NiOOH@CuO/Cu2O composite nanosheet array film as well as preparation method and application thereof

A nanosheet array and nanosheet technology, which is applied in the field of nanomaterials and their electrochemical energy storage, can solve the problems of unstable composition structure, difficult electrochemical activity, and poor cycle reversibility, and achieve good symmetry and good charge-discharge curves. Cycling stability, the effect of simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

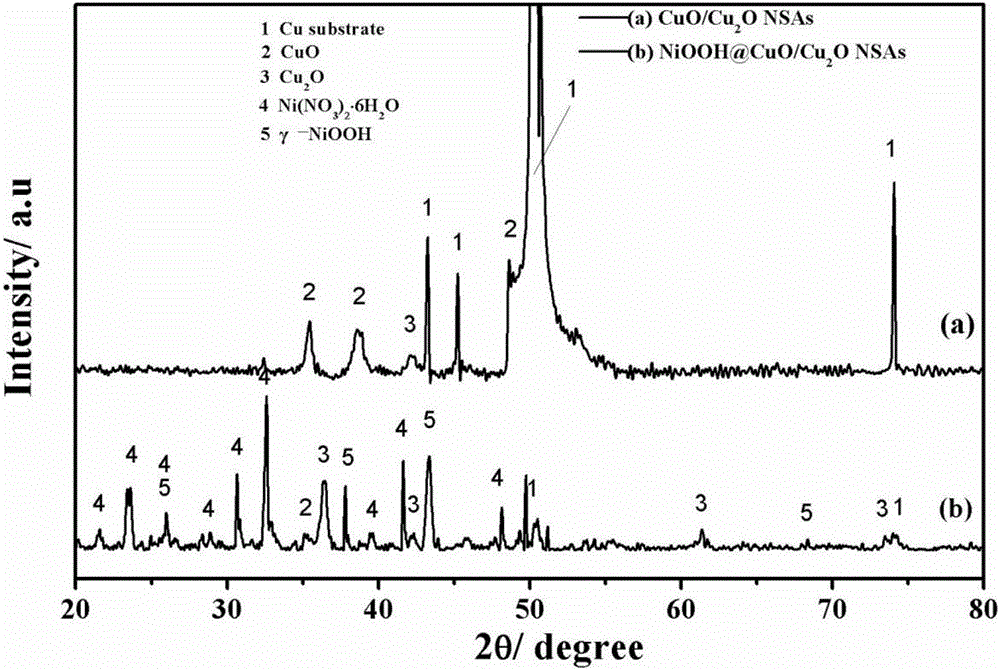

[0028] A NiOOH@CuO / Cu 2 The preparation method of O composite nanosheet array film, concrete steps are as follows

[0029] (1) Pretreatment of high-purity copper foil:

[0030] After cleaning the high-purity copper foil with distilled water, soak it in RY-522 copper chemical polishing solution at room temperature for 30s, then take it out and wash it with distilled water, neutralize it with 10g / L NaOH, clean it ultrasonically with distilled water, and set it aside.

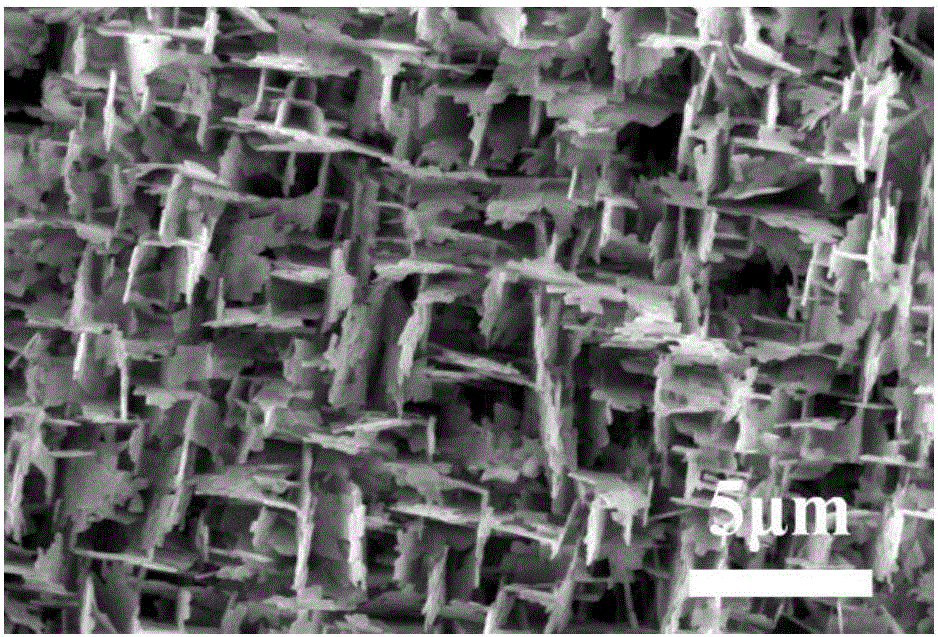

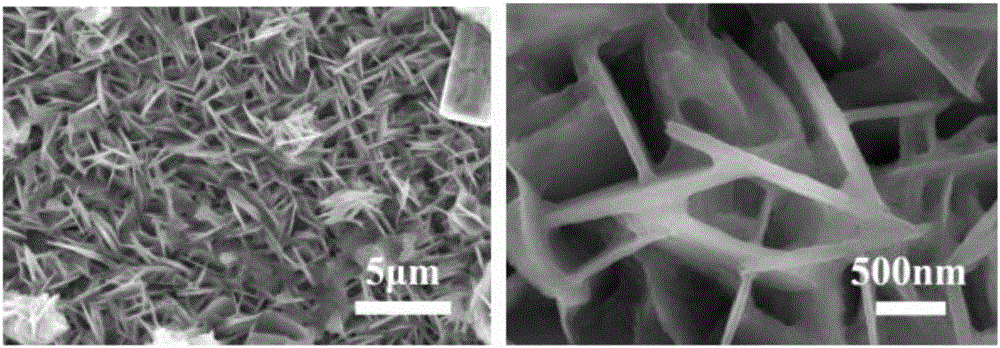

[0031] (2) Preparation of CuO / Cu by galvanostatic anodic oxidation 2 O nanosheet array film

[0032] The mixed solution of 40g / L sodium hydroxide, 150g / L sodium chloride and 1g / L polyethylene glycol 20000 is used as the electrolyte, the high-purity copper foil is used as the anode, and the high-purity titanium sheet is used as the cathode. The effective area of the pure titanium sheet is 3 times the effective area of the high-purity copper foil), put it into the electrolytic cell, connect the DC stabilized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com