Optical glass, glass cup for die pressing forming, glass forming body, optical element and manufacture method thereof

An optical glass, glass technology, applied in glass pressing, glass manufacturing equipment, glass molding, etc., can solve problems such as difficult color balance correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0315] In this example, the refractive index nd is 2.08313, the Abbe number (vd) is 22.23, the liquidus temperature is 1270°C, the viscosity at the liquidus temperature is 0.824dPa·s, and the glass transition temperature is formed by the method shown below. It is 701℃, the density at room temperature is 4.780, and the dynamic viscosity is 1.724×10 -5 m 2 / s, and if it is expressed in mass percentage, it contains 3.59% SiO 2 , 6.24% B 2 o 3 , 32.44% La 2 o 3 , 26.73% TiO 2 , 11.12% Nb 2 o 5 , 6.14% ZrO 2 , 13.74% BaO and 0.00% Sb 2 o 3 A round rod-shaped glass forming body formed of optical glass.

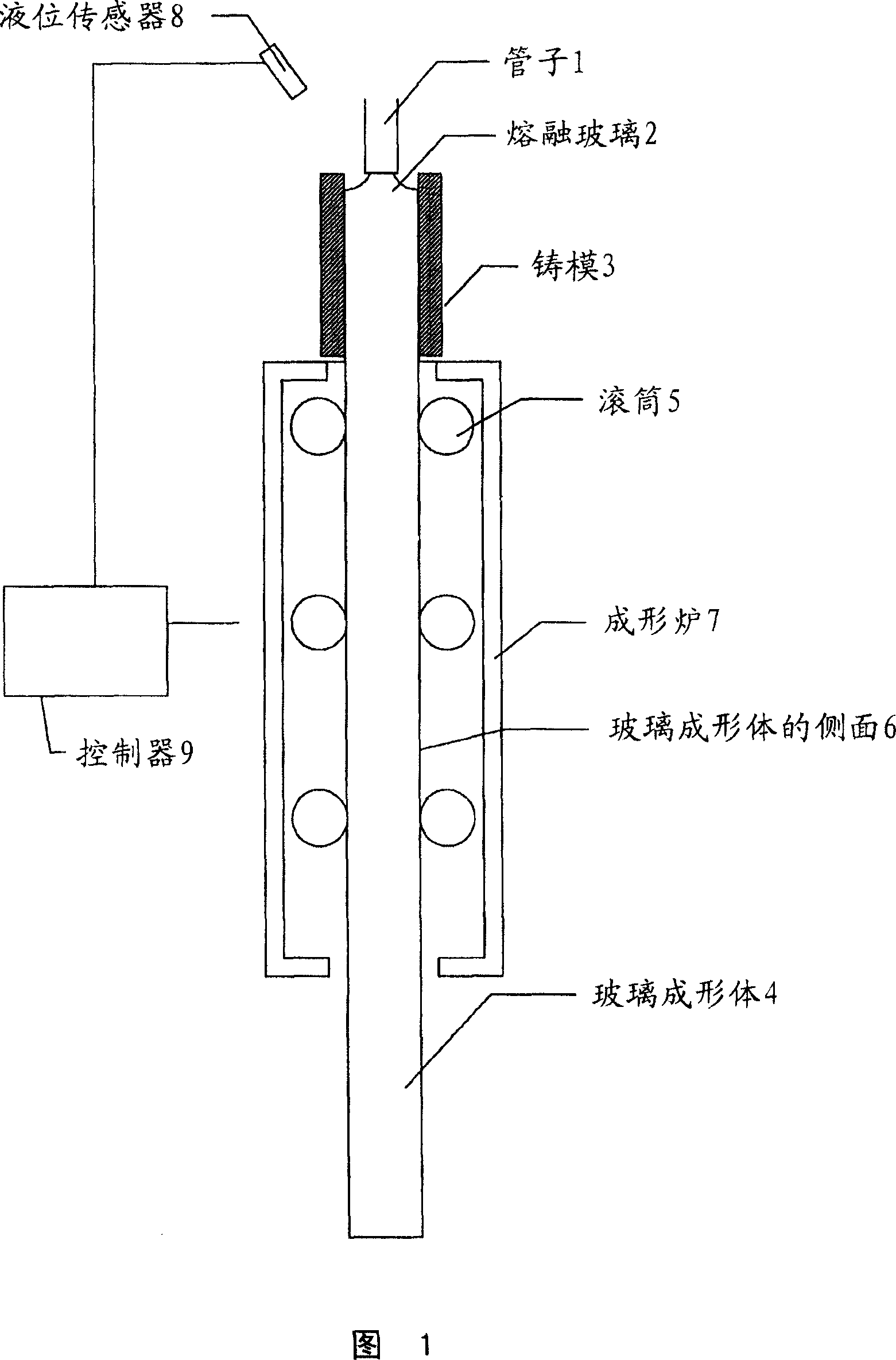

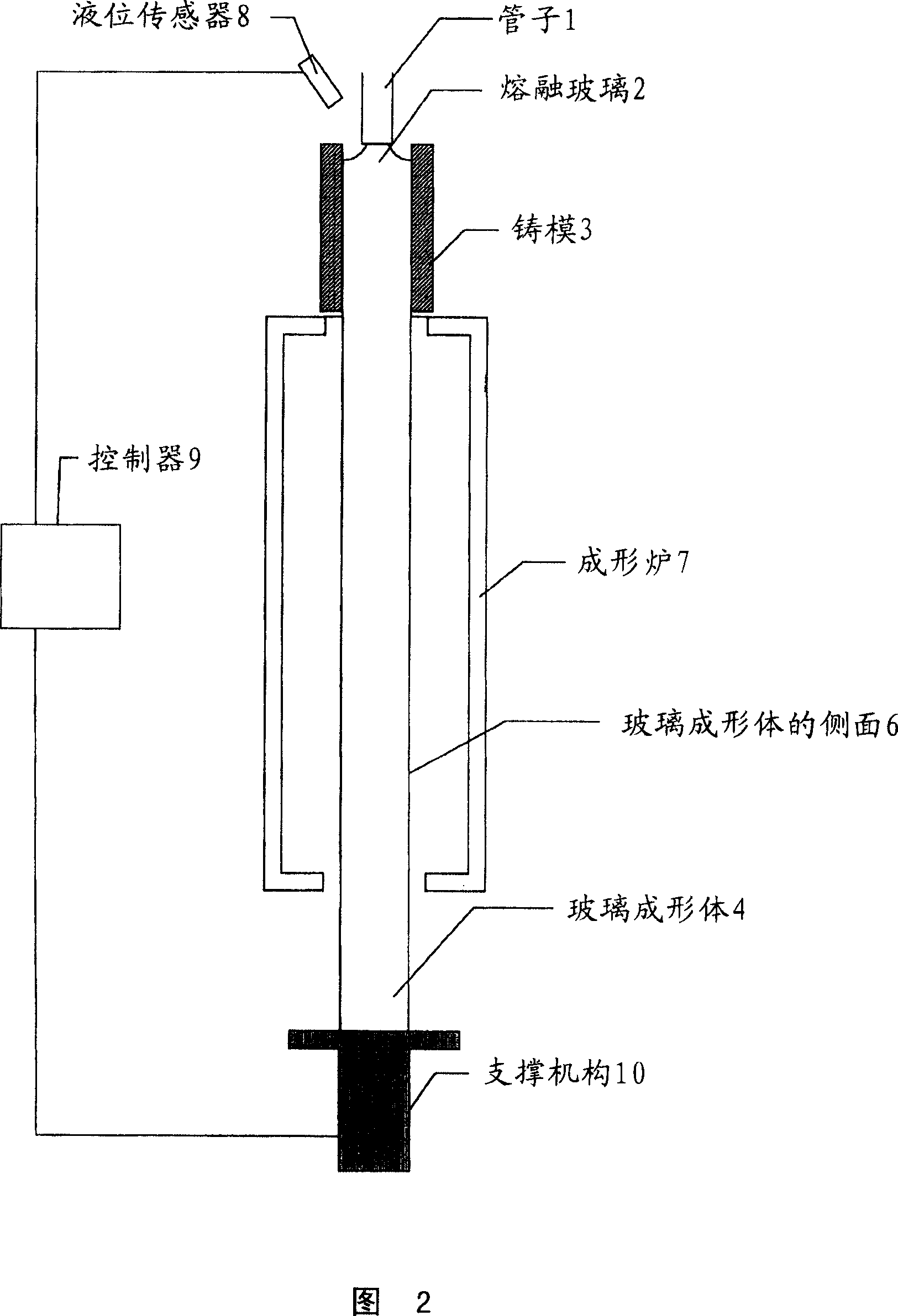

[0316] First, glass raw materials were weighed to obtain optical glass I shown in Table 1, and after being sufficiently mixed, they were introduced into a melting vessel and heated and melted. Secondly, make the fully clarified and uniform molten glass continuously flow out from the outlet of the vertically arranged tube with a viscosity of 0.6dPa·s and at a certain flow...

Embodiment 2

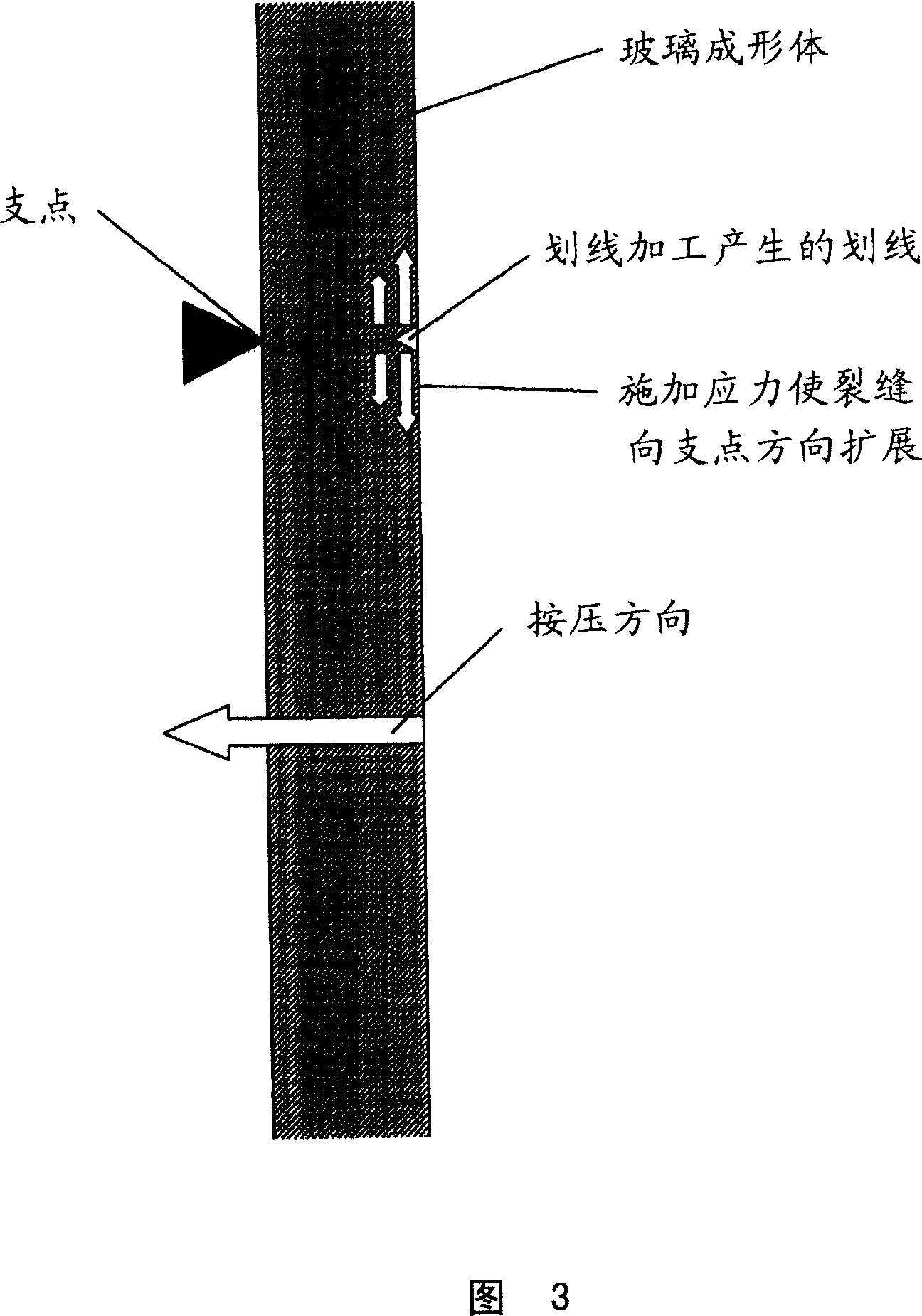

[0348] Using each slow-cooled round rod-shaped glass produced in Example 1, a glass gob for press molding was produced. First, a scribe line is formed on the cut portion of the side surface of the round rod-shaped glass by scribing process. Next, insert the round rod-shaped glass into the high-pressure container so that the part where the scribe line is formed is located in the center of the container. In order to limit the movement in the direction of the central axis, use the rubber sealing ring to clamp the round rod-shaped glass to the opening of the container, and fill the container with water. , so that there are no blisters inside.

[0349] Pressurize in this state so that the water pressure in the container reaches 20 MPa, and the glass is cut perpendicular to the central axis of the round rod-shaped glass at the scribed position. In this way, the round rod-shaped glass is cut at predetermined intervals to form cut pieces.

[0350] Next, the above-mentioned slices we...

Embodiment 3

[0352] The slices produced in Example 2 were ground and ground to produce a glass gob for press molding with a smooth surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com