Patents

Literature

9378 results about "Pore diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pore diameter. [′pȯr dī‚am·əd·ər] (design engineering) The average or effective diameter of the openings in a membrane, screen, or other porous material.

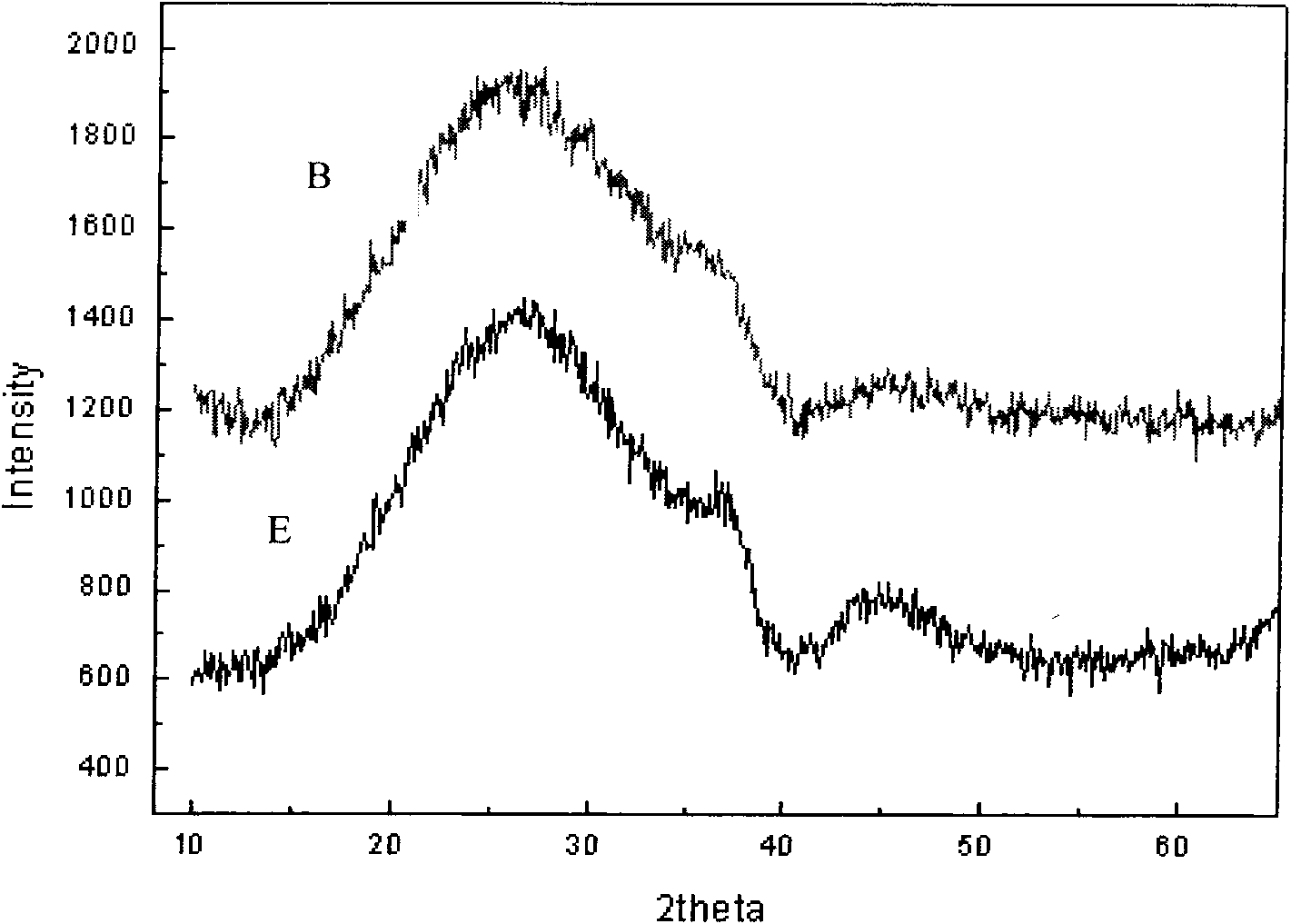

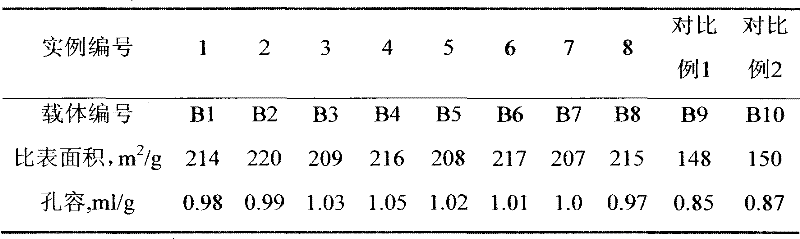

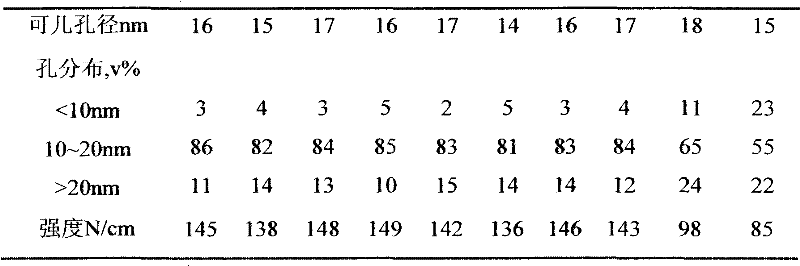

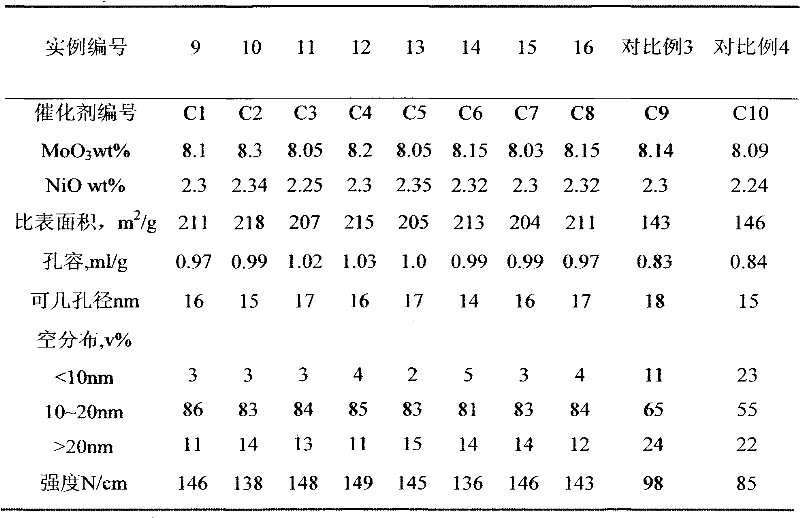

Composite molecular sieve and hydrodesulfurization catalyst prepared with composite molecular sieve as carrier

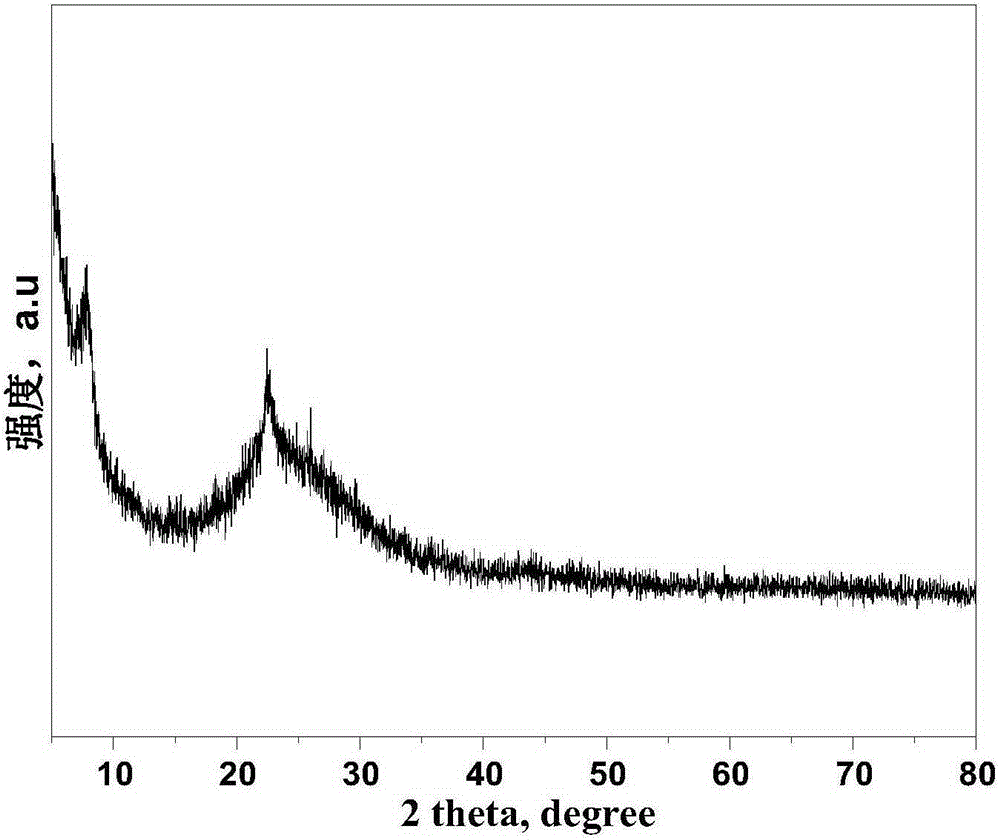

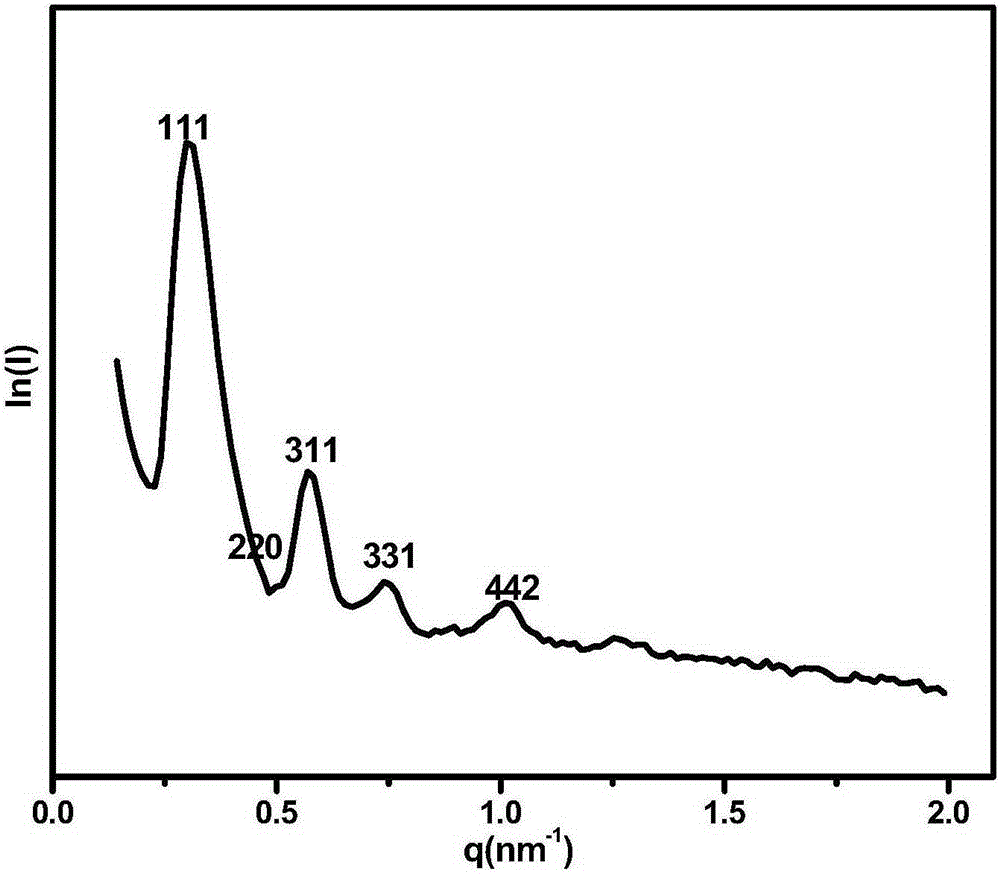

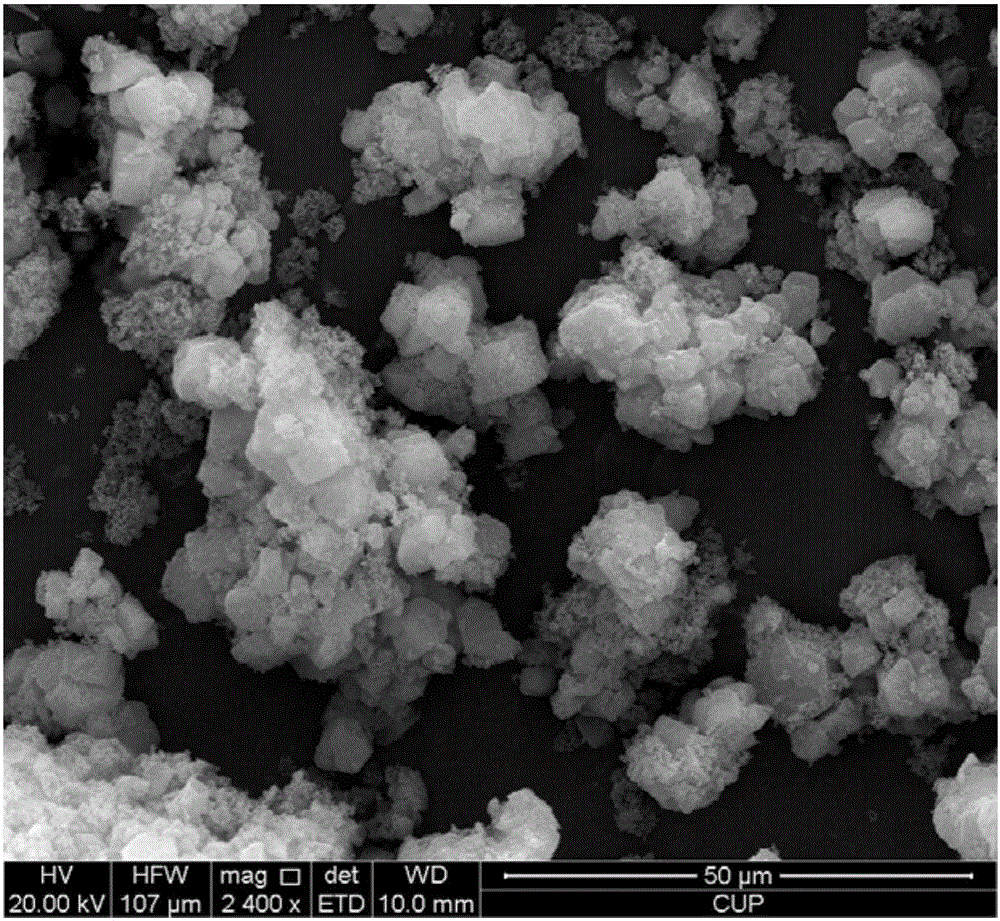

ActiveCN105251527AGood dispersionModerate dispersionMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

The invention provides a composite molecular sieve and a hydrodesulfurization catalyst prepared with the composite molecular sieve as a carrier. According to the composite molecular sieve and the hydrodesulfurization catalyst, the Beta-FDU-12 composite molecular sieve is of a bimodal porous structure, namely a Beta micropore and an FDU-12 mesoporous, the superficial area of the composite molecular sieve is 800-1000m<2>.g<-1>, the pore diameter is 14-25 nm, and the pore volume is 0.4-0.9 cm<3>.g<-1>.The hydrodesulfurization catalyst prepared with the Beta-FDU-12 composite molecular sieve as the carrier is outstanding in performance, the yield of FCC diesel oil can be higher than 99%, the denitrification percent can be higher than 98%, and the sulphur content is lower than 10 ppm.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

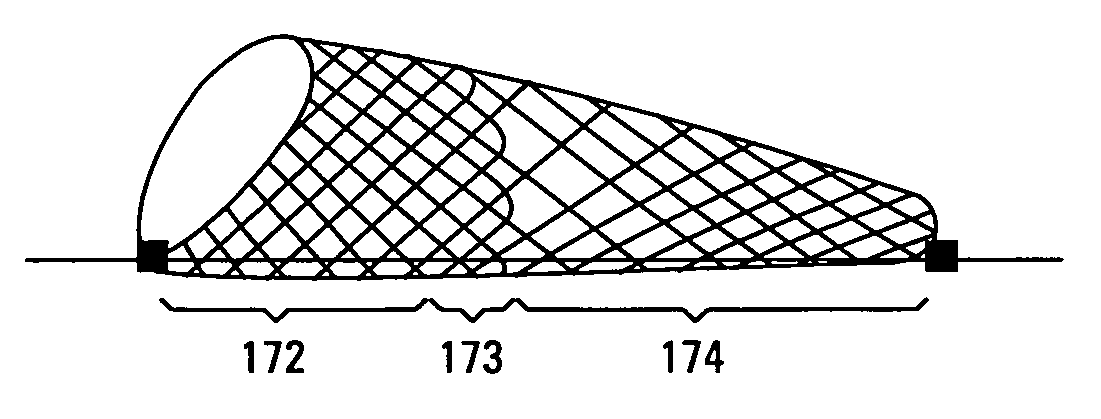

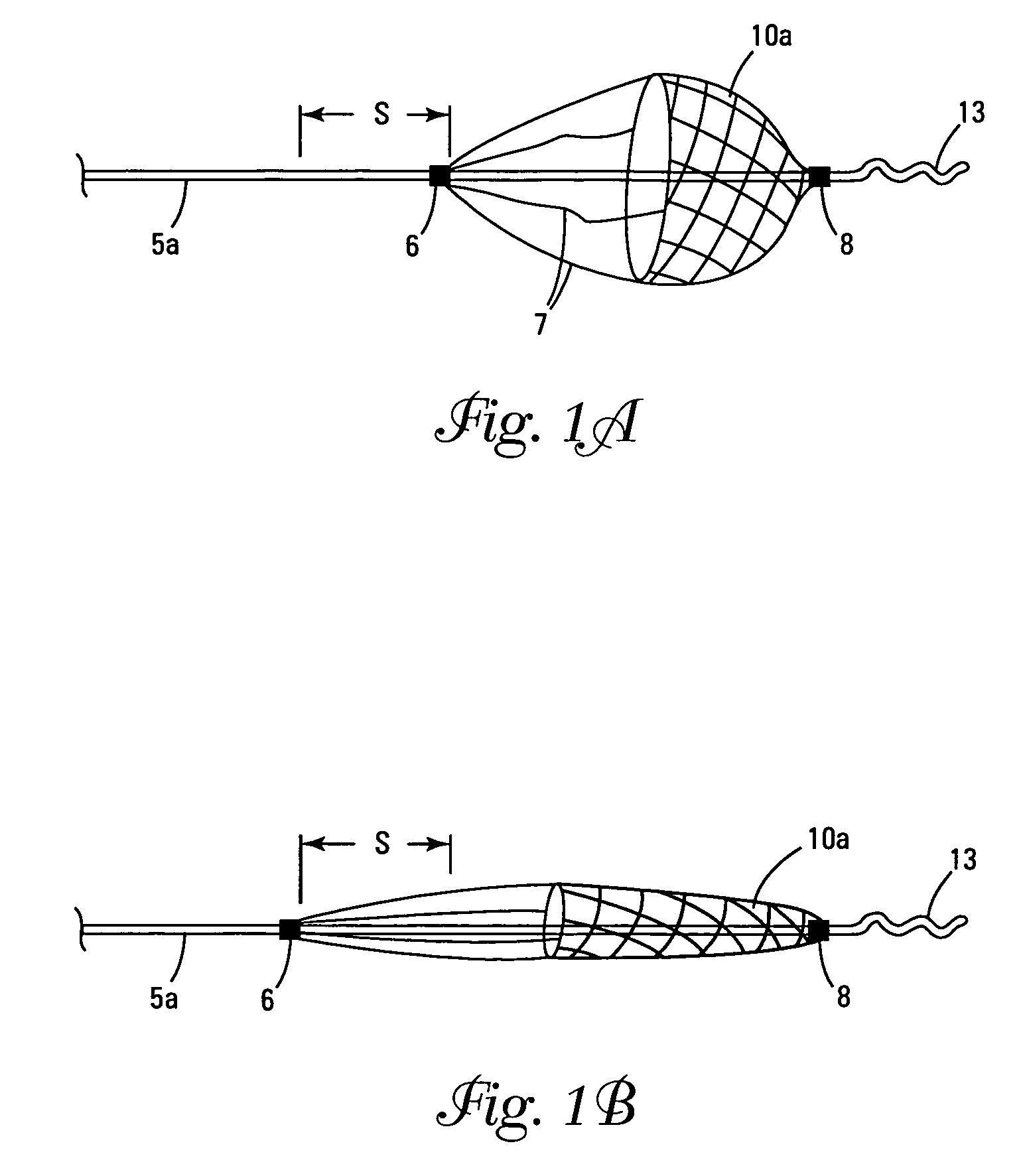

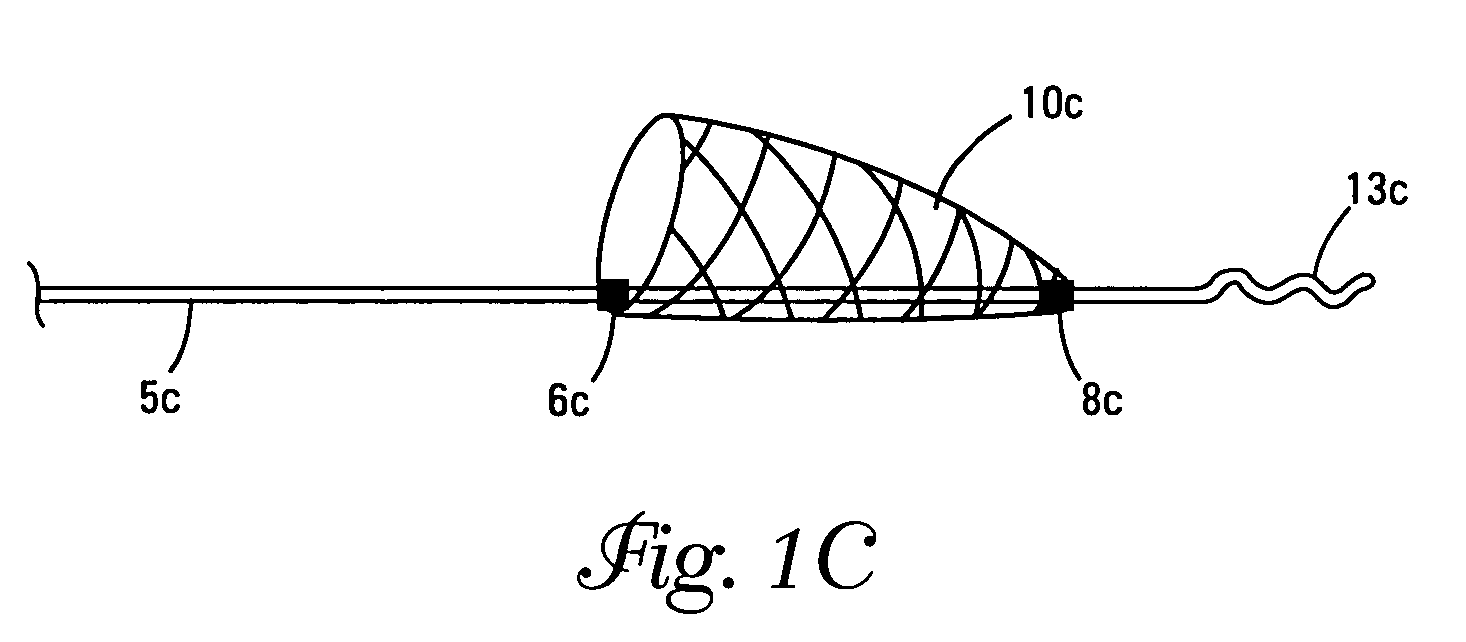

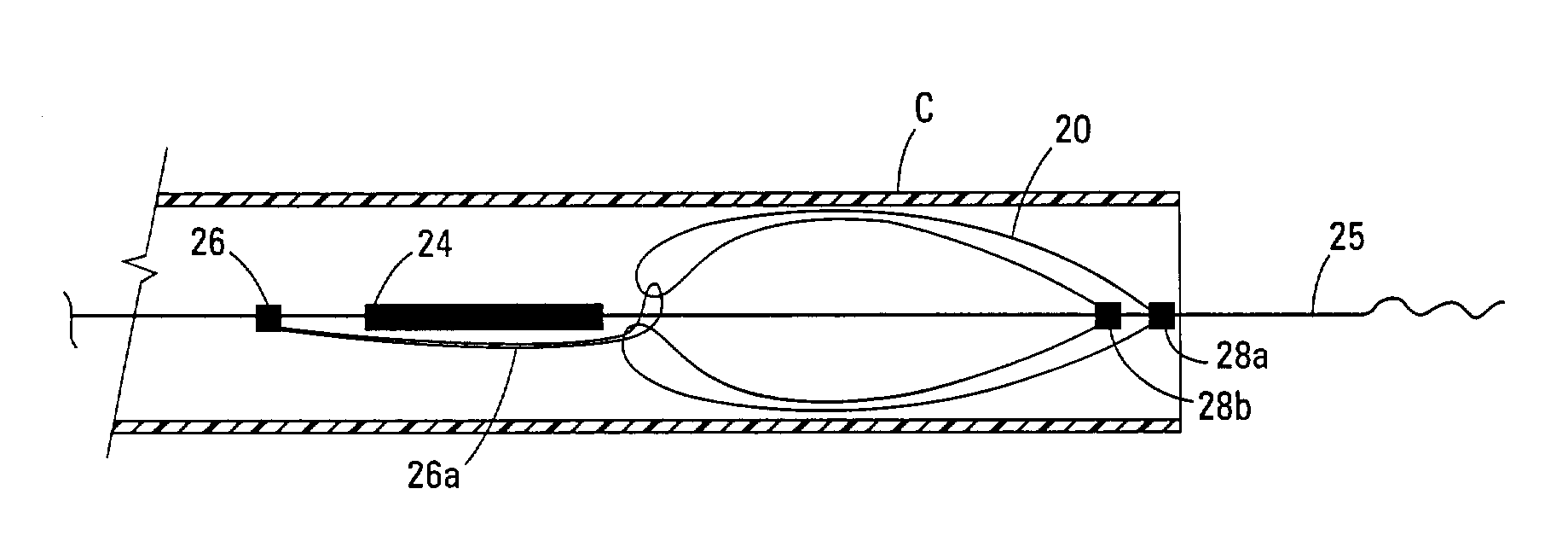

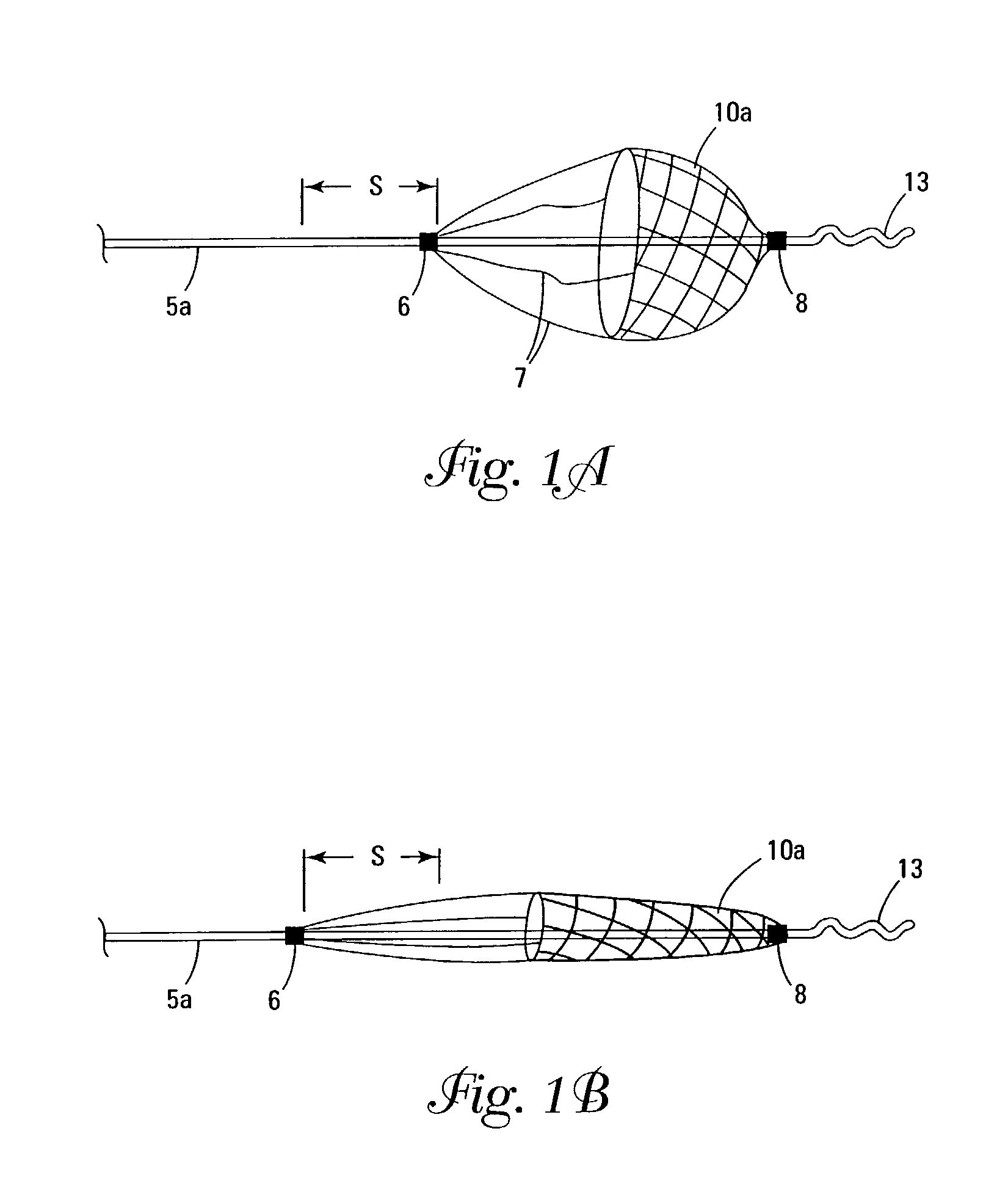

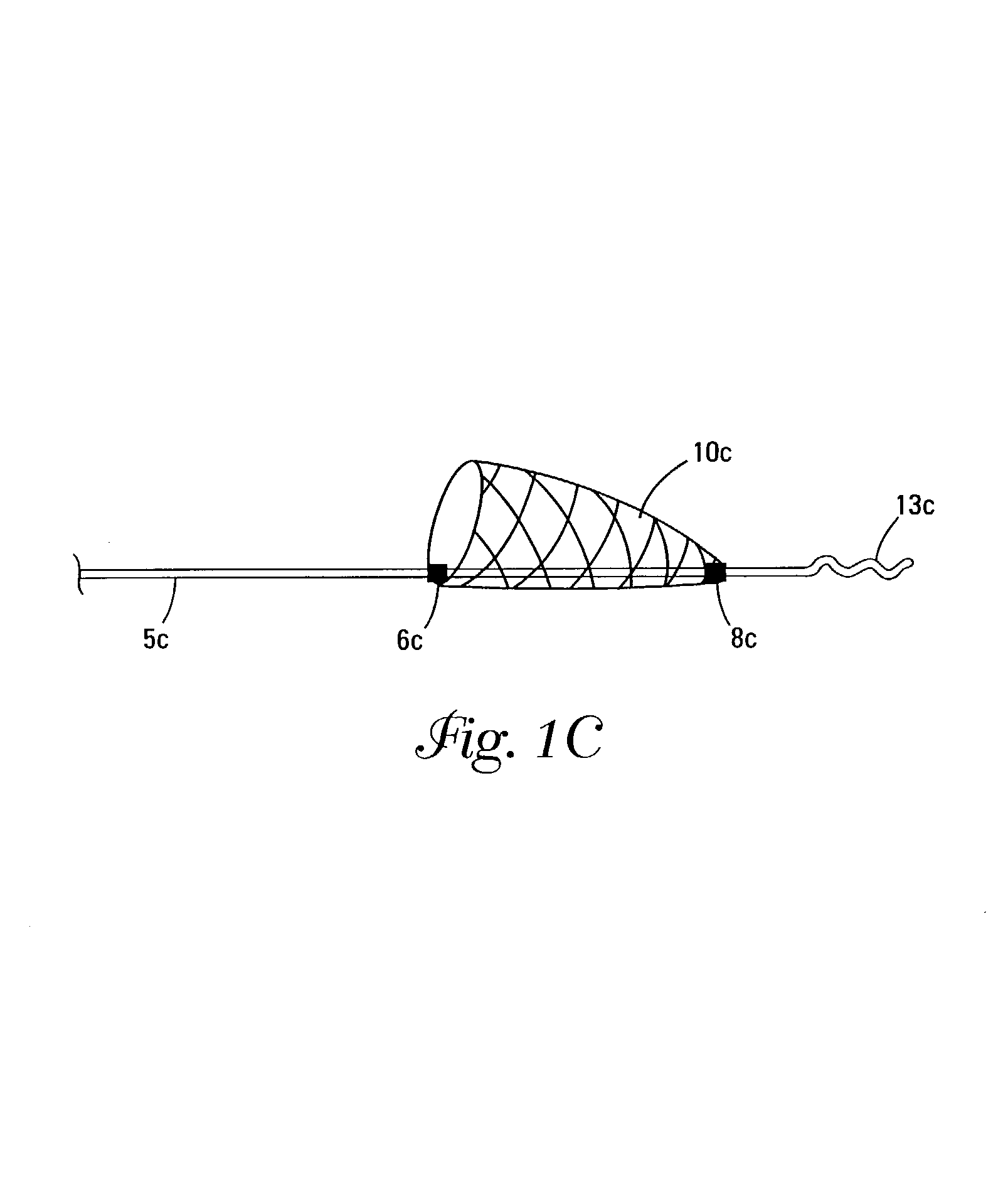

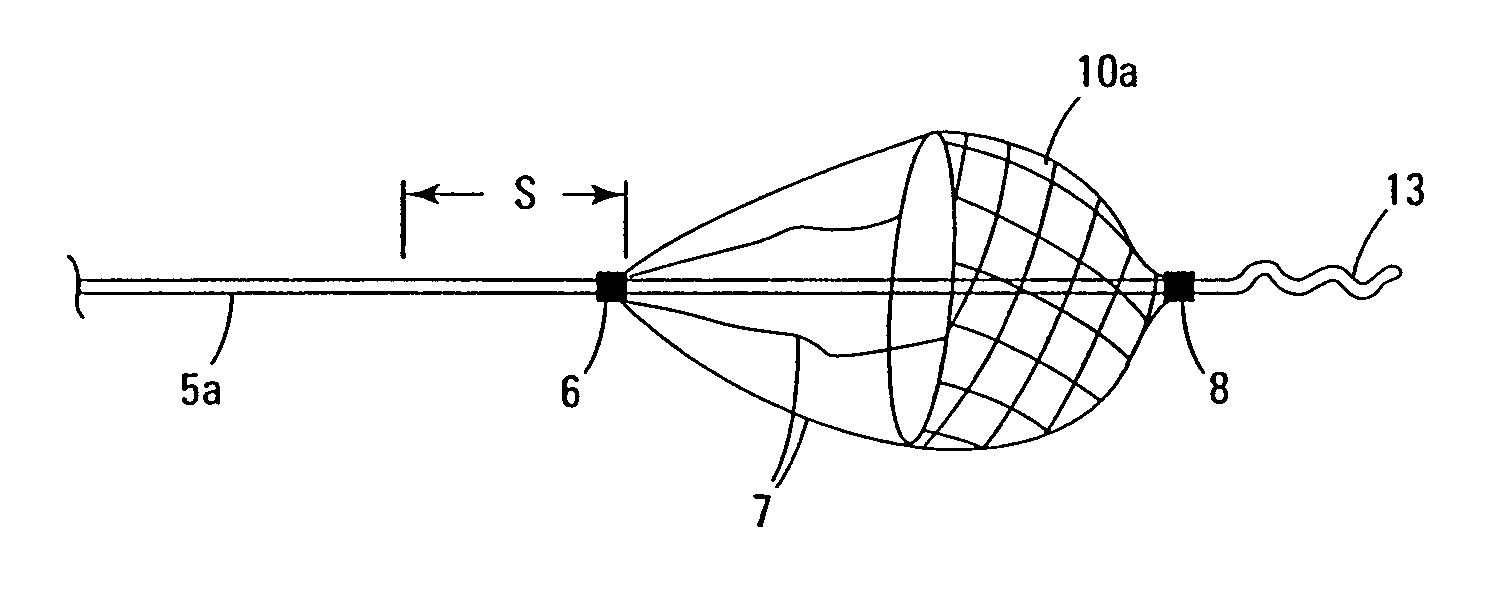

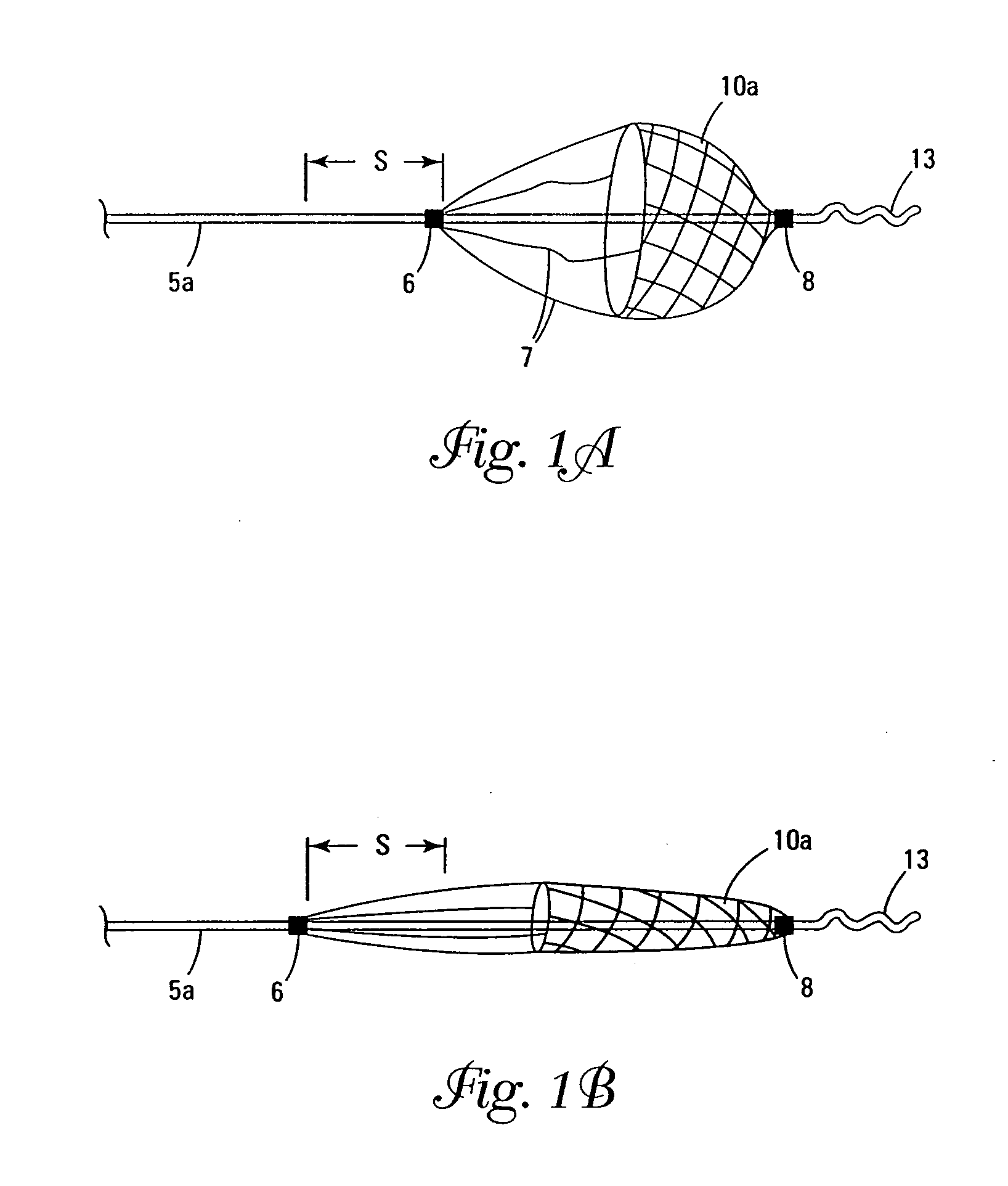

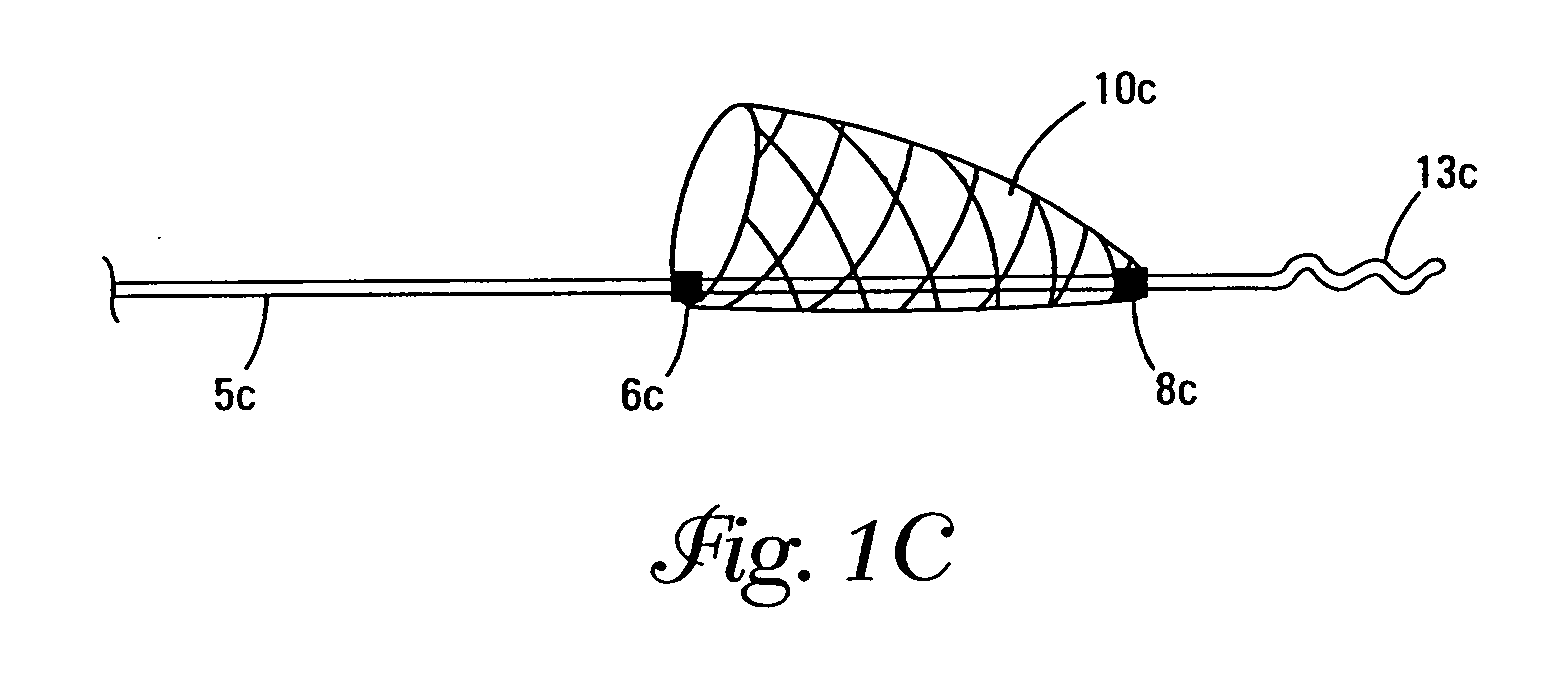

Embolic filters with controlled pore size

The invention provides a device for filtering emboli from blood flowing through a lumen defined by the walls of a vessel in a patient's body comprising a filter element. The filter is expandable from a collapsed configuration when the filter element is restrained to an expanded configuration when the filter element is unrestrained, and the filter element comprises a self-expanding material having pores. When the filter element is in the expanded configuration, the average pore size is from 30 to 300 microns and the standard deviation of the pore size is less than 20 percent of the average pore size.

Owner:COVIDIEN LP

Embolic filters having multiple layers and controlled pore size

The invention provides a device for filtering emboli from blood flowing through a lumen defined by the walls of a vessel in a patient's body comprising a filter element. The filter element is expandable from a collapsed configuration when the filter element is restrained to an expanded configuration when the filter element is unrestrained. When the filter element is in the expanded configuration, the average pore size is from 30 to 300 microns and the standard deviation of the pore size is less than 20 percent of the average pore size. The filter element has two or more filtering layers, each filtering layer having pores, each filtering layer being adjacent to at least one other filtering layer, and at least one of the filtering layers being made of a self-expanding material.

Owner:TYCO HEALTHCARE GRP LP

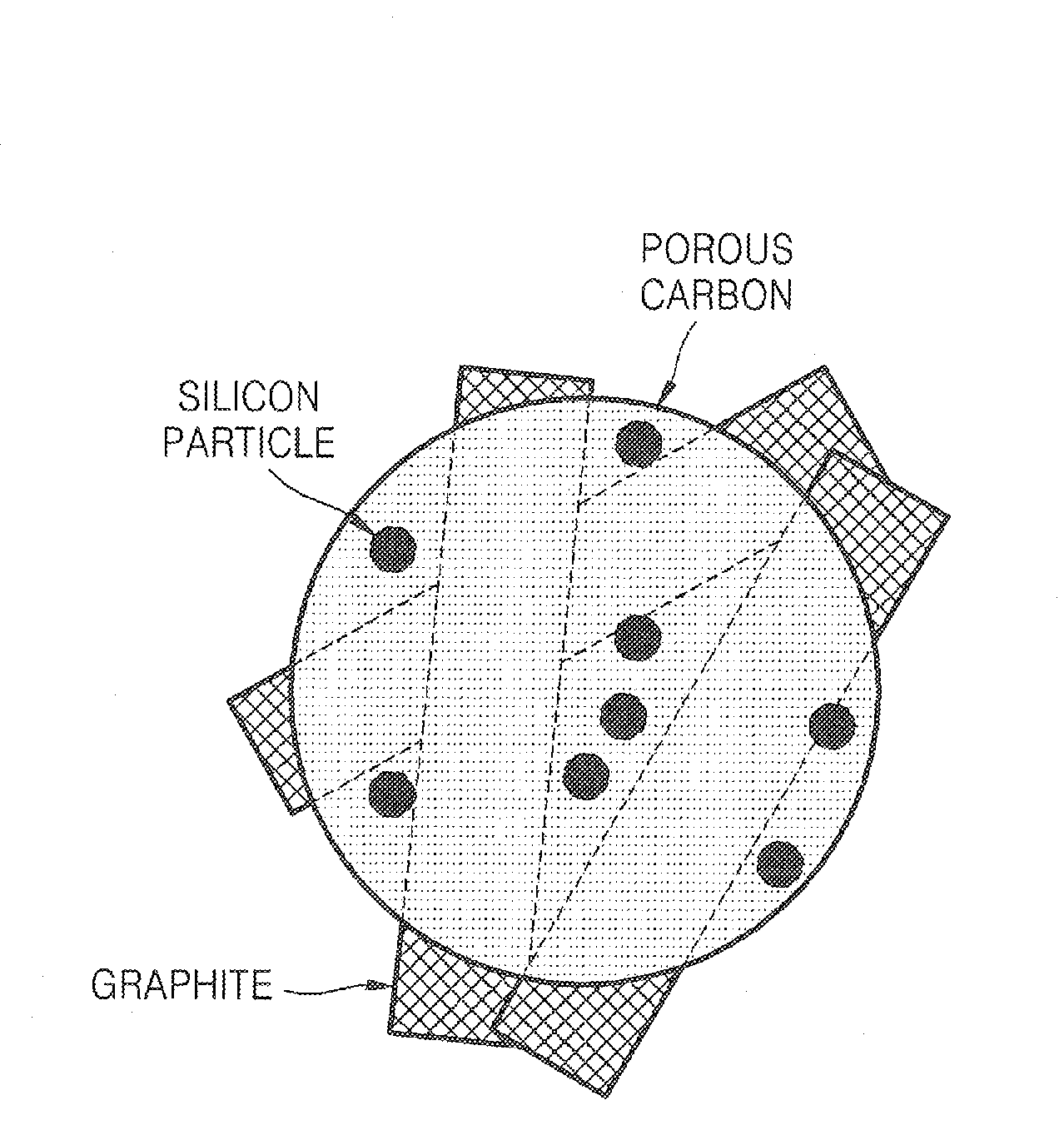

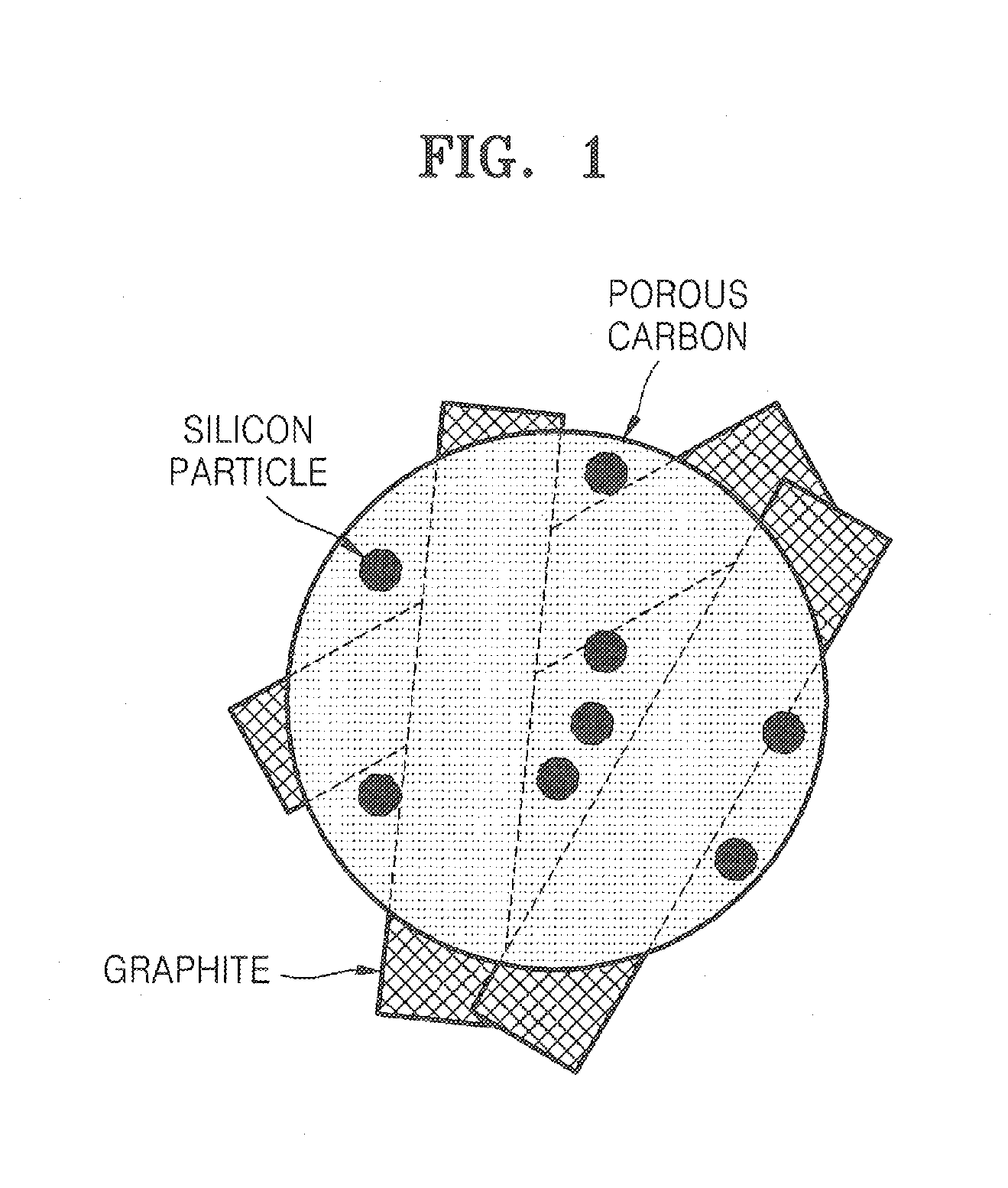

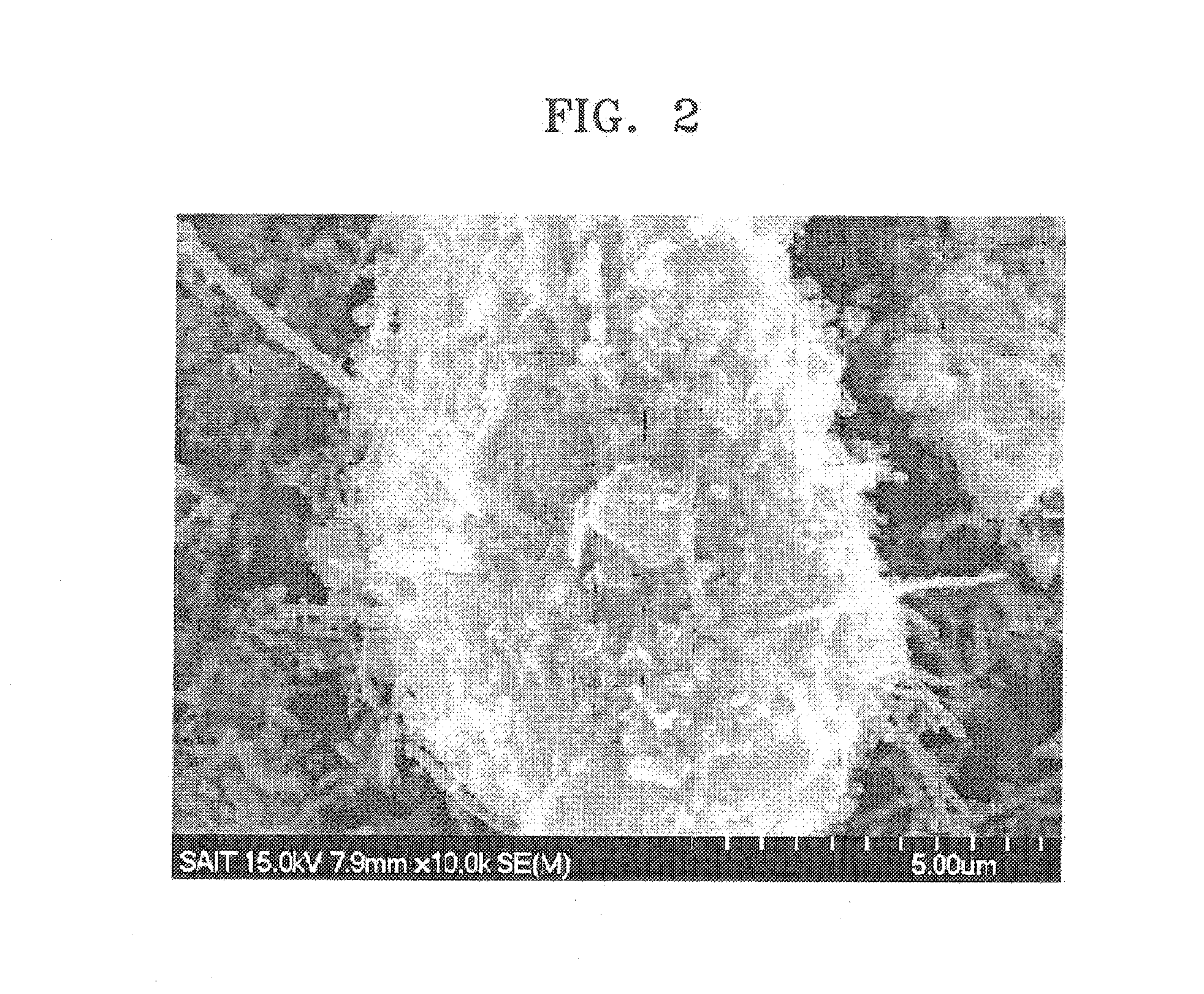

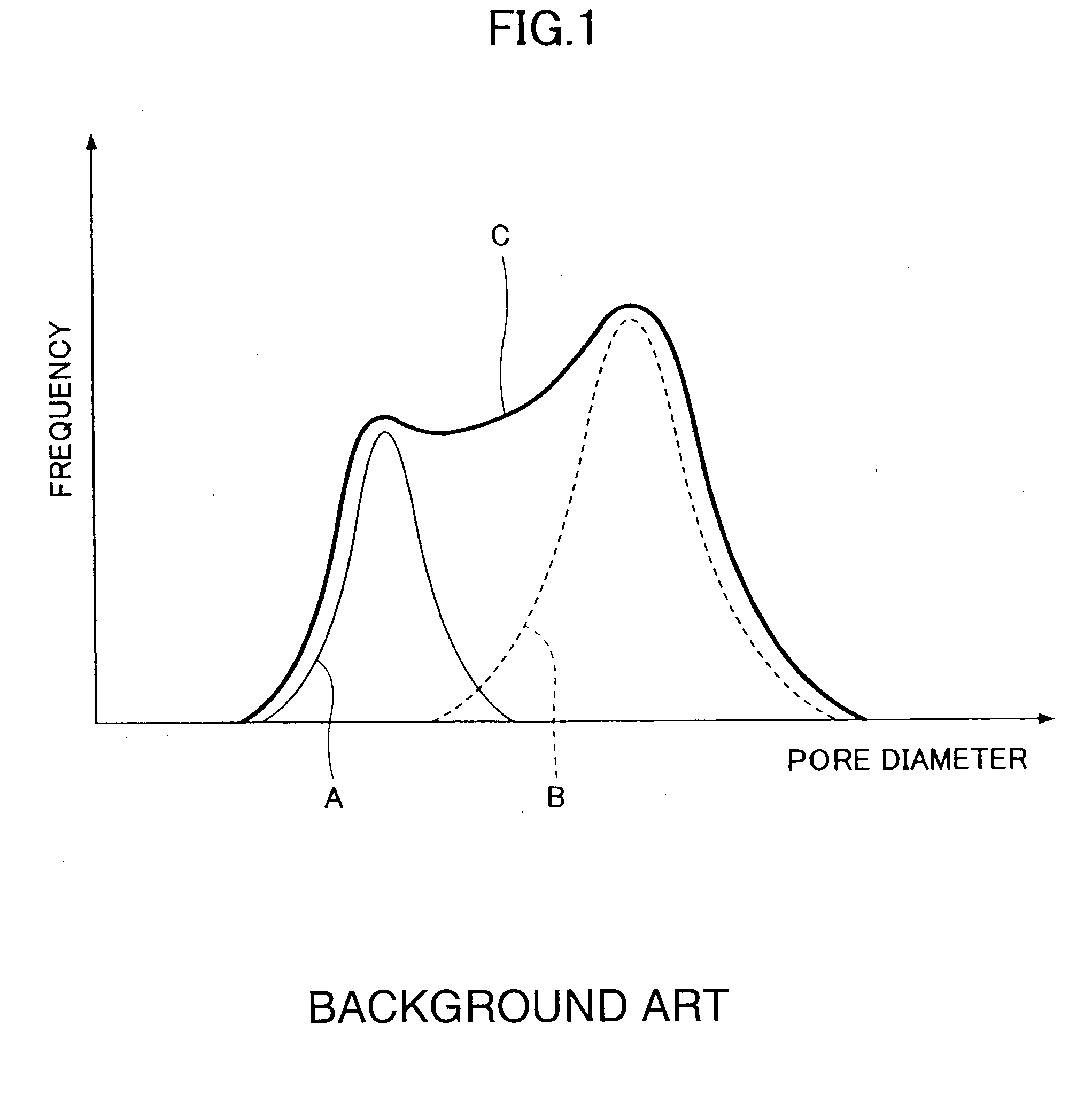

Porous anode active material, method of preparing the same, and anode and lithium battery employing the same

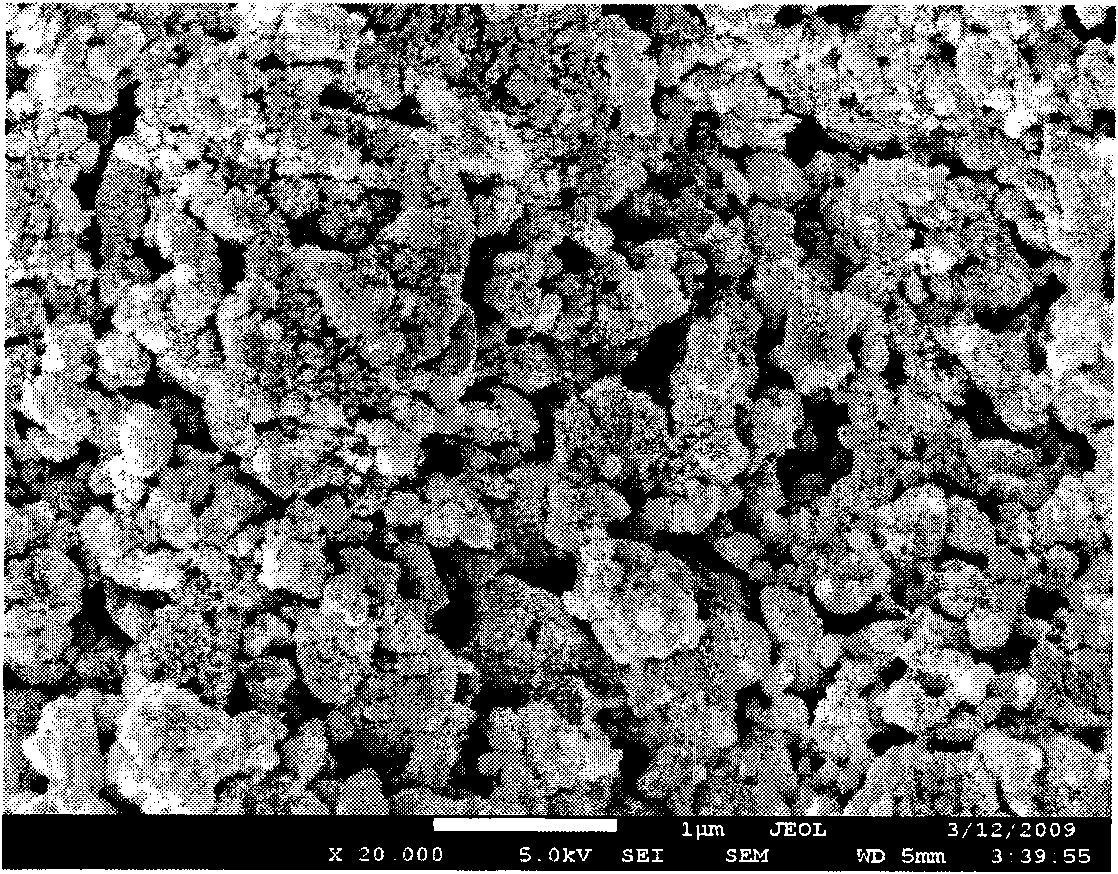

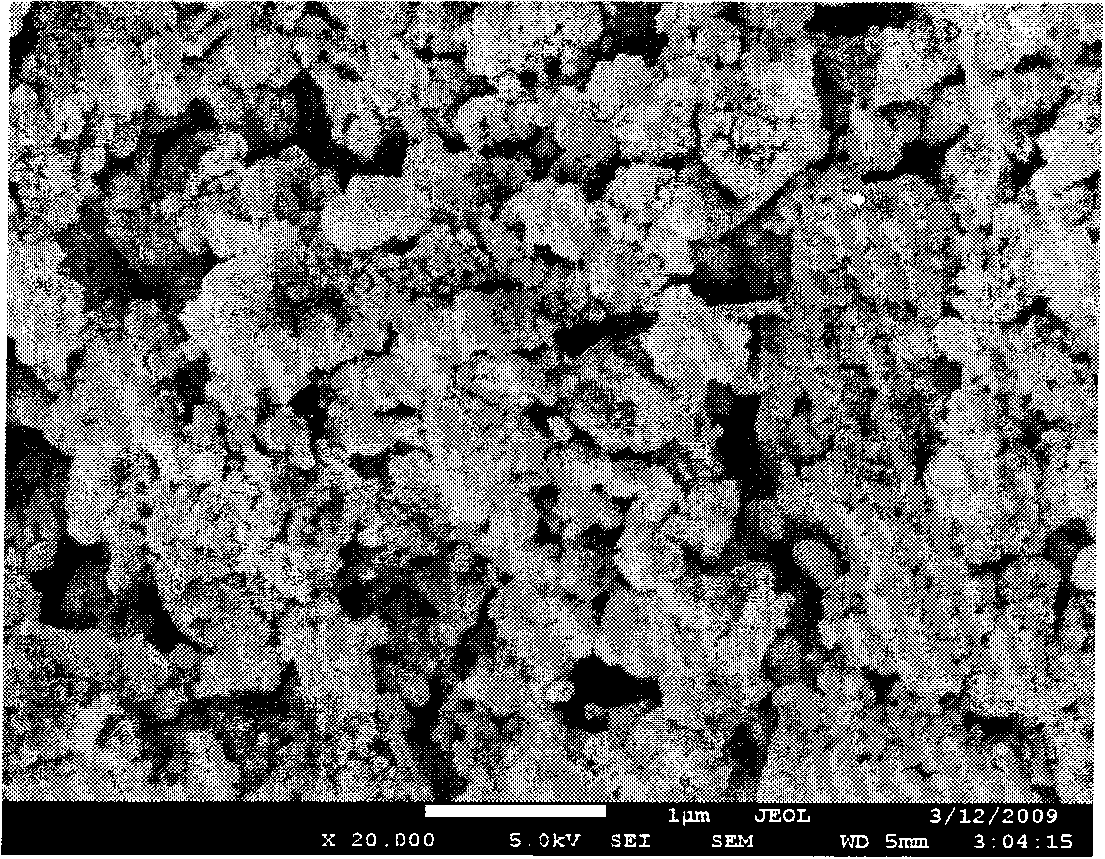

ActiveUS20080145757A1Efficiently remove stressExcellent charge and discharge characteristicsSilver accumulatorsMaterial nanotechnologyAlloyPore diameter

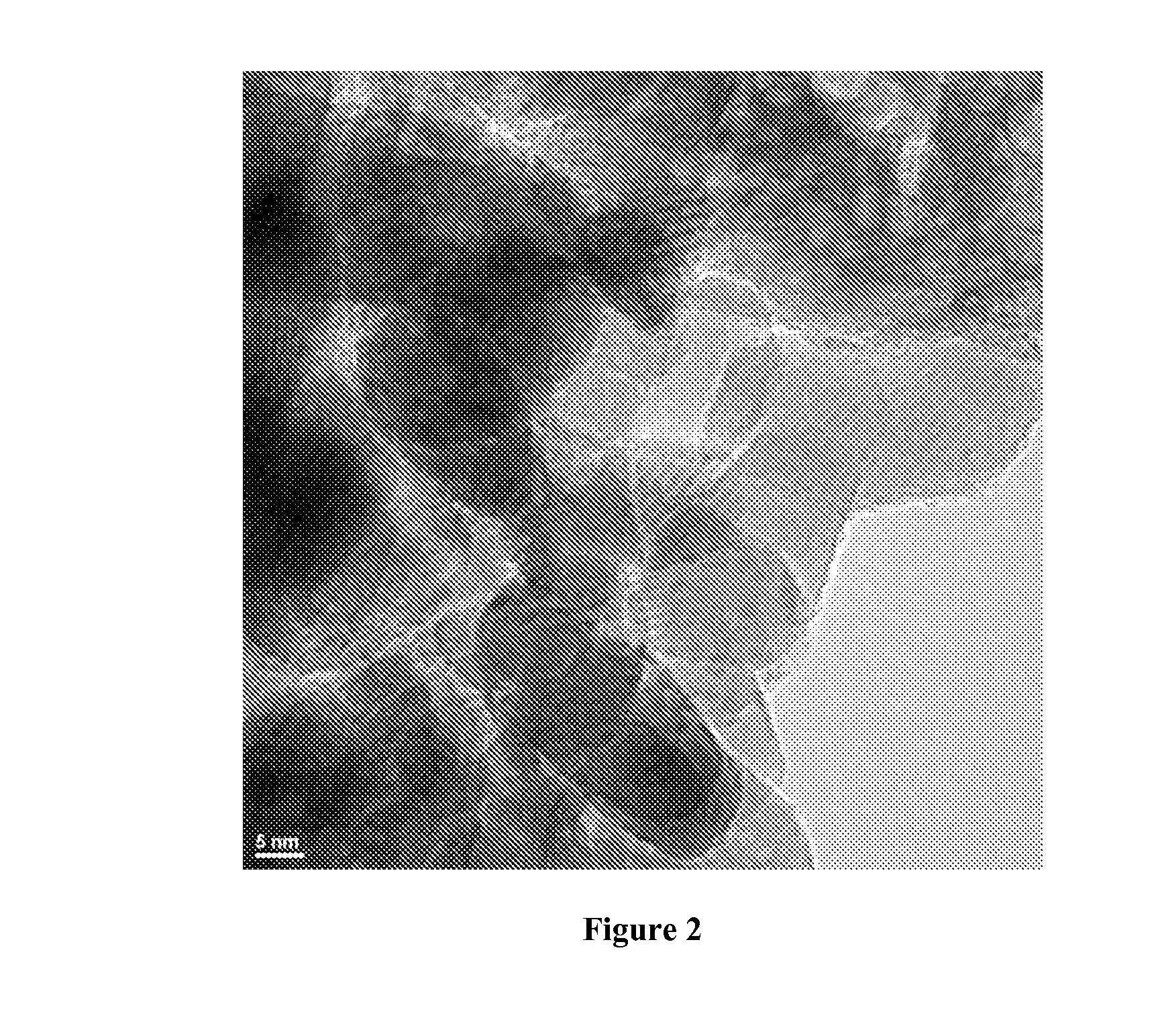

Provided are a porous anode active material, a method of preparing the same, and an anode and a lithium battery employing the same. The porous anode active material includes fine particles of metallic substance capable of forming a lithium alloy; a crystalline carboneous substance; and a porous carboneous material coating and attaching to the fine particles of metallic substance and the crystalline carboneous substance, the porous anode active material having pores exhibiting a bimodal size distribution with two pore diameter peaks as measured by a Barrett-Joyner-Halenda (BJH) pore size distribution from a nitrogen adsorption. The porous anode active material has the pores having a bimodal size distribution, and thus may efficiently remove a stress occurring due to a difference of expansion between a carboneous material and a metallic active material during charging and discharging. Further, the anode electrode and the lithium battery comprising the anode active material have excellent charge / discharge characteristics.

Owner:SAMSUNG SDI CO LTD

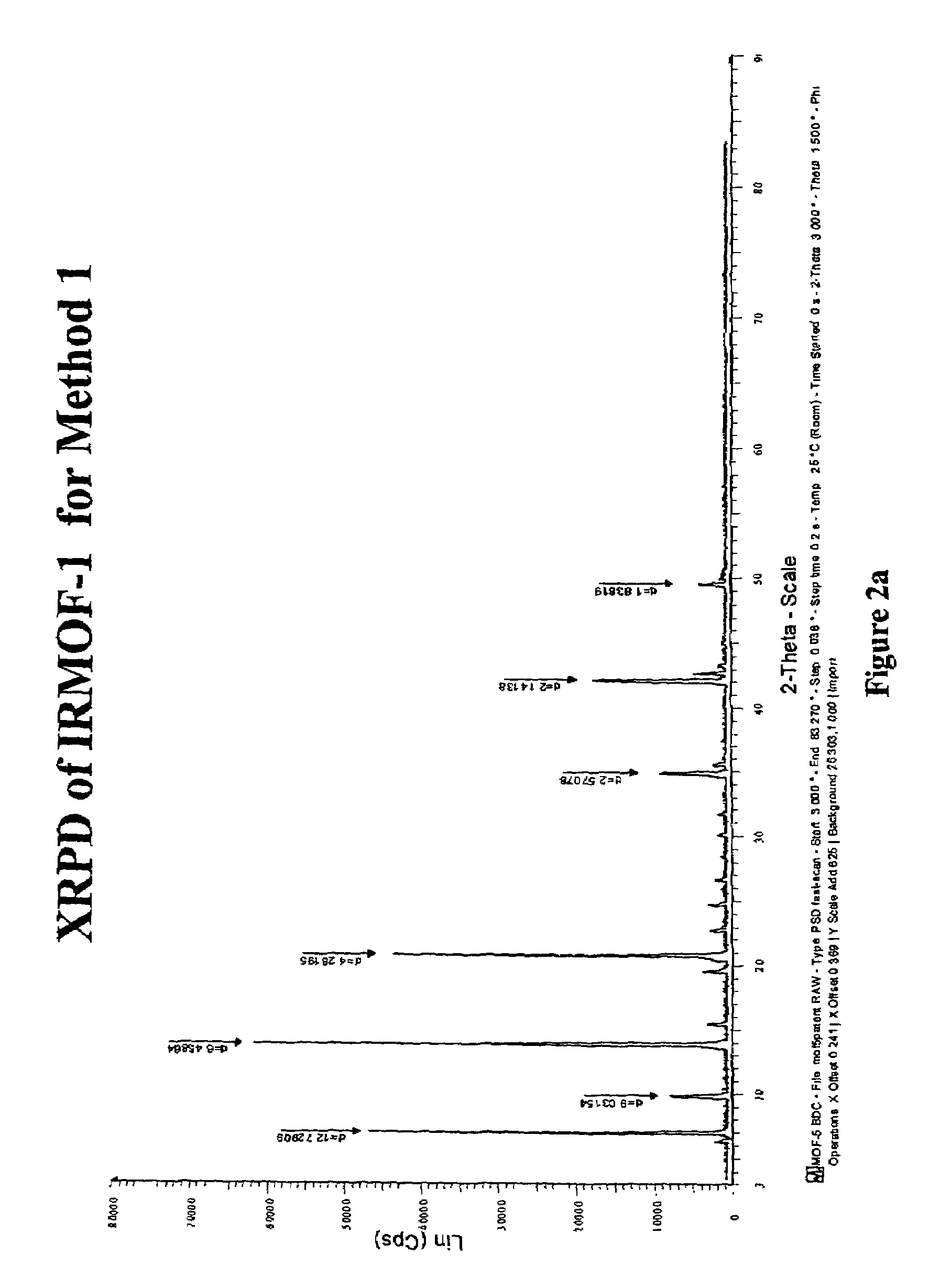

Isoreticular metal-organic frameworks, process for forming the same, and systematic design of pore size and functionality therein, with application for gas storage

InactiveUS7196210B2Group 8/9/10/18 element organic compoundsGroup 5/15 element organic compoundsSystems designMetal-organic framework

The ability to design and construct solid-state materials with pre-determined structures is a grand challenge in chemistry. An inventive strategy based on reticulating metal ions and organic carboxylate links into extended networks has been advanced to a point that has allowed the design of porous structures in which pore size and functionality can be varied systematically. MOF-5, a prototype of a new class of porous materials and one that is constructed from octahedral Zn—O—C clusters and benzene links, was used to demonstrate that its 3-D porous system can be functionalized with the organic groups, —Br, —NH2, —OC3H7, —OC5H11, —H4C2, and —H4C4, and its pore size expanded with the long molecular struts biphenyl, tetrahydropyrene, pyrene, and terphenyl. The ability to direct the formation of the octahedral clusters in the presence of a desired carboxylate link is an essential feature of this strategy, which resulted in the design of an isoreticular (having the same framework topology) series of sixteen well-defined materials whose crystals have open space representing up to 91.1% of the crystal volume, and homogeneous periodic pores that can be incrementally varied from 3.8 to 28.8 angstroms. Unlike the unpredictable nature of zeolite and other molecular sieve syntheses, the deliberate control exercised at the molecular level in the design of these crystals is expected to have tremendous implications on materials properties and future technologies. Indeed, data indicate that members of this series represent the first monocrystalline mesoporous organic / inorganic frameworks, and exhibit the highest capacity for methane storage (155 cm3 / cm3 at 36 atm) and the lowest densities (0.41 to 0.21 g / cm3) attained to date for any crystalline material at room temperature.

Owner:RGT UNIV OF MICHIGAN

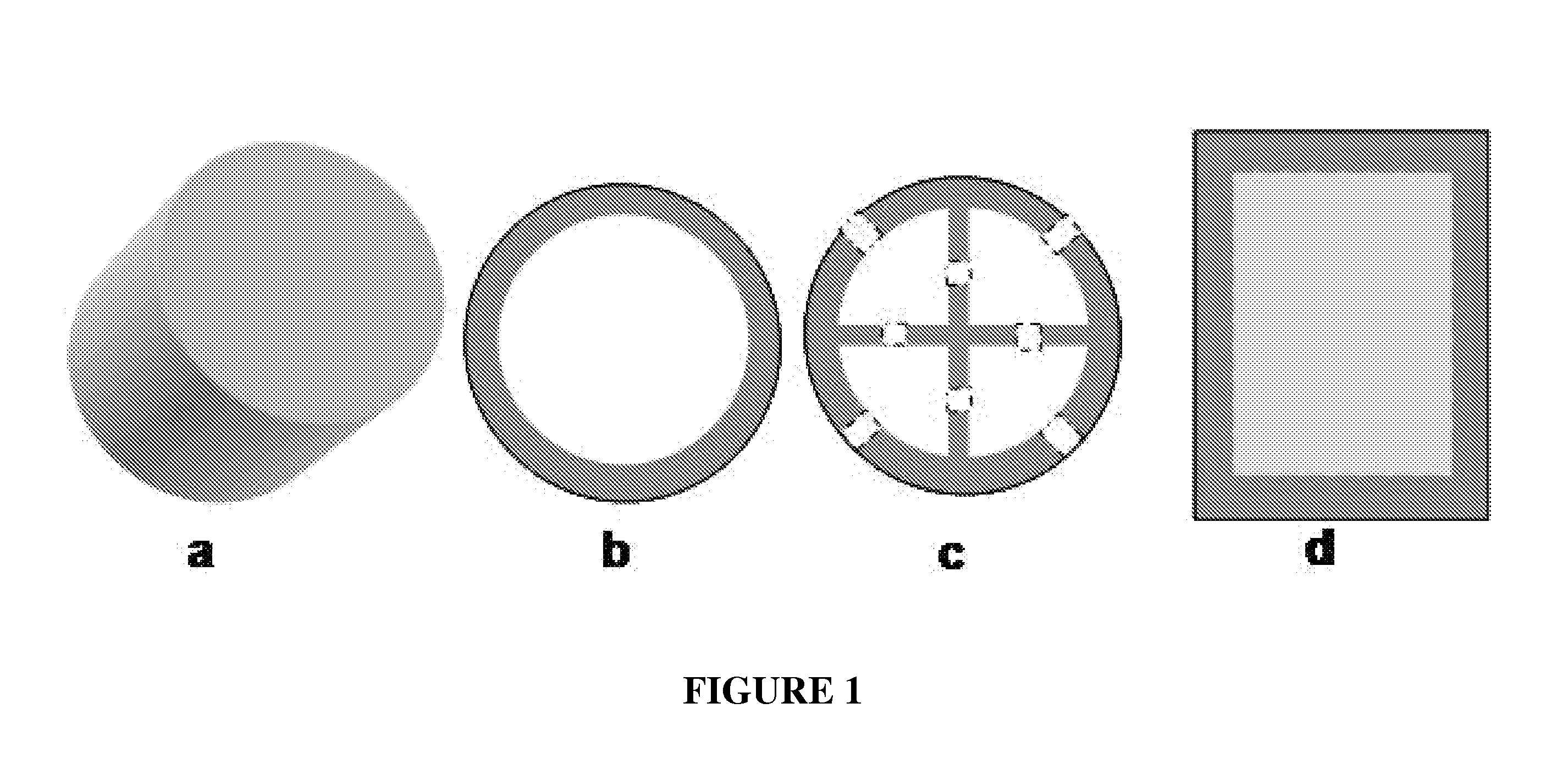

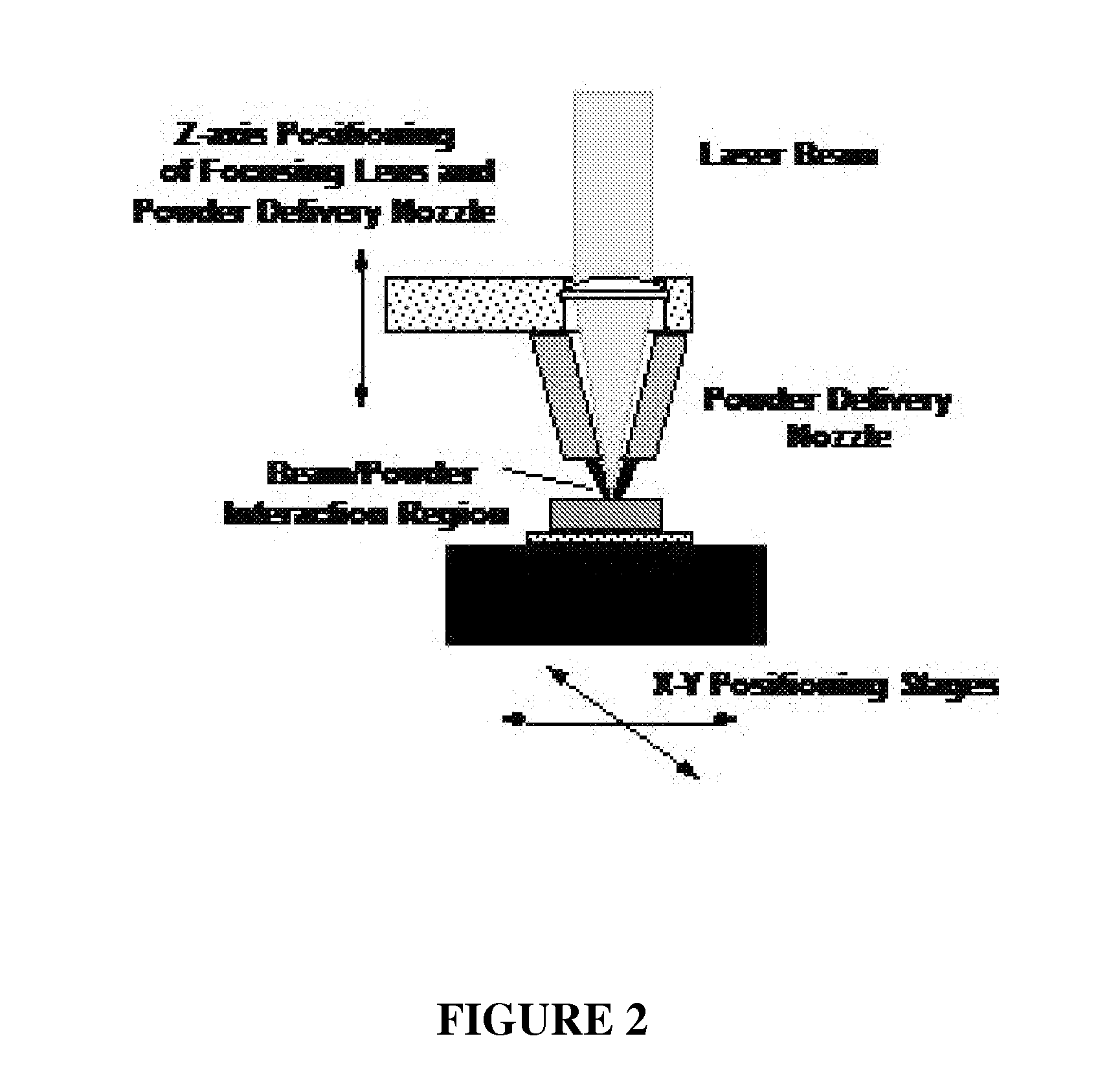

Bone replacement materials

ActiveUS20070203584A1Easy adhesionFacilitate cell growthAdditive manufacturing apparatusBone implantBone tissueBone tissue engineering

Particular aspects provide novel devices for bone tissue engineering, comprising a metal or metal-based composite member / material comprising an interior macroporous structure in which porosity may vary from 0-90% (v), the member comprising a surface region having a surface pore size, porosity, and composition designed to encourage cell growth and adhesion thereon, to provide a device suitable for bone tissue engineering in a recipient subject. In certain aspects, the device further comprises a gradient of pore size, porosity, and material composition extending from the surface region throughout the interior of the device, wherein the gradient transition is continuous, discontinuous or seamless and the growth of cells extending from the surface region inward is promoted. Additional aspects provide a device for bone tissue engineering, comprising a metal or metal-based composite member / material comprising an interior porous structure, wherein the pore size, porosity and material composition is selected to provide a device having an optimal density and / or elastic modulus and / or compression strength for a specific recipient. Novel methods for fabricating the devices are also provided.

Owner:WASHINGTON STATE UNIVERSITY

Embolic filters having multiple layers and controlled pore size

The invention provides a device for filtering emboli from blood flowing through a lumen defined by the walls of a vessel in a patient's body comprising a filter element. The filter element is expandable from a collapsed configuration when the filter element is restrained to an expanded configuration when the filter element is unrestrained. When the filter element is in the expanded configuration, the average pore size is from 30 to 300 microns and the standard deviation of the pore size is less than 20 percent of the average pore size. The filter element has two or more filtering layers, each filtering layer having pores, each filtering layer being adjacent to at least one other filtering layer, and at least one of the filtering layers being made of a self-expanding material.

Owner:COVIDIEN LP

Method for preparing carbon material with rich mesopores and macropores

The invention relates to a method for preparing a carbon material with rich mesopores and macropores. Inorganic nano-particles are used as pore-forming template agent to be uniformly distributed in a carbon-contained organic precursor and then the carbon-contained organic precursor carries out high-temperature carbonization, template agent washing-out and drying to obtain a porous carbon material. The carbon material prepared by the method has the specific surface area of 50-1,900 m / g and a pore diameter mainly between 2-900 nm, can be conveniently adjusted by the size control of the selected nano-particles, removes a template without using high corrosive HF and has the advantages of simple method, convenient operation, free pore diameter adjustment and control in a mesopore and macropore range, and the like. The carbon material has a wide application prospect in fields of electrochemical energy accumulation, macromolecular adsorption, catalyst carriers, composite materials, and the like.

Owner:NO 63971 TROOPS PLA

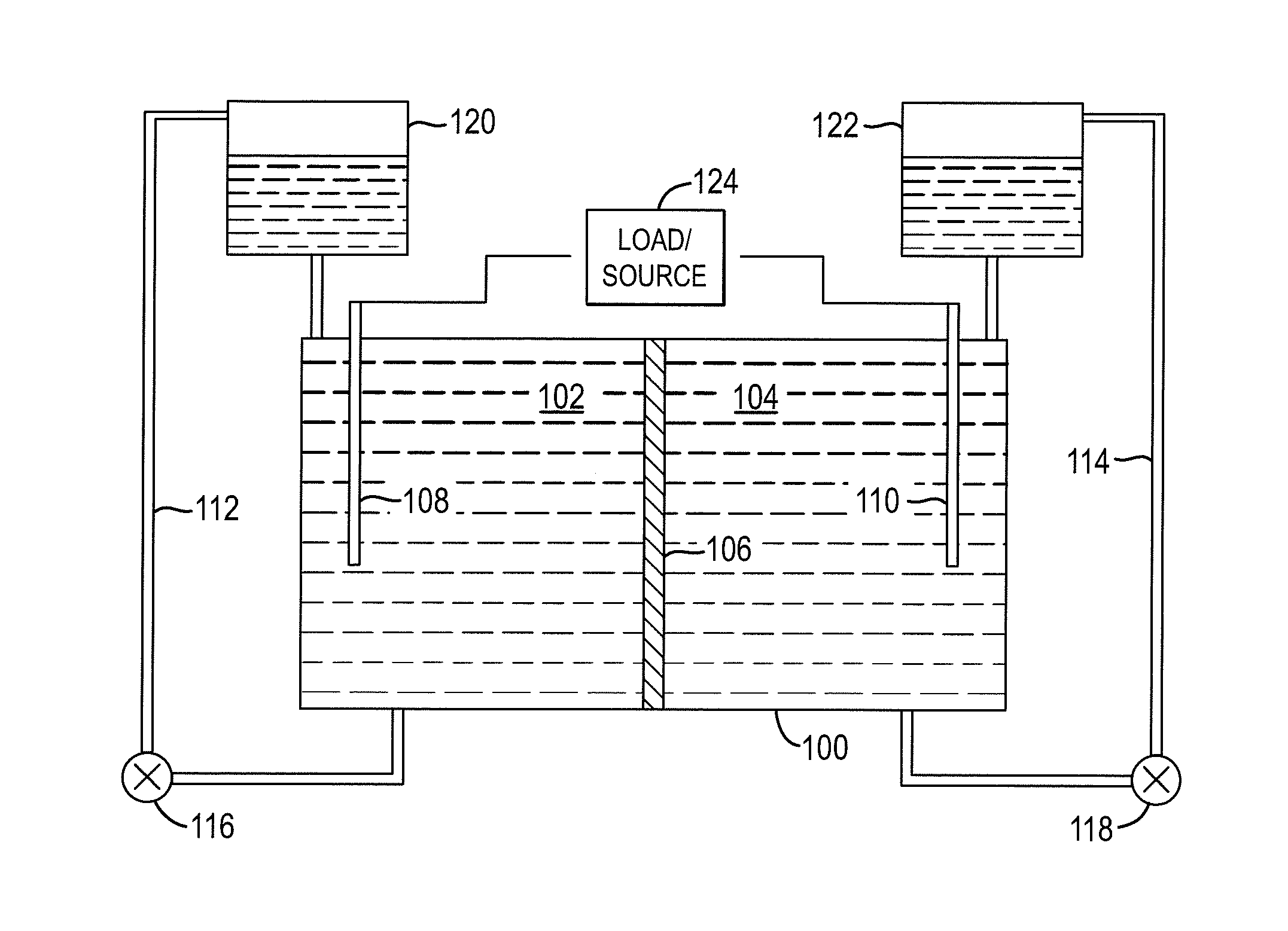

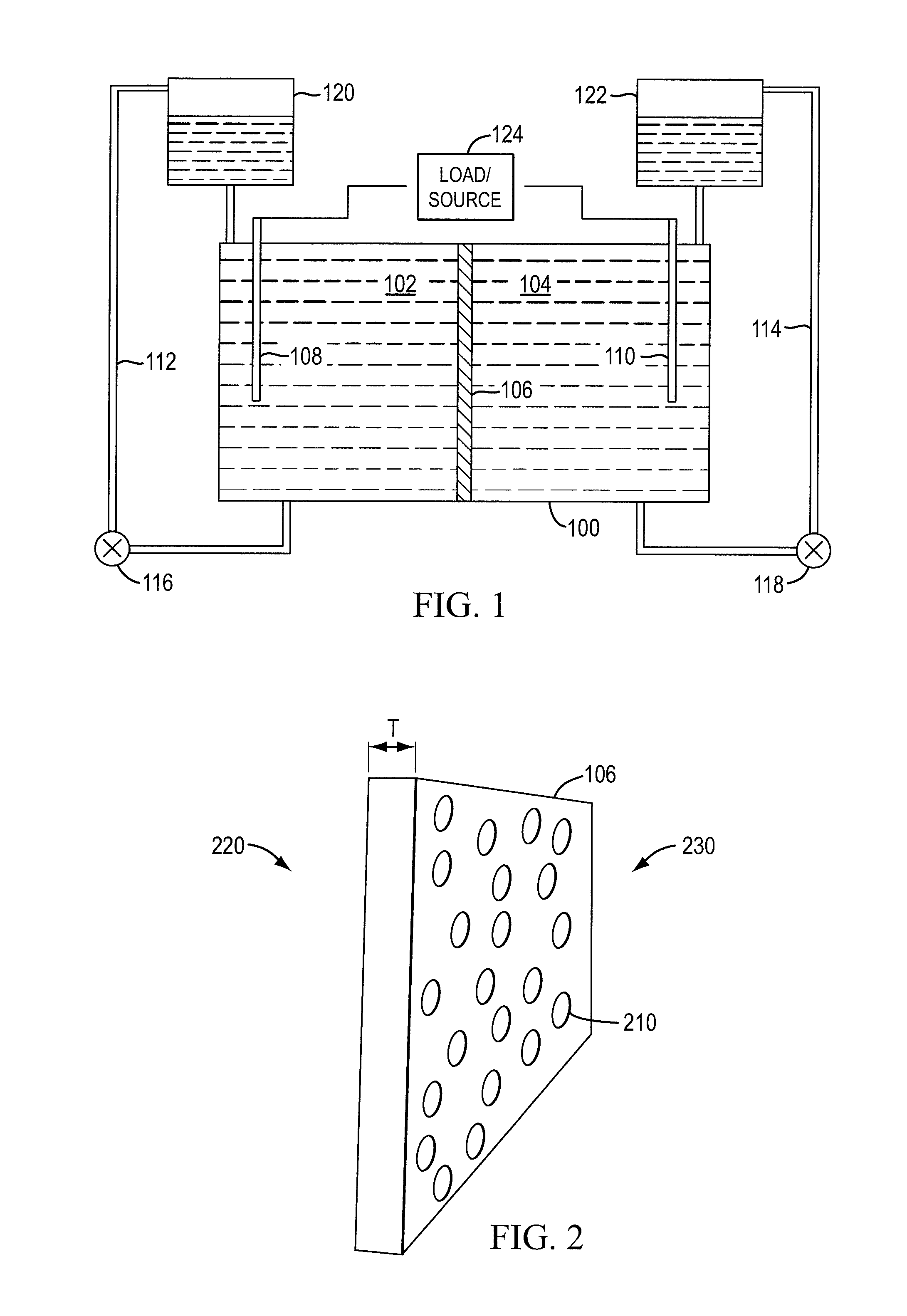

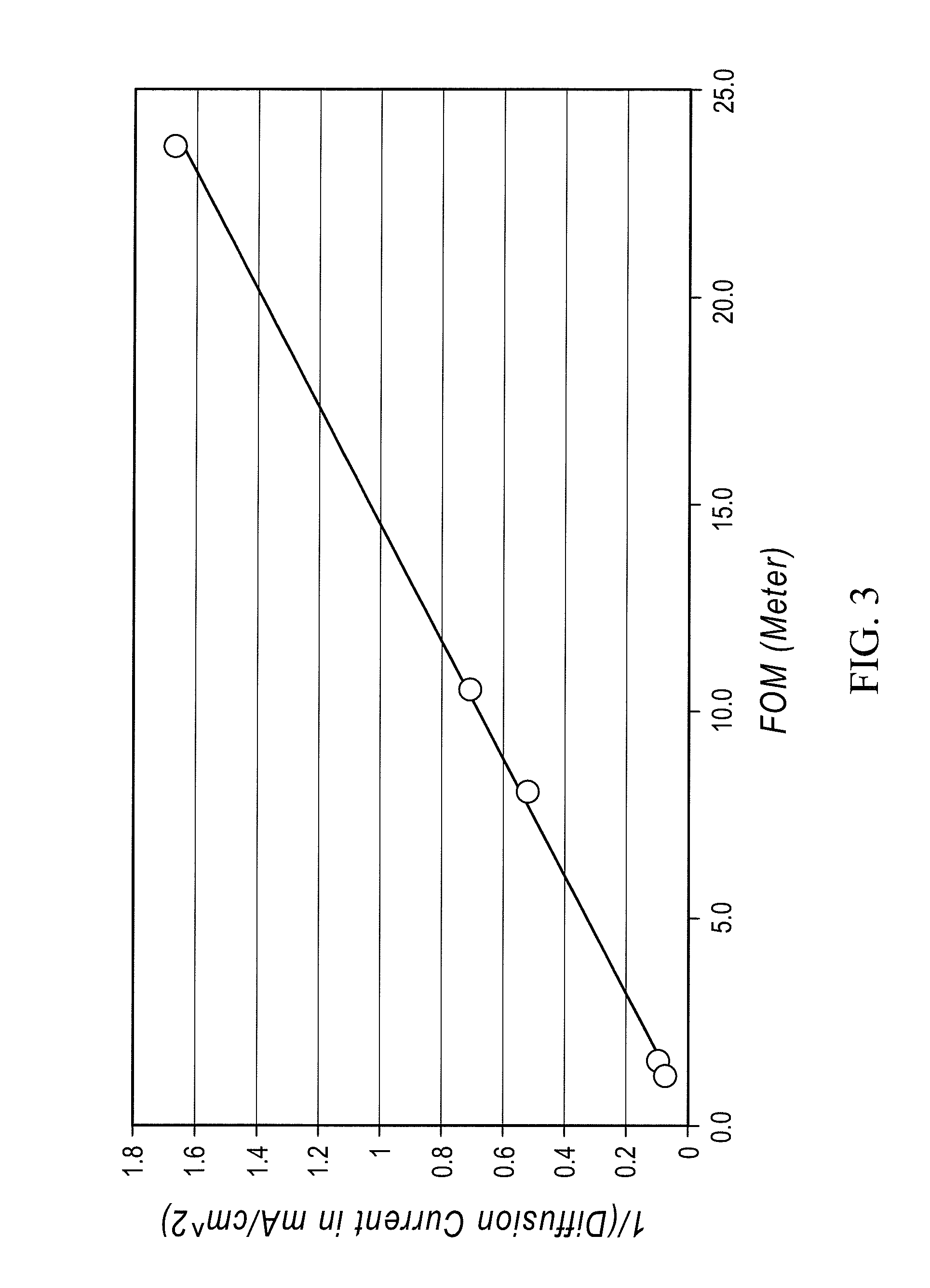

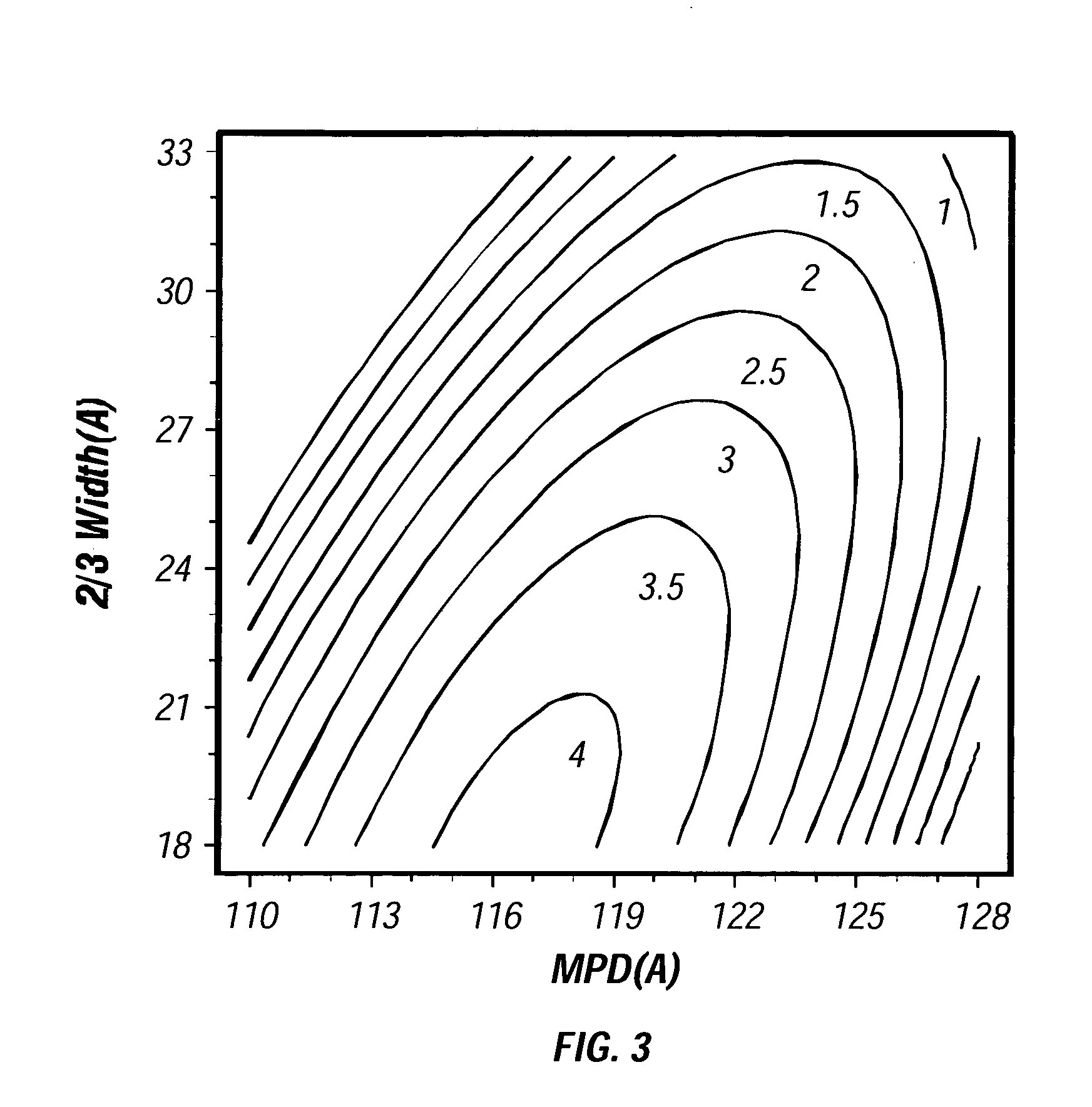

Redox flow cell

InactiveUS20100003586A1Facilitate ion exchangeCell electrodesFuel cell auxillariesFlow cellPorous membrane

A redox flow cell is presented that utilizes a porous membrane separating a first half cell and a second half cell. The porous membrane is chosen to have a figure of merit (FOM) is at least a minimum FOM. A method of providing a porous membrane for a flow cell can include determining a figure of merit; determining a first parameter from a pore size or a thickness for the porous membrane; determining a second parameter from the pore size or the thickness that is not the first parameter for the porous membrane, based on the figure of merit; and constructing a porous membrane having the pore size and the thickness.

Owner:IMERGY POWER SYST

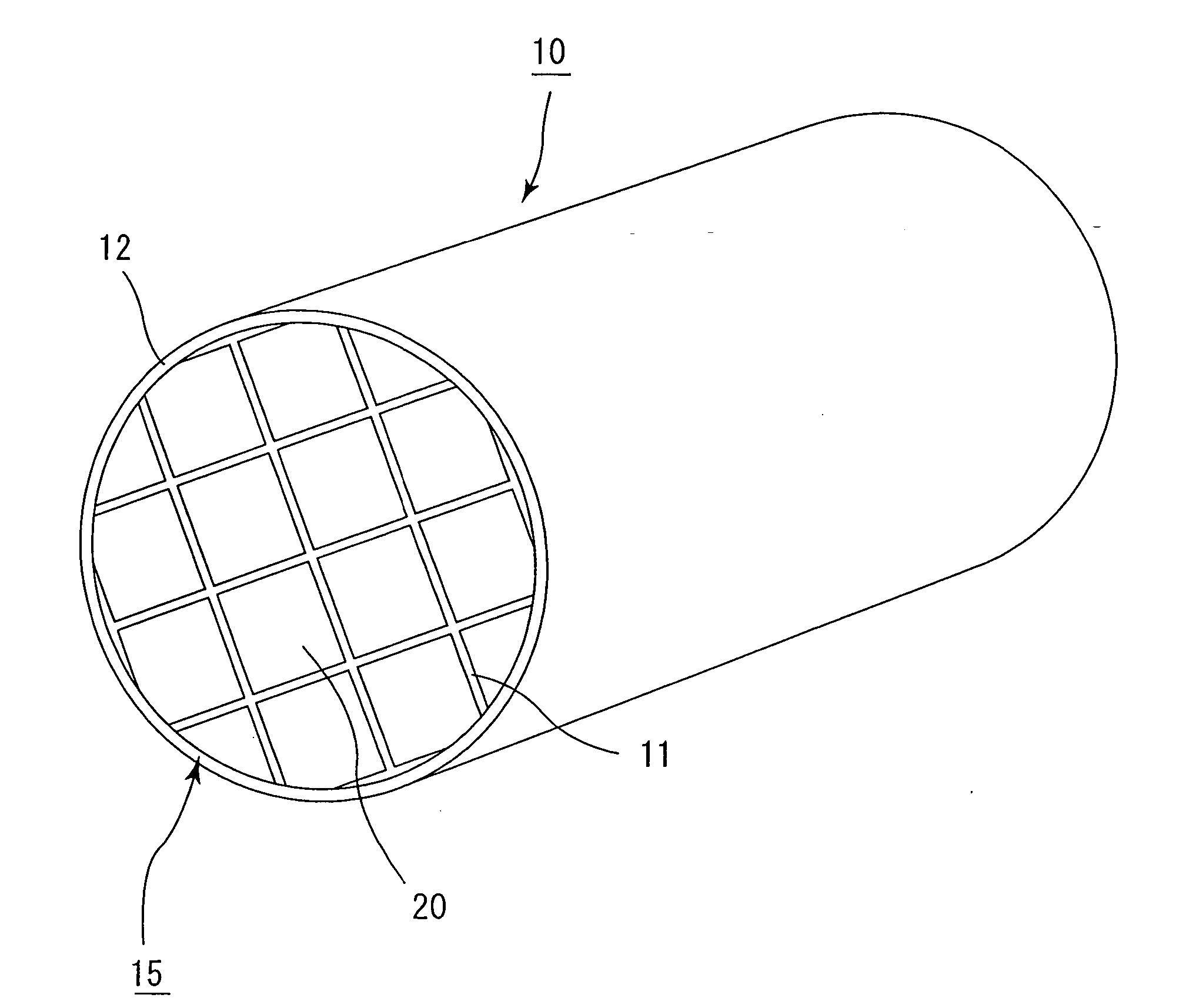

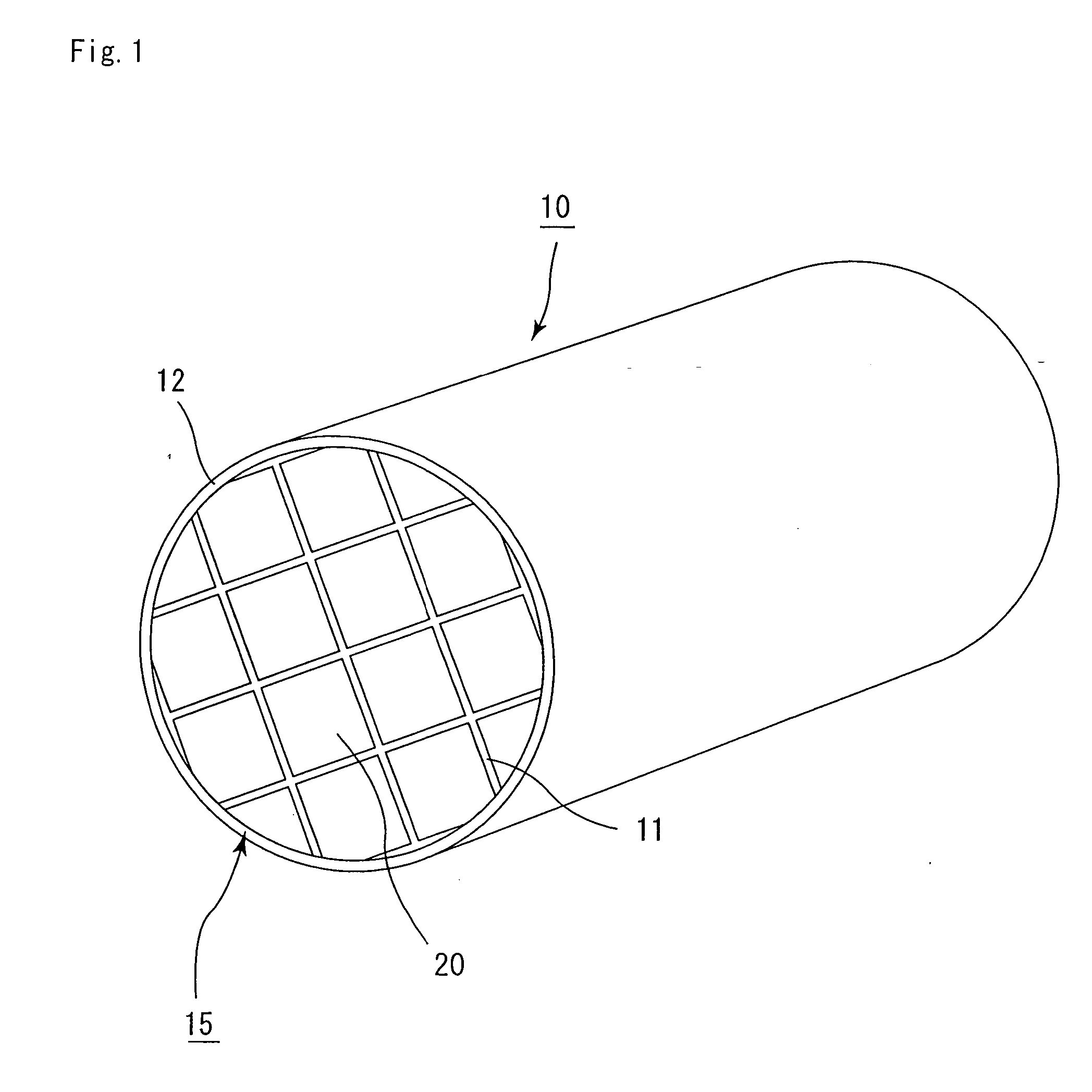

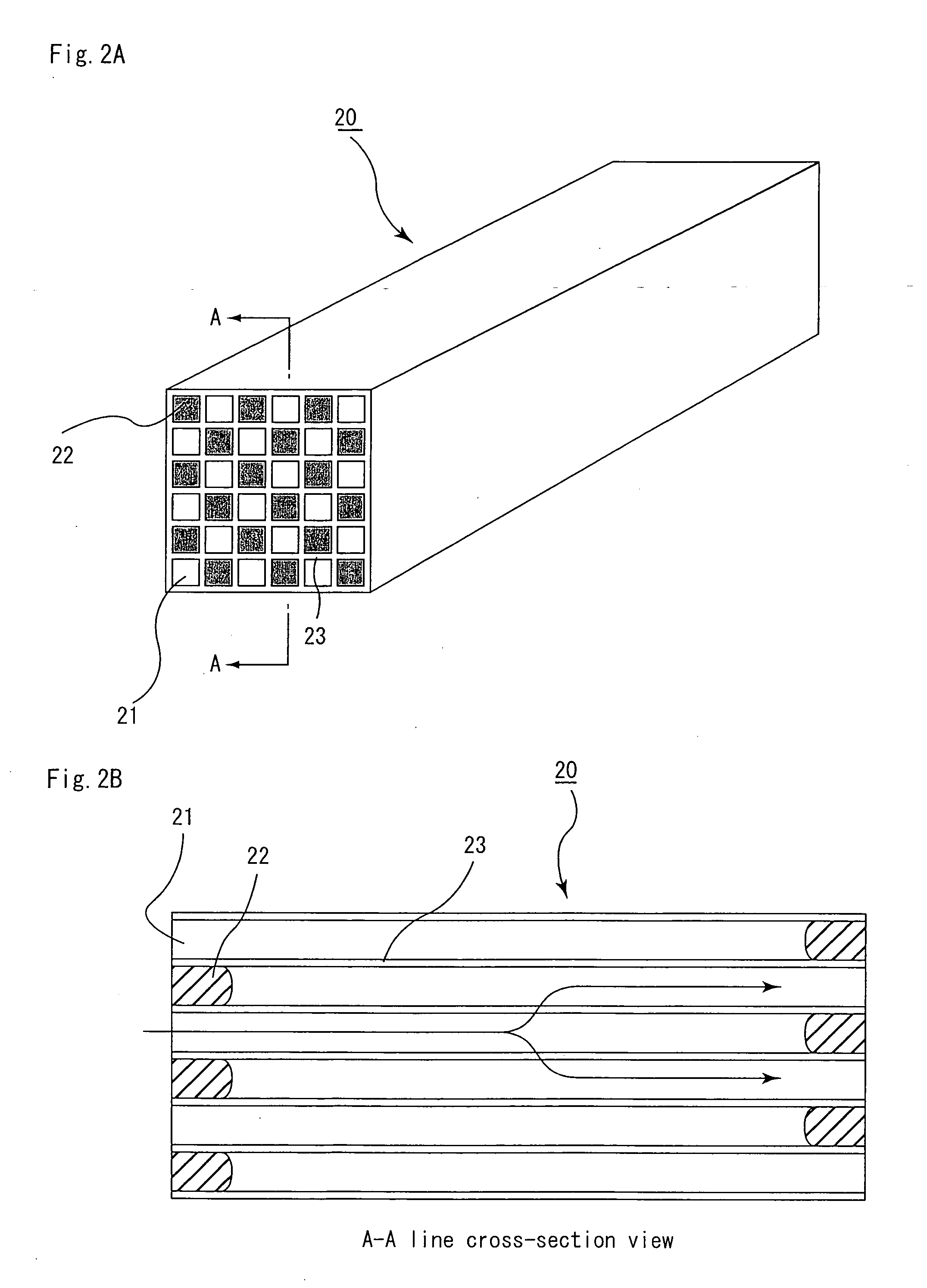

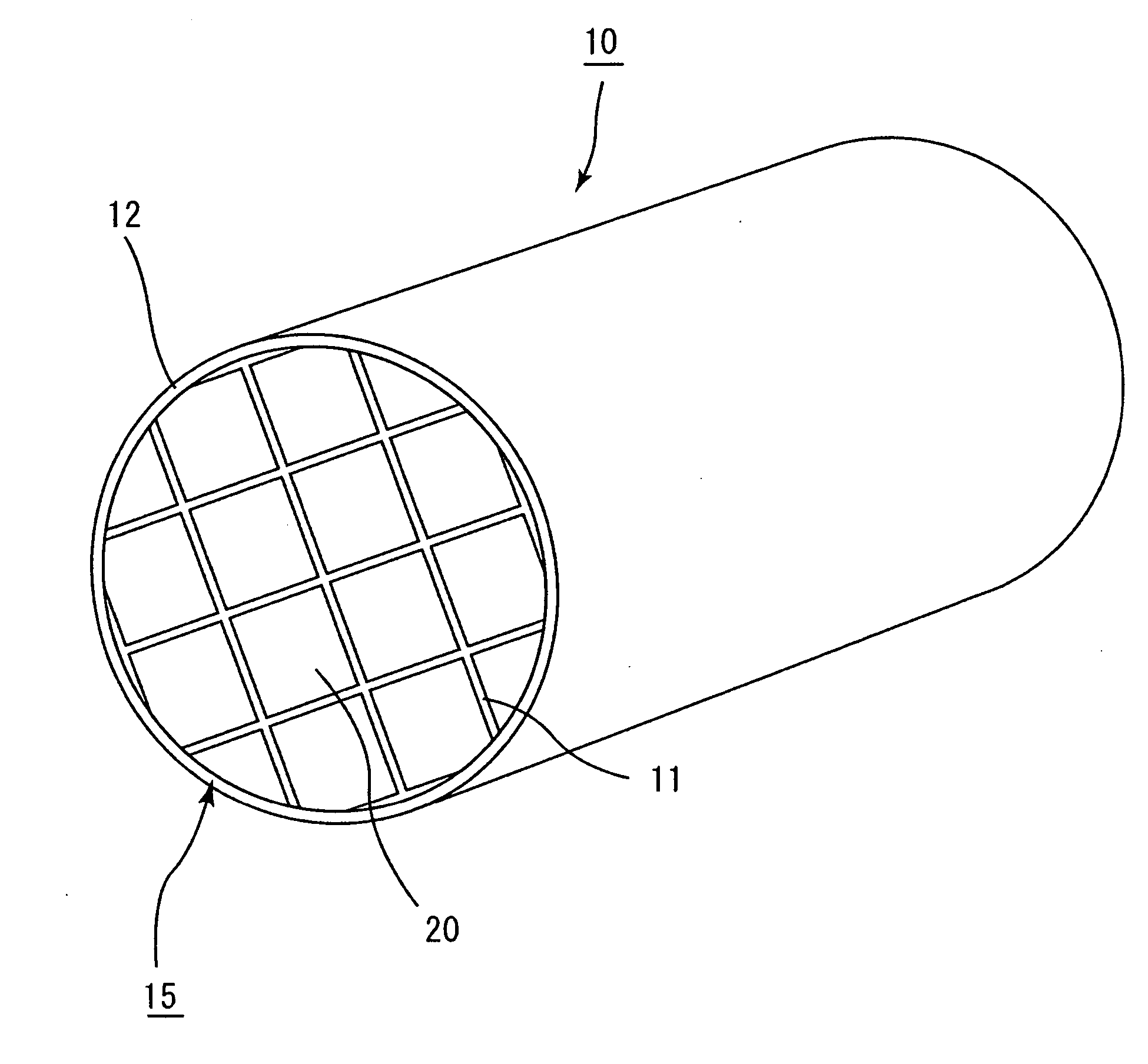

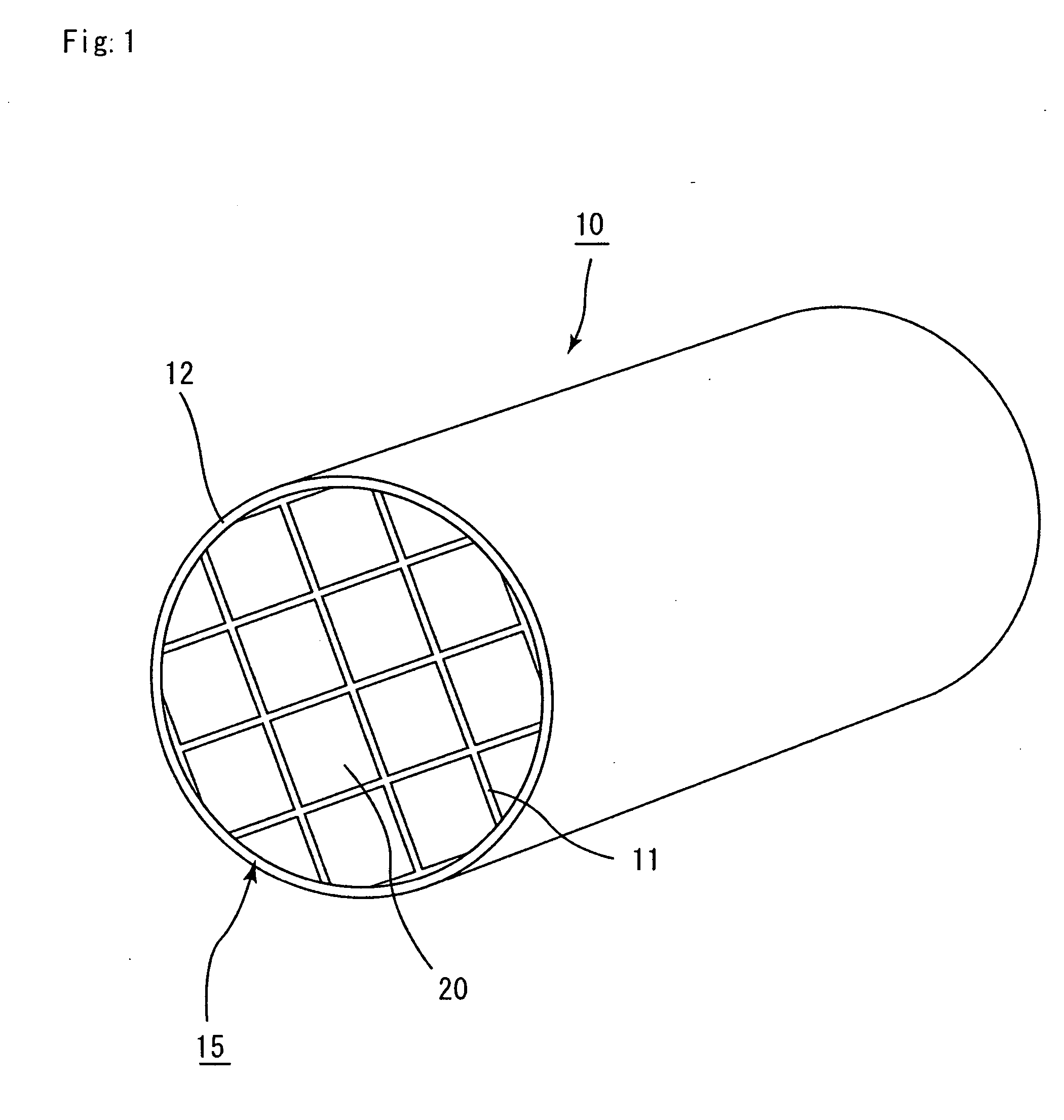

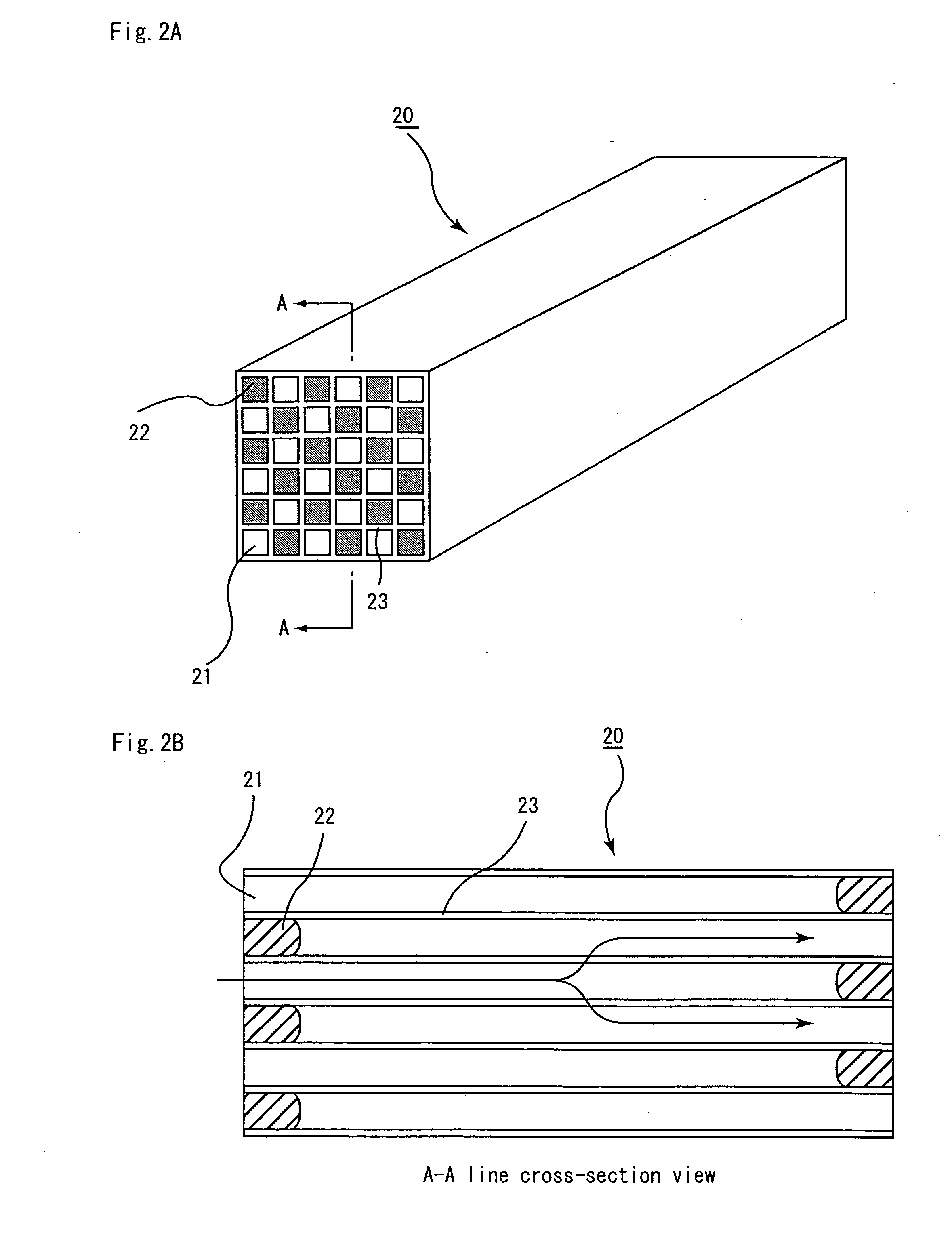

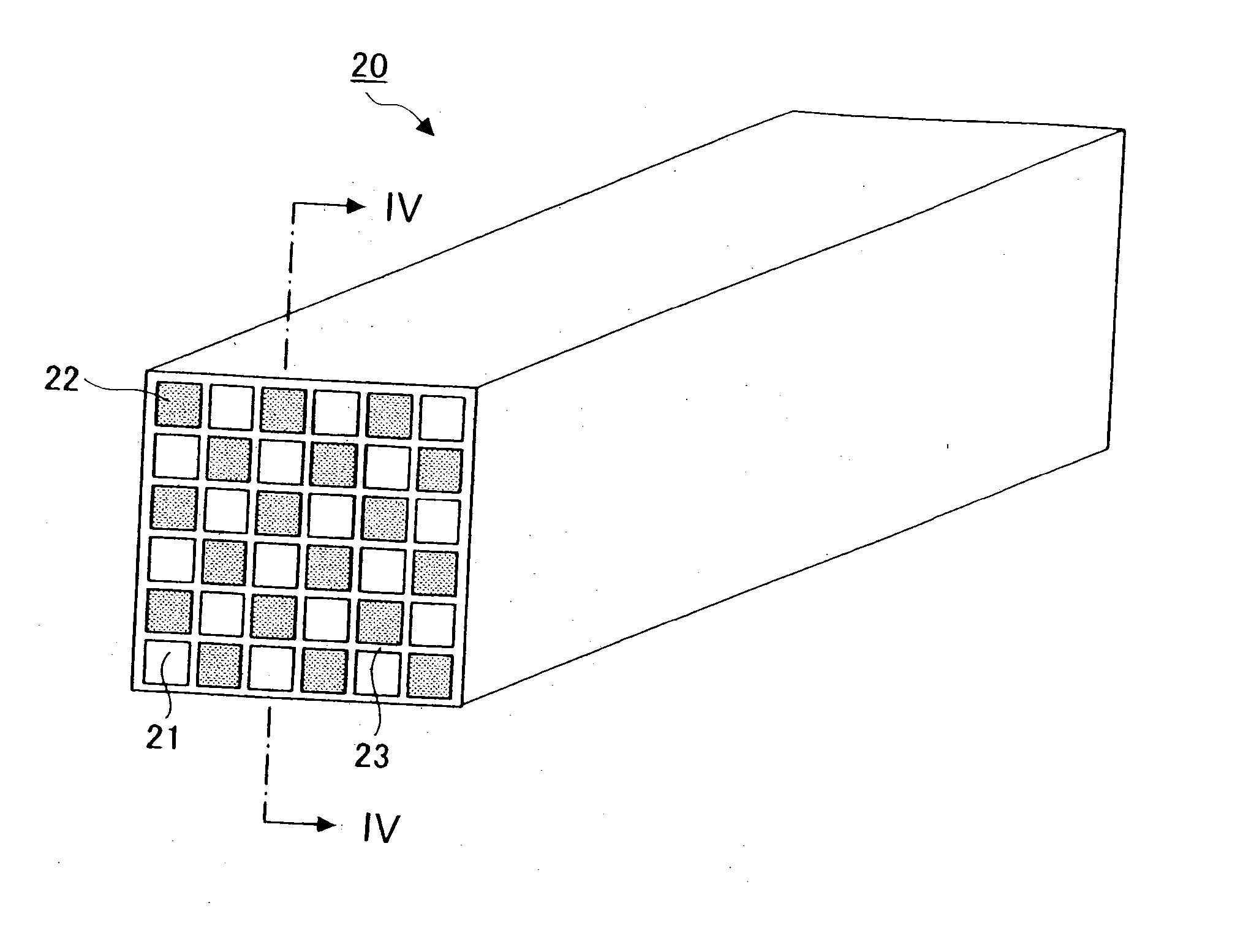

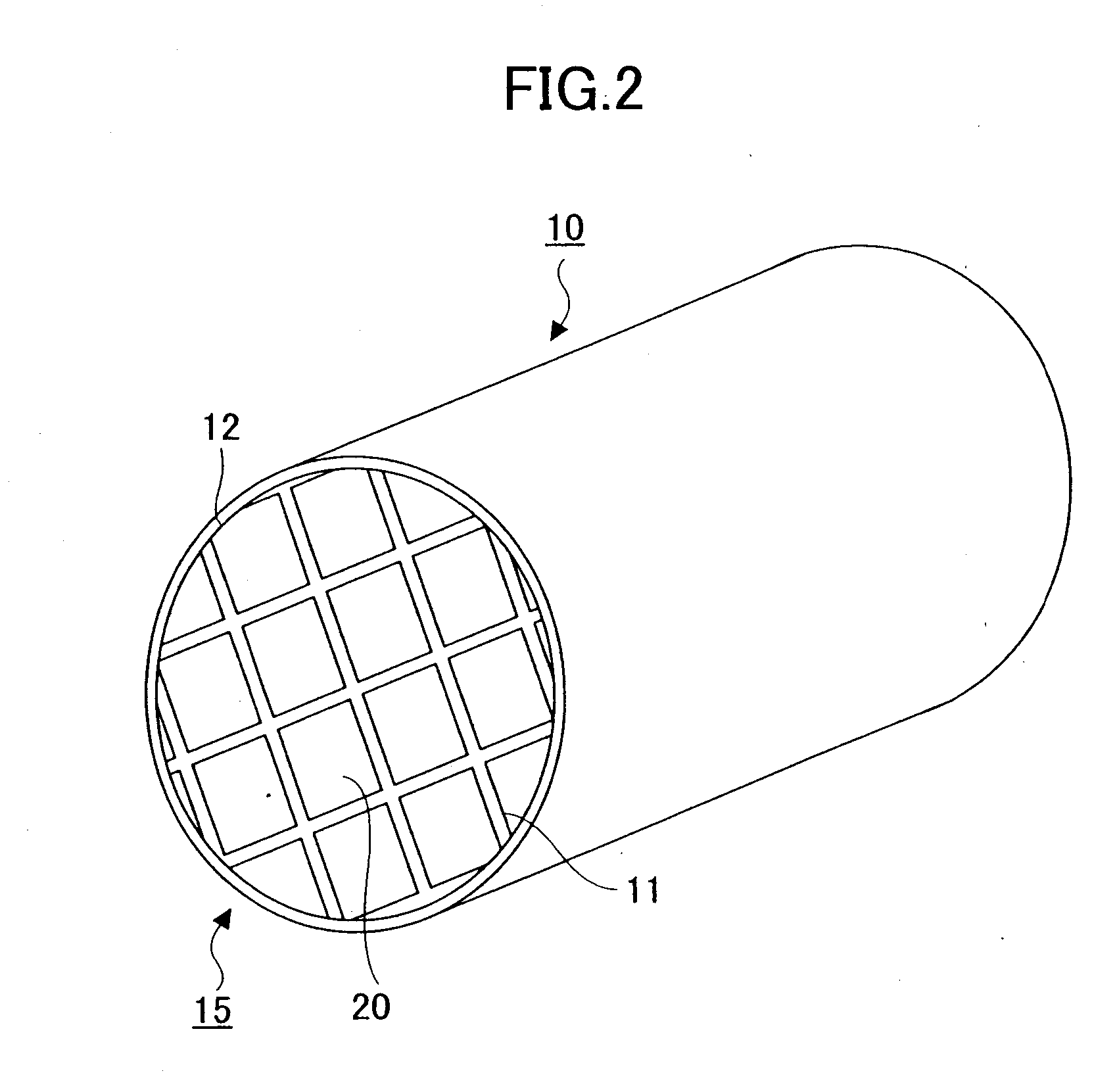

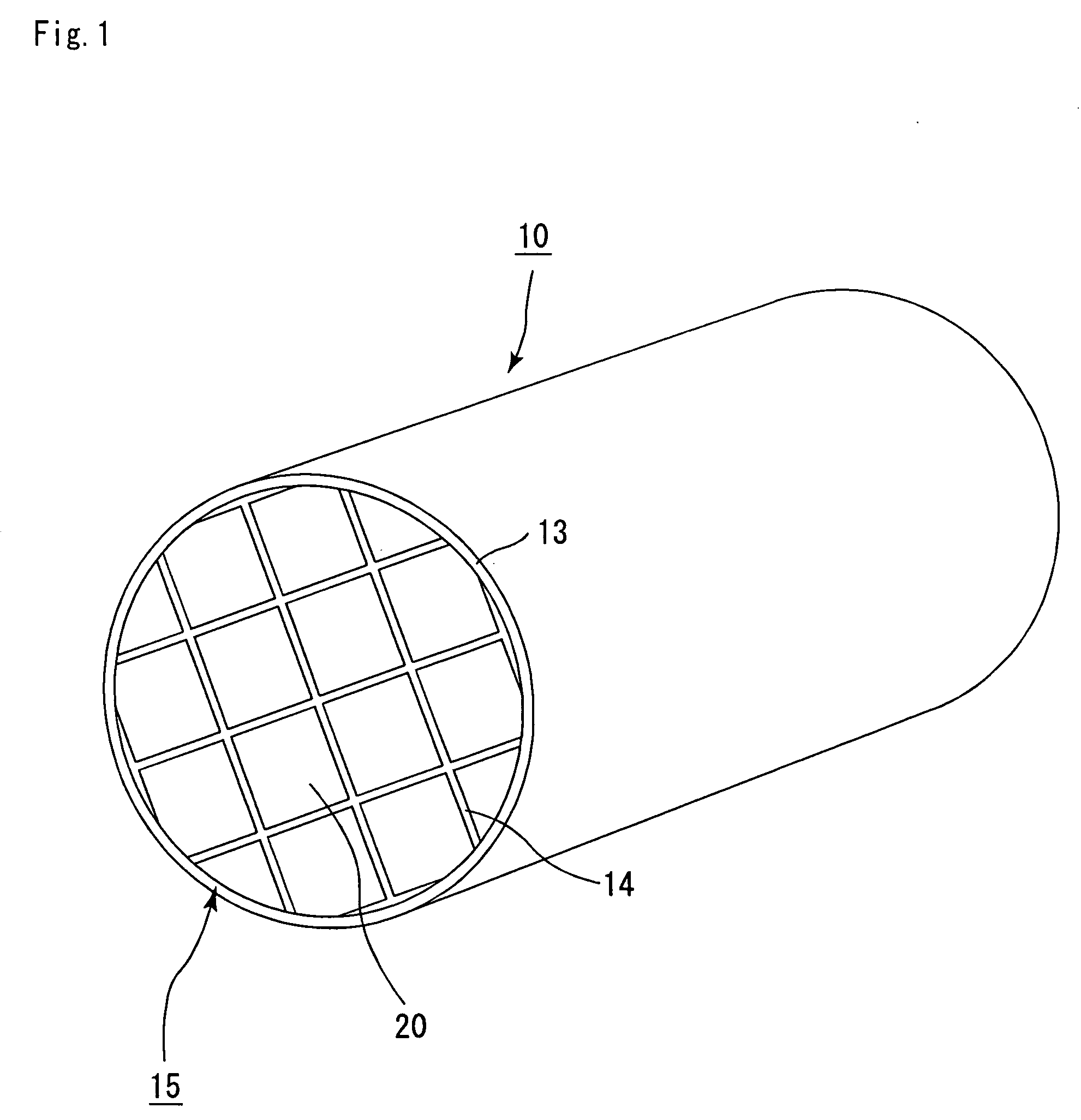

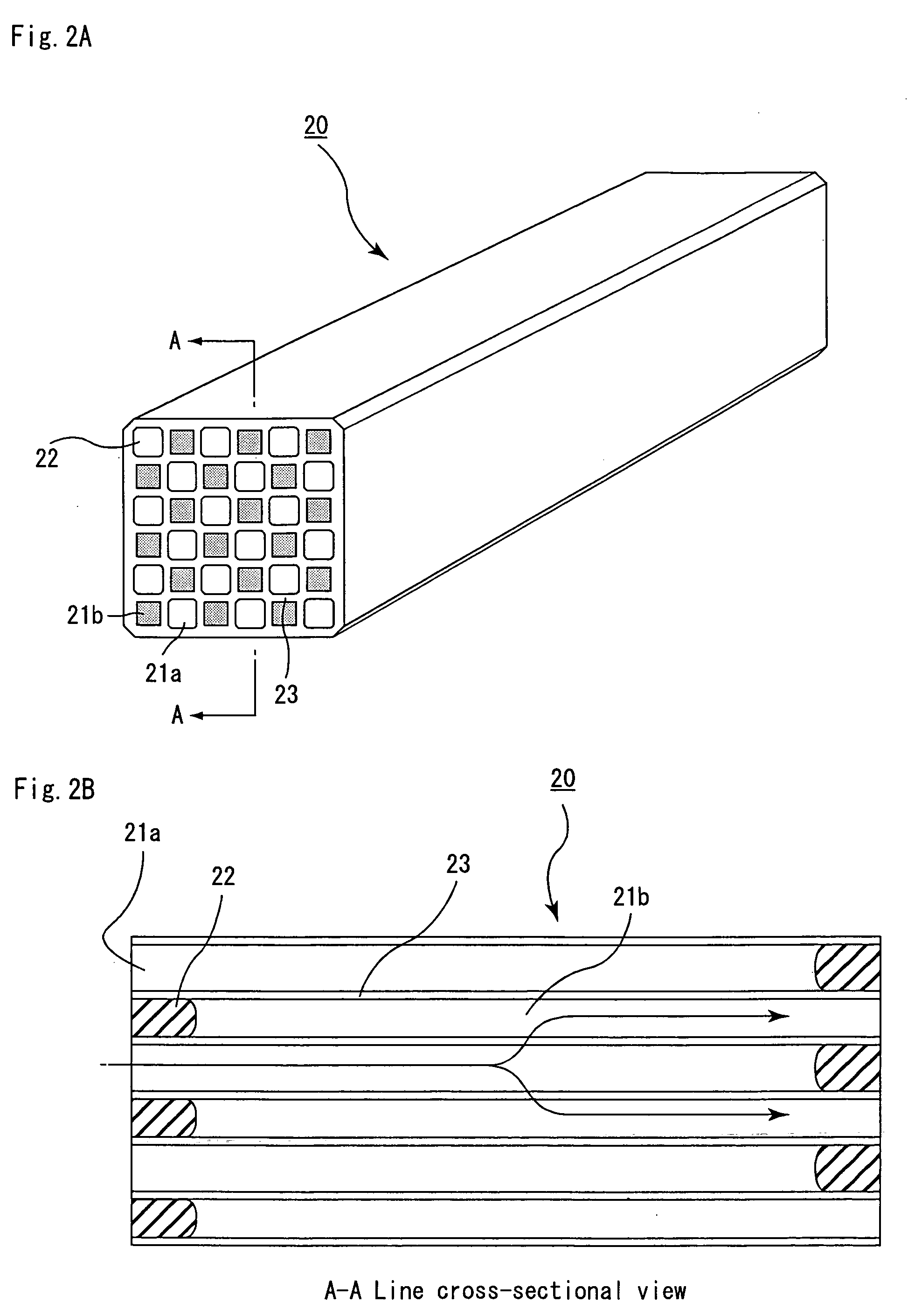

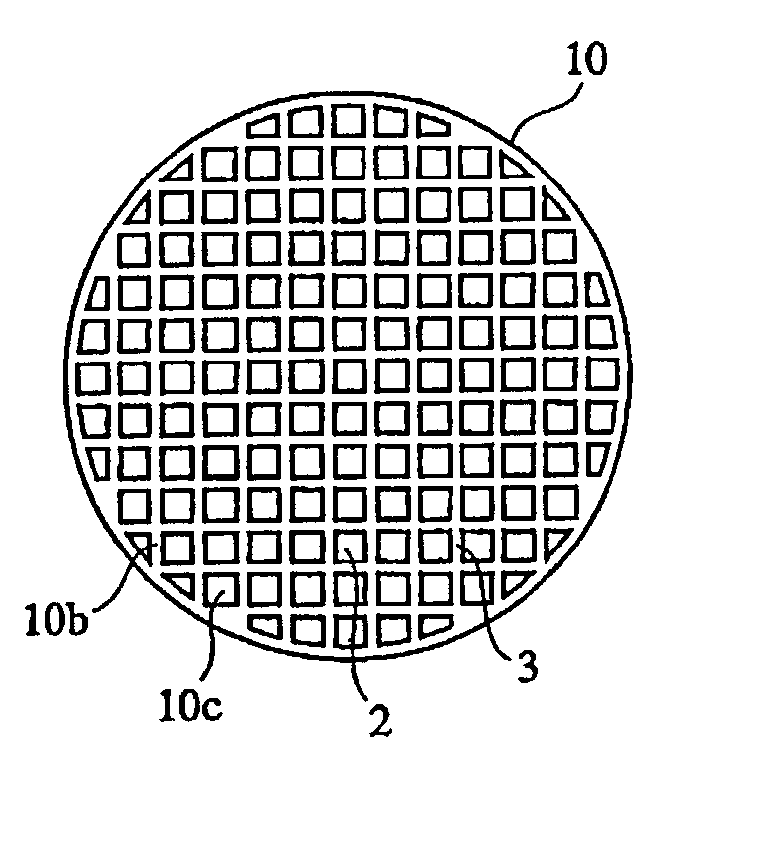

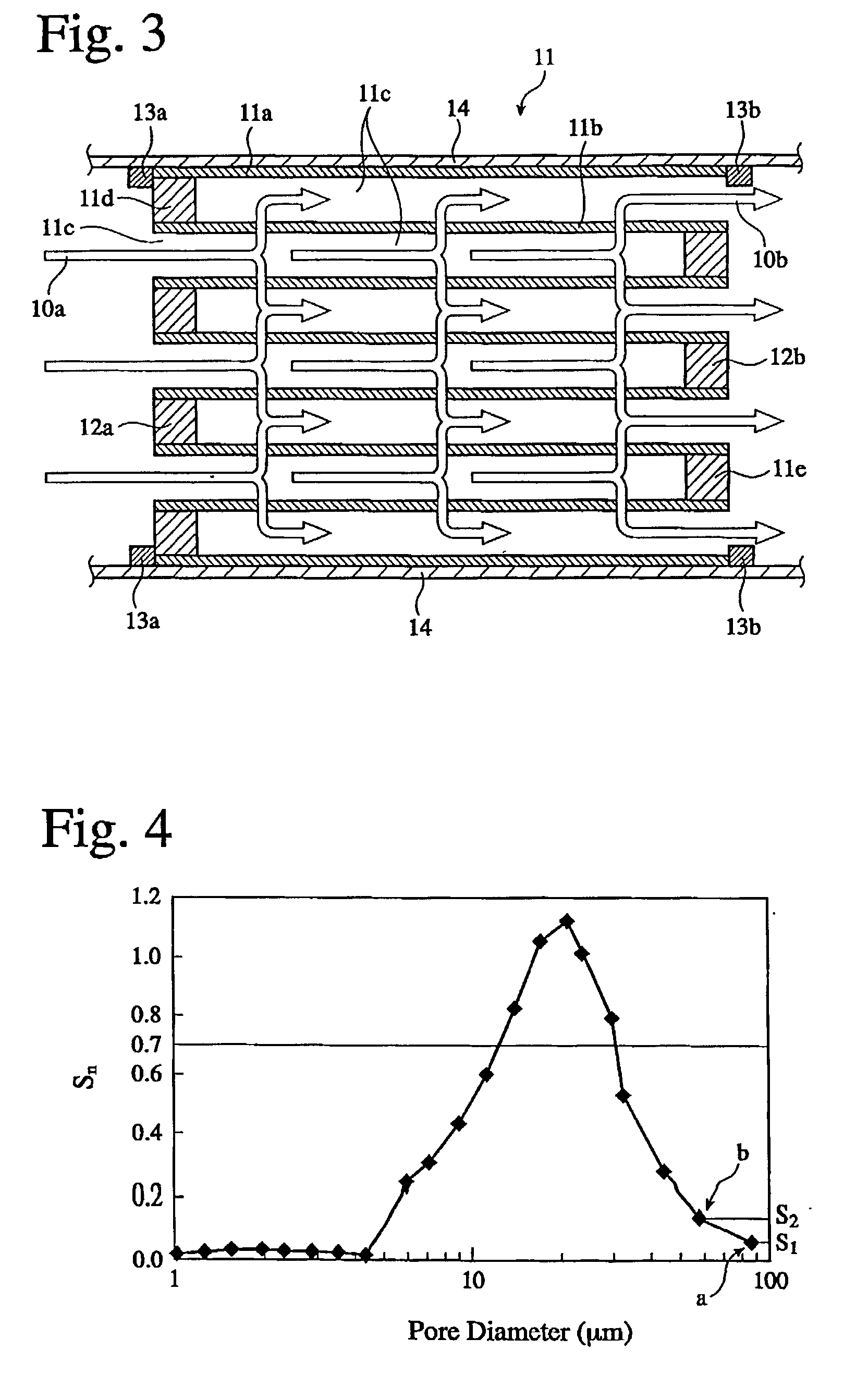

Honeycomb structured body

A honeycomb structured body of the present invention is a honeycomb structured body in which a plurality of porous ceramic members are combined with one another through an adhesive layer, each of the porous ceramic members having a plurality of cells which are allowed to penetrate in a longitudinal direction with a wall portion therebetween and either one end of which is sealed, with a catalyst supporting layer being adhered to the wall portion, wherein, supposing that the rate of the pore volume of pores having a pore diameter of 10 μm or less to the entire pore volume of the porous ceramic member is X1 (%), the porosity is Y1 (%) and the weight of the catalyst supporting layer is Z1 (g / l), these X1, Y1 and Z1 are allowed to satisfy the following expressions (1) and (2): X1≦20−Z1 / 10 (1), and Y1≧35+7Z1 / 40 (2) (where about 20≦Z1≦about 150).

Owner:IBIDEN CO LTD

Hydrotreating catalyst and preparation method thereof

ActiveCN102049265AImprove pore structureReduce manufacturing costMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsReactive siteNitrogen

The invention discloses a bulk hydrotreating catalyst and a preparation method thereof. The catalyst comprises three active metal components, namely Mo, W and Ni, and the sum of active metal oxides is 30 to 70 weight percent. In the method, a proper amount of water-soluble nitrogen-containing compound is added in the bulk catalyst gelatinating process, the pore structure of the catalyst is improved, more metal active sites are exposed on the surface of the catalyst, the utilization rate of active metals is improved, the catalyst has obviously high activity compared with the common bulk catalyst under the condition of the same metal content, and the consumption of the active metals for the common bulk catalyst can be reduced and the preparation cost of the catalyst can be reduced under thecondition of the equivalent activity. In addition, the bulk catalyst has increased pore diameter and pore volume, the Ni-W high active center is fully utilized, complicated macromolecules are easier to contact the active center, and the effect is particularly more obvious when the catalyst treats distillates with high macromolecule content.

Owner:CHINA PETROLEUM & CHEM CORP +1

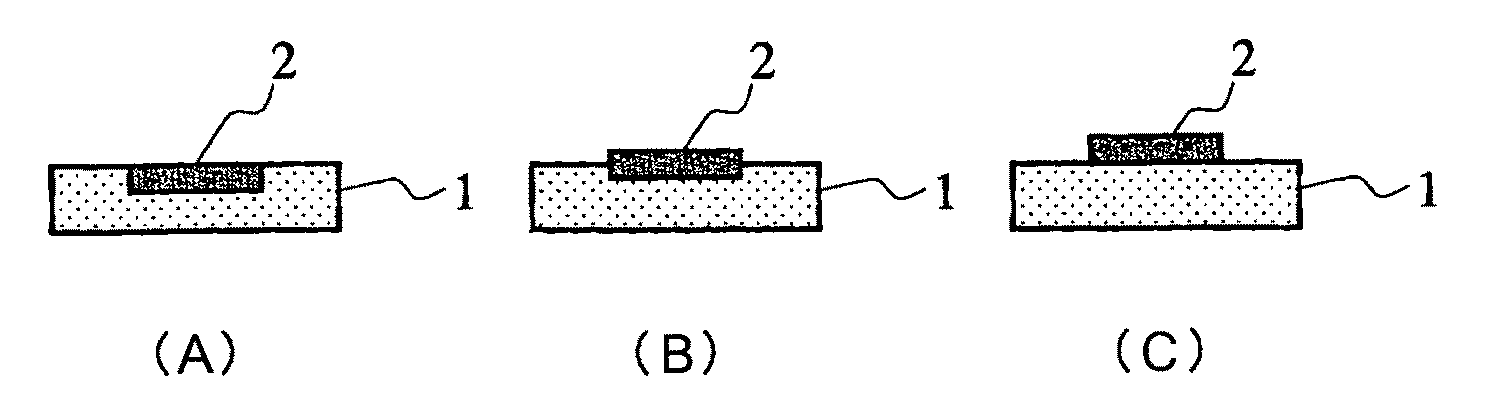

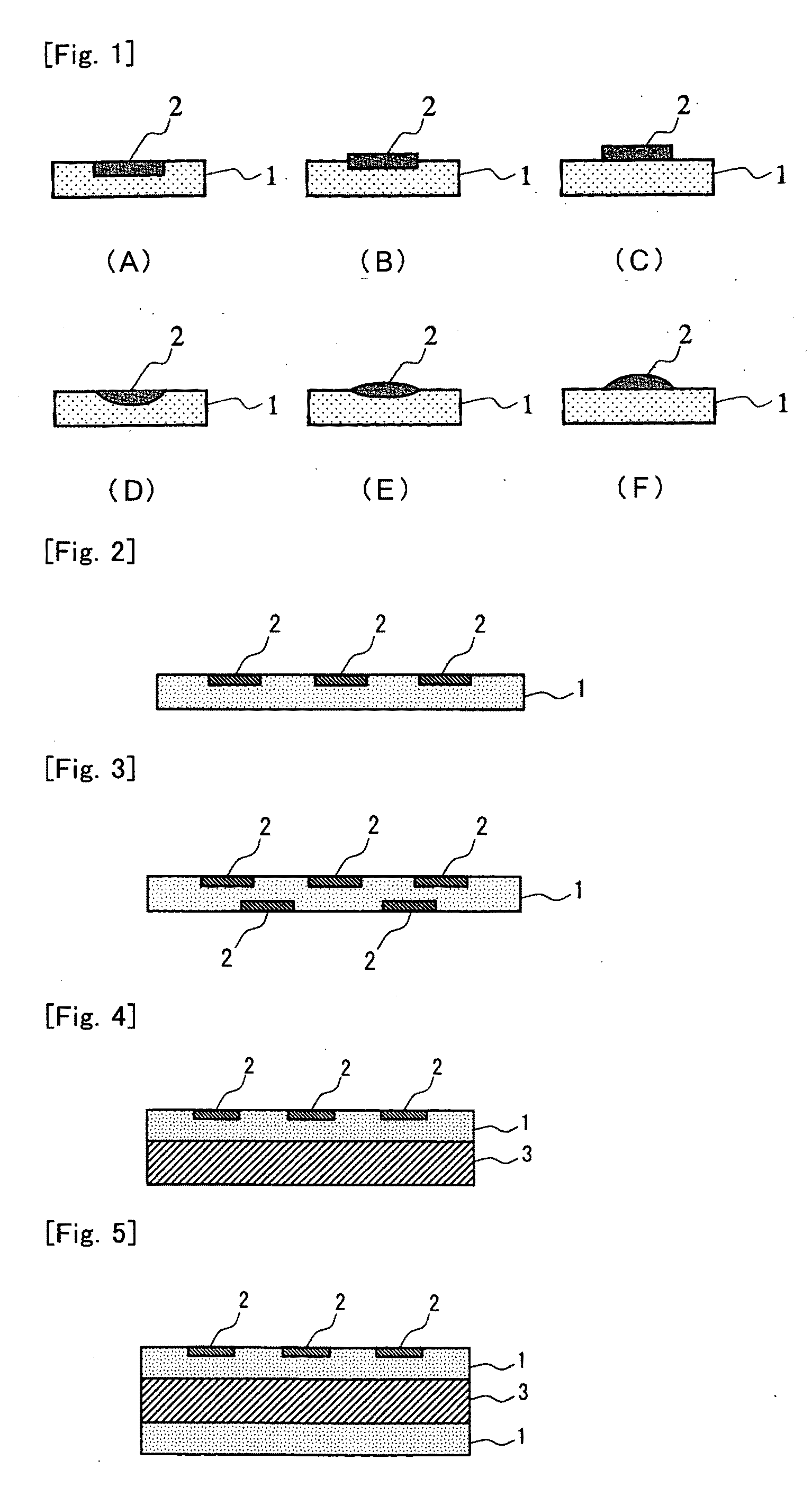

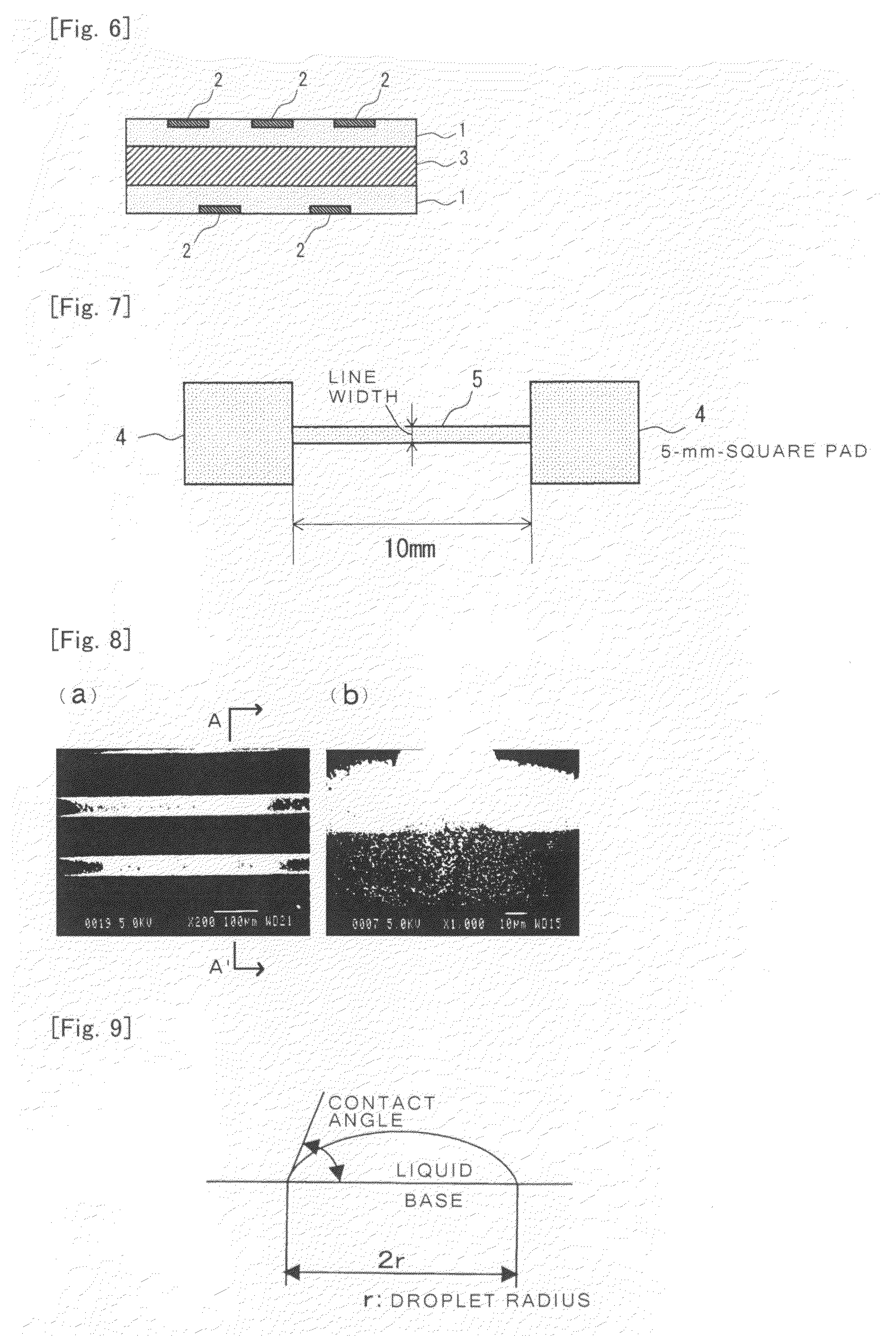

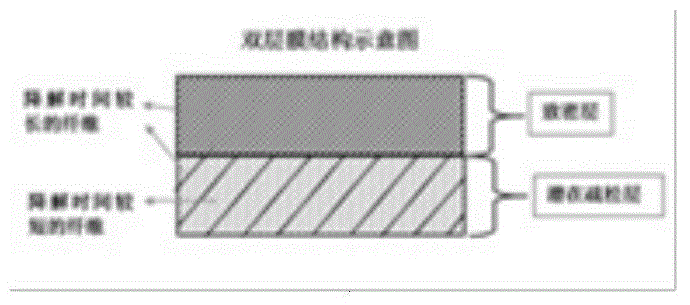

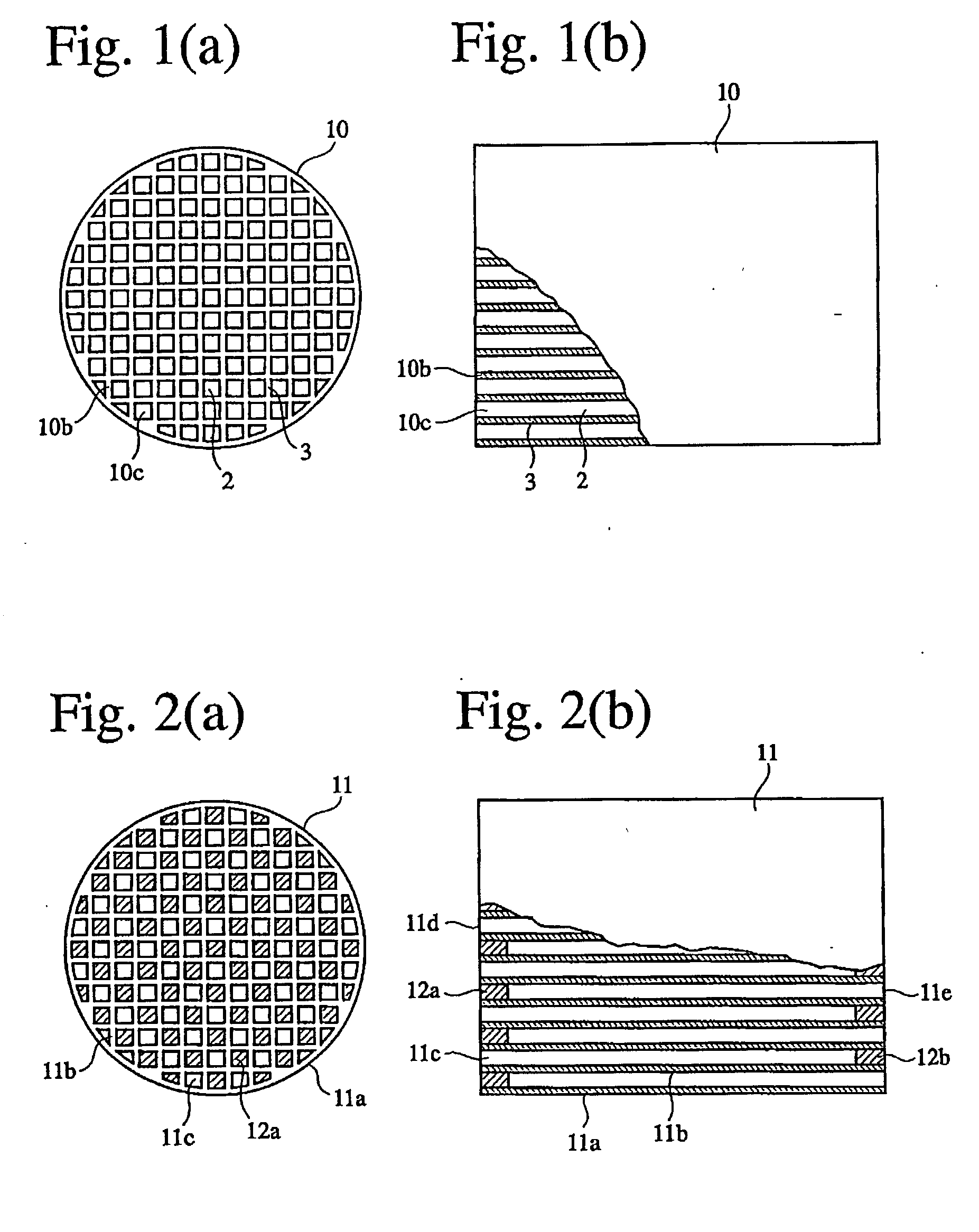

Porous Film and Multilayer Assembly Using the Same

InactiveUS20090008142A1Satisfactorily flexibleImprove porosityVacuum evaporation coatingSputtering coatingInterfacial delaminationPorous layer

[Object] To provide a multilayer assembly that excels in pore properties, is flexible, and is satisfactorily handled and processed; and a method of producing the multilayer assembly.[Solving Means] A multilayer assembly includes a base and, arranged on at least one side thereof, a porous layer and has a large number of continuous micropores with an average pore diameter of 0.01 to 10 μm. The multilayer assembly suffers from no interfacial delamination between the base and the porous layer when examined in a tape peeling test according to the following procedure:Tape Peeling TestA 24-mm wide masking tape [Film Masking Tape No. 603 (#25)] supplied by Teraoka Seisakusho Co., Ltd. is applied to a surface of the porous layer of the multilayer assembly and press-bonded thereto with a roller having a diameter of 30 mm and a load of 200 gf to give a sample; and the sample is subjected to a T-peel test with a tensile tester at a peel rate of 50 mm / min.

Owner:DAICEL CHEM IND LTD

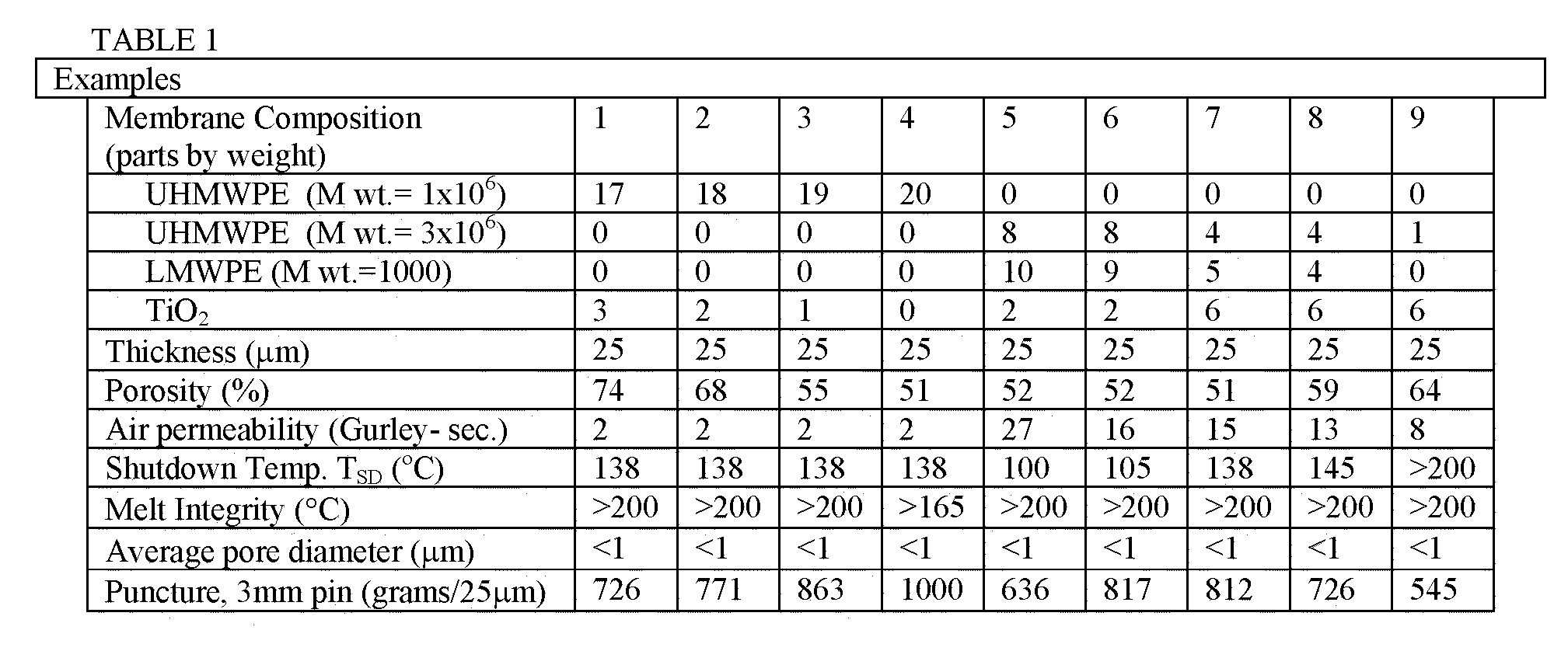

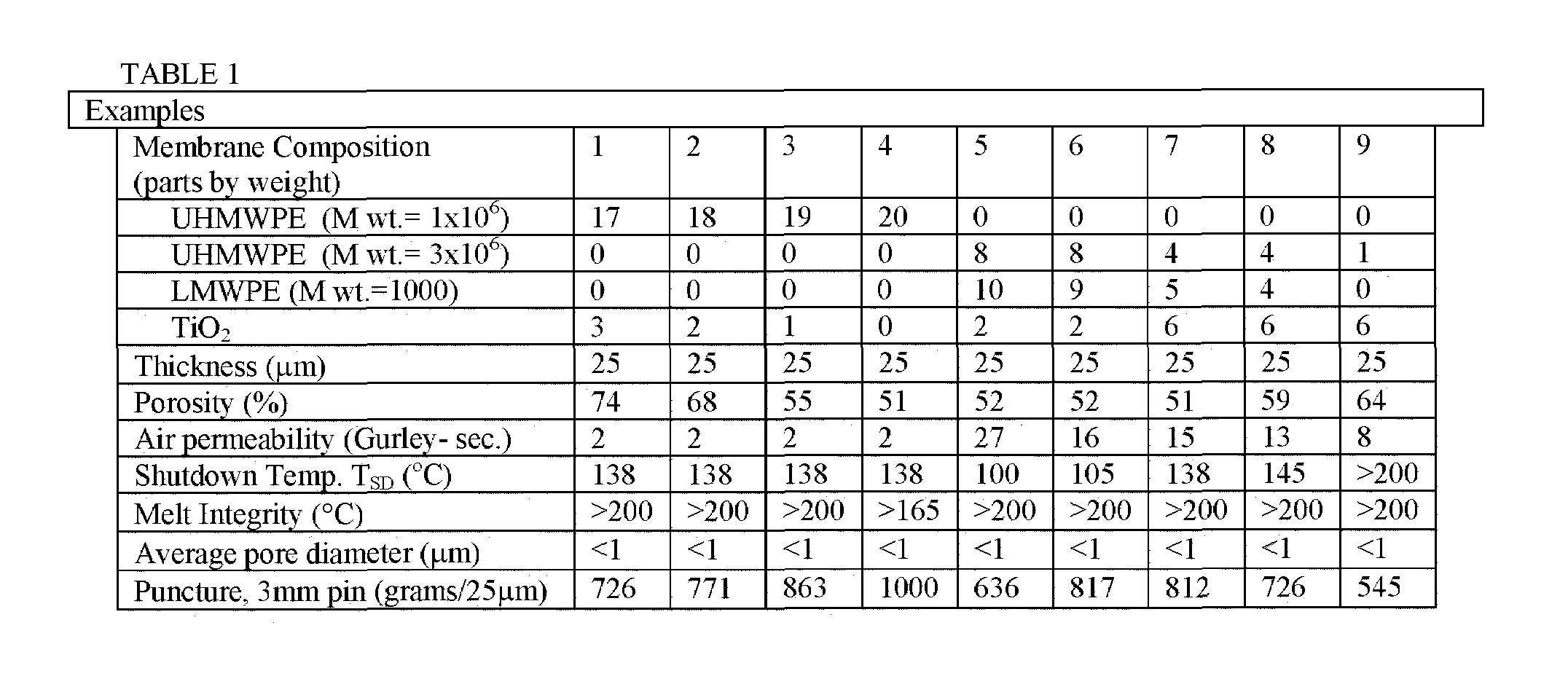

Shutdown separators with improved properties

InactiveUS6949315B1Improve propertiesReduced flexibilitySemi-permeable membranesMembranesPolymer sciencePolyolefin

Owner:ADVANCED MEMBRANE SYST INC

Honeycomb structured body

Owner:IBIDEN CO LTD

Porous sintered body, method of manufacturing porous sintered body, and method of manufacturing exhaust gas purifying apparatus

A method of manufacturing a porous sintered body includes mixing at least two groups of silicon carbide particles and a pore forming material having an average particle diameter Y μm to obtain a molding material. The at least two groups of silicon carbide particles have different average particle diameters and have a first group of silicon carbide particles whose blending quantity by weight in the molding material is greatest among the at least two groups of silicon carbide particles. The first group have an average particle diameter X μm. The relationships 15≦X, 0.5·X≦Z≦0.9·X, and 0.8·Z≦Y≦1.8·Z are satisfied, wherein Z μm is an average pore diameter of the porous sintered body no less than 10 μm and no greater than 20 μm.

Owner:IBIDEN CO LTD

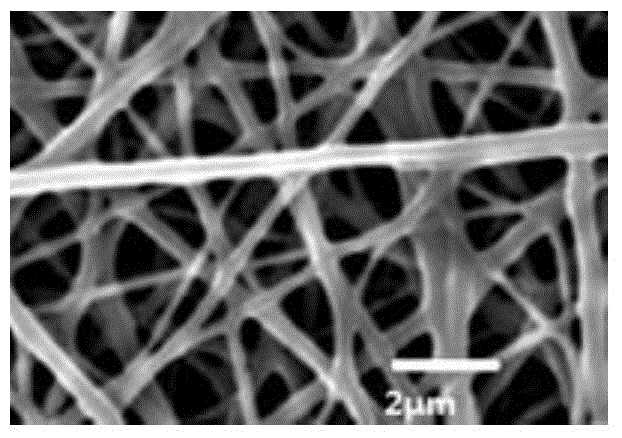

Tissue-engineering scaffolds containing self-assembled-peptide hydrogels

ActiveUS20080145934A1Good tissue responseSuitable mechanical propertyAnimal cellsCell culture supports/coatingPore diameterMechanical property

The present invention is directed to tissue-engineering scaffolds containing both a microporous scaffold made from a biocompatible material suitable for use in tissue-engineering scaffolds and a nanofiberous, nanoporous hydrogel formed from a self-assembling peptide, where at least a portion of the hydrogel is disposed within the pores of the microporous scaffold, thus providing tissue-engineering scaffolds having average pore diameters in the nanometer range and that provide both mechanical properties suitable for implantation into a body of a mammal and excellent tissue response once implanted in the body.

Owner:ADVANCED TECH & REGENERATIVE MEDICINE

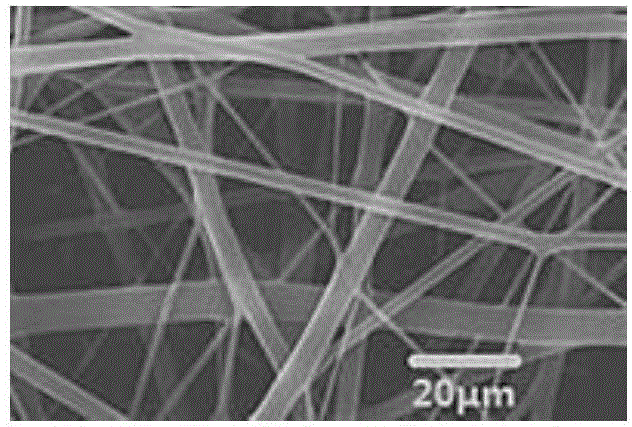

Guided tissue regeneration membrane as well as preparation method and application thereof

ActiveCN104474589APromote degradationLarge apertureCellulosic plastic layered productsProsthesisFiberTissue repair

Owner:烟台蓝创生物技术有限公司

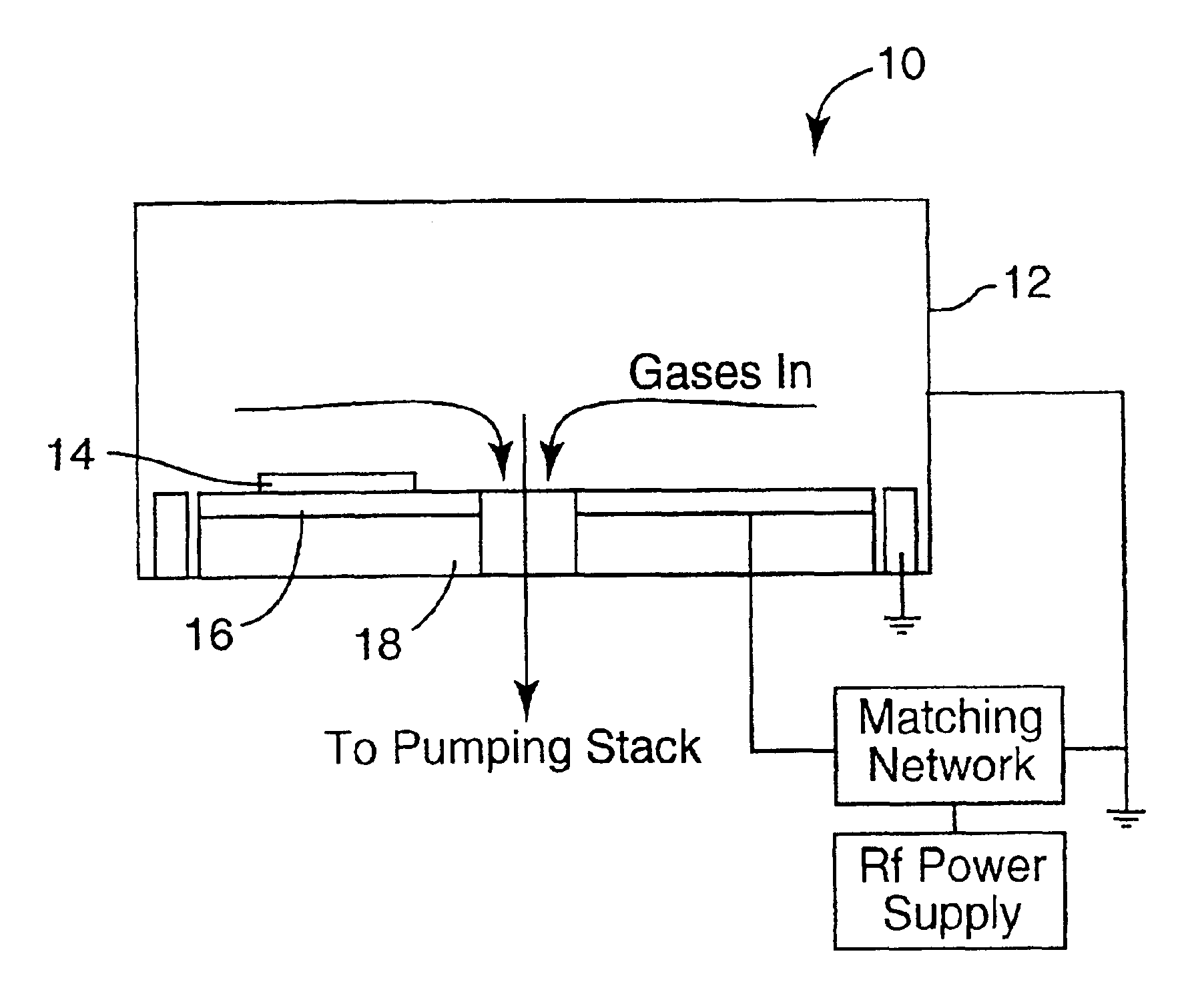

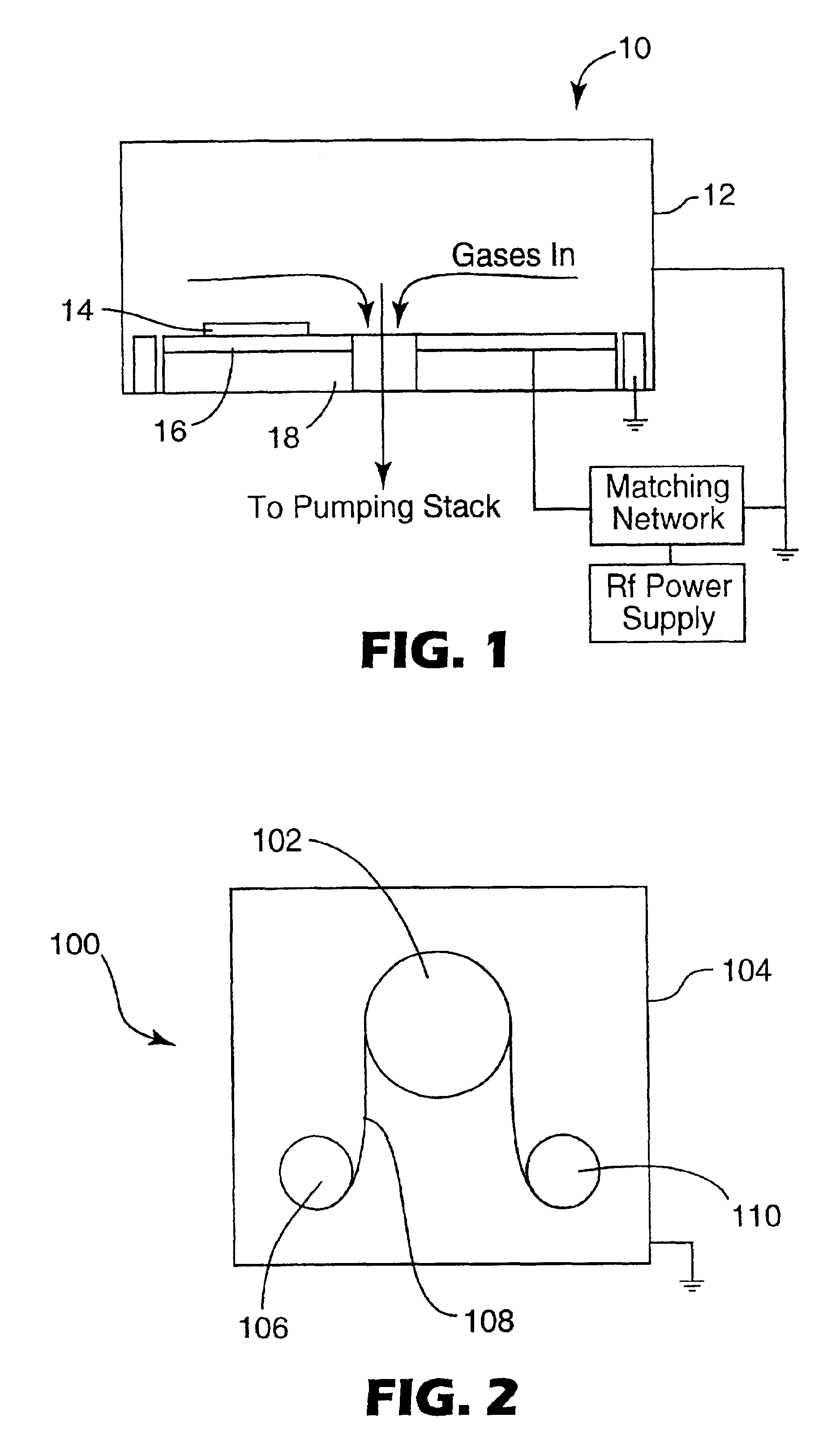

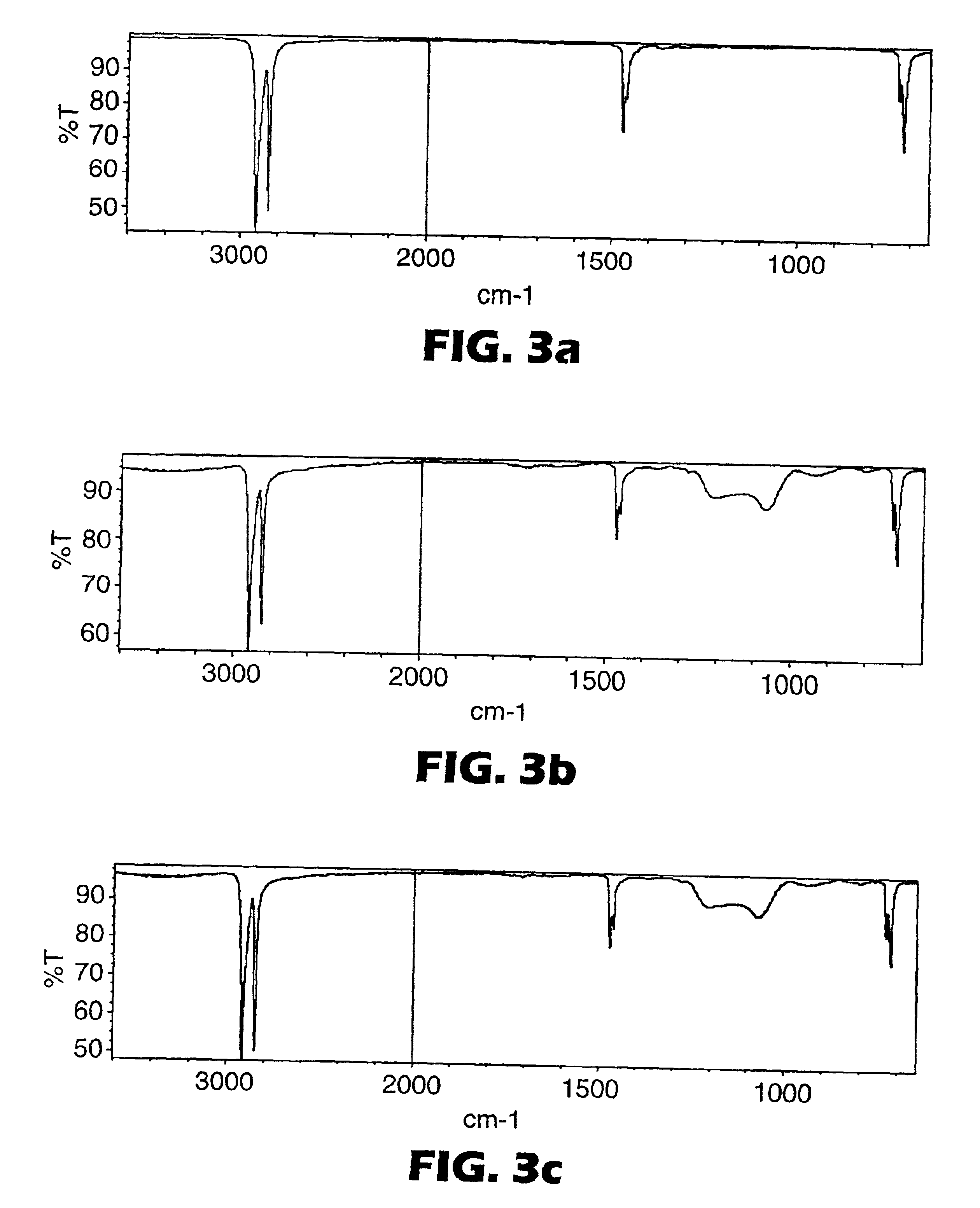

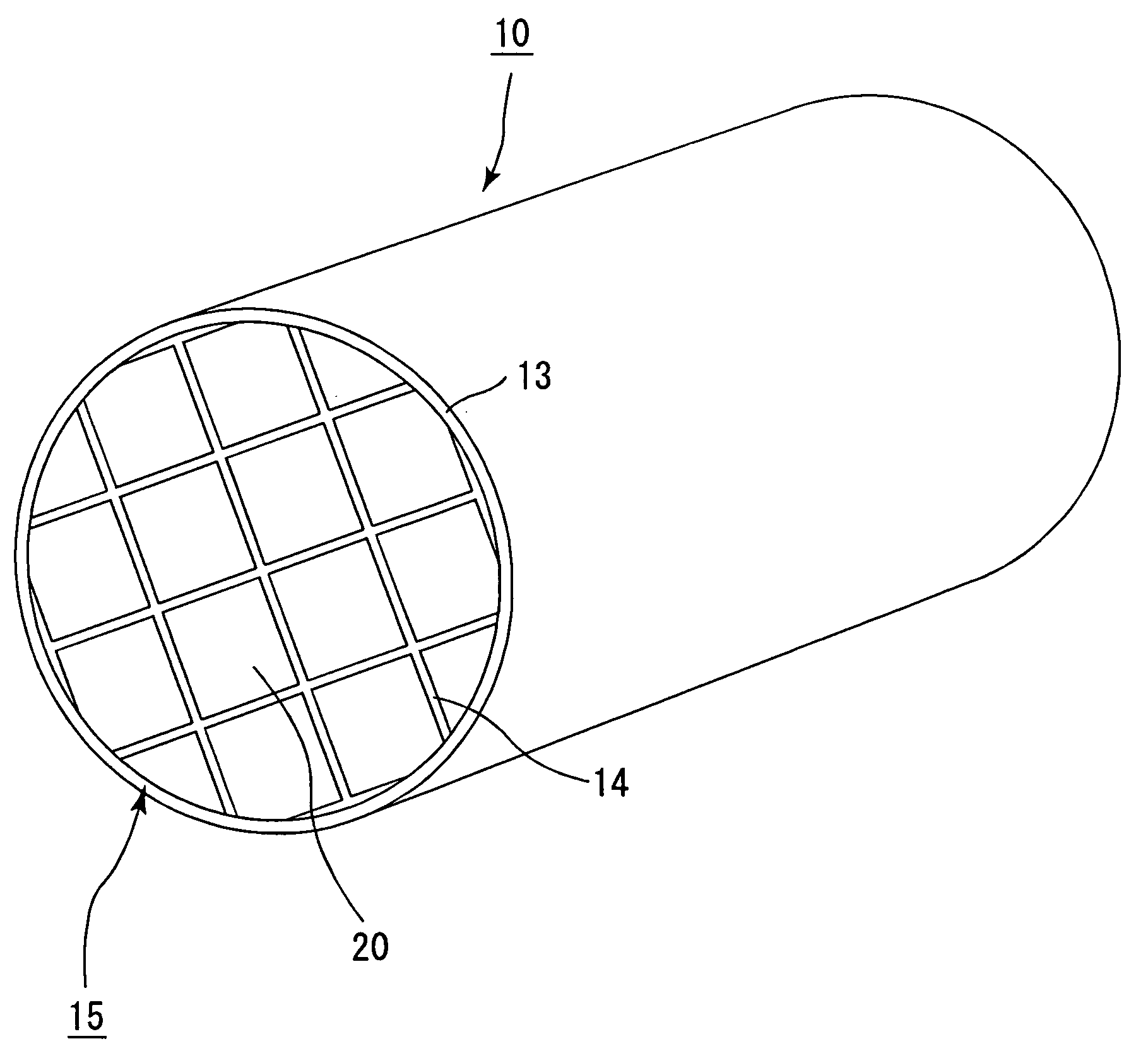

Plasma treatment of porous materials

InactiveUS6878419B2Improve wettabilityEfficient processingSemi-permeable membranesLayered productsCapacitanceMicrometer

Owner:3M INNOVATIVE PROPERTIES CO

Honeycomb structured body and exhaust gas purifying device

ActiveUS20060019061A1Improve heat resistanceCombination devicesGas treatmentExhaust fumesEngineering

The honeycomb structured body of the present invention is a pillar-shaped honeycomb structured body having a honeycomb structure that a number of through holes are placed in parallel with one another in the length direction with a wall portion interposed therebetween and one of ends of each through hole is sealed, wherein a relation between a volume Y (L) of said honeycomb structured body and an aperture ratio X (%) on an inlet side satisfies the following inequality (1):Y≦−1.1X+68.5 (wherein Y≦19, 35≦X≦56) (1).

Owner:IBIDEN CO LTD

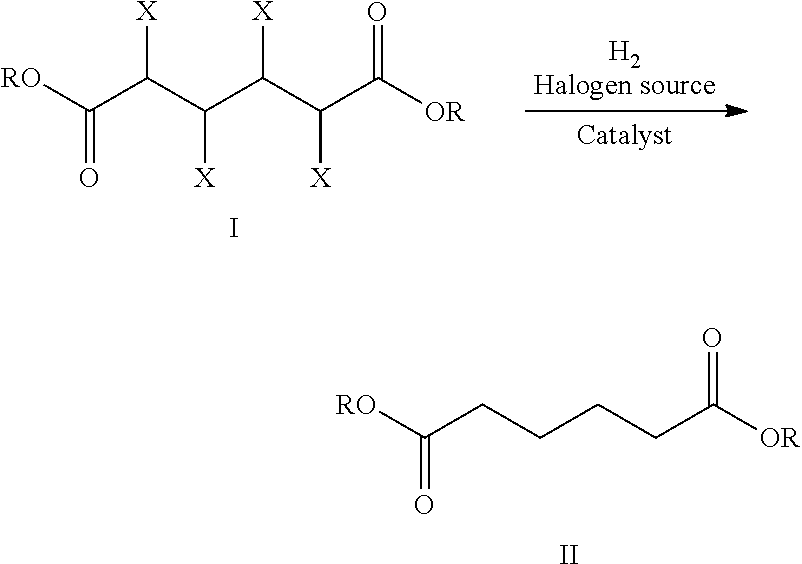

Reduction catalysts

Disclosed are catalysts comprised of platinum and rhodium on a support selected from the group of zirconia, stabilized (doped) zirconia, zirconia-metal oxide composites, and mixtures thereof, wherein the outer surfaces of the support are selected from the group of zirconia, stabilized zirconia, and mixtures thereof. More particularly, the supported catalysts comprise platinum and rhodium, wherein the molar ratio of platinum to rhodium is in the range of about 3:1 to about 1:2. The average pore diameter of the catalyst supports is in the range of about 5 nm to about 70 nm and the surface area is in the range of about 15 m2 / g to about 200 m2 / g. Also disclosed are methods for the hydrodeoxygenation of carboxylic acids, mono- and / or di-lactones thereof having at least one hydroxyl group on the backbone thereof to corresponding acids where the backbone hydroxyl group has been reduced in the presence of the catalyst.

Owner:ARCHER DANIELS MIDLAND CO

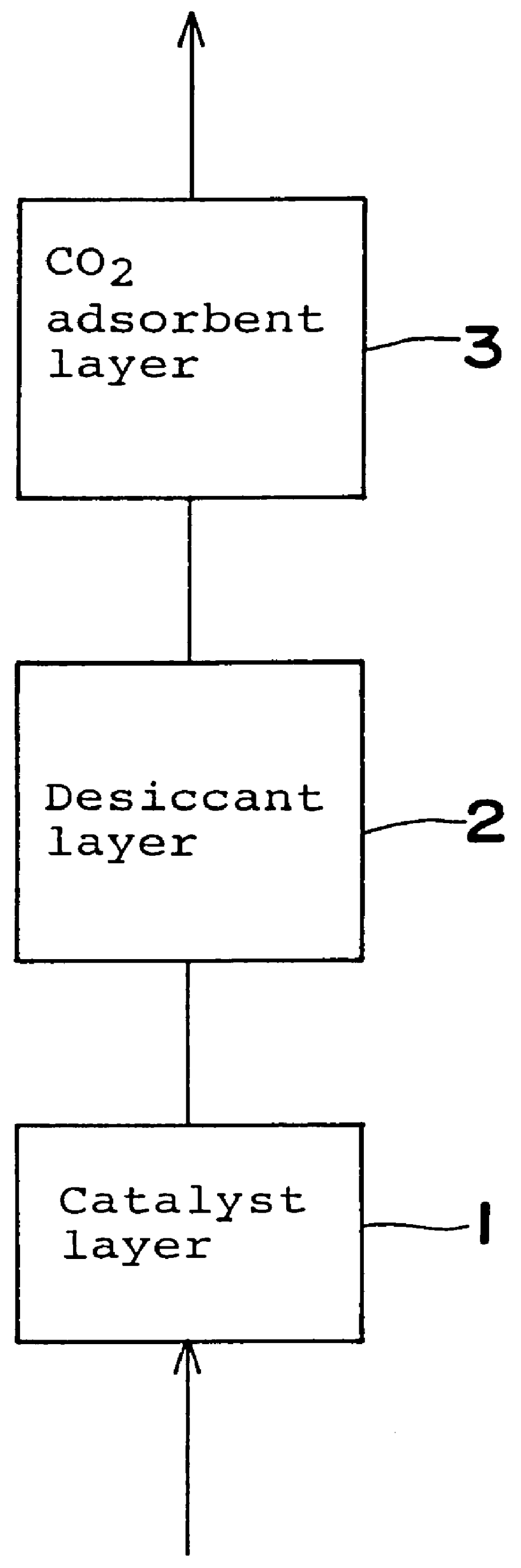

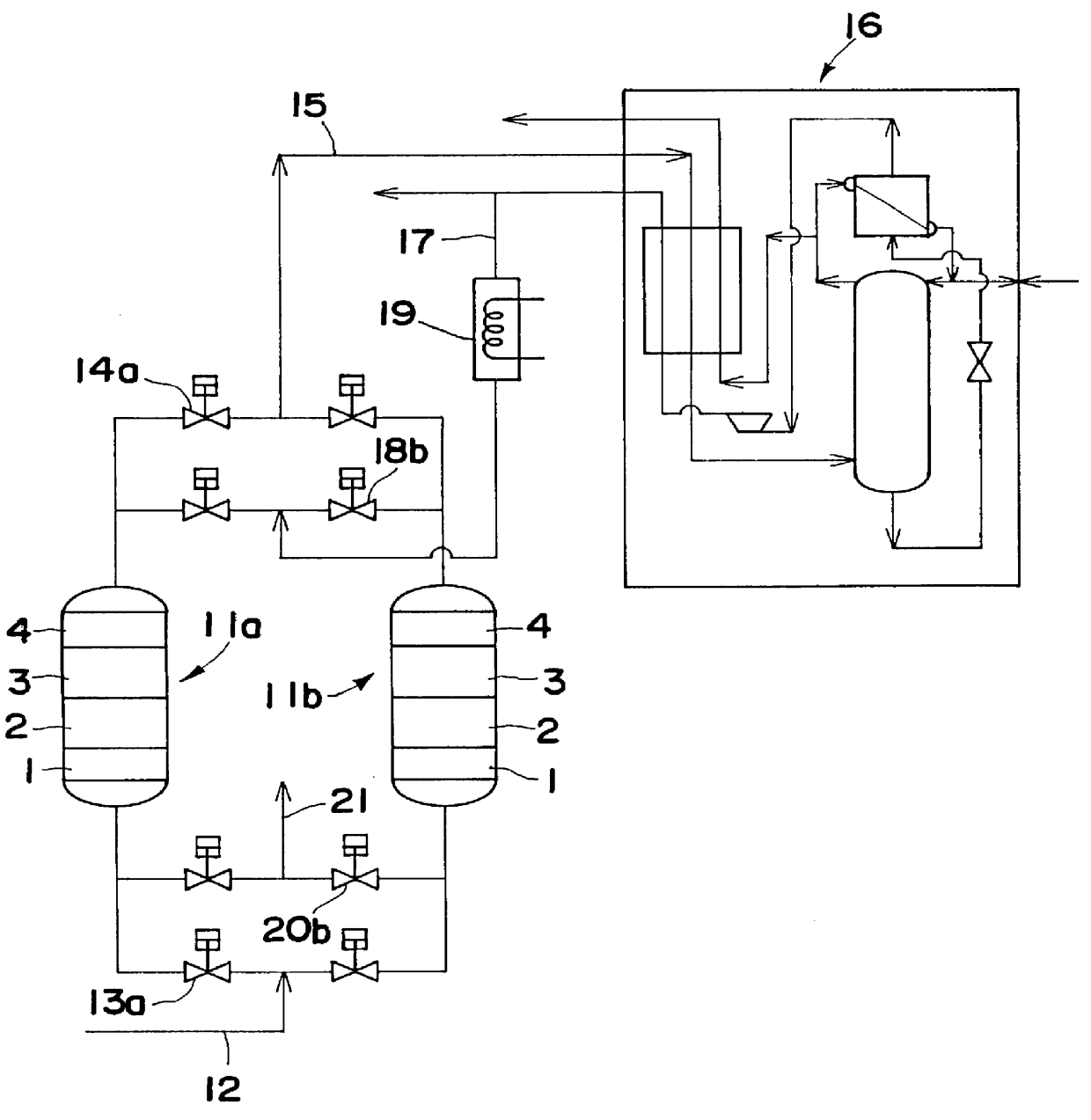

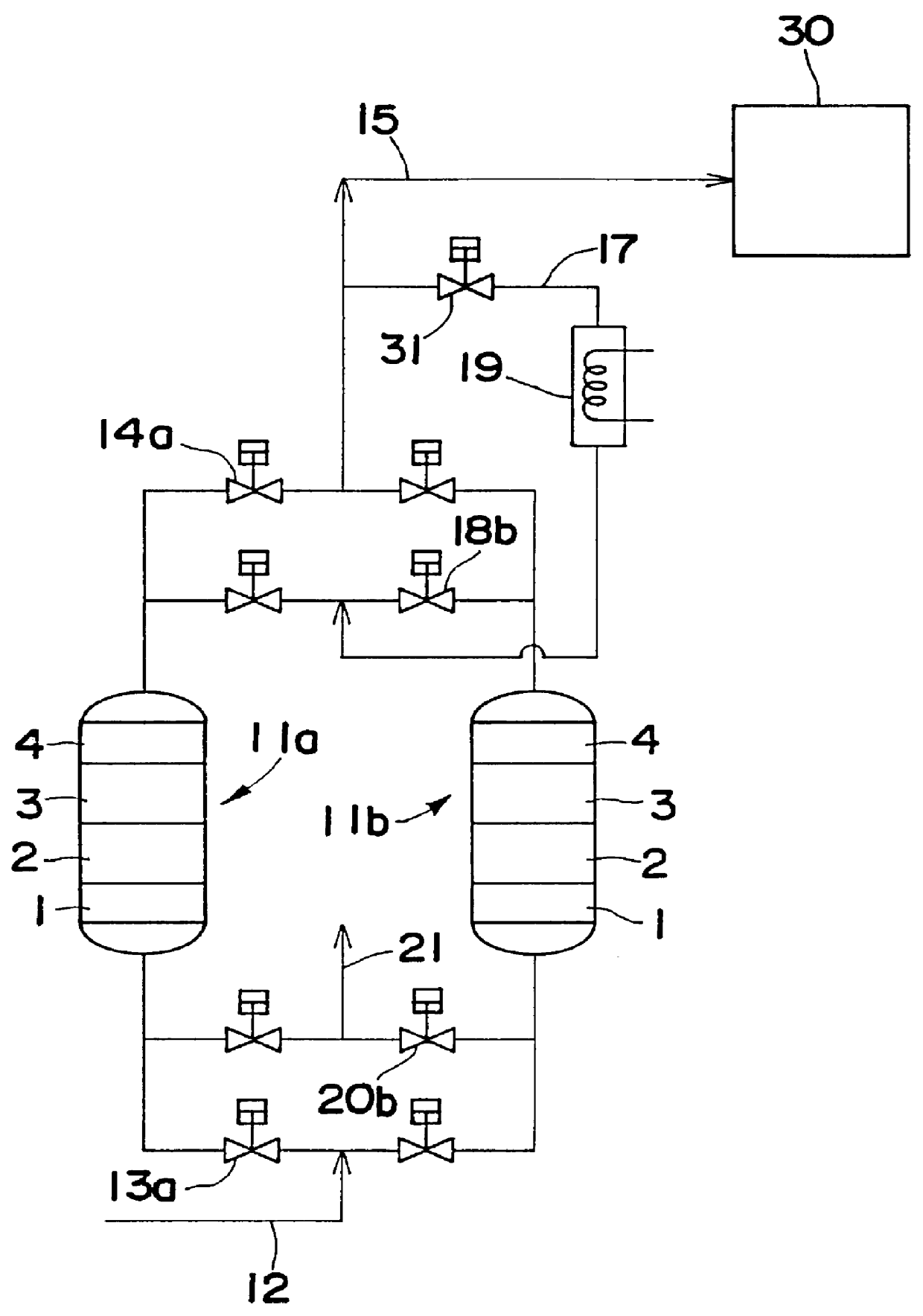

Gas purifying process and gas purifying apparatus

A method is provided for removing water, carbon monoxide and carbon dioxide out of a gas, such as air, by passing the gas through a packed column so that the gas sequentially contacts a catalyst consisting of platinum or palladium and at least one member selected from the group consisting of iron, cobalt, nickel, manganese, copper, chromium, tin, lead and cerium wherein the catalyst is supported on alumina containing substantially no pores having pore diameters of 110 Angstroms or less under conditions which oxidize the carbon monoxide in the gas into carbon dioxide; an adsorbent selected from the group consisting of silica gel, activated alumina, zeolite and combinations thereof under conditions in which water is adsorbed and removed from the gas and an adsorbent selected from the group consisting of calcium ion exchanged A zeolite; calcium ion exchanged X zeolite; sodium ion exchanged X zeolite and mixtures thereof under conditions which carbon dioxide is adsorbed and removed from the gas. The gas may also be subjected to a catalyst / adsorbent in the packed column to effect oxidation and removal of hydrogen in the gas.

Owner:NIPPON SANSO CORP

Porous carbons from carbohydrates

ActiveUS20050207962A1Small surface areaIncreased proportion of mesoporesHybrid capacitor electrodesCeramicwarePorous carbonPore diameter

A porous carbon characterized by a volumetric pore size distribution having two peaks, a first of said peaks being between 0.5 and 1.0 nm and a second of said peaks being between 1.0 and 5.0 nm. The porous carbon may have a volumetric capacitance in an organic electrolyte of at least 40 F / cm3, an average pore diameter between about 2 nm and about 30 nm, a surface area of at least 900 m2 / g, and / or a density of at least 0.4 g / cm3. A method for making such a carbon includes a) curing a mixture comprising a carbohydrate, a dehydrating component, and a nonmetallic cationic pore-forming agent and b) carbonizing the cured carbon under conditions effective to provide a porous carbon having a surface area between about 100 m2 / g and about 3000 m2 / g. The the dehydrating component and nonmetallic cationic component may comprise two moieties of one compound.

Owner:TDA RES

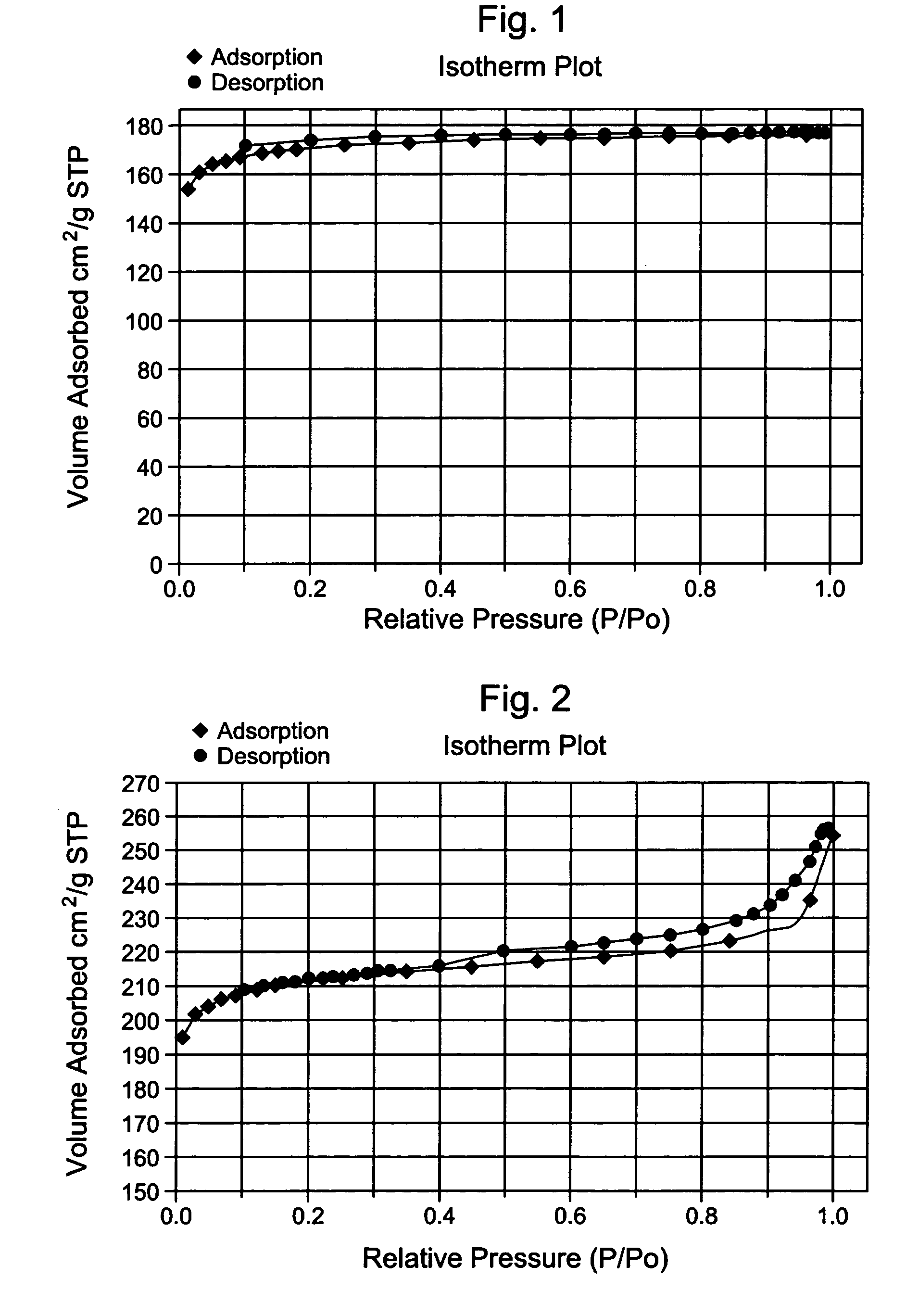

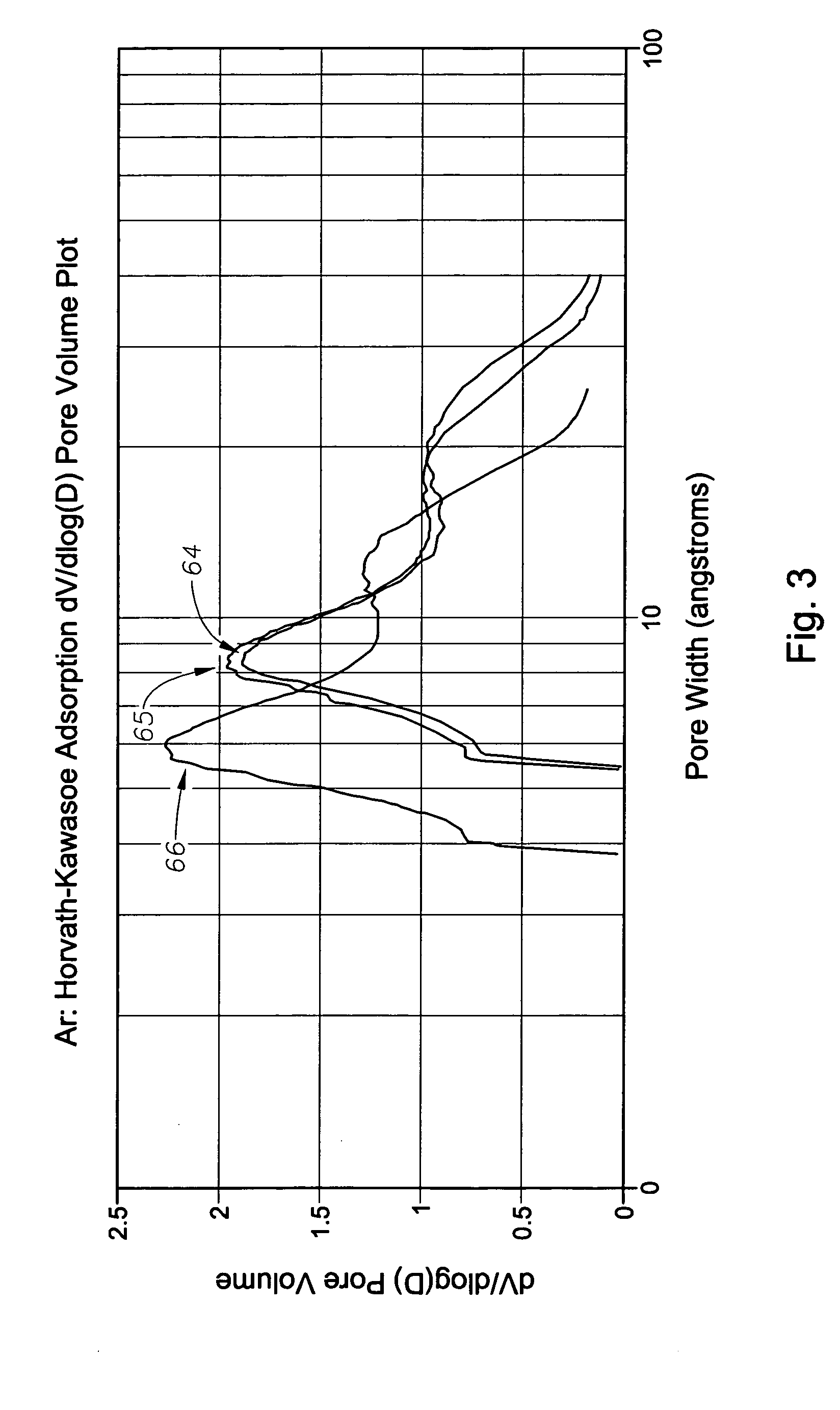

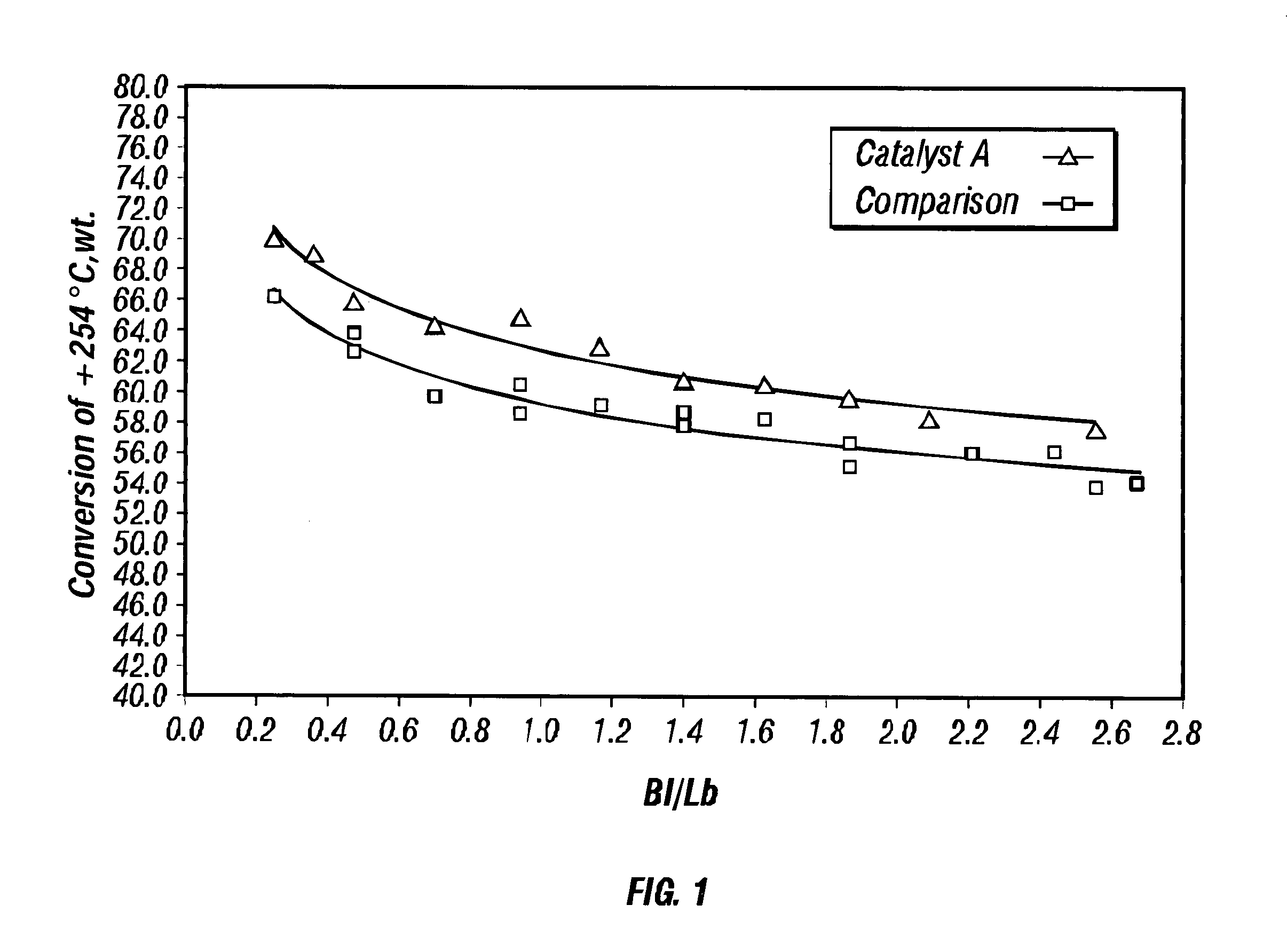

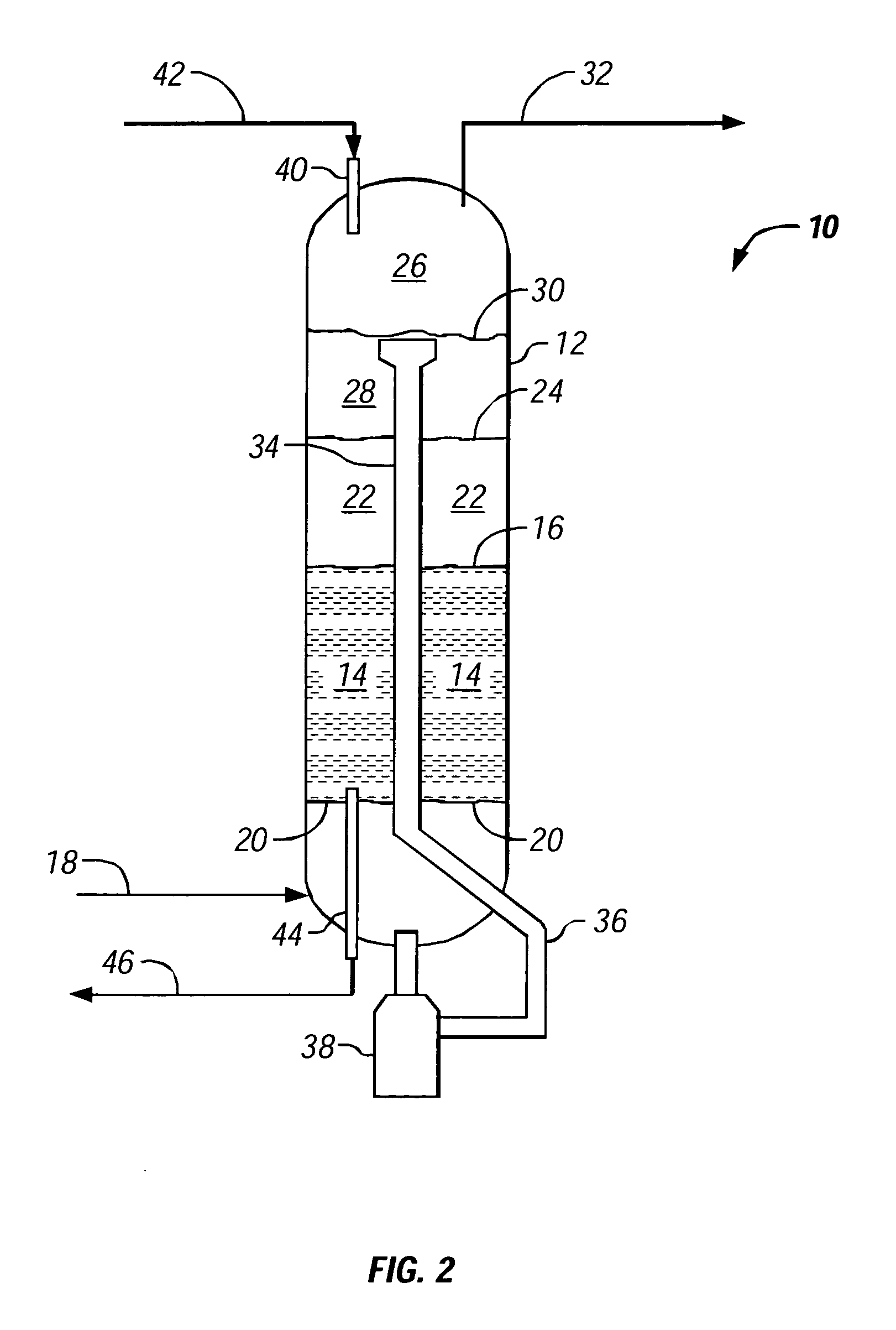

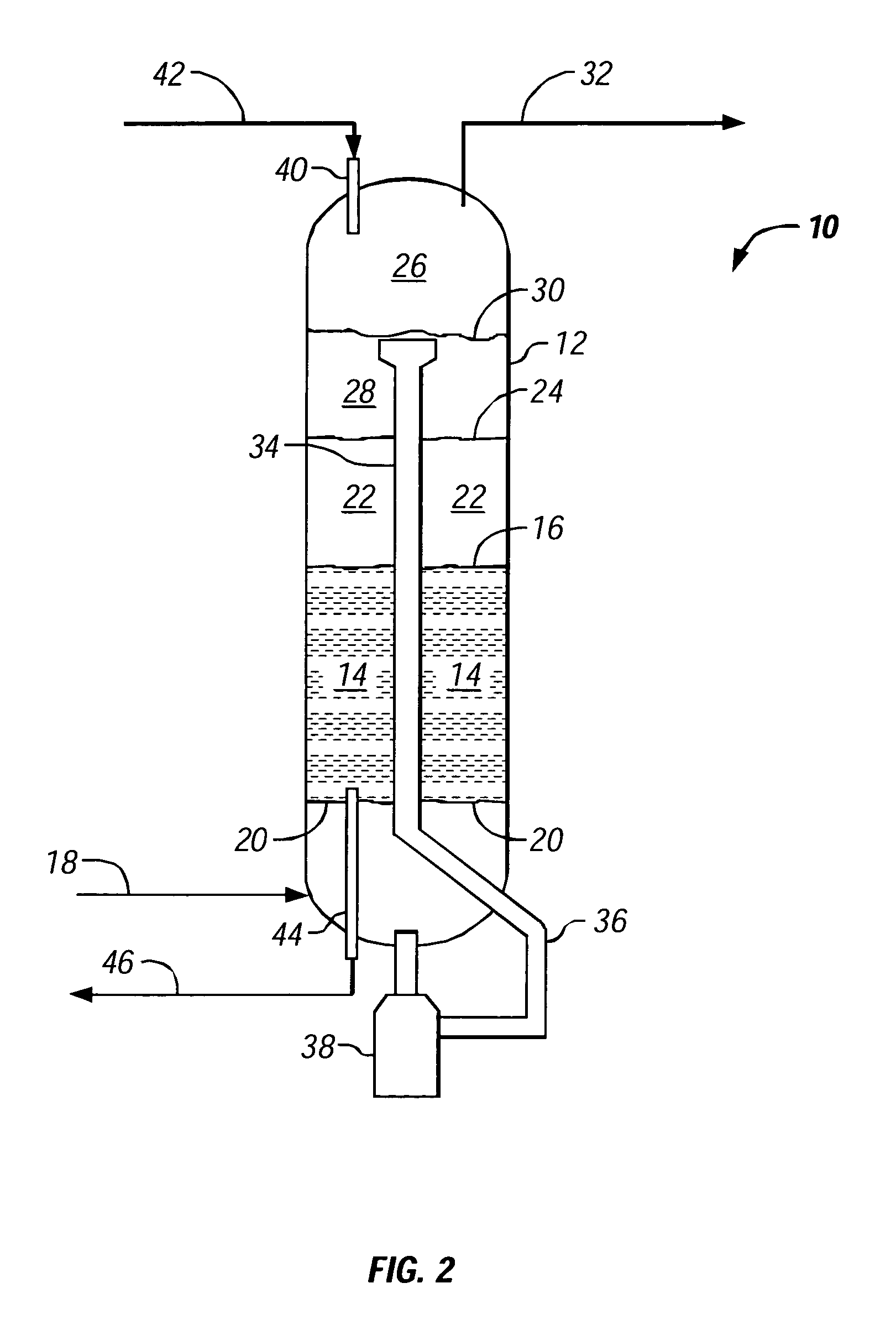

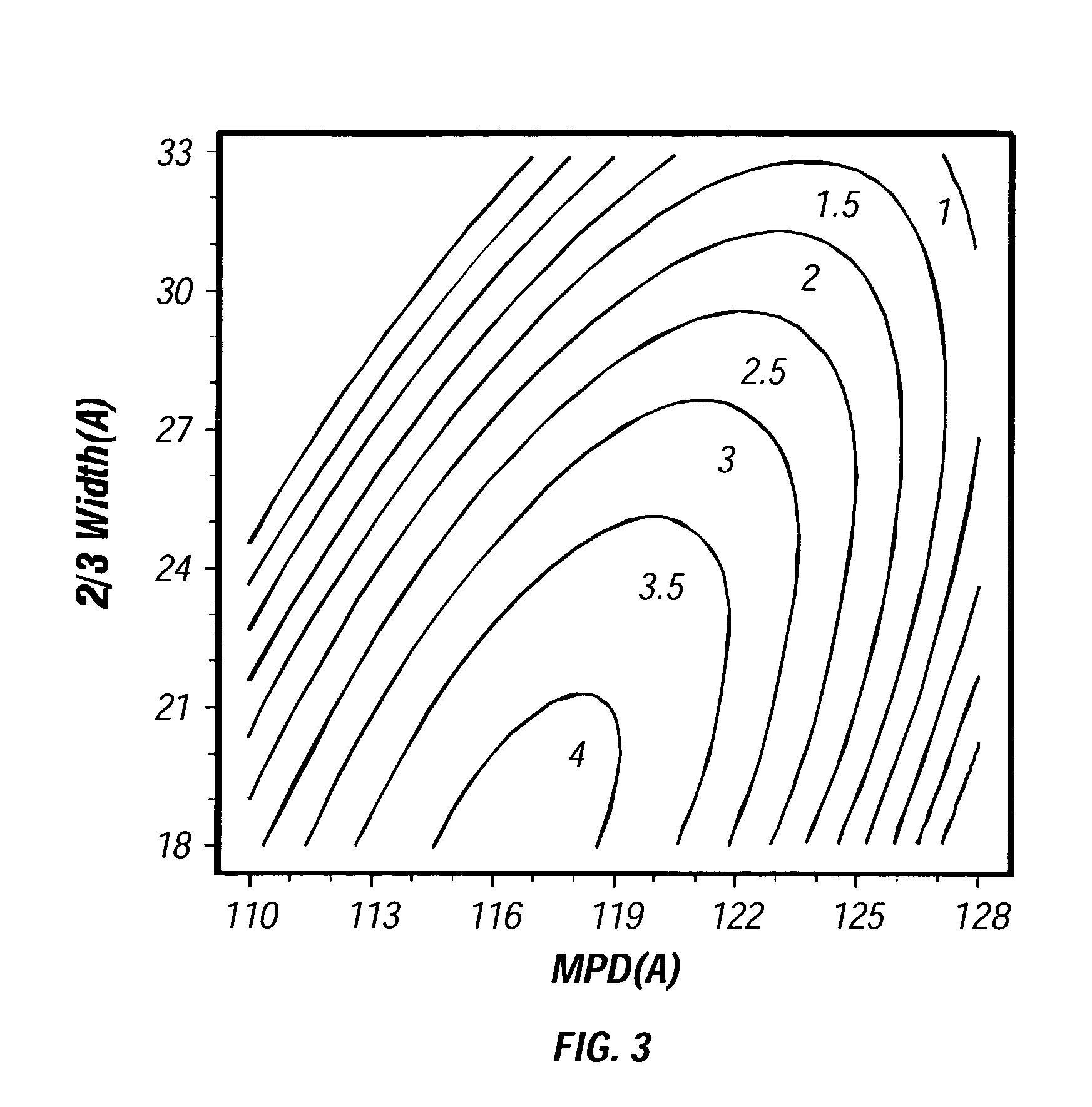

Process and catalyst for the hydroconversion of a heavy hydrocarbon feedstock

A method of hydroprocessing a heavy hydrocarbon feedstock using a hydroprocessing catalyst having specific properties making it effective in the hydroconversion of at least a portion of the heavy hydrocarbon feedstock to lighter hydrocarbons. The hydroprocessing catalyst comprises a Group VIB metal component (e.g., Cr, Mo, and W), a Group VIII metal component (e.g., Ni and Co) and, optionally, a potassium metal component that are supported on a support material comprising alumina. The alumina has novel physical properties that, in combination with the catalytic components, provide for the hydroprocessing catalyst. The hydroprocessing catalyst is particularly effective in the conversion of the heavy hydrocarbon feedstock. The alumina is characterized as having a high pore volume and a high surface area with a large proportion of the pore volume being present in the pores within a narrow pore diameter distribution about a narrowly defined range of median pore diameters. The support material preferably does not contain more than a small concentration of silica. The alumina component is preferably made by a specific method that provides for an alumina having the specific physical properties required for the hydroprocessing catalyst.

Owner:SHELL USA INC

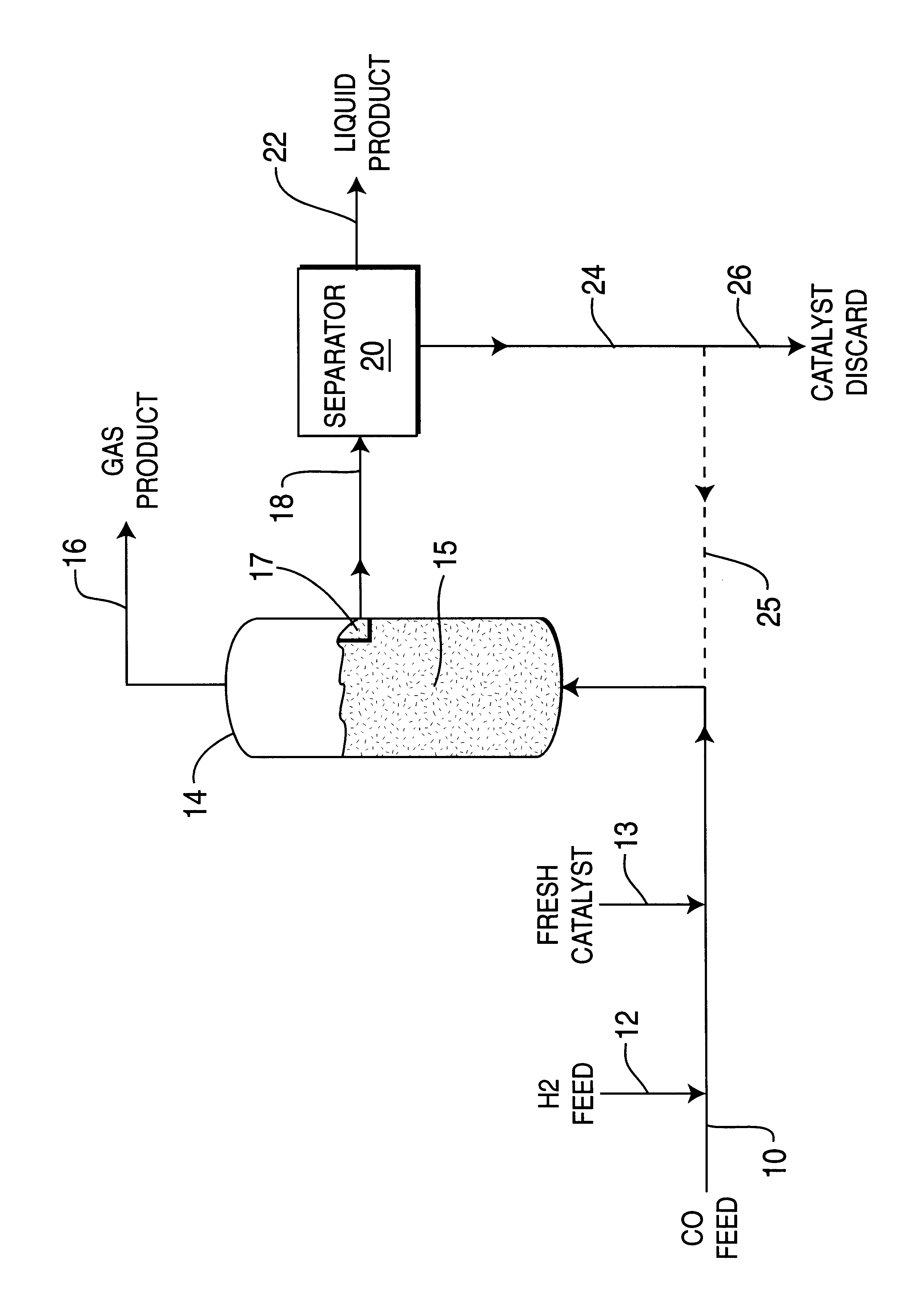

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS6277895B1High particle strengthGood attristion resistanceHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size, 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy pulverized particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen and to provide the smaller size skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-350° C. temperature, 0.5-3.0 mPa pressure and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:INST OF COAL CHEM ICCCHINESE ACADEMY OF SCI +1

Hydrocarbon-Producing Catalyst, Process for Producing the Same, and Process for Producing Hydrocarbons Using the Catalyst

InactiveUS20080064769A1Increase probabilityStably and smoothly promoteHydrocarbon from carbon oxidesOrganic compound preparationRutheniumLiquid hydrocarbons

An object of the present invention is to provide a catalyst which, in the FT process, exhibits a high chain growth probability, and a high catalytic activity, can stably and smoothly promote the reaction, exhibits a high productivity of C5+, and can efficiently produce liquid hydrocarbons, and a process therefor.The invention relates to a hydrocarbon-producing catalyst obtainable by supporting a ruthenium compound on a support composed of a manganese oxide and an aluminum oxide, and which satisfies at least one of characteristics (1) and (2): (1) the catalyst being treated with an aqueous alkaline solution and subsequently subjected to calcination treatment in the air at 150 to 500° C., (2) the aluminum oxide being an aluminum oxide wherein pore volume formed by pores having a pore diameter of 8 nm or more accounts for 50% or more of total pore volume.

Owner:JAPAN OIL GAS & METALS NAT CORP +1

Porous thin film and preparation method for porous thin film

The invention discloses a porous thin film and a preparation method for the porous thin film which are easy to achieve the high porosity, guarantee the possible formability in preparation and are simple and practical in preparation technology. The thickness of the porous thin film is 5-200Mum, the average pore size is 0.05-100Mum, and the porosity is 25-75%. The preparation method comprises the steps that 1, a support film is obtained, the support film is provided with a porous-shaped first material, and preliminary pores are formed in the first material; 2, a slurry is prepared, and the slurry contains a powdered second material; 3, the support film is coated with the slurry and then made into a rough-body; 4, the rough-body is sintered, reaction happens between the first material and the second material in sintering, a porous third material is generated, and meanwhile secondary pores communicated with the preliminary pores are generated; 5, the porous thin film is obtained by cooling after the sintering. Due to the fact that at least the preliminary pores and the secondary pores are contained, and therefore the high porosity of the porous thin film is each to be achieve.

Owner:CHENGDU INTERMENT TECH

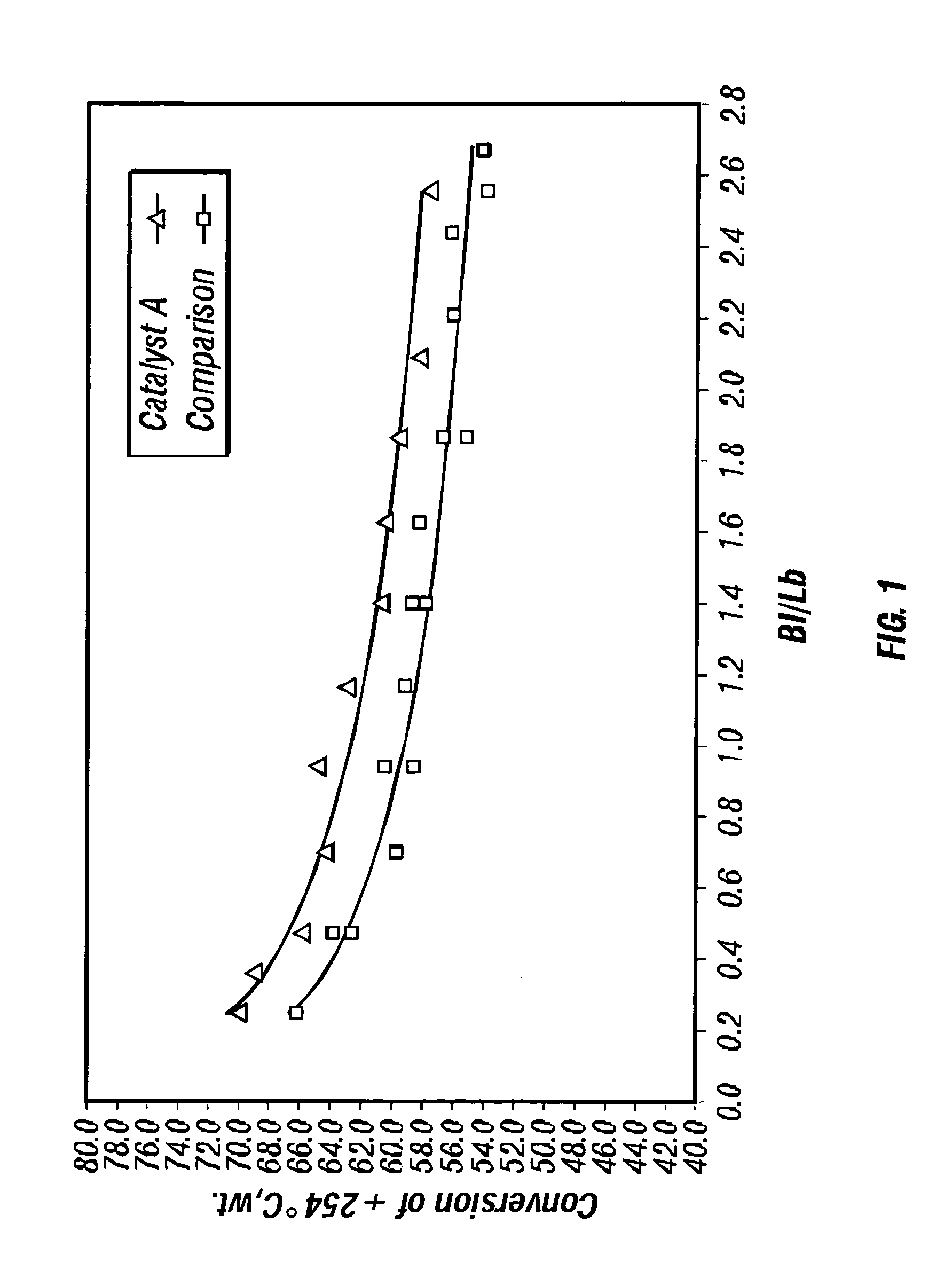

Ceramic honeycomb filter

InactiveUS20030093982A1Increased durabilityHigh strengthCombination devicesAuxillary pretreatmentParticulatesMeasurement point

A ceramic honeycomb filter comprising a ceramic honeycomb structure having porous partition walls defining a plurality of flow paths for flowing an exhaust gas through the porous partition walls to remove particulates from the exhaust gas, the predetermined flow paths among the flow paths being sealed at their ends, a catalyst being carried by the porous partition walls, the porous partition walls having a porosity of 60-75% and an average pore diameter of 15-25 mum when measured according to a mercury penetration method, and the maximum of a slope Sn of a cumulative pore volume curve of the porous partition walls relative to a pore diameter obtained at an n-th measurement point being 0.7 or more, the Sb being represented by the following formula (1): Sn=-(Vb-Vn-1) / [log Dn-log (Dn-1)] (1), wherein Dn is a pore diameter (mum) at an n-th measurement point, Dn-1 is a pore diameter (mum) at an (n-1)-th measurement point, Vn is a cumulative pore volume (cm3 / g) at an n-th measurement point, and Vn-1 is a cumulative pore volume (cm3 / g) at an (n-1)-th measurement point.

Owner:HITACHI METALS LTD +1

Process and catalyst for the hydroconversion of a heavy hydrocarbon feedstock

A method of hydroprocessing a heavy hydrocarbon feedstock using a hydroprocessing catalyst having specific properties making it effective in the hydroconversion of at least a portion of the heavy hydrocarbon feedstock to lighter hydrocarbons. The hydroprocessing catalyst comprises a Group VIB metal component (e.g., Cr, Mo, and W), a Group VIII metal component (e.g., Ni and Co) and, optionally, a potassium metal component that are supported on a support material comprising alumina. The alumina has novel physical properties that, in combination with the catalytic components, provide for the hydroprocessing catalyst. The hydroprocessing catalyst is particularly effective in the conversion of the heavy hydrocarbon feedstock. The alumina is characterized as having a high pore volume and a high surface area with a large proportion of the pore volume being present in the pores within a narrow pore diameter distribution about a narrowly defined range of median pore diameters. The support material preferably does not contain more than a small concentration of silica. The alumina component is preferably made by a specific method that provides for an alumina having the specific physical properties required for the hydroprocessing catalyst.

Owner:SHELL USA INC

Preparation methods for macroporous alumina carrier and hydrodemetallization catalyst

ActiveCN102441437AModerate mechanical strengthModerate bulk densityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPseudoboehmiteMetal catalyst

The invention discloses preparation methods for a macroporous alumina carrier and a hydrodemetallization catalyst. The preparation method for the macroporous alumina carrier includes the following steps: (1) dry pseudoboehmite gel powder is hydrothermally processed under high pressure; (2) the dry pseudoboehmite gel powder obtained in step 1 is kneaded into a plastic, and pore-expanding agent is added in step 1 or step 2; (3) the plastic obtained in step 2 is shaped, the shaped material is dried and baked, and thereby the macroporous alumina carrier is obtained. The impregnation method is adopted to prepare the hydrodemetallization catalyst. The hydrodemetallization catalyst prepared by the method has large pore volume and pore diameter, centrally distributed pores, moderate mechanical strength and high activity and activity stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

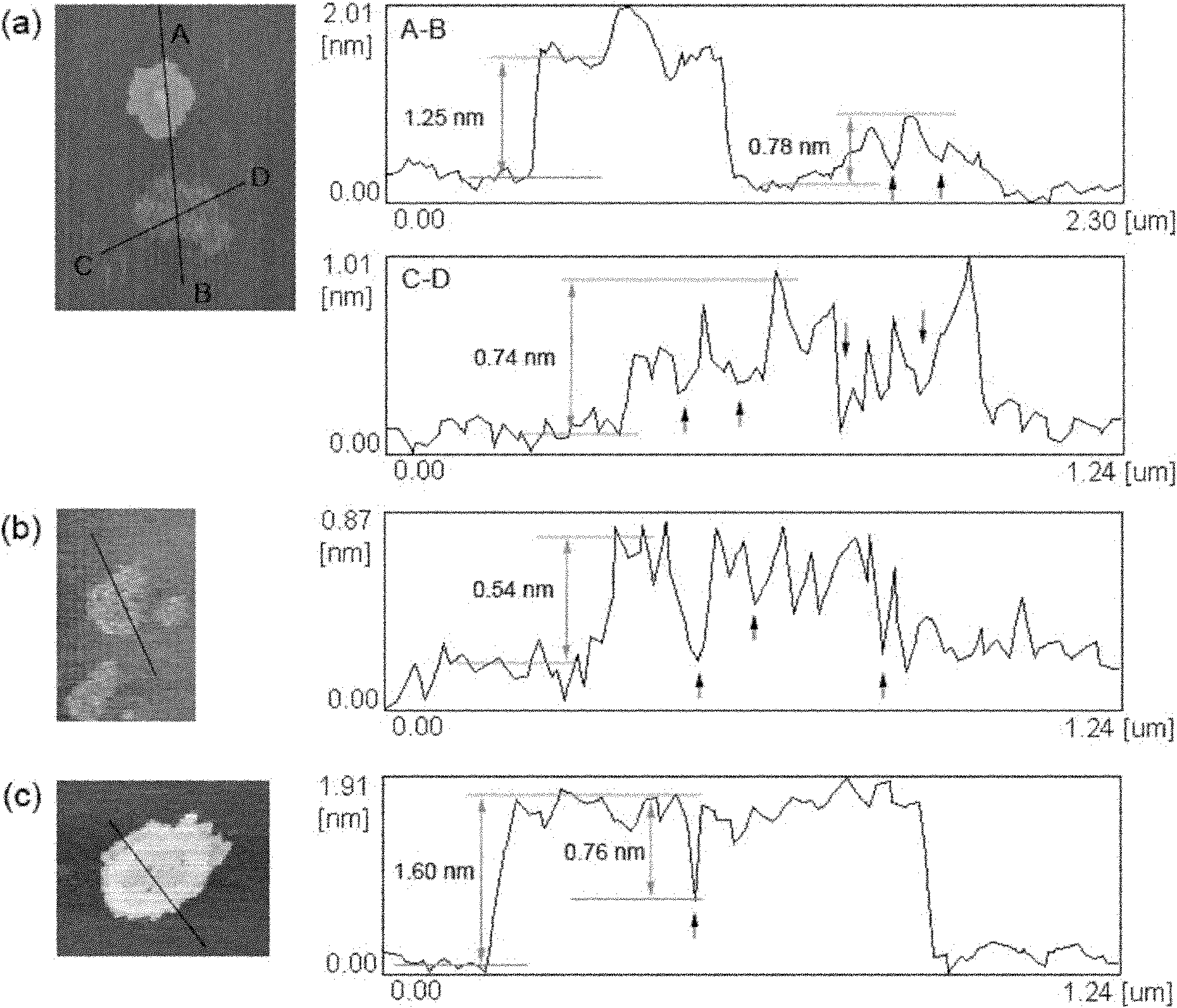

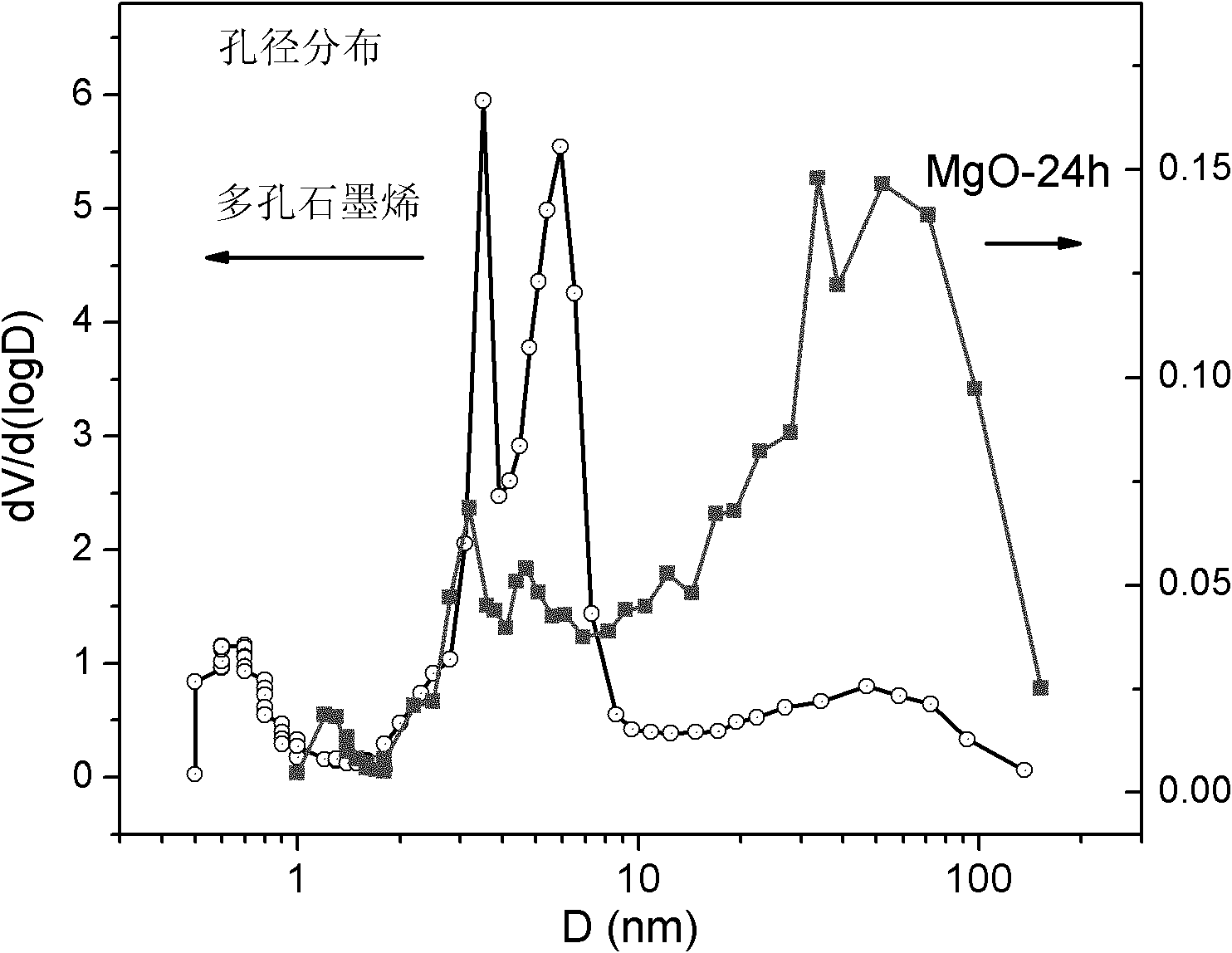

Graphene with porous structure and preparation method of graphene

The invention discloses a graphene with a porous structure and a preparation method of the graphene. The porous grapheme consists of a single-layer or multi-layer graphene structure unit, the single-layer or multi-layer grapheme structure unit has a pore-shaped structure (pore diameter is 0.1-200 nm) and a large specific surface area (300-2000 m<2> / g), thus the graphene has potential application value in the aspects of super-capacitors, conductive filling materials and the like. The preparation method of the porous grapheme is characterized in that MgO, Mg(OH)2, Al2O3, Al(OH)3, hydrotalcite compounds and / or corresponding calcined products of the substances are used as catalysts, or MgO, Mg(OH)2, Al2O3, Al(OH)3, hydrotalcite compounds and / or corresponding calcined products of the substances are used as carriers so as to further load one or more active components of Fe, Co, Ni and Mo and then the obtained substance is used as the catalyst ( the pore diameter of the catalyst is 1-200 nm, and the specific surface area is 10-300 m<2> / g); and then at the temperature of 300-1000 DEG C, the graphene is prepared by using inert gases such as nitrogen, argon, helium and the like and using a hydrocarbon chemical gas phase deposition method.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com