Patents

Literature

3118results about How to "Small granularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

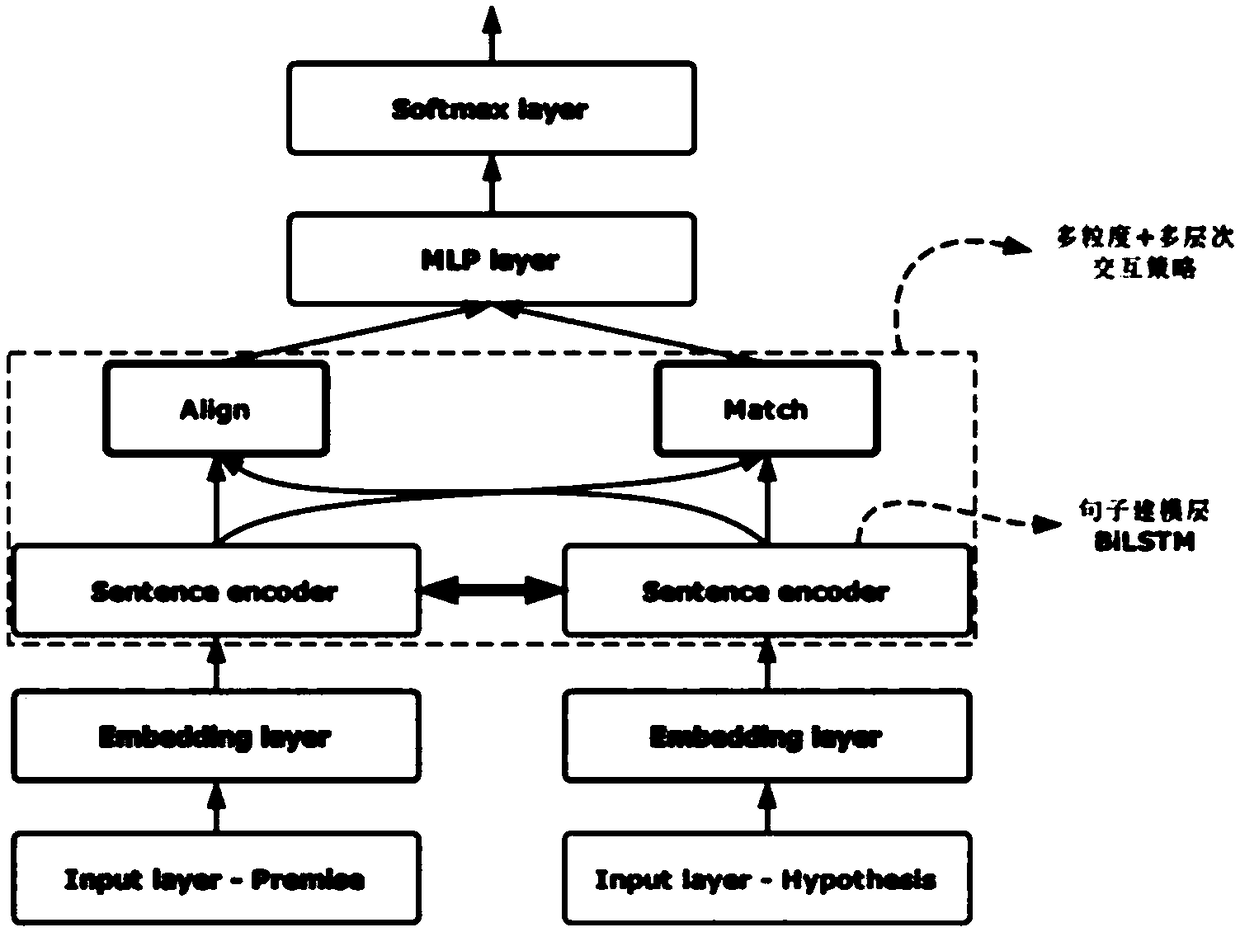

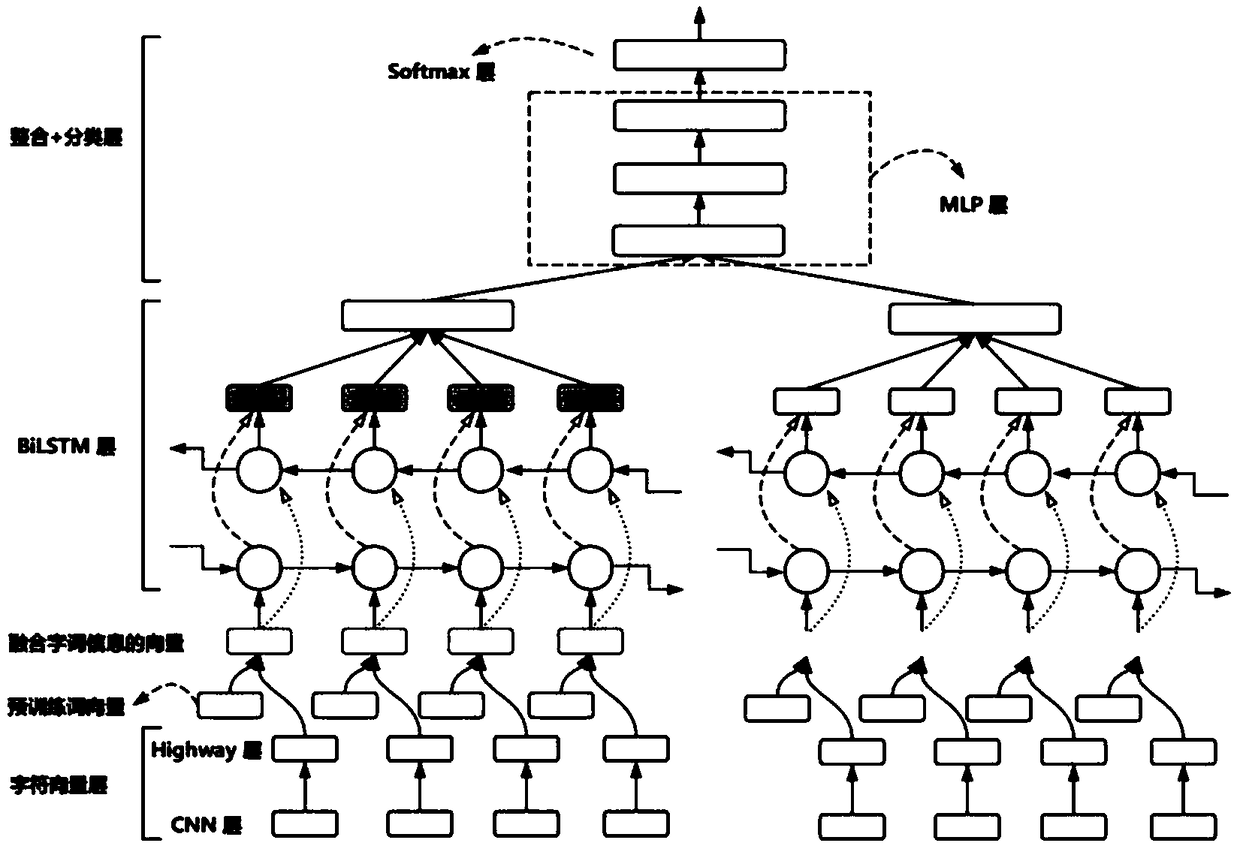

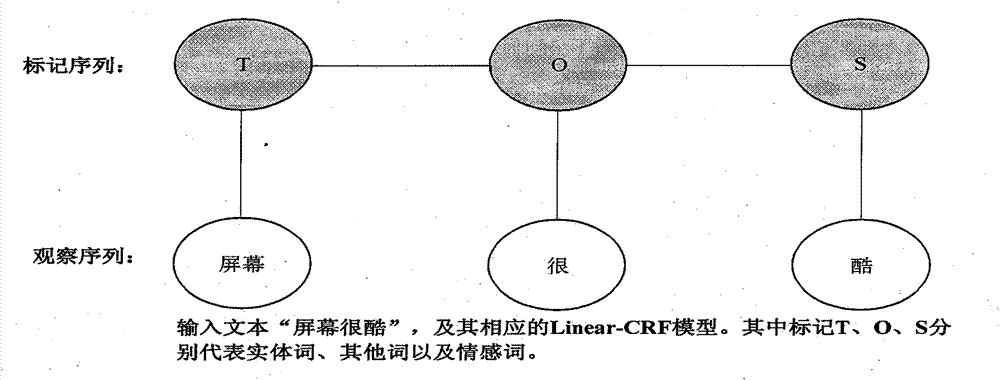

A text implication relation recognition method based on multi-granularity information fusion

ActiveCN109299262ASmall granularityQuality improvementSemantic analysisCharacter and pattern recognitionFeature learningGranularity

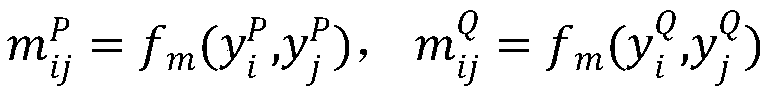

The present invention provides a text implication relation recognition method which fuses multi-granularity information, and proposes a modeling method which fuses multi-granularity information fusionand interaction between words and words, words and words, words and sentences. The invention firstly uses convolution neural network and Highway network layer in character vector layer to establish word vector model based on character level, and splices with word vector pre-trained by GloVe; Then the sentence modeling layer uses two-way long-short time memory network to model the word vector of fused word granularity, and then interacts and matches the text pairs through the sentence matching layer to fuse the attention mechanism, finally obtains the category through the integration classification layer; After the model is established, the model is trained and tested to obtain the text implication recognition and classification results of the test samples. This hierarchical structure method which combines the multi-granularity information of words, words and sentences combines the advantages of shallow feature location and deep feature learning in the model, so as to further improve the accuracy of text implication relationship recognition.

Owner:SUN YAT SEN UNIV +1

Cold spray formation of thin metal coatings

InactiveUS20060090593A1Small grain sizeSmall granularityTransportation and packagingMetal-working apparatusAluminiumThin metal

The invention relates to an adaptation of the cold spray process to provide a method of coating fine metal particles, including aluminum and copper, onto a work piece. In one embodiment, the invention is a metal agglomerated hard sphere composition capable of providing about a 1 micron or thicker coating of a metal on a work piece in a cold spray process. In another embodiment the invention is a method of coating metal particles, including metal particles having a particle size of about 0.01 to about 10 micron, onto a work piece. The method of the invention circumvents many of the problems associated with cold spray processing of very fine particles.

Owner:NANOMAT

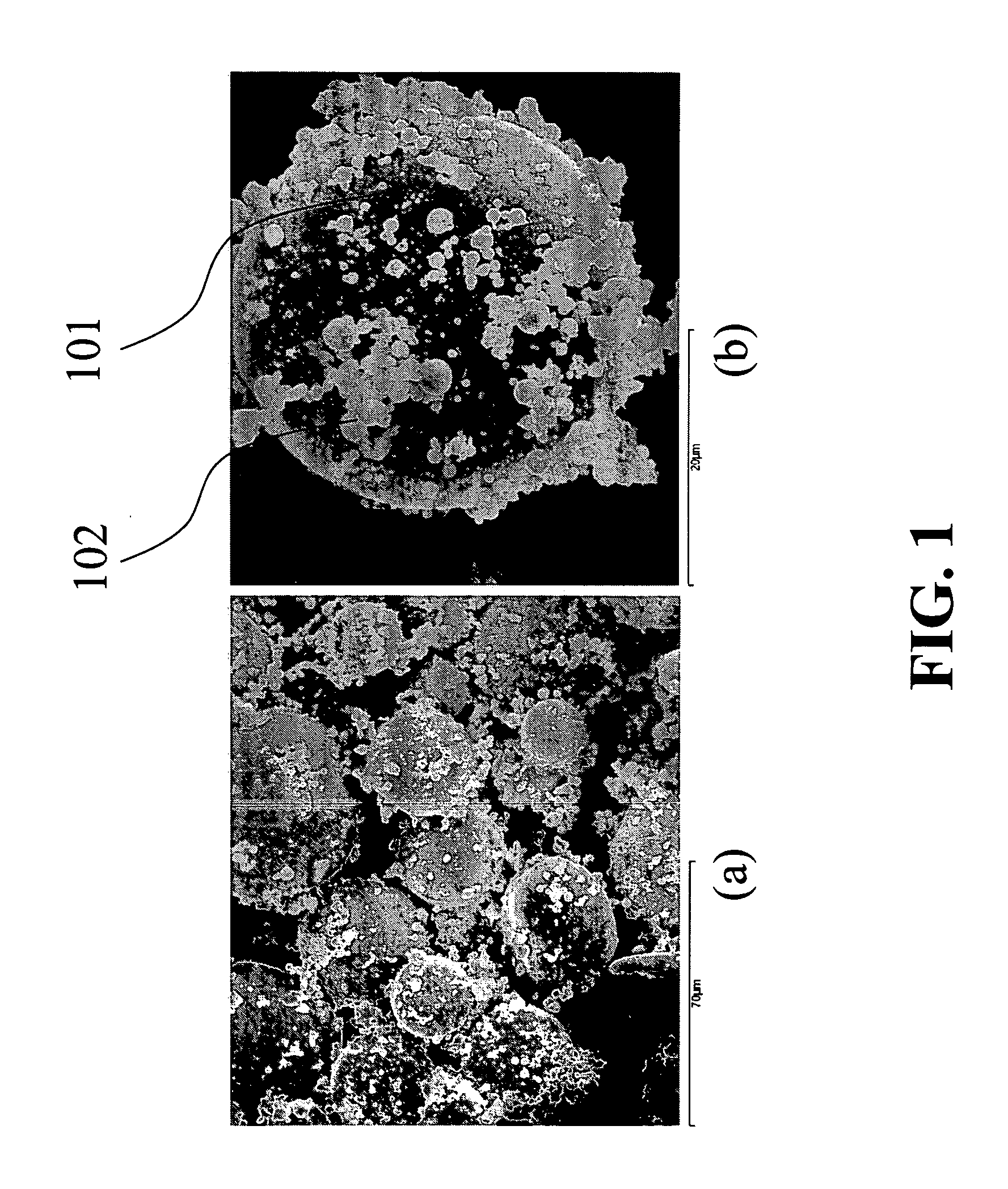

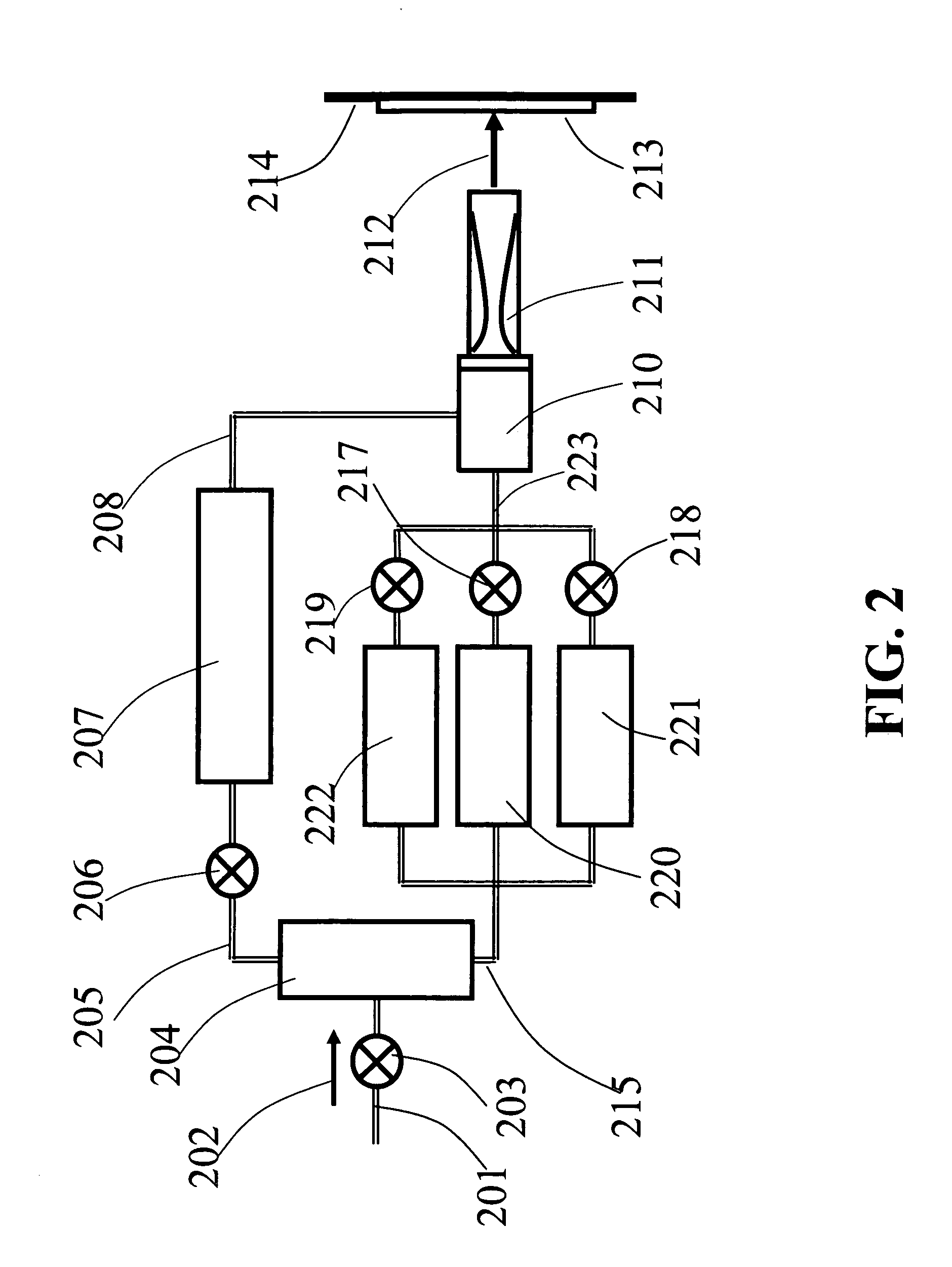

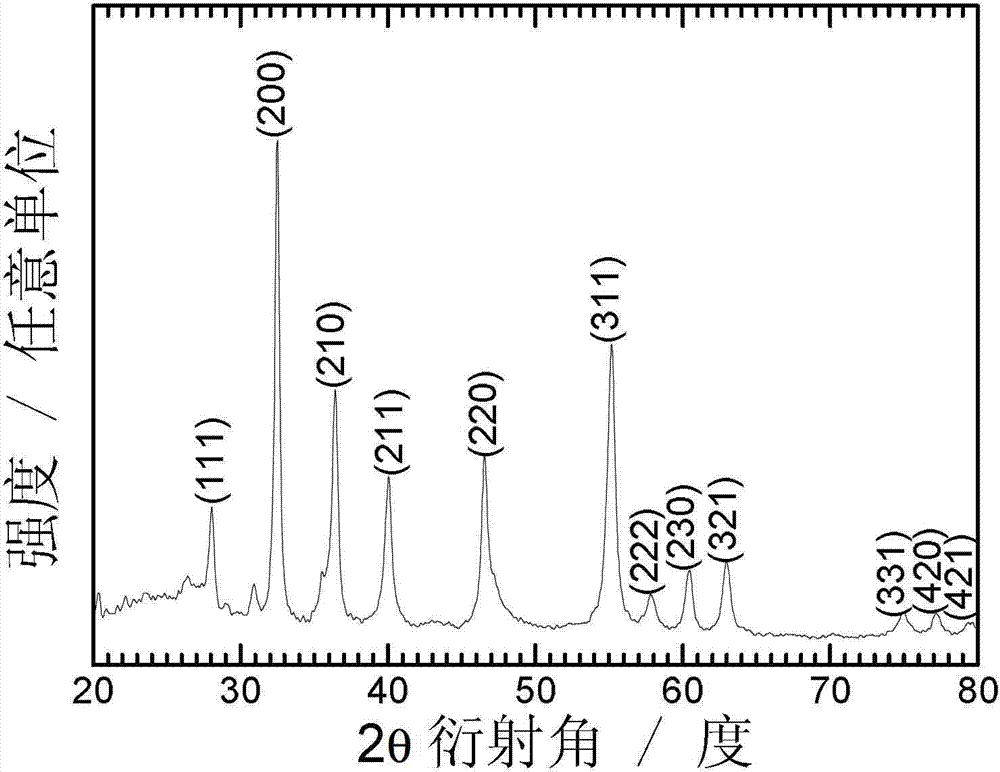

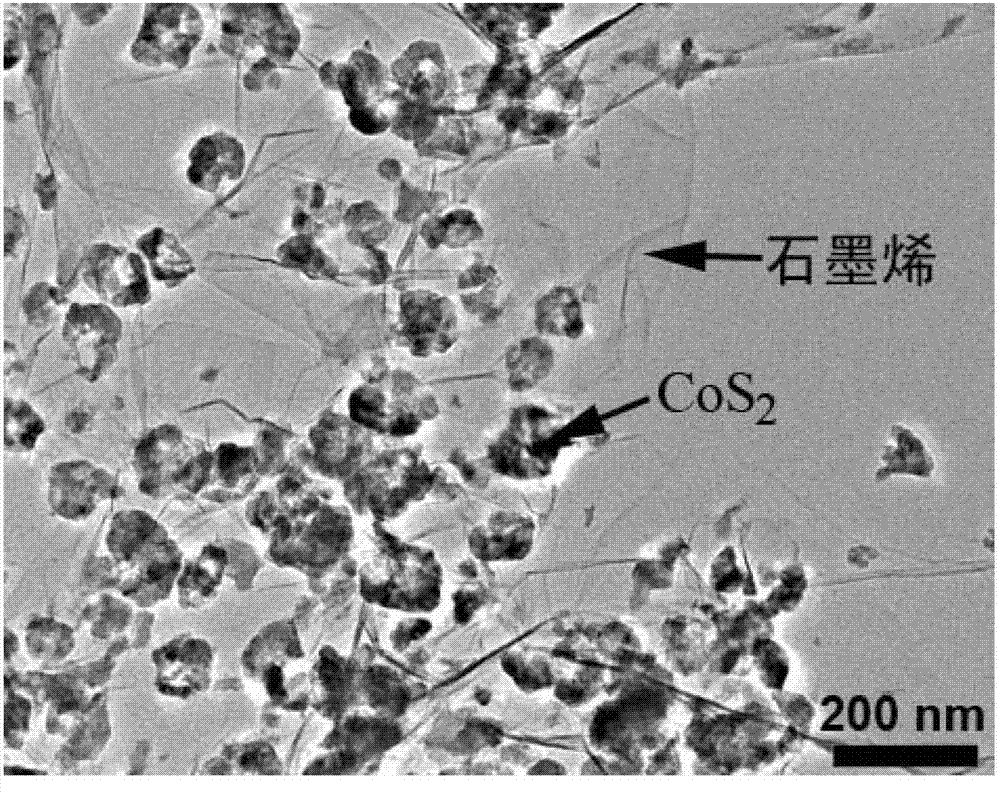

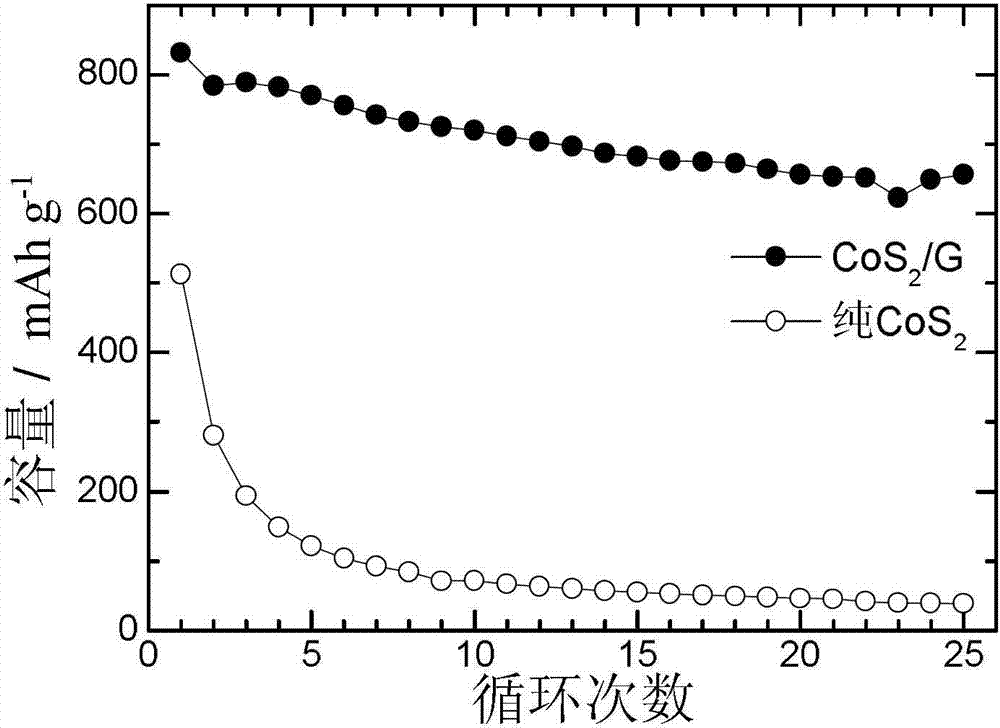

Transition metal sulfide/graphene composite material, and preparation method and application thereof

The invention discloses a transition metal sulfide / graphene composite material which is composed of a nano transition metal sulfide and graphene, wherein the transition metal sulfide is Ni2S3, NiS, FeS, FeS2, CoS, CoS2, CuS2, CuS, MnS or MnS2. Under the dispersion and loading actions of the graphene, the transition metal sulfide can be uniformly distributed and have small particle size, the stability and loop stability of the transition metal sulfide in the charging and discharging process can be effectively enhanced, and the composite material can be used as a lithium ion battery negative pole material. The invention also discloses a one-step low-temperature preparation method of the composite material, which has the advantages of simple technique, low cost, short cycle, low energy consumption and the like and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

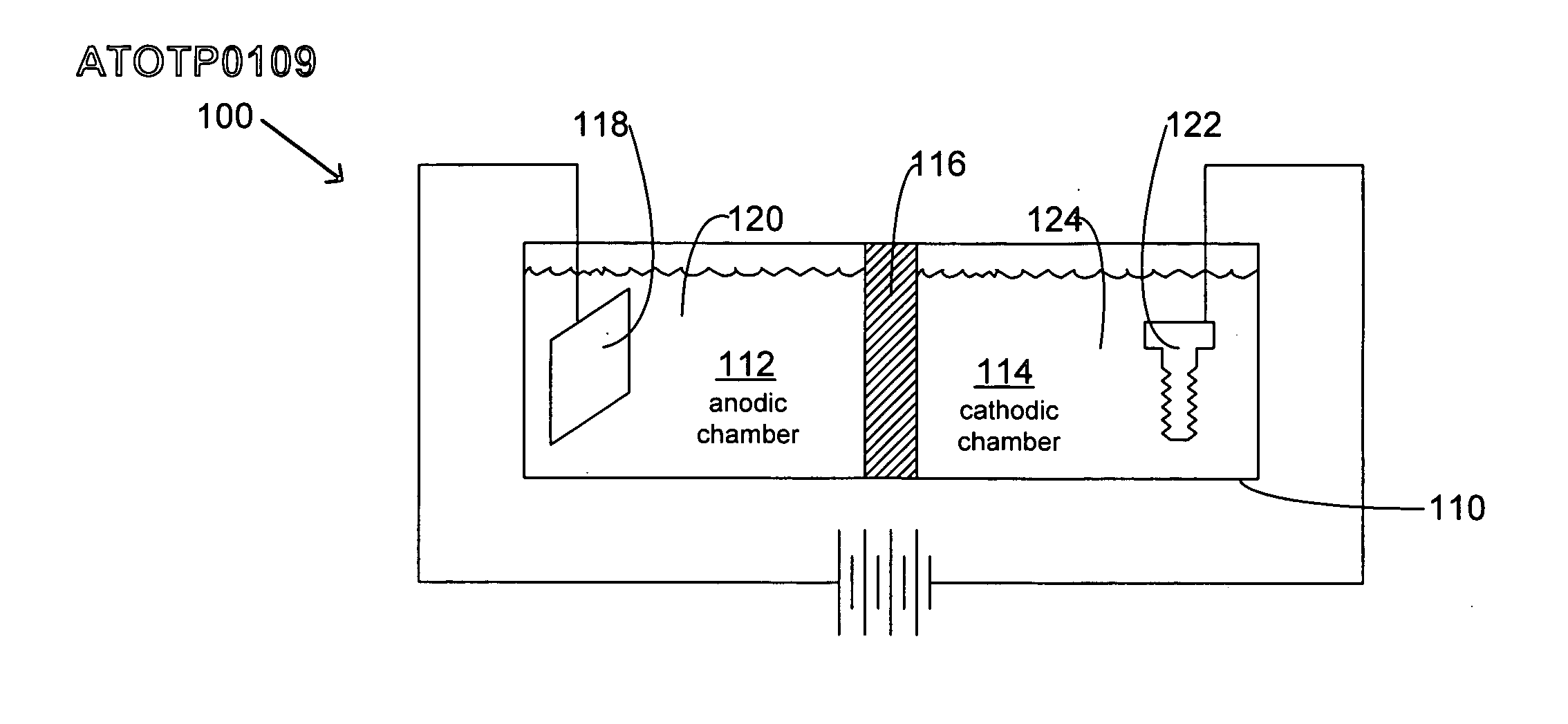

Articles with electroplated zinc-nickel ternary and higher alloys, electroplating baths, processes and systems for electroplating such alloys

An electroplating bath, a system, a process for, and the article obtained from, depositing a zinc-nickel ternary or higher alloy, a) zinc ions; b) nickel ions; and c) one or more ionic species selected from ions of Te+4, Bi+3 and Sb+3, and in some embodiments, further including one or more additional ionic species selected from ions of Bi+3, Sb+3, Ag+1, Cd+2, Co+2, Cr+3, Cu+2, Fe+2, In+3, Mn+2, Mo+6, P+3, Sn+2 and W+6. In some embodiments, the system includes a divider forming a cathodic chamber and an anodic chamber, with the electroplating bath in the cathodic chamber only. In various embodiments, the zinc-nickel ternary and higher alloys may provide improved properties to the conductive substrates upon which the alloys are deposited.

Owner:ATOTECH DEUT GMBH

Method for manufacturing titanium alloy wire with enhanced properties

A method for producing reinforced titanium alloy wire, comprising forming a billet of titanium alloy with grains of a precipitated discontinuous reinforcement material such as TiB and / or TiC. The billet may be formed by the hot consolidation of a titanium alloy powder formed by gas atomization. The billet is then hot formed to reduce it to rod or coil form. The rod or coil is then subjected to successive cold drawing operations to form a reinforced titanium alloy wire of reduced diameter. The cold drawing includes periodic annealing operations under low oxygen conditions to relieve work hardening and to recrystallize the reinforcement material grains to reduce the size thereof.

Owner:FMW COMPOSITE SYST

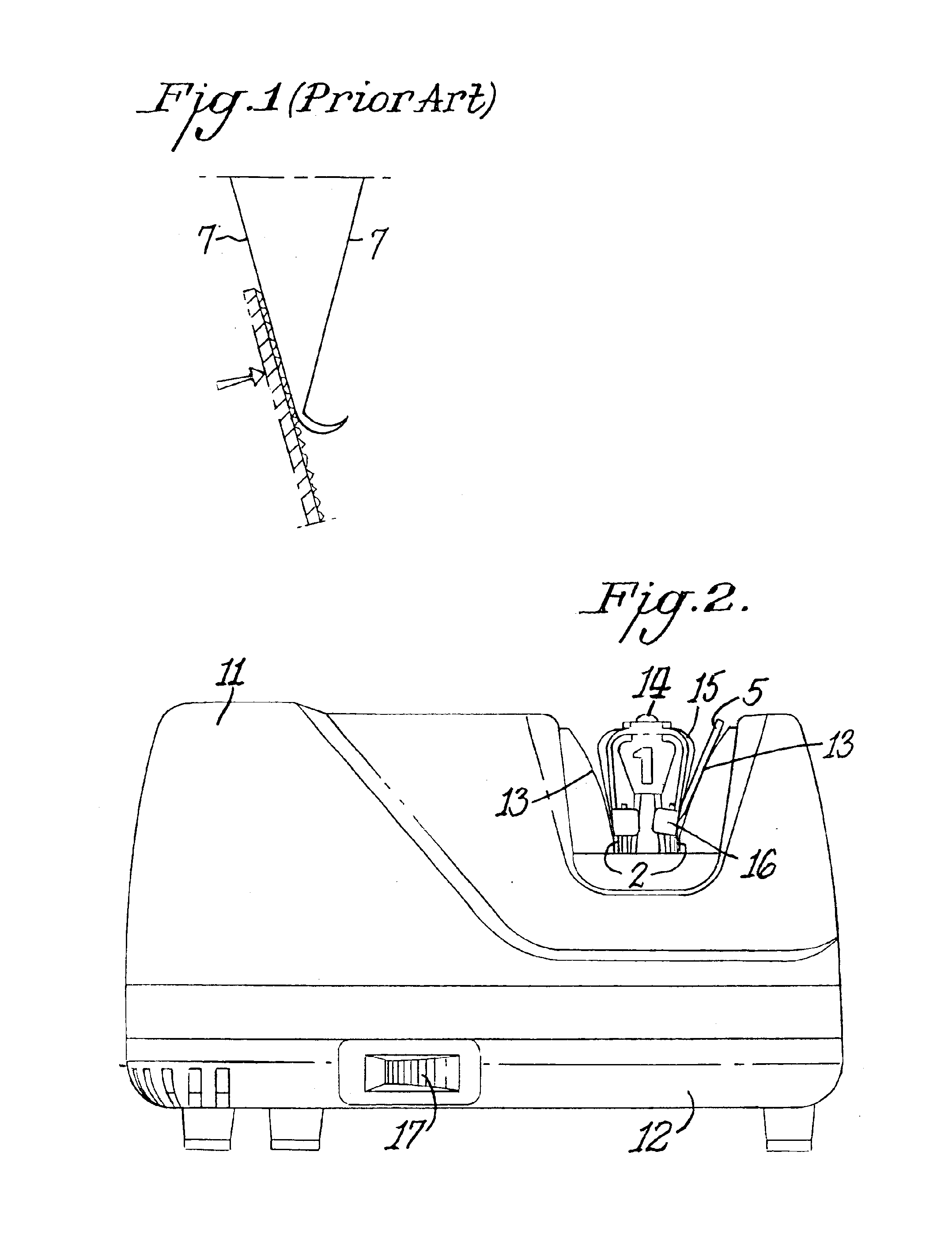

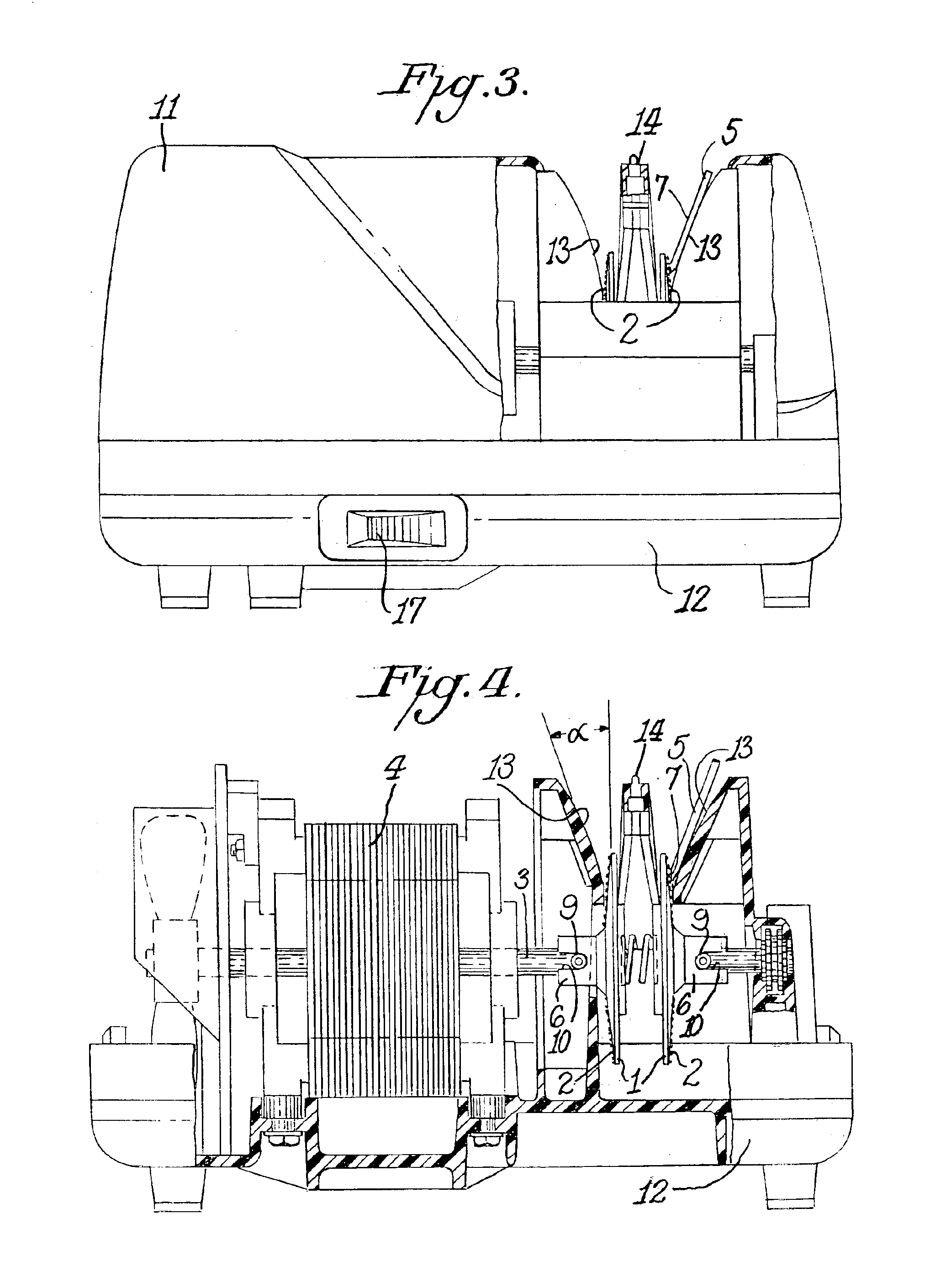

Sharpening device

ActiveUS6875093B2Highly effectiveReduce spring forceEdge grinding machinesPortable grinding machinesMotor driveUltra fine

A sharpener includes a motor driven shaft with at least one slidably mounted sharpening assembly consisting of a supporting hub structure mounted by its central bore hole on the shaft. The hub structure supports a symmetrically shaped rotating surface containing an ultra fine abrasive material. The rotating surface is pressed with a force of less than 0.2 lb. by a spring action to make sustained rotating abrading contact with a facet of a knife positioned by a knife guide to align the facet into contact with the surface containing the abrasive materials.

Owner:EDGECRAFT

Coprecipitation method for preparing ultra fine zinc oxide powder possessing high electric conductivity

ActiveCN1590302AImprove conductivityVolume resistivity is stableZinc oxides/hydroxidesIndiumGas phase

The invention relates to a preparation method for preparing nano-scale oxidized zinc powder with high conductivity. The method simultaneously drip mixed salt solution of zincic soluble salt and doping elements such as aluminum, gallium, indium, Yt, scandium, tin, germanium, silicon, as well as precipitating agent into water, to generate coprecipitation to generate doped zinc bloom precursor basic zinc carbonate in condition of controlling temperature and PH value of entire reaction system, and at last, calcining the product in mixed gas atmospheres of hydrogen gas and argon gas, doped superfine zinc bloom conductive powder material can be obtained. The powder material prepared by the invention has small particle-size, uniform grain fineness distribution, and which mean particle diameter is about 10 to 80 nanometer. The electric volume resistivity of the powder can reach 2.5*10^-3 omega.cm, thus its electro conductivity is better than the sample prepared by plasma method and gas-phase method in current market. The preparation method further enhances whiteness degree and conductivity of the oxidized zinc powder, and further reduces the cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

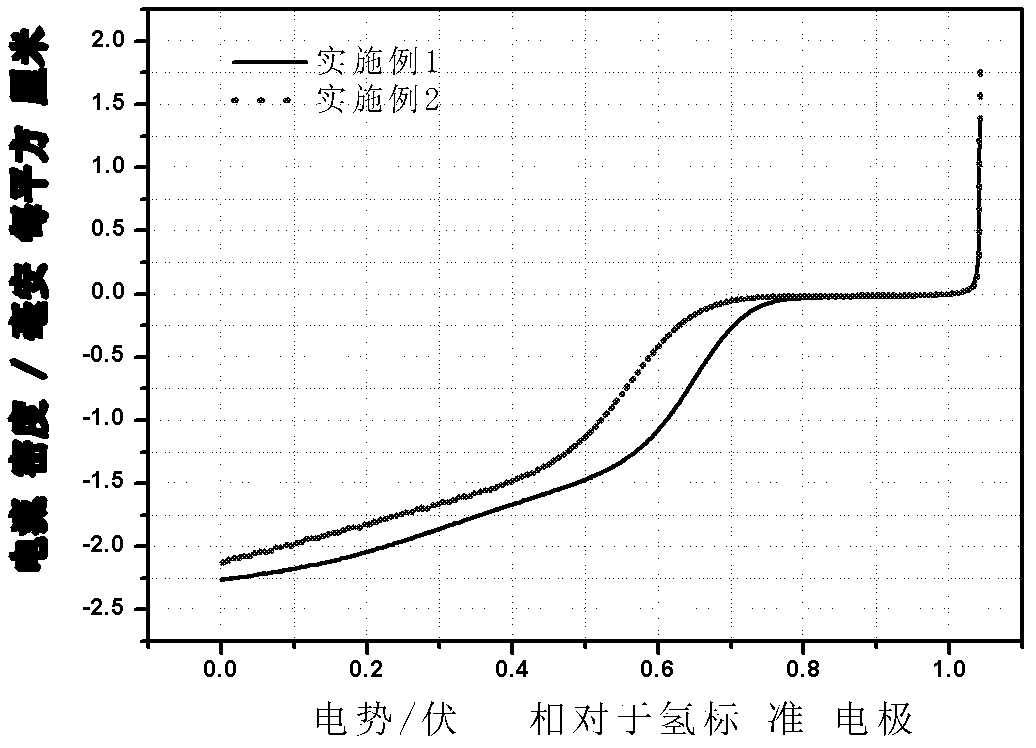

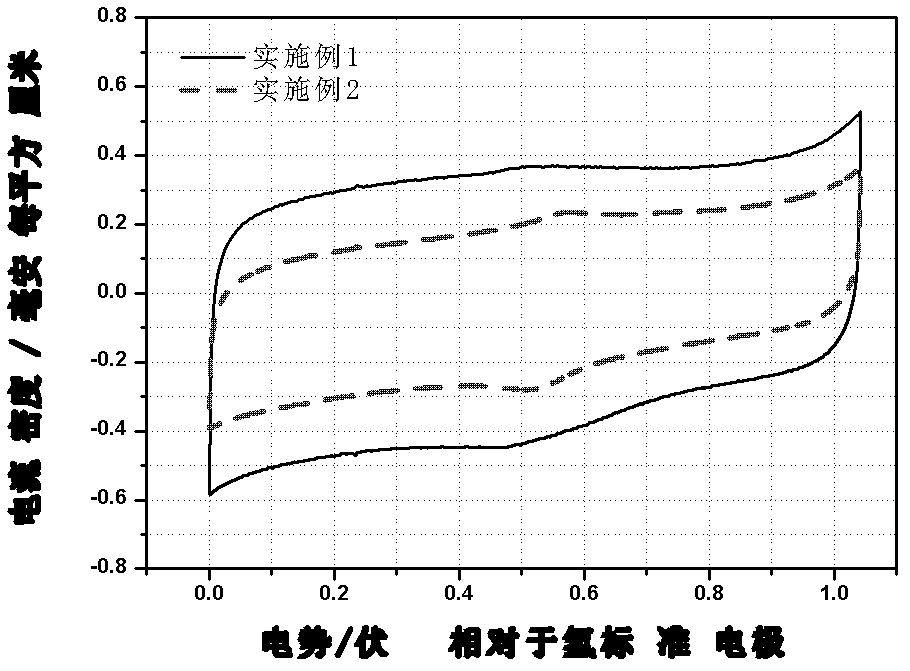

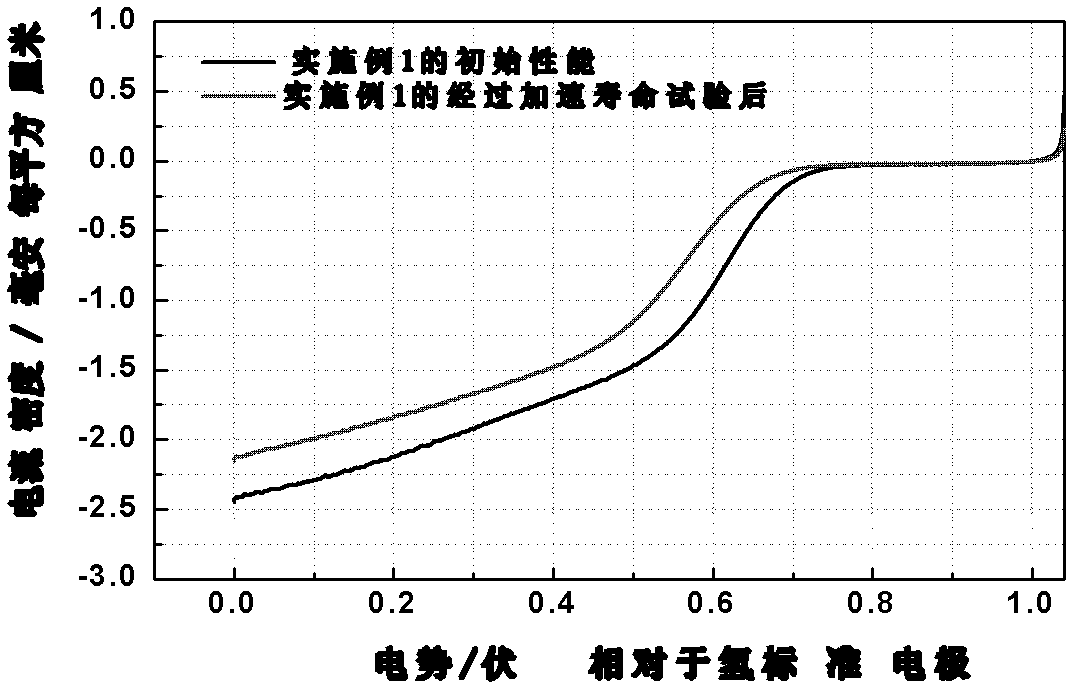

Nano carbon doped electrocatalyst for fuel cell, and application of nano carbon doped electrocatalyst

InactiveCN103050714AChange the microstructureChange Edge Face DefectsPhysical/chemical process catalystsCell electrodesMicrowave radiometryHigh heat

The invention relates to a nano carbon doped electrocatalyst for a fuel cell, and application of the nano carbon doped electrocatalyst. The electrocatalyst is prepared by adopting the steps of: complexing a nitrogen-containing and / or boron-containing organic precursor and a transition metal salt to form a composite; adding nano carbon as a carrier, and heating and reacting a mixture by adopting a microwave radiation method; and after the reaction is complete, filtering and drying, placing a product obtained after the reaction in an inert atmosphere and / or reducing atmosphere, and treating at a high temperature of 500-1500 DEG C to obtain the nano carbon doped electrocatalyst. The nano carbon doped electrocatalyst is very low in cost, high in activity and stability and excellent in anti-poisoning capacity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of zinc oxide nano-rod film on fibre product

InactiveCN101012621ASmall granularityHigh purityFibre treatmentLiquid/gas/vapor textile treatmentFiberChemical solution

The invention relates to a manufacturing method for nanometer rod film of zinc oxide on fiber product, comprising (1) by sol-gel method ZnO nano-crystal grain is prepared and a great deal of ZnO seed crystal is deposited on the surface of fiber product, molar concentrations of zinc salt and alkaline agent are all 0.001M-0.75M; (2) by hydrothermal method or precipitation of chemical solution pool, nanometer rod film of zinc oxide grows on fiber product, molar concentrations of zinc salt solution and complexing agent solution are all 0.001M-0.05M; ZnO nanometer rod film with equal surface and good directivity is obtained. The manufacturing method is provided with simple method and low cost. It is suitable for industrial production.

Owner:DONGHUA UNIV

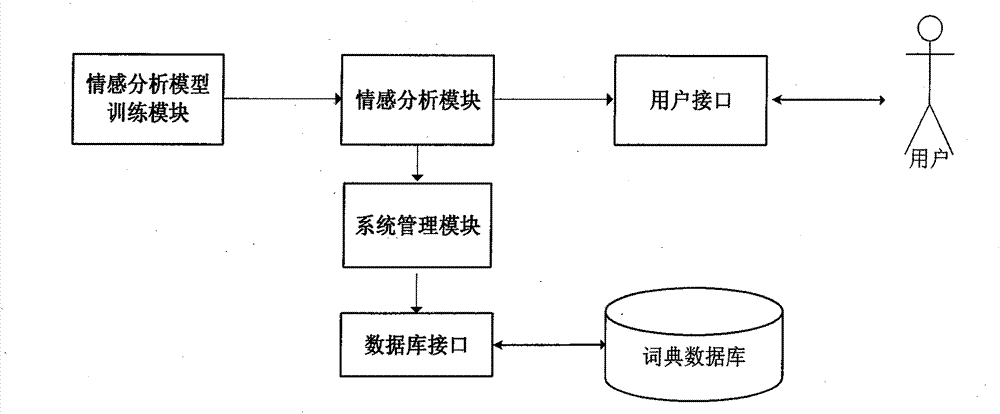

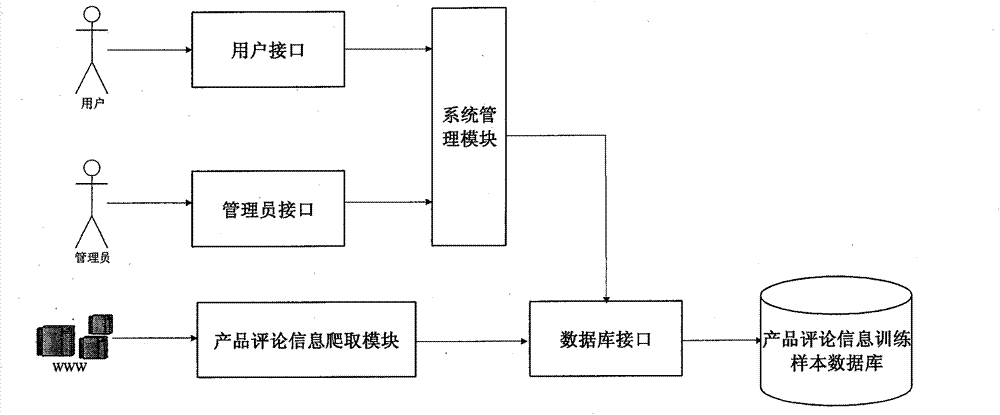

Fine-grained sentiment analysis system and method specific to product comment information

ActiveCN103207855ASmall granularityLarge amount of informationSpecial data processing applicationsMarketingSyntaxSentence segmentation

The invention discloses a fine-grained sentiment analysis system and method specific to product comment information. The system comprises a user interface, a product comment information training sample data base, a loading module of relevant dictionaries such as sentiment dictionaries, a text preprocessing module, a characteristic extraction module, a sentiment analysis model training module, a sentiment tendency judging module and a feedback module. A user can store and manage various tagged product comment information training samples and perform processes of sentence segmentation, word segmentation, part-of-speech tagging, syntactic analysis and the like by means of the system. The user can also add user-defined sentiment dictionaries to perform characteristic extraction and vectorization on well processed text information, train sentiment analysis models and use the sentiment analysis models to perform sentiment tendency judgment on vectorized text information. The system feeds sentiment analysis results back to the user to support the user to correct and store the analysis results.

Owner:GUANGDONG UNIV OF TECH

Target of intermetallic compound with B2-ordered lattice structure, production method thereof and magnetic recording medium having B2-structured underlayer

InactiveUS6159625AHigh bending strengthSmall grain sizeCellsBase layers for recording layersSputter depositionCrystallite

A target for sputter-depositing a B2-structured thin film for an underlayer of a magnetic recording medium. Since the target is made of a sintered body of an intermetallic compound being substantially a B2-ordered lattice structure, the target has a uniform small grain size and a high bending strength. The target produces a thin film with a small grain size and a minimized particle deposition.

Owner:HITACHI METALS LTD

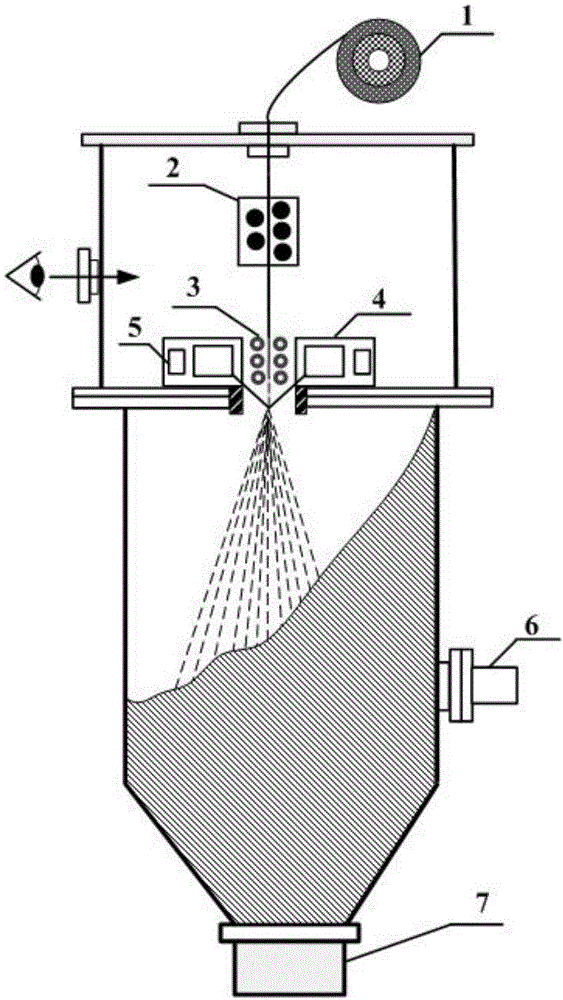

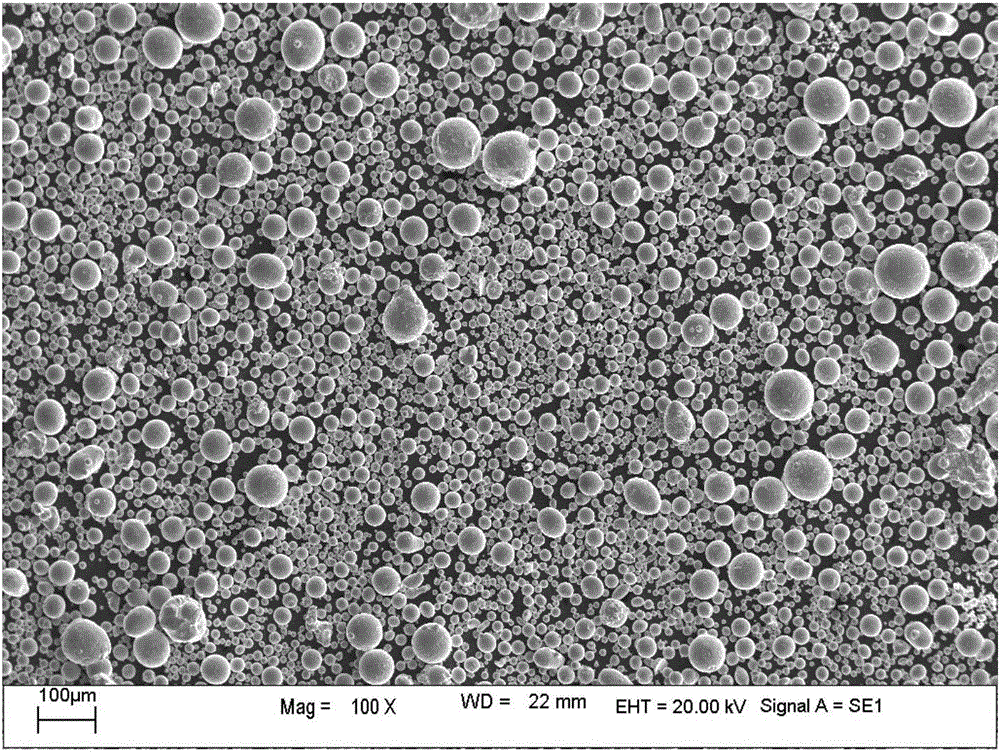

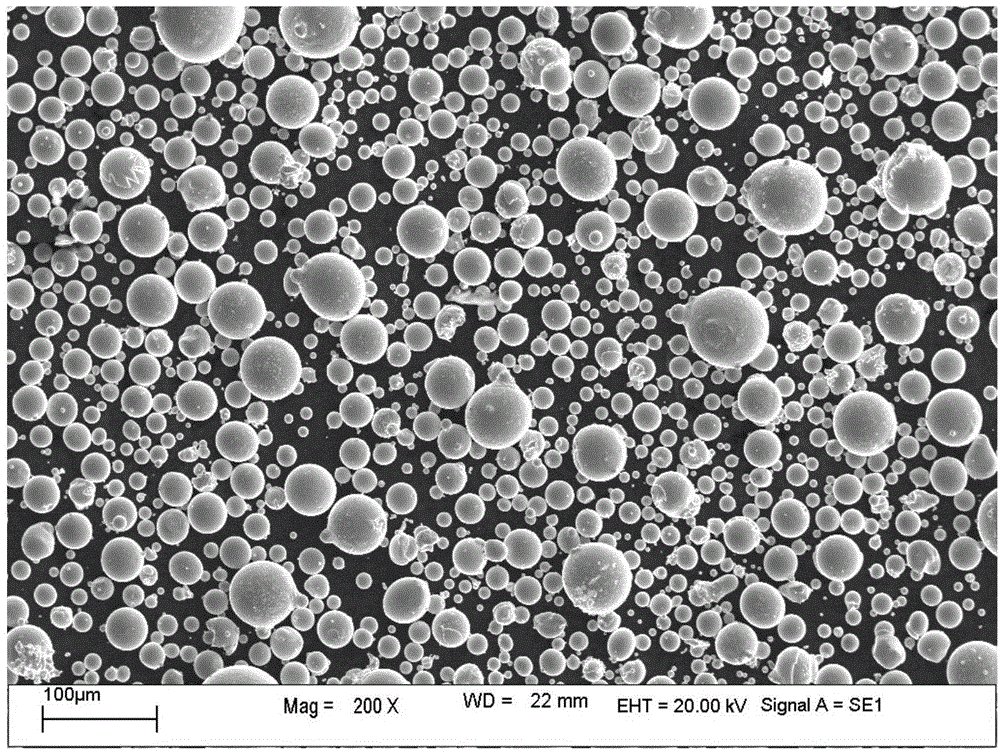

Manufacturing method of micro spherical titanium and titanium alloy powder

ActiveCN104475743AFast purification smeltingControlled purification smeltingSpherical shapedTitanium alloy

The invention relates to a manufacturing method of micro spherical titanium and titanium alloy powder, and belongs to the technical field of metal and alloy powder manufacturing. The manufacturing method comprises the steps that a titanium and titanium alloy wire or bar is manufactured by using sponge titanium in the national standard TA1 grade as a raw material; forvacuum treatment is conducted on a powder manufacturing device, and then the powder manufacturing device is filled with inert protective gas; the raw material wire or bar is fed into a smelting chamber through a continuous feeding mechanism and a straightener, the raw material is heated and smelted through a high-frequency induction coil, and the alloy raw material is molten to form stable liquid flow or drip flow; supersonic atomizing nozzles in atomizers are opened, and breakage, dispersion and forced cooling powder manufacturing are conducted on the molten liquid flow or the drip flow; powder is obtained through a powder collector, and is screened through an ultrasonic vibrating screen to obtain the micro spherical titanium and titanium alloy powder. The micro spherical titanium and titanium alloy powder manufactured through the manufacturing method is small in particle size, high in degree of sphericity, good in liquidity and low in impurity content, and has smooth surfaces.

Owner:有研增材技术有限公司

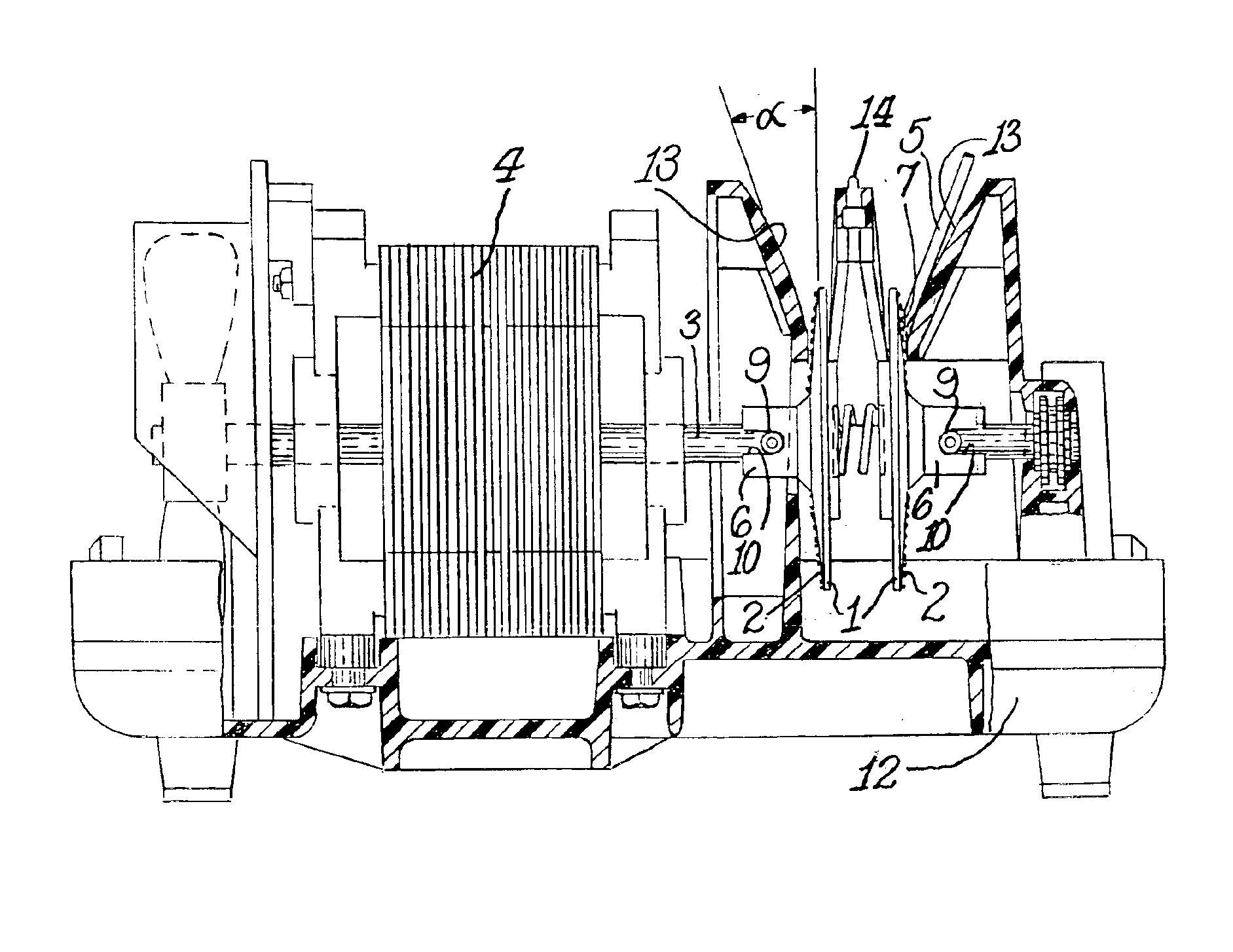

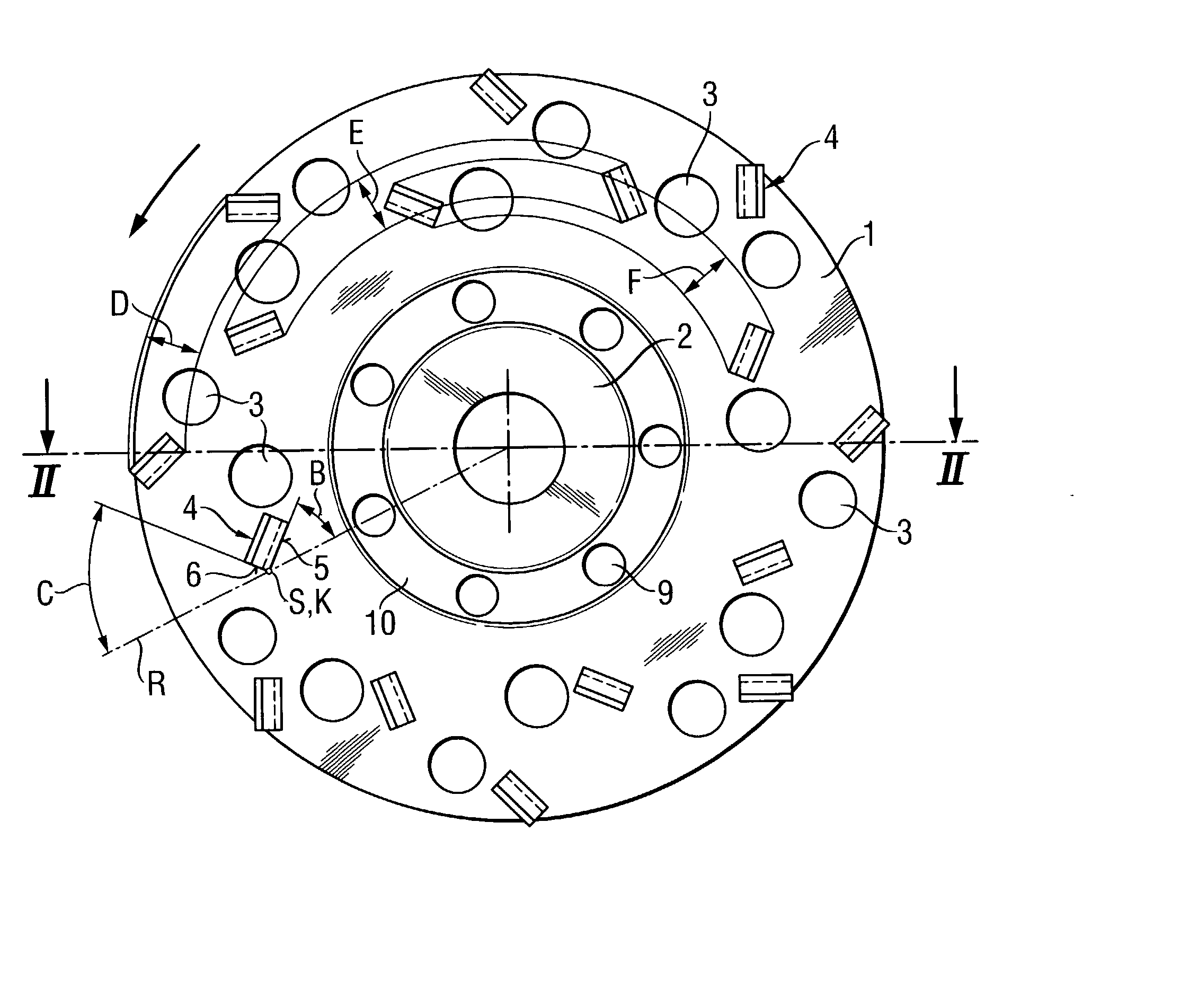

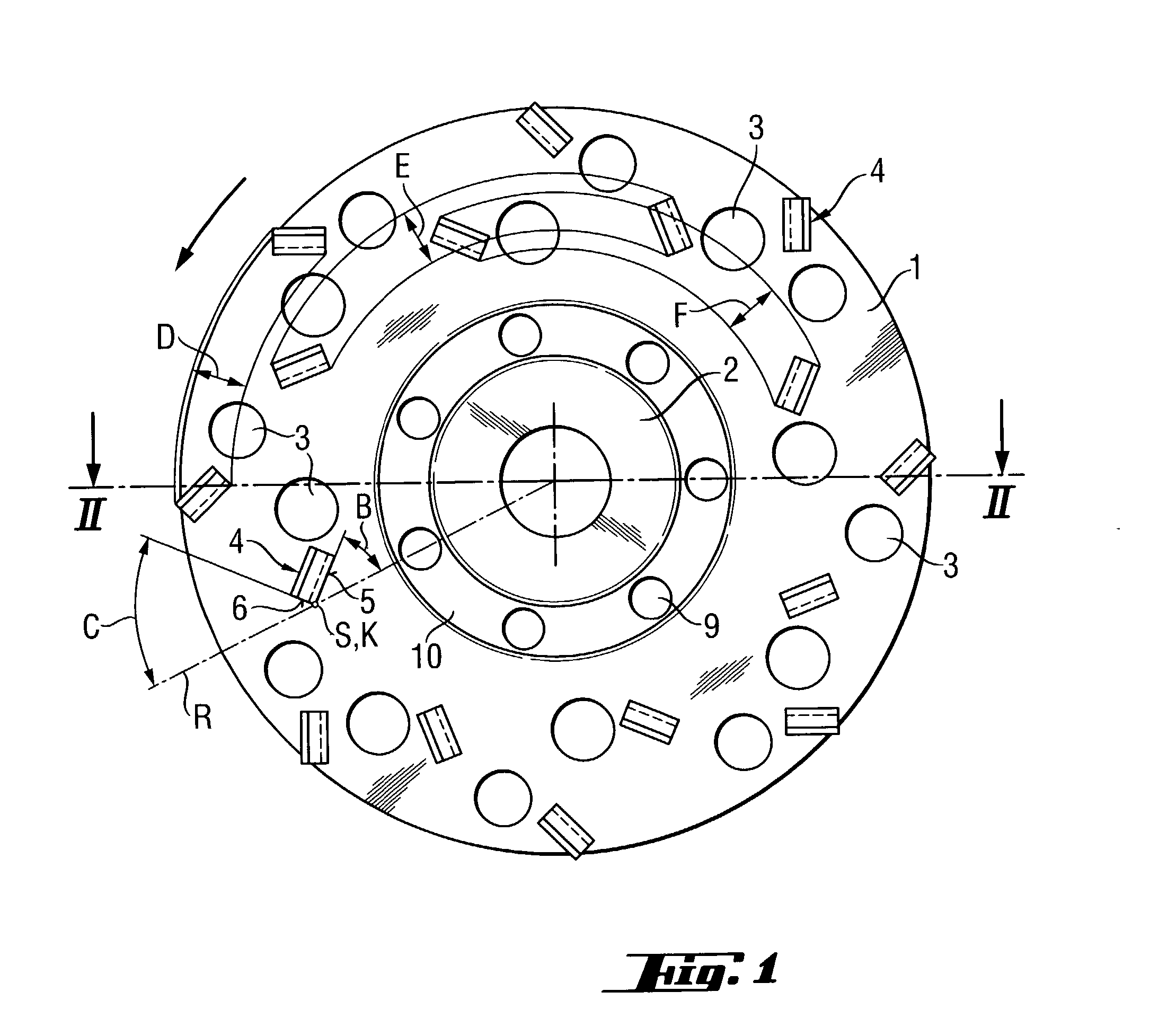

Grinding wheel

InactiveUS20030054746A1Easy to removeGood penetration behaviorRevolution surface grinding machinesGrinding feed controlEngineeringGrinding wheel

A grinding wheel including a circular grinding region (1) with a plurality of through-openings (3) formed therein, a central mounting region (2) coaxial with the grinding region (1), and a plurality of cutting bodies (4) having a rectangular base surface, projecting from the grinding region (1), and spaced from a center of the mounting region (2) by different radial distances, with each cutting body (4) having a longitudinal side (5) adjacent to the center of the mounting region (2) and a wide side (6) remote from the center of the mounting region (2), with the longitudinal side (5) and the wide side (6) forming together an edge (K), and with the longitudinal side (5) extending at an angle (B) of from 35° to 55° to a radial line (R) extending from the center of the mounting region (2) and passing tangentially to the edge (K).

Owner:HILTI AG

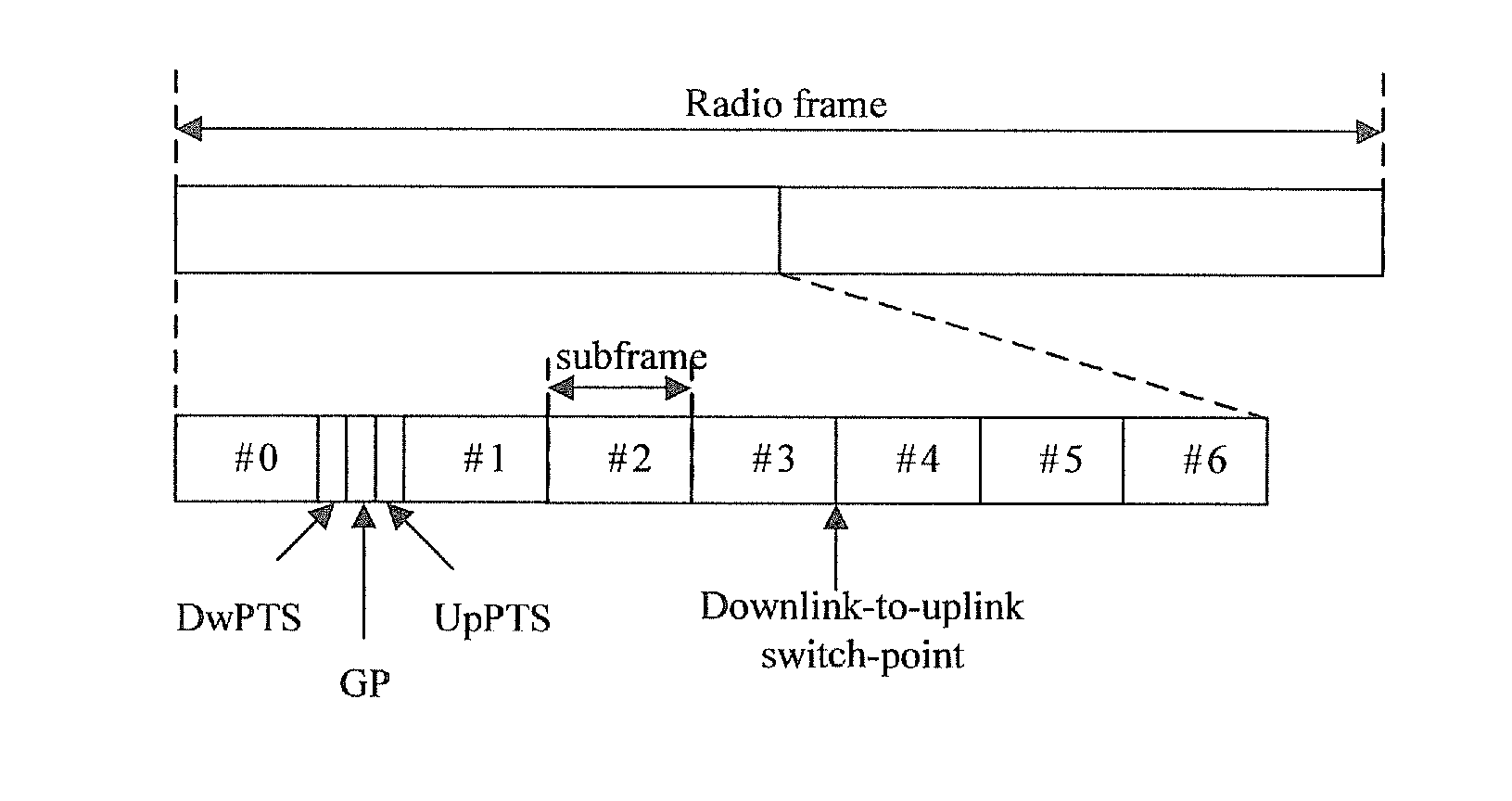

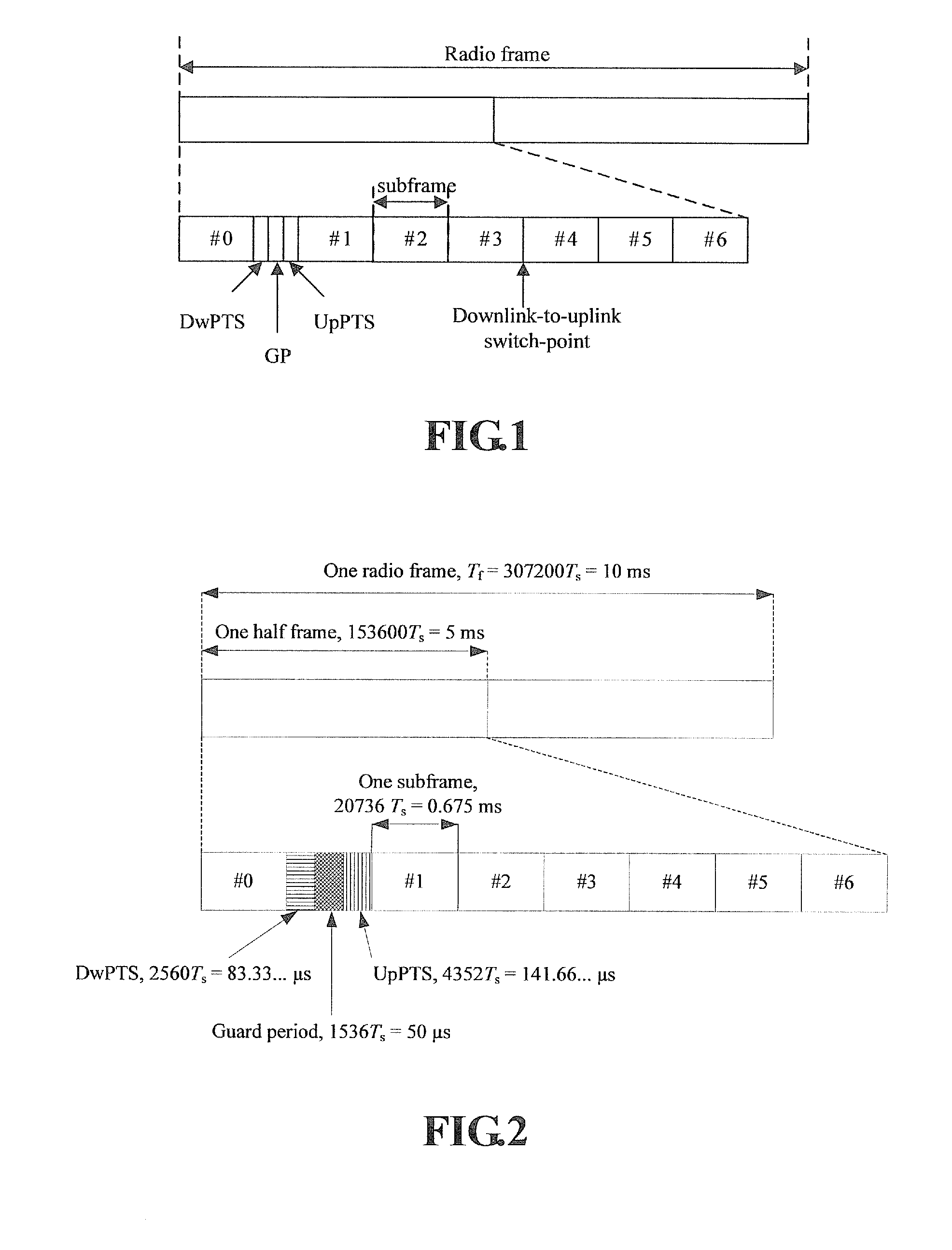

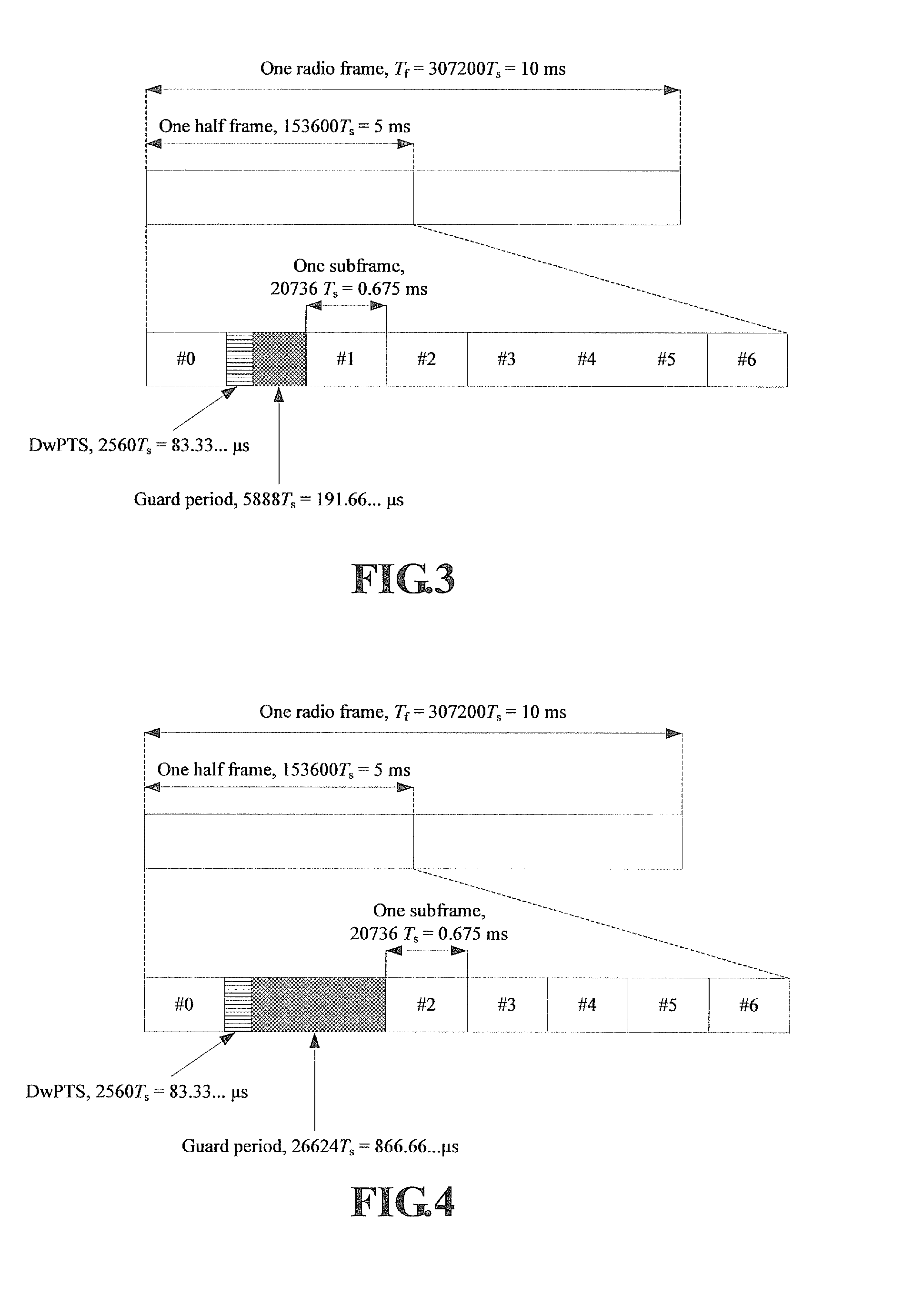

Method and apparatus for data transmission in a time division duplexing system

ActiveUS20100238847A1Reduce granularitySave radio resourceModulated-carrier systemsAssess restrictionFrame basedGranularity

A method for data transmission in a TDD system is disclosed. The method includes: configuring, by a base station, a length respectively for a Downlink Pilot Slot (DwPTS) and an Uplink Pilot Slot (UpPTS) within a special field of a radio half-frame based on a current coverage area taking one Orthogonal Frequency Division Multiplexing (OFDM) symbol as a unit, and issuing a configured result to a user device, wherein a total length of the DwPTS, a Guard Period (GP) slot and the UpPTS is kept to be 1 ms; constructing, by the base station, radio half-frames for data transmission according to the configured result. An apparatus for data transmission in the TDD system is also disclosed. According to the present invention, coverage area of different levels with smaller granularity is supported, radio resources are saved and transmission efficiency is increased.

Owner:DATANG MOBILE COMM EQUIP CO LTD

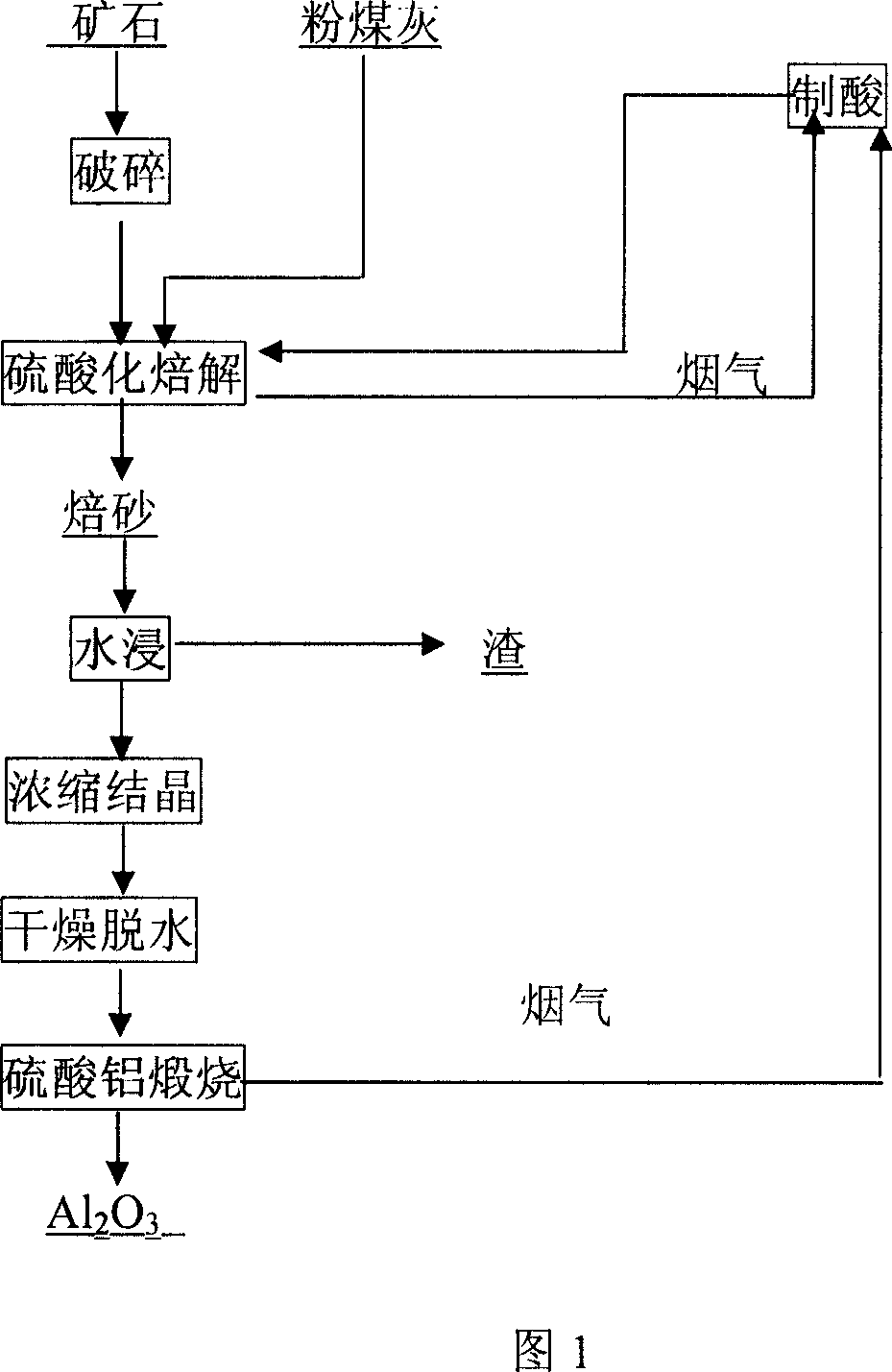

Method of acid extracting aluminium from high-silicon alumina-containing raw mineral materials

The invention relates the method of extracting aluminium from high-silicon siliceous mineral. The method comprises the following steps: mixing the aluminous ore and sulfuric acid, baking, leaching with water, filtering leachate, getting aluminium sulphate solvent, thickening filter liquor, separating out aluminium sulphate, drying, dewatering, getting anhydrous aluminium sulphate; calcining aluminium sulphate, and getting Al2O3. The invention can extracte aluminium from high-silicon siliceous mineral, coal gangue, coal ash, China clay, andalusite, feldspath, ganister, nepheline and vermiculite without baking. The method has the advantages of simple technology, little corrosion, easy operation and high recovery ratio.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

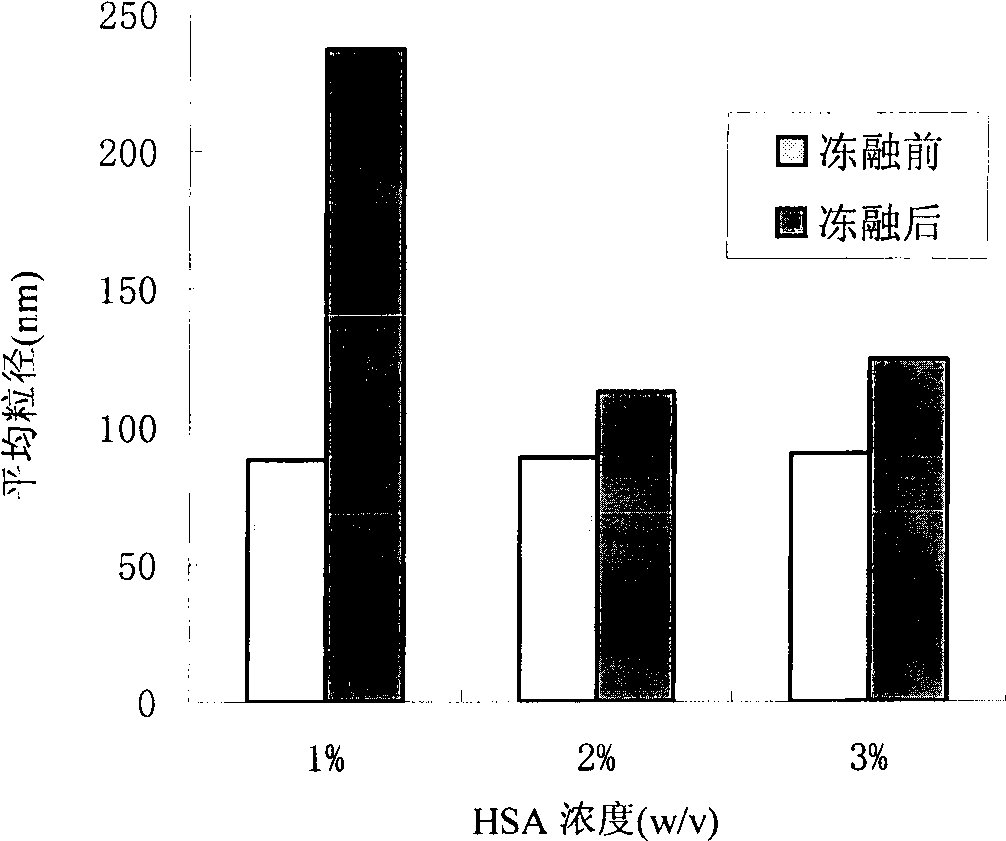

Drug delivery system and preparation method thereof

InactiveCN101485629AHigh feasibilityImprove stabilityLyophilised deliveryEmulsion deliveryOrganic solventSide effect

The invention belongs to the technical field of medicines, and discloses a delivery system based on protein-phospholipid. The system comprises a protein-phospholipid dispersion with the weight ratio of between 1:100 and 100:1, wherein the grain size of the protein-phospholipid is between 5 and 1,000nm, and the surface of the phospholipid or the surface and the inside of the phospholipid are coated / covered by a protein layer. The preparation method comprises: preparing a phospholipid containing phase, preparing a protein containing water phase, performing the homogenization treatment on the phospholipid containing phase and the protein containing water phase at a temperature of between 0 and 40 DEG C and under a pressure of between 400 and 40,000psi, and obtaining a dispersion system with the average grain size of less than 1,000nm. The delivery system has the advantages of realizing the delivery in various ways such as injection, oral taking, cavities and canals, skin and the like, and lowering side effects of medicines. The delivery system solves the problems of drug-loading rate and stability of protein nano-grain and liposome, and adopts low-toxicity organic solvent, even no organic solvent; and the preparation method is easy for industrialized application, and can prepare a liquid type protein-phospholipid containing delivery system.

Owner:SHENYANG PHARMA UNIVERSITY

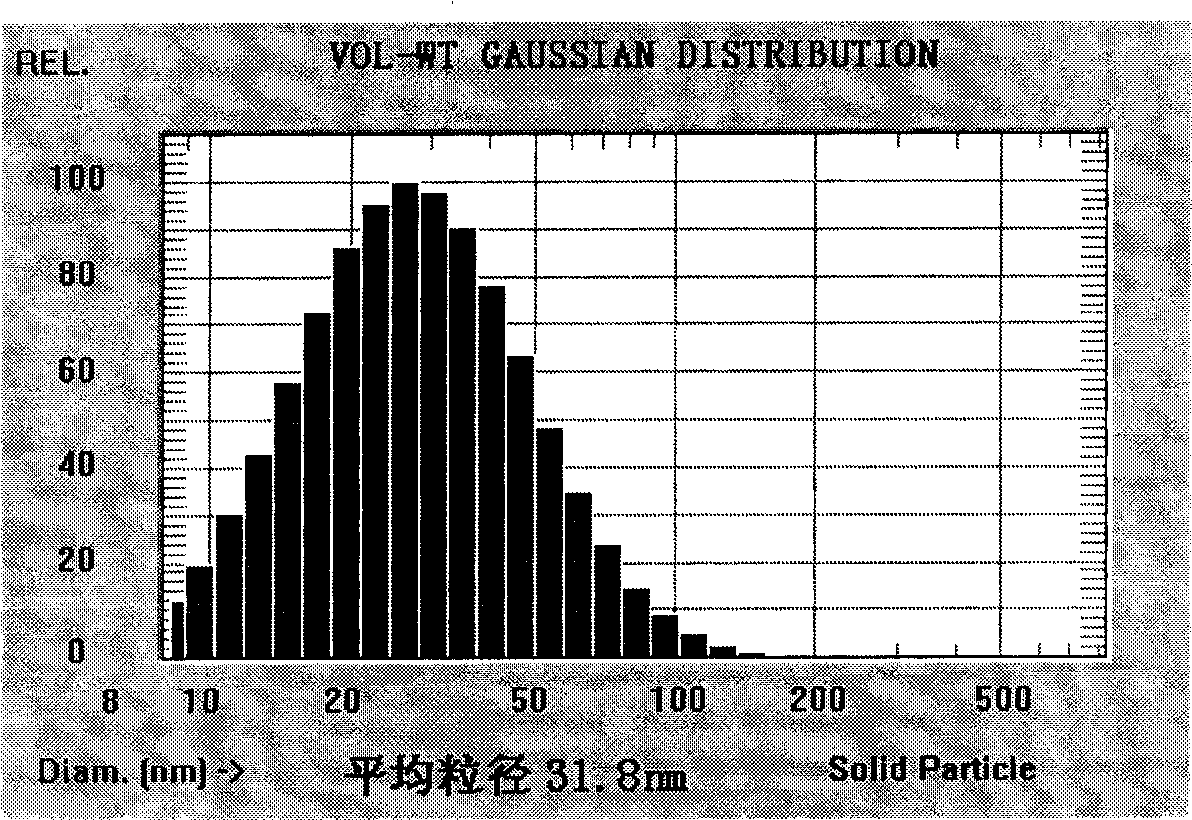

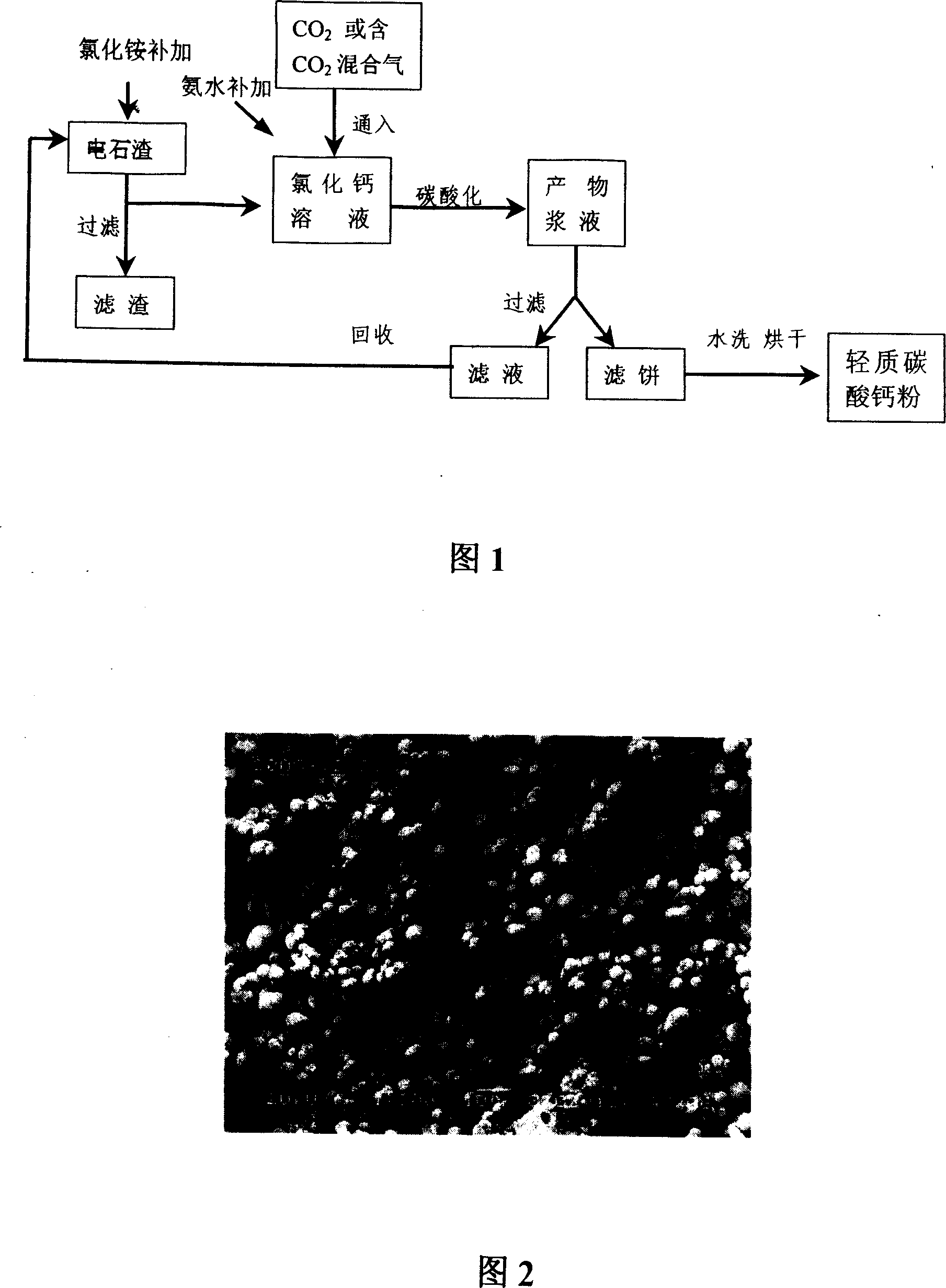

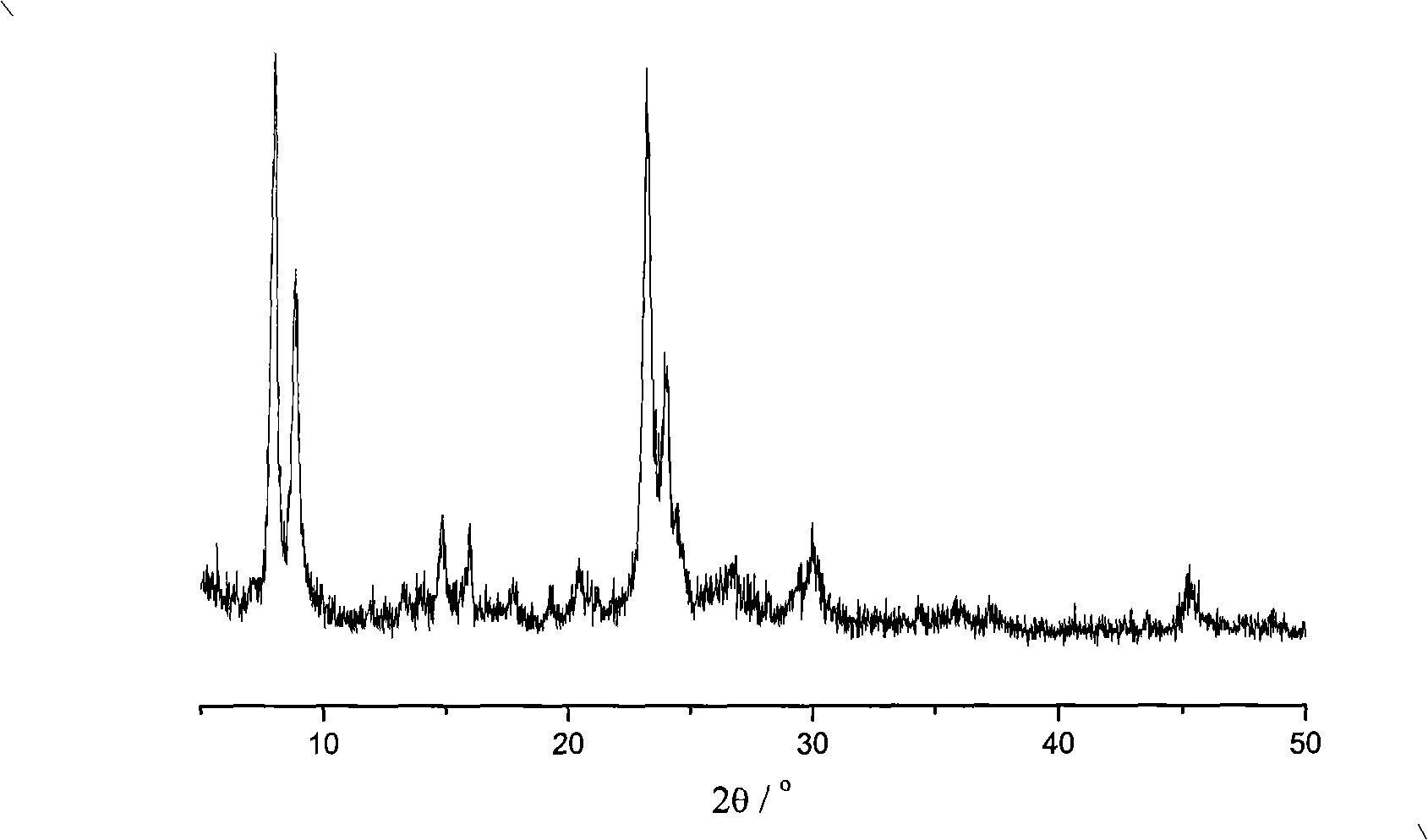

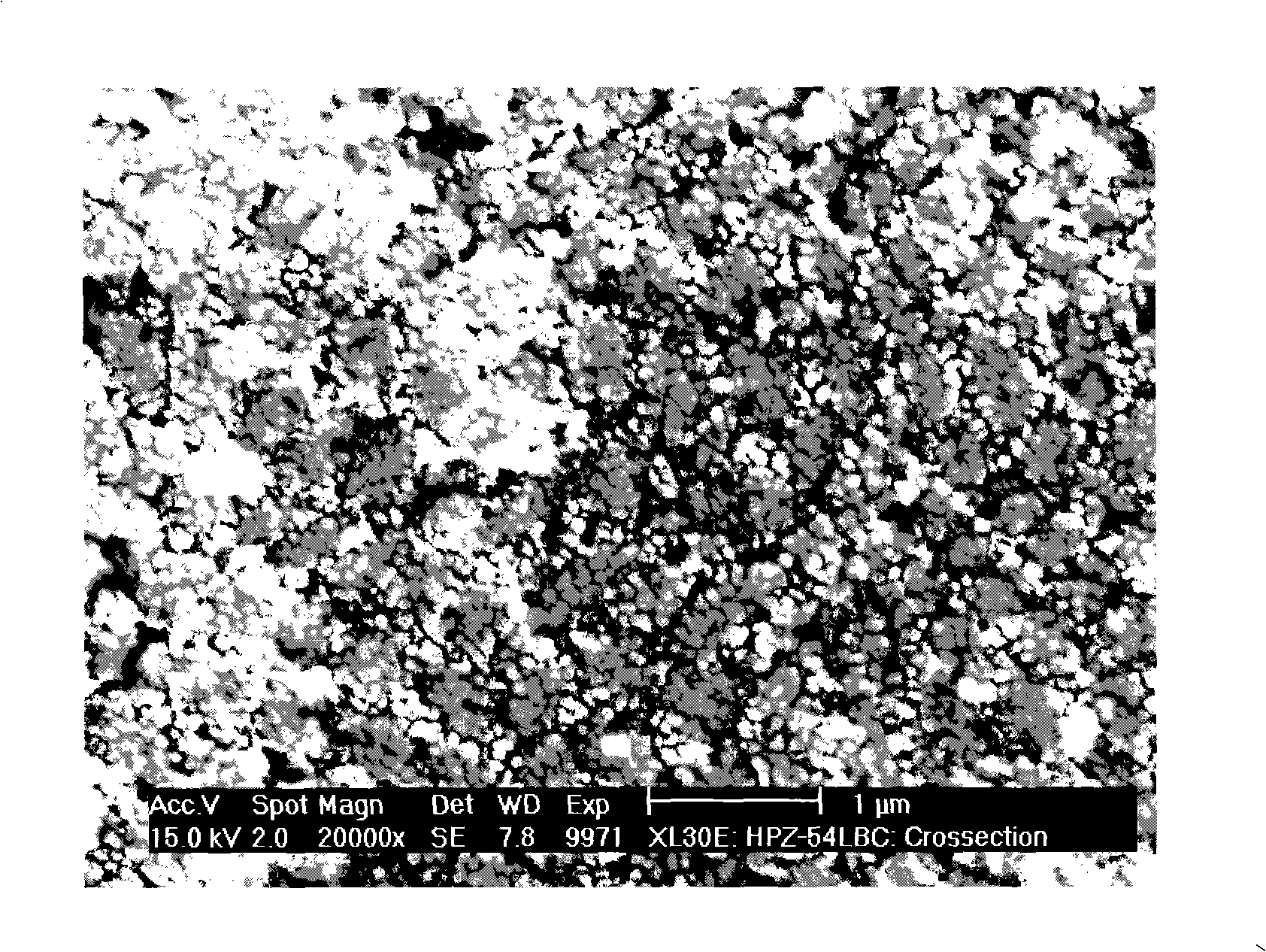

Process of preparing high purity light calcium carbonate fine powder with carbide residue

InactiveCN101020579AHigh purityReduce the difficulty of manufacturing processCalcium/strontium/barium carbonatesCalciteSlurry

The process of preparing high purity light calcium carbonate fine powder with carbide residue includes reacting carbide residue as one kind of industrial waste directly with ammonium chloride solution to produce mixture solution of calcium chloride and ammonia water, filtering, introducing CO2 gas for carbonating reaction, filtering the produced slurry, water washing the filter cake and stoving to obtain calcite type spherical light calcium carbonate fine powder, and circulating ammonium chloride solution for reuse. The present invention has simple technological process, lowered production cost, high product purity and high product quality.

Owner:NAT UNIV OF DEFENSE TECH

Preparation of binderless ZSM-11 zeolite

The invention relates to a method for preparing no-binding agent ZSM-11 zeolite, which mainly aims at overcoming the defects of difficult recovery, easy deactivation and easy aggregation existing in the practical application of the zeolite powder and the problems of small effective surface area and limited diffusion due to the addition of the binding agent in the forming process. In the invention, at least one of diatomaceous earth, carbon white, silicasol or water glass is taken as a silicon source, at least one of aluminum oxide, aluminum salt or aluminate is taken as an aluminum source, and proper quantity of necessary crystal seed guiding agents are added and subjected to pugging, extrusion and forming so as to obtain a precursor mixture with the mass ratio of XNa2O:YAl2O3:100SiO2, wherein x is between 0.5 and 14, and y is between 0 and 6, and the precursor mixture is subjected to hydrothermal crystallization treatment in the water solution containing tetrabutyl ammonium positive ions and converted to the no-binding agent ZSM-11 zeolite. The technical proposal of the invention better resolves the problems, and can be applied to the industrial preparation of the ZSM-11 zeolite molecular sieve catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

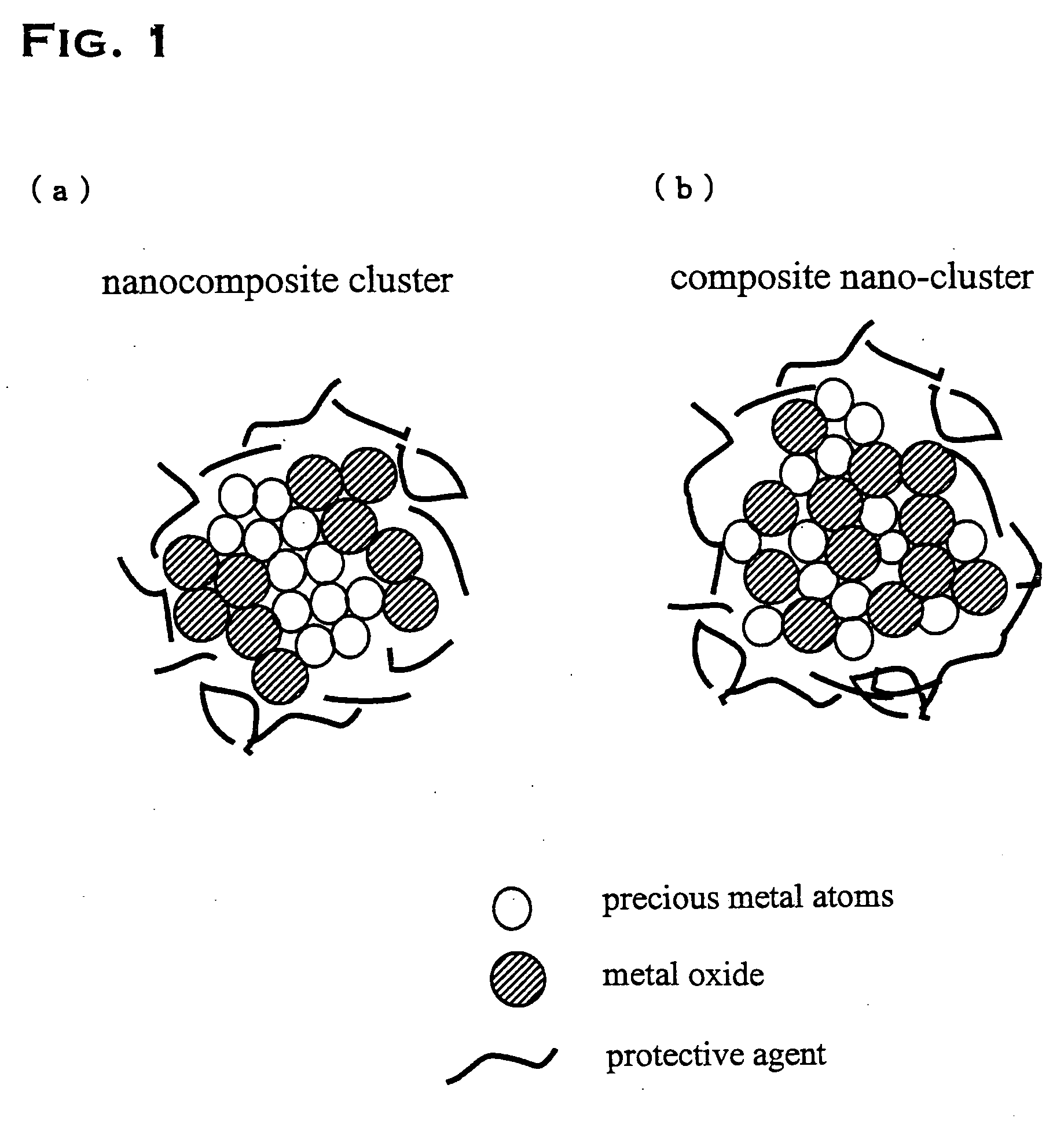

Precious metal - metal oxide composite cluster

InactiveUS20050065026A1Increase the effective surface areaSmall granularityMaterial nanotechnologyTransportation and packagingOxide compositeMaterials science

The present invention provides a precious metal—metal oxide composite cluster, wherein said cluster is formed as a single particle by combining a precious metal portion comprising a single atom or an aggregate of a plurality of atoms consisting of one or more precious metals, and a metal oxide portion comprising a single molecule or an aggregate of a plurality of molecules consisting of one or more metal oxides, and wherein said particle has a particle size between 1 and 100 nm.

Owner:TANAKA PRECIOUS METAL IND

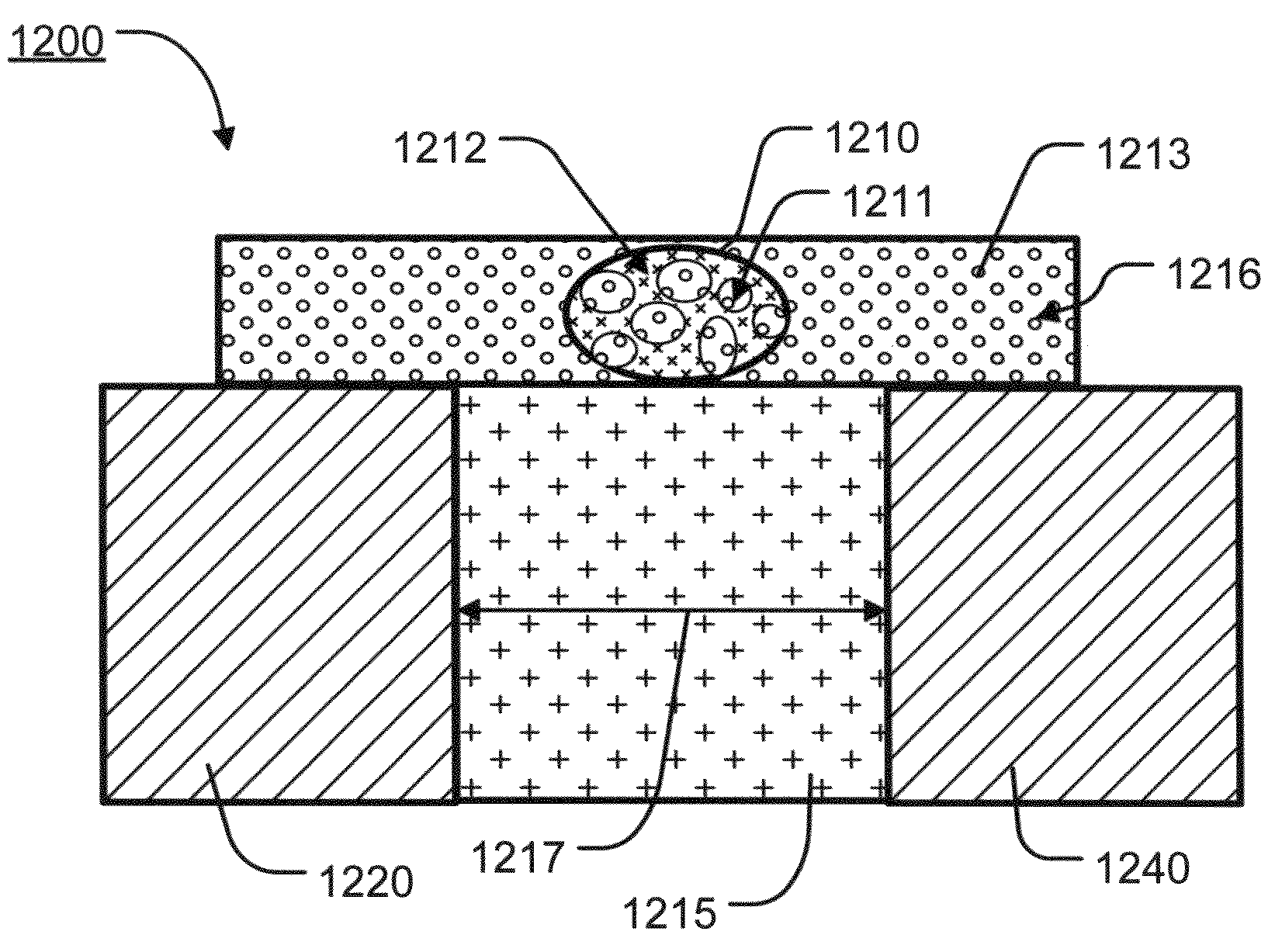

Dielectric mesh isolated phase change structure for phase change memory

ActiveUS20100084624A1Easy to optimizeSmall grain sizeSemiconductor/solid-state device manufacturingDigital storageDielectricPhase-change memory

A method for manufacturing a memory device, and a resulting device, is described using silicon oxide doped chalcogenide material. A first electrode having a contact surface; a body of phase change memory material in a polycrystalline state including a portion in contact with the contact surface of the first electrode, and a second electrode in contact with the body of phase change material are formed. The process includes melting and cooling the phase change memory material one or more times within an active region in the body of phase change material without disturbing the polycrystalline state outside the active region. A mesh of silicon oxide in the active region with at least one domain of chalcogenide material results. Also, the grain size of the phase change material in the polycrystalline state outside the active region is small, resulting in a more uniform structure.

Owner:GLOBALFOUNDRIES US INC

Nanometer modified epoxy sealing paint and its prepn

The nanometer modified epoxy sealing paint is used mainly for hot spraying or other coating to seal various micropores. It consists of two components separated packed, the component A includes filming material, inorganic nanometer material, pigment, filler, assistant and diluent; and the component B includes curing agent and diluting solvent. It has the advantages of low viscosity, high permeability, high attachment force and excellent anticorrosive performance.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

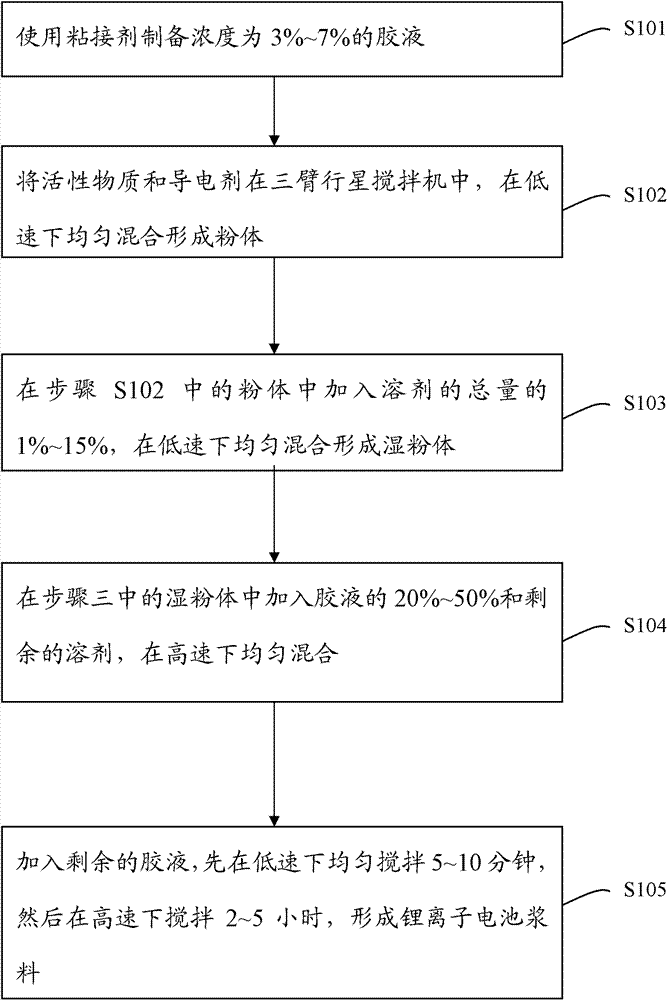

Lithium ion battery slurry, preparation method of the lithium ion battery slurry, and lithium ion battery

The invention discloses a preparation method of lithium ion battery slurry. The preparation method comprises the following steps of 1, preparing a glue solution having a concentration of 3 to 7% by an adhesive, 2, putting one or more active substances and one or more conducting additives into a three-arm planetary stirrer, and uniformly mixing the mixture into powder at a low speed, 3, adding 1 to 15% of a solvent into the powder obtained by the step 2, and uniformly mixing the mixture into wet powder at a low speed, wherein a ratio of the total mass of the solvent to the mass of the powder is in a range of (55: 4) to (50: 50), 4, adding 20 to 50% of the glue solution and the rest of the solvent into the wet powder, and uniformly mixing at a high speed, and 5, adding the rest of the glue solution into the mixture obtained by the step 4, uniformly stirring at a low speed for 5 to 10 minutes, and then stirring at a high speed for 2 to 5 hours to obtain the lithium ion battery slurry. The invention also discloses the lithium ion battery slurry and a battery pole piece prepared by the preparation method, and a lithium ion battery.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

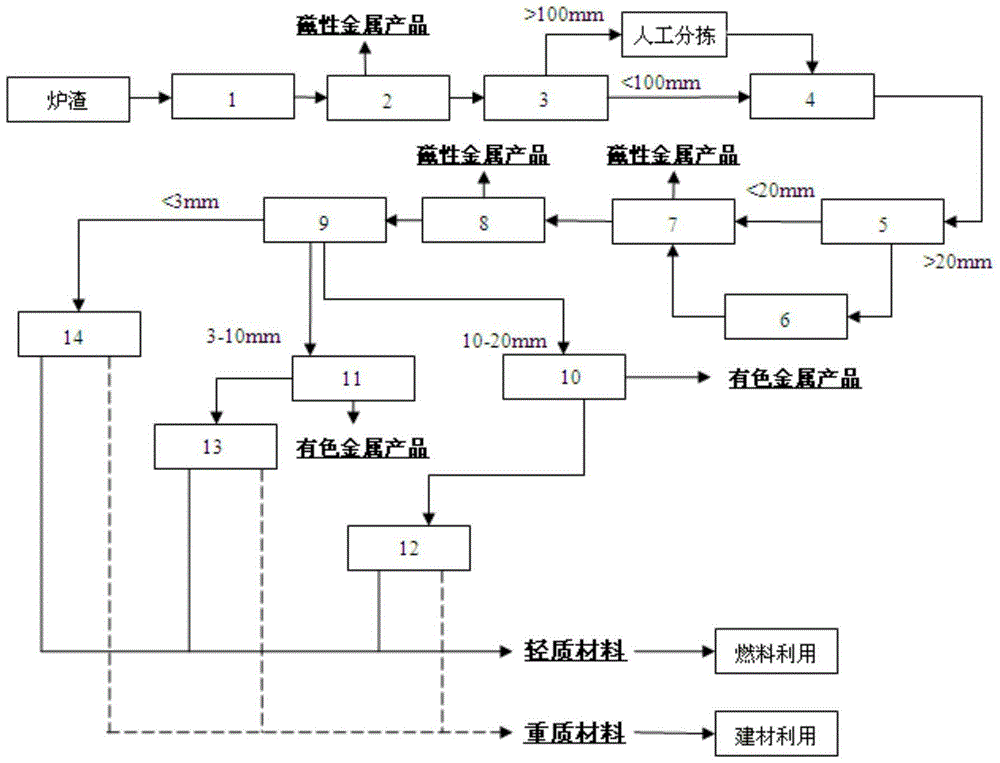

Method for recycling metal and combustibles from domestic waste incineration slag

The invention relates to a method for recycling metal and combustibles from domestic waste incineration slag, and belongs to the field of the solid waste harmless and recycling technology. By means of multi-stage gradient magnetic separation, separation of magnetic metal in the slag is achieved. By means of two-stage eddy current, nonferrous metal in the slag is separated and recycled. According to the grain size distribution and chemical morphological characteristics of the metal in the slag, the metal is crushed and screened in multiple steps so that separated slag particles can be uniform, the recycling rate of magnetic separation and eddy current separation is effectively increased, and finally, according to the density difference of materials, air separation is used for recycling the combustibles in the slag. Finally, the magnetic separation recycling rate of iron in the technological process is 60-80%, the recycling rate of the nonferrous metal aluminum is 60-70%, the recycling rate of the nonferrous metal copper is 40-50%, and separation of the metal in the slag and slag particles can be effectively achieved. The separated metal products can be directly sold or sold after refining, the combustibles can serve as waste incinerator fuel, and the remaining slag can be used as building materials.

Owner:TONGJI UNIV

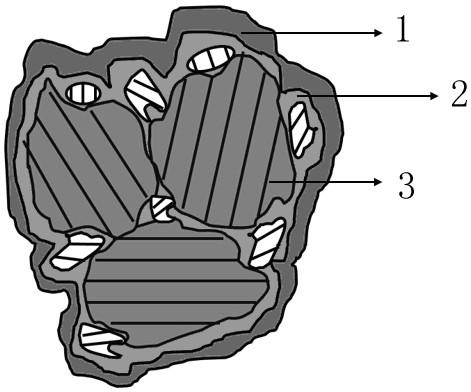

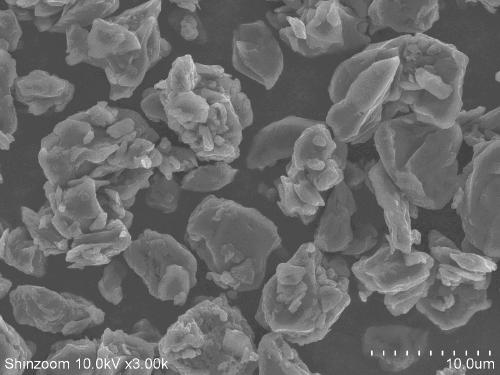

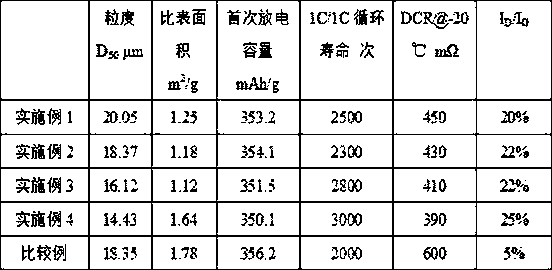

High-capacity rapid charge graphite negative electrode material and preparation method thereof

ActiveCN109748587AIncrease capacityLarge granularityCell electrodesSecondary cellsAsphaltLarge capacity

The invention provides a preparation method of a high-capacity rapid charge graphite negative electrode material. According to the method, easily-graphitized coke / high-crystallinity graphite and difficultly-graphitized coke / hard carbon are secondarily granulated, asphalt is mixed to perform composite reaction, mixture is crushed after the composite reaction, the crushed mixture is graphitized, andthe graphitized mixture is modified and carbonized. The negative electrode material prepared by the method takes secondary granules serve as a core, the surfaces of the negative electrode material are wrapped by double layers, and the negative electrode material has the advantages of high capacity and good rapid charge performance and solves the problem that the capacity and rapid charge performance cannot be taken into account in the prior art.

Owner:HUNAN SHINZOOM TECH

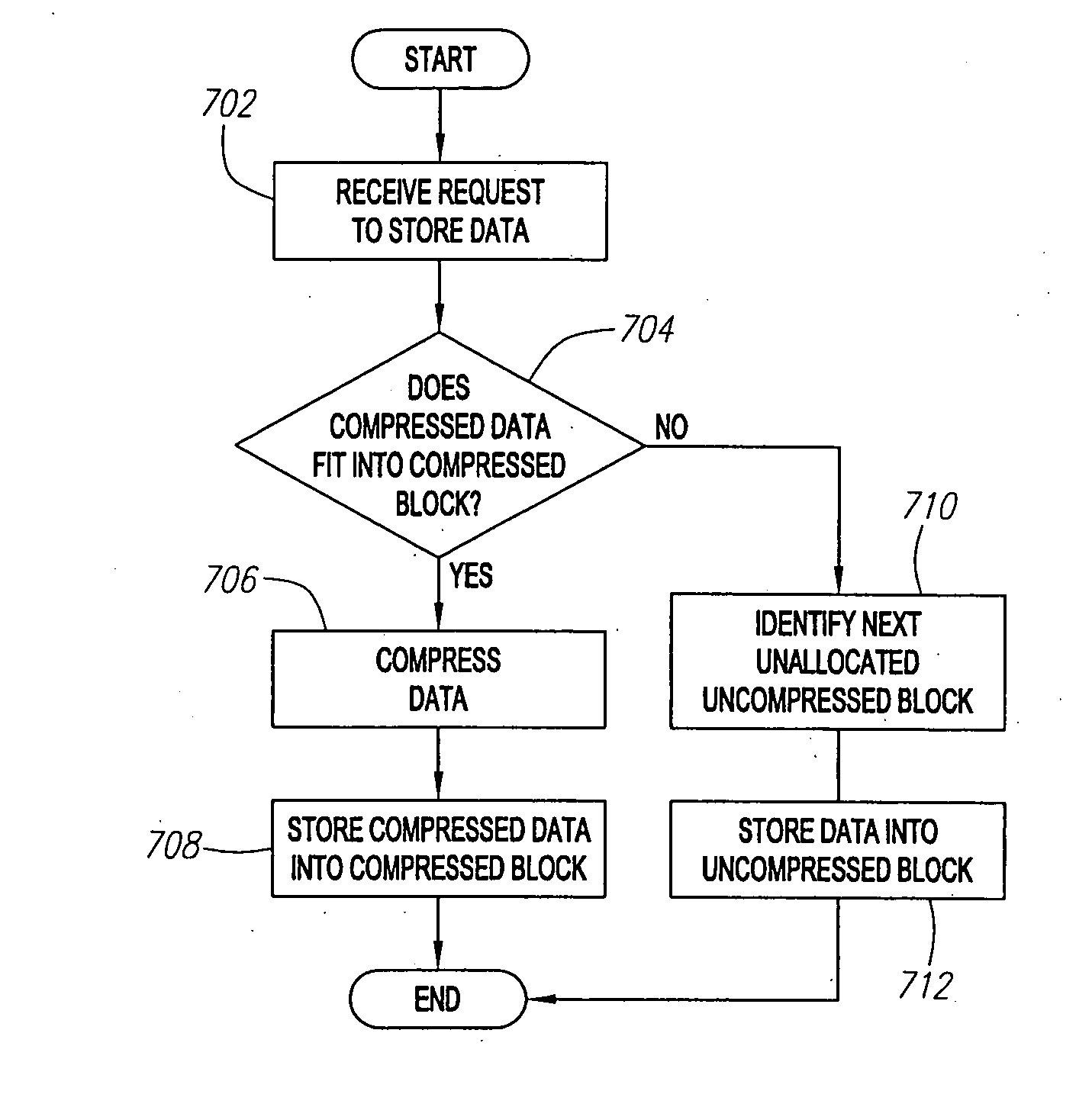

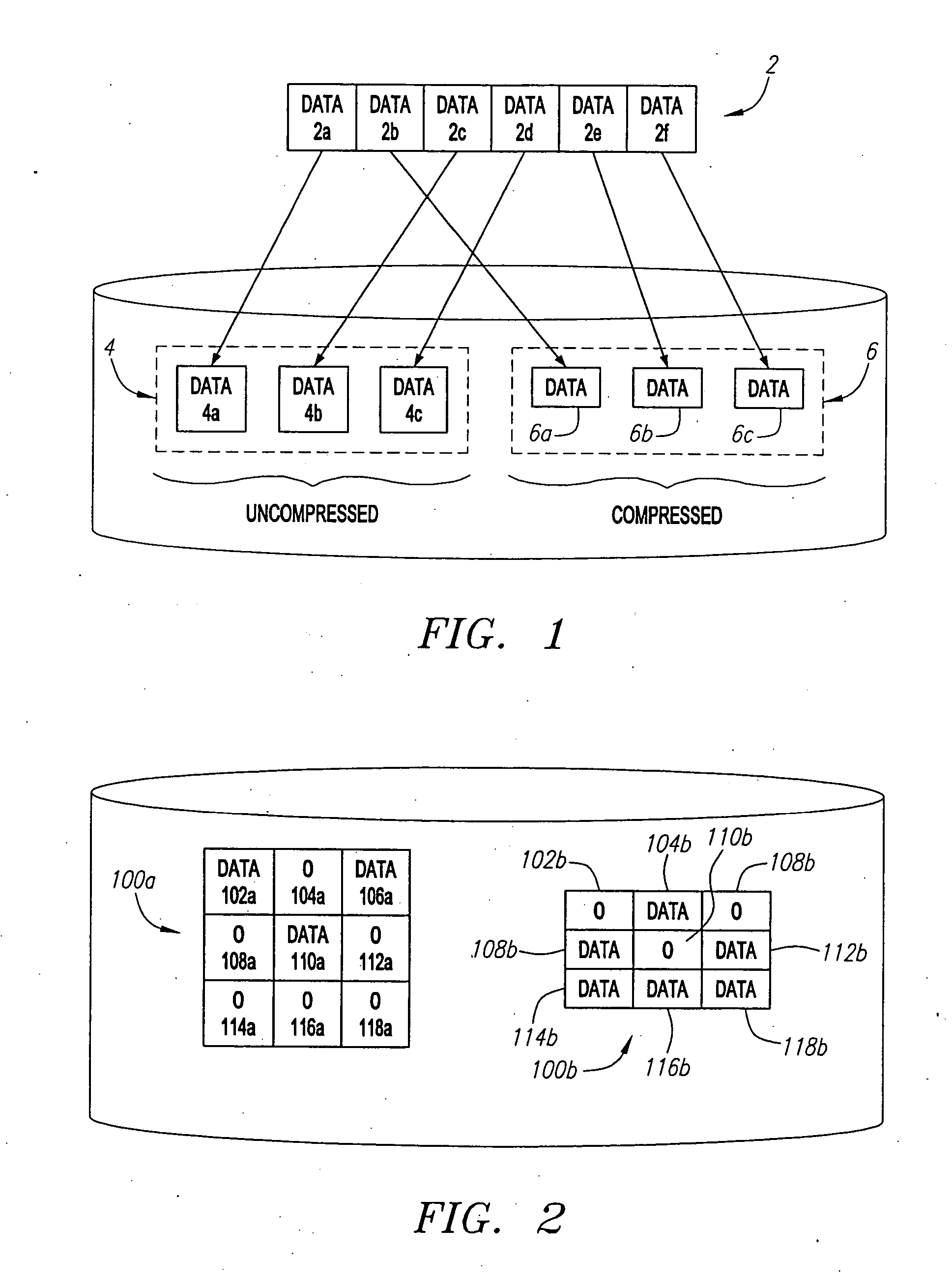

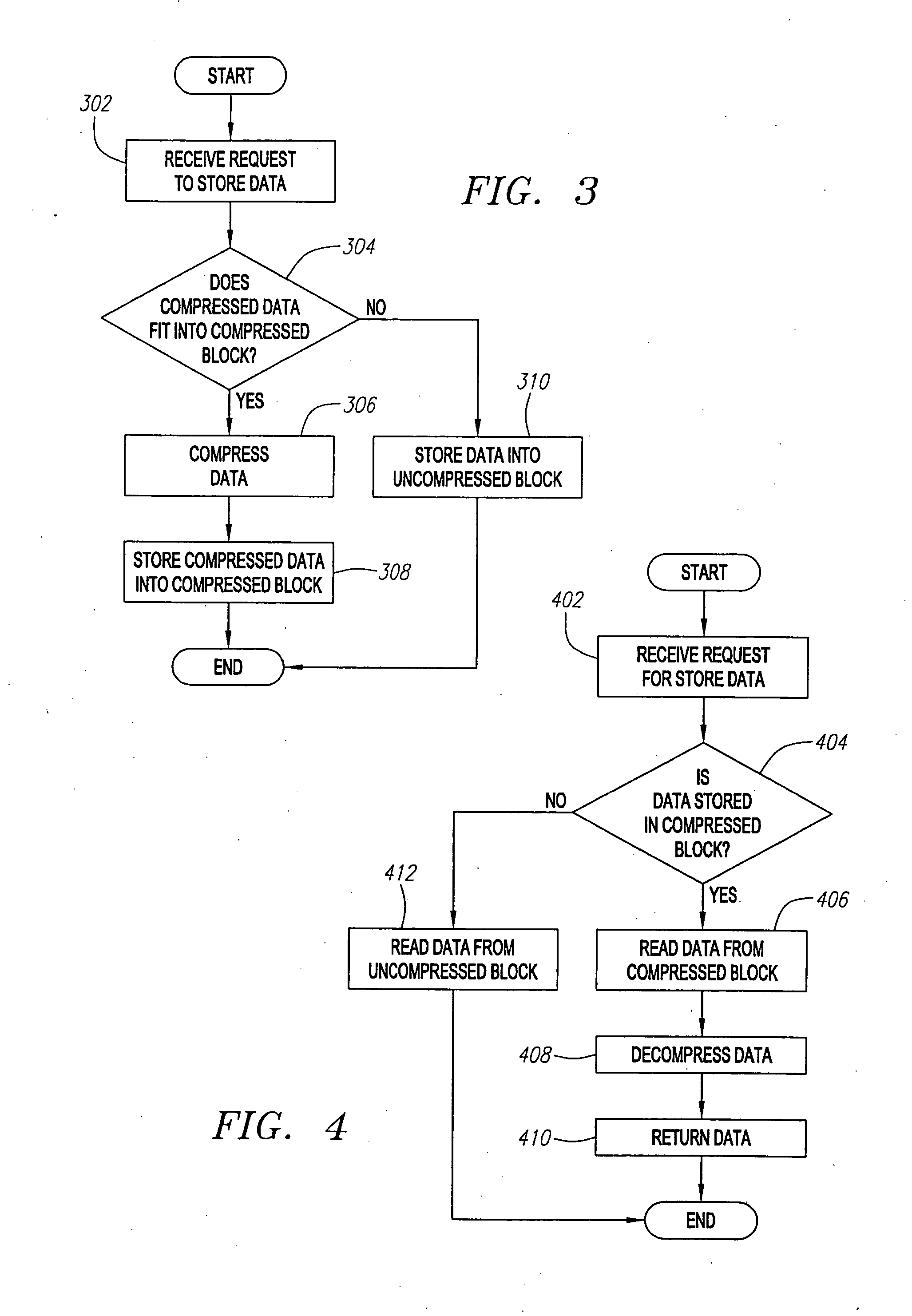

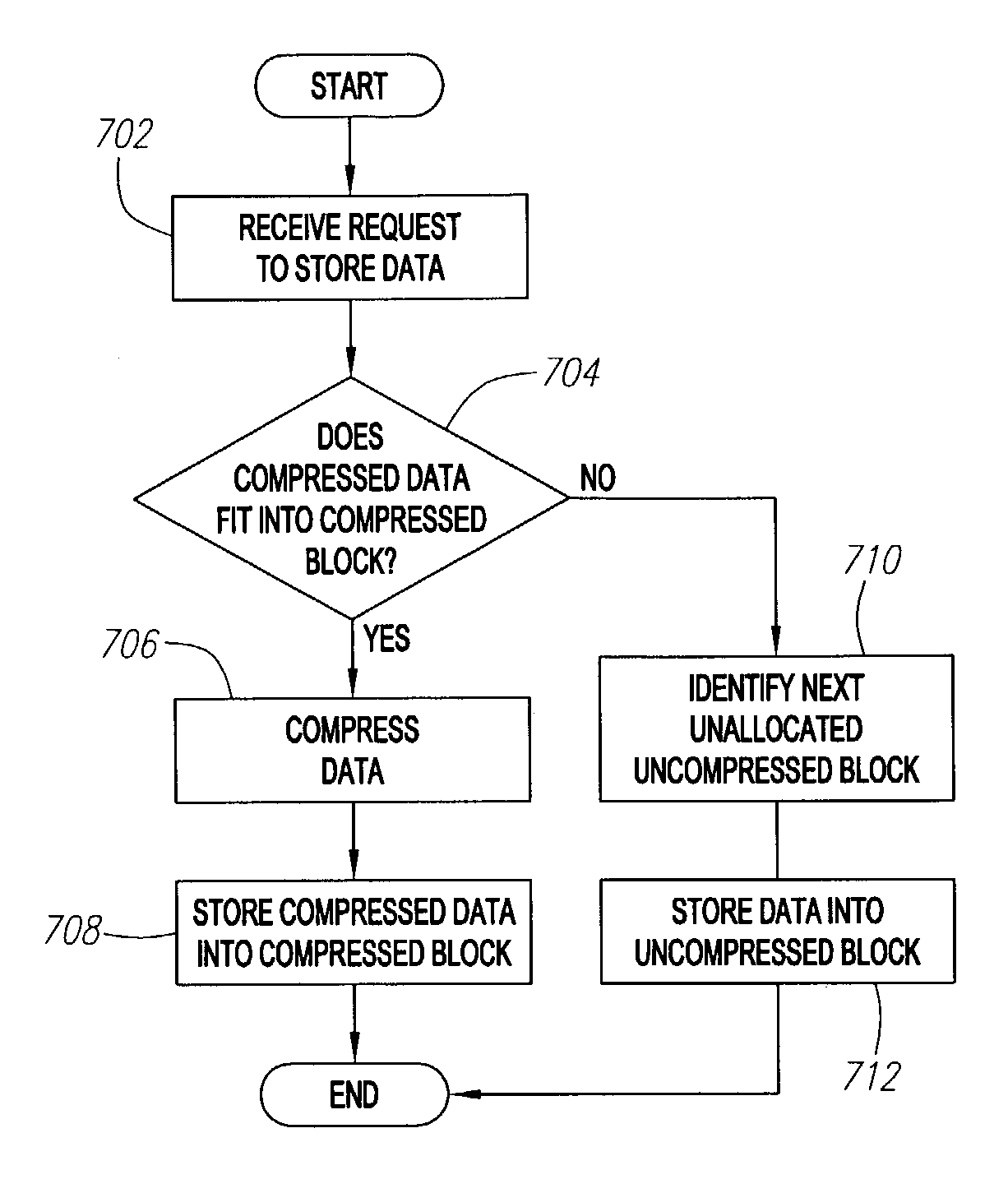

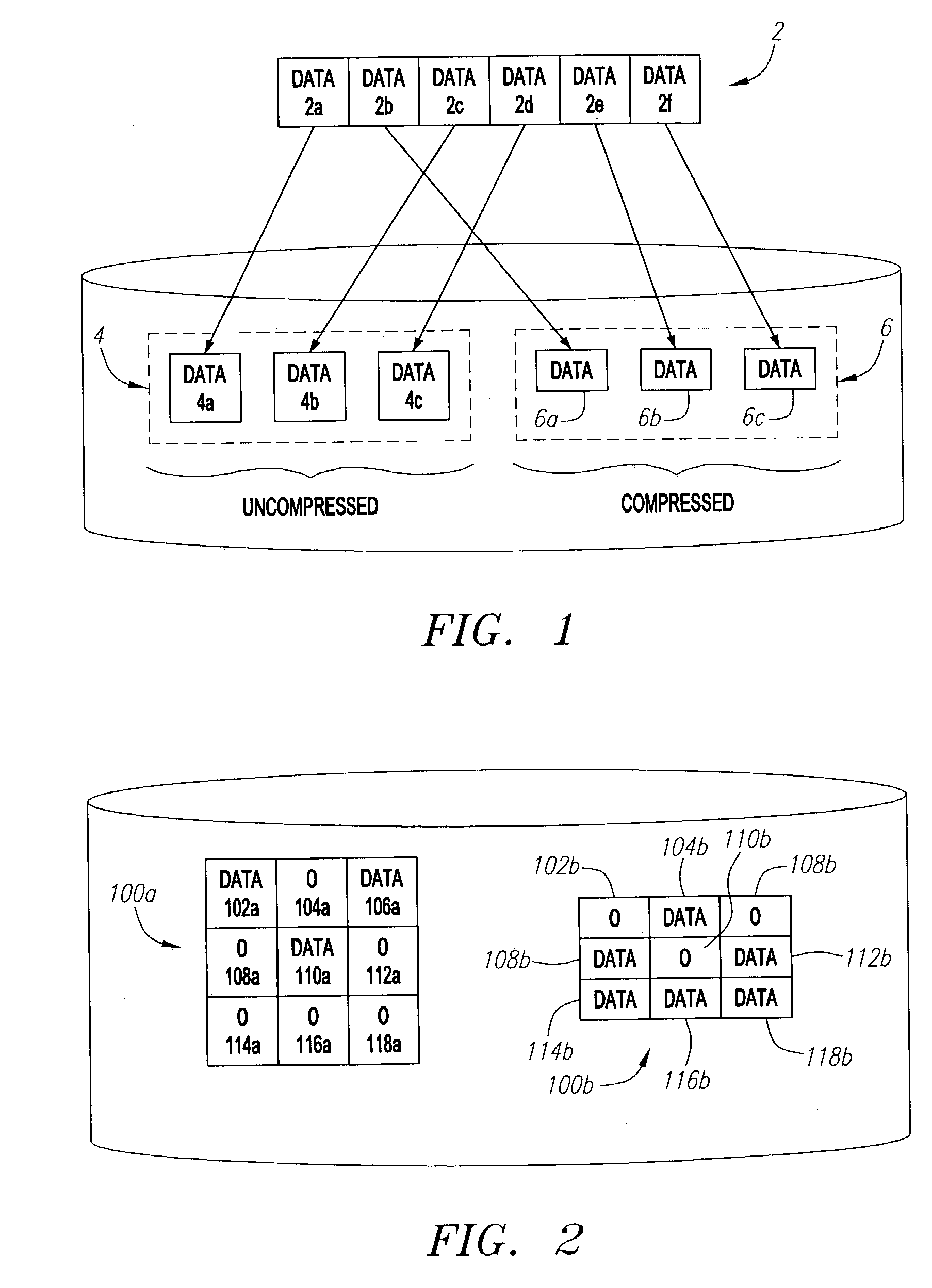

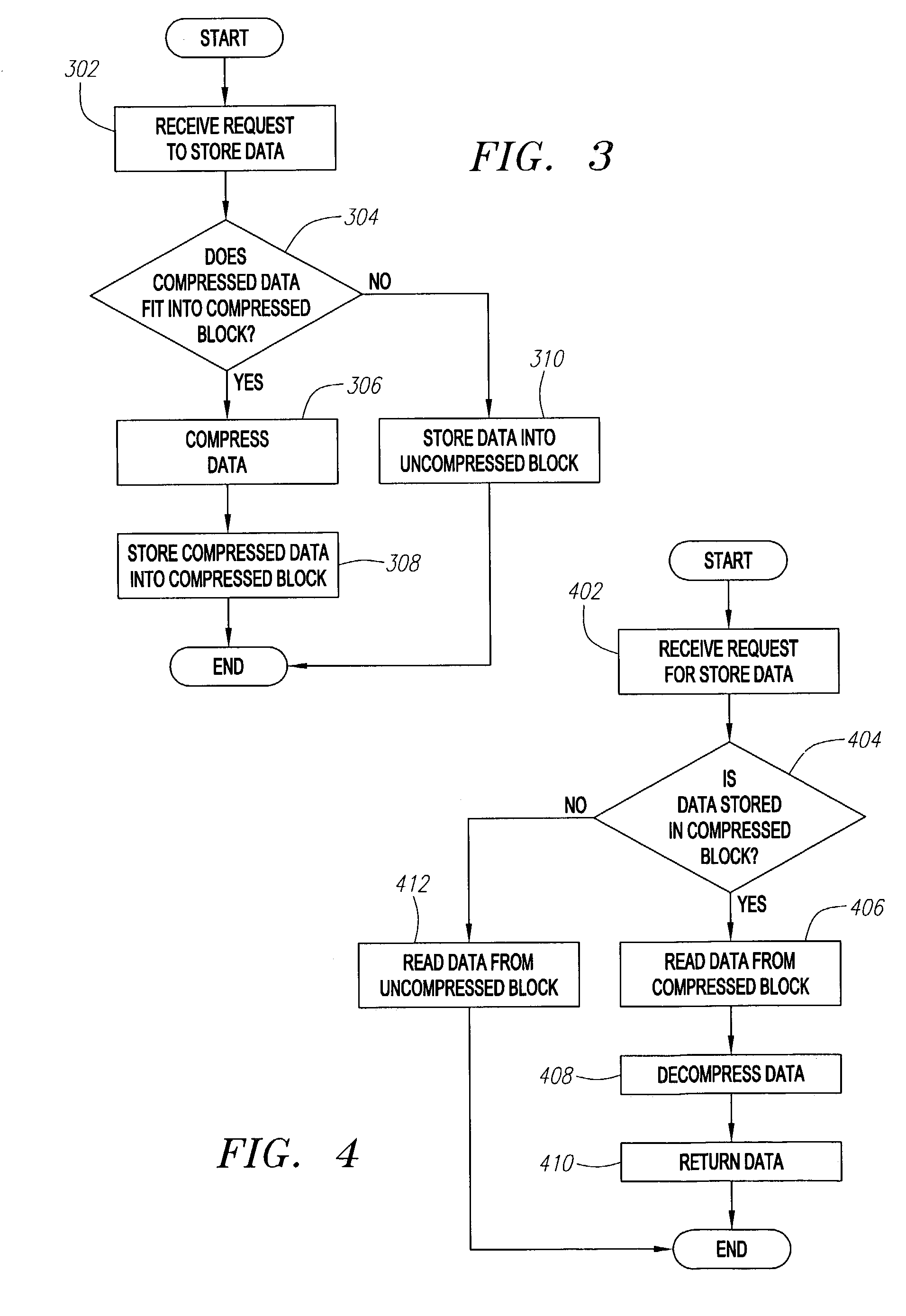

Method and mechanism for on-line data compression and in-place updates

InactiveUS20060212672A1Low costReduce data volumeInput/output to record carriersData processing applicationsData compressionOperating system

A method and mechanism is disclosed for implementing storage and compression in a computer system. Each granular portion of a file can be individually stored in either a compressed storage unit or an uncompressed storage unit. The storage units can be allocated apriori or on an as-needed basis.

Owner:ORACLE INT CORP

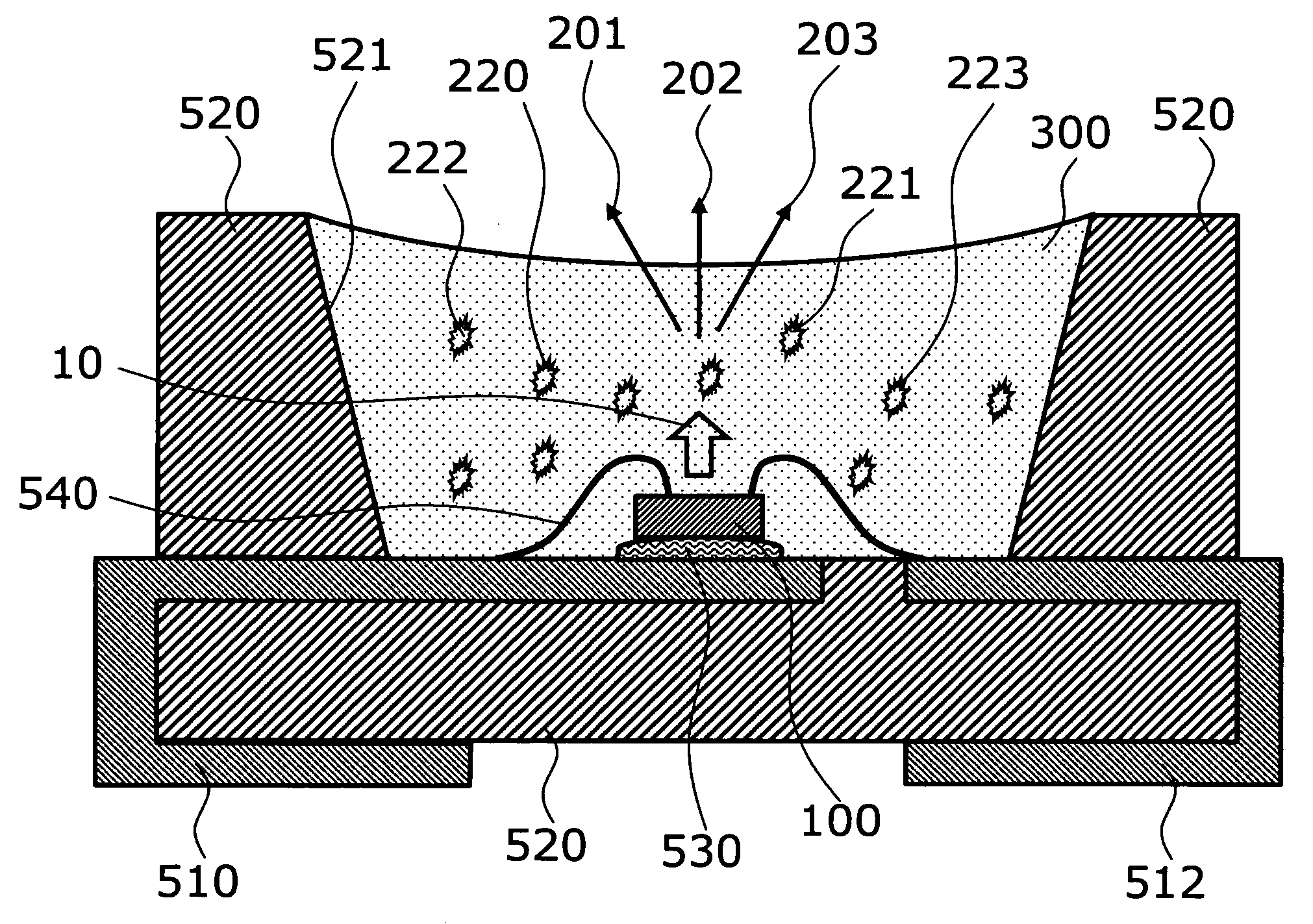

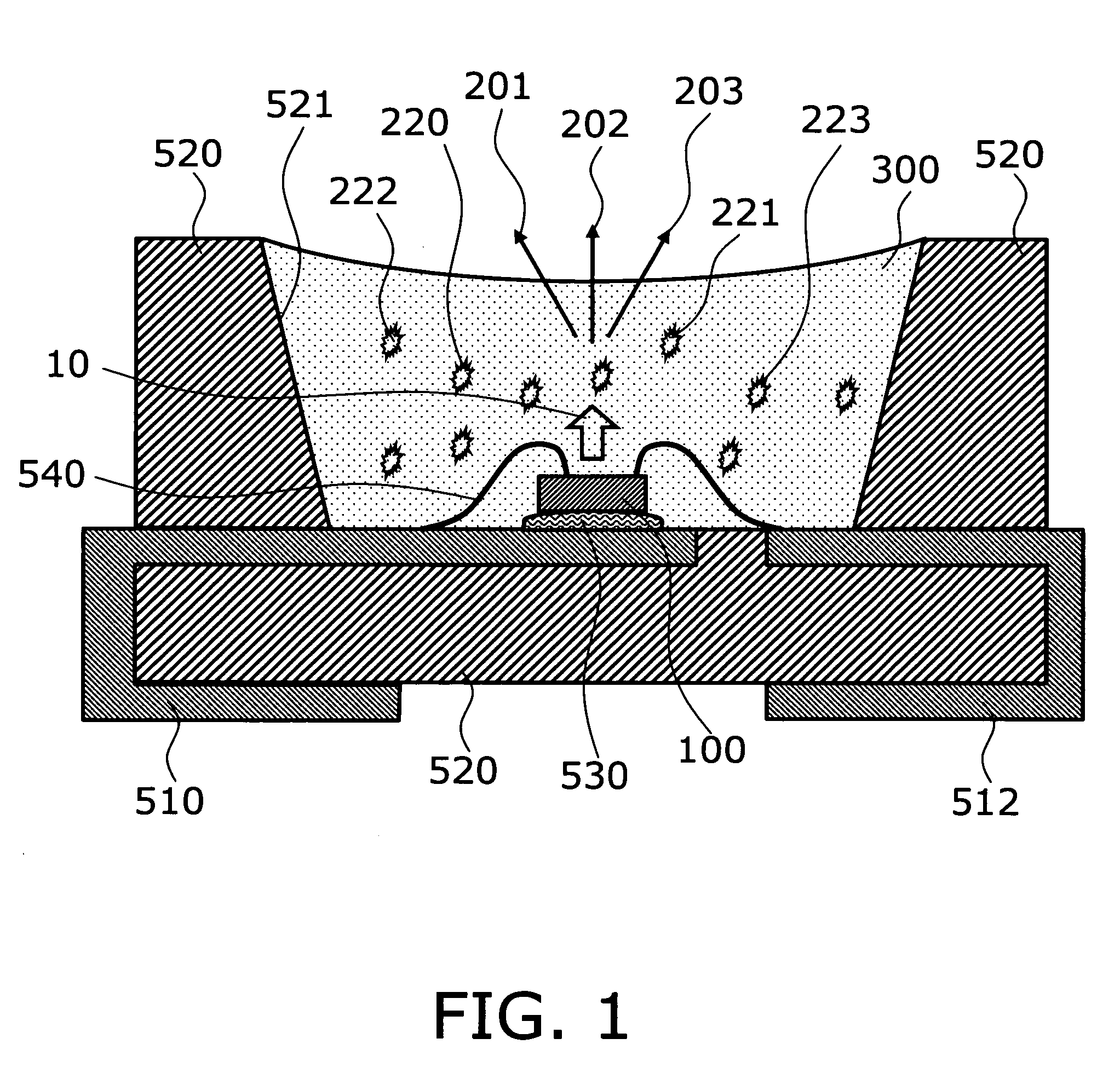

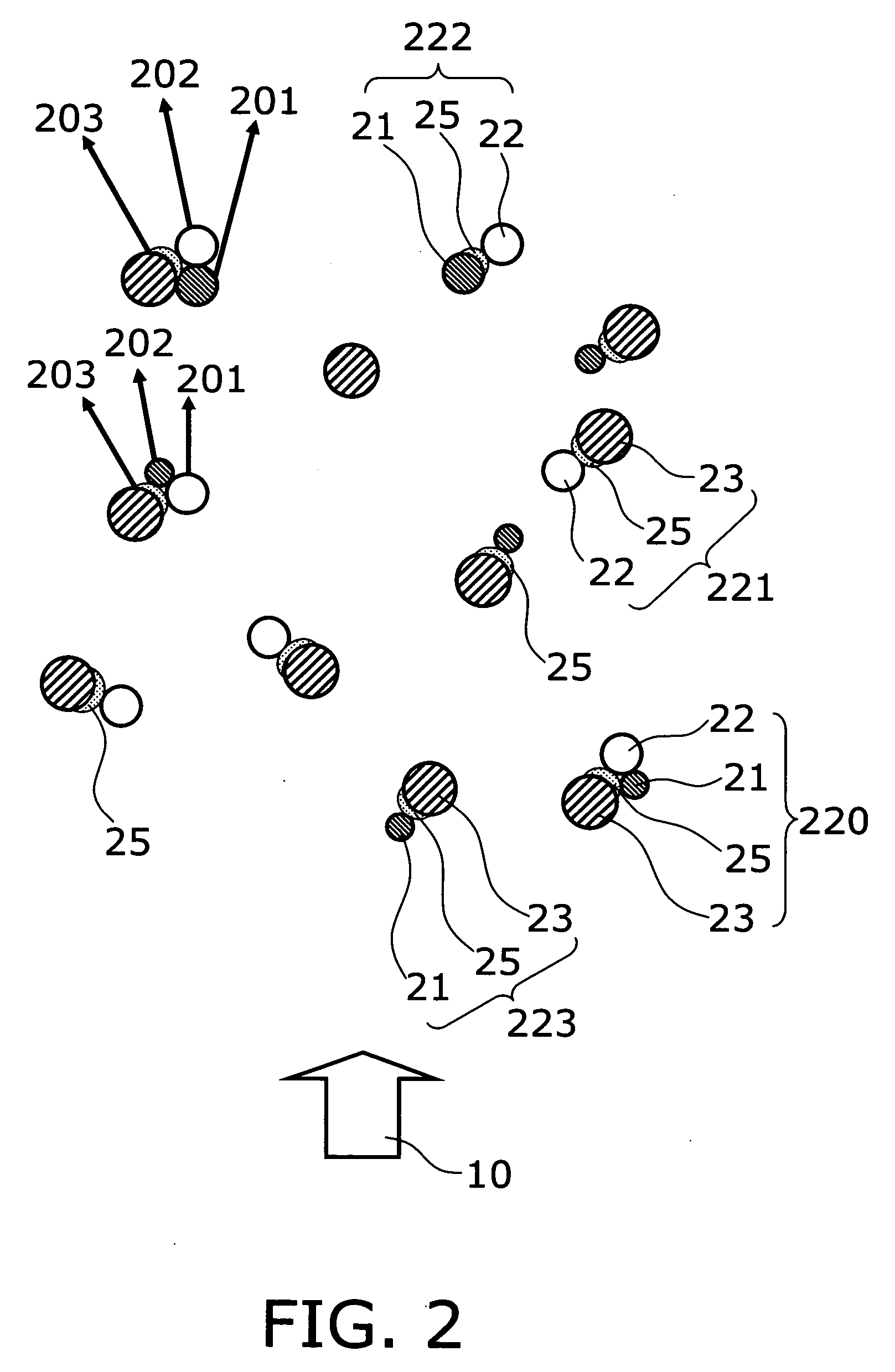

Semiconductor light emitting device

ActiveUS20060071591A1Small granularityDischarge tube luminescnet screensLamp detailsPhosphorLength wave

A semiconductor light emitting device comprises: a semiconductor light emitting element that emits light of a first wavelength; at least two kinds of phosphors that absorb the light of the first wavelength and then emit wavelength-converted light; sealing resin in which the at least two kinds of phosphors are dispersed and the semiconductor light emitting element is embedded; and binder resin. Combined bodies in which the at least two kinds of phosphors are combined by the binder resin are dispersed in the sealing resin.

Owner:SEOUL SEMICONDUCTOR

Method and mechanism for on-line data compression and in-place updates

InactiveUS7058783B2Small granularity of dataAffect maintainabilityData processing applicationsInput/output to record carriersStorage cellData compression

A method and mechanism is disclosed for implementing storage and compression in a computer system. Each granular portion of a file can be individually stored in either a compressed storage unit or an uncompressed storage unit. The storage units can be allocated apriori or on an as-needed basis.

Owner:ORACLE INT CORP

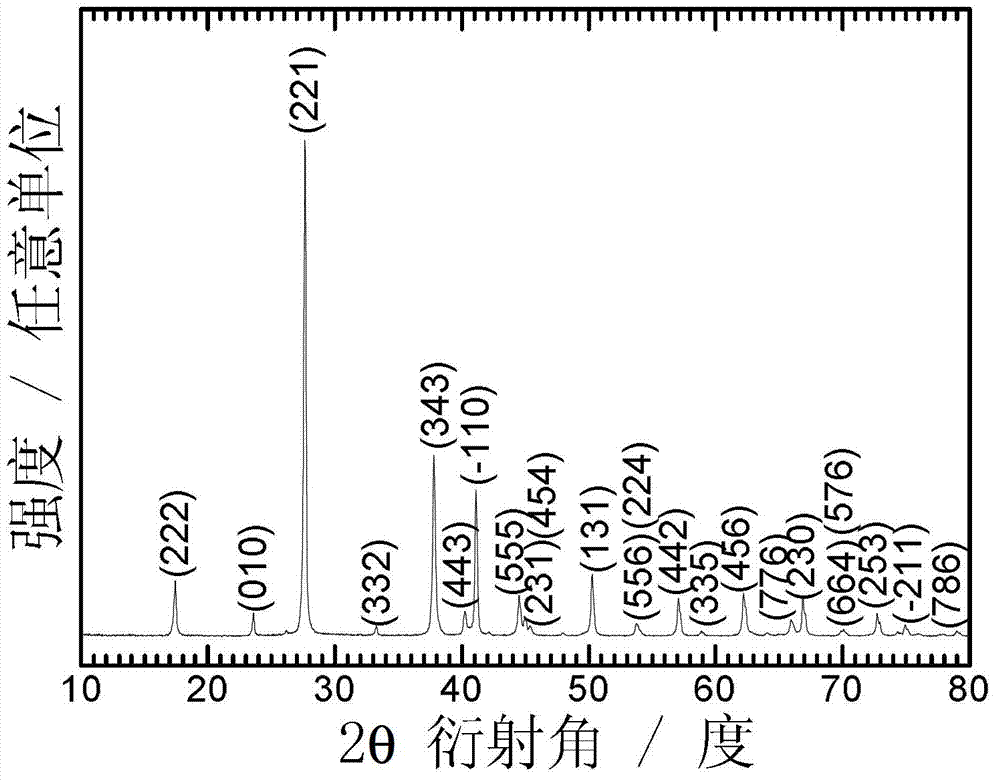

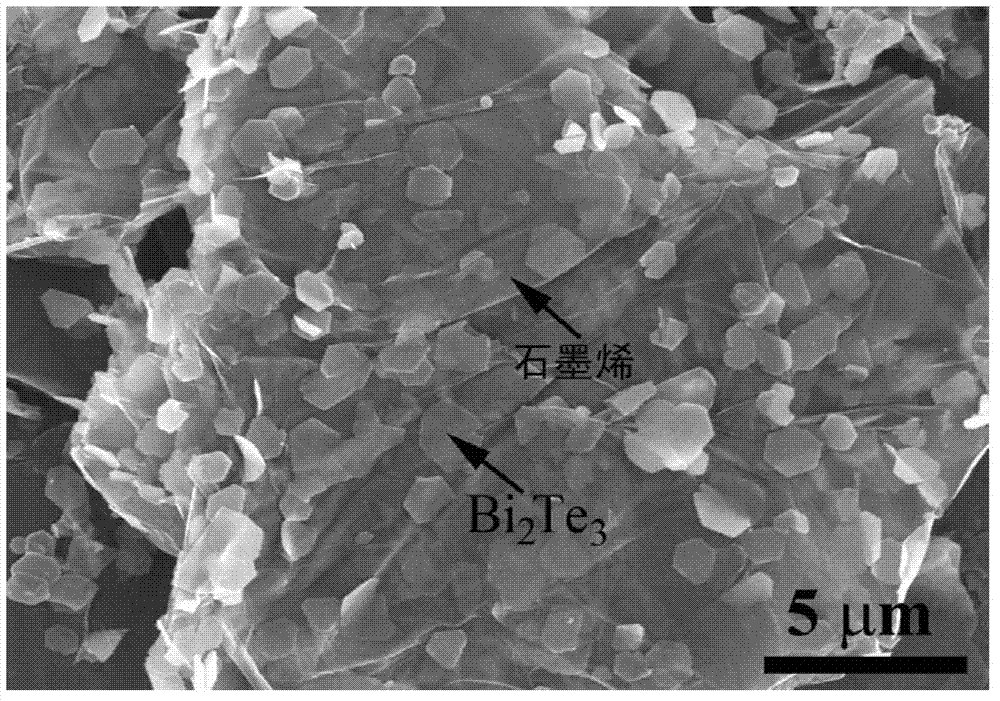

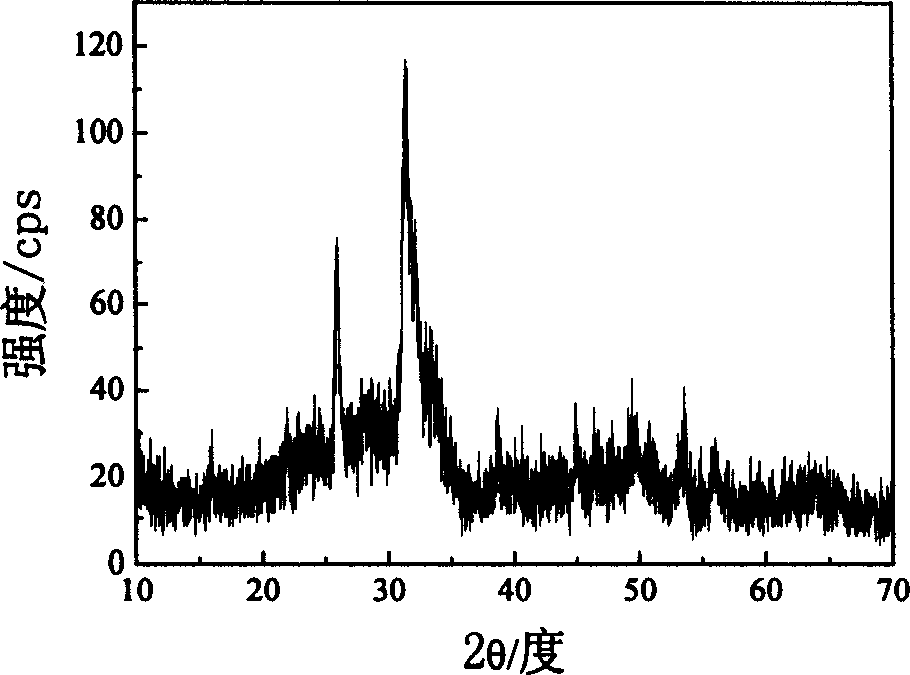

Bi2Te3 thin-piece/graphene composite material, preparation method and applications thereof

InactiveCN102760827AImprove thermoelectric performanceAvoid reunionGrapheneThermoelectric device junction materialsSolventCvd graphene

The invention discloses a Bi2Te3 thin-piece / graphene composite material. The Bi2Te3 thin-piece / graphene composite material consists of a micron-sized Bi2Te3 thin sheet and graphene. Due to the actions of dispersion, bearing and isolation of the graphene, the sintering of the micron-sized Bi2Te3 thin sheet in the heat-treatment process can be effectively prevented for maintaining effective scattering of the crystal boundary to phonons, and the great significance for improving the thermoelectric properties of the Bi2Te3 material is embodied. The composite material can be used as a thermoelectric material. The invention also discloses a preparation method of the composite material by a one-step hydrothermal method or a one-step solvothermal method, and has the advantages of simple process, low cost, short period and low energy consumption and the like.

Owner:ZHEJIANG UNIV

Nanometer hydroxyapatite powder preparation method

InactiveCN1544318AGood crystallizationSmall granularityEnergy based chemical/physical/physico-chemical processesPhosphorus compoundsCalcium nitrate tetrahydrateApatite

A process for preparing nano hydroxyapatite powder comprises the steps of, mixing Ca(NO3)-2-4H20 and NH4-2HPO-4 according to the mol ratio of Ca:P = 1.67-2.5:1, dissolving by charging distilled water, making the concentration of the Ca2++ ion to be 0.01-0.1 mol / L, charging aquadrate powder into the solution according the ratio of Ca(NO3)-2-4H2O : NH4-2HPO-4 = 1:5-12, conducting sound chemo synthesis through multiple frequency phonochemical generator, filtrating and washing the suspending liquid, placing the filtered material into vacuum drying oven for drying at the temperature of 80-100 deg. C, thus the nano hydroxyapatite powder can be obtained.

Owner:SHAANXI UNIV OF SCI & TECH

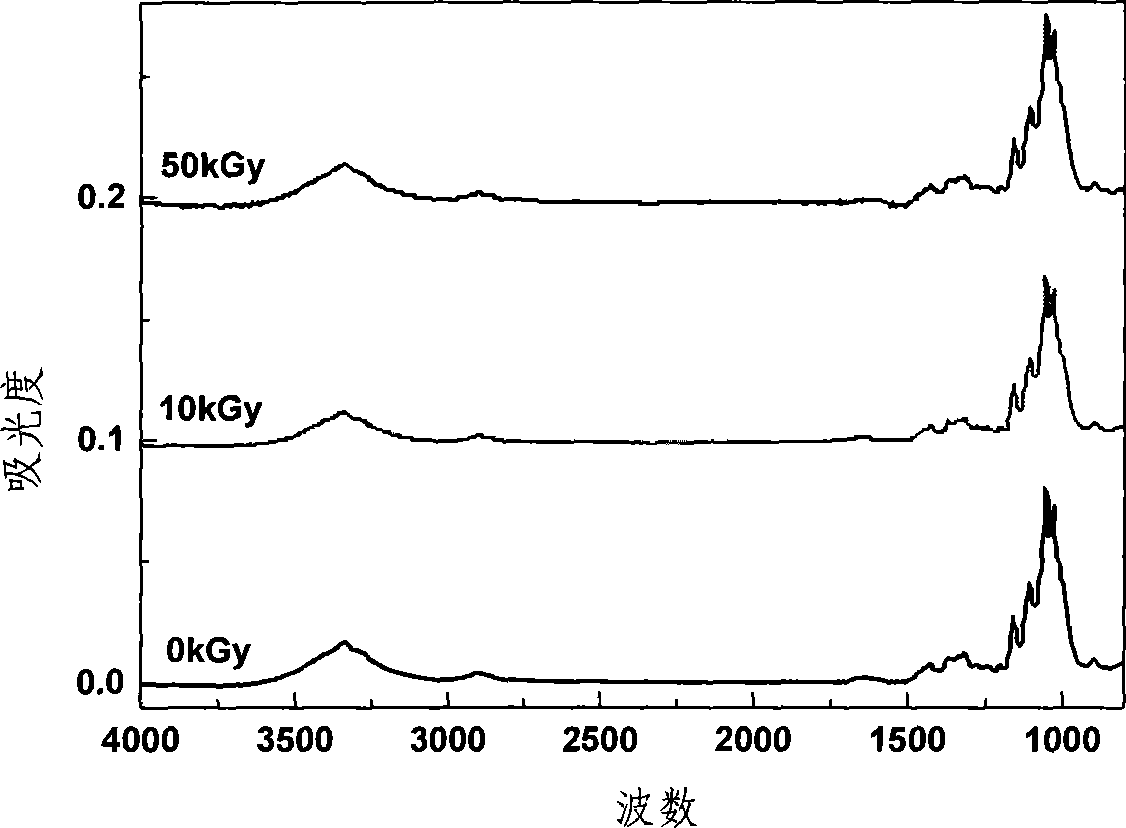

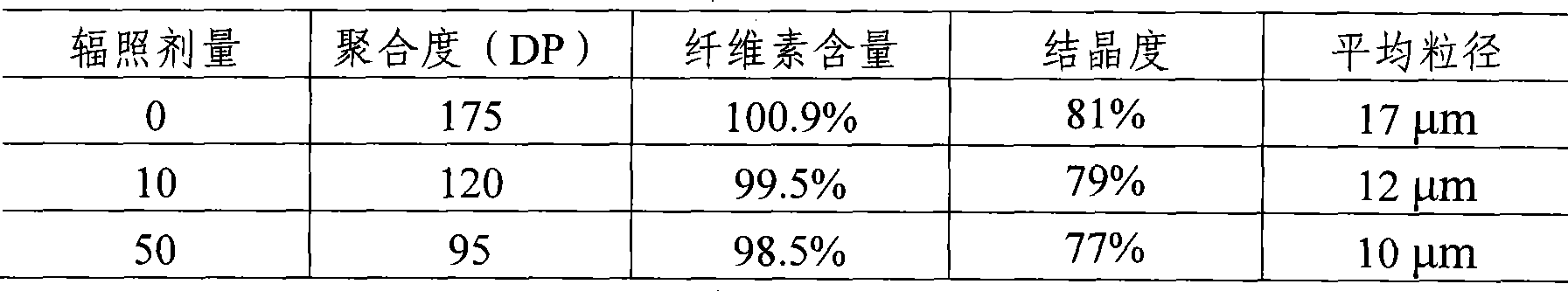

Ultra-fine microcrystalline cellulose and preparation thereof

InactiveCN101481424AGood dispersionImprove stabilityCosmetic preparationsToilet preparationsFood additiveEmulsion

The invention relates to superfine microcrystalline cellulose with particle size less than 10mum. The superfine microcrystalline cellulose with the particle size less than 10mum is obtained by degradation and superfine treatment of microcrystalline cellulose. The superfine microcrystalline cellulose can be widely applied to preparation of food additives, pharmaceutic adjuvants, emulsion stabilizers of cosmetics and thickening stabilizers of coating, and has high dispersibility and storage stability in water, better forming property, adhesiveness, water swellable property, thickening property, thixotropy and the like.

Owner:PEKING UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com