Preparation method of magenta silver paste printing ink

A technology of silver paste ink and magenta, applied in ink, household utensils, applications, etc., can solve the problems of large VOC emissions, single color, poor stability, etc., and achieve bright colors, high gloss, and good washing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

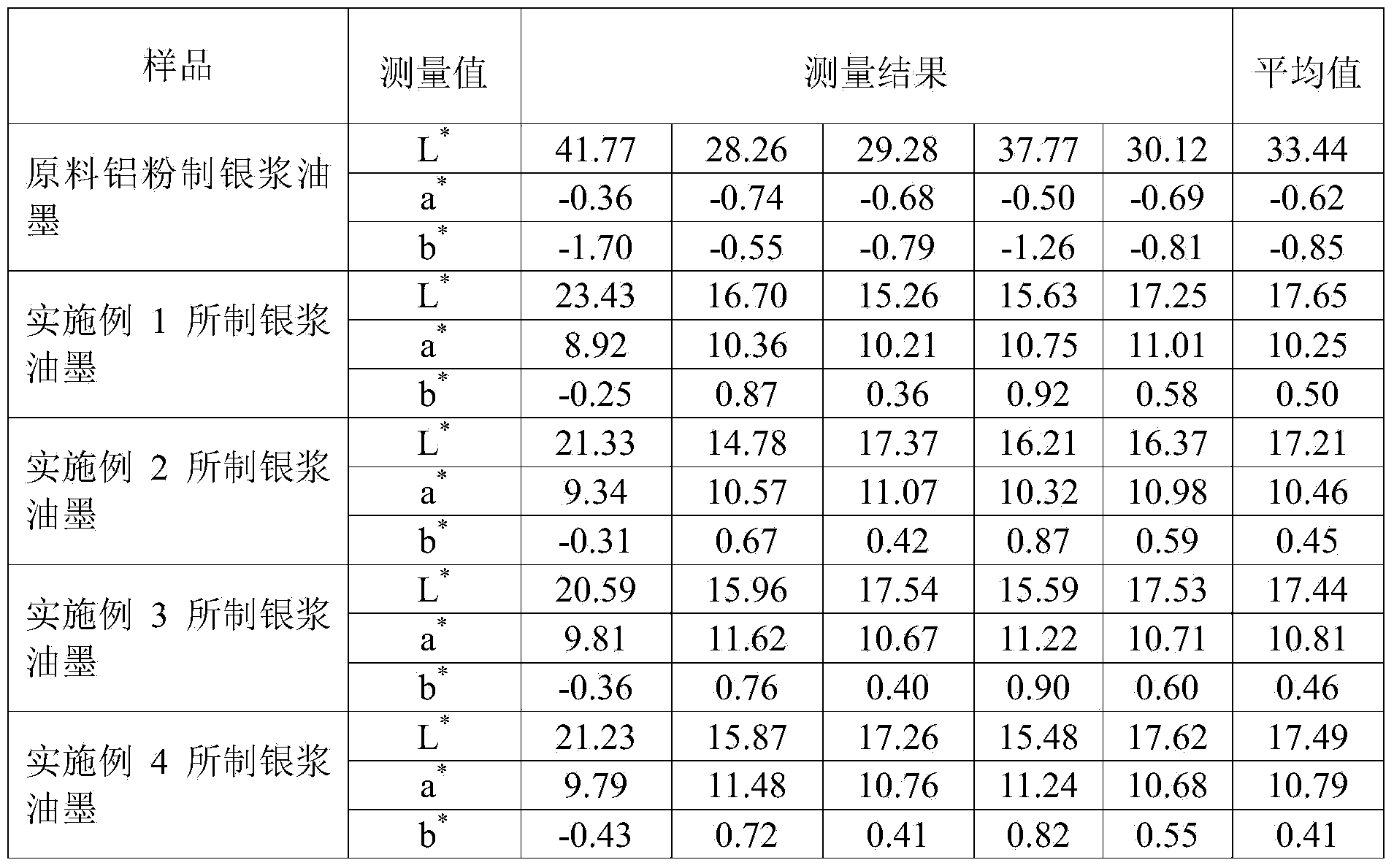

Examples

preparation example Construction

[0012] The preparation method of magenta silver paste ink of the present invention, comprises the steps:

[0013] Step 1: Add raw aluminum powder and solvent into a large beaker at the same time, stir with a magnetic stirrer at room temperature for a period of time, let it stand, then vacuum filter, and vacuum dry at 50°C to obtain pretreated aluminum powder;

[0014] The specifications of the raw material aluminum powder are 1000-1300 mesh,

[0015] The first solvent is absolute ethanol, distilled water or acetone, the ratio of aluminum powder (g): solvent (ml) is 1g: 5ml ~ 1g: 10ml, the stirring time is 2h ~ 3h, and the drying time is 2h ~ 3h.

[0016] Step 2, after mixing the pretreated aluminum powder, magenta pigment and solvent two, add them to a four-necked flask equipped with a precision booster electric stirrer and a reflux condenser, and place the flask in an electric heating constant temperature water bath Stirring under the protection of inert gas;

[0017] The ...

Embodiment 1

[0032] Magenta silver paste ink preparation method steps are as follows:

[0033] Step 1. Weigh 50g of raw aluminum powder (1000 mesh) and 250ml of absolute ethanol into a beaker, stir with a magnetic stirrer at room temperature for 2h, then let stand for 2h; then vacuum filter and dry in vacuum at 50°C 2h, obtain the pretreated aluminum powder;

[0034] Step 2, add 2g of pretreated aluminum powder, 2g of magenta pigment Cibacron Red4G-E and 20ml of absolute ethanol into a four-necked flask, and stir at room temperature for 1 hour under nitrogen protection to disperse the aluminum powder and magenta pigment evenly;

[0035] Step 3, warm up the water bath to 40°C, add 2ml orthosilicate methyl ester diluted with 10ml of absolute ethanol (liquid A) and 5ml of distilled water diluted with 10ml of absolute ethanol, 2ml of ammonia water, 2ml of vinyltrimethoxysilane (solution B) respectively. liquid), control the dropping rate to 1 drop / second, and the dropwise addition is complete...

Embodiment 2

[0038] The steps of the preparation method of highly dispersible aluminum-based silver paste ink are as follows:

[0039]Step 1: Weigh 50g of raw aluminum powder (1300 mesh) and 500ml of acetone into a beaker, stir with a magnetic stirrer at room temperature for 3h, and then let stand for 3h. Then vacuum filtration, and vacuum drying at 50° C. for 3 hours to obtain pretreated aluminum powder;

[0040] Step 2, add 2g of pretreated aluminum powder, 2g of magenta pigment Cibacron Red P-BN and 30ml of absolute ethanol into a four-necked flask, and stir at room temperature for 2 hours under nitrogen protection to uniformly disperse the aluminum powder and magenta pigment;

[0041] Step 3, warm up the water bath to 50°C, add 4ml orthosilicate methyl ester (solution A) diluted with 25ml of absolute ethanol and 10ml of distilled water diluted with 25ml of absolute ethanol, 4ml of ammonia water, 4ml of vinyltriacetoxysilane ( Liquid B), control the dropping rate to 1 drop / second, drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com