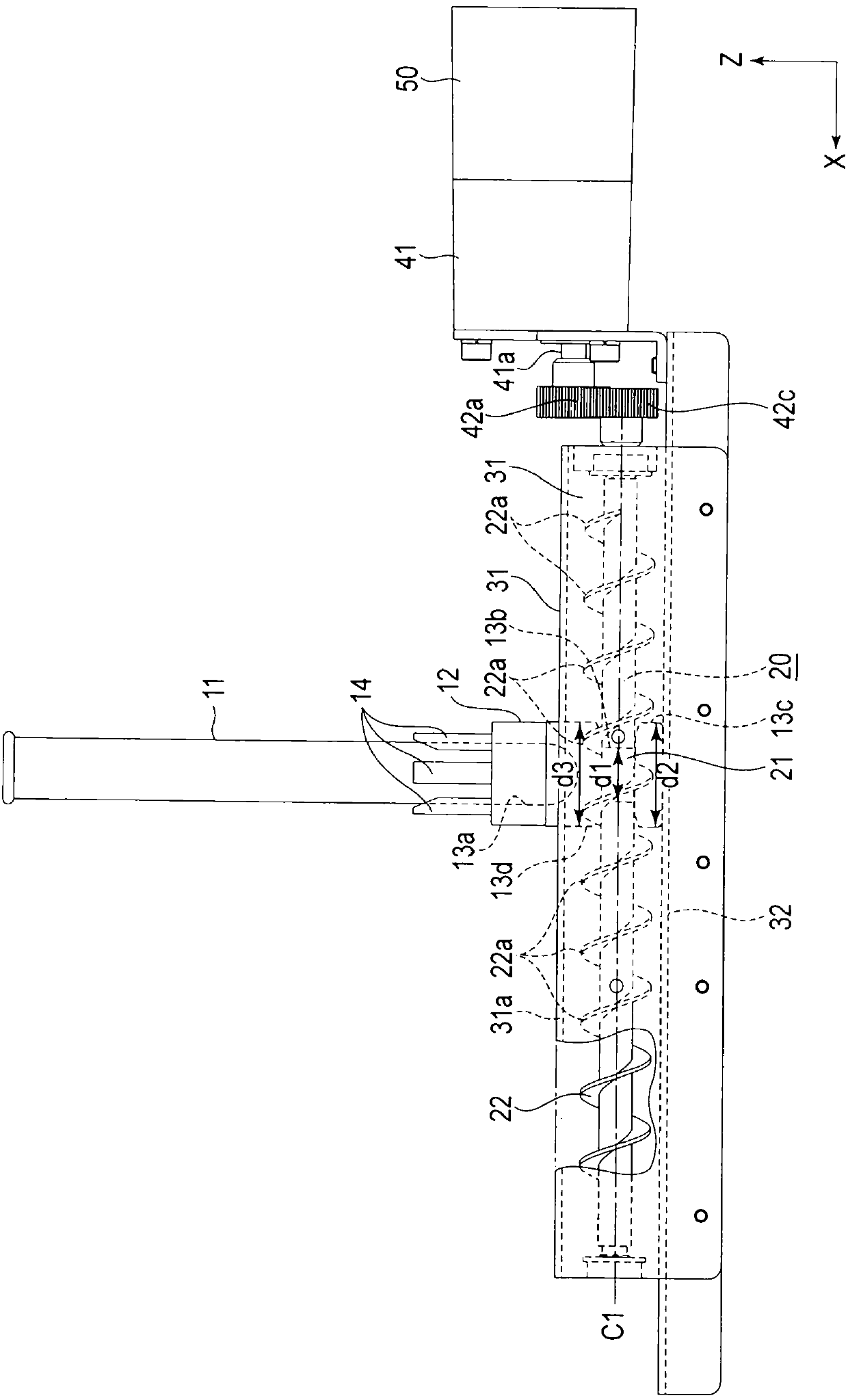

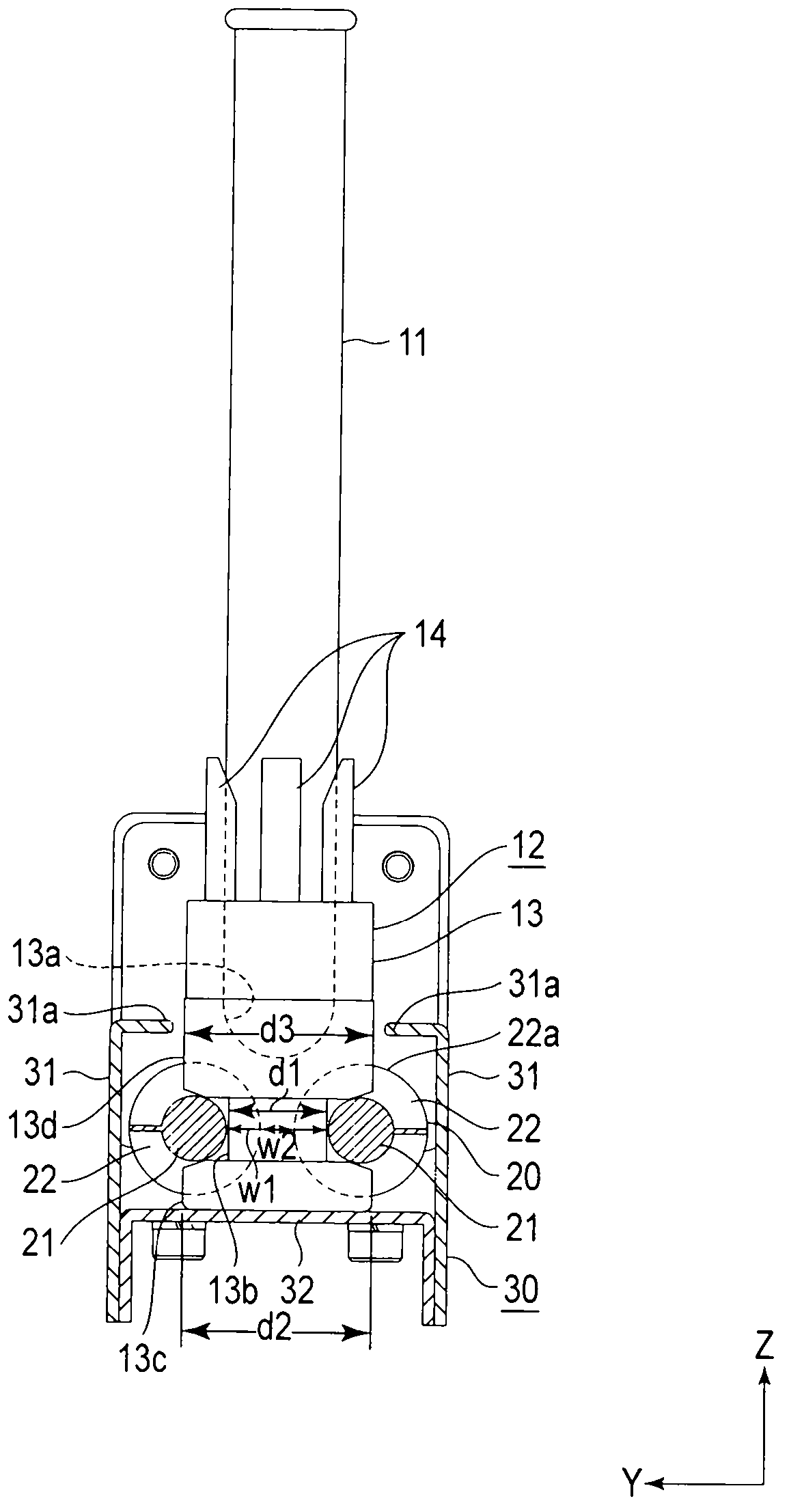

Transport system and transport method

InactiveCN103303639AReduced inspection workReduced parts countGearingBiological testingTransport systemTransport engineering

According to an embodiment, a transport system configured to transport a receptacle which accommodates an upright sample holder containing a sample, characterized by comprising, a screw comprising a rotatable shaft disposed along a predetermined transport path and a helical ridge protruding outward from an outer peripheral surface of the shaft, and a drive unit configured to rotate the screw. The transport method according to another shape utilizes a pair of parallel screws for conveying the receptacle, and conveys the receptacle which is held among a plurality of ridges which are arranged in an axial direction in a transportation path. The transport system and transport method of the invention have the following advantages: small number of components, simplified device structure, and reduced manufacturing cost.

Owner:AOI SEIKI

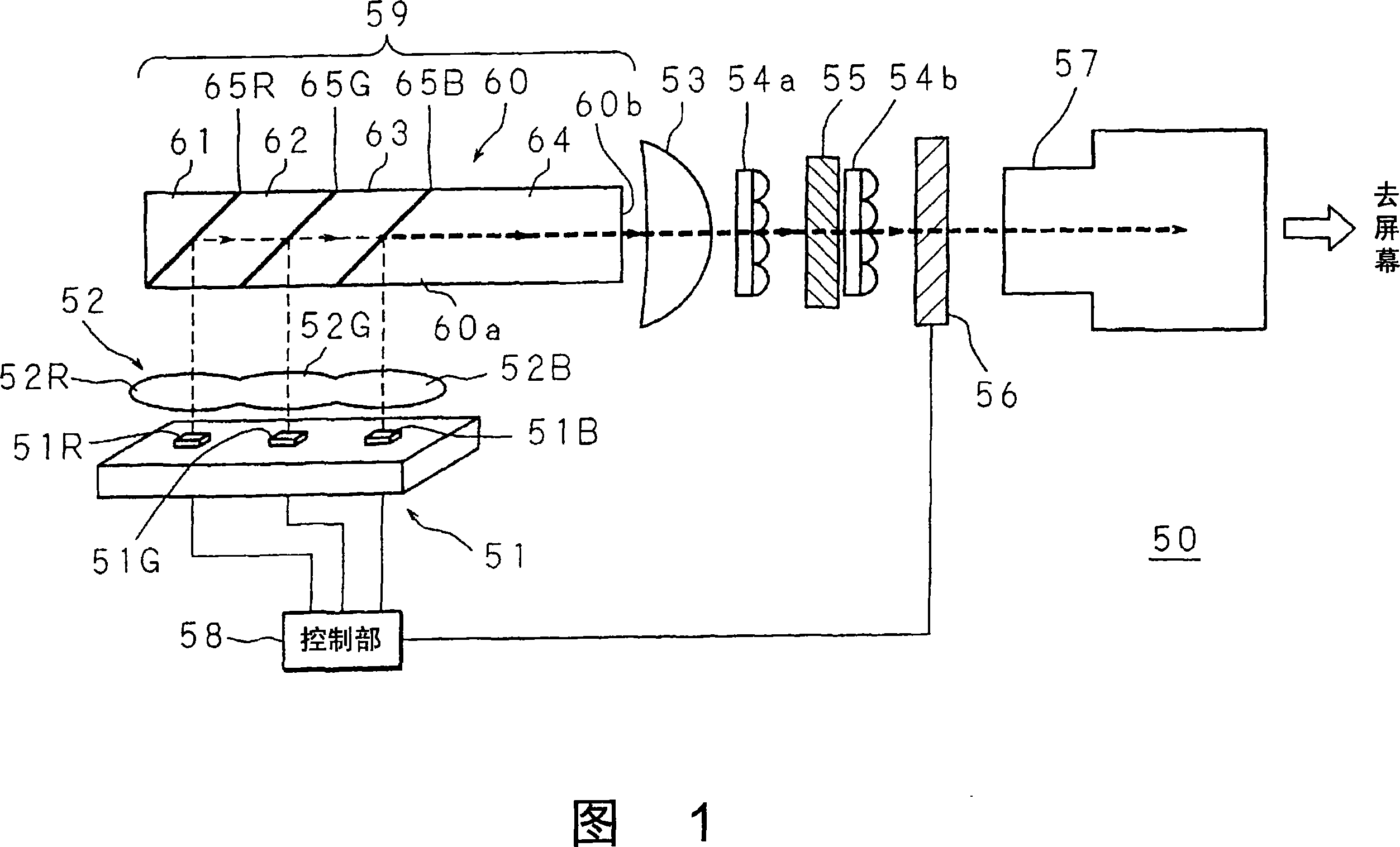

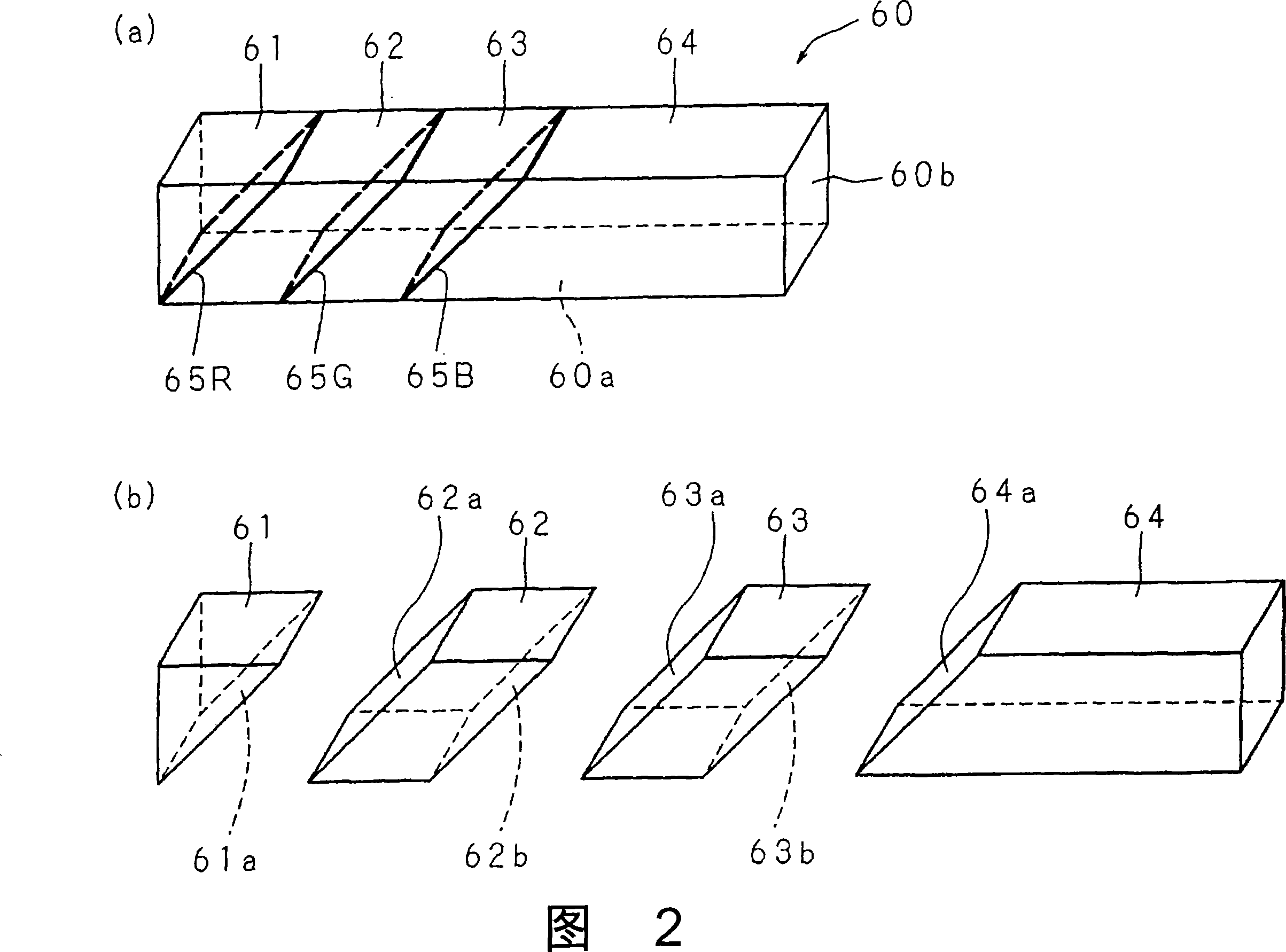

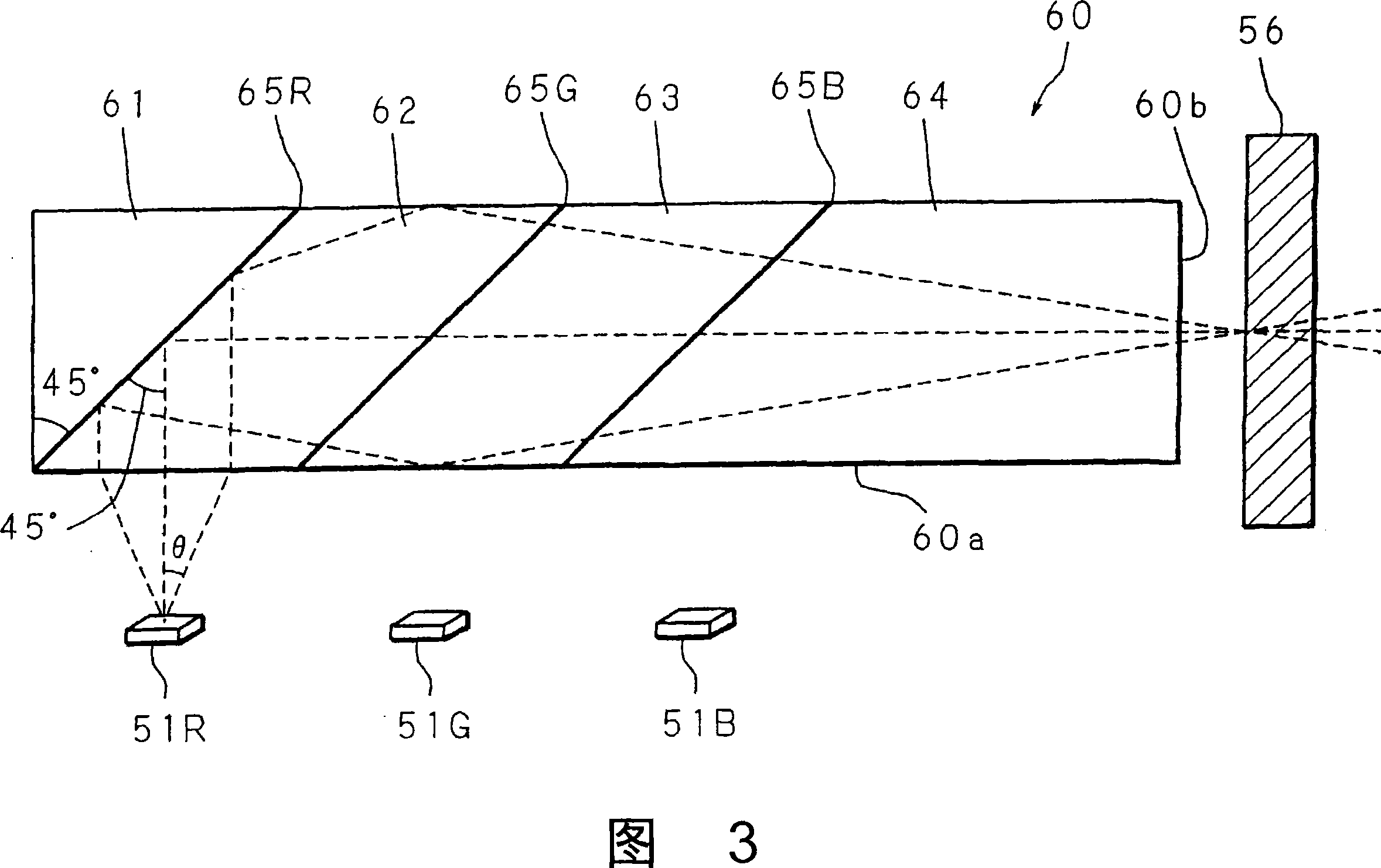

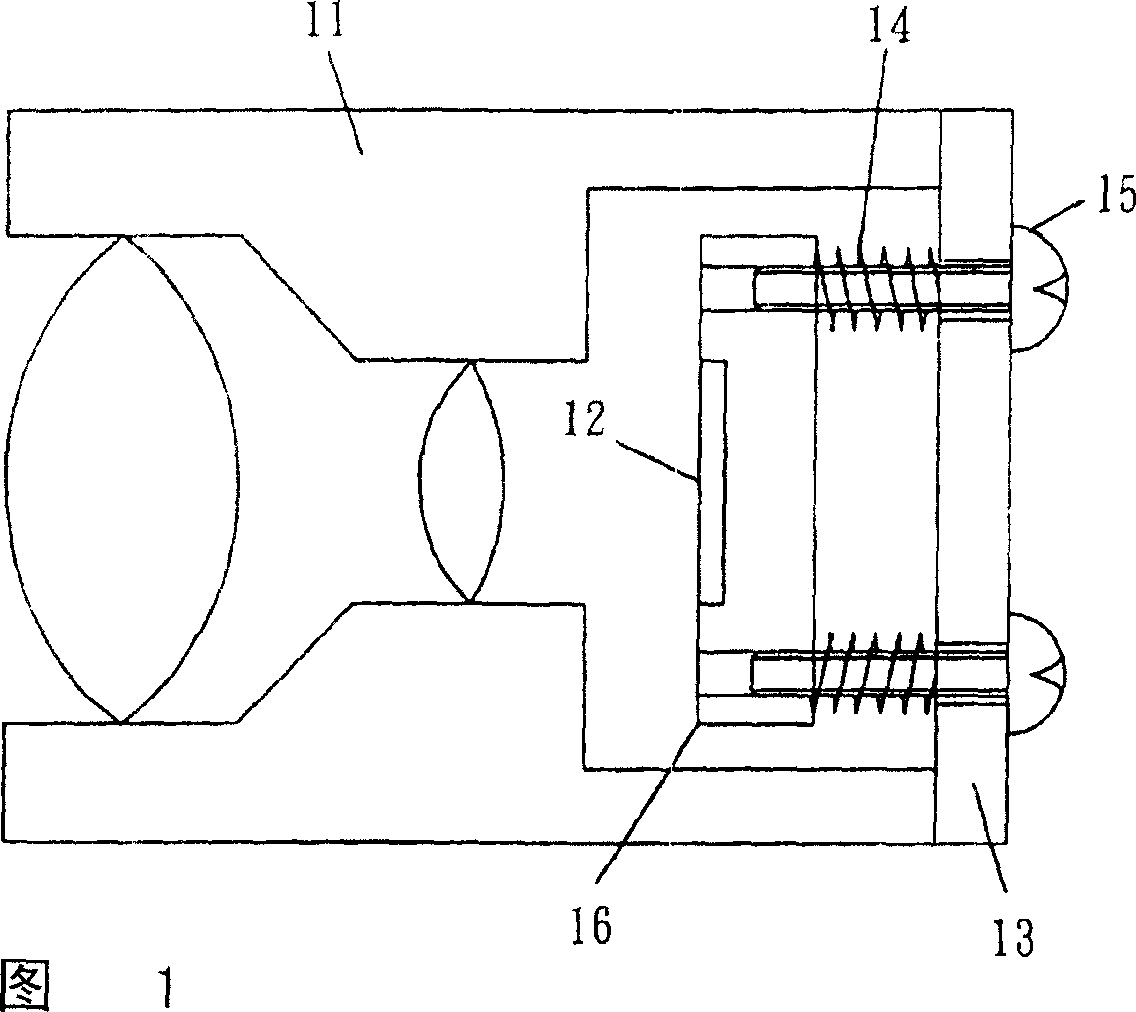

Optical integrator, illuminator and projection image display

InactiveCN101052915AUniform illuminationSimplify the change processProjectorsColor photographyIntegratorProjection image

Owner:SHARP KK

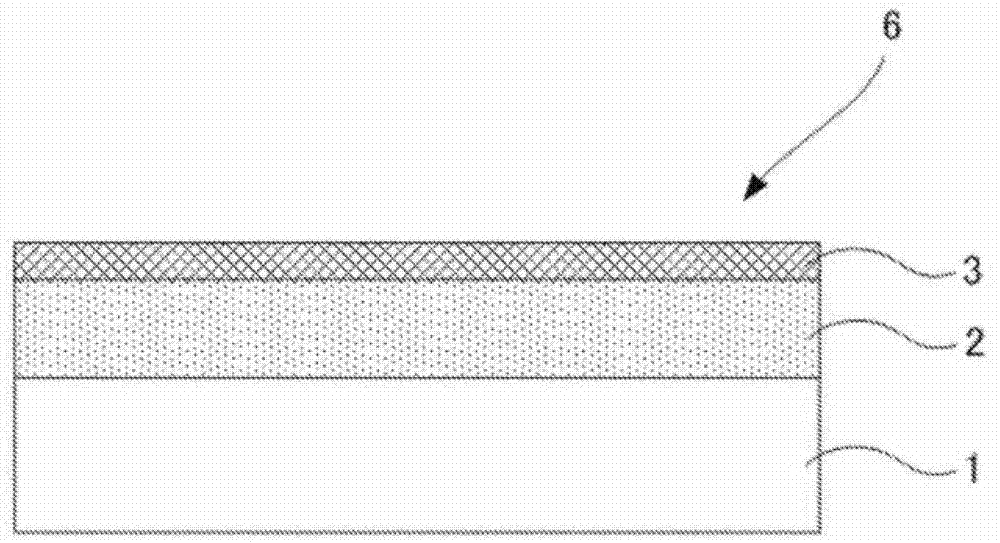

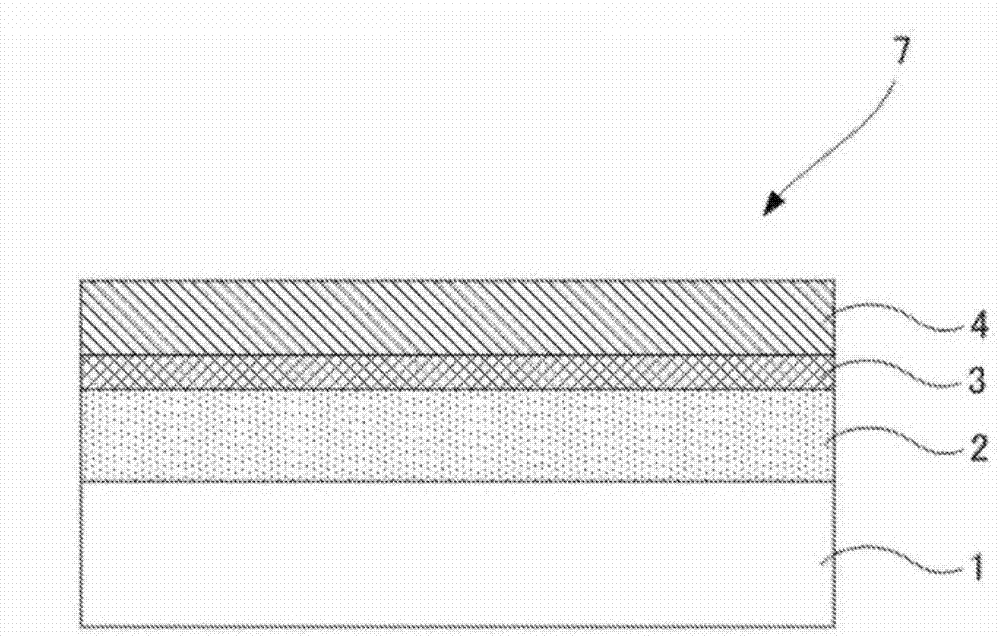

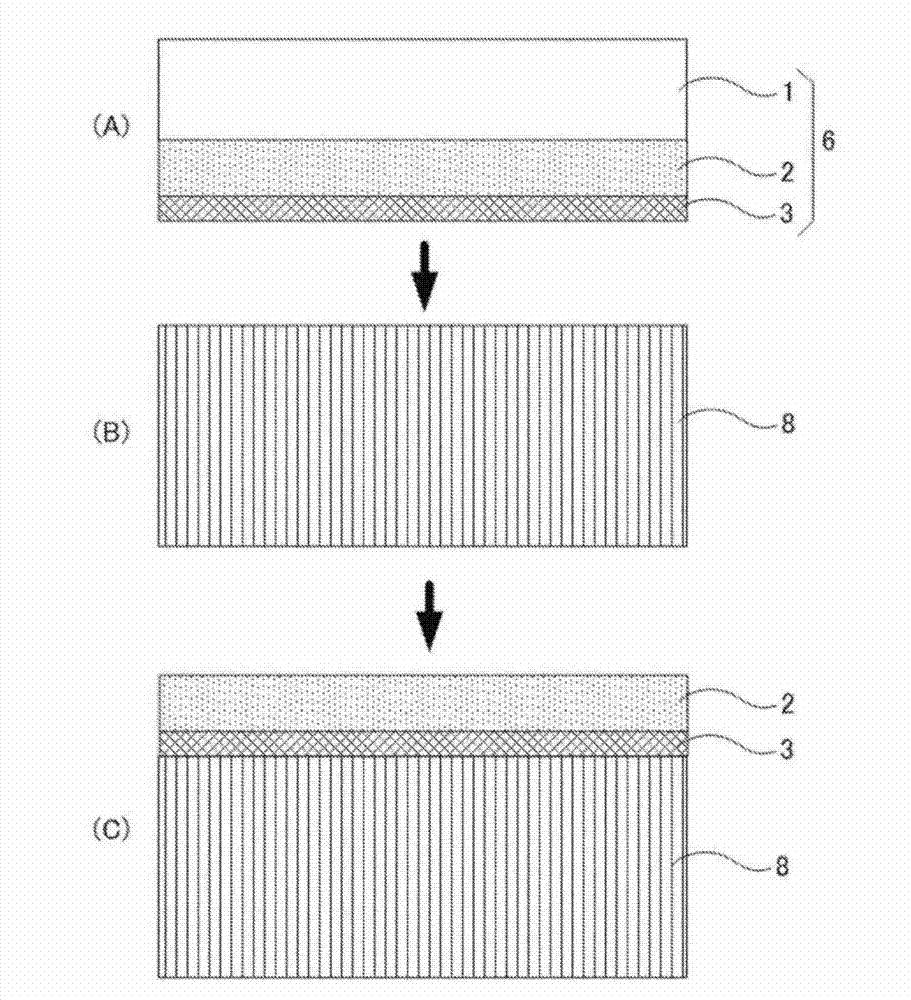

Conductive layer transfer material and touch panel

InactiveCN102971806AImprove uniformityGood transferabilityConductive layers on insulating-supportsSynthetic resin layered productsMetal nanowiresMechanical engineering

Disclosed are: a conductive layer transfer material which has good transferability and adhesion to a transfer-receiving body and exhibits improved transfer uniformity of a conductive layer; and a touch panel, which has a conductive layer that is transferred using the conductive layer transfer material, and which is reduced in the number of components and can be formed lightweight and thin. Specifically disclosed is a conductive layer transfer material which comprises: a base; and a cushion layer and a conductive layer that are arranged on the base in this order, said conductive layer containing metal nanowires that have an average minor axis length of 100 nm or less and an average major axis length of 2 [mu]m or more. The total average thickness (A) of the conductive layer and the cushion layer and the average thickness (B) of the base satisfy the relation: A / B = 0.1-0.7. The conductive layer has an average thickness of 0.01-0.2 [mu]m, and the cushion layer has an average thickness of 1-50 [mu]m.

Owner:FUJIFILM CORP

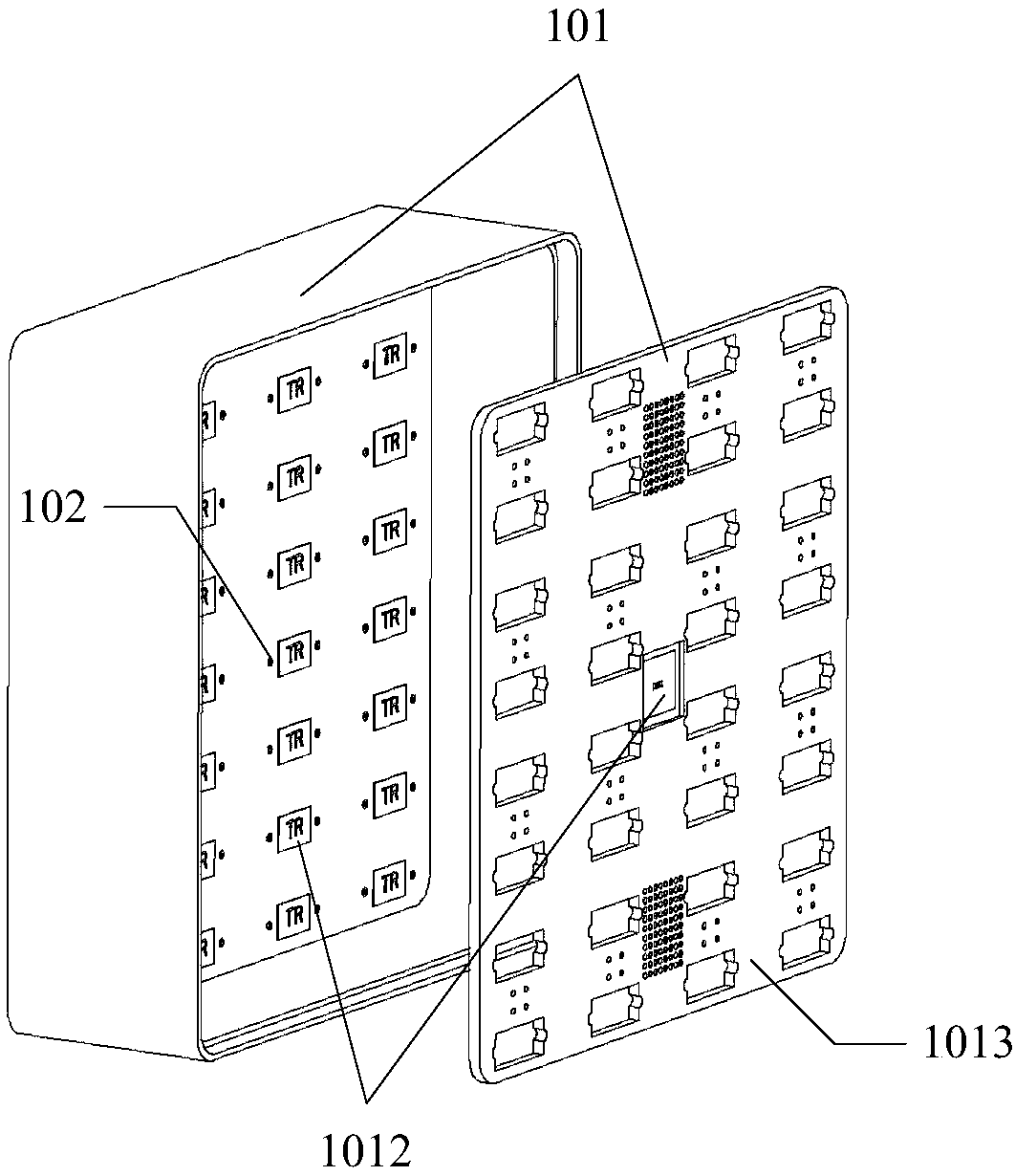

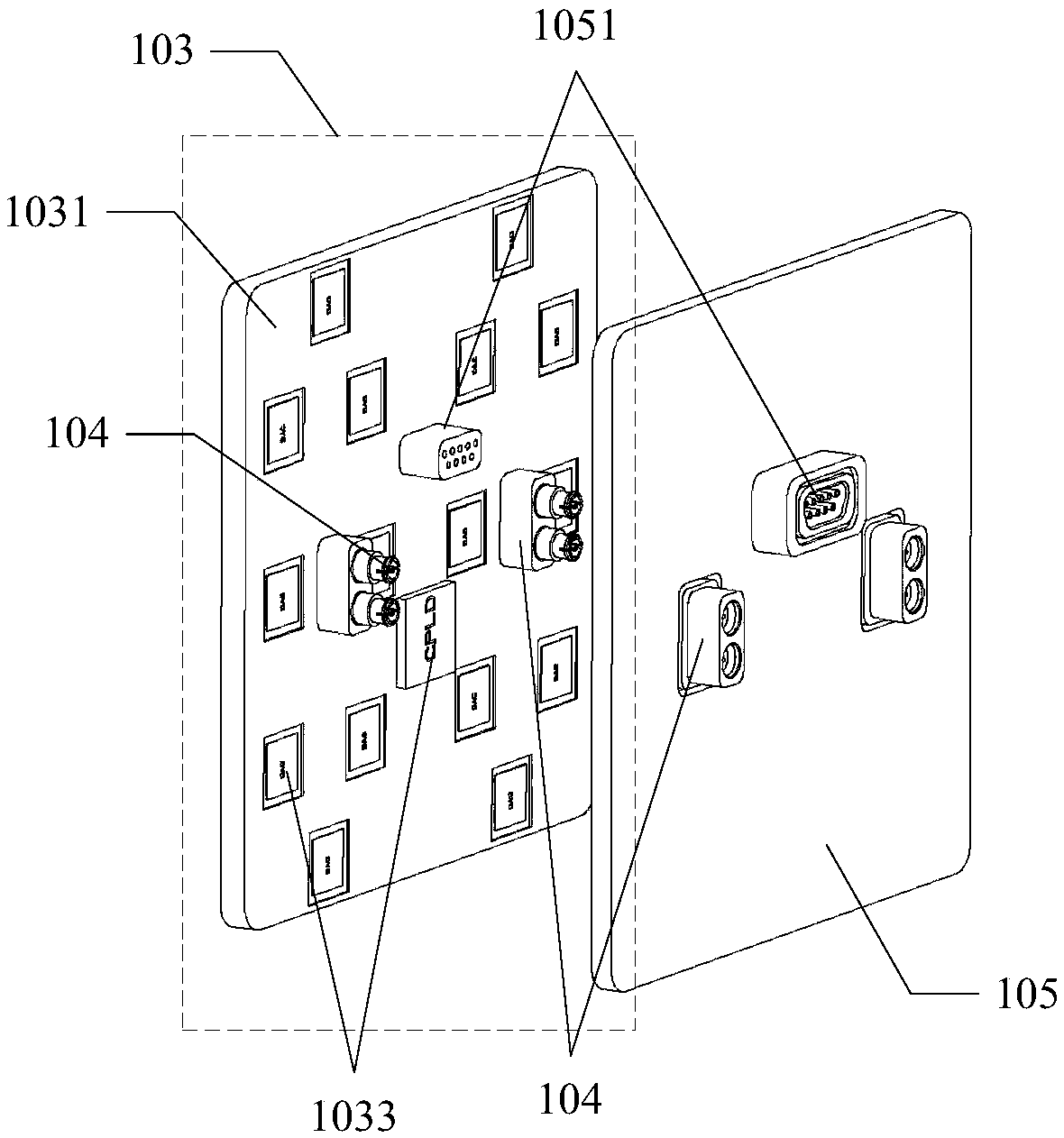

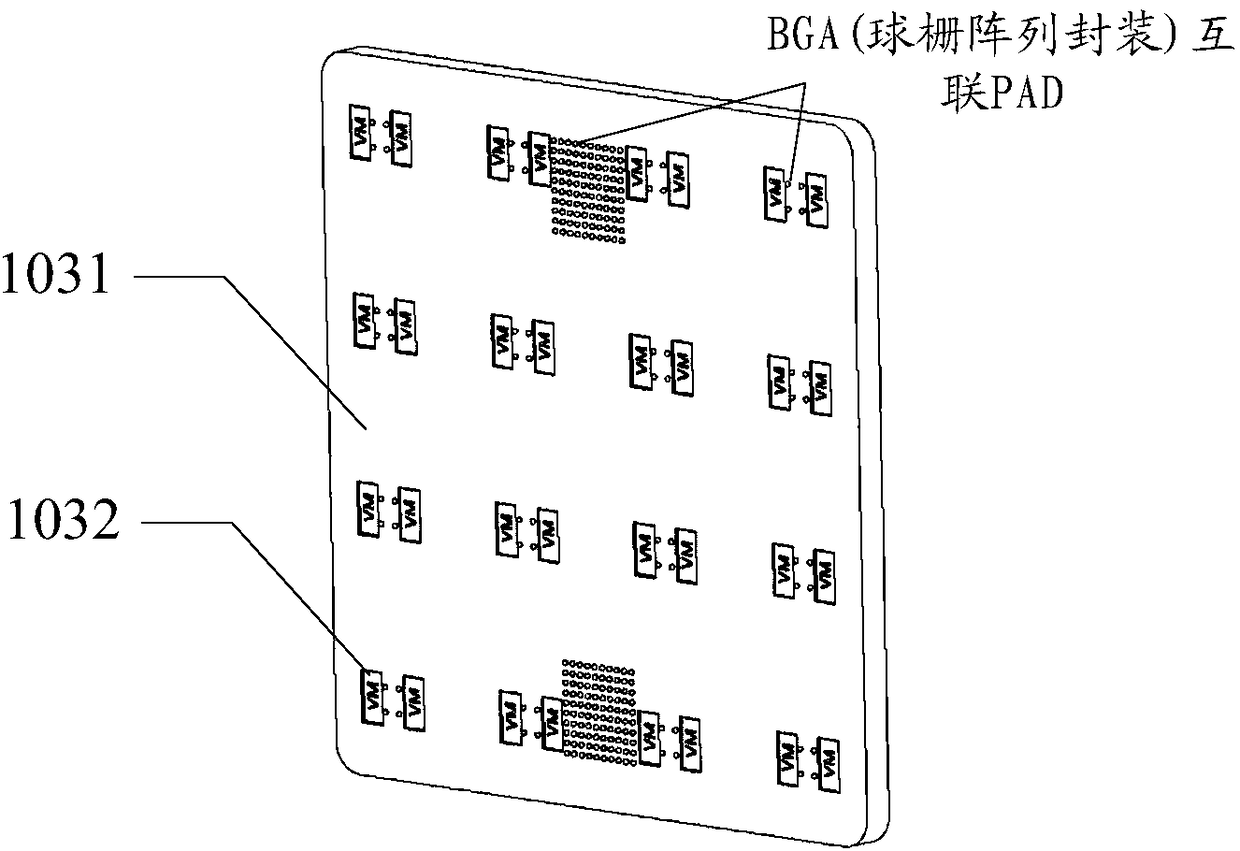

Multi-beam tile type TR component

The invention discloses a multi-beam tile type TR component, which can separately set an amplification processing module and a multi-beam amplitude-phase modulation module in a TR component, and thencan integrate a multi-beam forming function and an amplitude-phase modulation function through the multi-beam amplitude-phase modulation module. Thereby, the miniaturization and high-level integrationof a multi-beam phased array TR component can be achieved; and meanwhile, as a multi-beam vector modulation chip in the technical scheme of the embodiment of the application can perform independent amplitude modulation and phase modulation on multi-beam signals, great flexibility and scalability can be brought to the design of the multi-beam TR component, the size, weight and versatility of TR component application system equipment can be adjusted according to actual needs, and the technical effects of very extensive application values and applicability can be achieved in the field of microwave and millimeter wave radar communication with strict requirements for the above applications.

Owner:CHENGDU T-RAY TECH CO LTD

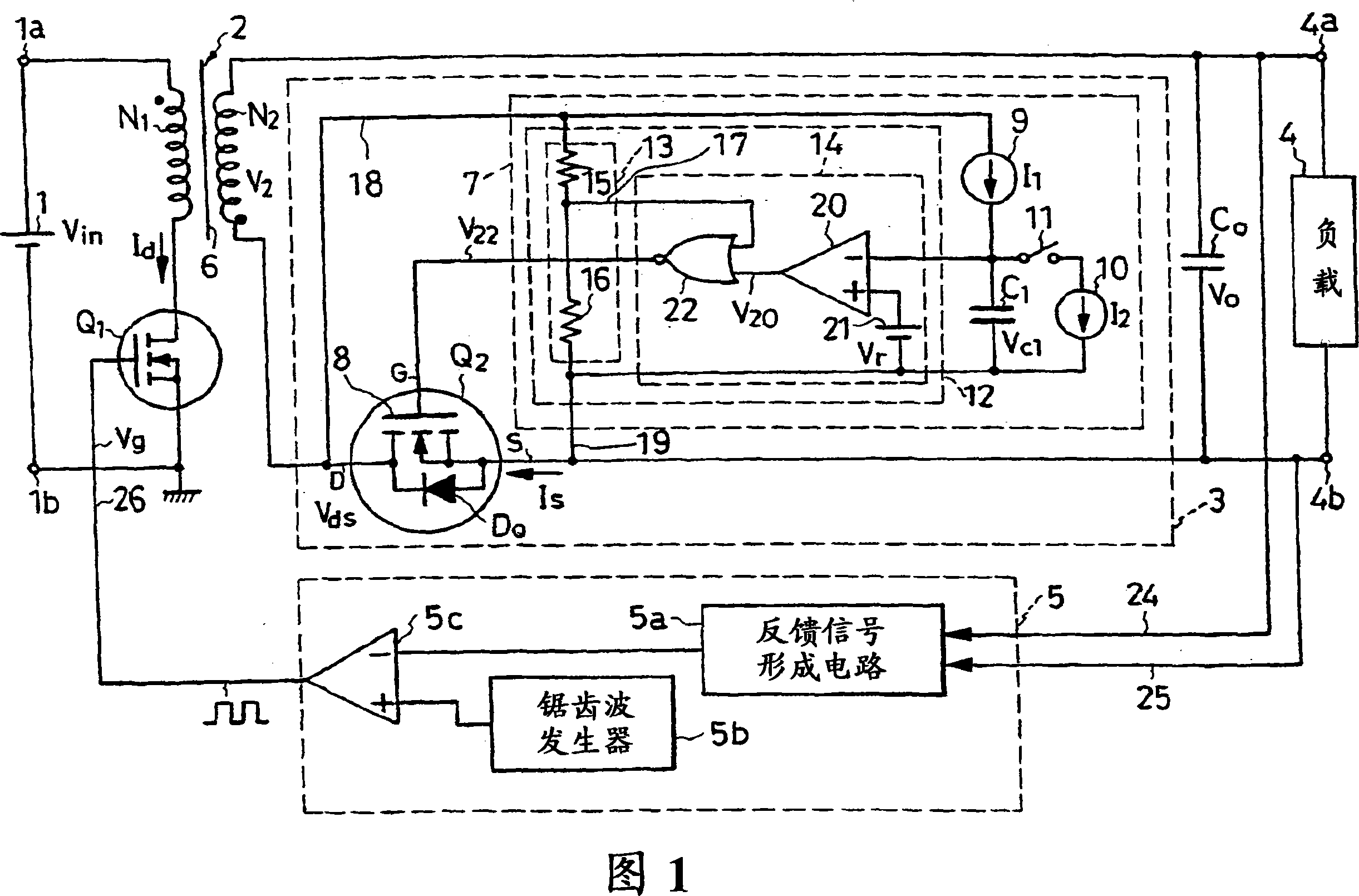

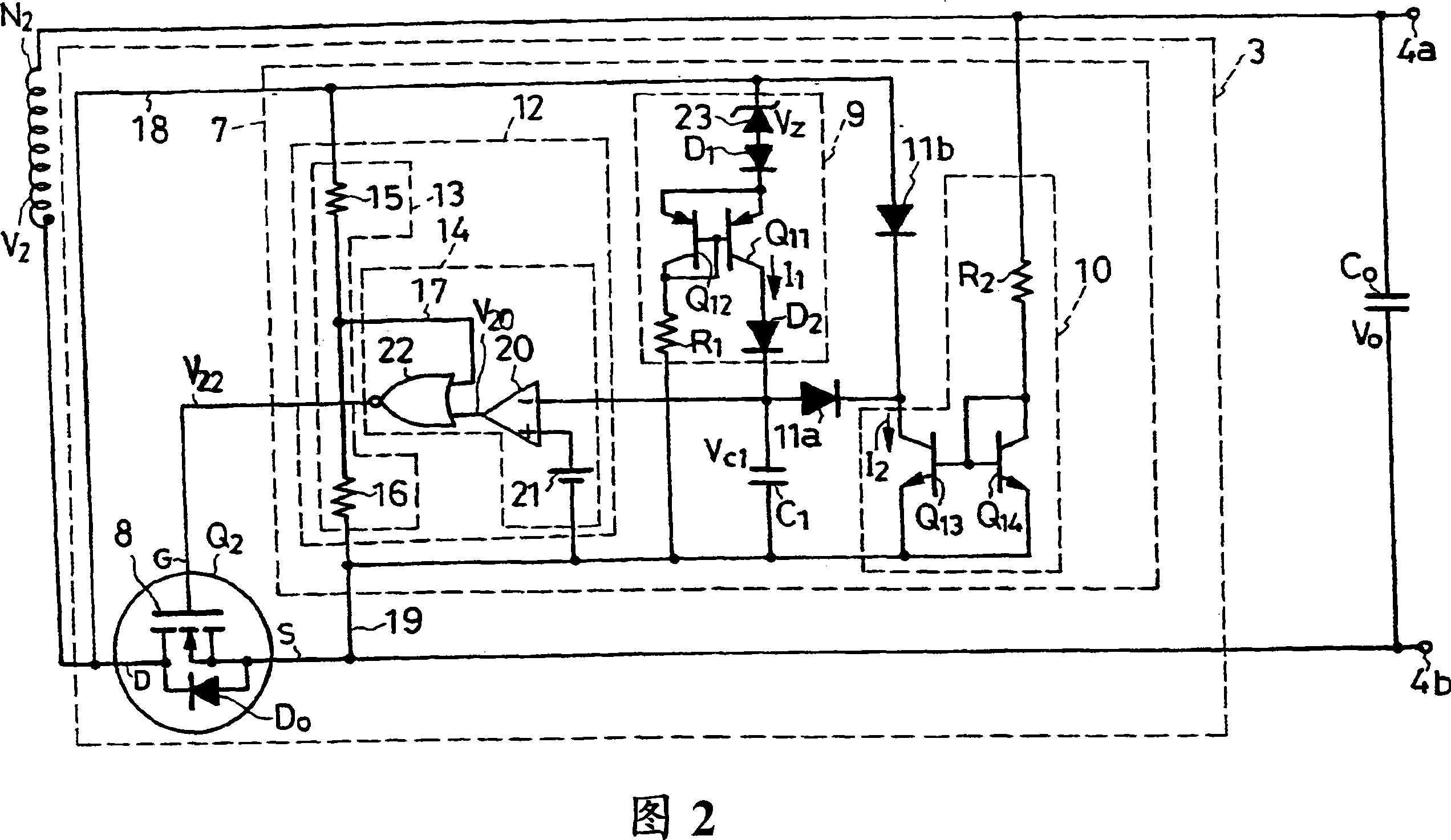

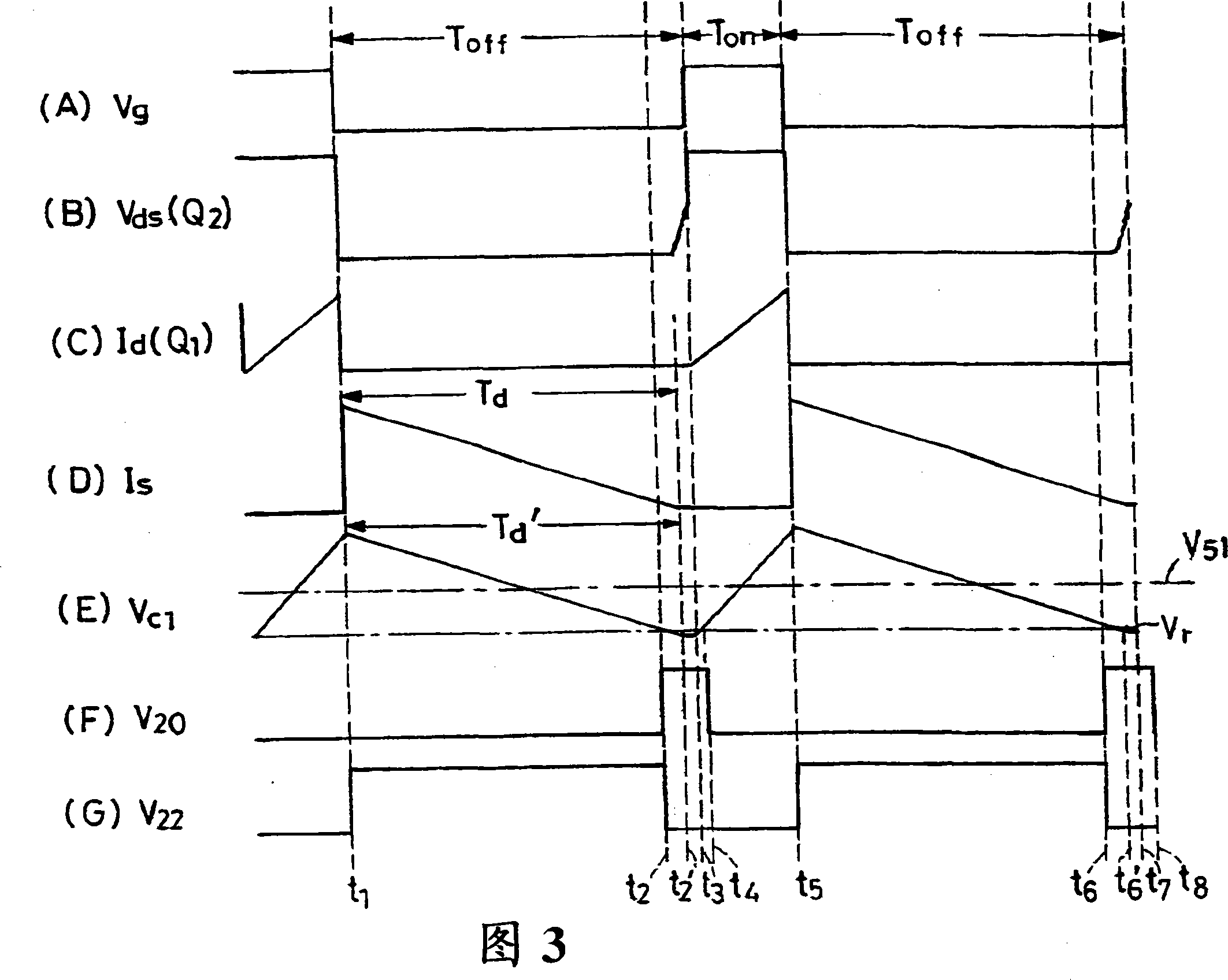

Switching-mode power supply

InactiveCN1965466AImprove efficiencyDisadvantages of inhibiting destruction, etc.Efficient power electronics conversionApparatus with intermediate ac conversionEngineeringConductor Coil

Owner:SANKEN ELECTRIC CO LTD

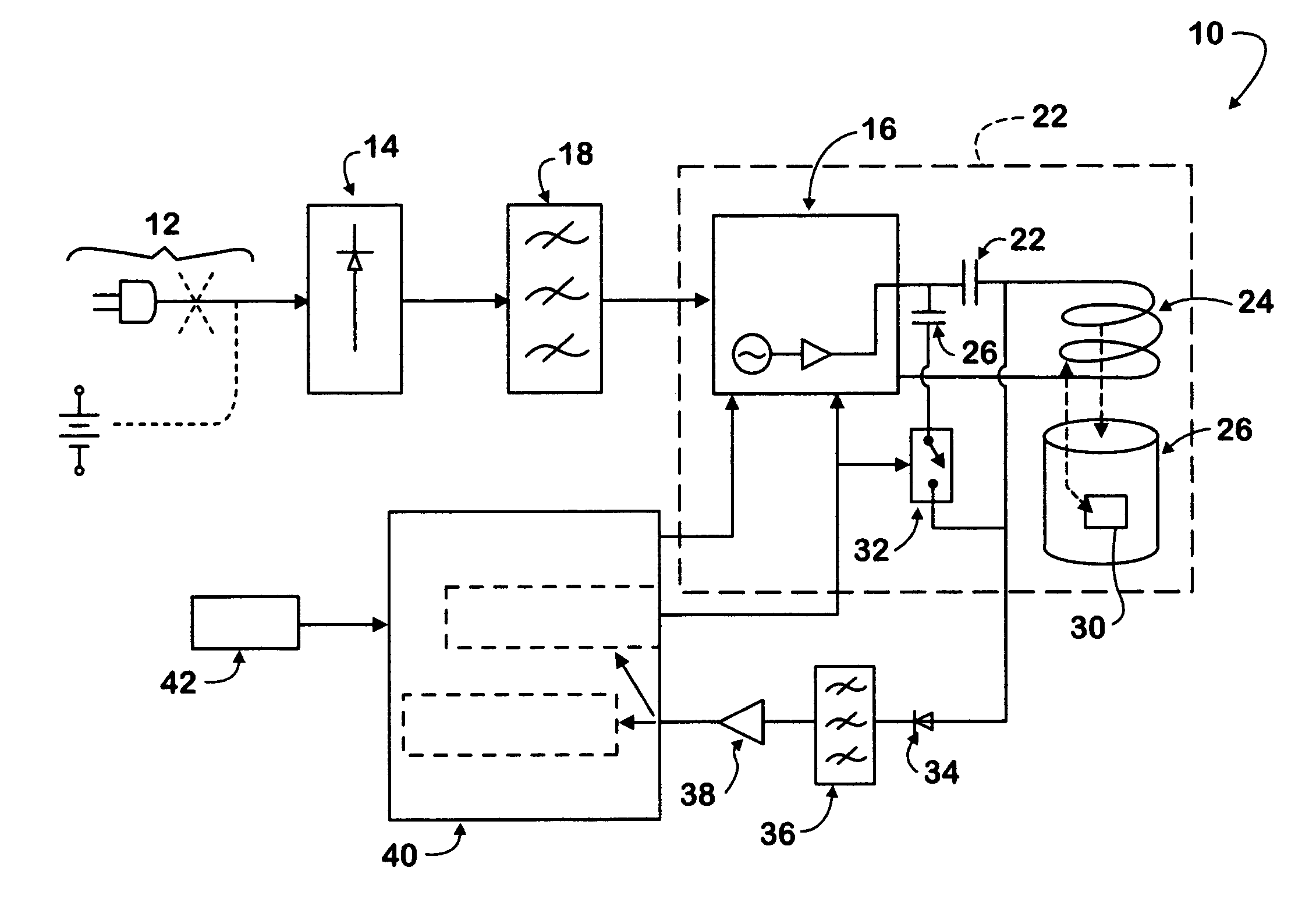

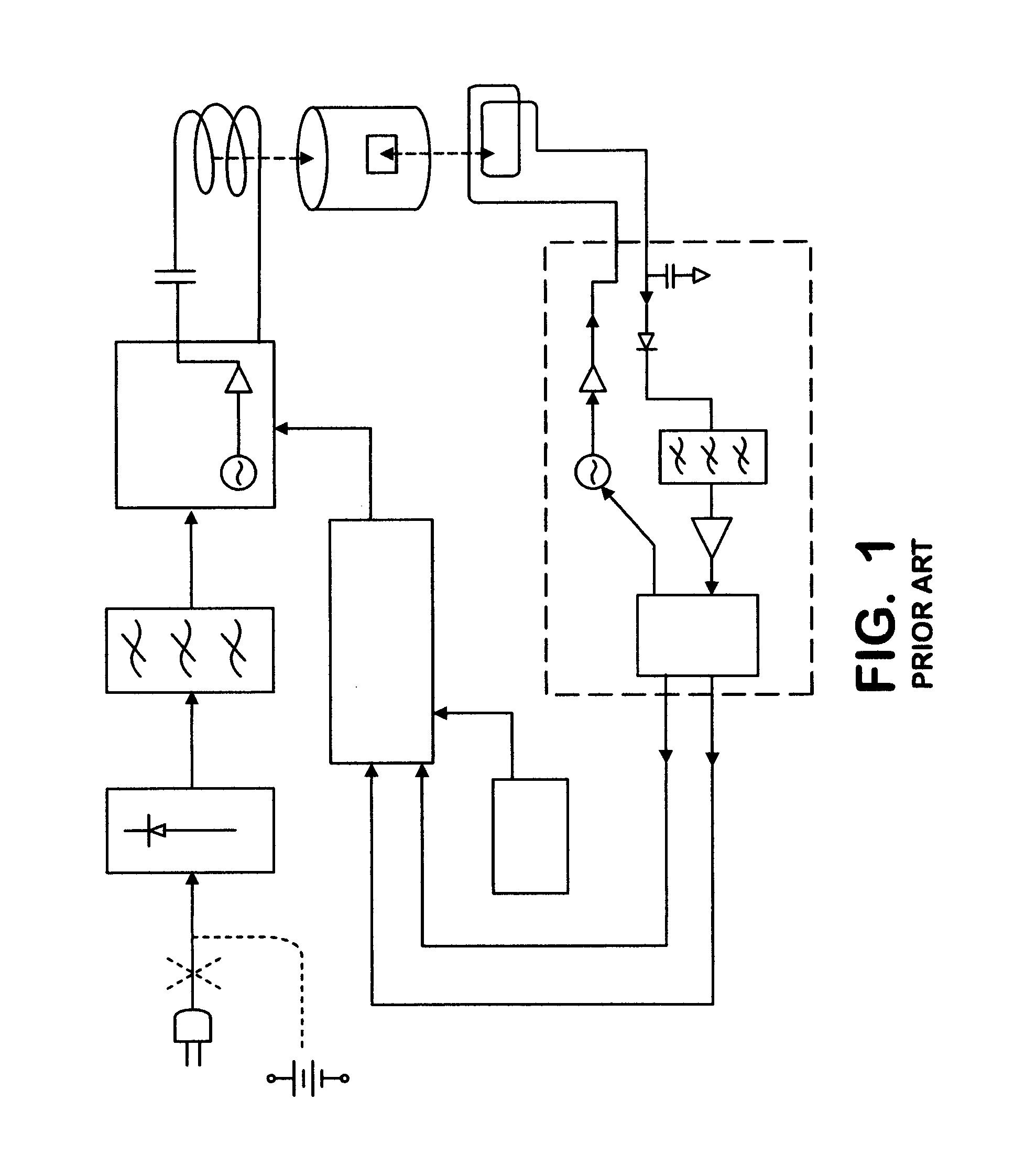

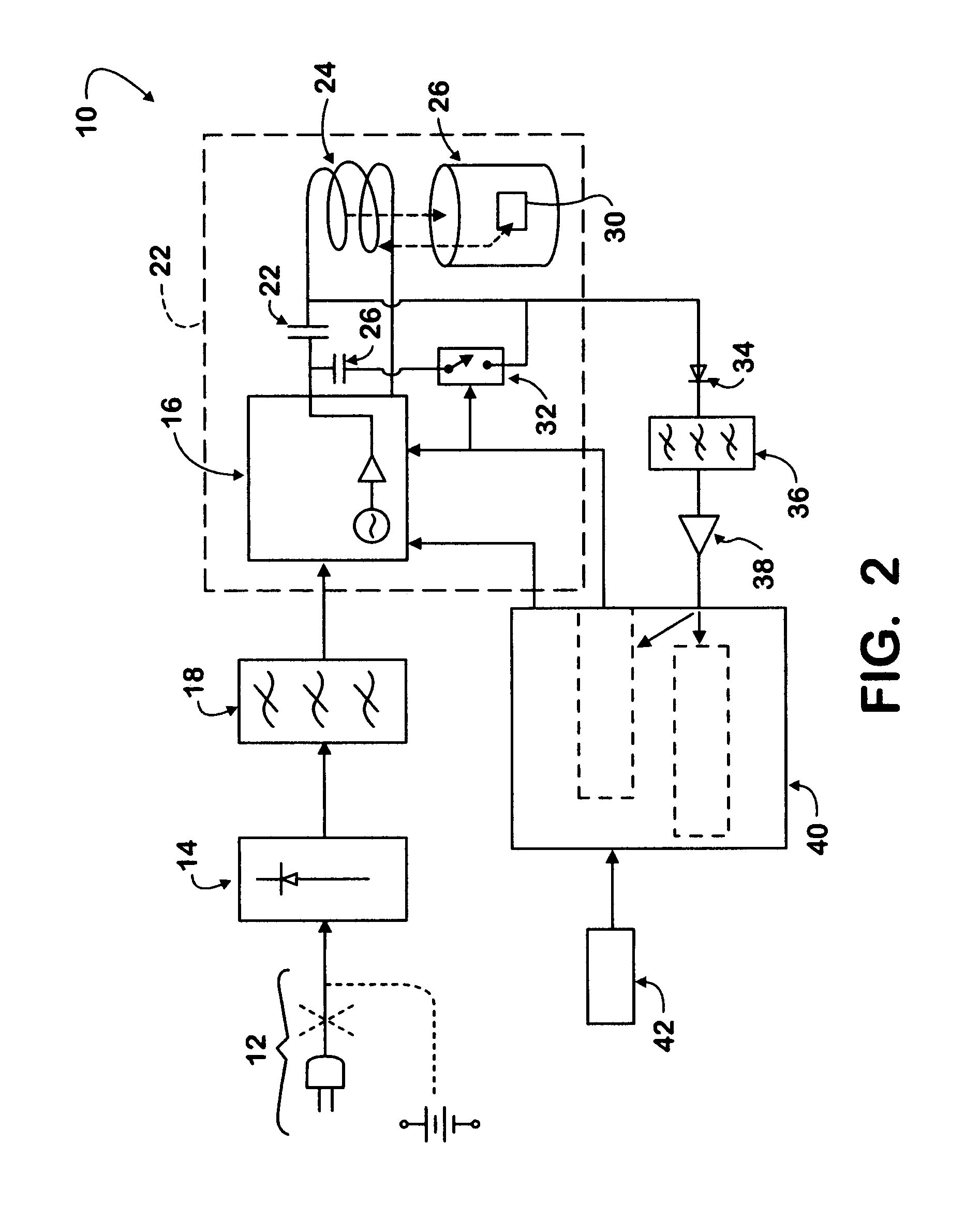

RFID interrogator/induction heating system

InactiveUS7557708B1Low costReduced parts countMemory record carrier reading problemsSubscribers indirect connectionEmbedded systemInduction heating

The system of the present invention deals with an electronically controlled, low cost RFID Interrogator / Induction Heating System which does not require a separate interrogator, rather utilizing components within the system for purposes of interrogation.

Owner:PACHOLOK DAVID +1

Vehicle headlamp

InactiveCN101761848AImprove assembly accuracyReduced parts countVehicle headlampsPoint-like light sourceProjection imageLight beam

A vehicle headlamp has semiconductor-type light sources and lenses. Emission surfaces of the lenses are made of free curved faces controlled to be curved so that: projection images of light emitting chips of the semiconductor-type light sources, which is emitted from the emission surfaces, are not convexly curved in an upward direction from cutoff lines on a screen light distribution of a light distribution pattern for low beam. As a result, the vehicle headlamp can achieve downsizing, weight reduction, and cost reduction. In addition, the precision of assembling an optical element can be improved.

Owner:ICHIKOH IND LTD

Valve actuating mechanism with self-diagnostic function and intelligent valve actuating mechanism

ActiveCN1525094AReduced parts countLow costOperating means/releasing devices for valvesConverting sensor outputWork statusSelf-diagnosis

A valve actuator in accordance with the present invention can be constructed as self-diagnosis valve actuator, which operates a valve to control the opening and closing state of a passage based on the status data from various sensors, for diagnosing deterioration of the device itself, and predicting the replacement time of female screw, seal and the like and estimating operating state so as to realize maintenance on self-diagnosis. This valve actuator may also be constructed as an intelligent valve actuator, which operates the valve to self-control the opening and closing state of a passage based on the status data from various sensors, for diagnosing deterioration of the device itself and predicting the replacement time of female screw, seal and the like and estimating operating state so as to realize operation and maintenance.

Owner:WEST ELECTRIC CO LTD

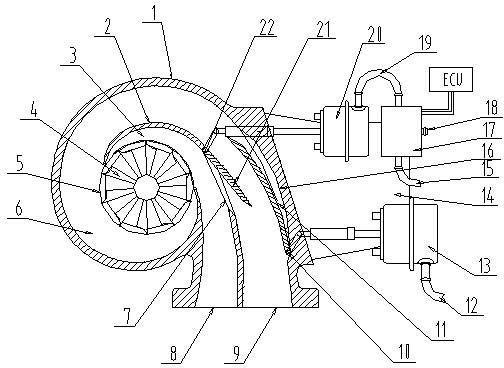

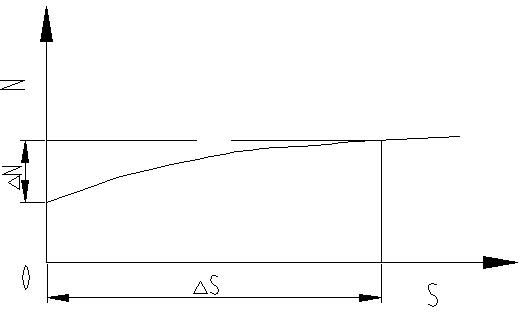

Staged flow-adjustable turbine shell

ActiveCN102536433AAvoid lateral flowReduce flow frictionInternal combustion piston enginesEngine componentsLow speedInlet flow

The invention discloses a staged flow-adjustable turbine shell, which comprises a turbine shell body. A turbine assembly and a waste gas inlet flow channel are mounted in the turbine shell body; an air inlet which is communicated with the waste gas inlet flow channel is arranged on the turbine shell body; an intermediate wall is disposed in the waste gas inlet flow channel and divides the waste gas inlet flow channel into an inner flow channel and an outer flow channel; a first valve device which can close the outer flow channel is disposed in the outer flow channel; and the intermediate wall is provided with a second valve device which can realize connection or disconnection of the inner flow channel and the outer flow channel. Waste gas energy is utilized sufficiently, rotation speed of a turbine rotor is increased, air inlet quantity of an engine in low speed work conditions is improved, so that the engine can apply more work, low speed torsion of the engine is increased, the low speed torque of the engine well matches with the low speed work conditions of the engine, and dynamic property and transient responsibility of the engine in low speed work conditions are improved.

Owner:康跃科技(山东)有限公司

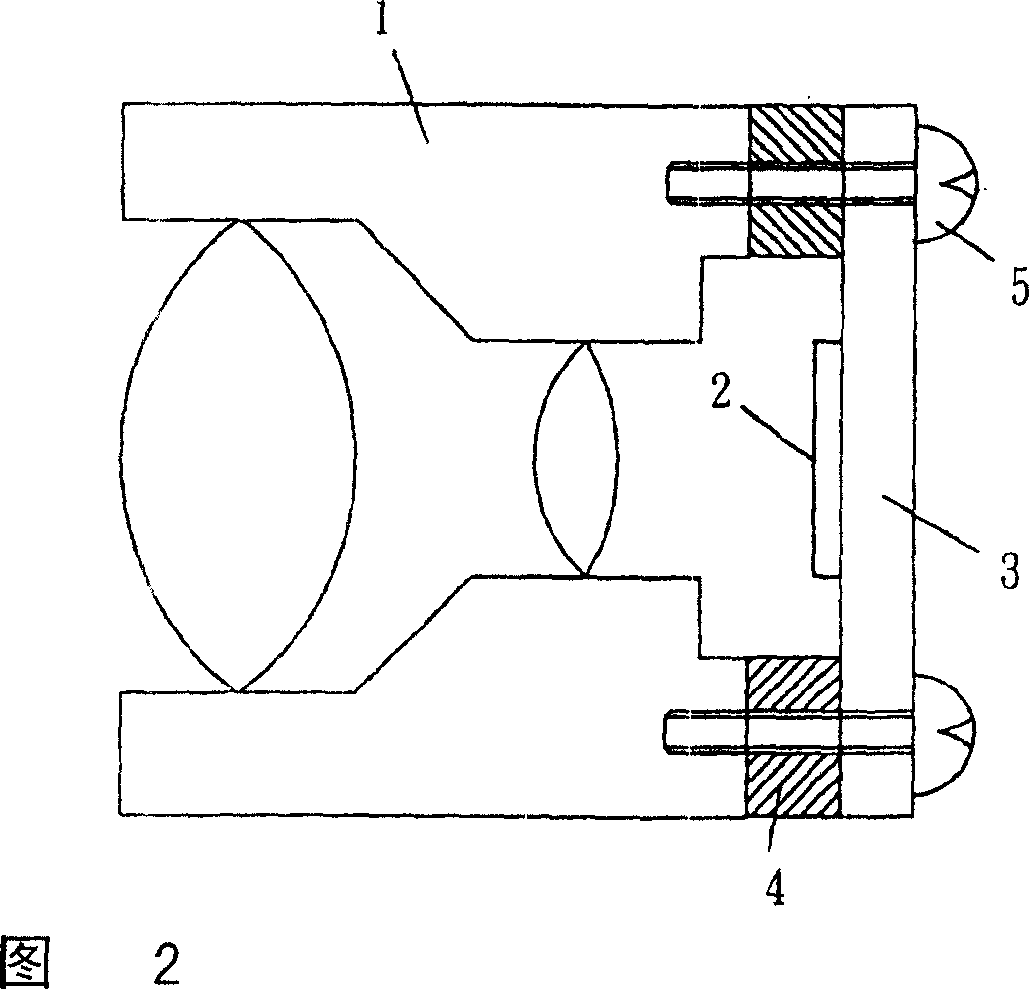

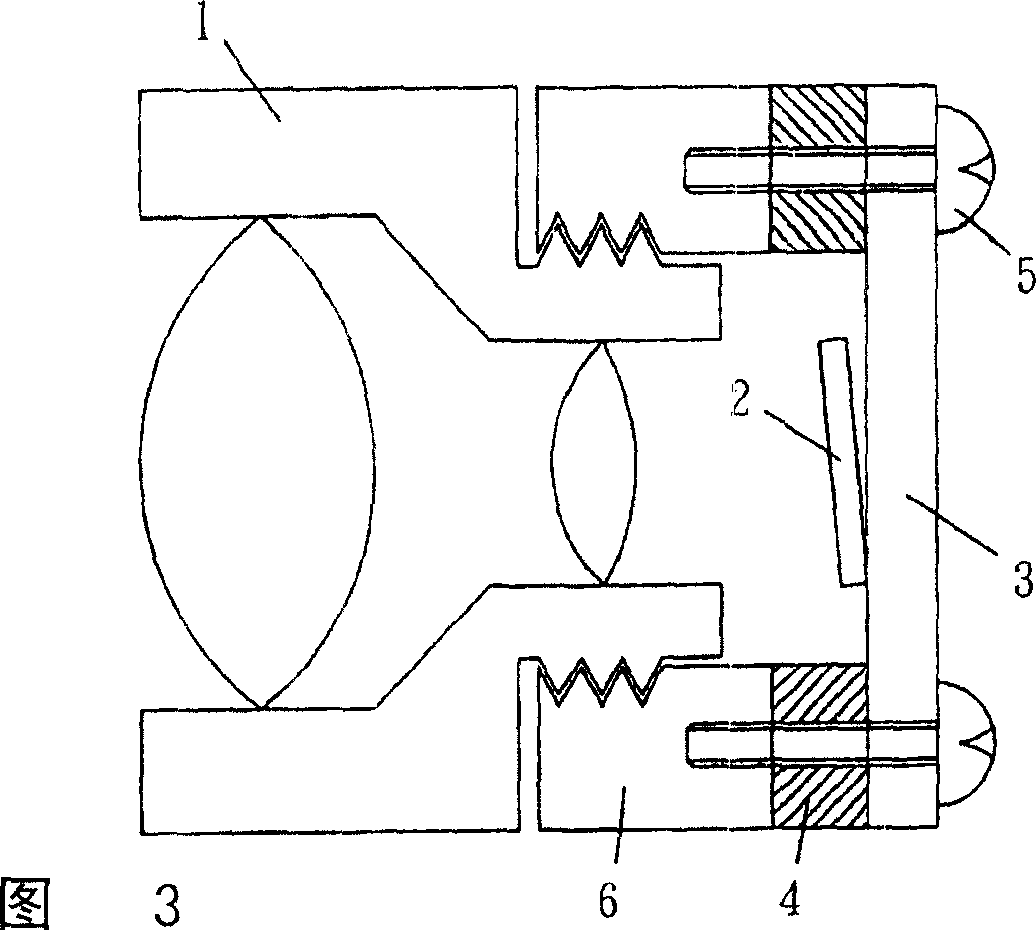

Lens installation mechanism, and installation method, as well as method for adjusting inclination and focusing plane of sensor

A method for erecting lens cone includes welding or binding transducer on base plate, sandwiching a rubber ring between lens cone and base plate and using screw to fasten them, setting contact surface between lens cone and rubber and contact surface between rubber and base plate to be state of non-transparently seal-jointed always, enabling to regulate verticality of light axle on transducer to light axle on lens cone by adjusting various screws.

Owner:SONY TAIWAN

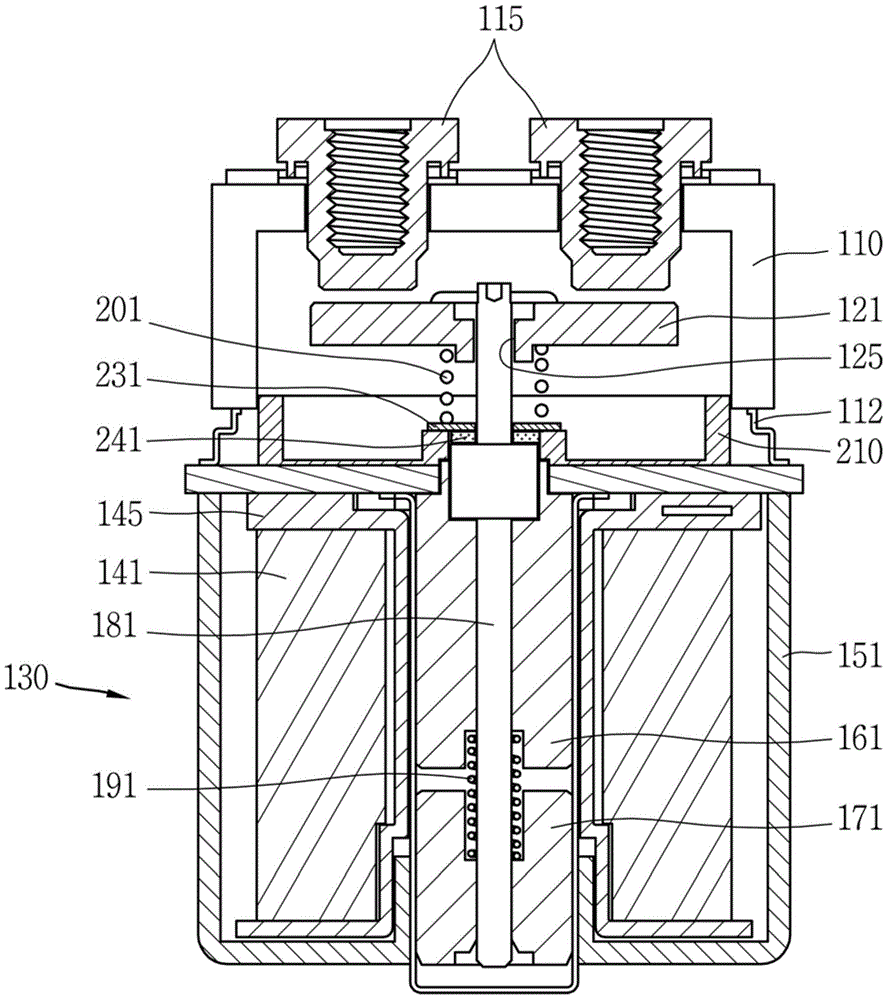

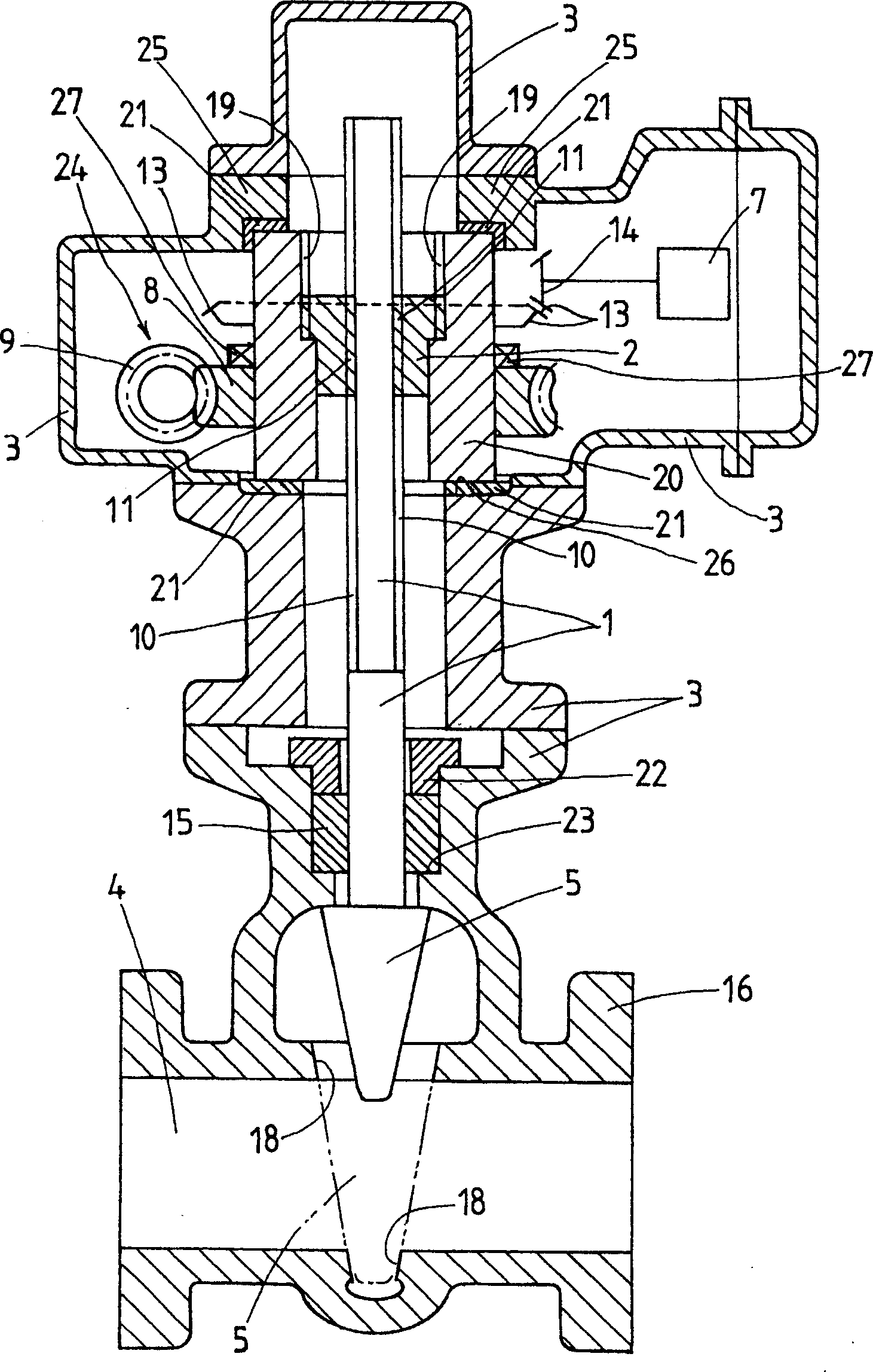

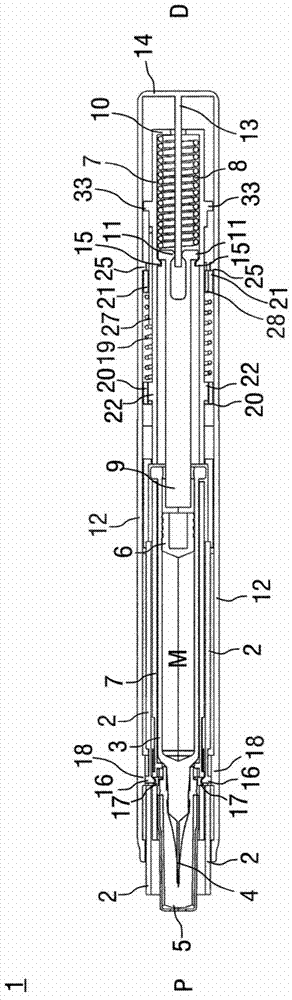

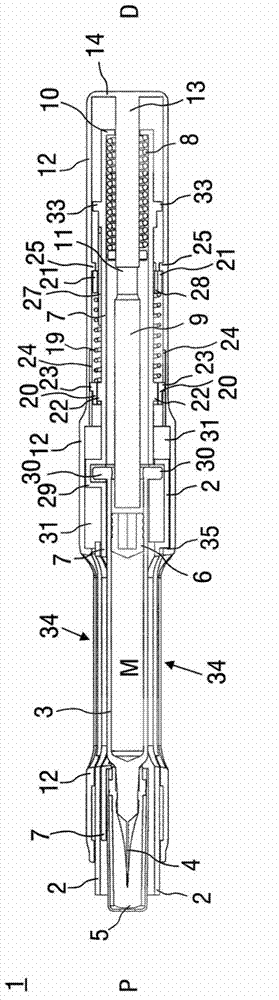

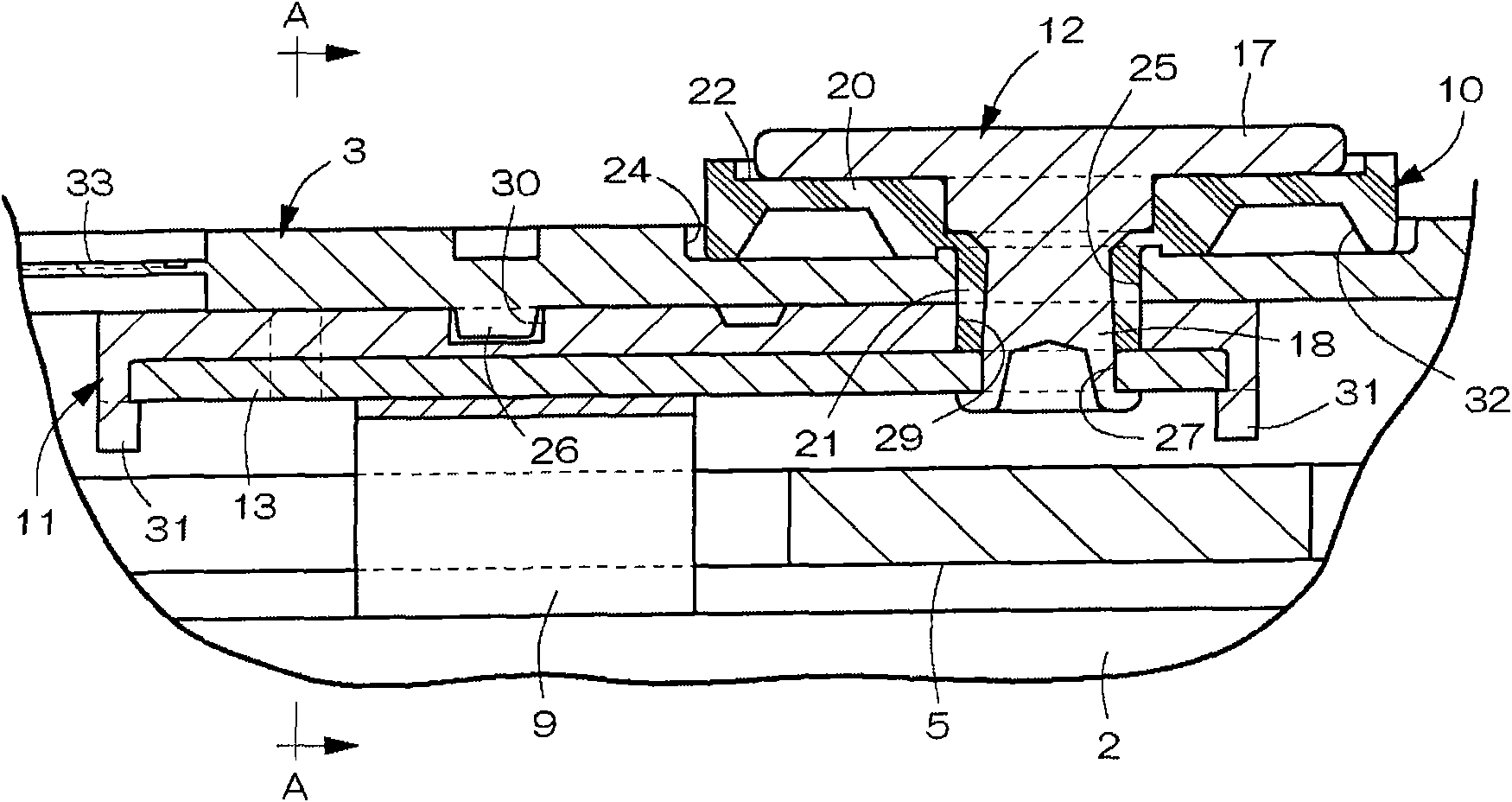

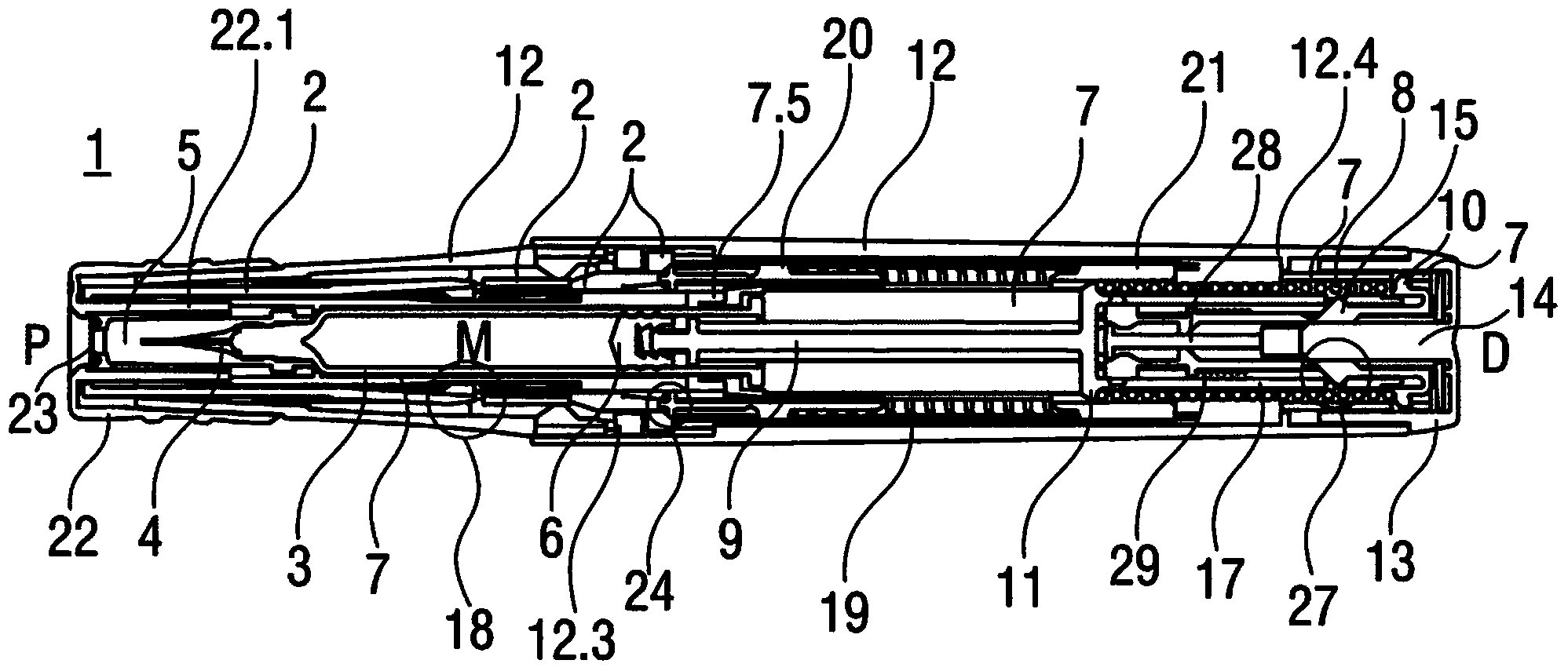

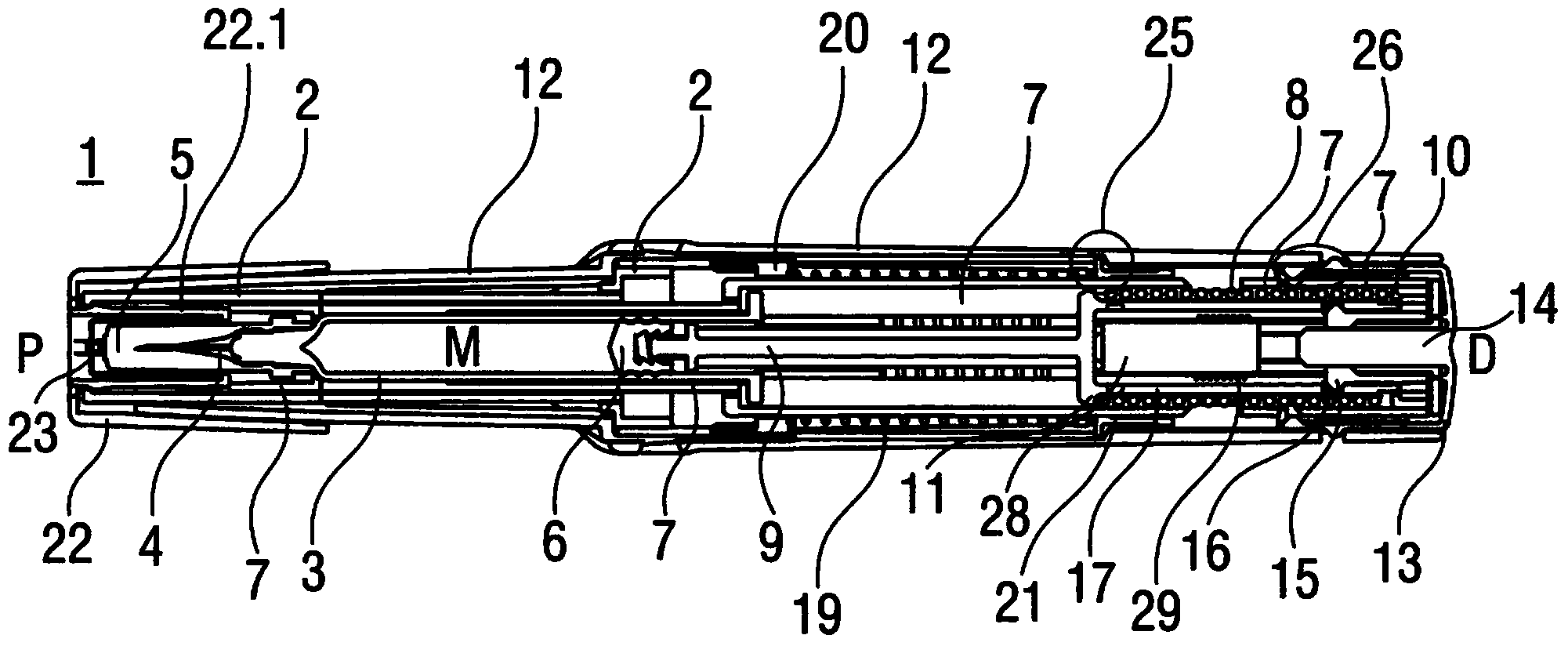

Auto-injector

ActiveCN103249443AReduced parts countReduce manufacturing costAutomatic syringesIntravenous devicesNeedle insertionPlunger

The invention refers to an auto-injector (1) and to a method for operating it, the auto-injector comprising: a tubular chassis (2), a carrier subassembly comprising a tubular carrier (7) slidably arranged in the chassis (2), the carrier (7) containing a syringe (3) with a hollow injection needle (4), a drive spring (8) and a plunger (9) for forwarding load of the drive spring (8) to a stopper (6) of the syringe (3), a wrap-over trigger sleeve (12) arranged over the distal end (D) of the auto- injector (1), the trigger sleeve (12) extending at least almost over the whole length of the auto-injector (1), a control spring (19) arranged around the carrier (7), first interlock means (20, 22, 23, 24) for coupling a proximal end of the control spring (19) to either the carrier (7) for advancing it for needle insertion or to the chassis (2) for needle retraction, second interlock means (11, 13, 15) arranged for releasing the drive spring (8) for injection, third interlock means (16, 17, 18) arranged for coupling the chassis (2) to the carrier (7) for joint axial translation relative to the trigger sleeve (12), fourth interlock means (21, 25, 26, 28) arranged for coupling a distal end of the control spring (19) to either the carrier (7) for needle retraction or to the trigger sleeve (12) otherwise.

Owner:SANOFI AVENTIS DEUT GMBH

Method for manufacturing sealed cell

ActiveCN101562238AShorten the timeAvoid short circuit conditionsCell component detailsEngineeringCathode

The present invention provides a method for manufacturing a sealed cell, capable of reducing labor and time for managing members of an insulated member and a down-lead body, preventing the down-lead body from contacting with an inner surface of a cell tank, and thinning the cell. An insertion throughhole (27) of the down-lead body (13) is cooperated in a matching pin (39) of a mold (35), the down-lead body is embedded between a pair of holding pins (41, 41) of the mold, and the down-lead body is mounted in an inner space of the mold. Then, a melting resin is injected into the inner space of the mold, such that the insulated member (11) covers the front and the back, the left and the right and the top of the down-lead body, such that the insulated member is integrated and formed on the down-lead body. Moreover, a negative terminal (12) is inserted in the throughhole (25) crossing a cover (3) in a mode of the intervention of the sealing member (10), the lower end part of the negative terminal is mounted with the down-lead body together with the insulated member, and the lower side of the down-lead body is connected with a cathode collector down-lead (9) extending from an electrode body (2).

Owner:MAXELL HLDG LTD

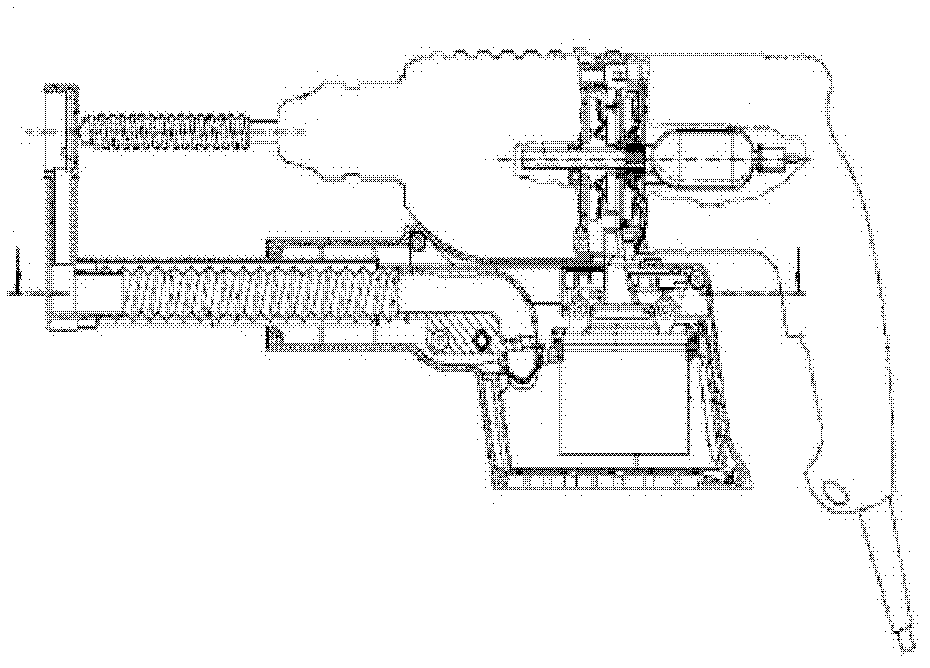

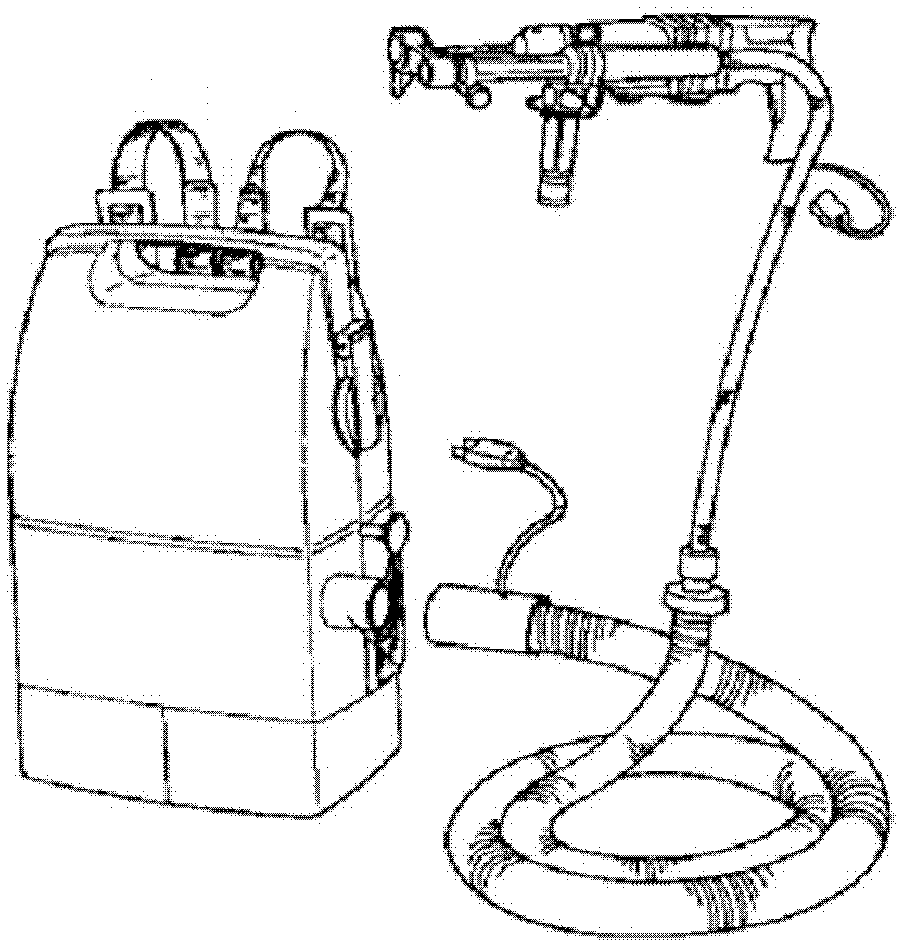

Dust collector for electric tool and electric tool with dust collector

InactiveCN103182702AReduced parts countSimple structurePortable percussive toolsPower toolEngineering

The invention discloses a dust collector for an electric tool and an electric tool with the dust collector. The electric tool comprises a processing head (5). The dust collector comprises a container (3) for collecting dust which is generated when the electric tool processes workpieces, wherein the container comprises an opening part (30), a connecting part (31) for connecting with the electric tool and a side part (32) for connecting with the opening part with the connecting part, wherein the opening part is provided with a dust collecting port (35) for propping against a workpiece surface to be processed so as to collect the generated dust in the container; the connecting part is provided with a hole (36) for the processing head to enter the container; and the dust collector further comprises a dust bag (2), wherein a discharge port (37) for connecting with the dust bag is formed in the container, and dust can enter the dust bag through the discharge port. The dust collector is provided a small quantity of parts, is simple in structure and convenient to operate, can be used as a separate accessory to be connected with various electric tools, and has a quite wide application scope.

Owner:BOSCH POWER TOOLS CHINA

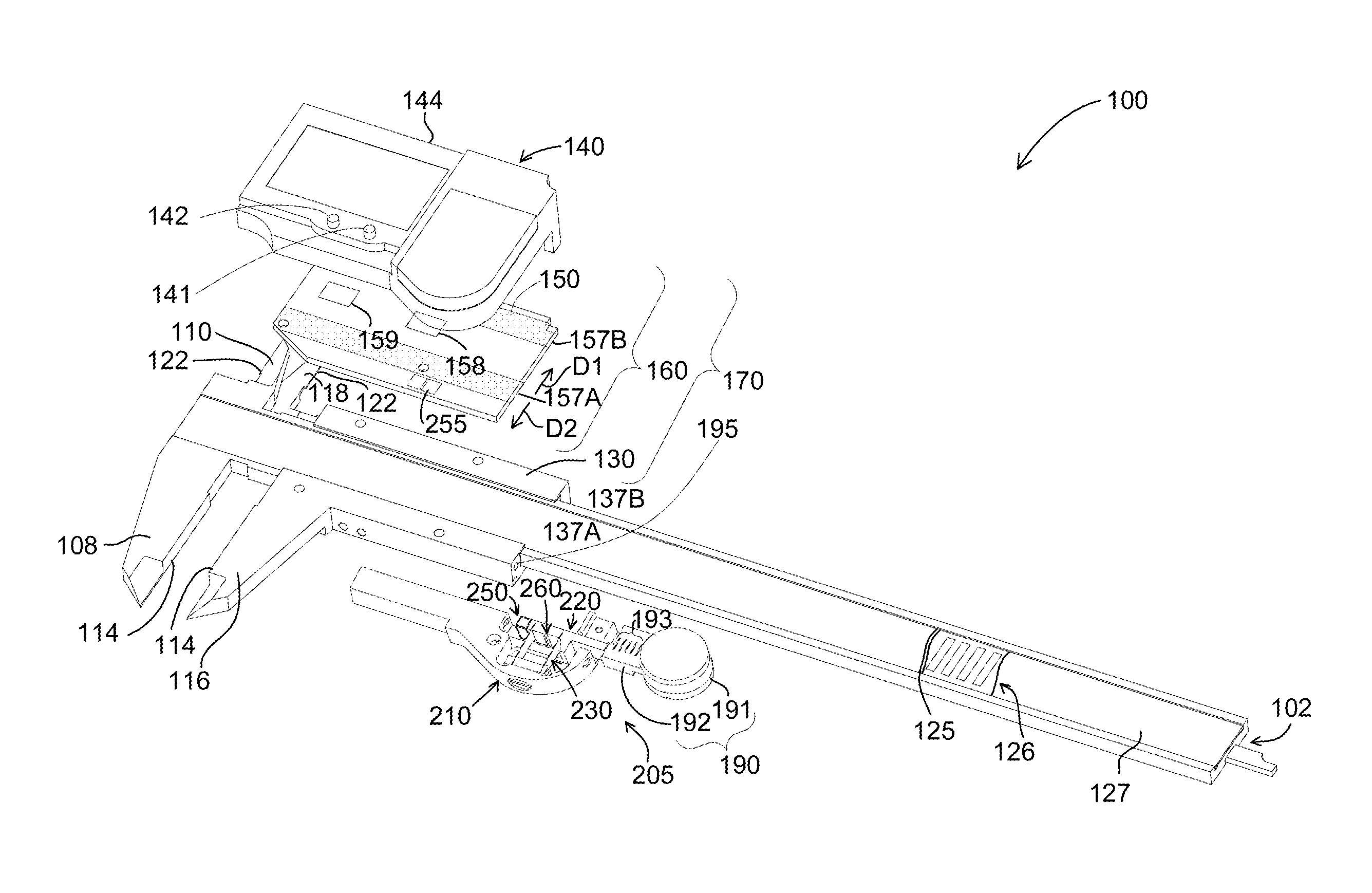

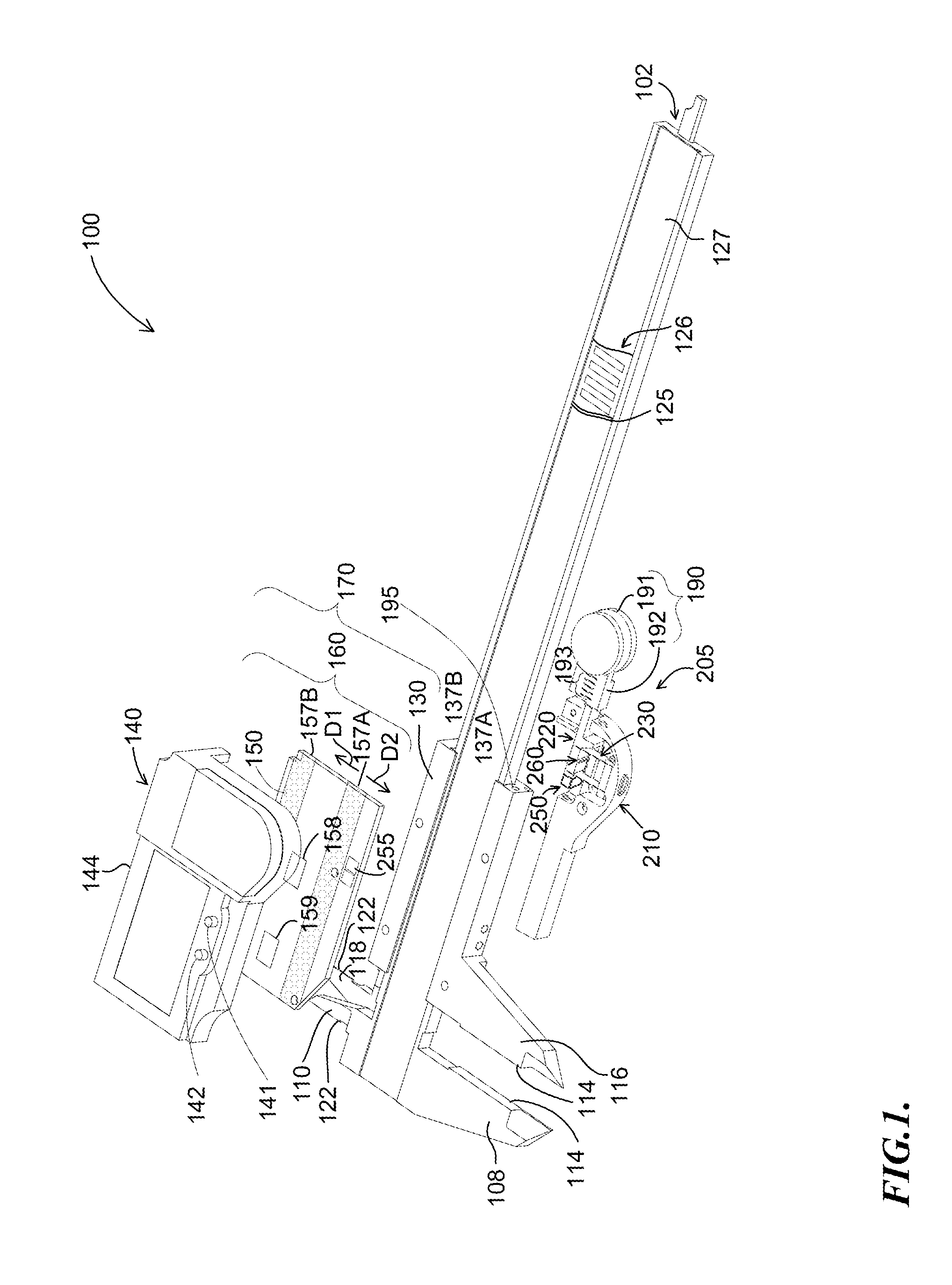

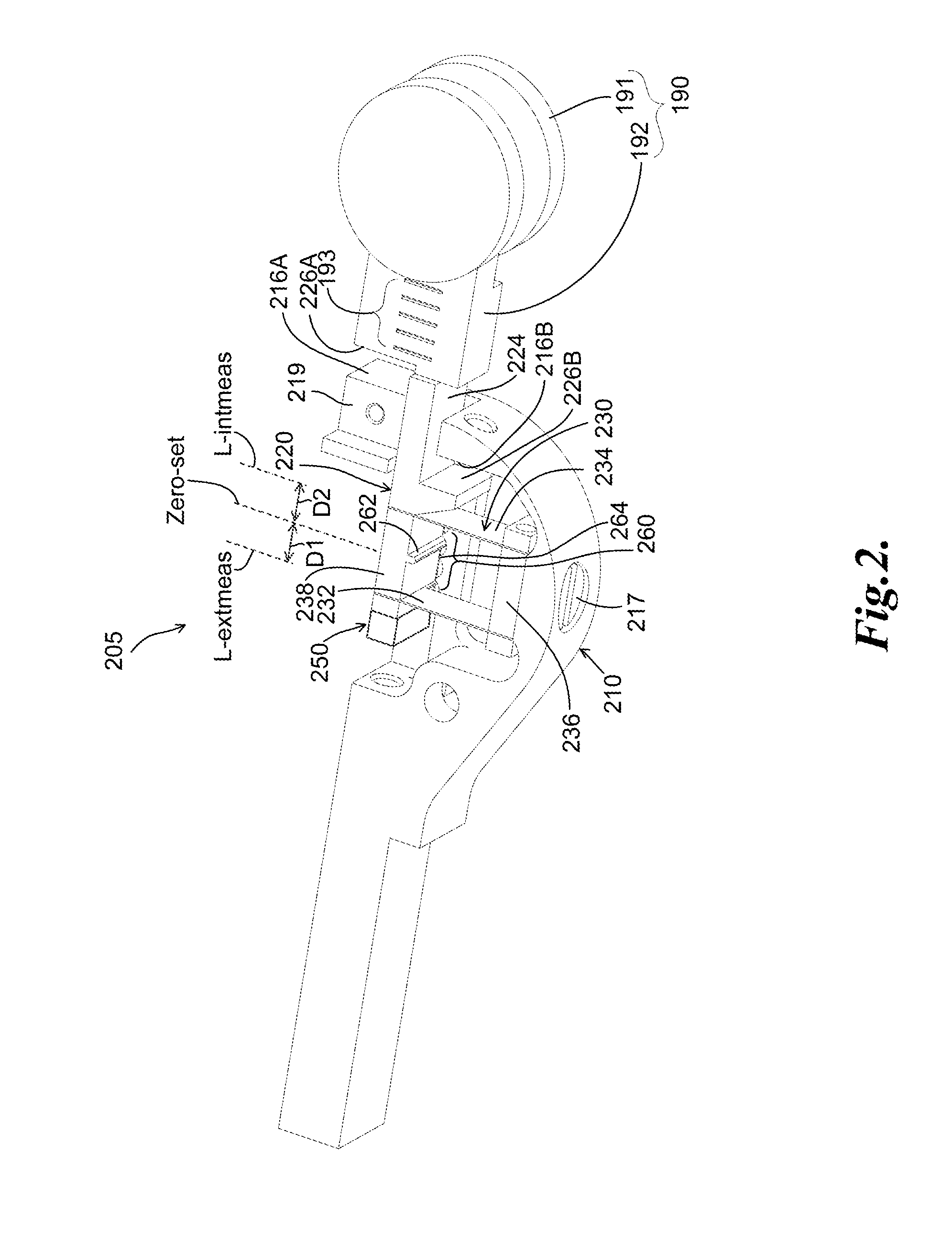

Flexible mount for coupling force actuator to caliper jaw

ActiveUS20150276366A1Reduced parts countLower assembly costsWalking sticksMicrometersCalipersActuator

A flexible mount is provided for coupling a force actuator to a caliper jaw. The flexible mount includes a first mounting portion for being coupled to the caliper jaw, a second mounting portion for being coupled to the force actuator, and a flexible element (e.g., a parallel flexure) coupled between the first and second mounting portions. When a force is applied to the force actuator (e.g., by a user pushing on a thumbwheel) along the measuring axis direction, the flexible element flexes to generate a measuring force that is applied to the caliper jaw. The use of the flexible mount results in more control and a better feel for a user when attempting to exert control to provide a desired amount of force during a measuring process. The flexible mount may also utilize a fastening configuration that is compatible with existing mounting features on existing caliper jaws.

Owner:MITUTOYO CORP

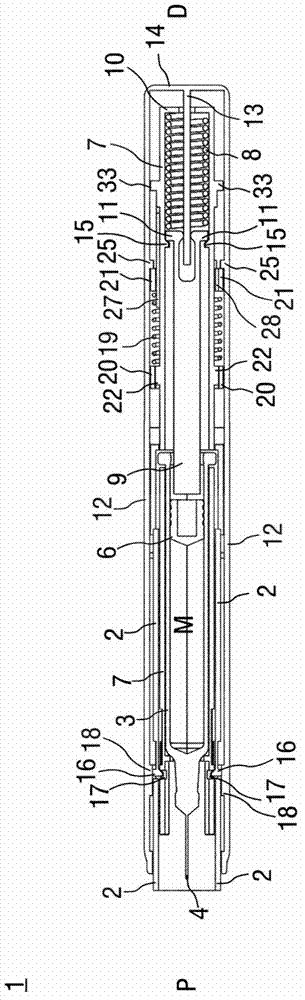

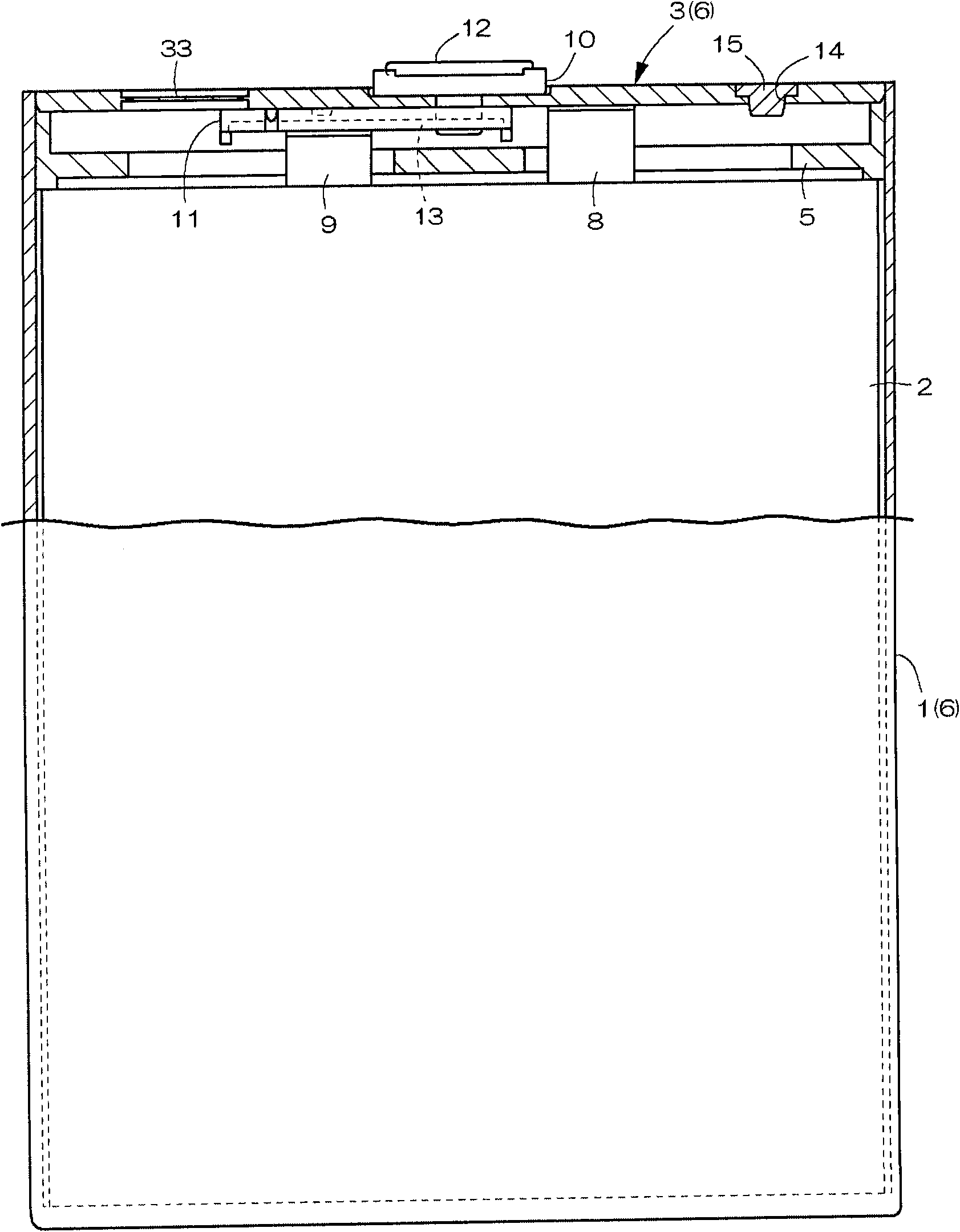

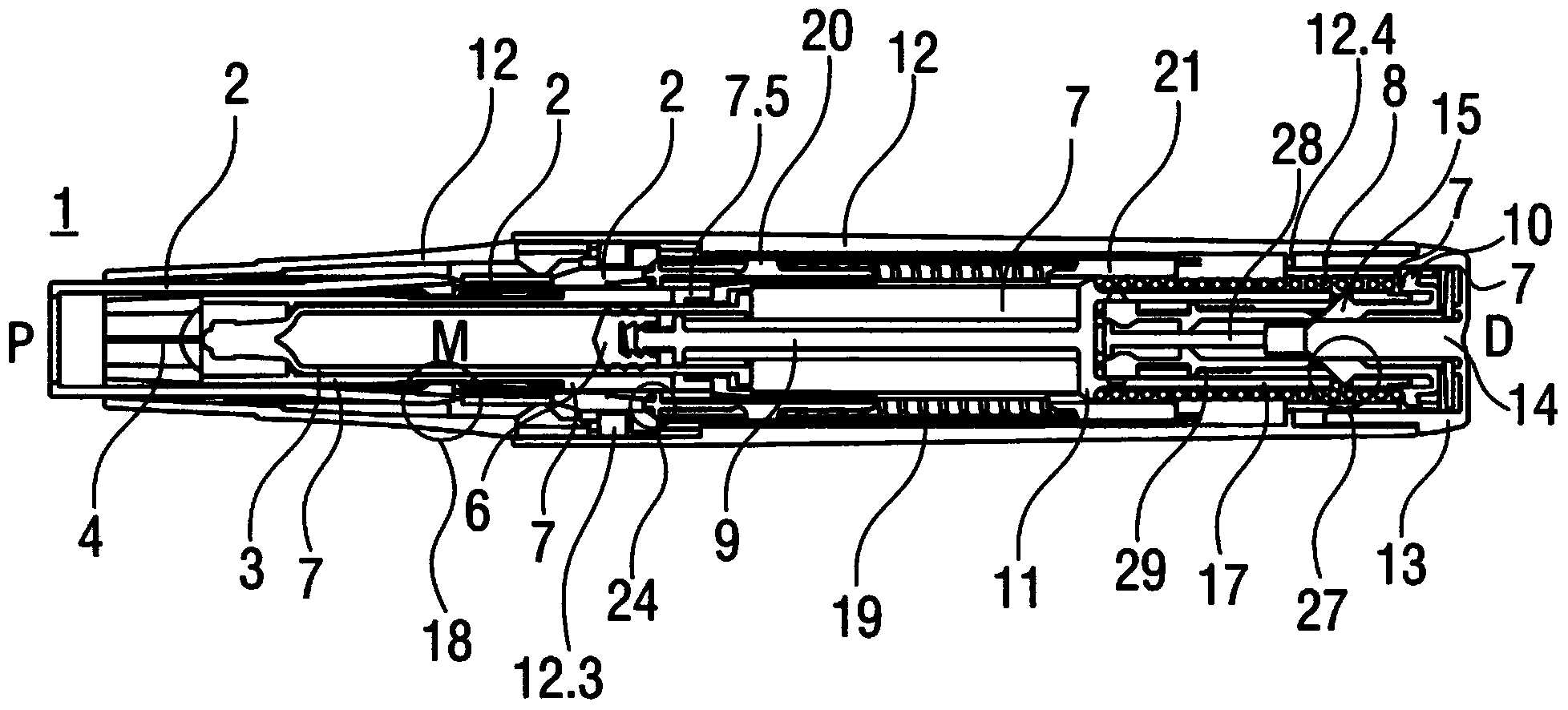

Auto-injector

ActiveCN103492002AImprove reliabilityNo damage insertionAutomatic syringesMedical devicesInsertion depthEngineering

The invention refers to an auto-injector (1) for administering a dose of a liquid medicament (M), comprising a tubular chassis (2) telescopable in a tubular case (12); a carrier subassembly comprising a tubular carrier (7) slidably arranged relative to the chassis (2) inside the case (12), the carrier (7) adapted to contain a syringe (3) with a hollow injection needle (4), a drive spring (8) and a plunger (9) for forwarding load of the drive spring (8) to a stopper (6) of the syringe (3), wherein the syringe (3) is lockable for joint axial translation with the carrier (7); a control spring (19) arranged around the carrier (7) for translating the carrier (7) in a proximal direction (P) for insertion of the needle (4) through the chassis (2) into an injection site, wherein the control spring (19) is arranged to bias the case (12) against the chassis (2) in a distal direction (D), so as to extend the chassis (2) out of a proximal end (P) of the case (12), wherein an insertion depth of the needle (4) is defined by the carrier (7) abutting the chassis (2) in a predefined position, wherein the case (12) is arranged to release or allow release of the control spring (19) for needle insertion on translation of the case (12) in the proximal direction (P) relative to the chassis (2) against the bias into an advanced position.

Owner:SANOFI AVENTIS DEUT GMBH

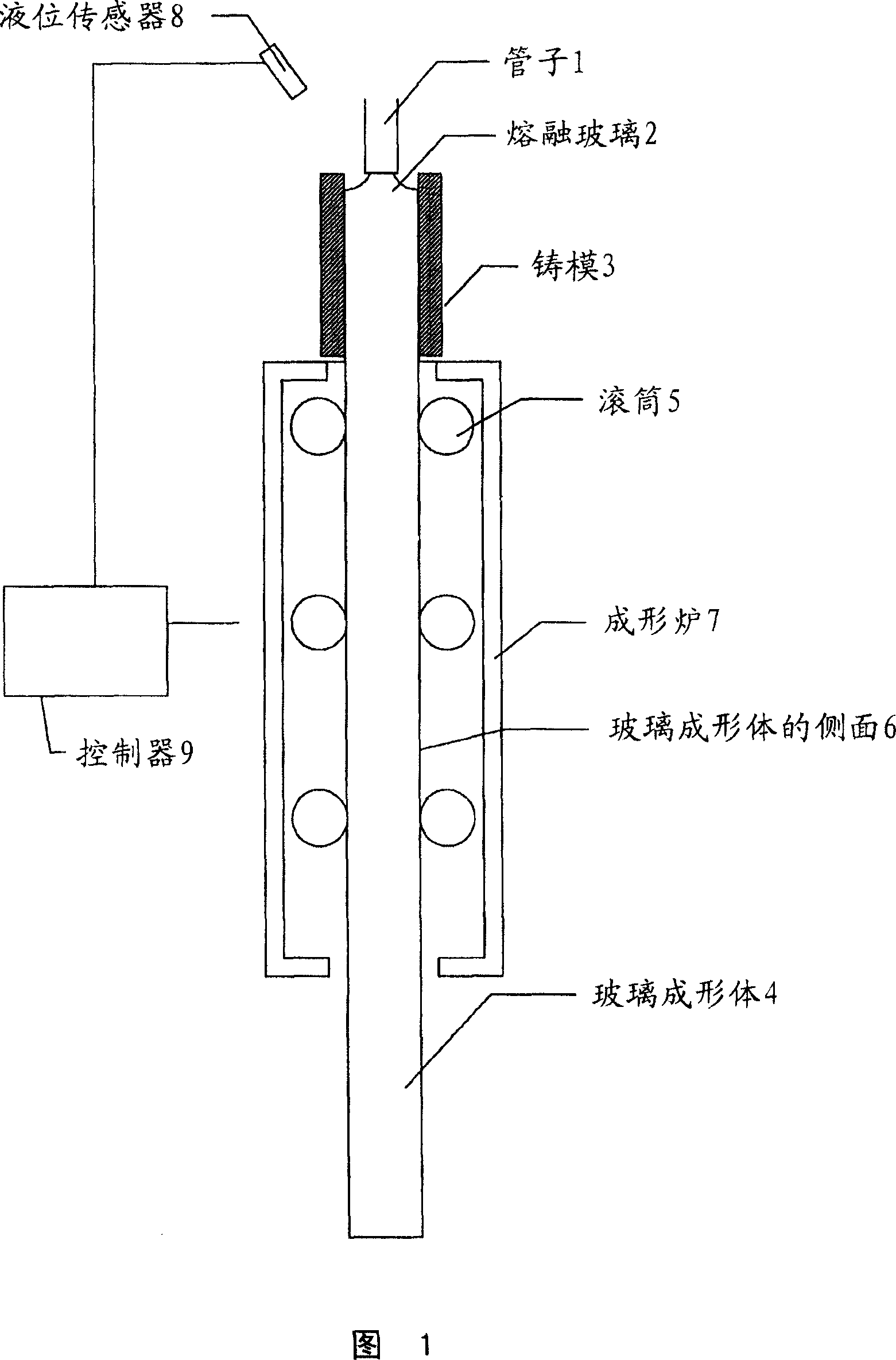

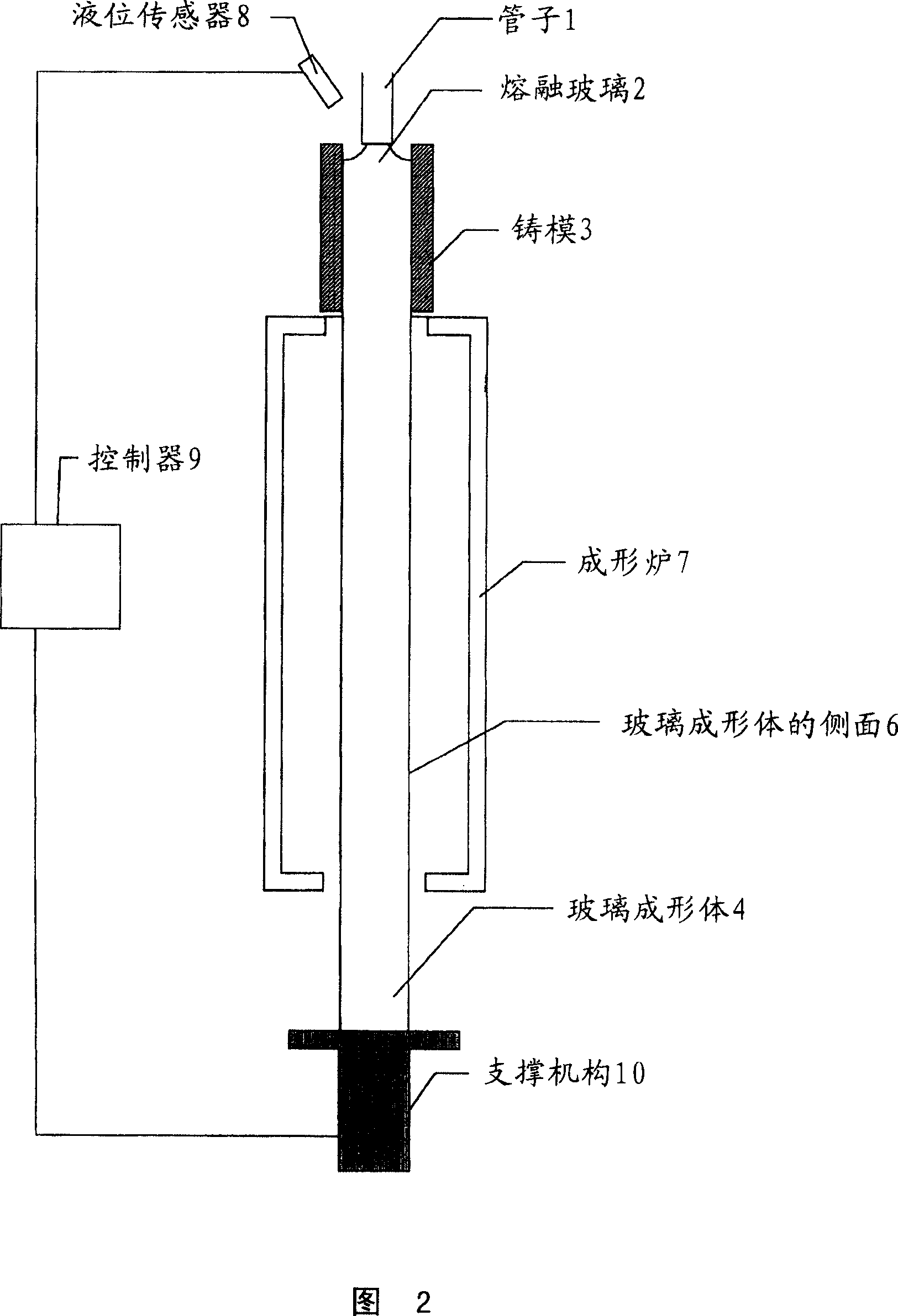

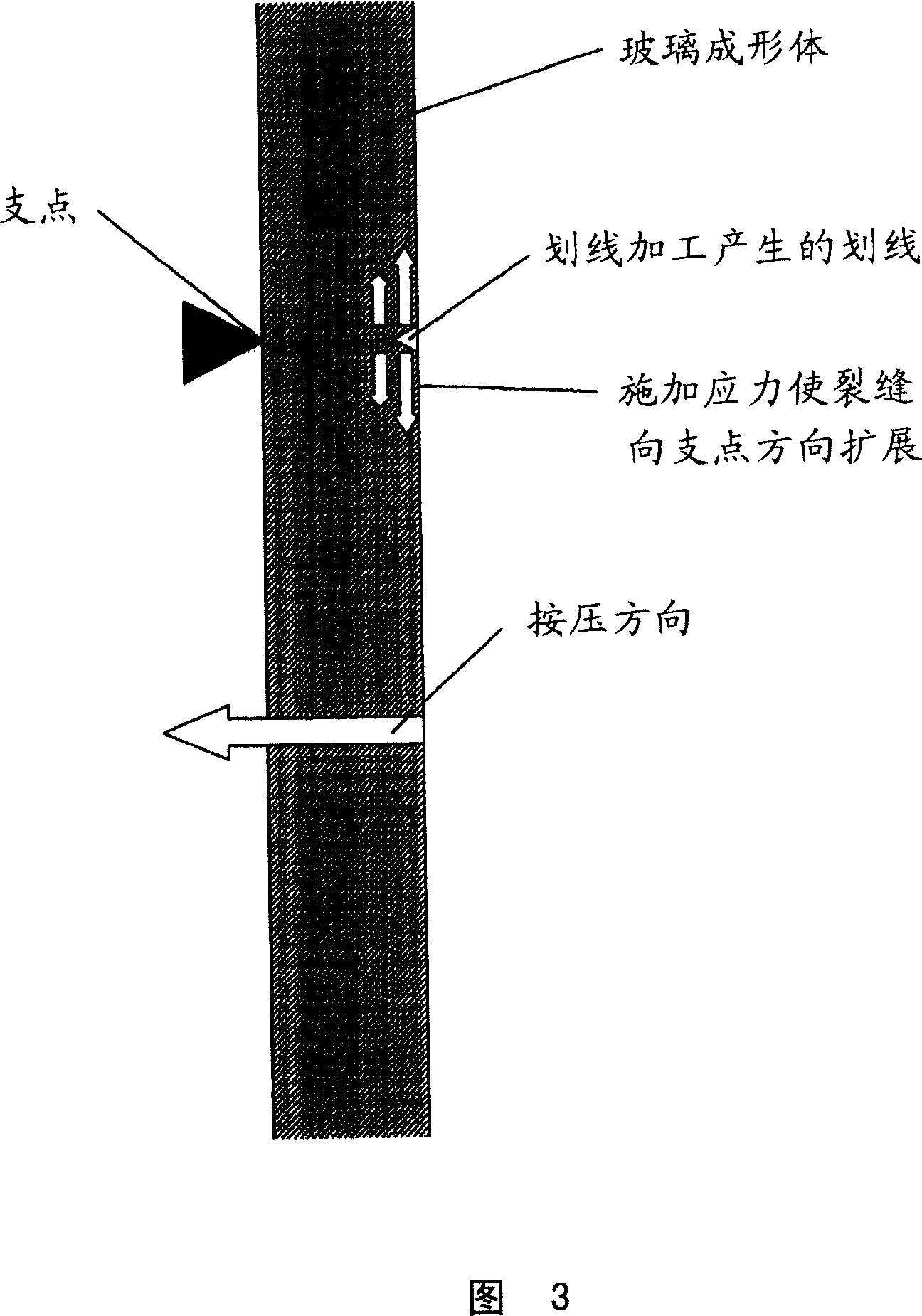

Optical glass, glass cup for die pressing forming, glass forming body, optical element and manufacture method thereof

ActiveCN1935716AHigh refractive indexLess coloringGlass pressing apparatusRefractive indexTransmittance

There is provided a high refractive optical glass capable of performing color balance correction, suitable for the miniaturization and high performance of optical instruments. The optical glass provided comprises borate system containing TiO2 as glass component. After heat treatment or controlling the species and quantity of additives, the transmittance characteristics of said optical glass satisfies the relation formula of (1) (lambada702-3009 multiplied by nd+2842 ellipsis(1)) when the wavelength lambada with 70% exterior transmittance and 10.0 mm thickness is set to 70 nm.

Owner:HOYA CORP

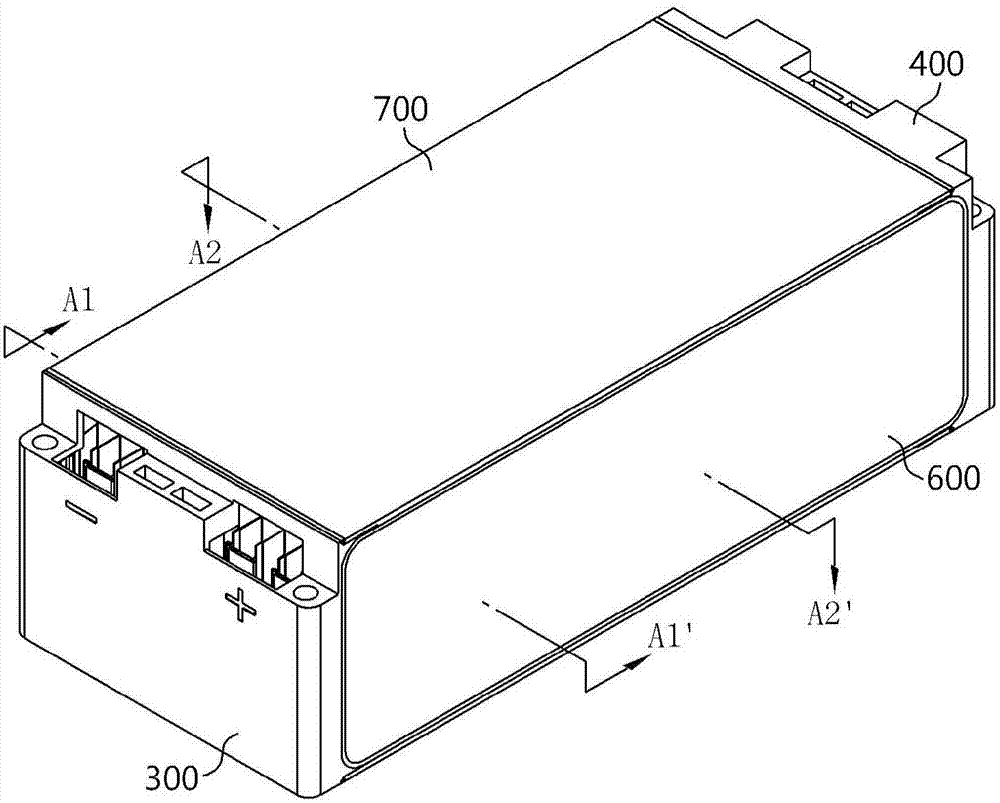

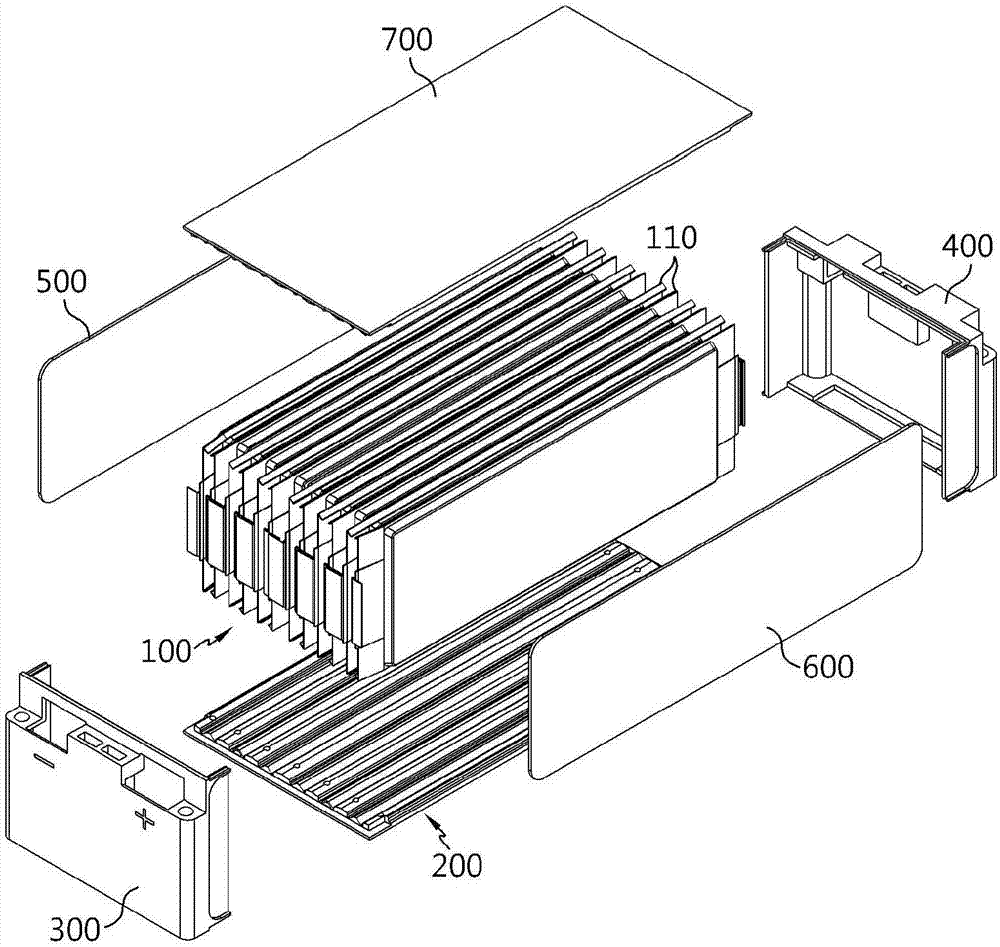

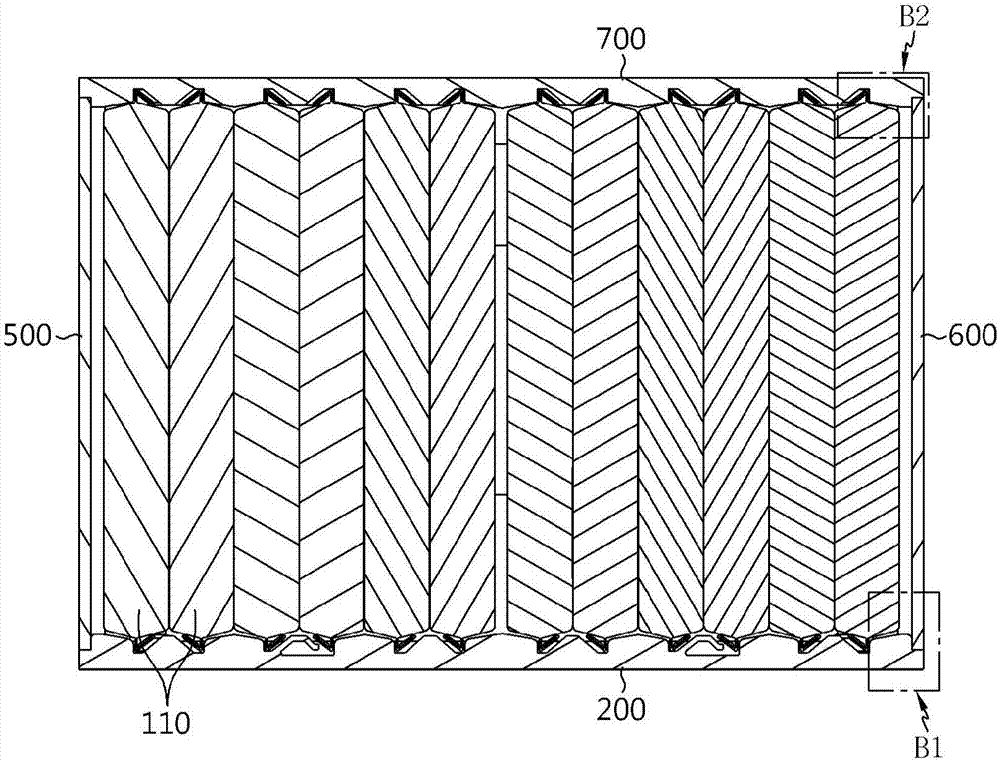

Battery module

ActiveCN107534196AImprove sealingGuaranteed tightnessSecondary cellsCell lids/coversEngineeringBattery cell

The present invention discloses a battery module having reliably secured strength and hardness, excellent sealability and assemblability, and improved productivity. The battery module according to thepresent invention comprises: a cell assembly; a cooling plate; a front cover having the bottom portion thereof welded to the cooling plate; a rear cover having the bottom portion thereof welded to the cooling plate; a left side cover having the bottom end portion thereof welded to the cooling plate and the rear end portion thereof welded to the rear cover; a right side cover having the bottom endportion thereof welded to the cooling plate, the front end portion thereof welded to the front cover, and the rear end portion thereof welded to the rear cover; and an upper plate having the left side end portion thereof welded to the left side cover, and the right side end portion thereof welded to the right side cover.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com