Patents

Literature

218results about How to "Stable mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Post-rolling cooling control method for small-size high-Cr 82B wire rods

ActiveCN104001741AGuaranteed uniformityAvoid it happening againTemperature control deviceWork treatment devicesWire rodTemperature control

The invention relates to a post-rolling cooling control method for high-Cr (the alloy content accounts for 0.30 percent-0.35 percent) SWRH82B wire rods. The method comprises the steps that post-rolling spinning temperature, cooling speed before spinning phase change, phase-transition temperature range, phase-transition cooling speed, Stelmor roller speed, fan delivery and Jialing air distribution are combined and controlled, and production equipment is adjusted to stabilize spinning mode so that the purpose of the stable production can be achieved. The spinning temperature is controlled to range from 860 DEG C to 880 DEG C. The cooling speed before post-rolling phase-transition is controlled to range from 10.0 DEG C / s to 14.0 DEG C / s. The phase-transition temperature is controlled to range from 580 DEG C to620 DEG C. The cooling speed in a phase-transition area is controlled to range from 1.5 DEG C / s to 3.0 DEG C / s. The base speed of the inlet segment of a Stelmor roller bed is controlled to range from 0.6 m / s to1.0m / s. After the technical scheme of the post-rolling cooling control of the wire rods is applied and implemented, it can be guaranteed that high strength is achieved, and plasticity does not decrease but is improved. Moreover, the situation that as cleaning rods are cooled in a non-uniform mode, so that the local positions produce low-temperature shift tissue such as martensite is avoided, and the uniformity of the cleaning rod tissue and the mechanical performance is guaranteed.

Owner:张家港联峰钢铁研究所有限公司

Liquid crystal medium mixture and liquid crystal display using same

ActiveCN102660299AImprove Optical TasteImprove performanceLiquid crystal compositionsNon-linear opticsLiquid-crystal displayReaction speed

The invention provides a liquid crystal medium mixture and a liquid crystal display using the same. The liquid crystal medium mixture comprises a liquid crystal material, a stabilizing agent and polymerizable monomers, wherein the polymerizable monomer contains two or more than two kinds of monomers in which at least one kind of quick reaction monomer and at least one kind of high orientation force monomer are included. The liquid crystal display comprises an upper substrate and a lower substrate which are arranged in parallel and the liquid crystal medium mixture arranged between the upper substrate and the lower substrate. According to the liquid crystal medium mixture and the liquid crystal display using the liquid crystal medium mixture, two or more than two kinds of polymerizable monomers with different functionalities are matched reasonably, so that the reaction speed of monomer polymerization reaction, the uniformity of formed polymers and the strength of the orientation force can be balanced simultaneously and are high in level, the optical taste and general expression of a panel can be improved, and the stable volume production can be realized.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

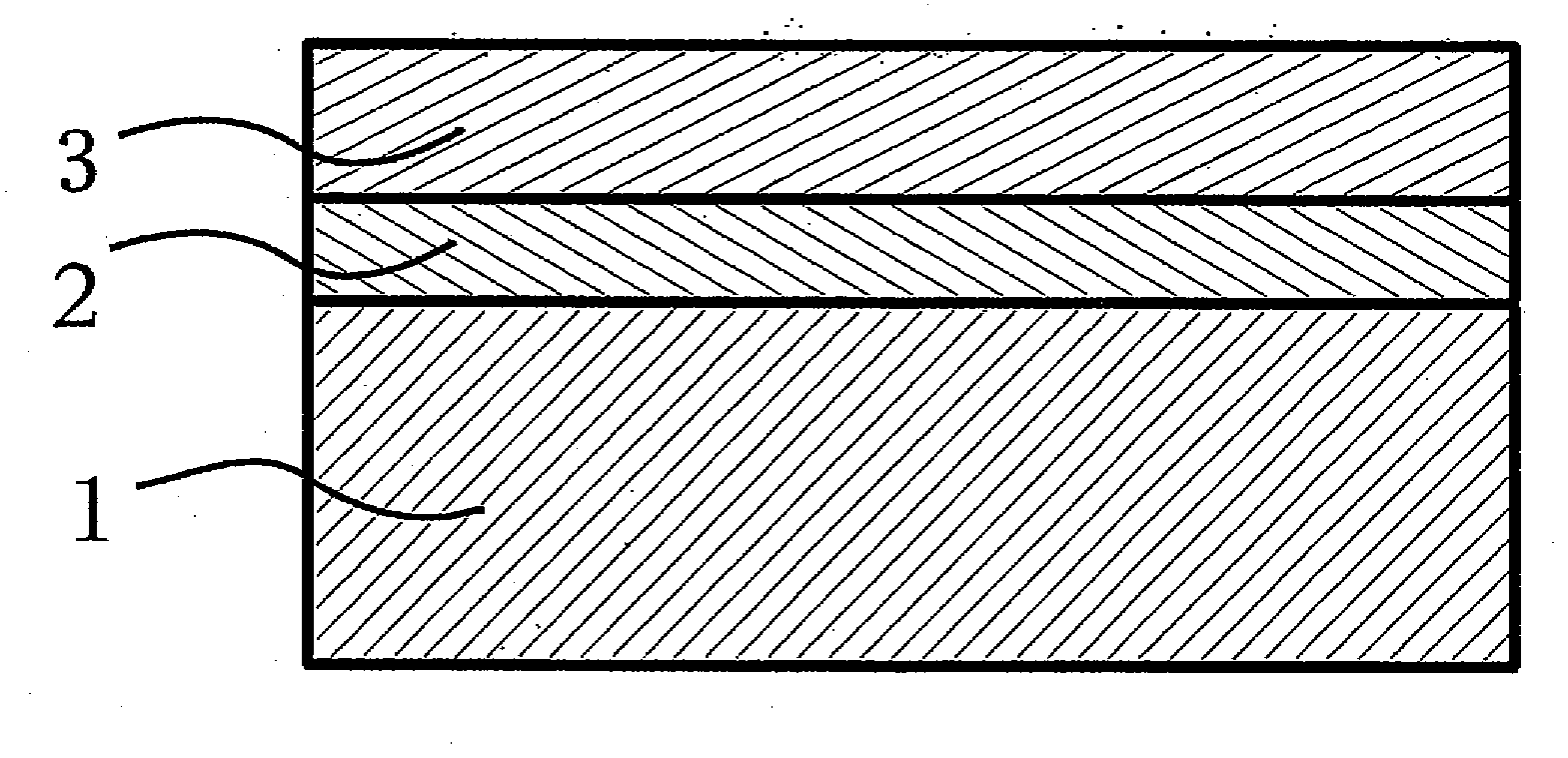

Protective coat and method for manufacturing thereof

InactiveUS20090324844A1Stable mass productionMaintain good propertiesLiquid surface applicatorsElectrical apparatusOptoelectronicsOxygen

A method for producing a protective coat formed on the top surface of a substrate, or on the top surface of a thin film layered body formed on the substrate is disclosed, wherein the protective coat comprises silicon oxynitride in which the atomic ratio of Si / O / N is 100 / X / Y (130≦X+Y≦180, 10≦X≦135, 5≦Y≦150), wherein the protective coat is formed by a sputtering method in which silicon nitride is used as a target material, an inert gas is used as a sputtering gas, and N2 is used as a reactive feed gas. The oxygen component of the obtained protective coat comprising the silicon oxynitride is incorporated into the composition of the protective coat by degradation of moisture that was present in the substrate or the thin film layered body or in the reaction apparatus.

Owner:HAOTO DAISAKU +1

Optical glass

InactiveCN1389414AExcellent devitrification resistanceLow costOptical elementsRefractive indexPhotochemistry

There is provided an optical glass suitable for precision mold pressing having optical constants of a refractive index (nd) within a range from 1.75 to 1.85 and an Abbe number ( nu d) within a range from 35 to 45, comprising in mass % on oxide basis: having a transition point (Tg) within a range from 500 DEG C to 590 DEG C and a yield point (At) within a range from 530 DEG C to 630 DEG C, and being free from devitrification in a devitrification test conducted under a condition of 950 DEG C / 2 hours.

Owner:OHARA

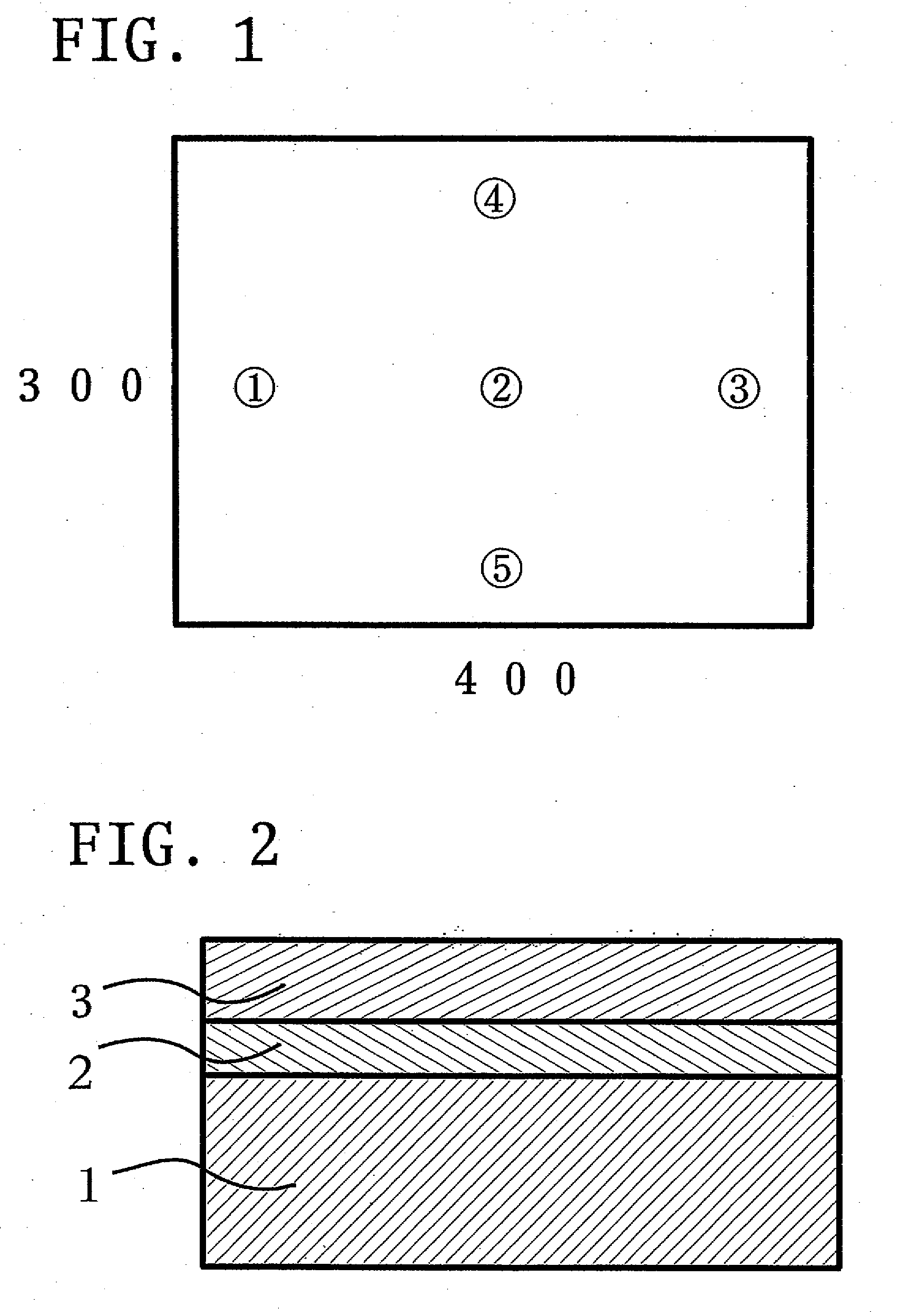

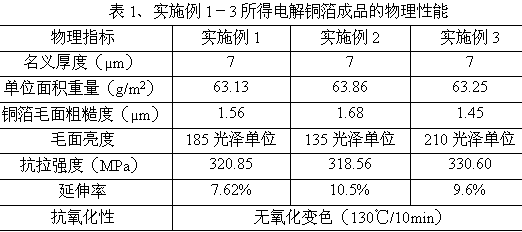

Additive for electrolytic copper foil and production process of electrolytic copper foil for 7-mu. m double-light lithium ion battery

The invention relates to an additive for an electrolytic copper foil. The additive is aqueous solution containing a brightening agent DPS and industrial gelatin, wherein the concentration of the DPS in the additive is 5-15g / L, and the concentration of the industrial gelatin is 1-4g / L. The invention further discloses a production process for preparing the electrolytic copper foil for a 7-mu. m double-light lithium ion battery by adopting the additive. The cost of the additive is lower, the performance index of the produced electrolytic copper foil meets a specified requirement, and the electrolytic copper foil can be taken as a copper foil special for a lithium battery.

Owner:LINGBAO WASON COPPER FOIL

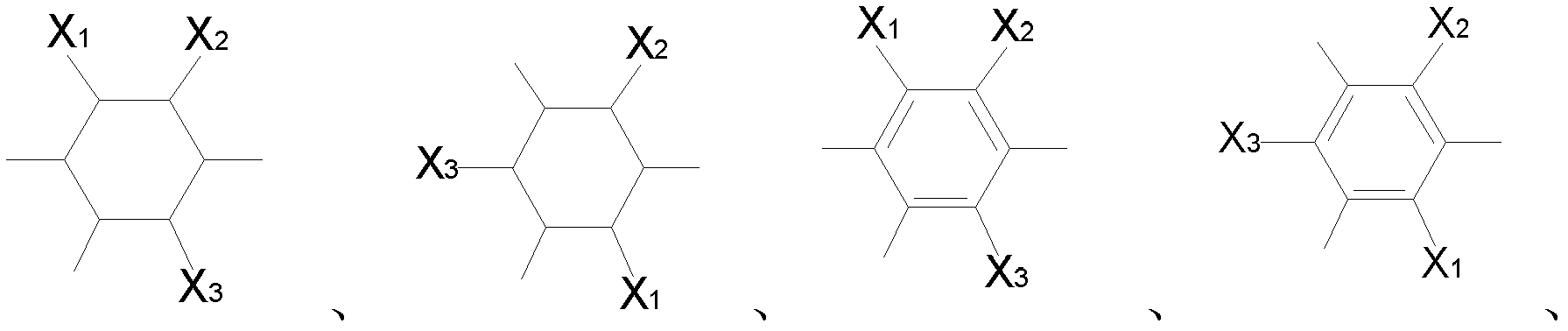

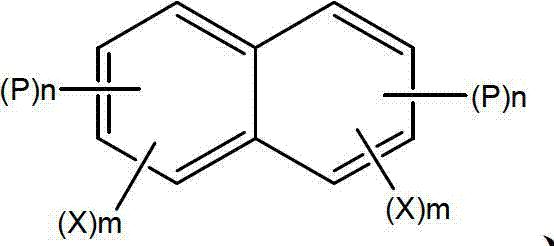

Liquid crystal medium composite as well as liquid crystal display using same and manufacturing method of liquid crystal medium composite

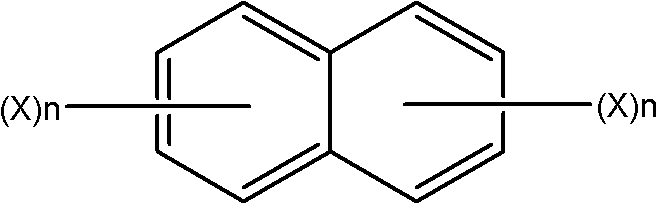

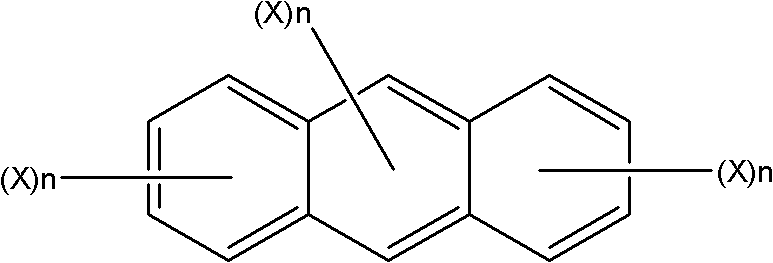

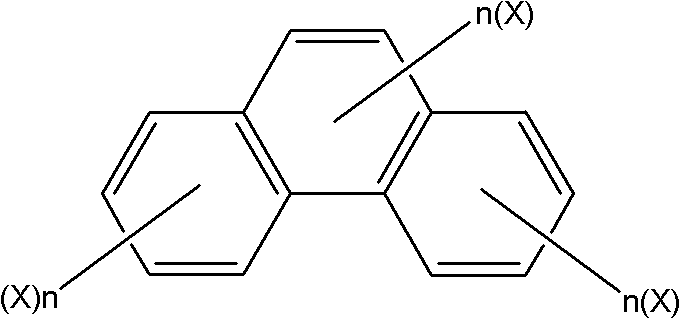

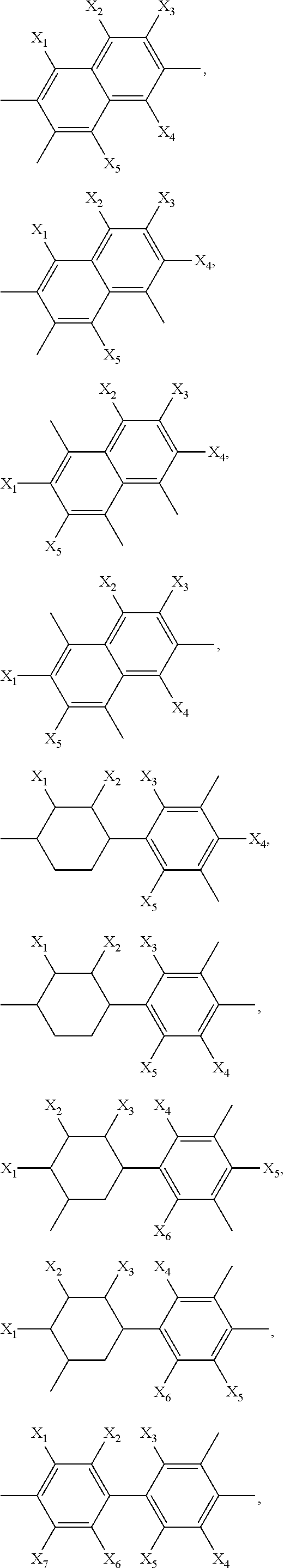

ActiveCN102660300AImprove uniformityImprove efficiencyLiquid crystal compositionsNon-linear opticsPolycyclic aromatic hydrocarbonLiquid-crystal display

The invention provides a liquid crystal medium composite as well as a liquid crystal display using the liquid crystal medium composite and a manufacturing method of the liquid crystal medium composite. The liquid crystal medium composite comprises the following components: a liquid crystal material, a polymerizable monomer, a stabilizing agent and a sensitizing agent, wherein the sensitizing agent has strong absorption on ultraviolet light with the wavelength in a range of 300-380 nm; and the structure is formed by connecting a polycyclic aromatic hydrocarbon formed by connecting a plurality of benzene rings, with an aromatic ring. The liquid crystal display comprises an upper substrate, a lower substrate and the liquid crystal medium composite, wherein the upper substrate and the lower substrate are arranged in parallel; and the liquid crystal medium composite is arranged between the upper substrate and the lower substrate. According to the invention, the stabilizing agent which has the strong absorption on the ultraviolet light with the wavelength in the range of 300-380 nm is used so that a reaction wavelength of the polymerizable monomer can be moved towards a long wavelength; the ultraviolet light with the wavelength in the range of 300-380 nm is used for irradiating to keep away from the absorption wave section of a liquid crystal material, so that the damage effect on the liquid crystal material and an alignment material PI (Polyimide) by the ultraviolet light is reduced, and the polymerization reaction efficiency and the uniformity of the polymerizable monomer can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

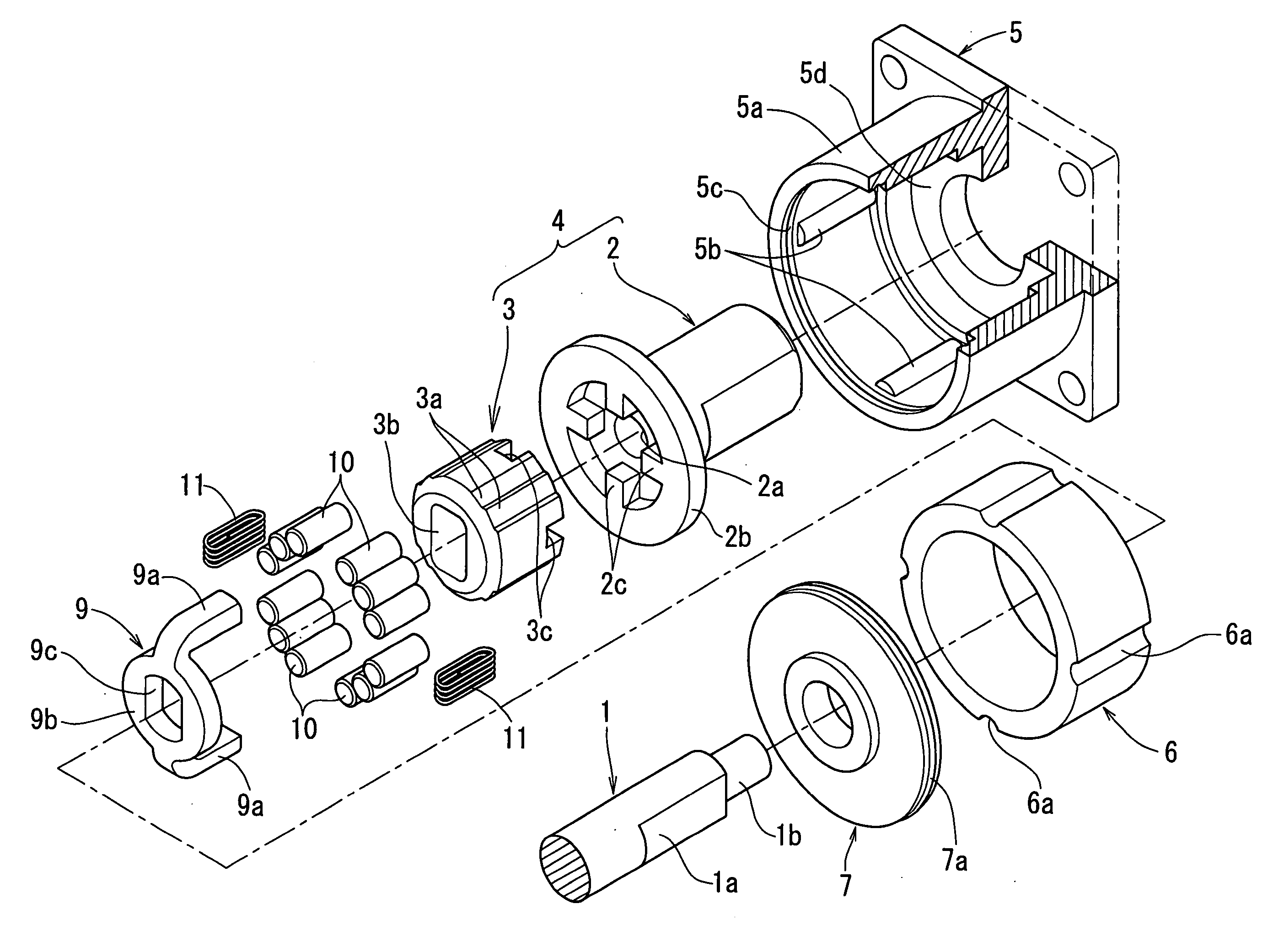

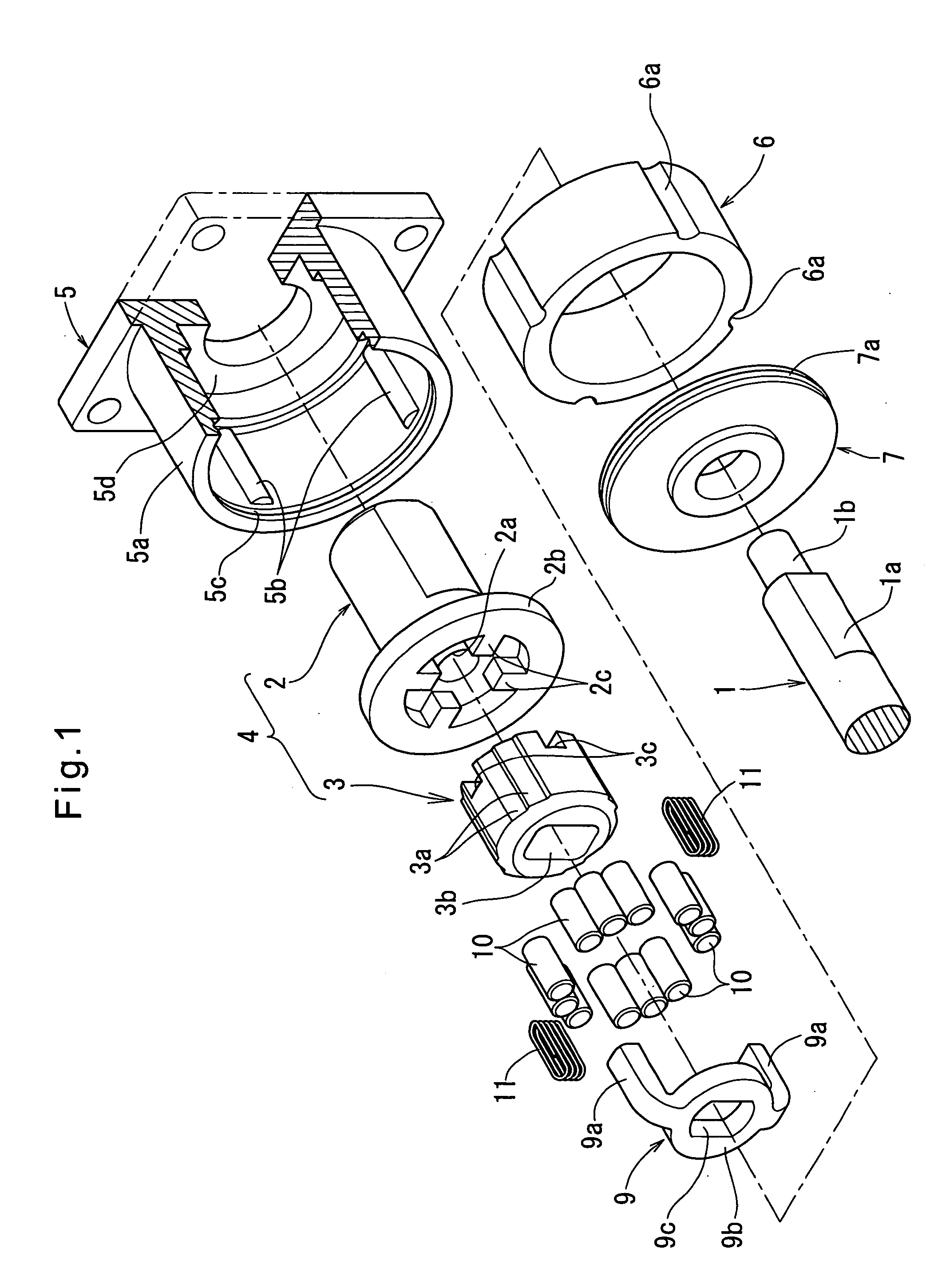

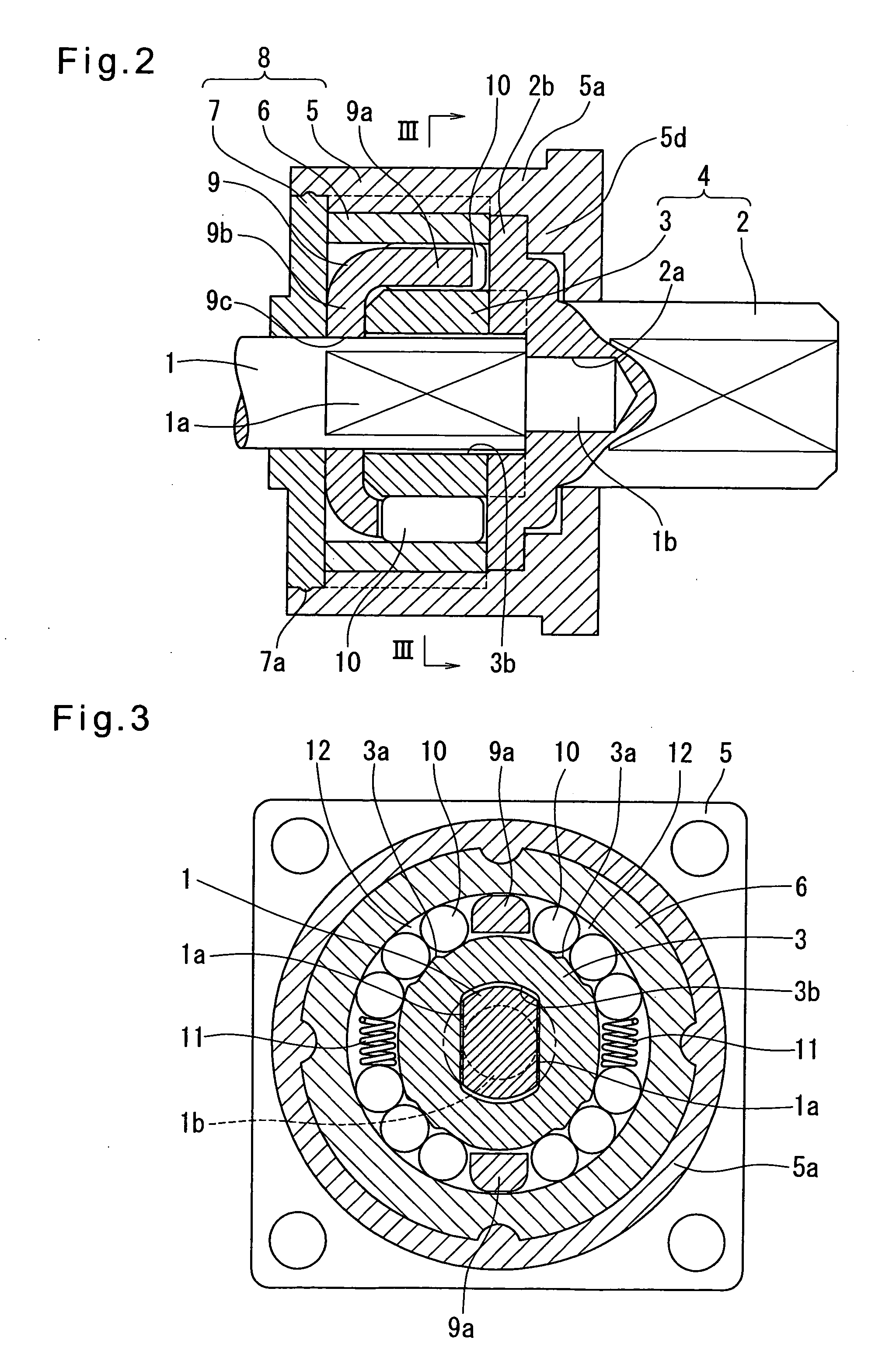

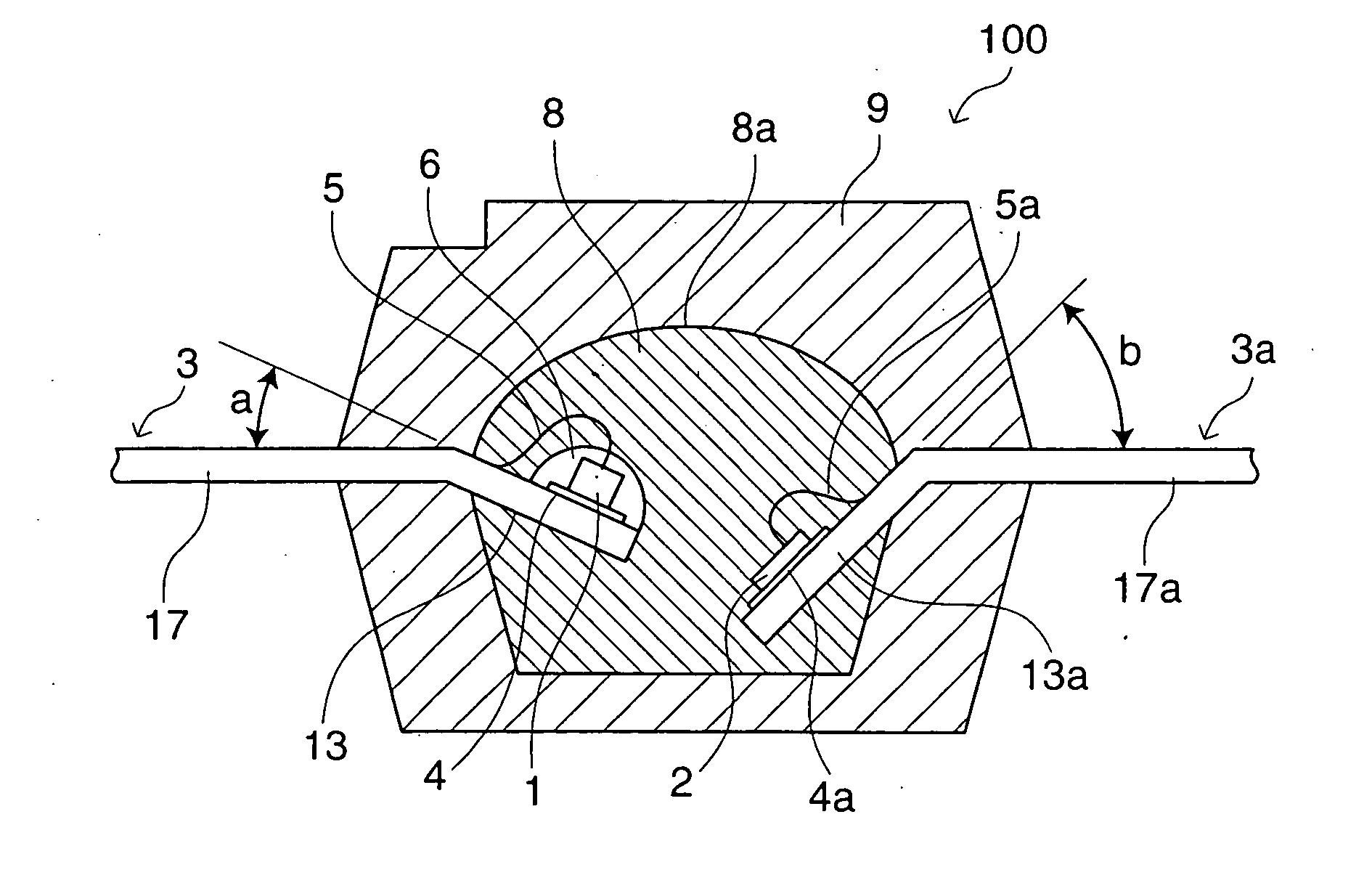

Anti-reverse input clutch

An anti-reverse input clutch is provided which includes an output member including an output shaft held so as to be rotatable about the axis of an input member, and a cam member which is a separate member from the output shaft and on which cam surfaces are formed. The cam member is rotationally fixed to the output shaft. Thus, each of the output shaft and the cam shaft can be easily formed, so that it is possible to significantly reduce the time and cost for manufacturing the output member and improve the freedom of design thereof.

Owner:NTN CORP

Method for preparing Nd-Fe-B alloys by using waste

A method of preparing alloy which contains neodymium iron boron by scraps, which relates to a preparation of permanent magnet of neodymium iron boron, especially by using the raw materials of scraps of neodymium iron boron alloy which own middle or high coercive force to prepare the permanent magnet of neodymium iron boron.. The characteristics is that the alloy contains 20 - 50% of the raw materials. Determine the chemic component of the scraps to confirm its constitution. Supplement pure materials of alloy by frame of reference. Enter 0.2 - 0.5% more Nb and 0.5 - 1.0% more Nd by frame of reference after the supplement of the weights which lost in sinter. The method of the present convention can callback 95 - 99% of scraps effectively, and reduce 8 - 10% of the cost of the raw materials. Increase the rate of the utilization of the stuff. The invention can produce large amount of neodymium iron boron production which contains high trademark steadily. It has the high value of production and utilization, and also have the integrative benefit of the society.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

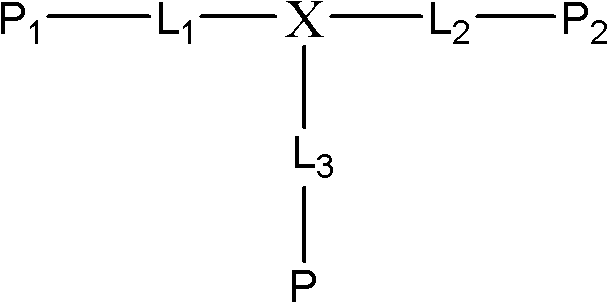

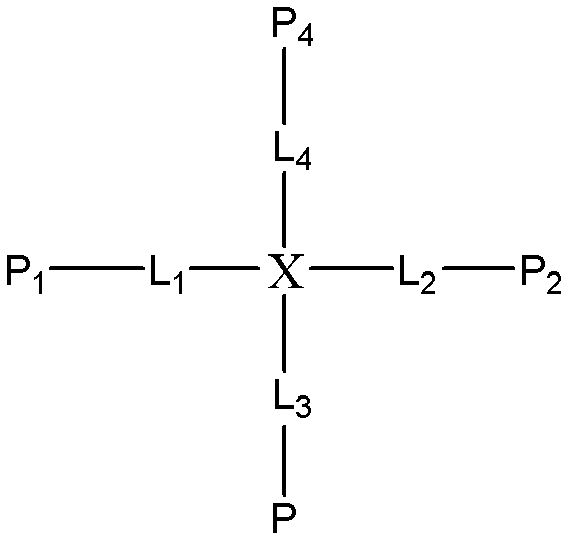

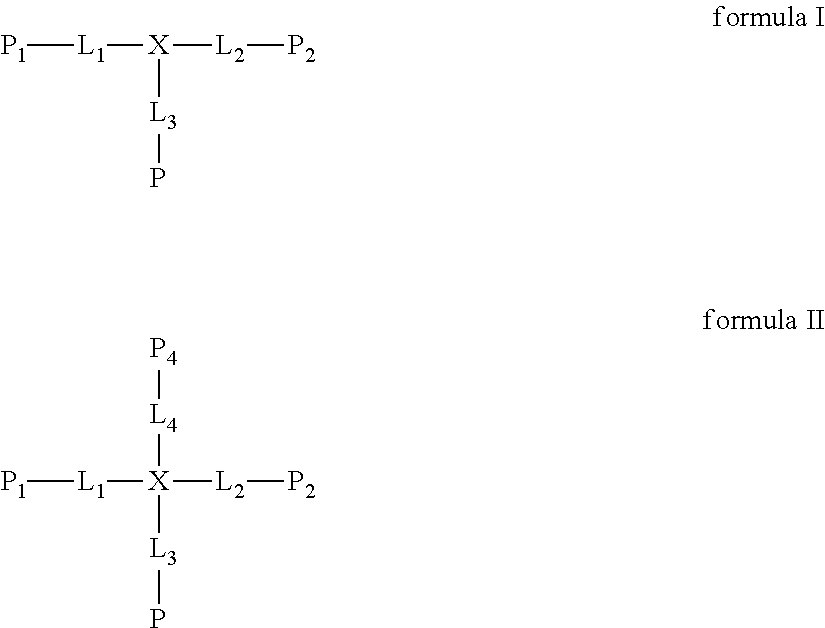

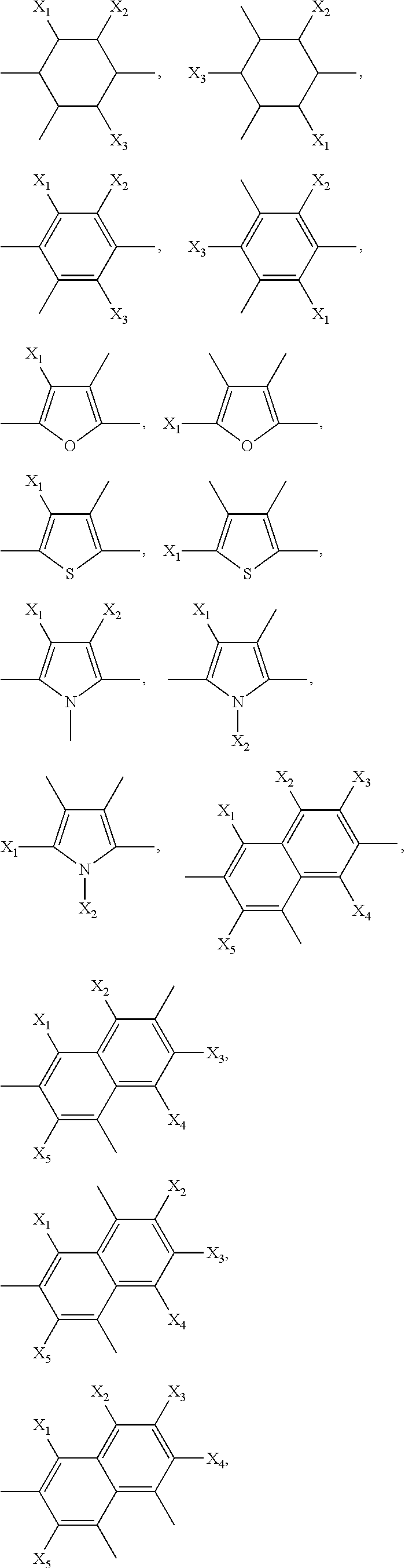

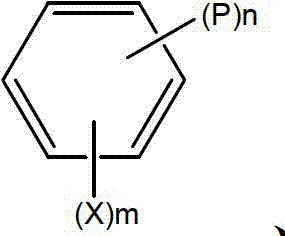

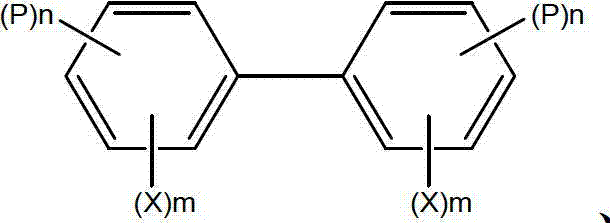

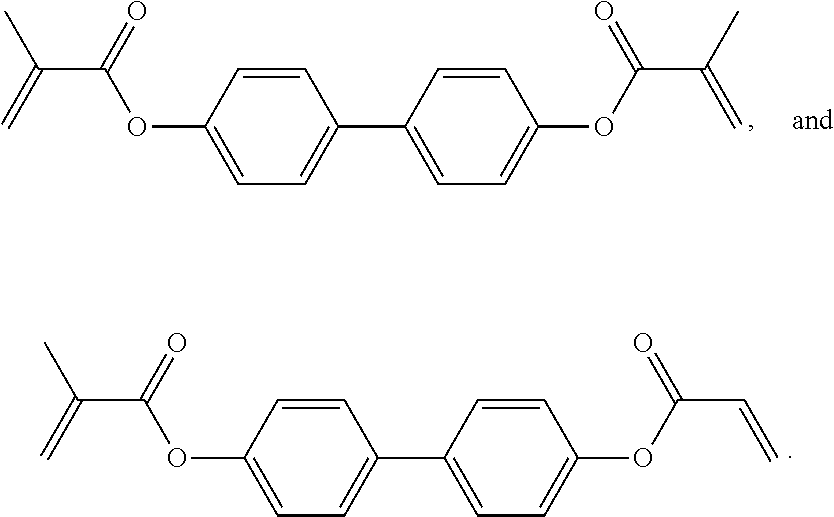

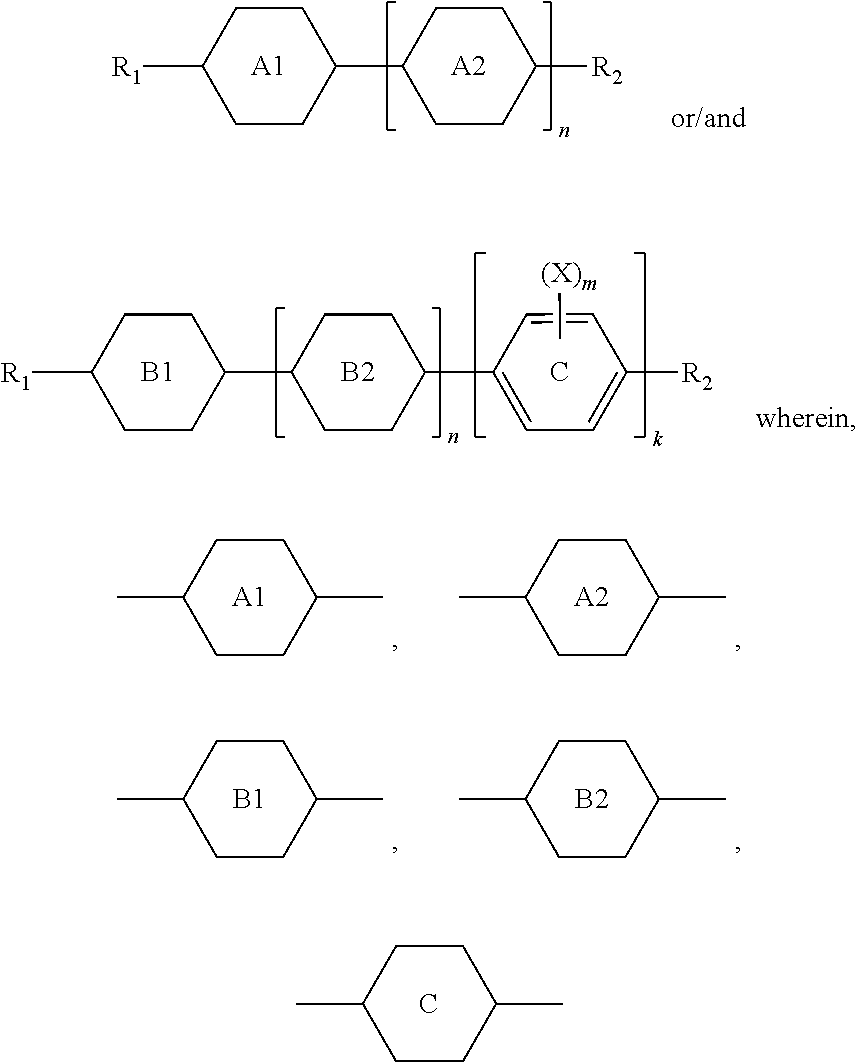

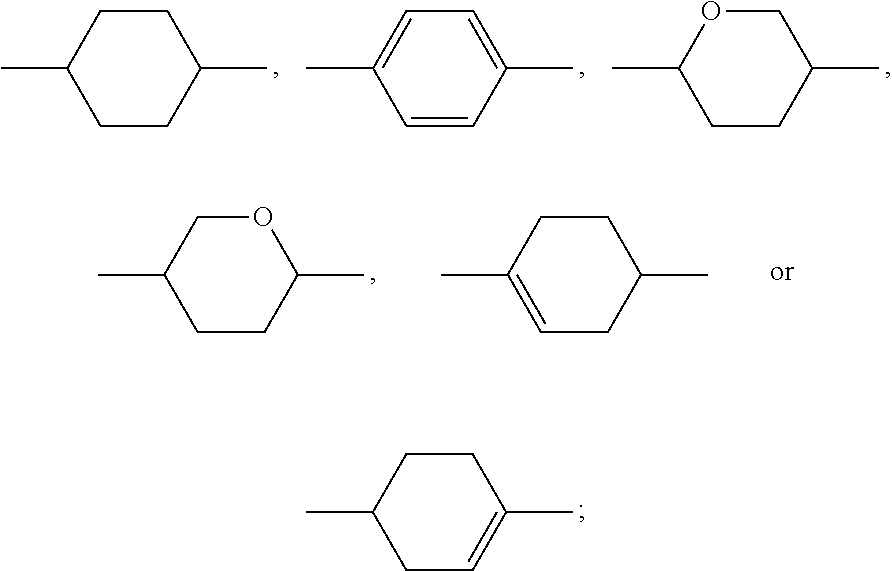

Liquid Crystal Medium Composition and Liquid Crystal Display Using Same

InactiveUS20130287970A1Stable mass productionImprove performanceLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The present invention provides a liquid crystal medium composition and a liquid crystal display using same. The liquid crystal medium composition includes a liquid crystal material, a stabilizer, and polymerizable monomers. The polymerizable monomers include at least two types of monomers, which include at least one highly reactive monomer and at least one strong anchoring monomer. The liquid crystal display includes upper and lower substrates that are arranged parallel to each other and a liquid crystal medium composition arranged between the upper and lower substrates. The liquid crystal medium composition includes two or more than two polymerizable monomers of different functionalities to mix in a reasonable manner so that balance can be reached among polymerization reaction rate, homogeneity of polymer formed thereby, and magnitude of anchoring force, all being of upgraded level. The optic quality and overall performance of a liquid crystal panel are enhanced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal medium mixture and liquid crystal display using same

InactiveCN102876338AAvoid misalignmentQuick responseLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The invention provides a liquid crystal medium mixture and liquid crystal display using the same. The liquid crystal medium mixture comprises the following components: at least one anisotropic liquid crystal material, and two or more polymerizable monomers which can be polymerized under UV (ultraviolet) irradiation, wherein the liquid crystal material comprises an alkenyl compound which is stable to a polymerization reaction during polymerization of the polymerizable monomers; and the polymerizable monomers account for 0.1-1% of the total amount of the liquid crystal medium mixture in part by weight. The liquid crystal medium mixture can be polymerized into polymer bulge with relatively small size and good uniformity by adopting the two or more polymerizable monomers which can be polymerized under the UV irradiation according to a proper ratio, so that poor liquid crystal alignment, and a light spot phenomenon of a liquid crystal panel in the dark state are avoided, thus increasing the response speed of the liquid crystal panel and achieving high contrast and stable massive productivity.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

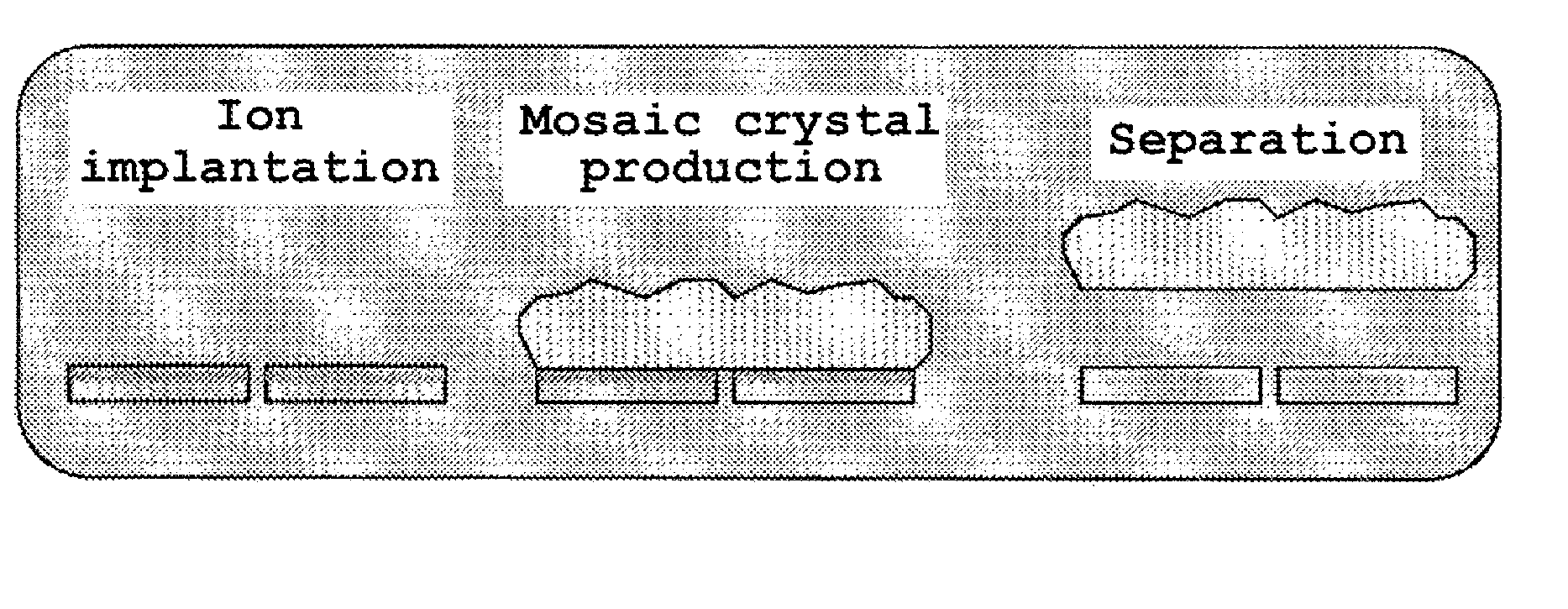

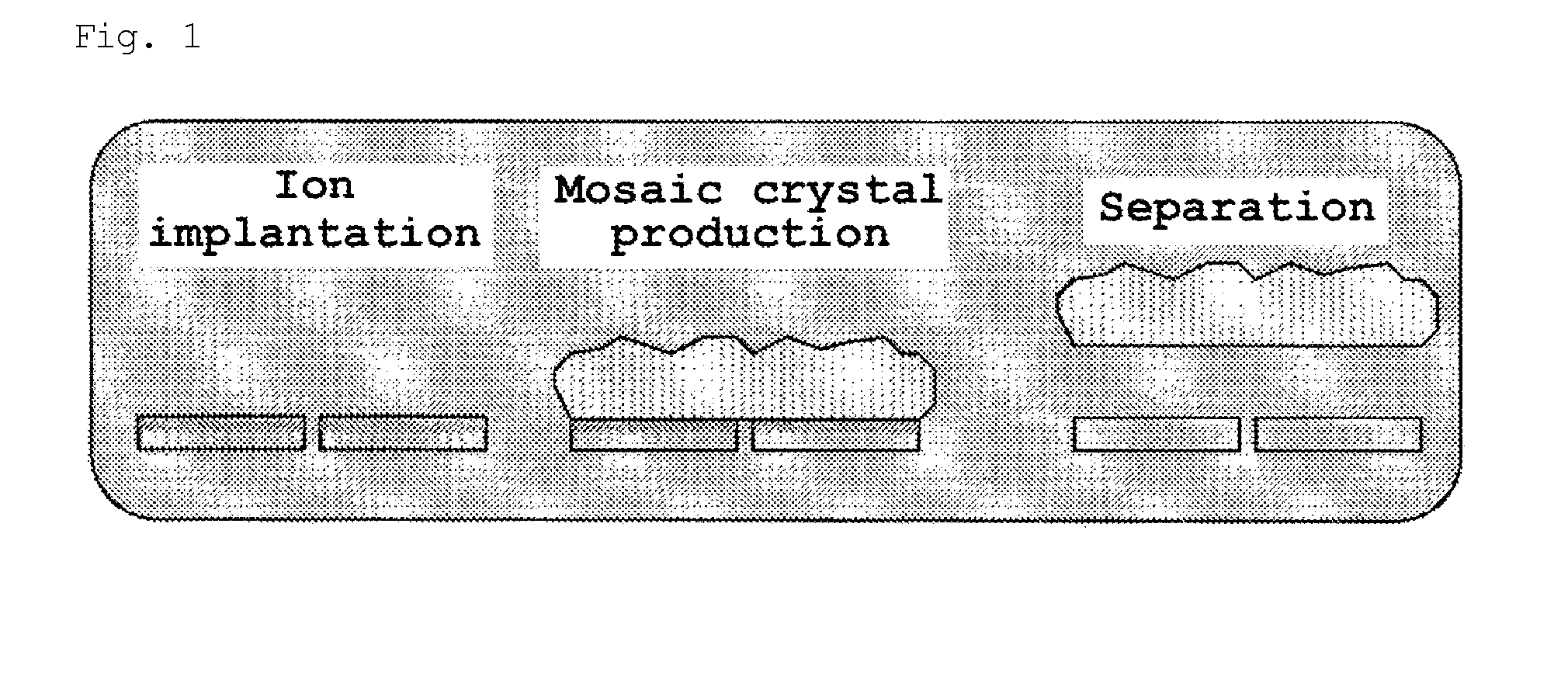

Method for producing mosaic diamond

InactiveUS20120302045A1Simple processStable mass productionPolycrystalline material growthDiffusion/dopingSynthesis methodsSingle crystal

The present invention discloses a method for producing a mosaic diamond comprising implanting ions in the vicinity of the surfaces of a plurality of single-crystal diamond substrates arranged in the form of a mosaic, or in the vicinity of the surfaces of mosaic single-crystal diamond substrates whose back surfaces are bonded by a single-crystal diamond layer, so as to form non-diamond layers; growing a single-crystal diamond layer by a vapor-phase synthesis method; and separating the single-crystal diamond layer above the non-diamond layers by etching the non-diamond layers. The method of the present invention prevents the destruction of single-crystal diamond substrates by using a process that is simpler than conventional methods, thus allowing a large quantity of mosaic diamond to be produced in a stable and efficient manner.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Protective coat and method for manufacturing thereof

InactiveUS20050037240A1Stable mass productionMaintain good propertiesElectroluminescent light sourcesVacuum evaporation coatingOptoelectronicsOxygen

A method for producing a protective coat formed on the top surface of a substrate, or on the top surface of a thin film layered body formed on the substrate is disclosed, wherein the protective coat comprises silicon oxynitride in which the atomic ratio of Si / O / N is 100 / X / Y (130≦X+Y≦180, 10≦X≦135, 5≦Y≦150), wherein the protective coat is formed by a sputtering method in which silicon nitride is used as a target material, an inert gas is used as a sputtering gas, and N2 is used as a reactive feed gas. The oxygen component of the obtained protective coat comprising the silicon oxynitride is incorporated into the composition of the protective coat by degradation of moisture that was present in the substrate or the thin film layered body or in the reaction apparatus.

Owner:DAI NIPPON PRINTING CO LTD

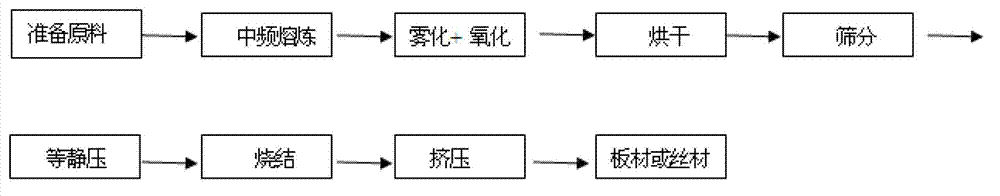

Method for preparing silver tin oxide material

The invention provides a method for preparing a silver tin oxide material. The method comprises the following steps: (1) preparing raw materials, wherein the raw materials are base stocks or mixture of the base stocks and additives; (2) performing intermediate frequency smelting on the raw materials, and performing oxidation treatment while water atomization is performed to obtain alloy powder; (3) drying and sieving the alloy powder, and enabling the alloy powder to form an isostatic pressing ingot blank after isostatic pressing; and (4) burning the isostatic pressing ingot blank in a hydrogen heating furnace, performing thermal extrusion on the burnt ingot blank, and extruding panels or wire stocks made of silver tin oxide materials. By means of the method for preparing the silver tin oxide material, oxidization is finished in an atomization process, the oxidization of the powder is full, the tissue is even, and processing performance of the material is improved; the content of oxide in a material system can be improved to 20%, and using requirements of large-current electrical equipment are met; and the preparation method of the material is free of environment pollution, the technological process is easy to control, the production period is short, and stable large-volume production can be achieved.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

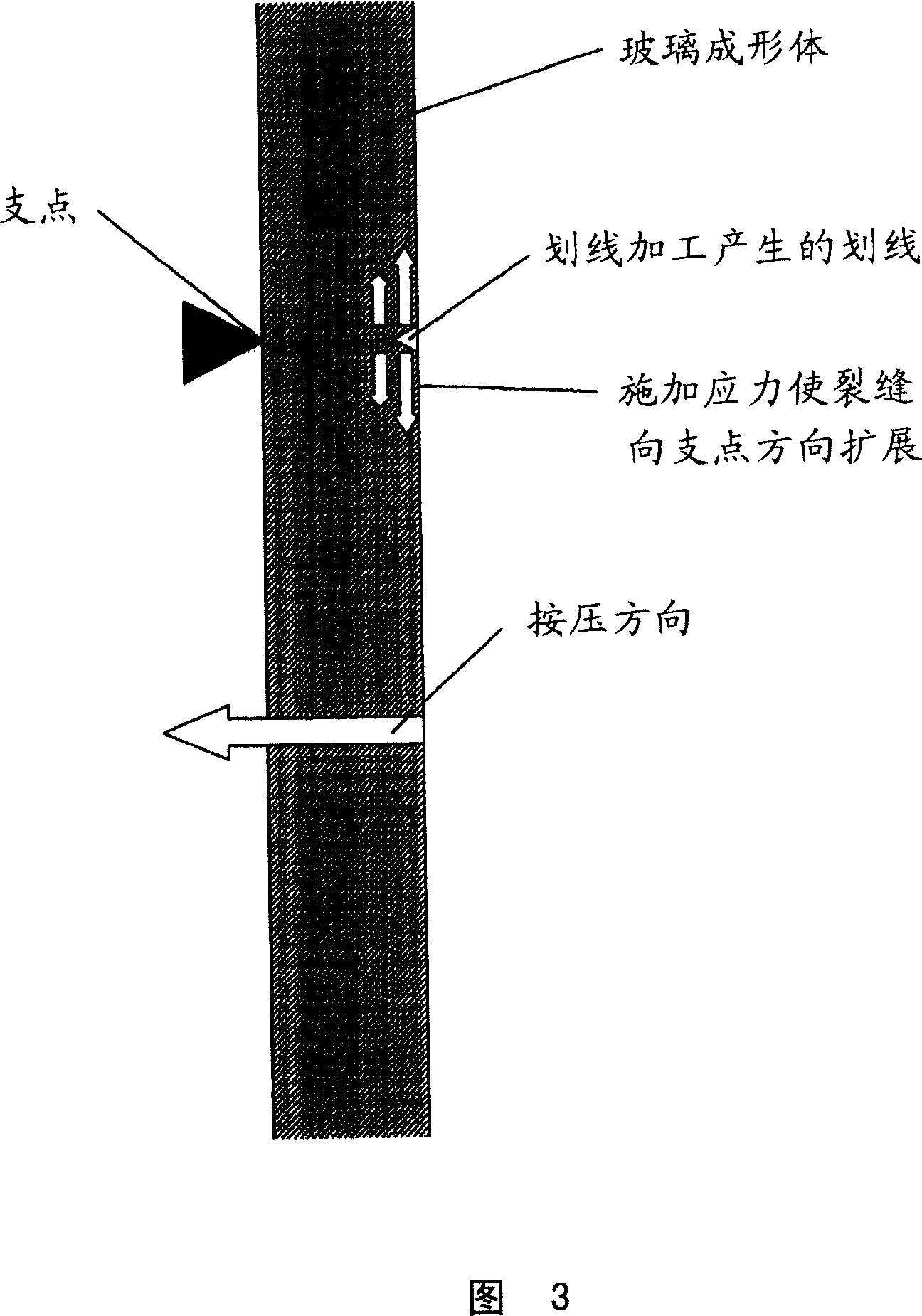

Optical glass, glass cup for die pressing forming, glass forming body, optical element and manufacture method thereof

ActiveCN1935716AHigh refractive indexLess coloringGlass pressing apparatusRefractive indexTransmittance

There is provided a high refractive optical glass capable of performing color balance correction, suitable for the miniaturization and high performance of optical instruments. The optical glass provided comprises borate system containing TiO2 as glass component. After heat treatment or controlling the species and quantity of additives, the transmittance characteristics of said optical glass satisfies the relation formula of (1) (lambada702-3009 multiplied by nd+2842 ellipsis(1)) when the wavelength lambada with 70% exterior transmittance and 10.0 mm thickness is set to 70 nm.

Owner:HOYA CORP

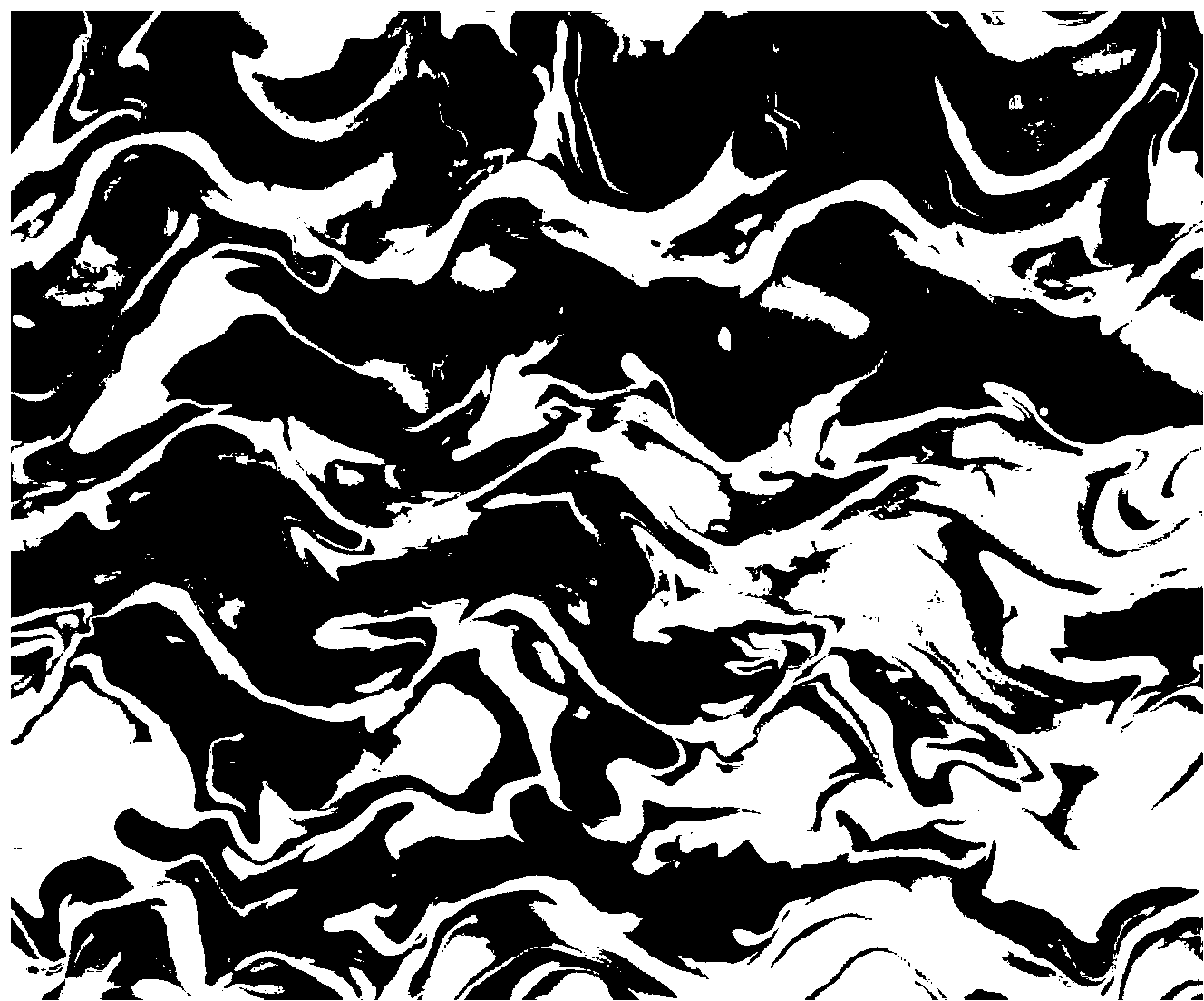

Production method of imitative natural stone texture porcelain tile

ActiveCN103213192AEase of Controlled RecyclingNatural and smooth textureCeramic shaping apparatusBrickSlurry

The invention discloses a production method of an imitative natural stone texture porcelain tile. By adjusting the caliber size and the shape of a slurry outlet of a distributing pipeline, and the arrangement position and swinging of the pipeline, different colors of slurry is sprayed onto the surface of a green brick under certain pressure to form different color gradients which are similar to patterns and lines formed by flowing, impact and extrusion of lava, the texture is natural and smooth, the effect is lifelike, the decorative effect is comparable to the decorative effect of natural stone, the working procedure is easy to control, and the mass production is stable. Meanwhile, by adopting the method provided by the invention, the slurry is easily recycled, and the overall production cost is effectively controlled.

Owner:GUANGDONG DOWSTONE TECH

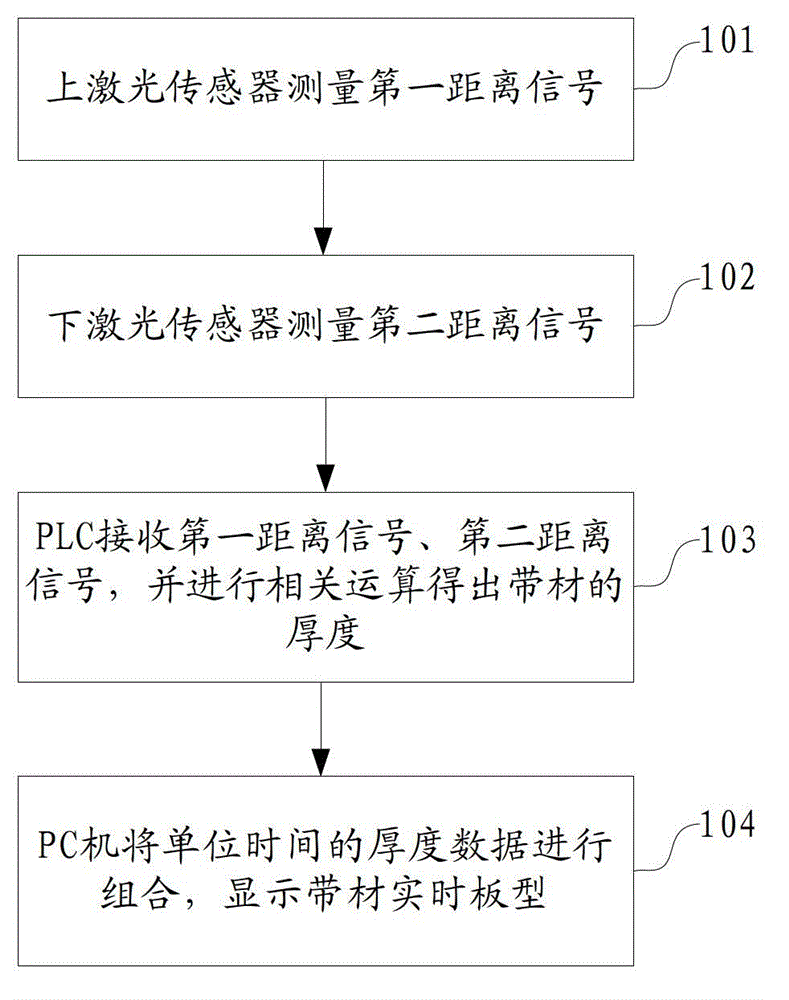

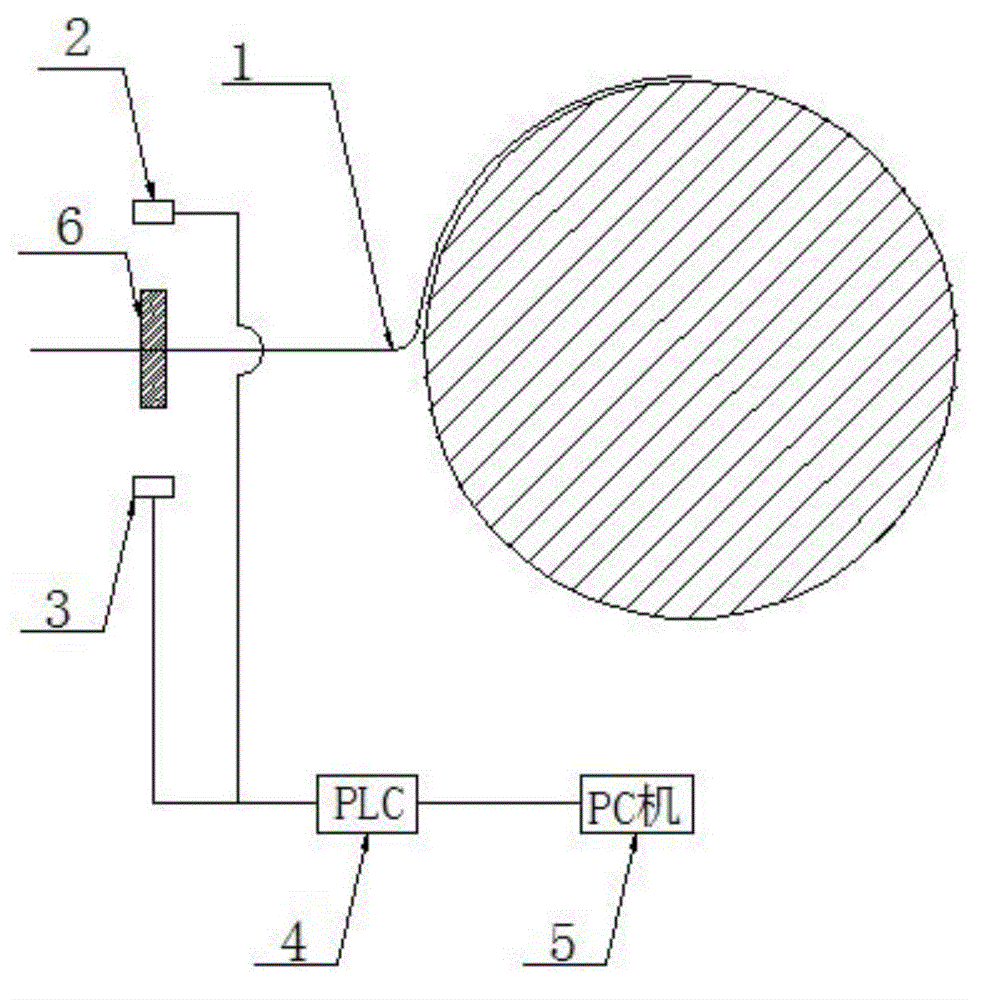

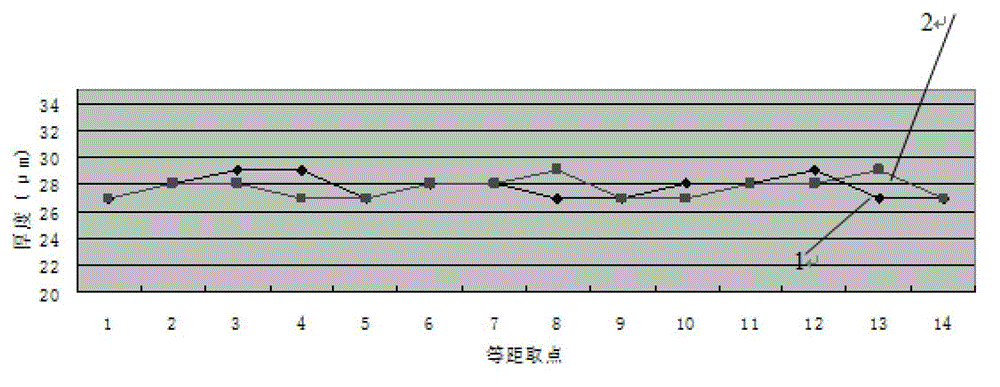

Method and device for measuring plate cut of belt material on line

InactiveCN103148801AStable mass productionEasy to operateUsing optical meansMeasurement pointProgrammable logic controller

The invention relates to a method and a device for measuring plate cut of belt material. The method includes: an upper laser sensor measures a first distance signal; a lower laser sensor measures a second distance signal; a programmable logic controller (PLC) receives the first distance signal and the second distance signal and carries out relevant calculation to obtain the thickness of the belt material; and finally by a personal computer (PC), thickness data in the unit time is combined to display the plate cut of the belt material. By utilization of a laser beam of which the top and the bottom are collimated and collinear, the belt material to be measured is irradiated, two measurement points are formed on the surface of the belt material, and by obtaining of the distance between the two measurement points, the real-time plate cut and physical parameters are obtained in the process of spraying. Compared with the prior art, the method and the device for measuring the plate cut of the belt material has the advantages of being easy to operate, low in cost, high in measurement accuracy and the like, and meanwhile provides a monitoring method for stable and mass production of the high-performance belt material.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

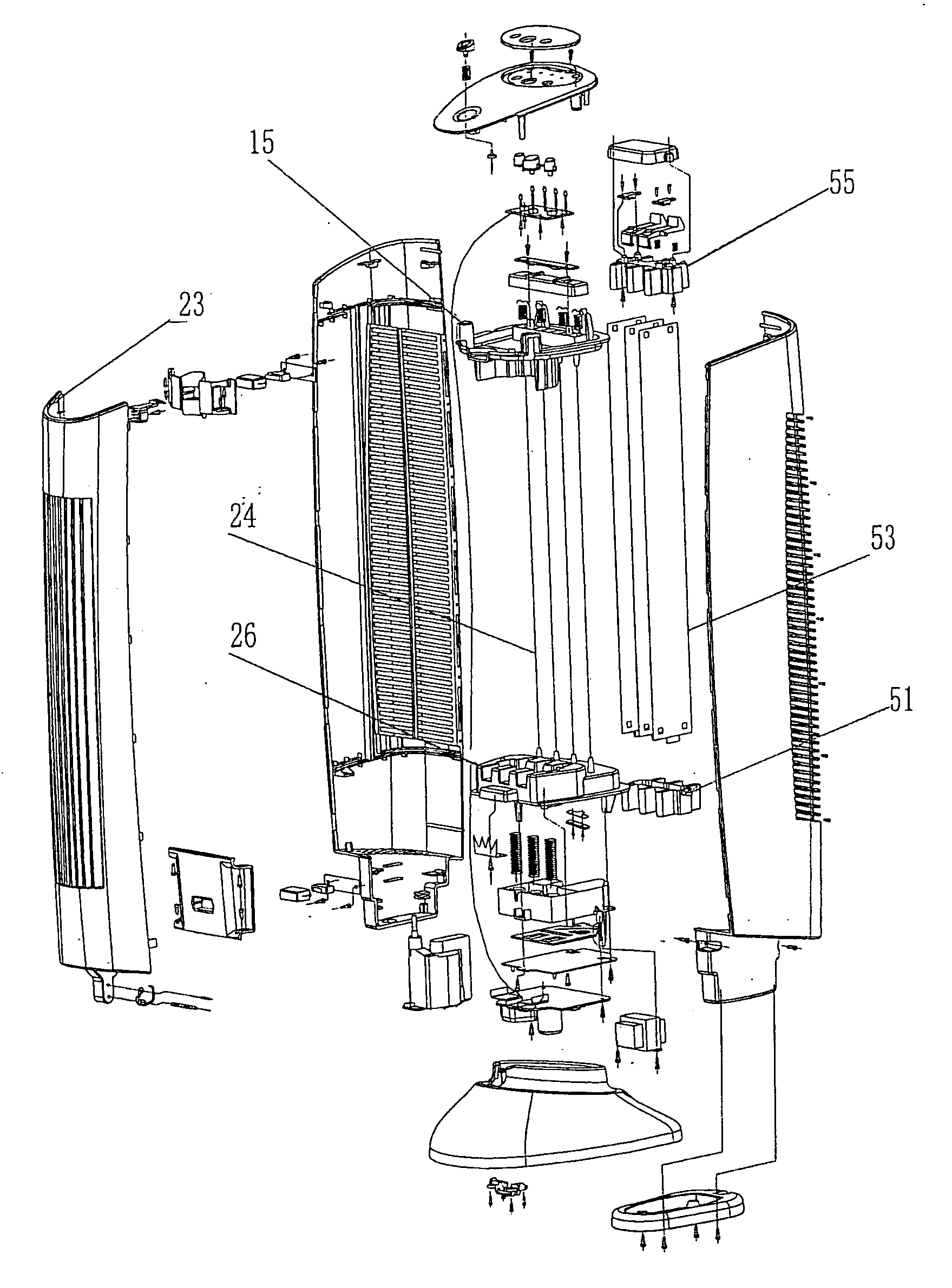

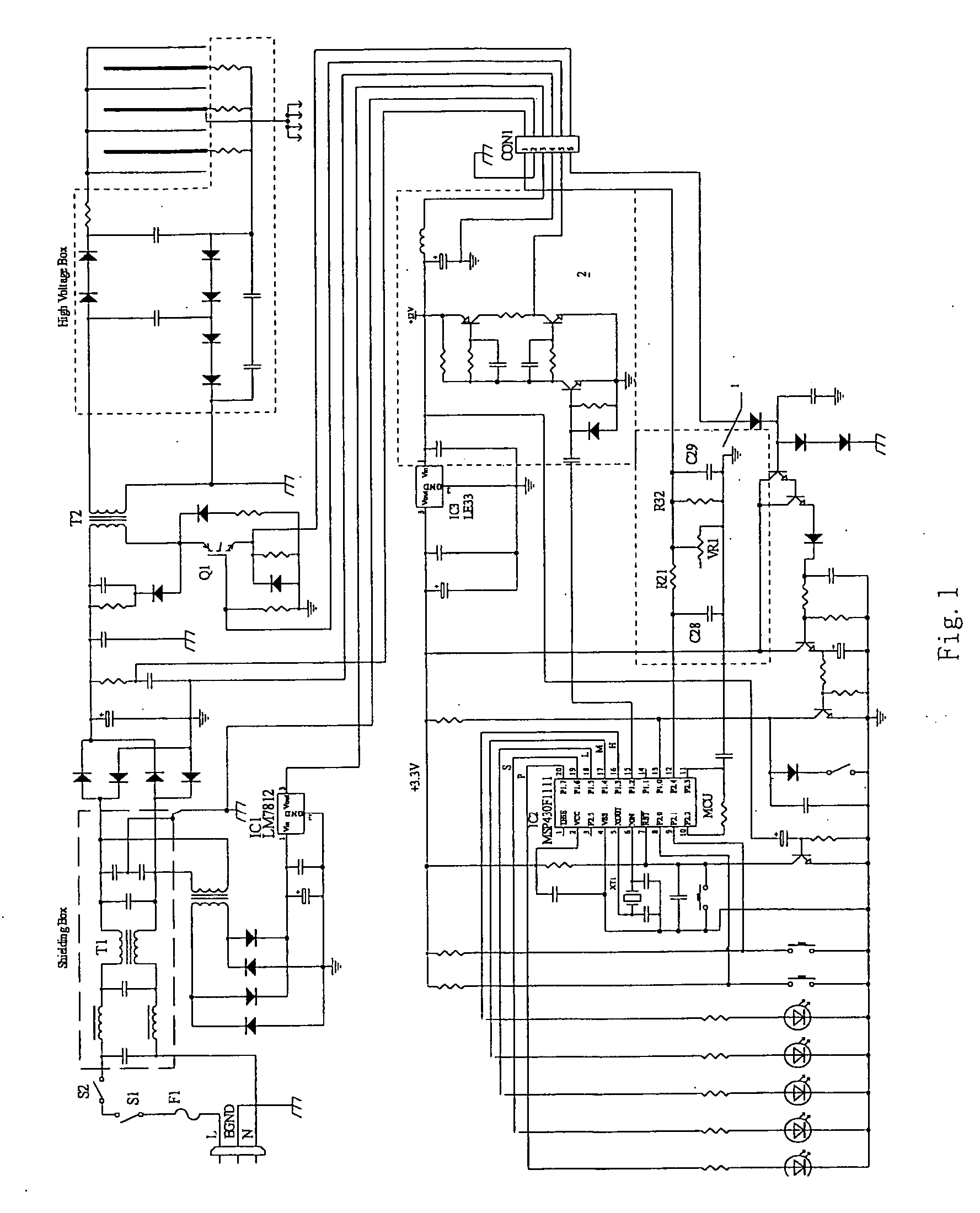

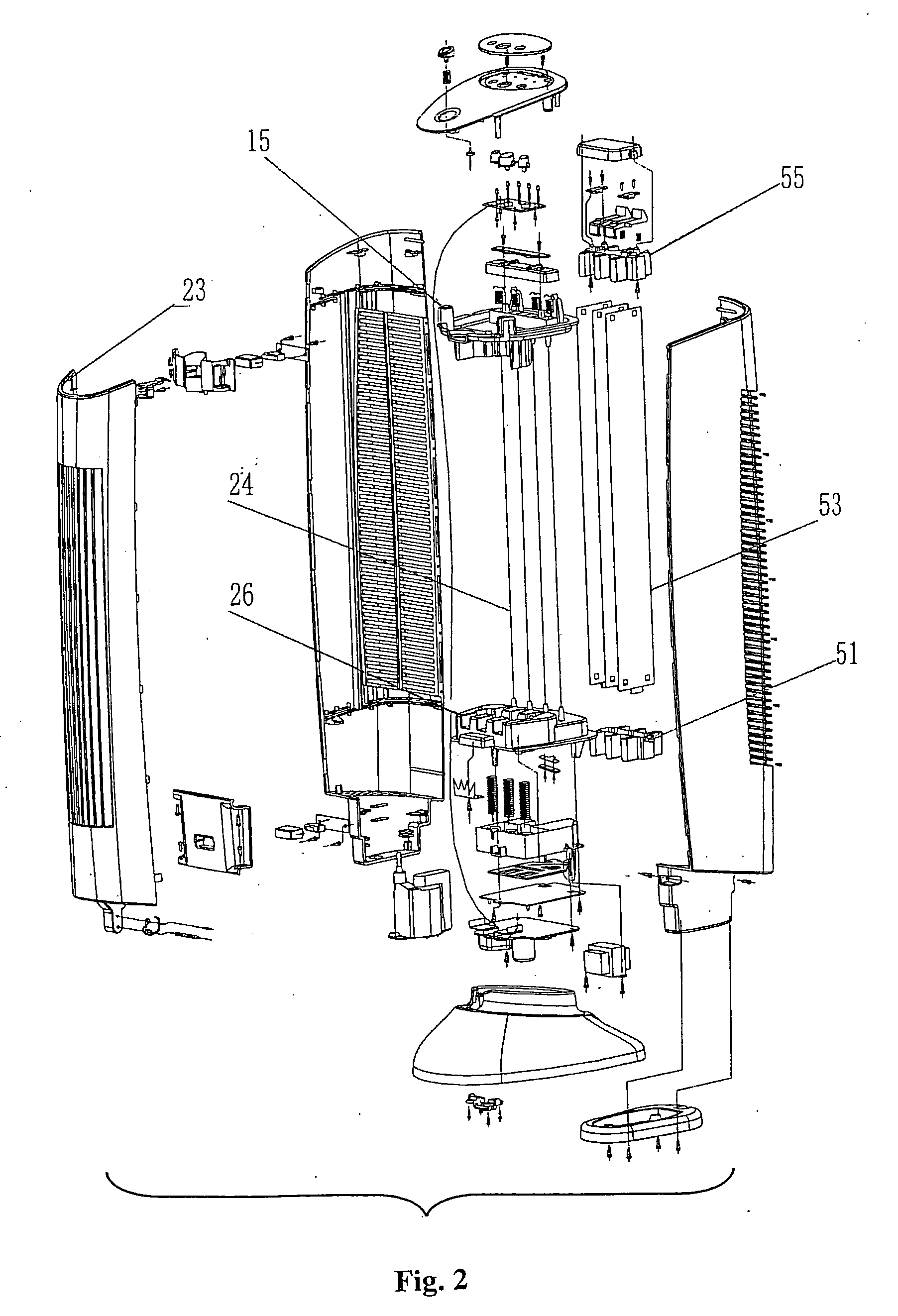

Negative ion air purifier

InactiveUS20060278080A1Improve functionalityGood electrical conductivityTransportable electrostatic unitsElectric supply techniquesVoltage regulationMains electricity

The utility model discloses a negative ion air purifier, comprising an electrostatic field-generating module and a voltage boost circuit. The voltage output end of the voltage boost circuit connects with the voltage input end of the electrostatic field-generating module. Said electrostatic field-generating module includes anodes and cathodes that are arrange alternately and equidistantly. A frequency conversion and voltage regulation module is further added, whose voltage signal sampling end connects with the voltage output end of said voltage boost circuit and whose control end connects with the voltage signal input end of said voltage boost circuit, thus making the device adapted to the fluctuation of the mains electricity between 180V to 240V and perform its functions steadily, and overcoming the disadvantages of existing products, such as the proneness to burnout and stop, unstable release of the ion flow, big noise and the difficulty in keeping effective.

Owner:HONG SHING HLDG +1

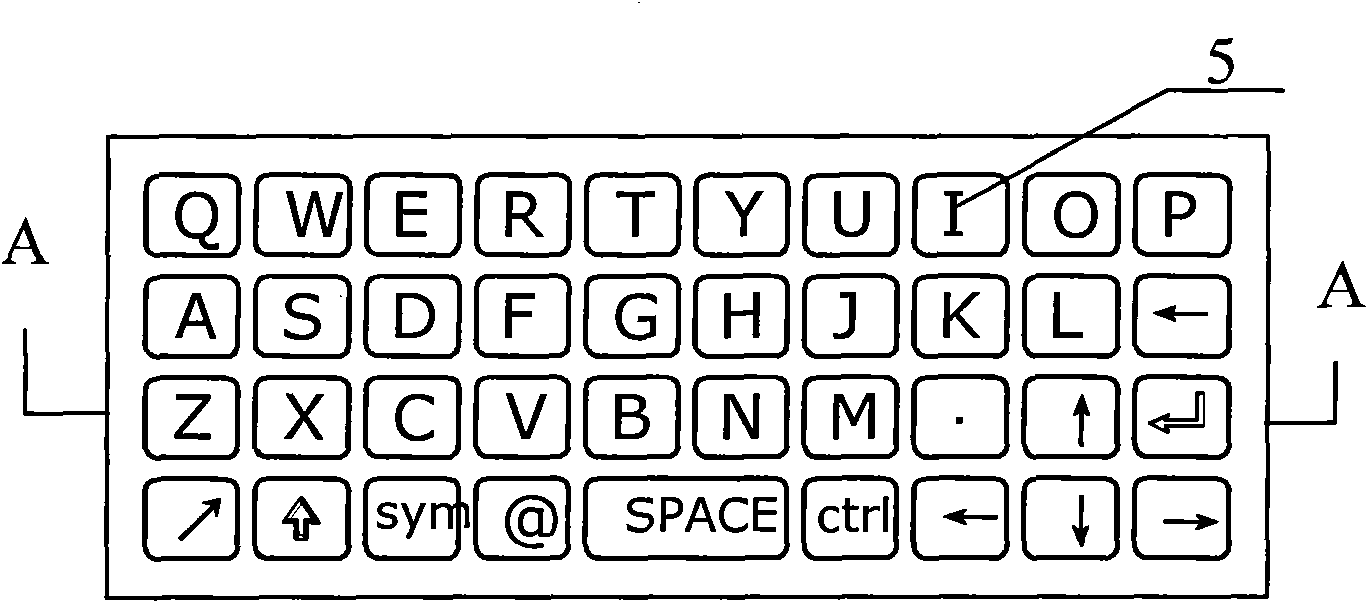

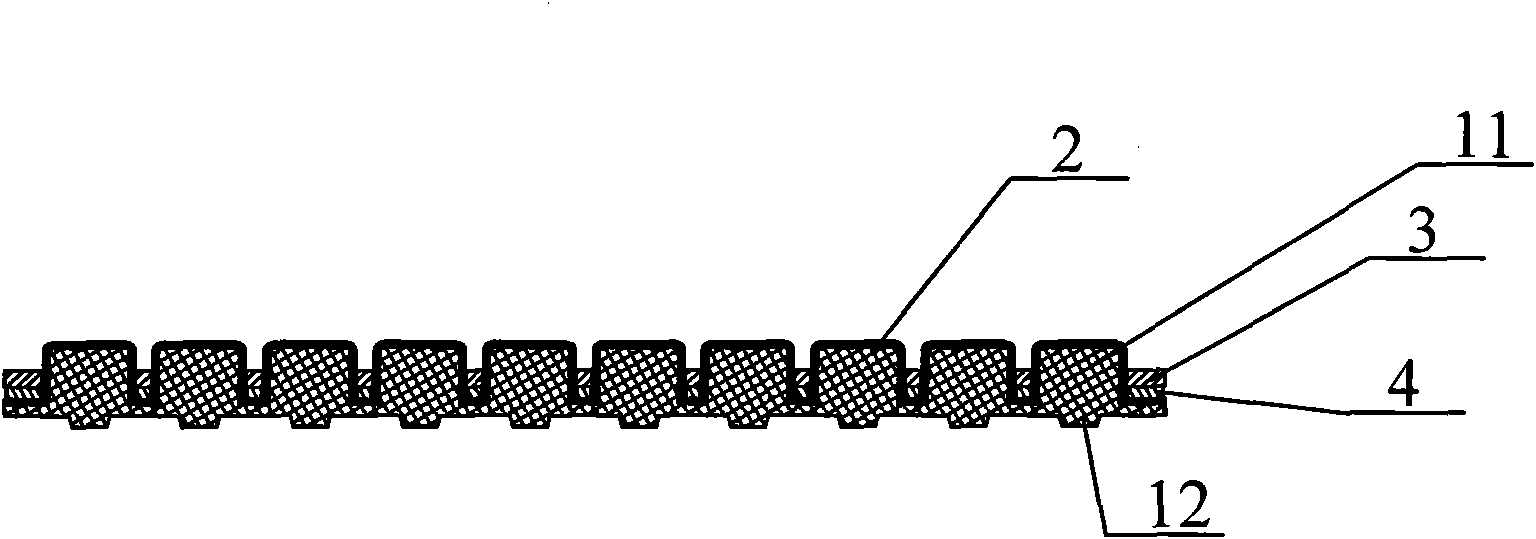

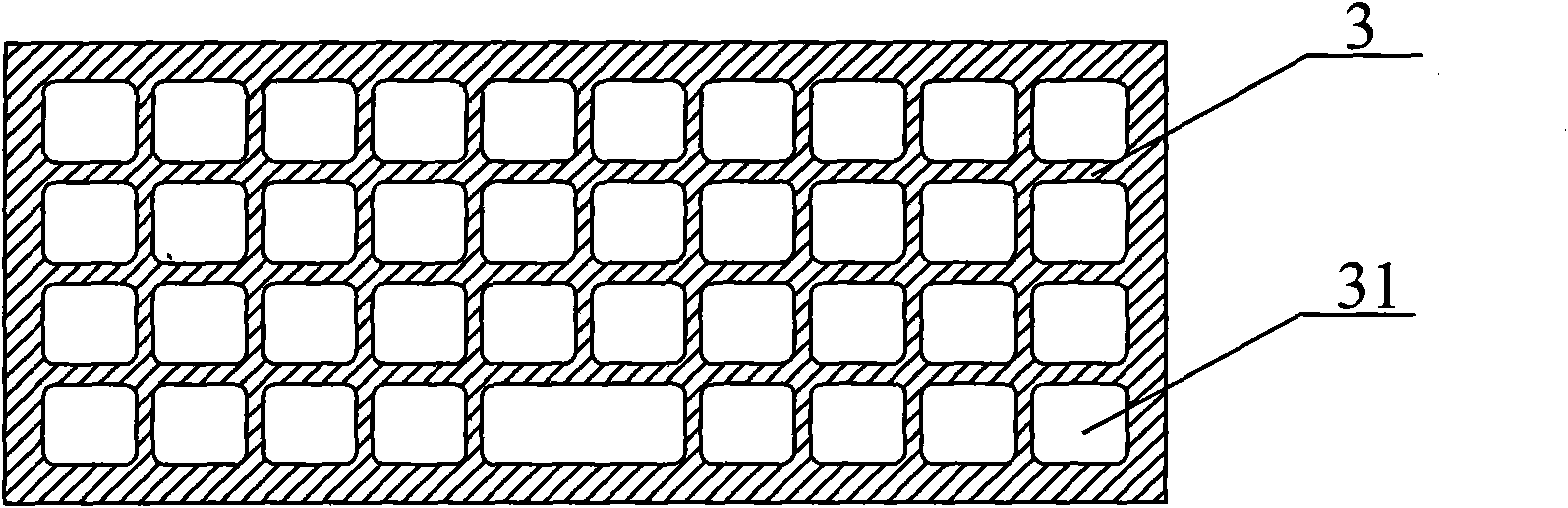

Full keyboard components, manufacturing method and full keyboard thereof

InactiveCN102034633AImprove rigidityIncrease productivityElectric switchesKey pressingAgricultural engineering

The invention provides full keyboard components which comprise a silica gel key body, wherein the key body comprises a plurality of first bulges on the upper surface, the first bulges are the key parts of the full keyboard components, and the key body also comprises a plurality of second bulges on the lower surface; film layers covered on the surface of the key body and coated the first bulges; and a bracket body sleeved at the bottoms of the first bulges. The thickness of the full keyboard components provided by the invention are thinner, a full keyboard has good rigidity, furthermore packaging technology is simple, the manufacturing method of the full keyboard components provided by the invention has simple technology and high production efficiency, and can enable the production quantity to be stable. In addition, because the second bulges at the corresponding position of each key are contact with a metal sheet, thereby ensuring the accuracy of each contact; and the thin film layer connected between keys is very thin, has much strong deformability, in addition, because of the support and fixation effects of the bracket body, the first bulges are discontinuous, thereby solving the linkage problem.

Owner:SUZHOU SHIHAO BUILDING MATERIAL NEW TECH ENG

Mixture for Liquid Crystal Medium and Liquid Crystal Display Using the Same

InactiveUS20140085593A1High levelStrength be balanceLiquid crystal compositionsNon-linear opticsHigh contrastLiquid-crystal display

The present invention provides a mixture for liquid crystal medium and a liquid crystal display using the same. The mixture for liquid crystal medium comprises: at least one anisotropic liquid crystal material and two polymerizable monomers which will polymerize under UV irradiation. The weight percentage of the polymerizable monomers accounts for 0.1% to 1% of the total mixture for liquid crystal medium. In the mixture for liquid crystal medium and a liquid crystal display using the same according to the present invention, by using two or more polymerizable monomers which will polymerize under UV irradiation and the appropriate content ratio, the polymer bump with small size and good uniformity can be obtained within the mixture for liquid crystal medium after the polymerization, which avoids the bad liquid crystal alignment and the light spot occurred at the dark state of the liquid crystal panel, and then increases the response rapid of the liquid crystal panel to obtain high contrast ratio and stable mass production.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

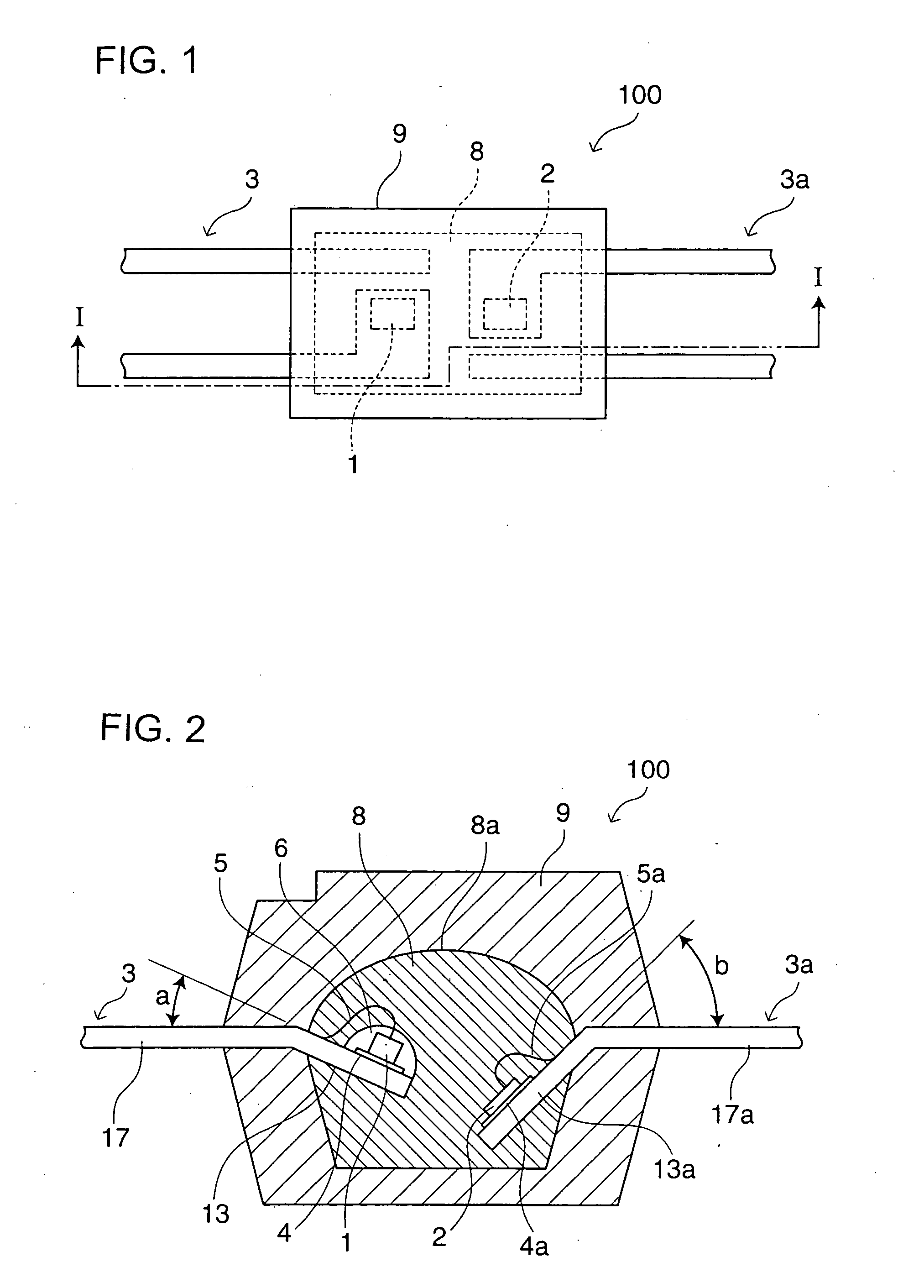

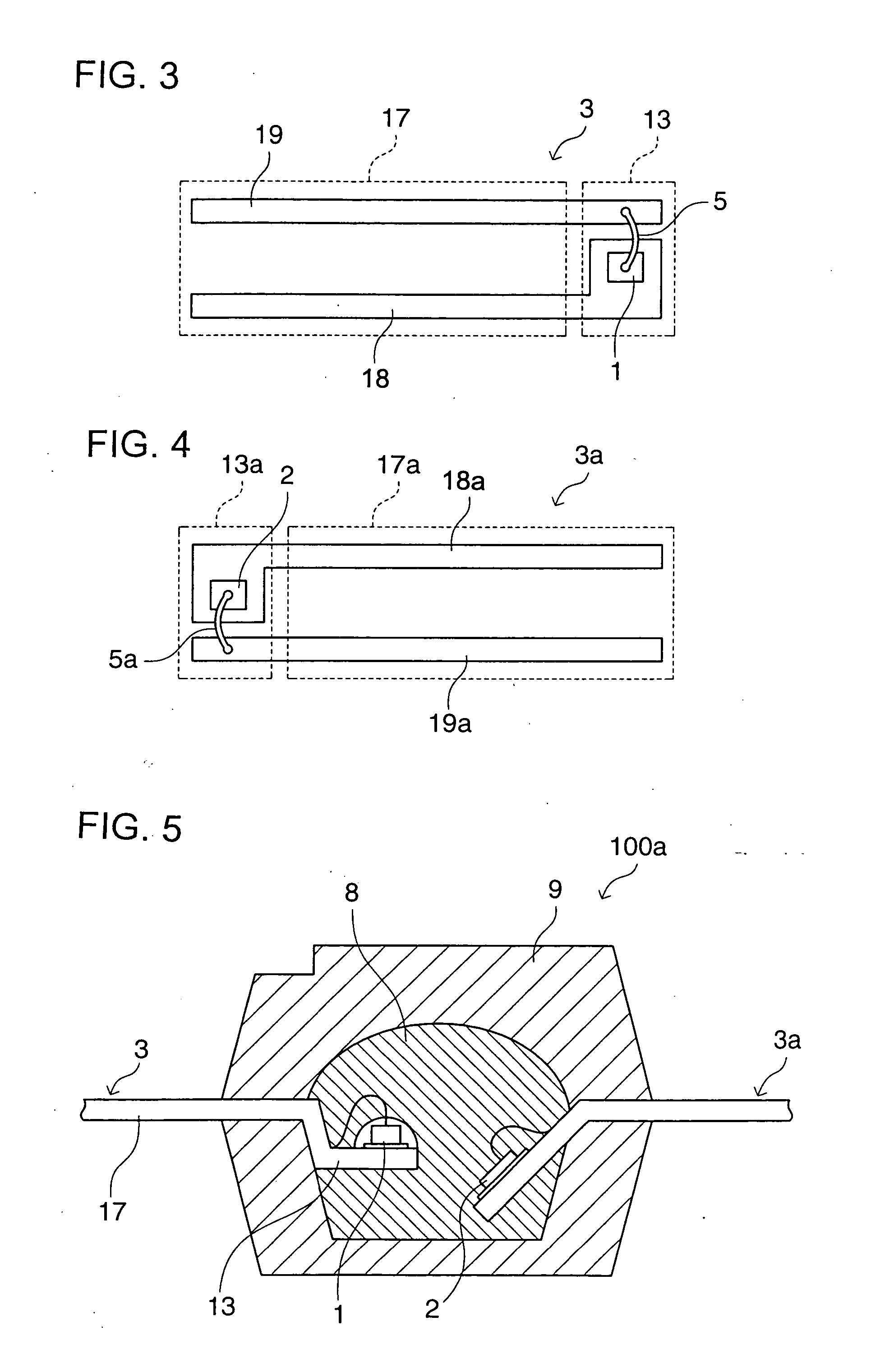

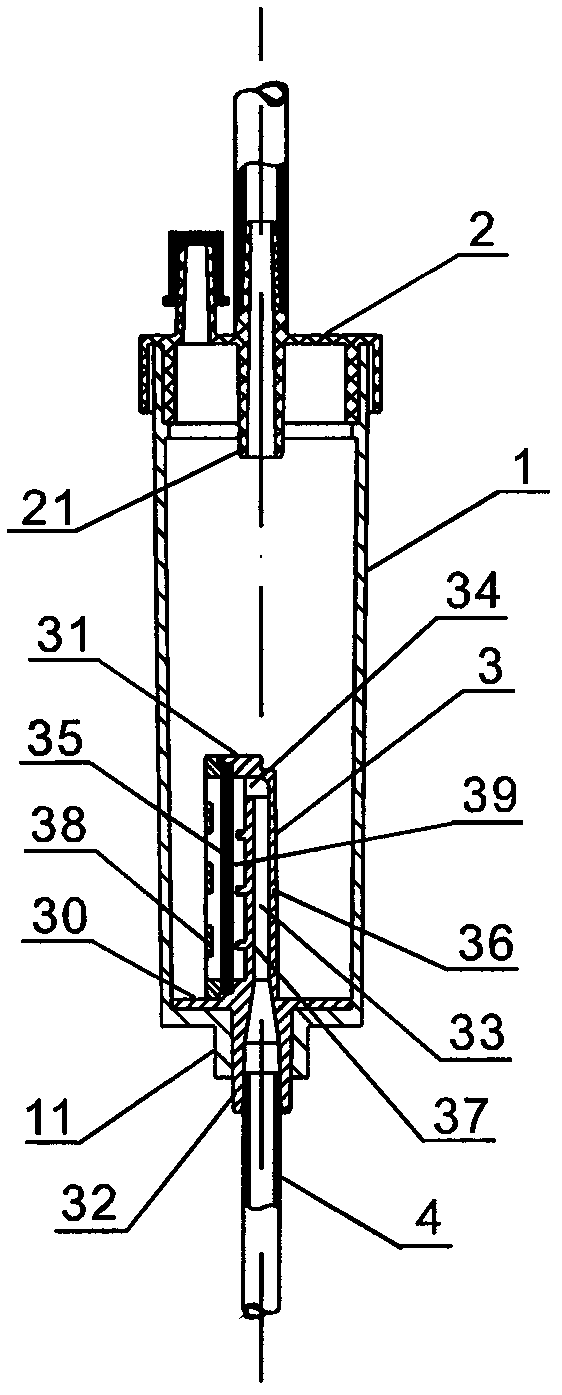

Photo-coupler semiconductor device and production method therefor

InactiveUS20040149995A1Improve light transmission efficiencyImprove heat resistanceSolid-state devicesSemiconductor/solid-state device manufacturingEpoxyEngineering

A photo-coupler semiconductor device includes first and second planar lead frames each having a main portion and a distal portion, a light emitting element and a light receiving element respectively mounted on upper surfaces of the distal portions of the first and second lead frames, a light-transmitting resin member which covers the light emitting element and the light receiving element, and supports the distal portions of the first and second lead frames in spaced opposed relation with the light emitting element and the light receiving element being mounted on the upper surfaces of the distal portions so that the main portions of the first and second lead frames are located in coplanar relation, and a opaque resin member which covers the light-transmitting resin member, and supports the main portions of the first and second lead frames. The light-transmitting resin member and the opaque resin member are each composed of an epoxy resin as a base resin.

Owner:SHARP KK

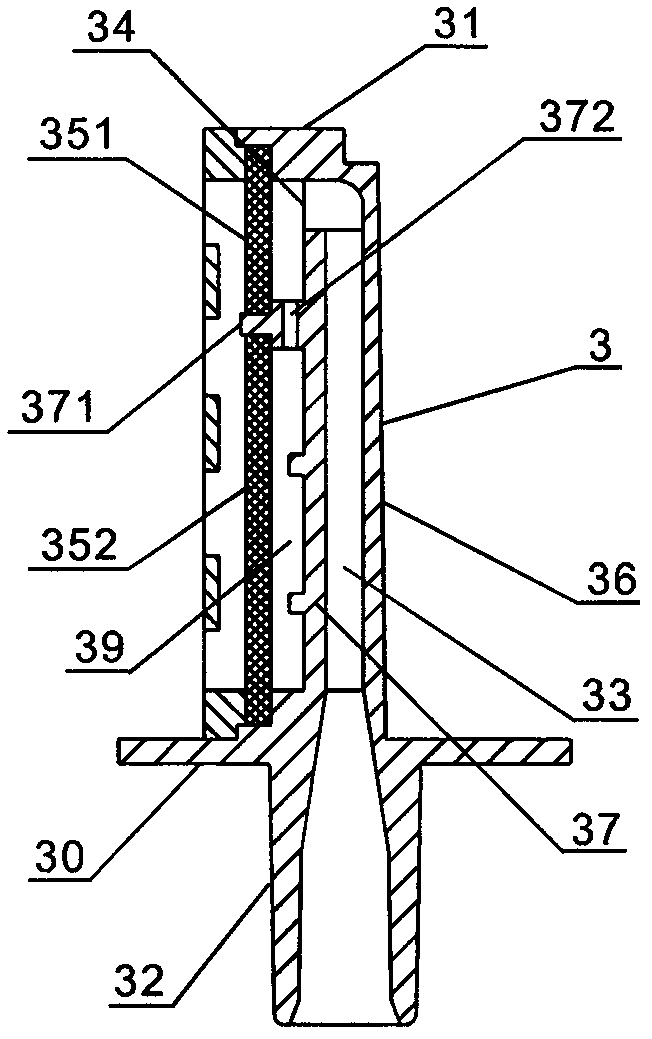

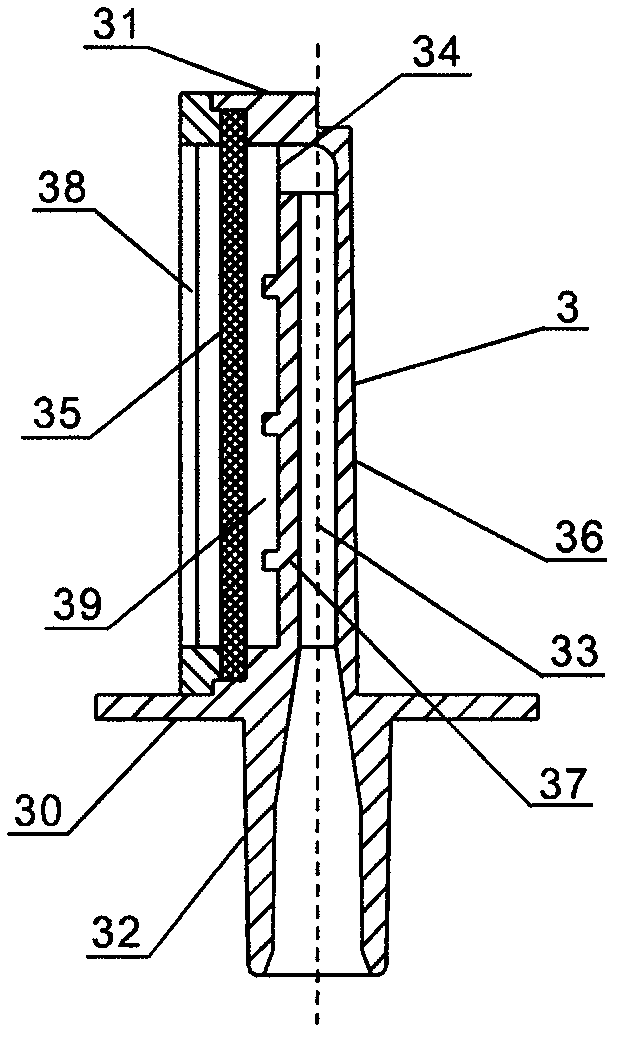

Automatic exhausting and liquid stopping multiple-effect infusion set

The invention relates to the technical field of medical equipment, in particular to an automatic exhausting and liquid stopping multiple-effect infusion set. The bottom of a dripping hopper is provided with an exhaust filter pipe sealed with a vertical filter membrane of which the bubble point pressure of 7.85-25.0kPa; the vertical filter membrane is gradually submersed when liquid is injected, so that a mode that the liquid is accumulated at the lower end and gas is exhausted at the upper end is realized; and by combining the special structure of the exhaust filter pipe, the multiple-effect aims of automatically exhausting, filtering a liquid medicine, eliminating bubbles and automatically stopping the liquid are skillfully fulfilled.

Owner:李林风

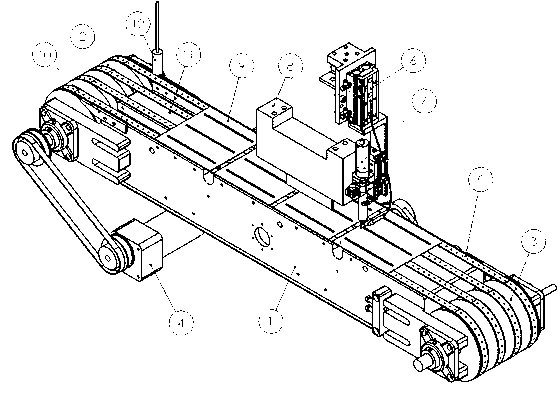

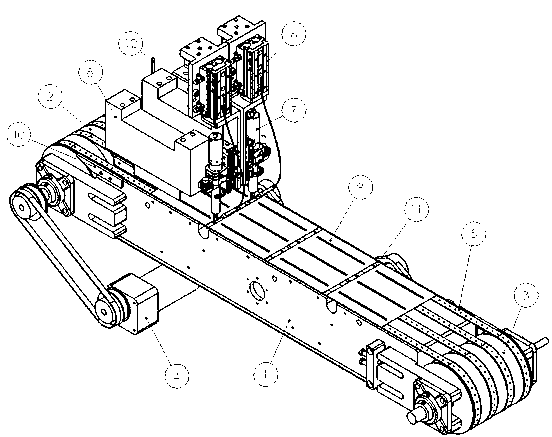

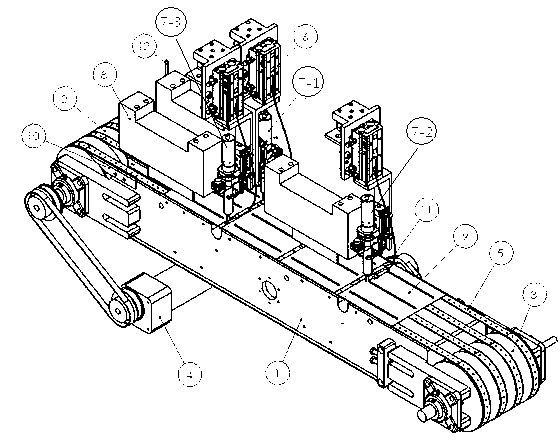

Device for forming tin electrode wire on solar cell sheet

InactiveCN103258890AHeating up fastLow costSoldering apparatusPhotovoltaic energy generationDrive wheelElectrical battery

The invention relates to the technical field of manufacturing equipment of semiconductors or micro-electronics or solar cells, in particular to a device for forming a tin electrode wire on a solar cell sheet. The device for forming the tin electrode wire on the solar cell sheet comprises a vacuum box, a driving wheel is arranged on one end of the vacuum box, and a driven wheel is arranged on the other end of the vacuum box. The driving wheel is provided with a constant speed motor, a conveyer belt is hung between the driving wheel and the driven wheel, and the conveyer belt runs continuously through the driving wheel and the driven wheel to form a continuous circulating conveying device. A lifting starting valve is arranged above the box, the lifting starting valve is provided with one or more ultrasonic welding joints, and an infrared heating source is arranged in front of each ultrasonic welding joint to carry out pre-heating on a substrate. According to the device for forming the tin electrode wire on the solar cell sheet, tin or tin alloy is connected to the solar cell sheet through the ultrasonic welding joints to form a conductive electrode. A device can control multiple electrode wires simultaneously. An infrared technology is used for heating, the substrate can be warmed to a preset temperature fast, high-speed welding is achieved, the producing capacity of one device can achieve 1200 sheets / hour, and device cost is low.

Owner:CHANGZHOU BITAI TECH

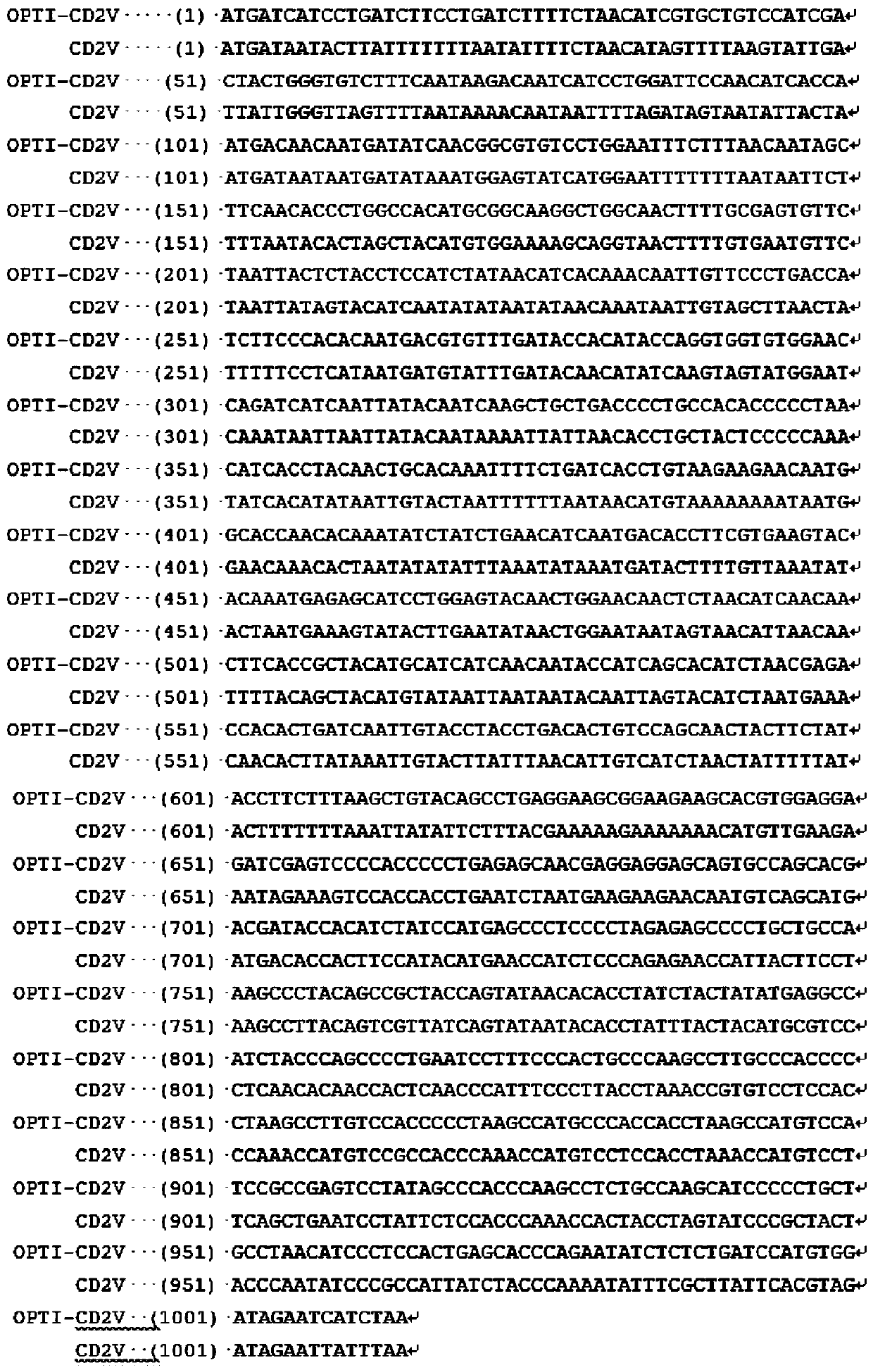

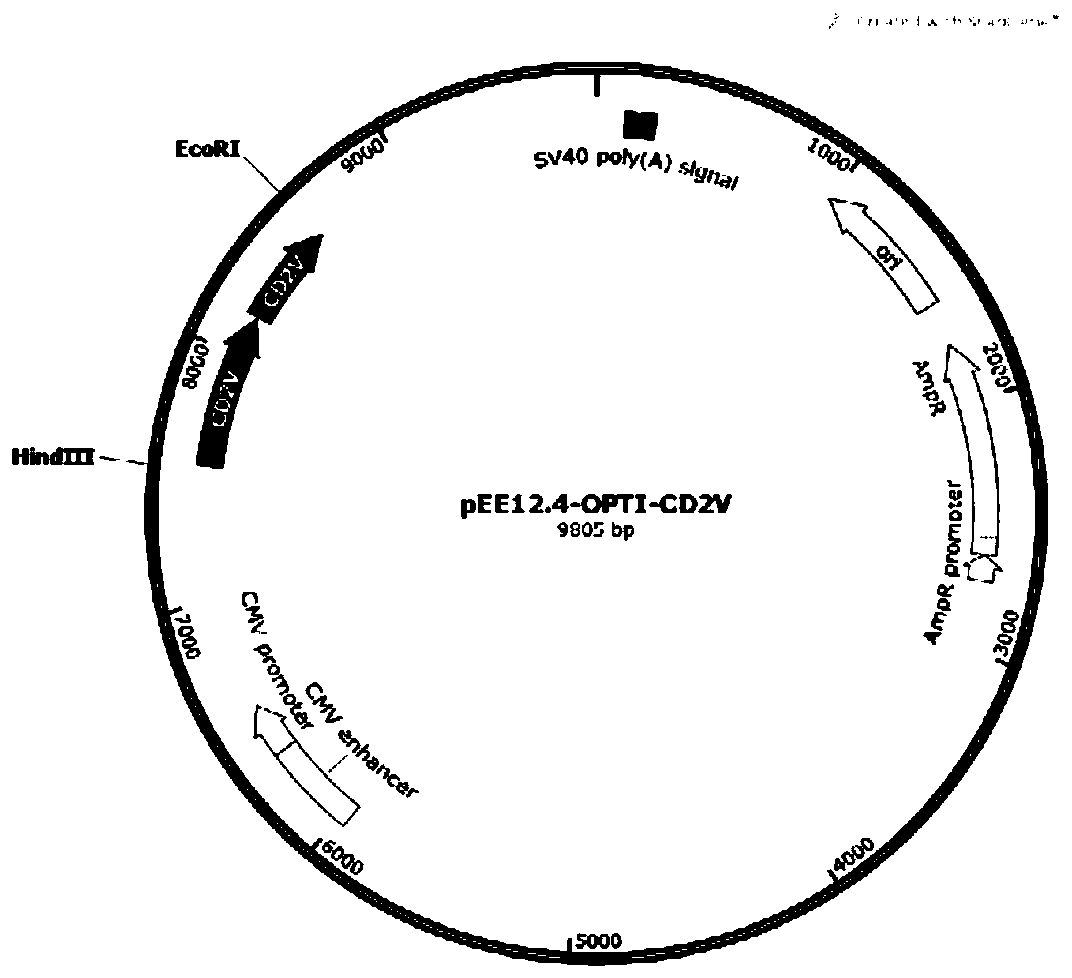

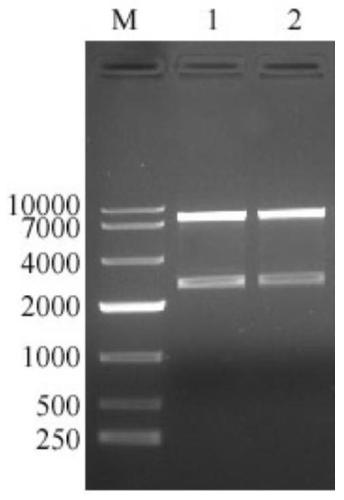

Recombinant African swine fever virus CD2V subunit protein as well as preparation method and application thereof

PendingCN111471089ABatch-to-batch stabilityImprove controllabilityViral antigen ingredientsVirus peptidesAdjuvantAfrican swine fever

The invention discloses a recombinant African swine fever virus CD2V subunit protein as well as a preparation method and application thereof. The protein comprises an extracellular region and an intracellular region of African swine fever virus surface envelope protein, and the amino acid sequence of the protein is shown as SEQ ID NO.3. The preparation method comprises the following steps: 1) cloning a codon-optimized gene sequence shown as SEQ ID NO.1 into an eukaryotic expression vector; 2) transfecting a recombinant expression vector containing the African swine fever virus subunit proteincoding gene into CHO cells; 3) culturing, screening and domesticating a CHO cell strain in the step 2) to obtain a highly-expressed cell strain; 4) fermenting and culturing the cell strain in the step3), and performing purifying to obtain the African swine fever virus CD2V subunit protein; and 5) mixing the CD2V protein with a pharmaceutically acceptable adjuvant to obtain a subunit vaccine. Theinvention can provide the African swine fever surface CD2V subunit protein which can be industrially produced on a large scale, the preparation method is simple and low in cost, and the prepared vaccine can reach the existing national standard.

Owner:NOVO BIOTECH CORP

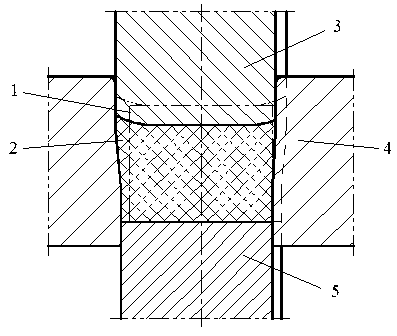

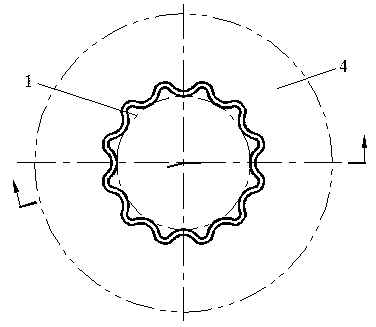

Precision forming method of straight/helical tooth cylindrical gear

ActiveCN102764847AIncrease in sizeReduce volumeMetal-working apparatusWheelsEngineeringProcess conditions

The invention relates to a precise forming method of a straight / helical tooth cylindrical gear. The precise forming method disclosed by the invention is characterized by being realized by the following two steps while a 'diameter-increasing half long ridge-tooth space splitting' way is adopted: firstly, closed die forging is carried out on cylindrical blank to form a pre-formed part, wherein one end of the pre-formed part is larger in radial dimension, sectional area and edge axial dimension and the other end of the pre-formed part is equal to the required value of the sectional area and has slightly smaller radial dimension, the two ends transit in a bevel angle manner, and a cylindrical surface is in a 'diameter-increasing half long ridge' state; and secondly, the pre-formed parts penetrate through a final forming die each tooth space of which is correspondingly provided with a splitting wedge in a sequence from big end to small end, wherein a splitting edge and a working surface of the splitting wedge are in a tilted state, a rim is split, extruded and deforms, and each slot base is deepened and the top of each ridge is lifted, thus a gear tooth with complete tooth profile is obtained. The gear tooth / tooth space obtained by the invention is clear and full, a required forming force is relatively small, an equipment action is simple, a structure of a die is not complex, a workpiece is easy to demould, requirement to technological conditions is low, and adaptability is wide.

Owner:SHENZHEN AIDELI ELECTROMECHANCIAL

Production method of low-cost continuous casting round billet for ultra-supercritical high-pressure boiler tube

The invention belongs to the technical field of metallurgy and mainly relates to a production method of a low-cost continuous casting round billet for an ultra-supercritical high-pressure boiler tube.The production method comprises the following steps: primarily smelting molten steel in an electric arc furnace, wherein the phosphorus content and the harmful element content of the molten steel arelow; melting chromium iron, molybdenum iron, tungsten iron and other alloys in an intermediate frequency furnace; after the steel tapping operation in an electric furnace, collecting molten alloy steel from the intermediate frequency furnace, injecting the molten alloy steel into an argon oxygen furnace, and performing the decarburization operation, the desulfurization operation and the oxygen nitridation operation, wherein the top-bottom composite smelting mode is adopted for the argon oxygen furnace; and after the steel tapping operation in the argon oxygen furnace, performing fine alloy adjustment in a ladle refining furnace, performing vacuum degassing in a VD furnace, casting the continuous casting round billet on a vertical continuous casting machine after the vacuum degassing operation in the VD furnace, wherein the inner diameter of the continuous casting round billet reaches 400-800 mm. The continuous casting round billet produced according to the production method provided by the invention is low in production cost, high in composition uniformity and high in macroscopic quality; and the quality and the market competitiveness of an ultra-supercritical high-pressure boilertube billet can be improved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Preparation method of para-aramid nanofibers

ActiveUS20180155853A1Short in production processSimple equipmentArtificial filament recoveryArtificial filament washing/dryingChemistryBatch production

The present invention relates to a preparation method of para-aramid nanofibers, and belongs to the technical field of novel polymer materials. The para-aramid nanofibers prepared in the present invention have a diameter of 10-100 nm, and a length of hundreds of microns. The preparation method includes: adding a certain amount of surfactant in a PPTA low-temperature polymerization process, and controlling aggregation of PPTA molecules along with growth of a PPTA molecule chain, thereby preparing the para-aramid fibers with a uniform size and an adjustable nano-scale diameter under assistance of other means (e.g., a coagulator and high-speed shearing dispersion). The present invention is short in production process and simple in equipment, can realize stable batch production to meet needs of large-scale production of the para-aramid nanofibers, has wide application prospects and can be applied to preparing a lithium-ion battery separator, a high-performance composite material and the like.

Owner:TSINGHUA UNIV

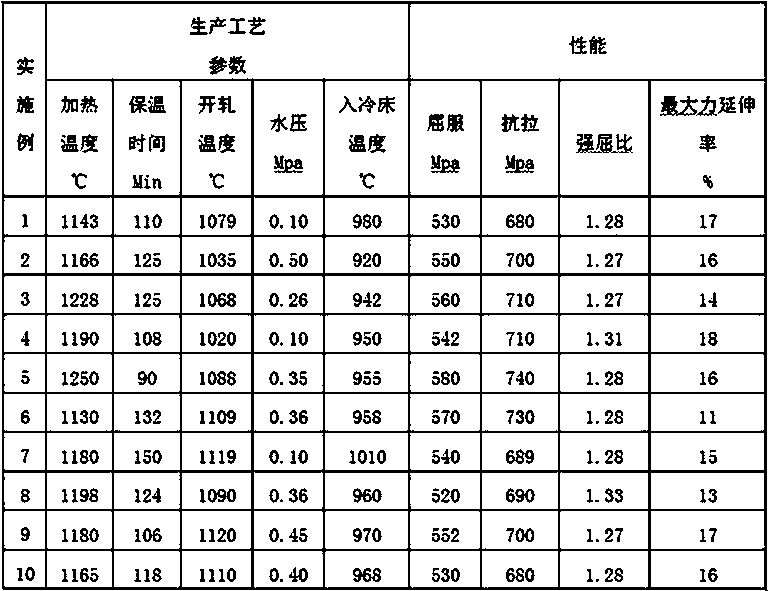

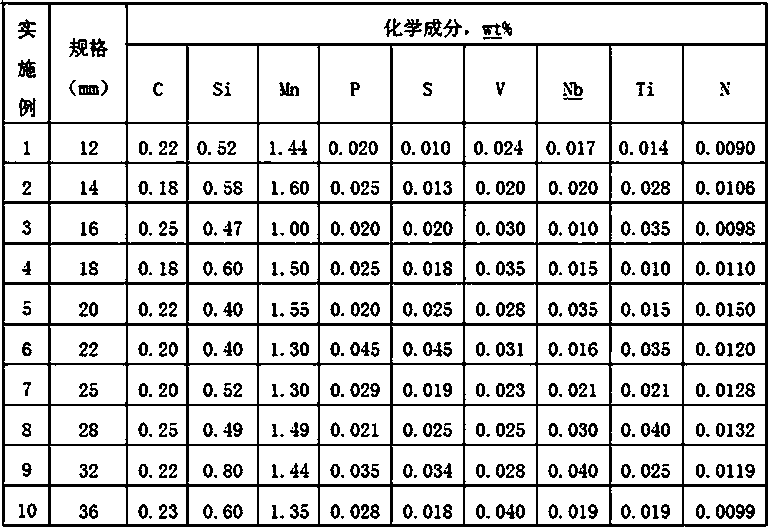

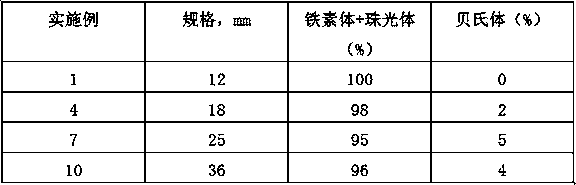

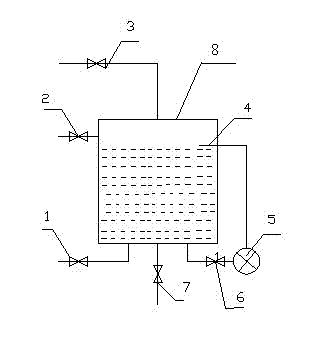

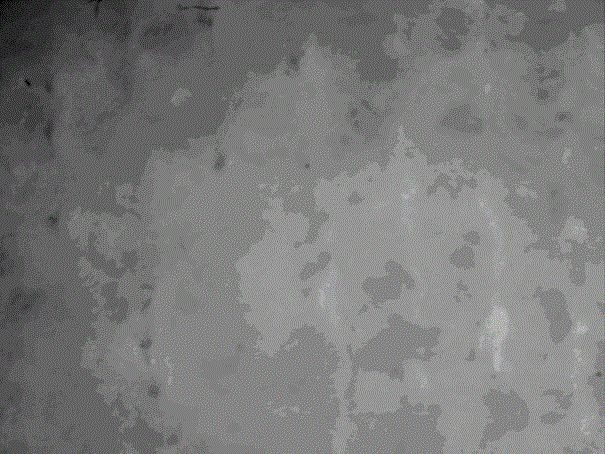

500 MPa level high-nitrogen composite microalloyed steel bar and production method thereof

InactiveCN109576583AImprove pourabilityGuaranteed Yield StrengthChemical compositionNational standard

The invention relates to a 500 MPa level high-nitrogen composite microalloyed steel bar and a production method thereof. The 500 MPa level high-nitrogen composite microalloyed steel bar comprises thefollowing chemical components of, by mass, 0.18-0.25 parts of C, 0.40-0.80 parts of Si, 1.30-1.60 parts of Mn, less than or equal to 0.045 parts of P, less than or equal to 0.045 parts of S, 0.020-0.040 parts of V, 0.010-0.040 parts of Nb, 0.010-0.040 parts of Ti, 0.0090-0.0150 parts of N, and the balance iron and unavoidable impurity elements. In the production method, after the continuous casting process is completed, a continuous casting billet is heated to 1130-1250 DEG C and subjected to heat preservation for 90-150 minutes, and then cooled to 1020-1120 DEG C for rolling; after the rolling, water cooling is carried out with the water pressure being 0.1-0.5 MPa and the temperature of an upper cooling bed being controlled at 920-1010 DEG C; and the steel bar is naturally cooled after entering the cooling bed, so that the high-nitrogen composite microalloyed steel bar is obtained. The mechanical properties of the steel bar meet the requirements of the national standard, the production cost is low and a production process is simple and easy to implement.

Owner:HANDAN IRON & STEEL GROUP +1

Process and device for producing high-oxygen sponge titanium

The invention provides a process and a device for producing high-oxygen sponge titanium through adding oxygen directly in a smelting process of the sponge titanium. The oxygen content of titanium tetrachloride is controlled to control the oxygen content of the sponge titanium stably. According to requirements for the oxygen content by a titanium alloy, titanium dioxide is not needed to add during a smelting process of the sponge titanium for production of the sponge titanium with satisfactory oxygen content, therefore composition segregation and local defects caused by addition of the titanium dioxide are avoided, the alloy mixing difficulty is reduced simultaneously, uniform components and stable quality of titanium ingots are guaranteed, and performances of titanium alloy materials are improved effectively.

Owner:朝阳金达钛业股份有限公司

Full penetration printing production process of 34-inch thick double-sided polar fleece

ActiveCN104553419ACreativeAdvancedWeft knittingHeating/cooling textile fabricsScreen printingTextile printer

The invention relates to a full penetration printing production process of 34-inch thick double-sided polar fleece. The process is characterized in that an entire set of optimal technical scheme of system engineering design is established through technical means such as weaving, dyeing and finishing and microscopic computer image analysis. The process comprises the following steps: weaving a blank; performing dyeing and finishing pretreatment on fabric; tentering and shaping the fabric before printing; performing microscopic computer image analysis; performing rotary screen printing, evaporation, washing and emulsification on the fabric; tentering and shaping the fabric after printing; galling, combing, shearing and fleecing; shaping billet. The process has the beneficial effects that 1, the difference value of printing and dyeing color yield percentage of front and back faces of the fabric is reduced, and the front and back faces of the finished product are attractive in color, and 2, the finished fabric is full, fluffy and soft in raising, the problem of hard handfeel of the thick double-sided fleece fabric is solved, and a high added value of the product is further improved. The fleece is most suitable for making middle and top grade thermal vests, jacks, underwear, (woolen) shirts, overcoats, bedding articles, carpets, gloves, scarves, hats, back cushions and the like.

Owner:QINGDAO JIFA GROUP

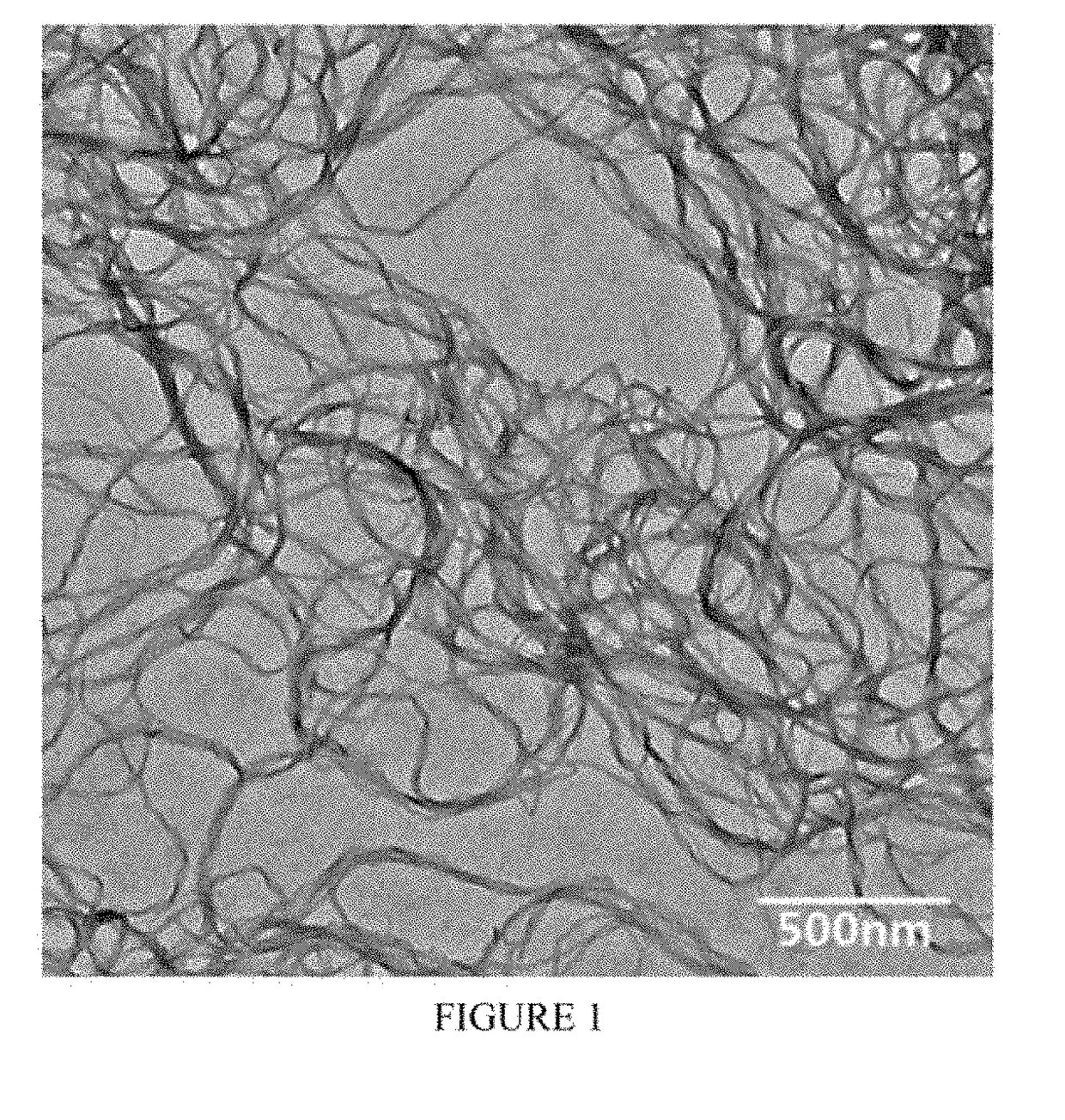

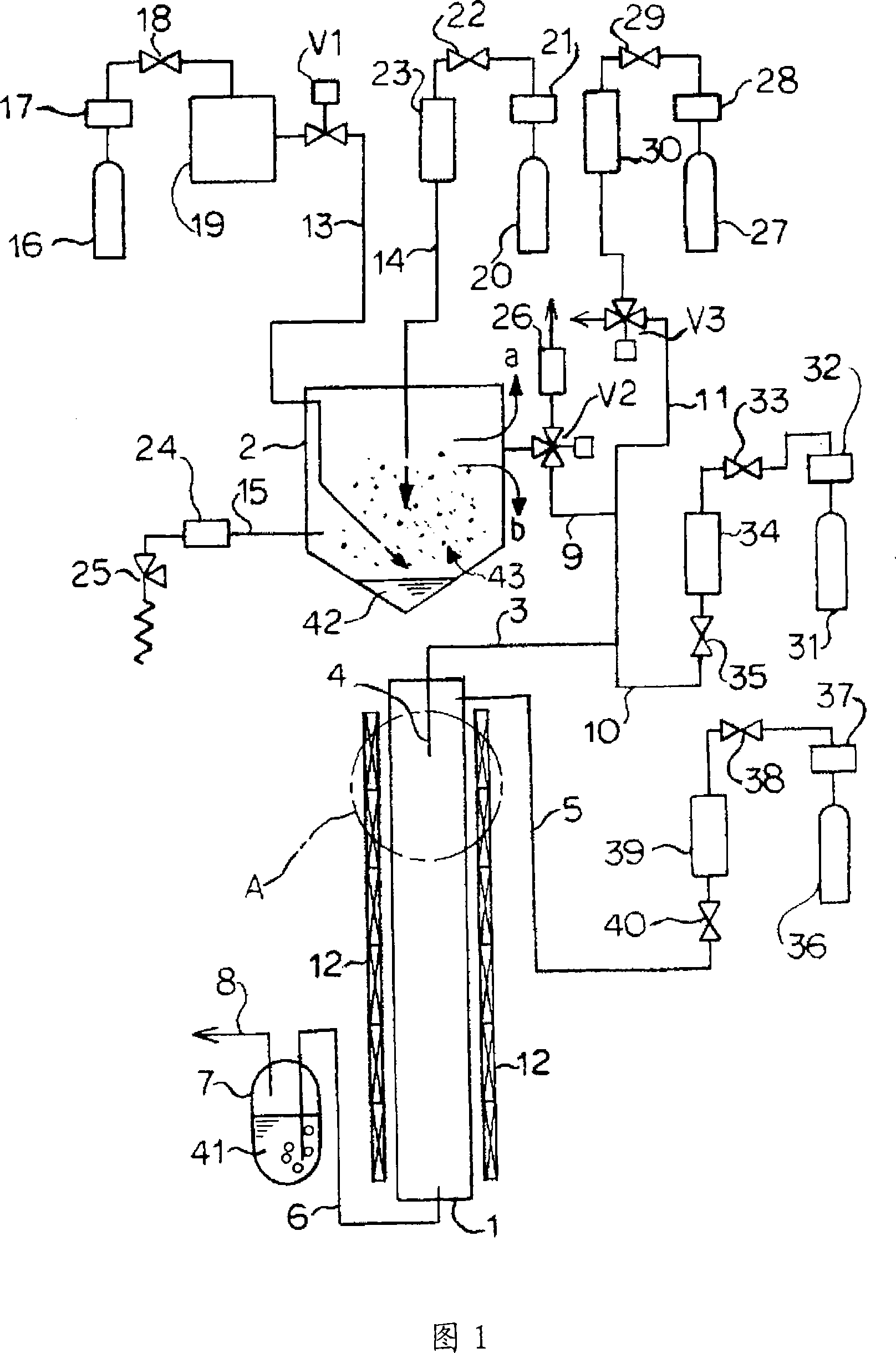

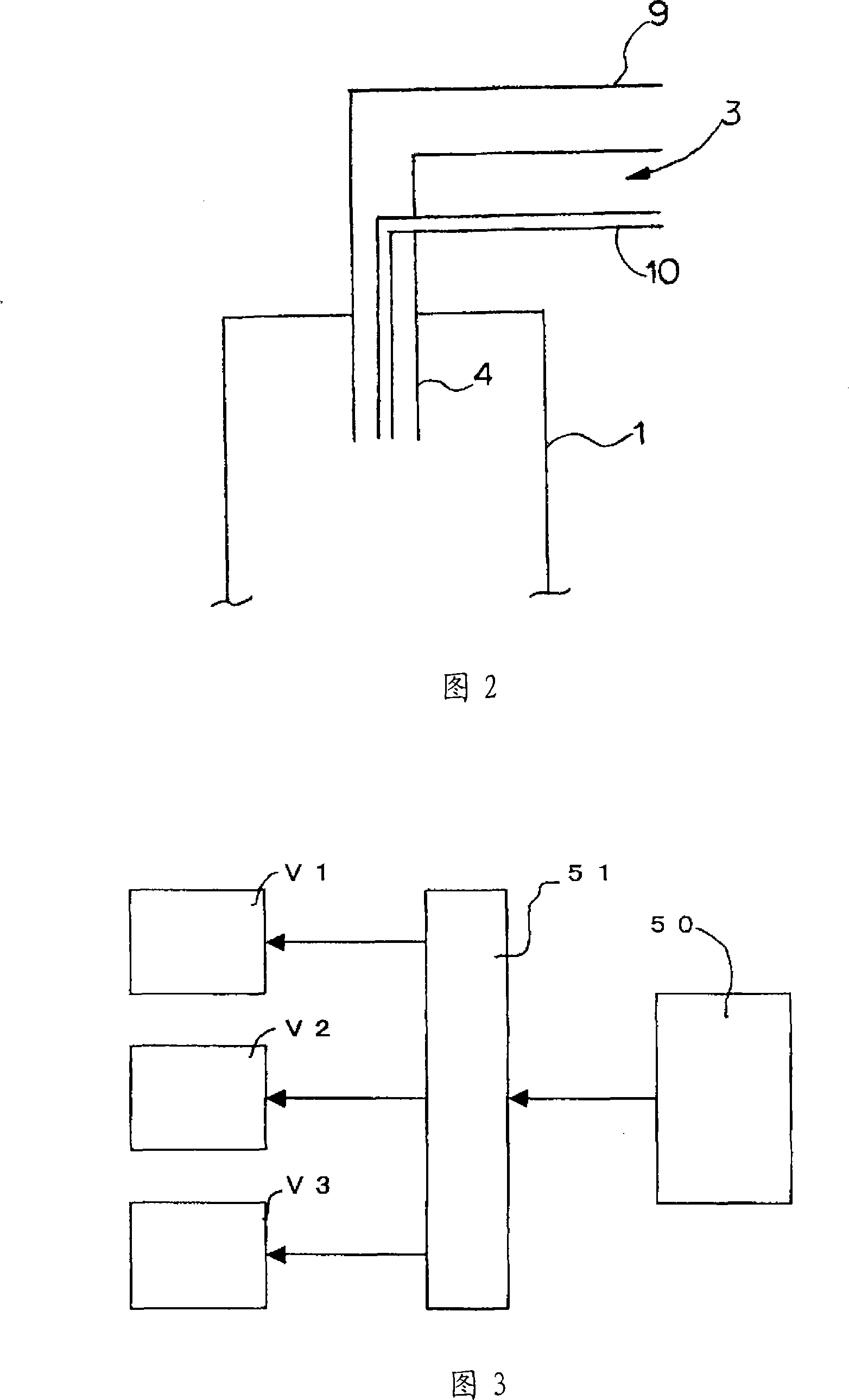

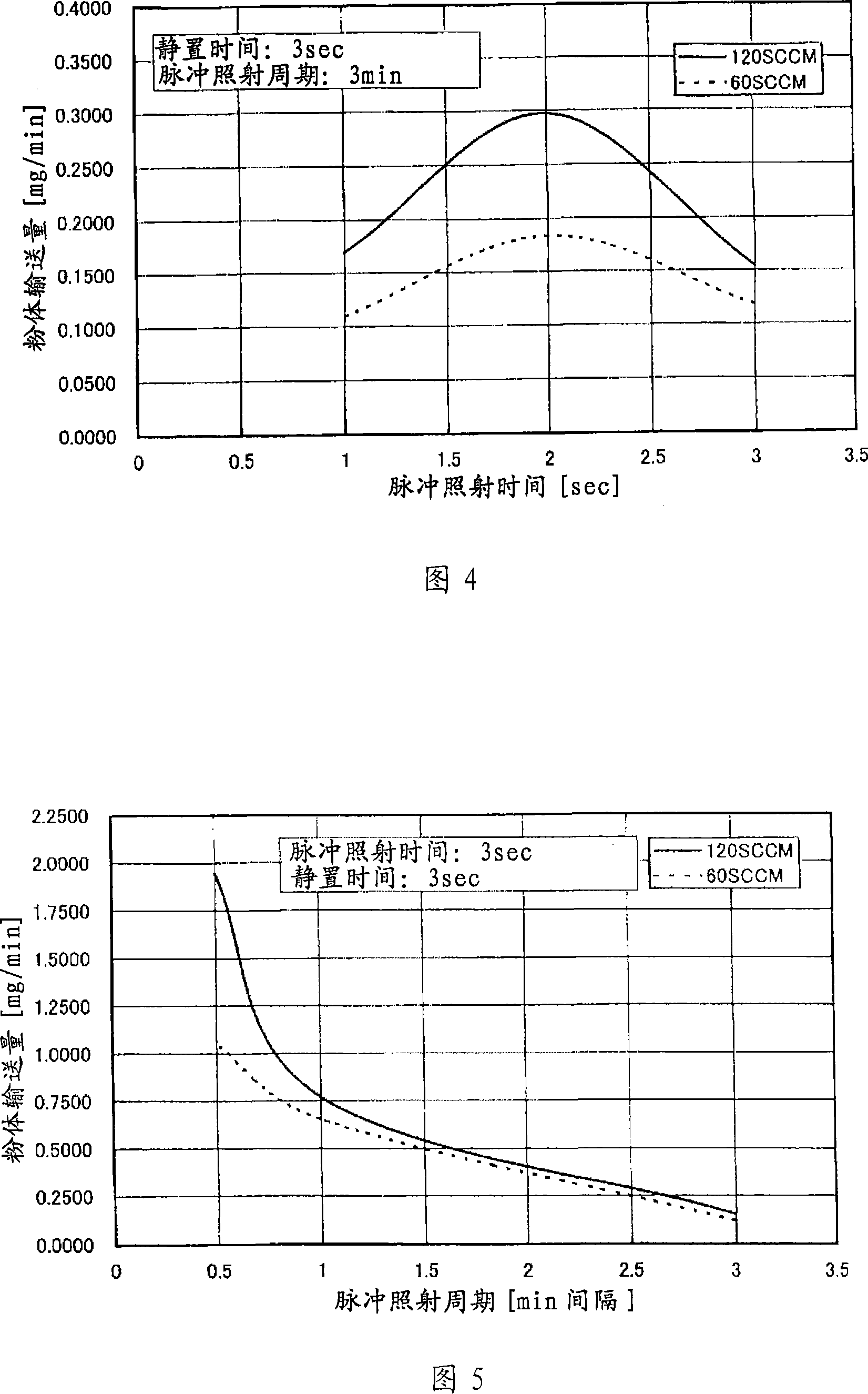

Process for producing catalyst patricle diameter control type carbon nanostructure production, production apparatus therefor, and carbon nanostructure

InactiveCN101018737AHigh yieldContinuous manufacturing processMaterial nanotechnologyNanostructure manufactureMicroparticleHigh pressure

A process for producing a carbon nanostructure, comprising effecting contact of a raw gas with catalyst microparticles, while allowing them to flow, in a reactor furnace, wherein a high-pressure pulse gas is instantaneously blown to the catalyst microparticles to thereby float the same, then the floating of catalyst microparticles is discontinued so as to allow the catalyst microparticles to freely fall, and selection of particle diameter is carried out, and wherein catalyst microparticles having been selected in accordance with appropriate particle diameter control thus performed is transferred and fed into the reactor furnace. By this process, a carbon nanostructure can be continuously produced stably at low cost without being influenced by a dispersion of particle diameter inherent in catalyst raw materials. Further, there is provided a carbon nanostructure comprised of a curly carbon nanotube of 1 to 300 nm diameter, the curliness being one with a three-dimensional configuration having bending points irregularly incorporated therein.

Owner:JAPAN SCI & TECH CORP +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com