Lithium-ion battery anode material, non-aqueous electrolyte lithium-ion battery and preparation method of non-aqueous electrolyte lithium-ion battery

A lithium-ion battery and non-aqueous electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as unstable lithium dendrites in liquid electrolytes, and achieve the effects of improving electrochemical performance, reducing interface impedance, and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

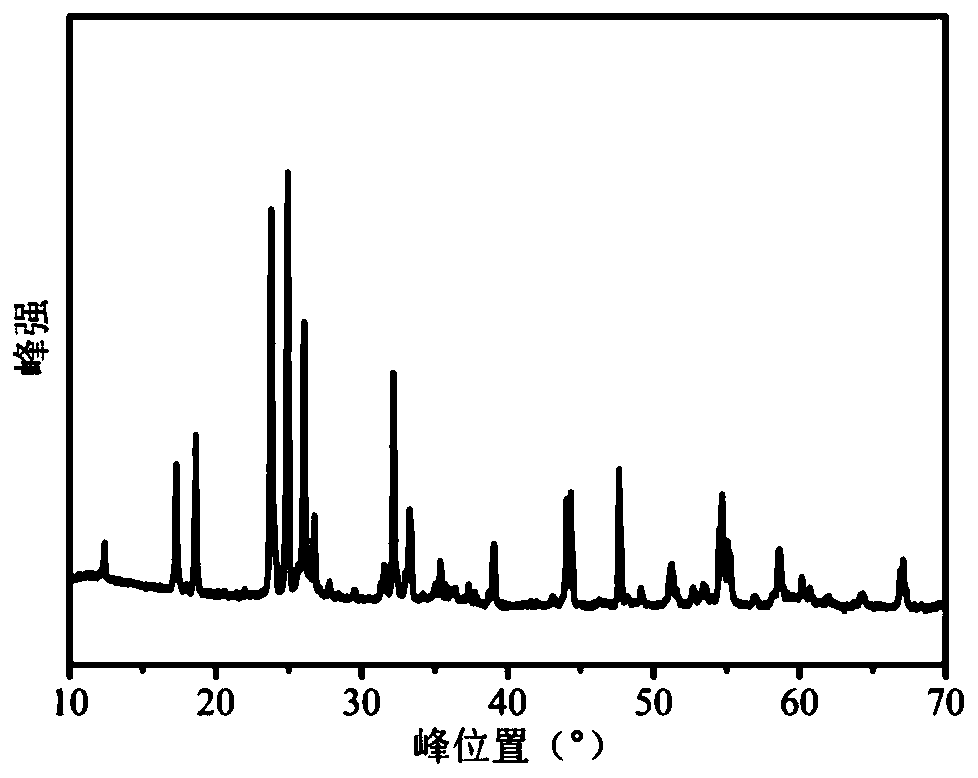

[0069] As a further embodiment, the lithium ion battery negative electrode material M x Ti 2+xy-5x Nb 10+x(4-y) O 29 The preparation method includes solid phase method, solution method, template method and electrospinning method. The following are the specific steps of each preparation method.

[0070] Solid phase method:

[0071] The solid phase method includes the following steps: mixing the metal M source, Ti source, and Nb source in a molar ratio of M:Ti:Nb=x:(2+xy-5x):[10+x(4-y)], and then Perform high-energy ball milling and high-temperature sintering in sequence to obtain M x Ti 2+xy-5x Nb 10+x(4-y) O 29 Powder; the high temperature sintering temperature is 1100~1400℃, and the high temperature sintering time is 3~5h.

[0072] Wherein, the metal M source is M oxide and / or M salt, and the M salt is acetylacetone M and / or M acetate; the Ti source is titanium dioxide, tetraisopropyl titanate, tetrabutyl titanate, hydrated titanium oxysulfate One or any combination;...

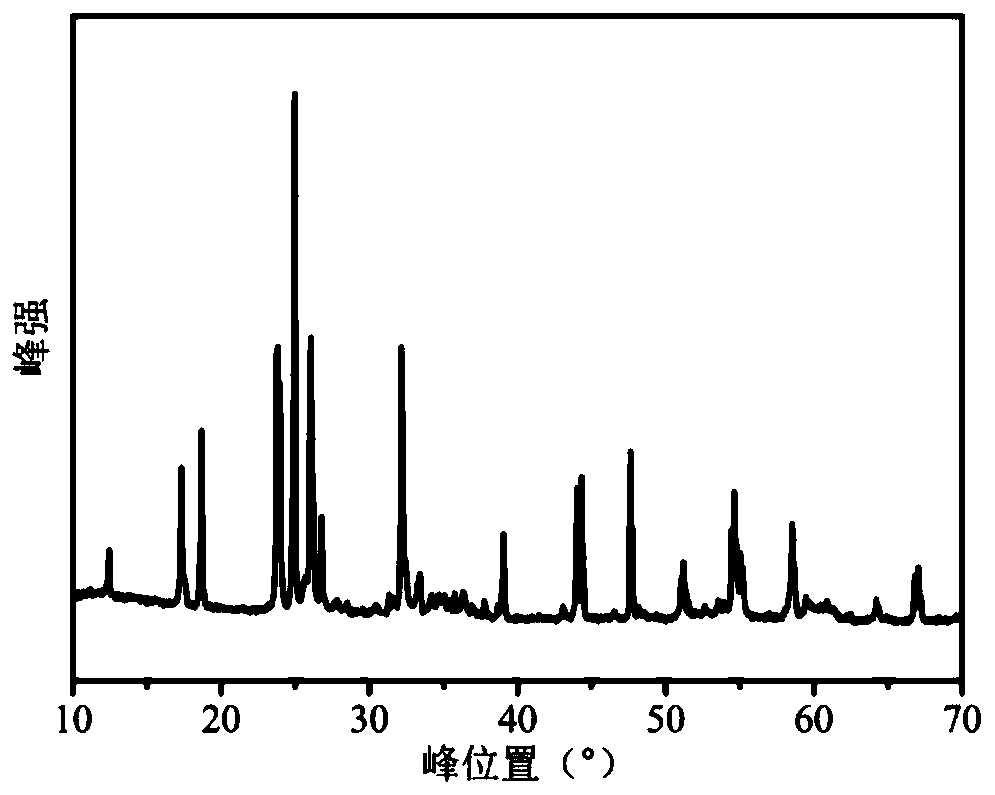

Embodiment 1

[0110] 本实施例提供了一种采用固相法制备Cu 0.3 Ti 1.1 Nb 10.6 o 29 电极材料的方法,其包括以下步骤:

[0111] After mixing the proportion of copper oxide, titanium dioxide, and penta oxide according to the proportion of Moore ratio 0.3: 1.1: 10.6, it can be mixed with a high -energy ball milling method. 0.3 Ti 1.1 Nb 10.6 o 29 powder.

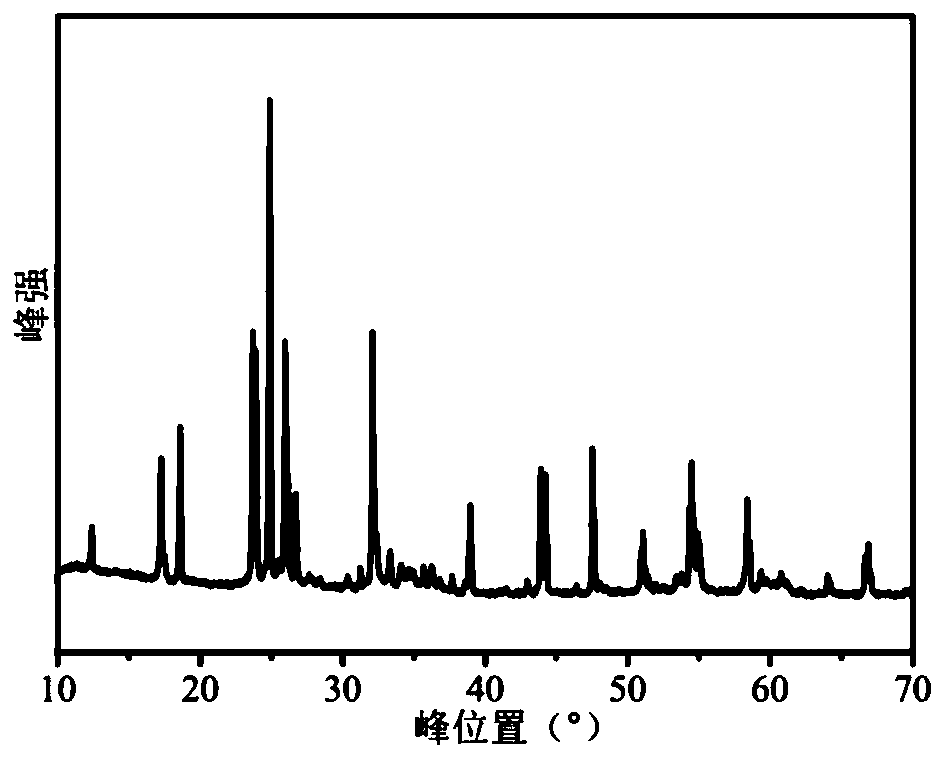

Embodiment 2

[0113] 本实施例提供了一种采用固相法制备Mg 0.3 Ti 1.1 Nb 10.6 o 29 电极材料的方法,其包括以下步骤:

[0114] After mixing with a high -energy ball mill method based on the ratio of Moore ratio 0.3: 1.1: 10.6, it can be mixed at 1300 to get MG 0.3 Ti 1.1 Nb 10.6 o 29 powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com