Mesoporous photocatalytic material and preparation method thereof

A technology of photocatalytic materials and mesoporous materials, applied in the field of photocatalytic composite materials, can solve the problems of difficult recovery and easy deactivation, and achieve the effects of uniform distribution, good stability and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Dissolve 1.7g of template agent P123 and 3g of NaCl in 100ml of 1mol / L hydrochloric acid solution to form an acid solution, and stir at room temperature until clear.

[0035] (2) Add 4g of ethyl orthosilicate and stir at 35°C for 24h.

[0036] (3) Add 1.63g of isopropyl titanate and continue to stir for 7h, then let the product stand at 100°C for 24h to allow it to precipitate.

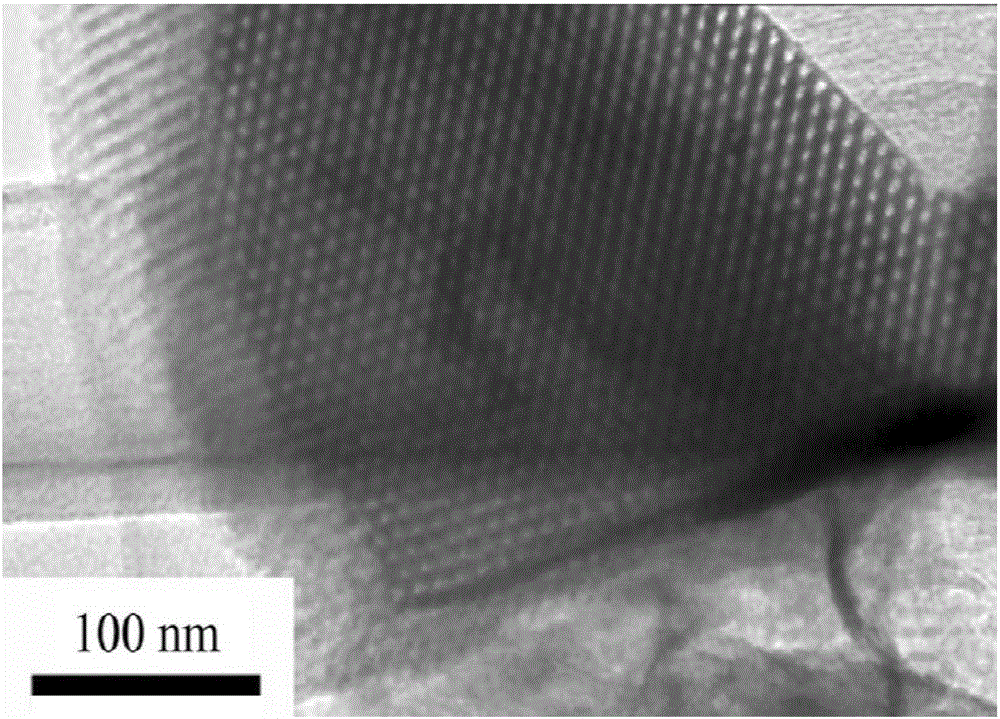

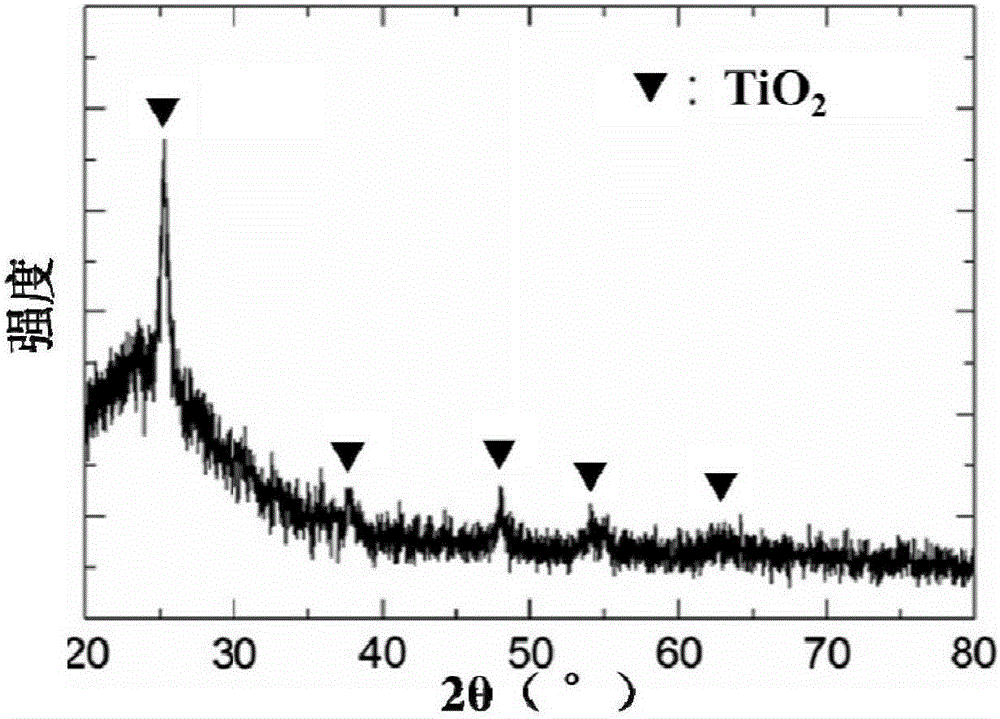

[0037] (4) Suction filter the product after standing, wash with deionized water and ethanol to remove excess P123, and calcinate at 550°C for 5h to obtain TiO 2 -SiO 2 Mesoporous material powder. combine figure 1 Medium TiO 2 -SiO 2 The transmission electron microscope image of the mesoporous material shows that the material template has an ordered tubular mesoporous structure with an aperture of about 8nm; figure 2 Medium TiO 2 -SiO 2 The X-ray diffraction (XRD) pattern of the mesoporous material clearly shows that the TiO 2 Diffraction peaks of anatase. It can be seen that the me...

Embodiment 2

[0041] (1) Dissolve 1.7g of template agent P123 and 2.55g of NaCl in 80ml of 1mol / L hydrochloric acid solution to form an acid solution, and stir at room temperature until clear.

[0042] (2) Add 3.5g ethyl orthosilicate and stir at 30°C for 23h.

[0043] (3) Add 1.43 g of isopropyl titanate and continue to stir for 6 h, then let the product stand at 90° C. for 22 h to allow it to precipitate.

[0044] (4) Suction filter the product after standing, wash with deionized water and ethanol to remove excess P123, and calcinate at 500°C for 4h to obtain TiO 2 -SiO 2 Mesoporous material powder.

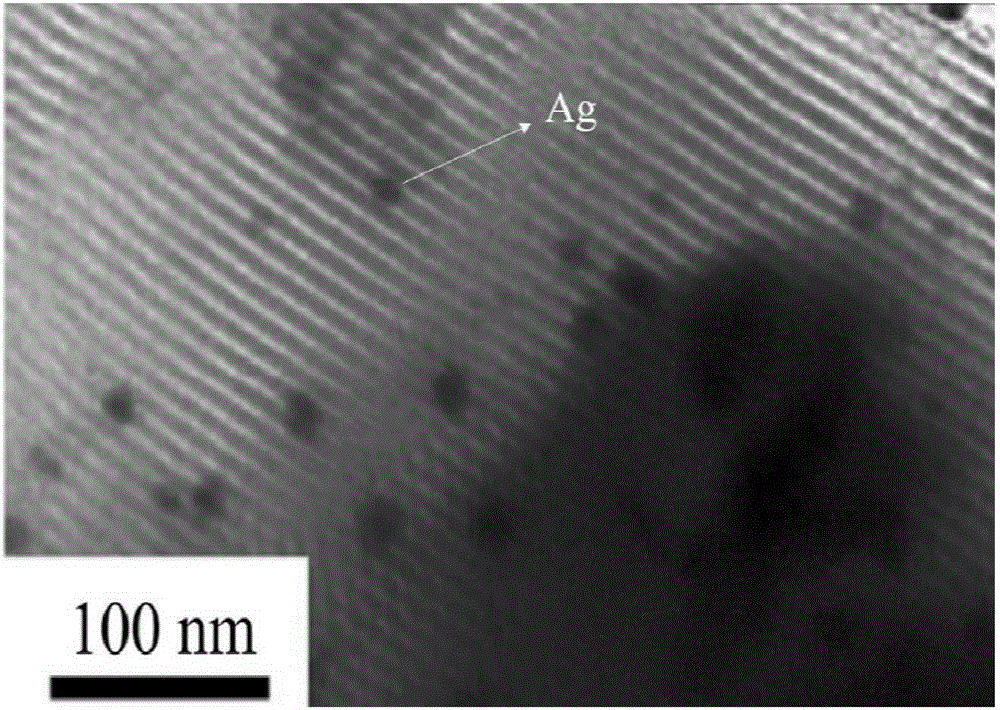

[0045] (5) Take 0.6gTiO 2 -SiO 2 The mesoporous material powder is dissolved in a mixed solution containing 1.2mL1mmol / L silver nitrate solution, 6ml deionized water and 7.2ml methanol, and the temperature is controlled at 30°C, the wavelength is 320~400nm, and the power is 0.6mW / cm 2 Stir for 5 min under UV light irradiation.

[0046] (6) The product was suction filtered, washed with ...

Embodiment 3

[0048] (1) Dissolve 1.7g of template agent P123 and 3.4g of NaCl in 120ml of 1mol / L hydrochloric acid solution to form an acid solution, and stir at room temperature until clear.

[0049] (2) Add 4.25g ethyl orthosilicate and stir at 40°C for 22h.

[0050] (3) Add 1.73g of isopropyl titanate and continue to stir for 8h, then let the product stand at 110°C for 20h to allow it to precipitate.

[0051] (4) Suction filter the product after standing, wash with deionized water and ethanol to remove excess P123, and calcinate at 600°C for 6h to obtain TiO 2 -SiO 2 Mesoporous material powder.

[0052] (5) Take 0.6gTiO 2 -SiO 2 Dissolve the mesoporous material powder into a mixed solution containing 2.4mL1mmol / L silver nitrate solution, 12ml deionized water and 14.4ml methanol, and control the temperature at 27°C, at a wavelength of 320~400nm, and a power of 0.85mW / cm 2 Stir for 2 min under UV light.

[0053] (6) The product was suction filtered, washed with deionized water and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com