Patents

Literature

957results about How to "Increase the support area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

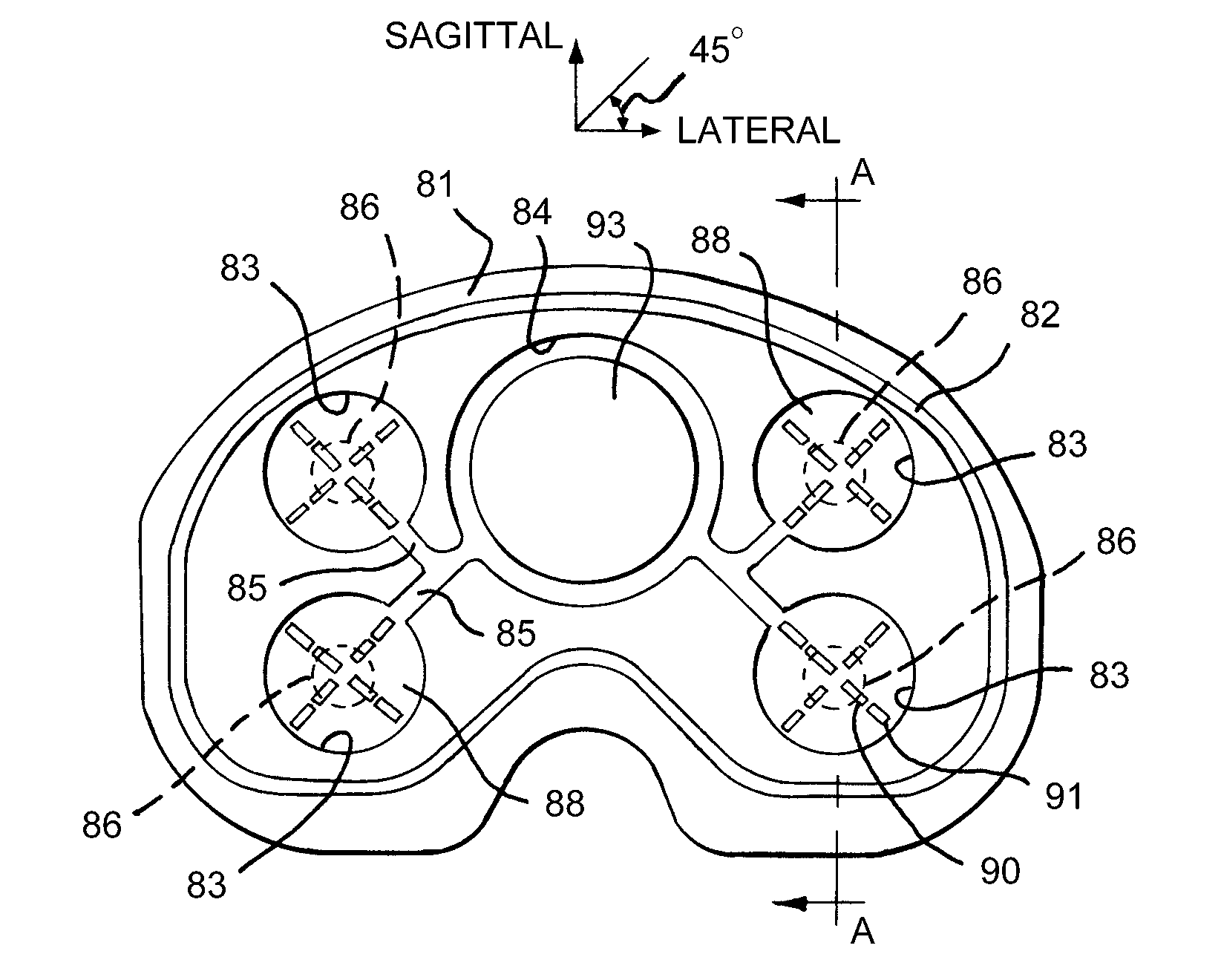

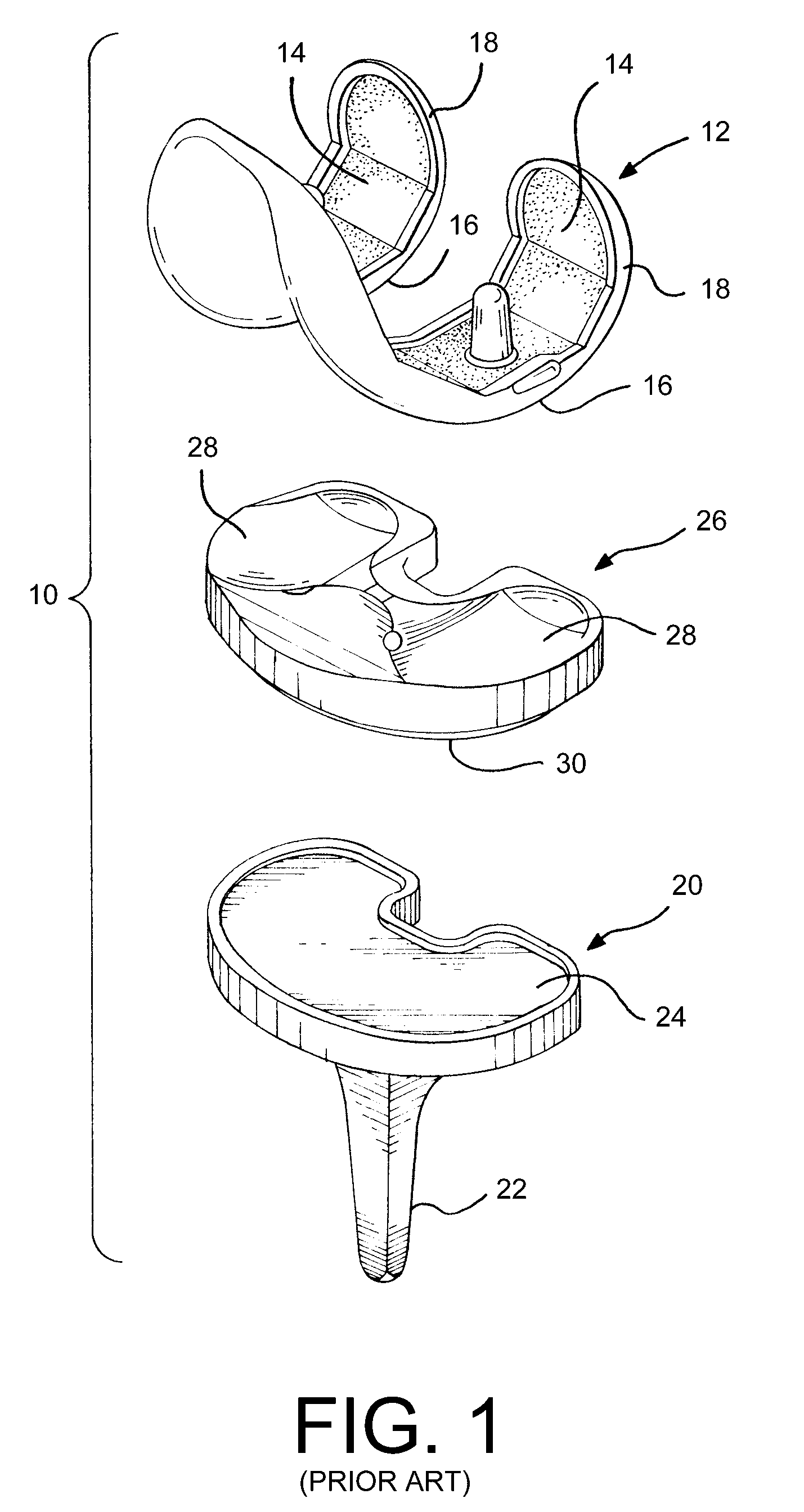

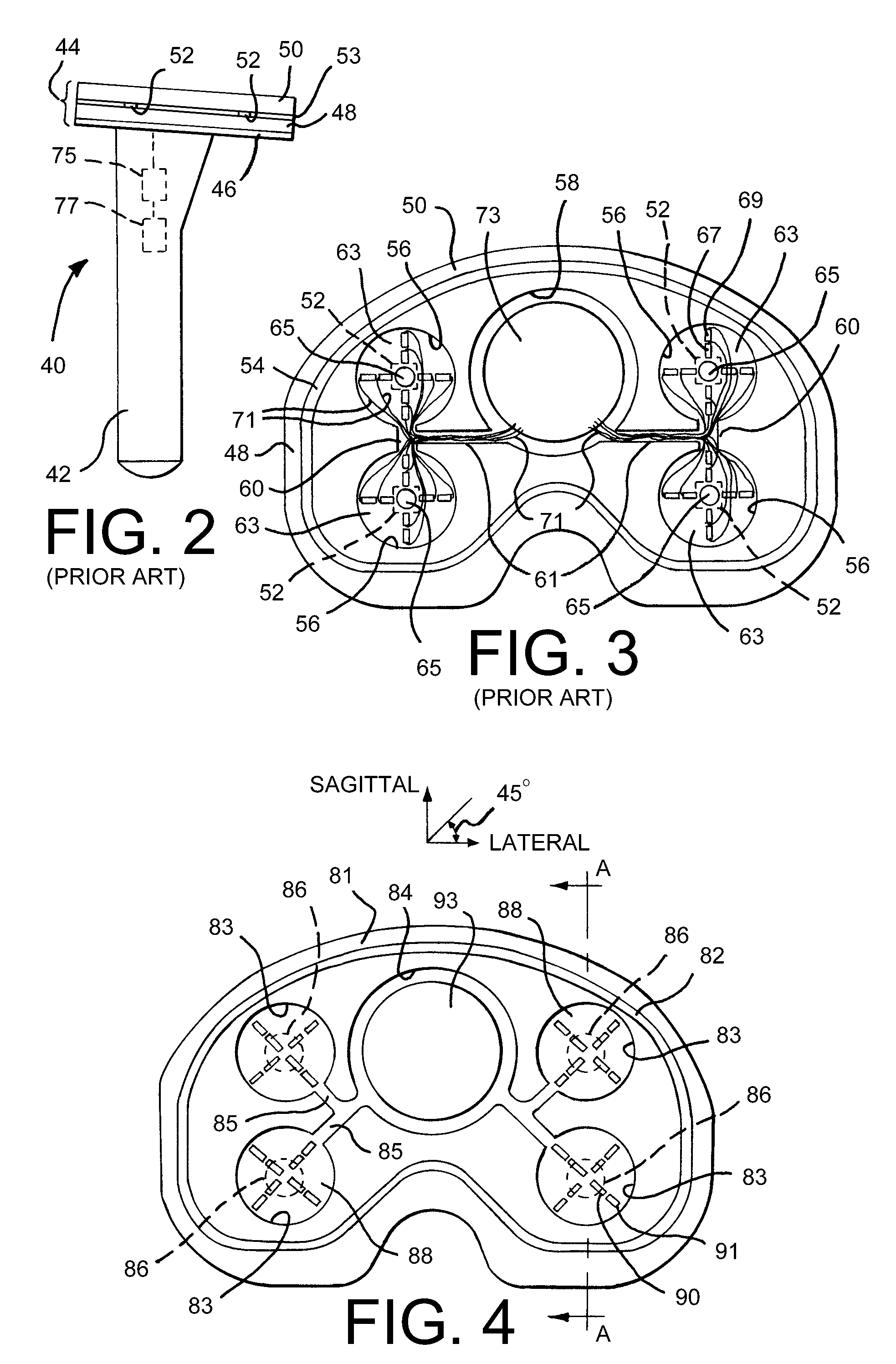

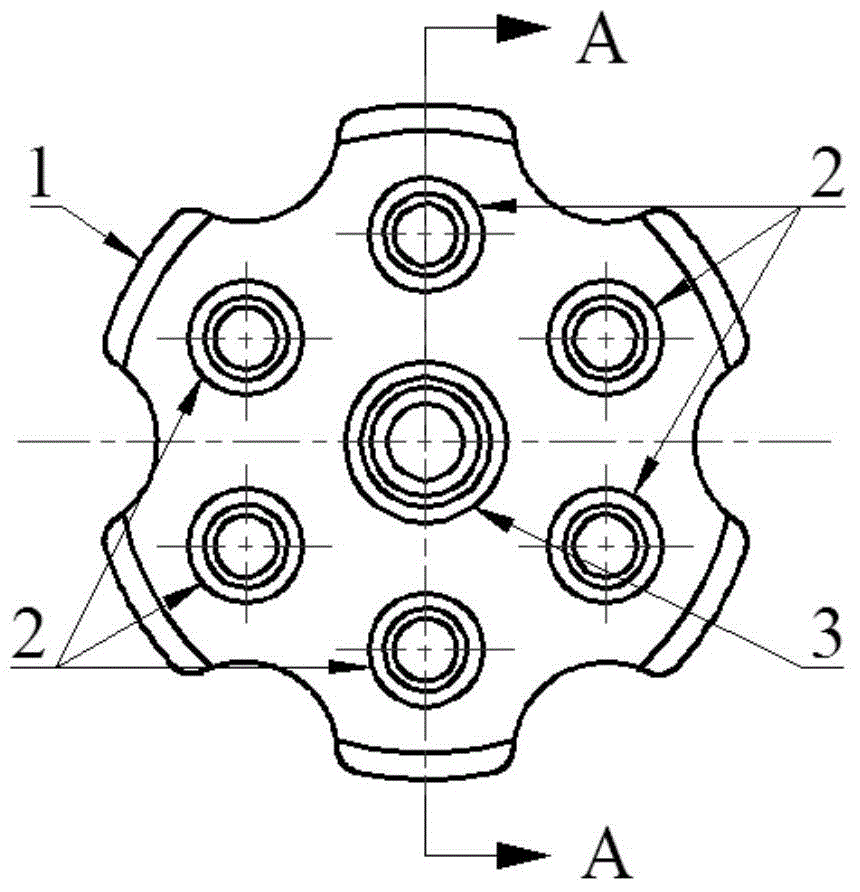

Telemetric tibial tray

ActiveUS20050010302A1Reduce riskEliminates stress riserSurgeryPerson identificationStrain rateKnee Joint

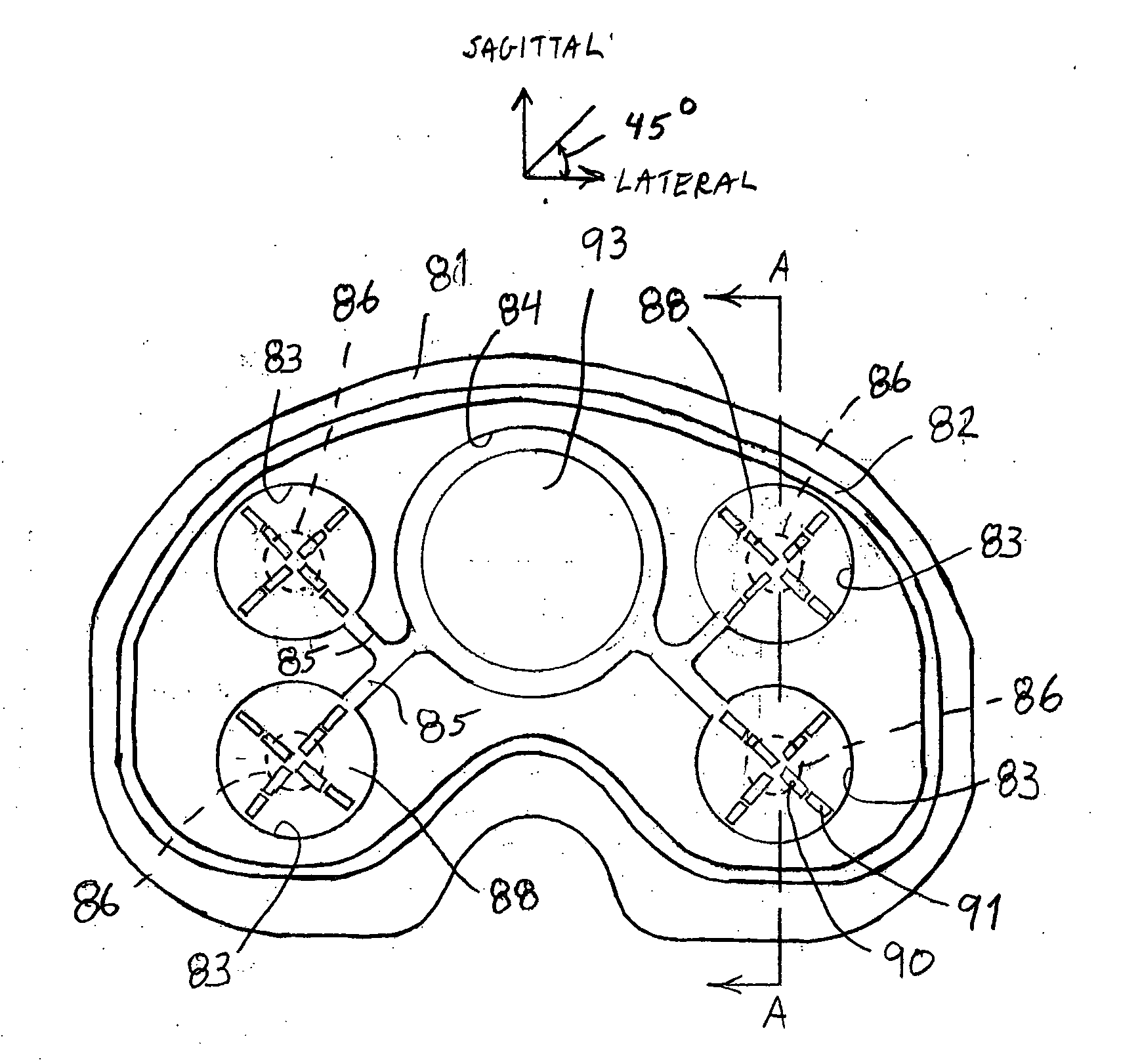

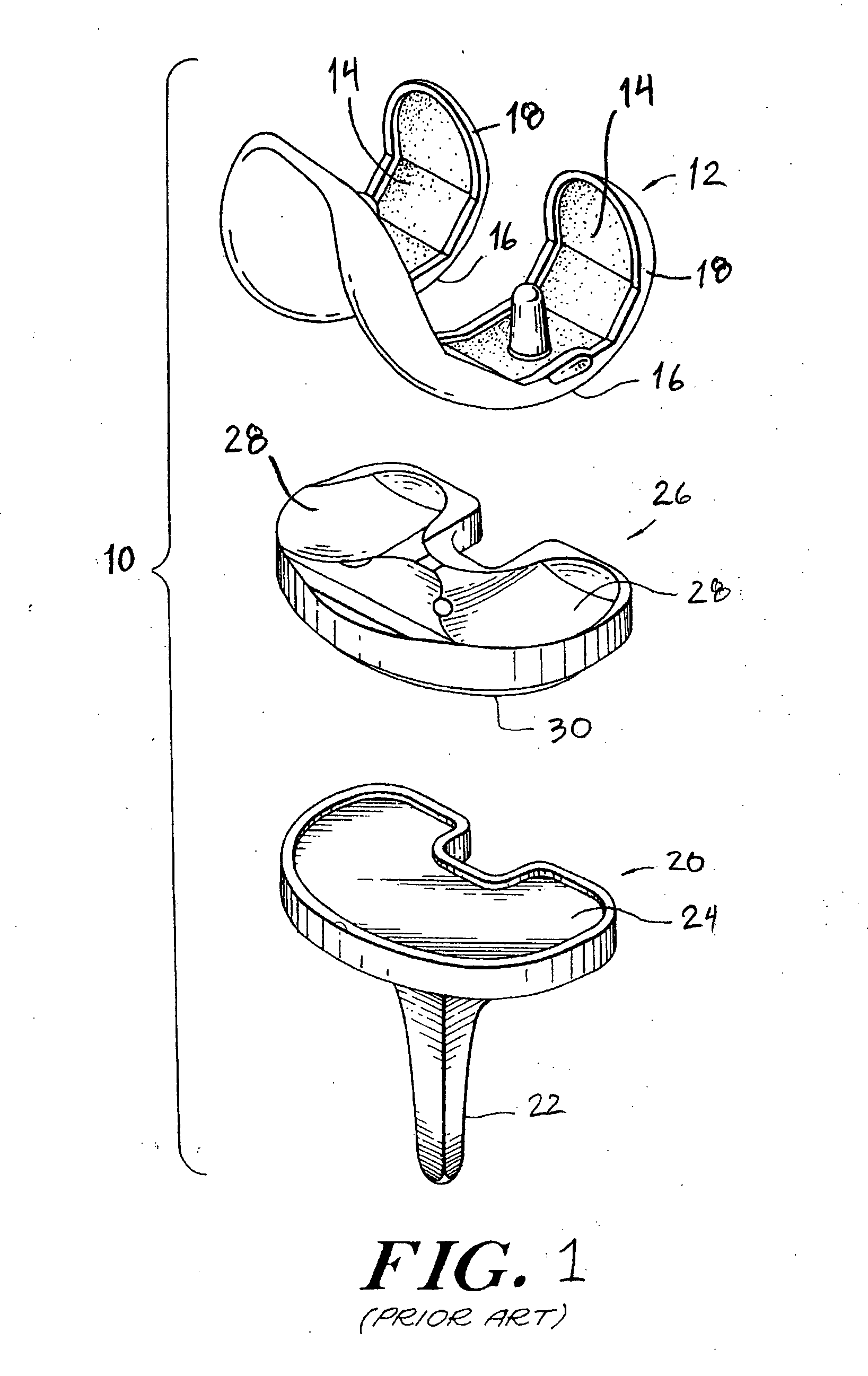

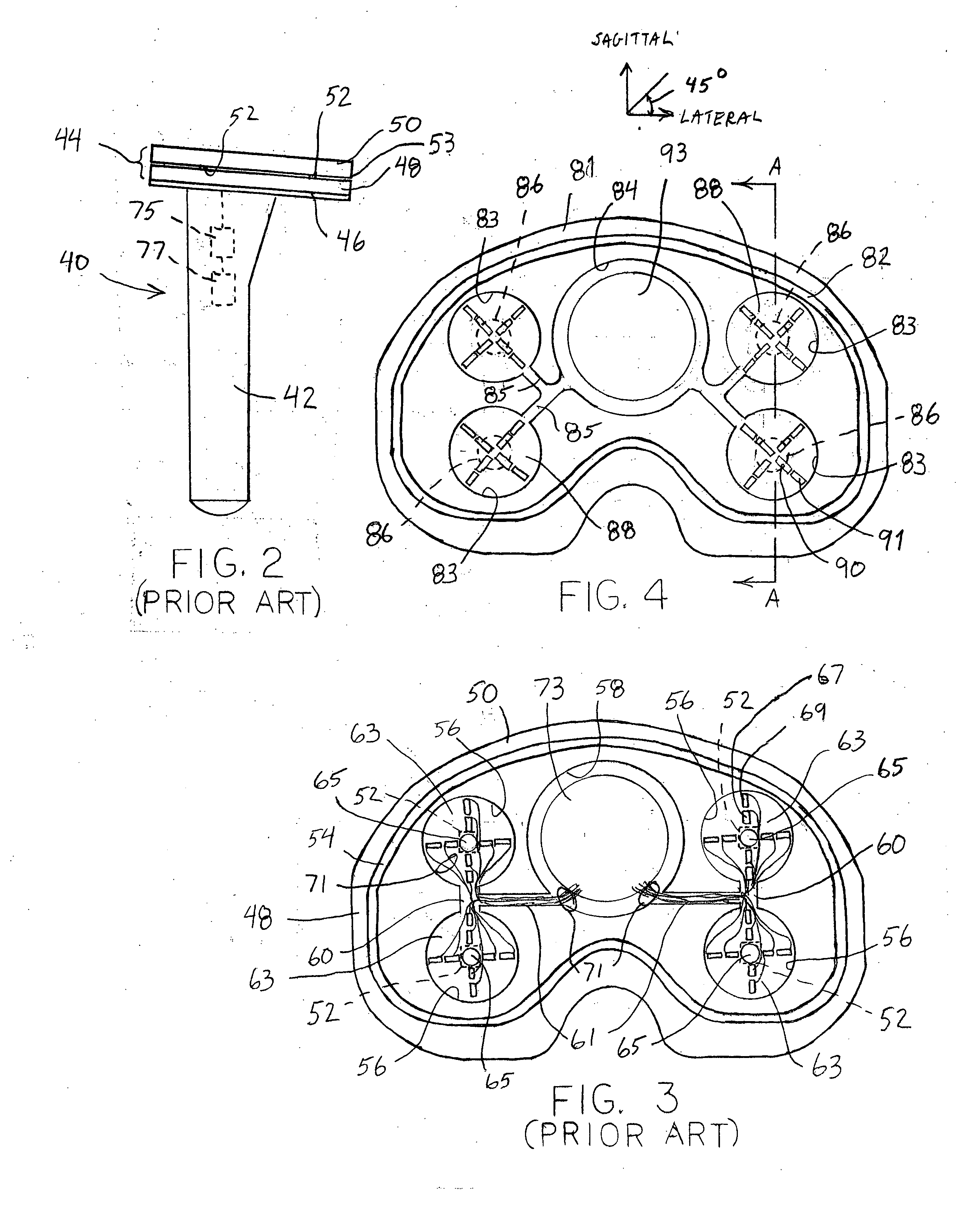

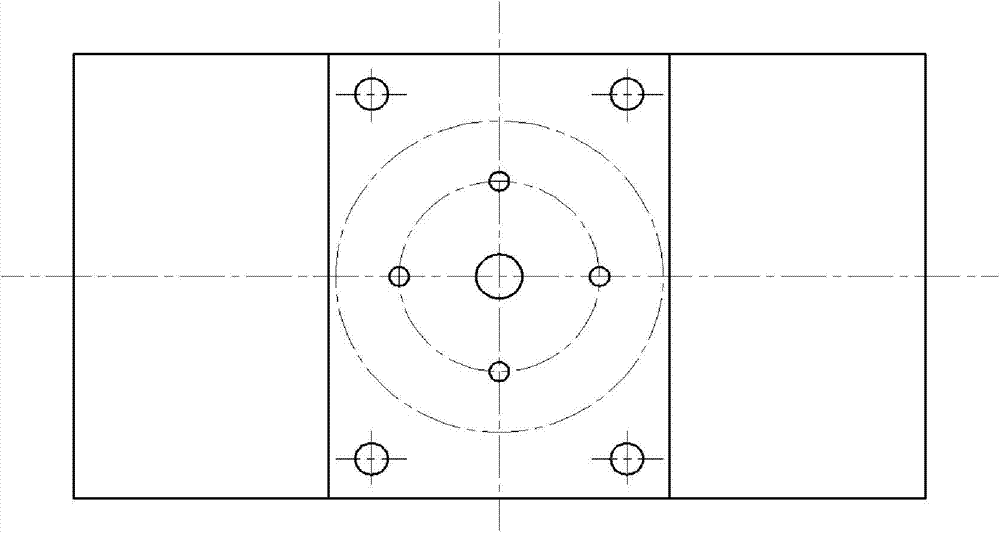

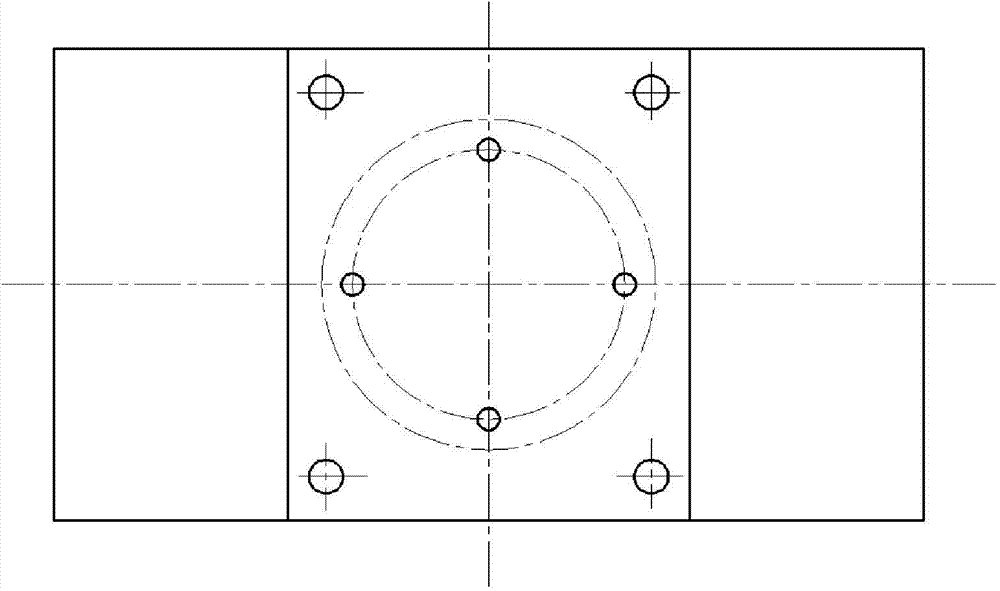

A telemetric tibial tray includes a lower plate that defines a plurality of cylindrical transducer cavities having circular load diaphragms. An upper plate is attached to the lower plate through support posts projecting from the load diaphragms. The support posts have a circular cross-section and a diameter of about 5.0 mm. The lower plate further defines wiring channels communicating between the transducer cavities and a central cavity housing the circuit board for the telemetric tray. The wiring channels are arranged at a 45 degree angle relative to the sagittal plane of the knee joint in order to reduce the effects of the wiring channel intersection on the strain sensitivity of the tray. Each transducer cavity includes a radial strain gage array with four pairs of radially aligned strain gages, each pair aligned at a 45 degree angle relative to the sagittal plane of the knee joint. Each pair of strain gages includes an inner gage positioned at the point of maximum positive micro-strain across the diaphragm when loaded, and an outer gage positioned at the point of maximum negative micro-strain, to thereby increase the differential strain measured by the gages and increase the strain sensitivity of the tibial tray.

Owner:DEPUY PROD INC

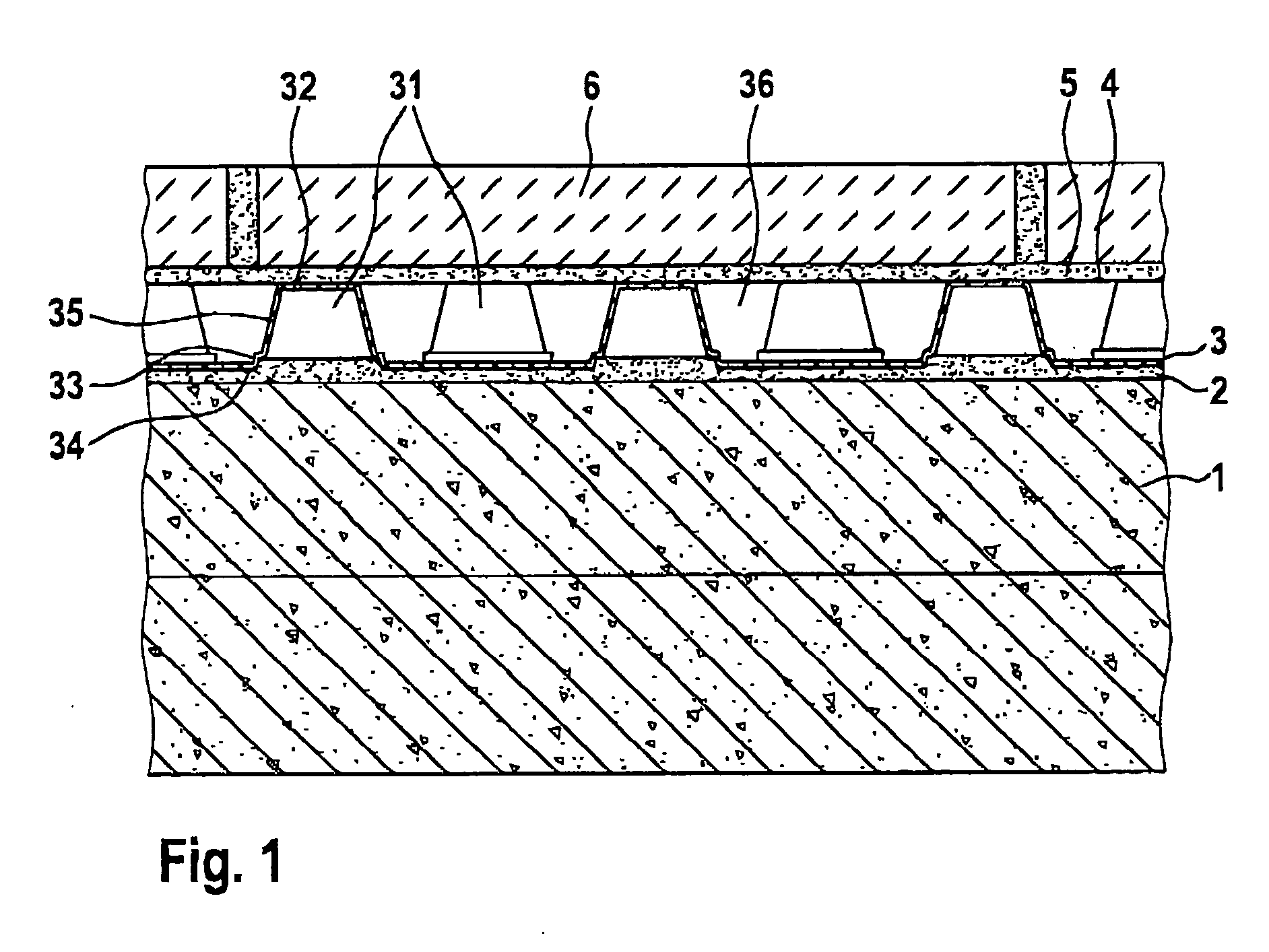

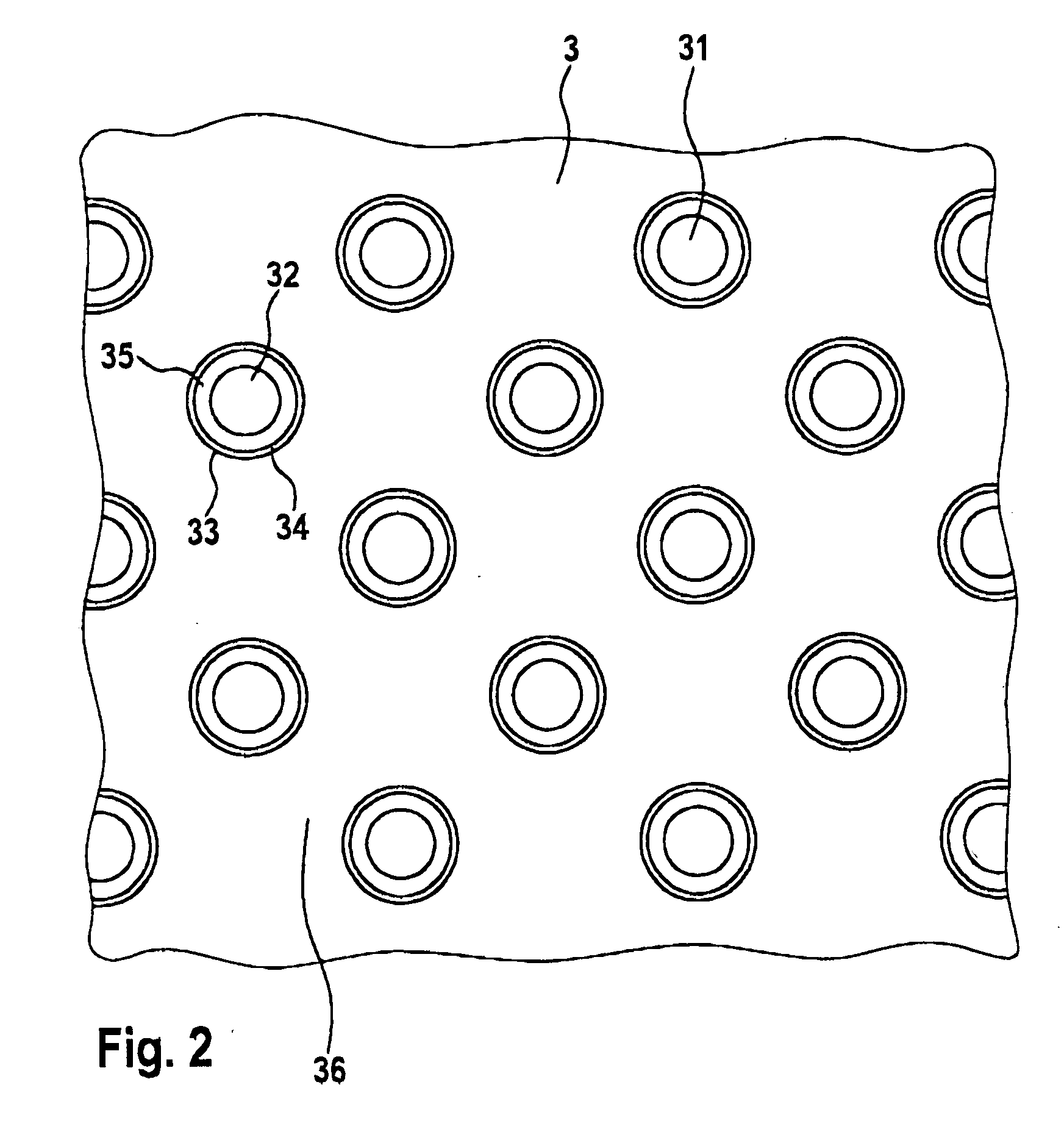

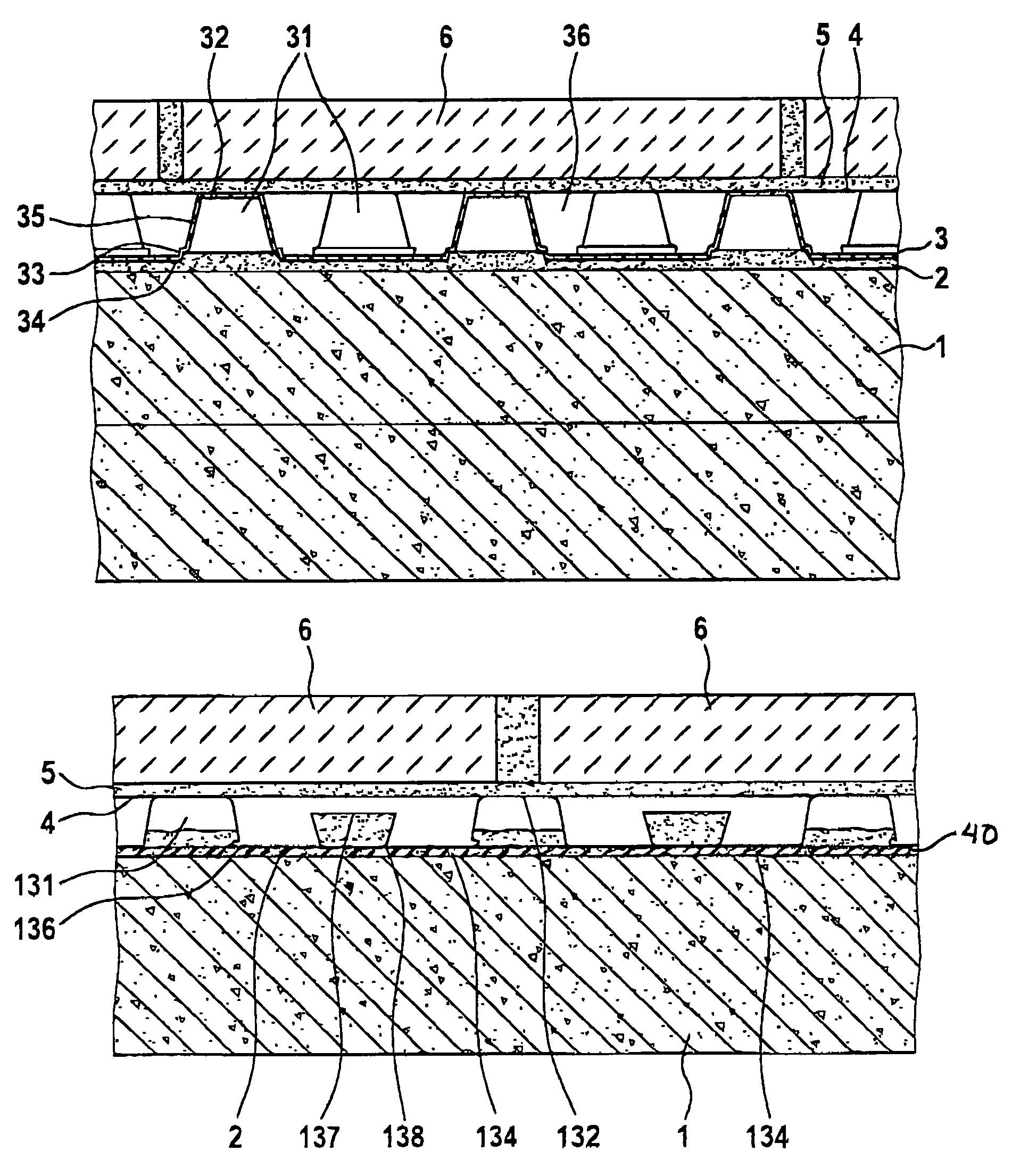

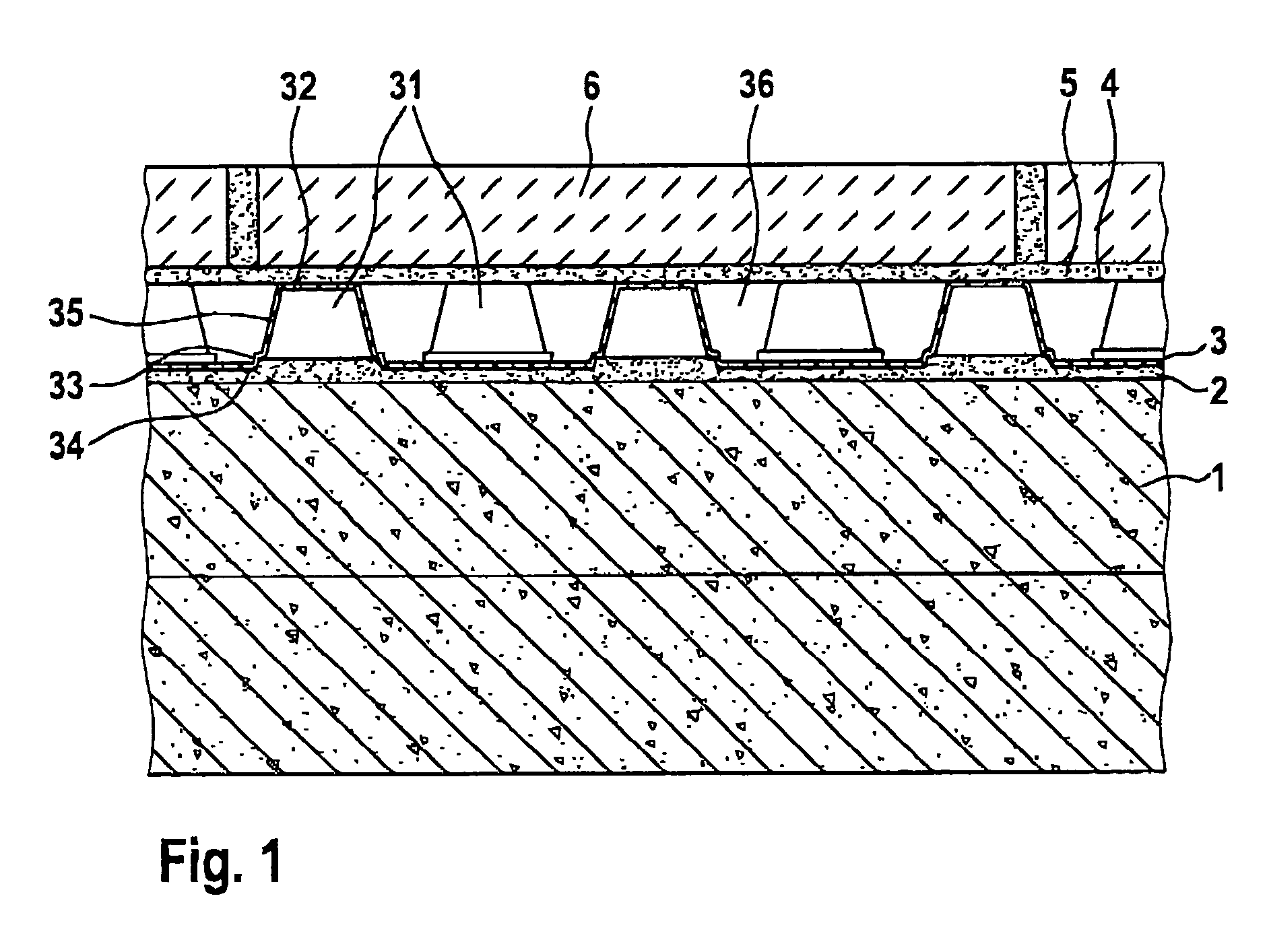

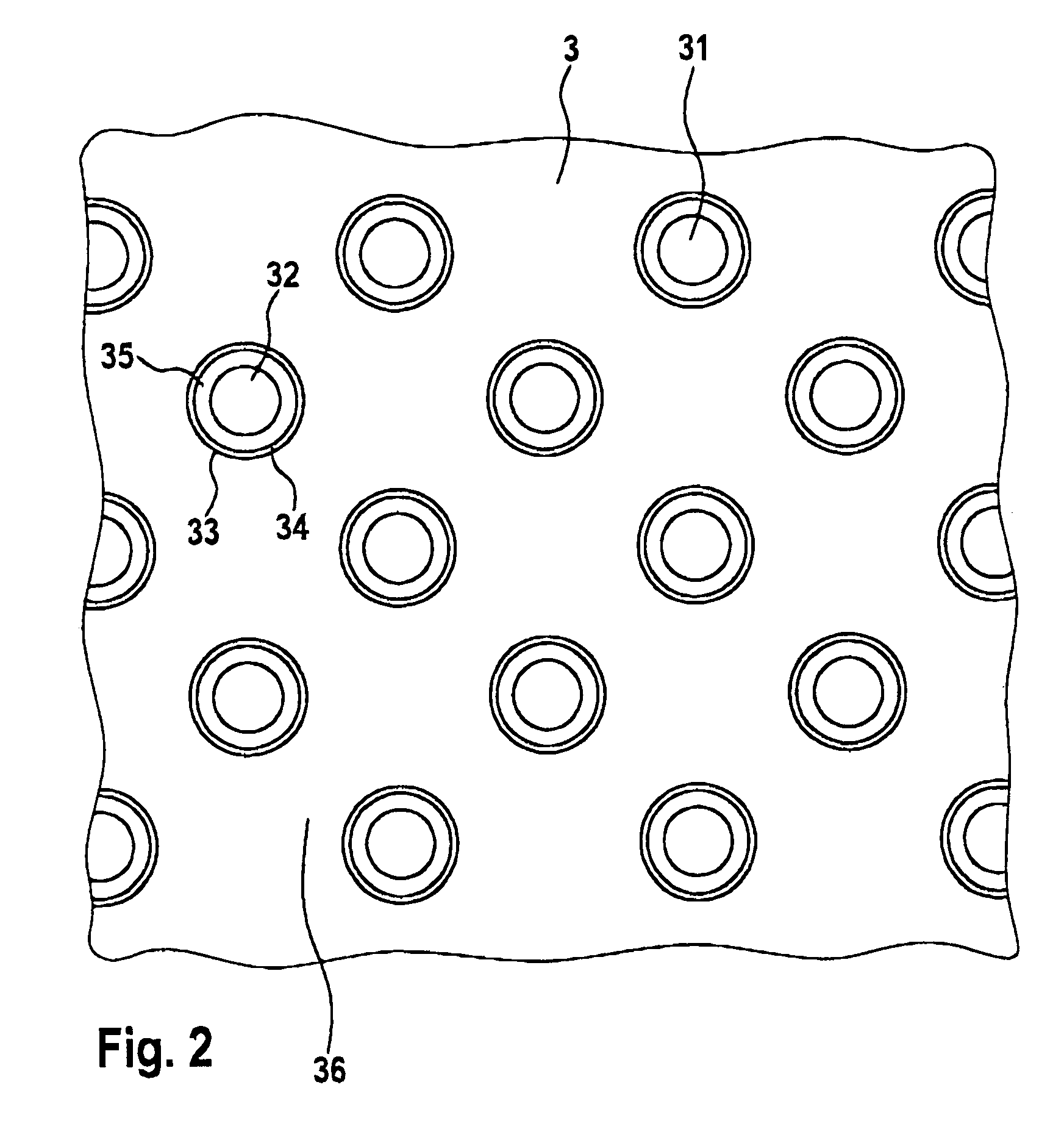

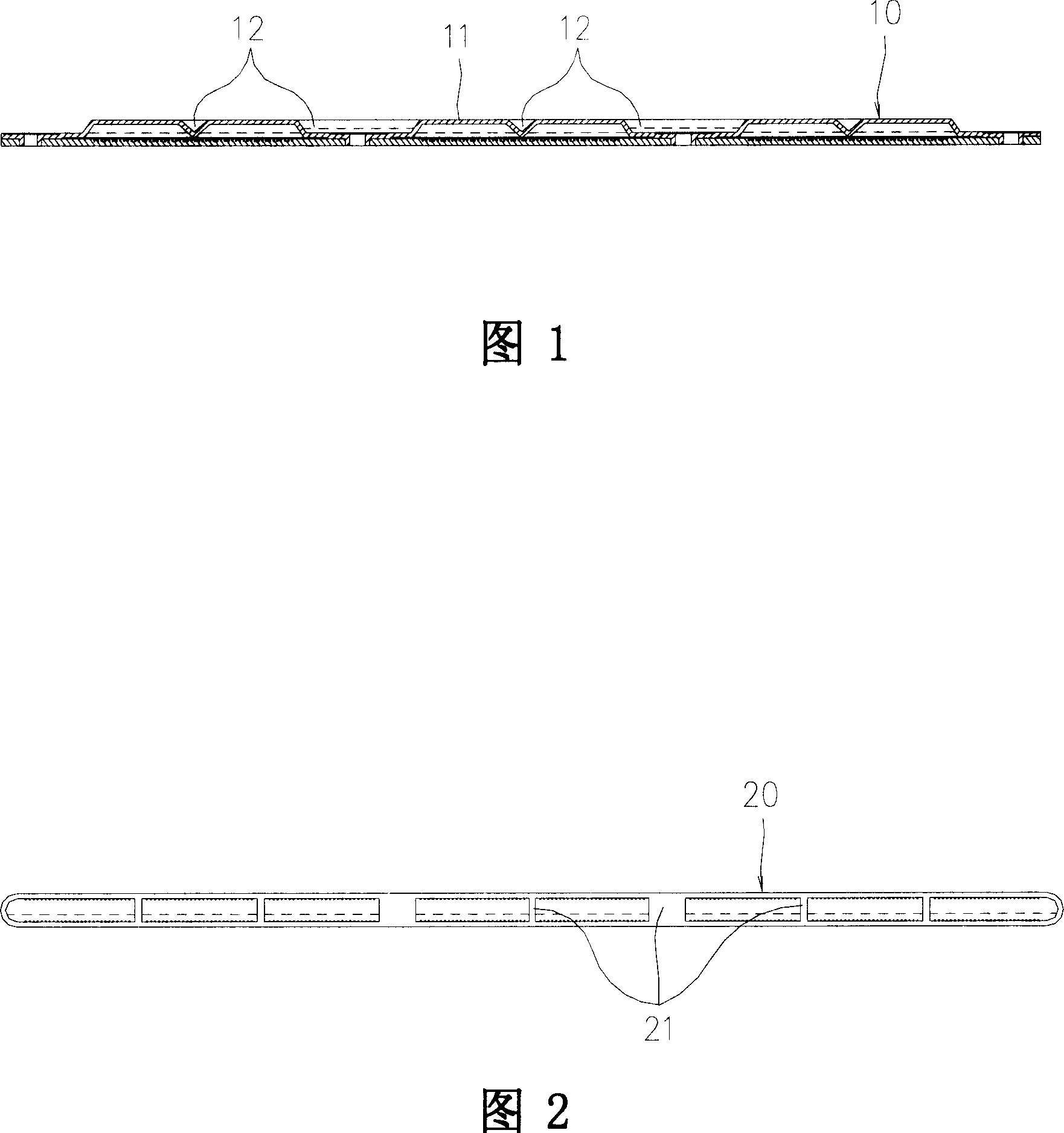

Floor construction covered with ceramic tiles

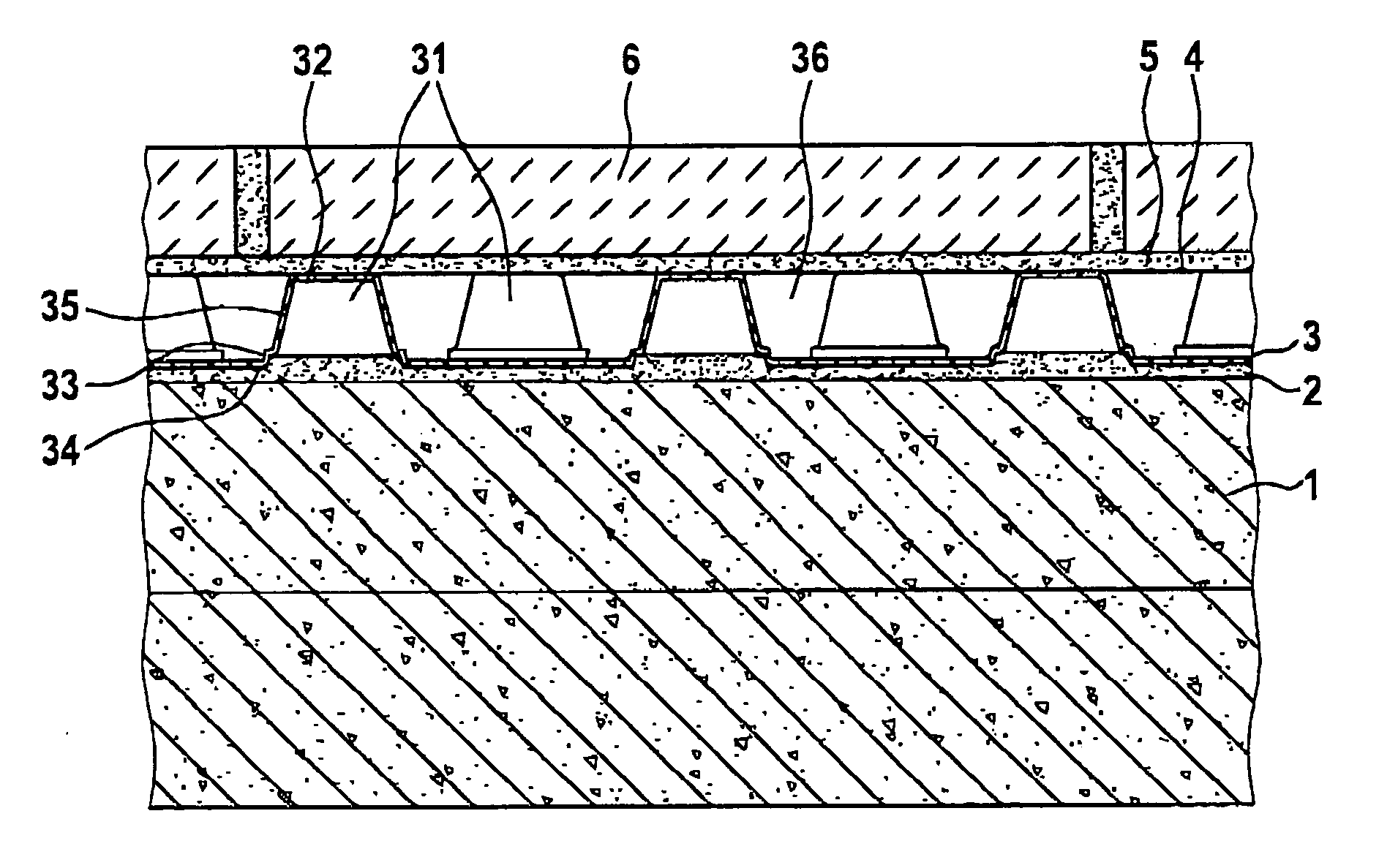

ActiveUS20060260233A1Reduce the overall heightSufficient load distributionCovering/liningsFloorsOpen waterBrick

A floor construction covered with ceramic tiles, in which a film-like plastic mat having support elements disposed in a uniform area distribution, hollow towards the underside, capable of support, projecting out beyond the top of the mat, is applied on the sub-floor. Channels carrying open water are formed between the support elements, and a water-permeable or vapor-permeable covering in the manner of a non-woven fabric or woven fabric is disposed on the support elements. The plastic mat is embedded and attached, supported in a still soft, hardening thin-bed mortar layer on the sub-floor, over its full area, in the region of its lower contact surfaces. The ceramic tiles are laid and attached on the covering in the manner of a non-woven fabric, directly, with a thin-bed mortar layer.

Owner:SCHLUTER SYST LP

Floor construction covered with ceramic tiles

A floor construction covered with ceramic tiles, in which a film-like plastic mat having support elements disposed in a uniform area distribution, hollow towards the underside, capable of support, projecting out beyond the top of the mat, is applied on the sub-floor. Channels carrying open water are formed between the support elements, and a water-permeable or vapor-permeable covering in the manner of a non-woven fabric or woven fabric is disposed on the support elements. The plastic mat is embedded and attached, supported in a still soft, hardening thin-bed mortar layer on the sub-floor, over its full area, in the region of its lower contact surfaces. The ceramic tiles are laid and attached on the covering in the manner of a non-woven fabric, directly, with a thin-bed mortar layer.

Owner:SCHLUTER SYST LP

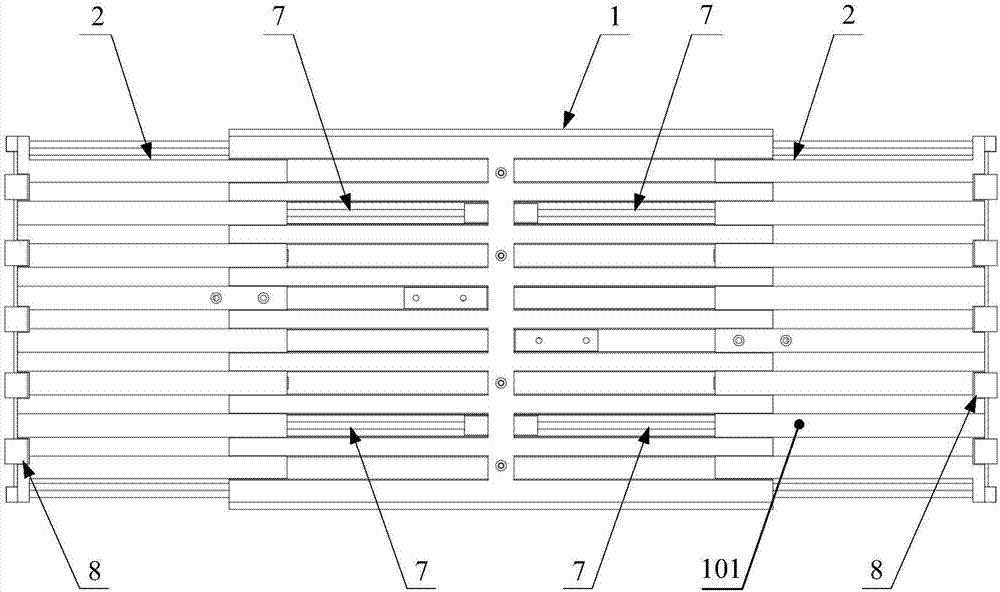

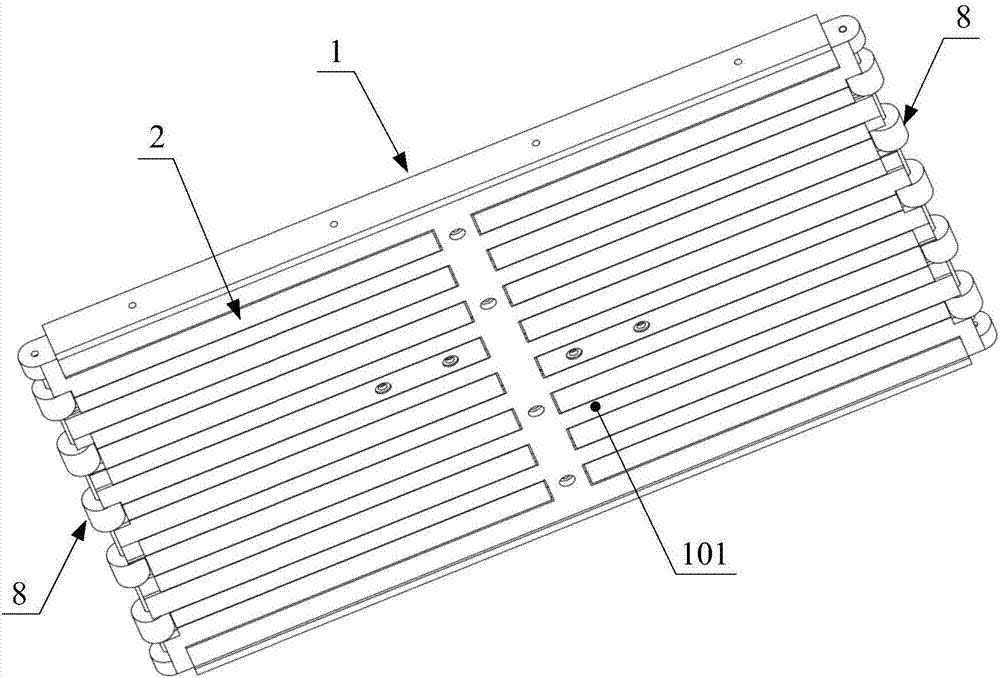

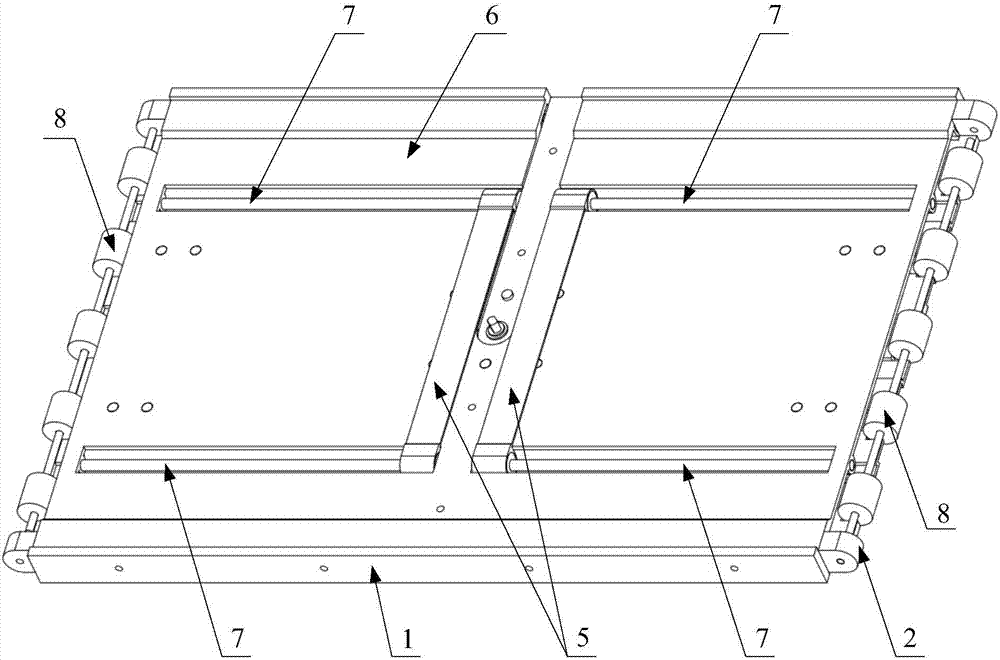

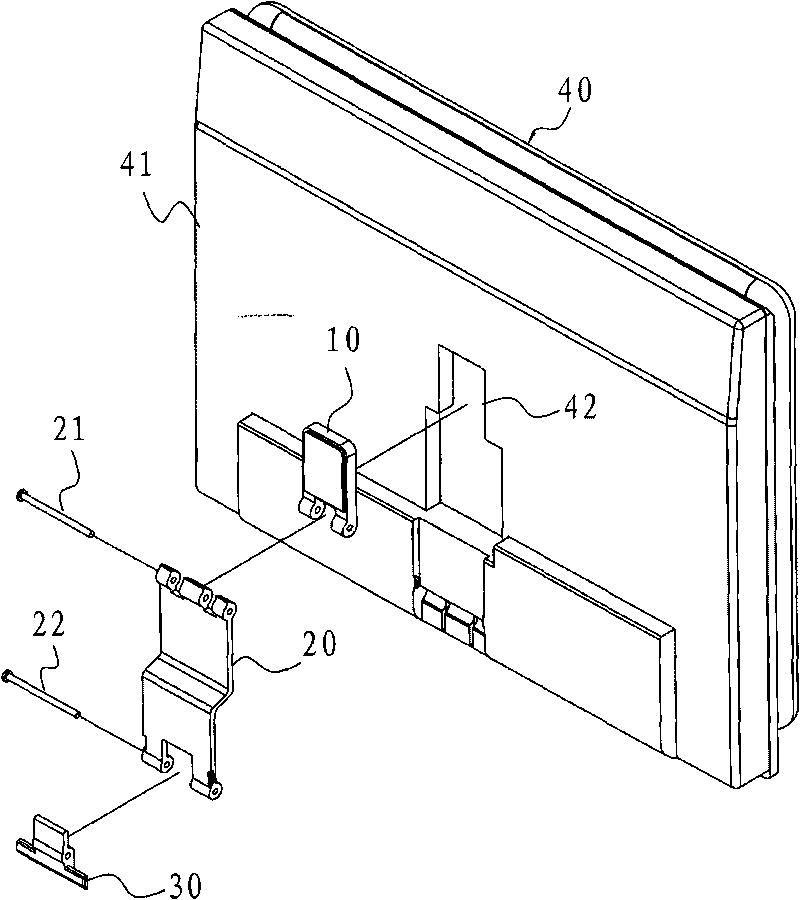

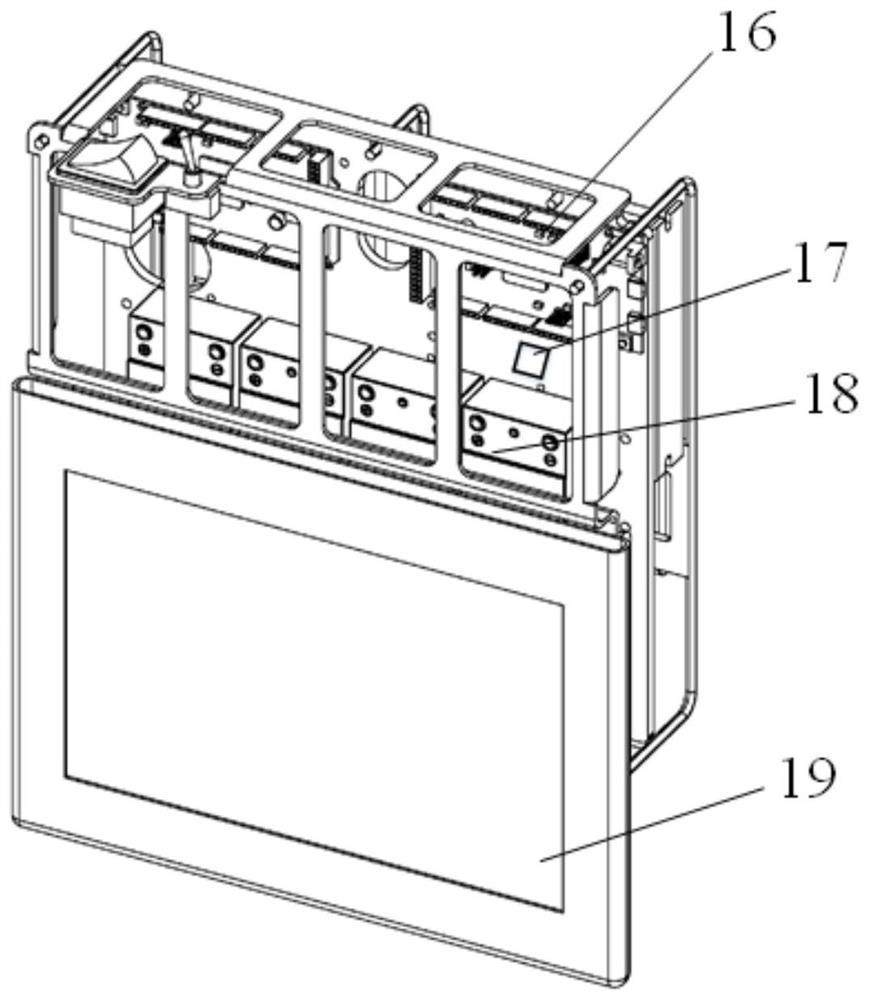

Electronic equipment and flexible connecting mechanism

ActiveCN106884867AReduced support areaIncrease the support areaDigital data processing detailsCasings/cabinets/drawers detailsEngineeringElectric equipment

The invention discloses a flexible connecting mechanism which comprises a fixed supporting piece, mobile supporting pieces slidably or rotatably connected with the fixed supporting piece and a flexible piece. The flexible piece can be bent and can cover on the fixed supporting piece and the mobile supporting pieces, and at least one end of the flexible piece is slidably connected with the fixed supporting piece or the mobile supporting pieces. According to the flexible connecting mechanism, the area of supporting to the flexible piece can be changed through relative sliding or rotating of the fixed supporting piece and the mobile supporting pieces, and when the flexible piece is a flexible screen or is used for arranging a part of the flexible screen, the display area can be changed by changing the supporting area so that the size of the screen of electronic equipment can be flexibly changed according to different use needs, and the diversified use needs of a user are met. The invention further provides the electronic equipment provided with the flexible connecting mechanism.

Owner:LENOVO (BEIJING) CO LTD

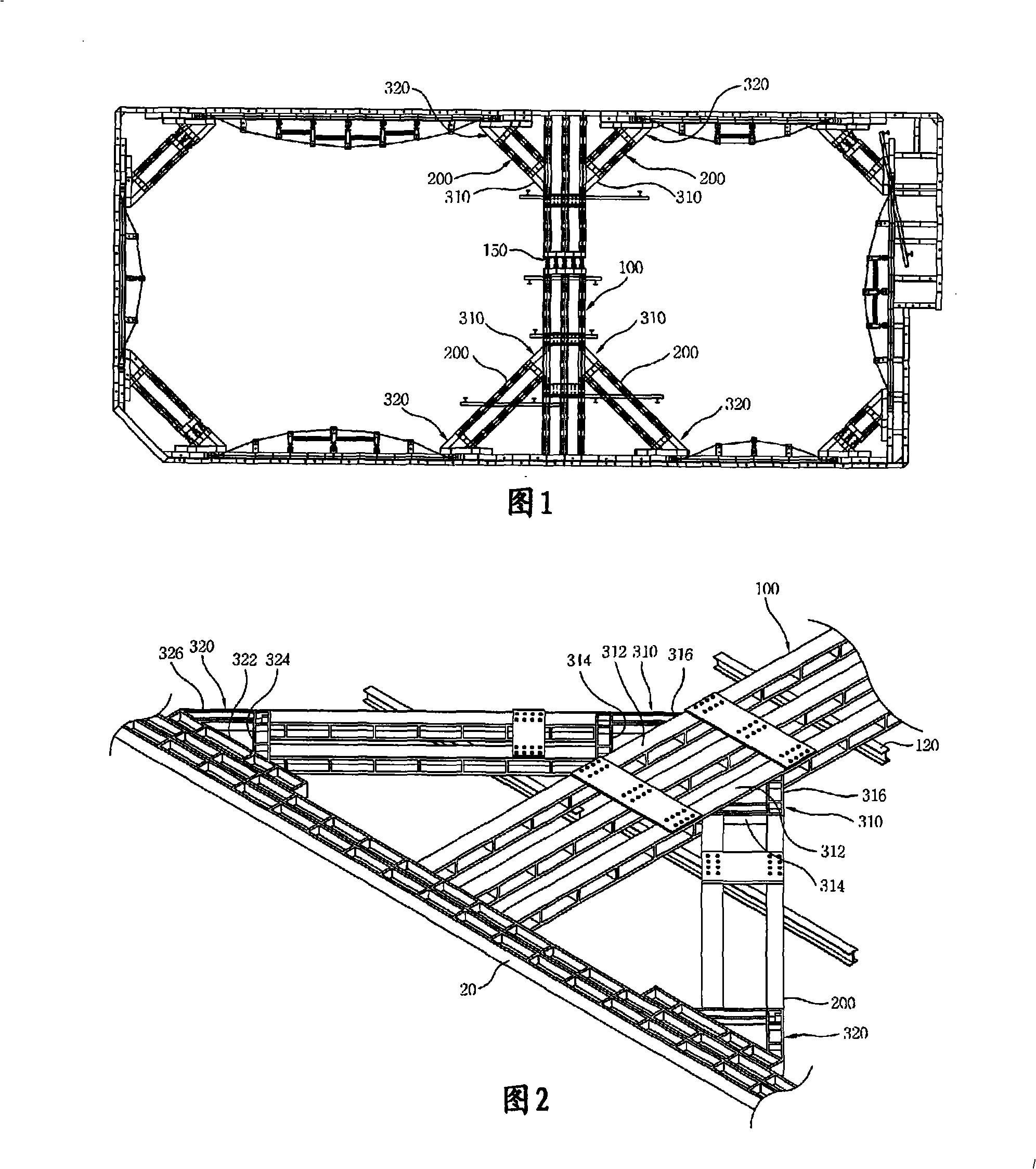

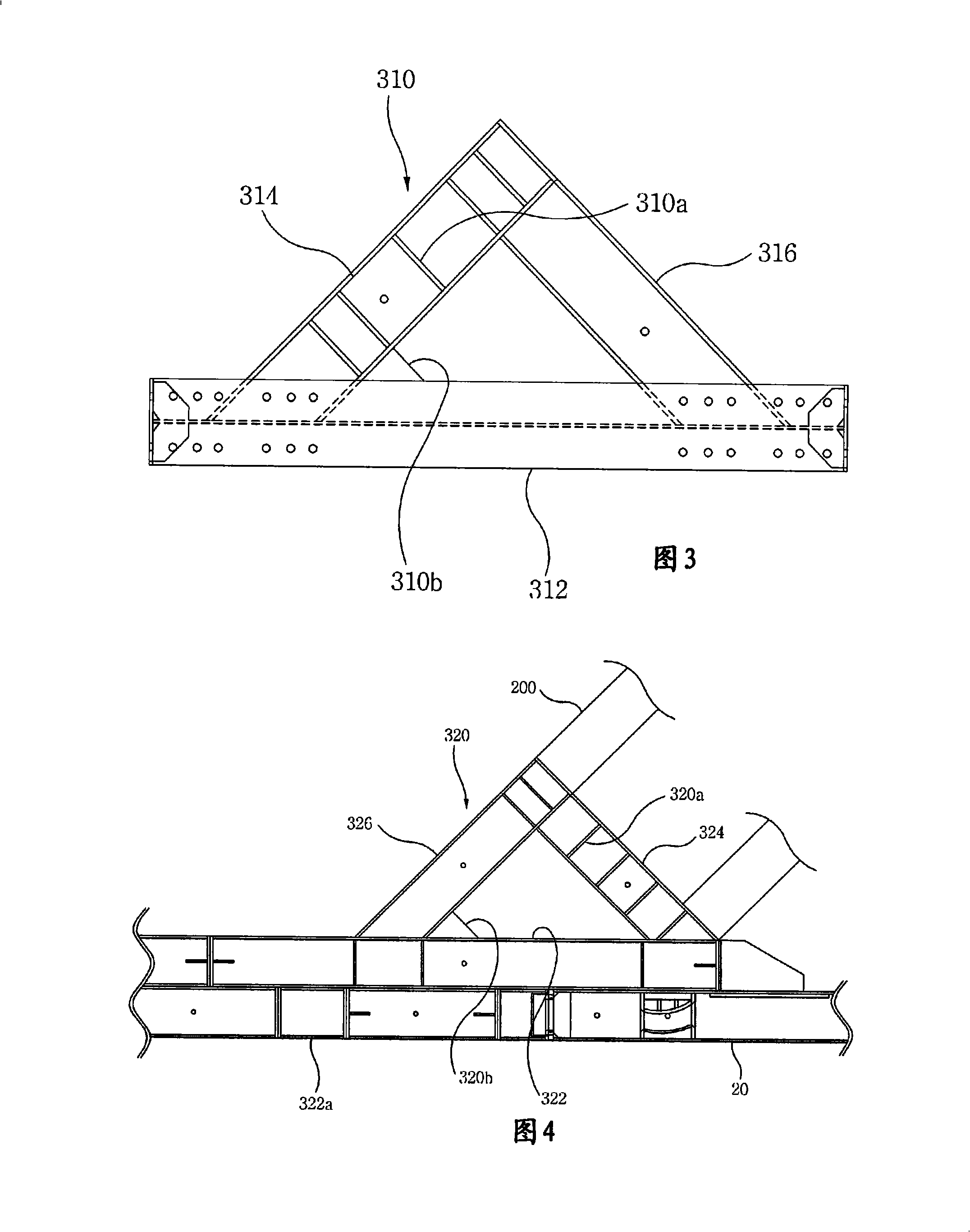

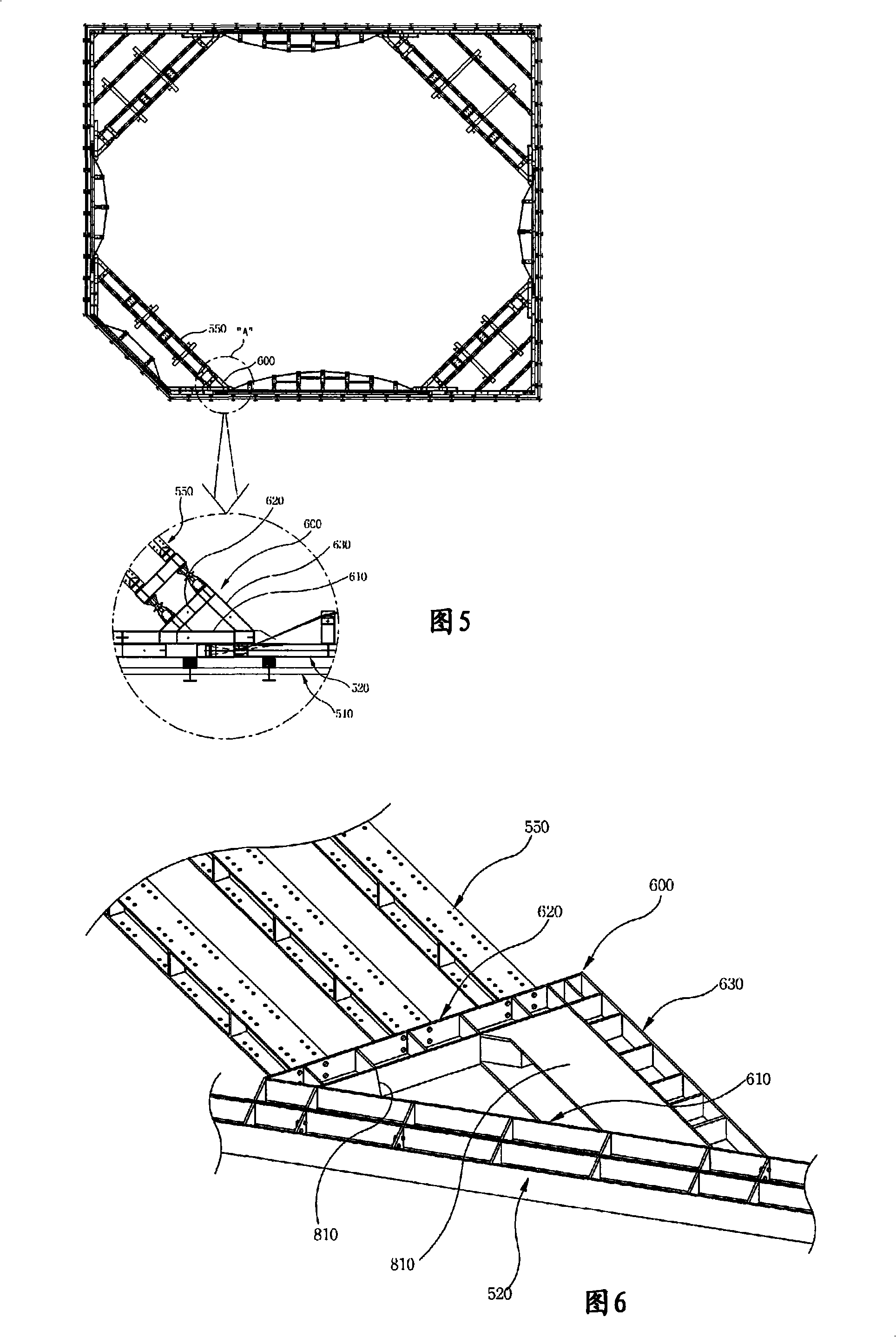

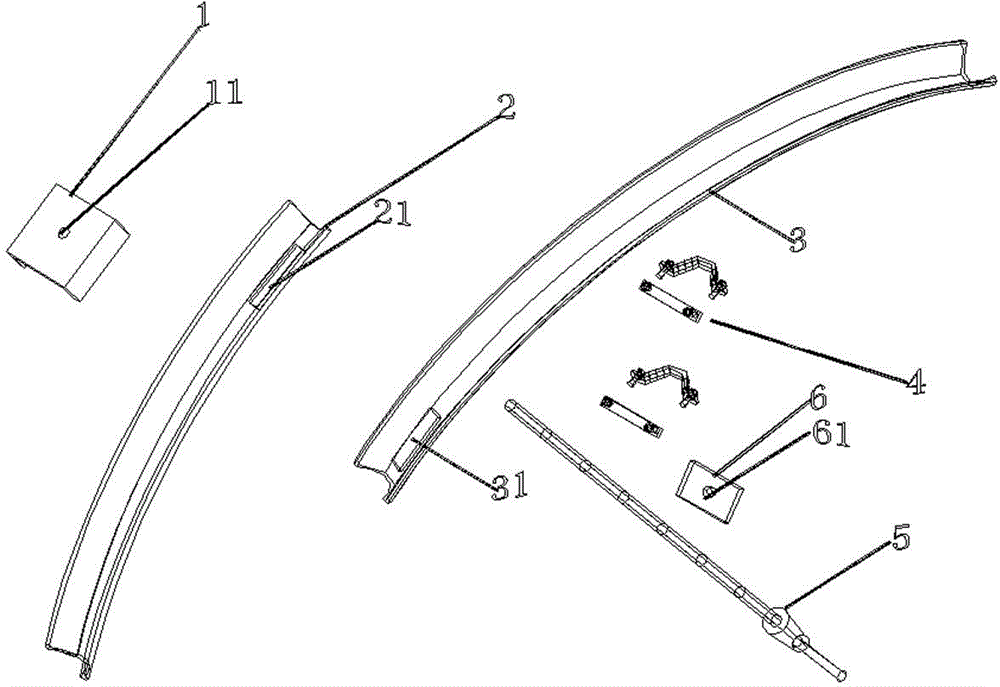

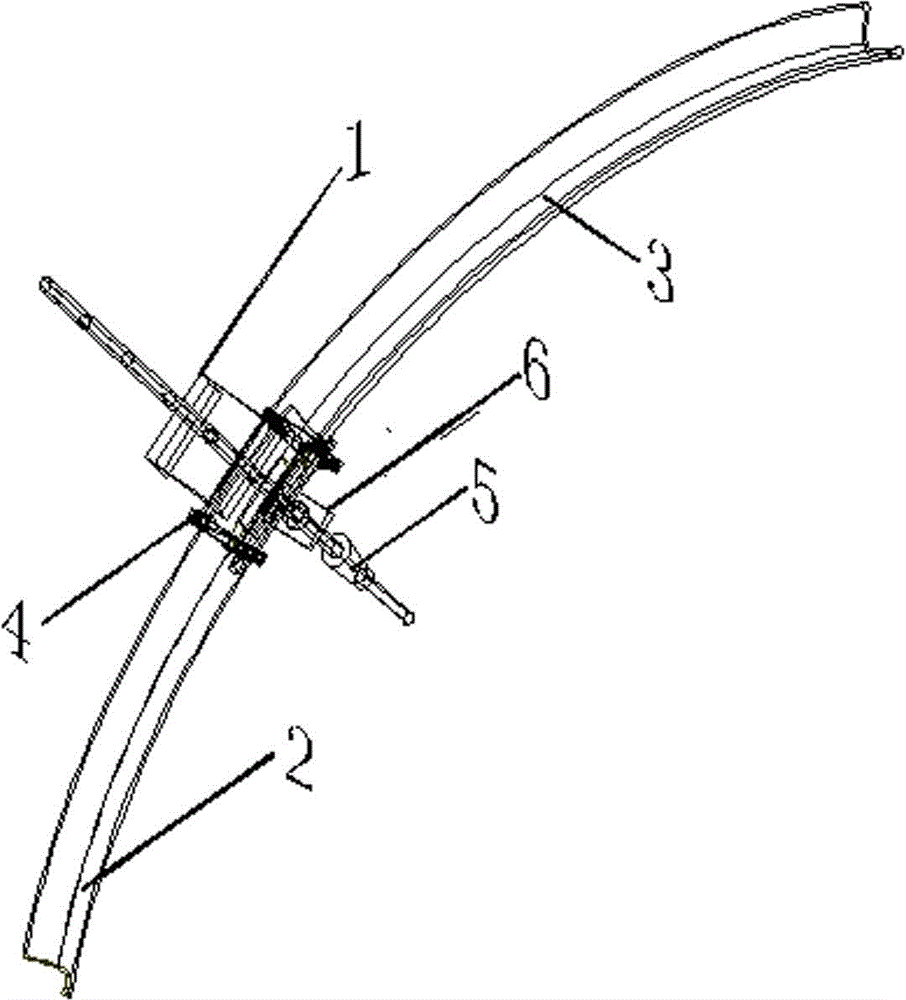

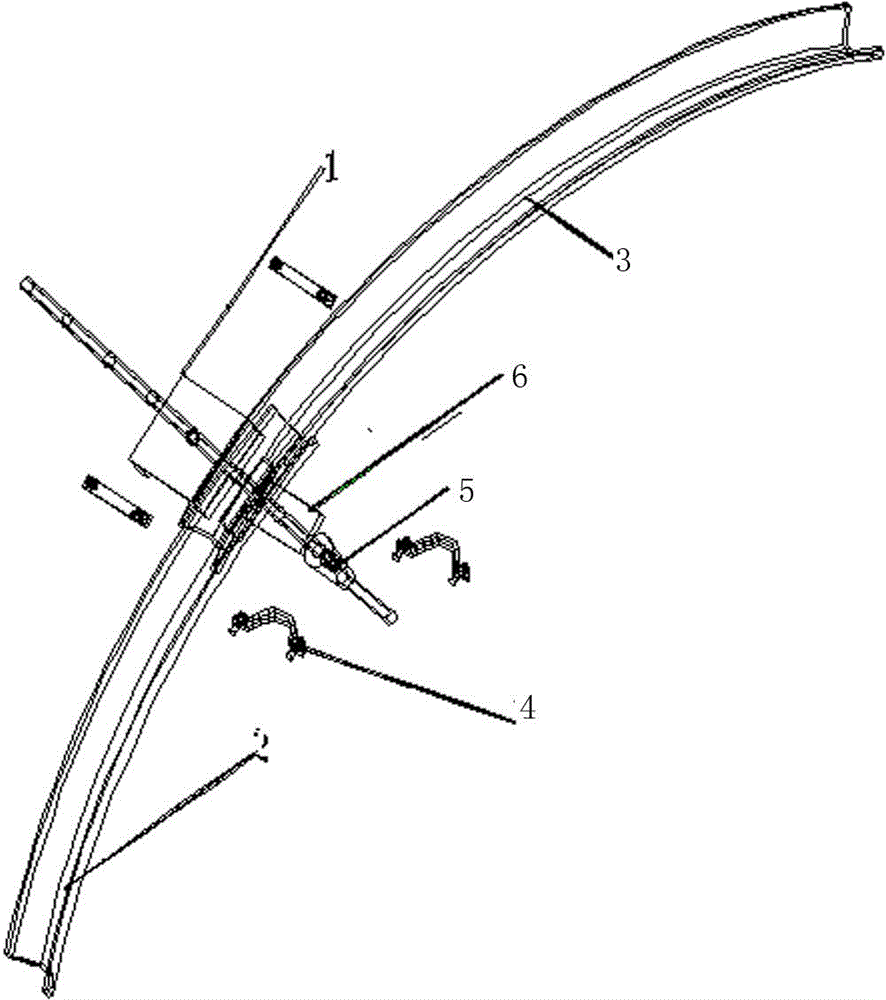

Temporary soil sheathing apparatus

A temporary soil sheathing apparatus supports a set of intermediate bracing beams in a triangular supporting structure during pit excavation work for constructing an underground structure, so that it can satisfactorily support soil pressure. Thus, it is possible to prevent space from being reduced by a complicated supporting structure, reduce construction costs through reduced use of materials, and increase work space to improve productivity. The temporary soil sheathing apparatus simplifies a corner connecting structure, and reinforces ability to withstand the soil pressure transmitted from the bracing beams and wales. Thereby, it is possible to prevent space from being reduced by a complicated supporting structure, reduce construction costs through reduced use of materials, and increase work space to thus improve productivity.

Owner:SUPPORTEC CO LTD

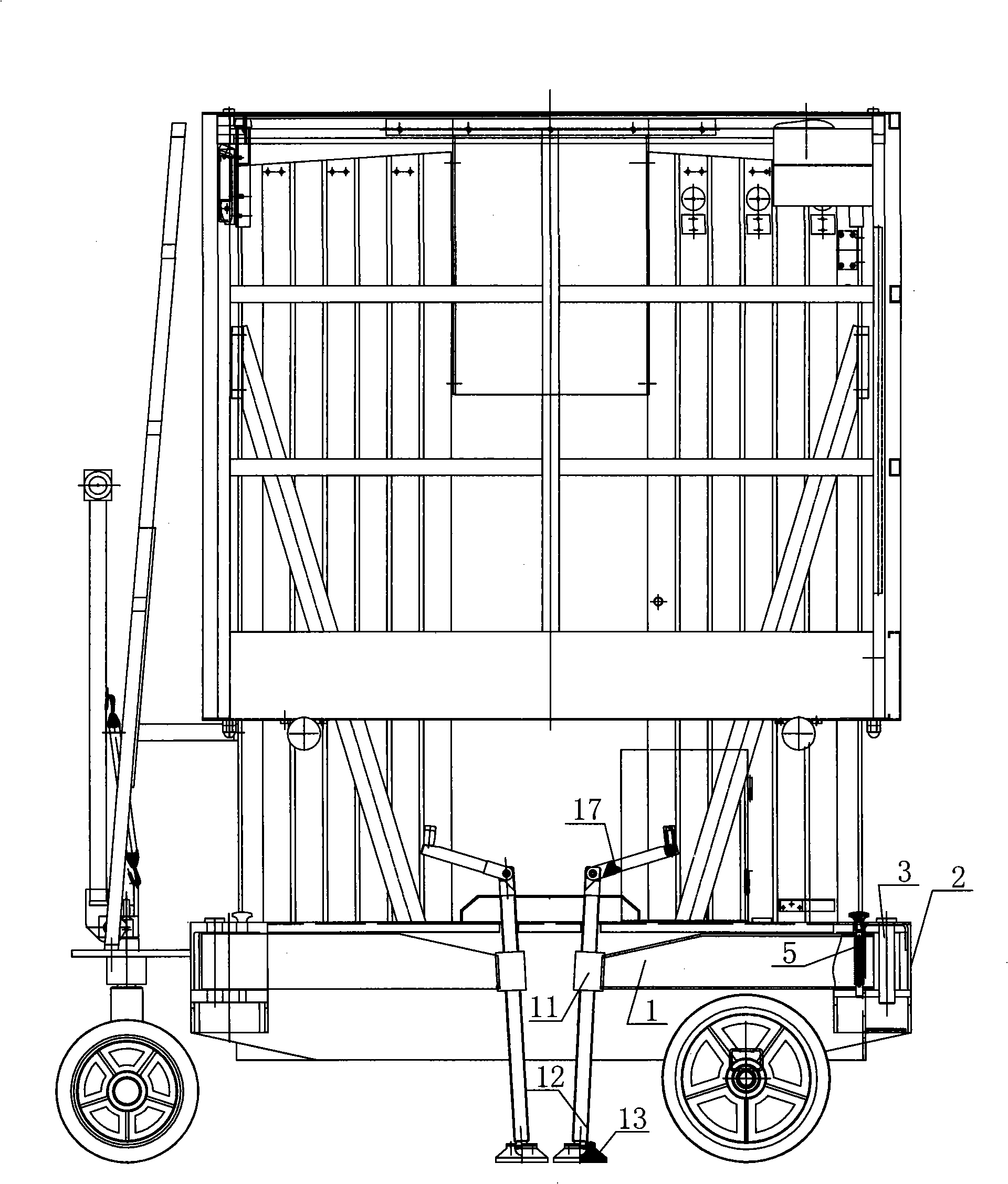

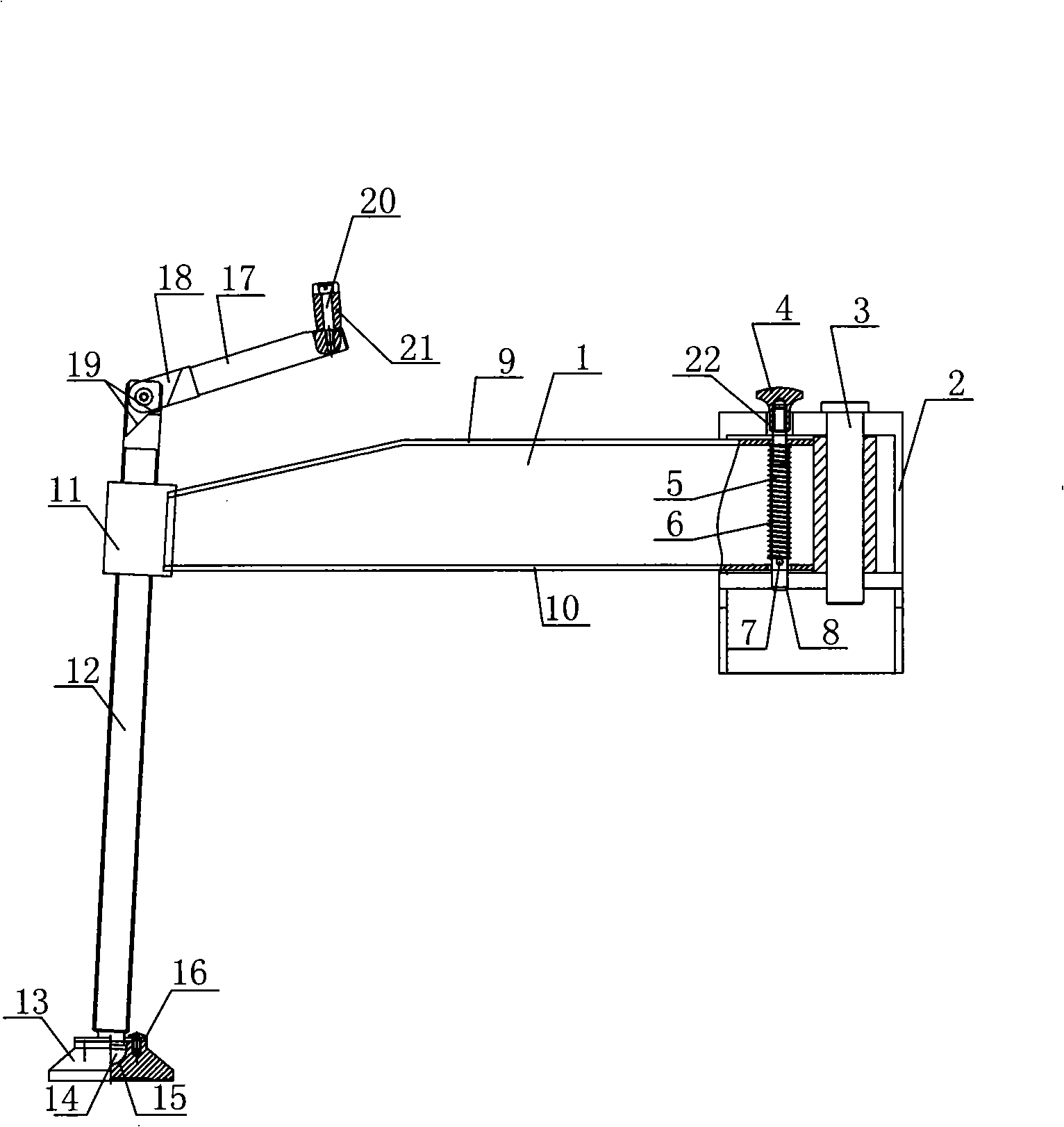

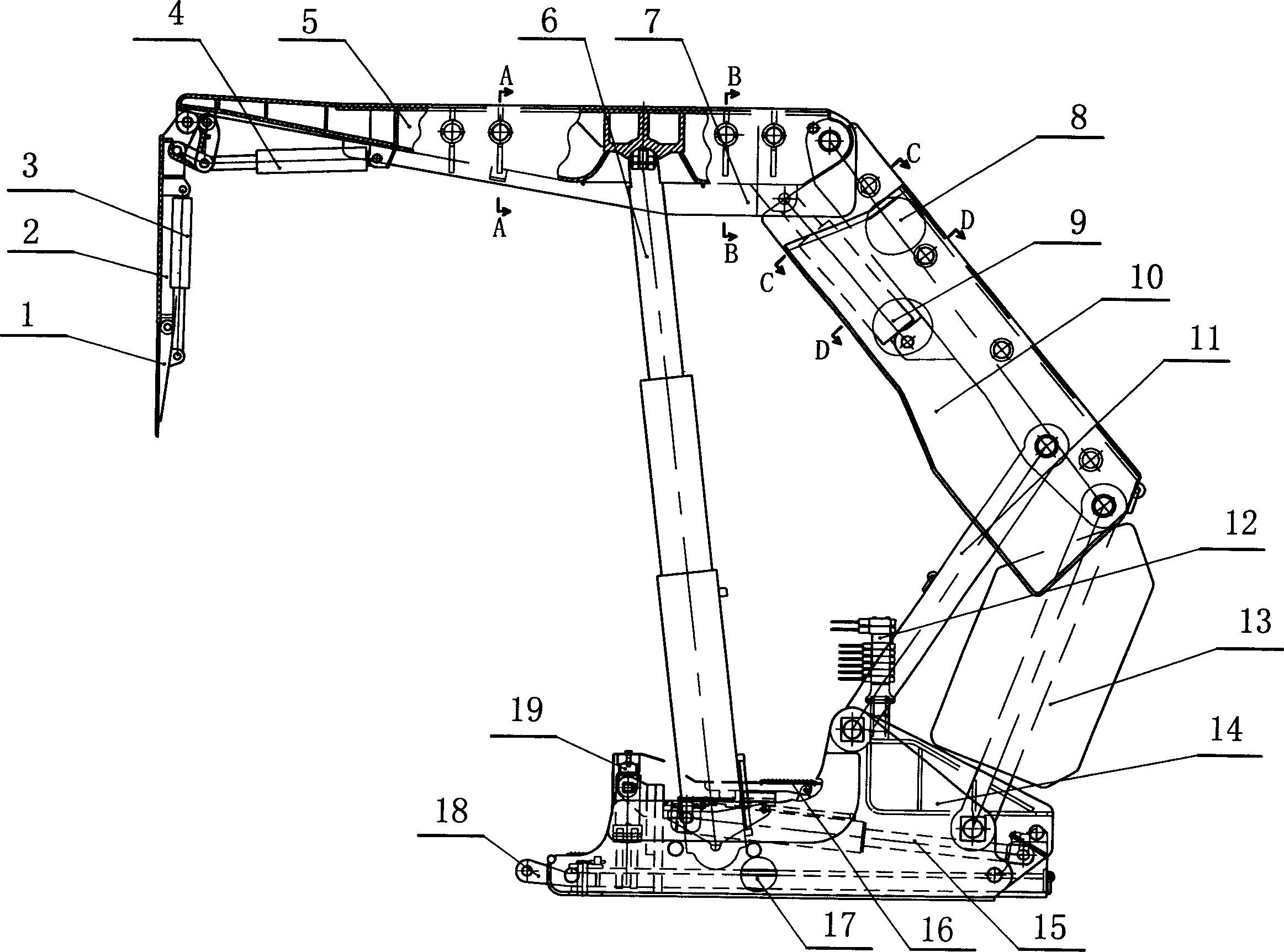

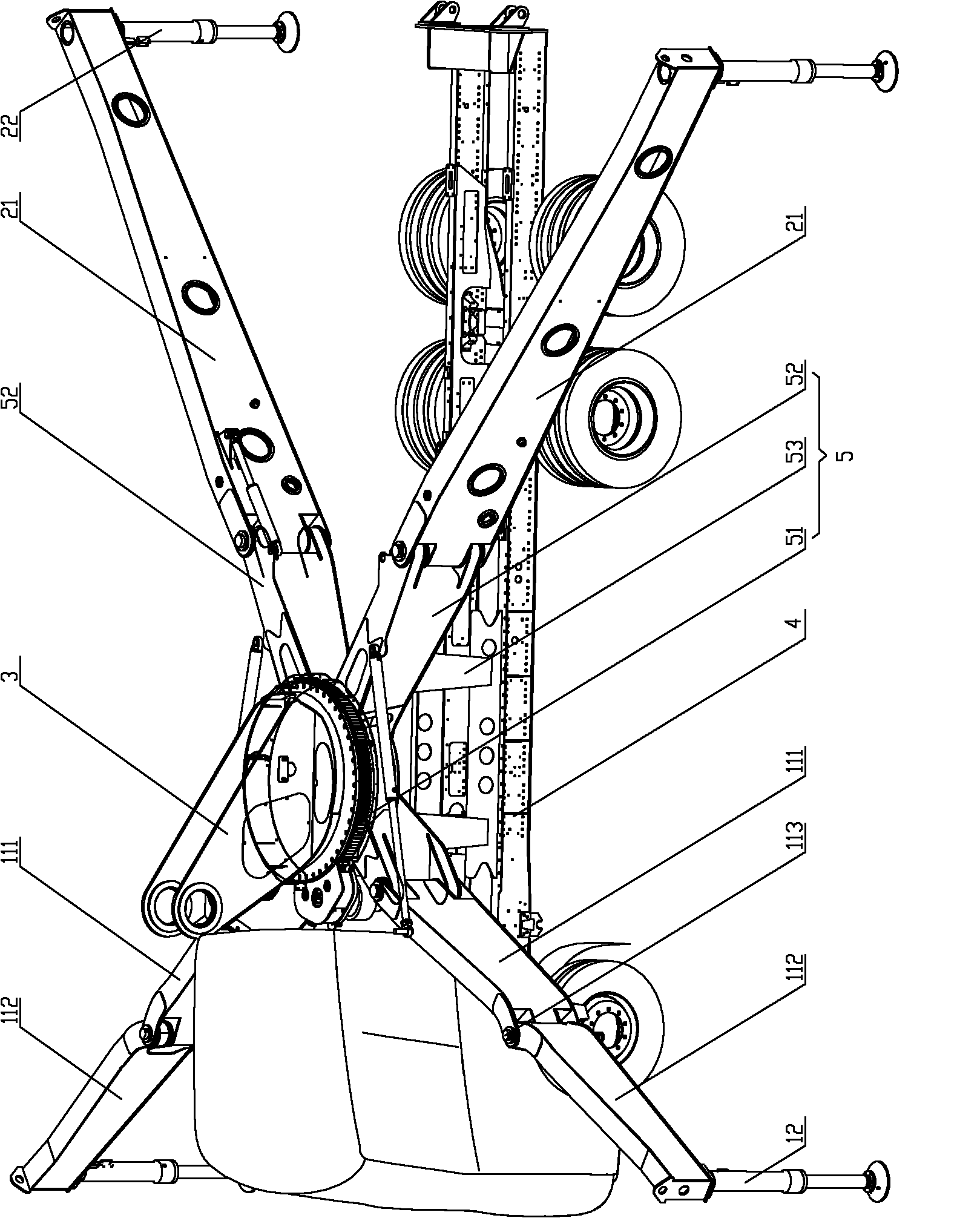

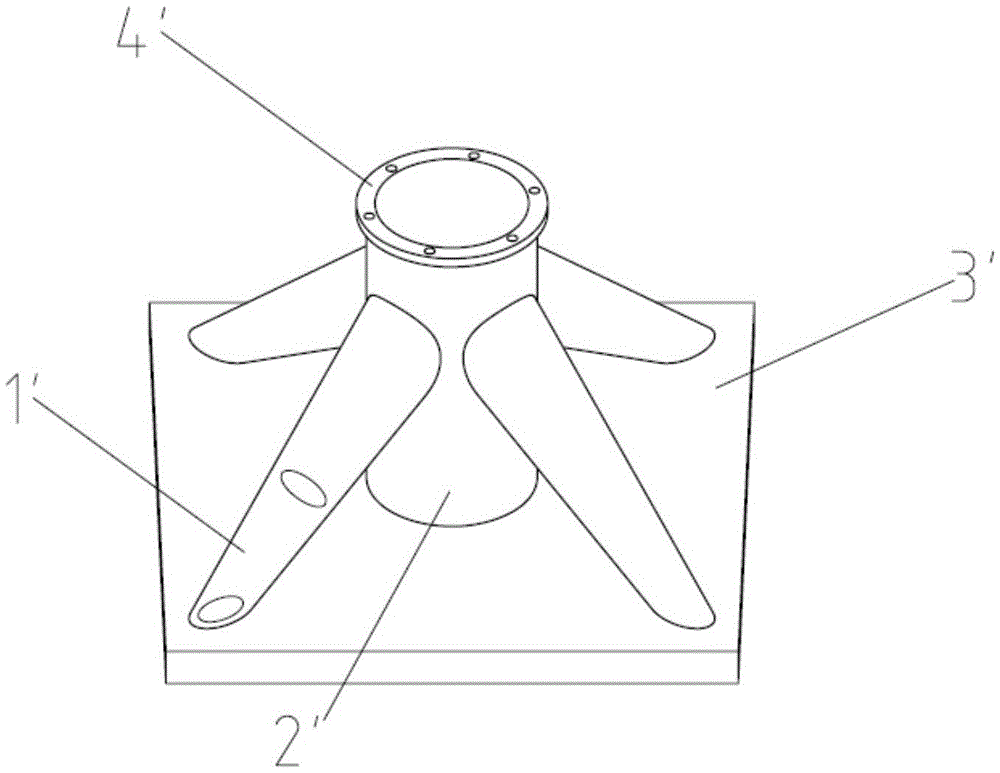

Tilt-proof and supported aerial platform

The invention relates to an aerial work platform, in particular to an aerial work platform with antiroll support devices. The antiroll supporting aerial work platform comprises a rack, a walking device, a lifting device and a work platform. The antiroll support devices are respectively arranged at the front and the rear parts on the two sides of the rack of the aerial work platform. Each of the antiroll support device comprises a pivoted arm, one end of the pivoted arm is pivotally connected on the rack through a rotating shaft, and a positioning device is arranged on the pivoted arm for positioning when the pivoted arm is folded; a turnbuckle is arranged on the other end of the pivoted arm, a screw is sleeved in the turnbuckle, a handle rod is arranged on the upper end of the screw, and a foot-stand is arranged on the lower end of the screw. 4 sets of antiroll support devices can be unfolded through the pivoted arm when in use, thereby enlarging the supporting area of the machine body and improving the stability of the machine body; when in nonuse, the support devices can be folded into the machine body, thereby causing no influence on the movement of the aerial work platform; the aerial work platform is characterized by simple structure and convenient usage.

Owner:ZHEJIANG DINGLI MACHINERY CO LTD

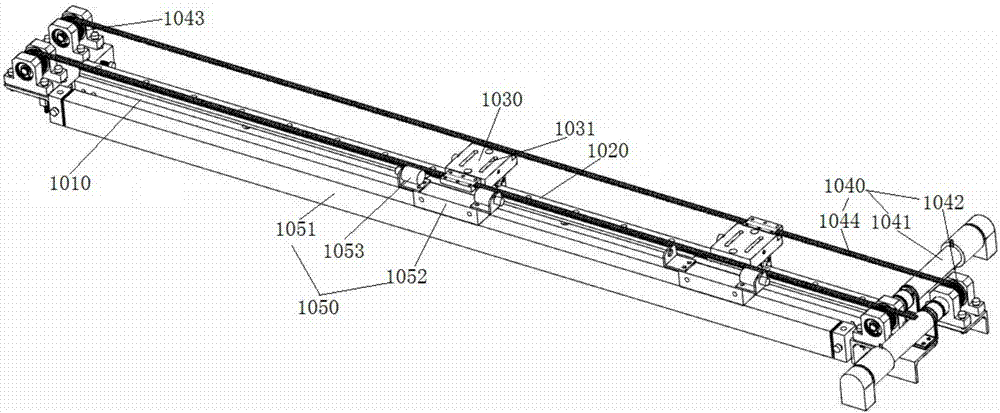

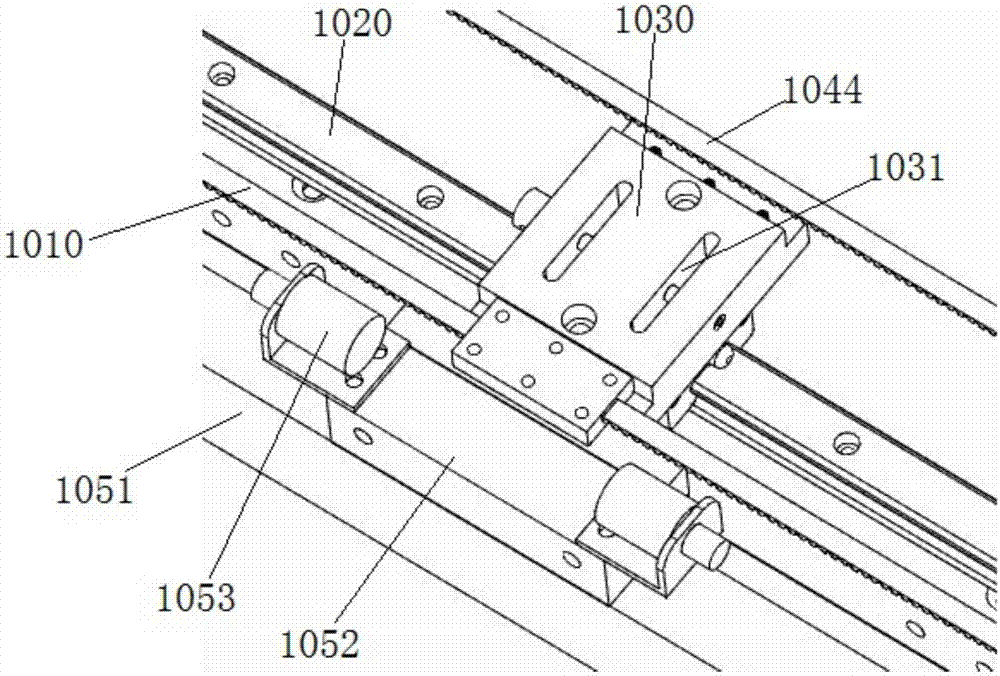

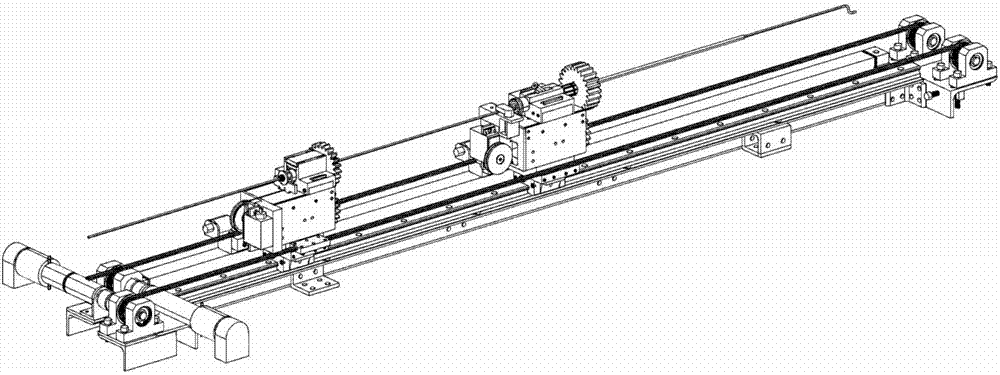

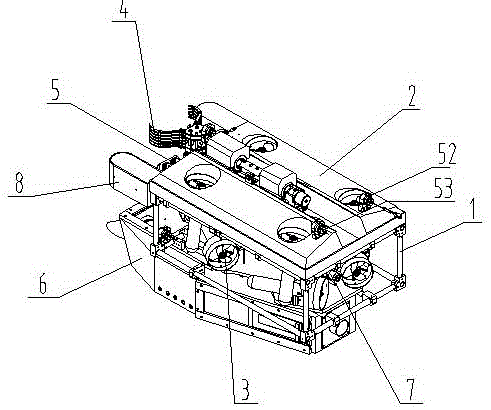

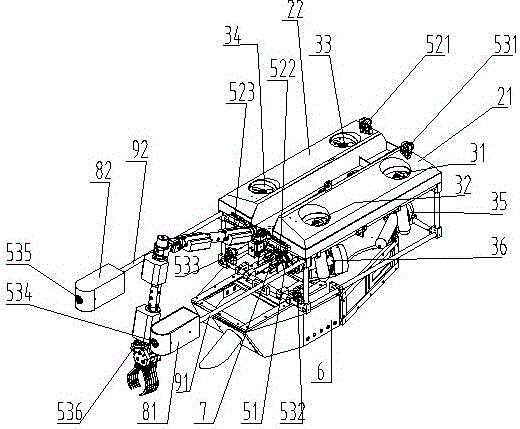

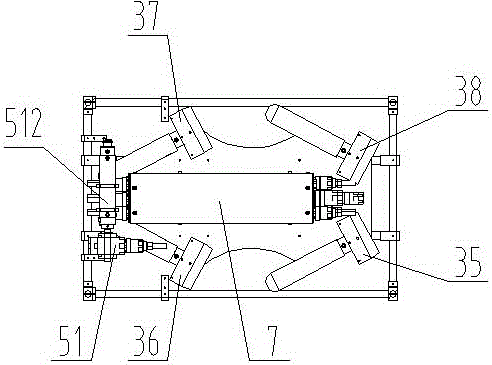

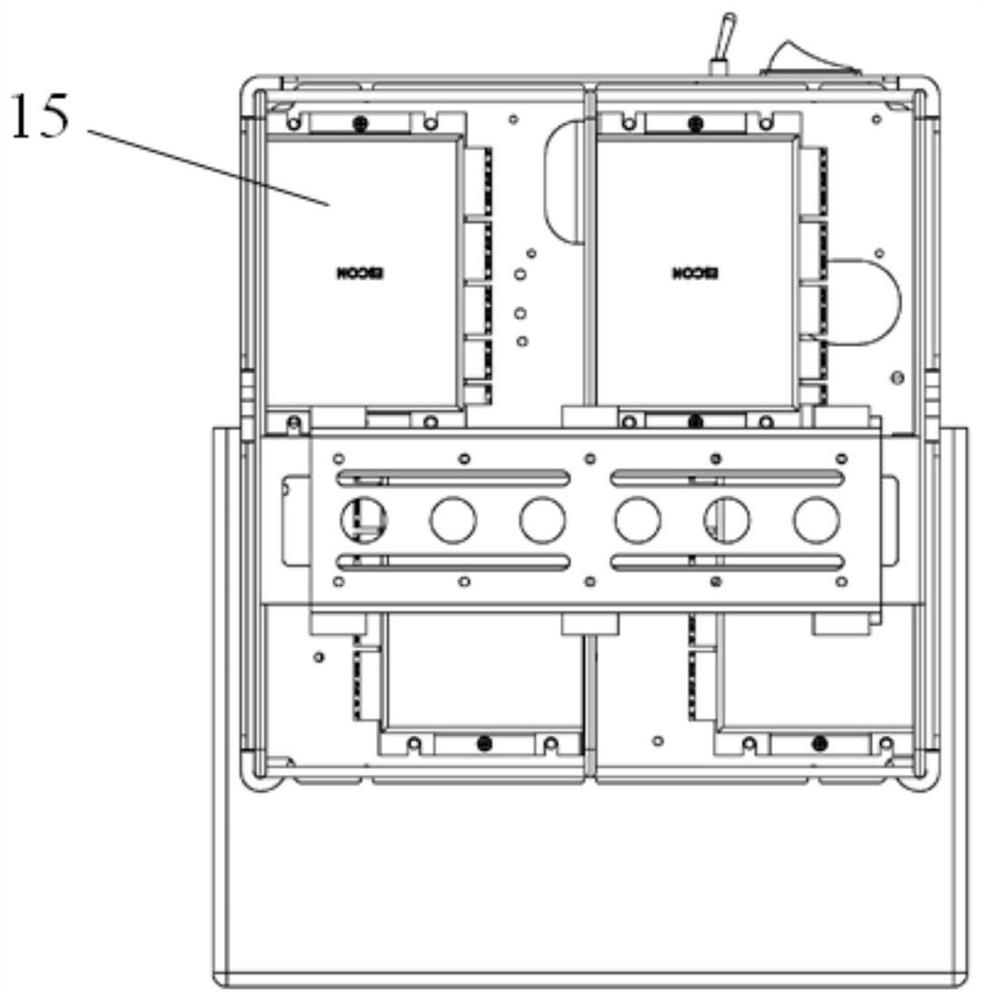

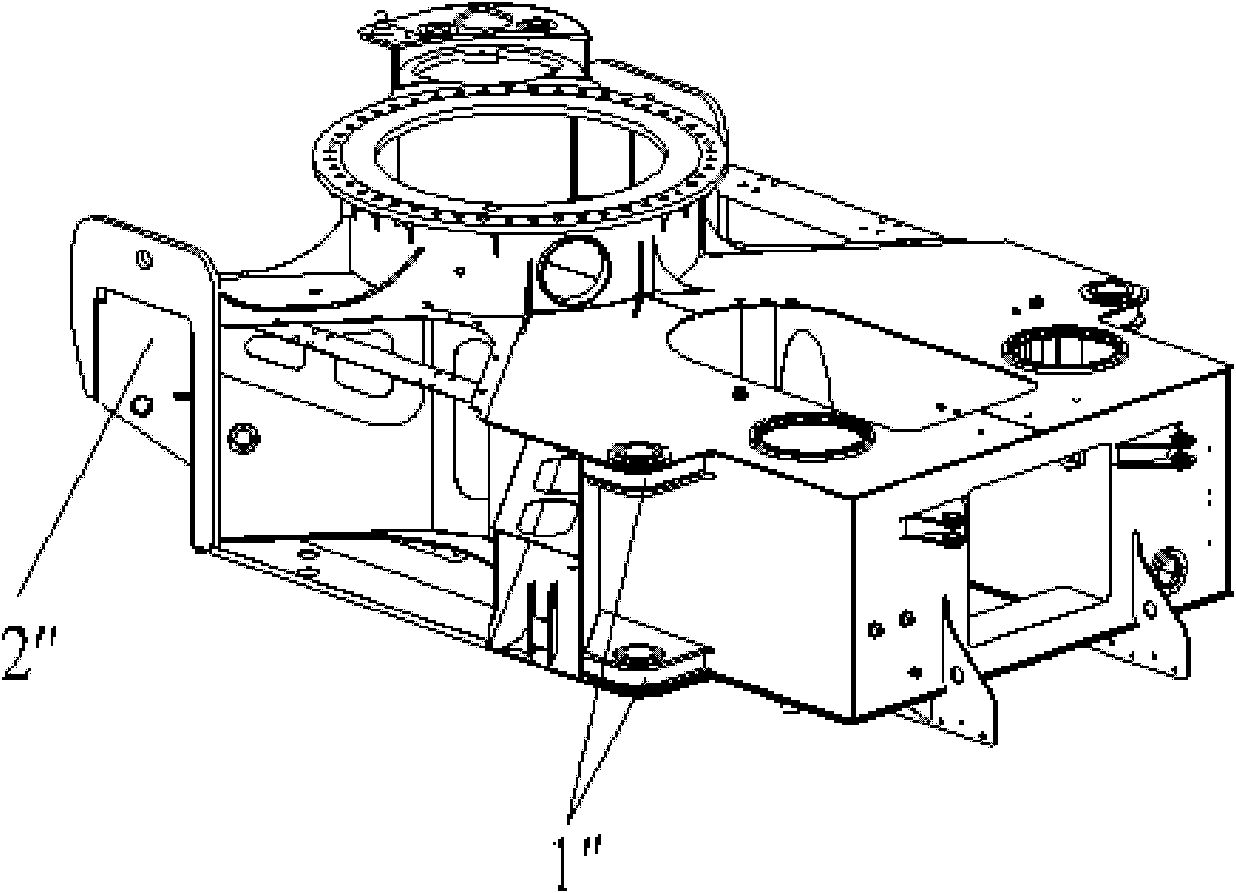

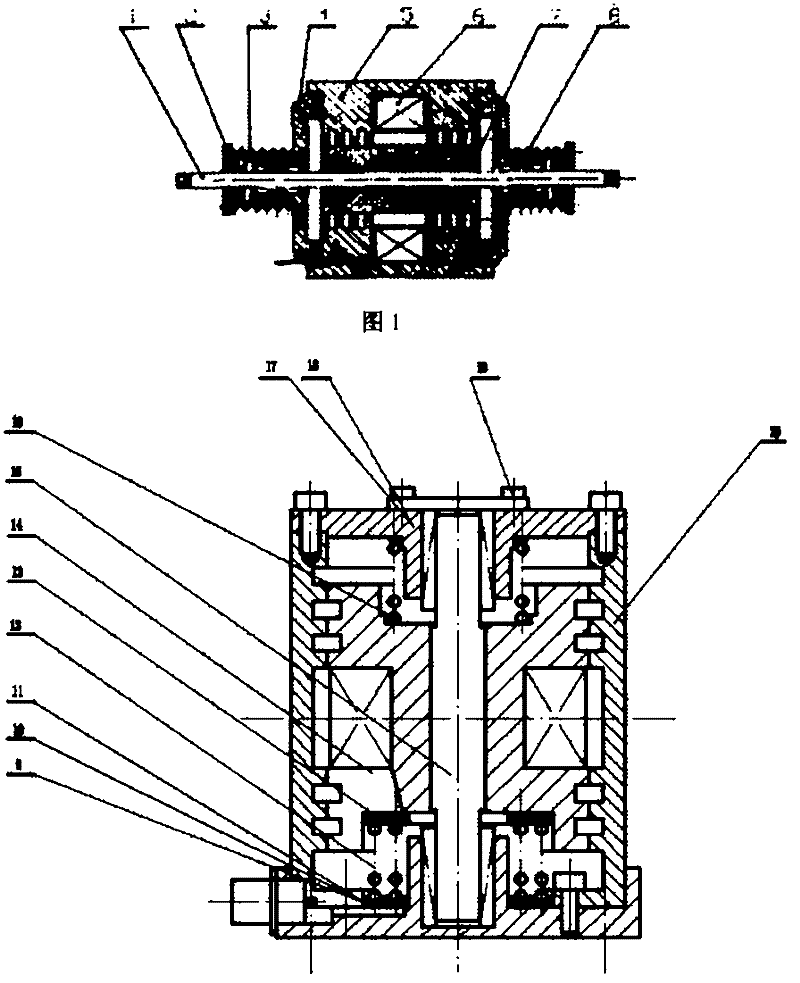

Interventional surgical robot subordinate end and mobile platform and control method of robot subordinate end

ActiveCN107374738AMeet the requirements for collaborative operationHigh transmission precisionDiagnosticsSurgical robotsSurgical robotThree vessels

The invention discloses an interventional surgical robot subordinate end and a mobile platform and a control method of the robot subordinate end and belongs to the technical field of minimally invasive blood vessel interventional operations. The mobile platform comprises a platform main beam, and platform connection blocks are arranged on the platform main beam through a linear guide rail pair D; the platform connection blocks are driven by a platform driving mechanism and used for installing a catheter controller or a guide wire controller. The interventional surgical robot subordinate end comprises the catheter controller, the guide wire controller and the mobile platform; the catheter controller and the guide wire controller are mounted on the two platform connection blocks respectively. According to the interventional surgical robot subordinate end, the catheter controller and the guide wire controller are installed on the mobile platform, and the problem is solved that it is difficult for an existing robot to complete co-operating of a catheter and a guide wire.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

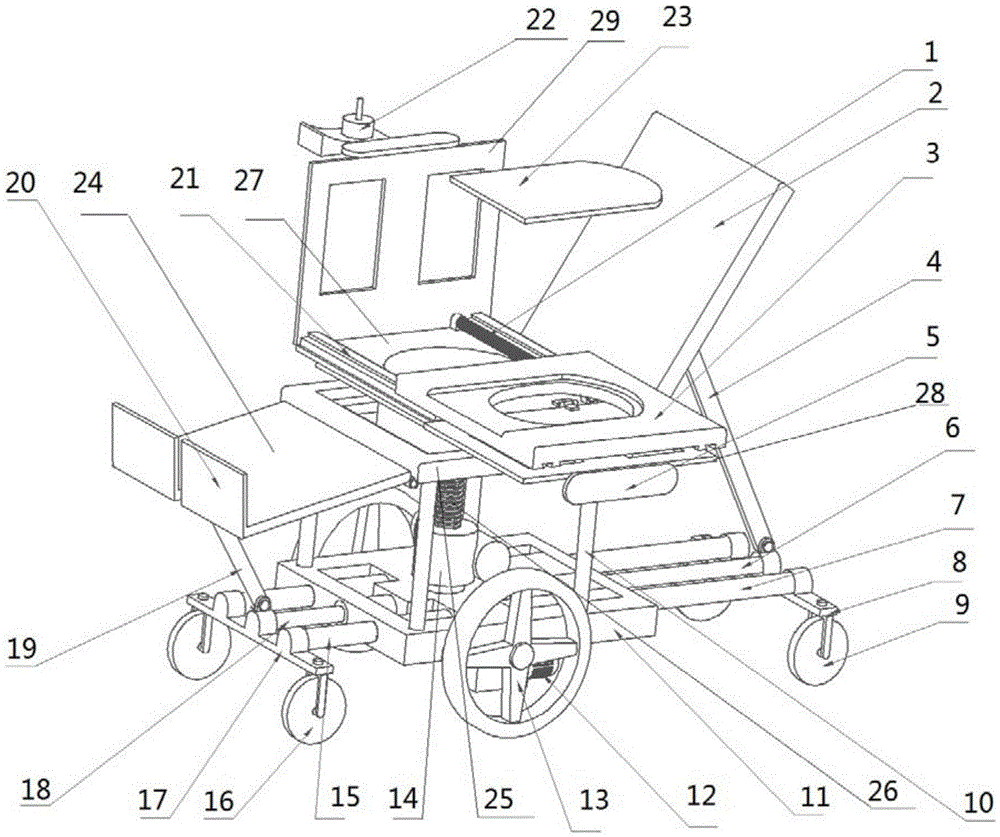

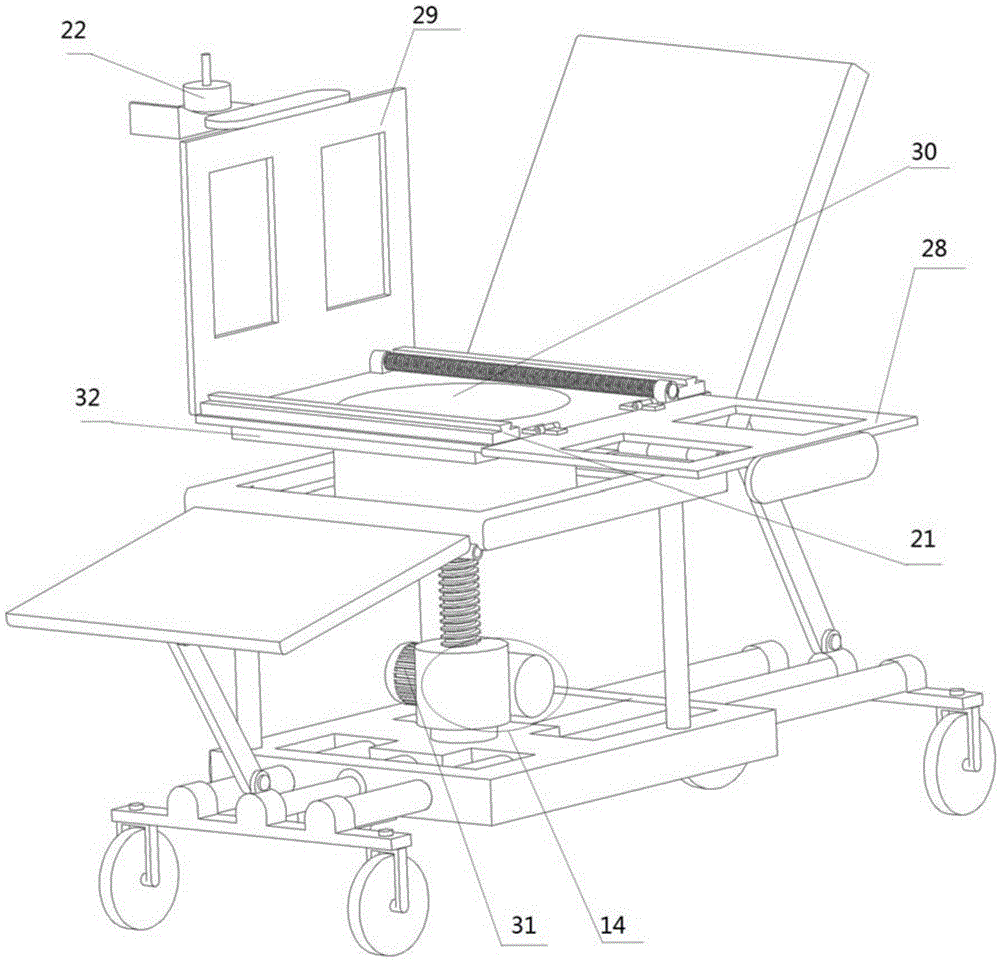

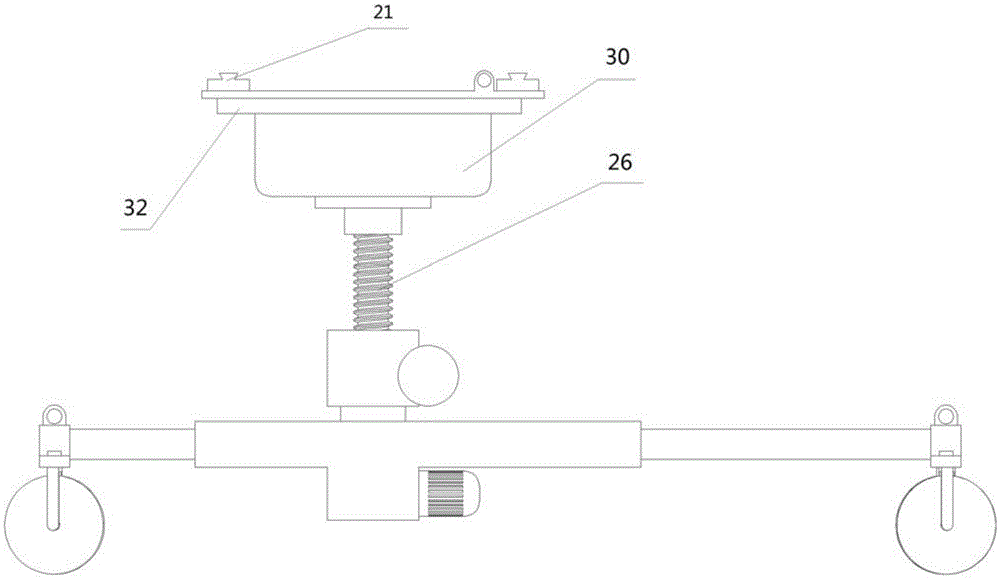

Multifunctional wheelchair capable of assisting patient to get in or out of bed and go to toilet

ActiveCN105640719AHeight adjustableReduce the burden onWheelchairs/patient conveyanceWheelchairEngineering

The invention aims to provide a multifunctional wheelchair capable of assisting a patient to get in or out of a bed and go to a toilet. The wheelchair mainly comprises a wheelchair body, a worm and gear lifting platform and a lateral movement mechanism. The wheelchair body consists of a wheelchair body base, a backrest, a leg supporting plate, wheels and a seat supporting plate, wherein a front and back wheel distance, a backrest angle and the leg supporting plate of the wheelchair can be synchronously adjusted. Two side armrest plates, a toilet device and a sliding rail are mounted on the lifting platform. The lateral movement mechanism consists of a first electric screw rod, a guide rail and a seat cushion sliding block. According to the wheelchair, the height of a seat can be adjusted to adapt to beds with different heights when the patient gets in or out of the bed, the patient can go to the toilet by the wheelchair, and the wheelchair can be folded into a chair or unfolded into a bed, so that the working burden of medical personnel and the physical burden of the patient are greatly reduced.

Owner:HARBIN ENG UNIV

Telemetric tibial tray

ActiveUS7470288B2Maximizes load-bearing areaSacrificing flex responsivenessSurgeryPerson identificationTibiaSagittal plane

A telemetric tibial tray includes a lower plate that defines a plurality of cylindrical transducer cavities having circular load diaphragms. An upper plate is attached to the lower plate through support posts projecting from the load diaphragms. The support posts have a circular cross-section and a diameter of about 5.0 mm. The lower plate further defines wiring channels communicating between the transducer cavities and a central cavity housing the circuit board for the telemetric tray. The wiring channels are arranged at a 45 degree angle relative to the sagittal plane of the knee joint in order to reduce the effects of the wiring channel intersection on the strain sensitivity of the tray. Each transducer cavity includes a radial strain gage array with four pairs of radially aligned strain gages, each pair aligned at a 45 degree angle relative to the sagittal plane of the knee joint. Each pair of strain gages includes an inner gage positioned at the point of maximum positive micro-strain across the diaphragm when loaded, and an outer gage positioned at the point of maximum negative micro-strain, to thereby increase the differential strain measured by the gages and increase the strain sensitivity of the tibial tray.

Owner:DEPUY PROD INC

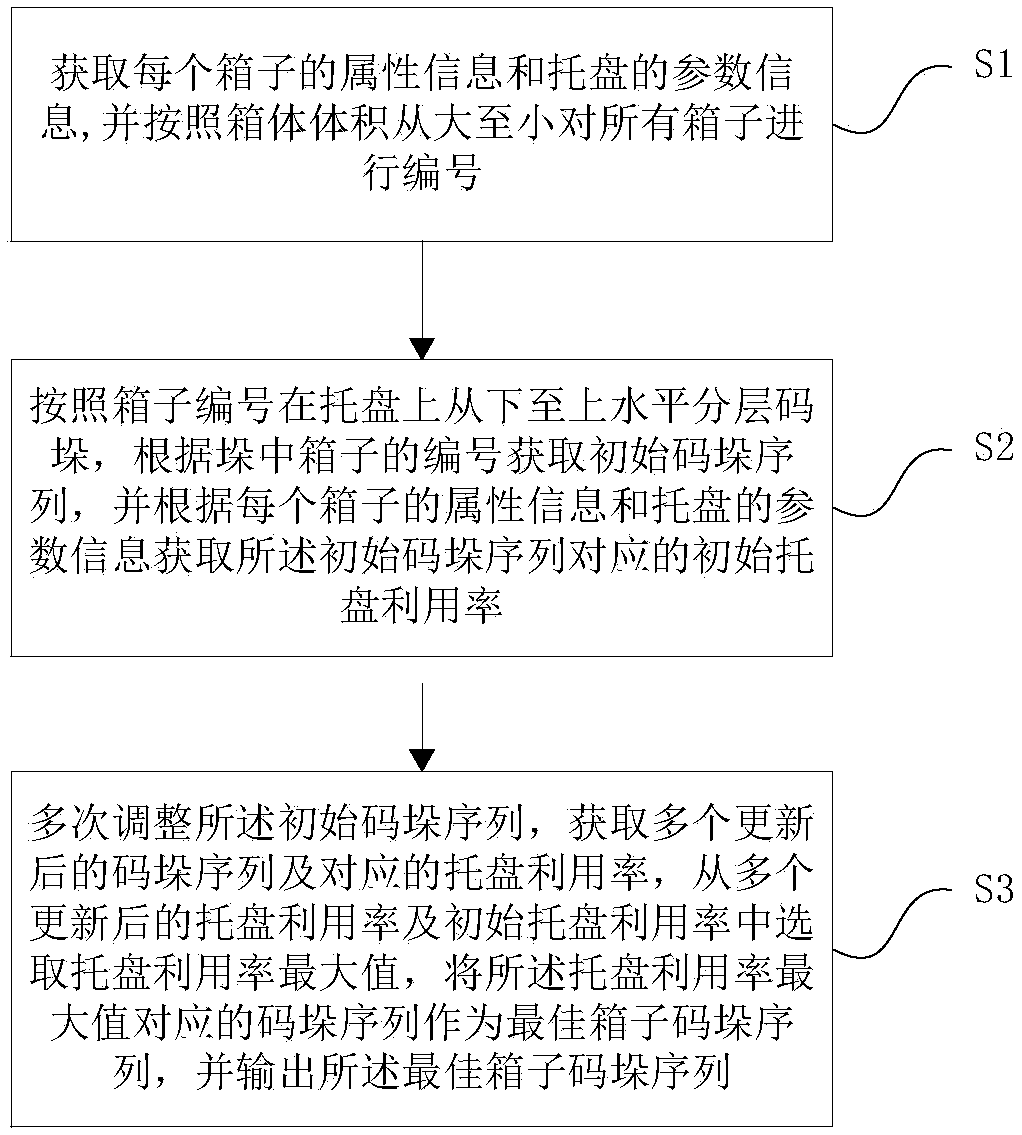

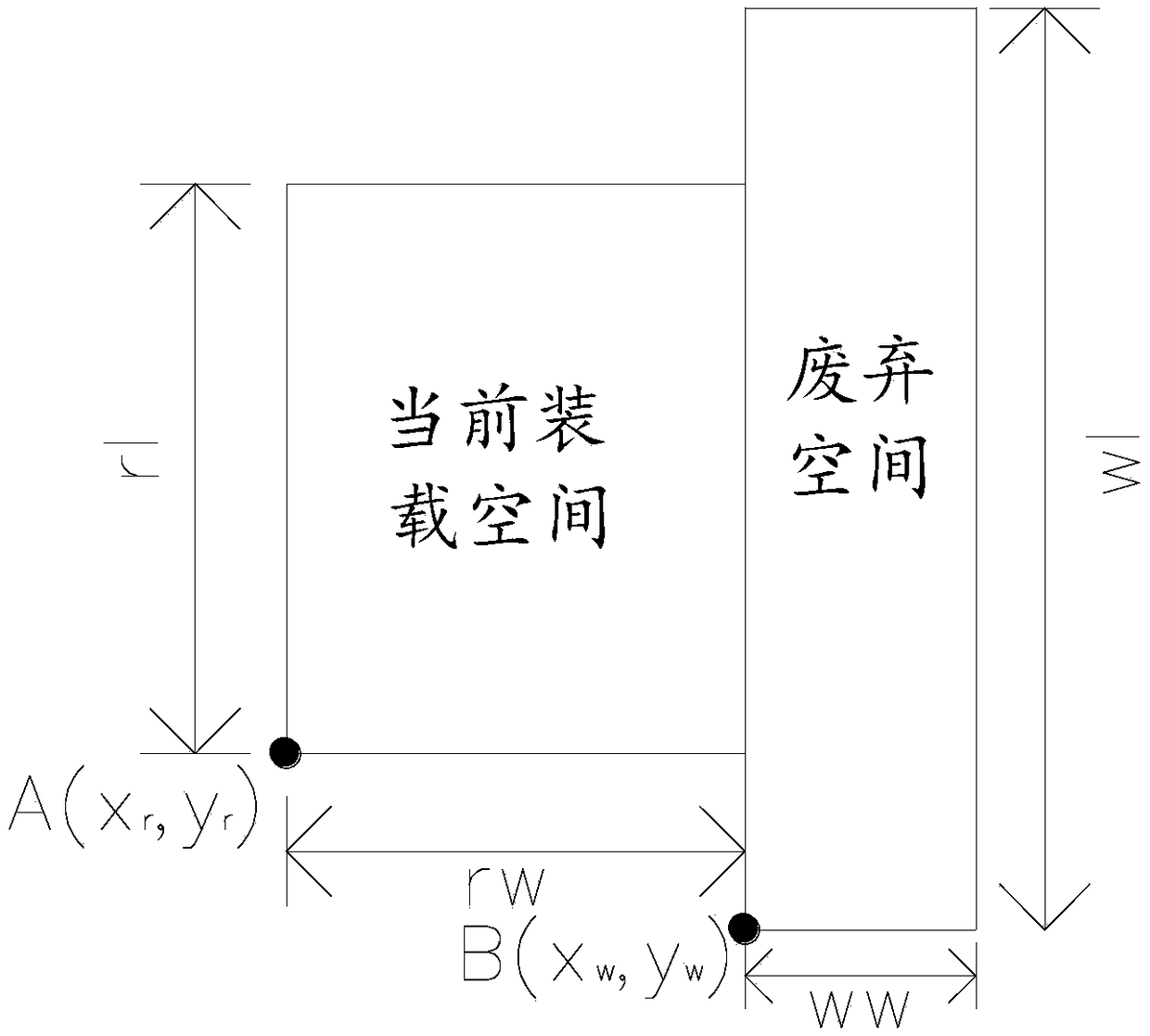

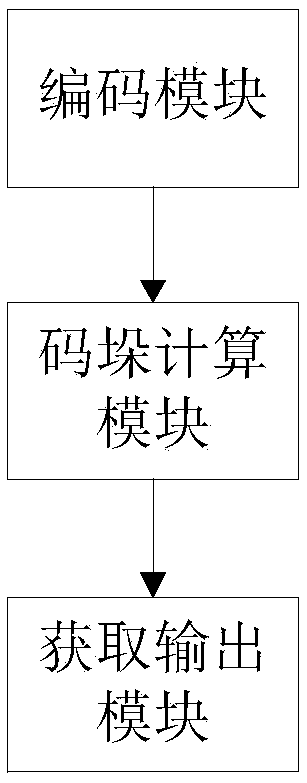

Offline hybrid stacking method and system

ActiveCN108750685AEnsure stack stabilityRealize horizontal layered palletizingConveyorsStacking articlesEngineeringUtilization rate

The invention relates to an offline hybrid stacking method and system. The method comprises the steps of acquiring the attribute information of each box and the parameter information of a tray, and numbering all boxes according to the volumes of the boxes from big to small; stacking the boxes on the tray from bottom to top according to the number of the boxes in a layered manner, and acquiring aninitial stacking sequence and the utilization rate of a corresponding initial tray; regulating the initial stacking sequence for many times, and acquiring the maximum value of the tray utilization rate; and taking the stacking sequence corresponding to the maximum value of the tray utilization rate as the optimal stacking sequence of the boxes, and output the optimal stacking sequence. According to the offline hybrid stacking method, cuboid boxes of different sizes can be stacked in a hybrid manner, and the stacking stability can be ensured; the horizontal layered stacking is achieved, and theoffline hybrid stacking method has the advantages that the stacking stability is high, and the stacking by a robot is facilitated; the utilization rate of the tray is high, etc., and the automation and intelligence of the hybrid stacking process are achieved.

Owner:哈尔滨库柏特科技有限公司

Manipulator backpack type underwater robot

A manipulator backpack type underwater robot is composed of a main body frame, a buoyancy block system, a multi-joint manipulator, a collection box system, a control cabinet, an auxiliary adjusting buoyancy block system, a propeller system and a shooting and illuminating system. The whole manipulator backpack type underwater robot is arranged in a horizontal compressed mode, and continuous operation is facilitated; the eight-propeller power system is adopted so that the robot can reach a working zone more conveniently and rapidly; through the auxiliary adjusting buoyancy block system and extension-length-adjustable push-pull rods matched with the auxiliary adjusting buoyancy block system, the robot can adapt to the complex underwater working environment; the shooting and illuminating system similar to binocular vision is adopted for the working zone, so that the working zone is more tridimensional and visual, and the manipulator can perform operation conveniently and accurately; the multi-joint design is adopted for the manipulator, so that the manipulator is more flexible and can grab and place objects more conveniently, and the working range is relatively enlarged; and the manipulator can be folded or unfolded, so that the space utilization rate is improved.

Owner:远洋探海机器人东台有限公司

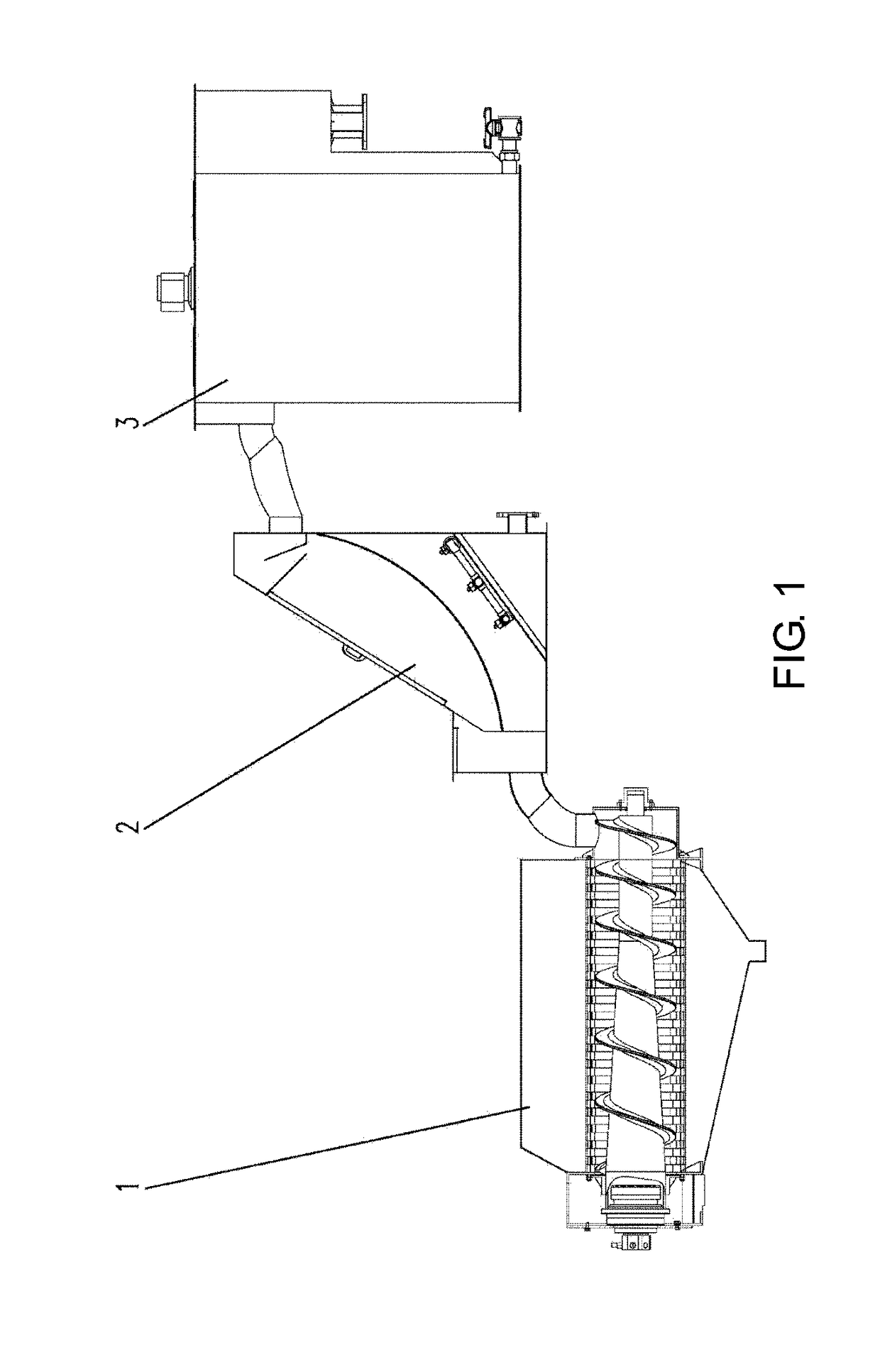

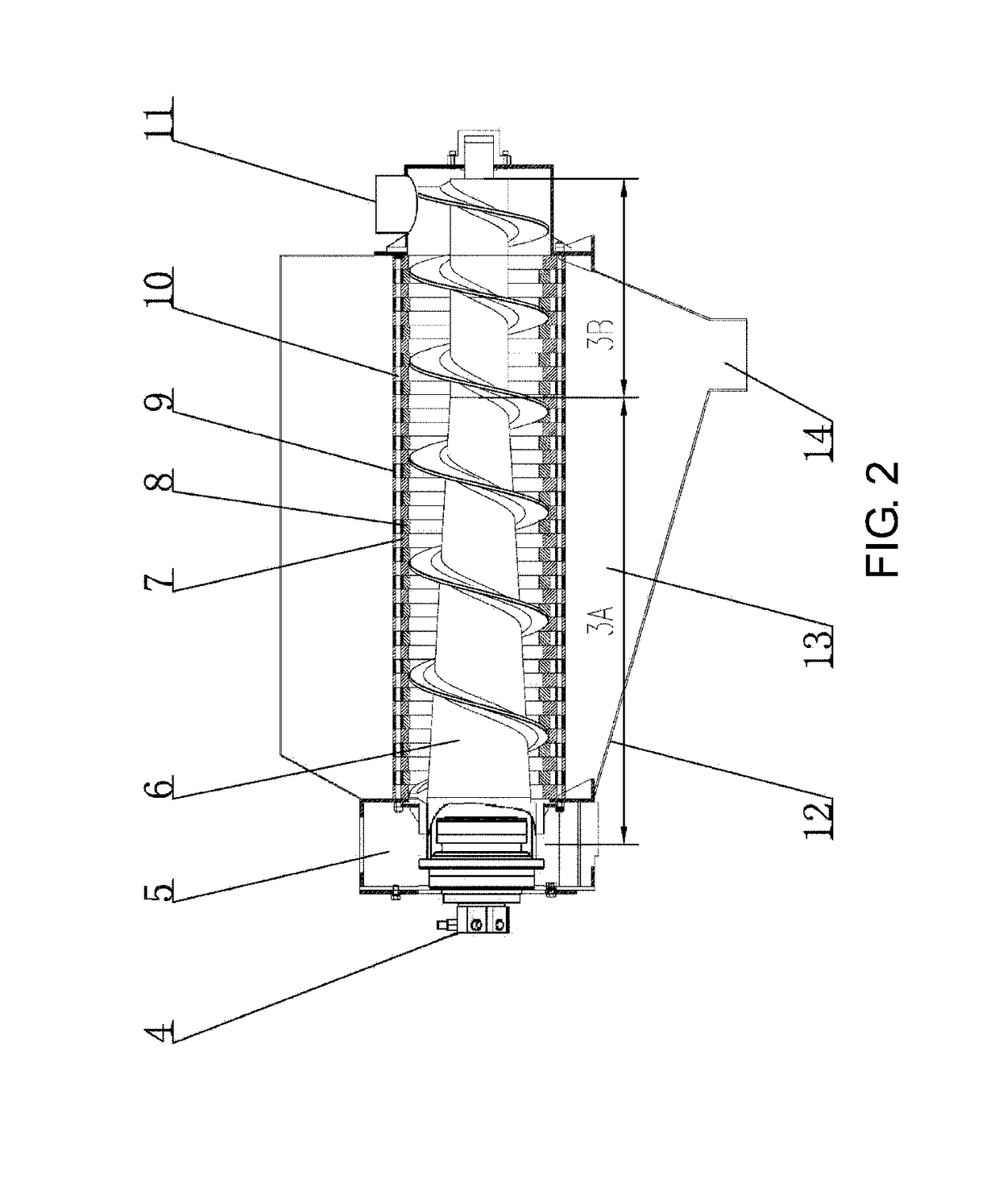

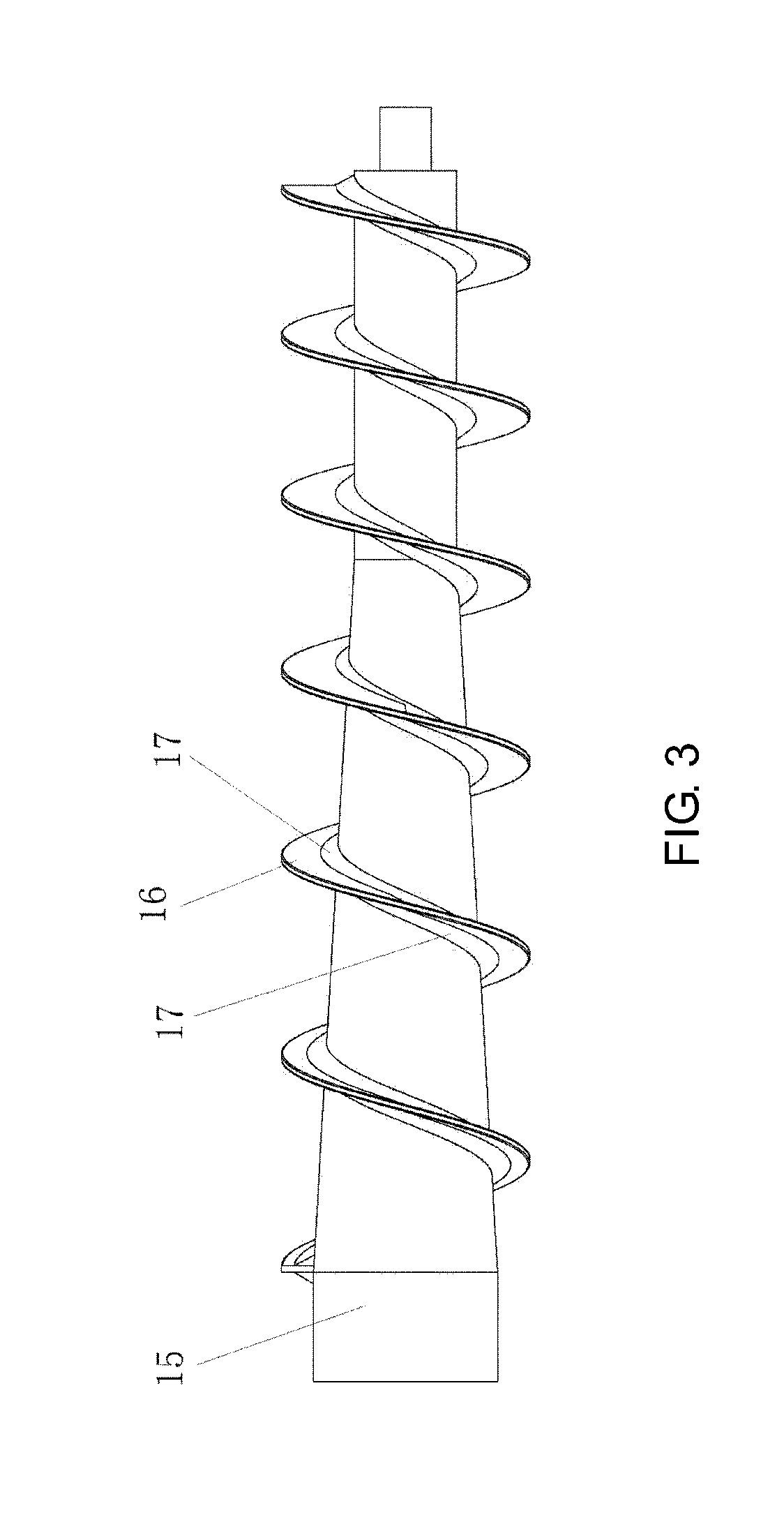

Multi plate screw press sludge dewatering machine

ActiveUS20180346362A1Convenience to workReduced footprintSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesHelical scanHelical blade

The present invention provides a multi plate screw press sludge dewatering machine and a helical shaft thereof. The multi plate screw press sludge dewatering machine includes fixed rings, movable rings, the helical shaft, a sludge inlet tank and a sludge discharging tank; the helical shaft adopts a variable diameter variable pitch helical shaft, a lead angle arrangement sequence of a helical blade of the whole helical shaft is gradual reduction from the sludge discharging tank to the sludge inlet tank, and the lead angle arrangement sequence is gradually reduced from 16°-22° to 6°-14°; a pitch of the helical shaft is gradually increased along a direction from the sludge inlet tank to the sludge discharging tank; a diameter of a shaft body of the helical shaft is gradually increased along with a direction of the sludge discharging tank from a ⅓ position of a shaft length; and blockage prevention plates are arranged on two sides of the bottom of the helical blade. The helical shaft in the present invention is specially designed, so that the pitch is more reasonable, a helical angle is gentler, frictional resistance when sludge passes through the helical shaft may be effectively reduced, and phenomena of shaft blockage and shaft sticking of the sludge may be reduced.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

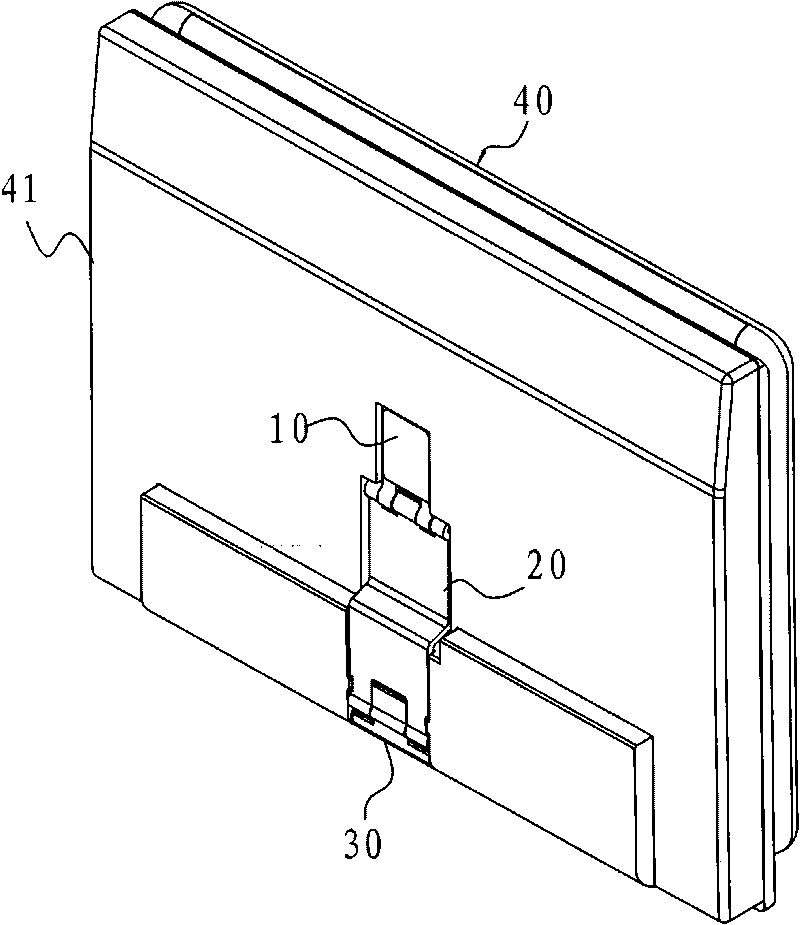

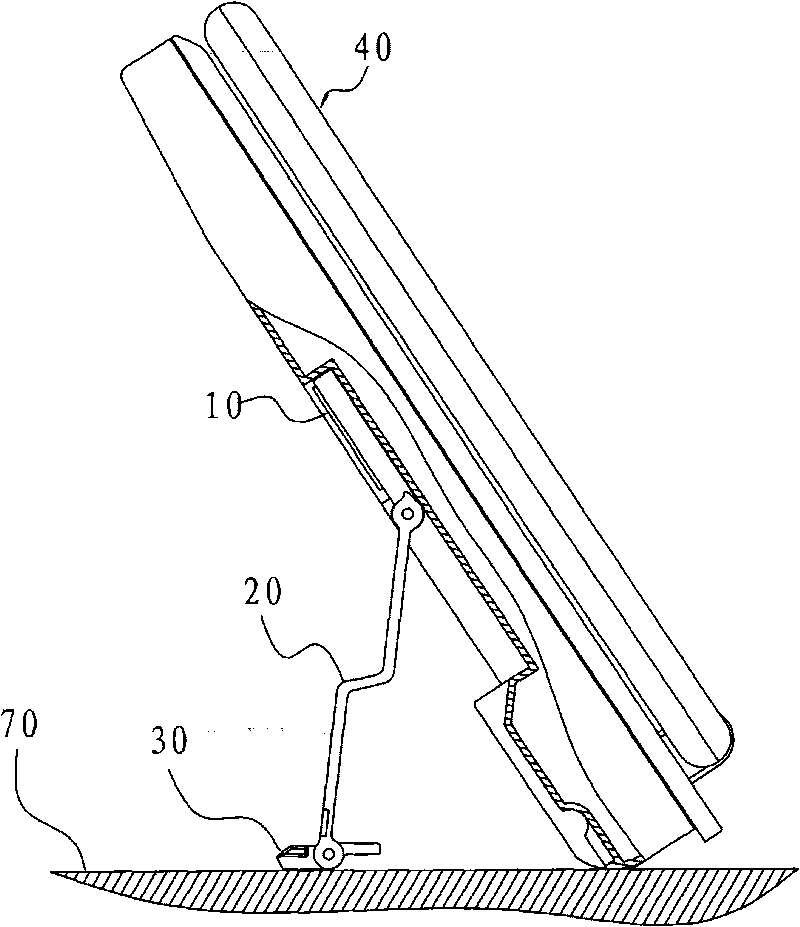

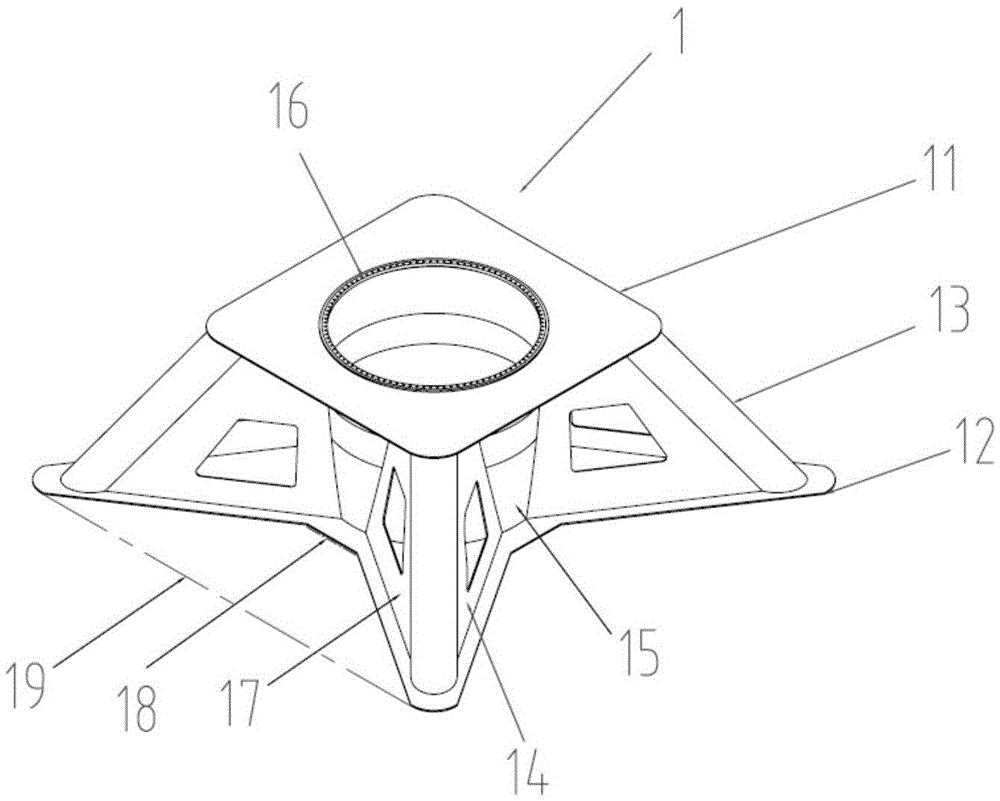

Electronic device with magnetic supporting foot rack

ActiveCN101751074AImprove stabilityEasy to useDigital data processing detailsStands/trestlesEngineeringMagnetic components

The invention relates to an electronic device with a magnetic supporting foot rack, which comprises an electronic device machine body and the magnetic supporting foot rack. The magnetic supporting foot rack comprises a magnetic element, a connecting rod and a foot rack. The magnetic element is absorbed at the back face of the electronic device machine body, one end of the connecting rod is pivoted at the magnetic element, and the foot rack is pivoted at the other end of the connecting rod. Under the function of the connecting rod, the foot rack is placed at the storing position at the back face of the electronic device machine body; under the function of the linkage of the connecting rod, the foot rack is stretched to the supporting position that can support the electronic device machine body; when the foot rack is placed at the supporting device and the load of the electronic device is over high, the magnetic element can be separated from the electronic device machine body so as to prevent the foot rack and the connecting rod from being permanently damaged.

Owner:ASUSTEK COMPUTER INC

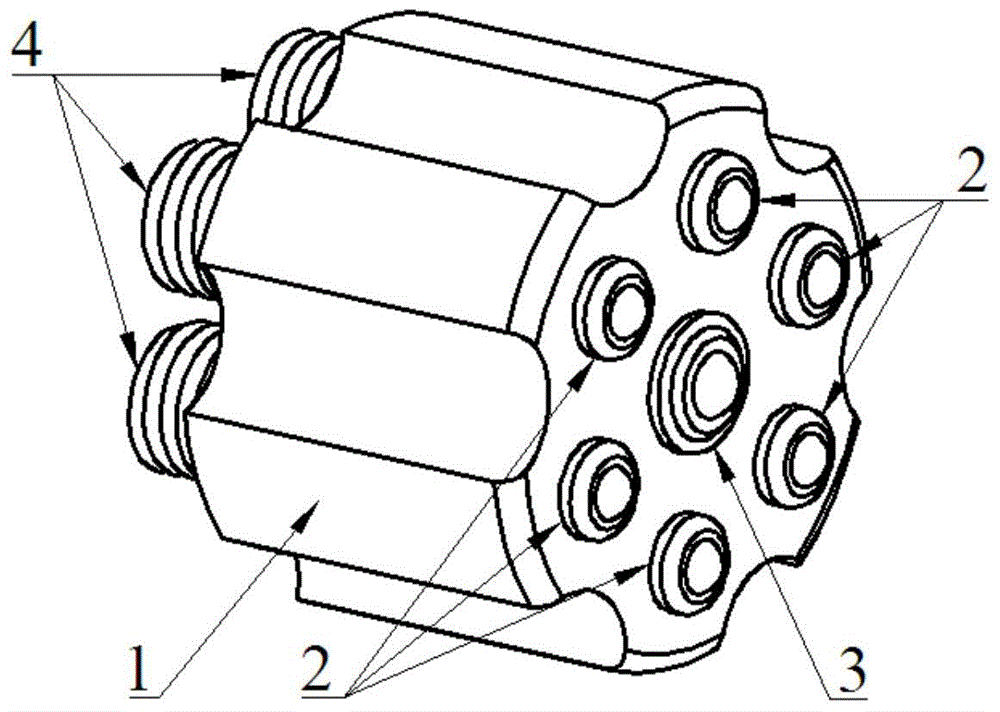

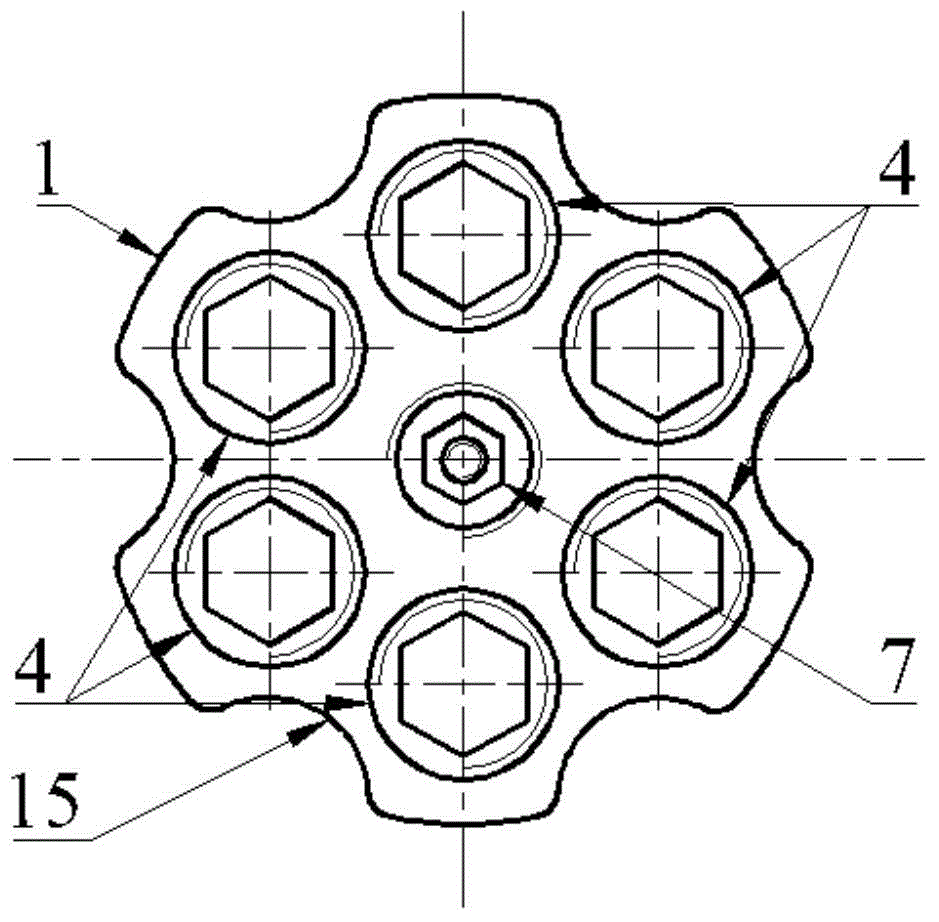

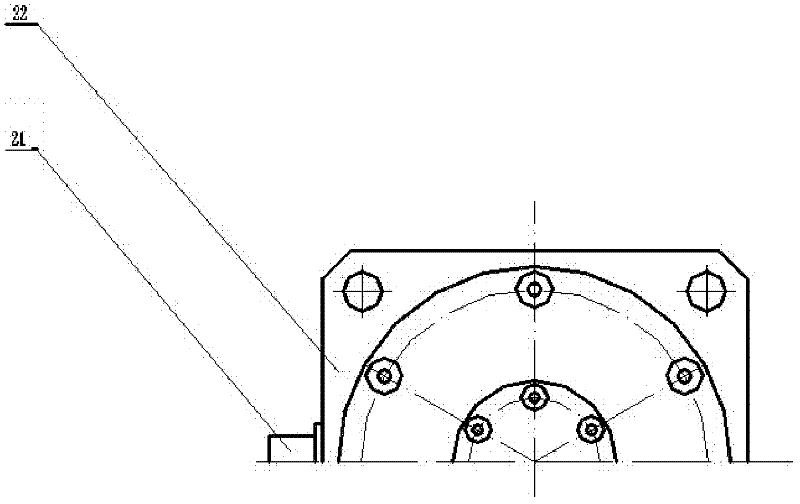

Hard-soft multipoint follow-up supporting head used for image processing

ActiveCN104668989AReduce flutterPrecise positioningPositioning apparatusMetal-working holdersImaging processingEngineering

The invention discloses a hard-soft multipoint follow-up supporting head used for image processing. The hard-soft multipoint follow-up supporting head comprises a base, multiple circumferential step through holes with axes parallel to one another are formed in the base uniformly along the circumferential direction, a central step through hole parallel to the axes of the circumferential step through holes is formed in the middle of the base, an internal thread is arranged on the left side of each of the circumferential step through hole and the central step through hole, a threaded connecting member, a left spring and a supporting rod where a right spring sleeves are sequentially mounted in each circumferential step through hole from left to right, the right end of each supporting rod is connected with an auxiliary universal ball, a left-side threaded end of a main supporting rod is fixedly connected at the right end of the central step through hole, the right end of the main supporting rod is connected with a main universal ball, and the auxiliary universal ball and the main universal ball are arranged outside the right end face of the base. According to the hard-soft multipoint follow-up supporting head, chattering of a thin-wall member is reduced due to flexible supporting, and the thin-wall member is positioned accurately due to rigid supporting; due to multipoint supporting, supporting area is increased, and controlling difficulty is lowered.

Owner:TIANJIN UNIV

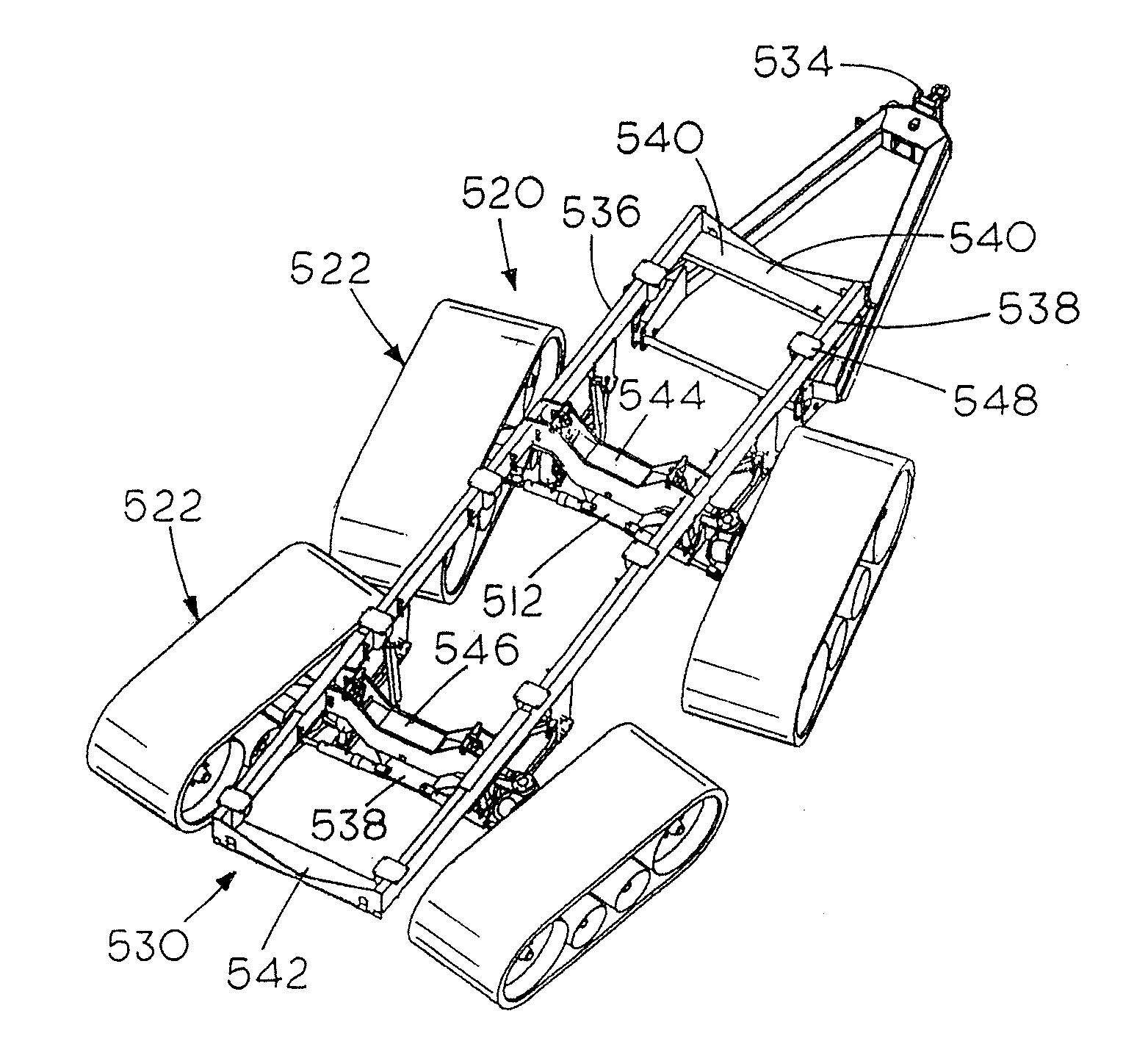

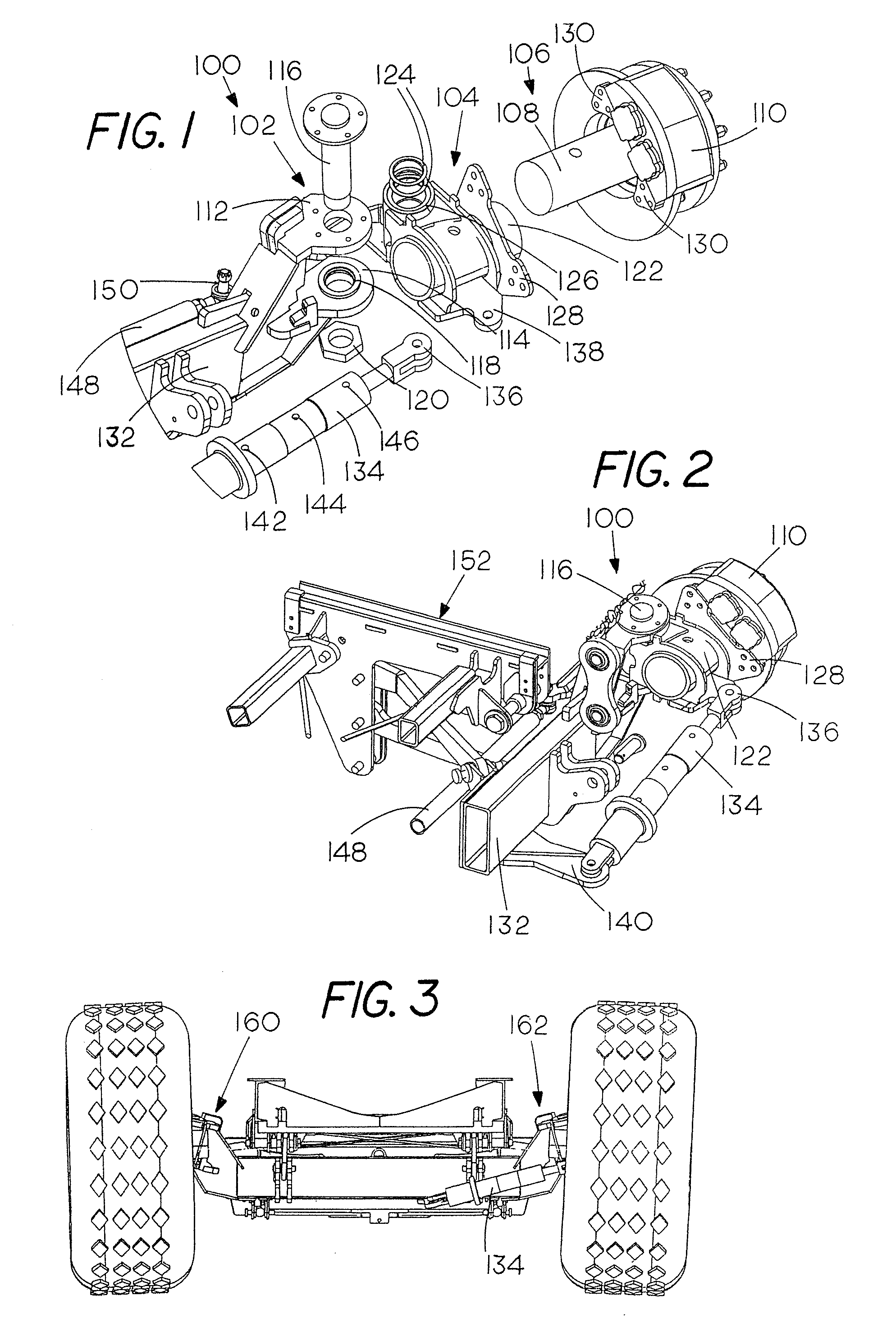

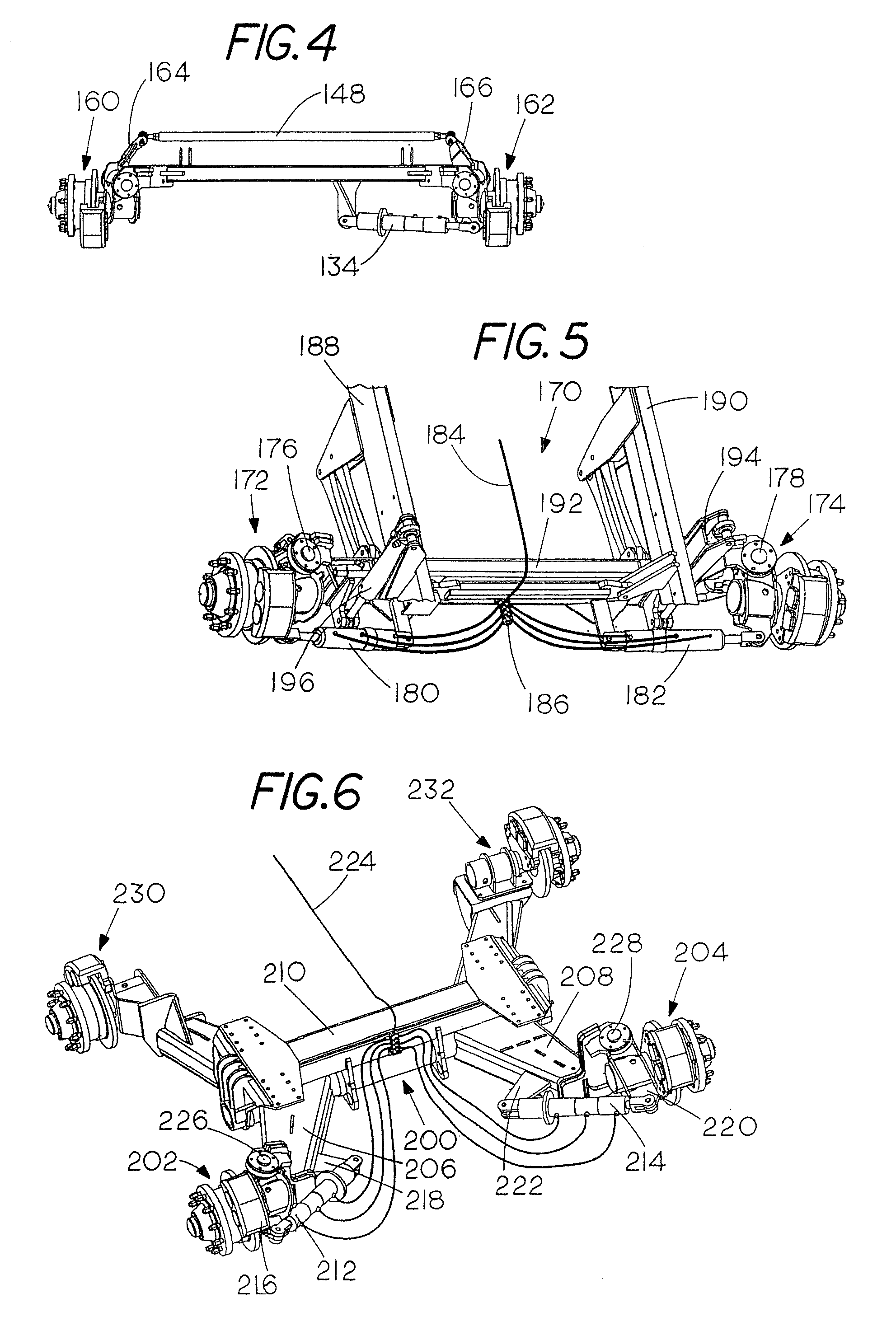

Self-steering agriculture grain carts and manure tanks

InactiveUS20130181431A1Convenient guidanceImprove safety and maneuverabilityTank vehiclesUnderstructuresAutomatic steeringEngineering

A frame and undercarriage track mounted assembly for a grain cart or manure tank unit designed to be pulled in a forward direction over and agricultural field by a farm tractor is disclosed. The invention involves a steering axle assembly that is adapted to turn dual spaced track assemblies. The steering axle is easily guided to improve the maneuverability and safety of the unit and reduce field compaction. The steering system design features compound angled kingpins that transfer some of the unit weight to assist in turns. Thus, the steering system reduces the resistance of the unit steering system to turning and the large footprint of the track assemblies minimizes ground compaction during turns.

Owner:BALZER

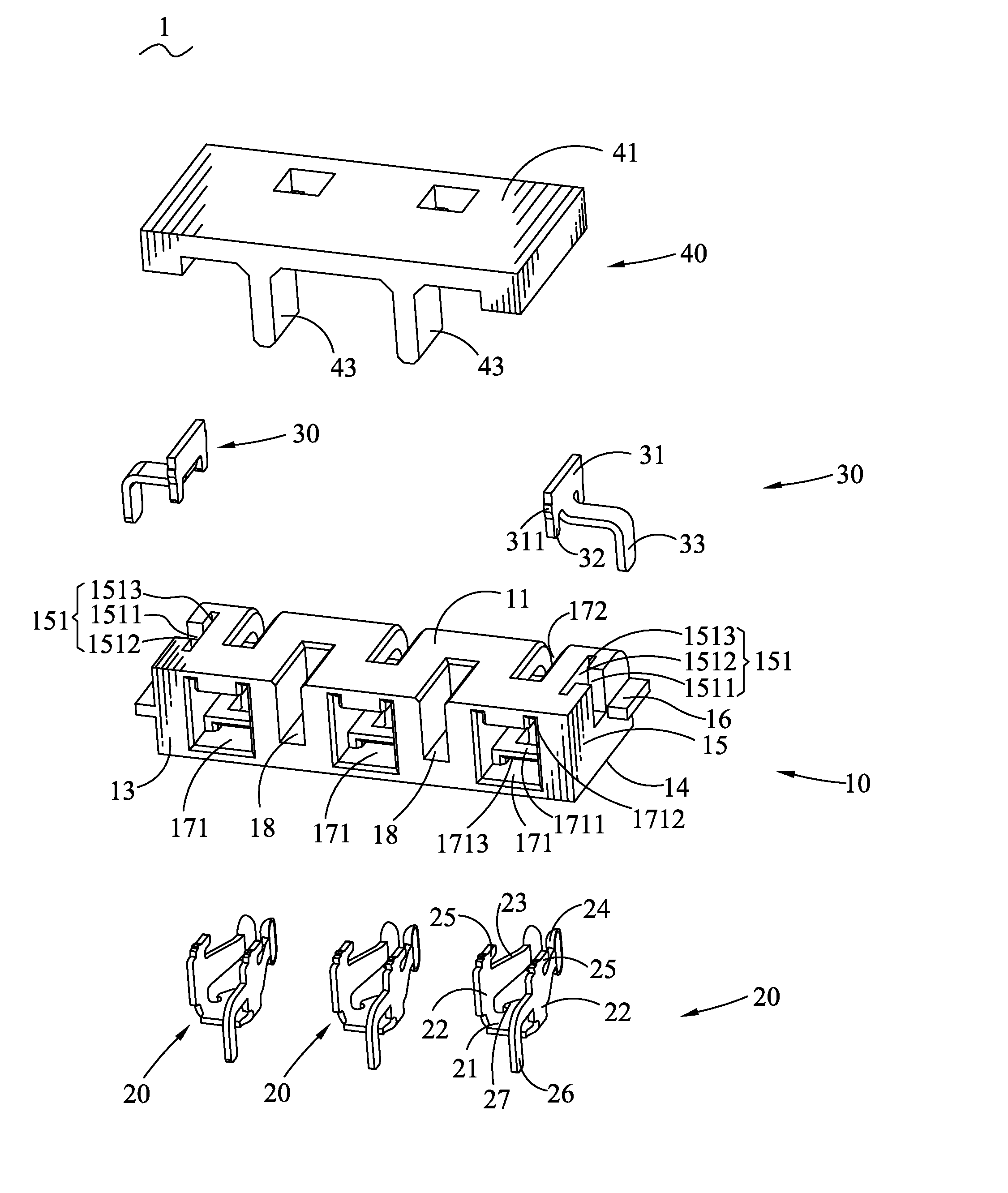

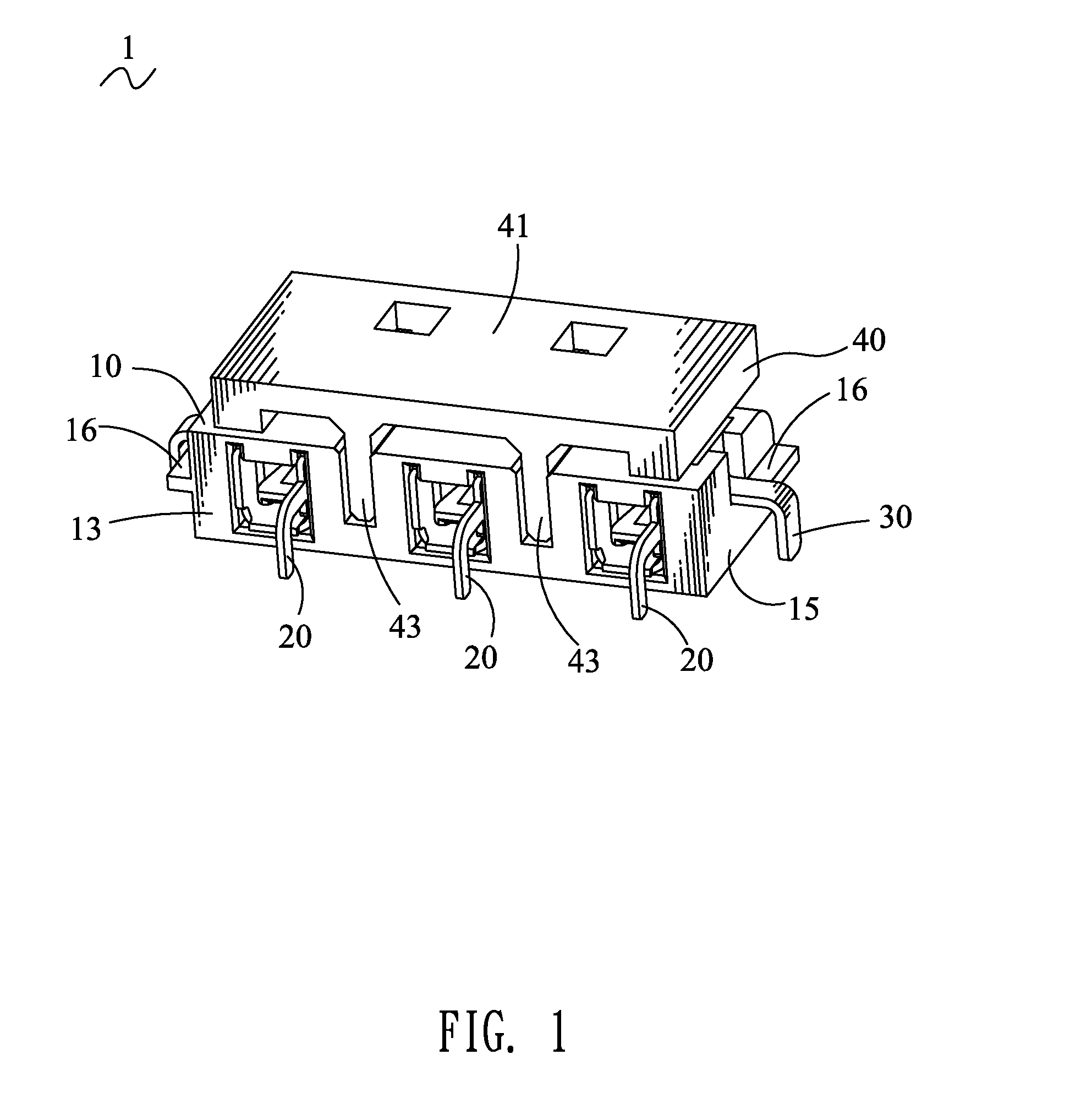

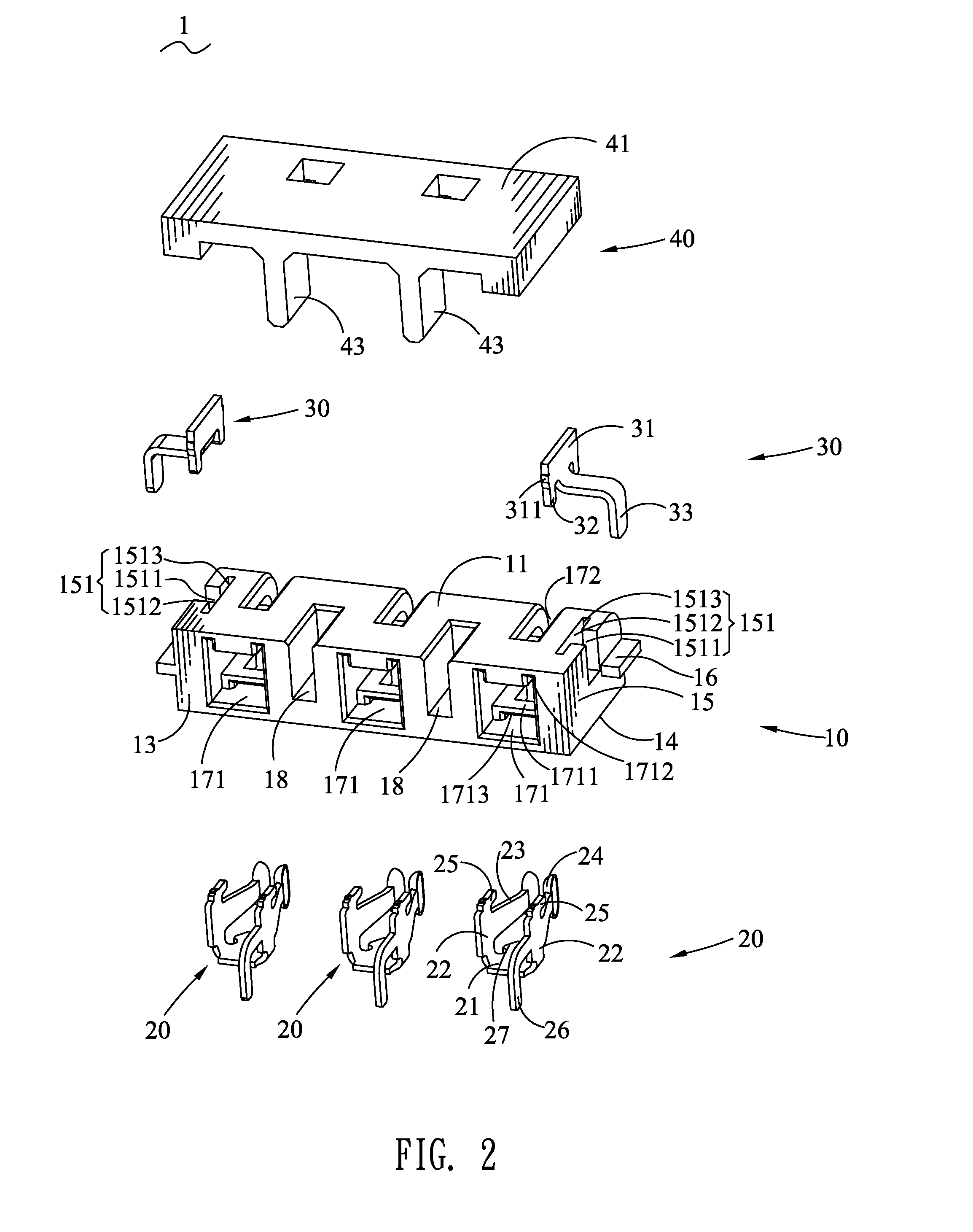

Battery connector

InactiveUS8092236B2Increase the support areaElectrically conductive connectionsSubstation/switching arrangement detailsEngineeringPrinted circuit board

A battery connector is adapted for being assembled to a printed circuit board. The battery connector includes an insulating housing, two holding elements and a plurality of terminals. The insulating housing has two opposite side surfaces. The insulating housing defines a plurality of terminal cavities and receiving grooves. Two holding grooves are opened in two opposite ends of the insulating housing. Each side surface of the insulating housing protrudes sideward to form a locating piece. Each holding element has a base plate mounted to the holding groove and a holding piece projecting out of the holding groove to be inserted into the printed circuit board. The terminals are respectively received in the terminal cavities. Each terminal has two contacting portions having an interstice therebetween and facing towards the receiving groove, and a soldering portion projecting out of the terminal cavity to be inserted in the printed circuit board.

Owner:CHENG UEI PRECISION IND CO LTD

Thick coal-bed shield hydraulic support

InactiveCN1851235AImprove stress conditionExtended service lifeMine roof supportsEngineeringHigh intensity

The invention is a thick coal bed hydraulic shield support, able to implement synthetic mechanized mining of thick coal beds, comprising top beam, shield beam, seat, column, balancing jack, front link rod, rear link rod, displacive jack and operating valve set, where the top beam and shield beam are equipped with side push jacks, and long and short guide rods inside and equipped with side backplates and hinged mutually; the top and bottom ends of the balancing jack are equipped on the top beam and shield beam, respectively; the top and bottom ends of the column are arranged on the lower part of the top beam and the seat, respectively; the upper ends of the front and rear link rods are hinged at the rear end of the shield beam and the lower ends of them are hinged on the seat; the displacive jack is equipped on the seat; the operating valve set is equipped on the bottom surface of the top beam. And it has large height regulating range and high moving speed, and improves force bearing conditions of the support and prolongs the service life of the support. And the support is made of high-intensity low-alloy steel sheet, small- bulk and lightweight.

Owner:ZAOZHUANG MINING GRP CO LTD

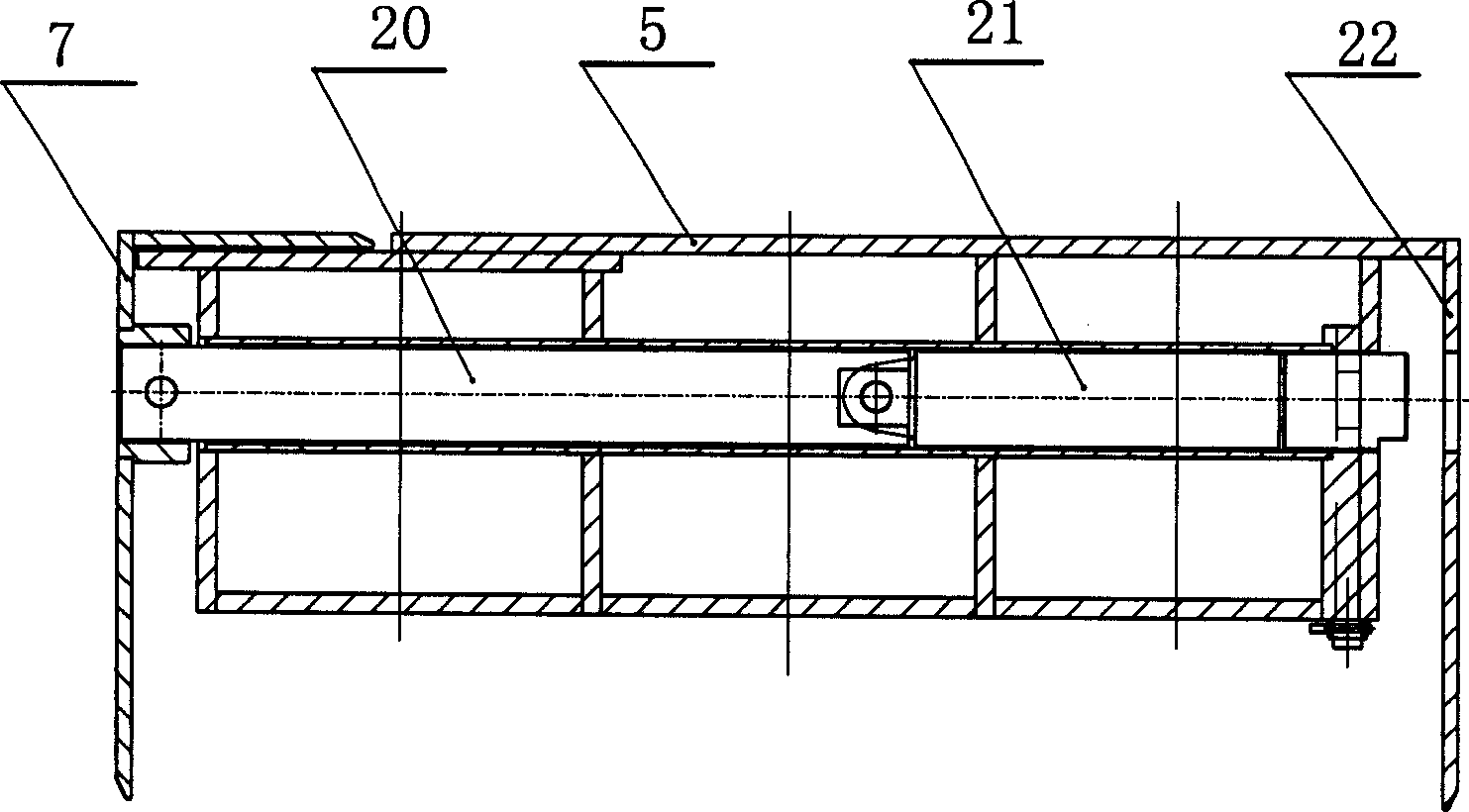

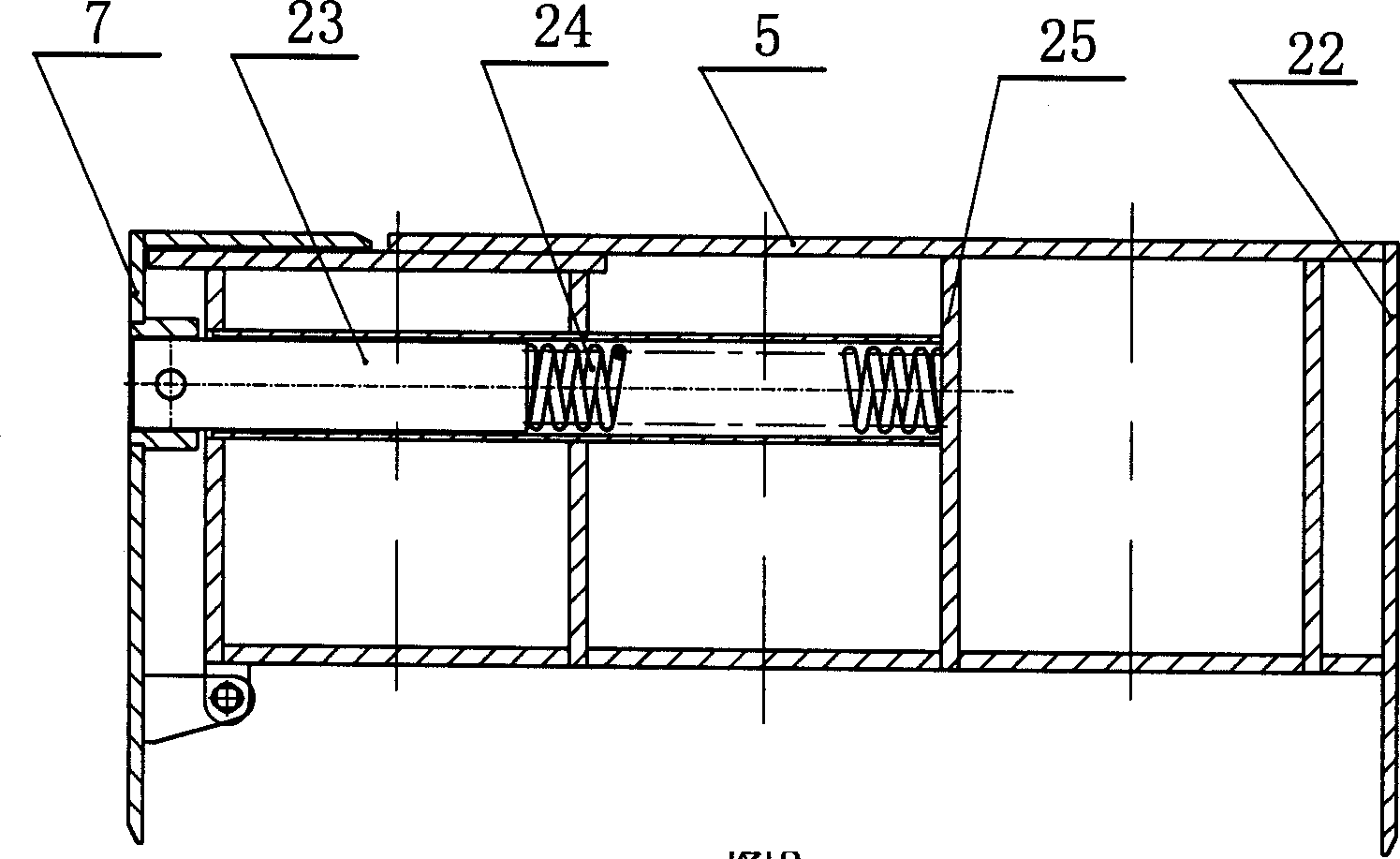

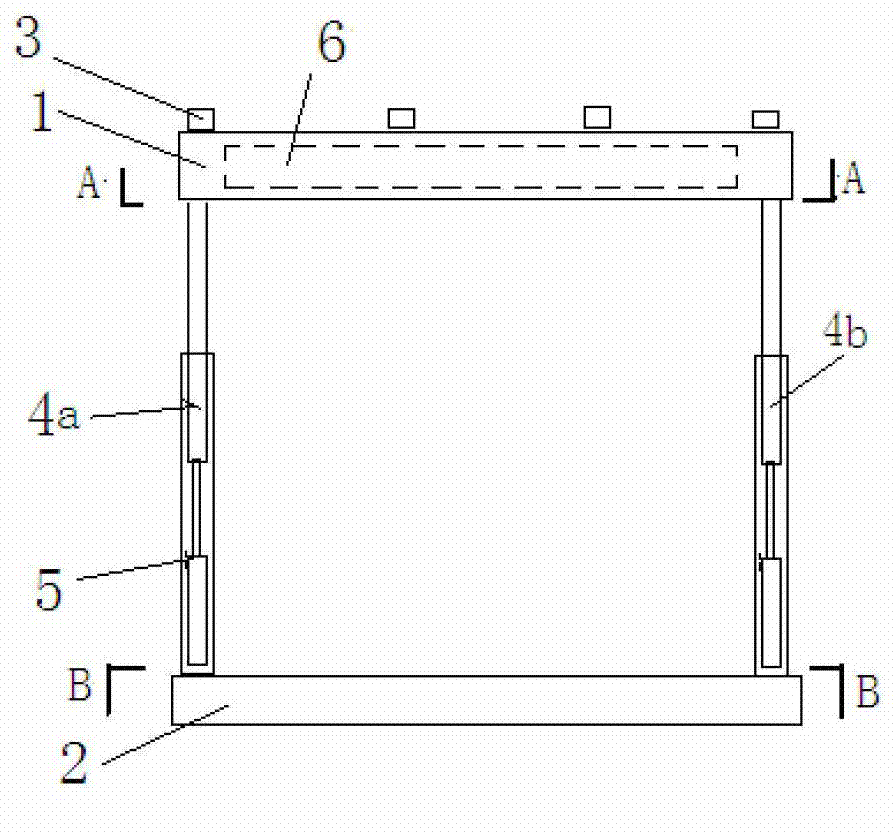

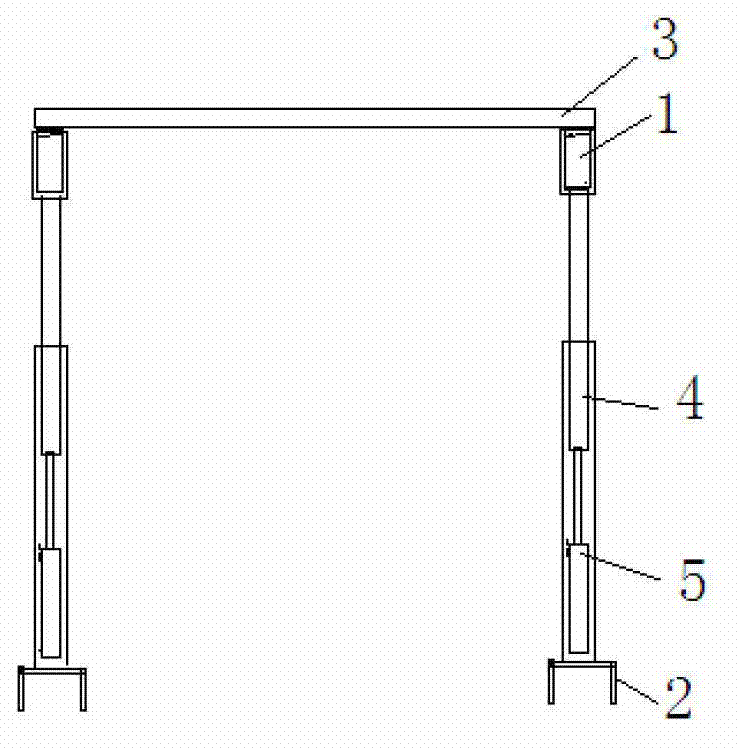

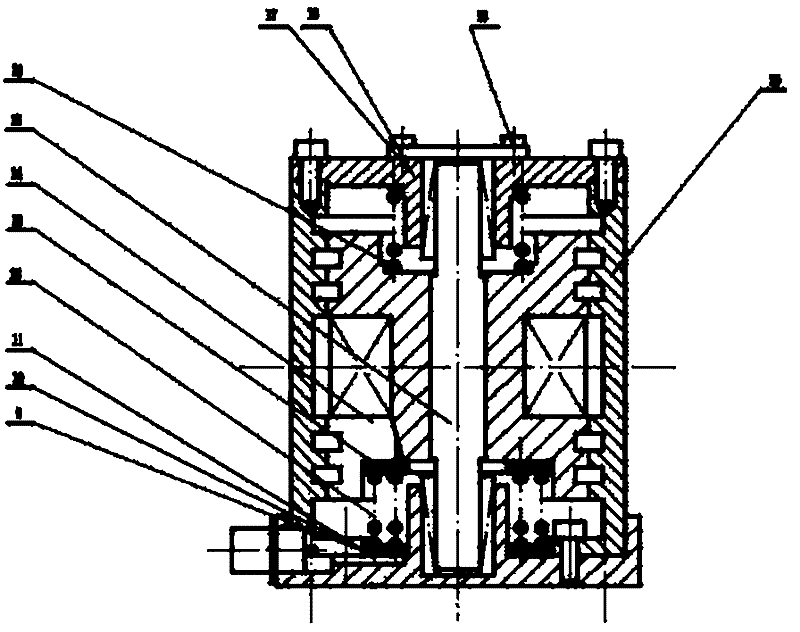

Driving face self-moving temporary support hydraulic support and support method thereof

InactiveCN103089286AImprove support strengthIncrease the support areaMine roof supportsTechnical supportTunnel construction

The invention discloses a driving face self-moving temporary support hydraulic support and a support method thereof. The driving face self-moving temporary support hydraulic support comprises a tetrastyle inner support, a tetrastyle outer support and a hydraulic system. The inner support and the outer support are both made of two transverse top beams, two transverse bottom beams and four elastic stand columns, a plurality of longitudinal beams are arranged on the two transverse top beams to form a top support of a supporting top plate, the tetrastyle inner support is embedded with the outer support to form a pull-draw type combined support, the hydraulic system enables the inner support and the outer support to be capable of lifting and mutually pulling and drawing, and forward movement of the hydraulic support along a working face is achieved. The driving face self-moving temporary support hydraulic support is a novel driving face mechanization temporary support device. The support is a tetrastyle support and can automatically move so that supporting intensity and supporting areas of the temporary support are improved, tunneling construction speed and safety can be substantially improved, and technical supports for rapid and safe tunneling are achieved.

Owner:SHANDONG UNIV OF SCI & TECH

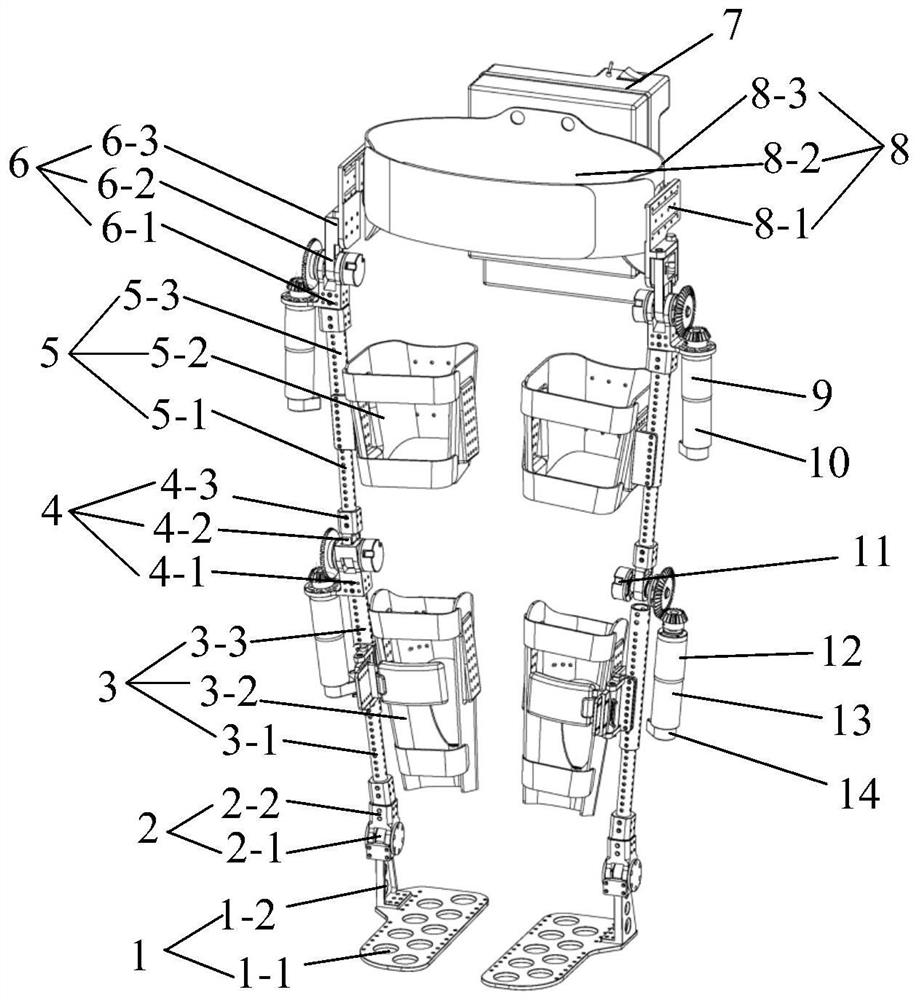

Motion control method suitable for exoskeleton robots

ActiveCN111604890AImprove convenienceImprove intelligenceProgramme-controlled manipulatorWalking aidsExoskeleton robotMultiple sensor

The invention provides a motion control method suitable for exoskeleton robots. By establishing a seven-link kinematics model, collecting exoskeleton-wearer system motion information based on a multi-sensor system, calculating the wearer's ground pressure center position, and designing an exoskeleton walking finite state machine, the wearer's walking motion intention and the state transitions in the walking finite state machine can be quickly, accurately and automatically recognized, effective and smooth motion assistance for paralyzed patients who have no perception and strength of the lowerlimbs is realized, the walking intention of the exoskeleton robot is automatically recognized and controlled, and the convenience and intelligence of using the exoskeleton robots are improved. At thesame time, by calculating the distance between the ankle joint of the front leg and the location of the crutches after the exoskeleton-wearer system moves forward with both crutches during the leg support period, the step length of the wearer under different walking conditions is determined, the exoskeleton joint motion reference trajectory is updated in real time, and real-time adjustment and control of the wearer's walking step length is realized.

Owner:HEFEI UNIV OF TECH

Cutting head type shortwall coal-winning machine and comprehensive mechanized coal mining technology

ActiveCN101798925AReduce cutting powerReduce electricity costsUnderground miningSlitting machinesControl systemElectrical control

The invention discloses a cutting head type shortwall coal-winning machine and comprehensive mechanized coal mining technology. A tunneller type cutting device is used, and the coal-winning machine is a hydromechatronics coal-winning machine which is in electric traction, electrically drags a cutting head, carries out hydraulic drive to change a cutting arm pitch angle and swings inside and outside the working face. The coal-winning machine mainly comprises a machine body, a cutting device, a travelling mechanism, a coal shovelling device, an auxiliary device, an auxiliary hydraulic system and an electrical control system. The coal-winning technology uses technical equipment, such as a coal-winning machine, a hydraulic support, a scraper conveyor, an elevating conveyor, a breaker, a crossheading belt, an advance support hydraulic support and the like. The technical flow is as follows: the coal-winning machine retracts to the working surface tail, a scraper-trough conveyer is pushed tocoal wall, coal is cut to the machine head, the machine is retracted, coal is cleaned, and the support is pulled. The coal-winning machine has compact structure, small volume and weight, strong adaptability and convenient installation and transportation, can solve a series of problems of four low, three high, two long and one poor in small and medium coal mining technology and provides matching coal mining technology.

Owner:闫振东

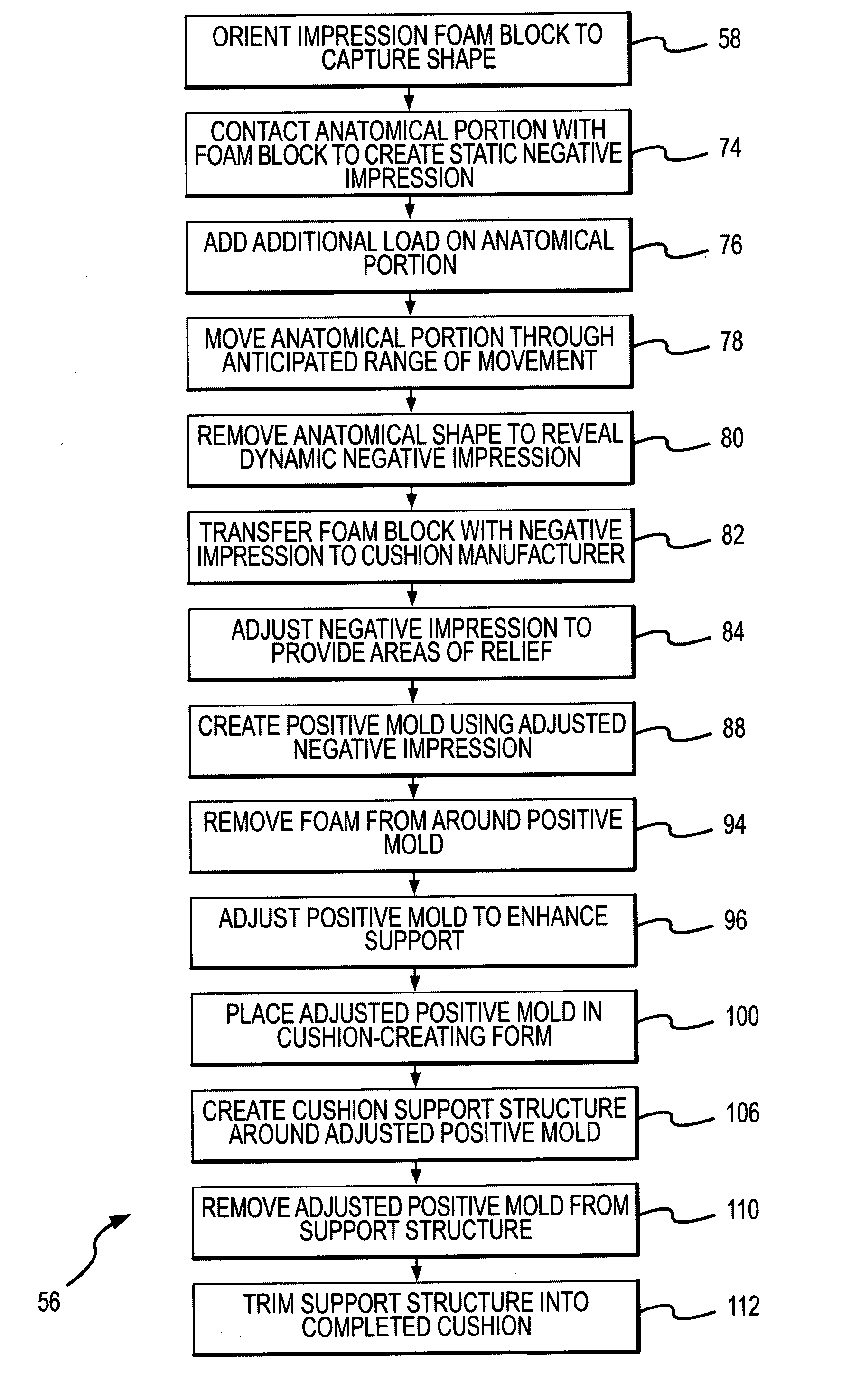

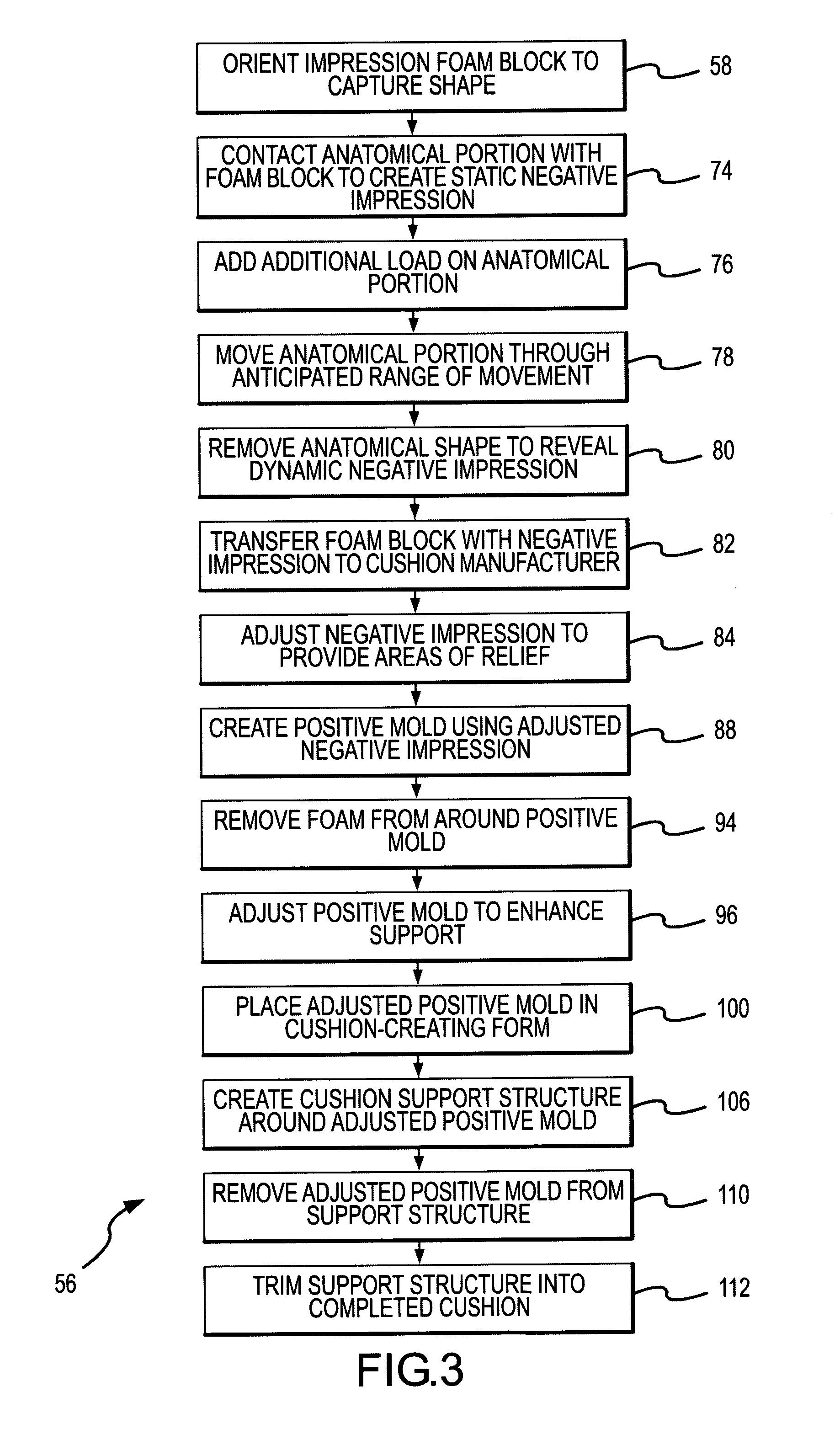

Individually-contoured seat cushion and shape capturing and fabricating method for seat cushion

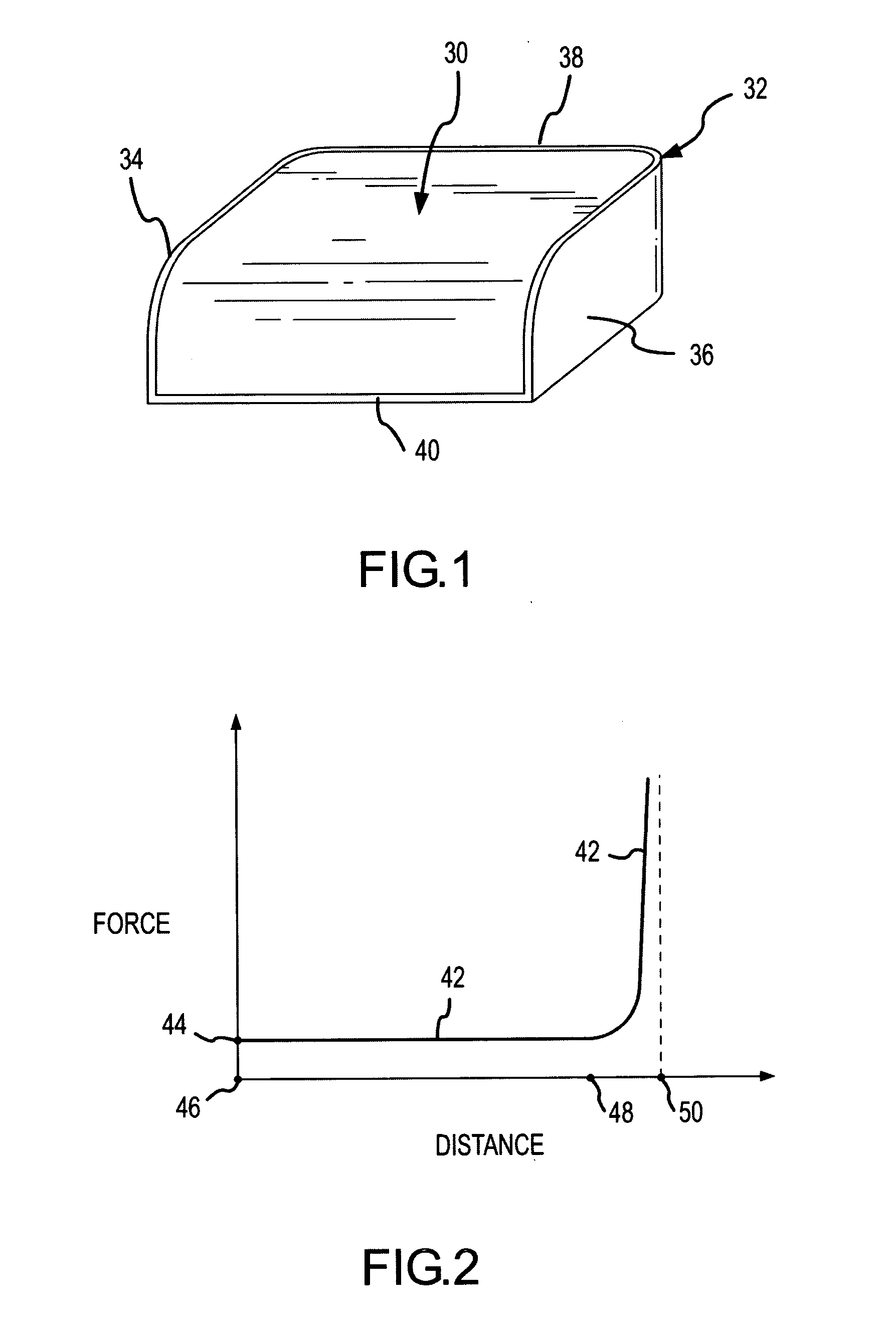

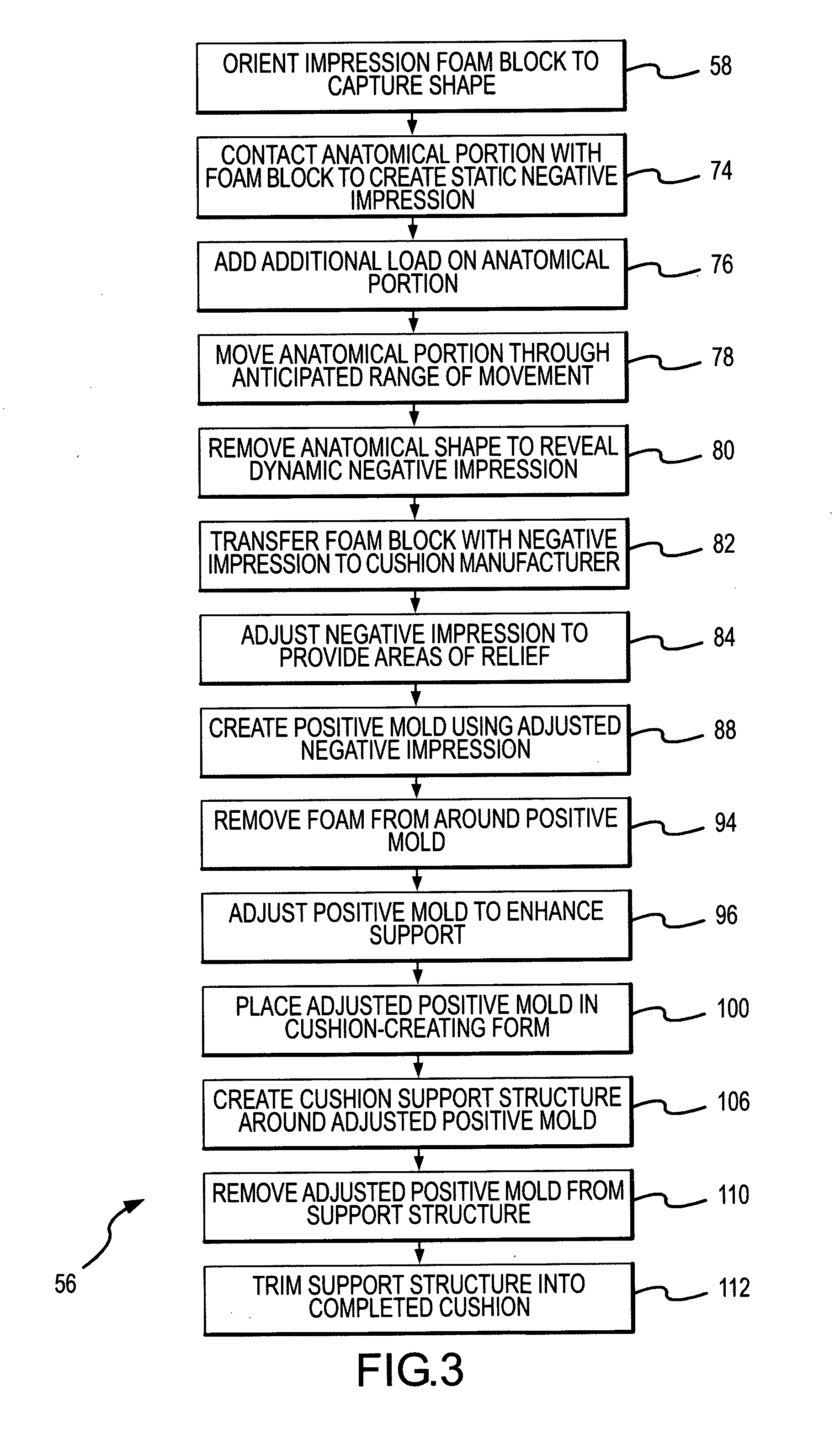

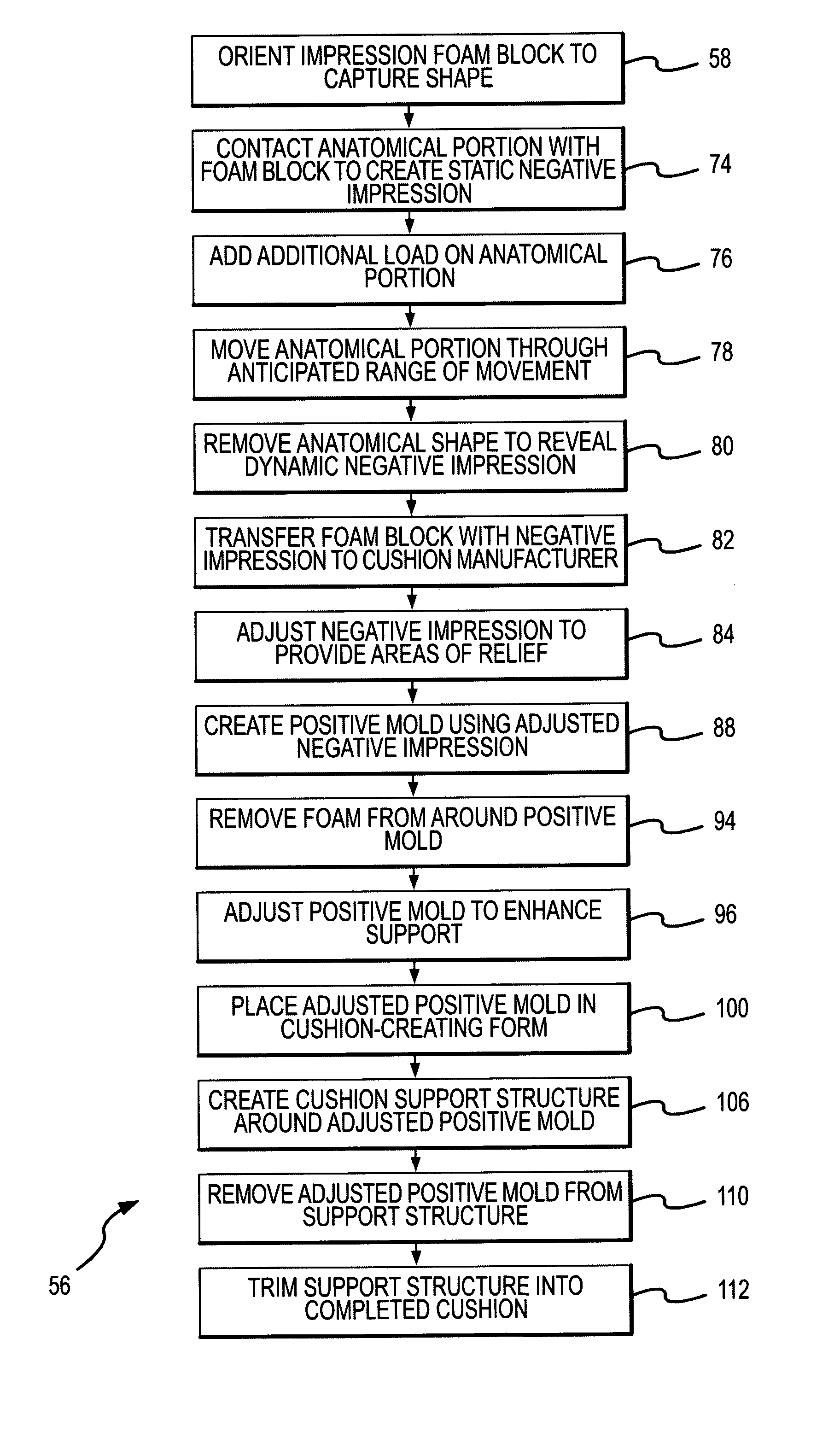

ActiveUS20050025953A1Easy to transportConvenient to accommodateLayered productsWheelchairs/patient conveyanceWheelchairConstant force

A negative impression of an anatomical portion of a person is captured by forcing the anatomical portion into impression foam to collapse the impression foam into the negative impression. The impression foam has a crush characteristic of approximately constant resistance force over a relatively wide predetermined range of collapse distances. The negative impression is obtained by collapsing the impression foam within the range of constant-force collapse distances, thereby creating the negative impression under conditions which reflect an equally-loaded anatomical portion. A cushion support contour created from the equally-loaded negative impression is beneficial in more appropriately supporting the anatomical portion. The present invention is particularly useful in fabricating wheelchair seat cushions.

Owner:ASPEN SEATING

Individually-contoured seat cushion and shape capturing and fabricating method for seat cushion

InactiveUS7220376B2Shape-capturing equipment of the invention is relatively inexpensiveEasy to transportWheelchairs/patient conveyanceNursing bedsWheelchairConstant force

A negative impression of an anatomical portion of a person is captured by forcing the anatomical portion into impression foam to collapse the impression foam into the negative impression. The impression foam has a crush characteristic of approximately constant resistance force over a relatively wide predetermined range of collapse distances. The negative impression is obtained by collapsing the impression foam within the range of constant-force collapse distances, thereby creating the negative impression under conditions which reflect an equally-loaded anatomical portion. A cushion support contour created from the equally-loaded negative impression is beneficial in more appropriately supporting the anatomical portion. The present invention is particularly useful in fabricating wheelchair seat cushions.

Owner:ASPEN SEATING

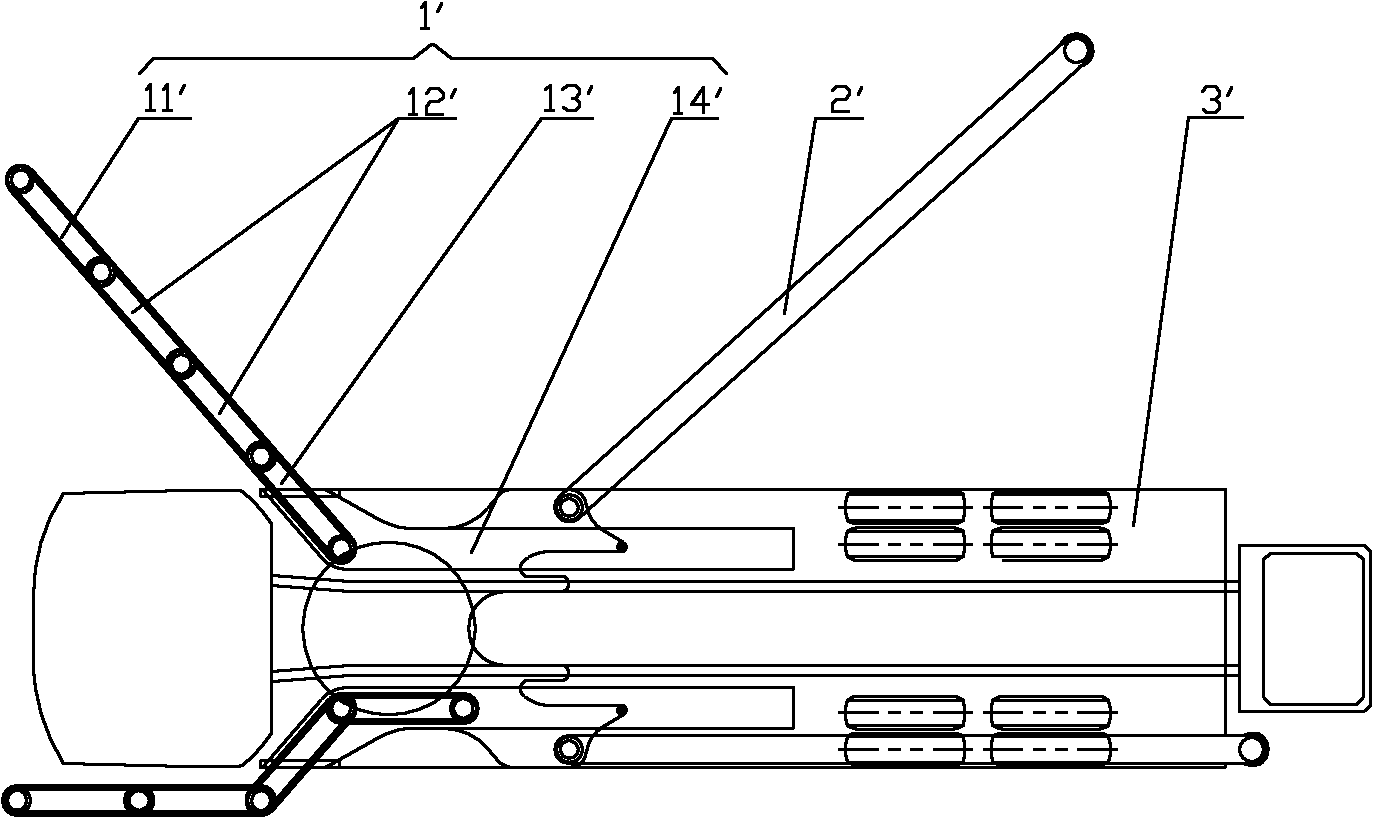

Engineering machine

ActiveCN102493654AFlexible deploymentExpand shortVehicle fittings for liftingBuilding material handlingEngineeringTower

The invention discloses an engineering machine comprising a chassis and a fixed rotating tower arranged on the chassis, wherein the fixed rotating tower is connected with a supporting leg device comprising a horizontal supporting leg and a first supporting leg connected to the tail end of the horizontal supporting leg; the fixed rotating tower comprises a turntable frame connected with a turntable of the engineering machine and a supporting leg frame fixed below the turntable frame, wherein the supporting leg frame comprises at least two connecting arms, and the outer end of each connecting arm is hinged with the horizontal supporting leg; any two adjacent connecting arms are intersected or extending lines of any two adjacent connecting arms are intersected; the horizontal supporting leg comprises at least two arm joints hinged in sequence, and a second driving part for driving any two adjacent arm joints to unfold and fold is arranged between the two adjacent arm joints; a root end arm joint in each arm joint is hinged with the connecting arms, a first driving part for driving the root end arm joint to unfold and fold is arranged between the root end arm joint and the connecting arms, and the first supporting leg is connected to the tail end of a tail end arm joint in each arm joint.

Owner:SANY HEAVY IND CO LTD (CN)

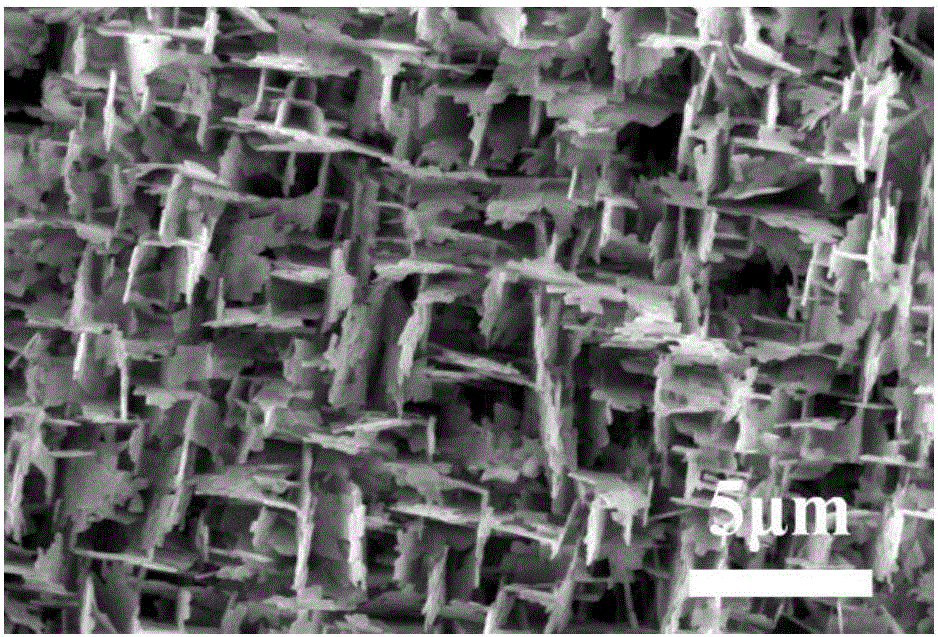

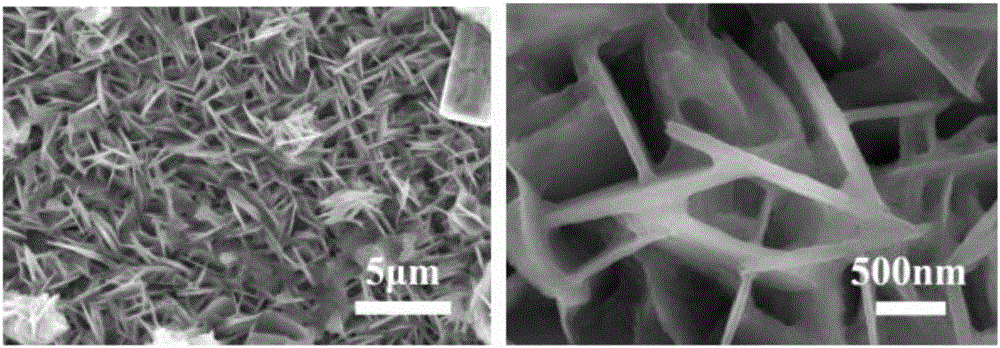

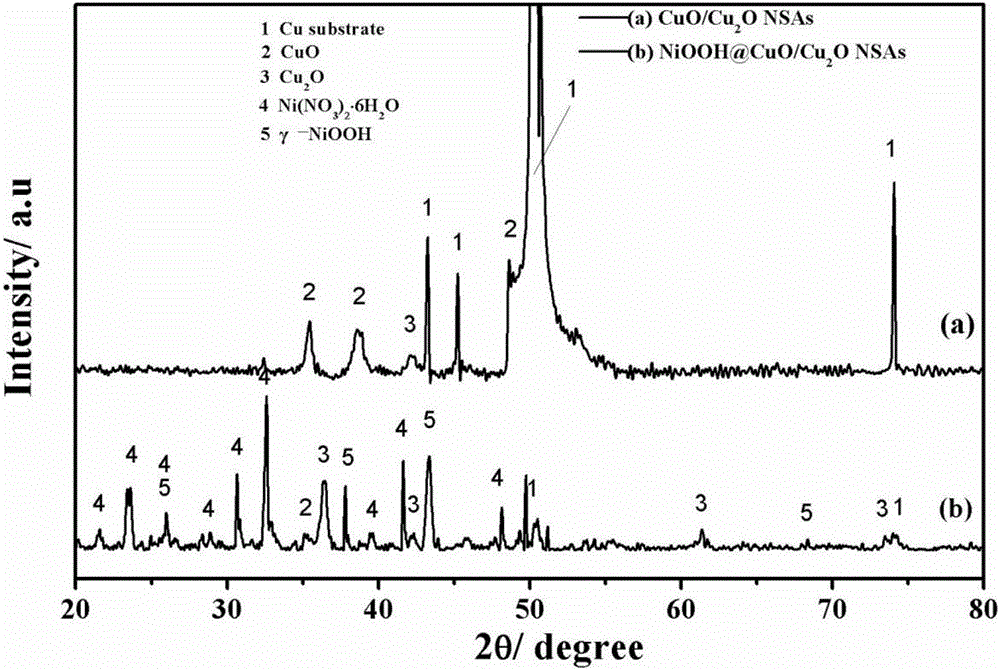

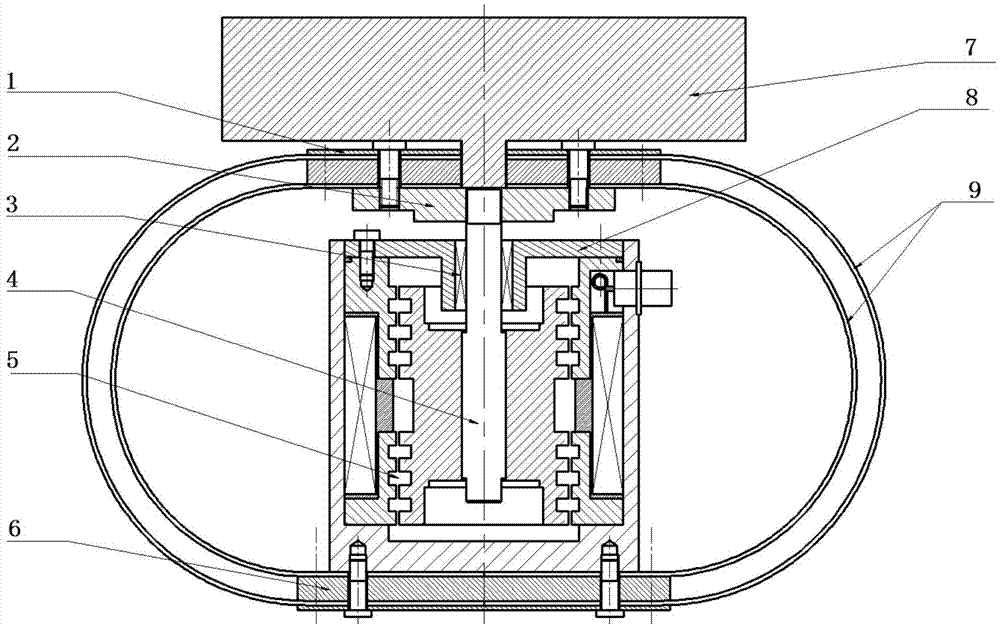

NiOOH@CuO/Cu2O composite nanosheet array film as well as preparation method and application thereof

ActiveCN106158408AHigh theoretical capacityImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesCapacitanceHydrothermal deposition

The invention discloses a NiOOH@CuO / Cu2O composite nanosheet array film as well as a preparation method and application thereof. The method comprises the following steps: growing CuO / Cu2O nanosheet arrays vertical to a substrate and in stagger arrangement on the surface of a high-purity copper material by adopting an anode oxidation technology; performing hydrothermal deposition treatment in an aqueous solution of nickel nitrate; and performing in-situ deposition of a nickel oxide hydroxide nano product on the nanosheet arrays to obtain a NiOOH@CuO / Cu2O nanocomposite. The prepared electrode material gives full play to the electrochemical synergism between the CuO / Cu2O nanosheet arrays and NiOOH, and shows ultrahigh specific capacitance property and good cycling stability while the preparation steps are simple and controllable; and therefore, the electrode material is a super capacitor electrode material with practical application value.

Owner:HEFEI UNIV OF TECH

Spring steel disc type dynamic vibration absorber with adjustable rigidity

ActiveCN103615488AImprove linearityOvercome the disadvantage of being affected by the installation preloadMagnetic springsShock absorbersMechanical equipmentVibration absorption

The invention provides a spring steel disc type dynamic vibration absorber with the adjustable rigidity. The spring steel disc type dynamic vibration absorber comprises an electromagnetic spring part and a mass block, the bottom of the electromagnetic spring part is fixedly installed inside an annular spring structure, the upper end of a center shaft of the electromagnetic spring part is connected with the annular spring structure, and the mass block is fixedly installed on the upper portion of the annular spring structure. The electromagnetic spring part is additionally arranged on the spring steel disc type dynamic vibration absorber, so that the spring steel disc type dynamic vibration absorber has the advantage of being rapid in frequency change response, the rigidity can be changed only by changing the current, the on-line continuous adjustment can be achieved, the frequency of changes is tracked, working condition changes of mechanical equipment are adapted, and the vibration absorption requirements under different conditions can be better met.

Owner:HARBIN ENG UNIV

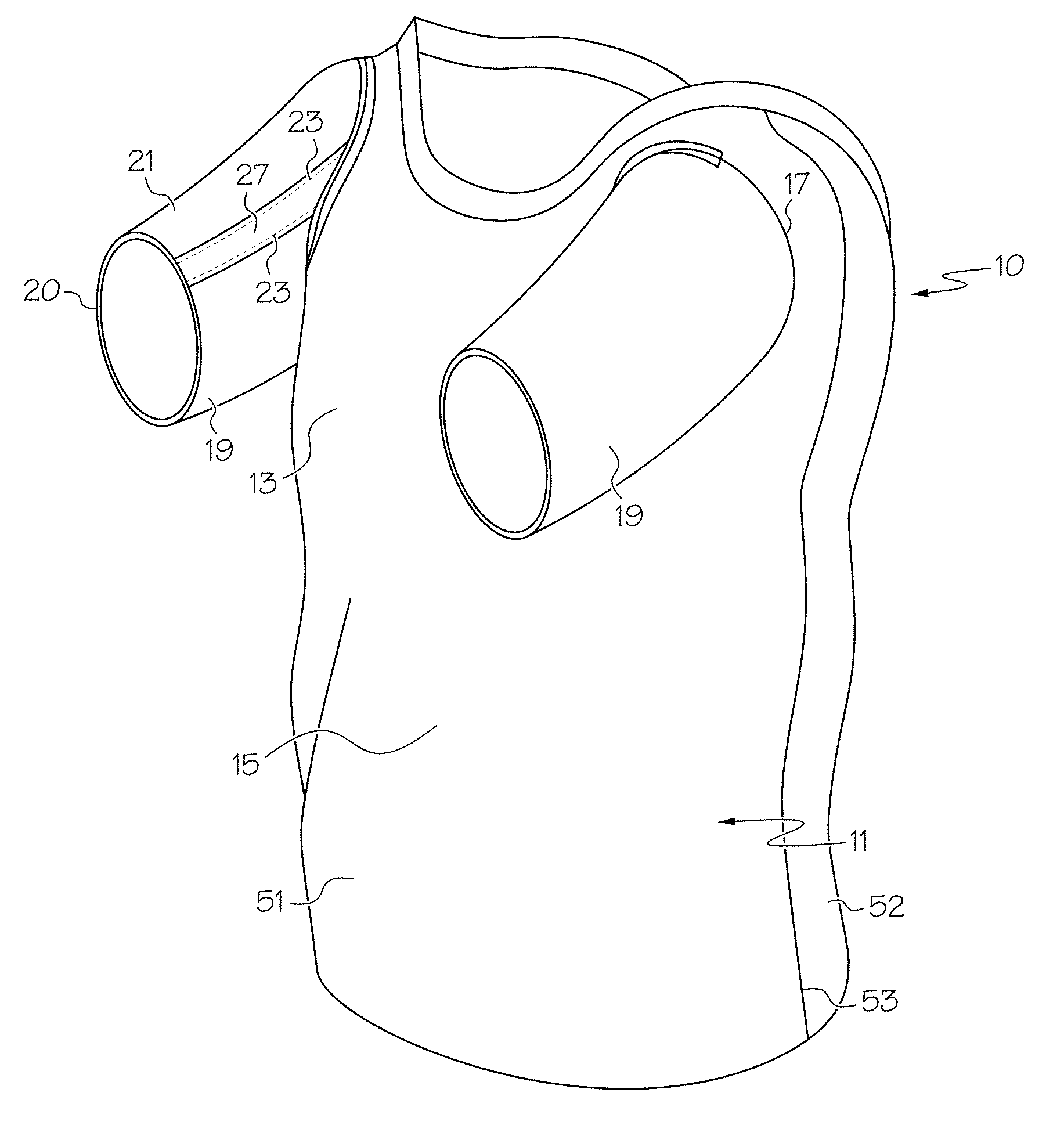

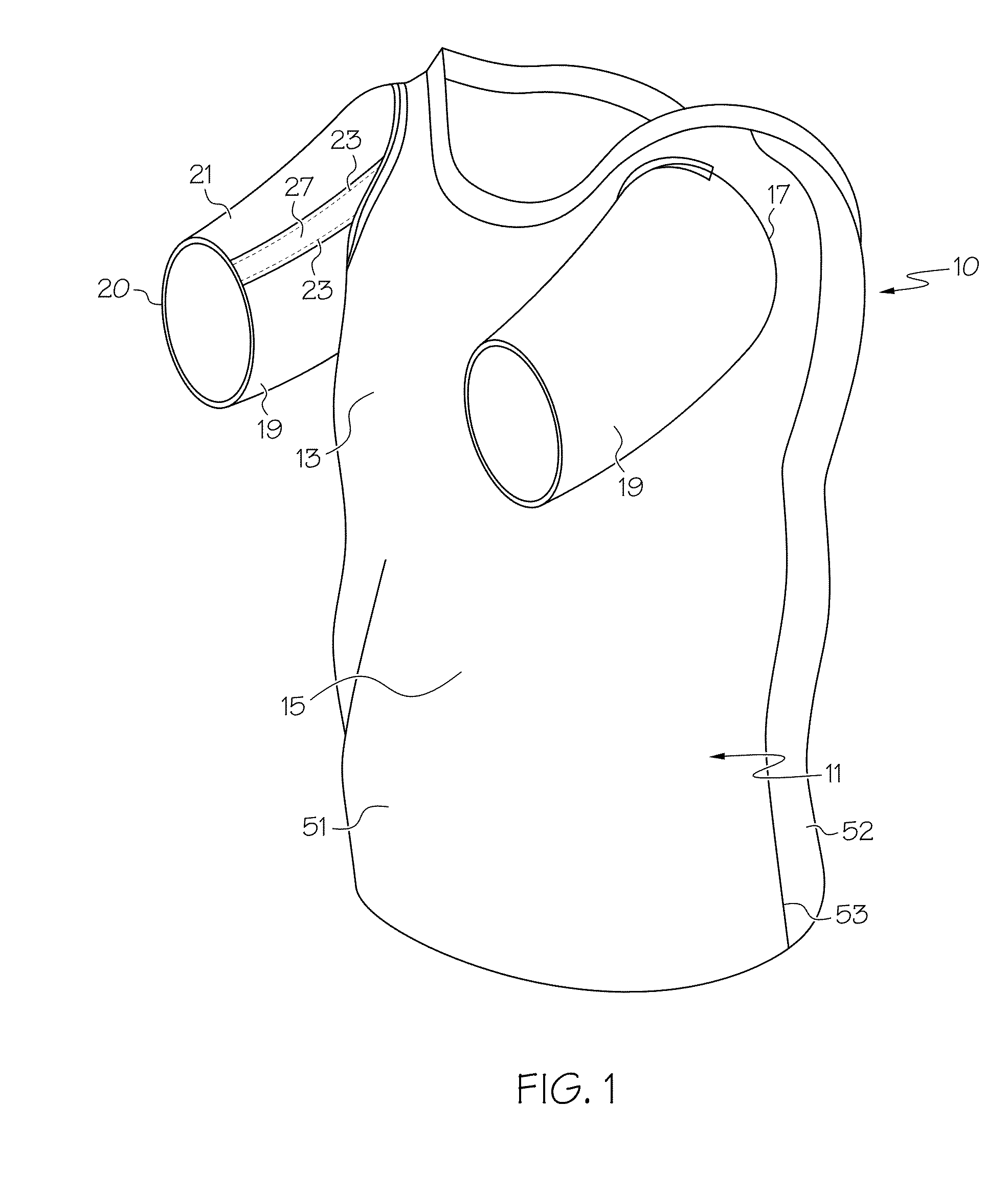

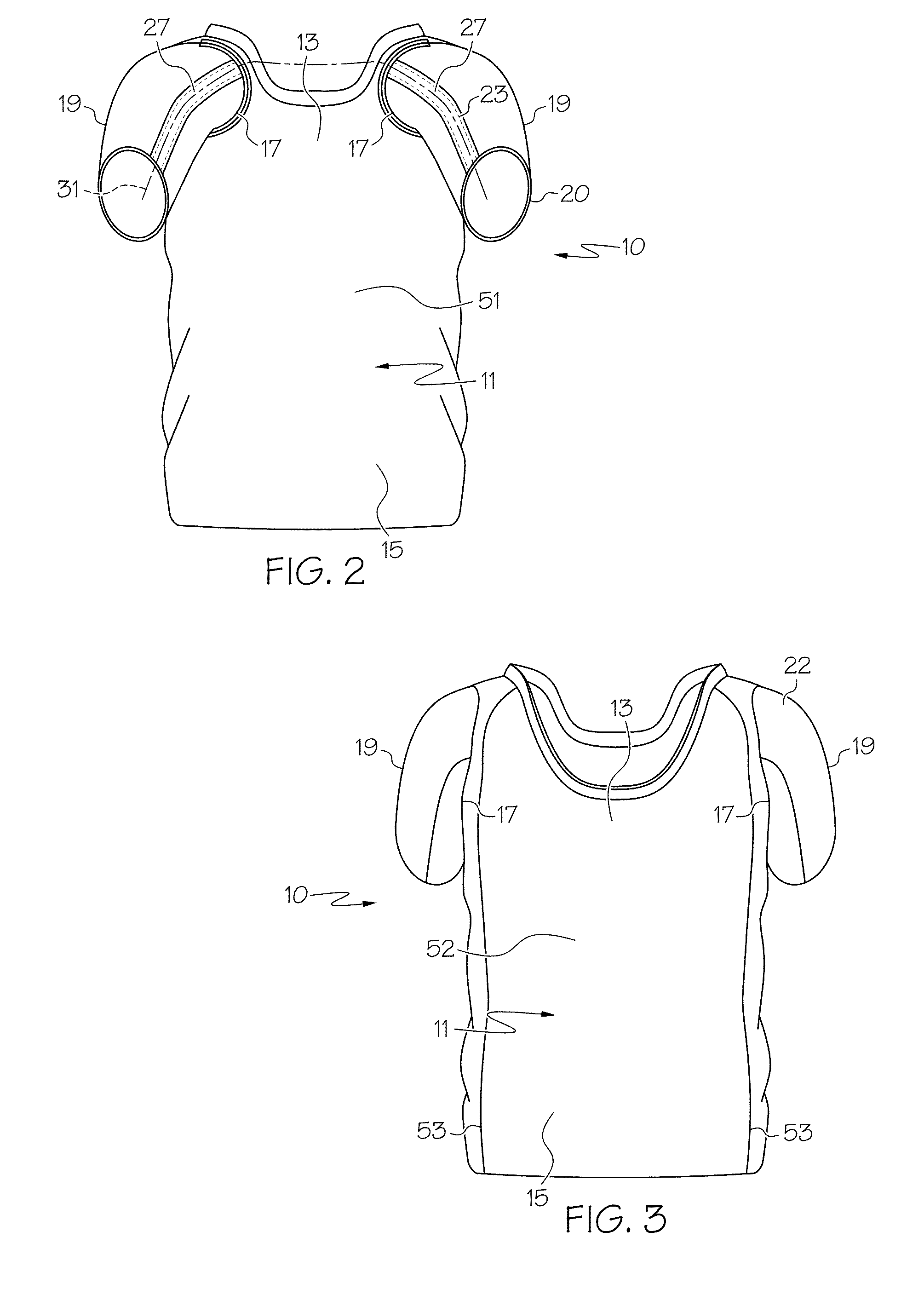

Support shirt with sleeve reinforcement regions

ActiveUS20150196072A1Increase the support areaEasy to adjustProtective garmentMuscle exercising devicesEngineering

Owner:INZER ADVANCE DESIGNS INC

U-shaped steel and anchor cable collaborated support structure for laneway with large-deformation deep part

InactiveCN103953360ASimple structureLow costUnderground chambersTunnel liningStructural engineeringUltimate tensile strength

Owner:HUNAN UNIV OF SCI & TECH

Coil built-in semiactive vibration absorber with closed structure

InactiveCN102364156AQuality improvementImprove effective qualitySpringsNon-rotating vibration suppressionEngineeringGravity center

The invention aims to provide a coil built-in semiactive vibration absorber with a closed structure. The coil built-in semiactive vibration absorber comprises an outer shell, a base, a shaft, an armature, a spring, an upper cover and a ferromagnetic coil, wherein the outer shell is connected with the base; the upper cover is arranged on the outer shell; the armature is arranged in the outer shell and is connected with the outer shell; the shaft passes through the armature and is arranged on the base; a spring for positioning is arranged between the shaft and the armature; the outer shell, the base and the upper cover form the closed structure; an annular slot is formed on the central outer wall of the armature; and the ferromagnetic coil is arranged in the annular slot. A base supporting mode replaces a shaft supporting mode, so the gravity center is reduced, the supporting area is increased, the installation stability is improved, and the anti-swing capacity of the supporting mode is about within 45 degrees. A coil winding is combined with an active cell mass block, so the mass of a stator is reduced relatively and the mass of an active cell is increased; therefore, the volume of the whole vibration absorber is reduced, the effective mass of the vibration absorber is increased and the working efficiency and the applicability are improved.

Owner:HARBIN ENG UNIV

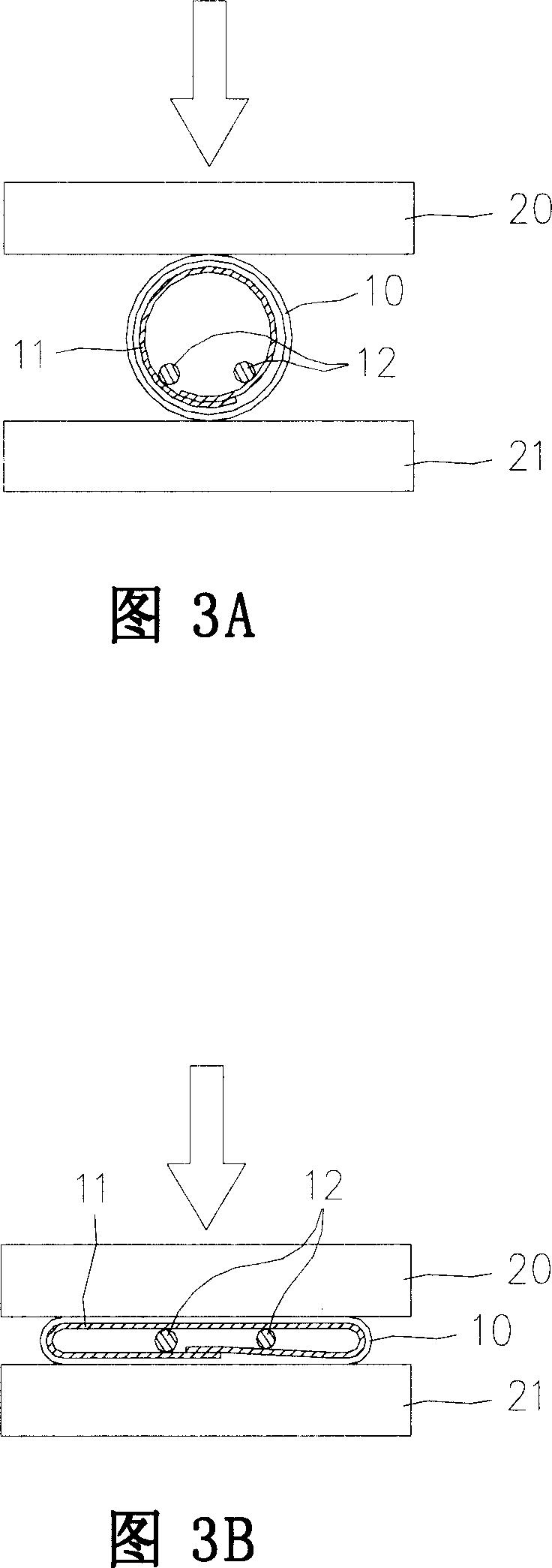

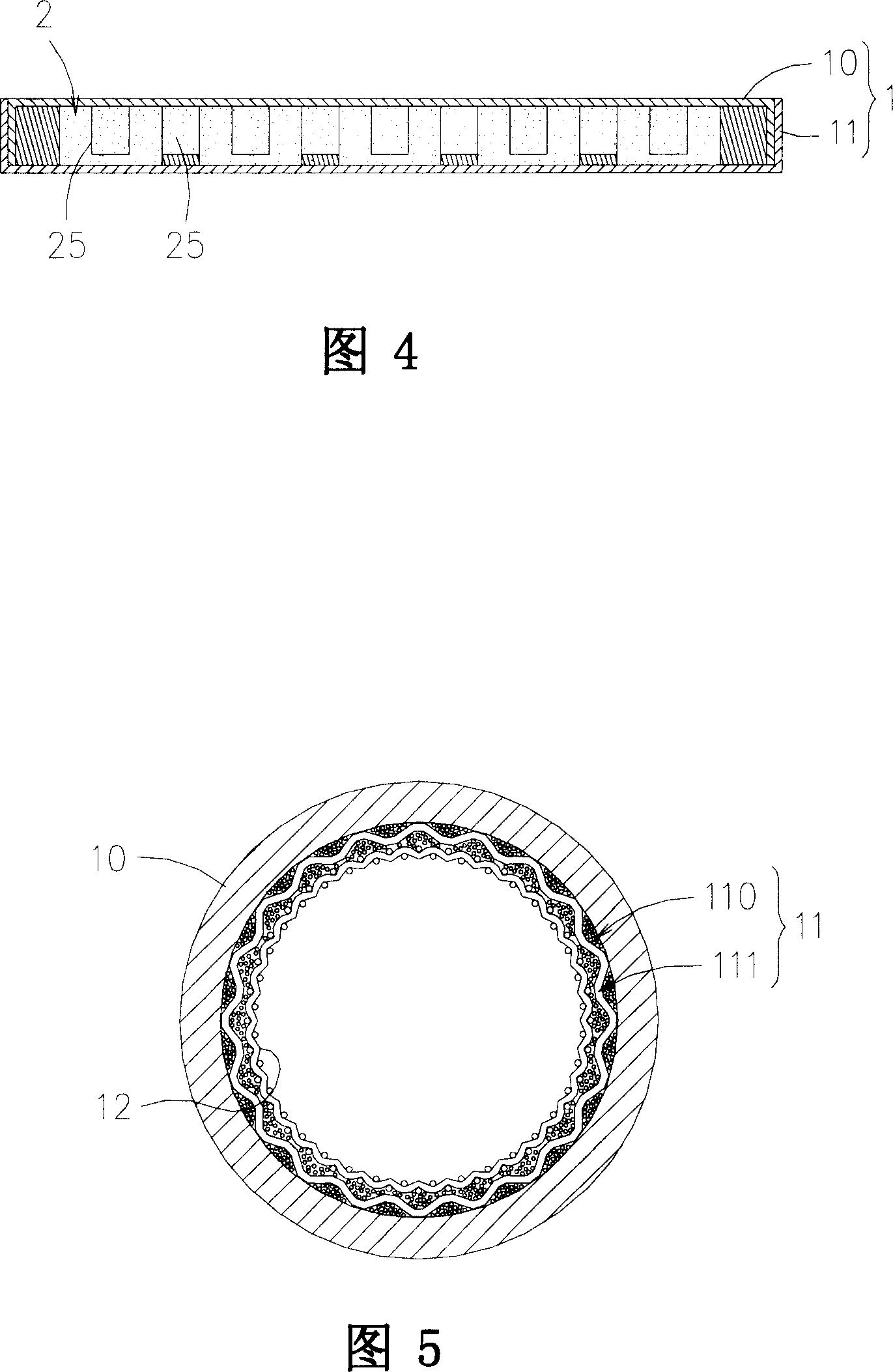

Penetrating support structure and its production

The inventive structural support is made of the braided wire or is made of sheet or block material to form a sheet-shaped concave-convex structure with several throughholes by punching, etching, electroplating or electroforming processes. The structural support is combined in the cavity of liquid-vapour two phases cooling assembly and is fit with a capillary structural layer.

Owner:奇科技股份有限公司

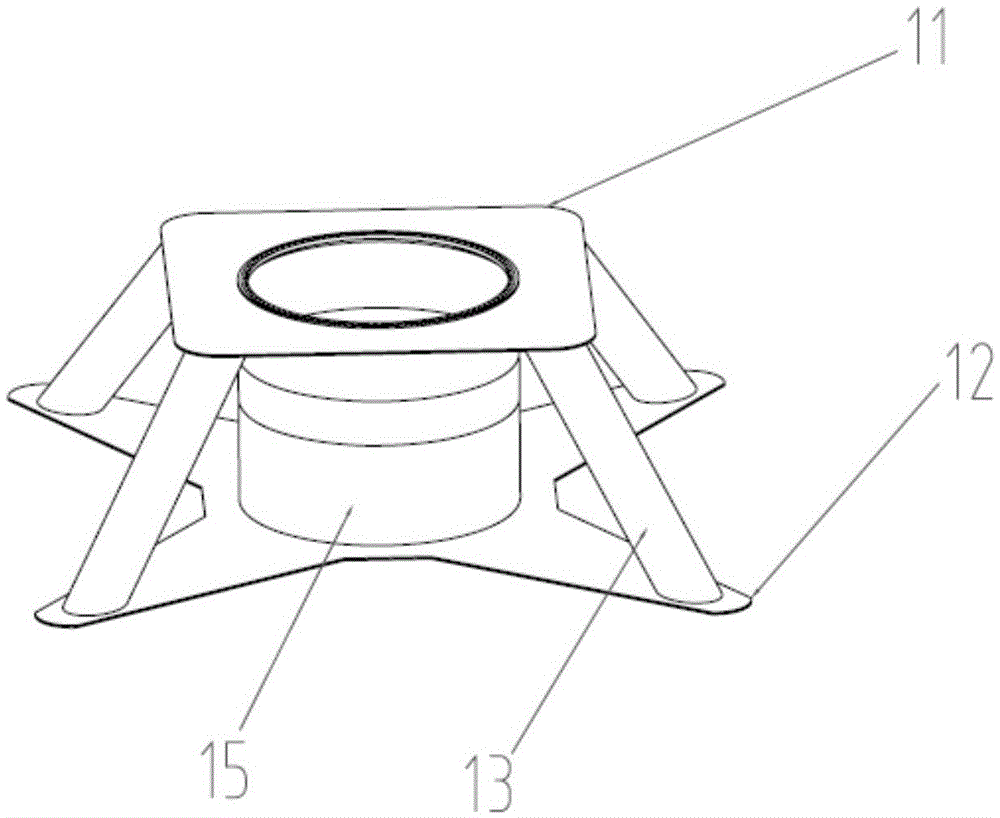

Offshore wind power jacket foundation transition section and offshore wind power jacket foundation

InactiveCN105569068AExtended service lifeAvoid concentrationFoundation engineeringStress concentrationEngineering

The invention provides an offshore wind power jacket foundation transition section and an offshore wind power jacket foundation. The offshore wind power jacket foundation transition section comprises a top plate, a bottom plate, a main barrel and a plurality of supporting pieces, wherein the top plate fixedly sleeves the upper end of the main barrel; the bottom plate fixedly sleeves the lower end of the main barrel; the supporting pieces are arranged in the peripheral direction of the outer side of the main barrel; the upper end of each supporting piece is fixedly connected with the top plate; and the lower end of each supporting piece is fixedly connected with the bottom plate. When the offshore wind power jacket foundation transition section is used, because the top plate fixedly sleeves the upper end of the main barrel, the area of the upper end of the main barrel is increased; and the supporting pieces are fixedly connected with the top plate, so that the supporting area of the upper end of the offshore wind power jacket foundation transition section is increased, load on the upper end of the offshore wind power jacket foundation transition section can be dispersed, and is transmitted uniformly, stress concentration is avoided, and the service life of the offshore wind power jacket foundation transition section is prolonged.

Owner:ZHEJIANG HUA YUN OFFSHORE ENG & TECH SERVICE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com