Patents

Literature

1264results about How to "Reduce melt viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

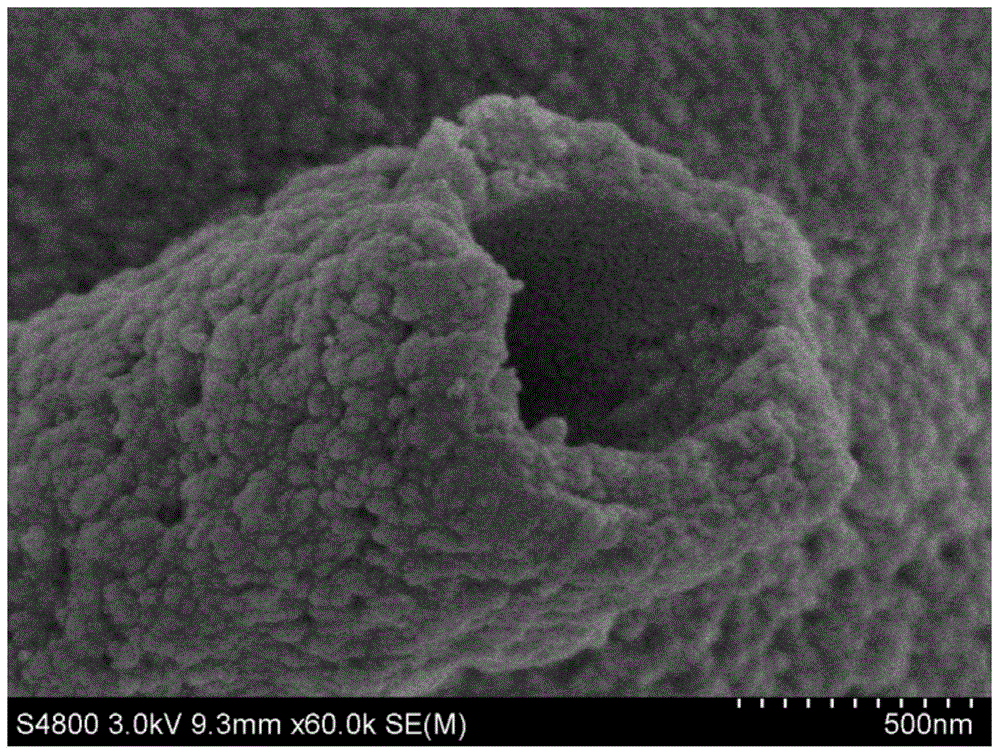

Preparation method of porous fiber non-woven fabric

ActiveCN103981635AReduce melt viscosityReduce degradationFilament forming substance formingMelt spinning methodsDiluentNonwoven fabric

The invention relates to a preparation method of a porous fiber non-woven fabric. The aim of the preparation method is to improve the product performance of the conventional non-woven fabric, so that the non-woven fabric meets the requirements on high-precision and high-performance filter. The technical scheme is that the preparation method of the porous fiber non-woven fabric comprises the following steps in sequence: (1) uniformly mixing a polymer and a diluent to obtain a blend with 10 to 60 percent of polymer; (2) melting and extruding the blend in the step (1) by adopting a screw extruder granulator, and directly cooling and granulating in air; (3) producing master batches in the step (2) by melt-down equipment to obtain a primary non-woven fabric; (4) extracting to remove the diluent from the primary non-woven fabric in the step (3), performing pore-forming on fibers in the non-woven fabric, and drying to obtain the porous fiber non-wave fabric; (5) recovering mixed waste liquid of the diluent and an extraction agent for reuse.

Owner:浙江省轻工业品质量检验研究院

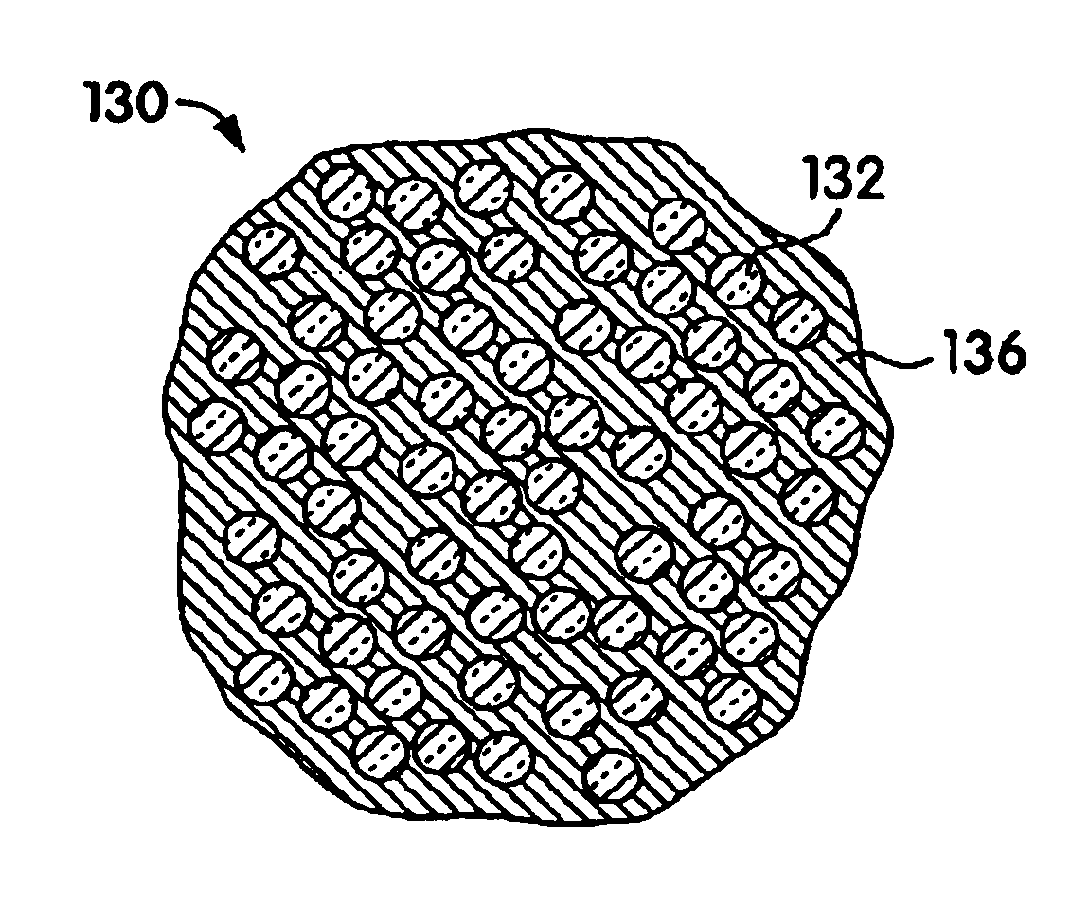

Thermally conductive thermoplastic

InactiveUS6162849AImprove thermal conductivityImprove mechanical propertiesPlastic/resin/waxes insulatorsMixingThermoplasticPolymer science

This invention relates to a thermally conductive moldable polymer blend comprising a thermoplastic polymer having a tensile at yield of at least 10,000 psi; at least 60% by weight of a mixture of boron nitride powders having an average particle size of at least 50 microns; and a coupling agent. The composition displays a thermal conductivity of at least about 15 W / m DEG K and it is capable of being molded using high speed molding techniques such as injection molding.

Owner:FERRO CORP

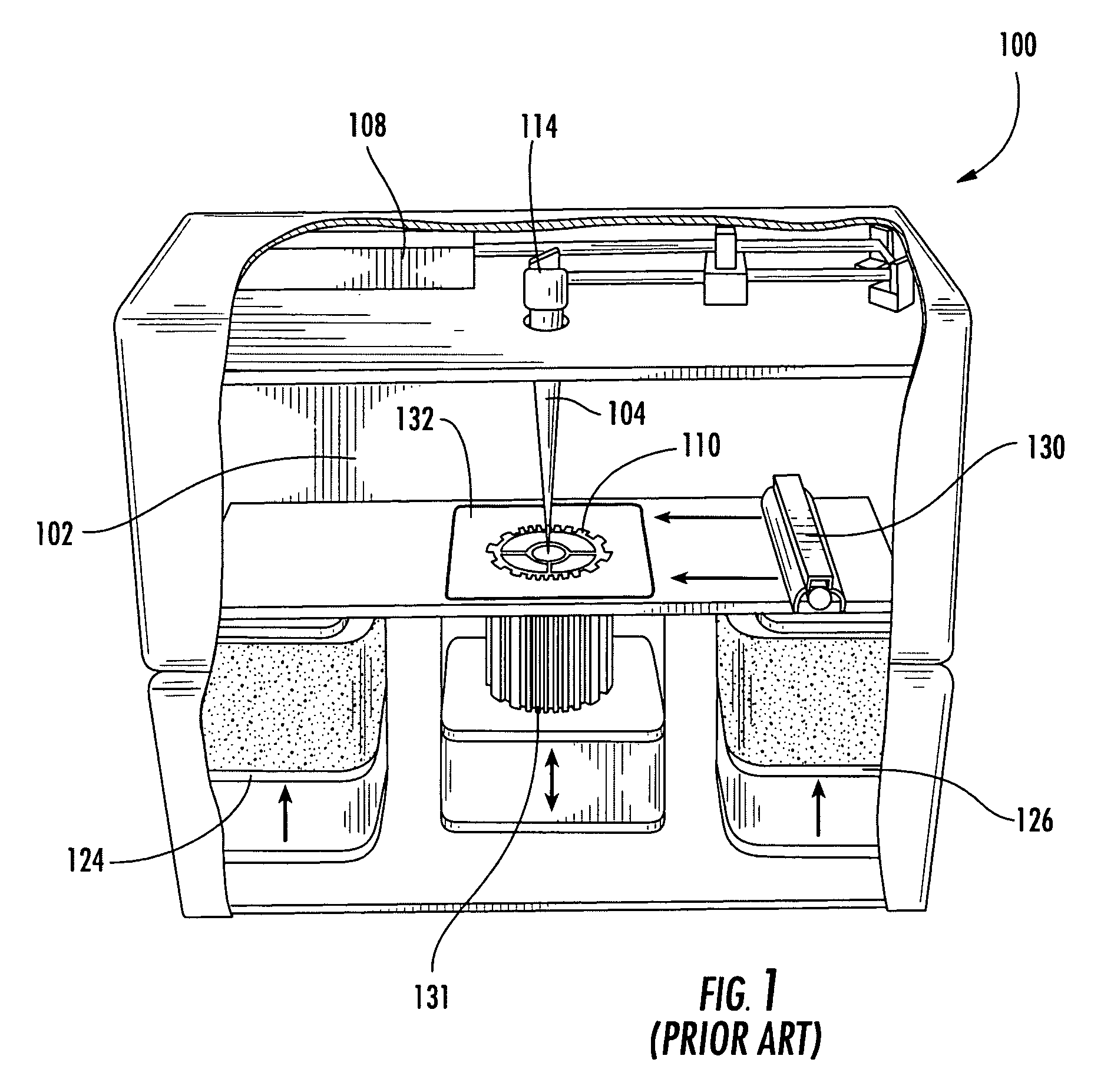

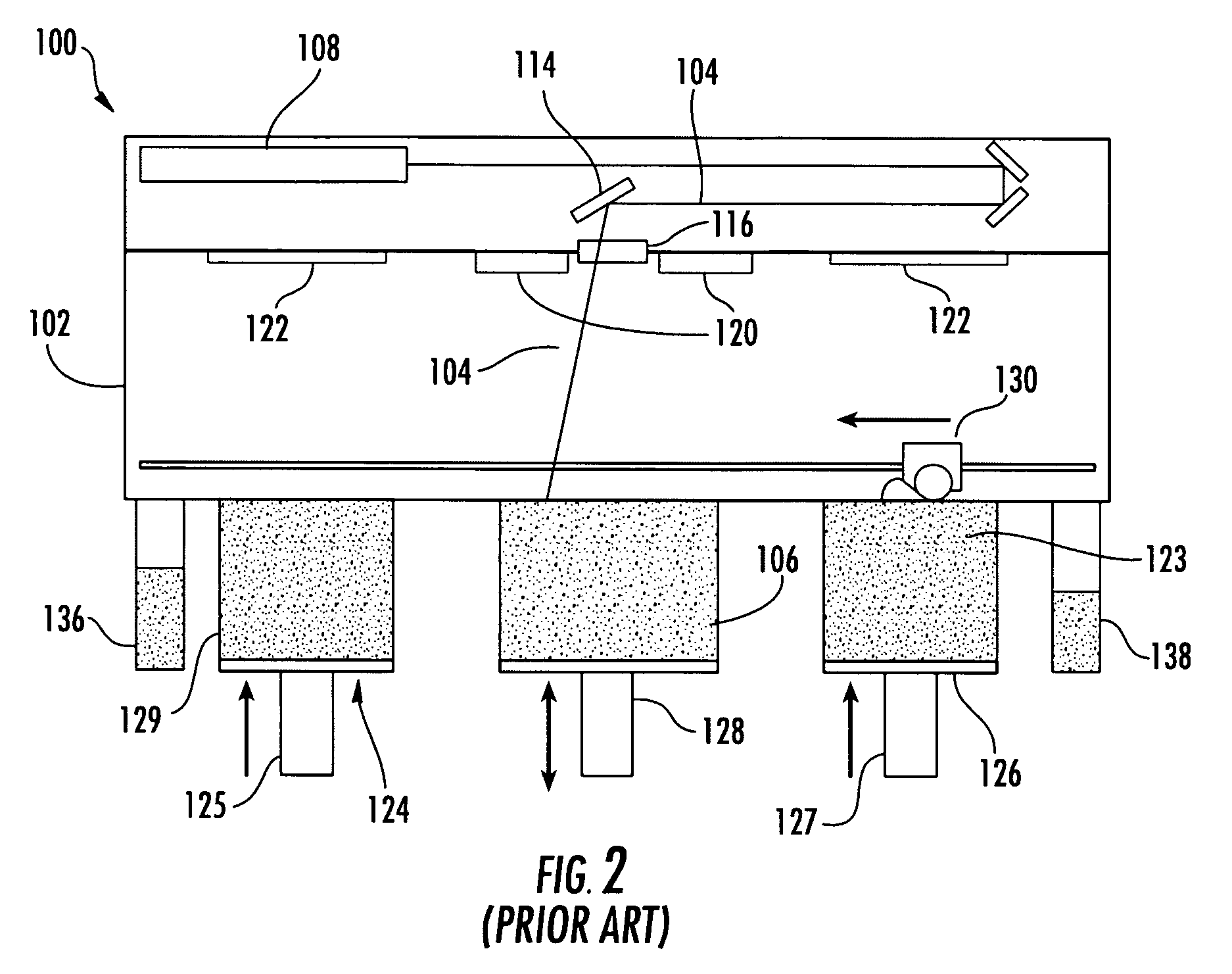

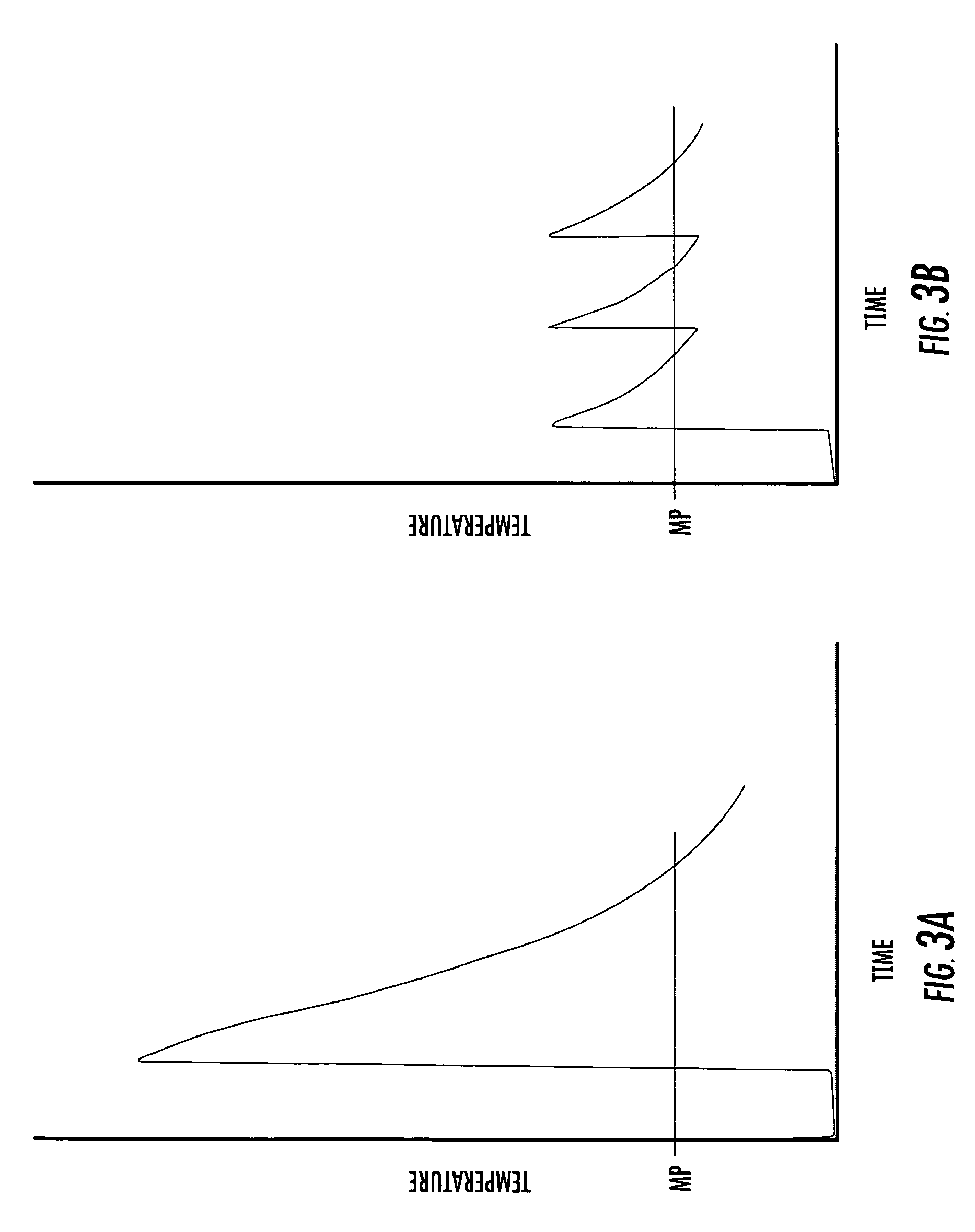

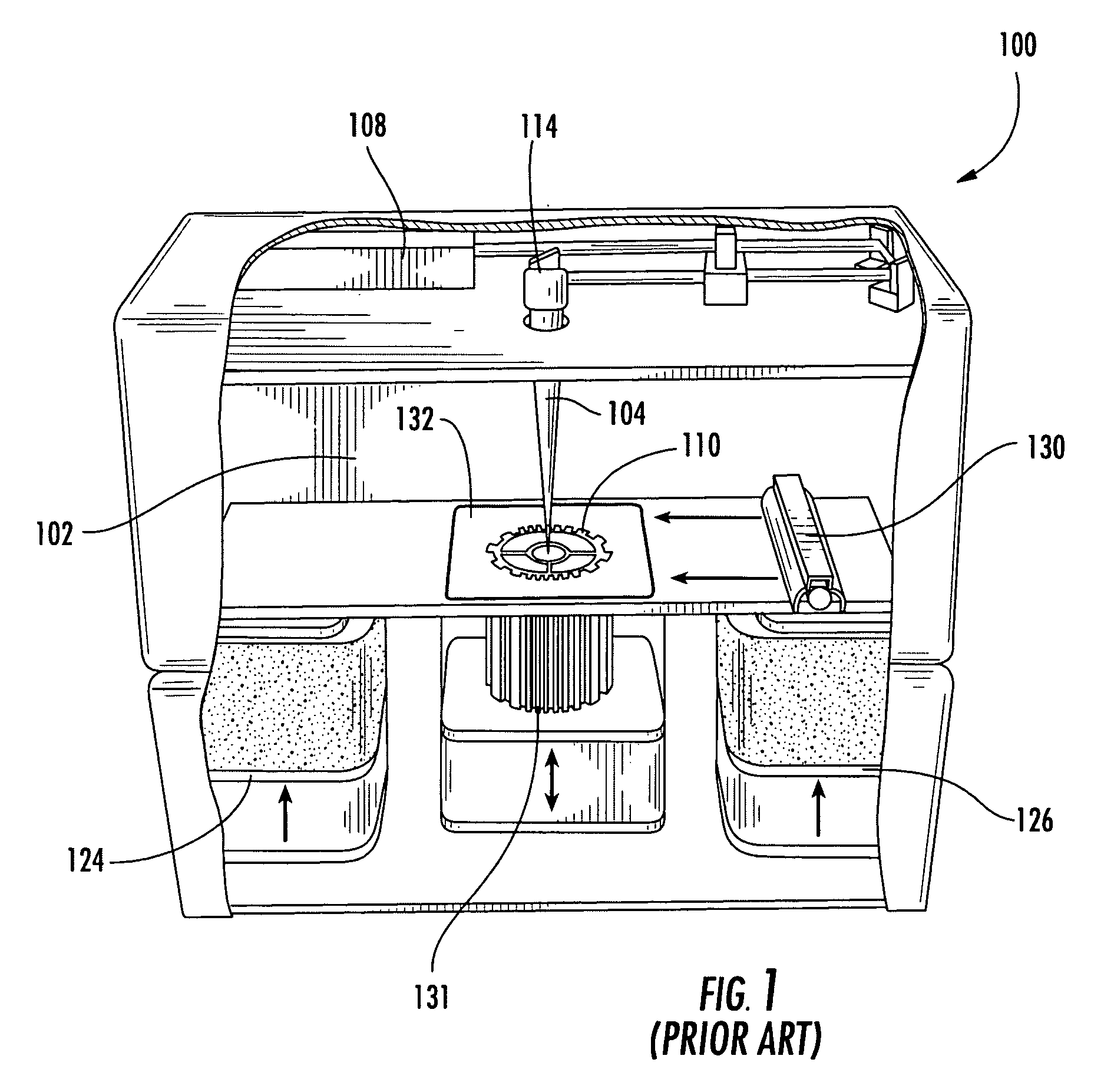

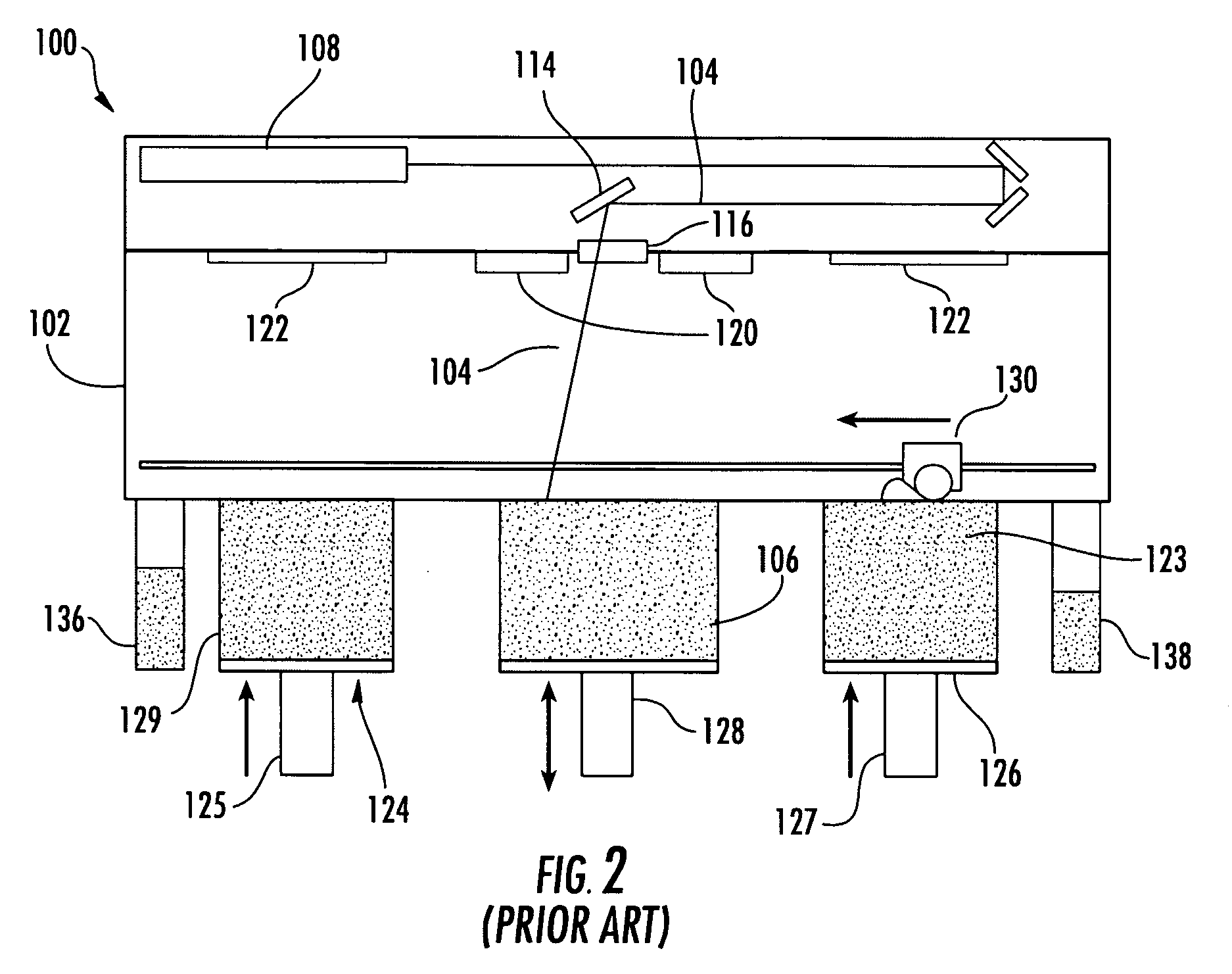

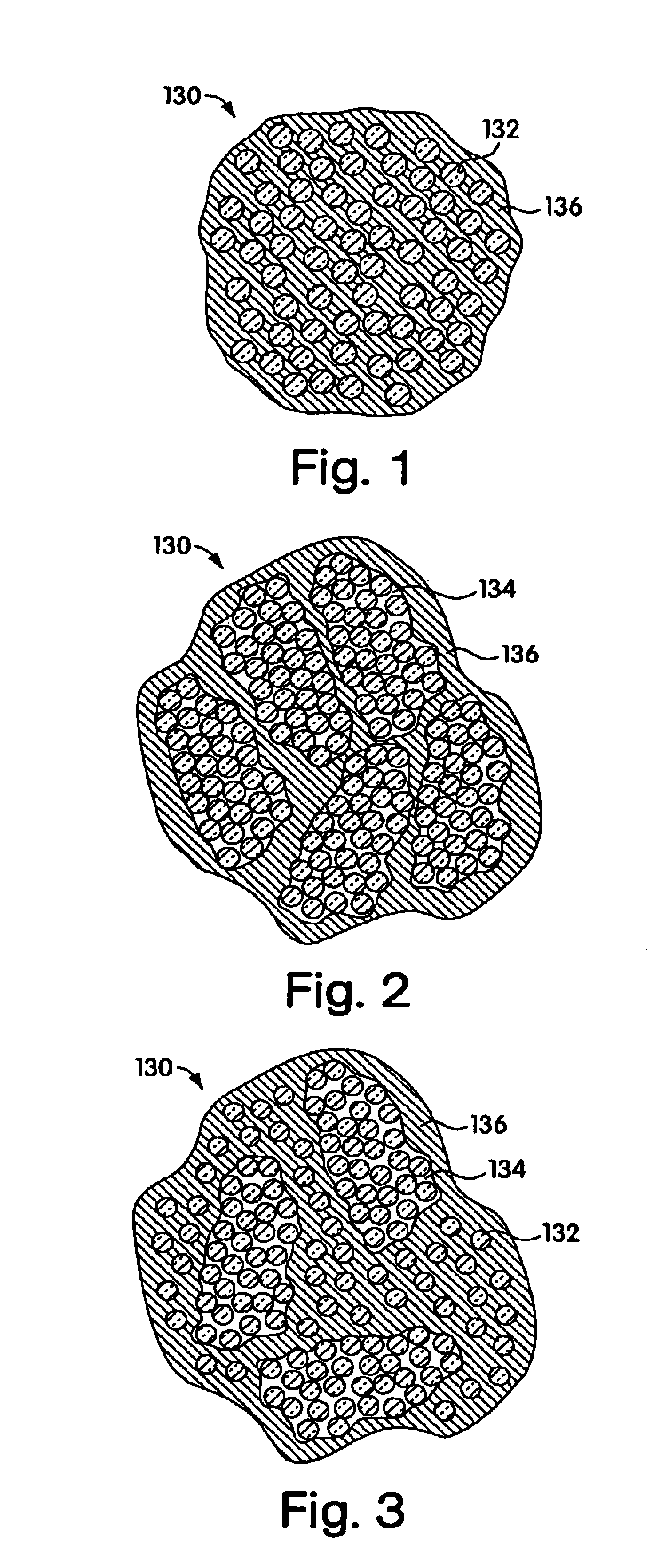

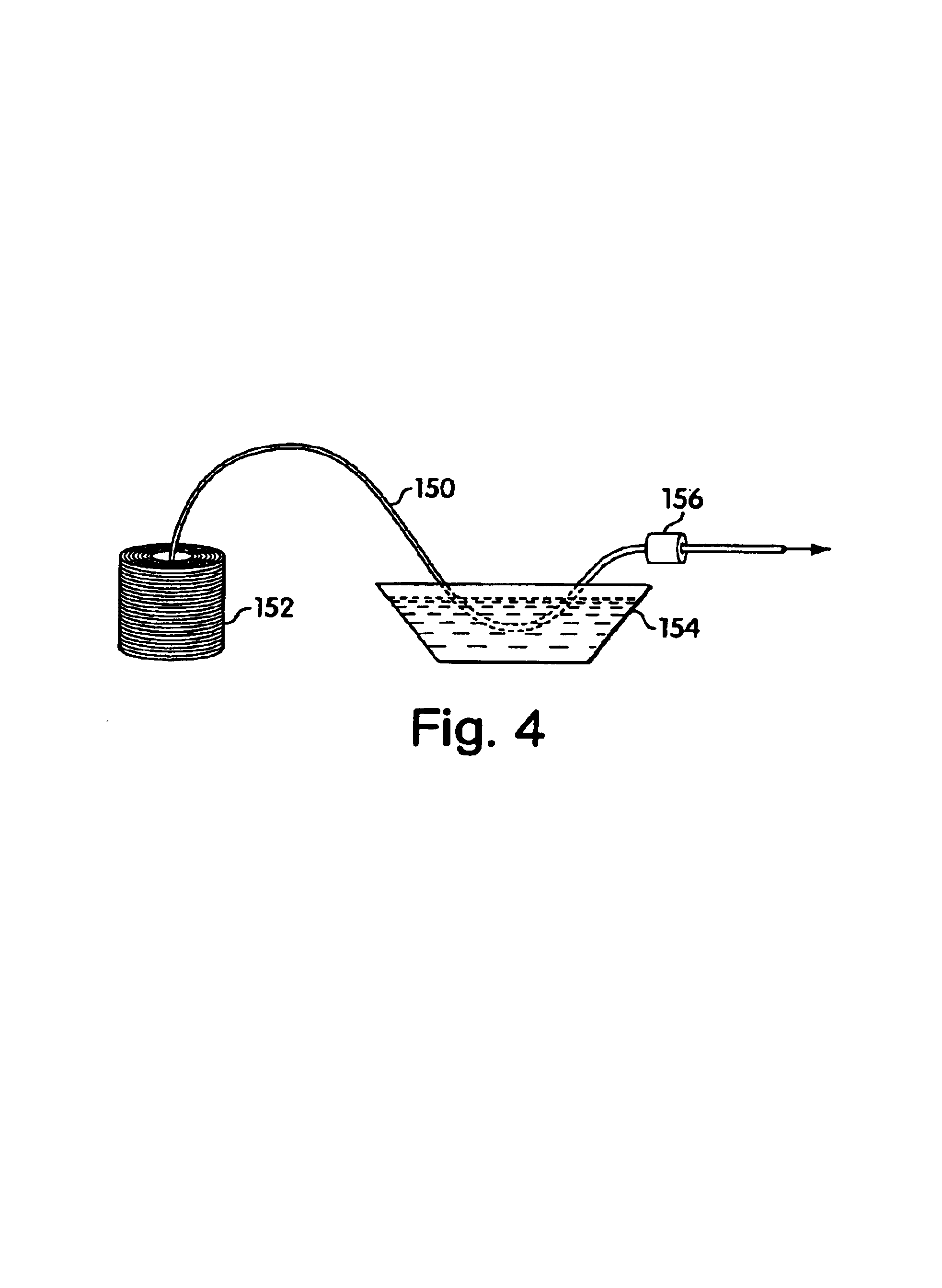

Controlled densification of fusible powders in laser sintering

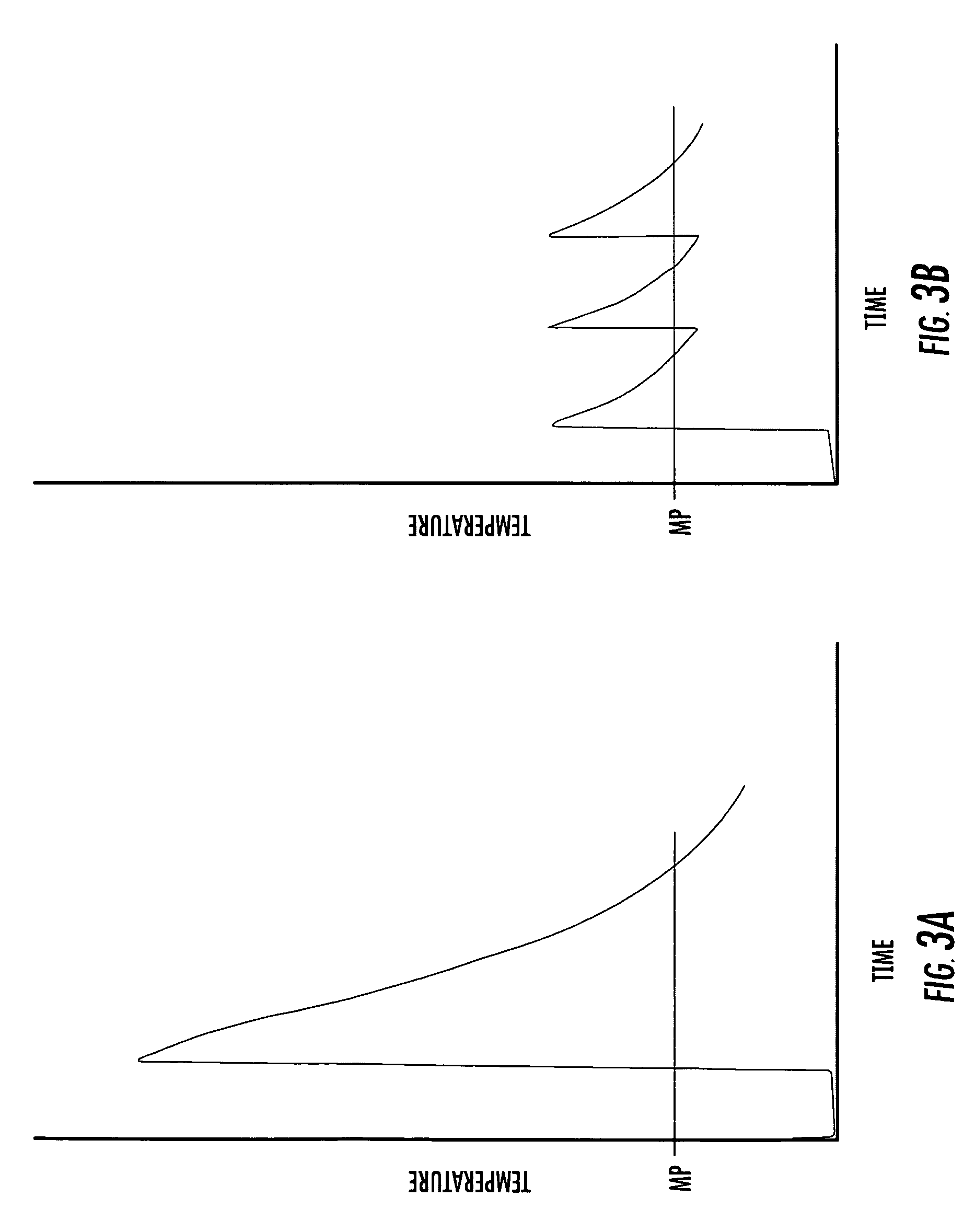

ActiveUS7569174B2Heat dissipationSimple methodAdditive manufacturing apparatusAuxillary shaping apparatusHigh energyTime segment

The invention relates to a method producing parts using laser sintering wherein a fusible powder is exposed to a plurality of laser scans at controlled energy levels and for time periods to melt and densify the powder and in the substantial absence of particle bonding outside the fusion boundary. Strength is improved up to 100% compared to previous methods. An example includes a relatively high energy initial scan to melt the powder followed by lower energy scans controlled to densify the melt and separated in time to dissipate heat to the surrounding part cake. The rate and extent to which the powder particles are fused together can be controlled so that each successive scan can be used to fuse the particles together in discreet incremental steps. As a result, the final dimensions of the part and its density and mechanical properties can be improved compared to conventional methods and part growth avoided.

Owner:3D SYST INC

Controlled densification of fusible powders in laser sintering

ActiveUS20060119012A1Heat dissipationSimple methodAdditive manufacturing apparatusAuxillary shaping apparatusHigh energyLaser scanning

The invention relates to a method producing parts using laser sintering wherein a fusible powder is exposed to a plurality of laser scans at controlled energy levels and for time periods to melt and densify the powder and in the substantial absence of particle bonding outside the fusion boundary. Strength is improved up to 100% compared to previous methods. An example includes a relatively high energy initial scan to melt the powder followed by lower energy scans controlled to densify the melt and separated in time to dissipate heat to the surrounding part cake. The rate and extent to which the powder particles are fused together can be controlled so that each successive scan can be used to fuse the particles together in discreet incremental steps. As a result, the final dimensions of the part and its density and mechanical properties can be improved compared to conventional methods and part growth avoided.

Owner:3D SYST INC

Melt-fabricable core/shell perfluoropolymer

InactiveUS7763680B2High viscosityIncrease in critical shear rateFibre treatmentCoatingsPolymer sciencePolymer

Owner:THE CHEMOURS CO FC LLC

Nanostructured chemicals as alloying agents in fluorinated polymers

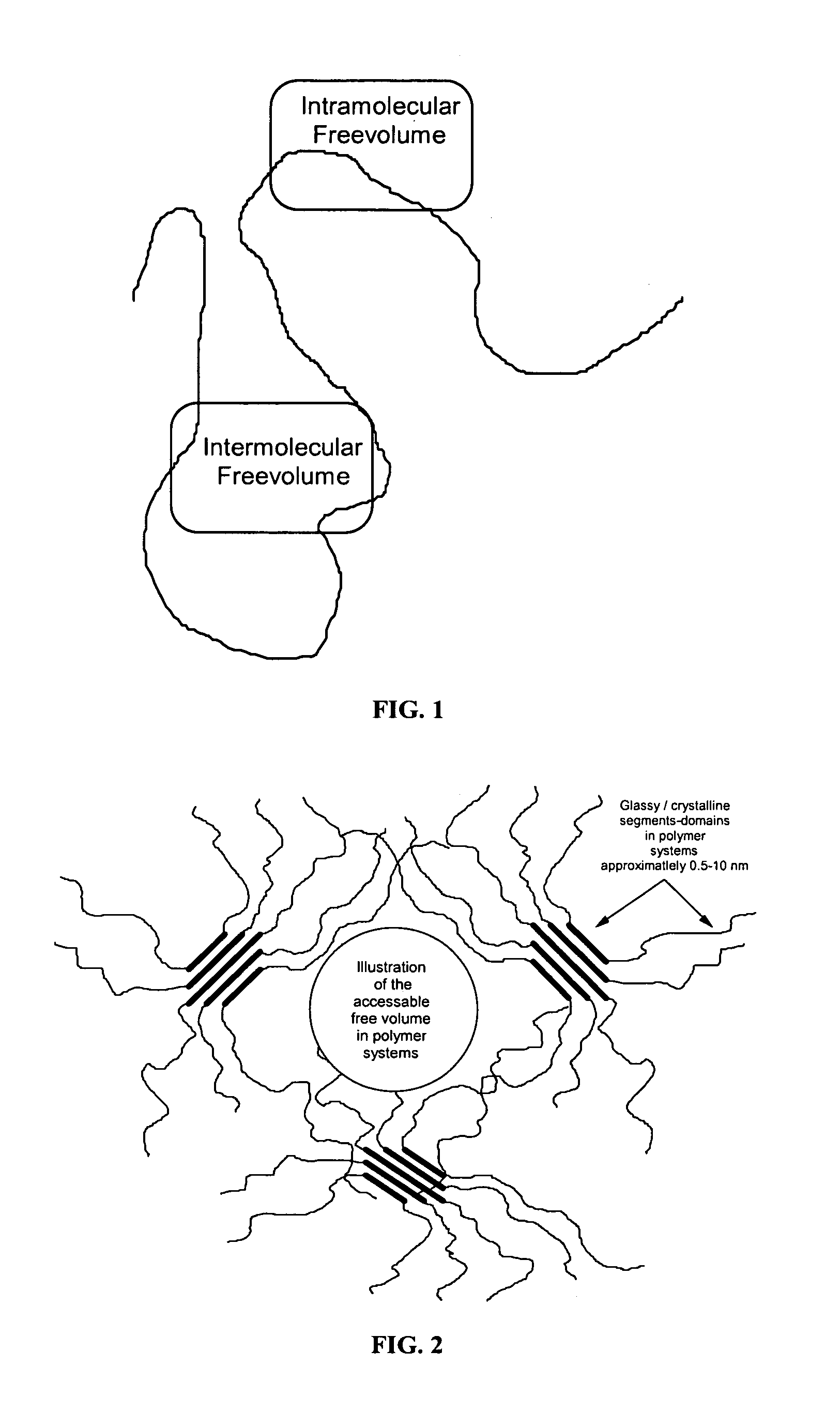

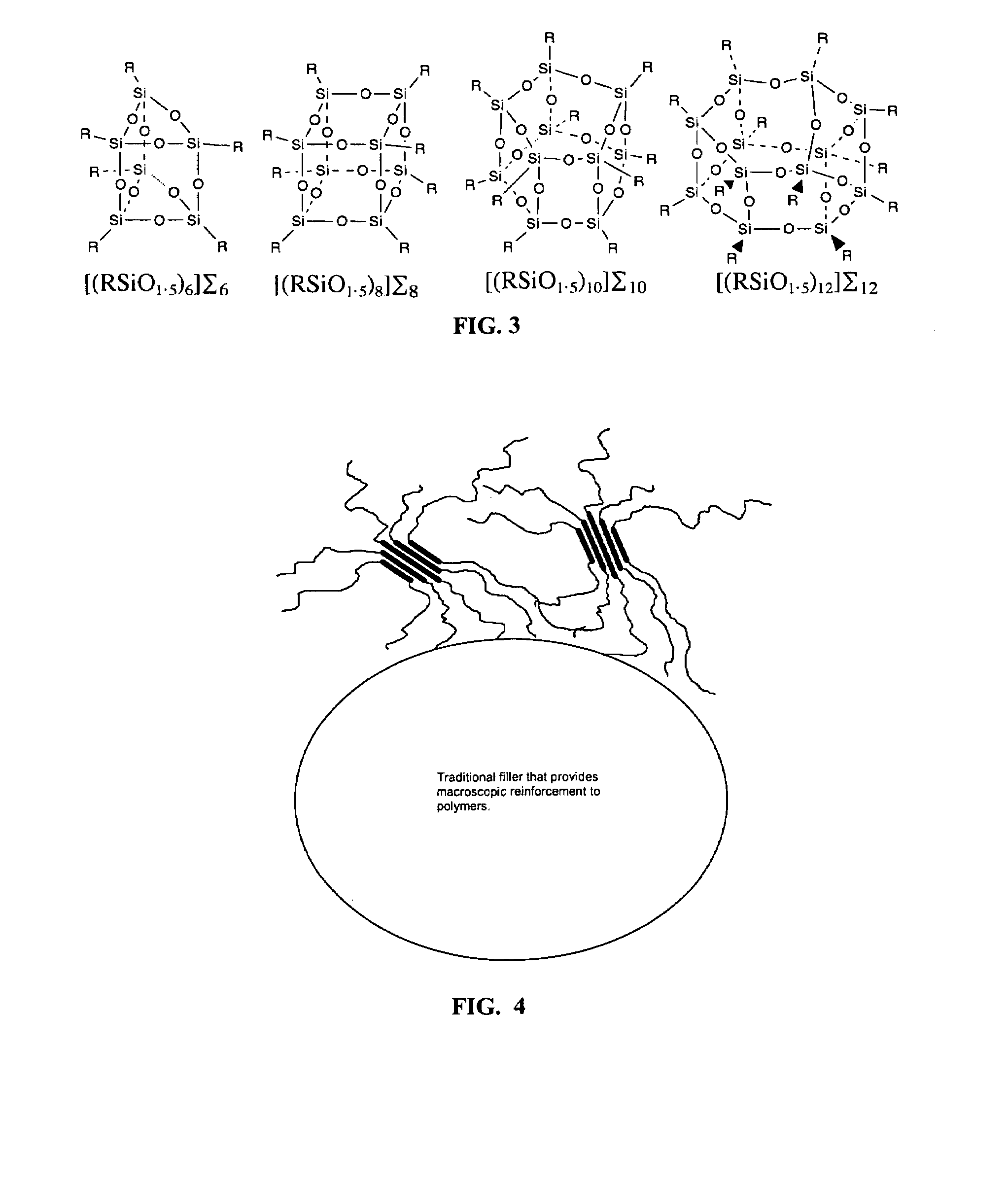

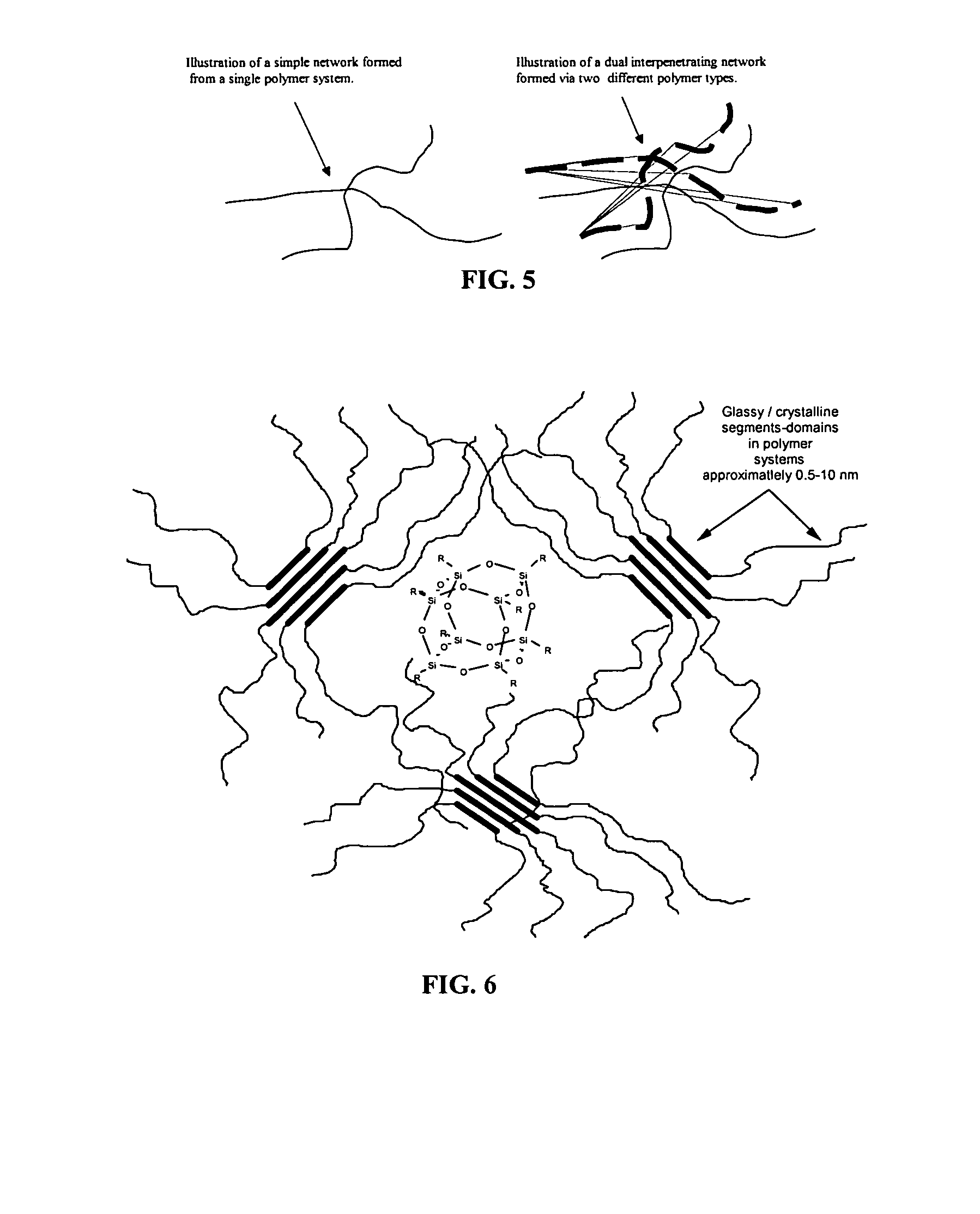

InactiveUS7193015B1Reduce melt viscosityLow dielectric constantMaterial nanotechnologyMolecular levelCompression set

A method of using nanostructured chemicals as alloying agents for the reinforcement of flouropolymer microstructures, including polymer coils, domains, chains, and segments, at the molecular level. Because of their tailorable compatibility with fluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending processes. Properties most favorably improved are time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and abrasion resistance. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, fire resistance, and improved oxygen permeability. These improved properties may be useful in a number of applications, including space-survivable materials and creep resistant seals and gaskets. Improved surface properties may be useful for applications such as anti-icing or non-wetting surfaces or as low friction surfaces.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

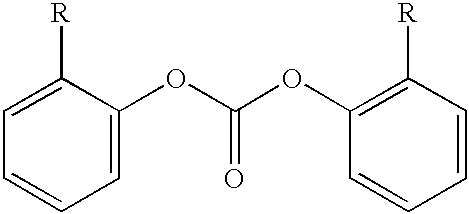

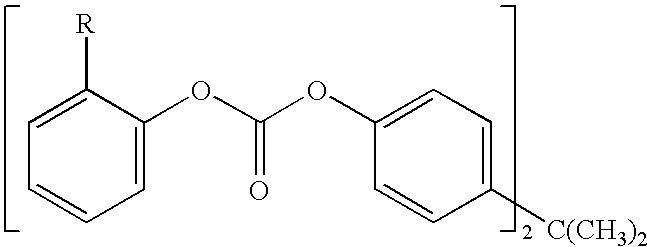

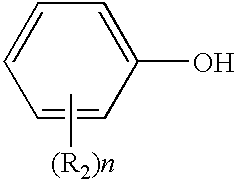

Method for end-capping polycarbonate resins and composition for use in same

A method for end-capping polycarbonate resins, comprising the step of processing a mixture comprising a polycarbonate having free hydroxyl-end groups and an end-capping reagent in a melt transesterification reaction to produce a polycarbonate resin, wherein the end-capping reagent comprises a mixture of: (a) at least one species of a symmetrical activated aromatic carbonate, and (b) at least one species of an optionally-substituted phenol, whereby said end-capping reagent reacts with at least some of the free hydroxyl end-groups of the polycarbonate to produce an end-capped polycarbonate resin.

Owner:SABIC GLOBAL TECH BV

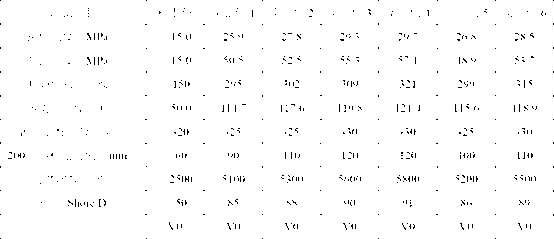

Low cost, high performance, rodent resistant, flexible reinforcement for communications cable

InactiveUS6897382B2Low costImprove performancePlastic/resin/waxes insulatorsPower cables with screens/conductive layersTelecommunicationsCopper

A low cost, high performance flexible, rodent resistant reinforcement member that can be used for both optical and copper communications cable. The reinforcement members made according to the preferred process are more rigid than known reinforcement members, but are less rigid than glass pultruded rods. Communications cables utilizing these members are lightweight and exhibit an improved combination of strength and flexibility compared to traditional communications cables. Further, these communication cables may then be installed into underground ducts using more economical and faster installation techniques.

Owner:NEPTCO JV LLC

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

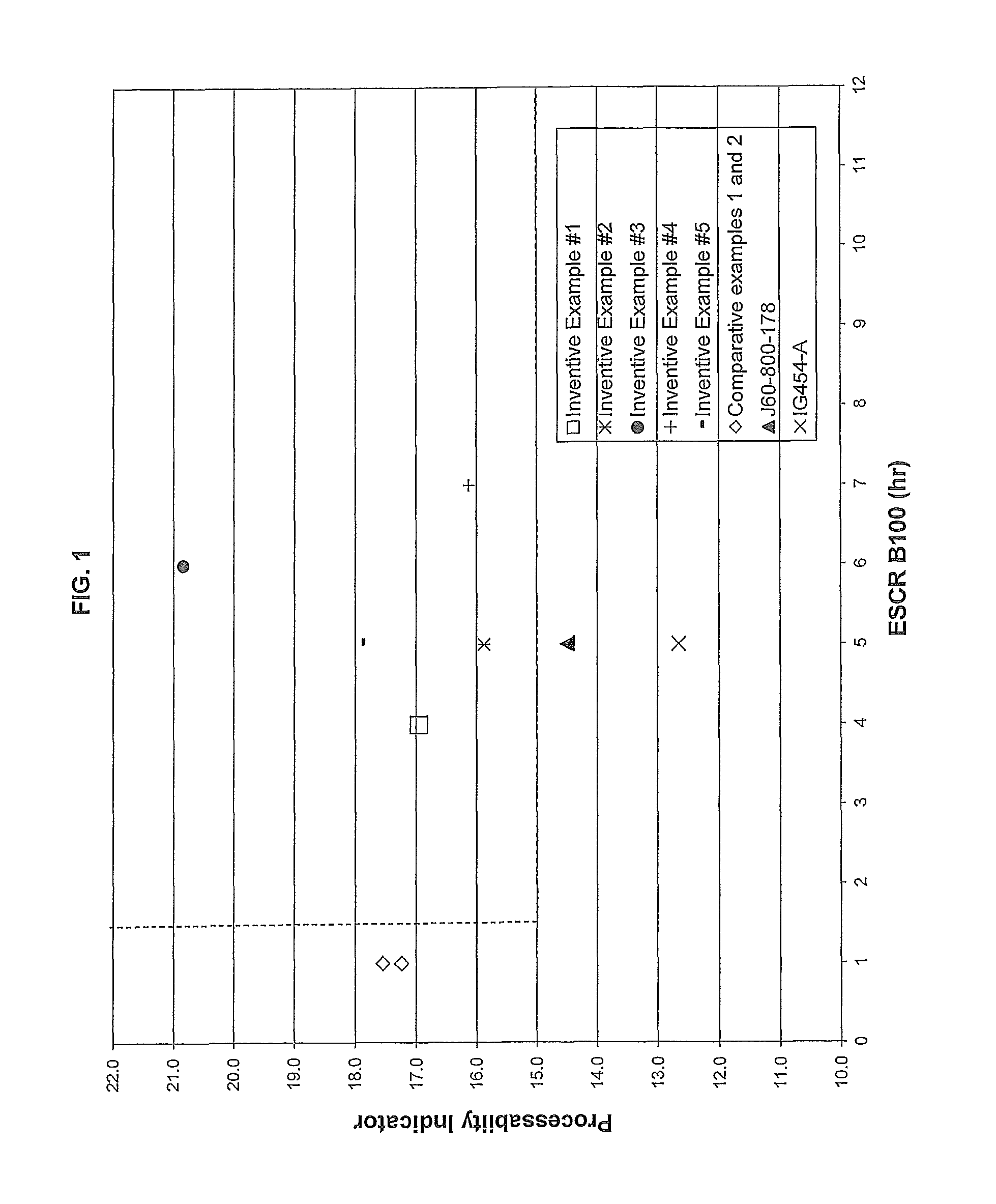

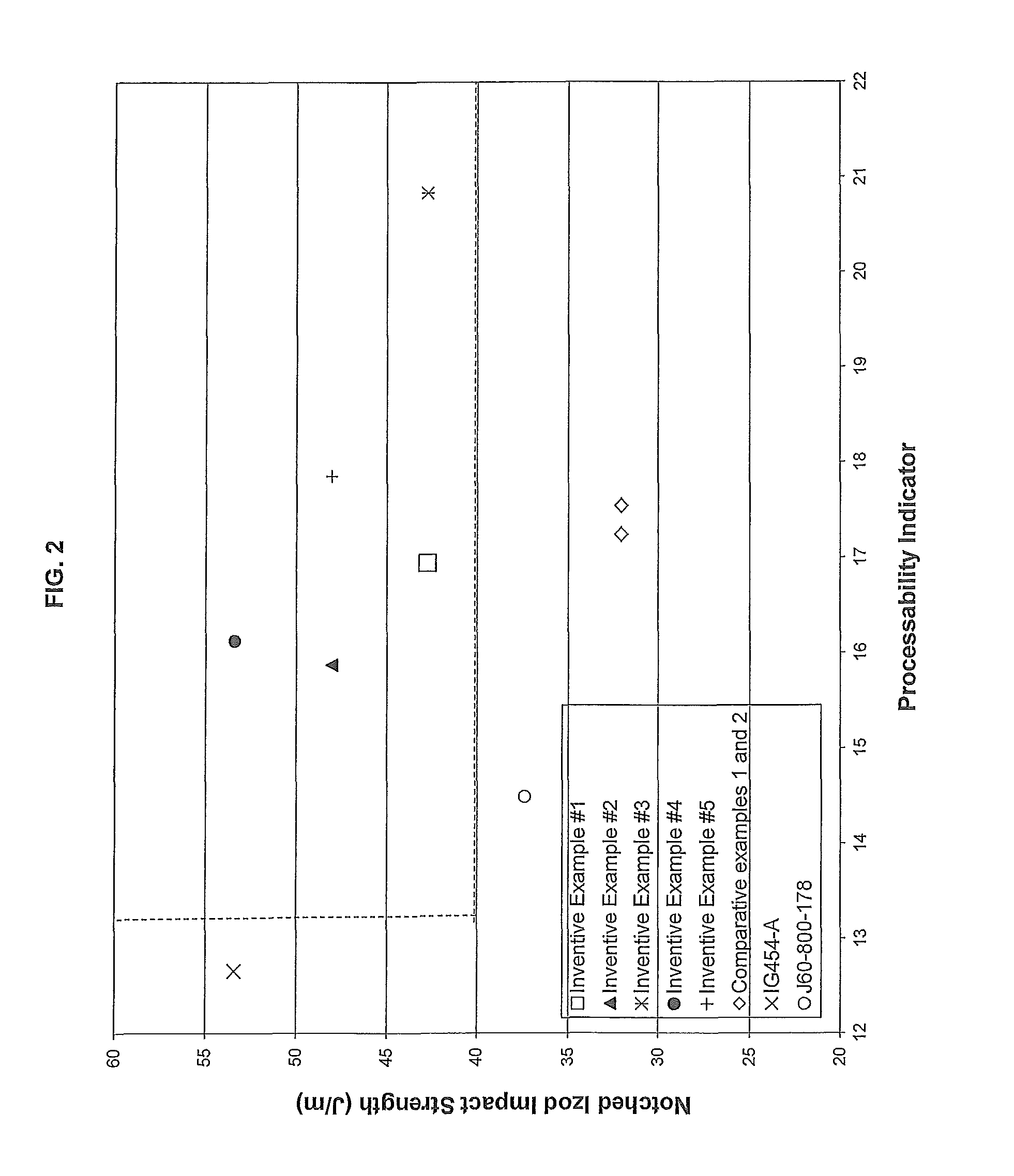

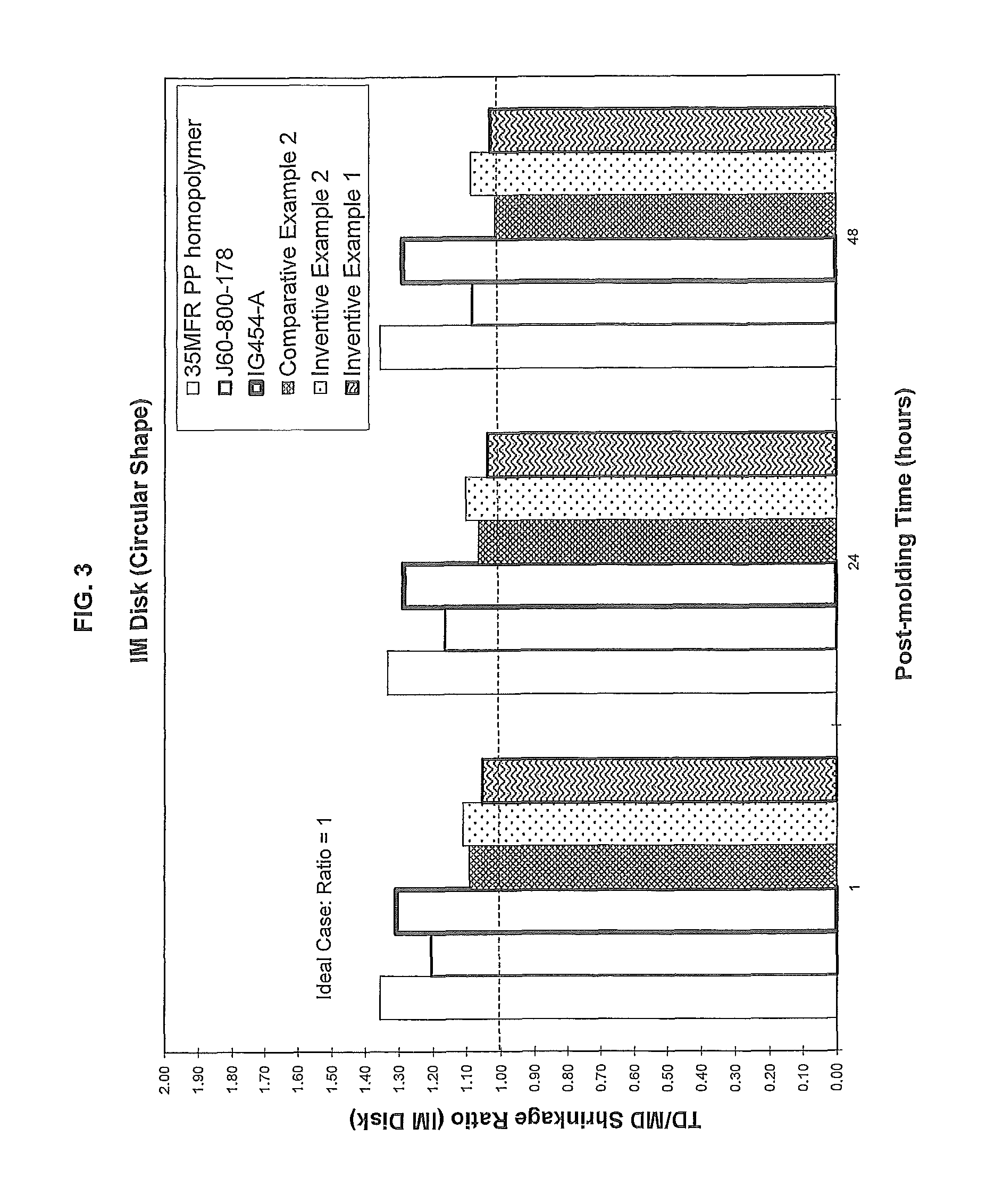

Polyethylene compositions having high dimensional stability and excellent processability for caps and closures

ActiveUS9074082B2Isotropic shrinkage ratioShrinkage differentialCapsClosure capsCompression moldingPolymer science

A dual reactor solution polymerization process gives high density polyethylene compositions containing a first ethylene copolymer and a second ethylene copolymer and which have high dimensional stability, excellent processability as well as good organoleptic properties and reasonable stress cracking resistance. The polyethylene compositions are suitable for compression molding or injection molding applications and are useful, for example, in the manufacture of caps and closures for bottles, and for example, in bottles containing non-pressurized liquids.

Owner:NOVA CHEM (INT) SA

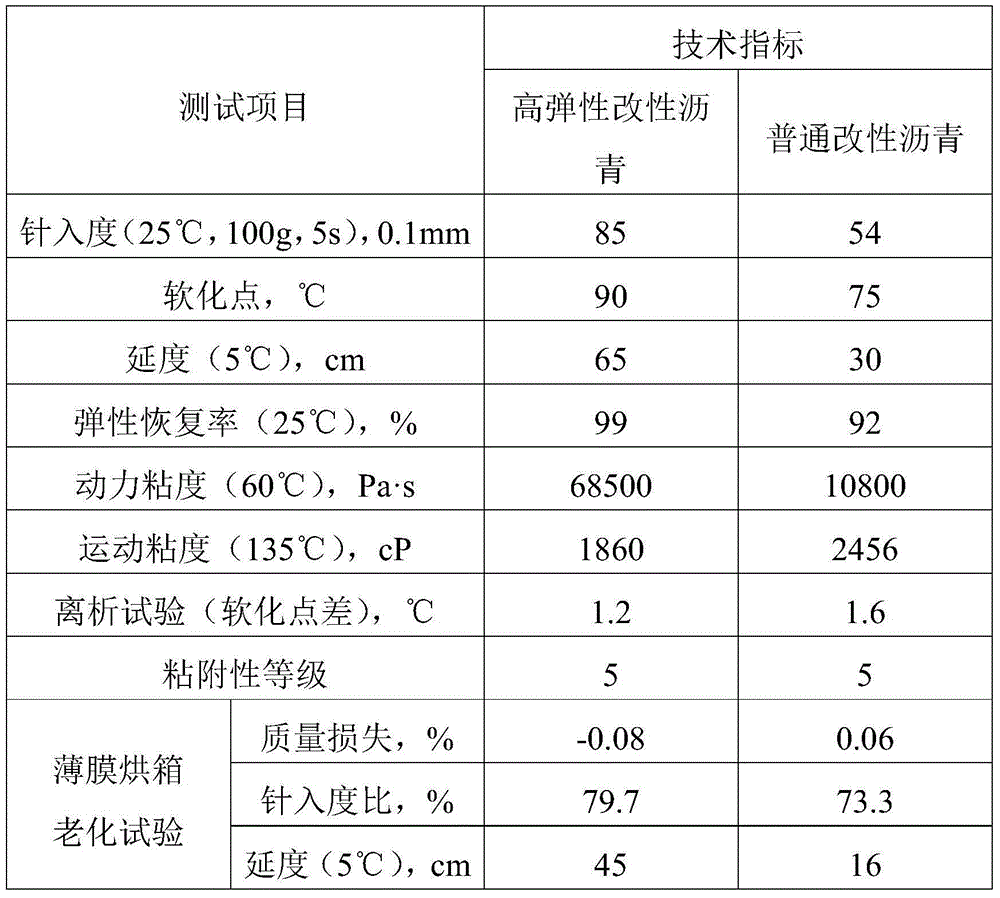

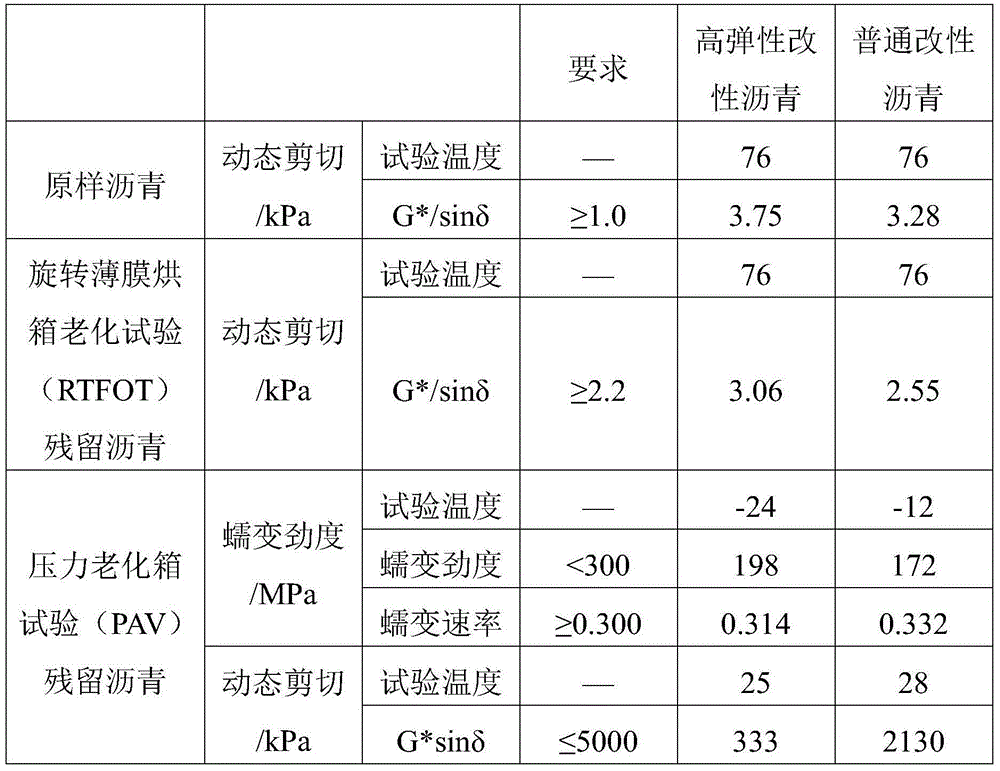

High-elasticity asphalt modified composition, modifier, modified asphalt, modified asphalt mixture and preparation method

ActiveCN104629391AImproved high temperature stability and elastic recoveryReduce melt viscosityBuilding insulationsButadiene-styrene rubberPlasticizer

The invention relates to a high-elasticity asphalt modified composition, a modifier, modified asphalt, a modified asphalt mixture and a preparation method. The modified composition comprises 100 parts of a styrene-butadiene-styrene segmented copolymer, 20-40 parts of a tackifier, 20-40 parts of a softener, 3-8 parts of a warm mixing agent, 15-40 parts of a plasticizer and 2-6 parts of a stabilizer. The preparation method of the modifier comprises the following steps: (1) mixing the styrene-butadiene-styrene segmented copolymer, the tackifier and the warm mixing agent according to a formula to obtain a melt; and (2) mixing the softener, the plasticizer and the stabilizer with the melt, and then extruding, cooling and dicing. The modified asphalt is prepared by doping the modifier into matrix asphalt and uniformly mixing. The modified asphalt mixture is prepared by mixing the modified asphalt and a raw material of a mineral mixture. The modified asphalt provided by the invention has good high-temperature and low-temperature stabilities and anti-fatigue capacity, and the modified asphalt mixture is strong in construction workability and good in pavement performance.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Hot melt adhesive

InactiveCN102653665ASuitable for production process requirementsReasonable formula designMacromolecular adhesive additivesEpoxyPolyolefin

The invention discloses a hot melt adhesive which comprises the following components in parts by mass: 5-10 parts of EVA (ethylene-co-vinyl acetate), 2-6 parts of tackifier, 5-10 parts of diluent, 0.5-1.5 parts of antioxidant and 0.5-1.5 parts of plasticizer. The tackifier is one of rosin resin, petroleum resin, terpene resin, phenolic resin and epoxy resin; the diluent includes one or both of wax and low-molecular polyolefin; the antioxidant is phenolic antioxidant; and the plasticizer is DCHP (Dicyclohexyl phthalate). The EVA contains 20-30% of vinyl acetate monomer; and the wax is microcrystalline wax with molecular weight of 3,000-4,000 and melting point of 65-85 DEG C.

Owner:成都鑫三洋科技发展有限公司

Powdered thermoplastic polyolefin composition having resilient properties

InactiveUS6218474B1Improved melting behaviourReduce melt viscosityCoatingsGeological measurementsElastomerCross-link

A thermoplastic polyolefin composition having resilient properties is provided for producing interior trims for motor vehicles by slush moulding. The composition contains (a) around 95-5 parts by weight, preferably 97-10 parts by weight of a matrix consisting of at least one polymer containing at least 50 mol % of propylene and at least one at least partially cross-linked polyolefin elastomer; (b) around 3-95 parts by weight, preferably 5-90 parts by weight of at least one polymer containing at least 50 mol % of ethylene; and (c) 0-6 parts by weight of an internal release agent per 100 parts by weight of components (a) and (b).

Owner:VISTEON SYST INTERIEURS

Process for preparing block copolymer and resulting composition

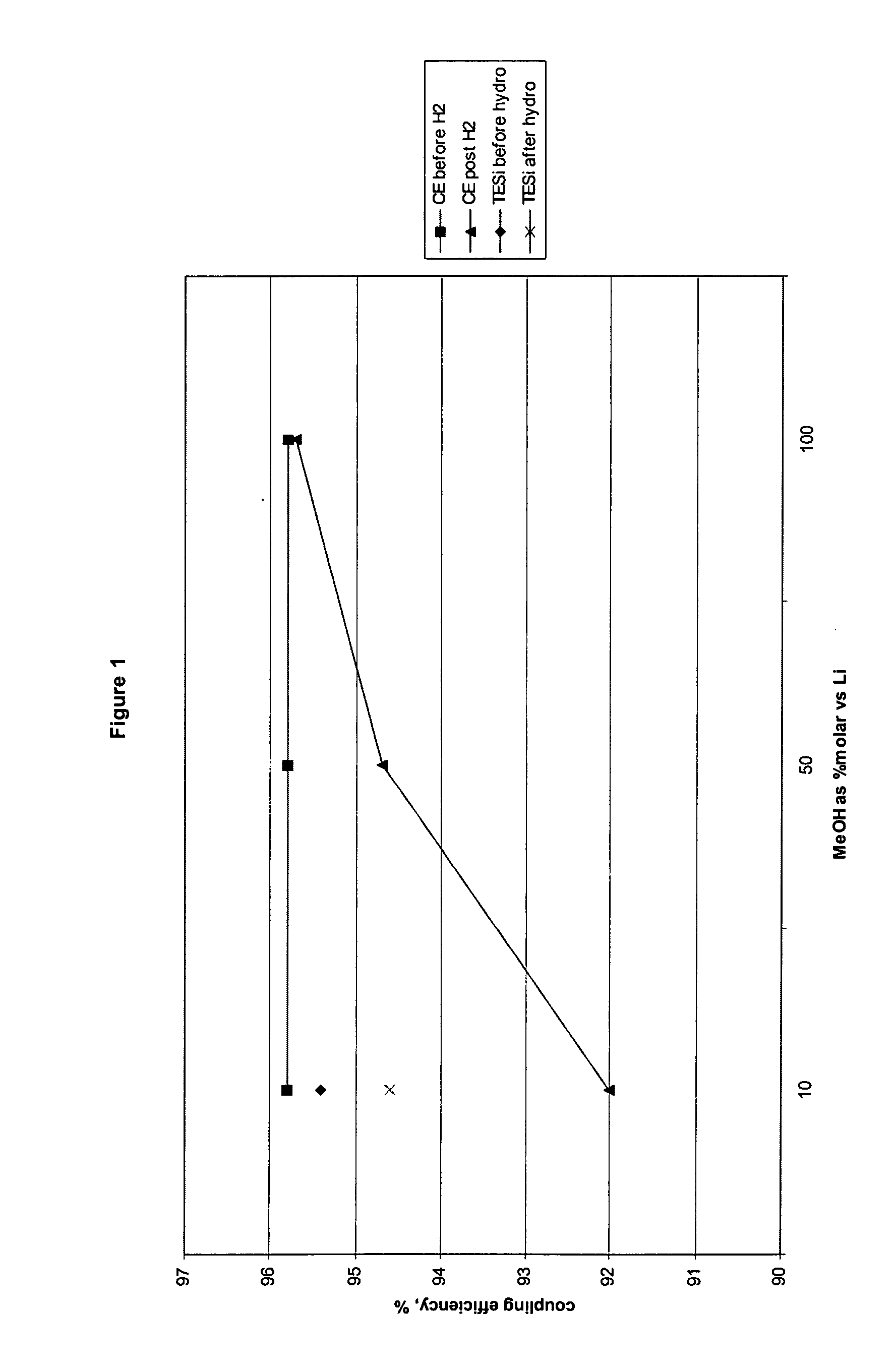

Lithium-terminated polymers of one or more conjugated dienes and of one or more mono alkenyl arenes are coupled by reaction with an alkoxy silane coupling agent having the formula Rx—Si—(OR′)y, where x is 0 or 1, x+y=4, R and R′ are the same or different, R is selected from aryl hydrocarbon radicals, linear alkyl hydrocarbon radicals and branched alkyl hydrocarbon radicals, and R′ is selected from linear and branched alkyl hydrocarbon radicals, such that the resulting polymer composition contains less than about ten weight percent of uncoupled polymer diblock. The polymer compositions are subsequently selectively hydrogenated, and are useful in a variety of compounds and end use applications.

Owner:KRATON POLYMERS US LLC

Method to prepare processable polyimides with reactive endgroups using 1,3-bis (3-aminophenoxy) benzene

InactiveUS6133401AImprove adhesionImprove composite effectSynthetic resin layered productsThin material handlingSolubilityAdhesive

Polyimide copolymers were obtained containing 1,3-bis(3-aminophenoxy)benzene (APB) and other diamines and dianhydrides and terminating with the appropriate amount of reactive endcapper. The reactive endcappers studied include but should not be limited to 4-phenylethynyl phthalic anhydride (PEPA), 3-aminophenoxy-4'-phenylethynylbenzophenone (3-APEB), maleic anhydride (MA) and nadic anhydride (5-norbornene-2,3-dicarboxylic anhydride, NA). Homopolymers containing only other diamines and dianhydrides which are not processable under conditions described previously can be made processable by incorporating various amounts of APB, depending on the chemical structures of the diamines and dianhydrides used. By simply changing the ratio of APB to the other diamine in the polyimide backbone, a material with a unique combination of solubility, Tg, Tm, melt viscosity, toughness and elevated temperature mechanical properties can be prepared. The copolymers that result from using APB to enhance processability have a unique combination of properties that include low pressure processing (200 psi and below), long term melt stability (several hours at 300 DEG C. for the phenylethynyl terminated polymers), high toughness, improved solvent resistance, improved adhesive properties, and improved composite mechanical properties. These copolyimides are eminently suitable as adhesives, composite matrices, moldings, films and coatings.

Owner:NAT AERONAUTICS & SPACE ADMINSTRATION NASA THE

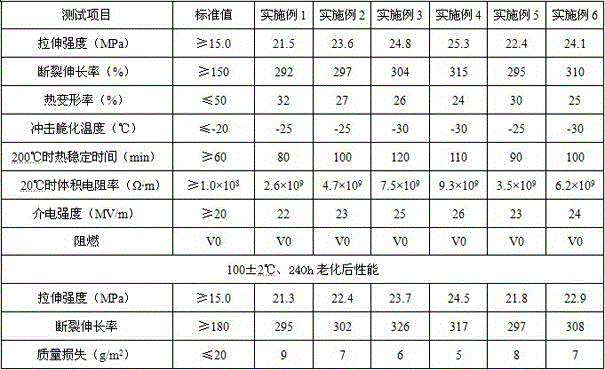

High-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and preparation method thereof

ActiveCN103059470AImprove wear resistanceImprove wet skid resistancePolymer sciencePolyvinyl chloride

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a high-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and a preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials. The modified materials comprise following raw materials, by weight, 80-120 parts of PVC resin, 5-15 parts of stuffing bulking agents, 31-70 parts of plasticizer, 1-10 parts of abrasion resistant modifying agents, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 10-20 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to the weight and are blended, after the raw materials are stirred, the stirred raw materials are extruded to be granulated into particles through a double-screw extruder to produce the modified materials. The prepared modified materials are good in abrasion resistant property, environment-friendly, high in strength, good in flame retardant efficiency, strong in compression property and toughness, good in processing property, and good in comprehensive property. The preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials is simple in craft, convenient to operate and control, stable in quality and high in production efficiency and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

High-temperature resistant flame-retardant environment-friendly PVC (polyvinyl chloride) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

Novel fire resistant polyimide foam and method of producing the same

The invention relates a novel high temperature resistant polyimide foam and the preparation process thereof is as follows: (1) firstly, 2, 3, 3', 4'-biphenyl tetracarboxylic dianhydride or 2, 3, 3', 4'-biphenyl tetracarboxylic dianhydride and another type of aromatic dianhydride are heated and refluxed in a fatty alcohol solution so as to change the tetracarboxylic dianhydride into diacid diester; (2) in accordance with a certain proportion, the obtained diacid diester is synthesized into a precursor solution with one type or more of aromatic diamine and a blocking agent of acetylenyl benzene and a certain quantity of foam stabilizer is added into the solution; (3) the solution is heated to remove tiny molecule volatile matter and obtain a polymide precursor powder; and (4) the precursor powder is filled into a mould to be frothed at high temperature and carries out imidization so as to obtain the polyimide foam. The density of the novel high temperature resistant polyimide foam is 10 kg / m<3> to 500 kg / m<3> and the vitrified transformation temperature is over 350 DEG C; and the foam is characterized by excellent high temperature resistance, low temperature resistance, mechanical properties and functions of anti flaming, heat insulation or noise reduction.

Owner:SHENZHEN HIFUTURE ELECTRIC

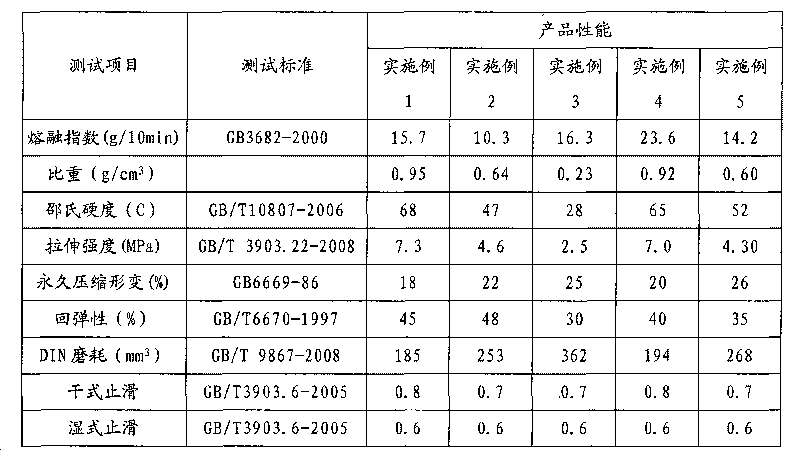

Styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, preparation method and application method thereof

The invention discloses a styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, a preparation method and an application method thereof. The preparation method takes styrene-butadiene copolymer mixing random structure with block structure as base material, and adds flow modifier or softener to regulate the fluidity of rubber. Rubber compositions manufactured by the method have good fluidity and can be molded directly through injection. Chemical foaming agents added reduces product density and effectively achieves the aim of obtaining lightweight material. Post partial chemical crosslinking can be performed so as to improve the stress cracking resistance and wear resistance of the material. Meanwhile, as the partial physical crosslinking of the styrene-butadiene copolymer allows the material to overcome the defect that all-chemical crosslinked rubber cannot be regenerated, the material can be recycled and regenerated.

Owner:浙江仕峰实业有限公司

Hydrotalcite-rare earth-calcium zinc stablizer for PVC and its preparation method

InactiveCN101007878AImprove long-term thermal stabilityGood initial colorabilityChemical synthesisHydrotalcite

The invention discloses a PVC hydrotalcite- rare earth- calcium zinc stabilizing agent and the method for preparing the same, which in detail erlates to plastic composite stabilizing agent and the preaparing method, belonging to chemical field. The main component for stabilizing comprises column- supported hydrotalcite, unsaturated rare earth, and epoxy aliphatic acid calcium zinc, and it is prepared through chemical synthesis, reformed treatment and optimization compound. The product is characterized by outstanding thermal stabilizing effect, good first stage coloring property, sound plasticizing property, good transparenty, weatherability, improved quality, high effeciciency, no toxicity, no pollution, low cost. It can replace expensive organotin thermal stabilizing agent and is widely used in PVC product preparation, such as water- supply pipes, section bar, transparent granulate, film, medical apparatus, toy, fridge stamp and box sheet material.

Owner:扬州科宇化工有限公司

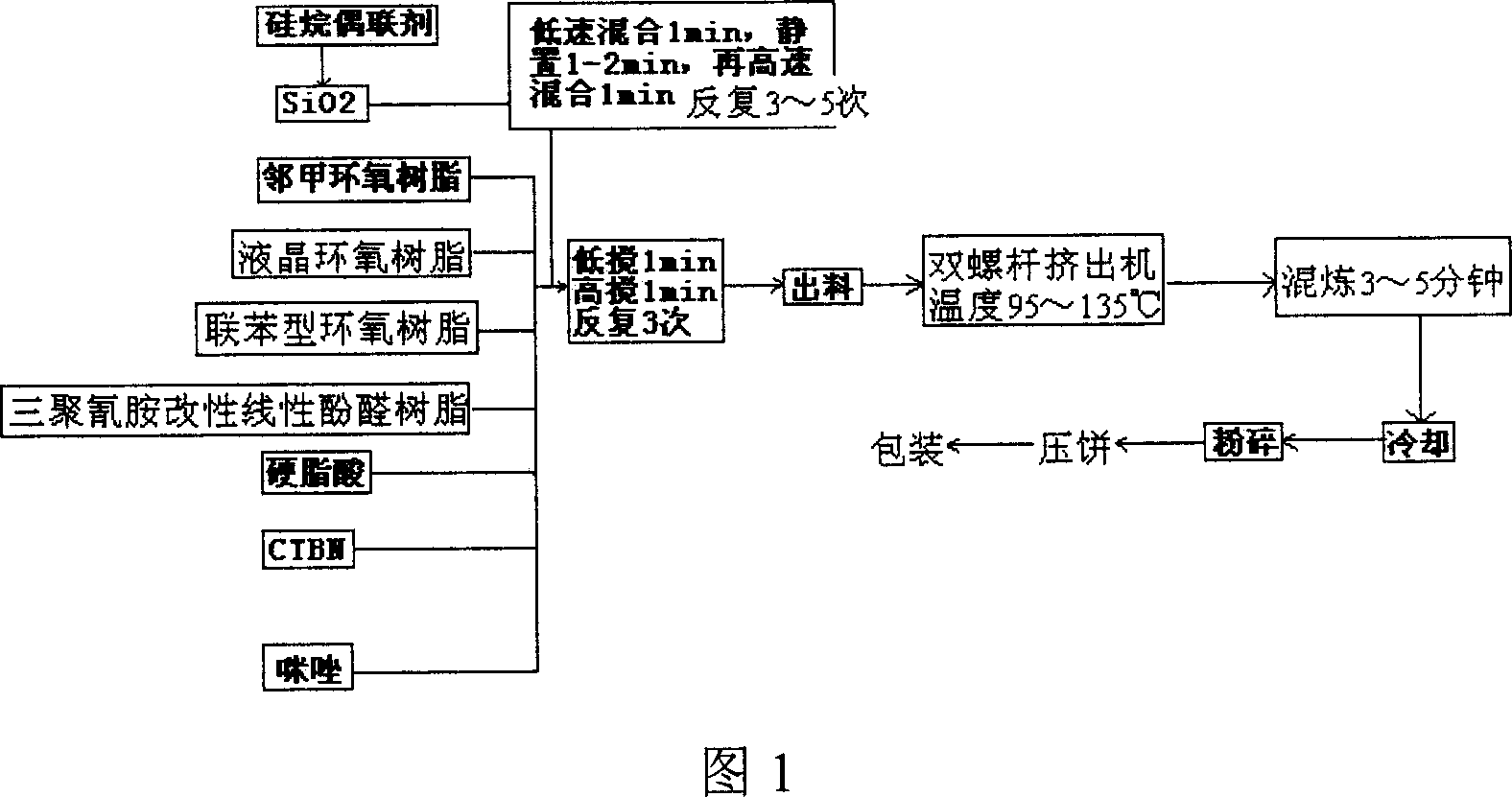

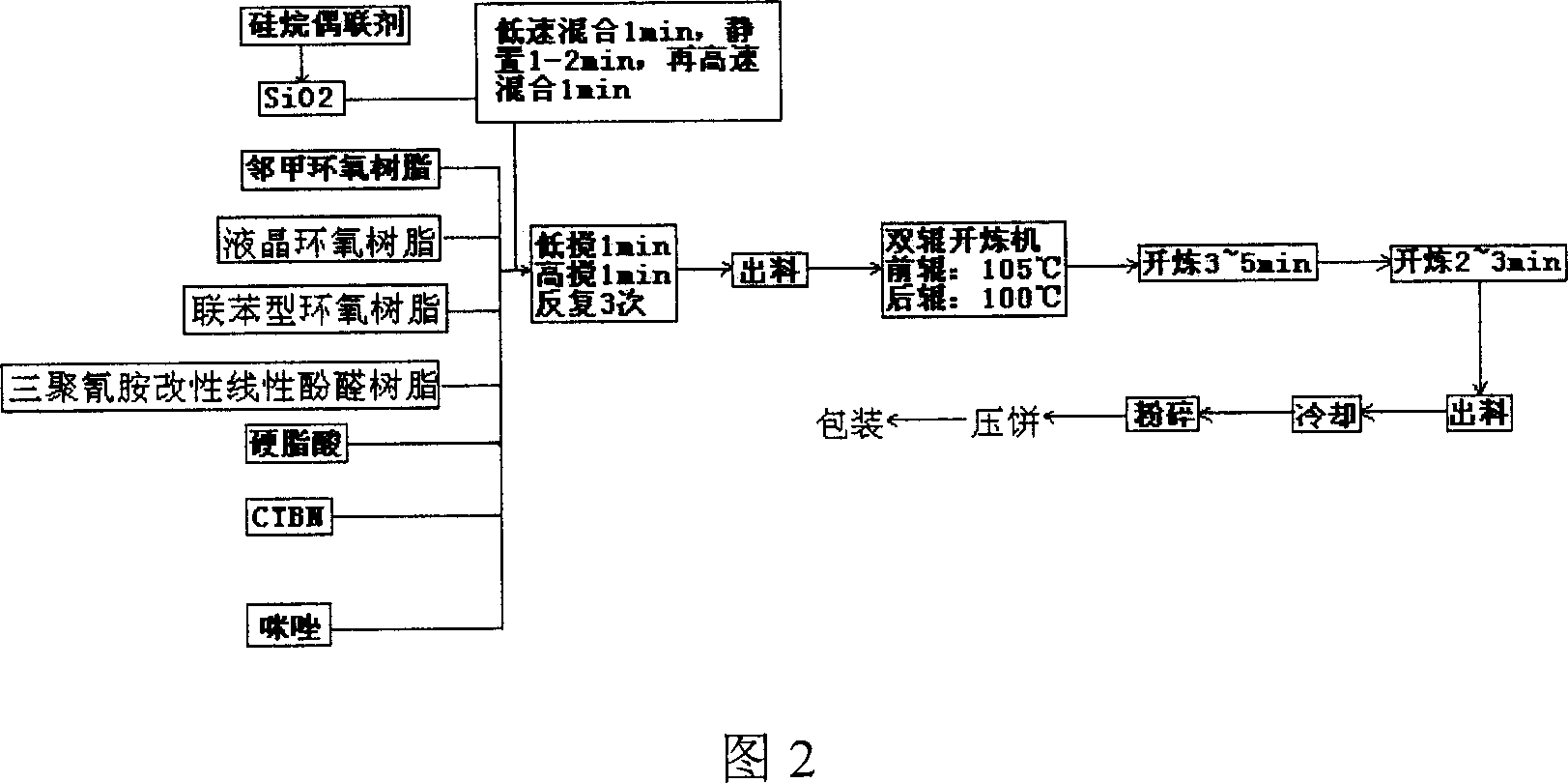

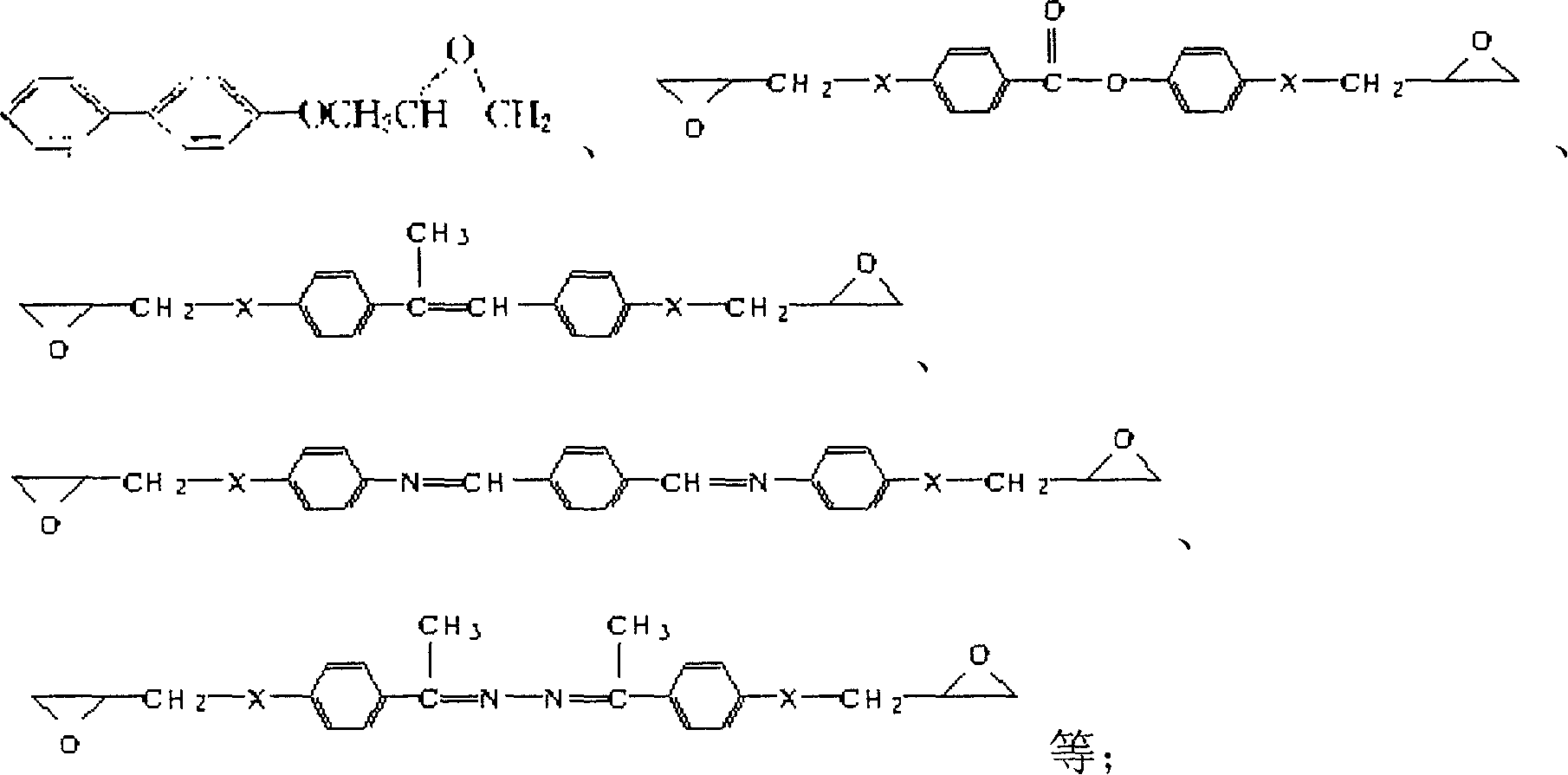

Epoxy-resin mould plastic for packing IC circuit and its production

InactiveCN101029165AHigh glass transition temperatureReduce melt viscositySemiconductor/solid-state device detailsSolid-state devicesEpoxyThermal expansion

An epoxy resin mold plastic and its production are disclosed. The mold plastic consists of liquid-crystal epoxy resin, methyl-phenolic epoxy resin, epoxy resin containing biphenyl unit structure, melamine modified linear phenolic resin, silicone micro-powder, imidazo curing improver, toughening agent and silane coupling agent. The process is carried out by treating silicone micro-powder in mixer by coupling agent for 2-5mins, adding into other components, mixing for 3-5mins, melt milling at 95-135 degree for 3-5mins, cooling, crushing, mesh screening, pressing into material cake and storing below 6degree. Its advantages include low thermal expansion coefficient, excellent heat and fire resistances, better toughness and fluidity, no phosphor, no antimony and environmental pollution. It can be used to pack large-scale circuit and electronic devices.

Owner:GUANGDONG RONGTAI IND

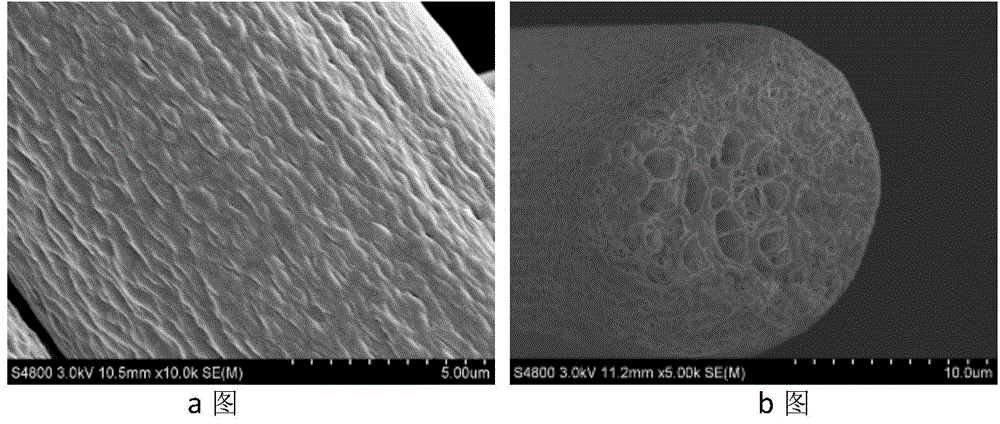

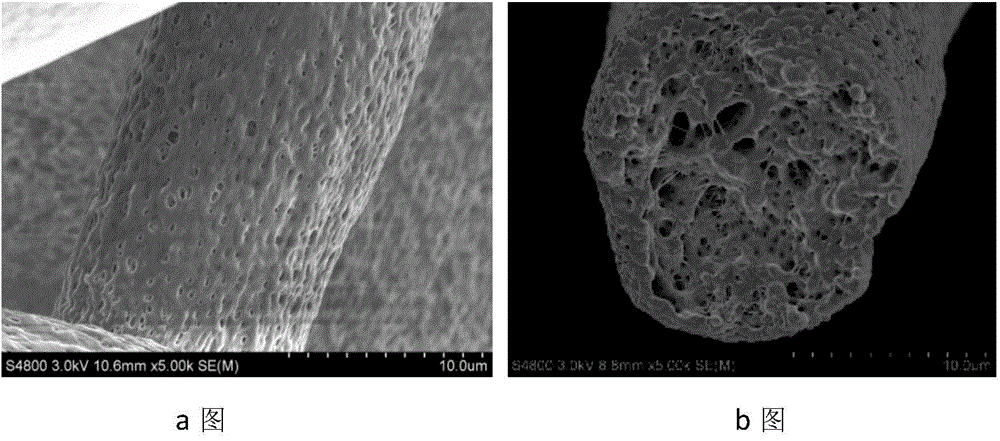

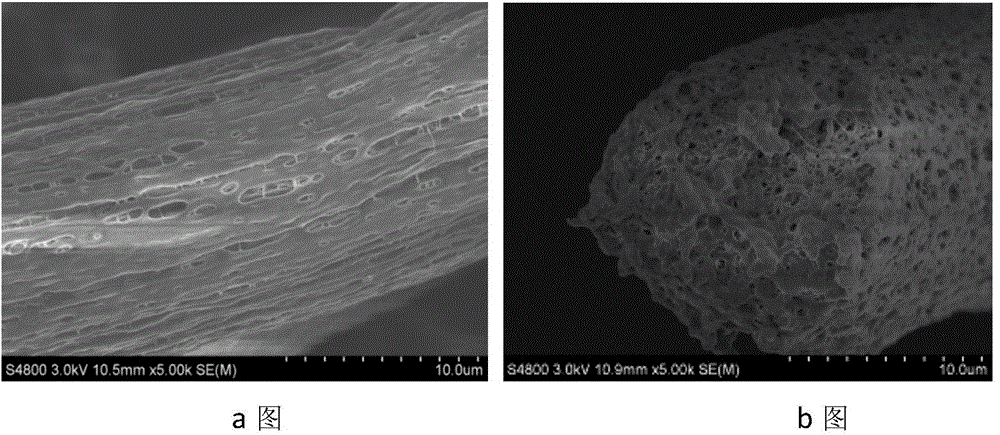

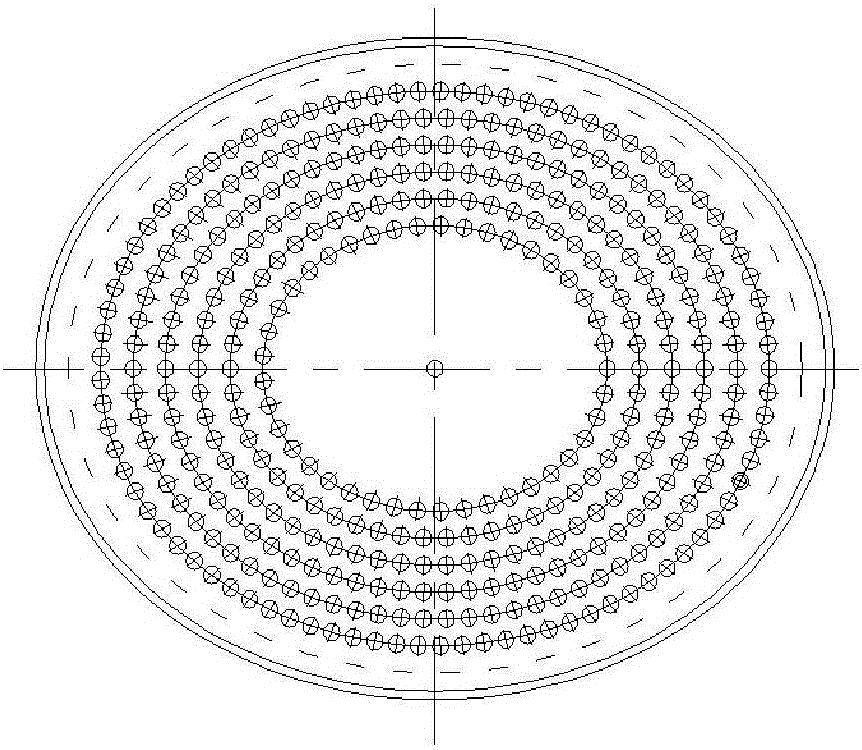

Multi-hole polyester fiber DTY (draw textured yarn) and preparation method thereof

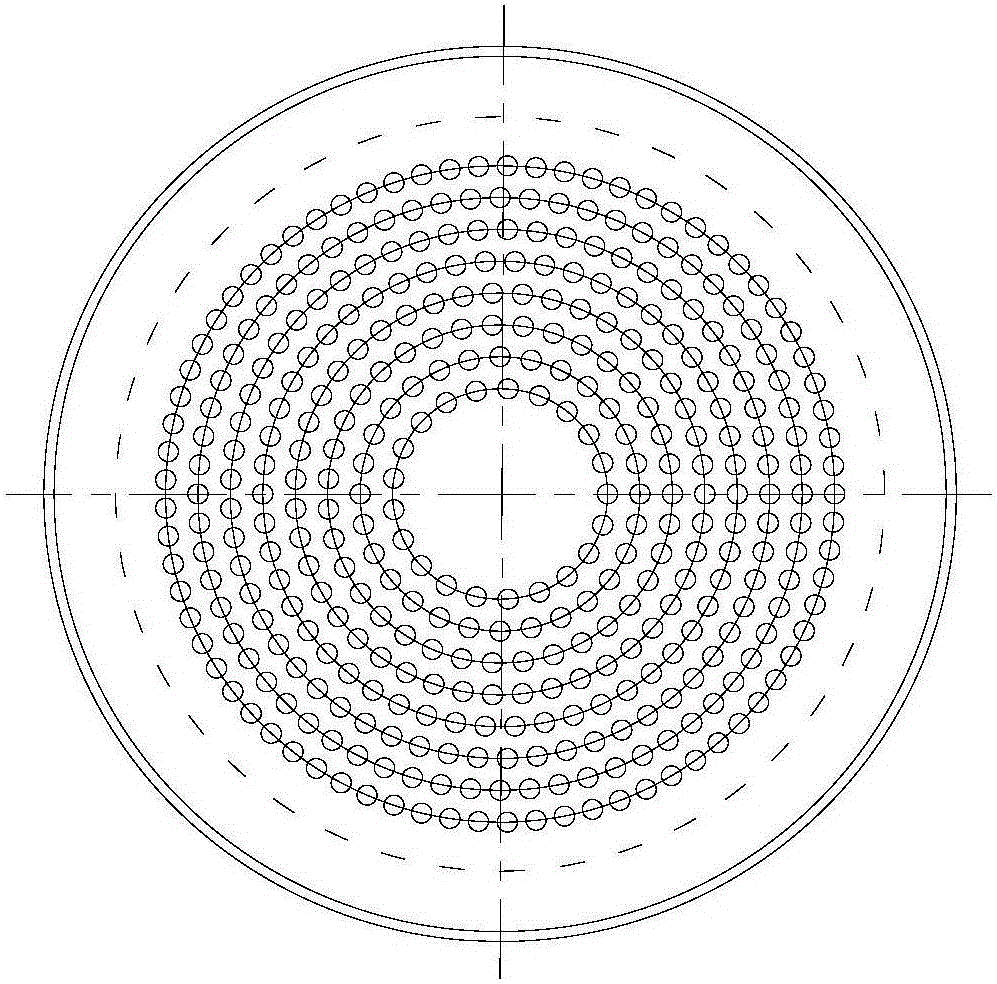

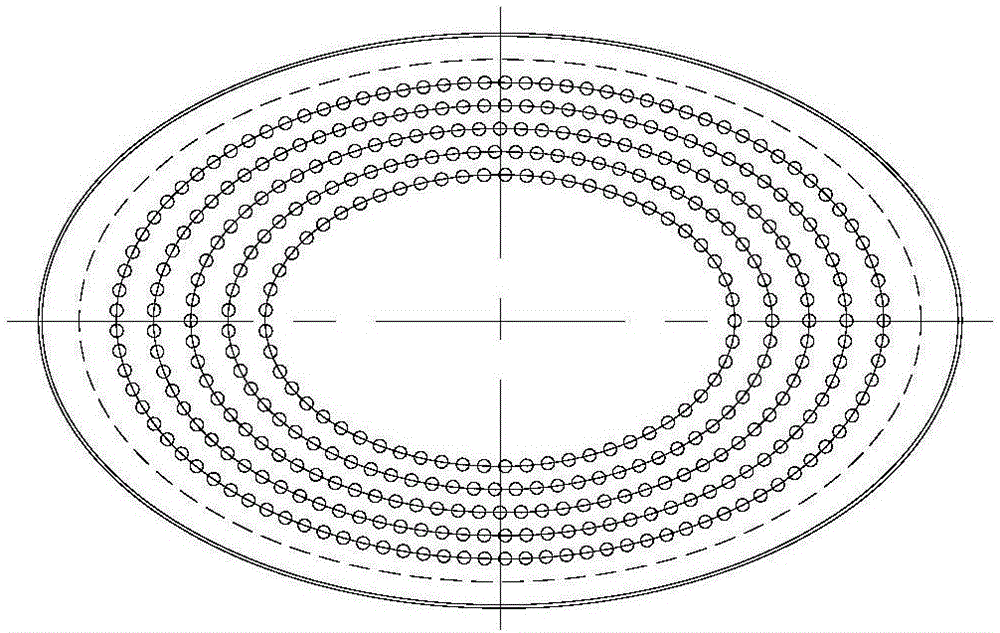

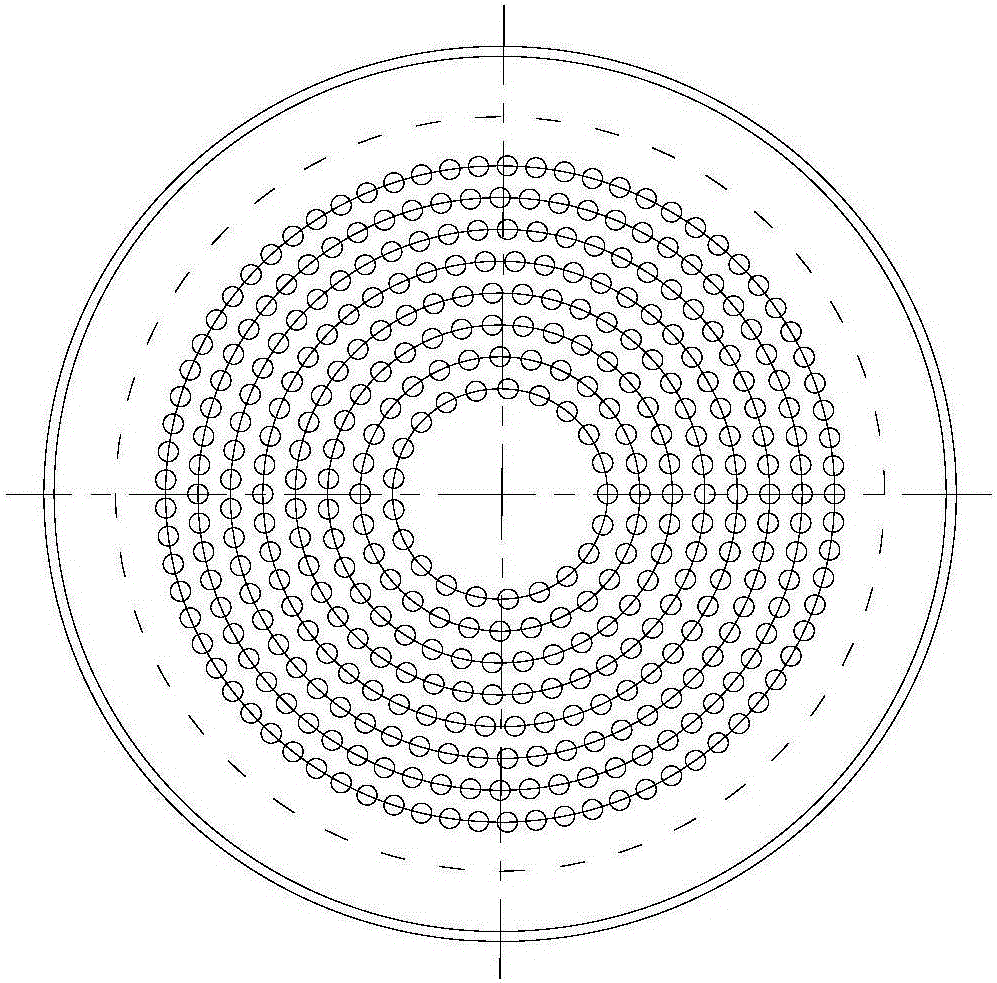

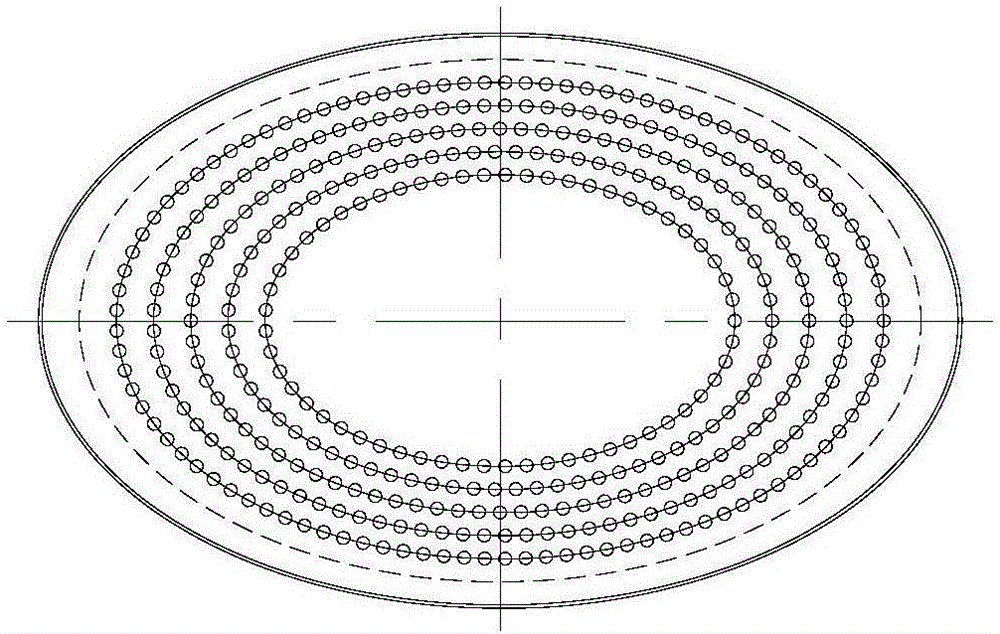

ActiveCN106283253AIncreased access to polyester interiorImprove cooling effectSpinnerette packsMonocomponent copolyesters artificial filamentFiberYarn

The invention relates to a multi-hole polyester fiber DTY (draw textured yarn) and a preparation method thereof. According to the preparation method, modified polyester is spun to prepare the multi-hole polyester fiber DTY by the aid of a multi-hole spinneret plate; spinneret holes in the multi-hole spinneret plate are elliptically arrayed, namely, the hole centers of the spinneret holes are positioned on concentric ellipses, the concentric ellipses are series ellipses, long axes of the all ellipses are collinear, short axes of the all ellipses are collinear, the modified polyester is used for preparing a POY (polyester pre-oriented yarn) and then further processed to obtain the multi-hole polyester fiber DTY. A preparation method of the modified polyester includes the steps: performing reaction for terephthalic acid and ethylene glycol to prepare terephthalic acid ethylene glycol ester; adding the terephthalic acid and dihydric alcohol with branching chains, and performing reaction for mixture to prepare terephthalic acid dihydric alcohol ester; continuing to react to obtain the modified polyester. According to the method, prepared fibers are excellent in performance, the deviation ratio of linear density of the DTY is smaller than or equal to 2.0%, a breaking strength CV (variation coefficient) value is smaller than or equal to 4.0%, a breaking elongation CV value is smaller than or equal to 8.0%, and a CV value of crimping shrinkage rate is smaller than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

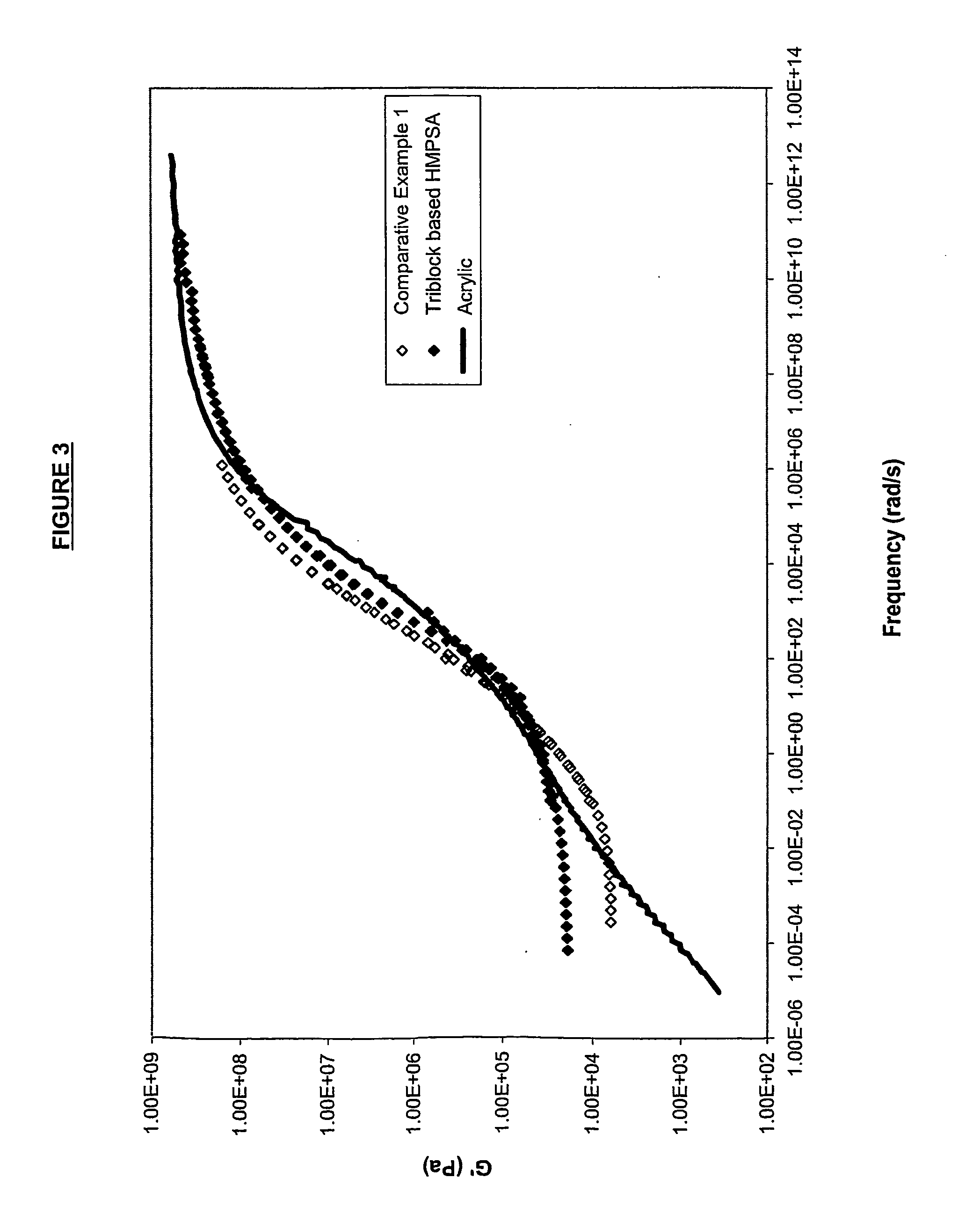

Aromatic vinyl/isoprene block copolymer, process for the production thereof, and hardenable pressure-sensitive adhesive composition containing the same

An aromatic vinyl compound-isoprene block copolymer composition comprising (i) 5-50 wt. % a branched copolymer of the formula: (A-B)nX wherein A is a polymer block of an aromatic vinyl monomer, B is a polymer block of isoprene, and X is a residue of a polyfunctional coupling agent, and (ii) 50-95 wt. % of a diblock copolymer of the formula: A-B wherein A and B are as defined above. This copolymer composition is produced by allowing an aromatic vinyl monomer to contact with an organic lithium initiator to prepare a polymer block A; incorporating isoprene thereto to prepare a diblock copolymer A-B; and then, adding a polyfunctional coupling agent to convert a part of the diblock copolymer A-B to the branched copolymer (A-B)nX. This block copolymer composition is useful for an adhesive or pressure sensitive adhesive composition.

Owner:ZEON CORP

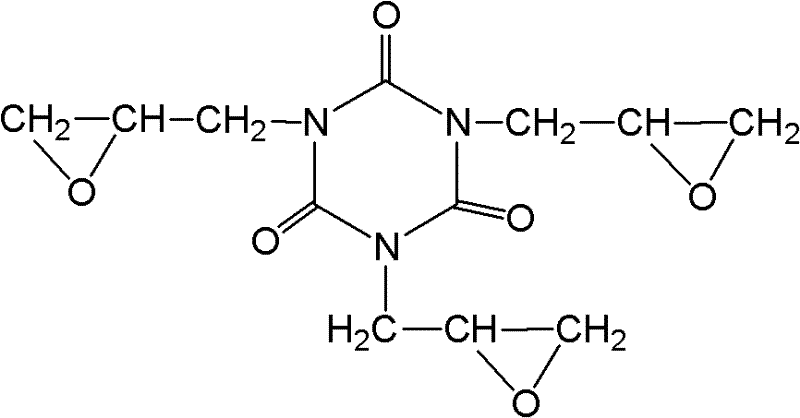

Powdery paint for aluminum profile and preparation method thereof

ActiveCN102516855AStrong adhesionSimple recipePowdery paintsPolyester coatingsComminutionOrganic matter

The invention discloses a powdery paint for aluminum profile and a preparation method thereof. The powdery paint is composed of carboxyl-terminated saturated polyester resin, triglycidyl isocyanurate (TGIC), titanium dioxide, precipitated barium sulfate, a brightener, a leveling agent and benzoin. The preparation method contains the following steps of: batch mixing, melt extrusion, crushing and ultrafine comminution. The powdery paint for aluminum profile has low curing temperature. By the adoption of the powdery paint, volatilization amount of residual TCIC low molecular organic matter is reduced. The powdery paint is beneficial to environmental protection and the health of human body. In addition, the appearance of the film is more flattening and fine.

Owner:广东华江粉末科技有限公司

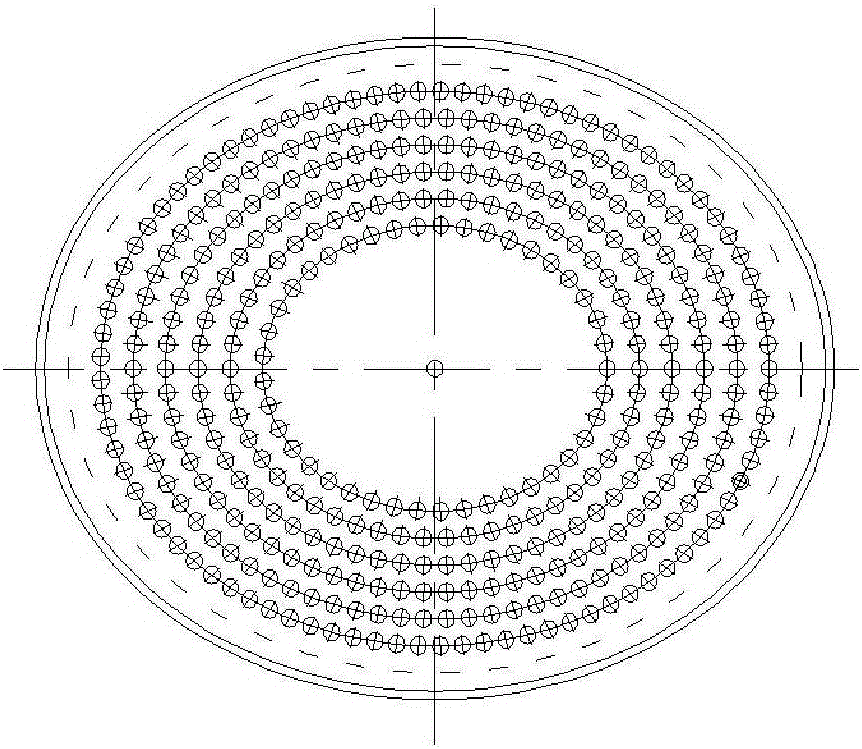

High-uniformity polyester industrial yarn used for safety belt and production method thereof

ActiveCN106381557AIncreased free volumeReduce melt viscositySpinnerette packsHollow filament manufactureYarnLow vacuum

The invention relates to a high-uniformity polyester industrial yarn used for a safety belt and a production method thereof. The raw material of the high-uniformity polyester industrial yarn is modified polyester composed of a terephthalic acid chain segment, a glycol chain segment and a branched chain-containing dihydric alcohol chain segment. The production method is characterized in that terephthalic acid and branched chain-containing dihydric alcohol are subjected to an esterification reaction under catalysis of concentrated sulfuric acid to obtain dihydricalcohol terephthalate; then terephthalic acid and glycol are prepared for the esterification reaction to obtain ethylene terephthalate; finally ethylene terephthalate and dihydricalcohol terephthalate are stirred and mixed, under a catalyst and a stabilizing agent, the condensation polymerization reactions under a low vacuum phase and a high vacuum phase are carried out to prepare the modified polyester, and the modified polyester is subjected to metering, extrusion by a porous spinneret, cooling, oiling, stretching, thermoforming and reeling to prepare the high-uniformity polyester industrial yarn.

Owner:JIANGSU HENGLI CHEM FIBER

Method for preparing polystyrene-polyisoprene-polystyrene ternary segmented copolymer hot melt pressure-sensitive adhesive

InactiveCN101709201ALow costReduce manufacturing costMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesPolystyreneHot melt

The invention discloses a method for preparing polystyrene-polyisoprene-polystyrene ternary segmented copolymer hot melt pressure-sensitive adhesive, which comprises the following steps: orderly weighing polystyrene-polyisoprene-polystyrene ternary segmented copolymer, composite tackifier resin, softening agent and antioxidant in a mass ratio, and stirring the mixture at the rotating speed of 300 to 600 rpm / min; heating, stirring and melting the mixture till forming transparent glue solution at the temperature of between 150 and 180 DEG C after uniformly mixing; and then placing the transparent glue solution on a coating machine preheated at the temperature of between 80 and 120 DEG C, and adhering a piece of isolation paper after coating to obtain the polystyrene-polyisoprene-polystyrene ternary segmented copolymer hot melt pressure-sensitive adhesive. The method has the advantages of available raw materials, low cost, simplicity and feasibility, environmental protection, excellent comprehensive performance, and suitability for scale industrial production, and provides a new path for the preparation of the hot melt pressure-sensitive adhesive.

Owner:SHANGHAI INST OF TECH

Preparation method of polyester resin for mixing type powdery coating

InactiveCN1962717AReduce melt viscosityUniform molecular weightPowdery paintsPolyester coatingsPolymer sciencePolymer resin

Owner:GUANGZHOU QINGTIAN INDAL

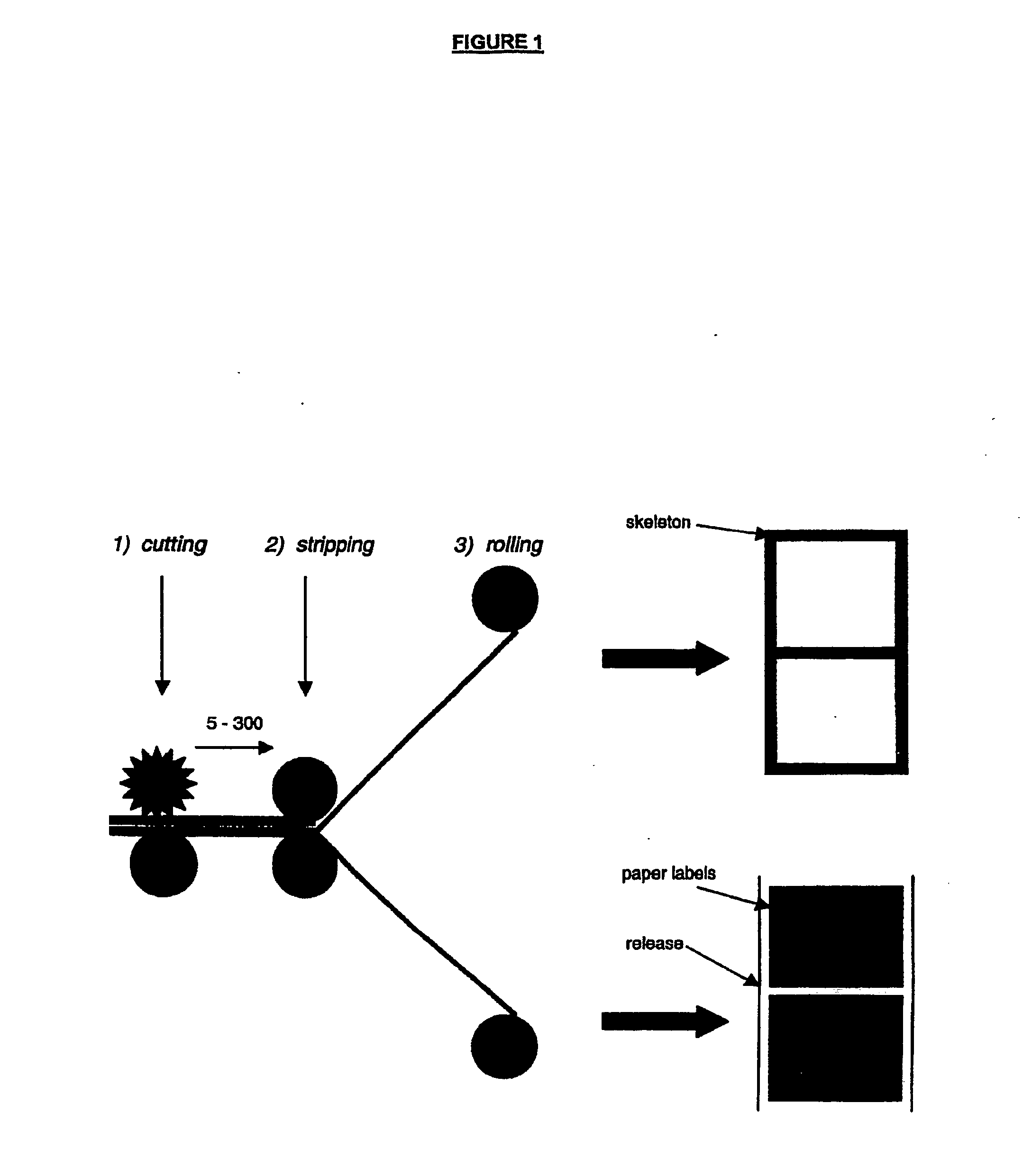

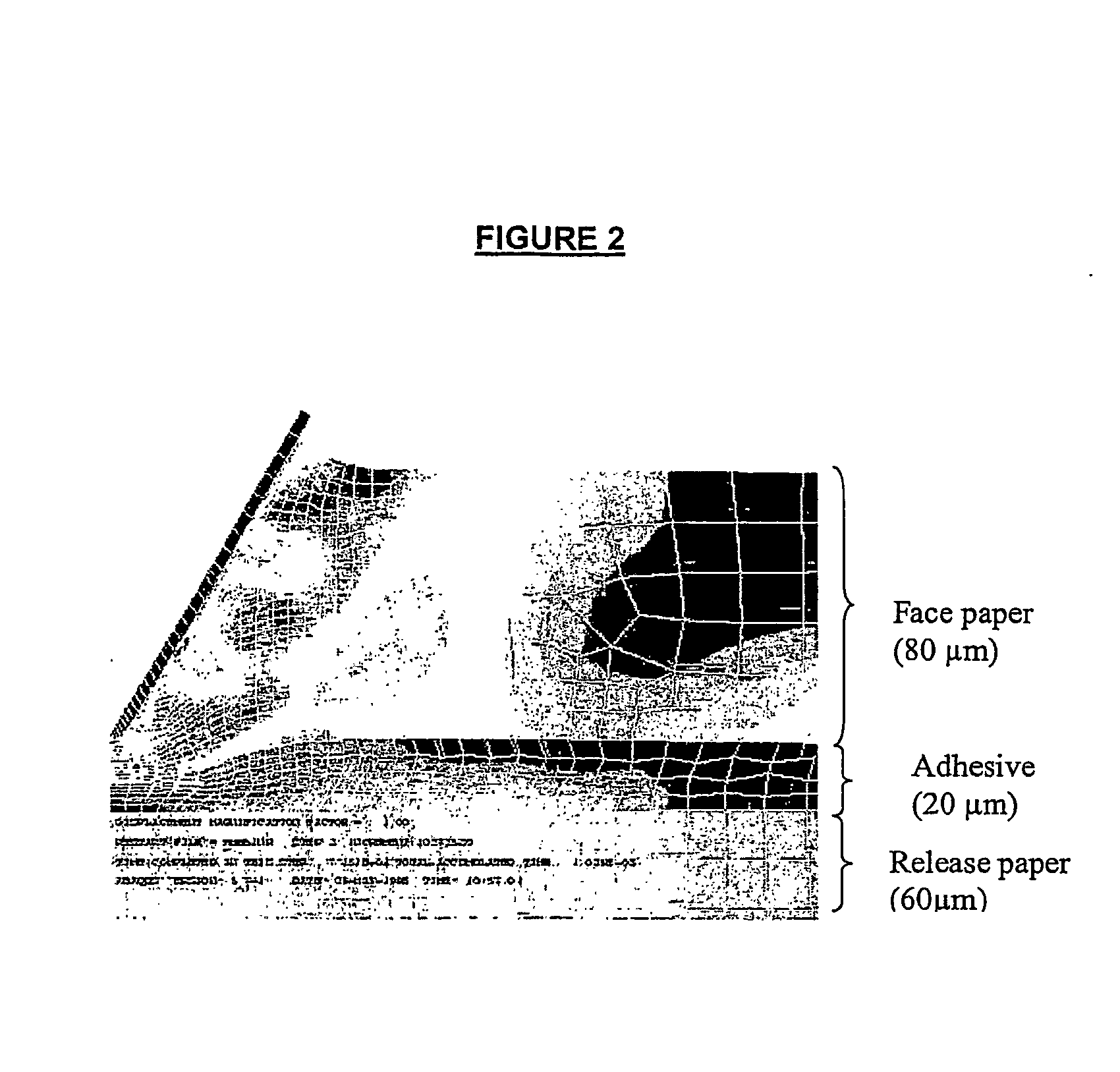

Radial block copolymers and adhesives based thereon with improved die-cutting performance

Improved adhesives are provided through the use of styrenic radial block copolymers, containing at lest 40 wt % diblock copolymers, the adhesives have improved adhesive properties and a reduced elastic behaviour under die-cutting conditions. Compared to conventional linear block copolymers of similar molecular weight, radial copolymers offer higher holding power and lower melt viscosity for the adhesive. They therefore contribute to an improved balance between processability and end-use properties.

Owner:EXXONMOBIL CHEM PAT INC +1

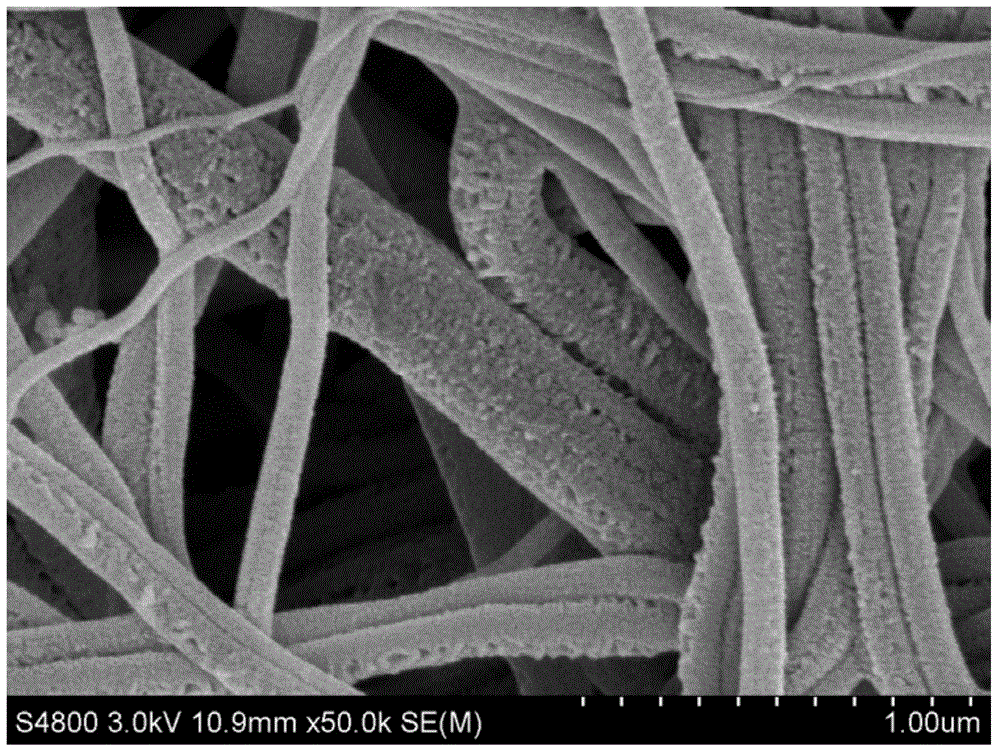

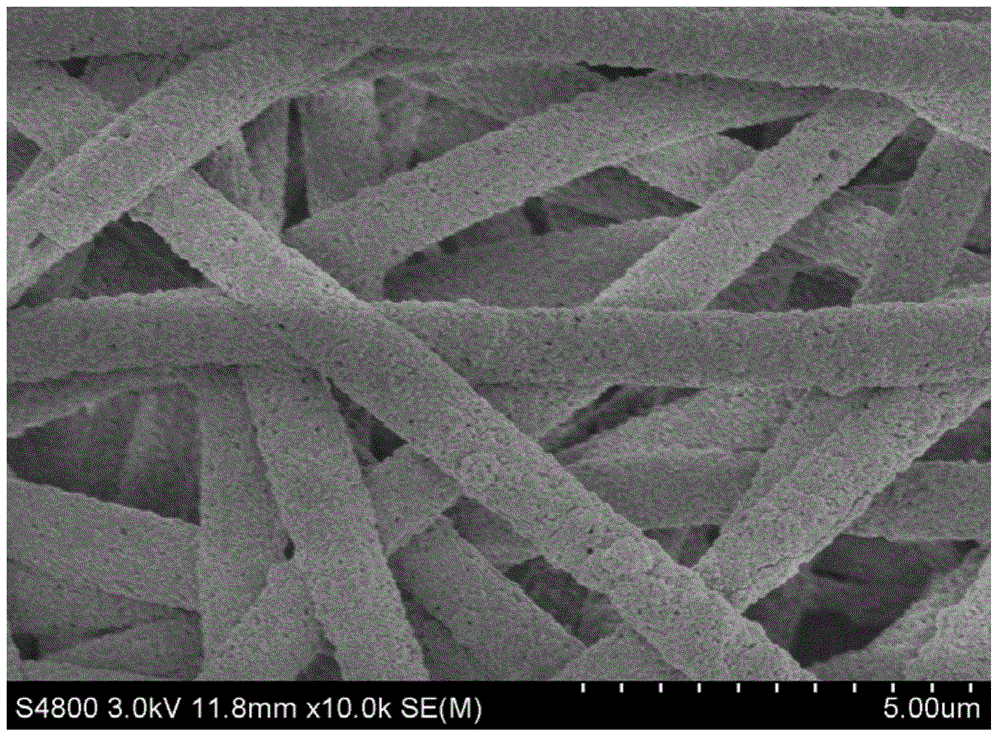

Preparation method of porous nanofiber non-woven fabric

InactiveCN103981633ALower melting temperatureImprove stabilityFilament/thread formingFiltration separationBoiling pointNanofiber

The invention relates to a preparation method of porous nanofiber non-woven fabric, and aims to provide a method capable of realizing large-scale preparation for porous nanofiber non-woven fabric. According to the technical scheme, the preparation method of the porous nanofiber non-woven fabric comprises the following steps in sequence: (1) stirring and dissolving polymers and a combined thinning agent uniformly in a reaction kettle at the temperature of 25-150 DEG C to prepare a polymer solution with the percent concentration of 10-60%, wherein the combined thinning agent is a mixture of a good solvent and a bad solvent, the mass ratio of the good solvent to the bad solvent is between 9: 1 and 1: 9, and the boiling point of the good solvent is lower than that of the bad solvent; (2) producing the polymer solution in the first step with melting blowing equipment to obtain primary non-woven fabric; (3) extracting and removing the combined thinning agent in the primary non-woven fabric in the second step and forming pores on fibers of the primary non-woven fabric, and drying to obtain the porous nanofiber non-woven fabric.

Owner:浙江省轻工业品质量检验研究院

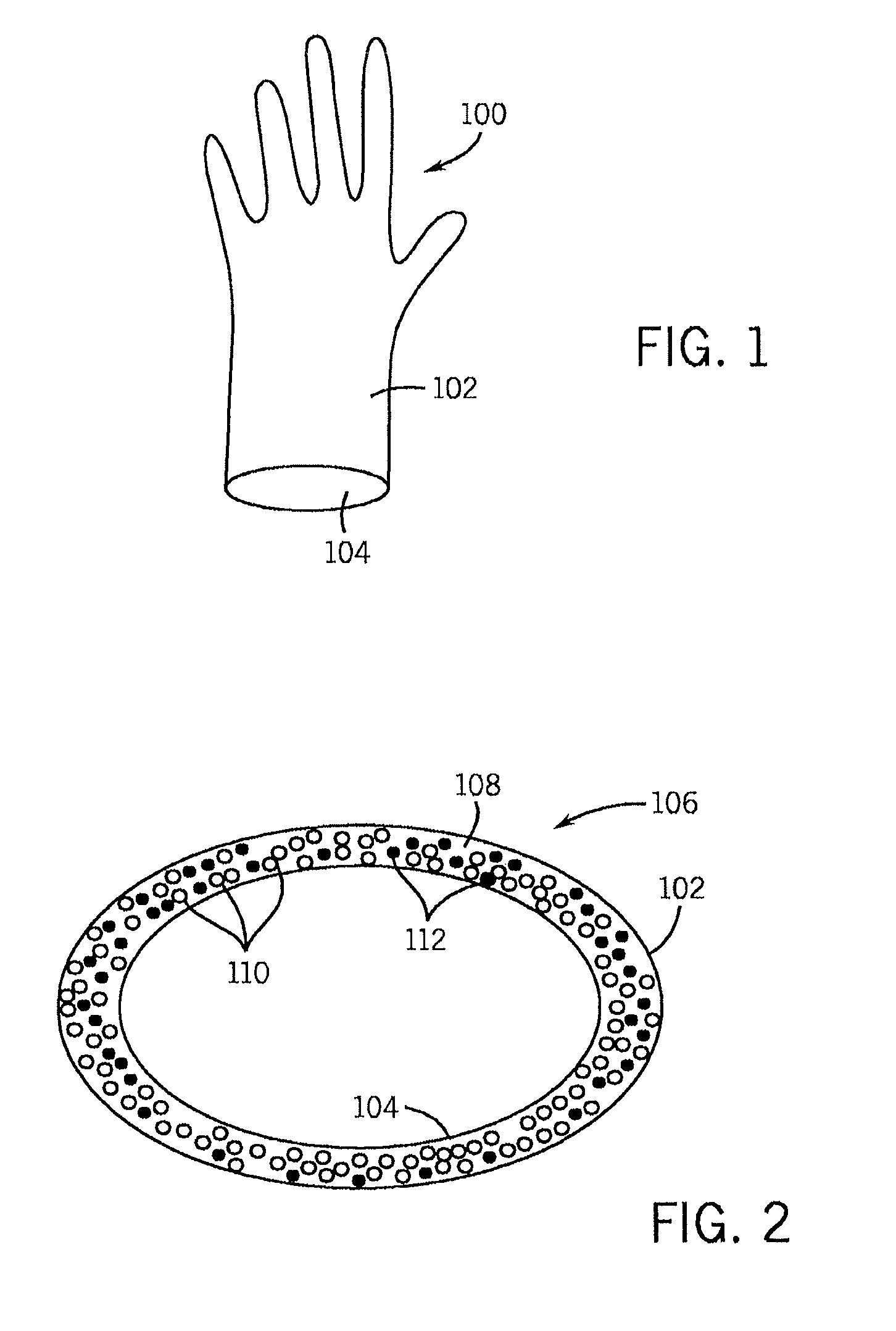

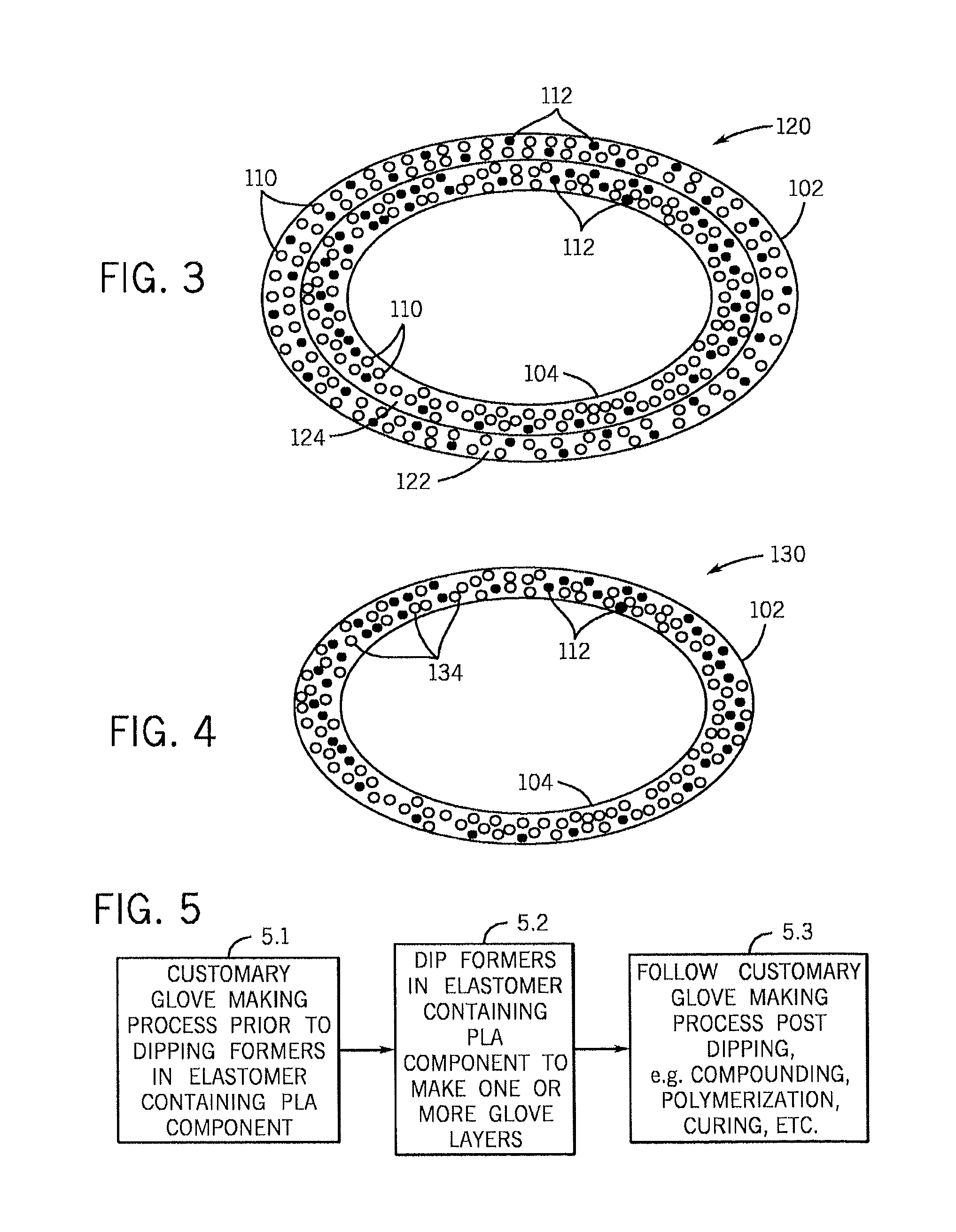

Polylactic acid gloves and methods of manufacturing same

InactiveUS20100257657A1Enhance their market appealBroad possible marketGarment special featuresSurgeryElastomerPolymer science

Biodegradable disposable gloves and methods of manufacturing the same are disclosed in which the elastomeric material used to manufacture the gloves includes a polylactic acid polymer component in combination with a biodegradable plasticizer.

Owner:SMARTHEALTH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com