Patents

Literature

152 results about "Titanium isopropoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium isopropoxide, also commonly referred to as titanium tetraisopropoxide or TTIP, is a chemical compound with the formula Ti{OCH(CH₃)₂}₄. This alkoxide of titanium(IV) is used in organic synthesis and materials science. It is a diamagnetic tetrahedral molecule. Titanium isopropoxide is a component of the Sharpless epoxidation, a Nobel-Prize-winning method for the synthesis of chiral epoxides.

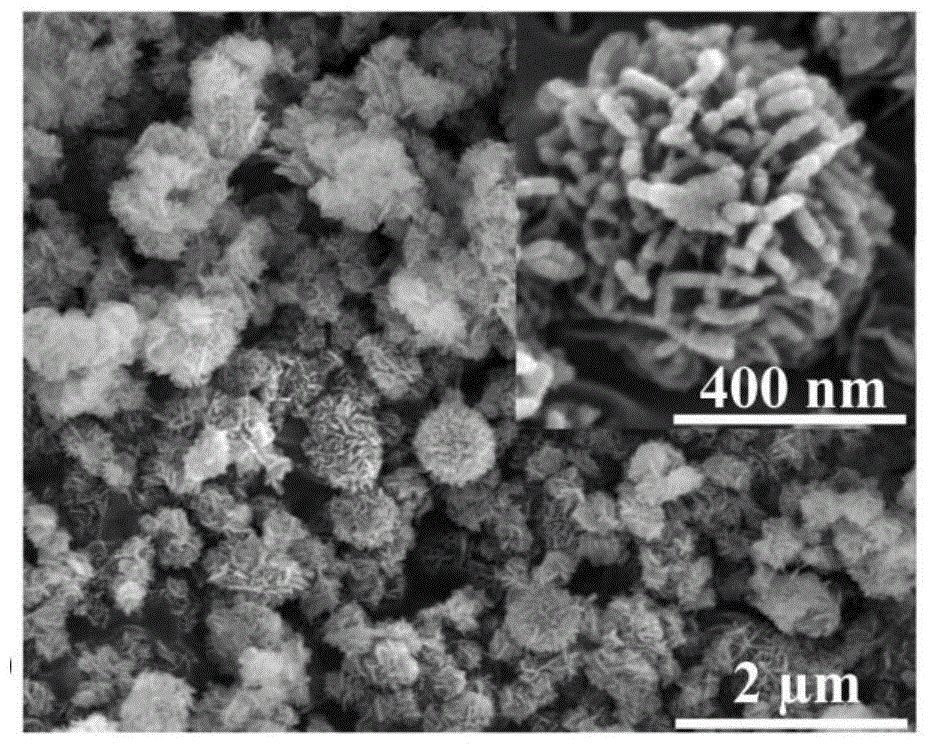

Carbon nitride/titanium dioxide nanosheet array heterojunction photocatalyst and preparation method

InactiveCN106944116AImprove photocatalytic hydrogen production activityImprove photocatalytic activityWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionDiethylenetriamine

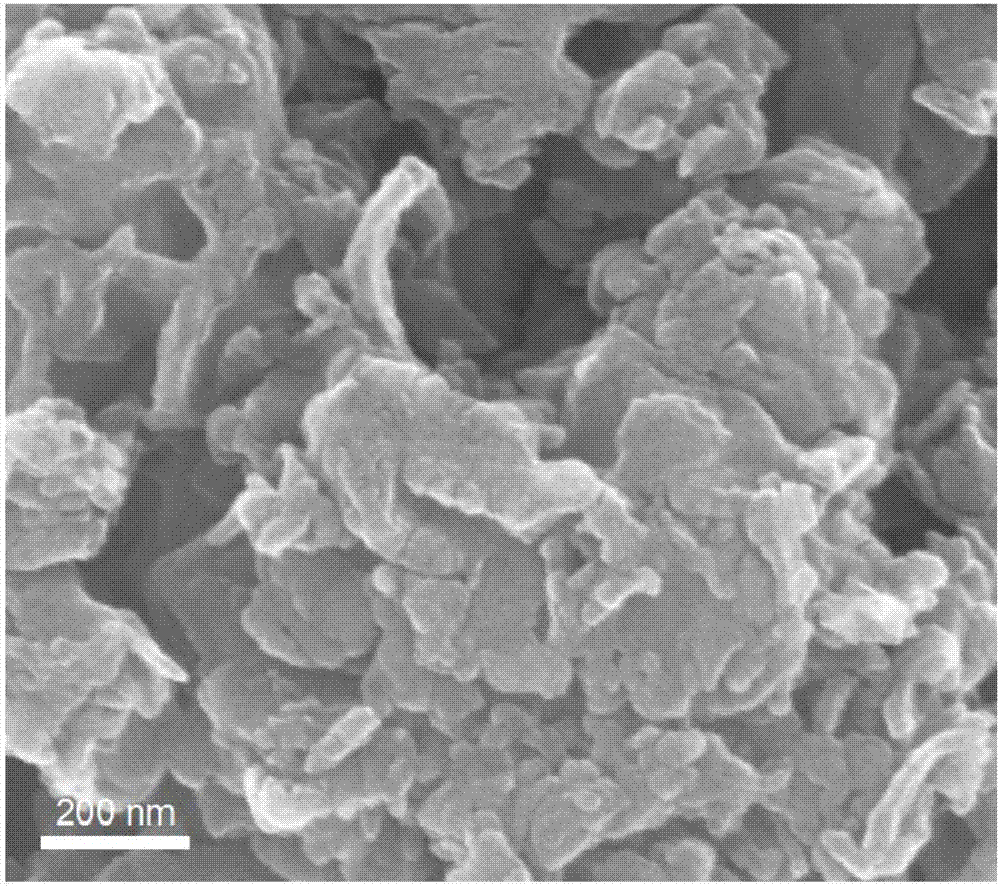

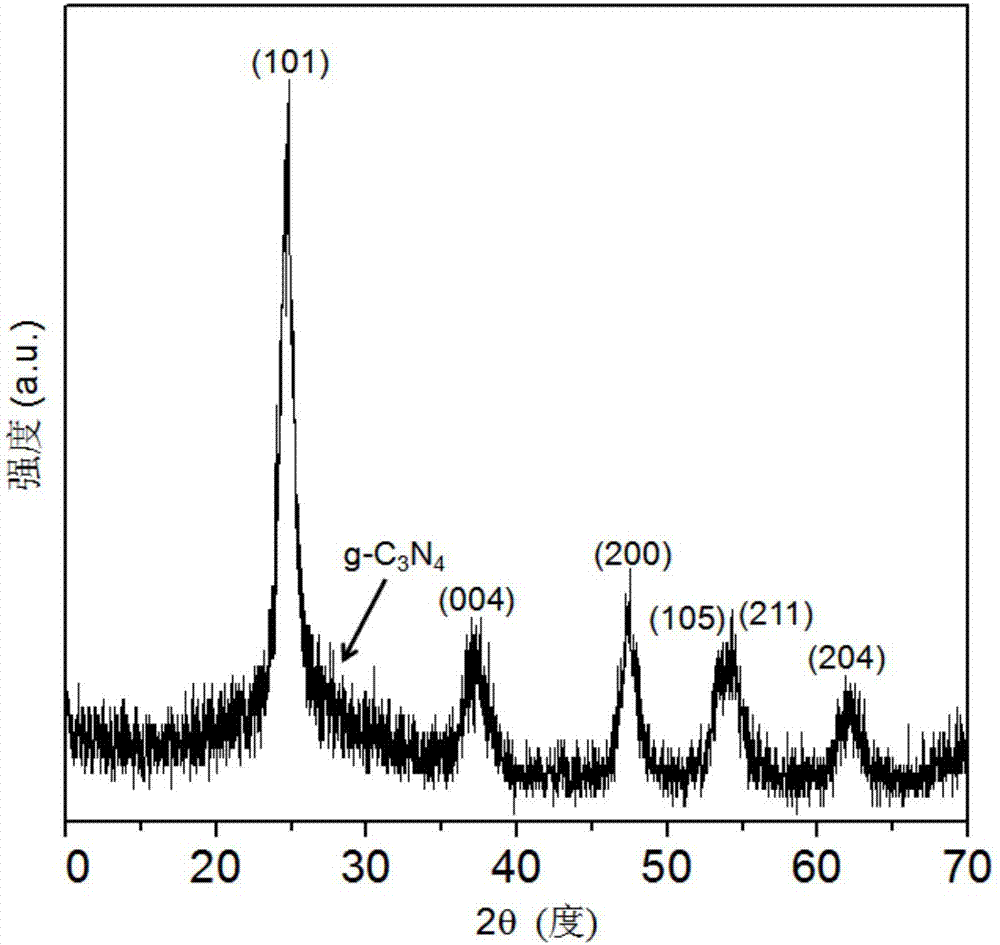

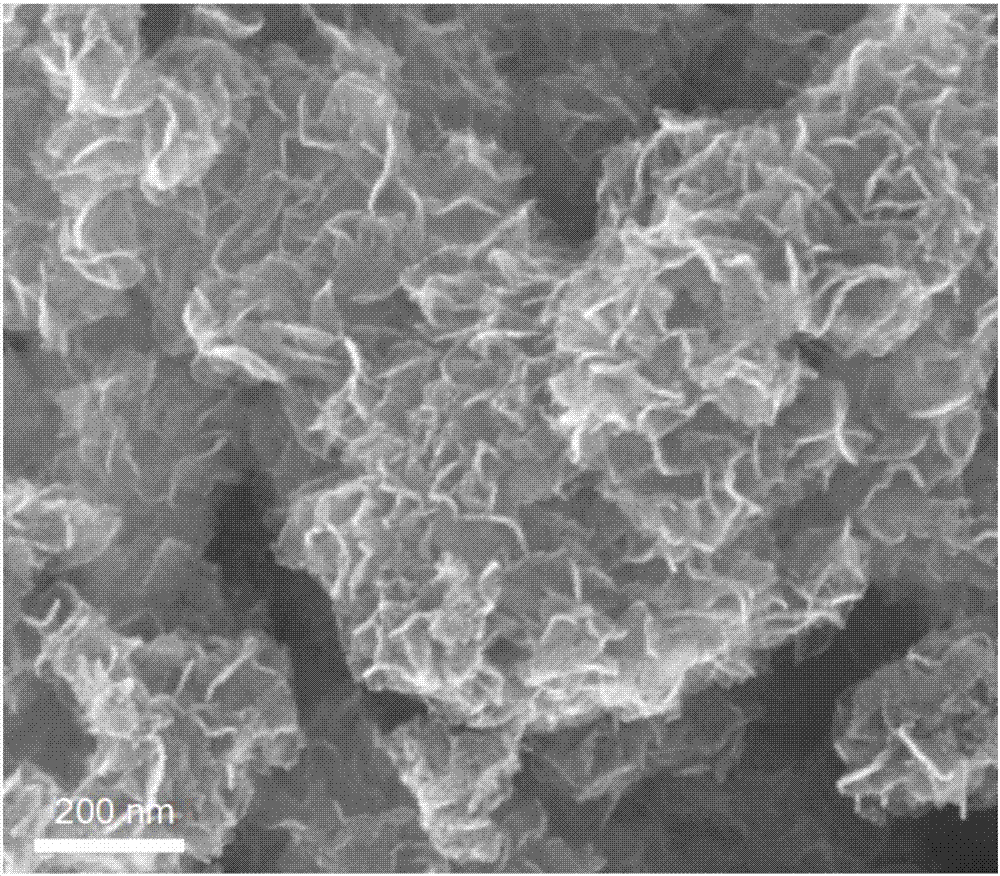

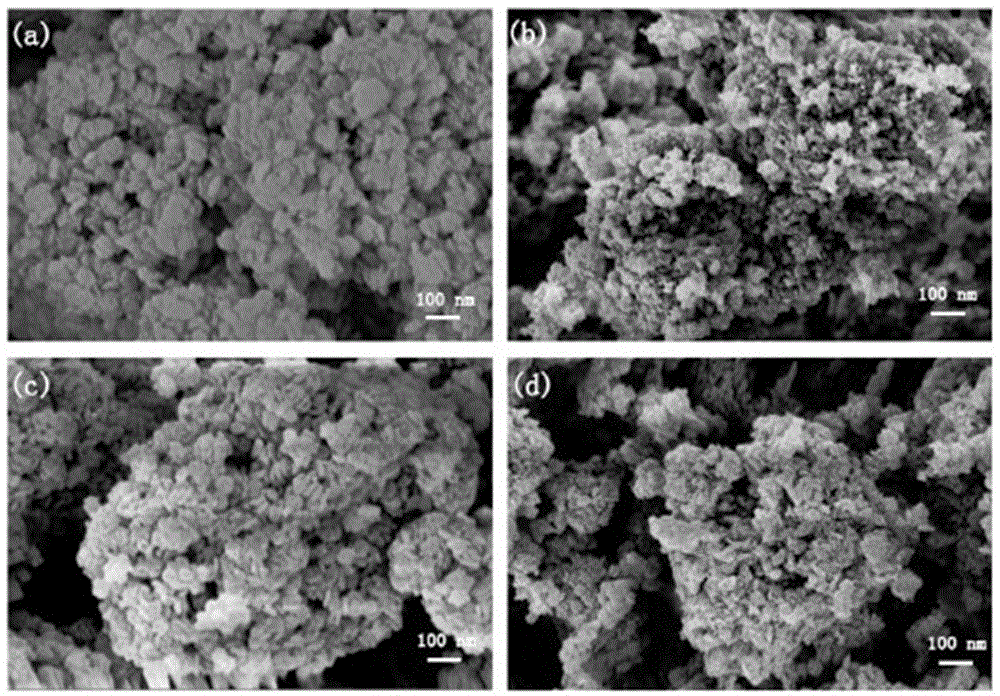

The invention relates to a carbon nitride / titanium dioxide nanosheet array heterojunction photocatalyst and a preparation method, belonging to the technical field of photocatalysis of nanometer materials. The catalyst is prepared through the following steps: with g-C3N4 as a carrier, titanium isopropoxide as a titanium source, diethylenetriamine as a morphology controlling agent and isopropanol as a solvent, performing a solvothermal method so as to prepare a g-C3N4 / TiO2 precursor, and carrying out calcination treatment so as to obtain a g-C3N4 / TiO2 nanosheet array heterojunction composite photocatalyst for the first time. The heterojunction composite photocatalyst shows pure and significantly-improved photocatalytic hydrogen production activity to g-C3N4 and anatase TiO2 nanosheet mesoporous spheres in a photocatalytic hydrogen production reaction. The preparation method has the advantages of simple and convenient operation, easy control, greenness, environmental protection and good application prospects. The series of catalysts has multilevel structure; and a g-C3N4 / TiO2 nanosheet array heterojunction structure is formed through vertical and staggered growth of anatase TiO2 nanosheets with regular shape and uniform size on the surface of g-C3N4. The catalyst has excellent photocatalytic hydrogen production activity, good stability, high repeatability and facilitation large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

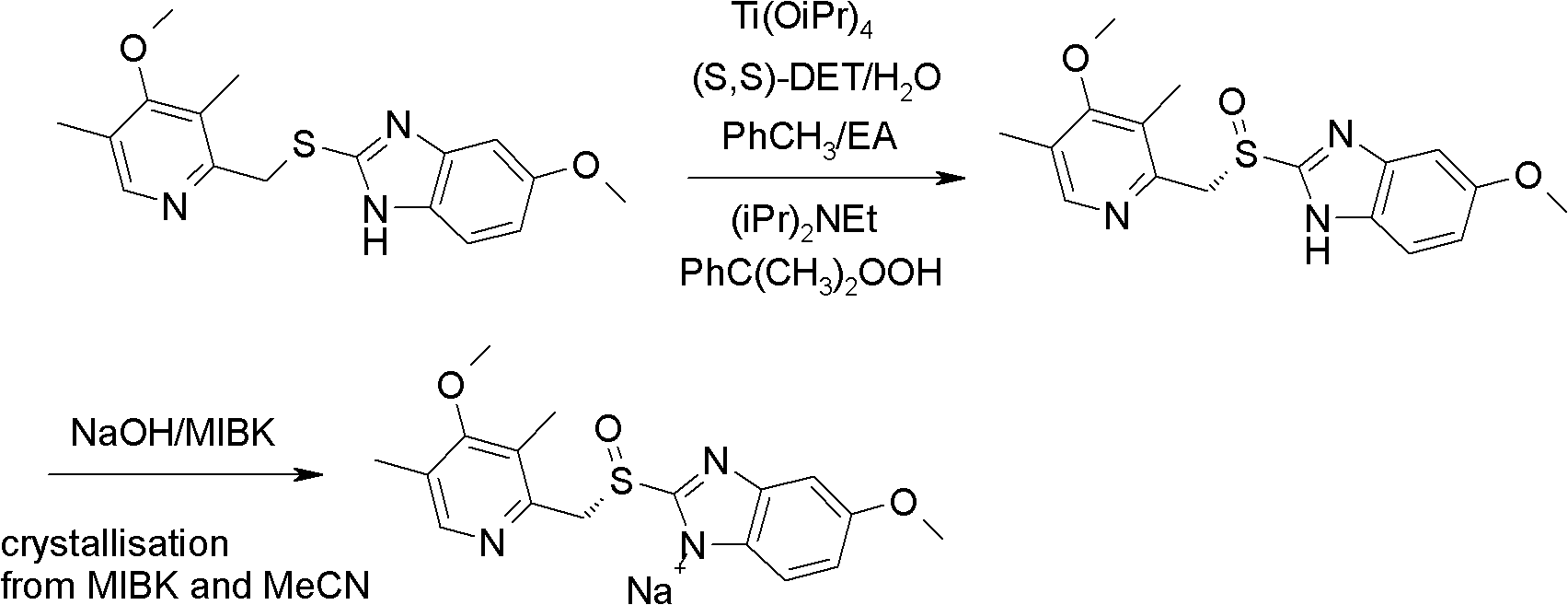

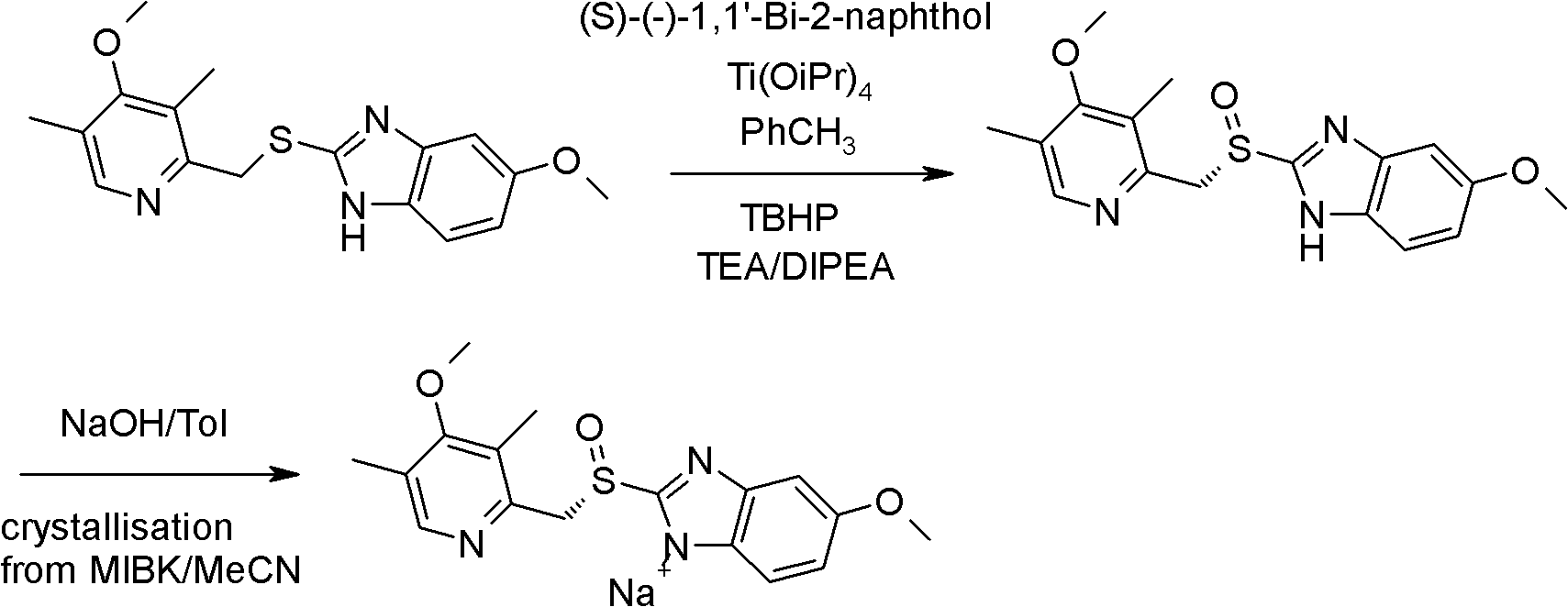

Industrial production method of high-purity esomeprazole sodium

ActiveCN102321071AReduce the impactOxidation reaction time is shortOrganic chemistryOrganic basePotassium hydroxide

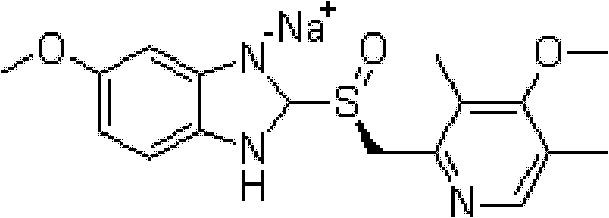

The invention relates to an industrial production method of high-purity esomeprazole sodium. The industrial production method is characterized by comprising the following steps: mixing a raw material 5-methoxy-2-(4-methoxy-3,5-dimethyl-2-pyridyl) methylthio-1H-benzimidazole with a solvent for dissolving 5-methoxy-2-(4-methoxy-3,5-dimethyl-2-pyridyl) methylthio-1H-benzimidazole; and successively adding water, D-diethyl tartrate and titanium iso-propoxide as well as an inorganic base, then adding cumene hydroperoxide, adding methanol or ethanol after reaction, filtering, carrying out posttreatment and salifying to prepare high-purity esomeprazole sodium, wherein the inorganic base is one of potassium carbonate, sodium carbonate, sodium hydroxide and potassium hydroxide. By using the method in the invention, the defects of high cost and serious environment pollution which are caused by using the organic base in the prior art are solved, and the defects of difficult posttreatment, poor repeatability and difficult industrialization in the prior art are solved simultaneously. According to the invention, the inorganic base is used as the raw material, thus the industrial production method has the advantages of low cost, little environment pollution, short reaction time and high product purity, is easy to operate and industrially produce.

Owner:NANJING HAIRUN PHARM CO LTD

Preparation method for synthesizing sheet-type cladding material by fluidized bed gas-phase method

ActiveCN103773084AImprove or change dispersionImprove or change surface activityChemical industryPigment treatment with non-polymer organic compoundsSilicic acidTitanium isopropoxide

The invention discloses a preparation method for synthesizing a sheet-type cladding material by a fluidized bed gas-phase method. According to the method, a sheet-type material is used as a matrix material, one or two of volatilizable metal or non-metal organic substances, such as titanium tetrabutoxide, isopropyl titanate, tetra(dimethylamino) titanium, tetra(dimethylamino) titanium, tetraethylortho silicate, 1,2-dimethyl silicon oxide, dichlorosilane, triisobutyl aluminium, carbonyl iron and chromium carbonyl, is or are used as a cladding raw material, and nitrogen, air, argon, helium or carbon dioxide is used as fluidizing gas, so that the sheet-type cladding material is prepared by pyrolysis through a fluidized bed. Metal oxide particles cladding the surface of sheet-type mica by the method can reach the nano level, are compact and uniform and have a wide application prospect in the aspects of decoration, catalysis, photocatalysis, batteries, gas storage and separation. The whole preparation process is executed in a closed container; the cladding raw material is recyclable, so that the preparation method is environmentally friendly, energy-saving and pollution-free; furthermore, the conversion rate o reactants is increased.

Owner:SHANXI LANHUA HUAMING NANO MATERIALS

Preparation method of upconversion material of core shell structure and application of conversion material in perovskite solar cell

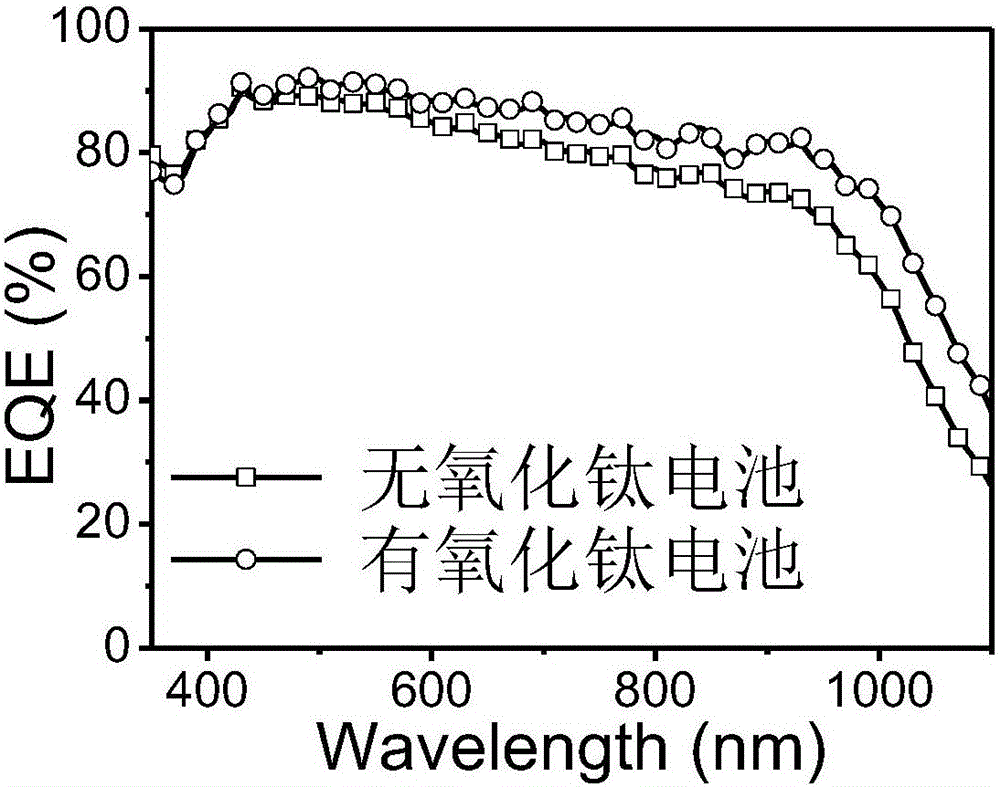

ActiveCN105428541AImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellTitanium tetraisopropoxide

The invention relates to a preparation method of an upconversion material of a core shell structure. The method comprises that NaYF4:Yb3+, Er3+ is dispersed into isopropanol, deionized water and ammonia water are added, and stirring is carried out to obtain a first mixed solution; ethyl orthosilicate is added into isopropanol, the isopropanol added with the ethyl orthosilicate is added into the first mixed solution slowly drop by drop, stirring, washing and centrifugal collection are carried out to obtain NaYF4:Yb3+, Er3+@SiO2; and the obtained NaYF4:Yb3+, Er3+@SiO2 deposition is re-dispersed into an isopropanol and DETA mixed solution, mixing is carried out to obtain a second mixed solution, titanium isopropoxide is added into isopropanol, and the isopropanol added with the titanium isopropoxide is added into the second mixed solution slowly drop by drop, stirring is carried out, the obtained solution is added into a hydro-thermal reactor for hydro-thermal processing, washing is carried out via deionized water and ethanol after cooling, the drying is carried out to obtain the upconversion material NaYF4:Yb3+, Er3+@SiO2@TiO2 of the core shell structure. The upconversion material of the core shell structure can serve as material of an upconversion layer of the perovskite solar cell, the perovskite solar cell can absorb infrared light more effectively via the upconversion material, and the efficiency of the cell is effectively improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

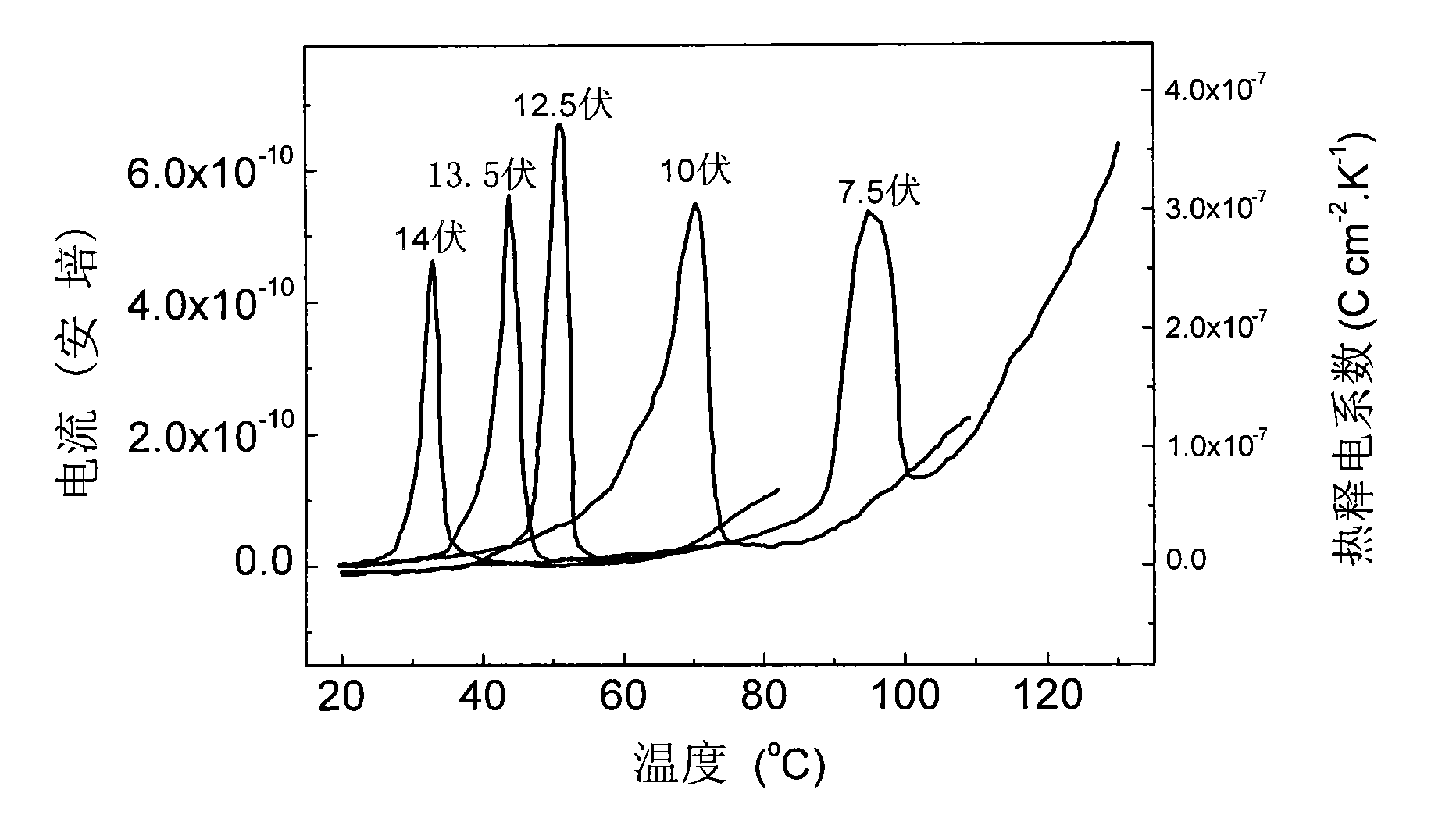

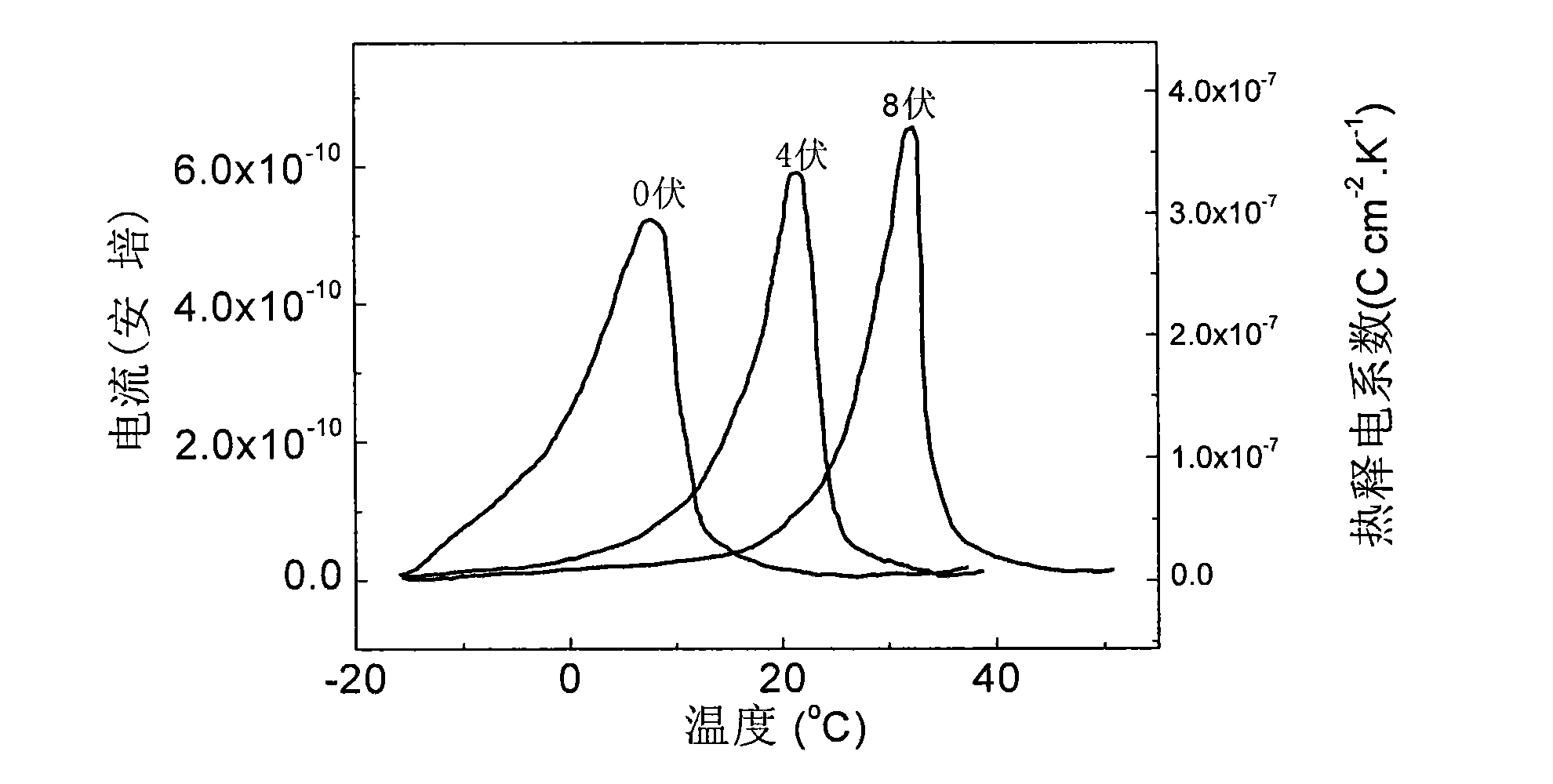

Antiferroelectric film with adjustable working temperature zone and higher pyroelectric coefficient and preparation method thereof

InactiveCN101670691AAdjust working temperatureHigh sensitivityLayered productsPyrometry using electric radation detectorsPyroelectric detectorsNiobium

The invention discloses an antiferroelectric film with adjustable working temperature zone and higher pyroelectric coefficient and a preparation method and application thereof. The antiferroelectric film (Pb,Nb)(Zr,Sn,Ti)O3 taken as the pyroelectric material is prepared by a sol gel method, the solute of precursor solution can be lead acetate, lanthanum acetate or niobium ethoxide, stannic acetate, zirconium isopropoxide and titanium isopropoxide, the solvent includes glacial acetic acid, ethylene glycol ethyl ether, acetylacetone and water, the final concentration of the precursor solution is controlled between 0.2-0.4 M, and the substrate comprises LaNiO3 / Pt / Ti / SiO2 / Si and Pt / Ti / SiO2 / Si. The antiferroelectric film is high in thermally stimulated current and adjustable in temperature andcan be used for a pyroelectric infrared detector, a smart device and a system.

Owner:TONGJI UNIV

Carbon nanofiber/zinc titanate composite for personal protection and production method of carbon nanofiber/zinc titanate composite for personal protection

InactiveCN102560890ALarge specific surface areaImprove adsorption capacityHeating/cooling textile fabricsNon-woven fabricsSpinningTitanium isopropoxide

The invention discloses a production method of carbon nanofiber / zinc titanate composite for personal protection, and the composite obtained by the production method. The production method is characterized by including the steps of: adding titanium isopropoxide and zinc acetate into ethanol solvent, and adding polyvinylpyrrolidone to obtain spinning dope A; adding polyacrylonitrile into N, N-dimethyl formamide solvent to obtain spinning dope B; subjecting the spinning dope A and the spinning dope B to electrostatic spinning to obtain composite fibrous membranes; and allowing the drawn composite fibrous membranes to stand in air to be pre-oxidized, and carbonizing the membranes under nitrogen protection. The carbon nanofiber / zinc titanate composite has the advantages of light weight, high rate of biochemical disintegration, and fine mechanical properties.

Owner:DONGHUA UNIV

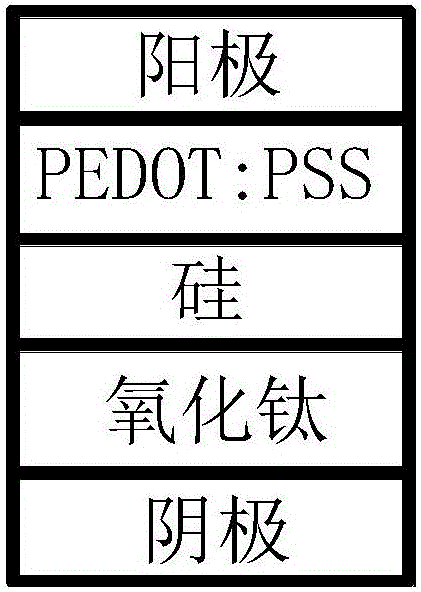

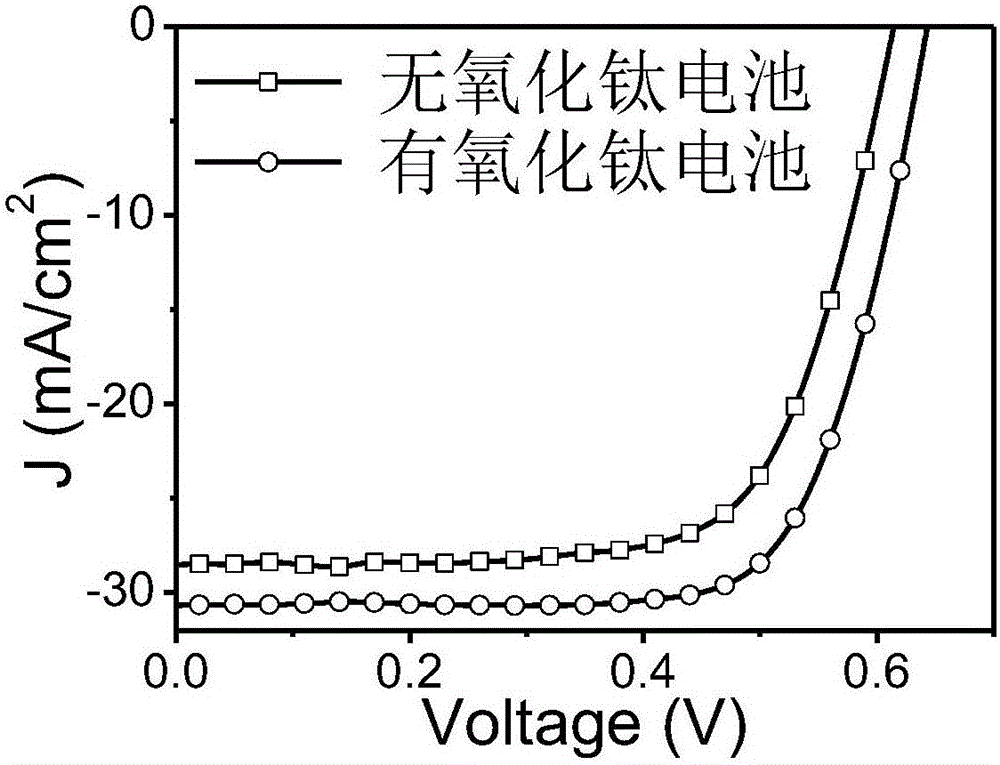

Manufacturing method of solar cell

InactiveCN106169537ASimple preparation processLow equipment requirementsFinal product manufactureSolid-state devicesEvaporationTitanium isopropoxide

The invention discloses a manufacturing method of a solar cell. The manufacturing method of the solar cell comprises the following steps: treating a silicon wafer; coating the treated silicon wafer with a passivation layer solution and a PEDOT:PSS aqueous solution in a spinning way; and performing evaporation to obtain the solar cell, wherein the passive layer solution is a titanium oxide precursor solution; and the titanium oxide precursor solution is prepared by the following steps: 1, dispersing titanium isopropoxide in an isopropanol solution to be diluted, and stirring the solution in order that the titanium isopropoxide is uniformly dispersed to obtain a solution I; 2, diluting a hydrochloric acid solution with isopropanol, dropwise adding the diluted hydrochloric acid solution into the solution I, and stirring the mixed solution to obtain a solution II; and coating the treated silicon wafer with the prepared solution II in a spinning way. The manufacturing method is simple in manufacturing process, and the manufactured solar cell has high physical performance.

Owner:SUZHOU UNIV

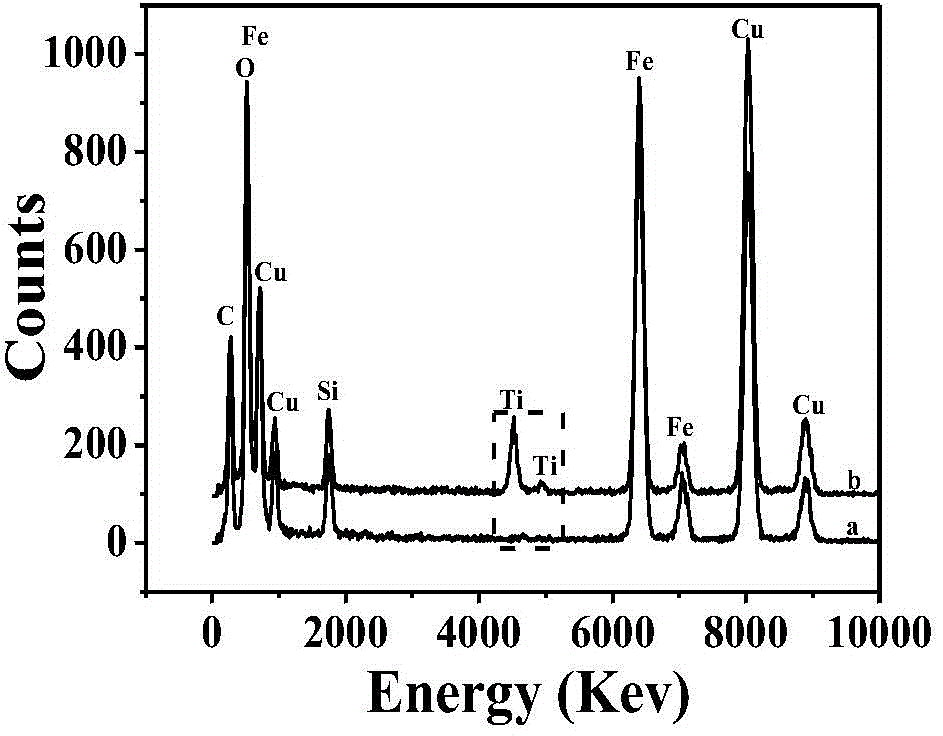

Metal oxide/TiO2 nanocatalyst and preparation method thereof

InactiveCN103816900AReasonable regulation of pore sizeEasy to manufactureMetal/metal-oxides/metal-hydroxide catalystsNano catalystPtru catalyst

The invention discloses a metal oxide / TiO2 nanocatalyst and a preparation method thereof. The method takes a metal organic compound as a template and comprises the steps of introducing a titanium source, hydrolyzing the titanium source and removing the template to prepare the metal oxide / TiO2 nanocatalyst, wherein the metal organic compound is one of CuBTC, MIL-101(Cr) or MIL-101(Fe); the titanium source is isopropyl titanate or butyl titanate. Through the preparation method, the metal organic compound is introduced as a template agent, so that the template agent has the advantages of being convenient to prepare, simple and available, and easy to remove in a later stage; according to the key point, pore diameters of the template can be flexibly adjusted by changing the type and the number of ligands, so that a TiO2 material with different pore diameters, a complementary structure of the metal organic compound and a high specific surface can be prepared; the TiO2 prepared by the method has a good structure and a great specific surface area and can realize breakthrough of application of the TiO2 in various fields.

Owner:FUZHOU UNIV

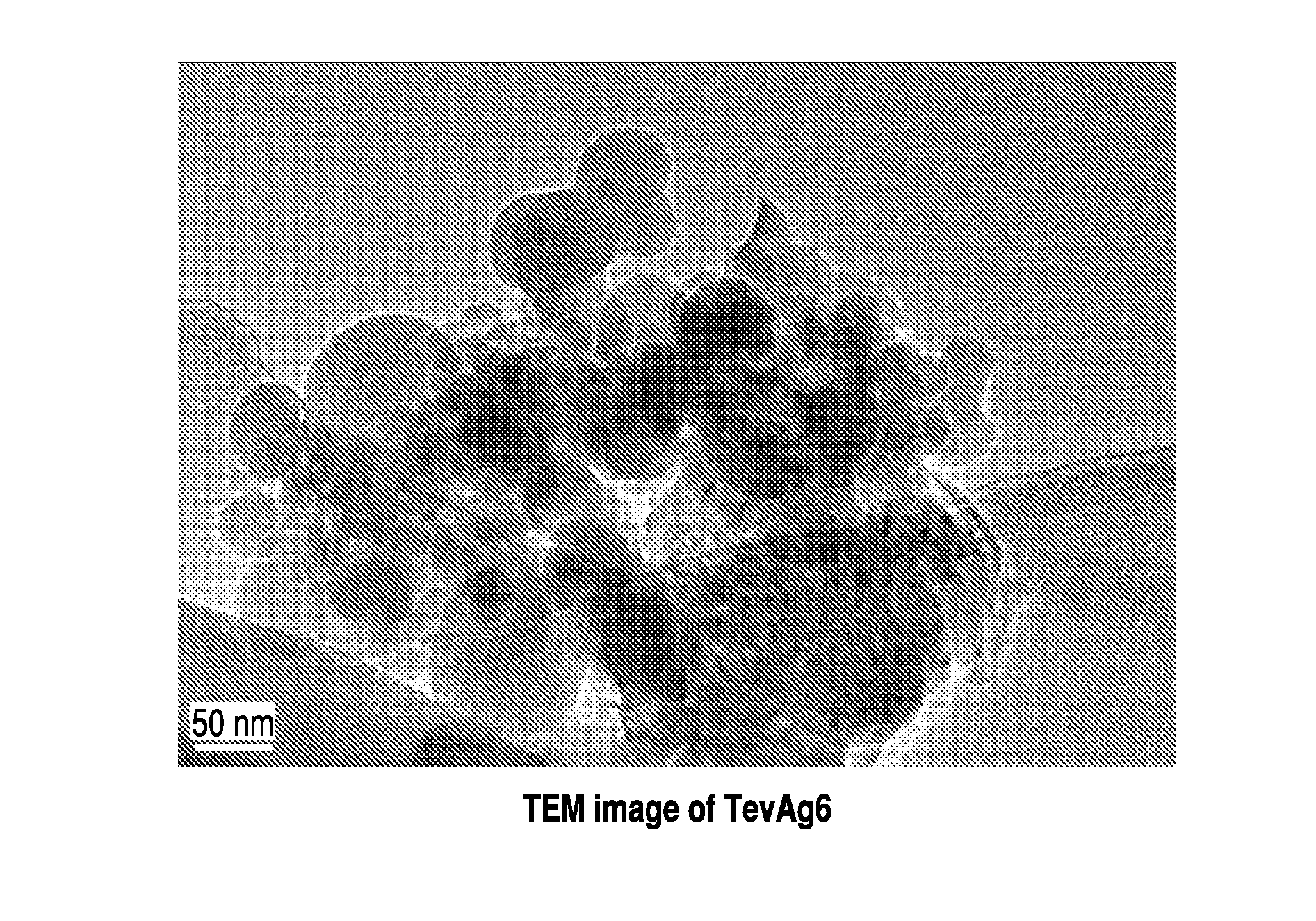

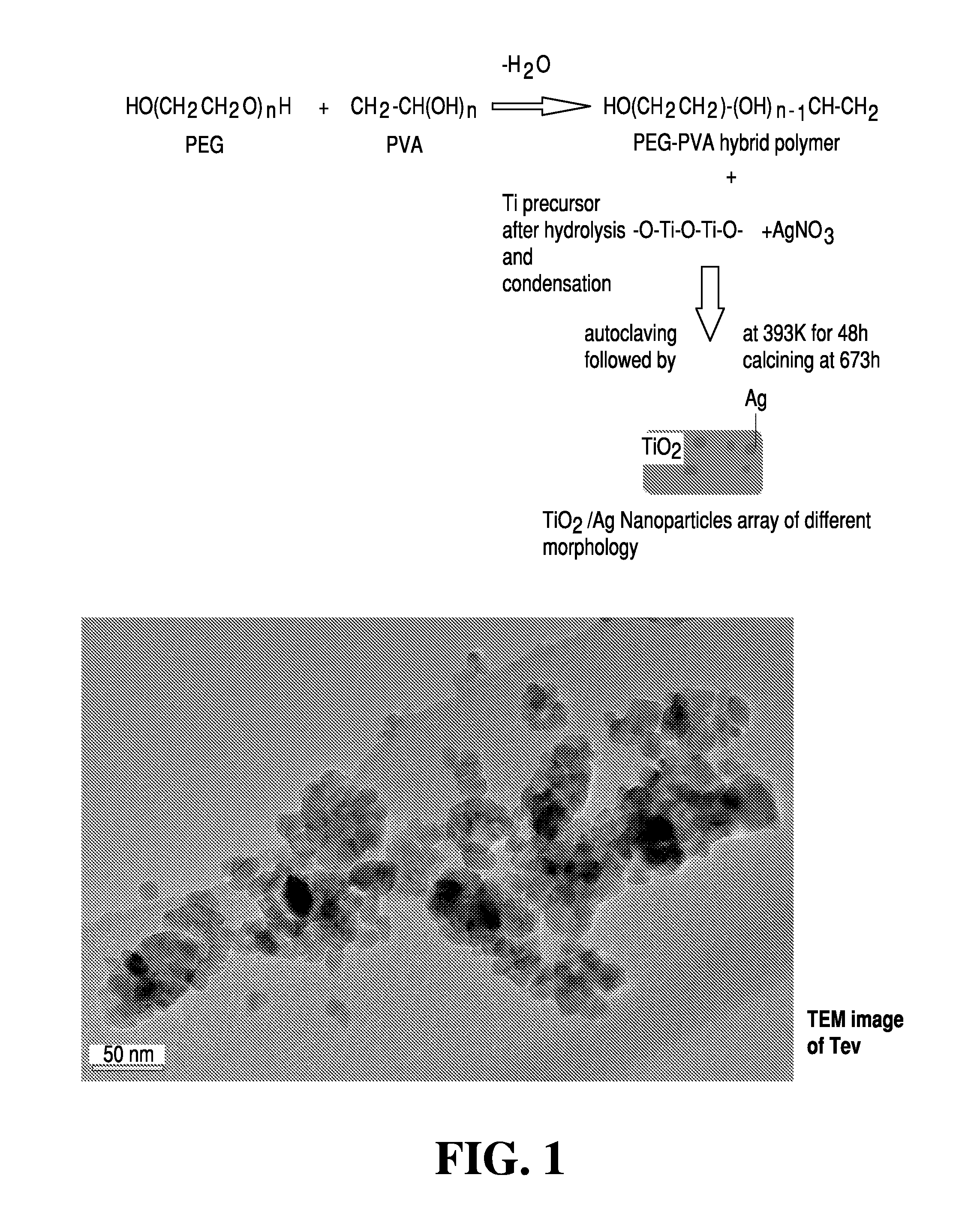

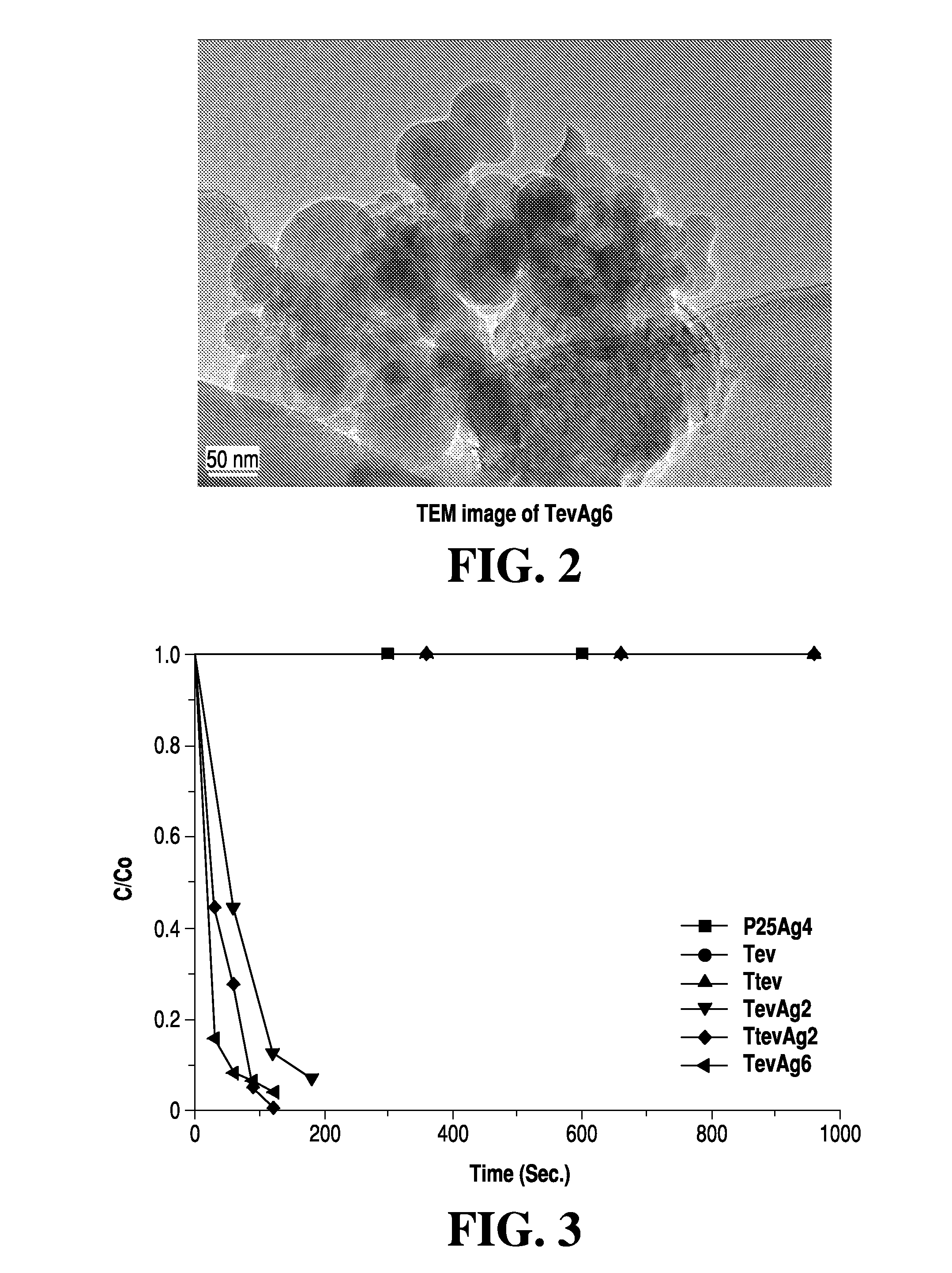

METHOD FOR SYNTHESIZING SILVER NANOPARTICLES ON TiO2 USING HYBRID POLYMERS

InactiveUS20150238935A1Catalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsChemical synthesisPolyvinyl alcohol

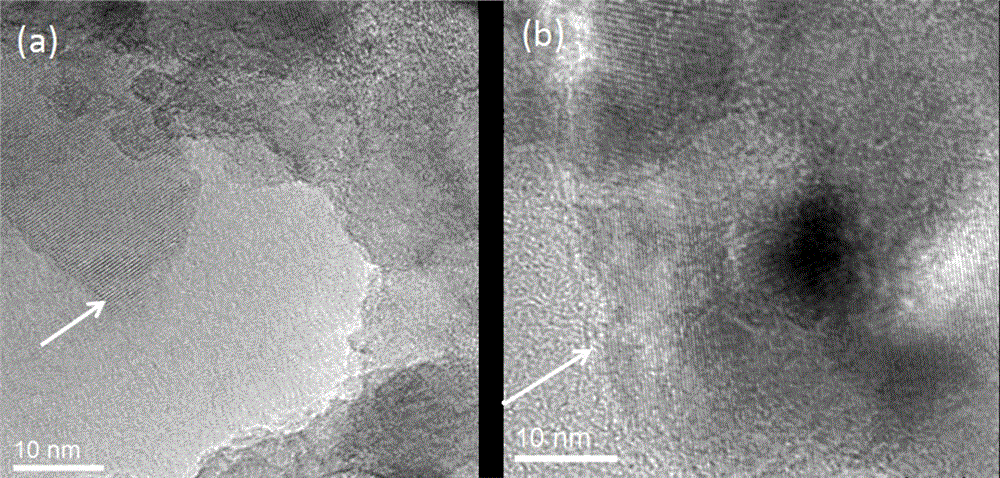

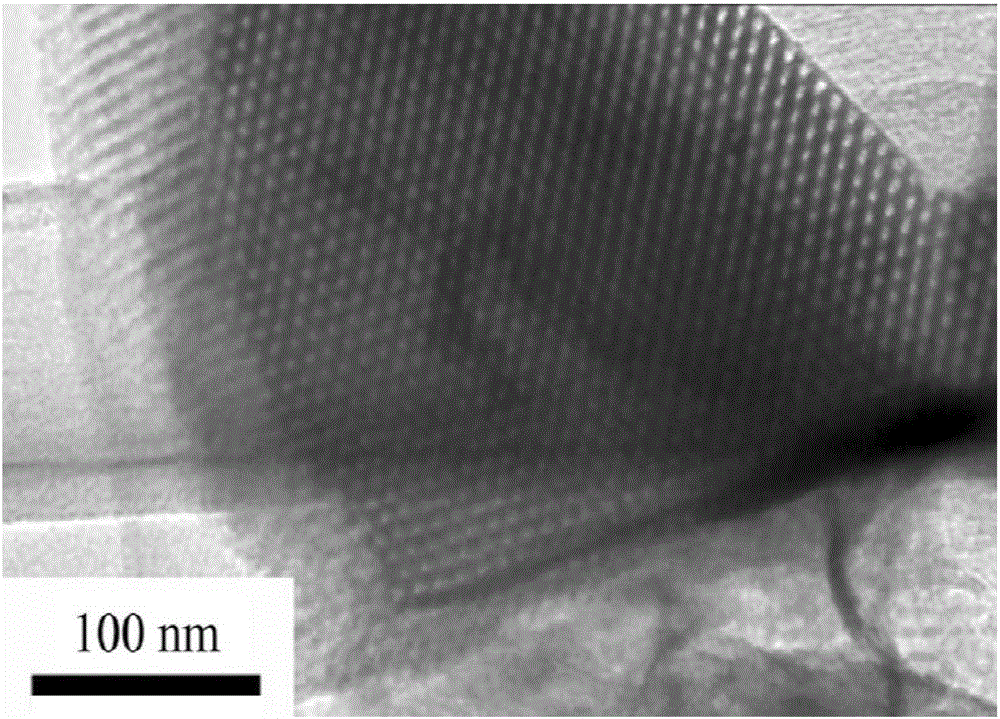

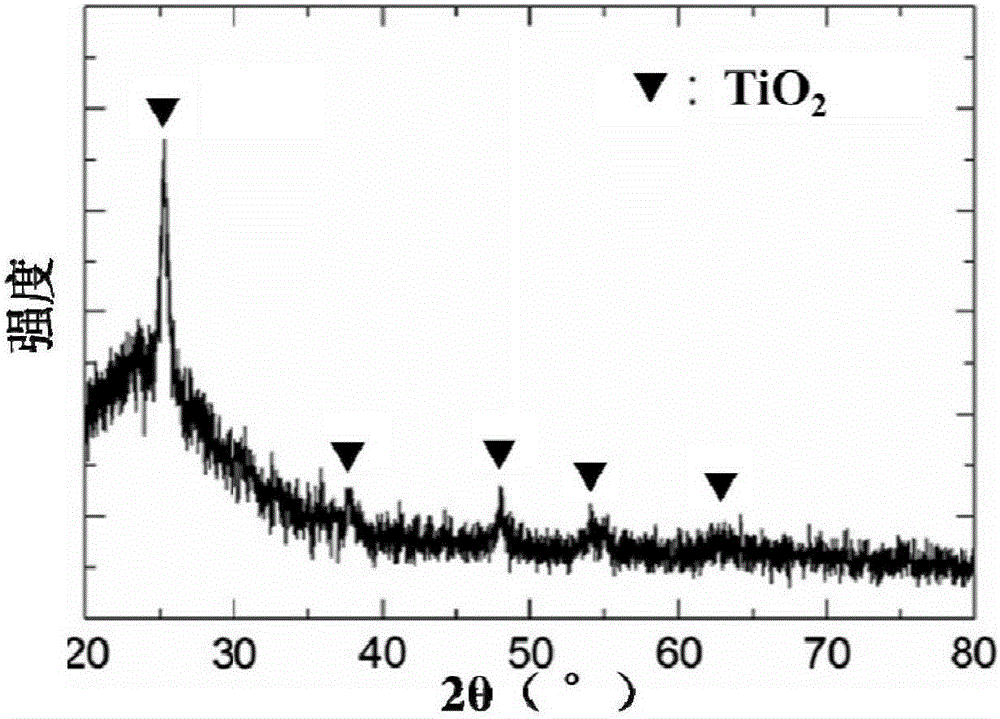

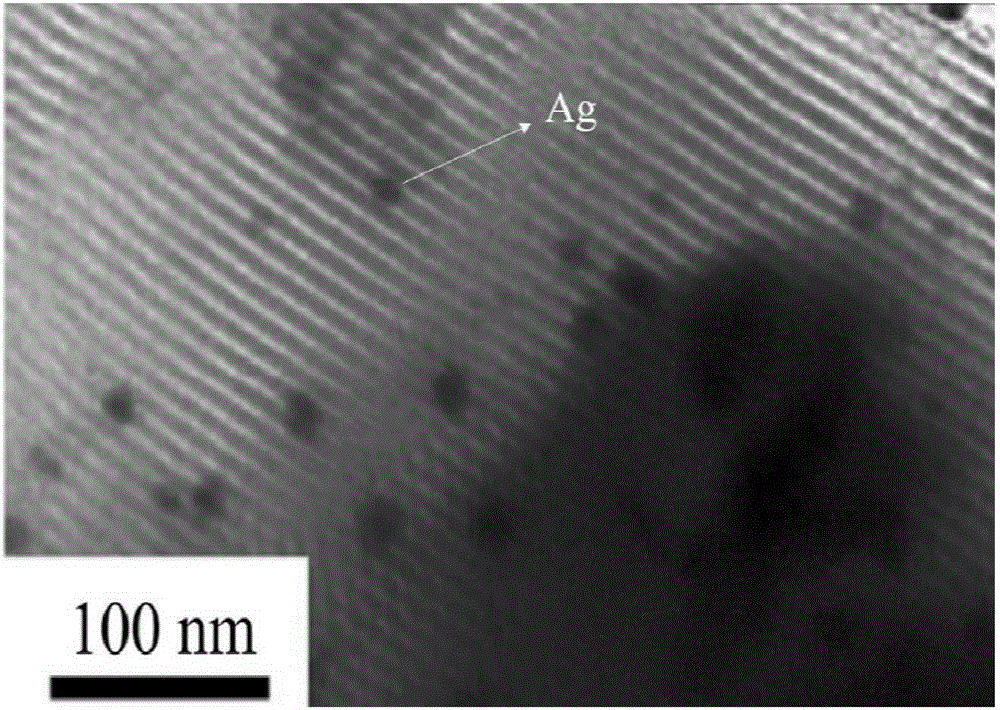

Hybrid TiO2 nanostructures with engineered morphologies (flakes, spheres and buds) supporting Ag nanocrystals were synthesized based on cooperative sol-gel chemistry of either titanium iso-propoxide or N-butoxide and assembled with polyvinyl alcohol and polyethylene glycol.

Owner:UMM AL QURA UNIVERISTY

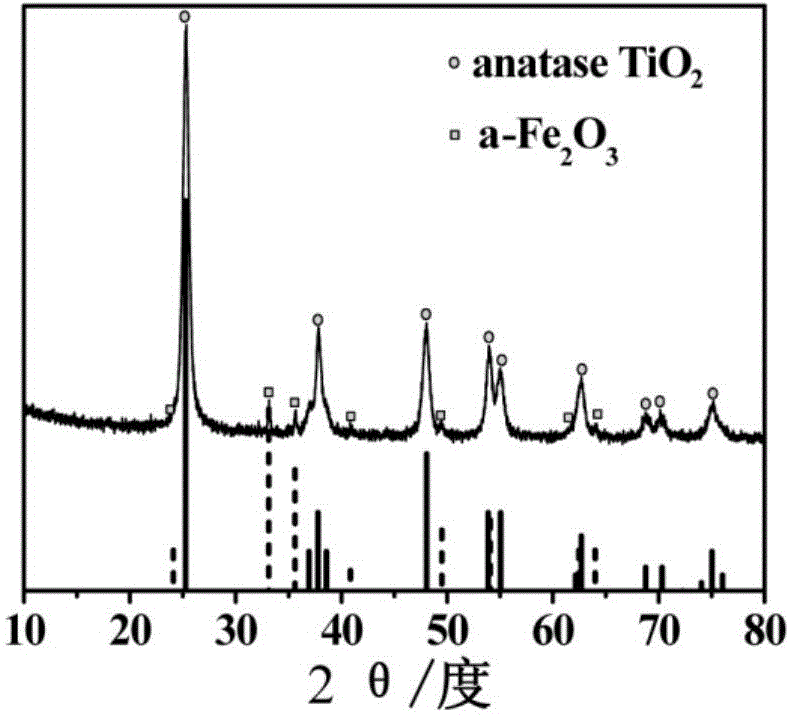

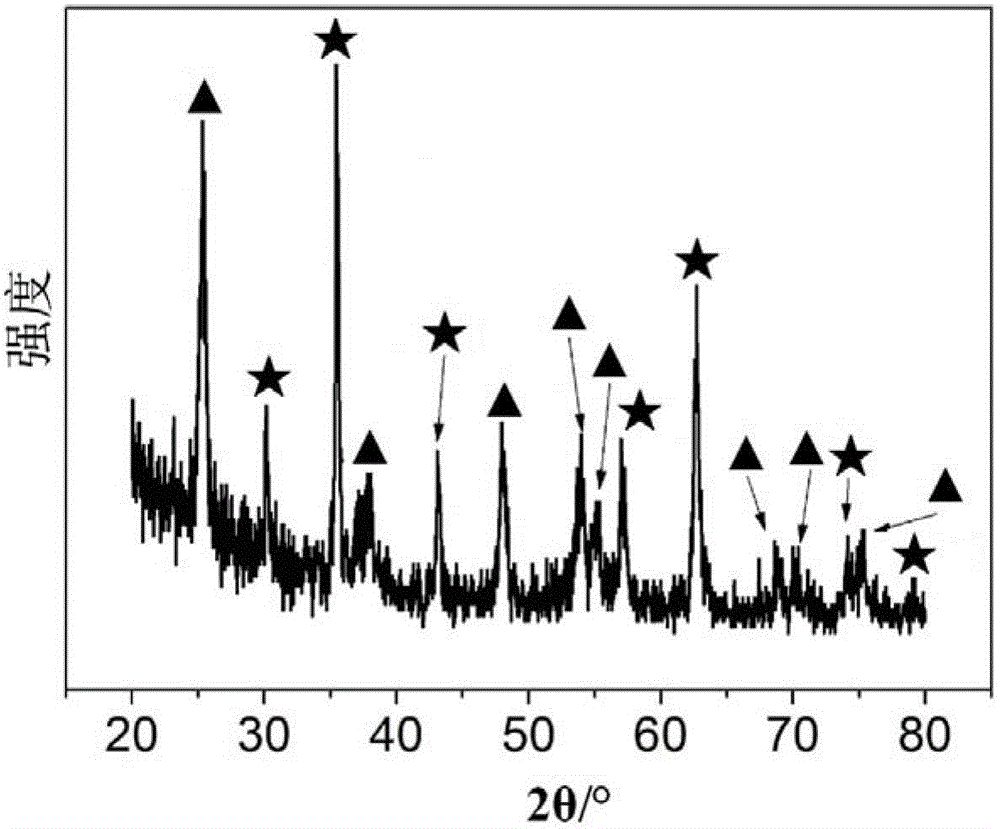

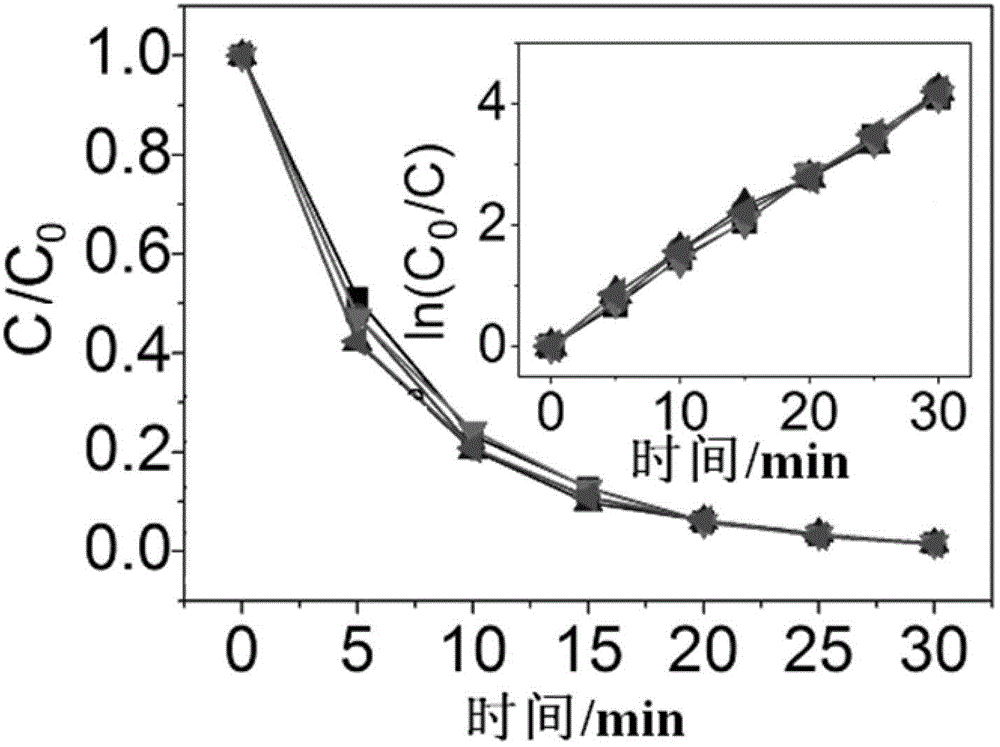

Hierarchical alpha-Fe2O3/TiO2 hollow sphere dual-functional photocatalyst and application thereof

ActiveCN104437495AImprove adsorption capacityEasy to recycleWater/sewage treatment by irradiationOther chemical processesPhotocatalytic reactionSulfate

The invention provides a hierarchical alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst. The alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst with a hierarchical structure is prepared by virtue of hydrothermal reaction from FeOOH as a substrate, and butyl titanate, titanium tetrachloride, titanyl sulfate or isopropyl titanate as a titanium source; next, the alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst is dispersed in water containing heavy metal ions and adsorption and light-catalyzed reaction are performed under the irradiation of simulated sunlight. The invention also provides new application of the hierarchical alpha-Fe2O3 / TiO2 hollow sphere difunctional photocatalyst in treating of heavy metal ion pollution in the water.

Owner:HEBEI UNIV OF TECH

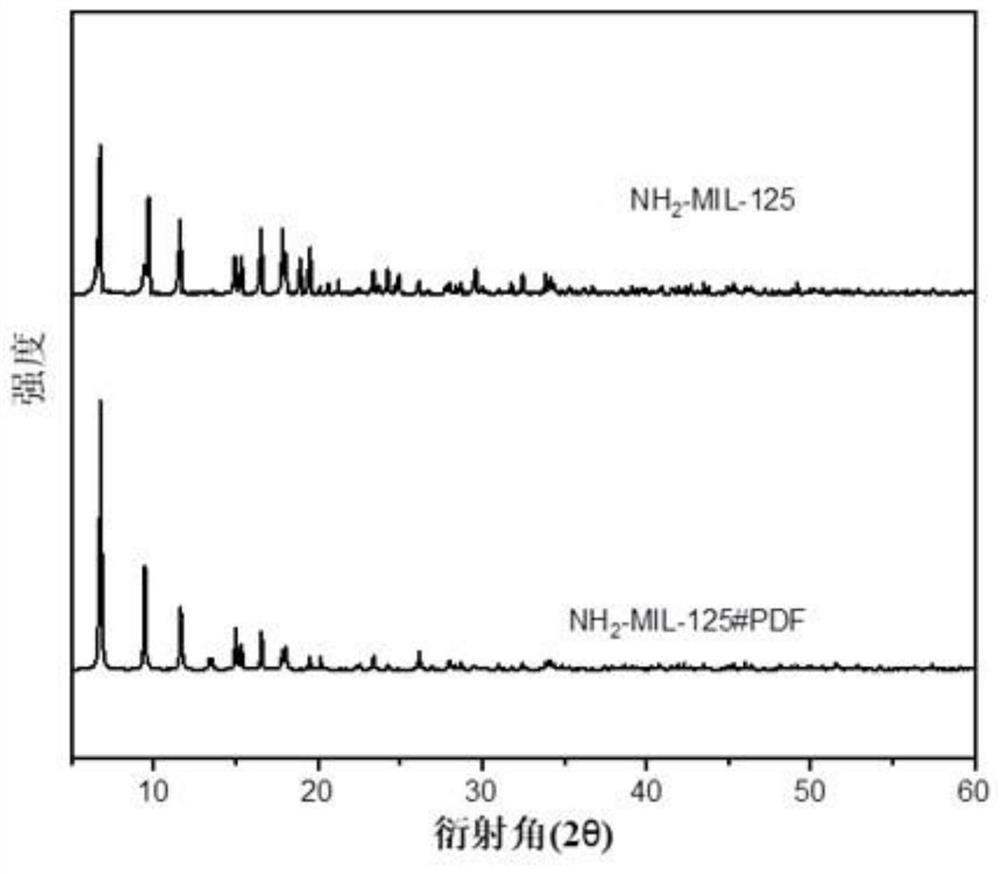

Preparation method of mixed-phase titanium dioxide visible-light-induced photocatalyst derived from MOF

ActiveCN112007629AGood photocatalytic degradation activitySimple manufacturing methodPhysical/chemical process catalystsWater/sewage treatment by irradiationWater methanolPtru catalyst

The invention relates to a preparation method of a mixed-phase titanium dioxide visible-light-induced photocatalyst derived from MOF. The preparation method comprises the following steps: dissolving 2-aminoterephthalic acid and titanium isopropoxide in a mixed solvent of N,N-dimethylformamide (DMF) and absolute methanol, transferring the obtained mixture into a high-pressure kettle, and keeping the temperature at 150 DEG C for 48 hours to prepare NH2-MIL-125; calcining the prepared NH2-MIL-125 at a high temperature under the protection of nitrogen so as to obtain the visible-light-induced photocatalyst. The preparation method has the beneficial effects that the preparation method is simple, the preparation conditions are easy to control, and the feasibility is high. The prepared MOF-derived mixed-phase titanium dioxide visible-light-induced photocatalyst is relatively good in photocatalytic degradation efficiency under visible light, and has a certain application prospect.

Owner:CHANGZHOU UNIV

Mildew-proof wear-resistant asphalt paint and preparation method thereof

InactiveCN104293069AGood weather resistanceImprove wear resistanceAntifouling/underwater paintsPaints with biocidesXylyleneTitanium isopropoxide

The invention discloses mildew-proof wear-resistant asphalt paint which is characterized by being prepared from the following raw materials in parts by weight: 17-23 parts of E-22 epoxy resins, 6-9 parts of benzyl transparent silicon resins, 8-11 parts of polyether acrylate, 4-7 parts of tetraethylenepentamine, 3-5 parts of tricresyl phosphate, 1-3 parts of nano bamboo fibers, 2-4 parts of zinc chromate, 37-43 parts of modified asphalt, 5-7 parts of modified waste resin sand, 1-2 parts of ammonium bromide, 2-4 parts of fungacetin, 3-4 parts of catechinic acid, 4-6 parts of epoxy linseed oil, 8-11 parts of amyl acetate, 6-9 parts of xylene, 5-7 parts of glycol, 1-2 parts of tri(dioctylphosphoryloxy) titanium isopropoxide and 2-4 parts of powdered aluminum. The mildew-proof wear-resistant asphalt paint is prepared by adding the epoxy resins on the basis of the modified asphalt, so that the characteristics of high corrosion resistance, weather fastness, waterproofness and thermal stability of the pain are ensured; the added tricresyl phosphate has the characteristics of favorable wear resistance, weather fastness, mildew resistance and radiation resistance; and the added modified waste resin sand has favorable fire resistance, antifouling property and anti-ageing property, so that the quality of the paint is improved and the waste is recycled to solve the problem of environment pollution.

Owner:TIANCHANG YINHU PAINT

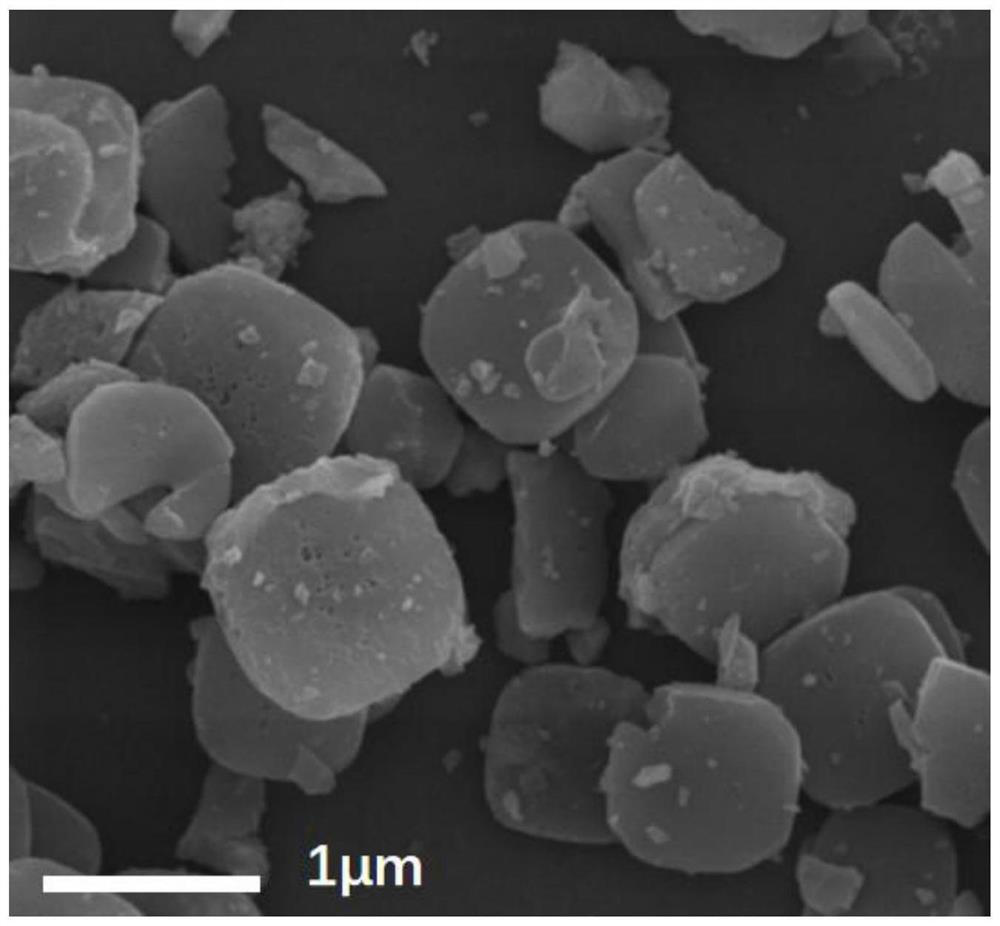

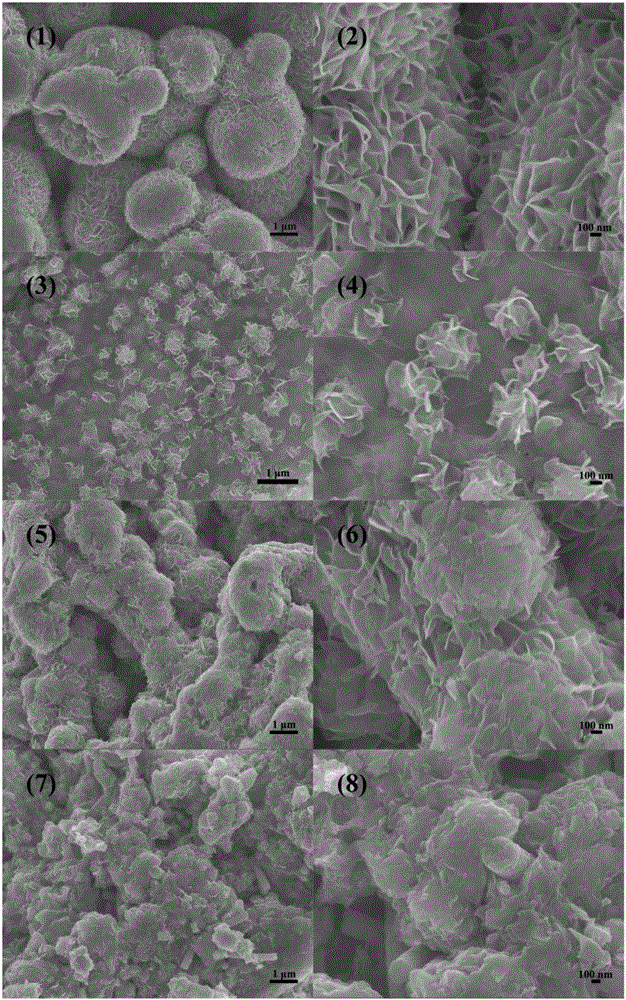

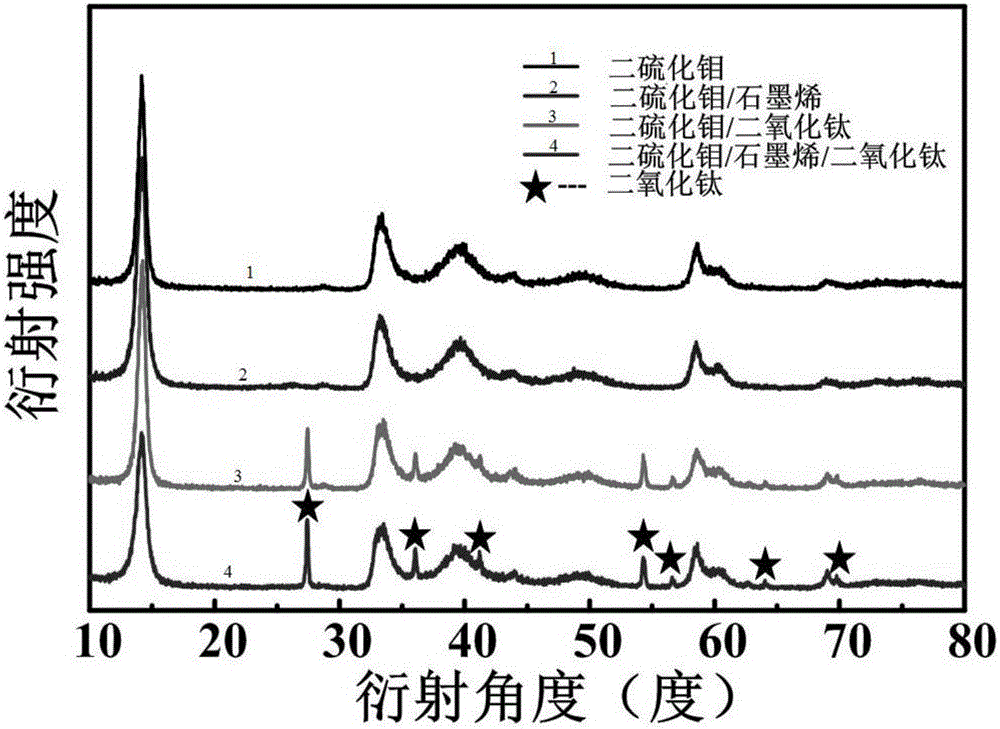

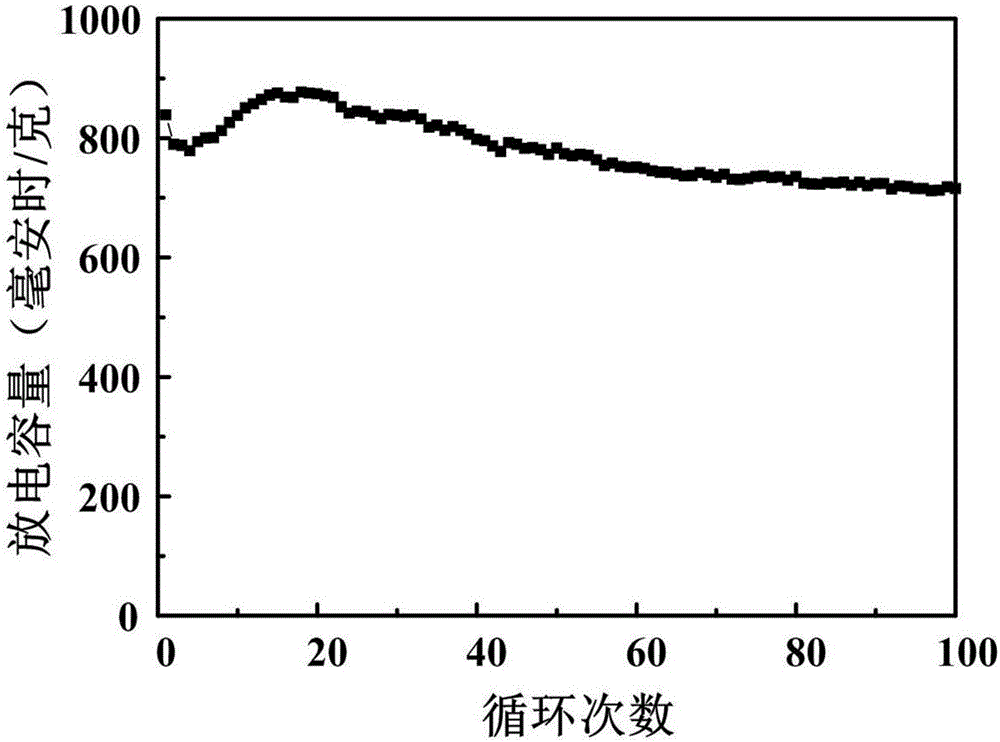

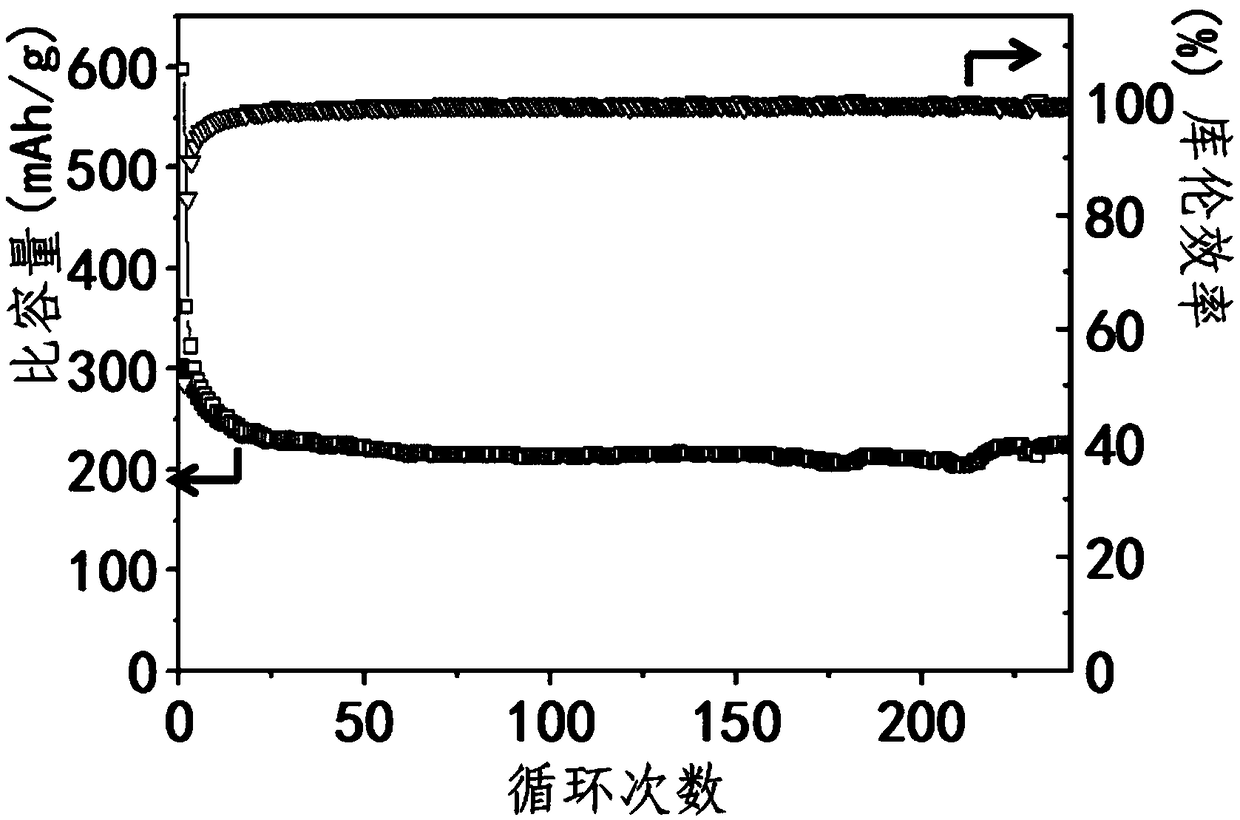

Method for improving charge-discharge cycling capacity of molybdenum disulfide by doping graphene and titanium dioxide

ActiveCN105161690AIncrease contact areaInhibition of volume changeCell electrodesCvd grapheneElectrospinning

The invention discloses a method for improving the charge-discharge cycling capacity of molybdenum disulfide by doping graphene and titanium dioxide. According to a molybdenum disulfide / titanium dioxide / graphene composite, graphene is adopted as a conductive modified phase, and titanium dioxide is adopted as a support and collaborative phase, so that the charge-discharge cycling performance of the composite is enhanced. Sodium molybdate, thiourea, graphite oxide, titanium tetraisopropoxide, absolute ethyl alcohol, acetic acid, polyvinylpyrrolidone and deionized water are selected, and after electrostatic spinning and a hydrothermal reaction, the molybdenum disulfide / titanium dioxide / graphene composite is obtained through vacuum drying. The production process is simple, cost is low, and the prepared molybdenum disulfide / titanium dioxide / graphene composite has excellent electrochemical performance.

Owner:JILIN UNIV

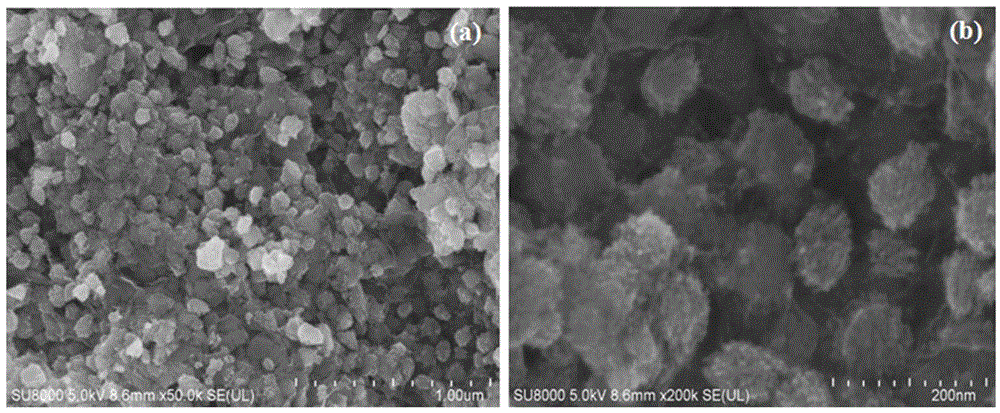

Preparation method of hollow porous TiO2 nanocubic material and application thereof

InactiveCN109286015ALow costEasy to prepareMaterial nanotechnologyCell electrodesN dimethylformamideTitanium isopropoxide

The invention discloses a preparation method of a hollow porous TiO2 nanocubic material. The method firstly mixes titanium isopropoxide and methanol, adds into a mixture of 2-aminoterephthalic acid and N,N-dimethylformamide for a reaction, obtains an amino-modified Ti-MIL-125 nanocube material, conducts stirring for the reaction after water, sodium hydroxide and absolute ethanol are added, obtainsa nano-precursor material, and finally conducts heat-treating to obtain the hollow porous TiO2 nanocubic material; the invention discloses application of the hollow porous TiO2 nanocubic material ina lithium ion battery. The method utilizes the characteristics that acidic ligands constituting the amino-modified Ti-MIL-125 nanometer material are not stable under the alkaline condition to conductself-etching, thereby ensuring the stability of the structure and performance; the hollow porous TiO2 nanocubic material is applied to the lithium ion battery to increase the specific capacity of thelithium ion battery.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

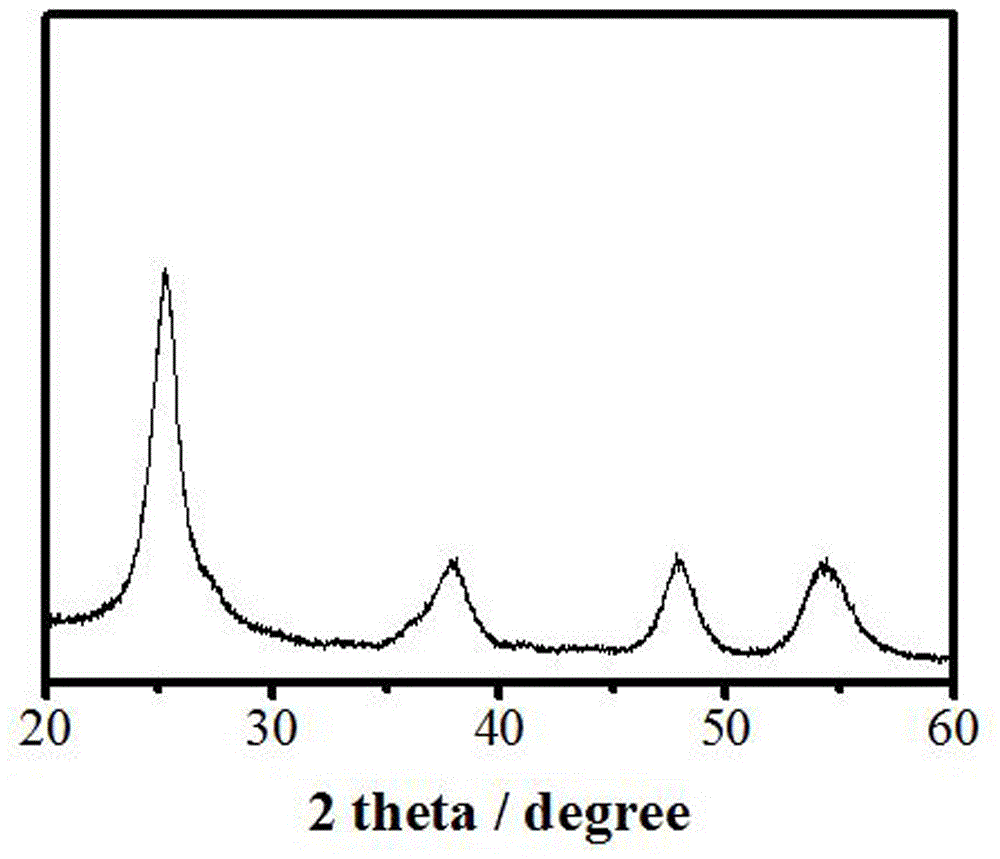

Method and application of in-situ synthesized TiO2 mesomorphase-carbon-graphene nanocomposite

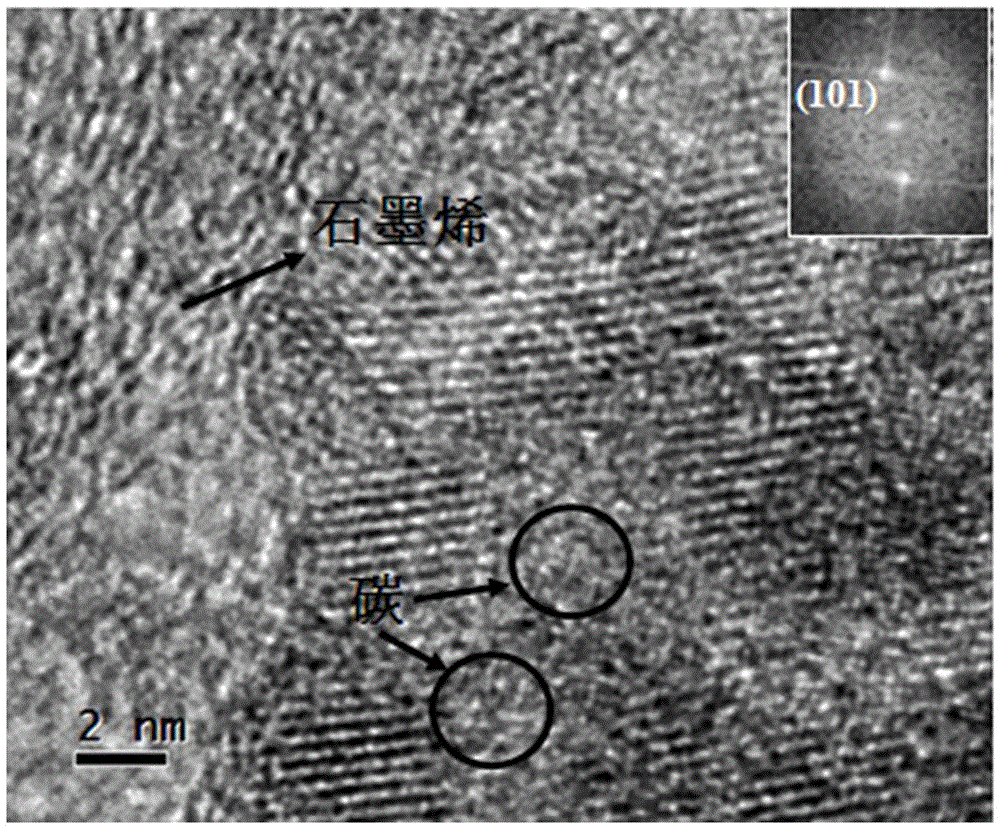

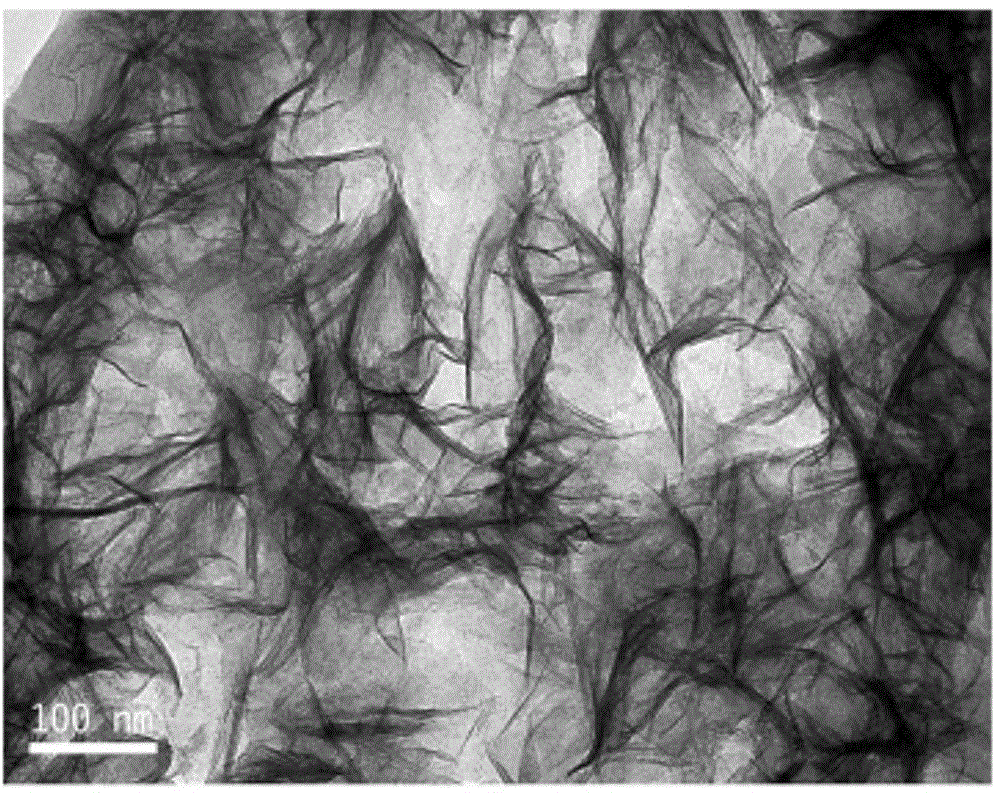

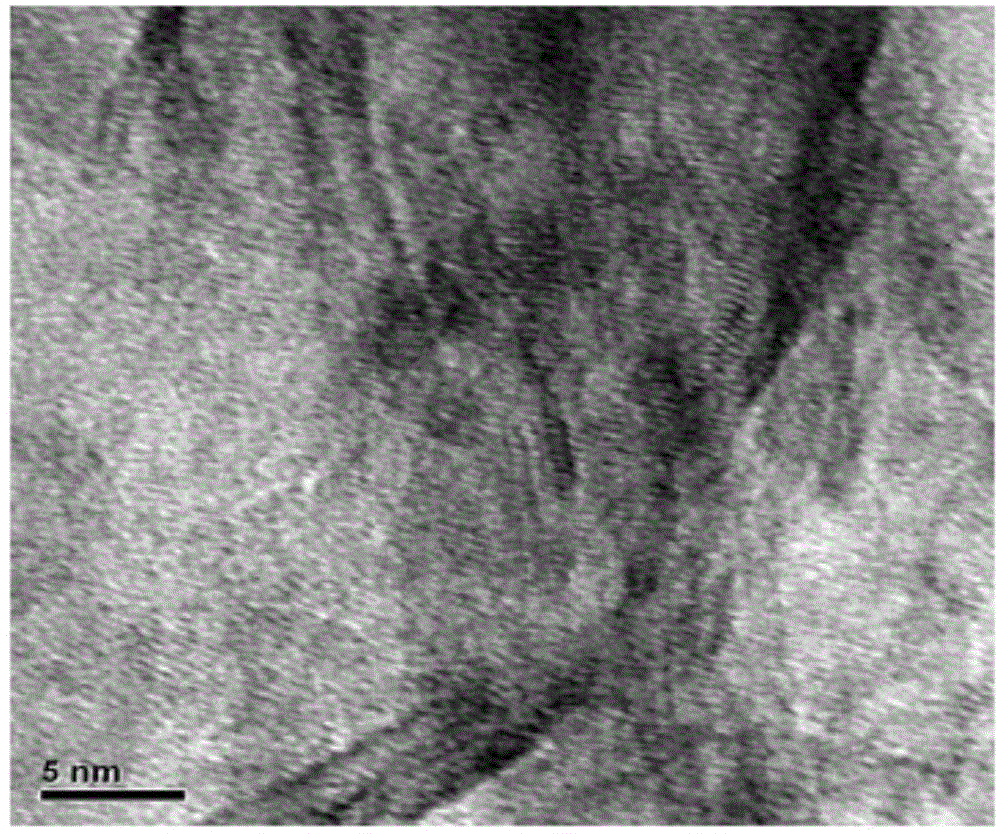

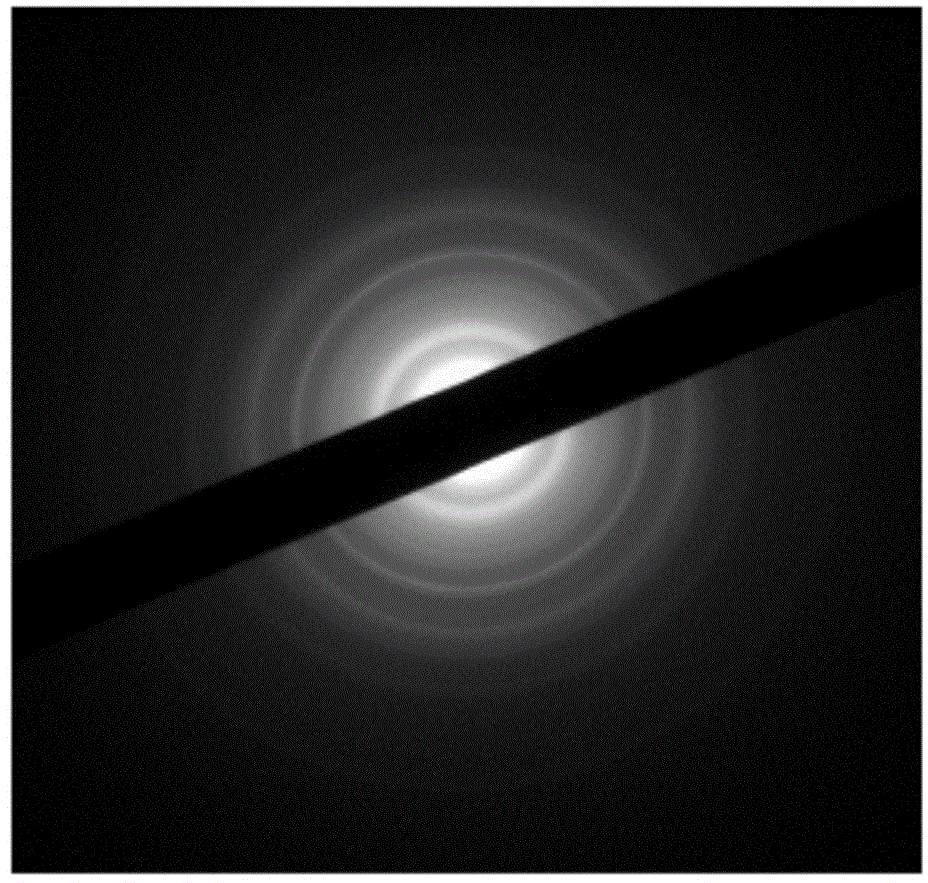

InactiveCN105810918ALarge specific surface areaImprove performanceMaterial nanotechnologyCell electrodesGraphene nanocompositesTitanium isopropoxide

The invention relates to a method and application of in-situ synthesized TiO2 mesomorphase-carbon-graphene nanocomposite. The method includes the steps of dispersing and dissolving polyvinylpyrrolidone, adding graphene oxide, cetyl sodium sulfate and titanium isopropoxide respectively, centrifuging, washing, annealing and carbonizing to obtain the nanocomposite. In the composite electrode material, the TiO2 mesomorphase is anatase TiO2, micro nanocrystallines are uniformly dispersed and embedded in the graphene, and then the graphene is uniformly coated with a layer of amorphous carbon, and the mixro nanocrystallines are in alignment along the direction of (101). The in-situ synthesized TiO2 mesomorphase-carbon-graphene nanocomposite has a very large surface area up to 280-290m<2>g<-1>. The nanocomposite has great electrical conductivity and good tenacity, is easy to operate, low in cost, high in purity, excellence in property and capable of large-scale synthesis, which can be popularized and applied to other fields of energies and catalysis.

Owner:FUJIAN NORMAL UNIV

Fluoride-free preparation method of titanium dioxide of similar graphene structure

The invention provides a fluoride-free preparation method of titanium dioxide of a similar graphene structure and belongs to the technical field of nanomaterial preparation. The material is composed of titanium dioxide nanosheets having the size of greater than 500nm. The preparation method mainly comprises the following steps: by taking ethylene glycol and ethanol as reaction solvents, inhibiting quick decomposition of titanium isopropylate by use of concentrated hydrochloric acid under the action Pluronic P123, performing a solvothermal reaction, growing micro flake titanium dioxide by virtue of self-assembly, and further growing to obtain titanium dioxide having a large area and an ultra-thin similar graphene structure. According to the preparation method, titanium dioxide having the large area and the ultra-thin similar graphene structure is synthesized for the first time and can be widely applied to photo / electro / chemocatalysis, the electrode materials of new energy batteries and the like.

Owner:SHANGHAI JIAO TONG UNIV

Magnetic nano functional material for extracting uranium from seawater, and preparation method thereof

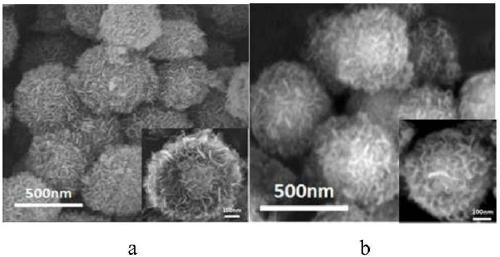

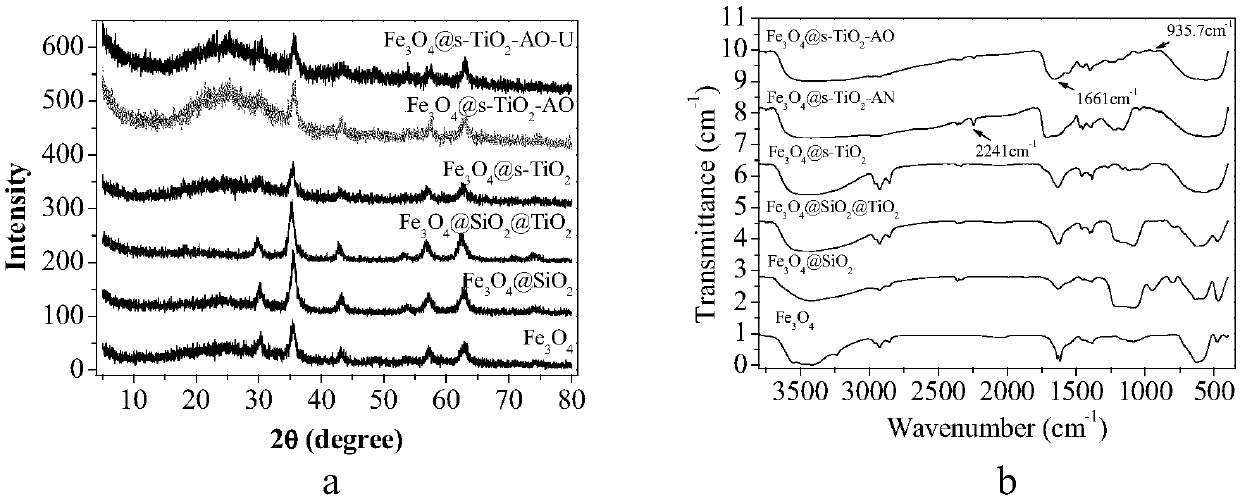

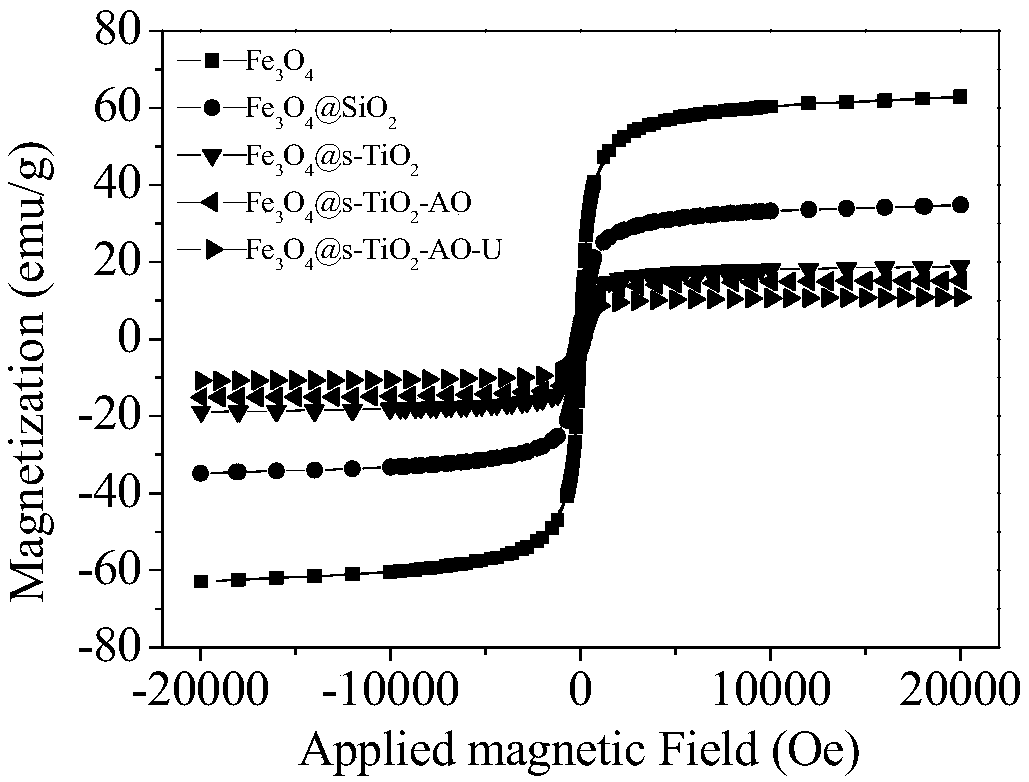

ActiveCN109569548ANot easy to reuniteStrong magnetismOther chemical processesSeawater treatmentCitrinin hydrateHydroxylamine Hydrochloride

The invention discloses a magnetic nano functional material for extracting uranium from seawater, and a preparation method thereof. The preparation method includes the following steps: step 1, reacting ferric chloride hexahydrate with trisodium citrate dihydrate to obtain Fe3O4 particles; step 2, preparing Fe3O4@SiO2 particles through a compound reaction; step 3, dispersing Fe3O4@SiO2 in a mixed solution of ethanol and ammonium hydroxide, adding titanium isopropoxide, and obtaining Fe3O4@SiO2@TiO2 particles after reaction; step 4, dispersing Fe3O4@SiO2@TiO2 in an NaOH solution, and performingcalcination after reaction to obtain Fe3O4@s-TiO2 particles with developed surfaces; step 5, dispersing Fe3O4@s-TiO2 in acetic acid, adding a crosslinking agent, and carrying out an oil bath reactionto obtain cyanated Fe3O4@s-TiO2-CN particles; step 6, dispersing Fe3O4@s-TiO2-CN in a mixed solution of methanol and water, adding hydroxylamine hydrochloride, adjusting the pH of the solution to 7, and carrying out an oil bath reaction to obtain amidoximated Fe3O4@s-TiO2-AO particles. The Fe3O4@s-TiO2-AO material prepared by the preparation method has a developed surface, good magnetic properties, high stability, durability and bio-resistance and excellent adsorption selectivity for the uranium, and can be used for eliminating the uranium in uranium-containing water bodies and extracting theuranium from the seawater.

Owner:LANZHOU UNIVERSITY

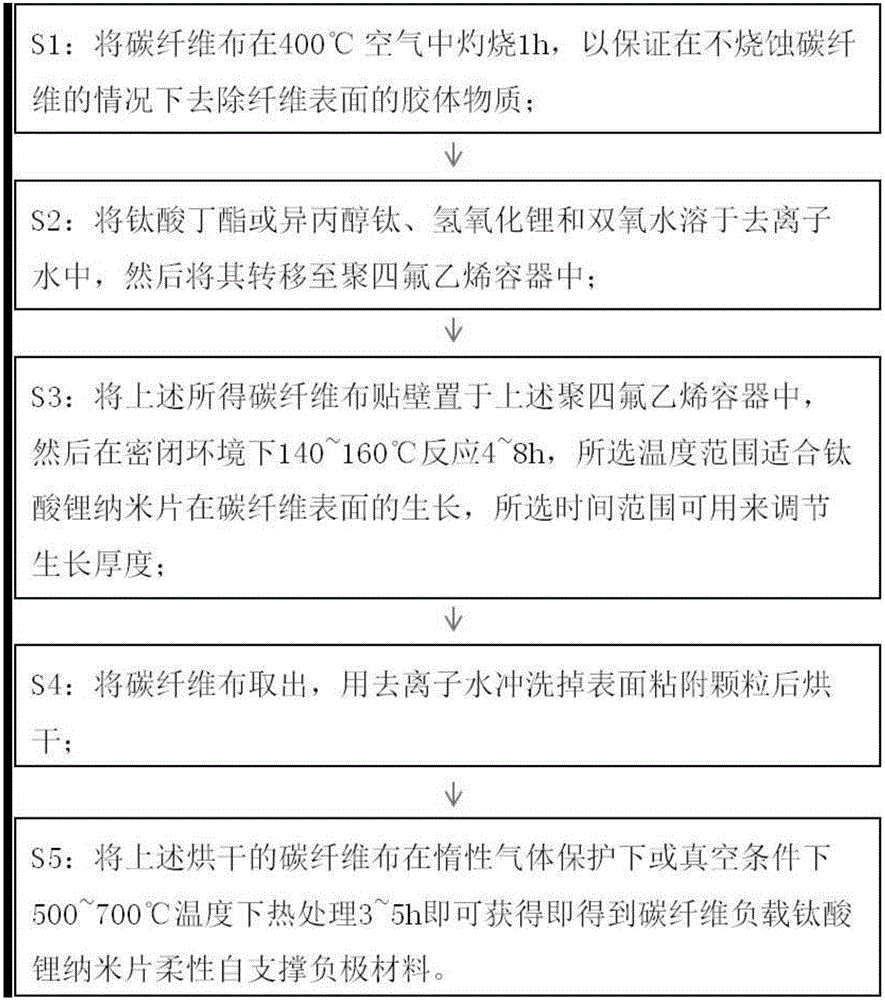

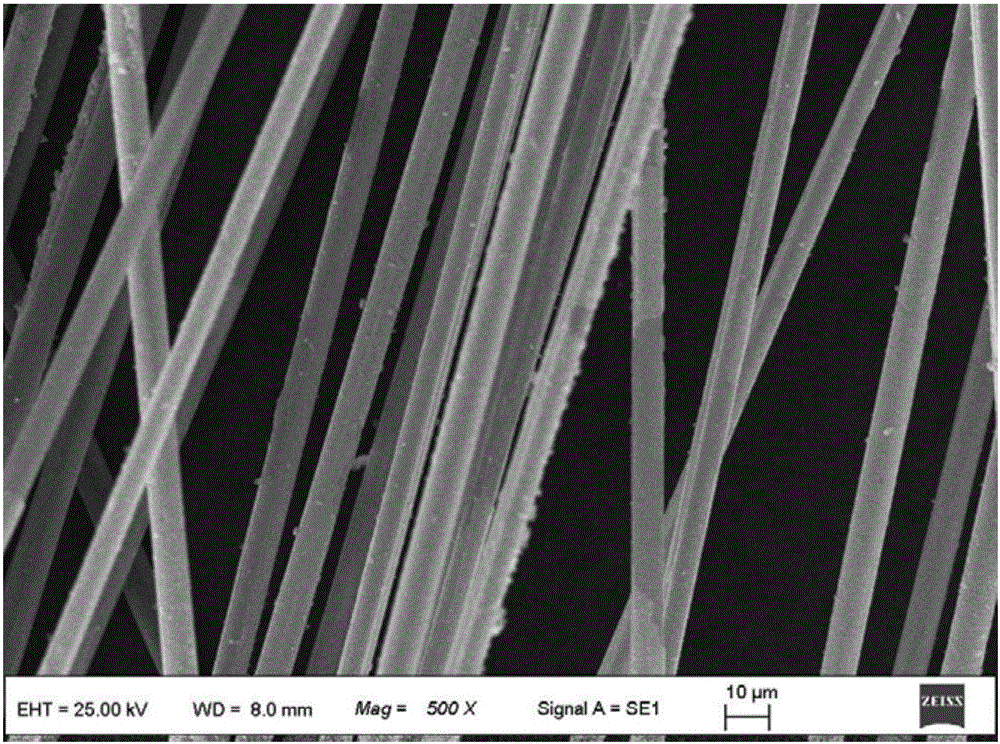

Flexible self-support negative electrode material with carbon fiber-loaded lithium titanate nanosheet and preparation method of flexible self-support negative electrode material

InactiveCN106532032ANo complicated production processHigh specific capacityCell electrodesSecondary cellsFiberCarbon fibers

The invention discloses a flexible self-support negative electrode material with a carbon fiber-loaded lithium titanate nanosheet and a preparation method of the flexible self-support negative electrode material. The method comprises the following specific steps of dissolving butyl titanate or titanium isopropylate, lithium hydroxide and hydrogen peroxide into deionized water and then transferring the mixture to a polytetrafluoroethylene container; putting burnt and degummed carbon fiber cloth into the polytetrafluoroethylene container and reacting at 140-160 DEG C in a closed environment for 4-8 hours; taking out the carbon fiber cloth, washing the carbon fiber cloth by using the deionized water, drying the carbon fiber cloth; and carrying out thermal treatment at 500-700 DEG C under inert gas protection or a vacuum condition for 3-5 hours. The invention further provides a battery of using the flexible self-support negative electrode material. According to the flexible self-support negative electrode material, a metal current collector, a conductive additive and a binder used in a conventional preparation process of a negative electrode of a lithium-ion battery do not need to be used, and the operation is simple; the flexible self-support negative electrode material has good conductivity and ionic conductivity, and relatively high battery specific capacity and rate capability; and meanwhile, the flexible self-support negative electrode material can be arbitrarily bended, folded and stretched.

Owner:XIAMEN UNIV OF TECH

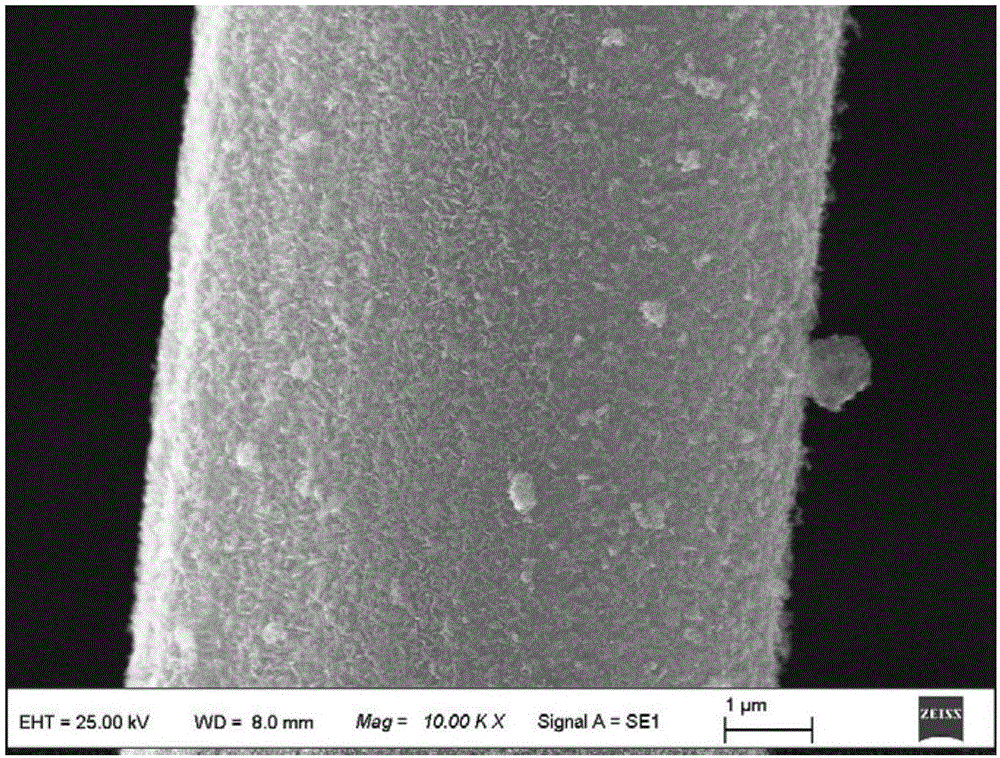

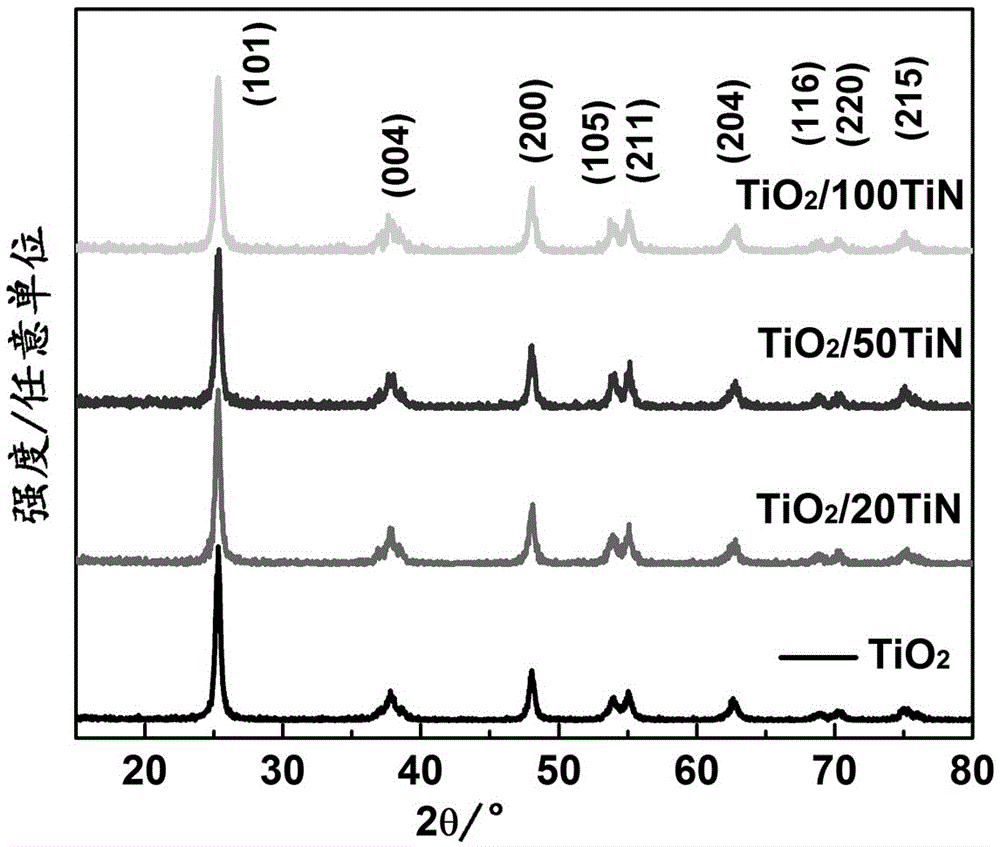

Preparation method of visible light catalyst of surface nitrogen modified titanium dioxide nano-particles based on ALD technology

ActiveCN106268903AImprove catalytic performanceIncrease profitCatalyst activation/preparationTitanium tetraisopropoxideRoom temperature

The invention discloses a preparation method of a visible light catalyst of surface nitrogen modified titanium dioxide nano-particles based on the ALD technology. The method comprises the steps that firstly, titanium dioxide power is transferred into an ALD reaction room, and an ultrathin TiN film is deposited and wrapped on the surface of the titanium dioxide power, wherein wrapping parameters are reaction room temperature which ranges from 100 DEG C to 500 DEG C; a titanium source which is titanium tetrachloride or tetradimethylamino titanium or titanium isopropylate; a nitrogen source which is ammonia gas or ammonia gas plasma; carrier gas, wherein high-purity nitrogen or argon is used as the carrier gas for the titanium source, the flow is 50-200 sccm, argon is used as the carrier gas for the nitrogen source, and the flow is 50-200 sccm; pulsing and cleaning time, wherein the pulse of the titanium source is 0.1-10 s, high-purity nitrogen is used for cleaning for 2-60 s immediately after each time of inorganic source pulsing, the pulse of the nitrogen source is 5-60 s, and high-purity nitrogen is used for cleaning for 2-60 s immediately to wash off reaction byproducts and residual reaction sources. The method is simple and easy to implement, and the visible light catalytic performance of products is remarkably enhanced.

Owner:NANJING UNIV

Mesoporous photocatalytic material and preparation method thereof

InactiveCN105195143AEvenly distributedEffective combinationMetal/metal-oxides/metal-hydroxide catalystsActive agentSilicic acid

The invention discloses a silver nanoparticle modification TiO2-SiO2 mesoporous photocatalytic material and a synthetic method thereof. A sol-gel method is adopted to synthesize the TiO2-SiO2 mesoporous material. A tubular center hole of the TiO2-SiO2 mesoporous photocatalytic material is modified by silver nanoparticles through a photodeposition method. The preparation method comprises the steps that a nonionic surfactant P123 is used as a template agent at first, and tetraethoxysilane and titanium isopropoxide are added for preparation of the TiO2-SiO2 mesoporous material; then silver nitrate is added, photodeposition is carried out under ultraviolet irradiation, and therefore the silver nanoparticle modification TiO2-SiO2 mesoporous photocatalytic material is obtained. The preparation method is easy to implement and low in cost, TiO2 and SiO2 can be effectively combined, the silver nanoparticles are stably distributed in the tubular center hole in the mesoporous material, and the photocatalytic activity of the material is significantly improved.

Owner:HOHAI UNIV

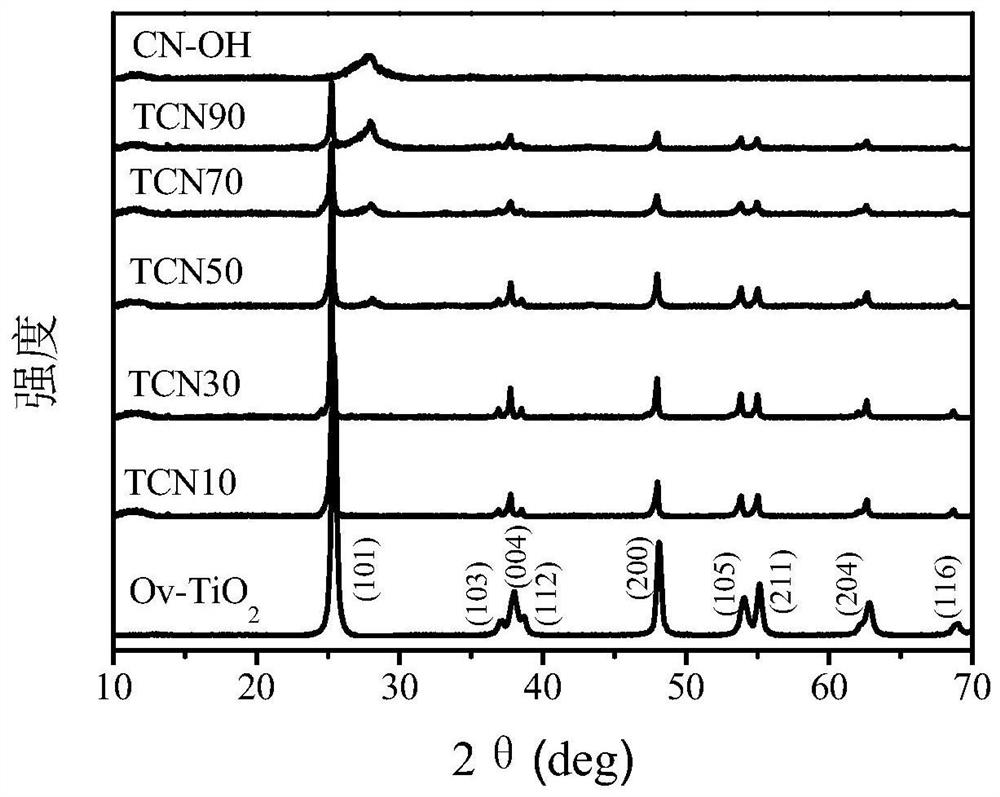

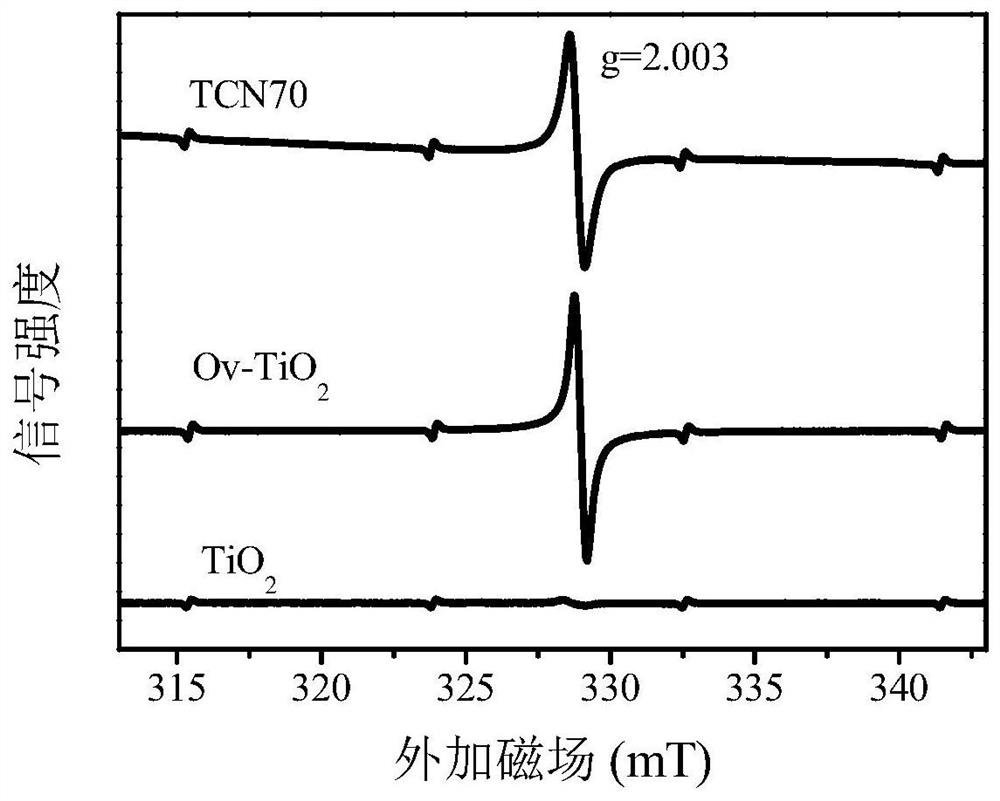

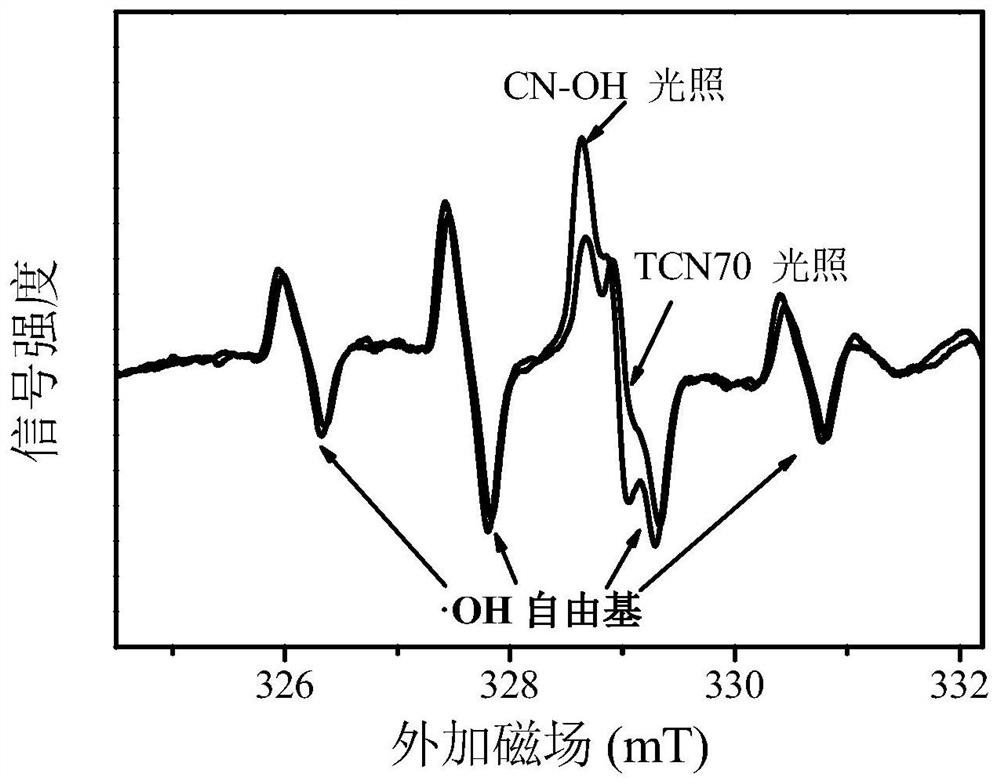

Oxygen-deficient titanium dioxide material compounded with hydroxylated carbon nitride and preparation method thereof

PendingCN112090440AImprove oxidation capacityImprove separation efficiencyWater/sewage treatment by irradiationWater treatment compoundsLight energyTitanium isopropoxide

The invention belongs to the technical field of photocatalysis, and discloses an oxygen-deficient titanium dioxide material compounded with hydroxylated carbon nitride and a preparation method thereof, wherein the oxygen-deficient titanium dioxide material is obtained by compounding the hydroxylated carbon nitride and the oxygen-deficient titanium dioxide material; and the hydroxylated carbon nitride accounts for 10%-90% of the mass fraction of the composite material. The preparation method of an oxygen-deficient titanium dioxide material of composite hydroxylated carbon nitride comprises thefollowing steps: preparing surface hydroxylated carbon nitride (CN-OH), synthesizing titanium dioxide by using titanium isopropoxide as a titanium source through a hydrothermal method, fully mixing the hydroxylated carbon nitride (CN-OH) and titanium dioxide (TiO2), and calcining in an Ar / H2 mixed atmosphere to obtain the oxygen-deficient titanium dioxide material, wherein oxygen defects are introduced into a titanium dioxide phase through the process, thereby compounding of the two materials is achieved at the same time. The separation efficiency of photon-generated carriers is enhanced through effective combination of the two, the compounded CN-OH / Ov-TiO2 material has high light energy utilization rate and oxidability, and the quantum efficiency of photocatalytic degradation of phenol can be further improved.

Owner:HAINAN NORMAL UNIV

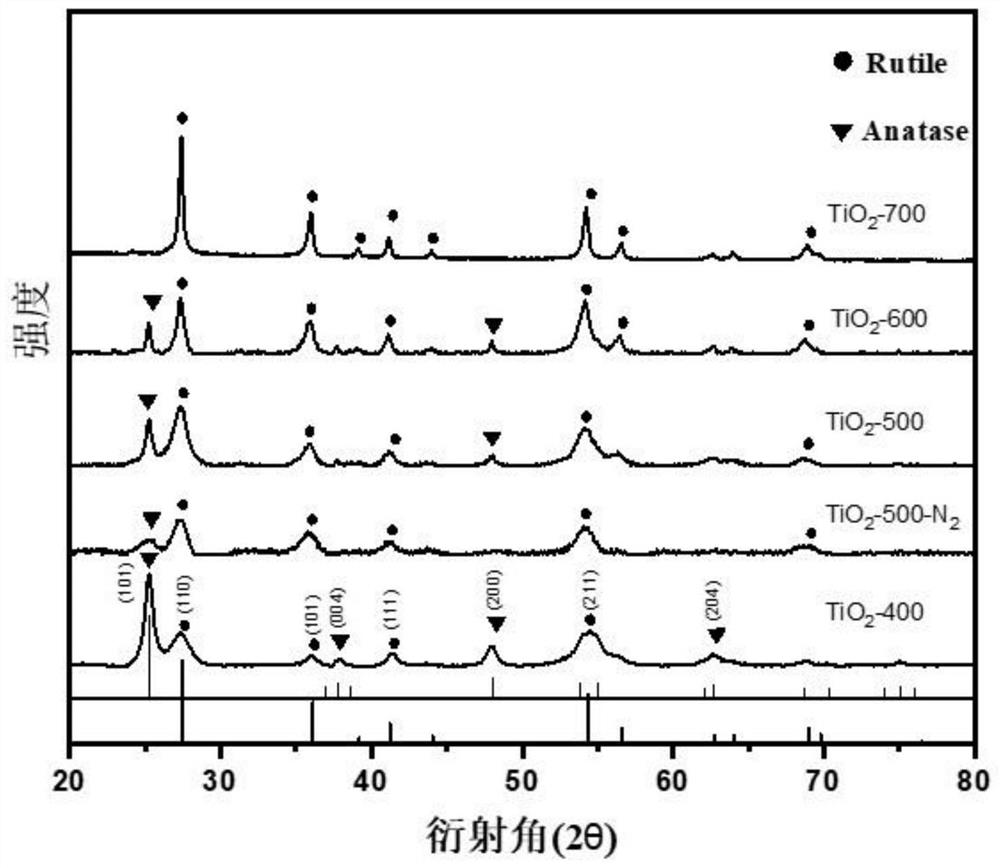

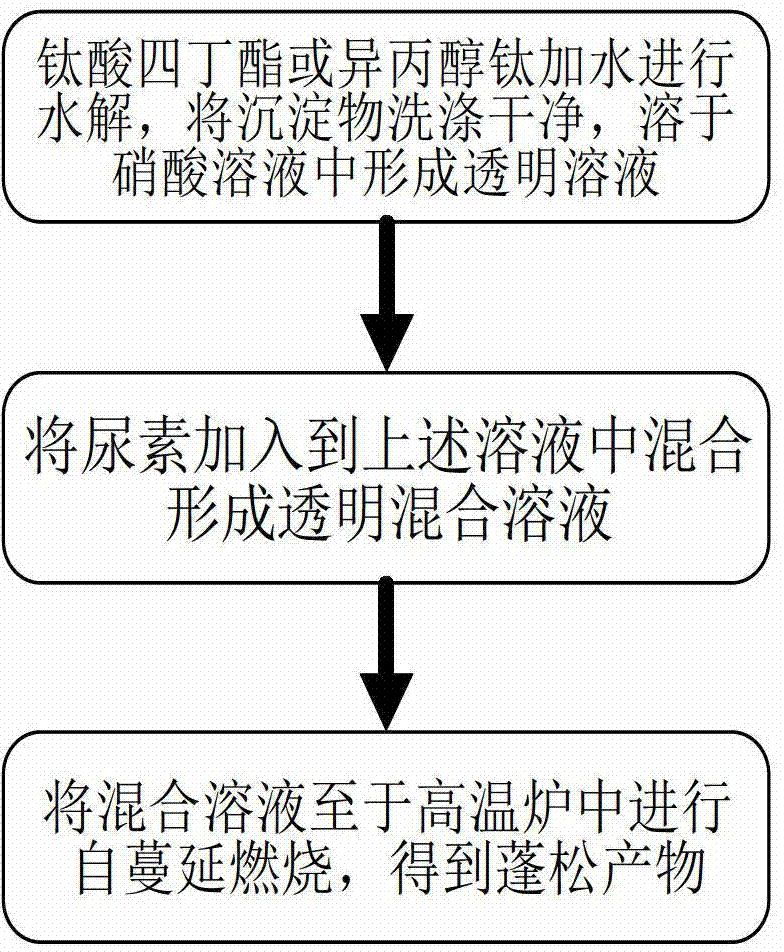

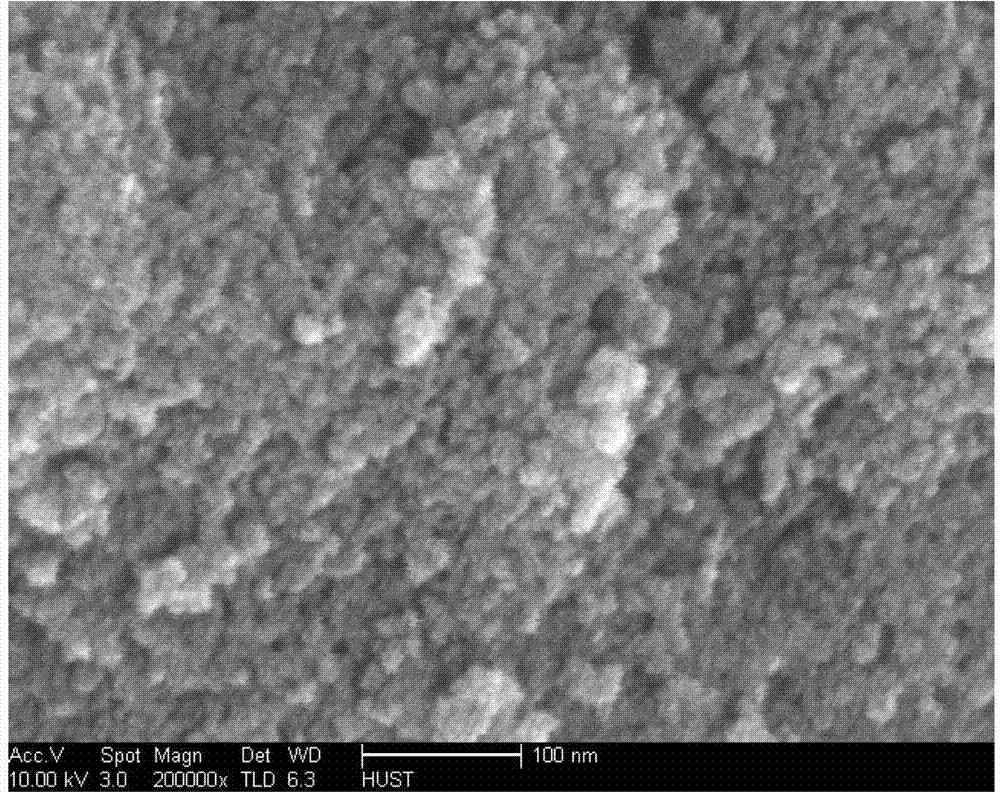

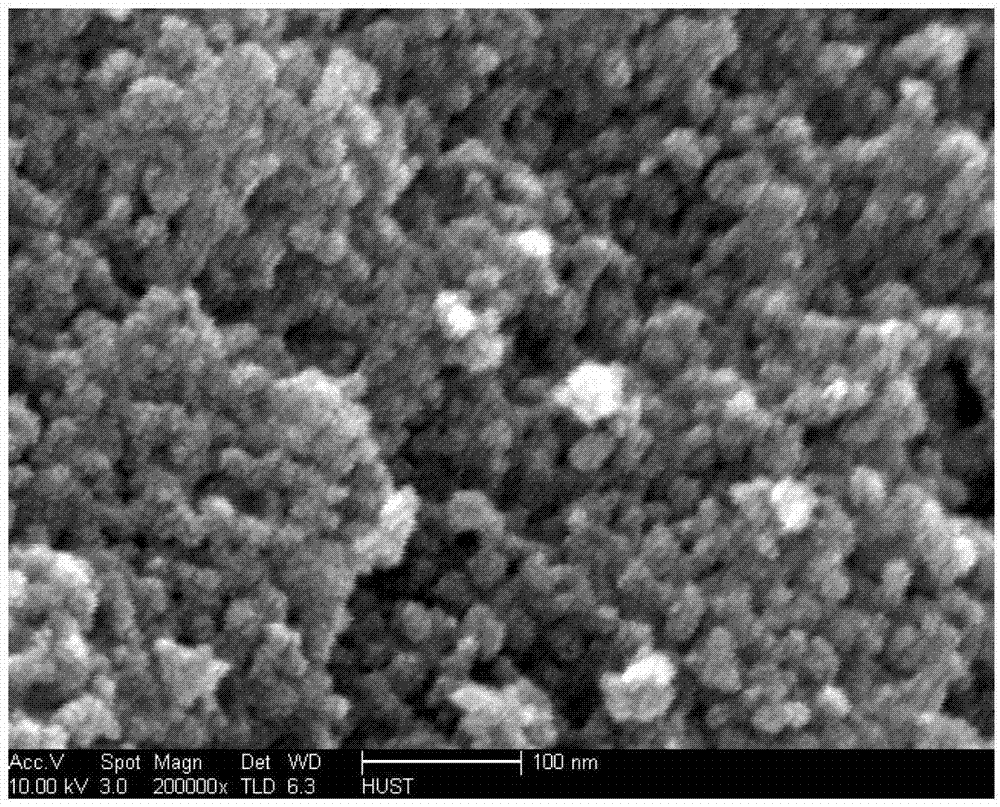

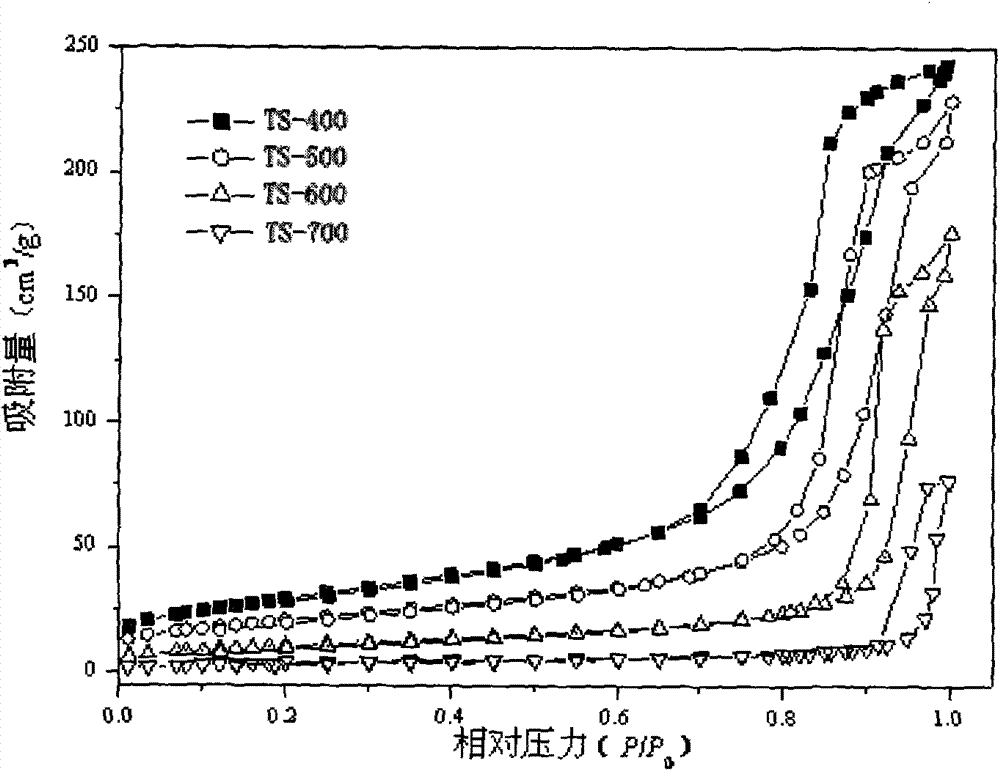

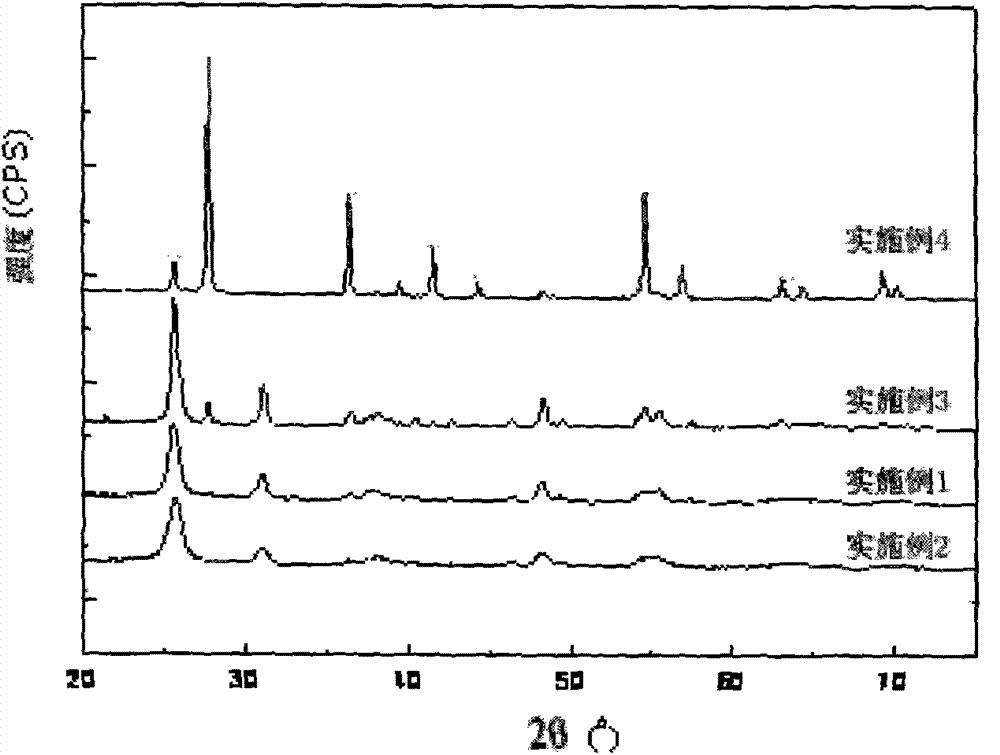

Method for preparing mixed crystal type titanium dioxide nano-powder and product thereof

ActiveCN102963926AAvoid introducingIncrease productivityMaterial nanotechnologyTitanium dioxideTitanium isopropoxidePhotocatalytic degradation

The invention discloses a method for preparing mixed crystal type titanium dioxide nano-powder containing anatase and rutile. The method comprises: (a) hydrolyzing and precipitating tetrabutyl titanate or titanium isopropoxide, and mixing the formed precipitate and nitric acid to form a titanium salt solution; (b) adding urea into the prepared titanium salt solution to form a mixed solution, with a mole ratio of the urea and the titanium ion in the titanium salt solution being 0.4 to 40; and (c) performing a self-propagating combustion for the mixed solution in a high-temperature furnace of 300 to 600 DEG C, so as to obtain a mixed crystal type titanium dioxide nano-powder simultaneously containing anatase and rutile. The invention further discloses corresponding preparation product. According to the invention, the nanoscale titanium dioxide powder can be obtained with simple process and low cost; and the prepared product simultaneously contains the anatase and the rutile, is small in grain size, uniform in granularity and excellent in photocatalytic degradation.

Owner:HUAZHONG UNIV OF SCI & TECH

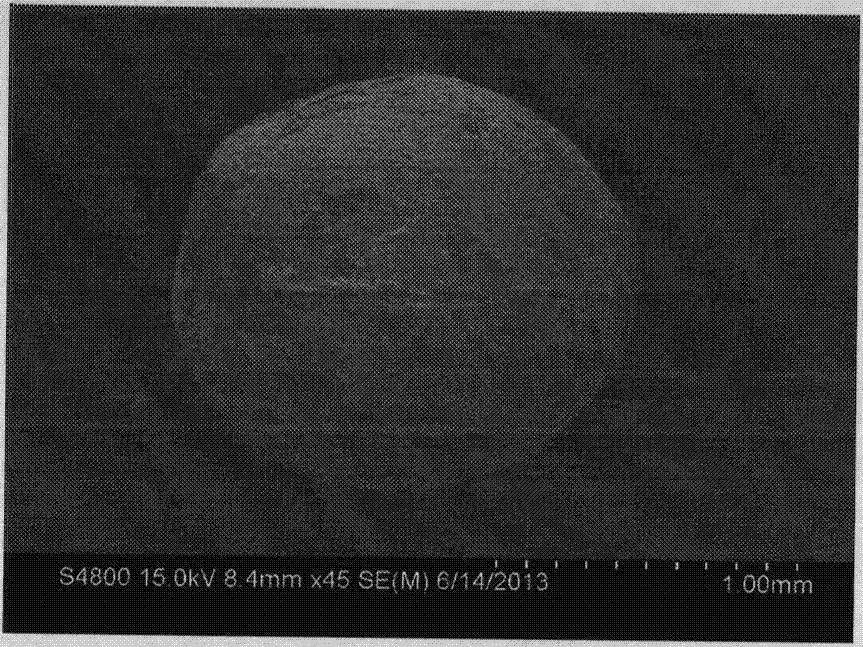

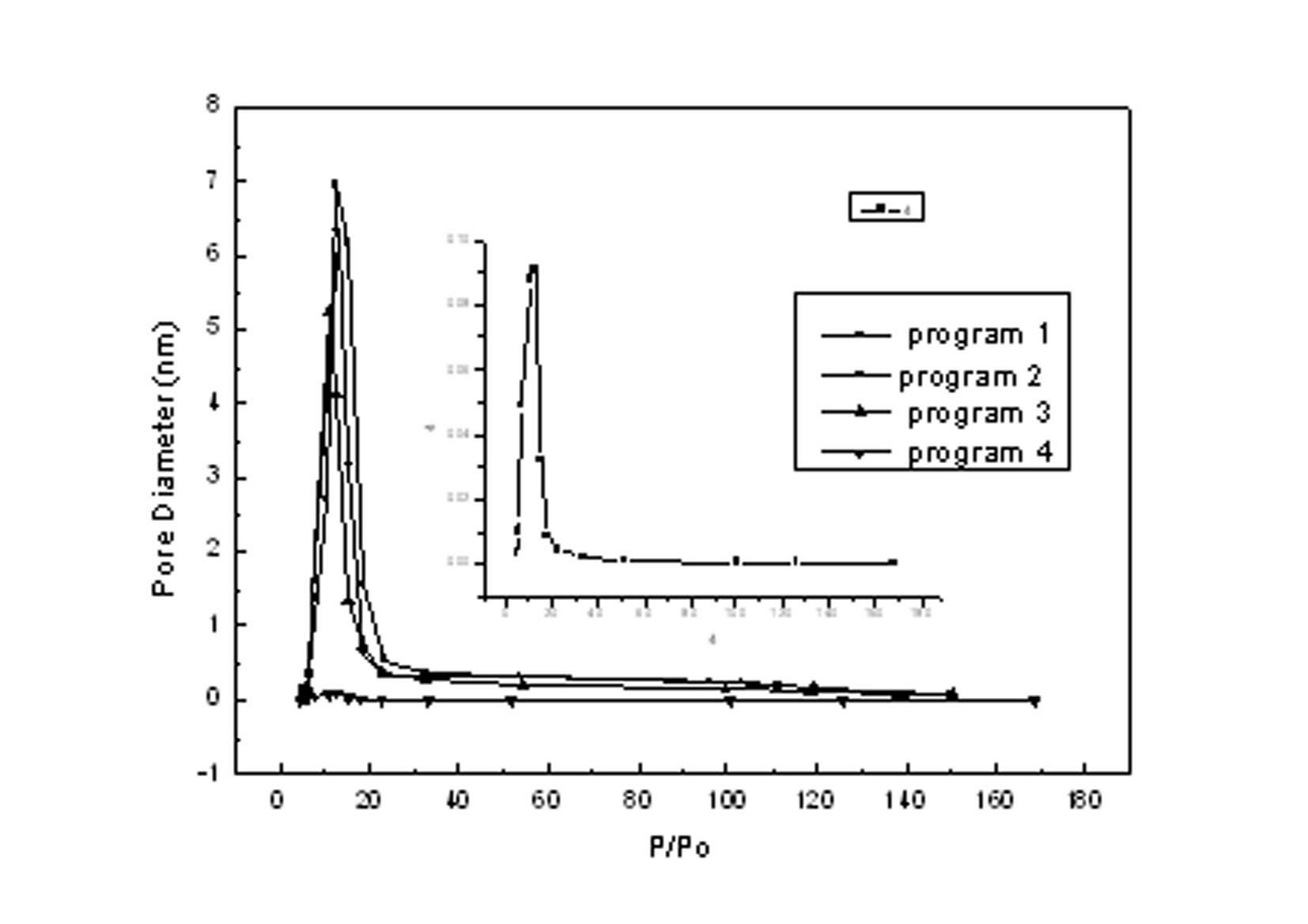

Dual-template preparation method of mesoporous TiO2 sphere

InactiveCN103570065AEasy to manufactureHas a mesoporous structurePhysical/chemical process catalystsOther chemical processesPolyvinyl alcoholTitanium isopropoxide

The invention discloses a dual-template preparation method of a mesoporous TiO2 sphere. The preparation method comprises the steps of respectively preparing a chitosan acetic acid solution and a polyvinyl alcohol water solution; mixing the two solutions in a certain proportion to form a mixed solution; dropwise adding the mixed solution into a sodium hydroxide solution through an injector to form a chitosan / polyvinyl acetate (PVA) hydrogel microsphere instantaneously; standing overnight, completely curing, respectively soaking the microsphere in double-distilled water, ethanol and isopropyl alcohol for 30min, and filtering to obtain a swelled porous microsphere; soaking the microsphere in a titanium isopropylate solution for 48 hours; soaking the chitosan / PVA microsphere loaded with the titanium isopropylate in excessive water for 24 hours, and washing the obtained microsphere to remove titanium hydroxide deposited on the surface of the porous chitosan / PVA polymer; drying the obtained microsphere to constant weight; and calcining a obtained sample to obtain the mesoporous TiO2 sphere. The method is simple and convenient to prepare, and the prepared TiO2 which is of a mesoporous structure has good adsorbability and photocatalysis.

Owner:TAIZHOU UNIV

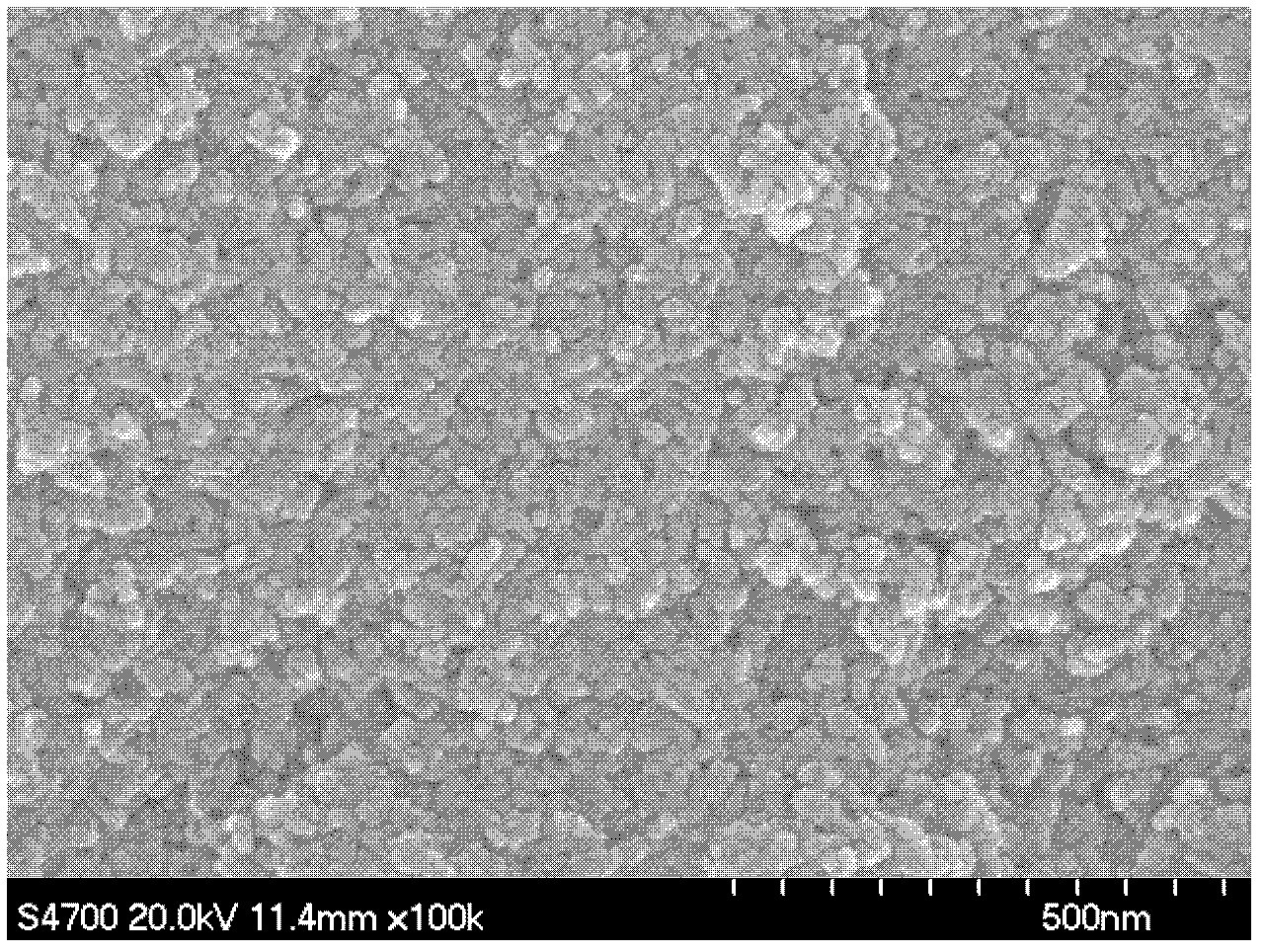

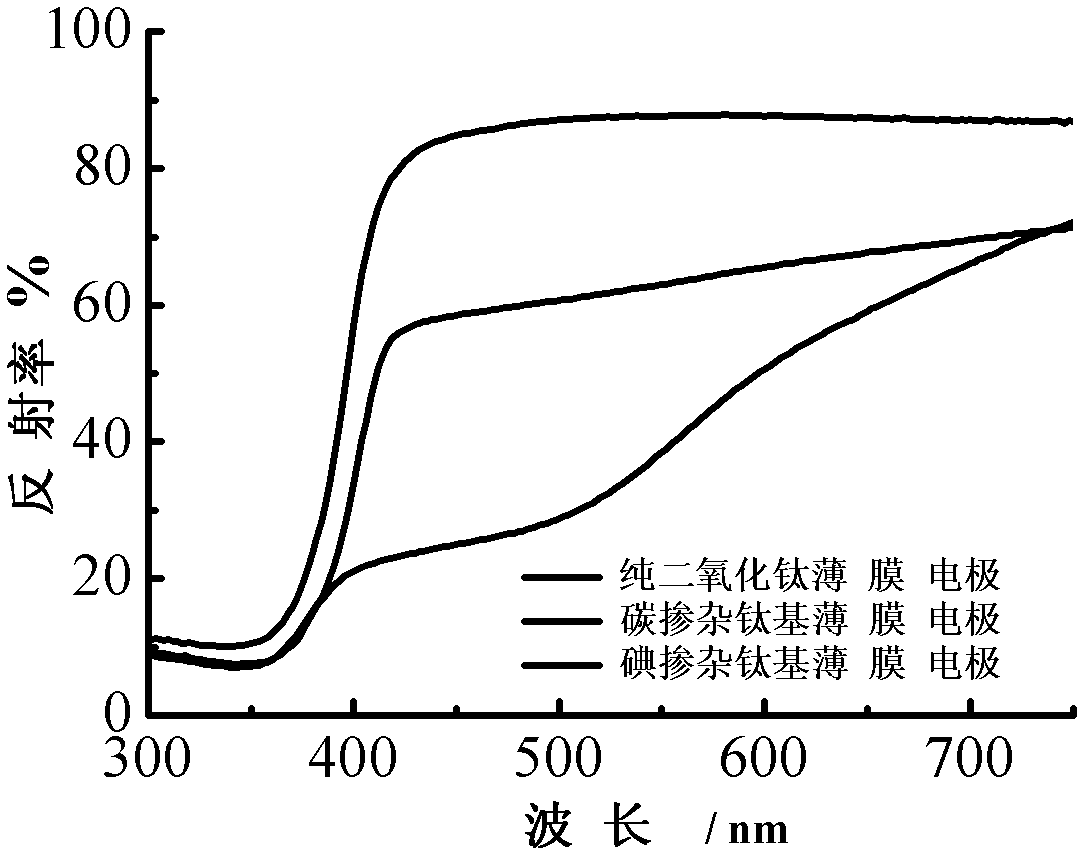

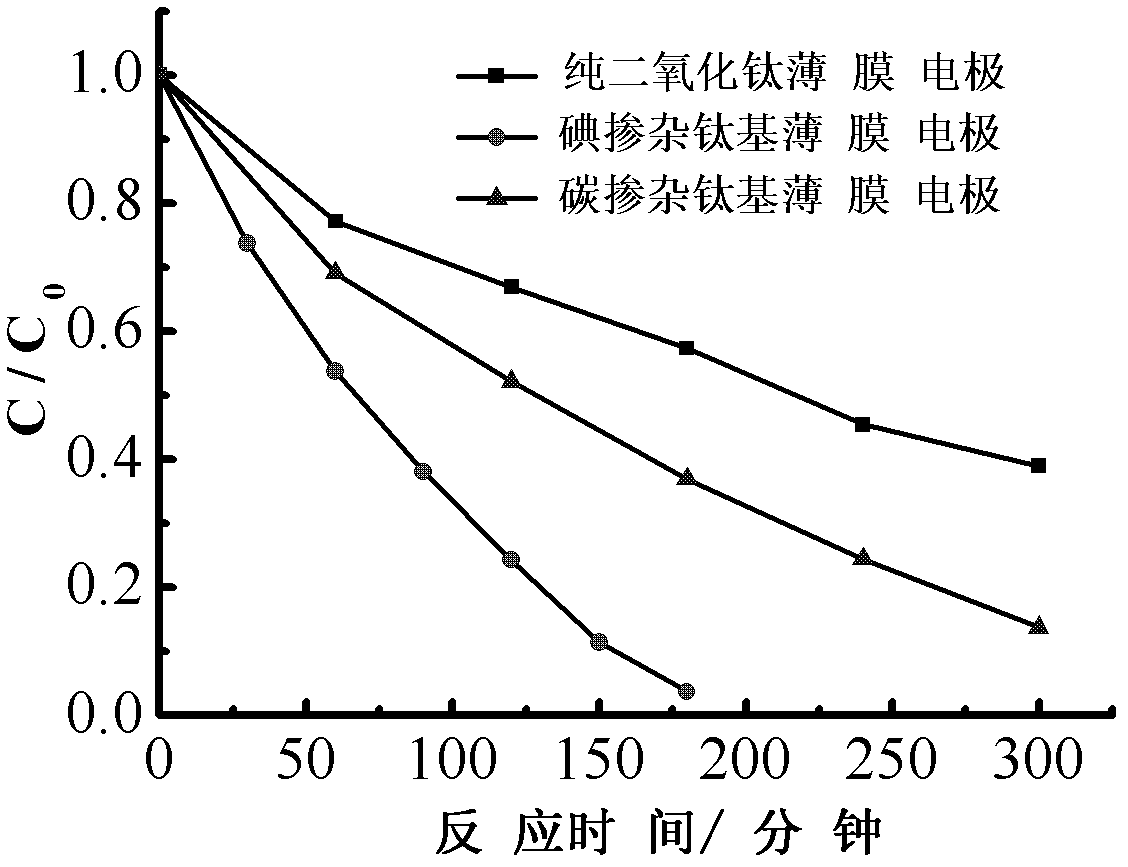

Nonmetal doped titanium-based film electrode as well as preparation method and application thereof

ActiveCN102491459AEasy to operateStrong controllability and repeatabilityWater/sewage treatment by irradiationEnergy based wastewater treatmentIonChemistry

The invention provides a nonmetal doped titanium-based film electrode as well as a preparation method and an application thereof and belongs to the photoelectric catalysis technical field of inorganic nonmetal materials. The preparation method comprises the following steps of: mixing and reacting an elementary substance or compound of a nonmetal element with titanium isopropoxide to prepare nonmetal doped TiO2 particles; preparing TiO2 nanocrystals; mixing the nonmetal doped TiO2 particles and a pore-forming agent with the TiO2 nanocrystal emulsion to prepare latex and coating; and then carrying out thermal treatment. The nonmetal doped titanium-based film electrode prepared by using the method is used for photoelectrocatalysis degradation of pollutants in water, such as paint, phenols, aldehydes, medicaments or heavy metal ions. The electrode provided by the invention has the advantages of visible light response, large specific surface area and strong adhesive power with a substrate.

Owner:BEIJING UNIV OF CHEM TECH

High-yield synthesis of brookite TiO2 nanoparticles

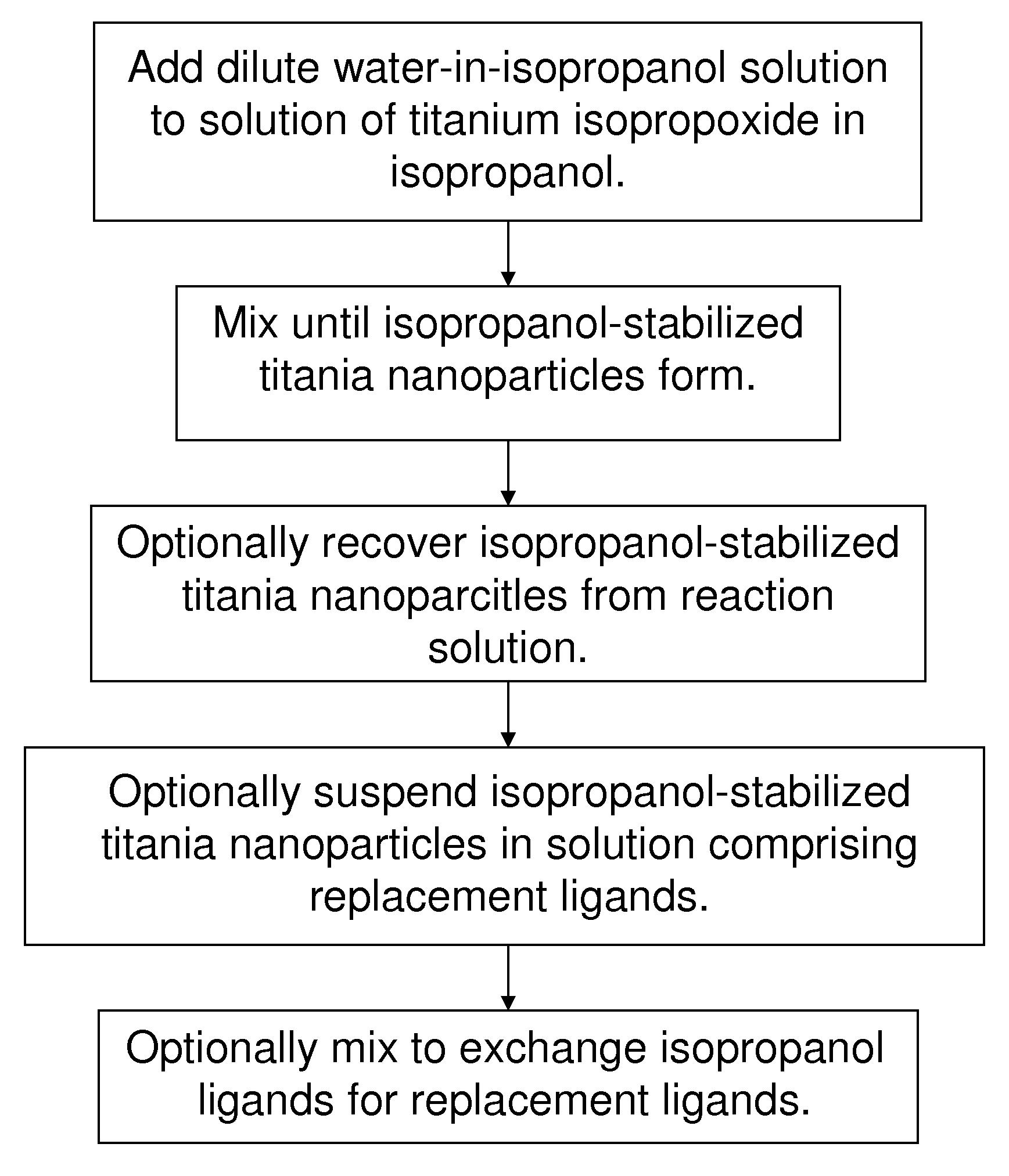

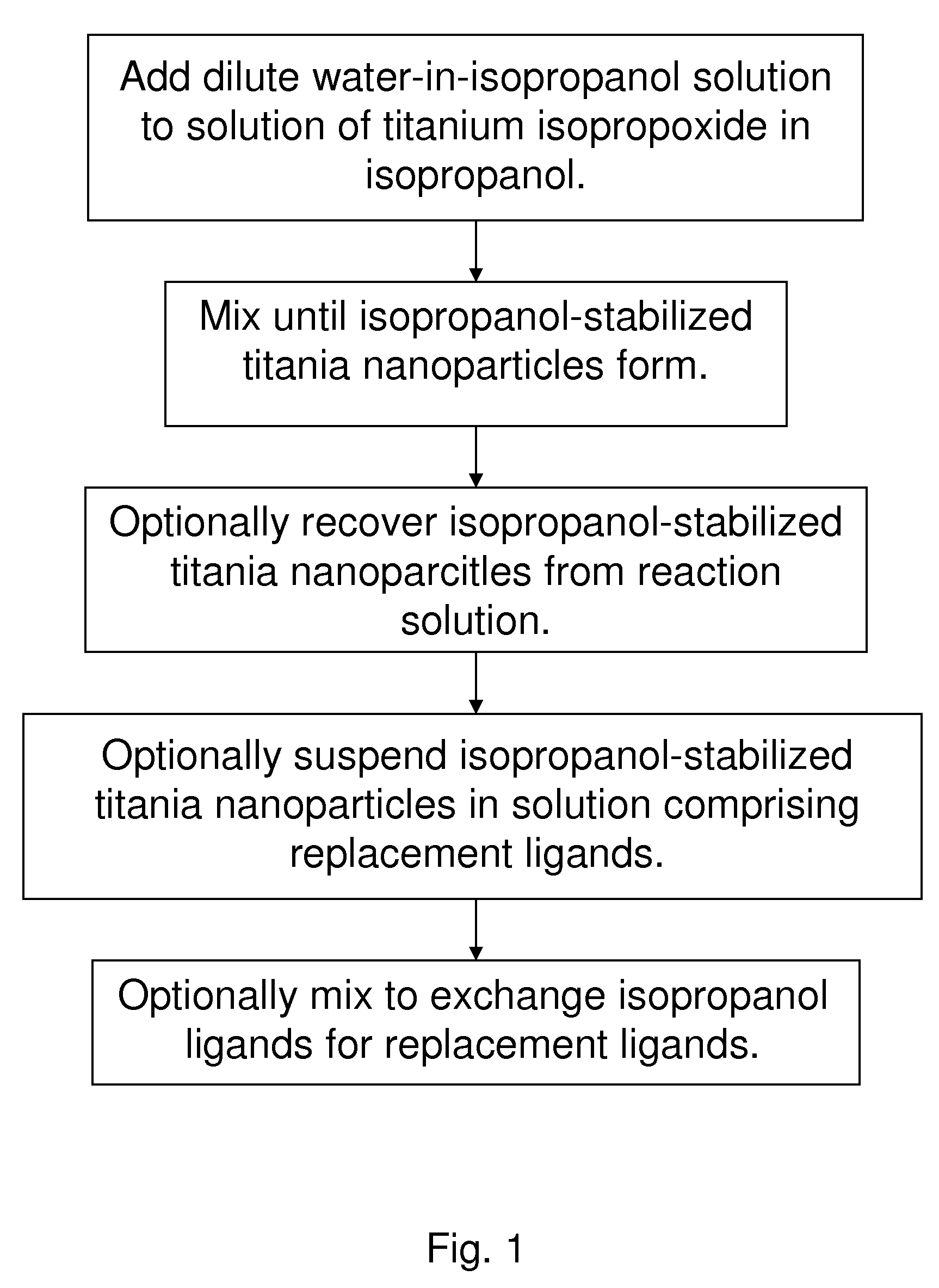

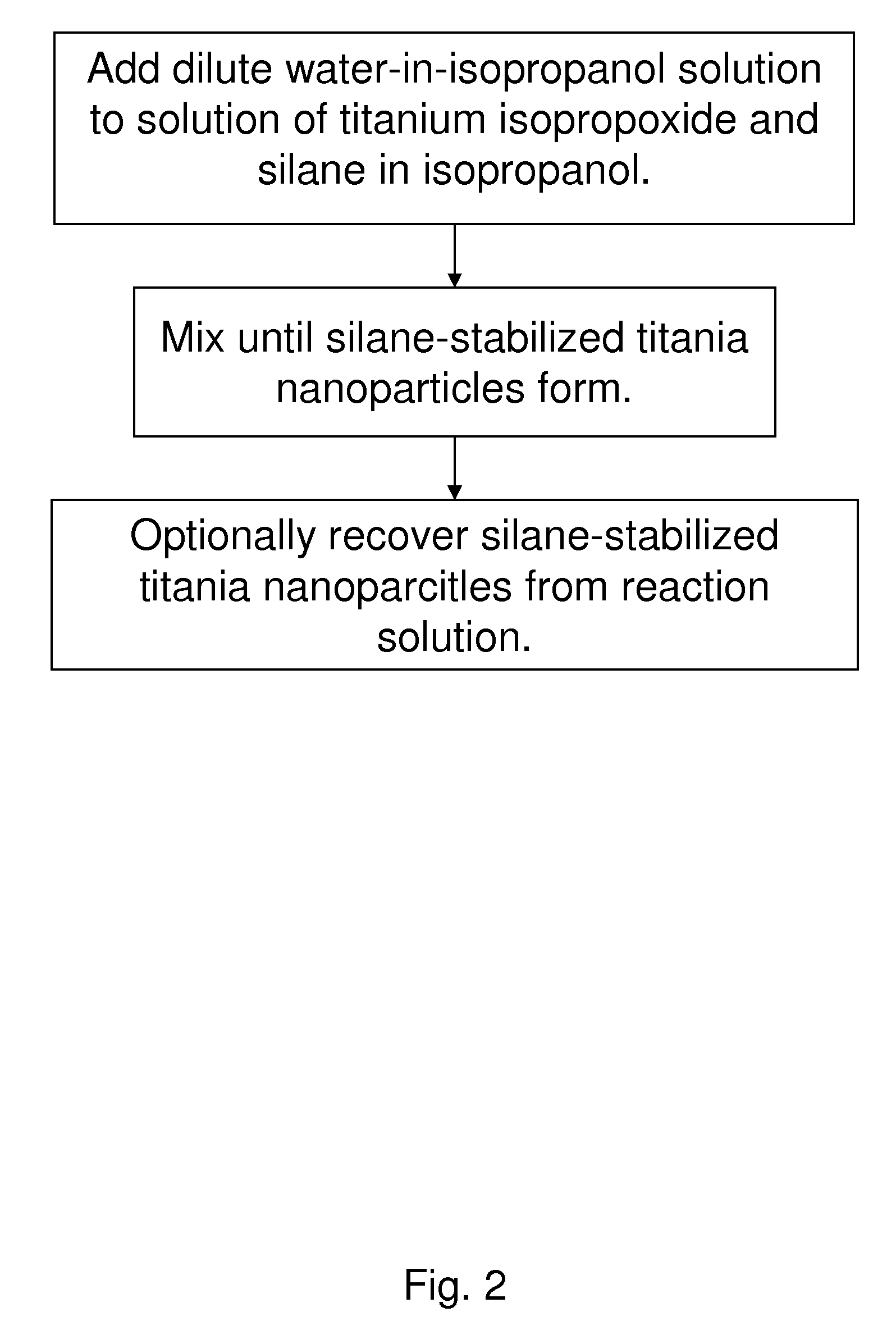

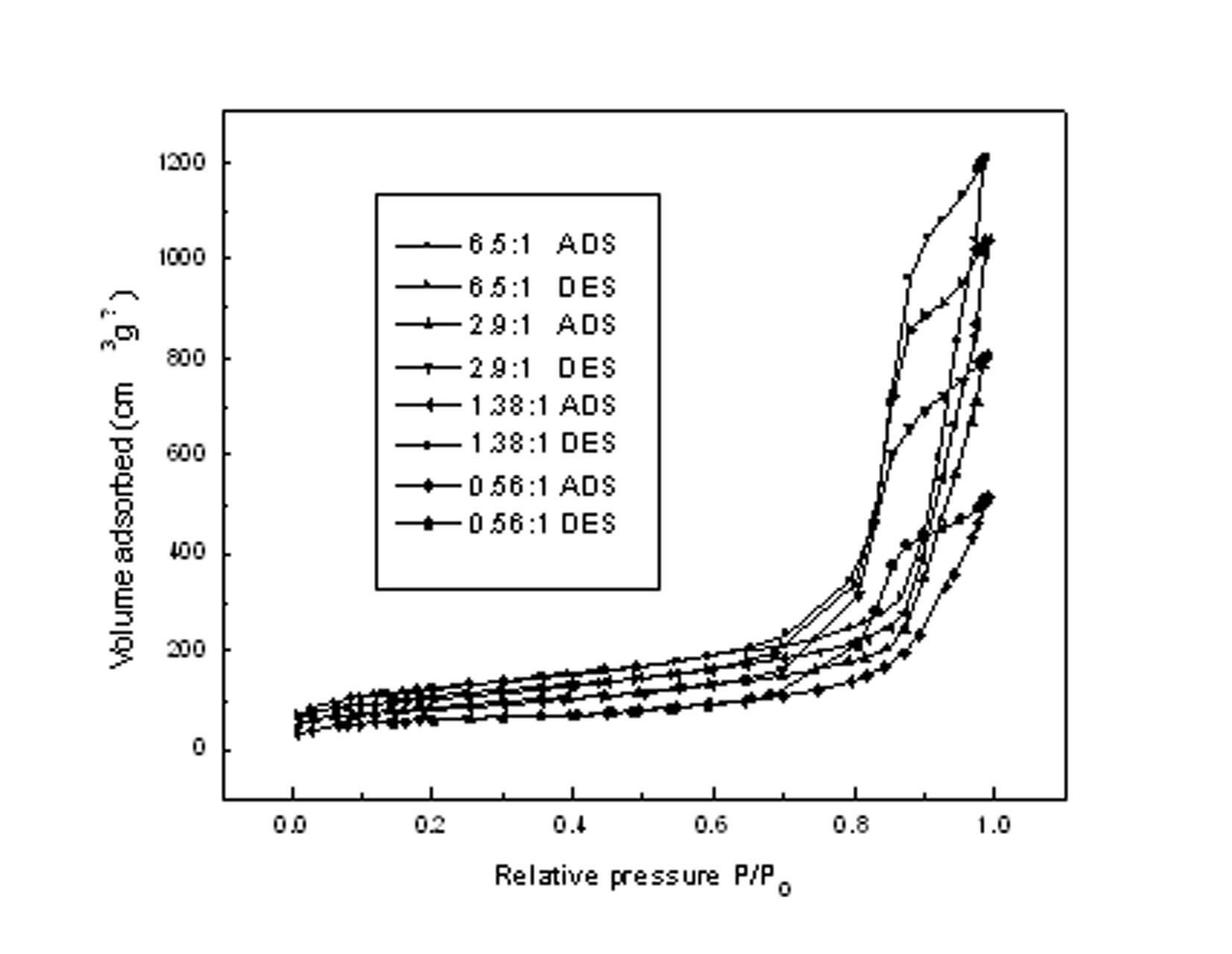

A method for forming non-agglomerated brookite TiO2 nanoparticles without the use of expensive organic surfactants or high temperature processing. Embodiments of this invention use titanium isopropoxide as the titanium precursor and isopropanol as both the solvent and ligand for ligand-stabilized brookite-phase titania. Isopropanol molecules serve as the ligands interacting with the titania surfaces that stabilize the titania nanoparticles. The isopropanol ligands can be exchanged with other alcohols and other ligands during or after the nanoparticle formation reaction.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

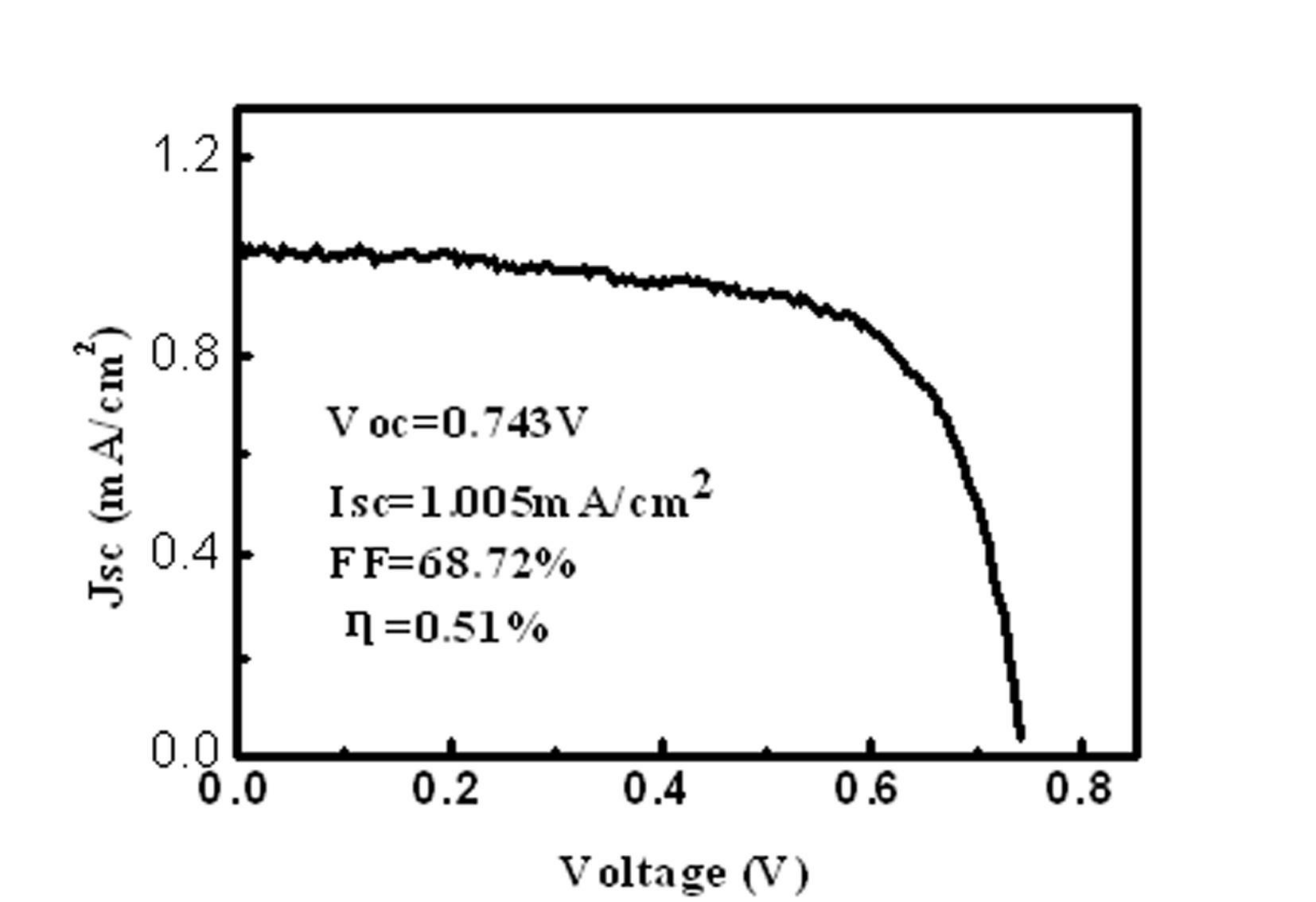

Method for preparing mesoporous titanium dioxide by template method and application of mesoporous titanium dioxide to preparation of dye-sensitized solar cells

InactiveCN102583529ANarrow distributionLight-sensitive devicesFinal product manufactureSilicic acidTitanium isopropoxide

The invention provides a method for preparing mesoporous titanium dioxide by a template method. The method comprises the following steps that: poly(glycol)-embedded-poly(propylene glycol)-embedded-poly(glycol) is added into water, then, ammonium fluoride and trimethylbenzene are added and are uniformly stirred with the water, and template solution is obtained; tetraethyl orthosilicate and isopropyl titanate are added into the obtained template solution and are uniformly stirred with the obtained template solution, then, the materials are transferred to an autoclave and are heated for 20 to 26 hours at 110 to 130 DEG C, and powder is obtained through filtering and drying; and the obtained powder is added into mixed solution of concentrated nitric acid and hydrogen peroxide, organic matters in the powder are removed through oxidation, and the mesoporous titanium dioxide is obtained. The mesoporous material obtained by adopting the method has the advantages that the bore diameter size distribution range is narrow, and the specific surface area is large; and dye-sensitized solar cells prepared from the mesoporous material have the advantages that the open circuit voltage can reach 0.74 V, the cell efficiency can reach 7.51 percent, and the filling factor can reach 75.7 percent.

Owner:NANJING UNIV +2

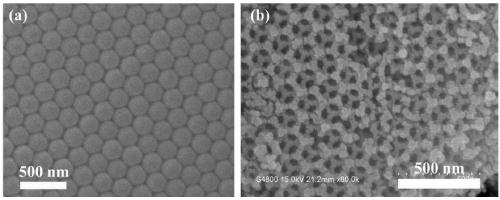

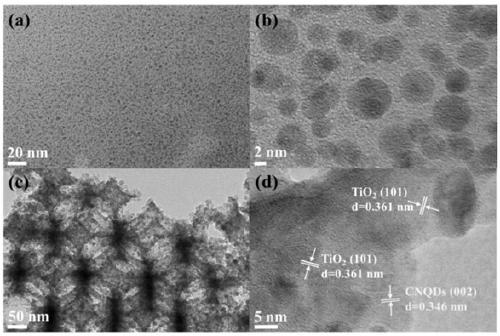

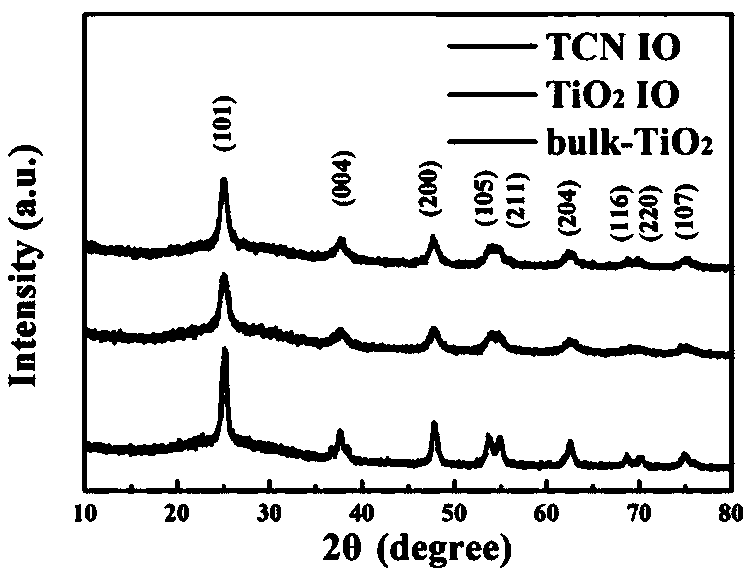

Preparation and application of CNQDs (Carbon nitride quantum dots)-modified TiO2 photonic crystal catalyst

InactiveCN109433241AImprove applicabilityLarge specific surface areaGas treatmentPhysical/chemical process catalystsProtein structurePhotocatalytic degradation

The invention provides a preparation method for a CNQDs (Carbon nitride quantum dots)-doped TiO2 photonic crystal for photocatalytic degradation of VOCs (Volatile organic compounds) and dyes. According to the method, an anti-protein structure photocatalyst which is controllable in pore sizes and in ordered arrangement is formed by the methods of performing perfusion, hydrolysis and high-temperature calcining treatment after adding a solution of the CNQDs prepared by a dialysis method into a precursor solution by taking polystyrene spheres as a template and taking titanium isopropoxide as a titanium source precursor. On one hand, the structure makes the material have a large specific surface area, which is beneficial to the adsorption of the VOCs and dye molecules to the surfaces of the catalyst; on the other hand, the utilization rate of the material to sunlight is improved by the slow light effect and the multiple light scattering effects of an inverse opal structure; and the materialhas good photocatalytic degradation activity, stability and renewability, and provides a practical and feasible solution for indoor air pollution and water body organic pollution.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparing method of electro-assisted photocatalysis cathode used for removing inorganic halite in water

InactiveCN105600866AStrong adsorptionImprove aggregate structurePhysical/chemical process catalystsWater contaminantsSolventIon

The invention relates to the technical field of electro-assisted photocatalysis water treatment, in particular to a preparing method of an electro-assisted photocatalysis cathode used for removing inorganic halite in water. The problems that the cathode surface is poor in adsorptivity, and a photoelectrocatalysis film is poor in uniformity and prone to cracking are solved. According to the scheme, the preparing method includes the steps that 1, activated carbon is mixed with concentrated nitric acid, soaked, cleaned to be neutral and dried; 2, a polyaluminium chloride compound solution is prepared and stirred; 3, the activated carbon is modified, stirred, soaked, dried and cooled; 4, the activated carbon, phenolic resin and graphite powder are mixed, pulverized and briquetted; 5, the mixture is activated in nitrogen to be prepared into a matrix; 6, titanium tetraisopropoxide and isopropanol solvent are mixed and added into a mixed solution to form sol; 8, the matrix is soaked in the sol, pulled and calcined. The preparing method has the advantages that the activated carbon is modified by the polyhydroxy complex, ionic selectivity is improved, powerful adsorption function is achieved, and more negative ions are adsorbed to the surface of the cathode. Absolute ethyl alcohol serves as the solvent, the gathering structure is improved, the porosity is reduced, compactness is improved, and cracking is reduced.

Owner:山西芮海环保科技有限公司

Durable waterproof engineering coating and preparation method thereof

InactiveCN110862736AEasy to prepareEasy to operateFireproof paintsAnti-corrosive paintsEpoxyPolymer science

The invention discloses a durable waterproof engineering coating, and is characterized in that the durable waterproof engineering coating is prepared from the following raw materials in parts by weight: 25-30 parts of an allylthiourea / 3-amino-3-(2-pyridine)acrylonitrile / 1-vinyl-1,2,4-triazole / titanium triisopropoxide methacrylate copolymer, 2-4 parts of epoxy modified 2,4,6-triphenylborazine, 20-30 parts of amino-terminated polyurethane, 1-4 parts of asphalt, 2-5 parts of vinyl-terminated fluorosilicone oil, 0.5-1.5 parts of a photoinitiator, 15-20 parts of a filler, 1-3 parts of a defoaming agent, 1-3 parts of a dispersing agent, 1-3 parts of an emulsifying agent and 20-30 parts of an organic solvent. The invention also provides a preparation method of the durable waterproof engineering coating. The durable waterproof engineering coating disclosed by the invention is remarkable in waterproof effect, good in comprehensive performance and excellent in weather resistance, mechanical property, heat resistance and wear resistance.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

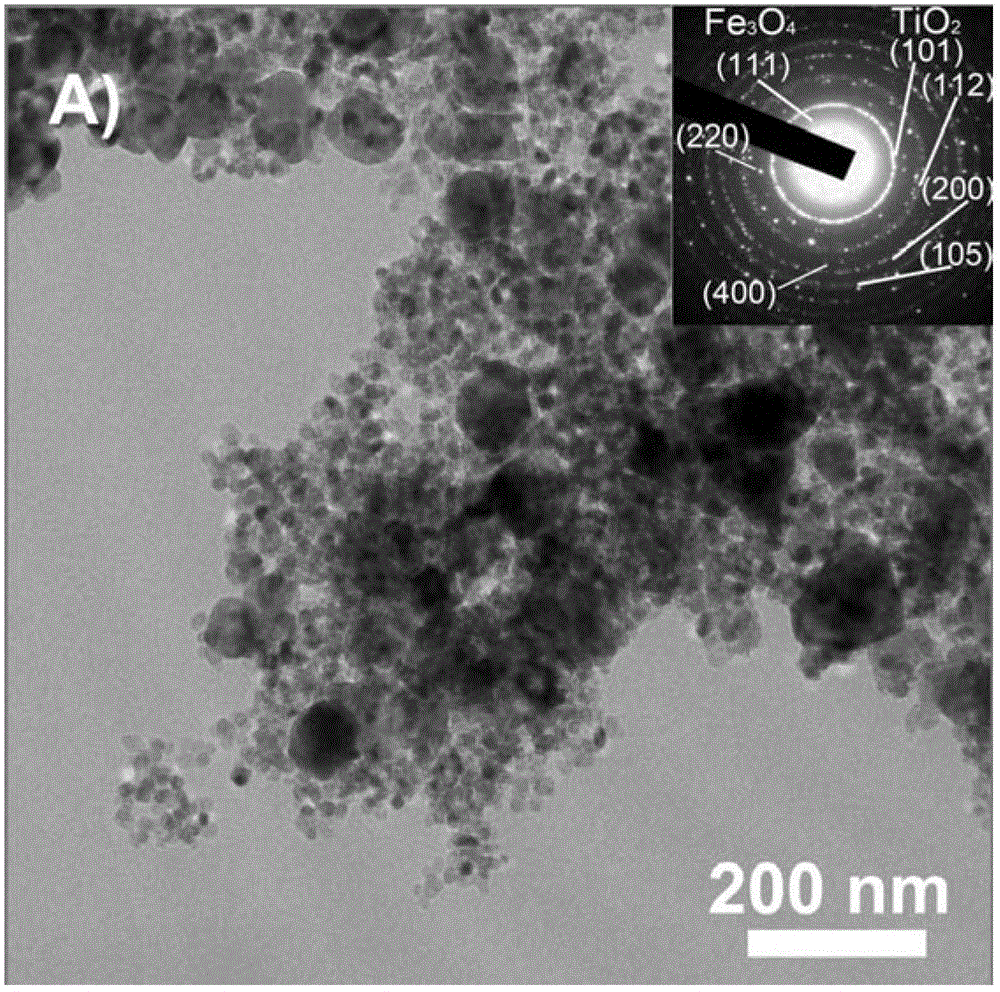

Recyclable and reusable organic dye photocatalyst and preparation method thereof

InactiveCN102716746AGuaranteed stabilityImprove stabilityWater/sewage treatment by irradiationWater contaminantsAlcoholOrganic dye

The invention provides a preparation method for a recyclable and reusable organic dye photocatalyst composite. The preparation method includes a) mixing graphene oxide liquor, titanium isopropoxide sulfuric acid and alcohol together to obtain mixed liquor; b) heating the mixed liquor and enabling the mixed liquor to react to obtain a graphene and titanium oxide composite; and c) mixing, heating and enabling the graphene and titanium oxide composite, liquor containing Fe2+ and Fe3+ and liquor containing OH- to react to obtain a graphene, titanium dioxide and ferroferric oxide photocatalyst. The invention further provides the photocatalyst composite which comprises a graphene layer, a titanium dioxide granular layer and a ferroferric oxide layer. The titanium dioxide granular layer is positioned on the graphene layer, and the ferroferric oxide layer is positioned on the titanium dioxide granular layer. The photocatalyst composite is fine in structural stability, and has high degradation rate after being used for degrading organic dye for multiple times.

Owner:UNIV OF SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com