Honeycomb stannic oxide material and preparation method thereof

A tin dioxide and honeycomb technology, applied in the field of honeycomb tin dioxide material and its preparation, can solve the problems of dispersive electron or ion transport obstacles, severe volume expansion, low agglomeration stability, etc., and achieve excellent electrochemical performance , the effect of enhancing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

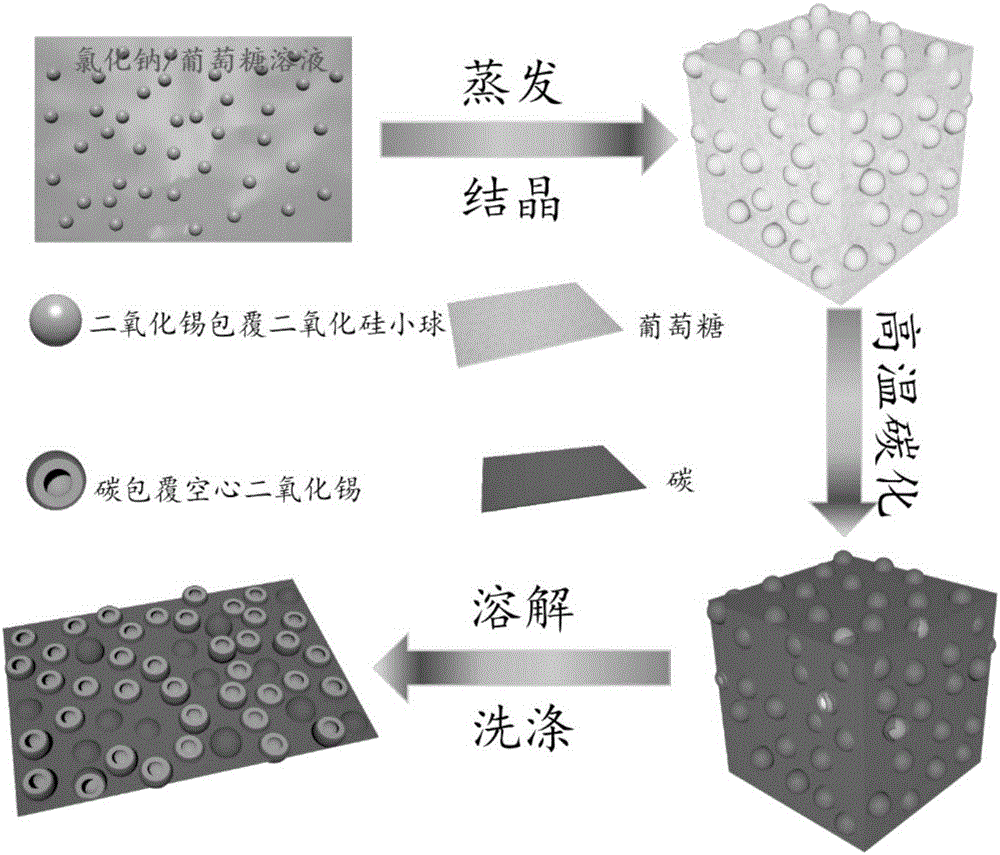

[0027] Specific embodiment one: present embodiment a kind of preparation method of honeycomb tin dioxide lithium (sodium) ion battery negative electrode material, realize according to the following steps:

[0028] Preparation of silica pellets: Measure 61.75mL of ethanol and 24.75mL of deionized water in the same beaker and mix evenly, then add 4.5mL of tetraethyl orthosilicate and 9mL of ammonia water with a mass fraction of 25% , stirred at room temperature for 8 hours, centrifuged and washed several times with deionized water and alcohol respectively and dried overnight at 60°C to obtain the product;

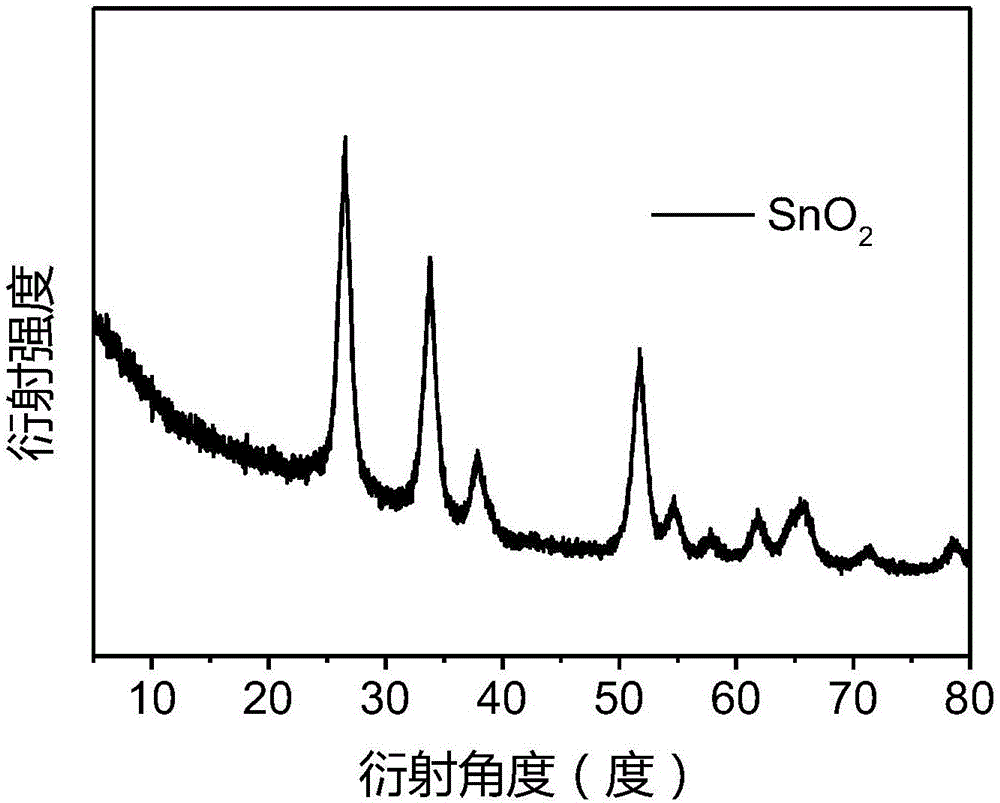

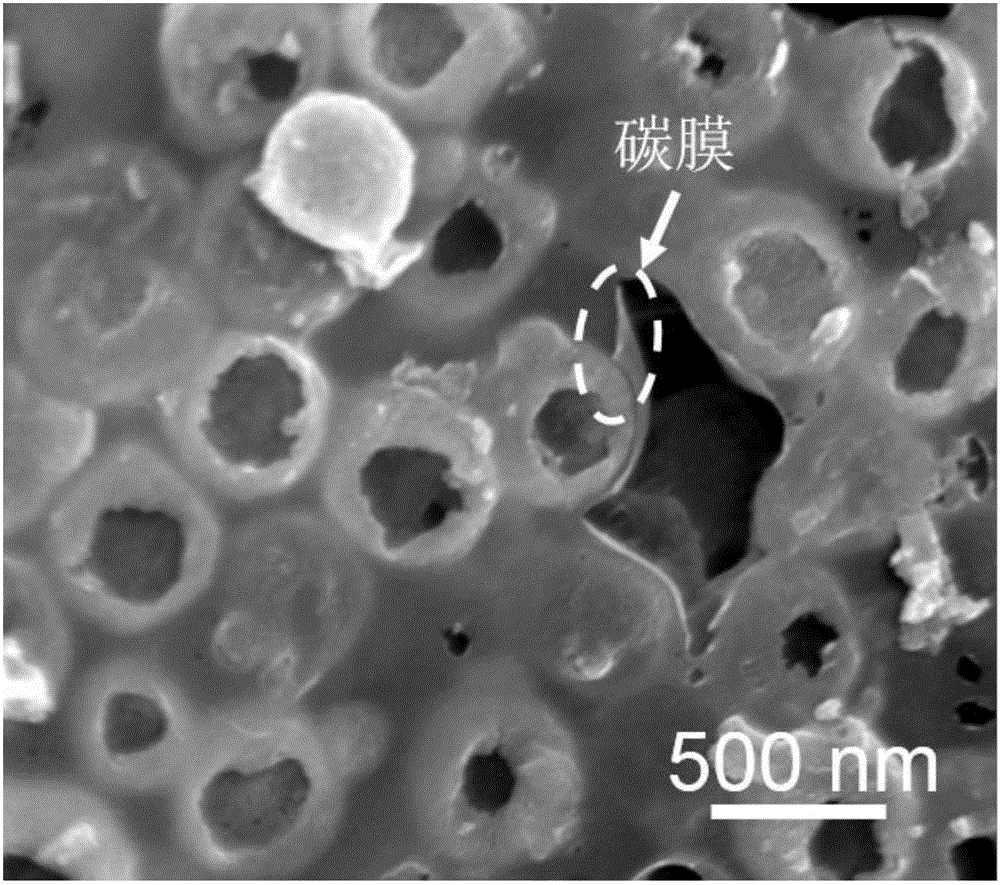

[0029] Preparation of tin dioxide-coated silica pellets: Weigh 0.04 g of silica pellets and ultrasonically disperse them in 60 mL of water-ethanol mixture to obtain a white suspension, wherein the volume fraction of ethanol is 37.5%; Then add 0.3g potassium stannate trihydrate and 1.8g urea and continue to stir for 5 minutes, transfer the suspension to a 100mL hydrothermal ke...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment is different from Embodiment 1 in that 0.2 g of glucose and 10 g of sodium chloride are dissolved in the dispersion in the step of preparing the honeycomb tin dioxide / carbon composite electrode material. Other parameters and specific implementation steps are the same as those in Embodiment 1. In Example 2, a larger proportion of carbon source was used, and the proportion of carbon in the prepared sample was increased to study the role played by the carbon layer in the designed structure.

[0033] In the steps of the above examples, under the condition that other steps and parameters remain unchanged, the amount of organic matter added in the preparation of the honeycomb tin dioxide / carbon composite electrode material is the key factor to control the experimental variables.

[0034] Two parameters are adopted in the embodiment, namely 0.1 g glucose and 0.2 g glucose. The difference between the two lies in the different proportions of organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com