Patents

Literature

40results about How to "Easy to absorb and handle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

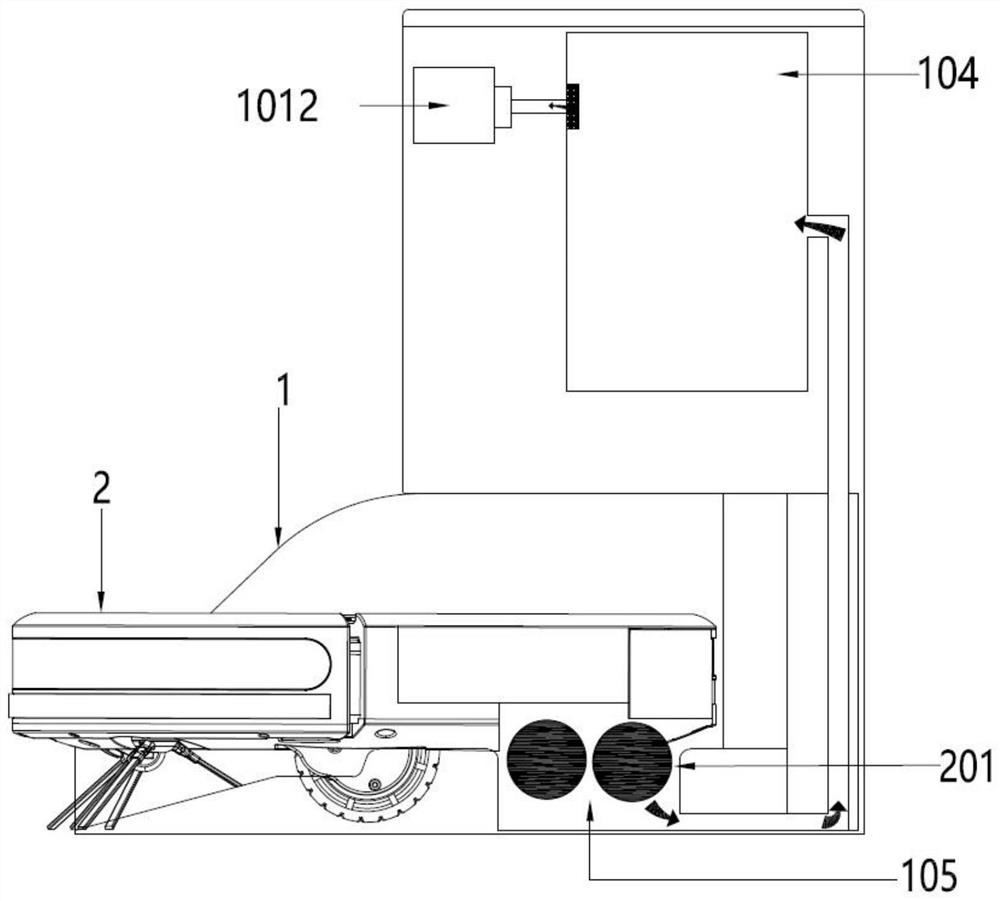

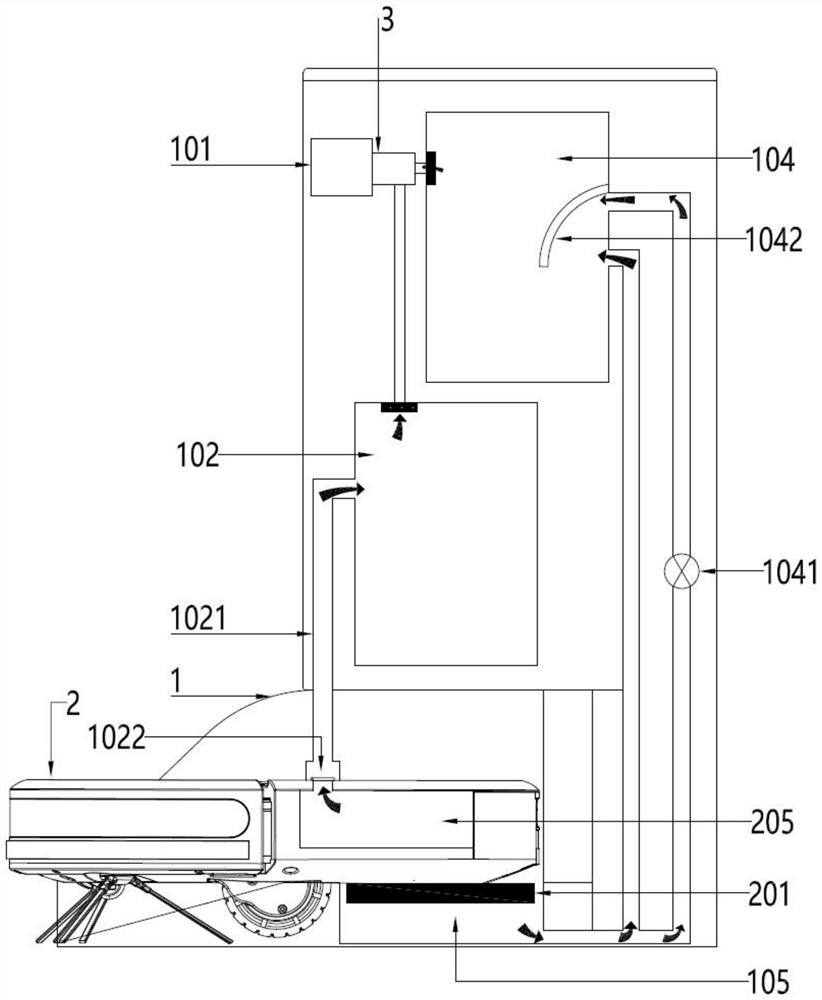

Control method of cleaning robot system

PendingCN112545394ARealize automatic cleaningIncrease frictionCarpet cleanersFloor cleanersRobotic systemsProcess engineering

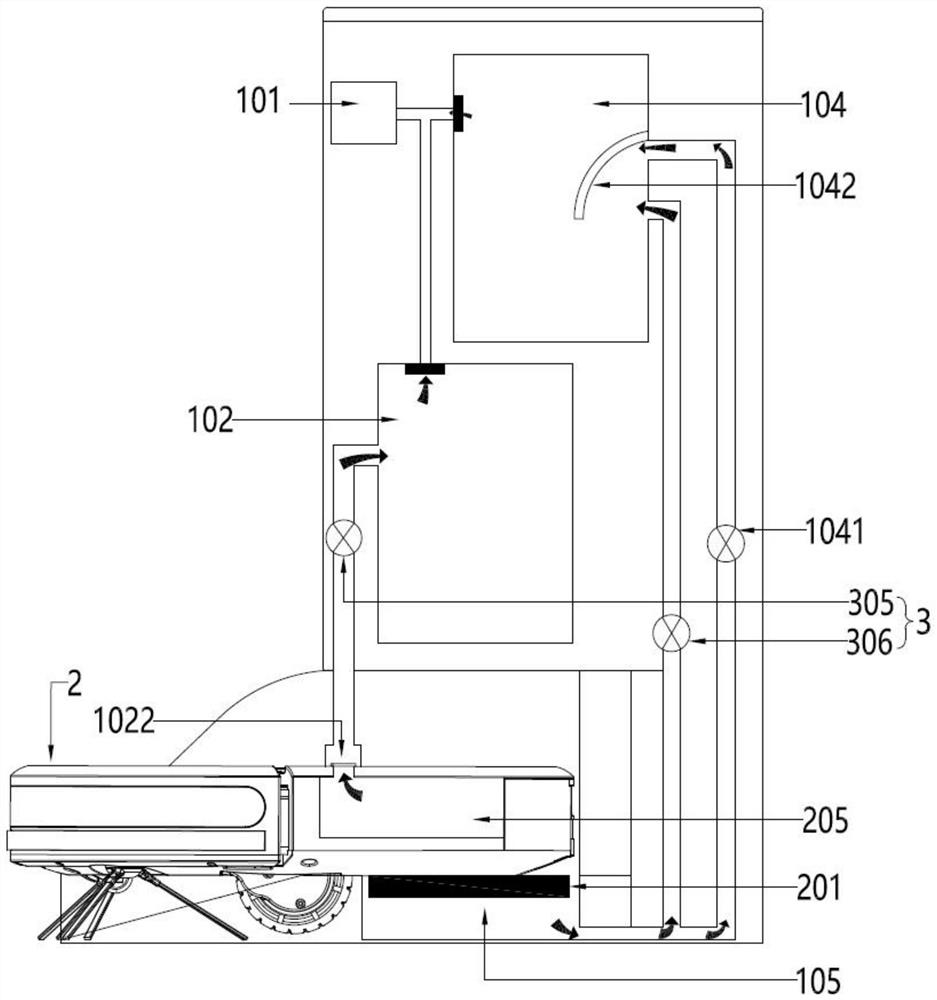

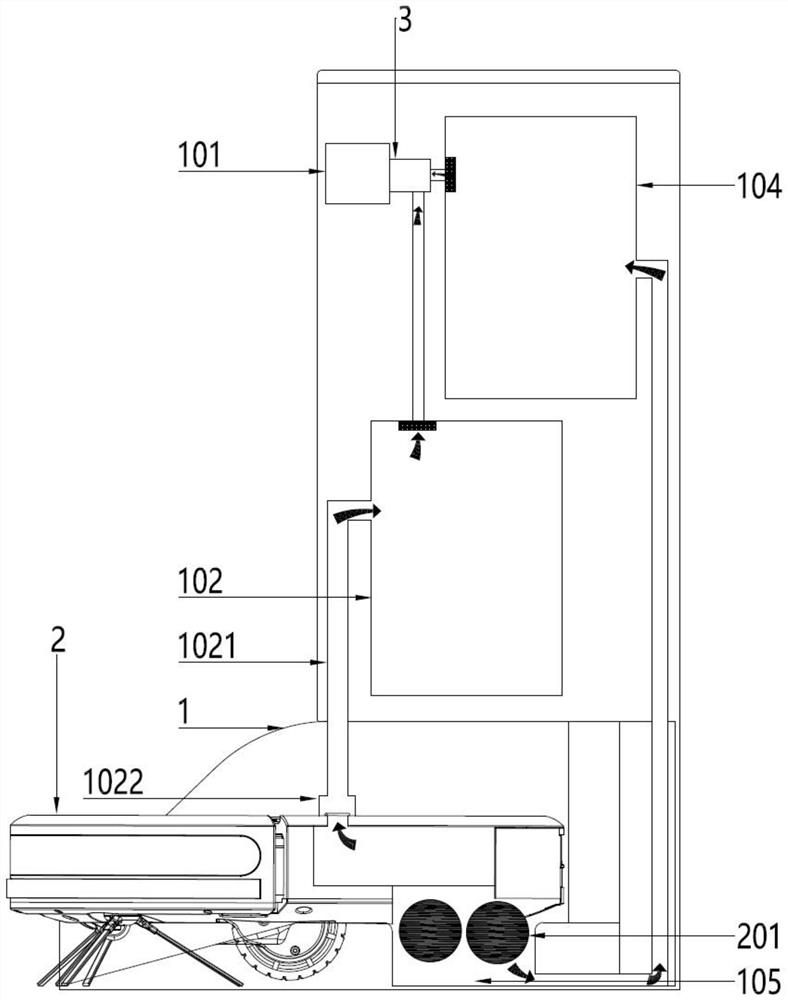

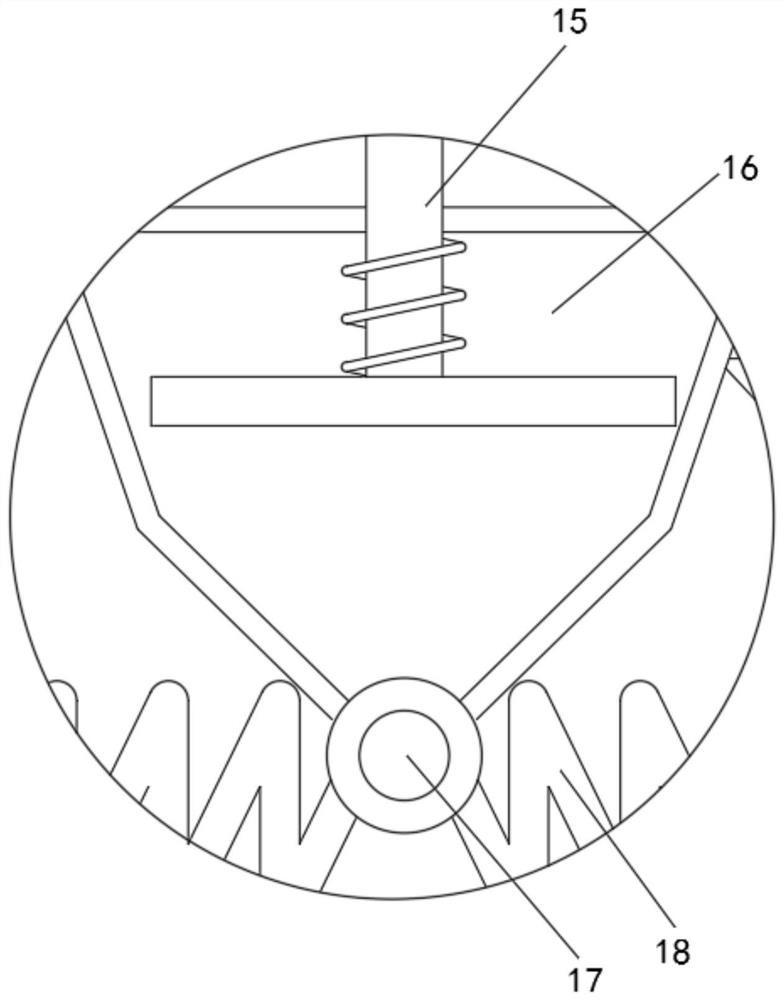

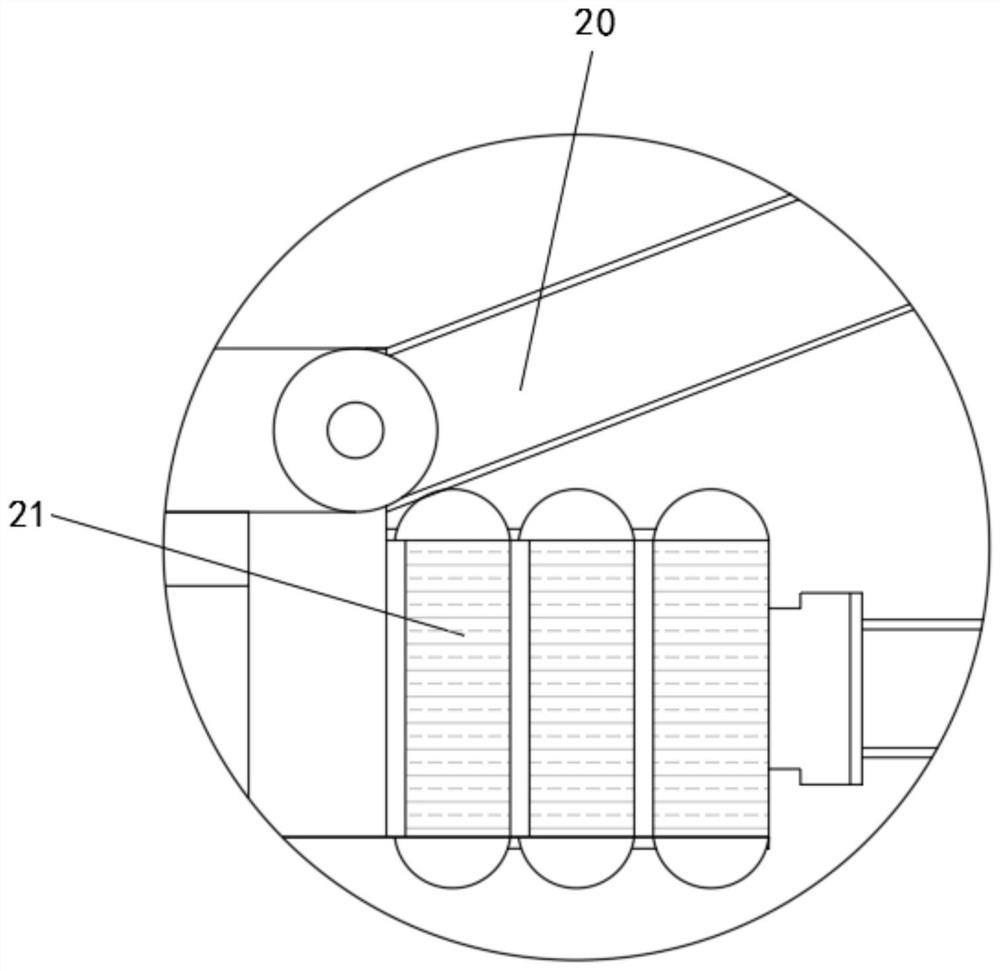

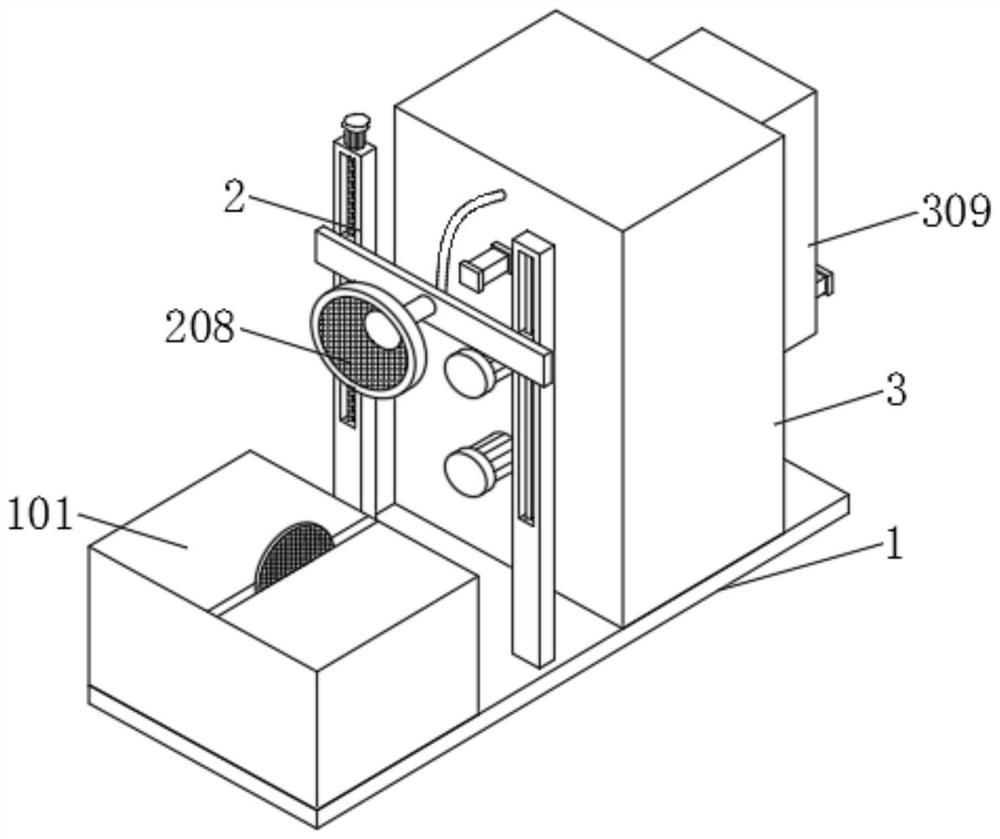

The invention relates to a control method of a cleaning robot system, which comprises a cleaning robot and an integration station, and the integration station is at least used for stopping the cleaning robot. The control method comprises the following steps that the cleaning robot walks from the indoor ground to the integration station to stop; when the cleaning robot stops in place, the dust collecting part on the integration station is in butt joint with the dust discharging part on the cleaning robot, and the cleaning part is located in a cleaning area; a control module controls a first airflow generator to start to work, so that the garbage cavity communicates with a dust collecting box, and garbage in the garbage cavity enters the dust collecting box through the dust discharging partand the dust collecting part; and / or the control module controls the power mechanism to start to work, so that the cleaning area is communicated with the sewage tank, and sewage in the cleaning area enters the sewage tank; according to the scheme, the problems that an existing cleaning robot is poor in mopping effect, garbage in a garbage cavity needs to be manually treated by a user, and mop cloth needs to be manually cleaned are solved, and meanwhile the problems that an existing base station is single in function and cannot meet use requirements are solved.

Owner:杭州匠龙机器人科技有限公司

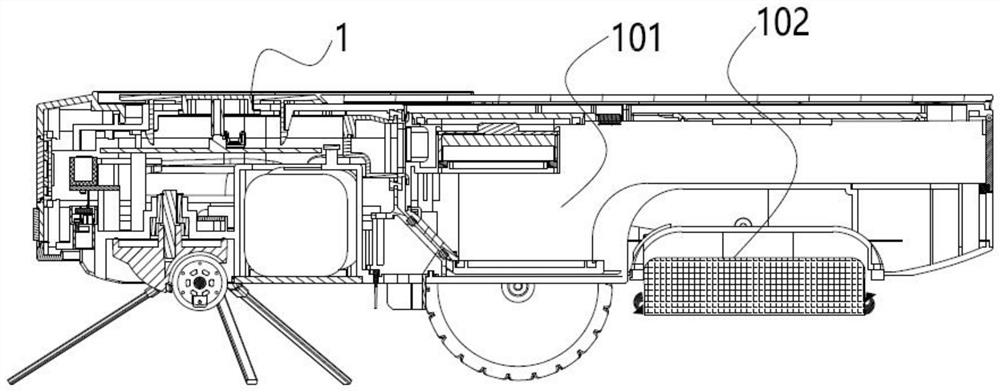

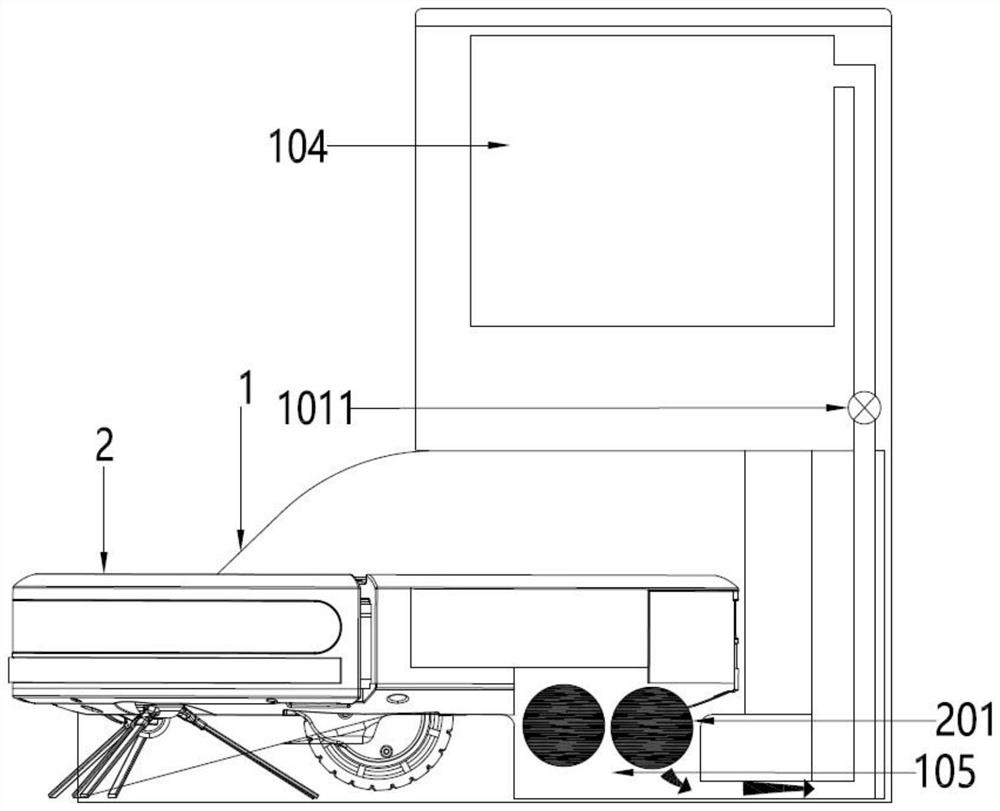

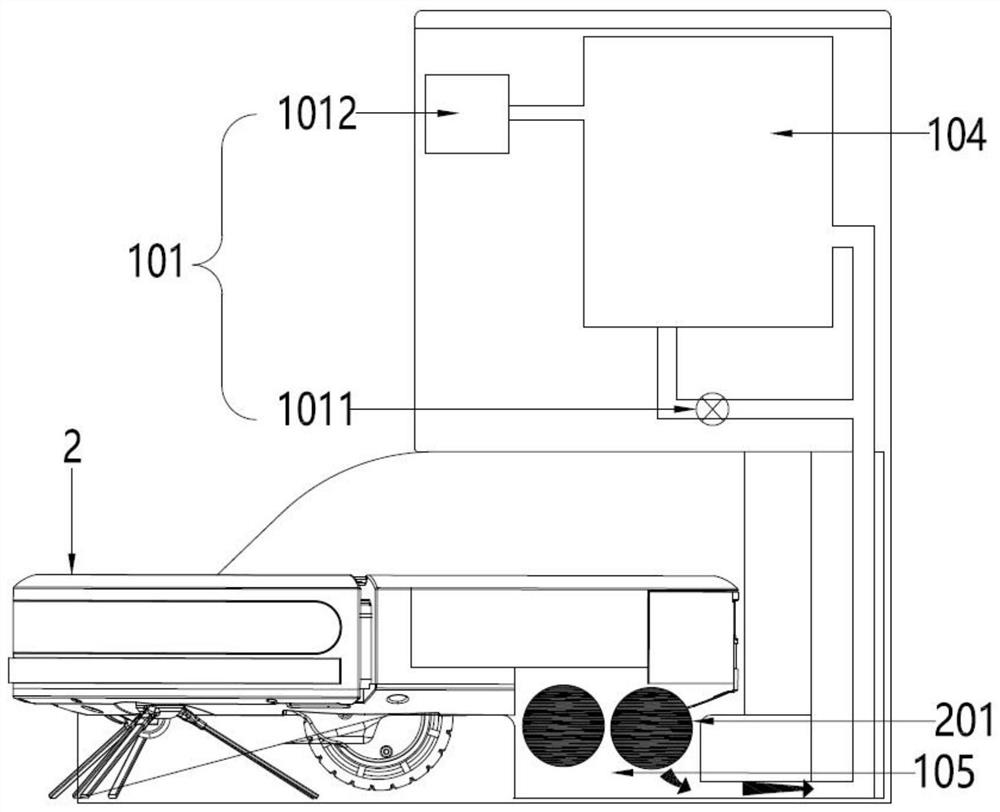

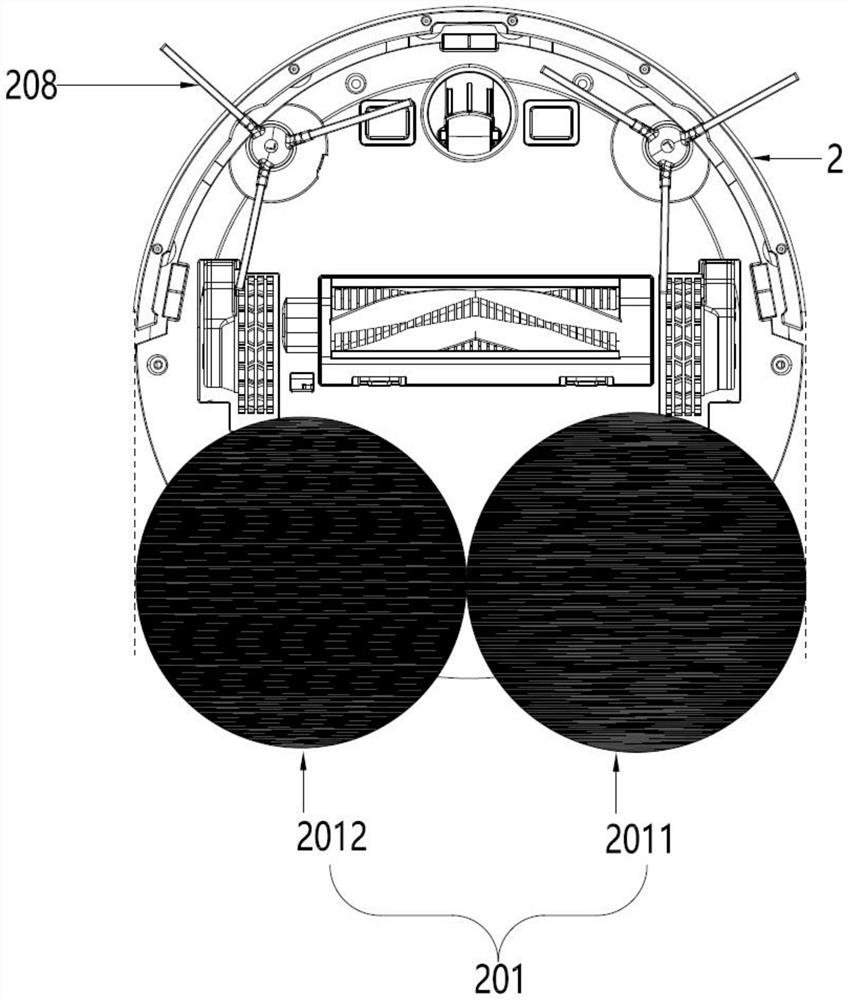

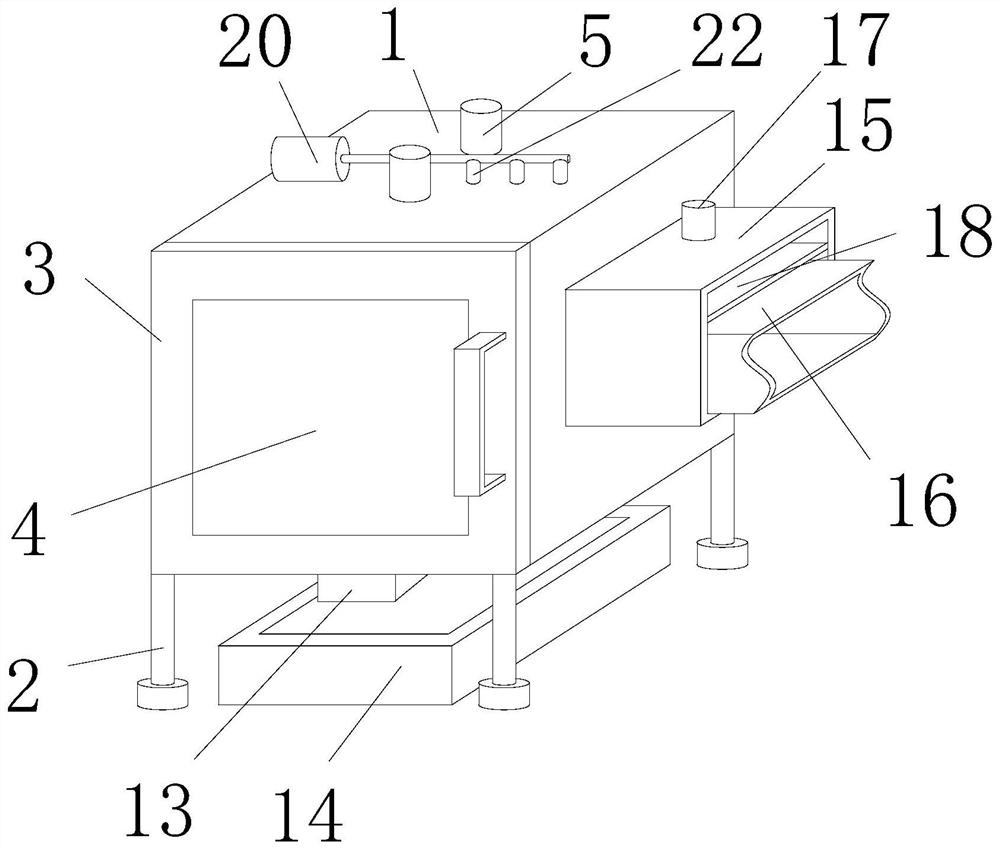

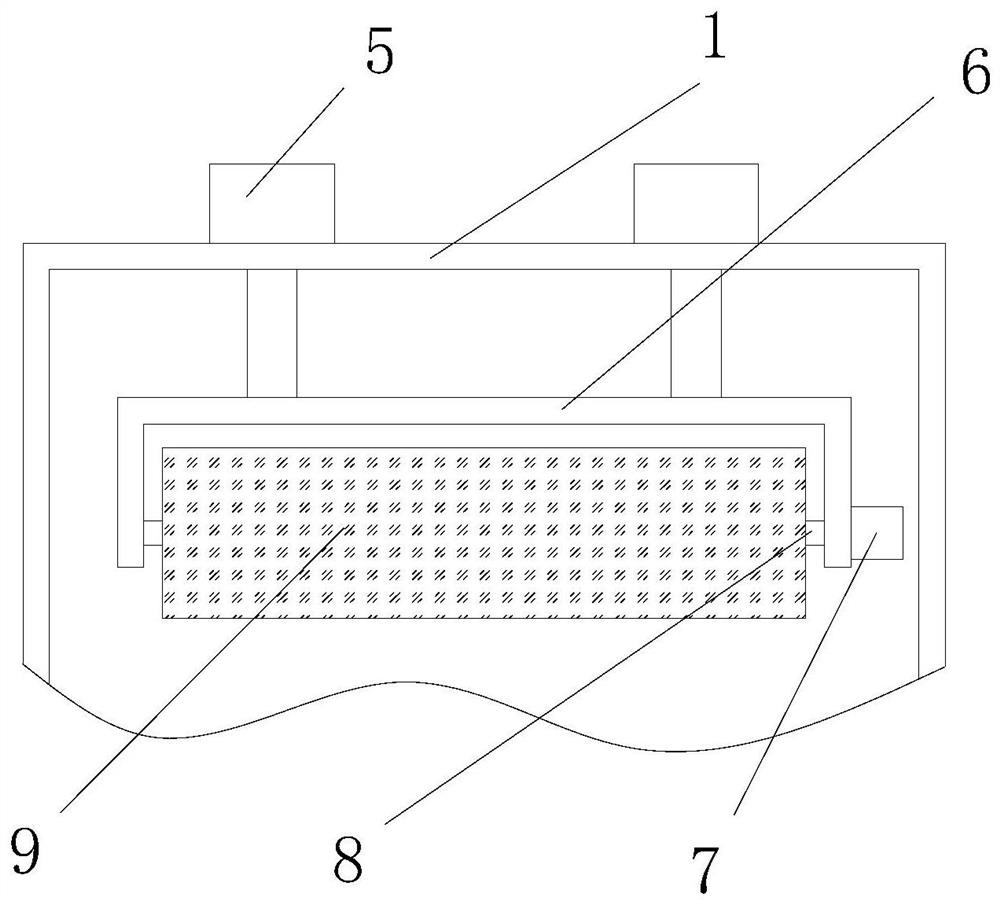

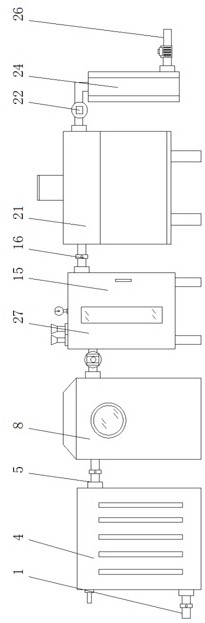

Cleaning station of cleaning robot

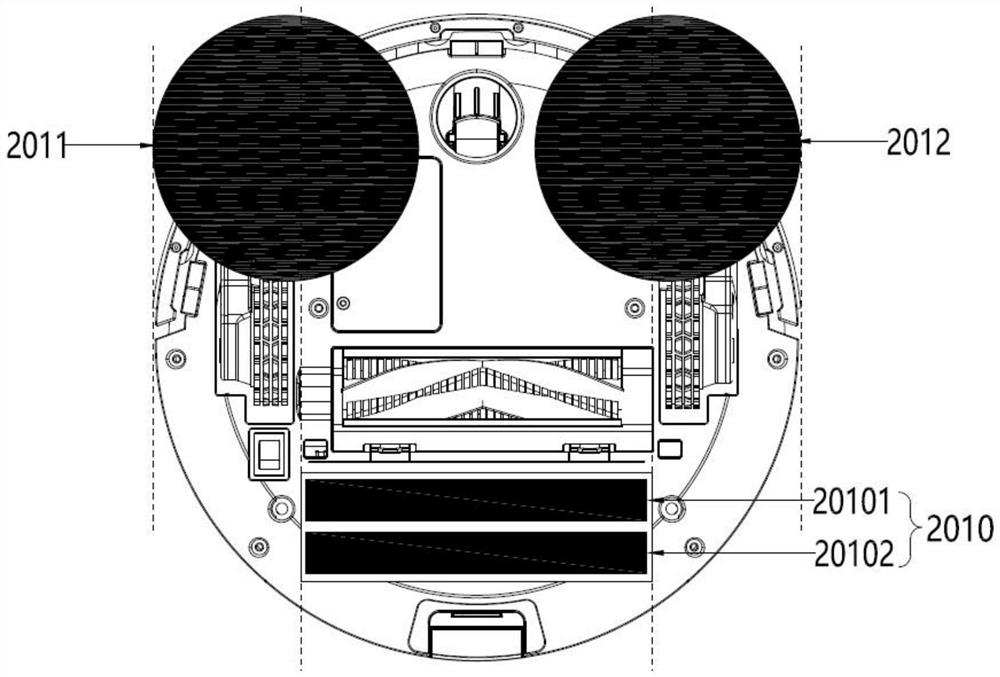

PendingCN112006618AEasy to absorb and handleRealize centralized suction processingCarpet cleanersFloor cleanersWater storage tankProcess engineering

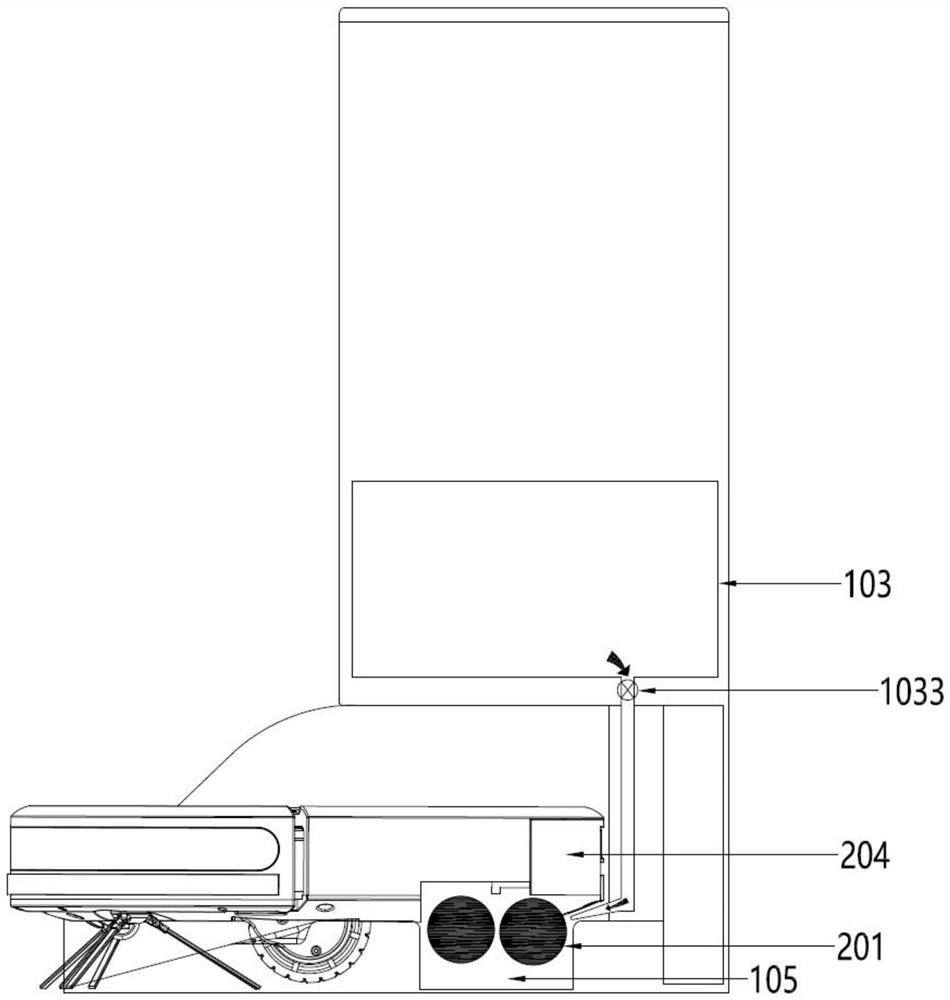

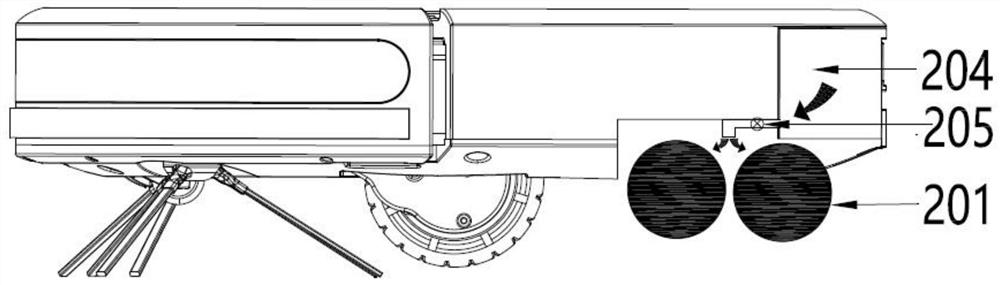

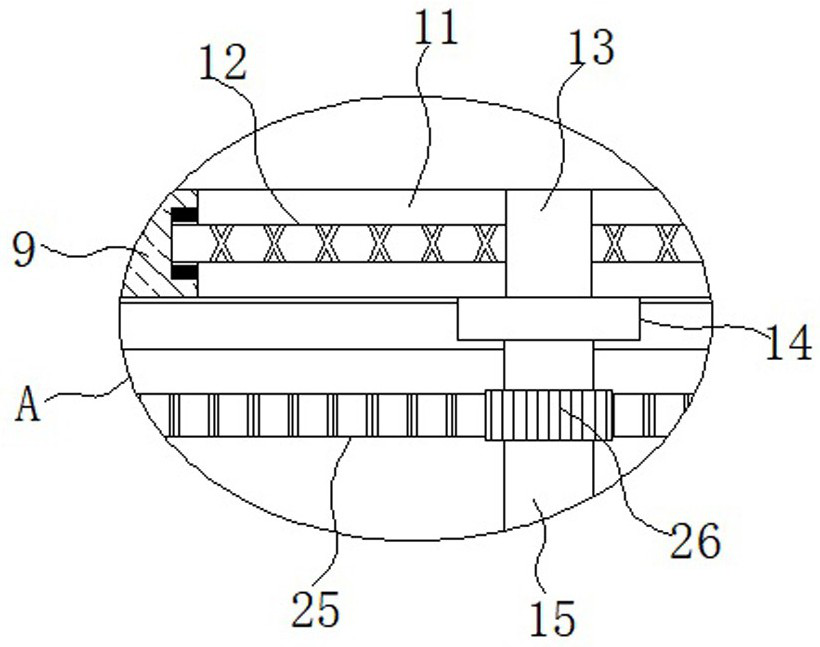

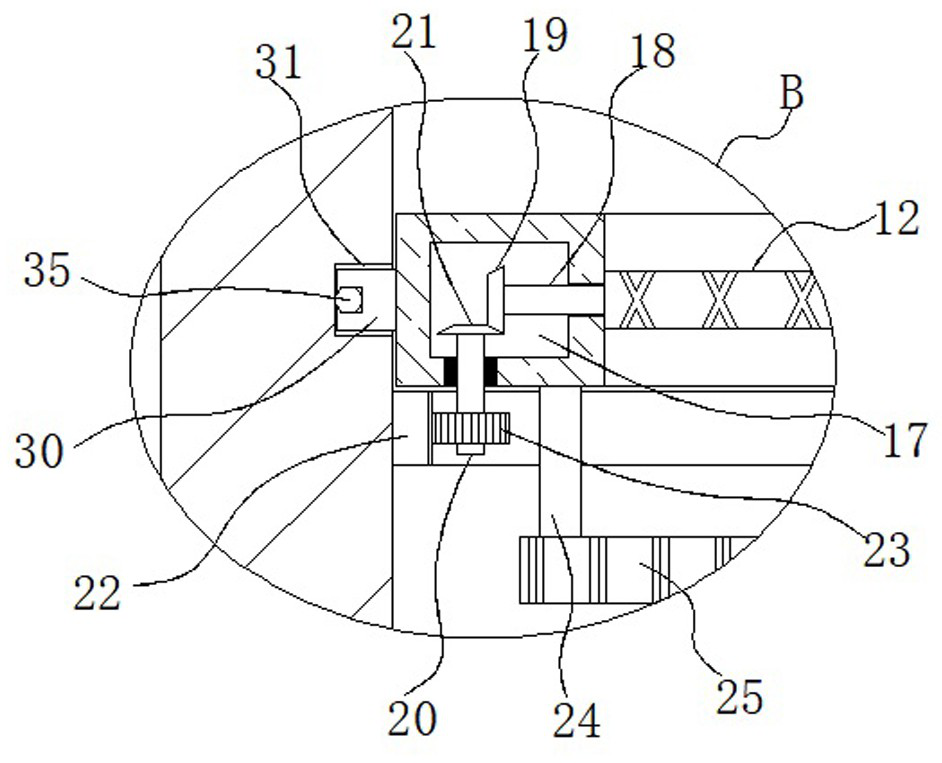

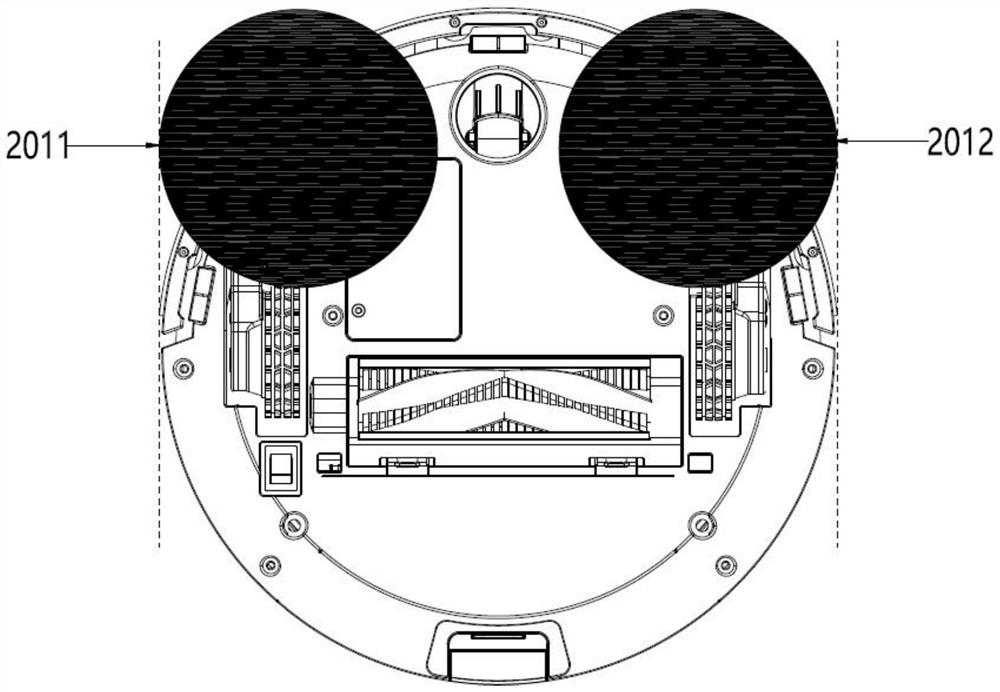

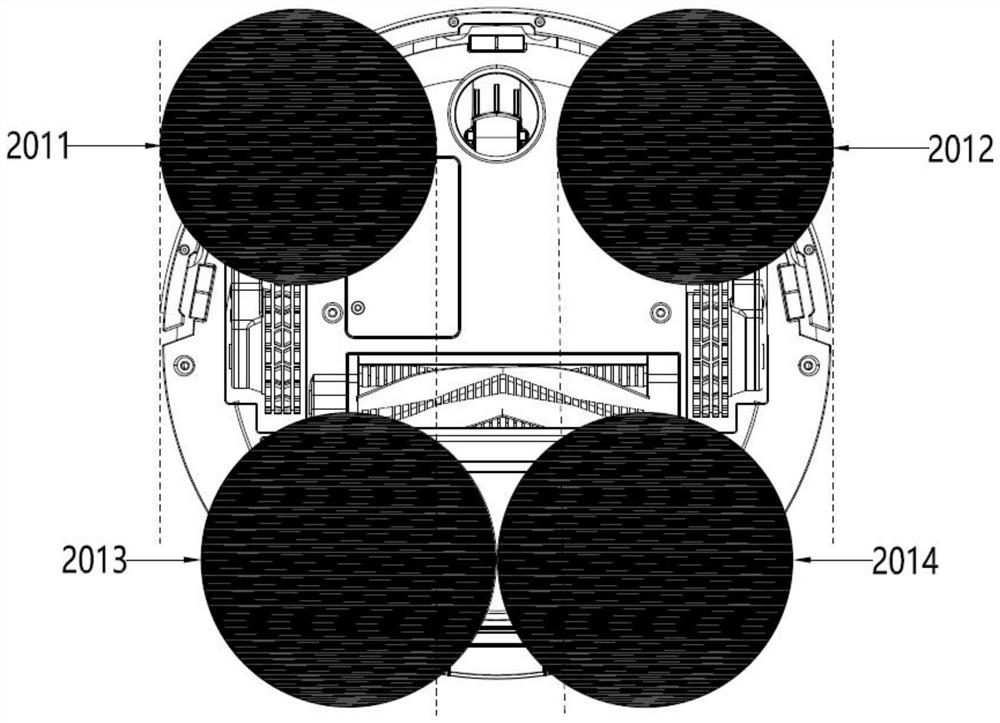

The invention discloses a cleaning station of a cleaning robot. The cleaning station is independently arranged relative to the cleaning robot, and the cleaning station is at least used for cleaning arotary mopping piece used for mopping the ground on the cleaning robot; the rotary mopping piece is arranged to mop and clean the ground, the rotary mopping piece is located at the bottom of the cleaning robot and can rotate and roll relative to the ground to mop and clean the ground, and when the rotary mopping piece makes contact with the ground, a plane structure is formed by the contact portion of the rotary mopping piece and the ground; the rotary mopping piece is automatically cleaned when the cleaning robot is located on the cleaning station by utilizing a rotatable rolling structure ofthe rotary mopping piece; a clean water tank can automatically supply water to the rotary mopping piece, a sewage tank automatically collects sewage and garbage after the rotary mopping piece is cleaned, water is automatically added into the water storage tank on the cleaning robot, the cleaning robot can automatically complete mopping cleaning, rotary mopping piece cleaning and automatic water adding without more participation of a user, and the mopping cleaning effect is better.

Owner:杭州匠龙机器人科技有限公司

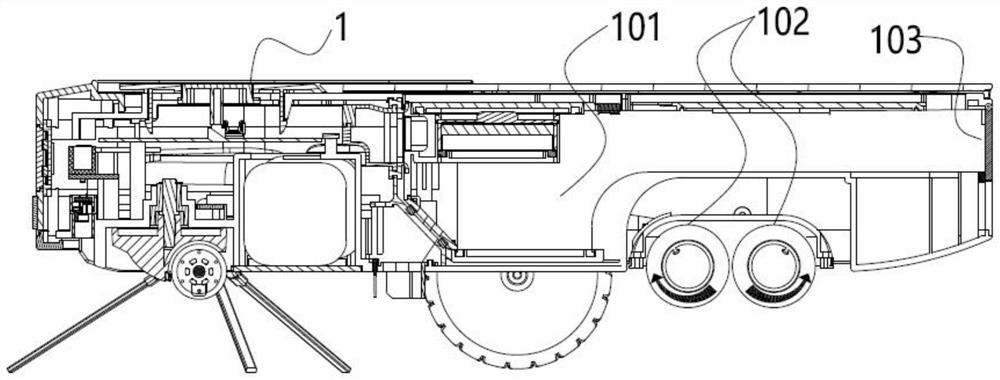

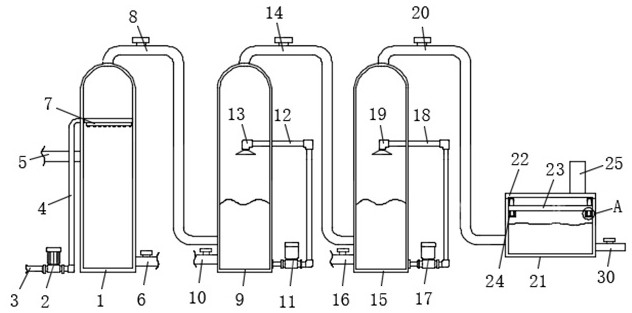

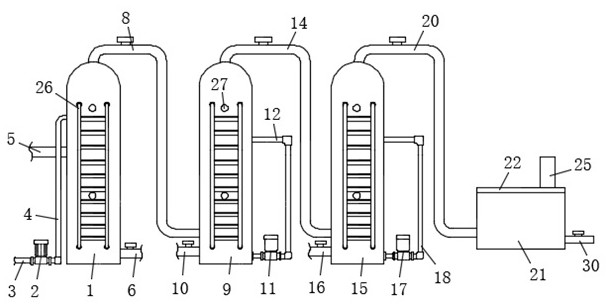

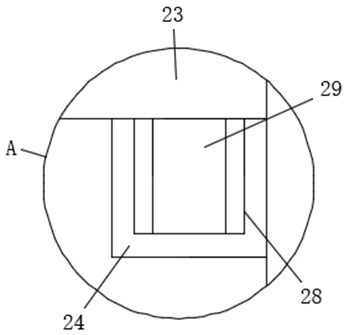

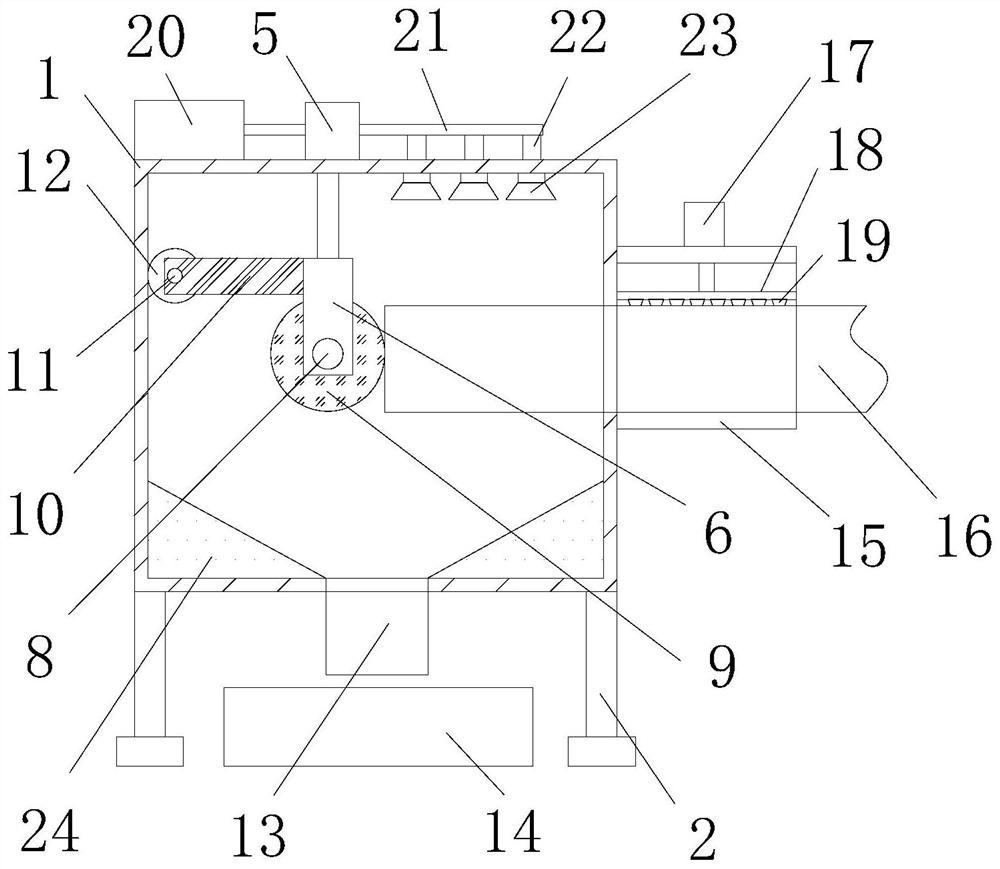

Integrated station of sweeping and mopping cleaning robot

PendingCN111973072AAchieve cleanupEasy to cleanCarpet cleanersFloor cleanersWastewaterProcess engineering

According to an integrated station of a sweeping and mopping cleaning robot in the scheme, the integrated station is independently arranged relative to the sweeping and mopping cleaning robot, and theintegrated station is at least used for conducting butt joint dust collection on the sweeping and mopping cleaning robot and cleaning a cleaning part, used for mopping the floor, of the sweeping andmopping cleaning robot; the garbage in a garbage cavity is sucked into a dust collecting box to be collected by butt joint for multiple times through butt joint dust collection; meanwhile, cleaning ofthe filter is completed in butt joint dust collection for separating out particulate matters on the filter; the cleaning part of the sweeping and mopping cleaning robot is automatically cleaned; in the automatic cleaning process, a clean water tank automatically supplies water to the cleaning part, a wastewater tank automatically collects wastewater and garbage generated after the cleaning part is cleaned, the sweeping and mopping cleaning robot can automatically complete dust collection cleaning and mopping cleaning on the indoor ground without more participation of a user, and the mopping cleaning effect is better.

Owner:杭州匠龙机器人科技有限公司

Integrated station of cleaning robot

PendingCN112006615AImprove experienceEasy to useCarpet cleanersFloor cleanersWater storage tankProcess engineering

The invention discloses an integrated station of a cleaning robot. The integrated station is independently arranged relative to the cleaning robot, and the integrated station is at least used for conducting butt joint dust collection on the cleaning robot and cleaning a cleaning piece, which is used for mopping the floor, on the cleaning robot; the garbage in a garbage cavity is sucked into a dustcollecting box to be collected by butt joint for multiple times through butt joint dust collection; meanwhile, cleaning of a filter is completed in butt joint dust collection; particulate matters onthe filter are separated; the cleaning piece of the cleaning robot is automatically cleaned; in the automatic cleaning process, a clean water tank automatically supplies water to the cleaning piece; asewage tank automatically collects sewage and garbage generated after the cleaning piece is cleaned, water is automatically added into a water storage tank on the cleaning robot, the cleaning robot can automatically complete dust collection cleaning and mopping cleaning on the indoor floor without more participation of a user, and the mopping cleaning effect is better.

Owner:杭州匠龙机器人科技有限公司

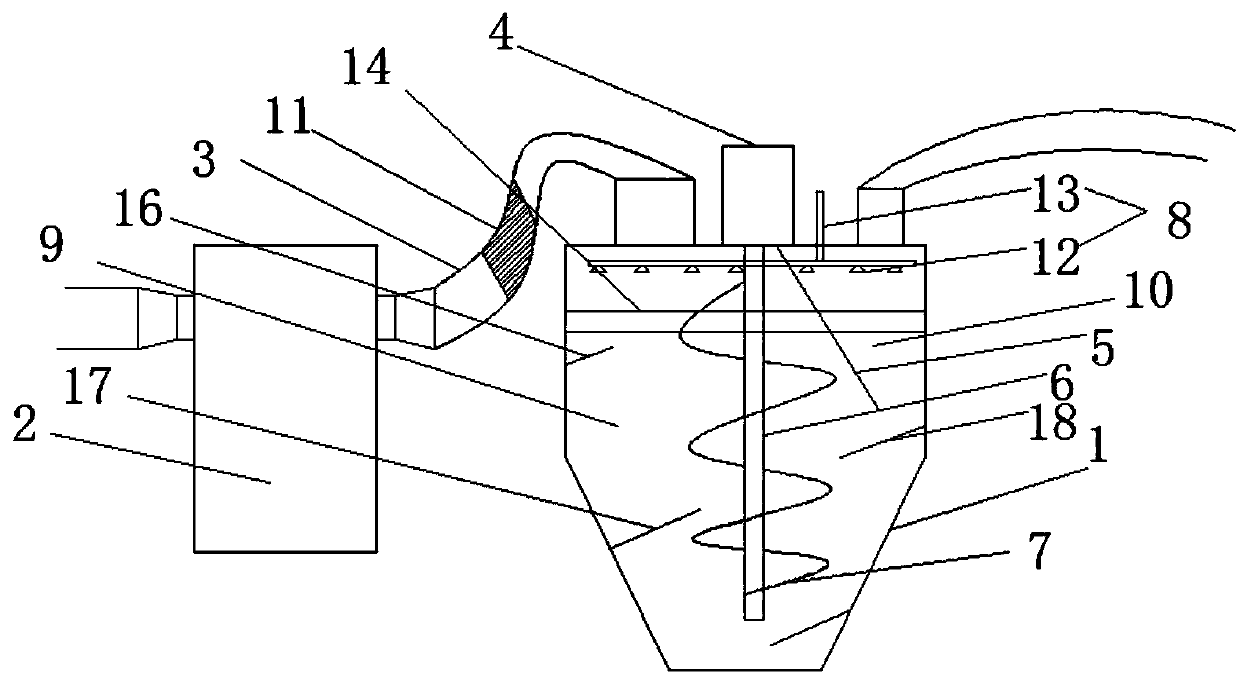

Dredging device for hydraulic engineering

InactiveCN107794959APrevent impossible cleanupEasy to absorb and handleMechanical machines/dredgersSludgeEngineering

The invention discloses a dredging device for water conservancy projects, which comprises a support frame, one side of the support frame is welded with a support plate in the horizontal direction, the other side of the support frame is installed with a push rod motor through screws, and the push rod motor The output end is connected with a push rod, and the end of the push rod is fixedly connected with a vertical connecting pipe, and one side of the connecting pipe is connected with a liquid inlet pipe, and the liquid inlet pipe is installed on the sludge pump, and one side of the sludge pump There is also a liquid outlet pipe, and the sludge is cleaned by a sludge pump. At the same time, a mounting plate is installed at the bottom of the connecting pipe, and a rotating motor is installed on the mounting plate. The stirring rod breaks up the sludge, which is convenient for the sludge pump to absorb and process, and prevents the sludge from being too large to be cleaned. At the same time, the support plate is used for support and the push rod motor is used for adjustment, which improves the adaptability of the equipment.

Owner:CHENGDU HUAXI NATURAL MEDICINE

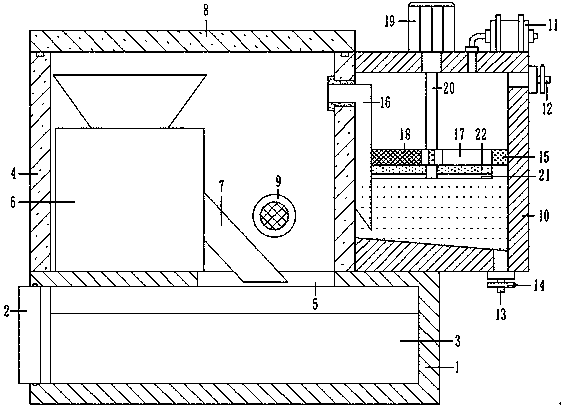

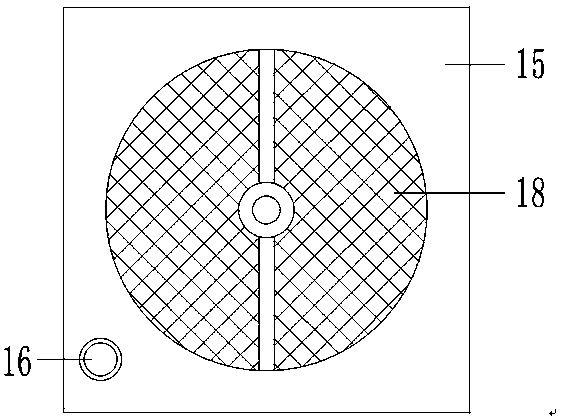

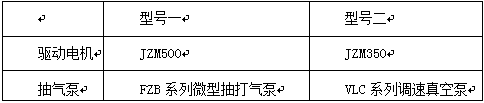

Grinding machine for producing plastic stabilizer

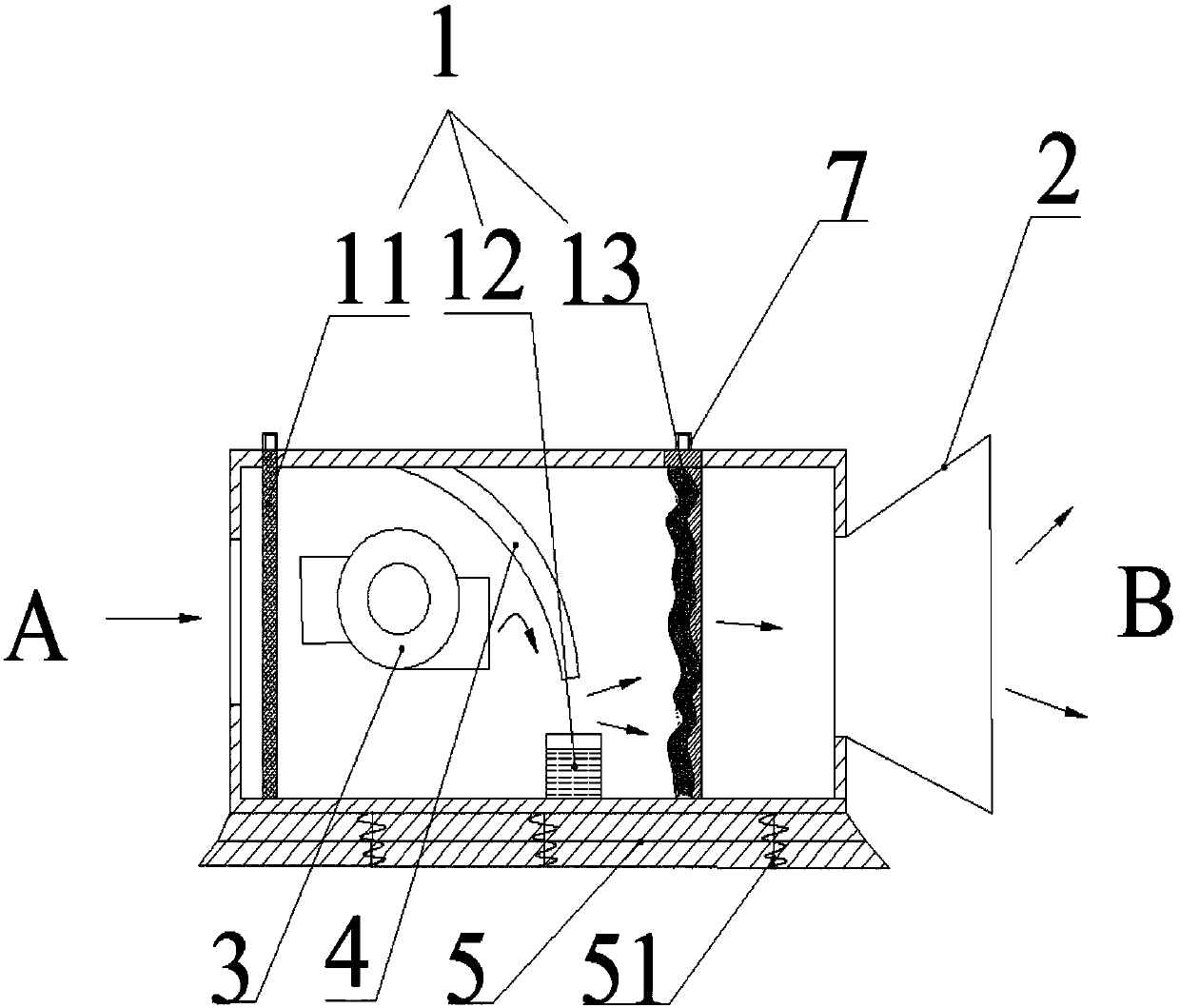

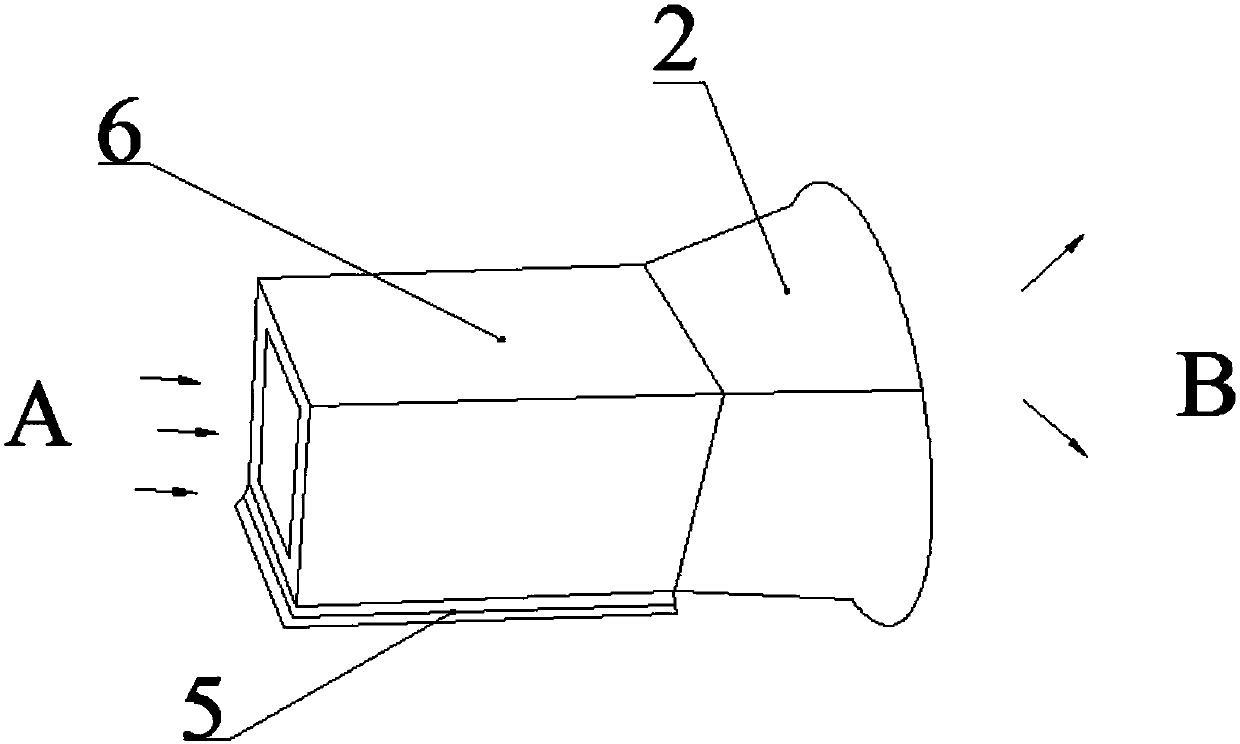

PendingCN110237923AEasy to absorb and handleHarm reductionCombination devicesDispersed particle filtrationActivated carbonFiber

The invention discloses a grinding machine for producing a plastic stabilizer. The grinding machine comprises a material containing box body, a working box body is fixedly connected to the top of the material containing box body, a discharging window is formed in the bottom of the inner cavity of the working box body, a grinding machine main body is arranged on the left side of the bottom of the inner cavity of the working box body, vent holes are formed in the lower end of the rear side wall of the work box body, a dust collection box body is fixedly connected to the right side of the work box body, a suction pump is arranged on the right side of the top of the dust suction box body, a supporting plate is fixedly connected to the inner cavity of the dust collection box body, a gas guide pipe is inserted into the left side of the top of the supporting plate, semicircular windows are symmetrically formed in the left side and the right side of the top of the supporting plate, the inner cavity of the semicircular windows are provided with activated carbon filter screens, the top of the dust suction box body is provided with a driving motor, the bottom of the driving motor is connected with a rotating shaft, brush rods are symmetrically and fixedly connected to the left side and the right side of one end of the inner cavity of the dust suction box body, dust removal fibers are fixedly connected to the top of the brush rods. According to the grinding machine, the harm to human body health is reduced, the possibility of explosion accidents is reduced, and the life and property safety is guaranteed.

Owner:南京金陵化工厂有限责任公司

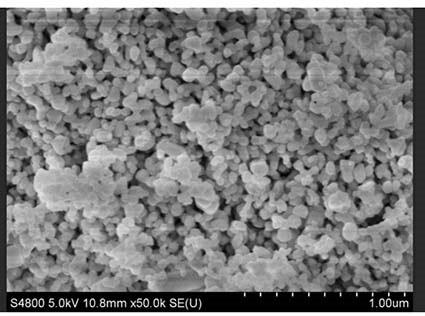

Preparation method of nano cerium oxide-graphene composite particles

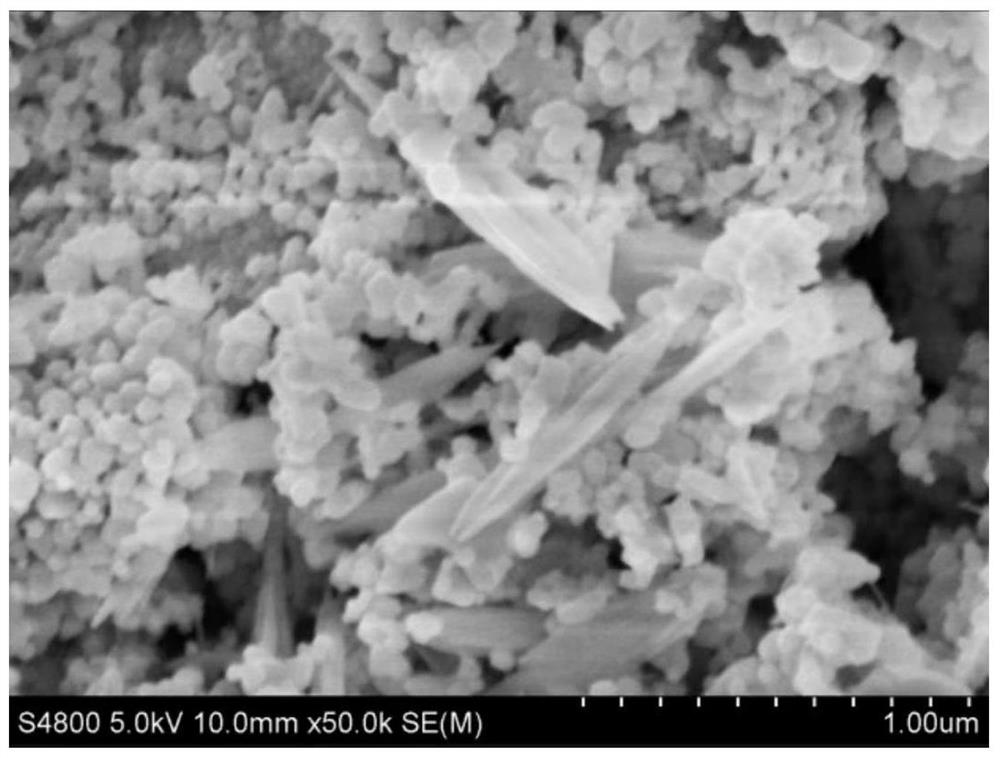

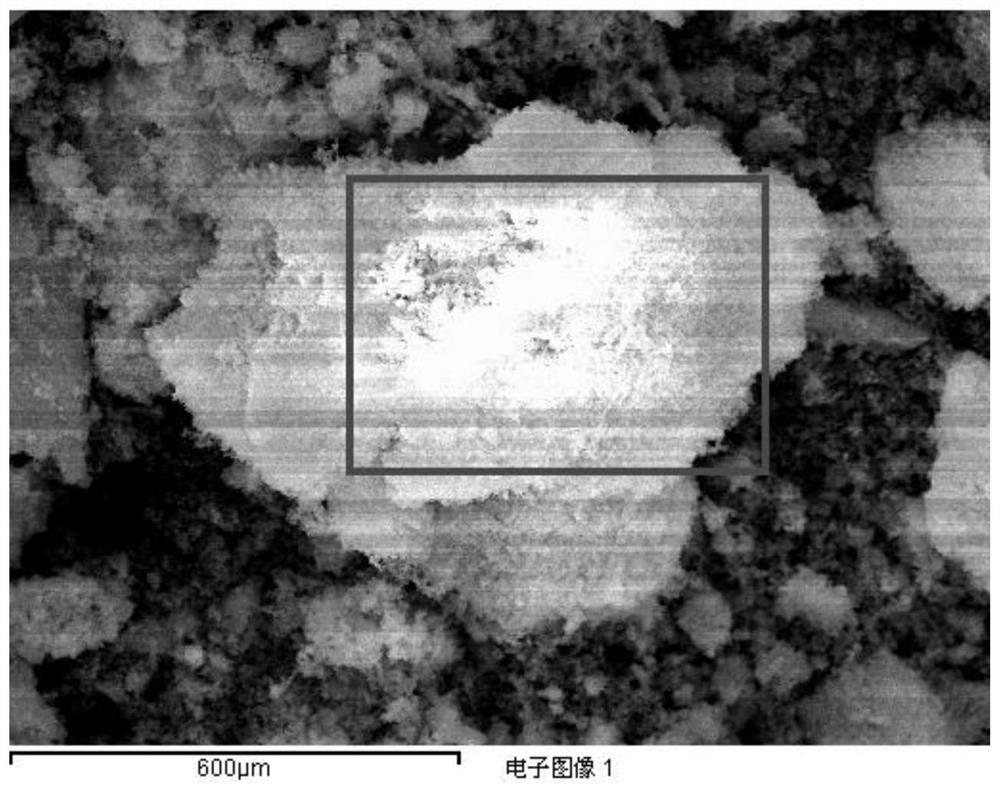

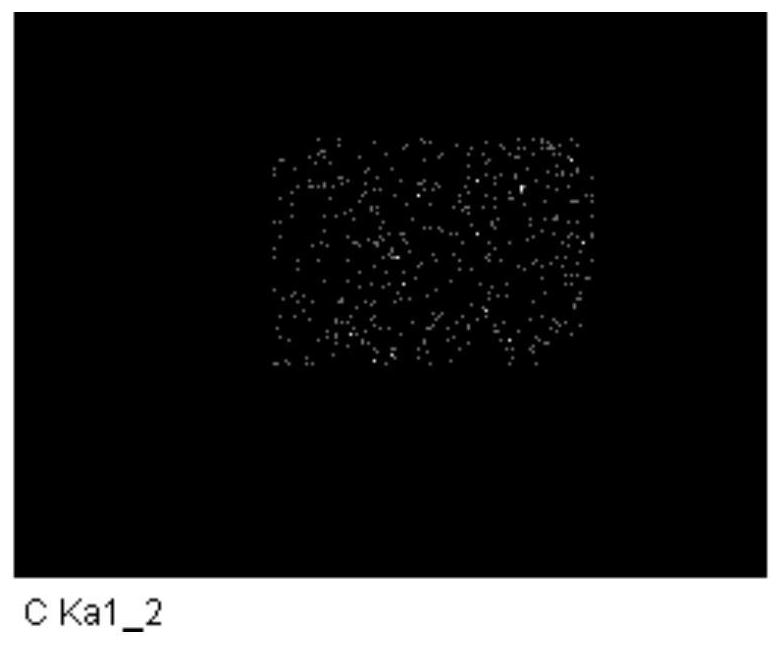

ActiveCN112961653AThe process method is simpleReduce processMaterial nanotechnologyOther chemical processesSurface oxidationCerium oxide

The invention relates to the technical field of semiconductor material preparation, in particular to a preparation method of nano cerium oxide-graphene composite particles. The preparation method of nano cerium oxide-graphene composite particles comprises the following steps: (1) preparing cerium oxide micro powder; (2) preparing a cerium oxide suspension; (3) preparing a graphene suspension; (4) preparing a cerium oxide-graphene composite particle crude product; and (5) calcining the cerium oxide-graphene composite particle crude product. The cerium oxide in the nano cerium oxide-graphene particles prepared by the method is well compounded on the surface of the graphene, the particle size of the cerium oxide is controllable in a range of 10-5000nm, the particle size distribution is narrow, and the cerium oxide is easy to disperse; and the composite particles can be applied to chemical-mechanical polishing and dispersing of polishing liquid in the field of semiconductors.

Owner:广西立之亿新材料有限公司

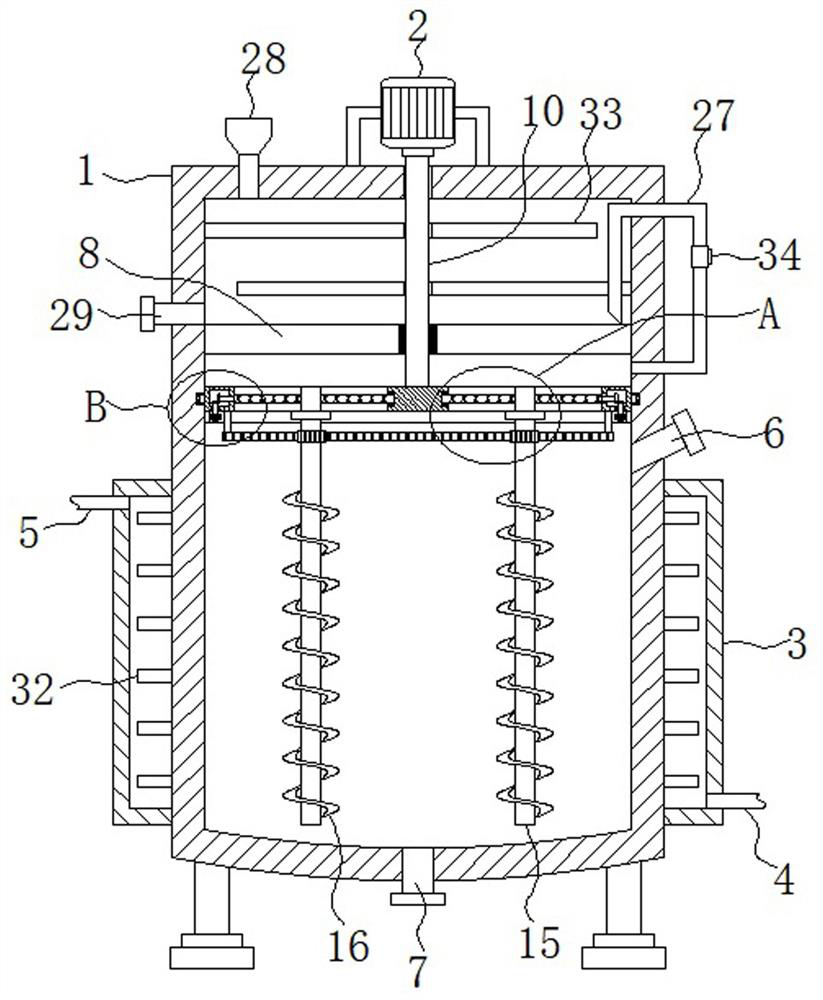

Environment-friendly nitration reactor

InactiveCN113244871AGood effectStir wellGas treatmentShaking/oscillating/vibrating mixersNitrogen oxidesElectric machine

The invention relates to the technical field of nitration reaction, and discloses an environment-friendly nitration reactor, which comprises a reaction kettle, a driving motor, a heat exchange jacket, a water inlet pipe, a water outlet pipe, a feeding port and a discharging port, wherein the driving motor is fixed to the top of the reaction kettle through a mounting frame, the reaction kettle is fixedly sleeved with the heat exchange jacket, the side wall of the bottom end of the heat exchange jacket is communicated with the water inlet pipe, the side wall of the top end of the heat exchange jacket is communicated with the water outlet pipe, the side wall of the reaction kettle is communicated with the feeding port, the bottom of the reaction kettle is communicated with the discharging port, and the interior of the reaction kettle is divided into a waste gas treatment cavity and a nitration reaction cavity from top to bottom through a partition plate. According to the environment-friendly nitration reactor, materials in the reaction kettle can be conveniently stirred in all directions, so that stirring dead angles are avoided, the nitration reaction effect is improved, nitrogen oxide waste gas generated in the nitration reaction process can be conveniently absorbed and treated, environment pollution is avoided, and environmental protection is facilitated.

Owner:山东彩客东奥化学有限公司

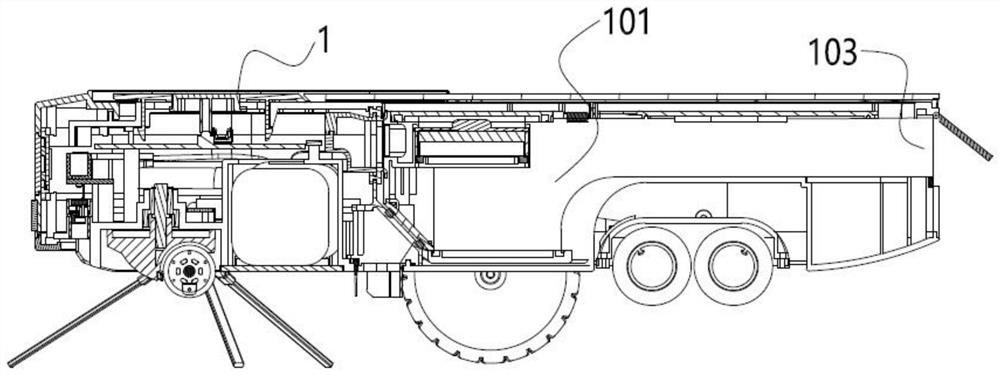

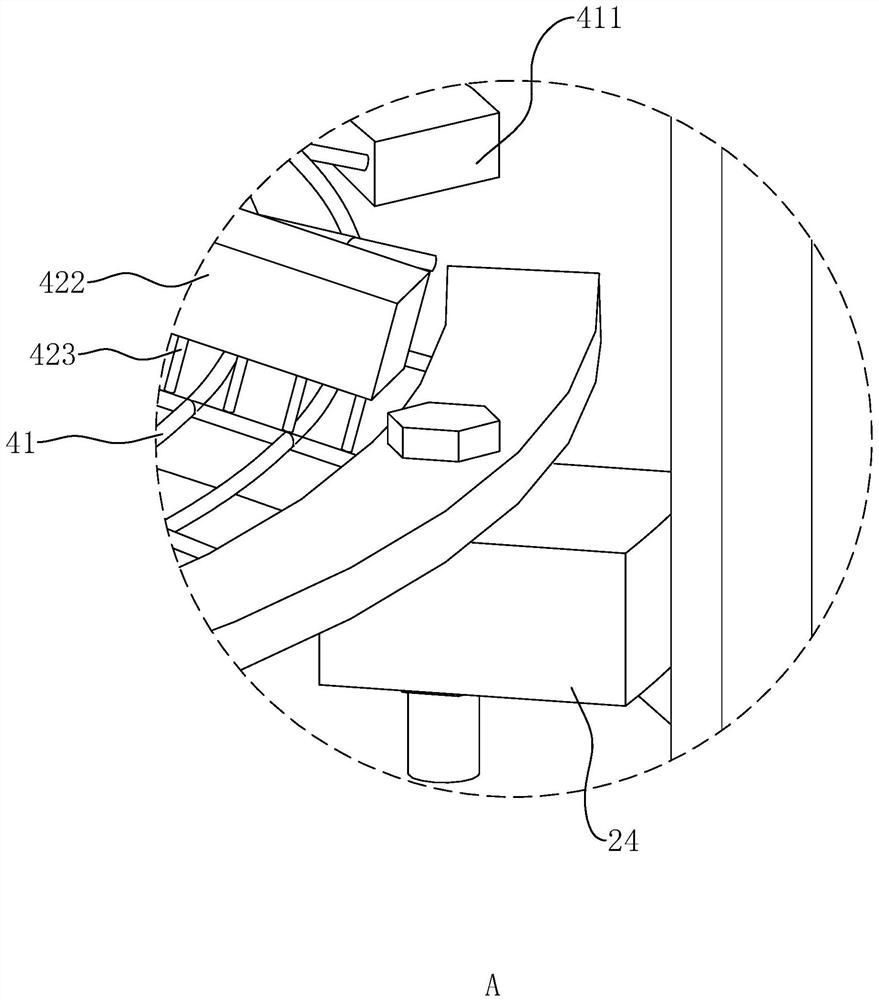

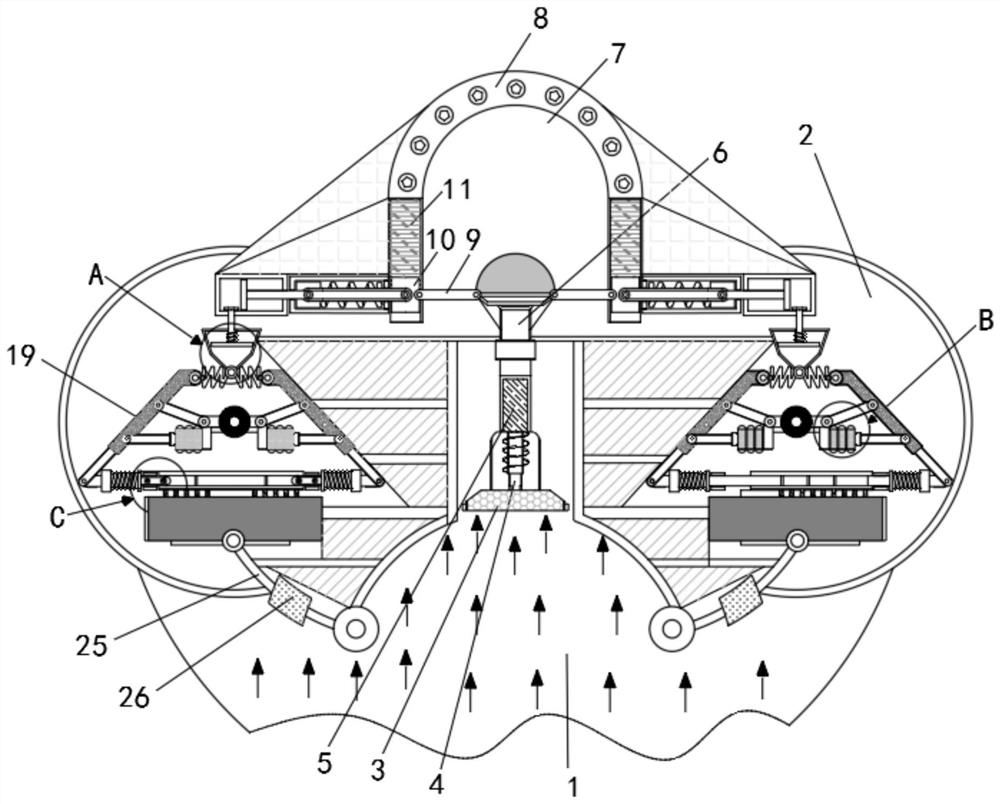

Integrated station of mopping and sucking cleaning robot

PendingCN111973090AIncrease the areaIncrease frictionCarpet cleanersFloor cleanersParticulatesProcess engineering

The invention discloses an integrated station of a mopping and sucking cleaning robot. The integrated station is independently arranged relative to the mopping and sucking cleaning robot, and the integrated station is at least used for conducting butt joint dust collection on the mopping and sucking cleaning robot and cleaning a cleaning part, used for mopping the floor, on the mopping and suckingcleaning robot; the garbage in a garbage cavity is sucked into a dust collecting box to be collected by butt joint for multiple times through butt joint dust collection; meanwhile, cleaning of a filter is completed in butt joint dust collection; particulate matter on the filter is separated; the cleaning part of the mopping and sucking cleaning robot is automatically cleaned; and in the automaticcleaning process, a clean water tank automatically supplies water to the cleaning part, a sewage tank automatically collects sewage and garbage generated after the cleaning part is cleaned, the mopping and sucking cleaning robot can automatically complete dust sucking cleaning and mopping cleaning on the indoor ground without more participation of a user, and the mopping and cleaning effect is better.

Owner:杭州匠龙机器人科技有限公司

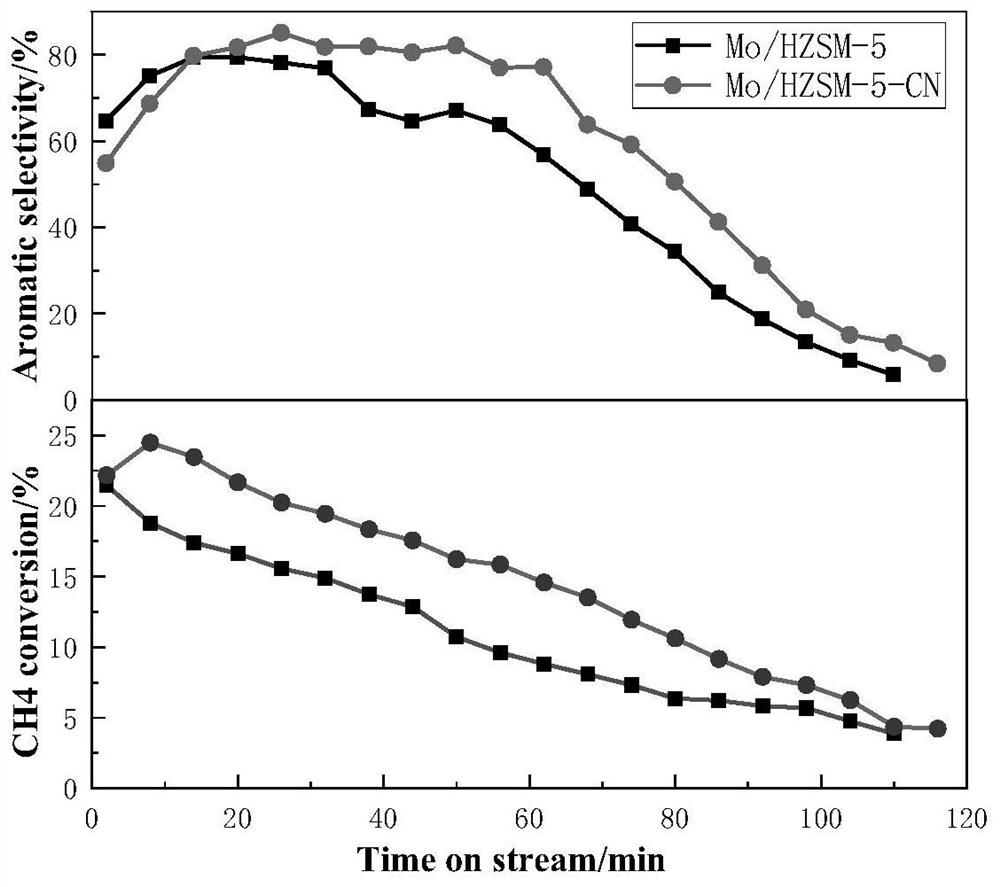

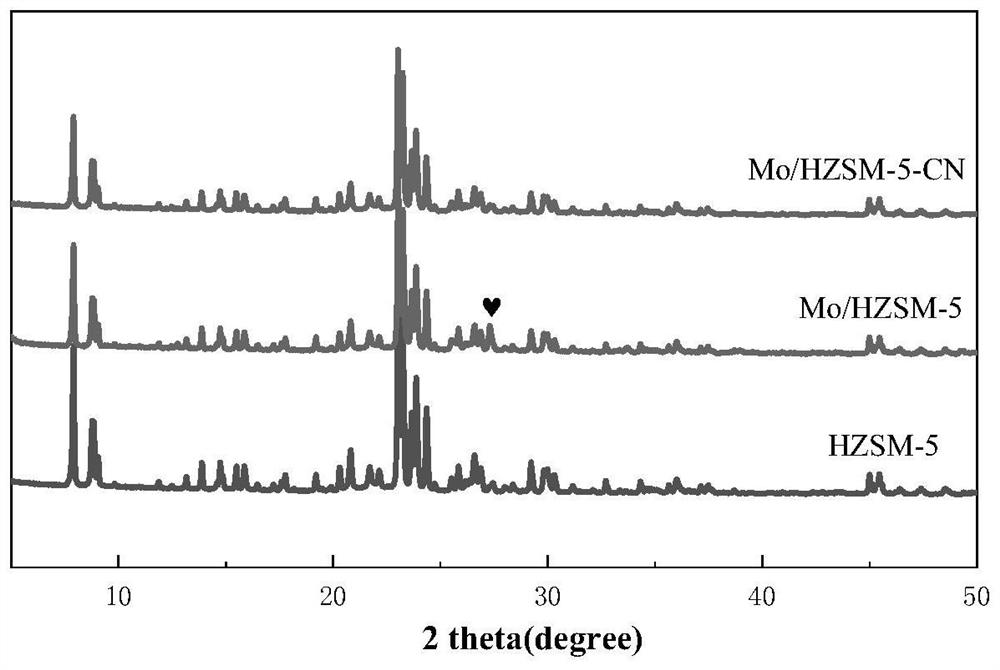

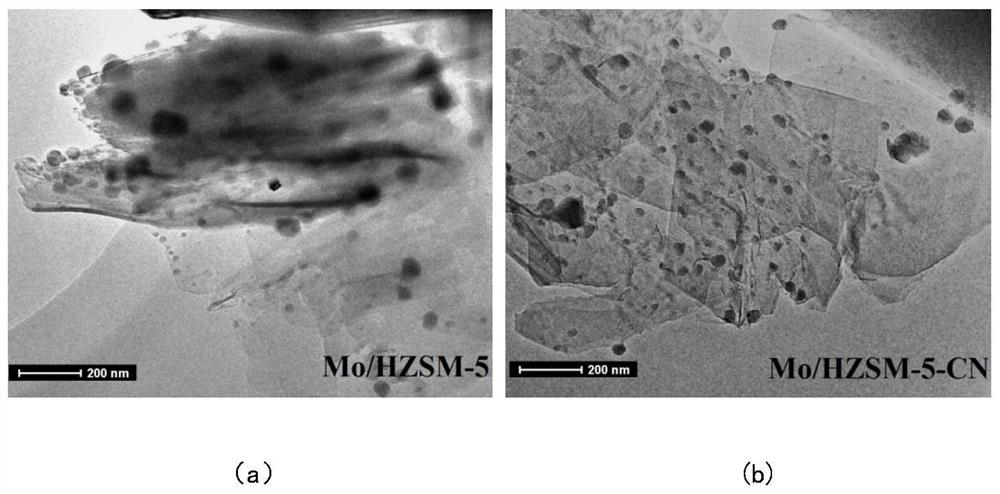

Catalyst for improving anaerobic aromatization reaction performance of methane and preparation method of catalyst

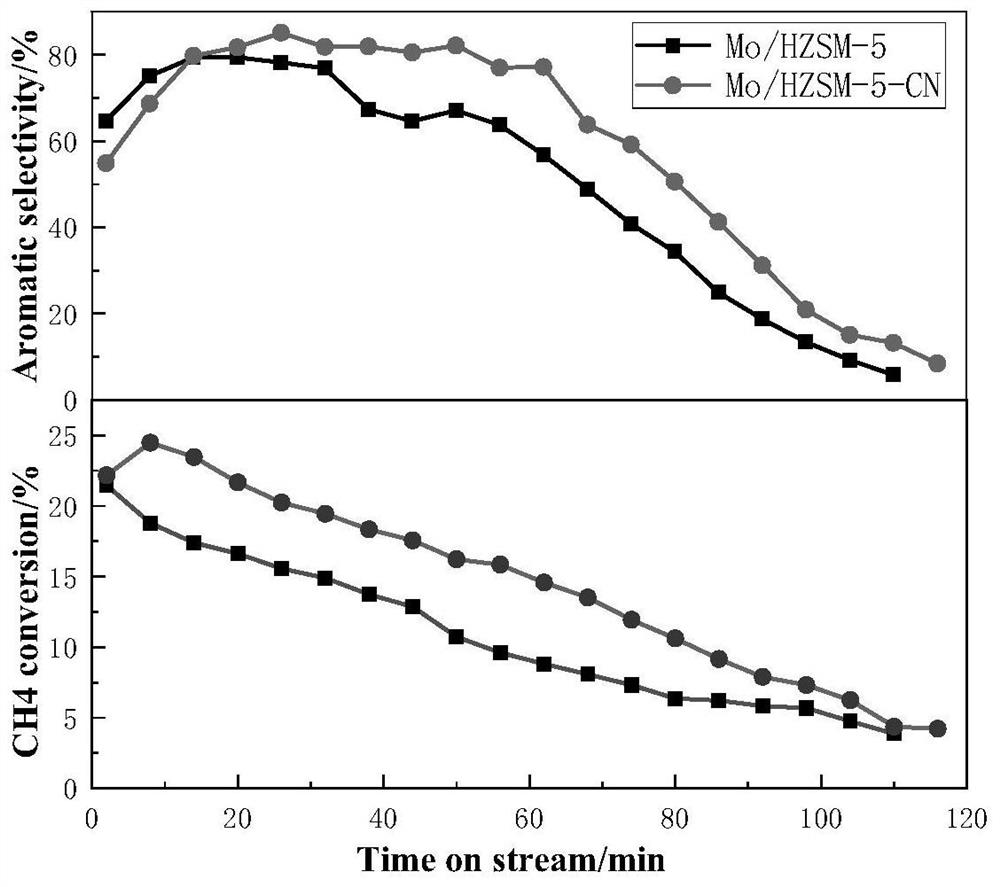

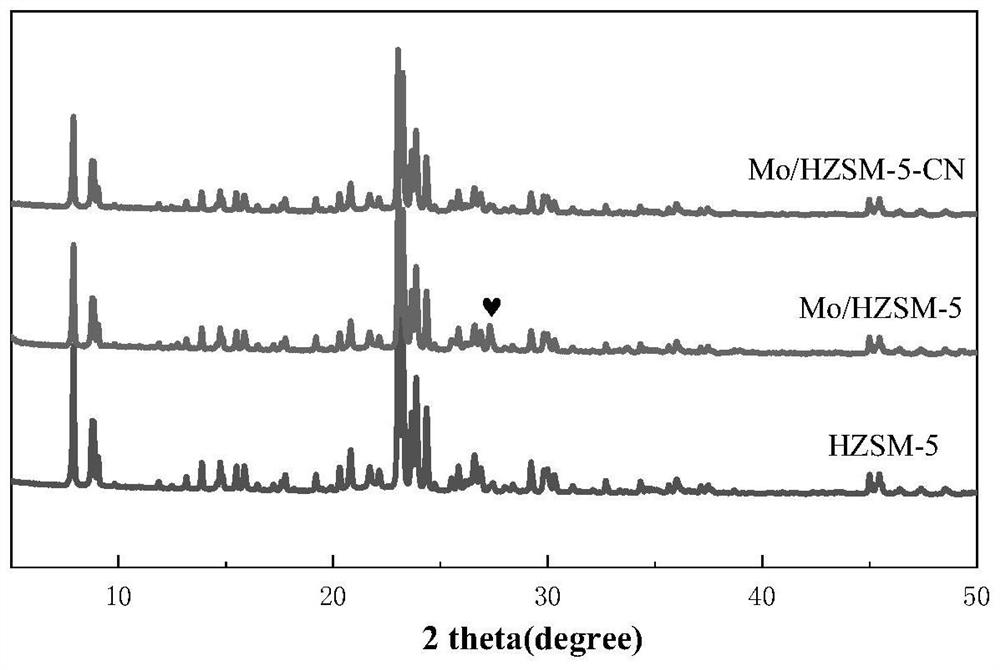

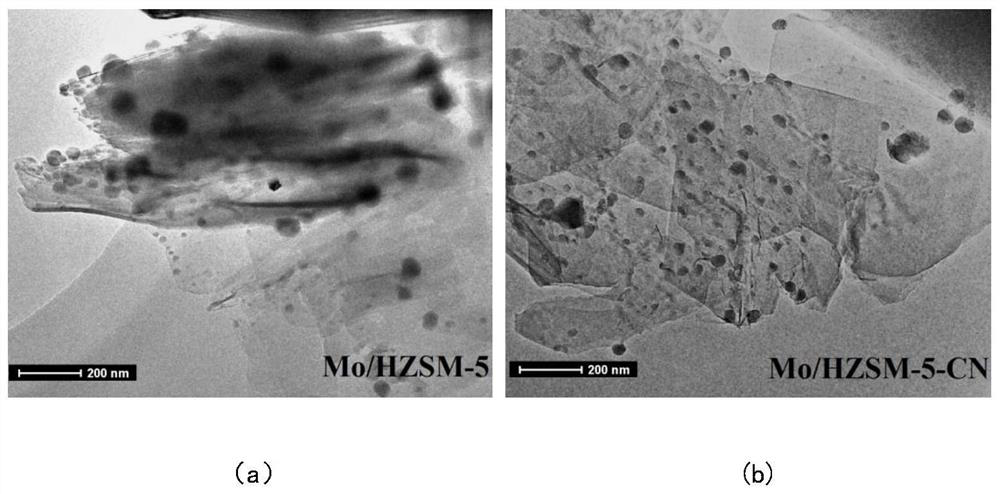

ActiveCN111871448AImprove conversion rateImprove stabilityMolecular sieve catalystsMolecular sieve catalystAir atmosphereMolecular sieve

The invention discloses a catalyst for improving anaerobic aromatization reaction performance of methane and a preparation method of the catalyst. The preparation method comprises the following steps:firstly, drying a carrier molecular sieve and an auxiliary falling object melamine for later use; dissolving ammonium molybdate tetrahydrate into deionized water to be subjected to ultrasonic dispersion, enabling the volume of the deionized water to be equal to the saturated water absorption capacity of the carrier molecular sieve, impregnating the carrier molecular sieve with the solution, uniformly stirring and mixing, impregnating at room temperature, and drying, so as to obtain a catalyst precursor for later use; weighing melamine, and fully and uniformly mixing melamine with the catalystprecursor in a solid-solid mixing or solution mixing evaporation manner; and heating and roasting the mixture in a nitrogen or air atmosphere to obtain the catalyst for improving the anaerobic aromatization reaction performance of methane. The preparation method is simple, green, efficient and high in economic benefit, raw materials are easy to obtain, and industrial production requirements are easy to meet.

Owner:NORTHWEST UNIV(CN)

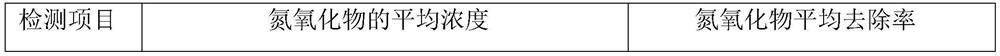

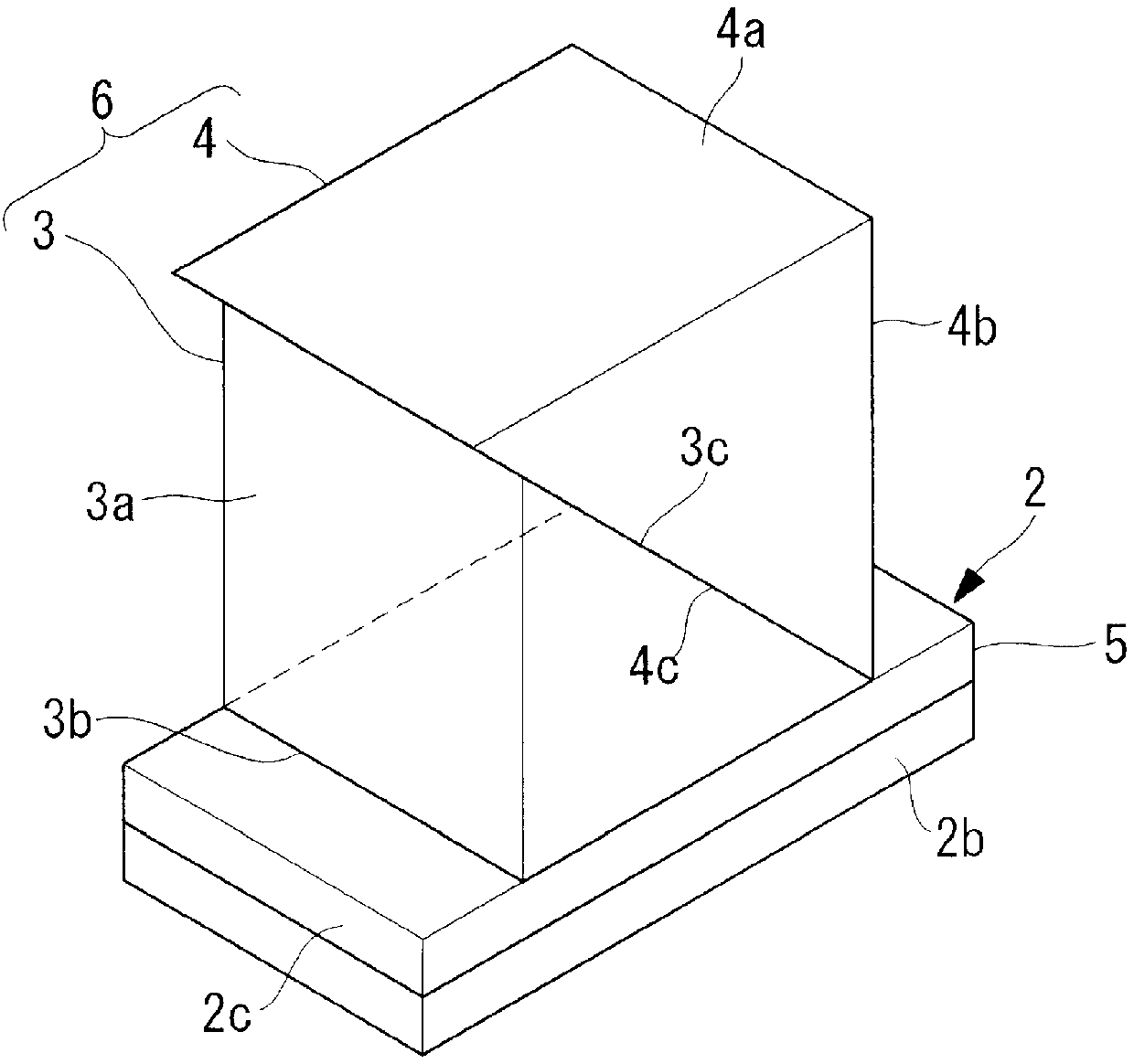

A green and efficient nitrogen oxide waste gas treatment method

ActiveCN109908733BEasy to operateReduce dependenceDispersed particle separationSucroseNitrogen oxides

The invention relates to a green and high-efficiency nitrogen oxide waste gas treatment method. The nitrogen oxide waste gas is treated by a one-step reduction method, the nitrogen oxide waste gas is passed into the waste gas treatment tower, and the nitrogen oxide waste gas is treated with a nitrogen oxide waste gas treatment liquid. Perform spray treatment. The nitrogen oxide waste gas treatment liquid includes the following components in mass percentage: 1%-5% soluble inorganic base, 10%-20% reducing agent, 0.5%-1% stabilizer, 1%-3% accelerator, and the remaining The amount is water. The accelerator comprises the following raw materials by weight: 20-30 parts of organic base, 5-10 parts of arginine, 30-40 parts of sucralose ionized trimethylglycine borohydride, 5-10 parts of glucose , 10-15 parts of tetraethylenepentamine. The green and high-efficiency nitrogen oxide waste gas treatment method disclosed by the present invention can realize the safe, environmentally friendly, fast and efficient treatment of nitrogen oxide waste gas, reduce the treatment cost, reduce the occurrence of secondary pollution, and the treatment process is simple, and the nitrogen oxide can be reduced by one step The substance is converted into non-toxic and harmless nitrogen.

Owner:苏州清控环保科技有限公司

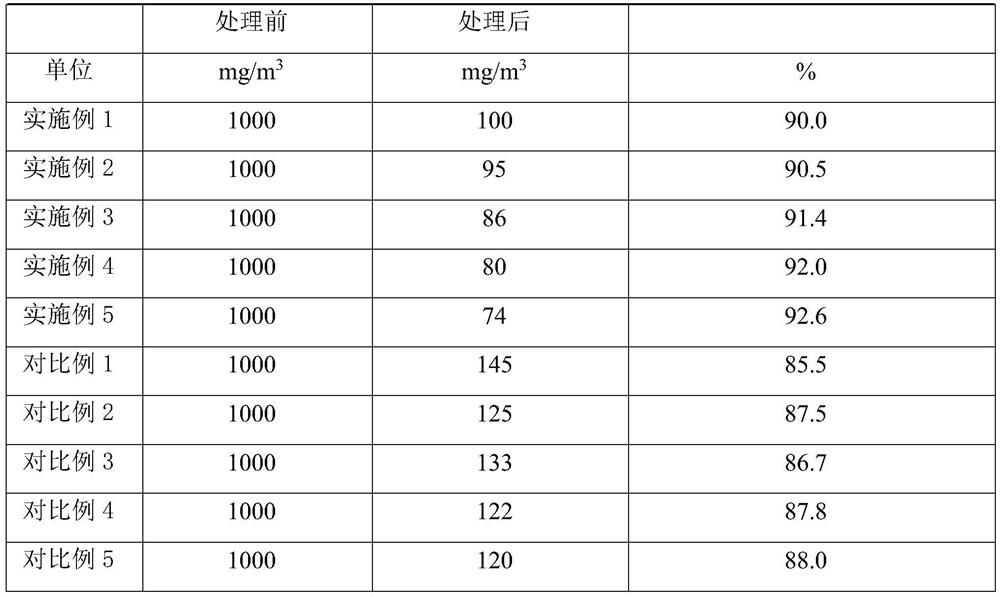

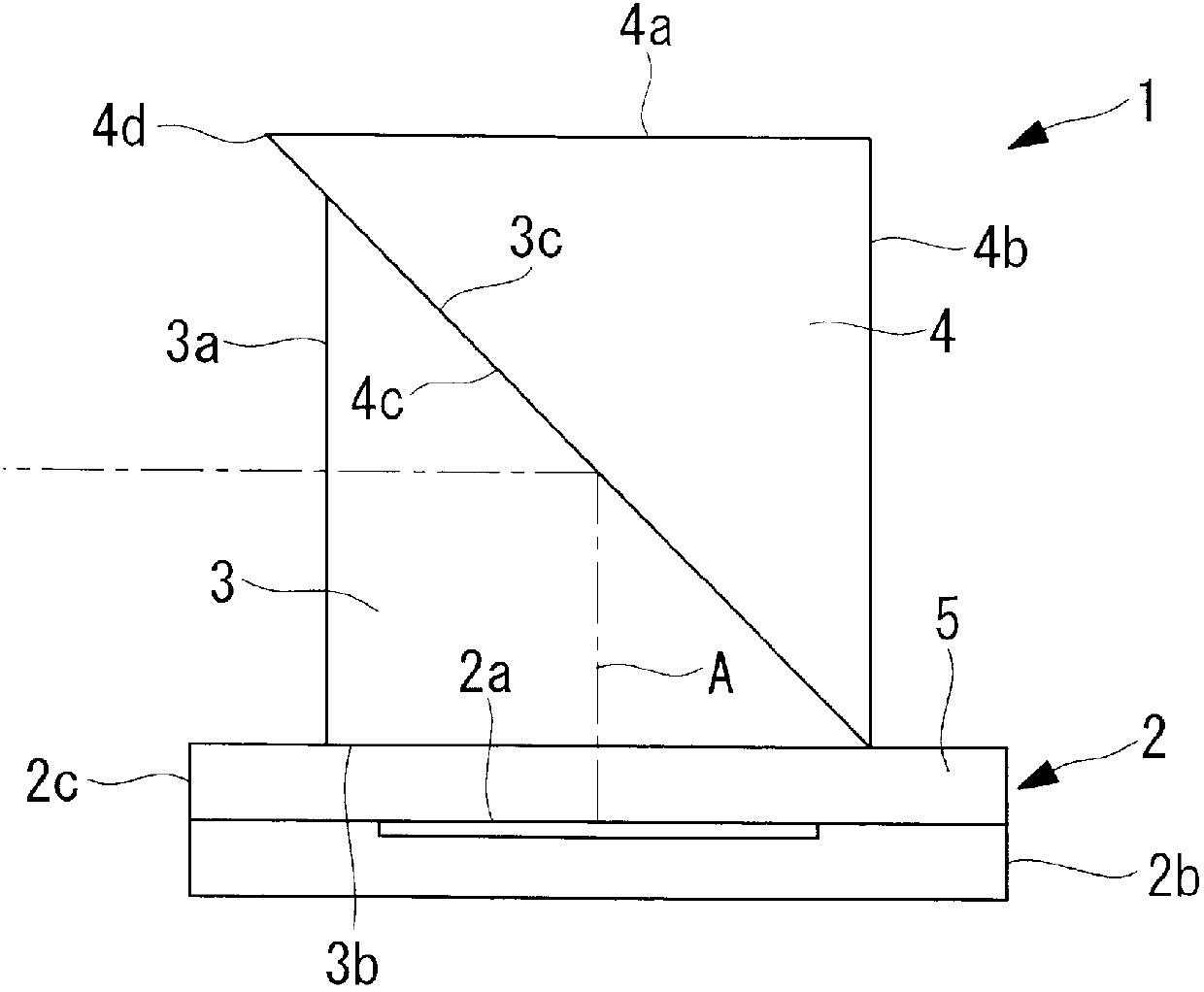

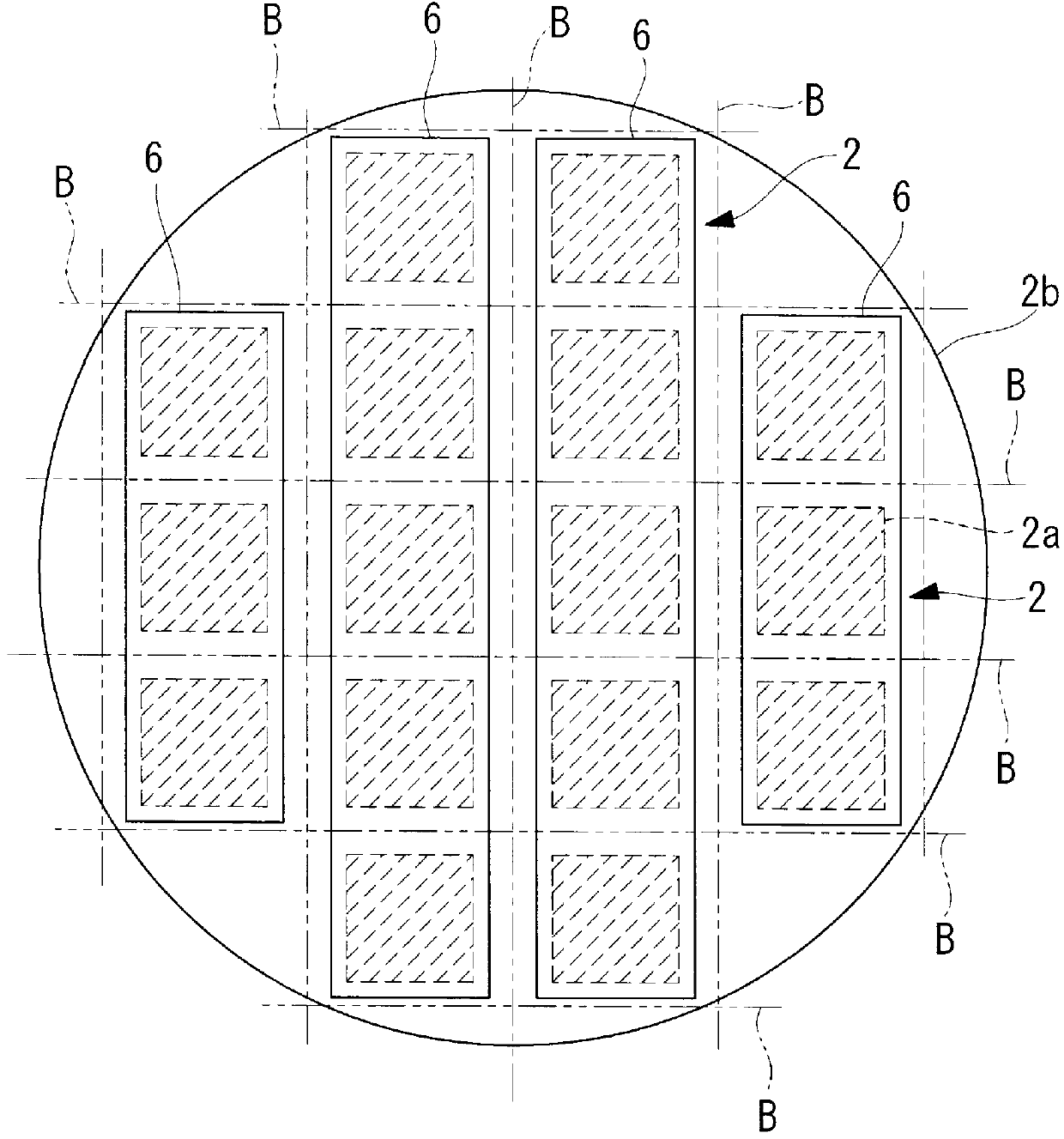

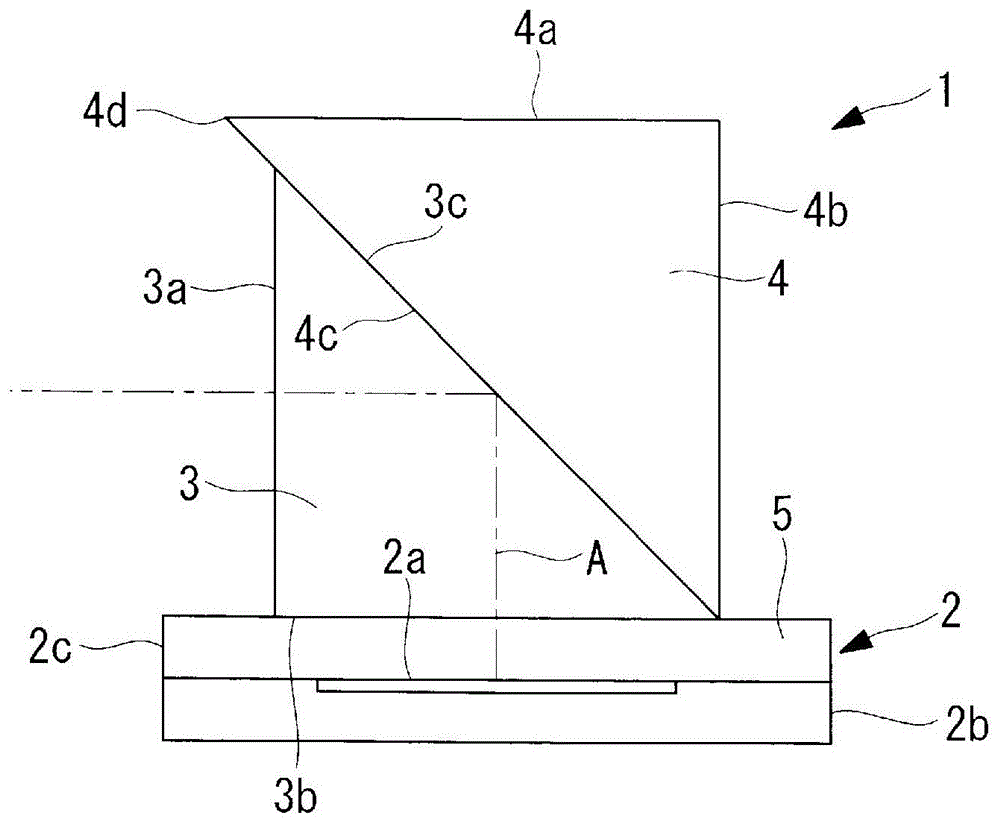

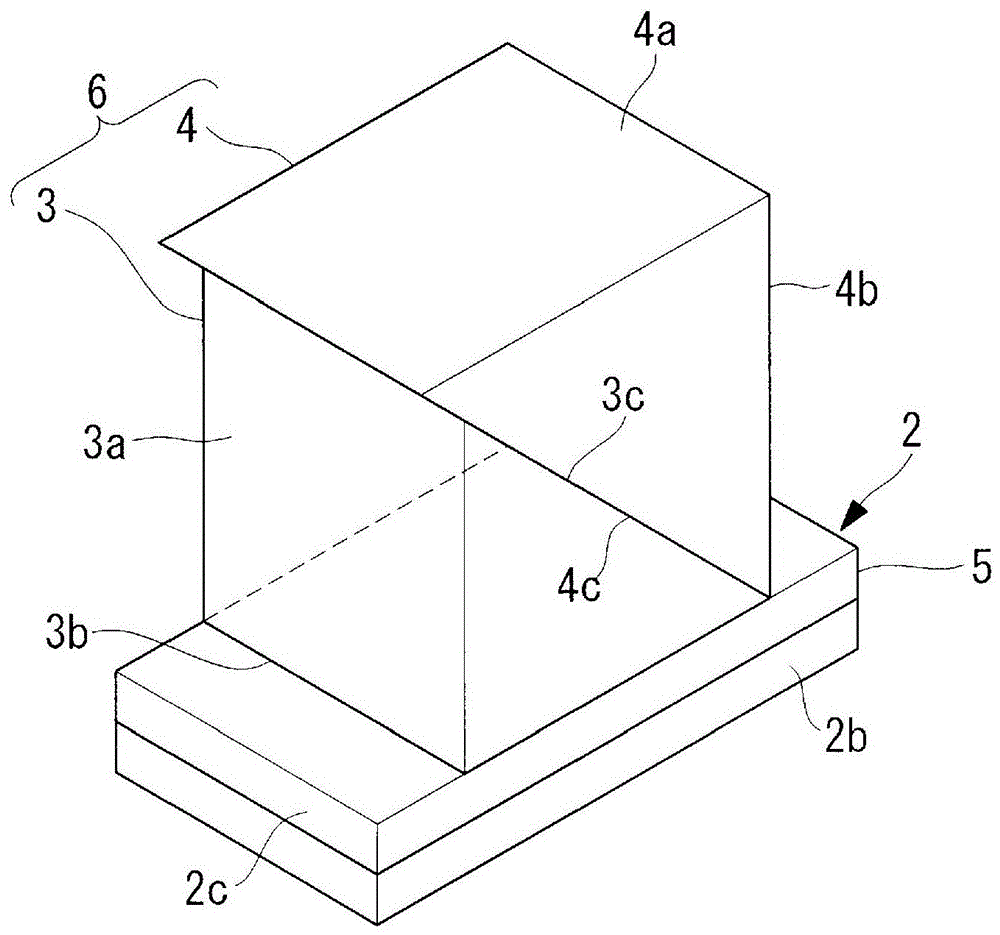

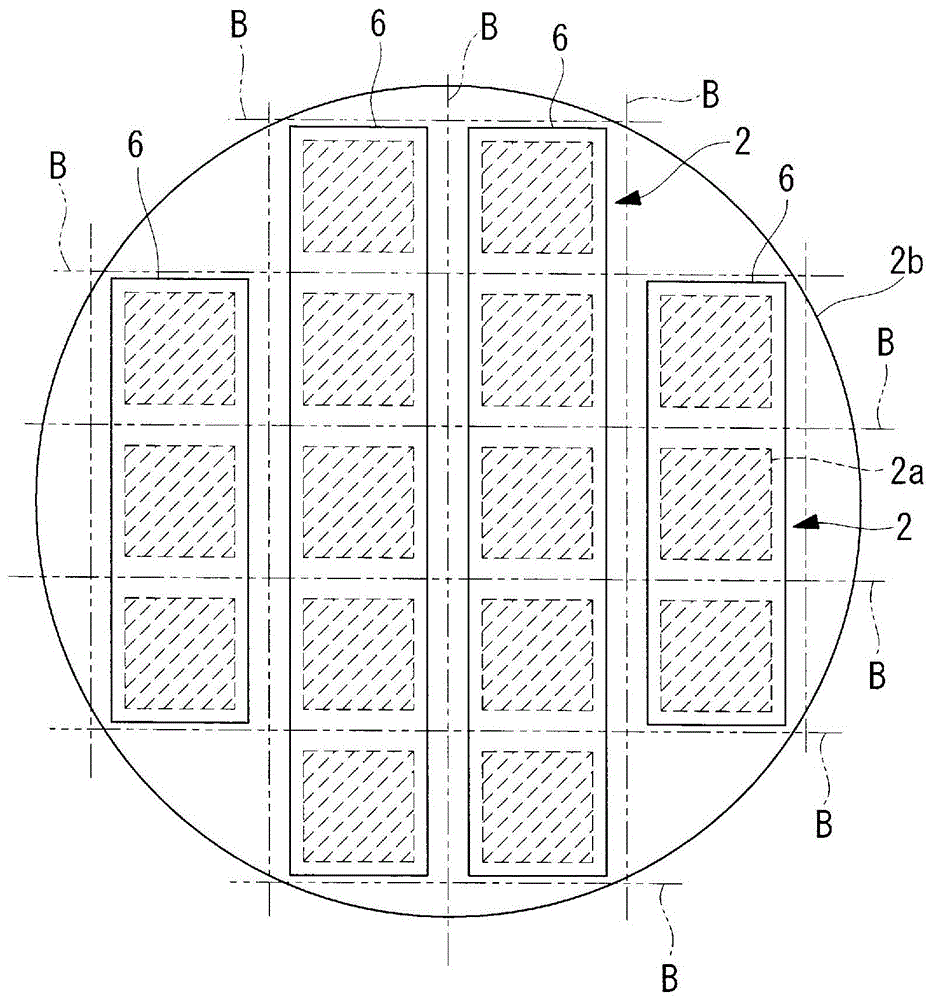

Image pickup device and method for manufacturing same

InactiveCN103314569AEasy to manufactureEasy to absorb and handleTelevision system detailsSolid-state devicesSeparated stateOptical axis

This image pickup device can be easily manufactured, and can be handled by being easily sucked even in an individually separated state. Provided is an image pickup device (1) having: an image pickup element (2); a prism (3), which is fixed to the image pickup element (2), and has a light input surface (3a) having light inputted thereto from the direction intersecting an optical axis (A) of the image pickup element (2), a light output surface (3b) substantially parallel to the image pickup surface (2a) of the image pickup element (2), and a reflecting surface (3c) that deflects the light inputted to the light input surface (3a) to the direction along the optical axis (A) of the image pickup element (2); and a cover member (4), which is fixed at a position that covers the reflecting surface (3c) of the prism (3), and has an outer surface (4a) substantially parallel to the image pickup surface (2a).

Owner:OLYMPUS CORP

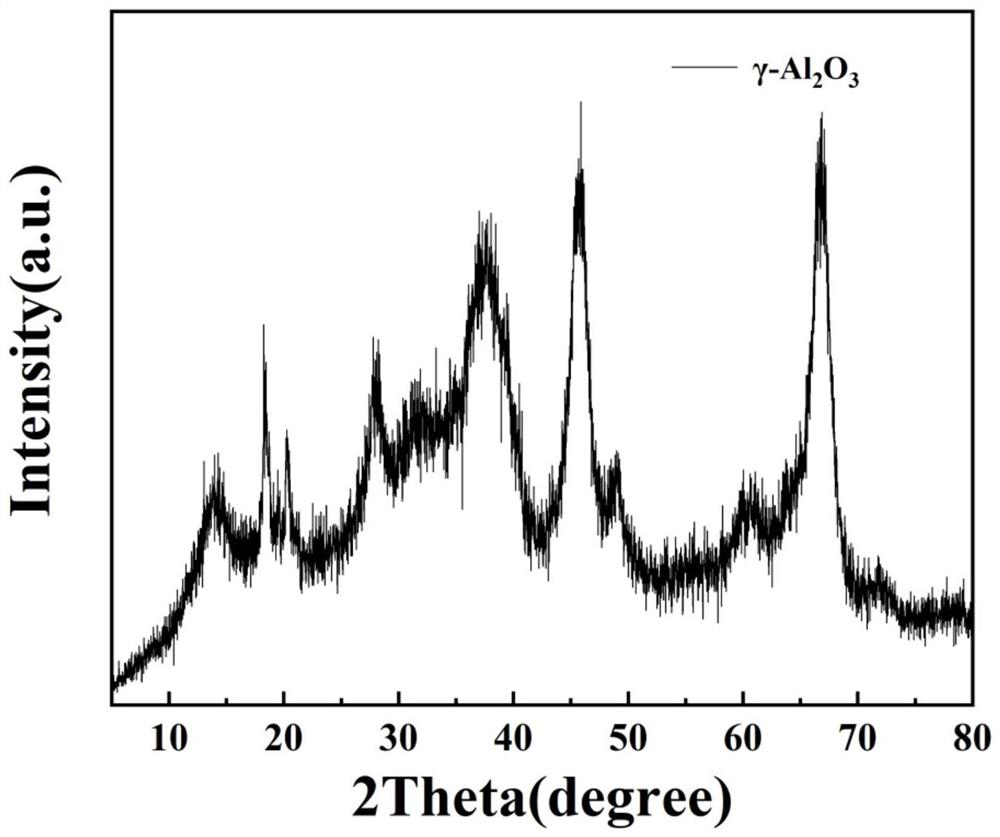

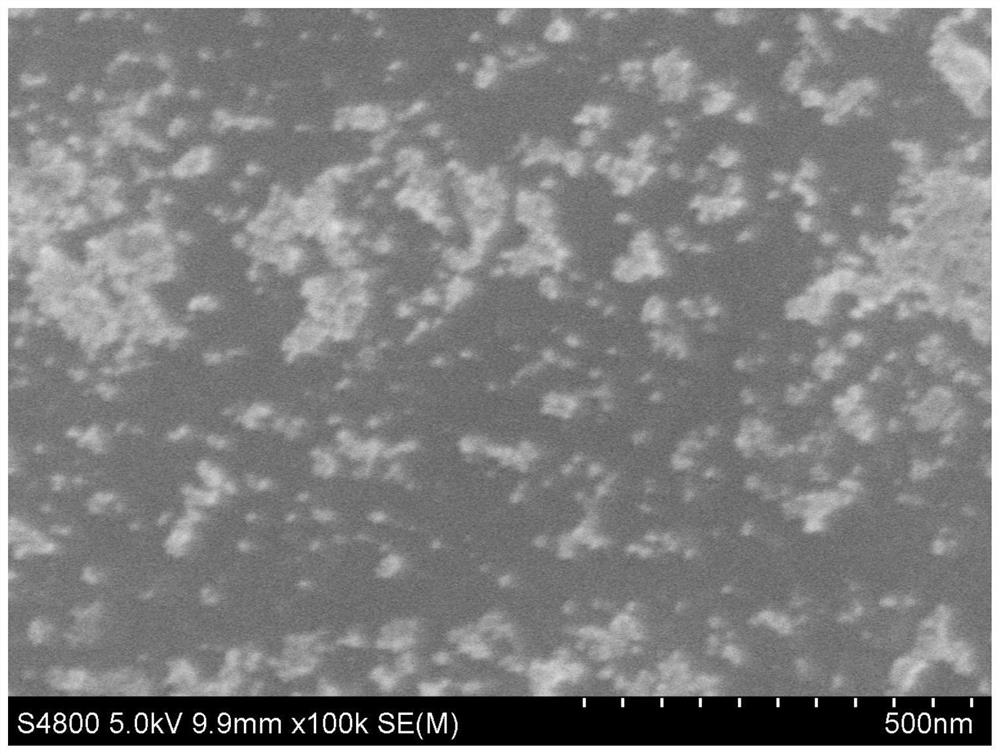

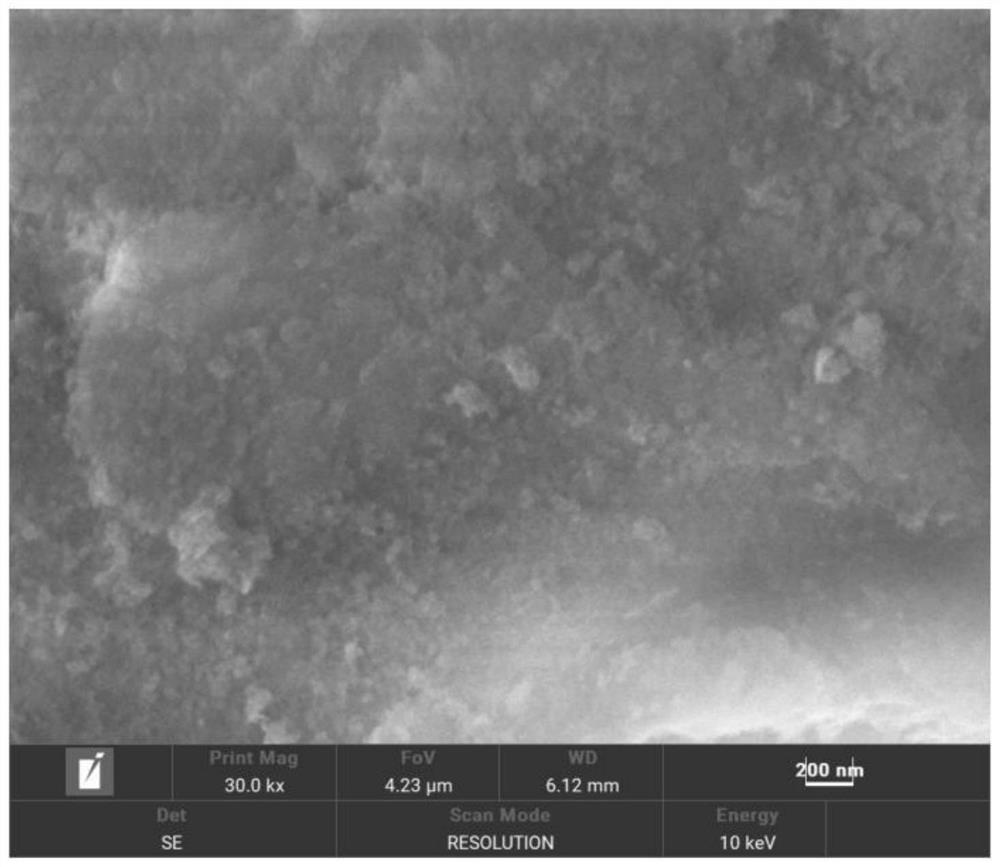

Preparation method of sphere-like nano gamma-aluminum oxide

PendingCN114105177AReduce typesEasy to absorb and handleMaterial nanotechnologyAluminium compoundsNano al2o3Inorganic compound

The invention discloses a preparation method of sphere-like nano gamma-aluminum oxide, which comprises the following steps: 1) taking ultrapure water for later use; 2) adding an organic or inorganic compound with low-temperature thermal decomposability into ultrapure water, dissolving, adding an additive, and stirring to obtain a solution; 3) slowly and gradually adding boehmite powder into the solution, and stirring to obtain a mixture; 4) putting the mixture into a ball mill for ball milling; 5) drying the ball-milled mixture to obtain dry solid particles; 6) crushing the dry solid particles to obtain dry powder; and calcining the dried powder to obtain the nano gamma-aluminum oxide. The preparation method has the advantages of simplicity, stability, few procedures, low requirements on equipment, few types of used raw materials, generation of tail gas easy to absorb and treat, and low production cost; the nano gamma-aluminum oxide produced by the method is spheroidic, has the particle size of 5-20nm, is uniform in particle size distribution, is concentrated in particle size distribution, and is easy to disperse; and the obtained powder is wide in application range.

Owner:无锡云岭半导体科技有限公司

Preparation method of nano-cerium oxide for silicon slice polishing

InactiveCN109734121AReduce typesEasy to absorb and handleNanotechnologyRare earth metal compoundsCeriumSlurry

The invention discloses a preparation method of nano-cerium oxide for silicon slice polishing. The preparation method includes the steps: a adding water and stirring and dissolving a certain quantityof silicate, adding insoluble cerium salt into solution of the silicate and the water, and ball-milling mixture to obtain uniformly dispersed slurry; b drying the slurry acquired in the step a in a flash evaporation manner to obtain dry, uniform and fine powder; c calcining the powder acquired in the step b to obtain the nano-cerium oxide. The method had the advantages that the method is simple inprocess and low in device requirement and production cost, generated tail gas is easily absorbed, particle diameters are 100-120nm and narrow in distribution, the nano-cerium oxide is easily dispersed and the like.

Owner:HUNAN UNIV

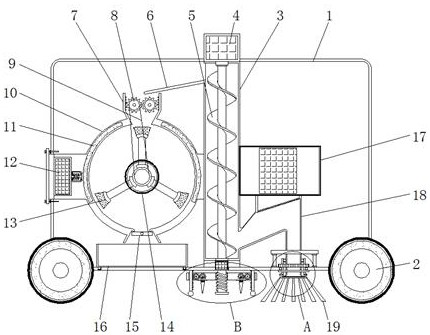

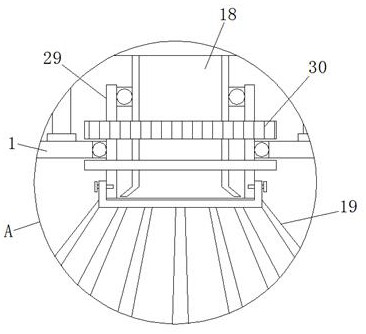

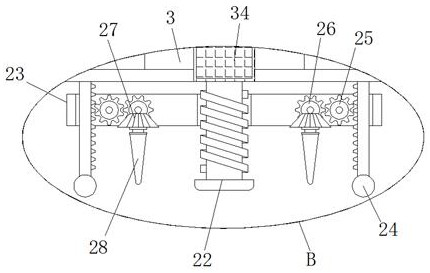

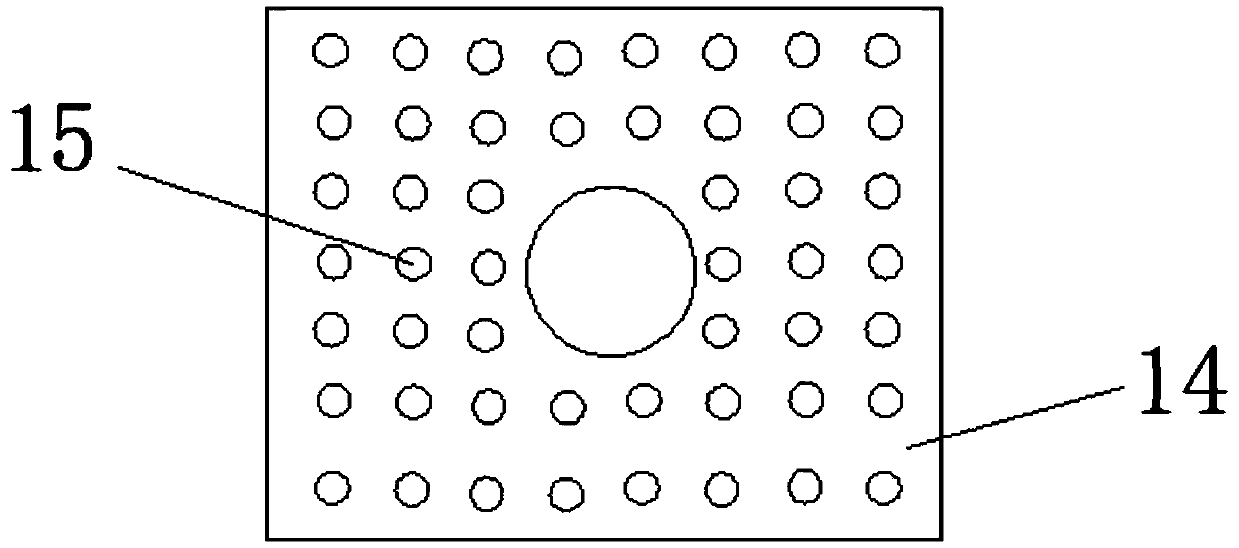

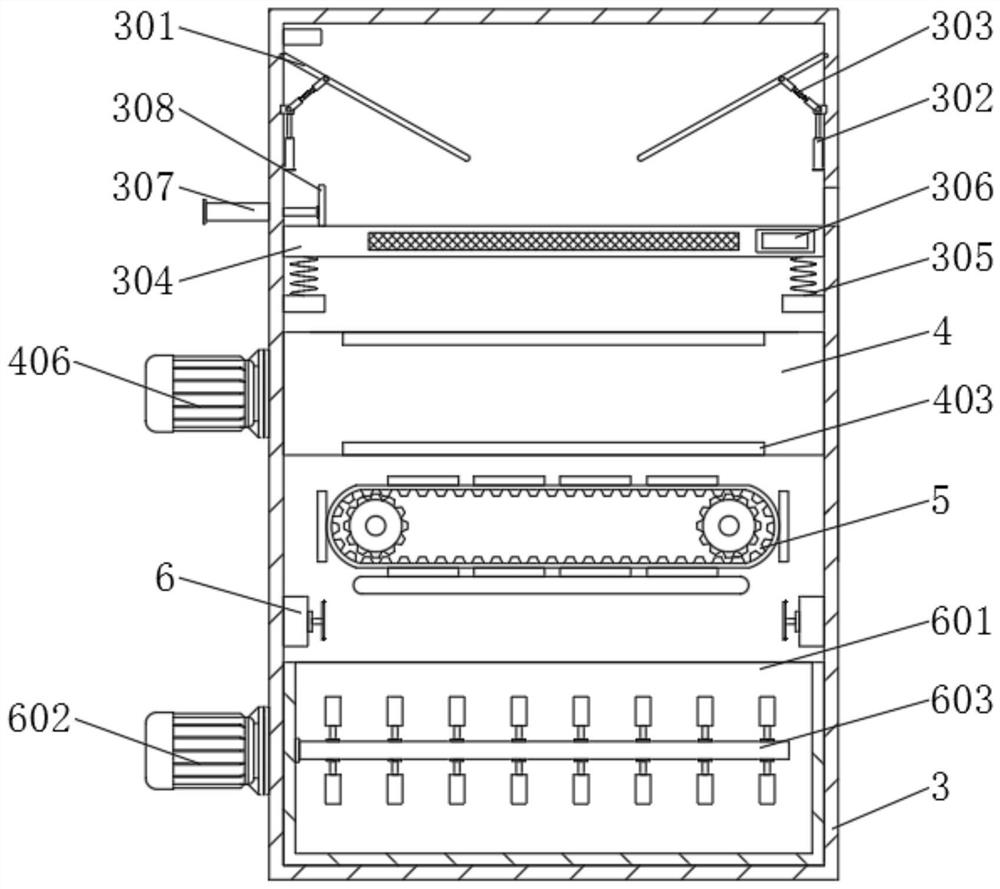

Civil engineering dust removing and sweeping device with construction waste crushing function

InactiveCN112718210AEasy extraction and cleaningSufficient extraction and cleaning treatmentRoad cleaningMagnetic separationVehicle frameGear wheel

The invention discloses a civil engineering dust removing and sweeping device with a construction waste crushing function. The civil engineering dust removing and sweeping device comprises a frame, a first motor, a second motor, a dust collector, a third gear and a fourth motor. Wheels are mounted and connected to the lower end of the frame, a screw rod is rotatably connected in a conveying cylinder, and the upper end of the screw rod is fixedly connected with the first motor through a bolt. The upper left end of the conveying cylinder is highly connected with a discharging rod, the left end face of the conveying cylinder is fixedly connected with a classification box, an electromagnetic block is mounted and connected to the inner wall of the classification box, and the left end of the electromagnetic block is electrically connected with a control switch. According to the civil engineering dust removing and sweeping device with the construction waste crushing function, large and small waste can be fully extracted and swept conveniently, collected waste can be classified conveniently, unrecyclable waste can be fully crushed conveniently, meanwhile, recyclable waste can be collected and stored conveniently, and recycling is facilitated.

Owner:陕西中科文鼎信息科技有限公司

Hydrogen sulfide absorption filtering apparatus

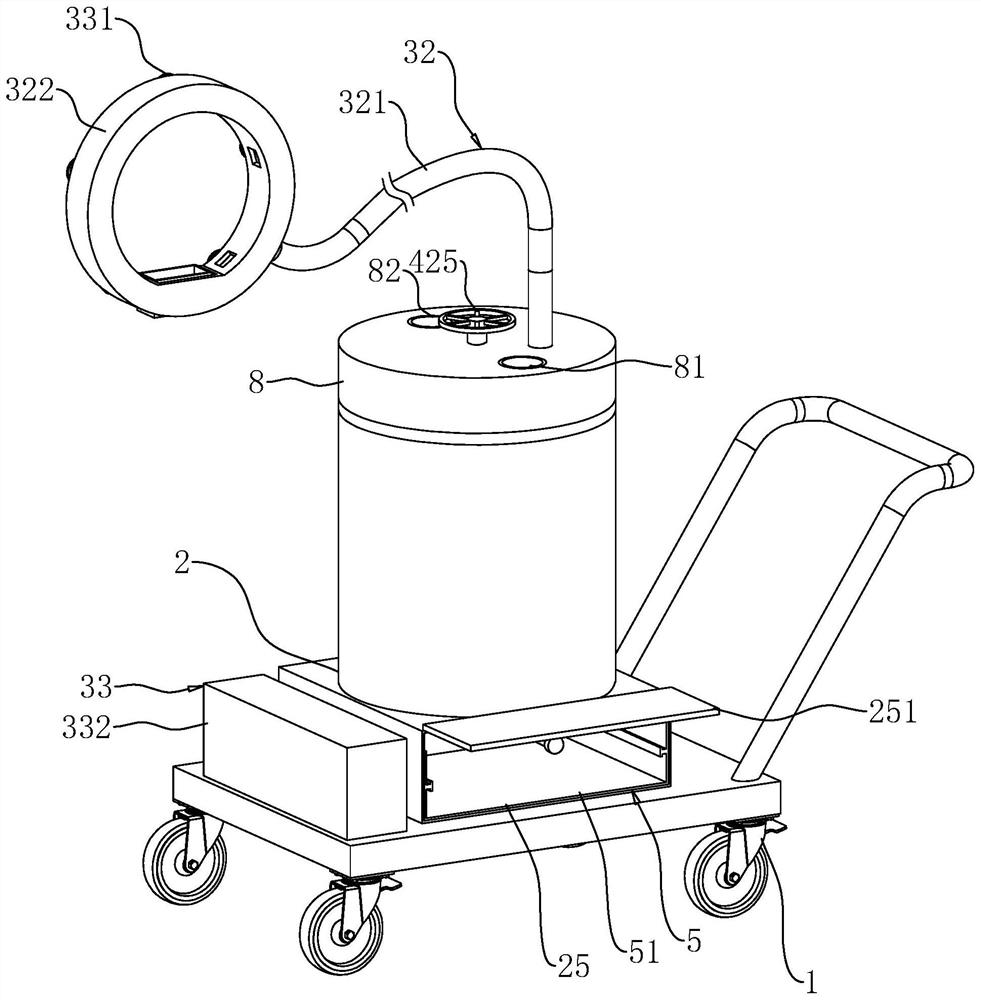

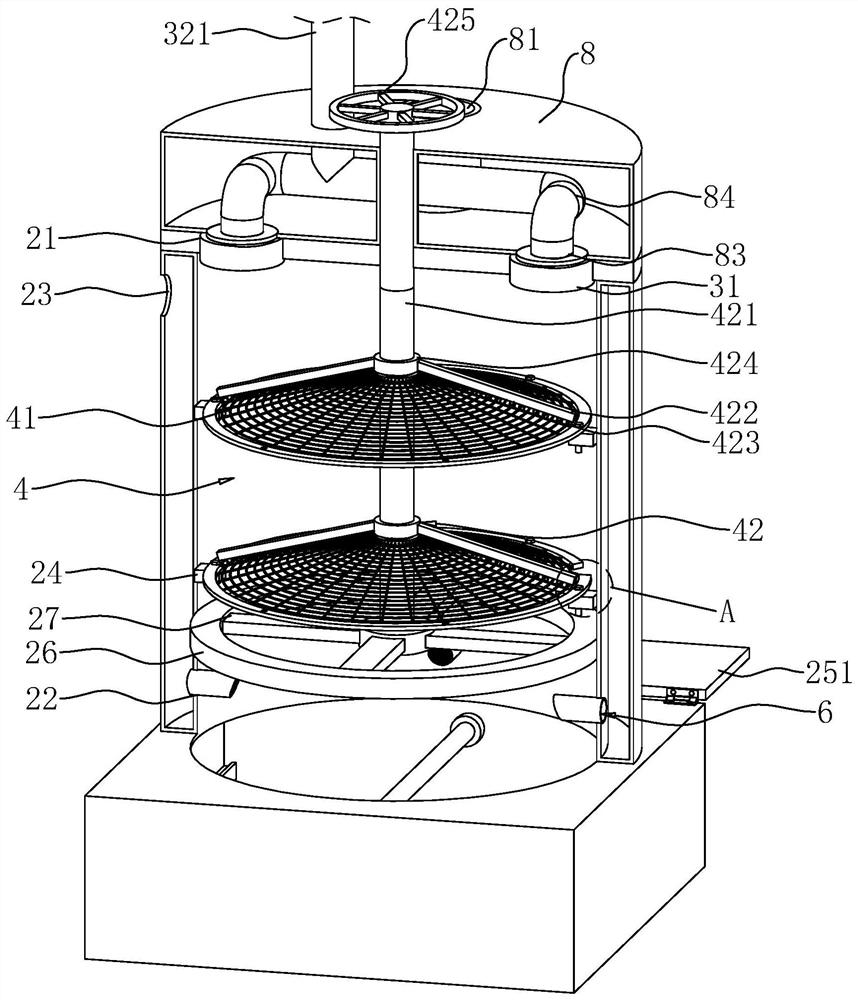

InactiveCN108014602AImprove shock absorptionPromote absorptionGas treatmentDispersed particle filtrationActive carbonProduct gas

The invention is suitable for the technical field of air purification, and provides hydrogen sulfide absorption filtering apparatus. The apparatus comprises a filter body, a blowing device and a purification device; a damping device is arranged at the bottom end of the filter body; an air cylinder is arranged at the output end of the filter body; the blowing device and the purification device areall positioned in the cavity of the filter body; the purification device comprises a filter screen, an organic solvent box and an adsorption layer; the blowing device is positioned between the filterscreen and the organic solvent box; an arc baffle is arranged at the output end of the blowing device; the material of the filter screen is active carbon; methanol is arranged in the organic solvent box; and the adsorption layer is a zinc oxide adsorption layer. Therefore, according to the invention, through the improvement of an air purifier, the purpose of purifying the hydrogen sulfide gas by the air purifier can be met.

Owner:WEIFANG HANXING CHLOROPHYLL

Indoor decoration dust isolation equipment

ActiveCN112843893AEasy to absorb and handleReduce diffuseDispersed particle filtrationTransportation and packagingEngineeringStructural engineering

The invention relates to the field of indoor decoration, in particular to indoor decoration dust isolation equipment which comprises a mounting carrier, a mounting box arranged on the mounting carrier, an air suction assembly arranged on the mounting box, a filtering assembly arranged in the mounting box and a collecting assembly arranged at the bottom in the mounting box. An air inlet is formed in the upper side of the mounting box, and an air outlet is formed in the lower side of the side wall of the mounting box; the air suction assembly comprises a fan arranged at the air inlet in the mounting box; the filter assembly is located between the air inlet and the air outlet, the filter assembly comprises a plurality of filter screens arranged in the mounting box and a cleaning piece arranged on the mounting box, and gaps exist between the outer side faces of the filter screens and the inner wall of the mounting box; the collecting assembly is located on the lower side of the air outlet. The dust collecting device has the effects that dust generated by decoration can be conveniently absorbed, the influence on the working process is reduced, and harm to the health of workers is not likely to be generated.

Owner:北京市金龙腾装饰股份有限公司

Treatment method for methylene blue dye wastewater based on short-range photocatalysis/alga biodegradation

InactiveCN111718071ALarge specific surface areaGood photocatalytic effectWater/sewage treatment by irradiationWater treatment compoundsPhoto catalysisMetal-organic framework

The invention discloses a treatment method for methylene blue dye wastewater based on short-range photocatalysis / alga biodegradation. The method specifically comprises the following steps: (1) short-range photocatalysis: adding a metal organic framework material UiO-67 into methylene blue dye wastewater with a concentration of 500-800 mg / L, and carrying out a short-range photocatalysis reaction under the irradiation of visible light so as to convert methylene blue into an intermediate product which is easy to biodegrade; (2) settling: after photocatalysis is completed, subjecting a treated solution to standing for a period of time so as to enable UiO-67 to naturally settle, thereby realizing separation of upper-layer liquid and lower-layer solid; and (3) alga degradation: further treatinga photodegradation intermediate product in the upper-layer liquid obtained in the step (2) with chlorella pyrenoidosa to completely degrade the photodegradation intermediate product. According to themethod, the removal rate of high-concentration methylene blue can reach 95% or above, used materials are easy to prepare, dye degradation efficiency is high, harmless effect is good, treatment cost islow, and the method has good application potential.

Owner:CHONGQING TECH & BUSINESS UNIV

Camera device and manufacturing method thereof

InactiveCN103314569BEasy to manufactureEasy to absorb and handleTelevision system detailsSolid-state devicesOptical axisEngineering

It can be easily produced, and can be easily adsorbed and handled even in the state of forming a single piece. Provided is an imaging device (1), comprising: imaging element (2); The incident surface (3a) that is incident in the direction of the imaging element (2), the outgoing surface (3b) that is approximately parallel to the imaging surface (2a) of the imaging element (2), and the direction of light incident on the incident surface (3a) is along the direction of the imaging element (2) A reflective surface (3c) deflected in the direction of the optical axis (A); and a cover member (4), which is fixed at a position covering the reflective surface (3c) of the prism (3), and has a substantially parallel to the imaging surface (2a) outer surface (4a).

Owner:OLYMPUS CORP

Preparation method of nano cerium-zirconium solid solution and nano cerium-zirconium solid solution prepared by same

PendingCN114433061AUniform particle sizeGood dispersionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsEmulsionCerium

The invention provides a preparation method of a nano cerium-zirconium solid solution. The preparation method comprises the following steps: S1, preparing slurry; s2, adding water into the slurry, carrying out ball milling, and sieving with a 80-mesh filter sieve to obtain a uniform emulsion / suspension; s3, dropwise adding the emulsion / suspension obtained in the step S2 into drying equipment in a stirring state, and carrying out spray drying to obtain dry powder with the water content not higher than 20wt%; and S4, calcining the dried powder obtained in S3 in a furnace body, and cooling to room temperature after calcining to obtain the nano cerium-zirconium solid solution. According to the method, the insoluble cerium salt and the insoluble zirconium salt are used as raw materials, and the nano cerium-zirconium solid solution with small particle size and uniform particle size distribution can be obtained. The invention further provides the nano cerium-zirconium solid solution.

Owner:HUNAN UNIV

Flue gas ultra-low emission system based on wet desulfurization and denitrification technology

InactiveCN112403206ACompact processSimple facilitiesDispersed particle separationFlue gasEnvironmental engineering

The invention belongs to the technical field of flue gas treatment, and discloses a flue gas ultra-low emission system based on a wet desulfurization and denitrification technology. The flue gas ultra-low emission system comprises a washing tower and a water pump, the middle upper end of the side wall of the washing tower is connected with a flue gas inlet pipe, the water inlet end of the water pump is connected with a water inlet pipe, and the water outlet end of the water pump is connected with a water outlet pipe; and the end, away from the water pump, of the water outlet pipe penetrates through the washing tower and extends to the upper end of the interior of the washing tower, a spraying disc is installed at the end, located in the washing tower, of the water outlet pipe, and a firstflue gas outlet pipe is connected to the top end of the washing tower. The flue gas treatment system is compact in flow, simple in facility, less in occupied land area, capable of effectively reducingthe cost investment of enterprises, very wide in application prospect and worthy of popularization. The washing tower is used for washing and cooling the flue gas firstly, subsequent absorption treatment is facilitated, then absorption is conducted twice, SO2 and NOx in the flue gas can be effectively treated, the treatment speed is high, and treatment of large-batch flue gas output is met.

Owner:JIANGSU LVDOU ENVIRONMENTAL ENG CO LTD

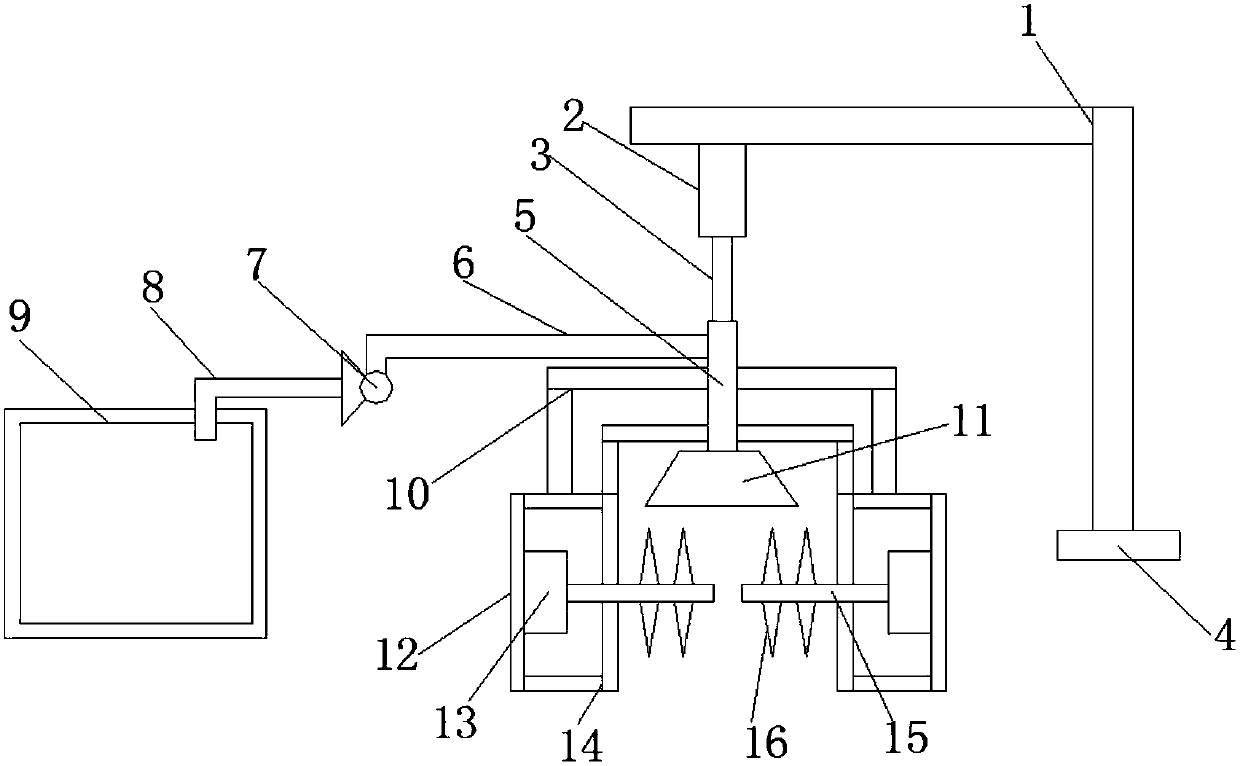

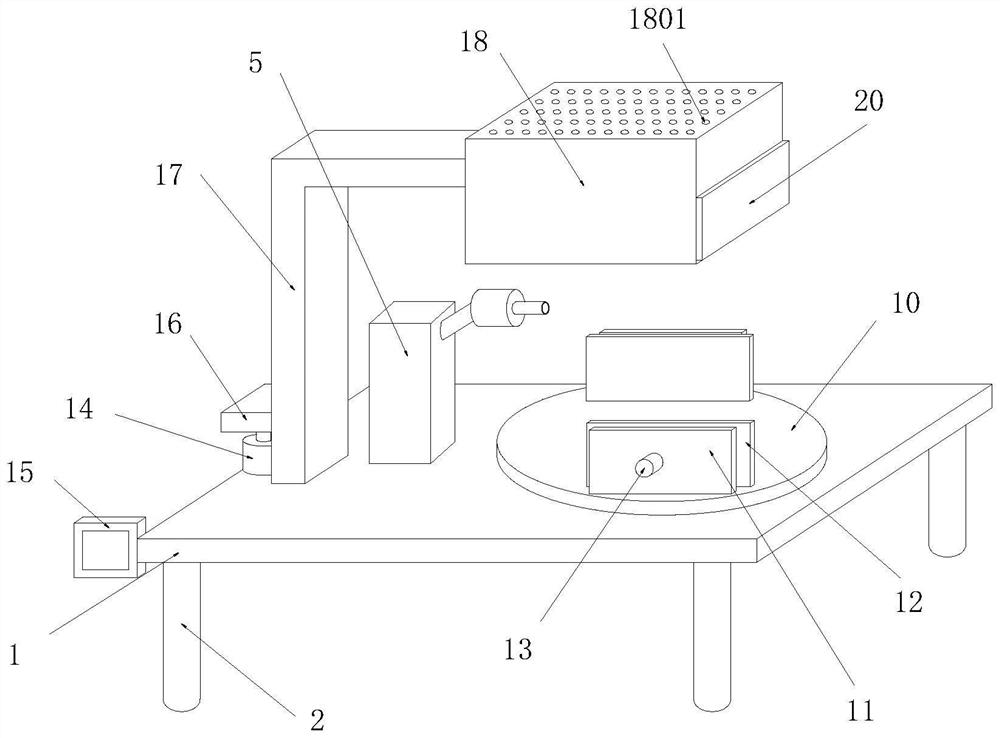

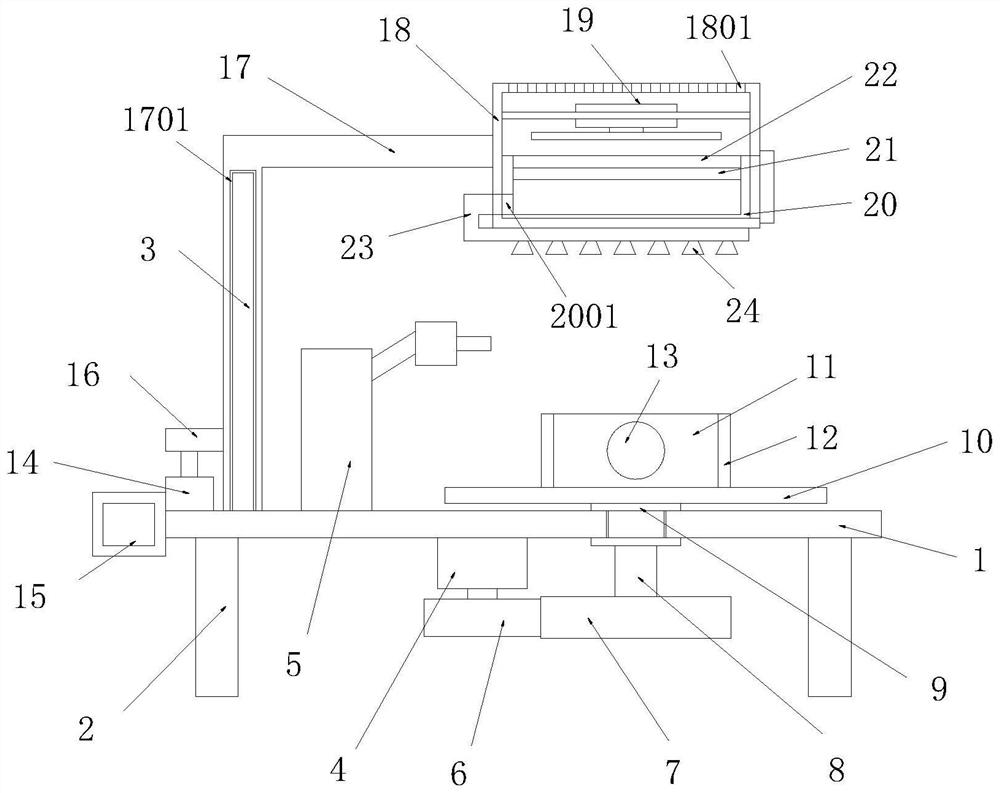

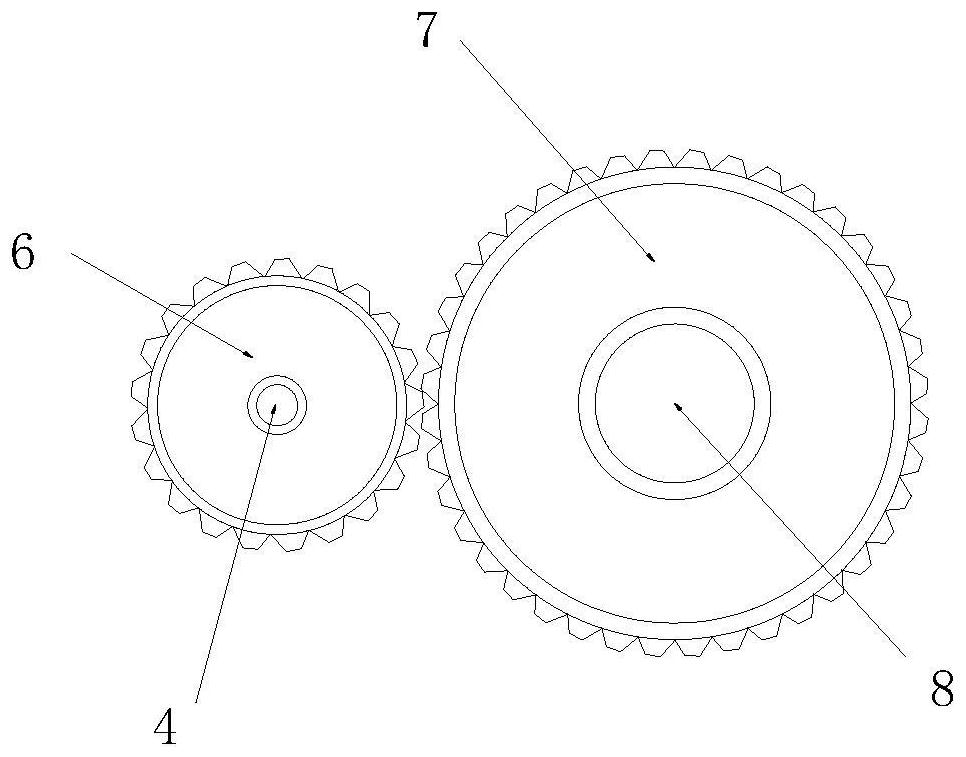

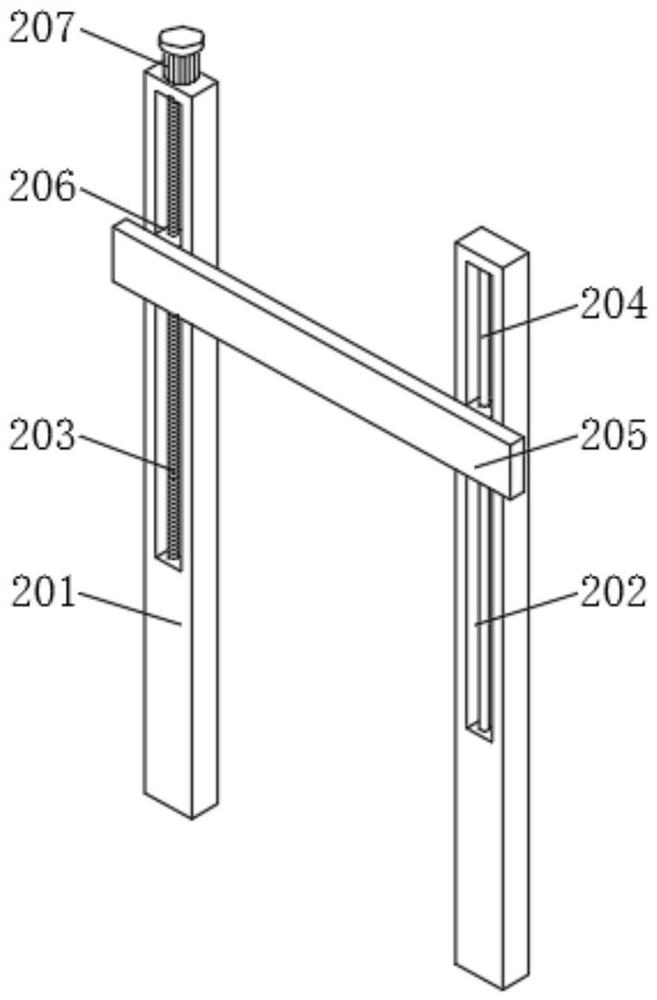

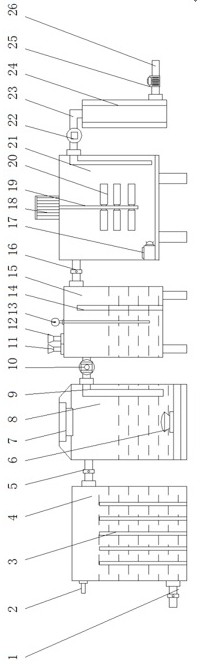

Automatic forming machining device for fan frame

PendingCN114227071AHeight adjustableAdjust placementWelding/cutting auxillary devicesAuxillary welding devicesGear wheelEngineering

The invention discloses an automatic forming machining device for a fan frame. The automatic forming machining device comprises a workbench, supporting legs, a supporting plate, an automatic welding robot, a clamping adjusting mechanism and a filtering treatment mechanism. Wherein supporting legs are fixedly connected to the surface of the bottom side of the workbench, a supporting plate is fixedly connected to the surface of the top side of the workbench, and an automatic welding robot fixedly connected to the surface of the top side of the workbench is arranged on the right side of the supporting plate; the clamping and adjusting mechanism comprises a limiting shaft, a rotating shaft, a first gear, a second gear, a servo motor, a rotary table, a fixing plate, an electric push rod and a clamping plate, the limiting shaft is rotationally connected to the surface of the workbench, the rotating shaft is fixedly connected to the surface of the bottom side of the limiting shaft, and the second gear is adjusted to the surface of the bottom end of the rotating shaft; the left side of the second gear is in engaged connection with a first gear, and a servo motor is fixedly connected to the surface of the bottom side of the workbench. The automatic forming machining device for the fan frame is novel in design and simple in structure.

Owner:武汉科沃斯风机有限公司

Flue gas purification device

The invention discloses a flue gas purification device. The device comprises a treatment barrel and an electrostatic dust collector, wherein the electrostatic dust collector communicates with the upper part of the treatment barrel through a flue gas pipe, a stirring motor is installed on the treatment barrel, an inclined baffle plate is arranged inside the treatment barrel, a stirring shaft is installed on the stirring motor, stirring blades are installed on the stirring shaft, and a purification mechanism is arranged inside the treatment barrel. The device solves the technical problem that flue gas cannot be completely purified in the prior art.

Owner:刘欢

Catalyst for improving performance of methane oxygen-free aromatization reaction and preparation method thereof

ActiveCN111871448BImprove conversion rateImprove stabilityMolecular sieve catalystsMolecular sieve catalystAir atmosphereMolecular sieve

The invention discloses a catalyst for improving the performance of methane anaerobic aromatization reaction and a preparation method thereof. Firstly, the carrier molecular sieve and the auxiliary drop melamine are dried for standby; then ammonium molybdate tetrahydrate is dissolved in deionized water Ultrasonic dispersion, the volume of deionized water is the saturated water absorption of the carrier molecular sieve, then impregnate the carrier molecular sieve with this solution, stir and mix evenly, dry after impregnating at room temperature, and obtain the catalyst precursor for later use; then weigh melamine, mix with the catalyst precursor The method of solid-solid mixing or solution mixing and evaporation is adopted to fully mix the two; the mixture is heated and roasted under nitrogen or air atmosphere to obtain a catalyst for improving the performance of methane anaerobic aromatization reaction. The preparation method of the invention is simple, the raw materials are easy to obtain, green and efficient, high in economic benefit, and easy to meet the needs of industrialized production.

Owner:NORTHWEST UNIV

Assembly for preventing water mist from forming electrolytic tank failure for OLED packaging

InactiveCN112563441AAvoid formingReduce air pressureSolid-state devicesSemiconductor/solid-state device manufacturingAir springSemiconductor

The invention relates to the technical field of semiconductor lighting, and discloses an assembly for preventing water mist from forming an electrolytic tank failure for OLED packaging, the assembly comprises a steam port, the top of the steam port is movably connected with a failure preventing mechanism, the middle of the failure preventing mechanism is movably connected with a steam table, and the top of the steam table is movably connected with a telescopic rod; the top of the telescopic rod is movably connected with a fixing rod. According to the assembly for preventing water mist from forming the electrolytic tank failure for OLED packaging, a trigger head drives a movable rod to move, so that the air pressure in a pneumatic bin is reduced, a connecting rod mechanism on the outer sideof an air spring loses support, a push plug injects air into a push bin, the air pressure in a processing bin is increased, so that high air pressure in the processing bin breaks the constraint of aone-way valve, a ventilation pipe can absorb water vapor, a packaging device is dehumidified, an OLED device is prevented from losing efficacy, and the brightness of the OLED device is improved.

Owner:吉文娟

Dust treatment device for wood processing

InactiveCN114669356AAchieve liftingAchieve absorptionElectrostatic separationUsing liquid separation agentDust controlPulp and paper industry

The dust treatment device for wood processing comprises a bottom plate, a processing table is fixed to one side of the top of the bottom plate, a dust collecting assembly is arranged on one side of the processing table, a treatment box is arranged on one side of the dust collecting assembly, a filtering plate is slidably connected to the inner wall of the treatment box, and a smashing box is fixed to the other side of the exterior of the treatment box; a crushing assembly is arranged in the crushing box, a feeding assembly is arranged below the filter plate, a dust removal assembly is arranged below the feeding assembly, and an absorption assembly is arranged below the dust removal assembly; the problems that in the prior art, due to the fact that a large amount of dust is sucked into a device at the same time, the feeding amount of the dust cannot be controlled, the treatment efficiency of the device is poor, a large amount of untreated dust is accumulated in the device, and the influence on the treatment efficiency of the device is reduced are solved; in the prior art, wood chips generated by wood processing can be accumulated on the surface of treatment liquid, and the subsequent dust absorption effect is seriously affected.

Owner:阜南县几何工艺品有限公司

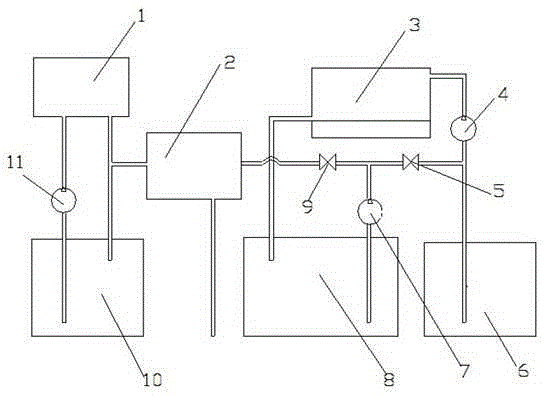

A kind of microalgae treatment sewage automatic control method

ActiveCN104496123BEasy to absorb and handleReduce manual laborWater treatment parameter controlWater/sewage treatment bu osmosis/dialysisAutomatic controlSewage

The invention relates to an automatic microalgae sewage treatment control method which comprises the following steps: feeding sewage into an adjusting tank of a sewage treatment device, detecting, feeding the sewage which is qualified in detection into a microalgae treatment tank for treatment, feeding the treated sewage into a detection tank for detection, if the sewage is not qualified in the detection, backflowing the sewage inside the detection tank to the adjusting tank for treatment, if the sewage is qualified in detection, backflowing a part of the sewage in the detection tank to the adjusting tank, feeding sewage which is qualified in treatment into a filtering membrane for separation, discharging out clean water, feeding a concentrated algae liquid into a grease induction accumulation tank, feeding the concentrated algae liquid into a spiral bent tube closed type reactor through a pump after the concentrated algae liquid is fed into the grease induction accumulation tank, implementing grease induction, feeding back the concentrated algae liquid to the grease induction accumulation tank, and repeating the operation. The automatic microalgae sewage treatment control method has the advantages that sewage can be well treated, automatic treatment is achieved, and the working intensity of operators is alleviated.

Owner:上海清浥环保科技有限公司

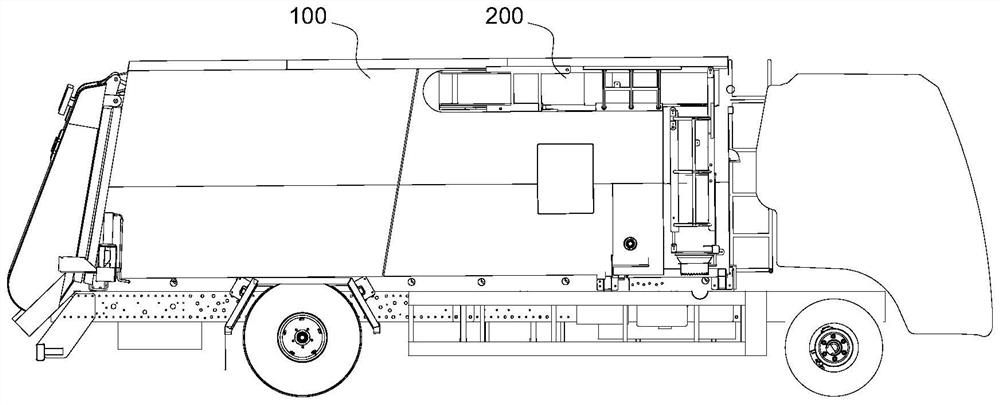

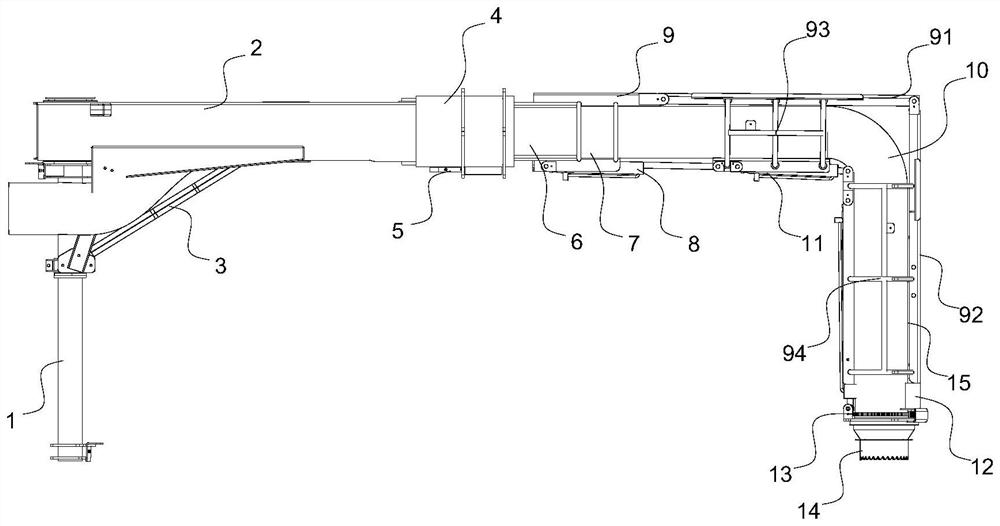

Kitchen garbage pumping and transporting equipment and method

PendingCN114408419AImplement cleanupAvoid Splash SituationsRefuse receptaclesRefuse cleaningSewageTruck

The invention belongs to the technical field of garbage collection and transportation equipment, and relates to kitchen garbage suction and transportation equipment and a kitchen garbage suction and transportation method. Comprising a garbage truck and a mechanical arm installed on the garbage truck. The mechanical arm comprises a rotating arm base connected to the garbage truck body, a rotating arm is installed on the rotating arm base and connected with a swing device and a telescopic device, the driving end of the swing device is connected with a connecting arm, a telescopic outer rod is installed in the connecting arm, a telescopic inner rod is arranged in the telescopic outer rod, and the driving end of the telescopic device is connected with the telescopic inner rod. And the telescopic inner rod is connected with a suction pipe. The rotating arm rotates on the rotating arm base, the swing oil cylinder drives the connecting arm to swing, the telescopic oil cylinder drives the telescopic inner rod to stretch out and draw back in the telescopic outer rod, the lifting oil cylinder stretches out and draws back to adjust the lifting angle of the suction pipe, the suction pipe sucks and cleans garbage in the garbage can, the structure is simple, control is convenient, and the practicability is high. According to the garbage can, garbage in the garbage can can be cleaned, and meanwhile, the situation that sewage splashes is avoided.

Owner:北京京环智慧环保科技有限公司

Tool for aluminum profile surface polishing and application method

PendingCN111993198AReduce driftQuality improvementEdge grinding machinesGrinding carriagesPolishingFixed frame

The invention discloses a tool for aluminum profile surface polishing and an application method. The tool includes a main shell body, support legs, a shell door, a transparent glass window, a first electric push rod, a connecting frame, an electric motor, a rotating shaft, a polishing roll, a fixing frame, a fixing shaft, a fixing cylinder, a discharging cylinder, a receiving shell, a connecting shell, an aluminum profile body, a second electric push rod, a press plate, a skid resistance rubber strip, a dust collector, a dust collection pipe, a connecting pipe, a dust collection shield and a discharging inclined plate. According to the tool for aluminum profile surface polishing and the application method, the design is novel, the structure is simple, the aluminum profile body is clamped and fixed stably and conveniently, the stability of the aluminum profile body is guaranteed during polishing, the polishing fixing effect of the aluminum profile body is improved, the usage requirements of workers can be met, and the operation is convenient. When the tool is used, through the action of an arranged polishing mechanism, the surface of an end head of the aluminum profile body is convenient to polish, meanwhile the stability of the connecting frame during moving can be guaranteed, and the end head of the aluminum profile body is convenient to polish.

Owner:ZHANGJIAGANG RUNSHENG SCI & TECH MATERIAL

Environment-friendly garbage penetrating fluid treatment device

InactiveCN112759174AThorough treatmentGood effectWater treatment parameter controlSpecific water treatment objectivesUltrafiltrationProcess engineering

The invention discloses an environment-friendly garbage penetrating fluid treatment device which comprises an ABR anaerobic reactor, an ultrasonic reaction device, a sedimentation tank, an ultrafiltration membrane bioreactor and a nanofiltration device. An air inlet pipe is arranged at the top end of one side of the ABR anaerobic reactor, and a liquid inlet pipe is fixed to the bottom end of one side of the ABR anaerobic reactor. The ultrasonic reaction device is arranged on the other side of the ABR anaerobic reactor, and the ultrasonic reaction device is communicated with the ABR anaerobic reactor through a first connecting pipe. A second transfer pump is mounted on a fourth connecting pipe. A water outlet pipe is fixed to the bottom end of the side, away from the ultrafiltration membrane bioreactor, of the nanofiltration device, and a water quality detector is mounted on the water outlet pipe. By arranging the ABR anaerobic reactor, the ultrasonic reaction device, the sedimentation tank, the ultrafiltration membrane bioreactor and the nanofiltration device, through a multi-stage filtration mode, garbage penetrating fluid treatment is more thorough, the effect is better, and use is convenient.

Owner:江苏中粼膜科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com