Cu-Sn-Bi electrode with high catalytic activity, and preparation method and application thereof

A high catalytic activity, cu-sn-bi technology, used in chemical instruments and methods, water pollutants, water/sewage treatment, etc. Simple formula for effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

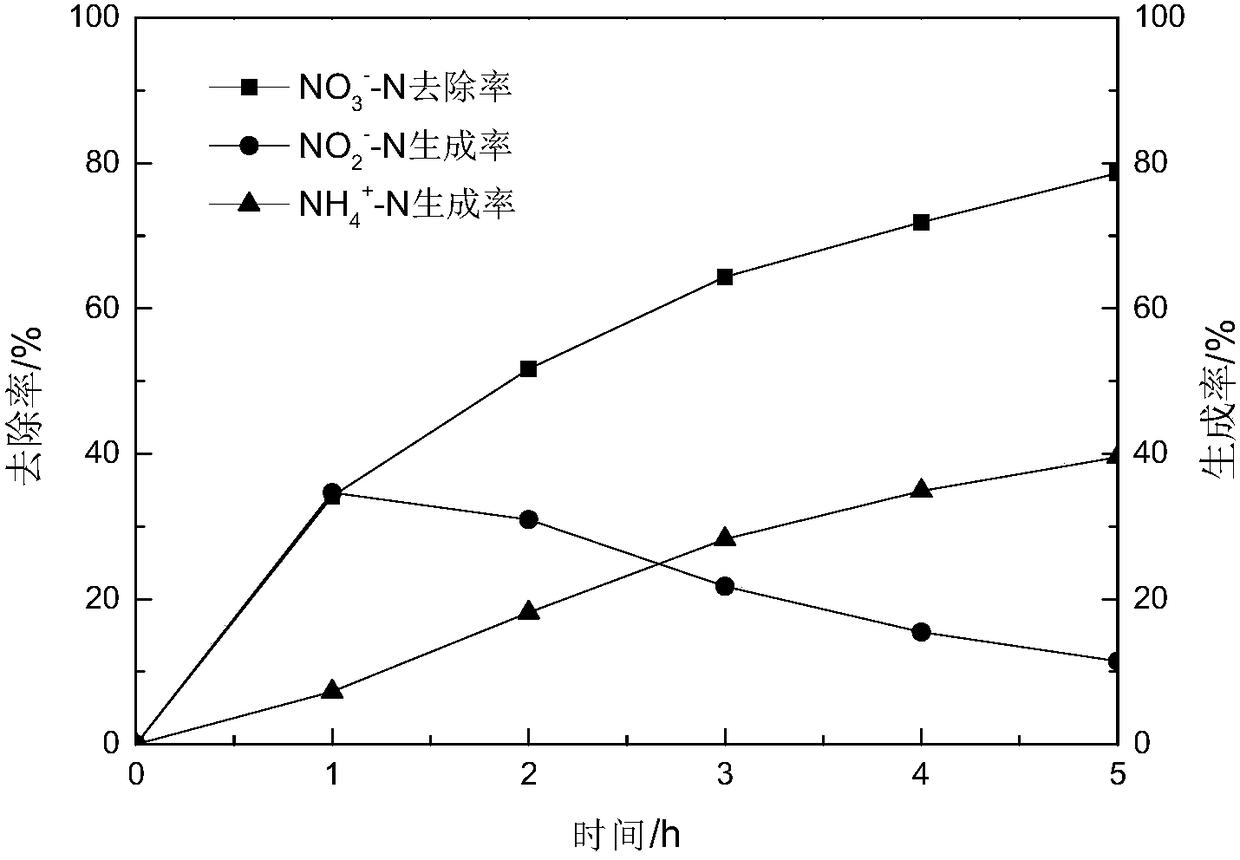

Examples

Embodiment 1

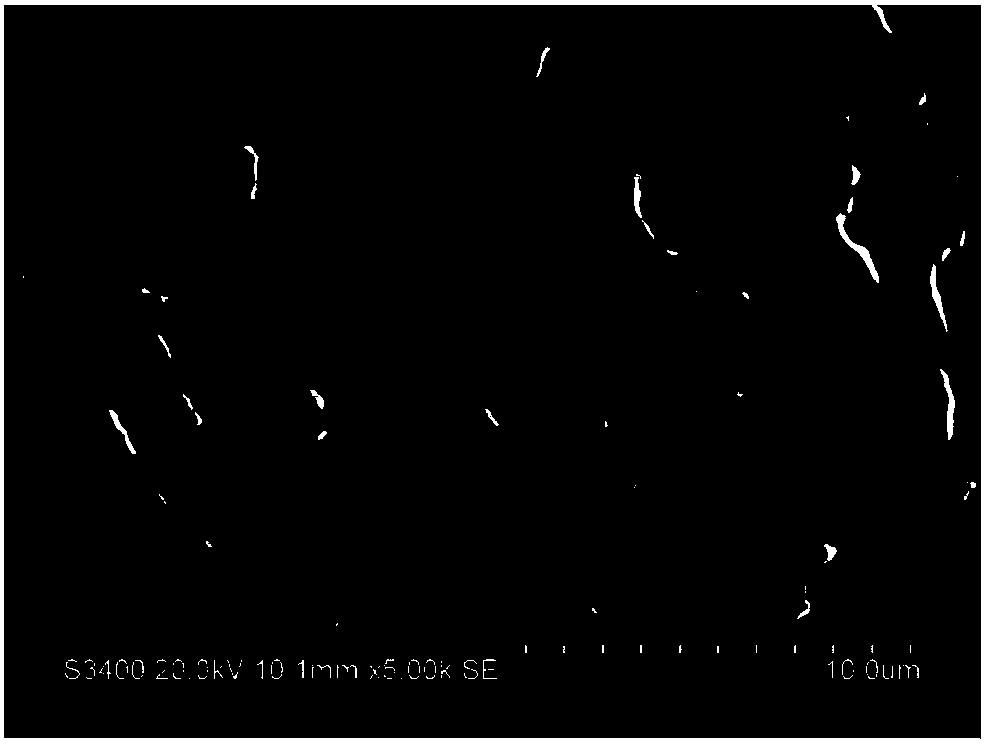

[0035] A kind of Cu-Sn-Bi electrode preparation and the method for degrading nitrate thereof, concrete steps are as follows:

[0036] Step 1, 57g / L Bi(NO 3 ) 3 ·5H 2 O, 38g / L CuP 2 o 7 , 2.7g / L SnP 2 o 7 , 50g / L KCl, 45g / L NaKC 4 h 4 o 6 4H 2 O, 86g / L EDTA-2Na, 120 / L C 7 h 6 o 6 S·2H 2O, 225g / LK 4 o 7 P 2 , 28g / L Na 2 HPO 4 and 25g / L N(CH 2 COOH) 3 Soluble in deionized water as electrodeposition solution;

[0037] Step 2. Cut the titanium plate so that its surface area is 40mm×50mm, and then polish it with sandpaper of two different specifications, 120 mesh and 240 mesh, and then treat the polished titanium substrate in a 40% NaOH solution at a temperature of 80°C for 1 hour Carry out surface degreasing, then put into slightly boiling 10% oxalic acid solution for 1 hour, carry out pickling and etching, and clean with deionized water, store in ultrapure water for later use;

[0038] Step 3: Connect the pretreated substrate to the negative pole of the DC po...

Embodiment 2

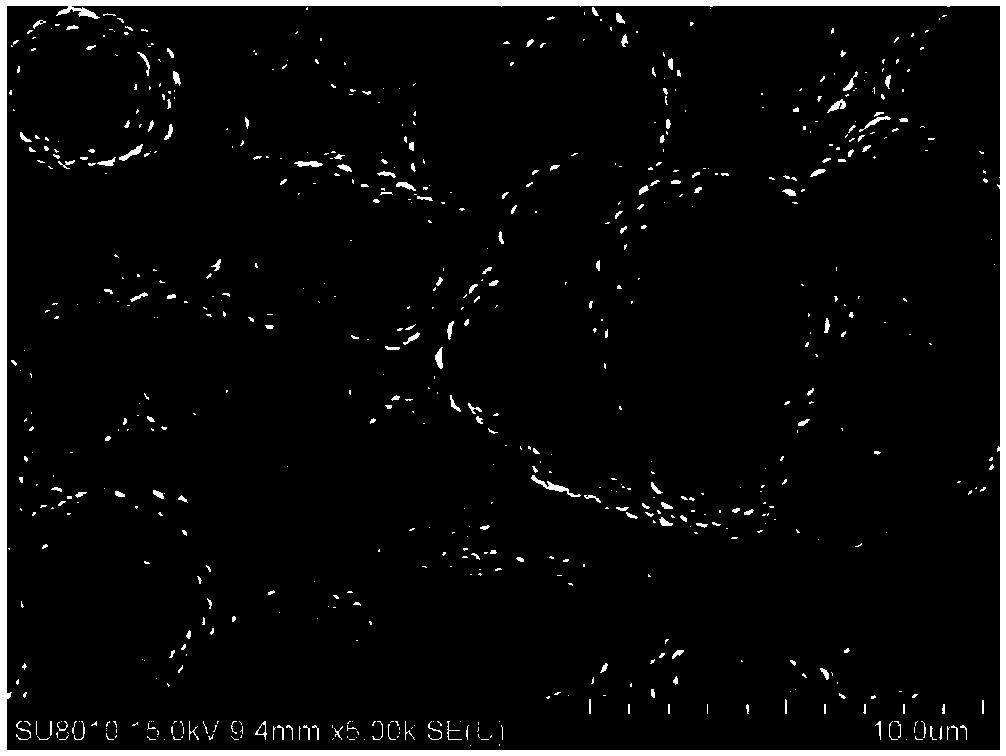

[0042] A kind of Cu-Sn-Bi electrode preparation and the method for degrading nitrate thereof, concrete steps are as follows:

[0043] Step 1, 60g / L Bi(NO 3 ) 3 ·5H 2 O, 42g / L CuP 2 o 7 , 2.6g / L SnP 2 o 7 , 60g / L KCl, 60g / L NaKC 4 h 4 o 6 4H 2 O, 90g / L EDTA-2Na, 120 / L C 7 h 6 o 6 S·2H 2 O, 240g / L K 4 o 7 P 2 , 30g / L Na 2 HPO 4 and 30g / L N(CH 2 COOH) 3 Soluble in deionized water as electrodeposition solution

[0044] Step 2. Cut the titanium plate so that the surface is 40mm×50mm, and then polish it with sandpaper of two different specifications, 120 mesh and 240 mesh, and then treat the polished titanium substrate in a 40% NaOH solution at a temperature of 80°C for 1 hour Degreasing the surface, then putting it into a slightly boiling 10% oxalic acid solution for 1 hour for pickling and etching, cleaning it with deionized water, and storing it in ultrapure water for later use;

[0045] Step 3: Connect the pretreated substrate to the negative pole of the DC...

Embodiment 3

[0049] A kind of Cu-Sn-Bi electrode preparation and the method for degrading nitrate thereof, concrete steps are as follows:

[0050] Step 1, 58g / L Bi(NO 3 ) 3 ·5H 2 O, 45g / L CuP 2 o 7 , 4.2g / L SnP 2 o 7 , 55g / L KCl, 65g / L NaKC 4 h 4 o 6 4H 2 O, 88g / L EDTA-2Na, 121 / L C 7 h 6 o 6 S·2H 2 O, 230g / L K 4 o 7 P 2 , 27g / L Na 2 HPO 4 and 25g / L N(CH 2 COOH) 3 Soluble in deionized water as electrodeposition solution;

[0051] Step 2. Cut the titanium plate so that the surface is 40mm×50mm, and then polish it with sandpaper of two different specifications, 120 mesh and 240 mesh, and then treat the polished titanium substrate in a 40% NaOH solution at a temperature of 80°C for 1 hour Carry out surface degreasing, then put into slightly boiling 10% oxalic acid solution for 1 hour, carry out pickling and etching, and clean with deionized water, store in ultrapure water for later use;

[0052] Step 3: Connect the pretreated substrate to the negative pole of the DC power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com