Fluidtight connector and connector assembly

A technology of connector components and connectors, which is applied to the parts, connections, electrical components, etc. of the connection device, can solve the problem of increasing the number of parts and achieve the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

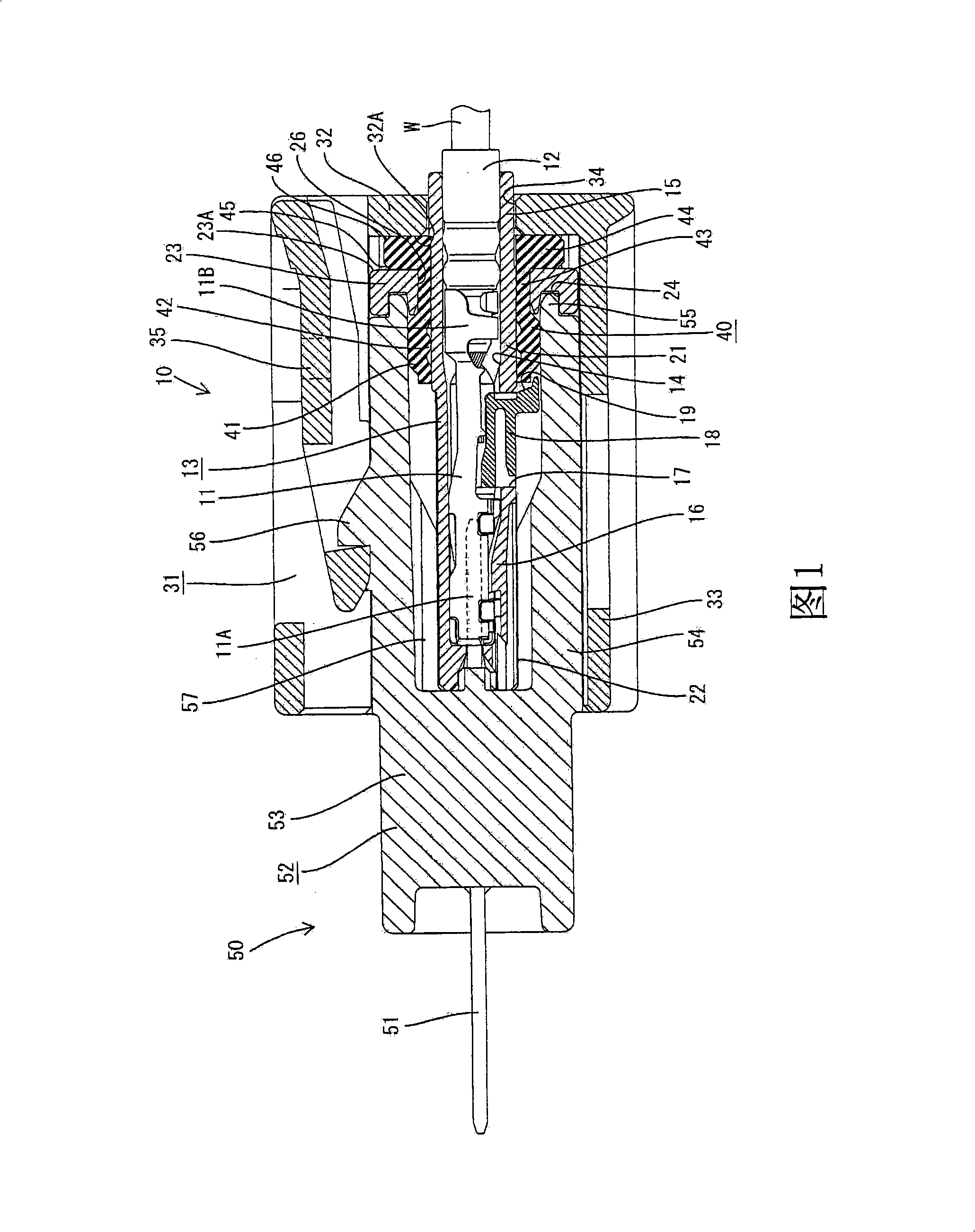

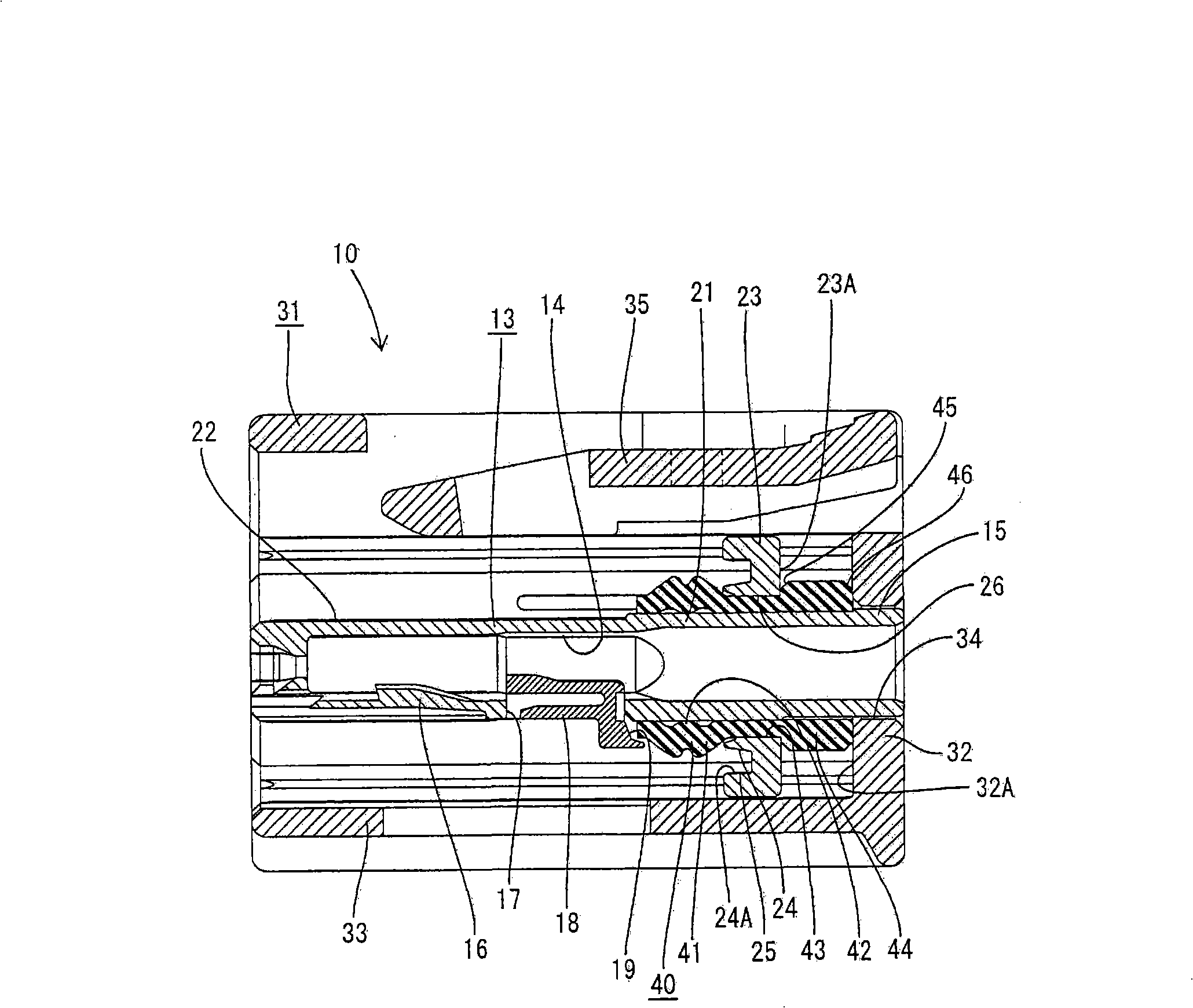

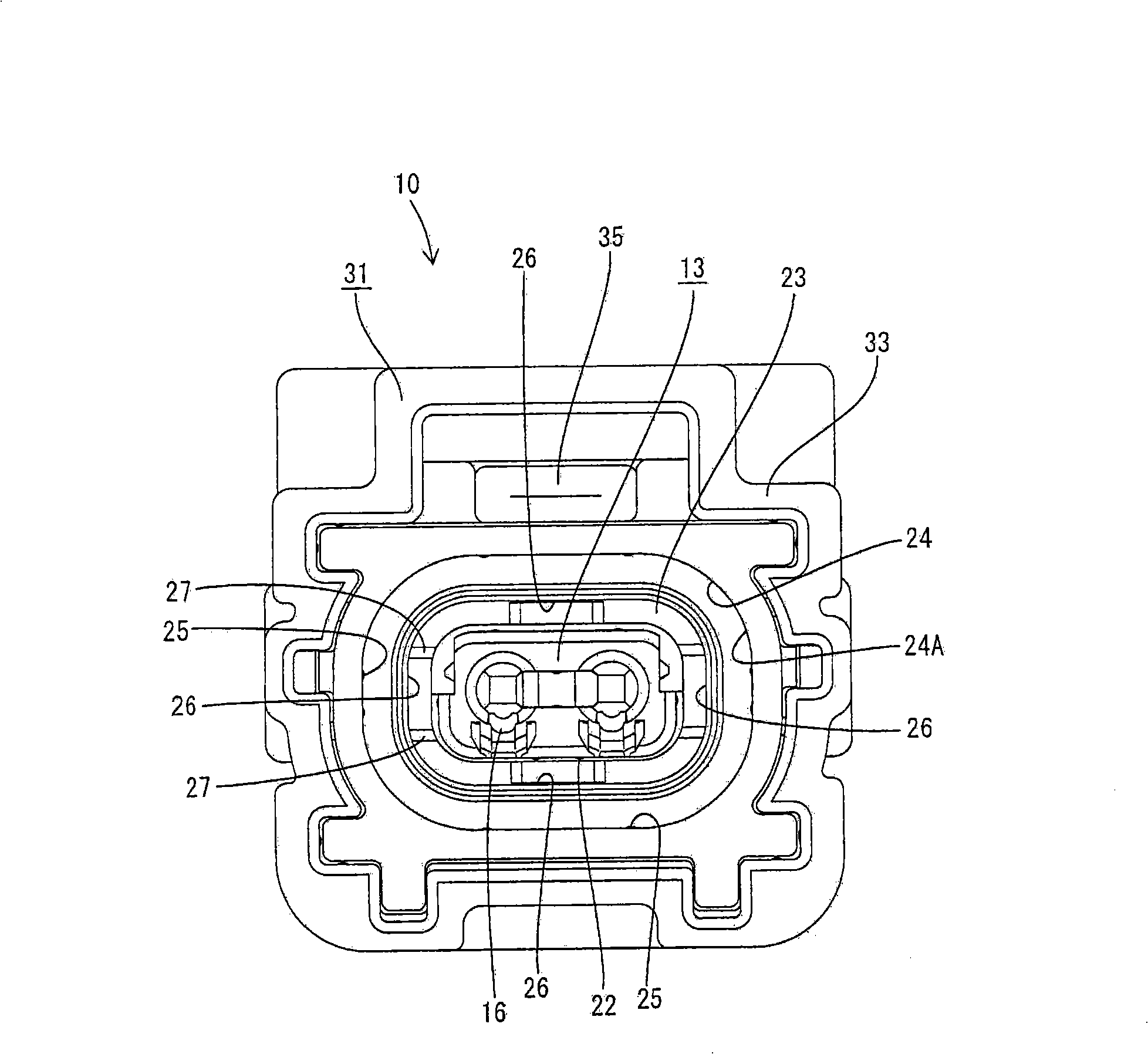

[0118] A preferred embodiment of the present invention will be described with reference to FIGS. 1 to 6 .

[0119] Preferably, the watertight connector according to this embodiment is a female connector (hereinafter referred to as "female connector 10") capable of being connected to a male connector 50 (corresponding to a preferred mating connector).

[0120] In the following, the side to be connected of the two connectors is referred to as the front side in the component parts and is marked with reference to the relative vertical direction of FIG. 1 .

[0121] The male connector 50 is provided with one or more, preferably two substantially elongated or longer male terminals 51 (corresponding to preferred mating terminals) in the forward and rearward directions, and is used to hold the one or more male terminals. Male housing 52 of terminal 51 . The male housing 52 is made of, for example, synthetic resin, and includes: a terminal holding portion 53 for holding the male termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com