Patents

Literature

3286results about How to "Improve surface properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

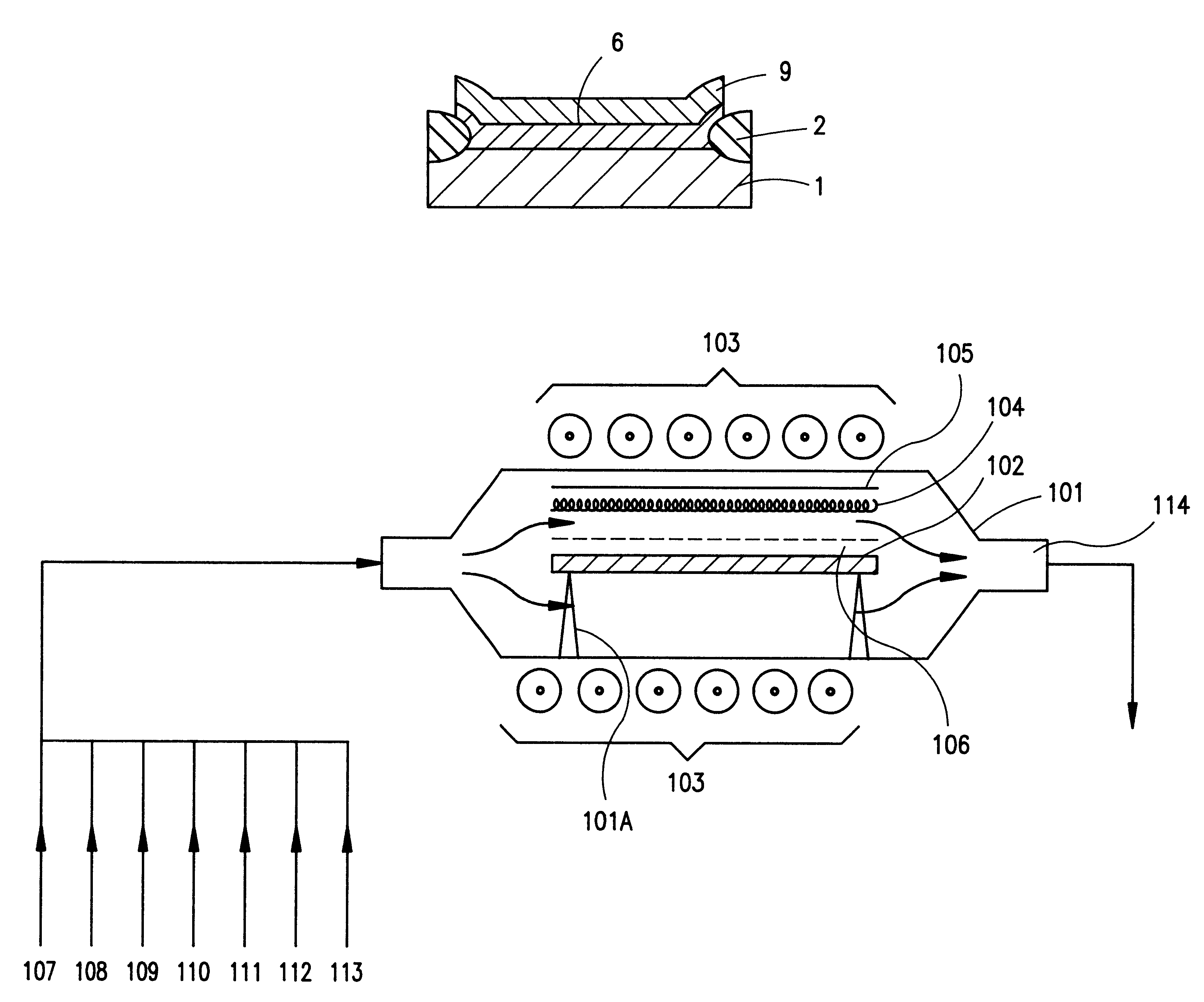

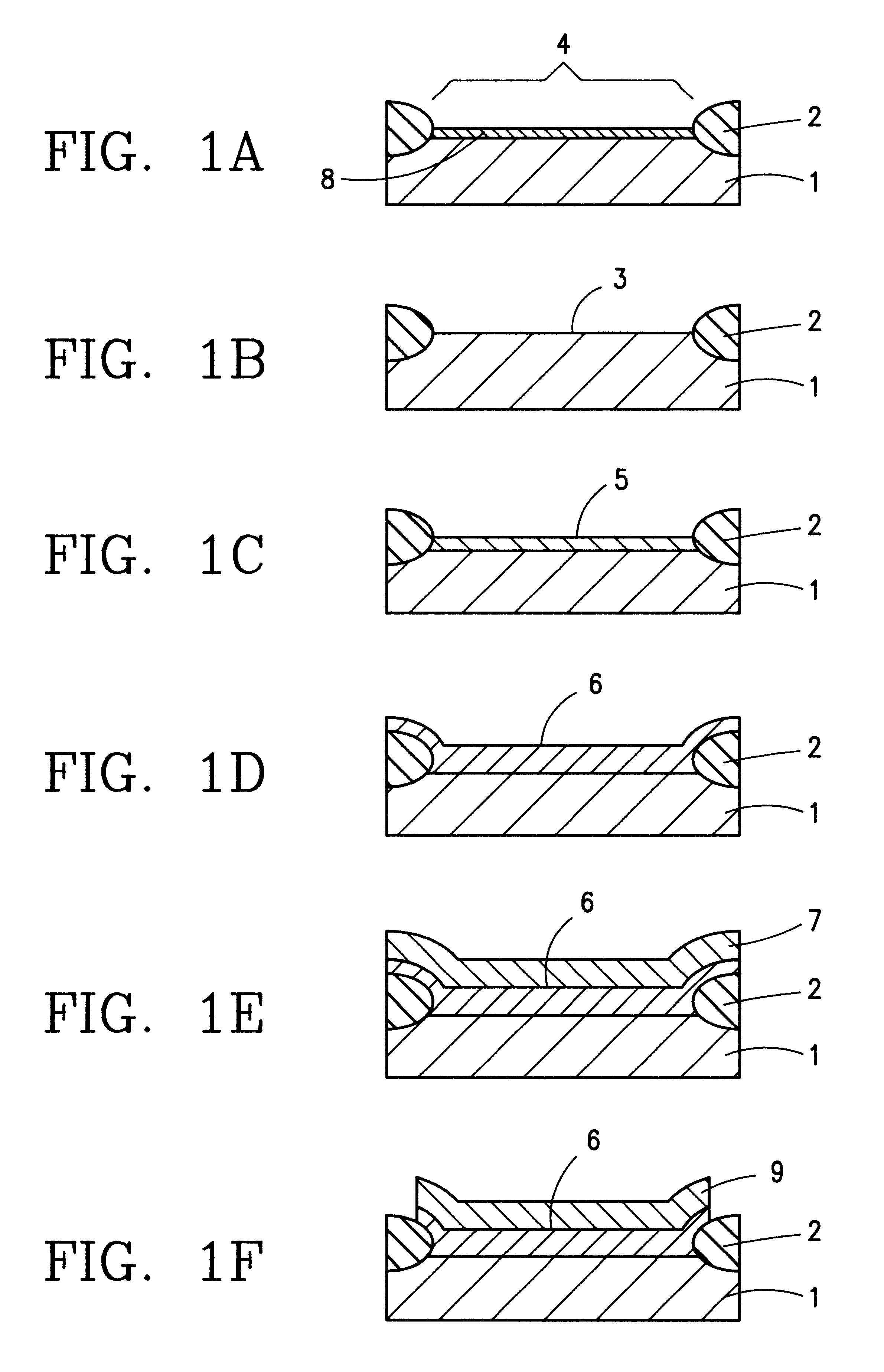

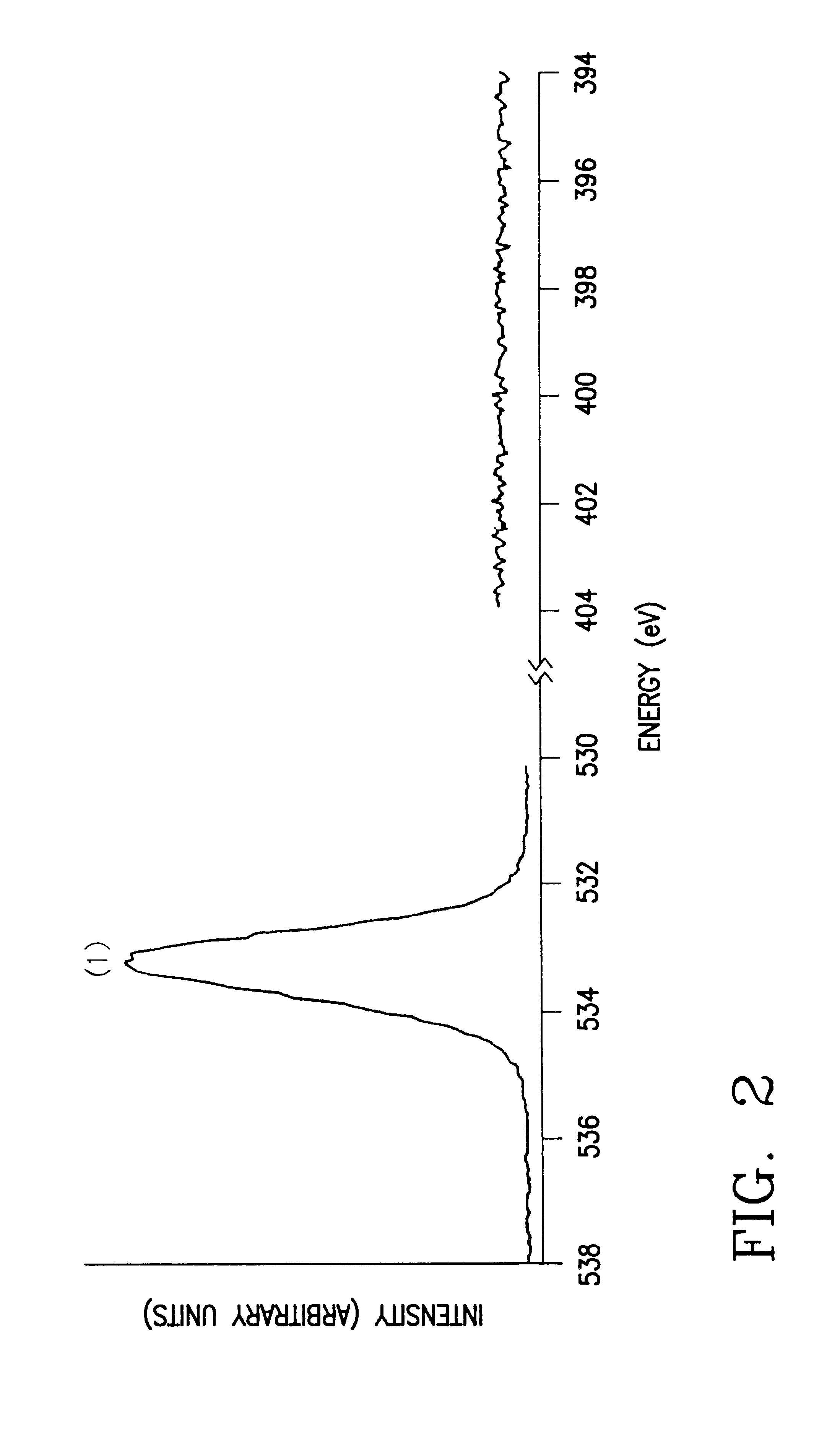

Method for forming an insulating film on semiconductor substrate surface and apparatus for carrying out the method

InactiveUS6265327B1Improve controllabilityQuality improvementElectric discharge tubesSemiconductor/solid-state device manufacturingNitrogenControllability

Disclosed are a method and apparatus for forming an insulating film on the surface of a semiconductor substrate capable of improving the quality and electrical properties of the insulating film with no employment of high-temperature heating and with good controllability. After the surface of a silicon substrate is cleaned, a silicon dioxide film having a thickness of 1-20 nm is formed on the substrate surface. The silicon substrate is exposed to plasma generated by electron impact, while the silicon substrate is maintained at a temperature of 0° C. to 700° C. Thus, nitrogen atoms are incorporated into the silicon dioxide film, obtaining a modified insulating film having good electrical properties.

Owner:JAPAN SCI & TECH CORP +1

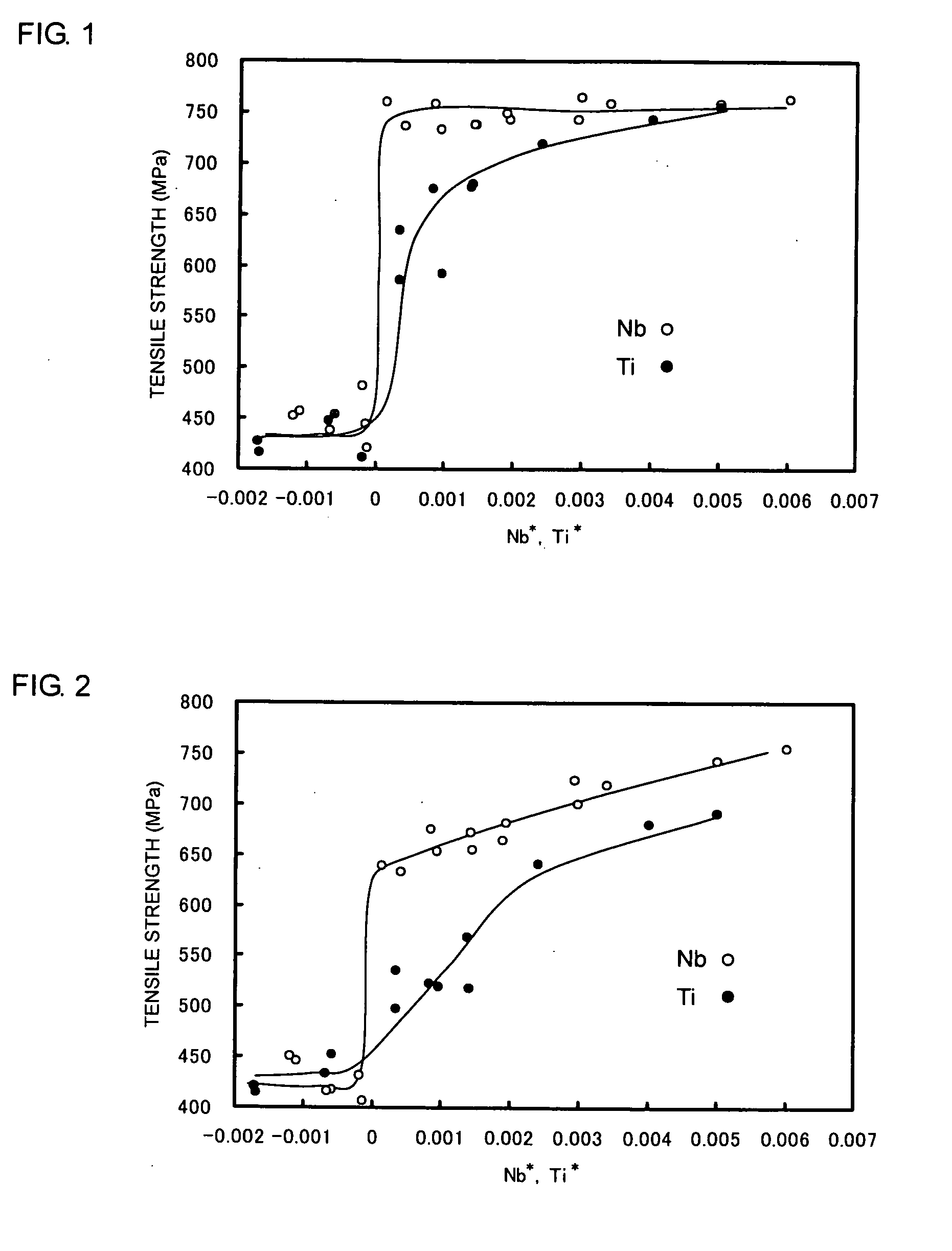

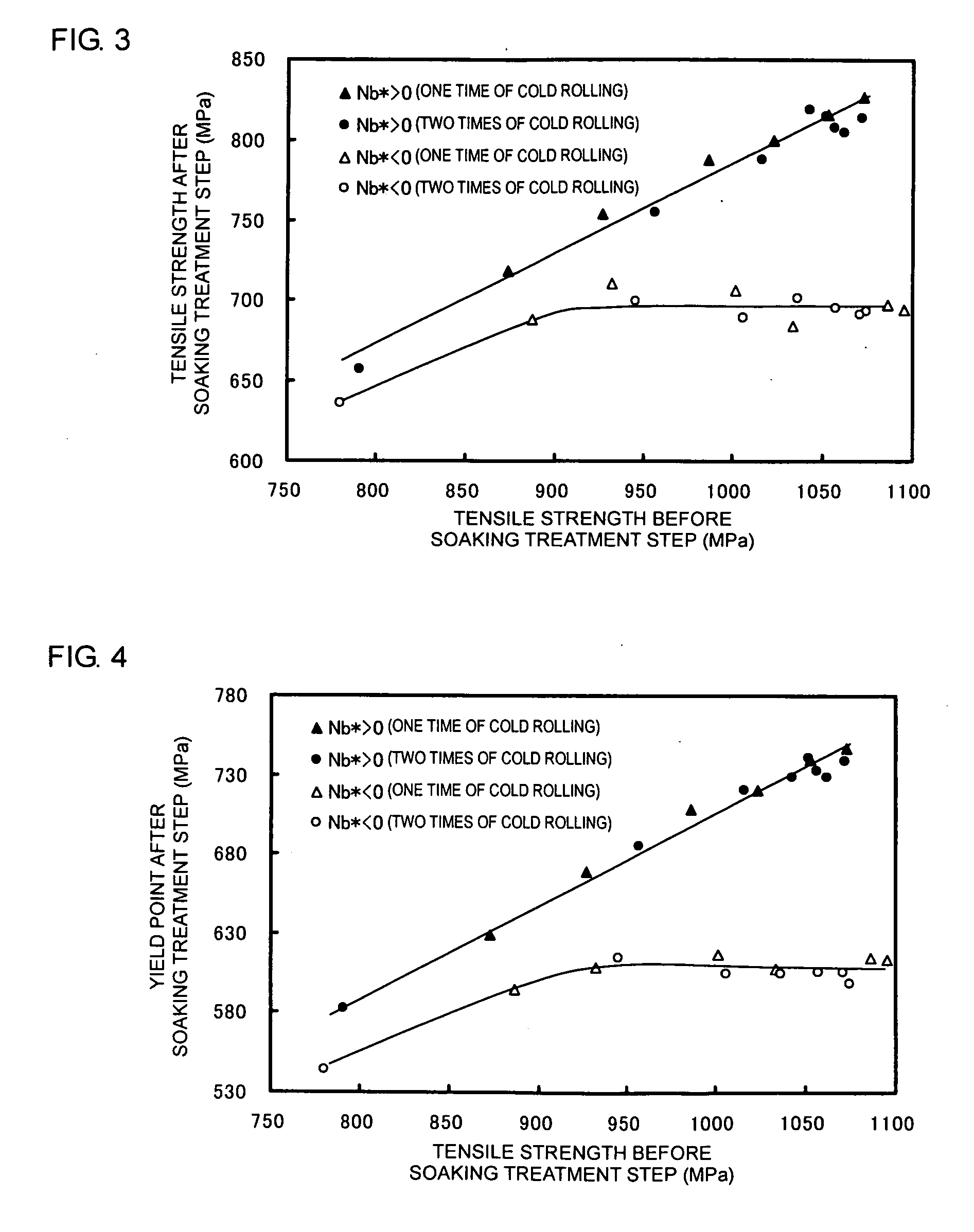

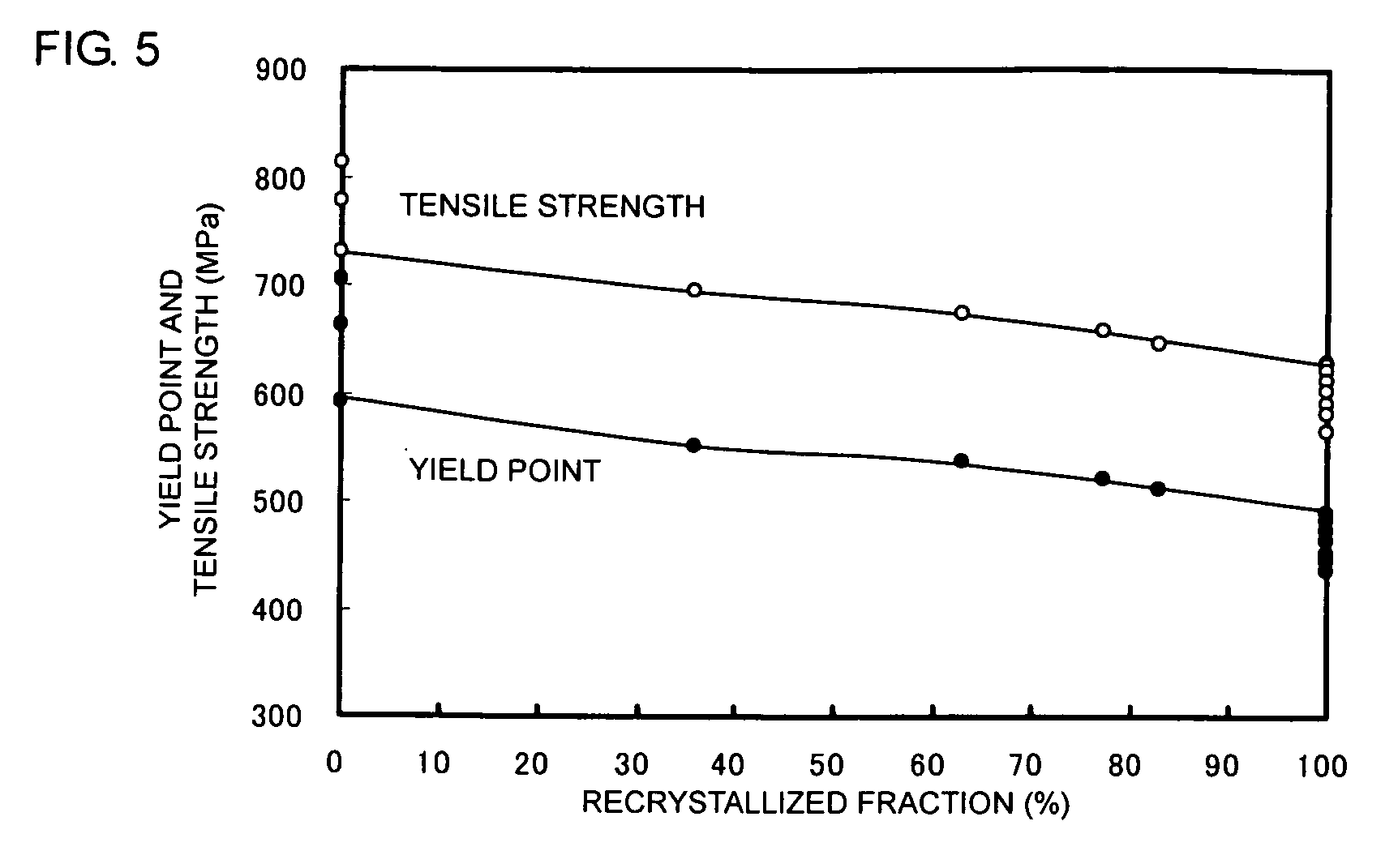

Non-Oriented Electrical Steel Sheet and Production Process Thereof

ActiveUS20090202383A1Excellent mechanical characteristicImprove surface propertiesInorganic material magnetismTransformers/inductances detailsElectrical steelMagnetic characteristic

A main object thereof is to provide a non-oriented electrical steel sheet being excellent in surface characteristics and having both excellent mechanical characteristics and magnetic characteristics necessary for a rotor of rotating machines such as motors and generators which rotate at a high speed, and a method for producing the same. To achieve the object, the present invention provides a non-oriented electrical steel sheet comprising in % by mass: 0.06% or less of C; 3.5% or less of Si; from 0.05% or more to 3.0% or less of Mn; 2.5% or less of Al; 0.30% or less of P; 0.04% or less of S; 0.02% or less of N; at least one element selected from the group consisting of Nb, Ti, Zr and Vin the predetermined range; and a balance consisting of Fe and impurities; and having a recrystallized fraction being less than 90%.

Owner:NIPPON STEEL CORP

Poly(ester amide) coating composition for implantable devices

InactiveUS20050271700A1Improve mechanical propertiesImprove surface propertiesSurgeryPharmaceutical containersPercent Diameter StenosisImplanted device

Owner:ABBOTT CARDIOVASCULAR

Process for preparing detergent particles having coating or partial coating layers

InactiveUS7022660B1Improved surface and appearance and flow propertyImprove surface propertiesInorganic/elemental detergent compounding agentsDetergent mixture composition preparationDouble saltWater soluble

A process for preparing a detergent particle having a coating layer of a water-soluble material is provided. The process comprises providing a particle core of a detergent active material and the particle core is then at least partially covered by a particle coating layer of a water soluble coating material including double salt combinations of alkali metal carbonates and sulfates that reduces the surface area of the particle.

Owner:THE PROCTER & GAMBLE COMPANY

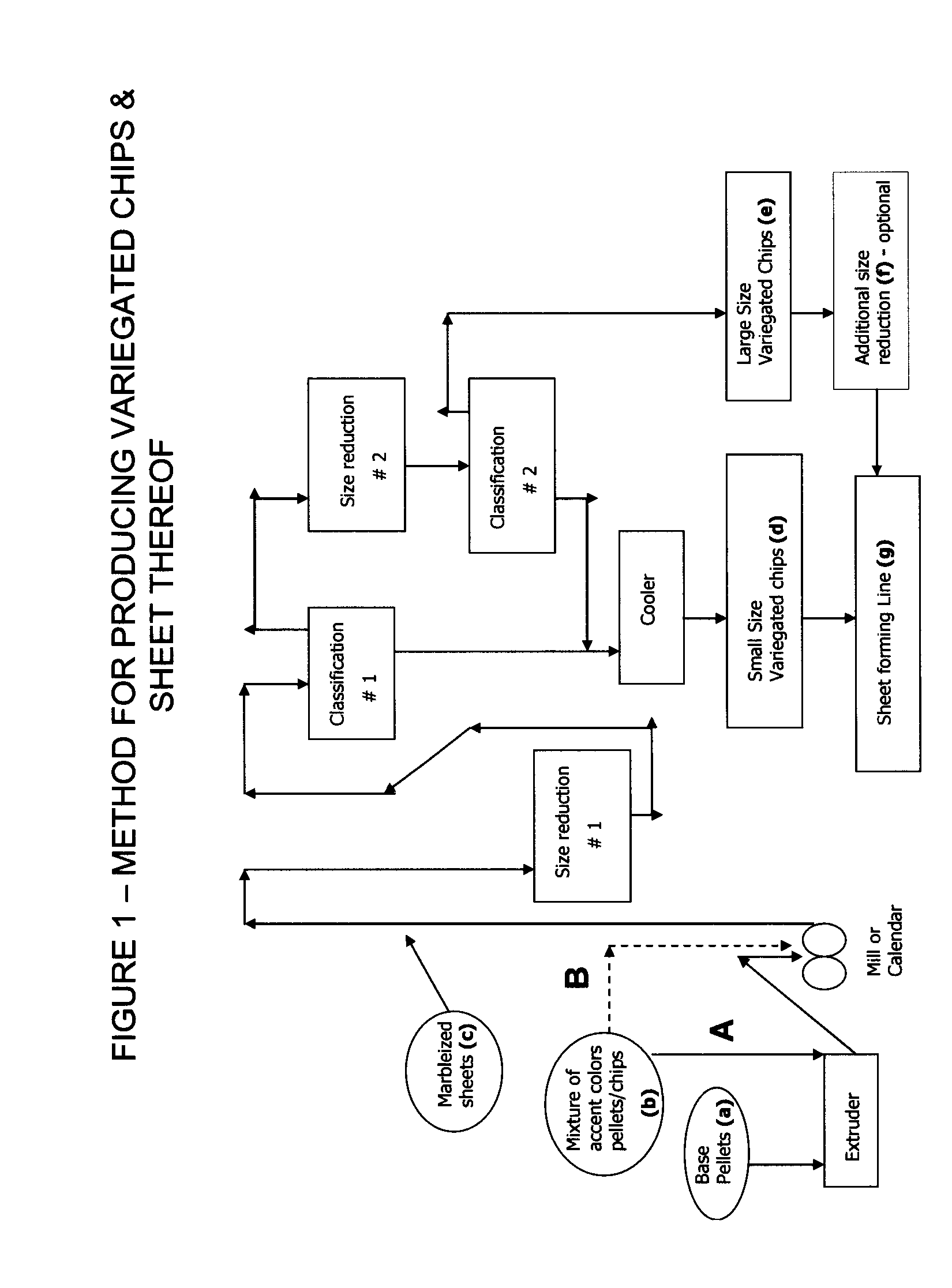

Floor Covering Composition Containing Renewable Polymer

ActiveUS20110305886A1Improve performanceReduce needAntifouling/underwater paintsFilm/foil adhesivesPolyolefinChemistry

A composition is described that includes at least one polyolefin, at least one thermoplastic bio-resin derived from starch or soy or both, and at least one compatibilizer having at least one polyolefin and at least one polar group. Surface coverings and floor coverings, such as laminated floor coverings, having the composition, are also described.

Owner:MANNINGTON MILLS

Organic silicon modified aqueous polyurethane

InactiveCN1854165AImprove water resistanceFeel goodFibre treatmentPolyureas/polyurethane adhesivesWater basedCross-link

An organic silicon modified water-based polyurethane and its production are disclosed.The polyurethane consists of low-polymer polybasic alcohol, vulcabond and chain extender. The production is carried out by dispersing pre-polymer in water, adding ammonia silane coupling agent into system, synthesizing pre-polymer, reacting amine base with residual vulcabond base, chain extending for pre-polymer while hydrolytic condensation polymerizing, cross-linked reacting and obtaining final product. It has better water resistance and handle, less surface performance and wider temperature range. It can be used for pigment, leather finishing agent and adhesive.

Owner:广州宏昌胶粘带厂

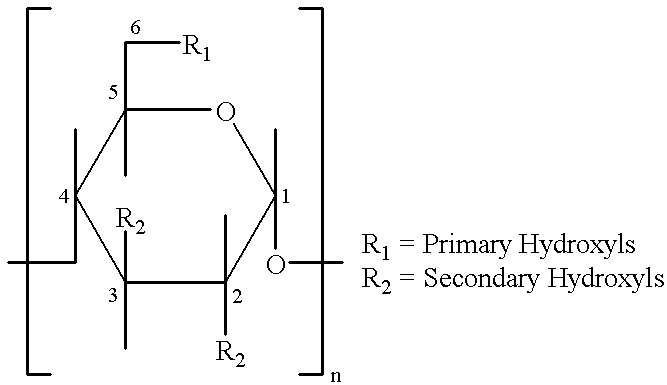

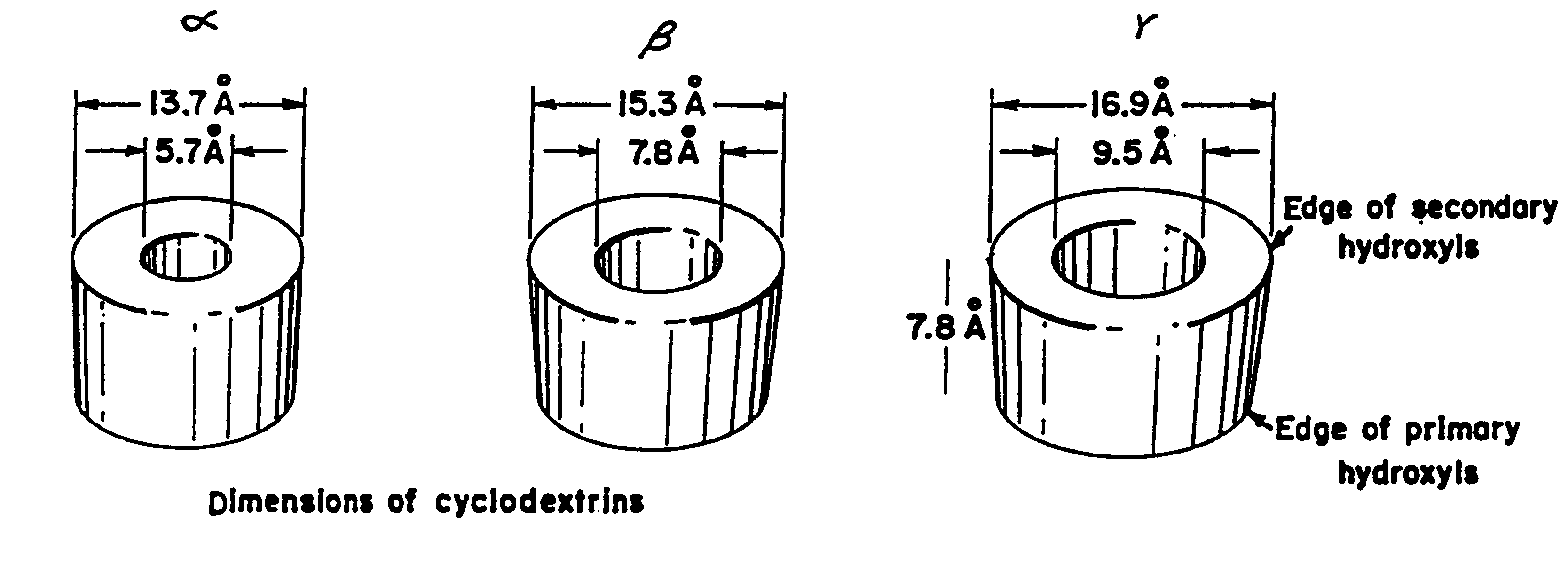

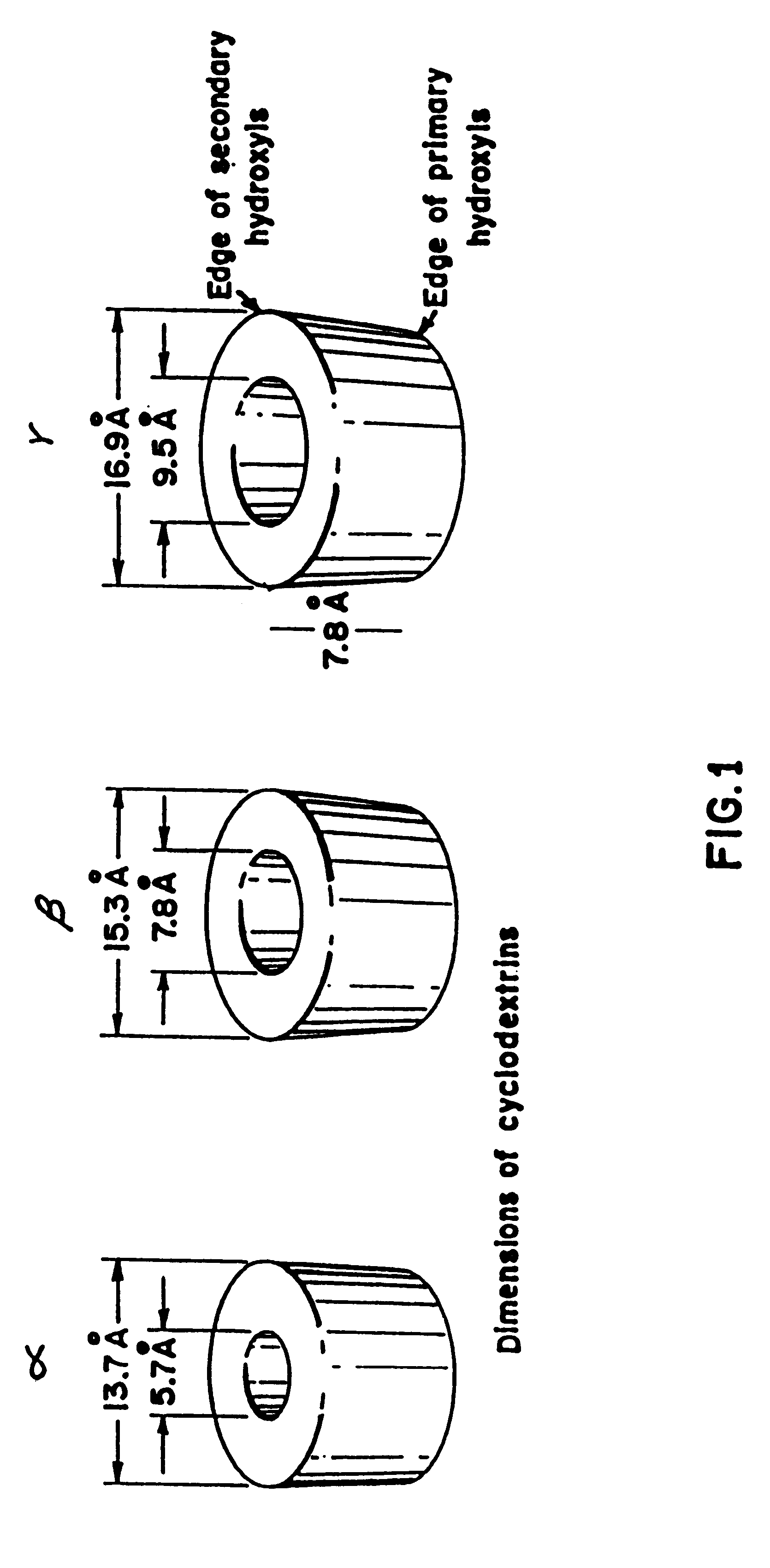

Barrier material comprising a thermoplastic and a compatible cyclodextrin derivative

InactiveUS6218013B1Easy to derivatizeImprove surface propertiesSemi-permeable membranesFlexible coversThermoplasticMoisture

A barrier film composition can comprise a thermoplastic web comprising a thermoplastic polymer and a dispersed cyclodextrin composition having substituents that compatibilize the cyclodextrin in the film. The thermoplastic / cyclodextrin film obtains substantial barrier properties from the interaction between the substituted cyclodextrin in the film material with a permeant. The substituents on the cyclodextrin molecule causes the cyclodextrin to be dispersible and stable in the film material resulting in an extrudable thermoplastic. Such materials can be used as a single layer film material, a multilayer film material which can be coated or uncoated and can be used in structural materials wherein the thermoplastic is of substantial thickness resulting in structural stiffness. The cooperation between the cyclodextrin and the thermoplastic polymer provides barrier properties to a web wherein a permeant can be complexed or entrapped by the cyclodextrin compound and held within the film preventing the permeant from passing through the film into the interior of a film, an enclosure or container. The permeant can comprise a variety of well known materials such as moisture, aliphatic or aromatic hydrocarbons, monomer materials, off flavors, toxic compounds etc.

Owner:CELLRESIN TECH

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

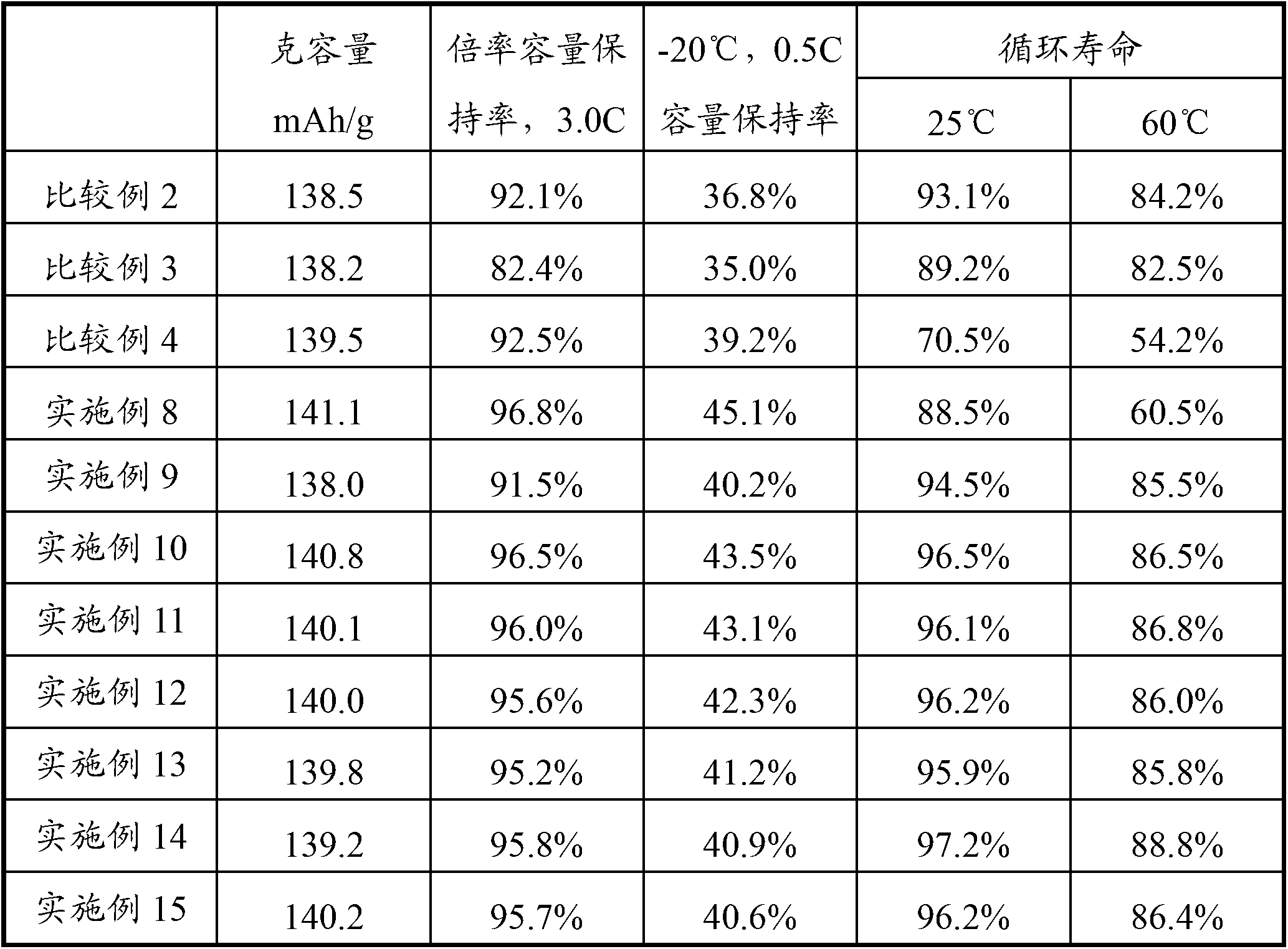

Lithium-ion secondary battery and electrolyte thereof

InactiveCN103078141AFacilitated DiffusionImproved magnification performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesMethyl carbonateCarbonate

The invention discloses a lithium-ion secondary battery and an electrolyte thereof. The electrolyte comprises a solvent, lithium salt and a film forming additive, wherein the solvent comprises a first solvent and a second solvent; the first solvent comprises linear carboxylic ester and ethylene carbonate; the second solvent is one or more of ethyl methyl carbonate, diethyl carbonate, dimethyl carbonate and propylene carbonate; and the film forming additive is one or more of fluoroethylene carbonate, vinylene carbonate, 1,3-propane suhone, succinonitrile, adiponitrile, lithium bis(oxalato)borate, and lithium oxalyldifluoroborate. Due to the collocation of linear carboxylic ester and ethylene carbonate, a solvent system with a higher dielectric constant and low viscosity is obtained; the film forming additive improves poor compatibility between linear carboxylic ester and graphite; and finally the lithium-ion secondary battery adopting the electrolyte presents high-power discharge capacity, excellent high-temperature cycling stability and low-temperature charge and discharge properties.

Owner:NINGDE AMPEREX TECH

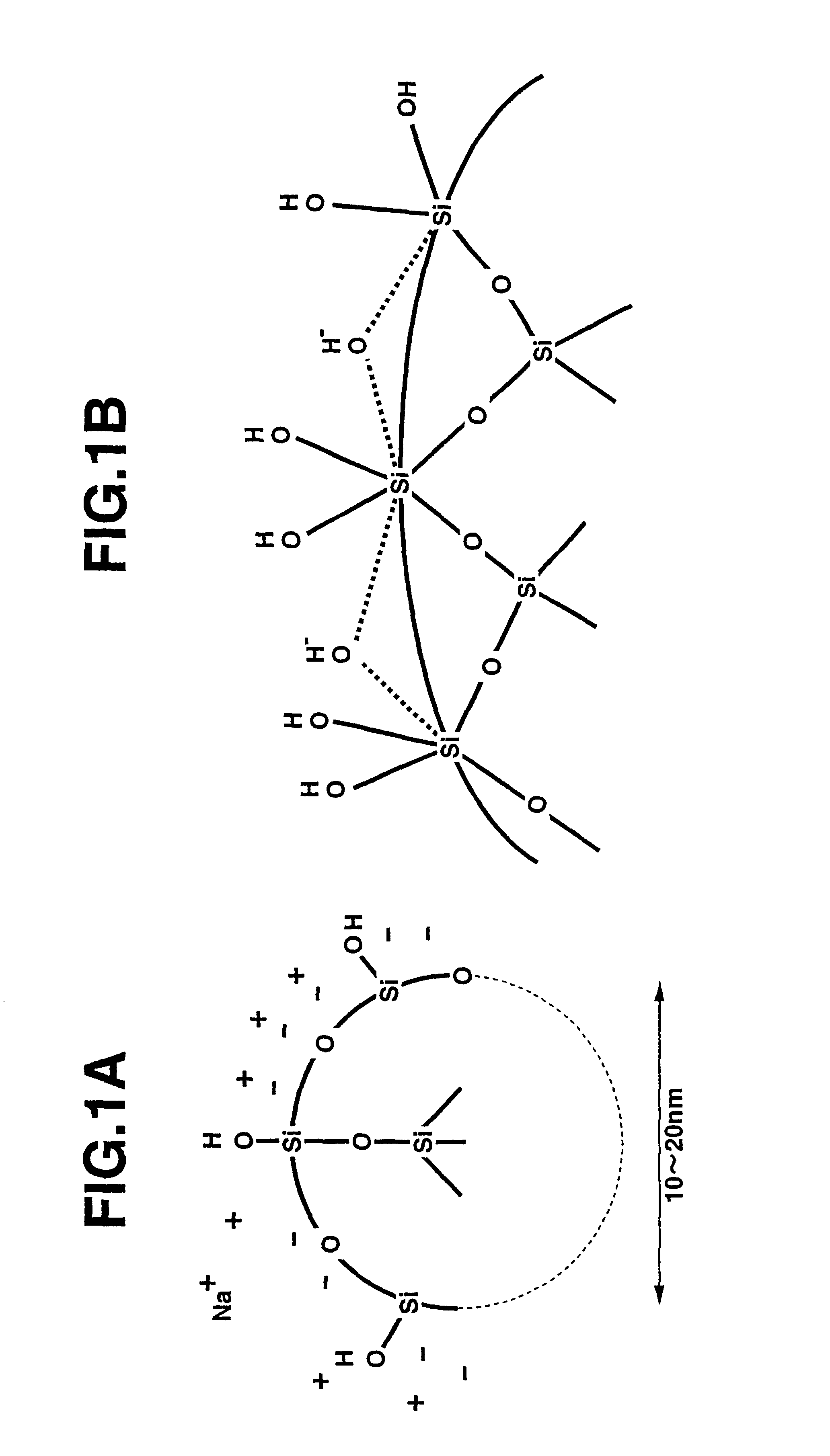

Exhaust gas purifying catalyst and method of producing same

InactiveUS6589901B2Improve heat resistanceReduce stickingInternal combustion piston enginesMolecular sieve catalystsColloidal silicaColloid

An exhaust gas purifying catalyst for exhaust gas discharged from an automotive internal combustion engine. The catalyst comprises a substrate over which a hydrocarbons adsorbing material layer is formed as a lower layer to absorb hydrocarbons contained in exhaust gas. The hydrocarbons adsorbing material layer contains zeolite and colloidal silica which has undergone firing. The colloidal silica is in a chain-like form and / or a spherical form before and after the firing. Additionally, a catalyst component layer is formed as an upper layer over the hydrocarbons adsorbing material layer. The catalyst component layer contains a catalyst metal.

Owner:NISSAN MOTOR CO LTD

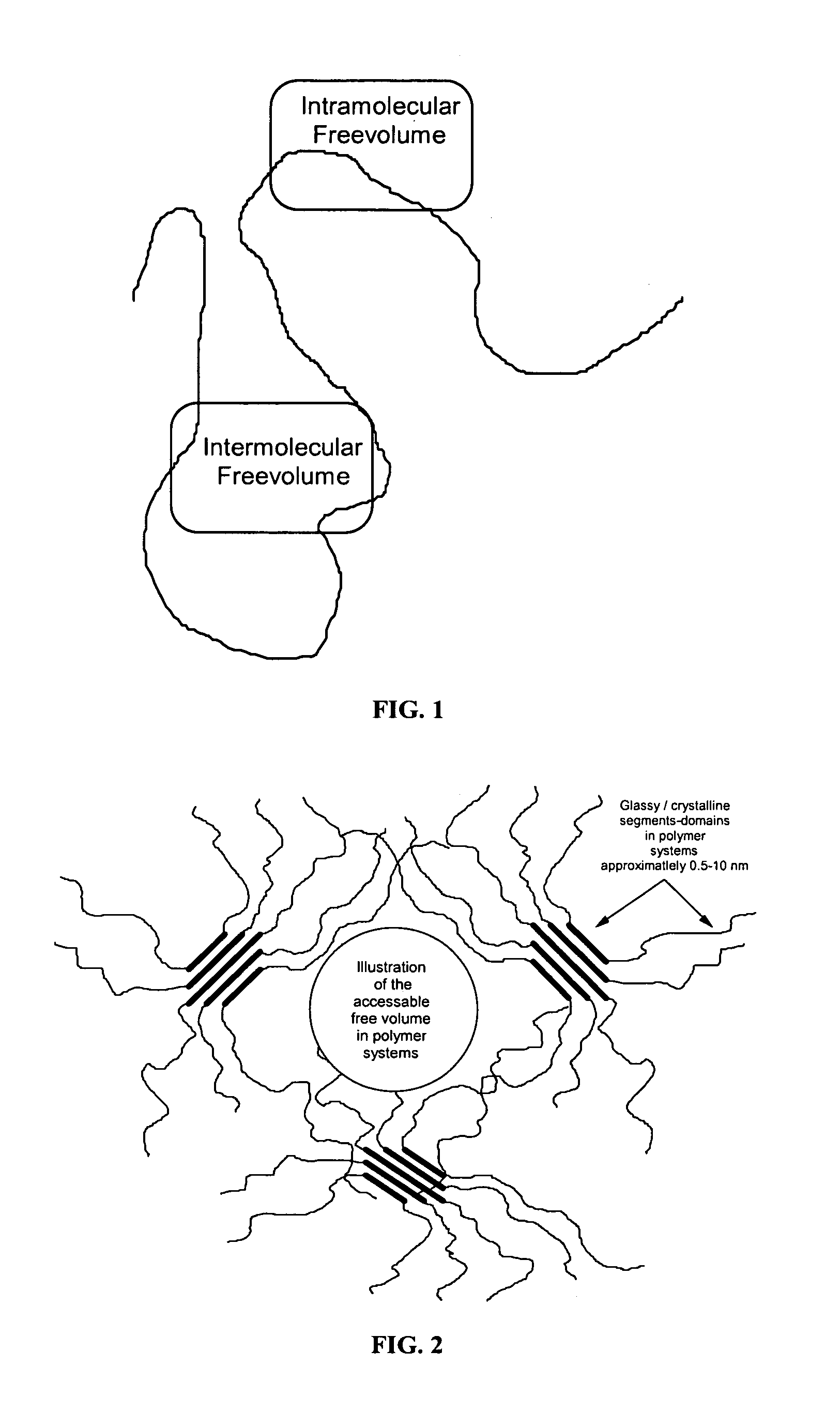

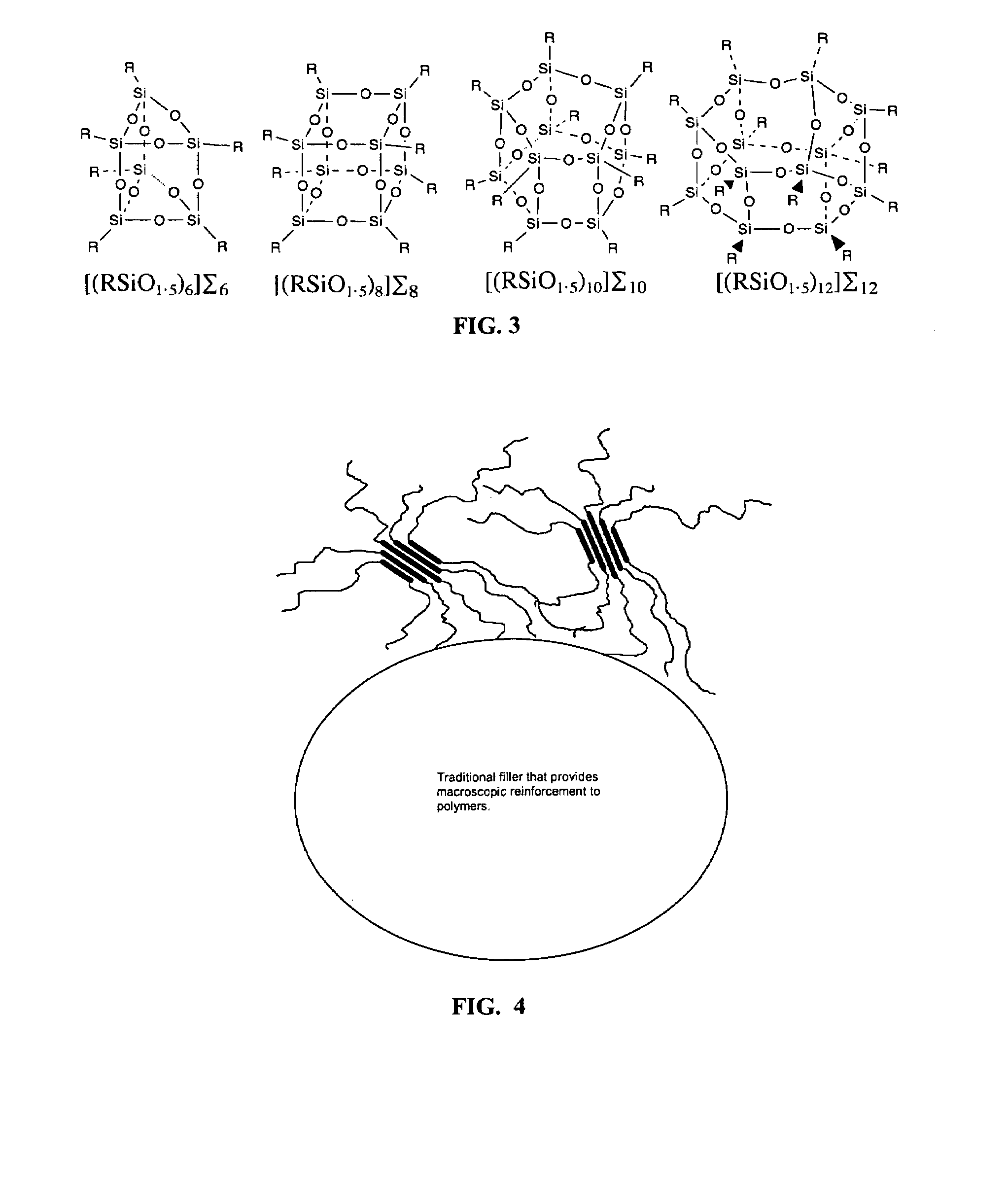

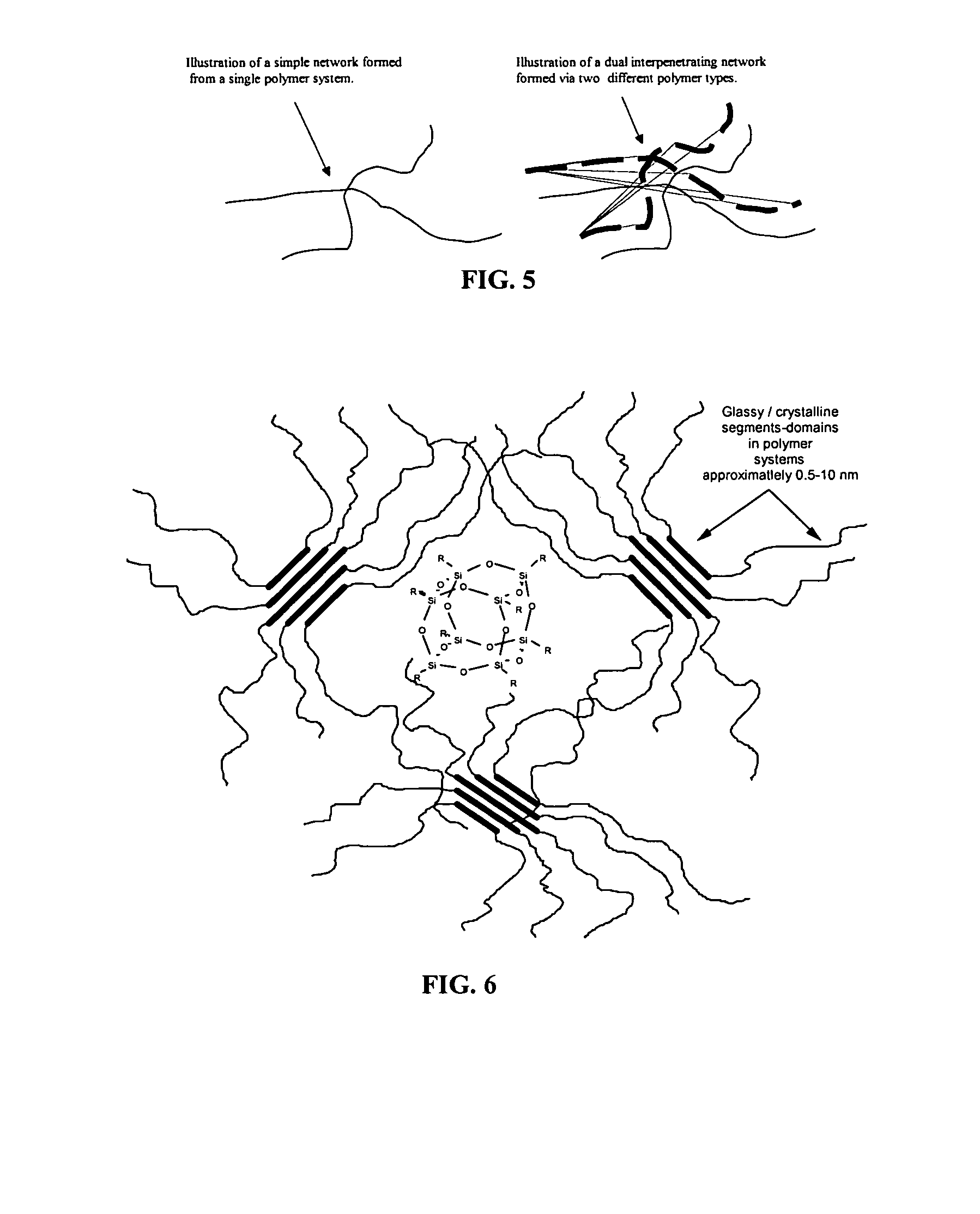

Nanostructured chemicals as alloying agents in fluorinated polymers

InactiveUS7193015B1Reduce melt viscosityLow dielectric constantMaterial nanotechnologyMolecular levelCompression set

A method of using nanostructured chemicals as alloying agents for the reinforcement of flouropolymer microstructures, including polymer coils, domains, chains, and segments, at the molecular level. Because of their tailorable compatibility with fluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending processes. Properties most favorably improved are time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and abrasion resistance. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, fire resistance, and improved oxygen permeability. These improved properties may be useful in a number of applications, including space-survivable materials and creep resistant seals and gaskets. Improved surface properties may be useful for applications such as anti-icing or non-wetting surfaces or as low friction surfaces.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

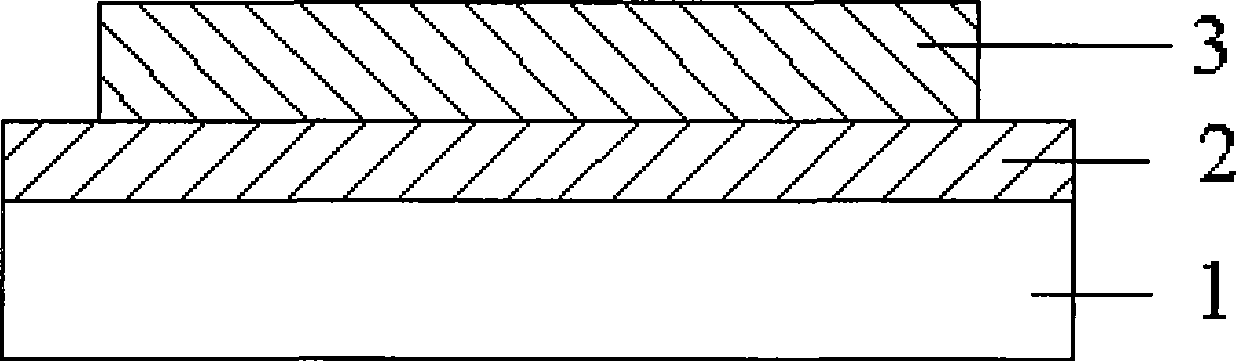

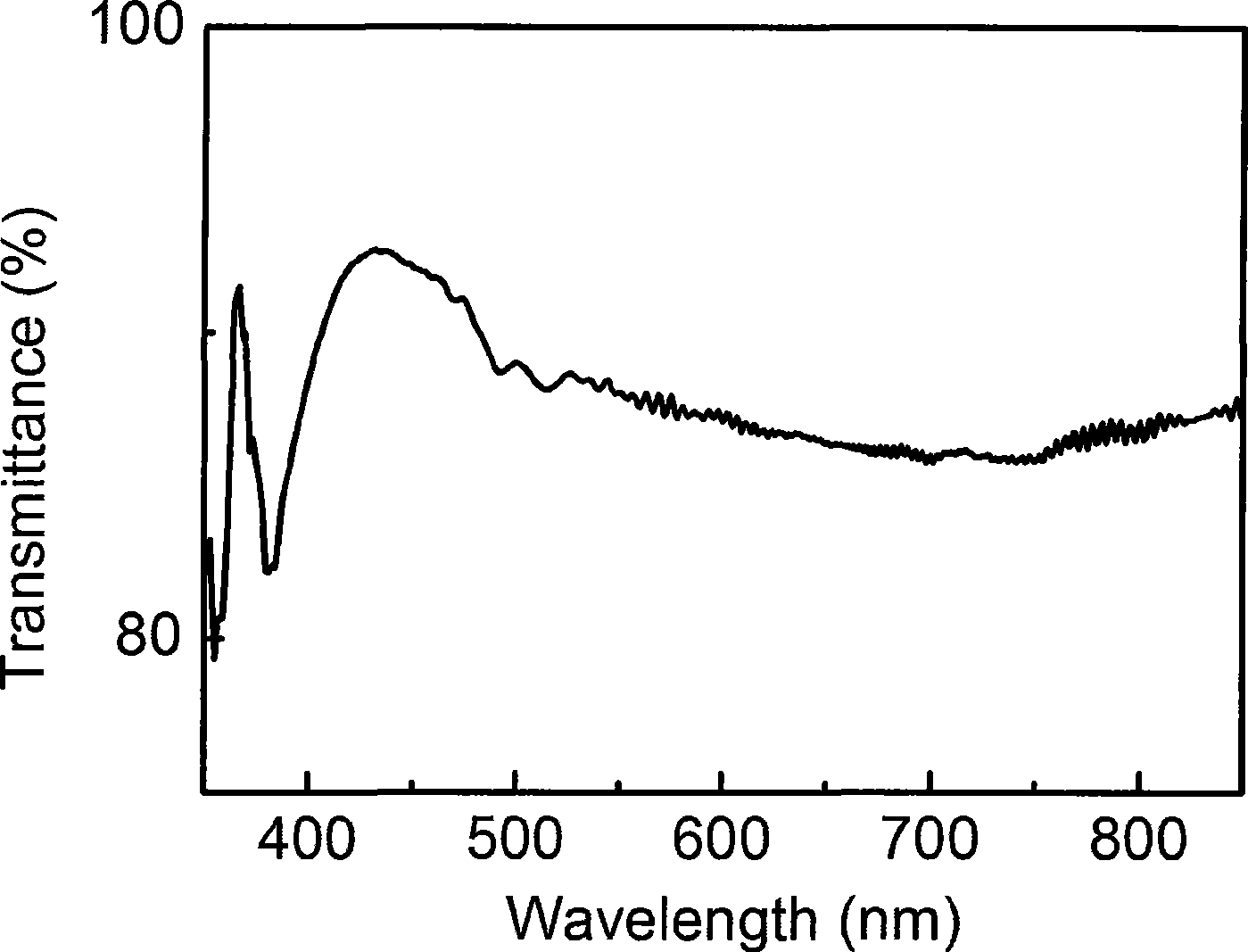

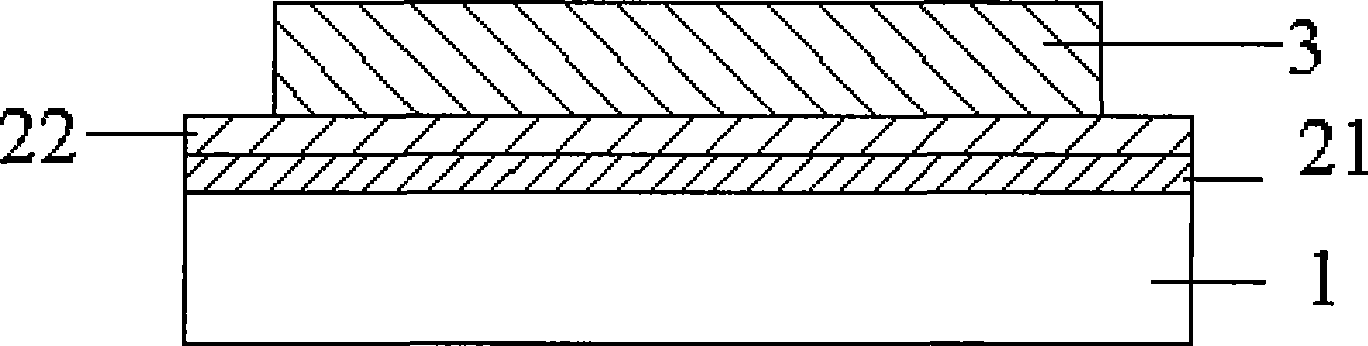

Substrate for flexible organic optoelectronic device and preparation method thereof

InactiveCN101465409AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingUV curingAdhesive

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; and the material of the bonding layer is an adhesive with a double-curing system comprising UV curing-thermal curing or UV curing-microwave curing or UV curing-anaerobic curing or UV curing-electron beam curing. The substrate solves the problem of poor adhesion between the deposited conductive thin film and the substrate due to low surface energy of the flexible substrate and improves the barrier properties of the substrate on water and oxygen, and also achieves good smoothing effect on the surface of the substrate; besides, the preparation method is simple and effective, which can significantly reduce the substrate production cost and process difficulty and increase the substrate yield rate in the etching process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Olefin based compositions and floor coverings containing the same

ActiveUS20080206583A1Improve performanceEliminating and decreasing needSynthetic resin layered productsThin material handlingPolyolefinFloor covering

A composition is described that includes at least one compatibilizer having at least one polyolefin and at least one polar group. The composition can include a blend of polymers. Surface coverings and floor coverings, such as laminated floor coverings, having the composition, are also described.

Owner:MANNINGTON MILLS

Low alloy steel resisting CO2 and H2S corrosion

The present invention is one kind of low alloy steel capable of being used in oil well pipe to resist CO2 and H2S corrosion. Chemically, its consists of C 0.01-0.30 wt%, Si 0.10-1.0 wt%, Mn 0.10-2.0, Cr 0.50-3.0 wt%, Mo 0.01-1.0 wt%, Ce 0.01-0.25 wt%, V 0.005-0.1 wt%, Cu 0.05-1.0 wt%, Al 0.01-0.10 wt% and small amount of Nb if necessary, except Fe and inevitable impurity, with impurity elements being less than 0.05 wt%. The alloy steel of the present invention after hardening and tempering has mechanical performance reaching the requirement on API 80 and 90 level steel but obviously improved CO2 and H2S corrosion resistance, and is economic oil well pipe steel with moderate cost.

Owner:BAOSHAN IRON & STEEL CO LTD

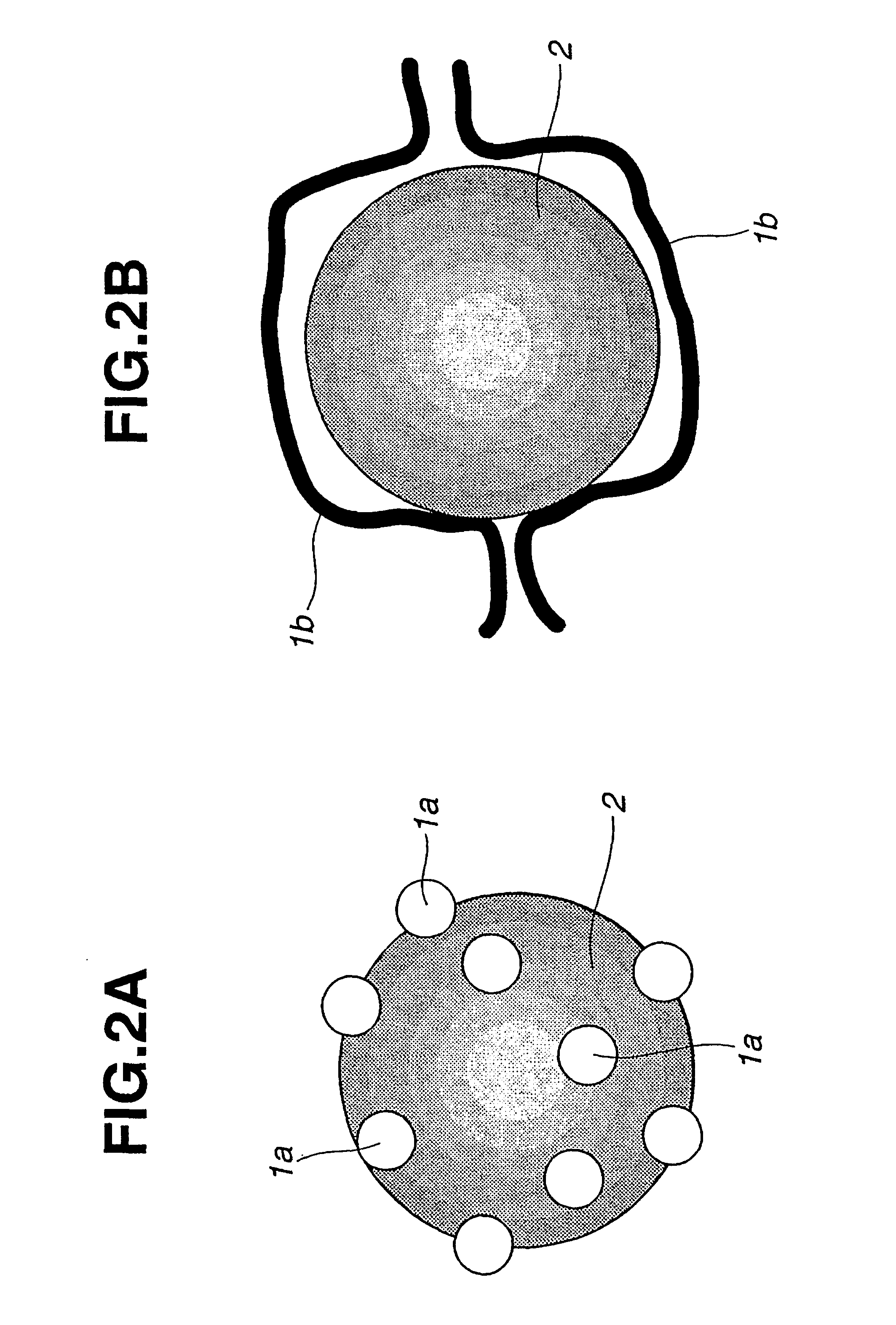

Modified positive electrode material of lithium ion battery and preparation method of modified positive electrode material

InactiveCN102738451AImprove performanceImproved performance characteristicsCell electrodesDischarge efficiencyElectrical conductor

The invention discloses a modified positive electrode material of a lithium ion battery and a preparation method of the modified positive electrode material. The modified positive electrode material is characterized in that the modified positive electrode material is made of a lithium fast ion conductor and a positive electrode material of lithium ion battery at a molar ratio of n:1, wherein n is larger than 0 and not larger than 0.15. The invention also discloses the preparation method of the modified positive electrode material of the lithium ion battery. The modified positive electrode material provided by the invention is improved in conductivity property performance and surface properties, thereby enhancing the specific volume of the lithium ion battery, and improving the charging-discharging efficiency, rate capacity, cycling performance and temperature adaptability of the lithium ion battery.

Owner:HENAN NORMAL UNIV

Microfluid Chip Cleaning

InactiveUS20090230044A1Simplify cleaning procedureSave resourcesOther chemical processesHollow article cleaningMicrofluidic chipMicrostructure

Owner:AGILENT TECH INC

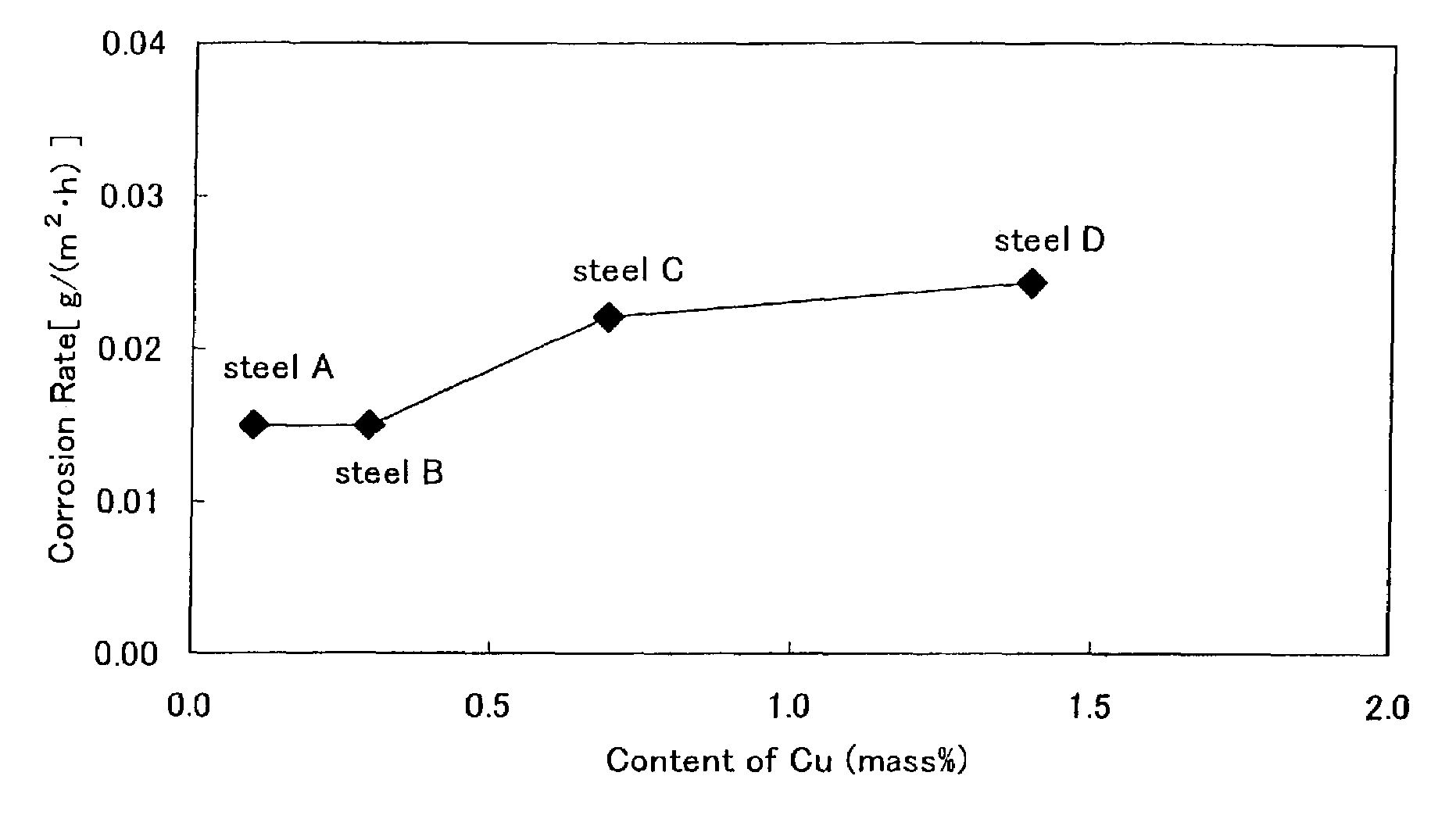

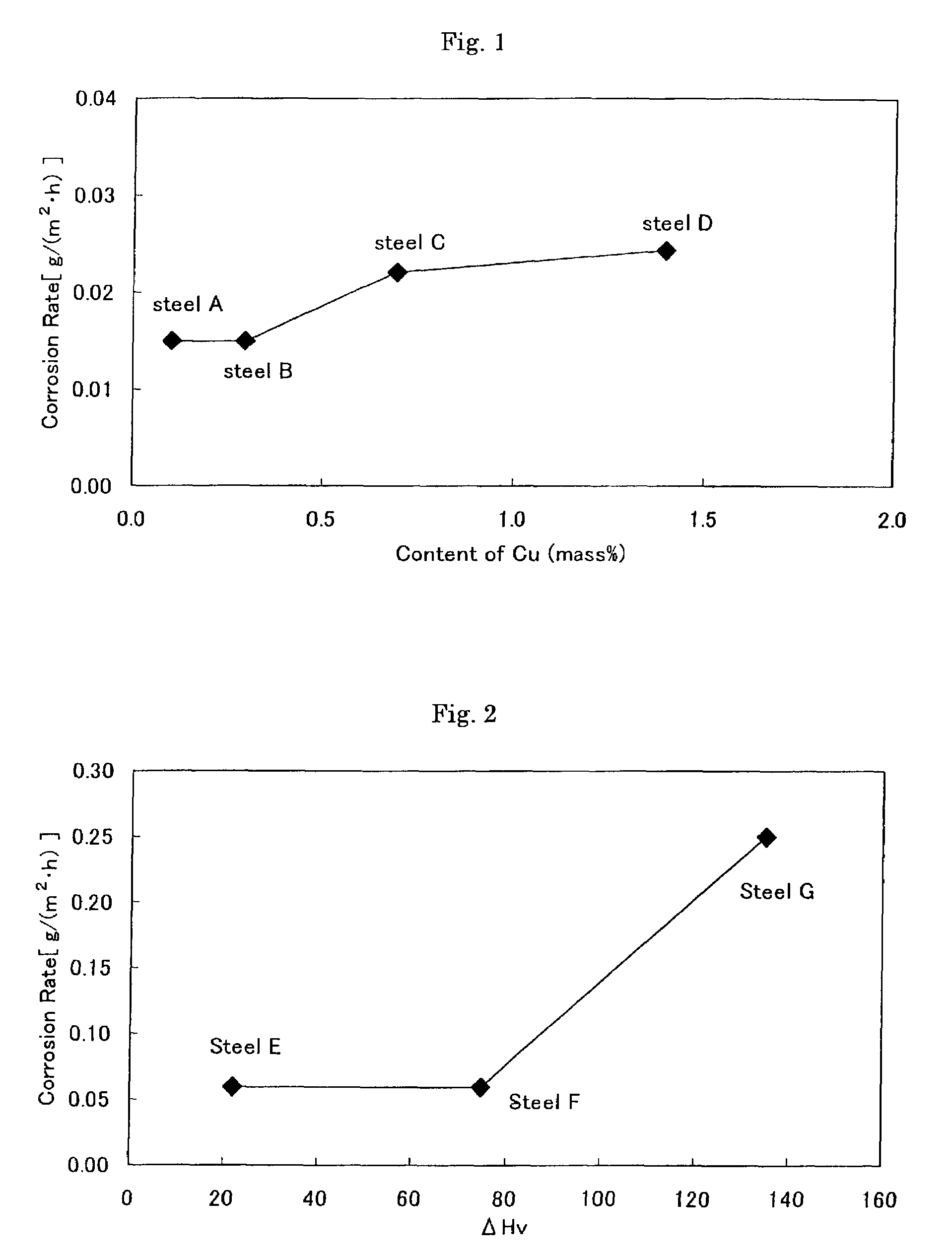

Duplex stainless steel for urea manufacturing plants

ActiveUS7347903B2Superior strength and corrosion resistanceGood surface propertyProductsReagentsUreaCorrosion

A duplex stainless steel for use in urea manufacturing plants, in mass %, consisting of C: 0.03% or less, Si: 0.5% or less, Mn: 2% or less, P: 0.04% or less, S: 0.003% or less, Cr: 26% or more, but less than 28%, Ni: 6-10%, Mo: 0.2-1.7%, W: more than 2%, but no more than 3%, N: more than 0.3%, but no more than 0.4%, with the balance being Fe and impurities, in which the content of Cu as an impurity is not more than 0.3%. The duplex stainless steel may also have Ca, Ce, and B content, and it is desirable that levels of Al and O (oxygen) as an impurities be no more than 0.05% and 0.01% respectively. Further, it is preferable that an increase in the Vickers hardness of the steel should not be more than 80, before and after the solution treated steel is subjected to the heat treatment of 800° C. for 30 minutes and subsequent water cooling. This duplex stainless steel possesses a high corrosion resistance.

Owner:NIPPON STEEL CORP +1

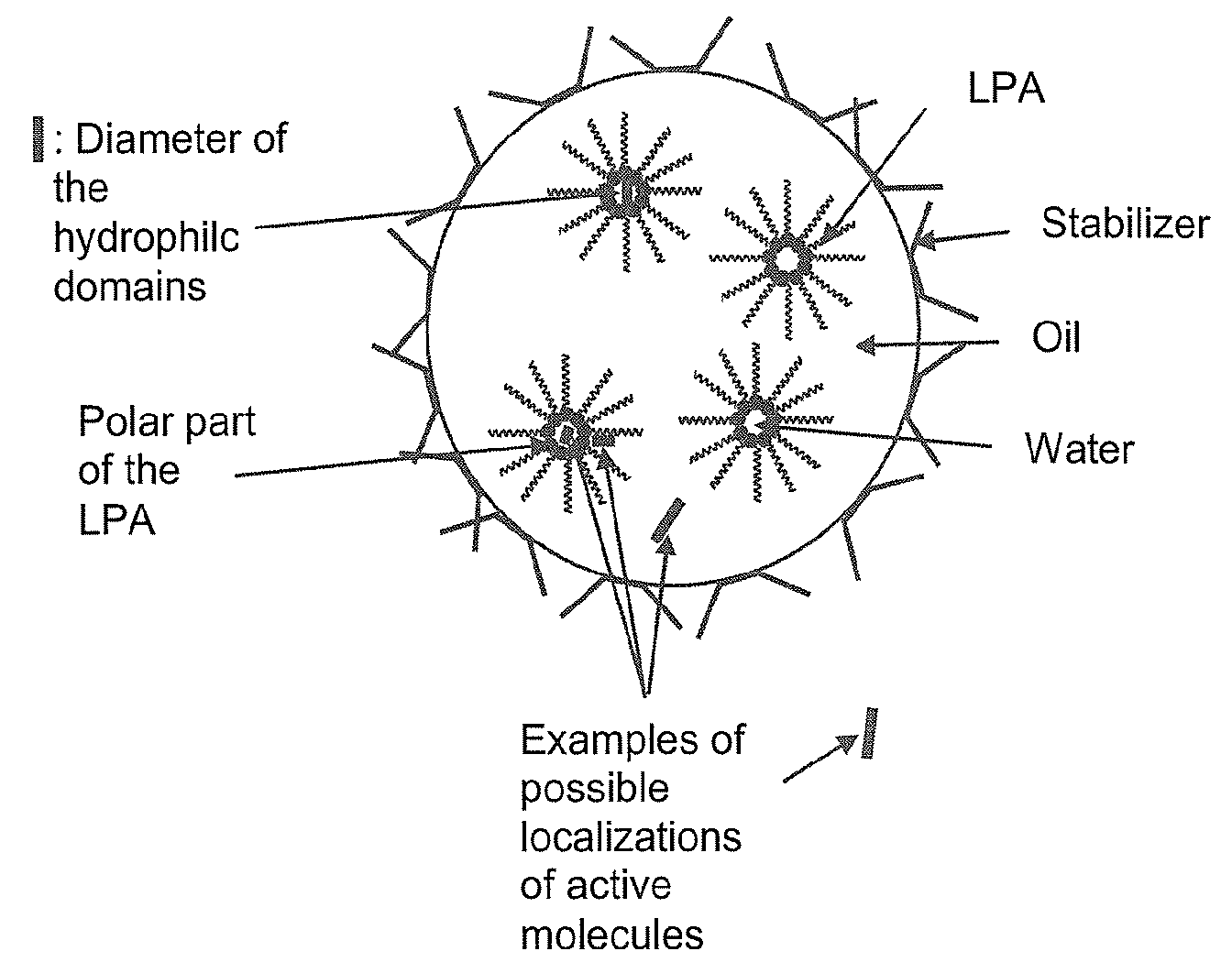

Oil-In-Water Emulsion and Its Use for the Delivery of Functionality

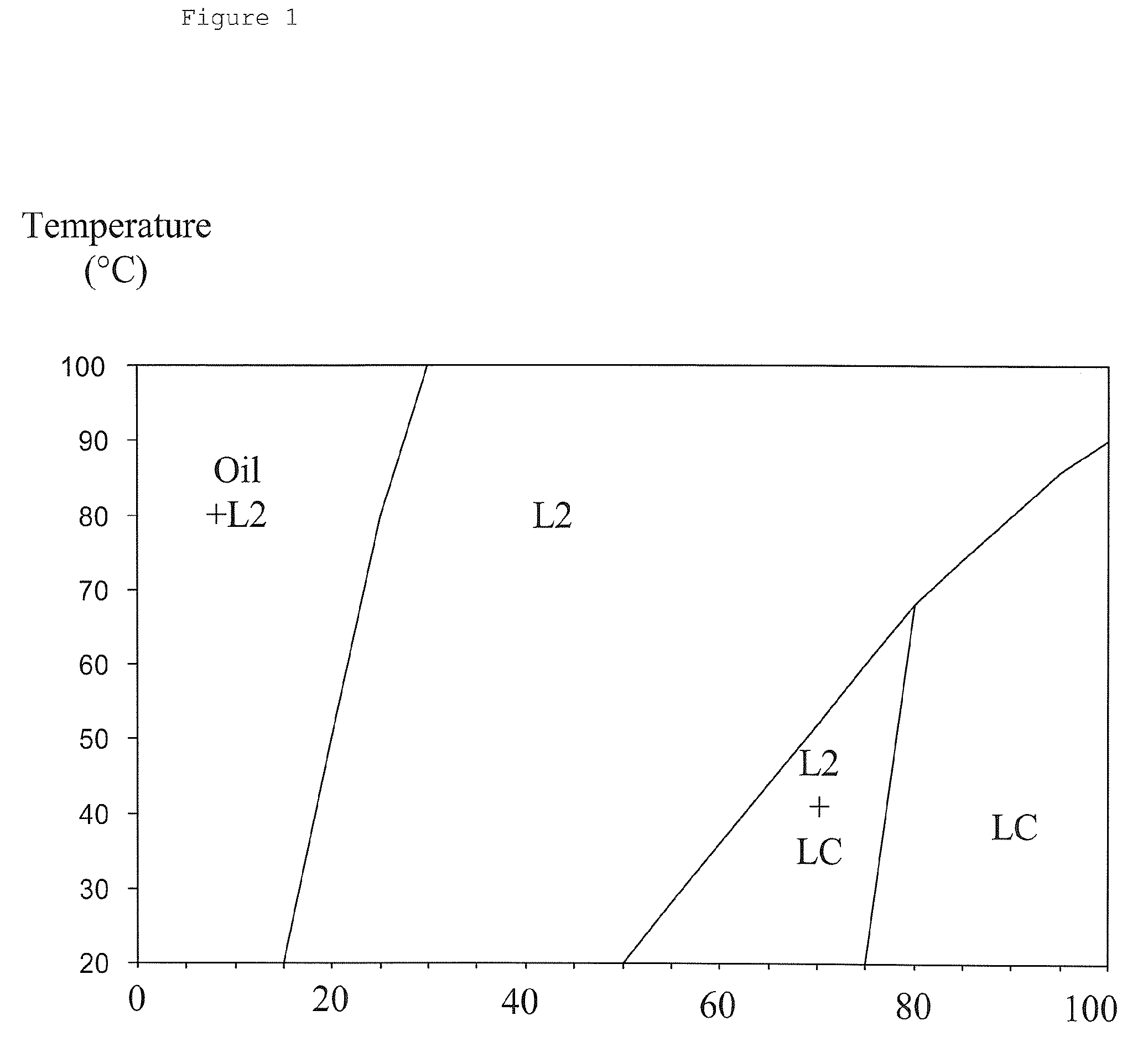

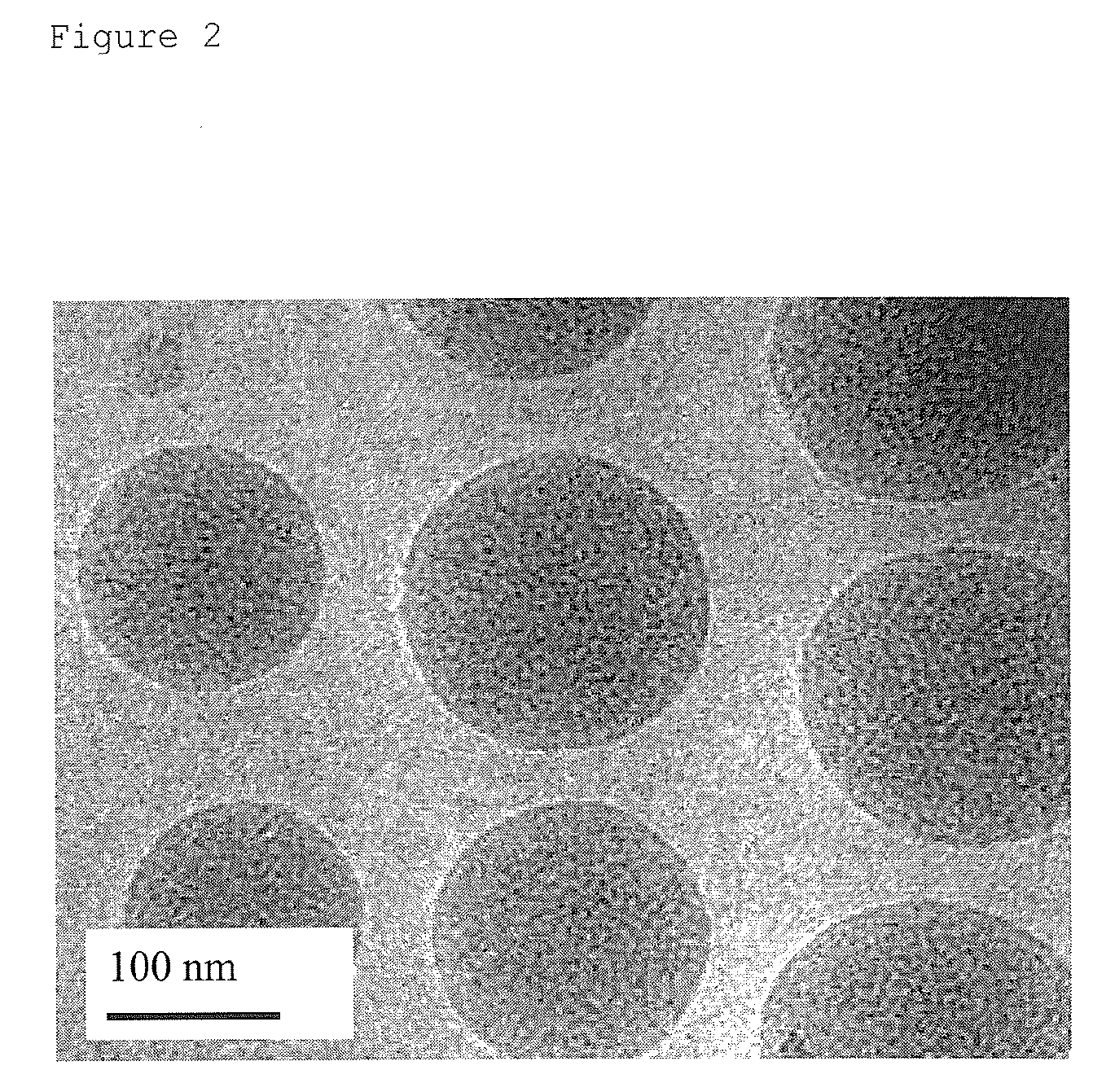

InactiveUS20080255247A1Improve protectionImprove stabilityBiocideCosmetic preparationsMicrometerNanometre

The present invention concerns an oil-in-water emulsion wherein the oil droplets of a diameter in the range of 5 nm to hundreds of micrometers exhibit a nano-sized self-assembled structurization with hydrophilic domains having a diameter size in the range of 0.5 to 200 nm, due to the presence of a lipophilic additive and the oil-in-water emulsion contains an active element being present in the range comprised between 0.00001 and 79% based on the total composition.

Owner:NESTEC SA

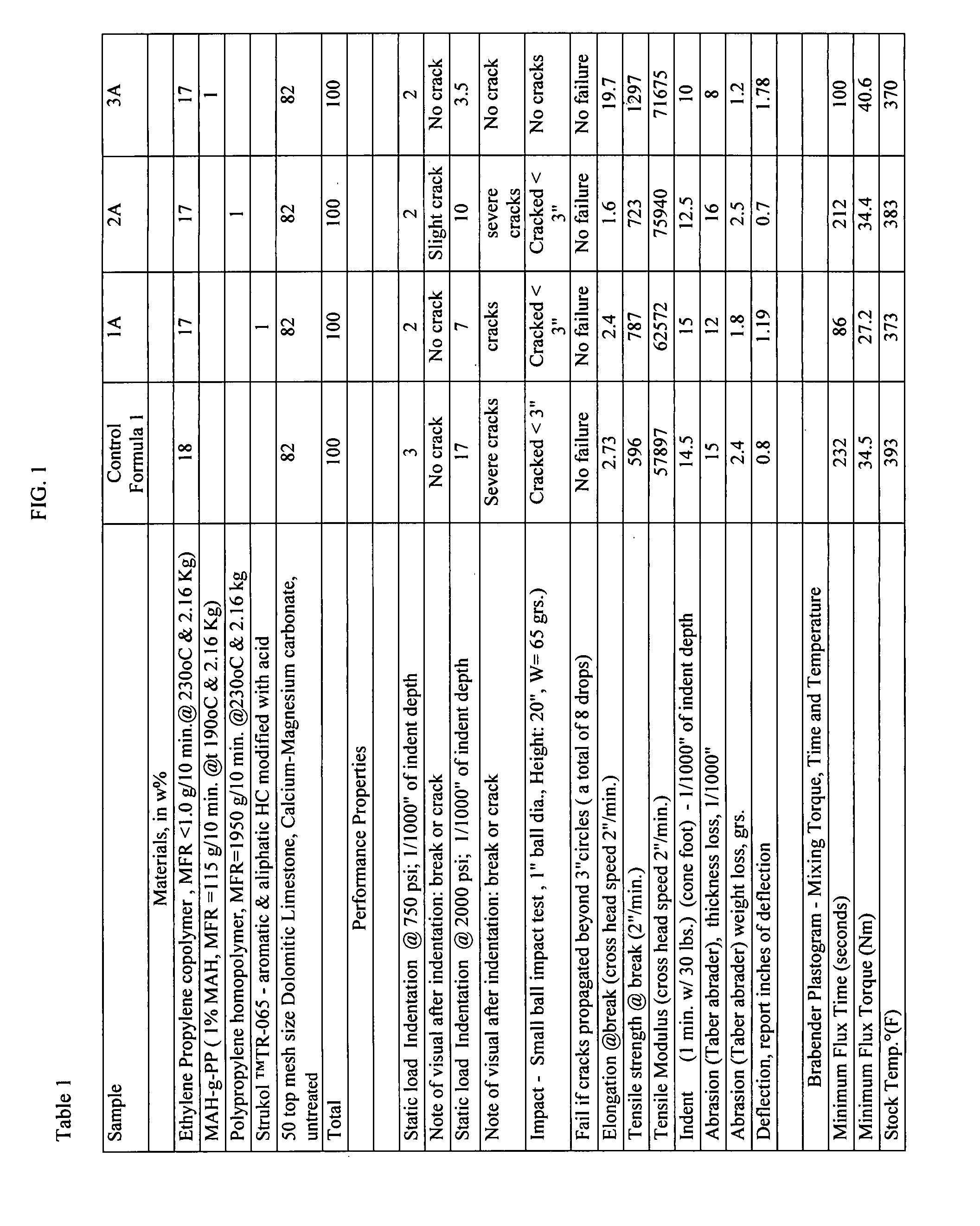

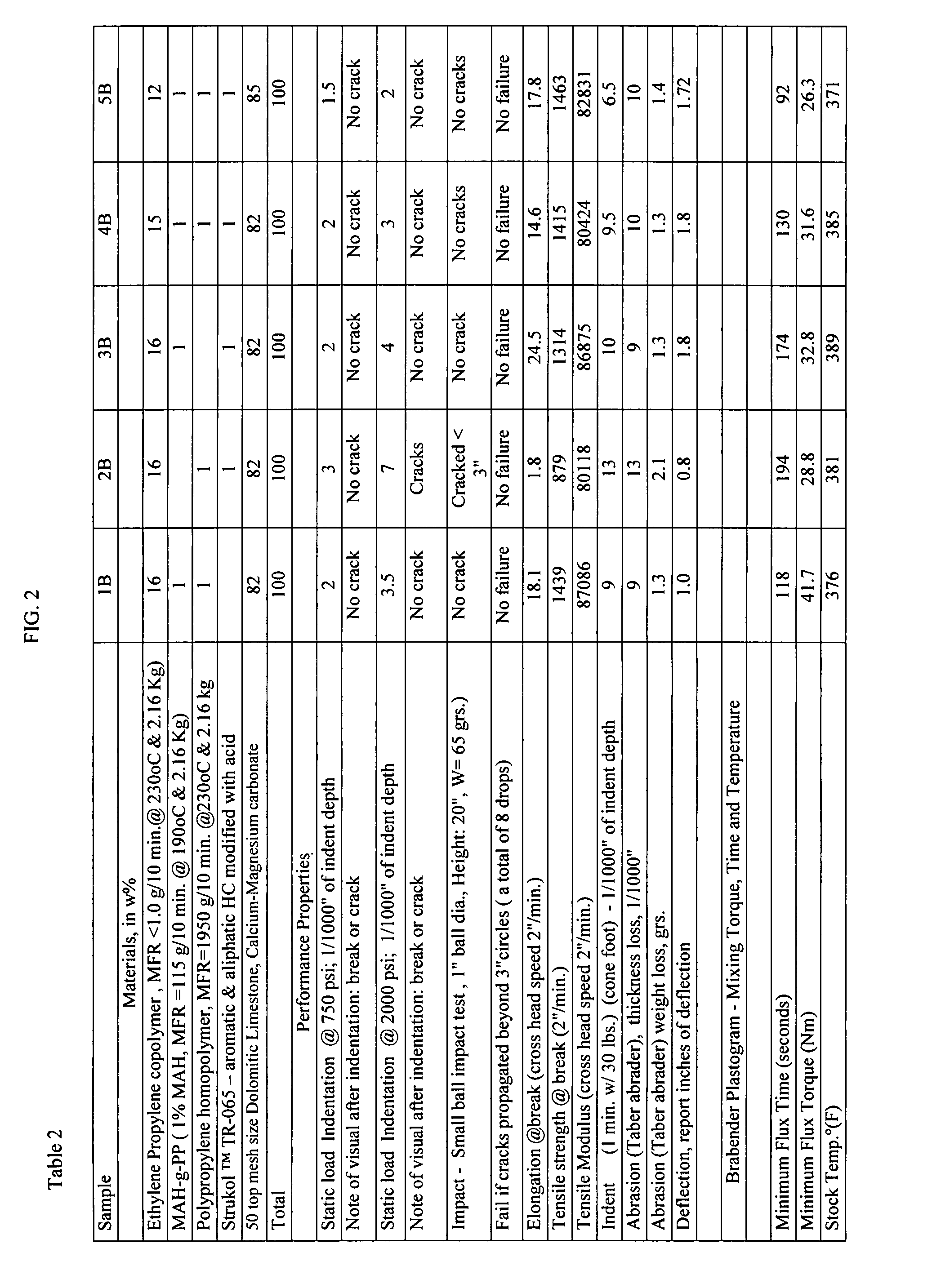

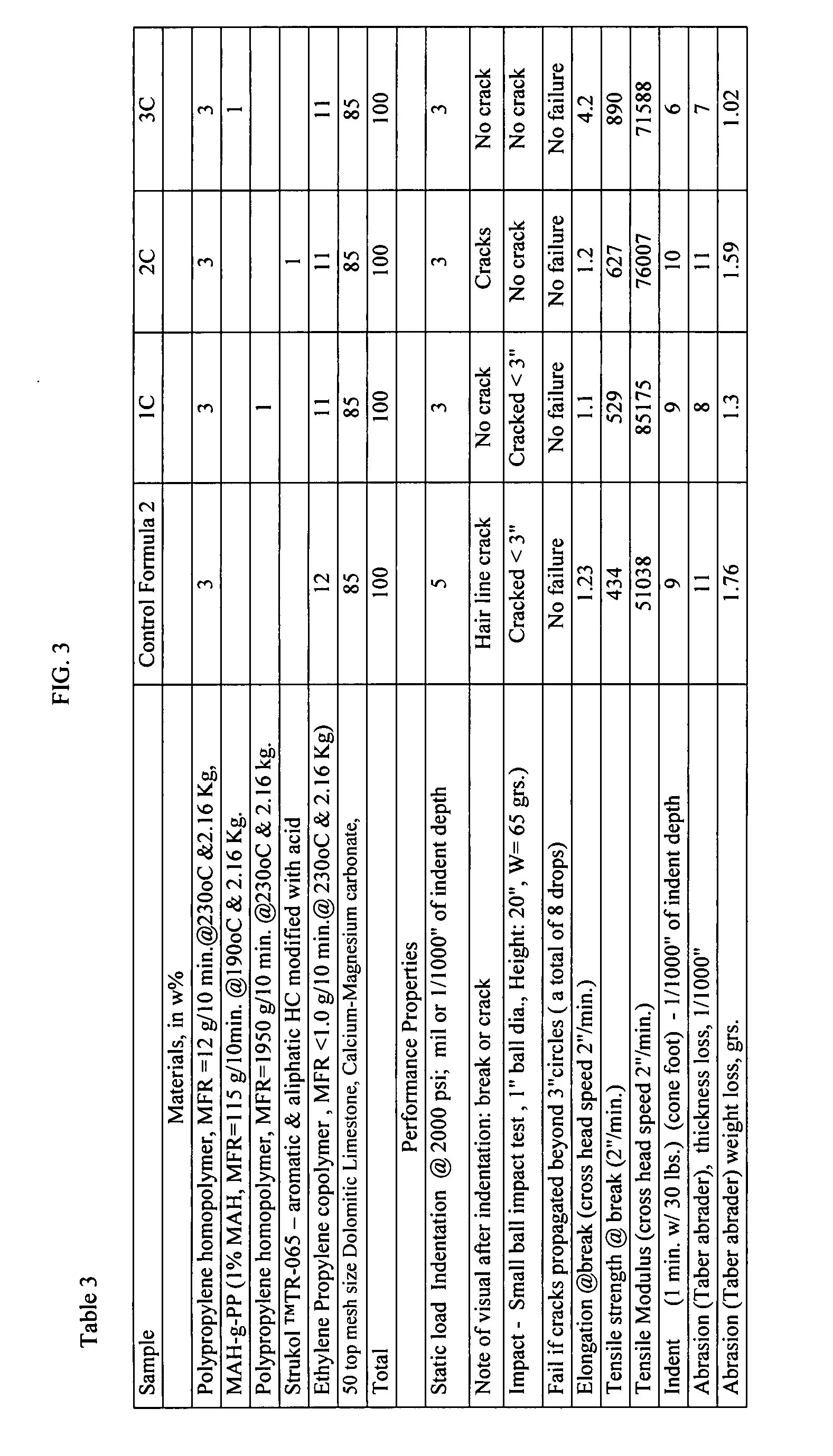

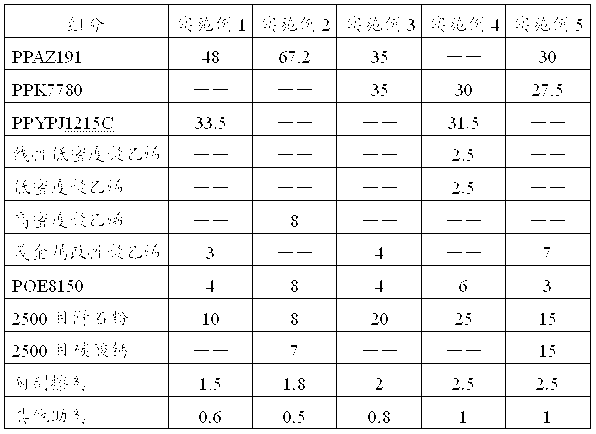

Polypropelene composition with scratch resistant capability and processes for producing same

ActiveCN101173074AImprove surface propertiesReduce coefficient of frictionMaleic anhydridePolypropylene

The invention relates to a polypropylene combination with anti-scoring property. The polypropylene combination is characterized in that the invention consists of the following raw materials by weight part: 40 to 100 parts of polypropylene, 0.5 to 5 parts of maleic anhydride or glyceryl methacrylate copolymer or graft Alpha- olefin copolymer, 0.2 to 2 parts of aliphatics acid amide, 0 to 40 parts of mineral filler, 0 to 20 parts of toughening agent, 0.1 to 1 part of antioxidant agent, and 0.1 to 1 part of retardant agent. The polypropylene combination of the invention is provided with good aging-resistant, flame retardant and anti-scoring properties, and is used for vehicle inner decorating pieces, home appliances shells, etc.

Owner:SHANGHAI KINGFA SCI & TECH +1

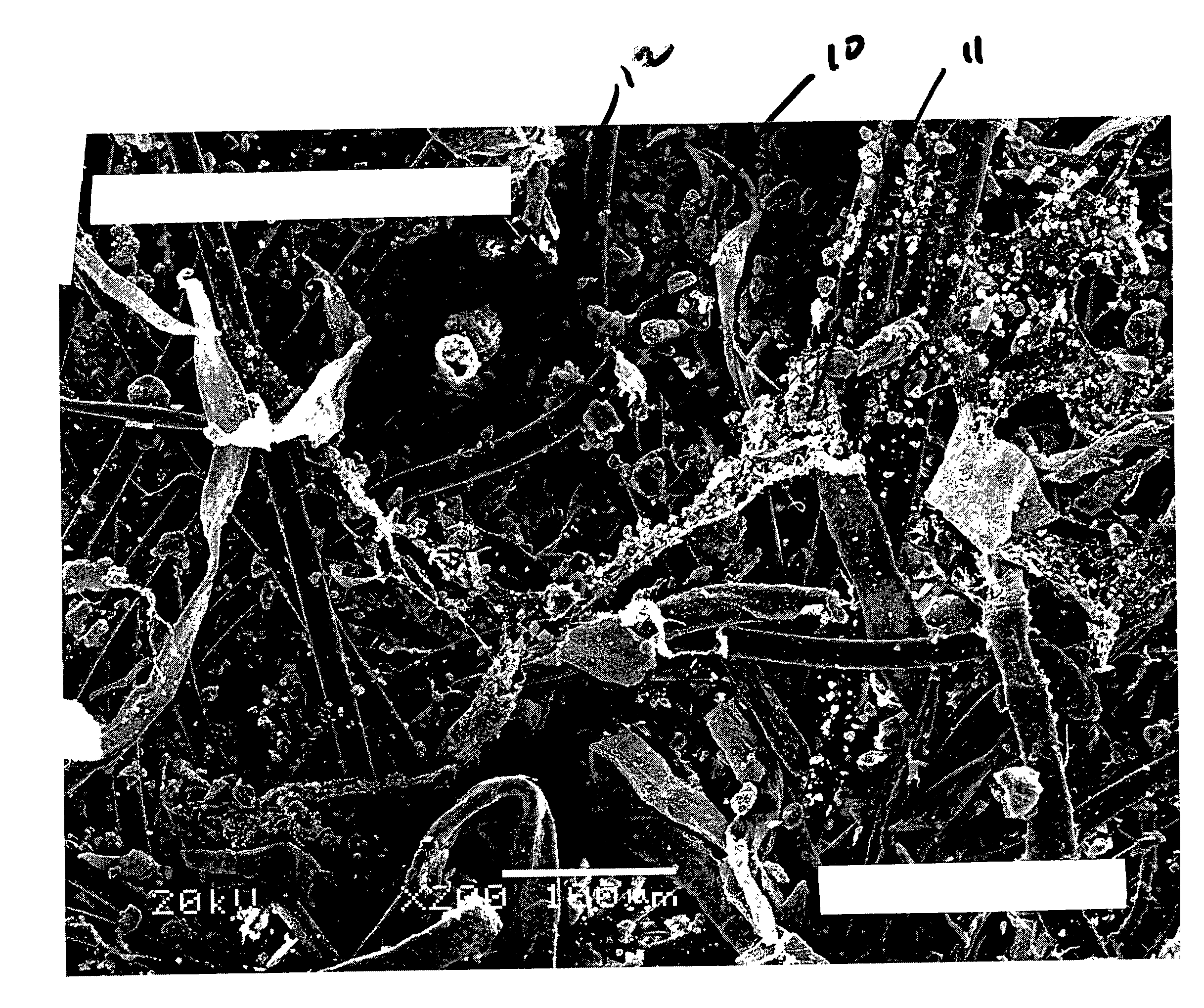

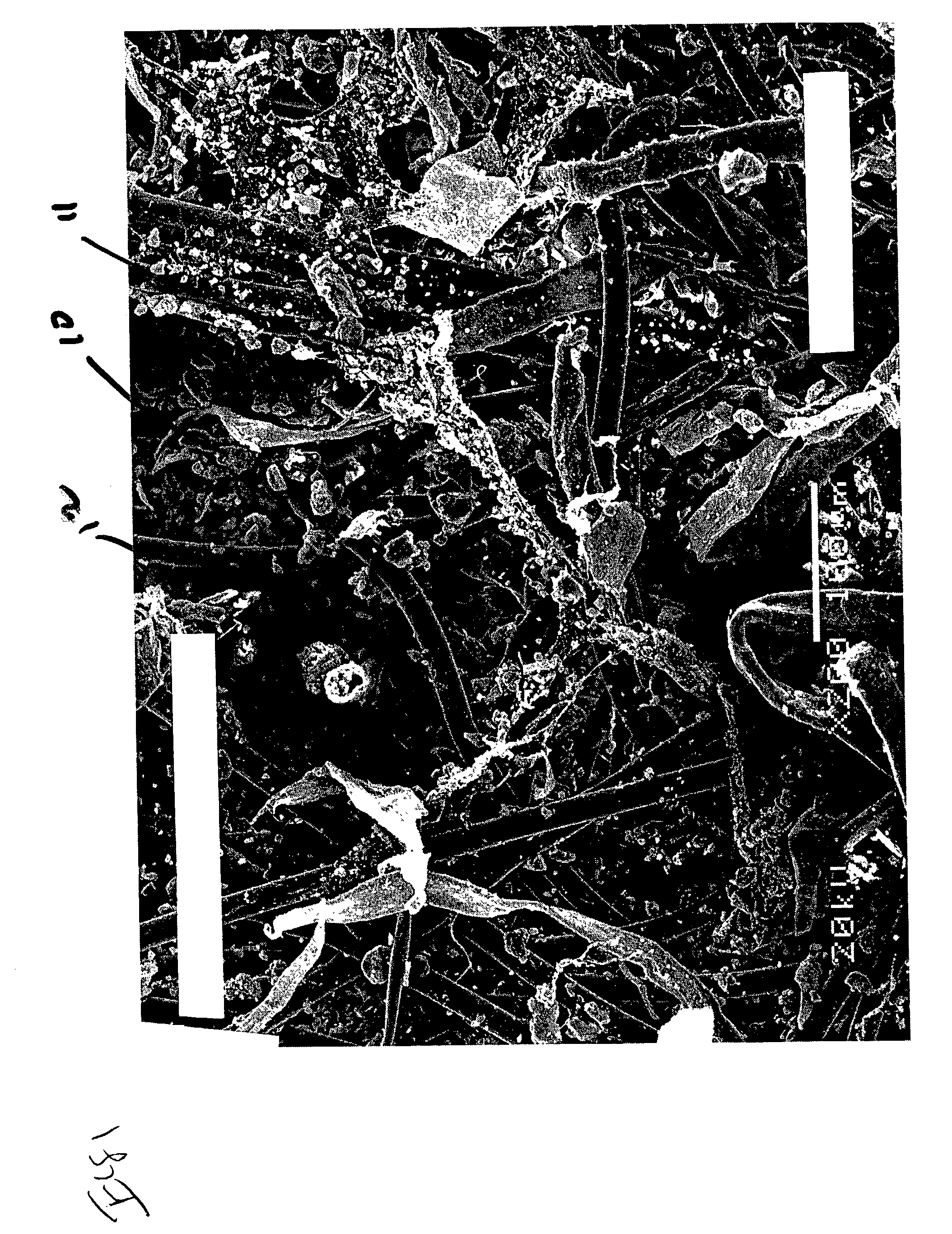

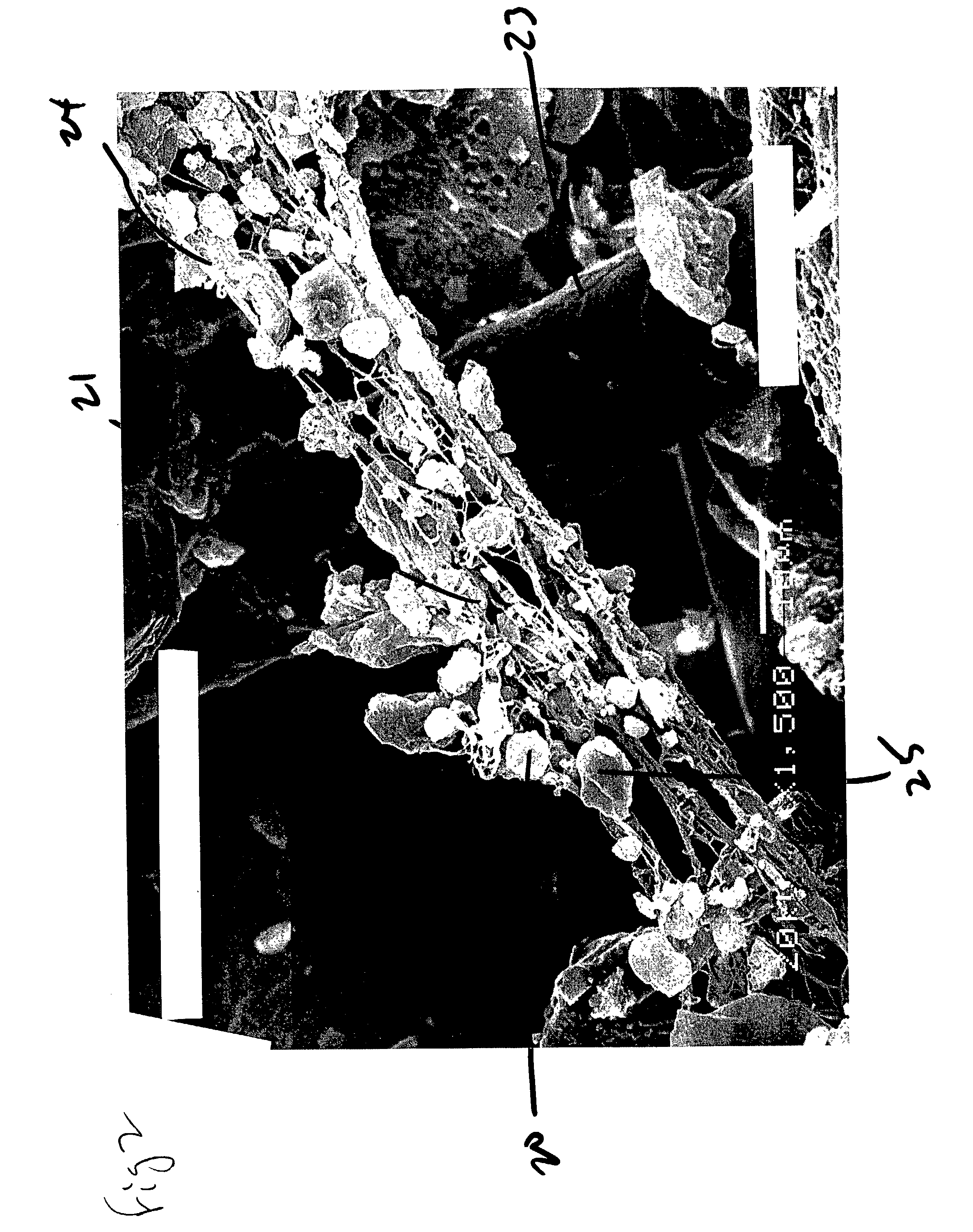

Wipe material with nanofiber layer

InactiveUS20040092185A1Unique flexibilitySmall sizeCleaning machinesCleaning equipmentNanometreFibrous layer

A flexible wipe comprising at least one conformable non-woven layer and at least one adhered nanofiber layer can be used to remove a variety of particulate soils from planar, curved or complex surfaces. The nanofiber layer is configured onto the flexible non-woven in a fashion such that particulate of a broad particle size range is trapped by the nanofiber layer and efficiently removed from the contaminated surface. The nanofiber layer comprises a web of spun fibers that can incorporate and trap soil particles for efficient soil removal.

Owner:DONALDSON CO INC

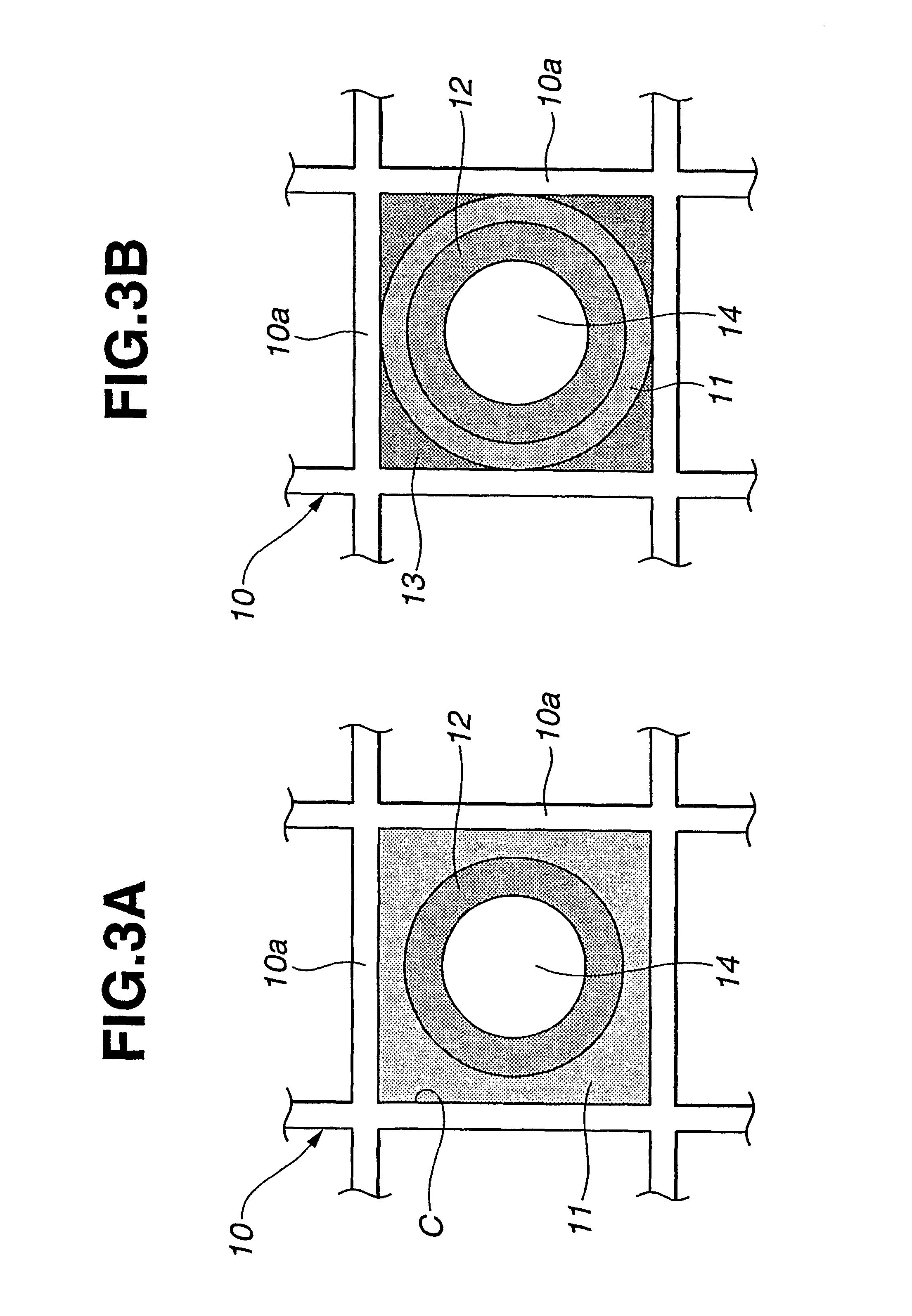

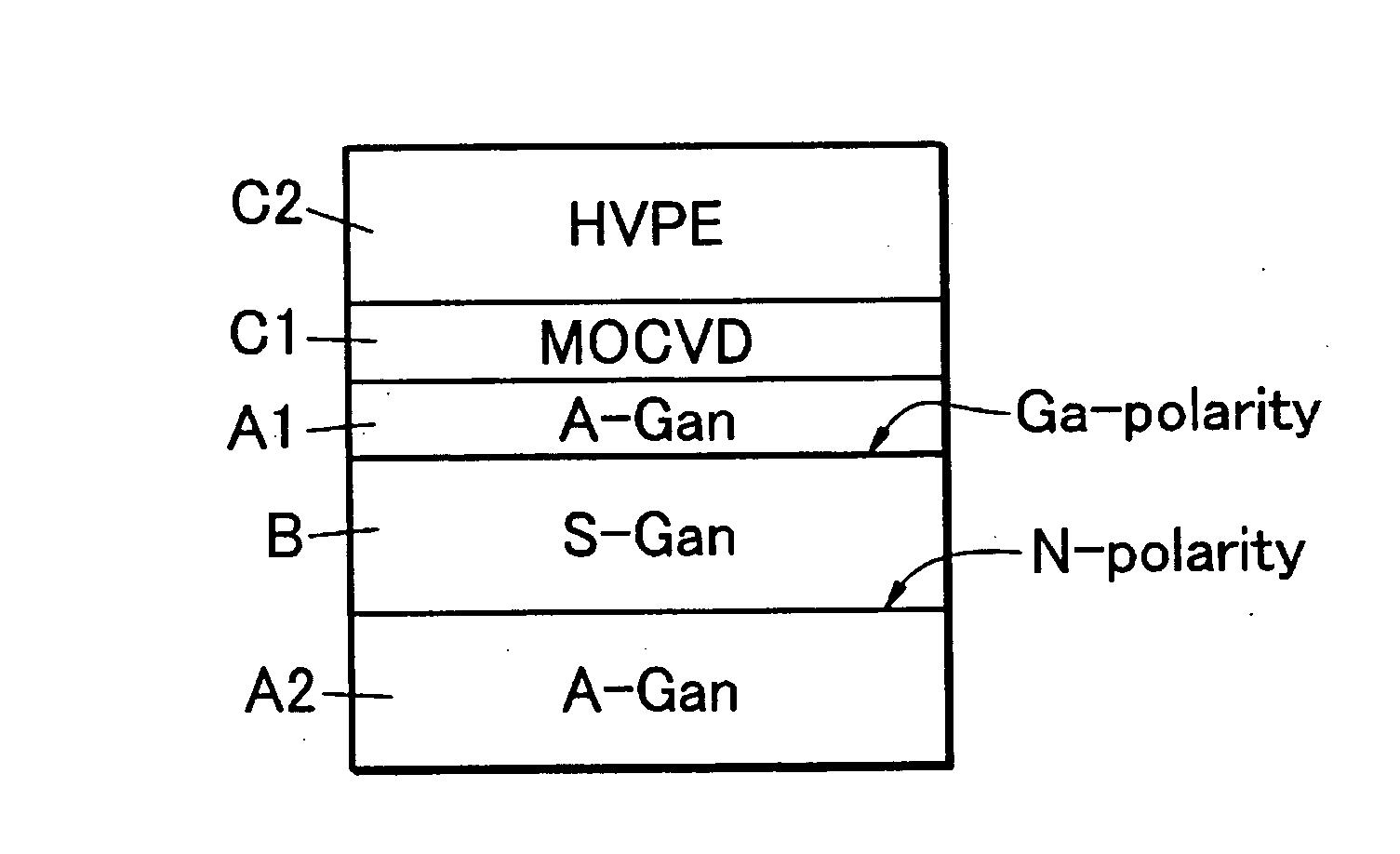

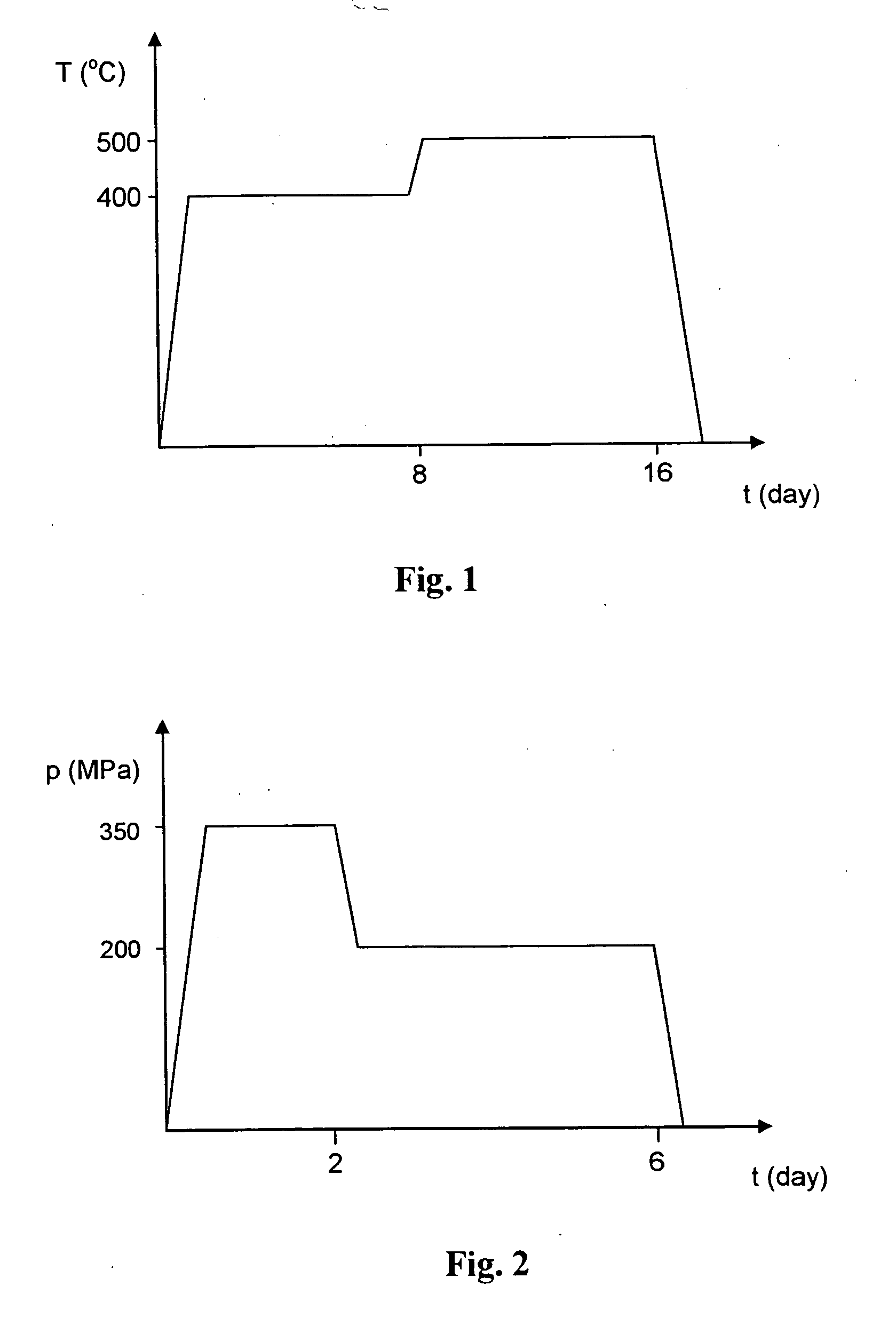

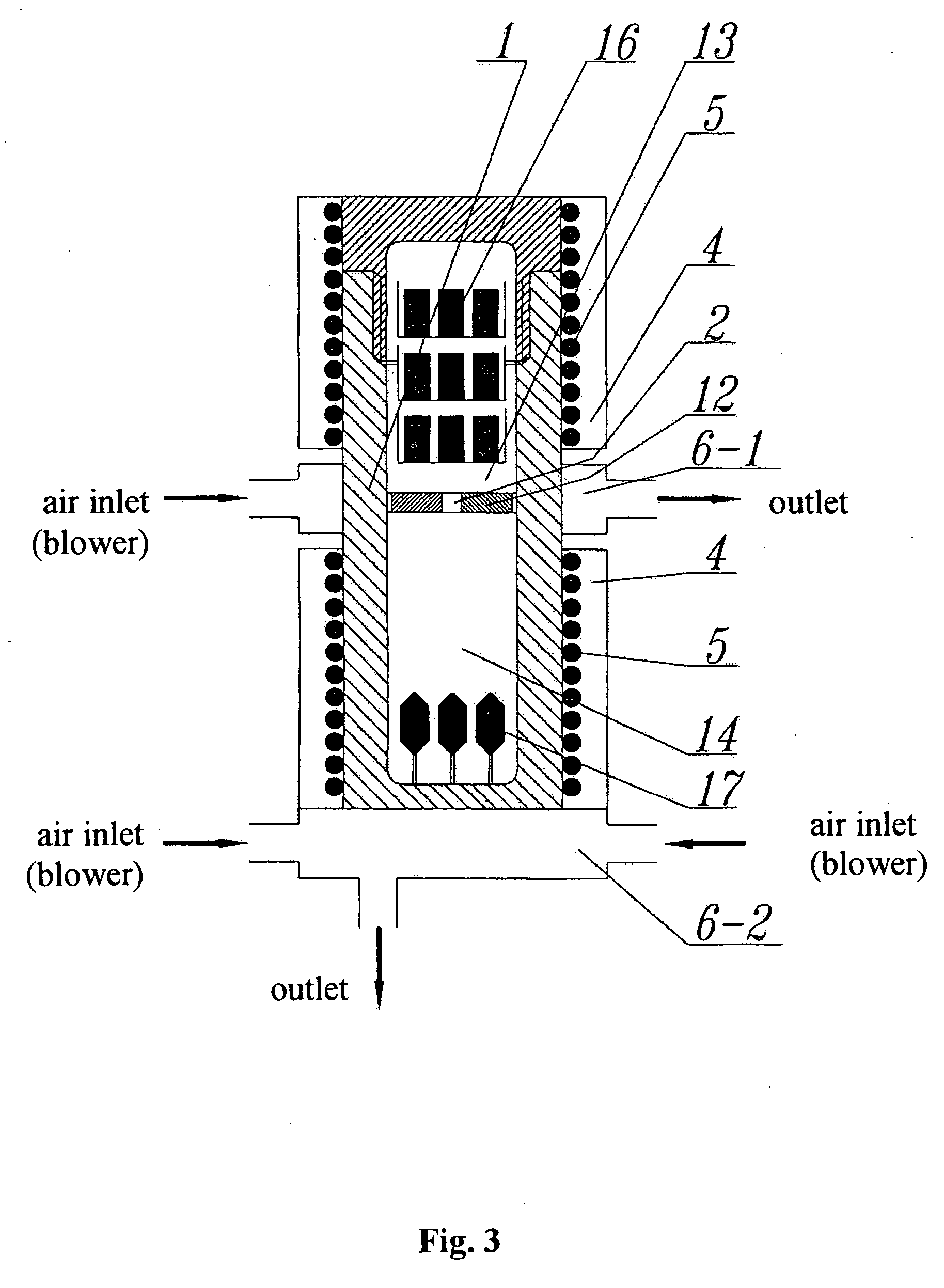

Template type substrate and a method of preparing the same

ActiveUS20060057749A1Improve surface propertiesImprove crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingMOSFETVapour phase epitaxy

The template type substrate is used for opto-electric or electrical devices and comprises A) a layer of bulk mono-crystal nitride containing at least one element of alkali metals (Group I, IUPAC 1989) and B) a layer of nitride grown by means of vapor phase epitaxy growth wherein the layer A) and the layer B) are combined at non N-polar face of the layer A) and N-polar face of the layer B). Therefore, the template type substrate has a good dislocation density and a good value of FWHM of the X-ray rocking curve from (0002) plane less than 80, so that the resulting template type substrate is very useful for the epitaxy substrate from gaseous phase such as MOCVD, MBE and HVPE, resulting in possibility of making good opto-electric devices such as Laser Diode and large-output LED and good electric devices such as MOSFET.

Owner:AMMONO SP Z O O (PL) +1

Water-based ultra-thin fire-retardant coating for steel structures and preparation method of fire-retardant coating

The invention discloses a water-based ultra-thin fire-retardant coating for steel structures. The fire-retardant coating comprises components as follows: a binder emulsion, an intumescent flame retardant system, filler, deionized water and additives, wherein the additives comprise a dispersing agent, an antifoaming agent, a mold inhibitor, an anti-flash-rust agent, a coalescing agent, a leveling agent and a thickener; the intumescent flame retardant system comprises a dehydration catalyst, a carbonizing agent and a foaming agent. The invention further designs a preparation method of the water-based ultra-thin fire-retardant coating for the steel structures. The components are mixed sequentially to be prepared into the water-based ultra-thin fire-retardant coating for the steel structures in a vertical sand mill and a dispersing tank. The prepared coating is large in adhesive force, high in hardness, good in fireproof property, good in anti-scratch performance and excellent in weather resistance and water resistance, the surface layer of the coating is fine and smooth, the decoration performance is improved significantly, and the preparation method is low in energy consumption and has the advantages that the harm to human bodies and the pollution to the environment during preparation are small and the like.

Owner:JIANGSU MARINE VICTORY COATING

Manufacturing technique of wash-resistant and flame-retardant blended fabric

ActiveCN102392356AImprove flame retardant performanceImprove wash resistanceHeating/cooling textile fabricsYarnGlass fiberPolyester

The invention provides a manufacturing technique of a wash-resistant and flame-retardant blended fabric. The technique comprises the following steps of: 1) preparing a cotton fiber flame-retardant coating adhesive; 2) coating the coating adhesive obtained in the step 1) on the cotton fiber and carrying out heat setting to the cotton fiber so as to obtain a flame-retardant cotton fiber; 3) preparing a glass fiber flame-retardant coating adhesive; 4) directly coating the coating adhesive obtained in the step 3) on the glass fiber and carrying heat setting on the coating adhesive so as to obtaina flame-retardant glass fiber; and 5) blending one of the flame-retardant cotton fiber obtained in the step 2) and a carbon fiber or the flame-retardant glass fiber obtained in the step 4) and one ofa flame-retardant polyester fiber or a flame-retardant nylon fiber so as to obtain the product of the invention. The manufacturing technique of the wash-resistant and flame-retardant blended fabric, provided by the invention, has the advantages of simple process, low cost, good product permeability, softness as well as good wash resistance and flame retardation. The manufacturing technique of thewash-resistant and flame-retardant blended fabric, provided by the invention, is mainly used for manufacturing products like smoke screens, fire-proof insulated curtains, bedspreads, flame-retardant furniture and the like.

Owner:应急管理部四川消防研究所

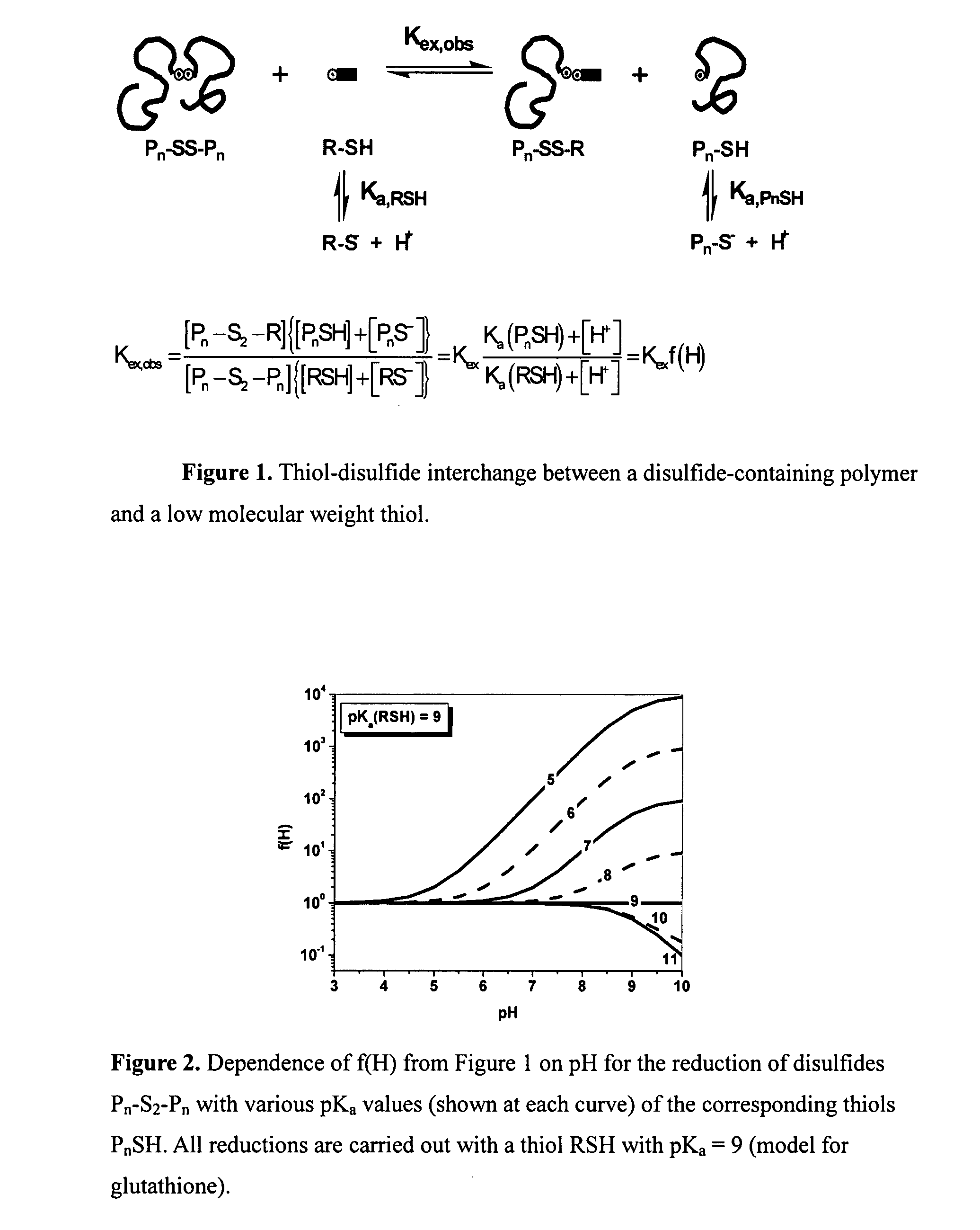

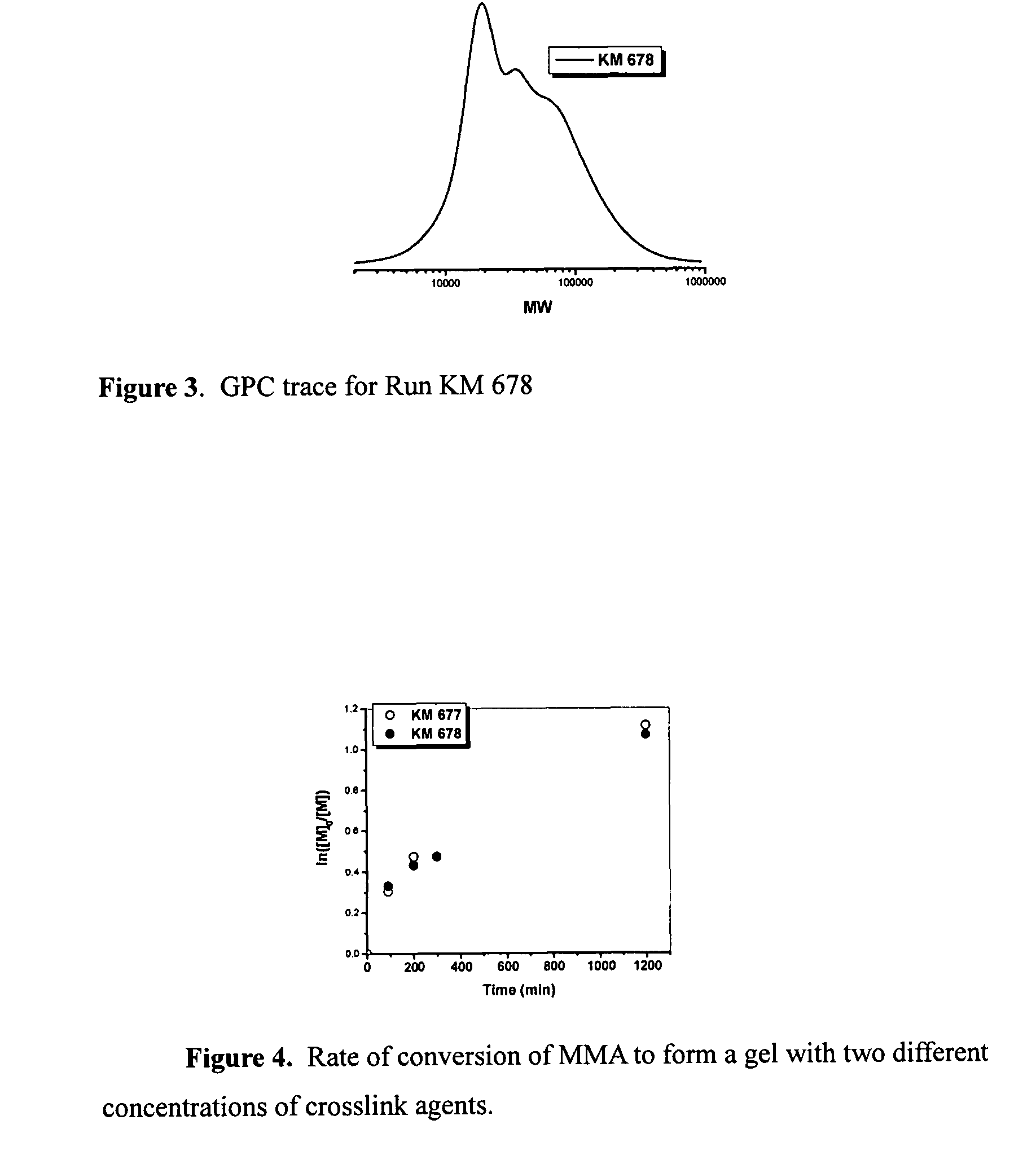

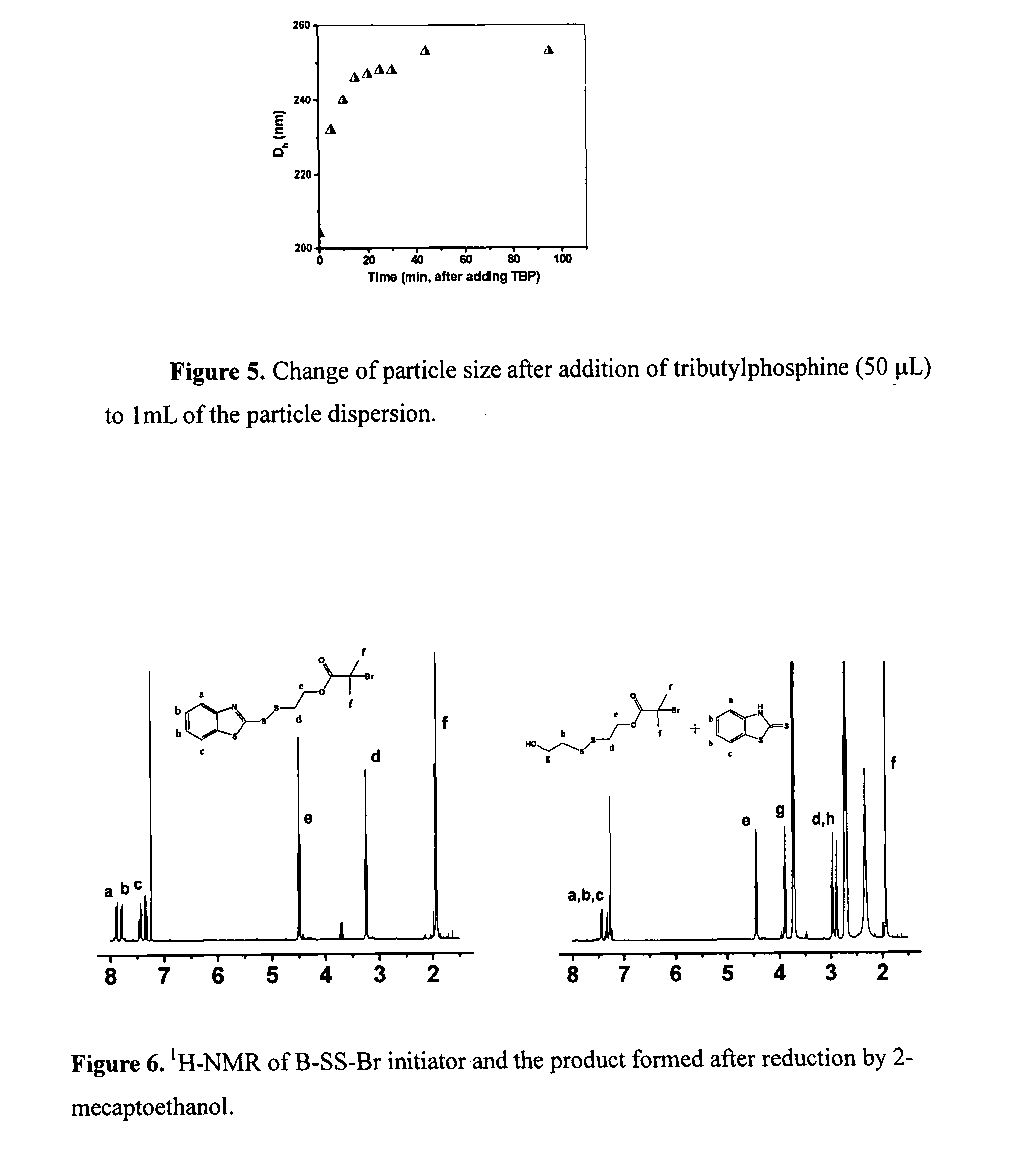

Preparation of functional gel particles with a dual crosslink network

ActiveUS8367051B2Improve surface propertiesAvoid rapid degradationPowder deliveryCosmetic preparationsCrosslinked polymersReactive agent

Functional gel particle formed from a crosslinked polymeric network including a fraction of stable crosslinks and a second fraction of cleavable crosslinks are disclosed. Functional compounds may be chemically or physically encapsulated within and / or released from the gel particle by selective cleavage of the cleavable crosslinks. The functional compounds may be delivered and released to a pre-selected target site. Peripheral or other accessible functionality on the surface of the gel particle allows attachment of a surface reactive agent, thereby modifying one or more surface properties of the gel particle. Processes of preparing the gel particles and processes of delivering the functional compounds to a target site are also disclosed.

Owner:CARNEGIE MELLON UNIV

Pre-irradiation polypropylene graft copolymer and preparation method thereof

The application relates to a pre-irradiation polypropylene graft copolymer and a preparation method thereof. At present, the exploration of methods for improving surface property remains a research hotspot in the field of modification of polypropylene always. The method comprises the following steps: performing pre-irradiation on polypropylene resin after having constant weight at the temperature of 60 DEG C by using a 60 Co radiation source or a DD-1.2 / 1.0-800 type high-frequency high-pressure electron accelerator in air, keeping the dosage rate at 300Gy / min, keeping the dose at 3-50kGy, adding the pre-radiated polypropylene resin into solution containing N, N'-methylenebis acrylamide, auxiliary monomers and additives, keeping the using amount of the N, N'-methylenebis acrylamide to be 0.5-5% by weight of the weight of polypropylene, performing nitrogen filling and oxygen removal on mixed solution for 30 minutes, then heating to 50-75 DEG C for performing reaction for 6 hours under magnetic stirring, nitrogen production and reflux conditions, washing the polypropylene resin which is filtered out with ethanol-water twice, further extracting with ethanol-water solution for 24 hours, drying at the temperature of 60 DEG C and enabling the weight to be constant. The method is used for preparing the polypropylene graft copolymer.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

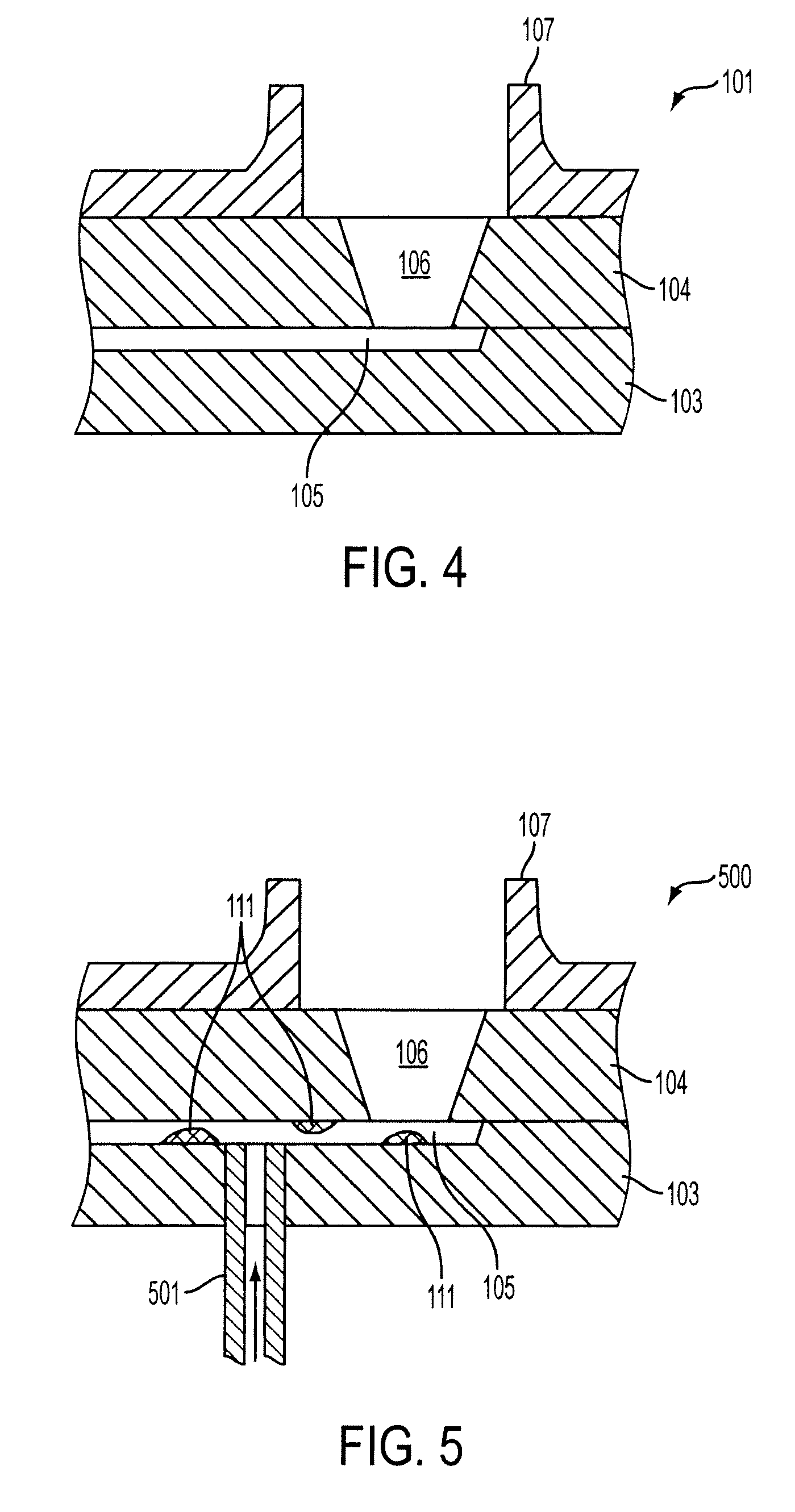

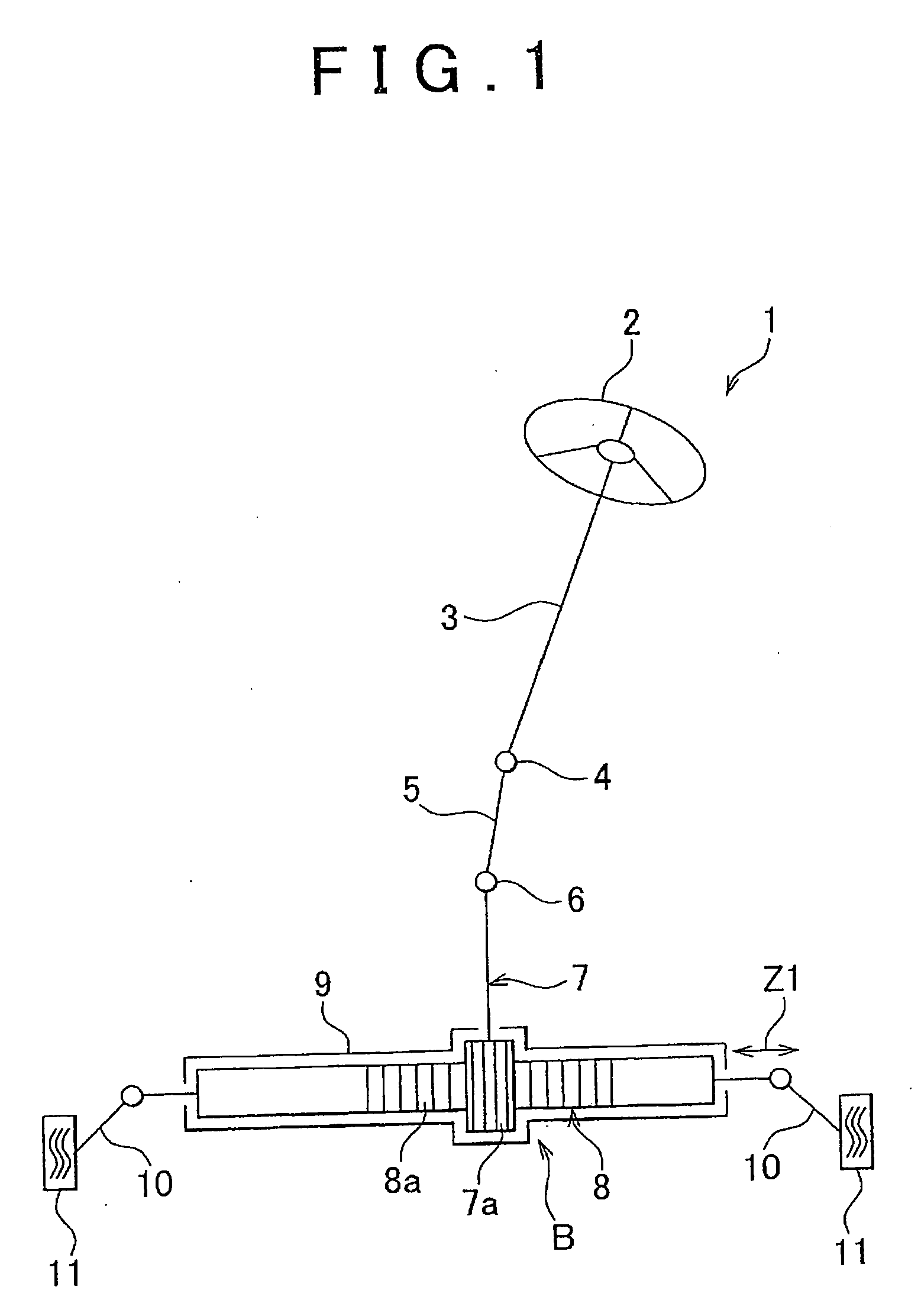

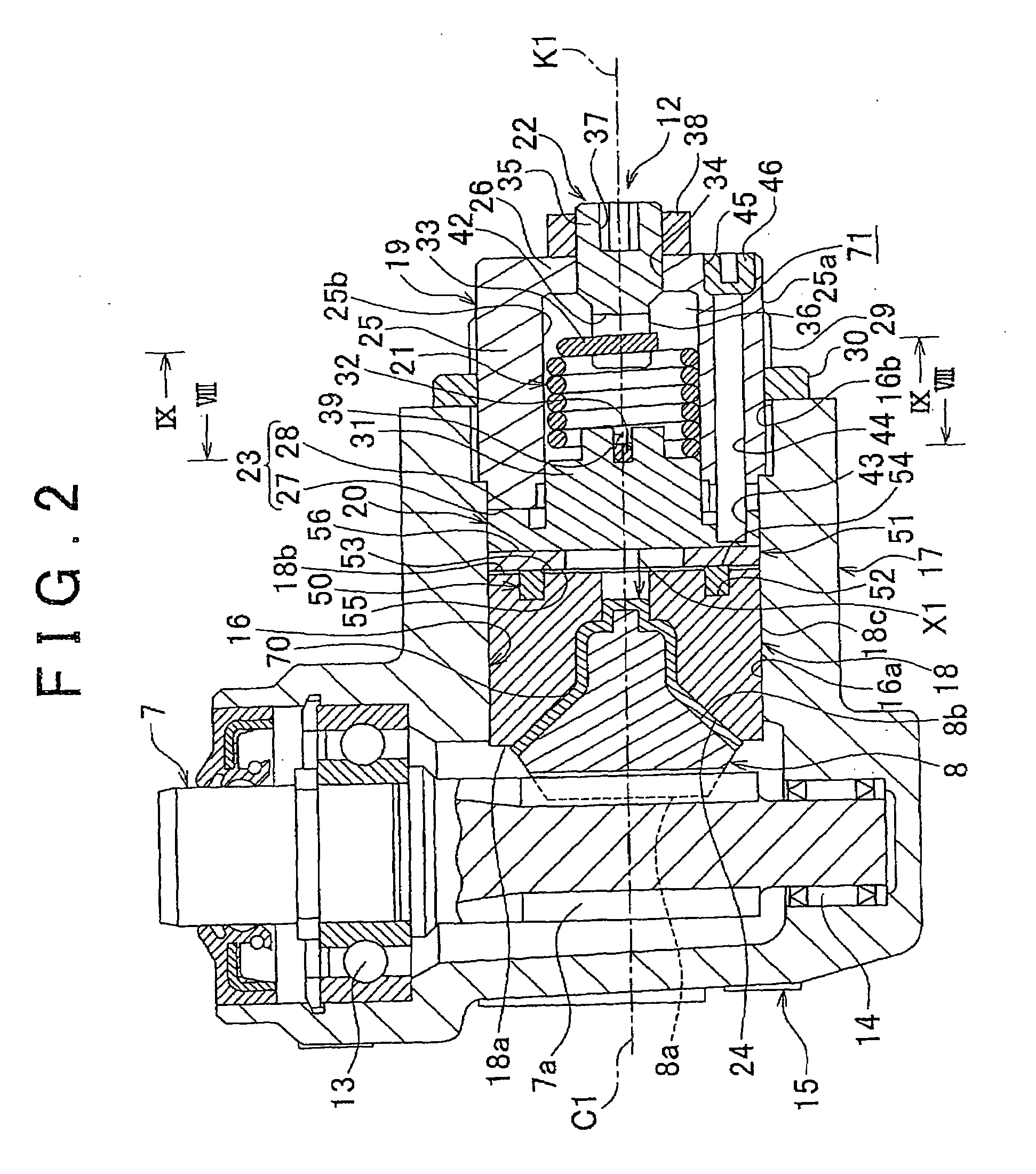

Rack shaft support device

ActiveUS20100024583A1Small frictional forceSmooth rotationPortable liftingToothed gearingsEngineeringCam

A rack shaft support device includes: a rack shaft support member that is accommodated inside a retention hole formed in a housing so as to slide in an axial direction of the retention hole, and slidably supports a rack shaft; a sealing member fixed to an inlet port of the retention hole; an intermediate member that is interposed between the rack shaft support member and the sealing member; a torsion spring that couples the sealing member and the intermediate member; a cam mechanism that converts a rotational force of the intermediate member induced by untwisting of the torsion spring to a force by which the intermediate member pushes the rack shaft support member; an opposing portion that opposes a rear surface of the rack shaft support member; and an annular elastic member that is interposed between the rear surface of the rack shaft support member and the opposing portion.

Owner:JTEKT CORP

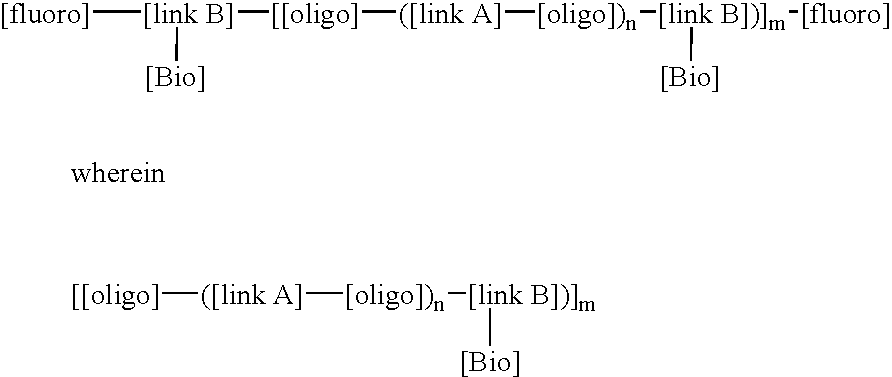

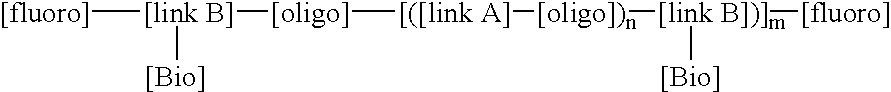

Bioactive surface modifiers for polymers and articles made therefrom

InactiveUS6770725B2Improve surface propertiesGood biocompatibilityPeptide/protein ingredientsPeptide sourcesCouplingBiomedical polymers

This invention relates to macromolecule modifiers containing biologically active drugs / biomolecules, or precursors thereof, and fluoroligomers; compositions comprising the macromolecules containing the drugs and fluoroligomers in admixture with polymers, particularly biomedical polymers; articles made from the admixtures, particularly medical devices. Specifically, the modifier has the general formulais a central portion comprising an oligomeric polymeric segment having a theoretical molecular weight of less than 15,000, and being compatible with said base polymer; wherein[oligo] is a first oligomeric segment;[link A] is a second coupling segment linking one [oligo] to another [oligo] within said central portion;n is 0 to 20;[fluoro] is a polyfluoro oligomeric group; and[link B] is a first coupling segment linking said central portion to said [fluoro] through said first coupling segment; and coupled to a bioactive moiety [Bio] or precursor thereof; andm is 1 to 20.

Owner:INTERFACE BIOLOGICS INC

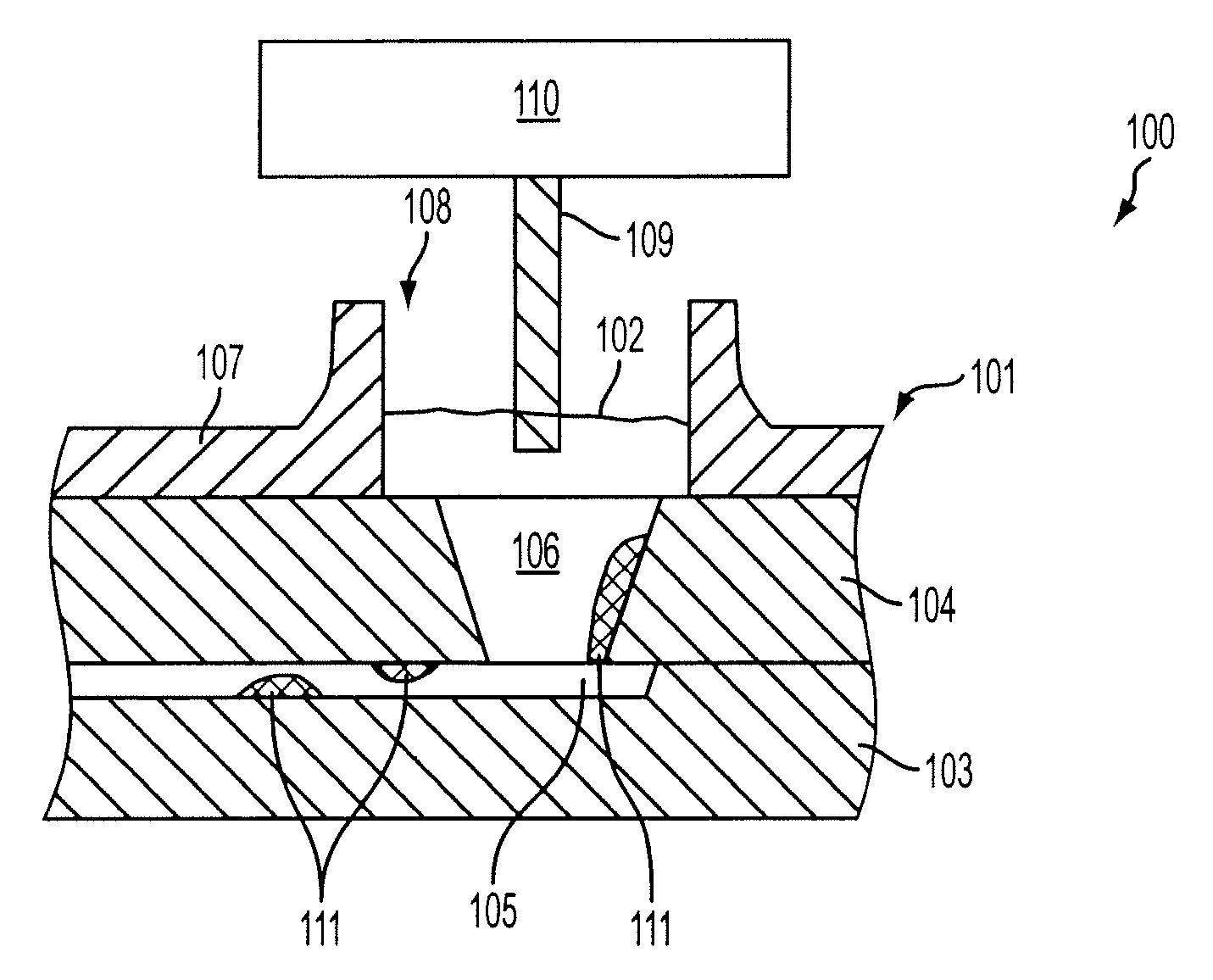

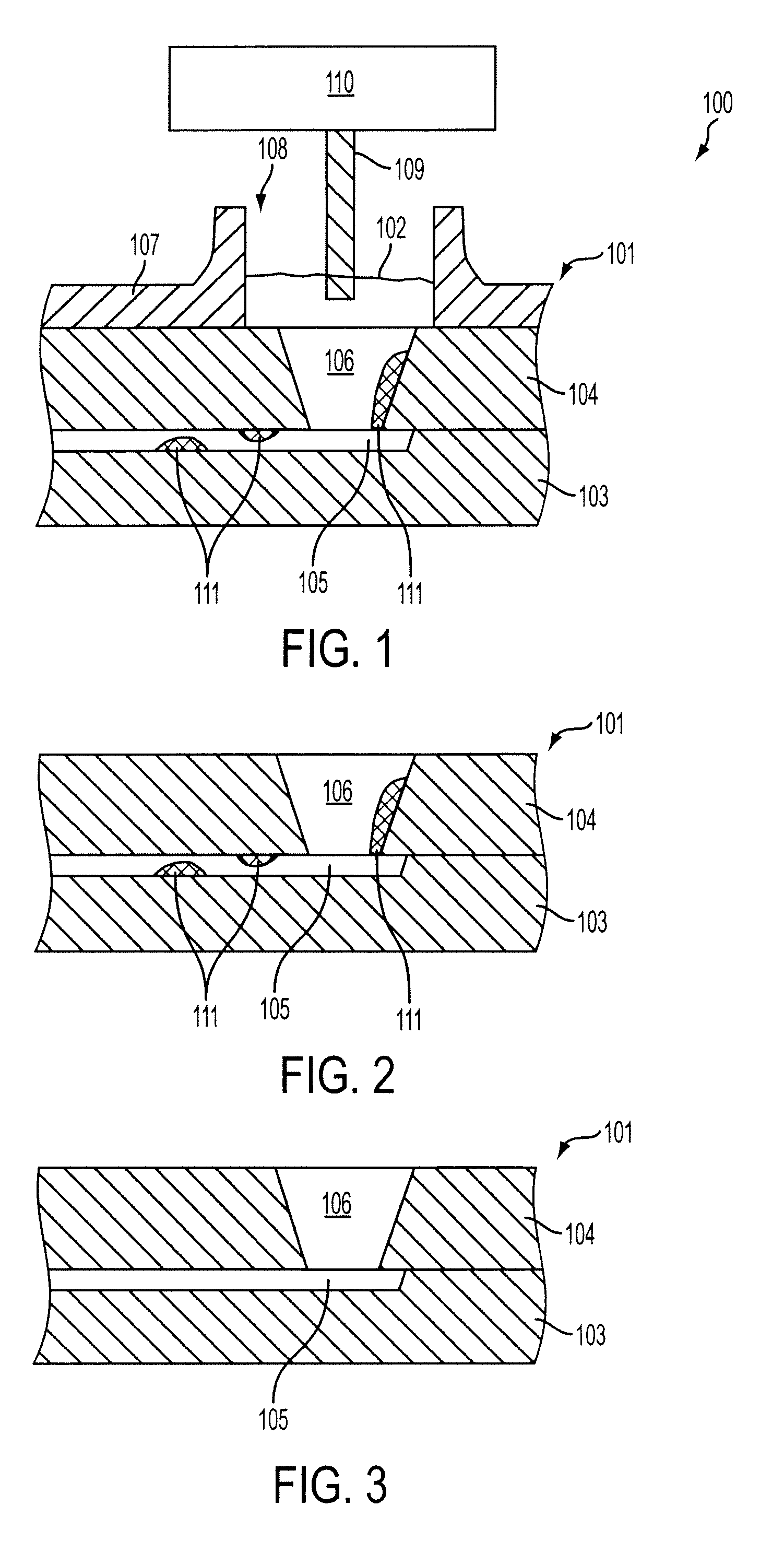

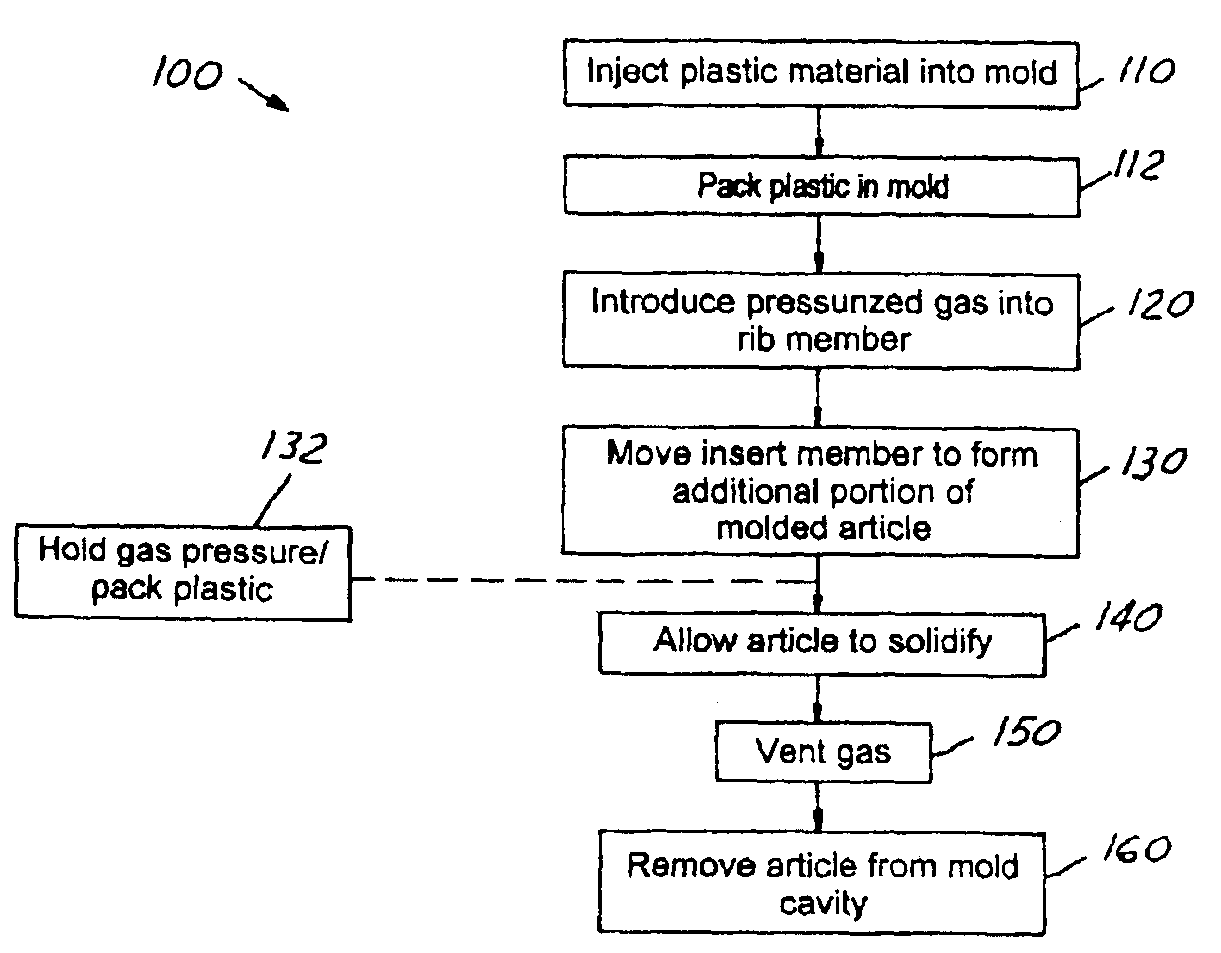

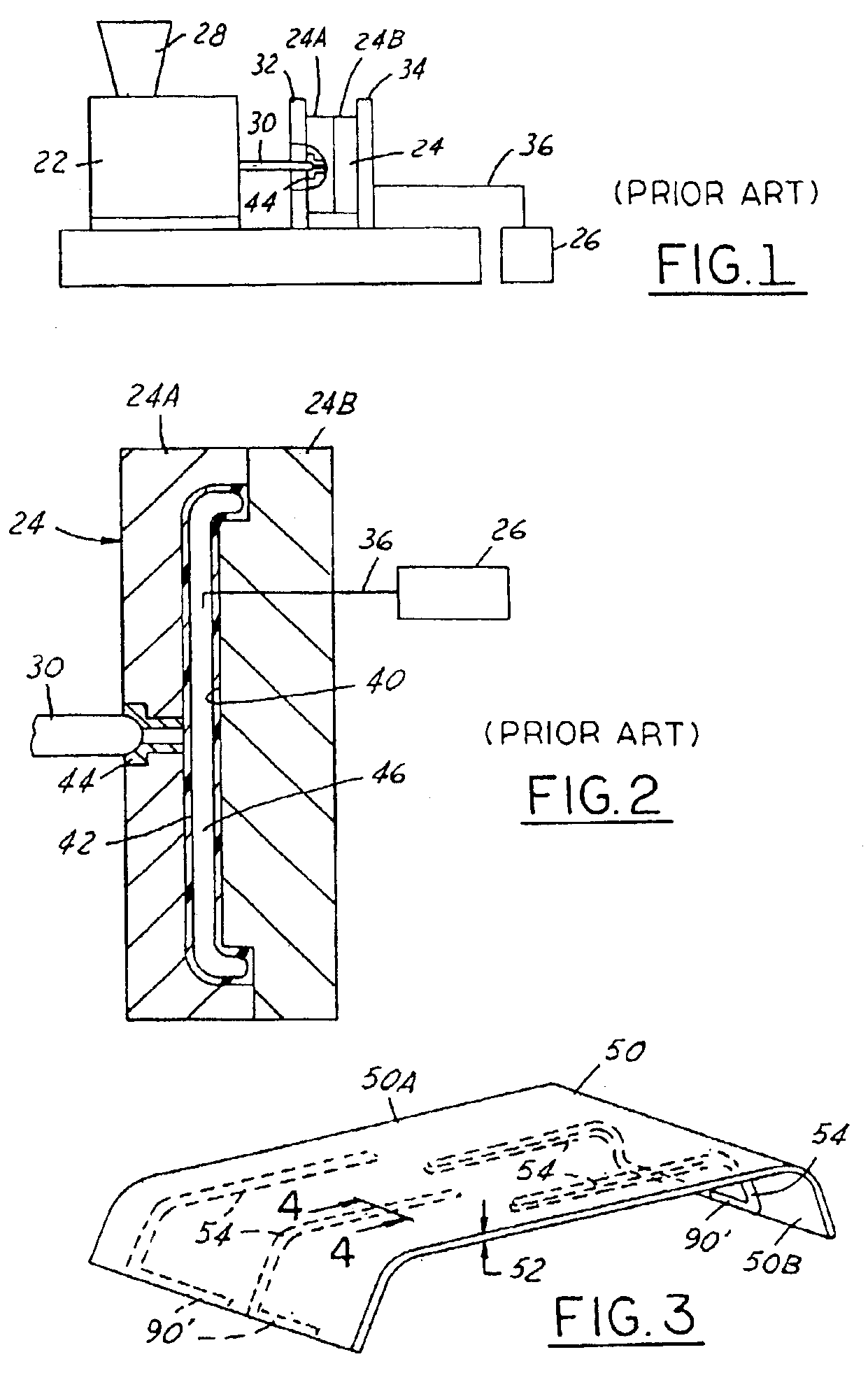

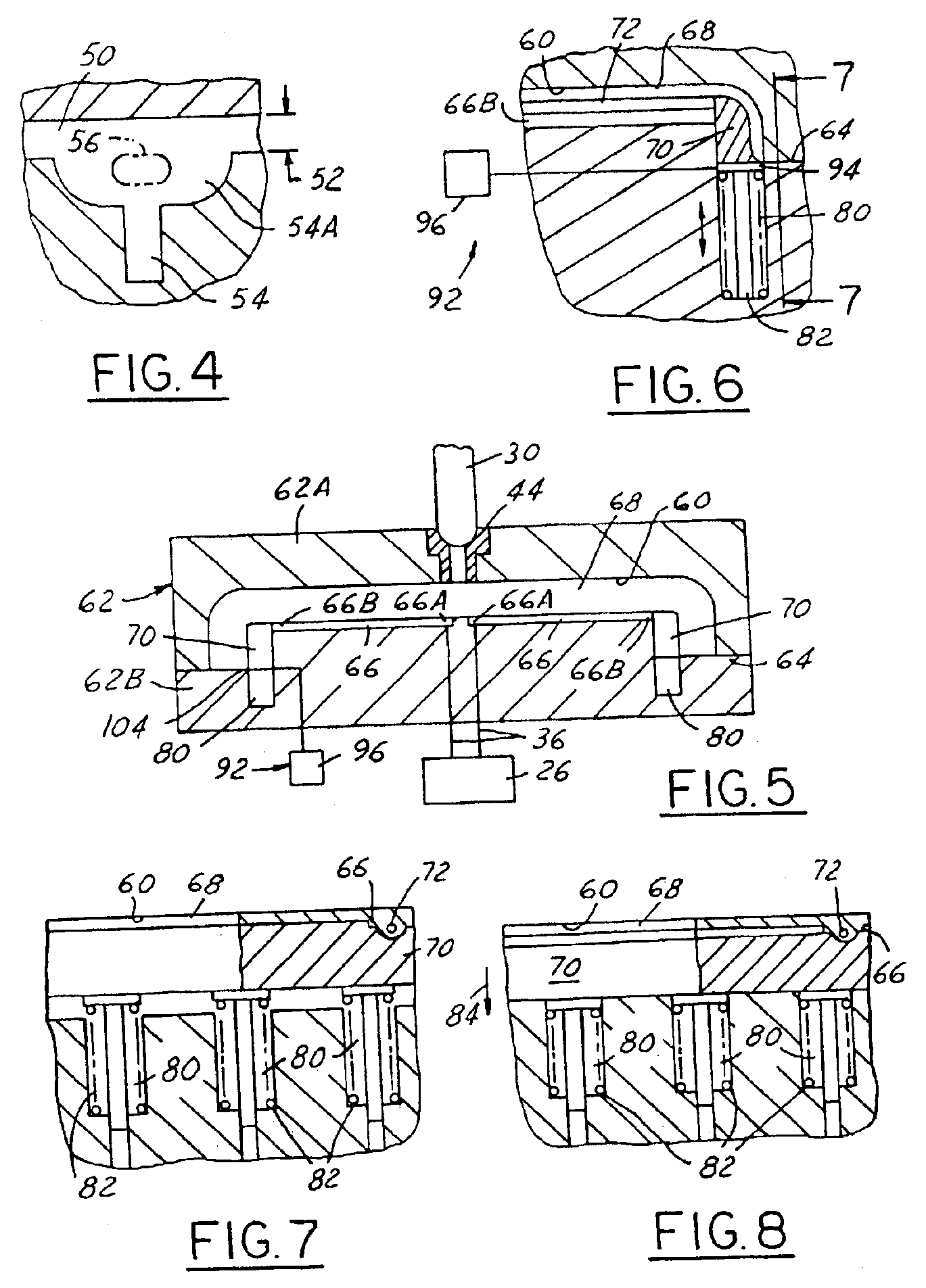

Plastic injection molding with moveable insert members

InactiveUS6939504B2Improve surface propertiesConfectionerySweetmeatsPlastic packagingPlastic injection molding

A method and system for producing hollow rib structures for trim components and panels using gas assisted injection molding. Movable insert members are provided in the mold cavity, particularly at the ends of the structural rib members. After the plastic material is injected into the mold cavity, the plastic is packed in the mold, and the insert members are locked in position. Selectively activatable locking mechanisms are used to lock up the insert members. Thereafter, gas or another fluid is introduced into the rib members in order to provide hollow channels therein. Movement of the insert members provides a recess or groove for placement of the displaced resin from the rib members. The displaced resin material completes the formation of the molded plastic article.

Owner:INT AUTOMOTIVE COMPONENTS GRP NORTH AMERICA INC

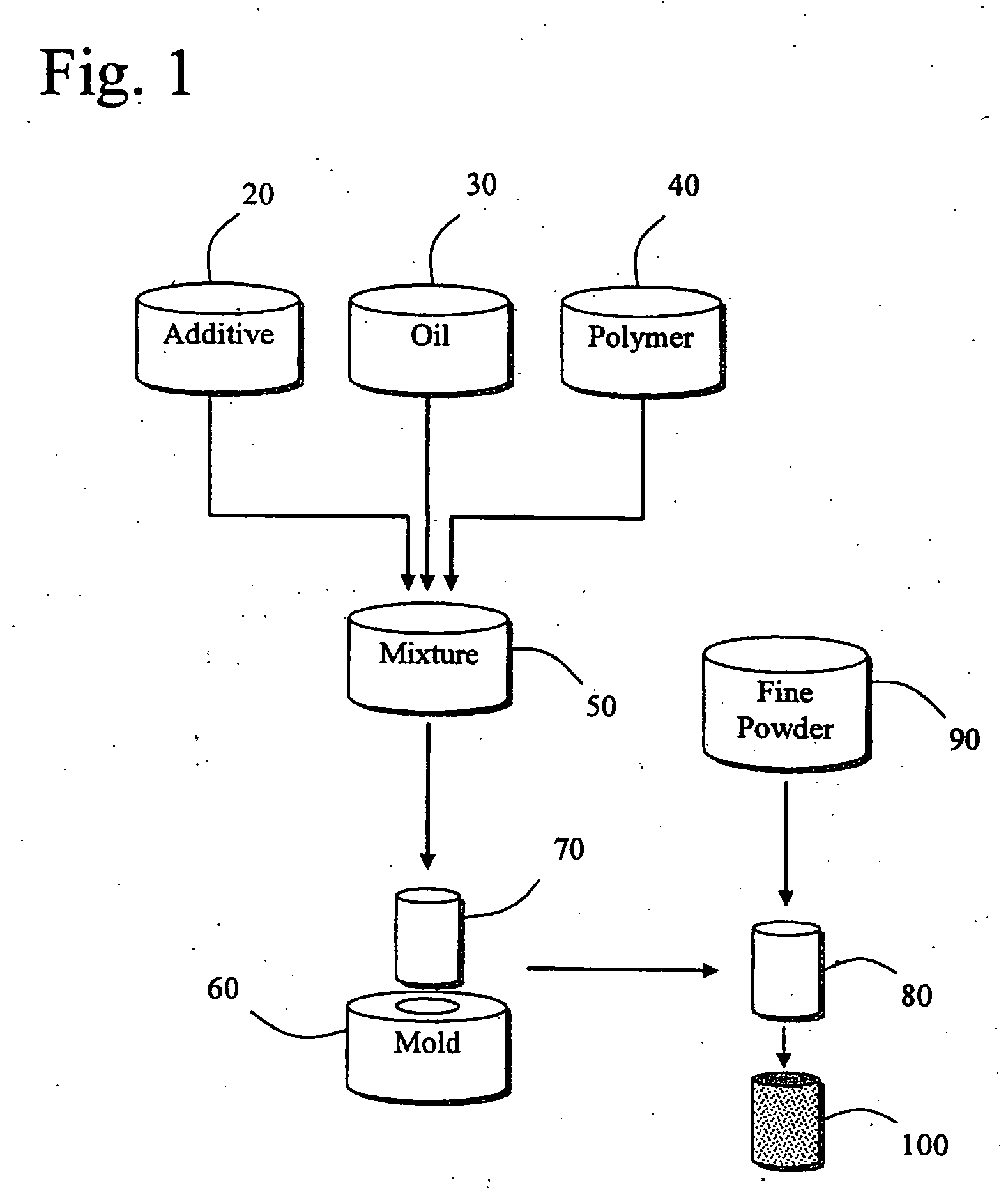

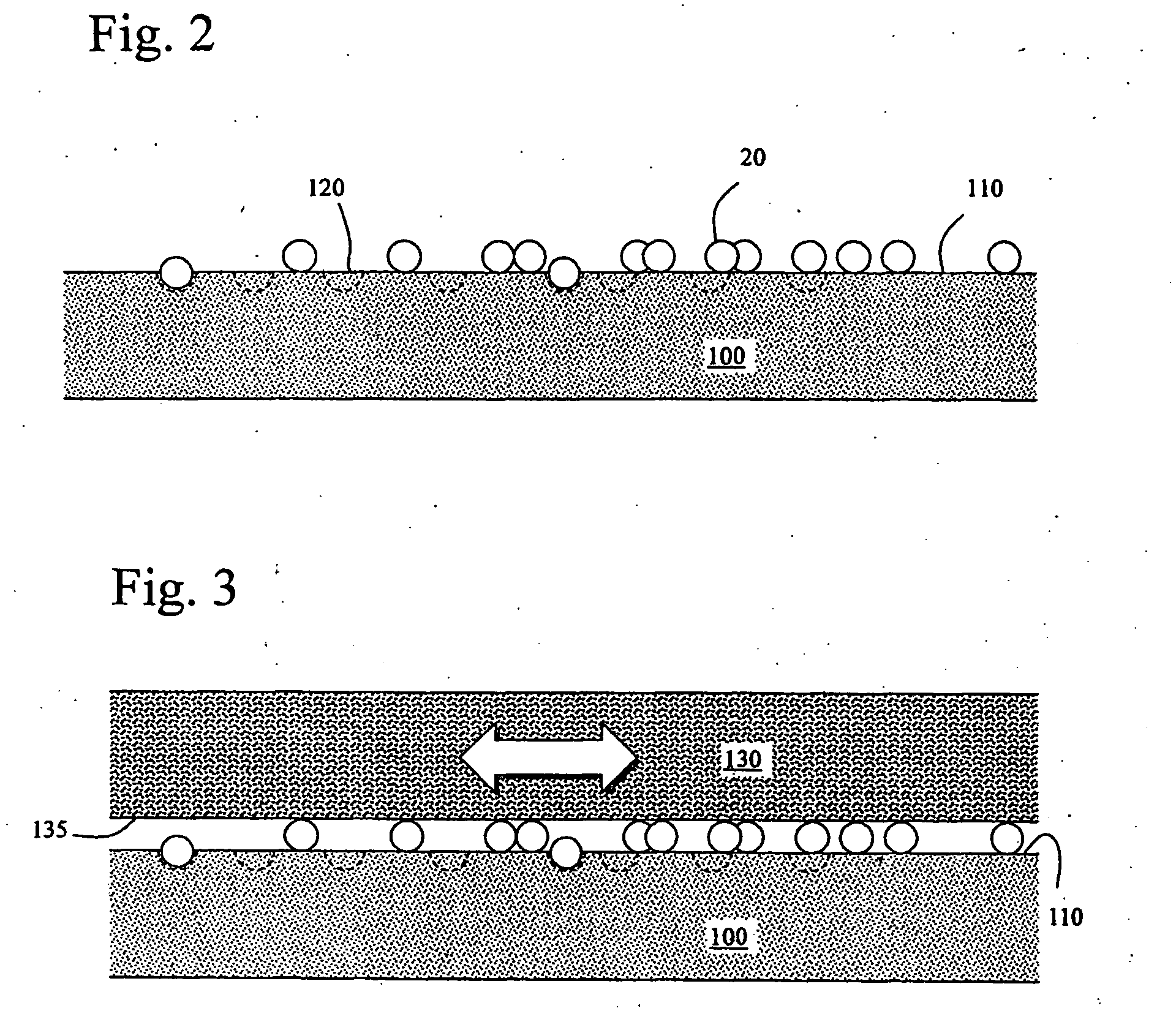

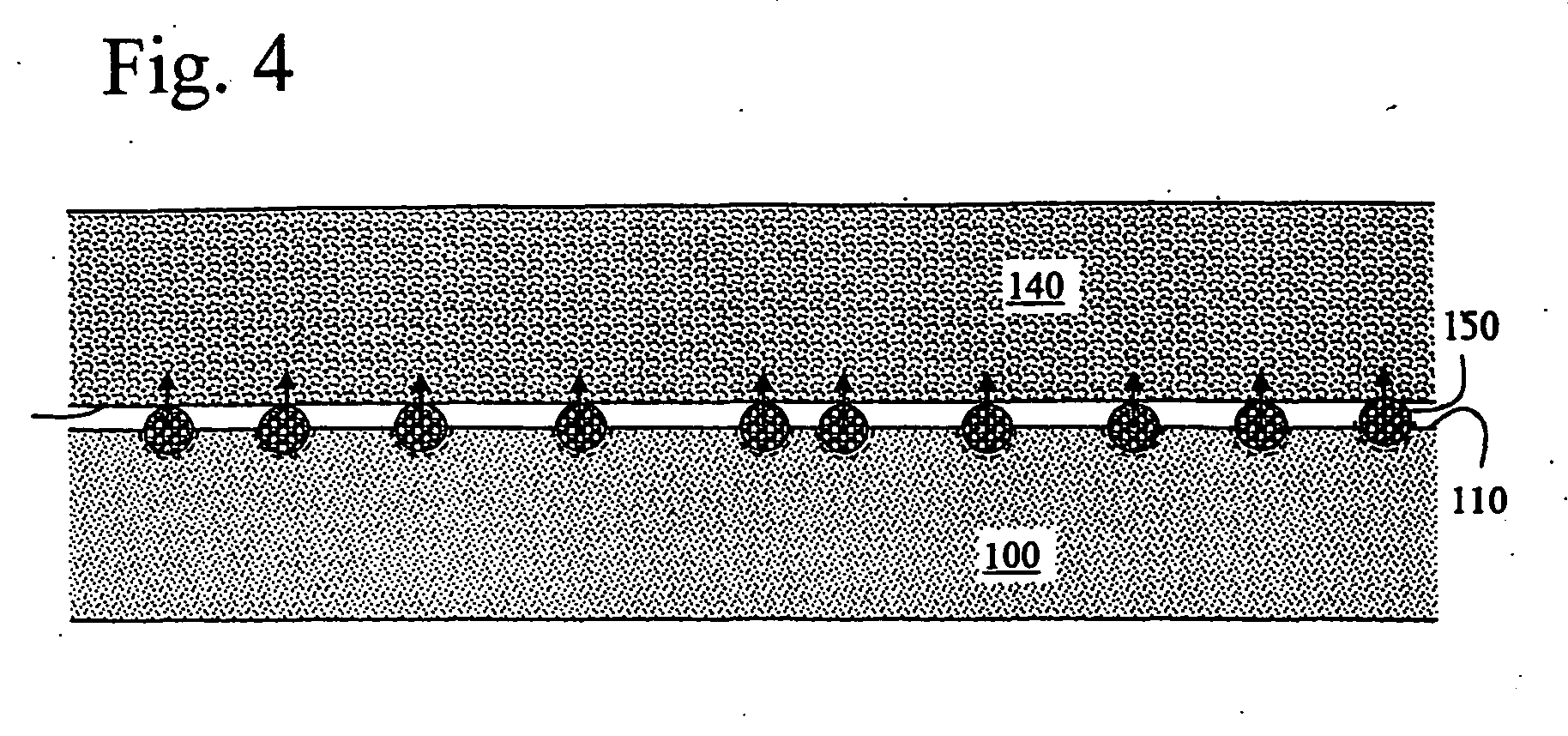

Surface modification of triblock copolymer elastomers

ActiveUS20060111485A1Avoid ischemiaMinimizes shear forceOrganic chemistryAntifouling/underwater paintsElastomerUrinary catheter

Thermoplastic elastomers may be manufactured by mixing together plasticizing oil, a triblock copolymer and one or more additives, e.g., an antioxidant, an antimicrobial agent, and / or other additives, to form a mixture which is melted then cooled into the thermoplastic elastomer. During cooling the thermoplastic elastomer may be molded or otherwise formed into any number of articles including, but not limited to, prosthetic liners, prosthetic sleeves, external breast prostheses, breast enhancement bladders, wound dressing sheets, wound dressing pads, socks, gloves, malleolus pads, metatarsal pads, shoe insoles, urinary catheters, vascular catheters and balloons for medical catheters both vascular as well as urinary.

Owner:ALPS SOUTH EURO

Scraping-resistant polypropylene combination with good appearance and manufacturing method and application thereof

The invention discloses a scraping-resistant polypropylene combination with good appearance. The combination comprises the components, by weight, of polypropylene of 57-82 parts, polyethylene of 3-8 parts, flexibilizer of 3-8 parts, mineral filler of 10-30 parts, scraping-resistant agents of 1.5-2.5 parts, and other assistant agents of 0.5-1 part. The invention further discloses a manufacturing method and application of the scraping-resistant polypropylene combination with the good appearance. According to the combination, by adding the polyethylene and the processing agents, phase interface problems of the combination are well improved, current ripple and tiger stripe problems existing in an injection process of the combination are well improved, so that great surface effect of an combination injection molding piece is achieved, and the scraping-resistant agents are added so that surface damage generated by scraping and friction during a using process of the combination injection molding piece is relieved. The requirements on the surface performance of the combination during the injection molding process and the later-stage using process and mechanical performance are considered in an overall mode, the requirements on inner ornaments and outer ornaments of an automobile are met, and good application prospect is achieved.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com