Five-element transition metal oxide high-entropy material for lithium-ion battery

A technology of lithium-ion batteries and transition metals, applied in electrical components, battery electrodes, secondary batteries, etc., can solve problems that are difficult to obtain large-scale promotion, achieve uniform chemical composition and microstructure, good rate performance, and large The effect of the first charge ratio capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

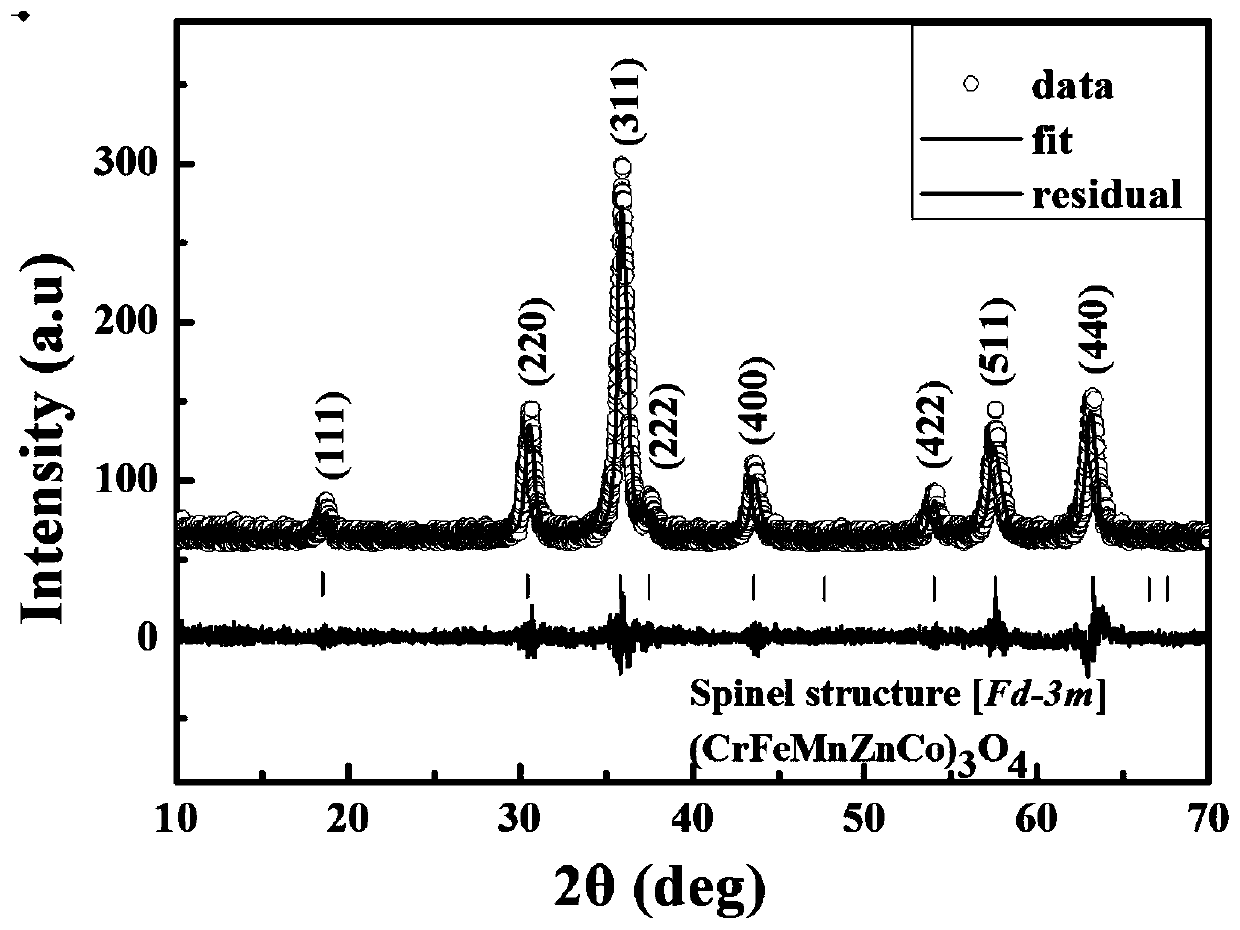

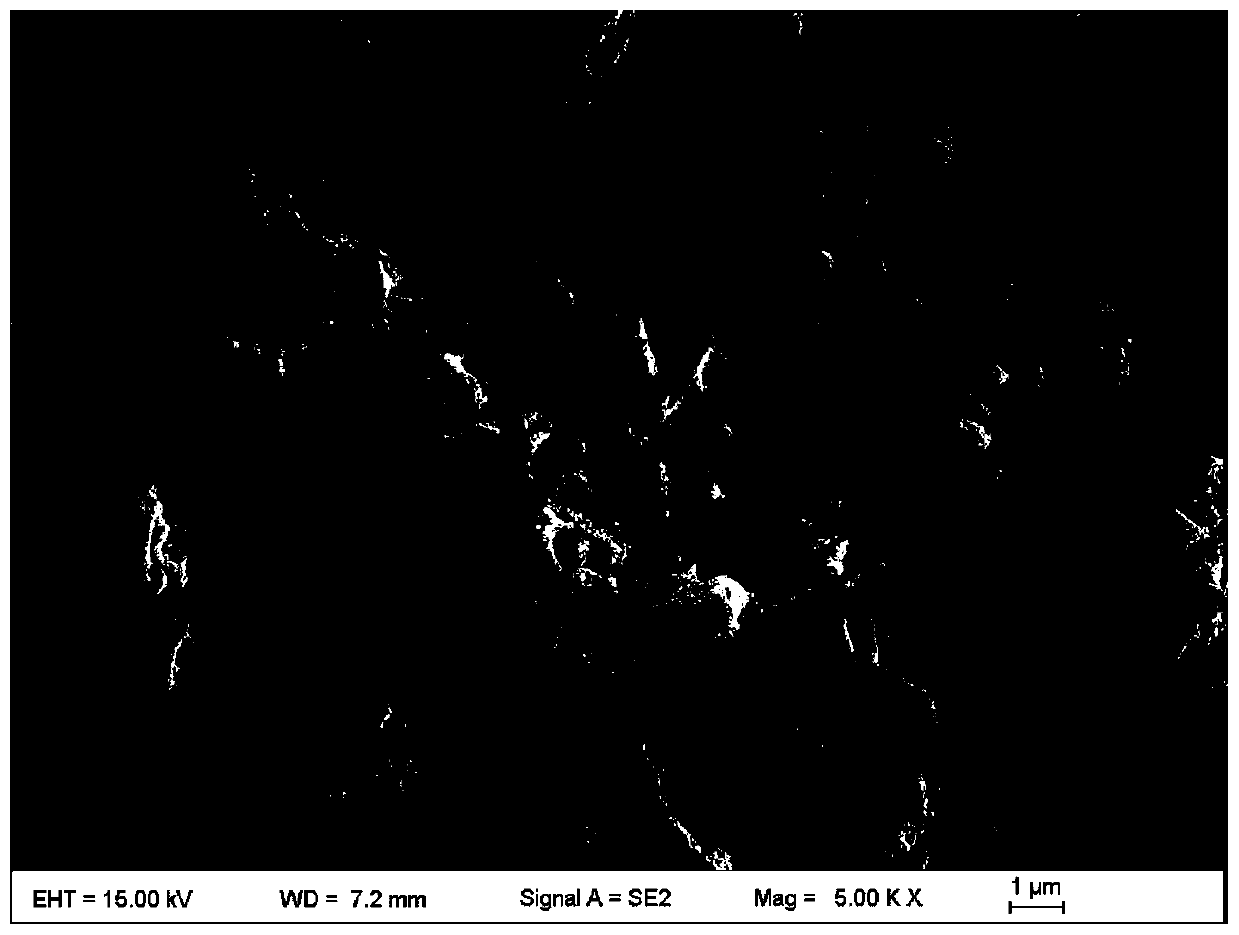

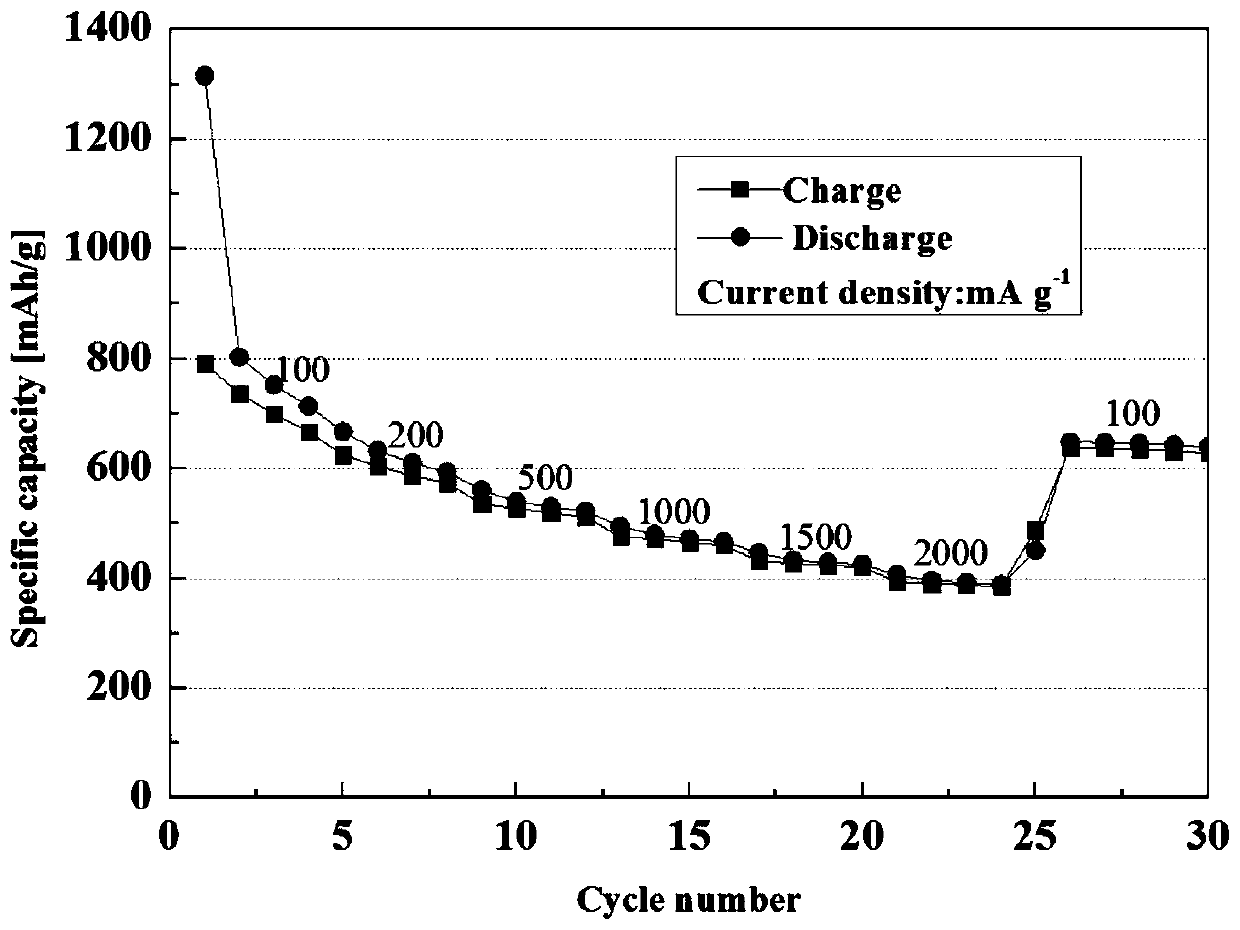

[0031] A five-element transition metal oxide high-entropy material for lithium-ion batteries was prepared by a solution combustion method, and the chemical composition of the high-entropy material was (Cr 0.2 Fe 0.2 mn 0.2 Zn 0.2 co 0.2 ) 3 o 4 . Weigh the metal nitrates of equimolar amounts according to the molecular formula, specifically: 4.002g of Cr(NO 3 ) 3 .9H 2 O, 4.040g of Fe(NO 3 ) 3 .9H 2 O, 2.870g of Mn(NO 3 ) 2 .4H 2 O, 2.975g of Zn(NO 3 ) 2 .6H 2 O and 2.910g of Co(NO 3 ) 2 .6H 2 O, dissolved in 10mL distilled water, stirred evenly at room temperature to obtain a mixed solution containing five metal cations; then weighed 3.003g glycine and added to the mixed solution, stirred evenly; then put the above transparent sol in an oven at 80°C After drying in medium temperature and evaporating water, a viscous gel was obtained; finally, the above gel was placed in a gold furnace and kept at 750°C for 30 minutes to obtain a spinel-type crystal structur...

Embodiment 2

[0034] A five-element transition metal oxide high-entropy material for lithium-ion batteries was prepared by a solution combustion method, and the chemical composition of the high-entropy material was (Cr 0.2 Fe 0.2 mn 0.2 Zn 0.2 Ni 0.2 ) 3 o 4 . Weigh the metal nitrates of equimolar amounts according to the molecular formula, specifically: 4.002g of Cr(NO 3 ) 3 .9H 2 O, 4.040g of Fe(NO 3 ) 3 .9H 2 O, 2.870g of Mn(NO 3 ) 2 .4H 2 O, 2.975g of Zn(NO 3 ) 2 .6H 2 O and 2.908g of Ni(NO 3 ) 2 .6H 2 O, dissolved in 2.5mL distilled water, stirred evenly at room temperature to obtain a mixed solution containing five metal cations; then weighed 2.252g glycine and 3.843g ethylenediaminetetraacetic acid and added to the mixed solution, stirred evenly; then The above-mentioned transparent sol was dried in an oven at 150°C, and a viscous gel was obtained after evaporating water; finally, the above-mentioned gel was placed in a muffle furnace and kept at 350°C for 1 hour ...

Embodiment 3

[0037] A five-element transition metal oxide high-entropy material for lithium-ion batteries was prepared by a solution combustion method, and the chemical composition of the high-entropy material was (Cr 0.2 Fe 0.2 mn 0.2 Zn 0.2 Ni 0.2 ) 3 o 4 : Take by weighing the metal nitrate of equimolar amount according to molecular formula, specifically: 4.002g of Cr(NO 3 ) 3 .9H 2 O, 4.040g of Fe(NO 3 ) 3 .9H 2 O, 2.870g of Mn(NO 3 ) 2 .4H 2 O, 2.975g of Zn(NO 3 ) 2 .6H 2 O and 2.908g of Ni(NO 3 ) 2 .6H 2 O, dissolved in 5mL distilled water, stirred evenly at room temperature to obtain a mixed solution containing five metal cations; then weighed 2.922g ethylenediaminetetraacetic acid and added to the mixed solution, stirred evenly; then put the above transparent sol in Dried in an oven at 150°C to obtain a viscous gel after evaporating water; finally put the above gel in a muffle furnace and keep it at 550°C for 1 hour to obtain a spinel crystal structure with a spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com