Super austenitic stainless steel welding technology and subsequent heat treatment process thereof

A technology of austenitic stainless steel and welding technology, applied in heat treatment furnaces, heat treatment equipment, welding equipment, etc., can solve the problems of corrosion resistance, cumbersome performance, and easy bending that are prone to cracks, so that it is not easy to bend and cracks, The effect of simple welding steps and strong firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention is further elaborated.

[0024] A kind of super austenitic stainless steel welding process provided by the present invention, described welding process comprises the following steps:

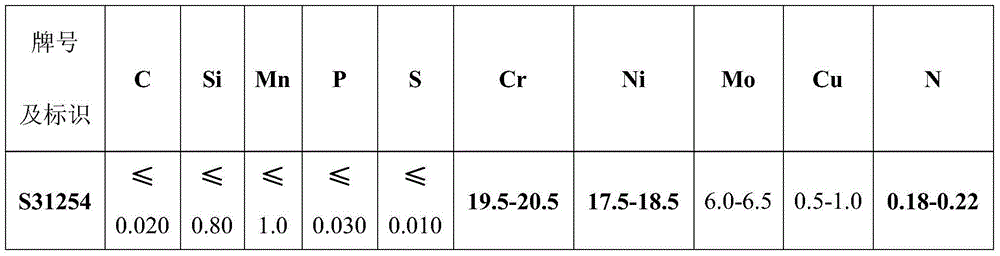

[0025] (1) Select the super austenitic stainless steel plate, the super austenitic stainless steel plate is in the form of V-shaped bevel with edge, the specification is 10mm×150mm×700mm, the model is SA240-S31254, the specific composition of the super austenitic stainless steel plate As shown in the following table:

[0026]

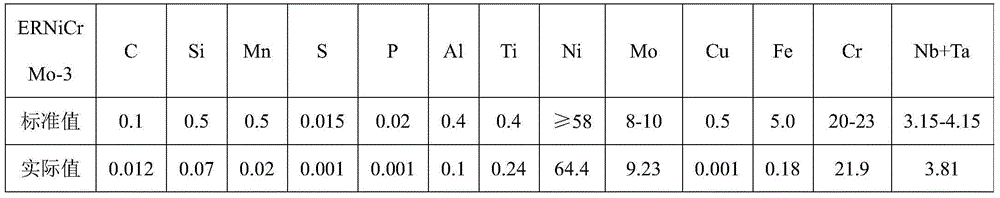

[0027] (2) Select SFA5.14-ERNiCrMo-3 welding wire and adopt tungsten argon arc welding method to conduct multi-layer welding of super austenitic stainless steel plate at 1G horizontal position. When welding, try to use small line energy and control interlayer temperature At less than 80°C, the specific compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com