Patents

Literature

142results about How to "Easy adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

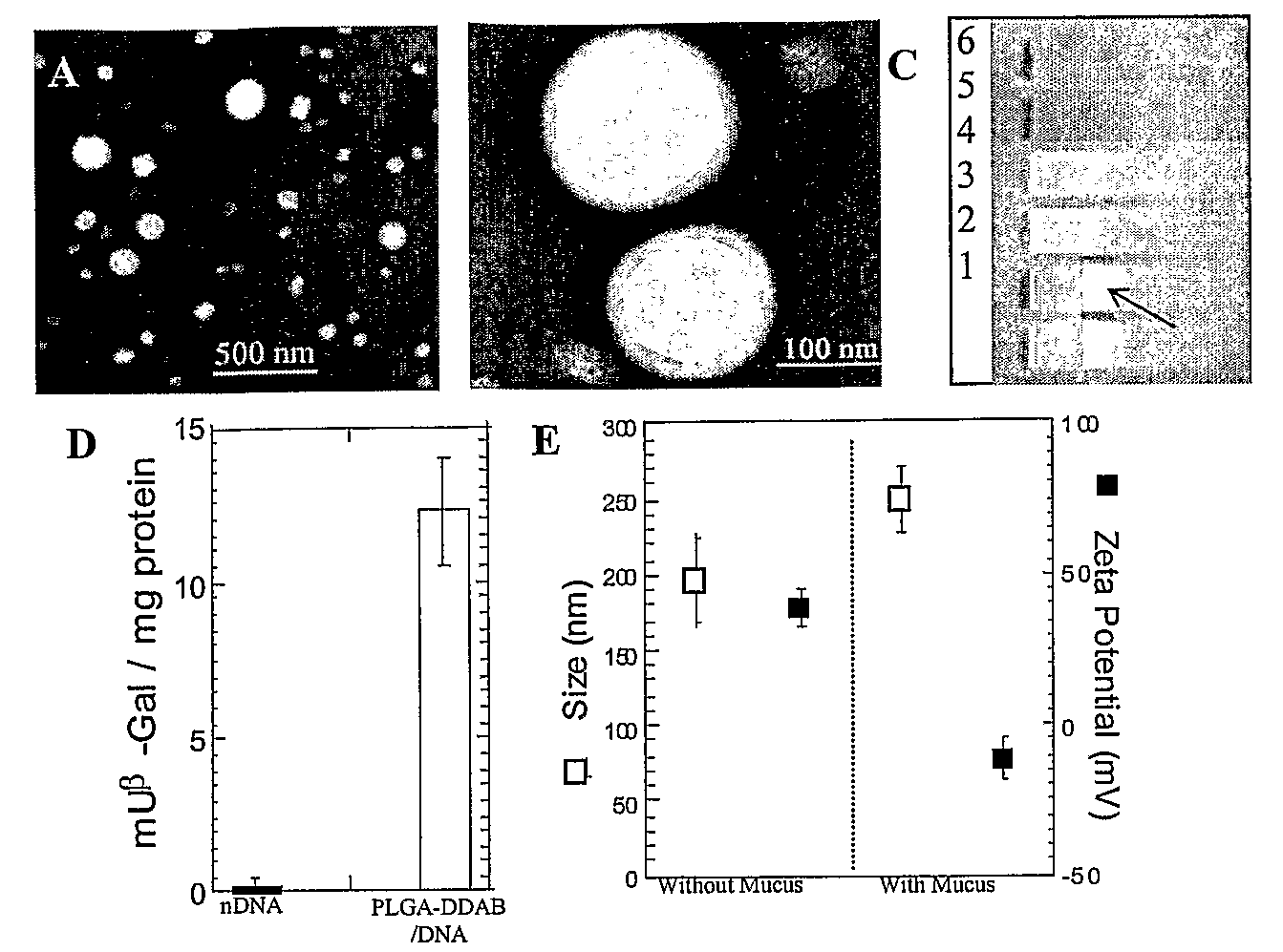

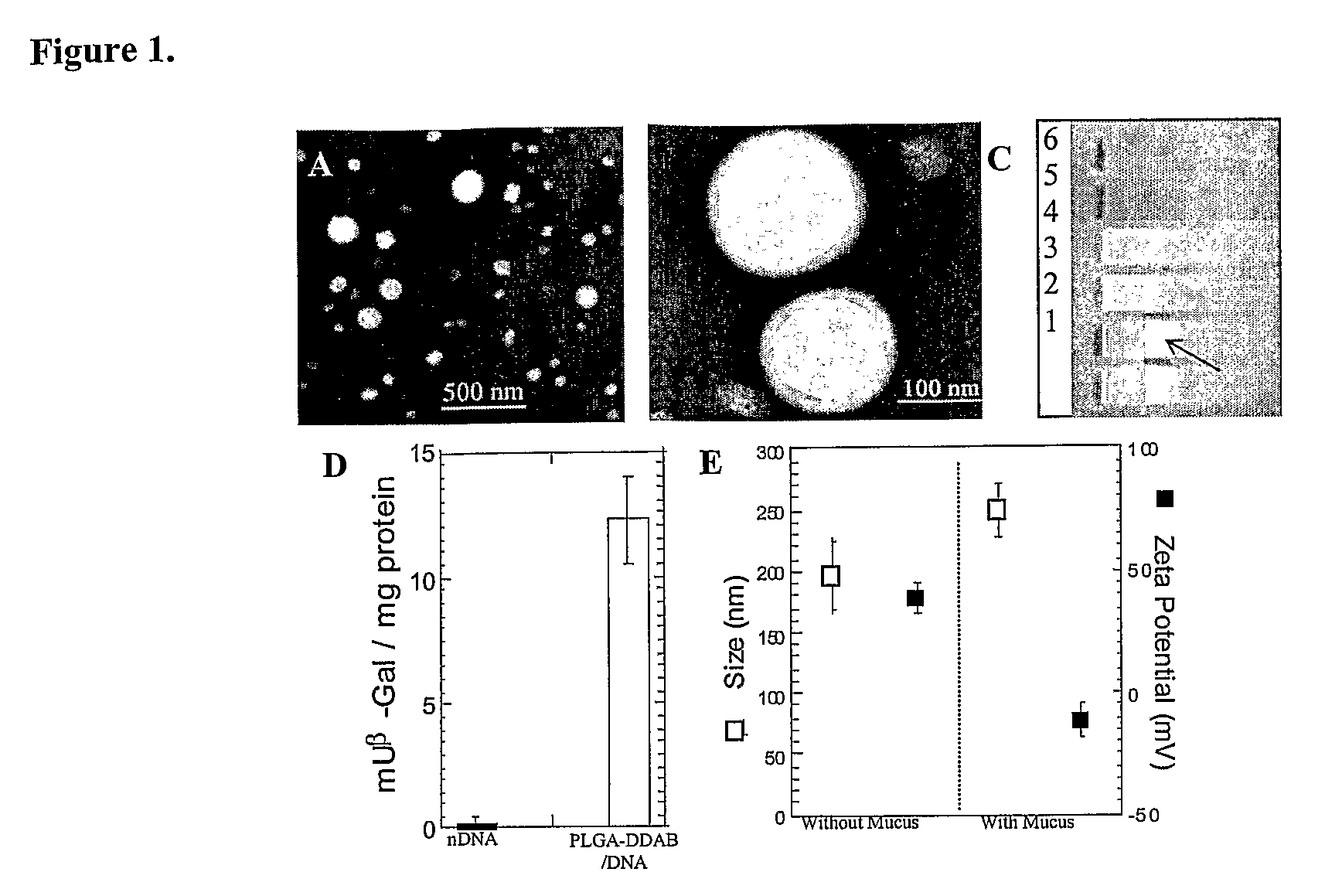

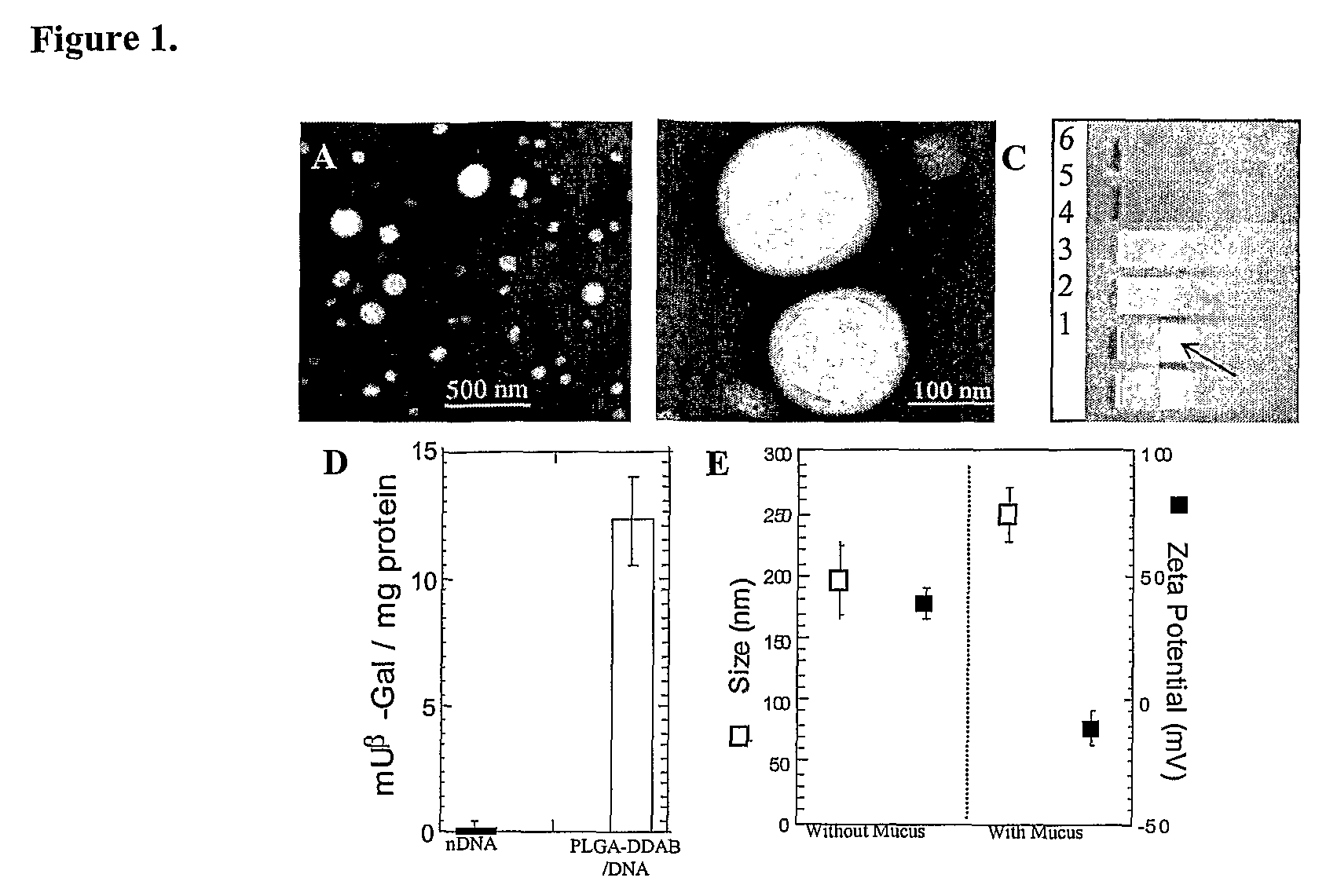

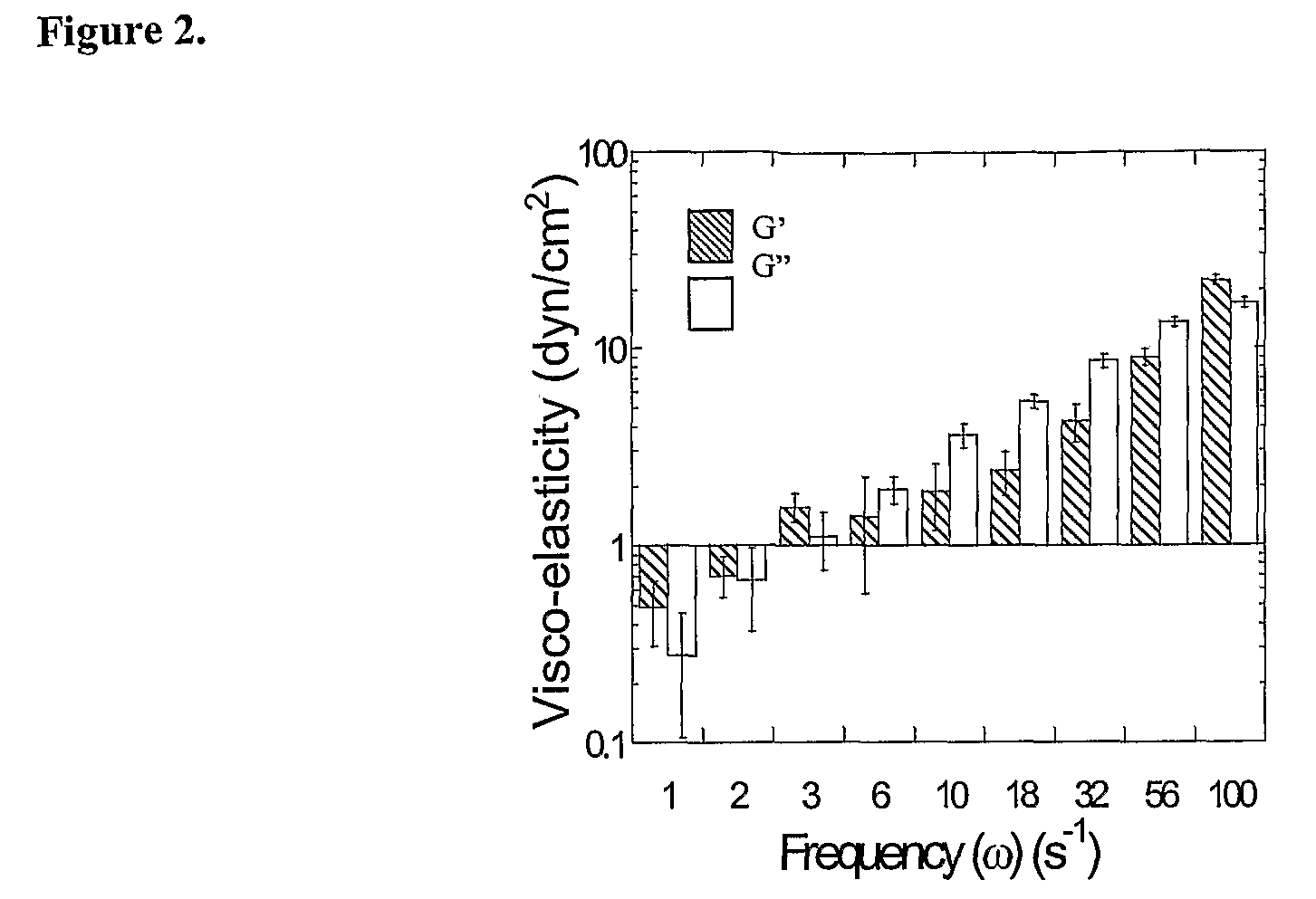

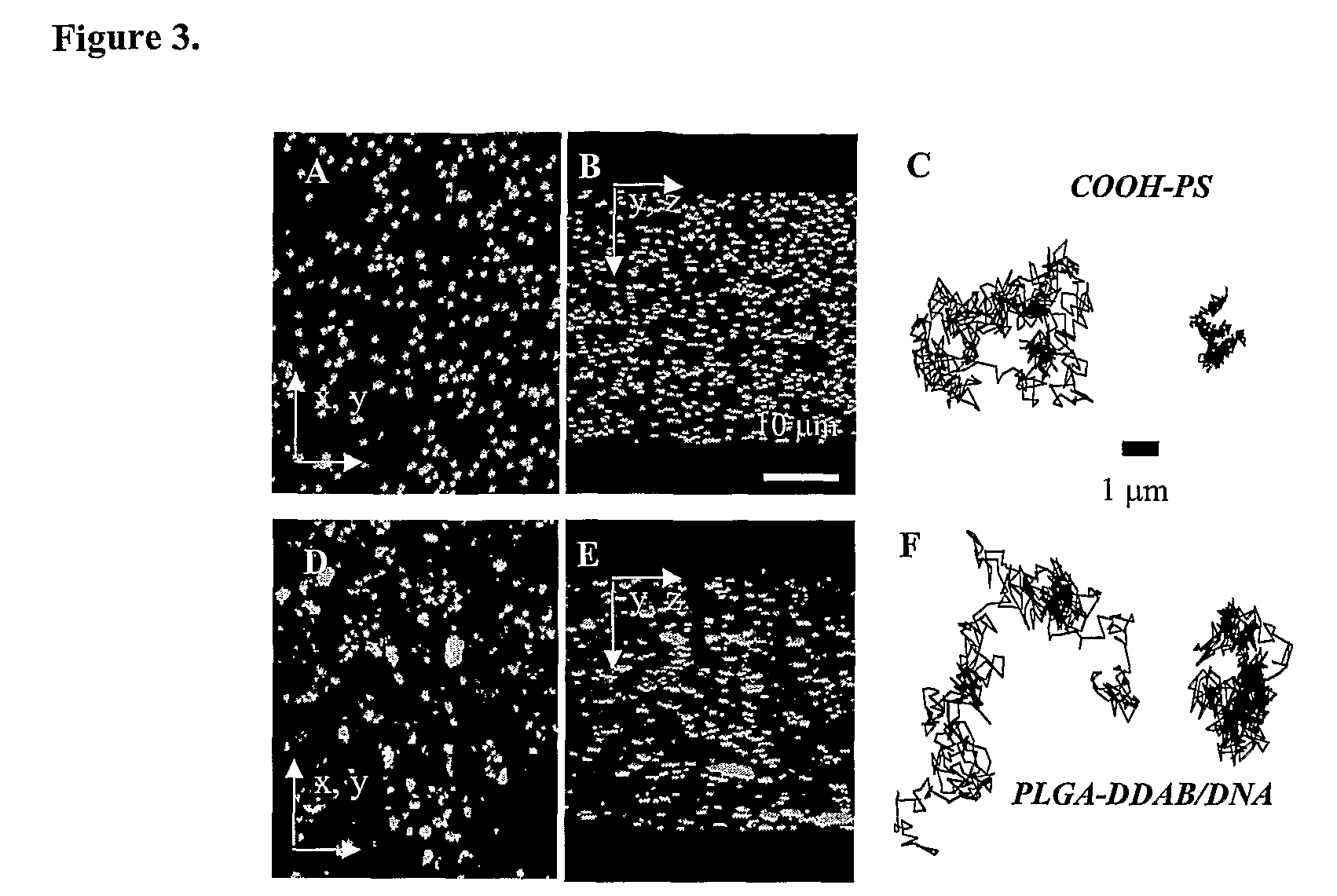

Drugs And Gene Carrier Particles That Rapidly Move Through Mucous Barriers

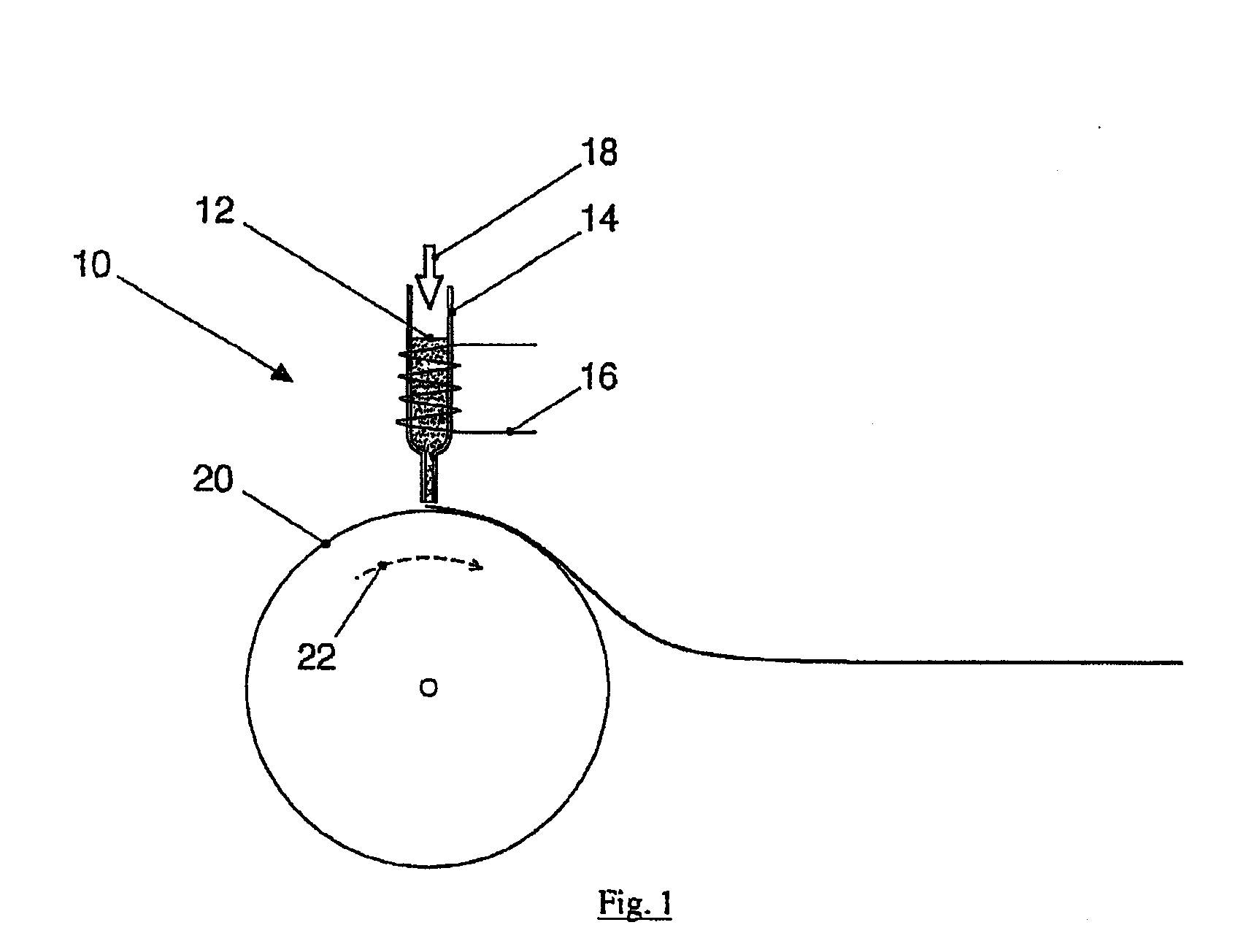

ActiveUS20080166414A1Easy adhesionPromote complexationPowder deliveryOrganic active ingredientsCrystallographyMucus

Owner:THE JOHNS HOPKINS UNIVERSITY SCHOOL OF MEDICINE

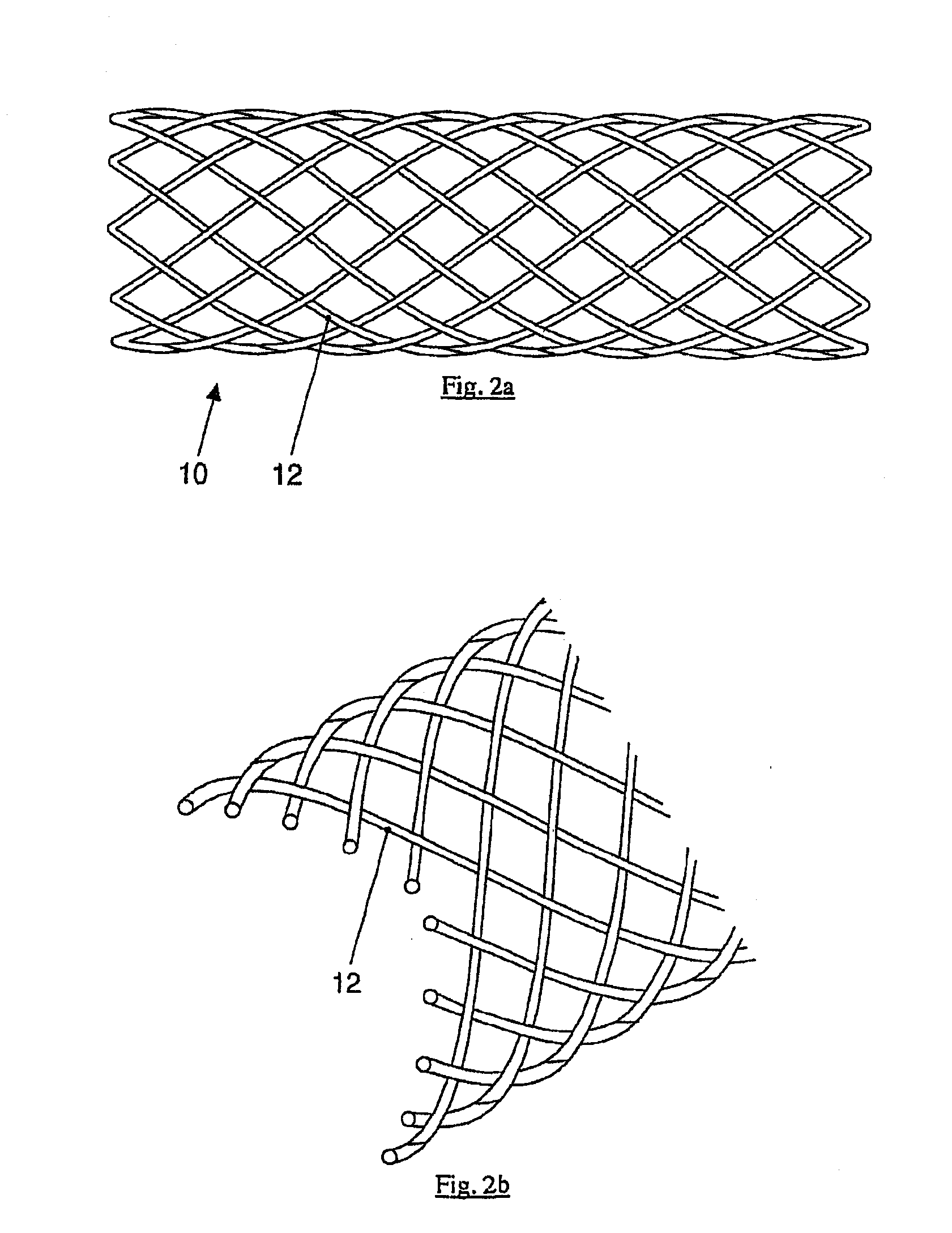

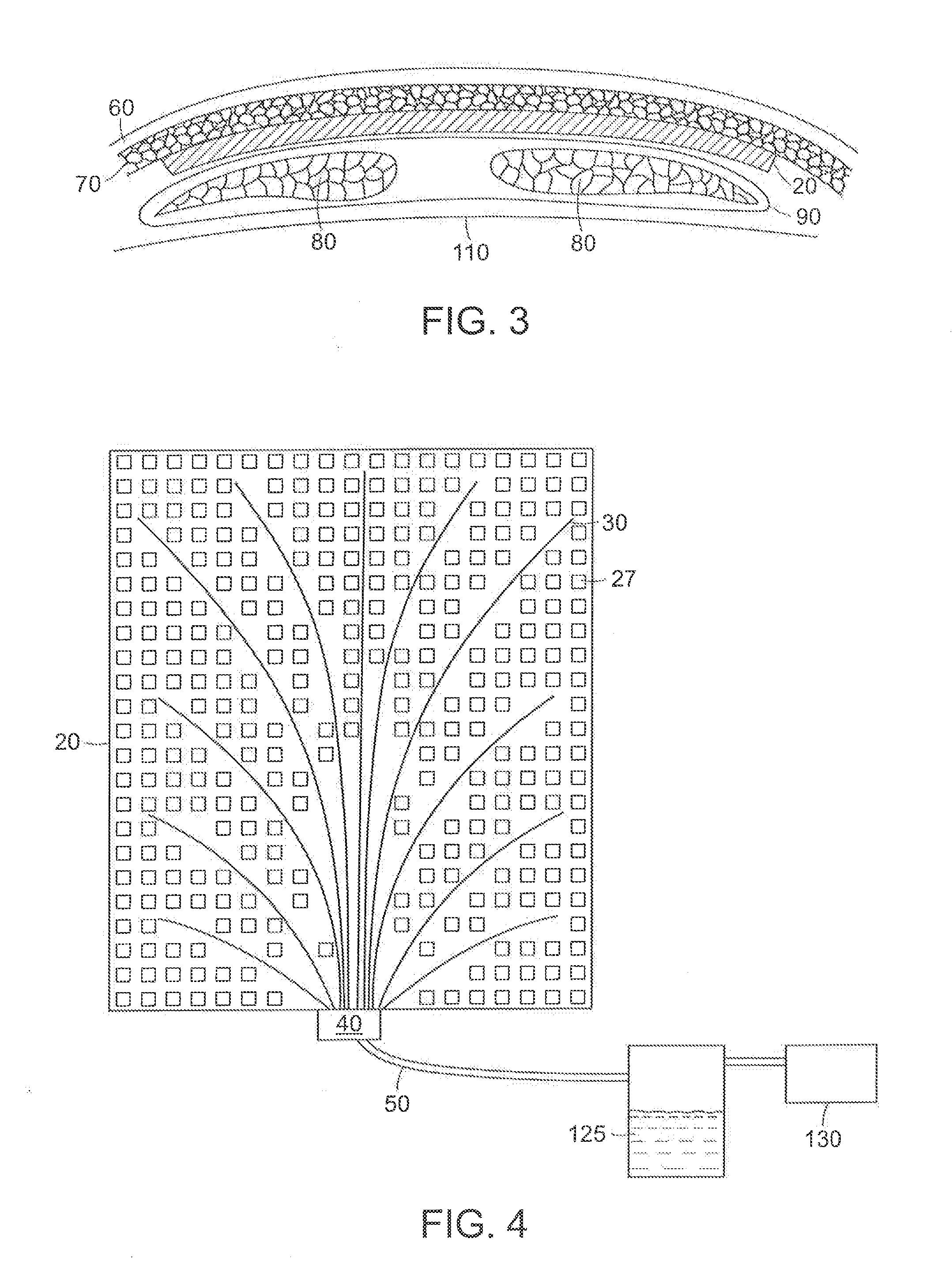

Soft tissue implants with improved interfaces

InactiveUS20060293760A1Facilitates dual functionInduce new tissue formationAnkle jointsBone implantHost tissueDual function

Specialization of the end(s) or host tissue contact points of biocompatible scaffolds brings a functionality to the scaffold that facilitates the dual function of inducing new tissue formation and facilitating attachment and site-specific tissue formation at the scaffolds' functionalized points of fixation.

Owner:DEPUY SPINE INC (US) +1

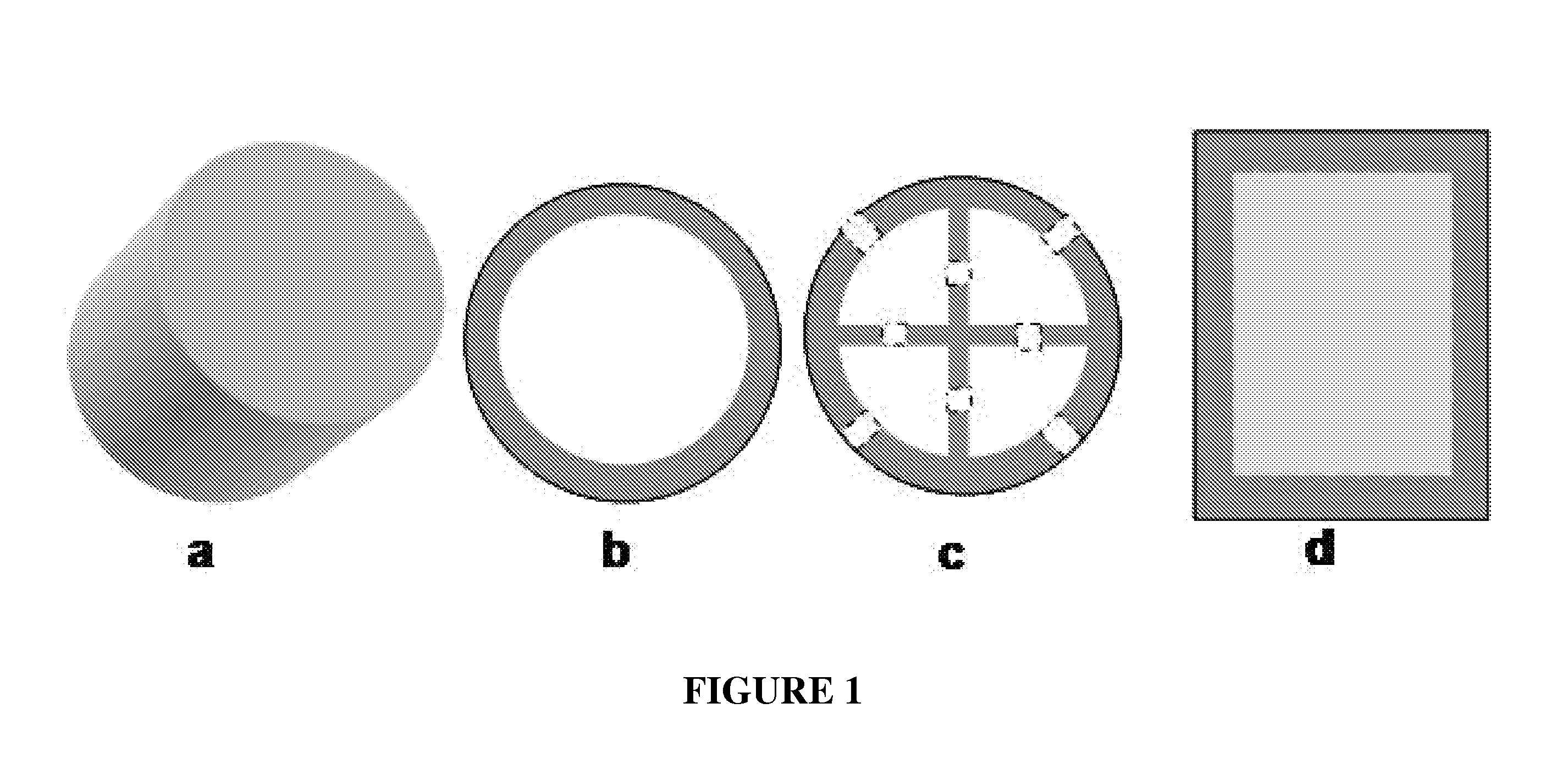

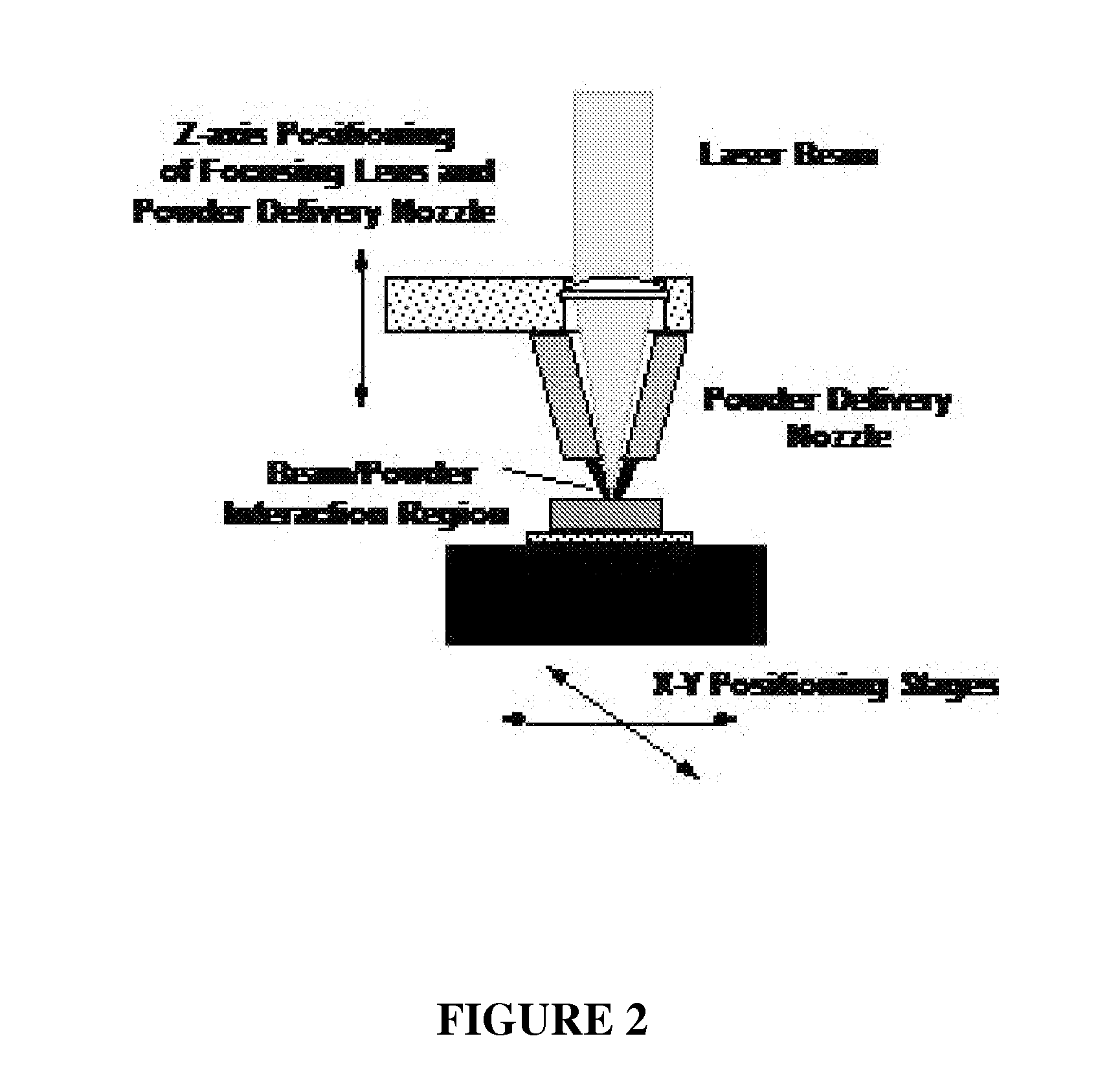

Bone replacement materials

ActiveUS20070203584A1Easy adhesionFacilitate cell growthAdditive manufacturing apparatusBone implantBone tissueBone tissue engineering

Particular aspects provide novel devices for bone tissue engineering, comprising a metal or metal-based composite member / material comprising an interior macroporous structure in which porosity may vary from 0-90% (v), the member comprising a surface region having a surface pore size, porosity, and composition designed to encourage cell growth and adhesion thereon, to provide a device suitable for bone tissue engineering in a recipient subject. In certain aspects, the device further comprises a gradient of pore size, porosity, and material composition extending from the surface region throughout the interior of the device, wherein the gradient transition is continuous, discontinuous or seamless and the growth of cells extending from the surface region inward is promoted. Additional aspects provide a device for bone tissue engineering, comprising a metal or metal-based composite member / material comprising an interior porous structure, wherein the pore size, porosity and material composition is selected to provide a device having an optimal density and / or elastic modulus and / or compression strength for a specific recipient. Novel methods for fabricating the devices are also provided.

Owner:WASHINGTON STATE UNIVERSITY

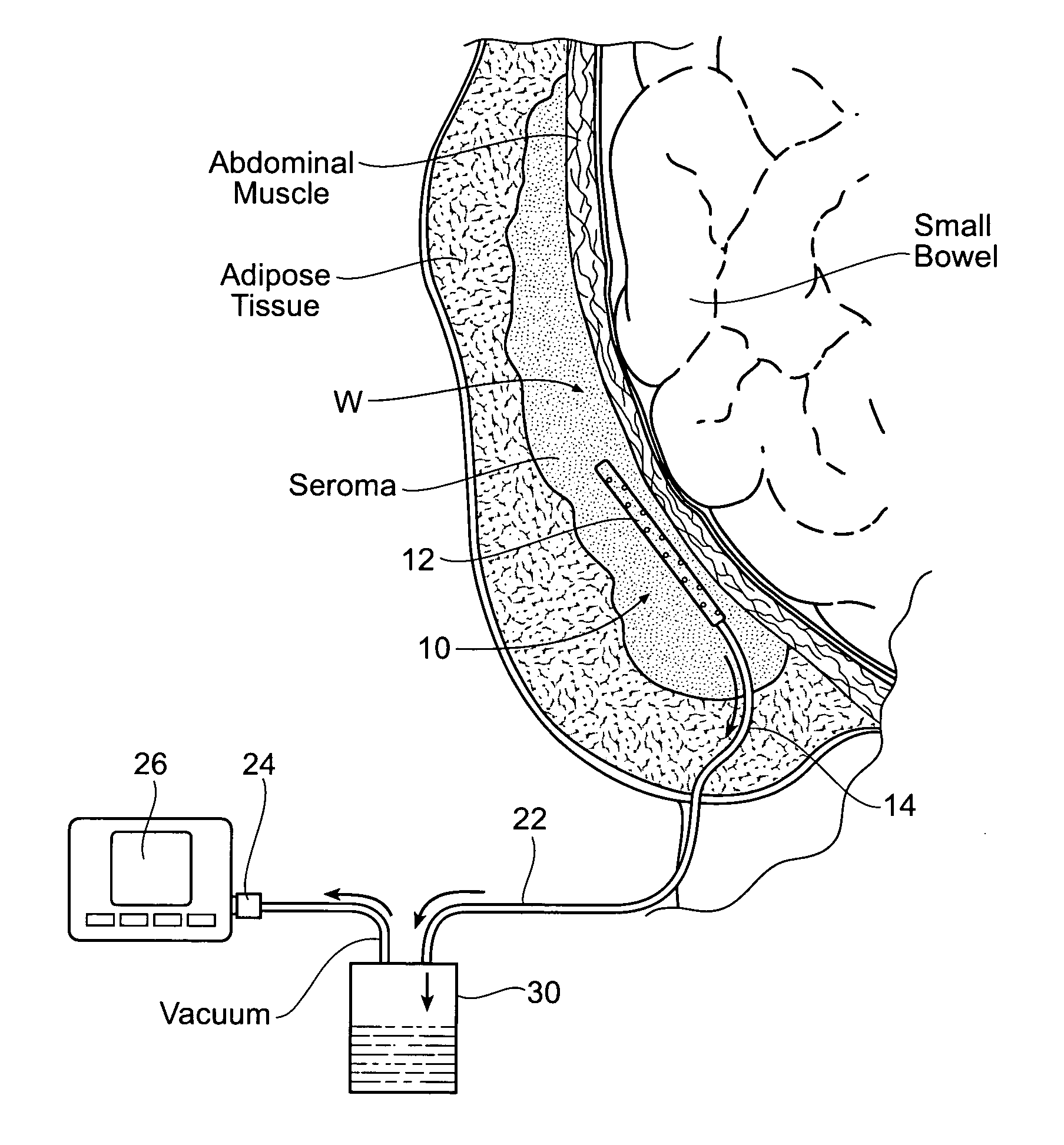

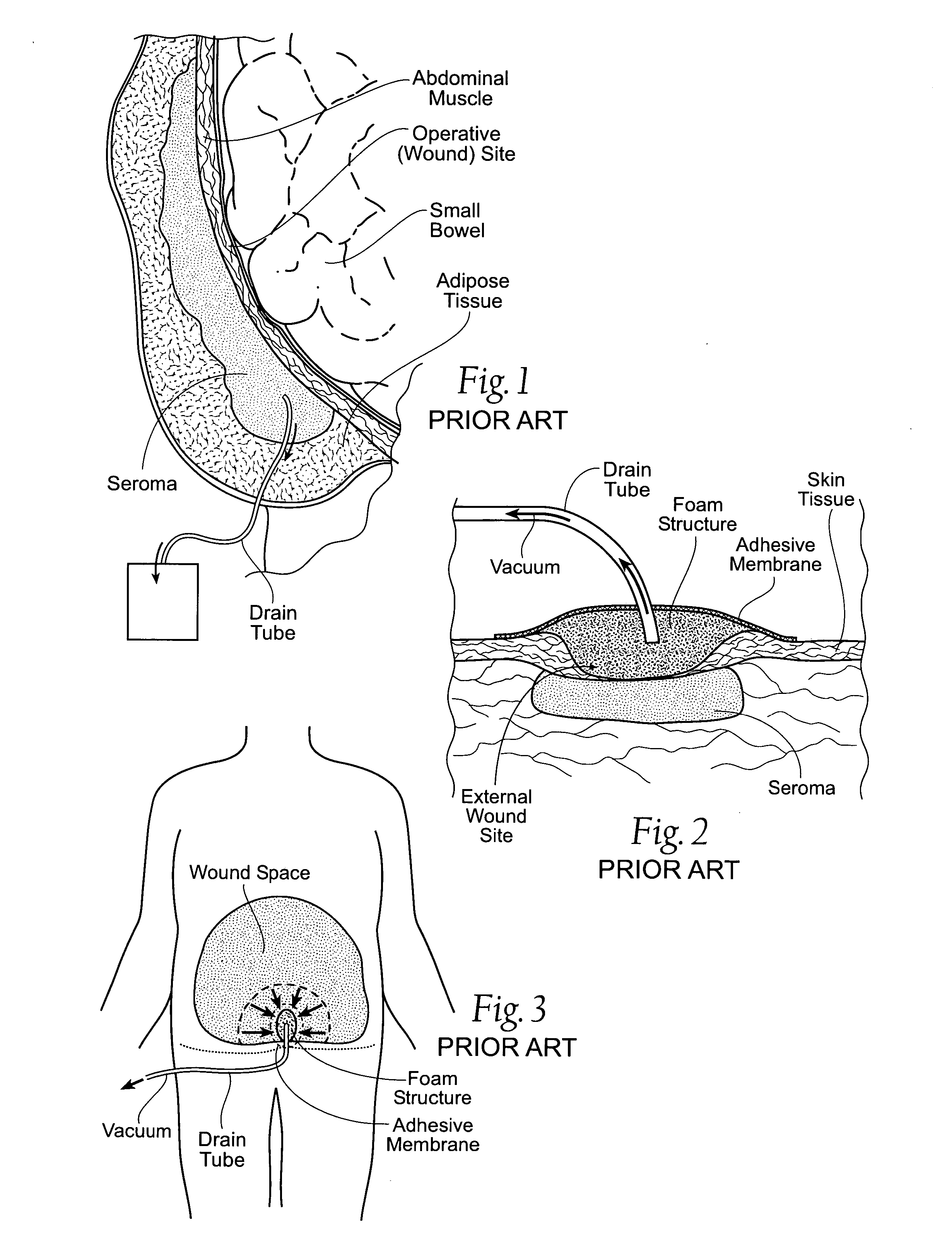

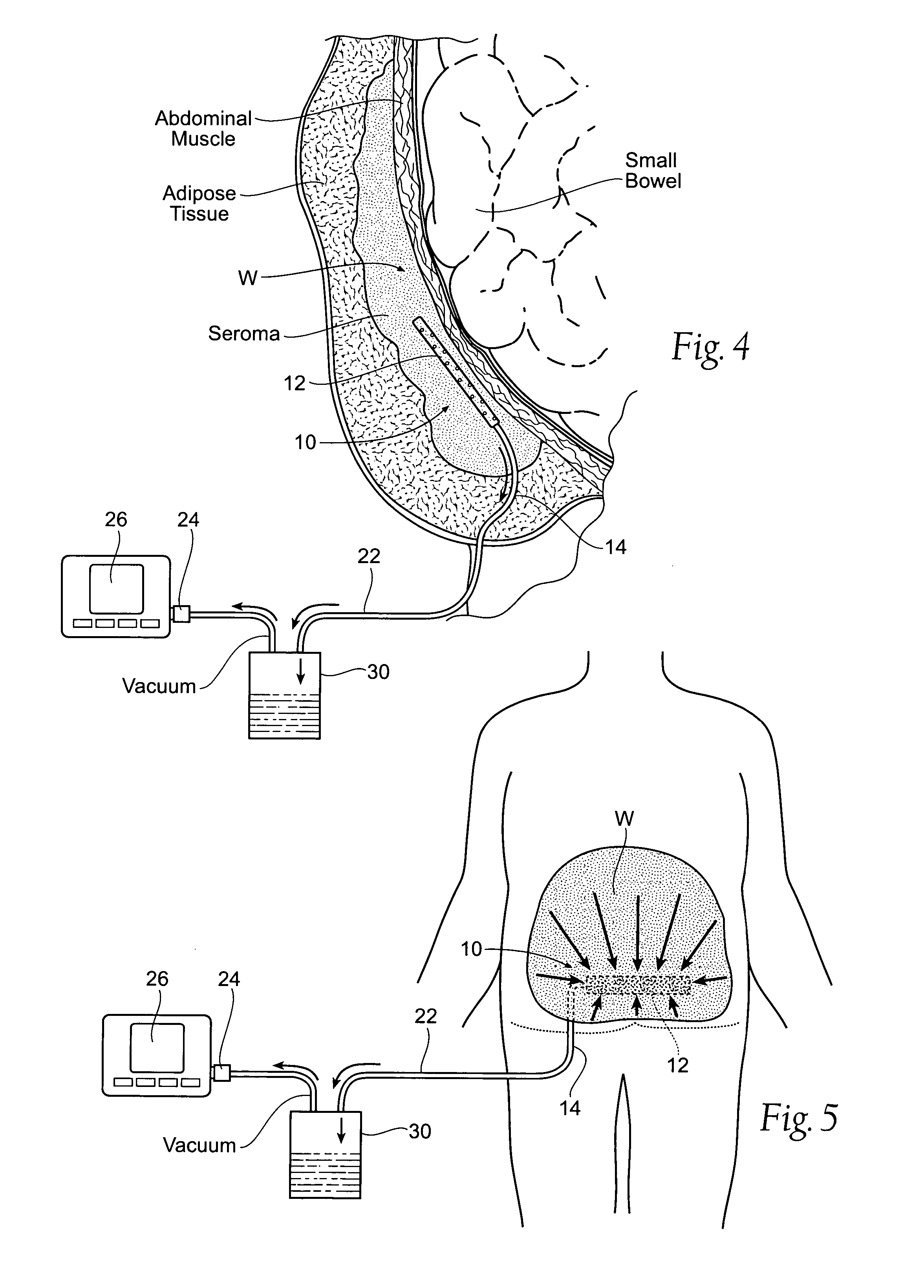

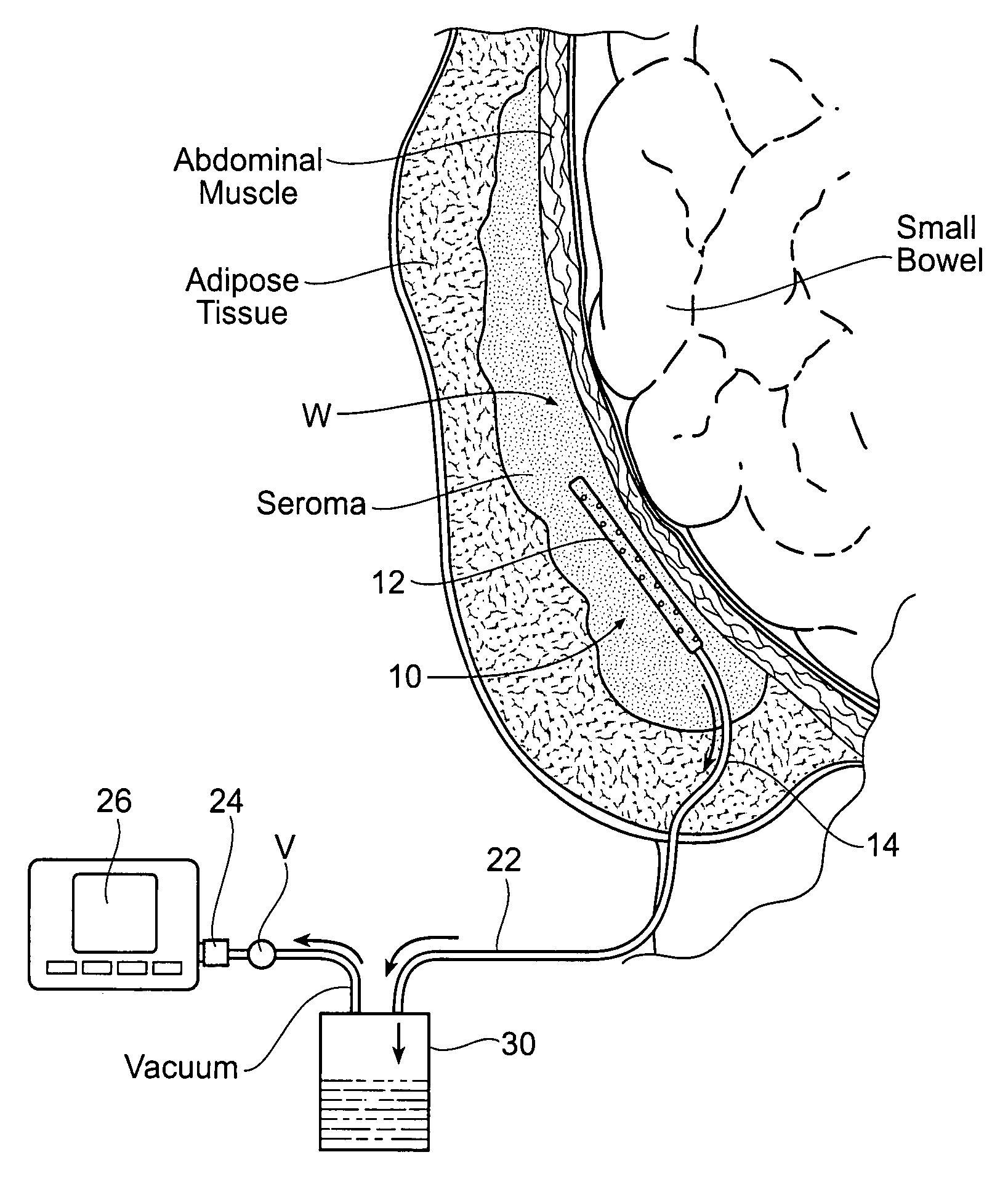

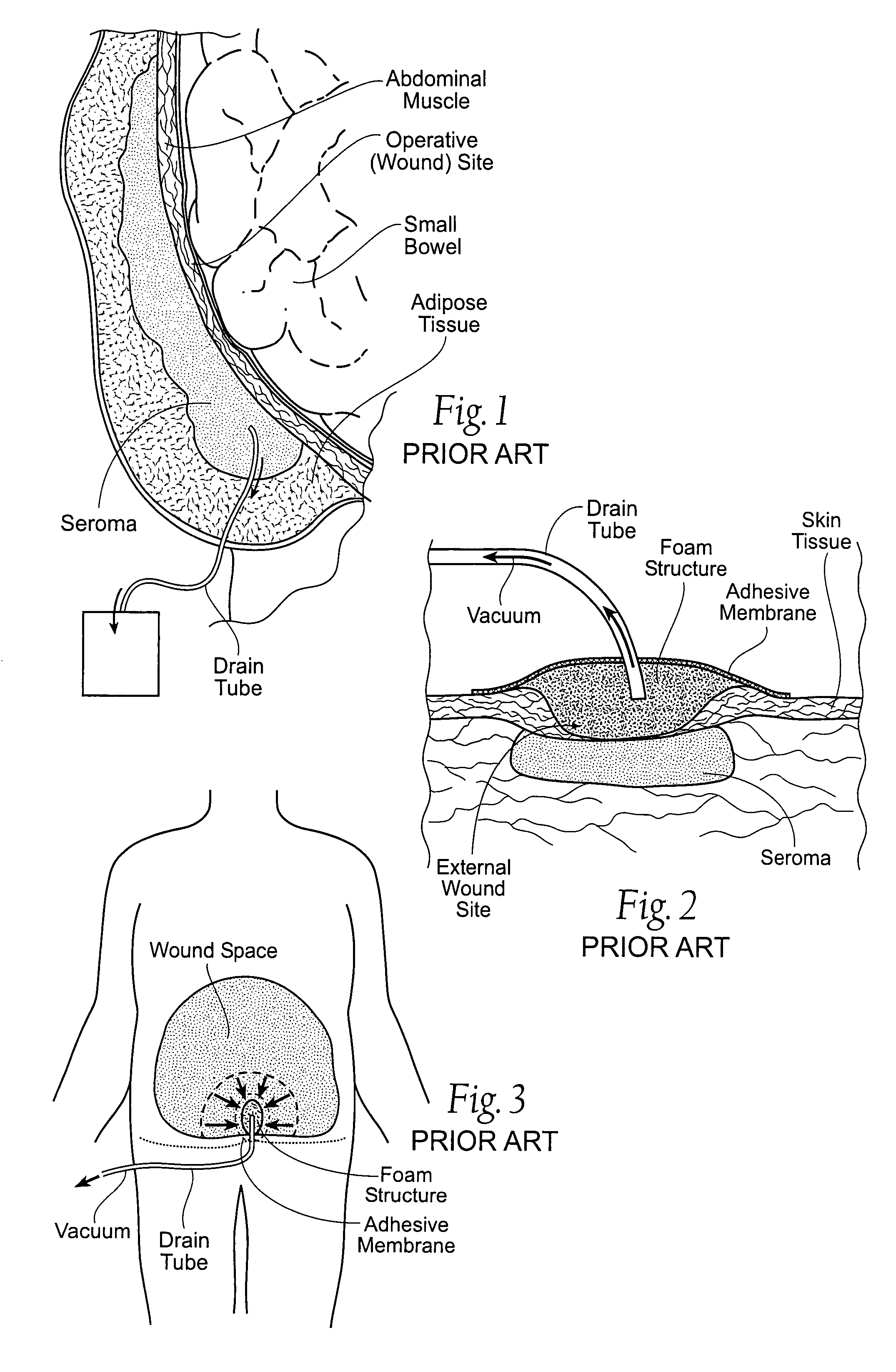

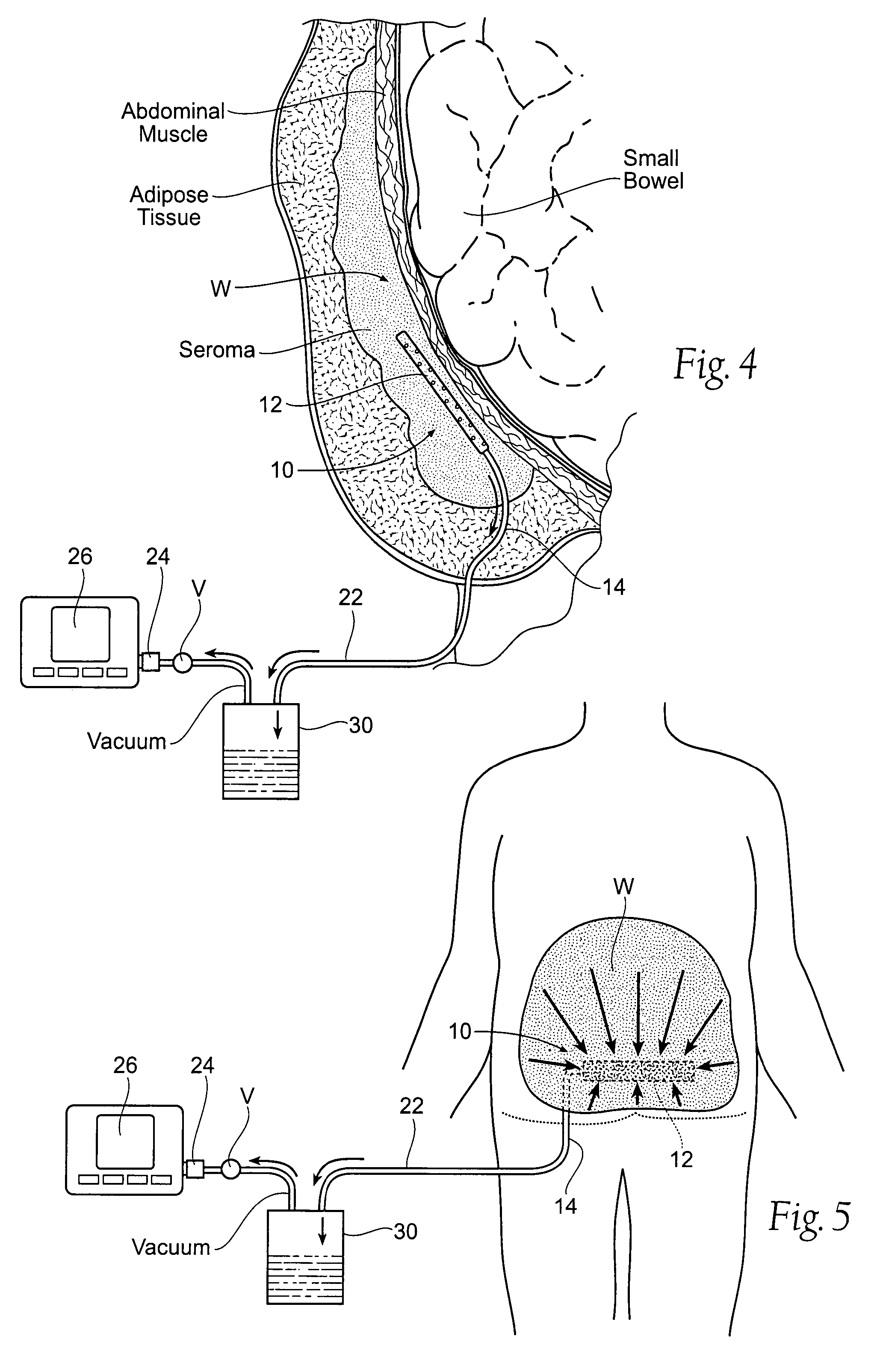

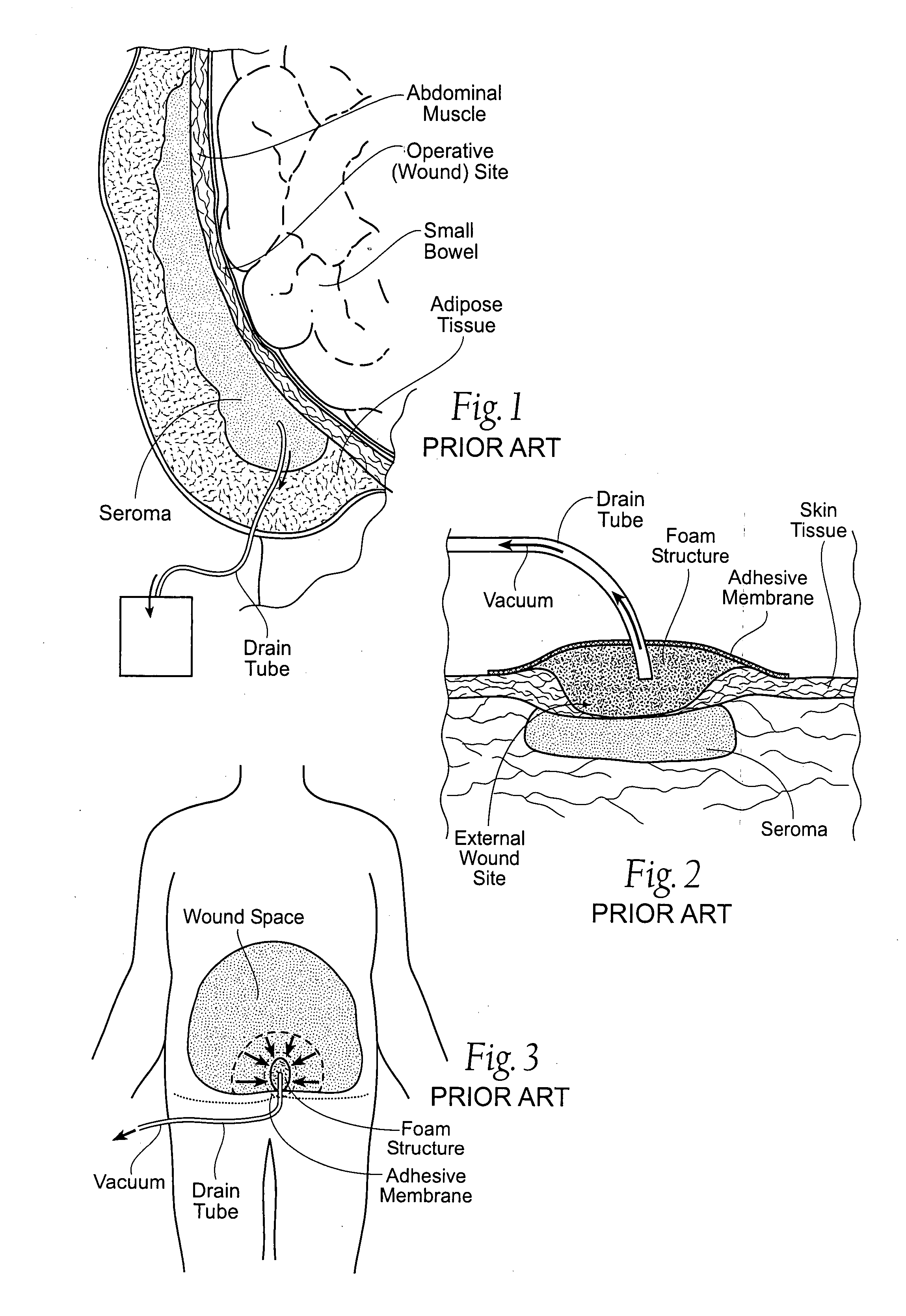

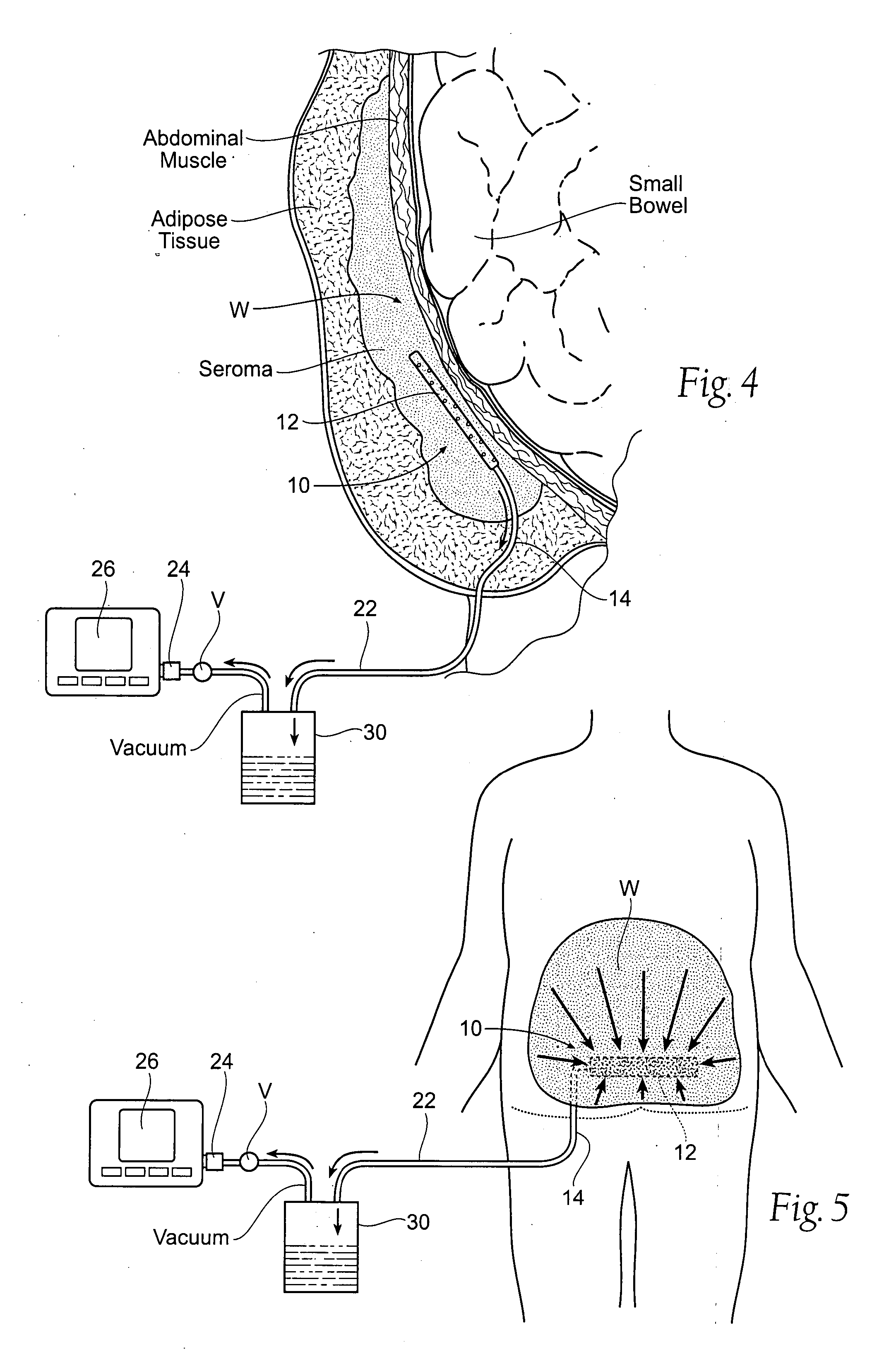

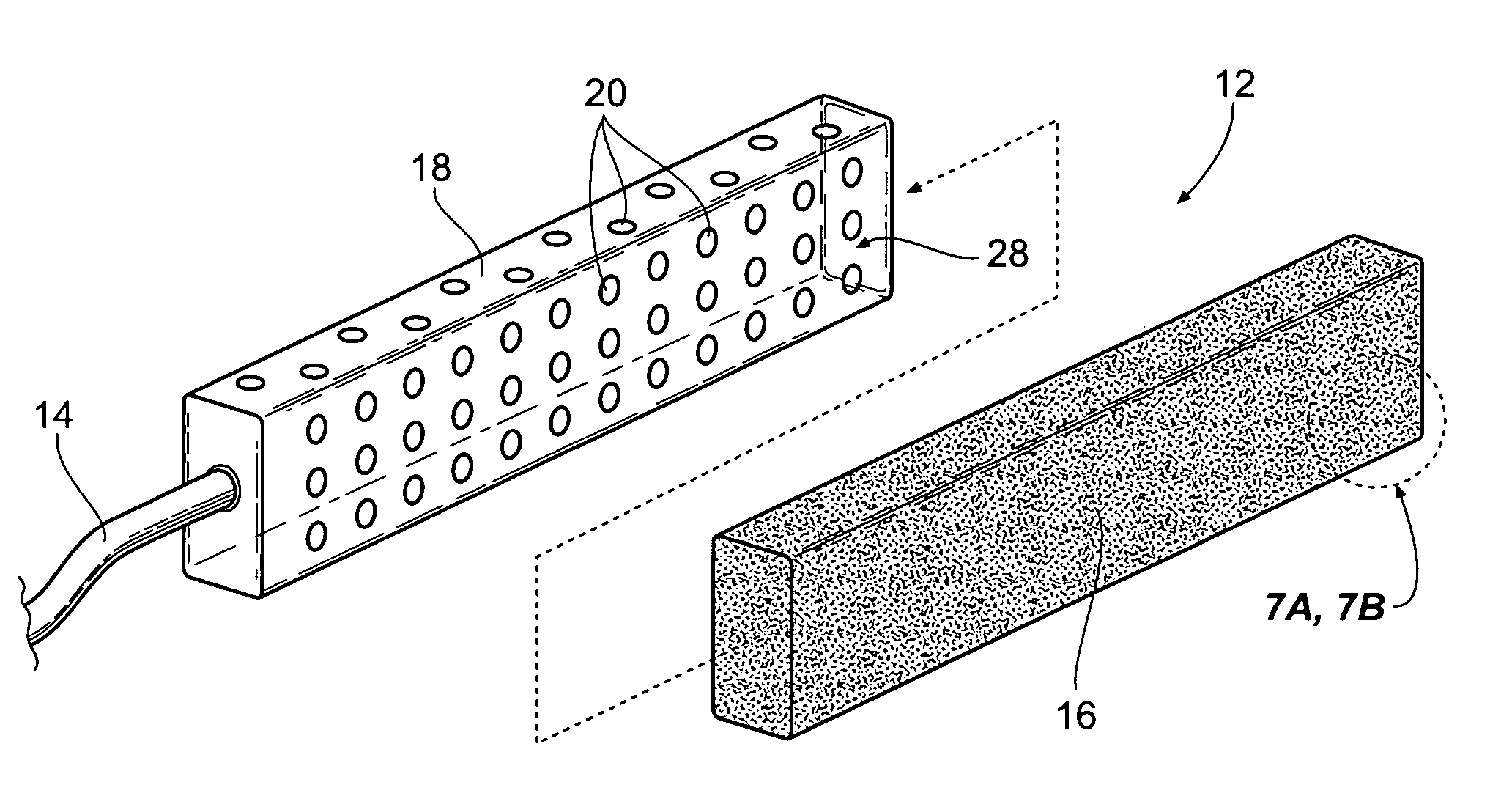

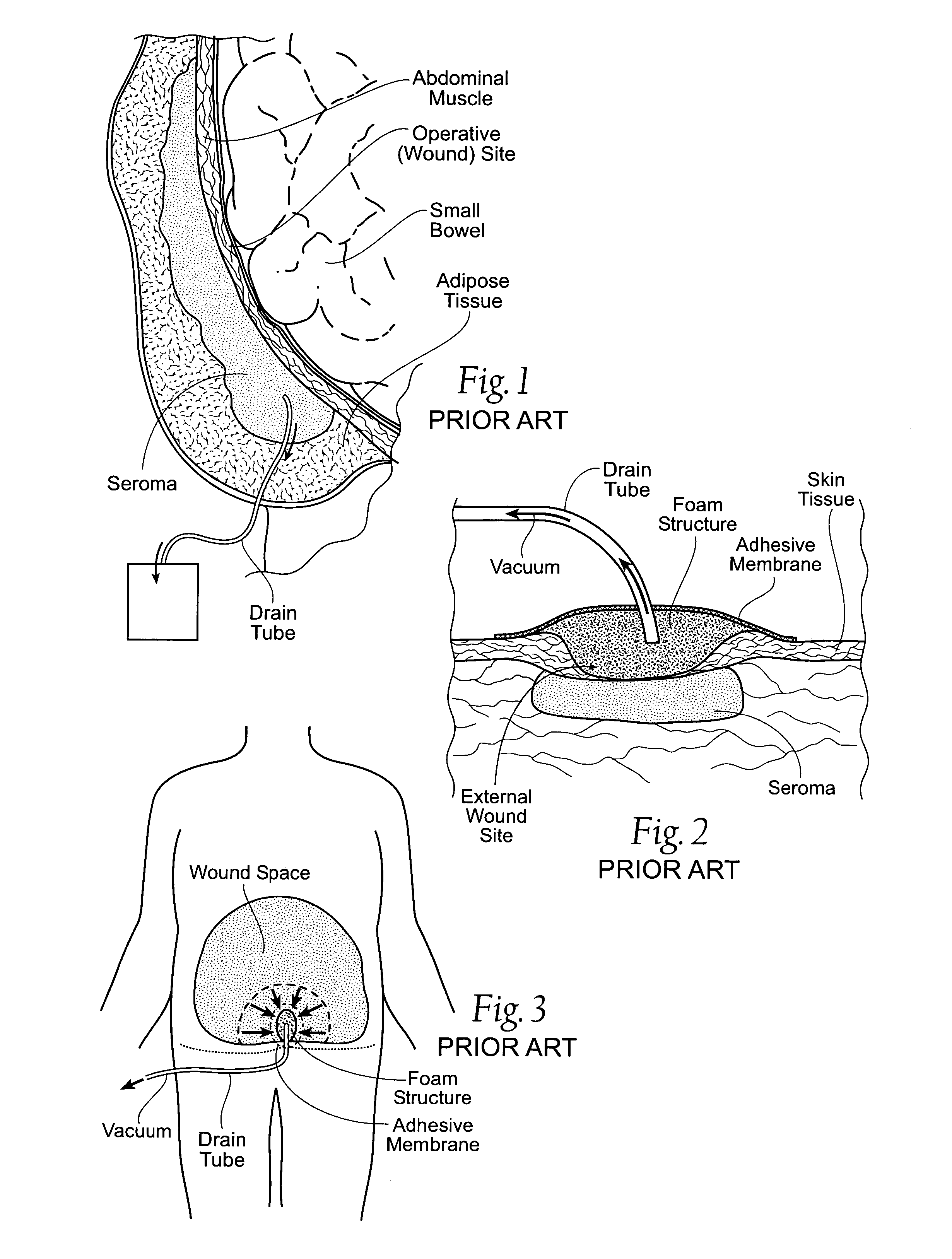

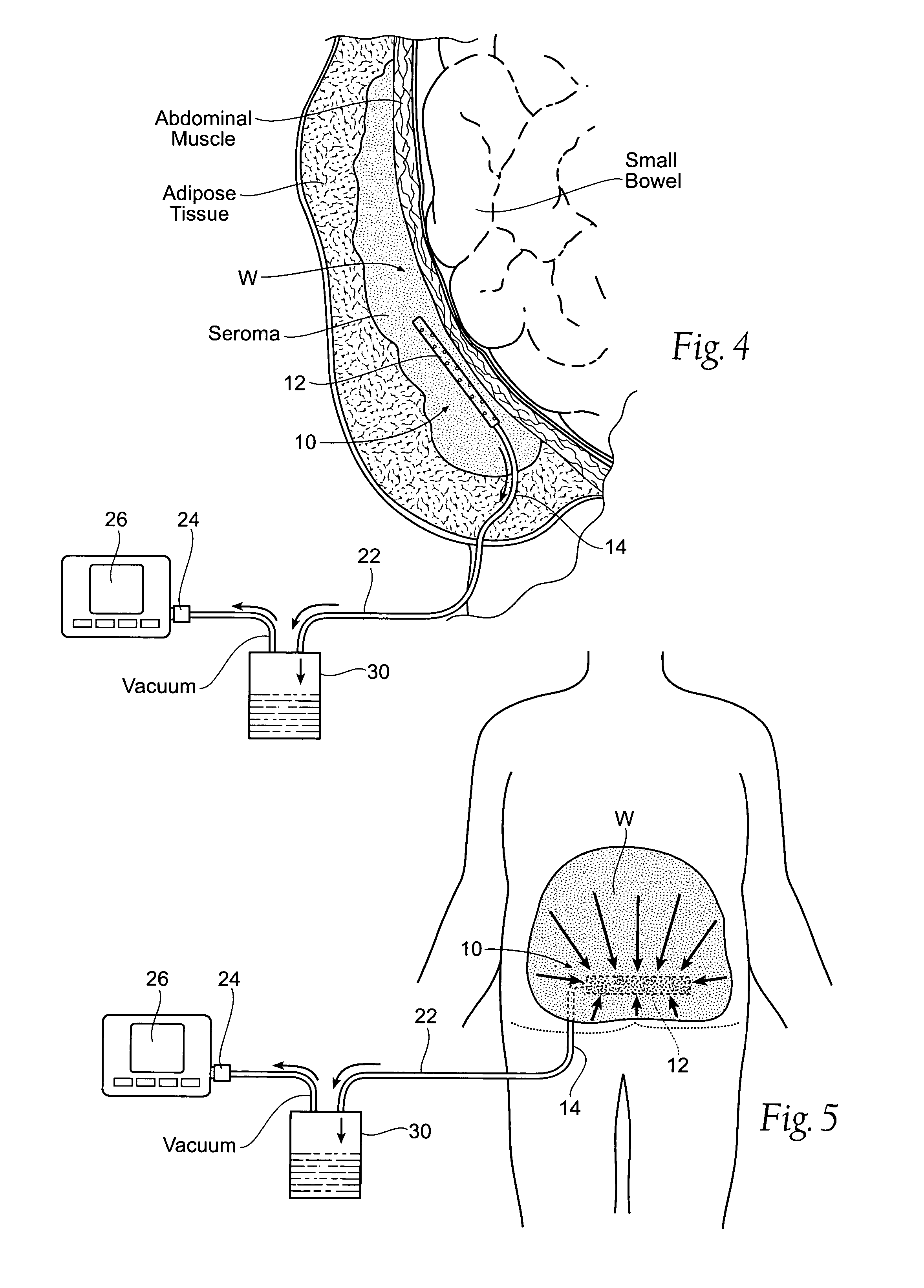

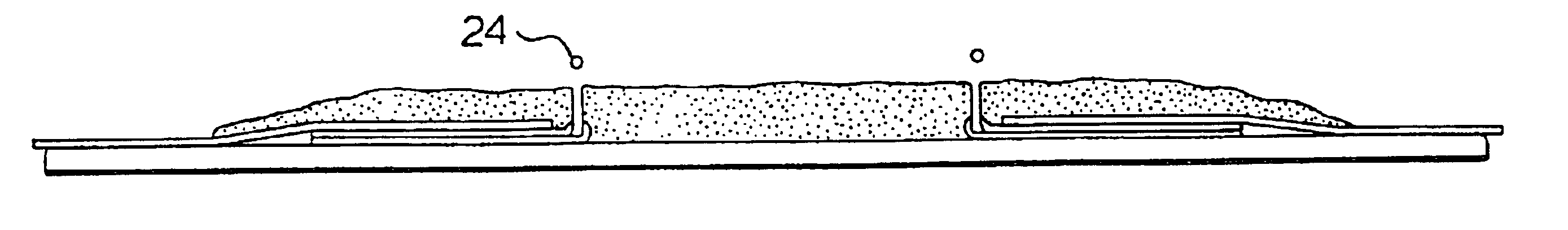

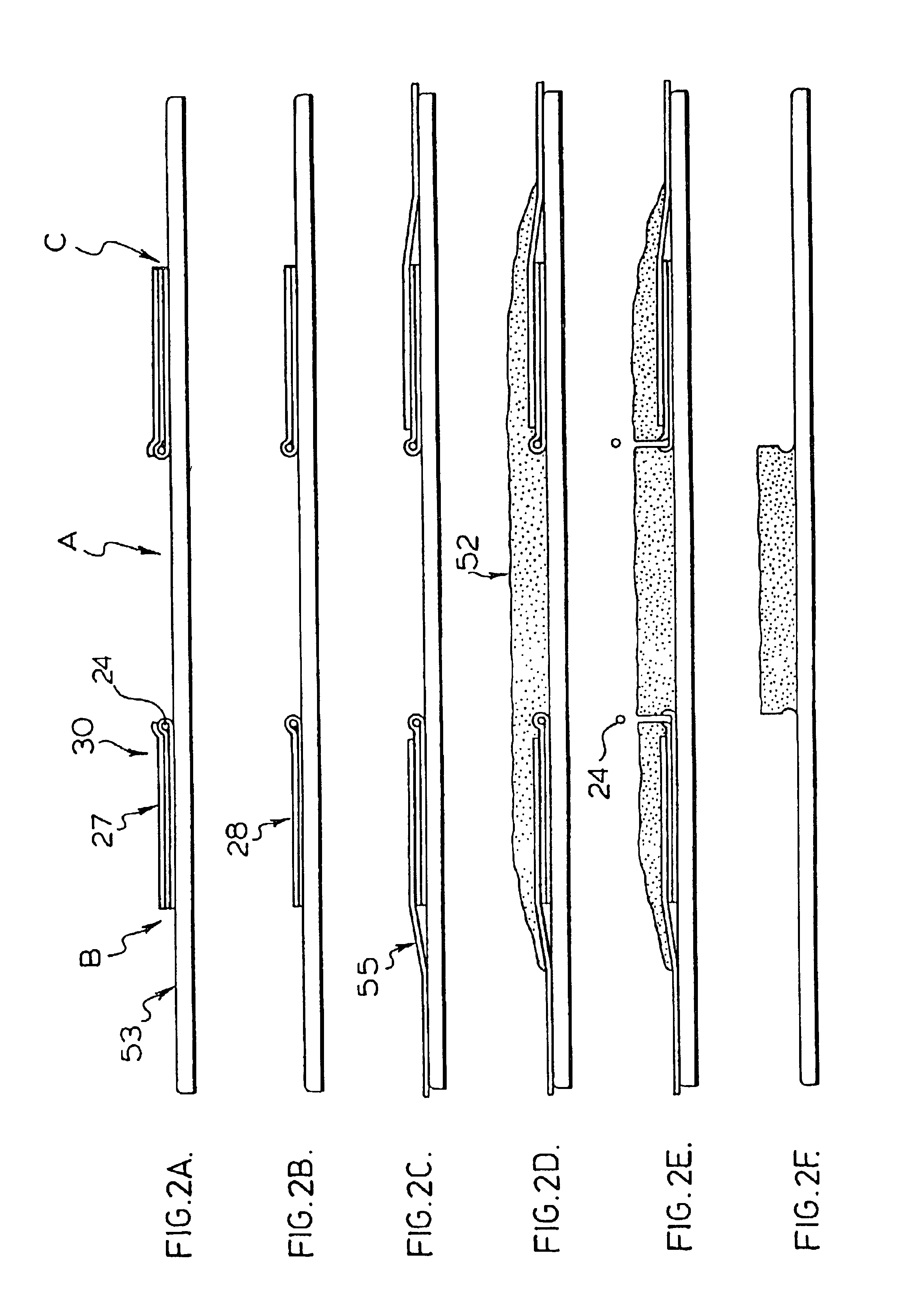

Assemblies, systems, and methods for vacuum assisted internal drainage during wound healing

ActiveUS20070282309A1Enhanced wound healing benefitDecreasing tissue edema of tissueWound drainsIntravenous devicesVacuum assistedMedicine

Assemblies, systems, and methods convey fluid from an internal wound site or body cavity by applying negative pressure from a source outside the internal wound site or body cavity through a wound drain assembly that is placed directly inside the internal wound site or body cavity.

Owner:IC SURGICAL INC

Assemblies, systems, and methods for vacuum assisted internal drainage during wound healing

ActiveUS7699831B2Decreasing tissue edema and swelling of and tissueImprove natureWound drainsIntravenous devicesVacuum assistedInternal wounds

Assemblies, systems, and methods convey fluid from an internal wound site or body cavity by applying negative pressure from a source outside the internal wound site or body cavity through a wound drain assembly that is placed directly inside the internal wound site or body cavity.

Owner:IC SURGICAL INC

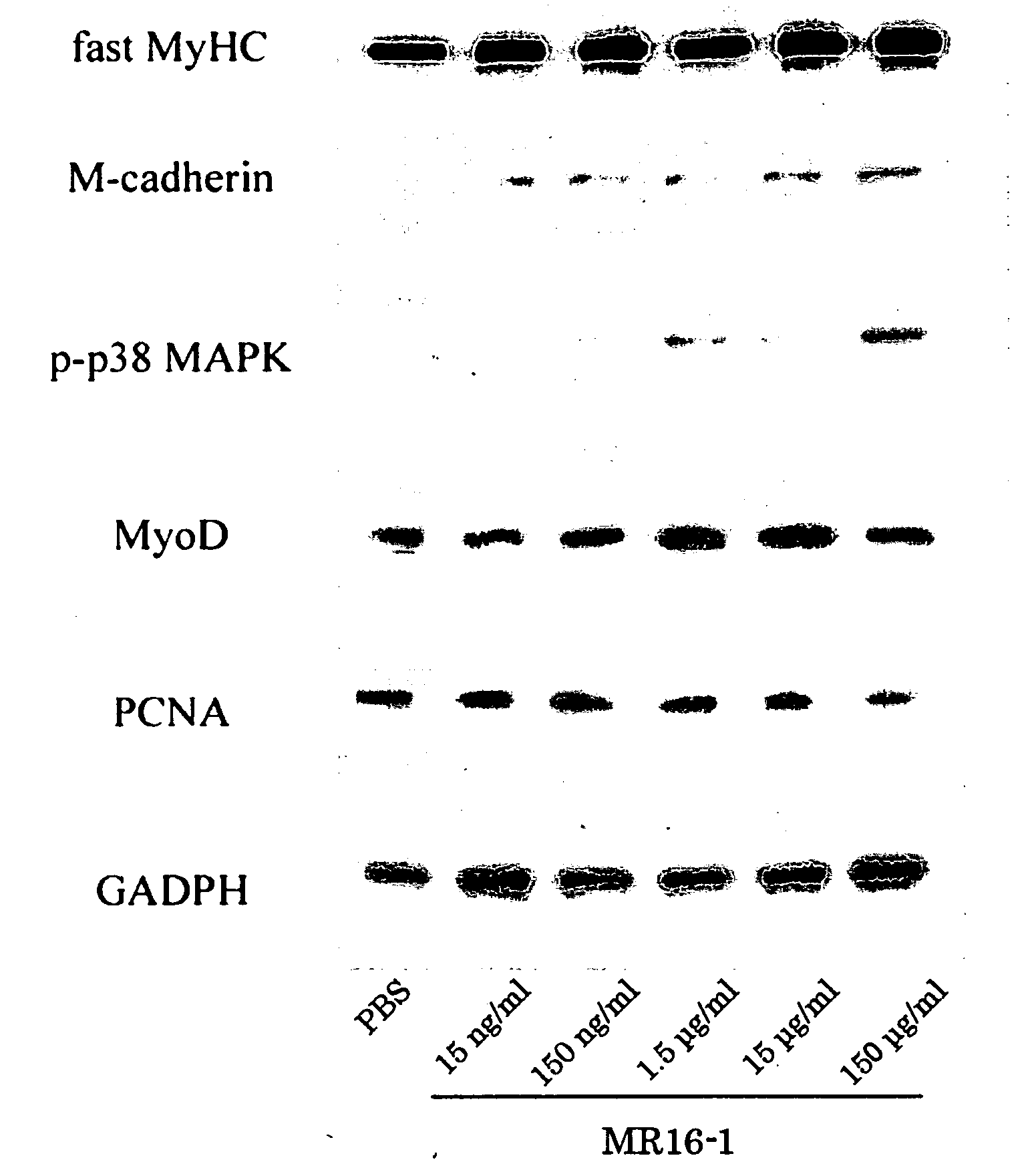

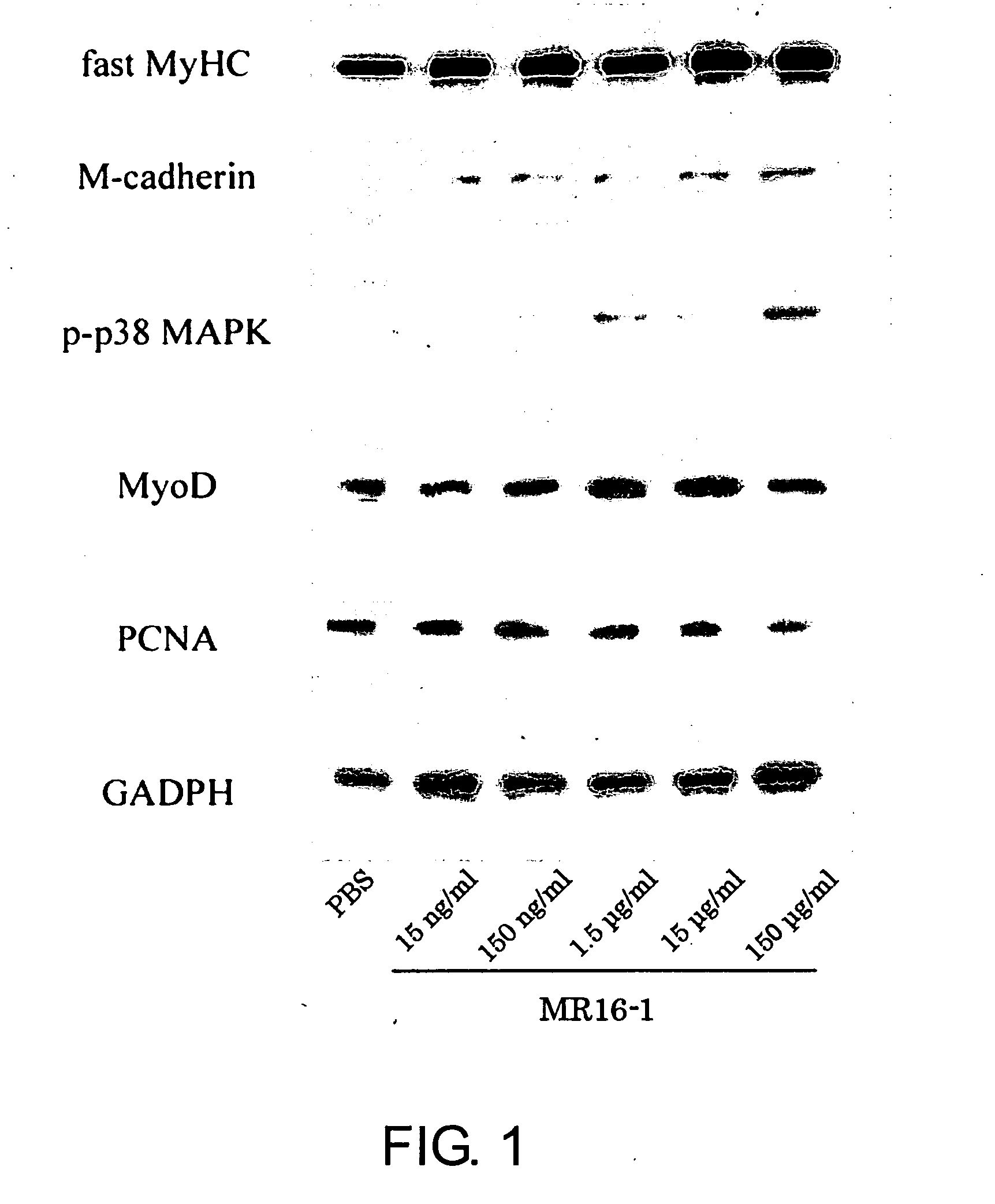

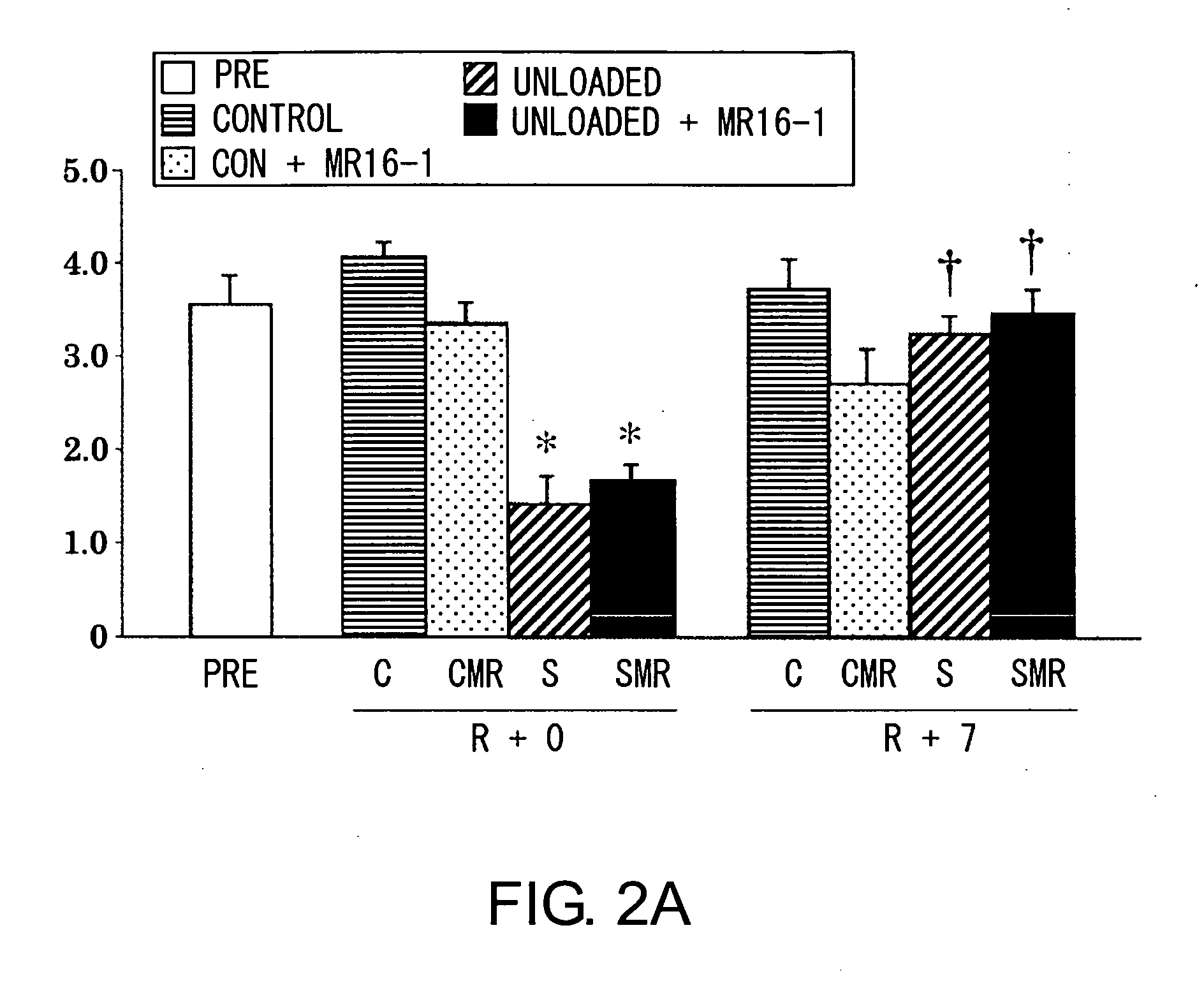

Muscle regeneration promoter

ActiveUS20100008907A1Promote muscle regenerationIncrease the number ofPeptide/protein ingredientsMuscular disorderCell growthSignal Pathways

Owner:OSAKA UNIV

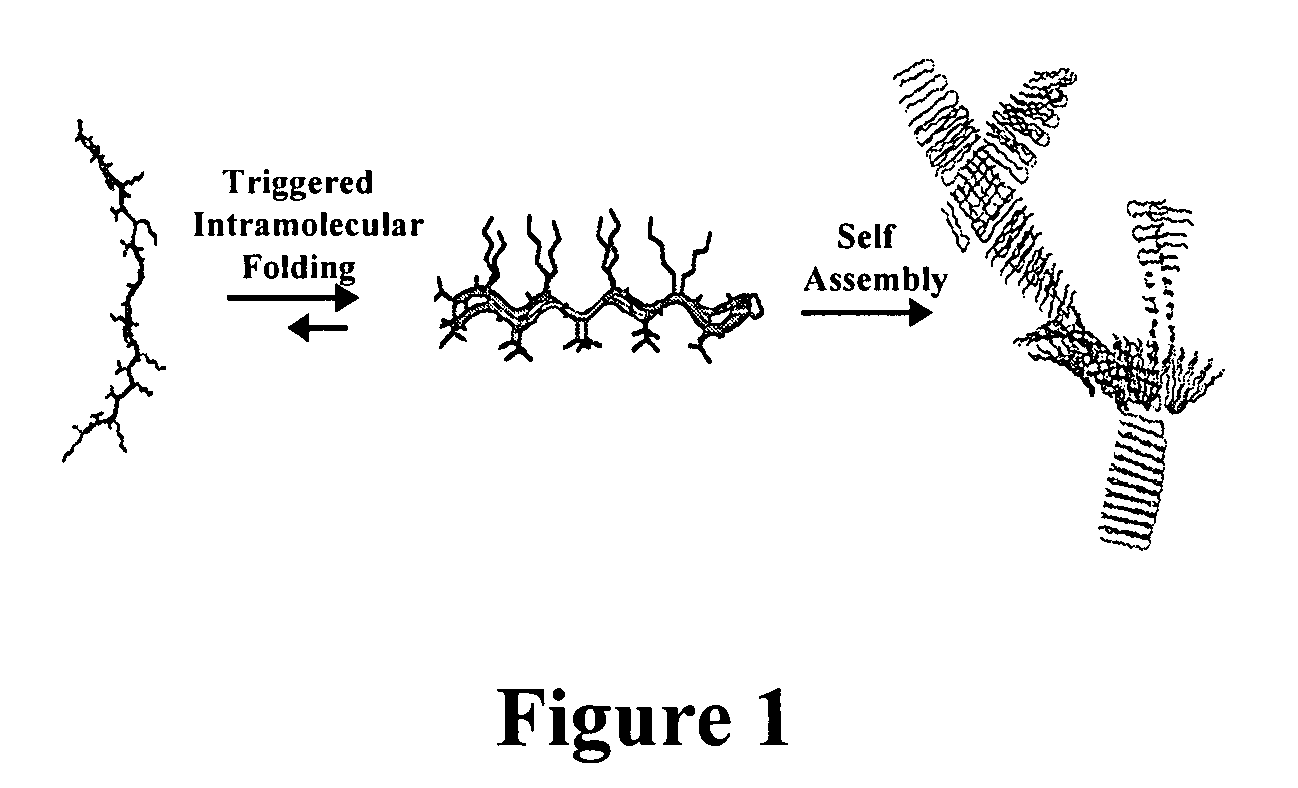

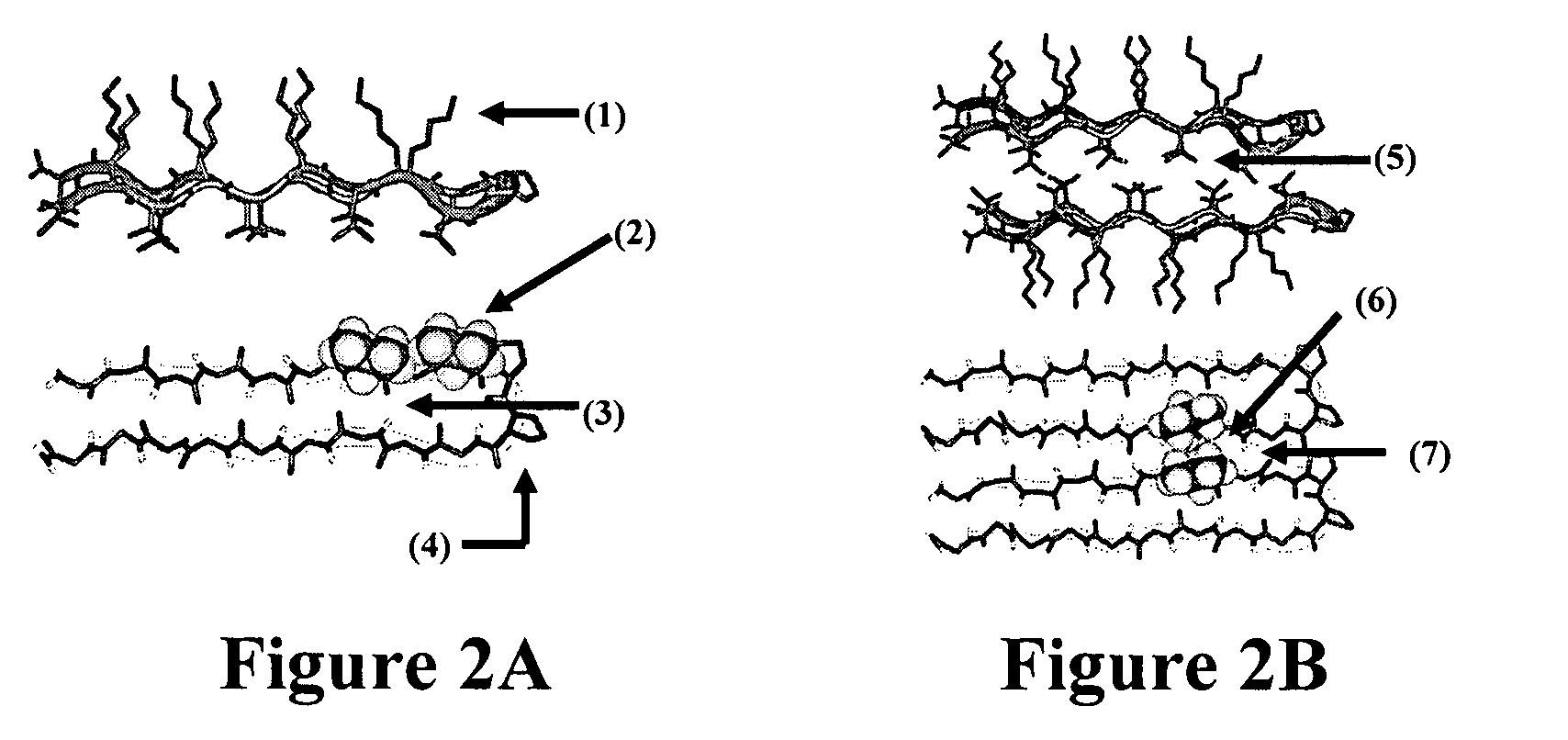

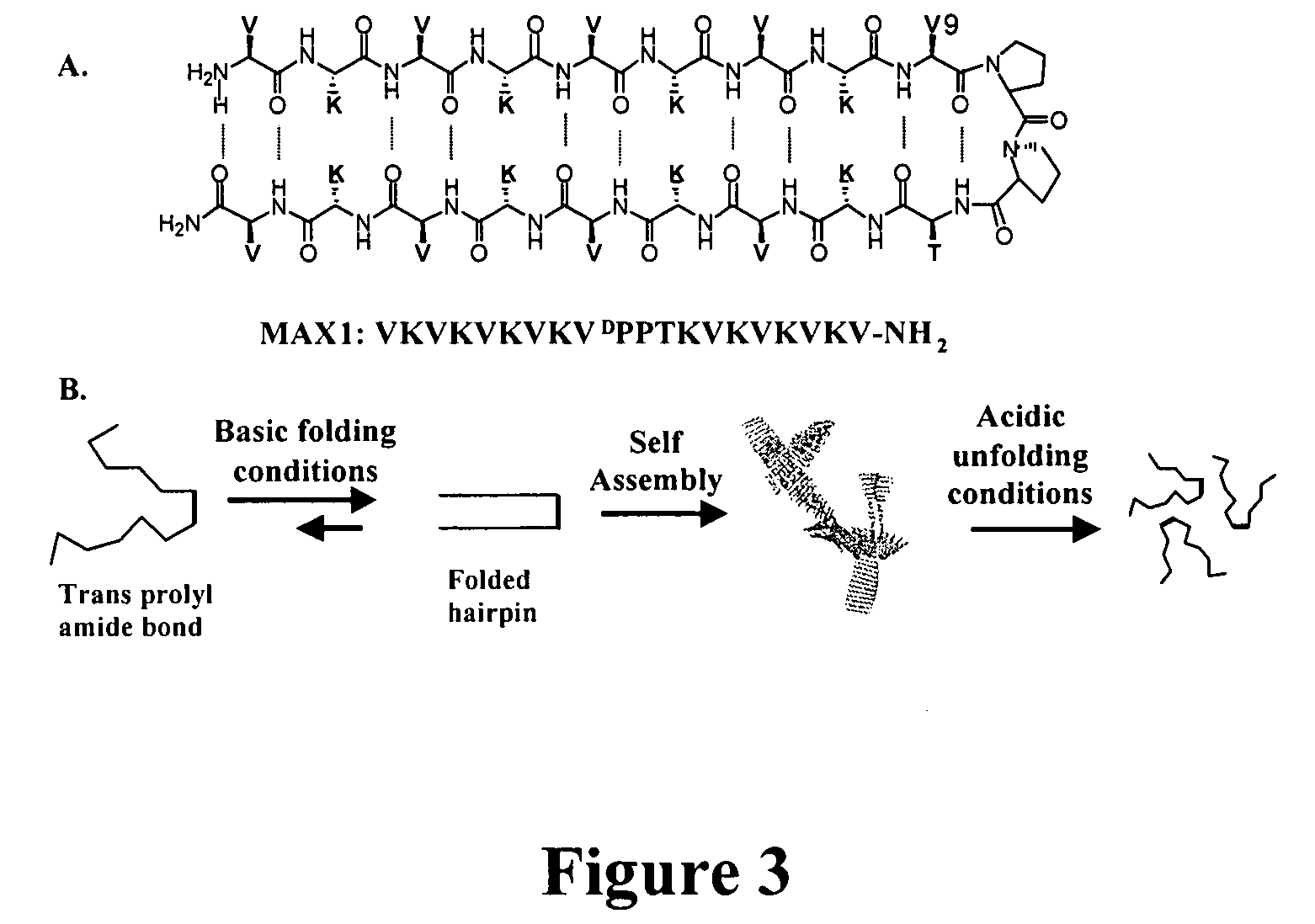

Novel hydrogels and uses thereof

ActiveUS20060025524A1Easy adhesionRapid isolationDrug photocleavageOintment deliveryIonic strengthUltimate tensile strength

The present invention provides novel hydrogels and methods of making and using such hydrogels. The present invention provides hydrogels that may be formed by the self-assembly of peptides in solution. Such self-assembly may be brought about by a change in one or more characteristics of the solution. Characteristics of the solution that may be changed include pH, ionic strength, temperature, and concentration of one or more specific ions. In addition, hydrogels of the invention may be disassembled by changing one or more characteristic of the hydrogel such as pH, ionic strength, temperature, and concentration of one or more specific ions.

Owner:UNIV OF DELAWARE TECH CORP +1

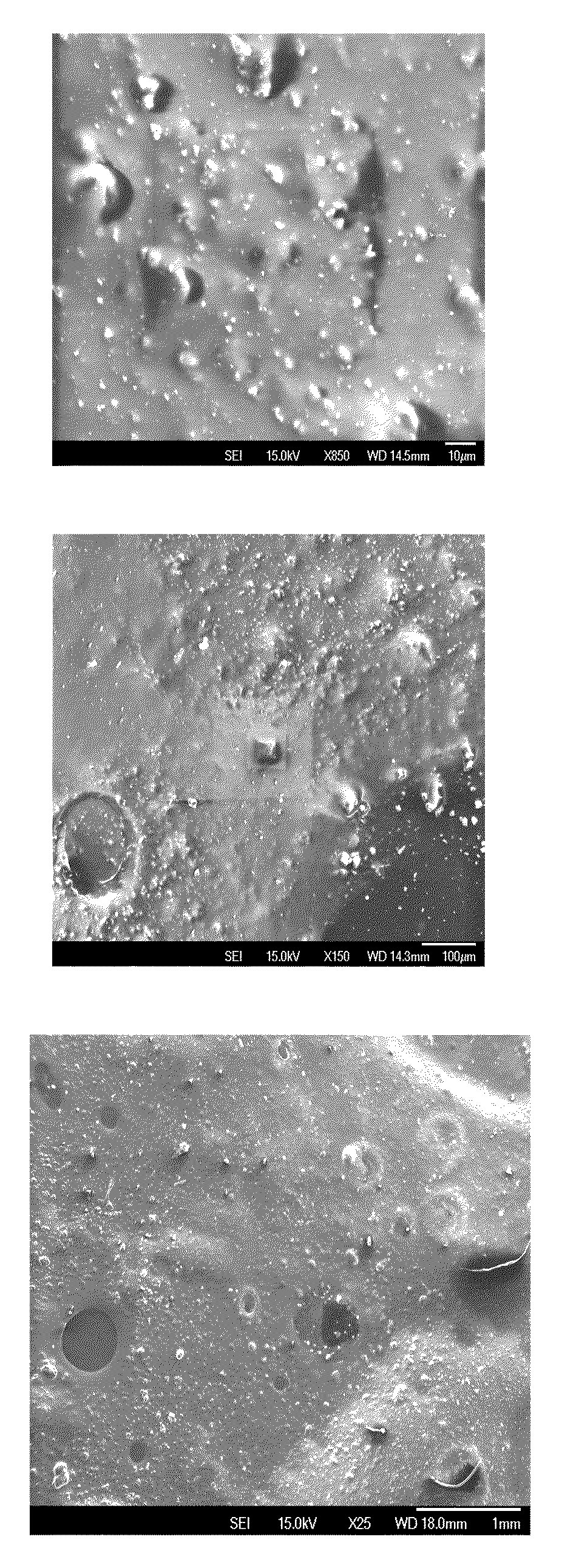

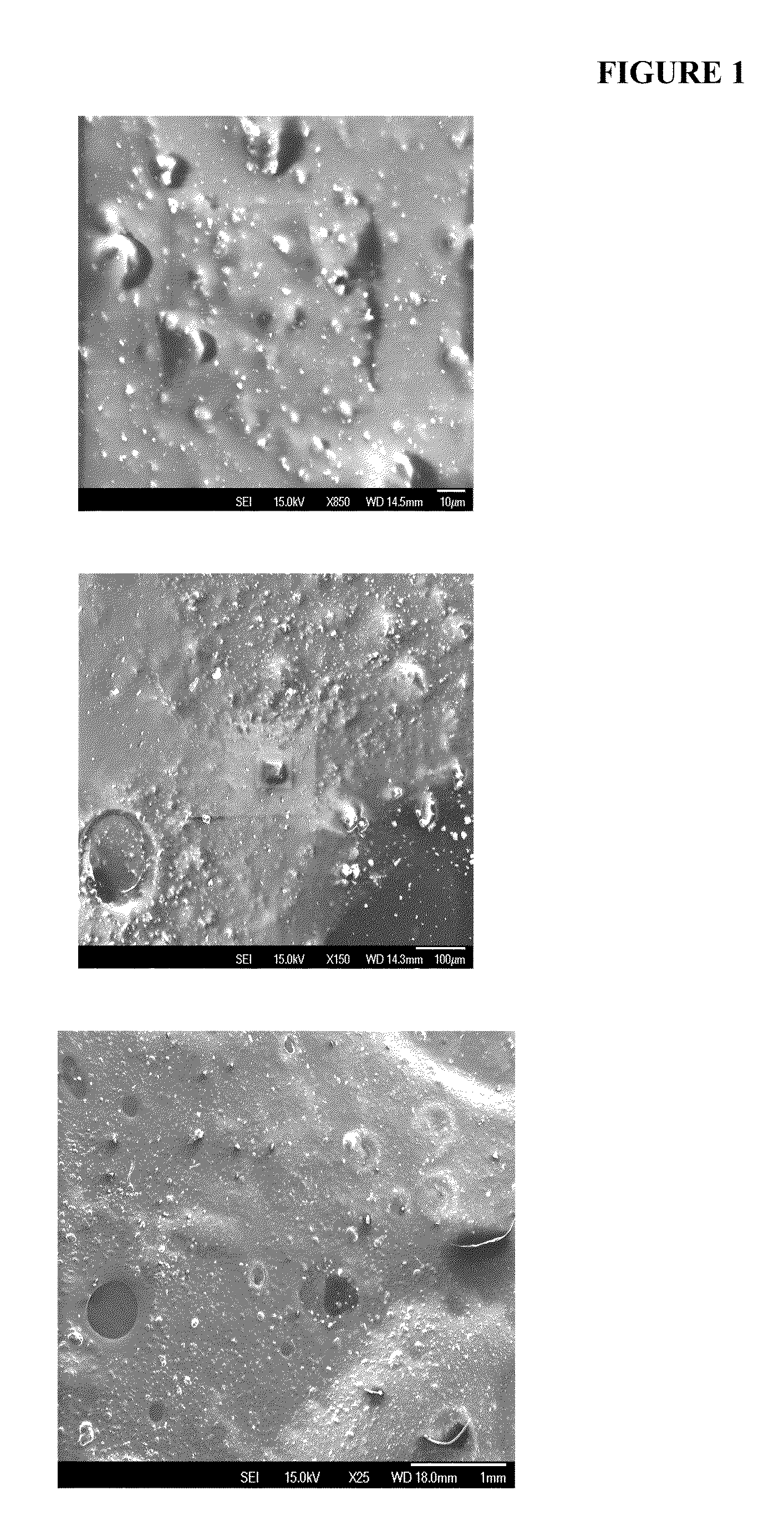

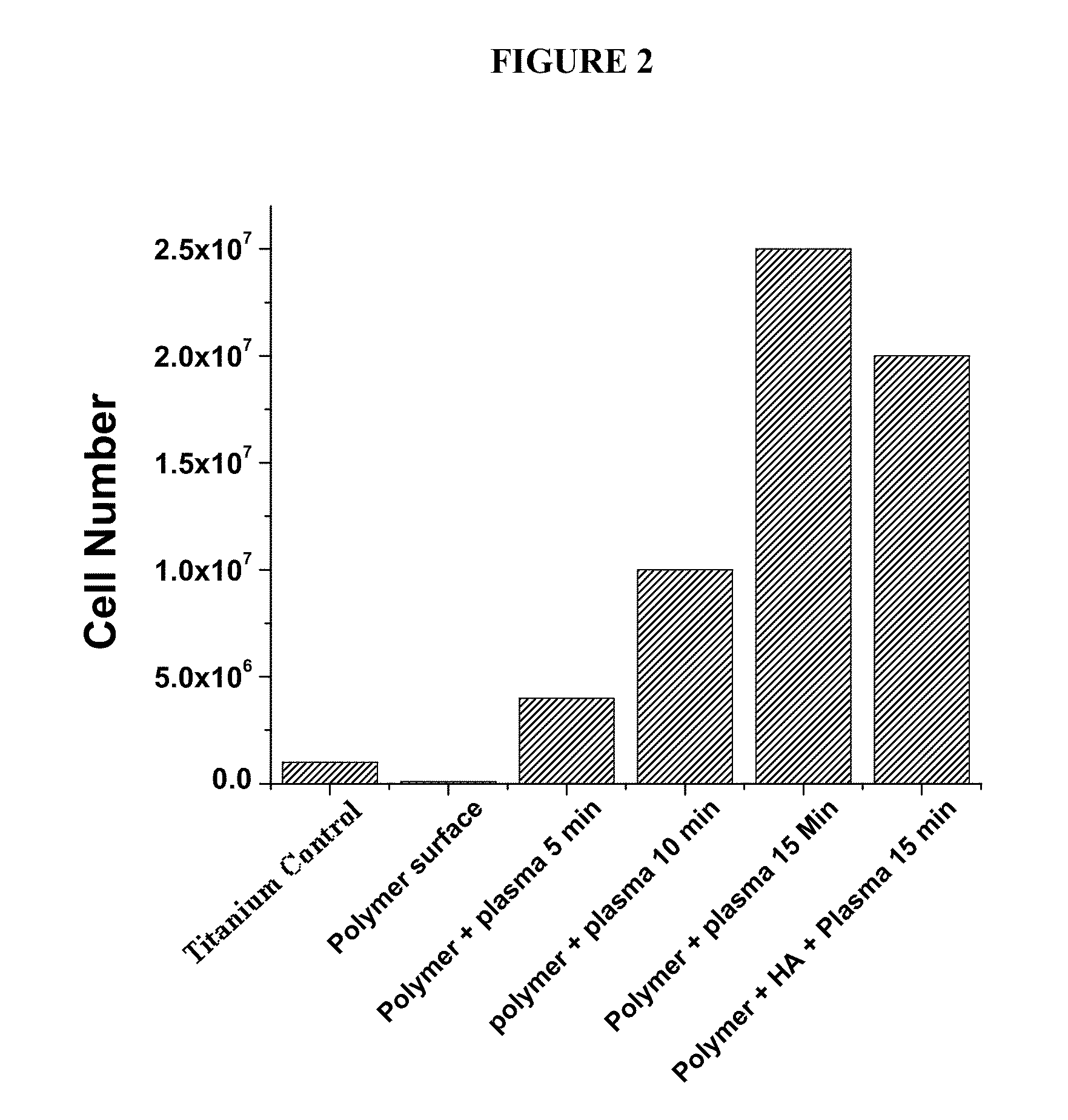

Advanced bio-compatible polymer surface coatings for implants and tissue engineering scaffolds

InactiveUS20100255447A1Improve bindingPromote cell adhesionOrganic active ingredientsDental implantsTissue engineering scaffoldChemistry

Disclosed herein are methodologies and compositions for coating materials, which can be used in a variety of biological applications.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Drugs and gene carrier particles that rapidly move through mucous barriers

ActiveUS8957034B2Easy adhesionPromote complexationPowder deliveryLiquid surface applicatorsActive agentMedicine

Owner:THE JOHNS HOPKINS UNIVERSITY SCHOOL OF MEDICINE

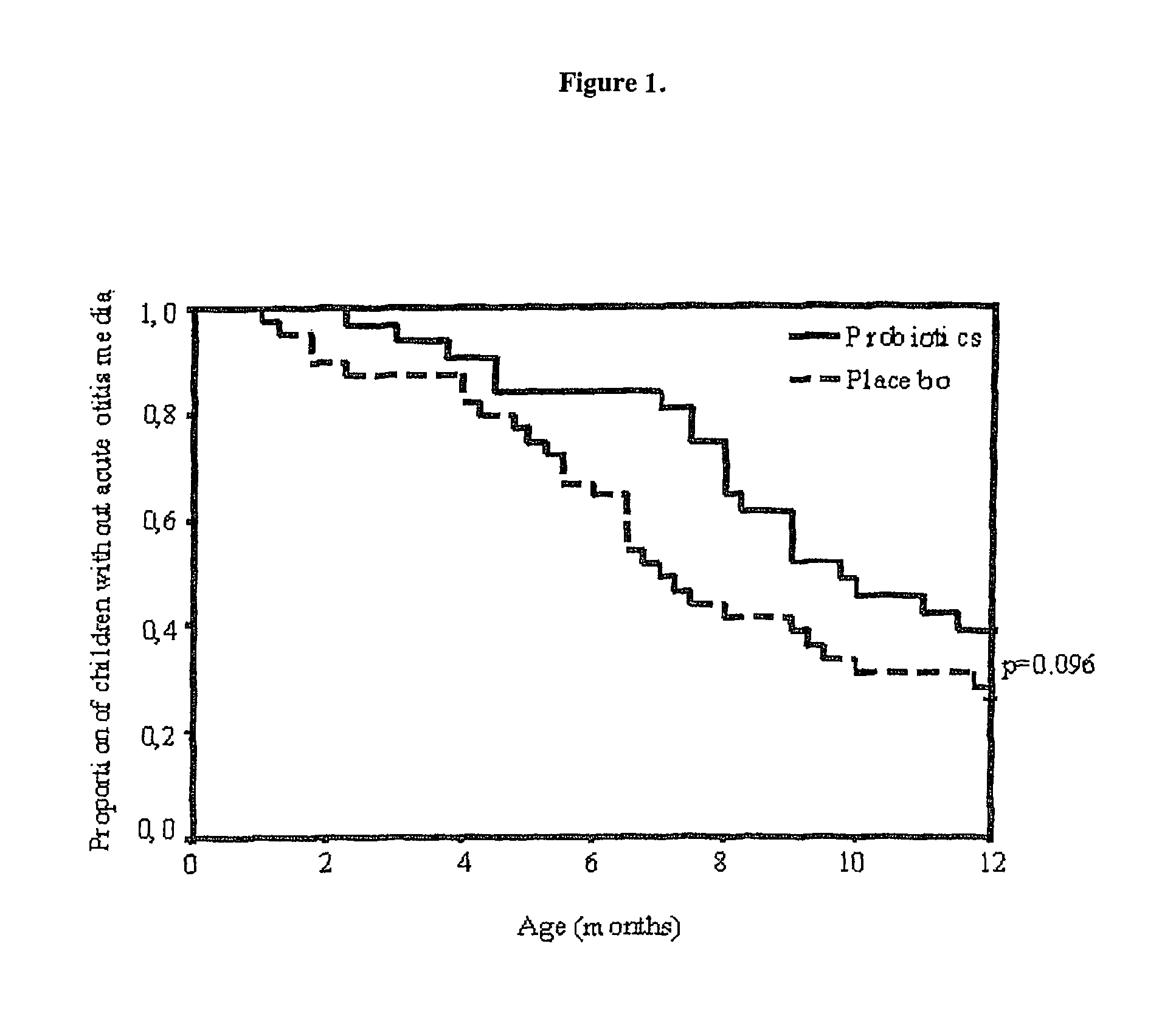

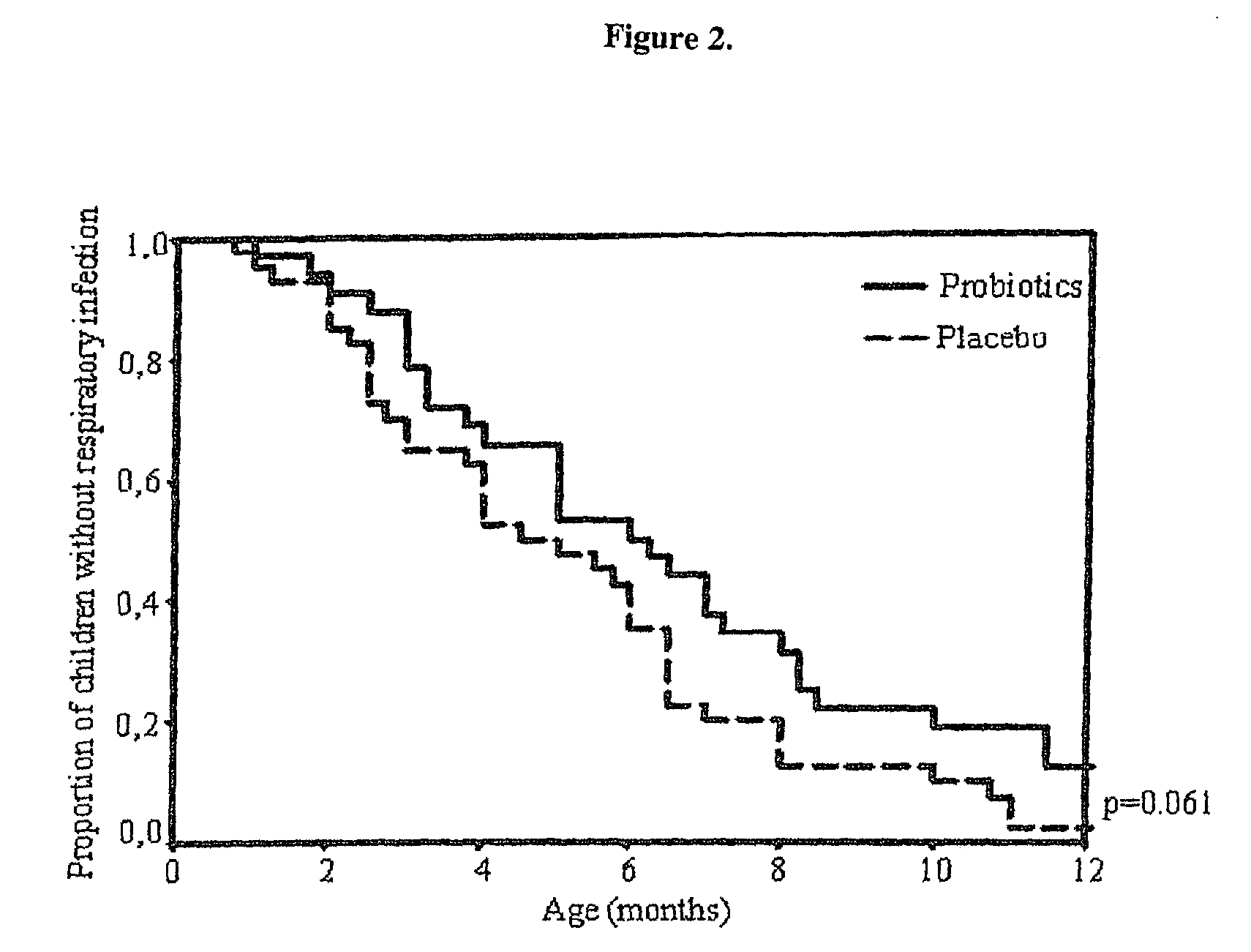

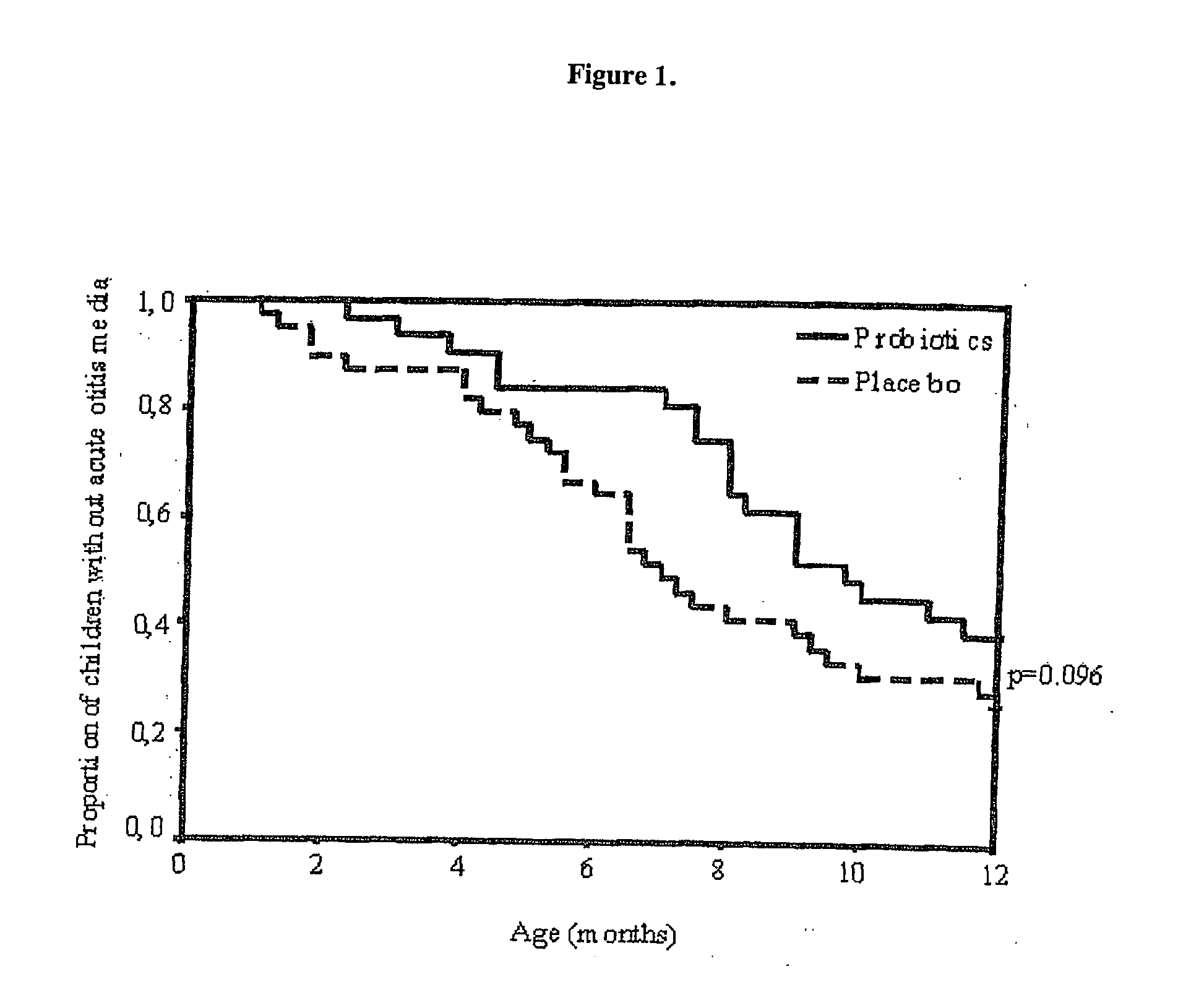

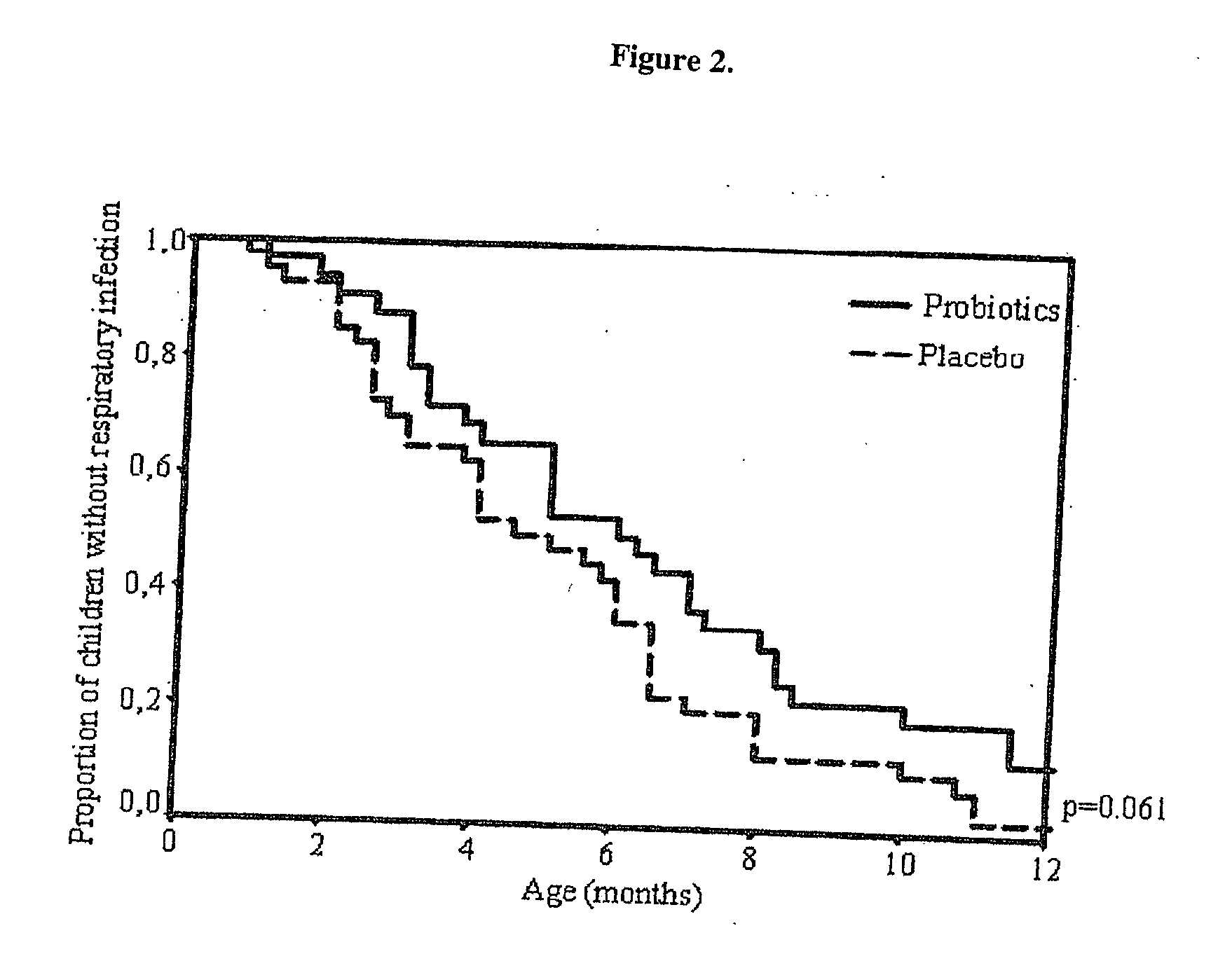

Method for preventing or treating respiratory infections and acute otitis media in infants using Lactobacillus rhamnosus LGG and Bifidobacterium lactis Bb-12

ActiveUS7862808B2Easy adhesionPromote growthBiocideSenses disorderLactobacillus rhamnosusProbiotic bacterium

The present invention is directed to a novel method for preventing or treating respiratory infections and acute otitis media in infants. The method comprises the administration of a therapeutically effective amount of a Bifidobacteria strain and an adherence-promoting probiotic, such as LGG, to the infant.

Owner:MEAD JOHNSON NUTRITION

Method for preventing or treating respiratory infections and acute otitis media in infants

ActiveUS20060018890A1Easy adhesionPromote growthBiocideSenses disorderBifidobacteriumRespiratory infection

The present invention is directed to a novel method for preventing or treating respiratory infections and acute otitis media in infants. The method comprises the administration of a therapeutically effective amount of a Bifidobacteria strain and an adherence-promoting probiotic, such as LGG, to the infant.

Owner:MEAD JOHNSON NUTRITION

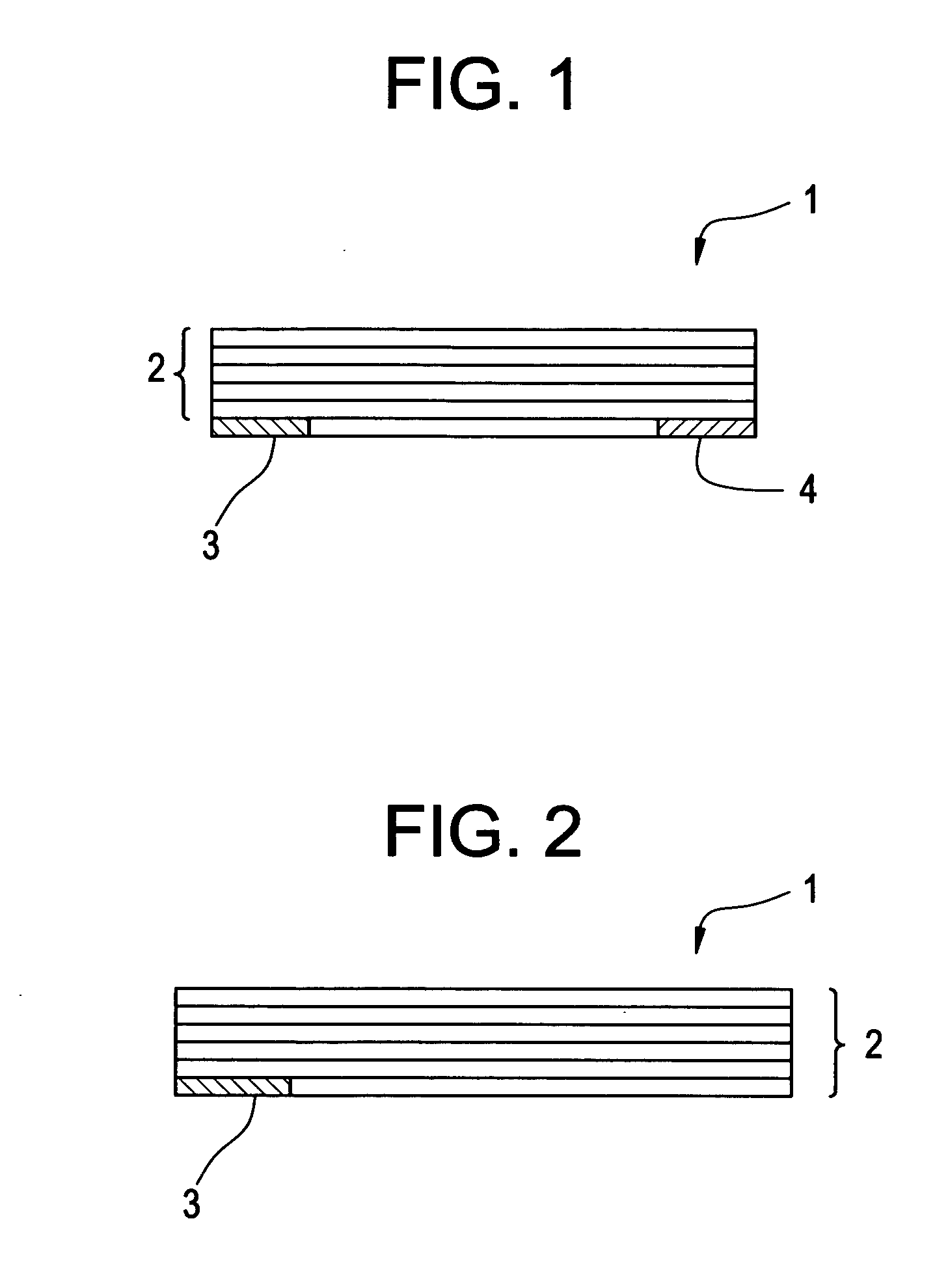

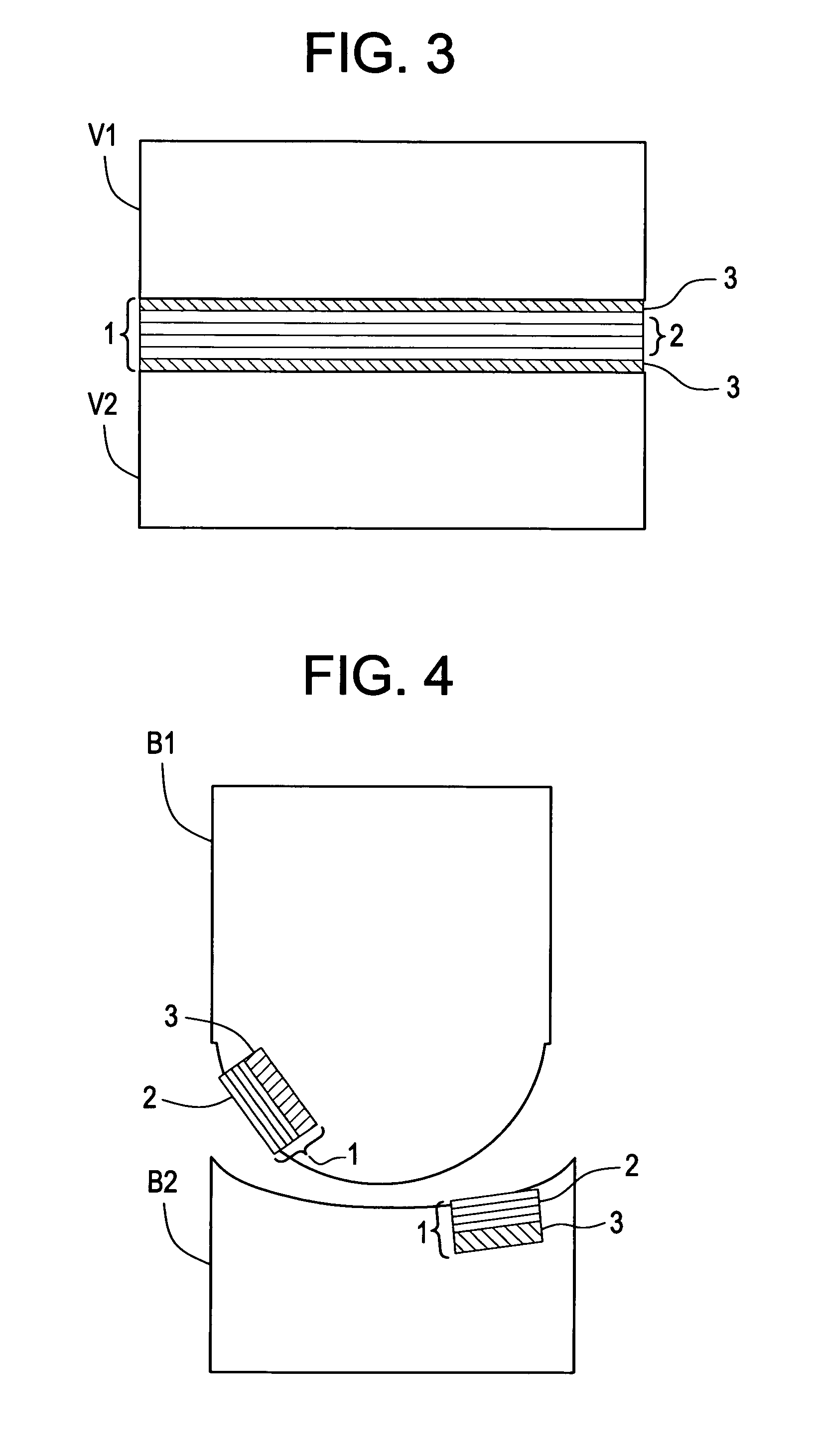

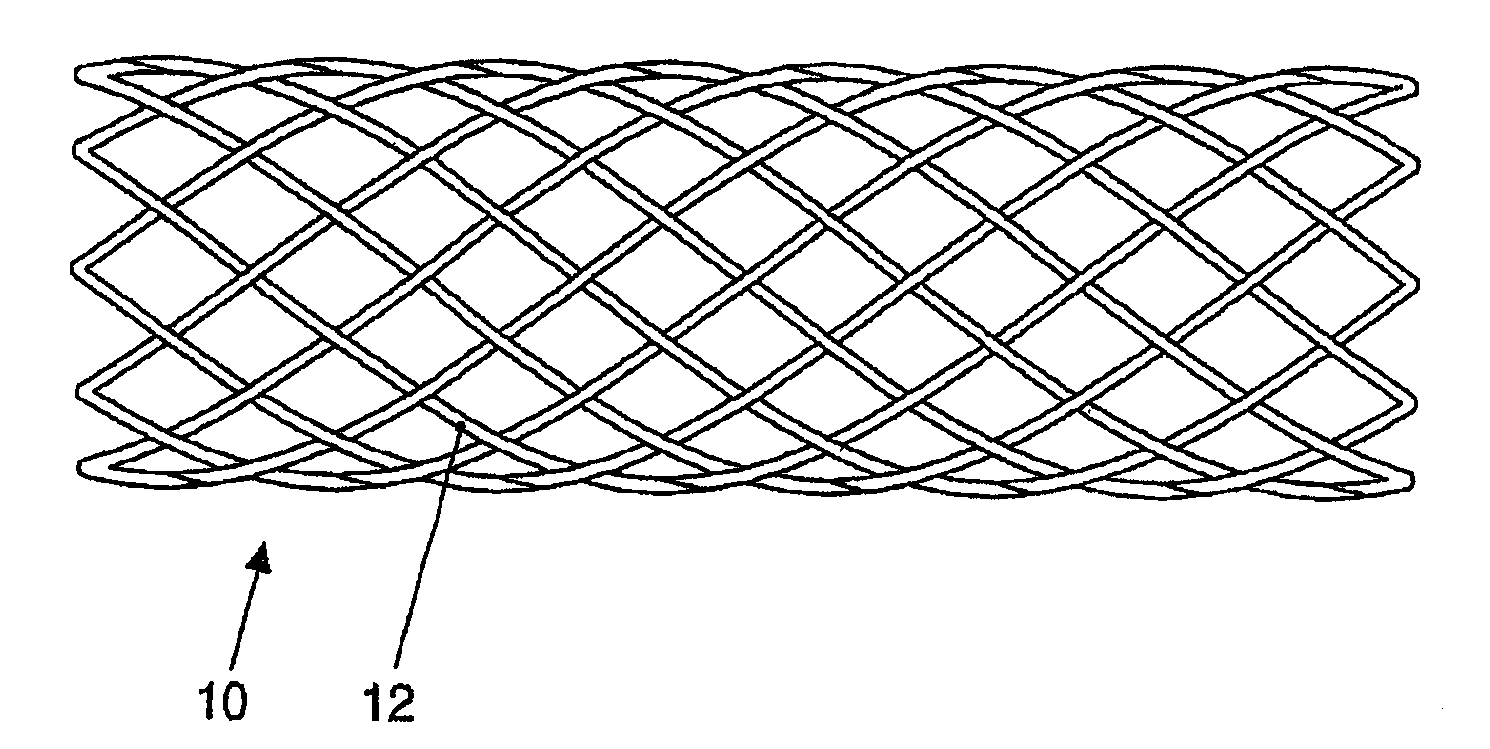

Absorbable Medical Implant Made of Fiber-Reinforced Magnesium or Fiber-Reinforced Magnesium Alloys

ActiveUS20080103594A1High biocompatibilityImproved propertyProsthesisStentsFibre reinforcementMagnesium alloy

A medical implant comprising a composite material which is composed of reinforcement fibers made of a magnesium-containing, bio-corrosive alloy, another bio-corrosive alloy containing a main component that is selected from the group consisting of Mg, Ca, Fe, and Y, or a non-biodegradable fiber material, embedded in a matrix made of crystalline magnesium or magnesium alloys.

Owner:BIOTRONIK

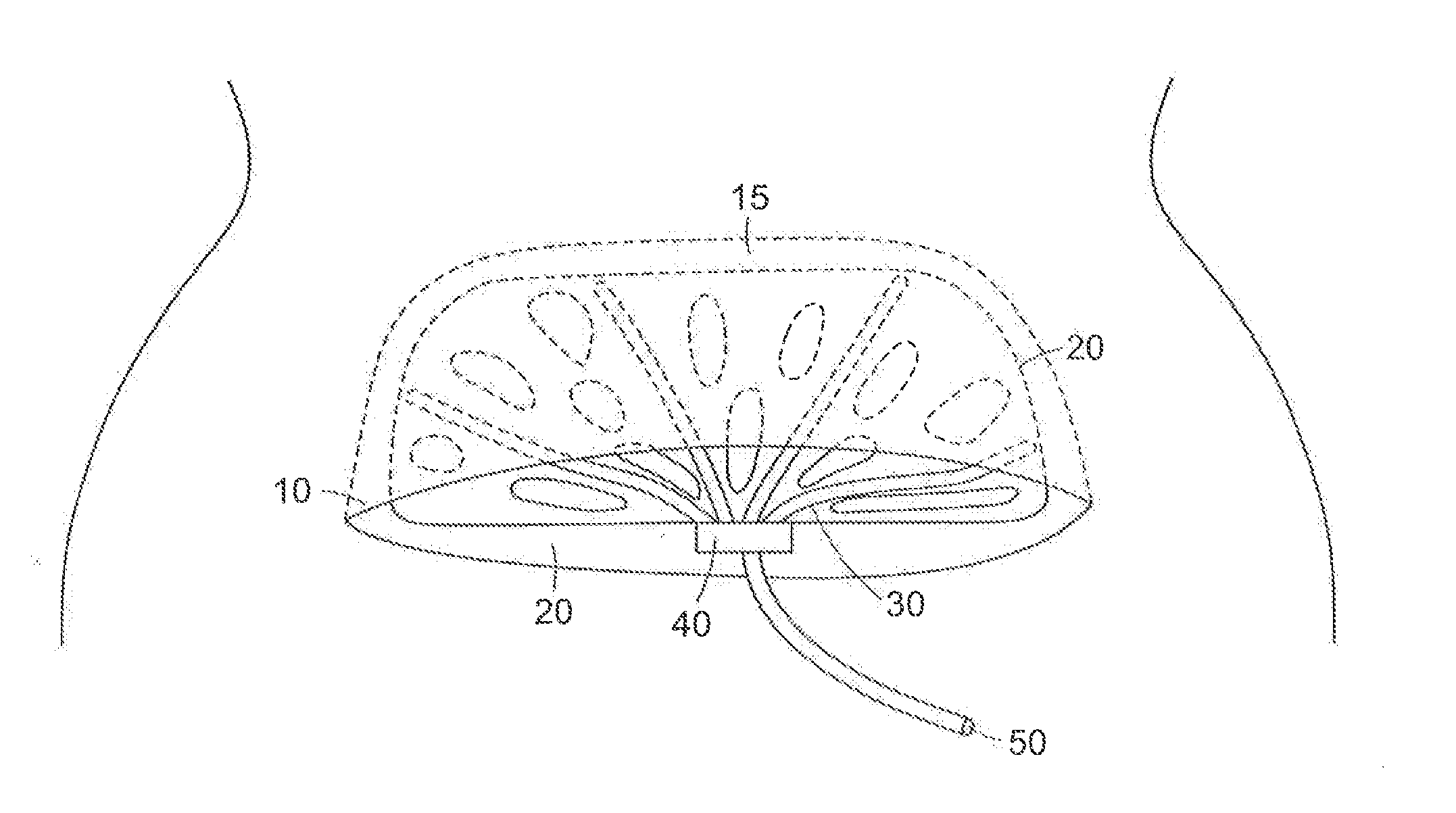

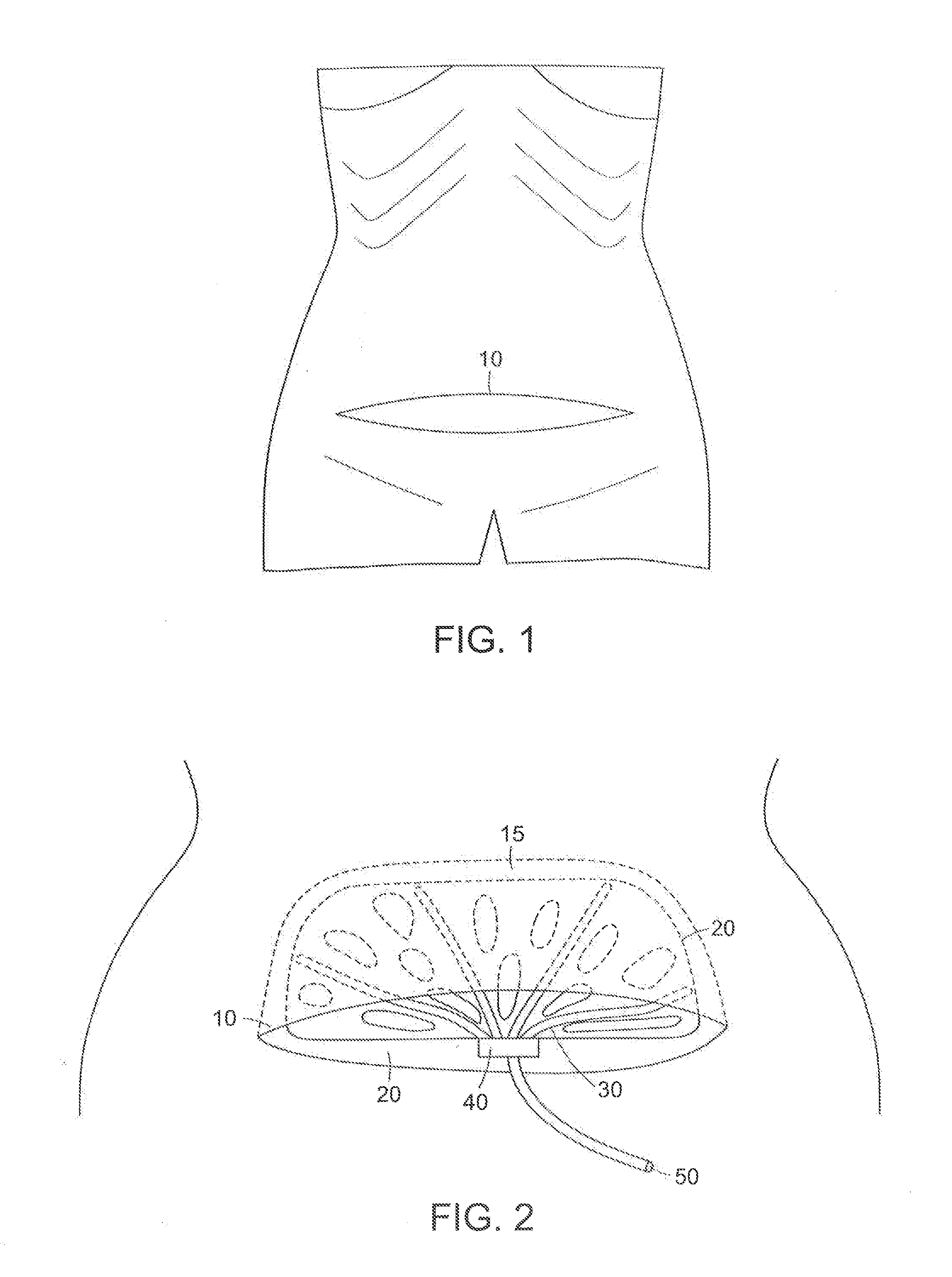

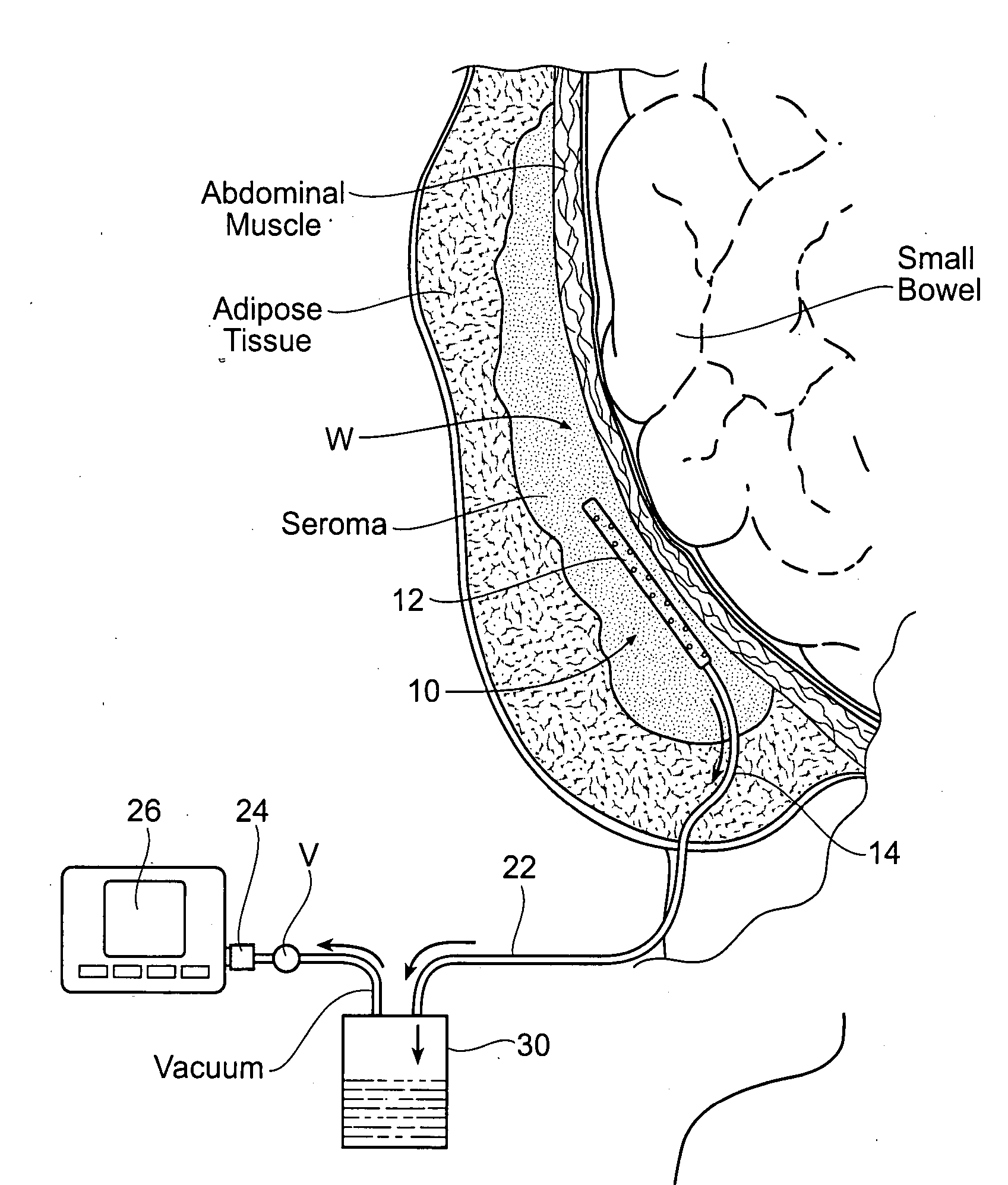

Surgical cavity drainage and closure system

ActiveUS20130274717A1Treating and preventing seromaGood drainageUltrasonic/sonic/infrasonic diagnosticsSuture equipmentsWound dressingSurgical department

A surgical drain device includes a matrix of biodegradable polymer material and a plurality of drain tubes attached to the matrix. The device is implanted within a surgical wound to treat the presence of seromas, for example, and is used to promote drainage, tissue adhesion, and wound closure. The drain tubes converge into a common collection tube that leads wound fluid outside the body under gravity feed or negative pressure applied to the collection tube. The matrix contains an array of apertures that allow tissue contact across the device. A preferred embodiment comprises a tissue anchoring system including anchor elements such as hooks or barbs. The device can be used with a negative pressure system to further improve the drainage band can also be used with a wound dressing. The device and systems containing the device are particularly useful to promote the healing of surgical wounds from abdominal surgery.

Owner:UNIV OF MASSACHUSETTS

Acrylic photovoltaic module backsheet

ActiveUS20110315189A1Easy to mergeEasy to stickPV power plantsSynthetic resin layered productsPolymer sciencePolyethylene terephthalate glycol

The invention relates to an acrylic layer (in the form of a coating, film or sheet) useful as part of a photovoltaic module backsheet. The acrylic layer contains at least 40 percent of one or more acrylic polymers, including an acrylic polymer matrix and optionally acrylic impact modifiers. The acrylic polymer is preferably a polymer, copolymer, or terpolymer containing at least 50 weight percent of methylmethacrylate monomer units. The acrylic layer is flexible and optionally contains high levels of white pigment. It may also contain fluoropolymers such as polyvinylidene fluoride to improve weathering, processibility and film formation. The acrylic layer adheres to a polymer support layer such as polyethylene terephthalate (PET). A preferred substrate is PET that is pre-treated to improve adhesion, but unprimed PET can also be used. The backsheet provides excellent weatherability, environmental stability and reflectivity as part of a photovoltaic module.

Owner:TRINSEO EURO GMBH

Assemblies, systems, and methods for vacuum assisted internal drainage during wound healing

ActiveUS20070282310A1Enhanced wound healing benefitDecreasing tissue edema of tissueWound drainsIntravenous devicesVacuum assistedInternal wounds

Assemblies, systems, and methods convey fluid from an internal wound site or body cavity by applying negative pressure from a source outside the internal wound site or body cavity through a wound drain assembly that is placed directly inside the internal wound site or body cavity.

Owner:IC SURGICAL INC

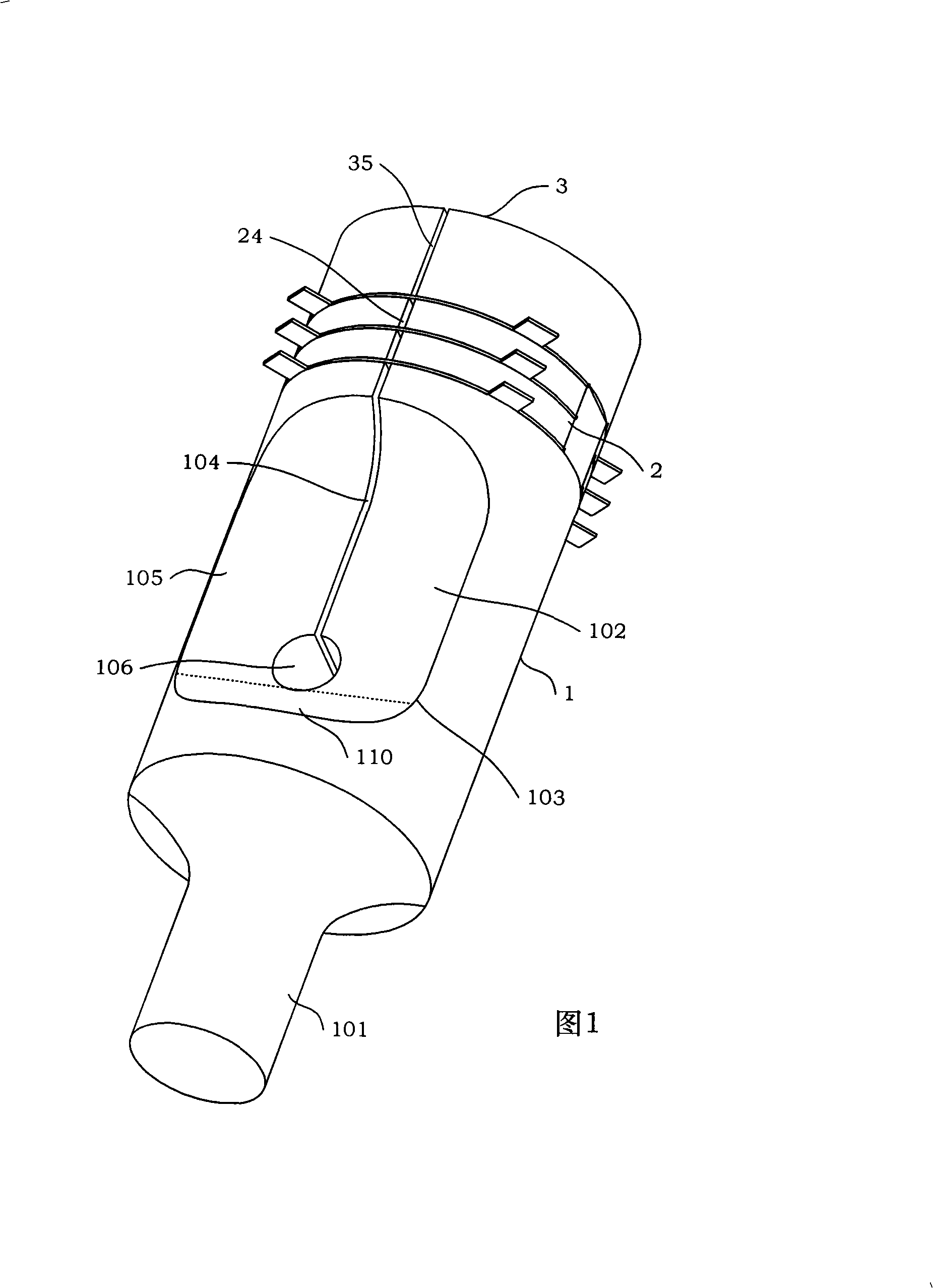

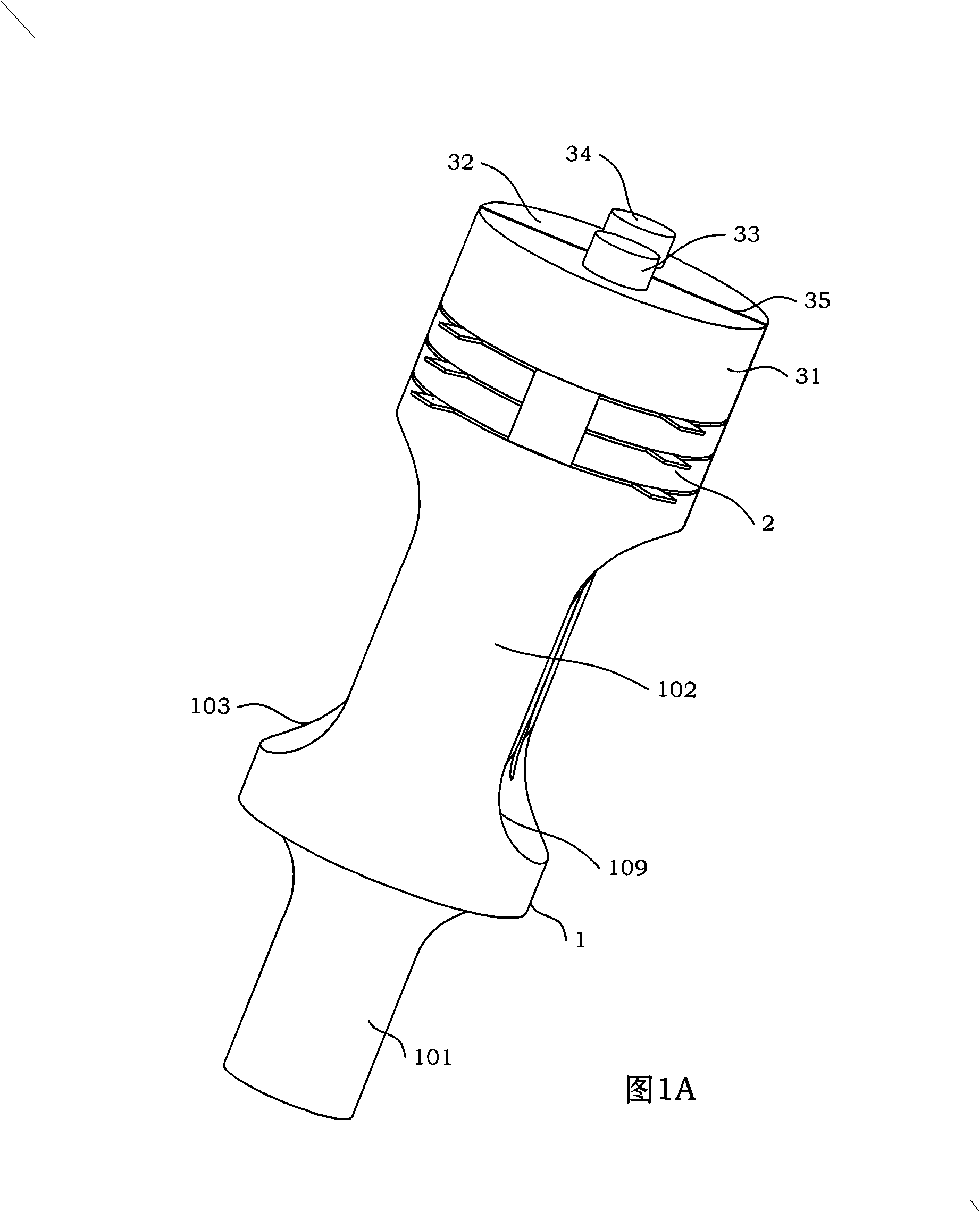

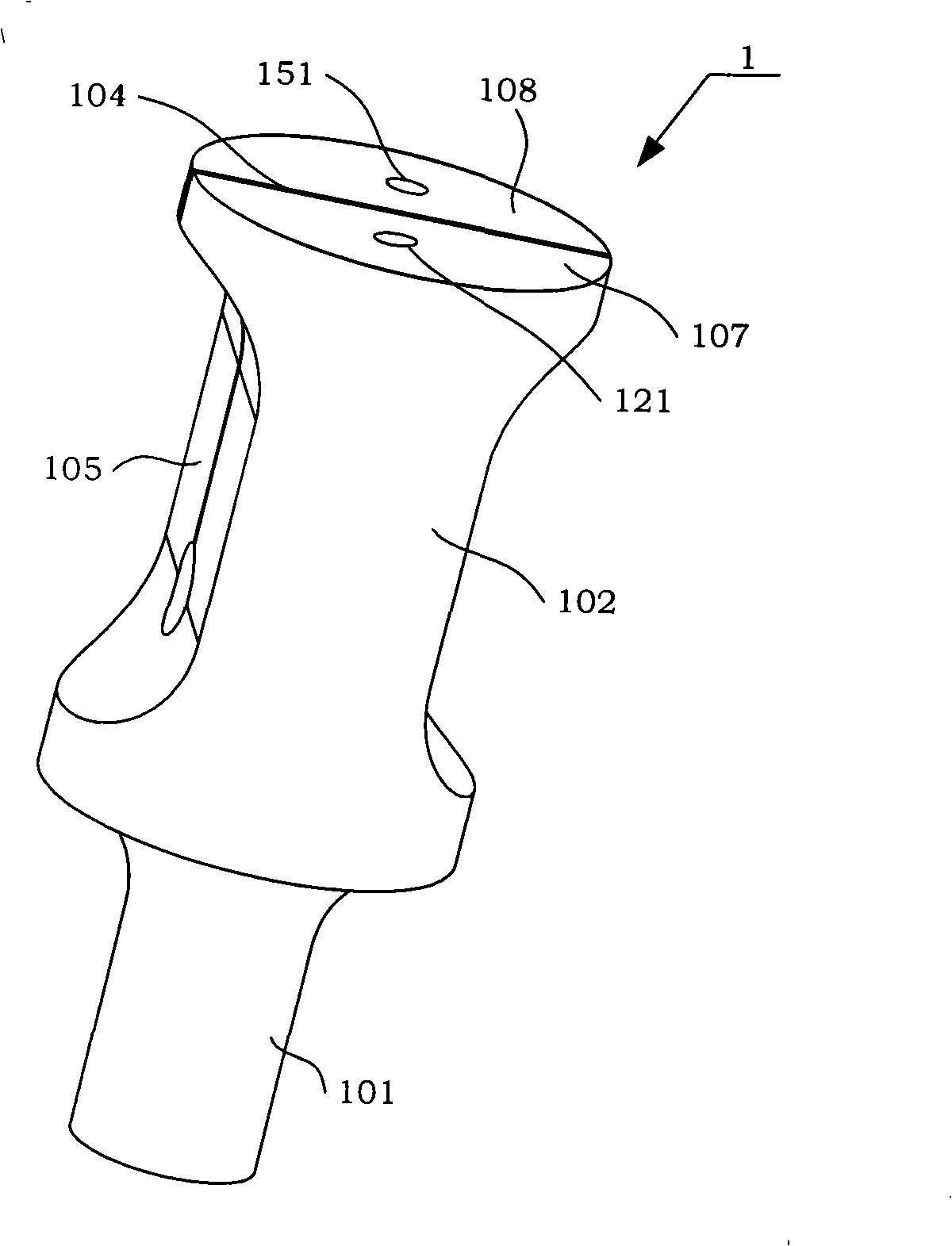

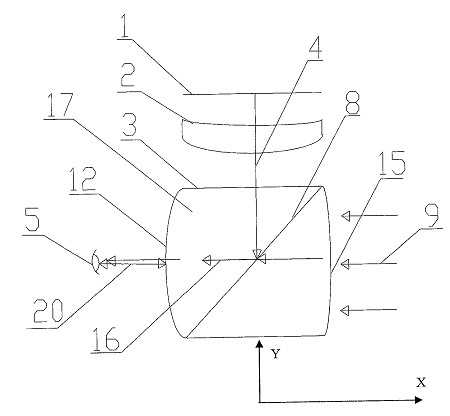

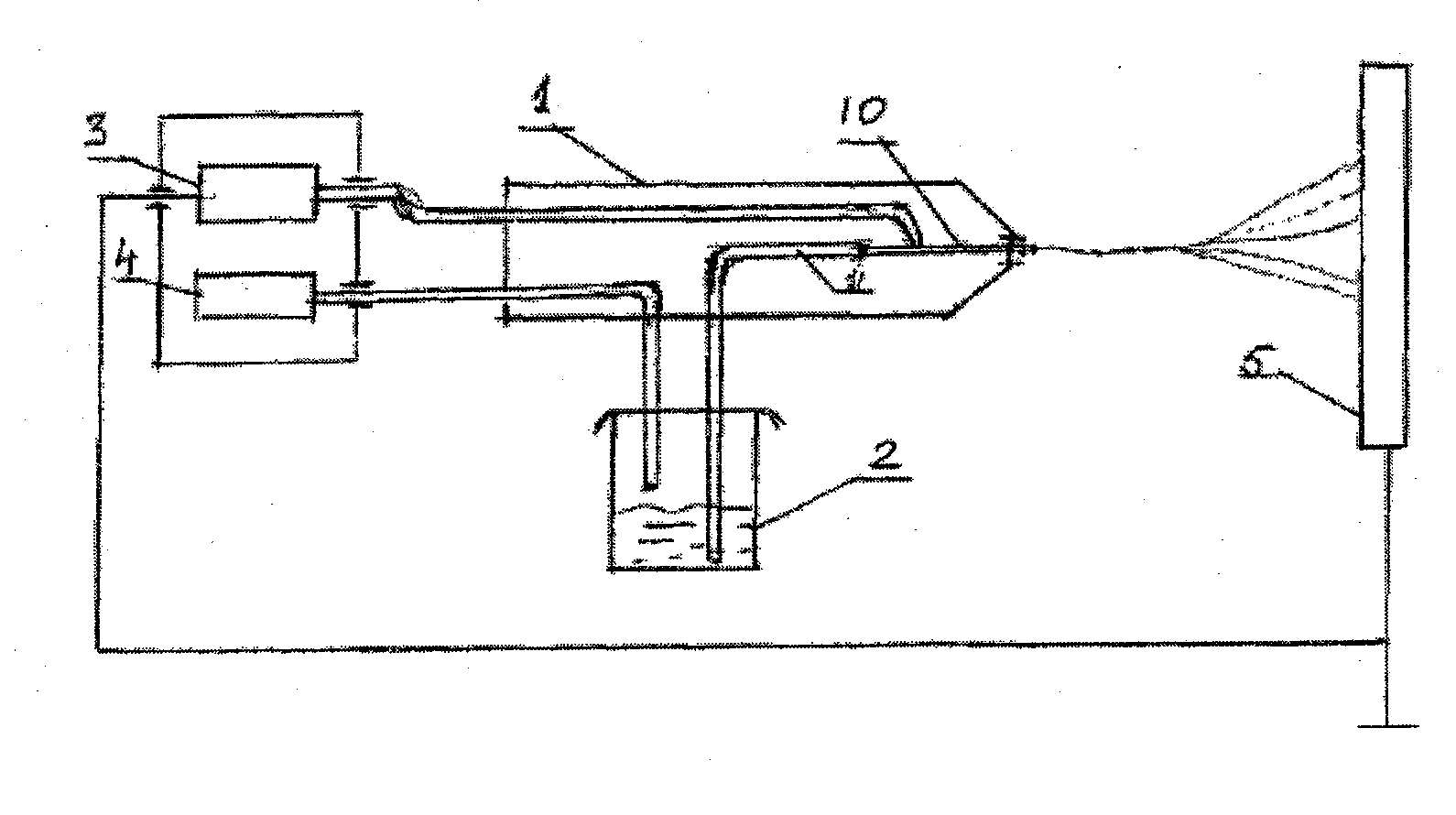

Bending mode conversion type ultrasound wave torsional vibration energy converter

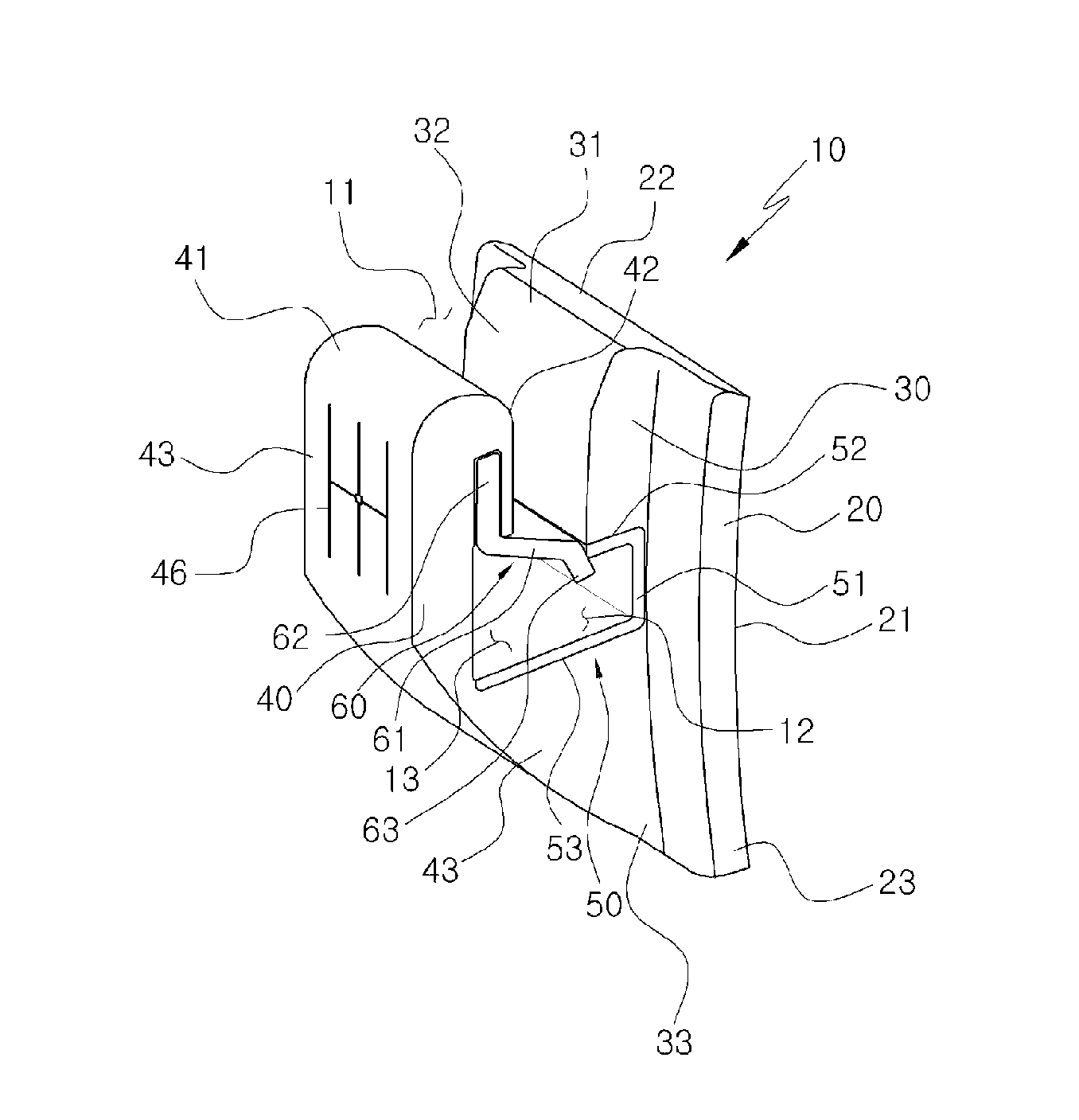

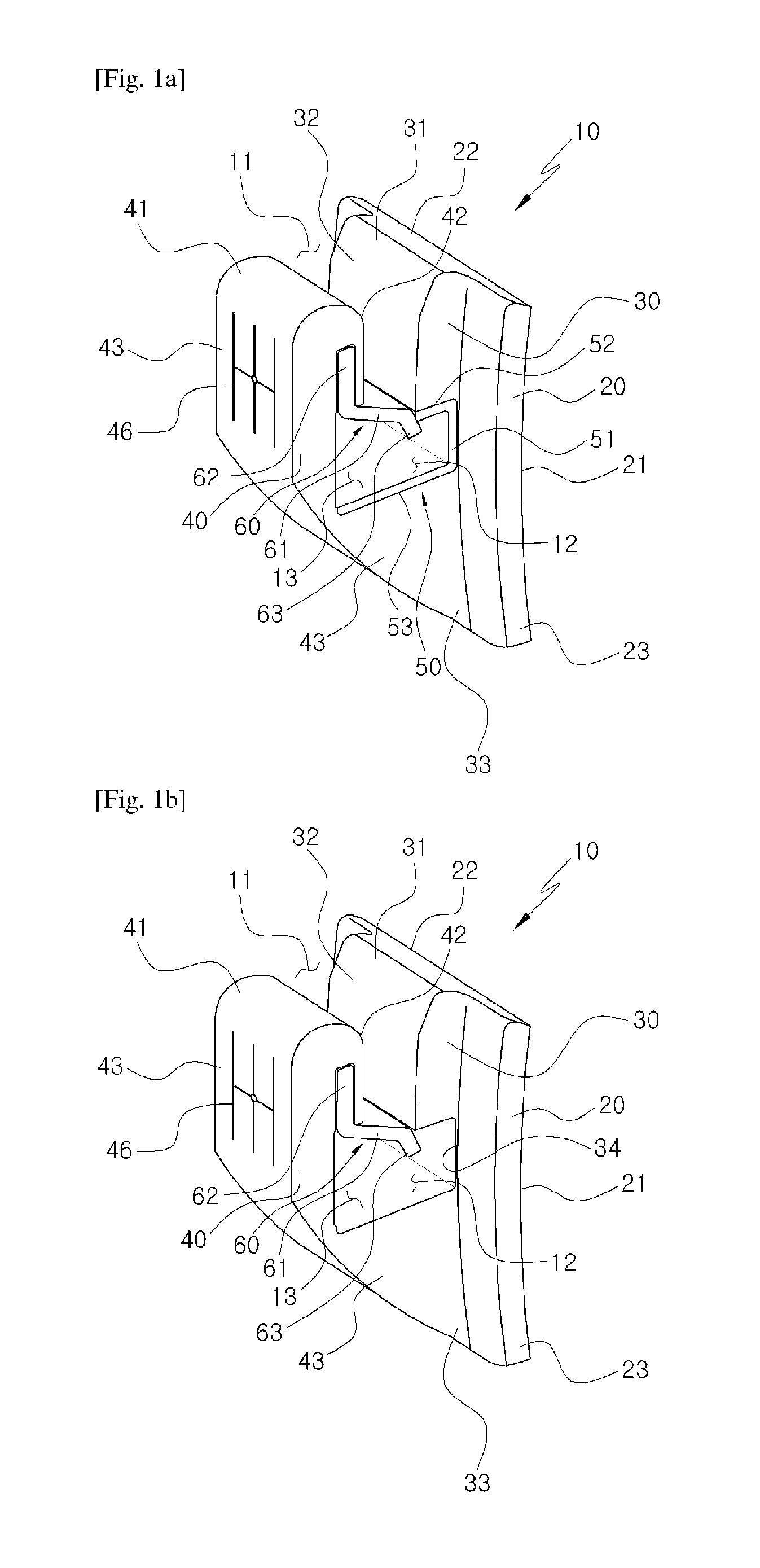

InactiveCN101259465ALarge vibration amplitudeHigh output powerMaterial analysis using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesTransformerTransducer

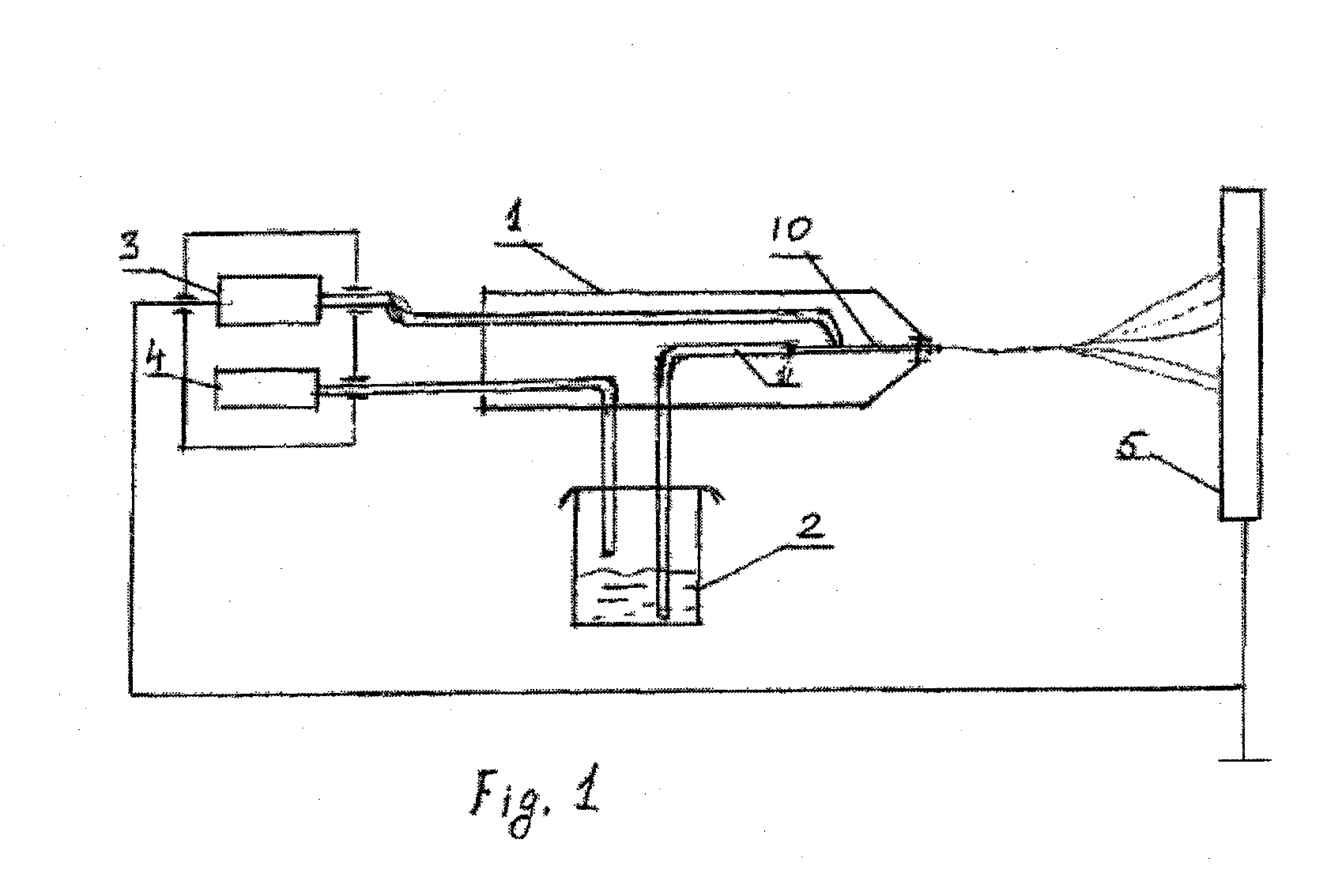

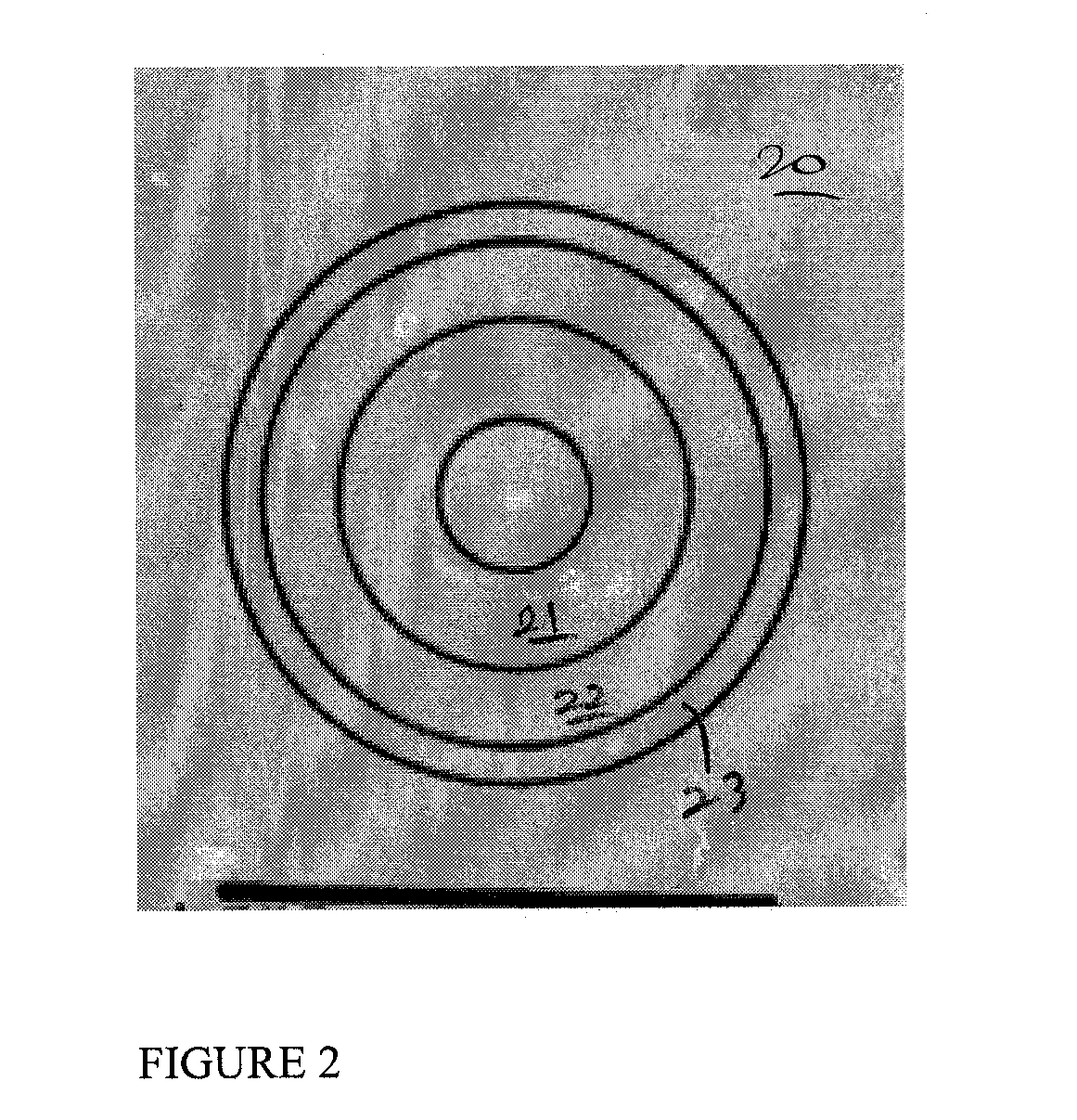

The invention discloses a bending-twisting conversion type ultrasonic torsion vibration transducer which comprises a bending-twisting vibrating body(1), a drive component (2) and a back cover (3) of the transducer; the drive component (2) is arranged between the bending-twisting vibrating body(1) and the back cover (3) of the transducer, and moreover, an A pretighting bolt (33) passes through the through hole of an A end cover (31), an A through hole (22) and an A pretighting screw hole (121) in turn through to arrange the A end cover (31) and an insulating block (21) on the A top surface (107) of the bending-twisting vibrating body(1); an B pretighting bolt (34) passes through the through hole of an B end cover (32), an B through hole (23) and an B pretighting screw hole (151) in turn to arrange the B end cover (32) and the insulating block (21) on the B top surface (108) of the bending-twisting vibrating body(1). A pair of bending vibrations with the same frequency swings and opposite vibrating directions generated by corresponding two groups of piezoelectric ceramics drive elements are amplified and transmitted to a converter by two bending arms; two bending vibrations are coupled and converted into a coupling torsion vibration (63) through a mode converter; a torsion vibration (64) is obtained and output after being amplified by an amplitude transformer (101), thus obtaining ultrasonic torsion vibration by a simpler mode.

Owner:BEIHANG UNIV

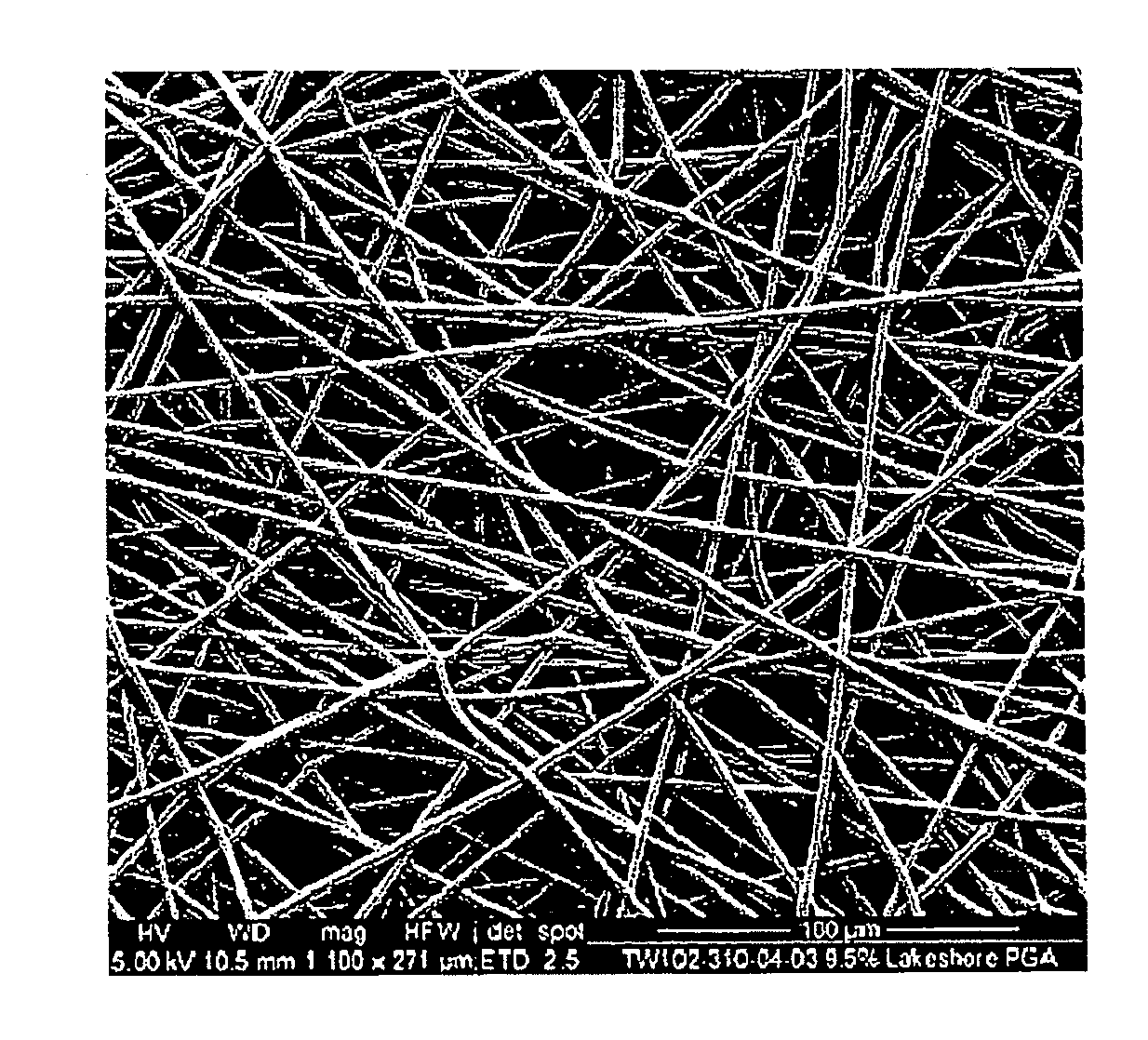

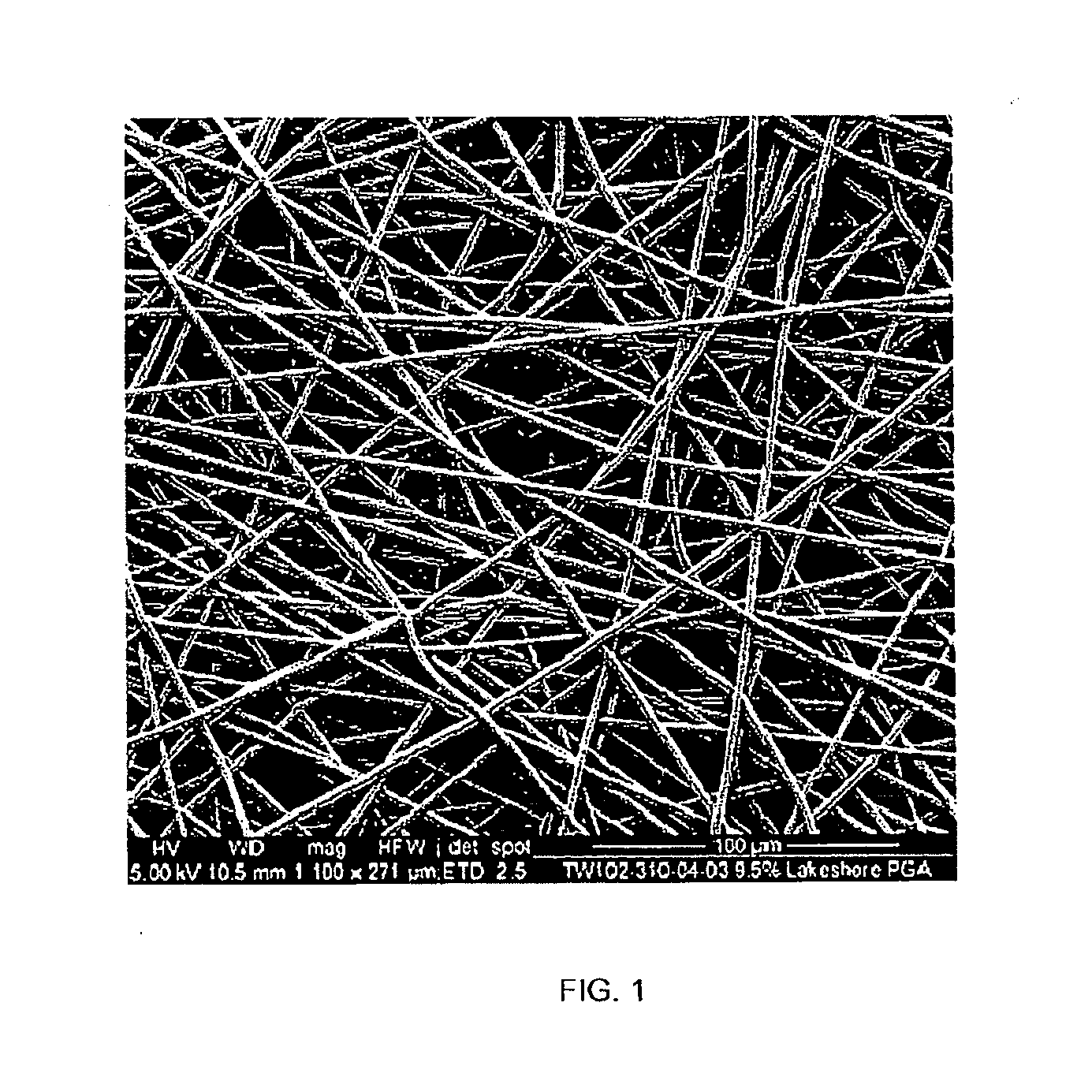

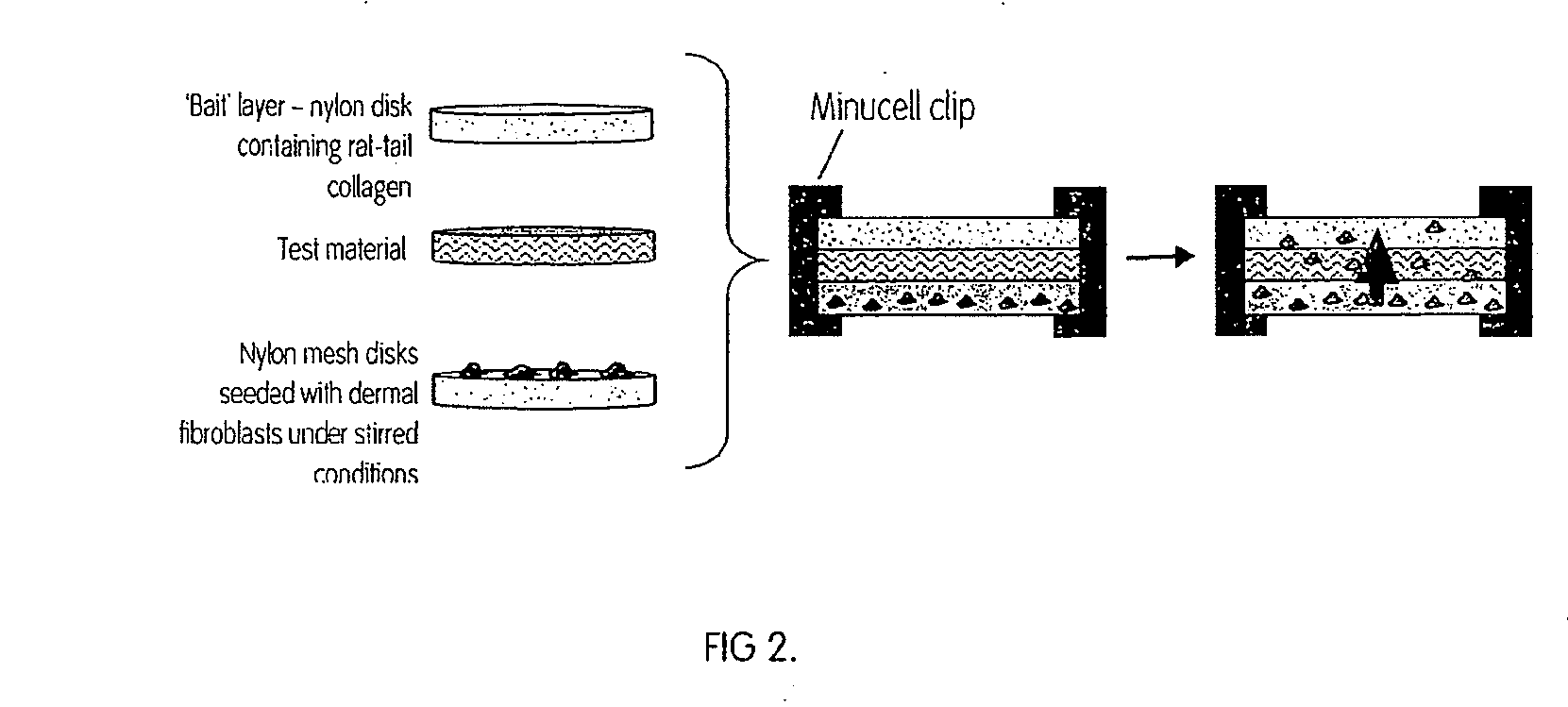

Scaffold

ActiveUS20100297208A1Fast seedingDimensional stabilityBiocideElectric discharge heatingFiberSource material

The present invention relates to scaffolds which can be used as medical devices for guided tissue regeneration and repair, in particular the invention is directed to a scaffold comprising fibres having a mean fibre diameter of between from about 1.2 to 4.0 microns, wherein the fibres comprise a glycolide. The invention further relates to the use of the scaffolds for the selective capture of cell populations for a cell source material.

Owner:SMITH & NEPHEW INC

Ice coating resistance paint composition

InactiveCN101514270AEasy to break awayReduce the amount of icingOther chemical processesCoatingsFluoropolymerSolvent

The invention relates to an ice coating resistance paint which has the following main components: 20-70% of fluoropolymer resin, 1-7% of fluorine-containing surfactant, 2-7% of aluminum hydroxide, 1-5% of nano-powder, 0.1-2% of metallic drier, 20-80% of solvent. The ice coating resistance paint composition can perform the best effect in ice coating resistance when applied to high-voltage cables, iron towers, communication lines and the like, thus reducing adhesive force of the ice on the surface of base material and ice concentration on the surface of the base material; then under the effect of wind and natural force, the ice is easy to be separated from the surface of the base material. The ice coating resistance paint has very good binding force on metal matrix, relatively high thermal conductivity, what is more, the outer surface of the paint features low surface tension, high hydrophobicity and ice-phobic property, thus reducing hydration adhesive force at utmost and facilitating the ice to fall off extremely easily and realizing the aim of preventing ice-forming and removing the ice. The method features simple and easy feasibility in engineering, convenient control, relatively low cost and good using effect.

Owner:HARBIN JINTUYUAN SCI & TECH

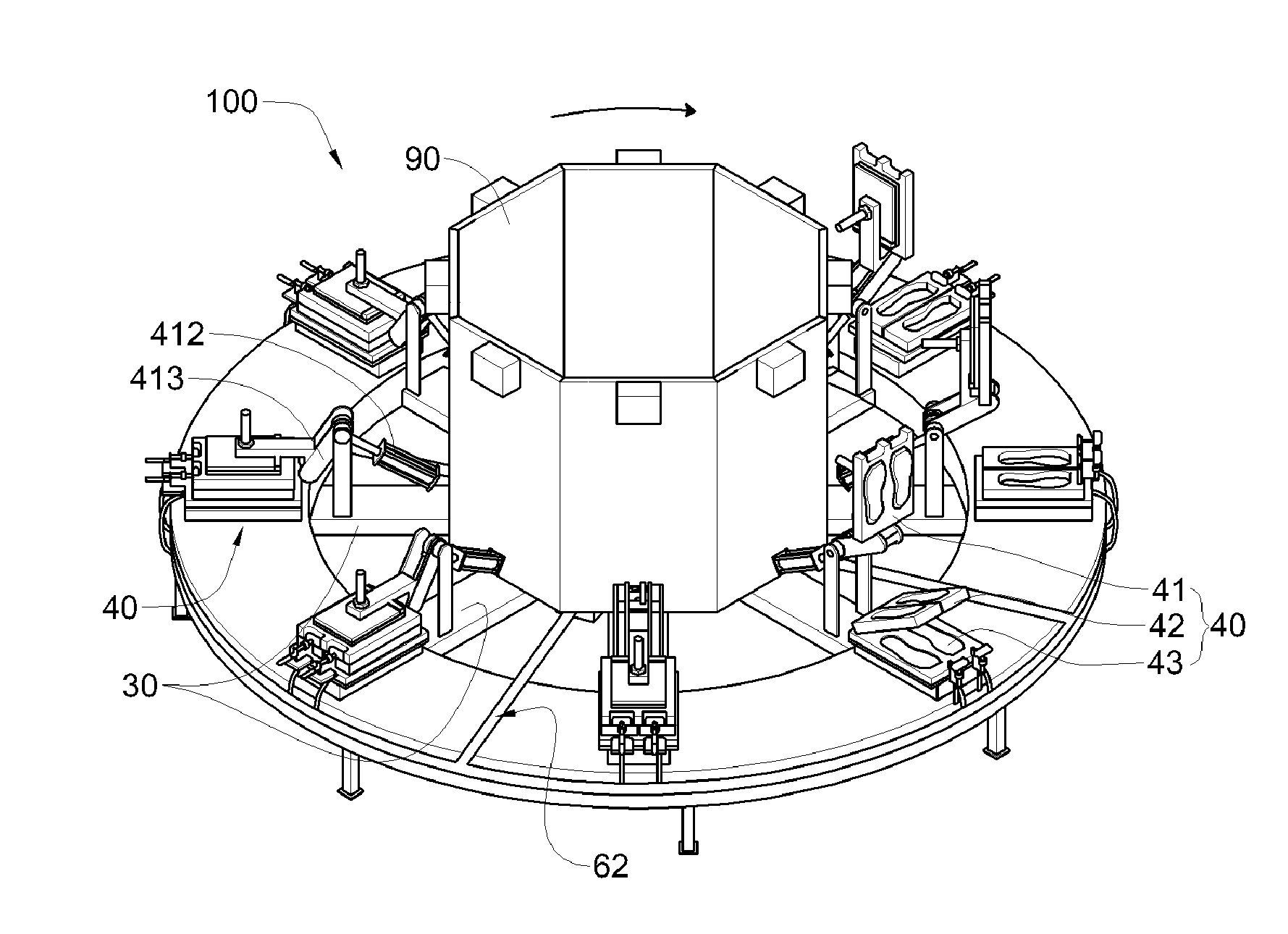

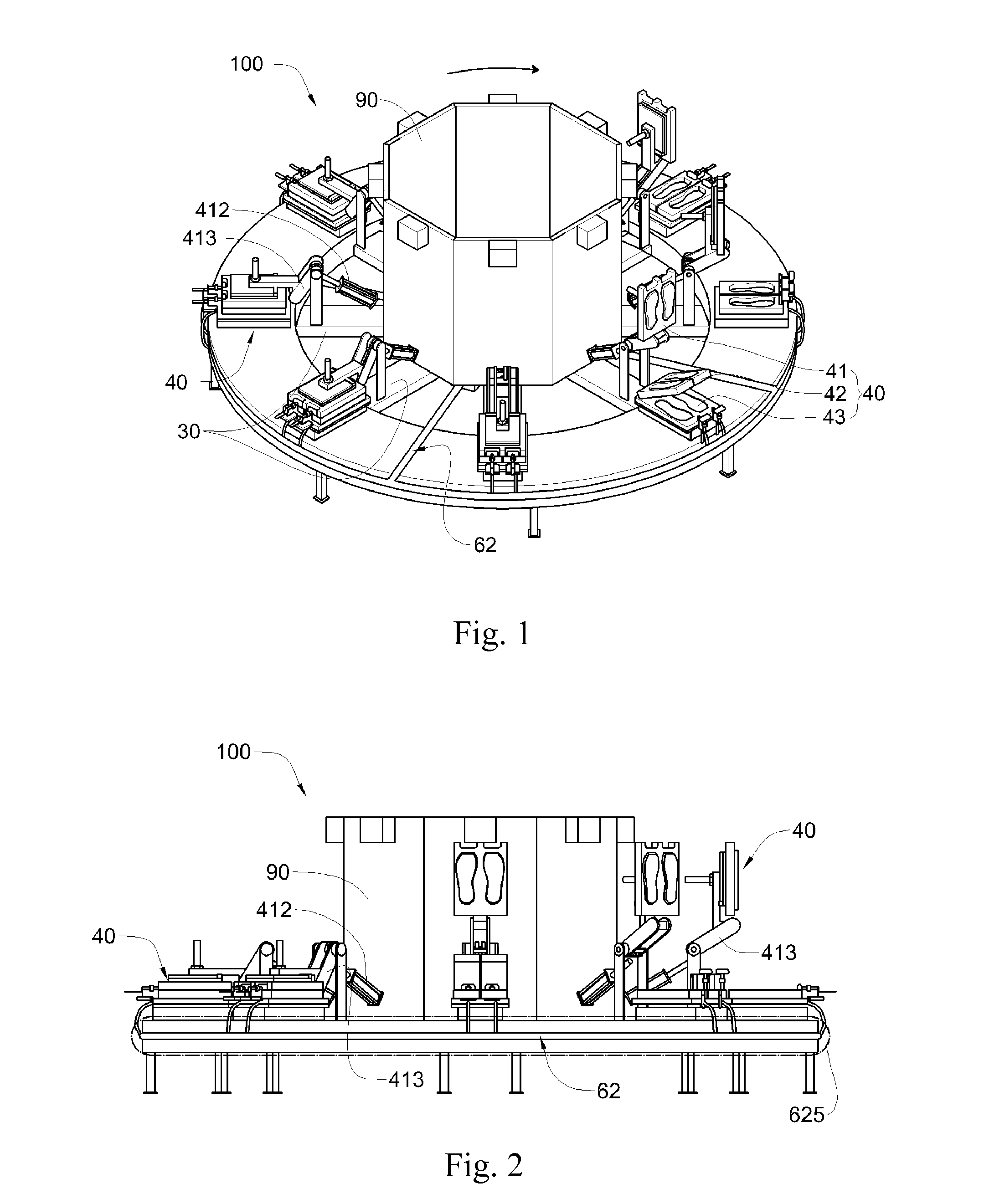

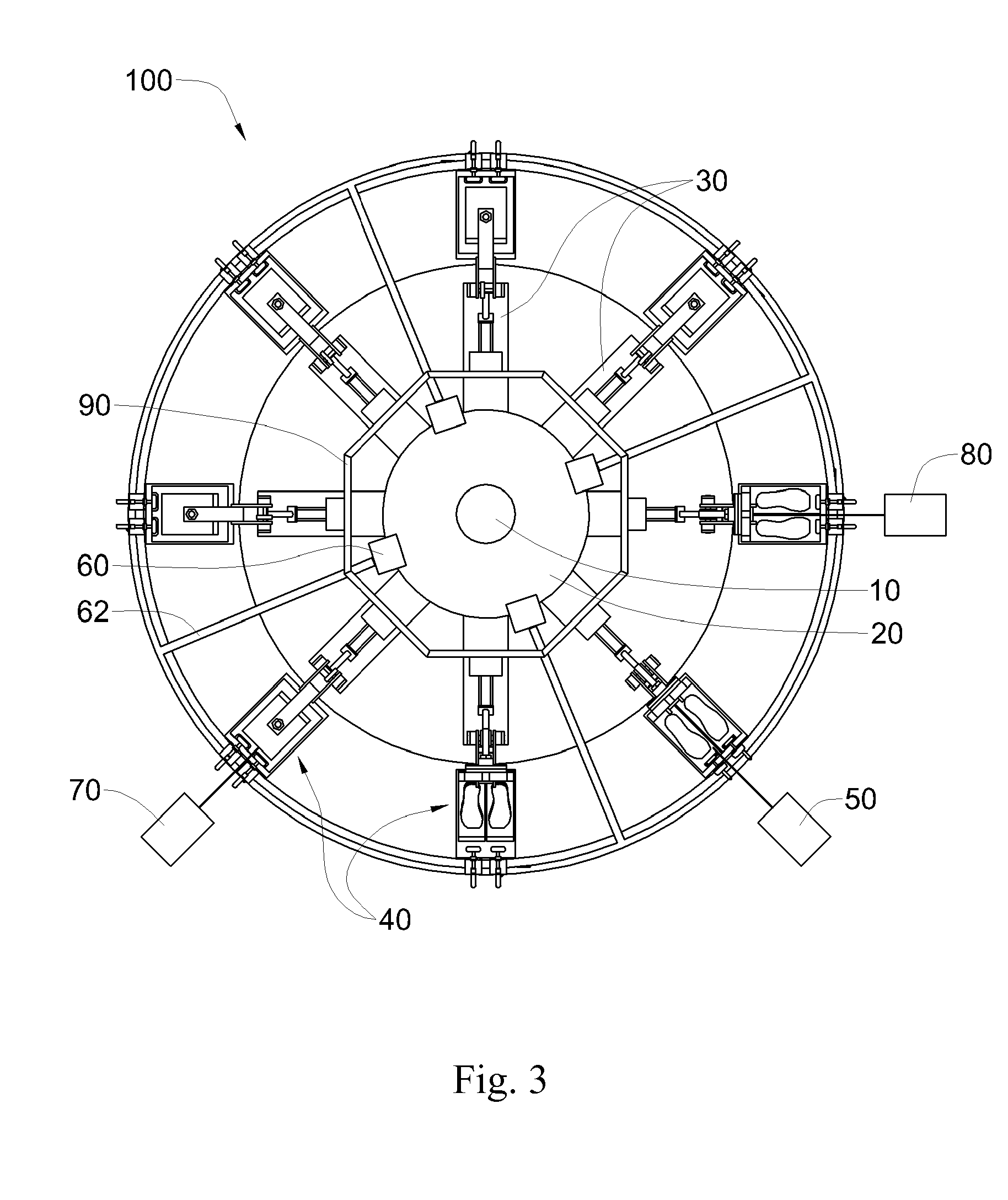

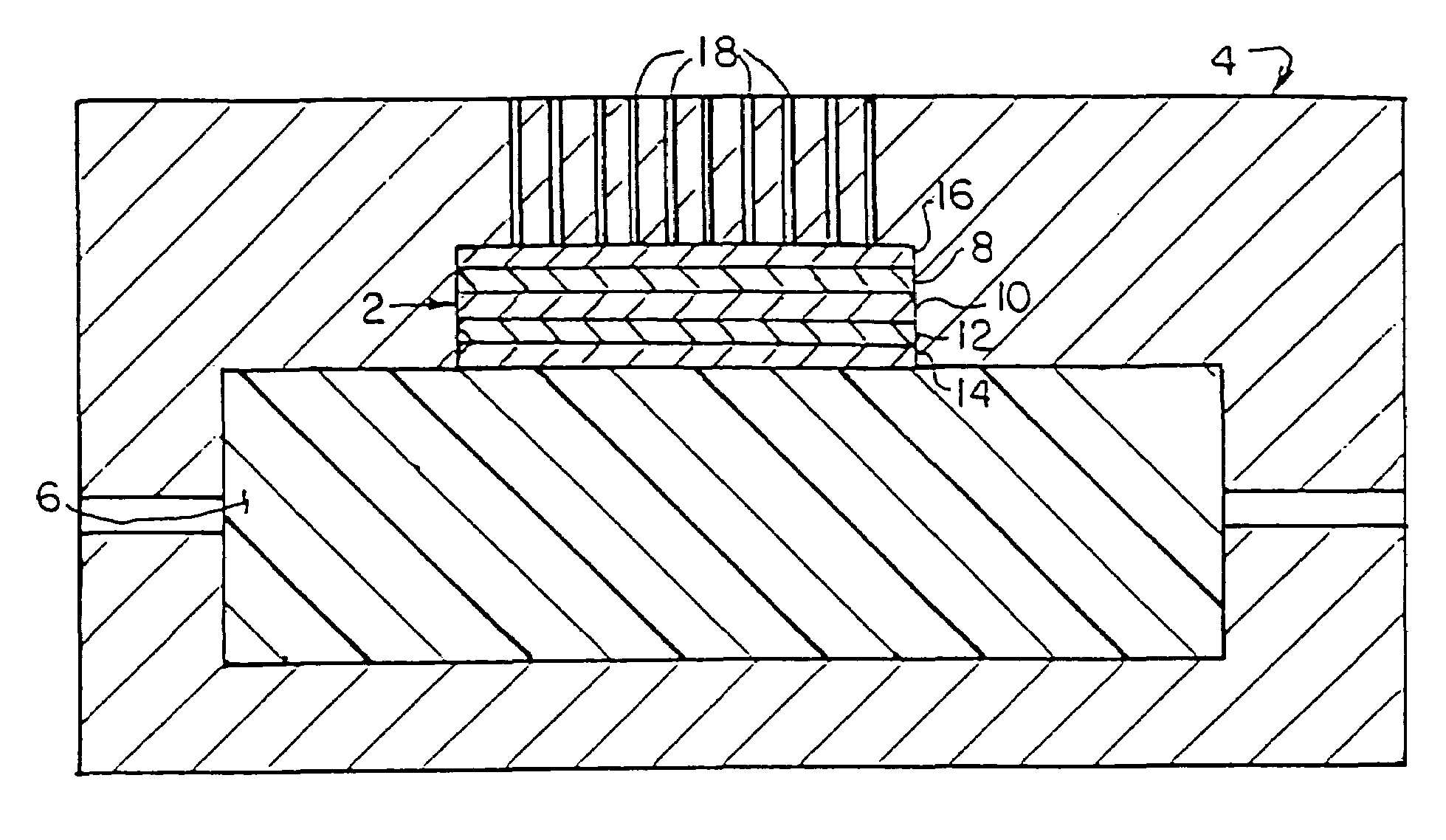

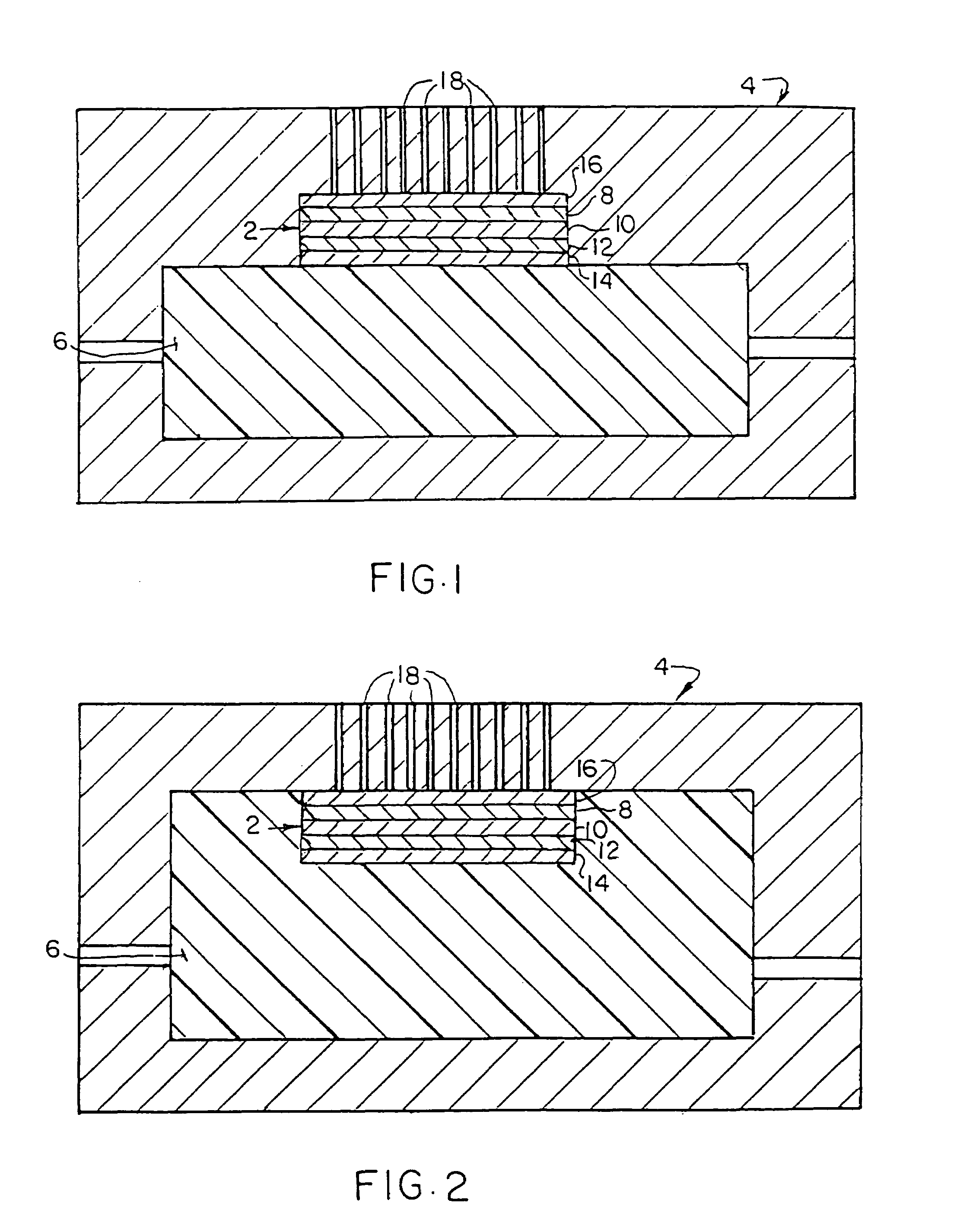

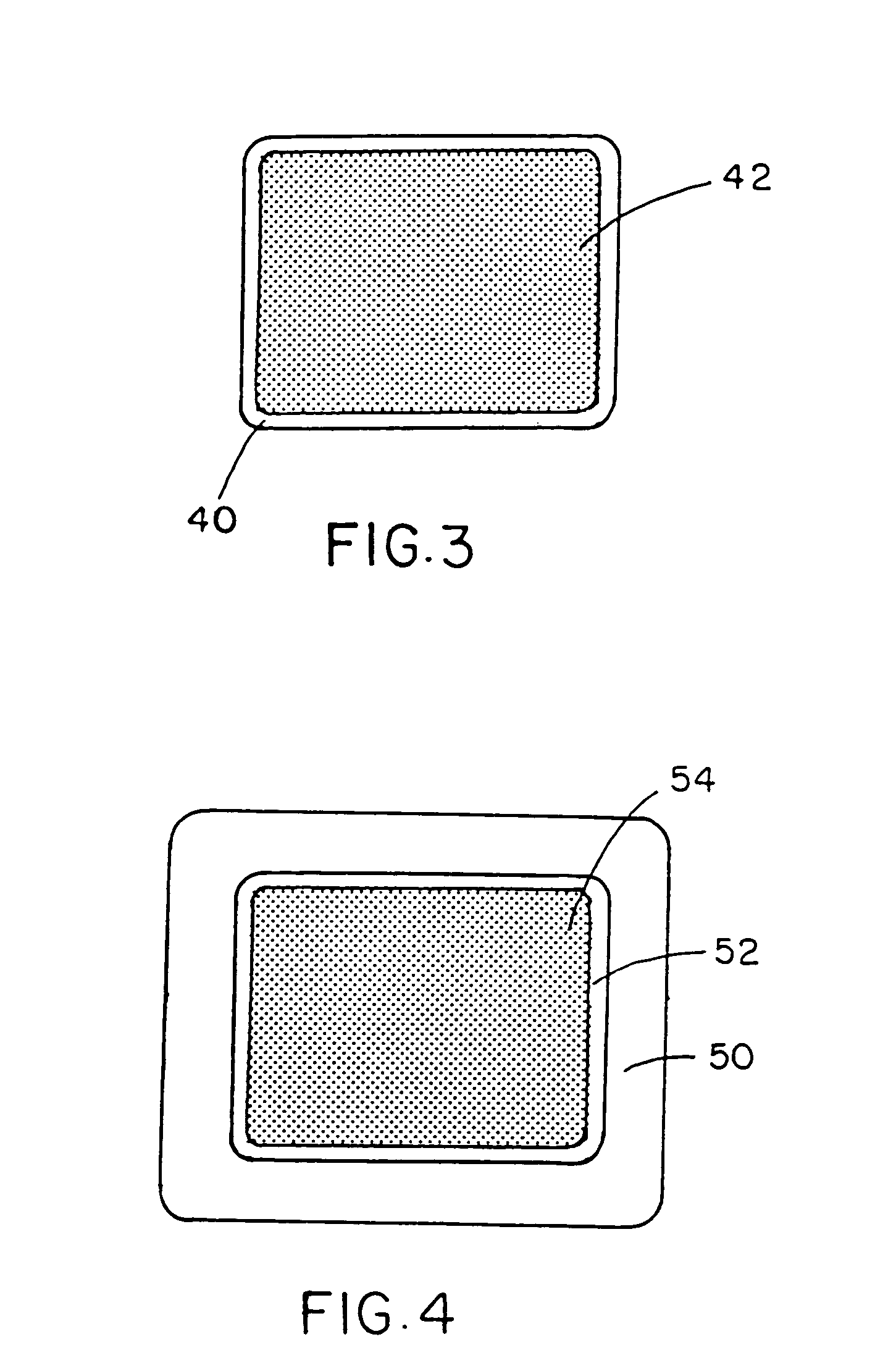

Polyurethane-coated spandex fabric-fused midsole and apparatus and method for manufacturing the same

ActiveUS20120056345A1Easily and conveniently manufacturedReduce laborTailstocks/centresConfectioneryEngineeringMechanical engineering

The present invention relates to a polyurethane-coated (PU-coated) spandex fabric-fused midsole, and an apparatus and method for manufacturing the same, which allow a shoe midsole to be easily and conveniently manufactured through a single automatic process, and allows a PU-coated spandex fabric to be easily fused to a surface of the midsole in the process of manufacturing the midsole. For this purpose, there is provided a polyurethane-coated (PU-coated) spandex fabric-fused midsole manufacturing apparatus including: a central axis rotated by a driving force of a motor; a rotary disc fitted on the central axis to be rotated together with the central axis; a plurality of midsole forming mold units, which are mounted on the outer ends of support members radially extending from the outer circumference of the rotary disc, respectively; a PU-coated spandex fabric supply apparatus installed above the trace of rotation of the midsole forming mold units to provide a PU-coated spandex fabric to each of the midsole forming mold units; vacuum means installed between the rotary disc and the midsole forming mold units to vacuum the inside of a midsole forming mold unit supplied with a PU-coated spandex fabric to such an extent that the PU-coated spandex fabric comes into close contact with the inner surface of the midsole forming mold unit; a resin introducing apparatus installed outside of the trace of rotation of the midsole forming mold units to introduce polyurethane (PU) resin into the midsole forming mold unit having the PU-coated spandex fabric film in contact with inner surface thereof; and a foam-molded product removal apparatus installed outside of the trace of rotation of the midsole forming mold units to remove a foam-molded product formed by foaming the polyurethane resin introduced into the midsole forming unit by leaving the polyurethane resin in the midsole forming mold unit at a predetermined temperature for a predetermined length of time.

Owner:LEE DONG GUN

Method of decorating a molded article

InactiveUS6929771B1Prevent seepageEasy adhesionLamination ancillary operationsBristlePolymer scienceShell molding

Owner:HIGH VOLTAGE GRAPHICS

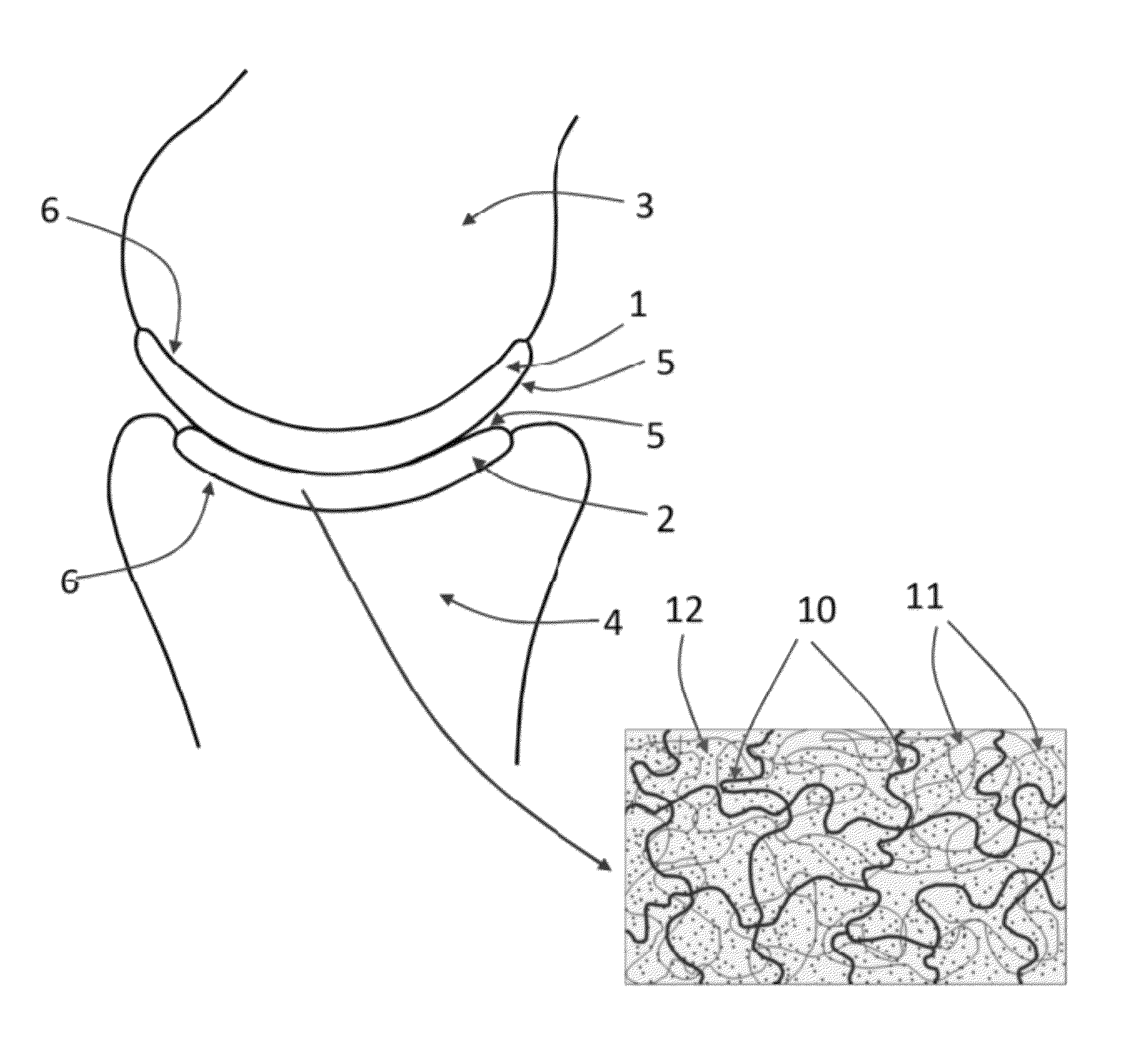

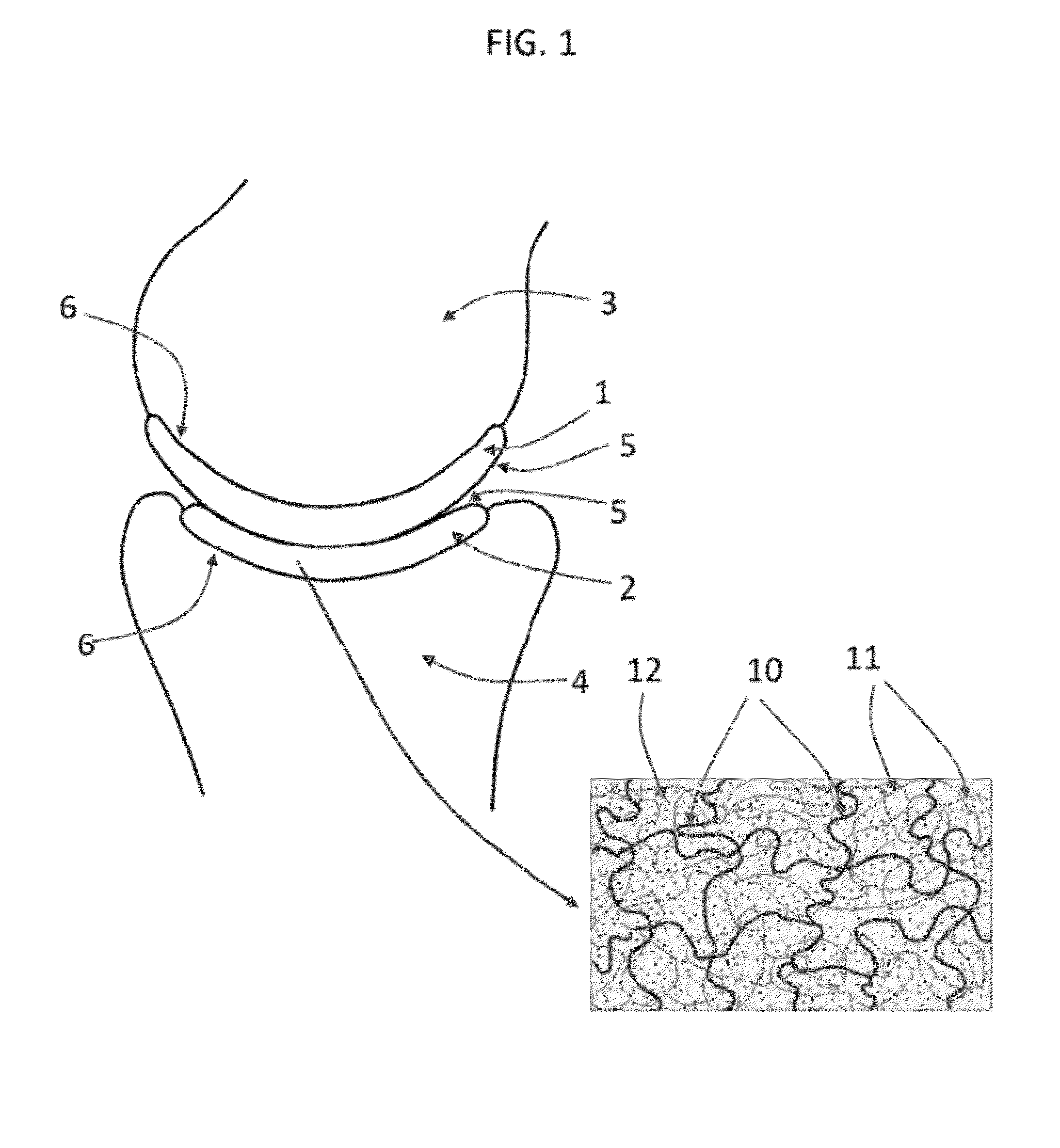

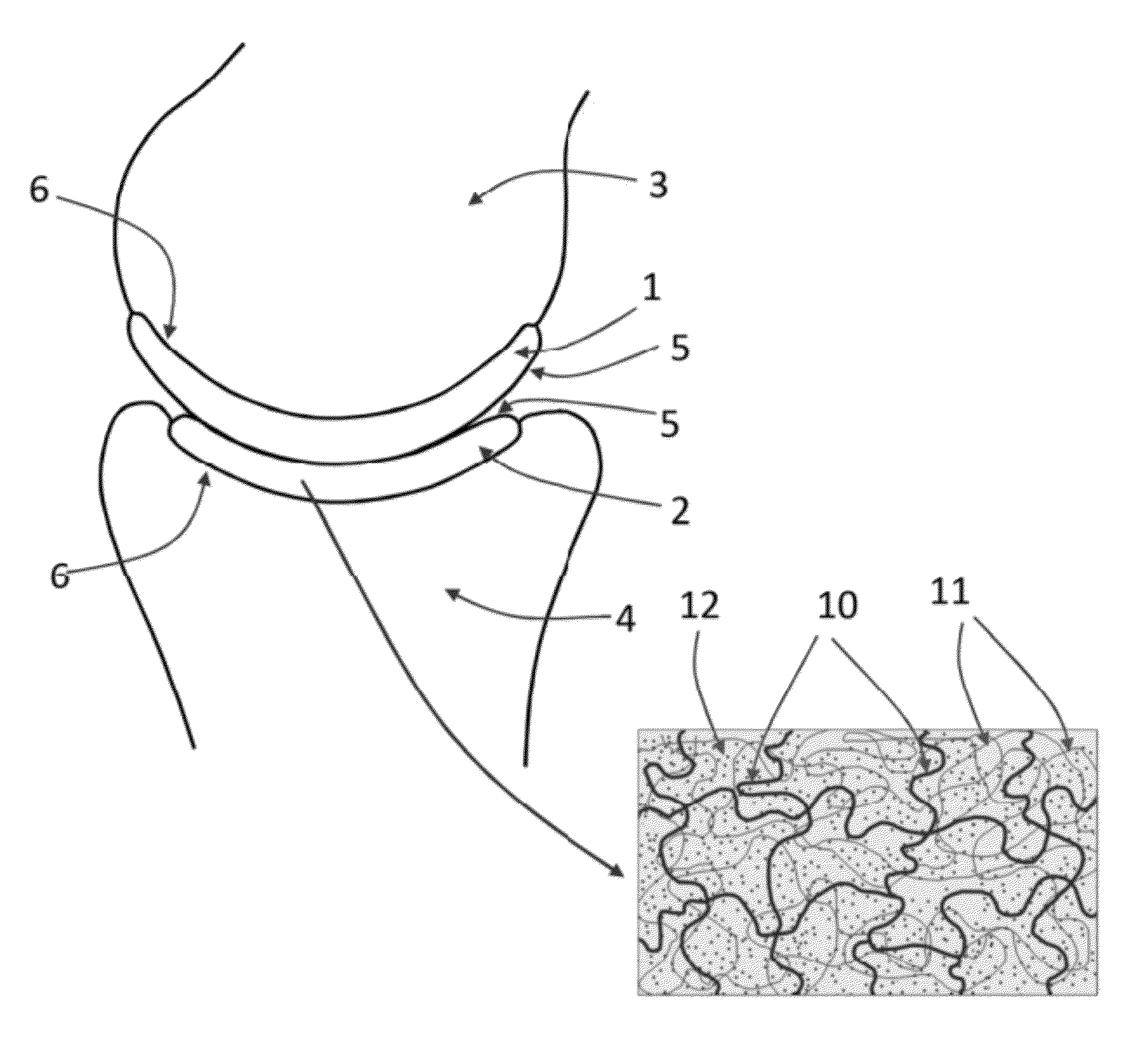

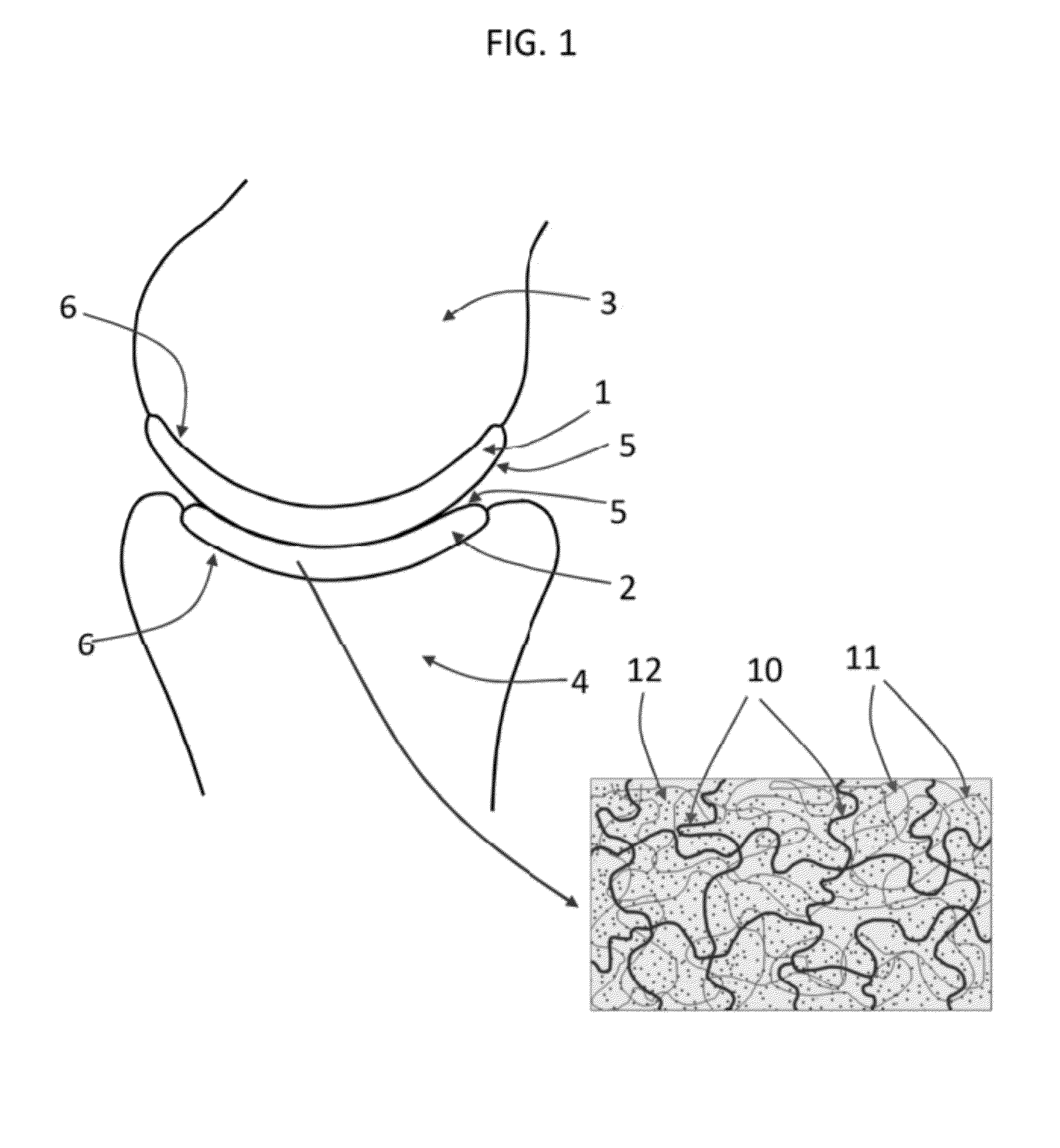

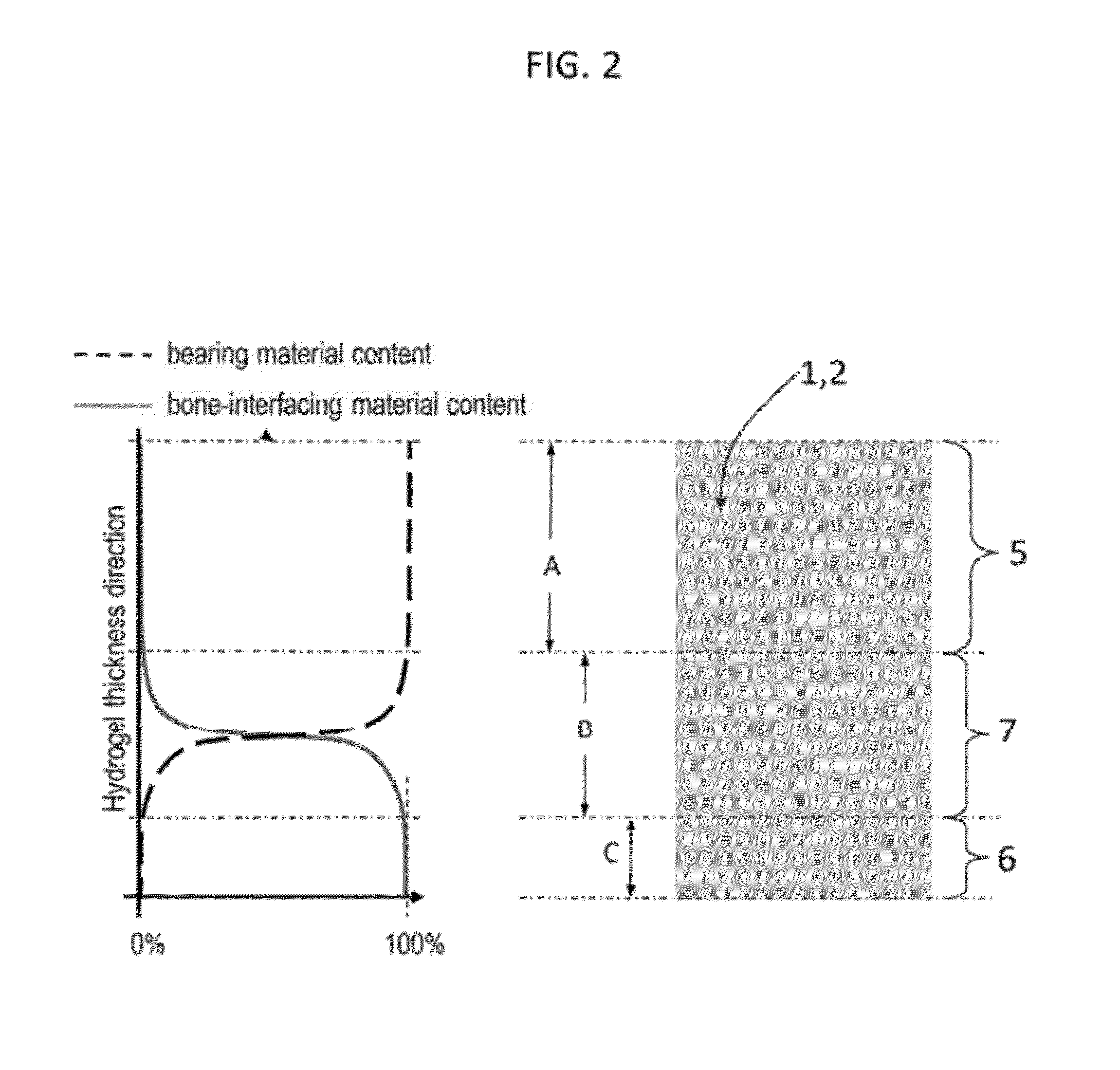

Hydrogel arthroplasty device

An arthroplasty device is provided having an interpenetrating polymer network (IPN) hydrogel that is strain-hardened by swelling and adapted to be held in place in a joint by conforming to a bone geometry. The strain-hardened IPN hydrogel is based on two different networks: (1) a non-silicone network of preformed hydrophilic non-ionic telechelic macromonomers chemically cross-linked by polymerization of its end-groups, and (2) a non-silicone network of ionizable monomers. The second network was polymerized and chemically cross-linked in the presence of the first network and has formed physical cross-links with the first network. Within the IPN, the degree of chemical cross-linking in the second network is less than in the first network. An aqueous salt solution (neutral pH) is used to ionize and swell the second network. The swelling of the second network is constrained by the first network resulting in an increase in effective physical cross-links within the IPN.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

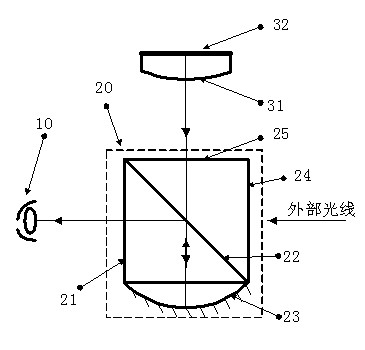

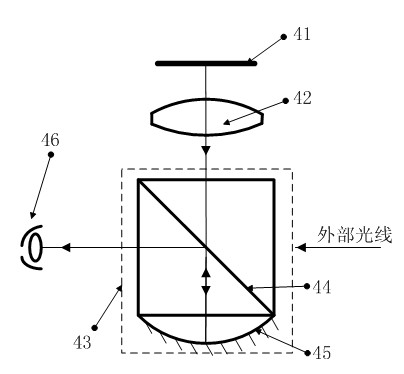

Optical system of helmet displayer

An optical system of a helmet displayer comprises a micro displayer, a bonding lens and an optical combiner. The micro displayer and the bonding lens are bonded integrally, the optical combiner comprises two tightly-adhered right-angle prisms forming a 45-degree angle and a concave-surface reflecting mirror, a narrow-band high-reflective optical surface is located at the bonding position of the two right-angle prisms and forms a 45-degree angle respectively with the horizontal optical axis and the vertical optical axis, the concave-surface reflecting mirror and the right-angle prisms are bonded integrally, and the concave surface is the high-reflective optical surface. Light beams are emitted from the micro displayer, are converged through the bonding lens, enter the optical combiner and pass through the narrow-band high-reflective optical surface, then transmitted light beams are converged through the high-reflective optical surface again, and reflected light beams become parallel light beams after the light beams pass through the narrow-band high-reflective optical surface again. An exit pupil is located at the position of a pupil of one human eye, extraneous light enters the optical combiner and passes through the narrow-band high-reflective optical surface, and then the transmitted light beams enter the pupil of one human eye. The optical system of the helmet displayer has the advantages of being compact in system, convenient to correct, good in aberration correction and high in reliability.

Owner:中航华东光电有限公司

Hydrogel Arthroplasty Device

An arthroplasty device is provided having an interpenetrating polymer network (IPN) hydrogel that is strain-hardened by swelling and adapted to be held in place in a joint by conforming to a bone geometry. The strain-hardened IPN hydrogel is based on two different networks: (1) a non-silicone network of preformed hydrophilic non-ionic telechelic macromonomers chemically cross-linked by polymerization of its end-groups, and (2) a non-silicone network of ionizable monomers. The second network was polymerized and chemically cross-linked in the presence of the first network and has formed physical cross-links with the first network. Within the IPN, the degree of chemical cross-linking in the second network is less than in the first network. An aqueous salt solution (neutral pH) is used to ionize and swell the second network. The swelling of the second network is constrained by the first network resulting in an increase in effective physical cross-links within the IPN.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

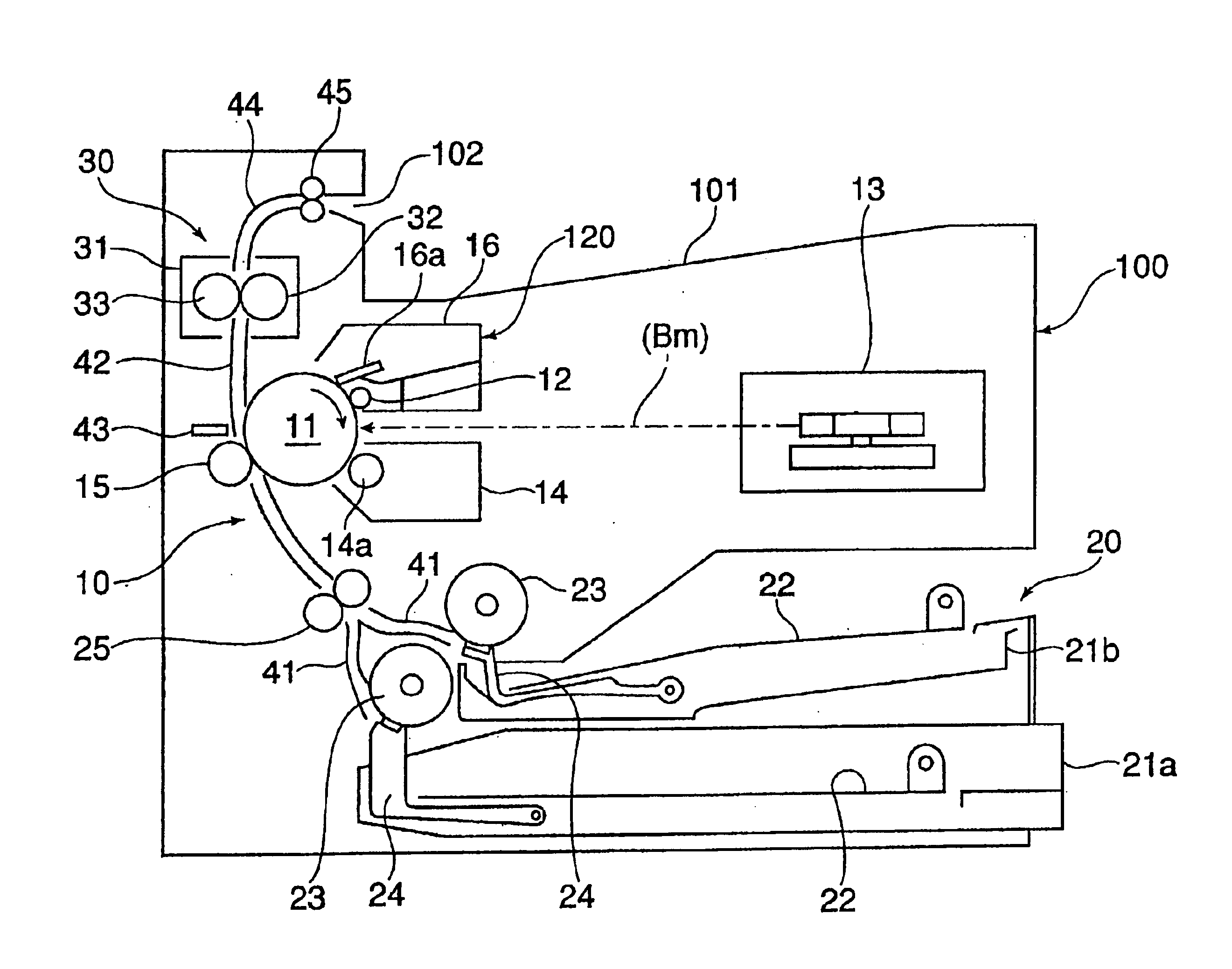

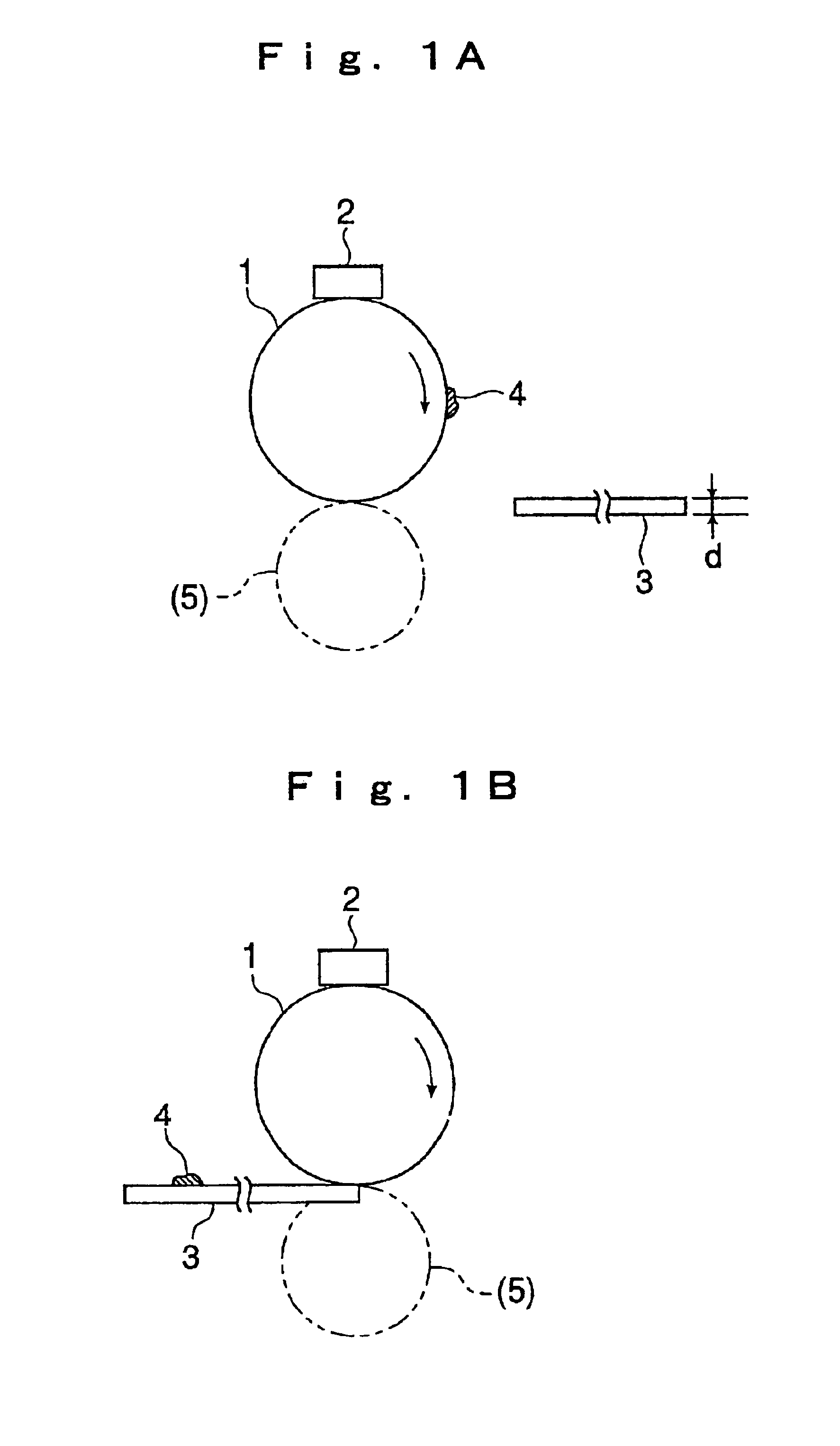

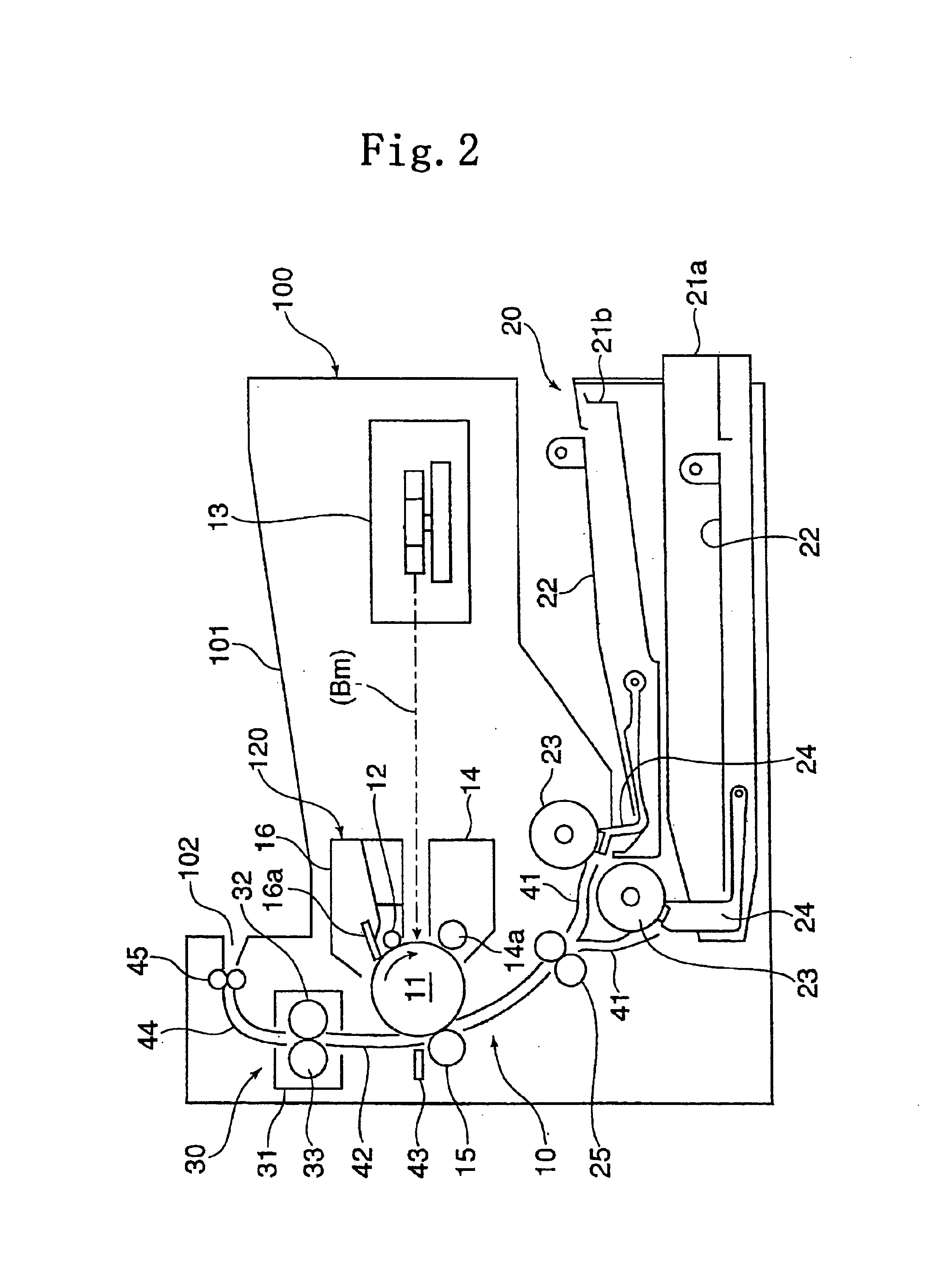

Cleaning sheet, cleaning method, and image forming apparatus

InactiveUS6845225B2Easy to disassembleFixed imageElectrographic process apparatusImage formationEngineering

Provided is a cleaning sheet adapted to clean a surface of a heating roll in a fixing device, which causes a recording sheet bearing a toner image formed of a magnetic toner containing a magnetic material to pass through the fixing device under a state in which the recording sheet is in press contact with the surface of the heating roll having arranged thereon a contact component in contact with the surface of the heating roll and heated to a fixing temperature to rotate, to perform fixing of the toner image, including a synthetic resin sheet with a thickness of 100 μm or more, which is made of a thermoplastic resin with a melting point higher than the fixing temperature and Rockwell hardness of M60 or more or thermosetting resin with Rockwell hardness of M60 or more.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Assemblies, systems, and methods for vacuum assisted internal drainage during wound healing

ActiveUS8715267B2Decreasing tissue edema and swelling of and tissueImprove natureWound drainsCatheterVacuum assistedInternal wounds

Assemblies, systems, and methods convey fluid from an internal wound site or body cavity by applying negative pressure from a source outside the internal wound site or body cavity through a wound drain assembly that is placed directly inside the internal wound site or body cavity.

Owner:IC SURGICAL INC

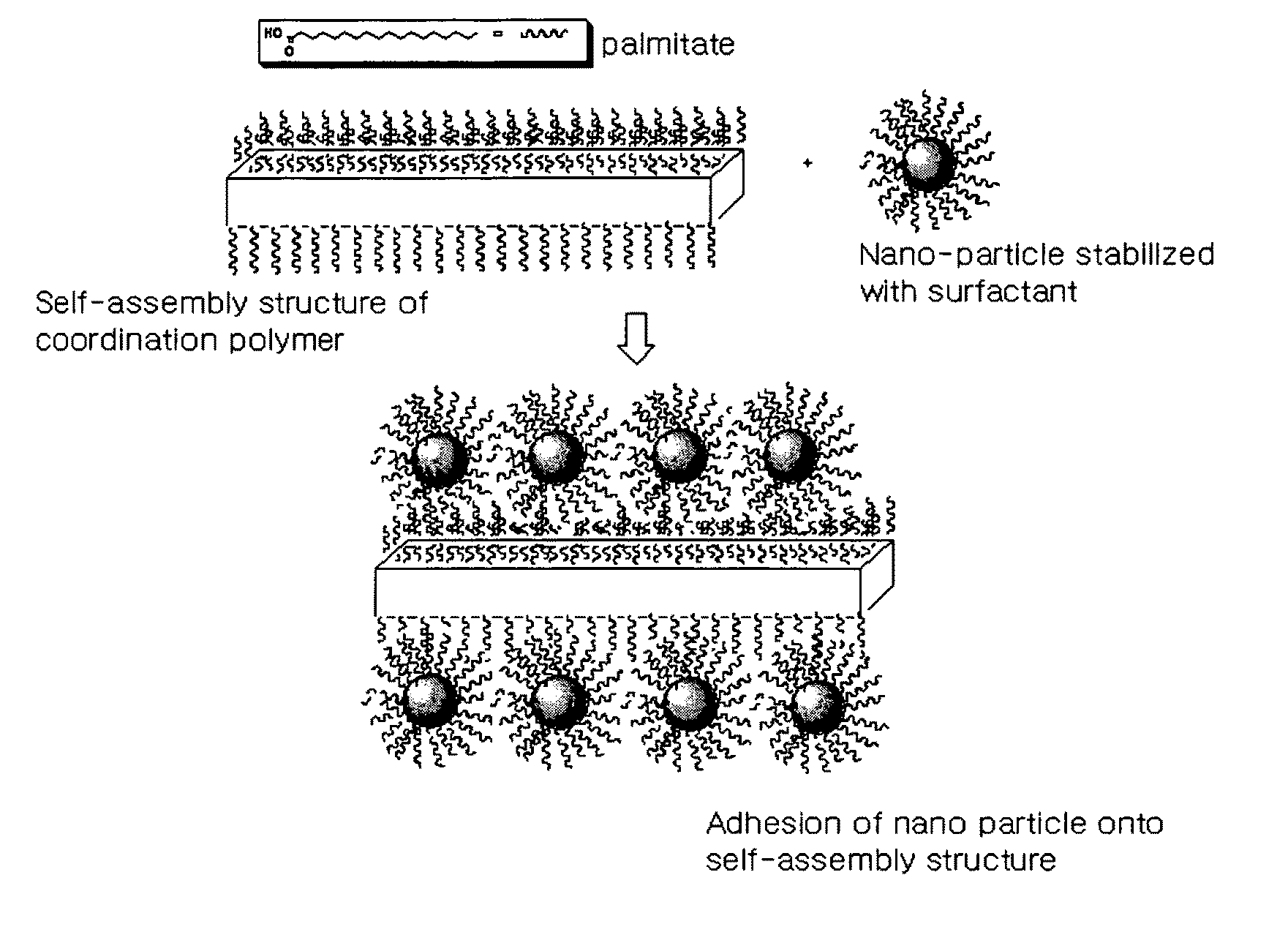

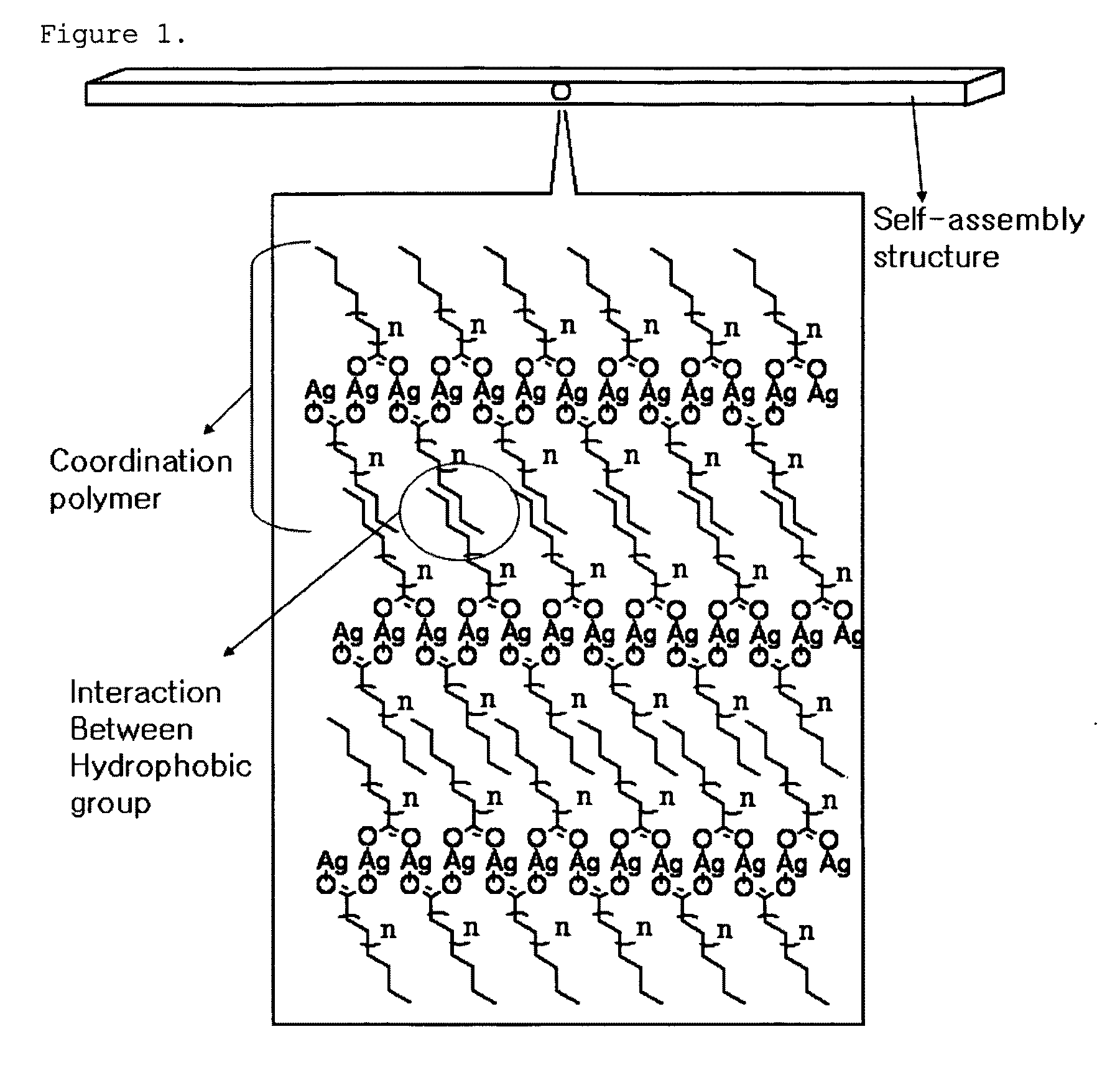

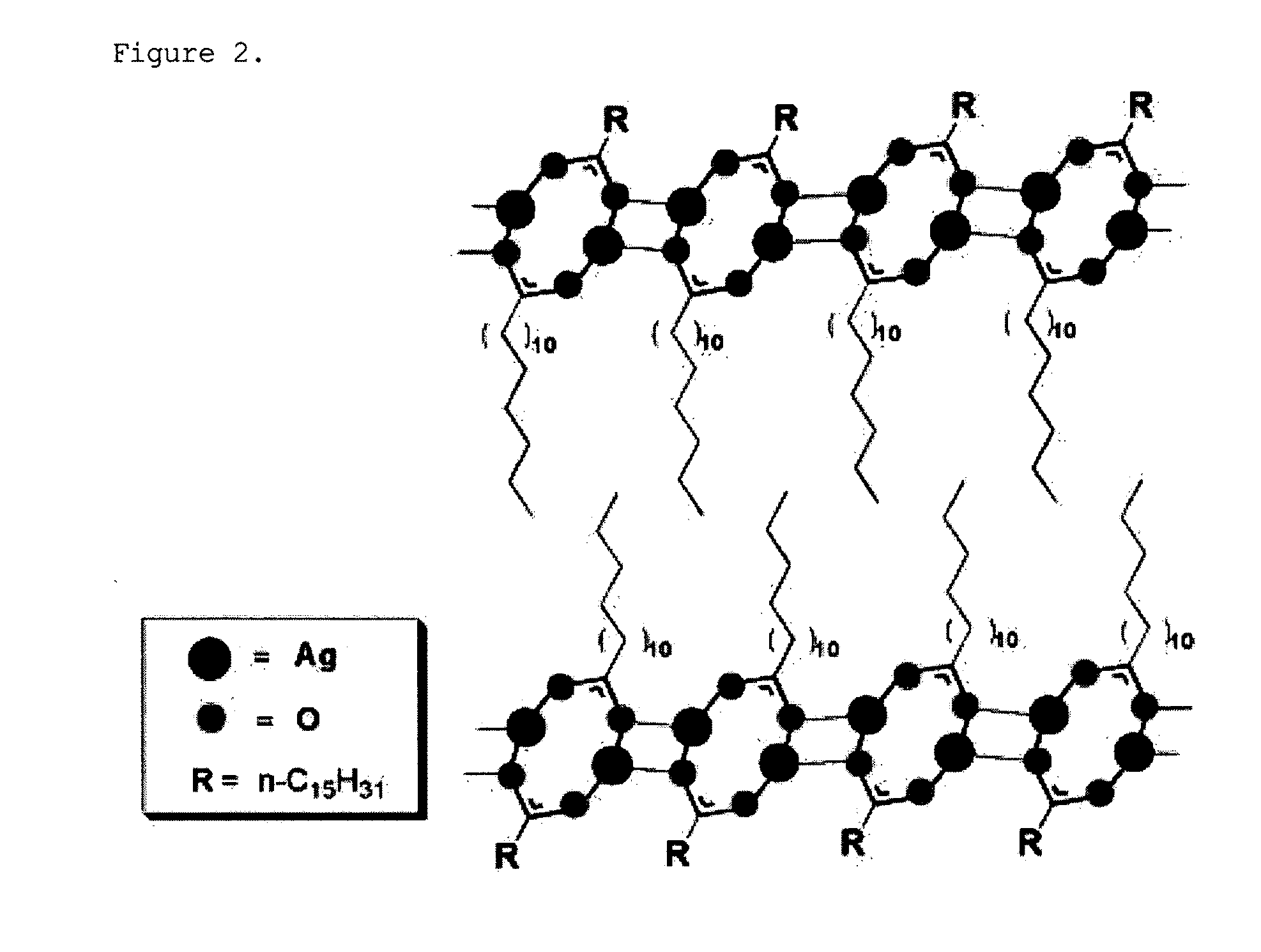

Organic-inorganic hybrid structures having nanoparticles adhering thereon and method for preparing the same

InactiveUS20090263656A1Good chemical stabilityDispersibility of in solution can be improvedMaterial nanotechnologyNanostructure manufactureSelf-assemblyChemistry

The invention disclosed herein provides an organic-inorganic hybrid structure having nanoparticles attached to the surface thereof, wherein the structure comprises a self-assembled structure of a coordination polymer, which includes a metal-organic ligand complex, as well as a preparation method thereof. According to the invention, through the use of the self-assembly phenomenon of coordination polymer and the use of nanoparticles having a surface component, which is the same as or similar to that of the surface of the coordination polymer, an organic-inorganic hybrid structure, which has nanoparticles attached to the surface of a self-assembled structure of coordination polymer, can be prepared in a relatively simple process without needing several steps.

Owner:LG CHEM LTD

Edge trimming tape and method of manufacture

InactiveUS6875469B2Simple and cost-effectiveWell formedFilm/foil adhesivesLayered productsMaterials scienceCoating materials

The present invention provides an adhesive filament-bearing adhesive tape comprising an adhesive substrate adapted to be releasably adhered to a surface to be coated, and a filament releasably adhered to an edge of that substrate, that is useful in trimming a coating applied to a surface.The invention further provides a method of trimming a coating applied to a surface comprising applying to the surface to be coated a masking material to define the area to be coated and a filament of material of sufficient tensile strength to cut the coating material; applying coating material to the surface; allowing the coating material to dry or cure until it obtains sufficient strength to hold a cut edge; and drawing the filament through the coating to cut the coating.Finally, the present invention provides an apparatus for making a filament-bearing adhesive tape comprising means for folding an adhesive substrate along a predefined line; means for applying a filament to the interior of the fold so formed; and means for closing said fold to retain said filament at the edge of the filament bearing tape.

Owner:LANGEMAN MFG

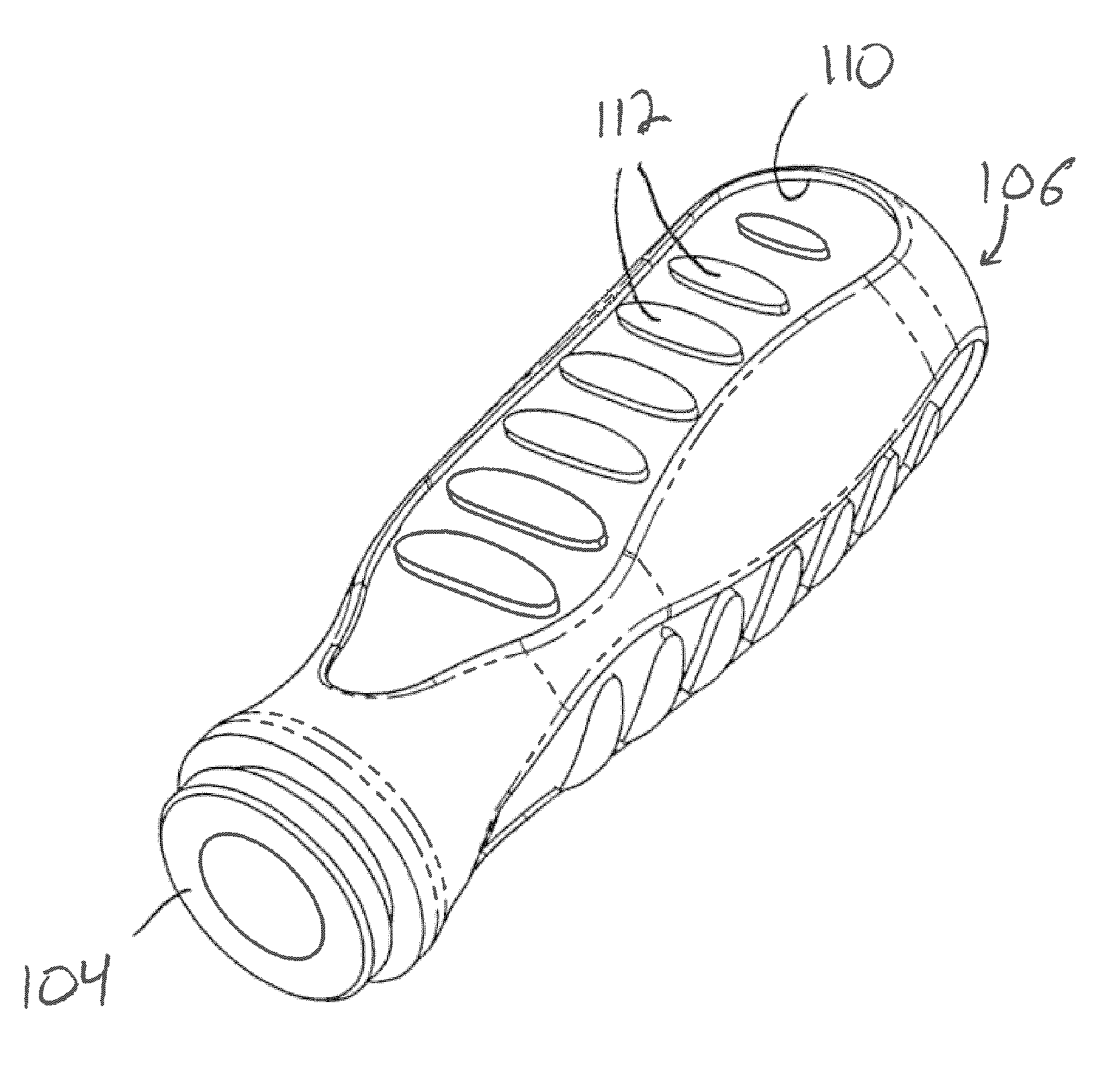

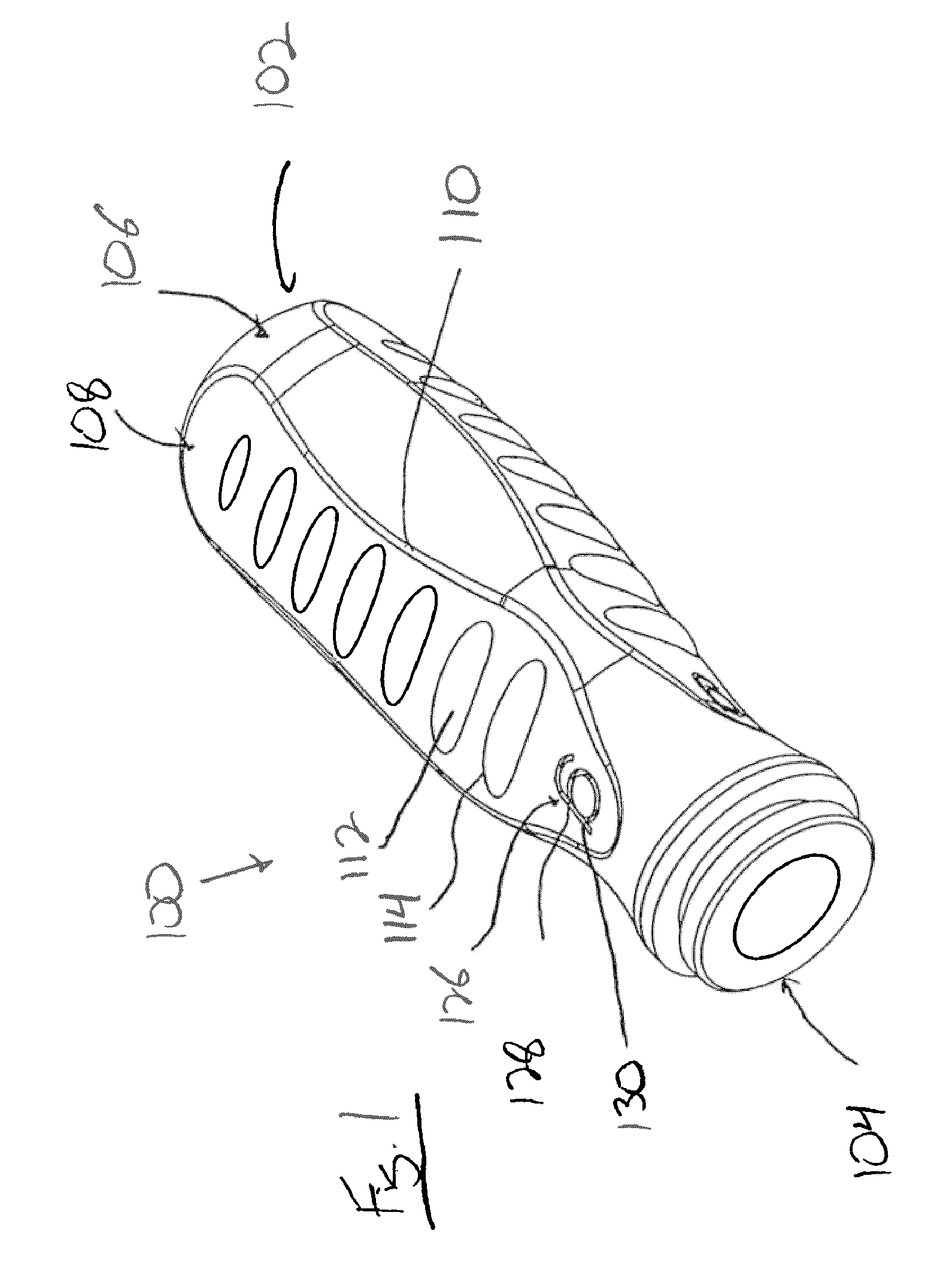

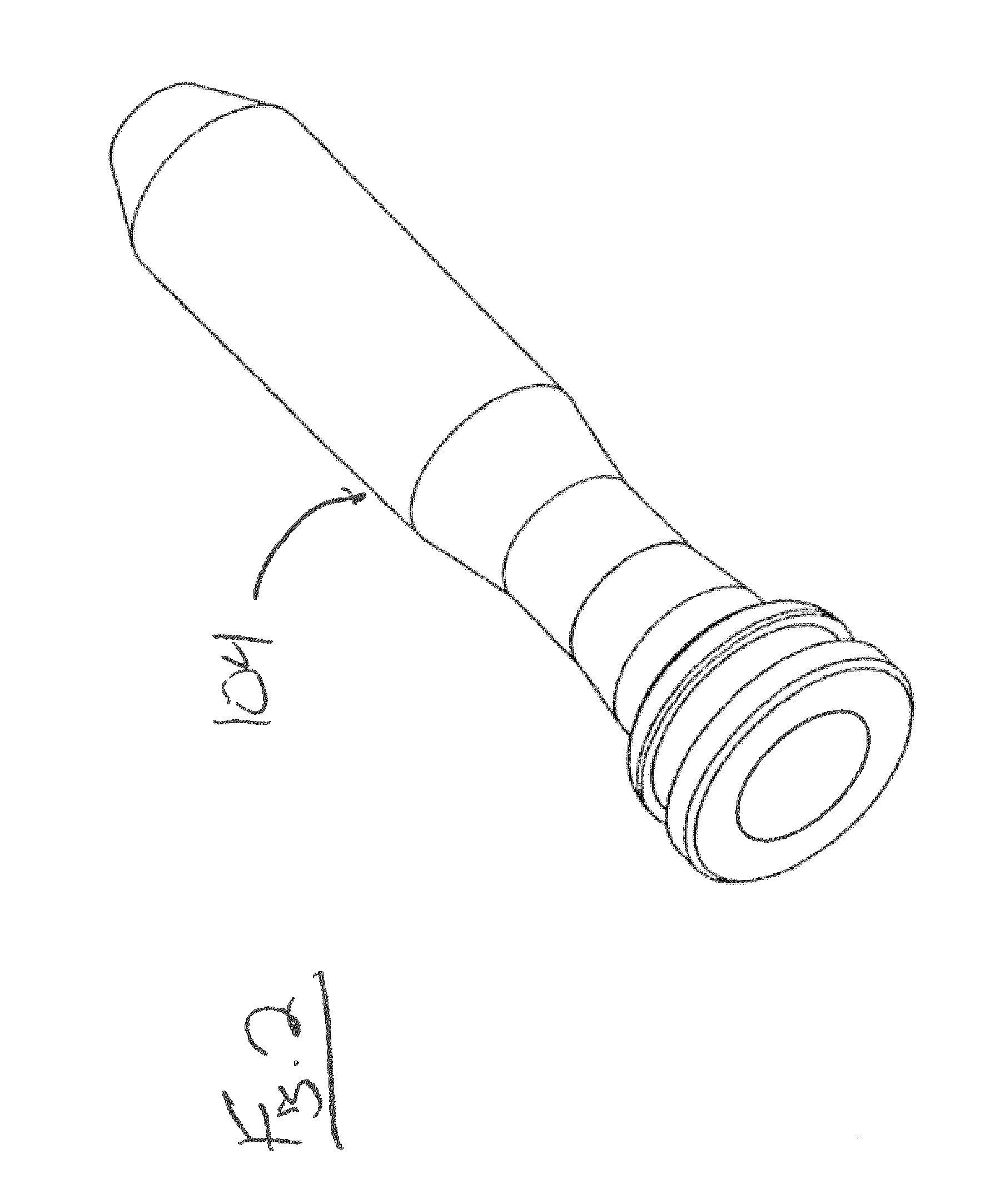

Molding process and products formed thereby

A process for producing molded products having portions formed with two separate materials is provided. The process involves forming a first component over a structural core in a first step, and forming a second component that is secured to the first component and the core in a second step. The second component can be formed directly over the first component or can be secured thereto after formation. The first and second components can additionally be formed with indicia thereon, or with recesses within which inserts containing the desired indicia can be positioned. Additionally, the first component can be formed with a ridge disposed on a projection formed on the first component that effectively seals off a portion of the first component when the second component is formed around the core and the first component to ensure the portion of the first component surrounded by the ridge remains visible after formation of the second component.

Owner:GAUTHIER BIOMEDICAL

Synthetic vascular prosthesis and method of preparation

InactiveUS20100125330A1Predictable biodegradation timeIncrease cell adhesionStentsPharmaceutical containersFiber architectureCell adhesion

A biocompatible small-diameter vascular graft, blood vessels conduit, or cell growth stimulator carrier composition which includes a completely biodegradable, hydrophilic non-gel material that has a controllable blood absorption or other biological liquid absorption ability, a controllable fiber architecture and pore sizes, and other biologically active properties, such as cell adhesion, proliferation and spreading, haemostatic and vascular tissue growth acceleration. The material retains its contour and shape when wet, and does not exhibit any swelling.

Owner:BELENKIY MAKSIM

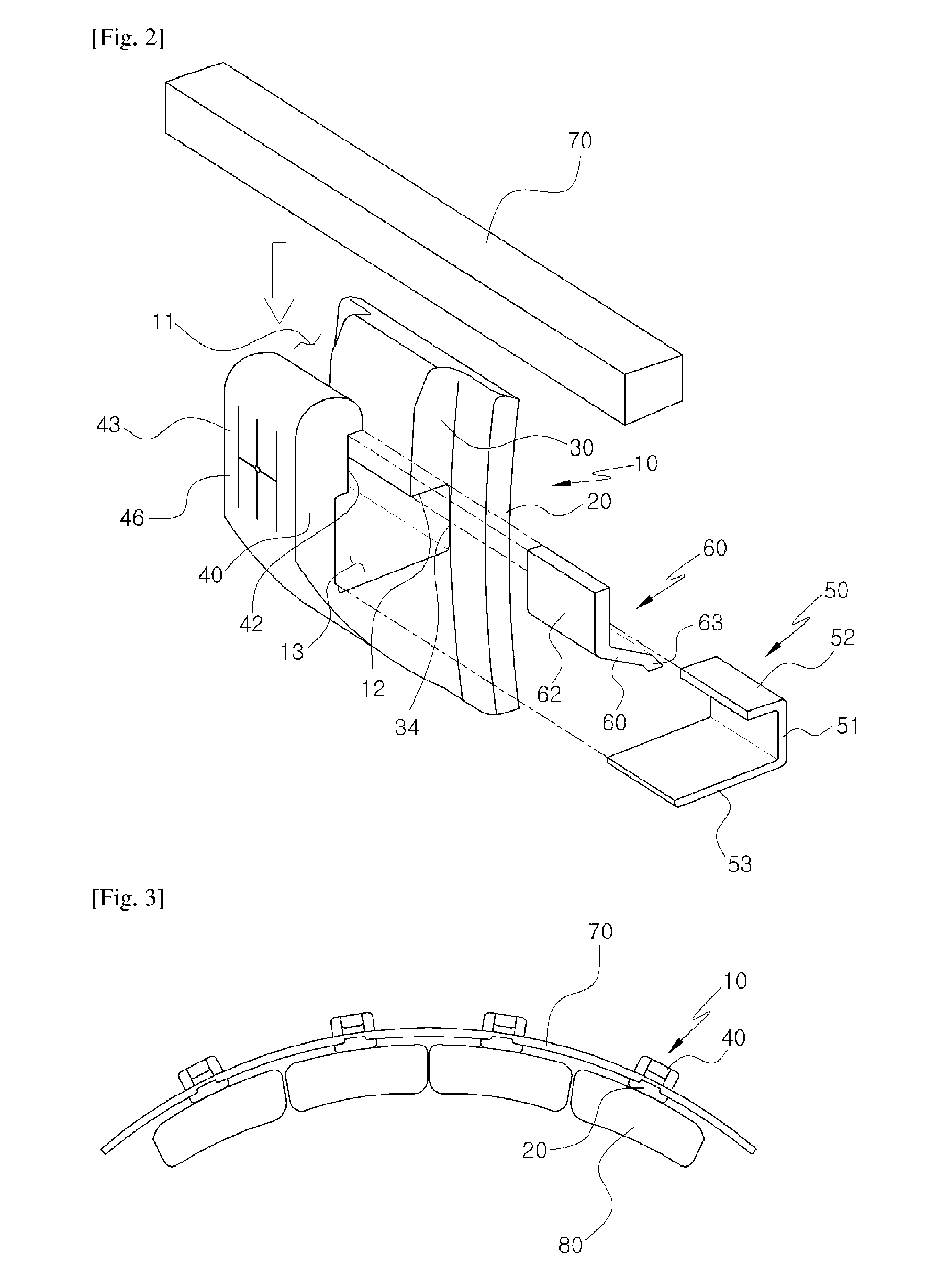

Orthodontic clip device

InactiveUS20160106522A1Stable and fixed conditionImprove convenienceArch wiresBracketsClip deviceNormal teeth

The present invention relates to a clip device for orthodontic treatment wherein appropriate force is applied to a tooth so as to move the tooth to a desired position, thereby correcting the tooth into a normal tooth alignment, and the clip device comprises: a clip base made of a ceramic material, having a base portion directly joined to a tooth, projecting an inner back portion toward the outside of the base portion, having a wire insertion hole with an opened upper portion formed between the inner back portion and an outer front portion, which is projected at a distance from the inner back portion, for allowing a connection wire to be inserted therein, and having a wire fixing hole and a clip operation hole formed below the wire insertion hole; and an elastic clip having a fixing clip, which is a fixing means made from a metal material, integratedly coupled to the wire fixing hole toward the inner back portion and the clip operation hole toward the outer front portion of which the spaces communicate with each other at the lower portion of the wire insertion hole, and formed from a resilient means made of a metal material at the upper portion of the clip operation hole, in order to resiliently support, bind and fix the connection wire inserted through the wire insertion hole of the clip ase to the wire fixing hole and to induce sliding in a binding operation of the connection wire.

Owner:KIM KI SOO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com