Patents

Literature

276 results about "Electrogalvanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

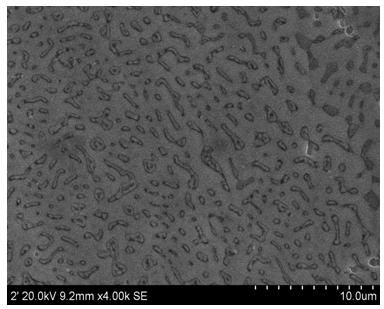

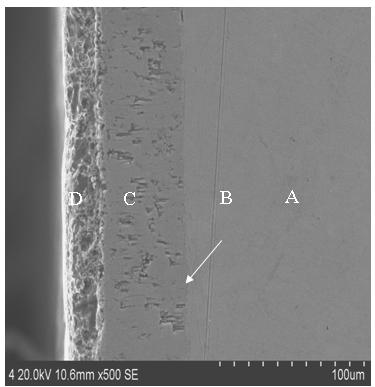

Electrogalvanizing is a process in which a layer of zinc is bonded to steel in order to protect against corrosion. The process involves electroplating, running a current of electricity through a saline/zinc solution with a zinc anode and steel conductor. Zinc electroplating maintains a dominant position among other electroplating process options, based upon electroplated tonnage per annum. According to the International Zinc Association, more than 5 million tons are used yearly for both hot dip galvanizing and electroplating. The plating of zinc was developed at the beginning of the 20th century. At that time, the electrolyte was cyanide based. A significant innovation occurred in the 1960s, with the introduction of the first acid chloride based electrolyte. The 1980s saw a return to alkaline electrolytes, only this time, without the use of cyanide. The most commonly used electrogalvanized cold rolled steel is SECC steel. Compared to hot dip galvanizing, electroplated zinc offers these significant advantages...

Methods for coating a metal substrate and related coated substrates

ActiveUS7749368B2Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsElectrogalvanizationMetallic substrate

Owner:PPG IND OHIO INC

Articles with electroplated zinc-nickel ternary and higher alloys, electroplating baths, processes and systems for electroplating such alloys

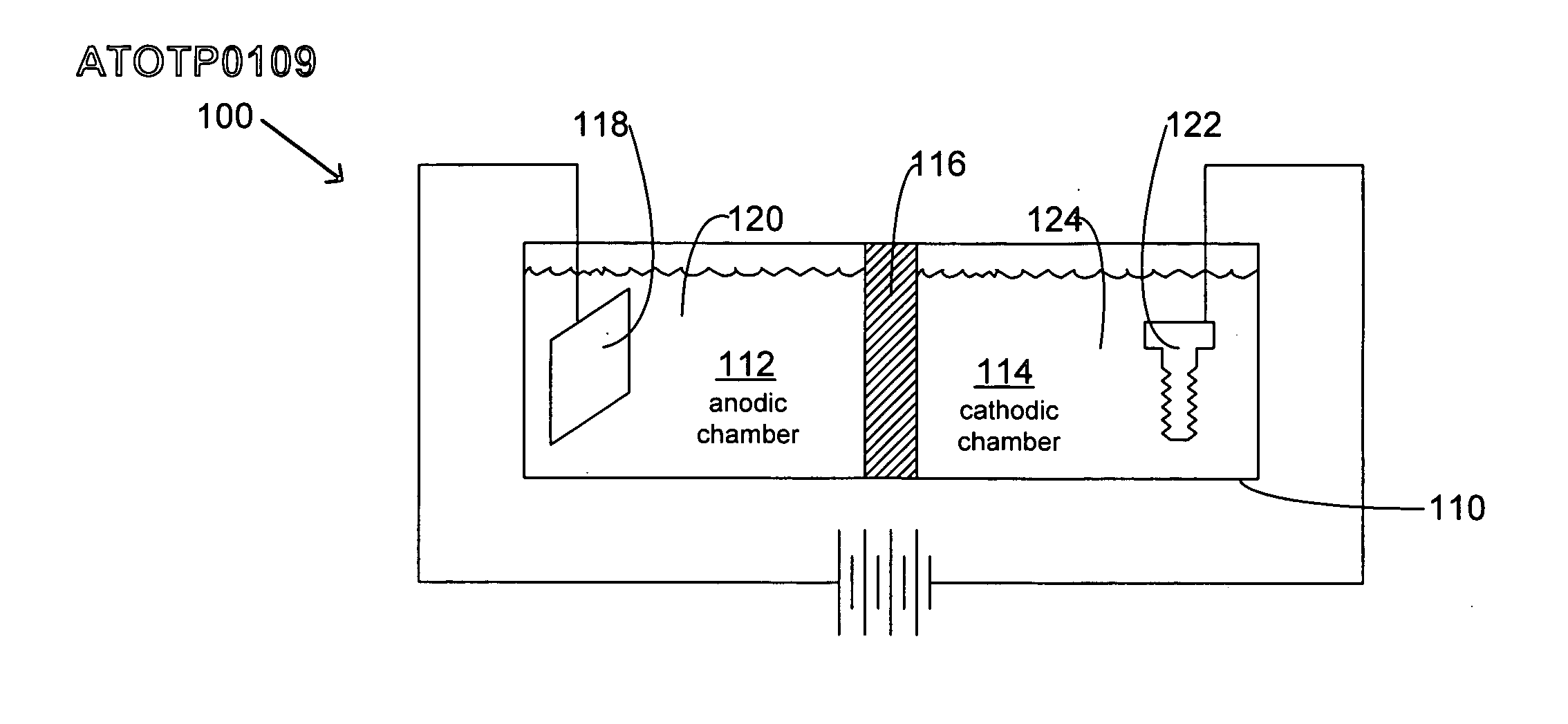

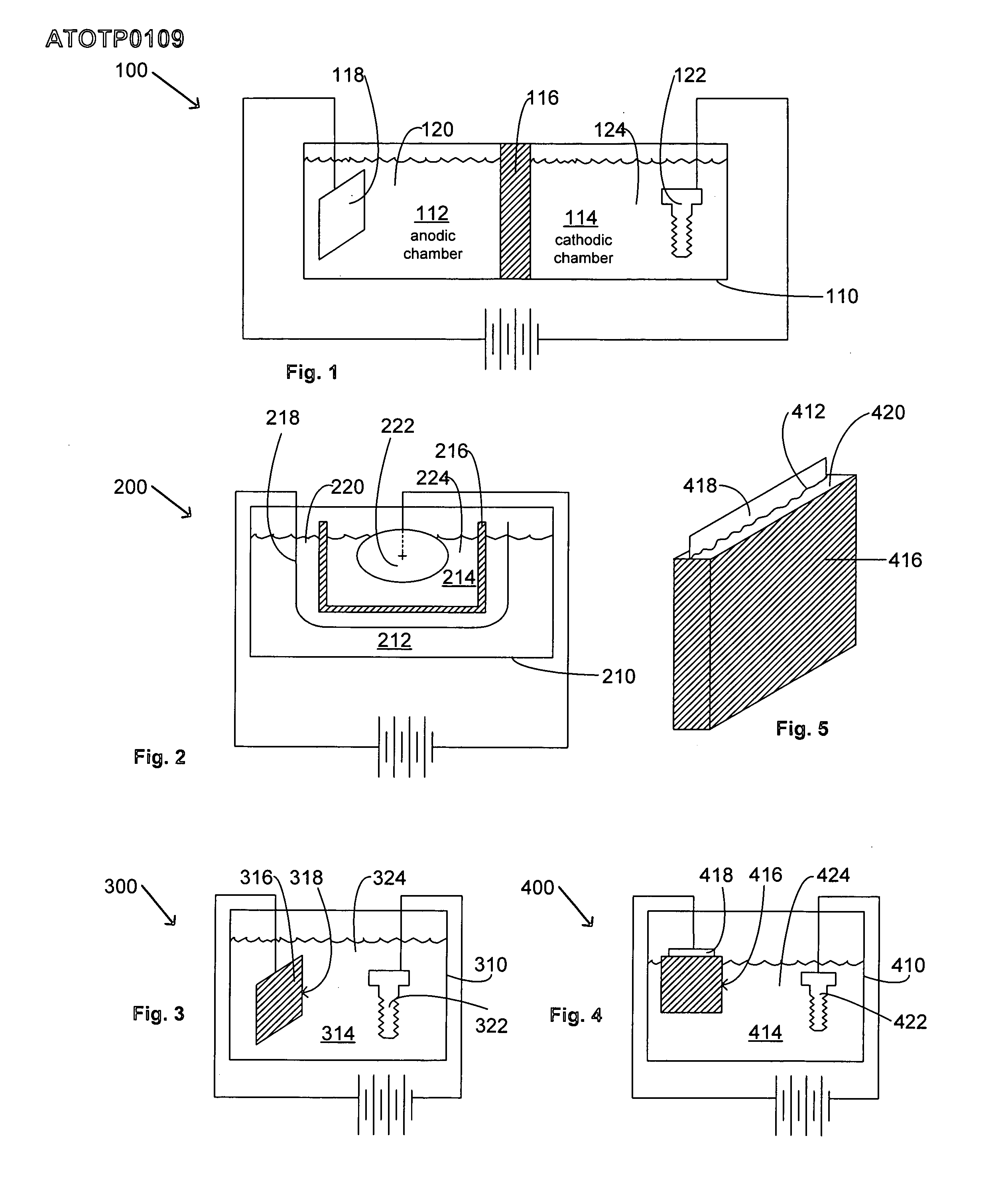

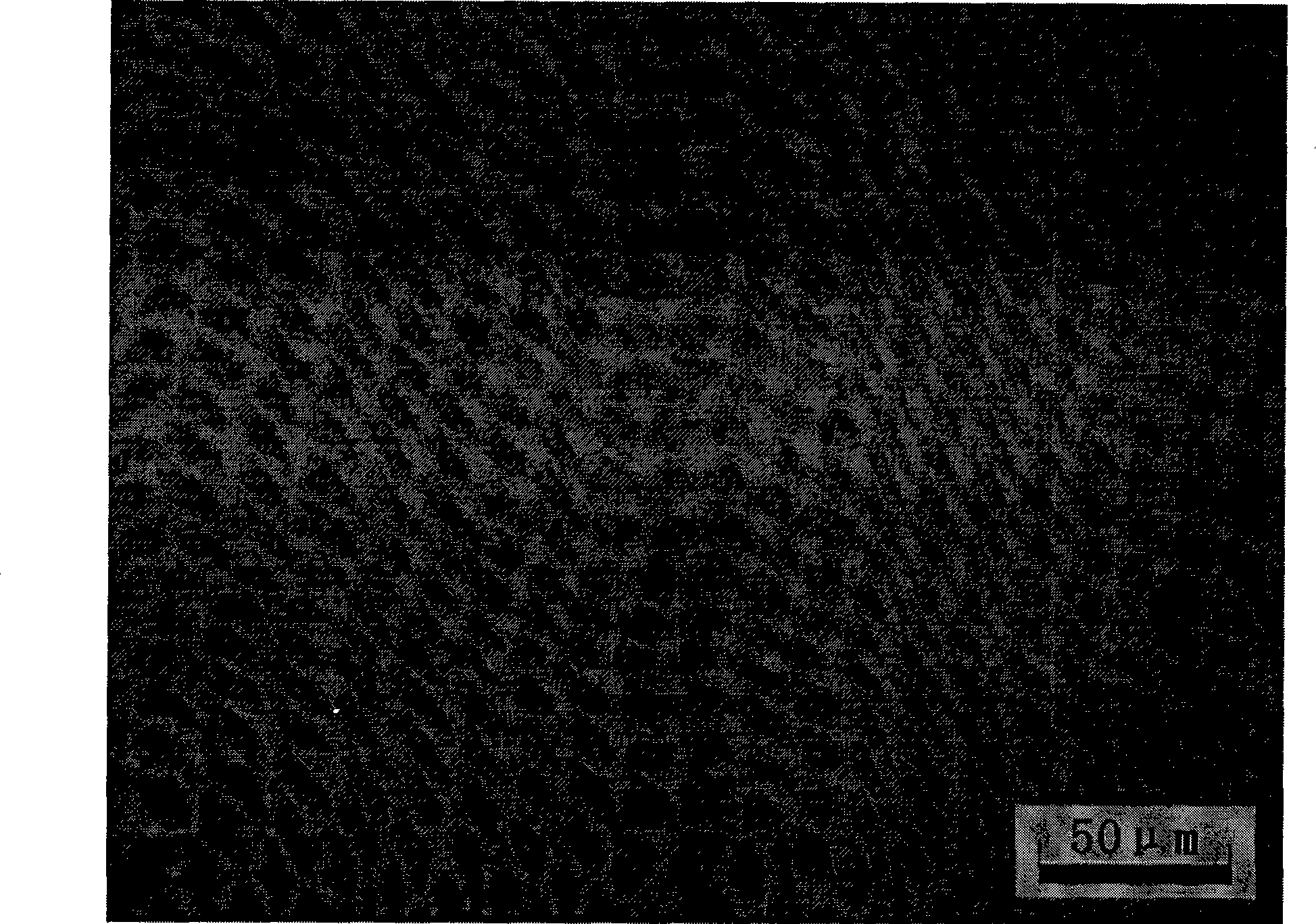

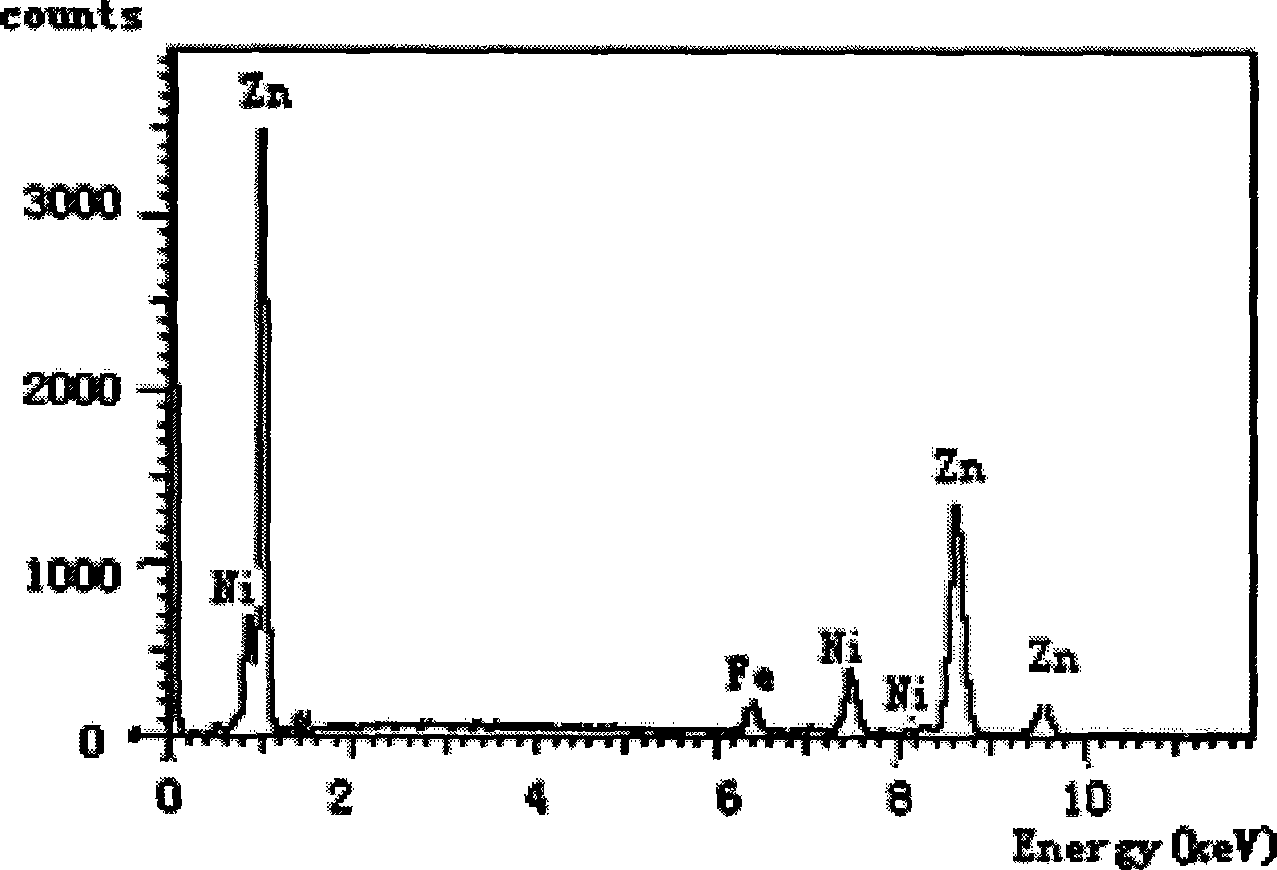

An electroplating bath, a system, a process for, and the article obtained from, depositing a zinc-nickel ternary or higher alloy, a) zinc ions; b) nickel ions; and c) one or more ionic species selected from ions of Te+4, Bi+3 and Sb+3, and in some embodiments, further including one or more additional ionic species selected from ions of Bi+3, Sb+3, Ag+1, Cd+2, Co+2, Cr+3, Cu+2, Fe+2, In+3, Mn+2, Mo+6, P+3, Sn+2 and W+6. In some embodiments, the system includes a divider forming a cathodic chamber and an anodic chamber, with the electroplating bath in the cathodic chamber only. In various embodiments, the zinc-nickel ternary and higher alloys may provide improved properties to the conductive substrates upon which the alloys are deposited.

Owner:ATOTECH DEUT GMBH

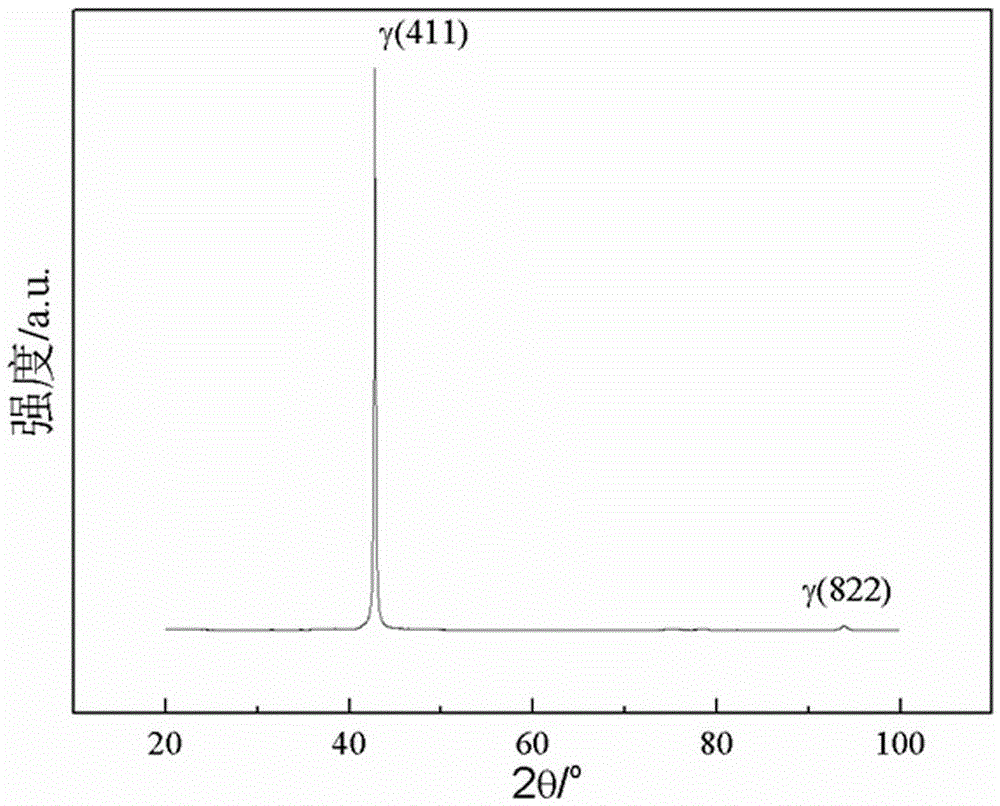

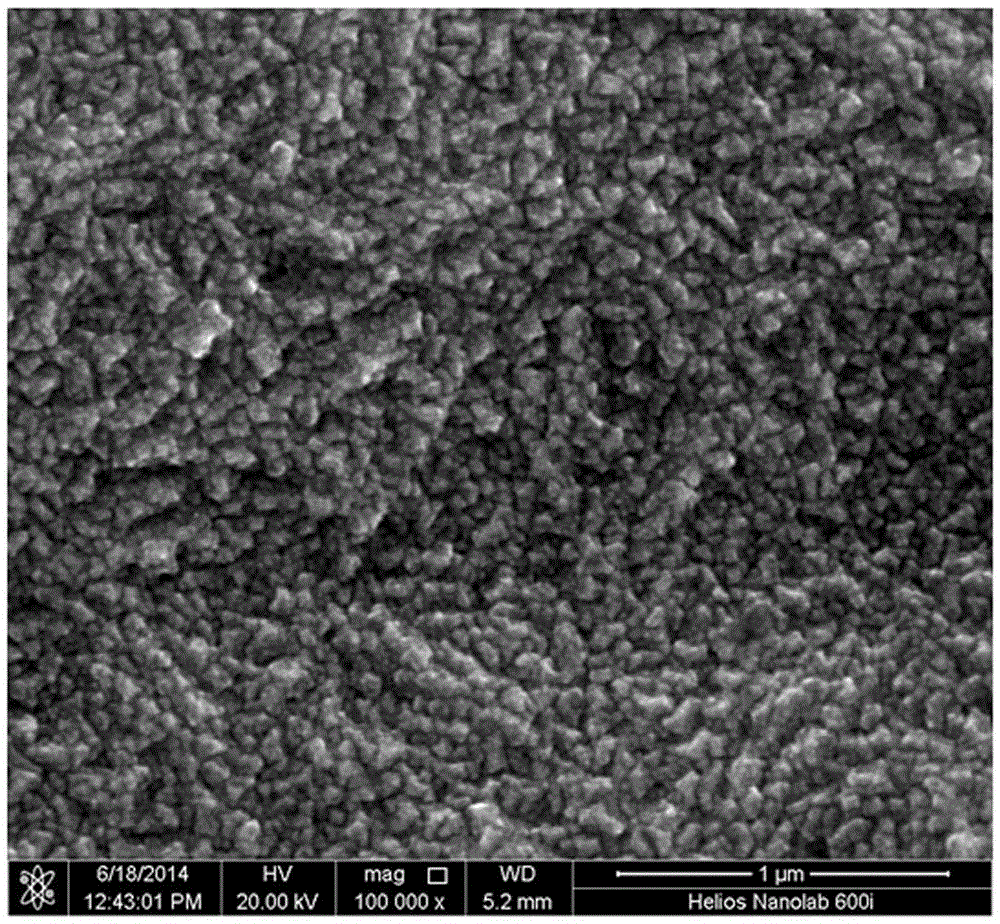

Method for plating zinc-nickel alloy in alkaline electroplate liquid

InactiveCN101240437ASolve the problem of large compositional changesImprove current efficiencyWater basedOrganic solvent

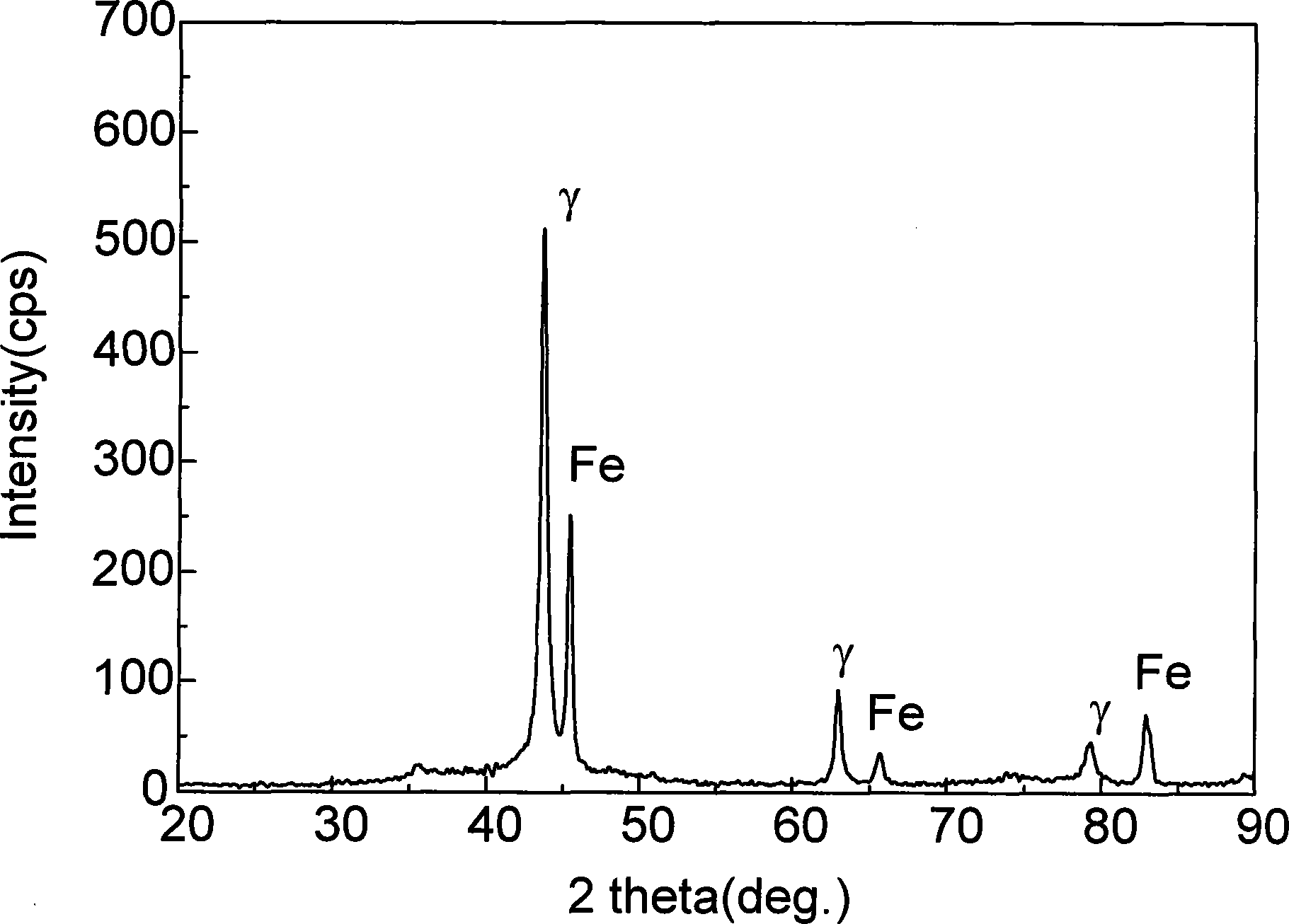

The invention discloses a method for electroplating alkaline Zn-Ni alloy, comprising the steps of: preparing alkali wash and acid wash, preparing electroplating Zn-Ni alloy plating solution, mechanical grinding, degreasing with organic solvent or water-based detergent, alkali washing, acid washing and electroplating. The invention provides a stable electroplating solution formula and complete electroplating process. The coating electroplated by the method is proved to have good flat surface, uniform coating distribution and alloy distribution, the coating is single gamma-phase, the nickel has a content of 10% to 15%; the coating has superior corrosion resistance, red rust appears on the non-passivated Zn-Ni coating after 1500 hours in a neutral salt spray test; compared with general alkali electroplating solution, the coating has high current efficiency, reaching up to 80% to 90%.

Owner:BEIHANG UNIV

Magnesium alloy with zinc and nickel compound plating layers and preparation method thereof

The invention discloses a magnesium alloy with zinc and nickel compound plating layers and a preparation method thereof. A zinc plating layer of the magnesium alloy is taken as a bottom layer with the width between 20 microns and 25 microns, a nickel plating layer is taken as a surface layer, and the total width of the zinc plating layer and the nickel plating layer is less than or equal to 40 microns. The method comprises the following steps: firstly, plating preliminary treatment, i.e. zinc is activated in an acid solution and then soaked in sulphate; secondly, zinc electrodeposition, i.e. after the zinc is soaked in the sulphate in the first step, the zinc layer of the magnesium alloy is electrodeposited; thirdly, nickel bright plating, i.e. the magnesium alloy which is nicely processed in the second step is brightly plated with nickel in a nickel plating solution; fourthly, sodium silicate water solution sealing. With the method, the obtained zinc plating layer is nicely combined with a base body, has uniform width and high corrosion resistance, can be taken as a protective plating layer to be singly used and can be also taken as a transition layer to carry out plating or chemical plating or other protective or decorative platings, and the nickel plating layer obtained from the zinc plating layer by plating is nicely combined with the zinc plating layer and is uniform, exquisite, bright and beautiful.

Owner:SOUTHEAST UNIV

Method for passivation of zinc and zinc alloy and chromium-free passivation solution

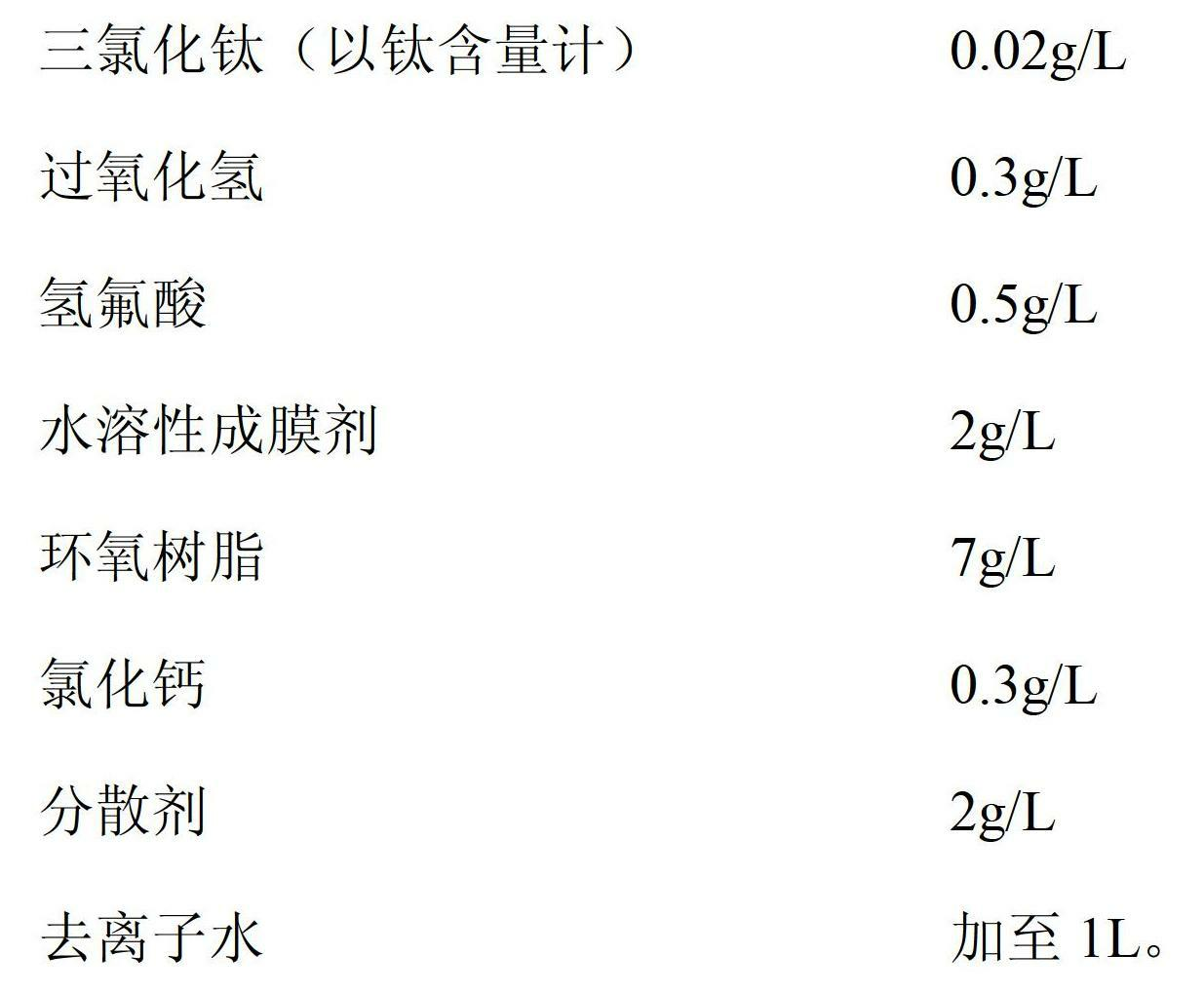

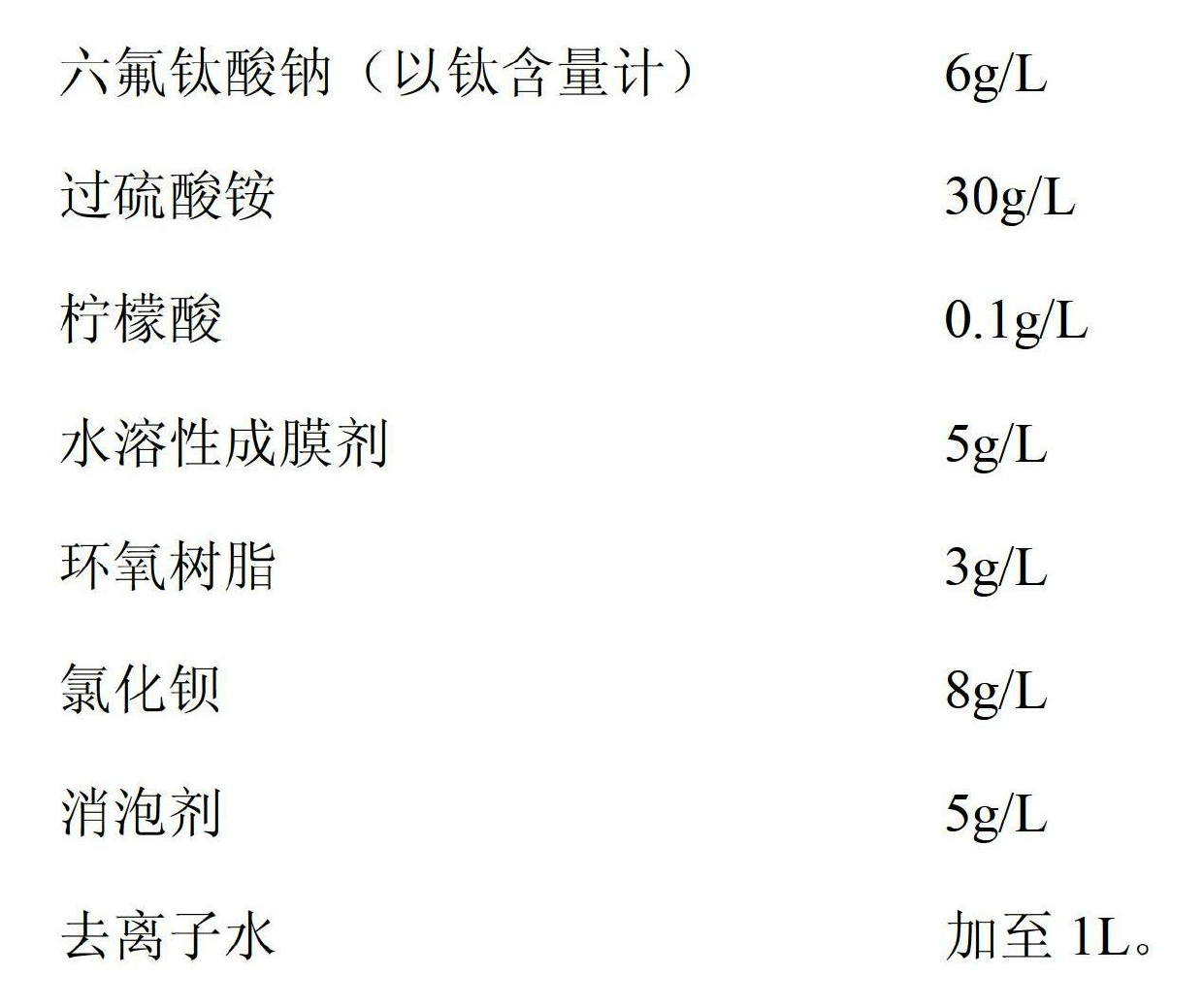

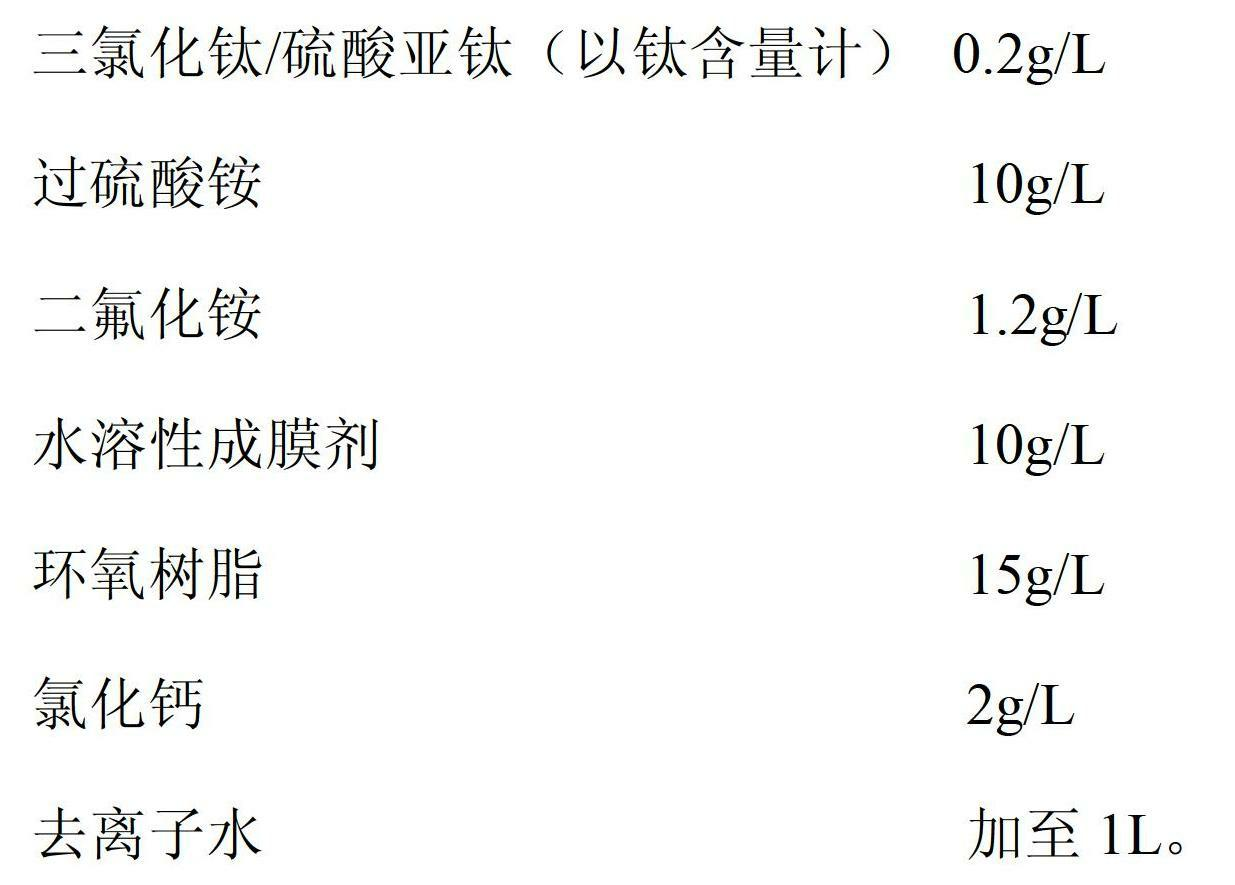

InactiveCN102634785ALow costAvoid harmMetallic material coating processesChromium freeElectrogalvanization

The invention relates to a method for passivation of zinc and zinc alloy and a chromium-free passivation solution. The passivation method comprises the following steps: soaking a workpiece electroplated with a zinc or zinc alloy layer into a chrome-free passivation solution and then standing in the air; re-soaking the workpiece into the chrome-free passivation solution, and then rinsing and blow-drying; finally drying the workpiece to complete passivation. The chromium-free passivation solution comprises the following components: a titanium salt, an oxidant, a complexing agent, a water-soluble film-forming agent, an accelerator, a Group II metal compound and water. The invention provides a chrome-free passivation solution that can generates blue or flash coating on the deposits of zinc and zinc alloy. The coating is uniform with excellent corrosion resistance, and can delay the appearance of white corrosion products. The passivation method provided by the invention is low in cost, easy in waste liquid treatment, and easy in operation and maintenance.

Owner:东莞市闻誉实业有限公司

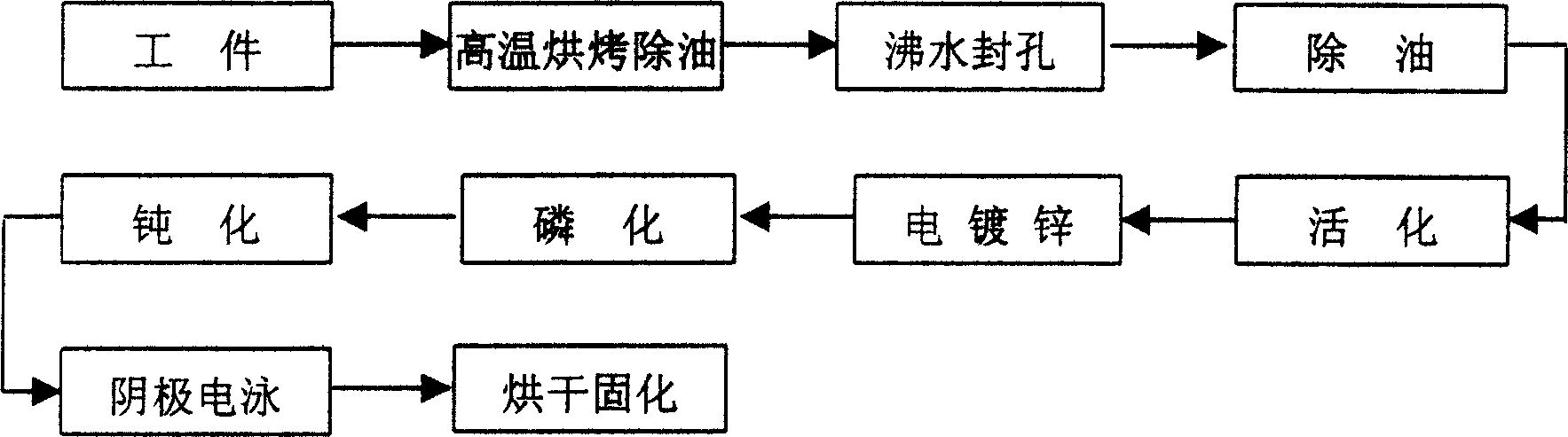

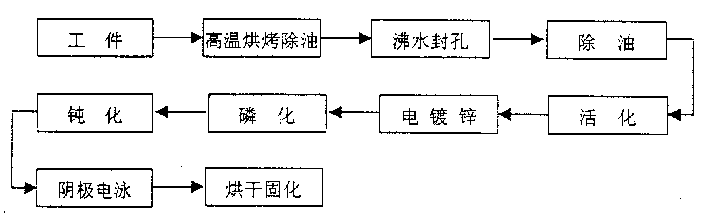

Neodymium-iron-boron magnet zinc plating and cathode electrophoresis composite protection process

InactiveCN1528952AImprove corrosion resistanceImprove water resistanceSuperimposed coating processElectrogalvanizationElectrophoresis

The invention is a kind of zinc coating and catelectrode electrophoresis compound protection method for neodymium iron boron magnet. The technology point is the combination of catelectrode electrophoresis technology and zinc coating technology, and that it carries on parkerising and passivating process after zinc coating, the process includes following steps: (1) high temperature baking deoil; (2) boiled water sealing (3) deoil; (4) rust cleaning; (5) activating; (6) cold galvanizing; (7) parkerising; (8) passivating; (9) catelectrode electrophoresis. The merits of the invention are: combines the zinc coating and catelectrode electrophoresis, and carries on parkerising process after zinc coating, it enhances the corrosion resisting and water enduring and adhesion propery of neodymium iron boron, the corrosion resisting effect is prominent, and prolongs the operating life to 4-5times.

Owner:沈阳工业学院

Method for preparing chromium-free passivation solution, and method for passivating electrogalvanizing or zinc alloy layer by using same

The invention provides a method for preparing chromium-free passivation solution, and a method for passivating an electrogalvanizing or zinc alloy layer by using the same, and relates to a method for preparing the passivation solution and a using method thereof. The method solves the problems that passivation of hexavalent chromium and trivalent chromium generates pollution, and white rust tested in a salt spray test has short time after the electrogalvanizing or zinc alloy layer is passivated by the passivation solution. The method for preparing the chromium-free passivation solution comprises the following steps: 1, preparing concentrated solution A; 2, preparing concentrated solution B; and 3, regulating pH value after the concentrated solution A, the concentrated solution B and deionized water are mixed, and heating or cooling the mixture to 20 to 60 DEG C to obtain the chromium-free passivation solution. The method for passivating the electrogalvanizing or zinc alloy layer by using the chromium-free passivation solution comprises the following steps: 1, secondarily passivating the electrogalvanizing or zinc alloy layer; and 2, aging the electrogalvanizing or zinc alloy layer to complete passivation on the electrogalvanizing or zinc alloy layer. After the electrogalvanizing or zinc alloy layer is passivated by the chromium-free passivation solution, the electrogalvanizing or zinc alloy layer is subjected to neutral salt spray test, and the white rust does not appears on the surface of a passivated film after 84-120 hours of continuous spraying.

Owner:HARBIN INST OF TECH

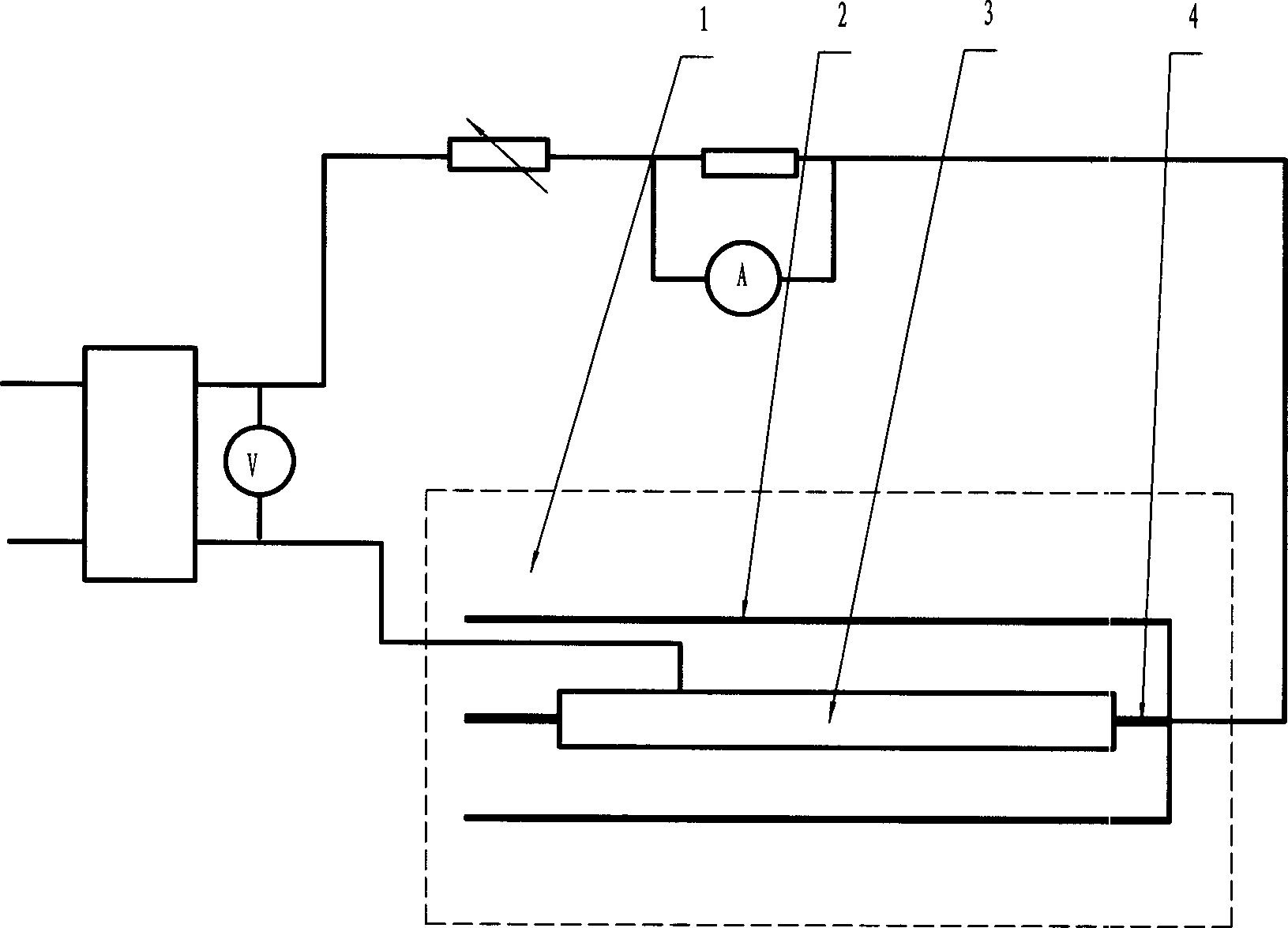

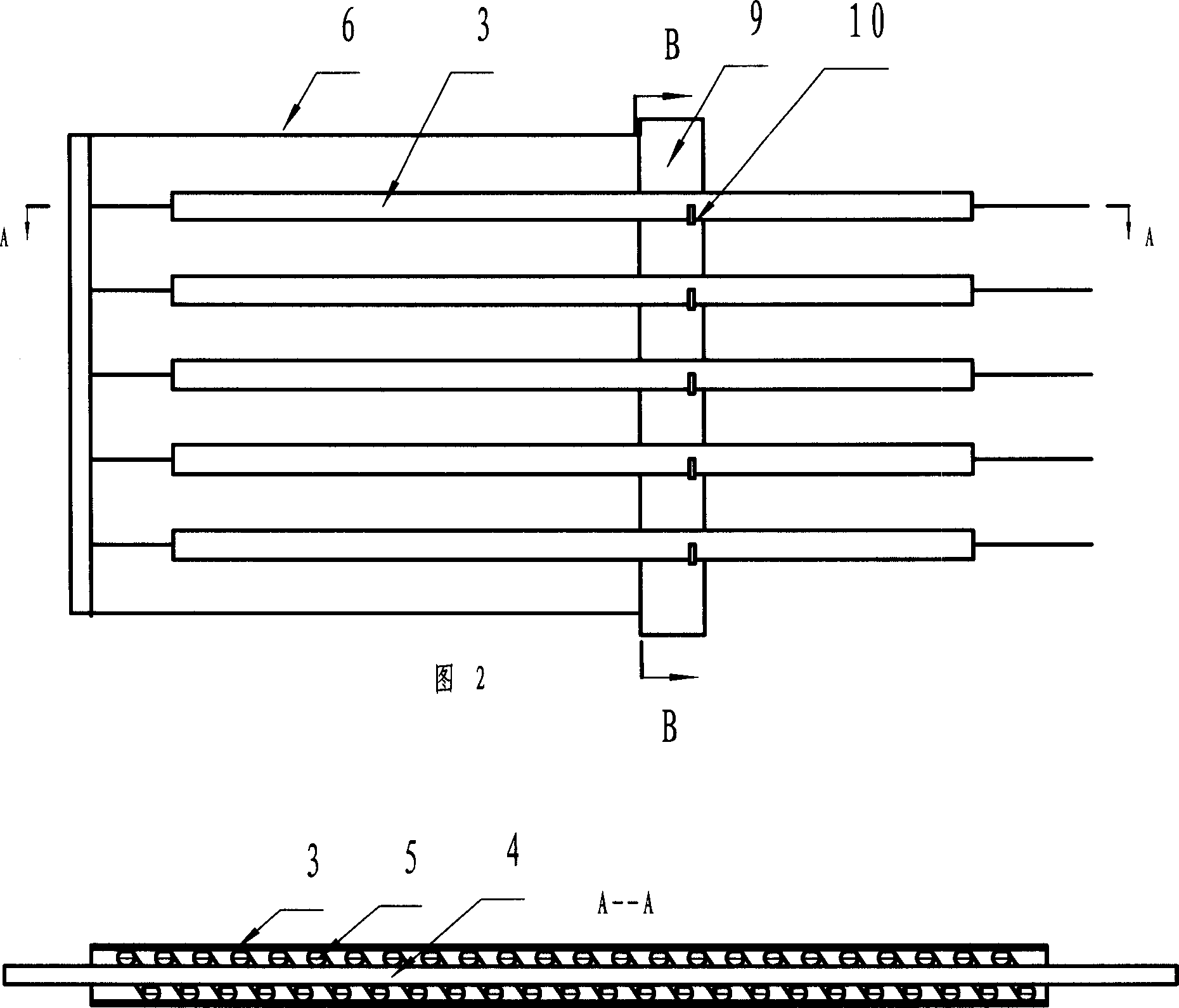

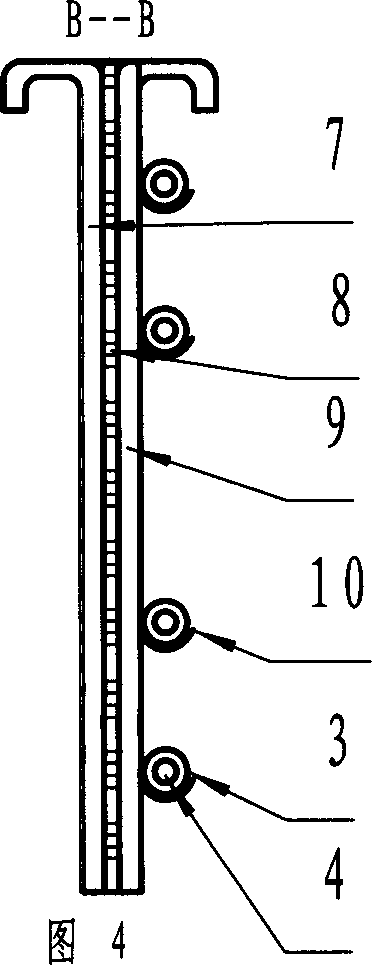

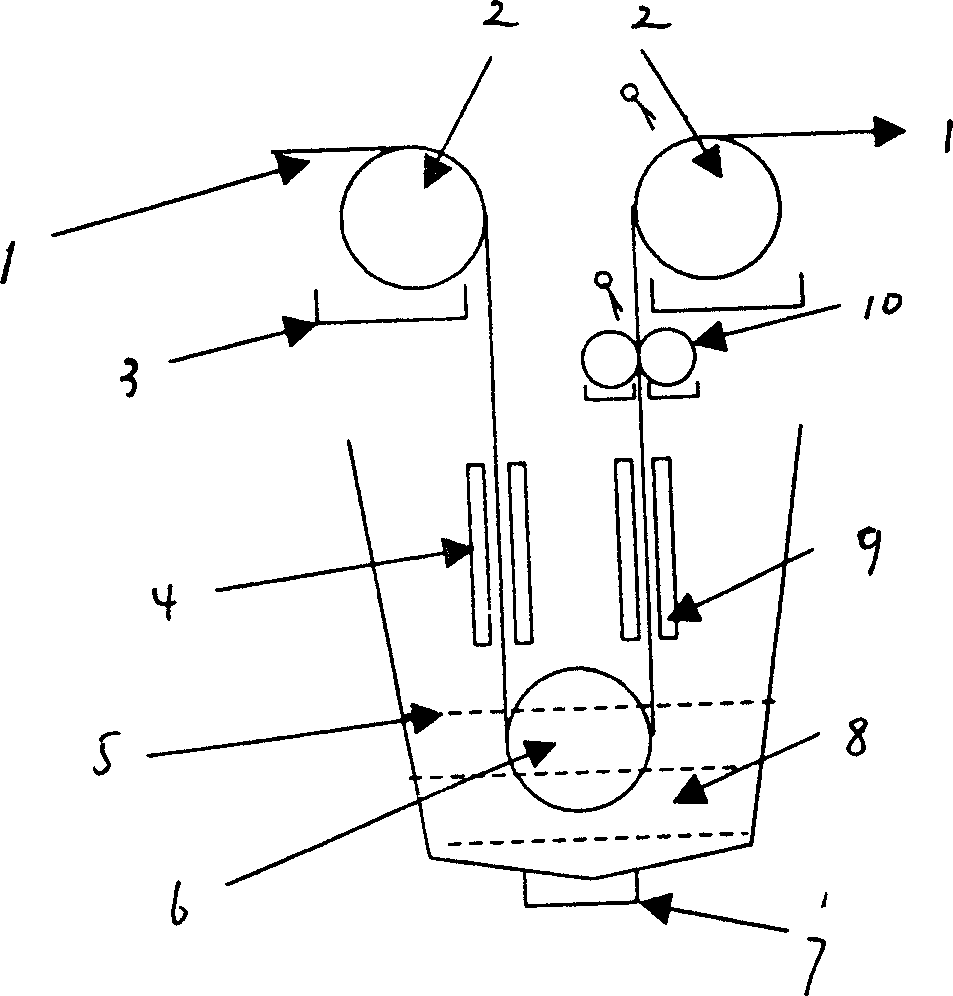

Process and special apparatus for electrogalvenizing inner and outer walls of steel pipe

InactiveCN1401823AFacilitates automatic cycle updatesImprove corrosion resistanceElectrolysis componentsElectrogalvanizationCyanide

A process for electroplating the inner and outer surfaces of steel tube with Zn is disclosed. It is characterized by that its electroplating liquid has the merits of both alkaline zincate and cyanide used for plating zinc. Its apparatus is characterized by that an auxiliary anode is additionally used inside the steel tube to be plated, that is, its hanger plays the roles of both cathode and anodes. Its advantages are high anticorrosion power of its plated layer and enough thickness of internal plated layer.

Owner:山东鲁宏塑窗机械集团总公司五金电镀厂

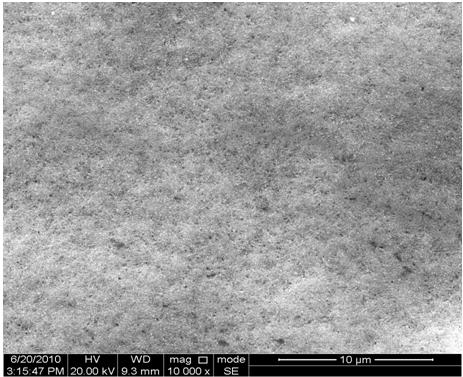

Surface treatment method for environment-friendly chromium-free zirconium-containing electro-galvanized fingerprint resistant steel sheet

The present invention relates to surface treatment of steel plate, and is especially zinc electroplating process to form homogeneous fine zinc layer onto the surface of cold rolled steel plate and environment friendly zirconium-containing no-chromium fingerprint resisting paint for producing zinc electroplating fingerprint resisting steel plate. Cold rolled steel plate is first electroplated with zinc and then coated with fingerprint resisting paint. The production process of fingerprint resisting steel plate features the production process including the first production of zinc electroplated steel plate via vertical anode electroplating process, coating with water-base fingerprint resisting paint with zirconium to replace chromium, and curing through roasting at temperature lower than 125 deg.c to form composite resin film. The electroplated zinc layer has stable and reliable quality and the organic composite resin film has no environmental pollution.

Owner:JIANGYIN CHANGFA FINGERPRINT RESISTANT STEEL PLATE

Zinc-zinc nickel electroplating method of neodymium iron boron magnet

InactiveCN106835209ASolve the corrosion resistanceNo increase in demagnetization lossSuperimposed coating processBiological activationBinding force

The invention provides a zinc-zinc nickel electroplating method of a neodymium iron boron magnet. The method comprises the steps of grinding and chamfering-deoiling-acid pickling-ultrasonic cleaning-galvanizing (acid)-activation-nickel alloy galvanizing-bright dipping-trivalent chromium passivation-drying. A neodymium iron magnet is prepared by the zinc-zinc nickel electroplating method of the neodymium iron boron magnet; a zinc layer is 2-5 microns; a zinc nickel layer is 5-10 microns; the corrosion resistance is achieved under the neutral salt mist environment for 2h and the environment of 40 DEG C and 90% of humidity for 168h; the binding force of the neodymium iron boron magnet can satisfy the requirement of falling by 1.8 m*30 times; the magnetic reducing loss is not increased (not more than 6%); the hexavalent chromium problem is solved (hexavalent chromium is not more than 1000 ppm); and the cost is lower than that of nickel electroplating of copper nickel.

Owner:BEIJING JINGCI ELECTRIC TECH CO LTD

Electrolytic plating assisting method for hot dip galvanizing of steel wire and electrolytic plating assistant

InactiveCN101948990AEasy to dryImprove protectionHot-dipping/immersion processesElectrolysisEthylic acid

The invention relates to electrolytic plating assistant for hot dip galvanizing of a steel wire. Electrolytic plating assistant comprises the following components: 30-220 g / L of zinc chloride, 0-150 g / L of potassium chloride, 0-150 g / L of sodium chloride, 2-90 g / L of ammonium chloride, 0-100 g / L of boric acid, 0-70 g / L of acetic acid, 1-25 g / L of sodium fluoride, 2-50 g / L of cerium chloride, 0-50 g / L of potassium fluozirconate, 0-50 g / L of methanol, 0.5-20 g / L of hydrogen peroxide and the balance of water. The electrolytic plating assisting method comprises the following steps: washing with alkali, removing oil, washing with water, washing with acid to remove rust, washing with water, activating with weak acid, electrolyzing to assist plating, drying, and purifying the electrolytic plating assistant. The method can reduce the generation of AlCl3, prevent skip plating and reduce the generation of smoke dust. The electrolytic plating assistant has the characteristic of relatively high melting point, and thus, can increase the drying temperature and shorten the drying time. The dried plating assistant has the characteristics of low brittleness, high compatibility with electrogalvanizing, and low tendency to shedding.

Owner:NORTHEASTERN UNIV

Making process of hot galvanized fingerprint-proof plate

ActiveCN1974836AHot-dipping/immersion processesAntifouling/underwater paintsElectrogalvanizationPerformance index

The making process of hot galvanized fingerprint-proof plate includes the following steps: uncoiling, leveling, end cutting, welding, rinsing, annealing, galvanizing, cooling, intermediate looping, smoothing, straightening, roller coating, drying, cooling, outlet looping, edge cutting, oiling and coiling. In the galvanizing step, galvanizing solution with Al in the concentration of 0.17-0.23 wt% and Pb in the concentration not higher than 0.003 % and at the temperature of 455-465 deg.c is used. Compared with electrolytic zinc plated fingerprint-proof plate, the hot galvanized fingerprint-proof plate has the same physical and chemical performance indexes reached except the slightly inferior surface quality, so that the hot galvanized fingerprint-proof plate may be used to replace partial electrolytic zinc plated fingerprint-proof plate.

Owner:MAANSHAN IRON & STEEL CO LTD

Preparation method of chromium-free passivated liquid and method for passivating electrogalvanizing or zinc alloy layer by same

The invention provides a preparation method of chromium-free passivated liquid and a method for passivating an electrogalvanizing or a zinc alloy layer by the chromium-free passivated liquid, wherein, the chromium-free passivated liquid is composed of passivated liquid and a sealing agent. The preparation method of the passivated liquid is characterized by comprising the following steps: adding nitric acid, potassium fluotitanate and titanium salt to water respectively according to the mass concentration range of 1-5g / L of titanate, 0.5-3.5g / L of fluotitanate and 2-5mL / L of nitric acid (mass concentration of nitric acid is 65-68%), stirring and dissolving to obtain solution, adding 5-20g / L (based on mass content) of silicon sol to the solution, evenly stirring, and adjusting pH to 2.0 with sodium hydroxide. The preparation method of the sealing agent comprises the following steps: hydrolyzing 5-30% of silane coupling agent, then adding 1.5-10% (based on mass content) of silicon sol, and finally adjusting pH to 8-9.

Owner:WUHAN JINZE NEW TIMES TECH

Production method of cold-rolled steel plate for electro-galvanization

The invention discloses a production method of a cold-rolled steel plate for electro-galvanization. The steel plate is smelted according to components. The production method comprises the following concrete technological steps: (1) pretreating liquid iron; (2) smelting in a rotary furnace; (3) finely tuning alloy; (4) refining in an RH furnace; (5) continuously casting; (6) performing hot rolling; (7) rolling; (8) performing cold rolling; (9) continuously annealing; (10) flattening. By precisely controlling the components in the steel and being combined with a production process of the cold-rolled steel plate for electro-galvanization, the production method disclosed by the invention can be used for obtaining the cold-rolled steel plate which is 150 to 40Mpa in yield strength, higher than 270MPa in tensile strength, larger than 37% in percentage elongation, capable of satisfying the requirements of deep drawing and molding, good in plate form and surface quality (above FC) and capable of satisfying the requirements of electro-galvanization and subsequent passivation and anti-fingerprint treatment; the surface quality of the steel plate for electro-galvanization can be improved; the steel plate for electro-galvanization is enabled to have the good plate form.

Owner:马钢(合肥)钢铁有限责任公司

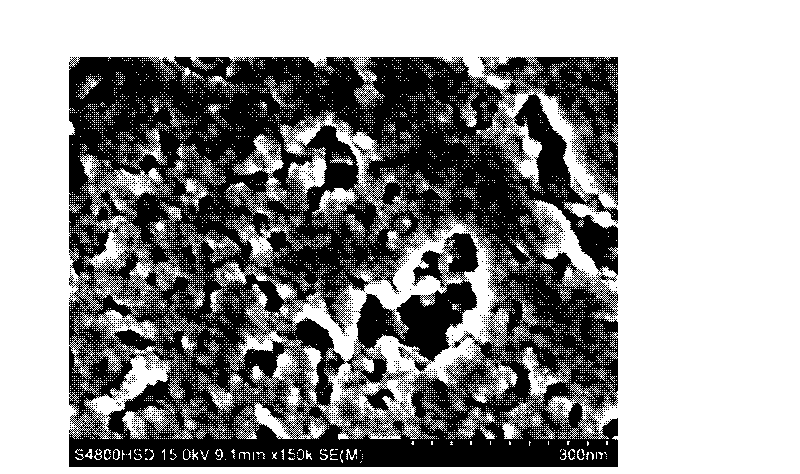

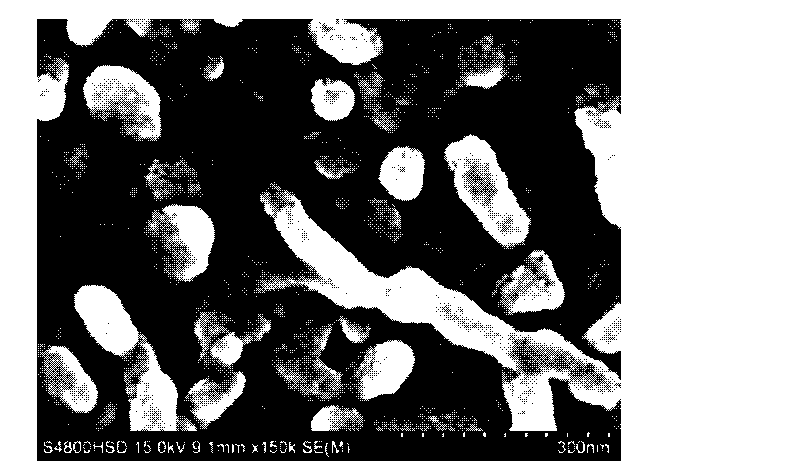

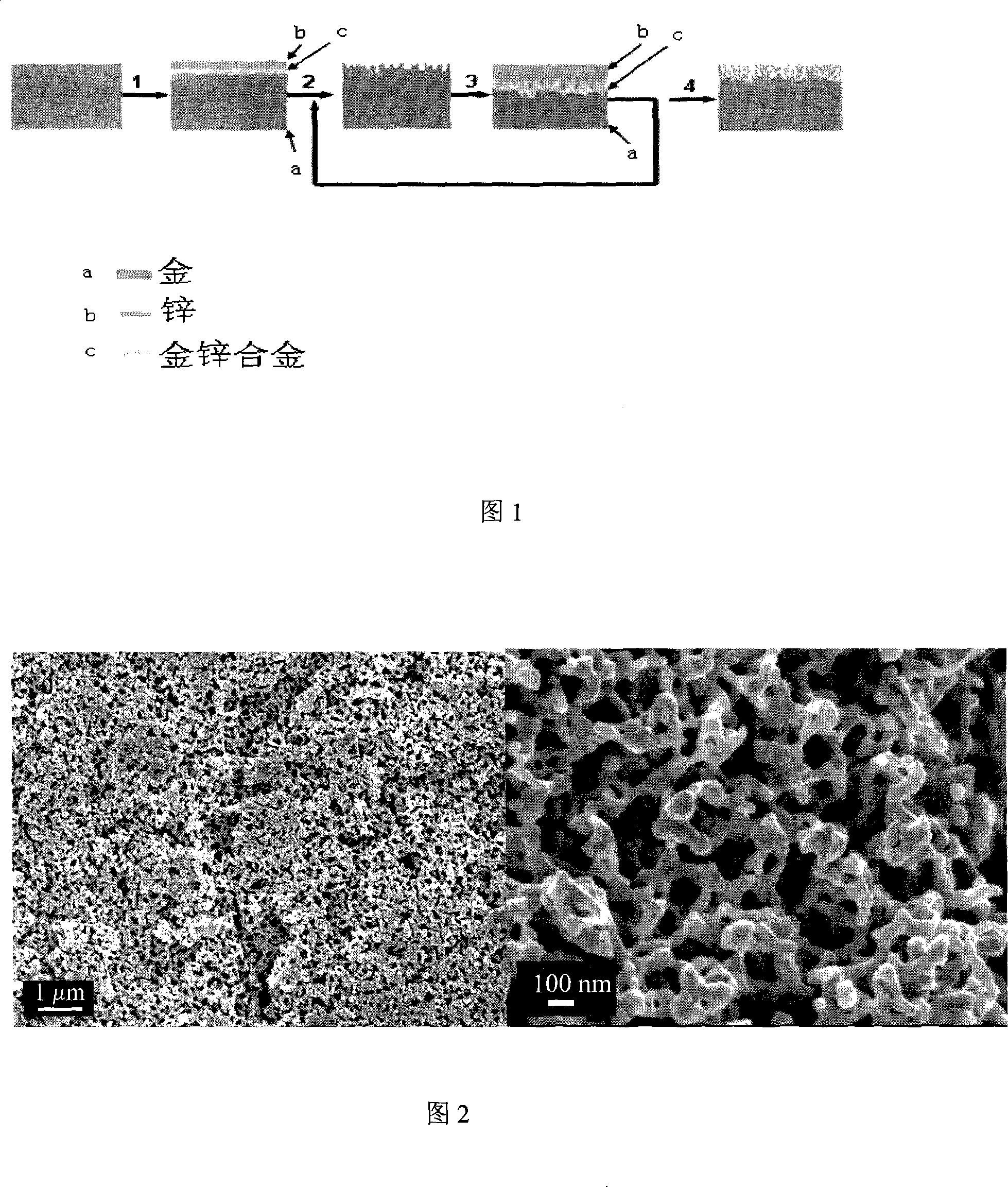

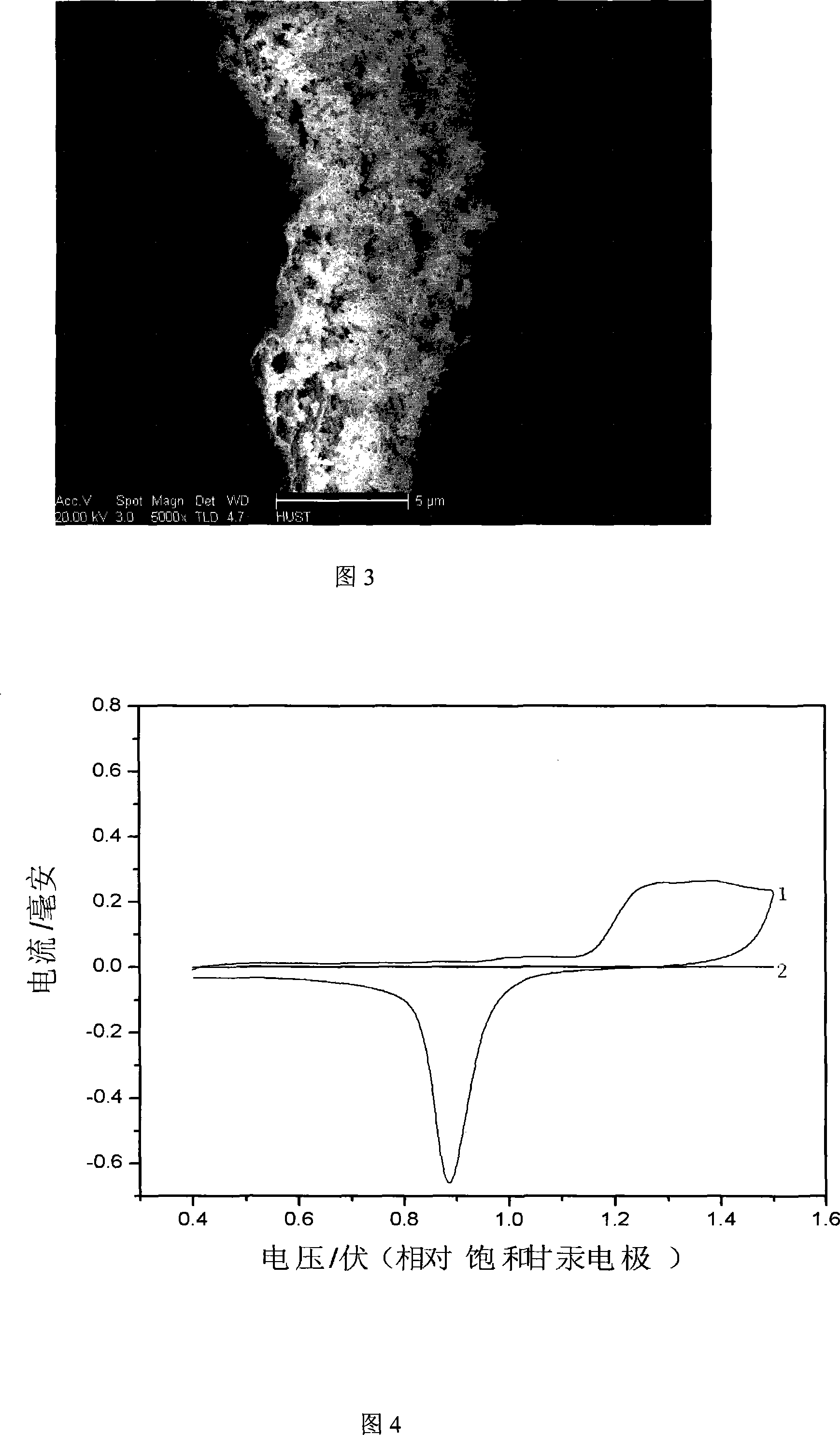

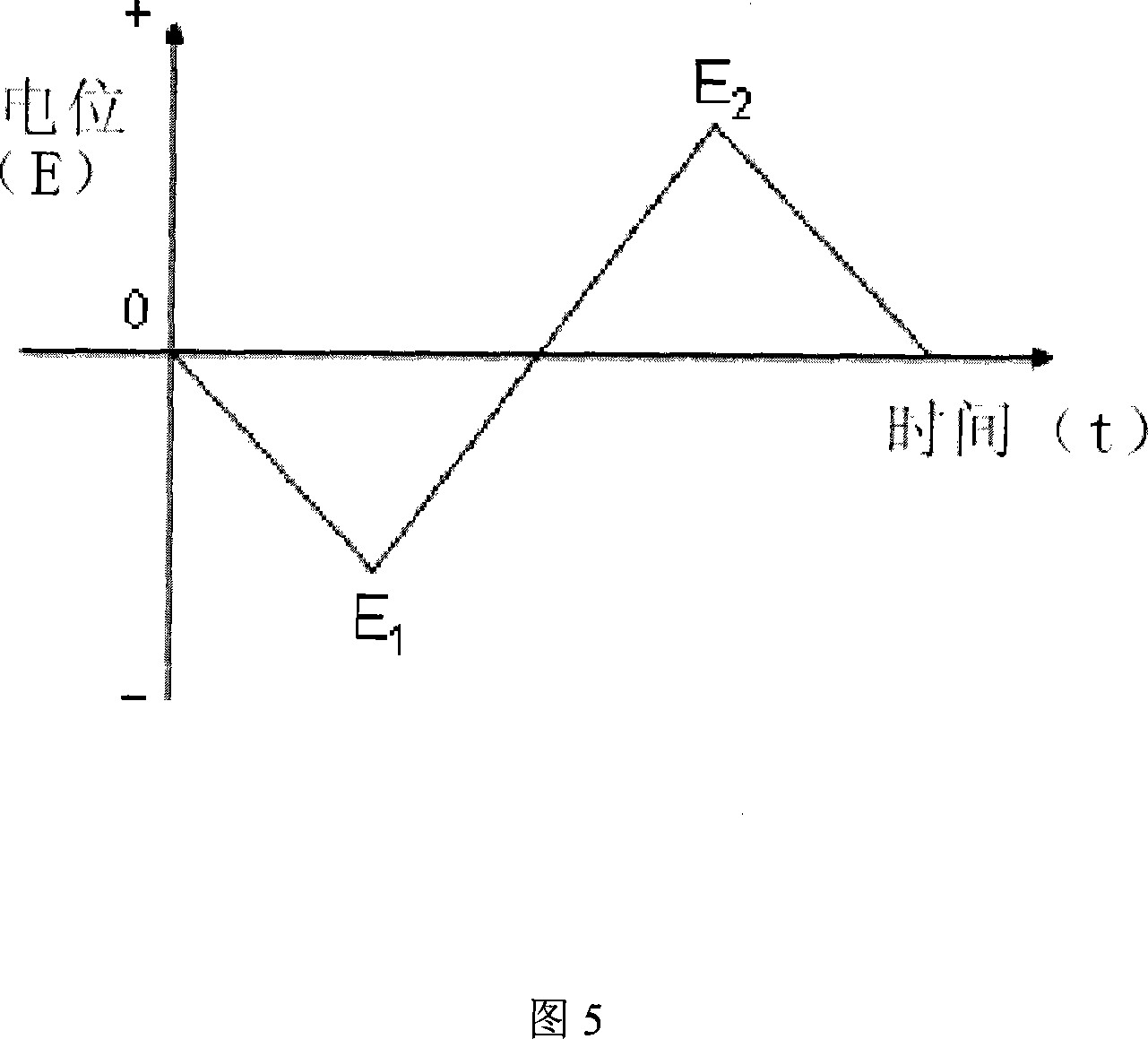

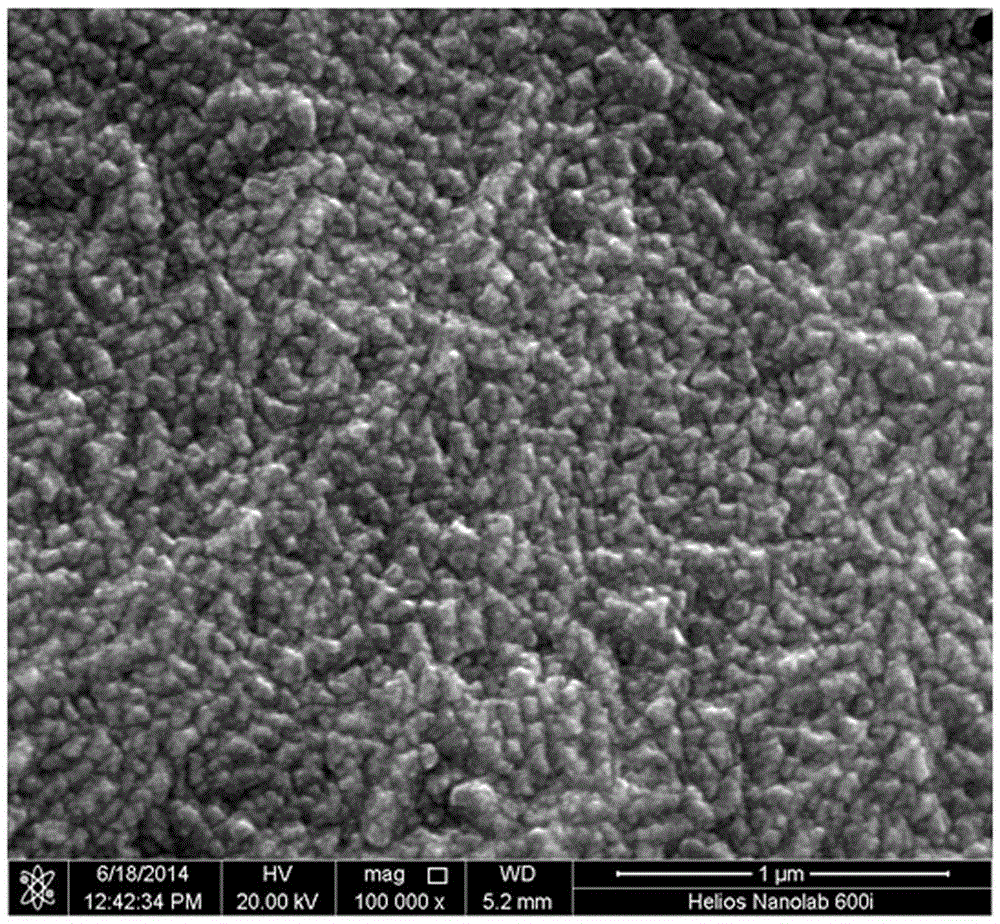

Preparation for gold electrode with nano-pore structure by electrochemistry alloying/dealloying method

InactiveCN101104940AHigh specific surface areaHigh sensitivityElectrode shape/formsMaterial electrochemical variablesMetallic electrodeAuxiliary electrode

A method for preparing metallic electrode with nano-pore structure by electrochemical alloying / dealloying process is provided. The method comprises: firstly adding a zinc salt into an organic solvent and heating to allow dissolution; then inserting a metallic electrode as working electrode, a zinc sheet as auxiliary electrode and an inert metal as reference electrode; electrochemically applying a circulatory potential scanning, wherein a Zn coating is formed on the surface of Au substrate during cathode potential scanning, and the deposited Zn reacts with Au substrate to form Zn-Au alloy with the solution temperature rise during the electrogalvanizing; and finally dissolving Zn from the alloy by the anode potential scanning and dealloying. The method can produce the metallic electrode with nano-pore structure, which has extremely-high roughness after treatment, substantially increase the effective response area of metallic electrode, and greatly improve the sensitivity and catalytic efficiency of metallic electrode in application. The invention has the advantages of simple operation, easily-accessible raw material, low cost, no toxicity, and no environmental pollution; and is used in analysis, catalysis and sensor fields.

Owner:HUAZHONG NORMAL UNIV

Electroplating metal fastener and its electroplating process and hydrogen embrittlement detection method

The invention discloses a plating metal fastener, which comprises the following steps: plating copper, nickel and zinc; sleeving metal fastener in the elastic pad; rotating metal fastener in the ferric board hole with two thirds force as standard torque until fastening tightly; placing tested screw in the refrigerator at -5 deg. c for 24h; fetching to restore to normal temperature; dropping ferric board vertically from one meter height; judging whether the end breaks; satisfying the standard if not breaking.

Owner:杨东佐

Chromium-free passivating liquid for surface treatment of electrogalvanized steel plate and use method thereof

InactiveCN101289741AImprove stabilityLong storage timeMetallic material coating processesChromium freeElectrogalvanization

The invention discloses a chromium-free passivating solution for the surface treatment of electro-galvanized steel plates, as well as a method for using the same. The mass percentages of the composition of the chromium-free passivating solution are: 0.2-20 percent of gamma-glycidyl ether oxygen propyl trimethoxy silane, 0.01-1.0 percent of polyvinyl alcohol, 0.1-3.0 percent of ammonium zirconium carbonate, water as a solvent, and the balance. The application method comprises the following steps that: the surface of a clean electro-galvanized steel plate is coated with the passivating solution, and then the passivating solution is baked to become a film; the thickness of a film layer is between 0.2 and 2.0 g / m<2>. The process treatment of the invention remarkably improves the corrosion resistance of the electro-galvanized steel plate, which is equivalent to chromate color passivation. In addition, through the treatment of the process, the coating performance of the electro-galvanized steel plate is remarkably improved as well.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Blue write chromate-free passivation liquid of electrogalvanized layer and method for passivating electrogalvanized layer by adopting same

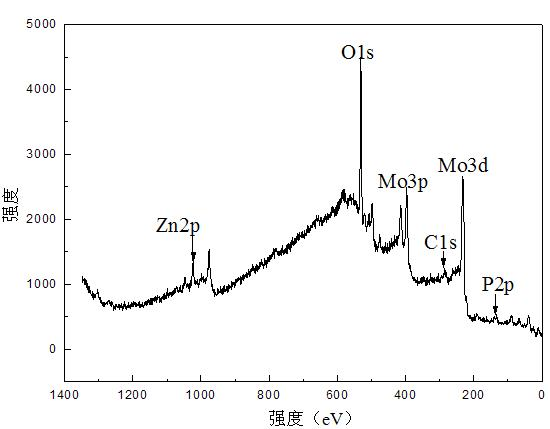

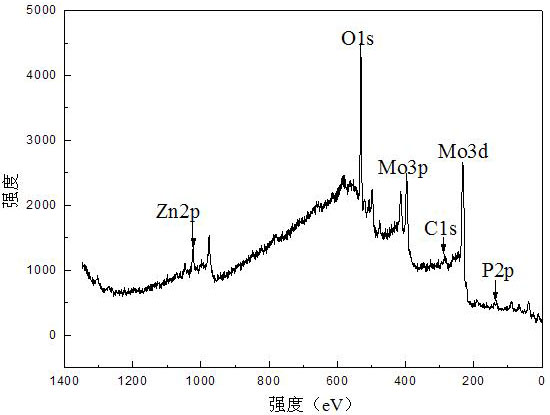

InactiveCN101906629AImprove compactnessImprove corrosion resistanceMetallic material coating processesElectrogalvanizationMolybdate

The invention relates to a blue write chromate-free passivation liquid of an electrogalvanized layer and a method for passivating the electrogalvanized layer by adopting the same, belonging to a chromate-free passivation liquid and a passivating method thereof. The invention solves the problem that the traditional passivation liquid contains toxic hexavalent chromium. The chromate-free passivation liquid contains molybdate, phosphate, sulfuric acid and organic matter. The passivating method comprises the steps of: dipping a treated galvanized steel sheet into the blue write chromate-free passivation liquid of the electrogalvanized layer with a temperature of 20-60 DEG C for passivating for 20-80s; and washing and drying to complete the process of passivating the electrogalvanized layer of the blue write chromate-free passivation liquid. The chromate-free passivation liquid does not contain the toxic hexavalent chromium and has good stability and stabilizing time exceeding 30 days.

Owner:HARBIN INST OF TECH

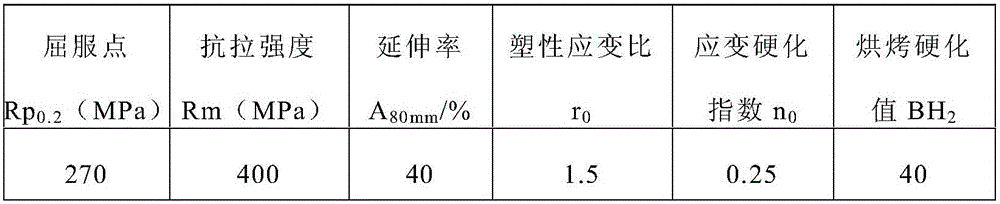

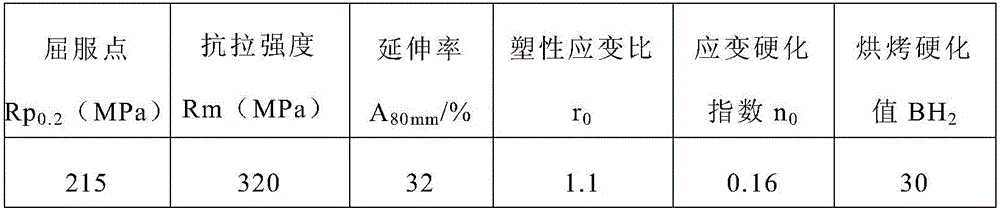

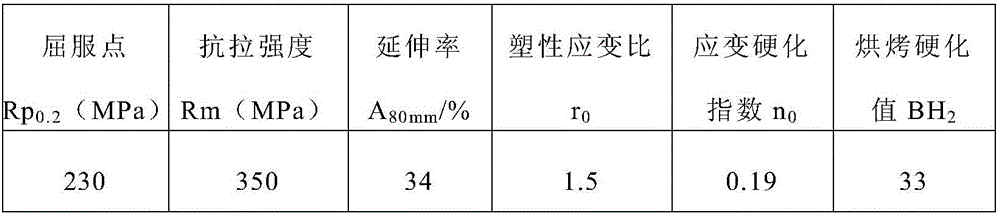

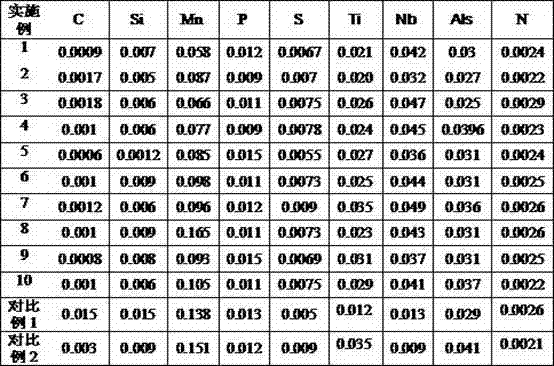

Production method for zinc electroplated baked hardened steel plate for automobile outer plate

ActiveCN105970094ANiobium is lowReduce carbon contentFurnace typesHeat treatment furnacesNatural agingCasting

The invention discloses a production method for a zinc electroplated baked hardened steel plate for an automobile outer plate and belongs to the field of cold-rolled deep-drawn zinc electroplating automobile steel. The production method comprises the following preparation steps that (1) constituent selection of the zinc electroplated baked hardened steel plate is conducted; (2) a plate blank is obtained through smelting and casting; (3) hot rolling is conducted after conventional heating; (4) conventional water cooling is conducted to the coiling temperature, and coiling is conducted; (5) cold rolling is conducted; (6) continuous annealing is conducted; (7) flattening is conducted; (8) conventional alkali washing, brushing, electrolytic degreasing and rinsing are conducted; and (9) zinc electroplating is conducted through a gravity method. According to the production method, the steel plate prepared through a conventional production technique is good in forming performance and baking and hardening performance, natural aging is avoided even if the steel plate is placed at the room temperature for months, and the performance is stable.

Owner:武汉钢铁有限公司

Neodymium-iron-boron magnet with composite coating and preparation process thereof

InactiveCN107937948AImprove corrosion resistanceThermal demagnetization has no effect onMagnetsMagnetic materialsSalt spray testNeodymium iron boron

Owner:YANTAI DONGXING MAGNETIC MATERIALS INC

Steel with extending rate larger than or equal to 44 percent for electrogalvanizing automobile outer plate and production method

Disclosed is steel with the extending rate larger than or equal to 44 percent for an electrogalvanizing automobile outer plate. The steel comprises, by weight, C smaller than or equal to 0.0018 percent, Si smaller than or equal to 0.015 percent, Mn ranging from 0.05 percent to 0.18 percent, P smaller than or equal to 0.015 percent, S smaller than or equal to 0.010 percent, Ti ranging from 0.02 percent to 0.03 percent, Nb ranging from 0.03 percent to 0.05 percent, Als ranging from 0.02 percent to 0.05 percent and N smaller than or equal to 0.003 percent. The production steps comprise smelting and continuous casting to form a billet, hot rolling, reeling, cold rolling, continuous annealing and cooling. The method comprises the steps of slow cooling and then rapid cooling, finishing, alkaline washing, brushing, electrolytic degreasing and rinsing, and electrogalvanizing through a gravitational method. The steel has the advantages of being good in surface quality, stable in performance, free of aging, excellent in forming performance, excellent in welding performance and the like; according to the material object performance (perpendicular to the rolling direction) of a finished electrogalvanizing super-deep punching board DC07+ZE for the automobile outer plate, the yield strength is 100 MPa to 150 MPa, the tensile strength is 250 MPa to 310 MPa, the plastic strain ratio r<90> is larger than or equal to 2.3, the work-hardening exponent n<90> is larger than or equal to 0.25, and the extending rate A80 mm is larger than or equal to 44 percent.

Owner:武汉钢铁有限公司

Alkaline non-cyanide zinc plating nickel alloy plating solution and electroplating process thereof

The invention discloses an alkaline non-cyanide zinc plating nickel alloy plating solution and an electroplating process thereof. The plating solution is prepared with hydantoin or a hydantoin derivative as a main coordination agent by adding an auxiliary coordination agent, zinc sulfate, nickel sulfate, potassium carbonate and water. The plating solution comprises 20 g-400 g / L of the main coordination agent, 5 g-300 g / L of the auxiliary coordination agent, 5 g-200 g / L of the zinc sulfate, 1 g-150 g / L of the nickel sulfate and 5 g-435 g / L of the potassium carbonate. The electroplating process of the plating solution comprises the steps of substrate pretreatment and zinc-nickel alloy electroplating. A constant current electroplating mode is adopted for zinc-nickel alloy electroplating. The electric current density is 0.5 A-5 A / dm2. The temperature of the plating solution is 30 DEG C-60 DEG C. The distance between a cathode and an anode is 0.5 cm-25 cm. The stirring speed of the plating solution is 0 rpm-3000 rpm. The electroplating time is 1 min-120 min. According to the plating solution and the electroplating process thereof, the hydantoin or the hydantoin derivative serves as the main coordination agent for the first time, and zinc-nickel alloy with the nickel content of 10 wt.%-13 wt.% is obtained through electro-deposition by using the main coordination agent and the auxiliary coordination agent in a combination mode. An obtained coating is good in corrosion resistance. The stability of the plating solution is improved immensely compared with using of a single coordination agent.

Owner:宏正(福建)化学品有限公司

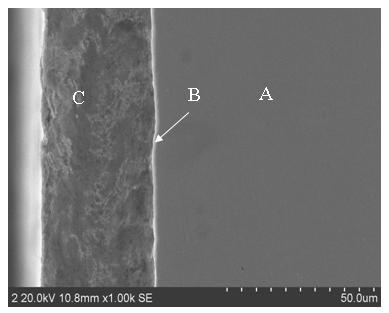

Magnesium and magnesium alloy high corrosion resitance composite cladding and its preparing process

InactiveCN1580325AImprove corrosion resistanceLiquid/solution decomposition chemical coatingSuperimposed coating processVolumetric Mass DensityDodecylsulfonic acid

The inventions are sorts of magnesium, magnesium alloy which is compound plating coat of high anti corrosion, and their preparation technics. Compound plating coat based on the chemical nickel coat, the thickness of which is between 20 and 25 micron. The callow of it is electrolytic zinc plating and nickel alloy, the thickness of which is between 8 and 10 micron. The following is the preparation craftwork: the chemical nickel plating of magnesium alloy adopts the standard B480-88 of American material experimentation association. Plating time is between 1.4 and 2 hours. The coating thickness is between 20 and 25 micron. The content of phosphor in the plating layer is 9-12%; electrolytic zinc plating and nickel alloy: the plating liquid of it and technics conditions are followed: sodium hydroxide 8-15%, zinc oxide 2-5%, nickelous chloride 0.5-3%, ethylamine 2-4%, tiethanolamine 2-4%, nylander reagent 0.5-3%, DE0.2-0.8%, sodium dodecanesulphonate 0.01-0.1%, the overmeasure is water. Curl density is 0.5-5A / dm2. Plating time is 30 minutes. The content of nickel in the plating coat is 13-18%; It adopts black passivation technics of zinc and nickel alloy. The thickness of plating coat of this invention doesn't exceed 35 micron.

Owner:SHANGHAI JIAO TONG UNIV

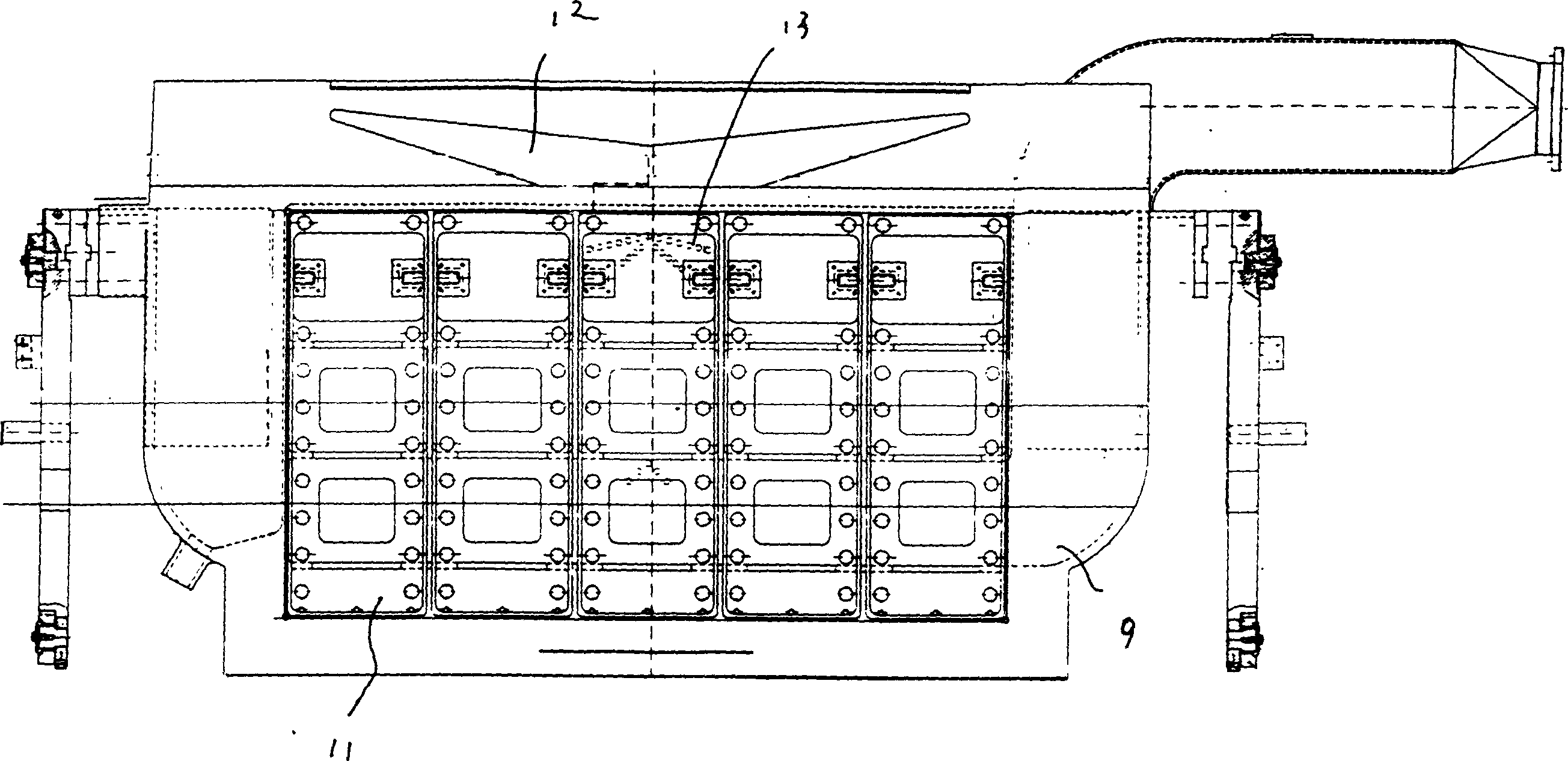

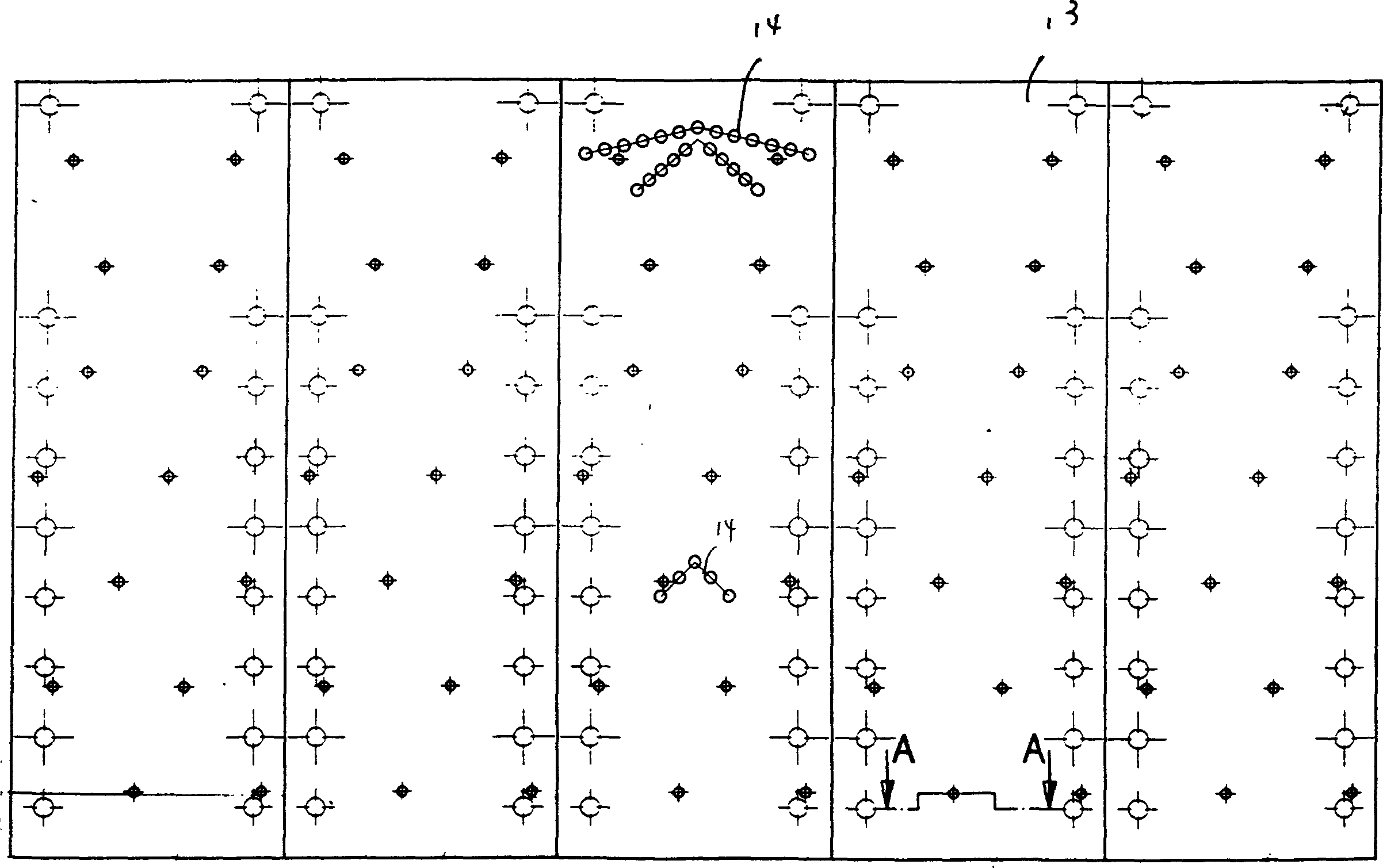

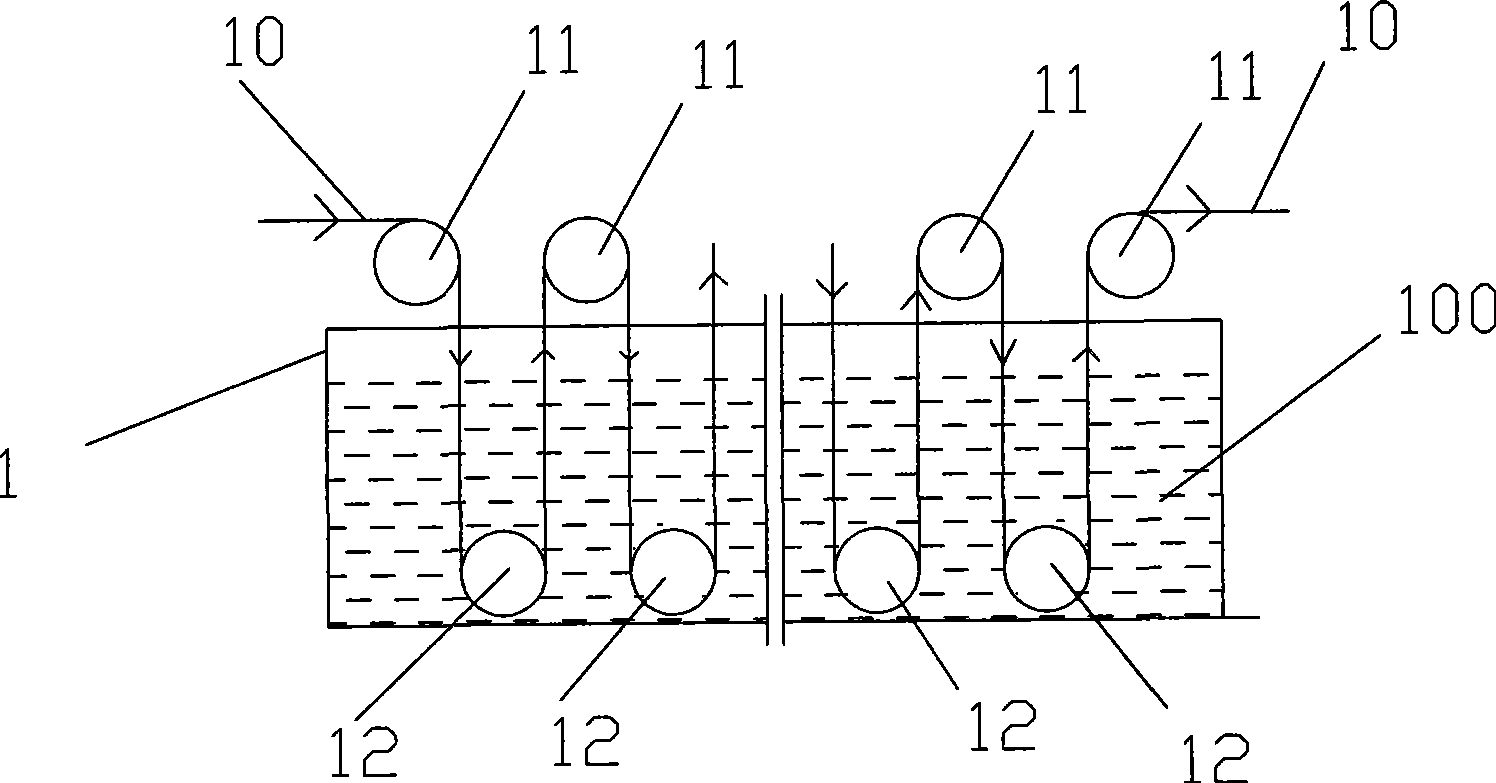

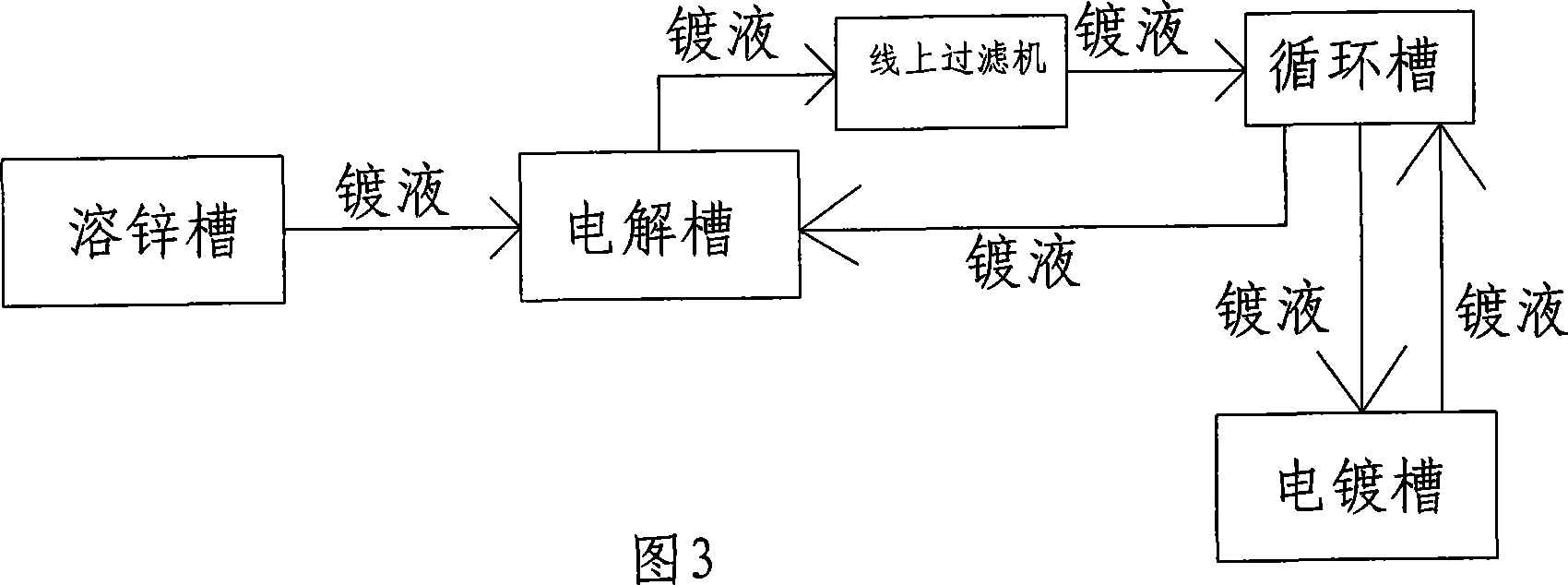

Apparatus and technology for controlling and improving plating solution PH value on fingerprint resistant production chain

The invention provides a technical method for controlling and raising the PH value of galvanizing solution on a fingerprint resistant continuous and automatic production line of the electro-galvanizing and roller coating of a rolled plate; the galvanizing solution rich in zinc ions enters a galvanizing bath from a dezincification bath; the technique is characterized in that: after entering the galvanizing bath from the dezincification bath, the galvanizing solution enters a circulating tank after going through an on-line filtering machine and then enters the galvanizing bath from the circulating tank; the galvanizing solution in the galvanizing bath returns to the galvanizing bath through the circulating tank; and the galvanizing solution is electrolyzed by the current density of 0.1A / dm<2> to 0.3A / dm<2> in an electrobath. The electrobath is internally provided with three anodes and two cathodes at intervals. The technical proposal has the advantages of not only removing hazardous metal impurities, but also increasing dezincification speed, particularly properly raising the PH value, increasing the overpotential of hydrogen, reducing hydrogen evolution, fining electro-galvanizing layers and reducing electric energy consumption, thereby greatly improving product quality.

Owner:长江润发(江苏)薄板镀层有限公司

Method for plating zinc and nickel on neodymium-iron-boron material

InactiveCN104233408AImprove corrosion resistanceReduce magnetic lossElectrogalvanizationSulfosalicylic acid

The invention relates to a method for plating zinc and nickel on a neodymium-iron-boron material, and belongs to the field of alloy plating processes. The method comprises the following steps of: (1) firstly carrying out roll finish chamfer treatment on the neodymium-iron-boron material by adopting vibrating type roll finish; (2) placing the neodymium-iron-boron material into a deoiling solution and carrying out ultrasonic deoiling; (3) then carrying out derusting treatment by adopting a nitric acid solution with the volume fraction of 10%; (4) carrying out hole sealing treatment by using a low-temperature particule plugging agent; (5) then carrying out activating treatment under the condition of room temperature by using a sulfosalicylic acid solution; (6) plating the neodymium-iron-boron material subjected to the treatment; (7) carrying out polishing treatment on the plated neodymium-iron-boron material, and then carrying out zinc-nickel alloy plating layer passivating treatment; (8) finally carrying out subsequent impregnation treatment by adopting passivated impregnating resin. The method for plating zinc and nickel on the neodymium-iron-boron material, which is disclosed by the invention, greatly enhances the corrosion-resistant capacity of a neodymium-iron-boron surface after the neodymium-iron-boron surface is treated and reduces the magnetic loss through the improvement of a process and has the advantages of simple process and easiness for popularization and use.

Owner:XIAN SANWEI SECURITY TECH

Galvanized layer chromium-free passivant and use method thereof

ActiveCN101717932AEliminate hazardsMetallic material coating processesChromium trioxideChromium free

The invention relates to a galvanized layer chromium-free passivant and a use method thereof, wherein the passivant comprises a passivation film-forming agent, an adhesion promoter, an emulsifying agent, acetone and an aqueous solution, when using, the chromium-free passivant and water are diluted according to the proportion of 1: 4 and then put in a passivation tank, a galvanized part is bright-dipped through diluted acid at a plating bath outlet of a continuous electrogalvanizing production line, then enters into the passivation tank under the normal temperature for passivating 5-20 seconds, taken out, flushed with water and dried by hot air. The galvanized layer chromium-free passivant forms a passivation film on the metal surface by reasonably utilizing certain chromium-free organic acids, and the like, has corrosion inhibition property, adopts resin as the promoter as well as the acetone and water as solvents, is prepared by adopting a compound method, free of chromium and used for carrying out passivating treatment instead of chromate and chromium trioxide and eliminates hazards to the environment and the human body from chromium pollution.

Owner:GUIZHOU WIRE ROPE

Blackening preventing electrogalvanized steel plate and manufacturing method thereof

InactiveCN101649473AExcellent anti-blackening performanceGood anti-blackening performanceSuperimposed coating processElectrogalvanizationElectrolysis

The invention provides a blackening preventing electrogalvanized steel plate and a method for manufacturing the steel plate. The surface of an electrogalvanized layer of the steel plate is provided with a nickel layer with the thickness of 0.05 to 10 mg / m <2>; and lubricating oil is coated on the external surface of the nickel layer and the thickness of the lubricating oil is 0.3 to 3 g / m <2>. Themethod for manufacturing the steel plate comprises the step of: soaking the electrogalvanized steel plate in an acid solution containing 0.5 to 50 g / L of Ni <2+> for more than one second, or performing cathodic electrolysis processing on the electrogalvanized steel plate through the acid solution containing the Ni <2+> for more than 0.5 seconds. After being added with nickel, the steel plate caneffectively prevent the blackening of the surface of the steel plate and simultaneously has good stamping forming performance and coating performance.

Owner:BAOSHAN IRON & STEEL CO LTD

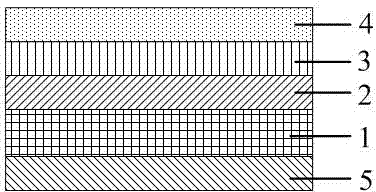

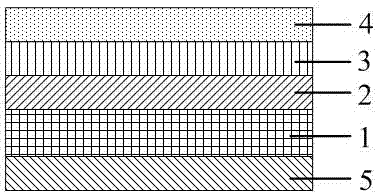

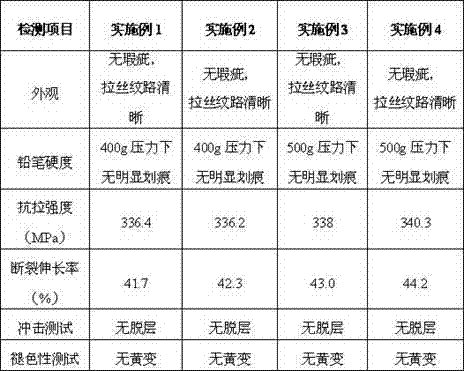

Metal wiredrawing composite steel plate and preparation method thereof

InactiveCN102442151ANo pollutionAchieve the appearanceNatural patternsSpecial ornamental structuresElectrogalvanizationElectroplating

The invention relates to a metal wiredrawing composite steel plate and a preparation method thereof. A base material of the metal wiredrawing composite steel plate is a hot galvanizing steel plate or an electro-galvanizing steel plate, a straight grain wiredrawing structure is formed on the front side of the base material through wiredrawing by using a metal surface wiredrawing machine, and a transparent fingerprint-resistant paint layer is formed on the straight grain wiredrawing structure through roller coating. During manufacturing, the method comprises the following steps of: performing wiredrawing process treatment on the front side of the base material by using the metal surface wiredrawing machine; performing degreasing cleaning on the base material subjected to the wiredrawing process treatment to remove oil stains on the surface; performing surface passivation in a sprinkling mode after the degreasing cleaning to form colorless paint bottom passive films on the front side and the back side of the base material, and drying in a drying oven; painting a back paint on the back side of the base material through roller coating at normal temperature after the passivation, and drying in the drying oven; painting a transparent fingerprint-resistant paint on the front side of the base material which is subjected to wiredrawing, degreasing cleaning and passivation; and coating a protective film on the surface of the transparent fingerprint-resistant paint layer. By directly treating the hot galvanizing steel plate or electro-galvanizing steel plate by using a wiredrawing process, and coating a transparent paint layer on the hot galvanizing steel plate or electro-galvanizing steel plate, an appearance effect of imitation stainless steel is achieved.

Owner:SUZHOU HESHENG NEW MATERIALS

Electroplating process of electroplated metal fastener

The invention discloses an electroplating process of an electroplated metal fastener. The electroplating process comprises the steps of copper electroplating, nickel electroplating and zinc electroplating in sequence, specially as follows: (1) preparing the solution for the copper electroplating process: 135mg / L of copper sulfate, 90mg / L of malic acid, 210mg / L of citric acid, 40mg / L of potassium citrate, 20mg / L of sodium hypophosphite, and 15mg / L of glucose, wherein the process conditions are as follows: the current density is 1.5A / dm<2>, an anode is of a 0.3%-phosphorus-containing copper plate, the area ratio of the anode to the cathode is 2:1, the temperature is 20-25 DEG C and the time lasts for 8 minutes; (2) electroplating nickel; and (3) electroplating zinc. By adopting the electroplating process, the problem of hydrogen embrittlement can be solved; the electroplated copper, the electroplated nickel and the electroplated zinc all adopt specific solution, the electroplated layer has no burr and is less rough, the surfaces of the electroplated layers can not produce pin holes, the phenomenon of leaking electroplating can not occur, the electroplated layers are combined more firmly, the electroplating deposition velocity is fast, and the corrosion resistance property is stronger.

Owner:LIUZHOU YUHUA TECH

Hot-rolled pickled steel plate for electrogalvanizing and production method thereof

InactiveCN111455259AEasy to shapeQuality improvementFurnace typesMetal rolling arrangementsElectrogalvanizationSurface roughness

The invention provides a hot-rolled pickled steel plate for electrogalvanizing and a production method thereof. The hot-rolled pickled steel plate for the electrogalvanizing is prepared from the components: 0.010-0.080% of C, less than or equal to 0.030% of Si, 0.10%-0.40% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.020%-0.060% of Al, less than or equal to 0.0050% of N, and the balance of Fe and inevitable impurities. Compared with the prior art, the hot-rolled pickled steel plate for the electrogalvanizing is produced by precisely controlling the componentsin steel and through the processes of hot rolling, pickling and leveling. According to the hot-rolled pickled steel plate produced by the method, in mechanical performance, the yield strength is 200-300MPa, the tensile strength is 320-440MPa, the A50 tensile elongation is greater than or equal to 35%, a surface roughness Ra value is 0.6-1.5[mu]m, the product thickness is 1.5-6.0 mm, the plate shape is good and surface quality is high, the surface color is uniform, and the requirements of the electrogalvanizing can be met.

Owner:MAANSHAN IRON & STEEL CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com