Patents

Literature

10624 results about "Carboxymethyl cellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

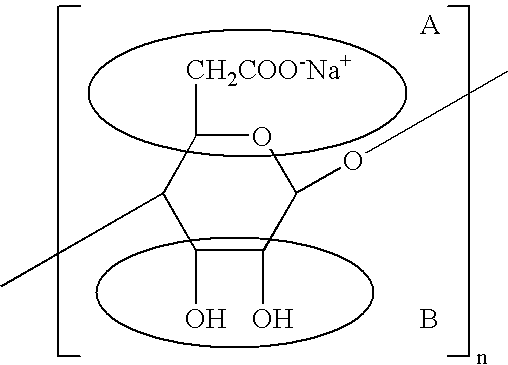

Carboxymethyl cellulose (CMC) or cellulose gum is a cellulose derivative with carboxymethyl groups (-CH₂-COOH) bound to some of the hydroxyl groups of the glucopyranose monomers that make up the cellulose backbone. It is often used as its sodium salt, sodium carboxymethyl cellulose. It used to be marketed under the name Tylose, a registered trademark of SE Tylose.

Compositions of polyacids and polyethers and methods for their use as dermal fillers

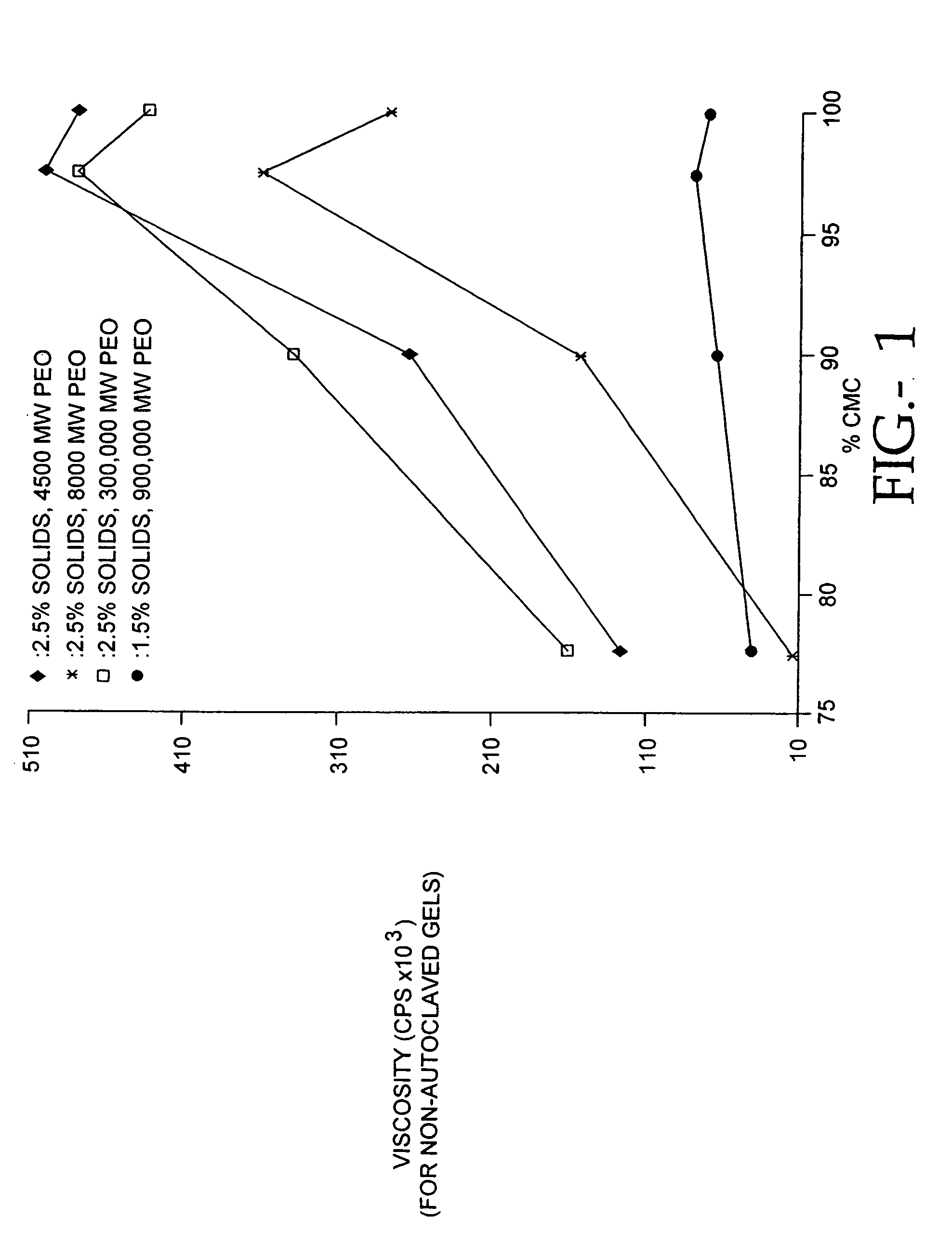

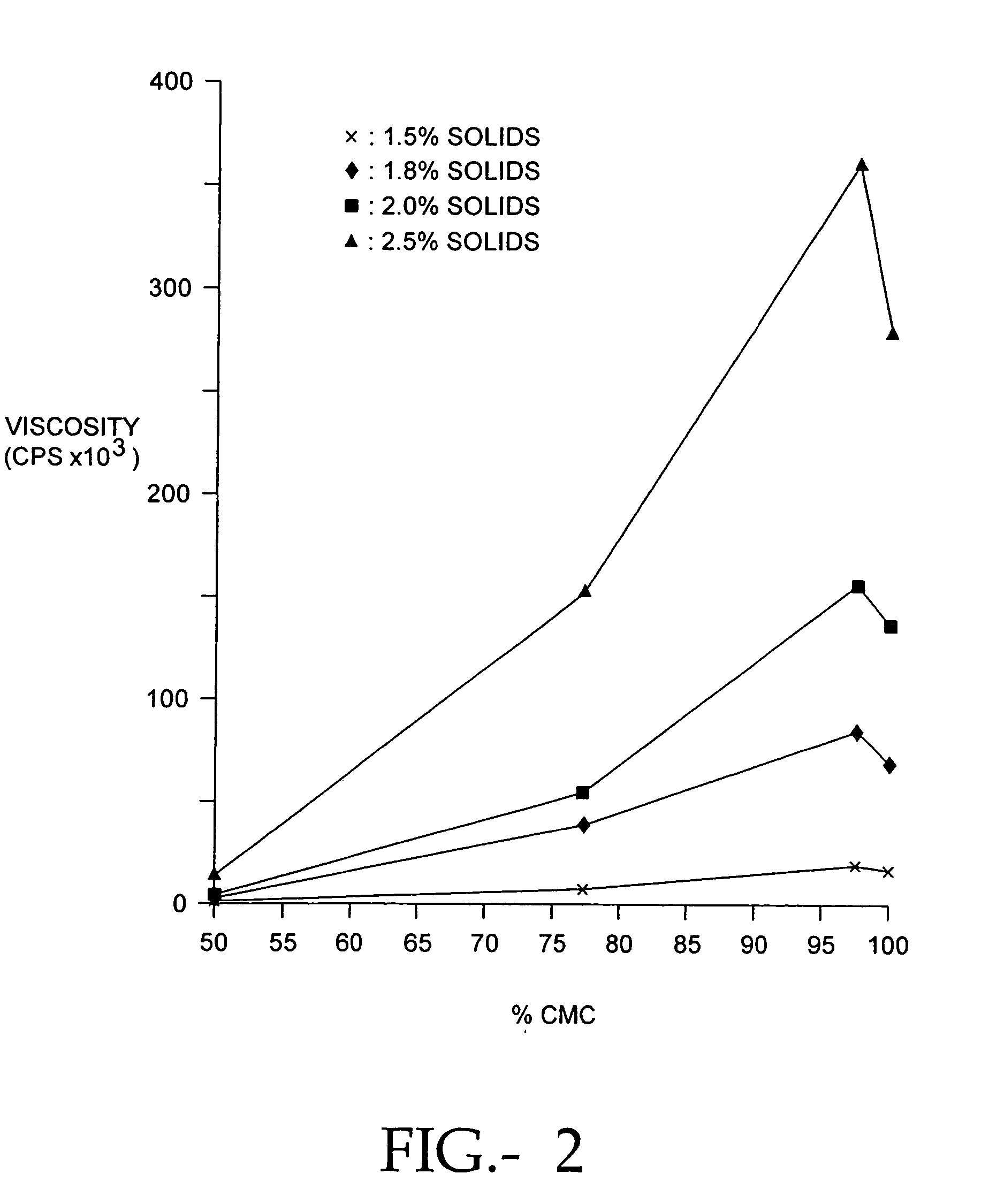

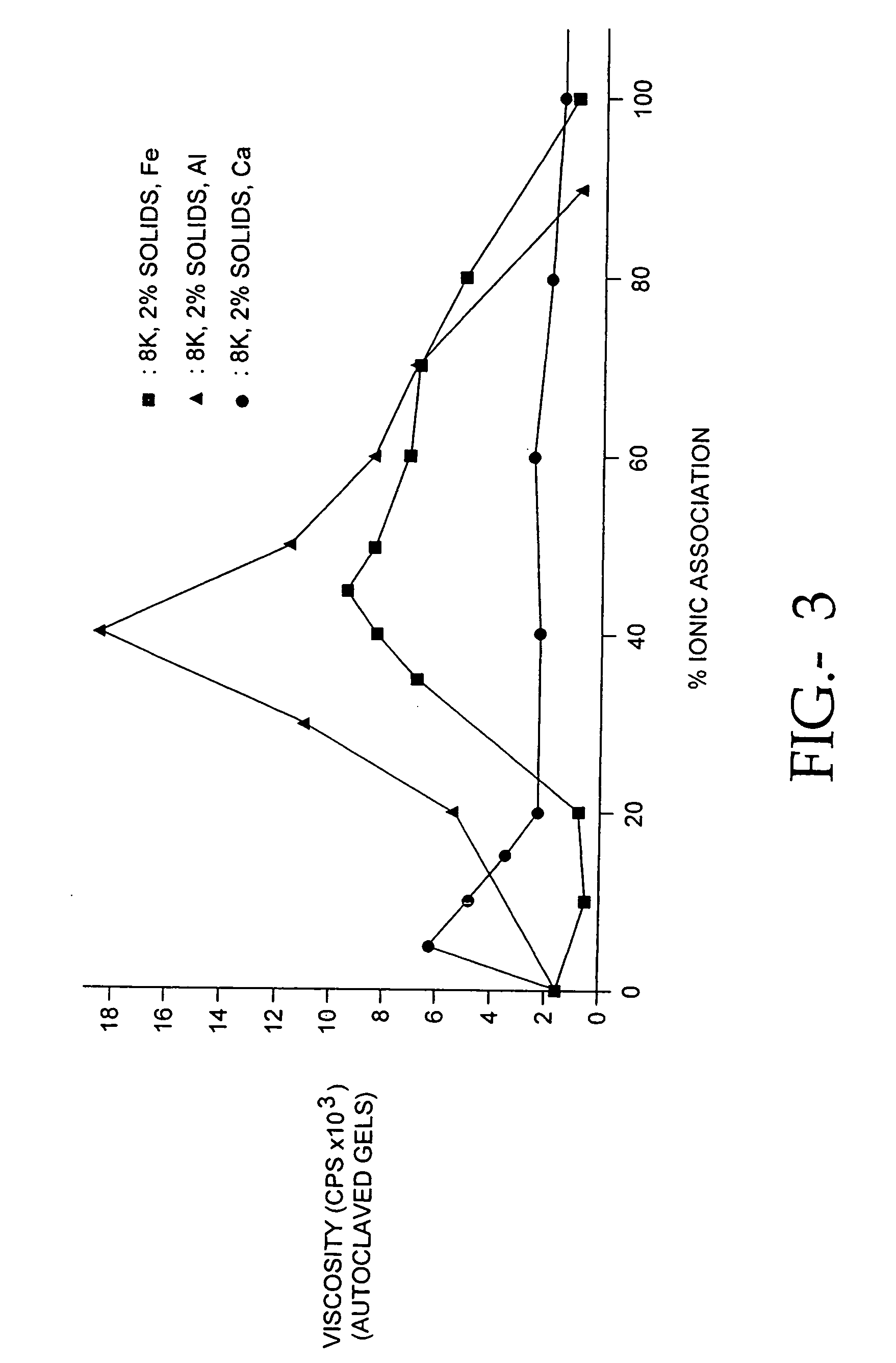

The present invention relates to improved methods for filling the skin for cosmetic or medical purposes. Compositions comprising carboxymethyl cellulose (CMC), polyethylene oxide (PEO) and calcium ions can be made and have physical properties that depend on the amounts and types of CMC, PEO, and calcium ions to form ioniclaly cross-linked gels. Compositions can be formed into microspheres, coascervates, gels, or membranes. Gels, microspheres and coascervates can be injected directly into a site for dermal filling. Membranes can be surgically introduced, where they swell to form hydrated gels. After introduction, the dermal filler persists for a period of time and then can disintegrate and be removed from the body.

Owner:FZIOMED

Stabilized Glycosaminoglycan Preparations and Related Methods

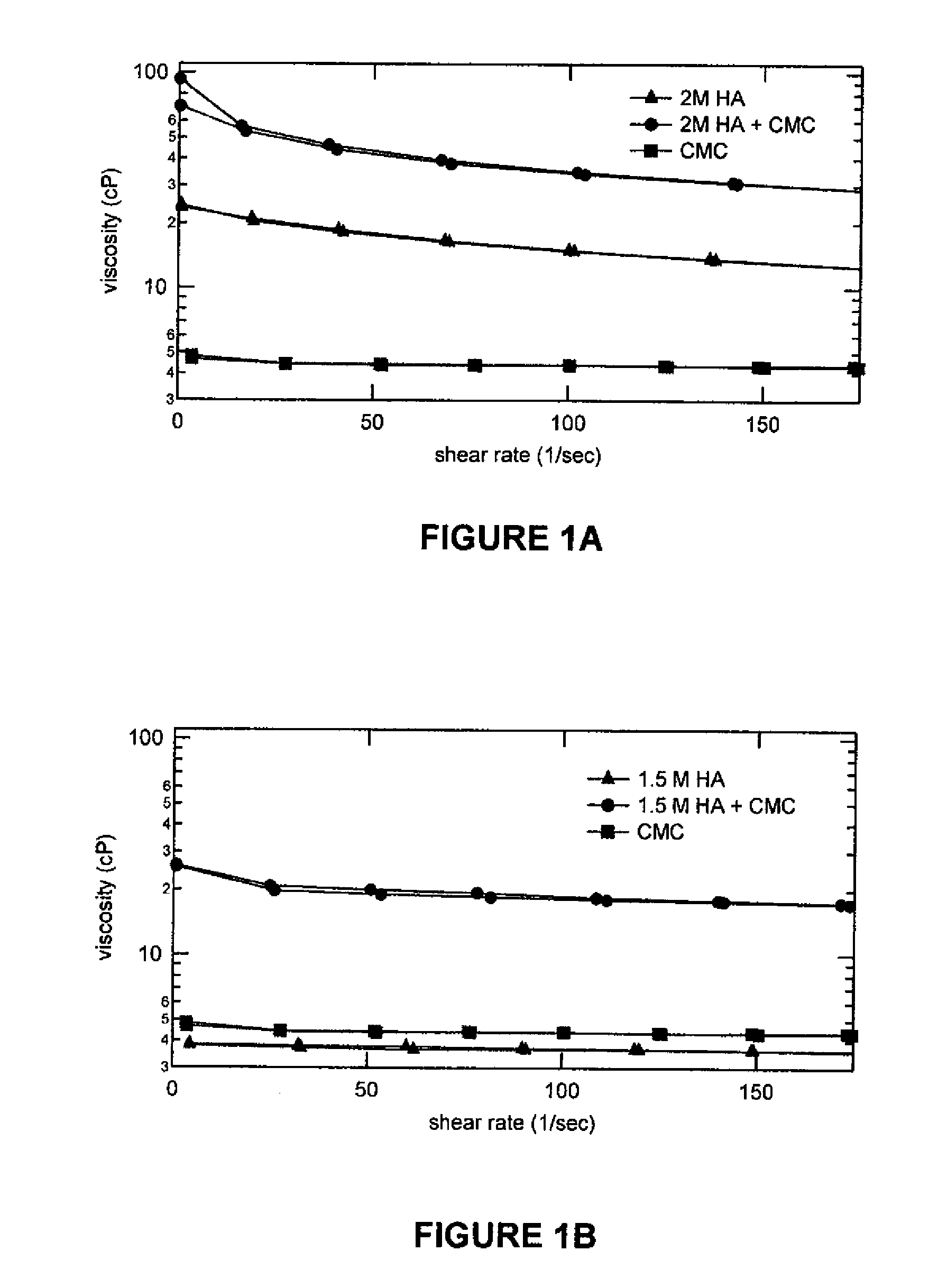

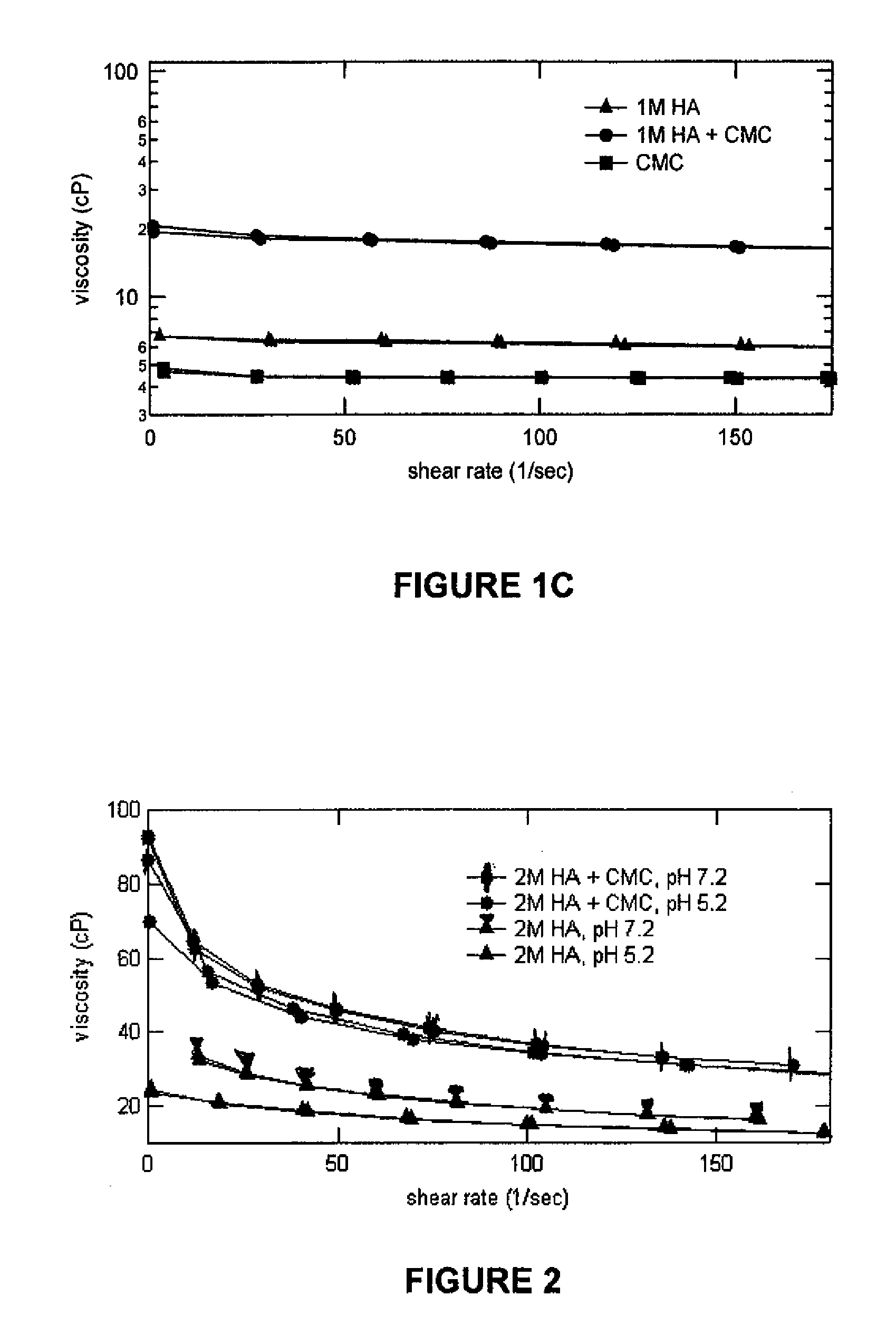

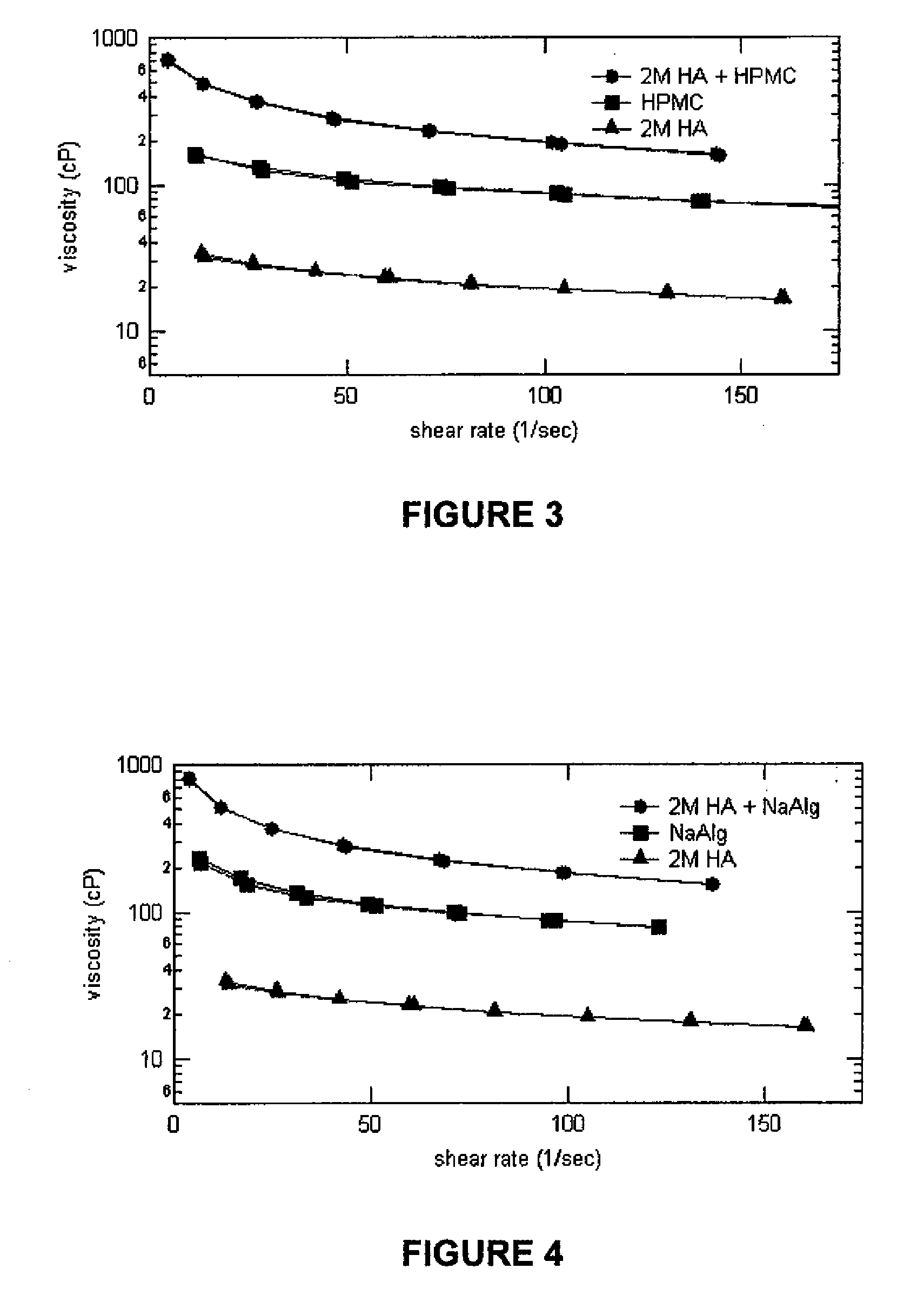

Compositions comprising a glycosaminoglycan (e.g., a hyaluronan, hyaluronic acid, hyaluronate, sodium hyaluronate, dermatan sulfate, karatan sulfate, chondroitin 6-sulfate, heparin, etc.) in combination with at least one component selected from; i) polyglycols (e.g., polyethylene glycol), ii) long chain hydroxy polyanionic polysaccharides (e.g., dextran, sodium alginate, alginic acid, propylene glycol alginate, carboxymethyl cellulose and carboxyethyl cellulose, hydroxyl ethyl starch, hydroxyl propyl methyl cellulose, hydroxy propyl ethyl cellulose, hydroxy propyl cellulose, methyl cellulose, polylysine, polyhistidine, polyhydroxy proline, poly ornithine, polyvinyl pyrolidone, polyvinyl alcohol, chitosan, etc.) and iii) long chain Nitrogen containing polymers (e.g., Polylysine, Polyvinylpyrrolidone, and polyvinyl alcohol). The invention also includes methods for using such compositions (e.g., as substance delivery materials, tissue fillers or bulking agents, as moistening or hydrating agents, etc.)

Owner:S K PHARMA INC

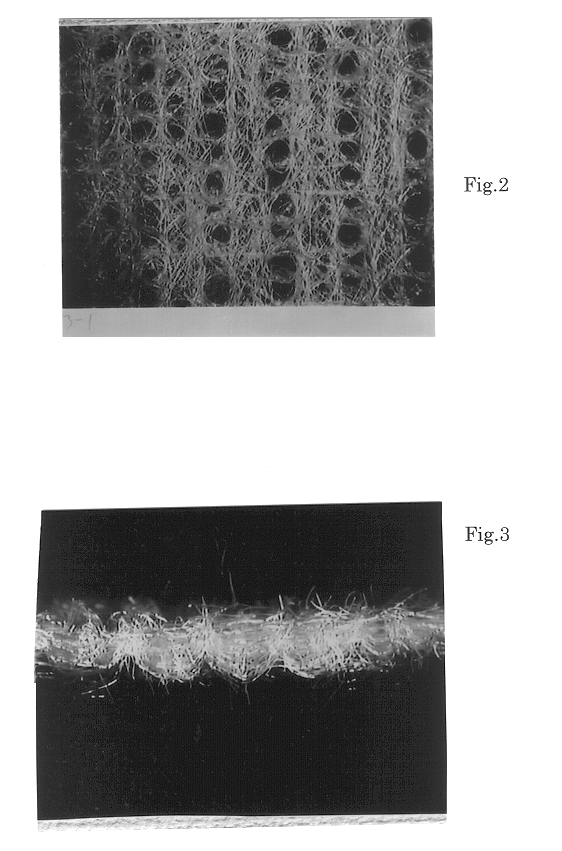

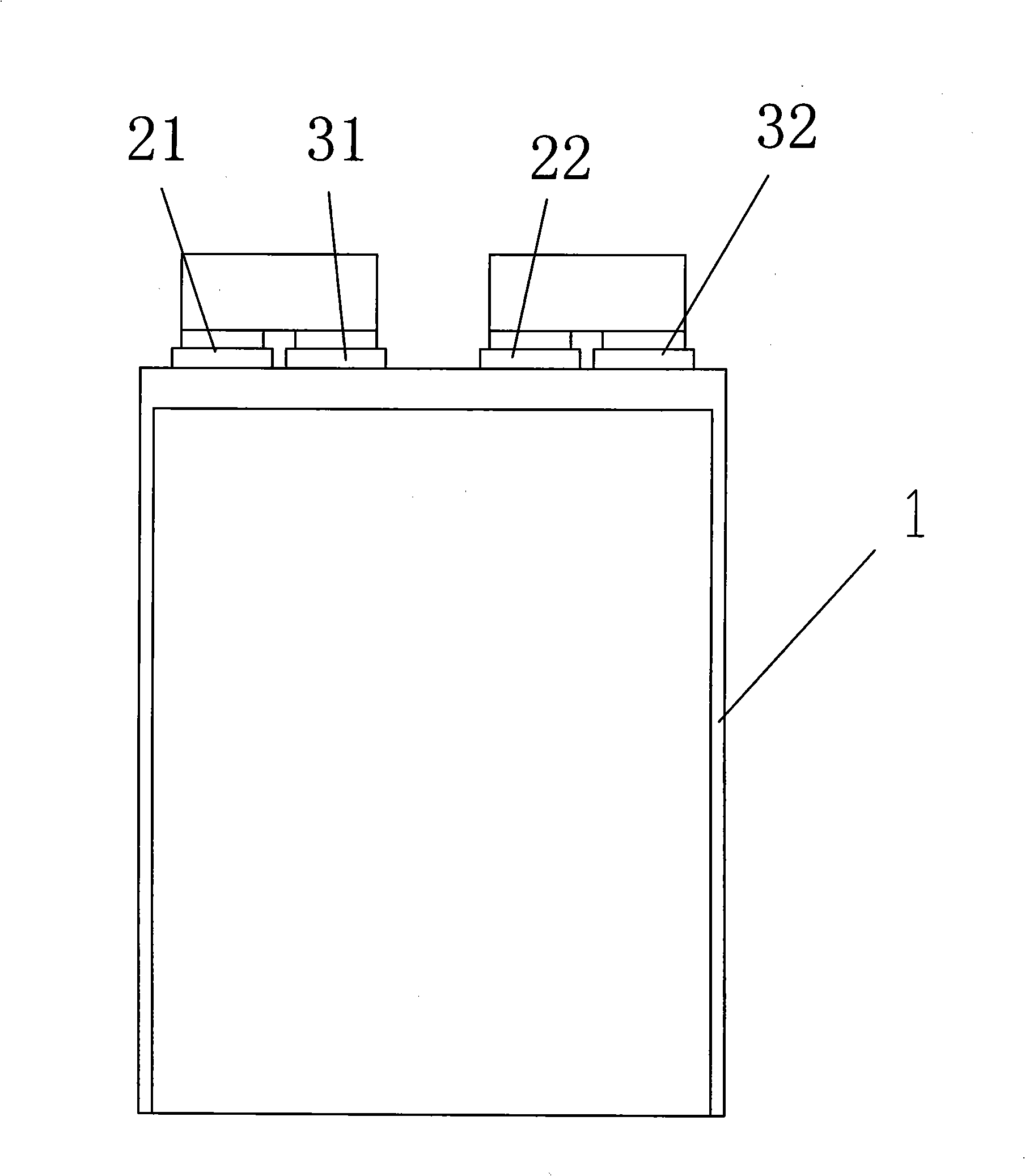

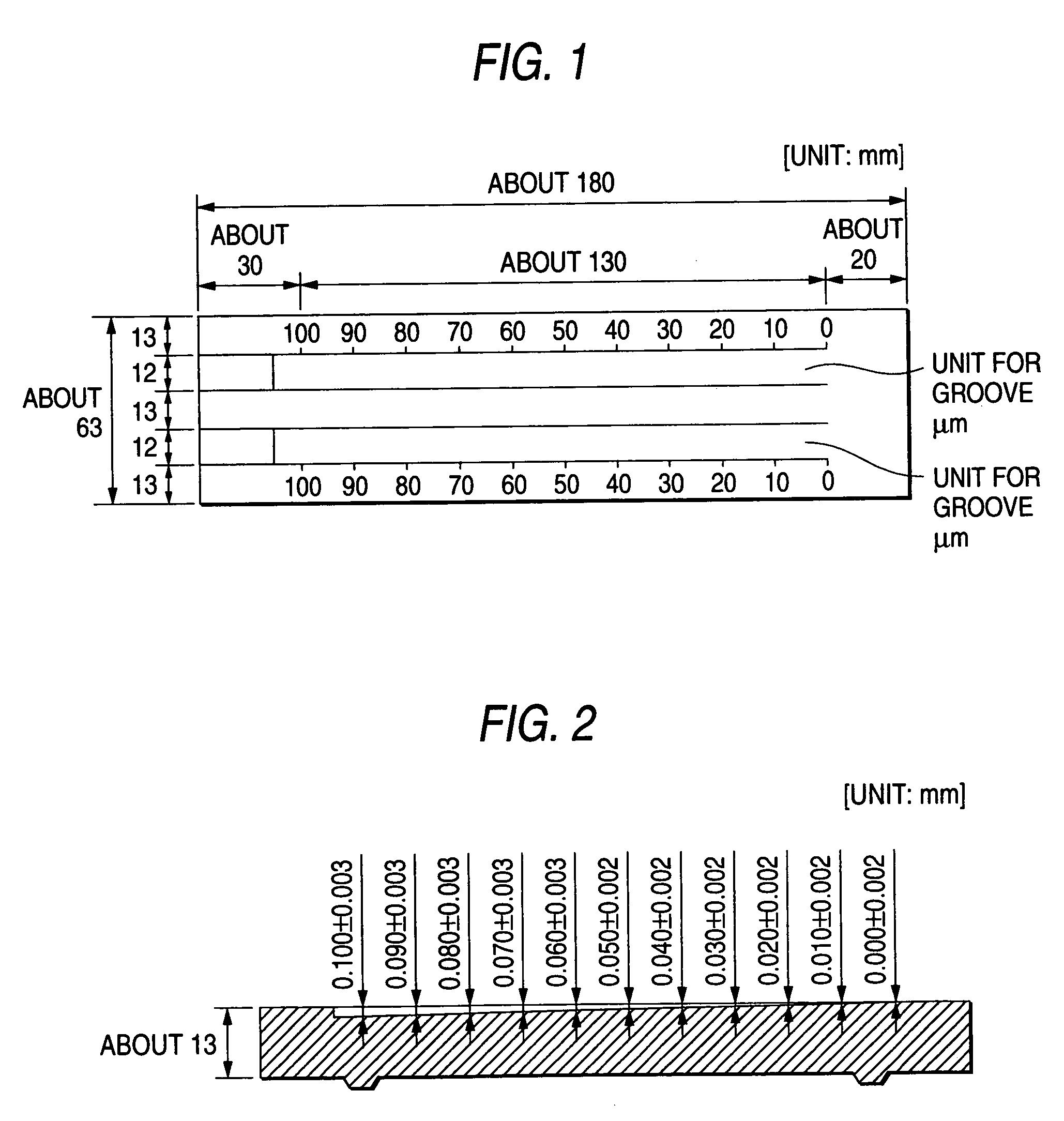

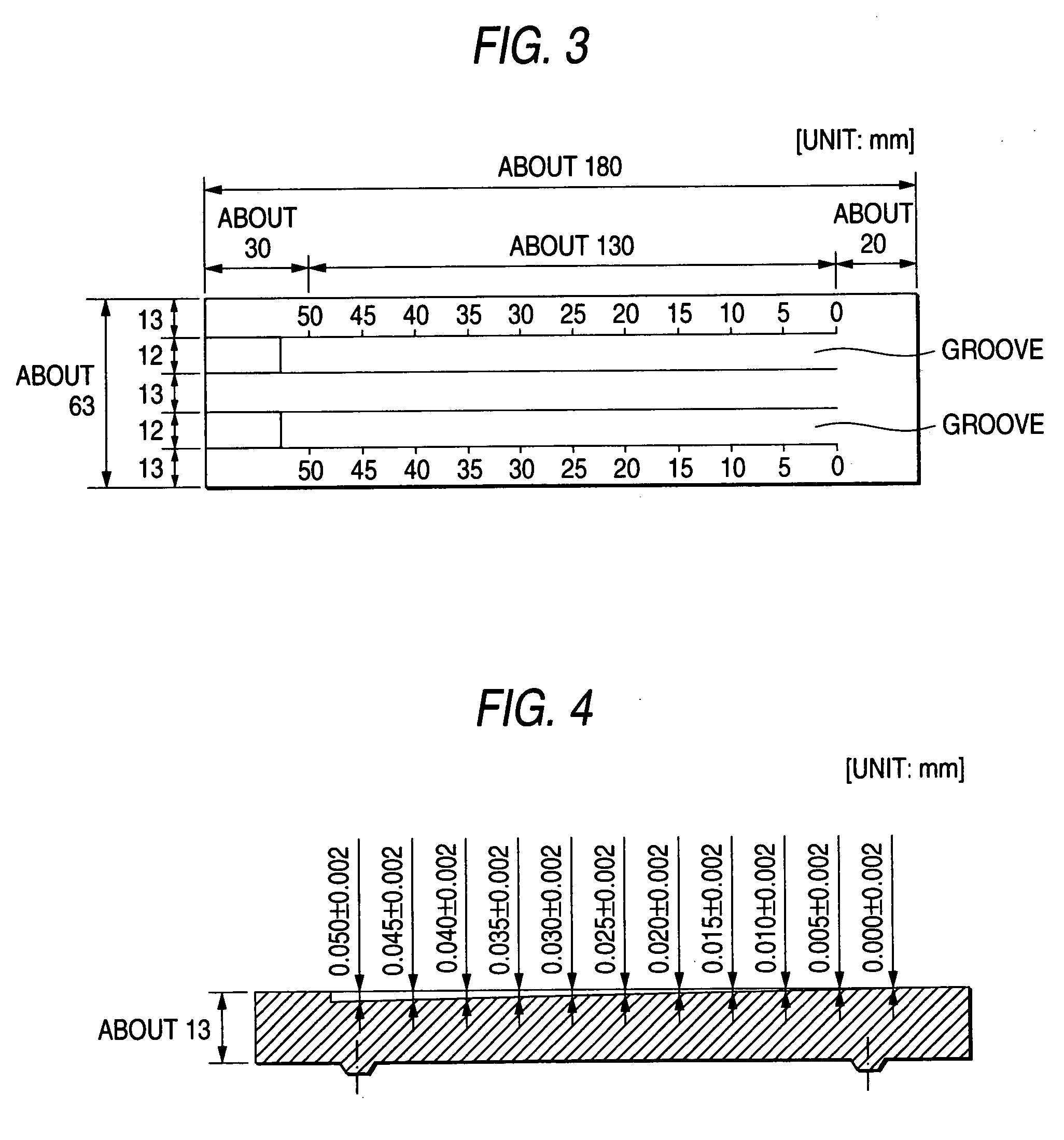

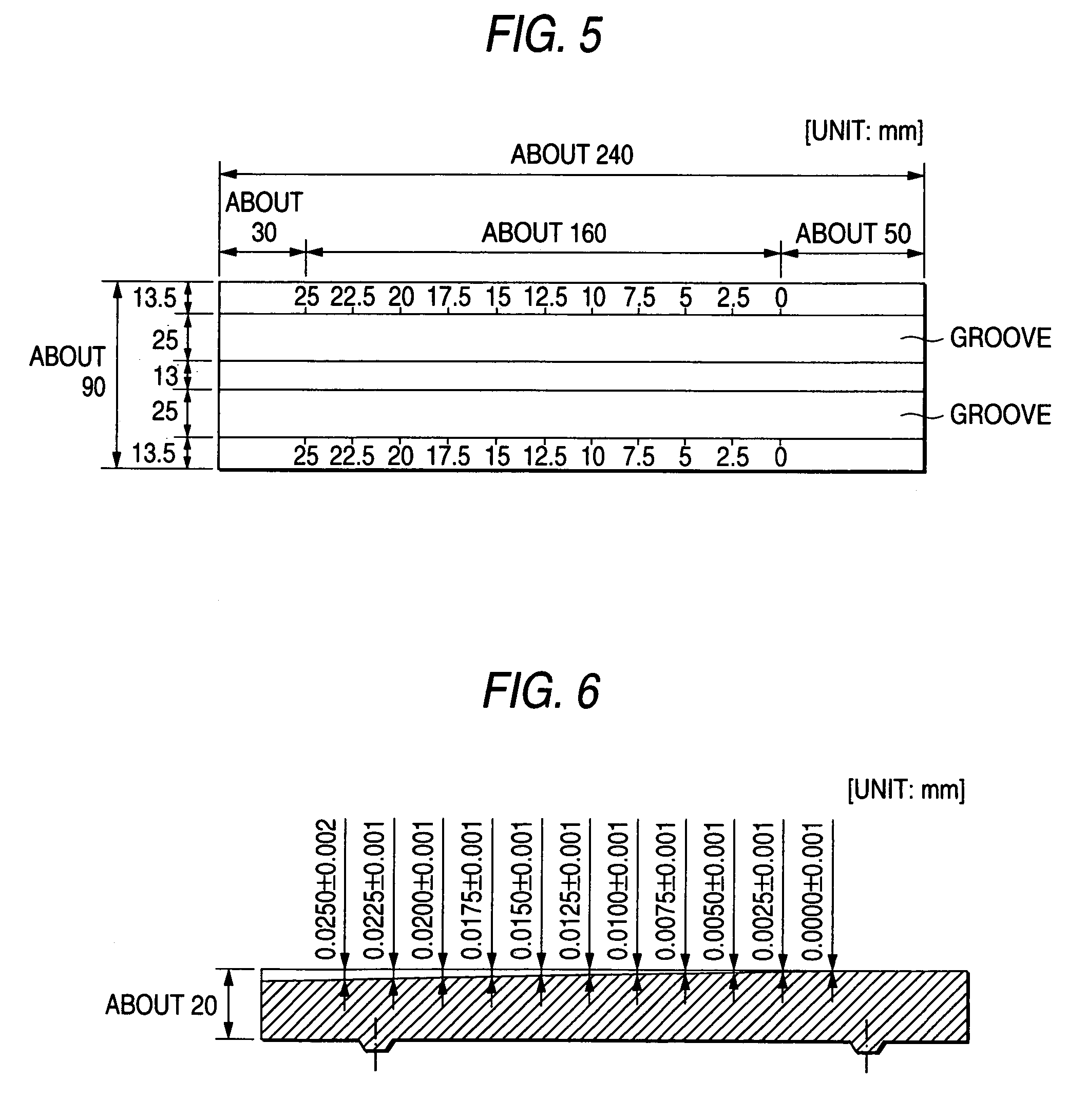

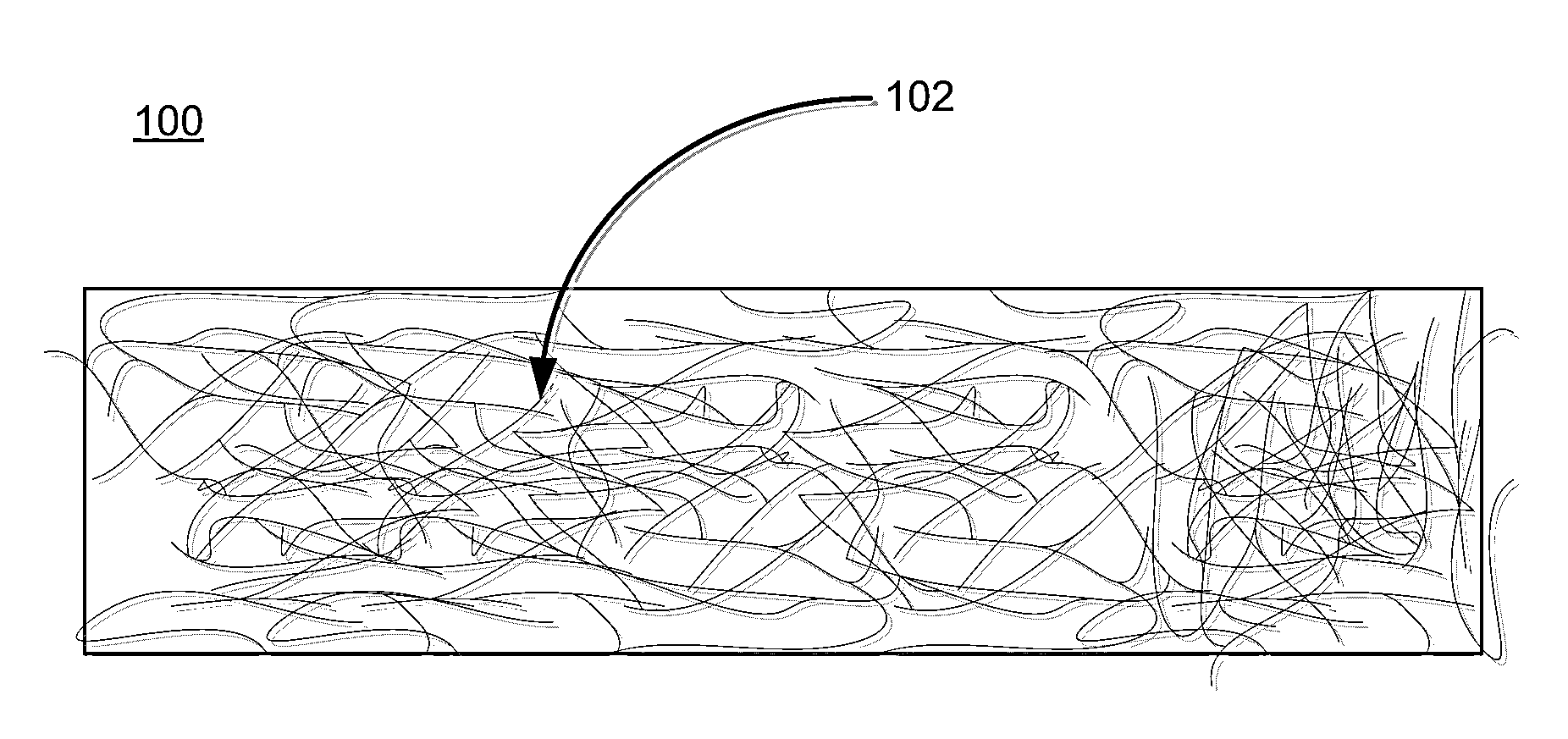

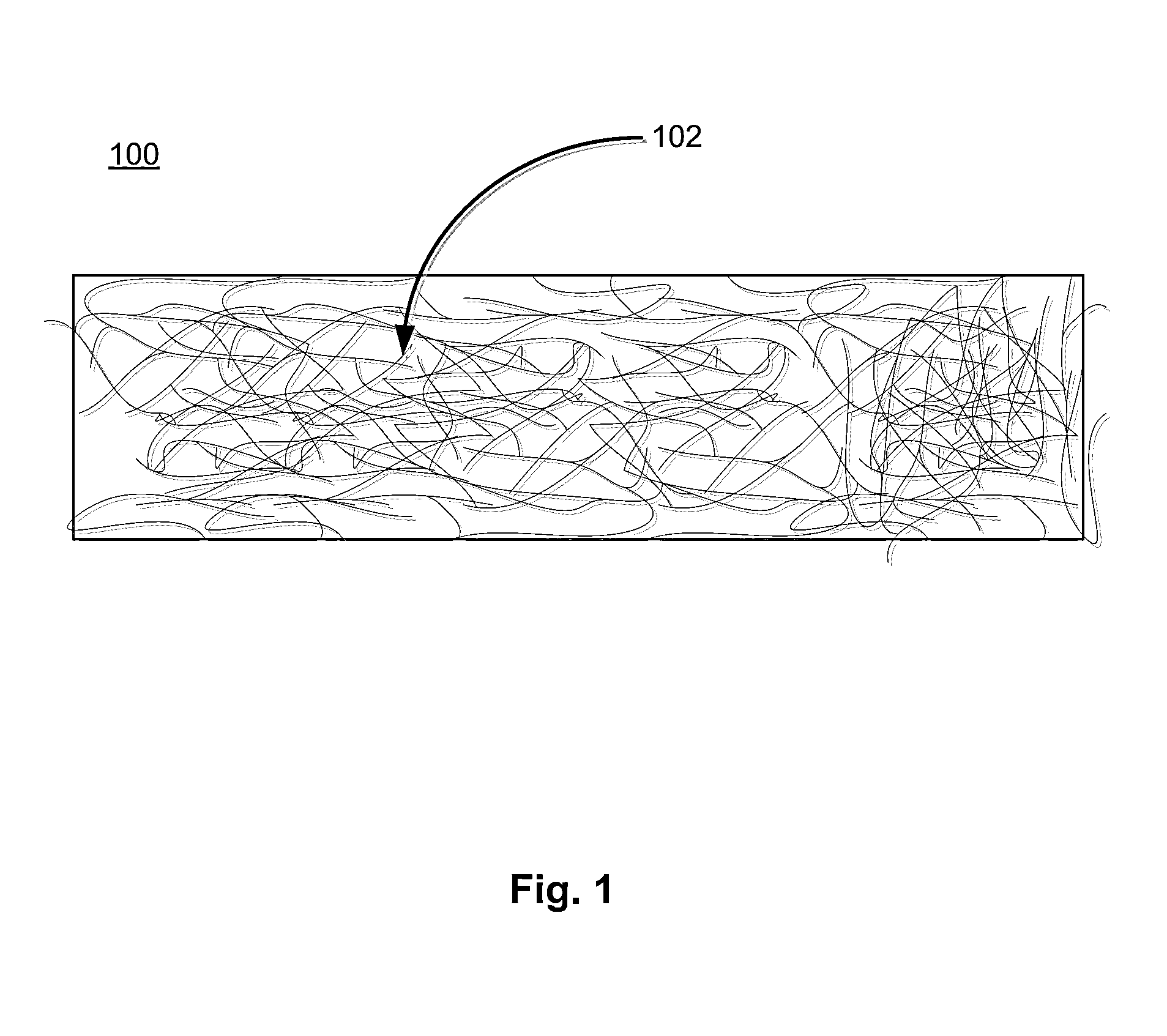

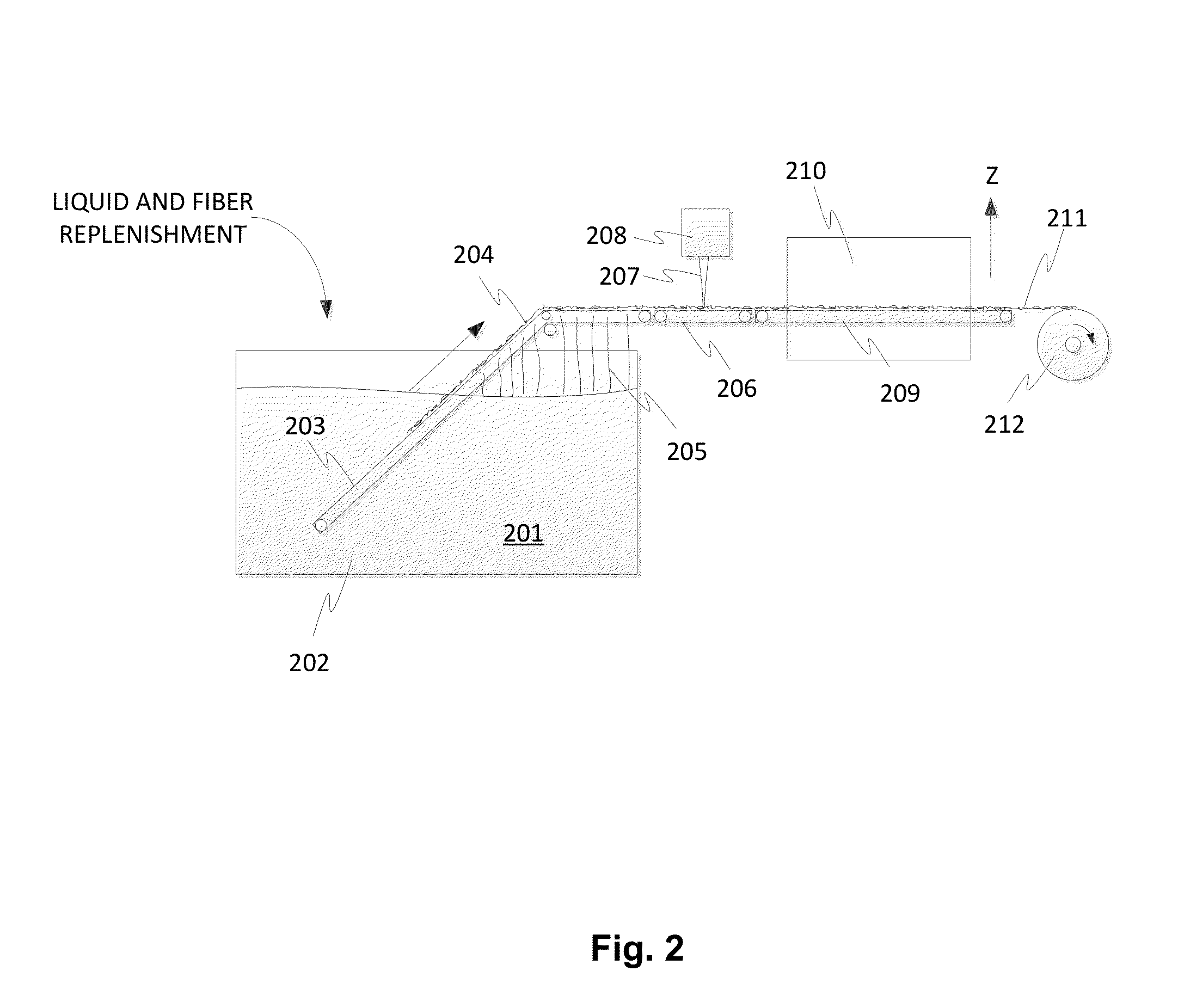

Method of manufacturing a water disintegratable non-woven fabric and the water disintegratable non-woven fabric

InactiveUS6451718B1Improve wiping effectNon-fibrous pulp additionSynthetic resin layered productsFiberCarboxymethyl cellulose

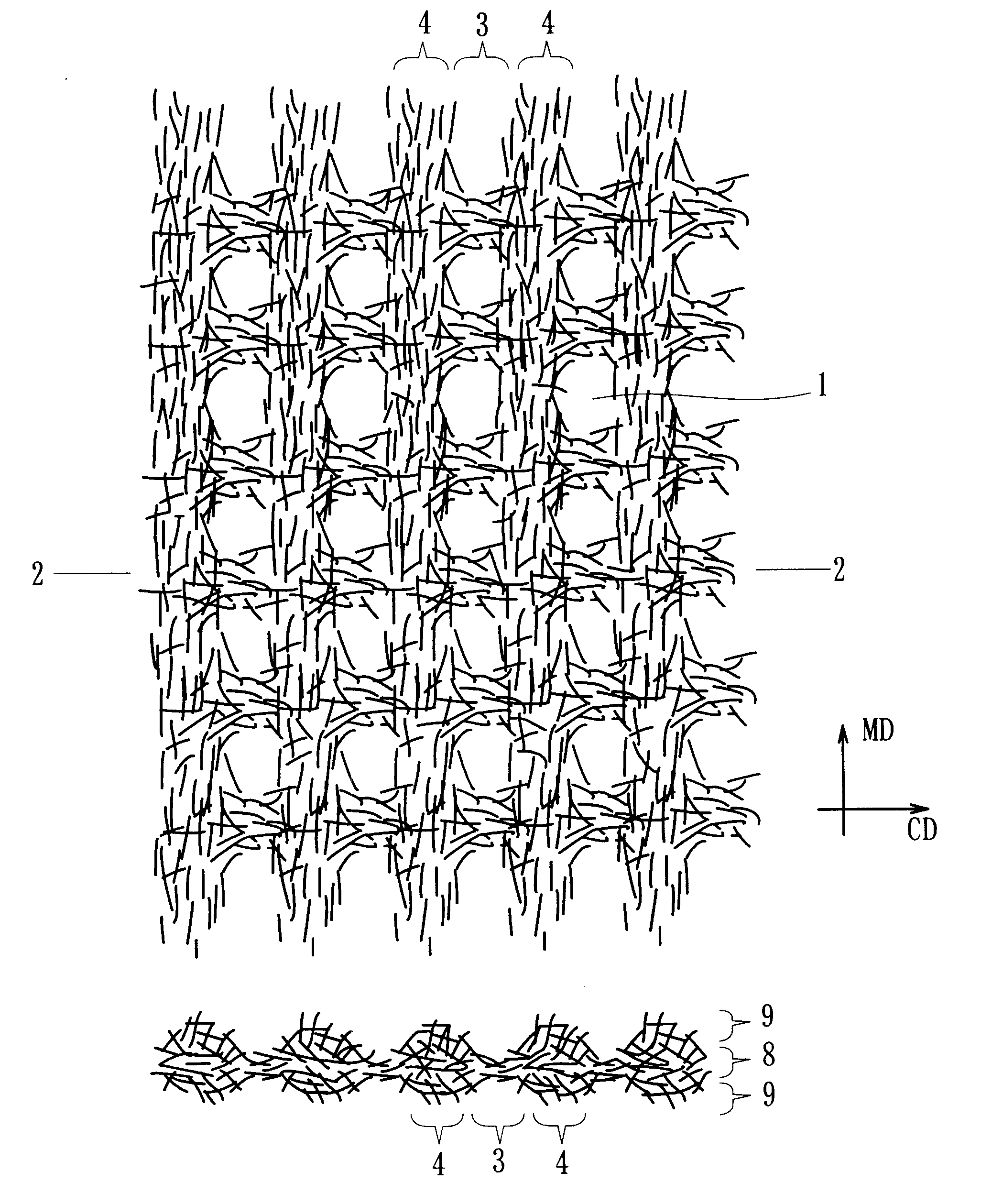

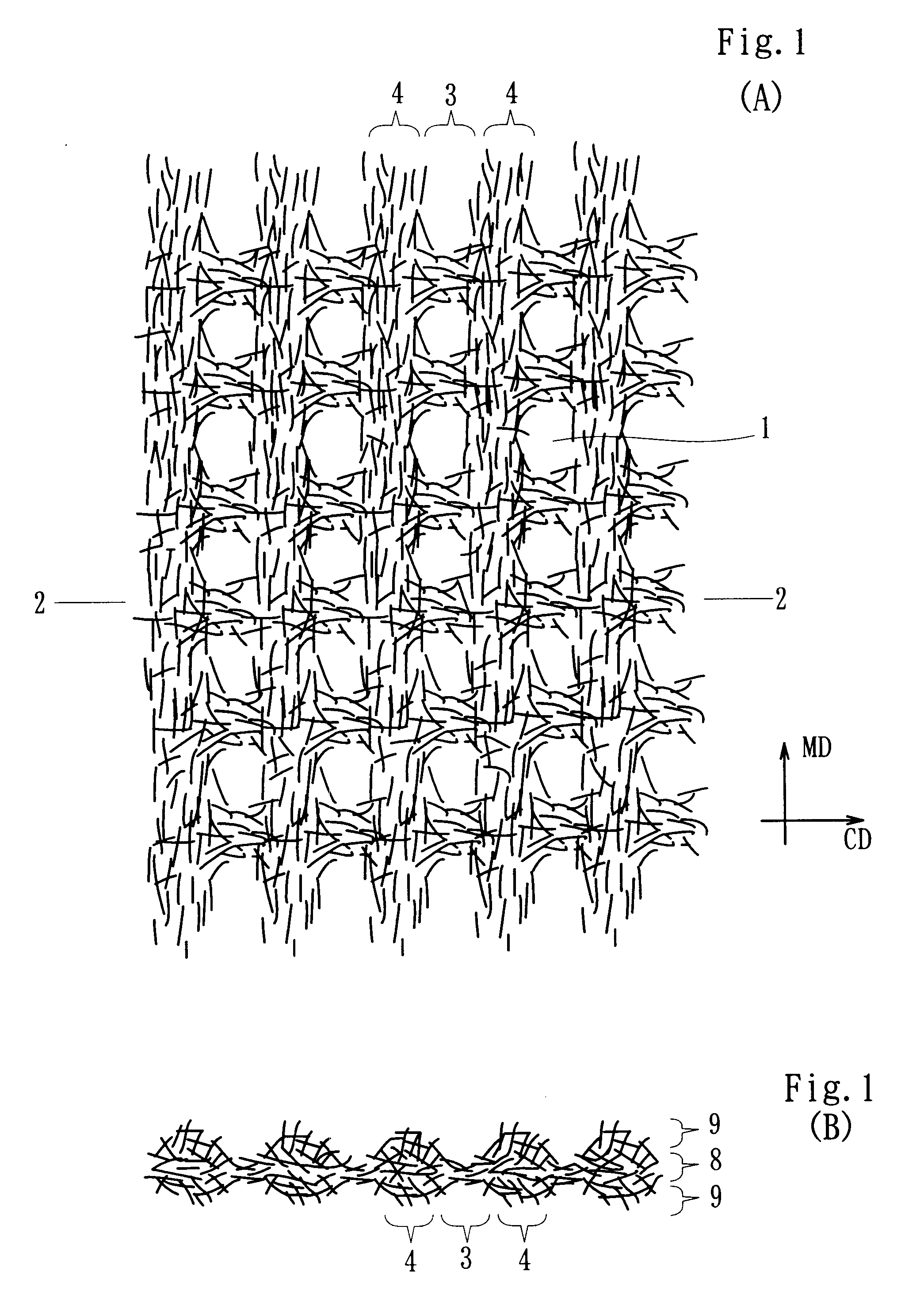

A water disintegratable non-woven fabric having excellent water disintegratability and high wet strength can be obtained by a step of forming a fiber web from fibers having a fiber length of 10 mm or less, a step of applying a water jet treatment to the fiber web to obtain a fiber sheet having wet strength of less than 100 g / 25 mm in MD and CD, the wet strength being defined by tensile strength at break of the fiber sheet, as measured by using a tensilon tester with a chuck distance of 100 mm, at a tensile speed of 100 mm / min to the fiber sheet which is cut into 25 mm width and 150 mm length and impregnated with water in an amount 2.5 times the weight of the fiber sheet, and a step of adding at least one binder selected from the group consisting of carboxymethyl cellulose, alkylcellulose, polyvinyl alcohol and modified polyvinyl alcohol to the fiber sheet. The water disintegratable non-woven fabric is sufficiently bulky and has an excellent wiping effect.

Owner:UNI CHARM CORP

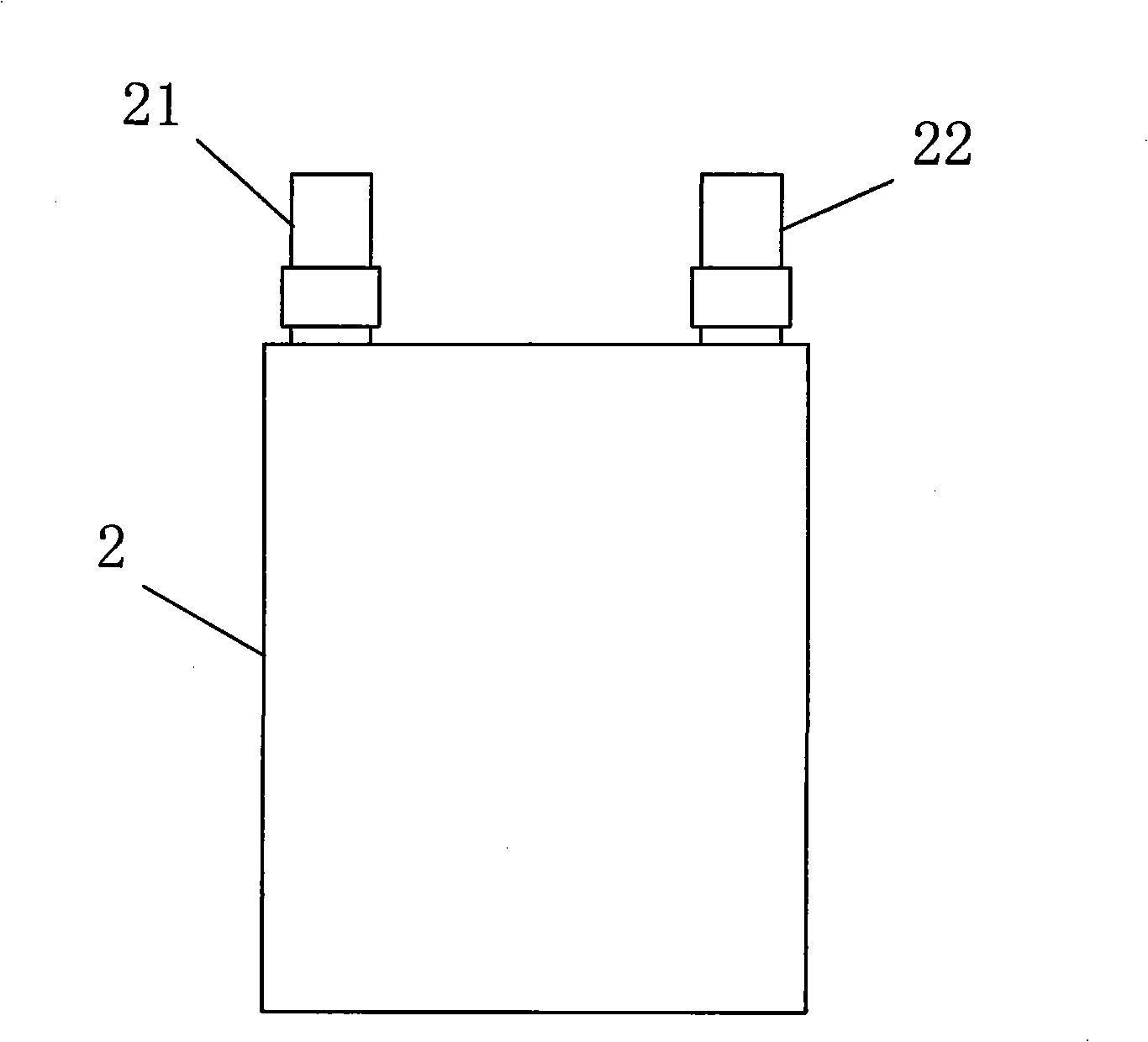

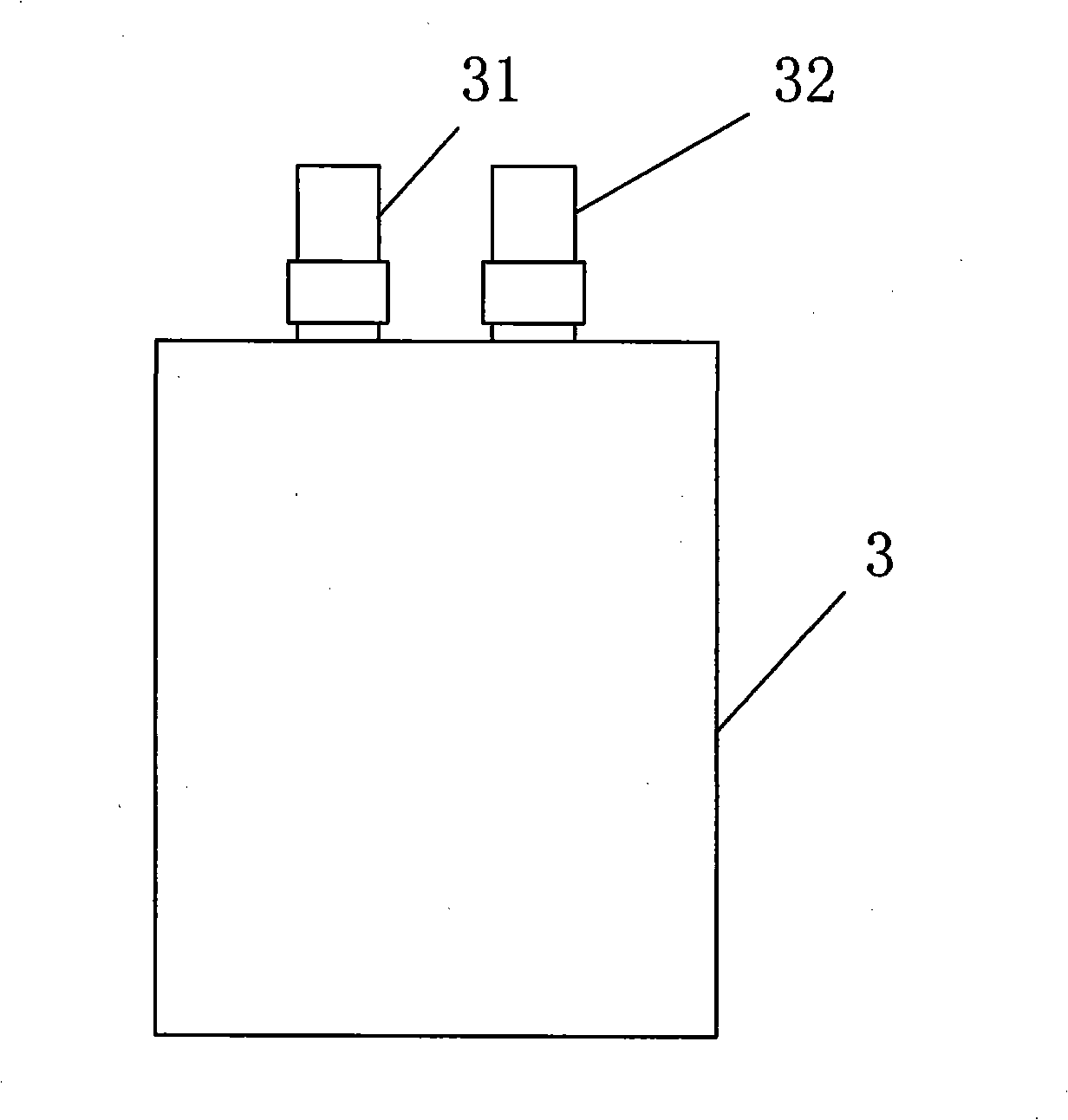

Large-capacity high power polymer ferric lithium phosphate power cell and preparation method thereof

InactiveCN101409369AImprove securityIncrease capacityElectrode manufacturing processesFinal product manufactureSlurryElectric vehicle

The invention discloses a large-capacity high-power polymer lithium iron phosphate power battery. The weight ratio of anode slurry is as follows: 81 to 85 percent of lithium iron phosphate, 1 to 5.5 percent of superconduction carbon, 0 to 2.5 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 0 to 2.5 percent of crystalline flake graphite, 0 to 2 percent of carbon nanometer tube as well as 6 to 7.5 percent of polyvinylidene fluoride; the weight ratio of cathode slurry is as follows: 89 to 91 percent of cathode material, 1 to 3.5 percent of superconduction carbon, 0 to 2 percent of conductive carbon soot, 0 to 4 percent of conductive black lead, 2.5 to 3.5 percent of styrene-butadiene rubber as well as 1.5 to 2 percent of sodium carboxymethyl cellulose; the steps for preparing the battery are as follows: preparing slurry, coating the anode and the cathode, rolling and pressing a polar plate, transversely and separately cutting the polar plate, baking the polar plate, welding the polar ears of the anode and the cathode, preparing a battery cell, putting the electric core into a shell and sealing, baking the electric core, injecting liquid into the battery as well as forming the battery and dividing the volume of the battery. The invention relates to a lithium-ion secondary battery which can provide drive energies for electric tools, electric bicycles, motor cars and electric vehicles.

Owner:MCNAIR TECH

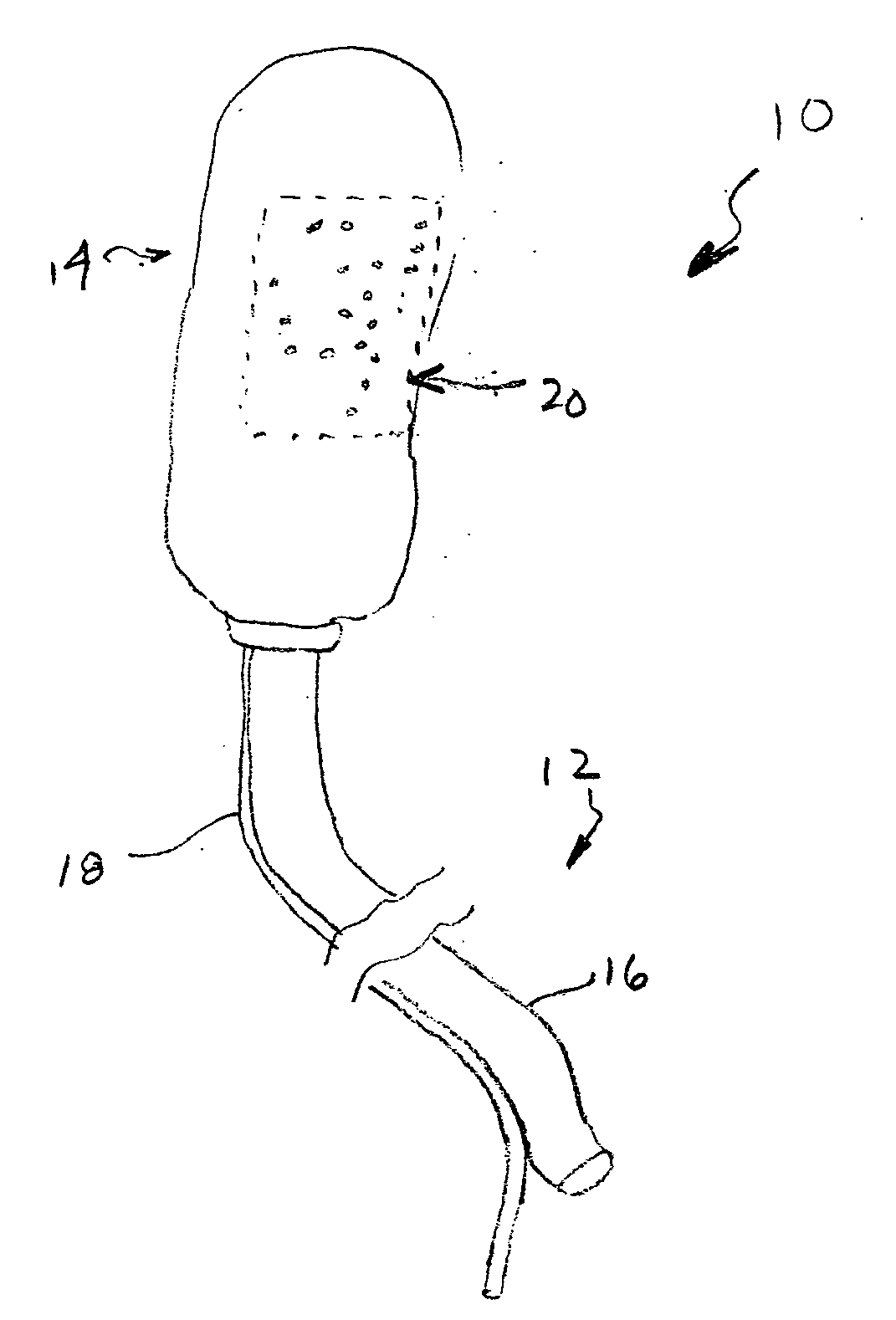

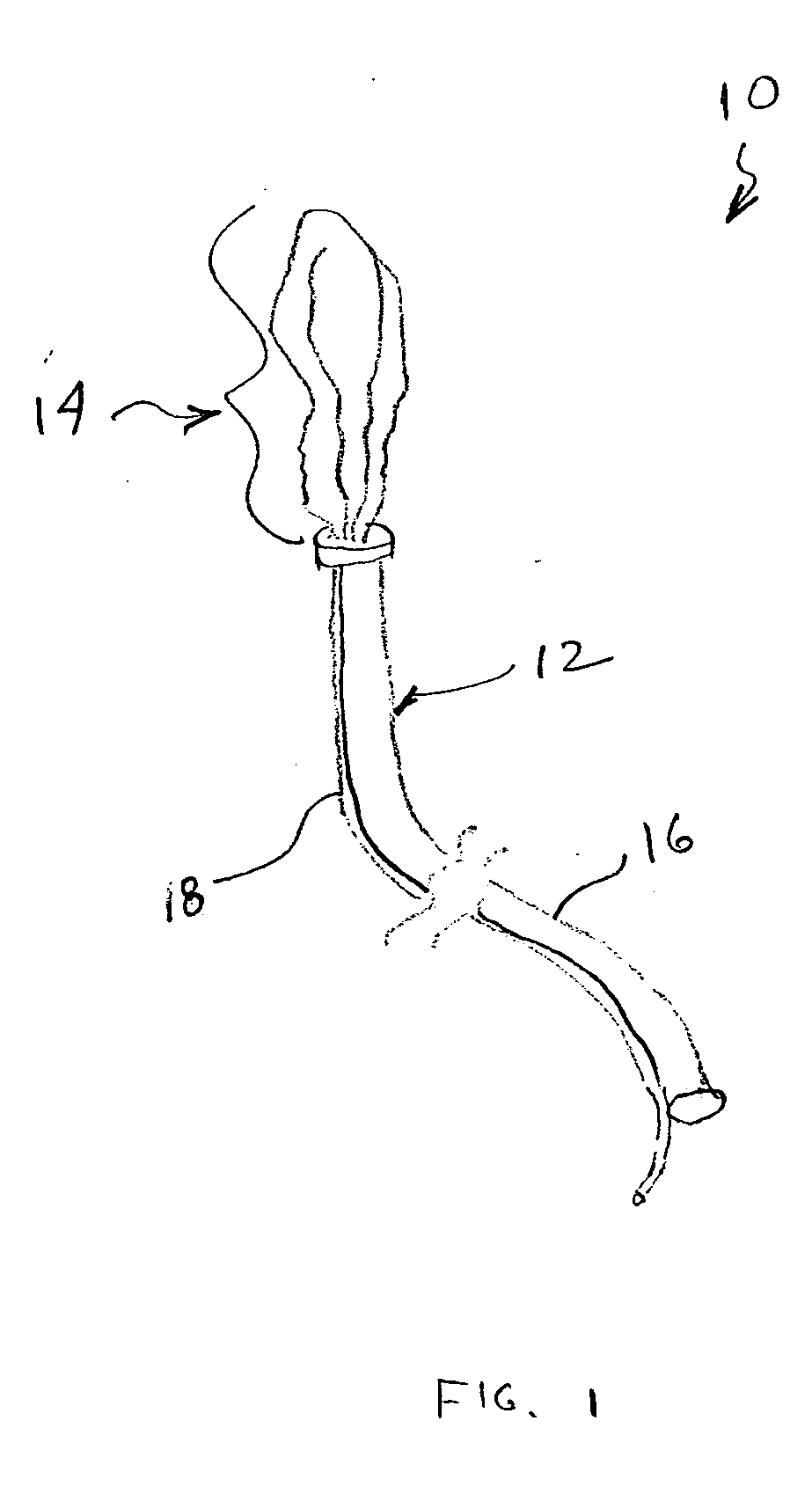

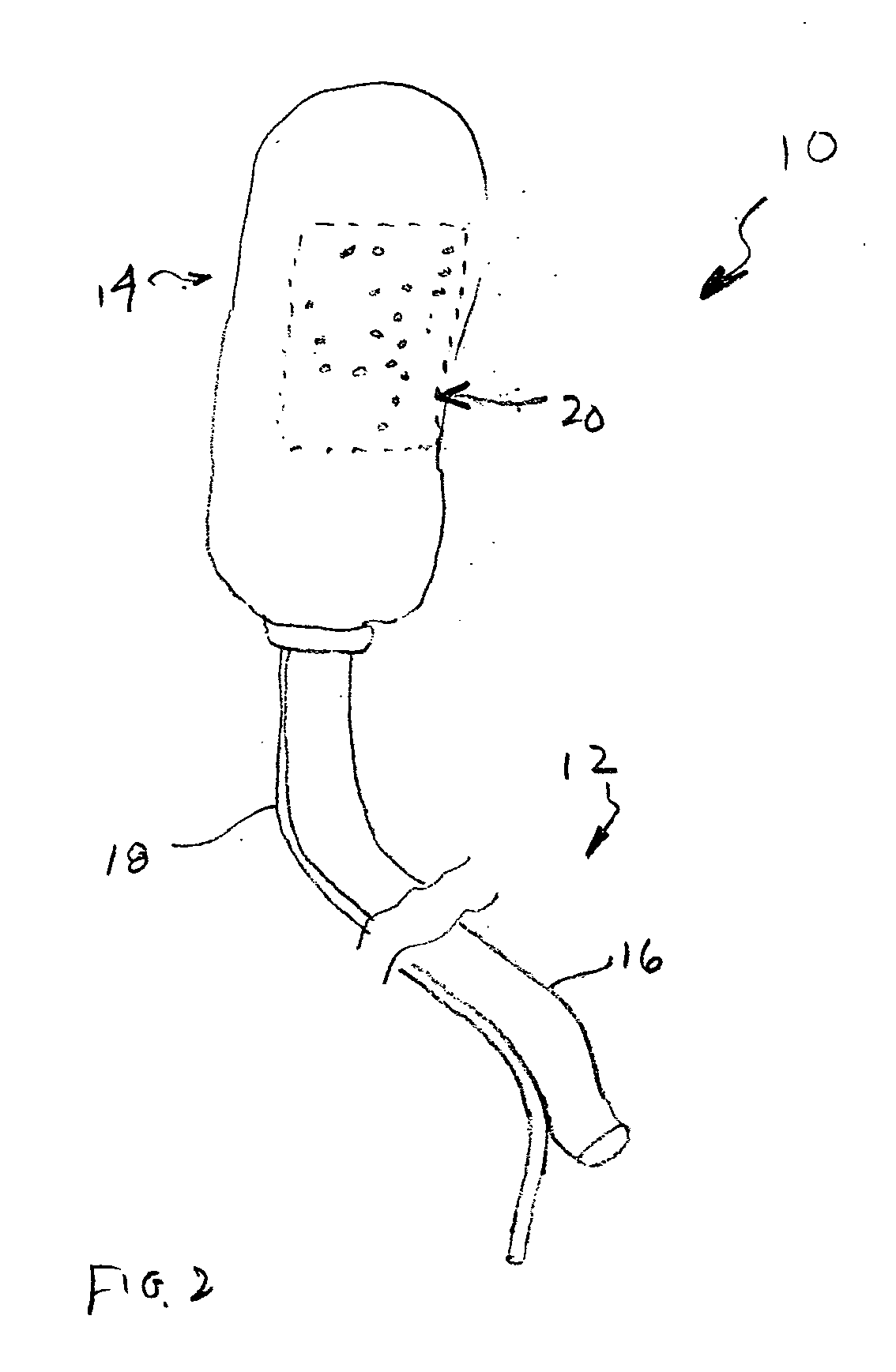

Devices and methods for promoting the formation of blood clots in esophageal varices

InactiveUS20070167971A1Inhibit injectionPromote formationBalloon catheterSurgeryThrombusSilicon dioxide

A device for promoting the clotting of blood in body cavities includes a flexible body portion; an expandable member located on the flexible body portion; and a blood clotting material attached to the expandable member. When used, insertion of at least a portion of the blood clotting material into the body cavity causes at least a portion of the blood clotting material to contact blood emanating from a bleed site. Methods of providing therapies to tube-shaped organs include the steps of providing suitable devices having expansion capabilities, positioning the devices at the appropriate bleed sites, and expanding the devices to cause blood clotting materials to contact the bleed sites. Materials that may be used as the blood clotting material include zeolites, molecular sieve materials, diatomaceous earth, clay, silica-based materials, oxidized cellulose, carboxymethyl cellulose, bioactive glass, biological hemostats, chitosan, and combinations of the foregoing.

Owner:TELEFLEX LIFE SCI LTD

High-strength FeOOH desulfurizer and preparation method thereof

ActiveCN101584962AHigh mechanical strengthAvoid lostDispersed particle separationCarboxymethyl celluloseSulfur

The invention relates to a high-strength FeOOH desulfurizer, which consists of 50 to 95 weight percent of amorphous FeOOH, 0 to 45 weight percent of carrier and 5 to 50 weight percent of organic binder, wherein the carrier is one or more of aluminium oxide, diatomite, natural zeolite and catalytic cracking spent catalyst; and the organic binder is one or more of sodium carboxymethyl cellulose, sesbania powder and cellulose powder. The invention further discloses a preparation method for the desulfurizer on the basis. The FeOOH desulfurizer prepared by the preparation method has high sulfur capacity, high mechanical strength and wider applicable desulfurization range.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Negative Electrode Material for Lithium Battery, and Lithium Battery

InactiveUS20070275302A1Lower electrode resistanceHigh electrode strengthNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsCarboxymethyl celluloseCarbon fibers

The present invention relates to a negative electrode material for a lithium battery characterized by comprising a carbonaceous negative electrode active substance having a specific surface area of 1 m2 / g or more, a binder formed of styrene-butadiene rubber and a carbon fiber having a fiber diameter of 1 to 1,000 nm; and to a lithium battery using the negative electrode material, which has excellent characteristics, i.e., low electrode resistance, high electrode strength, excellent electrolytic solution permeability, high energy density, and good high-speed charging / discharging performance. The negative electrode material contains carbon fiber in the amount of 0.05 to 20 mass % and the binder formed of styrene-butadiene rubber in 0.1 to 6.0 mass %, and may further contain a thickner such as carboxymethyl cellulose in the amount of 0.3 to 3 mass %.

Owner:SHOWA DENKO KK +1

Inorganic hydrated salt expanded graphite composite phase-changing heat storage material and preparation method thereof

The invention relates to an inorganic hydrated salt expanded graphite composite phase-changing heat storage material. In the preparation method thereof, 85-89 mass parts of inorganic hydrated salt sodium acetate trihydrate as a heat storage matrix, 5.5-6.5 mass parts of disodium hydrogenphosphate as a nucleating agent, 2.5-3.5 mass parts of carboxymethyl cellulose as a thickening agent, and 3-4.5 mass parts of expanded graphite is blended in an inorganic hydrated salt mixture as a material with a high thermal conductivity. Due to the use of the expanded graphite, the material not only maintains excellent properties of natural flake graphite such as good thermal conductivity, no toxicity and the like, but also has adsorbability which the natural flake graphite does not have. The invention solves the problems of sub-cooling degree, phase stratification and low thermal conductivity during the heat storage process. The composite phase-changing material has a low sub-cooling degree after the phase changing performance is improved, the solution thereof is uniform without sedimentation and stratification during the solid-liquid phase change, the performance is stable, the repeatability of good, and the phase-changing heat storage can be enhanced through improving the thermal conductivity of the material.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

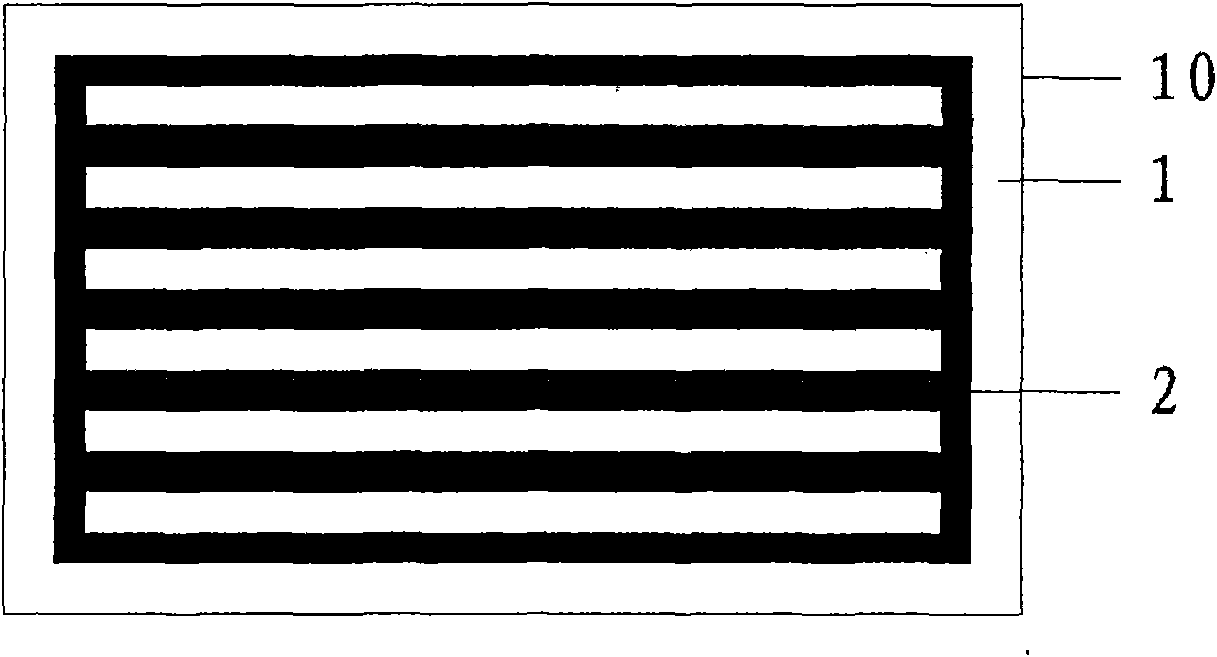

Conductive heating material, floor comprising same and manufacturing method

InactiveCN101600270AFacilitate industrialized mass productionLighting and heating apparatusElectric heating systemEpoxyCarboxymethyl cellulose

The invention relates to a conductive heating material. The material comprises a substrate and a conductive heating layer evenly adhered to the substrate, wherein the conductive heating layer is made from a conductive heating coating material; the conductive heating coating material comprises a conductive heating base material and a bonding agent; the conductive heating base material is selected from natural graphite, artificial graphite and conductive carbon black; the bonding agent is selected from acrylic resin, epoxy resin, polyurethane resin, glutin, carboxymethyl cellulose, polyvinyl alcohol, and the like; and the substrate can adopt paper in a plurality of practical implementation modes. The conductive heating material can be used to make the conductive heating floor; the surface temperature of the floor can reach 15 to 70 DEG C within 5 minutes after the floor is energized with 220V voltage; moreover, the floor can maintain stable temperature for a long time. Therefore, the conductive heating floor can be used to replace the prior ground heating system and has low cost, reliable operation, energy saving, environmental protection and convenient maintenance and replacement.

Owner:上海尚兰格暖芯科技有限公司

Treatment solution for inkjet textile printing, method for inkjet textile printing, and inkjet textile printed product

ActiveUS20110102497A1High image densityExcellent in coating film durabilityOther chemical processesDuplicating/marking methodsTextile printerCarboxymethyl cellulose

The present invention has its object to provide a treatment solution for inkjet textile printing that causes few remaining marks even when applied to a fabric. The present invention relates to a treatment solution for inkjet textile printing, the treatment solution comprising at least: 1) a water-soluble polyvalent metal salt; 2) at least one resin component selected from the group consisting of a nonionic resin emulsion, an anionic resin emulsion, and a carboxymethyl cellulose; 3) at least one surfactant component selected from the group consisting of a nonionic surfactant, an anionic surfactant, and an amphoteric surfactant; and 4) an aqueous medium, the treatment solution being applied to a fabric before printing of an ink composition for inkjet textile printing.

Owner:SAKATA INX

Biological degradation liquid film and preparation method

InactiveCN101161718AHigh strengthImprove water resistanceOrganic fertilisersSoil conditioning compositionsCarboxymethyl cellulosePlasticizer

The invention belongs to a biodegradation liquid mulching film and the preparation method thereof. The invention prepares polyvinyl alcohol into an aqueous solution with mass fraction of 5-10 percent; carboxymethyl cellulose is also prepared into an aqueous solution with mass fraction of 5-10 percent; starch with mass fraction of 5-10 percent is added into a reactor having an agitator, a condenser and a thermometer and is gelatinized for 30 minutes under 75-85 DEG C and then becomes transparent and slabby starch paste, the prepared polyvinyl alcohol solution and carboxymethyl cellulose solution are then added into the reactor, and surfactant and plasticizer are also added into the solution. The PH value is set as 2-4, cross-linking agent is then added, and the biodegradation liquid mulching film is obtained after 1-2-hour reaction under 85-90 DEG C. The film can be sprayed to the land surface through spray method after being thinned up.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

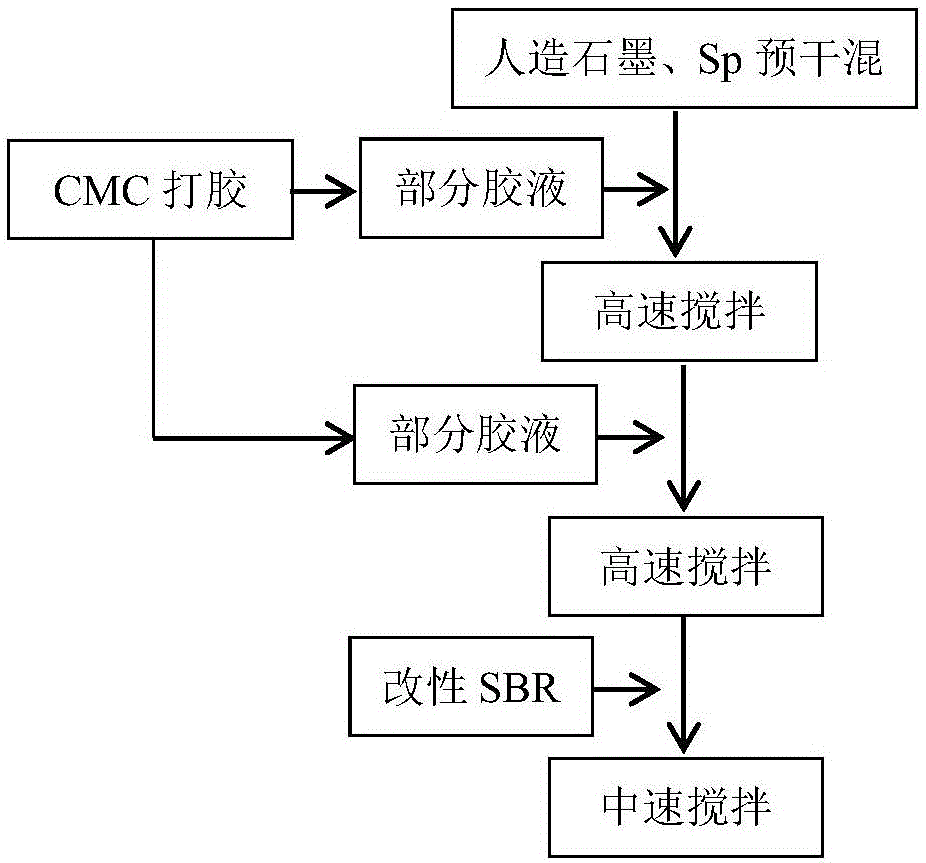

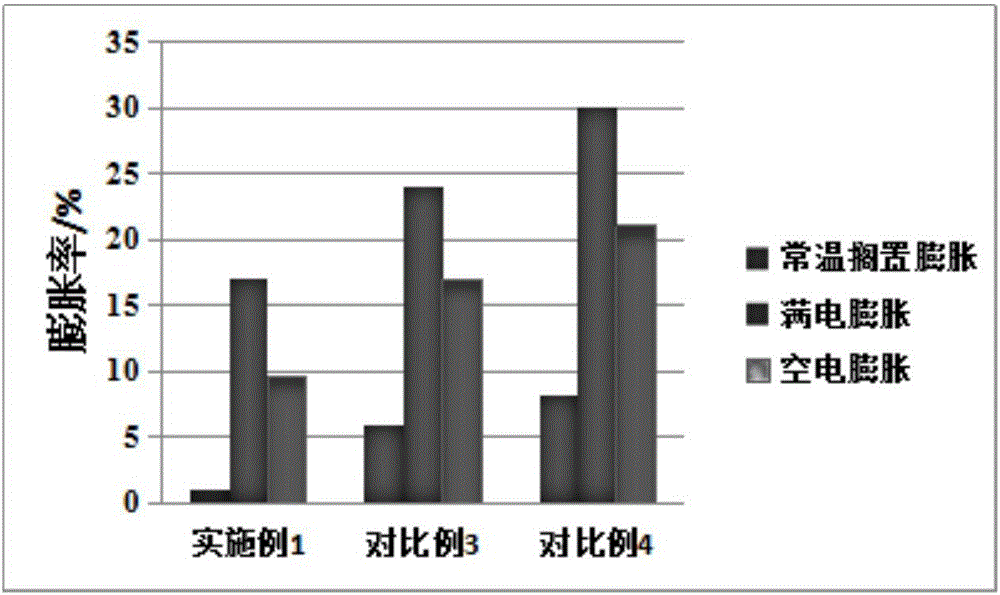

Preparation method of negative electrode slurry capable of reducing expansion of lithium ion battery

ActiveCN106159266AReduce bridgingChange structureCell electrodesSecondary cellsSlurrySodium-ion battery

The invention discloses a preparation method of negative electrode slurry capable of reducing the expansion of a lithium ion battery. The preparation method comprises the following steps of: carrying out dry blending on a negative electrode active substance and a conducting agent in advance; dissolving sodium carboxymethyl cellulose into de-ionized water to obtain a CMC (Carboxyl Methyl Cellulose) gel solution with the concentration of 1.0%-2.0%; adding one part of the CMC gel solution into a mixture of the negative electrode active substance and the conducting agent and stirring at a high speed for 0.5-1h; adding the balance of CMC gel solution and stirring at a high speed for 1-3h; adding a modified SBR (Styrene Butadiene Rubber) binding agent and stirring at a middle speed for 0.3-1h; and adjusting the viscosity. By adopting the method of carrying out the dry blending on artificial graphite and the conducting agent in advance, adding the glue solution by two times and utilizing modified SBR as the binding agent, a bridge phenomenon of the artificial graphite is reduced, a pole piece structure is changed, the binding force between grains is improved and the expansion of a negative electrode is reduced; meanwhile, the slurry sedimentation of the artificial graphite is inhibited. The preparation method of the negative electrode slurry capable of reducing the expansion of the lithium ion battery has important meanings on ternary lithium ion batteries and improvement of machinability, capacity and safety of high-capacity power batteries.

Owner:南京国轩新能源有限公司

Paper sepiolite sustained-release antibacterial cat litters

InactiveCN103348922AGood antibacterial effectImprove adsorption capacityAnimal housingCarboxymethyl celluloseSodium phosphates

Owner:WUHU LEISURELY NURSING SUPPLIES POLYTRON TECH INC

Completely fused paper soap and its making process

InactiveCN1357613AImprove solubilityImprove decontamination abilityDetergent materialsPhenolFatty alcohol

The component of the paper soap include carboxymethyl cellulose sodium, fatty alcohol polyioxymethyl ethyleneethere sodium sulfate, sodium dodecyl benzene sulfonate, lauryl sodium sulfate, cocinin diethanolamide, nonly phenol polyoxyethyleneether, glycerine, quaternary ammonium salt and citric acid. Its preparation includes preparing carboxymethyl cellulose sodium mother liquor, adding the mixed solution of other components to prepare solution through stirring, spraying the prepared solution of PVC plate and drying in a sealed room and moisture extract at 35-40 deg.c to form film.

Owner:成都洁利康实业发展有限公司

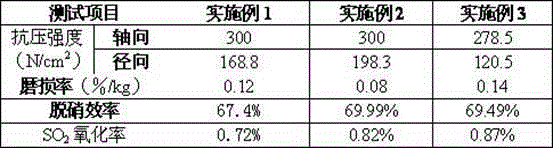

Honeycomb flue gas denitrification catalyst and preparation method thereof

ActiveCN103143396AHigh mechanical strengthWear-resistantOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCellulosePtru catalyst

The invention relates to a honeycomb flue gas denitrification catalyst and a preparation method thereof, belonging to the technical field of inorganic new materials. The honeycomb flue gas denitrification catalyst is mainly prepared by carrying out extrusion molding and sintering on the following raw materials in parts by weight: 68-92.8 parts of nano TiO2, 3-10 parts of nano SiO2, 2-10 parts of glass fiber, 0.1-0.5 part of extrusion aid, 0.1-0.2 part of carboxymethyl cellulose, 0.1-0.3 part of polyoxyethylene and 0.1-0.2 part of sesbania powder. The preparation method comprises the following steps: (1) weighing the nano TiO2 and nano SiO2 powder, adding the extrusion aid, adding water while stirring to obtain paste, and adding ammonia water to regulate the pH value to 7-11; (2) adding the rest of raw materials, evenly mixing, and extruding with an extruding machine to obtain a honeycomb blank; (3) drying the blank at 30-70 DEG C under the relative humidity of 20-100% for 7-15 days; and (4) calcining the dried blank at 250-300 DEG C for 8-15 hours, calcining at 380-420 DEG C for 5-10 hours, and calcining at 580-620 DEG C for 8-12 hours to obtain the finished product.

Owner:河南康宁特环保科技股份有限公司

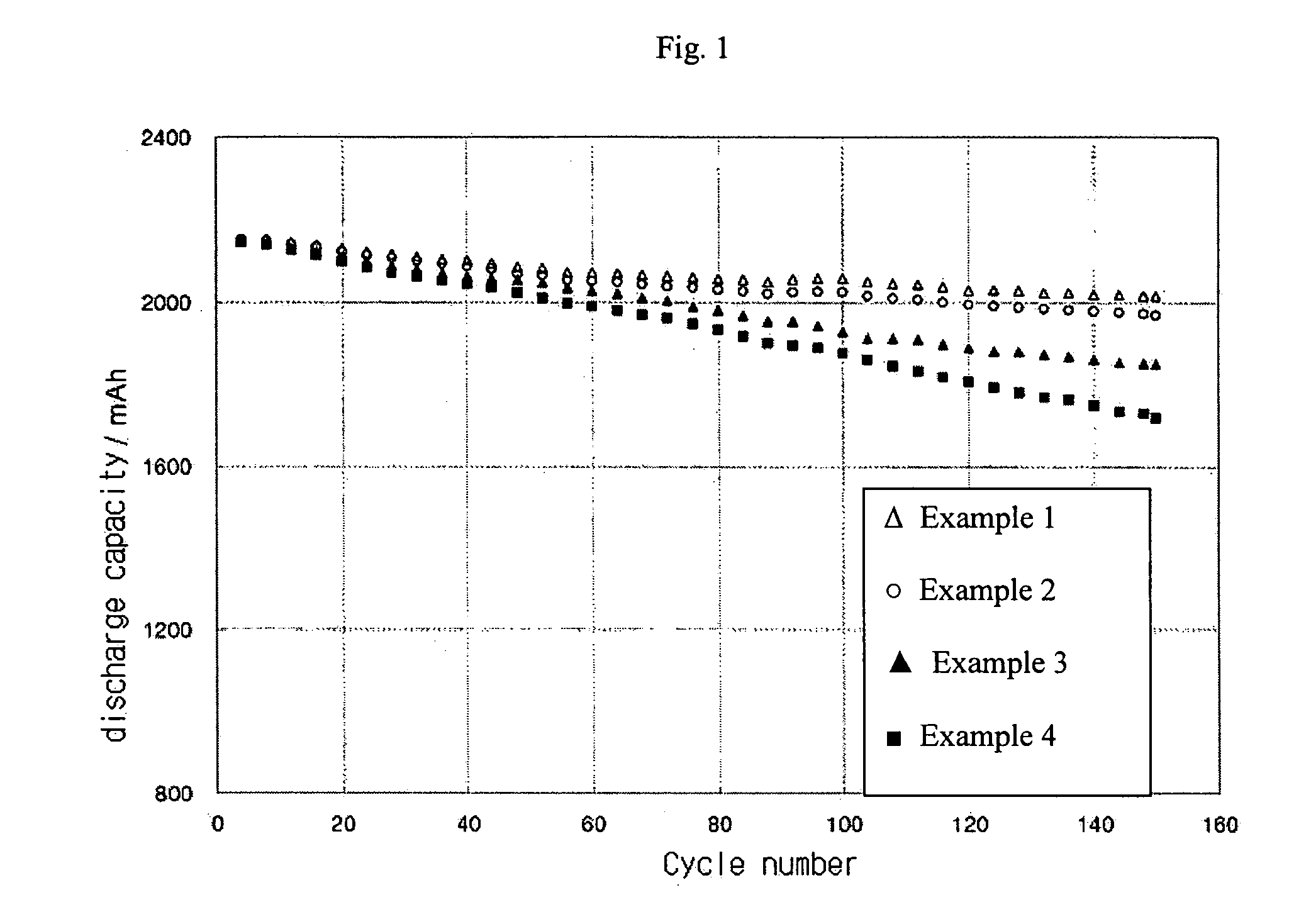

Negative-electrode active material for lithium secondary battery, negative electrode for lithium secondary battery, and lithium secondary battery

ActiveUS20060035146A1Reduce thicknessProlong lifeSecondary cellsNon-aqueous electrolyte accumulator electrodesLithiumCarboxymethyl cellulose

A subject for the invention is to provide a lithium secondary battery which can be improved in high-output / high-input characteristics based on a reduction in the thickness of an active material layer, has a long life, and is highly safe. The invention relates to: a negative-electrode active material for lithium secondary battery, which is in a carbonaceous powder form and in which when a dispersion prepared by dispersing 100 g of the active-material powder in 200 g of water together with 2 g of carboxymethyl cellulose is examined by the grind gauge method for determining the degree of dispersion in accordance with JIS K5400, the particle diameter at which particles begin to appear is 50 μm or smaller; a negative electrode for lithium secondary battery which comprises a current collector having provided thereon an active material layer comprising an active material and an organic material having binding and thickening effects, wherein the active material layer has a thickness of 50 μm or smaller and an arithmetic mean roughness (Ra) as measured in accordance with JIS B0601 of 5 μm or smaller; and a lithium secondary battery employing the negative electrode.

Owner:MITSUBISHI CHEM CORP

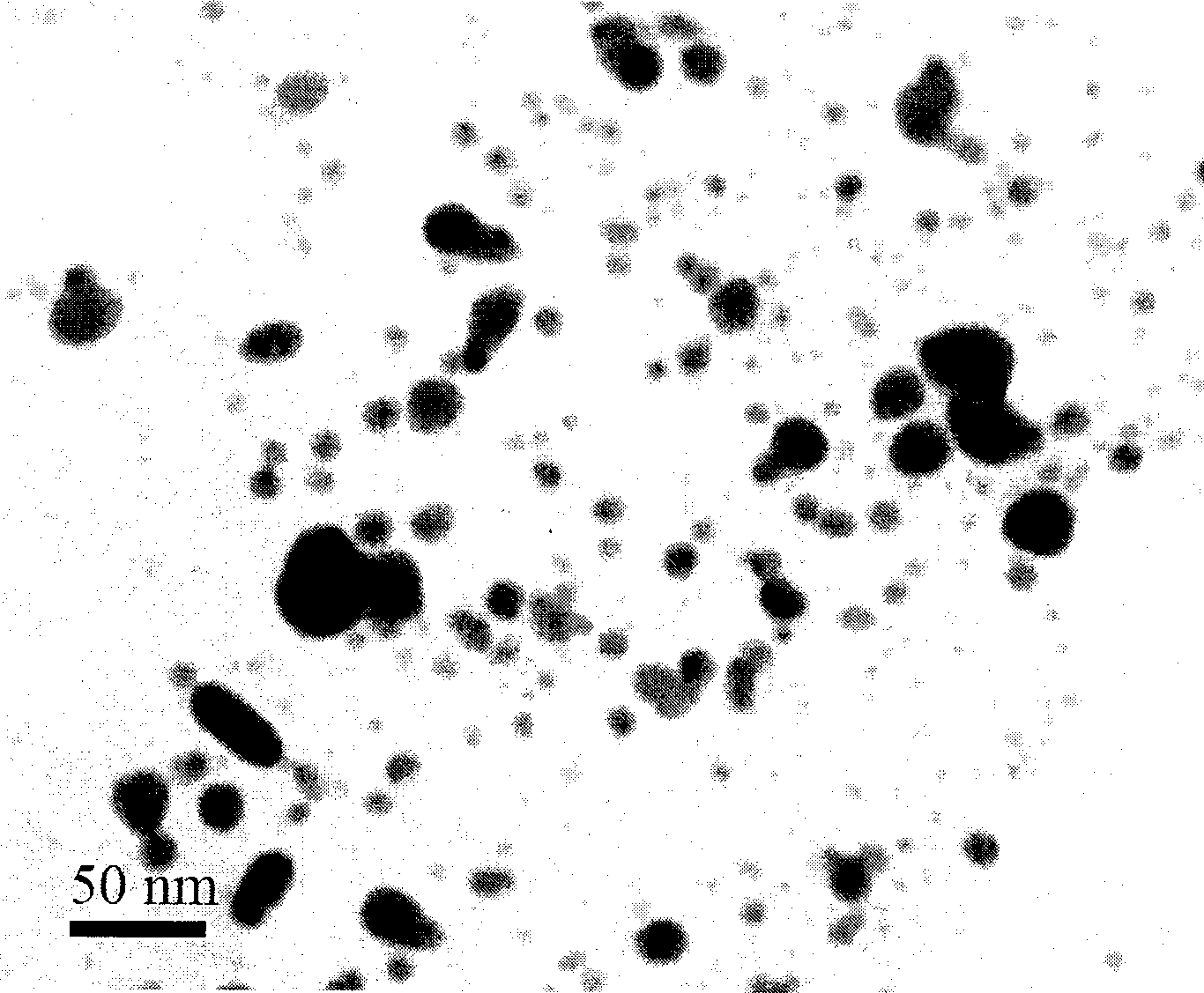

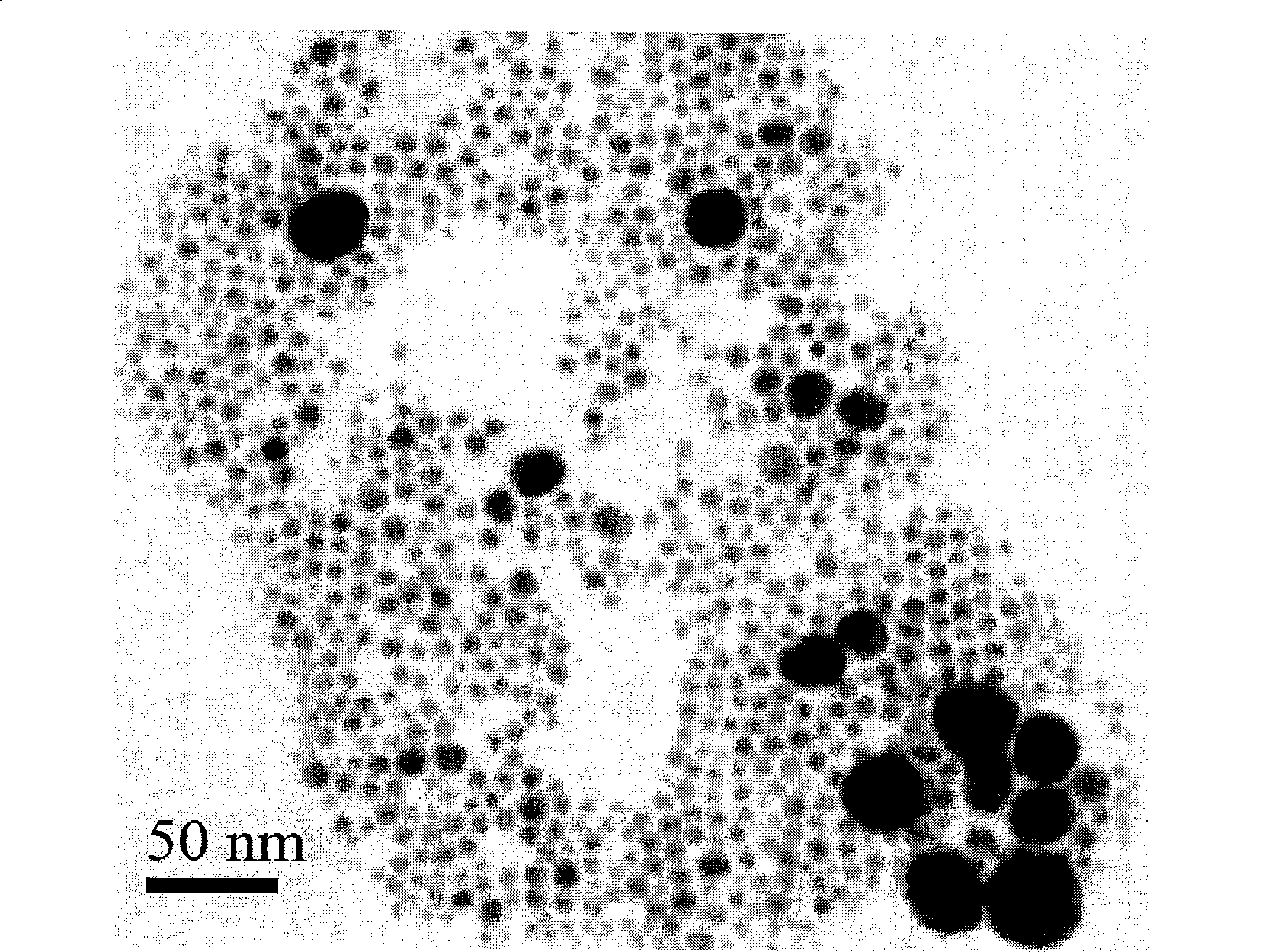

Nano silver colloid aqueous solution preparation method using sodium cellulose glycolate

The invention discloses a method for preparing a nanometer silver colloid aqueous solution by adopting sodium carboxymethyl cellulose. The method comprises the following steps: a silver nitrate solid is dissolved in deionized water so as to prepare a silver nitrate aqueous solution A; sodium carboxymethyl cellulose is dissolved in deionized water so as to prepare a solution B; the solution A and the solution B are mixed, wherein the concentration of silver nitrate is 5*10<-5>-2.5*10<-2> mol / l, and the concentration of the sodium carboxymethyl cellulose is 0.2 to 25 g / l; the pH value of the solutions is controlled between 7 and 11; and the solutions react for 2 to 20 hours at a temperature between 15 and 90 DEG C, so as to obtain the aqueous solution containing silver colloid particles with the average particle size less than 100 nanometers. The nanometer silver colloid aqueous solution obtained by the method is brownish-grey at high concentration and is transparent bright yellow after dilution. The prepared nanometer silver colloid particles are stable in shape, good in dispersibility, adjustable and controllable in particle size distribution. The method has the advantages that the method adopts a common reaction vessel for reaction, and is simple in process, little in equipment investment and easy to implement, and raw materials involved in the reaction are friendly to environment, free from pollution, few in product impurities and convenient for post-treatment.

Owner:TIANJIN UNIV

Coating for lost foam cast iron

InactiveCN101569918AStrong ability to absorb EPSExempt from cleanupFoundry mouldsFoundry coresSodium BentoniteHigh surface

The invention belongs to the technical field of coatings for lost foam, in particular to a coating for lost foam cast iron. The invention provides the coating for the lost foam cast iron, which comprises the following components (calculated as the weight): 70 portions of bauxite, 30 portions of quartz powder, 2 to 5 portions of bentonite, 0.5 to 2 portions of white latex, 0.5 to 1.0 portion of sodium carboxymethyl cellulose, 2 to 3 portions of water soluble phenolic resin, 0.5 to 2 portions of attapulgite, 2 to 5 portions of spodumene powder, 0.01 to 0.03 portion of surfactant, and 0.01 to 0.02 portion of defoaming agent. The coating has thin and even coatings and good air permeability; the surfaces of castings are smooth, clean, and level and easy to peel off, and black defects are eliminated; and the castings have level surfaces and high surface quality.

Owner:山东醴泉机械科技有限公司

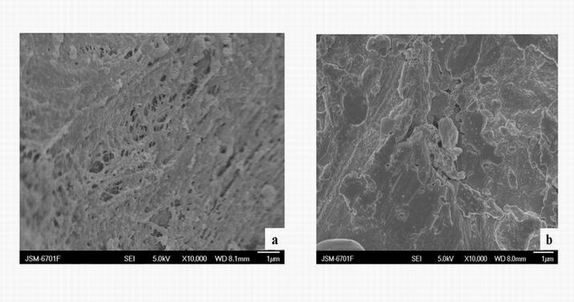

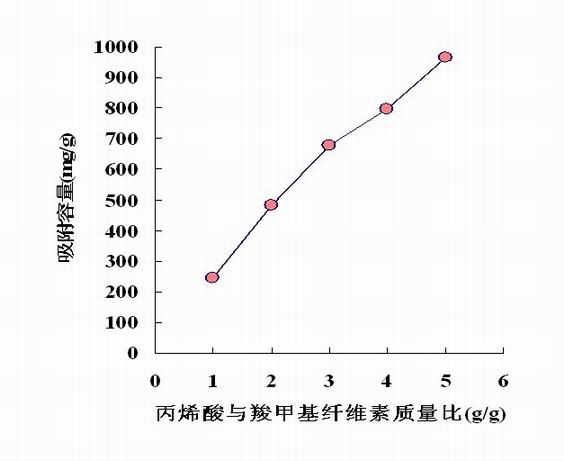

Preparation and application of carboxymethyl cellulose of wheat straw

InactiveCN101985479AReduce dosageImprove stabilityOther chemical processesWater contaminantsChloroacetic acidsChloroacetic acid

The invention discloses carboxymethyl cellulose of wheat straw. The wheat straw is crushed and subjected to pretreatment with dilute alkali, bleaching and alkalization, and then reacts with chloroacetic acid before being etherified so as to obtain the carboxymethyl cellulose of the wheat straw; and the carboxymethyl cellulose of the wheat straw is subjected to graft copolymerization together with acrylic acid to obtain a carboxymethyl cellulose-based polymer adsorbent. The adsorbent is applied to the treatment of wastewater containing heavy metal ions, has high adsorbability and large adsorption capacity and ensures high metal ion removal rate. After treatment, the adsorbent has high stability and can completely meet the requirements of heavy-metal wastewater treatment; and the treated wastewater is clear and transparent without odor and can meet the national emission standard. The invention has the advantage that the resources of raw materials are wide, the cost is low, the use of waste is realized, and secondary pollution caused by burning of the wheat straw is avoided, thus being conducive to environmental protection.

Owner:GANSU TIPTOP PLANT TECH CORP

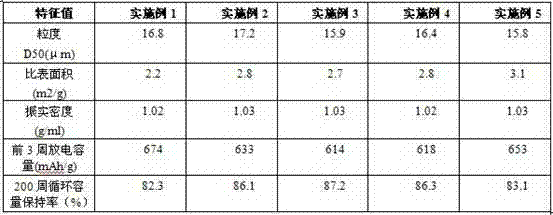

Silicon-carbon composite material for lithium ion battery and preparation method thereof

ActiveCN102891297AImprove cycle performanceIncrease capacityCell electrodesCarbon compositesCarboxymethyl cellulose

The invention discloses a silicon-carbon composite material for a lithium ion battery and a preparation method for the silicon-carbon composite material, and belongs to the field of lithium ion batteries. The silicon-carbon composite material is characterized in that carboxymethylcellulose sodium is used as a bonding agent, a liquid phase coating technology is used for silicon-carbon compounding, and a spray drying technology is used for drying granulation to prepare the silicon-carbon composite material with uniform granularity and excellent performance for the lithium ion battery. The silicon-carbon composite material and the preparation method thereof have the advantages that 1, the composite material for the lithium ion battery is prepared through a silicon-carbon compounding technology, and the capacity of the composite material is higher than that of the conventional graphite cathode material, reaches over 500mAh / g, and can meet requirements on the growing of the market of lithium ion batteries; 2, carboxymethylcellulose is used as a bonding agent which can be effectively coated and bonded on the silicon-carbon material to prevent efflorescence caused by silicon during charging and discharging, so that the cycling performance of the silicon-carbon composite material is effectively improved; and 3, the liquid phase coating and spray drying granulation technologies are adopted, so that the silicon-carbon material can be uniformly coated and bonded, has uniform granules, and is small in specific area, and the cycling performance of the silicon-carbon composite material is further improved.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

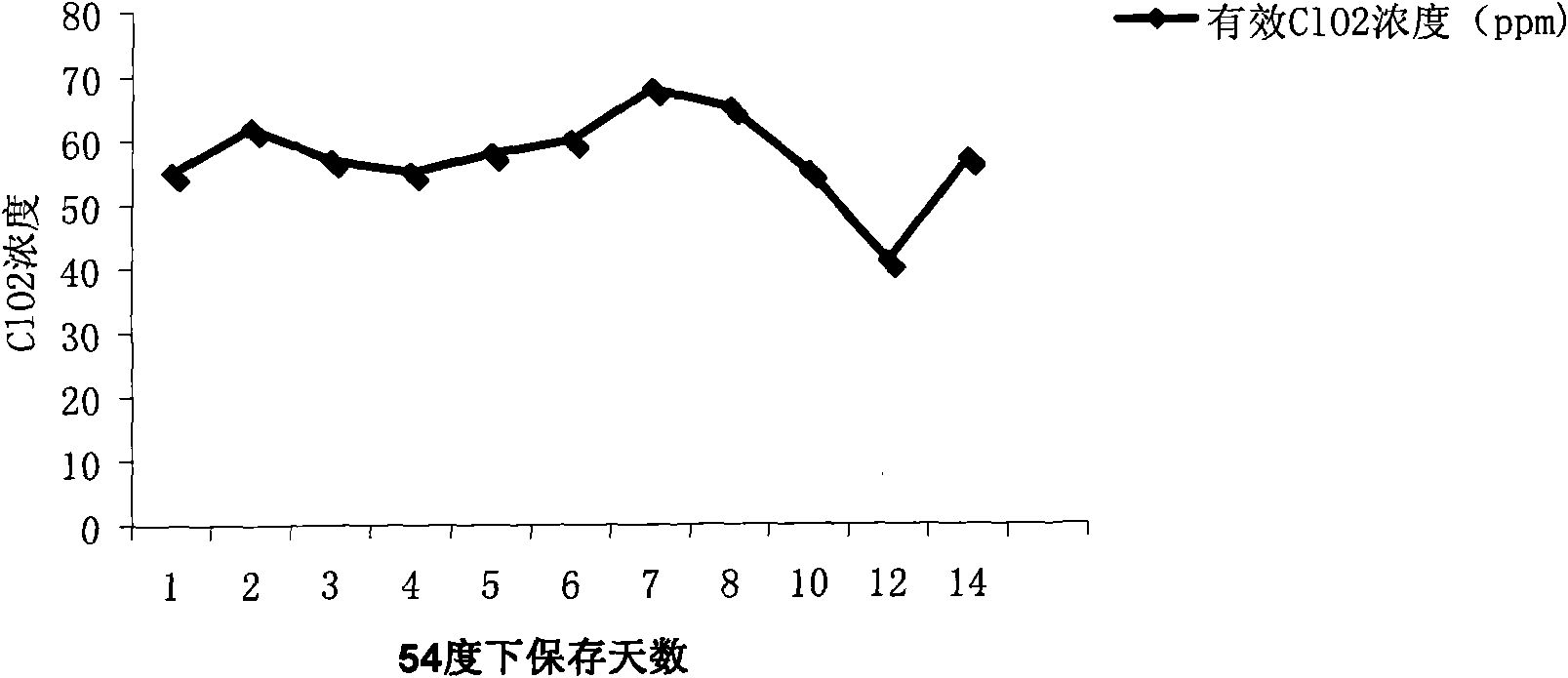

Germicidal antiviral composite containing chlorine dioxide

InactiveCN101669518AStable active ingredientsControl release speedBiocideDisinfectantsSodium laurateCarboxymethyl cellulose

The invention discloses a germicidal antiviral composite containing chlorine dioxide. The composite comprises a functional composition that can provide chlorine dioxide and a stabilizing agent, wherein the stabilizing agent is a compound that can cause the functional composition capable of providing the chlorine dioxide to stably exist in a solvent or a carrier and comprises one or more of EDTA, carboxymethyl cellulose, sodium laurate, polyethylene glycol, cyclodextrin, glucan, chitin, and mucopolysaccharide and the like. The technical means adopted in the invention solves the difficulty thatthe chlorine dioxide is instable in products or a complicated stabilizing and releasing technical means is needed in application of products, thus expanding the production and application range of products.

Owner:BEIJING OKEANOS TECH

Filter medium and preparation method thereof

InactiveCN101837213AReduce manufacturing costWide variety of sourcesOther chemical processesFiltration separationWater basedActivated carbon

The invention relates to a filter medium, in particular to a filter medium and a preparation method thereof. The preparation method is as follows: raw materials are taken according to the weight percent of a formula, are added with materials to be mixed and stirred evenly according to the prescribed steps, and then are formed by extrusion and punch in a prefabricated mold, and the forming body is dried and cured at certain temperature to form the filter medium. Absorbing raw materials such as activated carbon, kaolin, diatomaceous earth and the like, and a water based binder such as polyvinyl alcohol, sodium carboxymethyl cellulose, modified starch and the like adopted by the invention are of nontoxic and non-harmful raw materials, and are formed by extrusion and punch under the condition of normal temperature, and in the process of high-temperature curing, water can remove the blockage of the binder for micropores of the absorbing raw materials in the process of extrusion or punch when evaporating, so that the finished product keeps the original absorption characteristics of the absorbing raw materials and simultaneously overcomes the defects that medium raw materials are precipitated when the filter medium is used for filtering.

Owner:张顺

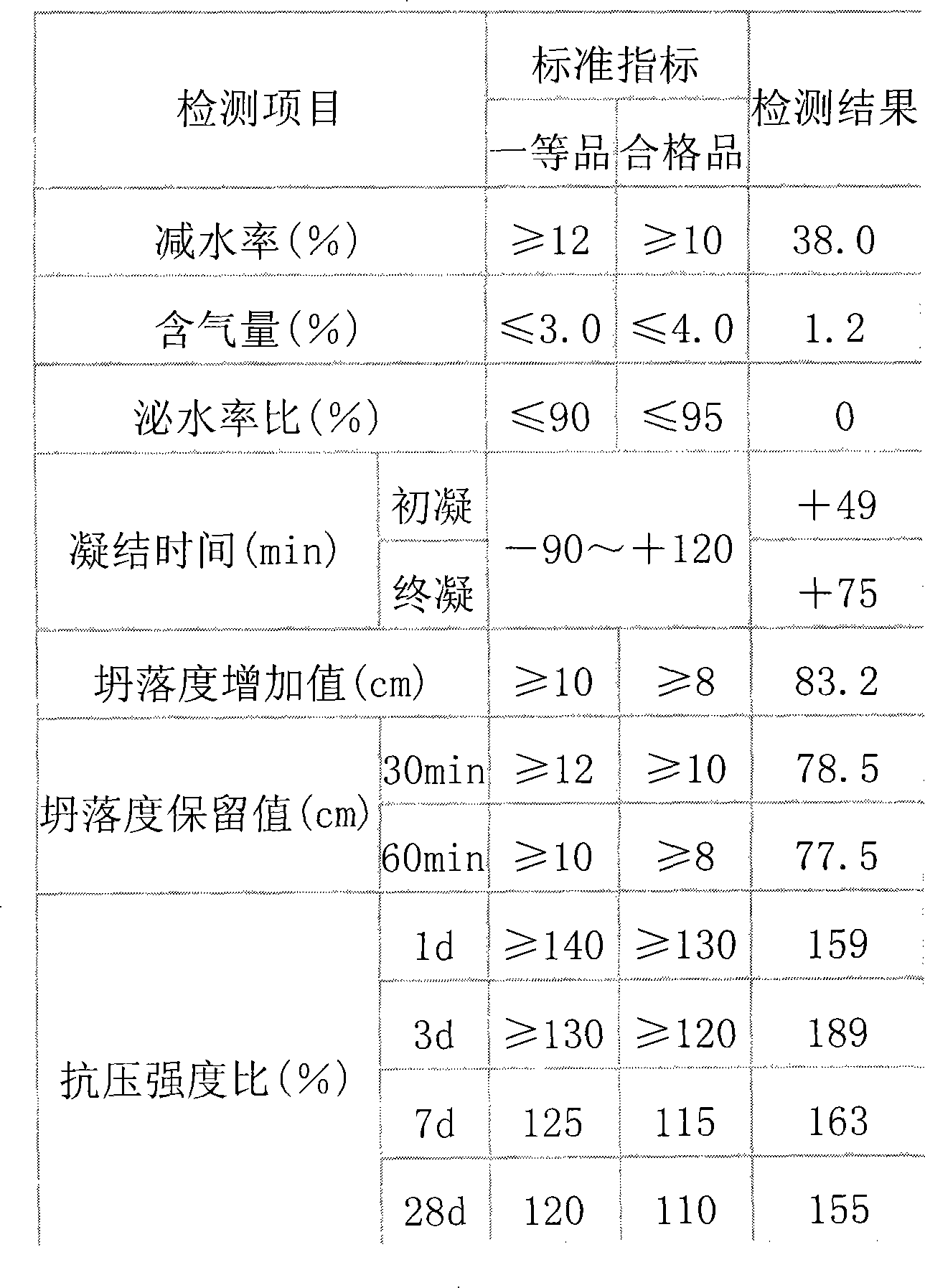

Highly durable high slump loss resistant no-bleeding concrete pump delivering agent

InactiveCN101244909AImprove appearance qualityEffectively change performanceCarboxymethyl celluloseMetallurgy

The invention relates to a non-bleeding concrete pumping admixture with high durability and high slump retaining, the raw material weight percentage composition of which is: 25 to 45 percent of naphthalene series water reducer, 2 to 6 percent of polycarboxylic series of water reducer, 1 to 4 percent of sodium lignosulfonate, 0.5 to 2 percent of sodium gluconate, 0.2 to 2 percent of triterpenoid saponin, 0.5 to 3 percent of carboxymethyl cellulose, 0.2 to 1 percent of silicon oil, and 40 to 65 percent of water; the non-bleeding concrete pumping aid with high durability and high slump retaining has the advantages of low slump loss and low cost, no bleeding, restraining the shrinkage of concrete, and controlling the fissure of concrete.

Owner:HUNAN CONSTR ENG GRP COR

Pet animal body waste treating material

InactiveUS6371050B1Small scuffingWell mixedOther chemical processesAnimal housingCarboxymethyl celluloseSodium Bentonite

A pet animal body waste treating material which enables disposal of pet animal body waste, such as urine, mollock or so forth, in a similar manner as household combustible waste, and which can be manufactured easily at low material cost, can maintain satisfactorily a large total water absorption area while forming relatively small block with only a portion absorbing water, and thus is quite economical. The pet animal body waste treating material is composed of a core portion, in which paper powder, powdered bentonite and water absorbing polymer are mixed, and a surface layer portion coating the core portion, and wherein in the surface layer portion paper powder, powdered bentonite, carboxymethyl cellulose and starch are mixed.

Owner:PEPAARETABUTO

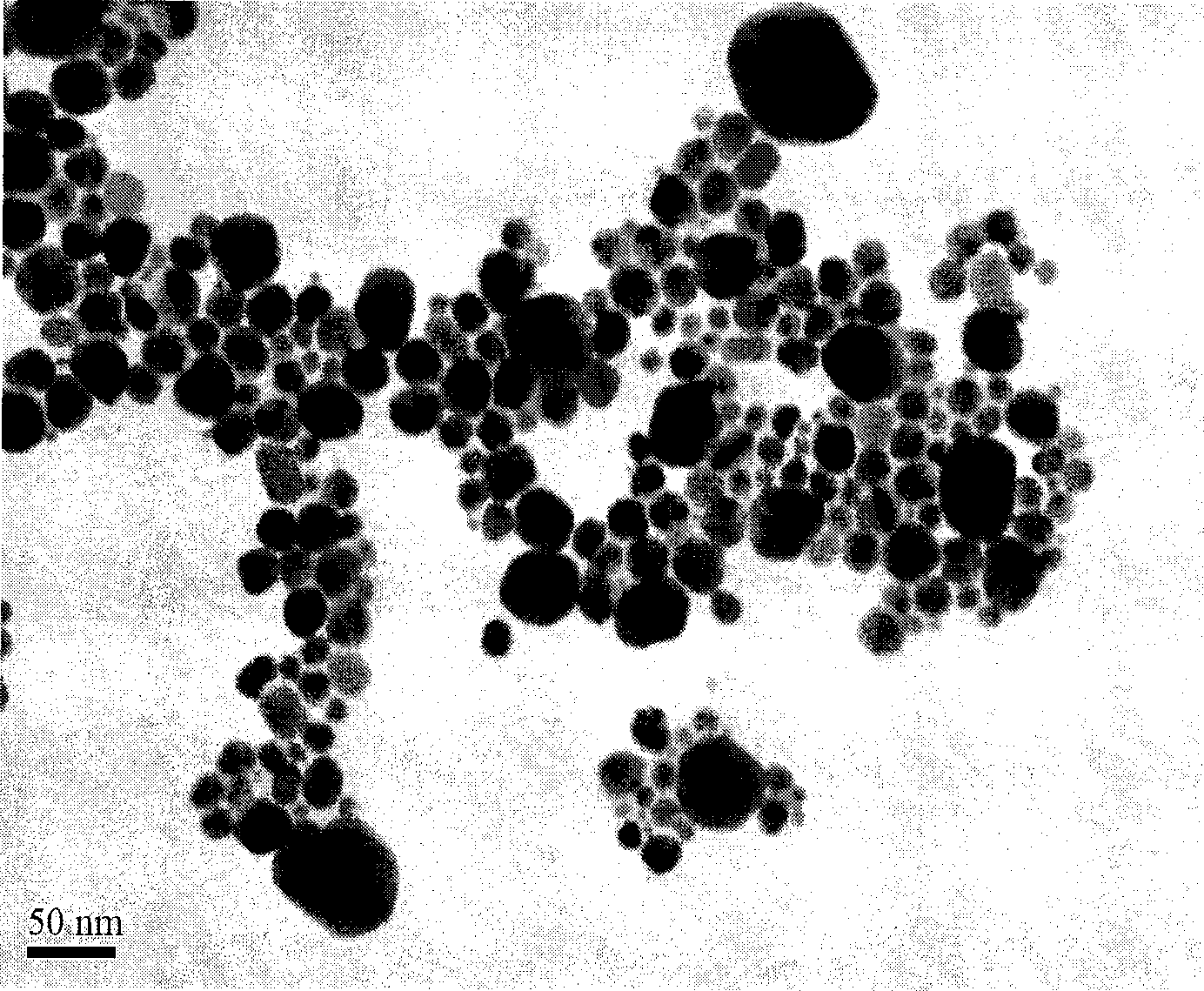

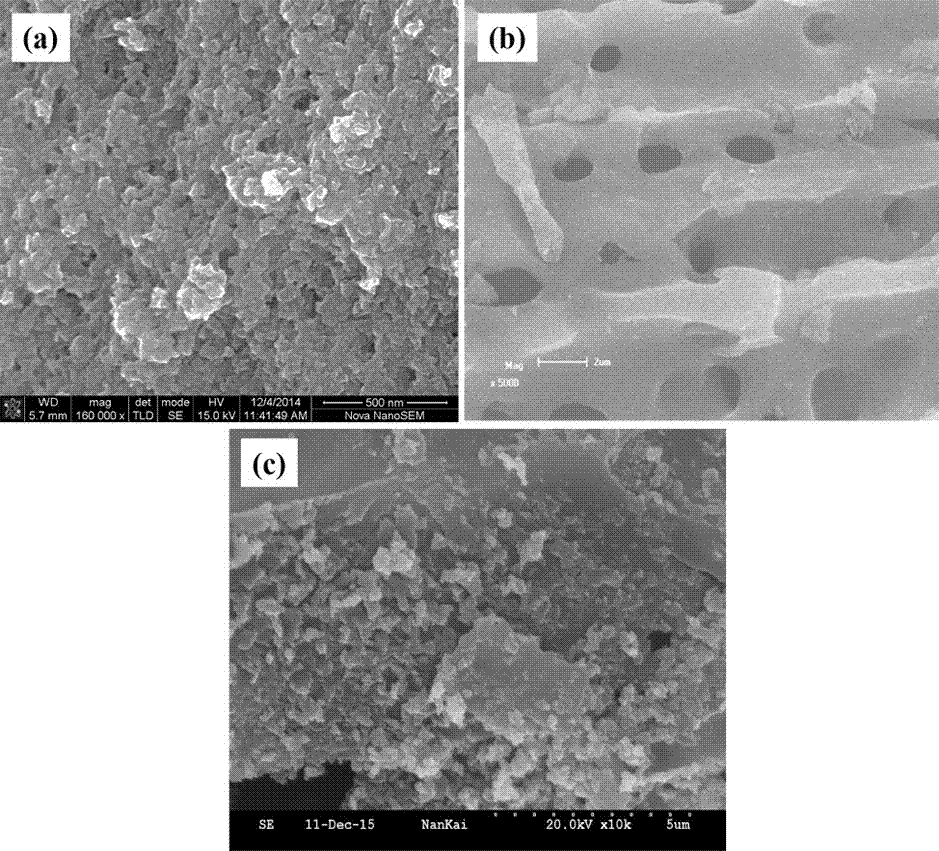

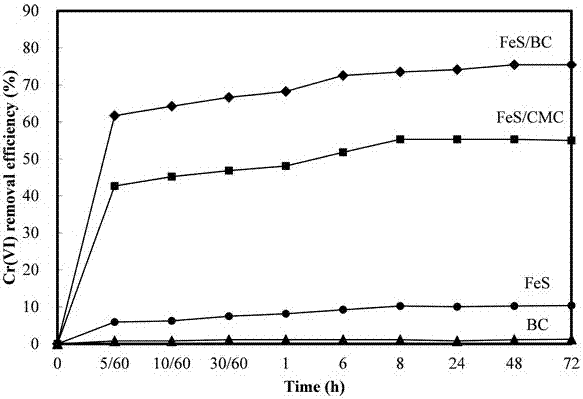

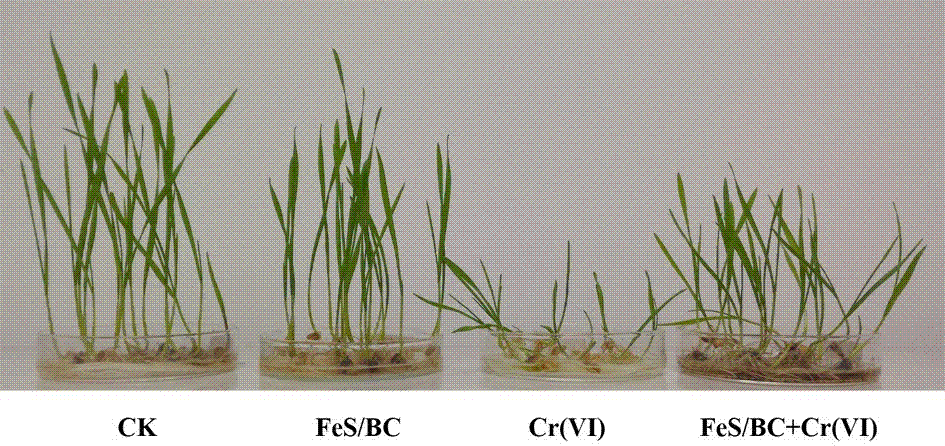

Preparation method and applications of ferrous sulfide/biological carbon composite material

ActiveCN106966456ALow biological toxicityEfficient removal abilityWater contaminantsWater/sewage treatment by sorptionCarboxymethyl celluloseSulfate

The present invention discloses an efficient ferrous sulfide / biological carbon composite material and a preparation method thereof, and applications of the ferrous sulfide / biological carbon composite material in repair of heavy metal pollution water bodies. According to the present invention, biological carbon is adopted as a carrier, a ferrous sulfate solution and the biological carbon are mixed, sodium carboxymethyl cellulose is added as a stabilizer and a dispersant, a sodium sulfide solution is added to the system in a dropwise manner under the nitrogen protection, and vigorous stirring is performed to make the generated ferrous sulfide nanoparticles uniformly grow on the surface of the biological carbon, such that the disadvantage that the ferrous sulfide nanoparticles are easily agglomerated is substantially improved so as to increase the effective contact area between the ferrous sulfide nanoparticles and the pollutant, and the adsorption ability and the oxidation reduction ability of the ferrous sulfide and the biological carbon are integrally combined so as to improve the pollutant removal ability; the preparation method has advantages of simple and rapid process, low production cost, environmental protection and no secondary pollution; and the efficient ferrous sulfide / biological carbon composite material can strongly repair the Cr(VI) polluted water body, can effectively reduce the biological toxicity of the Cr(VI) on wheat seeds, and has wide application prospects in the fields of repair of organic pollution and inorganic pollution in environments.

Owner:NANKAI UNIV

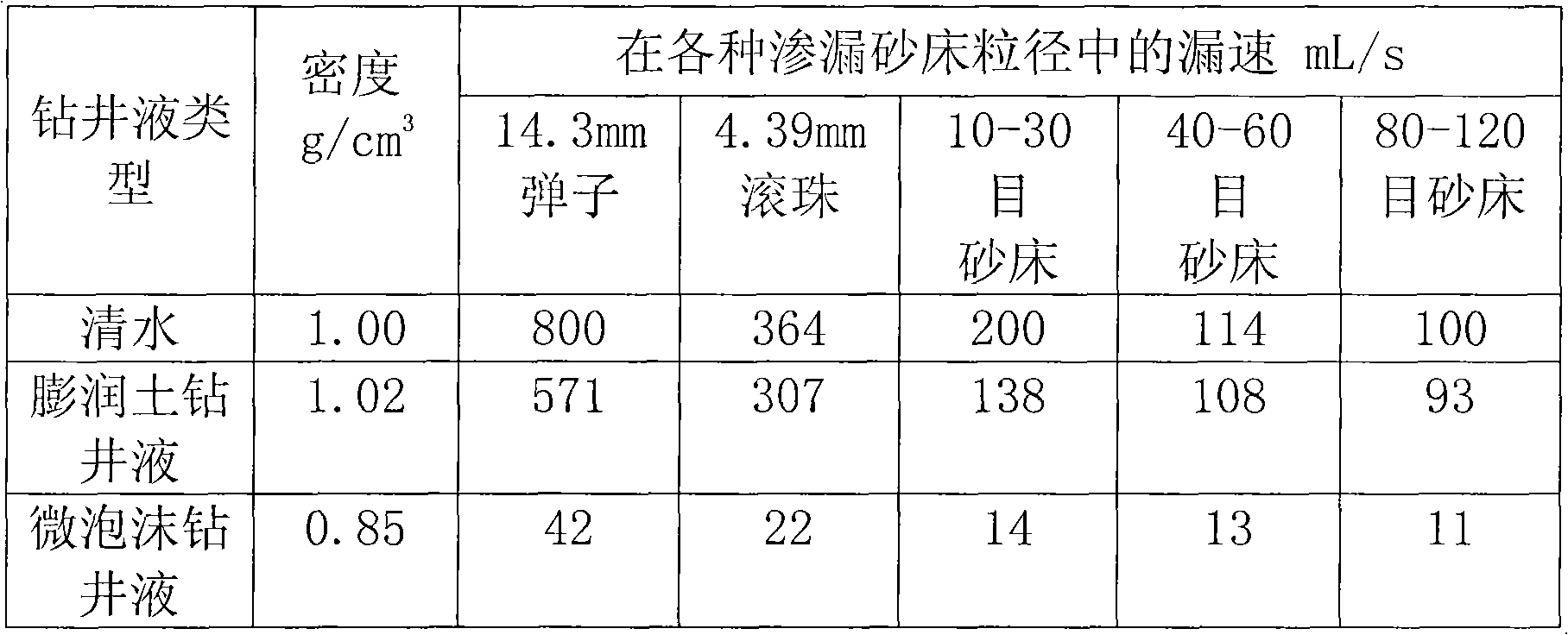

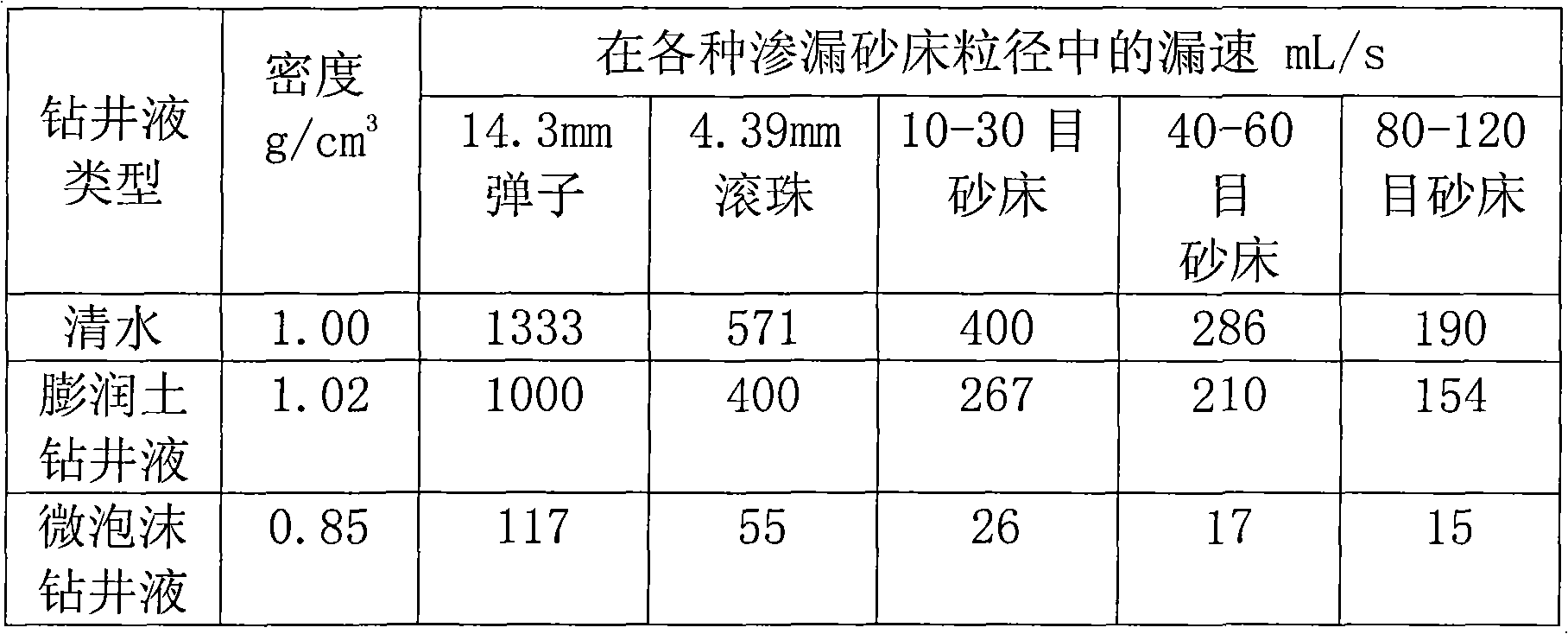

Micro-foam drilling fluid

The invention discloses a micro-foam drilling fluid. The micro-foam drilling fluid comprises the following compositions: 40 to 50 grams of bentonite, 3 to 5 grams of composite foaming agent, 2 grams of xanthan, 3 grams of high-viscosity carboxymethyl cellulose, 3 grams of sodium carbonate, 2 to 3 grams of strong zwitterionic coating agent, 5 grams of partially-hydrolyzed polyacrylonitrile ammonium salt, 5 grams of organic silicon humic acid kalium, 5 grams of lignite resin and 1 grams of viscosity reducer for the drilling fluid in each liter of the drilling fluid, wherein the composite foaming agent consists of lauryl sodium sulfate and sodium dodecyl benzene sulfonate according to mass ratio of 7:3. The drilling fluid has low density, good shielding effect and remarkable anti-leaking effect of a low-pressure easy-to-leak layer and can effectively improve the quality of well cementation.

Owner:DAQING PETROLEUM ADMINISTRATION +1

Viscosity modified formaldehyde-free binder compositions

ActiveUS20140134909A1High viscosityLaminate strength deterioratesNon-fibrous pulp additionNon-macromolecular adhesive additivesGuar gumHydroxyethyl cellulose

Viscosity-modified carbohydrate binder compositions are described. The binder compositions may include a carbohydrate, a nitrogen-containing compound, and a thickening agent. The binder compositions may have a Brookfield viscosity of 7 to 50 centipoise at 20° C. The thickening agents may include modified celluloses such as hydroxyethyl cellulose (HEC) and carboxymethyl cellulose (CMC), and polysaccharides such as xanthan gum, guar gum, and starches.

Owner:JOHNS MANVILLE CORP

Carboxymethyl cellulose-based binder material and lithium battery using the same

ActiveUS20050074669A1Good water solubilityStrong adhesionNegative electrodesLi-accumulatorsSolubilityCarboxymethyl cellulose

The present invention is related to compositions and methods for producing a lithium battery with enhanced performance. In particular, the present invention is directed to increasing the solubility of a carboxymethyl cellulose-based binder in water. When the solubility of the carboxymethyl cellulose-based binder is improved, the electrode manufacturing process may be stabilized, and the dispersibility and adhesive force of the electrode may also be improved. As a result, a lithium battery with excellent characteristics may be manufactured. Additionally, the present invention is also directed to an environmentally-friendly manufacturing process for fabricating an anode whereby water is used as the slurry medium, and a lithium battery containing the anode.

Owner:SAMSUNG SDI CO LTD

Preparation method of lithium carboxymethyl cellulose for lithium battery

InactiveCN102206286AEnhanced mass transferImprove heat transfer performanceCell electrodesSolubilitySlurry

The invention relates to a preparation method of lithium carboxymethyl cellulose for a lithium battery, belonging to the field of natural high-polymer chemical modification. The preparation method provided by the invention comprises the following steps: dispersing sodium carboxymethyl cellulose prepared by a slurry process into an organic solvent, adding a hydrochloric acid water solution, mixing, reacting at 20-50 DEG C, removing the liquid, washing with an 80-95 vol% organic solvent, removing the liquid, baking, and pulverizing to obtain carboxymethyl cellulose acid; and dispersing the carboxymethyl cellulose acid in an organic solvent, adding an LiOH.H2O water solution, reacting at 40-60 DEG C, neutralizing with glacial acetic acid until the pH value is 6-8, washing with a 75-85% organic solvent, removing the liquid, baking, and pulverizing to obtain the lithium carboxymethyl cellulose. The preparation method can be used for obtaining lithium carboxymethyl cellulose with different degrees of substitution, different viscosities and excellent water solubility, and provides a novel water-soluble binder with low price and excellent properties, thereby enhancing the cyclical stability and discharge capacity of the lithium battery.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

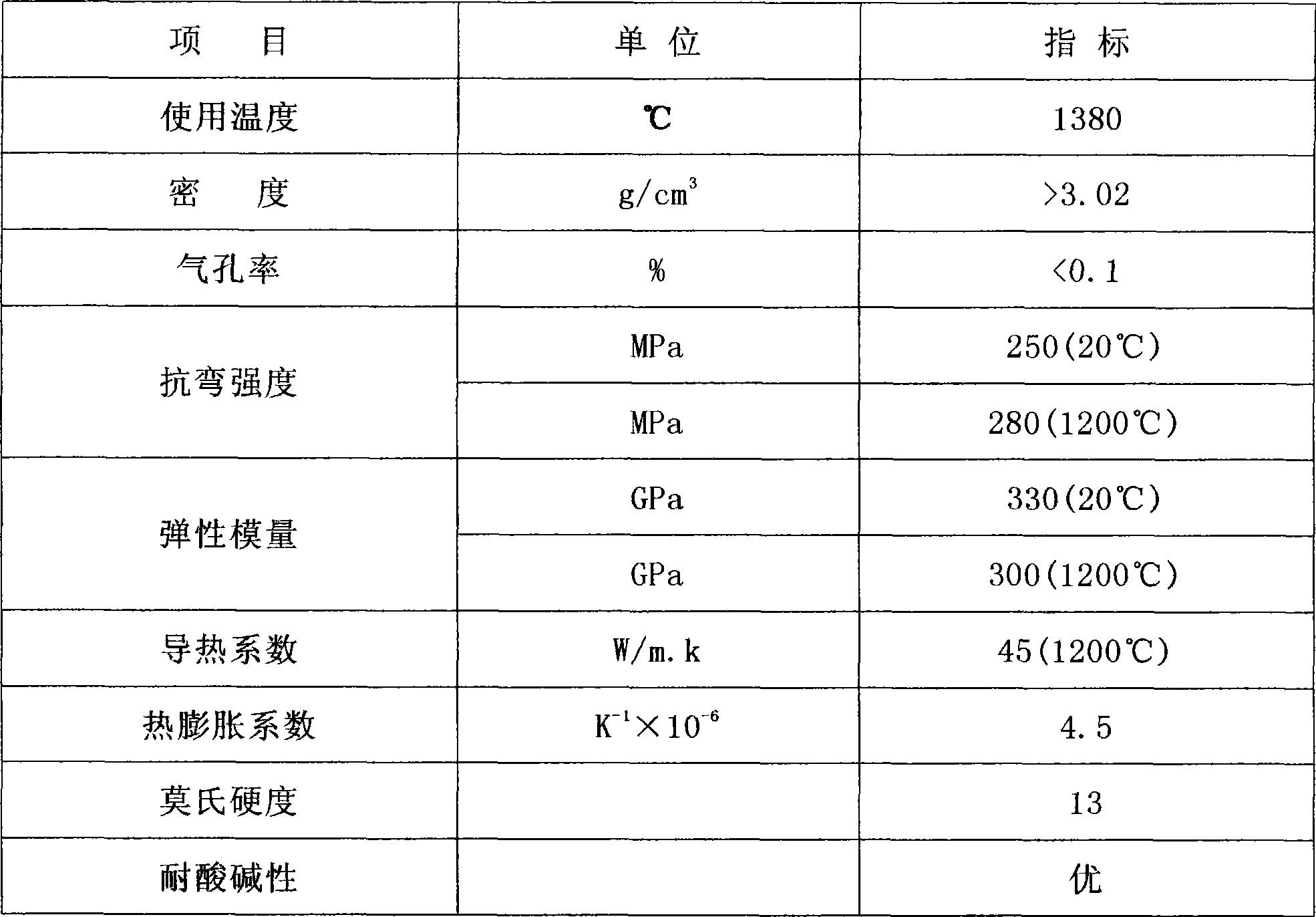

Reactively sintered silicon carbide ceramic and production process

InactiveCN101508570AImprove performanceHigh mechanical strengthPolyvinyl alcoholTemperature resistance

The invention discloses a reaction sintering silicon carbide ceramics and a manufacturing technique thereof. The materials of the ceramics comprise: 5-8 parts by weight of SiC powder with a granularity of 10-90 mum, 2-3 parts by weight of SiC powder with a granularity of 0.1-10mum, 0.5-1 part by weight of carbon black powder, 0.3-0.8 part by weight of graphite powder and 0.1-0.3 part by weight of polyvinyl alcohol or carboxymethyl cellulose liquid; the silicon carbide ceramics is manufactured after the pulping of materials, slip casting, drying, vacuum sintering and sand removing and oxidization. The manufacturing technique of the invention is mature and reliable, the silicon carbide ceramics of the invention is fine in product performance and stable in quality, and hardness, temperature resistance, wear resistance and corrosion resistance thereof all reach the standard of international reaction sintering silicon carbide ceramics. In addition, the ceramics of the invention is widely applied to fields such as ceramics kiln furniture, desulphurization nozzles, metallurgy, chemical engineering and the like, and the size deformation rate of the product is less than 0.1%.

Owner:WEIFANG HUAMEI FINE TECHN CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com