Automatic exhausting and liquid stopping multiple-effect infusion set

An automatic exhaust and infusion set technology, applied in the field of medical devices, can solve the problems of difficulty in accurately controlling the drain line, slowness, and instantaneous failure of the filter capsule.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

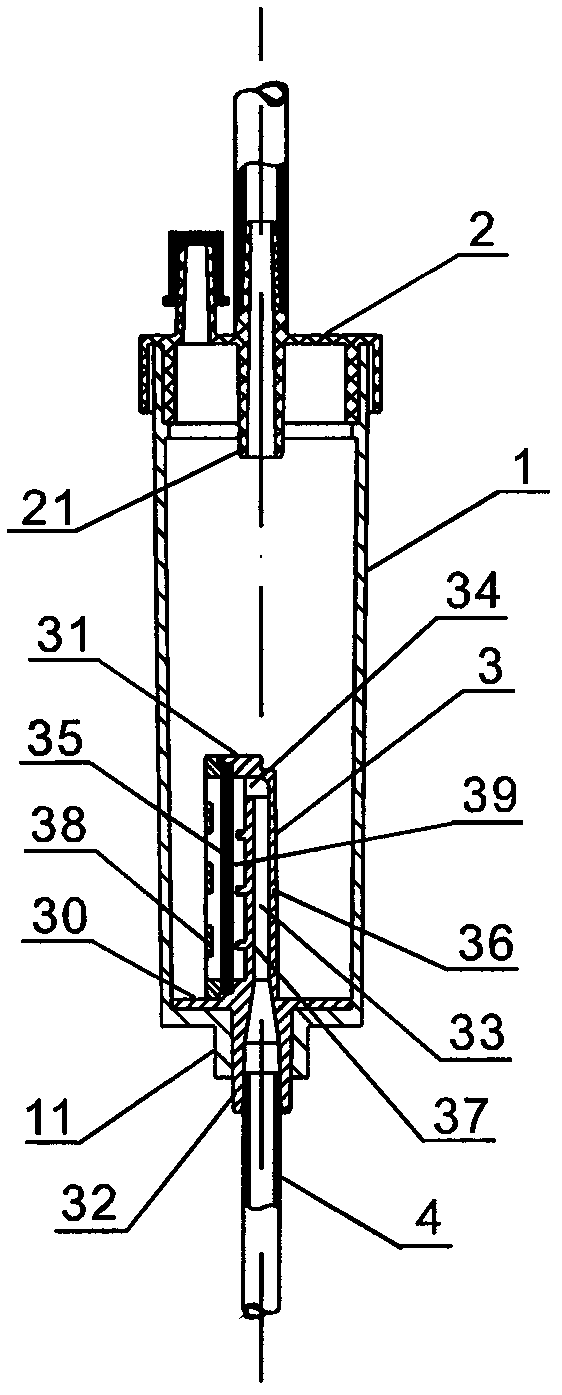

[0029] Such as figure 1 The shown multi-effect infusion set, the infusion set includes a drip funnel 1, a drip funnel cover 2, a dropper 21, an exhaust filter tube 3 and a conduit 4, and the dropper 21 is integrally formed and communicated with the drip funnel cover 2, so An access end 11 extends from the outside of the bottom of the dropping funnel 1, wherein the exhaust filter pipe 3 is composed of components comprising a top end 31, an extension pipe 32, a filter membrane 35, a base plate 36 and a spacer plate 37, and the filter membrane 35 is vertically Installed on the exhaust filter pipe 3, the top 31 of the exhaust filter pipe 3 is closed, and its sealing part covers the vertical filter membrane 35 at least longitudinally, and the top 31 of the exhaust filter pipe 3 forms with the filter membrane 35 and the bottom plate 36 A cavity body, which is divided into a filter cavity 39 and a liquid outlet cavity 33 by an intermediate plate 37, and the filter membrane 35, the fi...

Embodiment 2

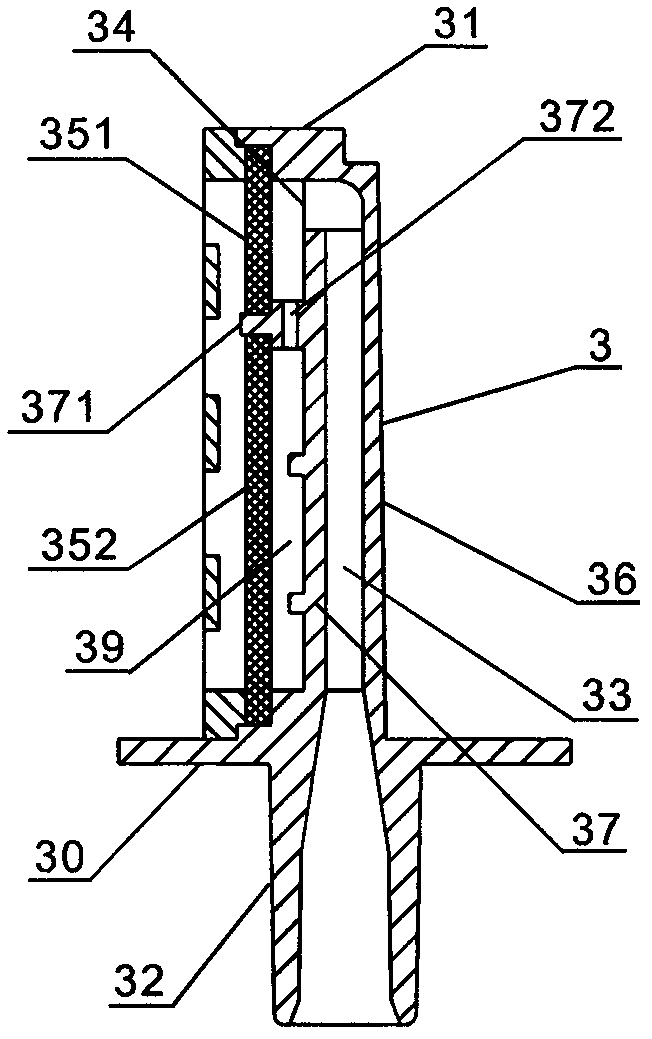

[0034] Such as figure 2The shown multi-effect infusion set, the infusion set includes a drip funnel 1, a drip funnel cover 2, a dropper 21, an exhaust filter tube 3 and a conduit 4, and the dropper 21 is integrally formed and communicated with the drip funnel cover 2, so An access end 11 extends from the outside of the bottom of the dropping funnel 1, wherein the exhaust filter pipe 3 is composed of components comprising a top end 31, an extension pipe 32, a filter membrane 35, a base plate 36 and a spacer plate 37, and the filter membrane 35 is vertically Installed on the exhaust filter pipe 3, the top 31 of the exhaust filter pipe 3 is closed, and its sealing part covers the vertical filter membrane 35 at least longitudinally, and the top 31 of the exhaust filter pipe 3 forms with the filter membrane 35 and the bottom plate 36 A cavity body, which is divided into a filter cavity 39 and a liquid outlet cavity 33 by an intermediate plate 37, and the filter membrane 35, the fi...

Embodiment 3

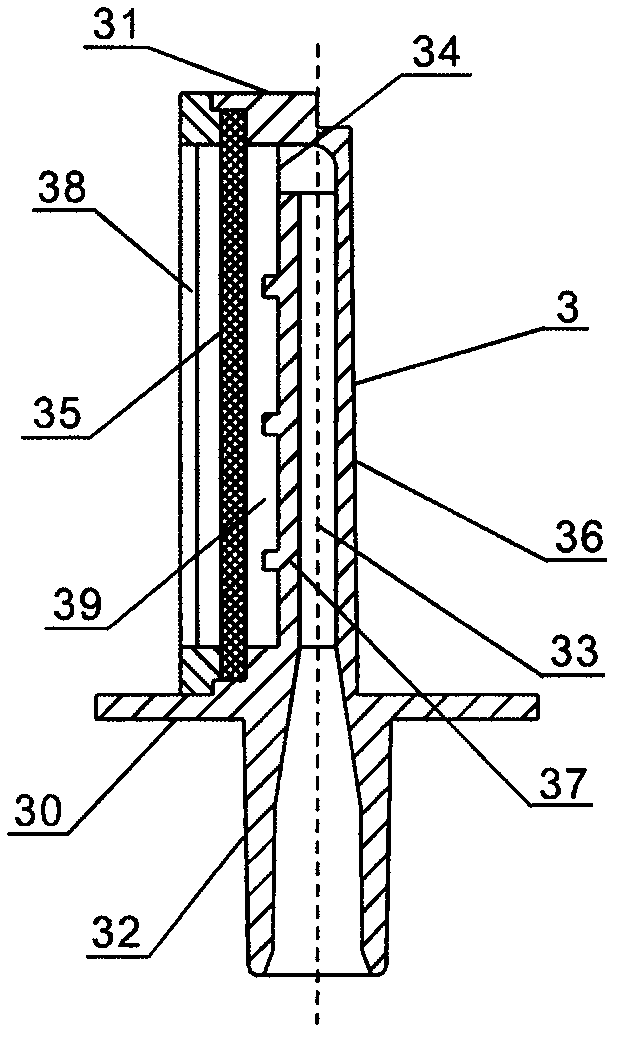

[0039] Such as image 3 The shown multi-effect infusion set, the infusion set includes a drip funnel 1, a drip funnel cover 2, a dropper 21, an exhaust filter tube 3 and a conduit 4, and the dropper 21 is integrally formed and communicated with the drip funnel cover 2, so An access end 11 extends from the outside of the bottom of the dropping funnel 1, wherein the exhaust filter pipe 3 is composed of components comprising a top end 31, an extension pipe 32, a filter membrane 35, a base plate 36 and a spacer plate 37, and the filter membrane 35 is vertically Installed on the exhaust filter pipe 3, the top 31 of the exhaust filter pipe 3 is closed, and its sealing part covers the vertical filter membrane 35 at least longitudinally, and the top 31 of the exhaust filter pipe 3 forms with the filter membrane 35 and the bottom plate 36 A cavity body, which is divided into a filter cavity 39 and a liquid outlet cavity 33 by an intermediate plate 37, and the filter membrane 35, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com