Catalyst for improving performance of methane oxygen-free aromatization reaction and preparation method thereof

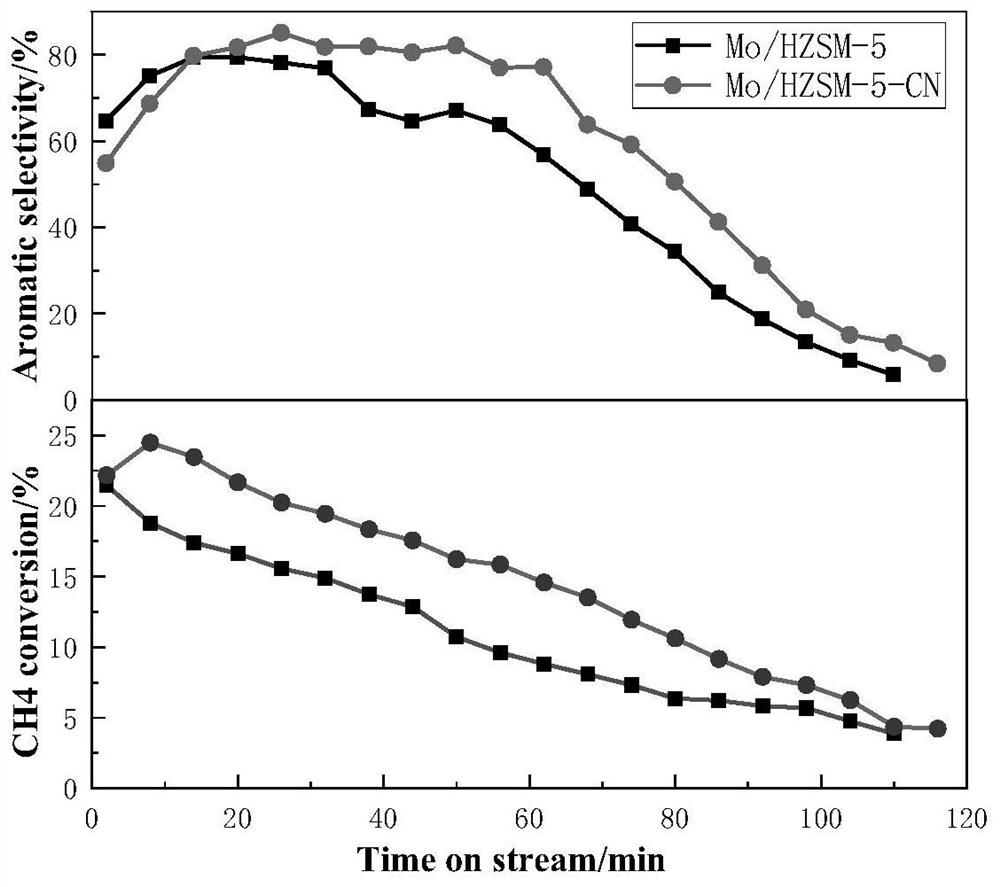

A technology of reaction performance and catalyst, applied in the direction of catalyst activation/preparation, carbon compound catalyst, physical/chemical process catalyst, etc., can solve the problems of reducing catalyst wear resistance, harsh conditions, time-consuming and labor-intensive, etc., and improve the resistance to carbon deposition. The performance, the conditions are easy to meet, and the economic effect is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

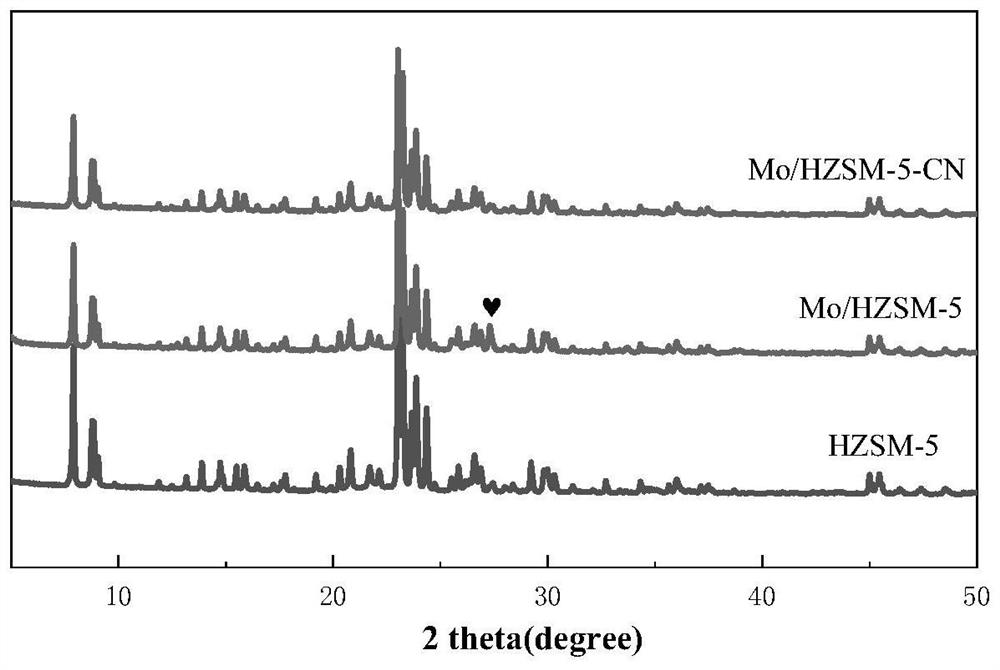

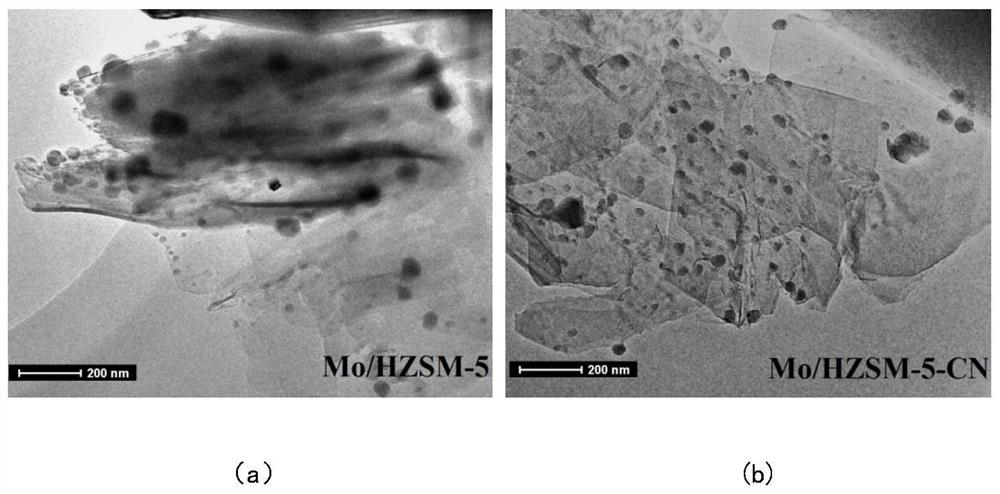

[0042] Take 0.26g of ammonium molybdate tetrahydrate in a 25ml beaker, add 1.1ml of deionized water, seal it and disperse the solution evenly with 32KHZ ultrasonic for 20min; then add dry 2g of HZSM-5 zeolite, stir for 15min, and place it at room temperature for 24h, The ammonium molybdate solution was uniformly impregnated in the zeolite channels, and then dried in a blast drying oven at 80°C, weighed 0.4g of dried melamine and mixed with the above catalyst precursor solidly, ground in a mortar for 15min, and then placed In a pyrolysis furnace under a nitrogen atmosphere at a heating rate of 2°C / min, it was raised to 550°C for 6 hours to obtain a finished amination catalyst with a loading capacity of 6% Mo / HZSM-5-CN (20%).

Embodiment 2

[0044]Take 0.26g of ammonium molybdate tetrahydrate into a 25ml beaker, add 1.1ml of deionized water, seal the seal and disperse the solution evenly with 32KHZ ultrasound for 20min; then add dry 2g of HZSM-5 zeolite, stir for 15min, place at room temperature for 24h, Evenly impregnate the ammonium molybdate solution in the zeolite channels, and then dry it in a blast drying oven at 80°C for use. Weigh 0.4g of dried melamine and add it to 1.5ml of methanol solution, ultrasonically disperse for 30min, and mix the above two Evenly, after standing at room temperature for 24 hours, dry at 60°C, and then place it in a pyrolysis furnace under a nitrogen atmosphere at a heating rate of 2°C / min to 550°C for 6 hours to obtain a loading capacity of 6% Mo / HZSM - 5-CN (20%) finished amination catalyst.

Embodiment 3

[0046] Take 0.26g of ammonium molybdate tetrahydrate into a 25ml beaker, add 1.1ml of deionized water, seal the seal and disperse the solution evenly with 32KHZ ultrasound for 20min; then add dry 2g of HZSM-5 zeolite, stir for 15min, place at room temperature for 24h, Evenly impregnate the ammonium molybdate solution in the zeolite channels, and then dry it in a blast drying oven at 80°C for use. Weigh 0.1g of dried melamine and add it to 1.5ml of methanol solution, ultrasonically disperse for 30min, and mix the above two Evenly, after standing at room temperature for 24 hours, dry at 60°C, and then place it in a pyrolysis furnace under a nitrogen atmosphere at a heating rate of 2°C / min to 550°C for 6 hours to obtain a loading capacity of 6% Mo / HZSM - 5-CN (5%) finished amination catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com