Patents

Literature

2671results about How to "Change structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

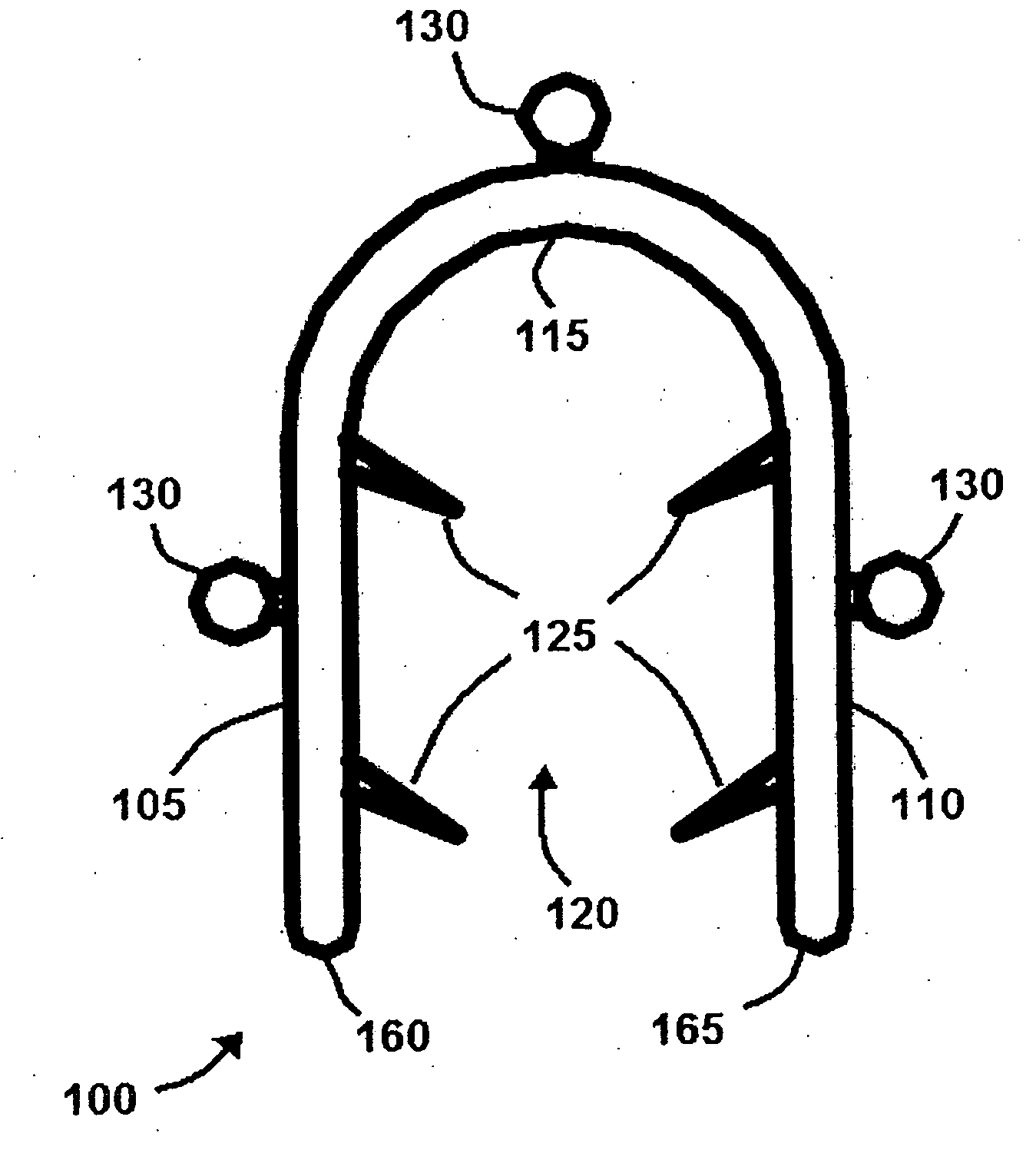

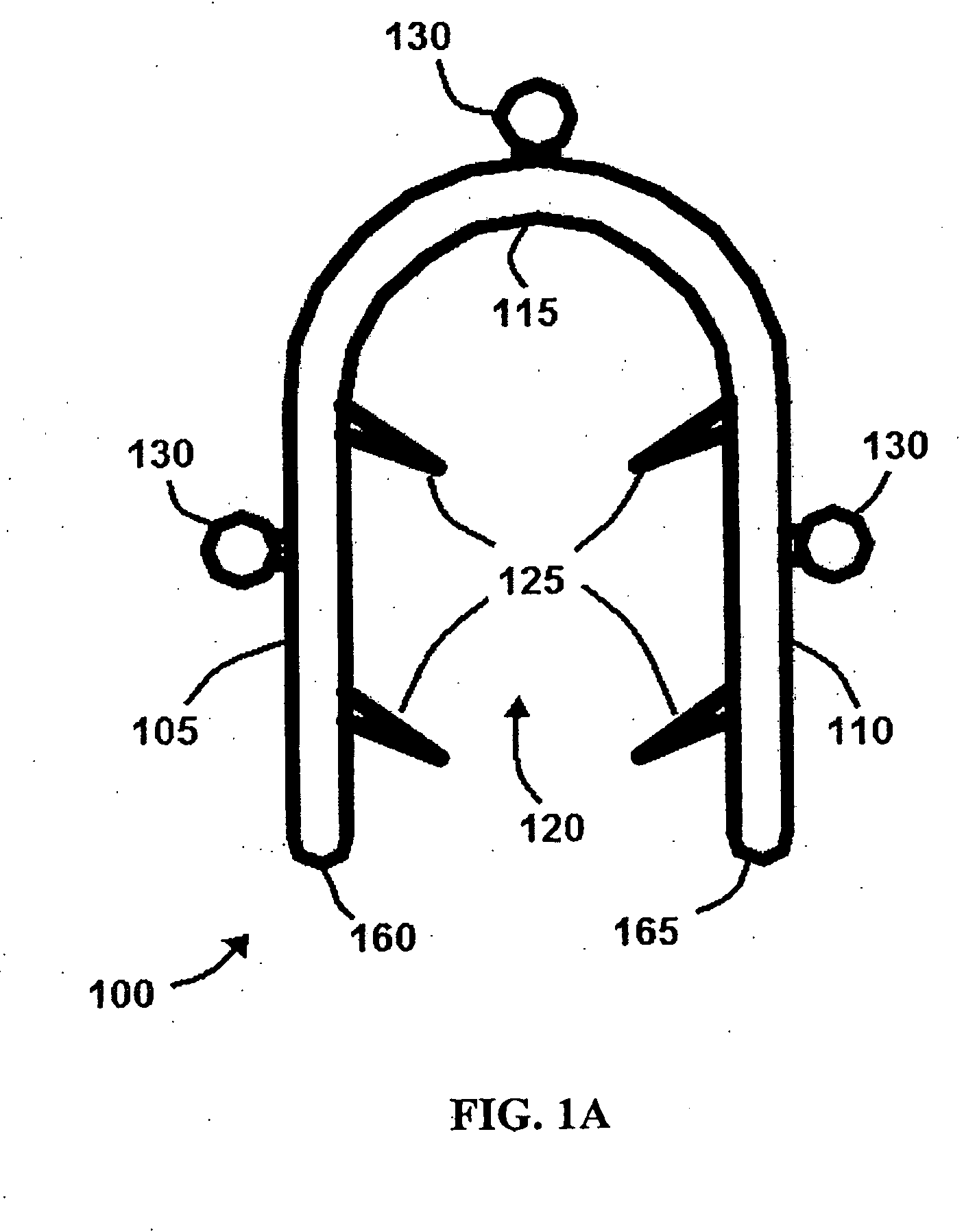

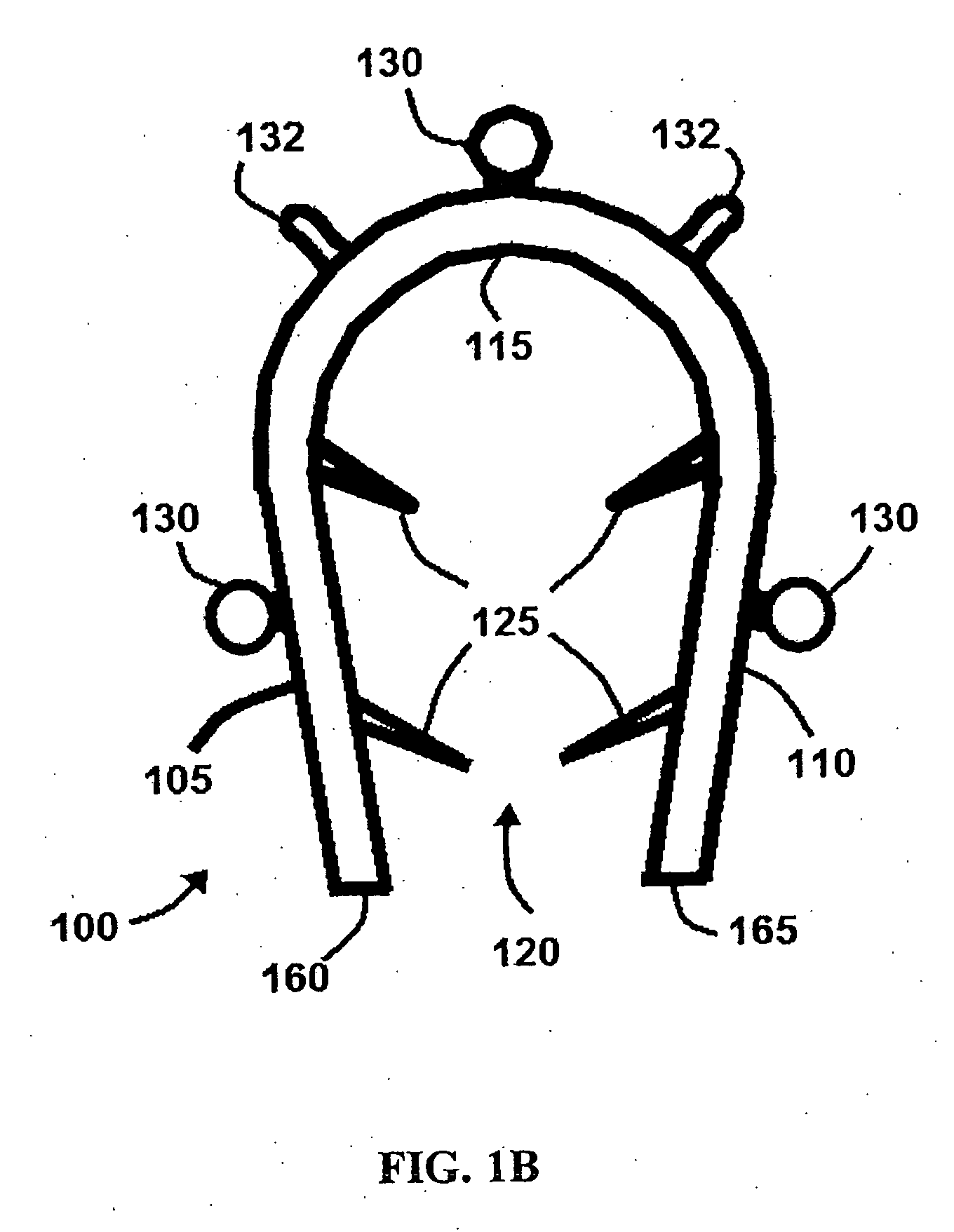

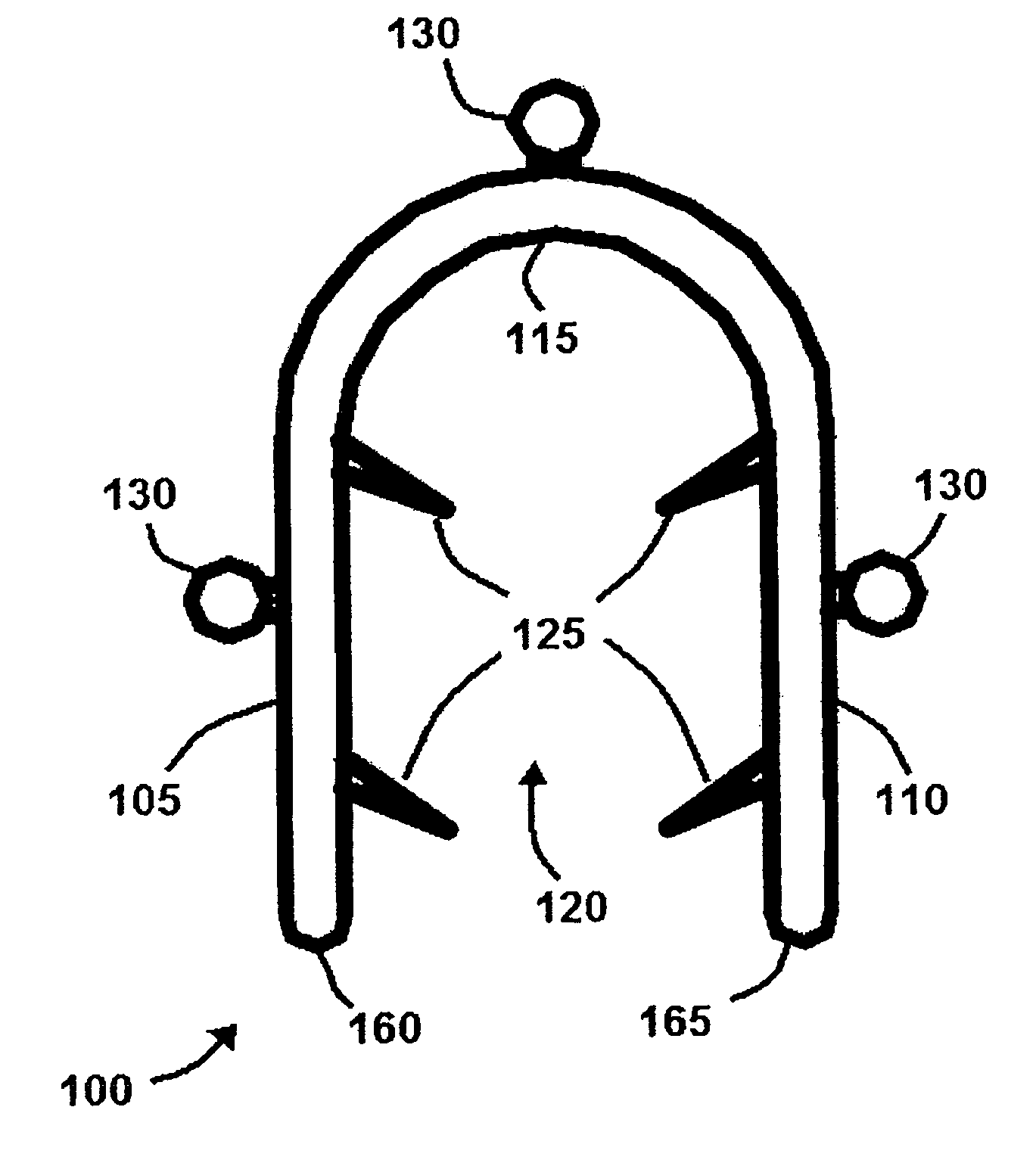

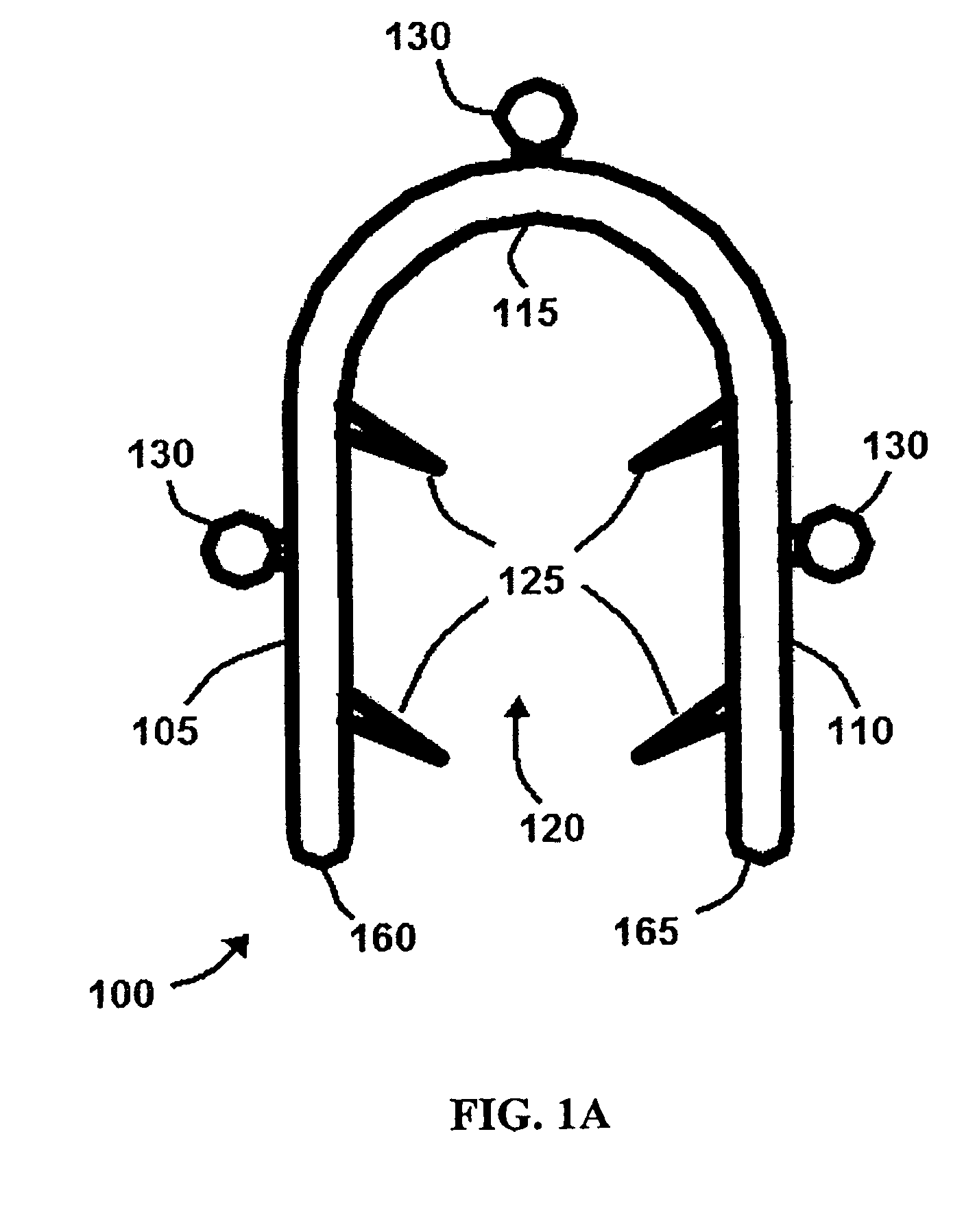

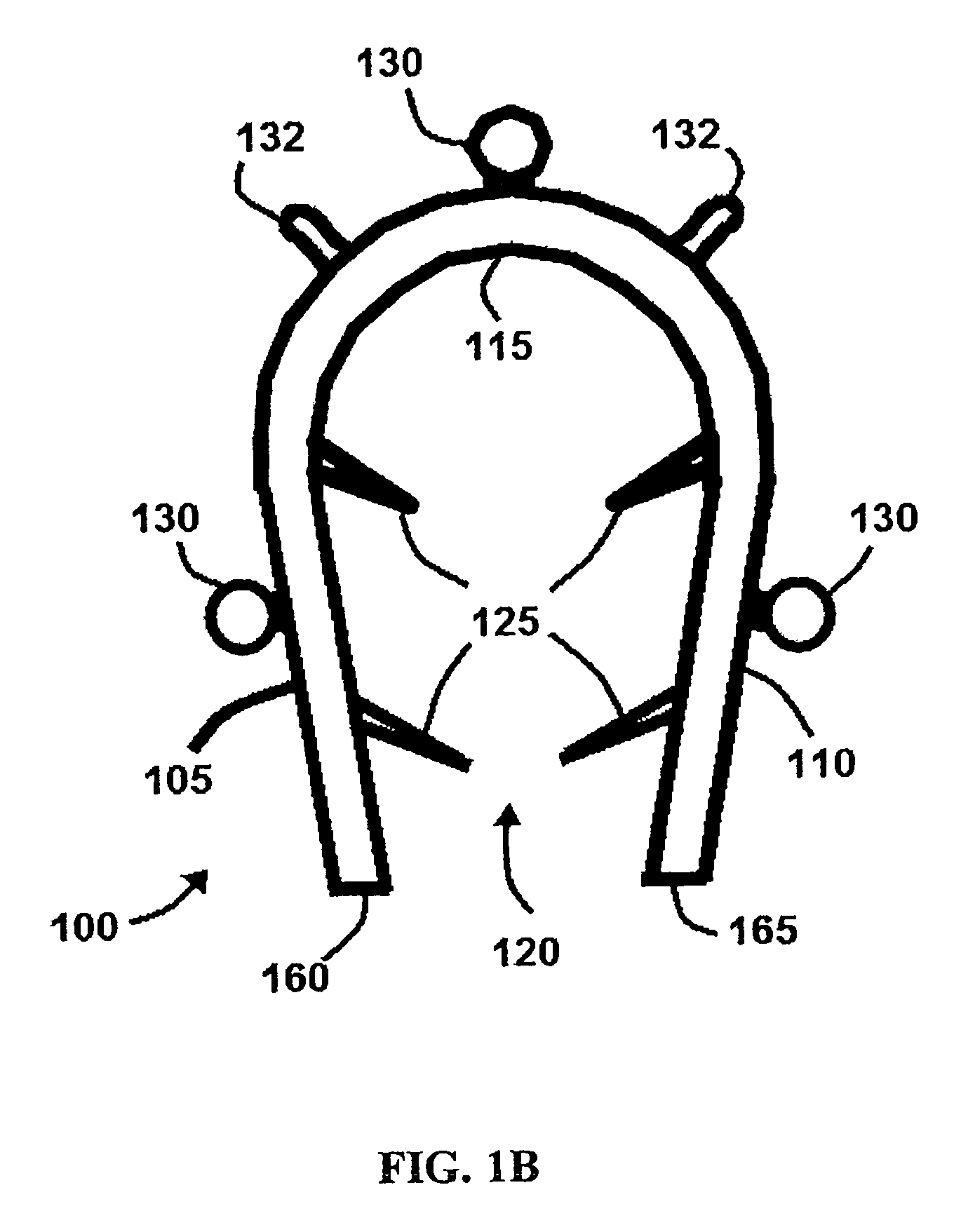

Bone tissue fixation device and method

ActiveUS20090198277A1Increase flexibilityEasy and safe to accessSuture equipmentsInternal osteosythesisBone tissueSpinous process

Systems, methods, and kits incorporating a clamp for securing to bone tissue. The clamp includes gripping members to secure the clamp to the bone tissue without the use of screws. The clamp may be used to treat spinal conditions, and may be secured to the spinous process of vertebrae. Systems, methods and kits can incorporate a fusion member configured to fuse between adjacent spinous processes.

Owner:WENZEL SPINE +1

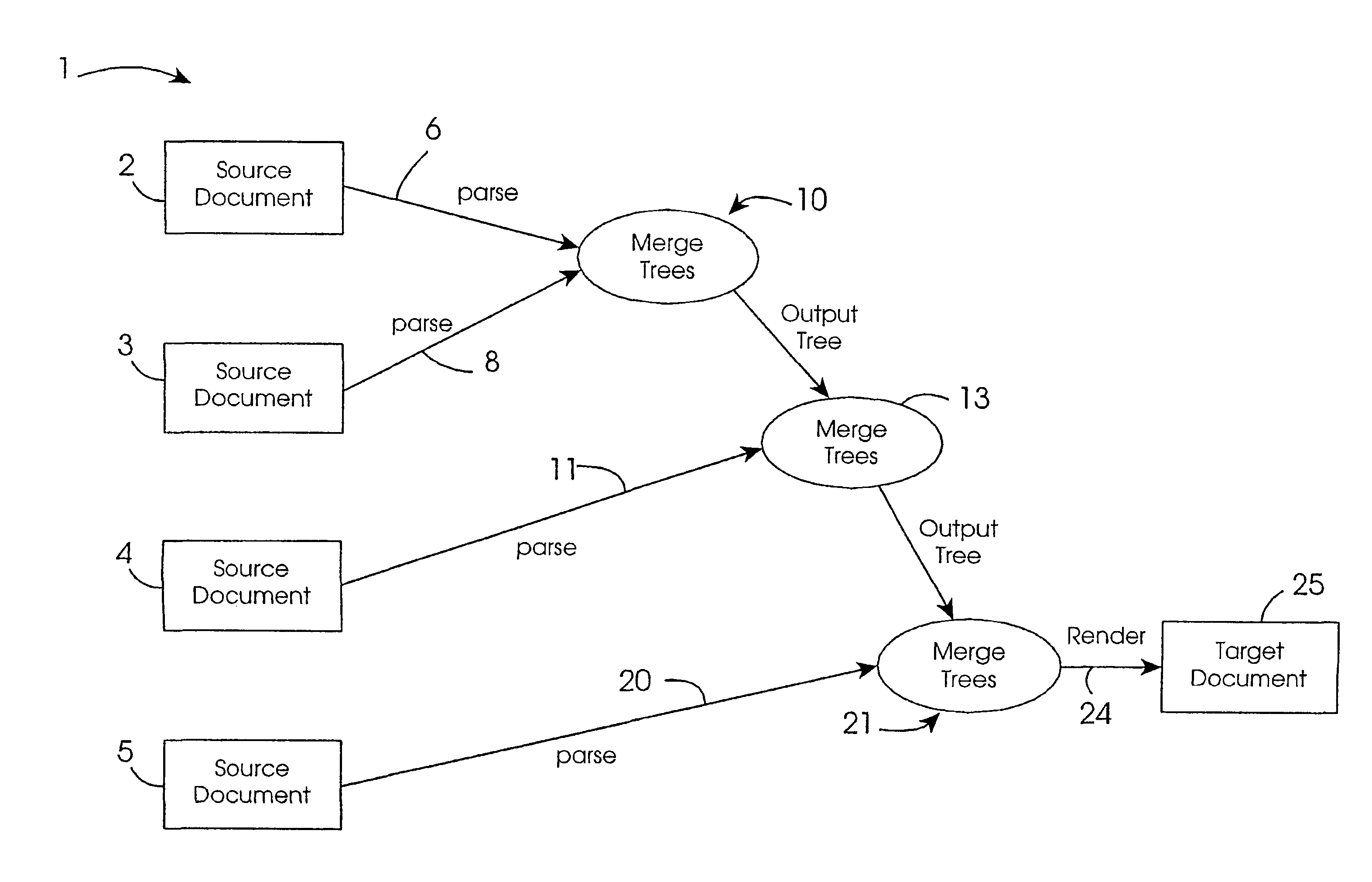

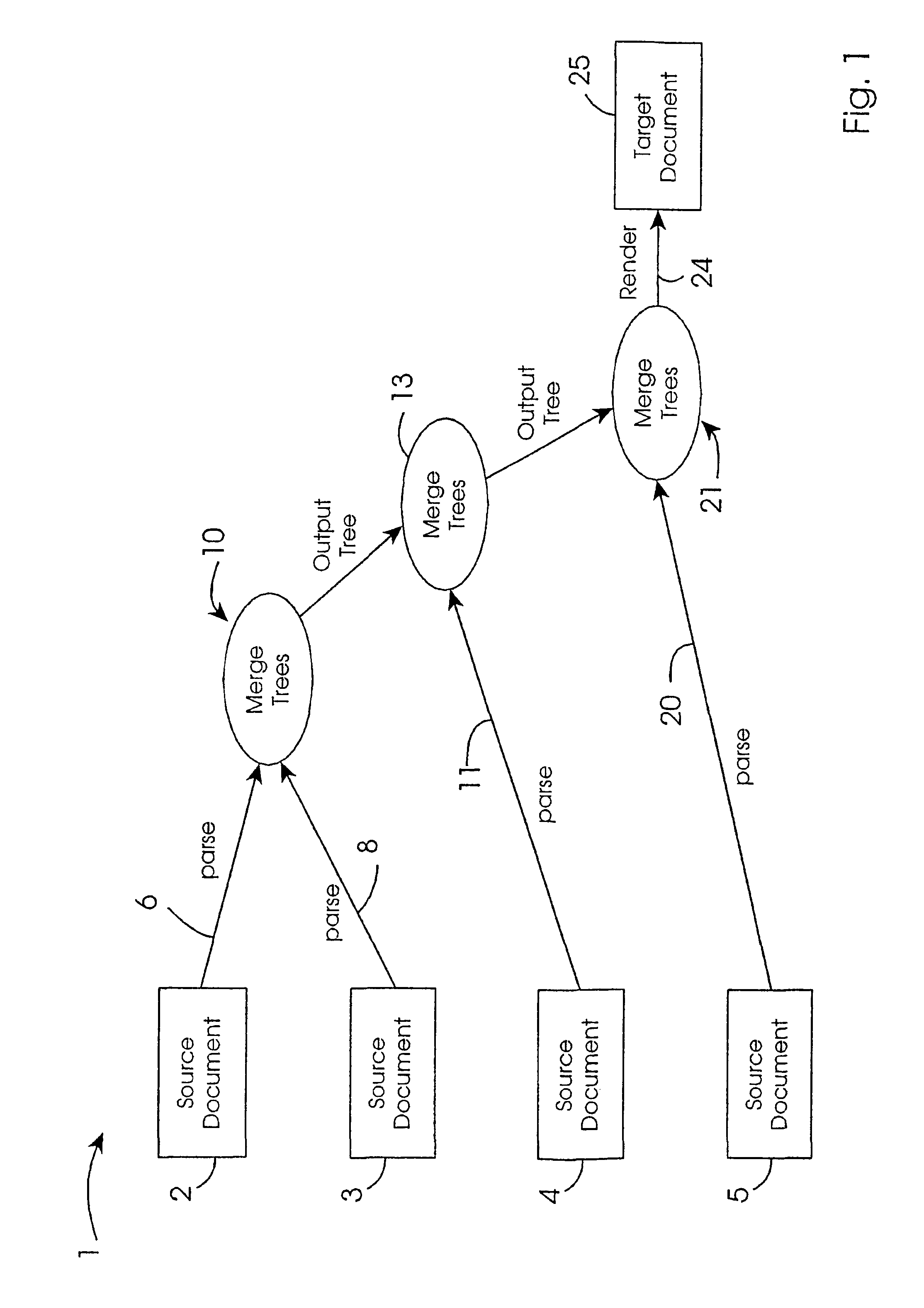

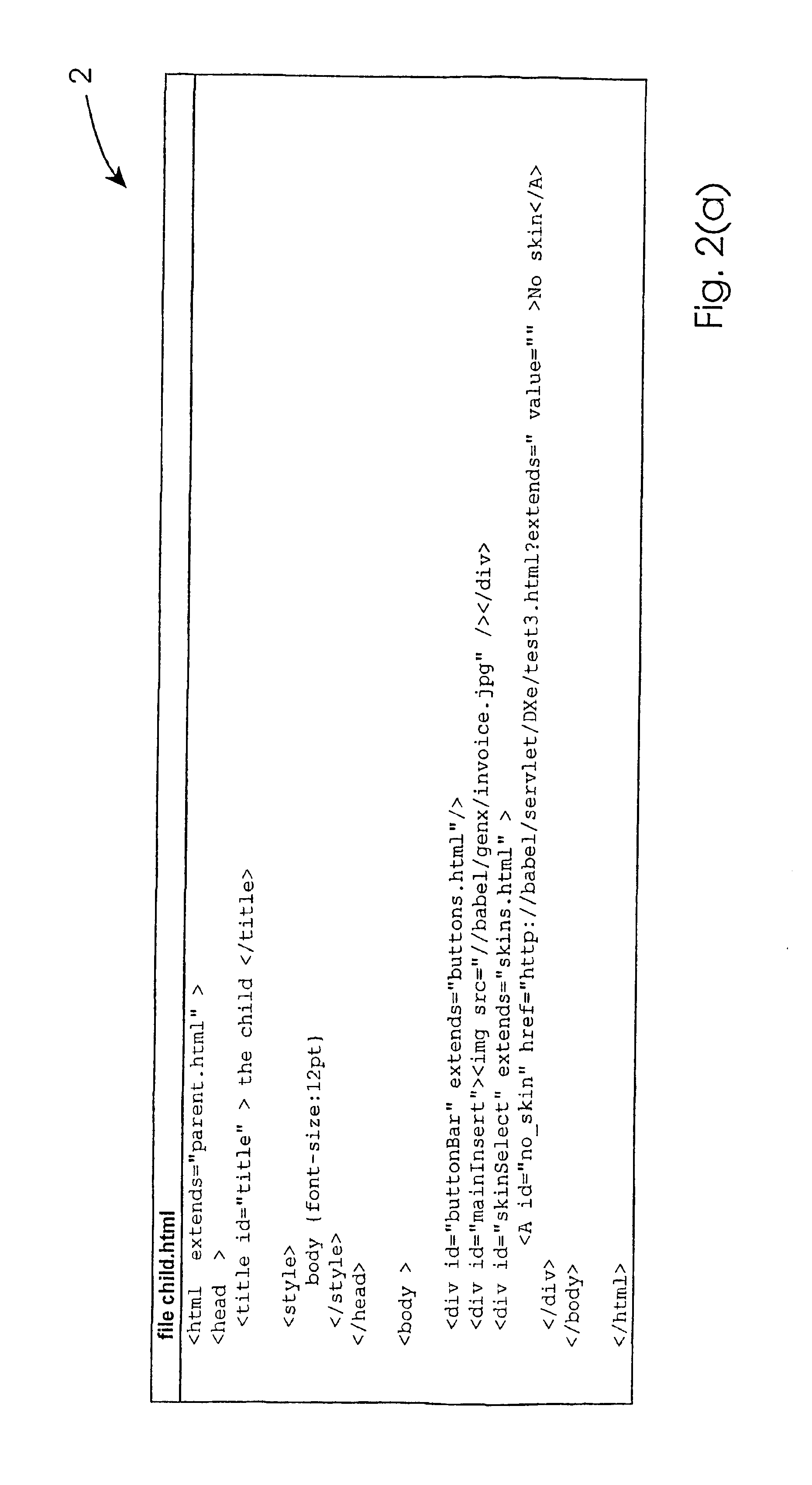

Electronic document processing system and method for merging source documents on a node-by-node basis to generate a target document

InactiveUS6772165B2More versatilityChange structureData processing applicationsNatural language data processingElectronic documentDocumentation

A target document (25) is generated by merging four source documents (2-5). There are three merge operations, an operation (10) for two source documents (2, 13), an operation (13) for an intermediate target document and a source document (4), and an operation (21) for a second intermediate target document and a final source document (5). In each merge operation one source document inherits from the other. An inheriting instruction is embedded within the inheriting document. Merging is performed by parsing a document (6, 8, 11, 20) into a hierarchical tree if it is not already in that form, and merging the trees. Matching nodes are identified and are combined or replaced according to a policy.

Owner:MEC MANAGEMENT LLC

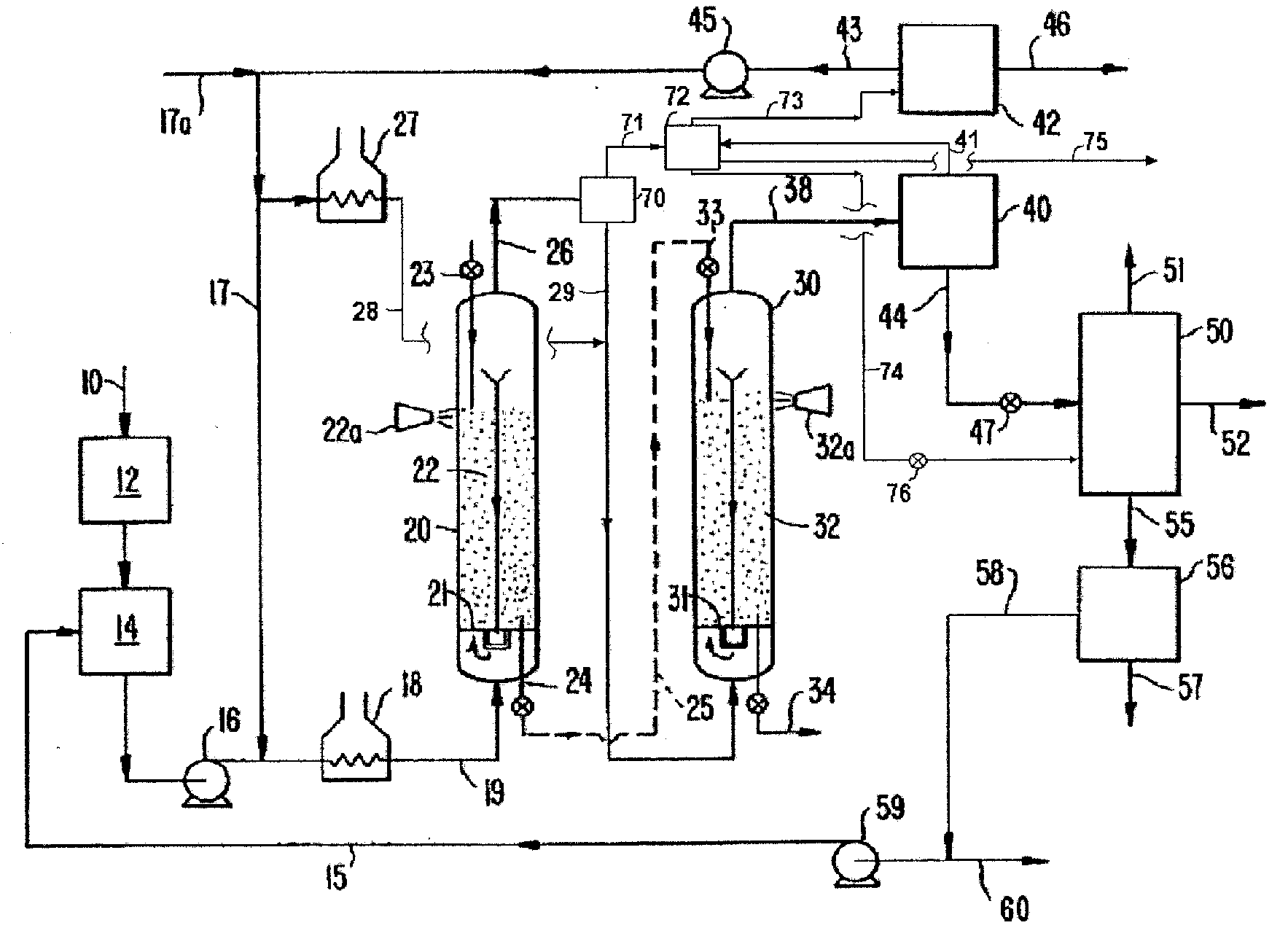

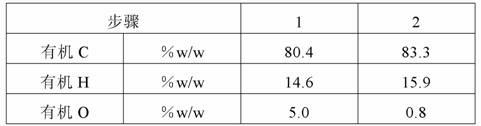

Direct biomass hydroliquefaction process comprising two ebullated bed hydroconversion steps

ActiveCN102127462AExtend your lifeEasy to operateBiofuelsWaste based fuelHydrogen pressureLignocellulosic biomass

A process for direct hydroliquefaction of biomass selected from algae, lignocellulosic biomass and / or of one or more constituents of lignocellulosic biomass selected from the group comprising cellulose, hemicellulose and / or lignin for producing fuel bases comprising two successive hydroconversion stages under high hydrogen pressure in ebullating bed reactors. Hydroconversion takes place in the presence of a supported catalyst of the type for hydroconversion of petroleum residue and a suspension composed of the biomass and a solvent, preferably a hydrogen donor solvent and preferably recycled from the process. The biomass can undergo a pretreatment of drying and / or roasting and / or grinding and / or demineralization prior to hydroliquefaction.

Owner:INST FR DU PETROLE

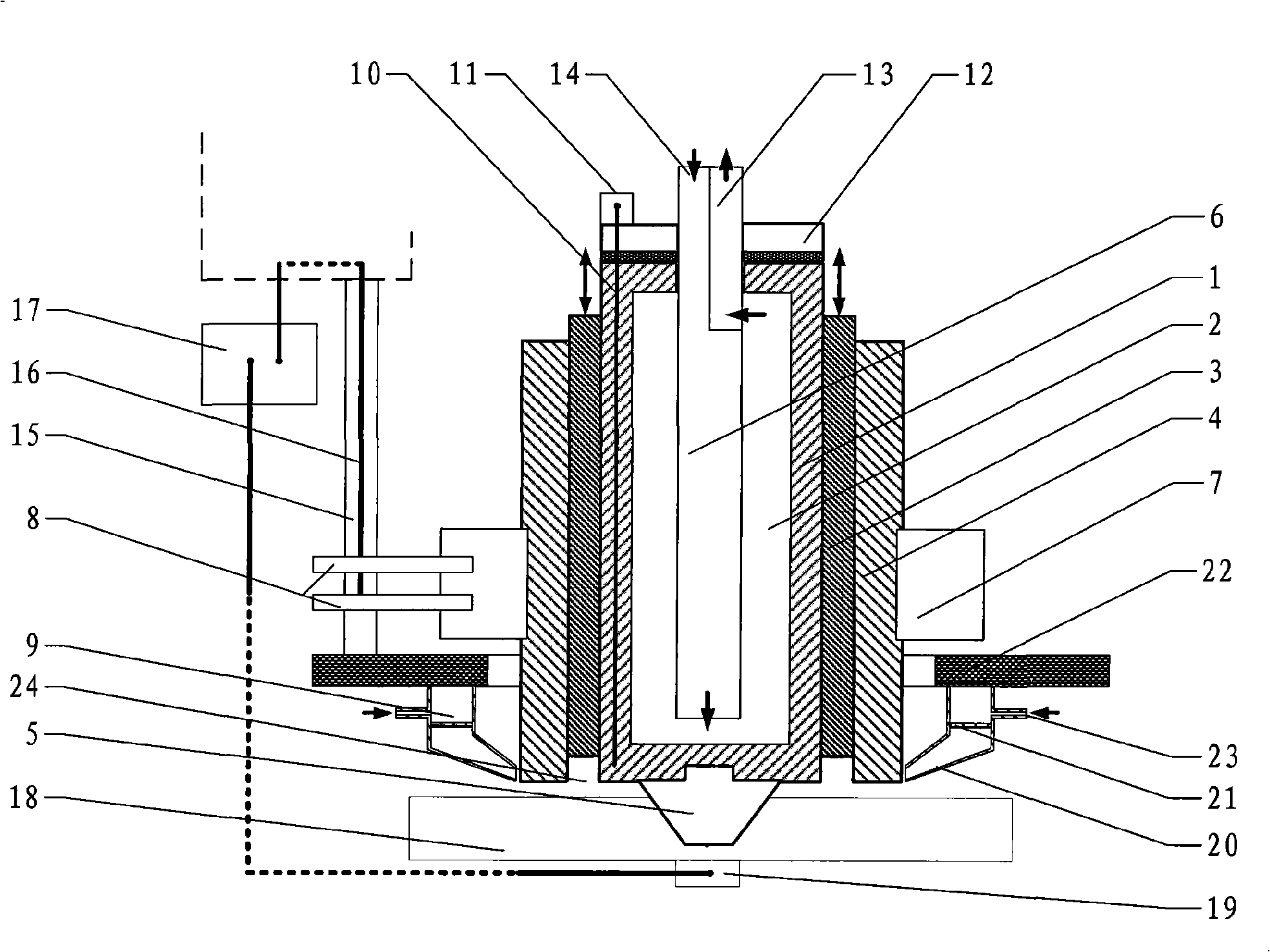

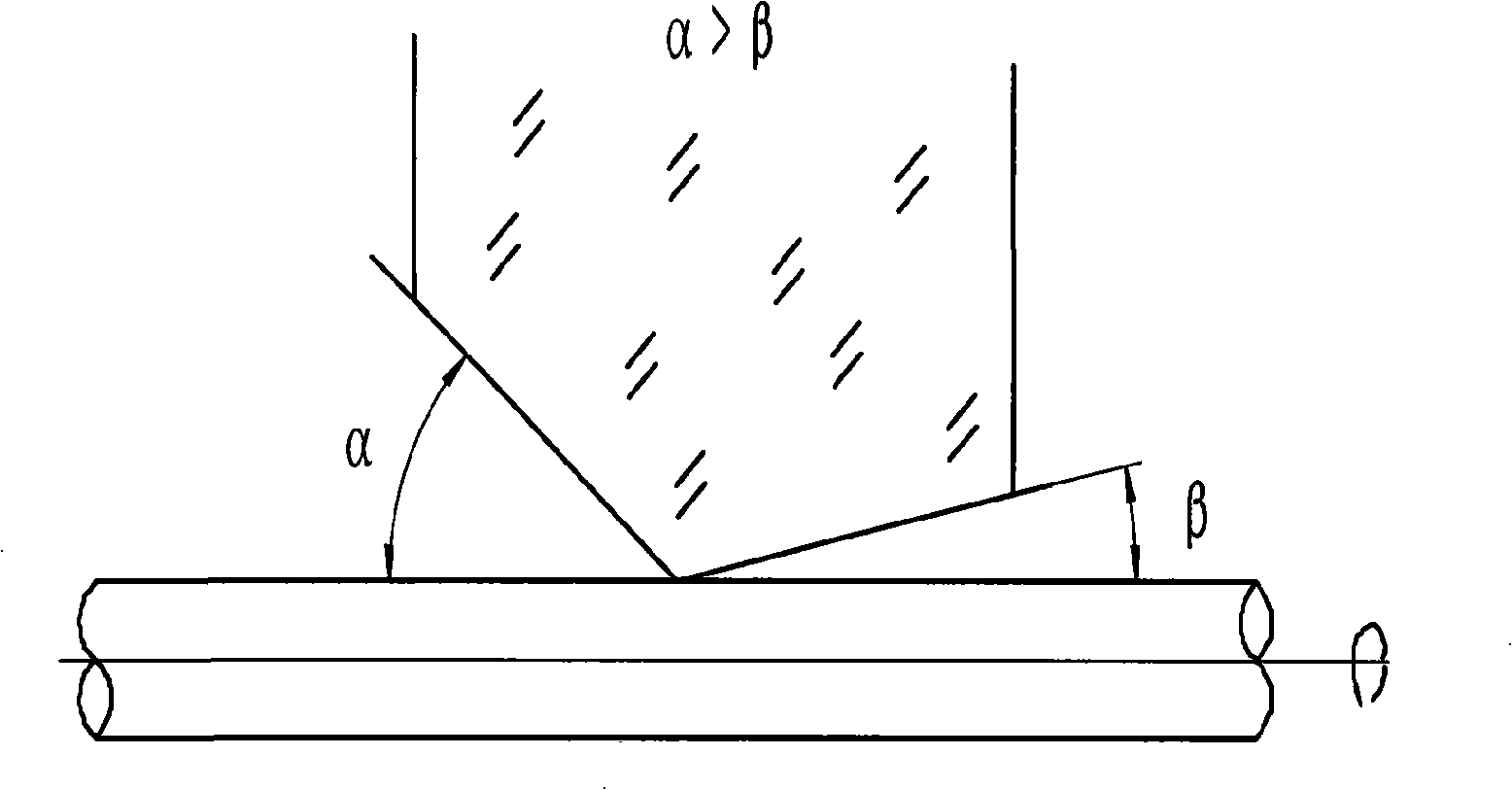

Integrated pin tool for friction stir welding and composite method of resistance-friction stir welding thereof

InactiveCN101537538AReduce wearExtended service lifeEngine sealsWelding/cutting media/materialsElectrical resistance and conductanceFriction welding

The invention discloses an integrated pin tool used for friction stir welding and a composite method of resistance-friction stir welding thereof. The pin tool comprises a pin tool body arranged on a friction welder and a tool pin arranged at the lower part of the tool pin body which is connected with the welder in a clamping and insulating manner; the pin tool also comprises a forced cooling system, a current carrying system, a gas shielding system, a temperature sensing and detecting system, a sealing and insulation system, an inner shaft shoulder and the tool pin, and is an integrated pin tool which has the functions of gas shielding, forced circulation cooling of internal liquid medium, automatic temperature sensing and detection, tool pin changing and composite non-keyhole resistance-friction stir welding. The invention overcomes the difficulty of friction stir welding of the high melting point metal and meets the harsh technical requirements of the friction stir welding of the low melting point metal, improves the quality of welding joints, prolongs the service life of the pin tool and realizes the friction stir welding of high melting point metal and low melting point light alloy, with low cost, high efficiency and excellent quality.

Owner:CHONGQING UNIV

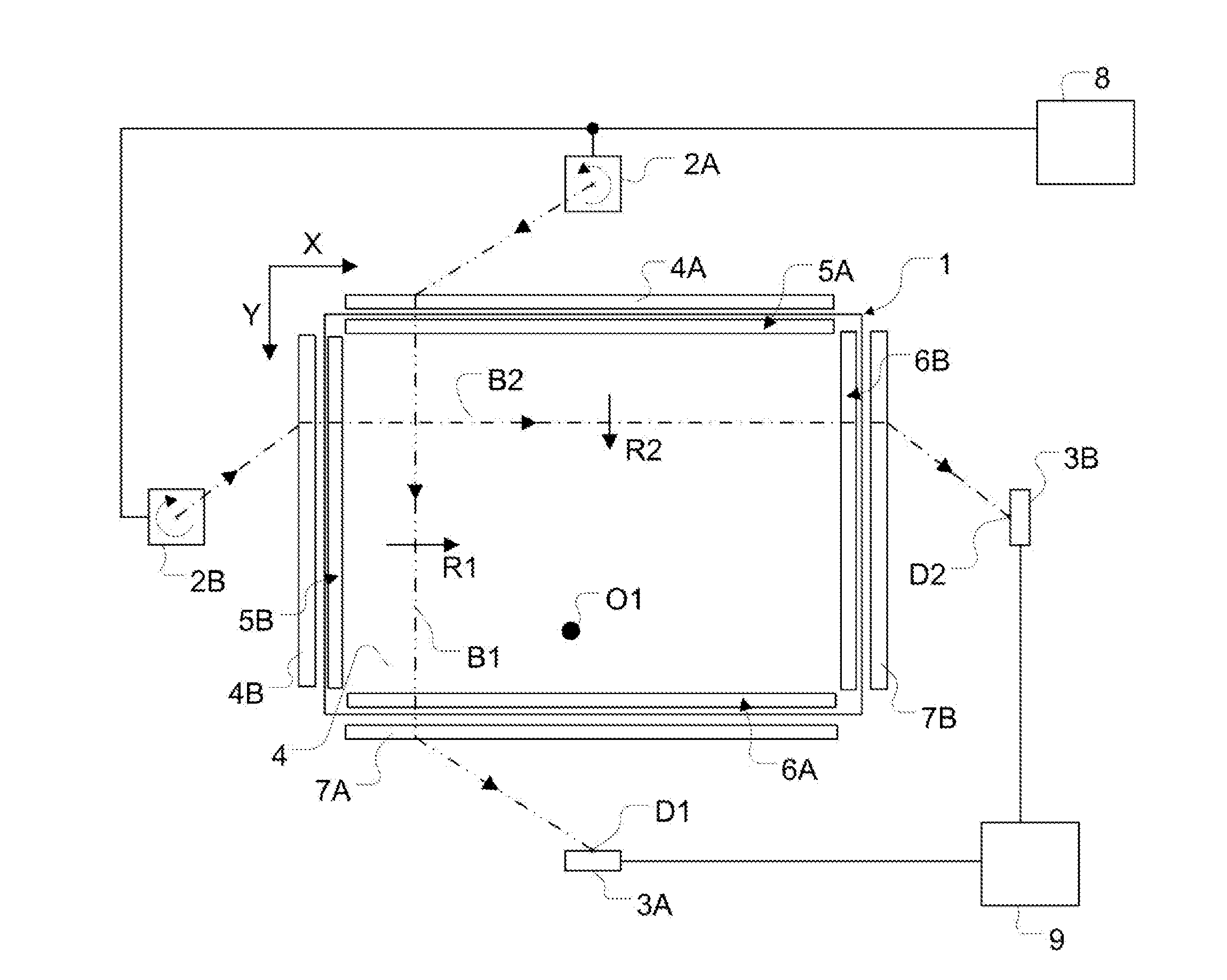

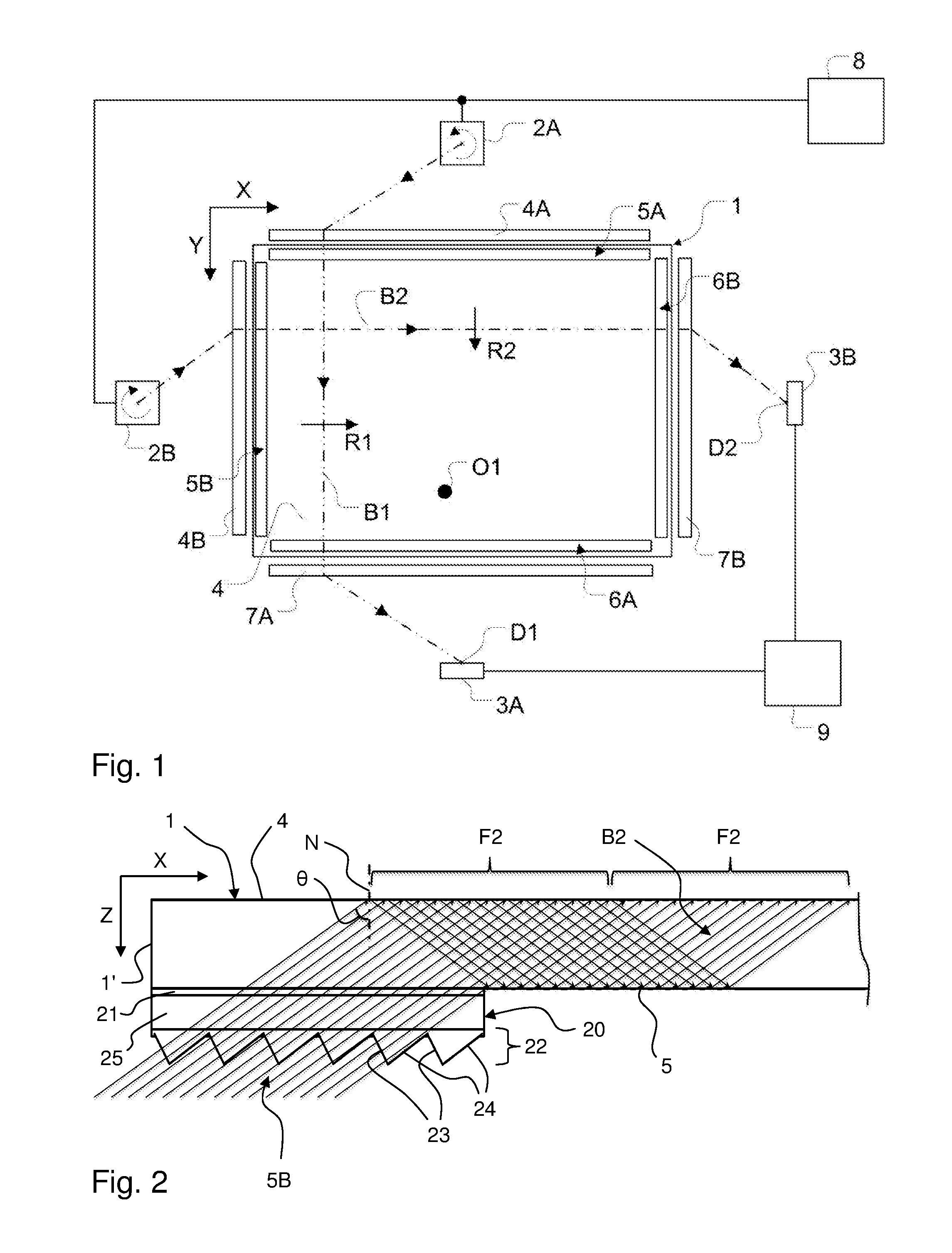

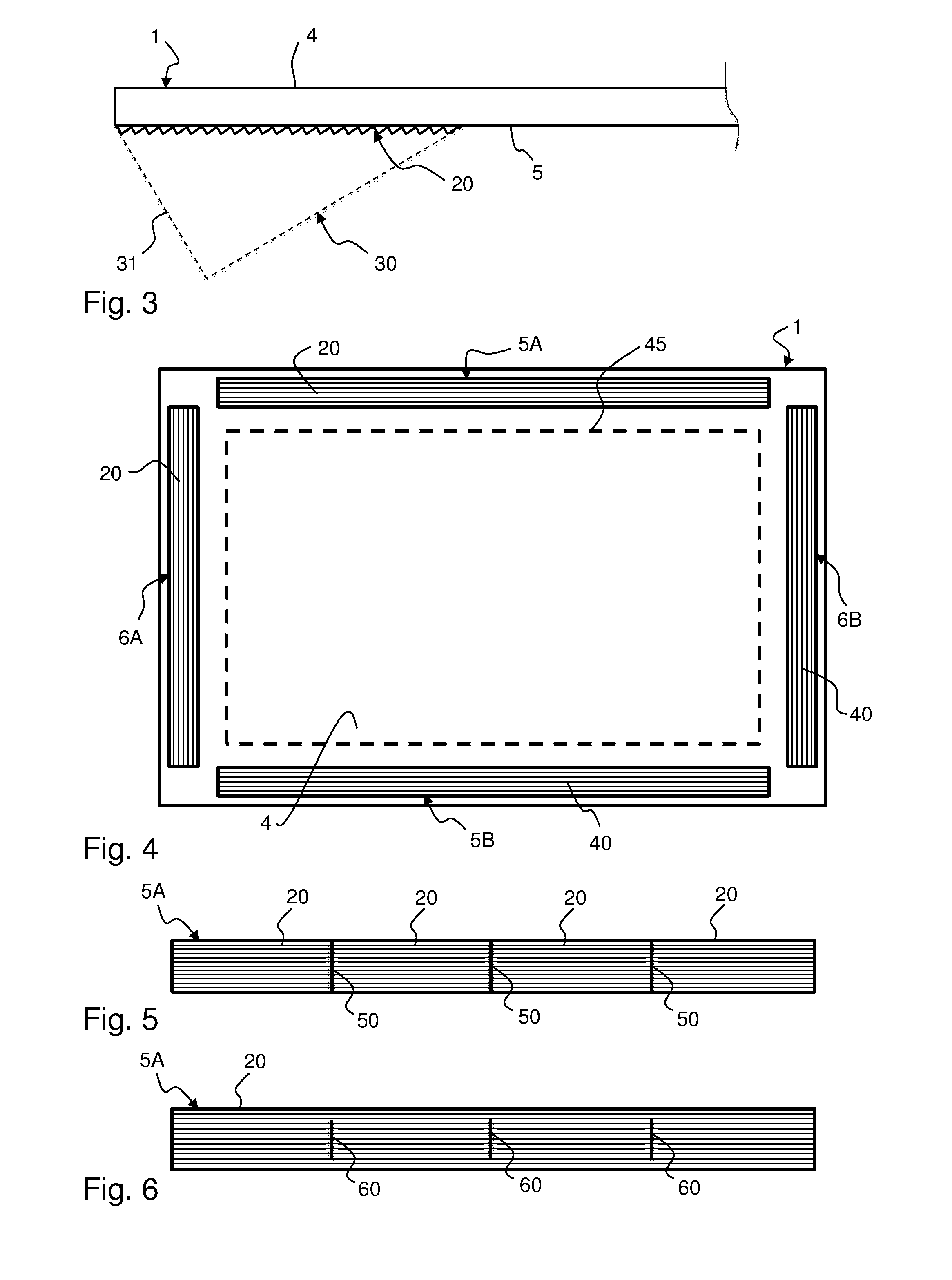

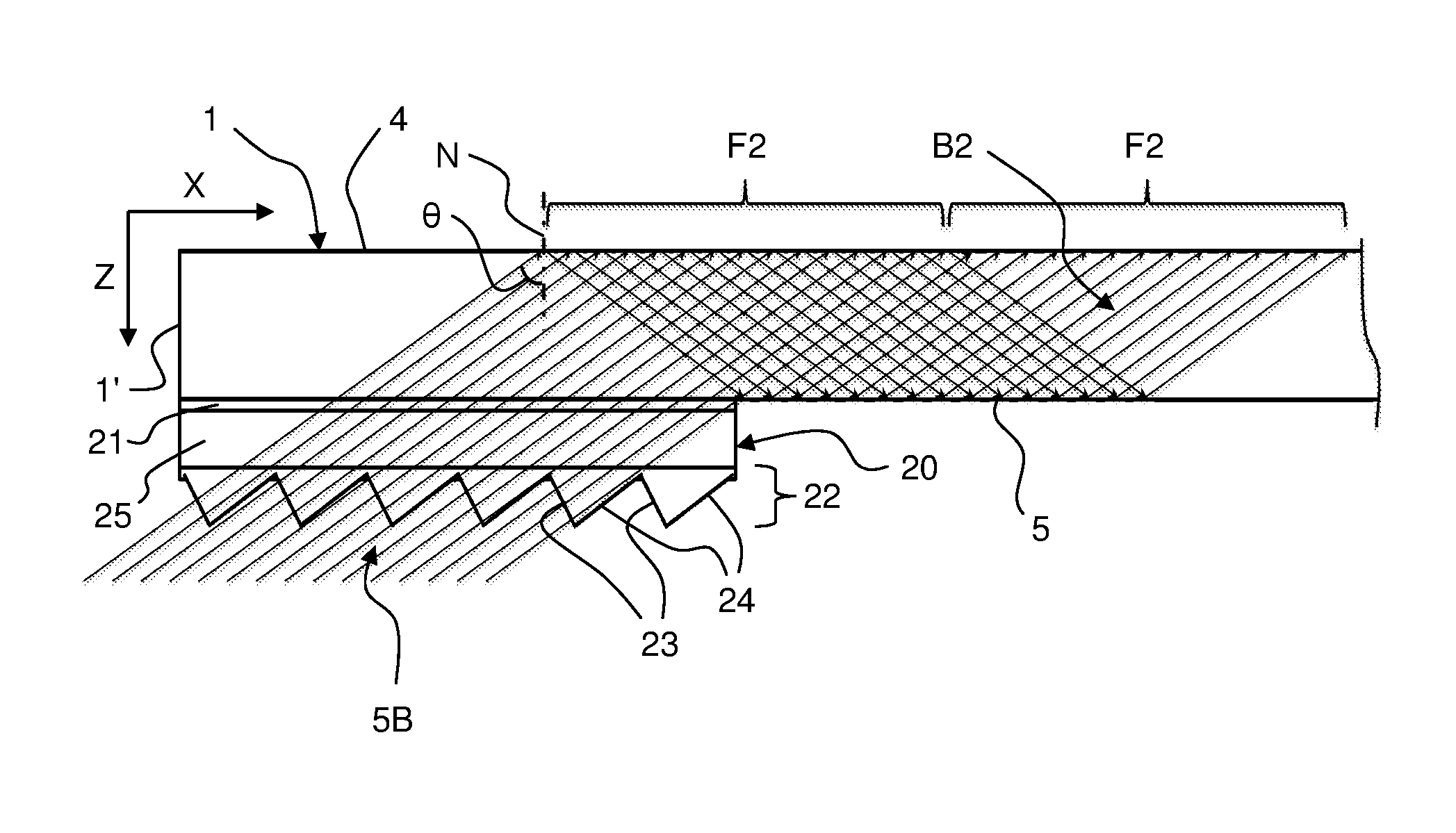

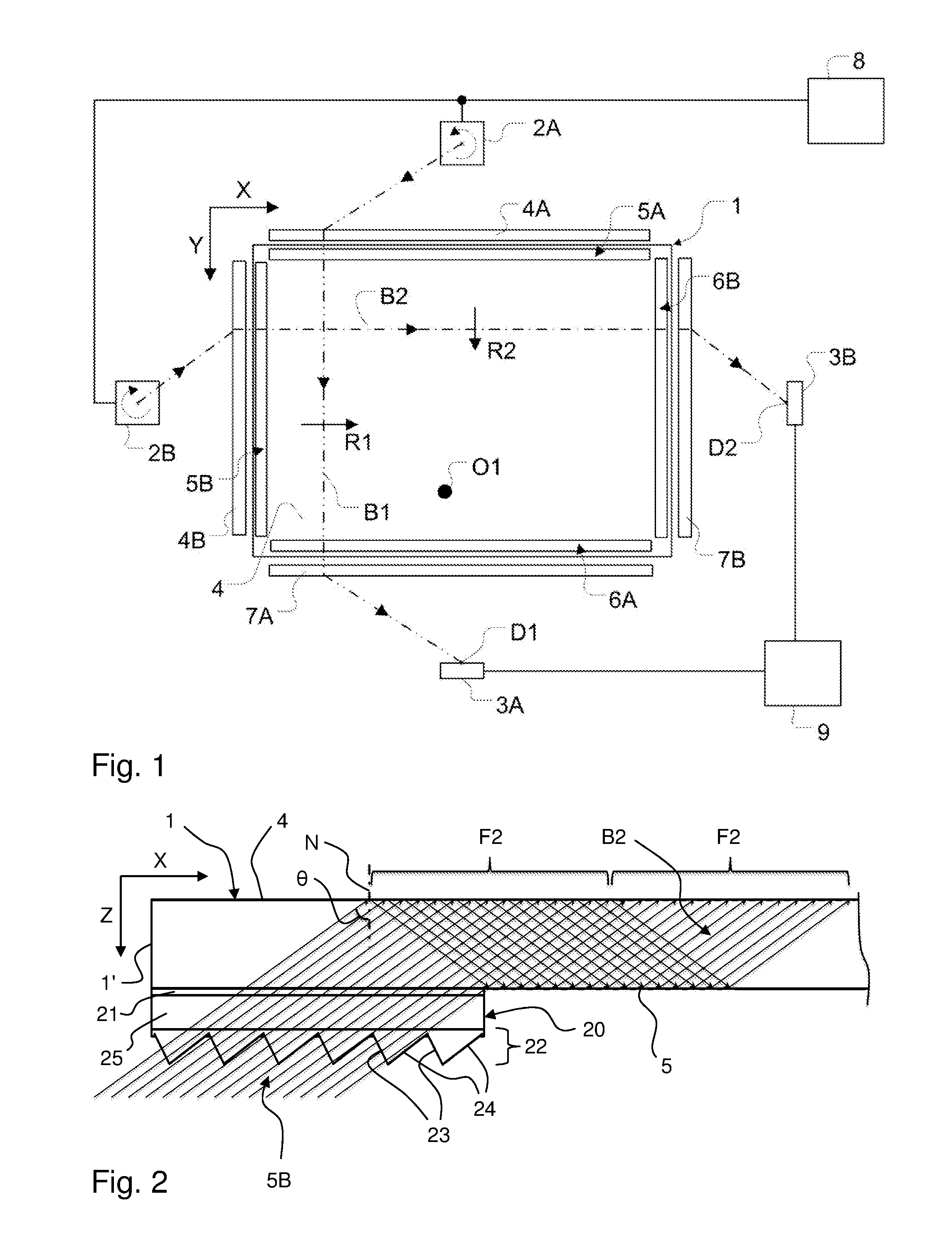

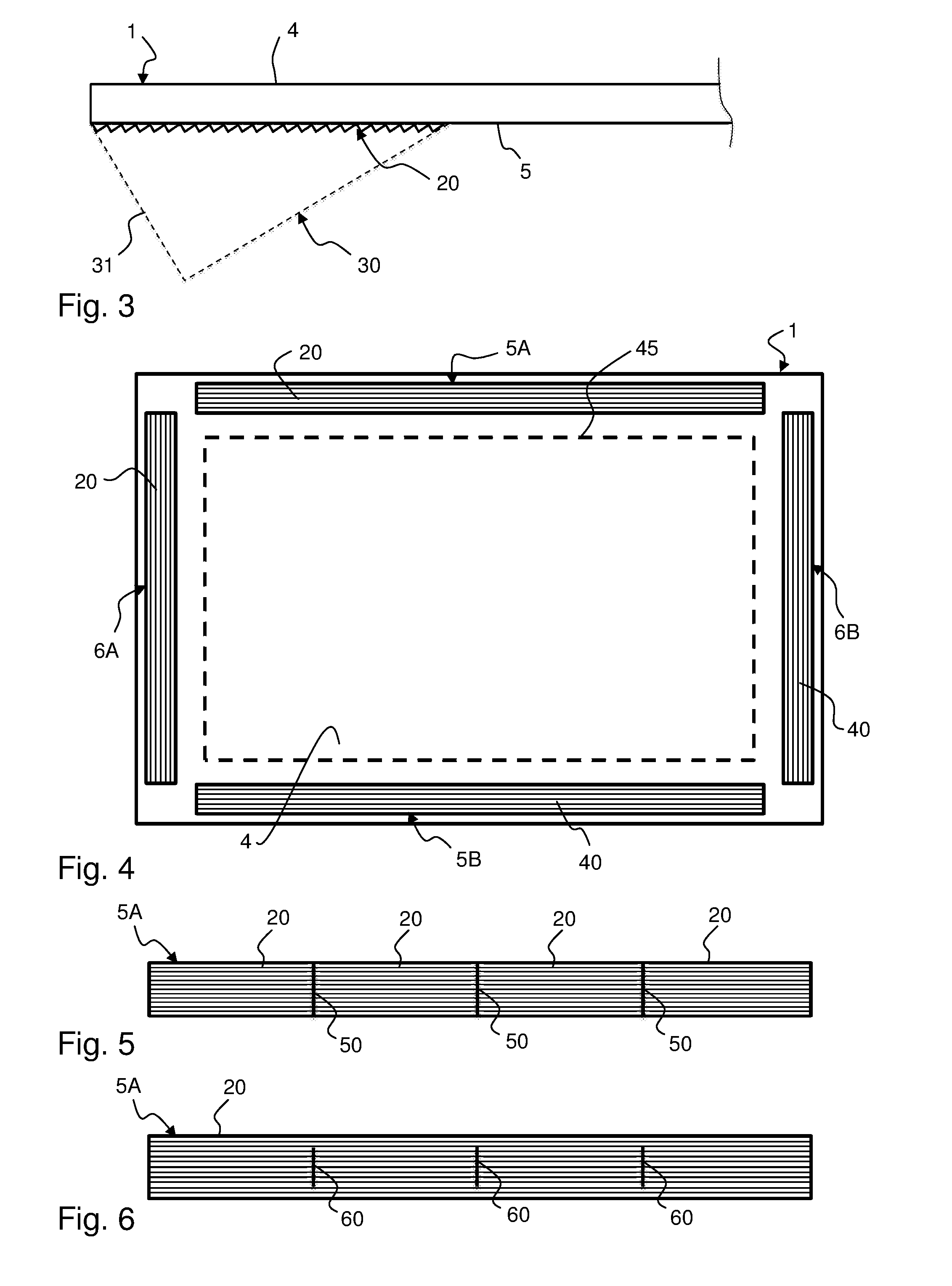

Optical incoupling for touch-sensitive systems

ActiveUS20130300716A1Efficient and robust couplingLess dependentPlanar/plate-like light guidesInput/output processes for data processingTotal internal reflectionAngle of incidence

A touch-sensitive apparatus comprises a light transmissive panel, an illumination arrangement and a detection arrangement. The illumination arrangement is configured to couple light into the panel via an incoupling site such that the light propagates by total internal reflection in opposite top and bottom surfaces of the panel and such that an object touching the top or bottom surface causes a change in the propagating light. The detection arrangement comprises a light detector arranged to detect the change in the propagating light. A compact and robust incoupling site is defined by a sheet-like micro-structured surface portion which is fixedly arranged on one of the top and bottom surfaces and configured to transmit light having an angle of incidence that enables light propagation by TIR inside the panel.

Owner:FLATFROG LAB

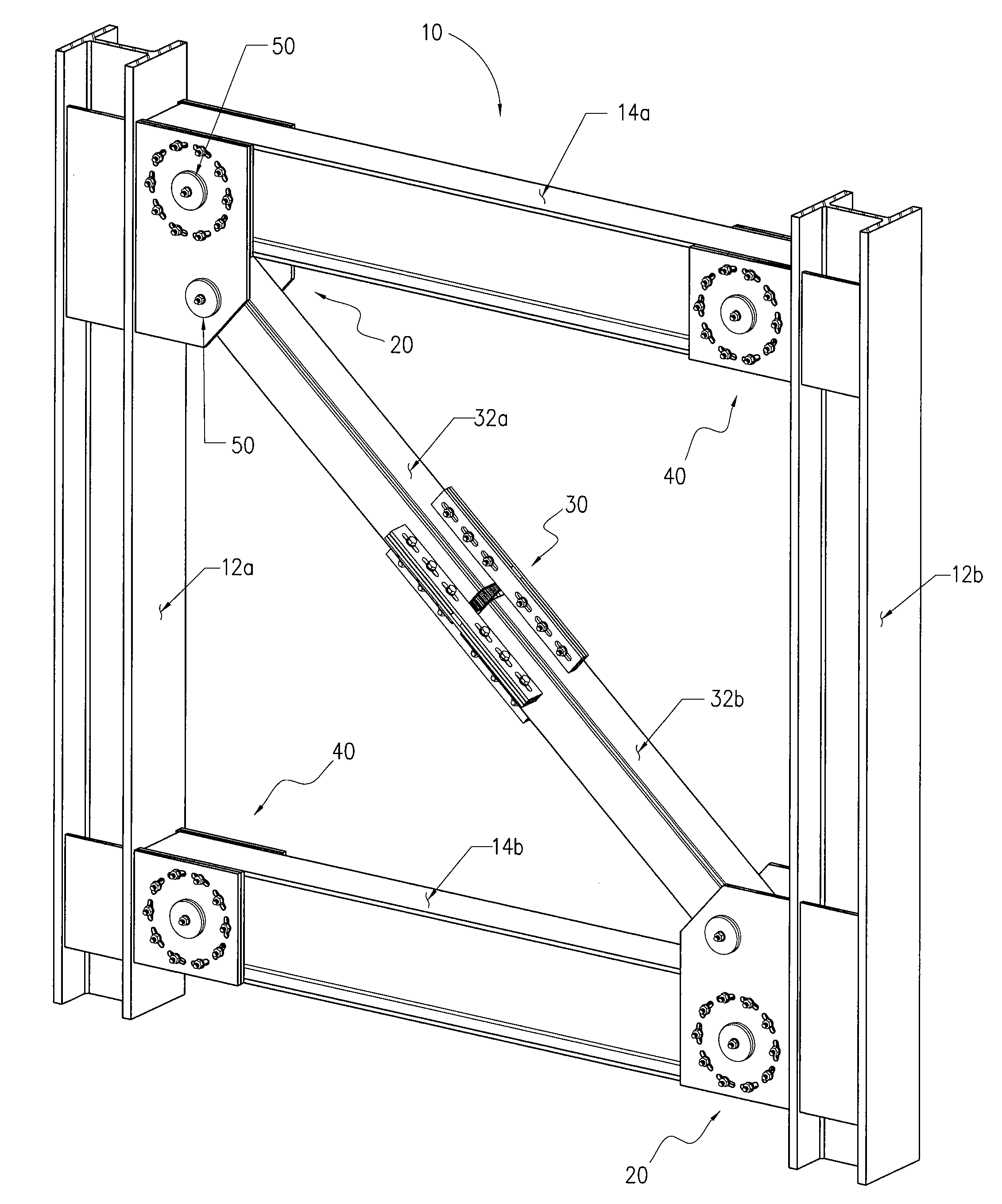

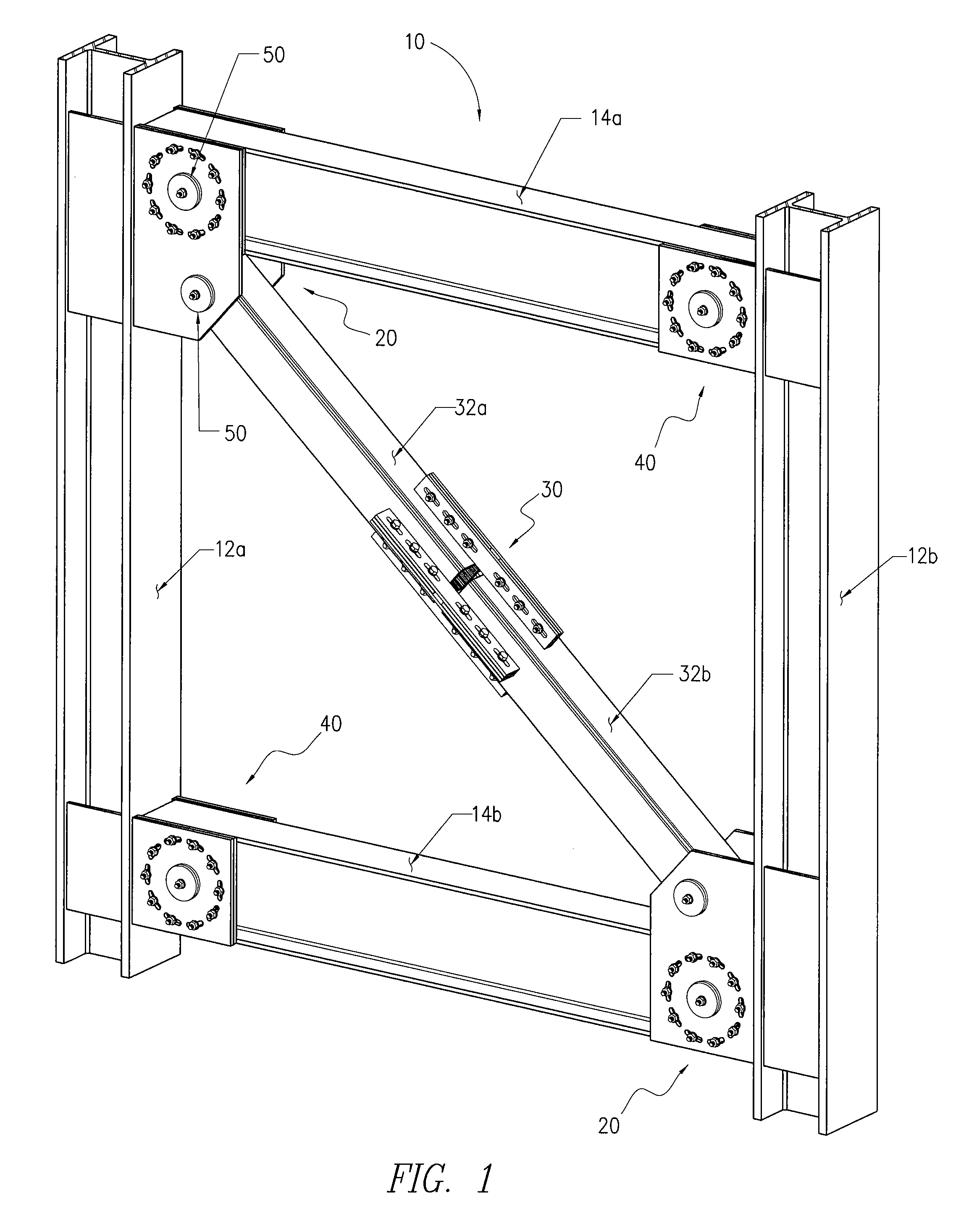

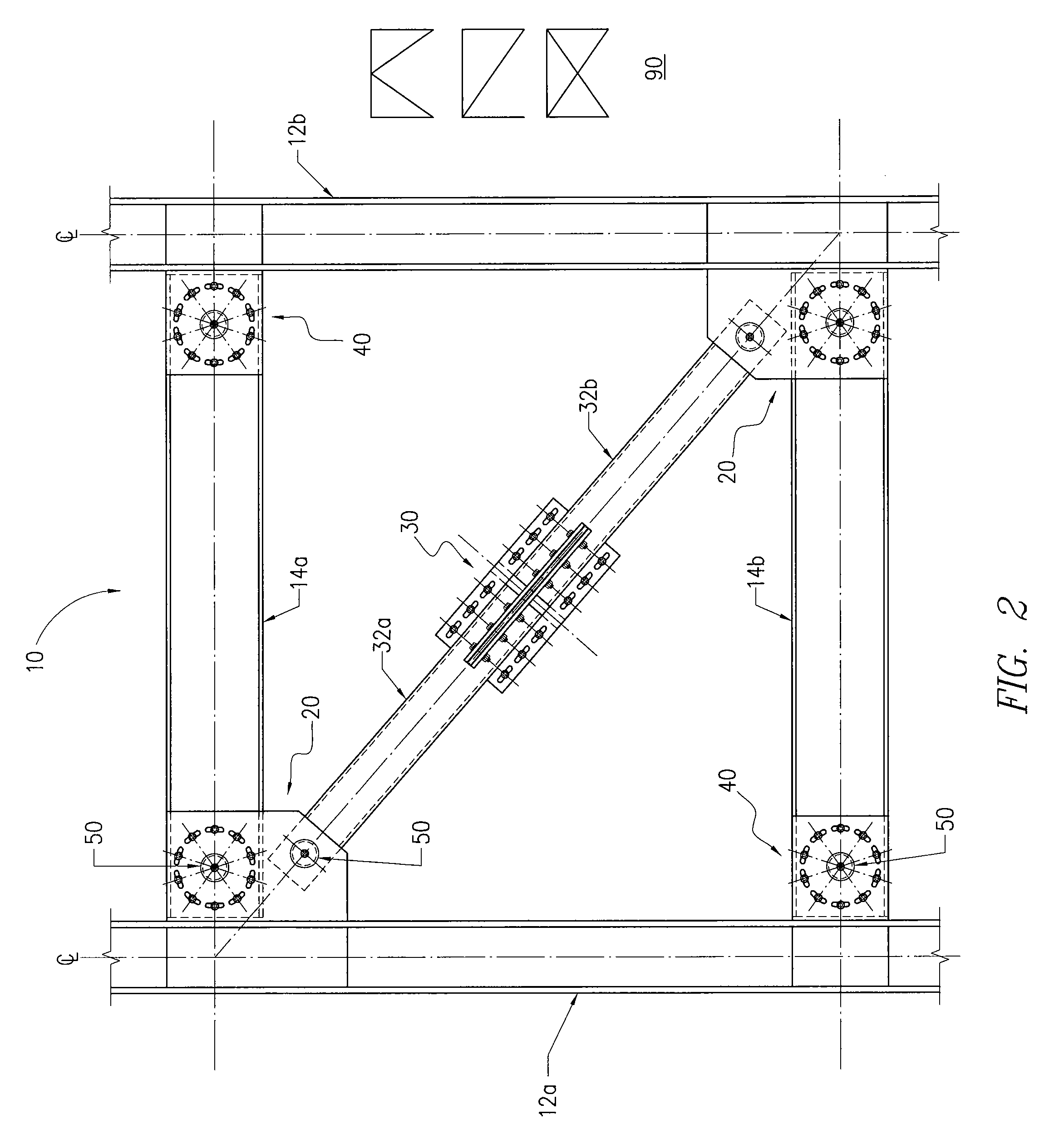

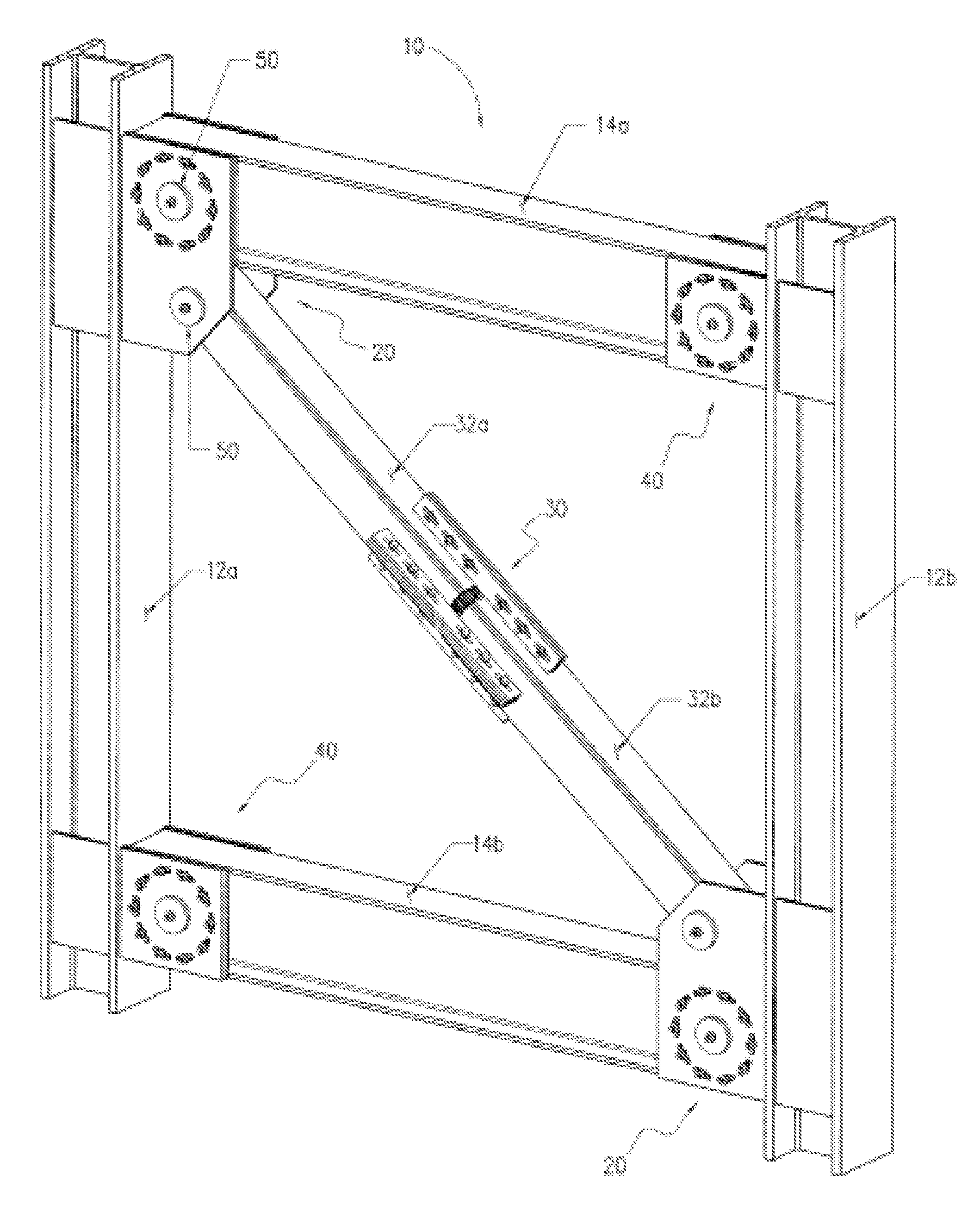

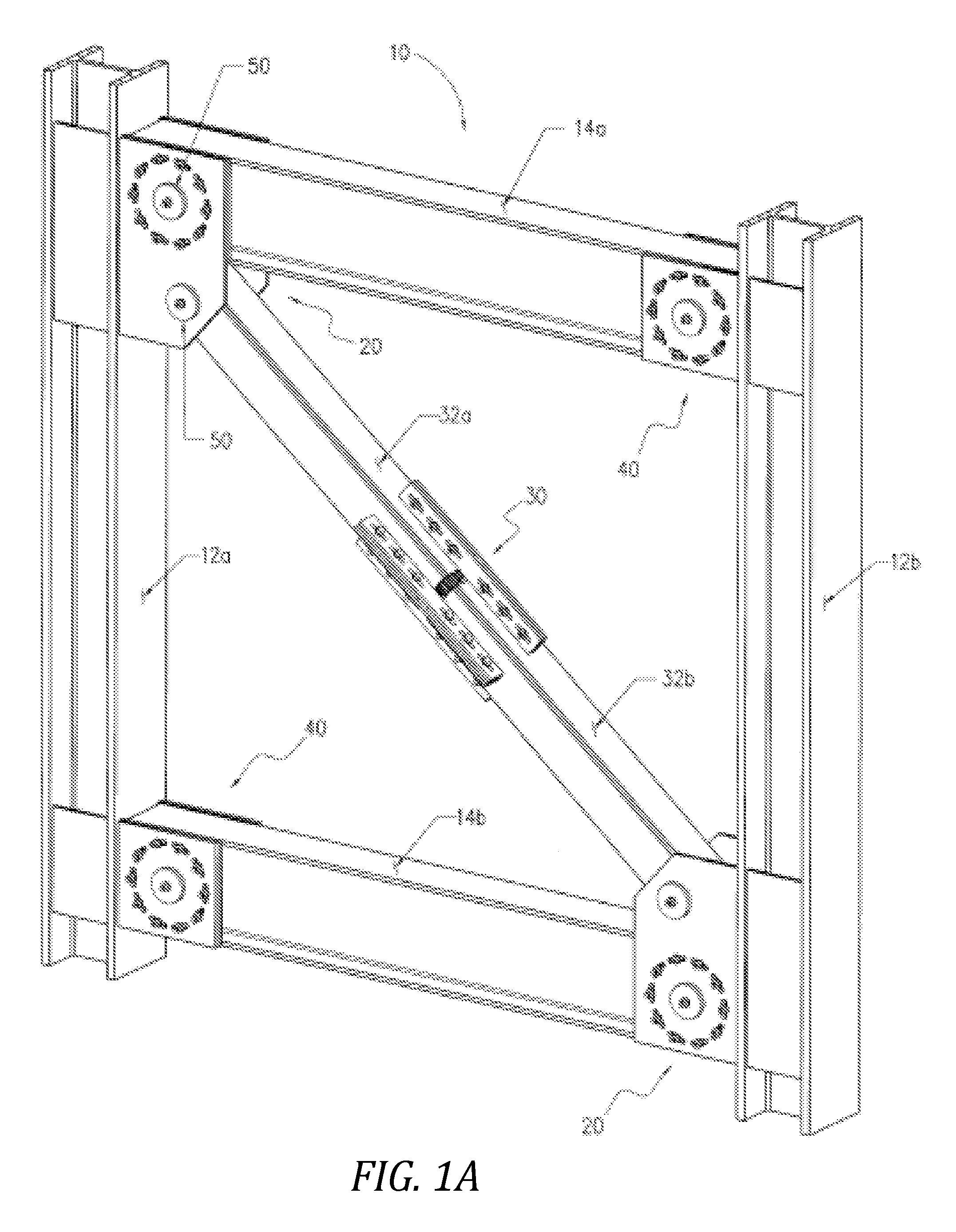

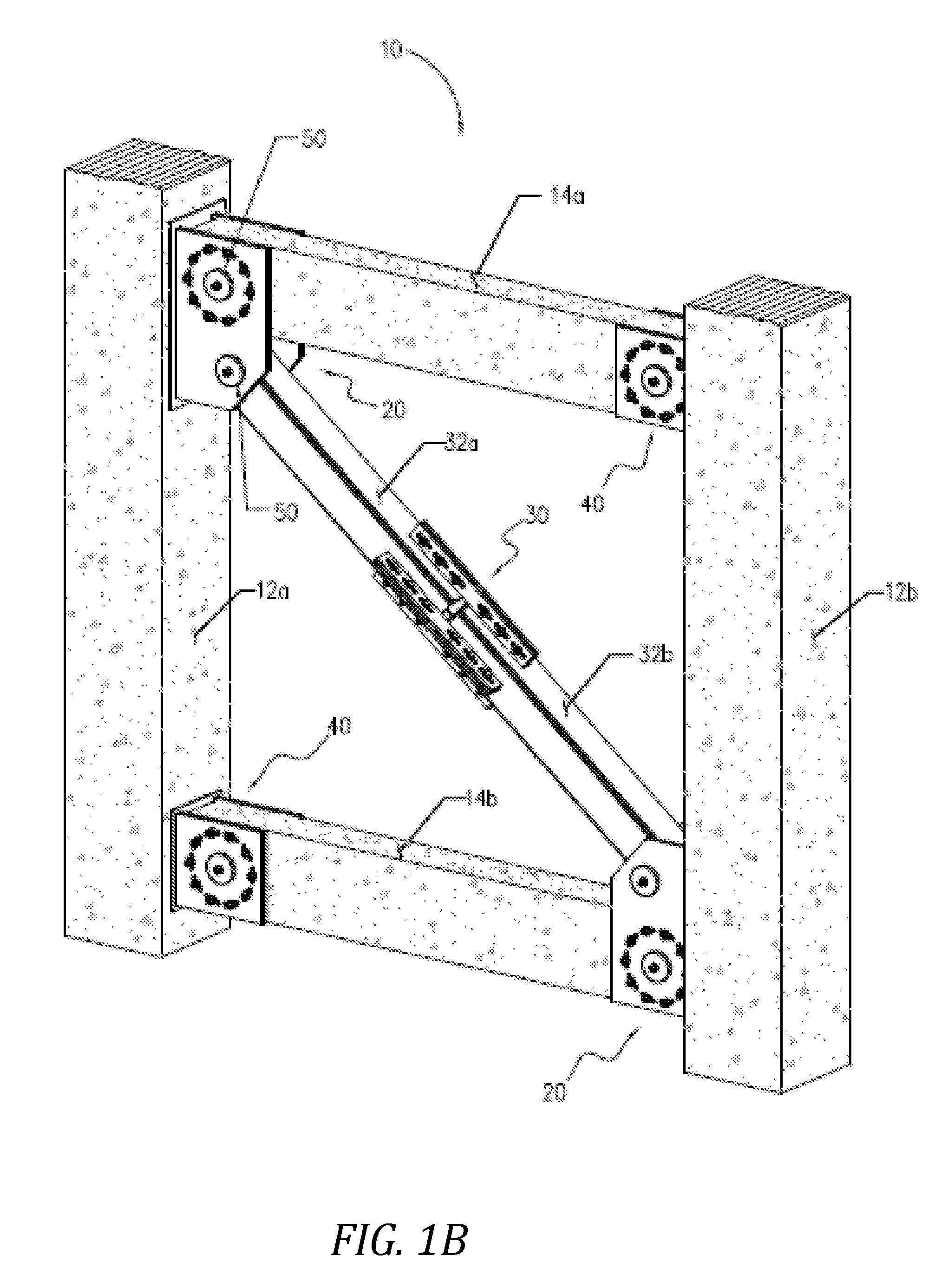

Seismic structural device

ActiveUS20080289267A1Simple structureChange structureTowersProtective buildings/sheltersExternal connectionEngineering

A pin-fuse frame is used in a frame assembly that may be subject to extreme seismic loading. The pin-fuse frame includes of columns, beams, plate assemblies that extend between columns and beams, and may included a diagonal brace. The plate assemblies are fixed to the columns and attached to the beams and brace via pin joints. A joint includes a pin connection through outer connection plates connected to a column and inner connection plates connected to a beam. Connecting rods positioned about the pin maintain a coefficient of friction until exposed to extreme seismic activity, at which time the joint accommodates a slippage of at least one of the inner and outer connection plates relative to each other rotationally about the pin. The diagonal brace is separated into two segments connected together with connection plates. These connection plates accommodate a slippage of the segments relative to each other.

Owner:SKIDMORE OWINGS & MERRILL

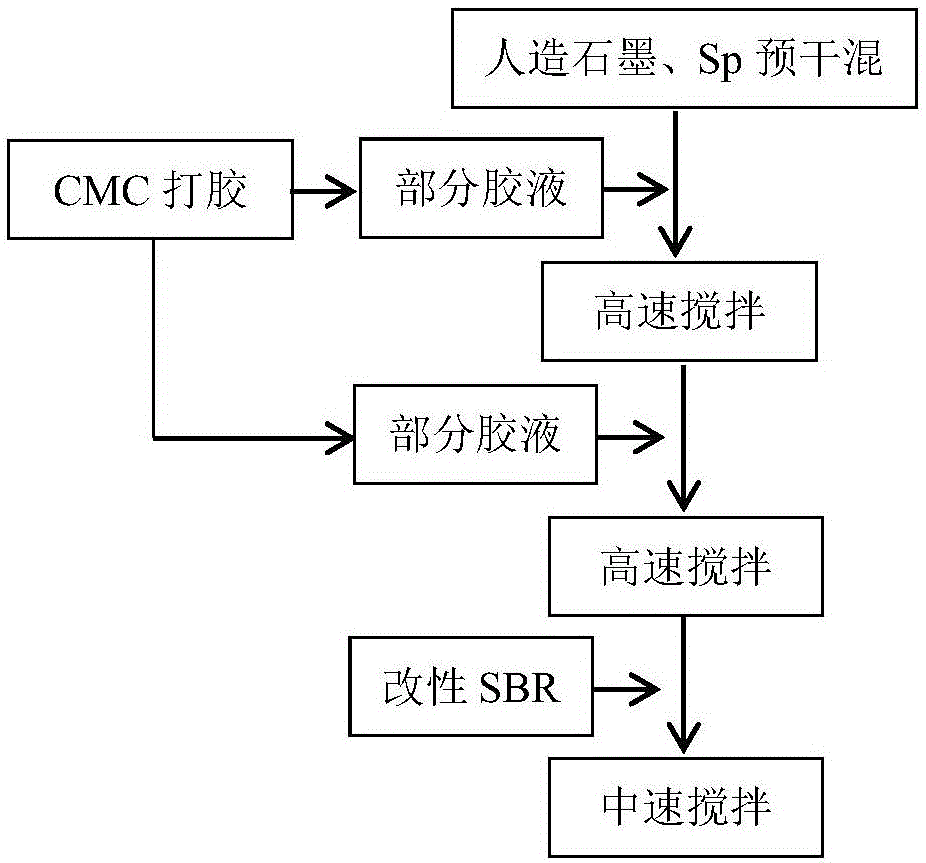

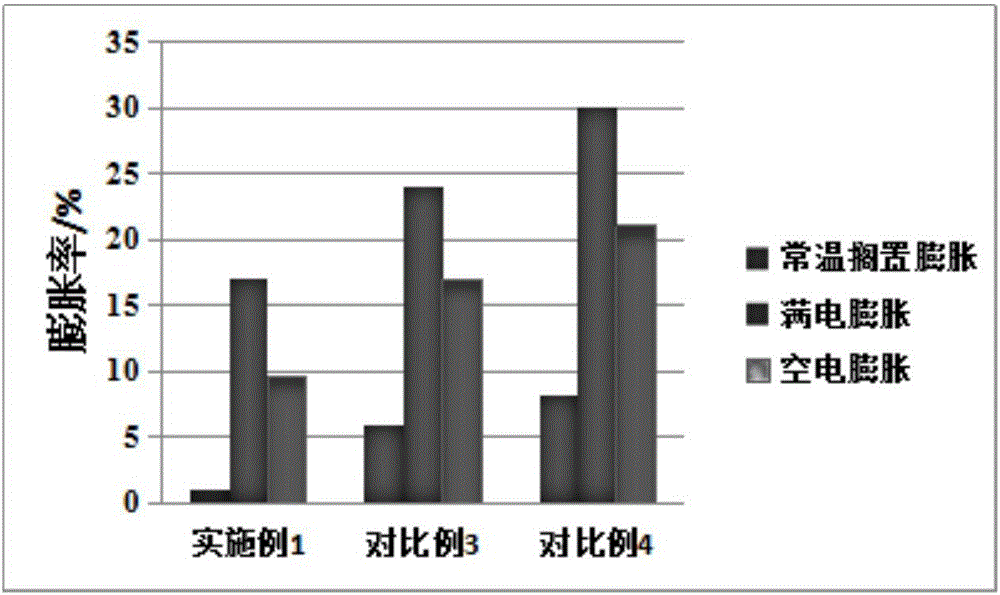

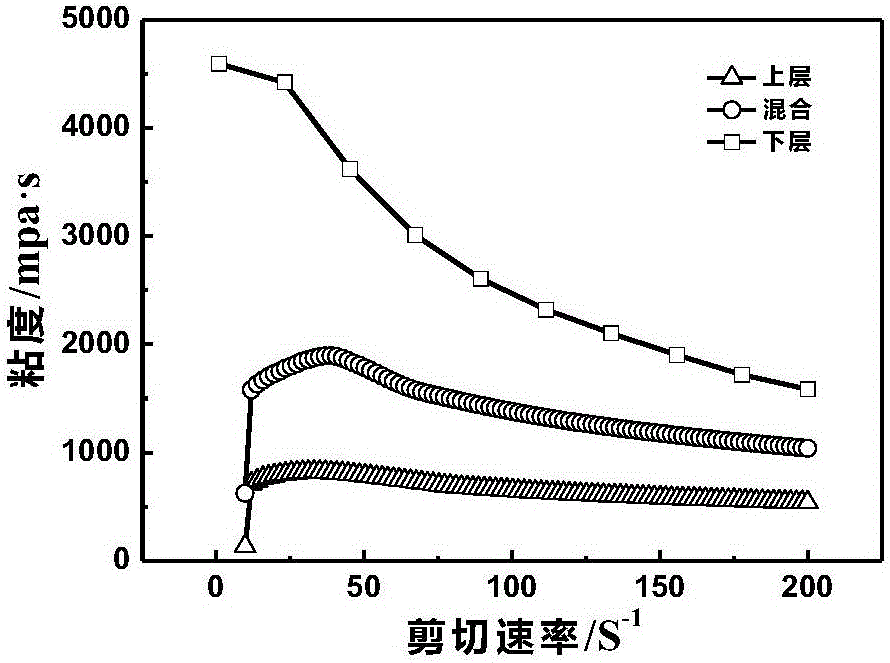

Preparation method of negative electrode slurry capable of reducing expansion of lithium ion battery

ActiveCN106159266AReduce bridgingChange structureCell electrodesSecondary cellsSlurrySodium-ion battery

The invention discloses a preparation method of negative electrode slurry capable of reducing the expansion of a lithium ion battery. The preparation method comprises the following steps of: carrying out dry blending on a negative electrode active substance and a conducting agent in advance; dissolving sodium carboxymethyl cellulose into de-ionized water to obtain a CMC (Carboxyl Methyl Cellulose) gel solution with the concentration of 1.0%-2.0%; adding one part of the CMC gel solution into a mixture of the negative electrode active substance and the conducting agent and stirring at a high speed for 0.5-1h; adding the balance of CMC gel solution and stirring at a high speed for 1-3h; adding a modified SBR (Styrene Butadiene Rubber) binding agent and stirring at a middle speed for 0.3-1h; and adjusting the viscosity. By adopting the method of carrying out the dry blending on artificial graphite and the conducting agent in advance, adding the glue solution by two times and utilizing modified SBR as the binding agent, a bridge phenomenon of the artificial graphite is reduced, a pole piece structure is changed, the binding force between grains is improved and the expansion of a negative electrode is reduced; meanwhile, the slurry sedimentation of the artificial graphite is inhibited. The preparation method of the negative electrode slurry capable of reducing the expansion of the lithium ion battery has important meanings on ternary lithium ion batteries and improvement of machinability, capacity and safety of high-capacity power batteries.

Owner:南京国轩新能源有限公司

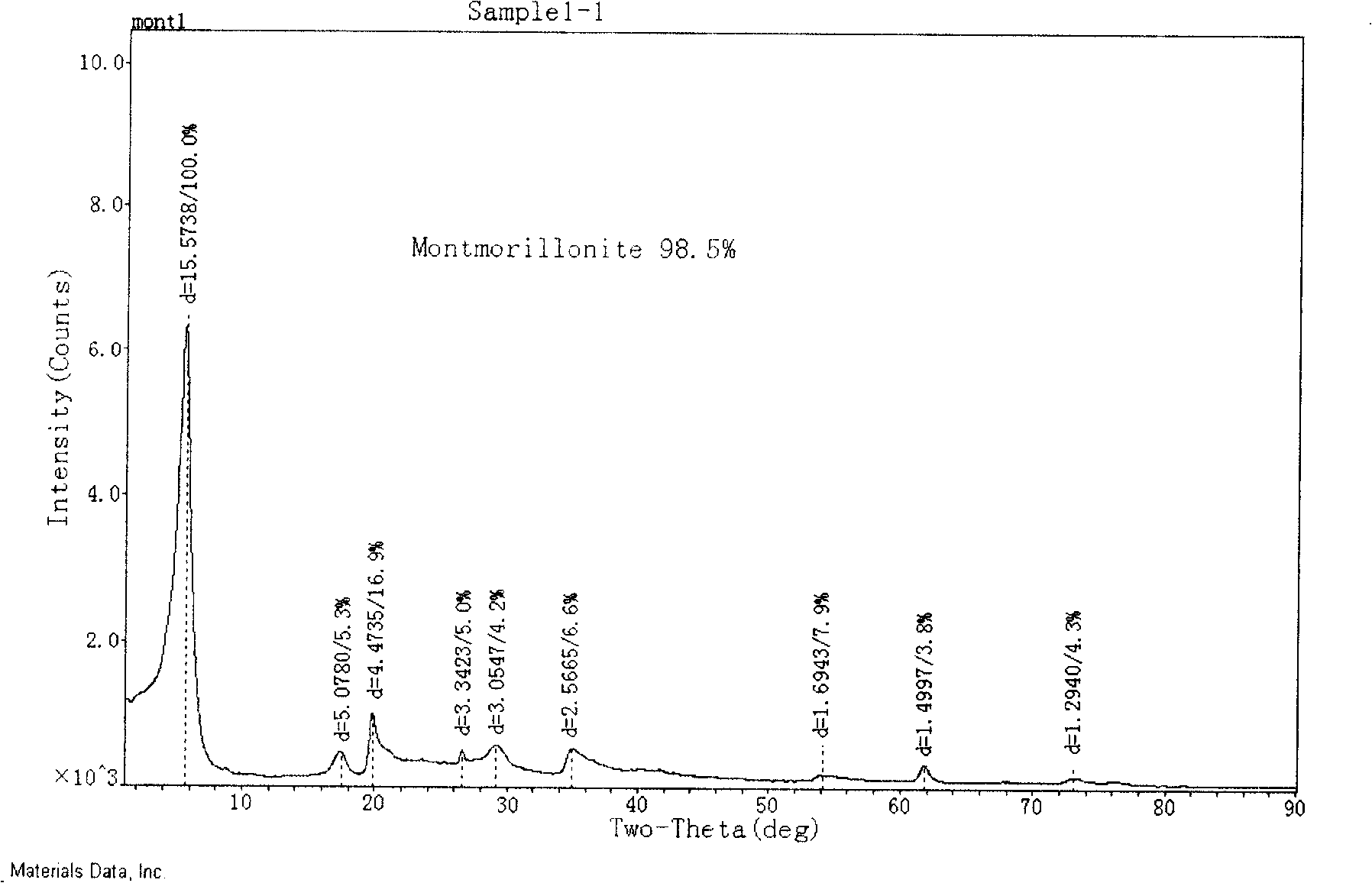

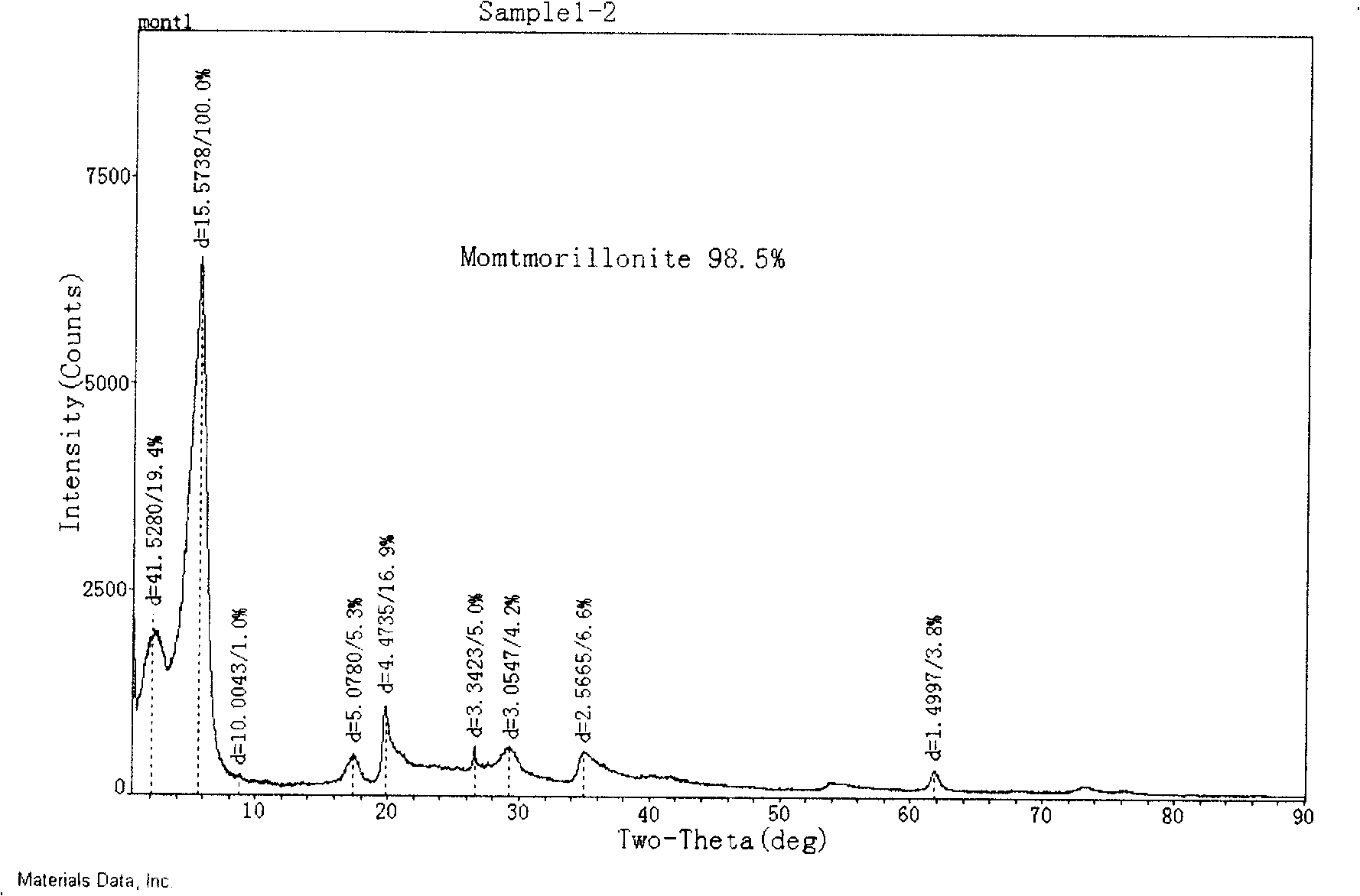

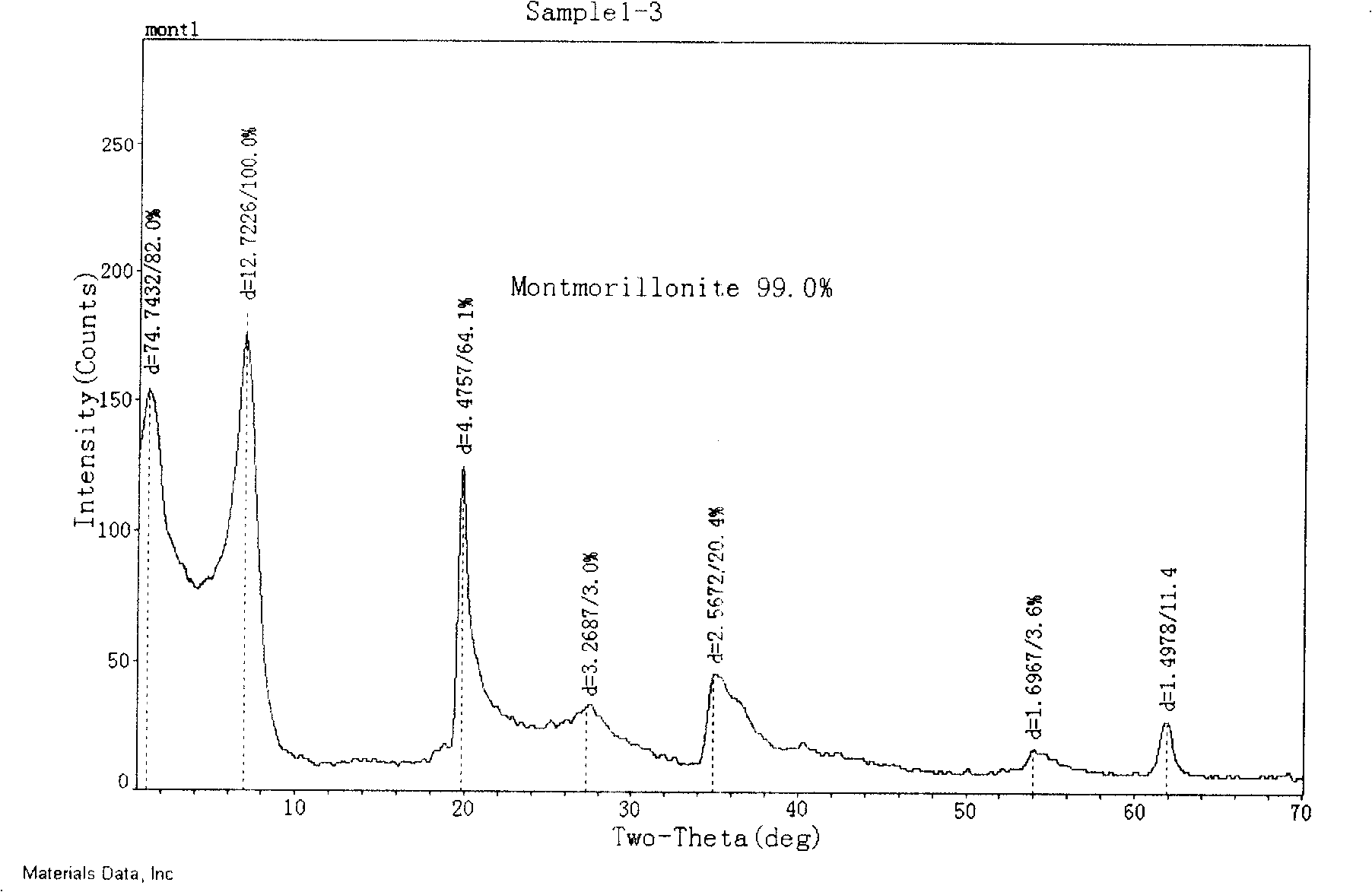

Modified smectite and method for producing the same and its application

ActiveCN101272986ANot easy to raise dustReduce moisture contentCosmetic preparationsOther chemical processesChemical compositionMontmorillonite

Disclosed is an inorganic medicine, particularly modified montmorillonite, method for preparing the same and use thereof. The said modified montmorillonite means that dioctahedron of natural montmorillonite is not destroyed and basic chemical composition for the same is not changed, and the microstructure stacked from dioctahedron layer is changed to decrease the thickness of stacking layer and to expose and increase the end face charge and the interlayer charge of montmorillonite, thereby resulting in its lower degree of C axis order. The present medical use of montmorillonite is thus significantly strengthened, particularly the reversal treatment effect on chronic atrophic gastritis. Also disclosed are a medicine composition containing modified montmorillonite and the reversal treatment effect of natural montmorillonite on chronic atrophic gastritis.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

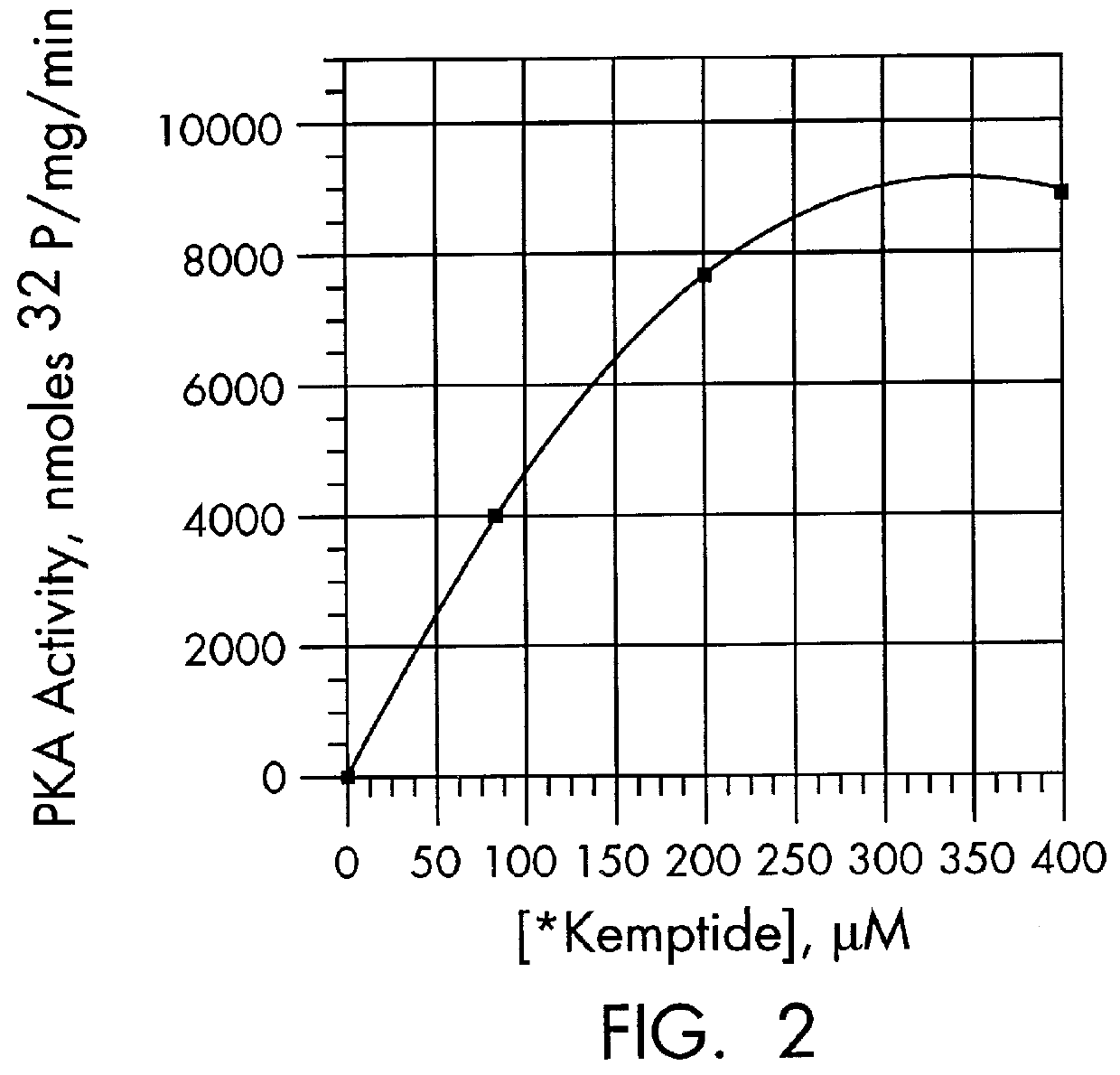

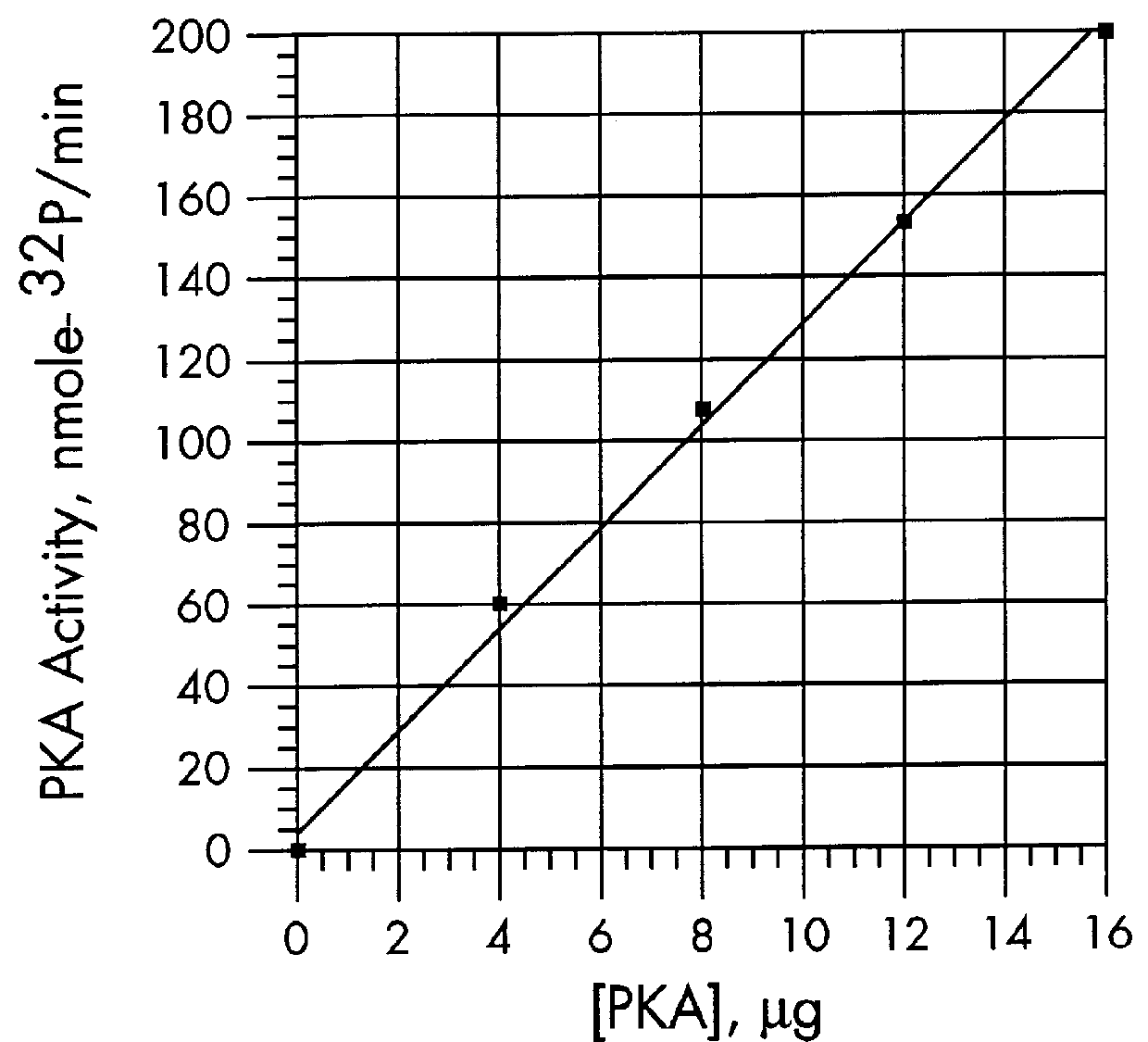

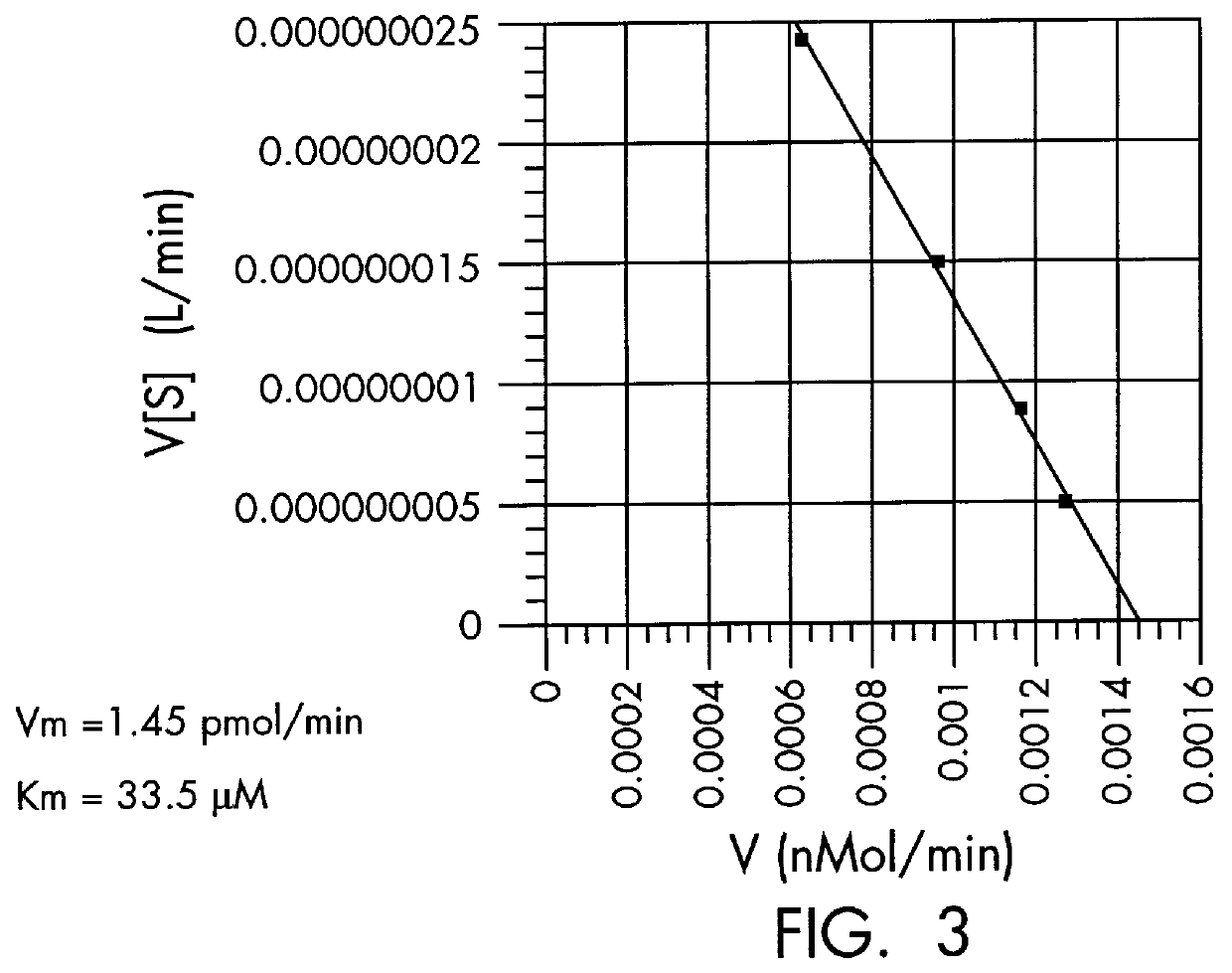

Quantitation of individual protein kinase activity

InactiveUS6066462AMinimal lossAccurate estimateMicrobiological testing/measurementPeptide preparation methodsPeptide substrateSufficient time

A method of quantitating the activity of a selected protein kinase on a peptide substrate is provided. The peptide substrate is conjugated to a binding compound. The modified peptide substrate is then added to a solution containing the selected protein kinase. The protein kinase and the peptide are incubated along with a label for sufficient time to form a modified peptide product having the binding compound and the label. The modified peptide product is then bound to a matrix having a high binding compound affinity. The bound peptide is then washed and the activity of the protein kinase is measured. Also provided is a kit for the stated method.

Owner:PROMEGA

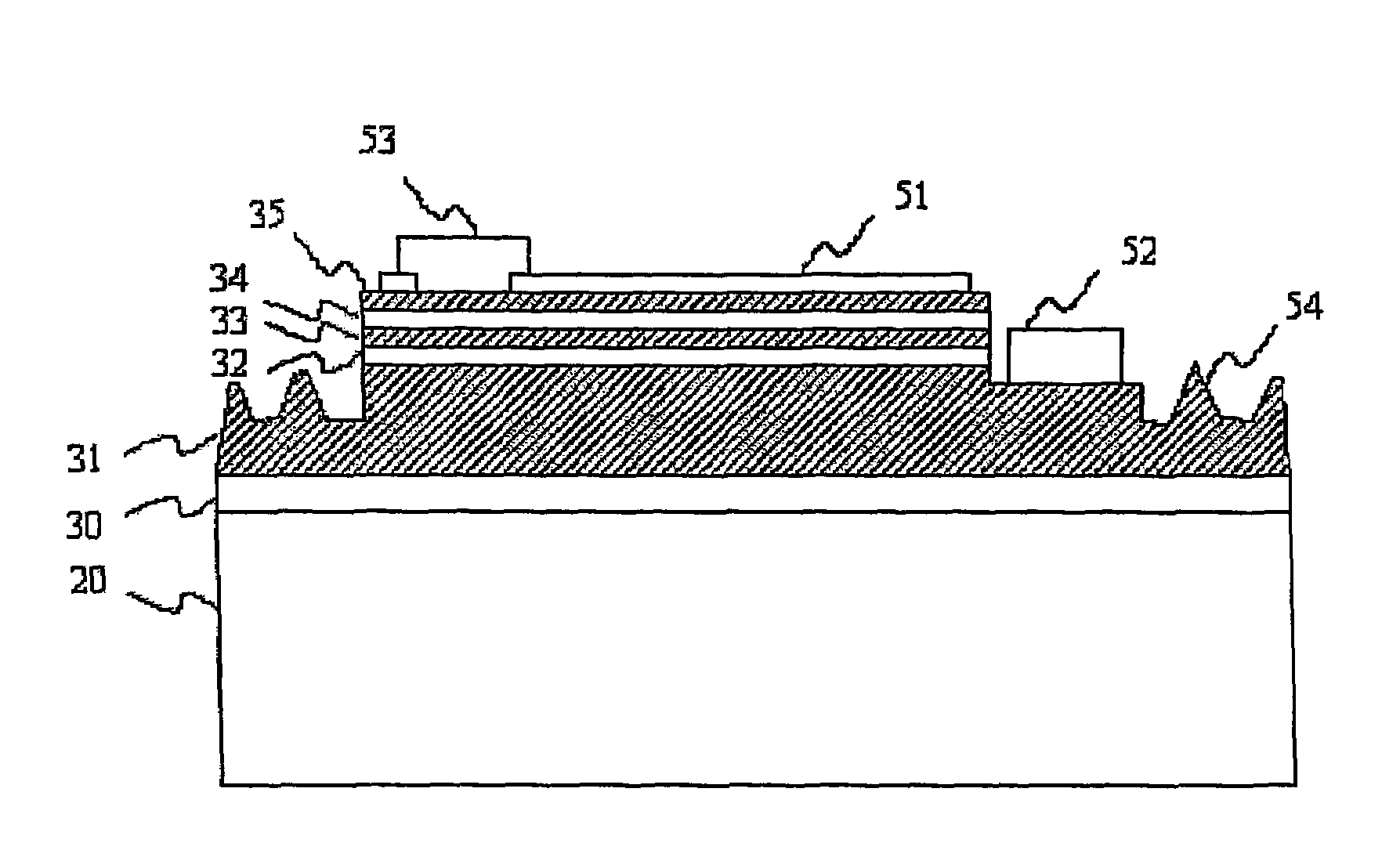

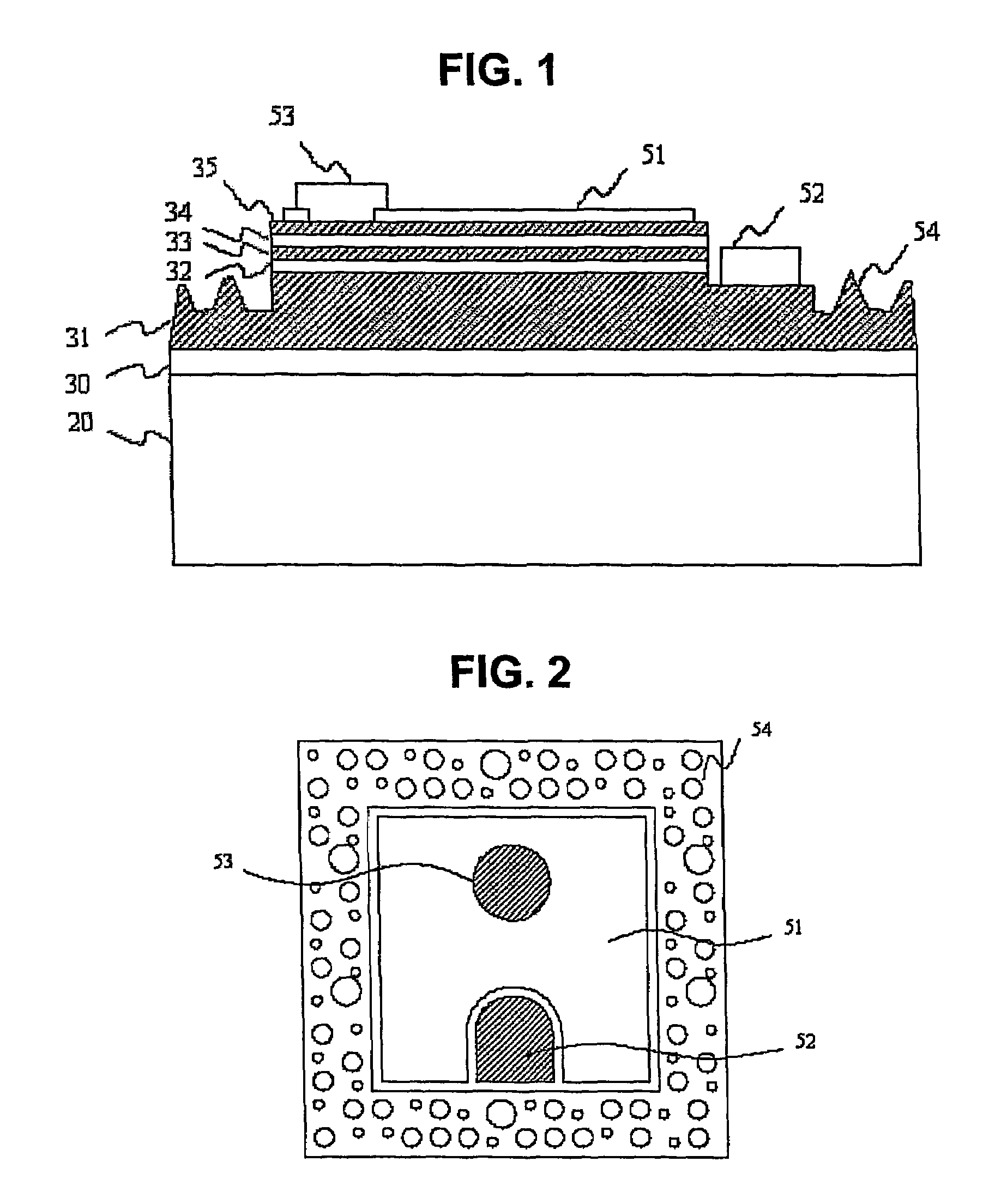

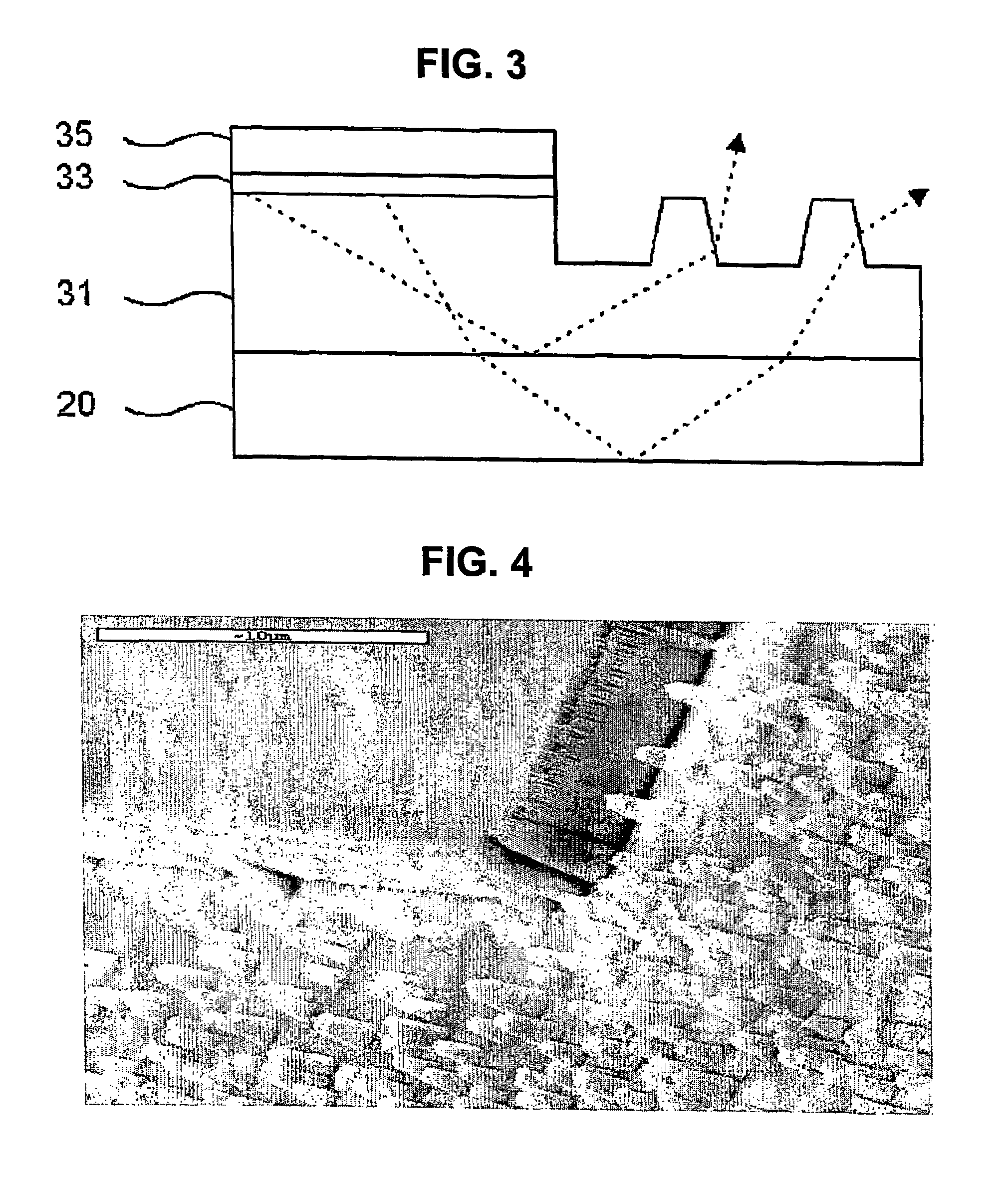

III-nitride compound semiconductor light emitting device

InactiveUS7622742B2Improve external quantum efficiencyChange structureLaser detailsSolid-state devicesQuantum efficiencyNitrogen

The present invention relates to a III-nitride semiconductor light-emitting device having high external quantum efficiency, provides a III-nitride compound semiconductor light-emitting device including an active layer generating light by recombination of electrons and holes and containing gallium and nitrogen, an n-type Al(x)ln(y)Ga(1-x-y)N layer epitaxially grown before the active layer is grown, and an n-type electrode electrically contacting with the n-type Al(x)ln(y)Ga(1-x-y)N layer, in which the n-type Al(x)ln(y)Ga(1-x-y)N layer has a surface which is exposed by etching and includes a region for scribing and breaking the device and a region for contact with the n-type electrode, and the surface of the region for scribing and breaking the device is roughened, thereby it is possible to increase external quantum efficiency of the light-emitting device.

Owner:EPIVALLEY

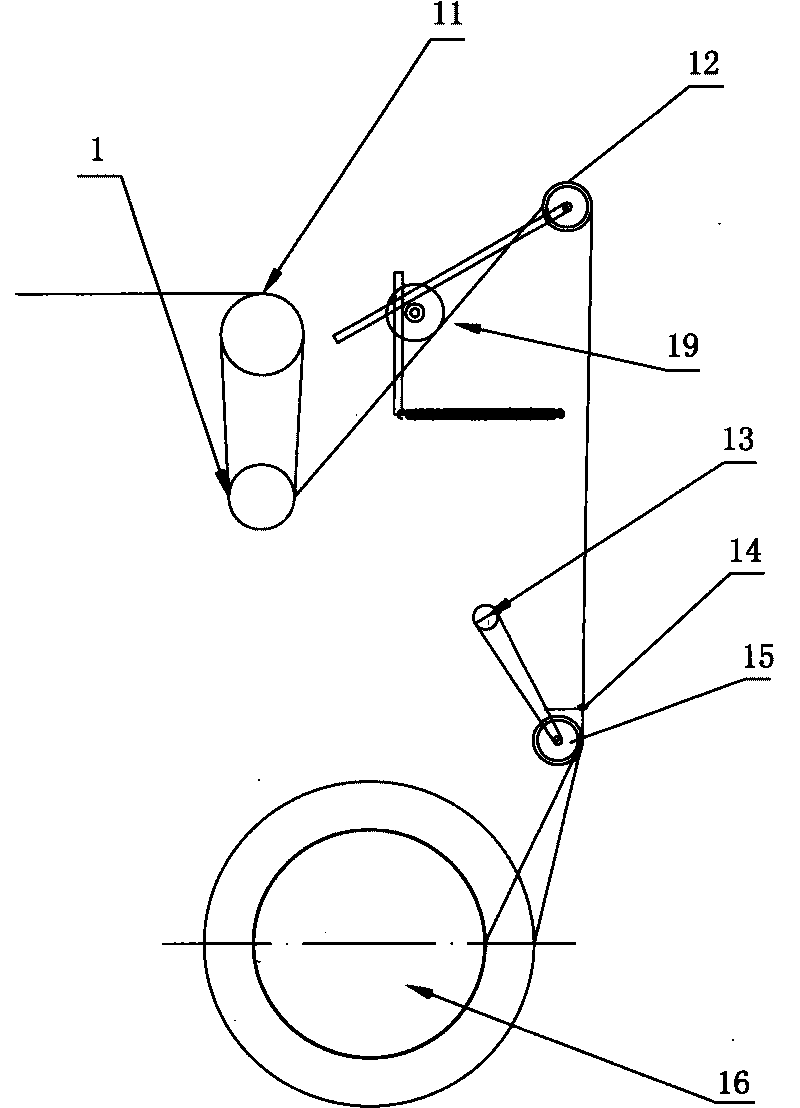

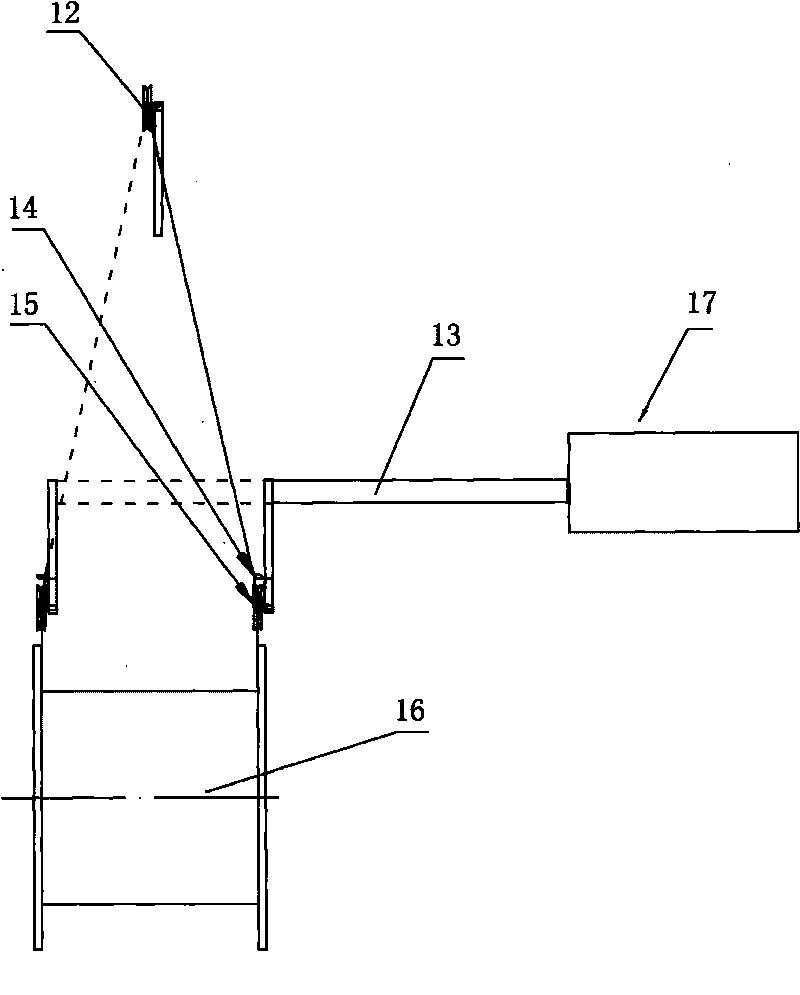

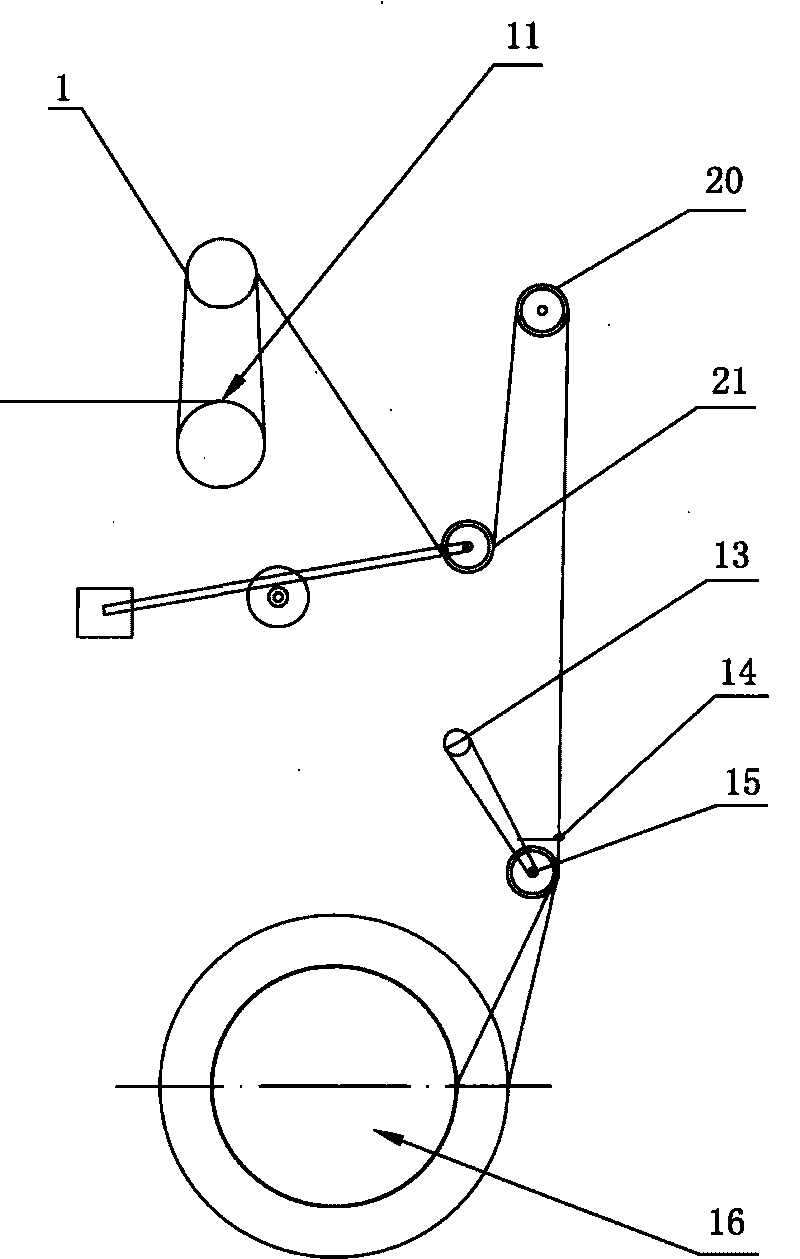

Digitally-controlled wire drawing machine and control method thereof

The invention relates to the technical field of digitally-controlled wire drawing machines, in particular to a digitally-controlled wire drawing machine and a control method thereof. The digitally-controlled wire drawing machine comprises a middle guide wheel, a steering guide wheel, a tension sensor for a branched guide wheel and a take-up reel speed-measuring device. A capstan, the branched guide wheel and the middle guide wheel are positioned on a first routing plane; the steering guide wheel and a winding guide wheel are positioned on a second routing plane; and the first routing plane is perpendicular to the second routing plane. The reciprocating linear movement of the winding guide wheel is left-to-right movement on the second routing plane, and the winding guide wheel is positioned at the lower left of the steering guide wheel. A rotating shaft of a take-up reel is parallel to the second routing plane. In addition, in the aspect of the control of the take-up tension, the tension detection structure and the control method are changed, so that the digitally-controlled wire drawing machine is more stable, reliable and easier to operate and maintain. A ceramic wave eyelet is removed, so that the wire is not scratched.

Owner:东莞市康汇聚线材科技有限公司

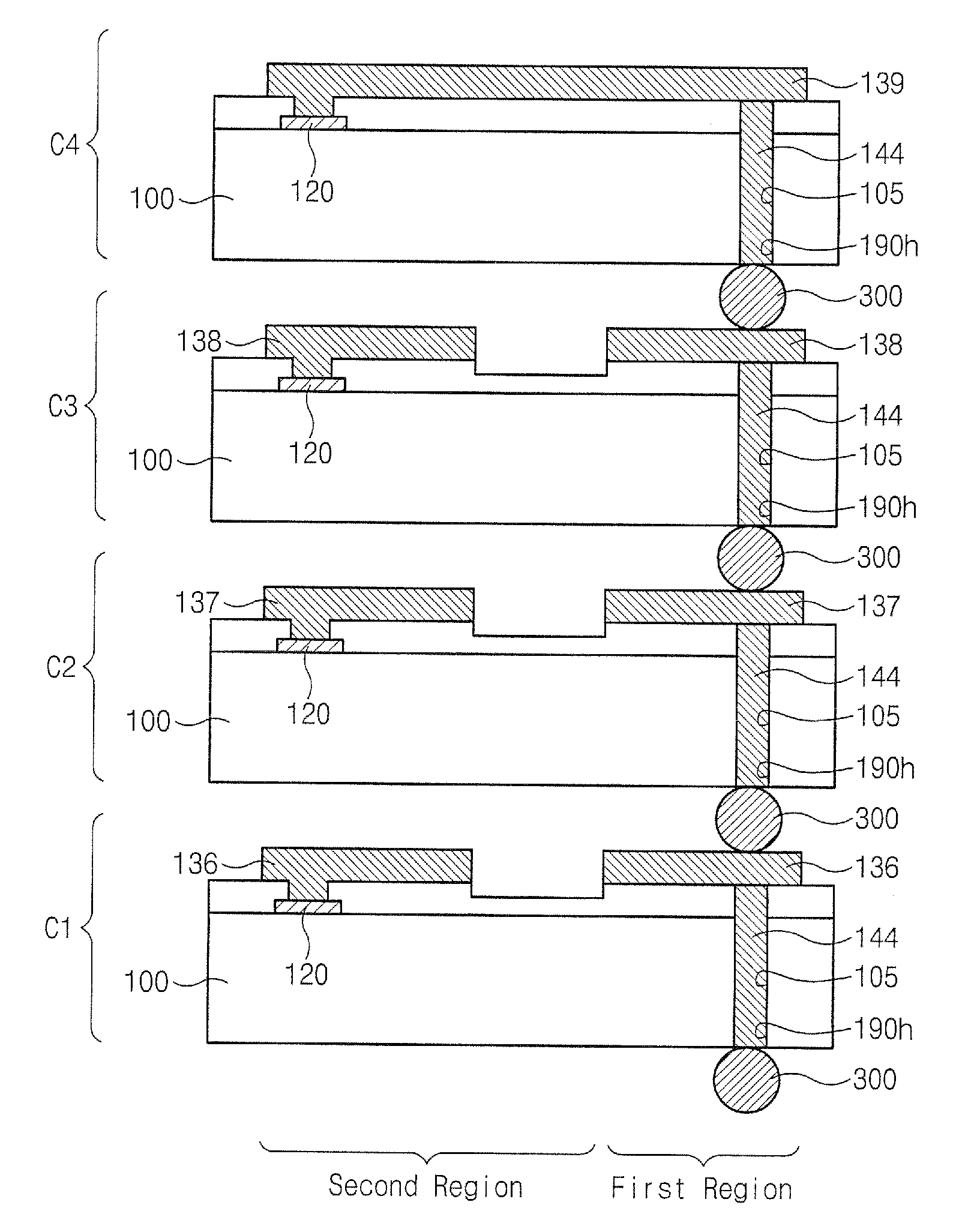

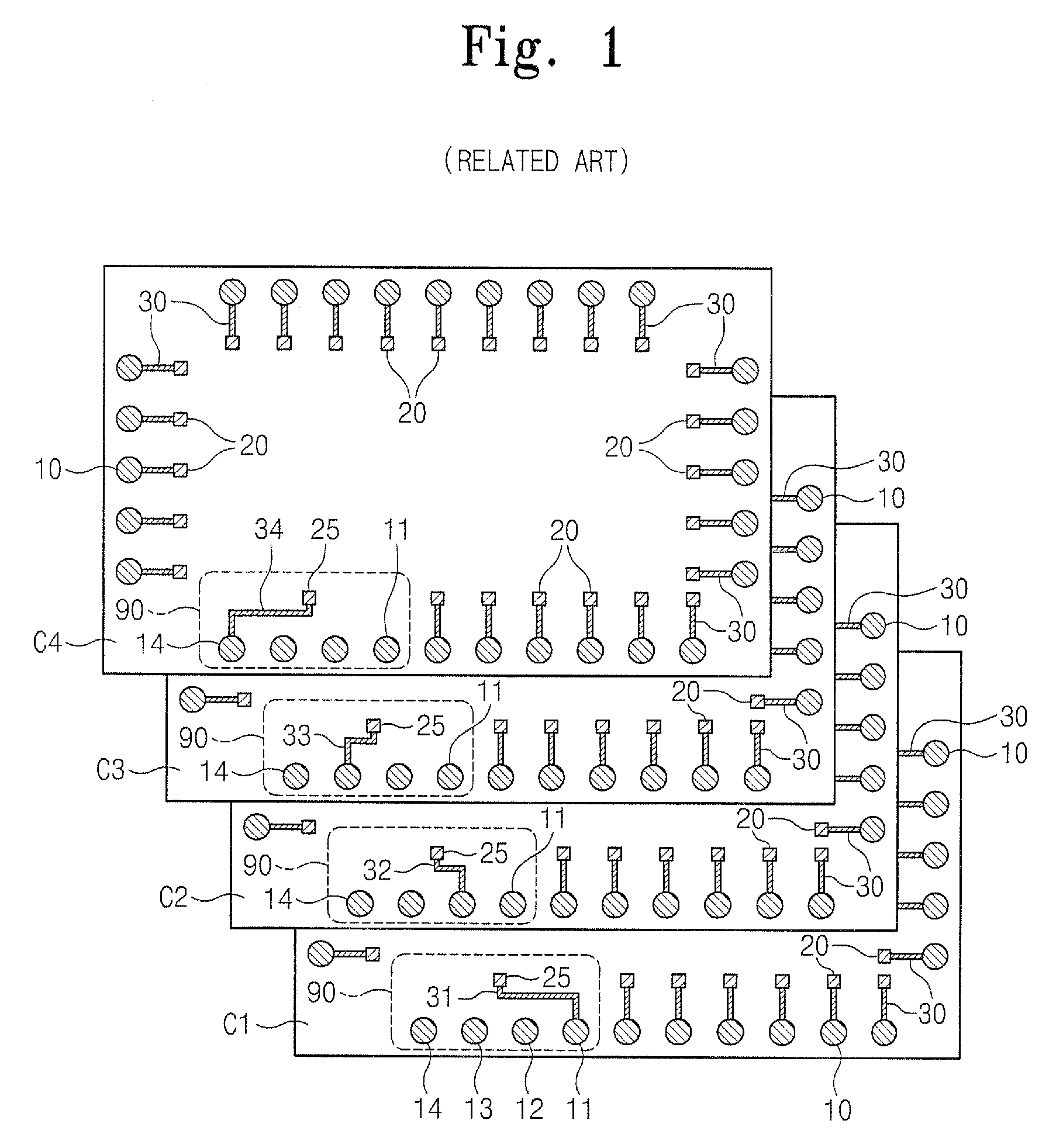

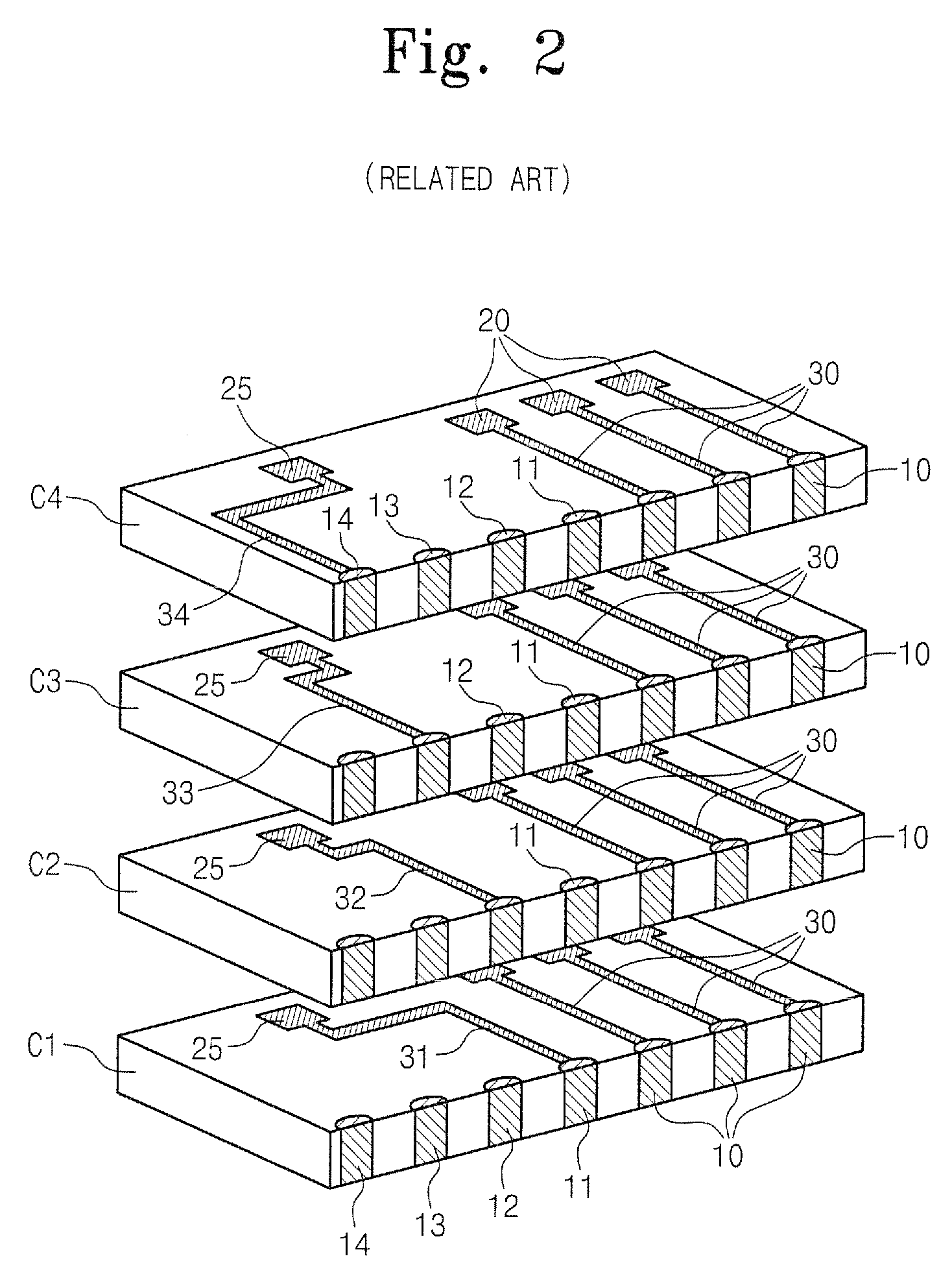

Semiconductor package structure and method of fabricating the same

ActiveUS20080088031A1Change structureIncrease flexibilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageSemiconductor chip

A semiconductor package structure and a method of fabricating the same are disclosed. A method of fabricating the semiconductor package structure can be characterized as including forming semiconductor chips on a semiconductor substrate. Each of the semiconductor chips includes chip pads. Through-vias are formed through the semiconductor chips. Redistribution structures and a chip selection interconnection layer are formed on the semiconductor chips, which connect the through-vias with the chip pads. The chip selection interconnection layers are patterned to form chip selection interconnection lines having different structures on at least one of the semiconductor chips. The semiconductor chips are stacked and electrically connected using the through-vias.

Owner:SAMSUNG ELECTRONICS CO LTD

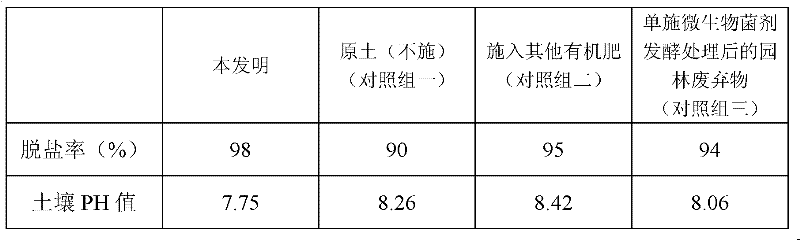

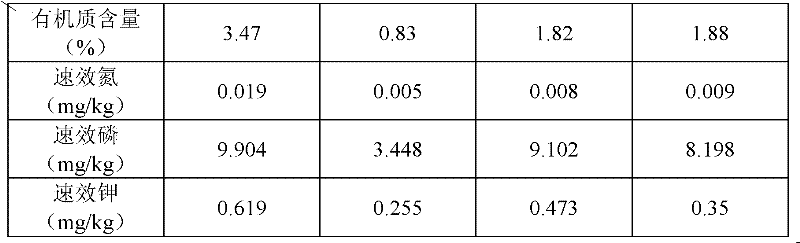

Soil melioration matrix prepared from garden waste and preparation method of soil melioration matrix

ActiveCN102585836AImprove physical and chemical propertiesHigh porosityAgriculture tools and machinesOther chemical processesPorosityNatural mineral

The invention discloses a soil melioration matrix prepared from garden waste and a preparation method of the soil melioration matrix. The soil melioration matrix comprises the following components in parts by weight: 0.05-0.08 part of garden waste subjected to fermentation treatment by a microorganism bacterium agent, 0.01-0.03 part of natural mineral and 0.005-0.01 part of polymaleic anhydride. According to the invention, the soil melioration matrix is added to saline soil, so that the physicochemical property of soil can be improved, the porosity is increased, the permeability is strengthened, the soil structure is improved, and the salt-obstruction and fertilizer conservation effects are remarkable.

Owner:TIANJIN TEDA GREEN GRP CO LTD

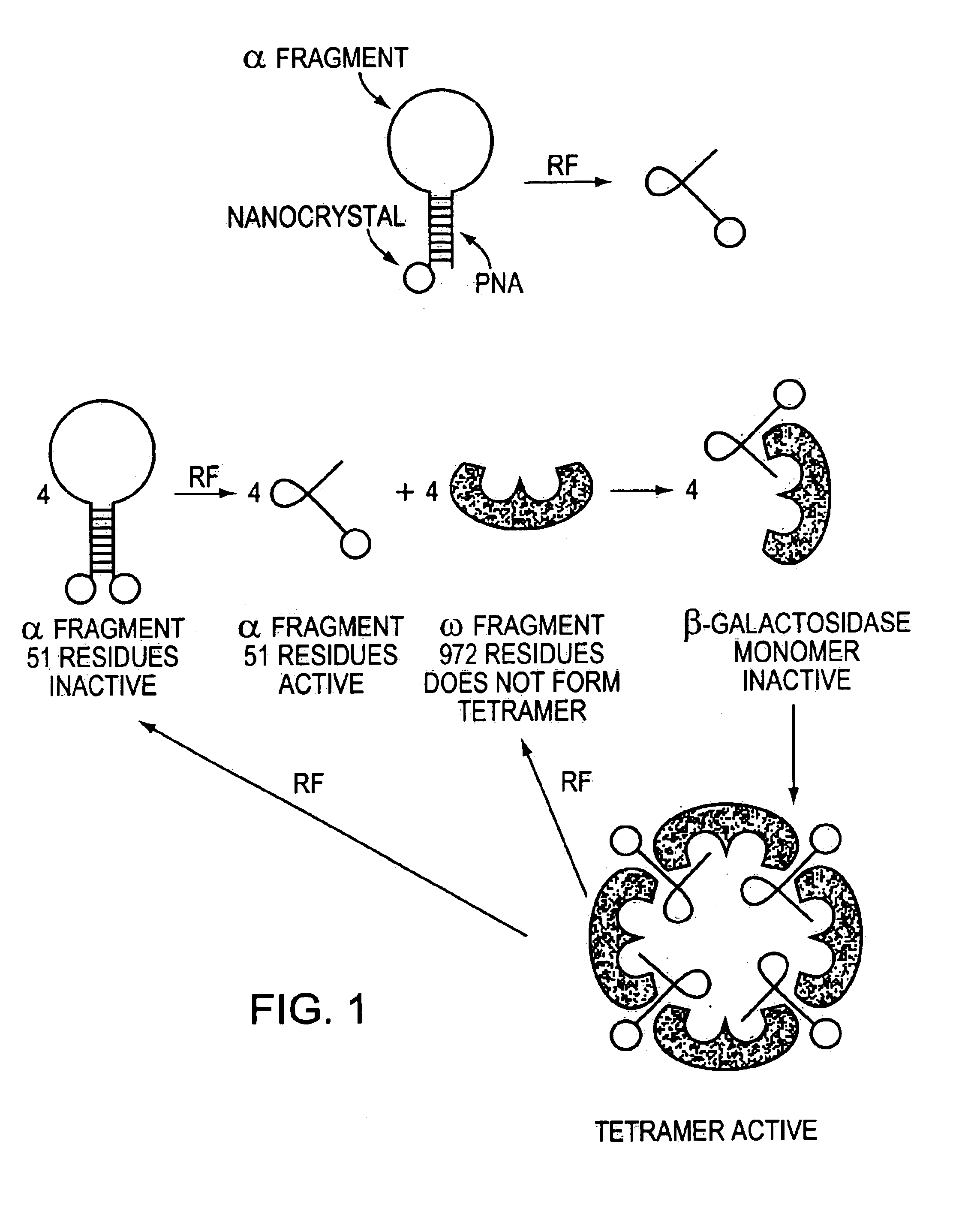

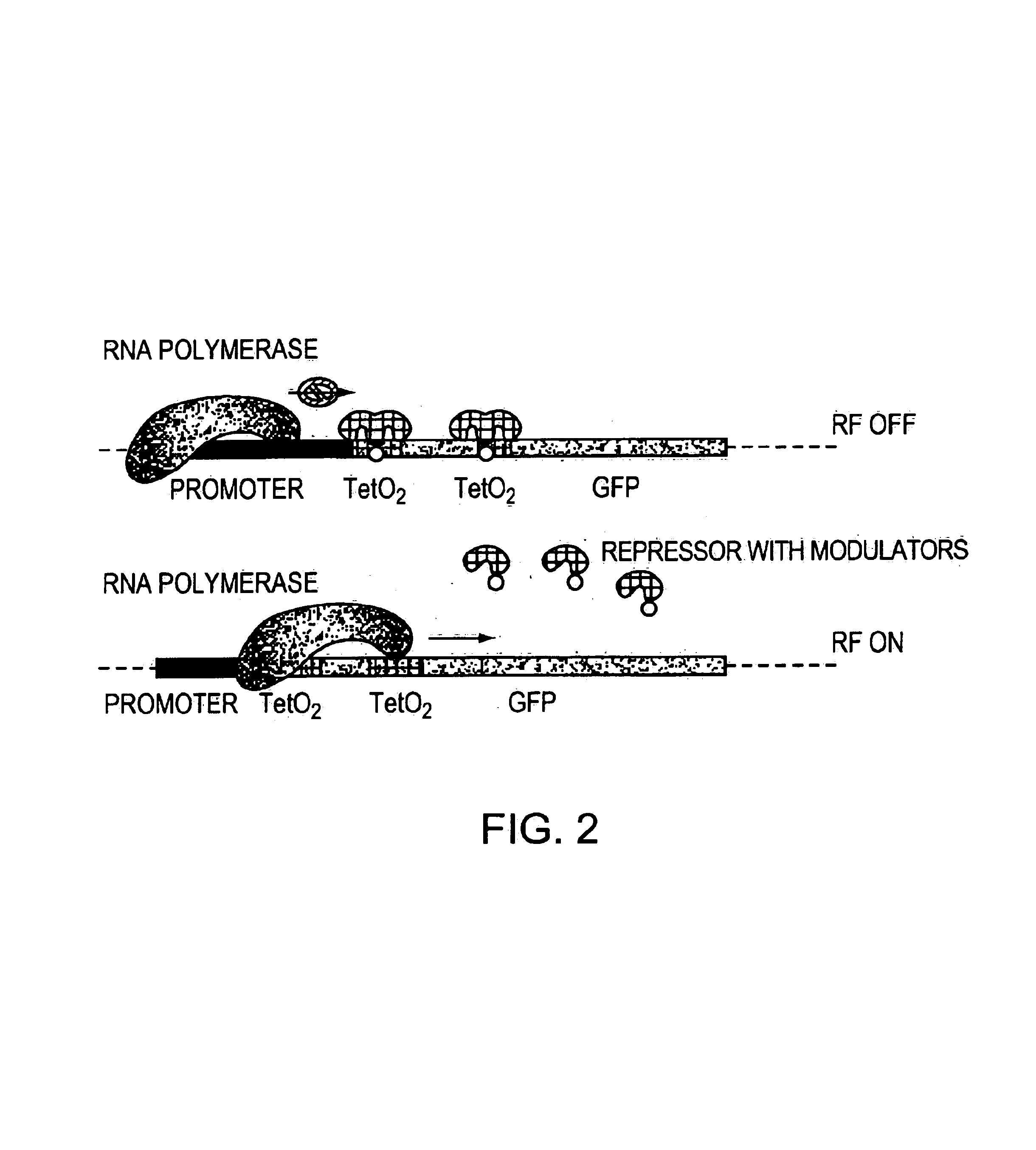

Direct, externally imposed control of polypeptides

InactiveUS6953656B2Altering functional propertyAltering structuralMicrobiological testing/measurementCell componentsEnergy transferProtein structure and function

Methods and compositions for rendering proteins directly responsive to an external signal utilizing modulators that themselves respond to the external signal and are associated with the proteins. In response to the external signal, the modulator alters physical properties of the specific protein molecule(s) with which it is associated, thereby altering the structural and functional properties thereof. The modulator may, for example, transfer applied energy to a protein, or to a portion of the protein, thereby changing the protein structure and function.

Owner:MASSACHUSETTS INST OF TECH

Optical incoupling for touch-sensitive systems

ActiveUS9552103B2Efficient and robust couplingLess dependentPlanar/plate-like light guidesInput/output processes for data processingTotal internal reflectionAngle of incidence

A touch-sensitive apparatus comprises a light transmissive panel, an illumination arrangement and a detection arrangement. The illumination arrangement is configured to couple light into the panel via an incoupling site such that the light propagates by total internal reflection in opposite top and bottom surfaces of the panel and such that an object touching the top or bottom surface causes a change in the propagating light. The detection arrangement comprises a light detector arranged to detect the change in the propagating light. A compact and robust incoupling site is defined by a sheet-like micro-structured surface portion which is fixedly arranged on one of the top and bottom surfaces and configured to transmit light having an angle of incidence that enables light propagation by TIR inside the panel.

Owner:FLATFROG LAB

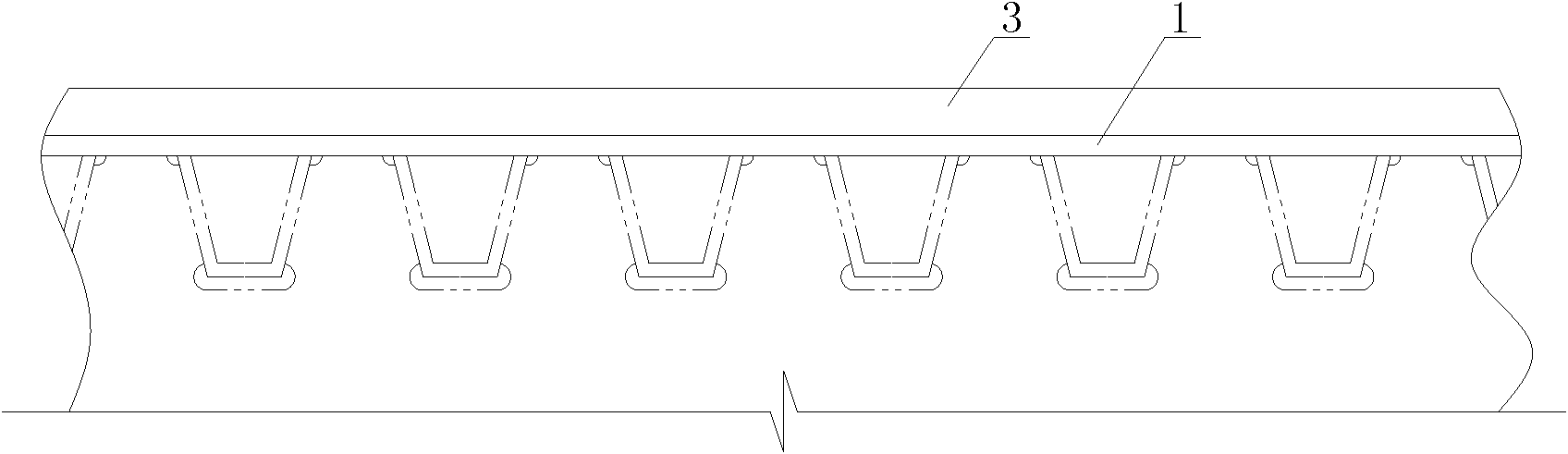

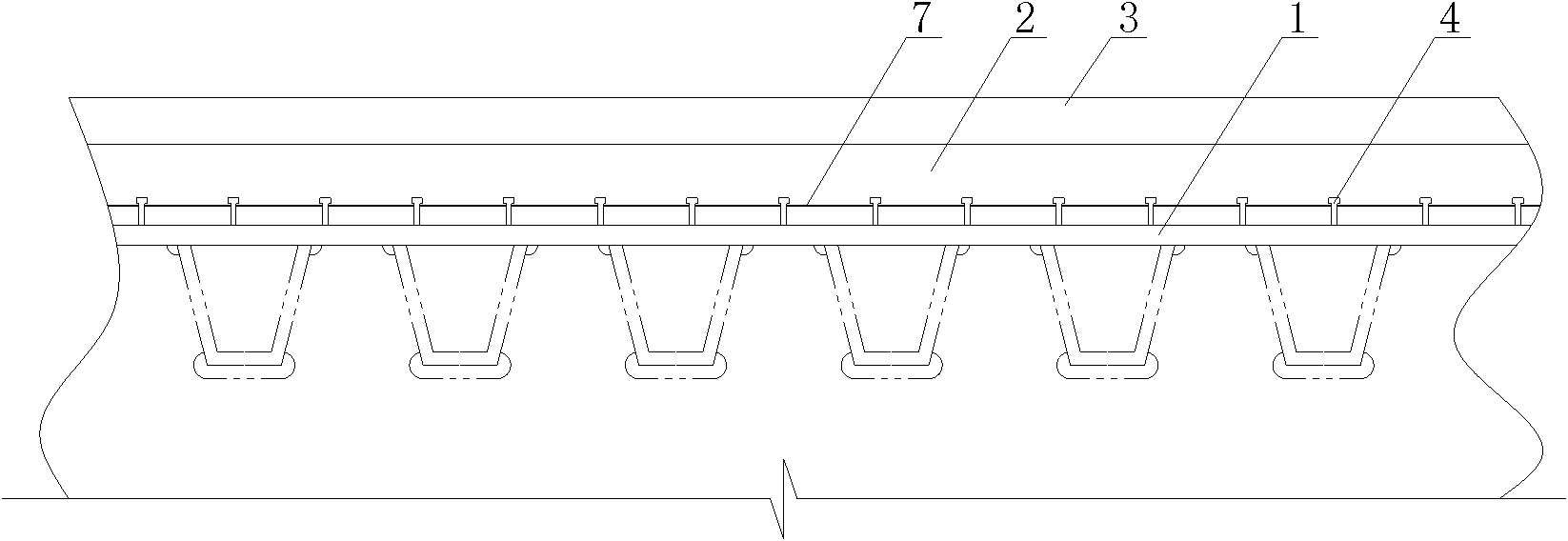

Steel and ultra-high performance concrete combined bridge deck structure

InactiveCN101858052AChange structureChange work statusBridge structural detailsBridge materialsBridge deckRebar

The invention relates to a bridge deck structure of a steel bridge, in particular to a steel and ultra-high performance concrete combined bridge deck structure, comprising a steel bridge deck, an ultra-high performance concrete layer is coated above the steel bridge deck, a bridge deck pavement layer is coated above the ultra-high performance concrete layer, and the ultra-high performance concrete layer is internally provided with reinforced bars. The steel and ultra-high performance concrete combined bridge deck structure has the advantages of small construction height, large stiffness, good binding performance between combined layers, good durability, good fatigue resistance, little vehicle impact and the like.

Owner:HUNAN UNIV

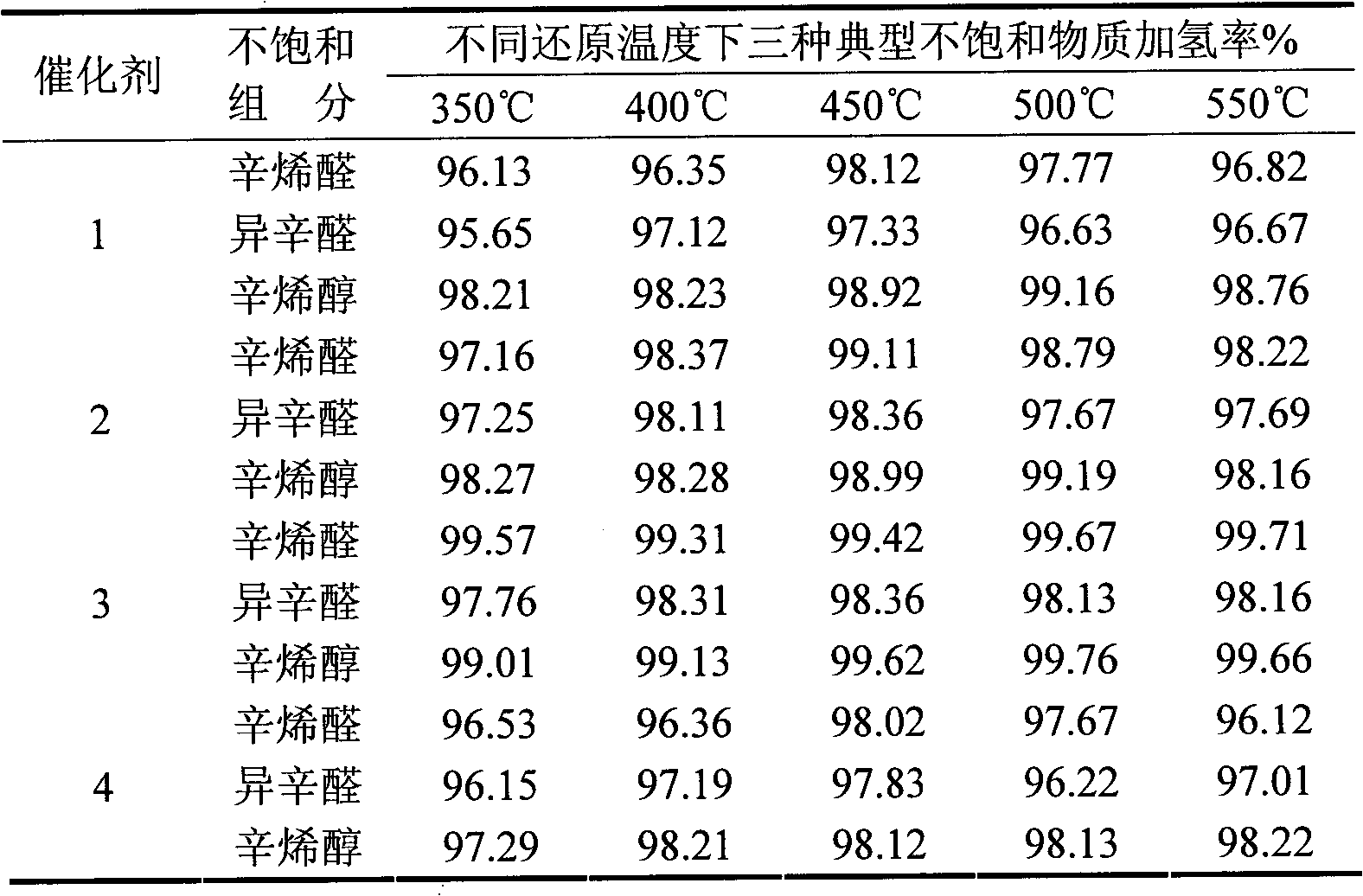

Lanthanum-modified nickel-copper octanol hydrorefining catalyst, preparation and application thereof

ActiveCN102059121AReduce generationReduce coalescenceOrganic compound preparationHydroxy compound preparationReaction temperatureOctanol

The invention relates to a lanthanum-modified nickel-copper octanol hydrorefining catalyst, preparation and application thereof. The catalyst is prepared by taking Gamma-Al2O3 as a carrier, taking lanthanum as an auxiliary agent, taking nickel-copper as a active component and adopting an immersion method; and the aluminum oxide accounts for 40-90%in the terms of 100% by mass, the content of nickel is 1-40% in the terms of NiO, the content of copper is 1-30% in the terms of CuO, and the lanthanum as the auxiliary agent is 0.1-10% in the terms of La2O3; and a hydrogenation evaluation result indicates that the catalyst is reduced at a temperature of 350-550 DEG C, and under the conditions that the reaction temperature is 120 DEG C, the reaction pressure is 2.5MPa, the volume ratio of hydrogen to liquid is 8:1 and the volume air speed is 3.0h<-1>, the hydrogenation rates of unsaturated substances such as octylene aldehyde, isooctyl aldehyde and octylene alcohol are all more than 95%.

Owner:PETROCHINA CO LTD +1

Bone tissue fixation device and method

ActiveUS8940019B2Increase flexibilityEasy and safe to accessSuture equipmentsInternal osteosythesisBone tissueSpinous process

Systems, methods, and kits incorporating a clamp for securing to bone tissue. The clamp includes gripping members to secure the clamp to the bone tissue without the use of screws. The clamp may be used to treat spinal conditions, and may be secured to the spinous process of vertebrae. Systems, methods and kits can incorporate a fusion member configured to fuse between adjacent spinous processes.

Owner:WENZEL SPINE +1

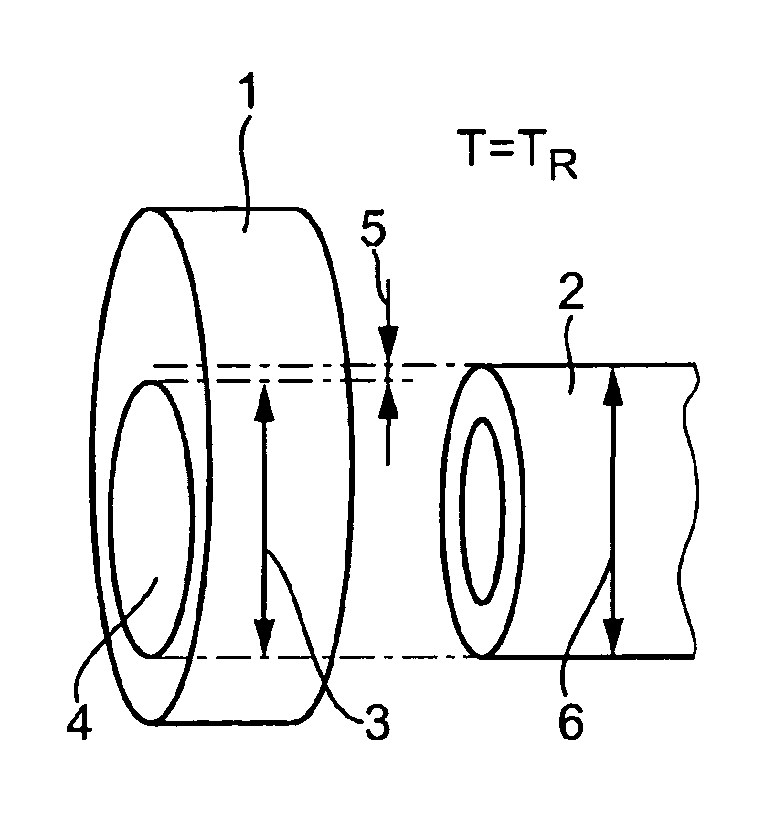

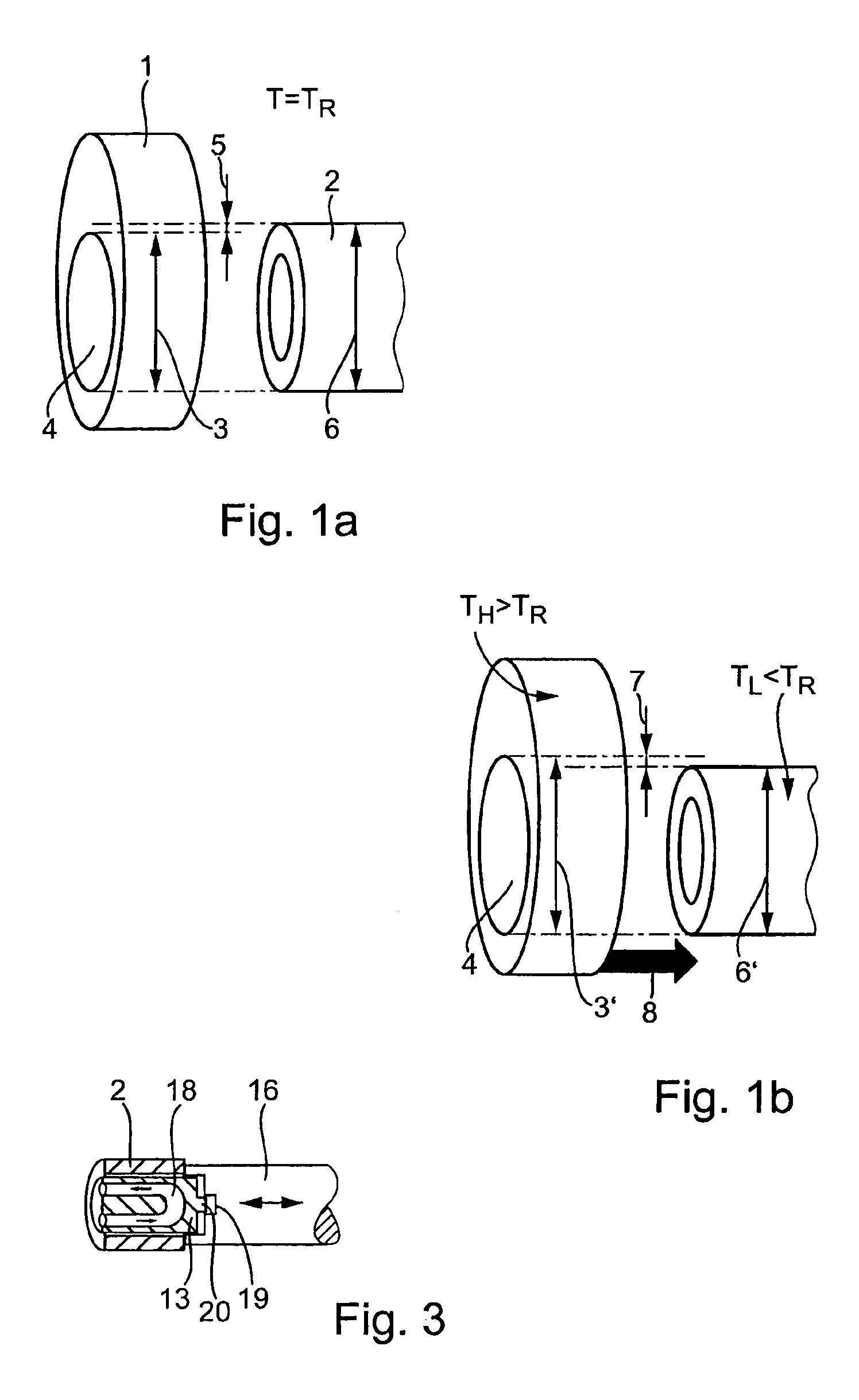

Method and assembly system for manufacturing an assembled camshaft

A method and an assembly system for manufacturing an assembled camshaft having a metallic shaft and at least one shrunk-on cam, includes initially heating the at least one cam, threading the at least one cam onto the shaft in a predetermined position in the heated state, and subsequently shrinking the at least one cam onto the shaft due to a cooling down. The shaft is cooled down prior to thread-on of the cams so that the cams are shrunk onto the shaft due to a temperature equalization which includes heating of the shaft and cooling down of the cams. The assembly system includes multiple drums in which the shafts and the cams to be fitted are accommodated and cooled and / or heated. The shafts are cooled preferably with the aid of a cooling lance inserted into a hollow space of the shaft.

Owner:DAIMLER AG

Antibacterial bacteriostatic polysulfone hollow fiber ultrafiltration membrane and preparation method thereof

InactiveCN101703892AImprove hydrophilicitySlow down the gelSemi-permeable membranesFiberUltrafiltration

The invention provides an antibacterial bacteriostatic polysulfone hollow fiber ultrafiltration membrane, which is a mixture consisting of polysulfone (PS) dissolved in solvent and nanometer antibacterial material. Based on parts by weight, the ultrafiltration membrane comprises 5 to 25 parts of polysulfone, 0.05 to 5 parts of nanometer antibacterial material, 2 to 10 parts of additives, 65 to 90 parts of solvent. The invention simultaneously discloses a preparation method, which comprises: (1) dissolving the polysulfone in the solvent in a spinning liquid tank, adding the nanometer antibacterial material and the additives, mixing well and obtaining membrane casting liquid; (2) standing and curing the obtained product; (3) extruding the cured material in the spinning liquid tank, filtering the cured material through a filter so as to remove impurities, metering the obtained product through a metering pump and filtering the obtained product through the filter so as to remove the impurities; (4) spurting membrane silk through a silk-spurting plate; (5) forming the membrane silk into a membrane in coagulating bath; and (6) soaking the formed membrane in pure water in washing bath, washing the solvent and the additives away, winding and outputting the polysulfone hollow fiber ultrafiltration membrane. The membrane has a good bacteriostatic effect.

Owner:SHANGHAI AQUA PURIFICATION EQUIP

Mineral filled low-shrinkage modified polypropylene composite material and preparation method thereof

The invention relates to a mineral filled low-shrinkage modified polypropylene composite material which belongs to the field of modified polypropylene composite materials and comprises the following ingredients in parts by weight: 40 to 85 polypropylene, 5 to 30 polyethylene, 5 to 20 elastic bodies, 5 to 30 mineral filler, 0.1 to 3 compatilizers and 0.1 to 3 accessory ingredients. The mineral filled low-shrinkage modified polypropylene composite material prepared by the invention has good mechanical property, ensures good apparent performance of the composite material and has lower shrinkage. In addition, the method is simple and feasible and can be popularized and applied in a large scale.

Owner:SUZHOU SUNWAY POLYMER

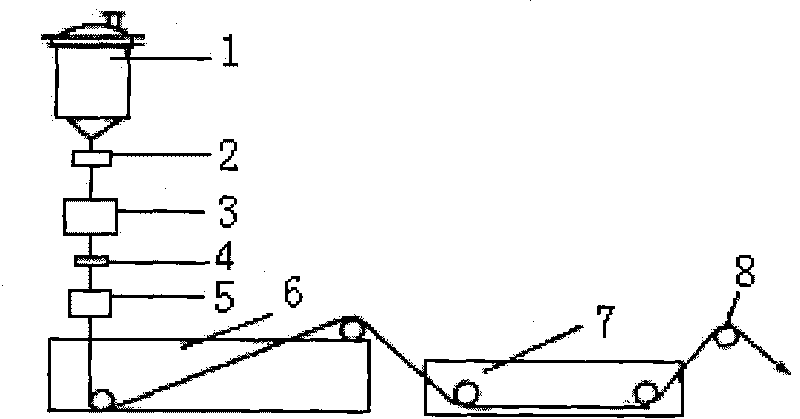

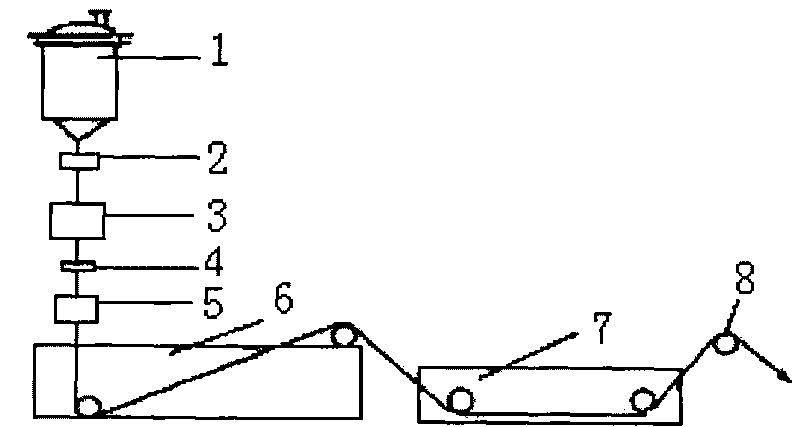

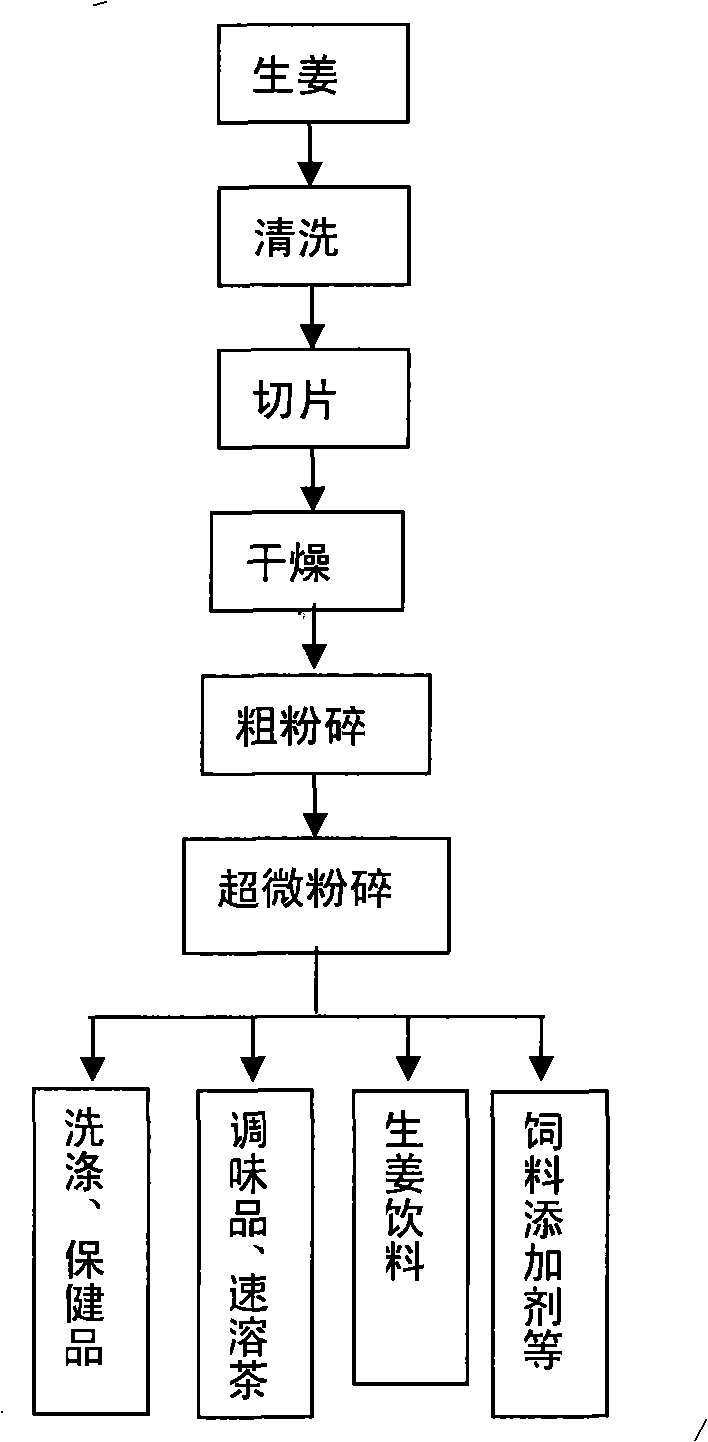

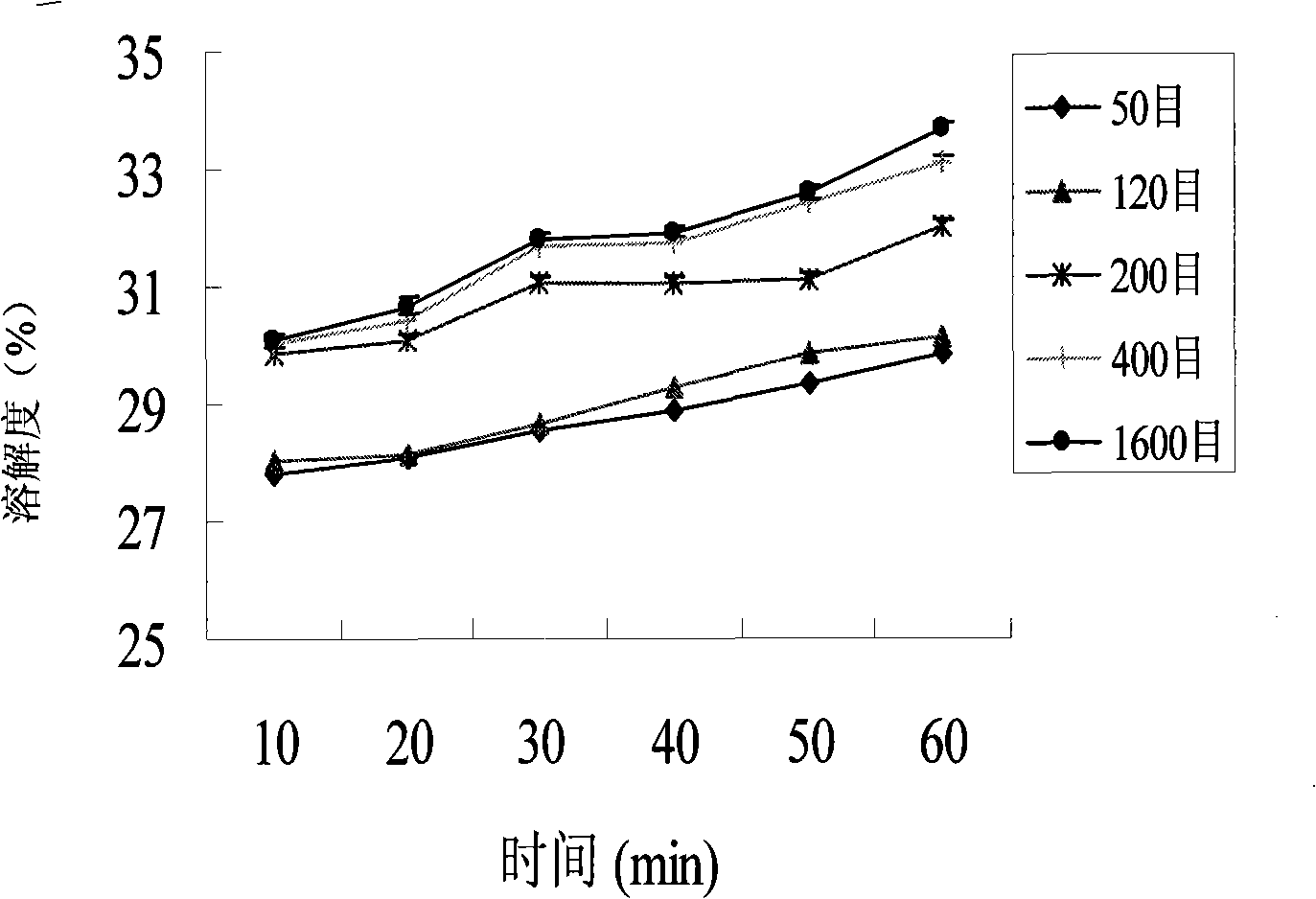

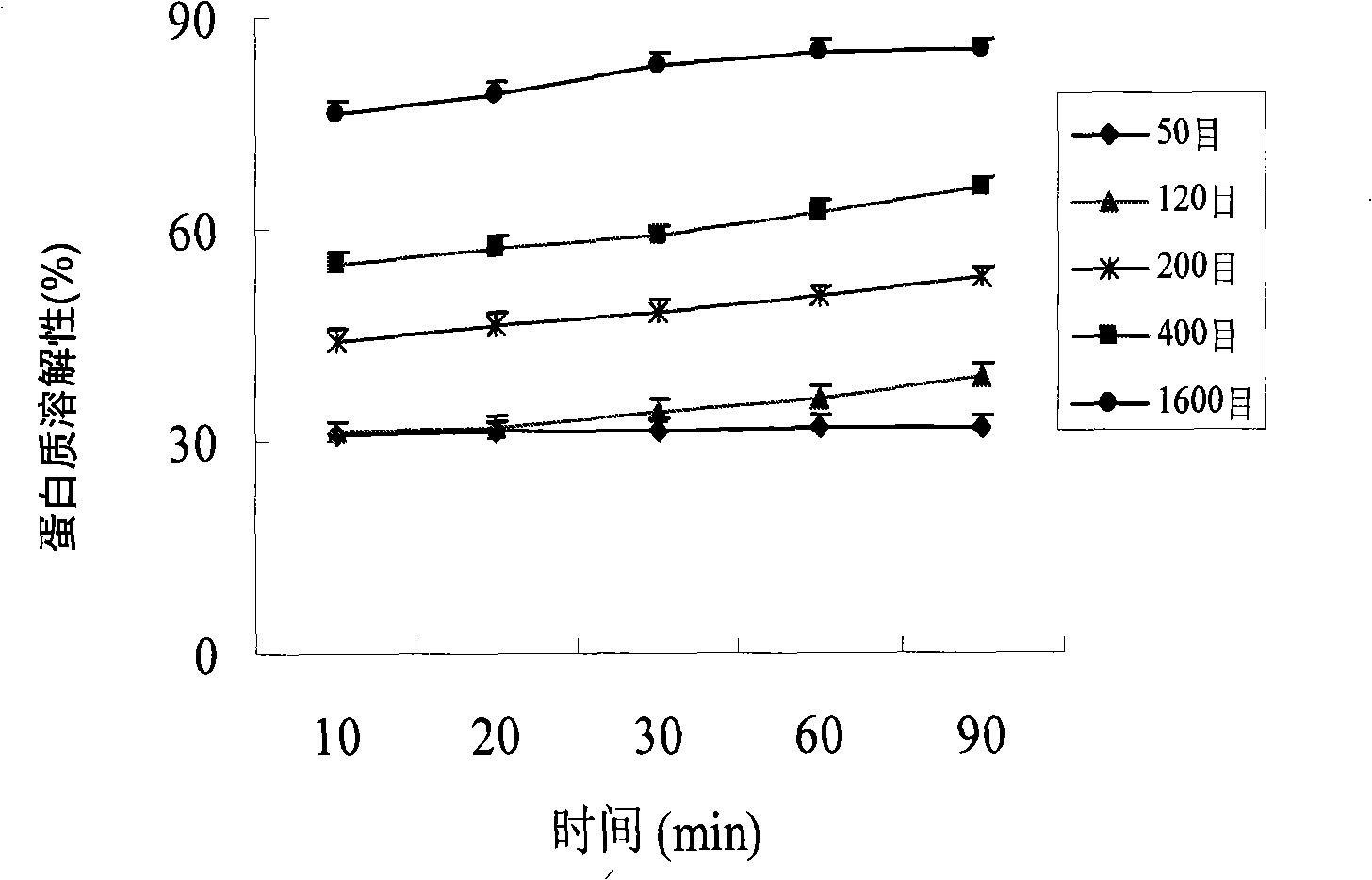

Ultramicro ginger powder and method for producing the same

InactiveCN101327016ASave resourcesChange structureCosmetic preparationsPowder deliveryProcess engineeringFood products

The invention discloses an ultramicro ginger powder processing method; the ultramicro ginger powder refers to the ginger powder with 700mesh to 2000mesh of grain size. The production method comprises the steps: raw material selection, slicing, drying, coarse grinding, ultramicro grinding, sterilization, packaging, etc. The method changes the traditional ginger grinding and processing technologies, injects the coarse ginger particles after coarse grinding into an air flow ultramicro grinding machine to prepare ultramicro powder by pressure or impulsion. The method solves the problems of the resource waste and poor solubility in the traditional ginger grinding processes; after the ultramicro grinding, the ginger powder has the advantages of high release speed of effective components, large release amount, convenient and fast use method, even distribution, etc., and is suitable to be promoted and applied in food, feed, cosmetics, health care and other industries.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

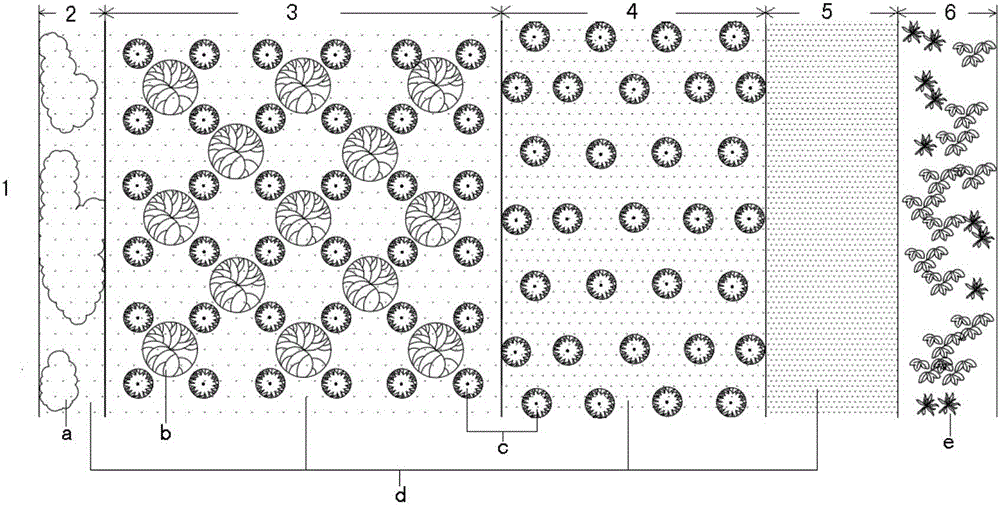

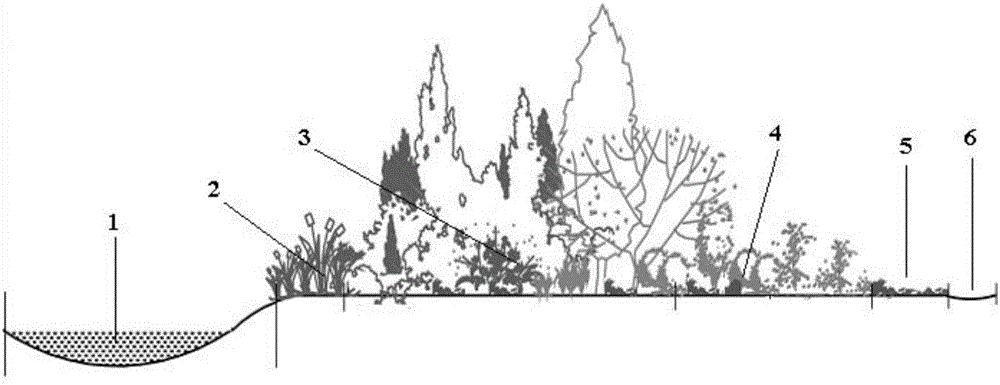

Riverbank ecological buffering band and construction method for same

InactiveCN105123189AEnhance the diversion capacity of revetmentGood landscape featurePlant cultivationCultivating equipmentsBuffer stripLand resources

The invention relates to a riverbank ecological buffering band and a construction method for the same. The construction method comprises the following steps of (1) selecting a construction area, (2) adjusting gradient of the construction area, (3) determining a group construction scheme, and (4) planting plants according to the group construction scheme. The invention further provides a riverbank ecological buffering band constructed according to the method. Plants are optimized without a change of an original soil layer structure of the riverbank buffering band, and sewage can be stopped and controlled before entering the river way; resistance of the sewage is increased when the sewage flows through the buffering band, working time of the sewage between the buffering band and plant roots and the soil micro-bial community can be increased; pollutants can be removed; water and soil loss can be reduced; load of pollutants flowing into the river can be reduced; and land resources can be conserved and environment can be beautified.

Owner:GUIZHOU UNIV OF ENG SCI +1

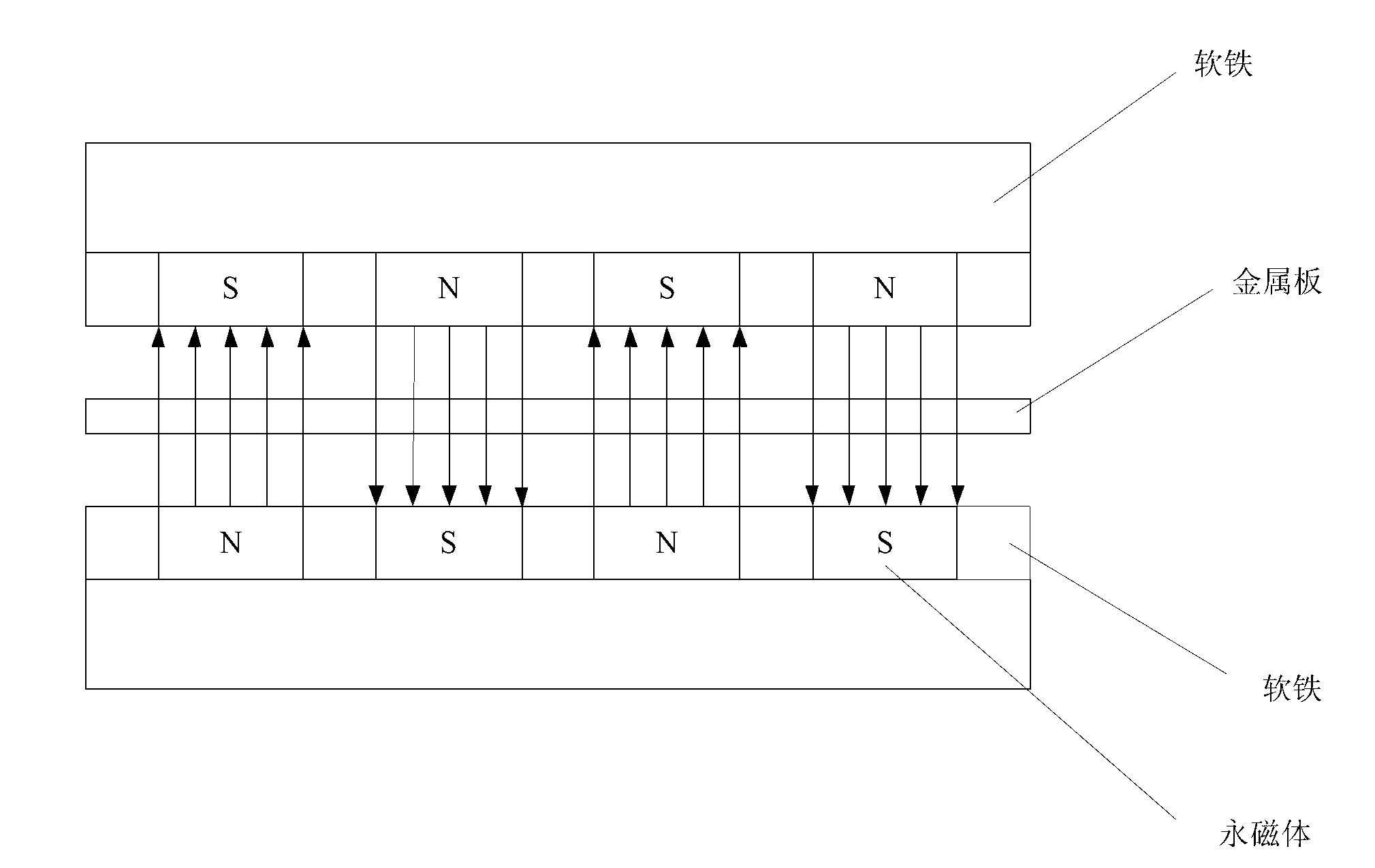

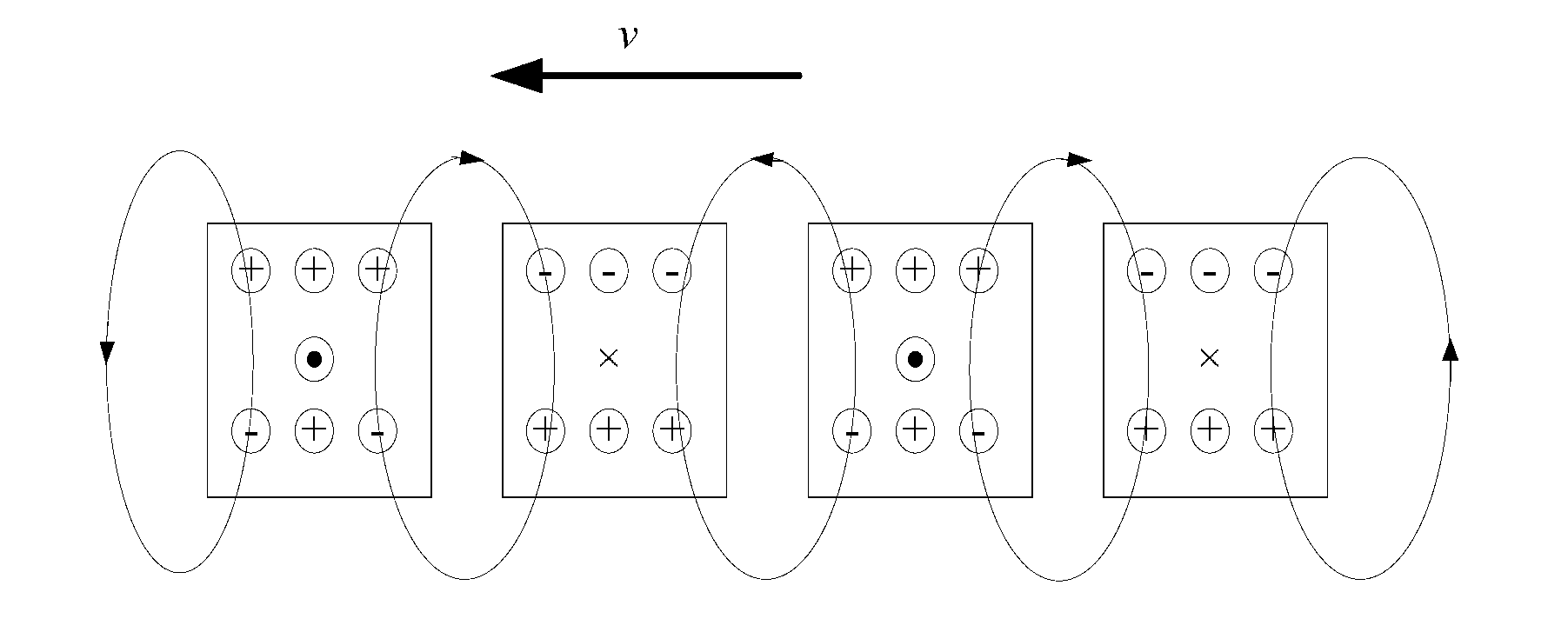

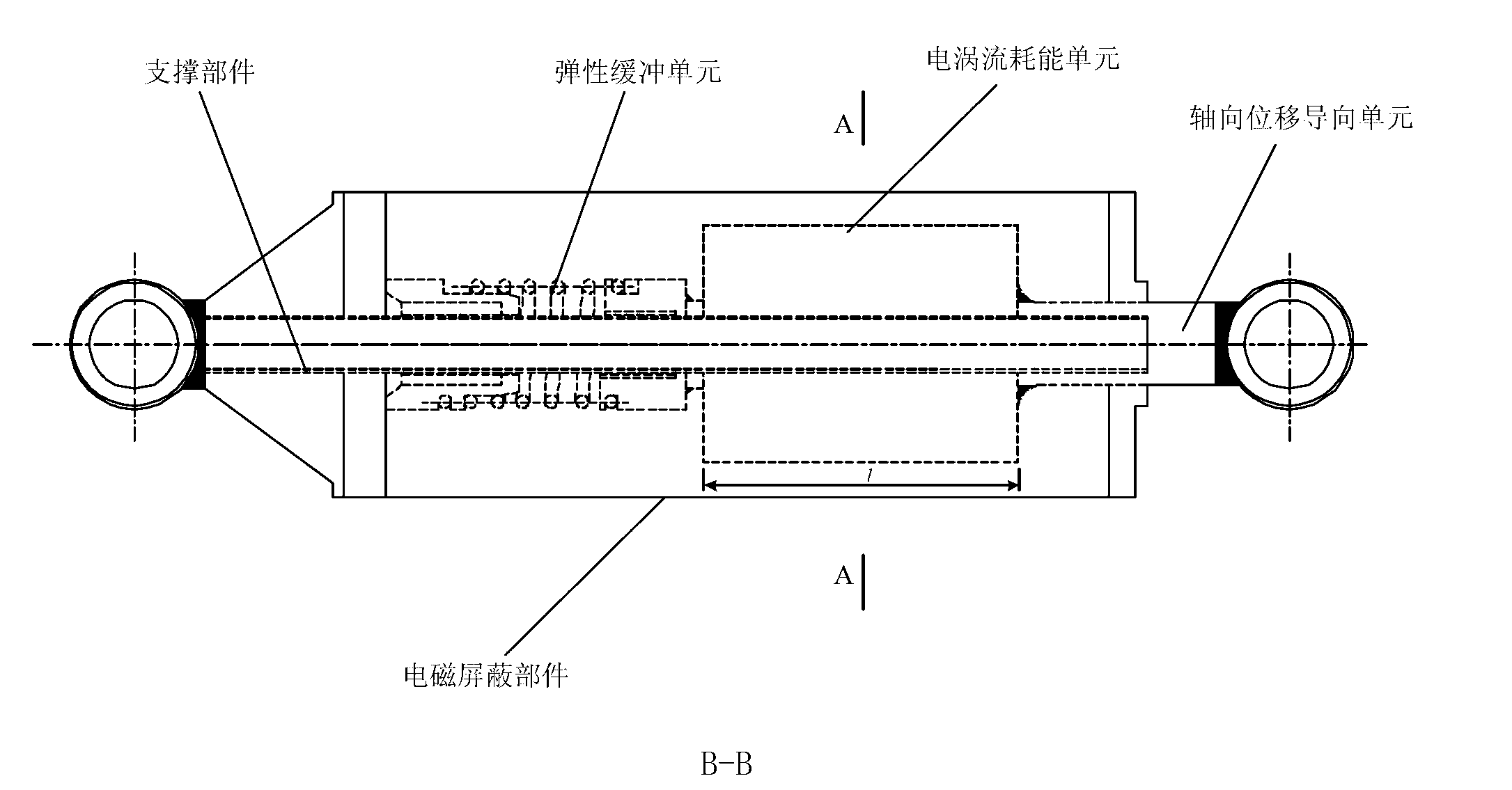

Array-type novel high-performance eddy current damper

InactiveCN102797786ACompact structureHigh damping force to damper mass ratioMagnetic springsShock absorbersElectricityEngineering

An array-type novel high-performance eddy current damper consists of an electrical eddy current energy consuming unit, an elastic buffer unit, an electromagnetic shielding component, an axial displacement guiding unit and a supporting component, wherein the elastic buffer unit, the electrical eddy current energy consuming unit and the axial displacement guiding unit are sequentially inlaid on the supporting component from the bottom up; the bottom of the electrical eddy current energy consuming unit serving as a core component of the damper is connected with the top of the elastic buffer unit; the top of the electrical eddy current energy consuming unit is connected with the bottom of the axial displacement guiding unit; a flexible spherical hinged support is arranged at the top end of the damper and is connected with the axial displacement guiding unit and an external load to output a damping force; and a flexible spherical hinged support is arranged at the bottom end of the damper and is used for fixing the damper. The array-type novel high-performance eddy current damper has the advantages of adjustable damping coefficient, high ratio of the damping force to the integral mass of the damper, compact structure, high reliability and the like; and in the technical field of structural vibration control, the array-type novel high-performance eddy current damper has relatively high practical value and wide application prospect.

Owner:BEIHANG UNIV

Seismic structural device

ActiveUS7712266B2Simple structureChange structureTowersProtective buildings/sheltersEarthquake resistant structuresEngineering

A pin-fuse frame is used in a frame assembly that may be subject to extreme seismic loading. The pin-fuse frame includes of columns, beams, plate assemblies that extend between columns and beams, and may included a diagonal brace. The plate assemblies are fixed to the columns and attached to the beams and brace via pin joints. A joint includes a pin connection through outer connection plates connected to a column and inner connection plates connected to a beam. Connecting rods positioned about the pin maintain a coefficient of friction until exposed to extreme seismic activity, at which time the joint accommodates a slippage of at least one of the inner and outer connection plates relative to each other rotationally about the pin. The diagonal brace is separated into two segments connected together with connection plates. These connection plates accommodate a slippage of the segments relative to each other.

Owner:SKIDMORE OWINGS & MERRILL LLP

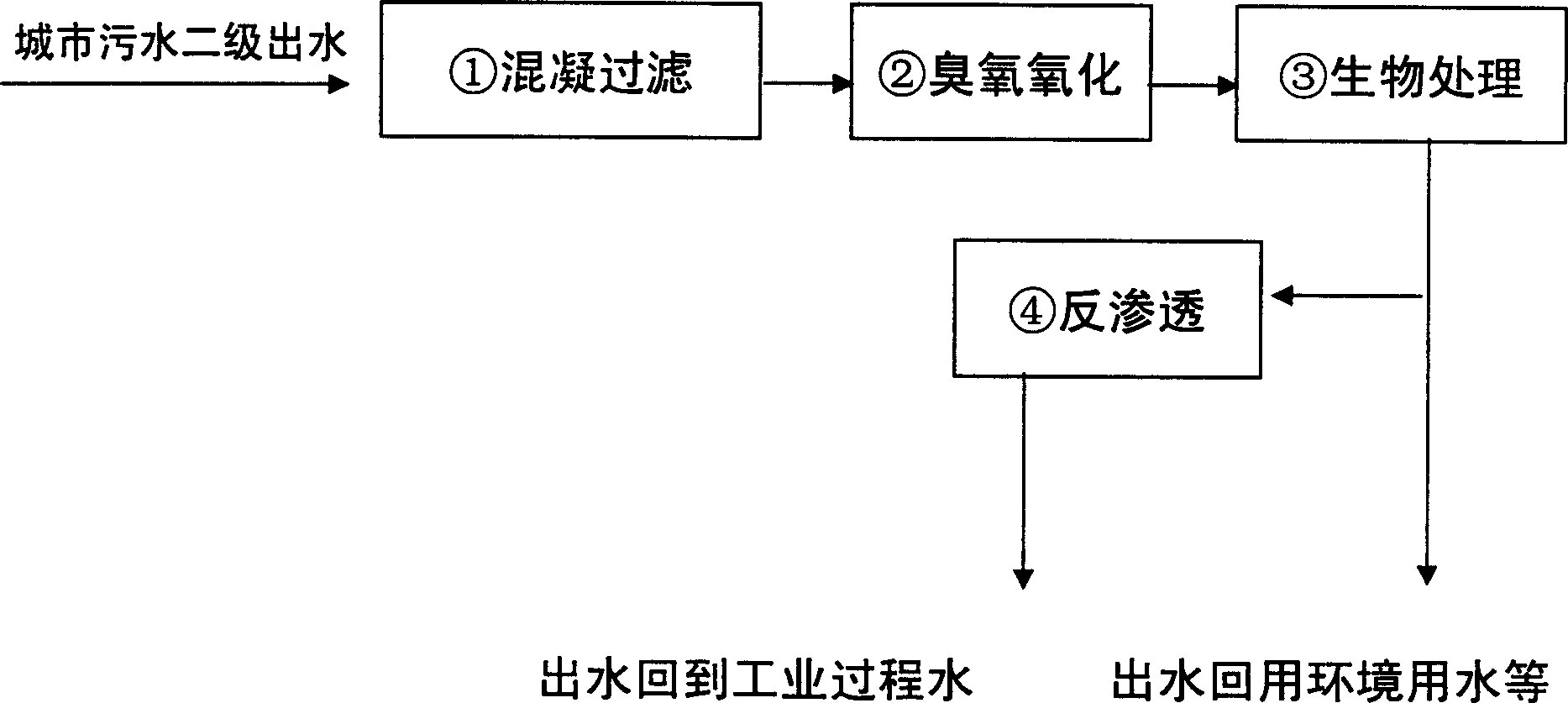

Method for processing urban sewage deeply

ActiveCN1796314AChange sizeChange structureTreatment using aerobic processesWater/sewage treatment bu osmosis/dialysisFiltrationReverse osmosis

This invention is related to a process of disposing urban sewage, which comprise the steps of coagulate filtration, ozone oxidation, biological oxidation to dispose urban sewage, so that the residual undegradable organic substances, bacteria and virus in the second-class urban sewage can be removed and the water can be recycled. According to different usages of the recycled water, the process also comprises reverse osmosis or nanoscale filtration treatment to further remove the residual organic and inorganic substances in the water. The process is a combination of coagulate filtration, ozone oxidation, biological oxidation and reverse osmosis, designed to resolve such problems as urban sewage disposal and water recovery. The process can obtain high-quality recycled water with a low cost, showing high cost performance, which is important to resolving urban water depletion, raising the utilization rate of water resources, reducing environmental pollution and promoting sustainable development of the society.

Owner:北京国中科创环境科技有限责任公司

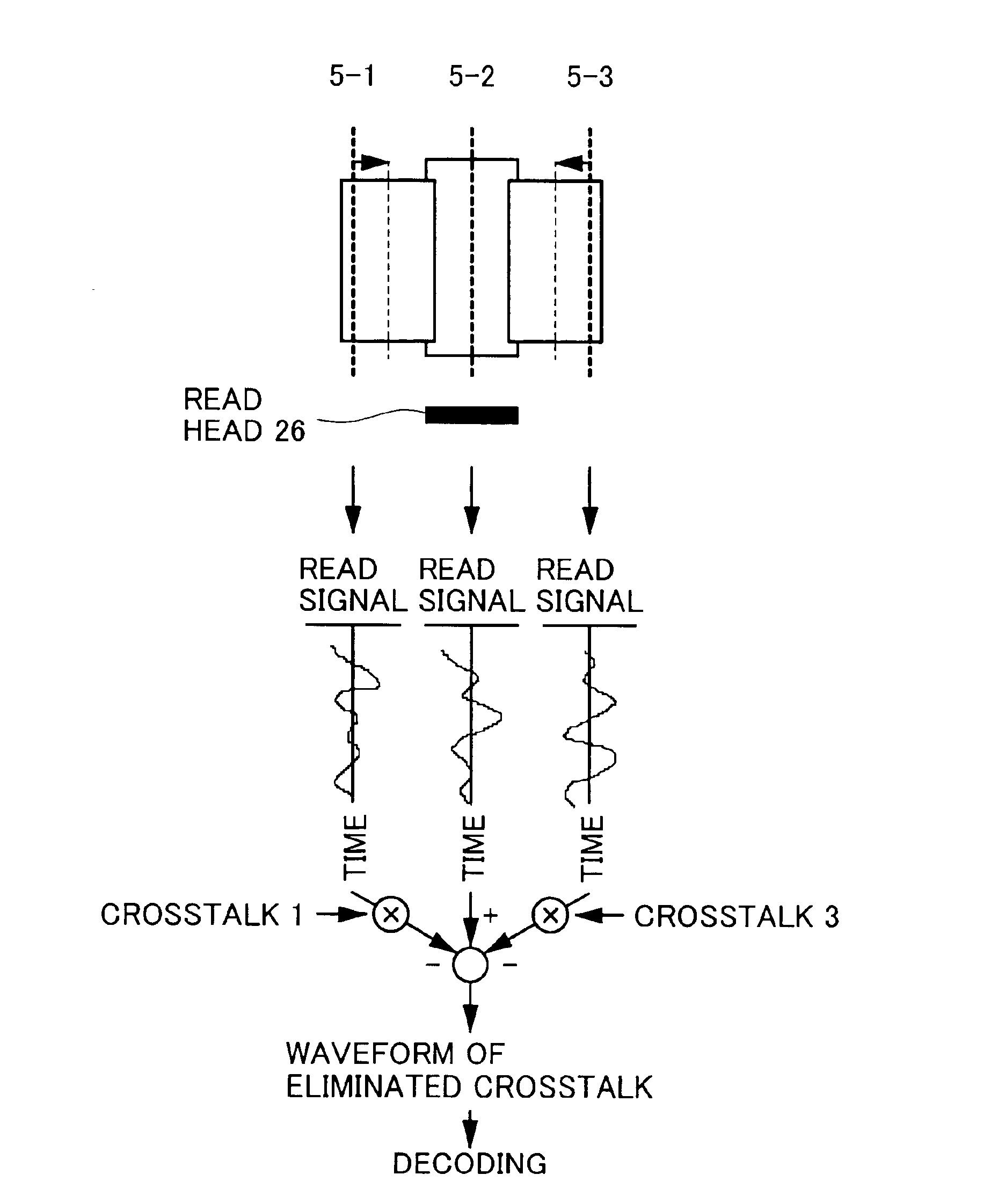

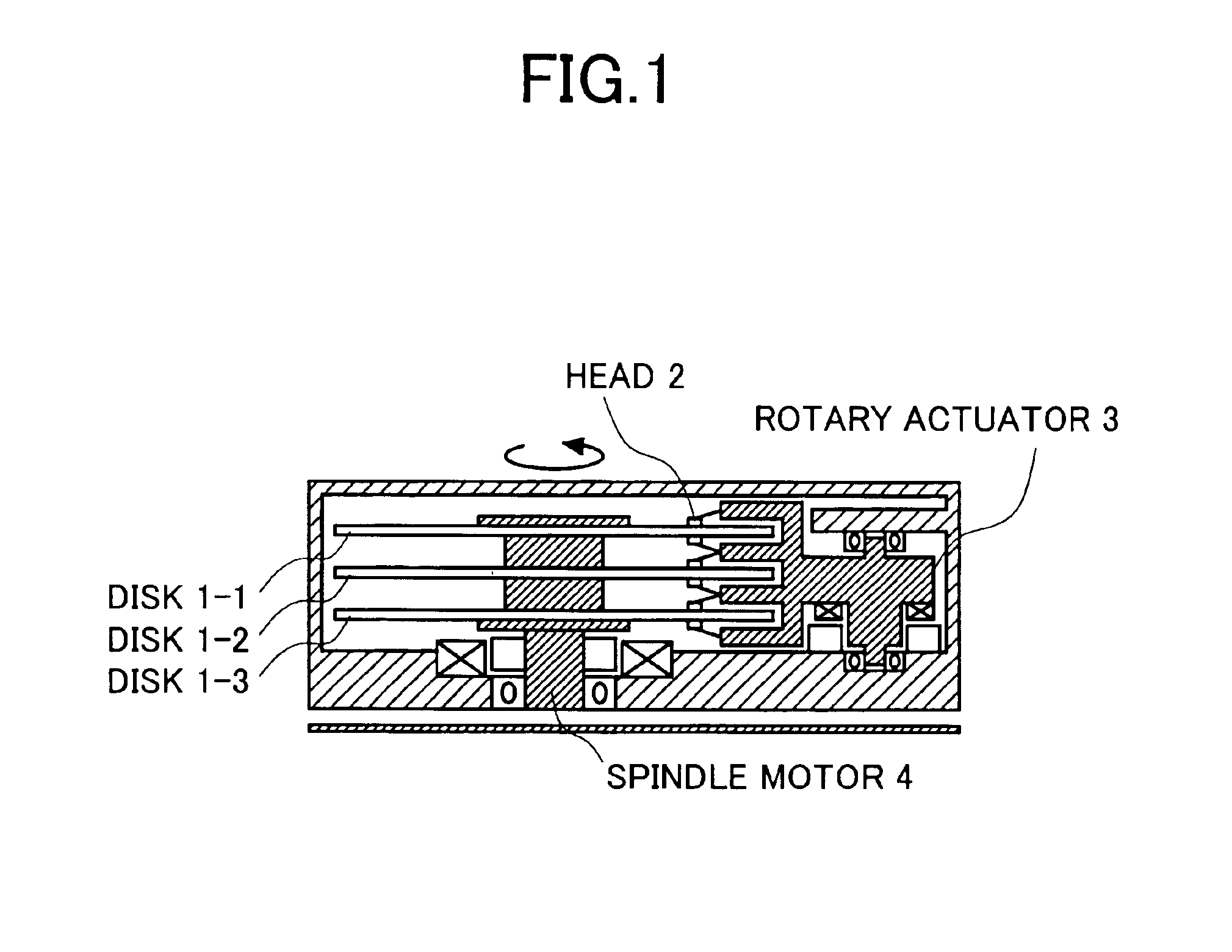

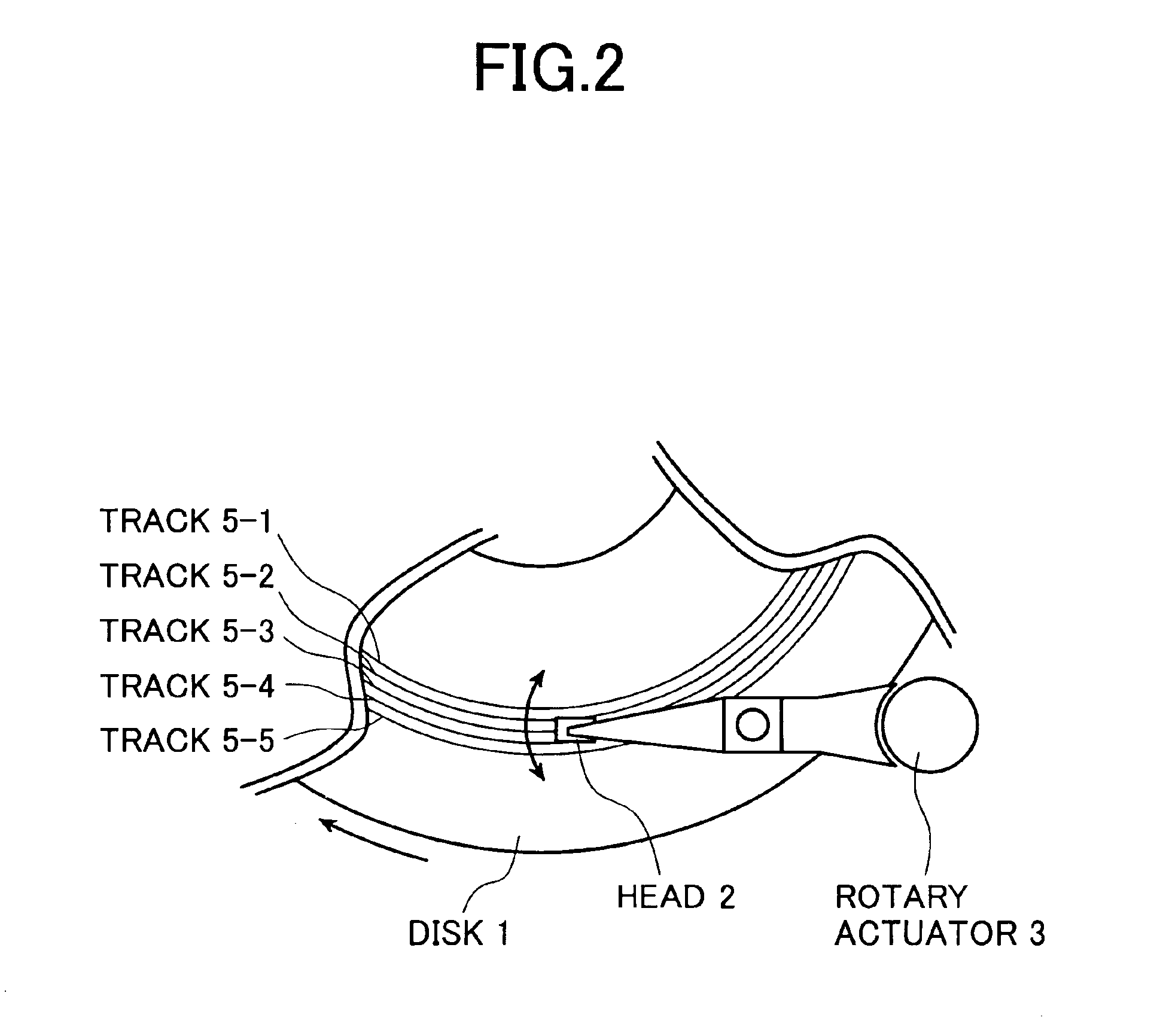

Magnetic recording/reproducing device

InactiveUS6909566B1Eliminate crosstalkReduce crosstalkTrack finding/aligningRecord information storageMagnetic disksEngineering

The invention relates to a magnetic recording / reproducing device in which a reproduce head is positioned where the crosstalk between adjacent tracks in a magnetic disk is minimized to maintain an adequate transfer rate in a system involving great crosstalk. The removal of crosstalk ensures the reproduction of the recorded data and thus increases the reliability of the magnetic recording / reproducing device. The magnetic recording / reproducing device according to this invention includes a magnetic disk on which a plurality of tracks are concentrically formed, and data are recorded at different frequencies on adjacent tracks.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

Ruthenium ammonia synthesis catalyst by using N-doped active carbon as carrier and preparation of ruthenium ammonia synthesis catalyst

InactiveCN104785255ALarge specific surface areaNitrogen doping amount controllableMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention belongs to the technical field of preparation of ammonia synthesis catalysts, and particularly relates to a ruthenium ammonia synthesis catalyst by using N-doped active carbon as a carrier and a preparation method of the ruthenium ammonia synthesis catalyst. The preparation method of the N-doped active carrier, disclosed by the invention, comprises the following steps: dissolving a precursor containing nitrogen in water so as to prepare a solution; loading the solution on graphitized active carbon by an equivalent-volume impregnation method; heating and evaporating the solution loaded on the graphitized active carbon at the temperature of 100 DEG C so as to be dried; then transferring the dried solution loaded on the graphitized active carbon into a tubular furnace, and roasting the transferred solution loaded on the graphitized active carbon at the temperature of 200 DEG C for some time; then performing the treatments of programmed warming and the like so as to obtain the N-doped active carbon carrier. The carrier is large in specific surface area and is high in activity, the doping content of nitrogen is controllable, and when the carrier is used for the ruthenium ammonia synthesis catalyst, the heat stability and the activity of the Ru / AC catalyst are improved.

Owner:FUZHOU UNIV

Cathode material of mid-temperature solid-oxide fuel battery and uses thereof

InactiveCN101304092AChange structureHigh activityCell electrodesSolid electrolyte fuel cellsDissociative adsorptionRare earth

The invention relates to a solid oxide fuel cell, in particular to medium temperature solid oxide fuel cell cathode material and application thereof. Being calculated by a weight percentage, the cathode material consists of 40-99 percent of perovskite-type composite oxides, 1-30 percent of CeO2 doped with rare earth oxides, and 0-59 percent of electrolyte material; the electrolyte material refers to ZrO2 stabilized by 5-20 mol percent of Y2O3 and / or ZrO2 stabilized by 5-20 mol percent of Sc2O3. The invention can change the structure of the active components of the cathode material, can improve the activity of the catalytic oxygen reduction reaction of the cathode material, can accelerate the dissociative adsorption of oxygen on the surface of the cathode material, the diffusion of oxygen species on the surface of the cathode material, the transmission process of the oxygen species in a three-phase bounded domain, charge transfer, and other electrochemical processes, and can increase the activity of the cathode of the solid oxide fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation process of sputtered rotary molybdenum-sodium-alloy tubular target

ActiveCN103045925AHigh densitySmall grain sizeVacuum evaporation coatingSputtering coatingSodium molybdateNiobium alloy

The invention discloses a preparation process of a sputtered rotary molybdenum-sodium-alloy tubular target. The preparation process comprises the following steps of: (1) preparing materials, wherein used powder comprises molybdenum powder and sodium molybdate powder, the physical property of the powder is as follows: the Mo content of the molybdenum powder is at least 99.95% with the granularity of 3-5 microns, and the sodium molybdate content of the sodium molybdate powder is at least 99.0% with the granularity of 20-40 microns; (2) blending the powder: weighing the molybdenum powder and the sodium molybdate powder proportionately, controlling the mass percentage content of the molybdenum powder to be 90-99% and that of the sodium molybdate powder to be 1-10%; (3) carrying out mechanical alloying: synthesizing nanometer molybdenum-sodium alloy powder; (4) filling into a die; (5) carrying out cold isostatic pressing; (6) sintering; (7) forging; (8) performing vacuum annealing; and (9) mechanically processing to obtain the sputtered rotary molybdenum-sodium-alloy tubular target. A produced molybdenum-niobium-alloy tubular target has characteristics of uniform elements, no segregation, fine grain size and high purity, completely meets requirements of CIGS (Copper Indium Gallium Selenide) photovoltaic cells and increases the use efficiency of the cells.

Owner:LUOYANG SIFON ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com