Method for preparing mesoporous metallic oxide material

A mesoporous silicon oxide and oxide technology, applied in the direction of oxide/hydroxide preparation, etc., to achieve the effect of simple operation, low cost, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

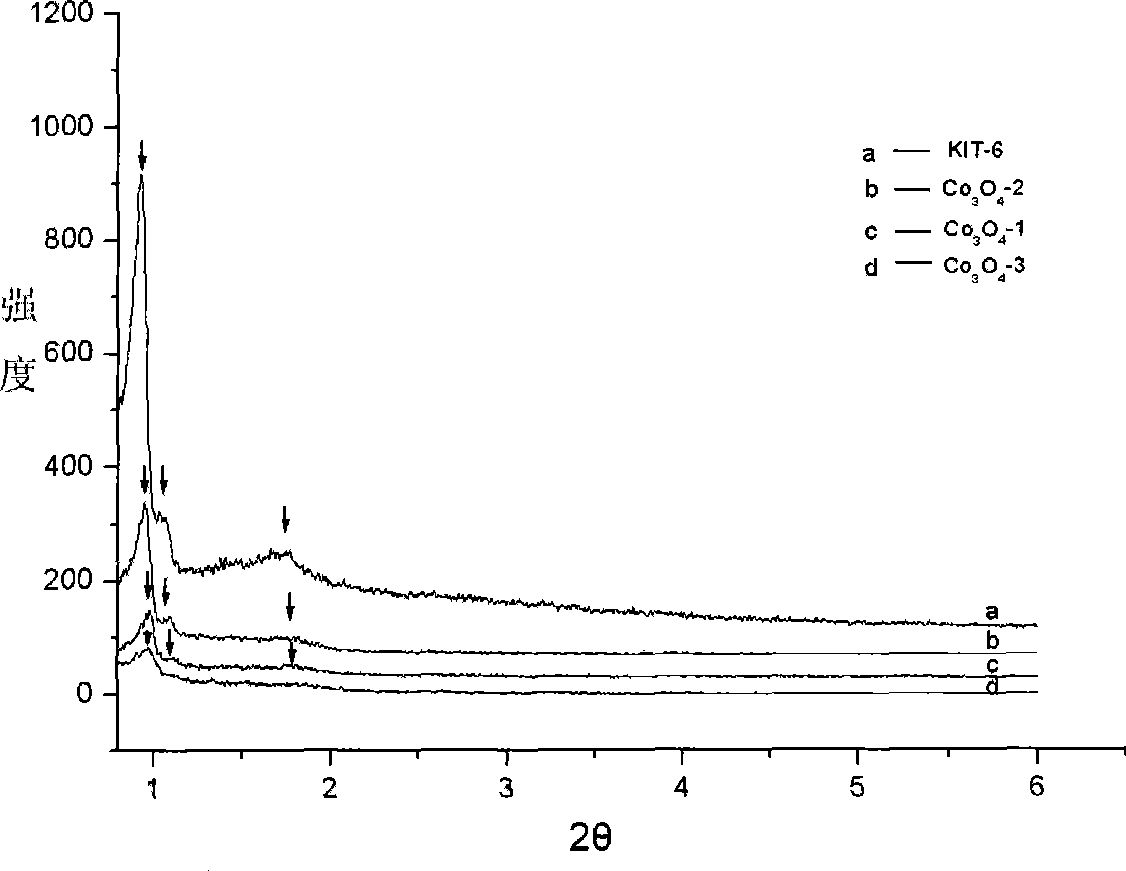

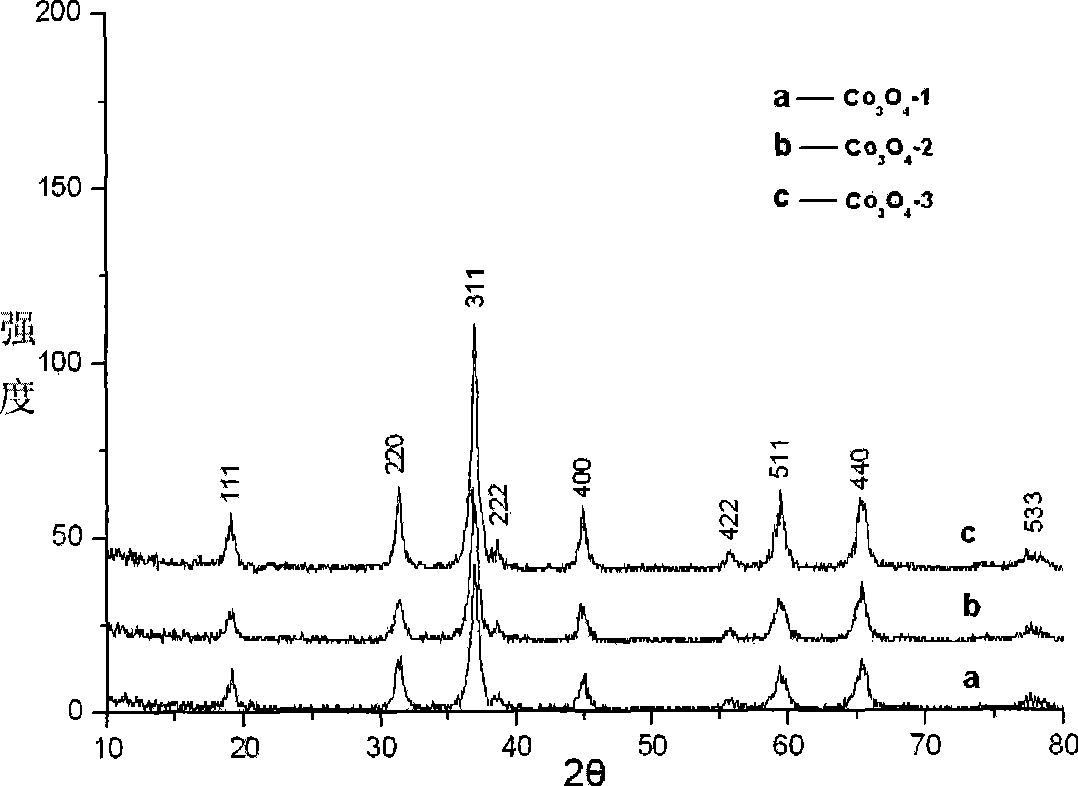

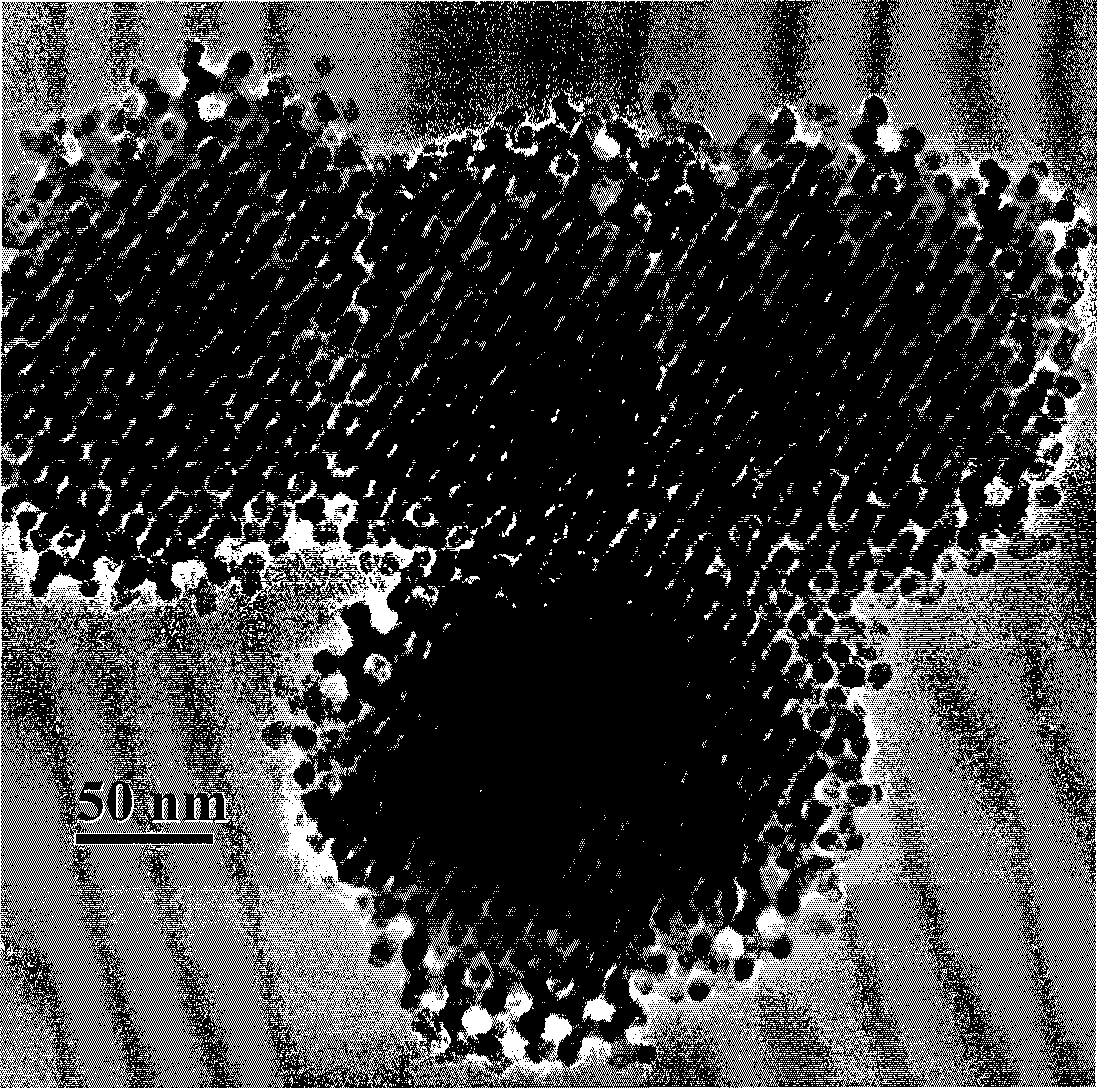

[0037] According to literature reports, a KIT-6 mesoporous silica template (pore volume of 1.2 cm 3 / g). Dissolve 1.8 g of cobalt nitrate hexahydrate in 1.5 mL of absolute ethanol and draw into the syringe. Take 1g of the KIT-6 template, and then add the cobalt nitrate solution in a dropwise manner. The obtained powder was dried in an oven at 70°C, and the dried powder was placed in a resistance furnace at a heating rate of 2°C / min to 500°C and maintained at this temperature for 2 hours. The obtained powder was removed twice with 2M sodium hydroxide solution at 80 °C, filtered, washed with deionized water, and then dried to obtain mesoporous cobalt oxide (Co 3 o 4 -1). The specific surface area of this sample is 97.7m 2 / g, the most probable pore diameter is 3.3nm.

[0038] The resulting mesoporous cobalt oxide (Co 3 o 4 -1) structural characterization see attached figure 1 , 2 and 3.

Embodiment 2

[0040] According to the process described (same as Example 1), but the powder infiltrated with the precursor was put into a resistance furnace at a heating rate of 2°C / min to 300°C and maintained at this temperature for 2h. Then repeat embodiment 1 (the precursor solution that drops is that the cobalt nitrate hexahydrate of 1.6g is dissolved in the ethanol of 1.3mL), the obtained mesoporous cobalt oxide is Co 3 o 4 -2. The specific surface area of this sample is 79.2m 2 / g, the most probable pore diameter is 2.8nm.

[0041] The resulting mesoporous cobalt oxide (Co 3 o 4 -2) structural characterization see attached figure 1 , 2 and 4.

Embodiment 3

[0043] According to the technical process described (same as Example 1), 1.93g of nickel nitrate hexahydrate was dissolved in 1.5mL of absolute ethanol, and sucked in the syringe. Others are the same as in Example 1, and mesoporous nickel oxide (NiO) is obtained. The specific surface area of this sample is 73.6m 2 / g, the most probable pore diameter is 2.8nm.

[0044] The structural characterization of the resulting mesoporous nickel oxide (NiO) is shown in the attached Figure 5 , 6 and 7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com