Patents

Literature

33results about How to "High bath stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of supersonic chemical plating nickel phosphorus of powder metallurgy material

InactiveCN1410592AUniform thicknessImprove corrosion resistanceLiquid/solution decomposition chemical coatingChemical platingPowder metallurgy

In the invention, the sodium hypopphosphite is as the reducing agent of the bath, nickel sulfate as the main salt, with the complexing agent, accelerating agent and stabilizing agent being added. Theultrasonic chemical plating is adopted that utilizes the mechanical energy of the ultrasonic vibration, making the bath deposit nickel and phosphor under the catalysis of the metal surface and the chemical reduction method controlled. The plating procedure includes the steps of oil removal, rust removal, activation, chemical plating and post treatment. The multiple complexing, accelerating and stabilizing agents raises the stability of the bath. The plating speed is adjustable. The even, compact nickel and phosphor plating layer covers the surface of the base body of powder metallurgical material so as to increase the service life of the material and provide wide application area.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Reduced-form composite complexing non-cyanide chemical gold plating liquid and method

InactiveCN105349972AHigh bath stabilityLiquid/solution decomposition chemical coatingCyanideWeather resistance

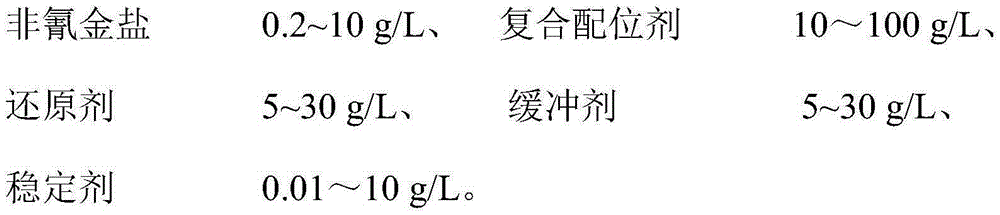

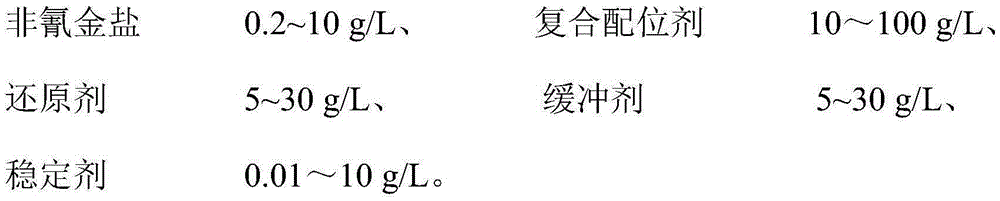

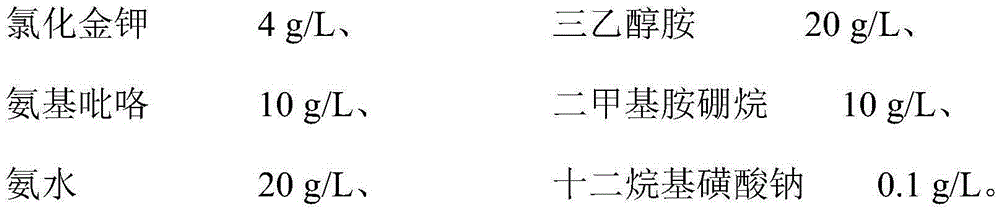

The invention discloses reduced-form composite complexing non-cyanide chemical gold plating liquid and a method. The reduced-form composite complexing non-cyanide chemical gold plating liquid is characterized by being preparing from 0.2-10 g / L of non-cyanide gold salt, 10-100 g / L of composition complexing agent, 5-30 g / L of reducing agent, 5-30 g / L of buffering agent and 0.01-10 g / L of stabilizing agent. The composition complexing agent used in the liquid can improve the stability of gold ions and enables a plated layer to be compact and smooth; and the reduced-form composite complexing non-cyanide chemical gold plating liquid has the beneficial effects that process stability is good, a long continuous production cycle is achieved, and the plated layer is bright in color, good in corrosion resistance and weather resistance and the like.

Owner:广东致卓环保科技有限公司

Alkaline non-cyanide zinc plating nickel alloy plating solution and electroplating process thereof

The invention discloses an alkaline non-cyanide zinc plating nickel alloy plating solution and an electroplating process thereof. The plating solution is prepared with hydantoin or a hydantoin derivative as a main coordination agent by adding an auxiliary coordination agent, zinc sulfate, nickel sulfate, potassium carbonate and water. The plating solution comprises 20 g-400 g / L of the main coordination agent, 5 g-300 g / L of the auxiliary coordination agent, 5 g-200 g / L of the zinc sulfate, 1 g-150 g / L of the nickel sulfate and 5 g-435 g / L of the potassium carbonate. The electroplating process of the plating solution comprises the steps of substrate pretreatment and zinc-nickel alloy electroplating. A constant current electroplating mode is adopted for zinc-nickel alloy electroplating. The electric current density is 0.5 A-5 A / dm2. The temperature of the plating solution is 30 DEG C-60 DEG C. The distance between a cathode and an anode is 0.5 cm-25 cm. The stirring speed of the plating solution is 0 rpm-3000 rpm. The electroplating time is 1 min-120 min. According to the plating solution and the electroplating process thereof, the hydantoin or the hydantoin derivative serves as the main coordination agent for the first time, and zinc-nickel alloy with the nickel content of 10 wt.%-13 wt.% is obtained through electro-deposition by using the main coordination agent and the auxiliary coordination agent in a combination mode. An obtained coating is good in corrosion resistance. The stability of the plating solution is improved immensely compared with using of a single coordination agent.

Owner:宏正(福建)化学品有限公司

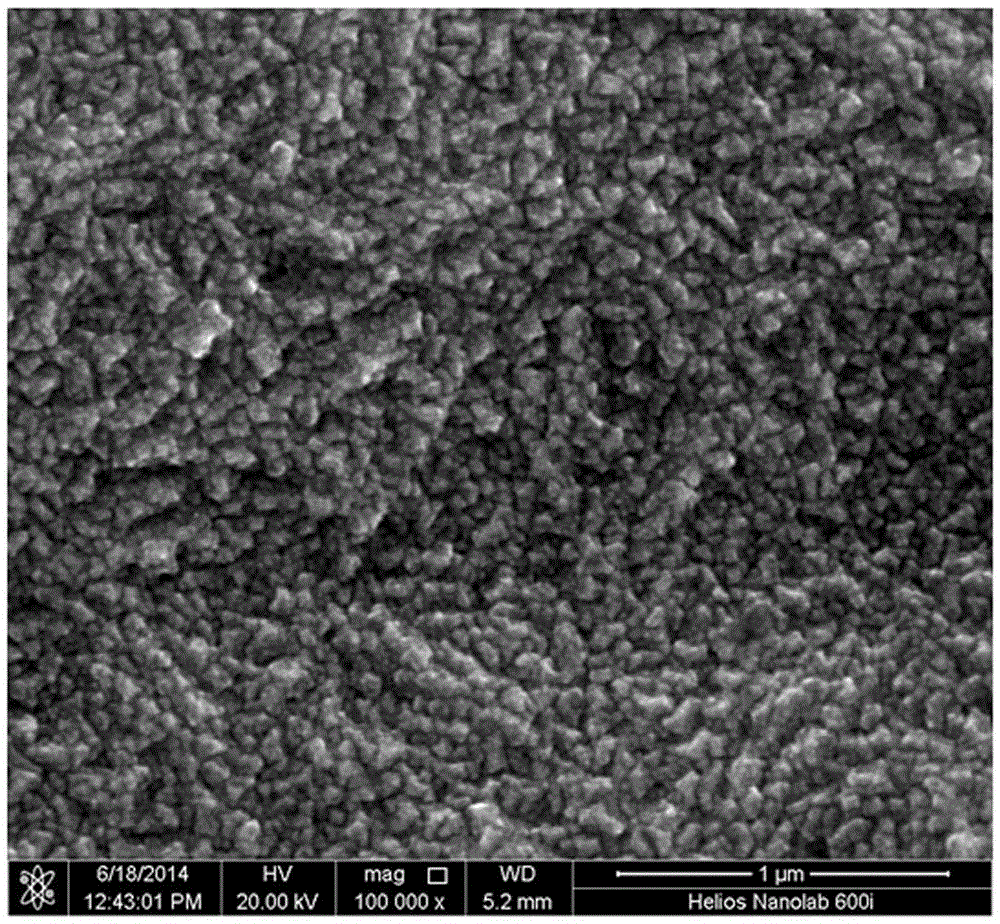

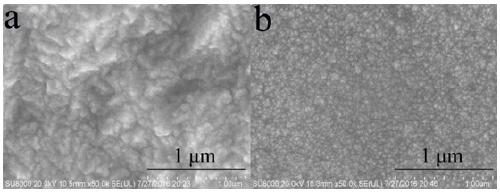

Preparation method of Ni-SiC compound coating on surface of aluminum alloy and electroplating solution thereof

ActiveCN105506526AImprove bindingHigh hardnessHot-dipping/immersion processesElectrolytic coatingsHardnessAmmonium bromide

The invention discloses a preparation method of a Ni-SiC compound coating on the surface of an aluminum alloy. The preparation method adopts an anode type surfactant which is hexadecyl trimethyl ammonium bromide for replacing a cathode type surfactant which is lauryl sodium sulfate adopted by the invention at present. The preparation method is characterized by increasing the concentration of an anode activator NiCl2 while reducing current density and the concentration of silicon carbide in a plating solution, obtaining a fine and dense compound coating at an electroplating rate of 1-2 micron per minute, stirring by using air with volume flow being 4-7L / min and fully dispersing the silicon carbide, simultaneously adding CTAB to improve the wettability of the silicon carbide and obtain a fine and dense compound coating with high content of uniformly-dispersed silicon carbide. Through the preparation method of the Ni-SiC compound coating on the surface of the aluminum alloy, the technical problem of low tensile performance and low abrasion resistance of the aluminum alloy can be solved; the Ni-SiC compound coating with high adhesion strength, high content of uniformly-distributed hard silicon carbide particles, high hardness and high abrasion resistance can be prepared on the surface of the aluminum alloy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

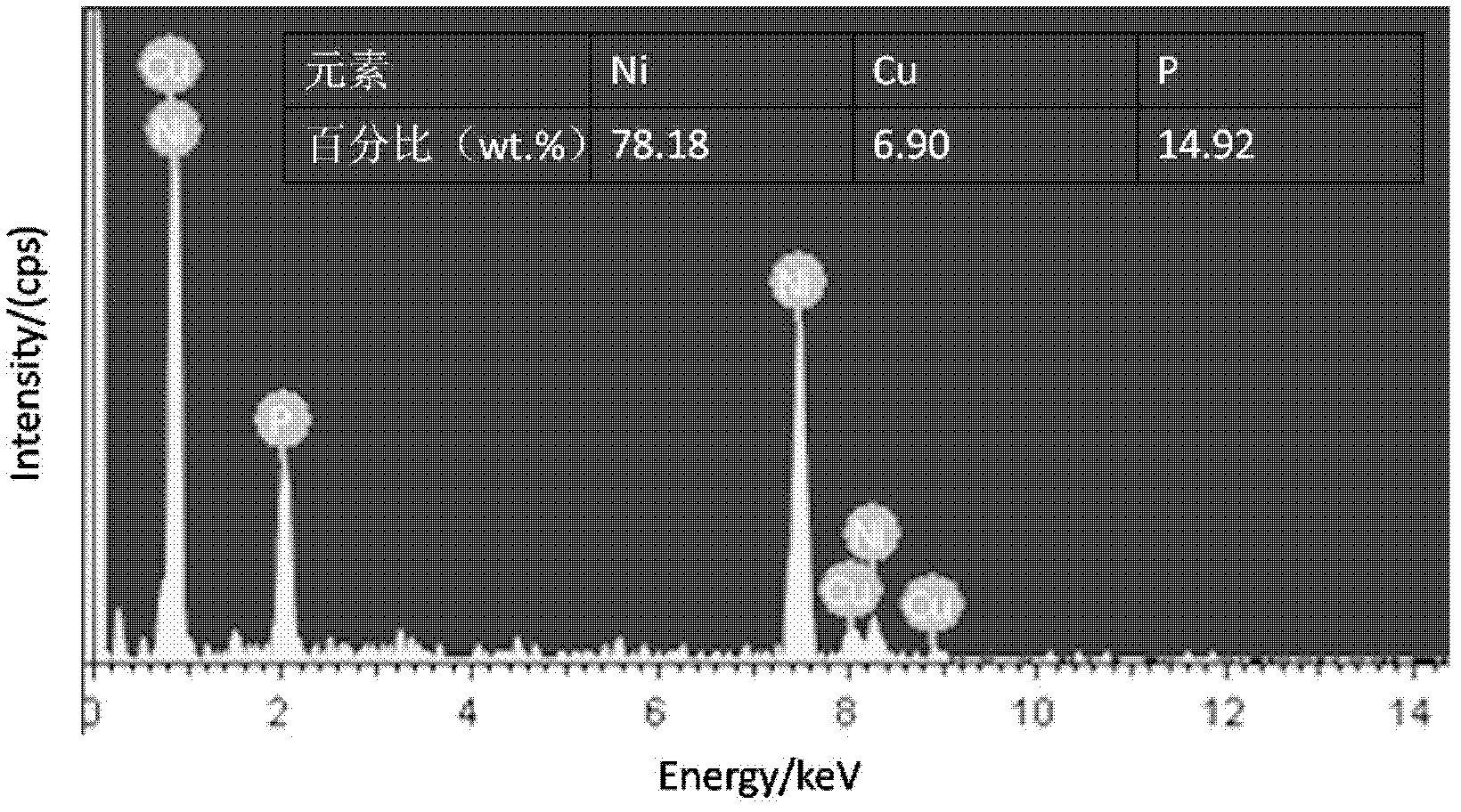

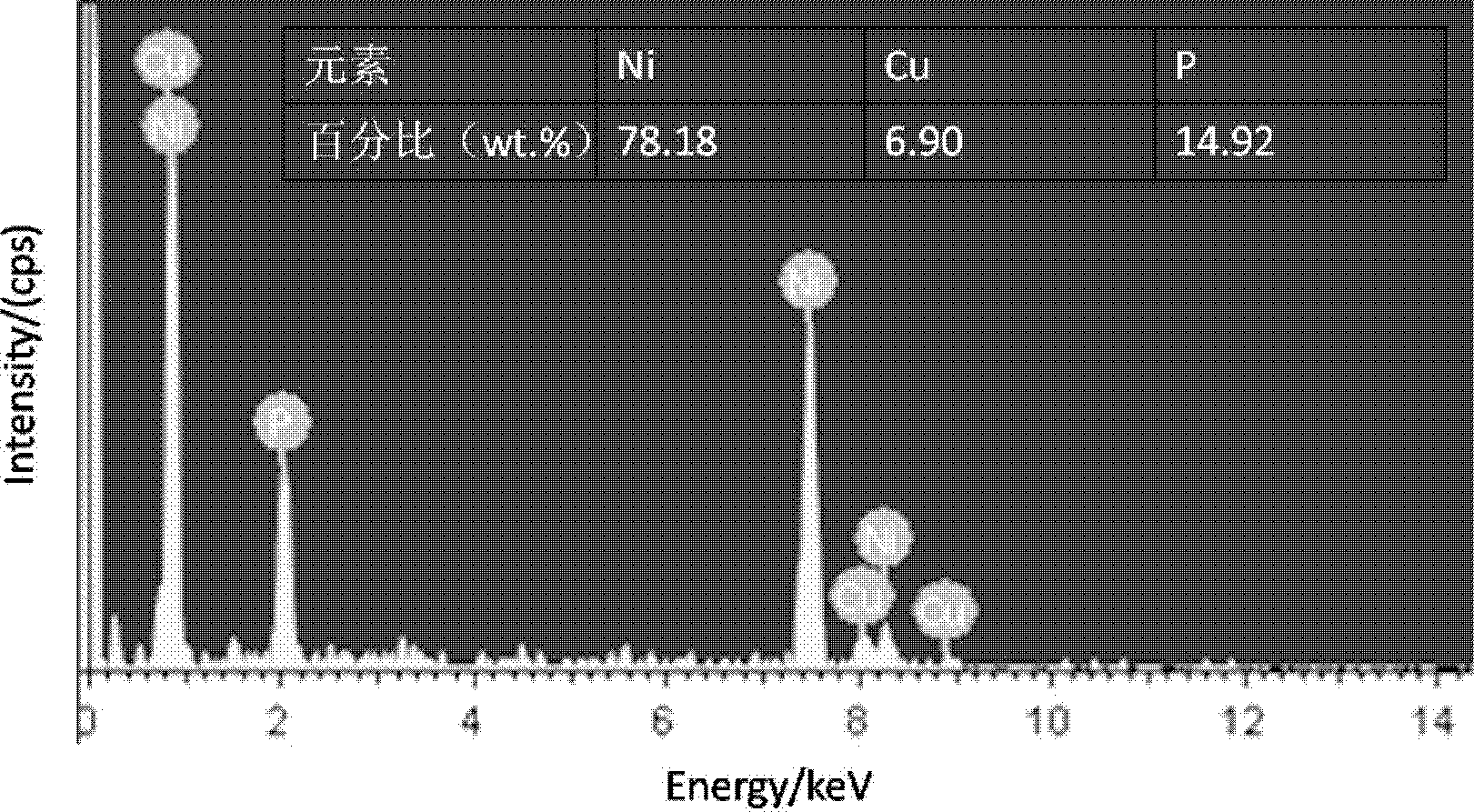

Ni-Cu-P ternary alloy coating serving as welding spot reaction barrier layer and electroplating preparation technology thereof

InactiveCN102560576AReduce energy consumptionHigh bath stabilitySoldering apparatusInterconnectionAlloy coating

The invention discloses a Ni-Cu-P ternary alloy coating serving as a welding spot reaction barrier layer and an electroplating preparation technology thereof. The Ni-Cu-P ternary alloy coating serving as the welding spot reaction barrier layer comprises the following components in percentage by weight: 70-90% of Ni, 3-10% of Cu and 7-20% of P. The thickness of the coating is 2-15mu m. The preparation method comprises the following steps of: putting an electroplated cathode piece (metallized Si chip or Cu piece) and an electroplated anode sheet (Pt piece) into electroplate liquid; introducing dipulse current for dipulse electroplating; and forming an Ni-Cu-P alloy coating on the surface of the cathode piece. The components of the Ni-Cu-P alloy coating prepared by using the electroplating preparation technology conform to the use requirement of a welding spot reaction barrier layer for electronic packaging and interconnection, the coating and the cathode piece substrate (metallized Si chip or Cu piece) are tightly combined, a plating layer is flat, and the Ni-Cu-P ternary alloy coating is fine in cellular tissue, even in thickness, and compact in structure and is basically free from holes.

Owner:HEFEI UNIV OF TECH

Highly anti-corrosion chemical nickel-plating liquid and preparation method thereof

InactiveCN109112509AStrong levelingCrystal fine and brightLiquid/solution decomposition chemical coatingSodium acetatePropanoic acid

The invention relates to highly anti-corrosion chemical nickel-plating liquid. The chemical nickel-plating liquid is prepared from the following components: basic chemical nickel liquid, a wetting agent, a brightener and a stabilizer, wherein the basic chemical nickel liquid is prepared from the following components by weight: nickel sulfate, sodium hypophosphite, citric acid, lactic acid, propionic acid and sodium acetate; the wetting agent is polyethylene glycol, the brightener is 2-mercaptobenzothiazole and polyimide, and the stabilizer is one or a mixture of a 3-sulfur-isothiourea propanesulfonic acid compound, 3-amino-5-mercapto-1,2,4-triazole and S-carboxyethyl isothiuronium betaine. According to the highly anti-corrosion chemical nickel-plating liquid, working temperature is 85-95 DEG C, plating speed can reach about 10-12 mu m / h, plating is even, compact, bright and good in corrosion resistance, all ordinary steel plating thickness is 10 mu m or above, and resistance to neutralsalt spray is 48 h or above.

Owner:CHONGQING LIDAO SURFACE TECH

Chemical plating solution and its use in low concentration standard gas packaging container

InactiveCN1566399AUniform surfaceFlat surfaceLiquid/solution decomposition chemical coatingChemical platingSulfate

The invention relates to a chemical plating solution and its use in low concentration standard gas packaging container which comprises, by using sodium hypophosphite as reducing agent, using nickel sulfate as the main salt as well as addition complexing agent, accelerating agent, stabilizing agent, wherein the inner surface of the container employs 5-15% H2SO4 as activating liquid, coating inert layer inside the container, conducting chemical plating and proceeding hole sealing treatment with CrO3.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Chemical nickel-plating method for capacitive touch screen indium tin oxide (ITO) wiring

InactiveCN102776495AFull coverageImprove performanceLiquid/solution decomposition chemical coatingSputteringIndium tin oxide

The invention provides a novel chemical nickel-plating method for capacitive touch screen indium tin oxide (ITO) wiring. Compared with the conventional vacuum sputtering technology, the novel chemical nickel-plating method is low in equipment investment, low in production cost and high in efficiency; and compared with the traditional chemical nickel-plating process on a nonmetallic matrix, the novel chemical nickel-plating method has high solution stability and selectivity. The novel chemical nickel-plating method comprises the following steps of: sequentially deoiling, etching, sensitizing, activating, reducing and performing chemical nickel-plating on the ITO film glass; and the key points are that the selectivity of the ITO film is improved during sensitization by adopting sensitizing solution containing Cu+, and the sensitizing solution is more stable than the traditional Sn2+ sensitizing solution; during etching, the etching process is stabilized by employing etching solution containing S2O82- or HS2O8-, and the etching effect is improved; and the chemical nickel-plating is performed at the low temperature of 55-65 DEG C, the plating solution is stable, and the plating layer is smooth and dense. The results prove that the method is easy to operate and high in speed; the ITO surface nickel layer is completely covered and has high adhesive force, and the glass matrix is not covered by the nickel layer and has high selectivity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Alkaline cyanide-free electro-deposition zinc-nickel alloy additive and application thereof

The invention discloses an alkaline cyanide-free electro-deposition zinc-nickel alloy additive and an application thereof. The alkaline cyanide-free electro-deposition zinc-nickel alloy additive is prepared from an additive and ultrapure water. The additive is an organic additive or a mixture of the organic additive and an inorganic additive and can be applied to an alkaline cyanide-free electro-deposition zinc-nickel alloy plating solution to replace a traditional cadmium coating and cyanide electro-deposition zinc-nickel alloy process. According to the alkaline cyanide-free electro-deposition zinc-nickel alloy additive and the application thereof, through additive screening and adding, an electroplating process for electro-deposition zinc-nickel alloy is optimized, and a zinc-nickel alloy coating which is bright in appearance, high in hardness and excellent in corrosion resistance is finally obtained; the obtained plating solution is good in stability, dispersity and covering capacity, and the problems that a conventional alkaline zinc-nickel alloy plating solution is poor in stability and low in current efficiency, and an obtained coating is poor in quality are solved fundamentally; and the industrialized application feasibility of the alkaline cyanide-free electro-deposition zinc-nickel alloy additive is improved.

Owner:HARBIN INST OF TECH

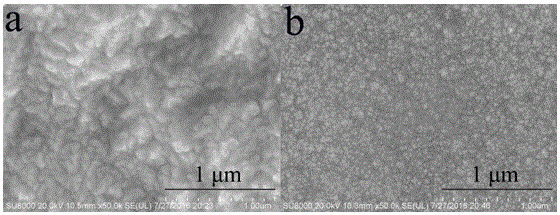

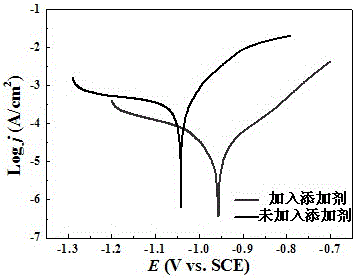

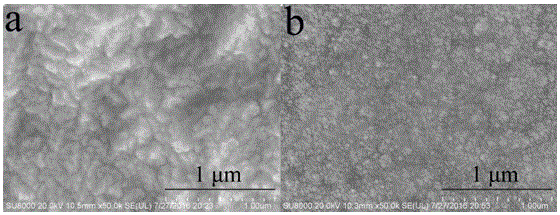

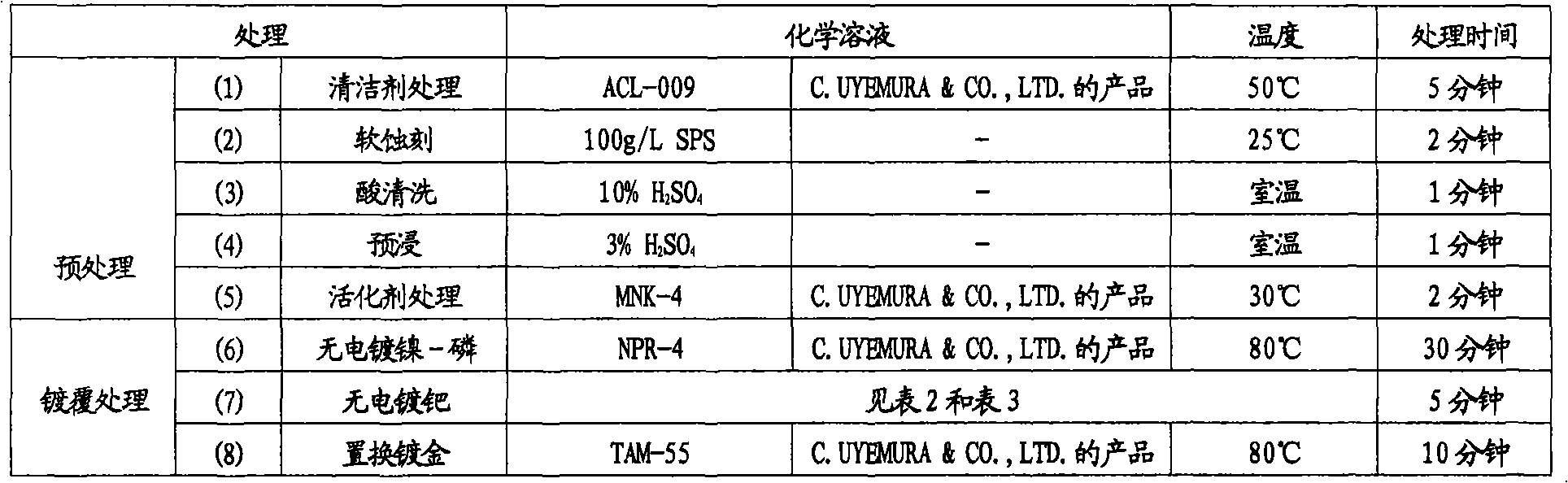

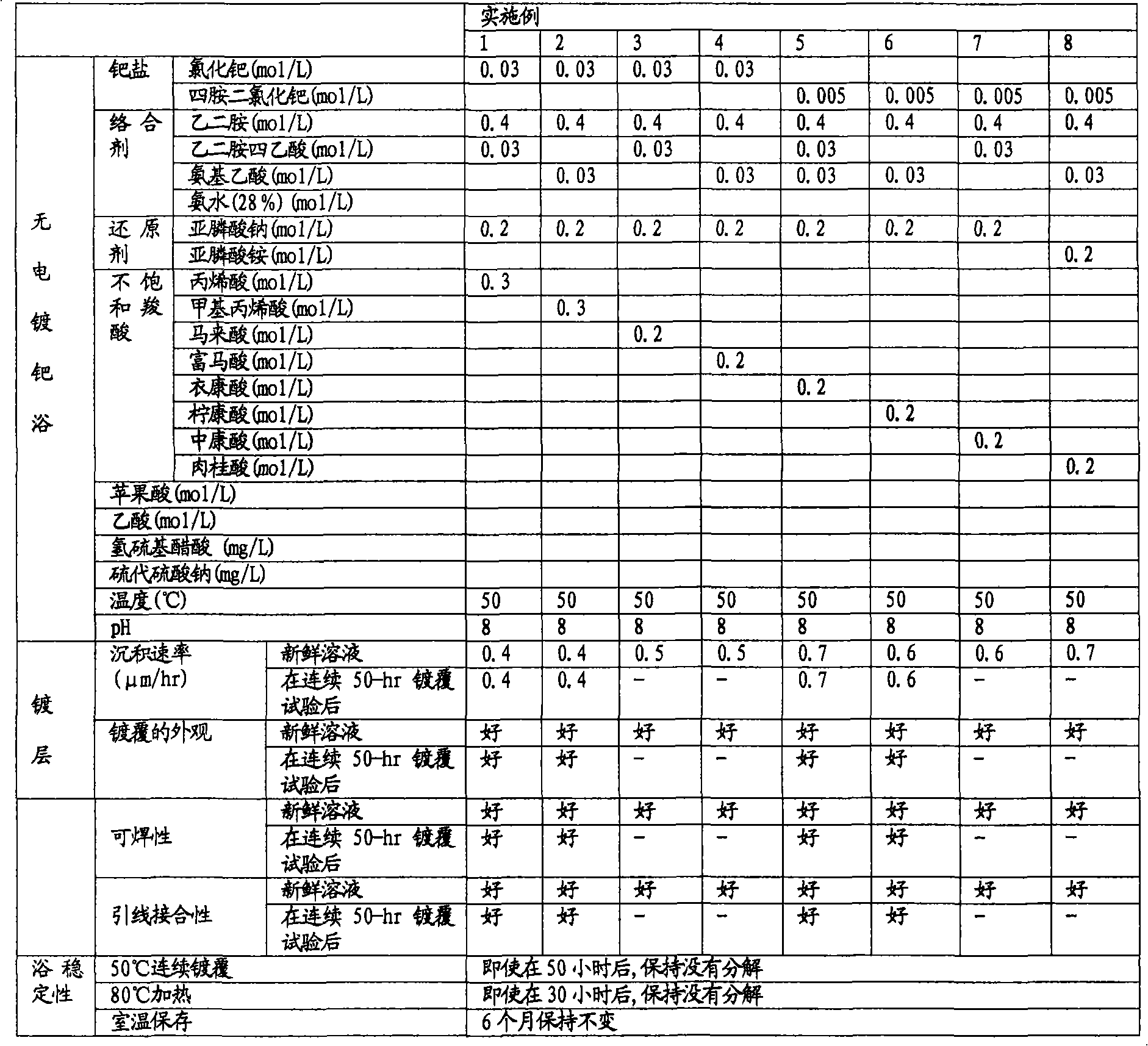

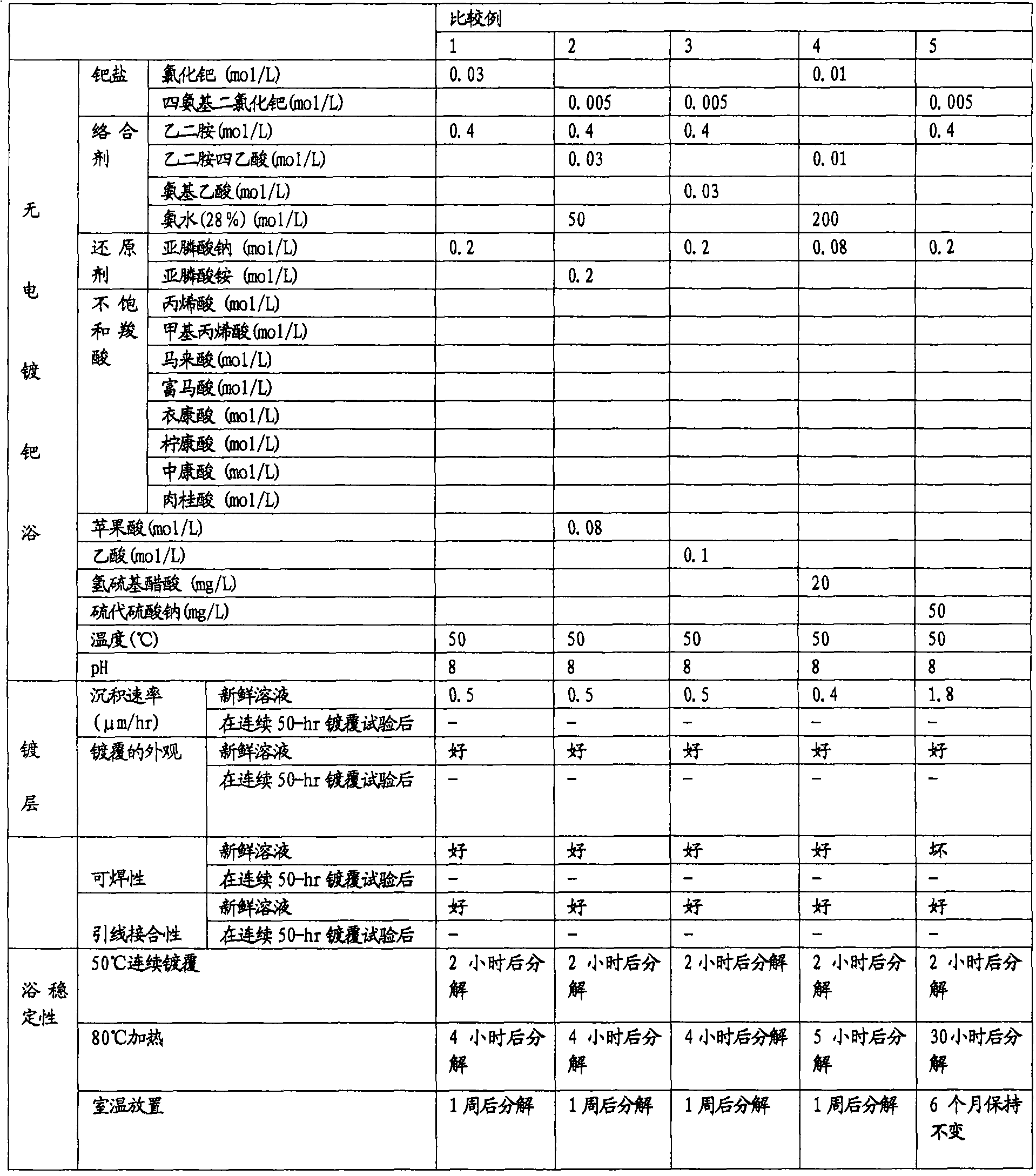

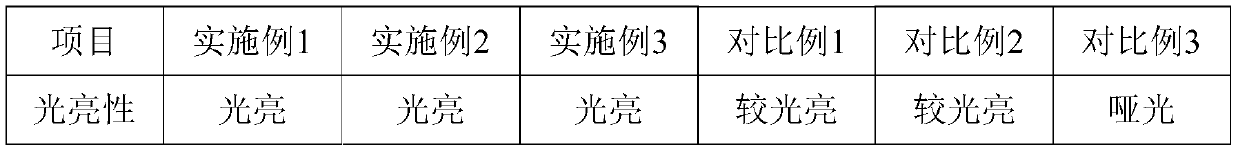

Electroless palladium plating bath and electroless palladium plating method

InactiveCN101356299AHigh bath stabilityLong bath lifeSolid-state devicesLiquid/solution decomposition chemical coatingPhosphinic AcidsCarboxylic acid

Owner:C UYEMURA & CO LTD

Chemical immersion tin plating solution and preparation method thereof

InactiveCN109055921AUniform and dense coatingGood solderability of the coatingLiquid/solution decomposition chemical coatingEnvironmental chemistryCompound (substance)

The invention relates to a chemical immersion tin plating solution and a preparation method thereof. The chemical immersion tin plating solution is composed of tin salt, an accelerant, a wetting agentand a stabilizer, wherein the mass concentration of the tin salt is 5-20 g / L, the mass concentration of the accelerant is 30-200 g / L, the mass concentration of the wetting agent is 0.1-0.5 g / L, the mass concentration of the stabilizer is 50-170 g / L. Under reasonable concentration proportioning and the synergistic effect of all the components, the chemical immersion tin plating solution is very stable, the plating layer is uniform, compact and semi-bright, moreover, the used working temperature is not high, the temperature is 35-45 DEG C, plating is carried out for 10-15 minutes, the thicknessof the plating layer can reach about 1.5-2 microns, and the plating layer is good in weldability.

Owner:CHONGQING LIDAO SURFACE TECH

Chemical tin plating liquid and preparation method thereof

ActiveCN110331392AImprove stabilityIncrease brightnessLiquid/solution decomposition chemical coatingTin platingReducing agent

The invention belongs to the technical field of chemical tin plating, and in particular, relates to chemical tin plating liquid and a preparation method thereof. The chemical tin plating liquid contains sulfuric acid, tin salt, complexing agents, multifunctional additives, reducing agents and function auxiliaries; and in the chemical tin plating liquid, the content of the sulfuric acid is 33-40 mL.L-1, the content of the tin salt is 10-15 g.L-1, the content of the complexing agents is 85-95 g.L-1, the content of the multifunctional additives is 0.5-1.2 g.L-1, the content of the reducing agentsis 25-40 g.L-1, and the content of the function auxiliaries is 1-2 g.L-1. The chemical tin plating liquid is excellent in stability, and accelerates the plating layer deposition speed when the stability of the plating liquid is improved.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

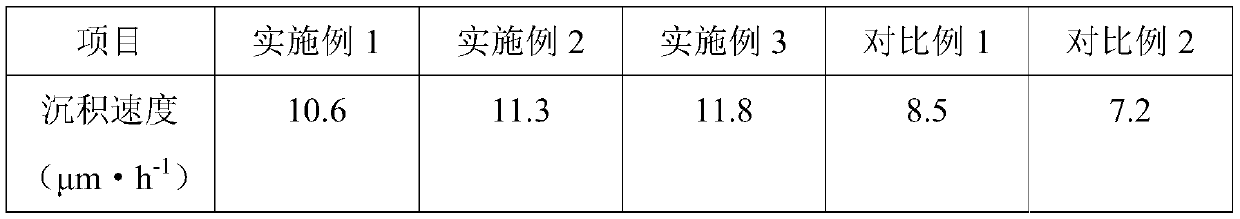

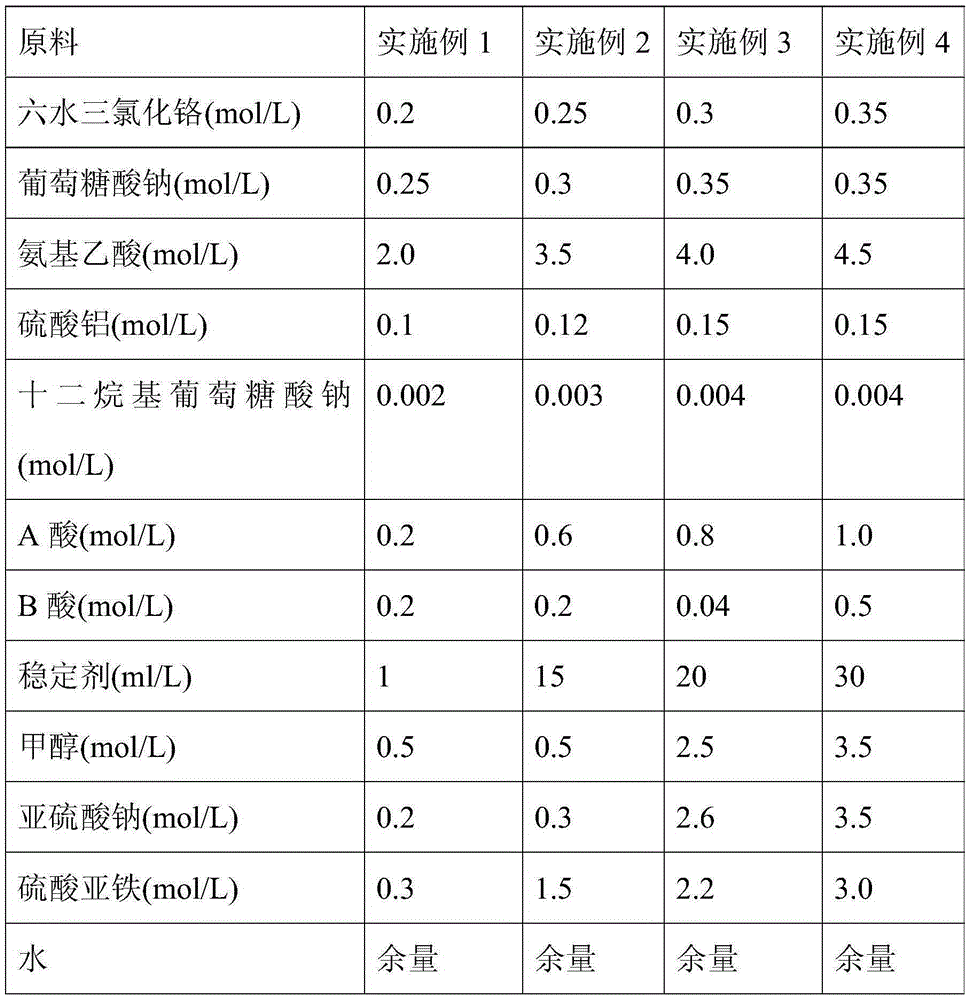

Trivalent chromium electroplate liquid and preparing method thereof

The invention discloses trivalent chromium electroplate liquid and a preparing method thereof. The trivalent chromium electroplate liquid comprises, by concentration, 0.2-0.35 mol / L of hexahydrate chromium trichloride, 0.25-0.35 mol / L of sodium gluconate, 2.0-4.5 mol / L of glycine, 0.1-0.15 mol / L of aluminum sulfate, 0.002-0.004 mol / L of dodecyl sodium gluconate, 0.4-0.8 mol / L of a complexing agent, 15-20 ml / L of stabilizer and the balance solvent water. The stabilizer is a water solution comprising 2-3 mol / L of methyl alcohol, 2-3 mol / L of sodium sulfite and 1-2 mol / L of ferrous sulfate. Compared with the prior art, the electroplate liquid is stable in performance and long in service life, and the quality of a coating is good. Meanwhile, the preparing method is simple, operation is easy, and very good application prospects and high using value are achieved.

Owner:WUXI QIAOYANG MACHINERY MFG

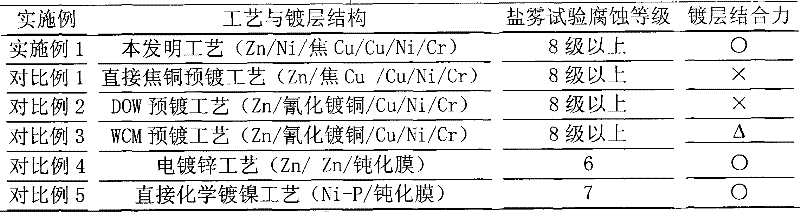

Process for reducing low internal stress of hub electroplated layer through semi-bright nickel electroplating procedure

The invention relates to a process for reducing the low internal stress of a hub electroplated layer through a semi-bright nickel electroplating procedure. In a semi-bright nickel electroplating step, a solution formula consists of 100-150g.dm<-3> of nickel sulfate (NiSO4.6H2O), 10-30g.dm<-3> of nickel chloride (NiCl2.6H2O), 20-30g.dm<-3> of boric acid (H3BO3), 1-2g.dm<-3> of sodium dodecyl sulfate, 1-2g.dm<-3> of butynediol and 0.1-0.2g.dm<-3> of sodium maltodextrin, and the operating conditions are that the temperature is 45-55 DEG C, the pH value is 2-3, the anode current density is 1-3A.dm<-2>, the time is 10-20 minutes, and air stirring and continuous filtration are performed. By adopting the process, a metal coating with high bonding force and high corrosion resistance can be obtained on the surface of a magnesium alloy motorcycle hub, the internal stress of the coating is reduced, and the phenomenon of cracking during use is avoided.

Owner:WUXI SANZHOU COLD ROLLED SILICON STEEL

Electroplating process for surface of magnesium alloy motorcycle hub

InactiveCN101280445BHarm reductionReduce pollutionSolid state diffusion coatingLiquid/solution decomposition chemical coatingCyanidePyrophosphate

The invention discloses a combined electroplating process on a magnesium alloy motorcycle wheel hub by adopting a non-cyanide and chrome free pre-plating treatment solution. Electroplated nickel and pyrophosphate copper are adopted as dual-layer bottoming coating, and then Cu / Ni / Cr combined coating electroplating is performed, to obtain the Cu / Ni / Cr combined metallic coating with high corrosion resistance on the surface of the magnesium alloy motorcycle wheel hub. The metallic coating obtained on the surface of the magnesium alloy motorcycle wheel hub by adopting the process has the advantages that the binding force is strong, and the corrosion resistance is high, and the combined electroplating process has the prominent advantages that the personnel health is guaranteed, and the environmental pollution is avoided.

Owner:GCI SCI & TECH +1

Tin plating solution

The invention relates to a tin plating solution with a formula comprising 20-50 g / L of stannous chloride,150-200 g / L of hydrochloric acid, 5-20 ml / L of a brightening agent, 20-30 ml / L of a stabilizer, 0.5-2 g / L of bismuth nitrate, 20-50g / L of a pH regulator composed of ammonia water and a complexing agent, and the balance being deionized water. Preparation environment of the solution is that a current density is 1.0-2.0 A / dm<2>; a temperature is 20-30 DEG C; a pH value of the plating solution is controlled within 1-2. The solution is reasonable in formula, has good welding properties and can effectively inhibit the growth of crystal whiskers. The plating solution has high stability and long service life.

Owner:谢柳芳

Chemical silver plating solution and silver plating method

ActiveCN109338343APlating solution is stablePrevent reaction effectsLiquid/solution decomposition chemical coatingSilver ionBinding force

The invention provides a chemical silver plating solution on a printed circuit board and a silver plating method. The chemical silver plating solution is prepared from the compositions of 1.0-2.0g / L of silver ions, 5-30g / L of a copper ion complexing agent, 0.5-1.8g / L of bithiazole-like compounds, 0.5-1.5g / L of azaindole-like-containedindole compounds, 0.05-0.075g / L of benzotriazole, 40-60ml / L of methanesulfonic acid, and 0.5-1.3 g / L of polyphenyl-tetramethyl-acyl-diphenyl-imide,a suitable pH value of the plating solution is 0.5-1, and the plating solution is put at the room temperature. By adopting the chemical silver plating solution, a bright white coating is obtained,especially the binding force and corrosion resistant properties are outstanding, meanwhile the process flow is shortened,pre-plating is not required, and reliability of the circuit board can be improved and the service life can be prolonged.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Double-bottoming electroplating method for nickel-plating magnesium alloy hub

The invention discloses a double-bottoming electroplating method for a nickel-plating magnesium alloy hub. The method includes the following operation steps that firstly, preplating treatment is conducted; secondly, preplating cyanide-free copper bottoming treatment is conducted, wherein a plating solution of preplating cyanide-free copper includes 120-130 g / L of copper sulfate, 160-180 g / L of sodium ethylenediamine tetramethylene phosphonate, 80-100 g / L of potassium tartrate and 0.3-0.5 g / L of 2-mercaptobenzothiazole, according to the technology of the plating solution of the preplating cyanide-free copper, the pH of the plating solution is 8.5-9.5, the temperature of the plating solution is 45-55 DEG C, the electroplating time is 15-25 min, the cathodic current density is 1.2-1.4 A / dm<2>, the anodic current density is 0.6-0.8 A / dm<2>, and gas stirring is adopted; thirdly, pyrophosphate copper plating bottoming treatment is conducted, wherein a plating solution of pyrophosphate copper plating treatment comprises 100-120 g / L of copper pyrophosphate, 140-160 g / L of potassium pyrophosphate, 6-8 mL / L of ammonia water with the concentration of 25-30%, 8-12 g / L of potassium citrate, 15-25 g / L of potassium sodium tartrate, 0.2-0.3 mL / L of a brightening agent and the balance water, according to the technology of the plating solution, the pH of the plating solution is 8.5-9.5, the temperature of the plating solution is 45-55 DEG C, the electroplating time is 25-35 min, the cathodic current density is 1.2-1.4 A / dm<2>, the anodic current density is 0.7-0.9 A / dm<2>, and gas stirring is adopted; and fourthly; nickel electroplating is adopted.

Owner:张颖

Method for the anodic electrophoretic enamelling and electrophoretic paints

InactiveCN1211441CGood compatibilityRedissolve lessPaints for electrolytic applicationsThin material handlingEpoxyAlcohol

The invention relates to a method for the anodic electrophoretic enamelling of conductive surfaces by dipping into an aqueous anodic electrophoretic bath and by connecting as an anode. An aqueous anodic electrophoretic bath is used which contains 1 to 15 % by weight of one or more phosphoric acid epoxy esters and / or phosphonic acid epoxy esters in relation to the binding agent solid of the electrophoretic bath. Said phosphoric acid epoxy esters and / or phosphonic acid epoxy esters are produced in the presence of alcohols.

Owner:EI DU PONT DE NEMOURS & CO

Nickel phosphorus chemical plating method of neodymium iron boron permanent magnet material

InactiveCN1150350CUniform thicknessPlay a protective effectLiquid/solution decomposition chemical coatingChemical platingMechanical energy

In the invention, the sodium hypophosphite is as the reducing agent of the bath, nickel sulfate as the main salt, with the complexing agent, accelerating agent and stabilizing agent being added. The ultrasonic chemical plating and second chemical plating method are adopted that utilizes the mechanical energy of the ultrasonic vibration, making the bath deposit nickel and phosphor under the catalysis of the metal surafce and the chemical reduction method controlled. The plating procedure includes the steps of edge rounding, oil removal, rust removal, activation, chemical plating and post treatment. The multiple complexing, accelerating and stabilizing agents raises the stability of the bath. The plating speed is adjustable. The even, compact nickel and phosphor plating layer covers the surface of the base body of powder metallurgical material so as to increase the service life of the material and provide wide application area.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Chemical palladium plating solution

InactiveCN101709462BStable pHAlkaline performance is goodLiquid/solution decomposition chemical coatingChemical platingPhysical chemistry

The invention relates to a chemical palladium plating solution, in particular to a chemical palladium plating solution which can directly form a palladium film with good adhesive force on a chemical nickel plating film formed on a printed circuit board (PCB) and does not affect the chemical nickel plating film serving as a base film. The chemical palladium plating solution contains a soluble palladium salt, a first complexing agent, a second complexing agent and a stabilizing agent, wherein the first complexing agent is one out of ammonia and diamine compounds, and the second complexing agentis one or more out of alcohol amine compounds with 2-7 carbon atoms, amine compounds with less than 7 carbon atoms and aminocarboxylic acid compounds. The palladium plating solution has stable pH, stable deposition rate, long bath service life and excellent bath stability, does not generate cracks, and can obtain the palladium plating film with very low phosphorus content and excellent corrosion resistance, solder connectivity and lead weldability.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

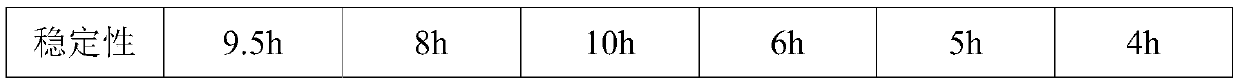

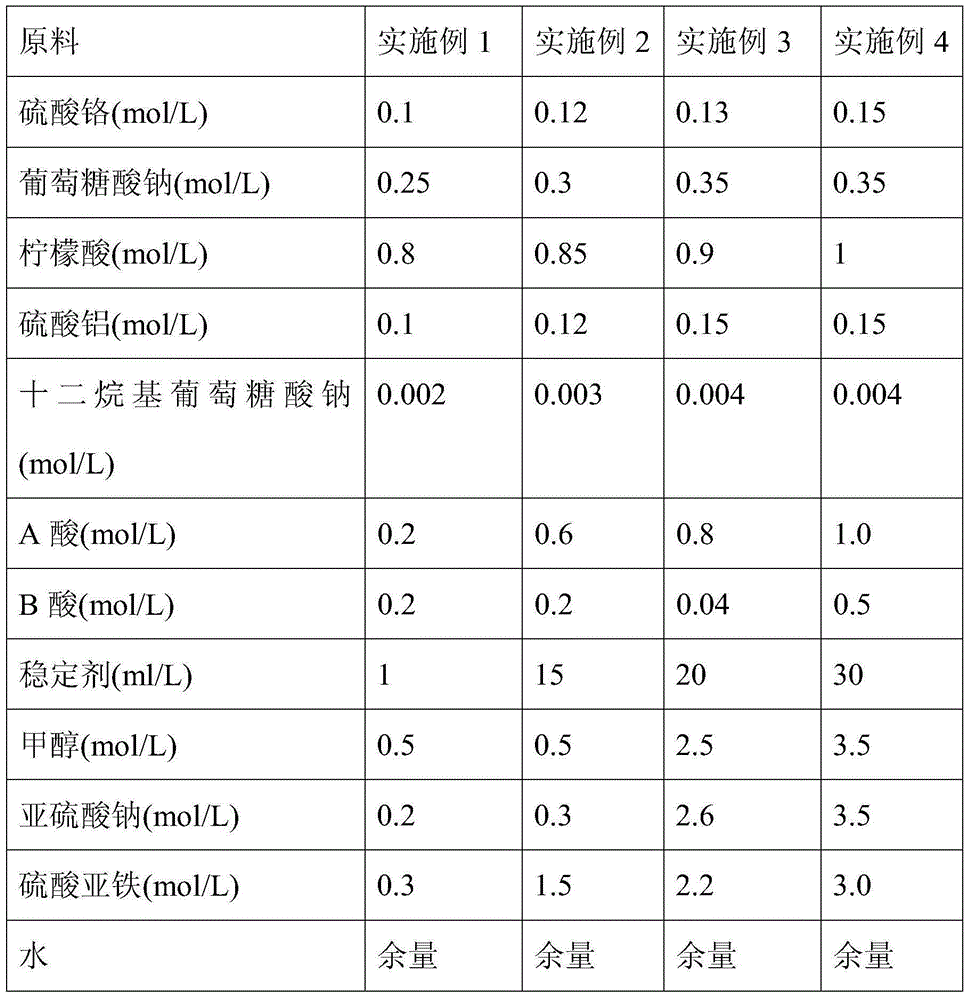

Trivalent chromium electroplate liquid and preparing method thereof

The invention discloses trivalent chromium electroplate liquid and a preparing method thereof. The trivalent chromium electroplate liquid comprises, by concentration, 0.1-0.15 mol / L of chromium sulfate, 0.25-0.35 mol / L of sodium gluconate, 0.8-1 mol / L of citric acid, 0.1-0.15 mol / L of aluminum sulfate, 0.002-0.004 mol / L of dodecyl sodium gluconate, 0.4-0.8 mol / L of a complexing agent, 15-20 mol / L of a stabilizer and the balanced solvent water. The stabilizer is a water solution which is formed by 2-3 mol / L of methyl alcohol, 2-3 mol / L of sodium sulfite and 1-2 mol / L of ferrous sulfate. Compared with the prior art, the trivalent chromium electroplate liquid has the beneficial effects that the performance is stable, the service life is long, the coating quality is good, the preparing method is simple, the operation is easy, and the great application prospect and the good use value are achieved.

Owner:WUXI QIAOYANG MACHINERY MFG

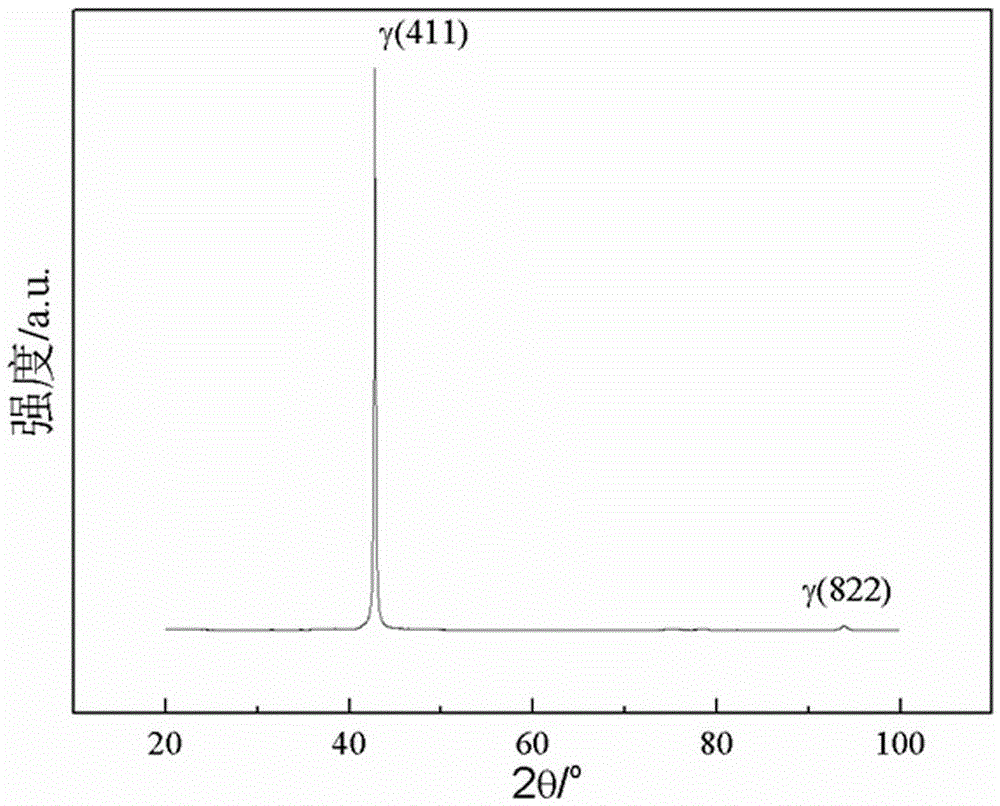

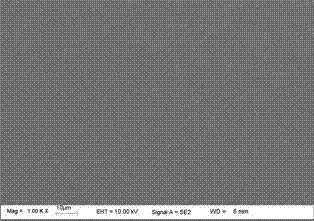

Manufacturing method of nickel-tungsten plating layer

The invention provides a manufacturing method of a nickel-tungsten plating layer. A plating solution consists of 0.15-0.45 mol / L nickel chloride, 0.1-0.25 mol / L nickel sulfate, 0.1-0.2 mol / L sodium sulfate, 0.1-0.3 mol / L sodium hydrogen phosphate, 0.5-2 mol / L citric acid, 0.001-0.005 ml / L OP-10, 0.1-0.2 g / L 1,4-dihydroxy-2-butyne, and 0.1-0.4 mol / L sodium tungstate. An electrodeposition technology comprises the following steps of enabling the current density to be 3-15 A.dm<-2>, and enabling the temperature of the plating solution to be 20-40 DEG C. The manufacturing method disclosed by the invention has the advantages of being simple in technology, low in cost, simple in pre-processing, high in stability of the plating solution, long in cycle life and the like, so that large-scale production of the nickel-tungsten plating layer can be realized.

Owner:TIANJIN RUISAIKE NEW MATERIAL TECH CO LTD

Environmental non-cyanide plating solution for silver-plating

Owner:FUJIAN NORMAL UNIV

A kind of electroless silver plating solution and silver plating method

ActiveCN109338343BPlating solution is stablePrevent reaction effectsLiquid/solution decomposition chemical coatingChemical platingSilver ion

The invention provides a chemical silver plating solution on a printed circuit board and a silver plating method. The chemical silver plating solution is prepared from the compositions of 1.0-2.0g / L of silver ions, 5-30g / L of a copper ion complexing agent, 0.5-1.8g / L of bithiazole-like compounds, 0.5-1.5g / L of azaindole-like-containedindole compounds, 0.05-0.075g / L of benzotriazole, 40-60ml / L of methanesulfonic acid, and 0.5-1.3 g / L of polyphenyl-tetramethyl-acyl-diphenyl-imide,a suitable pH value of the plating solution is 0.5-1, and the plating solution is put at the room temperature. By adopting the chemical silver plating solution, a bright white coating is obtained,especially the binding force and corrosion resistant properties are outstanding, meanwhile the process flow is shortened,pre-plating is not required, and reliability of the circuit board can be improved and the service life can be prolonged.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method of supersonic chemical plating nickel phosphorus of powder metallurgy material

InactiveCN1150349CUniform thicknessImprove corrosion resistanceLiquid/solution decomposition chemical coatingChemical platingMechanical energy

In the invention, the sodium hypopphosphite is as the reducing agent of the bath, nickel sulfate as the main salt, with the complexing agent, accelerating agent and stabilizing agent being added. The ultrasonic chemical plating is adopted that utilizes the mechanical energy of the ultrasonic vibration, making the bath deposit nickel and phosphor under the catalysis of the metal surface and the chemical reduction method controlled. The plating procedure includes the steps of oil removal, rust removal, activation, chemical plating and post treatment. The multiple complexing, accelerating and stabilizing agents raises the stability of the bath. The plating speed is adjustable. The even, compact nickel and phosphor plating layer covers the surface of the base body of powder metallurgical material so as to increase the service life of the material and provide wide application area.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Alkaline cyanide-free electrodeposited zinc-nickel alloy additive and its application

The invention discloses an alkaline cyanide-free electro-deposition zinc-nickel alloy additive and an application thereof. The alkaline cyanide-free electro-deposition zinc-nickel alloy additive is prepared from an additive and ultrapure water. The additive is an organic additive or a mixture of the organic additive and an inorganic additive and can be applied to an alkaline cyanide-free electro-deposition zinc-nickel alloy plating solution to replace a traditional cadmium coating and cyanide electro-deposition zinc-nickel alloy process. According to the alkaline cyanide-free electro-deposition zinc-nickel alloy additive and the application thereof, through additive screening and adding, an electroplating process for electro-deposition zinc-nickel alloy is optimized, and a zinc-nickel alloy coating which is bright in appearance, high in hardness and excellent in corrosion resistance is finally obtained; the obtained plating solution is good in stability, dispersity and covering capacity, and the problems that a conventional alkaline zinc-nickel alloy plating solution is poor in stability and low in current efficiency, and an obtained coating is poor in quality are solved fundamentally; and the industrialized application feasibility of the alkaline cyanide-free electro-deposition zinc-nickel alloy additive is improved.

Owner:HARBIN INST OF TECH

Chemical nano-silver plating solution and preparation method thereof, and silver plating method for copper part

InactiveCN102560451BTightly boundHigh bath stabilityMaterial nanotechnologyLiquid/solution decomposition chemical coatingChemical platingCopper

Owner:JIANGSU UNIV

Ni-Cu-P ternary alloy coating serving as welding spot reaction barrier layer and electroplating preparation technology thereof

InactiveCN102560576BReduce energy consumptionHigh bath stabilitySoldering apparatusInterconnectionAlloy coating

The invention discloses a Ni-Cu-P ternary alloy coating serving as a welding spot reaction barrier layer and an electroplating preparation technology thereof. The Ni-Cu-P ternary alloy coating serving as the welding spot reaction barrier layer comprises the following components in percentage by weight: 70-90% of Ni, 3-10% of Cu and 7-20% of P. The thickness of the coating is 2-15mu m. The preparation method comprises the following steps of: putting an electroplated cathode piece (metallized Si chip or Cu piece) and an electroplated anode sheet (Pt piece) into electroplate liquid; introducing dipulse current for dipulse electroplating; and forming an Ni-Cu-P alloy coating on the surface of the cathode piece. The components of the Ni-Cu-P alloy coating prepared by using the electroplating preparation technology conform to the use requirement of a welding spot reaction barrier layer for electronic packaging and interconnection, the coating and the cathode piece substrate (metallized Si chip or Cu piece) are tightly combined, a plating layer is flat, and the Ni-Cu-P ternary alloy coating is fine in cellular tissue, even in thickness, and compact in structure and is basically free from holes.

Owner:HEFEI UNIV OF TECH

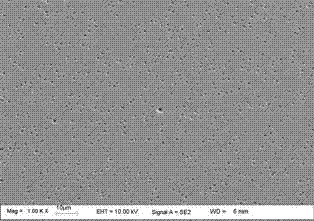

A kind of electroless nickel plating liquid and preparation method thereof

ActiveCN106148922BImprove corrosion resistanceHigh bath stabilityLiquid/solution decomposition chemical coatingAlcoholCompound (substance)

The invention provides chemical nickel-plating plating solution and a preparation method thereof. The chemical nickel-plating plating solution comprises basic chemical nickel-plating solution and an alcohol additive; the pH value of the chemical nickel-plating plating solution is 4.8 to 5.2; the alcohol additive is one or more selected from water-soluble monohydric alcohol, dihydric alcohol or trihydric alcohol. The chemical nickel-plating plating solution contains the alcohol additive, so that the plating solution has excellent stability, and the nitric acid resistant melanism capacity of a clad layer during application of the chemical nickel-plating plating solution can be remarkably improved.

Owner:德星化工(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com