Patents

Literature

135results about How to "Plating solution is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

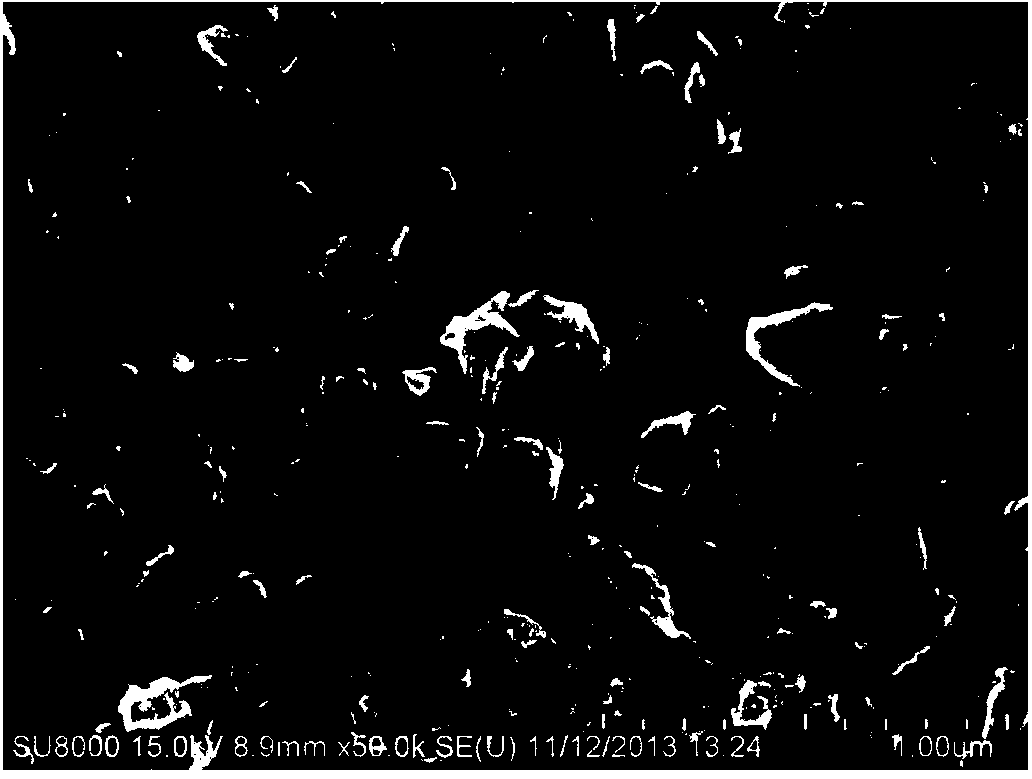

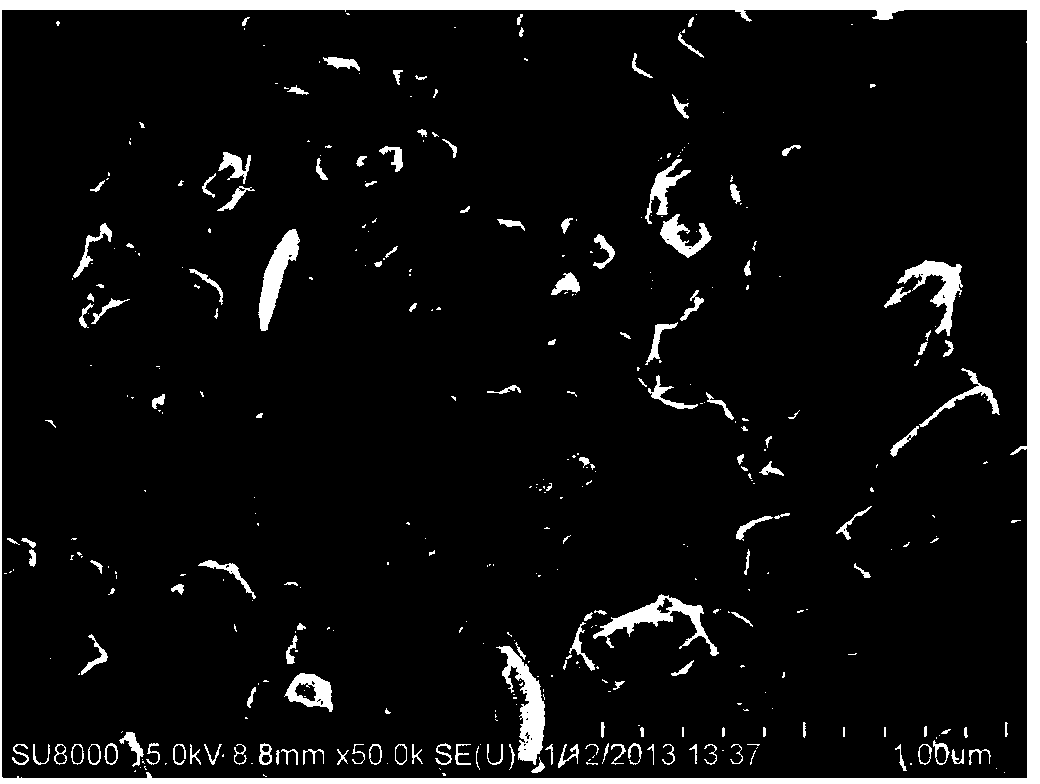

Palladium-free chemical copper plating method

InactiveCN105821396ACopper sinking speed is fastPlating solution is stableLiquid/solution decomposition chemical coatingCrystalliteCopper plating

The invention discloses a palladium-free chemical copper plating method. The method comprises the steps of firstly forming a poly-dopamine layer on the surface of a base body in a solution through the oxidation polymerization effect of dopamine, reducing silver ions to nano silver through poly-dopamine, catalyzing reduction of copper ions in chemical copper plating solutions with the nano silver serving as a catalytic center and finally forming a complete and compact metal copper layer on a surface to be plated. The method has the advantages that the operation is simple, the application range of material to be plated is wide, the requirement for equipment is low, the cost is low, coatings are firm, and the sizes of crystal grains are small.

Owner:SOUTH CHINA UNIV OF TECH

Chemical-copper plating liquid and copper plating production process

ActiveCN101654797AImprove bindingApplicable functionLiquid/solution decomposition chemical coatingPorosityCopper plating

The invention relates to chemical-copper plating liquid and a copper plating production process, which are used for copper plating of tubular steel and iron pieces and non-metal pieces, and are characterized in that: the chemical-copper plating liquid consisting of copper sulphate, a retarder, a complexant, a reductant and deionized water is used to pretreat a workpiece and then the workpiece is subjected to chemical-copper plating; an anode is 0.3 percent phosphor-containing copper plate; the area ratio of the anode and the cathode is 2:1; the current intensity in the cathode is 0.5 to 4A / dm<2>; the pH value of the copper plating liquid is 1.0 to 3.0; the temperature of the copper plating liquid is normal temperature; and the carrying capacity is 1 to 4dm<2> / kg; the copper plating time is8 to 10 minutes. The liquid and the process have the advantages of firm bonding between cladding and a substrate, stable process, high impurity resistance, long service life, crystalline simple copper cladding, fine cladding crystallization, low porosity, high anticorrosion performance, simple operation, convenient maintenance, no formaldehyde, no damages to human bodies and environment and environmentally-friendly product.

Owner:河北聚贤环保科技股份有限公司

Multi-coordination-agent cyanide-free electrogilding liquid and electrogilding process

ActiveCN103741181AExcellent bath performanceGood coating performancePotassium hydroxidePotassium carbonate

The invention relates to multi-coordination-agent cyanide-free electrogilding liquid and an electrogilding process, which belong to the technical field of electrogilding. The electrogilding liquid is prepared from a main coordination agent, an auxiliary coordination agent, potassium hydroxide, potassium carbonate, goldpotassium chloride, combined additives and ultrapure water. The electrogilding process comprises the following steps: 1, preprocessing a substrate; 2, electroplating an intermediate nickel plating layer; 3, electrogilding, namely washing the substrate after electroplating the intermediate nickel plating layer with ultrapure water, directly feeding the substrate into a plating cell containing the multi-coordination-agent cyanide-free electrogilding liquid to be electrogilded, taking out a sample from the electrogilding liquid after the electrogilding, washing the surface of the sample by utilizing distilled water, and drying the sample through cold air. Double coordination agents are used as the coordination agents of gold ions in the electrogilding liquid, so that a cyanide-free electrogilding system which has high current efficiency, smoothness and compactness in plating layer crystallization, wide current density range, wide temperature requirement and capability of guaranteeing the golden bright appearance of the plating layer compared with those of a single coordination agent system is obtained.

Owner:HARBIN INST OF TECH

Copper plating solution for PCB (printed circuit board) through holes, and preparation method and plating method thereof

InactiveCN103572335AGood throwing abilityImprove toughnessPrinted element electric connection formationCopper platingPhysical chemistry

The invention relates to the technical field of PCB (printed circuit board) plating, in particular to a copper plating solution for PCB through holes, and a preparation method and a plating method thereof. Each liter of the copper plating solution comprises the following components according to contents: 70-150g of copper sulfate pentahydrate, 100-300g of sulfuric acid, 30-100ppm of chlorine ions, 5-50g of brightener, 3-30g of carrier, 2-20g of leveling agent and the balance of deionized water, wherein the concentration ratio of the copper sulfate pentahydrate to the sulfuric acid is 1: (1.5-2). The plating method comprises the following steps: putting a PCB with through holes into a plating bath with the copper plating solution; plating during air agitation to obtain a copper plating layer. The copper plating layer formed by the plating method has a good uniform plating capability as high as 95% above, and is dense, smooth, relatively good in malleability, good in gloss, high in toughness and low in internal stress.

Owner:东莞市富默克化工有限公司

Cyanide-free bright electrogilding additive and application thereof

The invention discloses a cyanide-free bright electrogilding additive and an application thereof, which belongs to the technical field of electrogilding. The electrogilding additive is prepared from additives and ultra-pure water, wherein the additives are organic additives or mixtures of inorganic additives and organic additives; the concentration of each component in the additive is 0.5-30g / L. The cyanide-free bright electrogilding additive disclosed by the invention has the functions of improving the brightness of a plated layer, refining crystal grains, stabilizing plating liquid and reducing surface tension. Therefore, the additive can be applied to electrogilding plating liquid, and the addition amount is 0.1-100mL / L. By adopting the additive disclosed by the invention, the properties of the plating liquid and the plating layer of a multi-coordination agent cyanide-free electrogilding system can be effectively improved, the plating liquid has no unstable situations of decomposition, precipitation and the like under long-time working condition, and an electrogilding layer which is golden and full bright macroscopically, uniform and compact in micro crystal, flat and crackless can be obtained under the electroplating condition.

Owner:HARBIN INST OF TECH

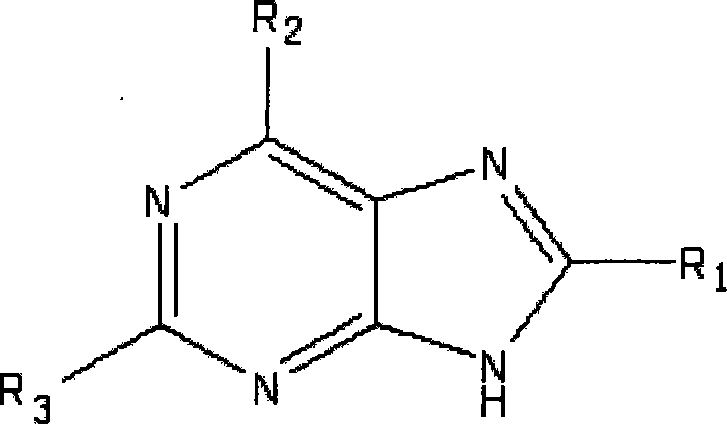

Electroplating solution without cyanogen for plating silver

This invention provides a cyanide-free silver-electroplating solution, which comprises: silver-containing organic or inorganic salt 1-200 g / L, purin coordination agent 1-800 g / L, supporting electrolyte 1-200 g / L, pH regulator 0-550 g / L, and additive system. The preparation method comprises: uniformly mixing the above components to prepare the cyanide-free silver-electroplating solution, and adjusting the temperature to 10-60 deg.C. Compared with the traditional formula, the cyanide-free silver-electroplating solution in this invention has such advantages as low or no toxicity, and high stability. Silver ions have a very low displacement rate with copper, nickel, iron, aluminum, chrome, titanium and alloy matrices. The work piece to be plated does not need preliminary silver plating or silver dipping. The silver-electroplating layer has such advantages as high adhesiveness and high shinness, and can be used in decorative and functional electroplating fields.

Owner:FUZHOU UNIV

Pyrophosphate copper plating used as grounding electroplate liquid for cyanogen-free copper plating

The invention discloses a strike bath solution with pyrophosphate plating copper as the cyanide-free copper, which contains a make-up agent and rehydration salt; the make-up agent contains the following raw materials: potassium pyrophosphate, copper pyrophosphate, ammonium citrate, sorbol, sulfosalt, phenyl carboxylate, dextrin, alkyl thiourea and nitrogen heterocyclic; the rehydration salt is as supplementation of all raw materials in the make-up agent during the plating process; the invention does not contain harmful substances, such as cyanidum, heavey metal, etc and is in compliance with EU RoHS Directive (2002 / 95 / EC) with stable bath solution and wide cathode current density range, and the plating layer prepared by the invention is fine, even and in a semi-bright state; and the make-up is conducted with original solution, supplementation is conducted with single rehydration salt, which is convenient in operation and simple in management; the plating layer is well adhesive to the matrix, with good straggling capability and covering capability. The invention is applicable in pre-plating of iron materials, zinc alloys, aluminum alloys and copper alloys, as well as barrel plating and suspension plating, with the waste water easy to dispose, which will not bring the secondary pollution.

Owner:江门市瑞期精细化学工程有限公司

Electroplating liquid and technology used in electrodeposition of trngsten series noncrystalline alloy cladding material or nanometer alloy cladding material

Owner:湖南纳菲尔新材料科技股份有限公司

Novel cyanide-free silver plating electroplating liquid and electroplating technology

InactiveCN105088293AImprove solderabilityExcellent discoloration resistanceSilver plateSurface-active agents

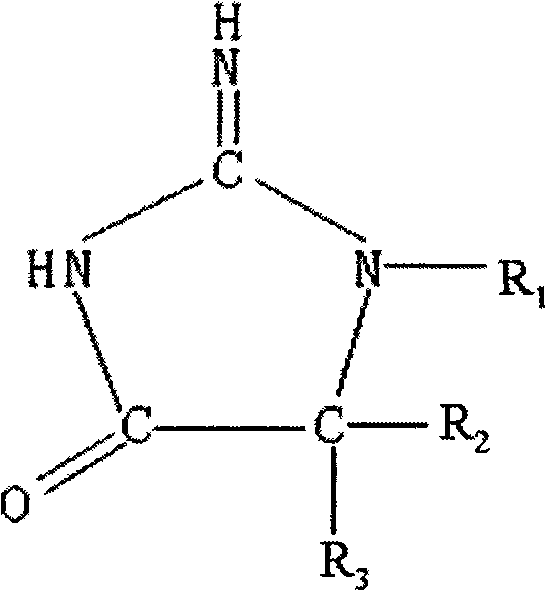

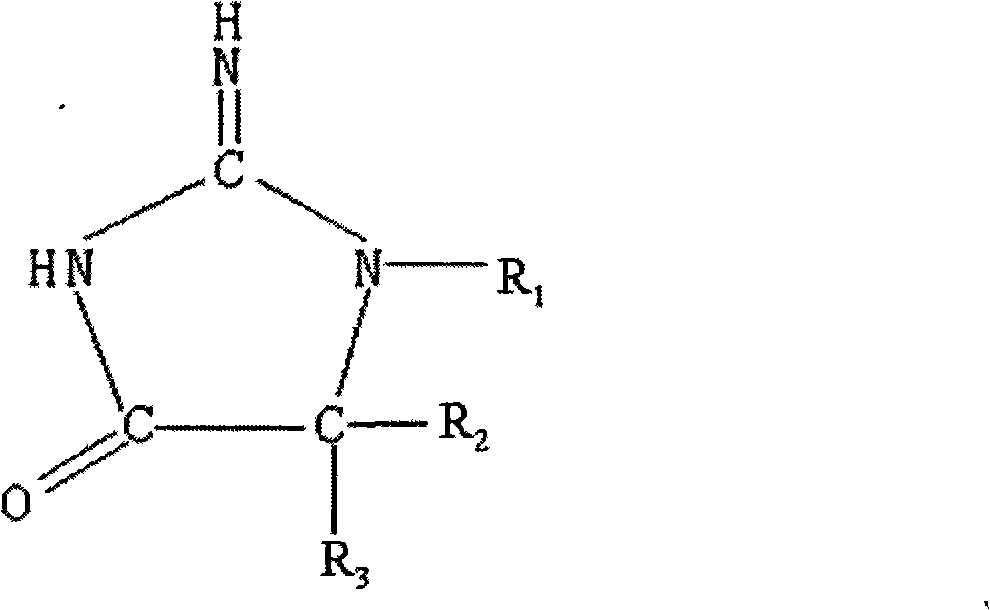

The invention provides novel cyanide-free silver plating electroplating liquid and an electroplating technology. The cyanide-free silver plating electroplating liquid comprises, by mass concentration, 1.5-4 g / L of silver nitrate, 2-50 g / L of potassium carbonate, 2-100 g / L of hydantoin, 0.1-100 g / L of potassium gluconate, 0.1-100 g / L of potassium malate, 0.1-150 g / L of citric acid, 0.1-280 g / L of hydantoin, 0.1-280 g / L of butynediol and 0.001-20 g / L of alkyl sulfonic acid surface active agent. The electroplating technology comprises the steps of pretreatment, washing, activating, washing, beforehand silver plating, silver plating, recycling, washing, adjusting treatment, washing, hot water washing (80 DEG C), washing and silver protective agent treatment. The novel silver plating technology has the main beneficial effects that firstly, the plating liquid is very stable and easy to control, the current efficiency of the plating liquid is high, and the dispersing capability and covering capability are good; secondly, a cyanide-free formula is adopted in the electroplating liquid, potential danger of cyanide is eliminated, and pollution to the environment is greatly reduced; and thirdly, the various properties of a plating layer are not lower than those of cyaniding silver plating, and a functional cyaniding silver plating technology can be thoroughly replaced.

Owner:CHONGQING LIDAO SURFACE TECH

Chemical nickeling liquid and its process

InactiveCN1896308ALower operating temperatureReduce energy consumptionLiquid/solution decomposition chemical coatingNickel saltCompound (substance)

The present invention discloses a chemical nickel bath that is composed of solvable nickel salt, complexing agent, buffer, pH regulator of alkali metal hydroxide, and stabilizer. The operation temperature of the bath is 50-55DEG C, and the pH value is 7.0-8.5. This invention is a mesothermal alkali chemical nickel plating process that has low energy consumption and stable bath. Furthermore, the pH value is nearly neural and not regulated by ammonia, which saves the cost and improves the work condition.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

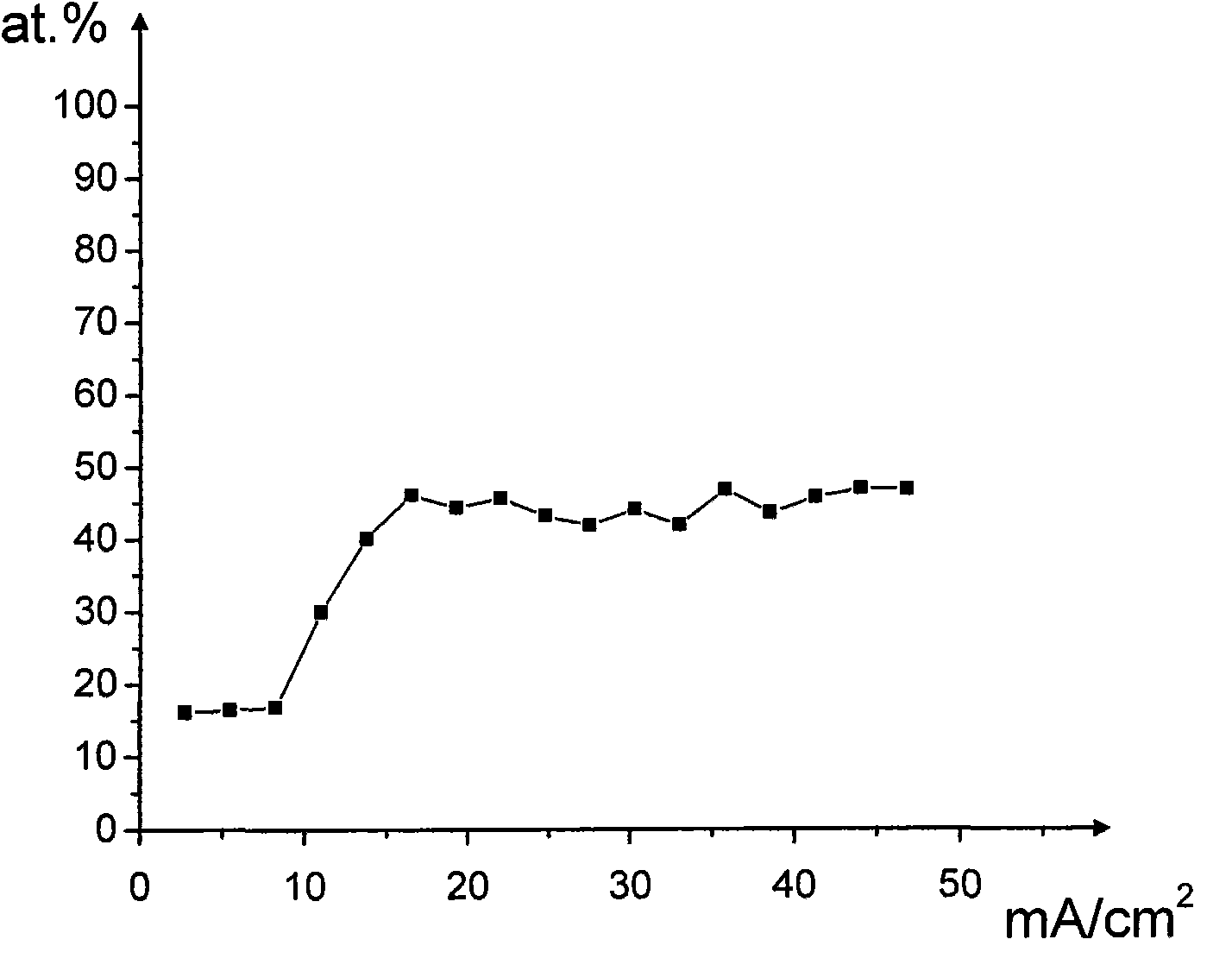

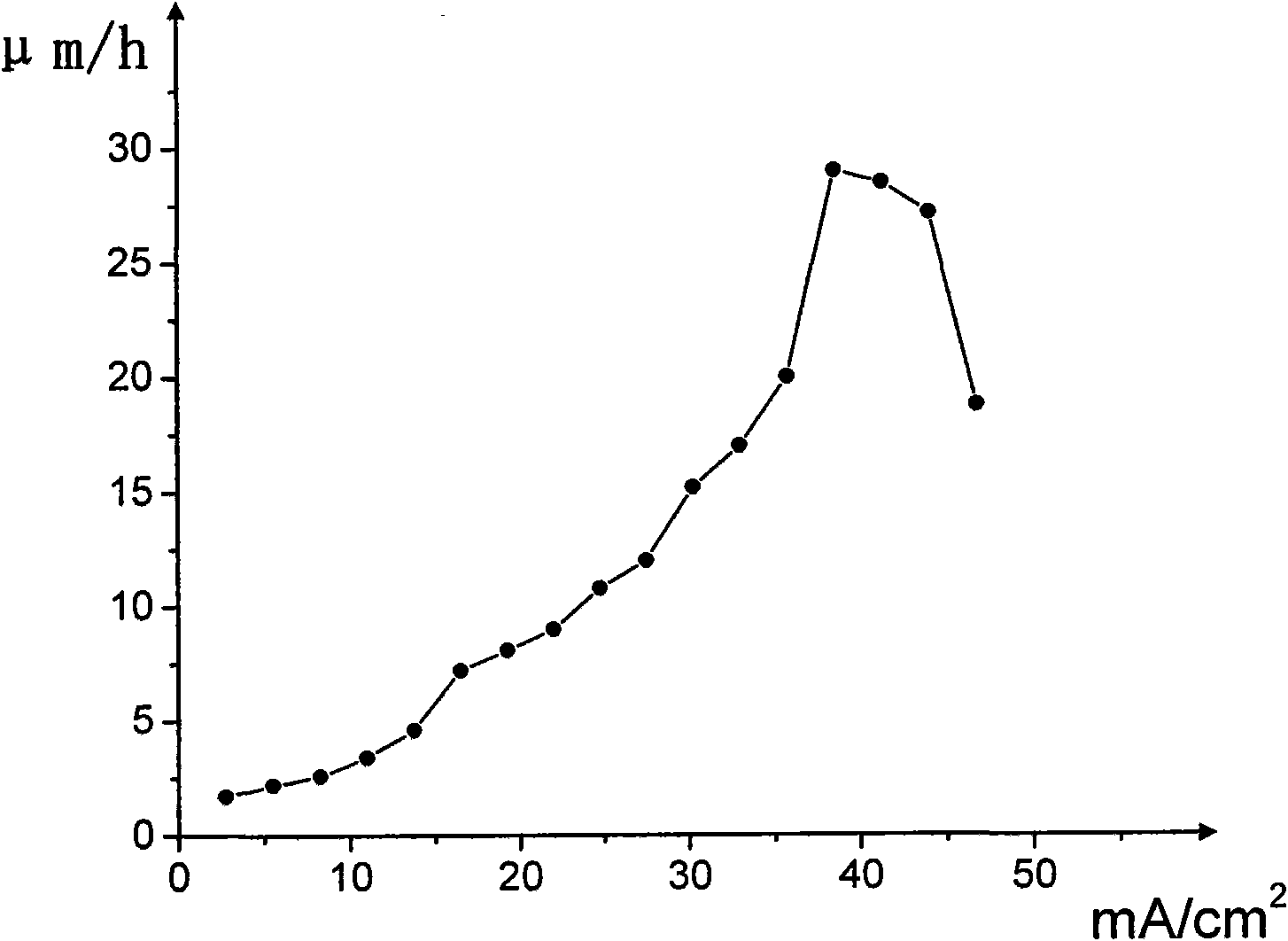

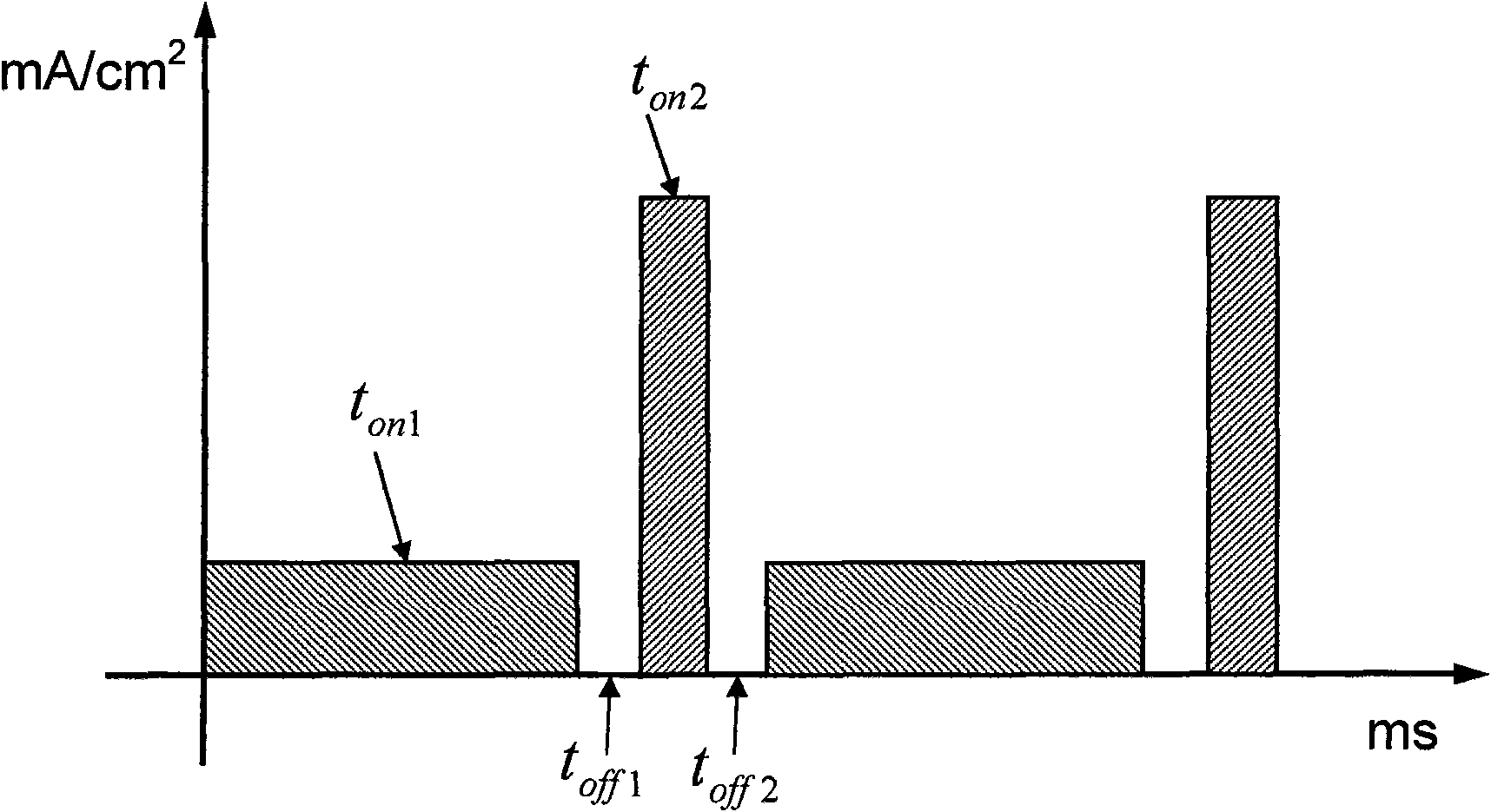

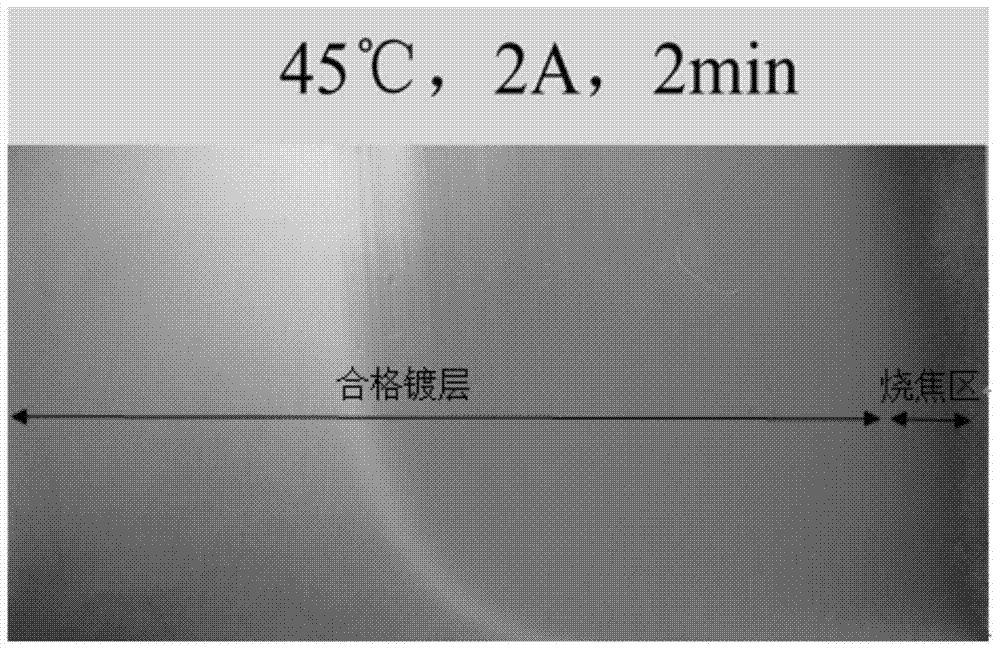

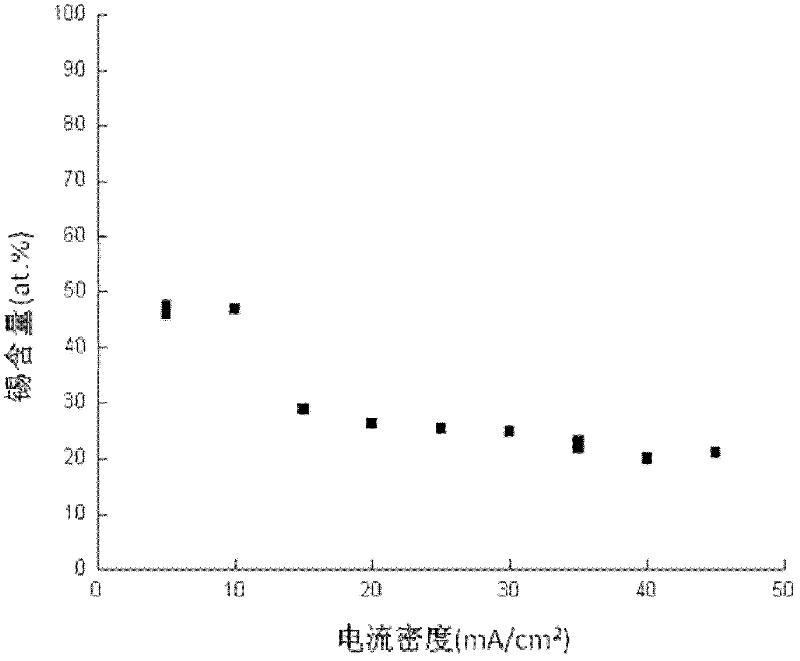

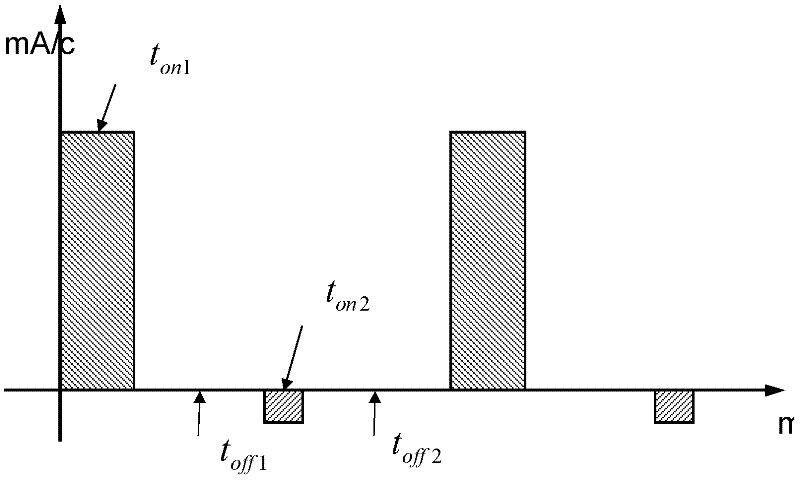

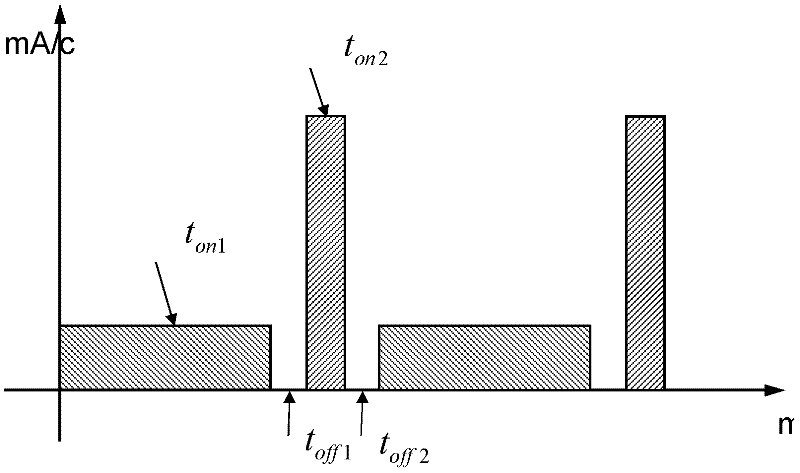

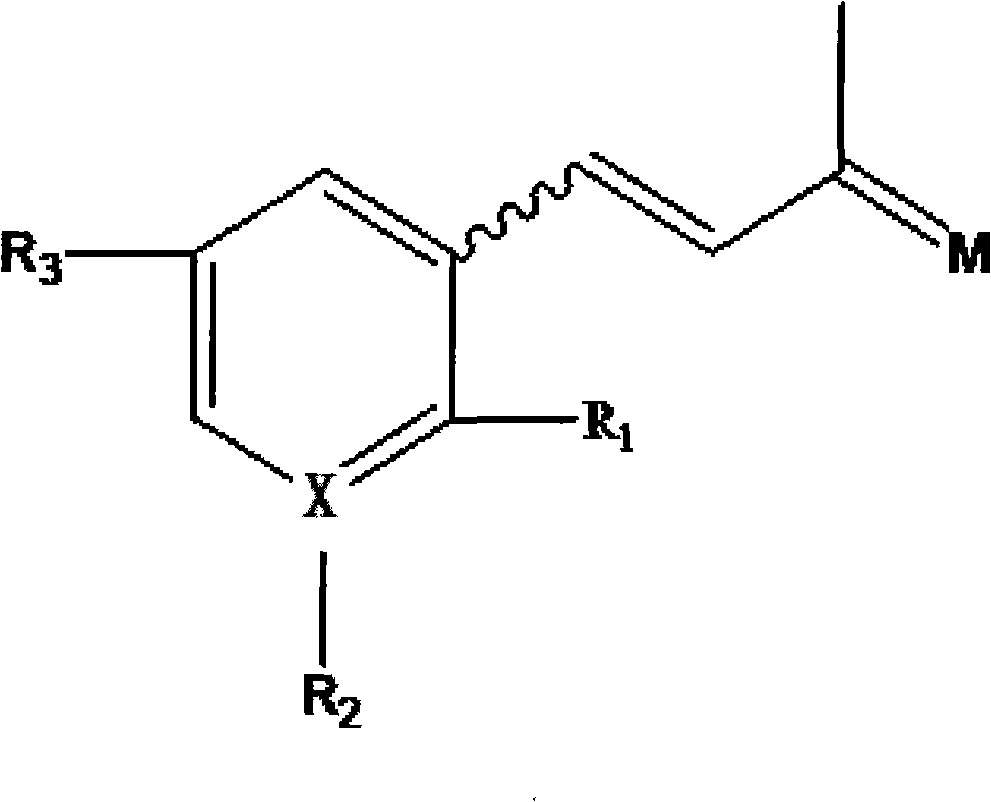

Co-deposition electroplating method with cyanogen-free Au-Sn alloy electrolyte

The invention relates to a co-deposition electroplating method for preparing Au-Sn alloy on an electroplating substrate and a cyanogen-free Au-Sn alloy electrolyte. The wave forms of electroplating current pulses are forward variable-amplitude pulses, namely that two different forward square wave pulses exist in one period, and the peak values and the conducting time of the electroplating current pulses respectively correspond to peak value current density and time which are required for generating Au5Sn and an Au-Sn alloy phase in a plating layer. In the electrolyte, sodium sulfite is adopted as a main complexing agent and ethylene diamine tetraacetic acid is adopted as an auxiliary complexing agent for the gold ion complexing agent, potassium pyrophosphate is used as a tin ion complexing agent, hydroquinone is used as an antioxidant, and the pH value of the electrolyte is from 8 to 9. When the method is used for preparing Au-30at.%Sn eutectic plated layer through electroplating, the plating speed reaches 13 mum / hour, the electrolyte is stable, the operation is simple, and the gold and tin content in the plated layer is easy to control. The method can be applied in microelectronics and photoelectron industry for connecting and encapsulating LED chips, connecting flip chips, forming welding pads or patterns on the surface of semiconductor devices or similar devices, etc.

Owner:DALIAN UNIV OF TECH

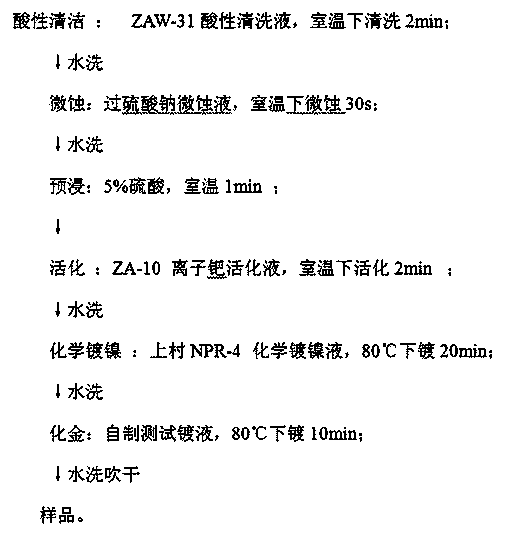

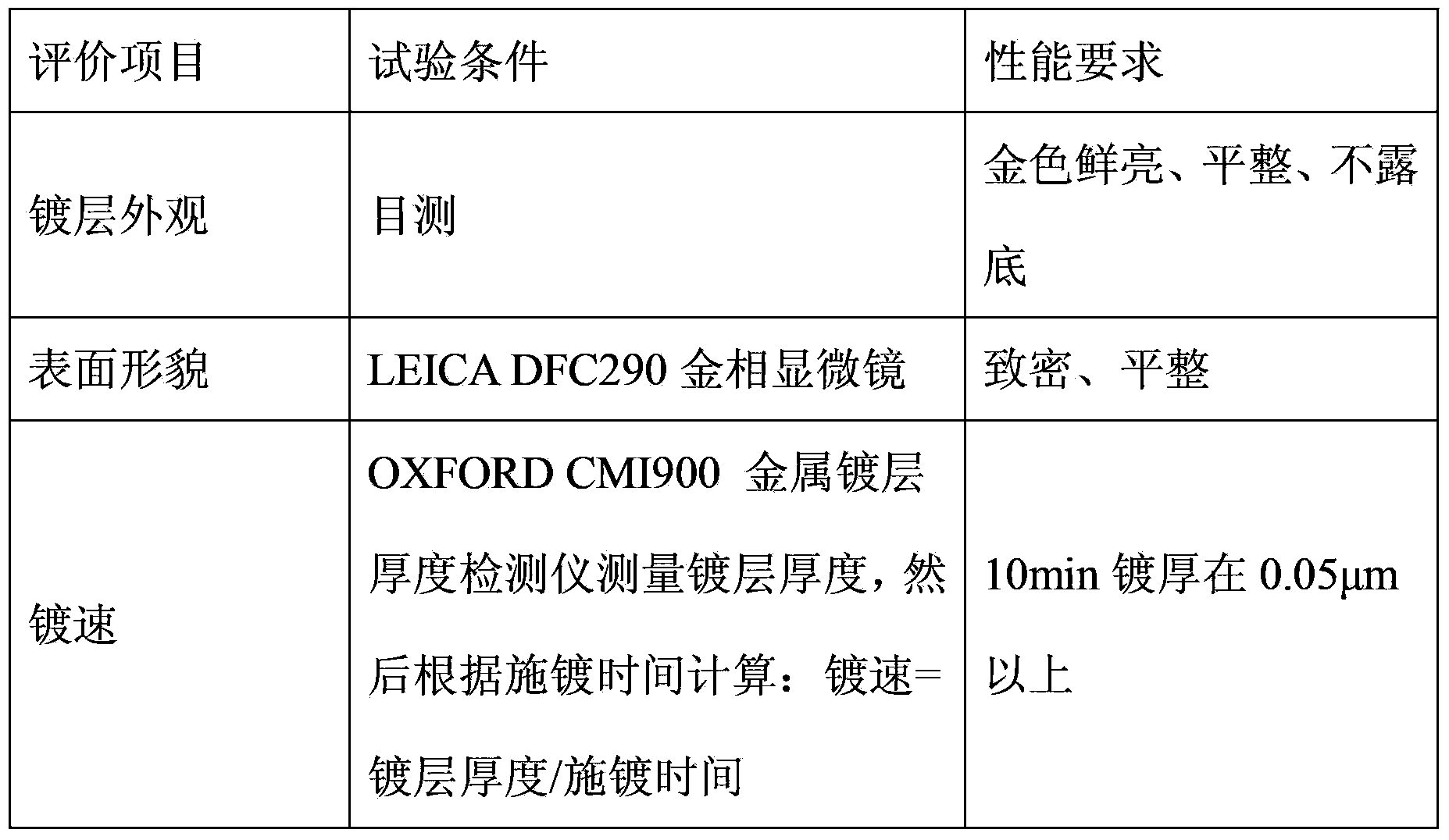

Environmentally-friendly chemical gilding liquid

InactiveCN104109848APlating solution is stableLong storage periodLiquid/solution decomposition chemical coatingIonHeavy metals

The invention discloses an environmentally-friendly chemical gilding liquid. The environmentally-friendly chemical gilding liquid comprises 0.5-5g / L of non-cyanide gold salt, 5-30g / L of gold ion complexing agents, 5-20g / L of an impurity screener, 0.1-10g / L of a stabilizing agent and 15-35g / L of a pH buffering agent. The non-cyanide gold salt is sodium gold sulfide or auric-sodium chloride, a sulfite is used as the main complexing agent, and through combined action of the auxiliary complexing agent, the impurity screener and the stabilizing agent, long-term stabilization of production and storage is realized. The environmentally-friendly chemical gilding liquid does not adopt cyanides and cyanogen-containing substances, does not contain limited heavy metals such as lead and cadmium, has the characteristics of long storage life, high continuous production stability, good weldability, bright color and good corrosion resistance and weatherability, can satisfy functional electron electroplating requirements and can be used as a decorative gilding liquid.

Owner:广东致卓环保科技有限公司

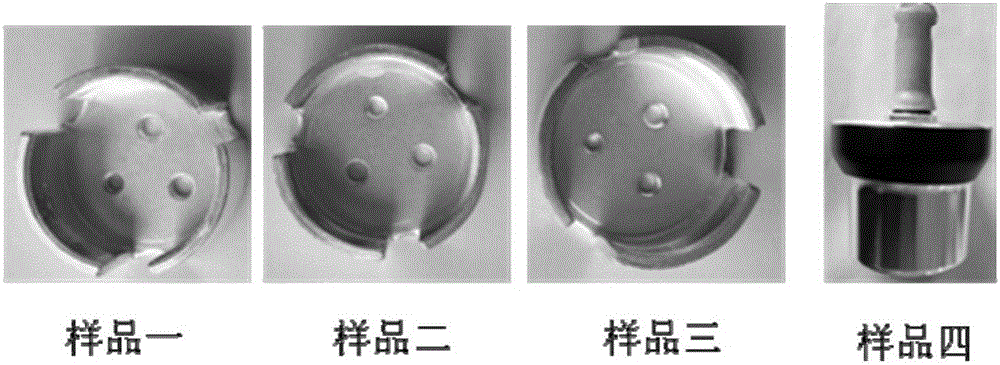

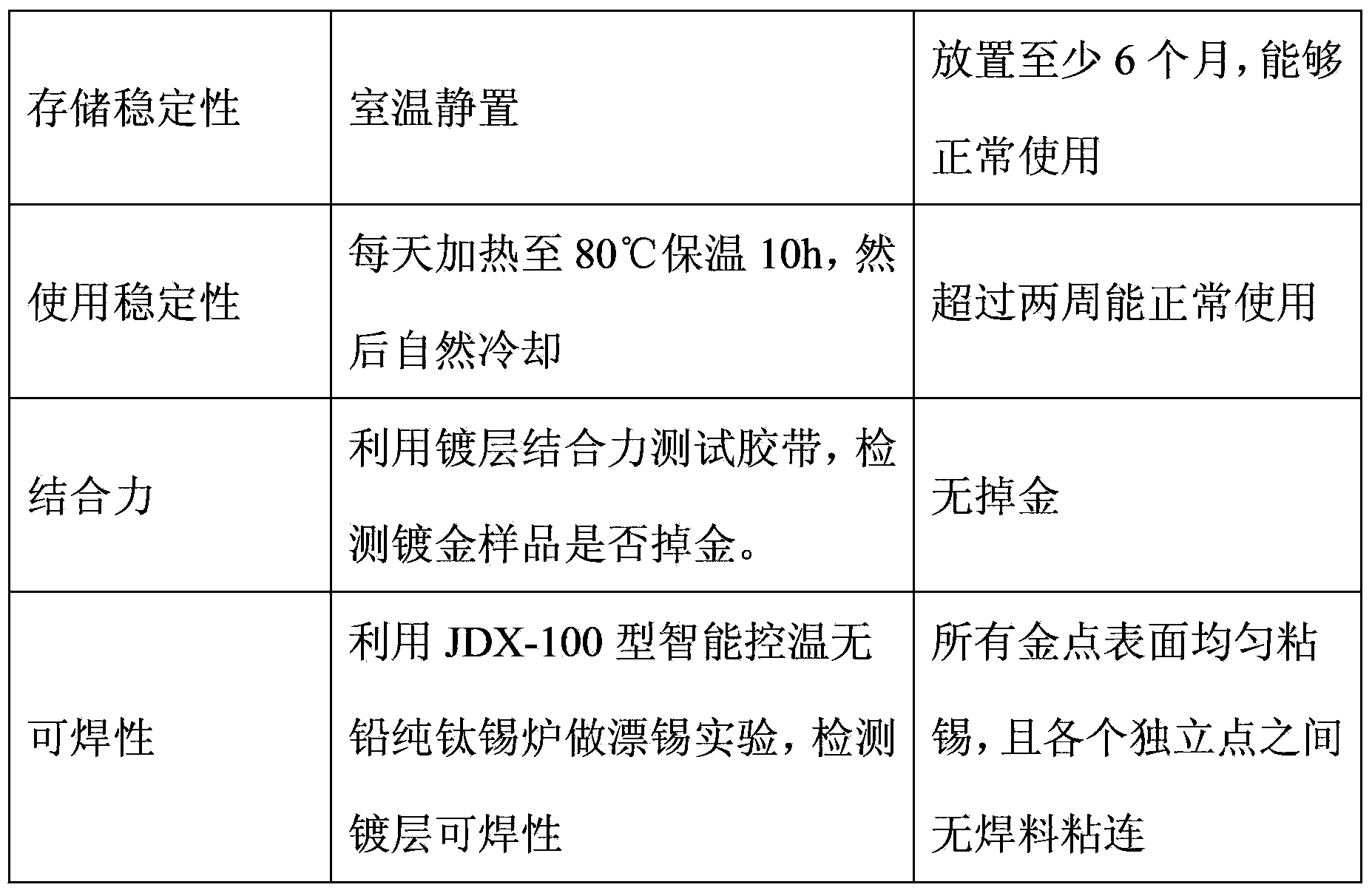

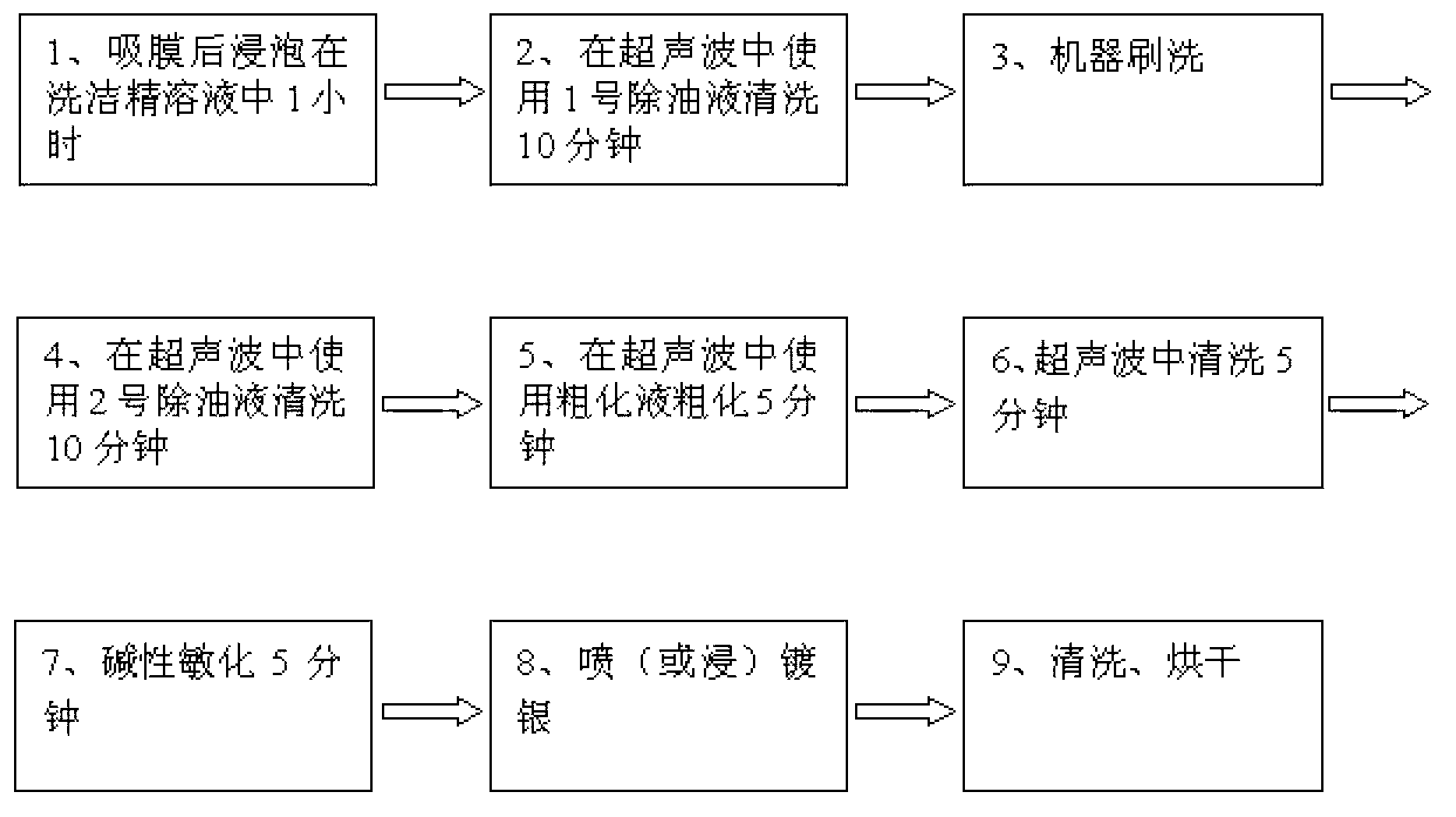

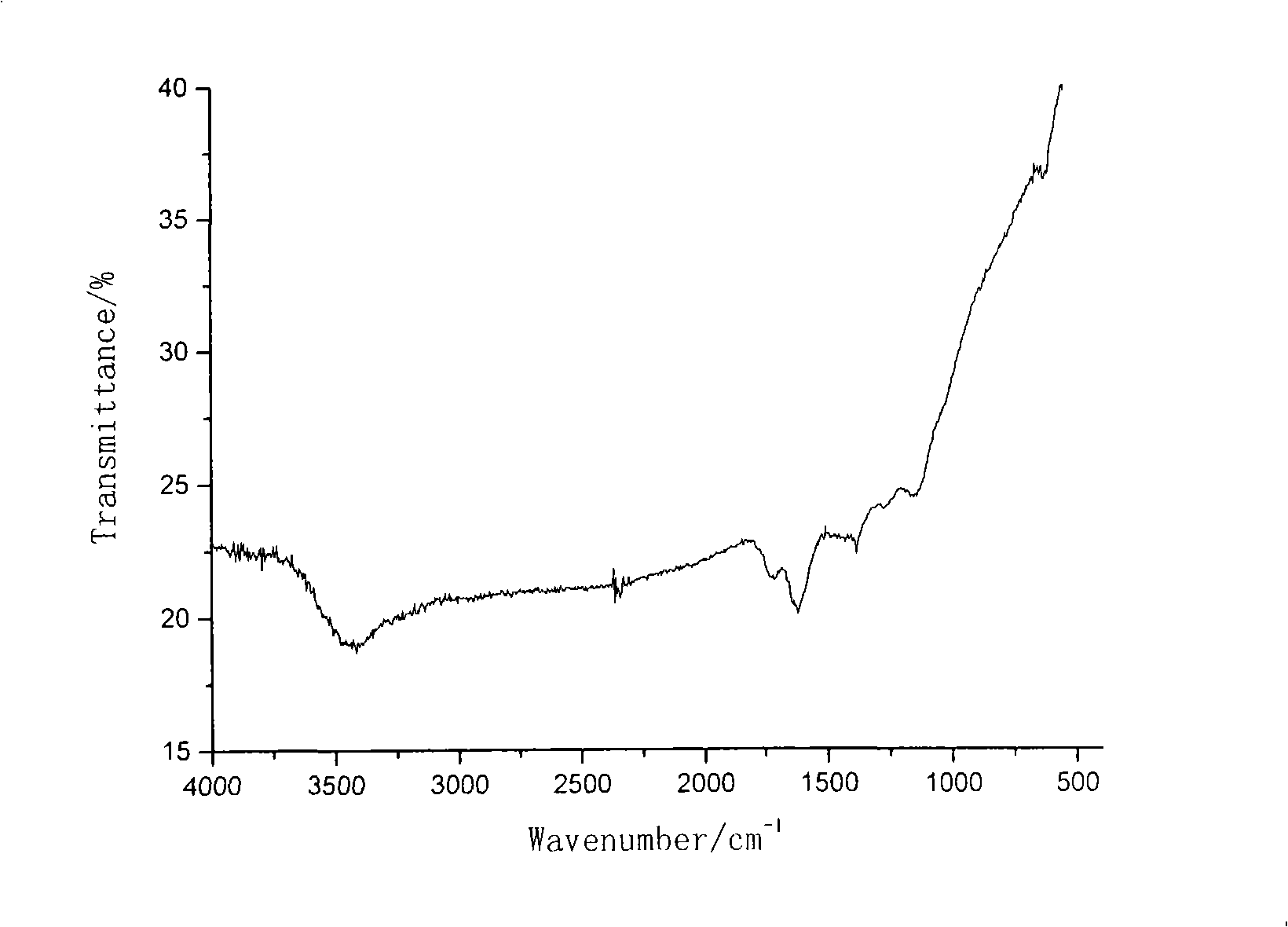

Chemical silvering and pretreatment process for synthetic quartz diamond pavilion

ActiveCN103014684AWash thoroughlyPerfect pre-treatment processLiquid/solution decomposition chemical coatingChemical platingPhysical chemistry

The invention discloses a chemical silvering and pretreatment process for a synthetic quartz diamond pavilion. The process comprises the following steps: wetting and rough washing, deoiling with deoiling liquid 1, scrubbing, deoiling with deoiling liquid 2, coarsening, cleaning and sensitizing; and then implementing the chemical silvering by using a jet plating or dip plating manner. At the same time of completing the pretreatment process, the process adopts proper coarsening and sensitizing process and silvering liquid formula, so that the silvering layer adhesion of silvered products is improved, and the phenomenon of silvered layers becoming yellow, black and white is avoided.

Owner:潘晓

Cyanide-free alkaline copper electroplating solution and electroplating technology

The invention discloses a cyanide-free alkaline copper electroplating solution and an electroplating technology and belongs to an environment-friendly high-performance copper electroplating technology. The technological process is as follows: fine polishing and grinding, chemical degreasing, electrolytic degreasing, pickling and activation as well as electroplating. On the premise that the good binding force between plating and a matrix is guaranteed, the covering power and the throwing power of the copper plating obtained through electroplating with the technology are superior to those of copper plating obtained through electroplating with a cyanide copper electroplating technology, the porosity and the toughness of the plating can reach the level of the cyanide copper electroplating technology, and the electroplating solution and the electroplating technology are suitable for direct copper electroplating of aluminium alloy and zinc alloy die-casting matrixes as well as copper electroplating of steel and copper matrixes. Meanwhile, the copper electroplating solution is good in stability and high in current efficiency, wastewater treatment is simple, and the plating is uniform, compact, soft and shining, has no hydrophobicity, requires no film removal and can be directly used for subsequent electroplating of other metals.

Owner:CHONGQING LIDAO SURFACE TECH

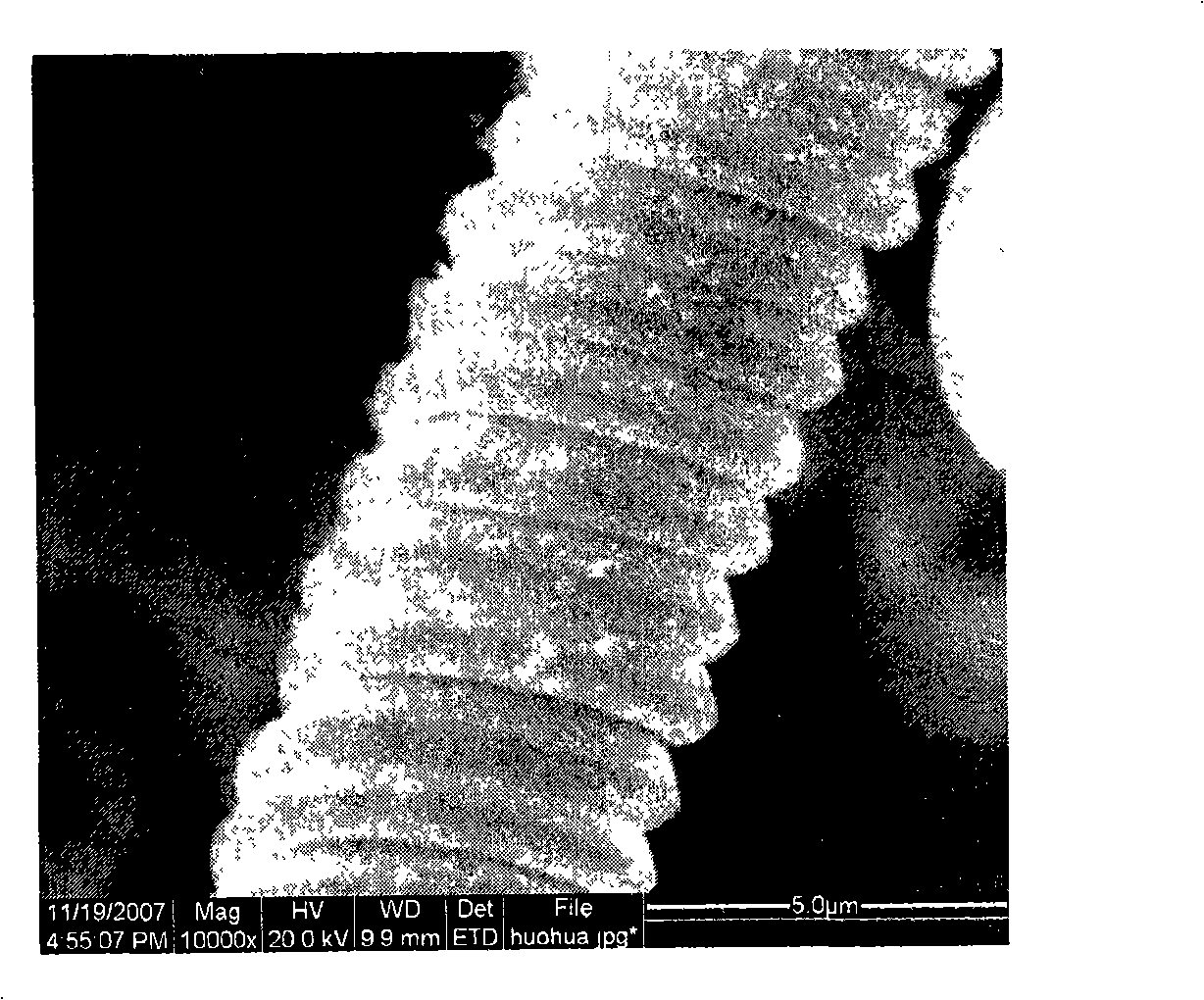

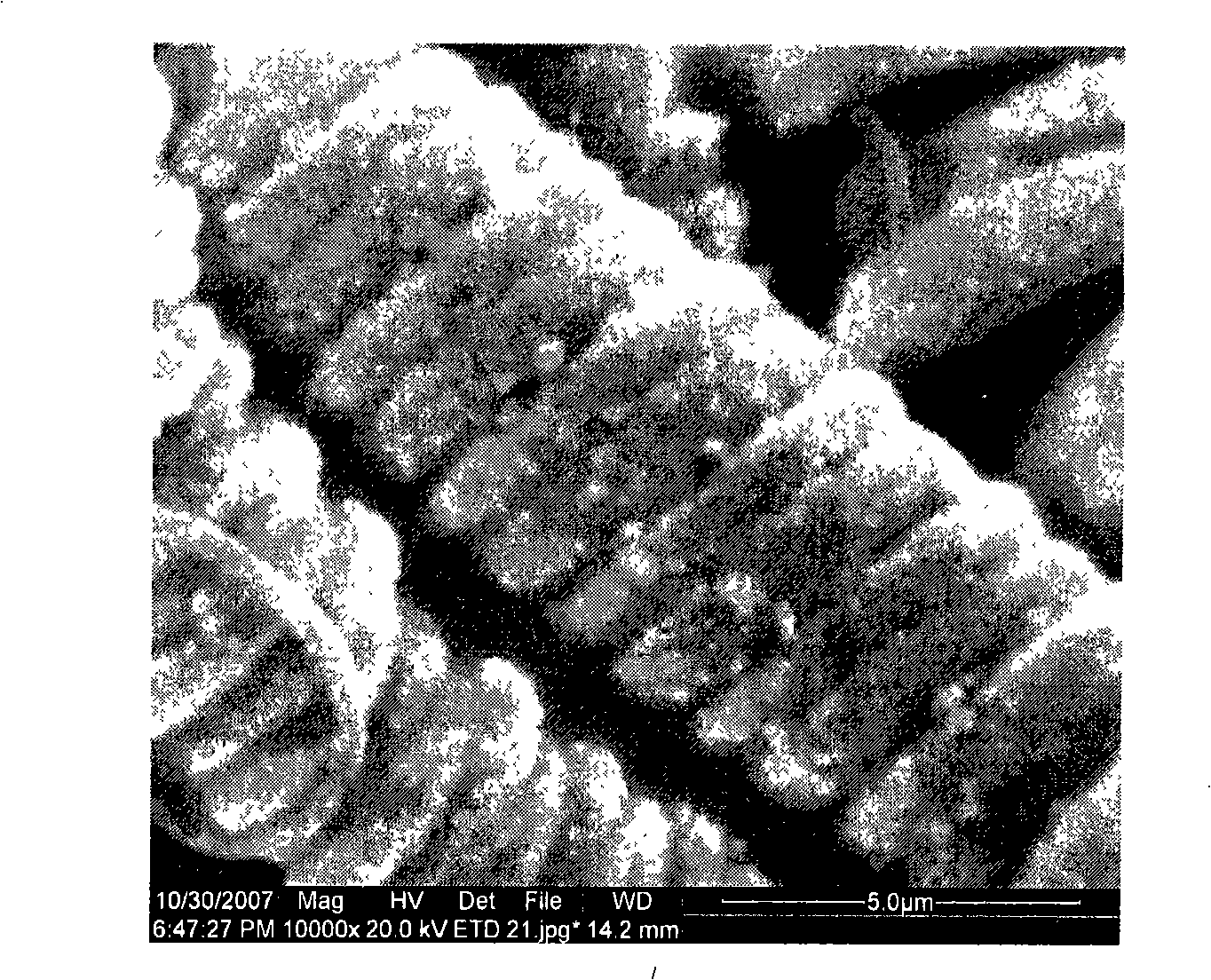

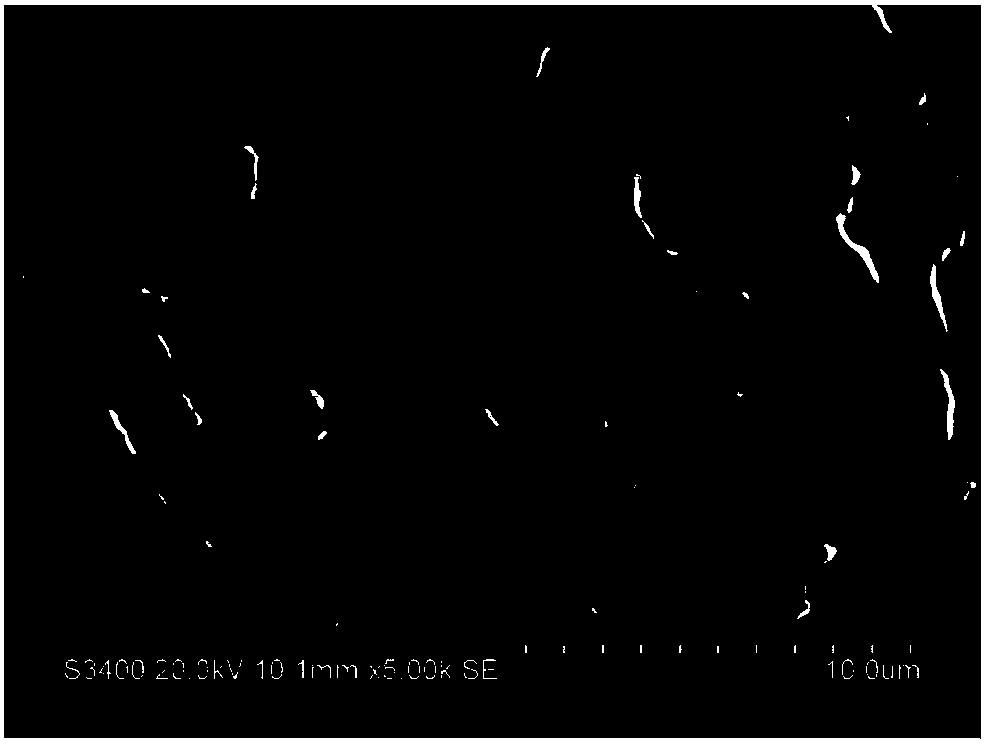

Process for preparing micro-coiled carbon fiber/Ni composite material by chemical nickel plating

InactiveCN101285180AGood particle dispersionThickness is easy to controlLiquid/solution decomposition chemical coatingFiberNickel salt

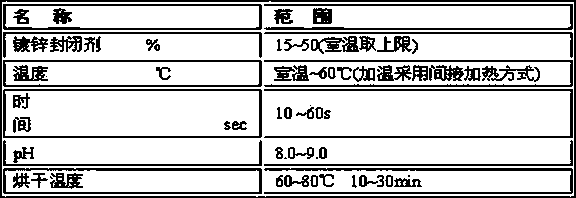

The invention relates to a method for preparing a micro-coiled carbon fiber / Ni composite material by utilization of chemical nickel plating. The method is characterized in that: firstly, surface roughenine treatment for micro-coiled carbon fiber particles is performed; sensibilization is performed in SnCl2 hydrochloric acid solution; activation is performed in PdCl2 hydrochloric acid solution; secondly, chemical nickel plating is performed. Plating solution for chemical nickel plating is prepared by nickel salt, sodium citrate, ammonium chloride, sodium hypophosphate, thiourea and sodium dodecyl benzene sulfonate. The technological parameters of the plating solution are pH: 8.0 to 9.0; temperature: 50 to 90 DEG C; time: 10 to 60 minutes. Afterward, the micro-coiled carbon fiber / Ni composite material is prepared by sintering under the function of shielding gas. The method has the advantages that: the micro-coiled carbon fiber surface chemical nickel plating formula and technique are simple and convenient and easy to operate; the plating solution is stable and difficult to go bad; a micro-coiled carbon fiber surface cladding obtained is compact and uniform; the particle dispersibility is good; and the thickness of a micro-coiled carbon fiber / Ni composite material cladding prepared is easy to control.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

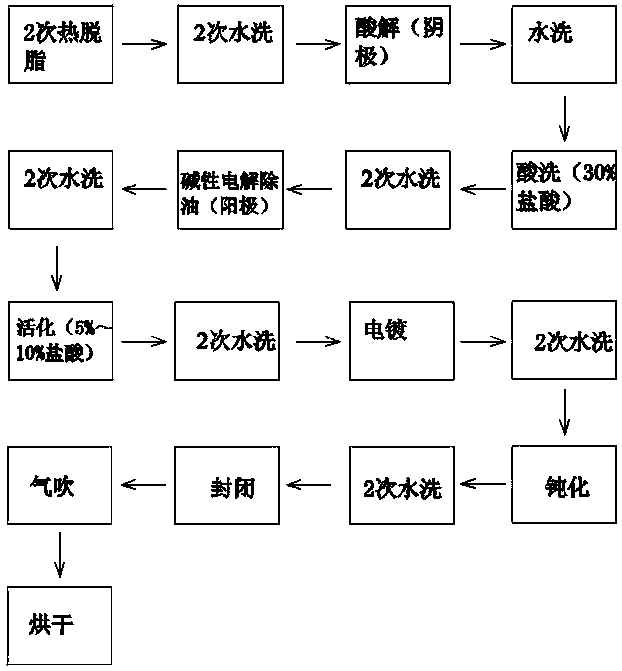

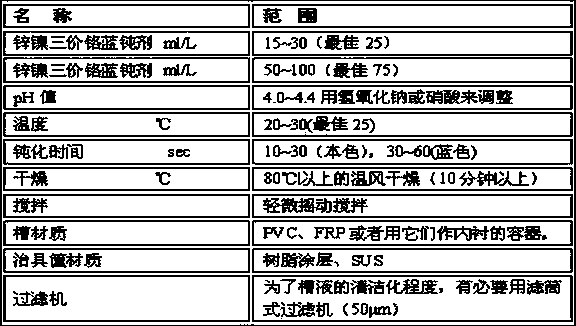

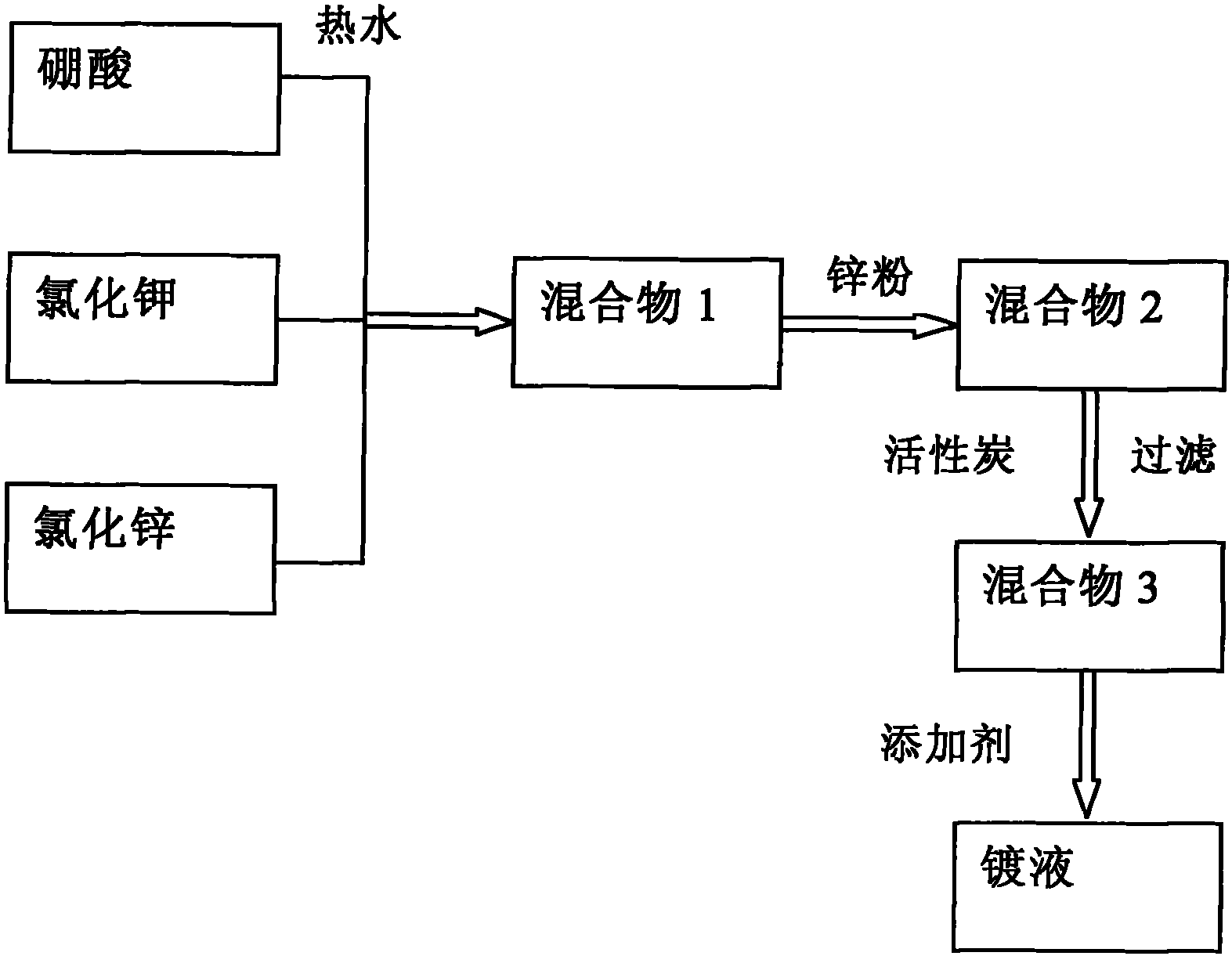

Zinc-tin alloy electroplating method

The invention discloses a technological process of a zinc-tin alloy electroplating method and a preparation method of an electroplating liquid prepared by using the process. The technical process comprises two times of thermal degreasing, two times of washing, acid hydrolysis (cathode), washing, acid washing (30% hydrochloric acid), two times of washing, oil removing through alkaline electrolysis (anode), two times of washing, activating (5-10% hydrochloric acid), two times of washing, and electroplating; meanwhile, the quality of the electroplating liquid is improved; a plurality of electroplating additives such as a complexing agent, a brightening agent, polyglycerol, a polarization type brightening agent and a reducing agent are added in the electroplating liquid. The electroplating liquid disclosed by the invention is high in stability, can be produced for a long time but not changing plating, is quick to deposit and is strong in depositing adhesion power; when the tin content of the formed electroplating layer is about 70 percent and the tin content of the formed electroplating layer is about 30 percent, the formed plating layer achieves relatively good corrosion resistance, has the salt mist property achieving 144 hr white rust and 1000 hr red rust, and has good corrosion resistance against sulfur dioxide and good plating layer softness; the plating layer can be subjected to a bending test.

Owner:GUANGZHOU HKS SURFACE TREATMENT CO LTD

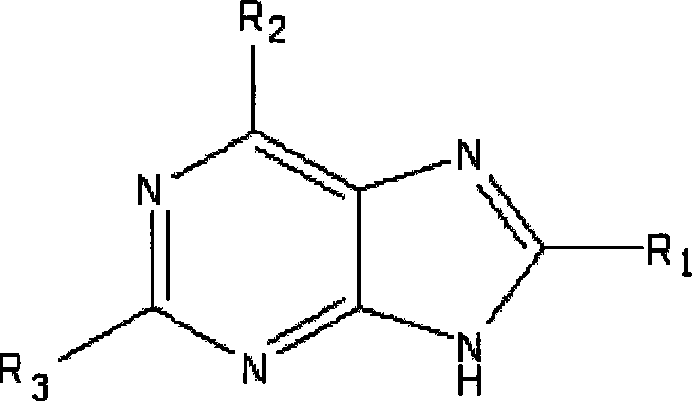

Non-preplating type non-cyanide silver-plating electroplate liquid

The invention provides non-preplating type cyanide-free silver-plating plating solution, which is characterized in that: the mass concentration of various compositions of the raw material dispensation of the plating solution is as follows: silver ion source materials of 1 to 200 grams per liter; coordination agent creatinine and creatinine derivatives of 1 to 800 grams per liter; supporting electrolytes of 1 to 200 grams per liter; plating solution pH regulators of 0 to 550 grams per liter; and the residual is an electroplating additive system. Compared with the prior cyanide-contained silver plating technological formula, the cyanide-free silver-plating plating solution is low in toxicity or nontoxic and has good stability; simultaneously, the displacement speed of silver ions, monometals such as copper, nickel, ferrum, aluminum, chromium, titanium and so on and alloy substrates in the plating solution is very slow; plating parts are not required to be preplated or immersed and a cladding has good binding force and is bright, thereby the application requirements in multiple fields such as decorative electroplating, functional electroplating and so on are met.

Owner:FUZHOU UNIVERSITY

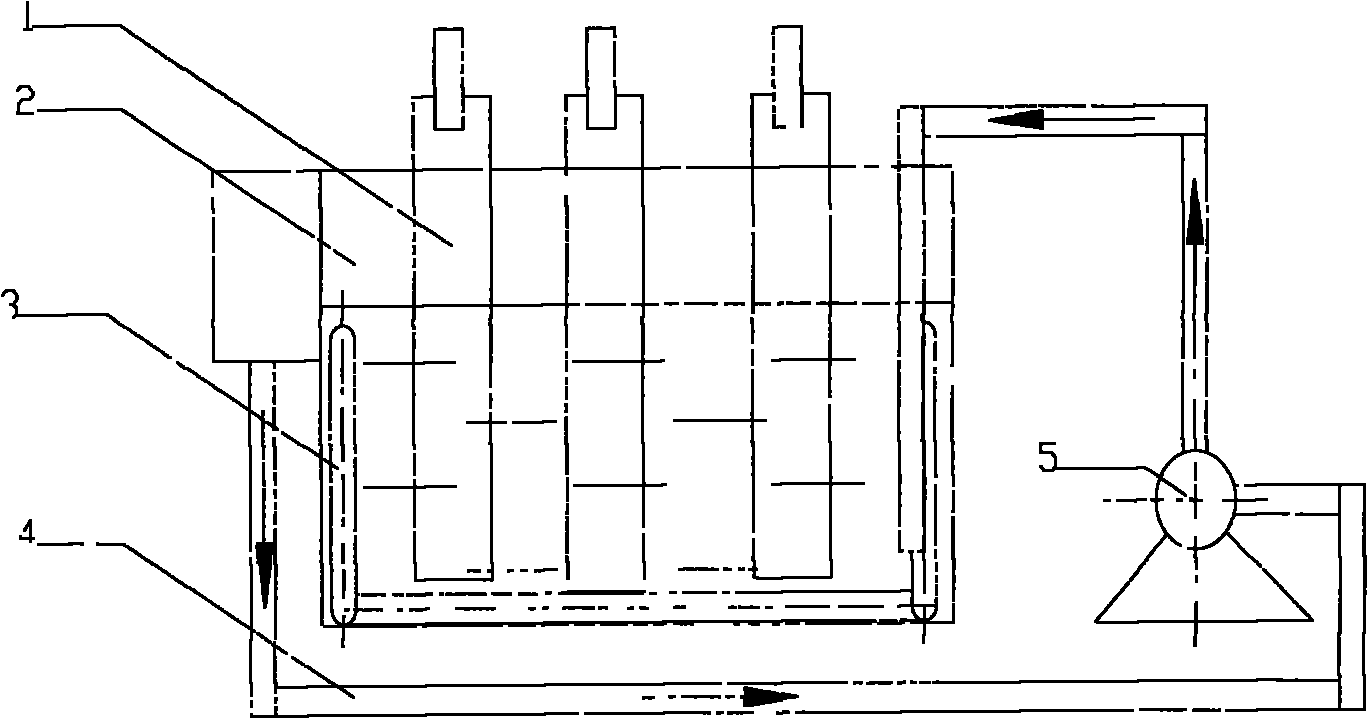

Process and special equipment for plating copper on special steel piece with deep/blind hole

InactiveCN101942682AImprove stabilitySimple and fast operationElectrolysis componentsCopper platingAlcohol

The invention discloses a process for plating copper on a special steel piece with a deep / blind hole, namely render copper. The process comprises the following steps of: chemical deoiling, washing with hot water, electrolytic deoiling, washing with hot water, washing with cold water, acid washing, secondary washing with cold water, neutralizing, washing with cold water, plating copper without cyanide, secondary washing with cold water, plating tin, secondary washing with cold water, neutralizing, washing with hot water, passivating, secondary washing with hot water, washing with hot pure water, dehydrating with alcohol, removing the residual water, drying and inspecting, wherein electroplate liquid used in the step of plating copper without cyanide has the following formula: 400 to 600ml / L of BH-580 non-cyanide alkaline copper cylinder plating bath solution, 1 to 2ml / L of BH-580 non-cyanide alkaline copper brightening agent and 7.5 to 12g / L of metal copper; and the pH value is 9.2 to 9.8. The process has the advantages of good stability of a plating liquid, simple and convenient operation, good dispersibility and good covering capability; the formed plating layer has the advantages of fine and compact crystallization, good adhesive force, stable and reliable production; and the method can effectively protect environment and the physical and psychological health of operators.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

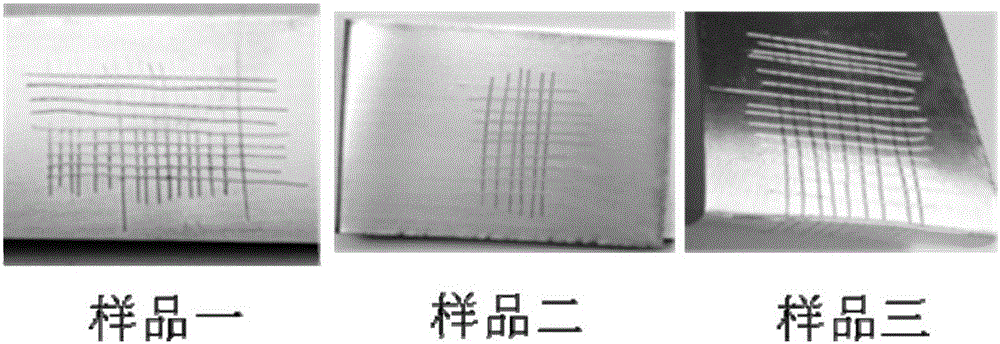

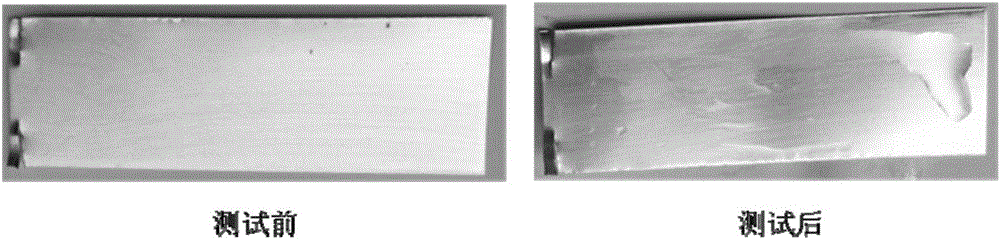

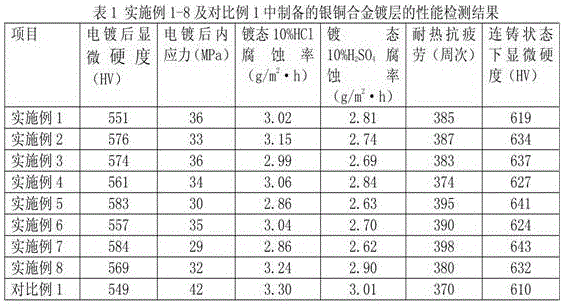

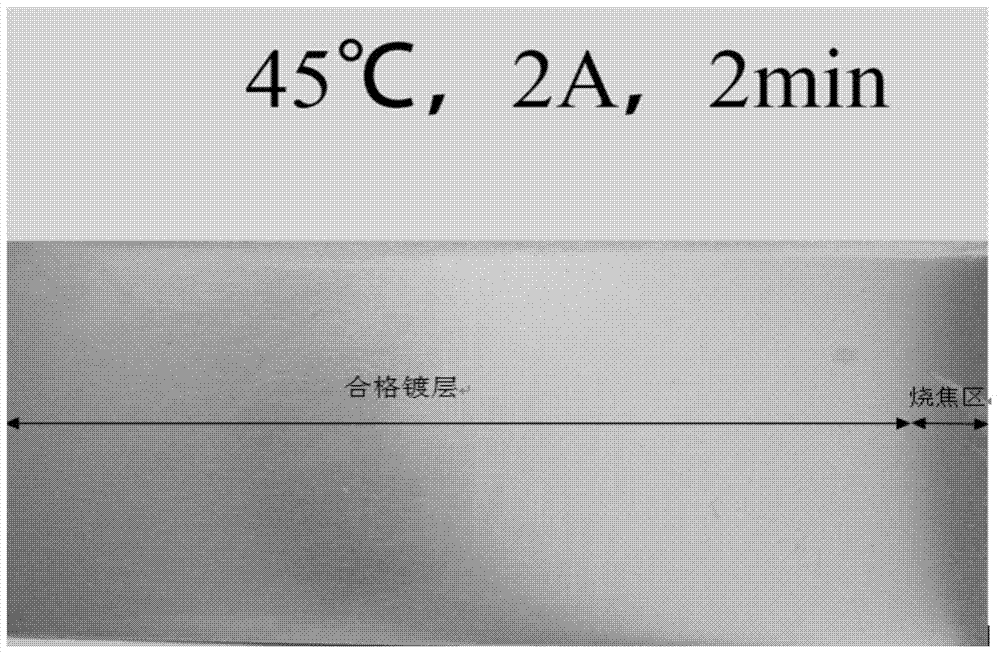

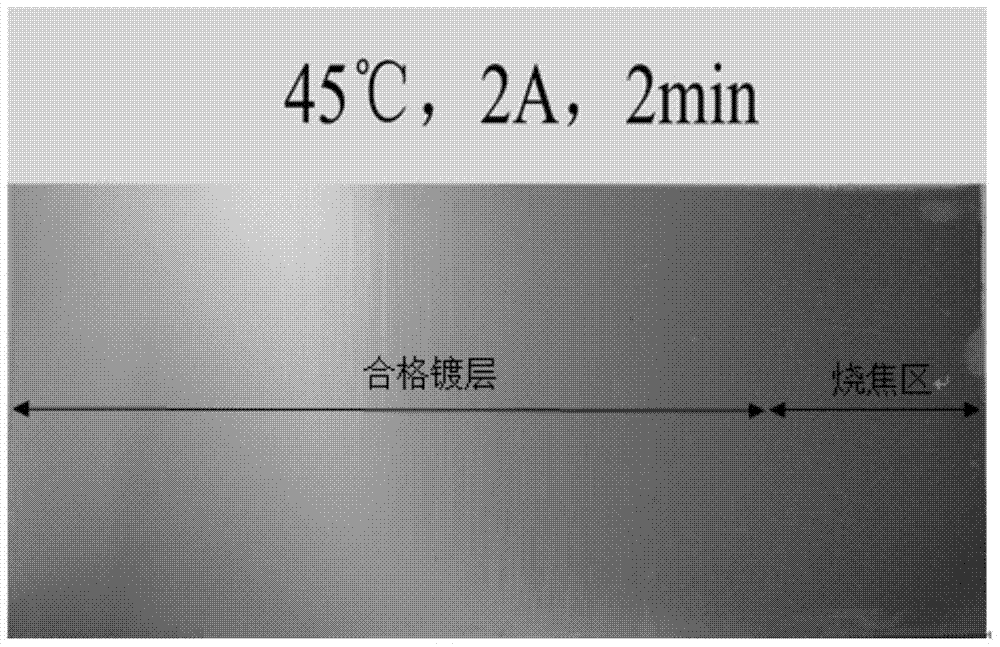

Repairing method of scrapped continuous casting crystallizer copper plate

ActiveCN105780063AImprove performanceExtended service lifeElectroforming processesSand blastingPre treatment

The invention discloses a repairing method of a scrapped continuous casting crystallizer copper plate. The repairing method comprises the steps of (1) pretreatment: carrying out degreasing treatment, mechanical sand blasting scuffing treatment, electrolytic degreasing treatment, ultrasonic degreasing treatment and acid spraying activating treatment on a copper plate base material subjected to machining, so as to obtain a to-be-cast copper plate base material; (2) electroforming solution injection: injecting an electroforming solution into an electroforming tank, adjusting the pH, and heating the electroforming solution till the temperature reaches a set value; and (3) electroforming: putting the to-be-cast copper plate base material adopted as a cathode into the electroforming tank, putting an anode into the electroforming tank, switching on the power, and stopping electroforming till the thickness of a silver-copper alloy plating reaches a set value. According to the repairing method, the crystallizer copper plate base material at the scrapping limit is repaired and reutilized through adopting an easy and feasible preparation method, the obtained crystallizer copper plate is excellent in performance, the service life of the crystallizer copper plate is prolonged through the silver-copper alloy plating, the production cost is improved, and the sustainable development property is high.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

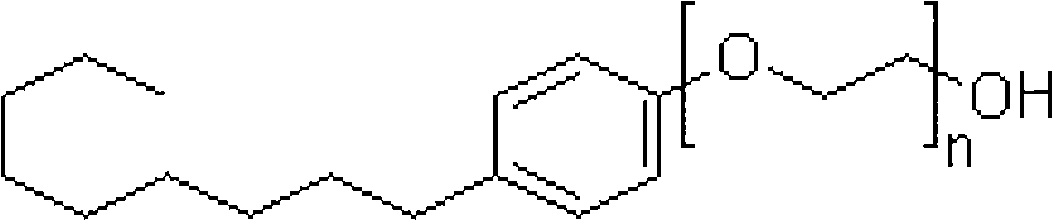

All-sulfate tin electroplating additive and plating solution thereof

The invention discloses an all-sulfate tin electroplating additive and a plating solution thereof. The additive comprises 0.1-200 mg / L defoaming agent, 0.1-50 g / L fine crystal agent, 0.01-20 g / L leveling agent and 0.1-40 g / L antioxidant. The plating solution comprises 5-100 g / L stannous sulfate, 0.1-100 ml / L sulfuric acid, and 0.1-200 mg / L defoaming agent, 0.1-50 g / L fine crystal agent, 0.01-20 g / L leveling agent and 0.1-40 g / L antioxidant used as the additive. The additive disclosed by the invention is free of anionic, cationic and amphoteric surfactants, polyformaldehyde, polyethylene oxide, polypropylene oxide homopolymer, aldehydes, heterocyclic ring compounds, amine compounds, polyaminocarboxylic acid, sulfur amino acids and any organic solvent. The plating solution can be used for obtaining a matte plating with fine crystals and uniform coverage at the on-line speed of 0-800 m / minute.

Owner:HARBIN INST OF TECH

Method for electrodepositing ornamental chromium coating in trivalency chromium coating solution

InactiveCN101078131AImprove corrosion resistanceMeet the requirements of Pollution Control Management MeasuresChlorideChrome plating

The invention discloses a method to produce the decorated chrome plating layer in trivalence chrome electroplate liquid. The invention is to select the proper additive and control the condition in the base electrolyte containing the chromium chloride to produce the non-crystal chrome plate with smooth surface and no crack, also which is the light and anti-corrosion as same as the sexivalent chrome plating. The process is stable, the operation condition is wide and the energy cost is low; also the ability of disperse, covering and current flow effect are high than sexivalent chrome plating process. The thickness of plating chrome is 0.5-1 mu m. So the invention can instead of the sexivalent process and be used in all anticorrosion and decorated field.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Non-cyanide electro cooper plating bath of EDTA system and use method thereof

The present invention provides a new non-cyanide electro cooper plating bath of EDTA system and use method thereof. In the electro copper plating bath, using disodium EDTA or dipotassium EDTA as main complexant, using copper sulfate or basic copper carbonate as main salt, using trisodium citrate, potassium citrate or potassium sodium tartrate as auxiliary complexant, using sodium nitrate or potassium nitrate as conductive salt, using sodium hydroxide or potassium hydrate as pH value regulator. The invention also provides a use method of the non-cyanide electro cooper plating bath. The invention has advantages: simple plating bath formula, easy control and operation, wide temperature range of plating bath using, high current efficiency, fine crystallization coating, good appearance color, stable plating bath, strong uniform plating and covering ability, low cost, easy wastewater treatment. The invention can be used for pre copper plating or direct electro-coppering instead of virulent cyaniding electro-coppering process.

Owner:KUNMING UNIV OF SCI & TECH

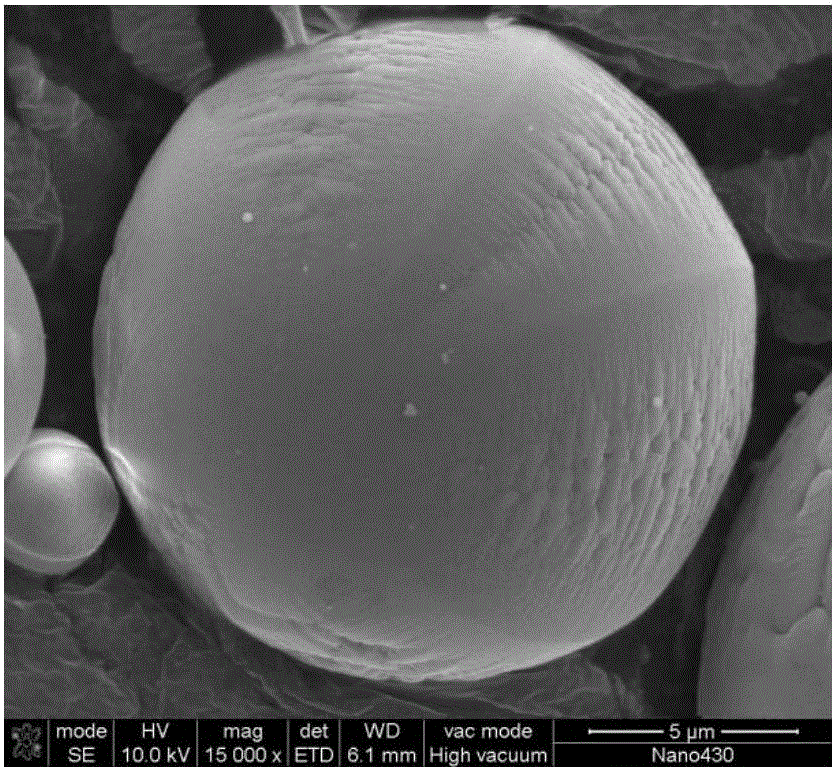

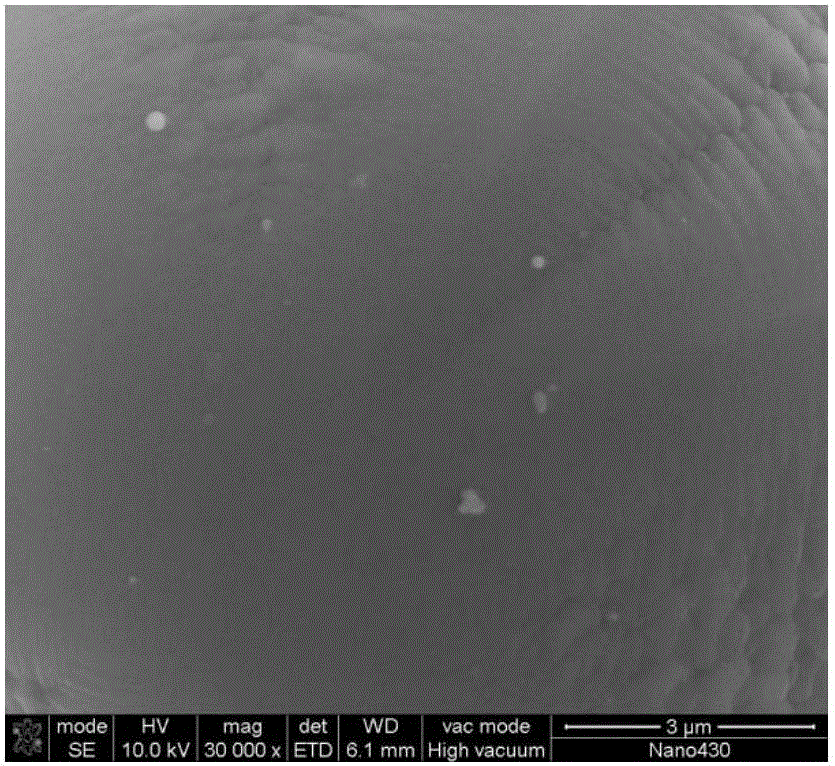

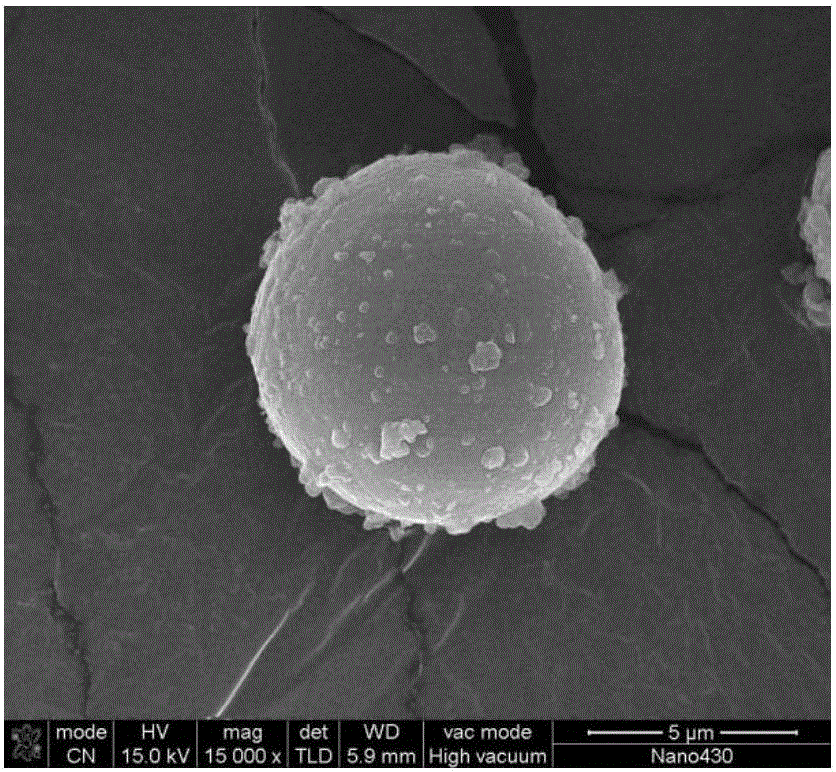

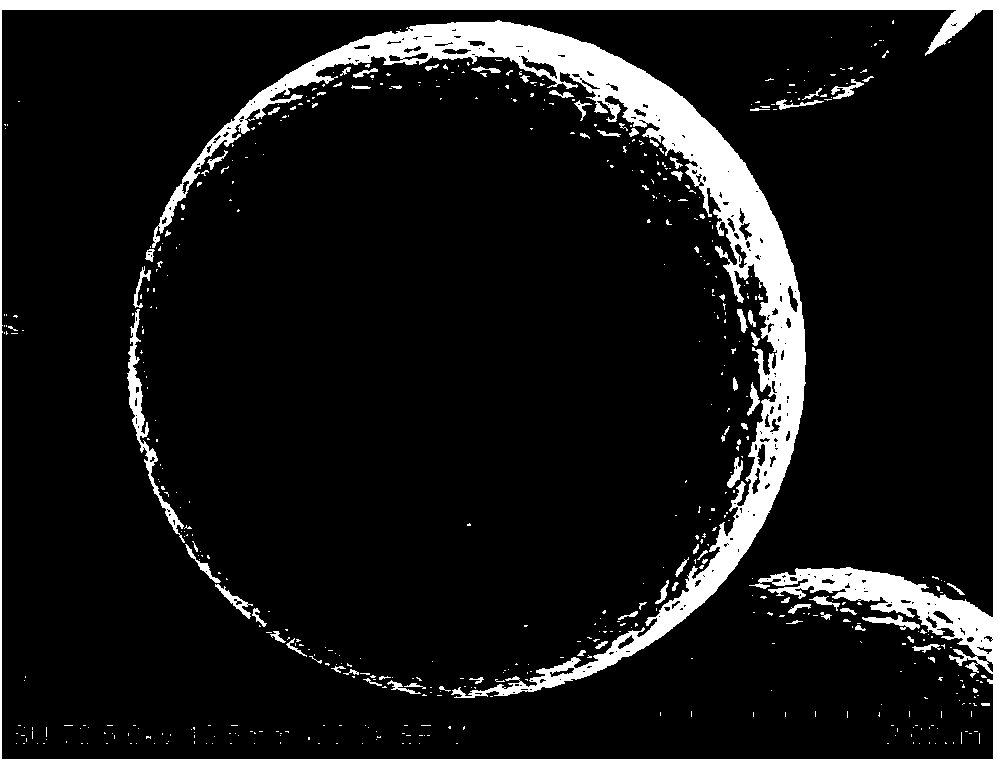

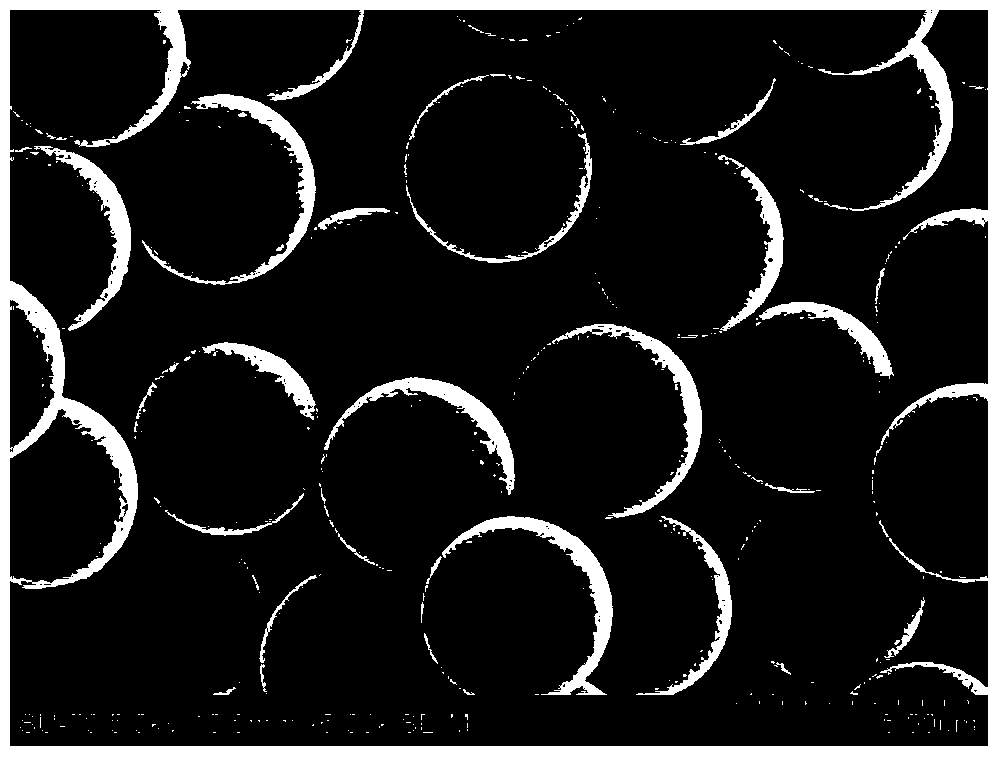

Cyanide-free gold plating method for preparing ACF (anisotropic conductive film) conductive gold spheres

ActiveCN104342646AHas catalytic activityStrong chemisorption bindingLiquid/solution decomposition chemical coatingAnisotropic conductive filmCyanide

The invention relates to a cyanide-free gold plating method for preparing ACF (anisotropic conductive film) conductive gold spheres, which comprises the following steps: 1. preparing swollen polystyrene microspheres; 2. preparing chloromethylated polystyrene microspheres; 3. adding 2,3-dimercaptopropanol into the chloromethylated polystyrene microsphere alkaline solution to prepare mercapto polystyrene microspheres; 4. preparing polystyrene microspheres of which the surface is adsorbed with gold ions; 5. dispersing the polystyrene microspheres of which the surface is adsorbed with gold ions in a reducing solution to obtain polystyrene microspheres of which the surface is adsorbed with simple substance gold; and 6. dispersing the polystyrene microspheres of which the surface is adsorbed with simple substance gold in a cyanide-free gold plating solution to obtain the conductive gold spheres. The method is simple and easy to implement; the obtained gold coating has the advantage of favorable binding force with the substrate and has fine and compact crystals; and the method avoids introducing impurity ions, avoids using cyanides, is safe to operate and can implement large-scale production.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

Cyanogen-free Au-Sn alloy electroplating liquid

The invention relates to cyanogen-free Au-Sn alloy electroplating liquid, which belongs to the field of electroplating. The cyanogen-free Au-Sn alloy electroplating liquid comprises following components including non-cyanogen soluble monovalence gold salt, sulfite, organic polybasic acid, soluble divalent tin salt, pyrophosphate, a tin ion oxidation inhibitor, dihydric phosphate and cobalt salt. The electroplating liquid is stable, electroplating speed is fast, operation is simple, Au-Sn alloy ingredients are easy to be controlled, and the cyanogen-free Au-Sn alloy electroplating liquid is applicable to production.

Owner:DALIAN UNIV OF TECH

Galvanized iron (vanadium) alloy process of acid system

The invention provides a galvanized iron (vanadium) alloy process of an acid system, belonging to the technical field of electrodeposited protective alloy coatings. An additive in the galvanized iron (vanadium) alloy process comprises a brightening agent and a complexing agent, wherein the brightening agent comprises a main brightening agent, a carrier brightening agent, an auxiliary brightening agent and a complexing agent. On a basis of original potassium chloride galvanized base fluid, the galvanized iron (vanadium) alloy process selects a suitable additive and suitable process conditions so as to surely form a Zn-Fe (V) alloy nano coating with favorable performance, wherein the coating contains 0.2-0.7 percent of iron and approximate 0.01 percent of vanadium. The additive provided by the invention has reasonable and advanced prescription, simple and reasonable preparation method, little environmental pollution, bright and smooth product surface, good quality stability and corrosion resistance, low production cost and simple process.

Owner:湖北奥美斯新材料有限公司

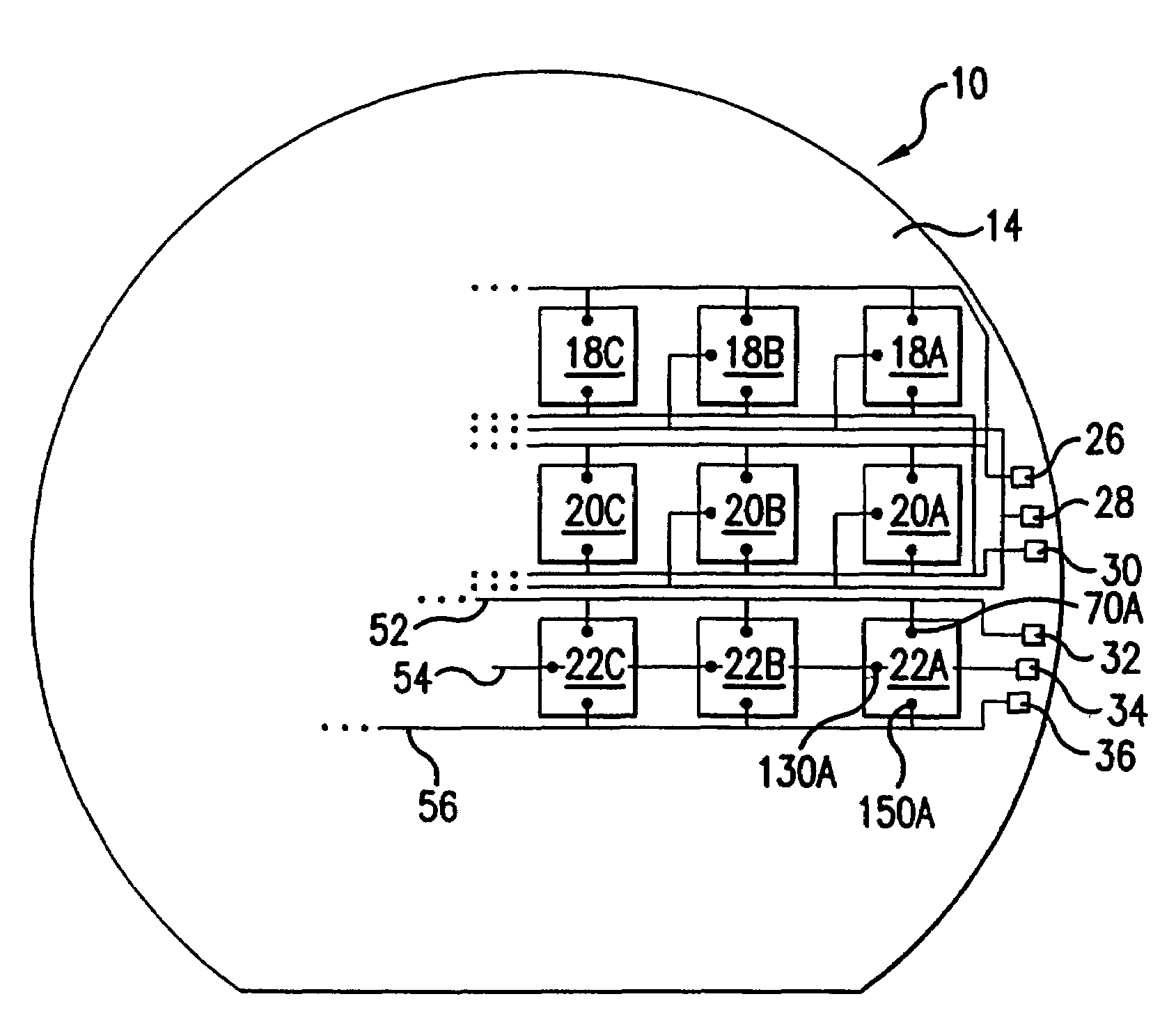

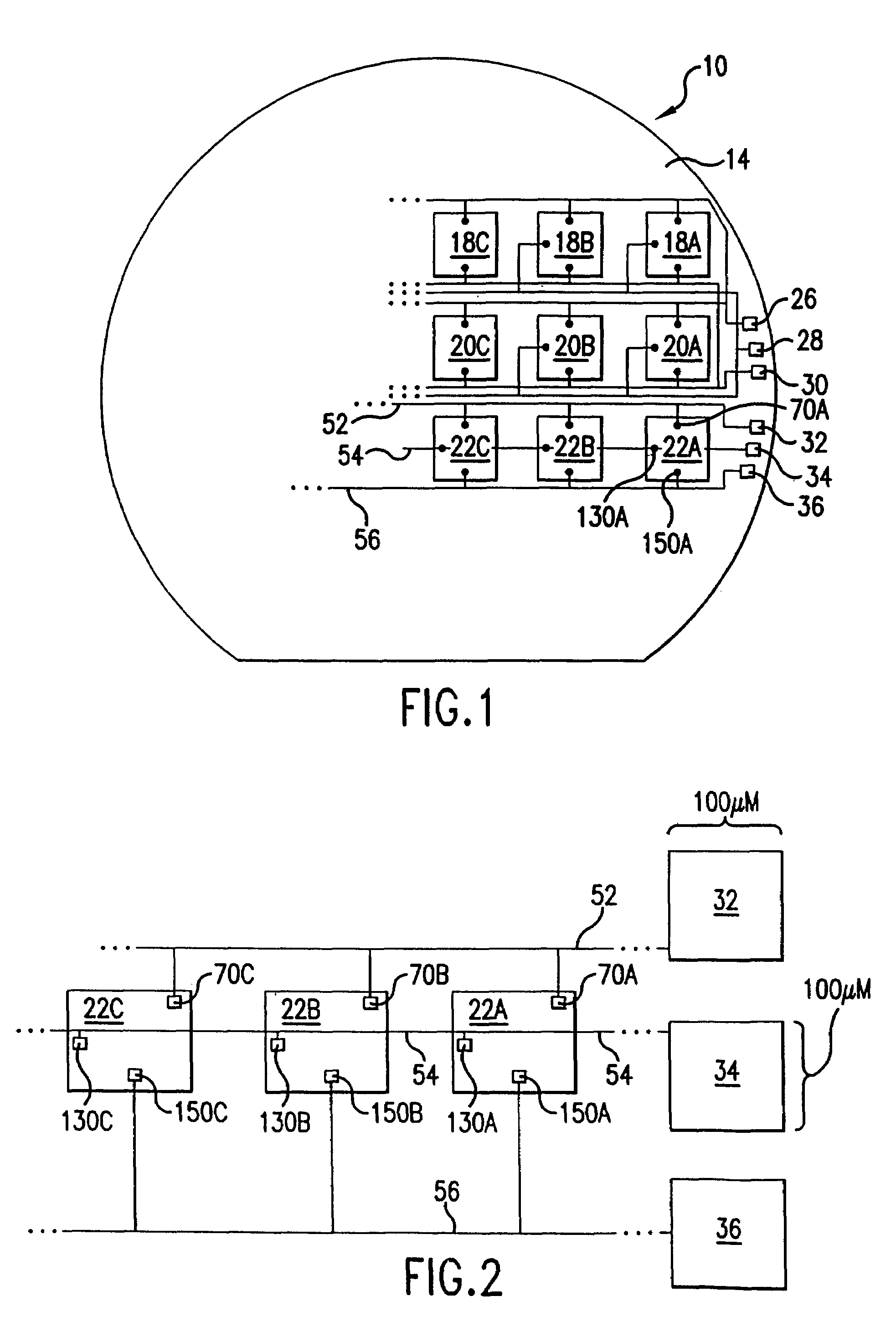

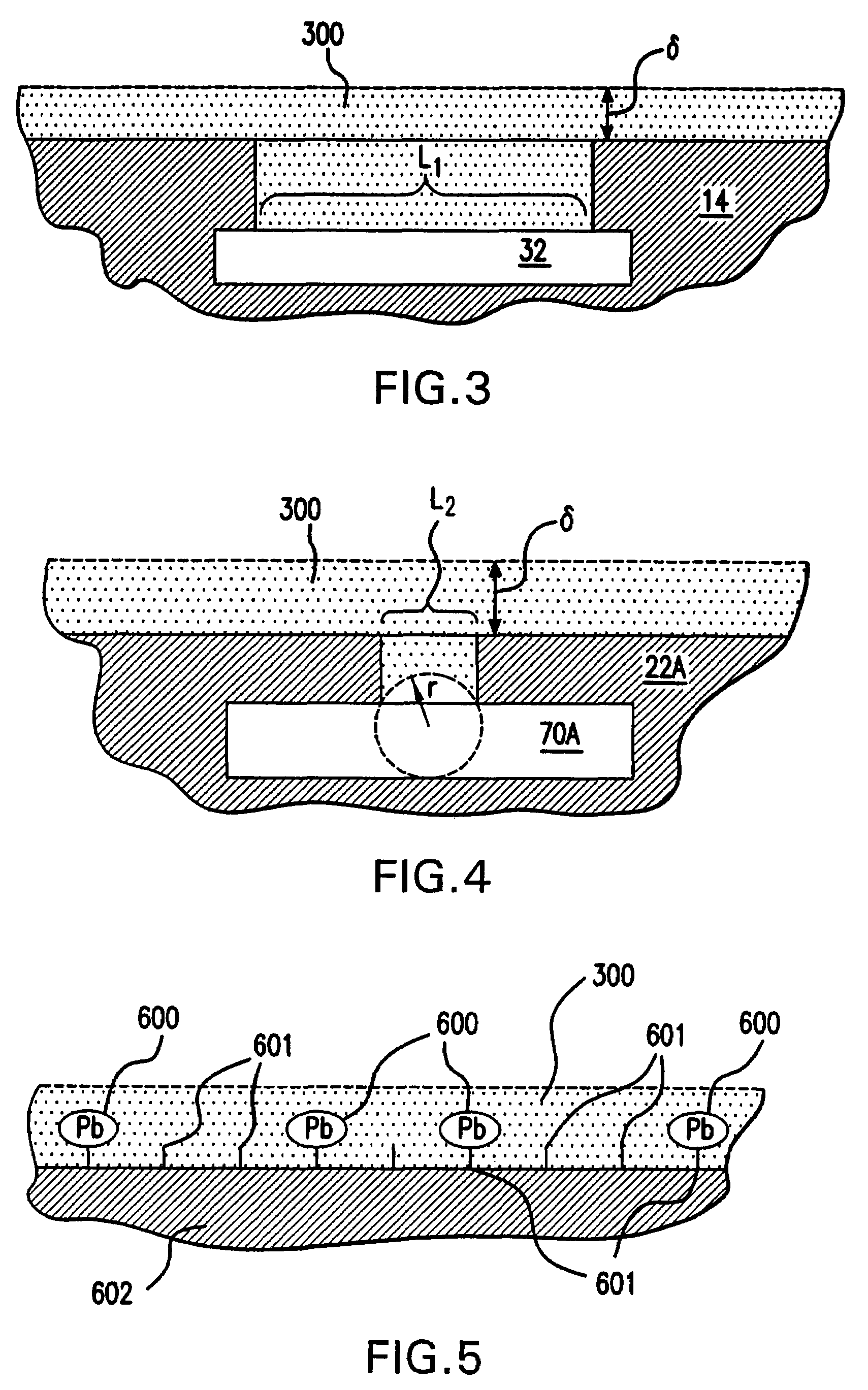

Stable electroless fine pitch interconnect plating

InactiveUS7052922B2Easy to PlatingPlating solution is stableSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringMechanical engineering

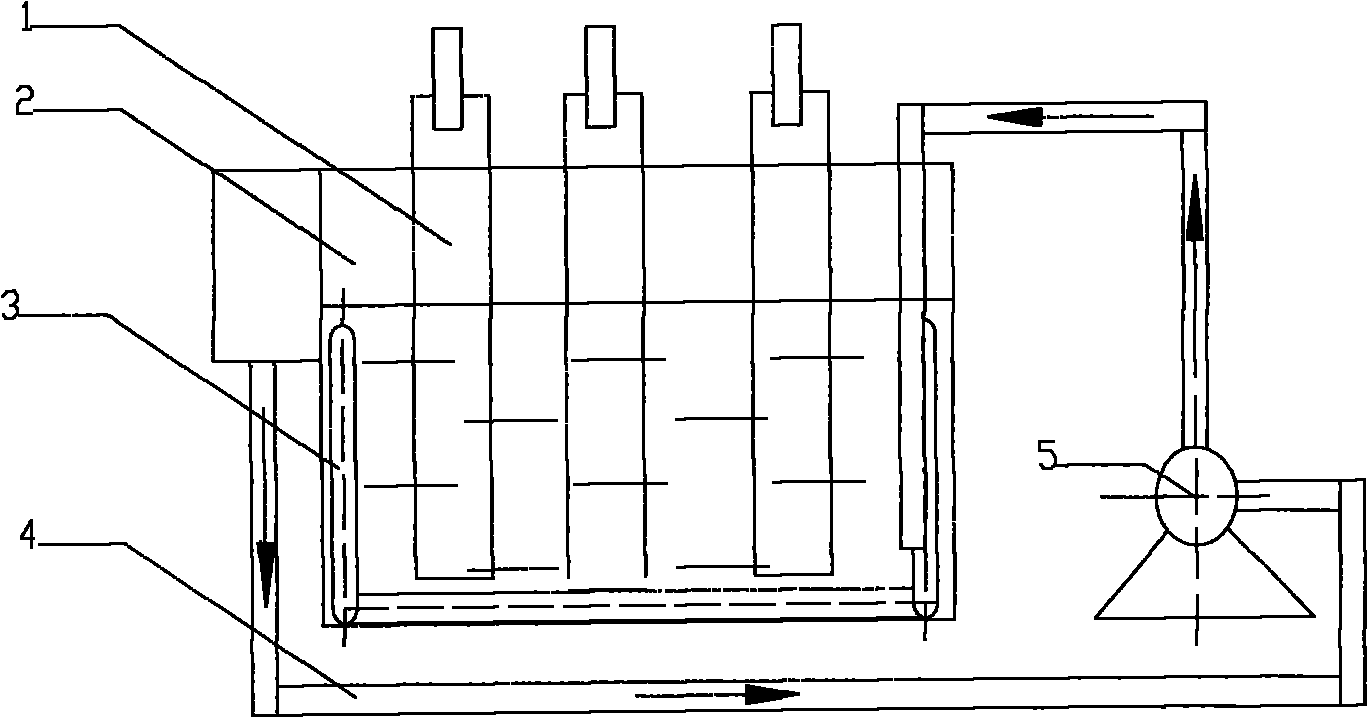

A method and apparatus for plating facilitates the plating of a small contact feature of a wafer die while providing a relatively stable plating bath. The method utilizes a supplemental plating structure that is larger than a die contact that is to be plated. The supplemental plating structure may be located on the wafer, and is conductively connected to the die contact. Conductive connection between the die contact and the supplemental plating structure facilitates the plating of the die contact. The supplemental plating structure also can be used to probe test the die prior to singulation.

Owner:MICRON TECH INC

Preparation technology of chemical plating Ni-P-PTFE composite coating

InactiveCN106958013AGood chemical stabilityGood chemical propertiesLiquid/solution decomposition chemical coatingChemical platingWear resistance

The invention discloses a preparation technology of a chemical plating Ni-P-PTFE composite coating, and belongs to the technical field of metal surface treatment. The preparation technology comprises the following steps: (1) a low-carbon steel heat exchange surface is subjected to preliminary treatment; (2) Ni-P-PTFE composite coating liquid is prepared, and a Ni-P-PTFE composite coating is prepared on the low-carbon steel heat exchange surface by employing the prepared Ni-P-PTFE composite coating liquid; and (3) the microbial fouling inhibition and alleviation performances of the Ni-P-PTFE composite coating are evaluated. The abrasive resistance and the drainage effect of the surface of the Ni-P-PTFE composite coating can be improved effectively, so that the Ni-P-PTFE composite coating can adapt to multiple complex environments. The form and stable Ni-P-PTFE composite coating is formed on a Q235 carbon steel base material, a plating solution is stable in a plating application process, and the uniform and stable Ni-P-PTFE composite coating can be obtained nearly without mixing.

Owner:NORTHEAST DIANLI UNIVERSITY

Cyanide-free electroplating bath for copper plating of iron and steel parts

InactiveCN102021617AThe composition of the plating solution is simplePlating solution is stableCopper platingPotassium thiocyanate

The invention discloses a cyanide-free electroplating bath for the copper plating of iron and steel parts. The electroplating bath provided by the invention comprises copper sulphate, potassium carbonate, one or more than two of organic phosphate and phytic acid, and one or more than two of sodium citrate, seignette salt and potassium thiocyanate. The electroplating bath provided by the invention is applied to the copper plating of the iron and steel parts, and has the advantages of fine and compact coating crystals, dispersing power and covering power both superior to those of cyaniding copper-plating solution, simple components, stability, no decomposition products, no need of heating, reduction in energy consumption and a strong binding force between a coating and a substrate.

Owner:GUANGZHOU JINHUI CHEM SCI TECH

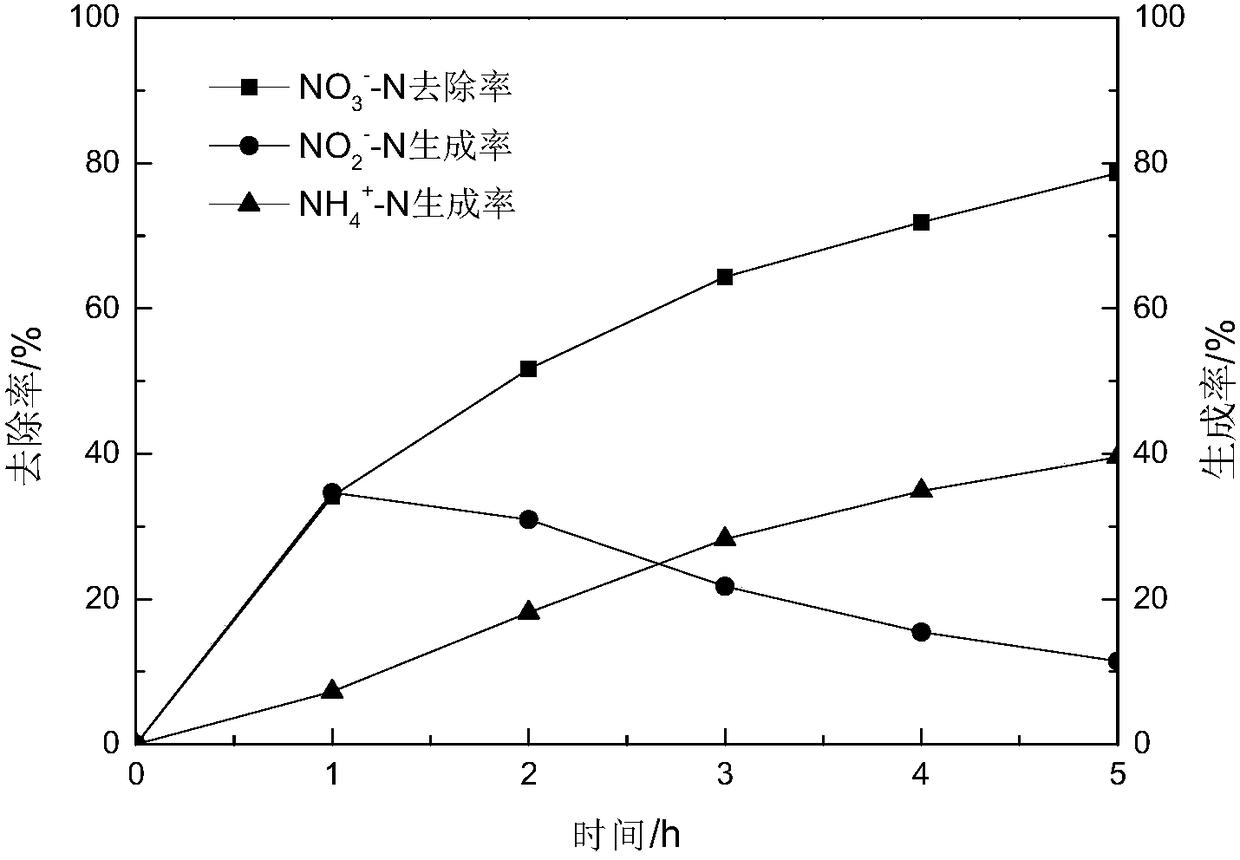

Cu-Sn-Bi electrode with high catalytic activity, and preparation method and application thereof

PendingCN108467091ACorrosion resistanceImprove stabilityWater contaminantsWater/sewage treatmentPolymer scienceNitrate

The invention provides a Cu-Sn-Bi electrode with high catalytic activity, and a preparation method and an application thereof. The electrode is prepared by dissolving the following components in deionized water by mass: 56 to 61 g / L of Bi(NO3)3.5H2O, 37 to 52.3 g / L of CuP2O7, 2.6 to 4.3 g / L of SnP2O7, 45 to 65 g / L of KCl, 45 to 65 g / L of NaKC4H4O6.4H2O, 85 to 92 g / L of EDTA-2Na, 118 to 123 g / L ofC7H6O6S.2H2O, 220 to 250 g / L of K4O7P2, 26 to 31 g / L of Na2HPO4 and 25 to 30 g / L N(CH2COOH)3. The process for preparation of the electrode provided by the invention has the following advantages: plating can be performed at a room temperature; working conditions are easy to maintain; a plating liquid has a simple formula with commonly-used chemicals with low price; no secondary synthesis is required; an obtained electrode plating layer is firmly bonded with a substrate; and the surface of the electrode is uniform. The Cu-Sn-Bi electrode provided by the invention has higher corrosion resistanceand good electrical conductivity, is used in the process of nitrate degradation, and has high catalytic efficiency.

Owner:SHENYANG POLYTECHNIC UNIV

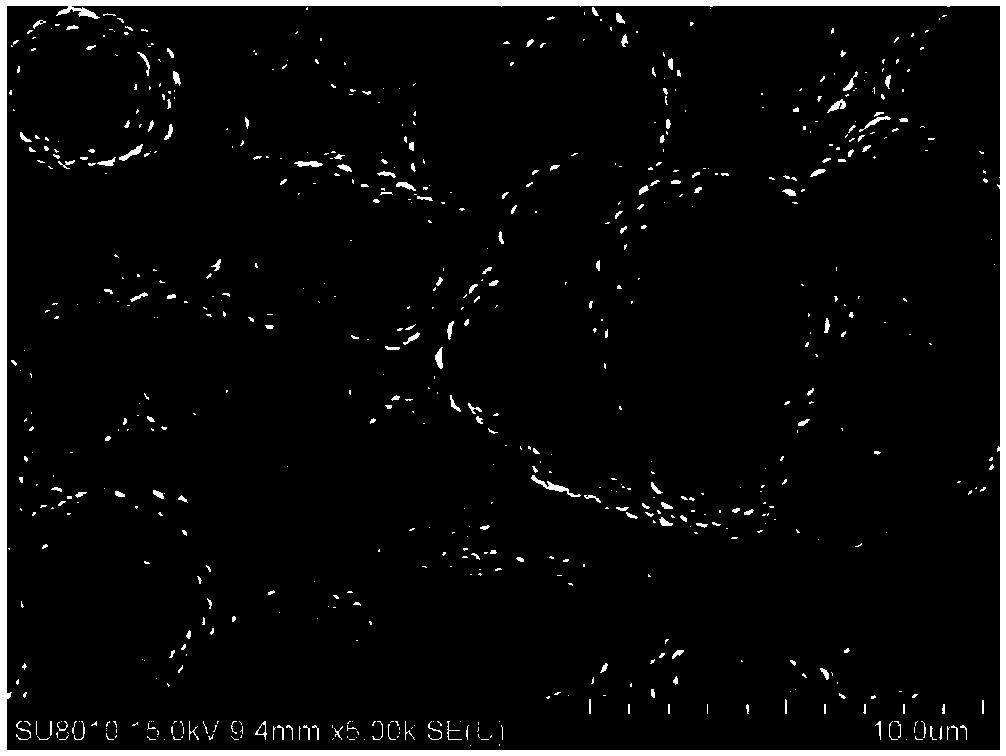

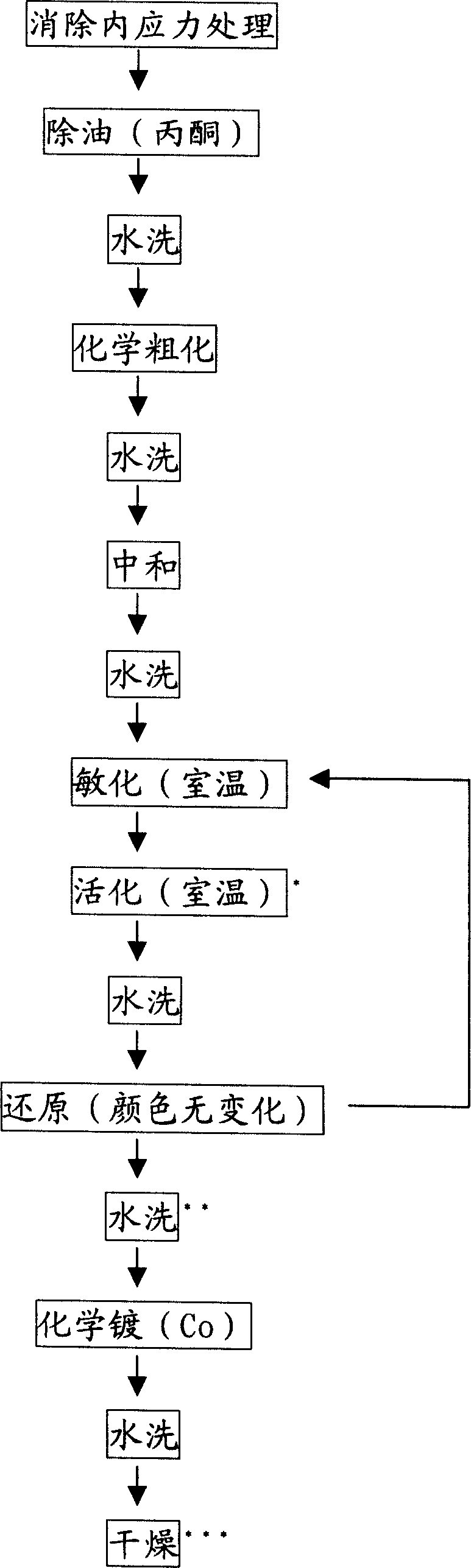

Formular and process of polymer powder chemical Co-plating

InactiveCN1752285AGood dispersionEasy to operateLiquid/solution decomposition chemical coatingCompound (substance)Potassium sodium tartrate

A chemical co-plating liquid for the polymer powder used for magnetic rheologic liquid or wave absorbing film is prepared from cobalt sulfate, potassium sodium tartrate, boric acid, ammonium sulfate, sodium citrate, and sodium hypophosphite. Its plating process is performed at 60-80 deg.C for 1-2 hr.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com