Composite material with anti-bacterial and purifying functions and preparation method of composite material

A technology of functional composite materials and antibacterial materials, which is applied in the field of antibacterial and purification functional composite materials and its preparation, can solve the problems of disordered industrial development and unfavorable industrial development, and achieve simple and convenient powder application, low cost, and less waste water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The antibacterial and purifying functional composite material is made of the following raw materials in parts by weight: 700g of mineral composite adsorption material, 30g of photocatalytic degradation material, 20g of rare earth inorganic antibacterial material, and 10g of additives.

[0064] The mineral composite adsorption material is made of 245g sepiolite, 70g diatomite, 210g medical stone and 175g attapulgite;

[0065] The photocatalytic degradation material is made of 15g titanium oxide, 9g tourmaline and 6g far-infrared ceramic powder;

[0066] The rare earth inorganic antibacterial material is made of 16g zinc oxide, 3g cerium oxide and 1g silver oxide;

[0067] Described additive is the mixture of 5g gac, 3g carboxymethyl cellulose and 2g pumice powder.

[0068] The preparation method of the described antibacterial purification functional composite material comprises the following steps:

[0069] (1) Mix and grind sepiolite, diatomite, medical stone and at...

Embodiment 2

[0076] The antibacterial and purifying functional composite material is made of the following raw materials in parts by weight: 950g of mineral composite adsorption material, 250g of photocatalytic degradation material, 150g of rare earth inorganic antibacterial material, and 100g of additives.

[0077] The mineral composite adsorption material is made of 570g sepiolite, 190g diatomite, 95g medical stone and 95g attapulgite;

[0078] The photocatalytic degradation material is made of 200g titanium oxide, 25g tourmaline and 25g far-infrared ceramic powder;

[0079] The rare earth inorganic antibacterial material is made of 138g zinc oxide, 4.5g cerium oxide and 3g silver oxide;

[0080] Described additive is the mixture of 75g gac, 10g carboxymethyl cellulose and 15g pumice powder.

[0081] The preparation method of the described antibacterial purification functional composite material comprises the following steps:

[0082] (1) Mix and grind sepiolite, diatomite, medical stone...

Embodiment 3

[0089] The antibacterial and purifying functional composite material is made of the following raw materials in parts by weight: 800g of mineral composite adsorption material, 100g of photocatalytic degradation material, 100g of rare earth inorganic antibacterial material, and 50g of additives.

[0090] The mineral composite adsorption material is made of 400g sepiolite, 240g diatomite, 40g medical stone and 120g attapulgite;

[0091] The photocatalytic degradation material is made of 60g titanium oxide, 25g tourmaline and 25g far-infrared ceramic powder;

[0092] The rare earth inorganic antibacterial material is made of 90g zinc oxide, 5g cerium oxide and 5g silver oxide;

[0093] Described additive is the mixture of 30g gac, 5g carboxymethyl cellulose and 15g pumice powder.

[0094] The preparation method of the described antibacterial purification functional composite material comprises the following steps:

[0095] (1) Mix and grind sepiolite, diatomite, medical stone an...

PUM

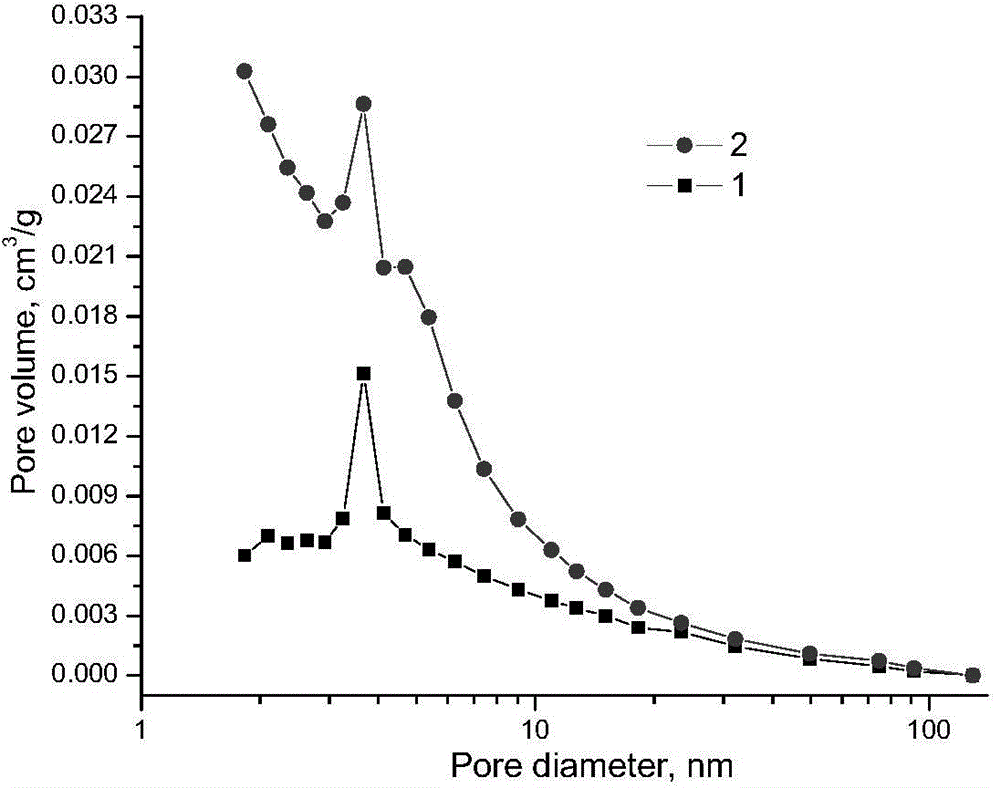

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com