Patents

Literature

385results about How to "Strong firmness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

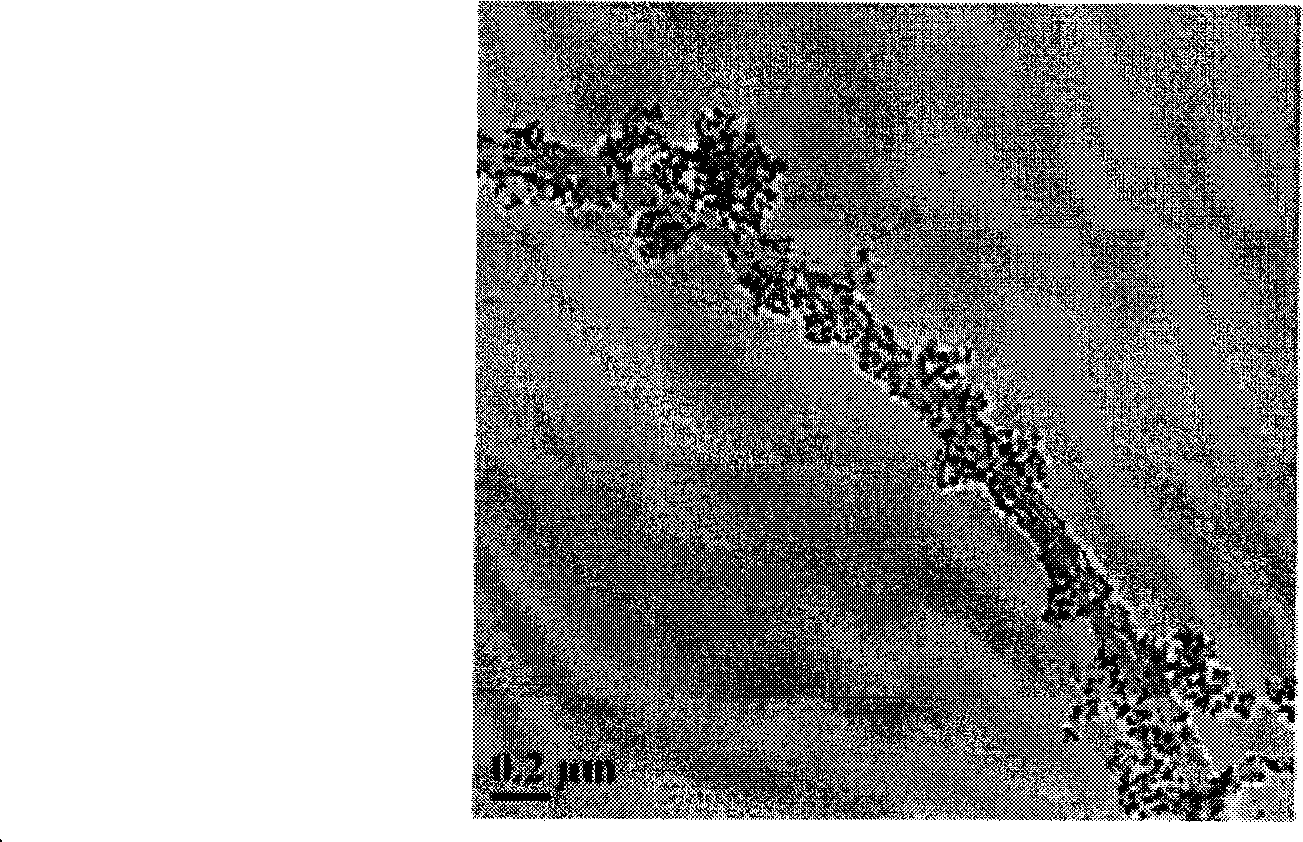

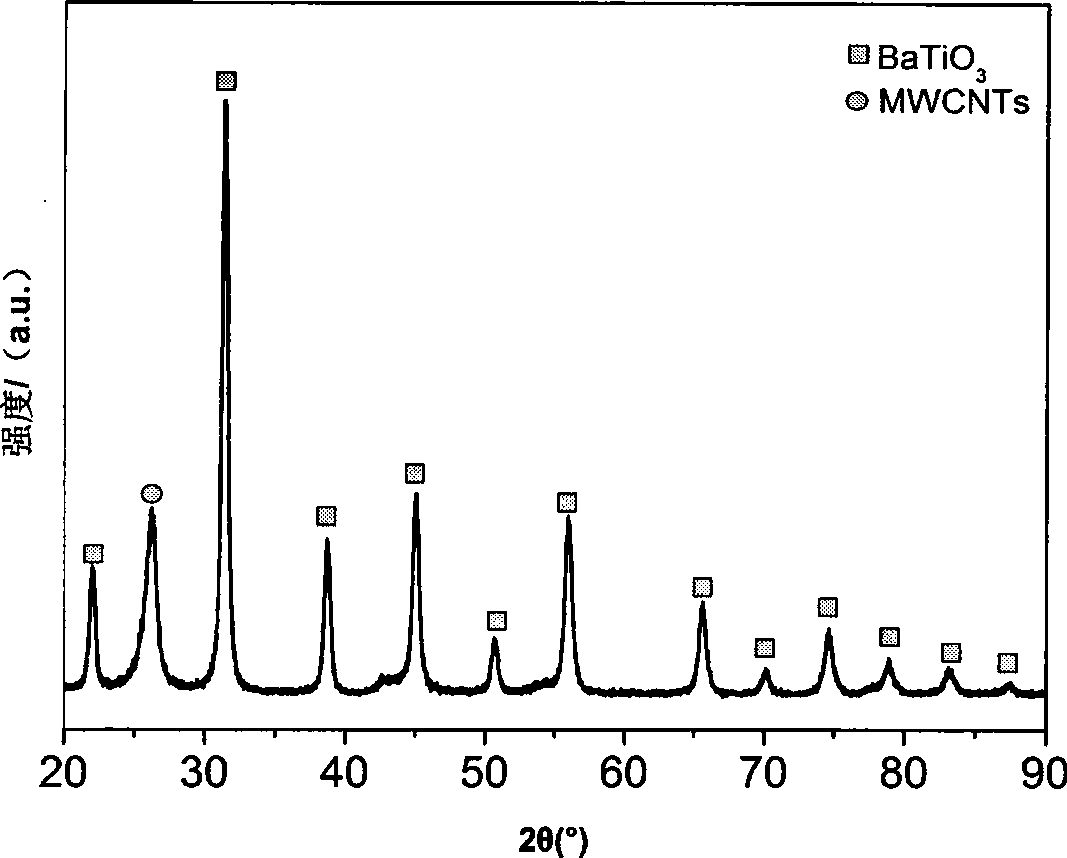

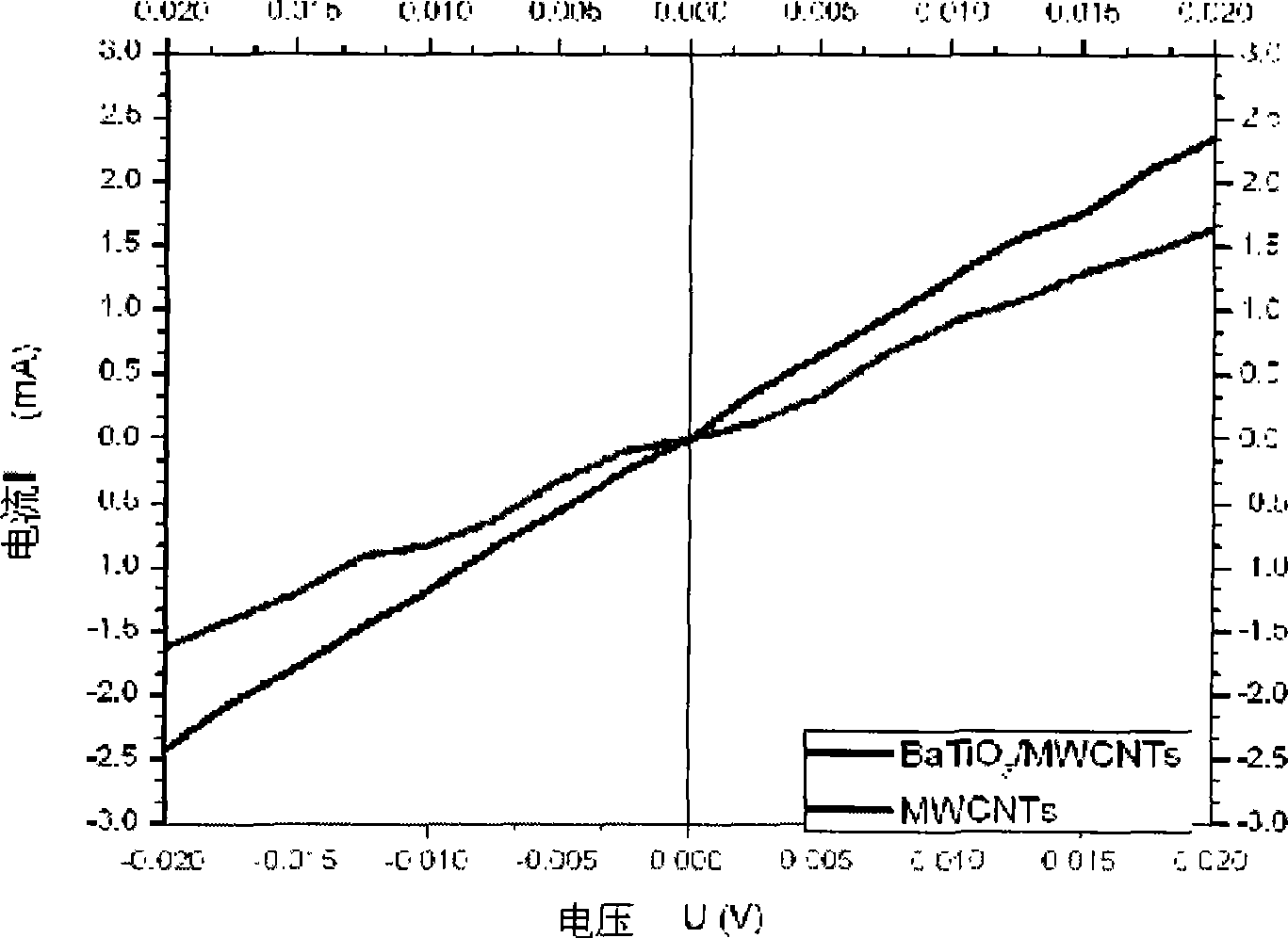

Method for preparing BaTiO3 / multi-wall carbon nano-tube (MWCNTs) nano composite material

InactiveCN101475161AImprove conductivitySmall particlesTitanium compoundsBarium titanatePolyethylene glycol

The invention relates to a method for preparing a BaTiO3 / MWCNTs nano composite material, which comprises the following steps: using MWCNTs, barium acetate, sodium hydrate and tetrabutyl titanate as initial raw materials, using deionized water, ethylene diamine and ethanolamine as solvents, adopting concentrated nitric acid to modify the surface of the MWCNTs, using a tetrabutyl titanate hydrolysis product as a titanium source, adding a dispersant, namely polyethylene glycol and plasmosan into the mixture, and adopting a solvent hot method to obtain the BaTiO3 / MWCNTs nano composite material. By changing the proportion of the MWCNTs, the barium acetate and the tetrabutyl titanate, the BaTiO3 / MWCNTs nano composite material with different compositions can be obtained. The prepared BaTiO3 / MWCNTs nano composite material has good electric conductivity, the synthesis process and the production equipment are simple, and industrialized production is easy to realize.

Owner:DONGHUA UNIV

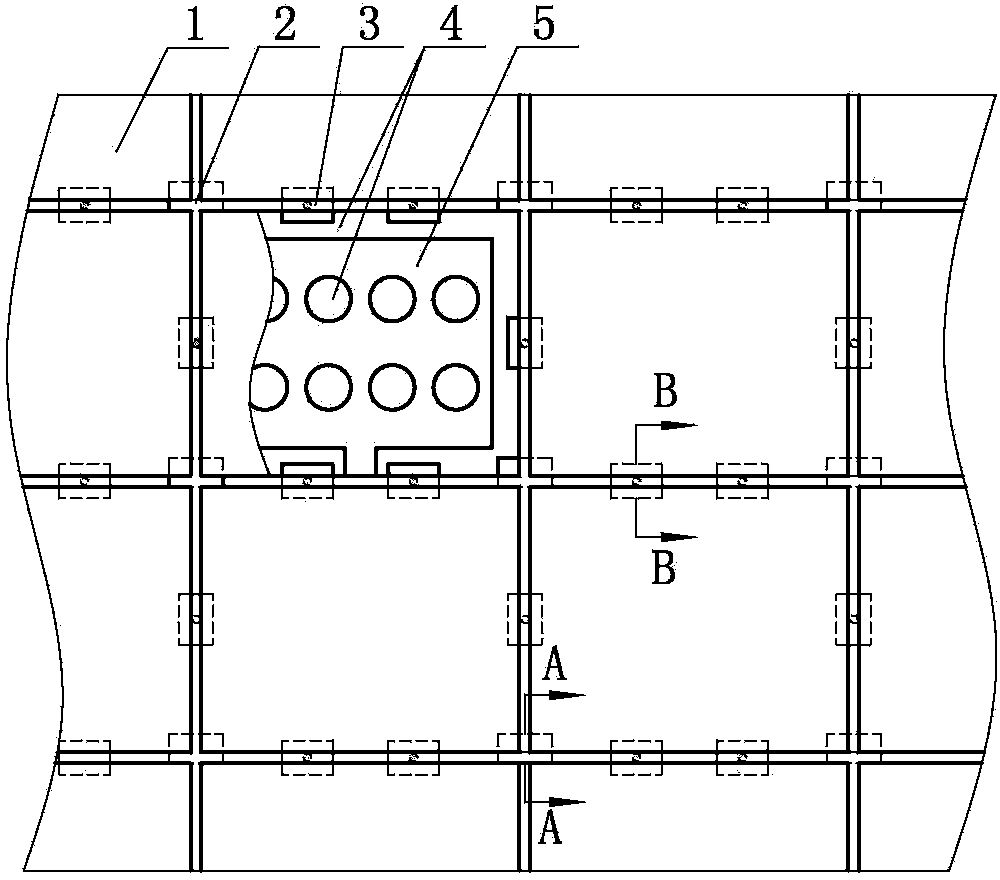

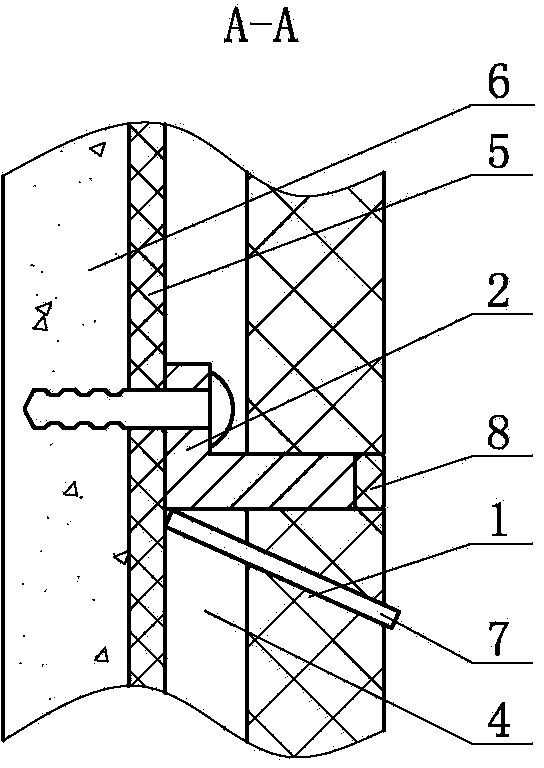

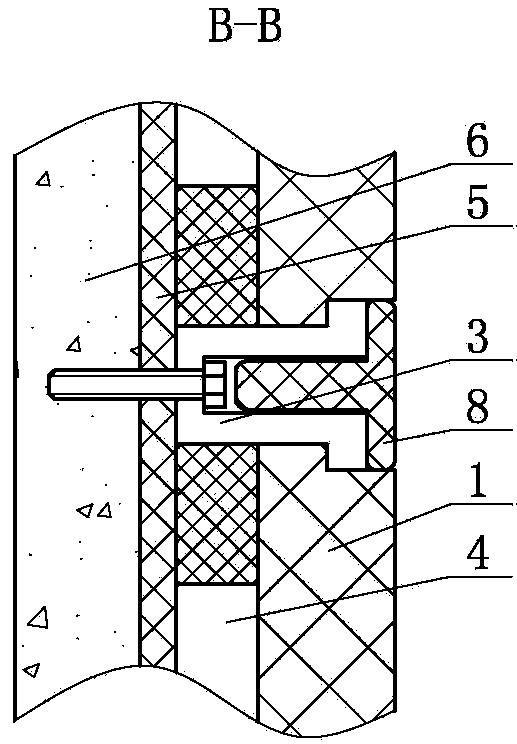

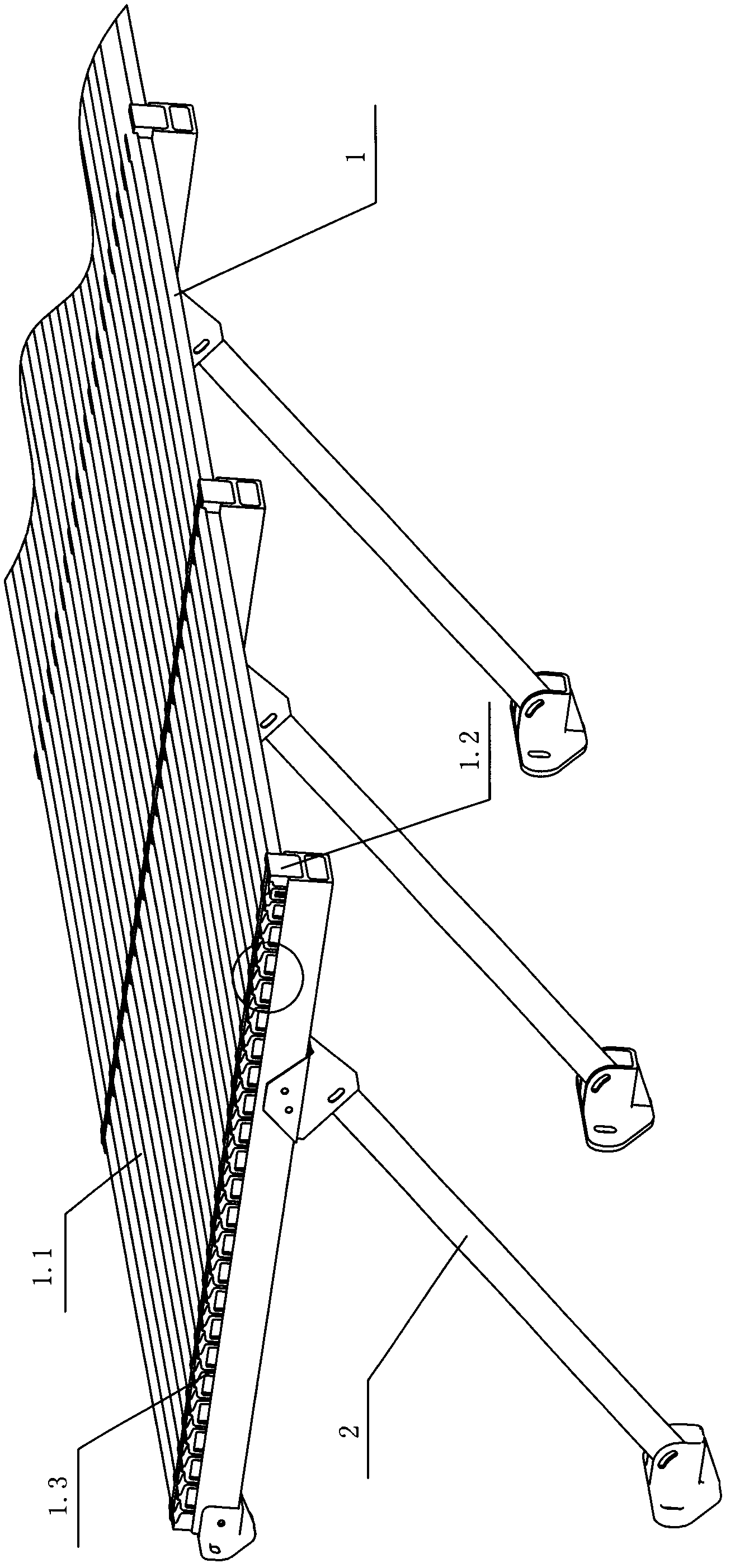

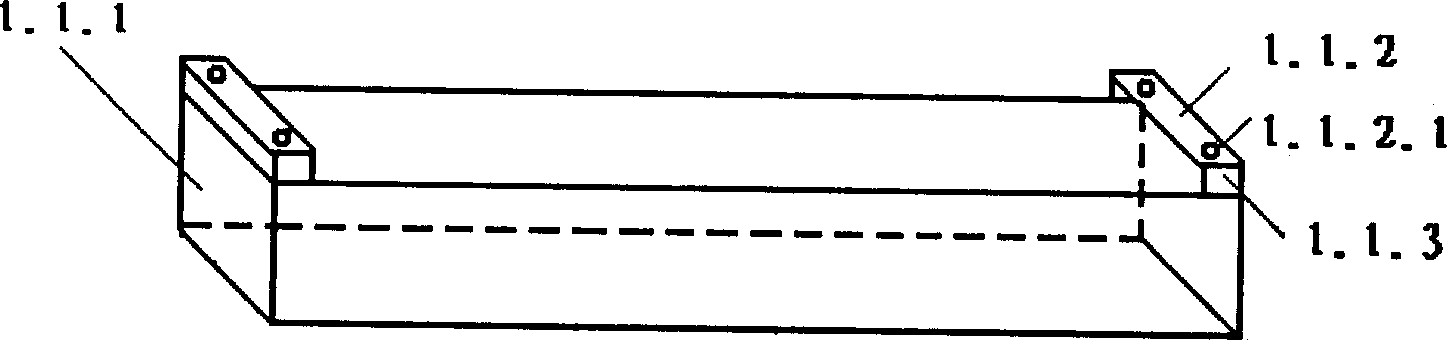

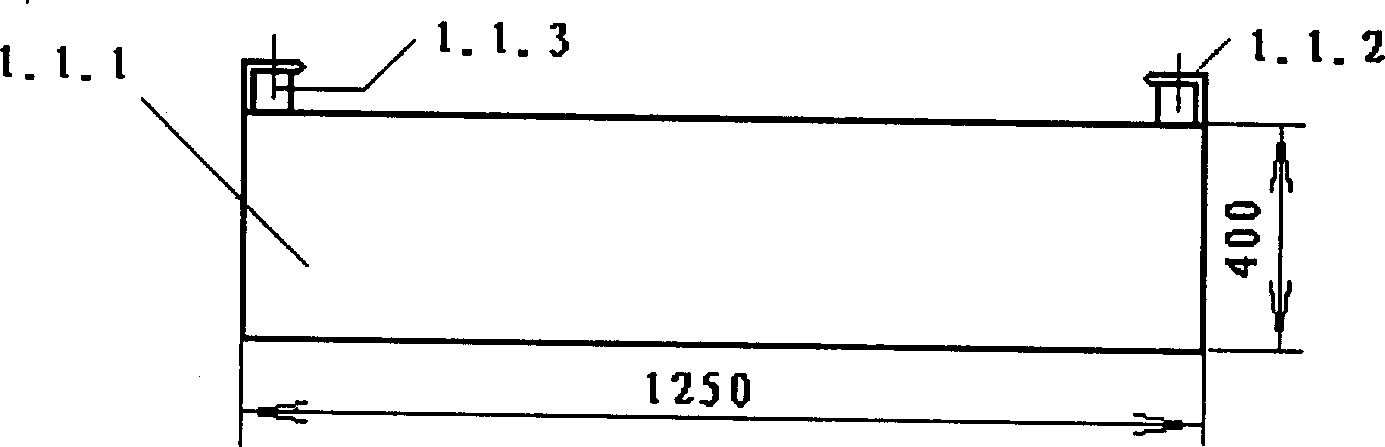

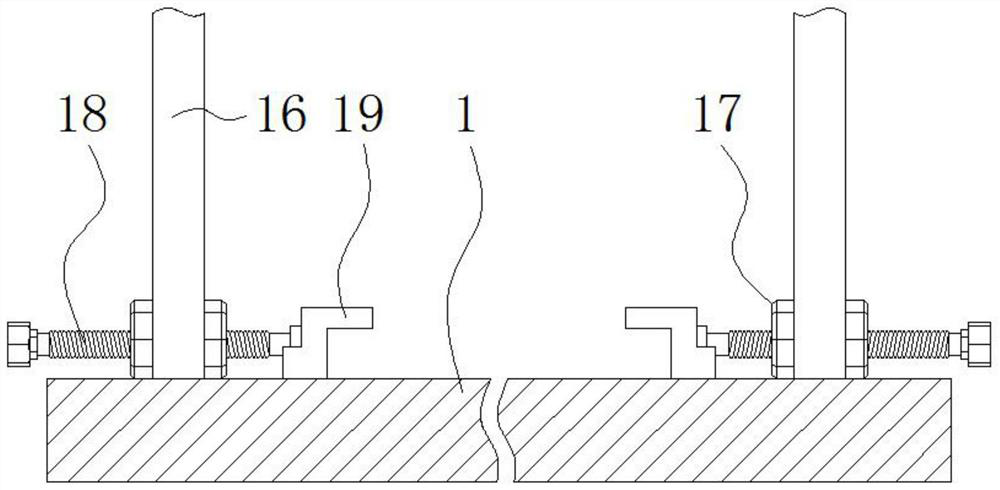

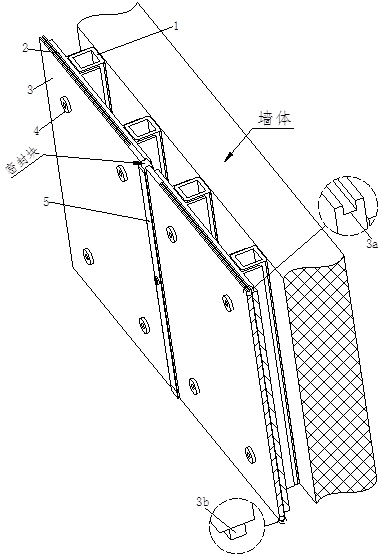

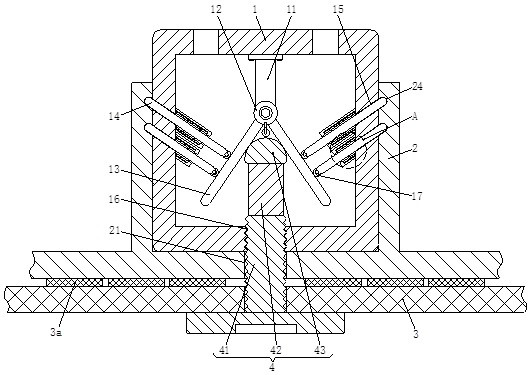

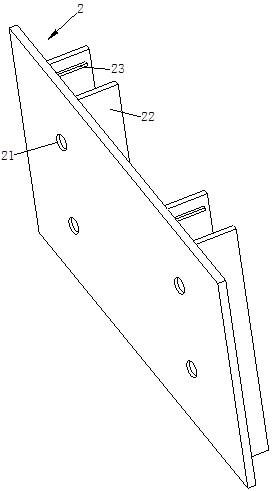

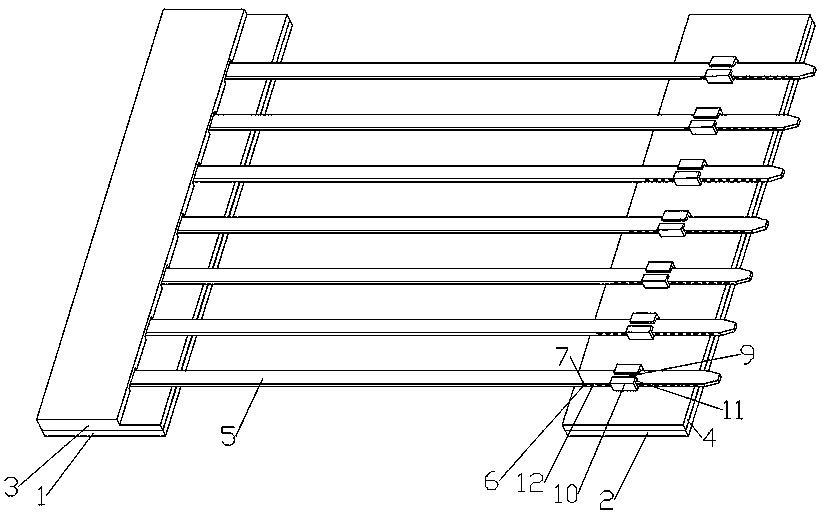

Inorganic thermal insulation decorative sheet and installation method thereof

ActiveCN103938822AImprove stabilityStrong firmnessCovering/liningsPolymer adhesiveThermal insulation

An inorganic thermal insulation decorative sheet comprises a leveling layer on the wall face of a basic wall. L-type brackets are anchored to the wall face of the basic wall. The brackets are composed of horizontal boards and vertical boards. The vertical boards of the brackets are anchored to the basic wall. Inorganic thermal insulation decorative sheet bodies adhere to the leveling layer. The lower portions of the sheet bodies are matched with the horizontal boards of the brackets. Multiple U-type clamping pieces are arranged between the adjacent sheet bodies and matched with the side edges of the sheet bodies. The U-type clamping pieces are anchored to the basic wall. Gaps between the adjacent sheet bodies are filled with sealant provided with venting plugs. One end of each venting plug is located in a gap between the leveling layer and the corresponding sheet body and an opening of the other end of each venting plug faces downwards and is communicated with the atmosphere. An installation method comprises the steps of treatment of the basic wall face, construction of wall face stay wires, cutting, machining of the inorganic thermal insulation decorative sheet bodies, installation of the brackets, preparation of polymer adhesive mortar, adhesion of the inorganic thermal insulation decorative sheet bodies, installation of the U-type clamping pieces, treatment of board seams and installation of the venting plugs.

Owner:SHANDONG LUTAI BUILDING MATERIAL SCI & TECH GRP CO LTD

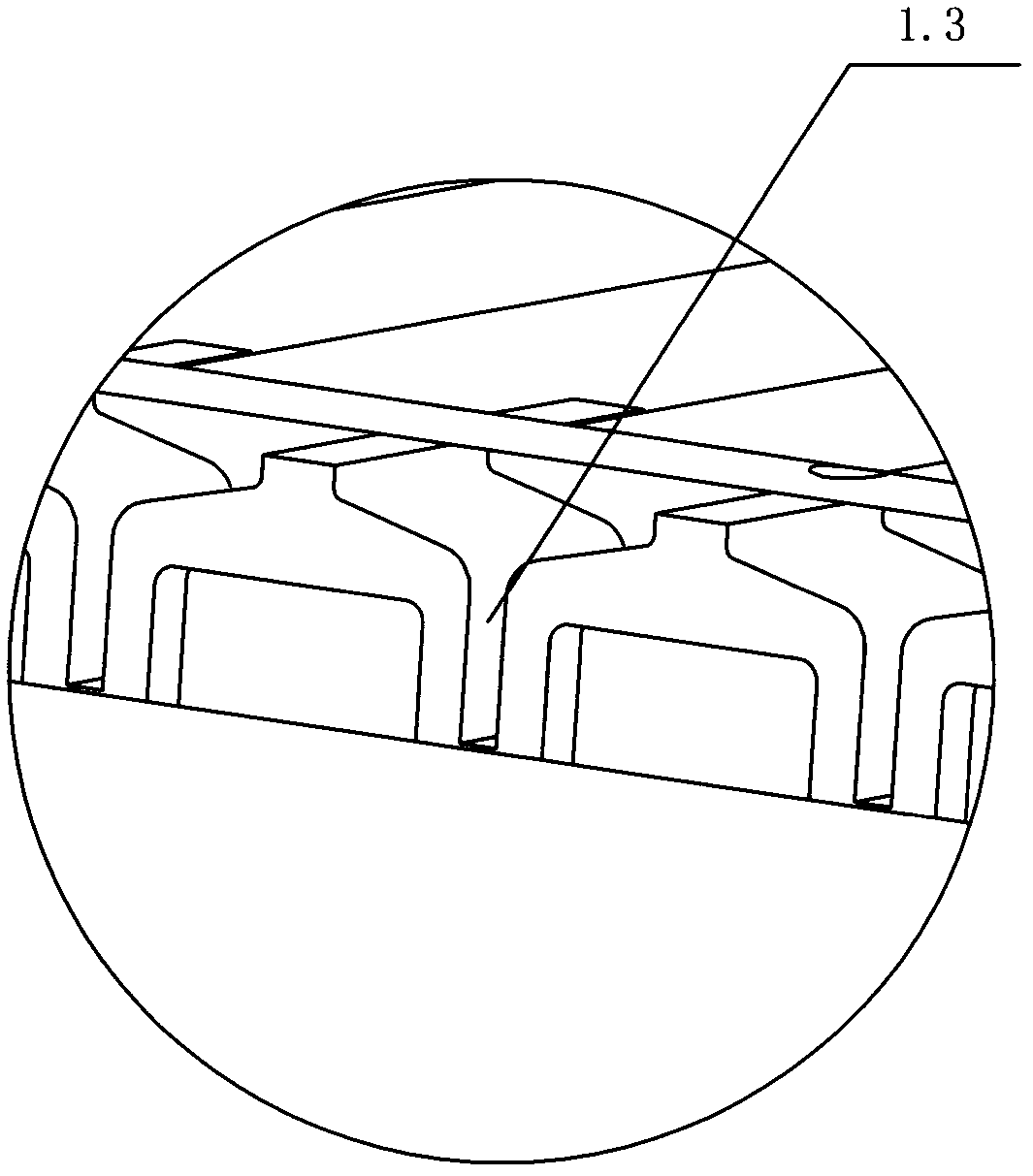

Phenolic glass steel and subway evacuation platform made of same

The invention discloses phenolic glass steel which is prepared from the following components in parts by weight through pultrusion: 70-78 parts of glass fiber yarns, 4-8 parts of continuous glass fiber mats, 15-20 parts of phenolic resin, 0.6-1.1 parts of curing agent, 0.4-0.6 part of promoter and 0.4-0.6 part of iron trioxide, wherein the temperature of a pultrusion mould is 140-280 DEG C. The invention also discloses a subway evacuation platform made of the phenolic glass steel, and the subway evacuation platform includes a grid-type platform and a plate-type platform, wherein the cross section of the grid-type platform is T-shaped, and the countertop of the plate-type platform is a flat surface without a gap on the upper surface. The phenolic glass steel and the subway evacuation platform made of the same, provided by the invention, have the characteristics of light weight, easiness for installation and low production cost, and can meet the requirements for subway environments, namely, low heating value, no smoke or toxin, high strength and high ablation resistance.

Owner:宁波华缘复合新材料有限公司

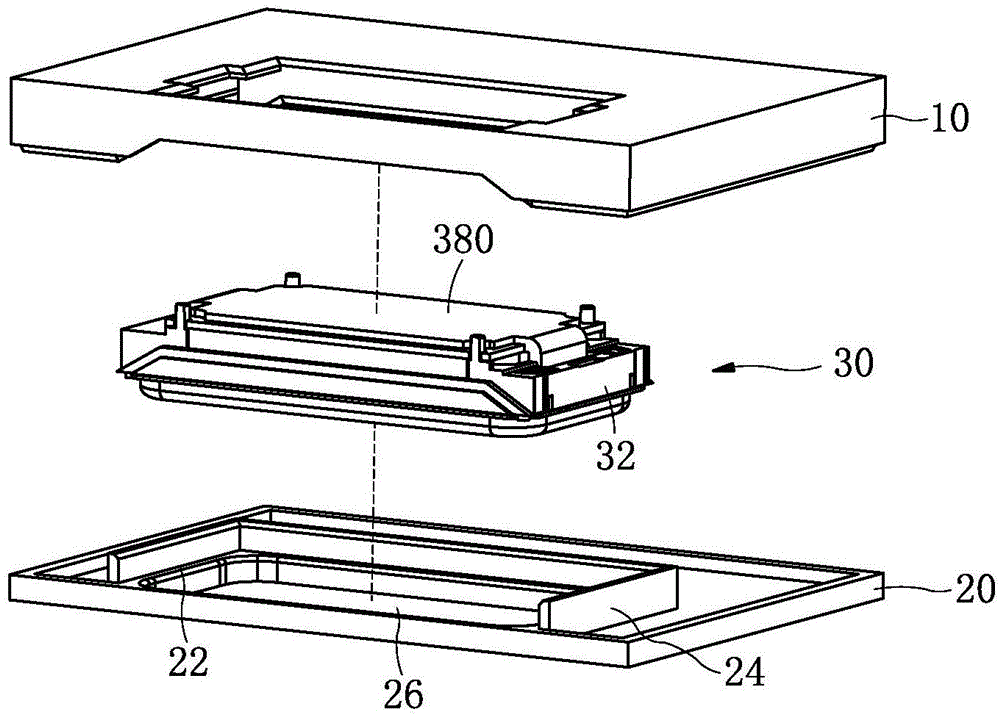

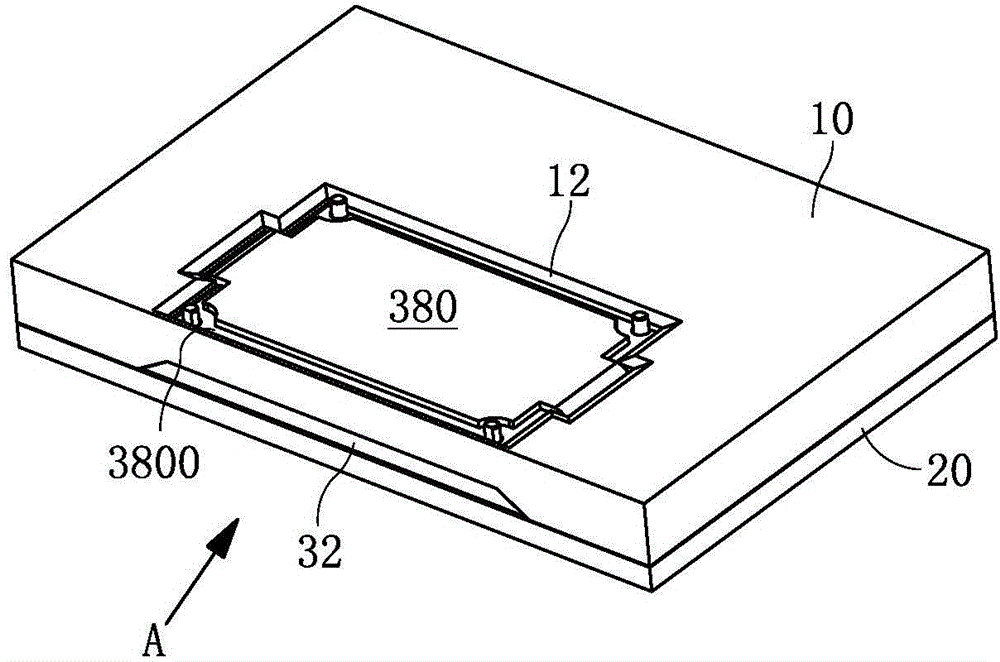

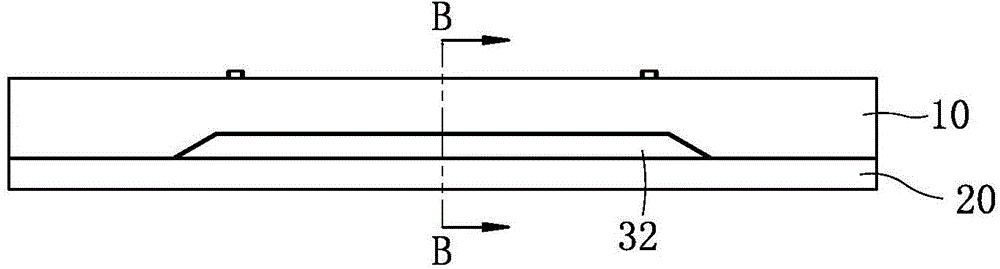

Speaker module

ActiveCN104796817AImprove acoustic performanceSmall lumen spaceLoudspeaker screensLoudspeaker transducer fixingEngineeringLoudspeaker

The invention discloses a speaker module and relates to the technical field of electroacoustic products. The speaker module comprises a housing; a single speaker is held within the housing; the single speaker comprises a single shell and a single front cover combined together; the single shell and the single front cover form a space in which a vibrating system and a magnetic circuit system are held; the end face of at least one sidewall of the single shell is provided with an ultrasonic face to be ultrasonically welded to the housing; the housing is provided with an ultrasonic line in ultrasonic joint with the ultrasonic face and corresponding to the ultrasonic face. The technical problems such that the prior speaker module is complex to assemble, poor in tightness and poor in appearance are solved; the speaker module is simple to assemble, good in tightness, high in appearance quality, good in acoustic performance, high in production efficiency and low in production cost.

Owner:GOERTEK INC

Degradable sebacic acid and propyl tri-alcohol ester styptic sponge and its preparation

InactiveCN101028543AGood biocompatibilityImprove toughnessSurgeryAbsorbent padsPolymer scienceAlcohol

A degradable styptic sponge with high safety, mechanical performance, adhesive speed and biodegradability is prepared from decanedioic acid and propanetriol through slowly raising temp to 100-160 deg.C while vacuum dewatering to obtain prepolymer, dissolving it in alcohol, adding pore-forming agent, moulding, washing with distilled water, and disinfecting by Co60 irradiation.

Owner:HARBIN INST OF TECH

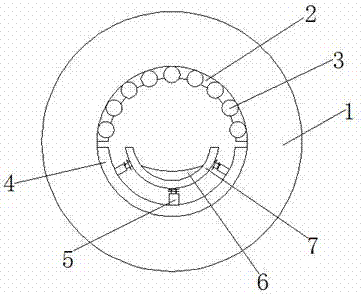

MPP electric power tube

The invention discloses an MPP electric power pipe, which comprises a pipe body, a positioning block is arranged on the top of the inner wall of the pipe body, balls are inlaid on the side of the positioning block away from the pipe body, and the bottom of the inner wall of the pipe body is fixedly connected with A ring block, and the top of the ring block is fixedly equipped with a telescopic rod, and the end of the telescopic rod away from the ring block is fixedly connected with a U-shaped bracket, the inside of the U-shaped bracket is provided with a buffer pad, and the pipe body includes an inner tube and outer tube. The MPP power pipe, through the improvement of the pipe body, improves the firmness of the pipe body itself, effectively protects the cable, and the setting of the buffer device not only achieves the protection effect of the pipe body when the cable is pulled, but also It also achieves the protective effect on the cable; the coordinated use of positioning blocks, balls, ring blocks, telescopic rods, U-shaped brackets and buffer pads further achieves the protective effect on the cable when pulling the cable, avoiding the Damage to cables.

Owner:RONGCHENG PIPE IND

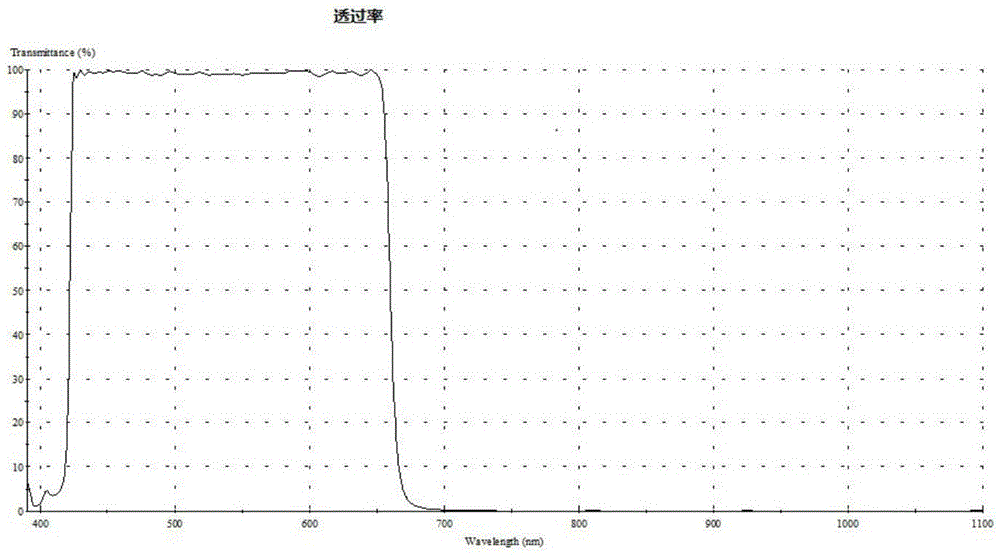

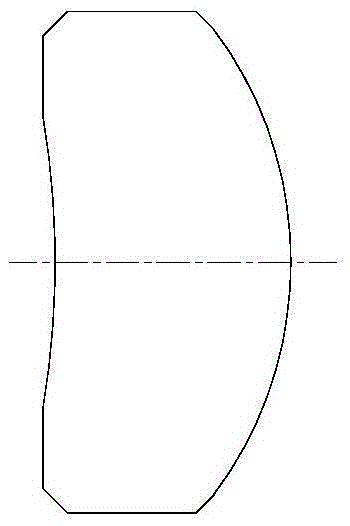

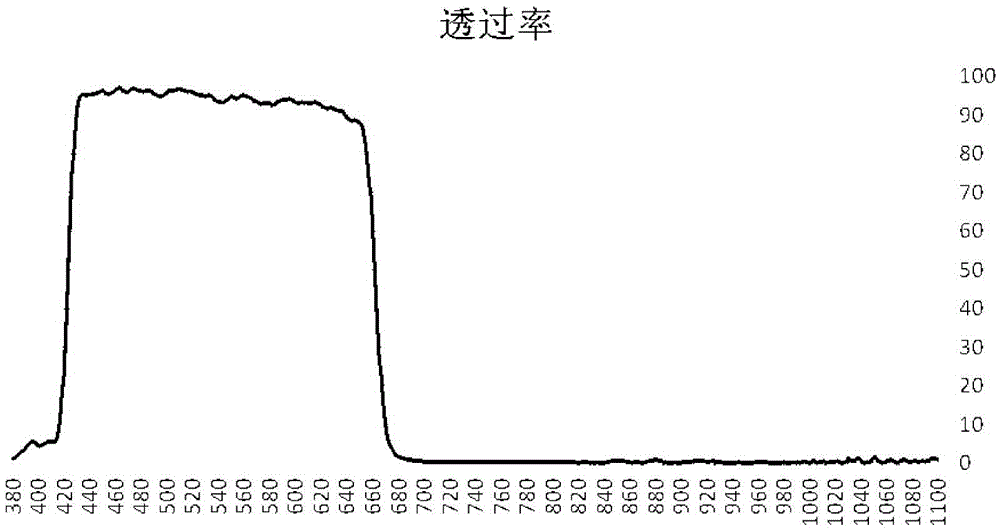

Infrared and ultraviolet cutoff filtering film structure for large curvature lens surface and manufacture method thereof

The invention provides an infrared and ultraviolet cutoff filtering film structure for a large curvature lens surface and a manufacture method thereof. The infrared and ultraviolet cutoff filtering film structure for the large curvature lens surface comprises a large curvature lens which is provided with an infrared and ultraviolet cutoff filtering film. The infrared and ultraviolet cutoff filtering film comprises low refractive index film layers and high refractive index film layers which are alternately stacked on the large curvature lens, the number of the low refractive index film layers is larger than or equal to 10, and number of the high refractive index film layers is larger than or equal to 10. The infrared and ultraviolet cutoff filtering film is a 45-layer multi-film-layer structure. The low refractive index film layers are made of SiO2, and the high refractive index film layers are made of Ti3O5 or Ta2O5. The infrared and ultraviolet cutoff filtering film structure has the advantages of a simple and reasonable structure, consistent film layer uniformity, and strong film firmness.

Owner:舜宇光学(中山)有限公司

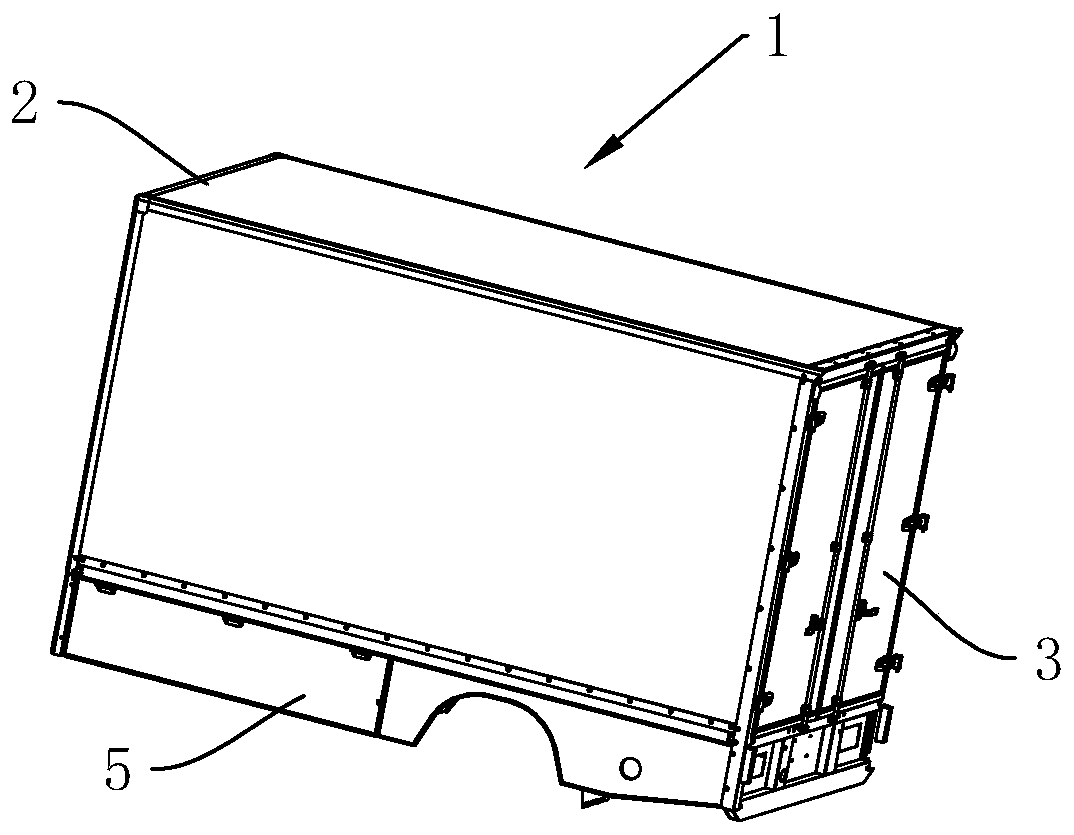

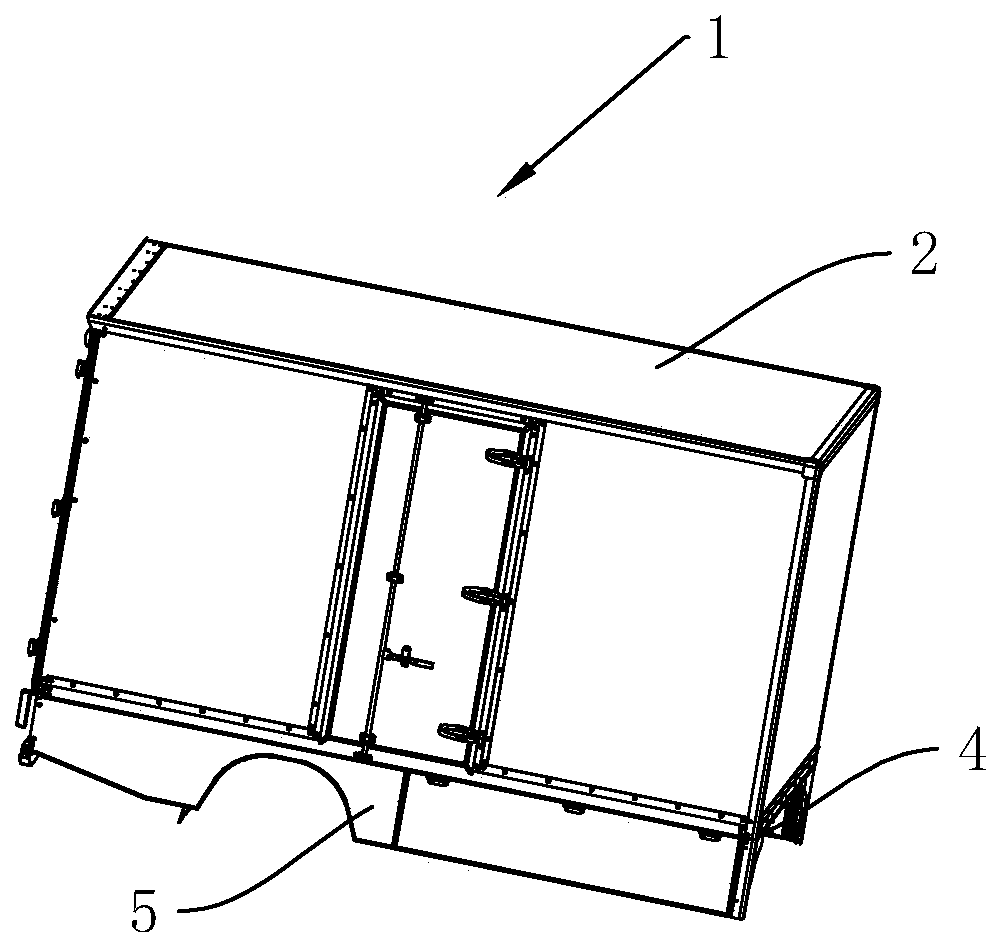

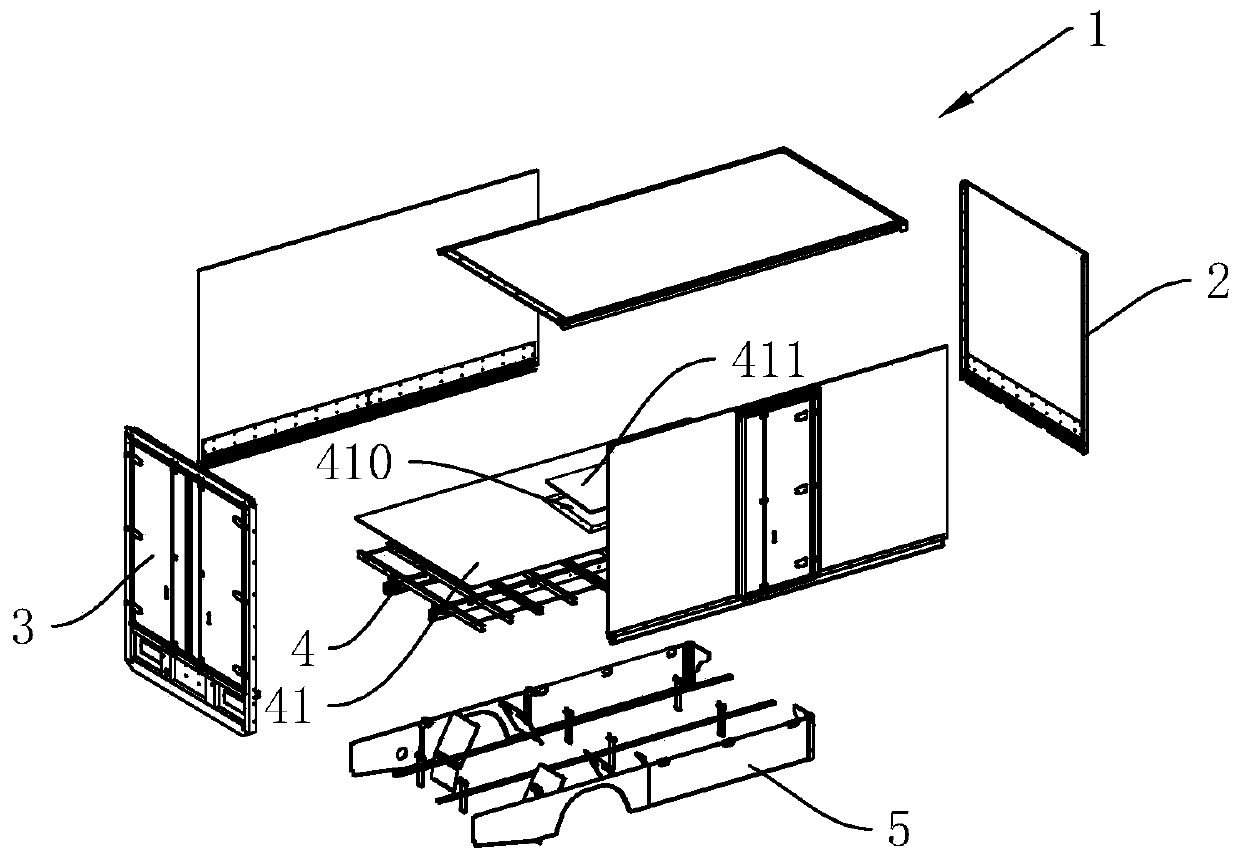

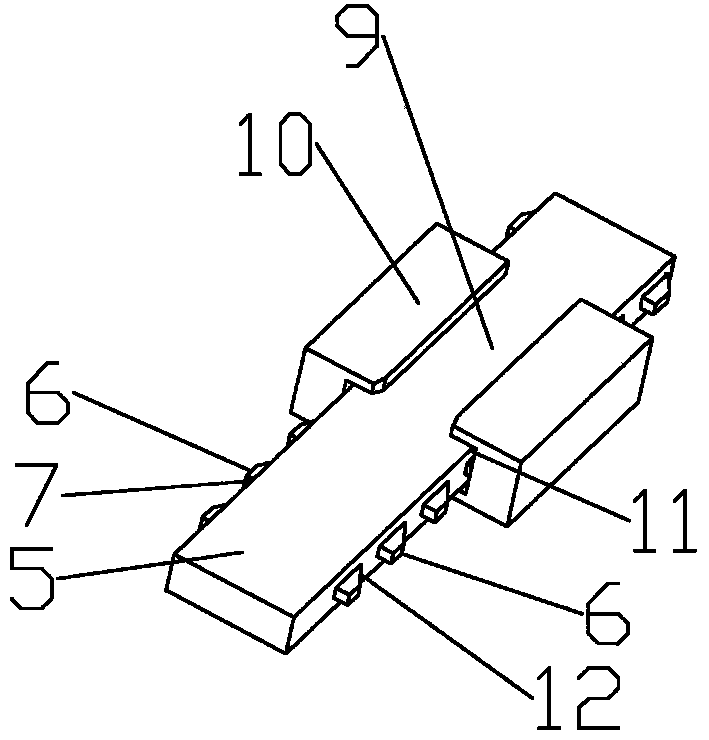

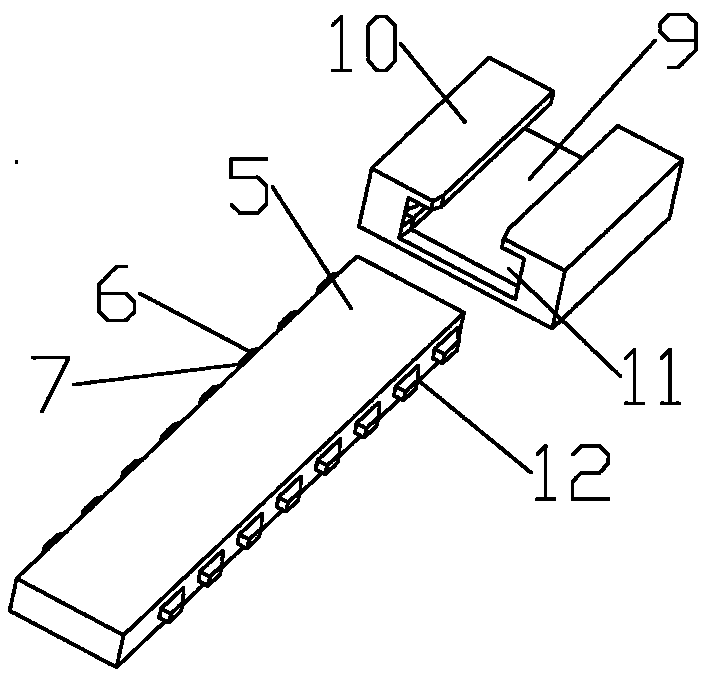

A new energy logistics vehicle, carriage, chassis and assembly method thereof

ActiveCN109515520BPrecise positioningEasy to assembleUnderstructuresLoading-carrying vehicle superstructuresLogistics managementNew energy

The invention discloses an underframe of a new energy logistics vehicle. The underframe of the new energy logistics vehicle comprises at least two longitudinal beams extending in the longitudinal direction; multiple transversely extending cross beams are distributed on the two longitudinal beams in the length direction; the cross beams are arranged above the longitudinal beams and fixedly connected to the longitudinal beams through fastening pieces; the multiple cross beams are arranged in the length directions of the longitudinal beams and located by using two locating strips; multiple locating holes are formed in the locating strips; through holes matched with the locating holes are formed in the two sides of each cross beam; and the cross beams are located and fixed to the locating strips by using the fastening pieces which penetrate through the through holes and the corresponding locating holes. According to the underframe of the new energy logistics vehicle, the cross beams and the longitudinal beams on the underframe are positioned by using the locating strips according to a mounting reference, the locating is accurate, the assembling is convenient, and the mounting is form.

Owner:HANGZHOU HOLYCORE COMPOSITE MATERIAL

Underground pipeline protection device and support method applying underground pipeline protection device

ActiveCN103670448AStrong enduranceImprove stabilityUnderground chambersTunnel liningUnderground pipelineSteel tube

The invention discloses an underground pipeline protection device and a support method applying the underground pipeline protection device. The device is formed by mutually buckling a plurality of pieces of channel steel, and the directions of adjacent channel steel openings are opposite; grouting steel tubes are welded in the channel steel; grouting holes are formed in the walls of the grouting steel tubes. The underground pipeline protection device has the beneficial effects that channel steel which is tightly buckled and closely lined in forward and reverse directions is horizontally deployed below a pipeline; the grouting steel tubes are welded in the slots of the channel steel; the soil is consolidated and gaps between the channel steel can be compacted through the grouting of the grouting steel tubes, so as to effectively isolate the pipeline from the vault of a tunnel and prevent the phenomena of pipeline damage, tunnel gushing and the like due to the collapse and sinking of soil on the vault, so that the safety factor is high; in addition, according to the support method, no special robot is needed for construction, a worker only needs to set the channel steel and grout, a construction method is simple, the reinforcing effect is significant, and the time of the worker is saved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

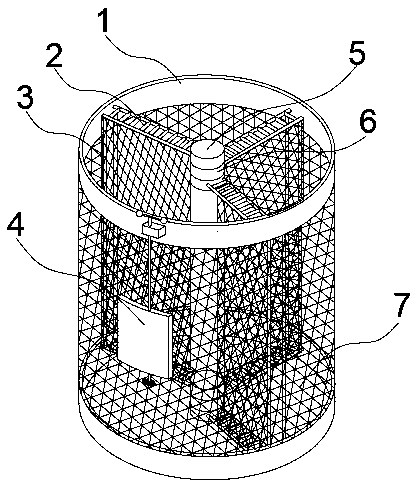

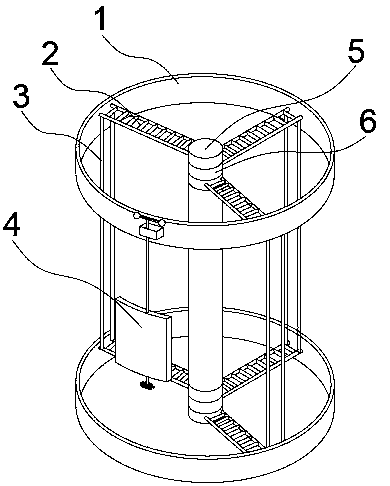

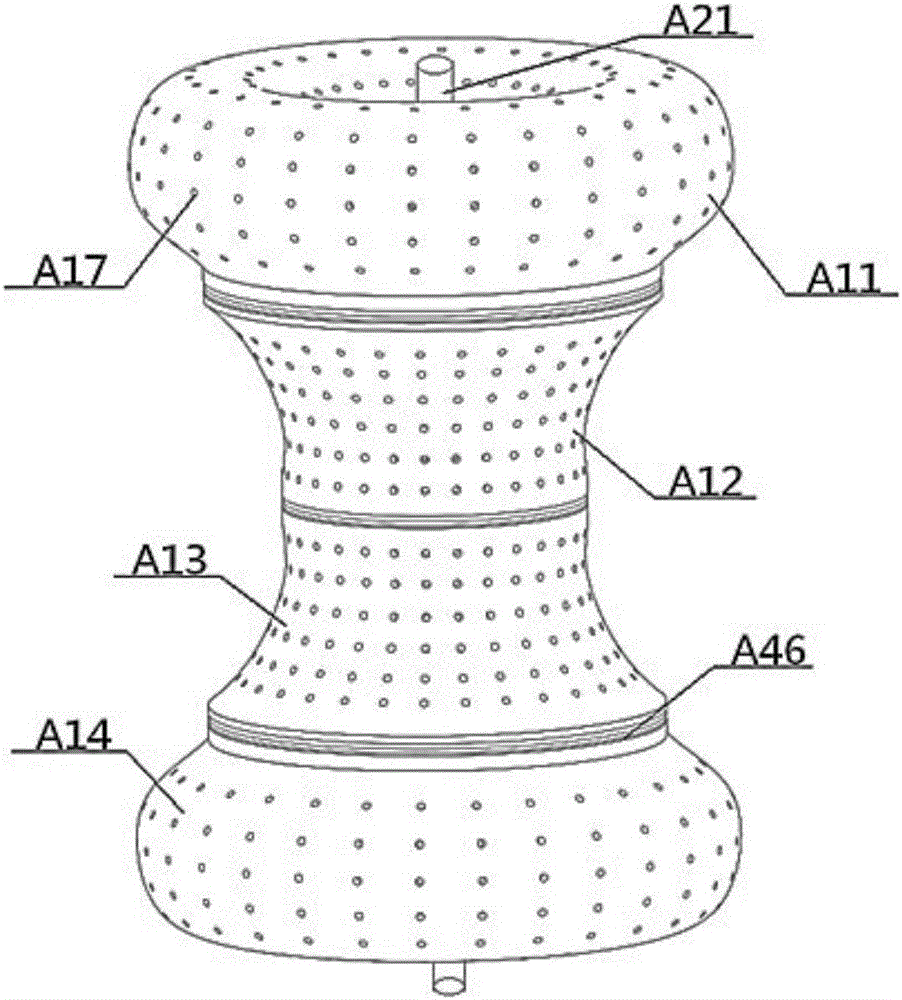

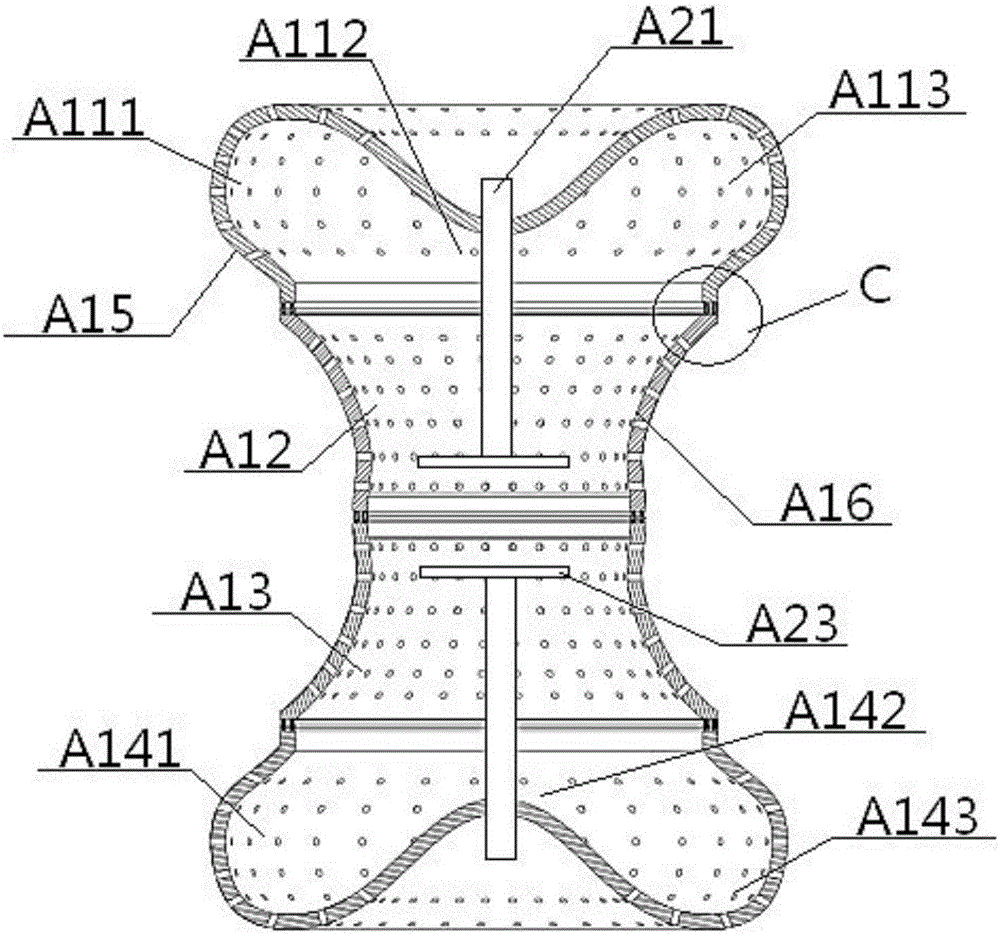

Folding culture net cage

ActiveCN107711651ABreeding capacity changesIncrease flexibilityClimate change adaptationPisciculture and aquariaEngineering

The invention discloses a folding culture net cage, belonging to the field of culture devices. The folding culture net cage comprises a net cage frame connected with a net, wherein the axis of the netcage frame is provided with a floating column; the upper and lower ends of the floating column are respectively provided with a slip ring which is connected with the net cage frame through floating bridges; the floating bridges on the upper and lower ends are connected through balanced connecting rods; and the side surface of the net cage frame is provided with a net opening sealing mechanism. The culture net cage disclosed by the invention can change the culture capacity and enhance the culture output, has the advantages of high culture safety, high wind wave resistance and high catching efficiency, and can be assembled in the culture region.

Owner:ZHEJIANG OCEAN UNIV

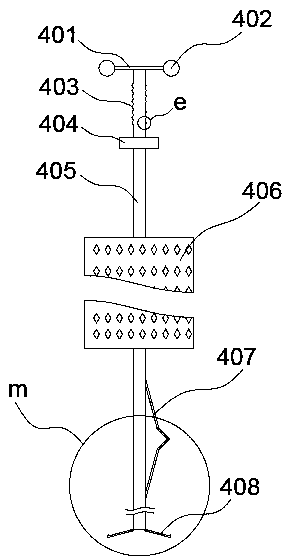

Automatic fish-culturing live box equipment and its feeding-time counting method

InactiveCN1387755ASimple structureEasy to manufactureClimate change adaptationPisciculture and aquariaAutomatic controlSimulation

The invented full automatic fish culture in net cage complete set equipment and its counting bait-throwing method relates to assembling float operation platform and automatic bait-throwing device andits counting bait throw method. The frame structure of net cage uses parts assembling structure, float and operation platform combined into one body, that is, the special metal cage not only is float, but also as operation platform, at same time as main structural parts of net cage. Bait throwing device is composed of all-weather set, working time set, stop doing time set, counting device, microprocessor, digital code display, storage, driver, electric bait throw machine etc.. The present invention is rational in structure, high in performance price ratio, good in stability, full automatic control etc.

Owner:鲍和平

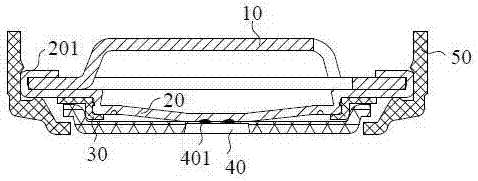

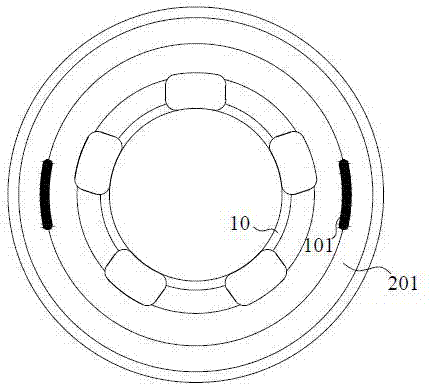

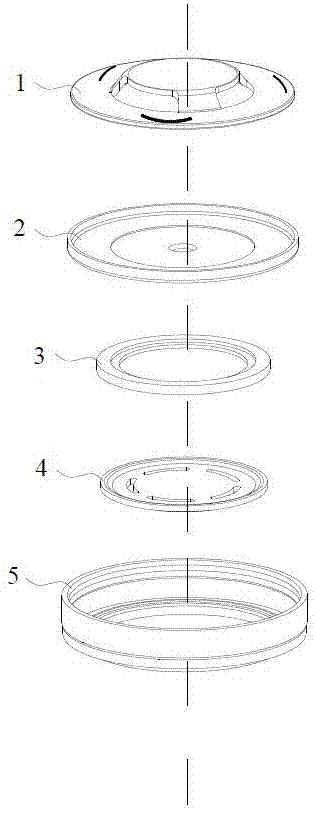

Anti-explosion cover cap assembly of power lithium battery

PendingCN107492604AIncrease effective capacityExtended service lifeCell lids/coversCell sealing materialsEffective capacityLaser

The invention discloses an anti-explosion cover cap assembly of a power lithium battery. The anti-explosion cover cap assembly consists of a top cover, an anti-explosion sheet, an insulating ring, a pore plate and a sealing ring from the top to bottom in sequence; a plurality of convex laser welding lines are arranged on the upper end plane of the top cover; and the laser welding lines are used for enabling the anti-explosion sheet and the top cover to be welded. The top cover and the anti-explosion sheet are welded through the laser welding lines, without needing an edge wrapping structure, so that an edge wrapping process is omitted and secondary damage to the anti-explosion sheet caused by the edge wrapping process also can be avoided; in addition, the laser welding lines are relatively attractive in appearance and high in reliability, so that the safety can be further reinforced; and meanwhile, the overall height of the cover cap is lowered and the effective capacity of the battery is improved, so that the service life of the battery is prolonged.

Owner:力神电池(苏州)有限公司

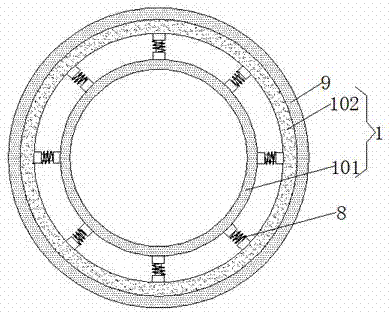

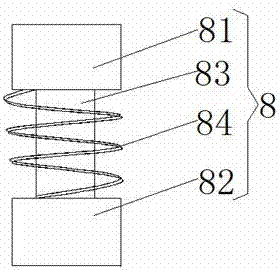

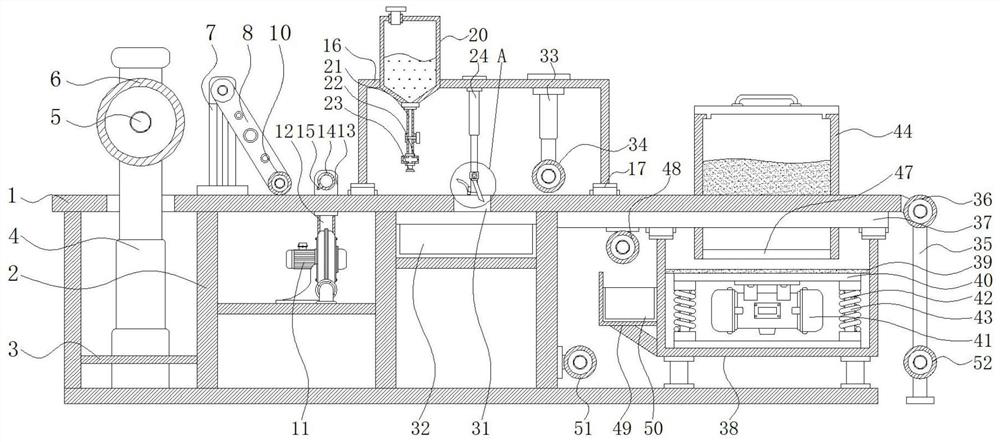

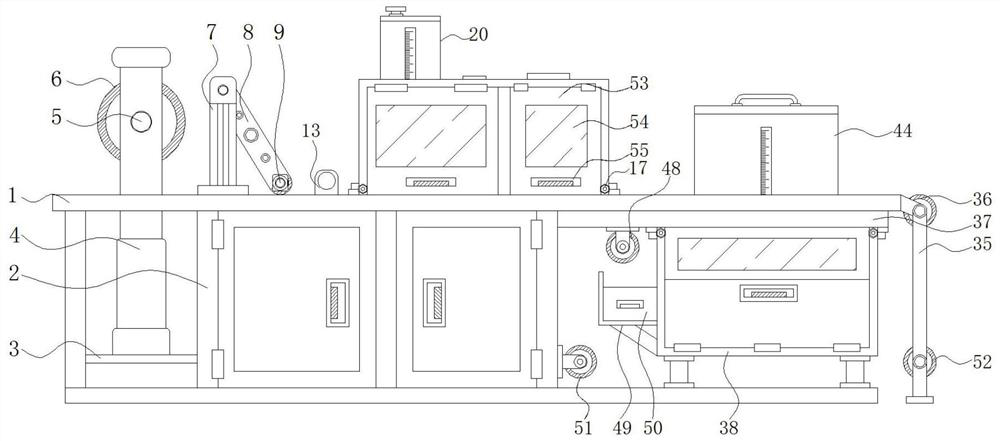

Equipment used for machining three-dimensional externally finned tubes

ActiveCN105057703AAchieve liftingRealize the reset functionAuxillary equipmentTurning toolsEngineeringMechanical engineering

The invention discloses equipment used for machining three-dimensional externally finned tubes. The equipment used for machining the three-dimensional externally finned tubes comprises a rack, a cutter and a workpiece feeding device. The cutter comprises cutter bodies, an upper die and a lower die. The cutter bodies are longitudinally inlaid in the upper die. Cone-shaped sleeves are longitudinally inlaid in the lower die. Each cutter body comprises a cutter rest and a group of cutter teeth. Each group of the cutter teeth are radially arranged at the end of the corresponding cutter rest evenly, and space is reserved between every two cutter teeth. Each cutter tooth comprises a cutter blade portion and a cutter point portion. The cutter blade portions are connected with the cutter rests. Included angles are arranged between the cutter point portions and the cutter blade portions, and the cutter point portions are close to the axes of the cutter rests. The cutter point portions are close to the large diameter sides of the cone-shaped sleeves in the lower die. The cutter rests are far away from the large diameter sides of the cone-shaped sleeves. According to the equipment, the defects that the uniformity of the depths, angles and thicknesses of fins cut through a cutter of existing equipment used for machining three-dimensional externally finned tubes are low and the strength and heat dissipation effect of the tubes are lowered are overcome. The equipment used for machining the three-dimensional externally finned tubes comprises the cutter, and the uniformity of the depths, angles and thicknesses of the fins cut through the cutter are high.

Owner:CHONGQING HUIKUN ELECTRICAL APPLIANCE +1

Preparation method of white water-resistant and oil-proof paper

ActiveCN111636247AHigh oil resistance levelHigh densityCoatings with pigmentsSpecial paperCellulosePolymer science

The invention relates to the technical field of papermaking, and provides a preparation method of white water-resistant and oil-proof paper so as to solve the problems of insufficient oil resistance and poor waterproof performance of the oil-proof paper. The preparation method comprises the steps: (1) preparing raw paper: mixing bleached chemical pulp, filler and cationic starch, dehydrating, squeezing and drying at a net part to obtain the raw paper; (2) coating for the first time: coating with a chitosan-culsageeite solution; (3) coating for the second time: coating with hydroxypropyl methylcellulose-silicon nano-particle coating liquid, and drying in sections; and (4) coating for the third time: coating with a polydimethylsiloxane solution dispersed by n-hexane. The double-proof paperhas extremely strong waterproof and oil-proof effects, and the surface of the double-proof paper is provided with multiple layers of liquid-proof coating layers and is provided with a compact internalstructure, so that the oil-proof paper is ensured to have high oil-proof grade, high density, good water resistance, low expansion rate, high strength and small paper banner thickness difference.

Owner:XIANHE CO LTD

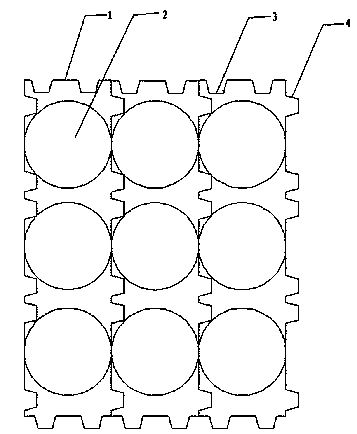

Splice lithium battery bracket

InactiveCN103811689AStrong firmnessSimple structureCell component detailsInjection mouldingBattery cell

The invention relates to a splice lithium battery bracket. The lithium battery bracket is formed by splicing a number of sub brackets. Each sub bracket comprises three lithium battery hole positions. A number of grooves are respectively arranged on both ends of the upper side and one side of each sub bracket. A number of protrusions are respectively arranged on both ends of the lower side and the other side of each sub bracket. Each groove and each protrusion are trapezoidal. The grooves and the protrusions have the same number and size. According to the lithium battery bracket provided by the invention, the original one-time injection molding is changed; the lithium battery bracket is formed by splicing a number of sub brackets; the length and the width of the bracket can be arbitrarily arranged according to the capacity of a battery; the splice lithium battery bracket is simple and convenient; the sub brackets are clamped through the trapezoidal grooves and protrusions, thus the firmness is high; the splice lithium battery bracket has the advantages of simple structure, reasonable design, easy processing, high firmness and good stability; and the sub brackets are clamped through the grooves and the protrusions.

Owner:JIANGSU YONGCHANG NEW ENERGY TECH

Abrasive paper production gluing device with anti-deviation structure

ActiveCN112691842ASave human effortImprove sanding effectLiquid surface applicatorsCleaning using gasesPaper productionElectric machinery

The invention discloses an abrasive paper production gluing device with an anti-deviation structure. The device comprises a table board, wherein a box body is installed at the bottom end of the table board, a material lifting plate is fixed to the lower portion of the left side of the box body, an electric push rod is installed at the top end of the material lifting plate, a fixing rod is fixed to the top end of the electric push rod, a paper material barrel is arranged outside the fixing rod, a pressing rod support is fixed to the right side of the electric push rod, a pressing rod is installed at the top end of the pressing rod support, a motor is fixed to the outer portion of the bottom end of the pressing rod, and a pressure roller is arranged in the bottom end of the pressing rod. Compared with an existing gluing device, the abrasive paper production gluing device with the anti-deviation structure is provided with the electric push rod, the electric push rod can ascend and descend from the upper portion of the material lifting plate and the upper portion of the table board, when the device needs to be fed, the paper material barrel can be placed on the material lifting plate and fixed to the top end of the electric push rod by means of the fixing rod, then the paper material barrel is lifted to a position above the table board for discharging, manual lifting, mounting and feeding are not needed, and manpower is saved.

Owner:江苏启航研磨科技有限公司

Fabricated building curtain wall and mounting method thereof

ActiveCN111851812AStrong firmnessImprove securityWallsBuilding material handlingRotational axisJoint (building)

The invention relates to a fabricated building curtain wall and a mounting method of the fabricated building curtain wall. The fabricated building curtain wall comprises steel stand columns, steel mounting plates, decorative plates, locking assemblies and a sealing mechanism. The steel stand columns are mounted on the outer wall of a wall body through expansion bolts. The steel mounting plates arearranged on the outer sides of the steel stand columns. The decorative plates are mounted on the outer walls of the steel mounting plates through the locking assemblies. First through holes are formed in the joints of the interiors of the decorative plates and the locking assemblies. The sealing mechanism is arranged at a gap between the two adjacent decorative plates. The inner walls of the steel stand columns are provided with support frames through bolts, one ends of the support frames are provided with rotating shafts, the outer walls of the rotating shafts are sequentially sleeved with deflection plates, positioning rods are correspondingly arranged at one sides of the two deflection plates, and inclined holes are formed in the joins of the interiors of the steel stand columns and the positioning rods. The fabricated building curtain wall and the mounting method have the beneficial effects that the connecting firmness of the device is improved effectively through a multi-stage fixing mode, the safety is higher, and the service life is long.

Owner:山东永胜建设集团有限公司

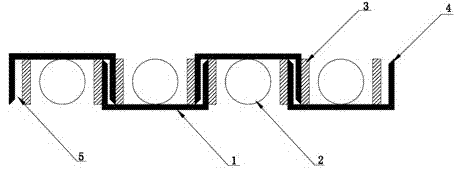

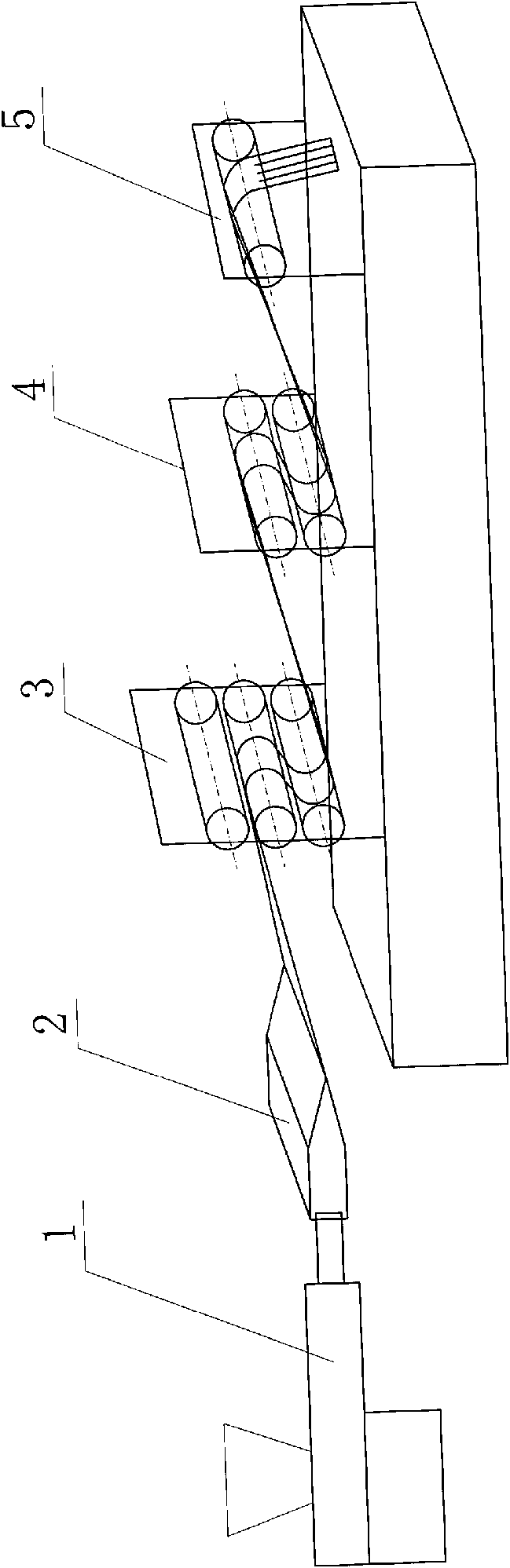

Process for preparing plastic hook fastener

InactiveCN101596034AExtended service lifeStrong firmnessSnap fastenersPress-button fastenersFastenerEngineering

The invention discloses a process for preparing a plastic hook fastener. The method is characterized in that after a toughened nylon material is melted, the material is extruded through an extruding machine (1); after passing through a flat sheet mold (2), the material becomes a continuous sheet material and enters a traction mechanism; after hook teeth are rolled on the flexible sheet material by a tooth making roller (3) with random hook teeth, the sheet material enters a flat pressing roller (4) for shaping; and the sheet material is split into a strip shaped fastener product by a splitting machine (5) for package.

Owner:陈胜华 +2

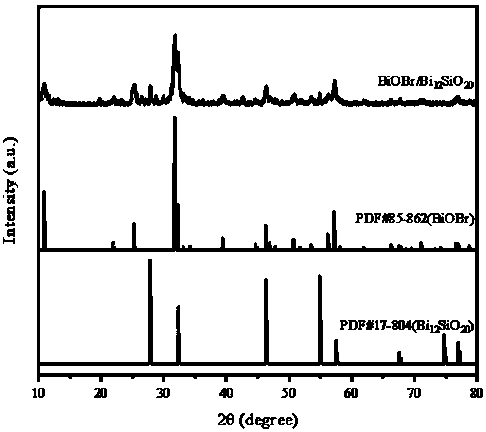

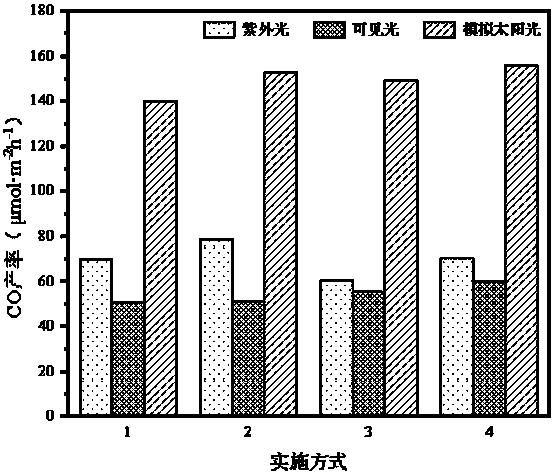

Electrochemical preparation method of BiOBr/Bi12SiO20 composite film photocatalyst and application of BiOBr/Bi12SiO20 composite film photocatalyst

ActiveCN110624575AEasy to useOvercoming the insufficiency of not being easy to separateCatalyst activation/preparationCarbon monoxideComposite filmSynthesis methods

The invention discloses an electrochemical preparation method of a BiOBr / Bi12SiO20 composite film photocatalyst and application of the BiOBr / Bi12SiO20 composite film photocatalyst, belonging to the fields of in-situ preparation of Bi-based composite materials, solar photocatalyst immobilization technology and artificial photosynthesis. The problems that existing synthesis methods are high in energy consumption and have difficulty in separation of powder catalysts from reaction systems can be solved. According to the invention, a BiOBr / Bi12SiO20 immobilized composite film is through one-step electrochemical synthesis at room temperature with a Bi plate, NaBr and Na2SiO3.9H2O as raw materials, water / EG as a solvent, nitric acid or a sodium hydroxide solution as an agent for adjusting a pH value and a Ti plate as a negative pole. The preparation method has the advantages of usage of cheap and easily available raw materials, no need for high temperature and high pressure, mild and controllable reaction conditions, easy operation, environment-friendly process, and no generation of harmful byproducts.

Owner:TAIYUAN UNIV OF TECH

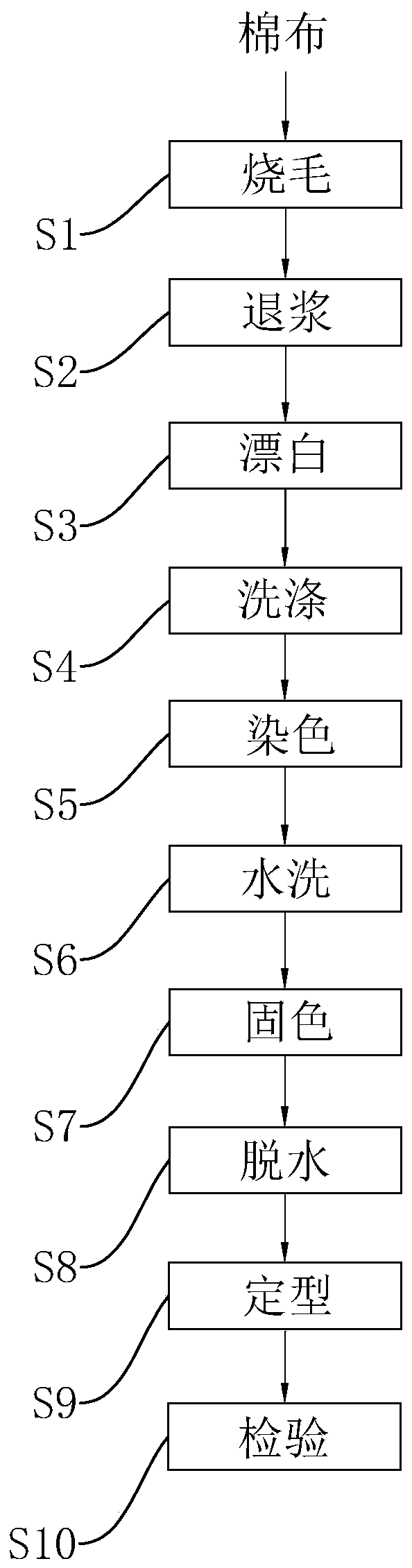

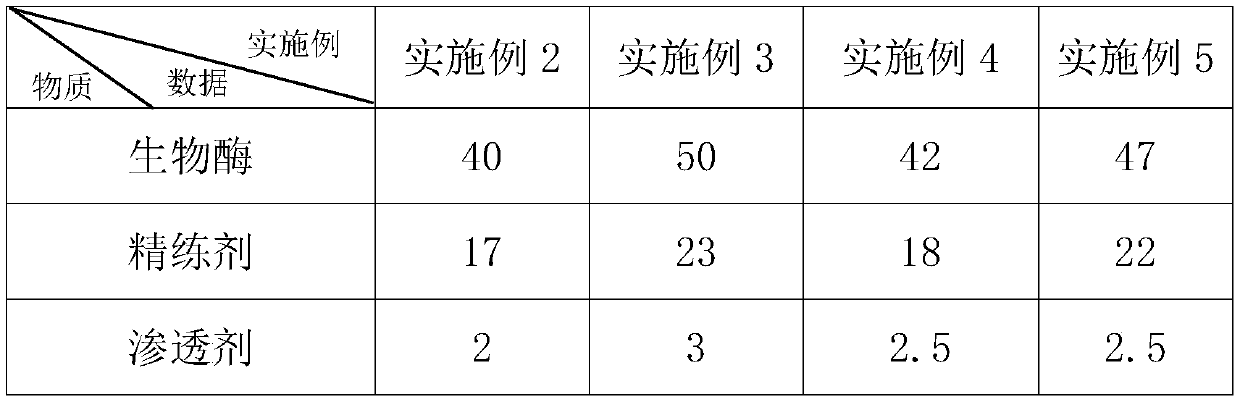

Dyeing technology for cotton cloth

InactiveCN110512444AImprove permeabilityImprove bindingDry-cleaning apparatus for textilesDyeing processCotton clothEngineering

The invention relates to the technical field of textile dyeing and finishing, and discloses a dyeing technology for a cotton cloth. The method for treating a cotton cloth gray fabric comprises the following steps of S1, performing singeing on the gray fabric; S2, performing resizing; S3, performing bleaching; S4, performing washing; S5, performing dyeing, wherein the gray fabric obtained after treatment in S4 is dyed, dyes adopted during dyeing are prepared from, by weight, 35-50 parts of active dyes, 7-10 parts of sodium carbonate, 3.5-5 parts of anhydrous sodium sulphate, 20-30 parts of a leveling agent, 5-8 parts of acetic acid, 11-23 parts of magnesium sodium silicate, 7-13 parts of imidazolidinyl urea, 2-5 parts of copper chloride and 80-110 parts of water; S6, performing washing; S7,performing color fixing; S8, performing dehydrating; S9, performing sizing, wherein after sizing in S9 is performed, the dyed cotton cloth is obtained. By adding magnesium sodium silicate and imidazolidinyl urea into dyes, active dyes can be promoted to continuously permeate cotton fiber, the imidazolidinyl urea can improve the combining capability of the active dyes and the cotton fiber, and finally the color fastness of the dyed cotton cloth is improved.

Owner:HANGZHOU XINSHENG PRINTING & DYEING

Preparation method of microcapsule antibacterial functional finishing agent

InactiveCN110344257AUniform pore sizeAperture ruleBiochemical fibre treatmentMesoporous silicaSilicon dioxide

The invention provides a preparation method of a microcapsule antibacterial functional finishing agent. According to the microcapsule antibacterial functional finishing agent, mesoporous silica coatedwith polyurethane serves as a wall material, aloin, lemon essential oil, vanilla oil and Chinese mugwort oil serve as core materials, and the weight ratio of the wall material to the core materials is 1:(1-5). A fabric finished by the finishing agent has good antibacterial effect, a combination action of the finishing agent and the fabric is high, and the antibacterial effect is more durable through sustained-release effect of a microcapsule. Antibacterial components used by the finishing agent are provided with natural extracts, safe and free from toxicity, and good health states of skins can be kept. The finishing agent has important application values in the field of textile.

Owner:SUZHOU INST OF TRADE & COMMERCE

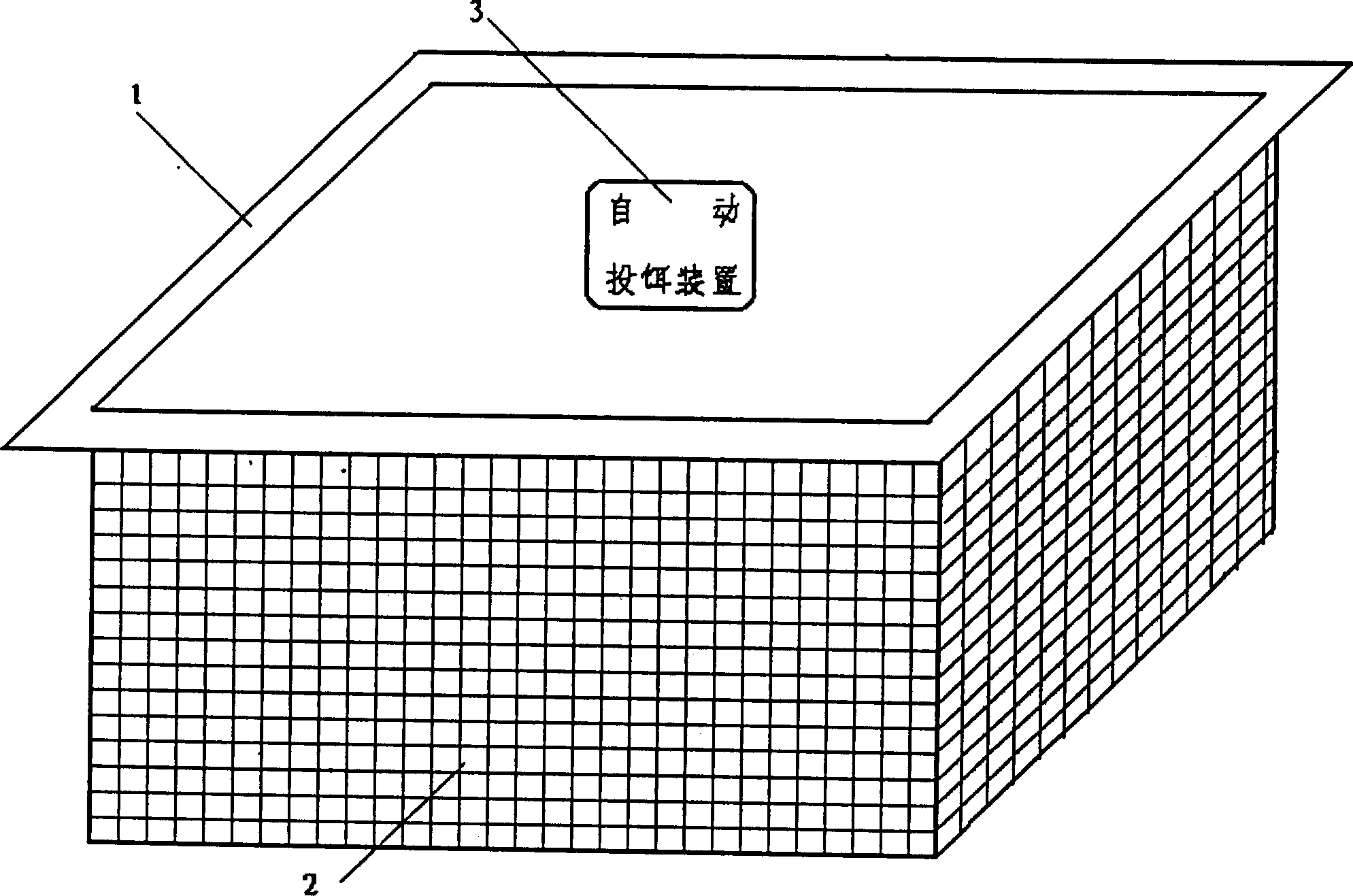

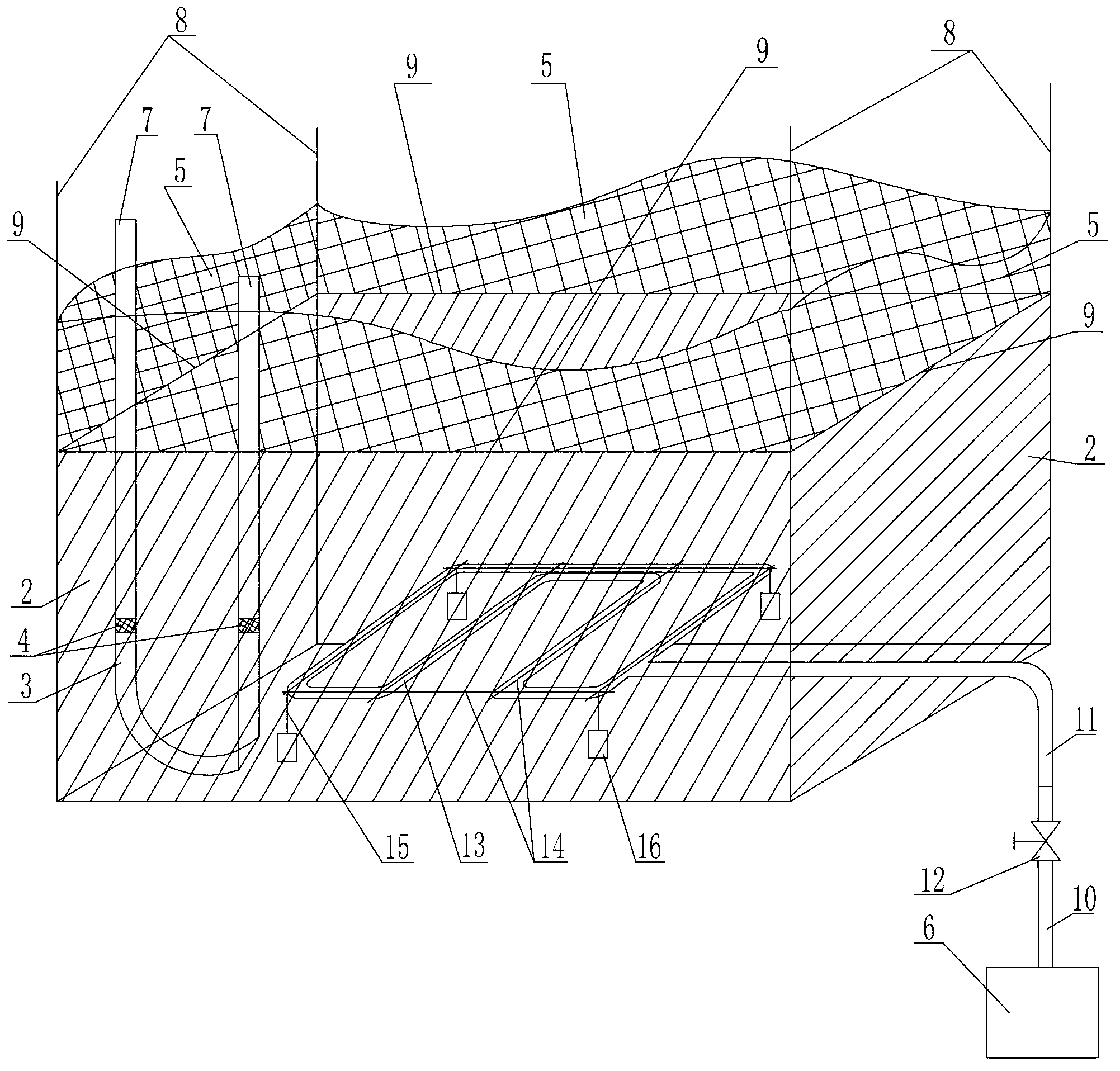

Pond field experimentation device and using method thereof

InactiveCN103210873AGuaranteed independencePrevent escapePisciculture and aquariaEcologic studyAeration

The invention discloses a pond field experimentation device and a using method thereof and relates to a device for experimental study of pond water area ecology and a using method thereof. The problems that the water oxygenation effect is bad, the water inlet and drainage are inconvenient, fishes are difficult to escape and the requirements of experimental study of pond water area ecology cannot be met in the conventional field experimentation enclosure ecosystem are solved. The pond field experimentation device comprises waterproof cloth, a U-shaped pipe, an oxygenation aeration device, an anti-escape net, two filtering nets, two straight pipes, four upright rods and four transverse rods, wherein the four upright rods are arranged in an array; a cross rod is connected between two upright rods; and the four upright rods and four transverse rods form a square frame. The field enclosure experimentation method mainly comprises the following steps: 1, inserting the upright rods on the square frame into the bottom of the pond; 2, injecting water into the square frame with the waterproof cloth; 3, oxygenating and aerating in water; and 4, draining water in the square frame. The pond field experimentation device is used for research of pond water area ecology.

Owner:HEILONGJIANG RIVER FISHERY RES INST CHINESE ACADEMY OF FISHERIES SCI

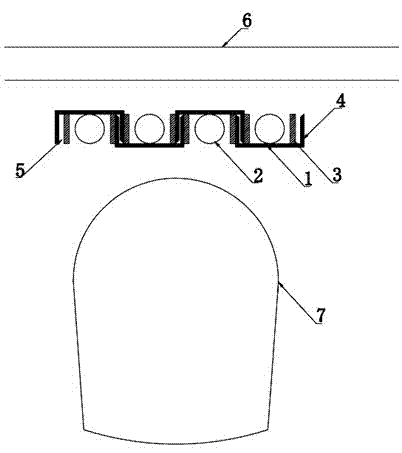

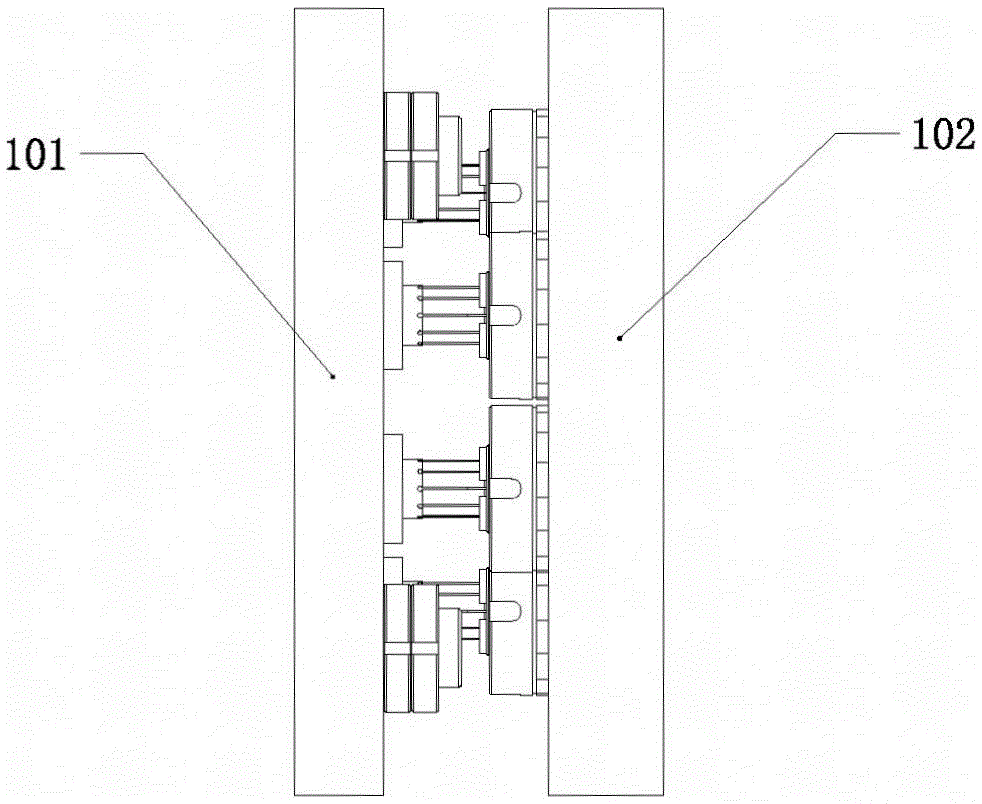

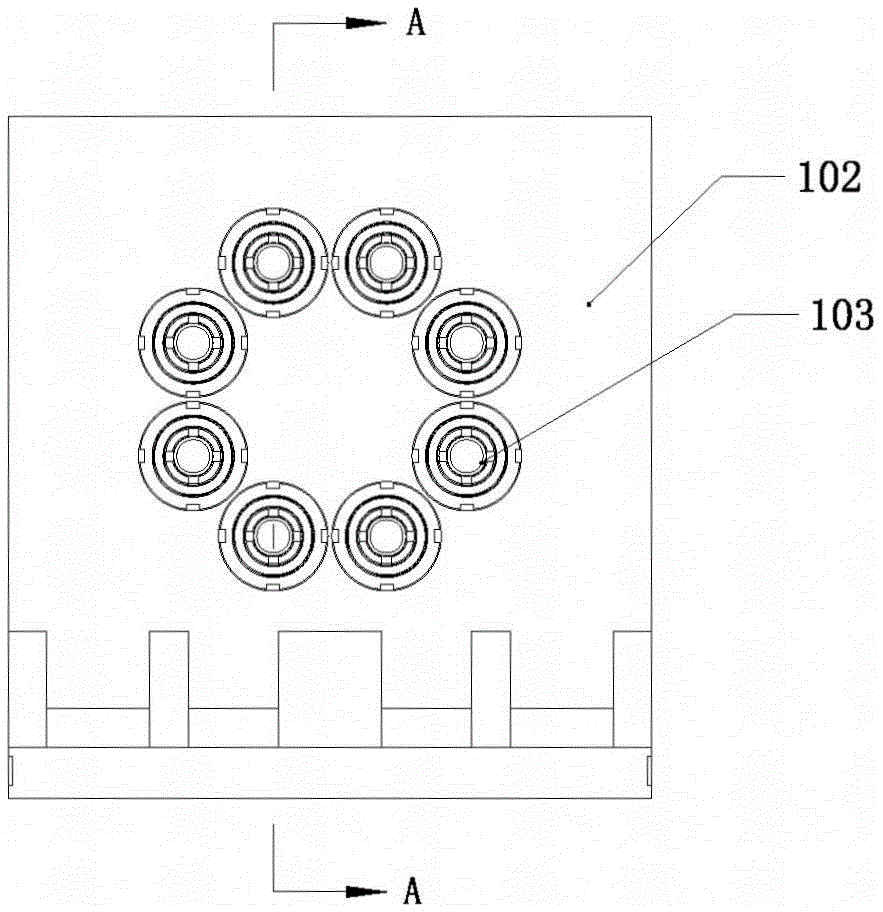

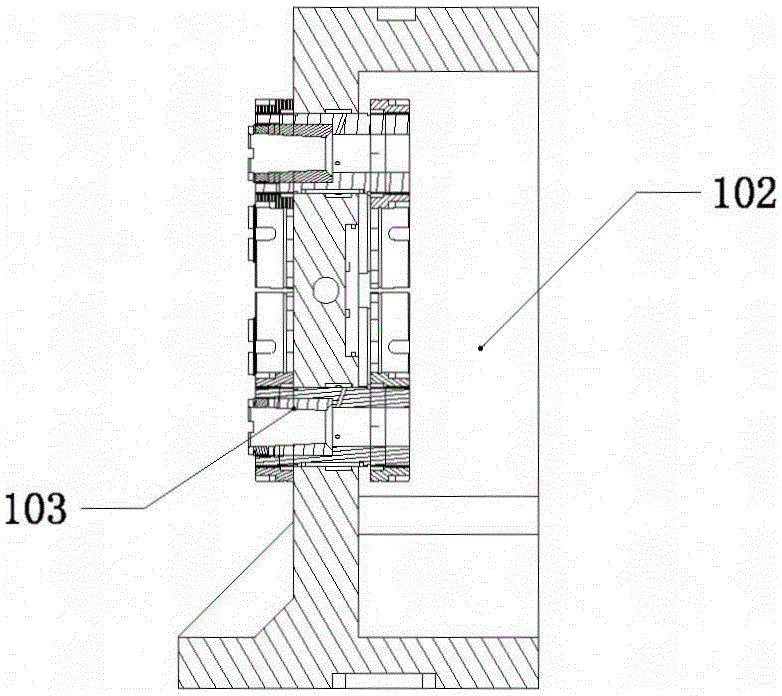

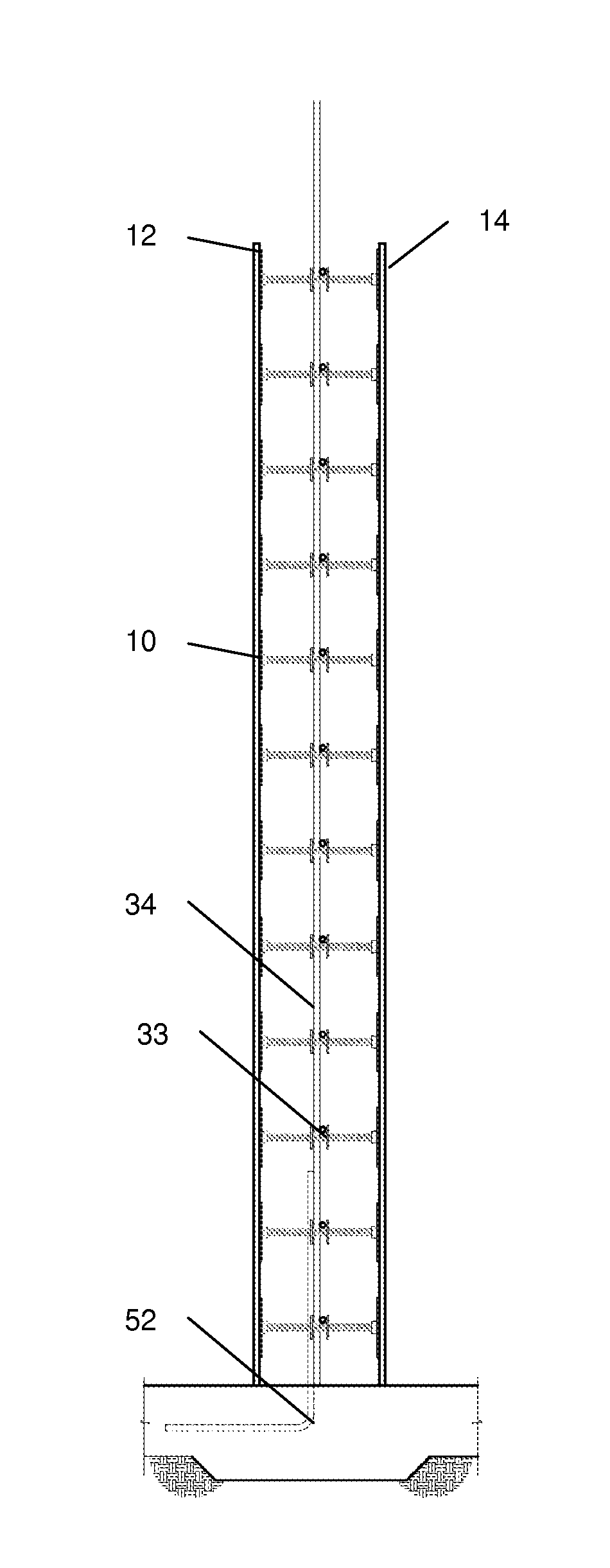

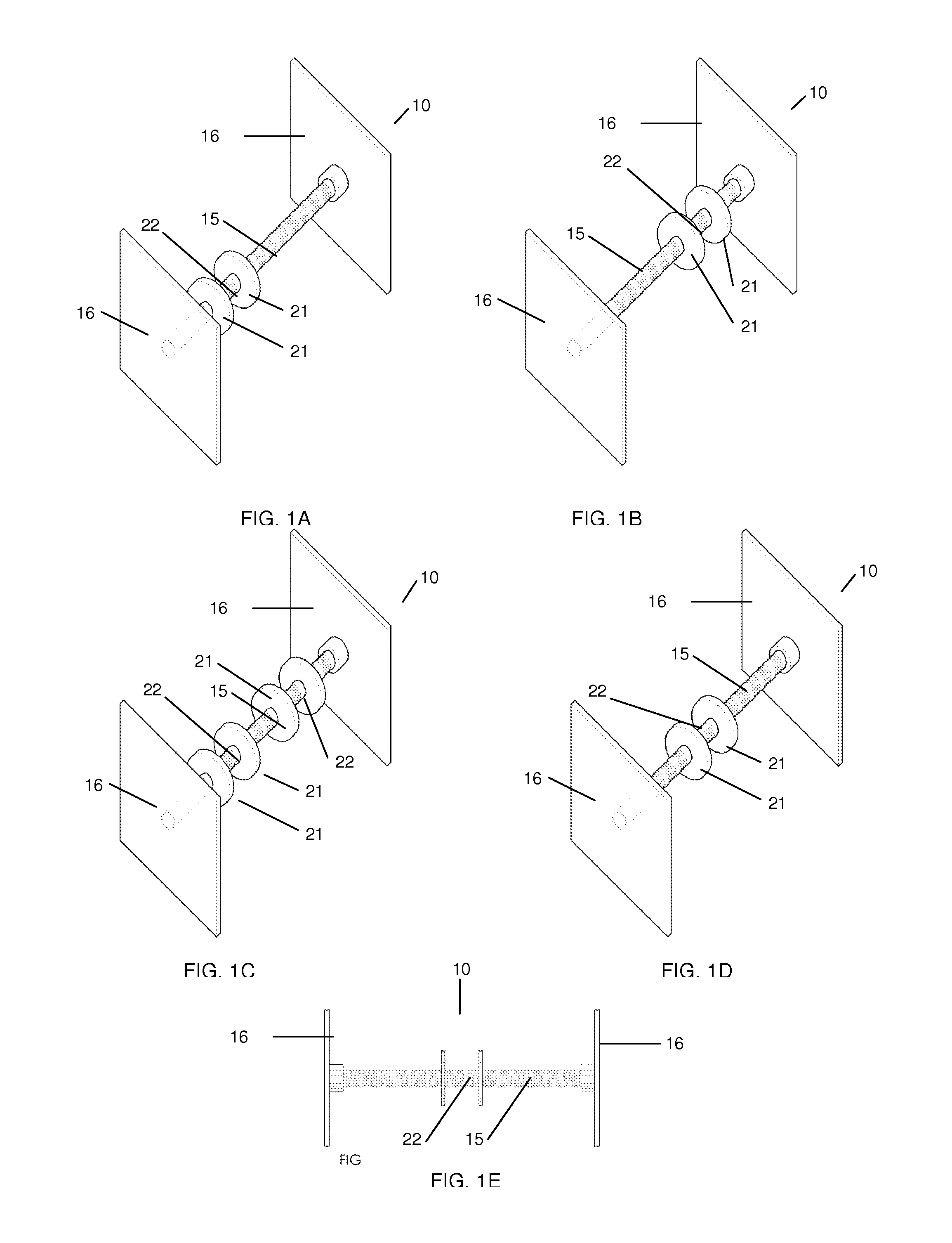

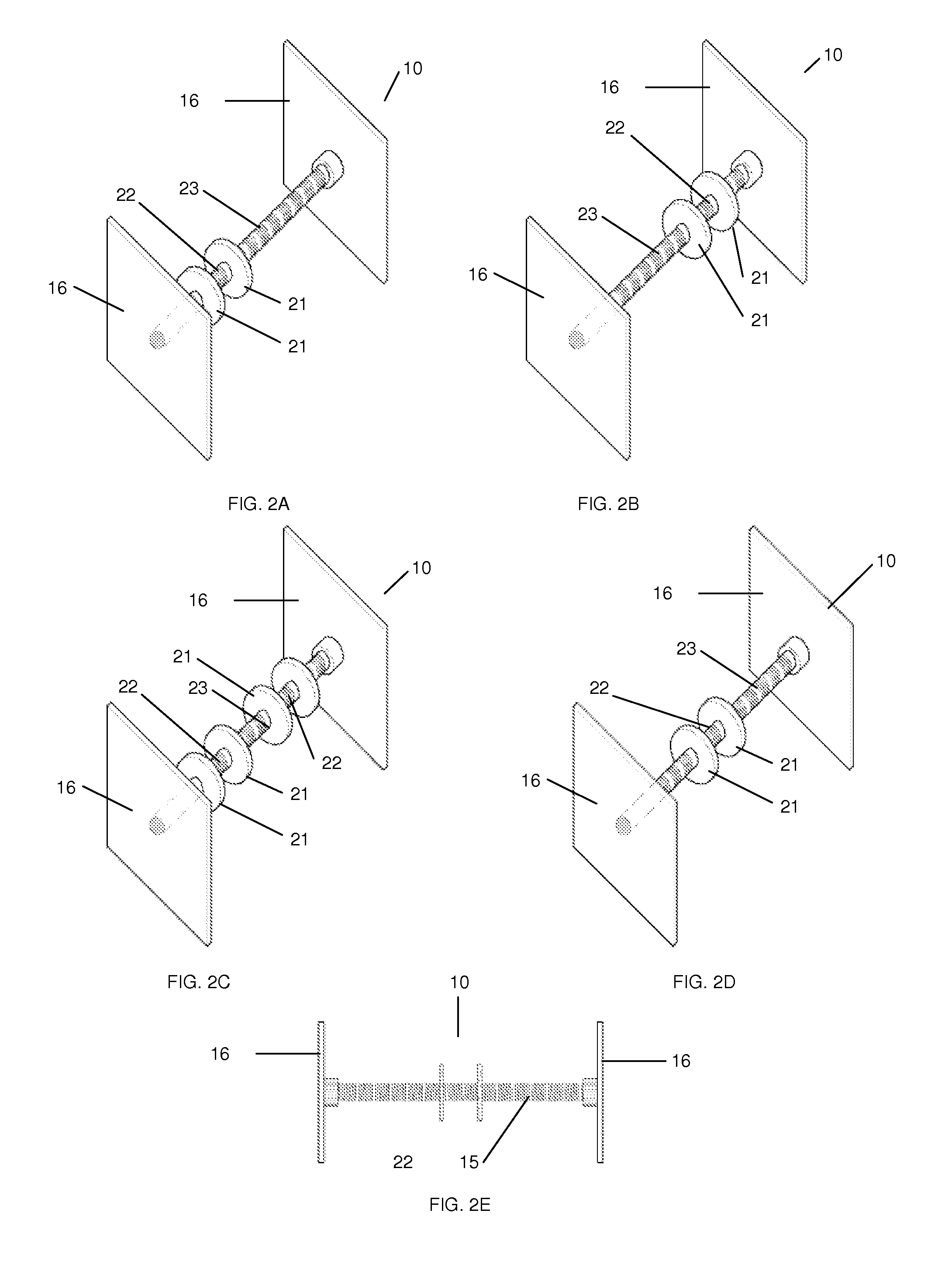

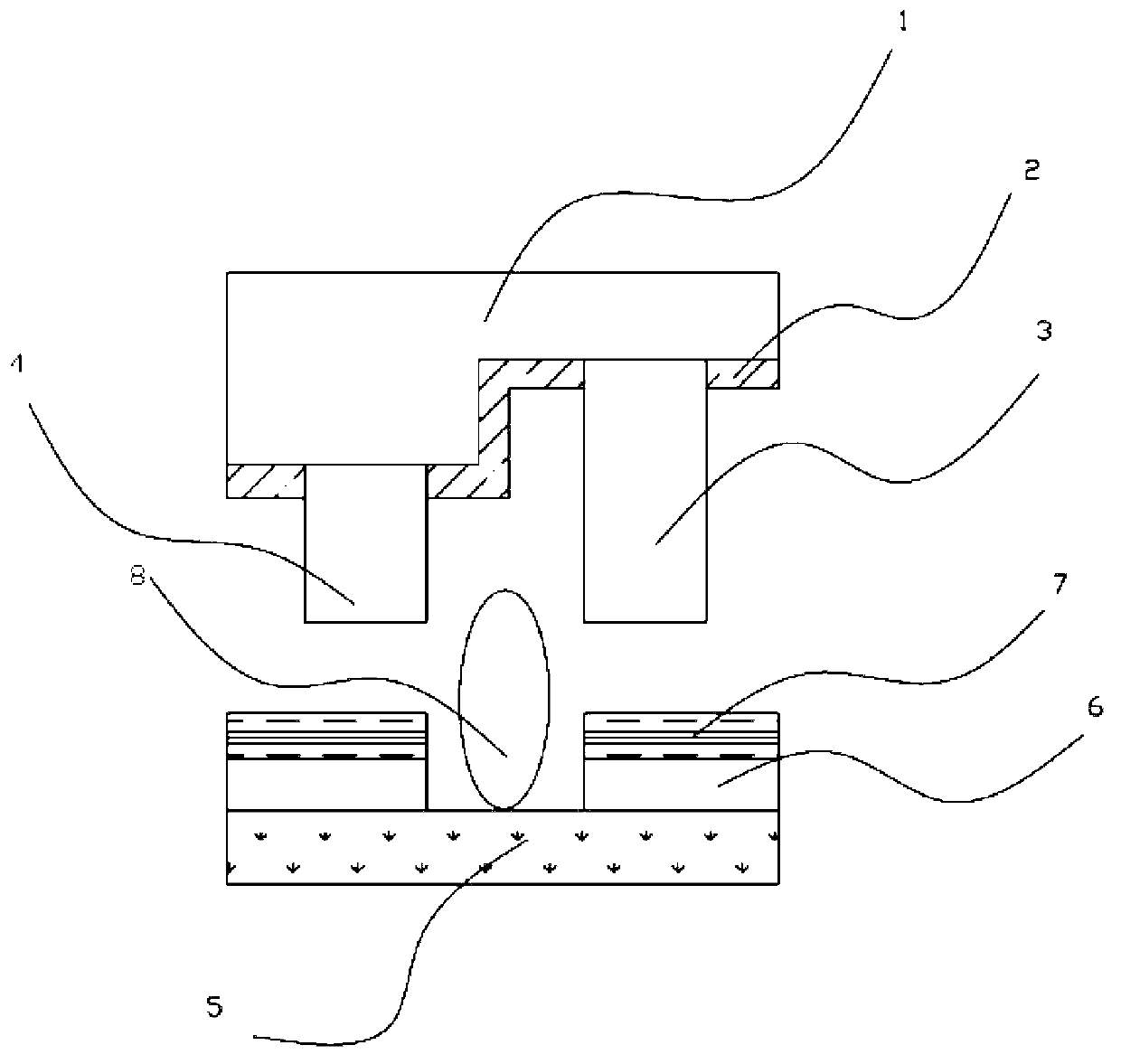

Holding Units for Stay in Place Molds

InactiveUS20140007537A1Strong firmnessImprove the immunityWallsAuxillary members of forms/shuttering/falseworksCement boardInternal cavity

The instant invention provides stay in place molds for the construction of concrete structures comprising two boards or panels held together by a series of holding units that are fastened only to the interior surfaces of the cement panels by fastening means that are kept inside of the width of said panels. The holding units are selectively distributed at the internal cavity of the molds and are designed by a main cylindrical body having at least two internal ring units inside and two supporting plates at each one of the extremes of the main cylindrical body. The external, flat surface of the plates is permanently fastened only to the internal surface of the cement boards, thus forming strong stay in place construction molds having smooth external surfaces.

Owner:QUILES PEREZ PEDRO

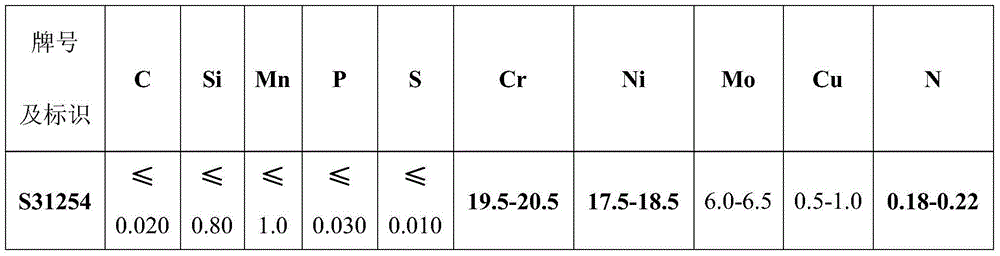

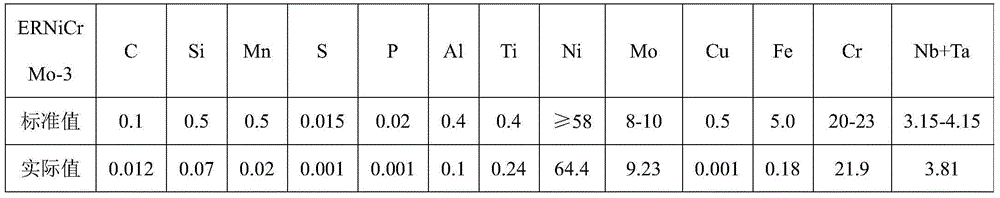

Super austenitic stainless steel welding technology and subsequent heat treatment process thereof

InactiveCN105750706AStrong firmnessNot easy to bendArc welding apparatusFurnace typesShielding gasAustenite

The invention discloses a super austenitic stainless steel welding technology; the welding technology comprises the following steps: (1) selecting a super austenitic stainless steel sheet; (2) selecting an SFA5.14-ERNiCrMo-3 welding wire to carry out multilayer pass welding on the super austenitic stainless steel sheet at a 1G horizontal position by a tungsten argon arc welding method, wherein interlayer-temperature is lower than 80 DEG C; (3) adopting a direct current (DC) power supply during welding, wherein polarity is welding wire connection, the specification of the welding wire is phi 1.2mm, welding current is 90-110A, welding voltage is 16-20V, welding speed is 100-120mm / min, protective gas in a welding gun and at the back of the welding gun is Ar gas, and the purity of the Ar gas is more than 99.997 percent. According to the super austenitic stainless steel welding technology and a subsequent heat treatment process of the welding technology, welding steps and post-weld heat treatment steps are simpler, and the post-weld super austenitic stainless steel sheet is enabled to be high in firmness, not to be easily bended and not to easily have cracks, so that the corrosion resistance of the super austenitic stainless steel sheet is guaranteed.

Owner:SHANGHAI KAIQUAN PUMP IND GROUP

Wound closure device

The invention discloses a wound closure device, which comprises a left adhesive strip and a right adhesive strip which are respectively distributed along both sides of a wound. The left adhesive strip and the right adhesive strip are respectively and fixedly provided with a left support belt and a right support belt; a plurality of locking devices connected with the left support belt and the right support belt are distributed on the left support belt and the right support belt; each locking device comprises a connecting band and a connecting device matched with the corresponding connecting band; a plurality of fixture blocks are respectively distributed in rows at both sides of each connecting band; one ends of the connecting bands are fixedly arranged onto the left support belt; the connecting devices are arranged on the right support belt; each connecting device comprises a muff-coupling part with an insertion hole; necks are respectively configured at both sides of the insertion hole of each muff-coupling part corresponding to the fixture blocks; one side, which faces the corresponding muff-coupling part, of each fixture block is provided with a first oblique plane; one side, which faces the left support belt, of each neck is provided with a second oblique plane matched with the corresponding first oblique plane; one side, which is far away from the corresponding muff-coupling part, of each fixture block is provided with a first stopping plane; one side of, which is far away from the left support belt, each neck is provided with a second stopping plane matched with the corresponding first stopping plane. According to the wound closure device disclosed by the invention, a centipede foot-like scar is not left after the wound is closured, drugs can be conveniently applied, and moreover, a better ventilation effect can be kept for the wound.

Owner:宋方昆

Encapsulating method for LED chips

The invention discloses an encapsulating method for LED chips. Firstly, tin is added on the surfaces of electrodes of a circuit board substrate, and then glue is arranged on the part, except the electrodes, of the upper surface of the circuit board substrate, an LED chip is arranged on the circuit board substrate, the salient point of the P electrode and the salient point of the N electrode correspond to the electrodes on the circuit board substrate, and the LED chip is heated and pressurized to enable the salient point of the P electrode and the salient point of the N electrode to be connected with the tin on the electrodes of the circuit board substrate in an eutectic melting mode. When the LED chip is heated, the glue is solidified to enable the LED chip to be fixedly connected with the circuit board substrate. Hereto, the encapsulation of the LED chip is completed. The encapsulating method for the LED chips is simple in technology, firm in connection between the LED chip and the circuit board substrate, and not prone to falling off.

Owner:SHANGHAI JIUJUN ELECTRONICS SCI & TECH

Skincare fiber as well as preparation method and application thereof

InactiveCN111379037AStrong firmnessLarge exposed areaFilament/thread formingArtifical filament manufactureChemistryWoven fabric

The invention discloses a skincare fiber as well as a preparation method and application thereof. The skincare fiber is a fibrous structural material prepared from a skincare component, wherein the skincare fibrous structural material is of a physical winding structure; and the elongation of the skincare fibrous structural material is more than or equal to 45% under a tension load of 0.001cN / dtexto 0.01cN / dtex. The fibrous structural material provided in the invention is high in fastness and large in exposed area for the skincare component; the skincare component is difficult to lose; the skincare function is lasting; a household textile obtained based on the skincare fiber can more sufficiently touch a human body in a use process; the absorption and metabolism of a skin are promoted; thedaily preservation demand of a user is met; and a healthy and comfortable lifestyle is provided.

Owner:LUOLAI LIFESTYLE TECH CO LTD +2

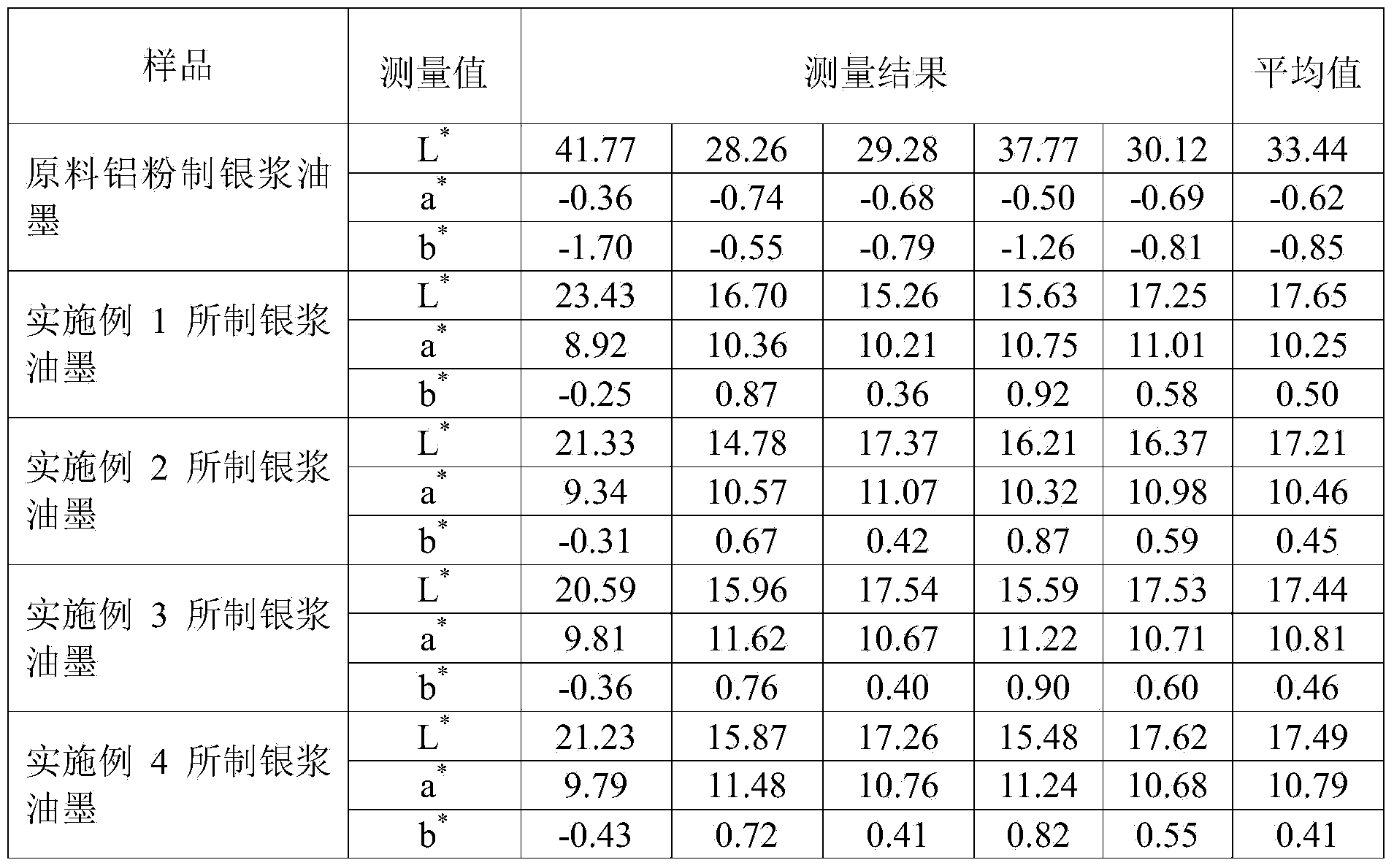

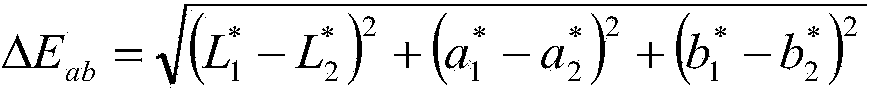

Preparation method of magenta silver paste printing ink

The invention discloses a preparation method of magenta silver paste printing ink, comprises the following steps: step one, magnetically stirring raw material aluminum powder and a first solvent, standing, filtering in vacuum, and drying in vacuum; step two, mixing the pre-treated aluminum powder, magenta pigment and a second solvent, and then feeding into a four-neck flask, stirring in a water bath pot; step three, configuring silicate ester diluted by the anhydrous ethyl alcohol, and a catalyst diluted by the anhydrous ethyl alcohol, distilled water and a silane coupling agent, respectively adding two configuration solutions in a separating funnel, continuously stirring after finishing the dropwise adding, filtering in vacuum, washing a product, drying in the vacuum to obtain the magenta modified aluminum powder; step four, dispersing the magenta modified aluminum powder by using distilled water, dispersing and adding resin and auxiliaries, manually stirring until the aluminum is uniformly dispersed in visual inspection to obtain the magenta silver paste printing ink. The magenta silver paste printing ink prepared by the method can completely meet the use requirement.

Owner:上海诚艺包装科技有限公司

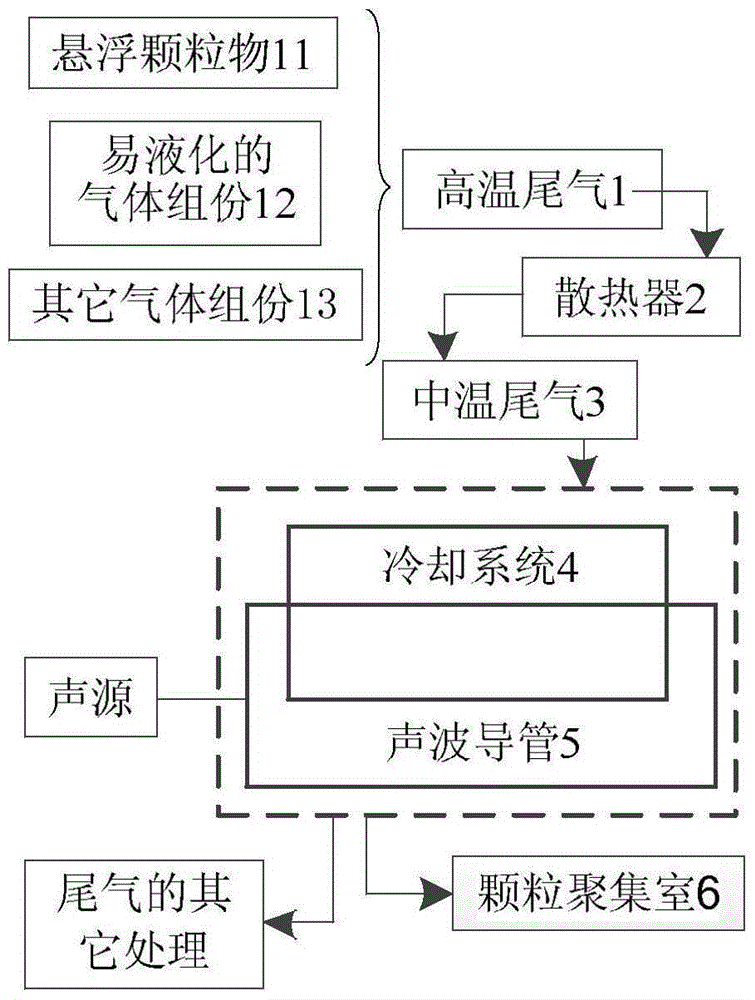

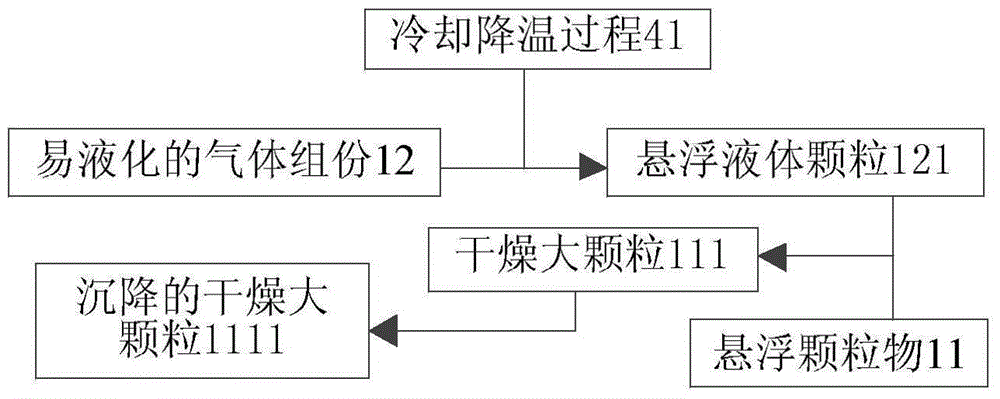

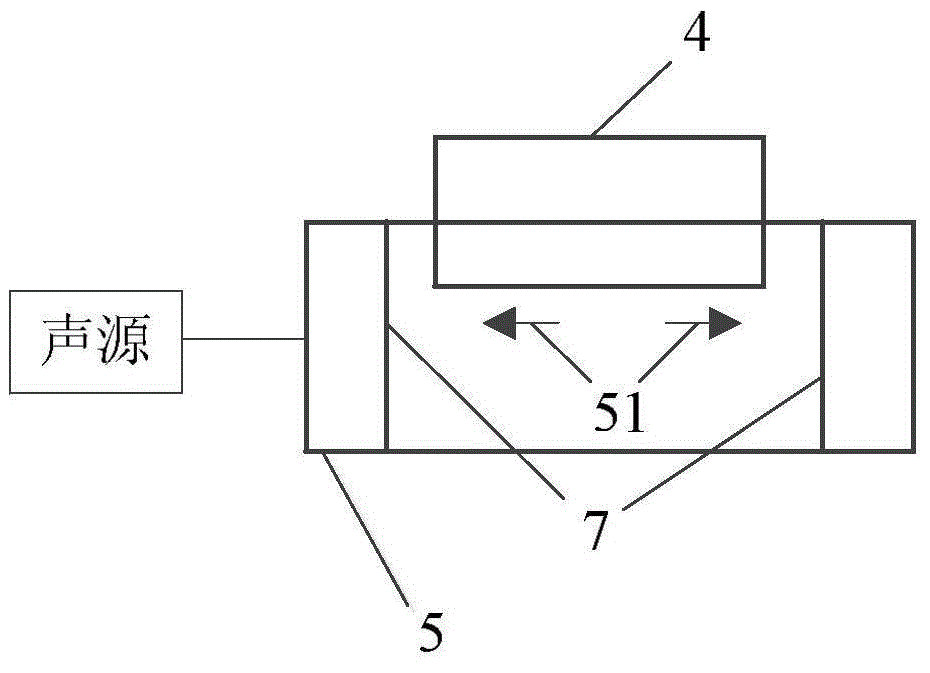

Method for reducing tail gas suspended particles of diesel engine in sound field environment

ActiveCN105089742AImprove wettabilityIncrease surface areaExhaust apparatusSilencing apparatusBrownian motionCooling temperature

The invention discloses a method for reducing tail gas suspended particles of a diesel engine in a sound field environment. High-temperature tail gas exhausted from a combustion chamber of the diesel engine mainly comprises suspended particles and easily liquefied gas components; the high-temperature tail gas becomes non-condensed moderate-temperature tail gas after being cooled by a radiator; the moderate-temperature tail gas is introduced into a strong sound standing wave sound wave guide pipe coupled with a cooling system and subjected to a cooling process gradually reinforced in a smoke flowing direction; the cooling temperature is slightly lower than the dew point temperature of gas components in the tail gas flowing through a cooling position; the gas components are liquefied to suspended liquid particles with smaller particle diameters; all the suspended particles are contacted with one another under the effects of sound force, inertia force, Brownian motion force and gravity; and the suspended particles grow to unbreakable dry large particles with the suspended liquid particles as adhesive, so that the removal of the suspended particles in the exhausted tail gas by fully using the easy-liquefied gas components in the tail gas is realized.

Owner:SOUTHEAST UNIV

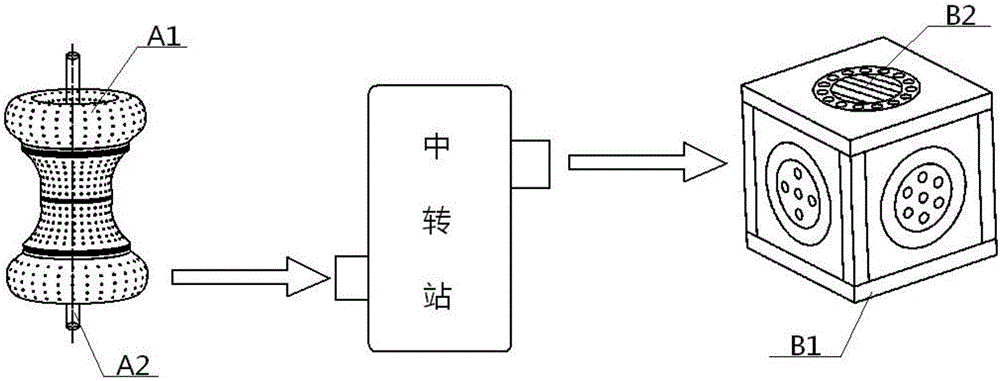

Refining and mixing system adopted in wet-process phosphoric acid refining process by solvent extraction method

ActiveCN106379879AImprove uniformityImprove stirring effectPhosphorus compoundsPhosphoric acidLubrication

A refining and mixing system adopted in a wet-process phosphoric acid refining process by a solvent extraction method is used for liquid-liquid mixing or liquid-powder mixing and comprises an A type mixing device, a transfer station and a B type mixing device which communicate with each other successively, wherein the A type mixing device has functions including that an external containing body can rotate, a heating body can be arranged and a rotating airflow can be generated, and a stirrer has three functions of body stirring, airflow stirring and enhanced stirring; the B type mixing device has functions including that an external containing body can generate a rotating airflow, a heating body can be arranged and a module can be replaced, and a stirrer has four functions of body stirring, airflow stirring, enhanced stirring, and midway addition of raw materials. The system can eliminate a fluid stagnation zone, can heat a mixed object, has the advantages of good mixing performance and high uniformity, can achieve rotation of an external container, strong lubrication effect, various stirring functions and midway addition, and has a wide range of application.

Owner:HUAZHONG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com