Patents

Literature

283 results about "Vertical filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

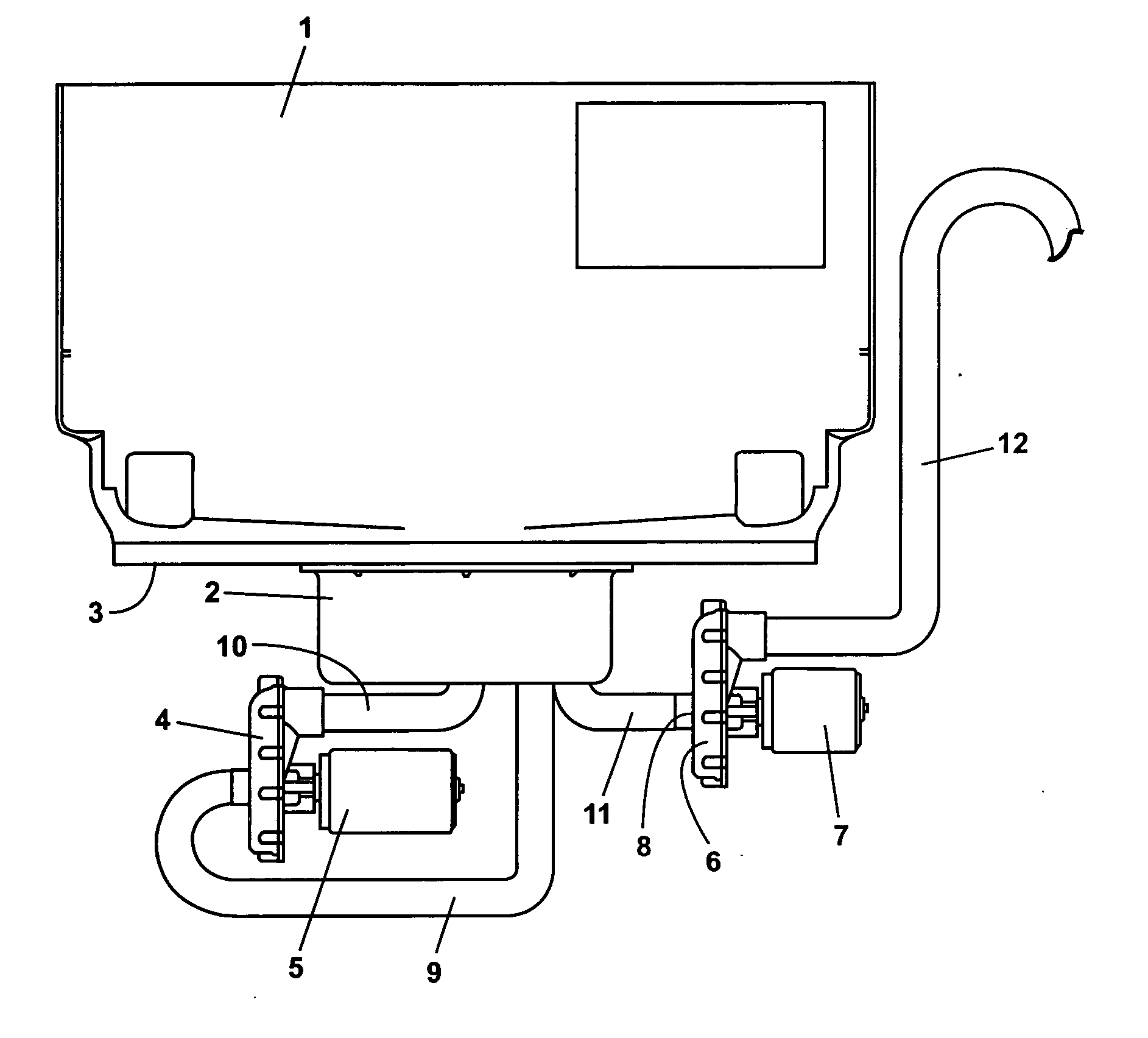

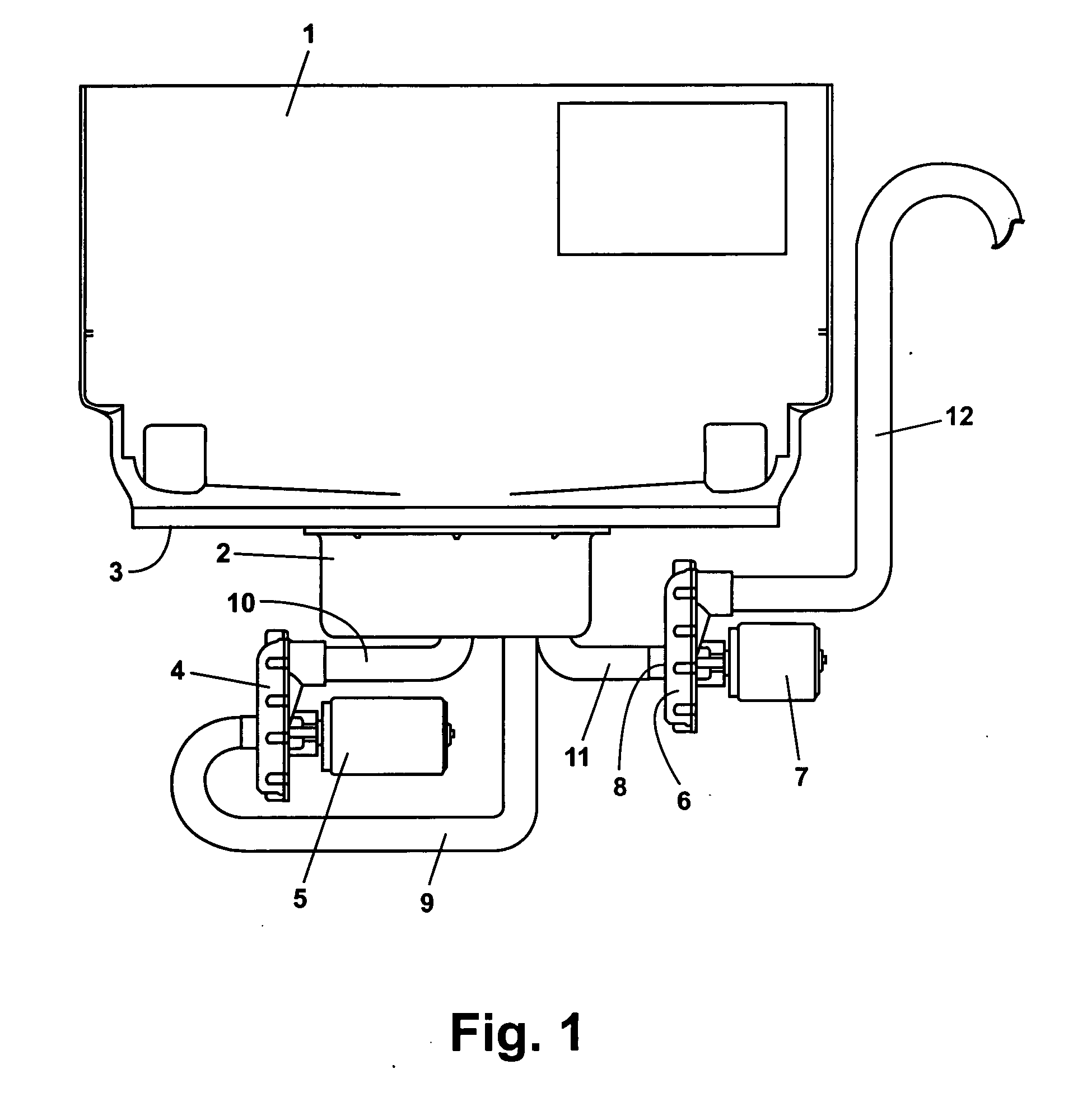

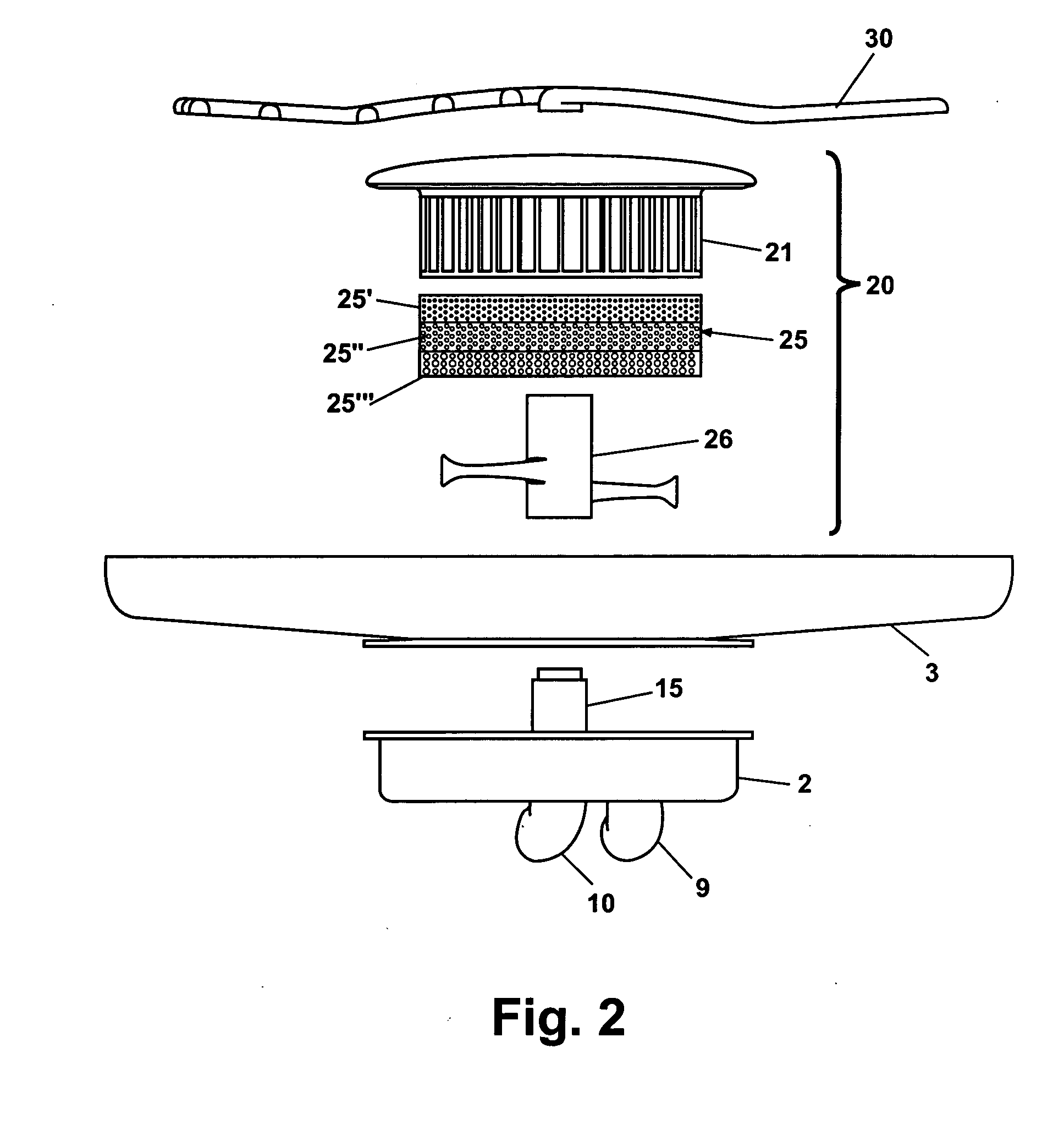

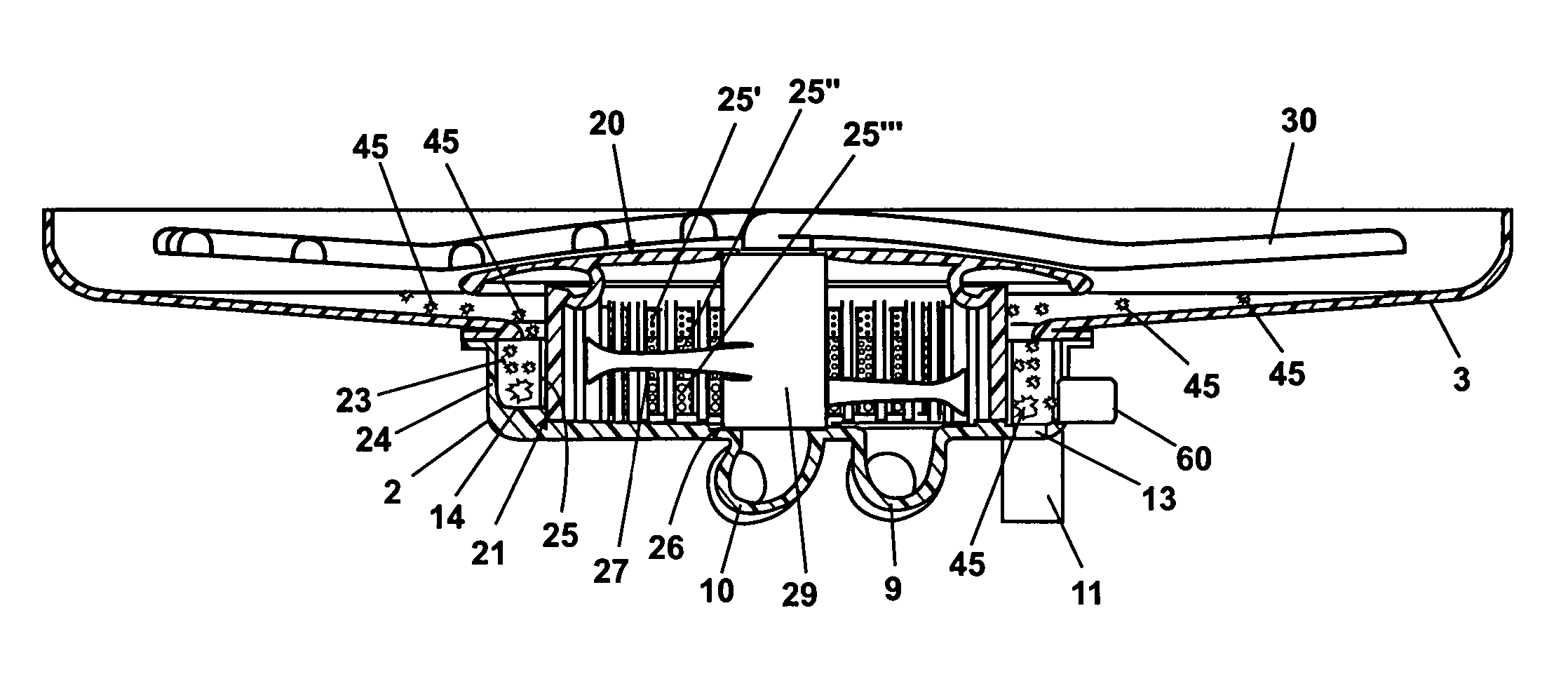

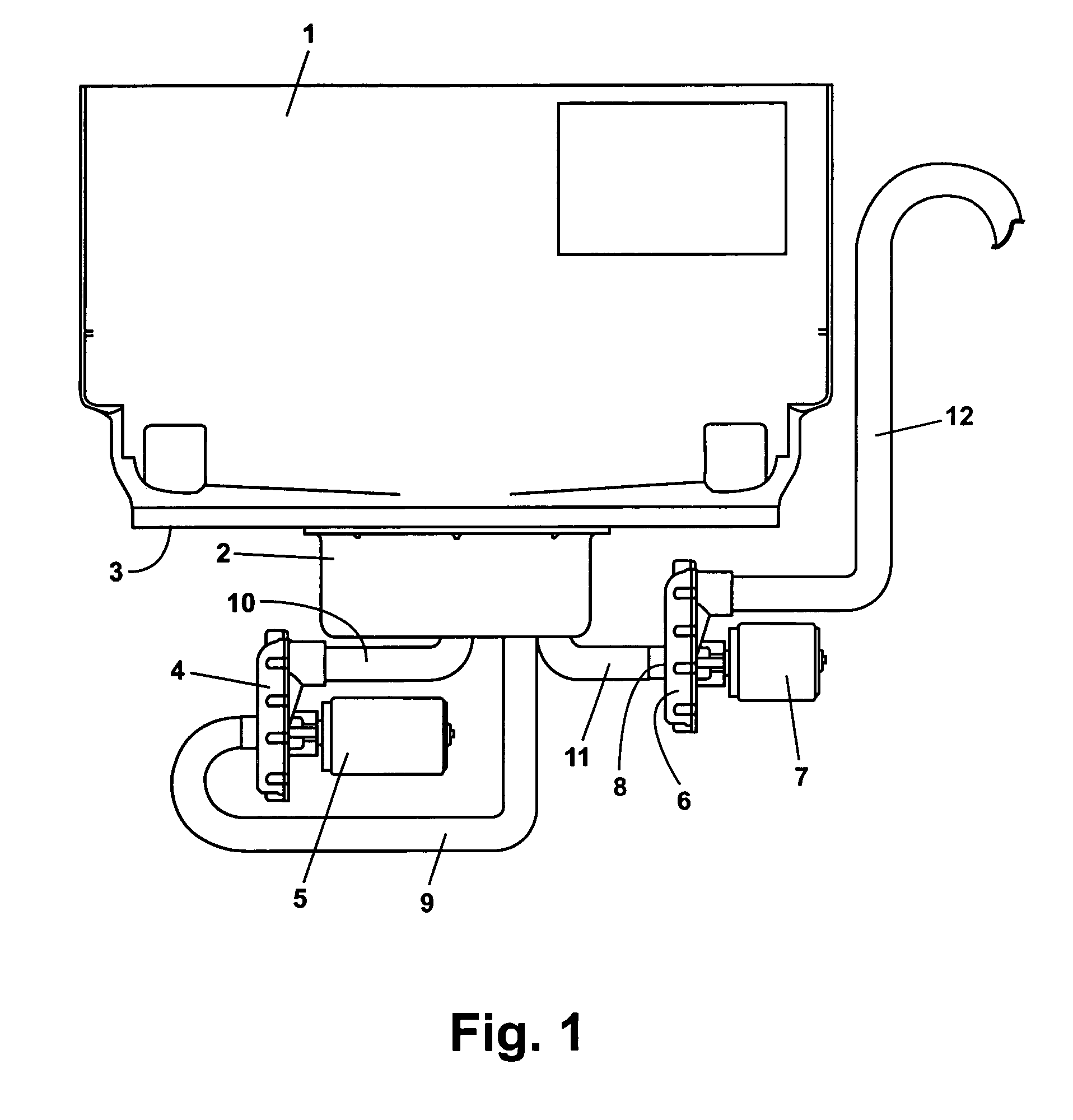

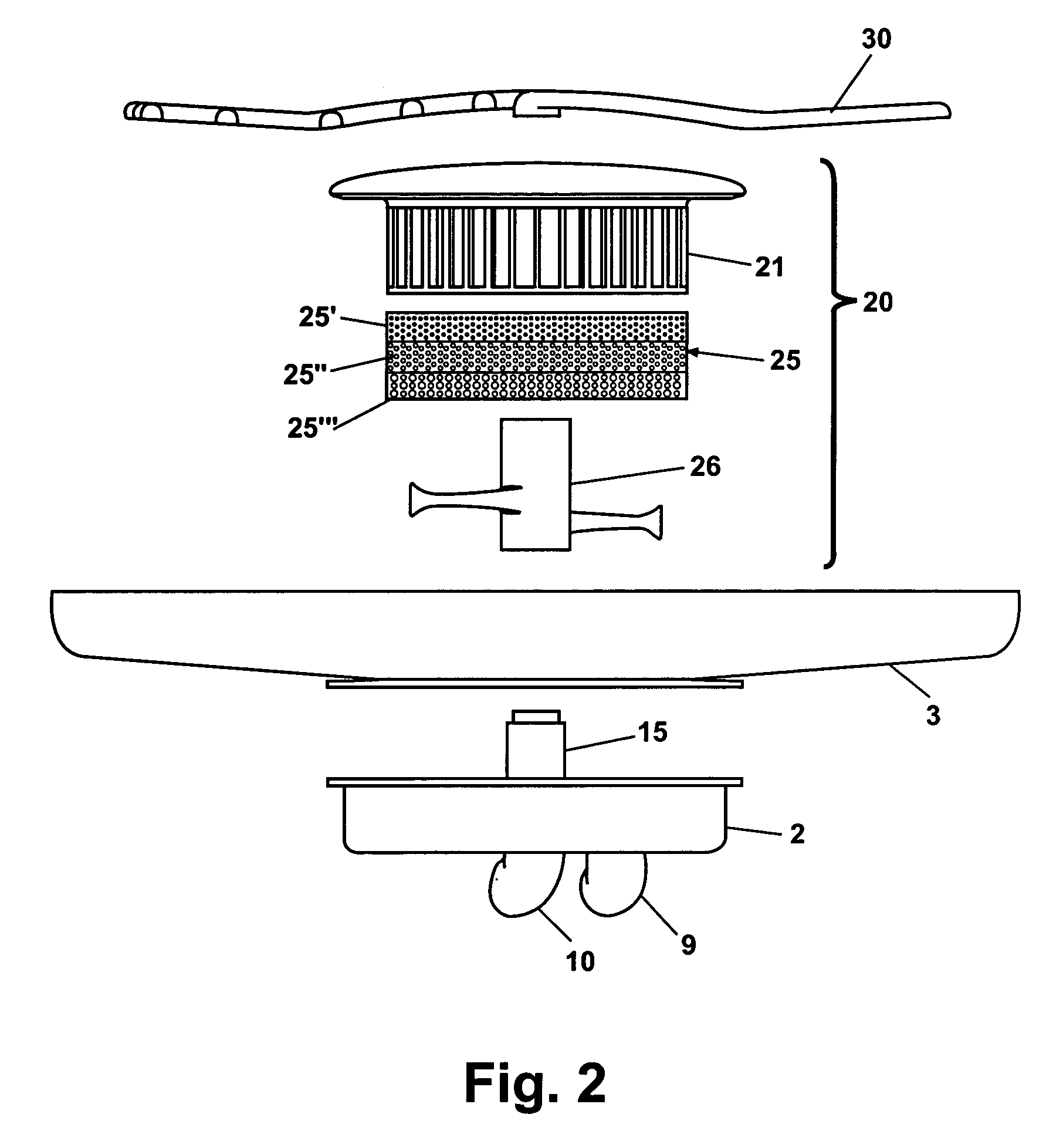

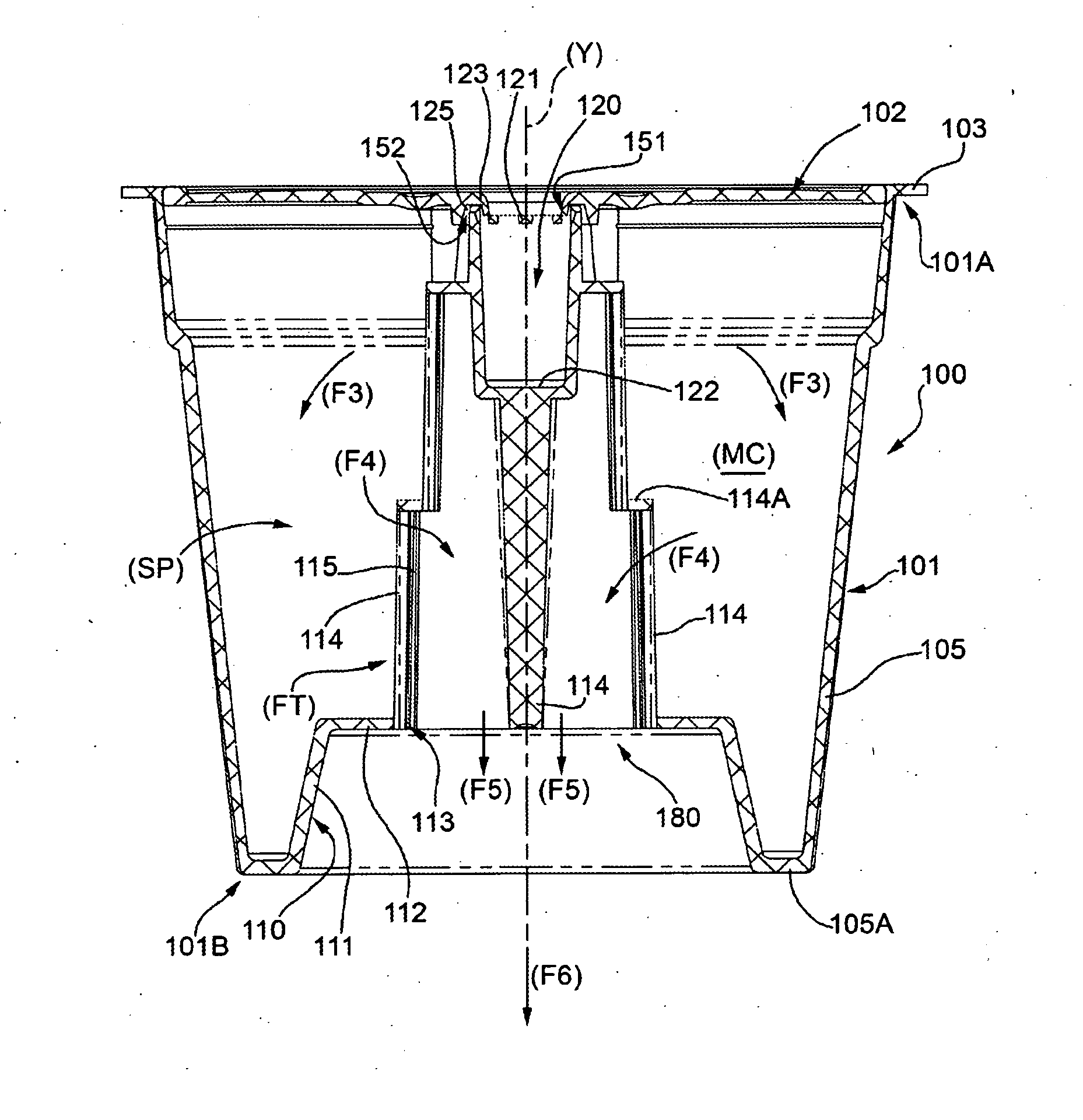

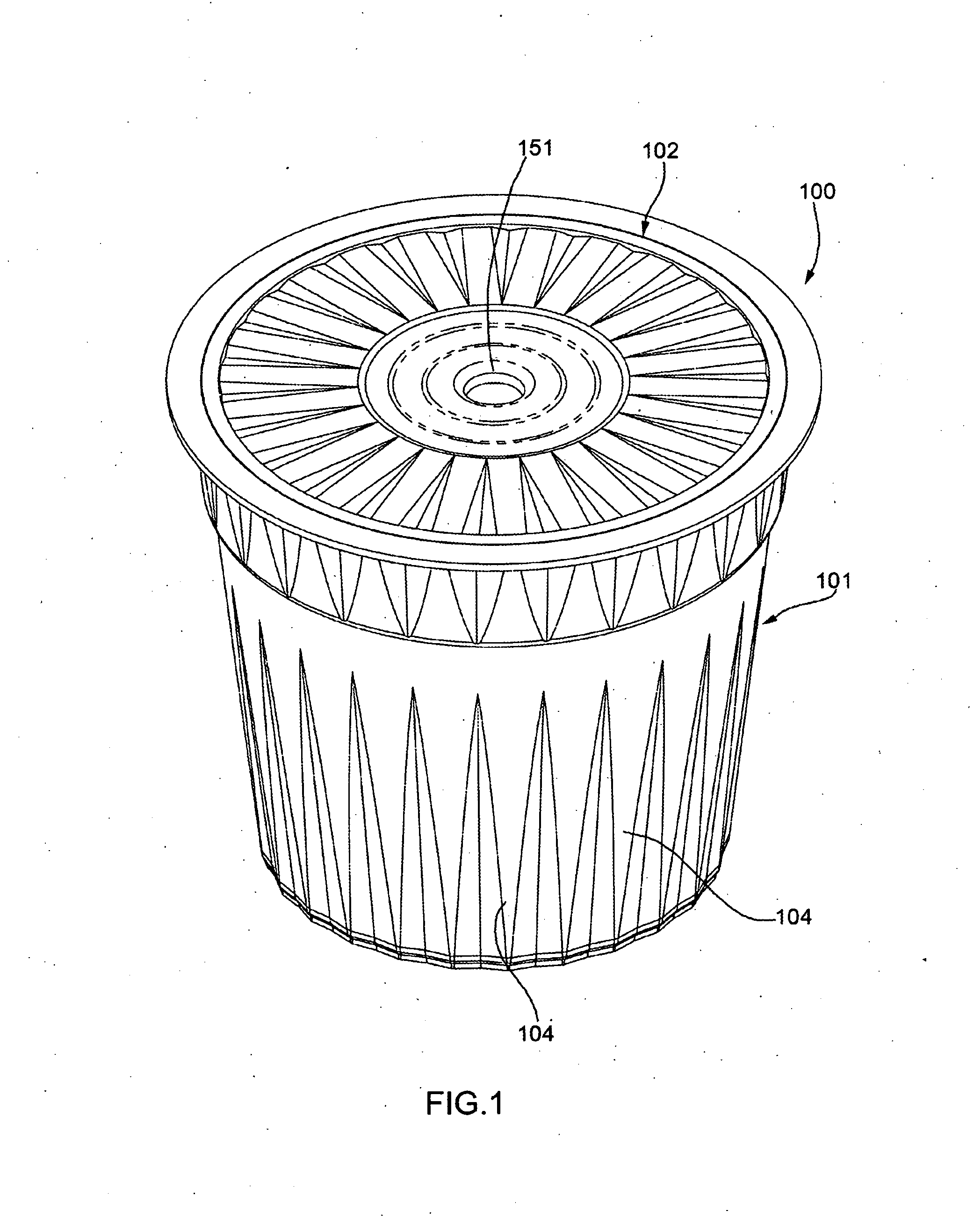

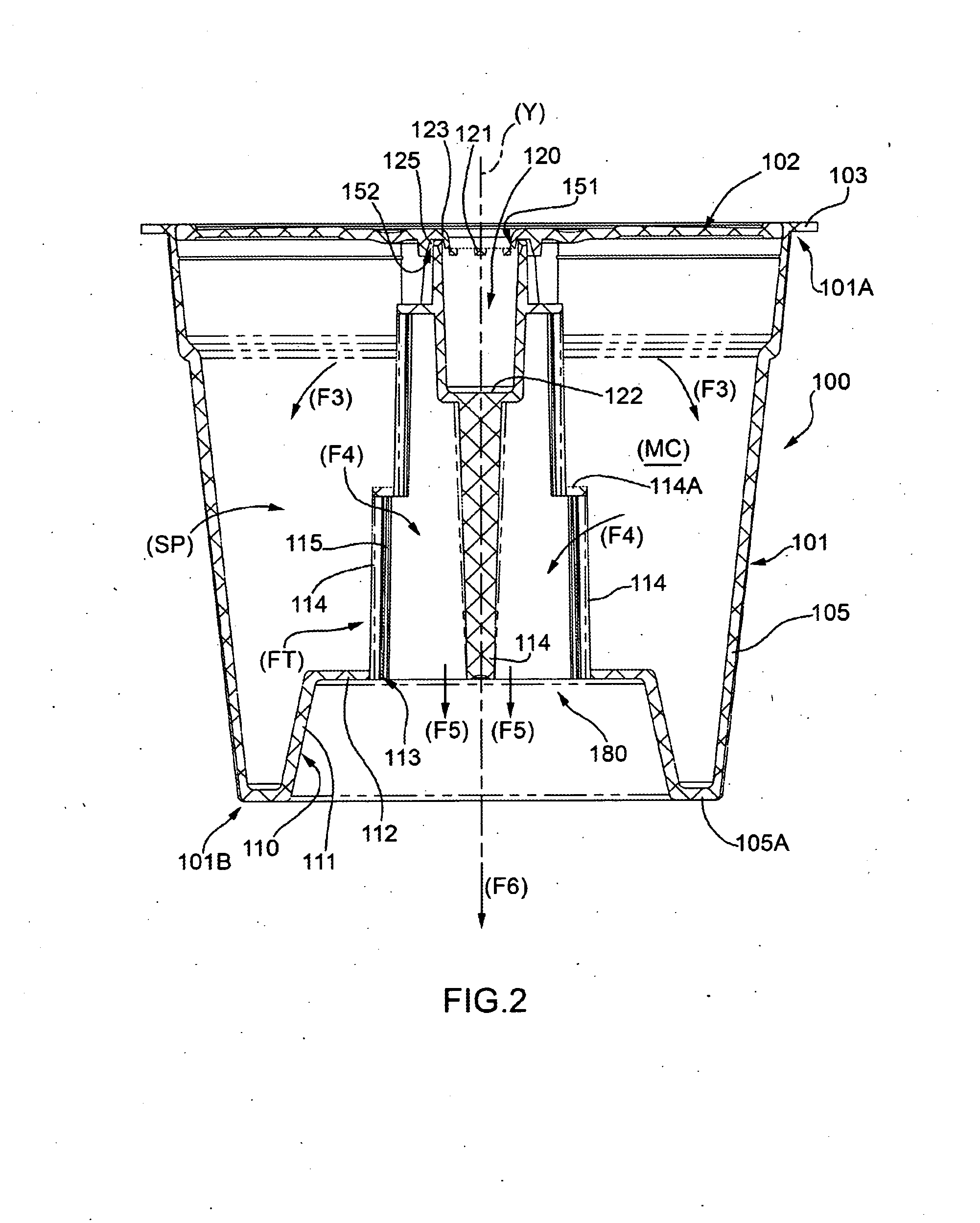

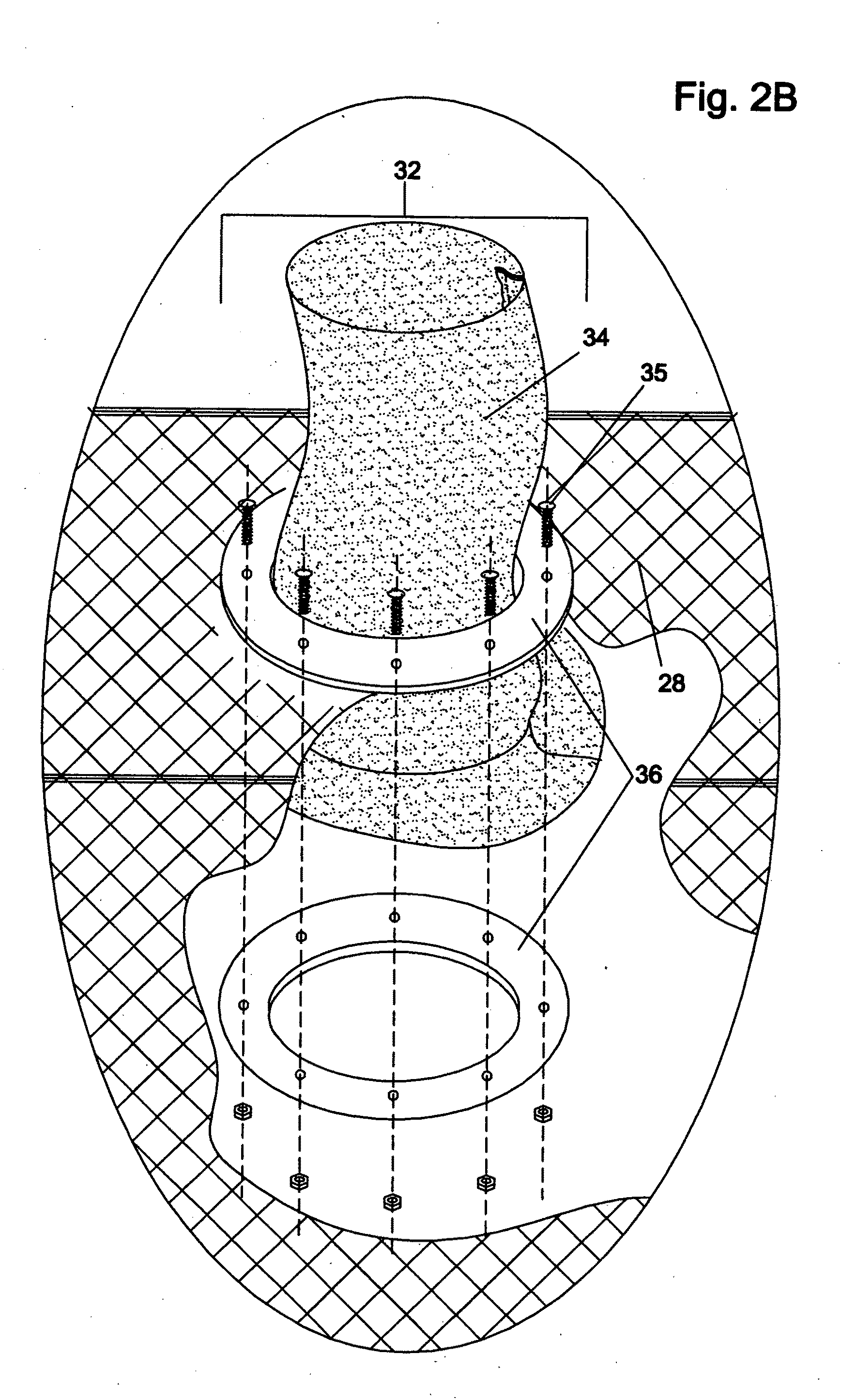

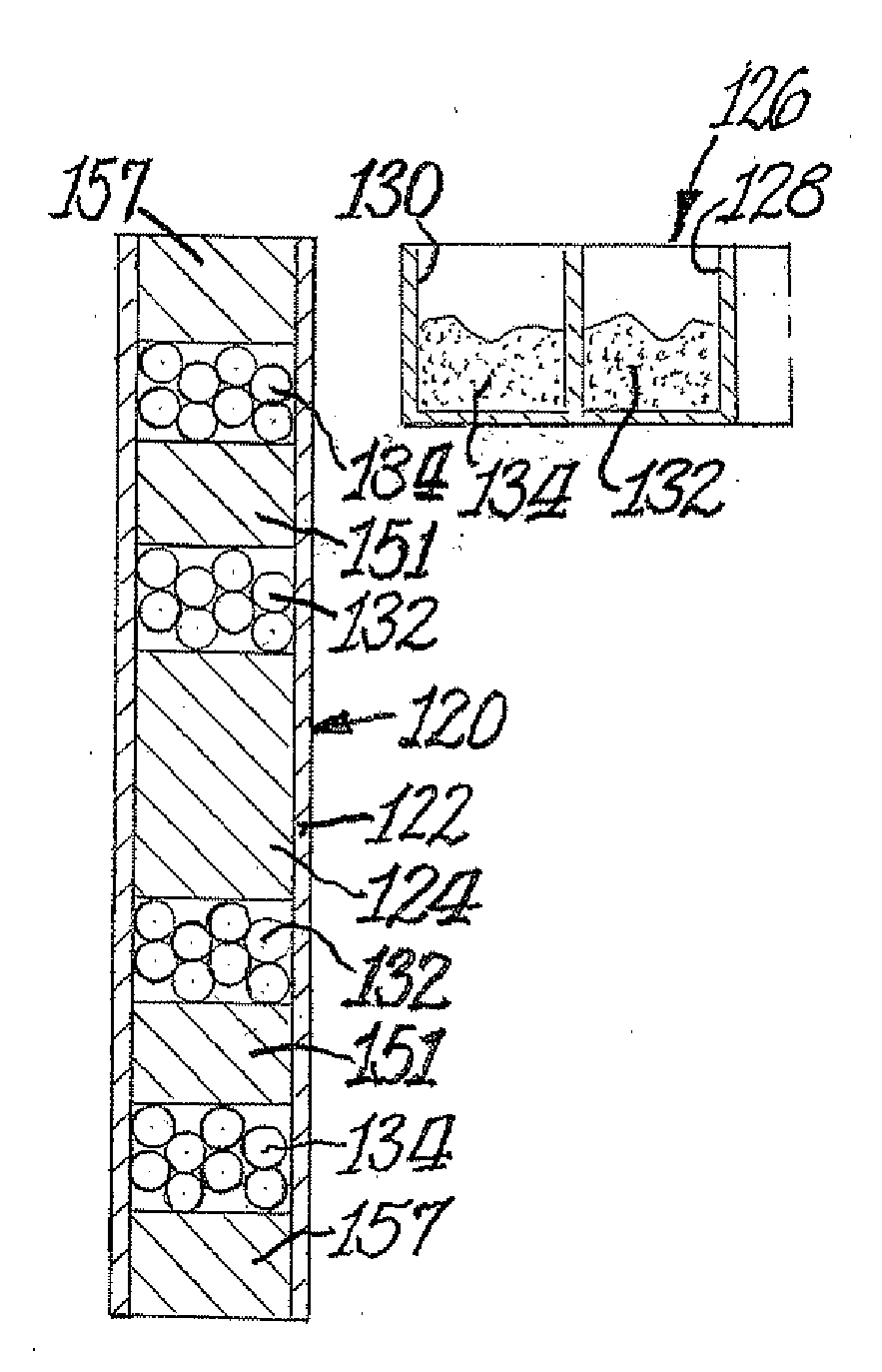

Dishwasher filter system

A filter system for dishwasher with a sump having inlets leading to a wash pump and a drain pump in the bottom wall. The filter assembly includes a vertical filter retainer an overlying perforate hood, a multiple porosity filter element carried on the filter retainer and a back wash sprayer rotatably mounted inside the filter retainer with at least one backwash nozzle directed toward the filter assembly. The inlet leading to the wash pump is positioned inside the filter element and the inlet to the drain pump is located outside the filter element. The filter element has openings that vary in size from the top to the bottom of the filter element. The filter element openings can be arranged in bands of different porosity openings including fine, medium and coarse porosity openings. The perforate hood can have coarse porosity openings.

Owner:WHIRLPOOL CORP

Dishwasher filter system

A filter system for dishwasher with a sump having inlets leading to a wash pump and a drain pump in the bottom wall. The filter assembly includes a vertical filter retainer an overlying perforate hood, a multiple porosity filter element carried on the filter retainer and a back wash sprayer rotatably mounted inside the filter retainer with at least one backwash nozzle directed toward the filter assembly. The inlet leading to the wash pump is positioned inside the filter element and the inlet to the drain pump is located outside the filter element. The filter element has openings that vary in size from the top to the bottom of the filter element. The filter element openings can be arranged in bands of different porosity openings including fine, medium and coarse porosity openings. The perforate hood can have coarse porosity openings.

Owner:WHIRLPOOL CORP

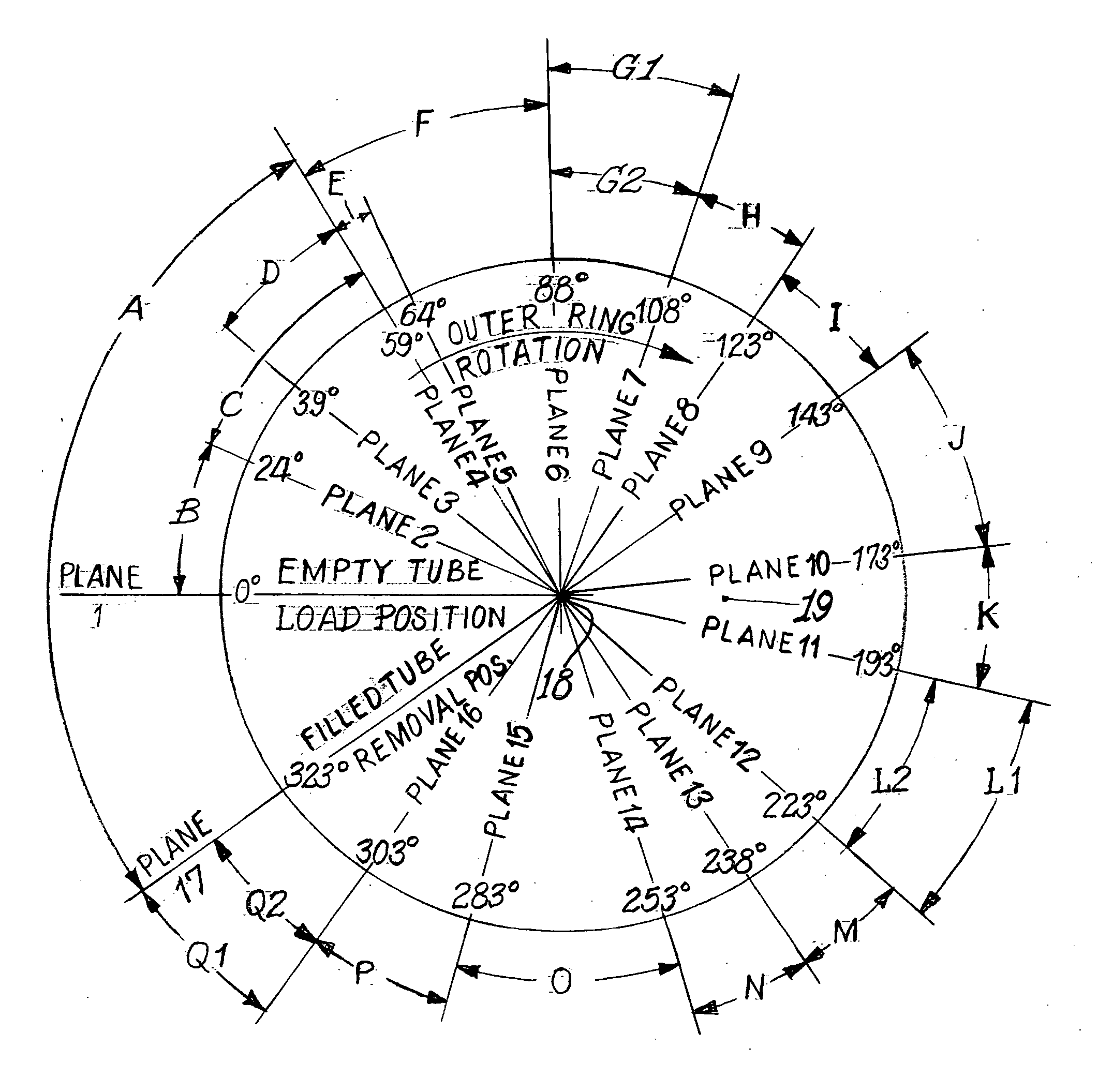

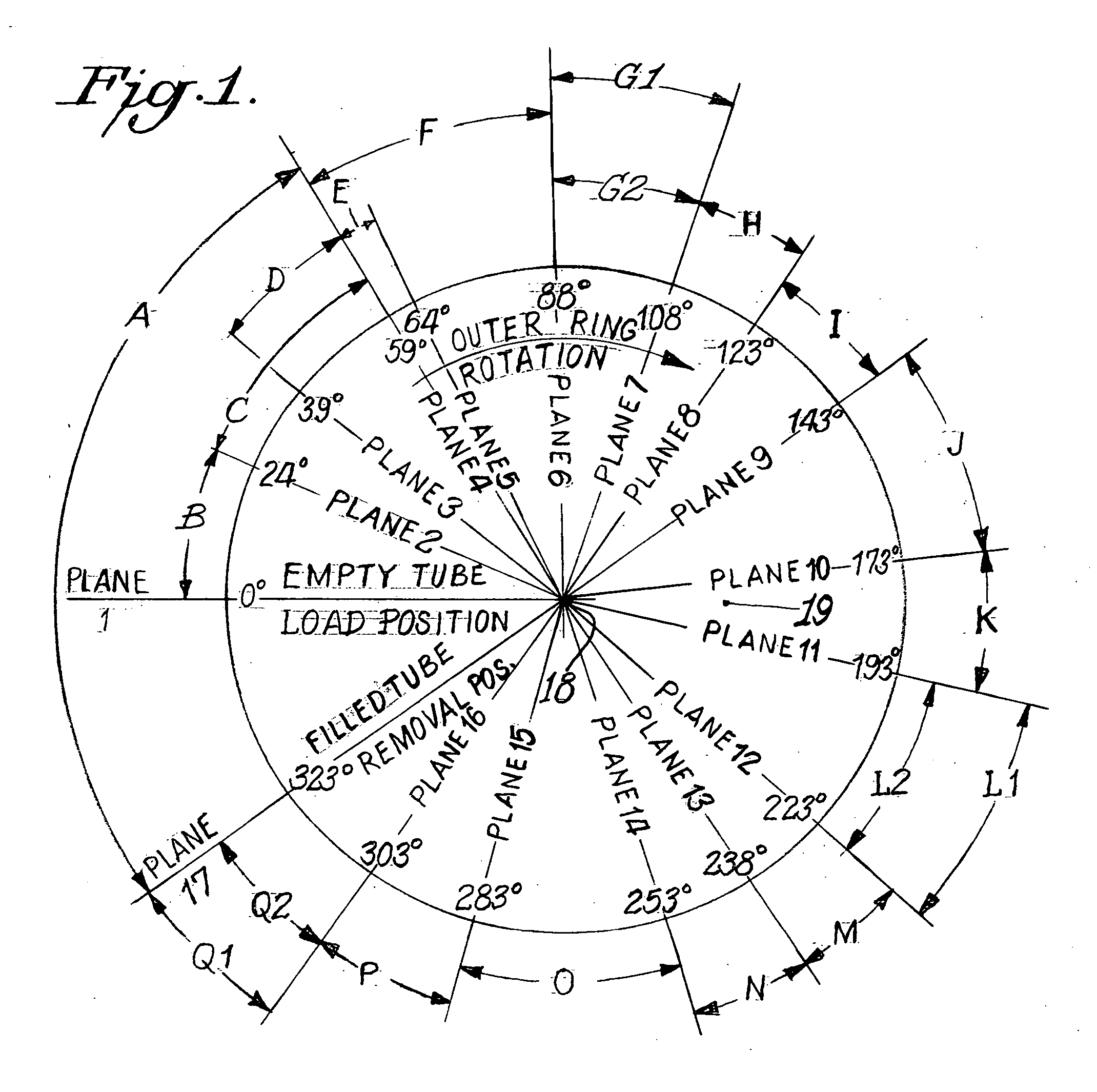

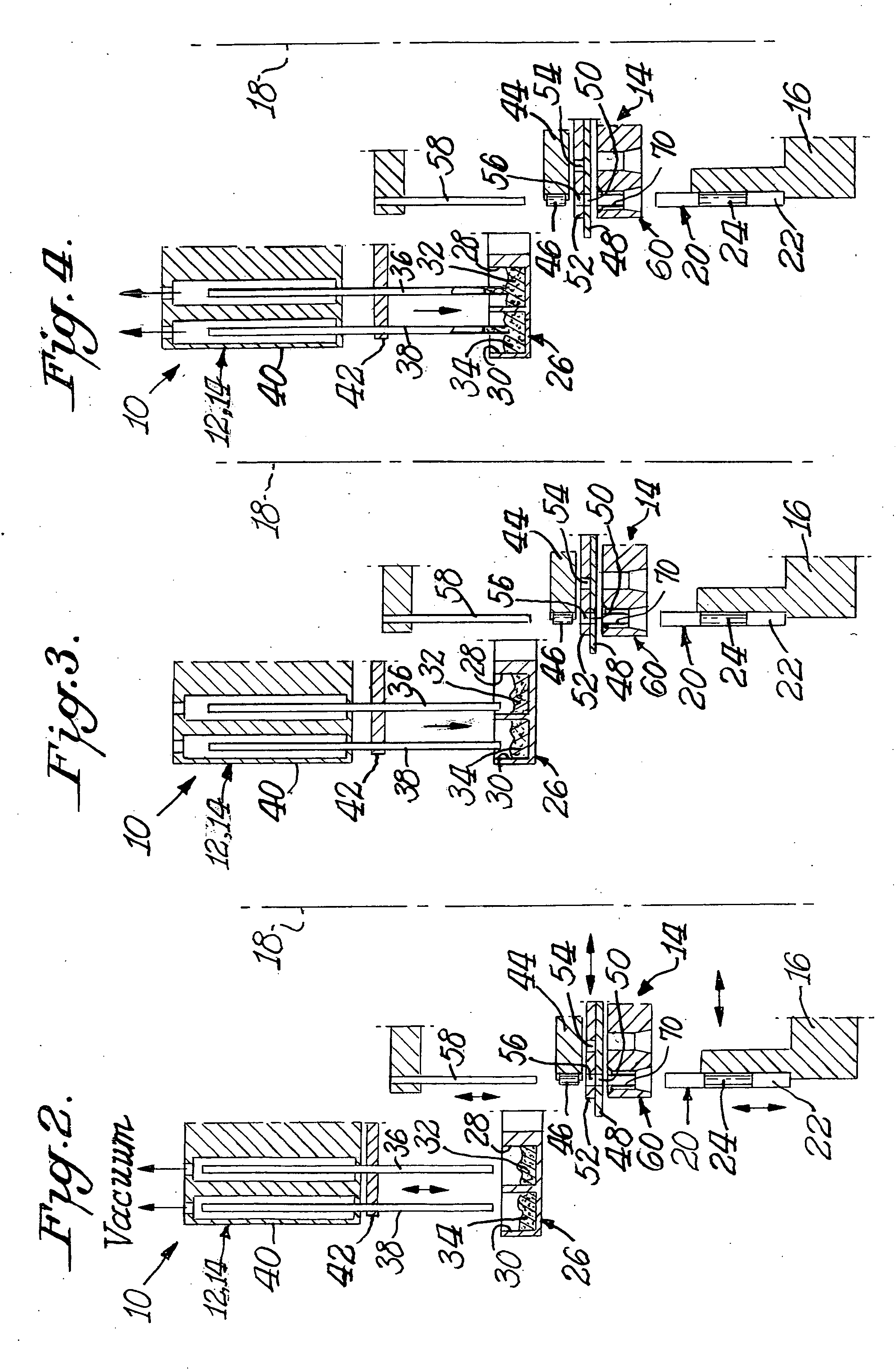

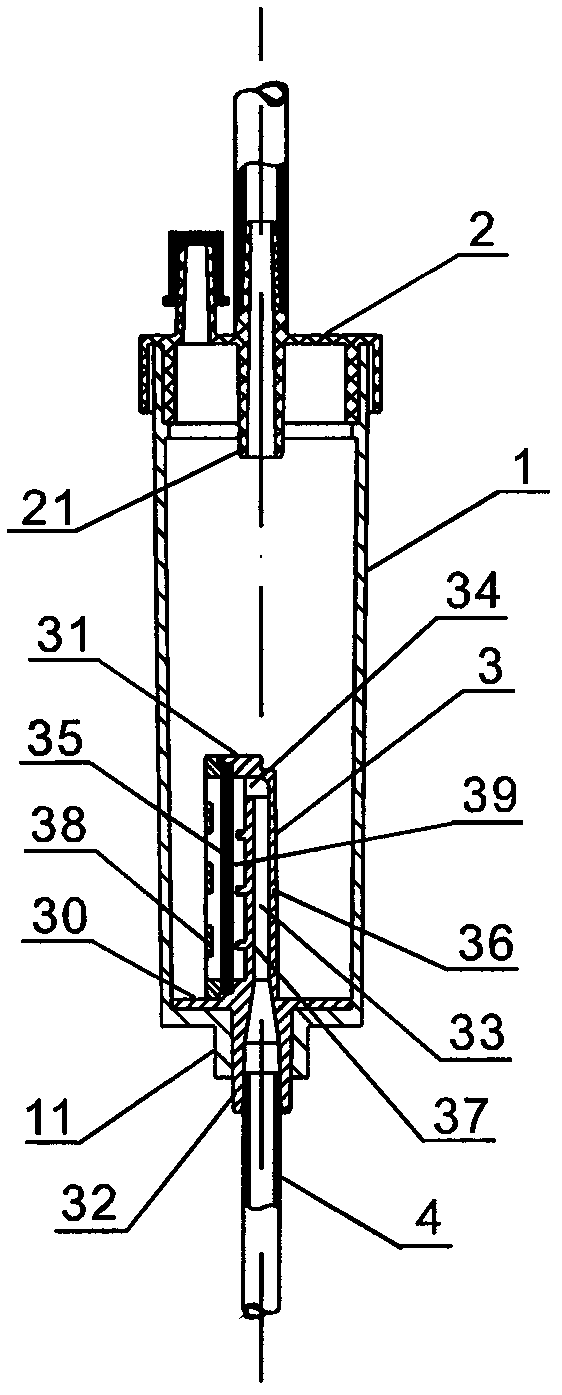

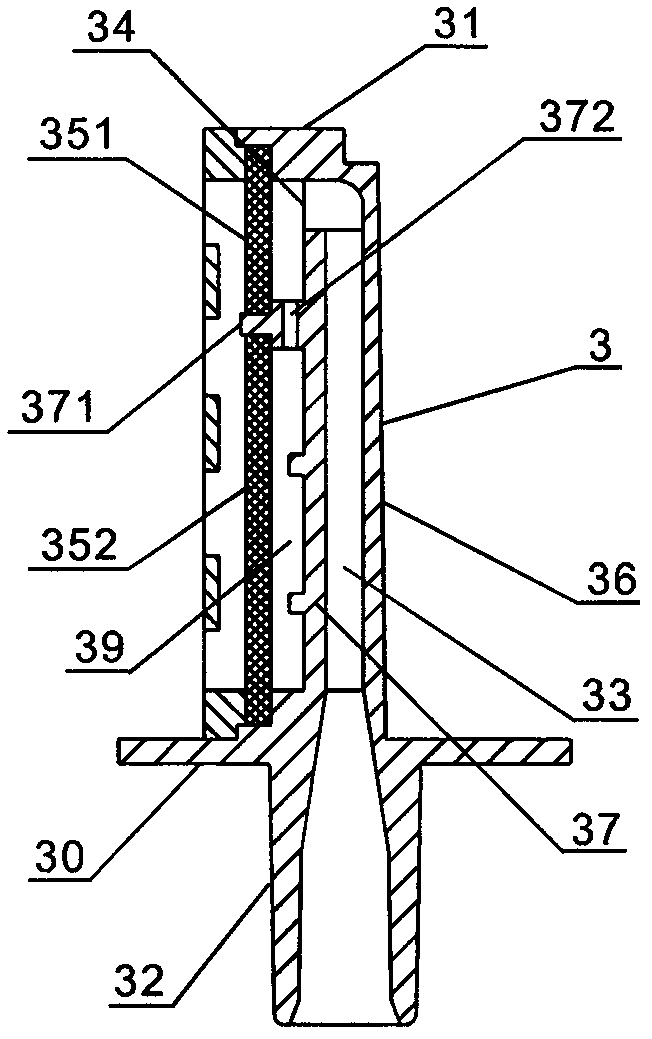

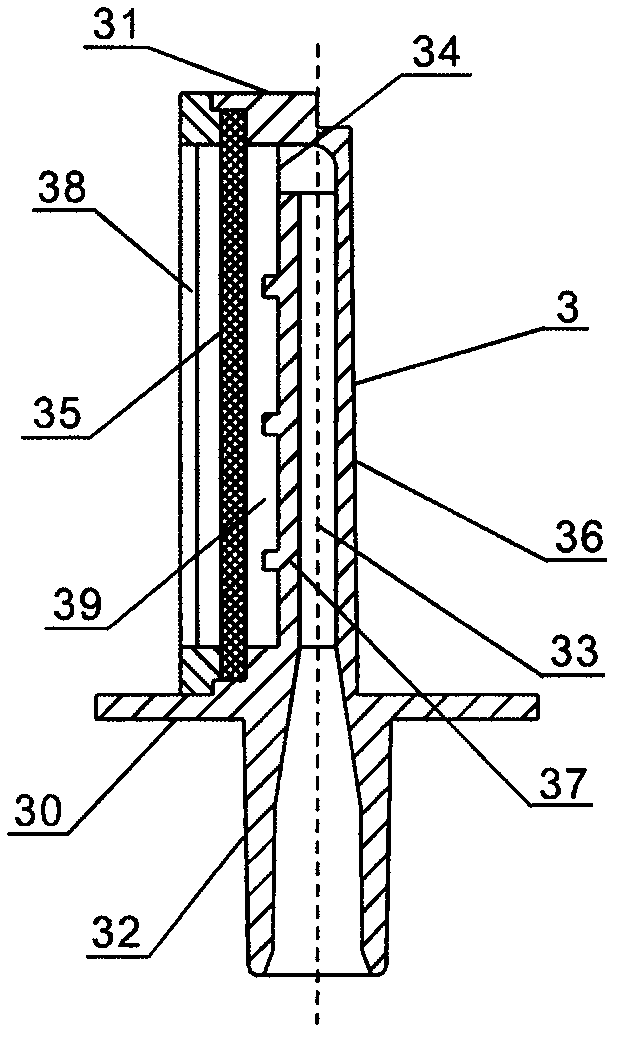

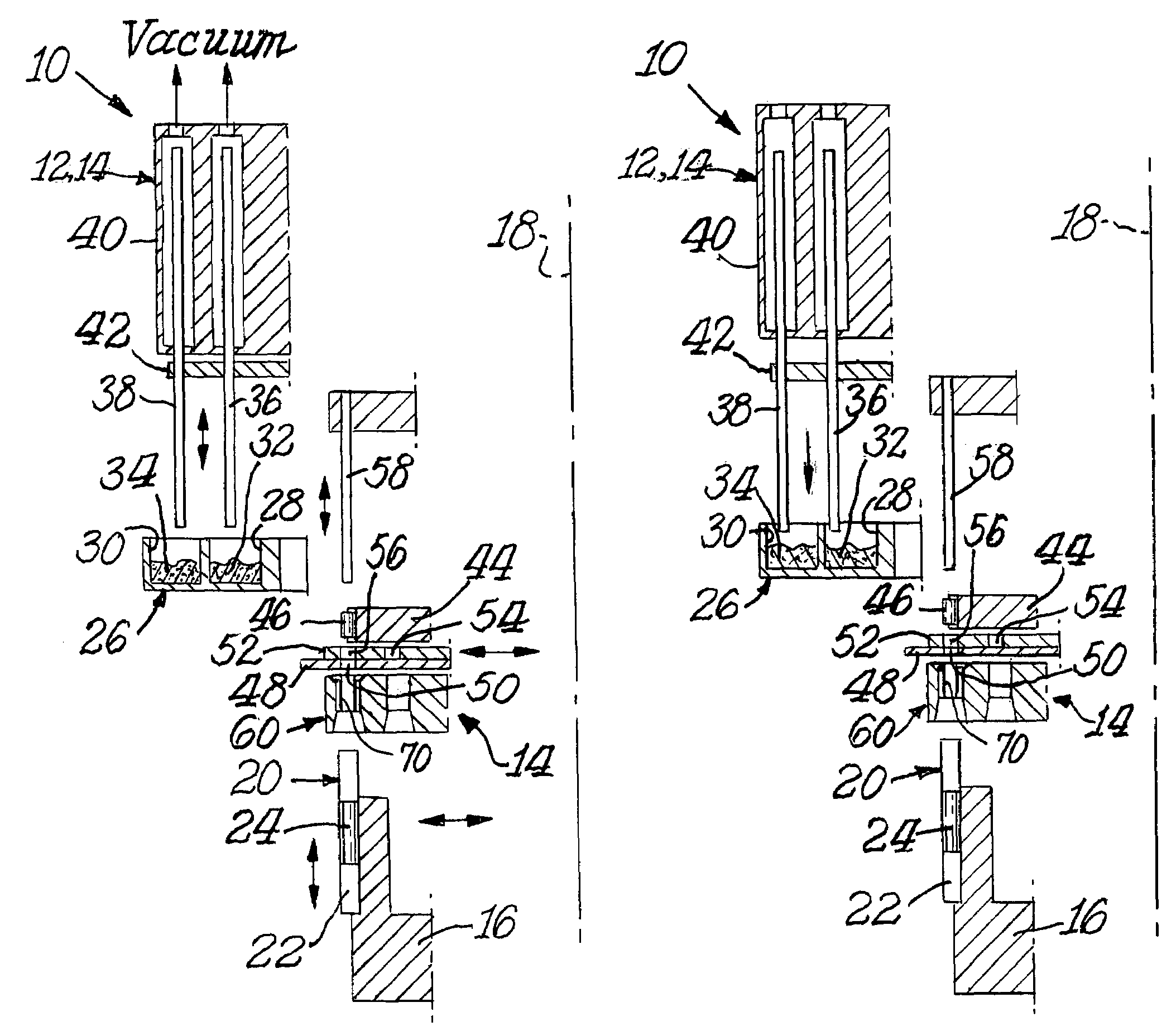

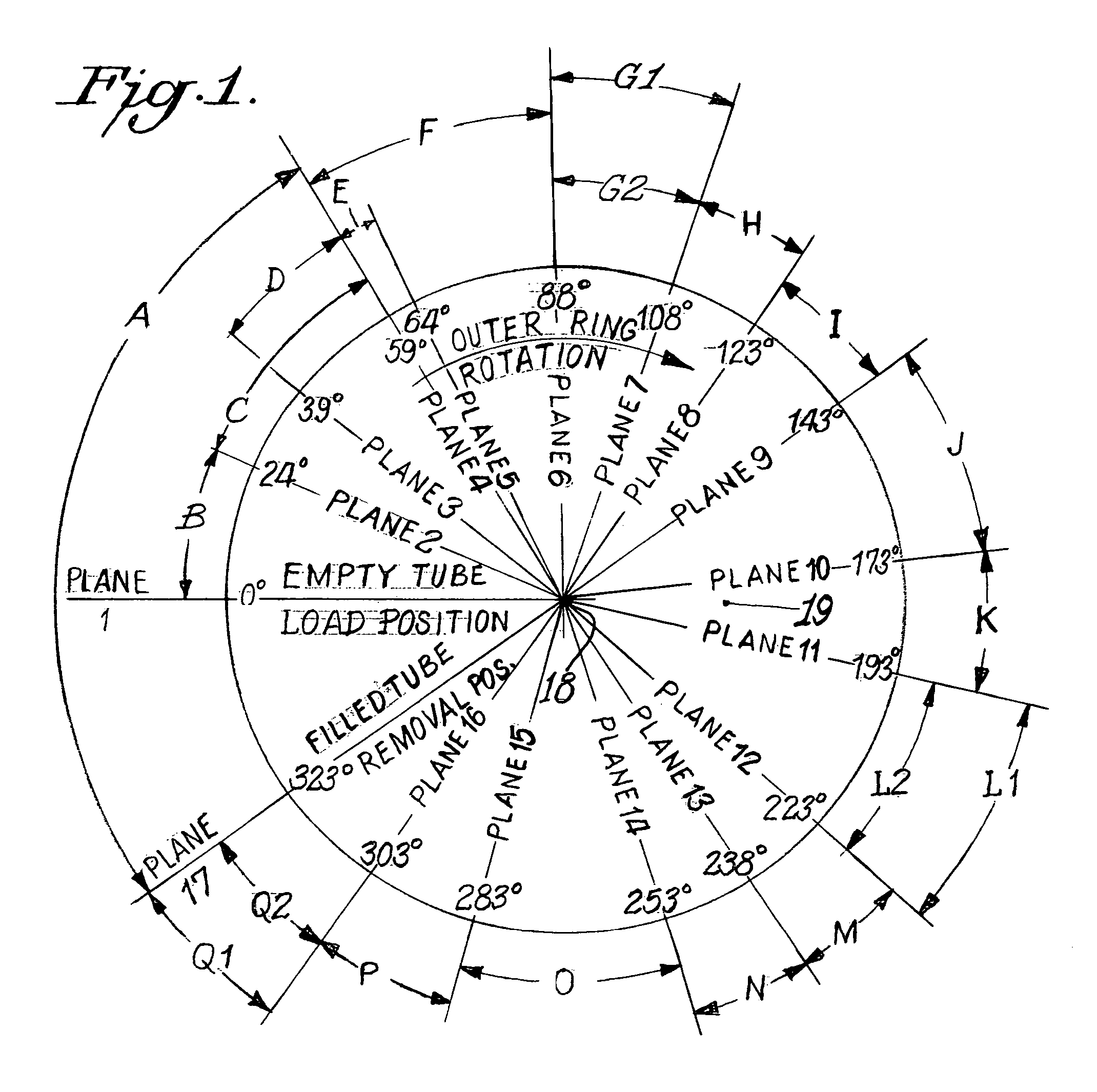

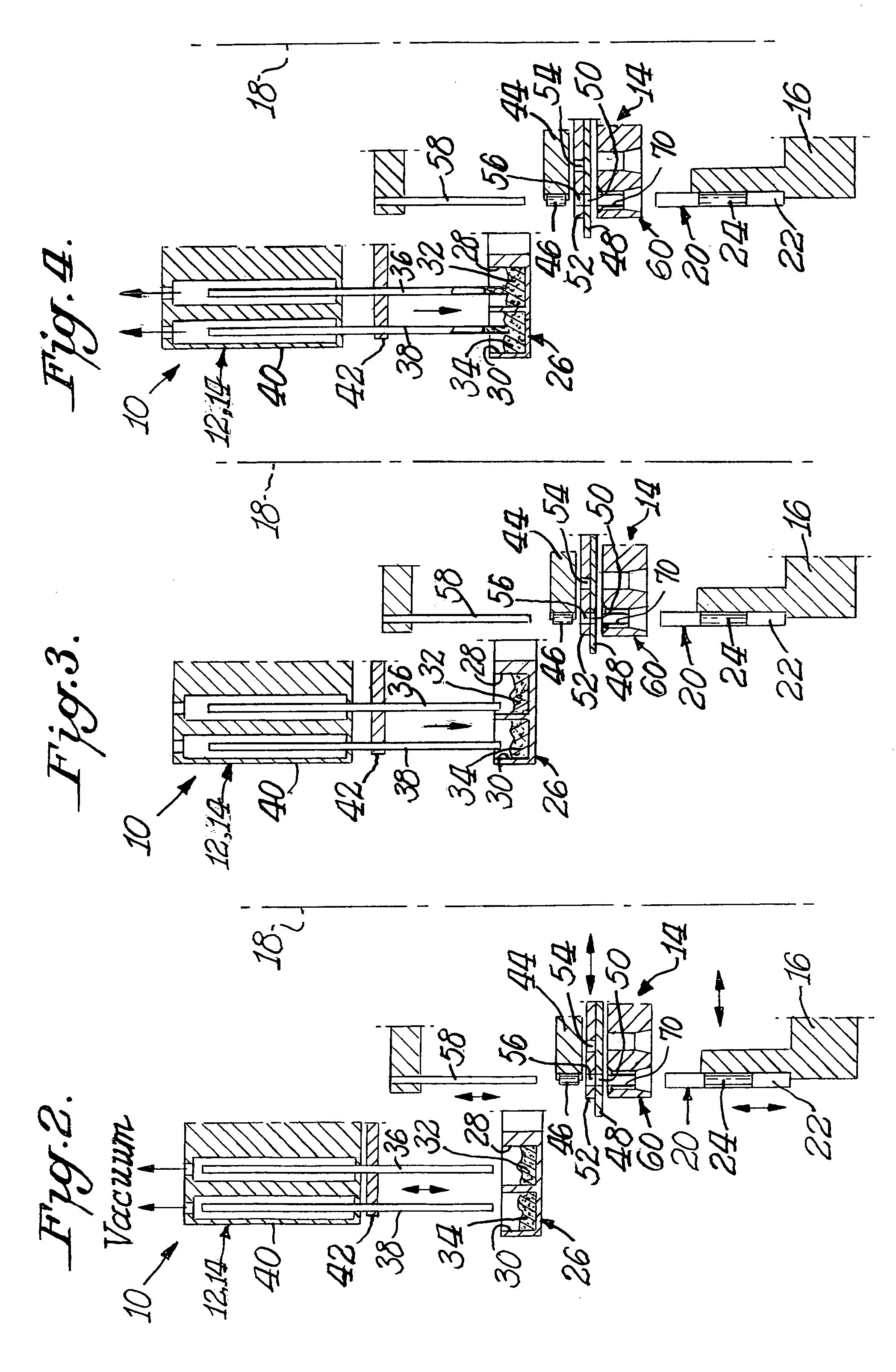

Vertical filter filling machine and process

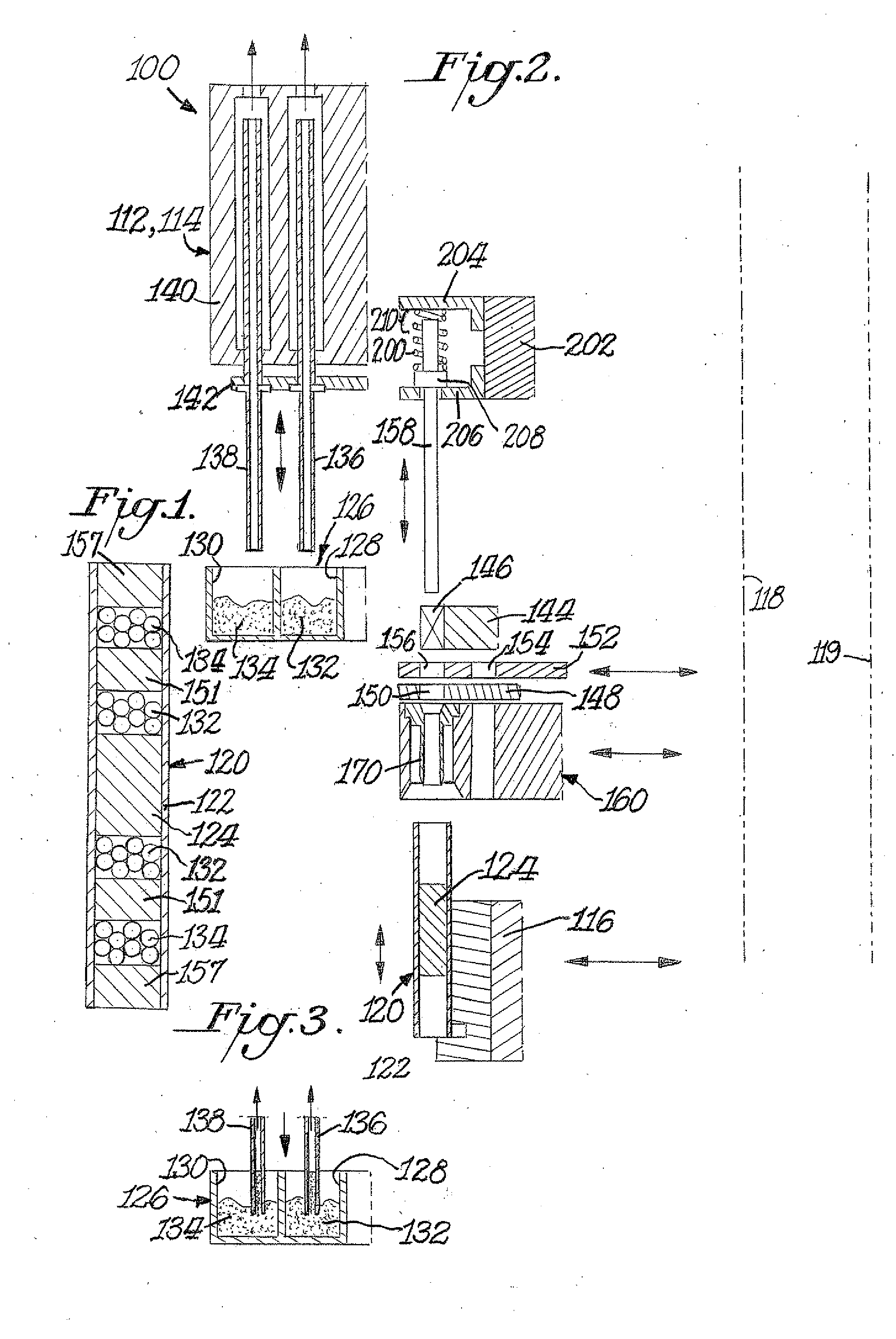

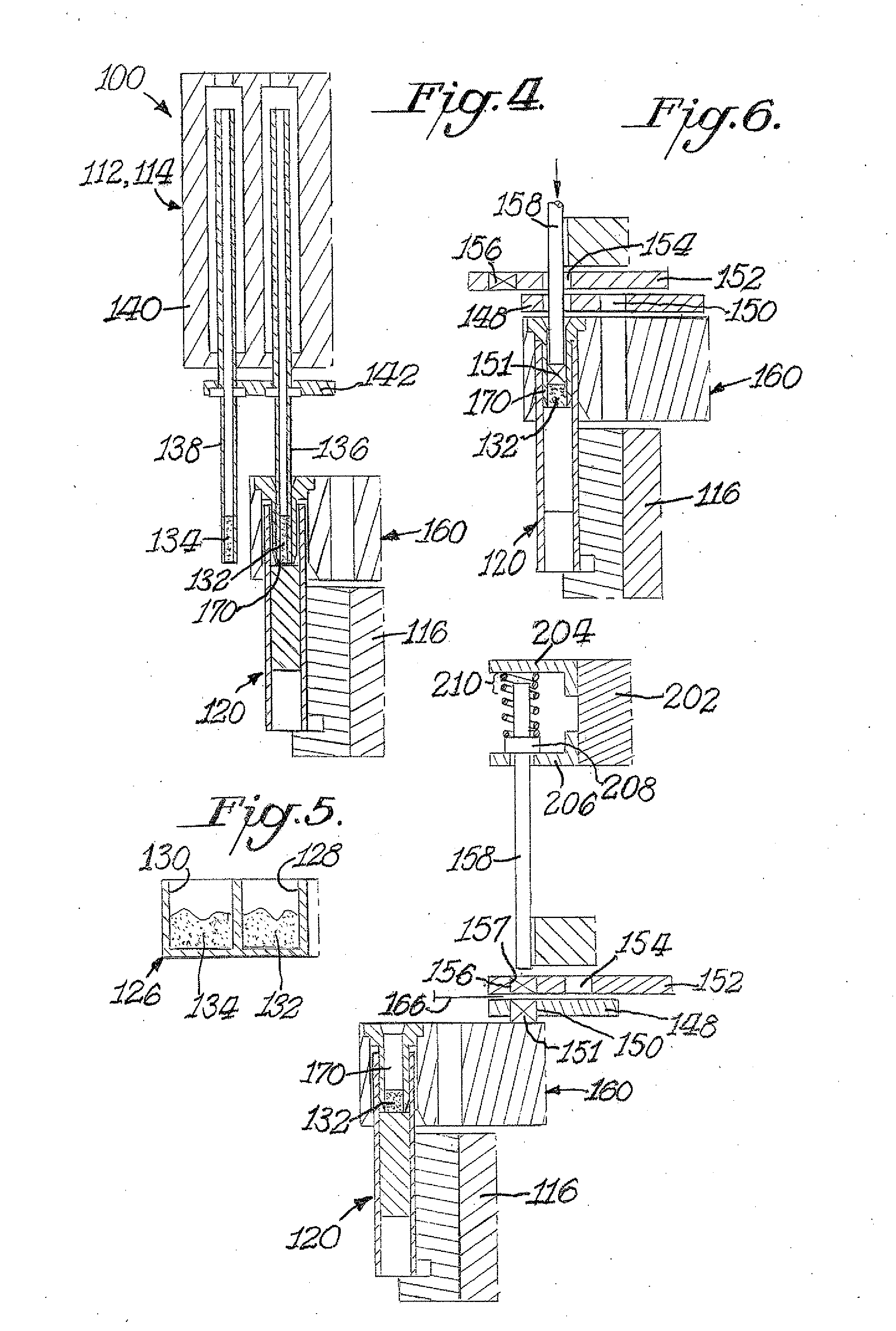

ActiveUS20060112963A1Efficient and economical mannerIncrease chanceTobacco treatmentPaper/cardboard wound articlesVertical filterFilter material

Process and apparatus for the mass production of compound cigarette filters function to deposit granular filter material into the open ends of vertically oriented filter tubes. Predetermined amounts of diverse granular material are withdrawn by suction from sources of such material, and these amounts are deposited into the tubes. Solid filter segments seal the granular material within the tube. After one half of each filter tube is filled with granular material and sealed, the tube is inverted and the opposite end is filled in substantially the same manner. When cut in half each filter tube produces two cigarette filters.

Owner:PHILIP MORRIS USA INC

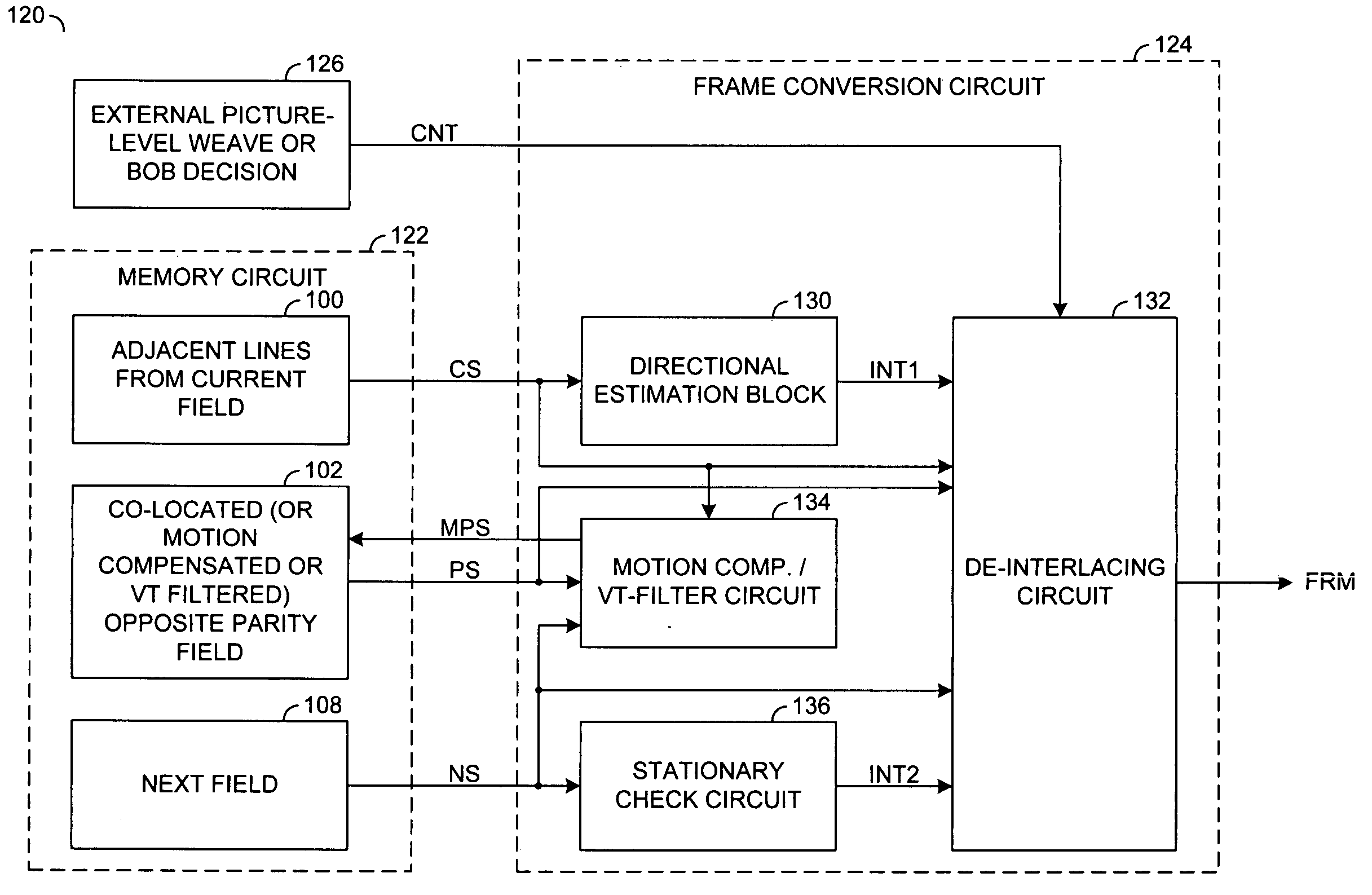

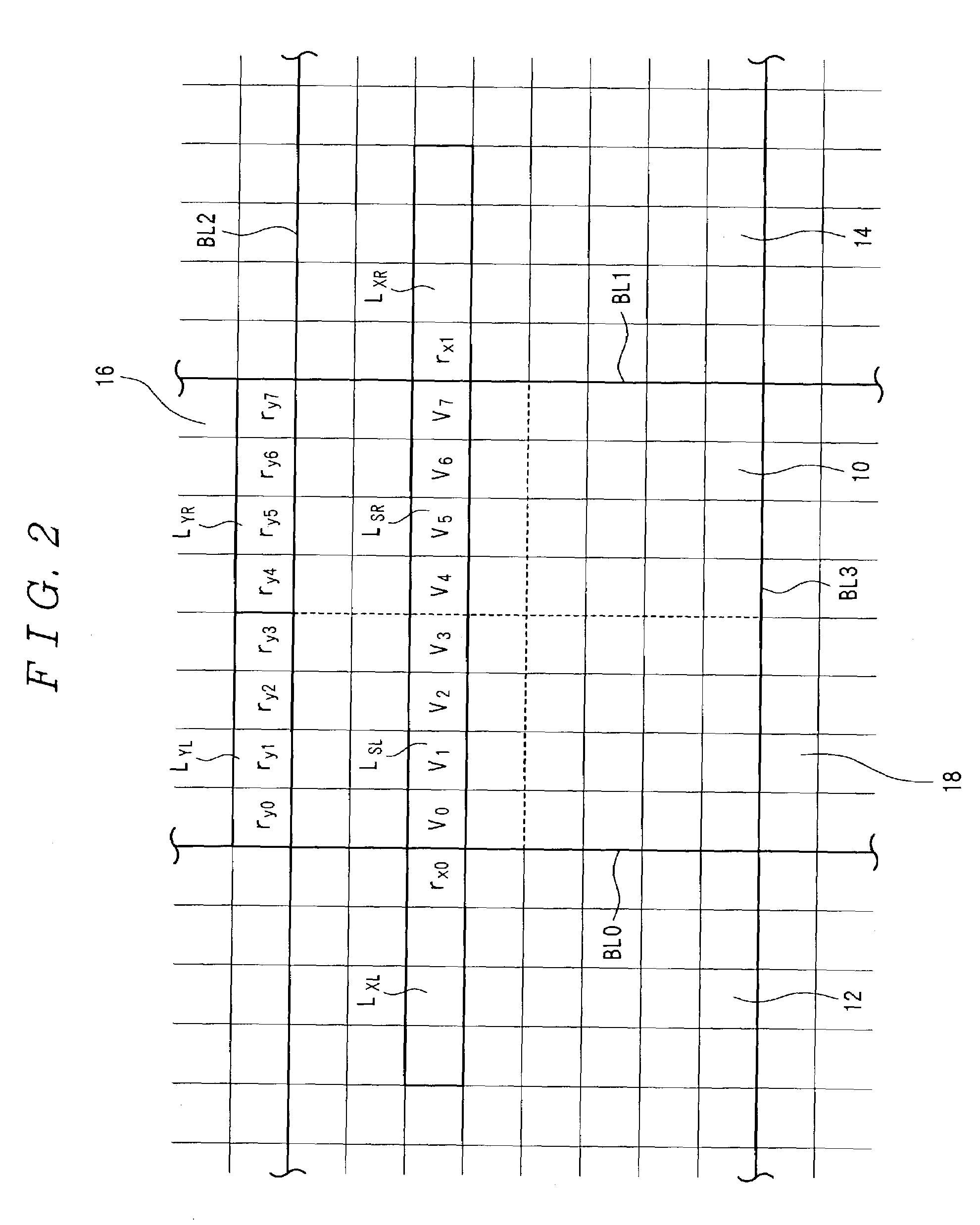

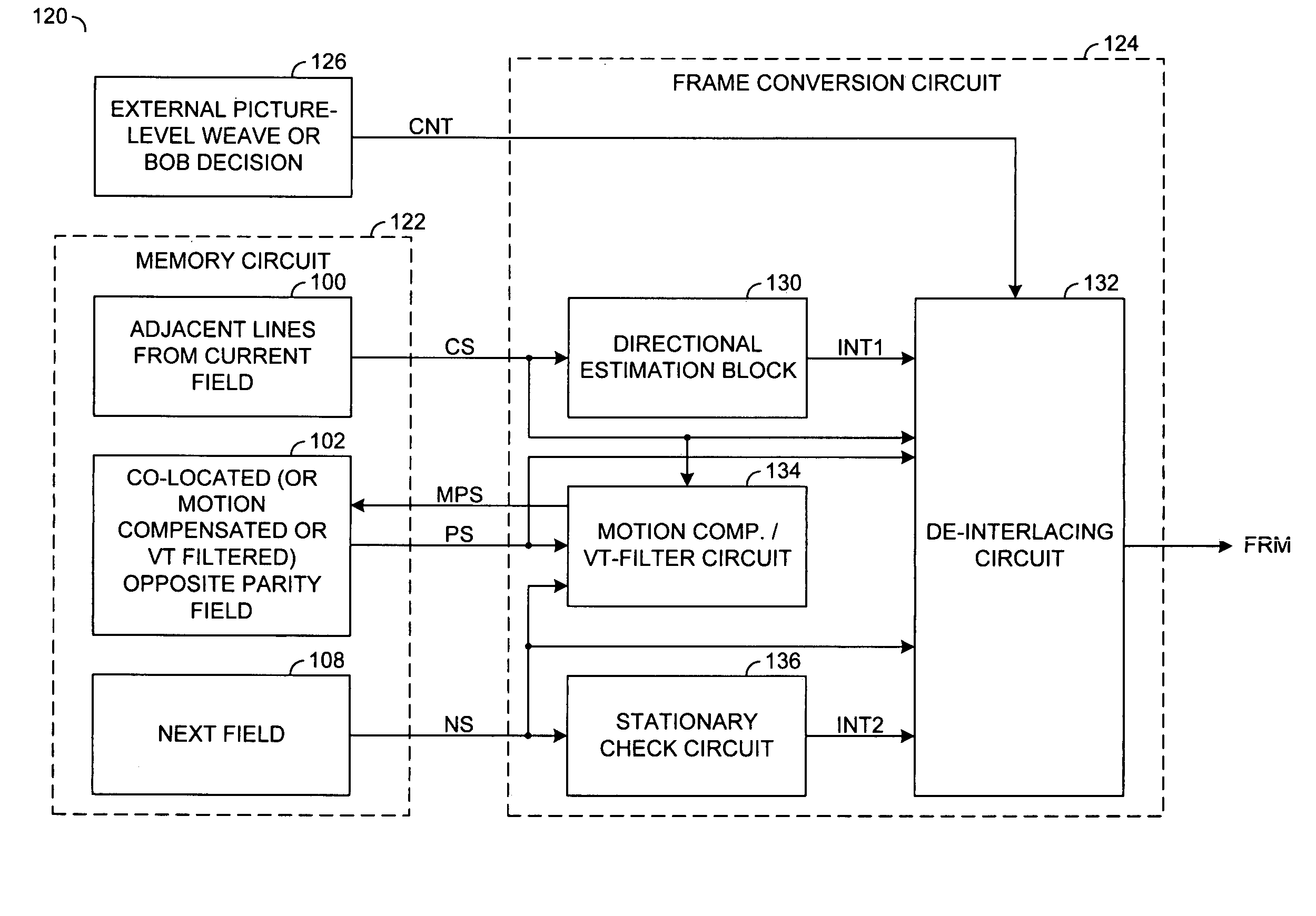

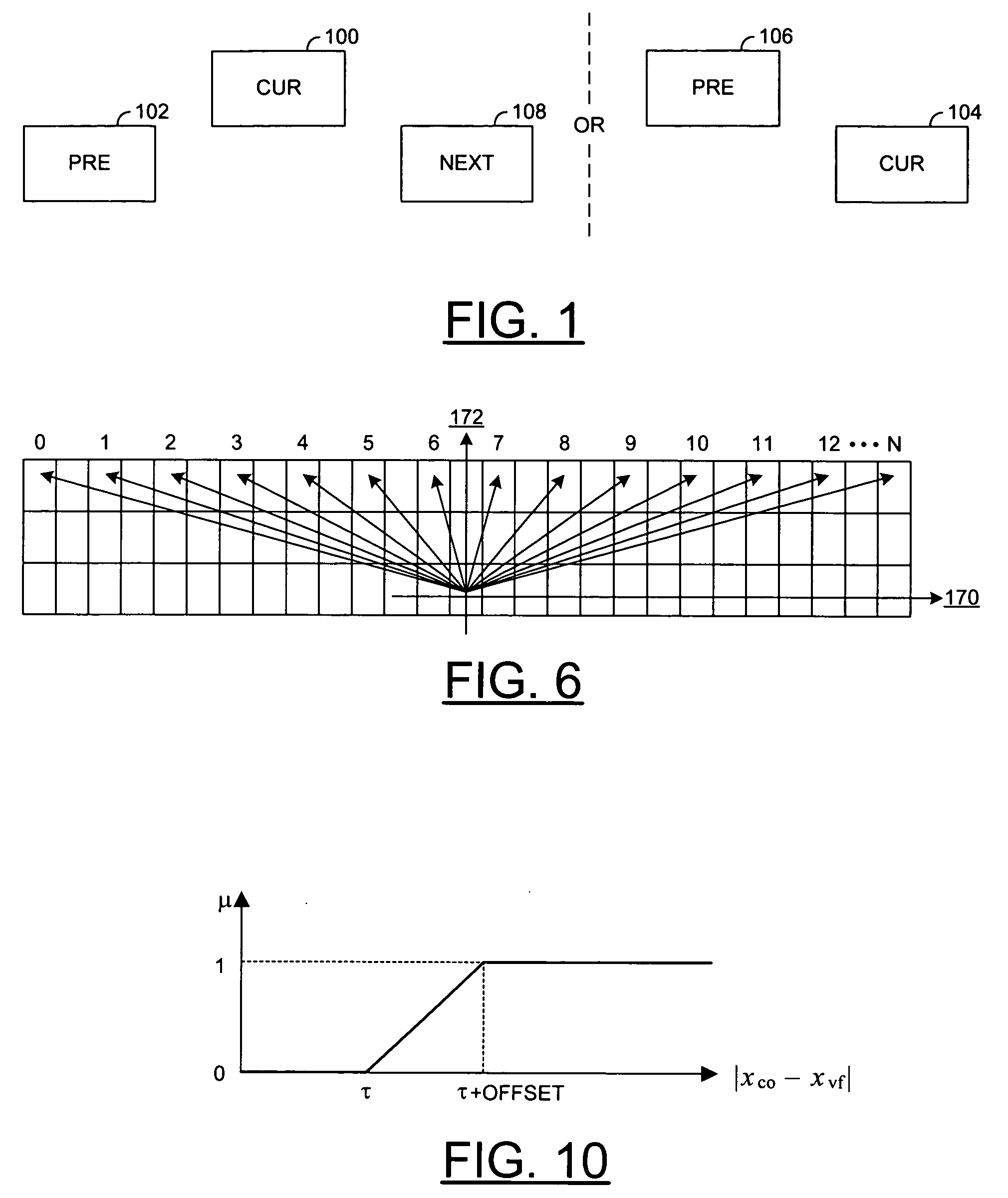

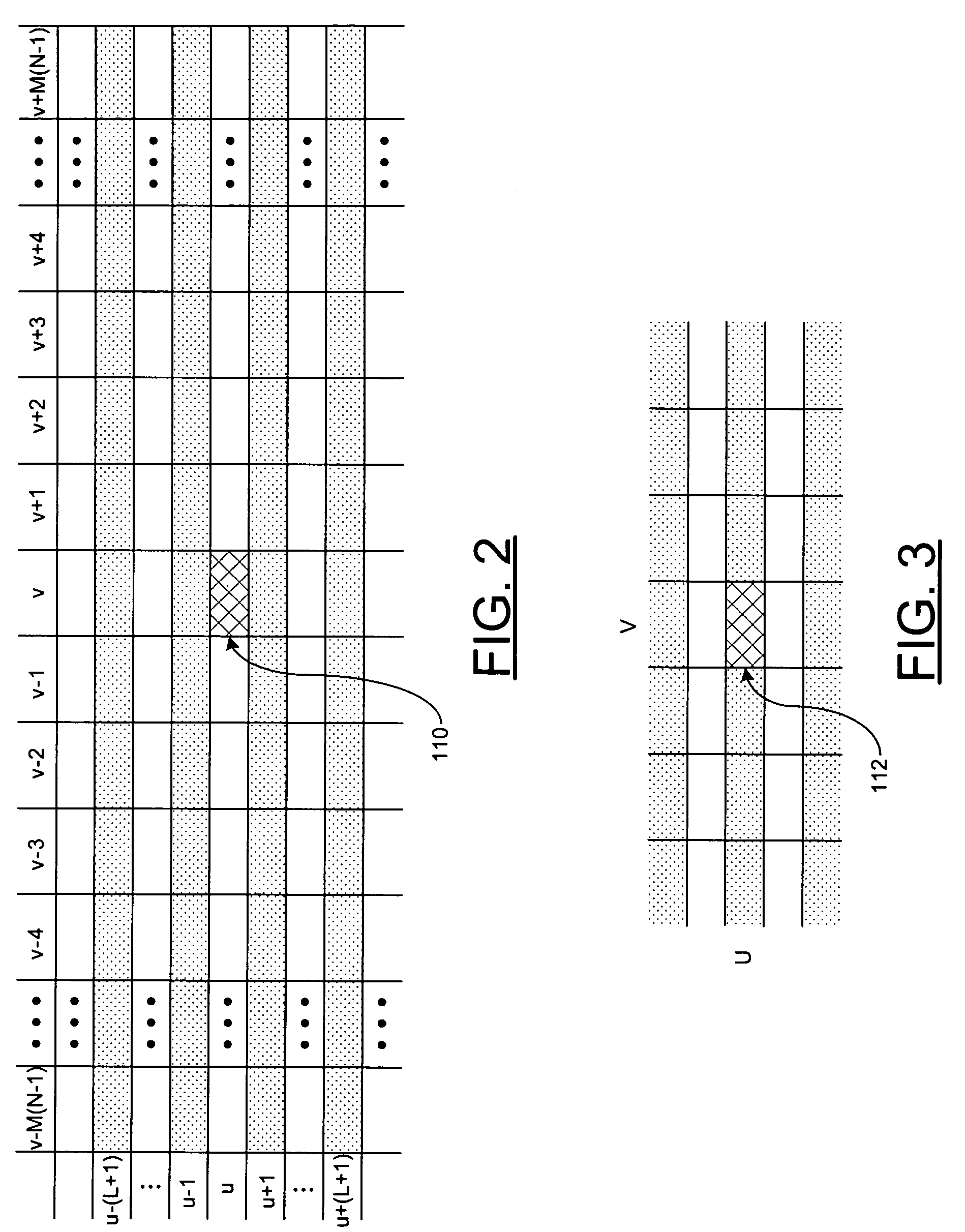

Method and apparatus for video and image deinterlacing and format conversion

ActiveUS20050122426A1Reduce flickerMinimal memory bandwidthTelevision system detailsPicture reproducers using cathode ray tubesLine segmentVertical filter

A method and apparatus for deinterlacing a picture is disclosed. The method generally includes the steps of (A) calculating a plurality of differences among a plurality of current samples from a current field of the picture, the differences being calculated along a plurality of line segments at a plurality of angles proximate a particular position between two field lines from the current filed, (B) generating a first sample at the particular position by vertical filtering the current field in response to the differences indicating that the particular position is a non-edge position in the picture and (C) generating a second sample at the particular position by directional filtering the current field in response to the differences indicating that the particular position is an edge position in the picture.

Owner:AVAGO TECH INT SALES PTE LTD

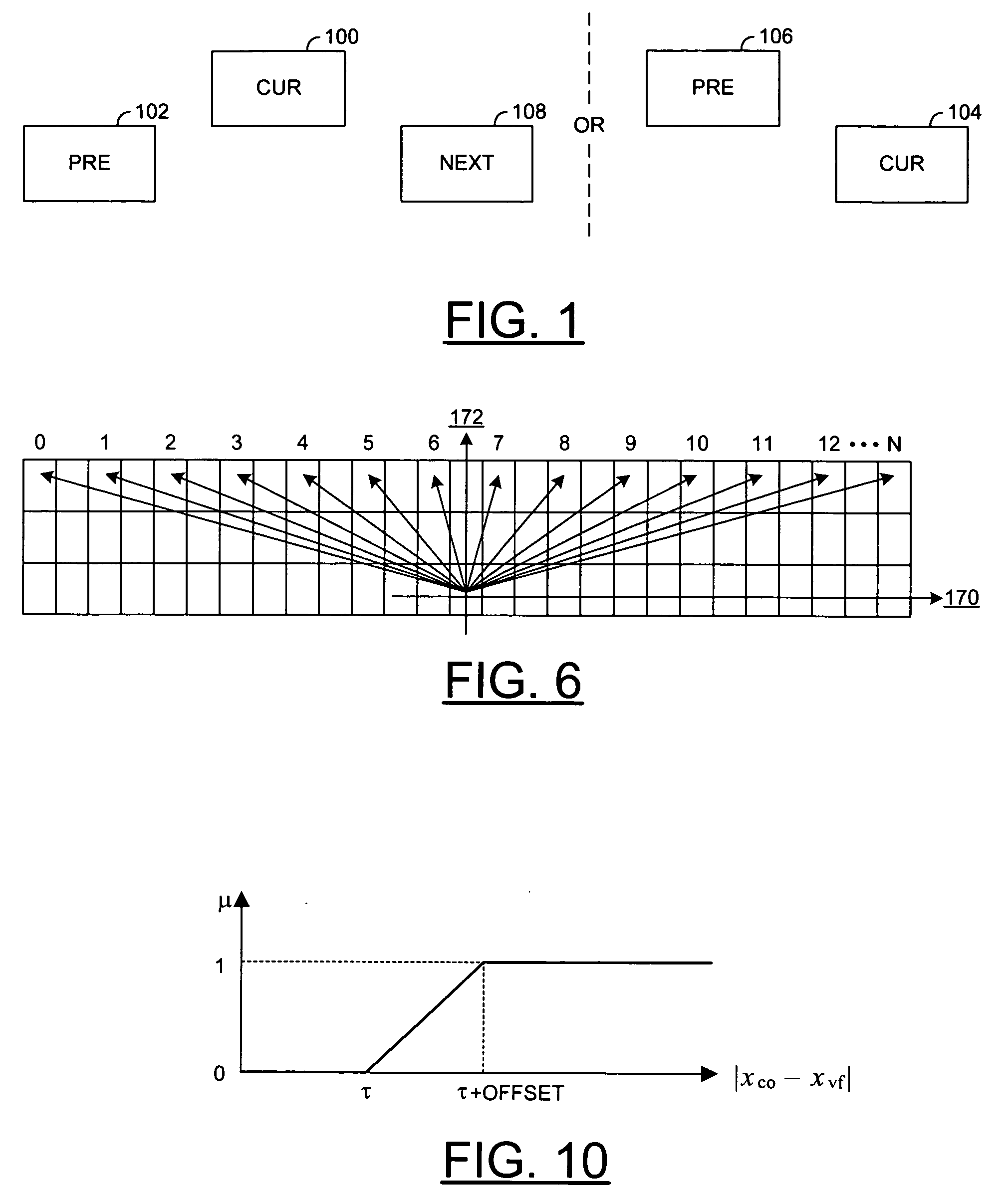

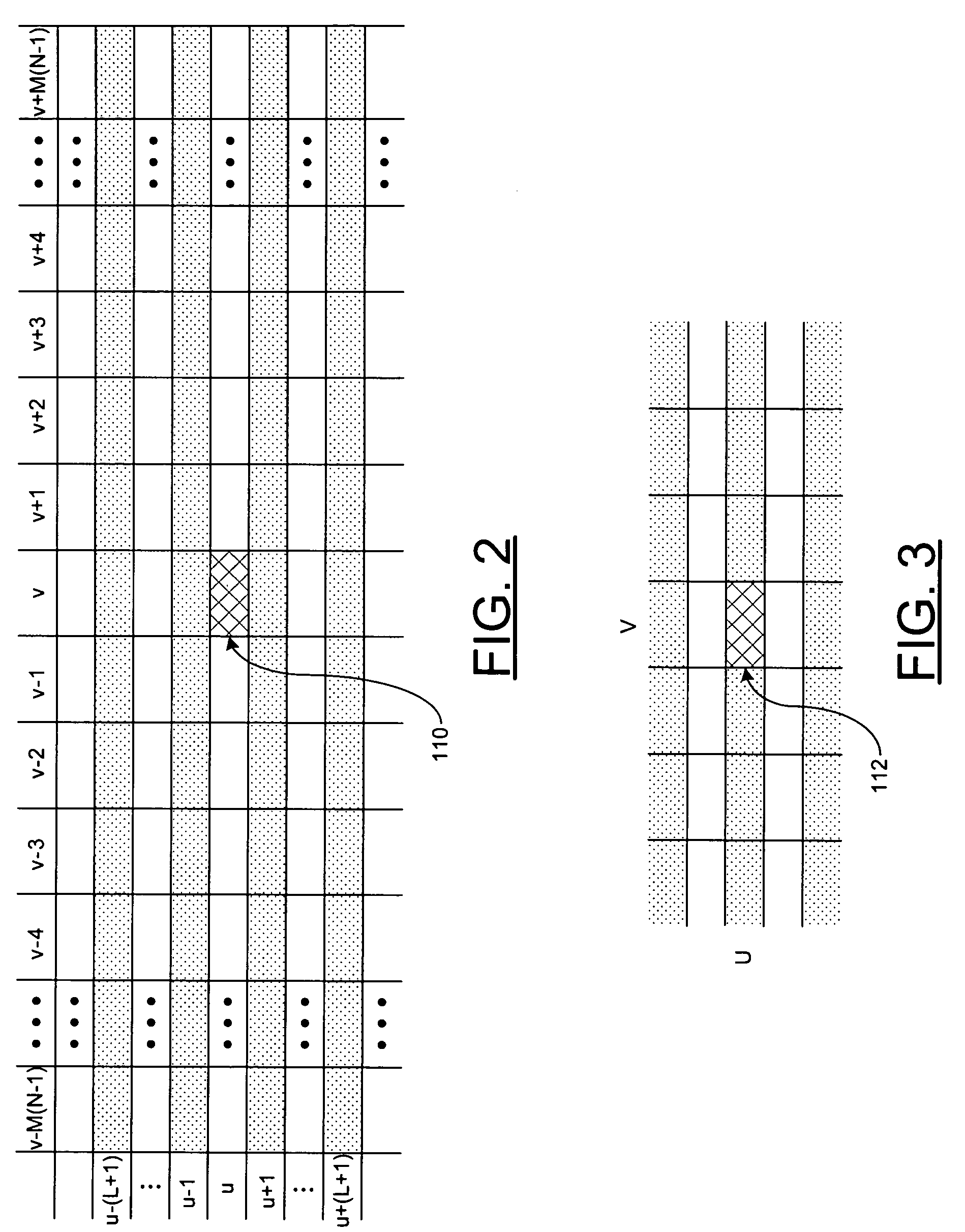

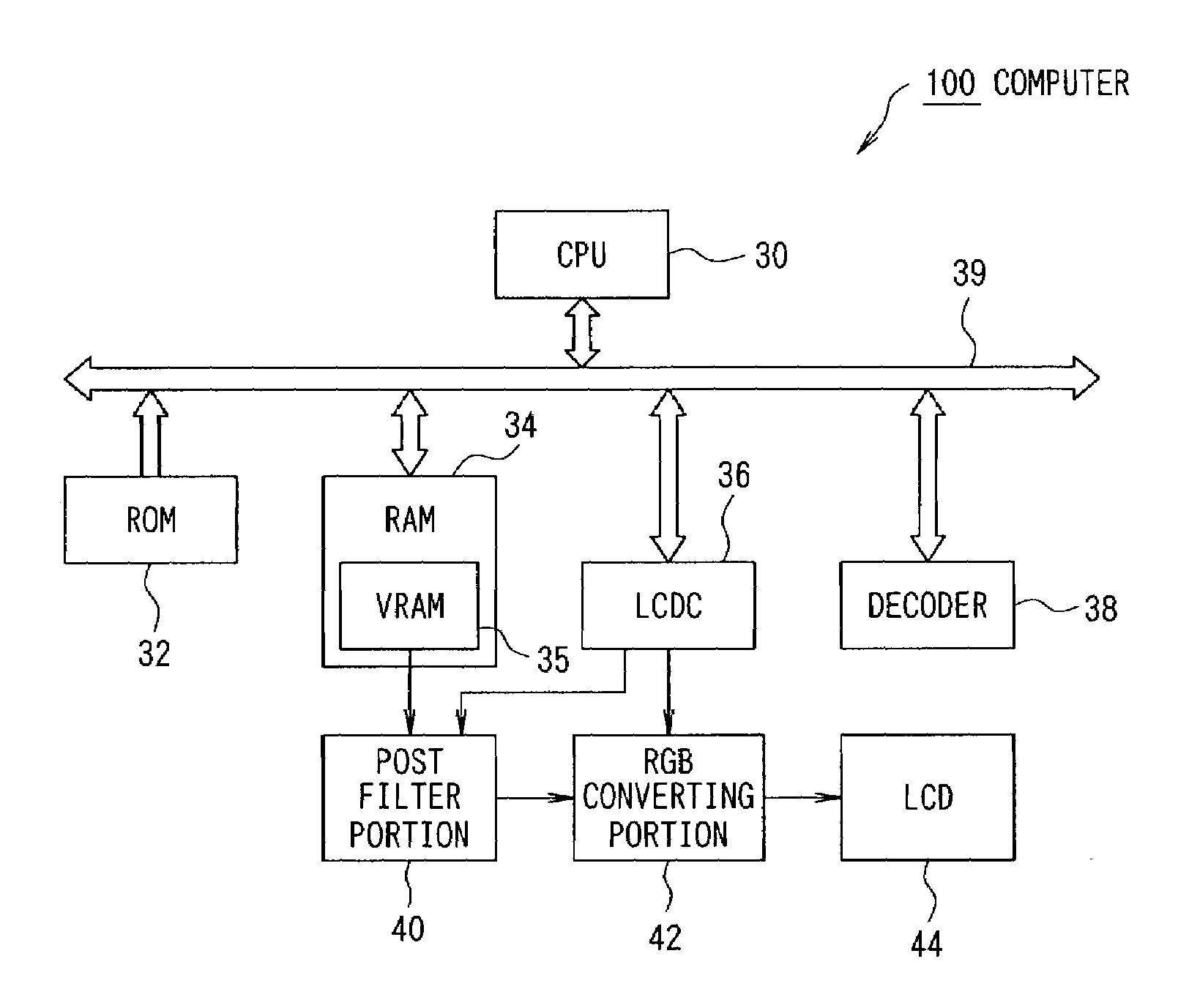

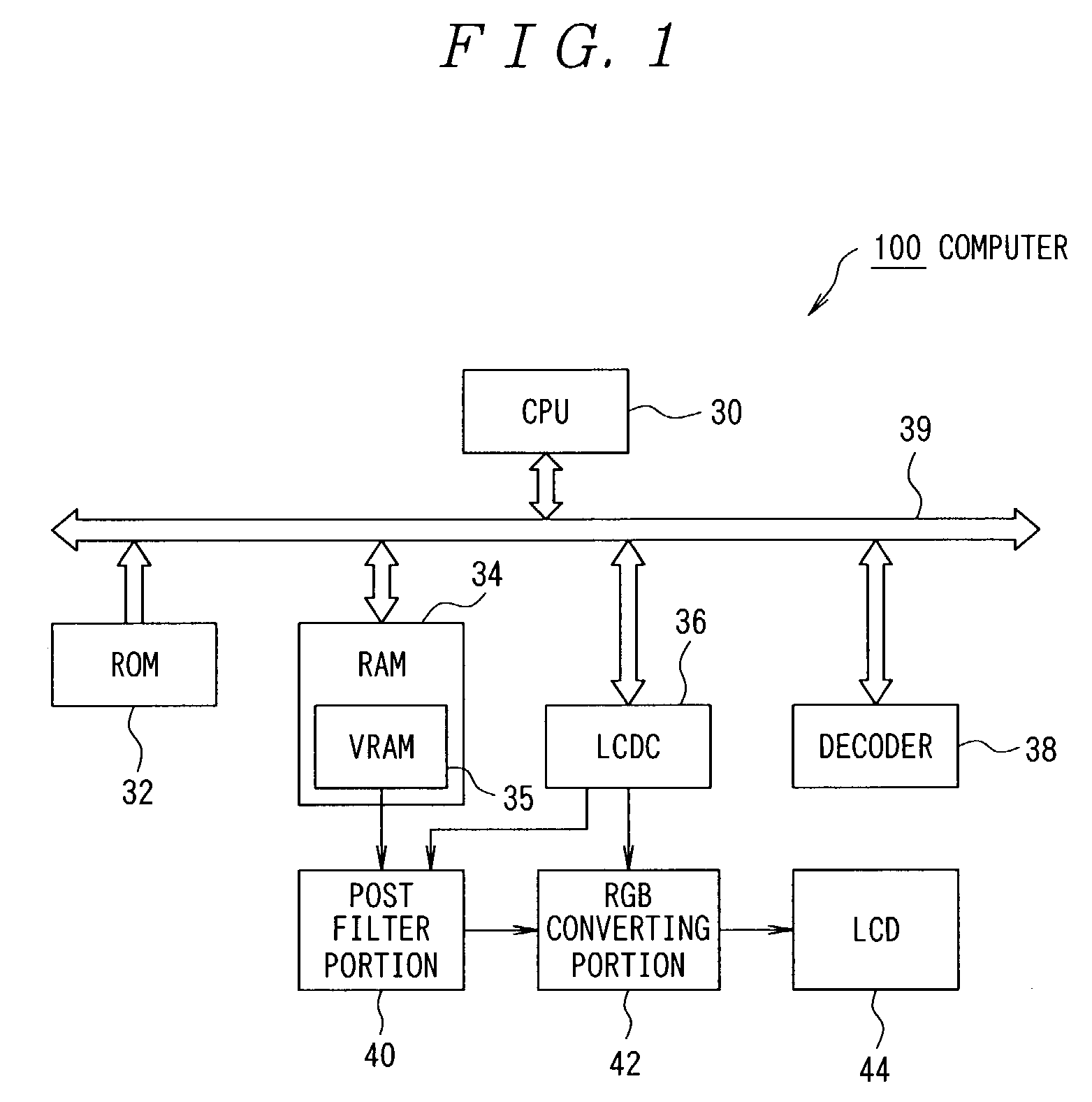

Image processing apparatus, image processing program and image processing method

InactiveUS7162090B2Simplifying and accelerating filtering processReduce memory capacityImage enhancementImage analysisImaging processingFilter effect

To provide an image processing apparatus suitable for simplifying and accelerating a filtering process at the time of decoding an image and implementing an effective filter effect. A deblock filtering process judges whether or not difference values between values of subject pixels v0 to v7 and values of reference pixels ry0 to ry7 are exceeding a threshold, performs horizontal filter operation as to the subject pixels v0 to v7 based solely on the values of the subject pixels v0 to v7 and the values of the reference pixels rx0 and rx1, determines whether or not to perform vertical filter operation as to the subject pixels v0 to v7 based solely on the judgment result, and performs the vertical filter operation as to the subject pixels v0 to v7 based solely on the values of the subject pixels v0 to v7 and the values of the reference pixels ry0 to ry7.

Owner:SEIKO EPSON CORP

Method and apparatus for video and image deinterlacing and format conversion

ActiveUS7170561B2Minimal memory bandwidthQuality improvementTelevision system detailsPicture reproducers using cathode ray tubesCurrent sampleField line

A method and apparatus for deinterlacing a picture is disclosed. The method generally includes the steps of (A) calculating a plurality of differences among a plurality of current samples from a current field of the picture, the differences being calculated along a plurality of line segments at a plurality of angles proximate a particular position between two field lines from the current filed, (B) generating a first sample at the particular position by vertical filtering the current field in response to the differences indicating that the particular position is a non-edge position in the picture and (C) generating a second sample at the particular position by directional filtering the current field in response to the differences indicating that the particular position is an edge position in the picture.

Owner:AVAGO TECH INT SALES PTE LTD

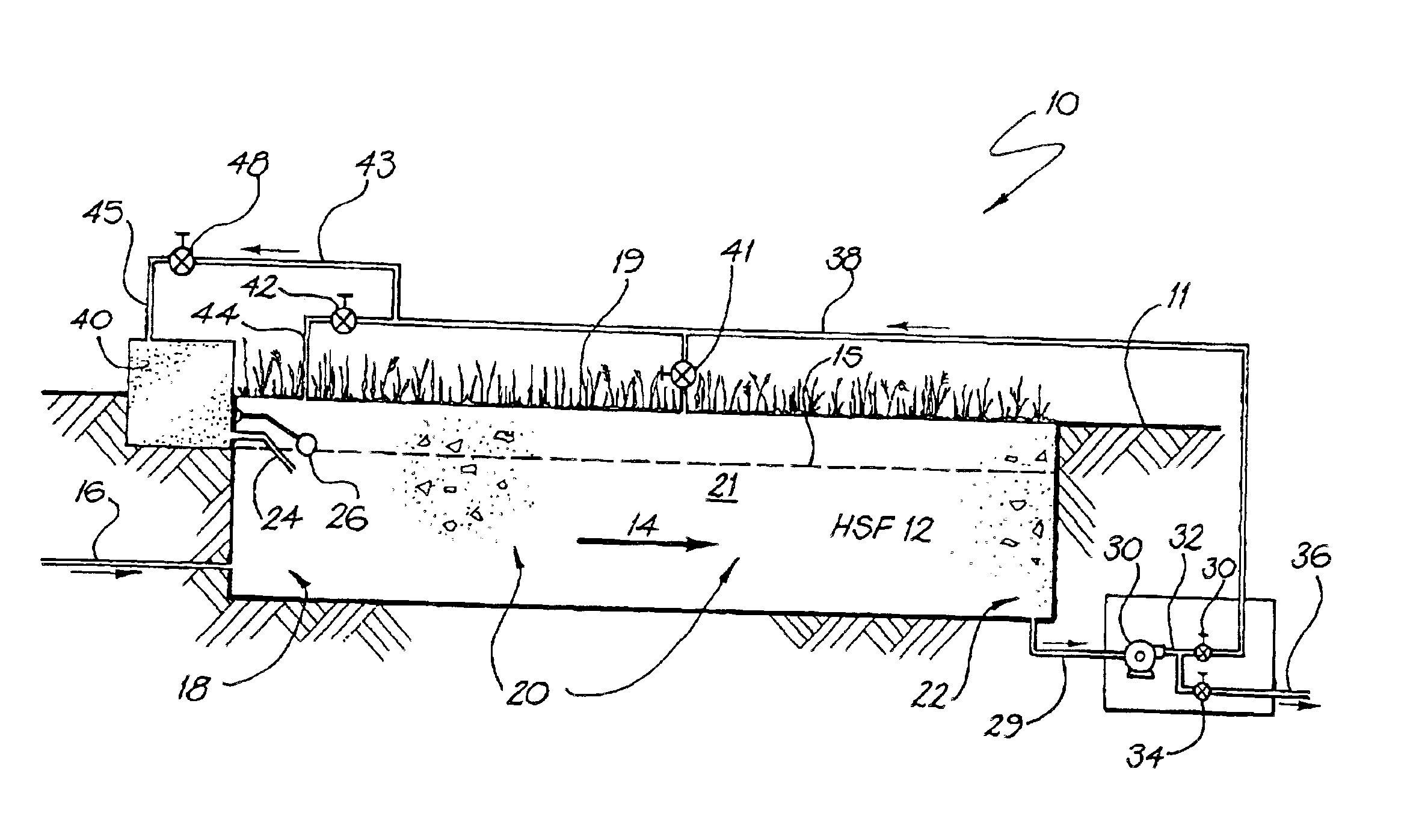

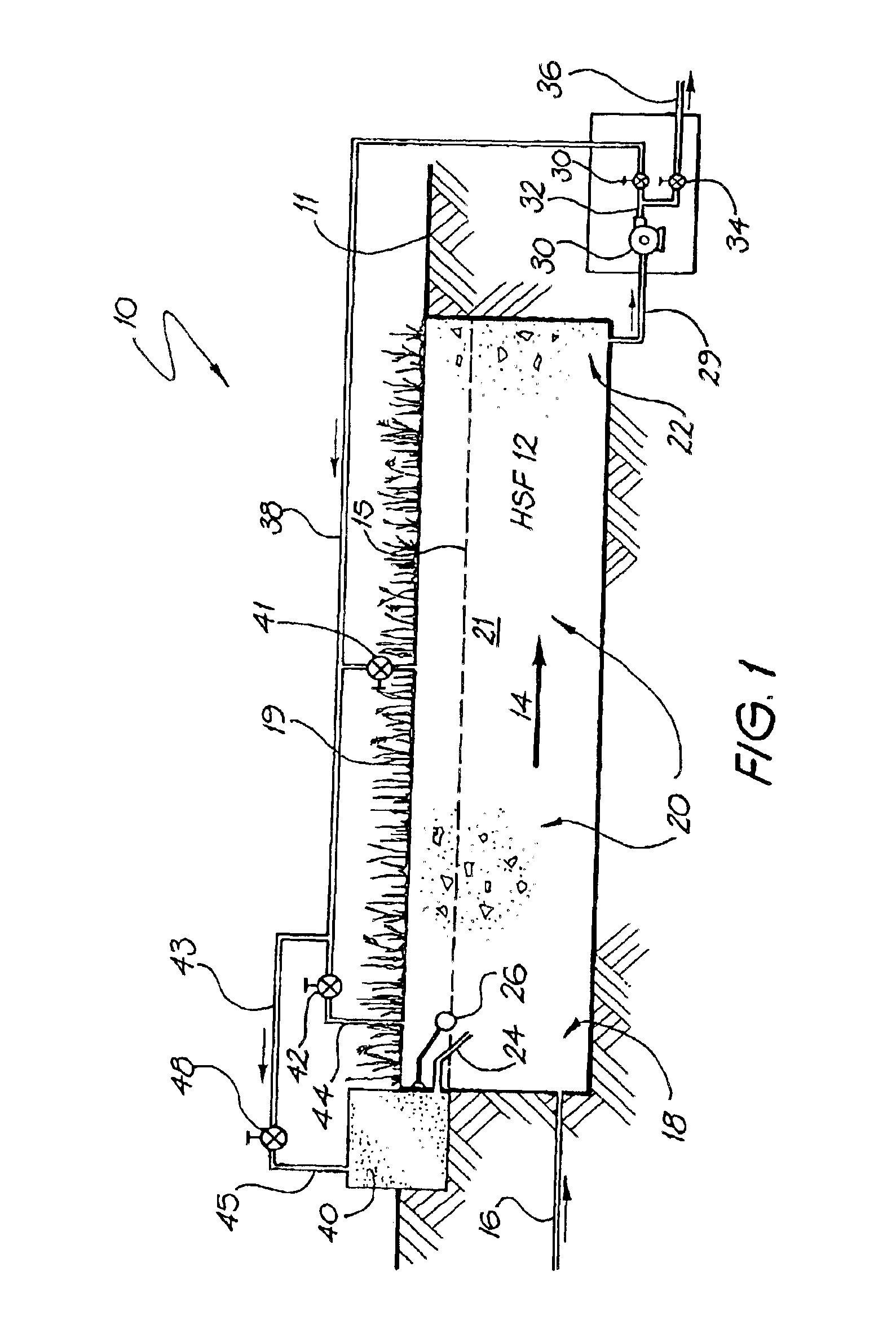

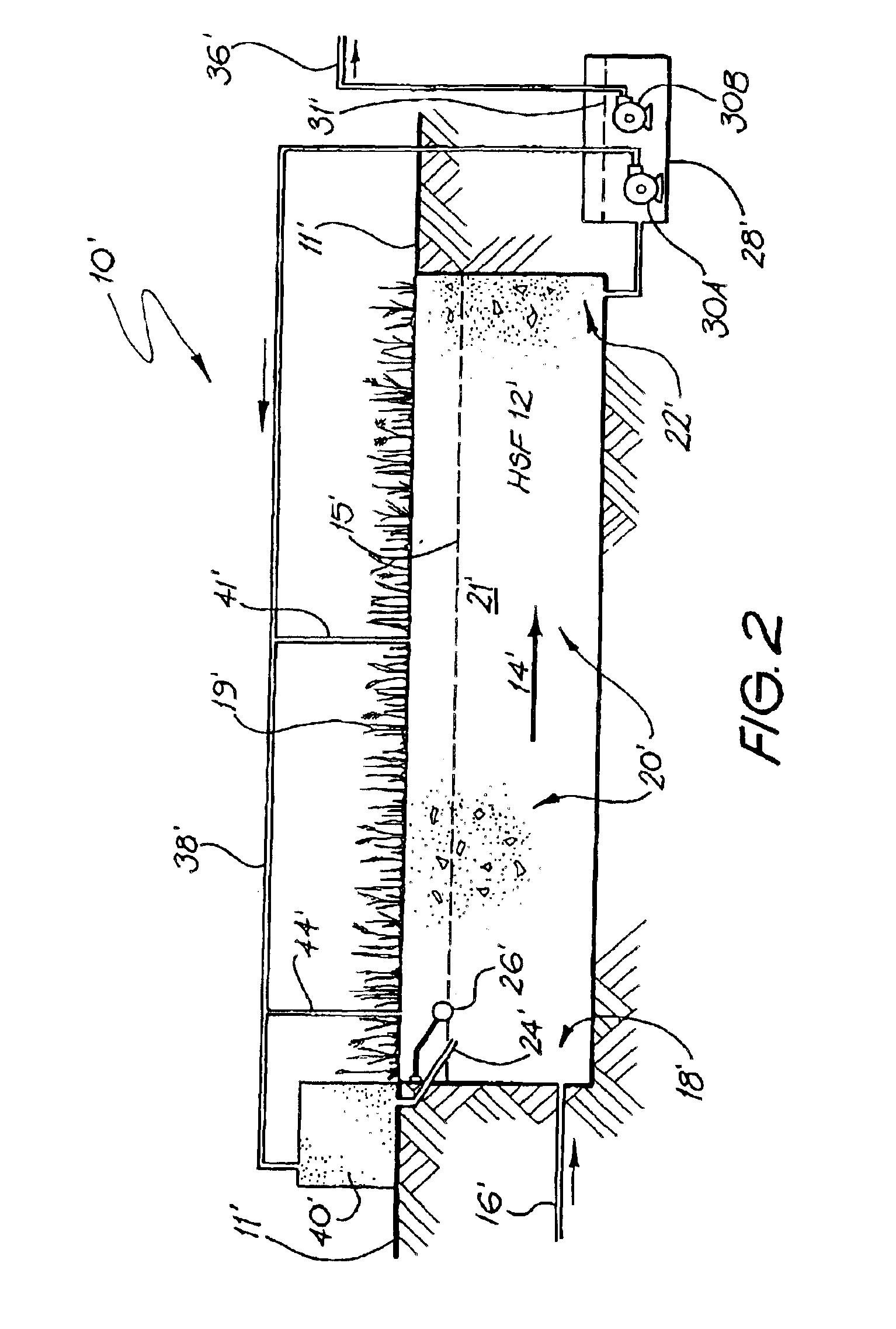

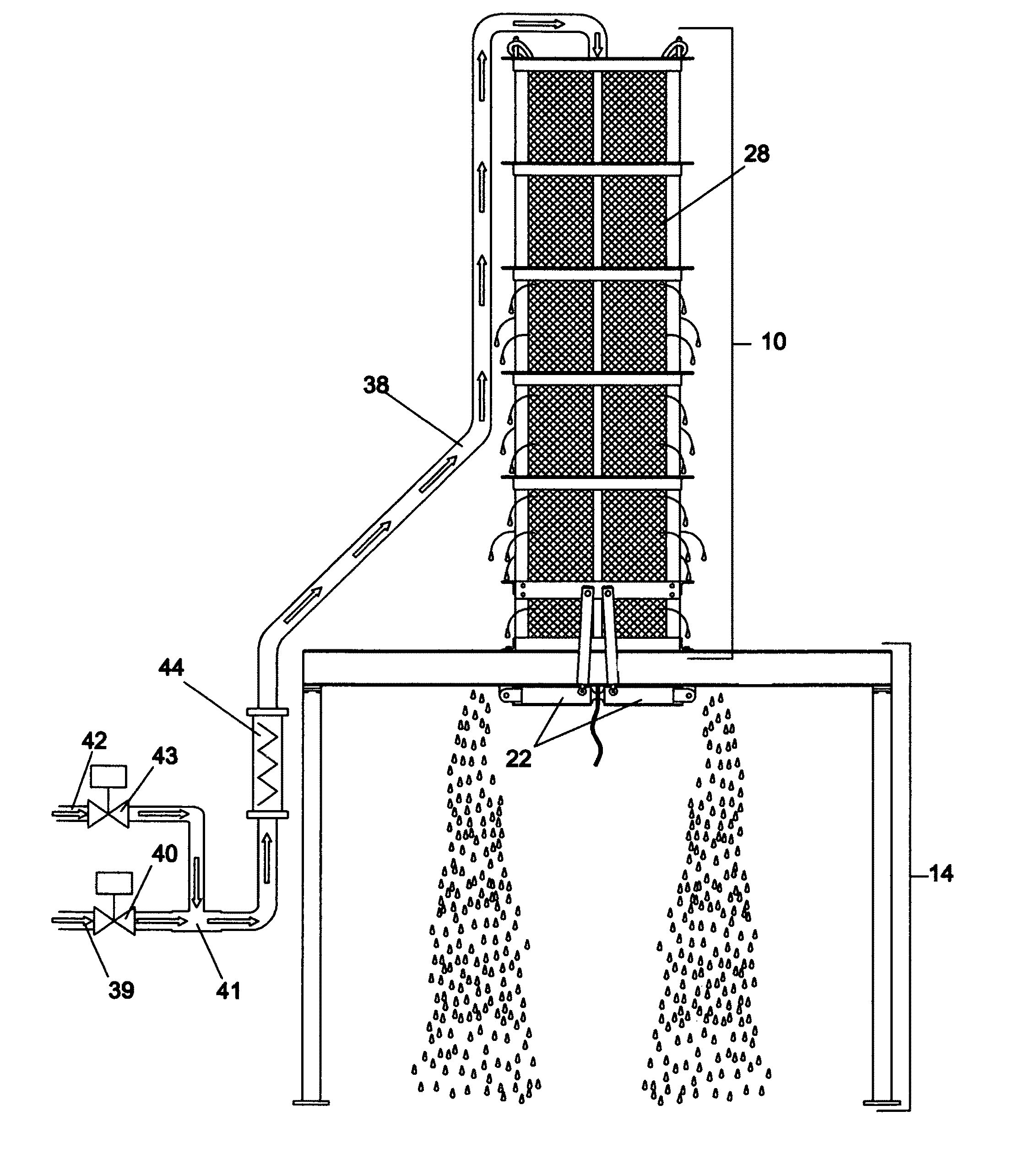

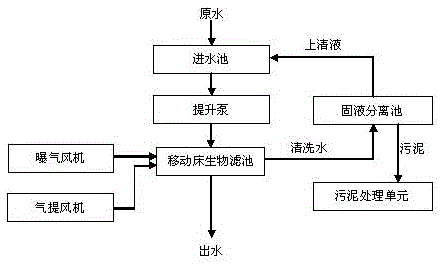

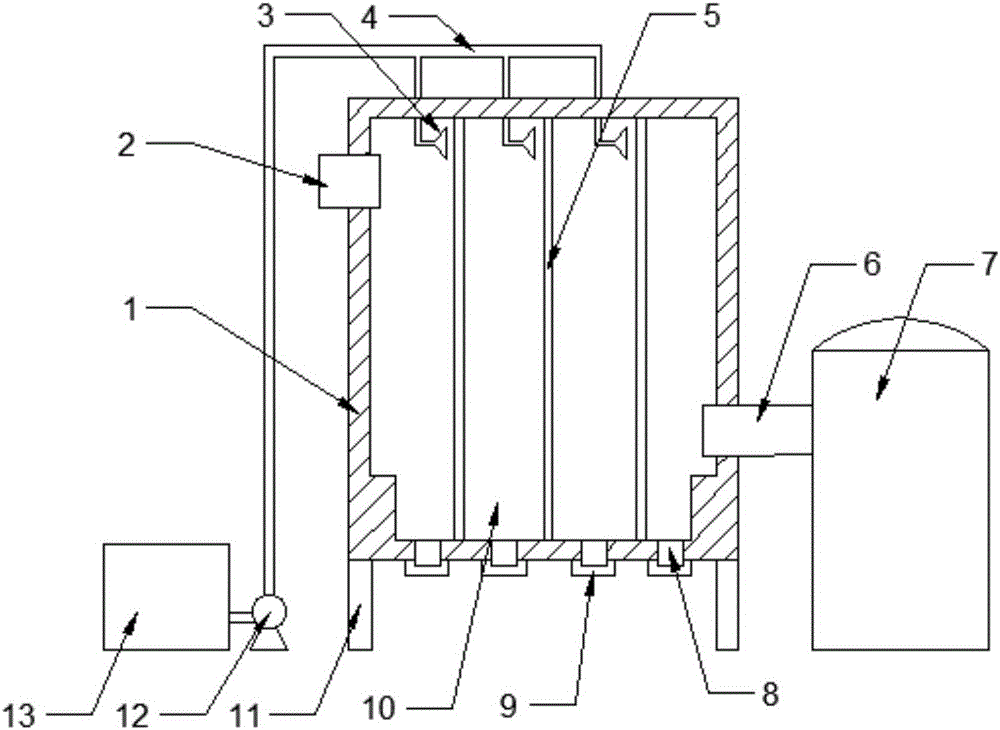

Polluted water treatment system

InactiveUS6858142B2Reduce the presence of impuritiesTreatment using aerobic processesBiological treatment regulationNitriteWater treatment system

A polluted water treatment system 10 operated to reduce impurities in sewerage polluted water to an acceptable level for dumping. The system includes a horizontal subsurface filter (HSF) 12 having an inlet zone 18 through which the inflow of polluted water is permitted to pass, a treatment zone 20 which permits the polluted water to undergo treatment by removal of at least some of the impurities of the polluted water and an outlet zone 22 from which the treated polluted water flows from the HSF 12. The impurities may include, for example, organic materials (BOD and COD) and oxidization processes within the HSF may reduce the quantity of the nitrites that are dumped from the outflow zone 22. The outlet zone 22 also includes a collection well 28 having a pump 30 located therein to recycle the treated effluent back to either the inlet zone 18 of the HSF 12 or to a secondary vertical filter 40. A level switch 26 located in the inlet zone 18 of the HSF 12 controls the level of water in the inlet zone to a set level 15 by regulating the amount of recycle water returned to the HSF 12 or indirectly via the vertical filter 40. The vertical filter 40 may be used to pre-treat any polluted water before it enters the HSF 12 and furthermore, it may also be used to remove phosphates from the polluted water.

Owner:ROOTZONE AUSTRALIA

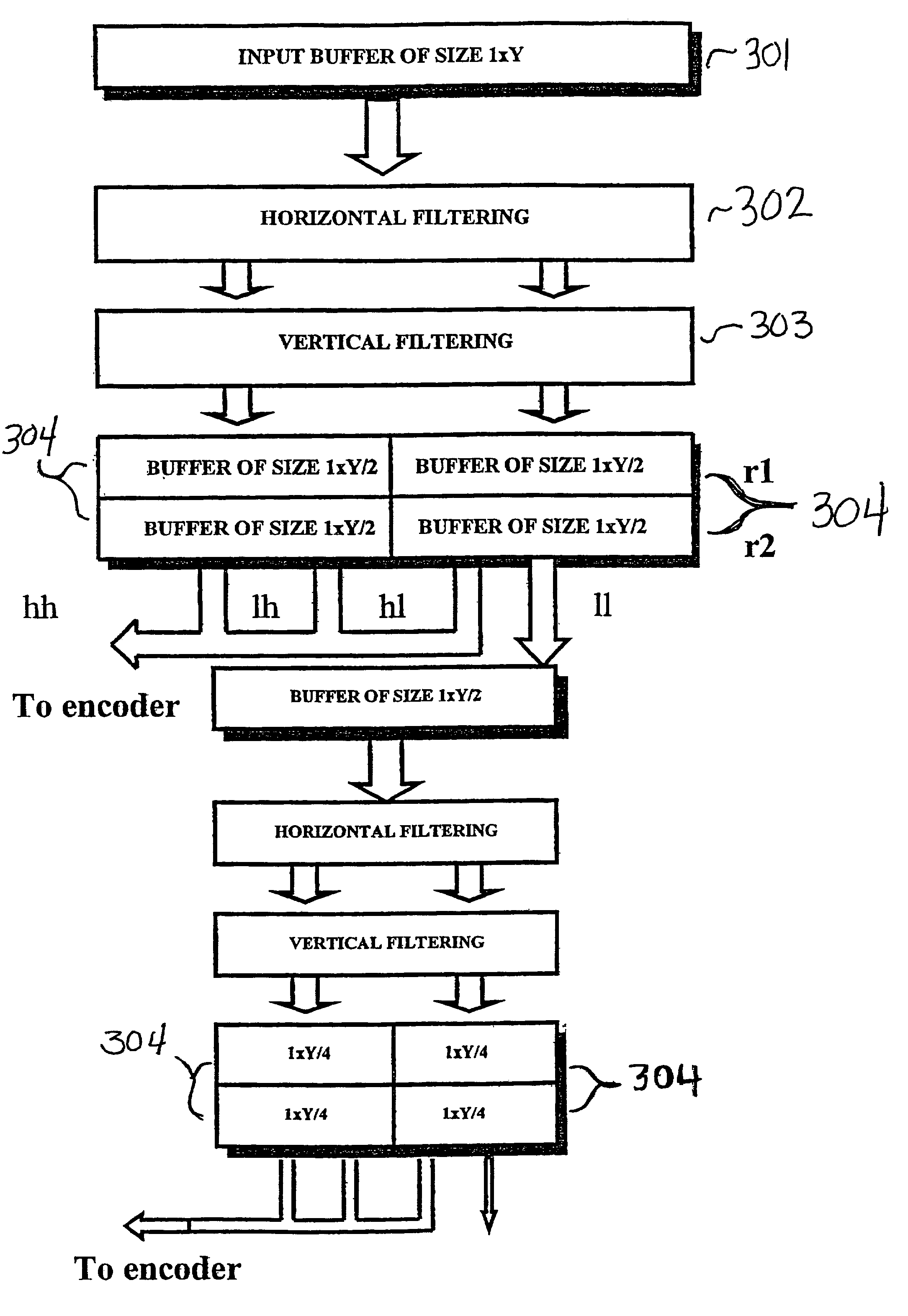

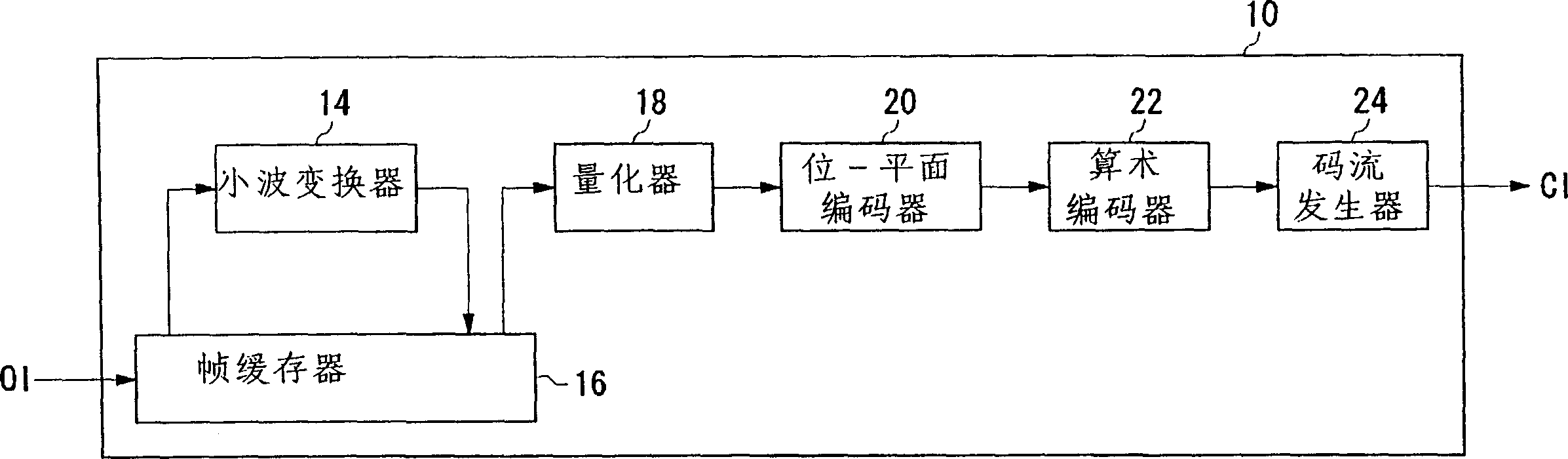

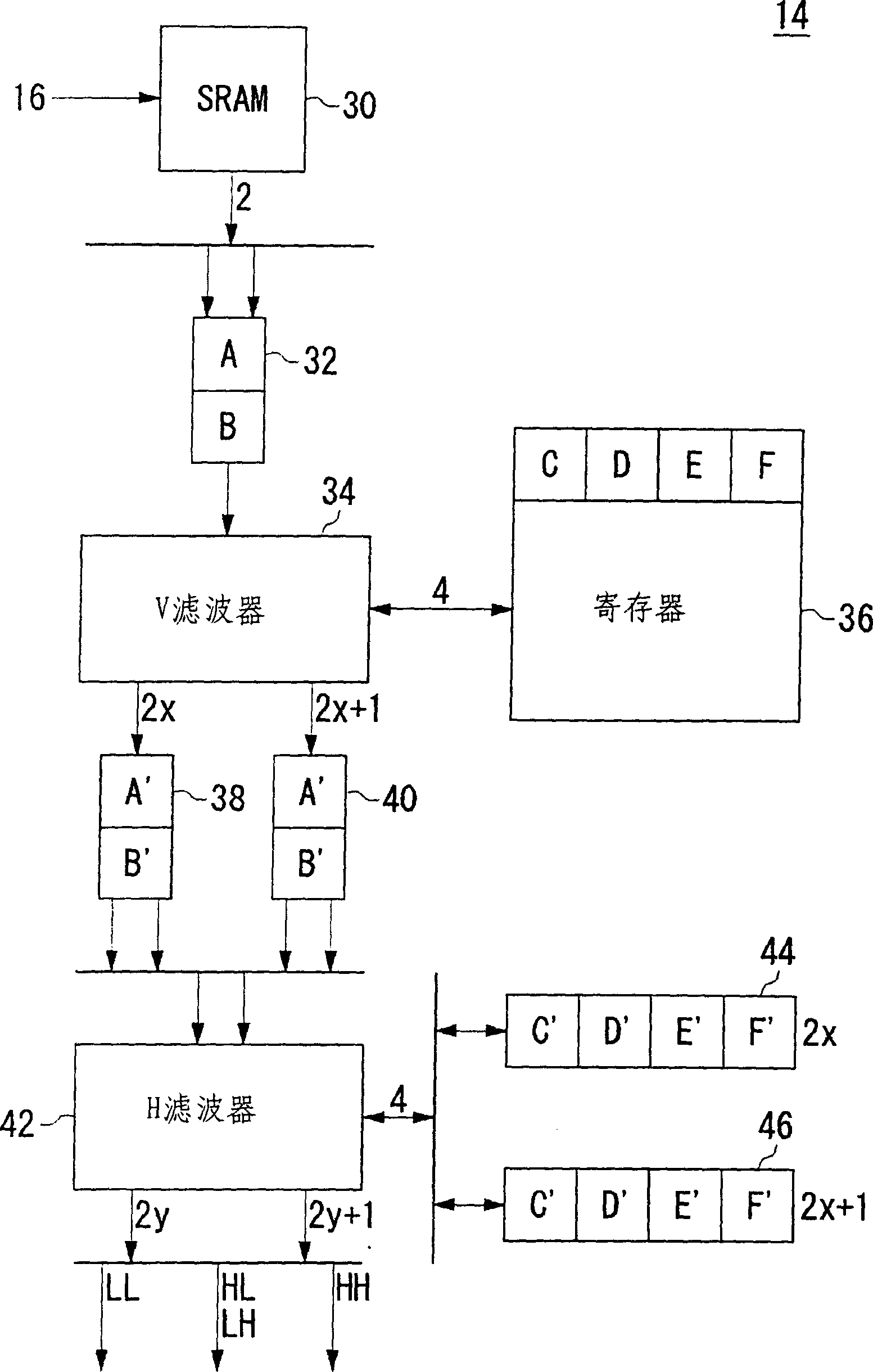

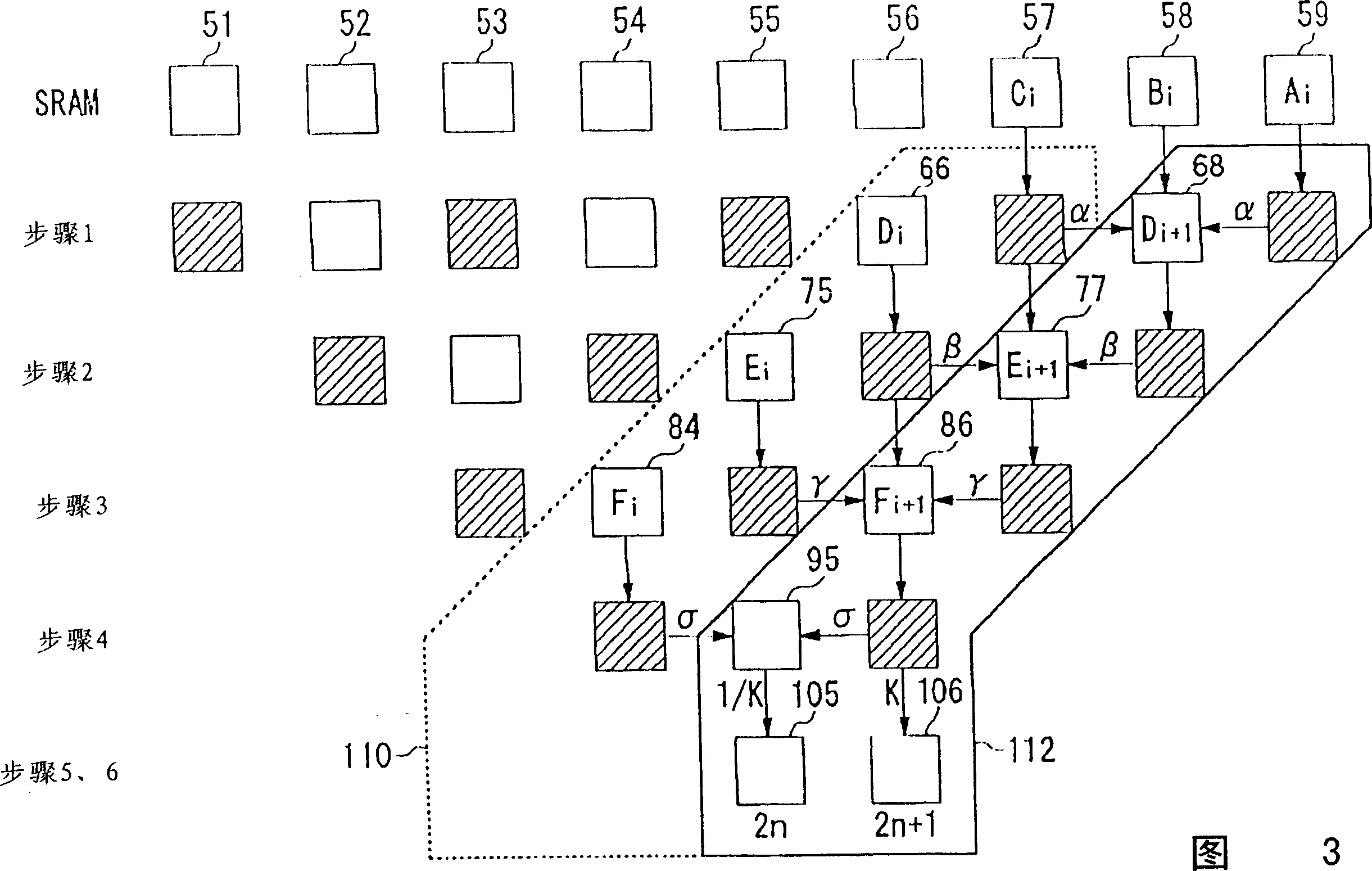

Apparatus and method for memory saving wavelet based video coding

InactiveUS6973127B1Low data rateReduce data rateColor television with pulse code modulationColor television with bandwidth reductionVertical filterRecursion

A method and apparatus for compressing video signals. The video compression may include row by row horizontal subband filtering of video data representing part of an image, and row by row concurrent vertical high and vertical low pass subband filtering of the results of the horizontal subband filtering. Less than the vertical filter length of rows of results of the horizontal subband filtering may be buffered at a time. The vertical high and vertical low pass subband filtering may include calculating a first result row by adding a first row of a recursion buffer to the results of multiplying a row of results from the horizontal subband filtering and a first vertical filter coefficient, calculating a second result row by adding the first row of the recursion buffer to the result of multiplying the row of results of the horizontal subband filtering and a second vertical filter coefficient, overwriting the first row of the recursion buffer with the second result row, and transmitting the first result row to be encoded.

Owner:XVD TECH HLDG LTD IRELAND

Interchangeable capsule for preparing an infusion of coffee, and method for obtaining an infusion of said coffee

A capsule suited to contain in its inside a mass of powdered coffee for preparing an infusion of coffee. The capsule comprises a container closed by a lid. The container is provided with a filter of the coffee / hot water infusion. The capsule is characterized in that the mass of powdered coffee is located in an annular space surrounding a central chimney. The infusion water, during at least one of its intermediate steps, converges from the annular space towards the central chimney passing first through a vertical filter.

Owner:MACCHIAVELLI

Method of dewatering solids laden liquids utilizing a reusable filter element

ActiveUS8070960B2Avoid insufficient lengthPrevent leakageSludge treatment by de-watering/drying/thickeningSemi-permeable membranesWaste streamFiltration

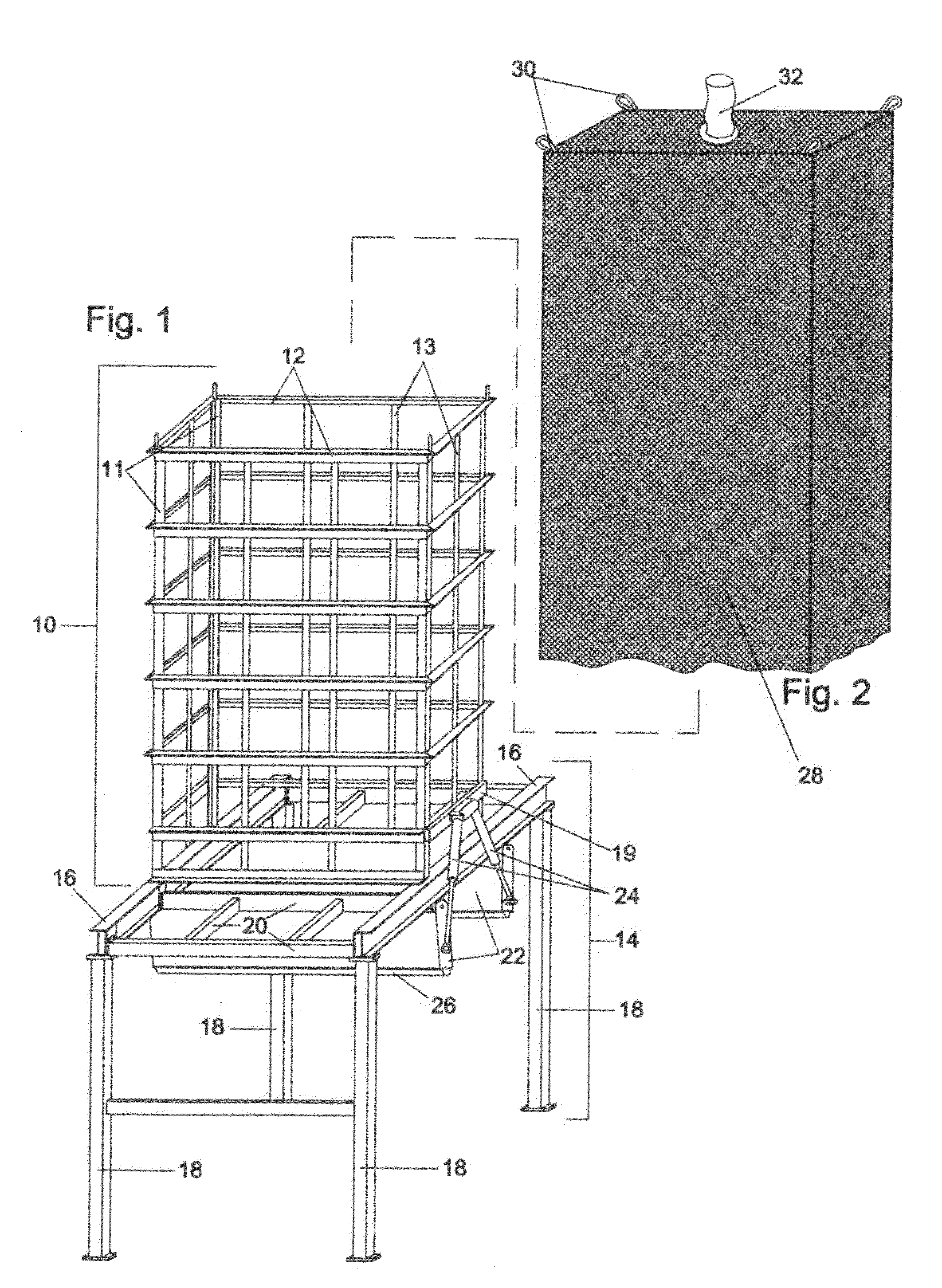

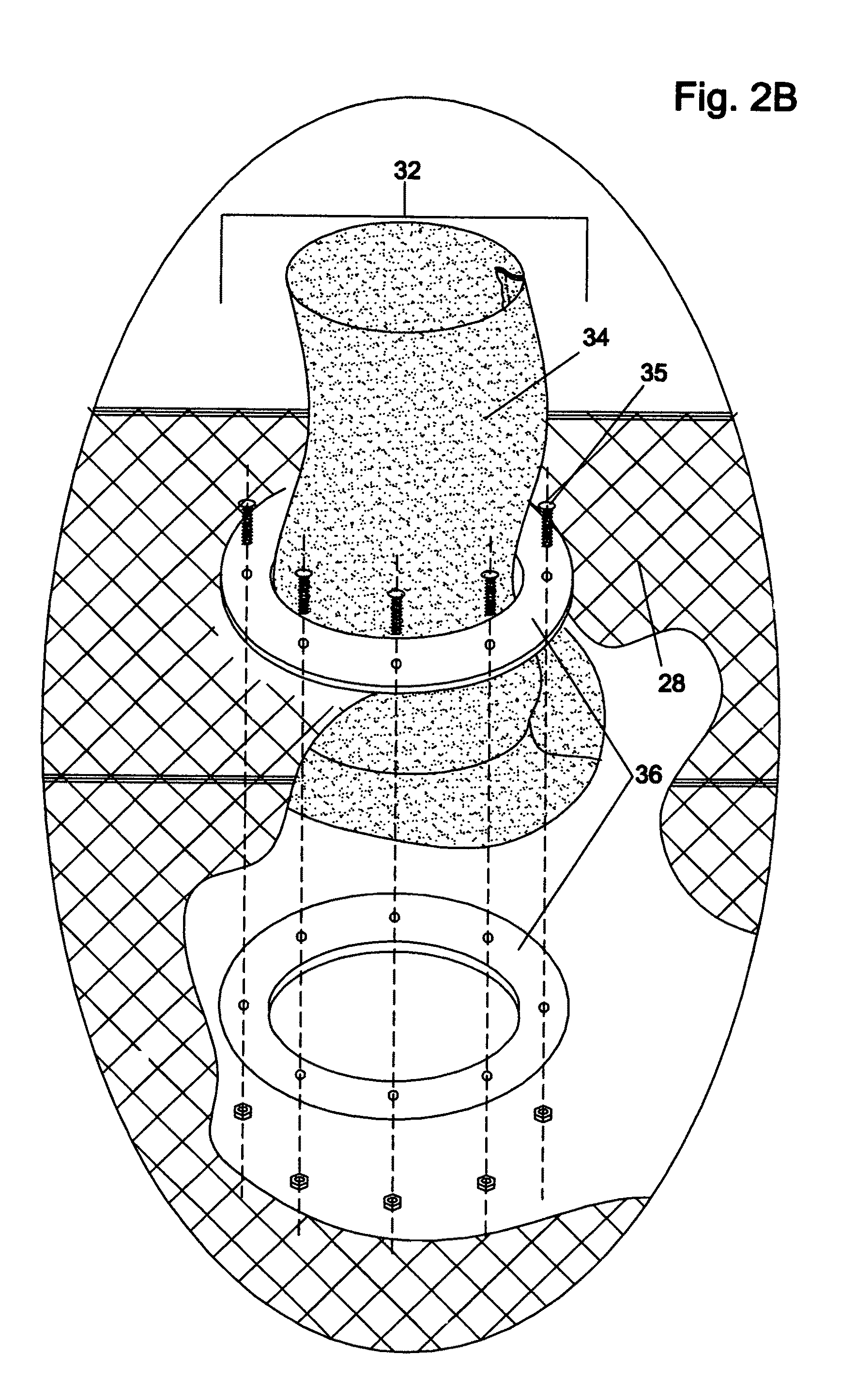

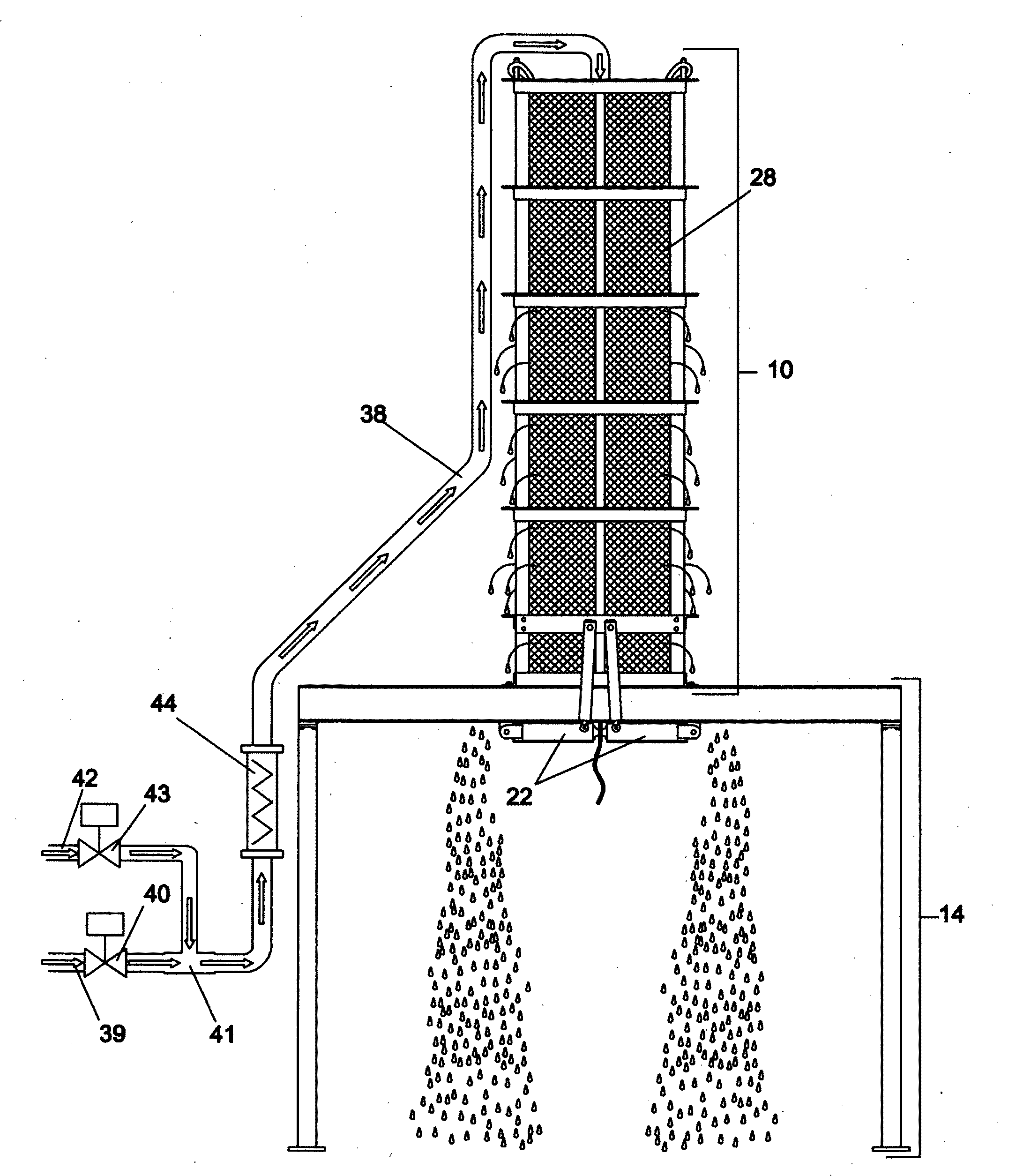

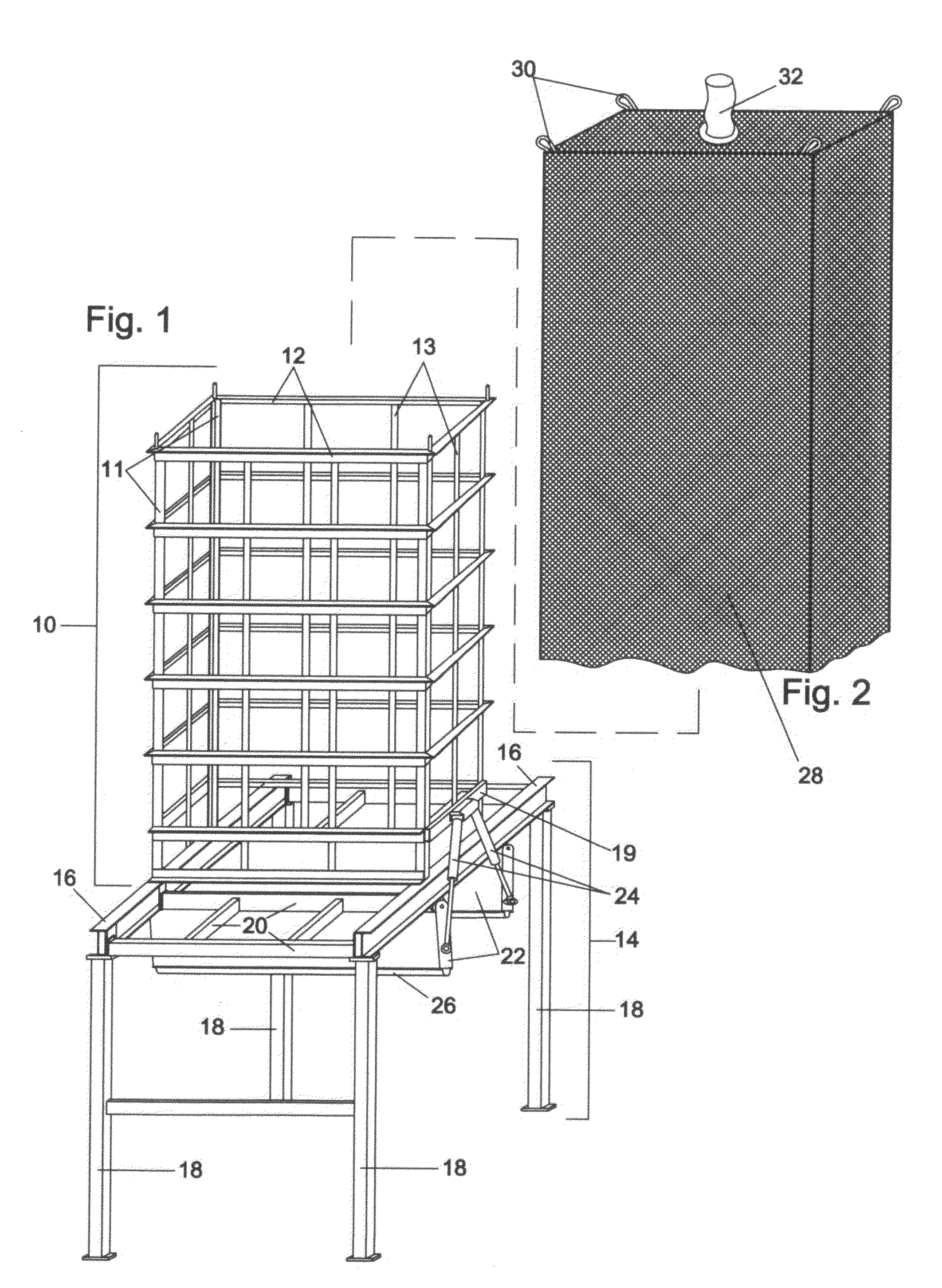

A method of dewatering a solids laden waste stream, whereby the slurry is pumped into a vertical filter retaining structure and the liquid is allowed to flow out through the pores of the filtration element while retaining the solids within the structure. After the solids have dewatered, doors or gates located at the bottom of the structure are opened and the solids drop out the bottom by gravity. The structure is elevated to allow a transport vehicle to be placed under the doors prior to dropping out the solids. One embodiment utilizes an open bottom, closed top filter bag that is closed off by the doors or sliding gates located at the bottom of the structure. Another embodiment disclosed would use rigid filter plates to retain the solids and drop out the accumulated solids by opening sliding gates at the bottom of the structure. The filter bag or plates is accessible from the side to allow either manual or automatic pressure washing of the filtration elements or filter bag after each dewatering cycle.

Owner:CONWELL MICHAEL K

Method of dewatering solids laden liquids utilizing a reusable filter element

ActiveUS20090314715A1Avoid insufficient lengthPrevent leakageUltrafiltrationSedimentation separationWaste streamFiltration

A method of dewatering a solids laden waste stream, whereby the slurry is pumped into a vertical filter retaining structure and the liquid is allowed to flow out through the pores of the filtration element while retaining the solids within the structure. After the solids have dewatered, doors or gates located at the bottom of the structure are opened and the solids drop out the bottom by gravity. The structure is elevated to allow a transport vehicle to be placed under the doors prior to dropping out the solids. One embodiment utilizes an open bottom, closed top filter bag that is closed off by the doors or sliding gates located at the bottom of the structure. Another embodiment disclosed would use rigid filter plates to retain the solids and drop out the accumulated solids by opening sliding gates at the bottom of the structure. The filter bag or plates is accessible from the side to allow either manual or automatic pressure washing of the filtration elements or filter bag after each dewatering cycle.

Owner:CONWELL MICHAEL K

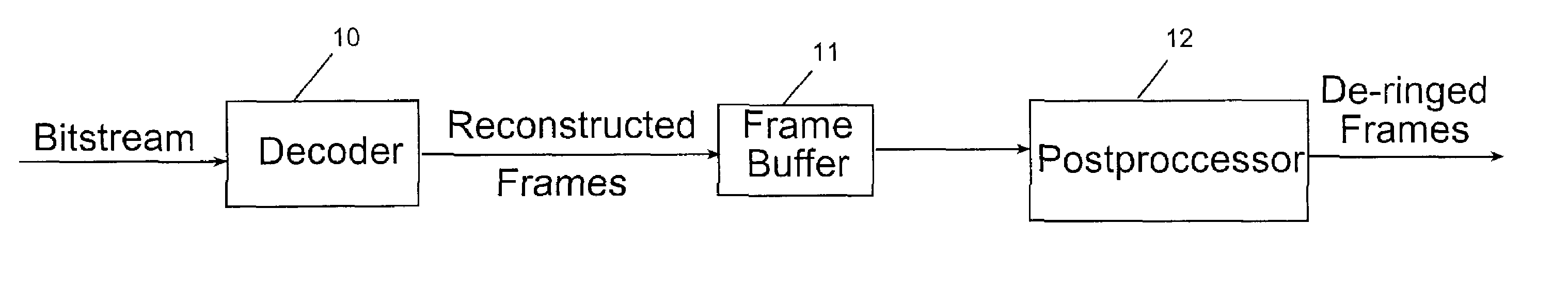

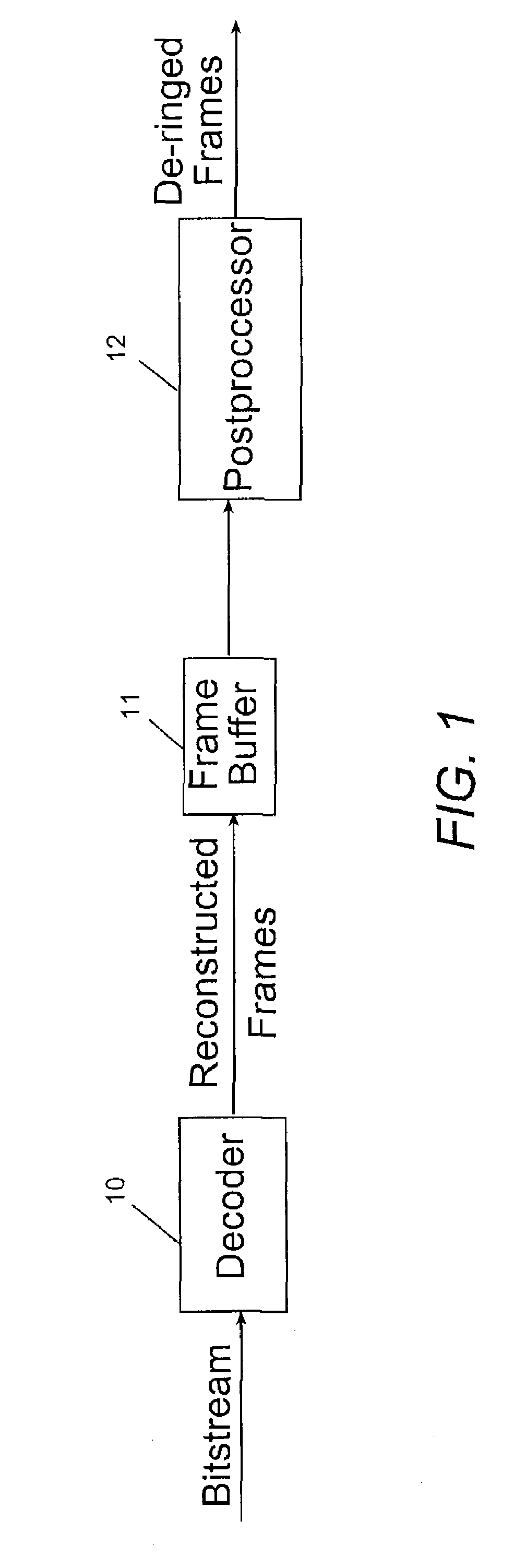

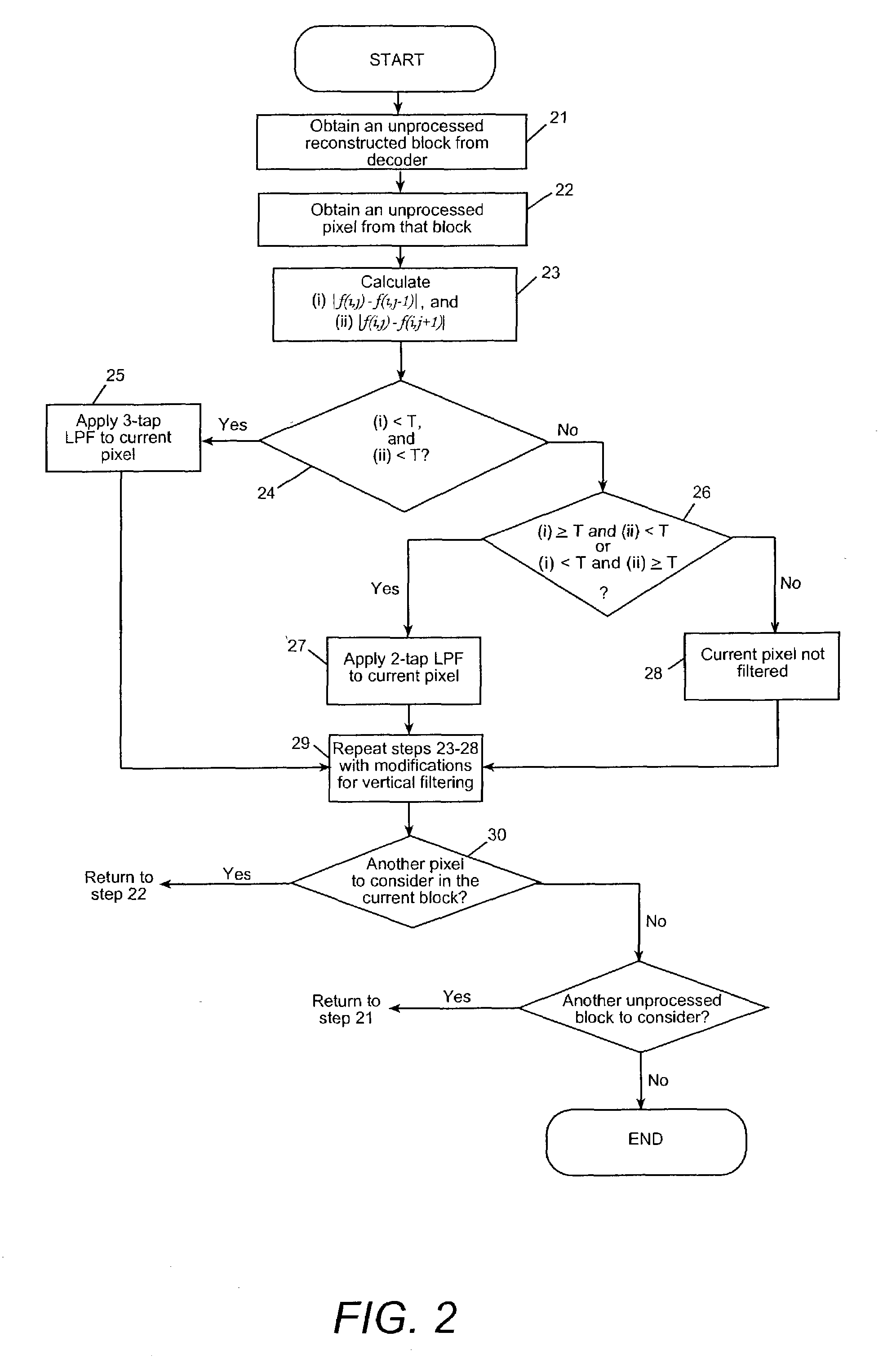

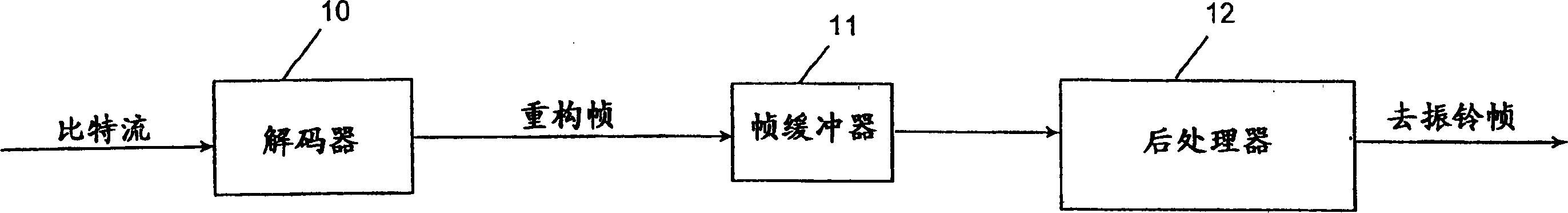

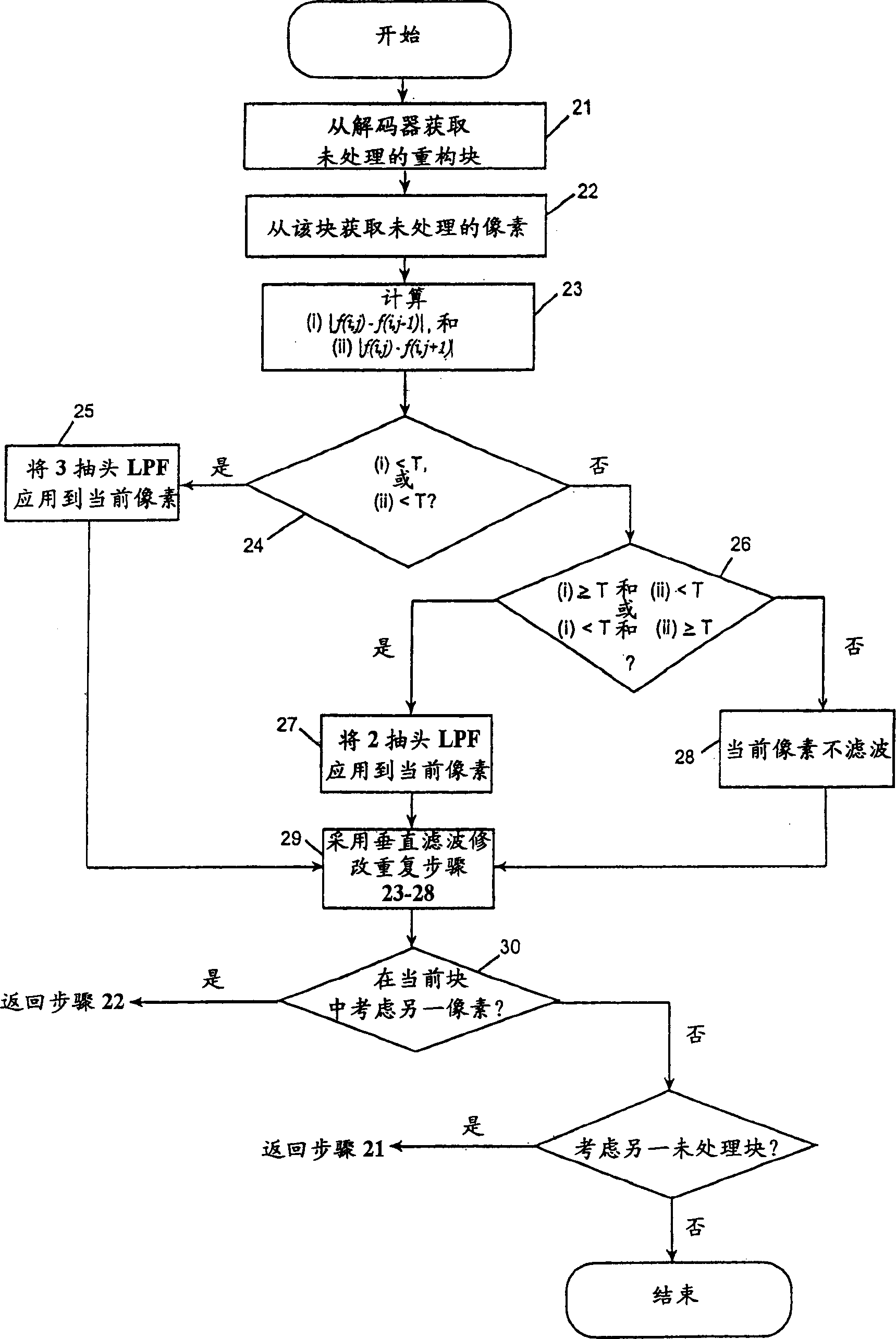

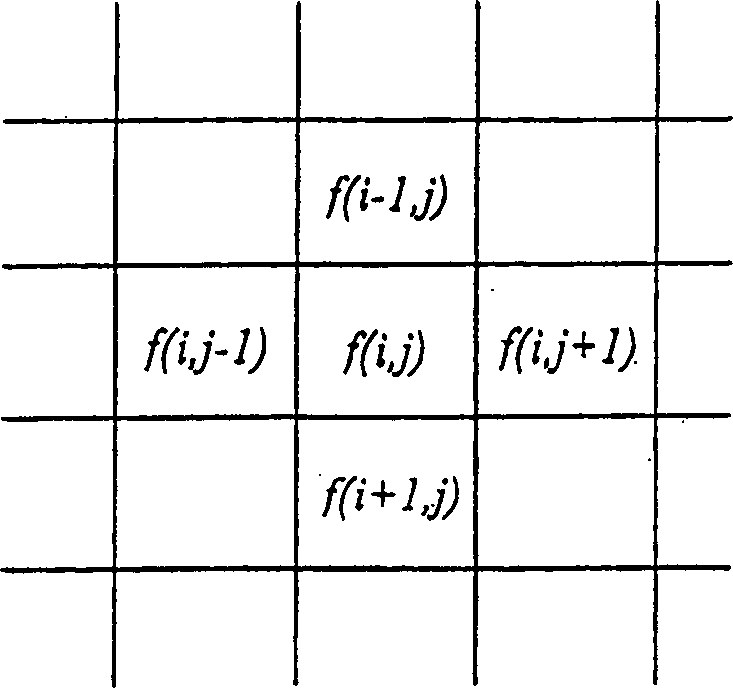

Adaptive post-filtering for reducing noise in highly compressed image/video coding

ActiveUS7031552B2Reducing ringing noiseReduce noiseImage enhancementImage analysisPattern recognitionVideo encoding

A technique to reduce ringing artifacts in highly compressed block-based image / video coding is applied to each reconstructed frame output from the decoder. For each pixel block of a reconstructed frame, low-pass filtering is then adaptively applied according certain calculated differences between adjacent pixel values. For each pixel, a determination is made as to what type of horizontal filter, if any, is to be applied. Depending on the results of that determination, the pixel may remain unfiltered or may have a 2- or 3-tap horizontal filter applied to it. A similar process is undertaken to determine what type of vertical filter, if any, is to be applied, no filter, a 2-tap or a 3-tap vertical filter.

Owner:GK BRIDGE 1

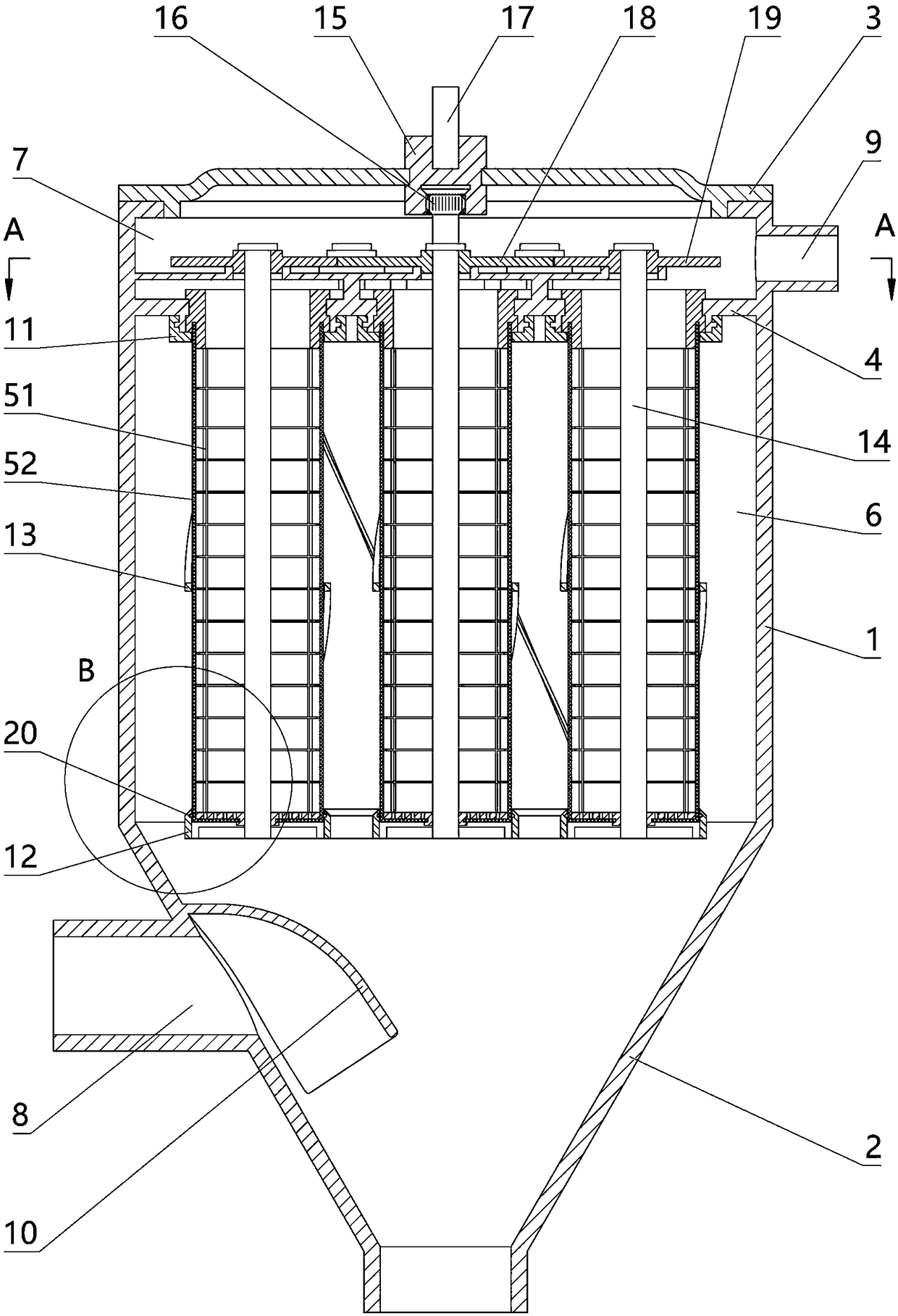

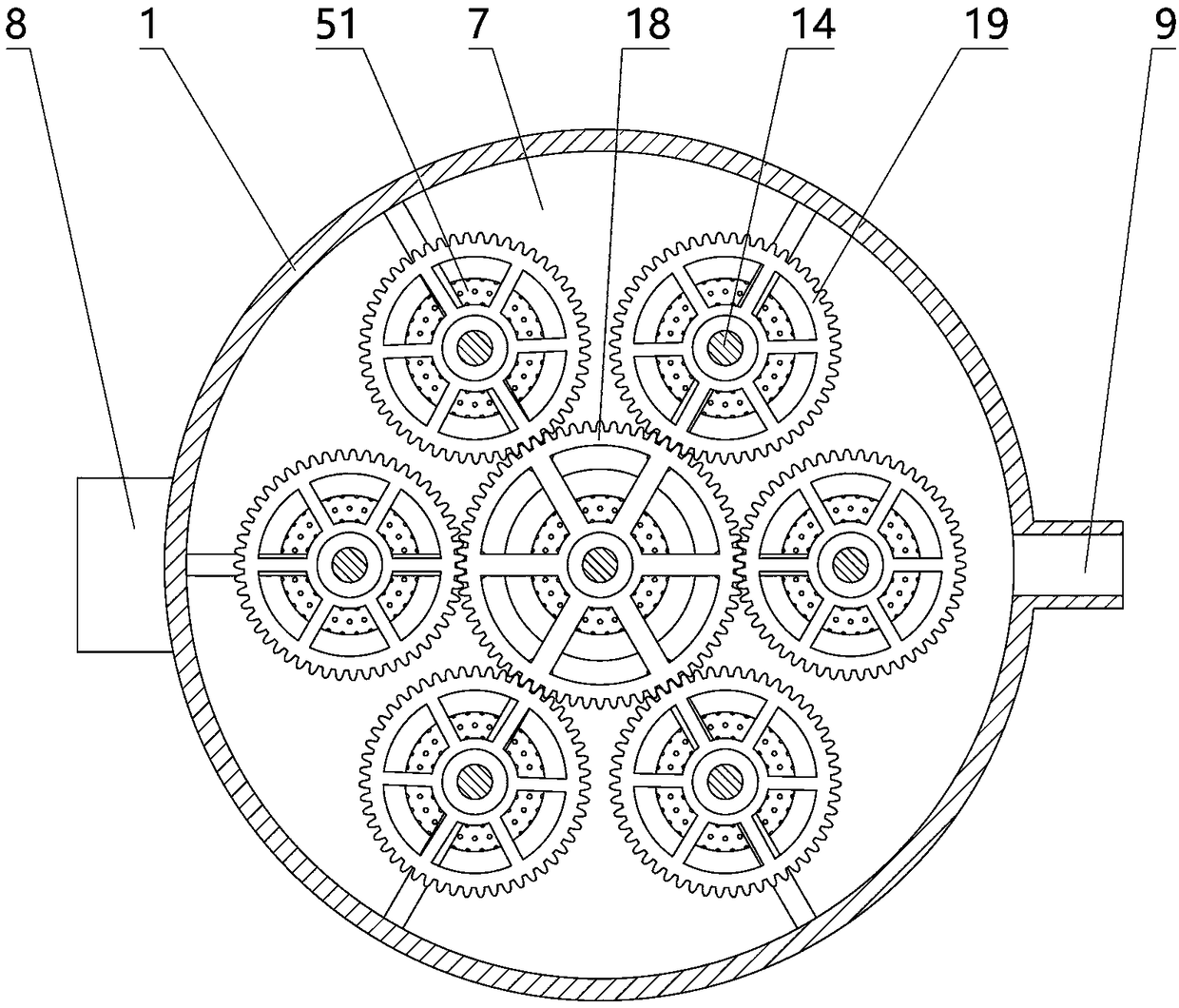

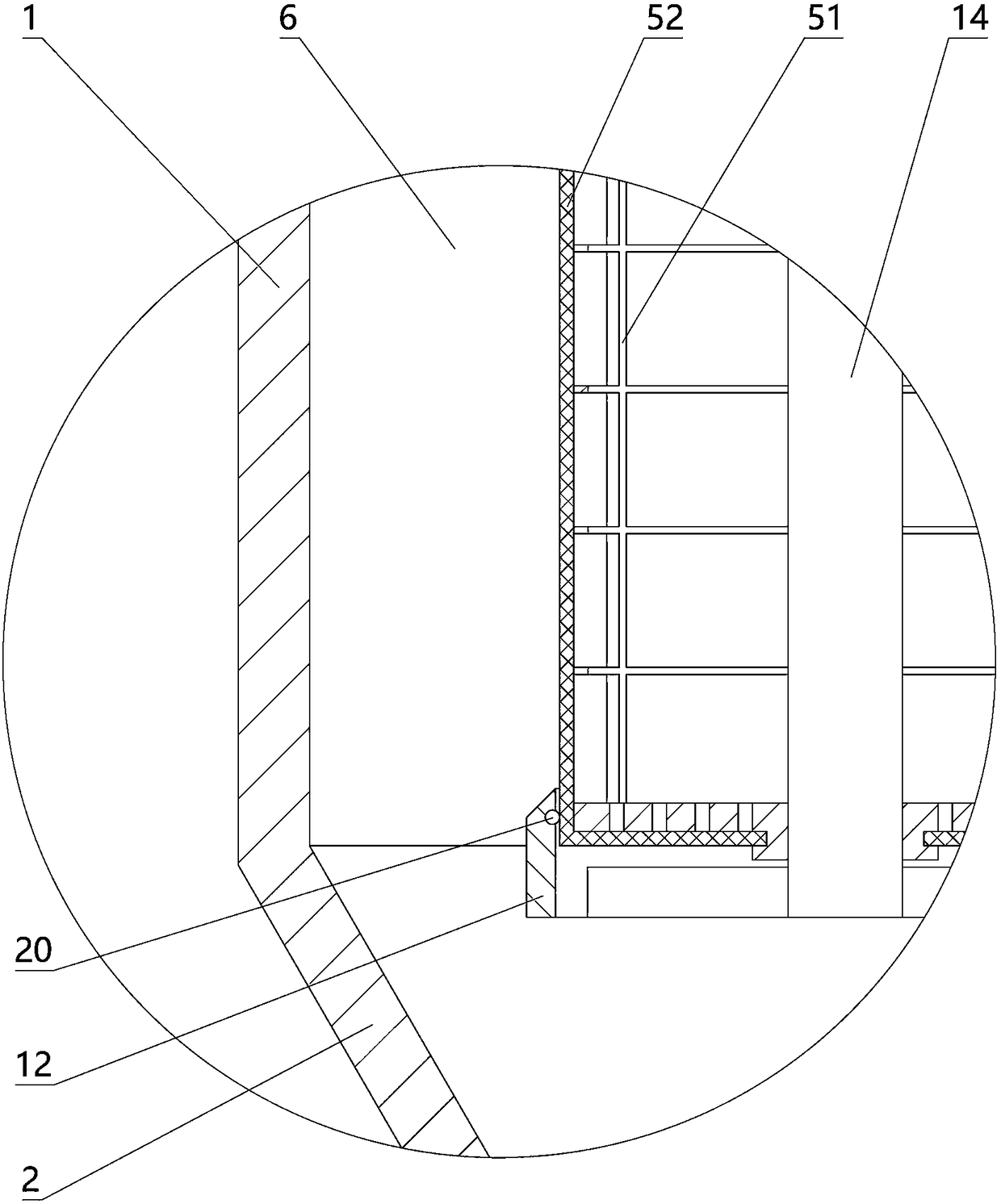

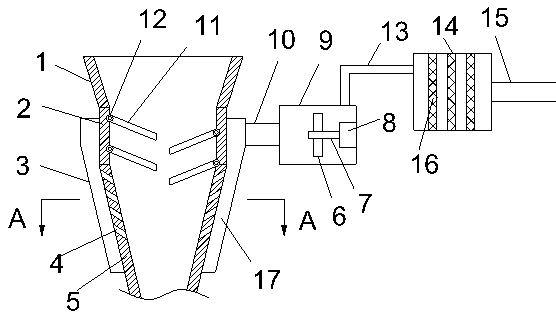

Mechanical-deashing bag-type dust collector

ActiveCN108854303AExtended service lifeBest Dust Removal StateCombination devicesDispersed particle filtrationBaghouseDrive shaft

The invention relates to a mechanical-deashing bag-type dust collector. The mechanical-deashing bag-type dust collector comprises a shell, a dust bucket, a cover plate, a horizontal separation plate and a plurality of vertical filter bags; the separation plate is arranged in the inner side of the shell and divides the inner side of the shell into a lower flow mixing chamber and an upper flow collection chamber; an air inlet is arranged on one side of the dust bucket, and an air outlet is arranged on one side of the shell; a flow guide plate in the flow mixing chamber is arranged on the dust bucket; the upper ends of the filter bags penetrate through the separation plate and are mounted on the separation plate; the separation plate is provided with sleeve rings which corresponds to filter bags coaxially one by one and sleeve the outside of the filter bags; rotating rings sleeve the lower ends of the filter bags, and are connected with the sleeve rings through a plurality of scrapping plates; rotating shafts are arranged on the rotating rings coaxially; the upper ends of the rotating shafts penetrate through the filter bags an are arranged above the separation plate; the rotating shafts are in sequential transmission connection though gear pairs; a coupling member which is arranged coaxially with any one of the rotating shafts is arranged on the cover plate; the upper end of anyone of rotating shafts is connected with the coupling member through a spline; a driving shaft above the cover plate is arranged on the coupling member.

Owner:湖南驰兴环保科技有限公司

Environment-friendly grain processing and discharging device with dust removal function

InactiveCN107824451AEasy to solveImprove dust removal effectGas current separationDispersed particle separationFiltrationEngineering

An environment-friendly grain processing blanking device with dust removal function, comprising a storage pipe, a buffer pipe and a discharge pipe, characterized in that a cylindrical buffer pipe is fixedly installed at the lower end of the storage pipe, and a buffer stop is arranged inside the buffer pipe The buffer baffle plate and the buffer baffle are installed on the inner wall of the buffer tube through the rotation of the torsion spring. The feeding tube is an inverted conical structure. Several dust suction channels are evenly arranged on the side of the feeding tube along the circumferential direction. The buffer tube and the dust collection sleeve The jacket is equipped with an inverted conical dust collection sleeve, and a dust collection cavity is formed between the dust collection sleeve, the buffer pipe and the dust collection sleeve; The wind cover, the drive shaft is provided with blades, the right end of the air outlet pipe is connected with a filter purification box, the right side wall of the filter purification box is provided with an exhaust pipe, and several filter mesh bags are vertically arranged in the filter purification box; the present invention effectively It avoids the dust rising caused by the grain in the process of falling, and achieves a good effect of dust removal and dust reduction.

Owner:朱峰

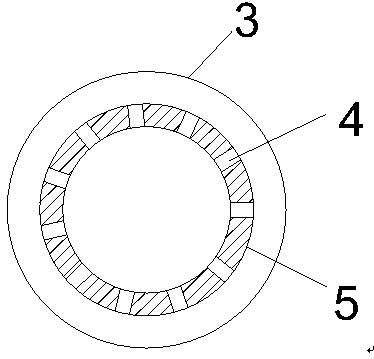

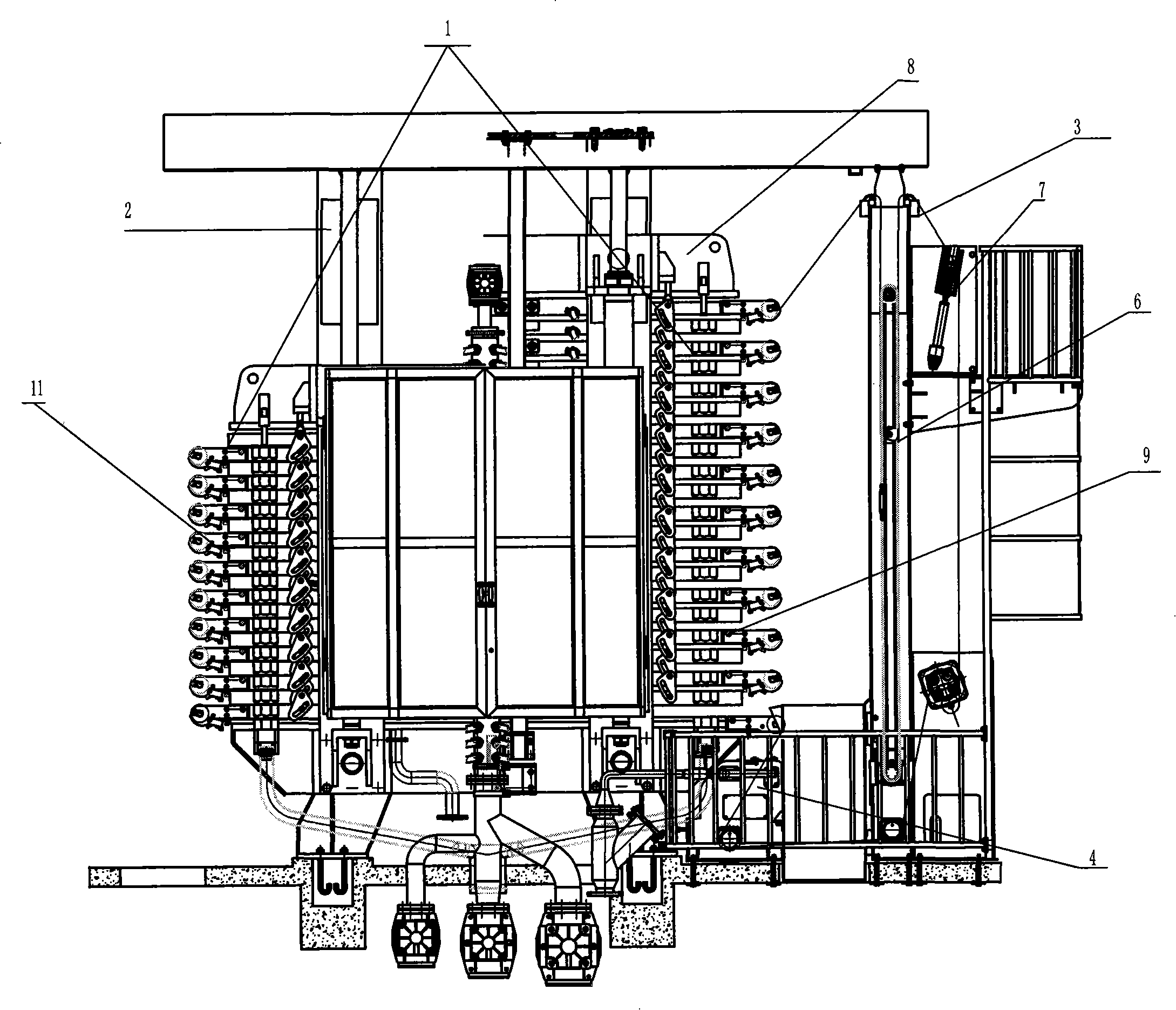

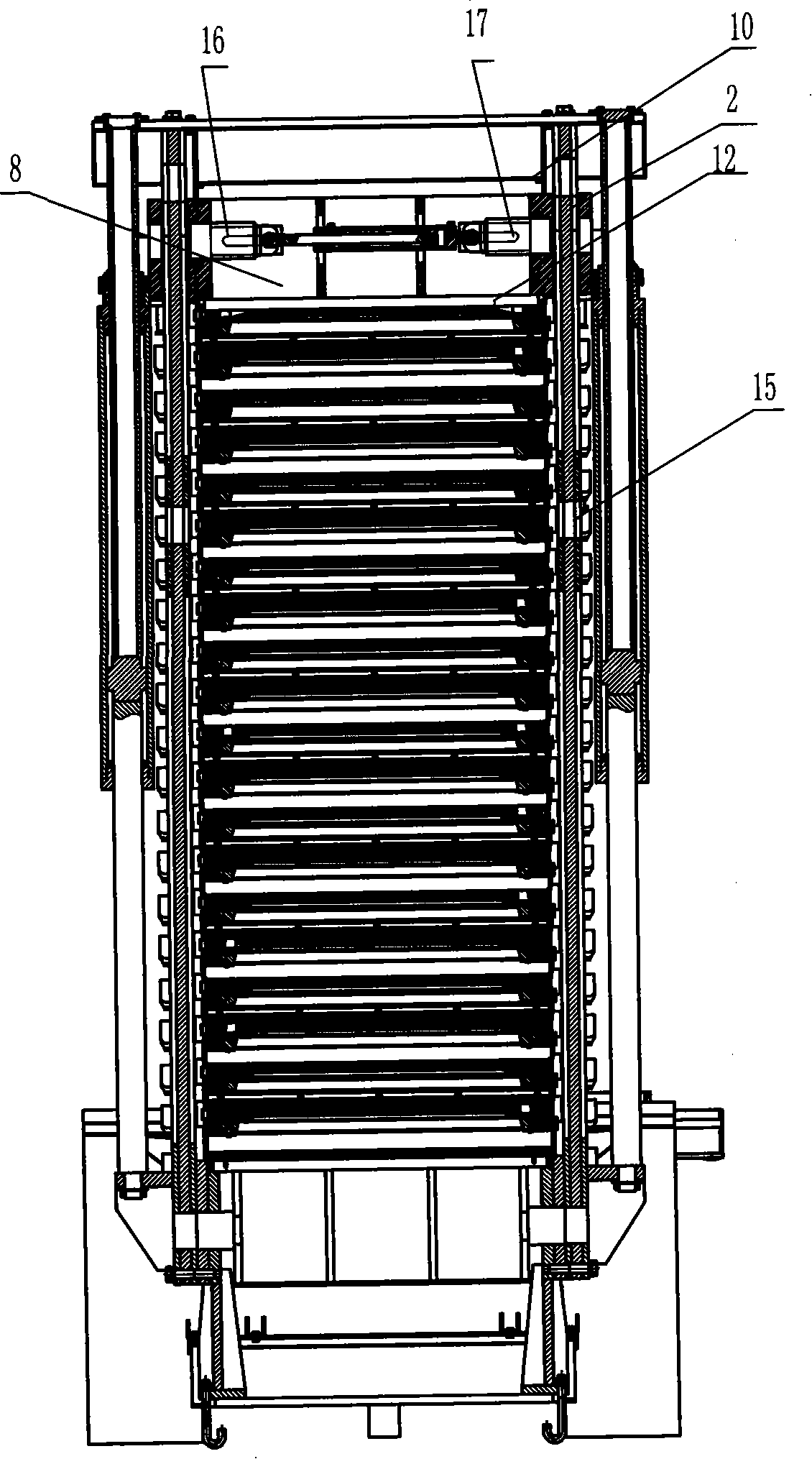

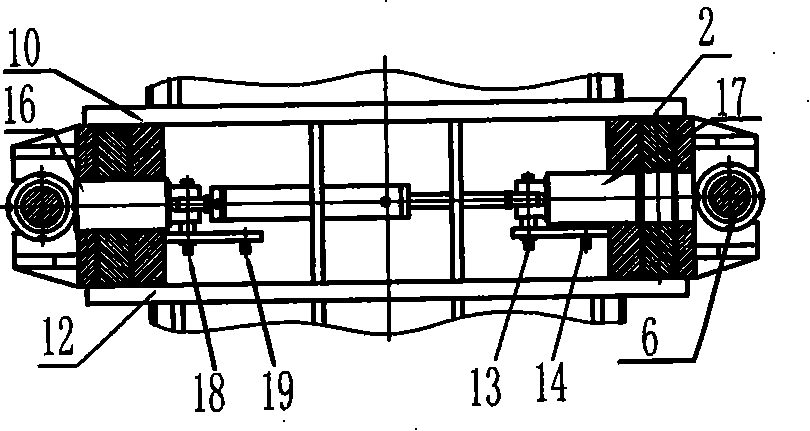

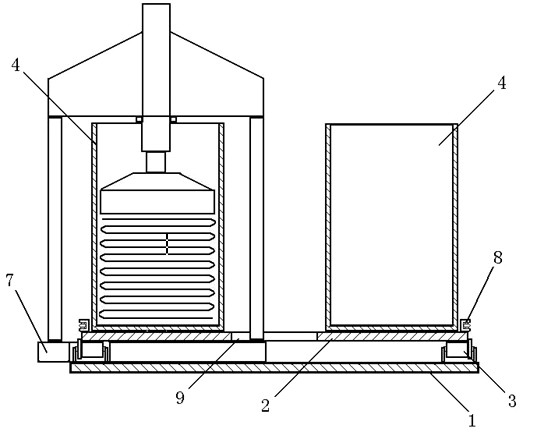

Vertical type blotter press

ActiveCN101249330AReduce the required powerReduce volumeFiltration separationHydraulic cylinderAutomatic control

The invention discloses a vertical filter press, the filter press includes a horizontal plate frame group (1) which is positioned in a main body frame (2), a plate frame group tension drive mechanism (6) and a filter cloth automatic circulating walking mechanism (3) which are arranged on the main body frame (2), a filter cloth washing device (4) and an automatic control system which are arranged below the plate frame group, wherein, a locking pin device (8) is arranged between a movable pressure plate of the plate frame group tension drive mechanism (6) and a plate frame bottom plate (12), and a correction hydraulic cylinder device (7) is arranged on the filter cloth automatic circulating walking mechanism (3). The locking pin device which is arranged thereon reduces the number of the main hydraulic cylinders and reduces the volume and the cost of the filter press; the hydraulic power replaces the pneumatic mode or the screw rod transmission mode of the filter cloth automatic walking system of the filter press, so as to overcome the shortcomings of high requirements and low sensitivity; furthermore, all the power supply of the whole filter press can be completed only by using an oil pressure pump of the original filter pressing system so as to perfect the automatic control system of the filter pressing system.

Owner:JIANGSU XINHONGDA GROUP

Automatic exhausting and liquid stopping multiple-effect infusion set

The invention relates to the technical field of medical equipment, in particular to an automatic exhausting and liquid stopping multiple-effect infusion set. The bottom of a dripping hopper is provided with an exhaust filter pipe sealed with a vertical filter membrane of which the bubble point pressure of 7.85-25.0kPa; the vertical filter membrane is gradually submersed when liquid is injected, so that a mode that the liquid is accumulated at the lower end and gas is exhausted at the upper end is realized; and by combining the special structure of the exhaust filter pipe, the multiple-effect aims of automatically exhausting, filtering a liquid medicine, eliminating bubbles and automatically stopping the liquid are skillfully fulfilled.

Owner:李林风

Self-adaptive post-filtering for reducing noise in highly compressed image/video coding

InactiveCN1450811AReduce ringing noiseImage enhancementTelevision system detailsPattern recognitionVertical filter

A technique to reduce ringing artifacts in highly compressed block-based image / video coding is applied to each reconstructed frame output from the decoder. For each pixel block of a reconstructed frame, low-pass filtering is then adaptively applied according certain calculated differences between adjacent pixel values. For each pixel, a determination is made as to what type of horizontal filter, if any, is to be applied. Depending on the results of that determination, the pixel may remain unfiltered or may have a 2- or 3-tap horizontal filter applied to it. A similar process is undertaken to determine what type of vertical filter, if any, is to be applied, no filter, a 2-tap or a 3-tap vertical filter.

Owner:GK BRIDGE 1

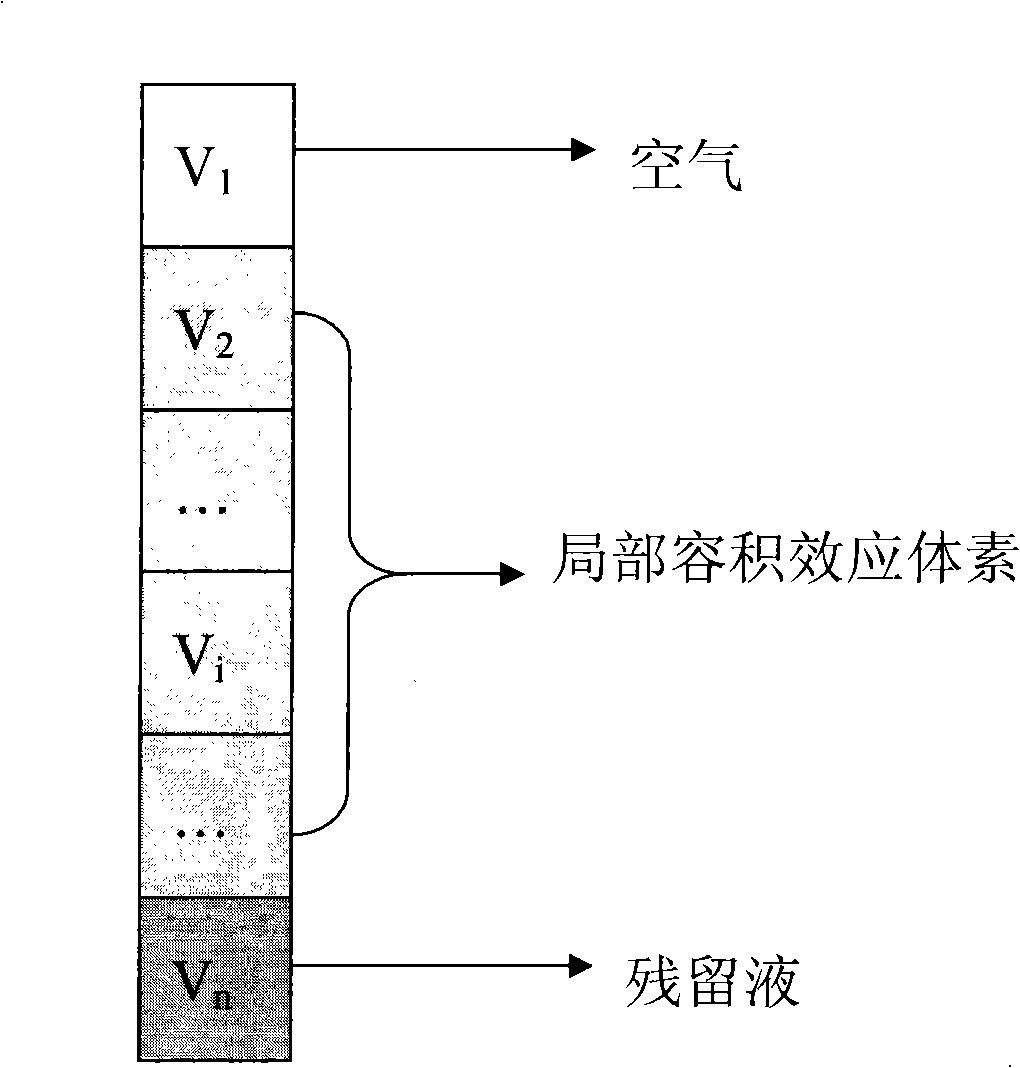

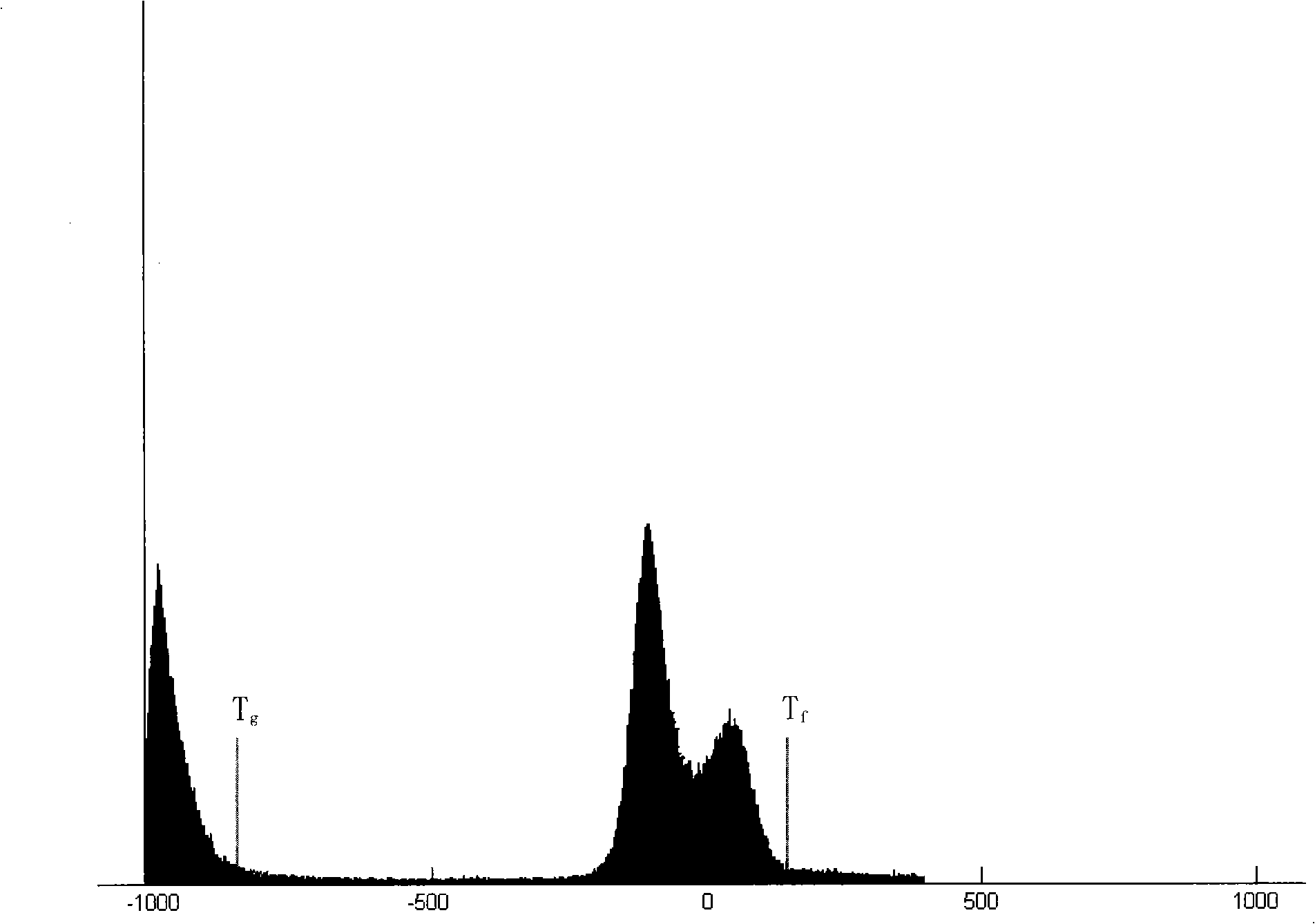

Mixed organization image full-automatic partition method of virtual colonoscope

InactiveCN101295404AAchieve segmentationImage enhancementImage analysisAutomatic segmentationGradient strength

The invention provides a full-automatic segmentation method for a mixed tissue image of a simulated colonoscopy, comprising the following steps of: selecting a suitable threshold value of the air and of the enteral residual liquid; carrying out an initial segmentation for the enteral area through a traditional threshold method; wiping a local volume effect between the air and the enteral residual liquid through a vertical filter; conducting an enteral segmentation through a region growing method; enhancing the boundaries of the colon and other issues through a gradient intensity region growing method; repeating a wiping of the local volume effect between the air and the enteral residual liquid through the vertical filter for the inner part of the colon with enhanced boundaries. The full-automatic segmentation method for the mixed tissue image of a simulated colonoscopy overcomes the problems of the traditional threshold segmentation, eliminates the impacts from the local volume effect, and renders the segmentation results better in conformity with the actual conditions.

Owner:SHAANXI HI TECH MEDICAL INFORMATION

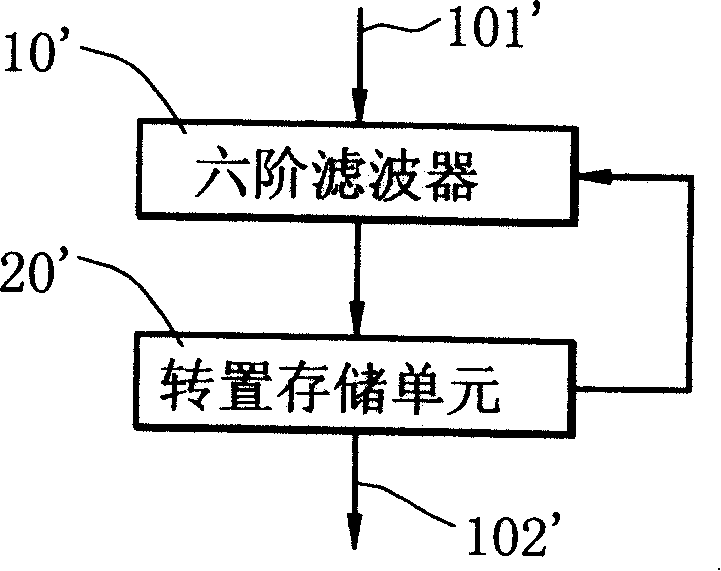

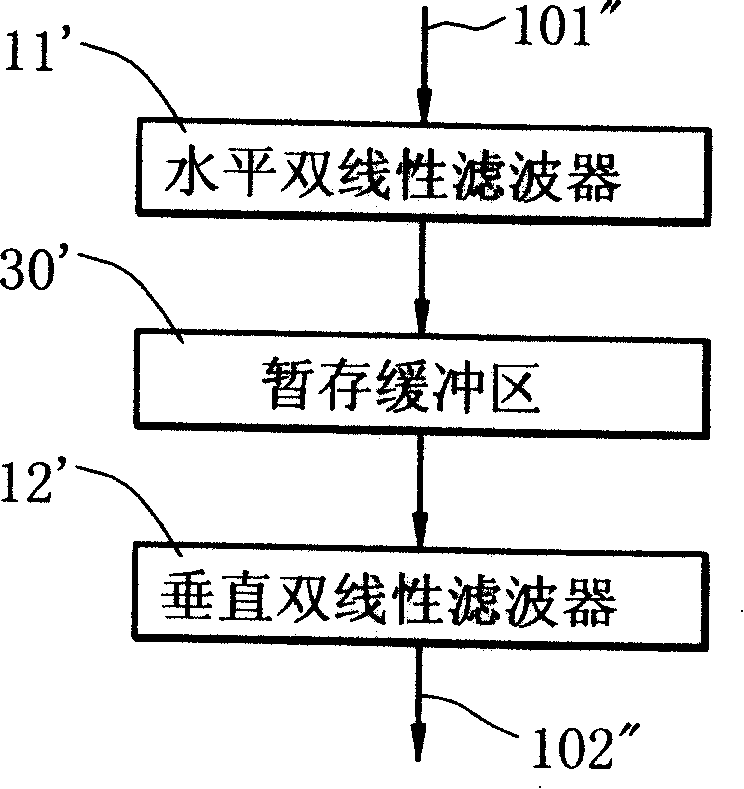

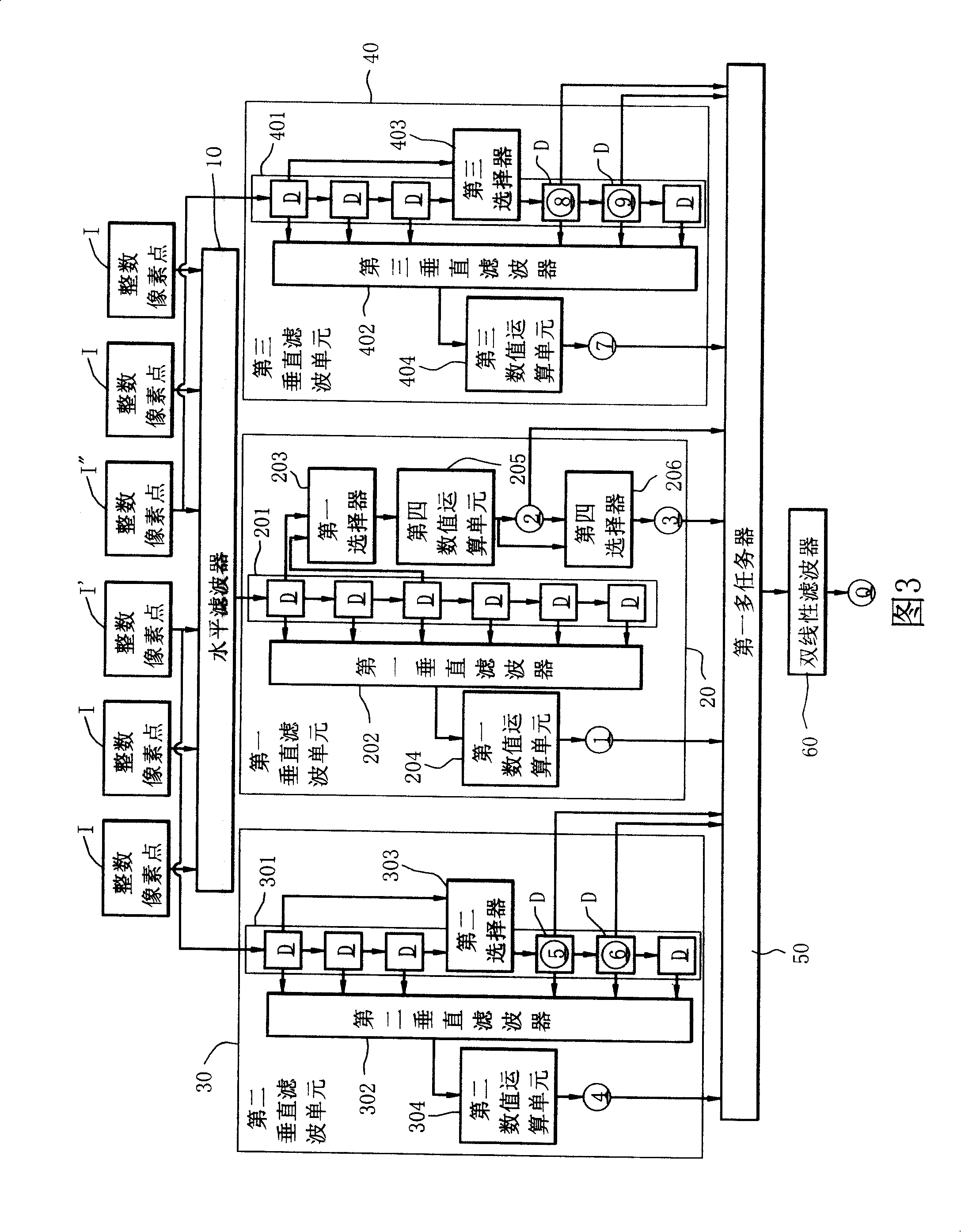

Non feedback value interposer for filtering dynamic compensation

InactiveCN101242506AApplicable dynamic compensation functionReduce the occupied areaTelevision system detailsColor signal processing circuitsMultiplexerInterposer

The present invention provides a non-feedback interpolator for compensating dynamic filter, the six-order interpolation and the bilinearity interpolation share same hardware circuit, and process brightness and color interpolation to an image block according to one interpolation operating position, including a horizontal filter, a first vertical filtering unit, a second vertical filtering unit, a third vertical filtering unit, a first multiplexer and a bilinearity filter, wherein, the delay-frequency of different filtering calculus are balanced by a selector and a bypass path in each vertical filtering unit. This interpolator can achieve interpolation calculus of integrated six-order filter and bilinearity filter to improve efficient and saving area.

Owner:ALICORP

Method and circuit arrangement for the memory-optimized processing of a composite video baseband signal CVBS signal

InactiveUS6118487AReducing cross-colour interferenceReducing interference cross-luminanceTelevision with combined individual color signalColor signal processing circuitsInterlaced videoCrosstalk interference

For compatible transmission of a television picture having an aspect ratio of 16:9 within a 4:3 system, transmission is effected in the letterbox format in accordance with the PALplus system specification. The receiver reconstructs the original picture with the aid of vertical filters and is able, furthermore, to suppress crosstalk interference from the luminance signals in the chrominance signals. To further improve the picture quality, the picture is displayed at a frame frequency of 100 Hz. For this purpose, the picture supplied at 50 Hz with line interlacing must be converted to a frame frequency of 100 Hz. Known concepts for PALplus decoding and 100 Hz conversion carry out these processes separately and in doing so require a great deal of memory space. By virtue of the memory control according to the invention, in which a field is stored in different memory areas (M1, M2), successive lines of a field not being stored in successive address areas or only partially being stored in successive address areas, the PALplus decoding and simultaneous 100 Hz conversion are possible with two memory modules. As a result, a decoder with 100 Hz reproduction is possible with reduced costs.

Owner:DEUTSCHE THOMSON-BRANDT GMBH

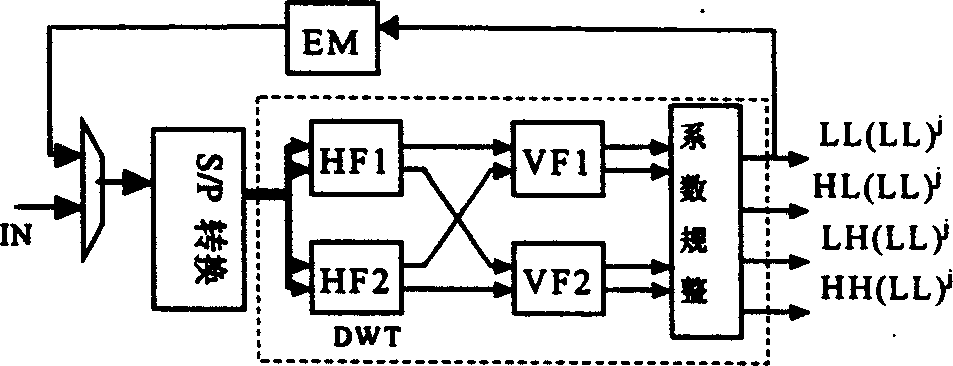

Circuit for realizing direct two dimension discrete small wave change

InactiveCN1588451AReduce power consumptionReduce control complexityImage codingData seriesExternal storage

The invention is a circuit for realizing direction two-dimension discrete wavelet transition, which belongs to image data processing technology field, especially relates to hardware realization of direct two-dimension discrete wavelet transition. The aim is to decrease hardware cost and system delay, and it can be applied to very large scale integration circuit structure design of high speed and low power direct two-dimension discrete wavelet transition of all limit length filters, the invention includes selector, data series and parallel converting interface circuit, primary converting circuit which are connected in order electrically; the primary converting circuit is 4 input and 4 output structure, includes the first parallel filter and the second parallel filter, the first vertical filter and the second vertical filter connected to them and output coefficient regulating unit, the parallel and vertical filters are 2 input and 2 output structure, the first vertical filter and the second vertical filter output is connected to the output coefficient regulating unit; one output electric signal of the output coefficient regulating unit is connected to an external memory, the latter is outputted to one input end of the selector.

Owner:HUAZHONG UNIV OF SCI & TECH

Vertical filter filling machine and process

ActiveUS20090036284A1Accurate measurementPacked tightlyPaper/cardboard wound articlesTobacco smoke filtersVertical filterFilter material

A process and apparatus for the mass production of compound cigarette filters function to deposit granular filter material into the open ends of vertically oriented filter tubes. Predetermined amounts of diverse granular material are withdrawn by suction from sources of such material, and these amounts are deposited into the tubes. Solid filter segments seal the granular material within the tube. After one half of each filter tube is filled with granular material and sealed, the tube is inverted and the opposite end is filled in substantially the same manner. When cut in half each filter tube produces two cigarette filters.

Owner:PHILIP MORRIS USA INC

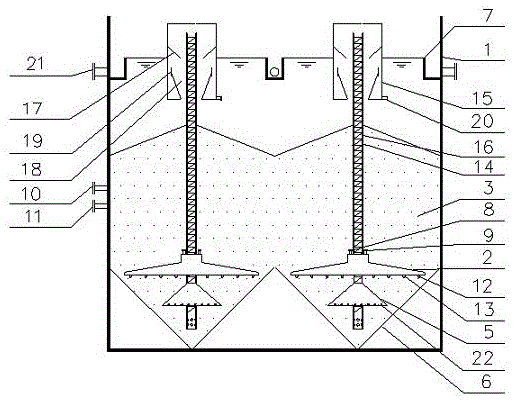

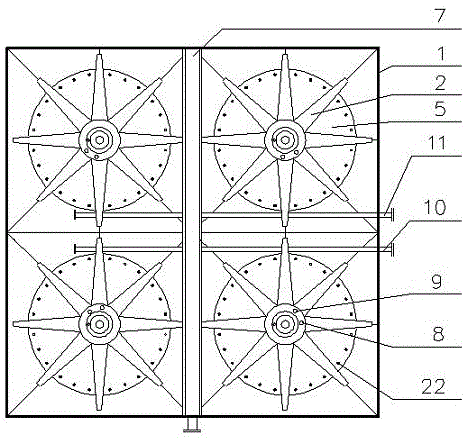

Biological aerated filter for automatically and continuously cleaning filter materials

ActiveCN105016462ARealize automatic cleaningSimple structureSustainable biological treatmentBiological water/sewage treatmentWater flowVertical filter

The invention relates to a biological aerated filter for automatically and continuously cleaning filter materials. The biological aerated filter comprises a pond body, wherein one or more vertical filter material circulators; each of the circulators is mainly composed of a filter material cleaner and a clean water guide device; the filter material cleaner comprises a lifting pipe which is internally provided with a water flow disturbance structure; the clean water guide device is internally provided with a guide plate and an overflow tank; a filter material guide hopper corresponding to the lifting pipe is arranged in the bottom of the pond body; the lower end opening of the lifting pipe is positioned in the filter material guide hopper; a central cylinder is arranged on the outer side of the lifting pipe in a sleeving manner; the filter material guide hopper is further internally provided with an integrated gas-water distributor and a filter material distributor. The biological aerated filter provided by the invention realizes automatic cleaning of the filter materials and is simple in structure, convenient to operate, less in power consumption and low in manufacturing and maintenance costs.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

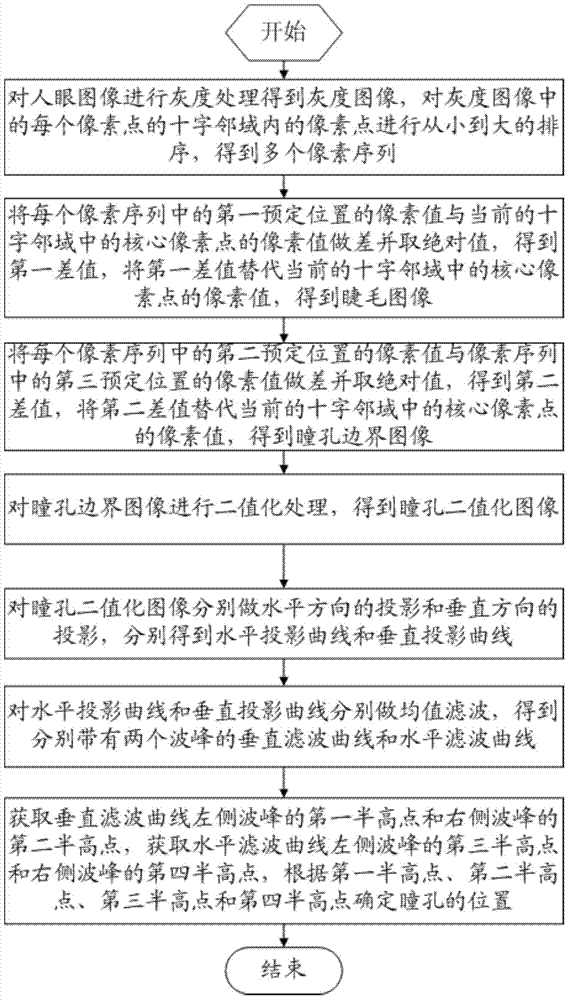

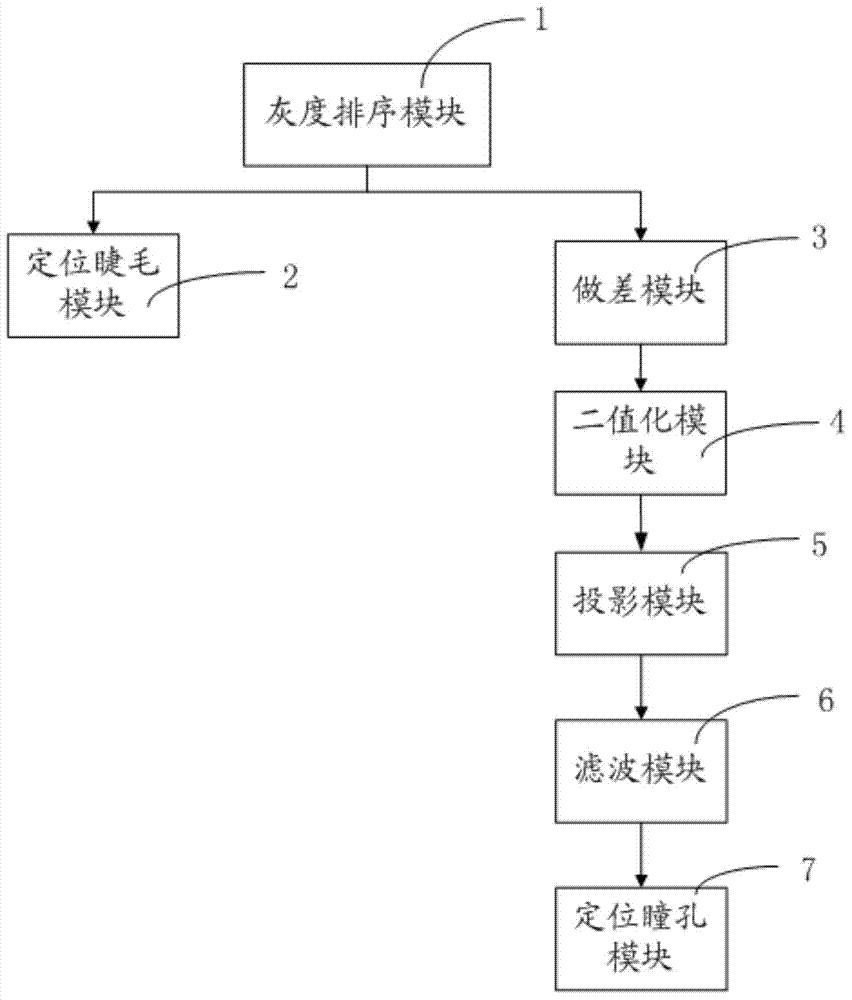

Method and device for extracting eyelash image and locating pupil through cross neighborhood method

ActiveCN103488990AEasy extractionCancel noiseCharacter and pattern recognitionVertical projectionEyelash

The invention relates to a method for extracting an eyelash image and locating a pupil through the cross neighborhood method. The method for extracting the eyelash image and locating the pupil comprises the following steps that gray processing is conducted on an eye image so that a gray image can be obtained and pixel points, in a cross neighborhood of each pixel point, of the gray image are ranked from large to small so that a plurality of pixel sequences can be obtained; according to a first difference value, the eyelash image is obtained; according to a second difference value, a pupil boundary image is obtained; binarization processing is conducted on the pupil boundary image, so that a pupil binarization image is obtained; a horizontal projection curve and a vertical projection curve are obtained according to the pupil binarization image; a vertical filtering curve and a horizontal filtering curve are obtained according to the horizontal projection curve and the vertical projection curve; the position of one pupil is determined according to a first half-height point, a second half-height point, a third half-height point and a fourth half-height point. According to the method for extracting the eyelash image and locating one pupil through the cross neighborhood method, the calculated amount can be effectively reduced, the processing speed can be improved, and noise in the eye image can be efficiently eliminated.

Owner:WUHAN HONGSHI TECH

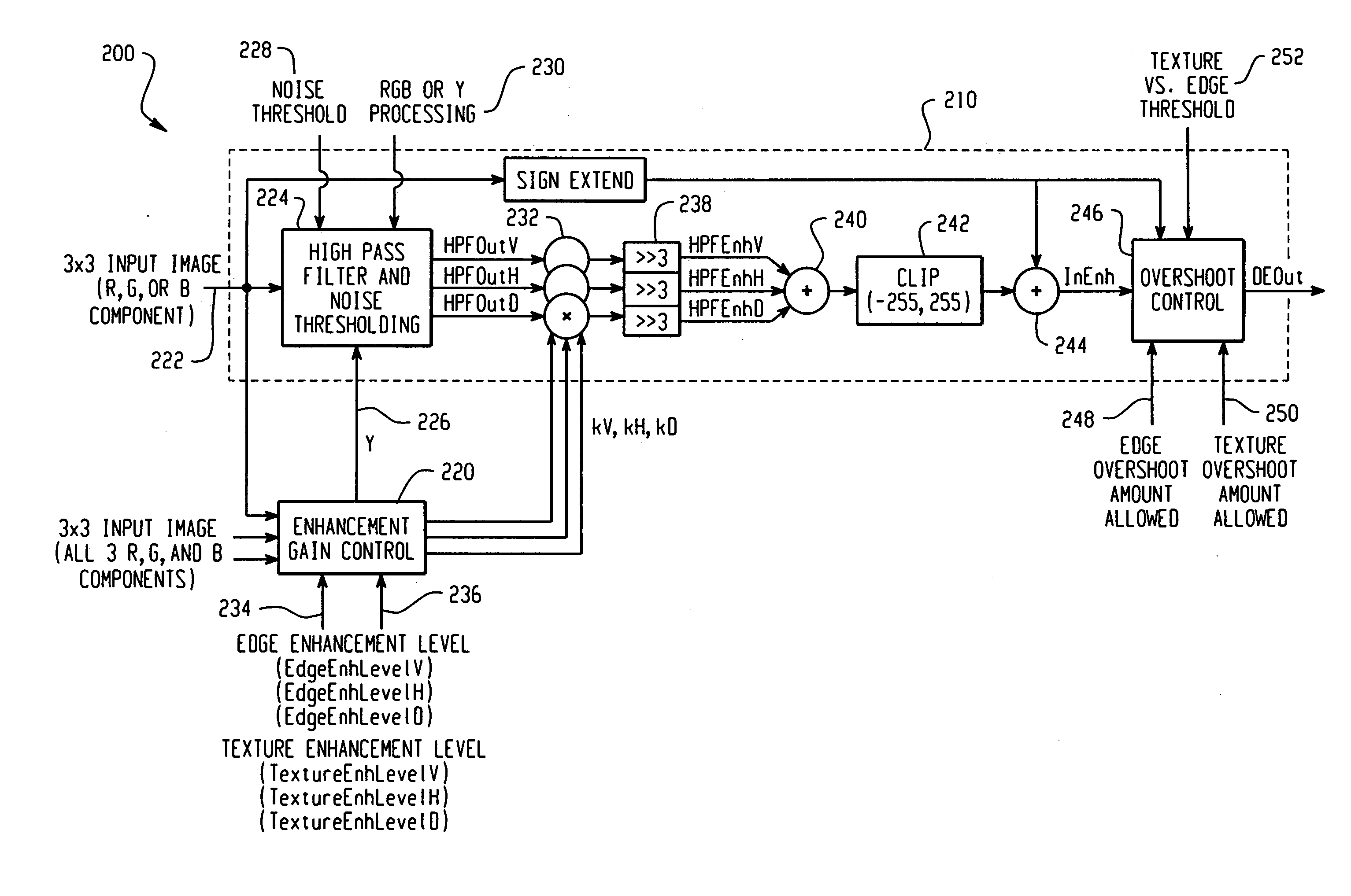

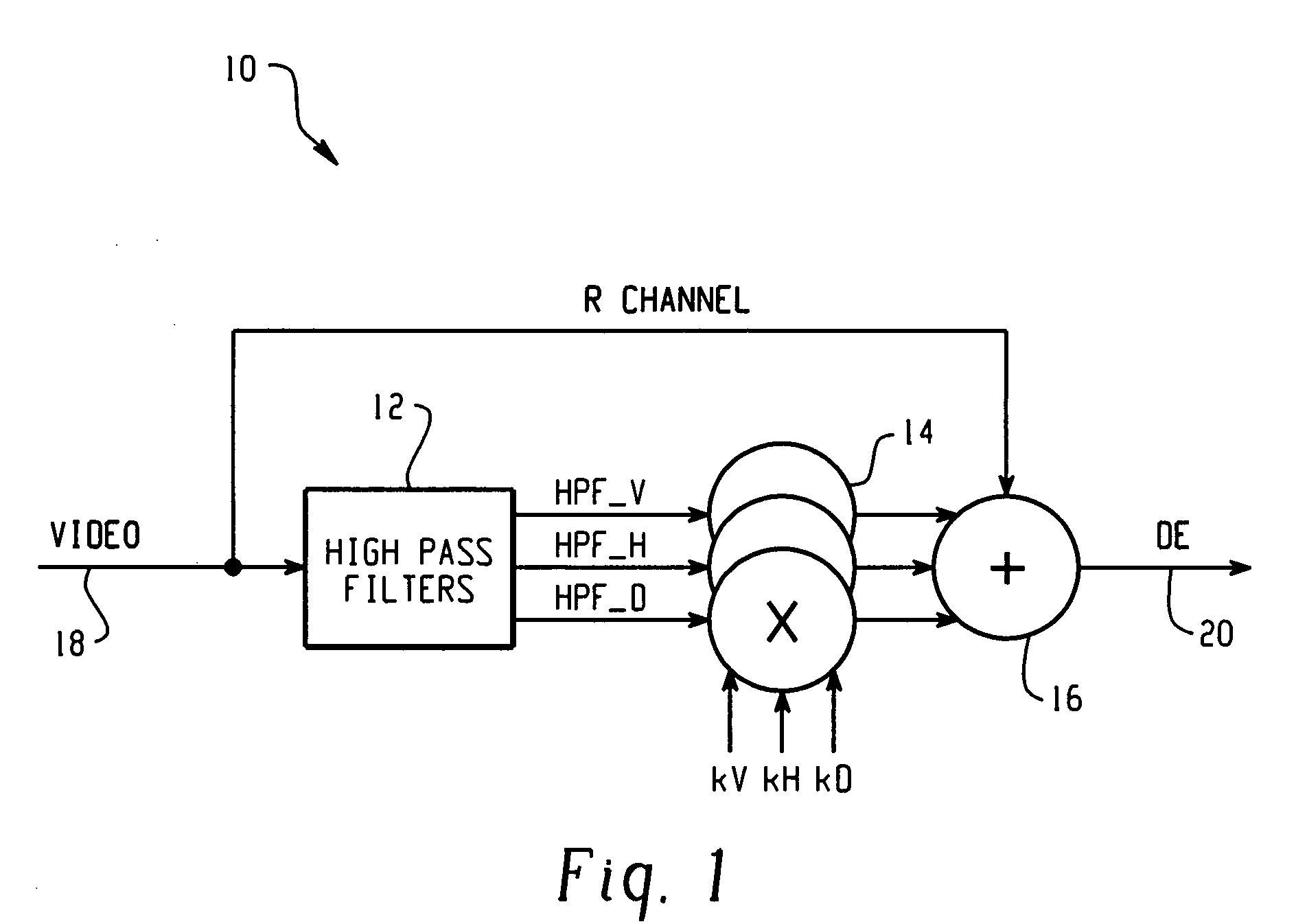

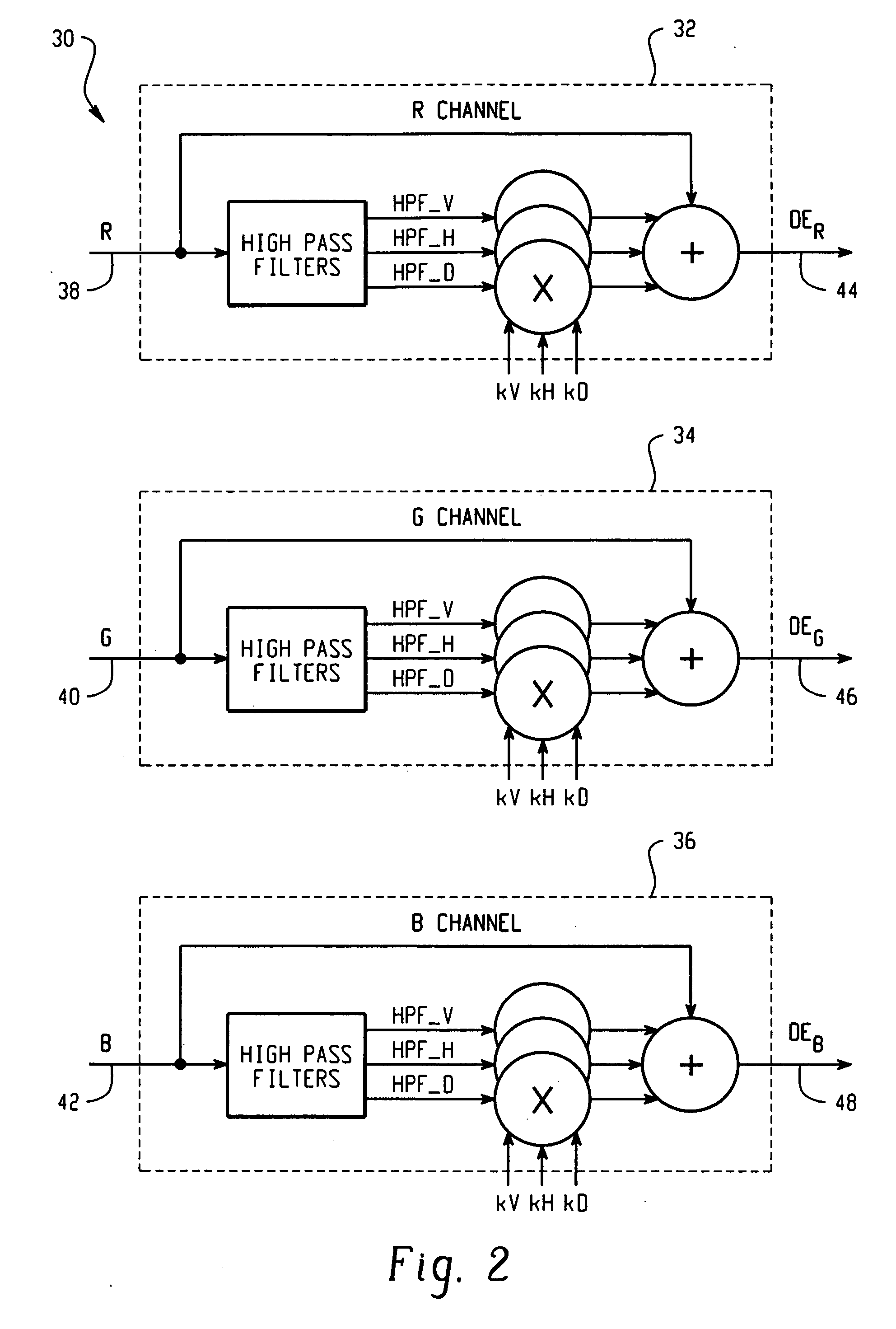

Video enhancement systems and methods

ActiveUS20070279530A1Improve image qualityImage quality is lowTelevision system detailsImage enhancementPattern recognitionImaging quality

In accordance with the teachings described herein, systems and methods are provided for enhancing the image quality of video. One or more filters may be used to filter a received video signal to generate a vertical filtered output, a horizontal filtered output and a diagonal filtered output. One or more amplification components may be used to apply separate gains to each of the vertical, horizontal and diagonal filtered outputs to generate a vertical enhancement signal, a horizontal enhancement signal and a diagonal enhancement signal. One or more summation components may be used to combine the vertical, horizontal and diagonal enhancement signals with the video signal to generate an enhanced video signal.

Owner:V SILICON SEMICON (HANGZHOU) CO LTD

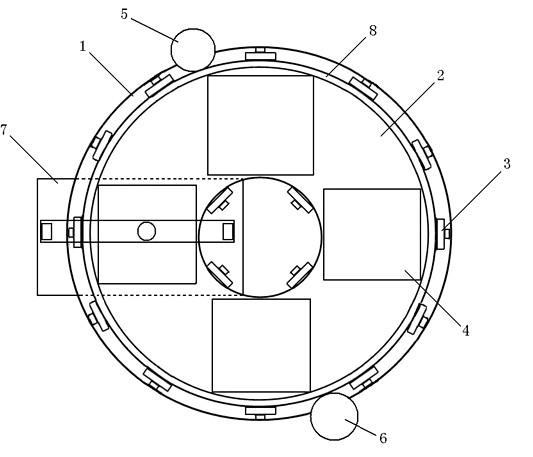

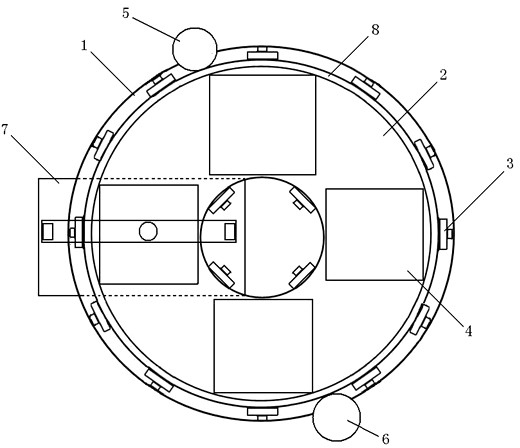

Turntable structure of ultrathin overlaid filtering layer vertical filter press

The invention discloses a turntable structure of an ultrathin overlaid filtering layer vertical filter press, which comprises a chassis and a turntable arranged above the chassis, wherein the turntable is supported by a plurality of riding wheels; the turntable is annular, the center of the turntable is provided with an inner hole, and four frame baskets are symmetrically arranged on the annular turntable; and one circle of chain is arranged on the periphery of the turntable and is connected with a chain wheel, a motor provides power for the chain wheel, and the turntable rotates through the chain. The invention has the advantages and the positive effects that according to the turntable structure of the ultrathin overlaid filtering layer vertical filter press, the four frame baskets are arranged on the turntable and respectively correspond to a spreading machine, a hydraulic machine, a discharging machine and an empty frame wait as well as respectively are a feeding workstation, a squeezing workstation, a discharging workstation and an empty frame waiting station. With the rotation of the turntable, different frame baskets can simultaneously complete three procedures of feeding, squeezing and discharging, thus the time is saved and the production efficiency is increased.

Owner:济南中合环保科技有限公司

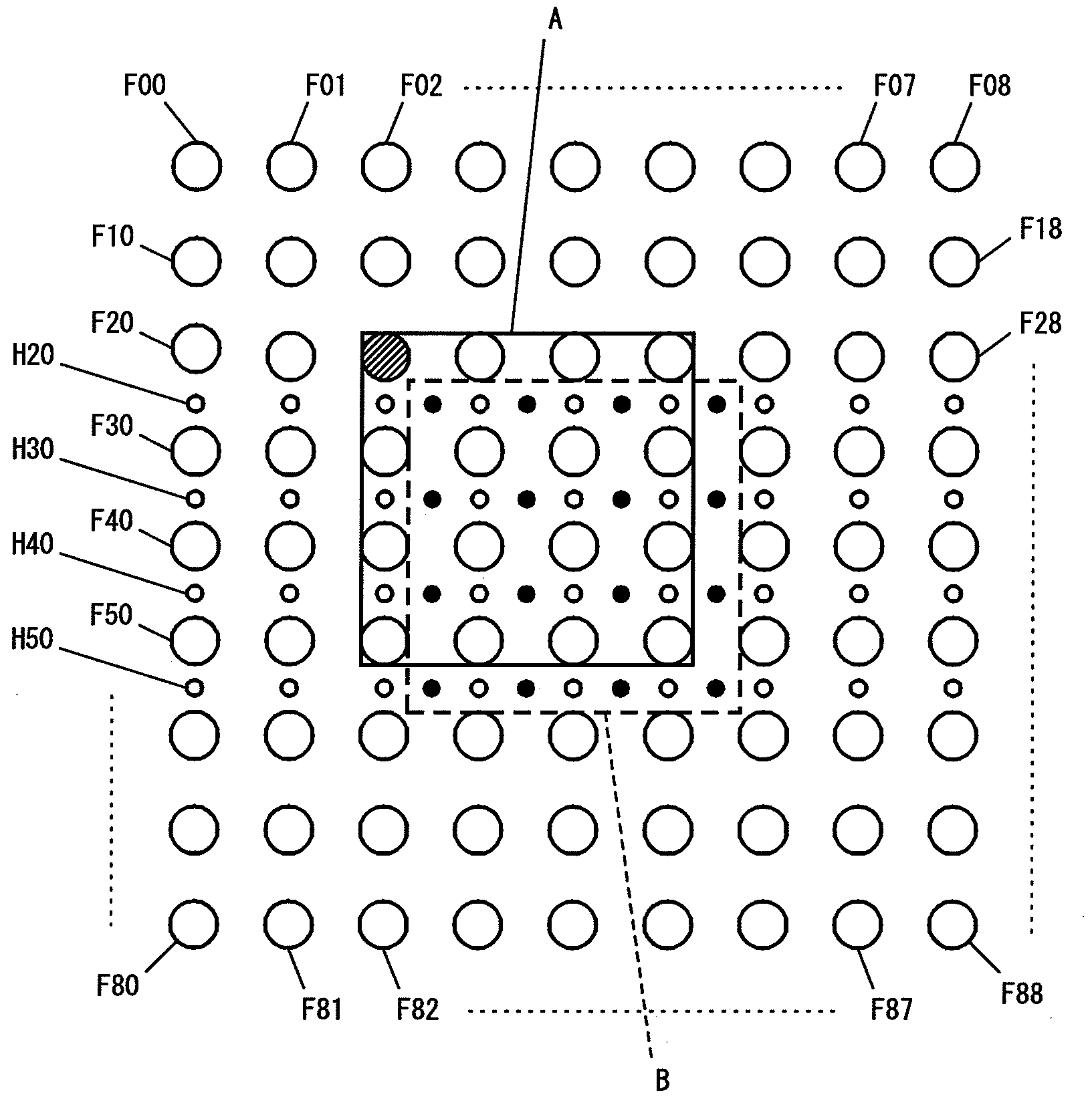

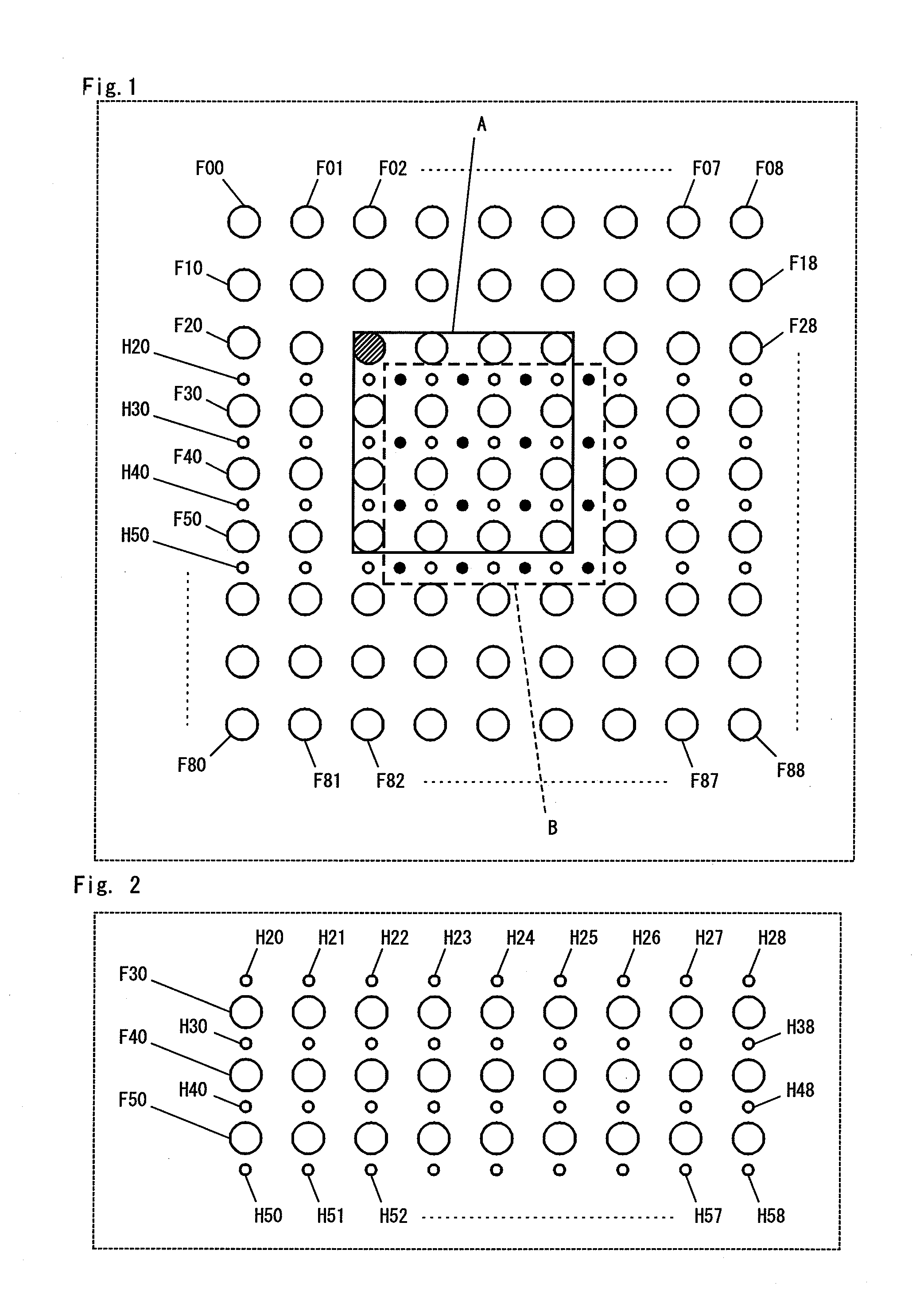

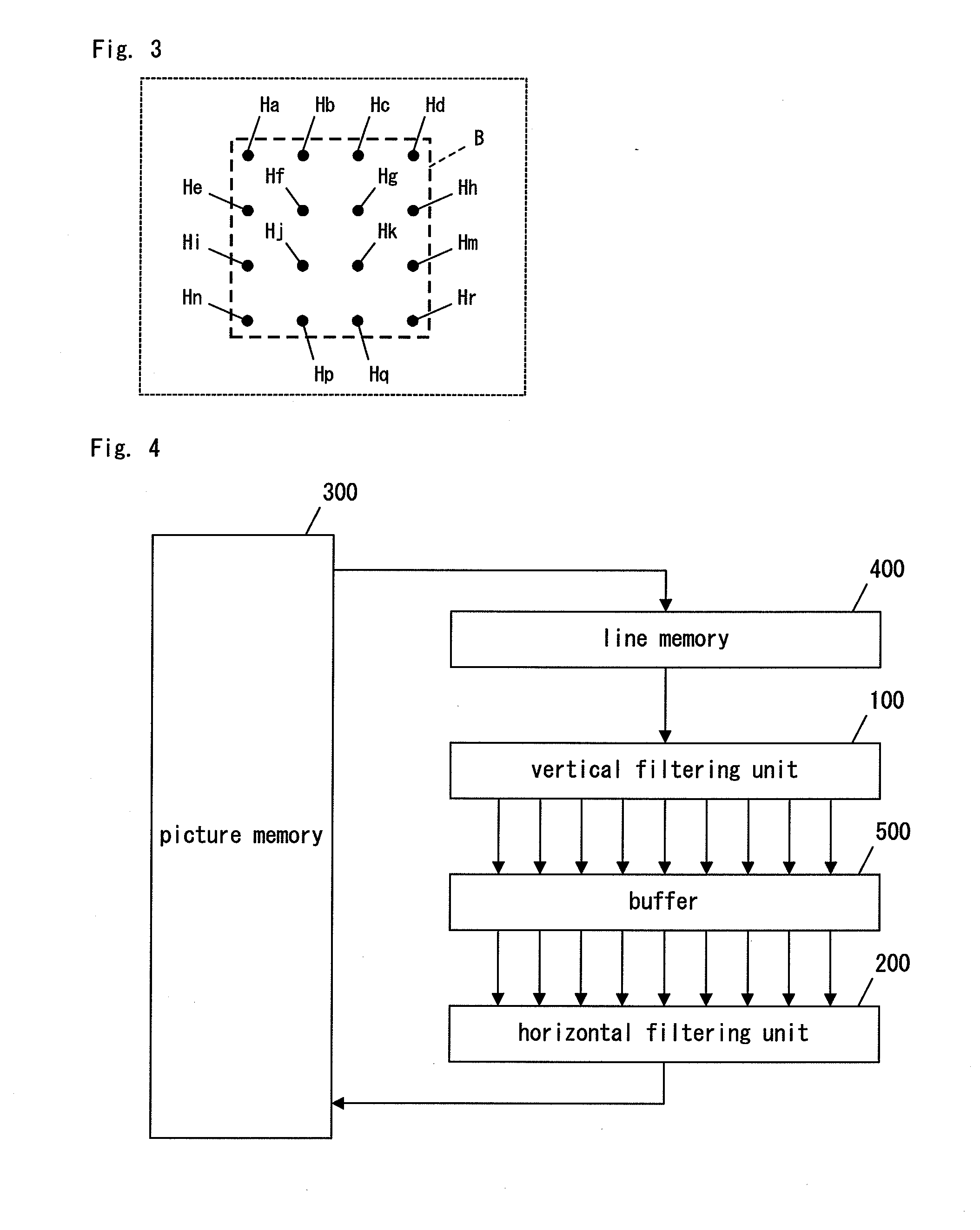

Two-dimensional filter arithmetic device and method

InactiveUS20100046851A1Easy to changeTelevision system detailsStatic indicating devicesPicture MemoryVertical filter

A two-dimensional filter arithmetic device comprises a picture memory (300), a line memory (400), a vertical filtering unit (100) which includes nine first filter modules installed in parallel, a buffer (500) for timing adjustments, and a horizontal filtering unit (200) which includes four second filter modules installed in parallel. From the line memory (400), the pixel values of nine full pels per line are inputted in parallel to the vertical filtering unit (100), nine vertically-filtered values of half pels are generated and inputted to the horizontal filtering unit (200); thereby, four two-dimensionally-filtered values of half pels are generated.

Owner:SOVEREIGN PEAK VENTURES LLC

Vertical filter filling machine and process

ActiveUS7479099B2Efficient and economical mannerIncrease chanceTobacco treatmentPaper/cardboard wound articlesVertical filterMechanical engineering

Owner:PHILIP MORRIS USA INC

Image transformation apparatus and method

InactiveCN1450810AInterconnection arrangementsDigital technique networkProcessor registerVertical filter

Owner:SANYO ELECTRIC CO LTD

Multifunctional filter

InactiveCN106268094ASimple structureReasonable designDispersed particle filtrationTransportation and packagingFiberVertical filter

The invention provides a multifunctional filter. The multifunctional filter comprises a box. An air inlet is formed in the upper side wall of the box, an air outlet is formed in the lower side wall of the box, and a water trough is formed in the bottom of the box. A plurality of vertical filter screens are arranged in an inner cavity of the box, the upper ends of the filter screens are fixedly connected with the top end of the inner cavity of the box, the lower ends of the filter screens are fixedly connected with the bottom of the water trough, and the mesh sizes of the filter screens are gradually reduced from the air inlet to the air outlet. The filter is simple in structure, reasonable in design and capable of filtering out cellosilk in air; the filtering efficiency of the dust remover is improved by designing the multiple layers of filter screens, cellosilk on the filter screens can be washed away by designing a spraying system, and the defect that an existing dust remover is high in cost and not suitable for middle and small-sized enterprises is overcome.

Owner:TIANJIN JIAXUAN TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com