Patents

Literature

443results about How to "Narrow pore size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

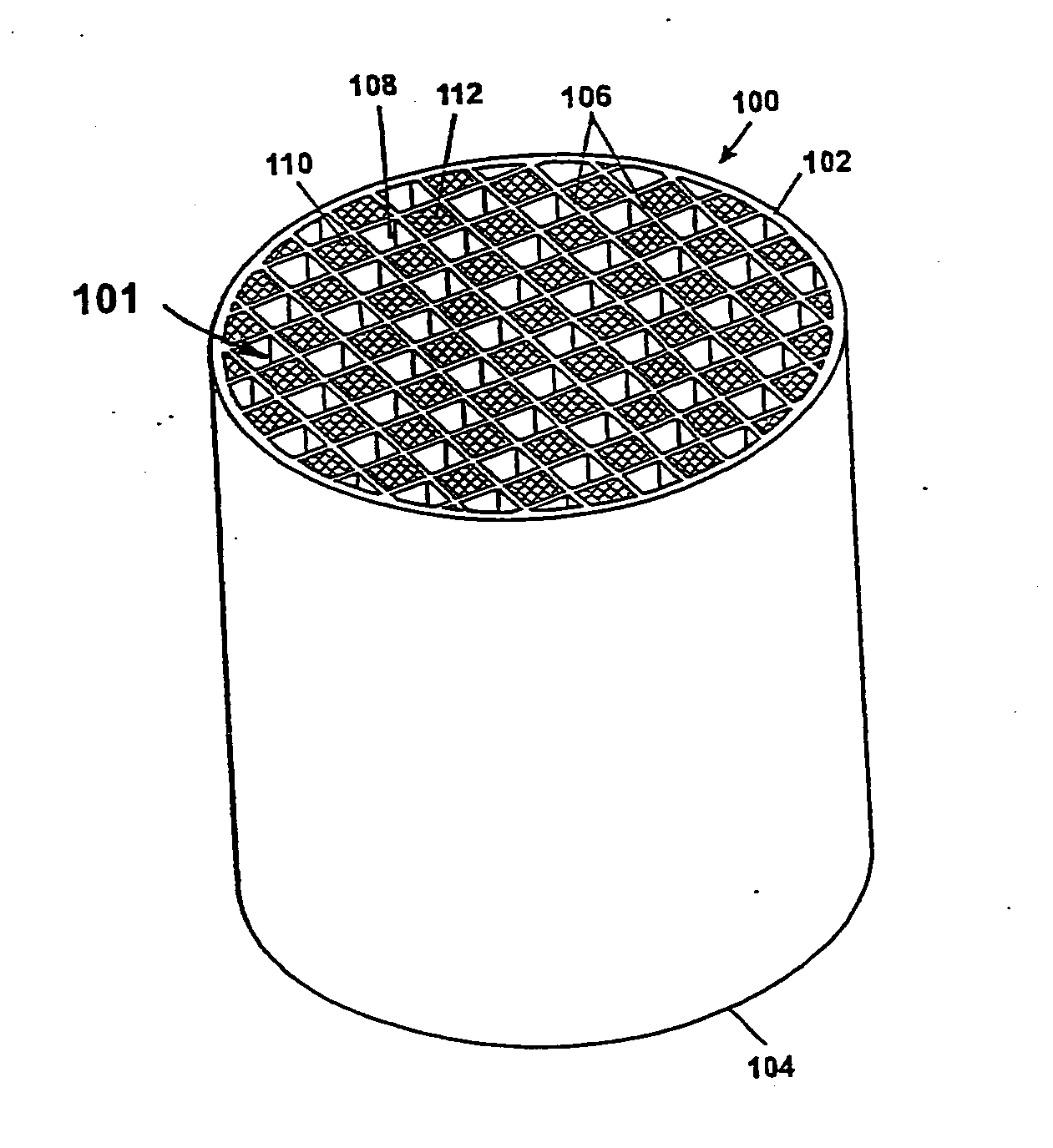

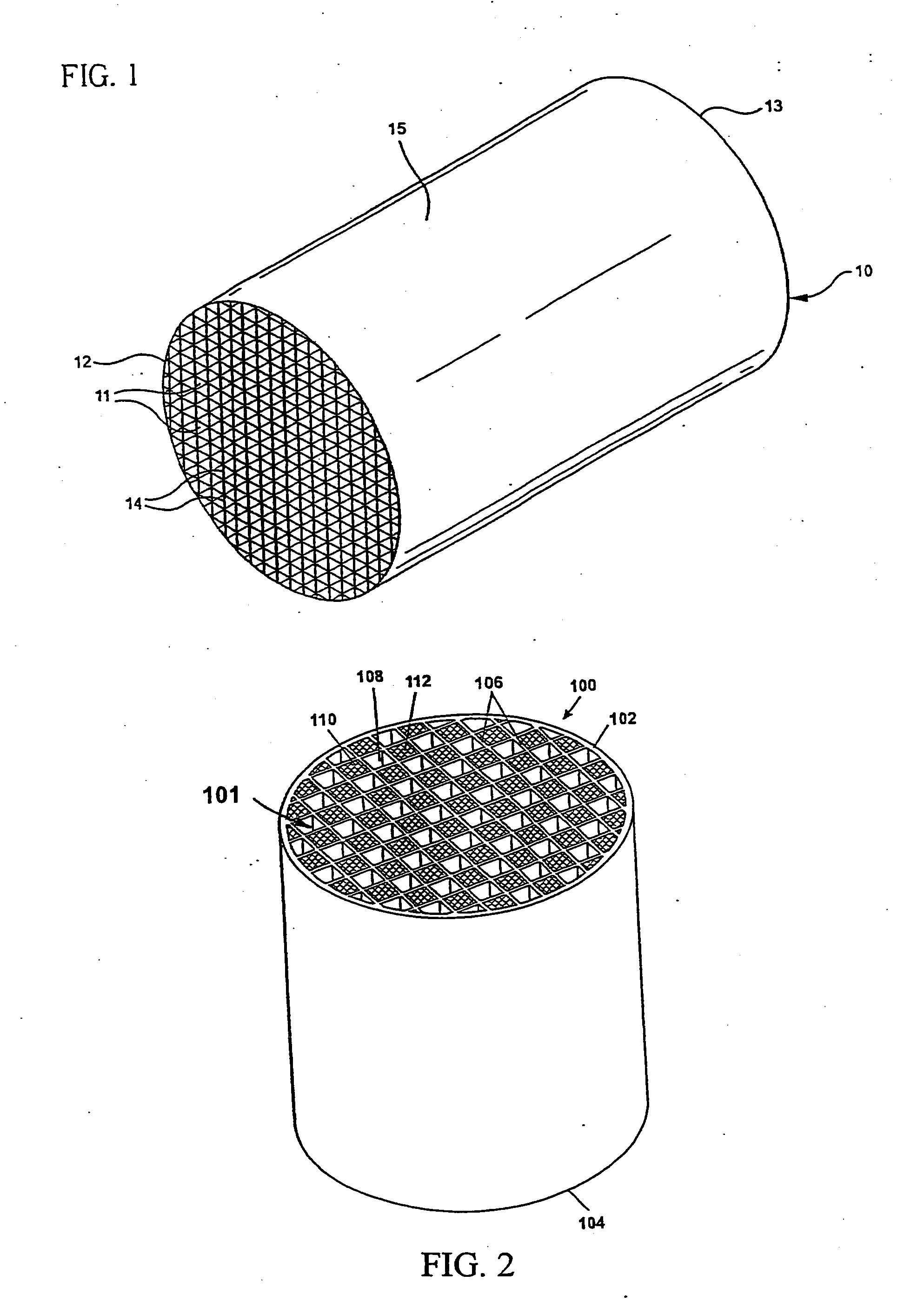

Controlled pore size distribution porous ceramic honeycomb filter, honeycomb green body, batch mixture and manufacturing method therefor

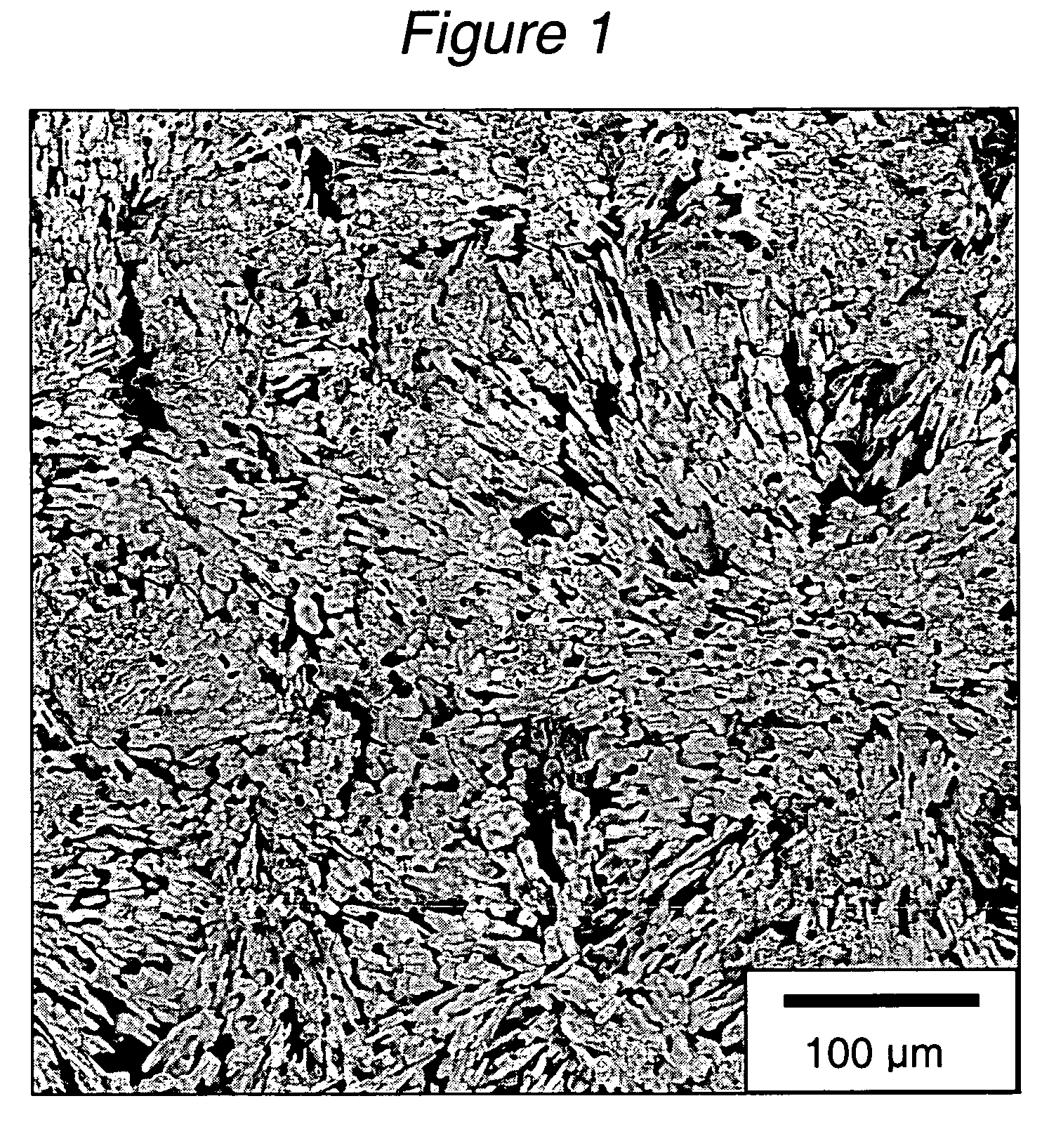

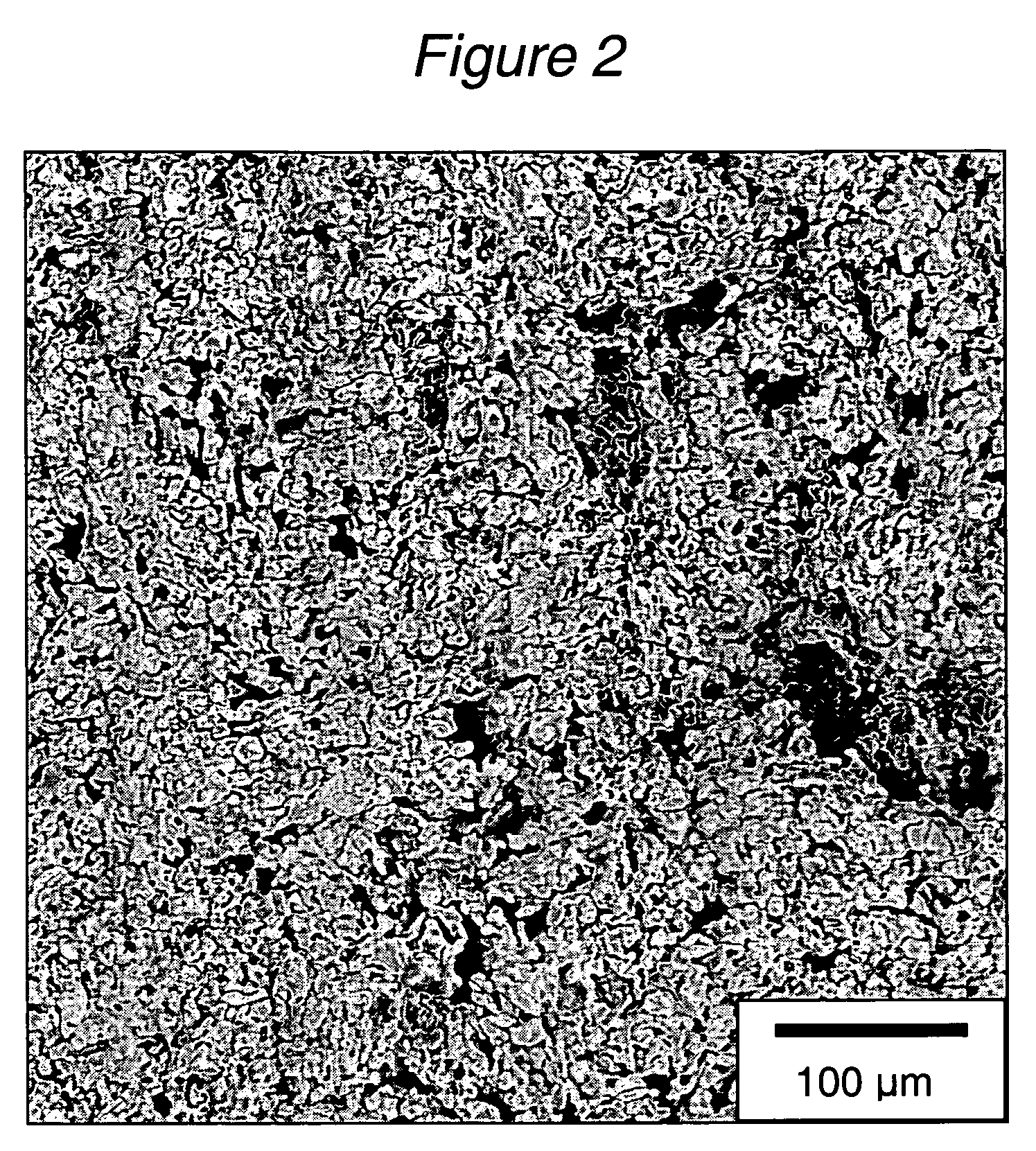

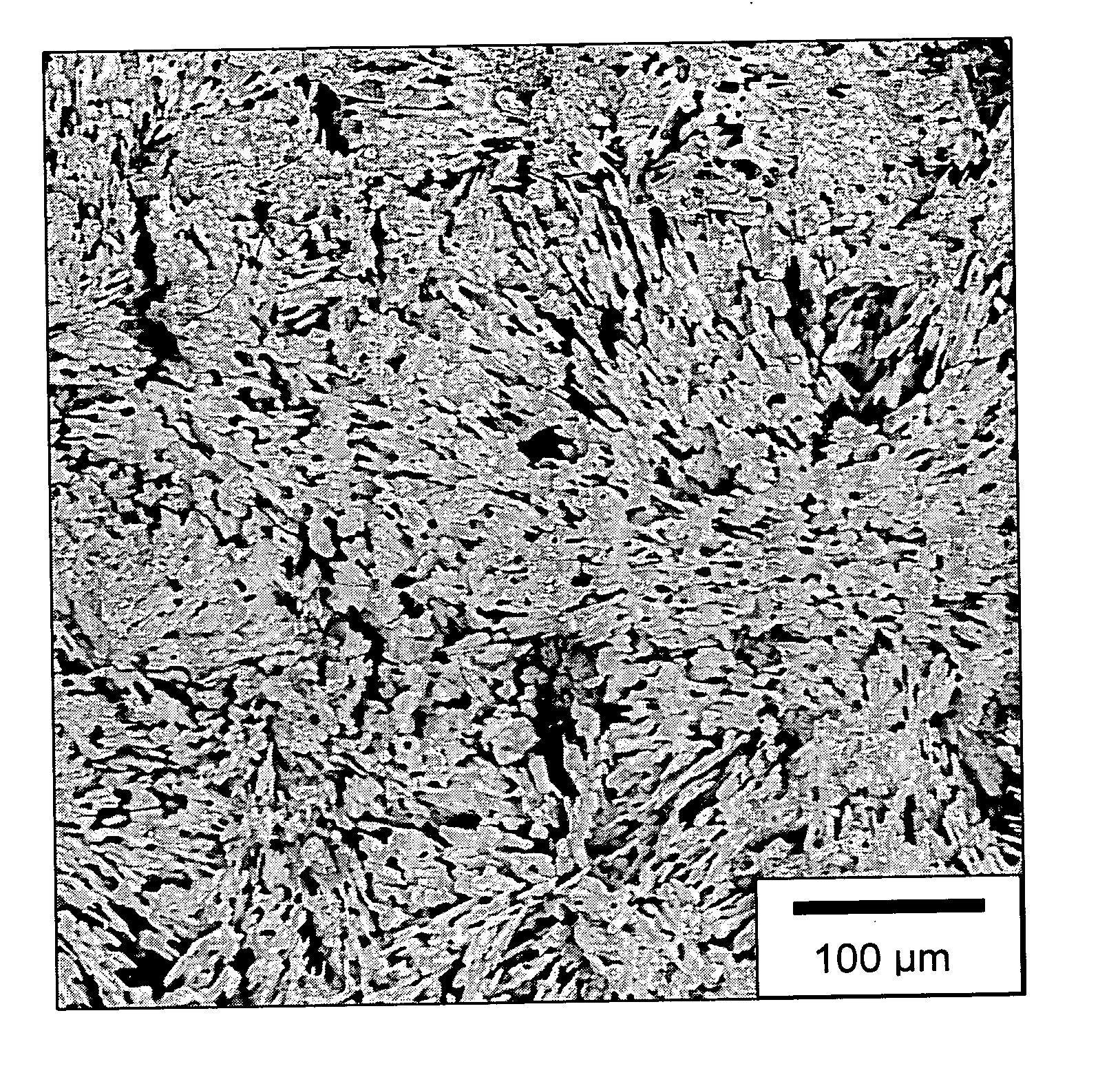

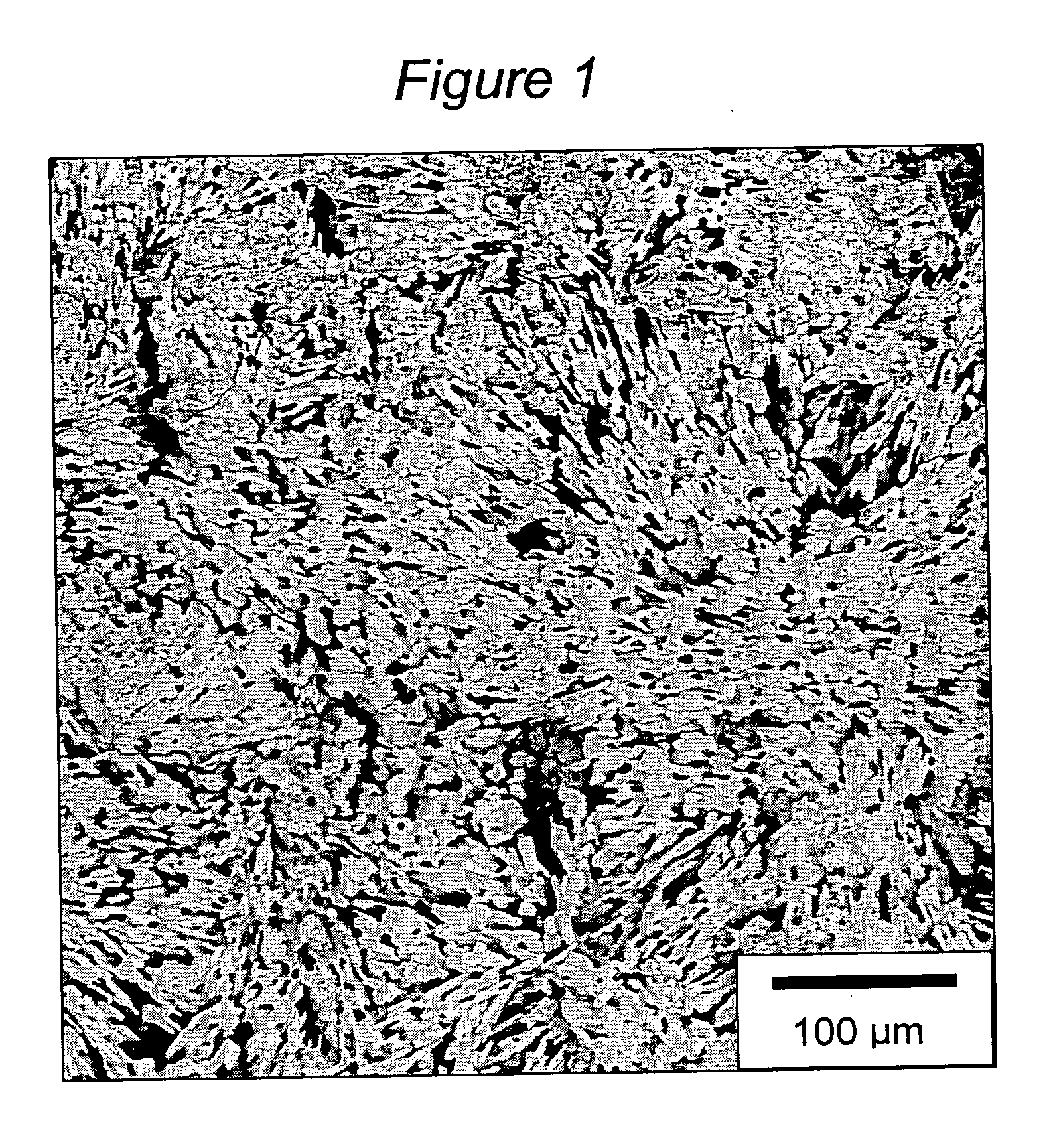

ActiveUS20070119135A1Lower wash-coated pressure dropQuantity minimizationCombination devicesExhaust apparatusSago palmSource material

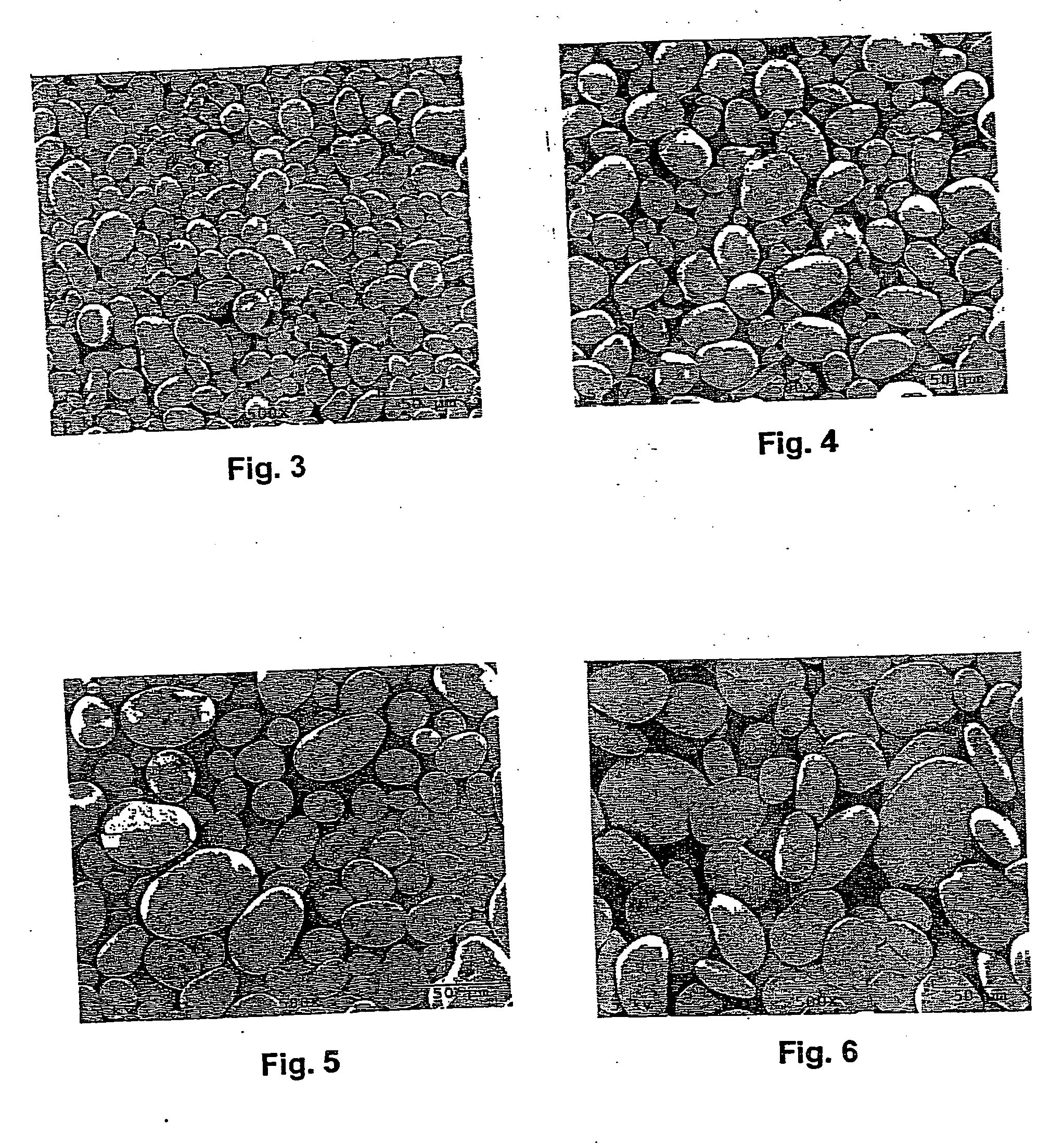

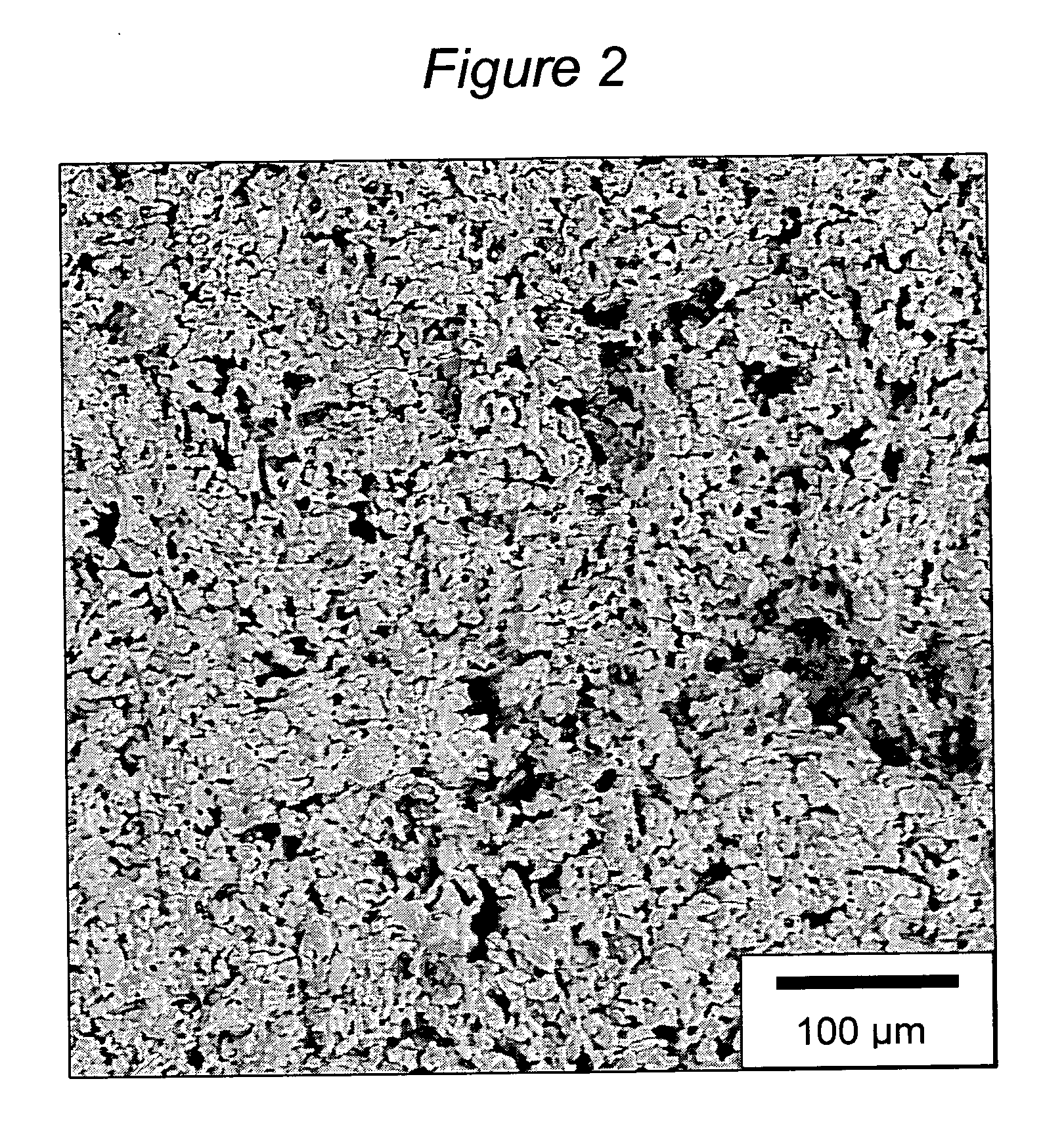

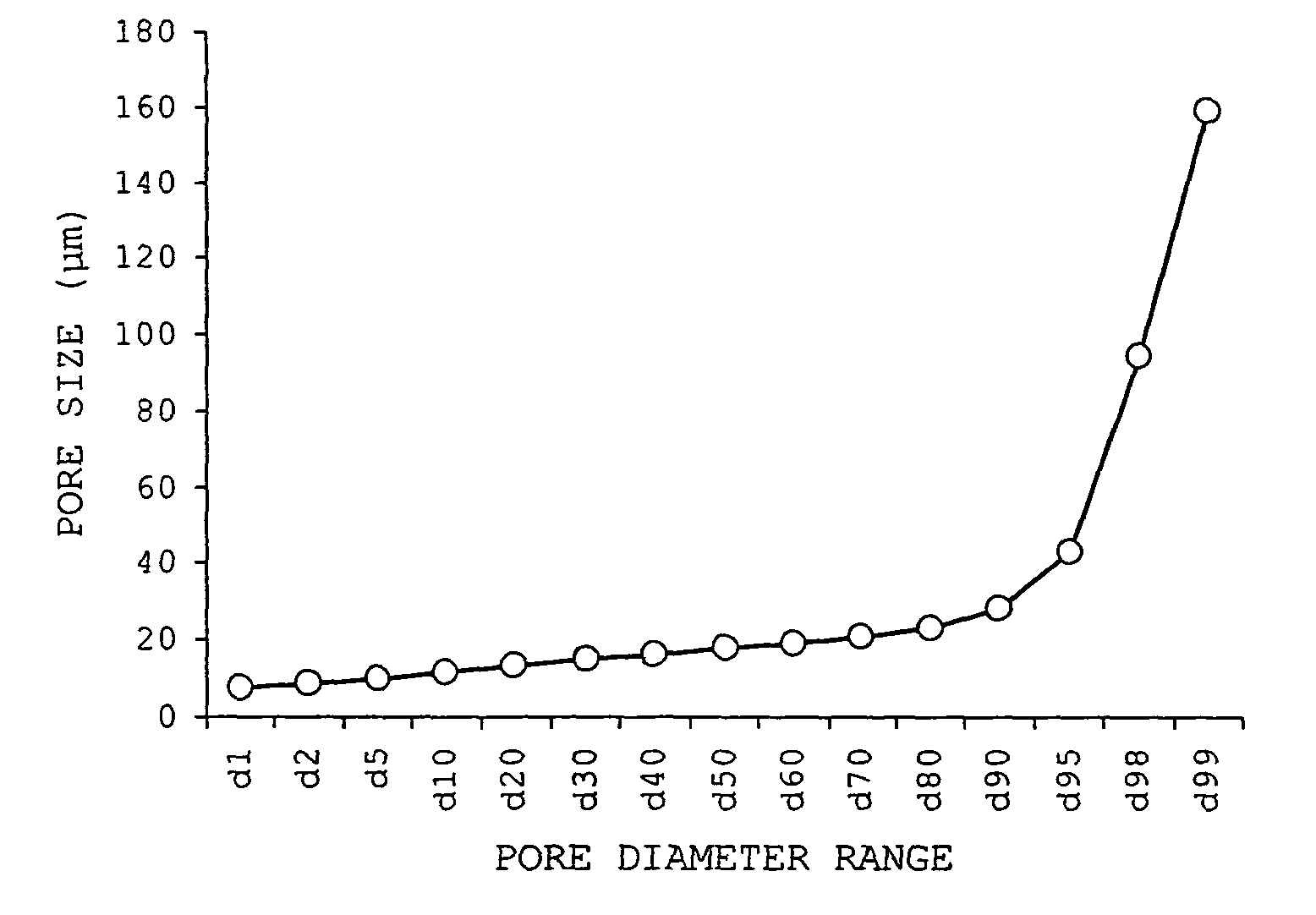

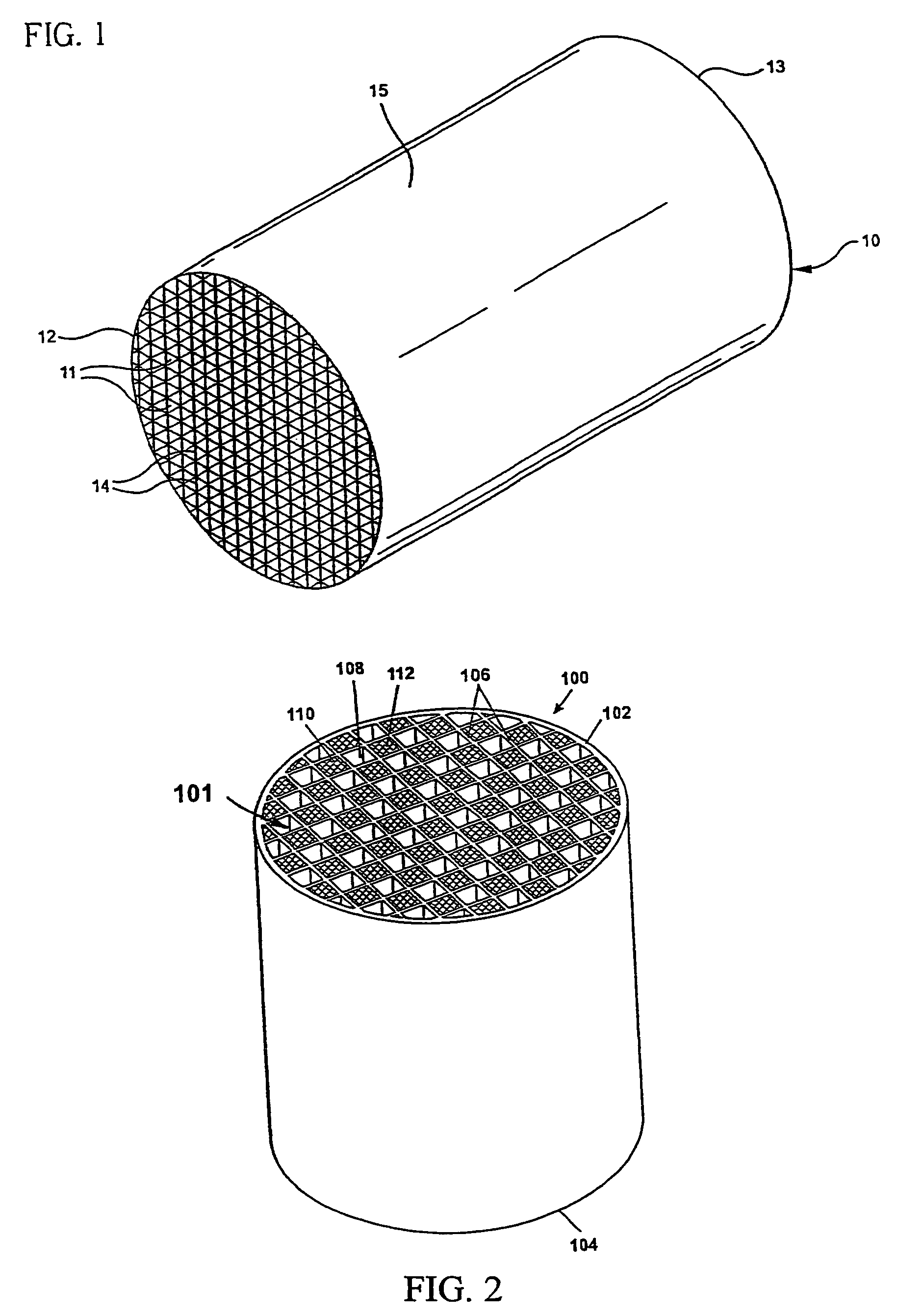

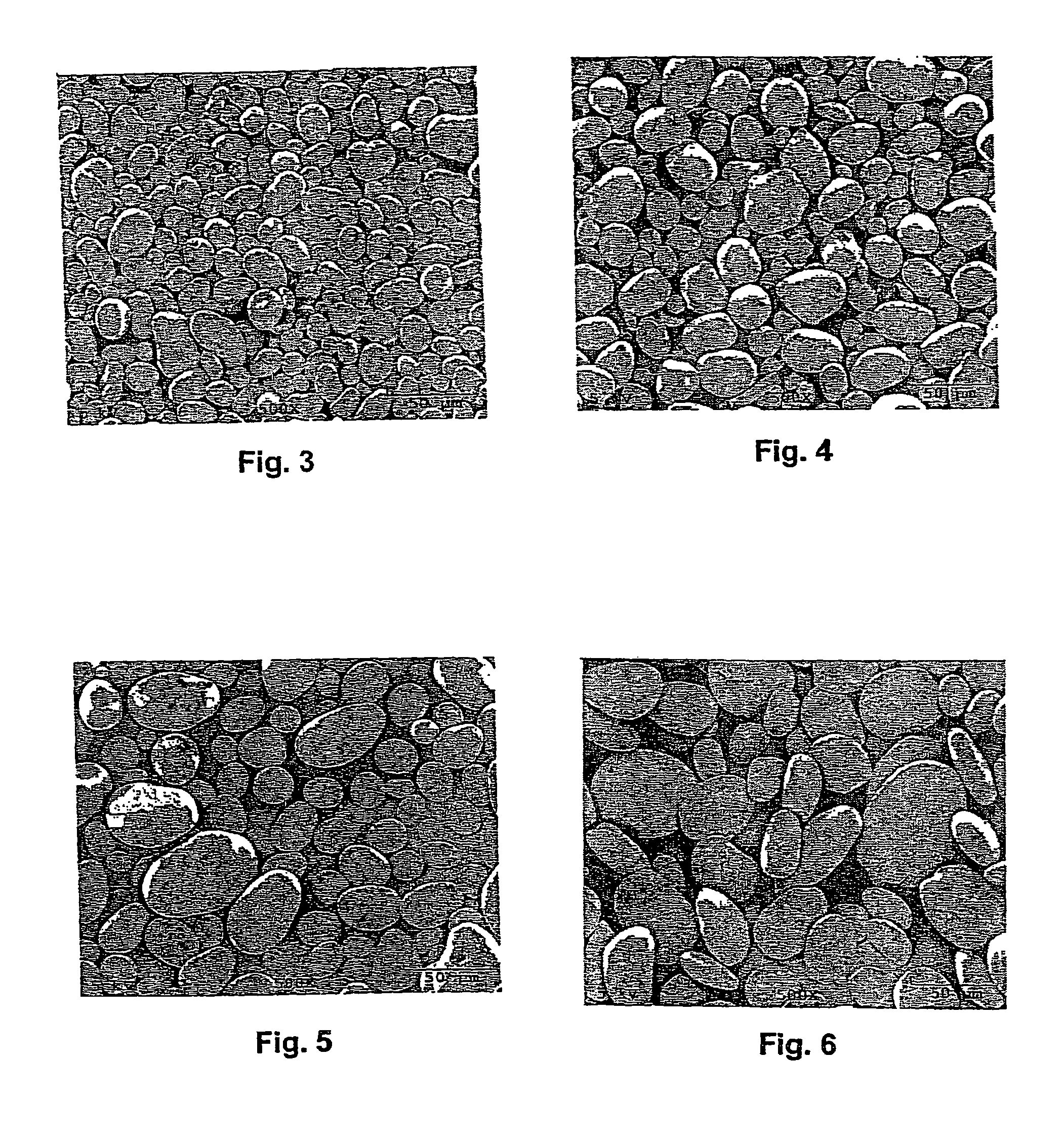

A porous ceramic honeycomb filter manufactured from an oxide-based ceramic material having a pore size distribution with d1≧7.0 microns. Preferably, the oxide-based material is cordierite or aluminum titanate. Alternatively, the filter contains a cordierite-containing ceramic body with a narrow pore size distribution with db≦1.00, wherein db=(d90−d10) / d50. Also disclosed is a batch mixture, method and honeycomb green body made from mixture of inorganic source materials selected from the group of magnesia sources, alumina sources, and silica sources, and a pore former having a narrow particle size distribution with dps≦0.90, wherein dps={(dp90−dp10) / dp50}. The pore former is preferably selected from a group consisting of canna starch, sago palm starch, green mung bean starch, and single-mode potato starch.

Owner:CORNING INC

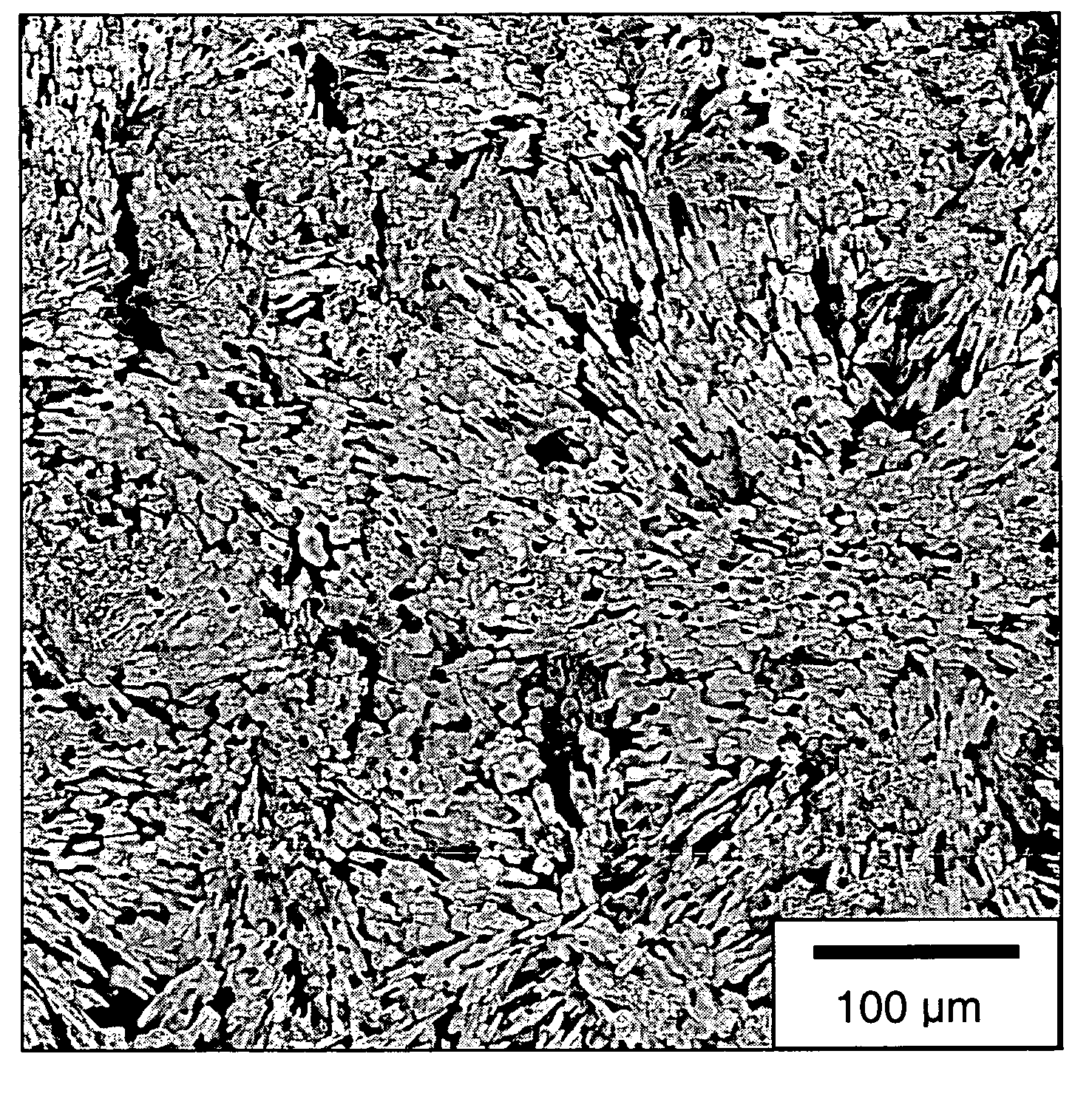

Mullite-aluminum titanate body and method for making same

InactiveUS20060021308A1Low thermal expansionHigh thermal shock resistanceInternal combustion piston enginesDispersed particle filtrationYttriumBismuth preparation

This invention relates to a mullite-aluminum titanate body having a low coefficient of thermal expansion of less than 15×10−7 C−1, a high porosity of at least 38% by volume, a median pore diameter of at least 8 microns, and a narrow pore size distribution as characterized by the relation (d50-d10) / d50 being less than 0.50 corresponding to a high degree of interconnected porosity. The inventive ceramic body also contains at least 0.10% by weight metal oxide, the metal being either yttrium, calcium, bismuth, a lanthanide metal or combinations of thereof. The inventive ceramic body is particularly useful as a wall-flow filter for diesel exhaust. A method of fabrication is provided where the sintering temperature is between 1375°-1550° C.

Owner:CORNING INC

Narrow pore size distribution aluminum titanate body and method for making same

ActiveUS20060021309A1Narrow pore size distributionCombination devicesAuxillary pretreatmentYttriumPore diameter

This invention relates to an aluminum titanate body having a narrow pore size distribution as characterized by the relation (d50-d10) / d50 being less than 0.50 corresponding to a high degree of interconnected porosity. The body also preferably exhibits a low coefficient of thermal expansion of less than 15×10−7 C−1, high porosity of at least 38% by volume, and at least 0.10% by weight metal oxide, the metal being either yttrium, calcium, bismuth, a lanthanide metal or combinations of thereof. MOR is preferably at least 450 psi. Median pore diameter is preferably at least 8 microns. The inventive ceramic body is particularly useful as a wall-flow filter for a diesel exhaust. A method of fabrication is provided where the sintering temperature is preferably between 1375°-1550° C.

Owner:CORNING INC

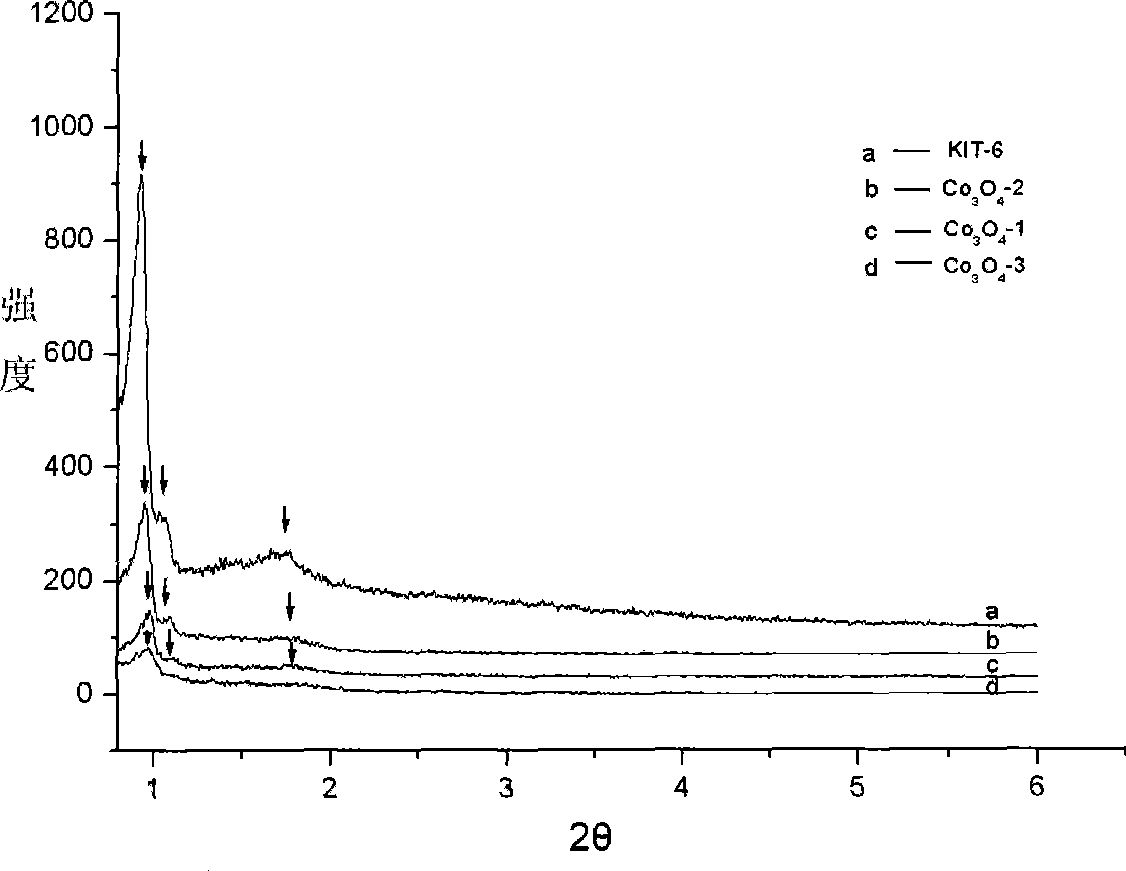

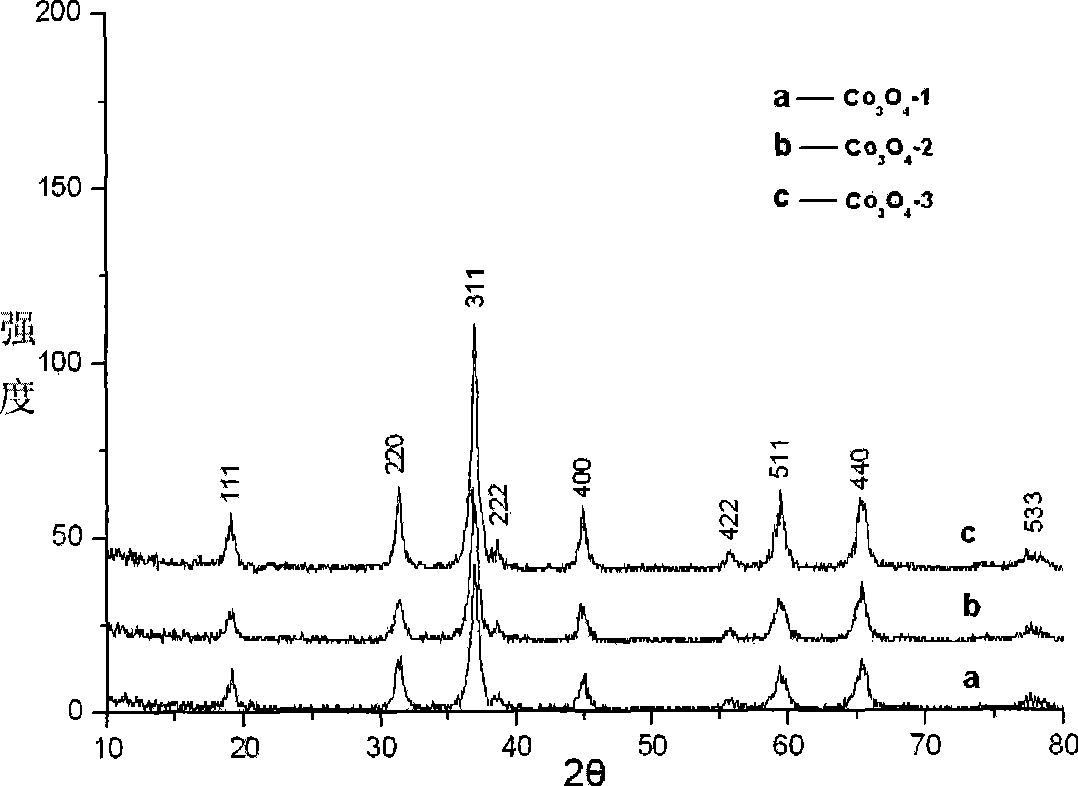

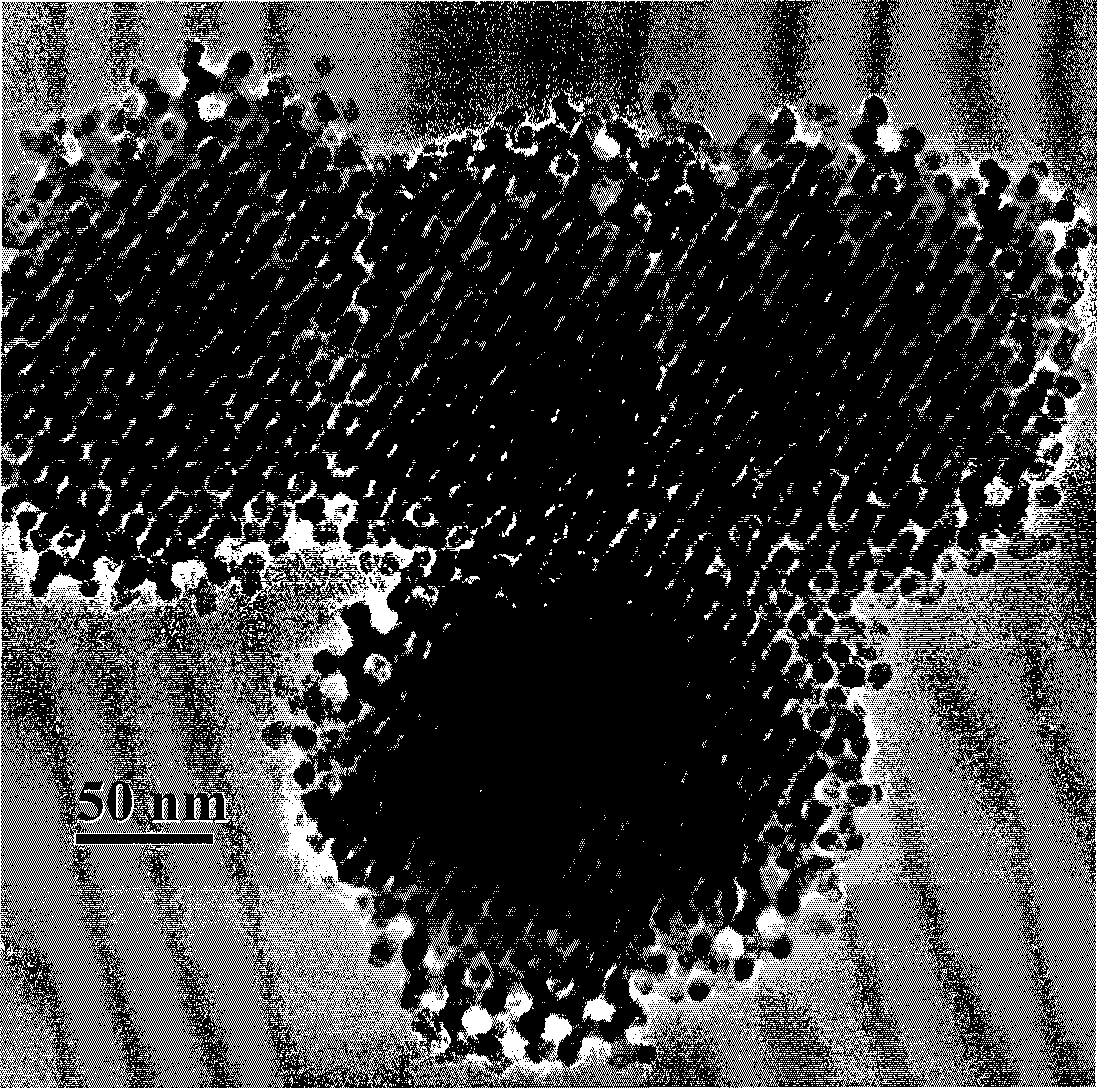

Catalyst used for synthesizing middle distillate from synthetic gas, its preparation method and application

InactiveCN1785515AHigh thermal and hydrothermal stabilityGood stabilityLiquid hydrocarbon mixture recoveryCatalyst activation/preparationCOBALTOUS NITRATENon noble metal

A catalyst for synthesizing the intermediate oil from synthetic gas by Fischer-Tropsch reaction contains Co (5-35 Wt%), mesoporous ZrO2 as carrier (53-93), noble metal (0-2) and oxide of non-noble metal. Its preparing process includes such steps as impregnating said carrier in the aqueous solution of nitrate containing the oxide of non-noble metal or the alcohol solution of organic alkydester, and impregnating it in the equeous solution of cobalt nitrate and the nitrate (or chloride) or noble metal. It has high activity, stability, selectivity and mechanical performance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

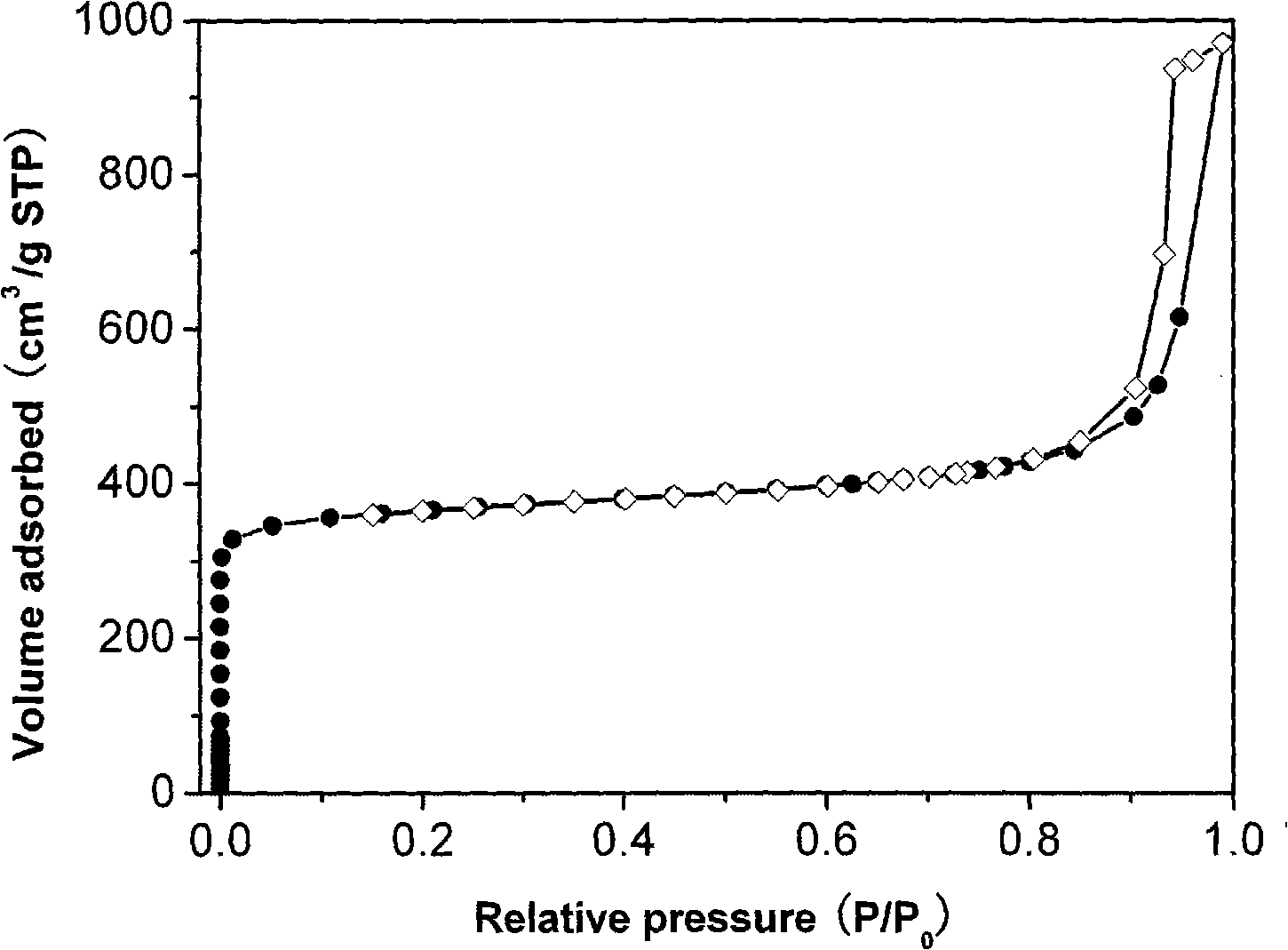

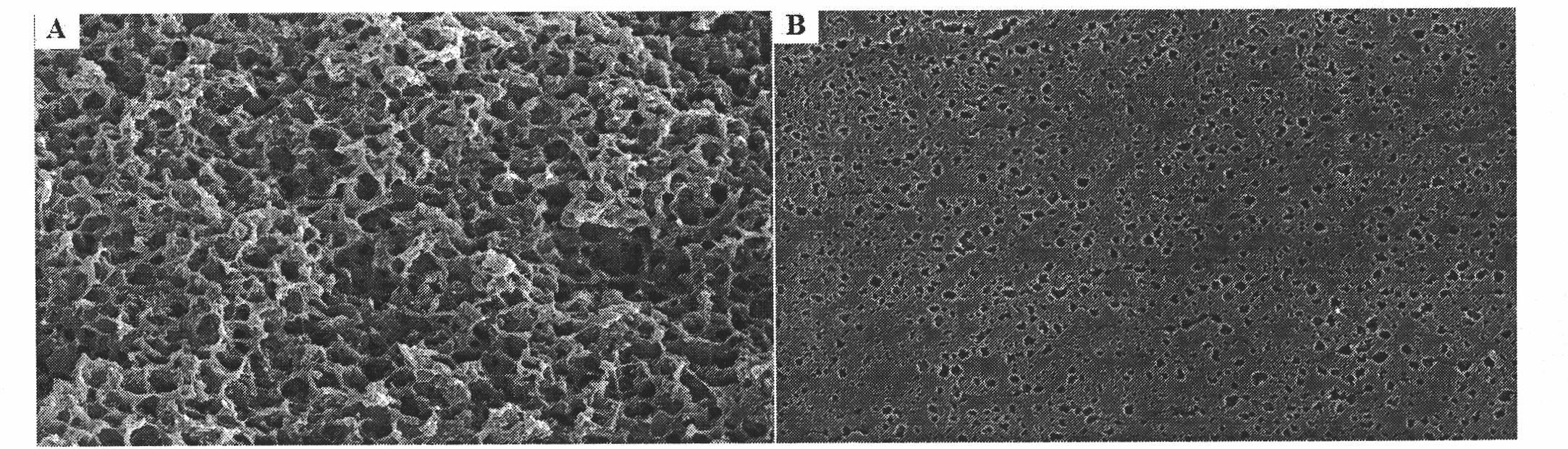

Hydrophilicity polyethylene hollow fiber micro-hole film and the preparation method

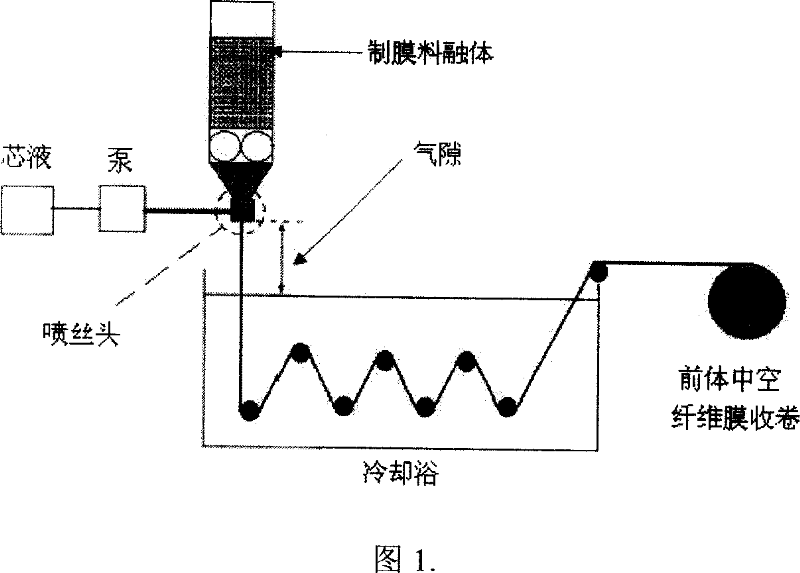

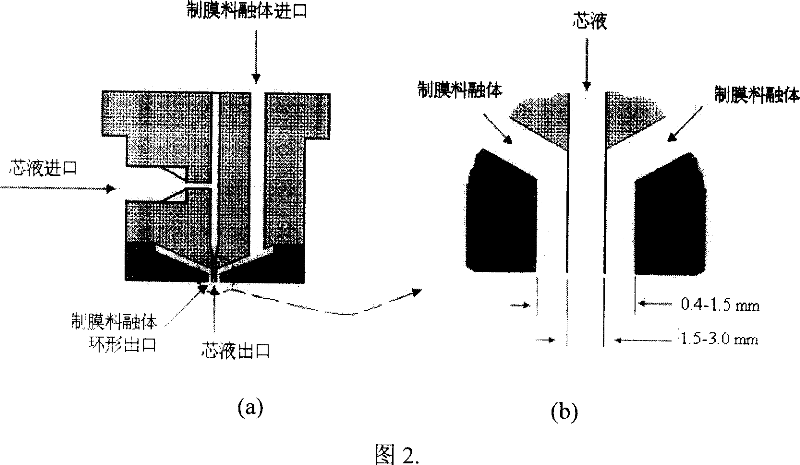

InactiveCN101036861AExtended cleaning cycleHydrophilic realizationSemi-permeable membranesFiberMolten state

The invention discloses hydrophilic polyethylene hollow fiber microporous membrane and preparation process thereof. Said membrane is characterized in that it mainly comprises polyethylene, amphoteric copolymer containing polyethylene oxide, and inorganic nano particles. The membrane preparing process is carried out based on thermally induced phpase separation and surface segregation principles, comprising the steps of (1) preparing membrane blank by fusion and blending of amphoteric copolymer containing polyethylene oxide, diluent, and inorganic nano particles; (2) preparing hollow fiber membrane precursor by hollow process spinning of membrane blank in molten state; (3) extracting diluent in hollow fiber membrane precursor by using organic solvent to obtain said hydrophilic polyethylene hollow fiber microporous membrane, wherein the porosity of said membrane is between 40% and 80%, and average pore diameter is between 0.1mum and 5.0mum. The microporous membrane in the invention has the characteristics of high hydrophilicity, narrow pore size distribution, high strength, and good chemical stability, and serves as micro-filtration and ultra-filtration membrane material with high performance, low cost, pollution resistance, and long serve life for water treatment.

Owner:ZHEJIANG UNIV

Method for preparing carbon molecular sieve adsorbent

InactiveCN101596445ALow costReduce pollutionOther chemical processesAdsorption purification/separationPolymer scienceSorbent

The invention discloses a method for preparing a carbon molecular sieve adsorbent. The steps are as follows: (1) solidification: polymer is used as a raw material and is arranged in a thermostatic drying oven to be solidified; (2) dry distillation: the solidified macromoleclar polymer is pulverized by a pulverizer and then is processed by dry distillation; (3) fine pulverization: the macromoleclar polymer which is pulverized and processed by dry distillation is further processed by fine pulverization in the premise that the particle diameter of the macromoleclar polymer does not meet the requirement, and ball milling or gas milling is used for preparing micro-particles; (4) molding: the macromoleclar polymer which is processed by fine pulverization is mixed and uniformly stirred with agglomerant by mass ratio, and the mixture obtained is pressed and molded by an oil hydraulic press and then is dried; (5) carbonization and activation: under the state of N2 protection, temperature is raised for carbonization so as to increase the CMS surface area; and (6) carbon precipitation and hole adjustment: the hole adjustment agent is decomposed in the carbon molecular sieve for carbon deposition, the particle diameter is shortened and is enabled to be uniform, and the carbon molecular sieve product can be obtained after cooling. The carbon molecular sieve has the advantages of high CH4 adsorbing capacity, high selectivity factor of adsorption, favorable strength, low cost and no pollution, and the performance achieves or surpasses the standard of a sample of Japan carbon molecular sieve.

Owner:ANHUI UNIV OF SCI & TECH

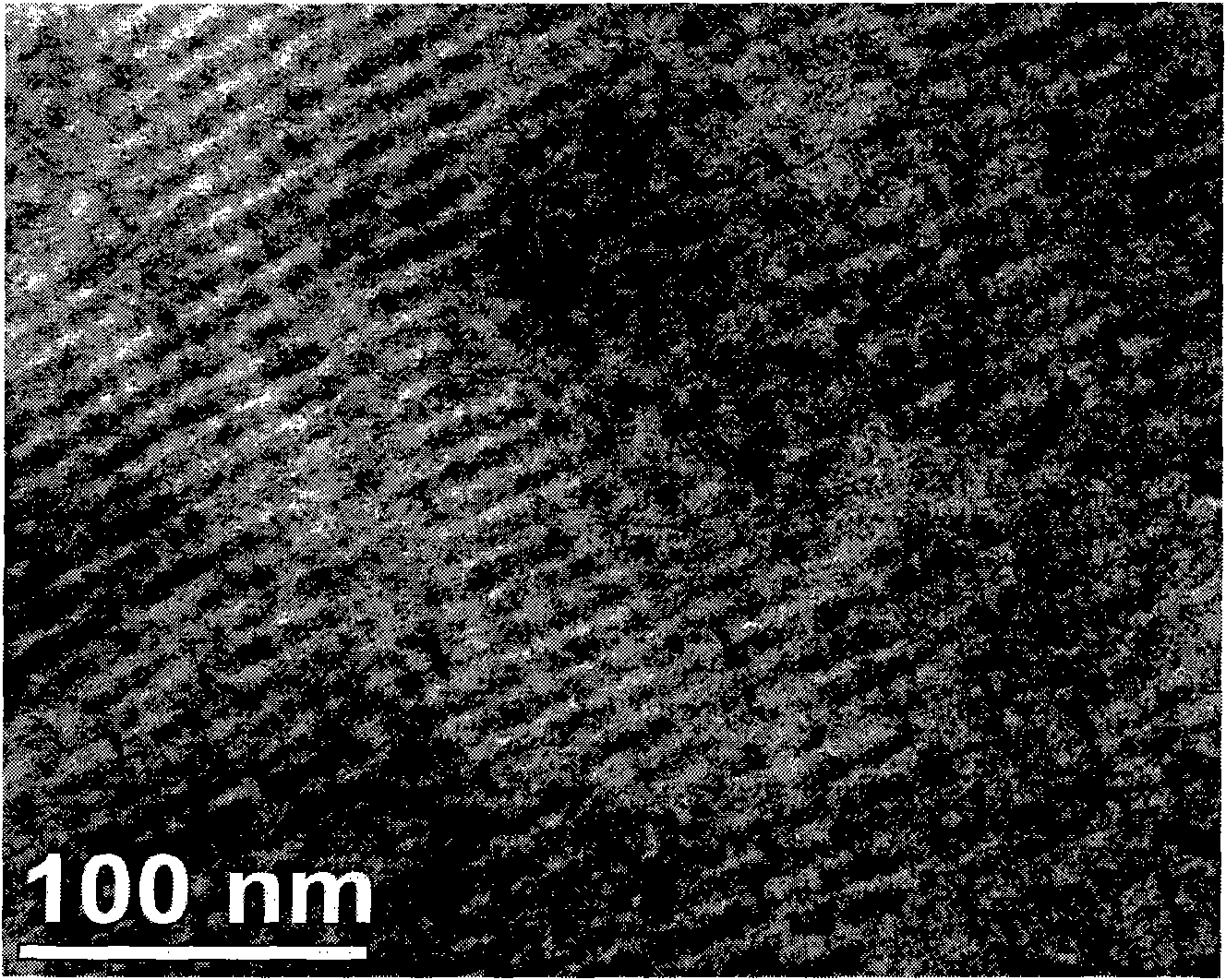

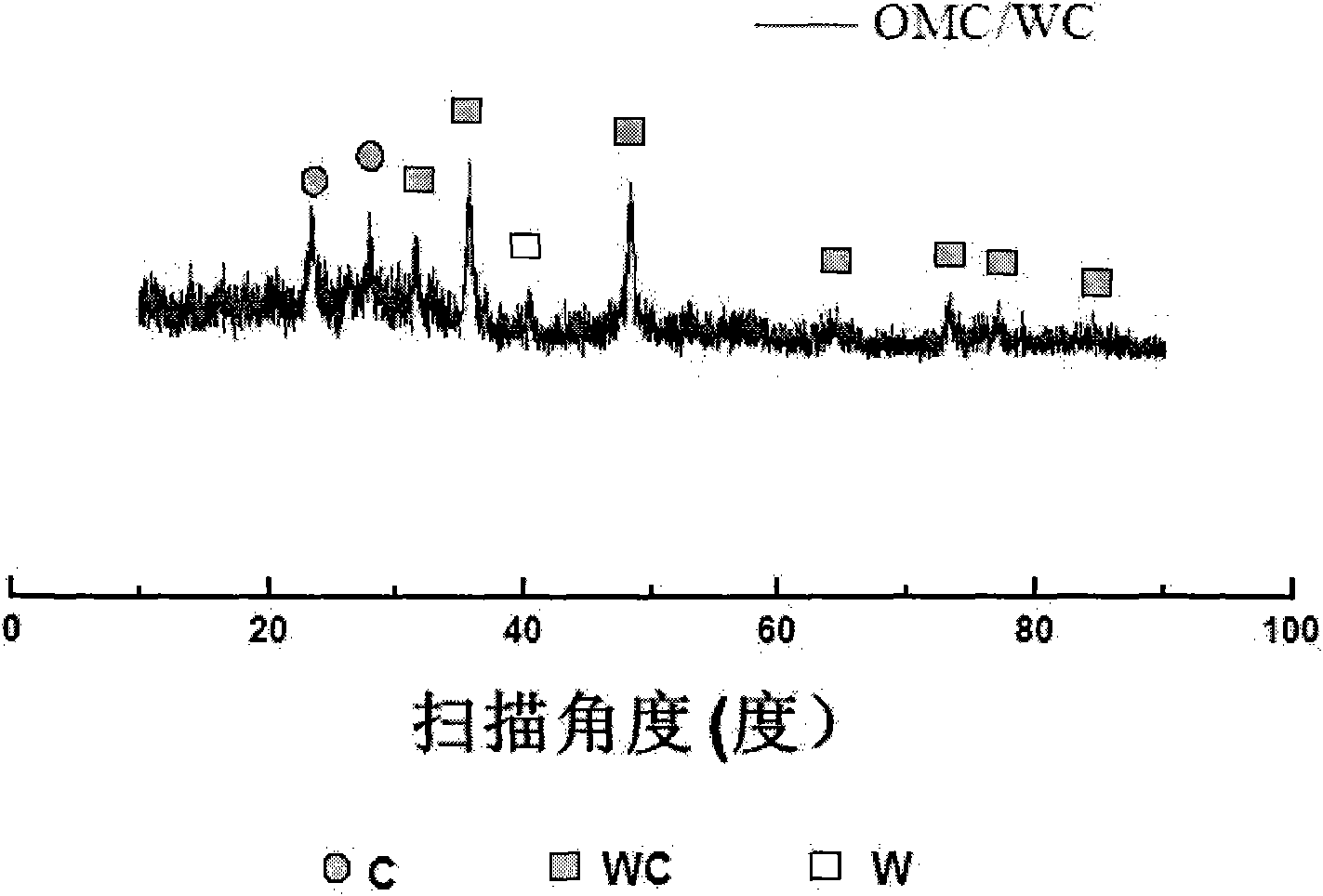

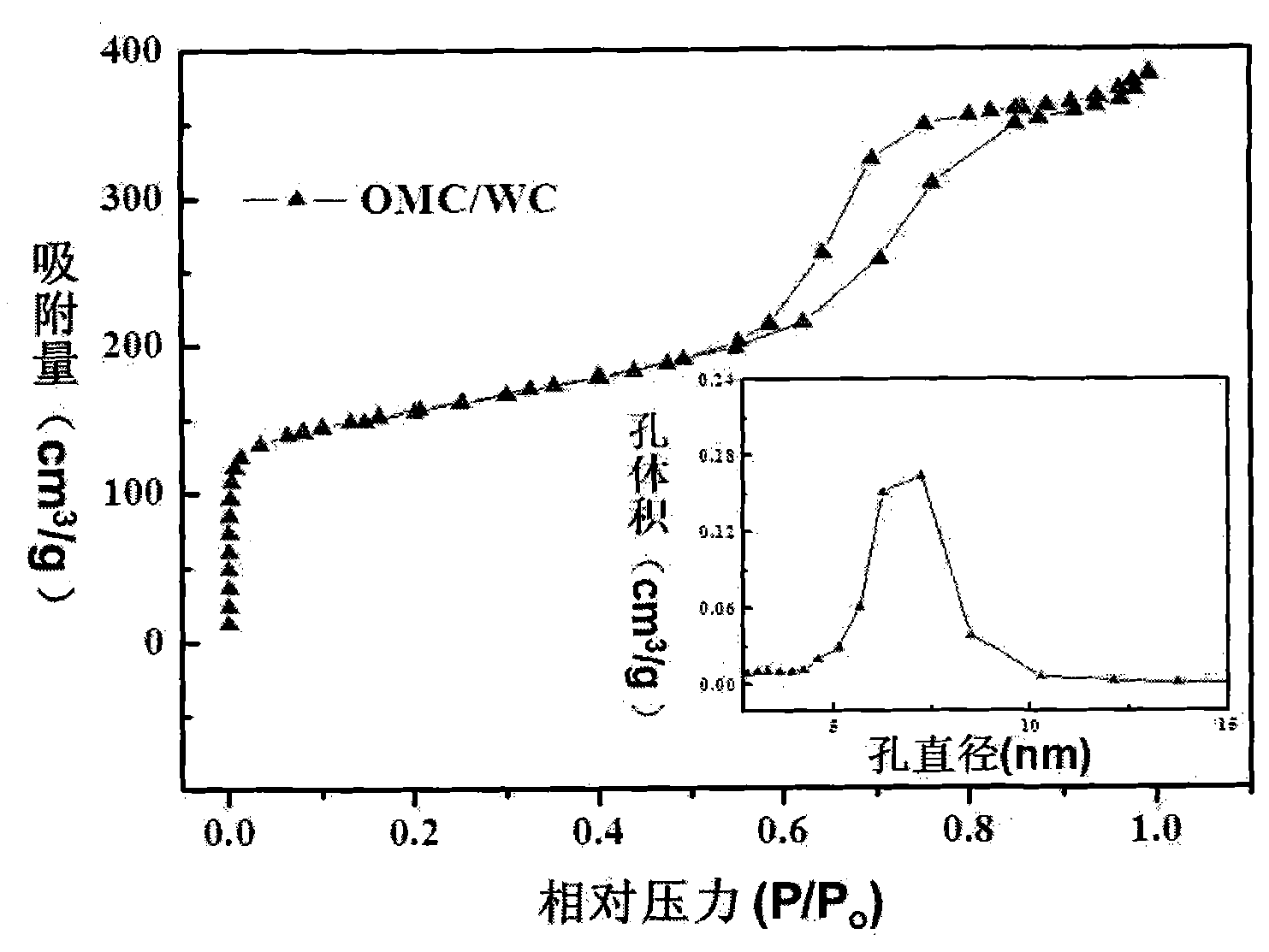

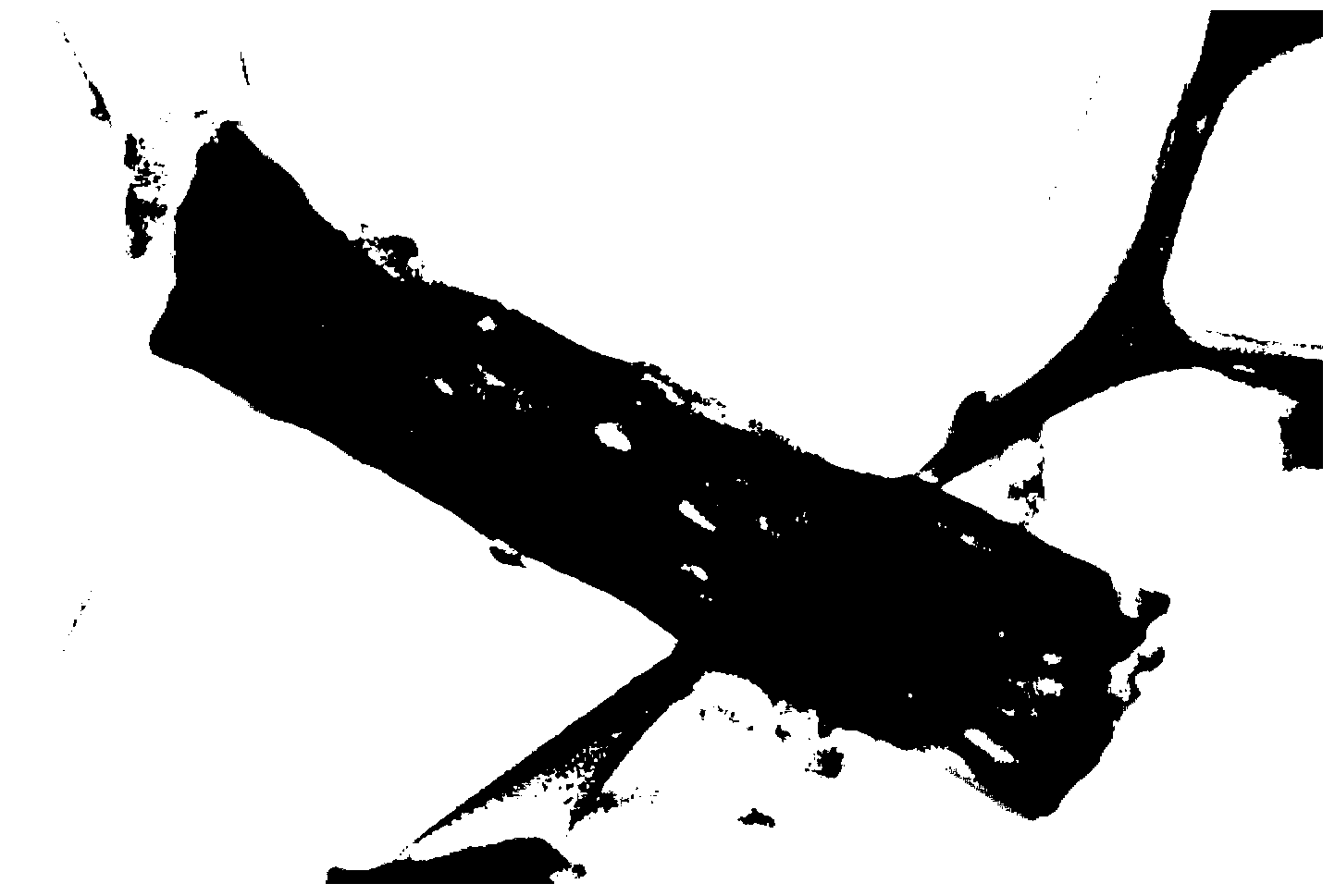

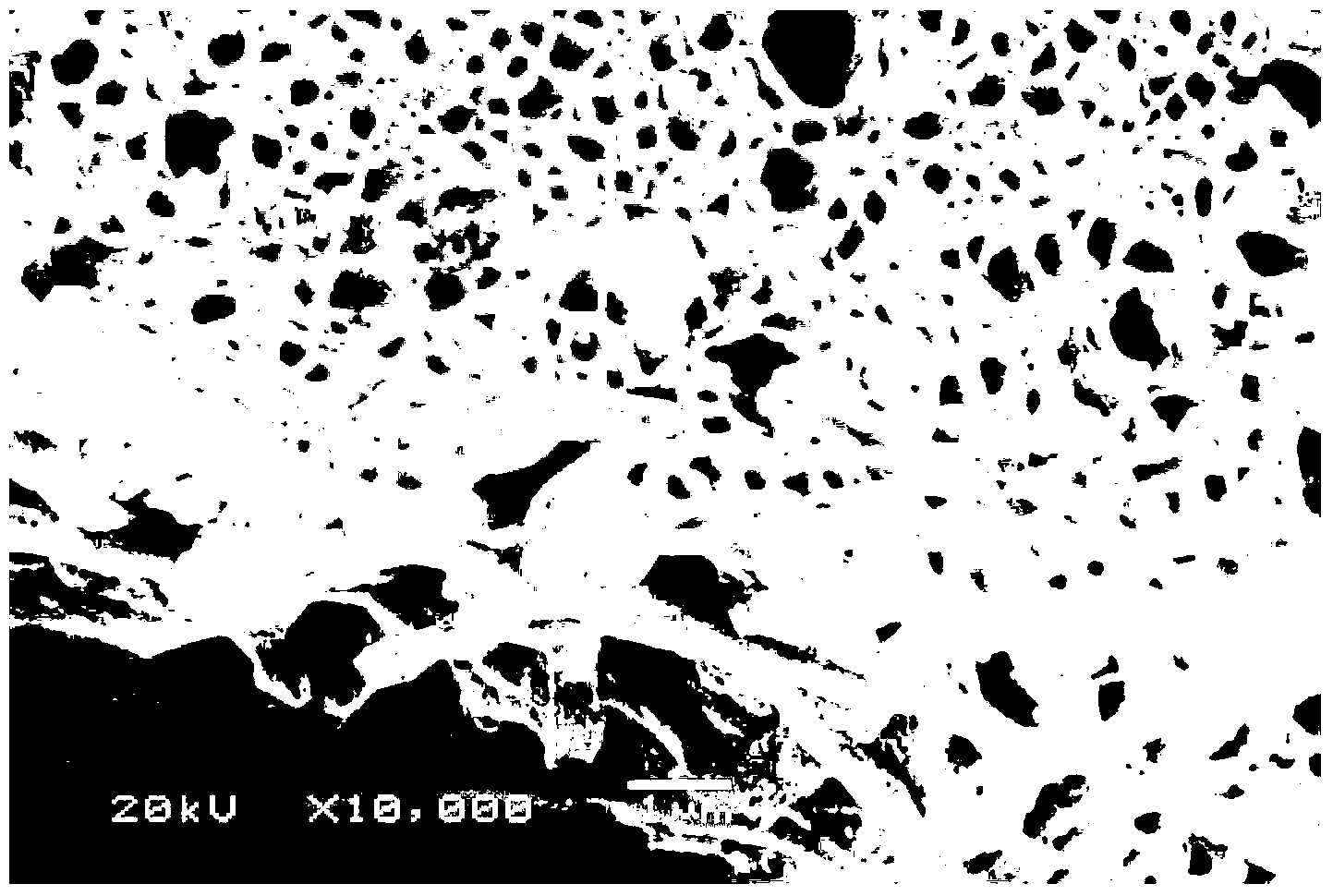

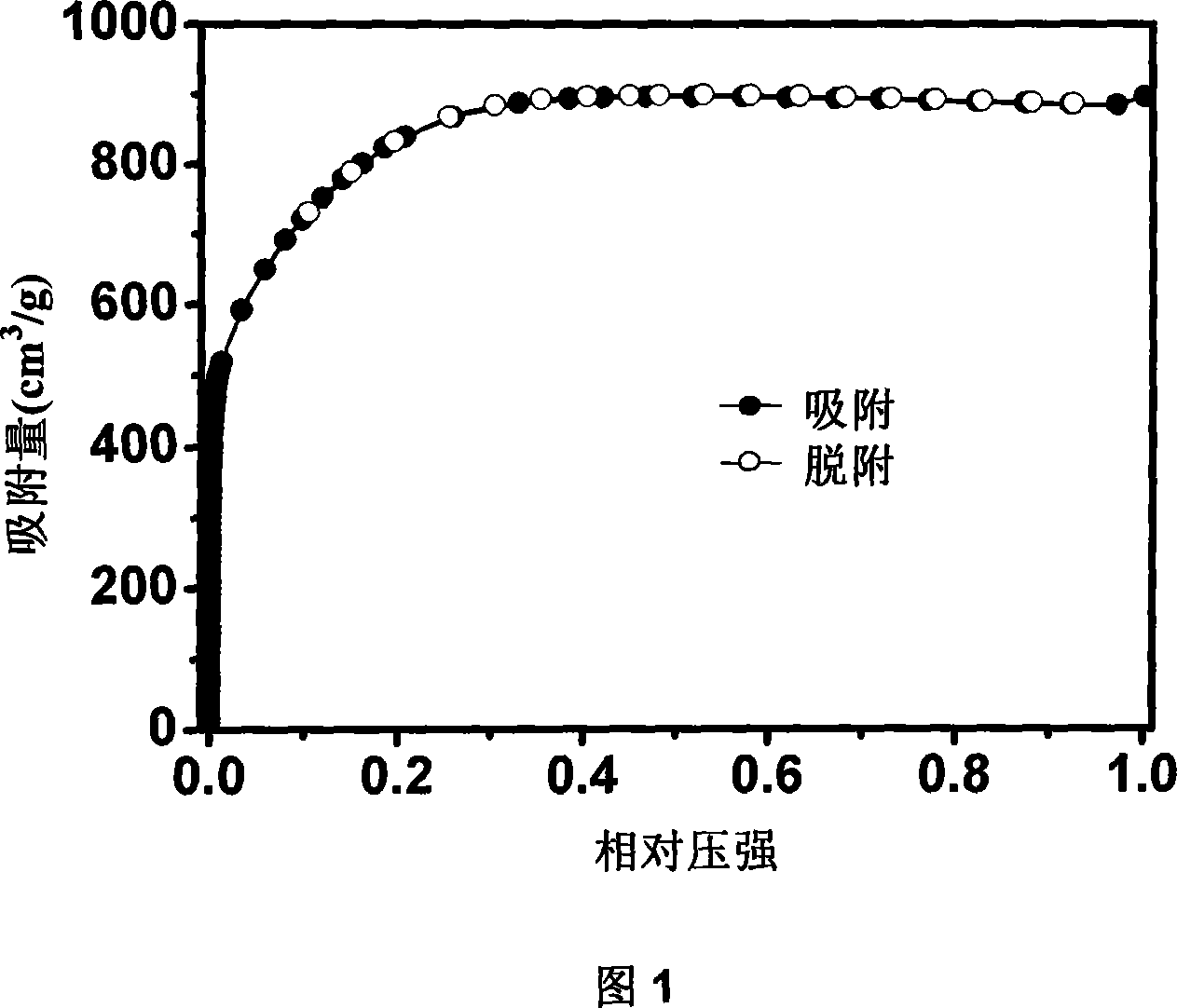

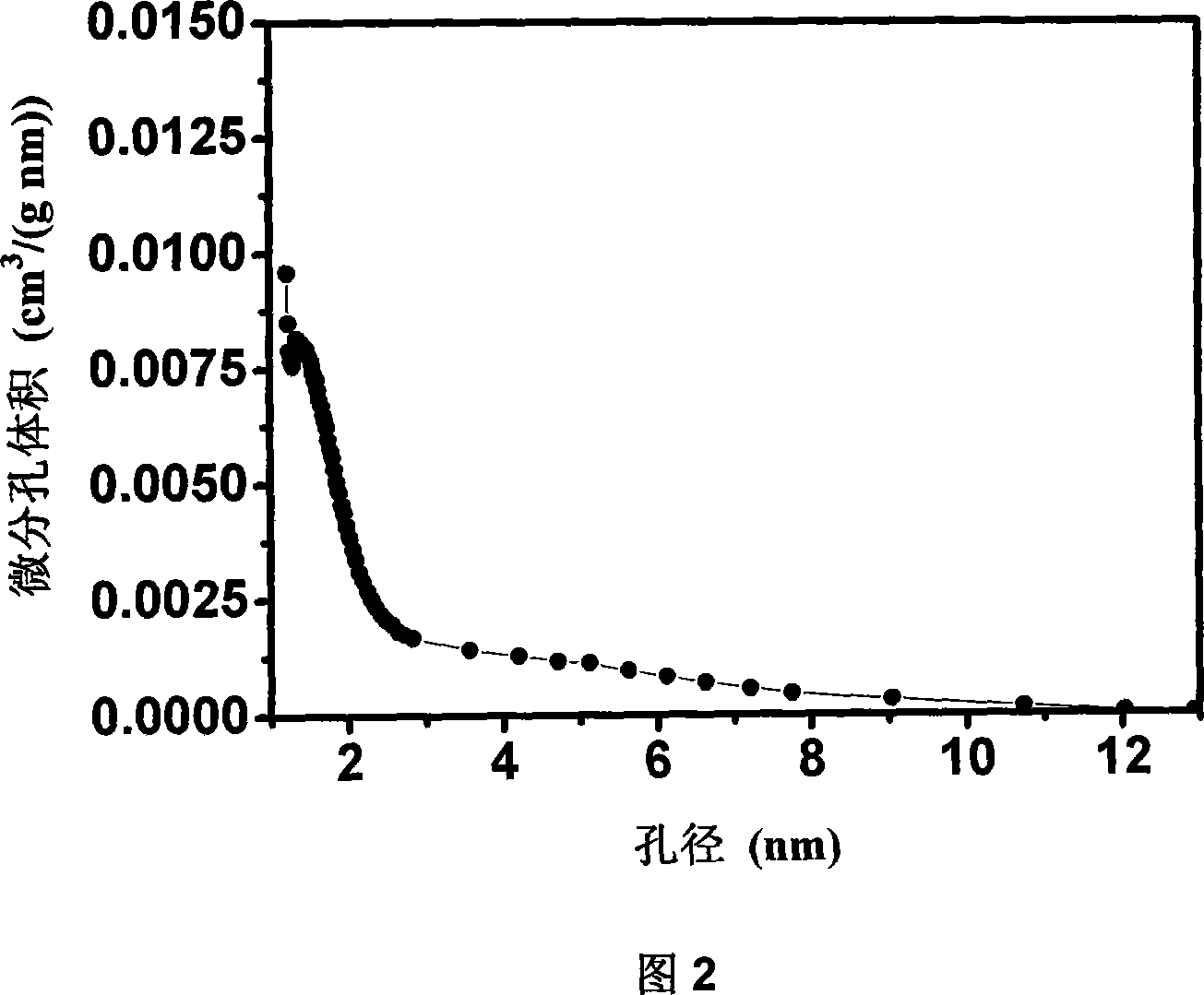

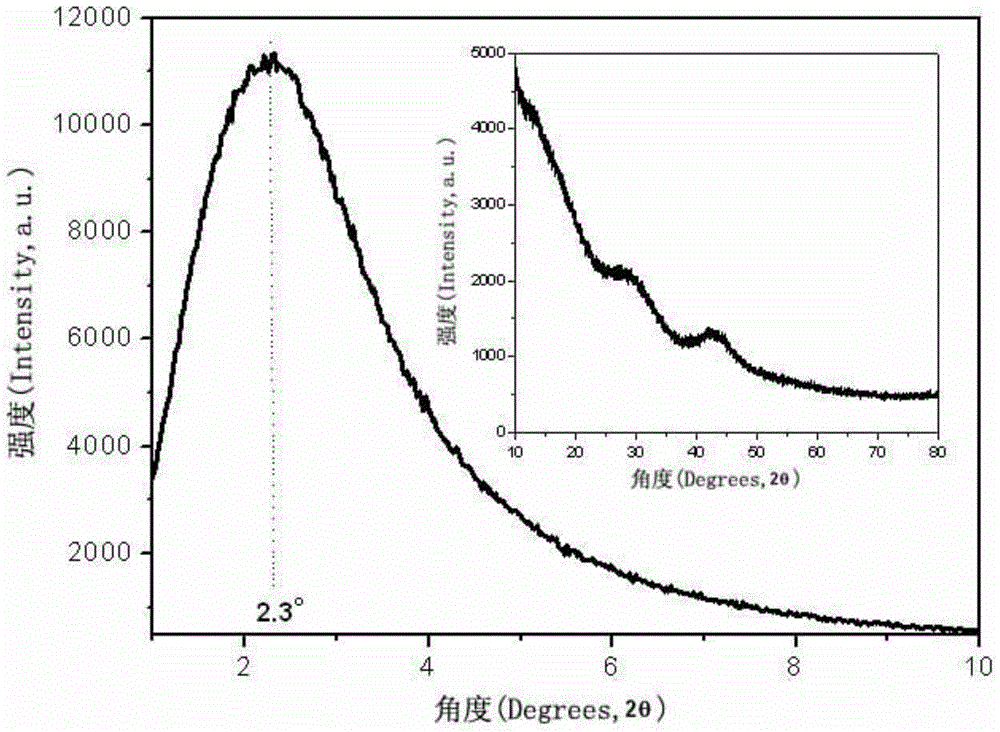

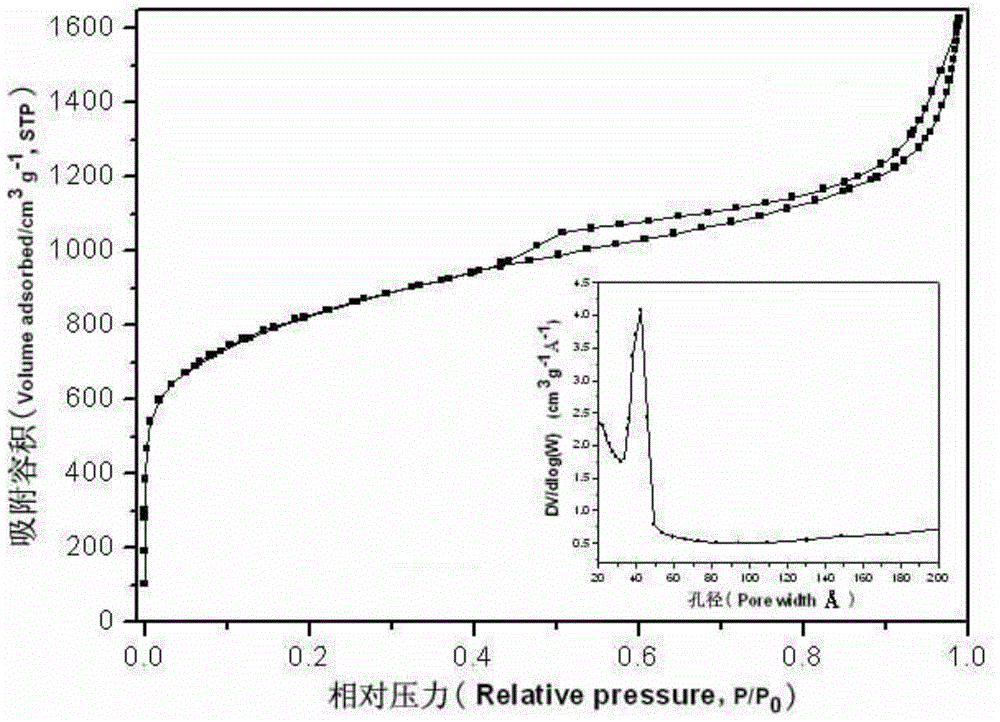

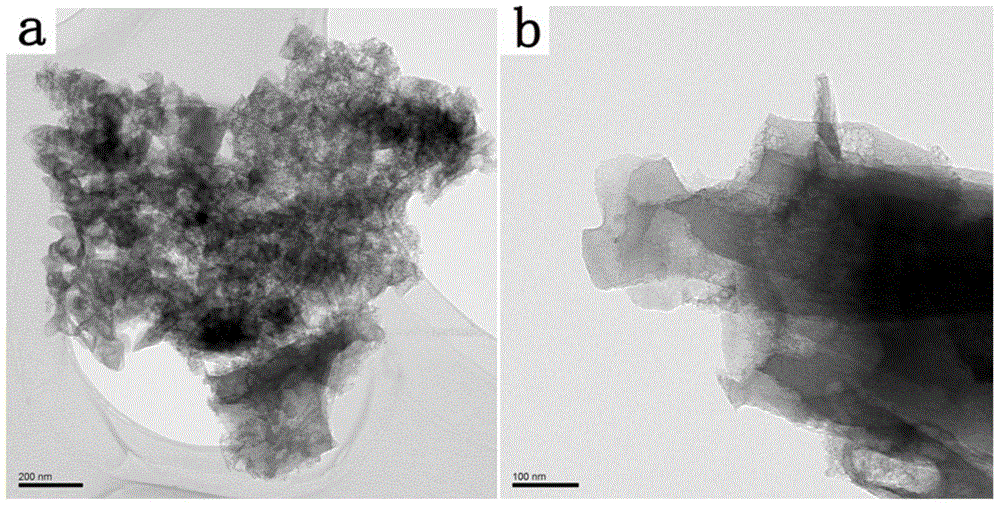

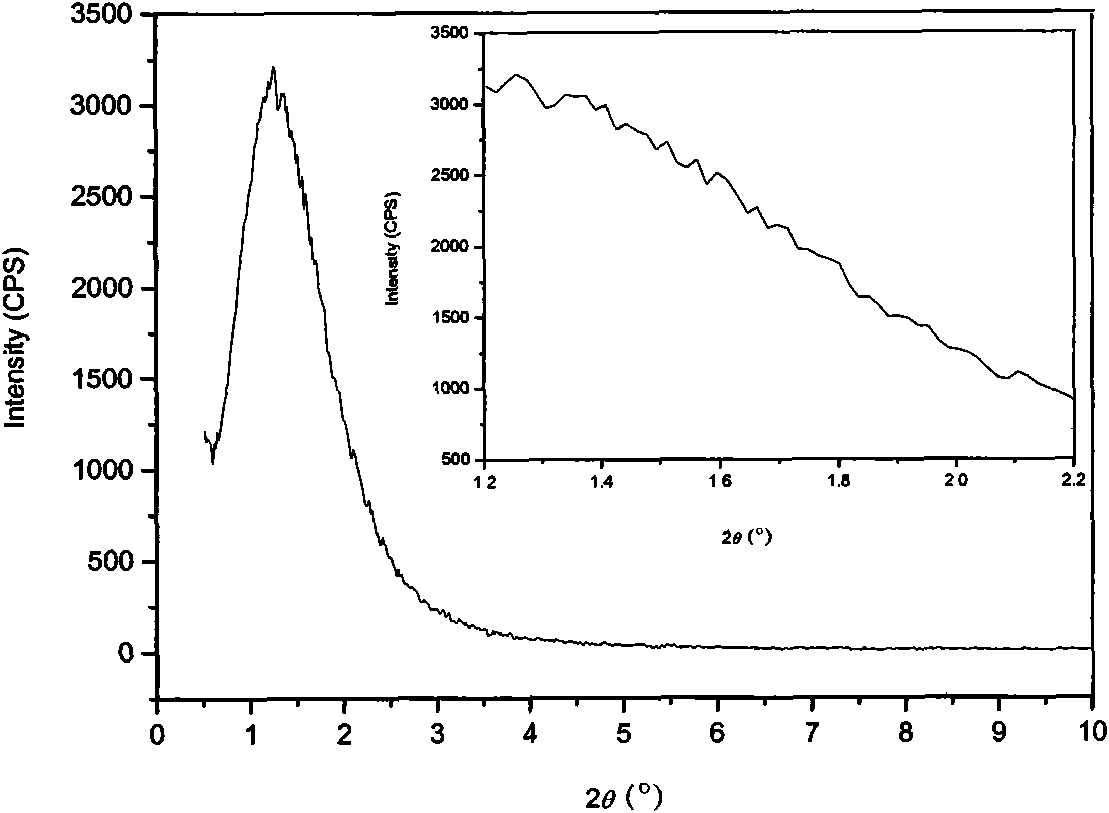

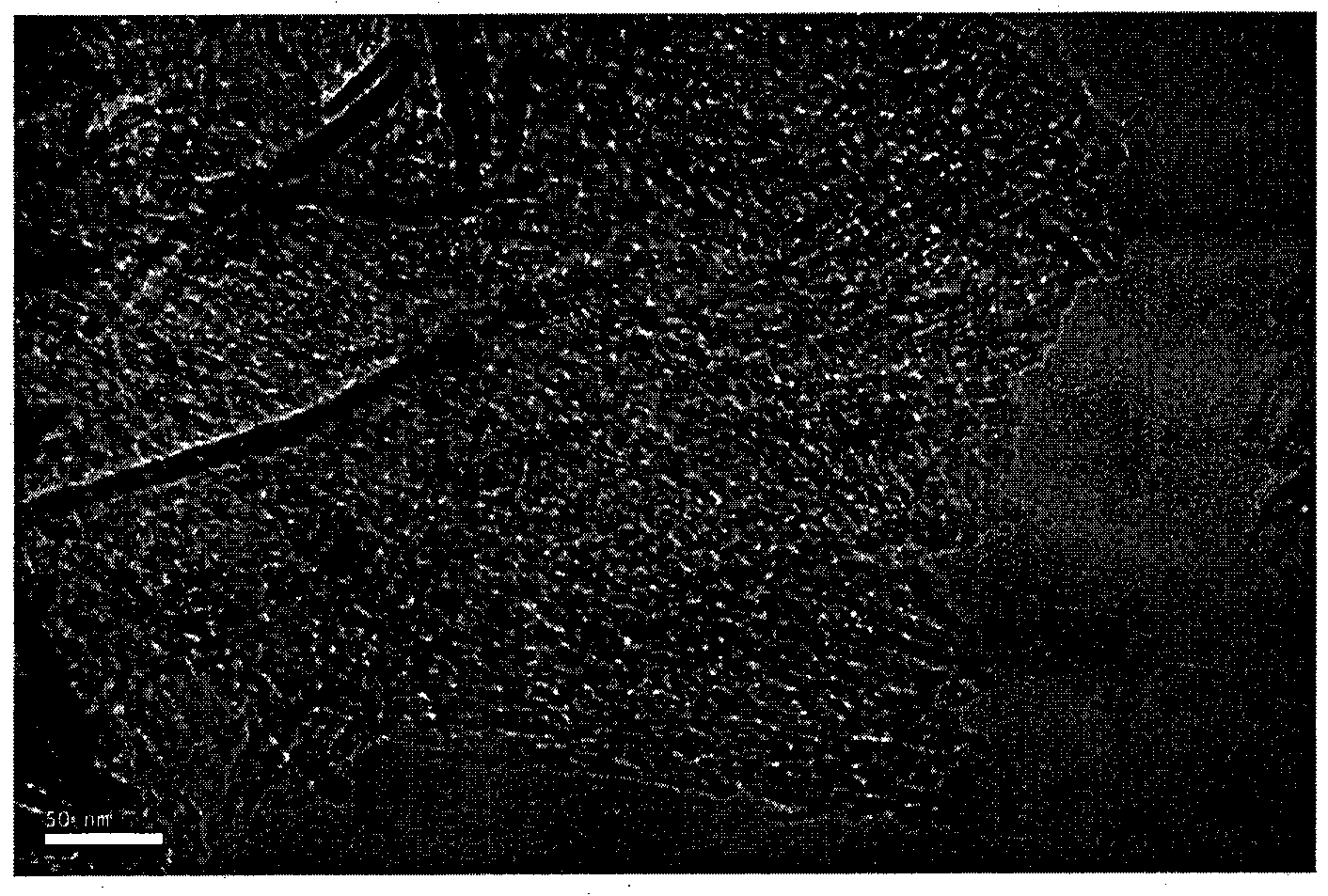

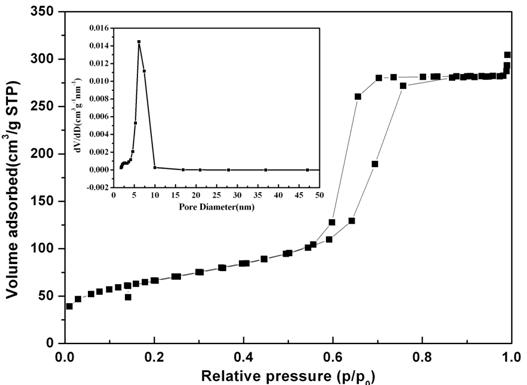

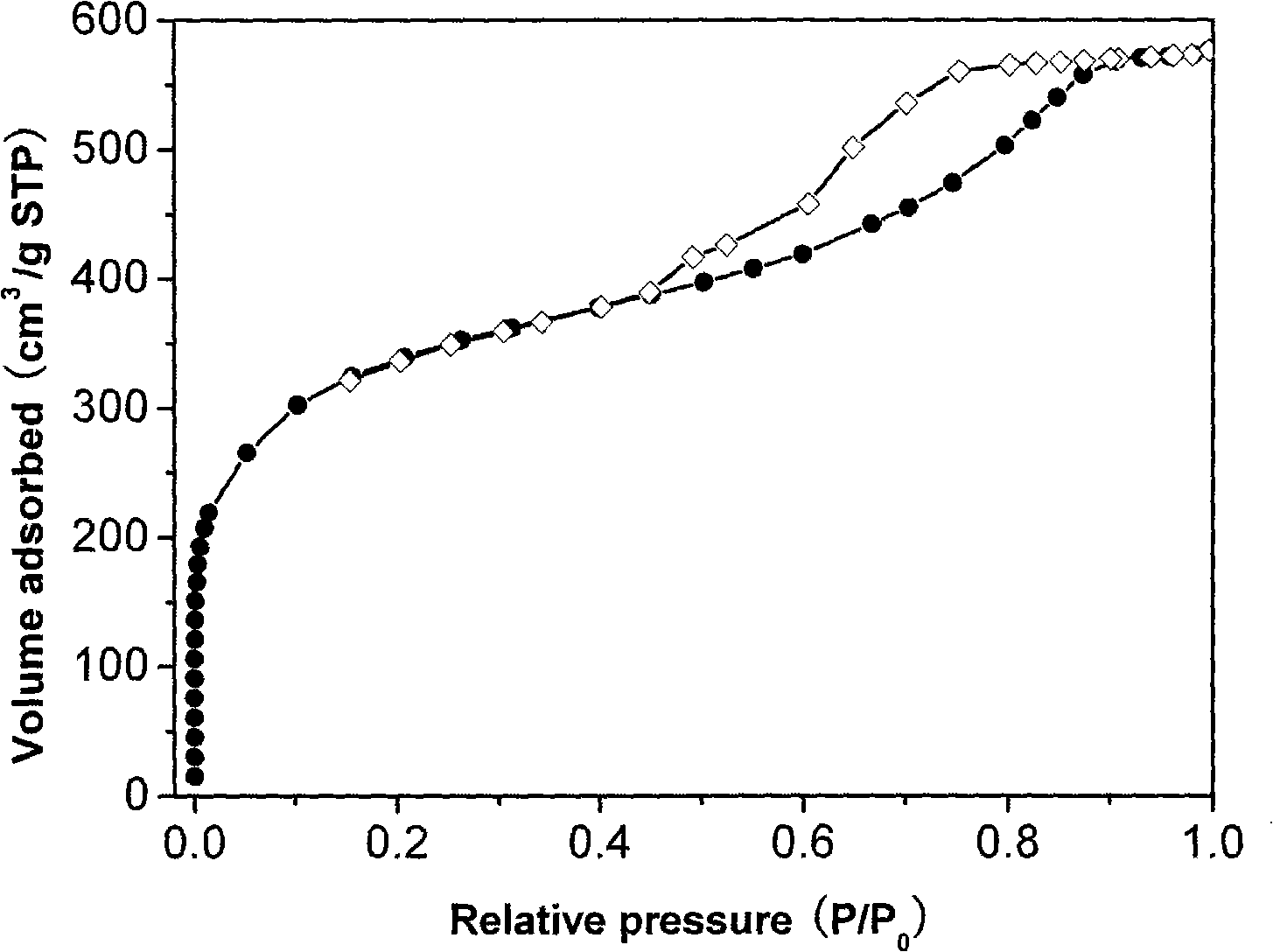

Ordered mesoporous carbon/tungsten carbide composite material and supported catalyst thereof and preparation method thereof

InactiveCN101869853AHigh degree of aperture orderNarrow pore size distributionCatalyst carriersCell electrodesSolventPt element

The invention discloses a preparation method for an ordered mesoporous carbon / tungsten carbide composite material and a supported catalyst thereof. In the method, an organic matter and a tungsten salt are separately used as a carbon source and a tungsten source, and the carbon source and the tungsten source are mixed with a surfactant; and a precursor of the ordered mesoporous carbon / tungsten carbide is synthesized by a solvent-evaporation induced self-assembly method, and then the precursor is subject to high-temperature treatment in the inert atmosphere to form the ordered mesoporous carbon / tungsten carbide composite material. The ordered mesoporous carbon / tungsten carbide composite material prepared by the method has the characteristics of high degree of order, narrow aperture distribution, large specific surface area (greater than 500 m<2> / g) and the like. The invention further comprises a supported catalyst prepared by supporting active components on the ordered mesoporous carbon / tungsten carbide composite material which is prepared by the method; and because of the synergistic effect and the structure effect of the ordered mesoporous carbon / tungsten carbide composite material, the catalyst has higher methanol electro-oxidation catalytic activity than a commercial carbon platinum-ruthenium catalyst.

Owner:SUN YAT SEN UNIV

Porous hollow carbon nanofiber as well as preparation method and application thereof

InactiveCN103233299AKeep shapeEasy hole makingHollow filament manufactureCarbonizationCarbon nanofiber

The invention discloses a method for preparing porous hollow carbon nanofiber by using metal salt pore-forming. The method comprises the following steps of: mixing metal salt with polyacrylonitrile to prepare outer-layer fluid; preparing inner-layer fluid by using soluble or volatile oil; respectively inputting the outer-layer fluid and the inner-layer fluid into the outer layer and the inner layer of a coaxial electrospinning spray head at a constant flow velocity and velocity ratio to carry out coaxial electrostatic spinning to obtain core-shell nano composite fiber; and carrying out ultrasonic washing, pre-oxidation, carbonization and ultrasonic pickling on the obtained core-shell nano composite fiber to obtain the porous hollow carbon nanofiber. The porous hollow carbon nanofiber prepared by using the preparation method has extremely wide application values in terms of gas adsorption, catalysis and battery electrode materials.

Owner:DALIAN JIAOTONG UNIVERSITY

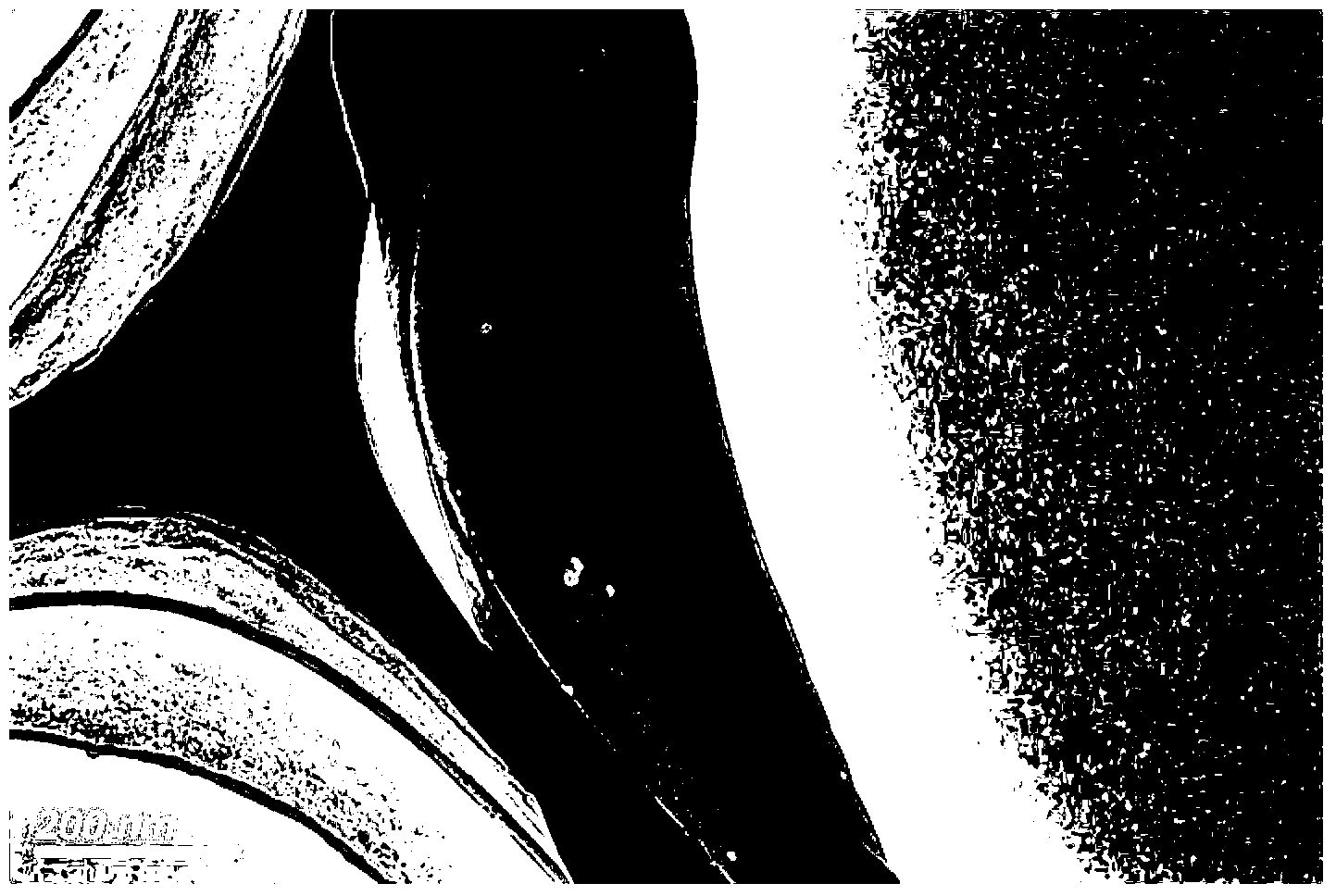

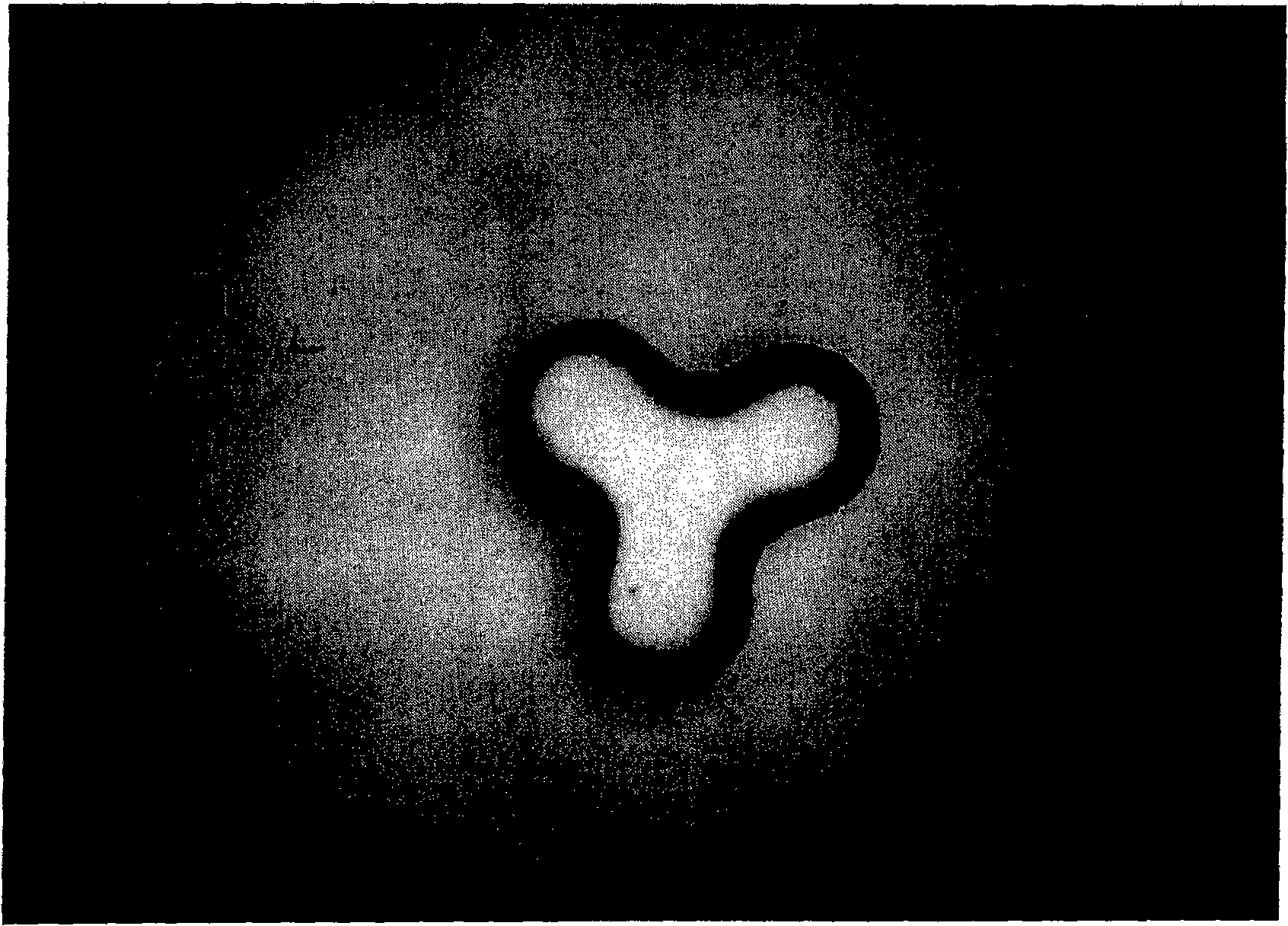

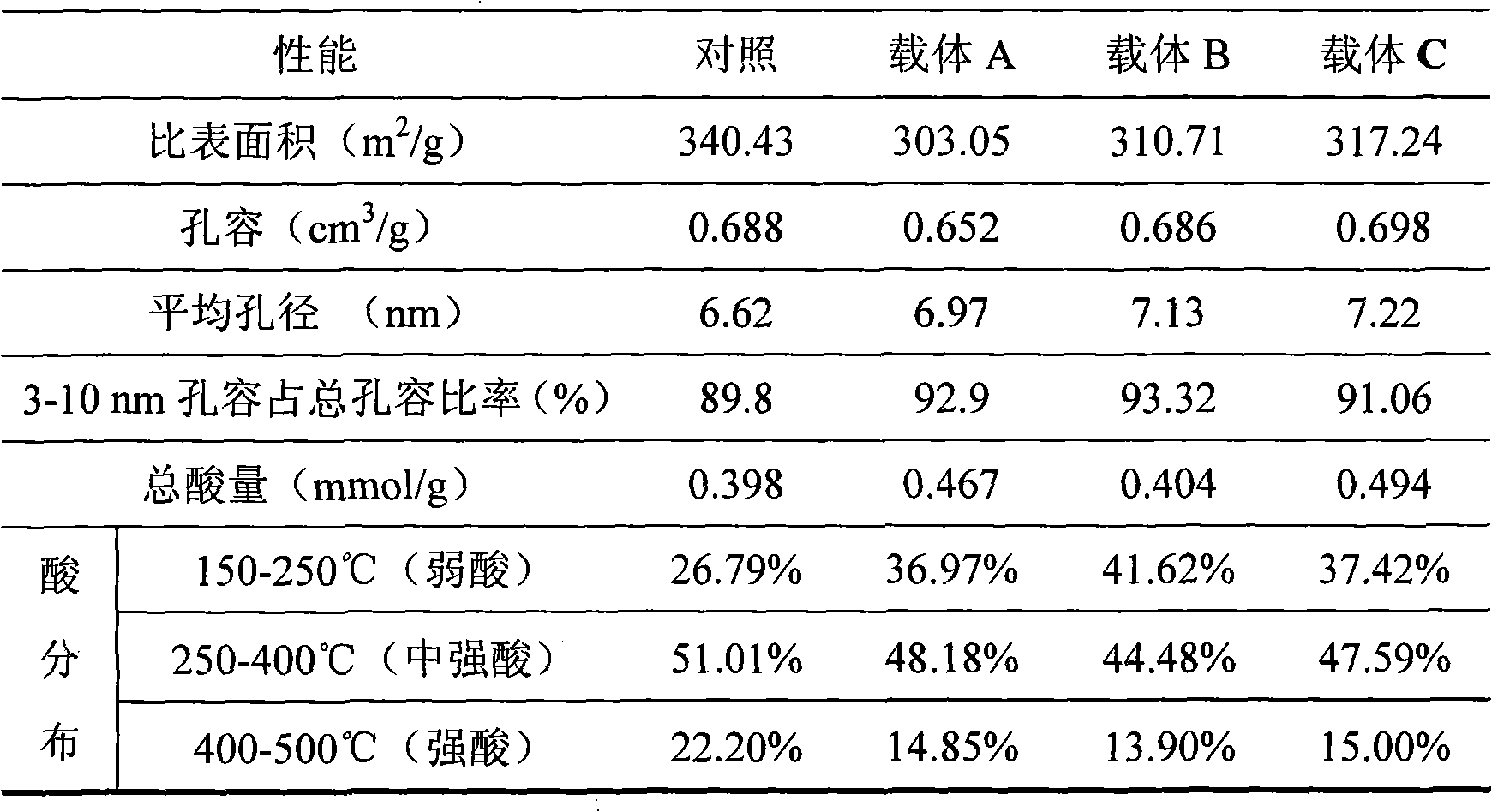

Modified carbon-coated alumina supporter with nucleocapsid structure and preparation method thereof

InactiveCN101327454ALarge specific surface areaLarge hole volumeCatalyst carriersCatalyst activation/preparationOil processingModified carbon

The present invention discloses a modified carbon-covered alumina support with a core-shell structure and a preparation method thereof. The modified carbon-covered alumina support of the present invention is a granule with the core-shell structure. A shell of the core-shell structure is alumina deposited with carbon, and an inner core of the core-shell structure is an industrial alumina support. The modified carbon-covered alumina support of the present invention has the advantages of high specific surface area, large pore volume, high mechanical strength, and the like; the aperture distribution is more concentrated; total acid quantity is increased obviously, and strong acid quantity is reduced; the modified carbon-covered alumina support can be directly used as a catalyst during certain processes and is more applicable to be used as a catalyst support, in particular as a hydrogenation treatment catalyst support during petroleum processing course.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing ZrO2 aerogel

ActiveCN101961626ANarrow pore size distributionSmall surface tension differenceColloidal chemistry detailsZirconium oxidesInorganic saltsWater baths

The invention discloses a method for preparing ZrO2 aerogel. The method sequentially comprises the following steps of: (1) dissolving a zirconium inorganic salt into an alcohol aqueous solvent, then sequentially adding a chelating agent, a drying control chemical additive and an epoxide and stirring for mixing; (2) carrying out a water bath on the obtained sol; (3) sequentially ageing, cleaning and soaking the sol subjected to the water bath; (4) drying the substance obtained in the step (3); and (5) carrying out heat treatment on the substance obtained in the step (4) at 400-700 DEG C for 3-8 hours to obtain the ZrO2 aerogel. In the invention, the specific surface area of the prepared ZrO2 aerogel is 400-800m<2> / g, the density is 100-500kg.m<-3>, the pore size distribution is narrow, and the ZrO2 aerogel is a nano scale. The ZrO2 aerogel has uniform and stable structure and can be widely applied to the fields of heat insulation, catalysis, environmental protection, and the like.

Owner:ZHEJIANG UNIV

Method for preparing high-hydrophobicity microporous membrane

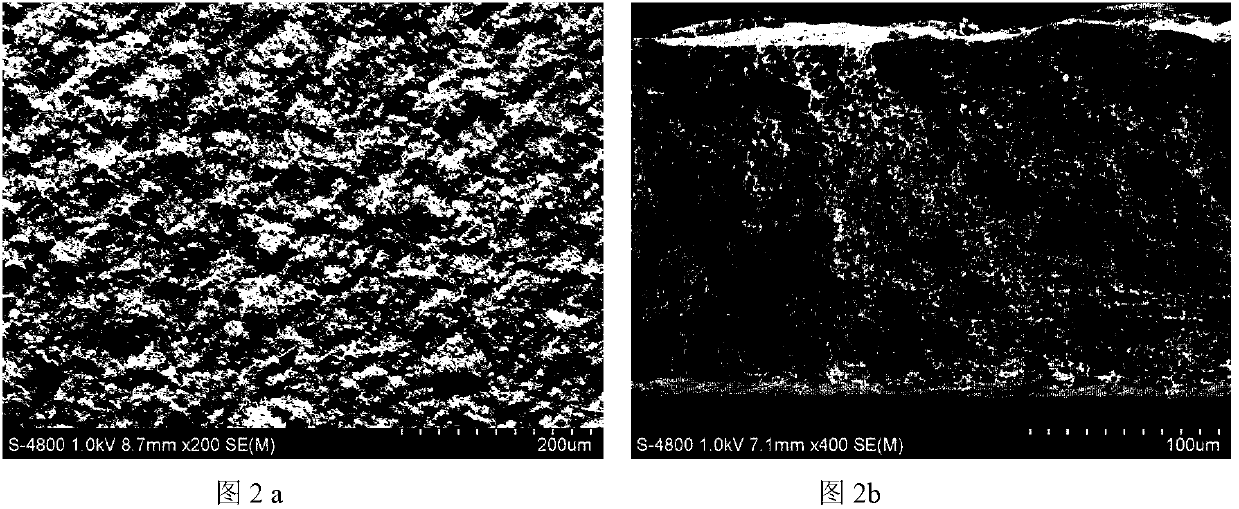

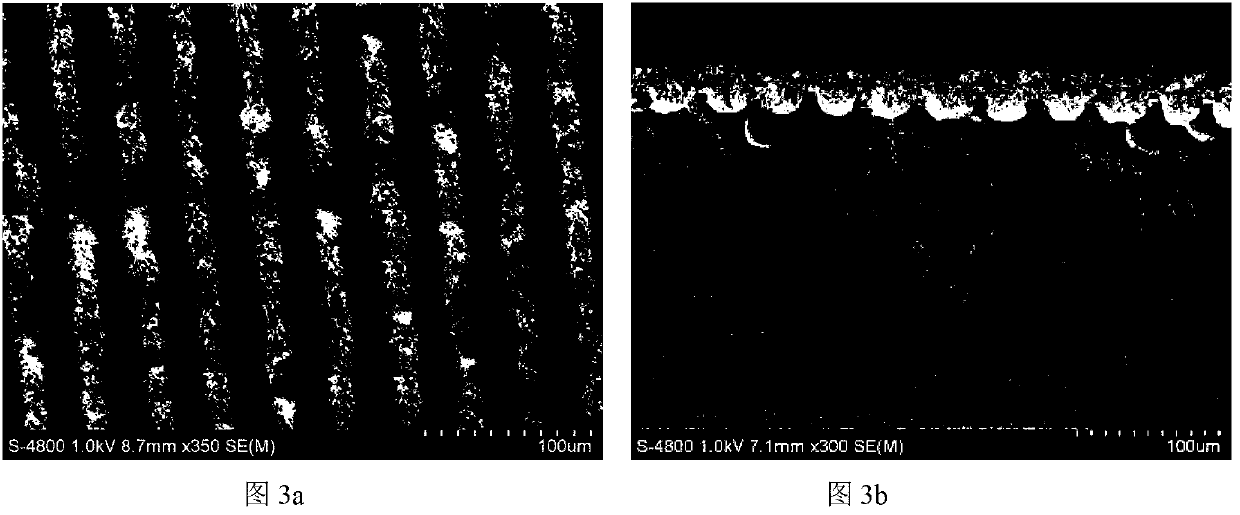

The invention relates to a method for preparing a high-hydrophobicity microporous membrane. A polymer and a membrane-making diluent membrane liquid are uniformly mixed and then are coated on a solid template on the surface of a micro structure by virtue of a thermally induced phase separation method under assistance of a solid template; the microporous membrane is prepared by the thermally induced phase separation method; and under the synergistic effect of the template and phase separation, the hydrophobicity of the membrane surface and other membrane properties are improved. The microporous membrane is high in hydrophobicity; a water contact angle is up to 165 degrees at most, and a rolling angle is 3 degrees, so that the ultra-high hydrophobicity is reflected; the permeation performance is high; the nitrogen flux under the 0.1MPa membrane penetration pressure difference is more than or equal to 260 m<3> / (m<2>.h); an aperture distribution range is small; the maximum aperture is less than or equal to 0.5 microns; the mechanical performance is high; the tensile strength is more than or equal to 3.0 MPa; and the breakage elongation is more than or equal to 68 percent.

Owner:HEBEI UNIV OF TECH

Method of preparing biomass high specific surface micro-pore carbon material

The present invention belongs to the preparation field of micropore carbon material, and relates to the preparation method for micropore carbon material with high specific surface area and narrow pore distribution by biomass. The biomass is cleaned and cut into subparagraph with a length of 1~3 centimeter, and then is subjected to carbonizing at 300~500 DEG C for 3~4 hours in the presence of inert atmosphere. The obtained carbonizing product is immerged into an alkaline solution for 20~24 hours until the carbonizing product is totally wetting, and then the carbonizing product is separated from the solution and is activated for 1.5~3 hours at 700~800 DEG C in the presence of inert atmosphere, and then is scrubbed by water until the pH value of the scrub solution is 7~8, and then the carbonizing product is immerged into a diluted acid solution for 4~5 hours and is scrubbed by water until the pH value of the scrub solution is 6~7, finally, the carbonizing product is dried at 80~120 DEG C to obtain micropore carbon material. The preparation method for the present invention has the advantages of that the preparation process is simple, the raw material is cheap and abundant, the preparation condition is free from zone limit; besides, the preparation method is adapted to industrial production.

Owner:JILIN UNIV

Method for preparing high-specific surface area active carbon by petroleum coke

The invention relates to a methjod for preparing activated charcoal with high specific surface area by using petroleum tar. It comprises following steps: disintegrating petroleum tar into grits # 80; immersing raw material into oxide medium for complete contact, oxidizing; mixing with alkali, activating in inert atmosphere, washing and getting said product. The specific surface area of got product is over 2000 m2 / g, the micropore volume is 1.2-2.1 cm3 / g, bore diameter is about 1 nm, the adsorbility is good, the alkali consumption is greatly reduced compared with current technology, the activating temperature is low and ratio of performance and cost is high.

Owner:DALIAN UNIV OF TECH

Method for preparing titanium dioxide mesoporous material

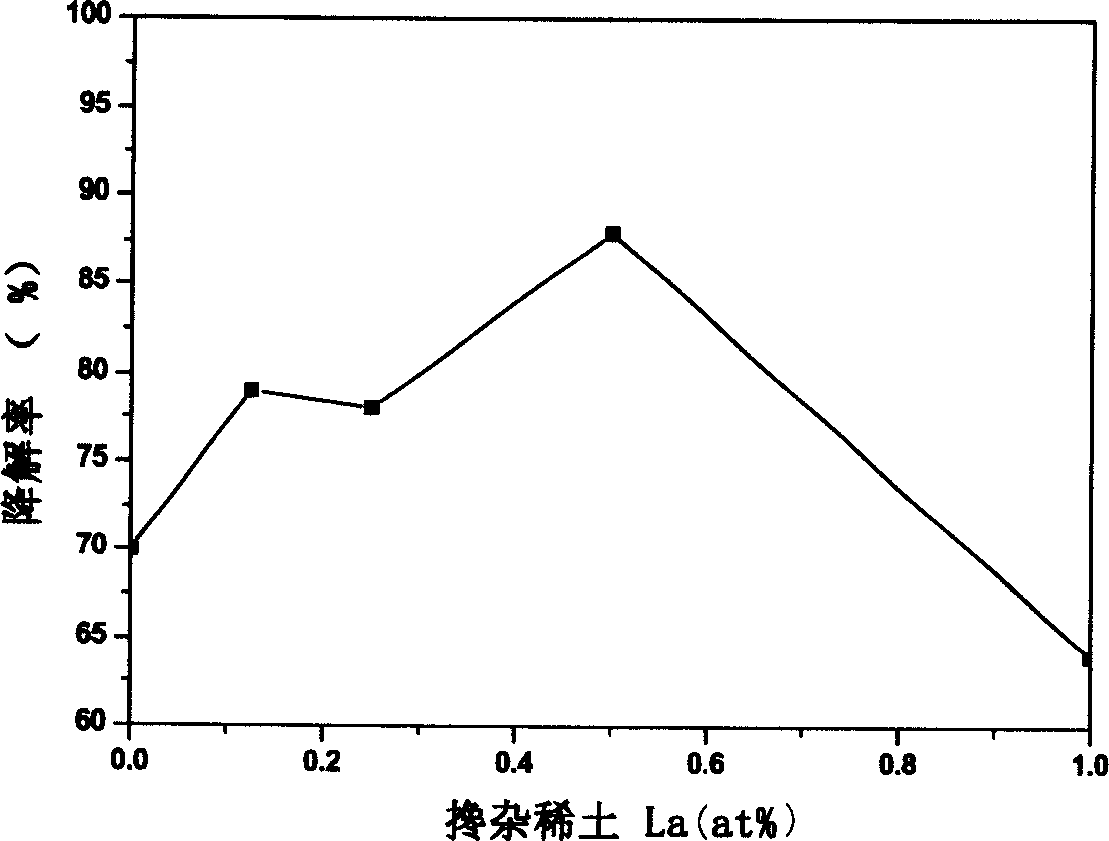

InactiveCN1594101ADoped with less rare earthImprove thermal stabilityTitanium dioxideRare earthMesoporous material

The invention relates to a method for preparing titanium dioxide mesoporous material which consists of, using segmented copolymer as mold plate, employing sol gel method to obtain large-hole diameter, high thermal stability and high optical catalytic activity rare earth doped titanium dioxide mesoporous material. The doped rare-earth salts can substantially improve the thermal stability and optical catalytic activity for the titanium dioxide mesoporous material.

Owner:EAST CHINA UNIV OF SCI & TECH

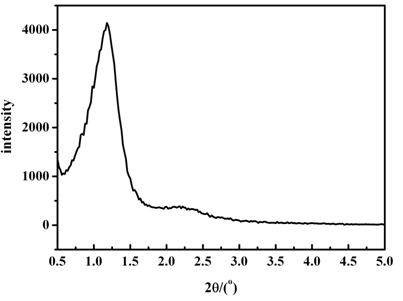

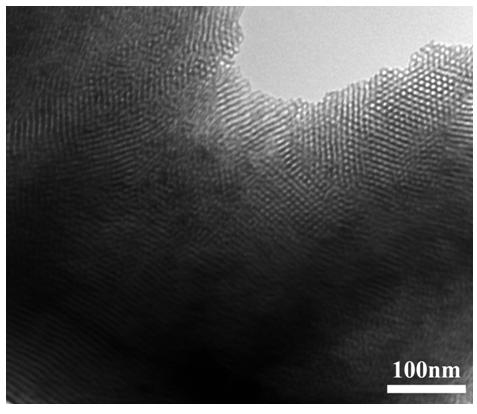

Preparation method of ordered mesoporous carbon material with high specific surface area by using metal organic skeleton

InactiveCN104418315ALarge specific surface areaNarrow pore size distributionMetal-organic frameworkSolvent

The invention discloses a preparation method of an ordered mesoporous carbon material with high specific surface area by using metal organic skeleton. Zinc salt and terephthalic acid as raw materials react under room temperature through simple stirring, solvent exchange and vacuum drying to obtain a metal organic skeleton material MOF-5 with cubic shape; and then metal organic skeleton material MOF-5 as a carbon source is directly carbonized at high temperature to obtain ordered mesoporous carbon material with high surface area and developed hole structure. The preparation method has the advantages of economic steps, low cost, simple operation process and mild conditions; the target product has narrow pore size distribution, large specific surface area and amorphous and graphitic carbon structure, can be used suitable as an adsorbent, a catalyst carrier, an electrode material and hard template for synthesis of other mesoporous materials, and has certain market application prospect.

Owner:SUZHOU OST ADVANCED MATERIALS +1

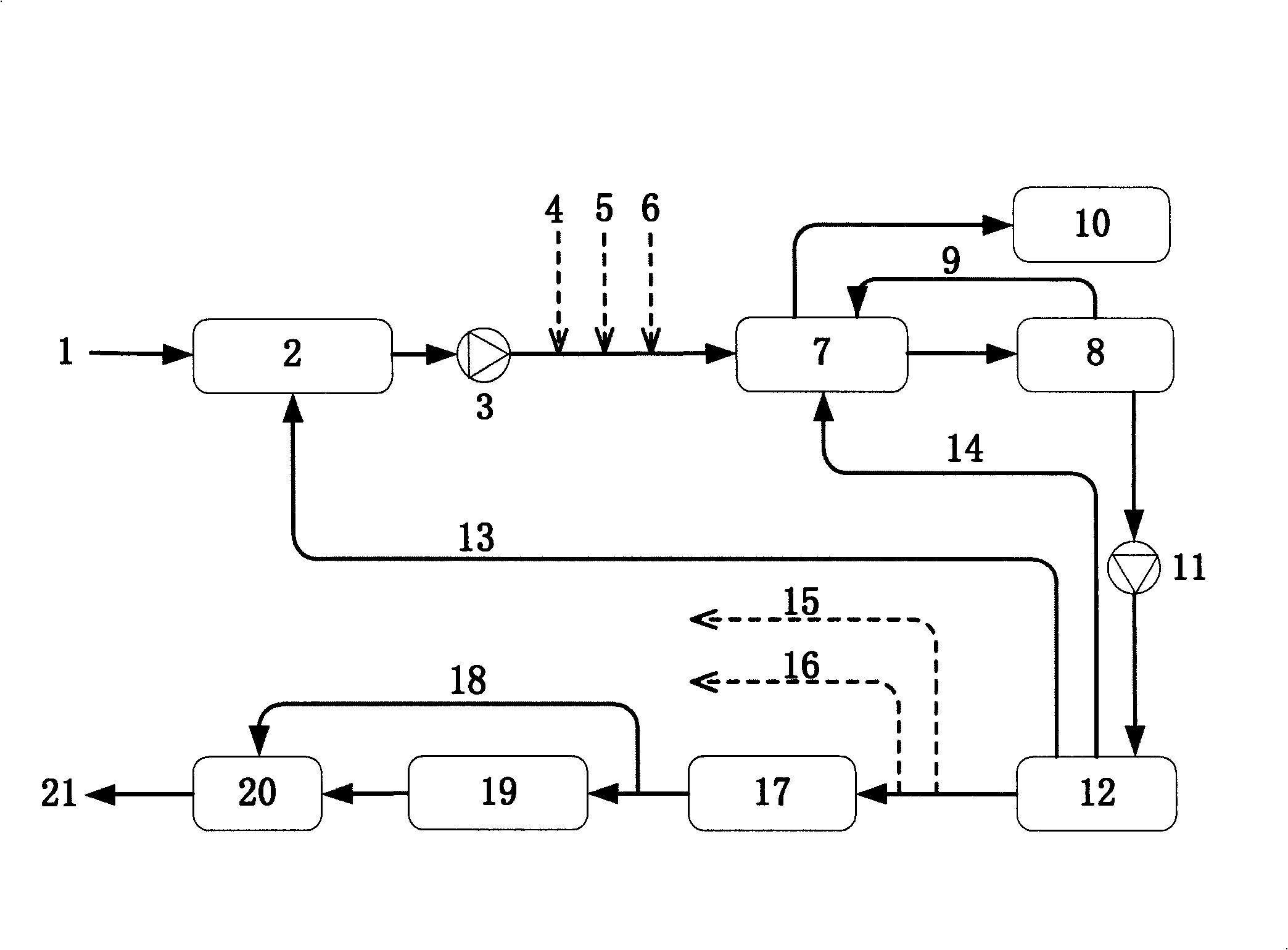

Method and device for treating a great variety of waste emulsion of high concentration using hyperfiltration membrane method

ActiveCN101311127AGood demulsification effectEasy to handleUltrafiltrationWater/sewage treatment bu osmosis/dialysisHigh concentrationLiquid waste

The invention discloses a method for treating the waste emulsion with high concentration and a plurality of varieties by an ultrafiltration membrane method and a device thereof, which belongs to the technical field of waste water and waste liquid treatment. The main technique of the invention is 'dissolved air flotation-ultrafiltration membrane-electrolysis floatation', which can effectively reduce the dosage of medicament and improve emulsion breaking effect by adopting an efficient dissolved air flotation system, moreover, the water for dissolved air flotation, which is taken from a subsequent intermediate water tank, can flexibly adjust and dilute the concentration of the waste water, thus improving the running stability and the shock resistant loading capability of the system. An ultrafiltration membrane with large flux, high separative efficiency and long service life is adopted in an ultrafiltration system to realize oil-water separation and to concentrate the emulsion for a plurality of times and then floating oil is recovered, the waste water generated in ultrafiltration washing is treated again after reflow, thus reducing waste liquid discharging. Electrolysis floatation can remove residual emulsified oil and dissolved oil in the waste water, thus further lowering the COD value of yielding water. When the quality of raw water is changed, an activated carbon adsorption unit can guarantee the quality of the yielding water to be standard. The method and the device of the invention can process waste emulsion with high concentration and a plurality of varieties and have simple and reasonable technique, good quality of yielding water, compact layout of the device, thus facilitating automatic control and realizing recovery of emulsion and recycle economy as well as changing waste to be profitable simultaneously.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

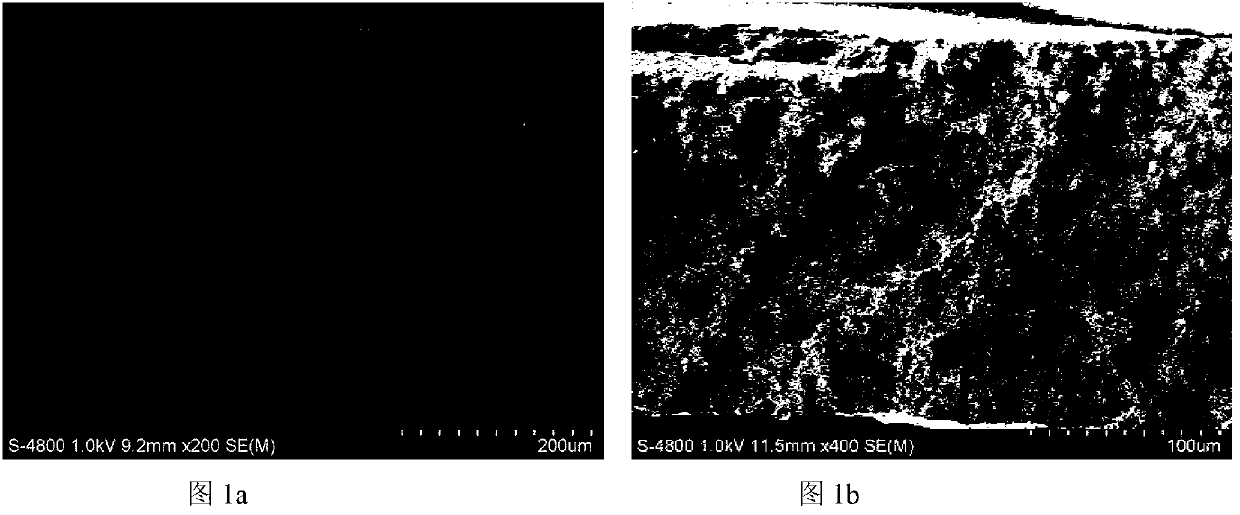

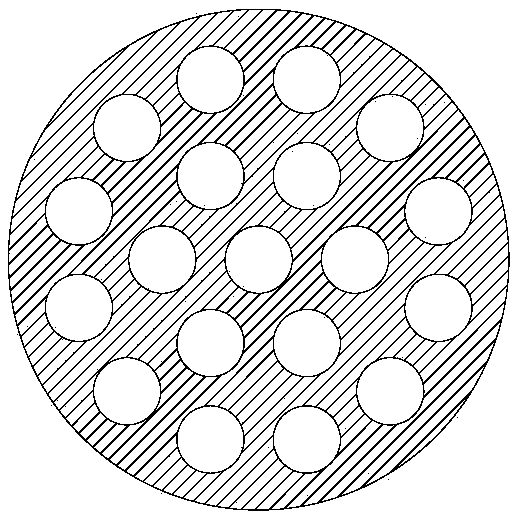

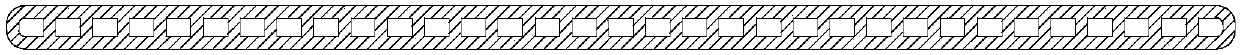

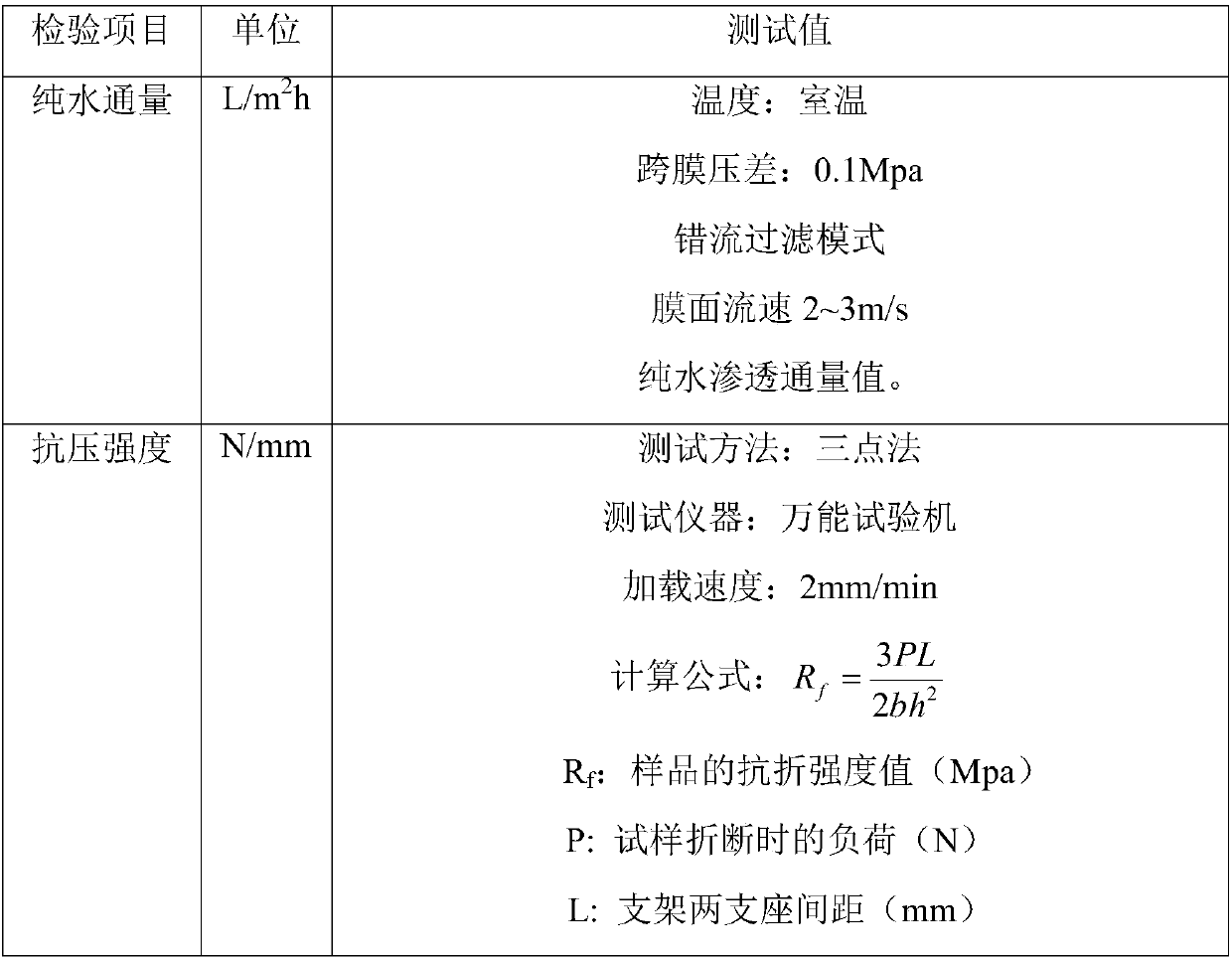

Preparation method of low-temperature sintering acid and alkali resistant porous silicon carbide ceramic film

ActiveCN107663088AImprove hydrophilicityImprove pollutionCeramicwareSeparation technologyPorous ceramics

The invention relates to the technical field of porous ceramic materials and film separation, in particular to a low-temperature sintering acid and alkali resistant porous silicon carbide ceramic filmand a preparation method thereof. The method sequentially comprises the following steps of (1) support body manufacturing; (2) transition layer processing; (3) filtering layer processing; (4) film sintering process. The method provided by the invention has the characteristics that the sintering temperature is low; the production energy consumption is low; the process method is simple; the equipment requirements are low; the production cost and the investment cost are low; the control is flexible; the shaping is easy; the method is suitable for industrial customization and meets the scaled production. The porous silicon carbide ceramic film produced by the method has the characteristics of good hydrophilcity, great filtering flux, high porosity, high filtering precision, high mechanical intensity, good acid and alkali resistant performance and long service life.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing medium pore carbon of narrow aperture and high degree of graphitization

The invention discloses a making method of narrow-aperture high-graphitizing degree middle-hole carbon, which comprises the following steps: allocating metal compound and carbon primer with weight rate at 0.1-6:1; dissolving metal compound in the solution with carbon primer; stripping solvent; solidifying in the air for 0.1-20h under 80-400 deg.c; charring for 0.1-3h under inert gas at 500-1200 deg.c; proceeding acid washing until the metal element is not detected; obtaining the product.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

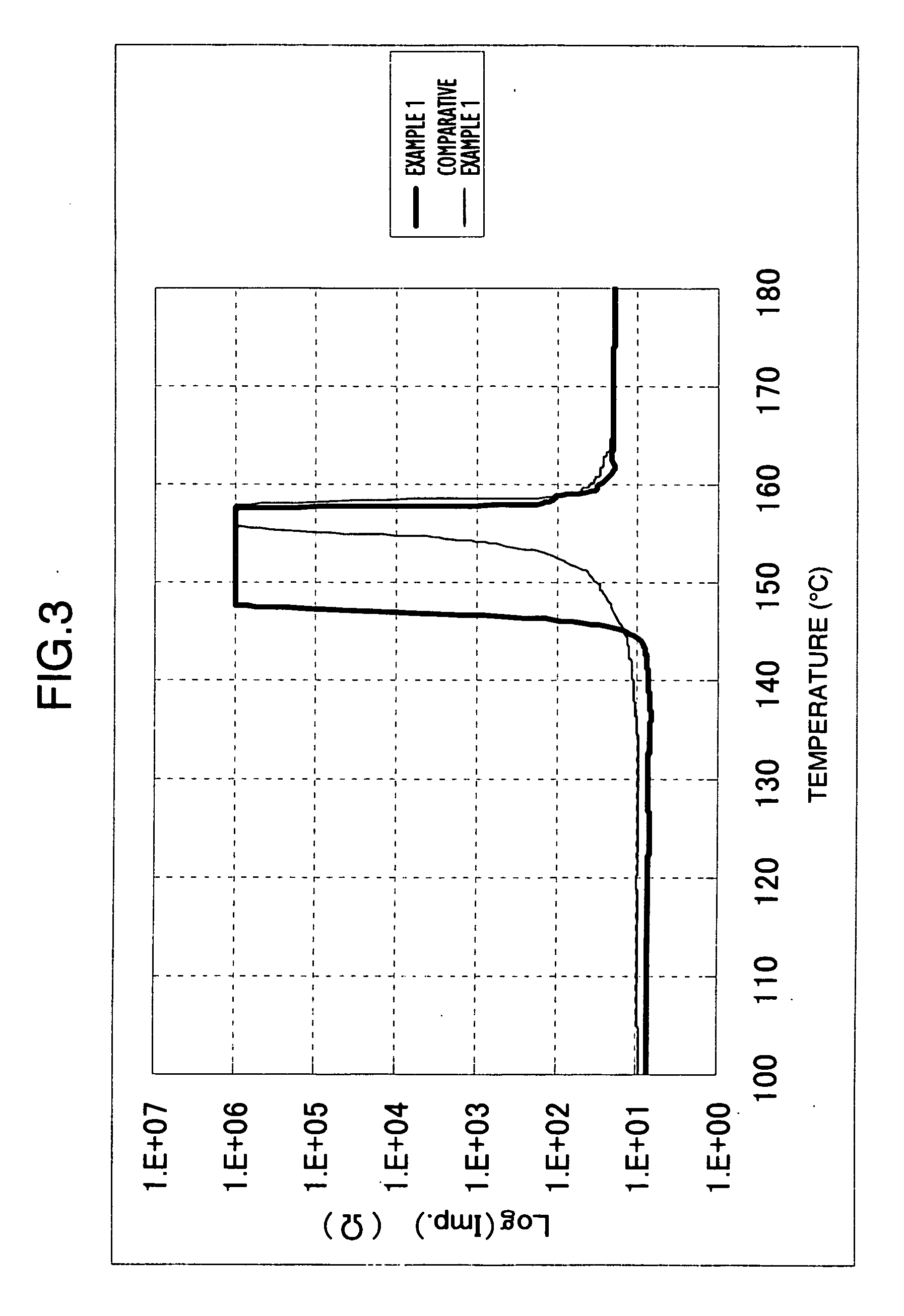

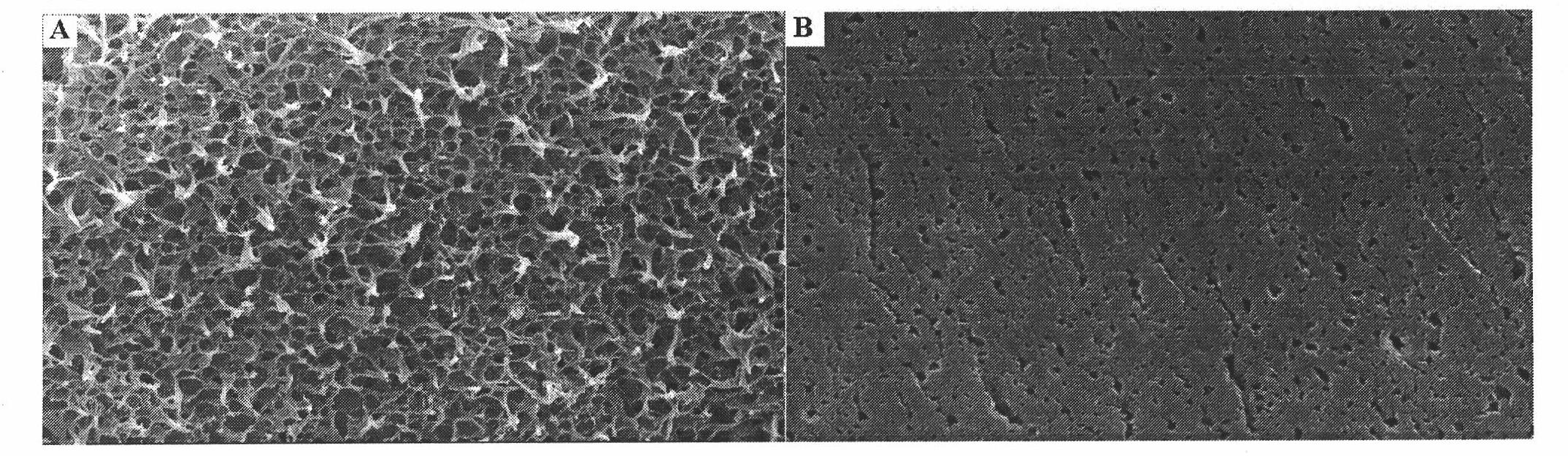

Microporous membrane made from polyolefin

InactiveUS20070148552A1Improve puncture strengthModerate pore sizeMembranesSemi-permeable membranesPolymer sciencePolyolefin

Disclosed is a microporous membrane made from a polyolefin wherein the thickness is 1-30 μm, the porosity is 30-60%, the air permeability is 50-250 sec / 100 cc, the puncture strength is 3.5-20.0 N / 20 μm, the maximum pore diameter determined by a bubble point method is 0.08-0.20 μm, and the ratio between the maximum pore diameter and the average pore diameter (maximum pore diameter / average pore diameter) is 1.00-1.40. Since this microporous membrane made from a polyolefin is highly safe while maintaining a high permeability, it is useful especially as a separator for recent small-sized, high-capacity nonaqueous electrolyte batteries.

Owner:ASAHI KASEI CHEM CORP

Method for inorganically synthesizing organized mesoporous alumina

InactiveCN101993102ALow costLarge specific surface areaOther chemical processesCatalyst activation/preparationAluminium chlorideNano structuring

The invention belongs to the field of inorganic nano structure materials, in particular to a method for inorganically synthesizing organized mesoporous alumina, which is characterized in that inorganic matters of sodium aluminate and aluminum chloride are in acid-base pairing to prepare mesoporous alumina which has large specific surface area, narrow pore-size distribution, organized pore channel and high hydrothermal stability; and methyl cellulose which is used as a template agent in a synthesizing process has thermosensitivity and is beneficial to recycle. The method for inorganically synthesizing organized mesoporous alumina has the characteristics that raw materials have low cost, the template agent can be recycled, the technology is simple and easy to control, and the like. The method for inorganically synthesizing organized mesoporous alumina is easy to realize industrial production, and the obtained organized mesoporous alumina has wide application prospect in the fields of catalytic reaction, adsorption, separation, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for polyolefin porous film mfg. method

InactiveCN1978037ANarrow pore size distributionHigh strengthSemi-permeable membranesSolventPolyolefin

The present invention relates to a preparation method of polyolefine microporous membrane. Said invention adopts thermal phase separation process to prepare said polyolefine microporous membrane, said process includes the following steps: mixing polyolefine compound and first solvent, melting them by using extruder, extruding melt, cooling and forming to obtain a colloidal material, making said colloidal material undergo the processes of supercritical extraction, thermal stretching and setting so as to obtain the invented product.

Owner:TIANJIN DG MEMBRANE

Preparation method for ordered mesoporous gamma-Al2O3

InactiveCN102424411ALarge specific surface areaNarrow pore size distributionAluminium oxides/hydroxidesEngineeringOrganic chemistry

The invention discloses a preparation method for ordered mesoporous gamma-Al2O3. The preparation method comprises the steps of a synthesis reaction, aging, drying and calcining so as to obtain the ordered mesoporous gamma-Al2O3. The method provided in the invention is simple and easily practicable, is safe to operate and is easy for industrial production; the obtained gamma-Al2O3 has the advantages of a large specific surface and high thermostability.

Owner:JINAN UNIVERSITY

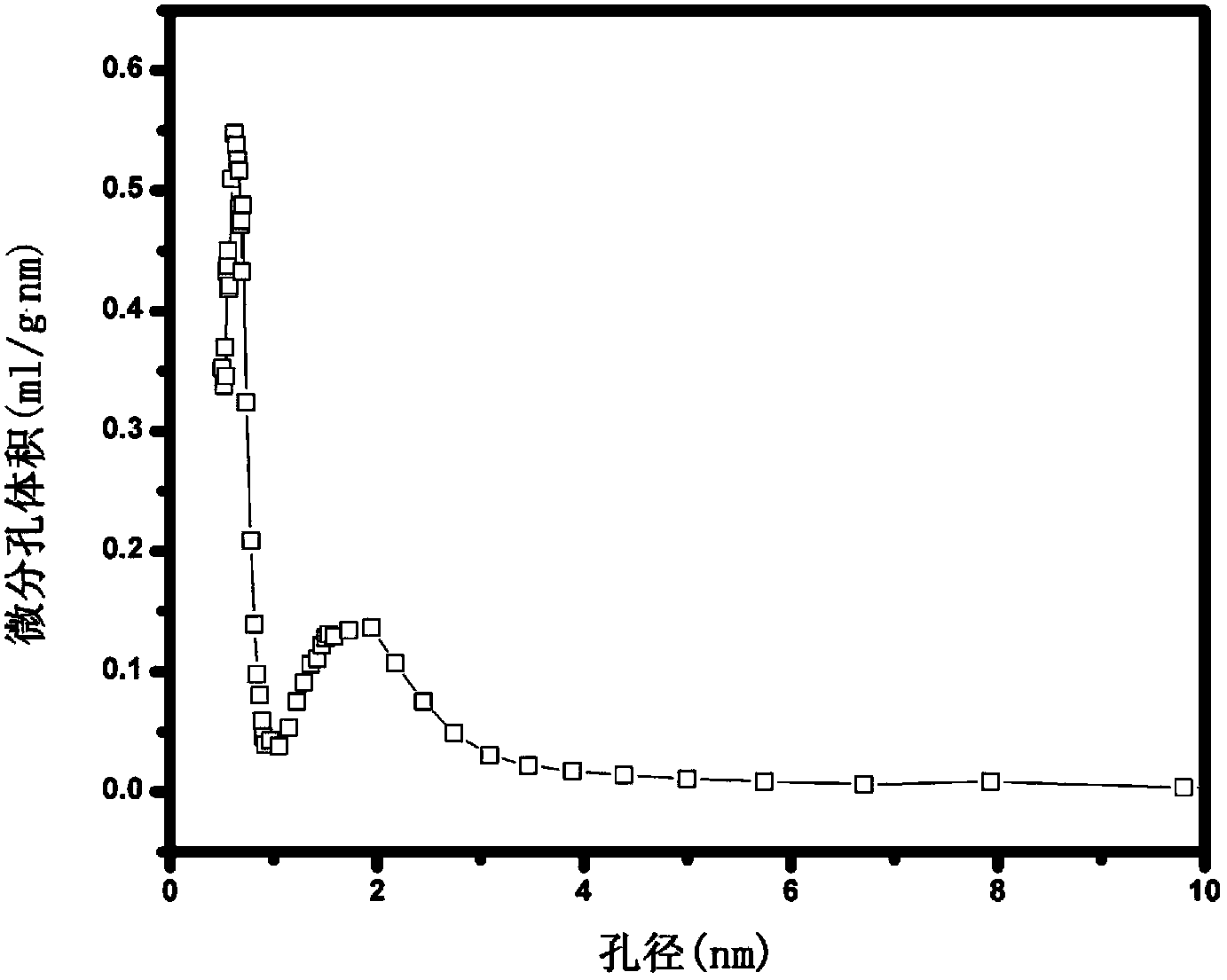

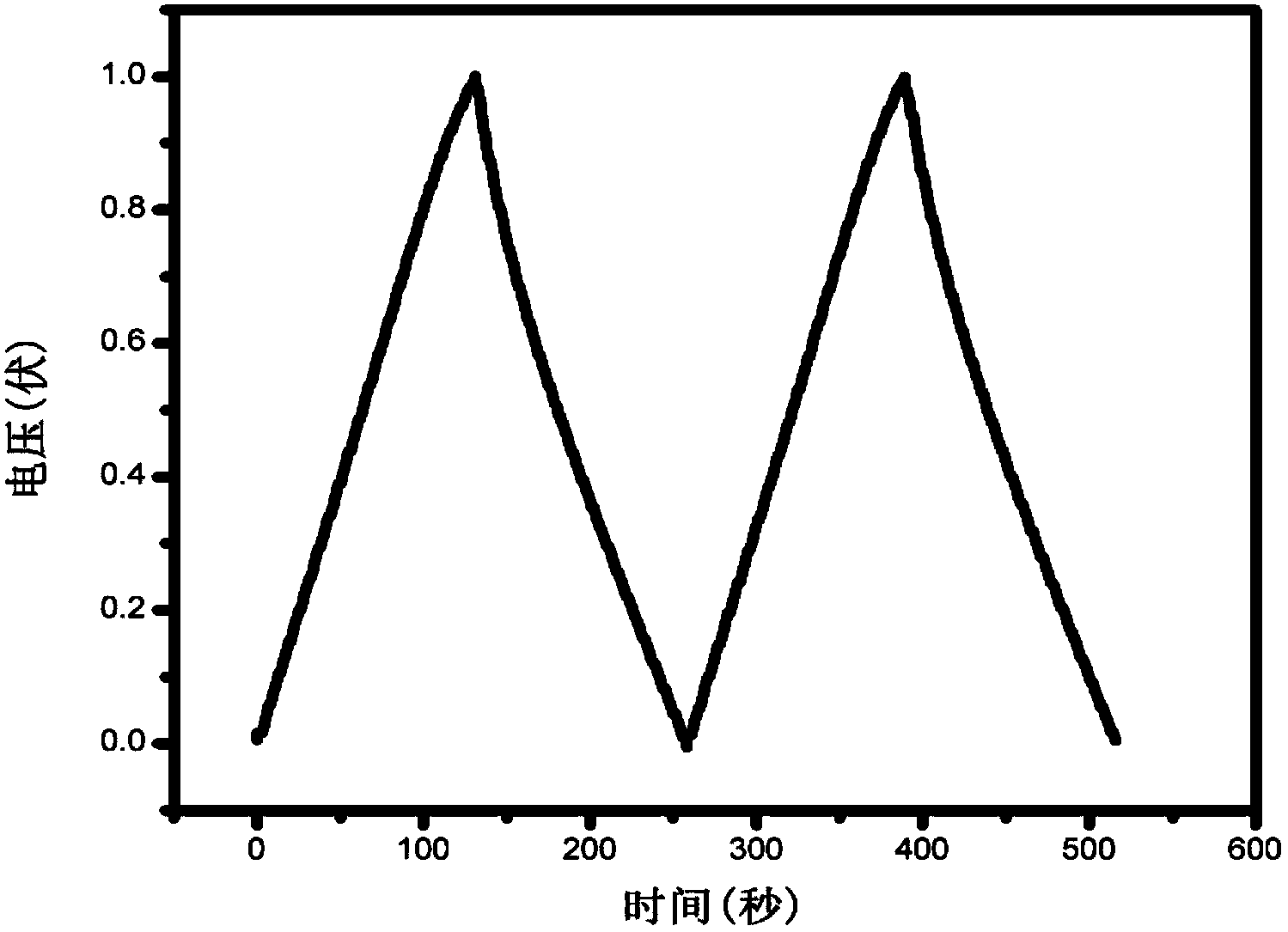

Preparation method for coproduction of high-specific-capacitance active carbon and nano silicon dioxide from rice hull

InactiveCN103408009AExcellent specific capacitanceImprove charge and discharge performanceMaterial nanotechnologySilicaCapacitanceCarbide

The invention discloses a preparation method for coproduction of high-specific-capacitance active carbon and nano silicon dioxide from rice hull, and belongs to the technical field of resource comprehensive utilization and electrochemical supercapacitors. The preparation method comprises the steps of (1) cleaning, drying and grinding rice hull; (2) carbonizing the rice hull ground in the step (1) under a non-oxidizing condition, processing the carbonized rice hull through an acid solution, washing with water and drying to obtain carbide; (3) mixing the carbide obtained from the step (2) with strong base by a certain proportion, adding a certain amount of water, uniformly mixing, drying, controlling a temperature-increasing speed and activating to obtain an activated product; (4) soaking the activated product obtained from the step (3) in hot water, filtering and washing to be neutral, drying and grinding the product to 150-300 meshes to obtain a high-specific capacitance rice hull-based active carbon material; and (5) recovering filtrate obtained from the step (4), adding the acid solution at certain temperature, controlling a speed of dropping acid, regulating pH, aging, filtering and drying to obtain a nano silicon dioxide product.

Owner:JILIN UNIV

Controlled pore size distribution porous ceramic honeycomb filter, honeycomb green body, batch mixture and manufacturing method therefor

ActiveUS7744670B2Small amountQuantity minimizationCombination devicesExhaust apparatusPotato starchSource material

A porous ceramic honeycomb filter manufactured from an oxide-based ceramic material having a pore size distribution with d1≧7.0 microns. Preferably, the oxide-based material is cordierite or aluminum titanate. Alternatively, the filter contains a cordierite-containing ceramic body with a narrow pore size distribution with db≦1.00, wherein db=(d90−d10) / d50. Also disclosed is a batch mixture, method and honeycomb green body made from mixture of inorganic source materials selected from the group of magnesia sources, alumina sources, and silica sources, and a pore former having a narrow particle size distribution with dps≦0.90, wherein dps={(dp90−dp10) / dp50}. The pore former is preferably selected from a group consisting of canna starch, sago palm starch, green mung bean starch, and single-mode potato starch.

Owner:CORNING INC

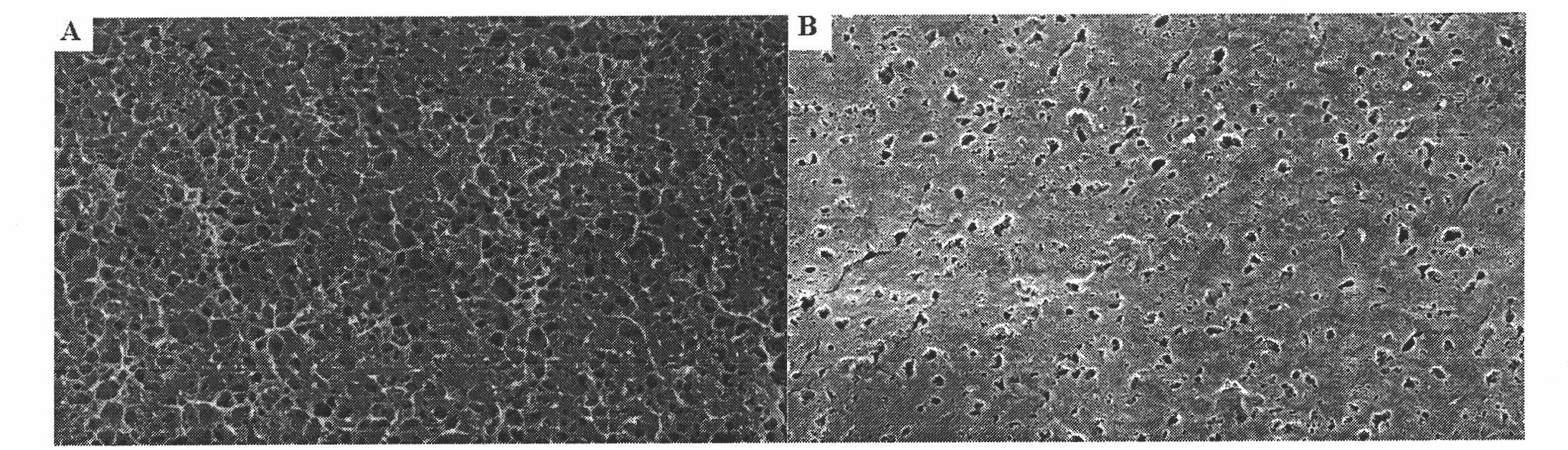

Polyether-ether-ketone porous film and preparation thereof

InactiveCN101234304AHigh temperature resistanceHigh strengthSemi-permeable membranesFiltrationTemperature resistance

The invention discloses a porous membrane of PEEK and a preparation method thereof. The porous membrane of PEEK is produced by polymer material that contains the PEEk with the inner pore diameter of 0.09 to 0.2Mum and porosity rate of 70 to 90 percent. The invention adopts the PEEK material with excellent performance as the membrane material which is dissolved at the high temperature and then heterogeneous separated at low temperature to prepare the porous membrane of PEEK of high strength, high temperature resistance and solvent-resistance. Compared with the porous membranes of polyvinylidene fluoride, polyethylene and polypropylene, etc., the porous membrane of PEEK has the advantages of narrowly distributed pore diameter, high porosity rate, high strength, high temperature resistance and solvent-resistance which can be widely applied to the fields such as micro-filtration and ultra-filtration, especially the membrane process of ultra-filtration and micro-filtration at high temperature, and even can replace the inorganic membrane.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing mesoporous metallic oxide material

InactiveCN101391753AImprove protectionEasy to operateOxide/hydroxide preparationMaterial synthesisHeat treated

The invention provides a mesoporous metal oxide preparation method belonging to the inorganic nano material synthesis field. The invention adds a precursor solution into a mesoporous template powder so as to lead the precursor solution to penetrate into mesoporous channels through capillary force. After the following drying and heating, the mesoporous template is removed to obtain the corresponding mesoporous oxide. The preparation condition is simple; the cost is low; the productivity is high; the operation is easy and the environment protection can be guaranteed; and the prepared metal oxide is better, the mesopore structure is ordered and the wall is crystallized.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing spherical activated carbons with narrow mesoporous size distribution

InactiveCN102862982ASimple process routeReduce process stepsCarbon compoundsWater vaporBiological activation

The invention discloses a method for preparing spherical activated carbons with narrow mesoporous size distribution, which comprises the following steps of: preparing water liquid with 5-10 wt % of a dispersant so as to obtain dispersion liquid; adding phenol, formaldehyde, sodium hydroxide and ionic liquid into the dispersion liquid, and stirring for 10-60 min; raising the temperature of the obtained object to 70-85 DEG C at a speed of 0.5-2 DEG C / min in a stirring state, and carrying out reaction on the obtained object for 1-3 hours at the temperature so as to obtain phenolic resin balls, wherein the adding amount of each material is as follows: through calculating by adding each material in 1000 ml of the dispersion liquid and taking 20g phenol as a benchmark, the mole ratio of the phenol, the formaldehyde, the sodium hydroxides and the ionic liquid is 1:2:0.1:(0.05-0.5); and raising the temperature of the obtained phenolic resin balls to 800-1000 DEG C at a speed of 2-5 DEG C / min under the protection of nitrogen, and carrying out water vapor activation on the phenolic resin balls for 1-2 hours at the temperature so as to obtain spherical activated carbons with narrow mesoporous size distribution. The method disclosed by the invention has the advantages of simple process route and less process steps, and capability of having narrow mesoporous size distribution.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Meso-microporous metal-organic compound and preparation method thereof

InactiveCN101337192ALarge specific surface areaNarrow pore size distributionOrganic-compounds/hydrides/coordination-complexes catalystsInorganic saltsOrganic solvent

The invention relates to a microporous and mesoporous organometallic compound as well as the preparation method thereof, and mainly provides an organometallic compound with multilevel pores, as well as the preparation method thereof. The preparation method comprises the following steps: metal inorganic salts and organic carboxylic acid coordination polymers are dissolved in water or an organic solvent; the mixed solution is crystallized for 10-100 hours under the condition that the temperature is 100-220 DEG C; after being naturally cooled down and taken out, the reaction product is taken out; the microporous and mesoporous organo-metallic compound is prepared through suction-filtering, washing, drying and baking. The preparation process of the invention is simple, the cost is low, and the microporous and mesoporous organo-metallic compound can be prepared under mild conditions. The prepared material with the multilevel pores has wide application prospect on aspects of adsorption, separation, catalysis, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

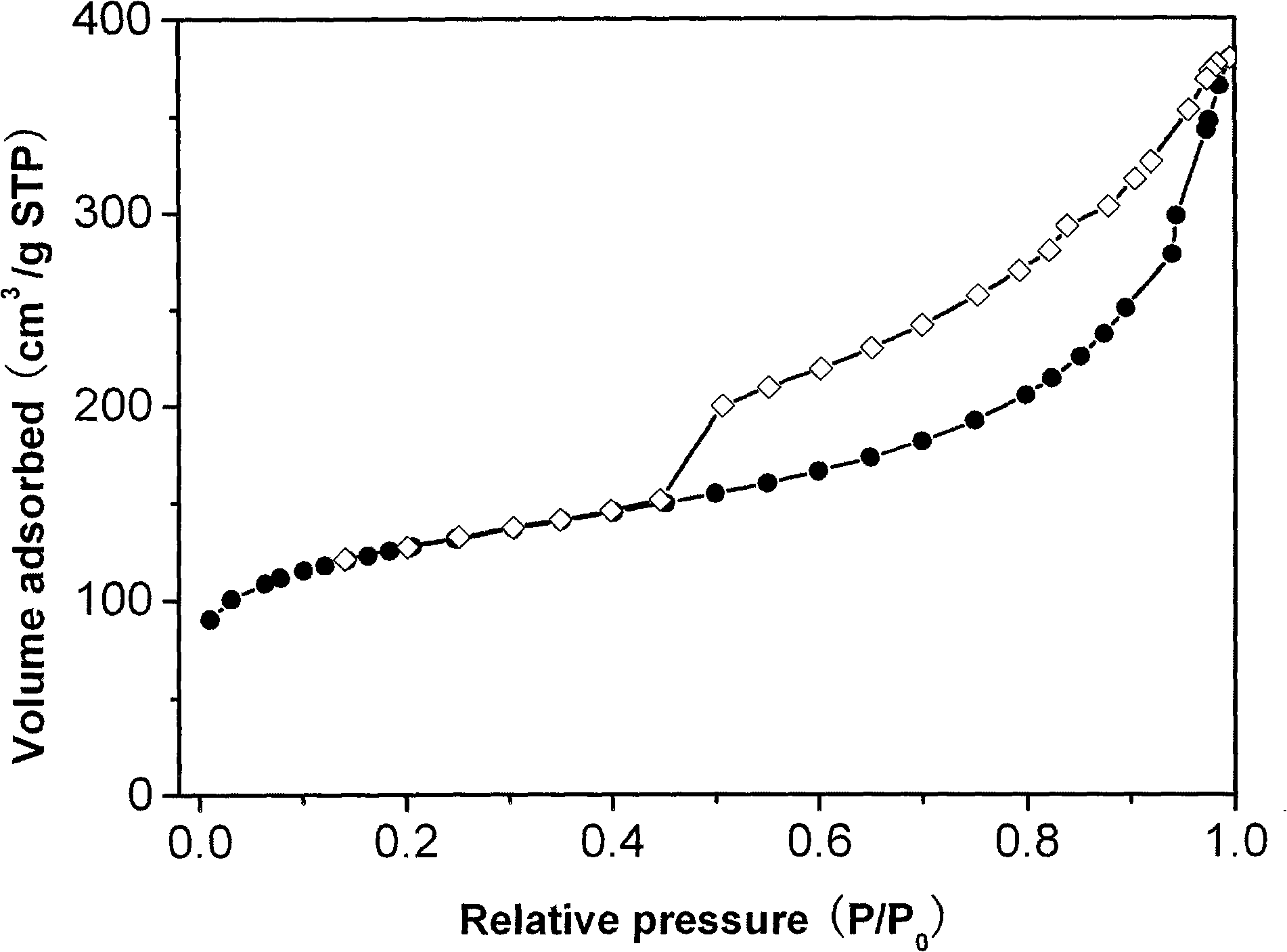

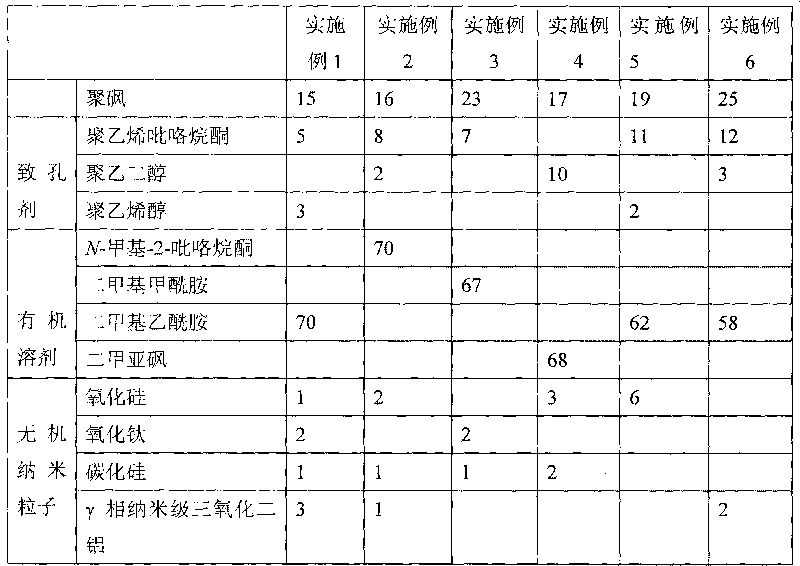

Blending modified hollow polysulfone fiber film, preparation method and application thereof

InactiveCN101711954AImprove featuresGood biocompatibilitySemi-permeable membranesSuction devicesFiberPolyethylene glycol

The invention relates to a blending modified hollow polysulfone fiber film which comprises the following components in percentage by weight: 3-40 percent of polysulfone, 0.5-20 percent of porogen, 50-90 percent of organic solvent and 0.5-20 percent of inorganic nano particles, wherein the inorganic nano particles are one or the mixture of more than two of silicon oxide nano particles, titanium oxide nano particles, silicon carbide nano particles and gamma-phase aluminium oxide nano particles; the viscosity-average molecular weight of the polysulfone is 40,000-200,000; the organic solvent is one of N-methyl-2-pyrrolidone, dimethyl acetamide or dimethyl sulfoxide; and the porogen is one or a mixture of any two of polyvinylpyrrolidone, polyethylene glycol and polyvinyl alcohol. The invention improves the surface property, the hydrophilic property and the mechanical strength of the film through modifying the hollow polysulfone fiber film, has simple film preparation process, and can realize industrial mass production.

Owner:江苏朗生生命科技有限公司

Polyester flat microporous membrane and preparation method thereof

InactiveCN101985085AAchieve hydrophilicAchieve hydrophilizationSemi-permeable membranesCell seperators/membranes/diaphragms/spacersPolyesterMicrometer

The invention discloses a polyester flat microporous membrane and a preparation method thereof. The microporous membrane comprises the following materials in percentage by mass: 60-99.9% of polyester and 0.1-40% of modifier; or 20-40% of non-woven fabric, 60-79.9% of polyester and 0.1-30% of modifier. The preparation method is realized on the basis of a thermally induced phase separation process and comprises the following steps: mixing the polyester, the modifier and diluter into a homogeneous solution at high temperature; scraping the homogeneous solution into a liquid membrane, cooling andcuring into a membrane so as to form a precursor membrane subject to microphase separation, and extracting to obtain a flat microporous membrane. The prepared polyester flat microporous membrane is in a spongeous structure with the pore diameter of 0.05-5.0 micrometers and the porosity of 30-80%, and has the advantages of narrow pore diameter distribution, uniform pore size, easily controlled pore size, high strength, symmetrical structure and the like, thereby being a filter membrane material for water treatment and a lithium ion battery diaphragm material with high performance, low cost andlong life.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com