Environment-friendly grain processing and discharging device with dust removal function

An environmentally friendly, grain-based technology, applied in the direction of separating solids from solids with airflow, solid separation, and dispersed particle separation, can solve the problems of dust rising, small specific gravity, and easy to cause respiratory diseases, etc., to avoid dust rising, Excellent dust removal effect, good dust removal and dust reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

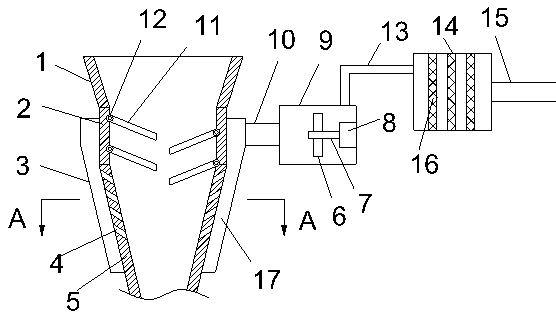

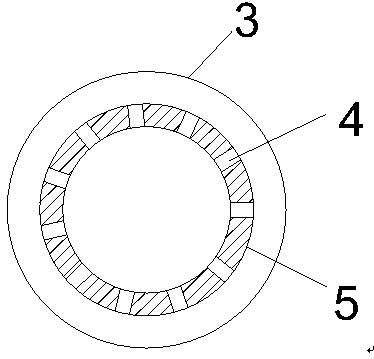

[0017] see Figure 1-2 , an environment-friendly grain processing blanking device with dust removal function, comprising a storage tube 1, a buffer tube 2 and a blanking tube 5, characterized in that the storage tube 1 is a trumpet-shaped opening structure, and the storage tube 1 A cylindrical buffer tube 2 is fixedly installed at the lower end, and a buffer baffle 11 is arranged inside the buffer tube 2, and the buffer baffle 11 is rotatably installed on the inner wall of the buffer tube 2 by a torsion spring 12, and the buffer baffle 11 is inclined And mutually interlaced arrangement; Described buffer pipe 2 bottoms are fixedly installed with unloading pipe 5, and unloading pipe 5 is inverted conical structure, and the side of unloading pipe 5 is evenly provided with several dust-absorbing passages 4 along the circumferential direction, and described T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com