Optical system of helmet displayer

A helmet-mounted display and optical system technology, applied in the field of optical systems, can solve the problems of difficult movement of optical components, increased processing costs, and complicated assembly processes, and achieve easy fixing and bonding, reduced processing costs, and a large adjustment range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

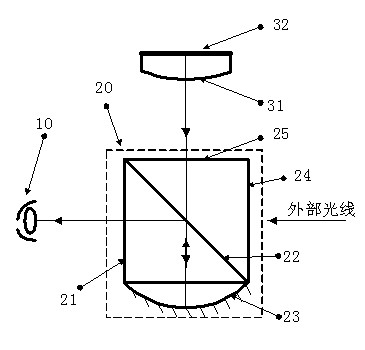

[0036] see figure 1 , the optical system of a head-mounted display in the present invention includes a microdisplay 32 , a glued mirror 31 and an optical combiner 20 . The microdisplay 32 and the glued mirror 31 are glued together as a whole.

[0037]The optical axis is perpendicular to the pixel surface of the microdisplay 32 and passes through its center. The micro-display 32 is a high-brightness, high-resolution micro-display.

[0038] The cemented mirror 31 is a plano-convex lens, the flat side is cemented with the microdisplay 32 and is perpendicular to the optical axis, and the convex side is spherical.

[0039] The optical combiner 20 comprises two rectangular prisms with an angle of 45 degrees and a concave mirror, wherein the optical surface 25 close to the doubled mirror 31, the optical surface 21 close to the pupil 10 of the human eye, and the optical surface 24 close to the external light are all planes , and are perpendicular to the optical axis. The narrow-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com