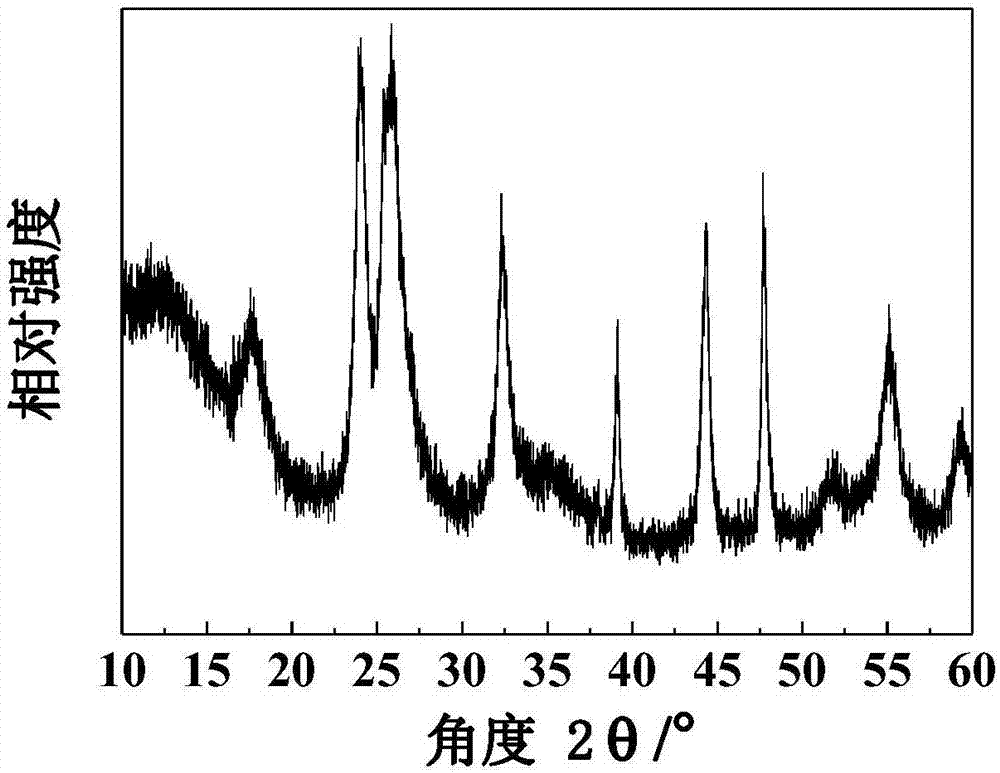

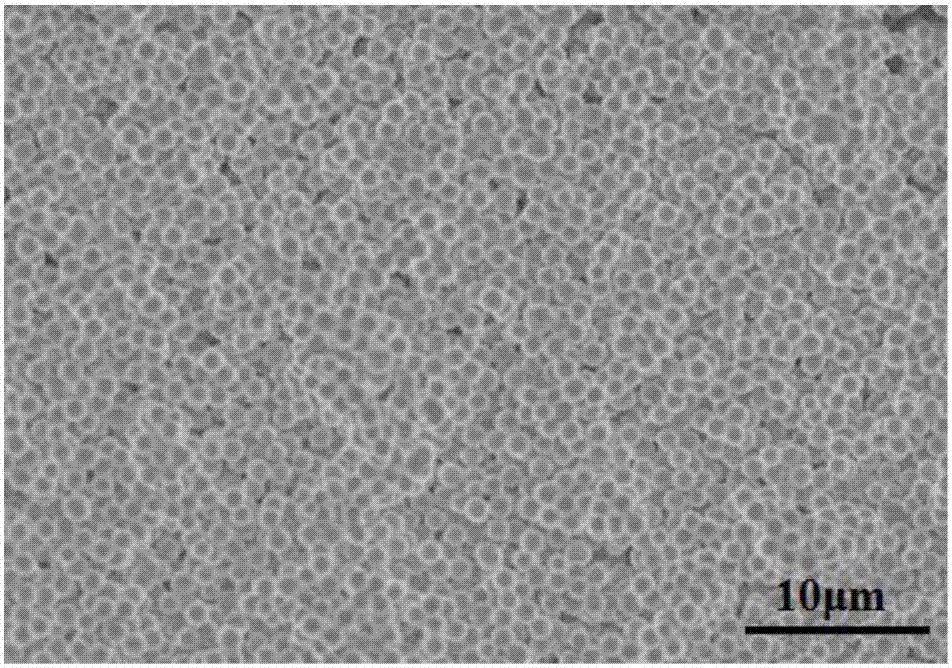

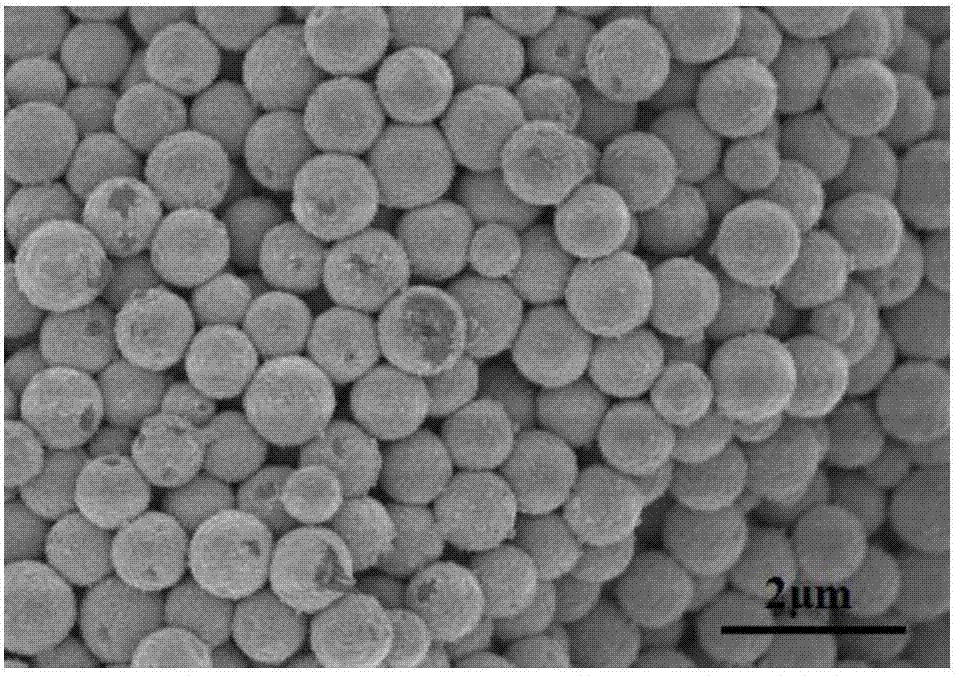

Preparation method of hollow TiNb2O7 microsphere

A microsphere and hollow technology, applied in chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve the problems of not very good cycle performance, unstable structure, capacity fading, etc., to improve cycle performance and rate performance, and prepare Short cycle time, stress relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 8.9 g of glucose, measure 70 ml of deionized water, pour them into 100 ml beakers, and magnetically stir for 0.5 h to obtain a clear glucose solution; pour the glucose solution into a 100 ml hydrothermal reaction kettle, and Insulate at 140°C for 8 h; after cooling to room temperature, they were alternately centrifuged twice with absolute ethanol and deionized water, respectively, and placed in an oven at 70°C for 9 h to obtain carbon spheres. Weigh 0.4 g of carbon sphere powder, measure 20 ml of absolute ethanol, pour them into 50 ml beakers, place them in an ultrasonic cleaner, and perform ultrasonic dispersion for 1.5 h to obtain a uniformly dispersed suspension of carbon spheres; weigh 0.52g of niobium pentachloride, 0.28g of titanium isopropoxide, and pour them into the suspension of carbon spheres, and magnetically stir at room temperature for 2 h; finally, pour the uniformly mixed suspension into 50 ml of In the reaction kettle, it was kept at 160 °C for 24...

Embodiment 2

[0025] Weigh 9.0 g of glucose, measure 80 ml of deionized water, pour them into 100 ml beakers, and magnetically stir for 1 h to obtain a clear glucose solution; pour the glucose solution into a 100 ml hydrothermal reaction kettle, and Insulate at 150 °C for 10 h; after cooling to room temperature, they were washed by alternating centrifugation with absolute ethanol and deionized water for 3 times, and placed in an oven at 80 °C for 10 h to obtain carbon spheres. Weigh 0.5 g of carbon sphere powder, measure 22 ml of absolute ethanol, pour them into 50 ml beakers, place them in an ultrasonic cleaner, and carry out ultrasonic dispersion for 2 h to obtain a uniformly dispersed suspension of carbon spheres; 0.54 g of niobium pentachloride, 0.30 g of titanium isopropoxide, and pour them into the suspension of carbon spheres, and magnetically stir at room temperature for 3 h; finally, pour the uniform suspension into 50 ml of In the reaction kettle, it was kept at 170 °C for 22 h, a...

Embodiment 3

[0027] Weigh 9.1 g of glucose, measure 90 ml of deionized water, pour them into 100 ml beakers, and magnetically stir for 1.5 h to obtain a clear glucose solution; pour the glucose solution into a 100 ml hydrothermal reaction kettle, and Insulate at 160 °C for 12 h; after cooling to room temperature, they were washed by alternating centrifugation with absolute ethanol and deionized water for 4 times, and placed in an oven at 90 °C for 12 h to obtain carbon spheres. Weigh 0.6 g of carbon sphere powder, measure 24 ml of absolute ethanol, pour them into 50 ml beakers, place them in an ultrasonic cleaner, and carry out ultrasonic dispersion for 25 h to obtain a uniformly dispersed suspension of carbon spheres; 0.56g niobium pentachloride, 0.32 g titanium isopropoxide, and pour them into the suspension of carbon spheres, stir magnetically at room temperature for 2 h; pour the uniformly mixed suspension into 50 ml of reaction In the still, it was kept at 180 °C for 26 h, and it was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com