Biological aerated filter for automatically and continuously cleaning filter materials

A biological aerated filter and filter material technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of heavy maintenance workload, large land occupation, large investment, etc. problem, to achieve the effect of long service life, simple structure and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

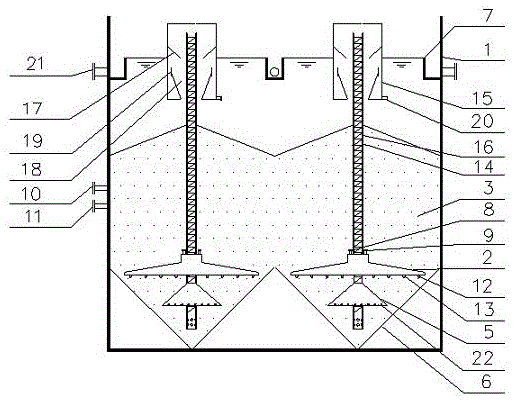

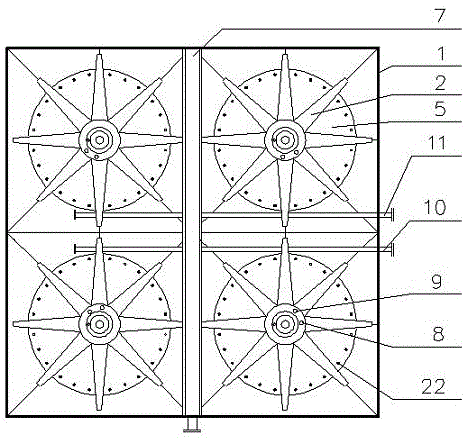

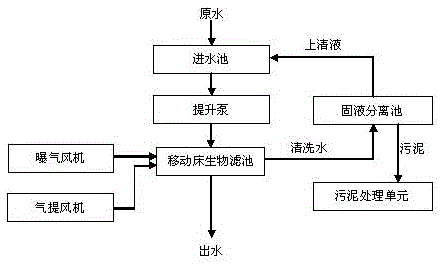

[0021] The present invention is a new sewage treatment device which can control the hardening of the filter material and continuously and automatically clean the filter material. It belongs to the biofilm filter reactor. The pollutants in the sewage adopt a different operation mode from the traditional biological filter, which can realize the continuous automatic cleaning of the filter material and the uninterrupted continuous operation of the equipment. The main features are as follows: first, it is equipped with a filter material circulator that can realize the automatic and continuous cleaning of the filter material by turbulent friction and gas friction cleaning, lifting and removing membranes, so that the filter material can circulate in the bed; The filter material distributor that can automatically and regularly perform compressed air "blasting" uses the huge vibration generated in a short time to control and prevent the local adhesion "hardening" and "overhead" problems...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com