Patents

Literature

1577results about How to "Small grain size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold spray formation of thin metal coatings

InactiveUS20060090593A1Small grain sizeSmall granularityTransportation and packagingMetal-working apparatusAluminiumThin metal

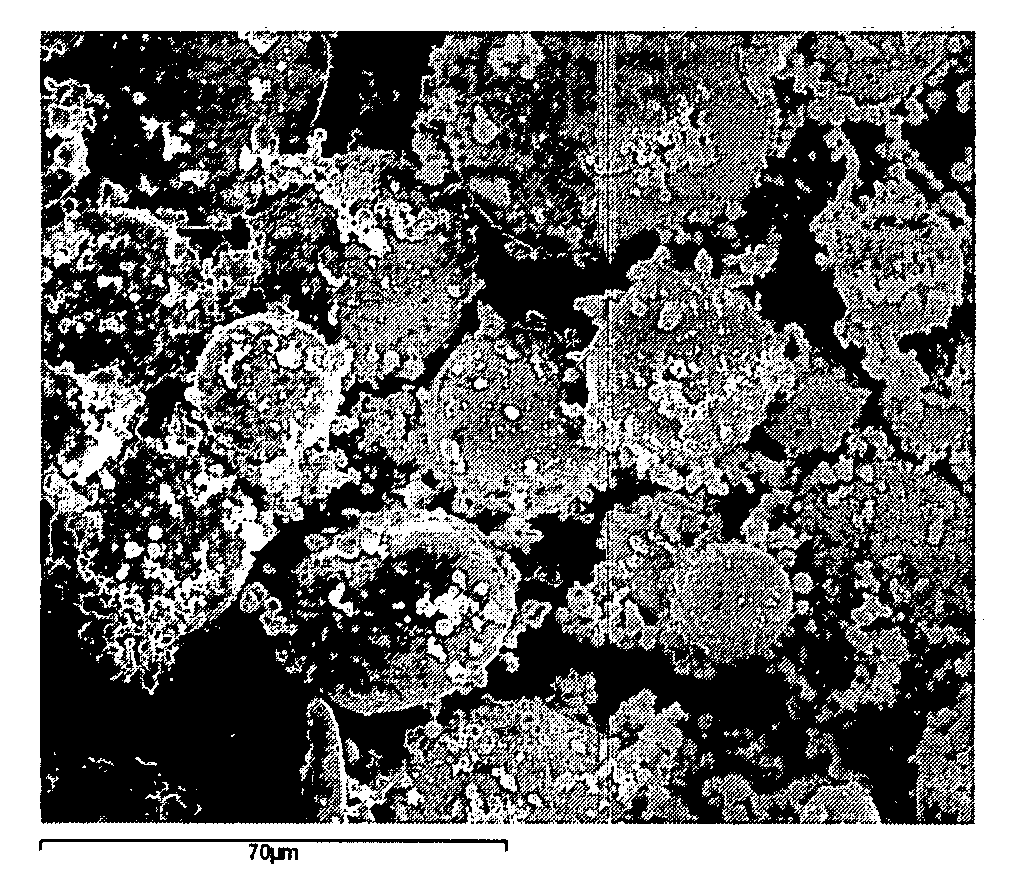

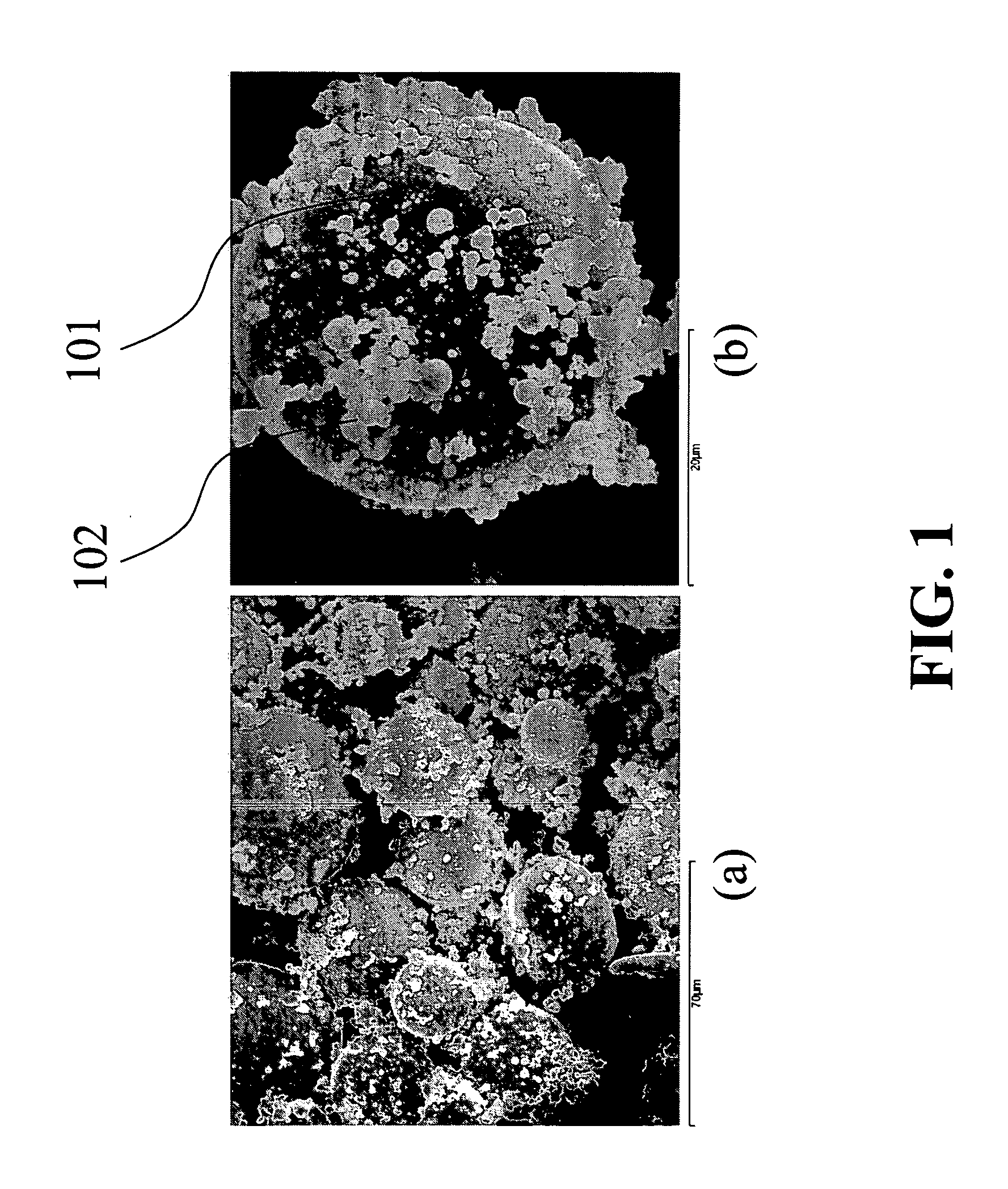

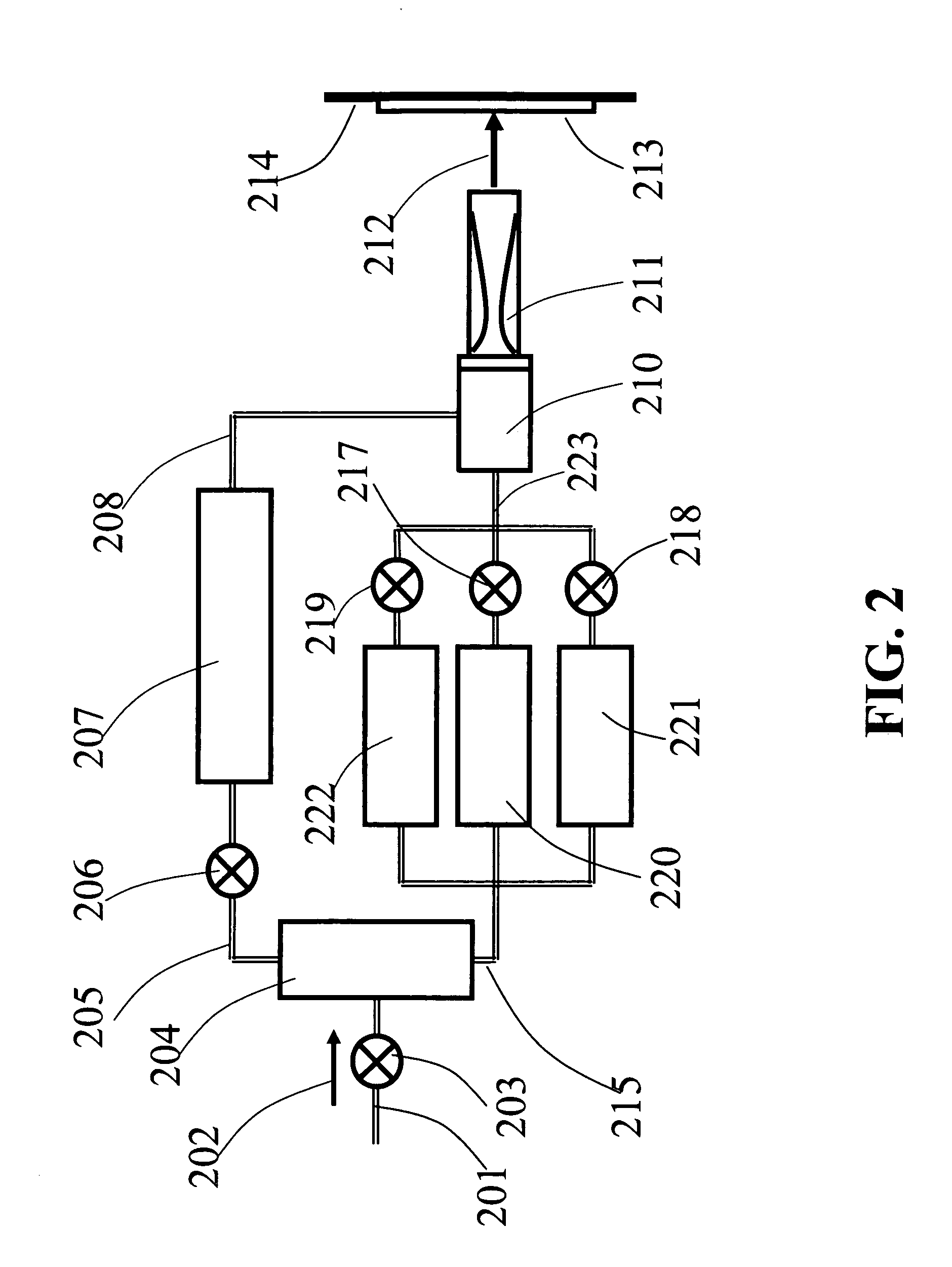

The invention relates to an adaptation of the cold spray process to provide a method of coating fine metal particles, including aluminum and copper, onto a work piece. In one embodiment, the invention is a metal agglomerated hard sphere composition capable of providing about a 1 micron or thicker coating of a metal on a work piece in a cold spray process. In another embodiment the invention is a method of coating metal particles, including metal particles having a particle size of about 0.01 to about 10 micron, onto a work piece. The method of the invention circumvents many of the problems associated with cold spray processing of very fine particles.

Owner:NANOMAT

Target of intermetallic compound with B2-ordered lattice structure, production method thereof and magnetic recording medium having B2-structured underlayer

InactiveUS6159625AHigh bending strengthSmall grain sizeCellsBase layers for recording layersSputter depositionCrystallite

A target for sputter-depositing a B2-structured thin film for an underlayer of a magnetic recording medium. Since the target is made of a sintered body of an intermetallic compound being substantially a B2-ordered lattice structure, the target has a uniform small grain size and a high bending strength. The target produces a thin film with a small grain size and a minimized particle deposition.

Owner:HITACHI METALS LTD

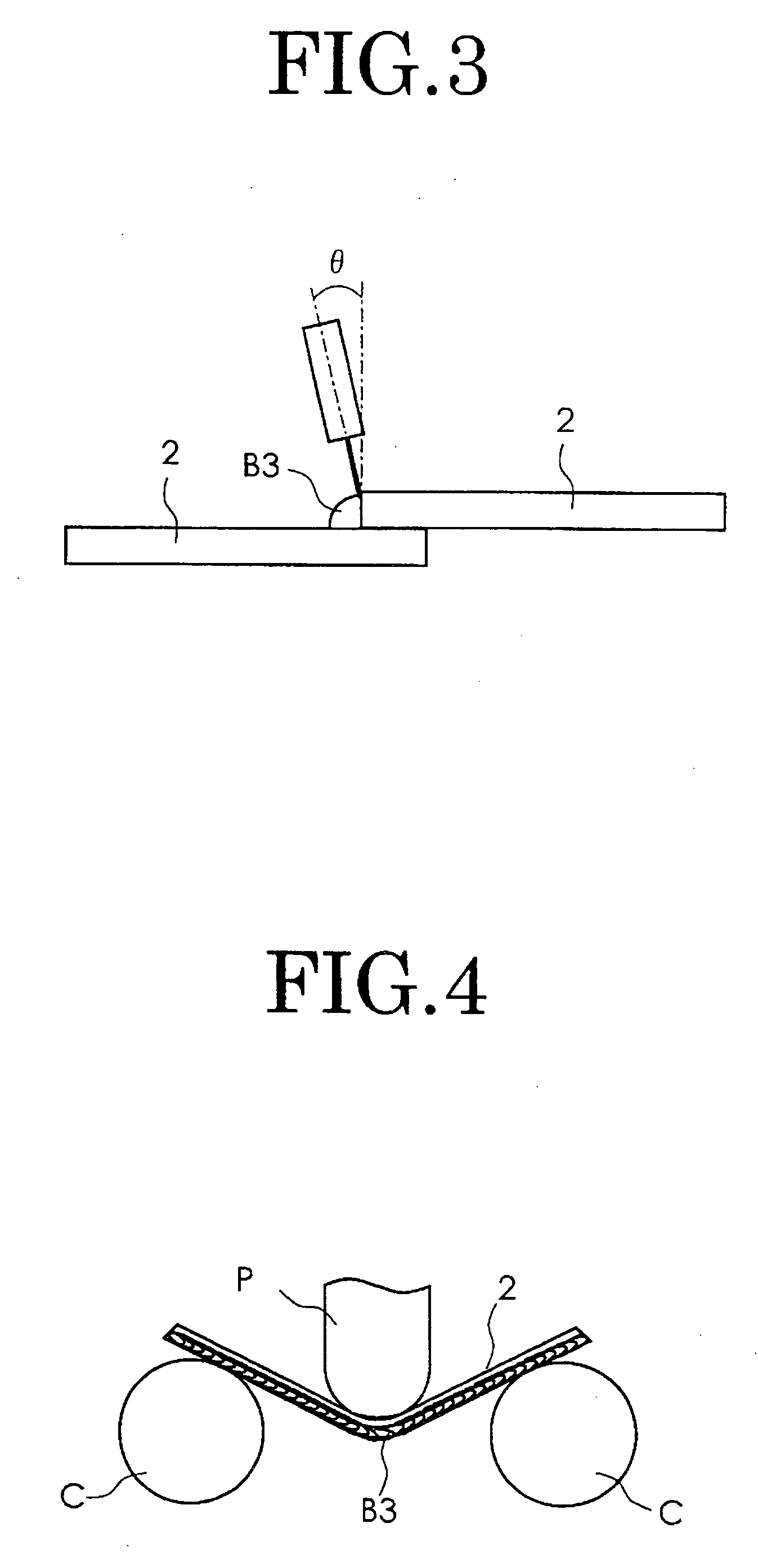

Ferritic stainless steel welding wire and manufacturing method thereof

ActiveUS20060163231A1Avoid breakingImprove crack resistanceWelding/cutting media/materialsSoldering mediaWire rodCrack resistance

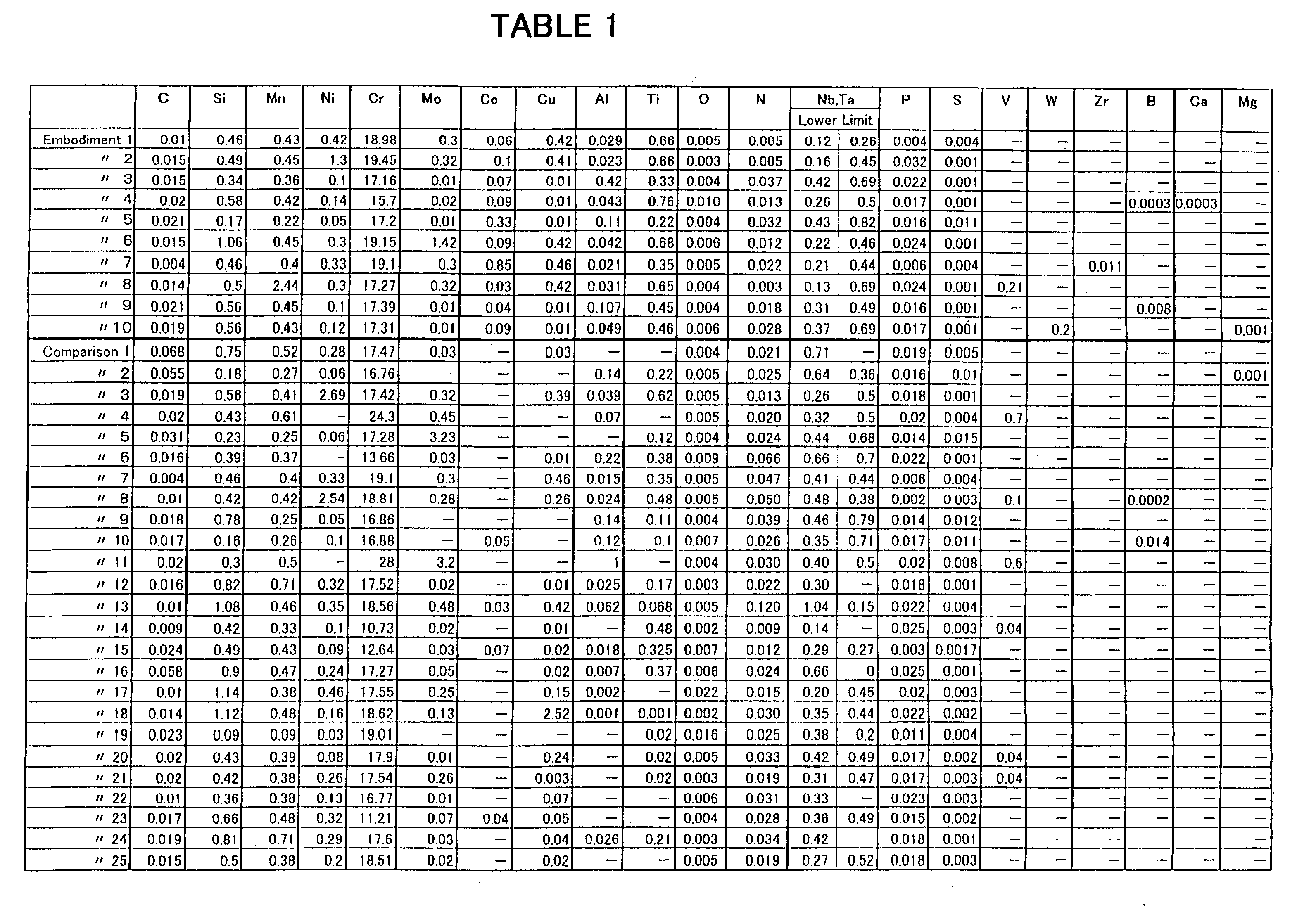

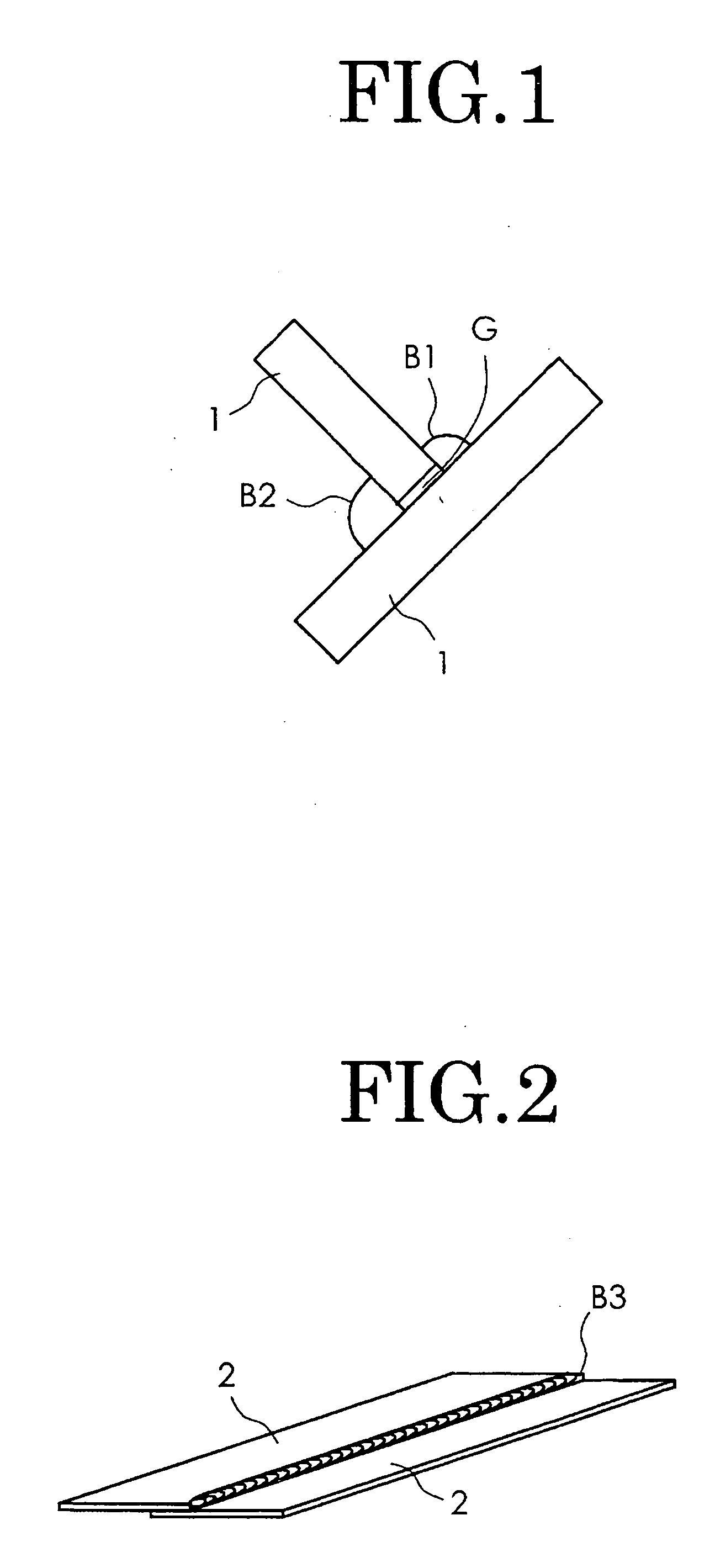

The present invention provides a ferritic stainless steel welding wire which allows prevention of wire breaking, fine refining of crystal grains, and increased cracking resistance. A wire rod used essentially consists of, in mass %, 0.03% or less of C, 3% or less of B, 3% or less of Mn, 2% or less of Ni, 11 to 20% of Zr, 3% or less of Mo, 1% or less of Co, 2% or less of Cu, 0.02 to 2.0% of Al, 0.2 to 1.0% of Ti, 0.02% or less of O, 0.04% or less of N, at least one of Nb and Ta, the mass % thereof being eight times the total mass % of the C and N to 1.0 mass %, and the balance of Fe and unavoidable impurities. When the number of crystals per square mm (mm2) of a cross section of the wire rod is defined as m, a grain number of the crystal expressed by an exponent (G) in an expression of m=8×2G is set to 3 to 10 by the heat treatment.

Owner:NIPPON WELDING ROD

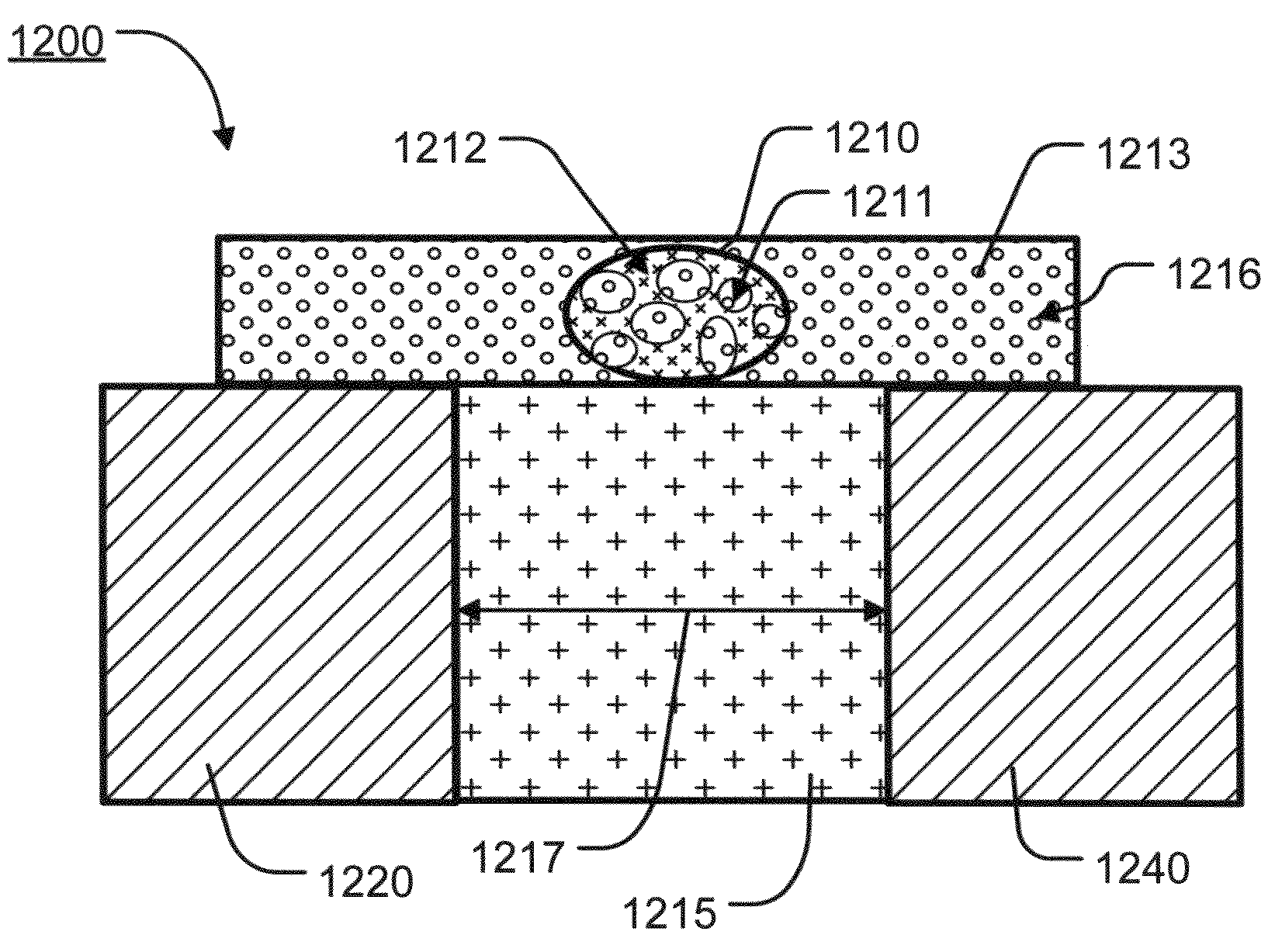

Dielectric mesh isolated phase change structure for phase change memory

ActiveUS20100084624A1Easy to optimizeSmall grain sizeSemiconductor/solid-state device manufacturingDigital storageDielectricPhase-change memory

A method for manufacturing a memory device, and a resulting device, is described using silicon oxide doped chalcogenide material. A first electrode having a contact surface; a body of phase change memory material in a polycrystalline state including a portion in contact with the contact surface of the first electrode, and a second electrode in contact with the body of phase change material are formed. The process includes melting and cooling the phase change memory material one or more times within an active region in the body of phase change material without disturbing the polycrystalline state outside the active region. A mesh of silicon oxide in the active region with at least one domain of chalcogenide material results. Also, the grain size of the phase change material in the polycrystalline state outside the active region is small, resulting in a more uniform structure.

Owner:GLOBALFOUNDRIES US INC

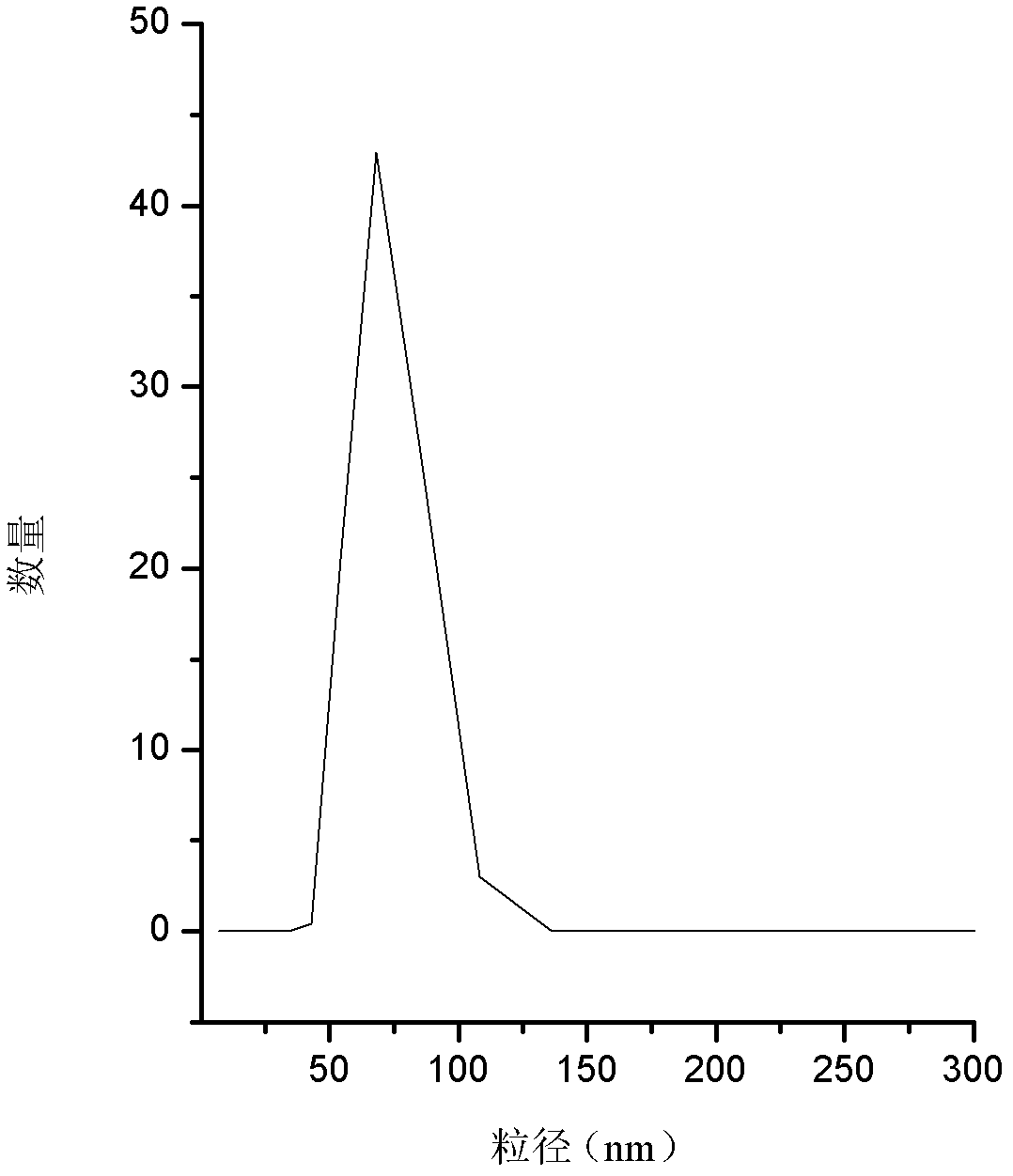

Nano zeolitic imidazolate frameworks crystal preparation method through dynamic crystallization

InactiveCN102220626AShortened nucleation timeSmall grain sizePolycrystalline material growthOrganic chemistrySolventChemistry

A nano zeolitic imidazolate frameworks crystal preparation method through dynamic crystallization. The method comprises the following steps: dissolving a metal precursor and an organic ligand in solvents respectively to prepare a metal precursor solution A and an organic ligand solution B; mixing the solution A and the solution B and placing the mixture in a reaction vessel with a stirring device; reacting at 30 DEG C-180 DEG C for 10min-96h, then cooling for crystal growth, and carrying out centrifugal separation and washing to obtain a target product. The method provided by the invention has simple synthesis conditions, is easy to operate and can effectively reduce crystal dimensions. Therefore, the method with a wide universality is suitable for various ZIFs crystal preparation.

Owner:DALIAN UNIV OF TECH

Method for preparing ultra-fine crystal WC-Co hard alloy

A preparation method of superfine crystal WC-Co hard alloys belongs to the field of high-performance functional materials. The powder mixture is composed of 8-11wt percent of Co, 0.001-0.7wt percent of VC, 0.001-0.8wt percent of Cr3C2, and WC with a grain size of 0.2-0.5 micron in balance. The powder mixture is weighed at the given weight ratio and then subjected to alloying treatment under such conditions that the ball-milling time is 15-60 min, the rotational speed of ball mill is 800-1400 r / min-1, the ratio of media-to-material is 5:1 to 10:1; and the level of ball milling media is 5-10 mm above the surface of the ball-milled material, so that the powder mixture is pre-formed to form a pre-forming blank with a density of 50-70 percent. The pre-forming blank is further processed into superfine WC-Co hard alloy by the ultra-high pressure sintering process in a six-face presser, under the following conditions: sintering voltage of 1.25-1.40V, sintering pressure of 10-12GPa, and sintering time of 60-120s. The method has the advantages that the powder is rapidly densified upon an extremely-high pressure and heating simultaneously; and the obtained produce has full density and high hardness (up to 93.1HRA) while the grain size of WC remains almost unchanged.

Owner:UNIV OF SCI & TECH BEIJING

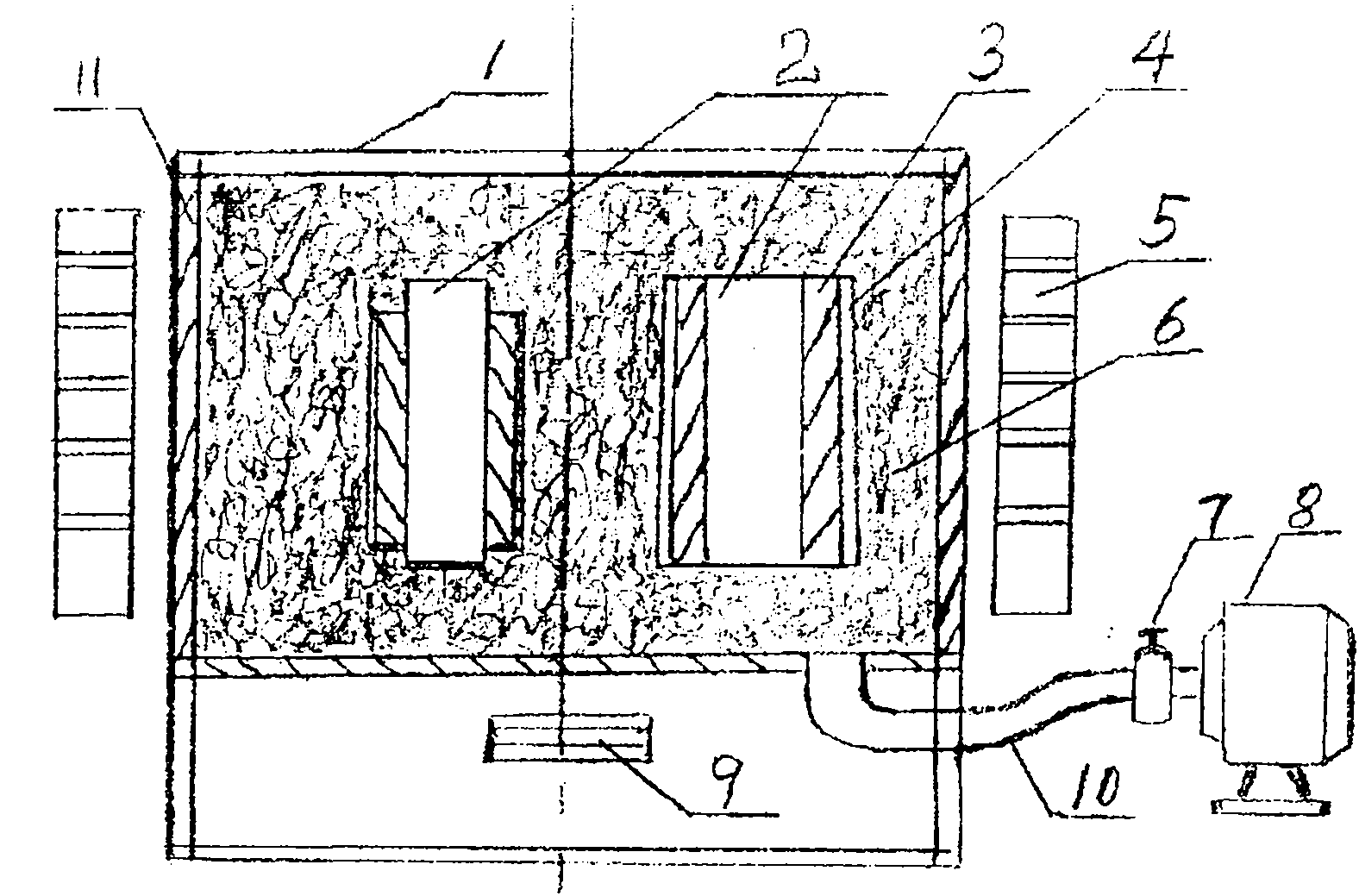

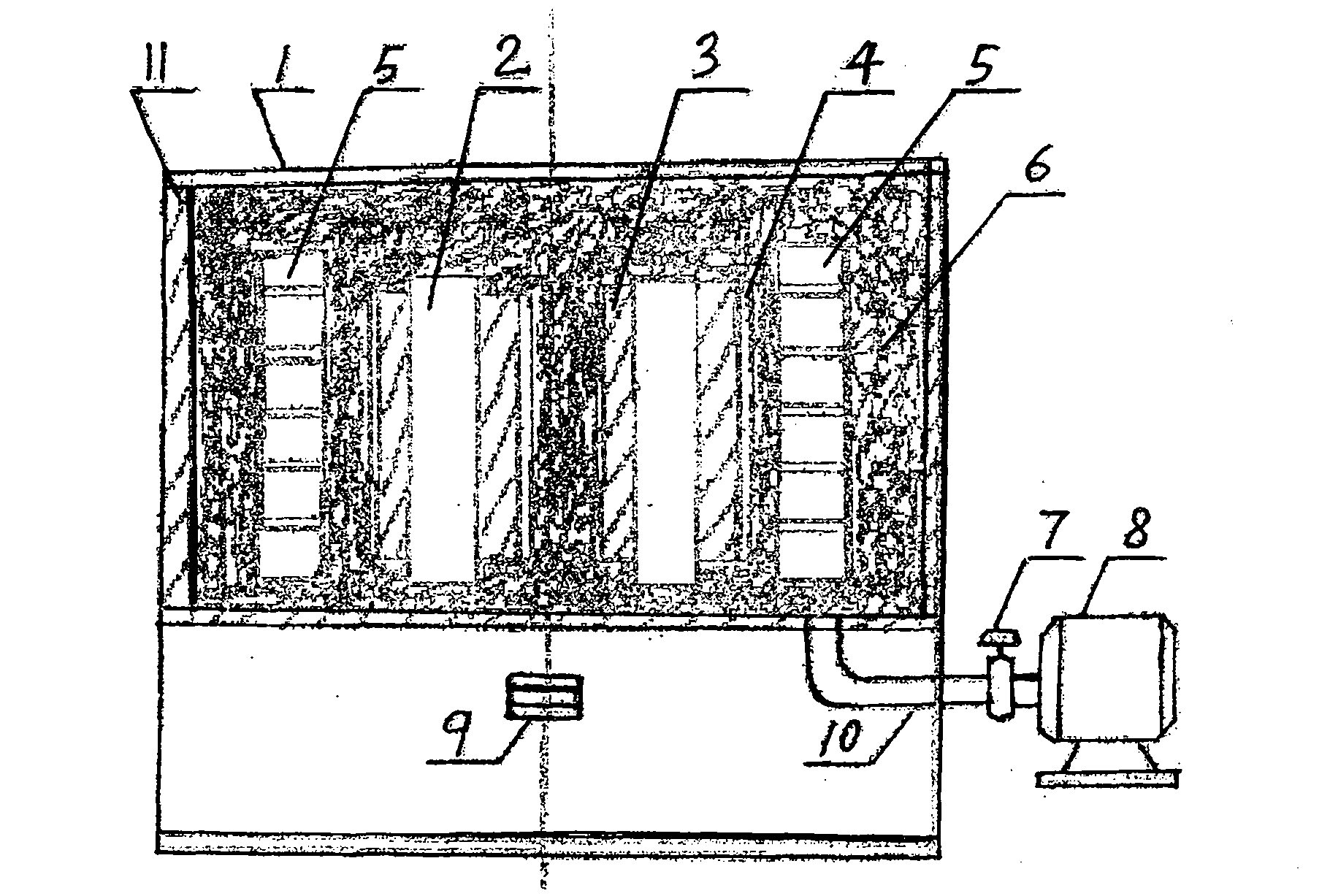

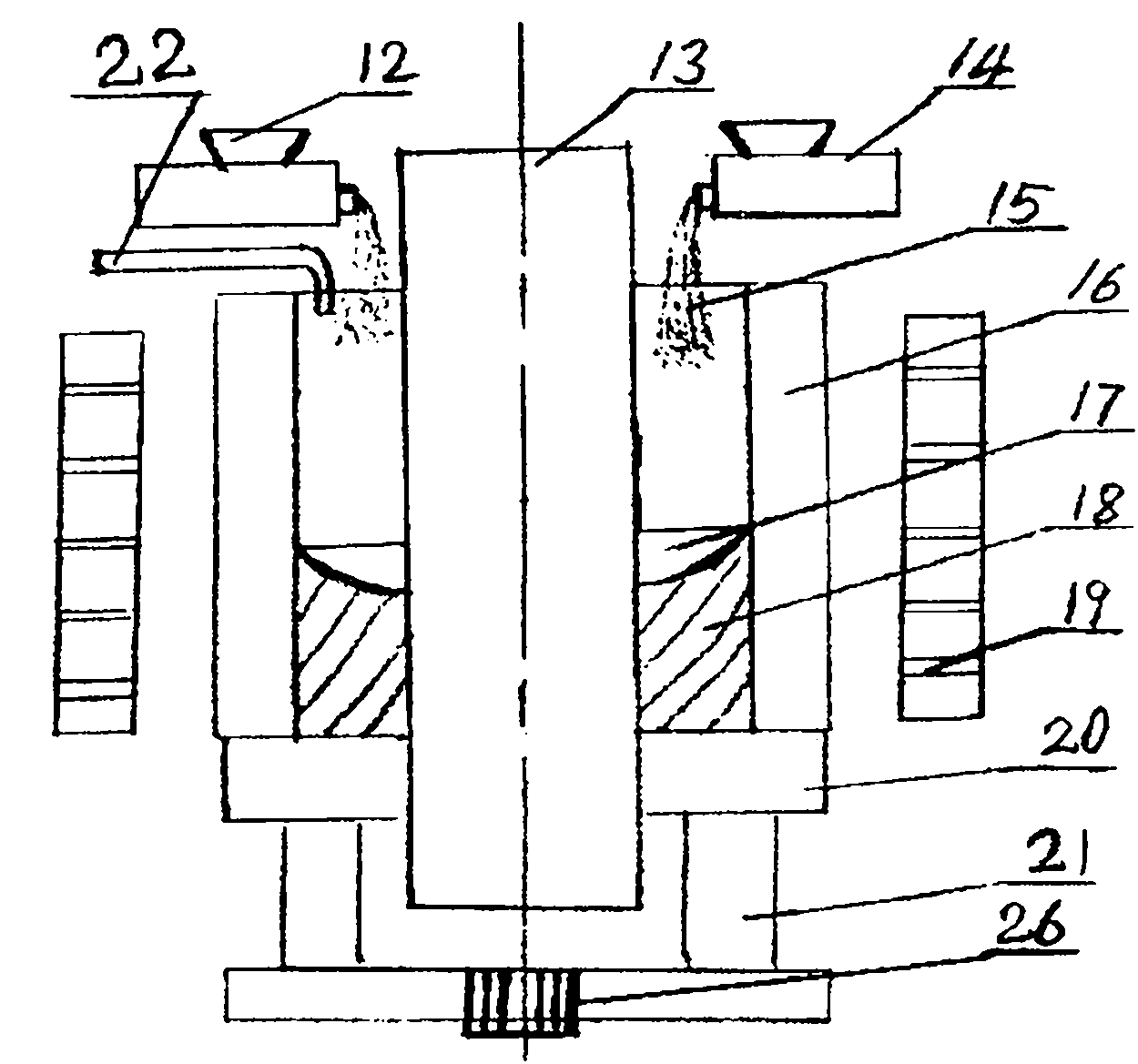

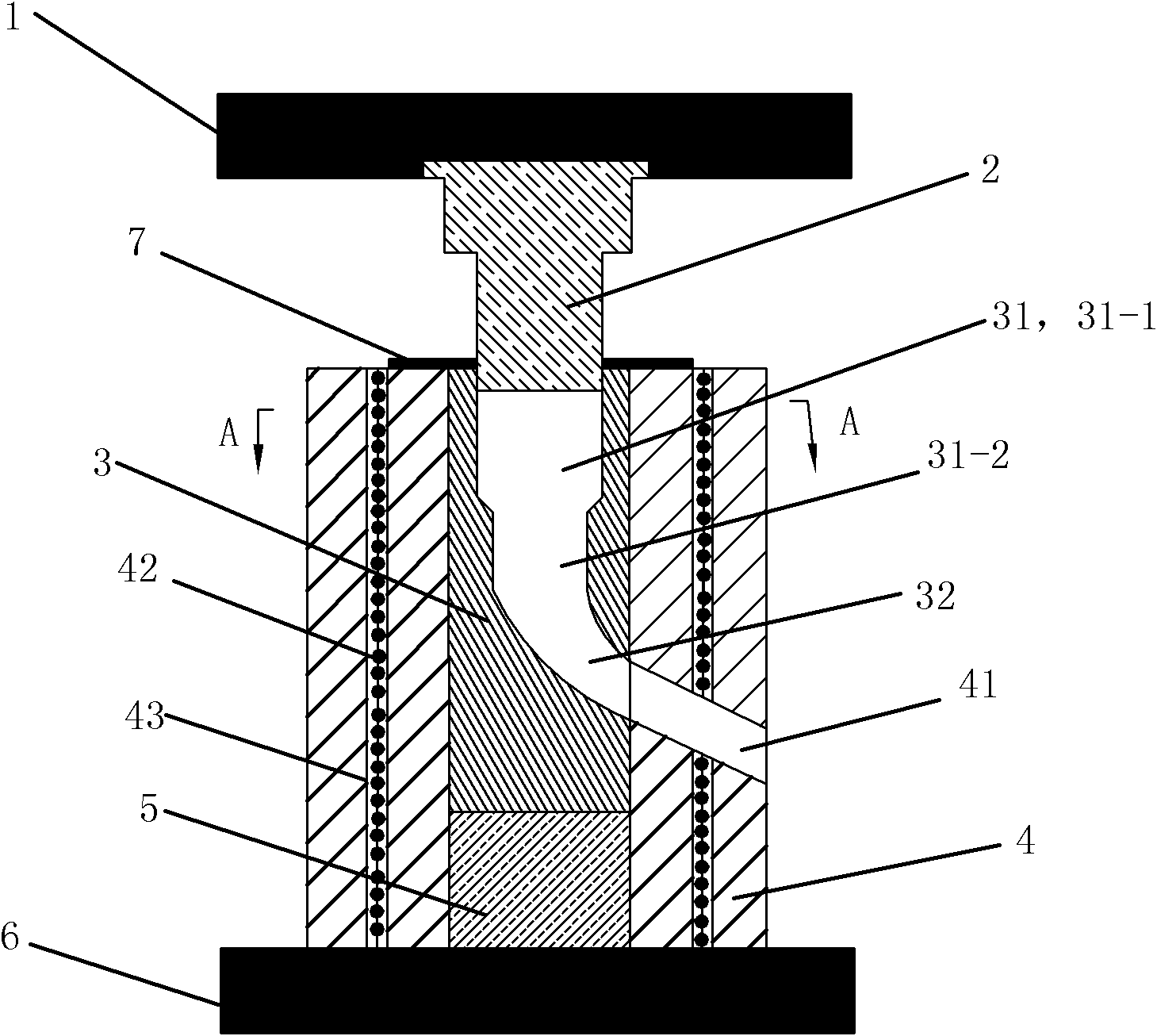

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

Coated body with nanocrystalline CVD coating for enhanced edge toughness and reduced friction

InactiveUS20020012818A1Small grain sizeMaterial nanotechnologyVacuum evaporation coatingCrystalliteProduct gas

An improved coated body having a nanocrystalline CVD coating of Ti(C,N,O) is disclosed. The coating is formed using the MTCVD process and including, as part of the gaseous mixture, CO, CO2 or mixtures thereof. The use of this dopant during the coating results in a much smaller, equiaxed grain size. The method of forming the body is also disclosed.

Owner:SECO TOOLS AB

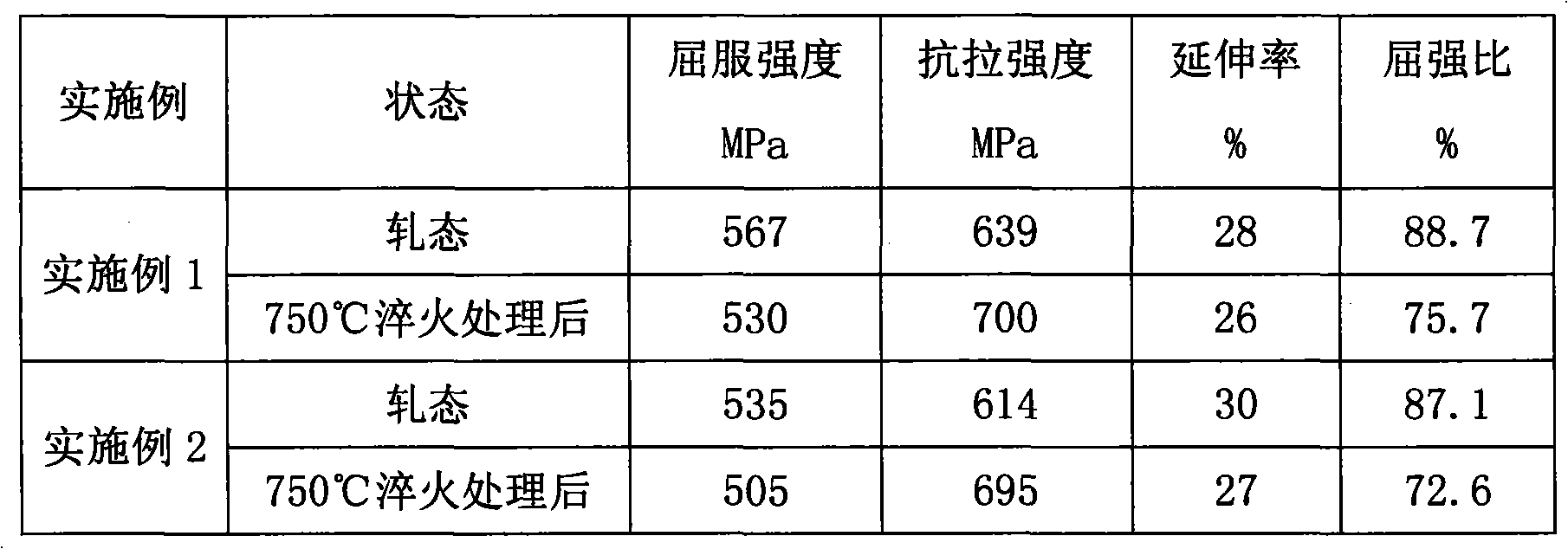

Pipeline steel plate with low yield ratio, fine grains and high strength and production method thereof

The invention discloses a pipeline steel plate with low yield ratio, fine grains and high strength and a manufacturing method thereof, and steel in the pipeline steel plate comprises the following chemical components by weight percent: 0.03-0.10% of C, 0.10-0.30% of Si, 1.20-1.80% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.040-0.060% of Nb, 0.006-0.020% of Ti, 0.10-0.40% of Cr, 0.10-0.30% of Ni, 0.010-0.050% of Al and the balance of Fe and inevitable impurities. The manufacturing method adopts a converter for smelting, adopts the TMCP (thermo mechanical control process) and the two-phase region subthermal quenching treatment at 720-750 DEG C, thereby obtaining the pipeline steel plate with low yield ratio, fine grains and high strength; and the manufacturing method has stable production process, strong operability, low cost and high performances.

Owner:NANJING IRON & STEEL CO LTD

Catalyst for wet oxidation technique and preparation method thereof

InactiveCN101185887AHigh catalytic activityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationActive componentSalt solution

The invention relates to a catalyst which is used for wet air oxidation technique and the preparation method in the field of environmental protection technology. The catalyst uses Gamma-Al2O3 as a vector and the oxide of transition metal Mn or Mn and rear earth element M or the oxide of the M as active components, wherein, M is one or two kinds in La and Ce and the loading of each metal relative to Gamma-Al2O3 vector is 5wt to 8wt percent. The catalyst takes Gamma-Al2O3 as the vector, is cleaned and roasted to be a consistent weight; the obtained Gamma-Al2O3 vector is immersed into the metallic salt solution of the rear earth element M and the transition metal Mn; the loading of each metal relative to the vector is 5wt to 8wt percent; the mixture after being immersed and dried is roasted in air to get the catalyst used in the wet air oxidation. The invention does not use expensive precious metal materials and greatly reduces the cost of the catalyst; at the same time, the catalytic activity of the catalyst is enhanced; the operation condition is improved; and the reaction time is shortened.

Owner:SHANGHAI JIAO TONG UNIV

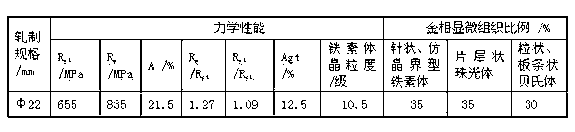

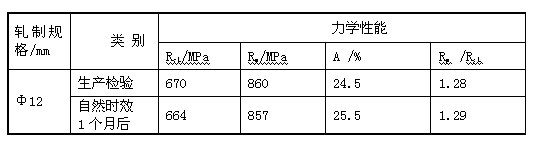

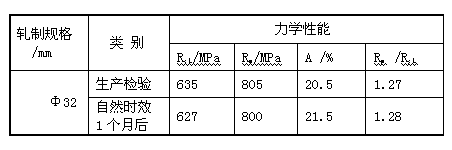

Niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar and production thereof

ActiveCN102796962ALow strain agingIncreased strain agingProcess efficiency improvementNiobiumTitanium

The invention provides a niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar and production of the niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar. Through molten steel smelting, molten steel casting, billet controlled rolling and controlled cooling, the niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcing bar is produced and comprises the following chemical constituents according to mass ratio: 0.14-0.18% of C, 0.30-0.50% of Si, 0.50-0.75% of Mn, 0.50-0.70% of Cr, 0.030-0.050% of Nb, 0.0015-0.0030% of B, 0.020-0.040% of Ti, no more than 0.045% of S, no more than 0.045% of P and the balance of Fe and unavoidable impurities. The niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcing bar has the characteristics of low production cost, technological applicability, strong controllability and the like, the steel microstructure is uniformly distributed and has good form, the refining effect of ferrite is obvious, and the niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcement has good low-strain timeliness, high strength, good toughness, good welding performance, excellent aseismic performance and excellent combination property.

Owner:WUKUN STEEL

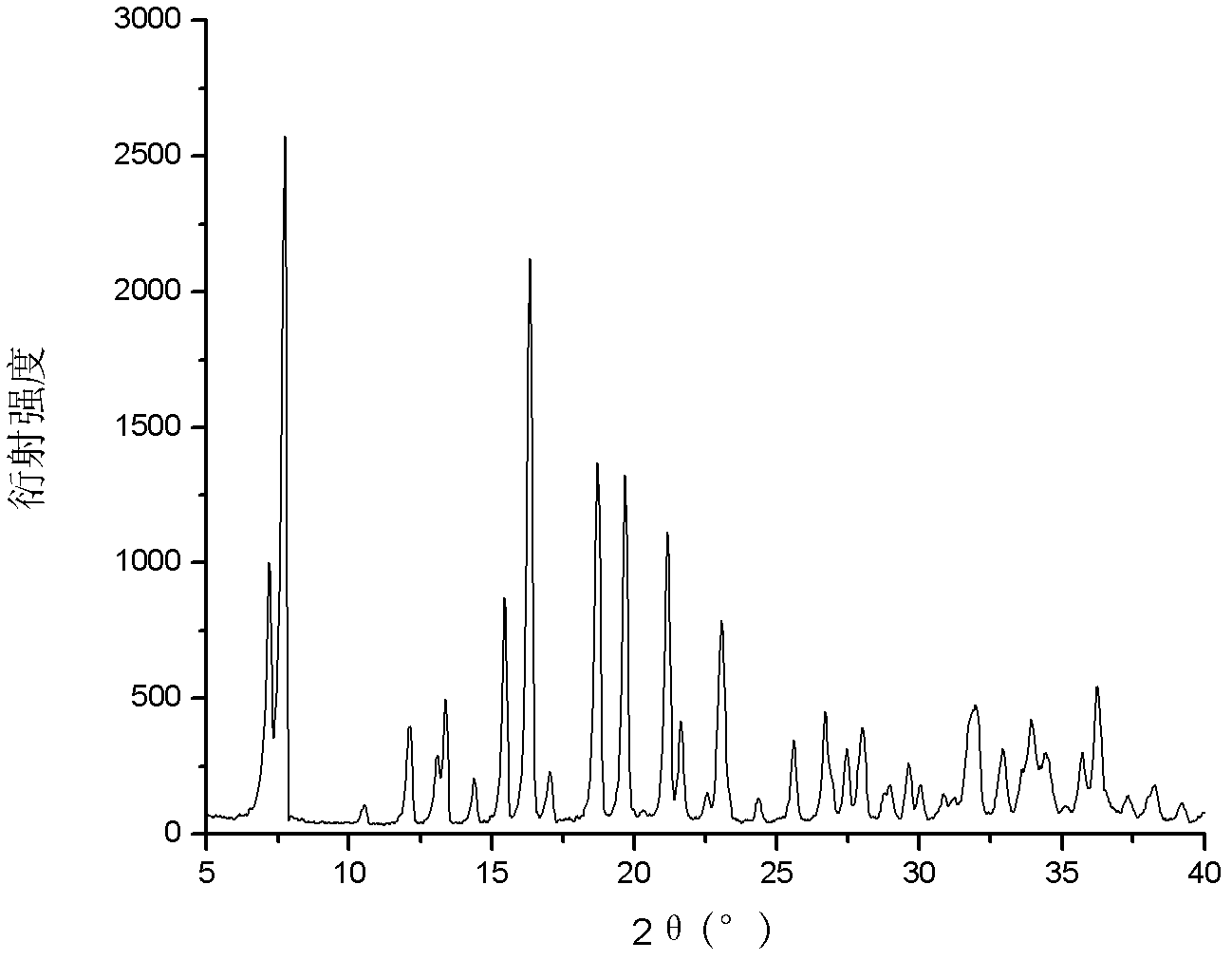

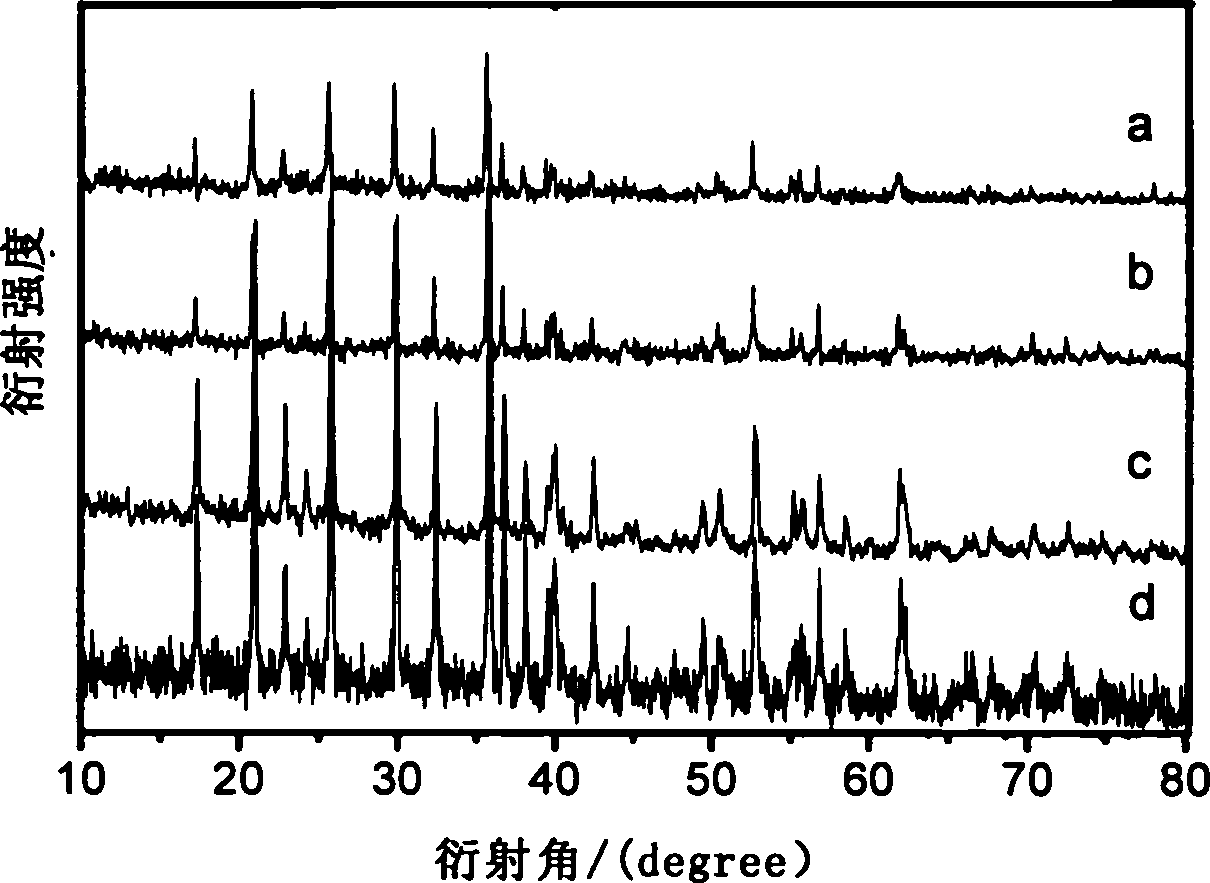

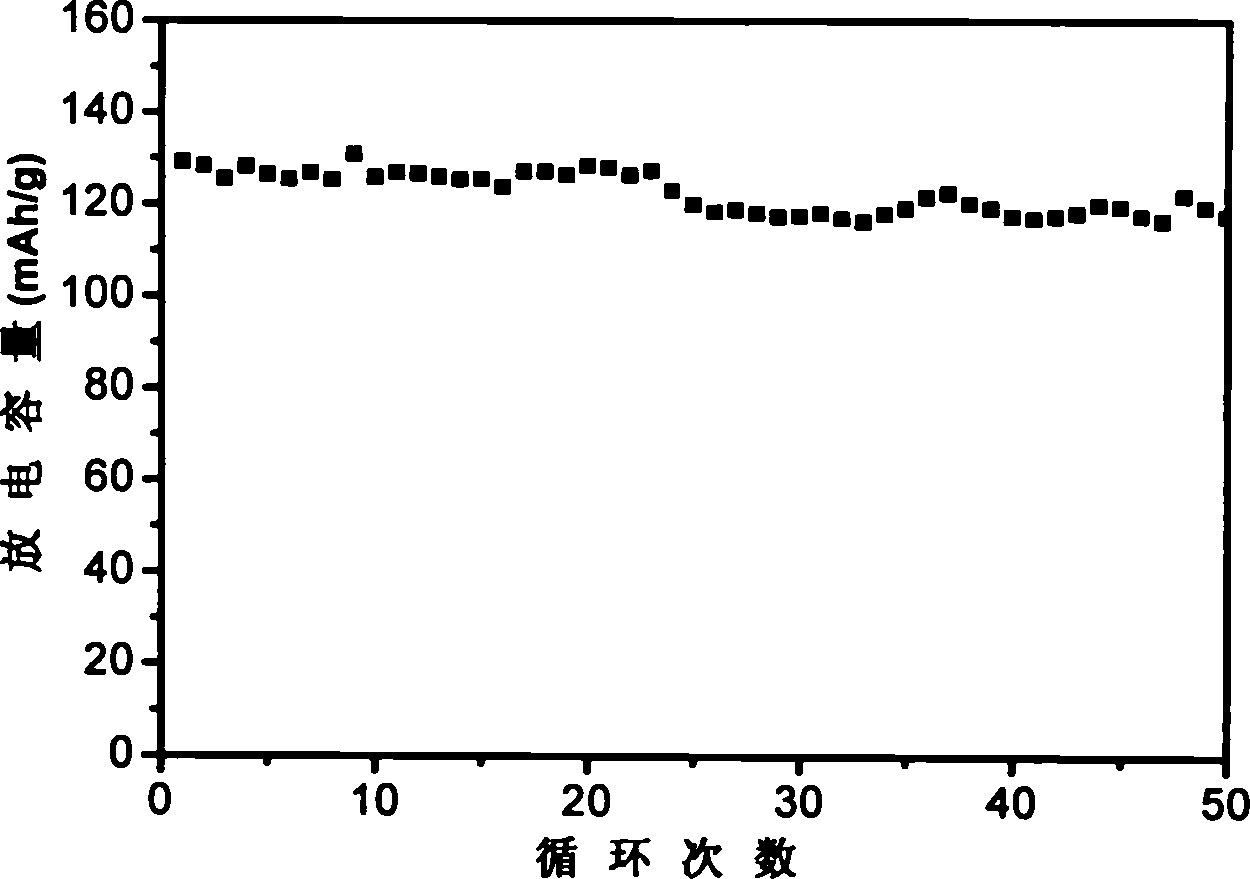

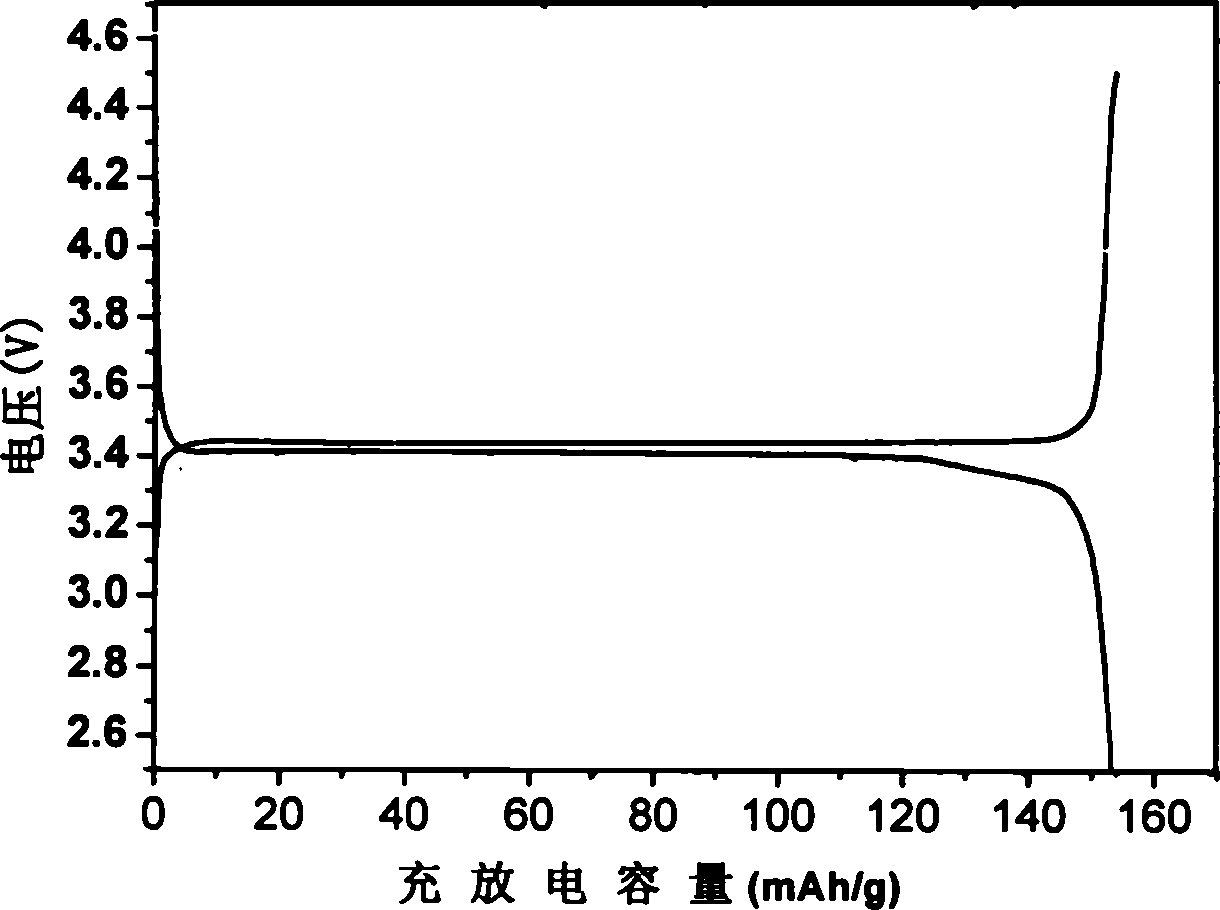

Process for solid phase synthesis of lithium iron phosphate anode materials under high pressure

InactiveCN1884053ALow reaction temperatureReduce manufacturing costCell electrodesPhosphorus compoundsAir atmosphereLithium iron phosphate

The invention discloses a synthesizing method of anode material of high-pressure solid-phase ferric-lithium phosphate, which comprises the following steps: blending lithium salt, ferric salt and phosphate according to 1:1:1 proportion evenly; grinding the material into ball for 6-24 h to obtain priority; disposing priority for 2-10 h at 200-350 deg.c in the air environment; cooling naturally; grinding to obtain powder material; adding carbon material in the powder material with weight percentage of carbon material at 1-20 percent; grinding again for 6-24 h; disposing for 4-24 h at 450-1000 deg.c in the 1-15 Mpa inert environment; cooling naturally to obtain the product.

Owner:SOUTH CHINA UNIV OF TECH

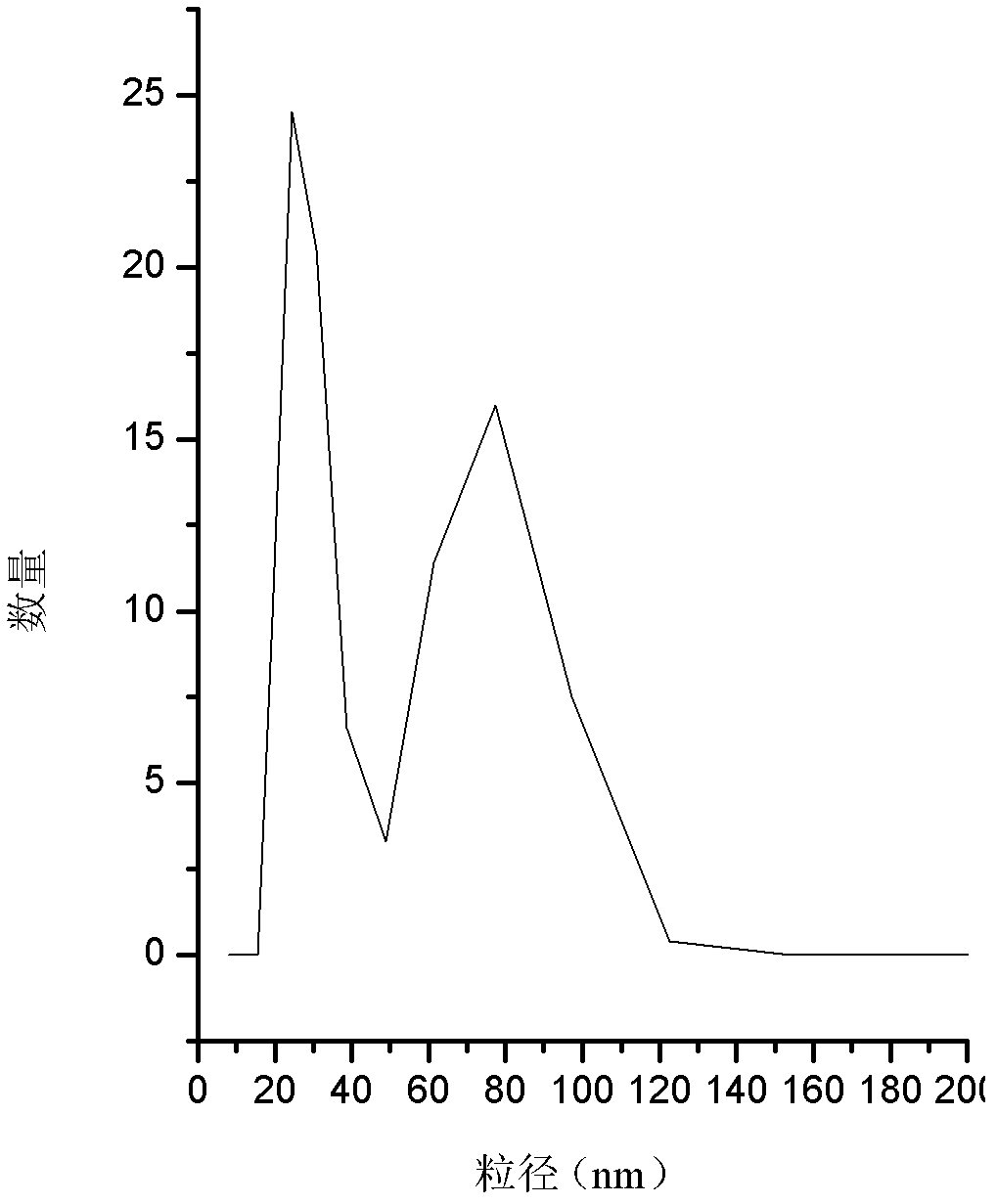

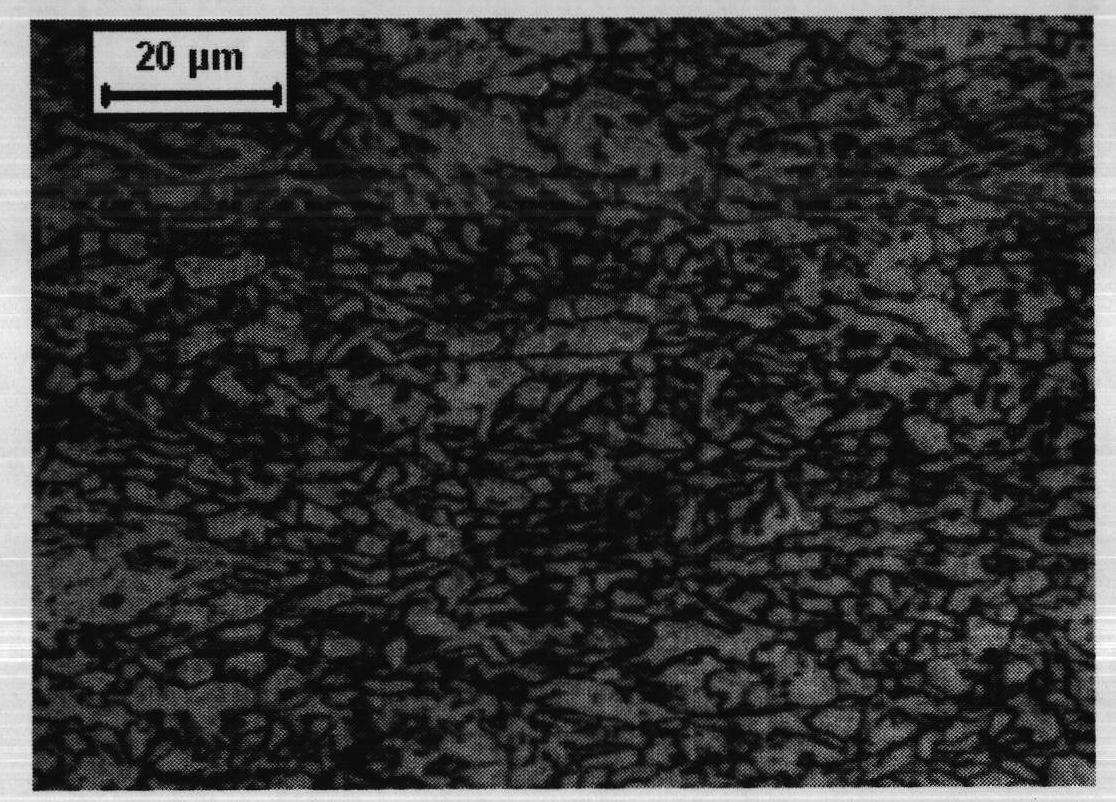

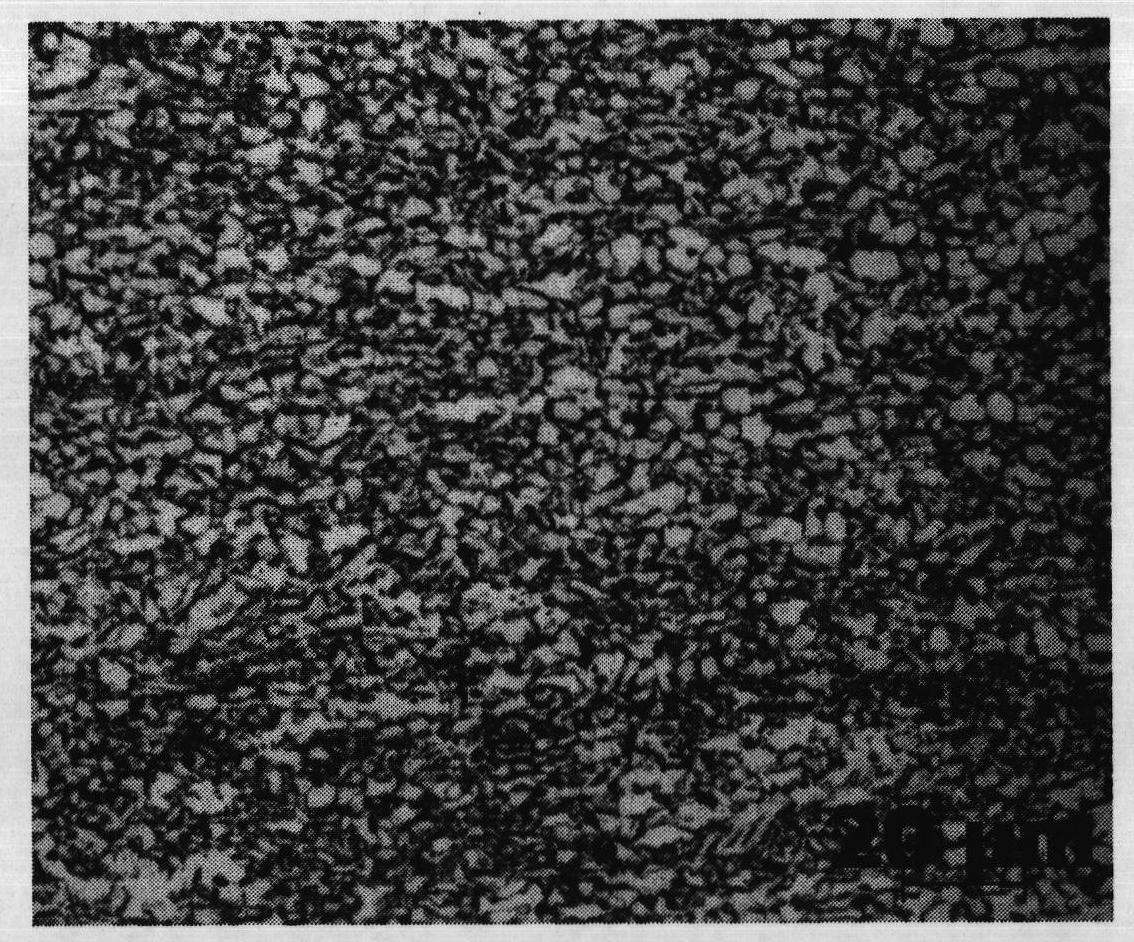

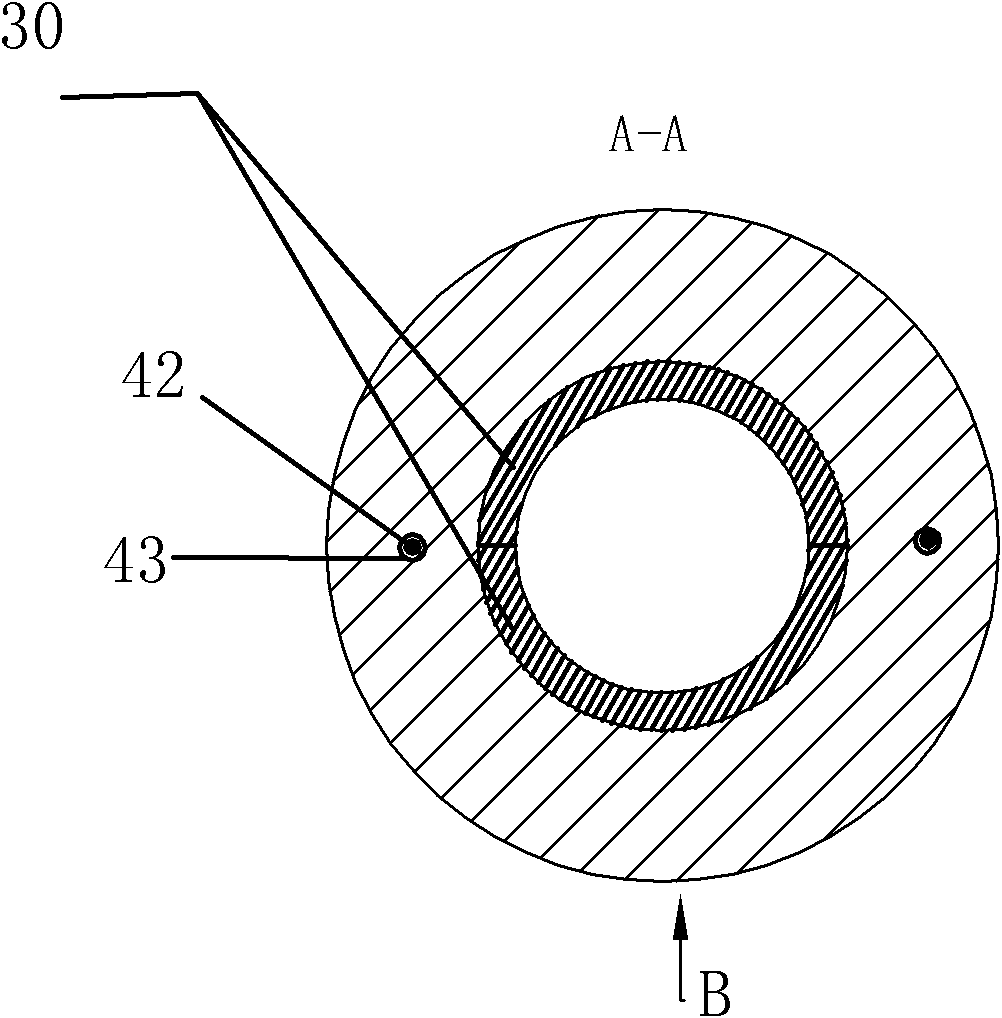

Method and die for forward extrusion and variable diameter bending extrusion of magnesium alloy semi-solid billets

InactiveCN101850376ASmall grain sizeSolve the problem of not being able to continuously prepare large-size semi-solid billetsExtrusion diesSemi solidLarge deformation

The invention discloses a method and a die for the forward extrusion and variable diameter bending extrusion of magnesium alloy semi-solid billets. The preparation method comprises a predeformation process and an isothermal spheroidizing heat treatment process, wherein in the predeformation process, uniform deformation of large deformation amount is realized by the die for the forward extrusion and variable diameter bending extrusion; cutting a magnesium alloy bar stock which is subjected to large deformation by a fixed size; heating the magnesium alloy bar stock cut by the fixed size at the temperature of between 520 and 580 DEG C under the protection of argon, and keeping the temperature of the obtained magnesium alloy bar stock for 10 to 30 minutes; and processing a bending extrusion angle of the die to be over 90 degrees. The method has the advantages of small predeformation resistance, large and uniform deformation, safety, reliability and no three-waste pollution. The grains of the prepared magnesium alloy semi-solid billets have fine size, are uniform and have a shape close to that of a sphere. The method solves the problem that the conventional SIMA method cannot continuously prepare the large-size semi-solid billets and meets the requirements of the semi-solid thixoforming workpieces for large-scale continuous production.

Owner:CHANGZHOU INST OF TECH

Ultrahigh-temperature high-entropy carbide powder and preparation method thereof

The invention relates to the technical field of ultrahigh-temperature ceramic powder, in particular to ultrahigh-temperature high-entropy carbide powder and a preparation method thereof. The ultrahigh-temperature high-entropy carbide powder adopts a chemical formula as follows: (Ti0.2Zr0.2Hf0.2Nb0.1W0.1Ta0.2) C, and is prepared from TiO2, ZrO2, HfO2, Nb2O5, WO3, Ta2O5 and carbon black as raw materials through wet mixing and a high-temperature carbothermal reduction reaction. The ultrahigh-temperature high-entropy carbide powder is small in grain size, low in heat conductivity and good in hightemperature stability, and is suitable to be used as a base material of an ultrahigh-temperature heat-resistant coating material, an ultrahigh-temperature heat-insulating material and an ultrahigh-temperature composite material; by the preparation method, a technology is simple, the raw material cost is low, and the high-purity ultrahigh-temperature high-entropy carbide powder can be obtained through once heating at relatively low temperature.

Owner:淄博星澳新材料研究院有限公司

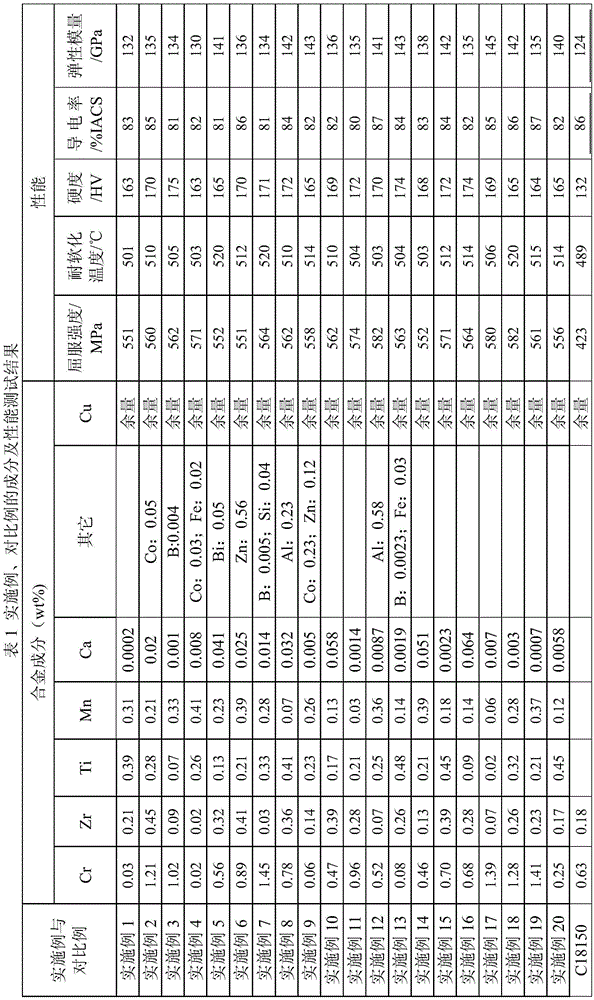

High-strength high-conductivity copper-chromium-zirconium alloy and preparation method of plate/strip thereof

The invention discloses a high-strength high-conductivity copper-chromium-zirconium alloy and a preparation method of a plate / strip thereof. This alloy comprises the chemical composition: 0.01-1.5 wt% of Cr, 0.01-0.5 wt% of Zr, 0.001-0.5 wt% of Ti, 0.01-0.5 wt% of Mn, 0.0001-0.07 wt% of Ca, and the balance of copper and unavoidable impurities; the position and process of the Cu-Cr-Zr alloy are optimized, the provided high-strength high-conductivity copper-chromium-zirconium alloy retains high conductivity (above 80% IACS), elastic modulus up to higher than 130 GPa, softening temperature resistance up to higher than 500 DEG C, yield strength up to higher than 550 MPa and hardness up to 160 HV, the copper-chromium-zirconium plate / strip is imparted high strength, high conductivity and excellent comprehensive performance, this comprehensive performance meets the requirements of products such as a lead frame and a connector upon base material stamping and machining performances, and this plate / strip material is mainly applied to electronic components such as connectors and lead frames.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD

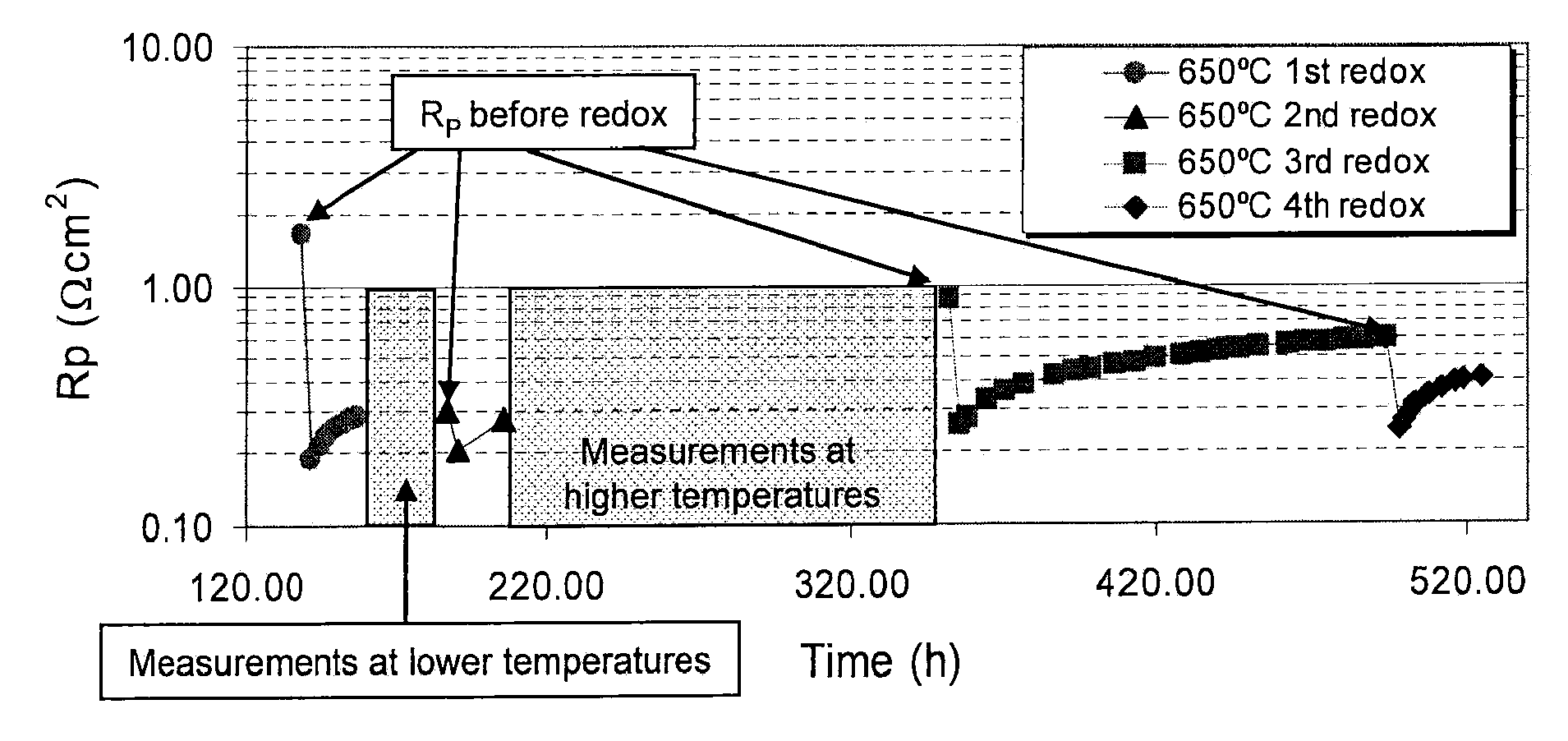

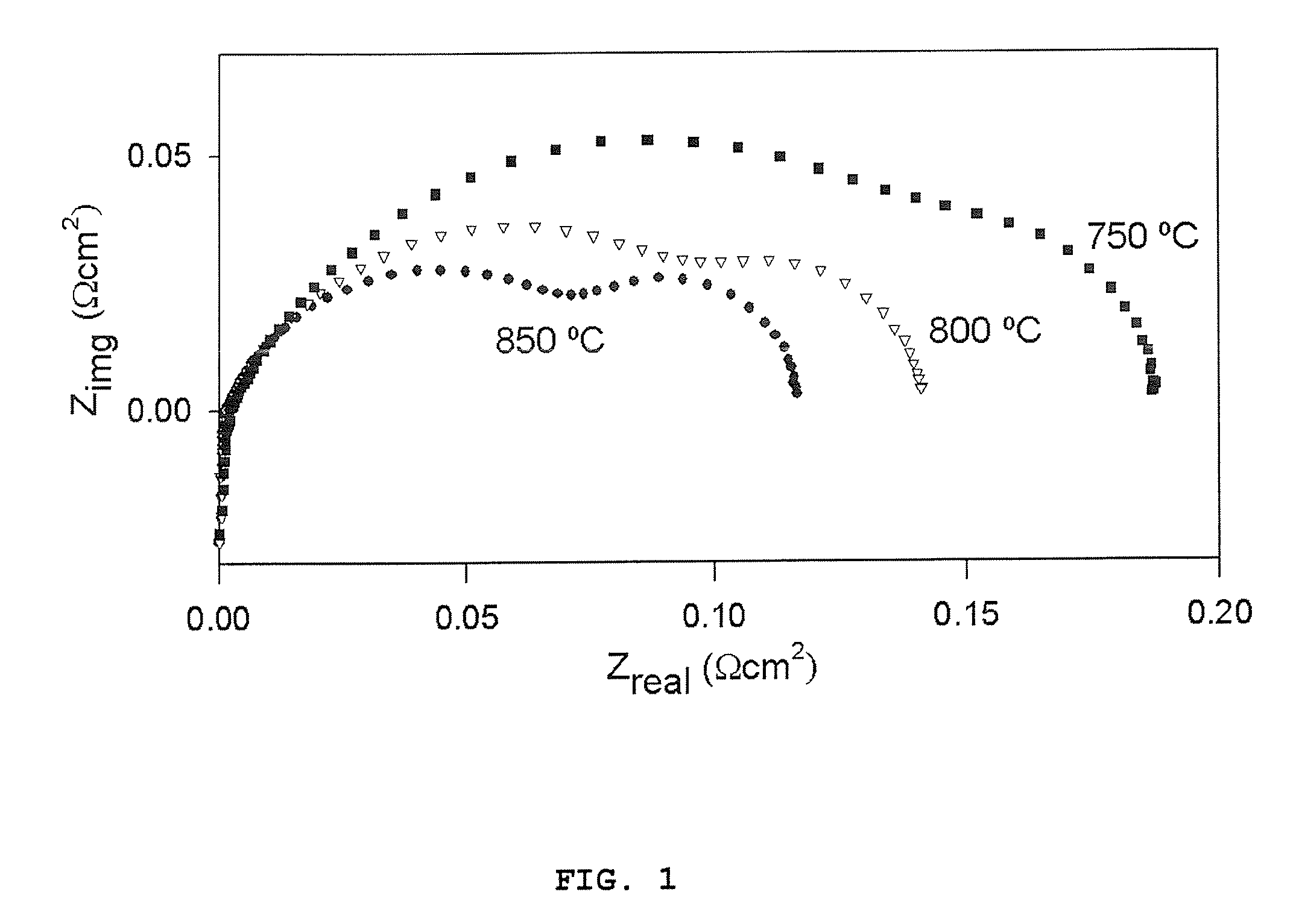

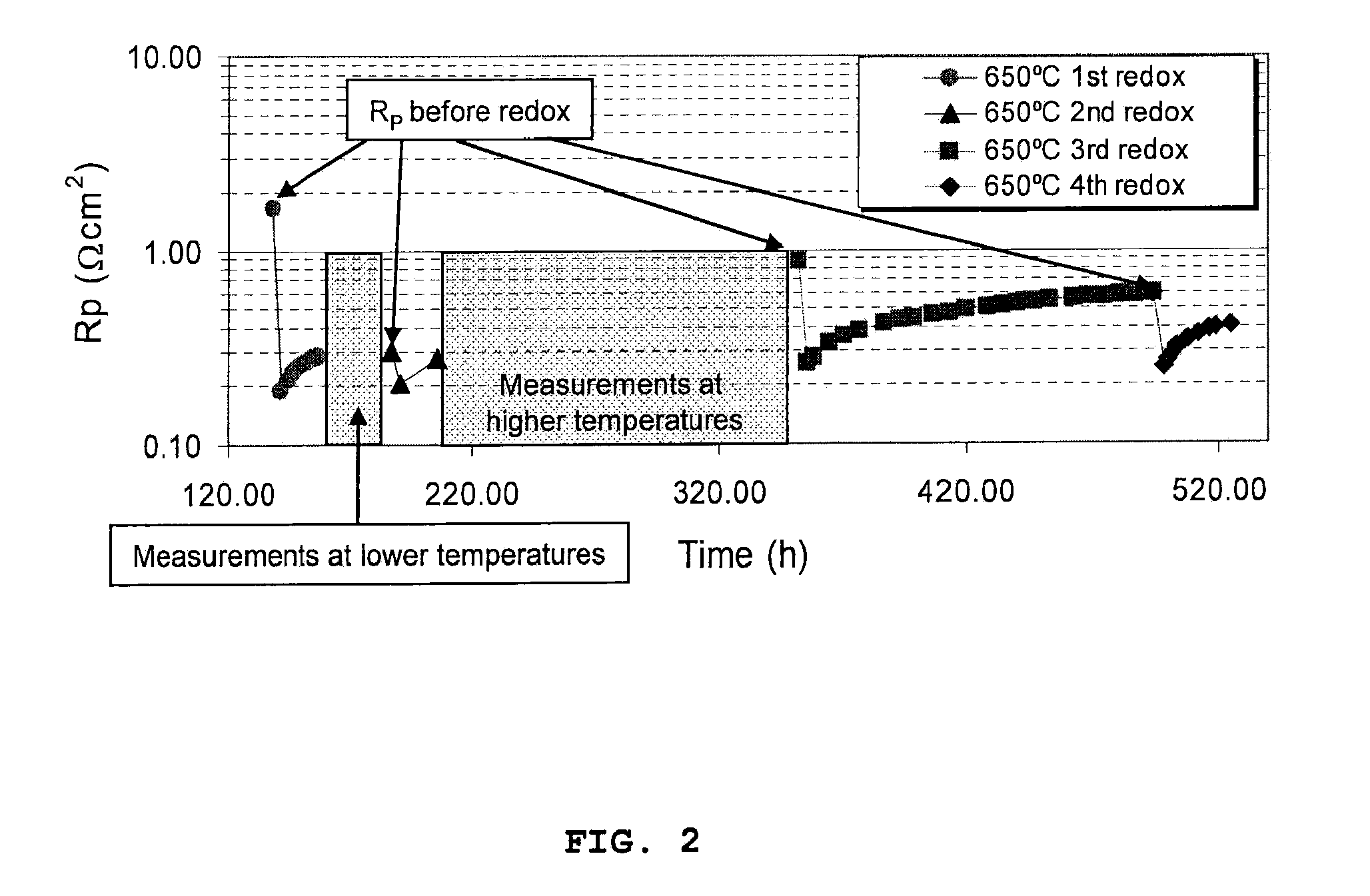

Ceria and strontium titanate based electrodes

InactiveUS20090061284A1High BET surface areaSpeed up calcination procedureFuel cells groupingCell electrodesStrontium titanateVanadium doping

A ceramic anode structure obtainable by a process comprising the steps of: (a) providing a slurry by dispersing a powder of an electronically conductive phase and by adding a binder to the dispersion, in which said powder is selected from the group consisting of niobium-doped strontium titanate, vanadium-doped strontium titanate, tantalum-doped strontium titanate, and mixtures thereof, (b) sintering the slurry of step (a), (c) providing a precursor solution of ceria, said solution containing a solvent and a surfactant, (d) impregnating the resulting sintered structure of step (b) with the precursor solution of step (c), (e) subjecting the resulting structure of step (d) to calcination, and (f) conducting steps (d)-(e) at least once.

Owner:DANMARKS TEKNISKE UNIV

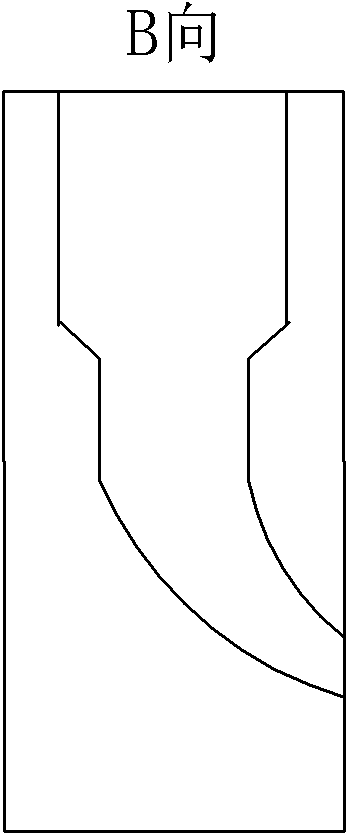

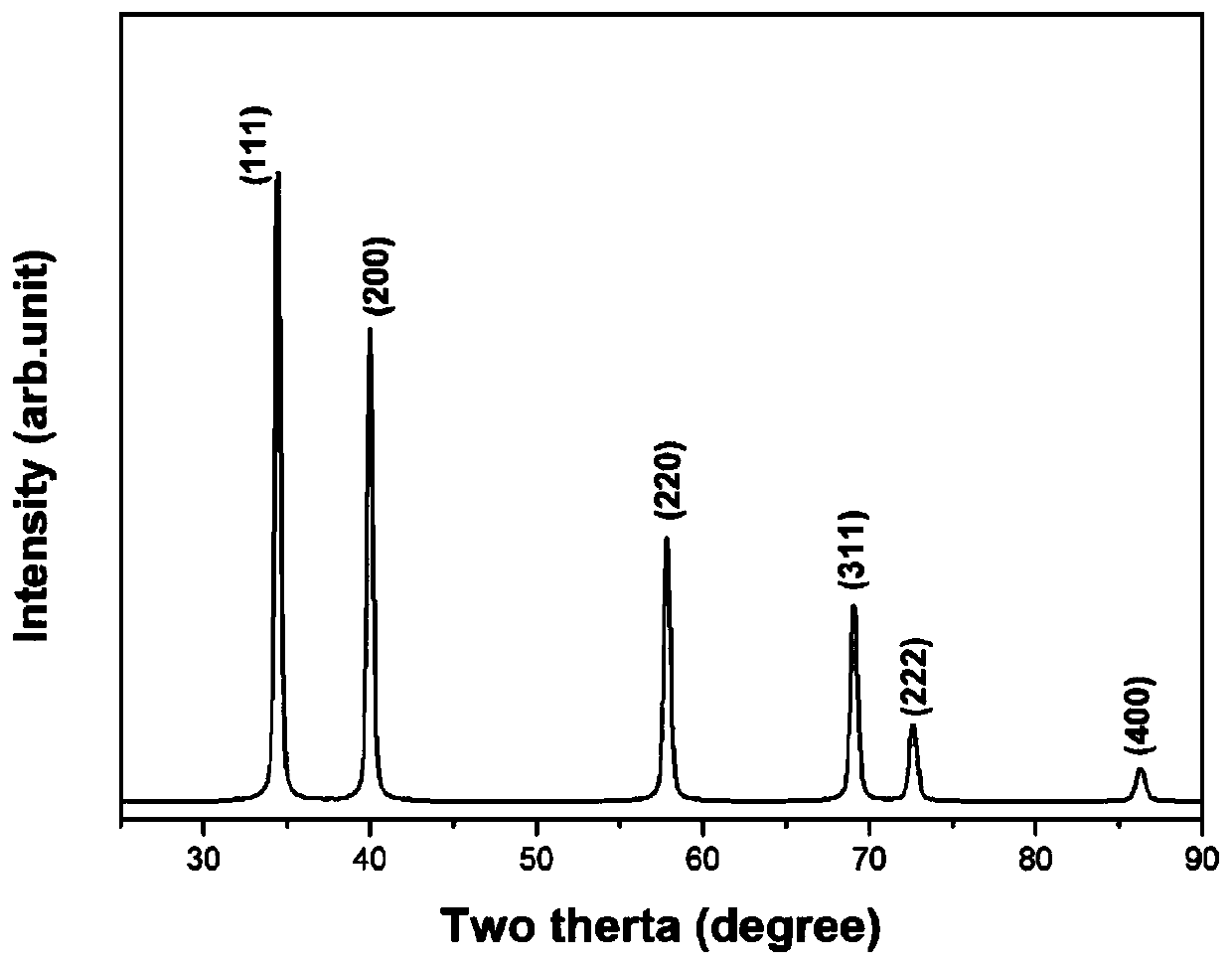

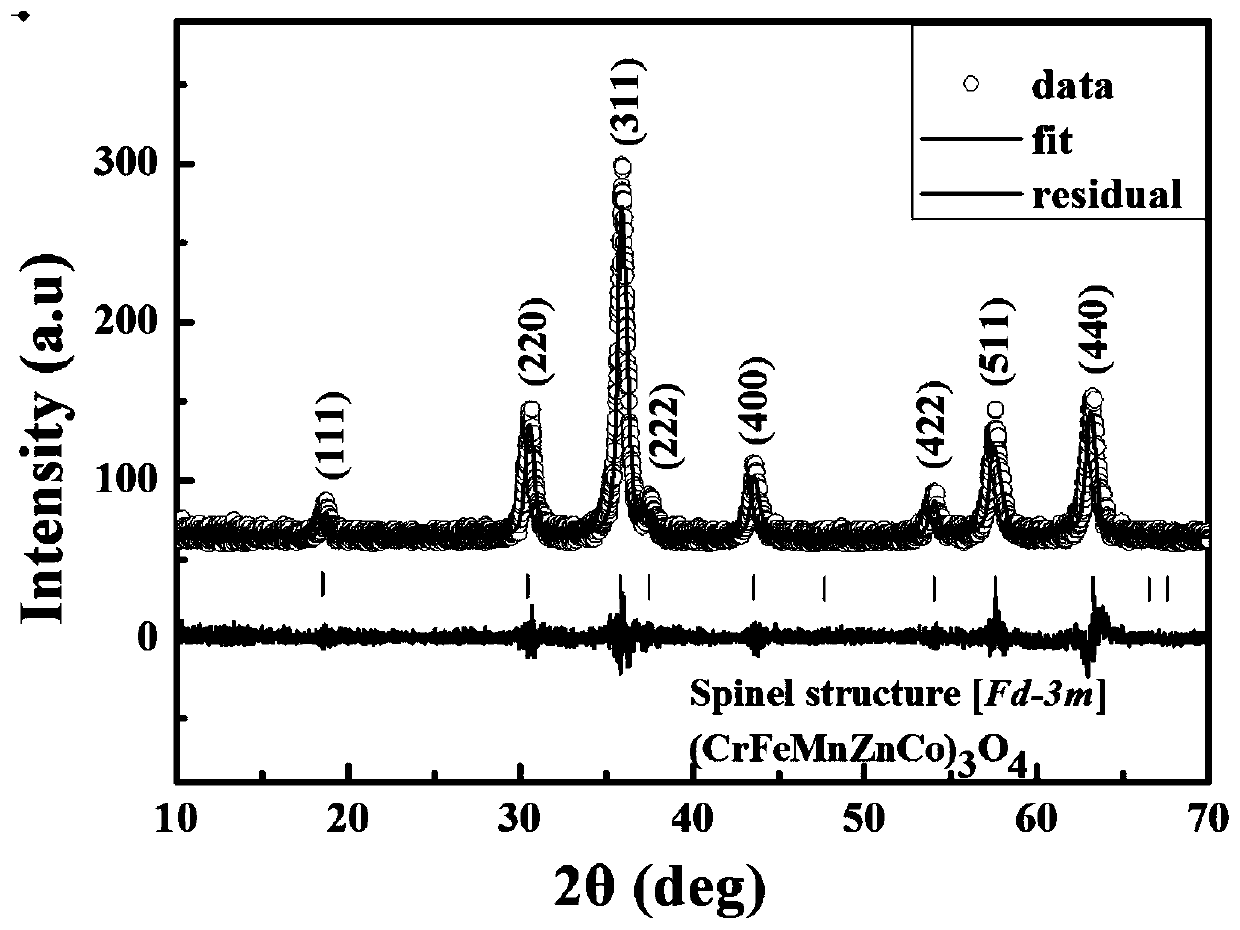

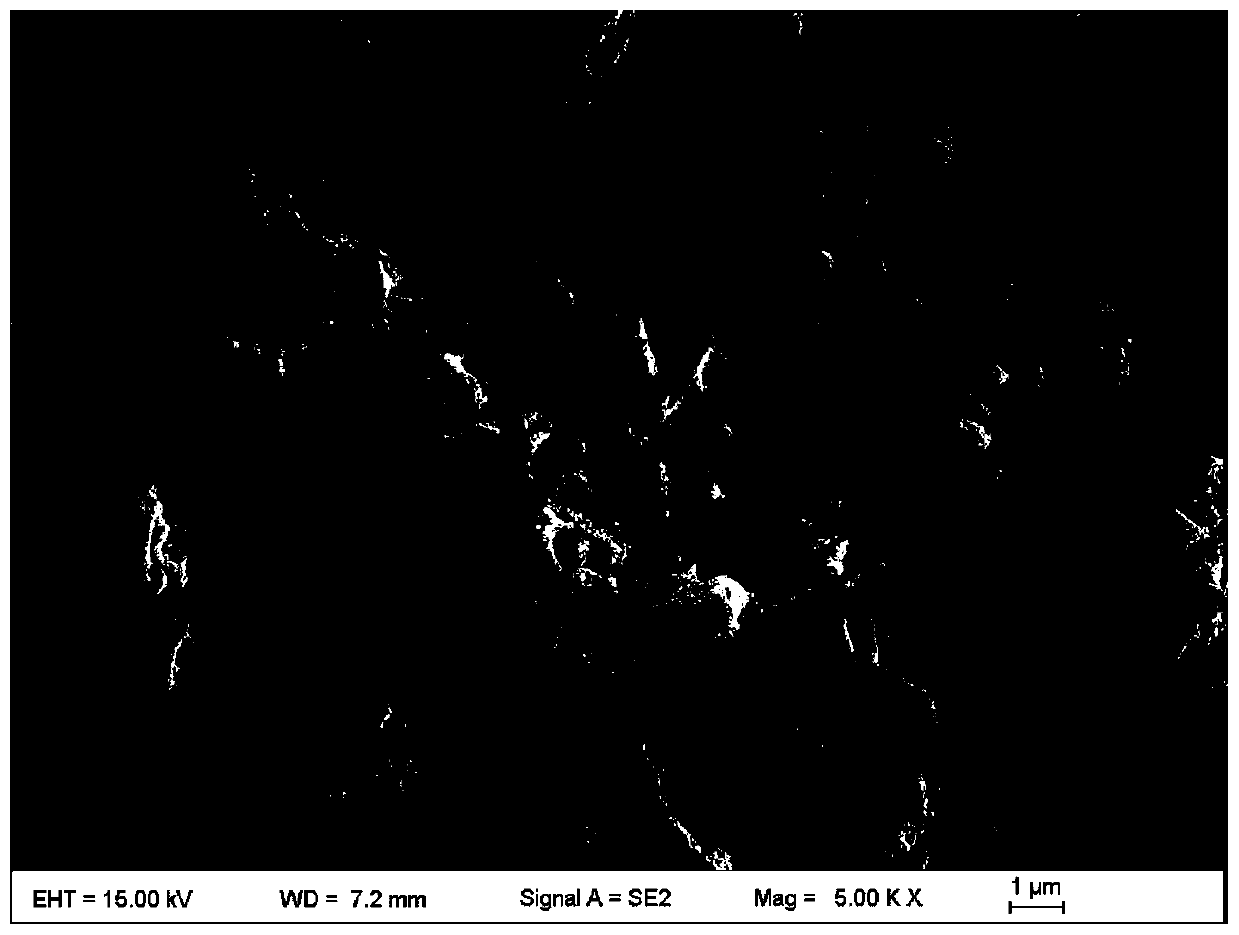

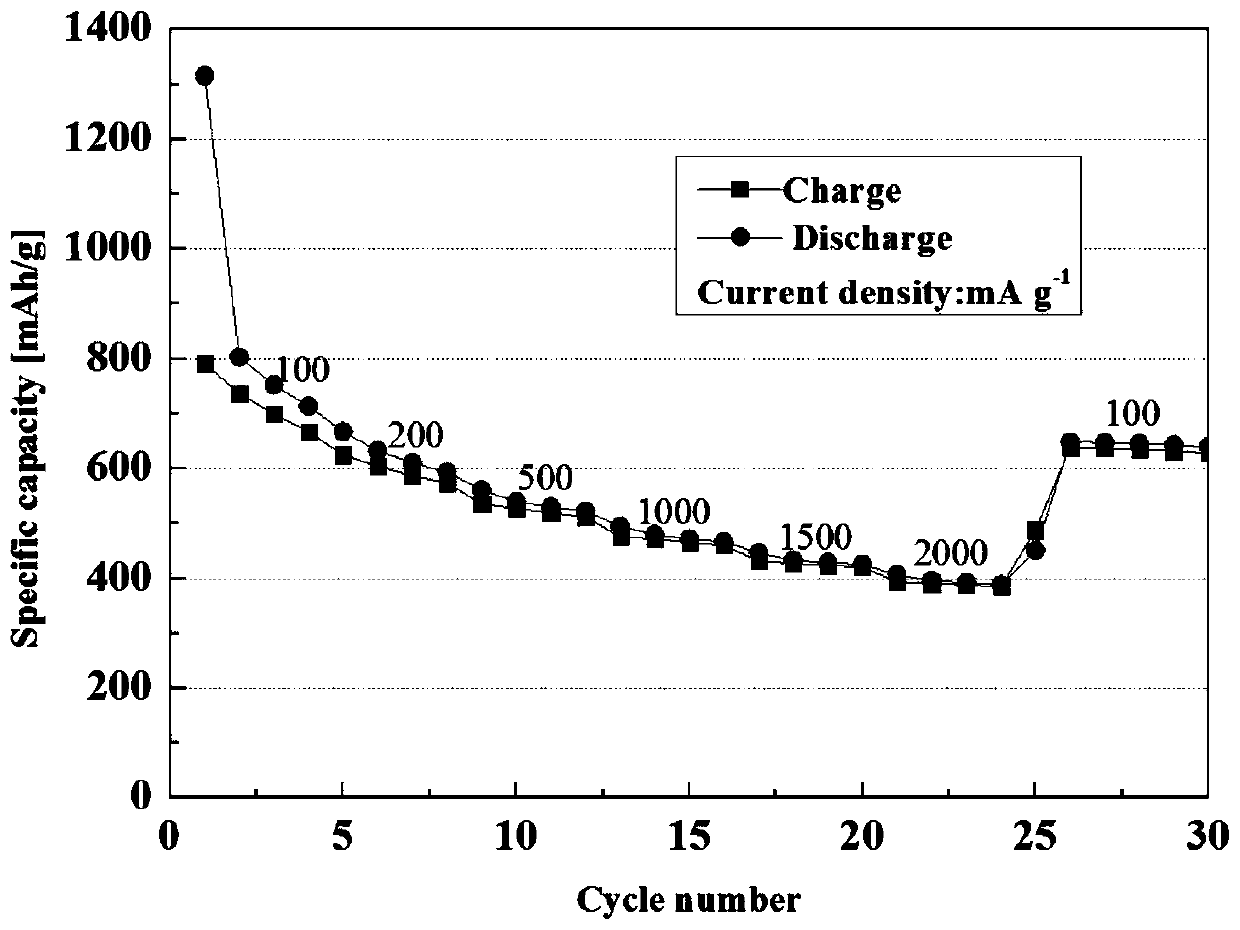

Five-element transition metal oxide high-entropy material for lithium-ion battery

ActiveCN110600703ACustomized electrochemical performanceMeet the needs of useNegative electrodesSecondary cellsSynthesis methodsLithium-ion battery

The invention discloses a five-element transition metal oxide high-entropy material for a lithium-ion battery. The high-entropy material is a five-element spinel type oxide high-entropy material formed by five transition metal positive ions, the chemical formula of the high-entropy material is (Cr0.2Fe0.2Mn0.2Zn0.2M0.2)3O4, wherein M is a divalent metal positive ion Co2+ or Ni2+. According to theinvention, a high-entropy oxide material with a spinel structure and different chemical compositions is regulated and controlled by changing the variety of divalent transition metal positive ions, sothat the electrochemical performance of the high-entropy oxide material is customized, and a nanocrystalline powder material with large specific surface area, small grain size and uniform chemical composition and microstructure is prepared through a combustion synthesis method. The five-element transition metal oxide high-entropy material for the lithium-ion battery has the advantages of large initial charge specific capacity, stable reversible specific capacity, good rate capability and good cycling stability.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

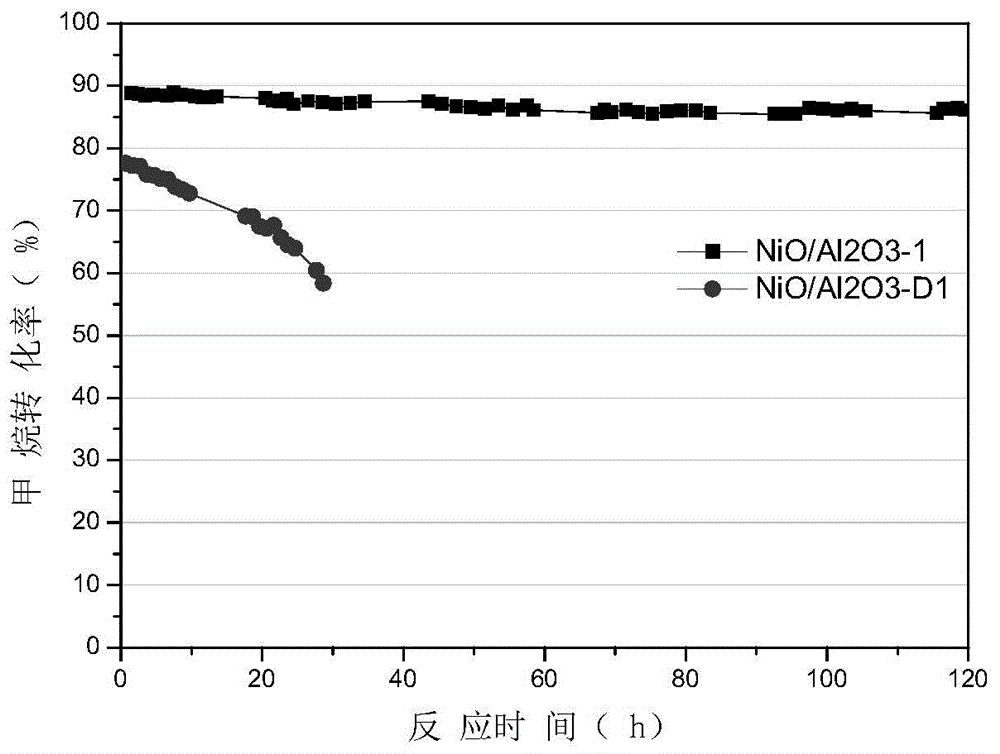

Methane dry reforming catalyst, preparation method and use of methane dry reforming catalyst and method for preparing synthetic gas through methane dry reforming

ActiveCN105561998AGood dispersionHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsDispersityActive ingredient

The invention relates to a methane dry reforming catalyst and a preparation method thereof. The preparation method comprises immersion of a carrier in an immersion solution, drying and roasting. The immersion solution contains a soluble compound of a metal active ingredient and a surfactant. The catalyst active metal crystal grains have small sizes and high dispersity. The preparation method has simple processes, a low equipment investment and low energy consumption. Compared with the same type of the existing catalyst, the catalyst obtained through the preparation method has higher catalytic reaction activity and better carbon deposition resistance and lays a foundation for the industrial application of methane dry reforming preparation of synthetic gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature abradable seal coating

InactiveCN101653998AReduce oxidation rateStop the spreadMolten spray coatingLayered productsSurface layerAlloy

The invention relates to high-temperature abradable seal coating with single-layer or multi-layer structure, wherein the high-temperature abradable seal coating with single-layer structure is providedwith a bonding bottom layer sprayed on a base body, and an oxygen barrier layer and a seal surface layer are sequentially sprayed on the bonding bottom layer; on the basis of the high-temperature abradable seal coating with single-layer structure, at least another seal surface layer is needed to be sprayed on the seal surface layer to form the high-temperature abradable seal coating with multi-layer structure; the bonding bottom layer is made of NiCrAlY or NiCoCrAlY alloy powder, the oxygen barrier layer is made of composite agglomerated powder of nano yttria, partially stable zirconia and nano Alpha-Al2O3, and the seal surface layer is made of nano Y-PSZ based high-temperature seal coating materials. The high-temperature abradable seal coating has better high temperature stability, thermal shock resistance and abradability during the use.

Owner:WUHAN UNIV OF TECH

Casting extruding compound shaping method of magnesium alloy automobile hub

InactiveCN1429717AFine internal organizationDense internal organizationDisc wheelsGraphiteSuperficial mass

A technology for forming the Mg-alloy hub of car features three procedures of preshaping, upsetting-squeezing formation and fine trimming and includes such steps as casting a blank; after preshaping,making allowance for apsetting-squeezing formation; upsetting-squeezing formation and deformation degree during isothermal squeezing by using the critical-controlled deformation method; coating graphite lubricant inside the die; and fine trimming. Its advantages are fine crystal grains, and high mechanical performance and surface quality.

Owner:ZHONGBEI UNIV

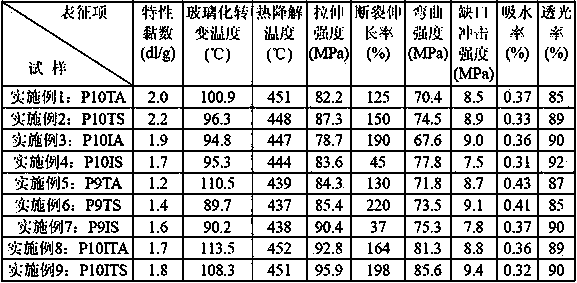

Semi-aromatic transparent polyamide material and preparation method thereof

The invention discloses a semi-aromatic transparent polyamide material and a preparation method thereof, belonging to the field of high-molecular materials. The material consists of a random copolymer of semi-aromatic amide salt and aliphatic amide salt and necessary auxiliaries; the intrinsic viscosity is 1.0-2.2dl / g, and the degree of crystallinity is less than 15%; the semi-aromatic amide salt is selected from amide salt 9T, amide salt 9I, amide salt 10T and amide salt 10I; and the aliphatic amide salt is selected from amide salt 610 and amide salt 1010. The preparation method comprises the following steps: adding the semi-aromatic amide salt, aliphatic amide salt and auxiliaries into a polymerization kettle; adding water which is 0.3-1.0 times the total mass of the semi-aromatic amide salt and aliphatic amide salt; in a protective gas atmosphere, stirring and heating to 160-210 DEG C within 1-2 hours, and performing constant-temperature pre-polymerization for 1-3 hours; heating to 240-300 DEG C, increasing pressure to 1-3MPa, and maintaining the pressure for reaction for 1-3 hours; slowly degassing to normal pressure within 1-4 hours; continuously stirring at constant temperature for 1-4 hours; and discharging after the reaction.

Owner:ZHENGZHOU UNIV

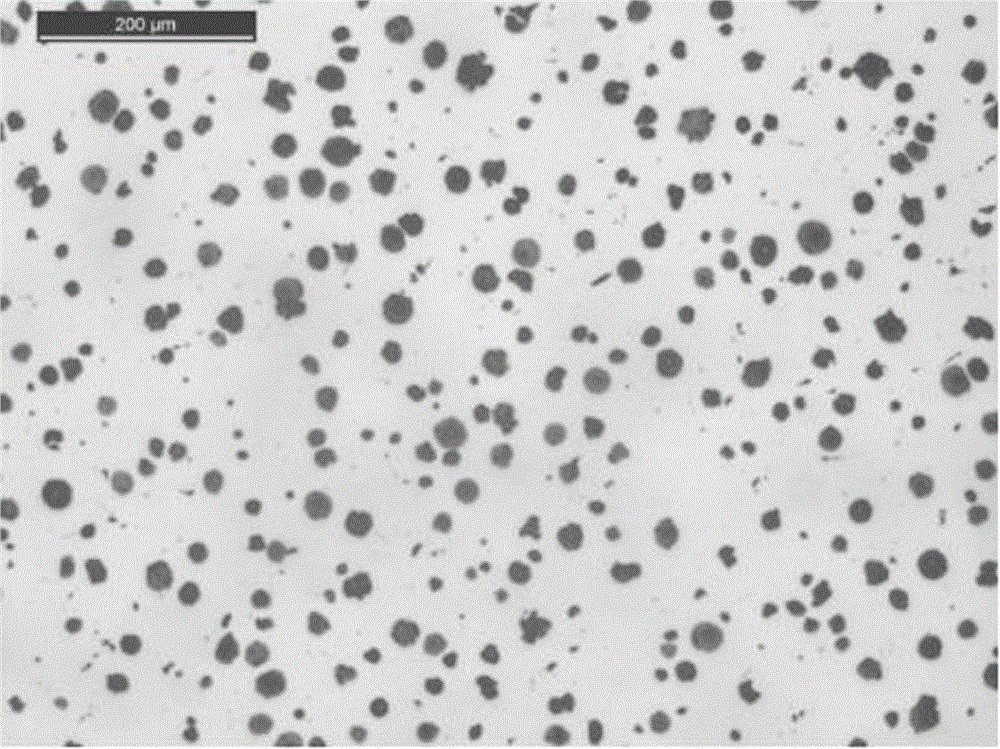

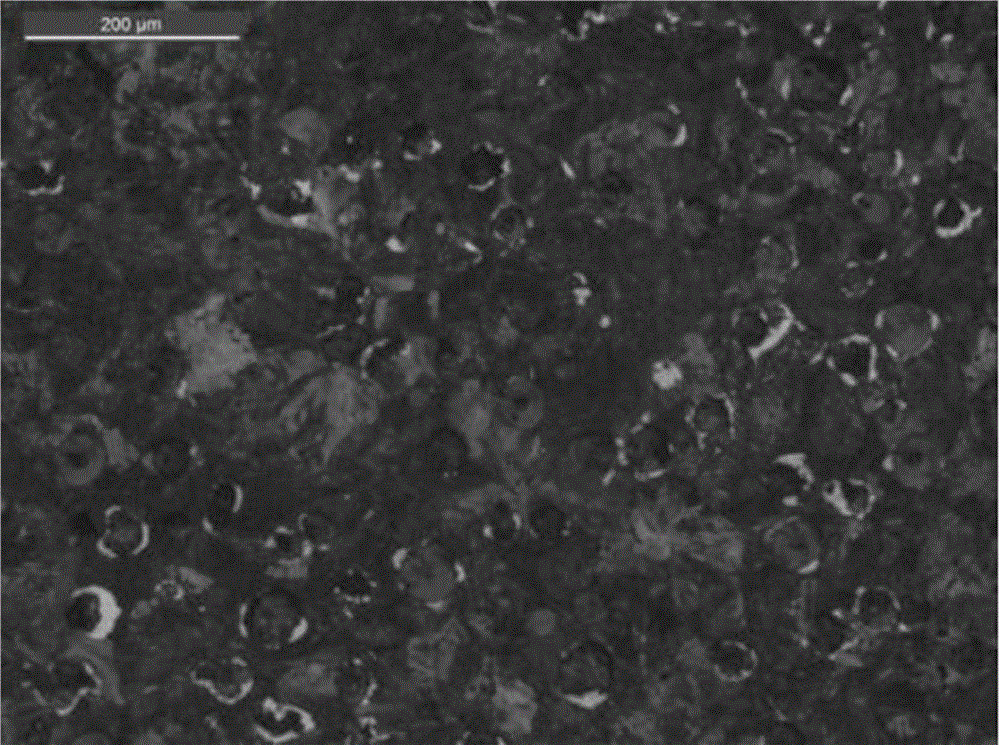

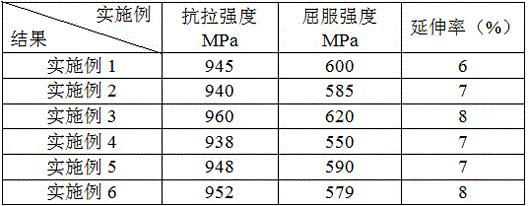

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

Preparation process of sputtered rotary molybdenum-sodium-alloy tubular target

ActiveCN103045925AHigh densitySmall grain sizeVacuum evaporation coatingSputtering coatingSodium molybdateNiobium alloy

The invention discloses a preparation process of a sputtered rotary molybdenum-sodium-alloy tubular target. The preparation process comprises the following steps of: (1) preparing materials, wherein used powder comprises molybdenum powder and sodium molybdate powder, the physical property of the powder is as follows: the Mo content of the molybdenum powder is at least 99.95% with the granularity of 3-5 microns, and the sodium molybdate content of the sodium molybdate powder is at least 99.0% with the granularity of 20-40 microns; (2) blending the powder: weighing the molybdenum powder and the sodium molybdate powder proportionately, controlling the mass percentage content of the molybdenum powder to be 90-99% and that of the sodium molybdate powder to be 1-10%; (3) carrying out mechanical alloying: synthesizing nanometer molybdenum-sodium alloy powder; (4) filling into a die; (5) carrying out cold isostatic pressing; (6) sintering; (7) forging; (8) performing vacuum annealing; and (9) mechanically processing to obtain the sputtered rotary molybdenum-sodium-alloy tubular target. A produced molybdenum-niobium-alloy tubular target has characteristics of uniform elements, no segregation, fine grain size and high purity, completely meets requirements of CIGS (Copper Indium Gallium Selenide) photovoltaic cells and increases the use efficiency of the cells.

Owner:LUOYANG SIFON ELECTRONICS

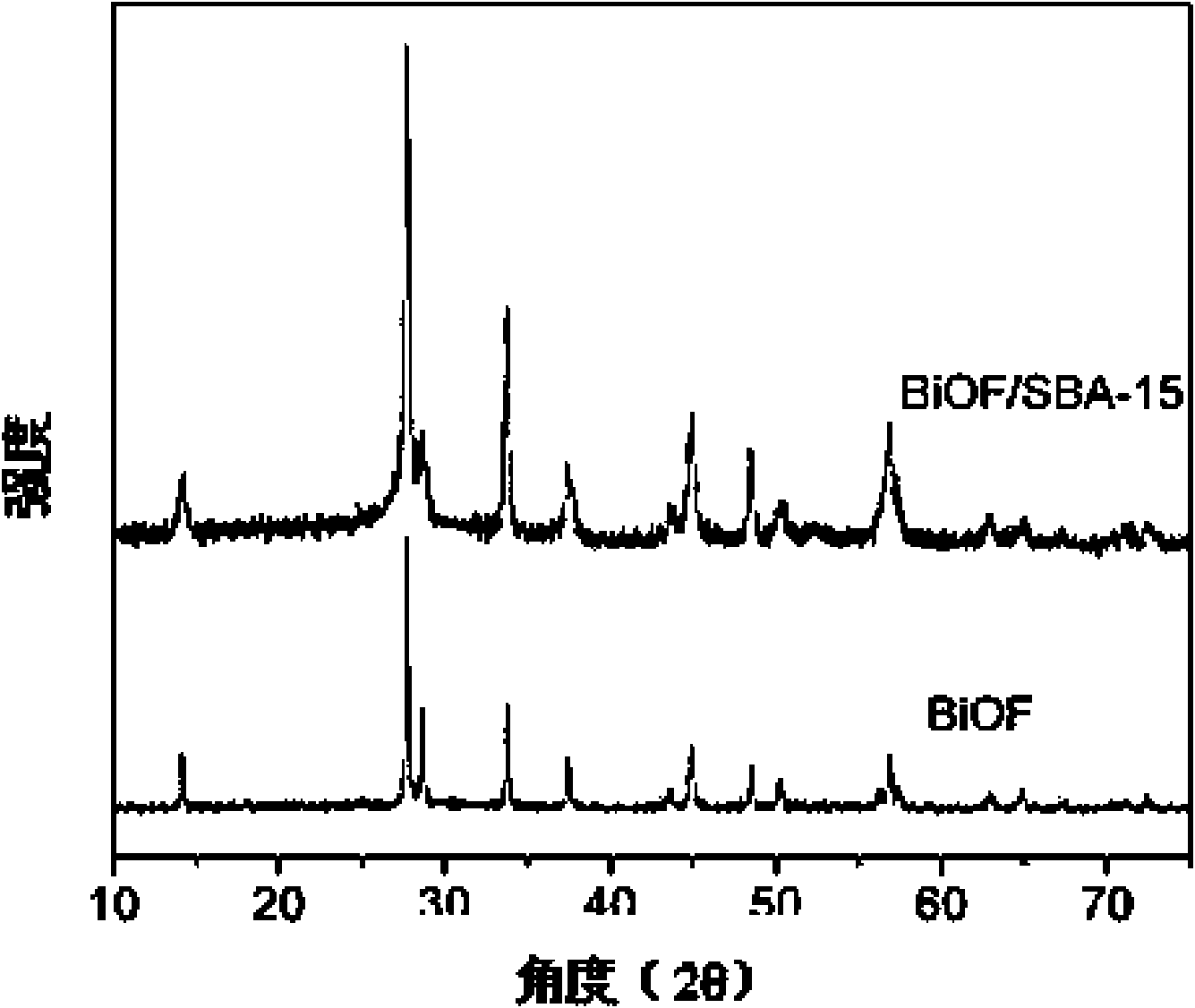

Molecular sieve loaded BiOX photocatalyst, preparation method and application thereof

ActiveCN101653732AInhibition of agglomerationSmall grain sizeMolecular sieve catalystsChemistryBenzene

The invention provides a molecular sieve loaded BiOX photocatalyst, a preparation method and an application thereof, belonging to the technical field of photocatalysis. The catalyst is a loaded catalyst using one or more of SBA-15, ZSM-5 and HY as a carrier and BiOX as an active component. The preparation method comprises the following two steps: soaking a molecular sieve into an organic solutionof bismuth nitrate and ammonium fluoride or ammonium chloride; and adding a precipitating agent to prepare the loaded BiOX catalyst. The catalyst is used for removing gas phase organic matters. The molecular sieve is led into the catalyst to be used as a carrier, thereby increasing the specific surface area of the catalyst, reducing the grain size and obviously improving the benzene degradation activity by the catalyst; and the preparation method is simple and easy and is beneficial to mass generalization.

Owner:FUZHOU UNIVERSITY

CIGS powder, CIGS target, CIGS film and preparation method thereof

InactiveCN101613091ALow costSmall grain sizeSelenium/tellurium compundsVacuum evaporation coatingCompression moldingManufactured material

The invention provides CIGS powder, a CIGS target, a CIGS film and a preparation method thereof. The CIGS powder has a pure CuInxGa1-xSe2 phase, wherein x is more than 0 and is less than 1; and the CIGS target has a homogeneous CuInxGa1-xSe2 phase, and is obtained from the CIGS powder through cold isostatic pressing or compression molding and then sintering. The method for preparing the CIGS film comprises the steps of: depositing a layer of film by the CIGS target through a magnetron sputtering method, and then performing heat treatment on the film. The relative density of the CIGS target reaches over 95 percent, and the CIGS target has uniform components, has the homogeneous CuInxGa1-xSe2 phase, and has low production cost and steady performance. The preparation technology for the CIGS film greatly simplifies the prior process, and improves the utilization rate of raw materials and production efficiency.

Owner:CENT SOUTH UNIV

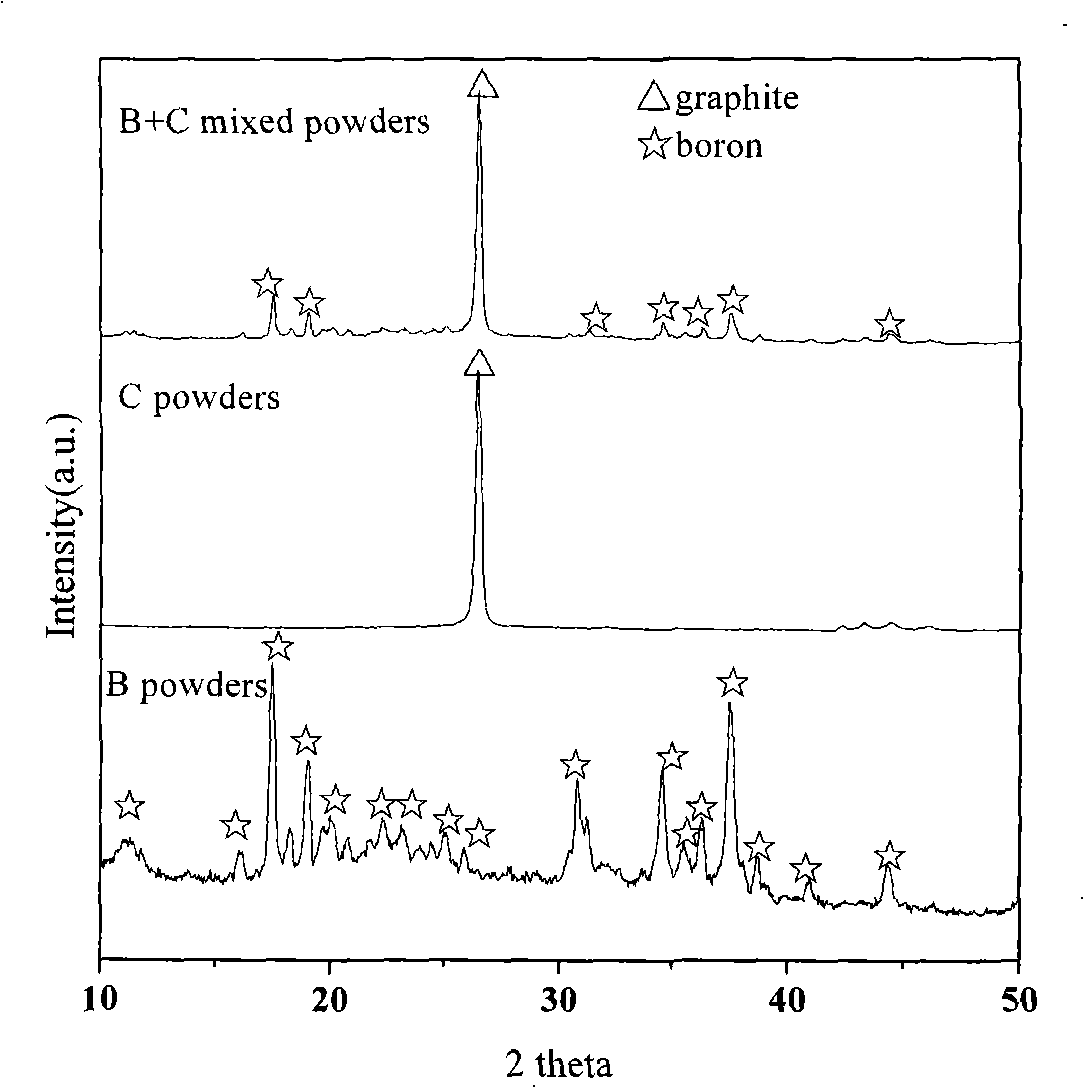

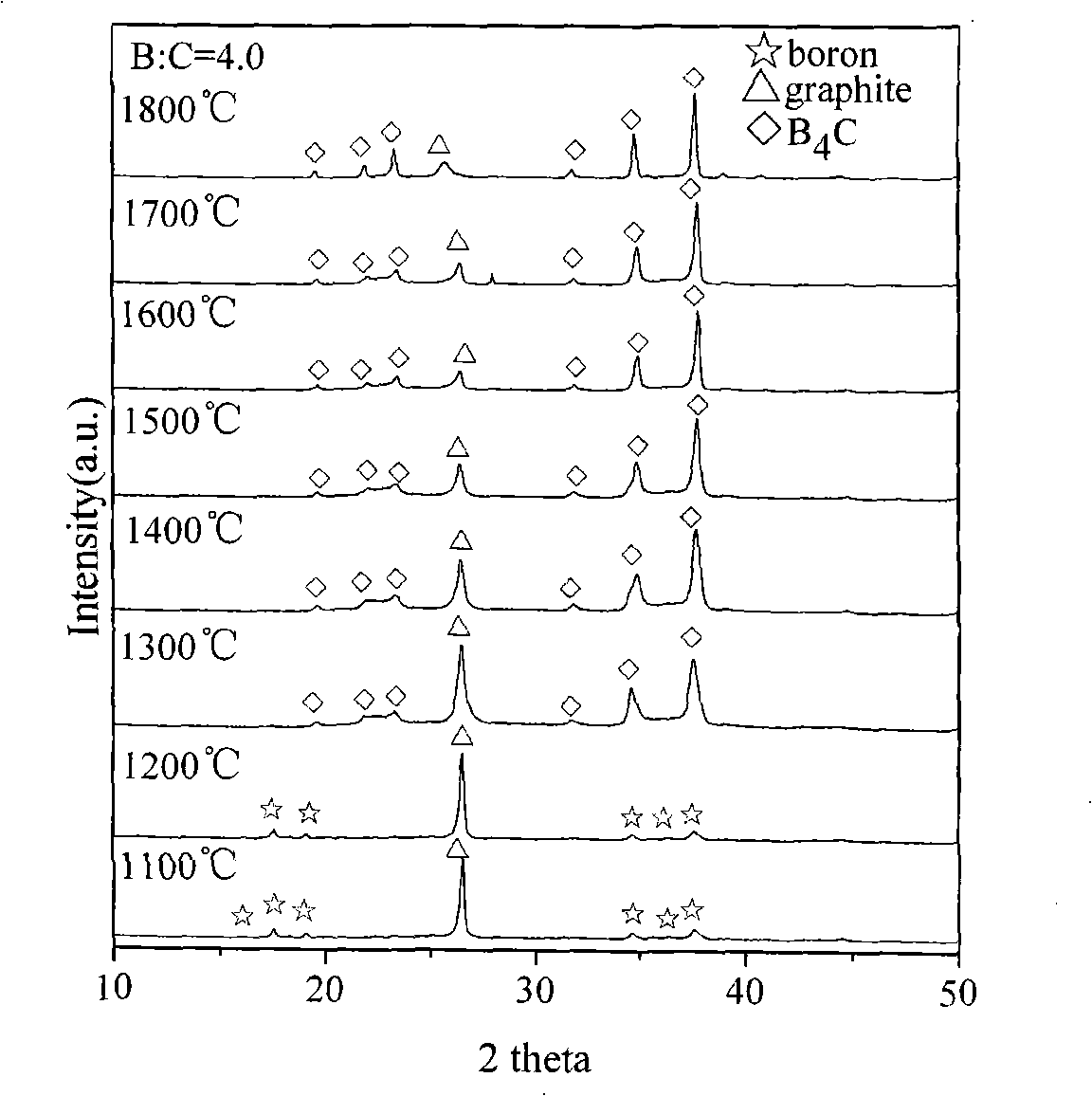

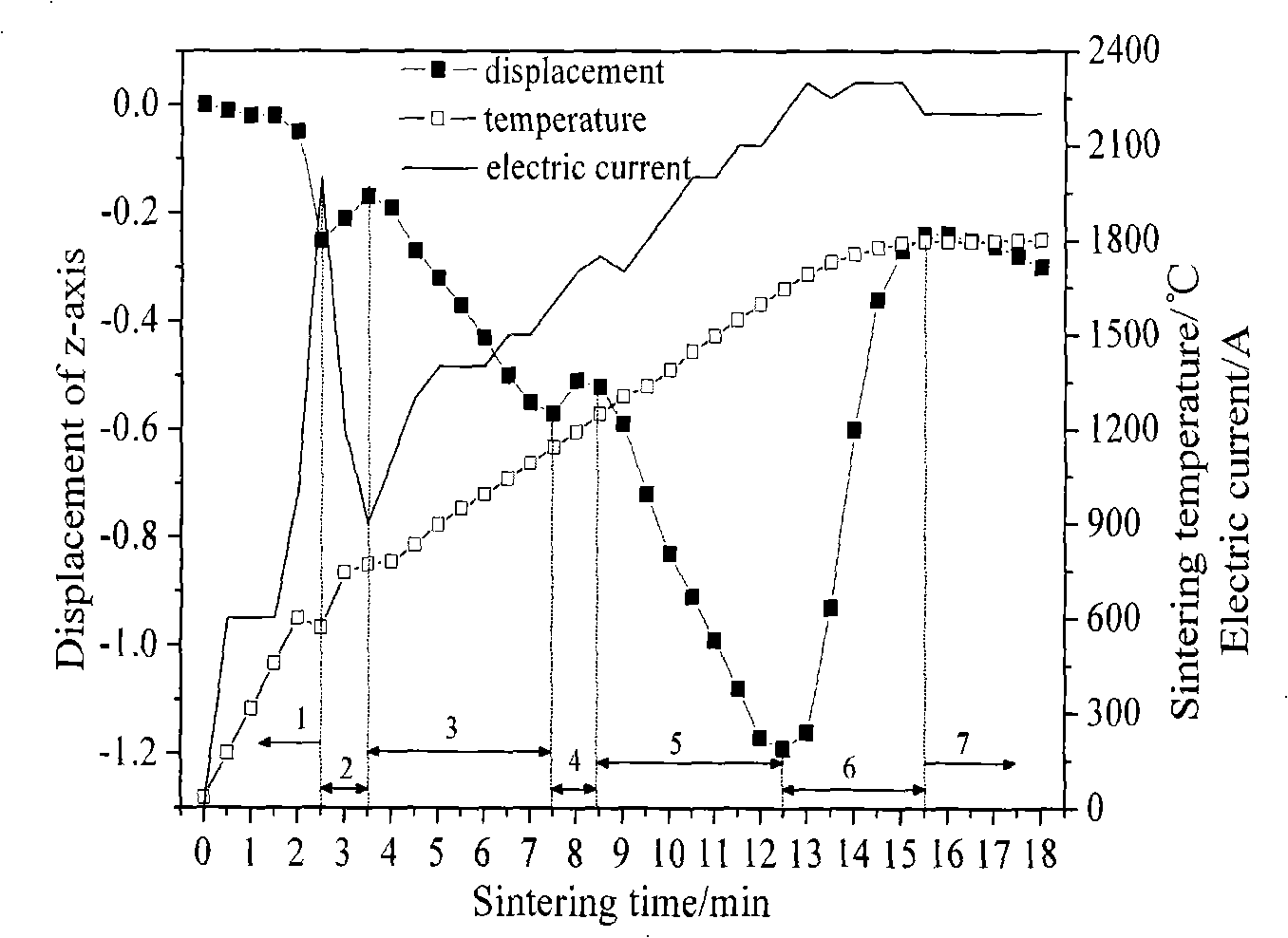

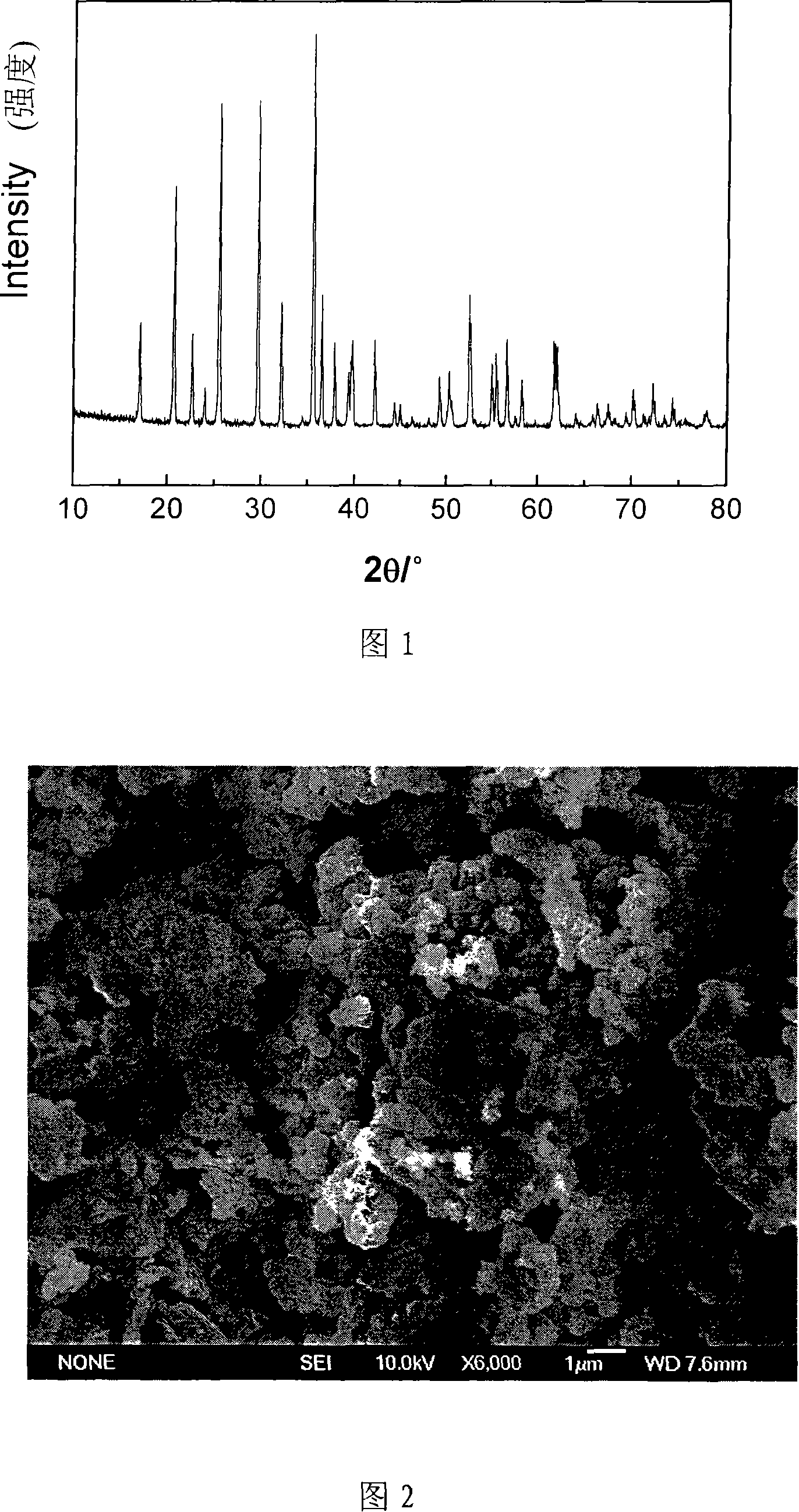

Method for preparing boron carbide ceramic

The present invention relates to a preparation method of boron carbide ceramics. In particular, the preparation method comprises the following steps: first, boron powder and carbon powder are weighed and mixed with the molar ratio of boron and carbon equal to 0.5 to 22.5; secondly, the powder prepared in the first step is arranged in a die and transmitted to discharging plasma sintering equipment for sintering, and the temperature is raised to be between 1300 and 2200 DEG C under the vacuum conditions; thirdly, the die is taken out from the discharging plasma sintering equipment and cooled to be at the room temperature; then the die is drawn away and thus the final product is prepared. In the preparation method, the direct synthesis and densification of boron carbide are completed in one step; the powder is sintered under the vacuum conditions; and the prepared boron carbide ceramics has the advantages of high purity, variety in the ratio of boron and carbon, and high hardness.

Owner:WUHAN UNIV OF TECH

Anode material lanthanum or Ac adulterated LiFePO4 of lithium ion secondary battery and its making method

InactiveCN101150191AHigh charge and discharge capacityPromote crystallizationCell electrodesPhosphorus compoundsPhosphateVolumetric Mass Density

This invention relates to FeLiPO4 doped with La or Ac, positive material of Li ionic secondary cells and its preparation method characterizing that the formula is: LiMxFe1-xPO4 (M is La or Ac, 0.01<-x<-0.05) in the structure of olivine, the preparation includes the following steps: taking Li compound, Fe, phosphate, La or Ac as the raw materials to add them into a ball mill for wet mill then putting them into N2 and H2 mixed atmosphere for pre-calcining, then wet-grinding them and drying them and then ball-milling them, then putting them into N2 and H2 mixed atmosphere for secondary calcining to get the invented positive material. Advantages: fine crystalizatin, conduction performance of ions is good and discharge performance of heavy current is good, tap density is great and the problem of easy oxidation of Fe2+ is solved.

Owner:TIANJIN B&M SCI & TECH

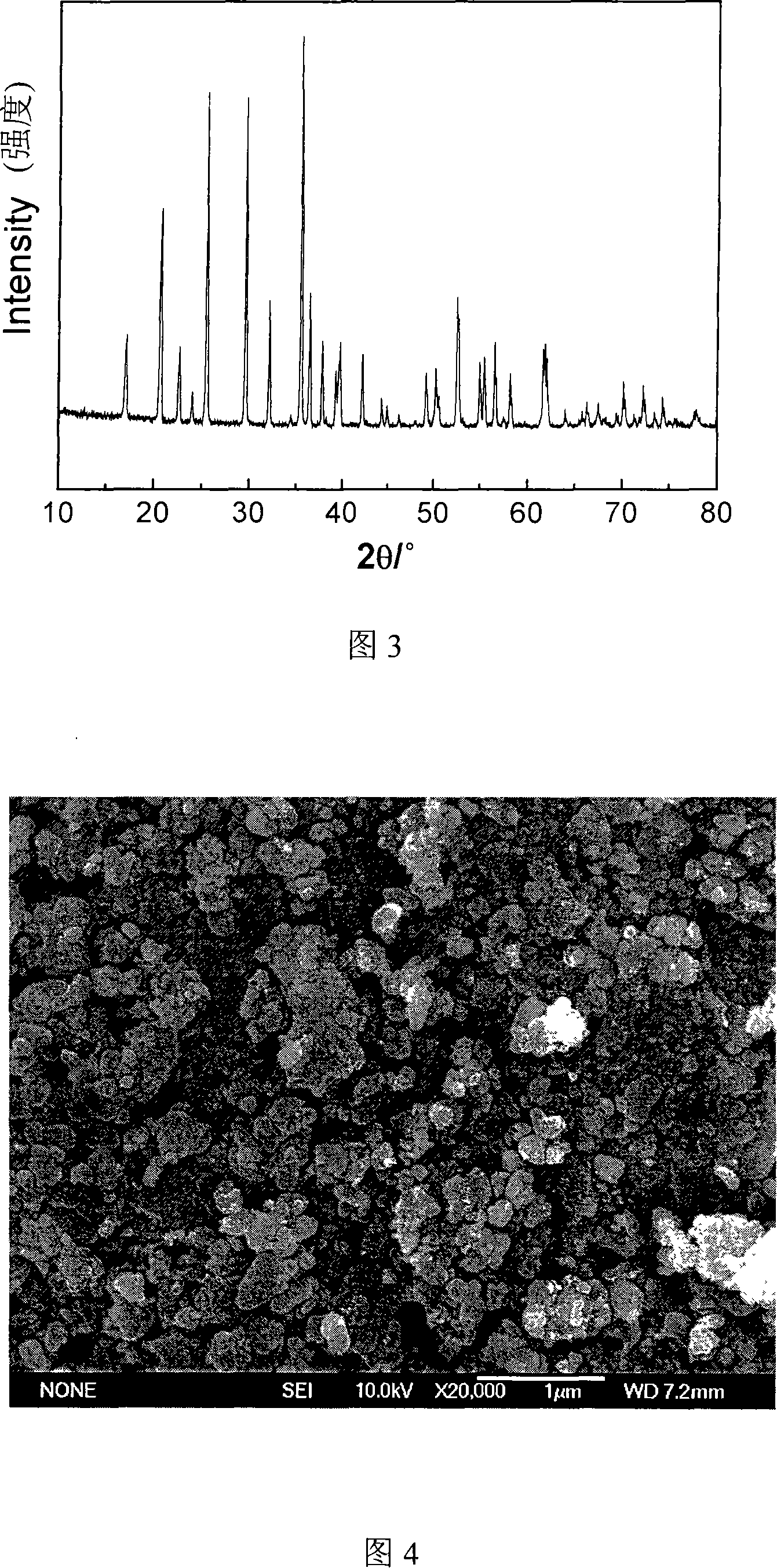

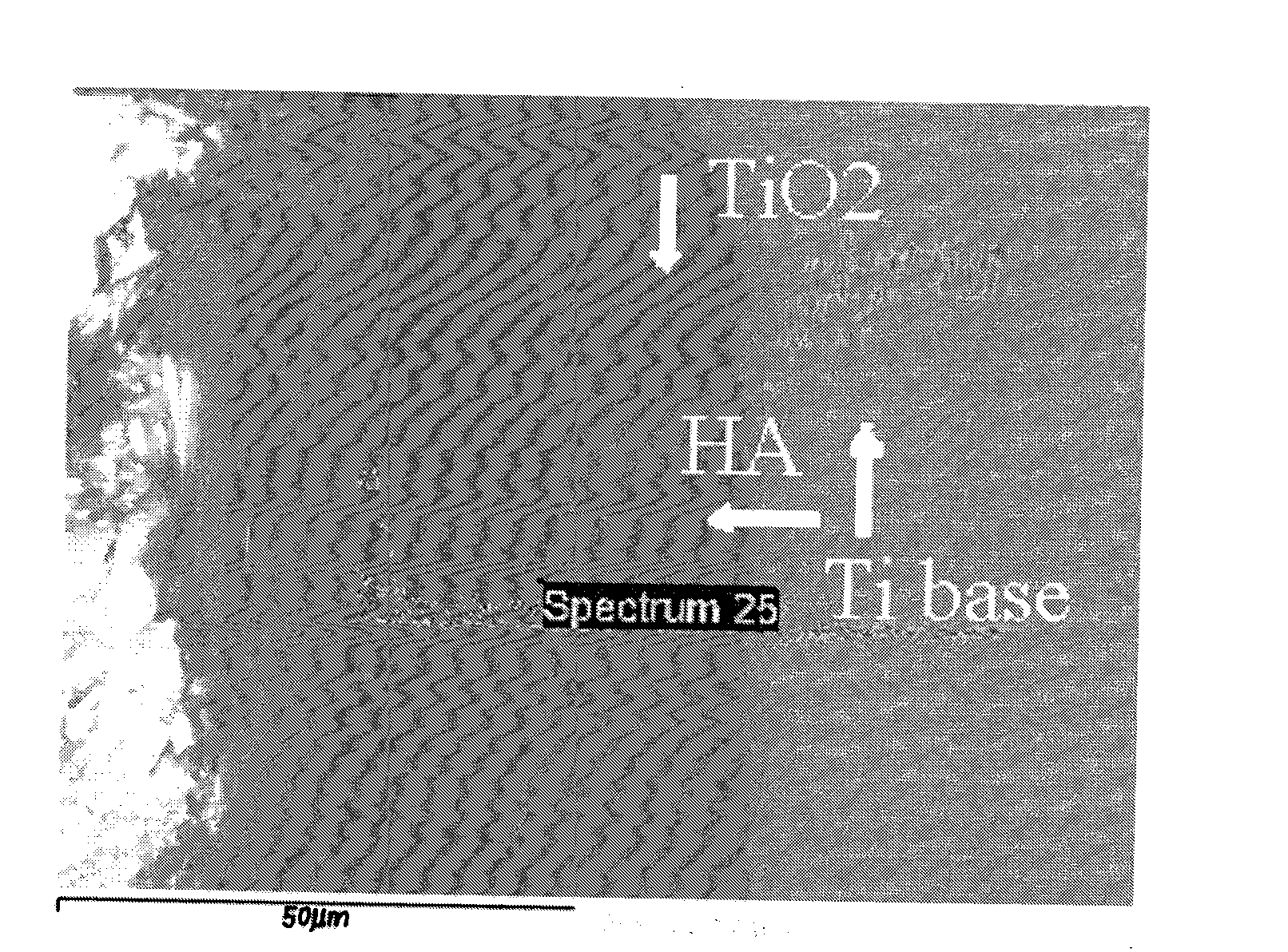

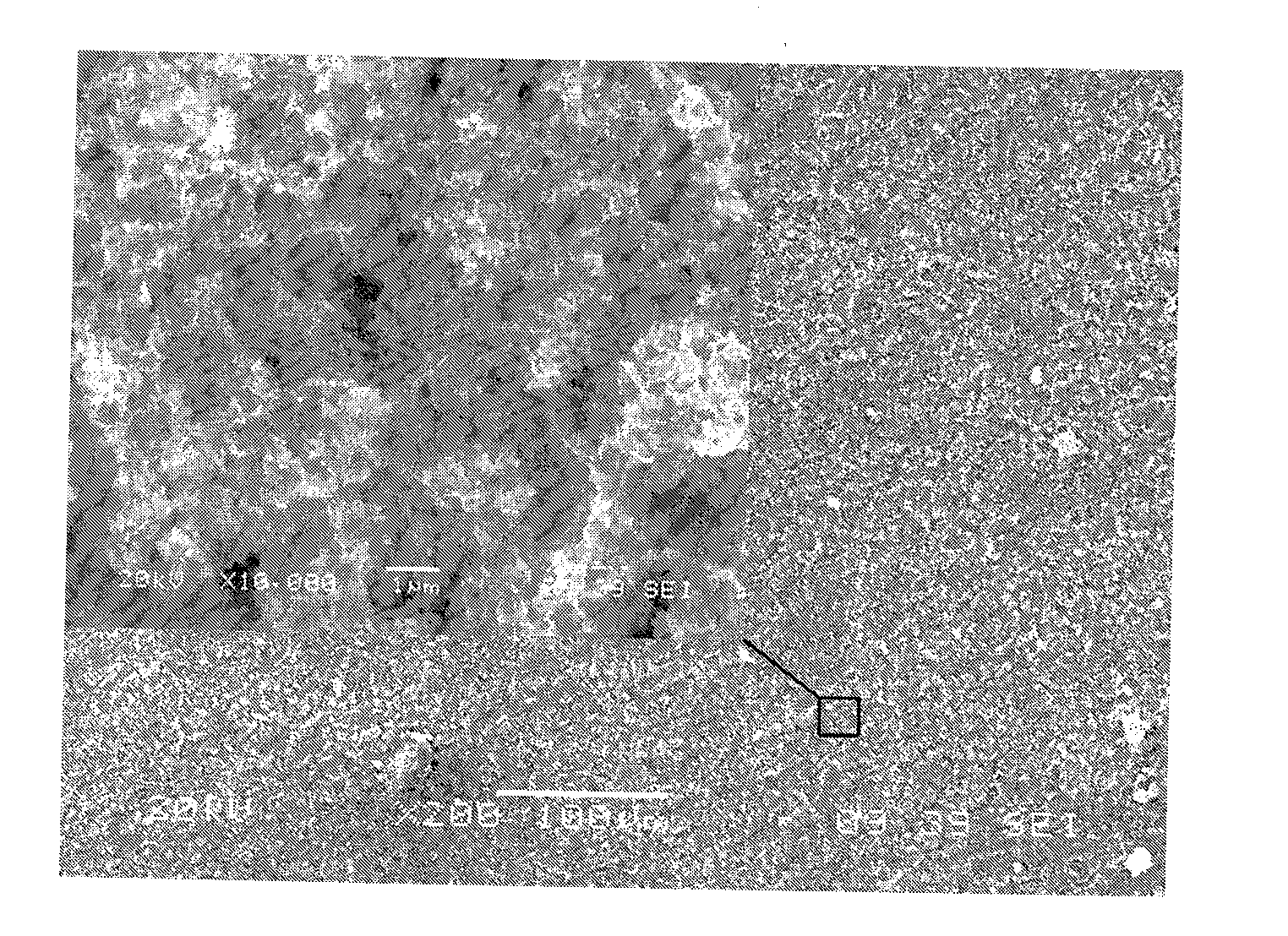

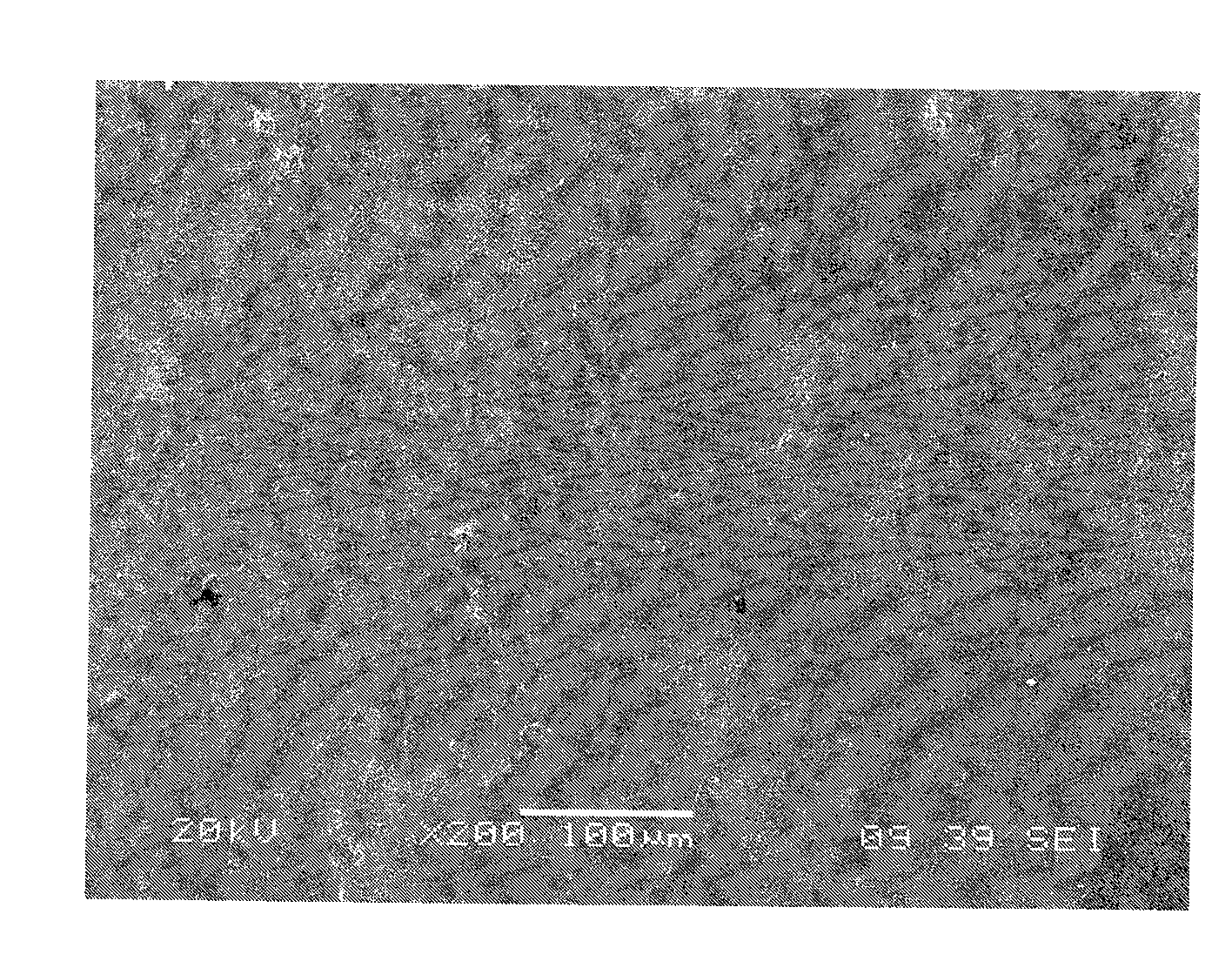

Preparation method of hydroxylapatite/titanic oxide composite biological coatings

The invention provides a method for preparing a hydroxyapatite / titanium dioxide composite bioactive coating on the surfaces of medical metals such as a titanium alloy, and the like, and belongs to the technical field of the preparation of bioactive coatings on the surface of the titanium alloy. The composite coating is prepared by preparing precursor sols of HA and TiO2 respectively, then mixing the precursor sols of the HA and the TiO2, and performing aging, coating, drying and heat treatment. The coating has high bioactivity, low cost of preparation technology, and high bonding strength with a matrix, is applicable to the preparation of surface coatings of various complicated geometric structures, and can be used for surface modification of surgical implants such as artificial hip joints and dental implants as well as orthopedic instrument products.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

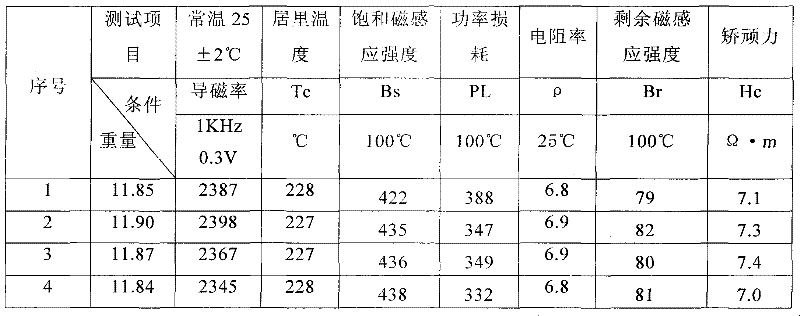

Soft magnetic ferrite material and preparation process thereof

ActiveCN102194561AHigh saturation flux densityReduce magnetic lossInorganic material magnetismMetallurgyMaterials science

The invention discloses a soft magnetic ferrite material and a preparation process thereof. The soft magnetic ferrite material comprises the following components: 52 to 55 mol of Fe2O3, 39 to 42 mol of Mn3O4, 5-8 mol of ZnO, 0.1 to 0.6 mol of additive 1, 0.1 to 0.2 mol of additive 2 and 0.006 to 0.06 mol of ZrO2, wherein the additive 1 is one or more of SnO2, CaCO3 and V2O5; and the additive 2 isone or more of Nb2O5, K2CO3, CaCO3, Ta2O5, SnO2 and V2O5. The soft magnetic ferrite material prepared by the process overcomes defects of the prior art and has the advantages of high frequency, high saturation magnetic flux density and low magnetic loss.

Owner:WUXI SPINEL MAGNETICS

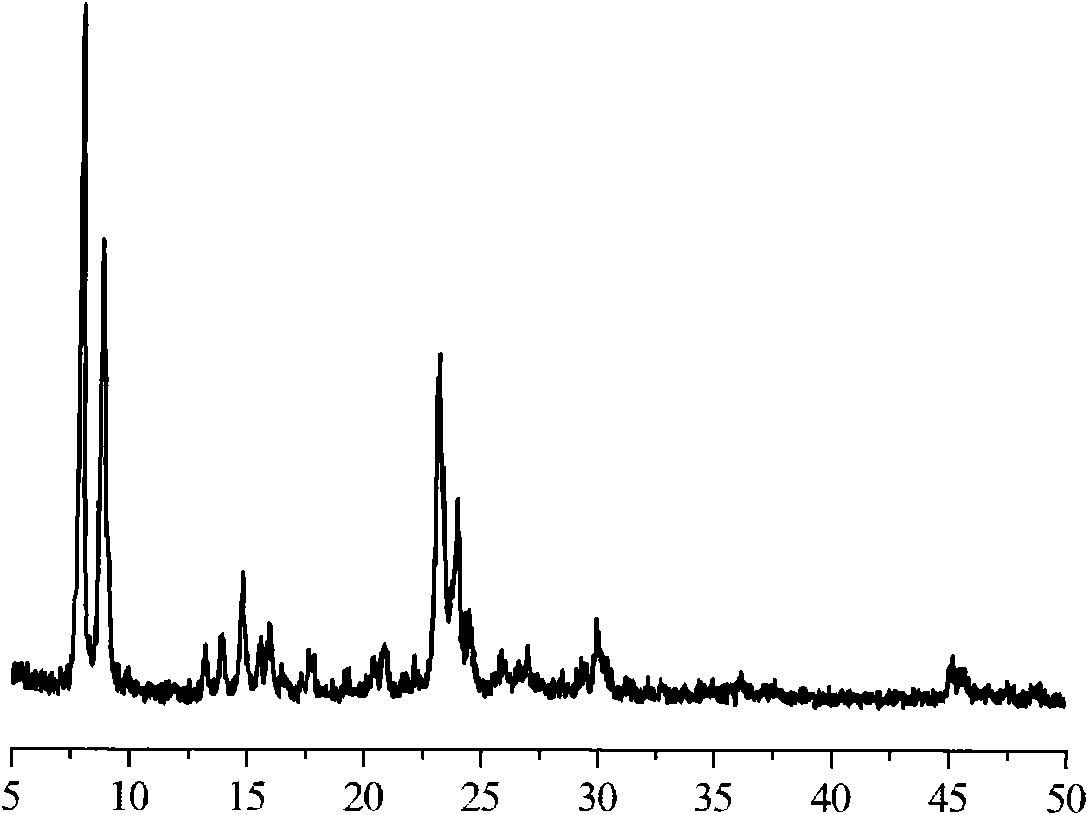

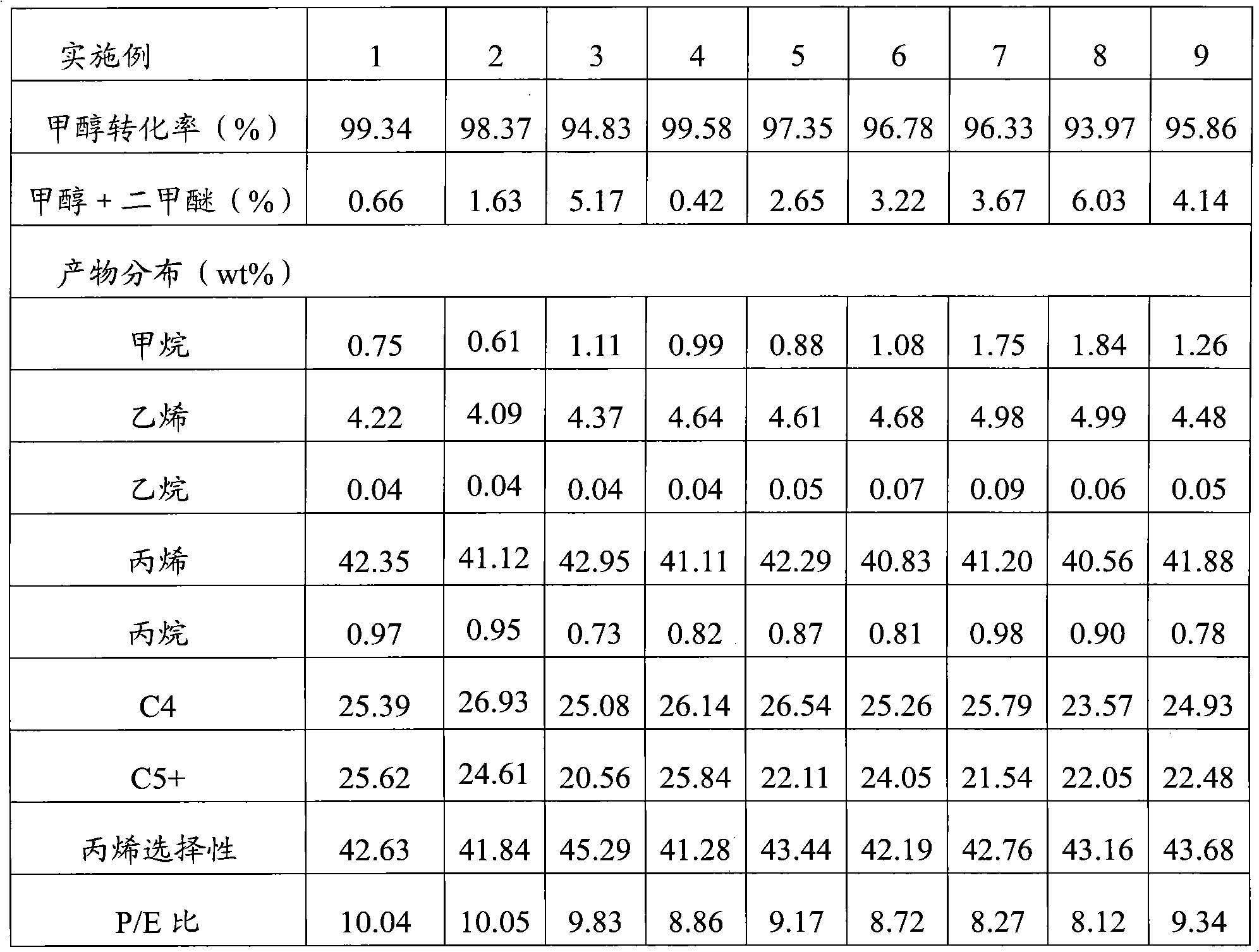

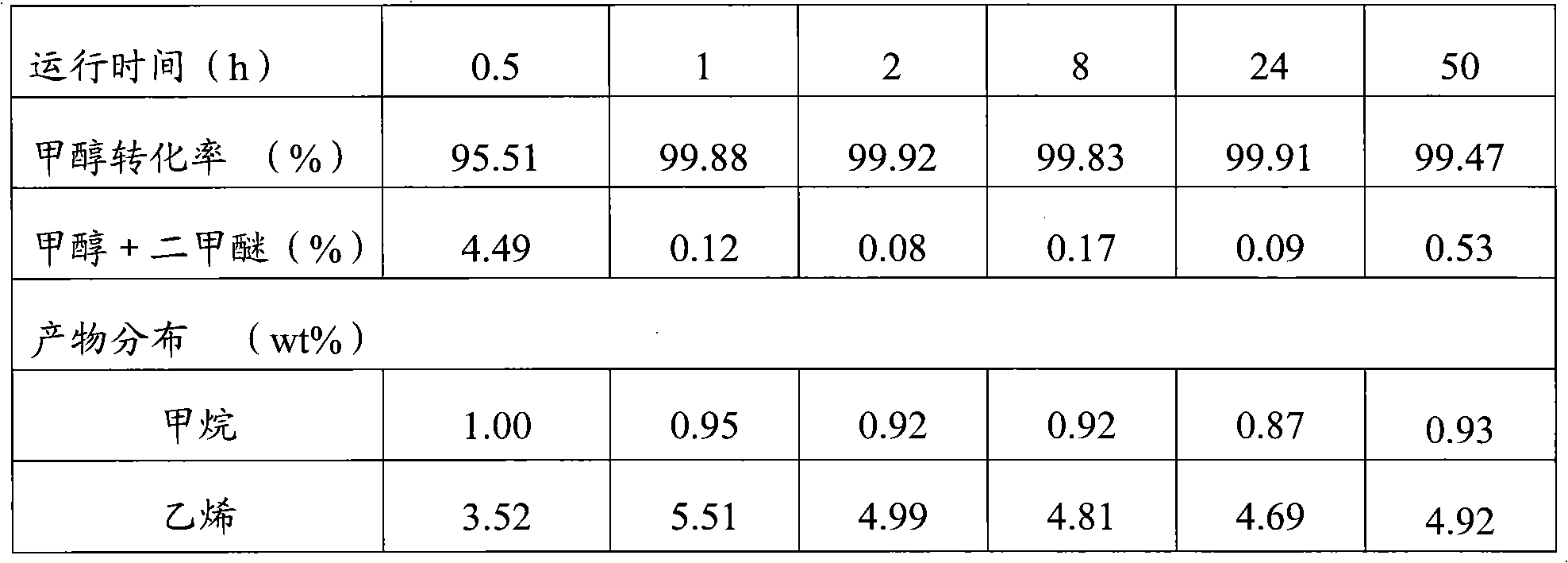

H-ZSM-5 zeolite catalyst for preparing propylene from methanol and application thereof

InactiveCN102125866ALarge specific surface areaImprove catalytic performanceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrothermal synthesisEthylene

The invention provides an H-ZSM-5 zeolite catalyst for preparing propylene from methanol and an application thereof. An H-ZSM-5 zeolite with small crystal grains obtained by directional preparation through the hydrothermal synthesis technology has small crystal grain size and high specific surface area, and can achieve the purpose of shortening the length of a diffusion path of molecules of a product, improving the diffusion performance of the catalyst and reducing the secondary reaction of a low-carbon olefin product. The H-ZSM-5 zeolite catalyst is used in the reaction for preparing the propylene from the methanol, the yield of the propylene and the P / E (propylene / ethylene) weight ratio are greatly improved, and the P / E weight ratio is above 8.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com