Patents

Literature

611results about How to "High foaming ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

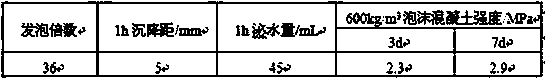

Early-strength composite foam concrete foaming agent and preparation method thereof

The invention belongs to the technical field of building materials, and particularly relates to an early-strength composite foam concrete foaming agent and a preparation method thereof. The early-strength composite foam concrete foaming agent comprises the following components in percentage by mass: 40%-80% of composite foaming components, 1.0%-5.0% of foam stabilizing components, 3.3%-22% of early-strength components and 10%-45% of water, wherein the composite foaming components are formed by compounding synthesized surface active agent foaming agents and protein foaming agents. The early-strength composite foam concrete foaming agent prepared through the method disclosed by the invention has the advantages of high foam expansion, excellent foam stability and good compatibility with general cement pastes; the early-strength composite foam concrete foaming agent disclosed by the invention is applied to foam concrete; the prepared foam concrete has no recess phenomenon and is fast enhanced in early strength, and the foam concrete with a density grade equal to 300 kg / m<3> or above is more easily prepared.

Owner:中建商品混凝土(福建)有限公司 +1

Styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, preparation method and application method thereof

The invention discloses a styrene-butadiene copolymer chemical foaming composition containing polystyrene micro-blocks, a preparation method and an application method thereof. The preparation method takes styrene-butadiene copolymer mixing random structure with block structure as base material, and adds flow modifier or softener to regulate the fluidity of rubber. Rubber compositions manufactured by the method have good fluidity and can be molded directly through injection. Chemical foaming agents added reduces product density and effectively achieves the aim of obtaining lightweight material. Post partial chemical crosslinking can be performed so as to improve the stress cracking resistance and wear resistance of the material. Meanwhile, as the partial physical crosslinking of the styrene-butadiene copolymer allows the material to overcome the defect that all-chemical crosslinked rubber cannot be regenerated, the material can be recycled and regenerated.

Owner:浙江仕峰实业有限公司

Method for preparing thermoplastic polymer foamed beads

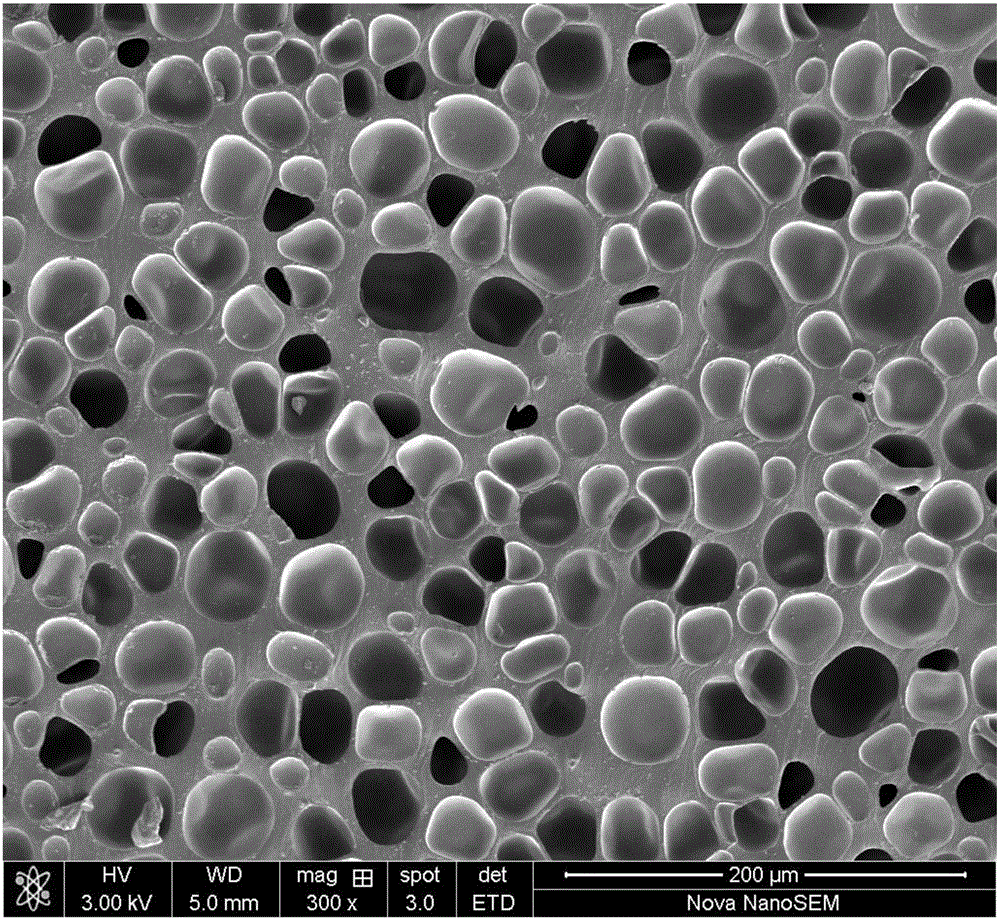

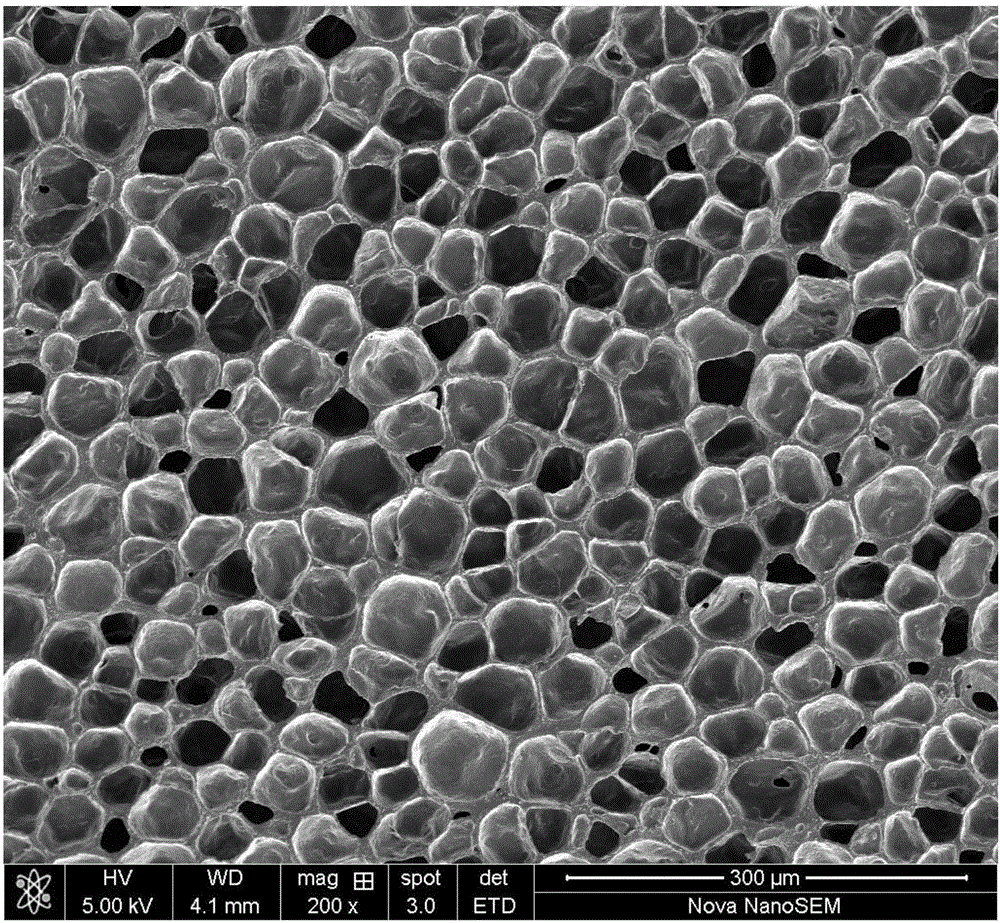

The invention discloses a method for preparing thermoplastic polymer foamed beads. The method comprises the following steps: 1) putting polymer particles into a sealed container heated to a foaming temperature, and putting the sealed container in a vacuum environment; 2) introducing supercritical fluid into the sealed container, and performing swelling diffusion; 3) after swelling diffusion of the supercritical fluid lasts for 5-60 minutes, releasing the pressure of the sealed container to discharge out the supercritical fluid, and controlling the pressure release velocity to induce nucleation and growth of foam pores so as to enable the polymer particles to swell and grow; 4) leading the polymer particles inside the sealed container into the vacuum environment to further swell and grow, thereby obtaining the polymer foamed beads with a high foaming ratio, wherein the foaming temperature in the step 1) is a temperature that the polymer particles can generate plastic deformation but cannot flow yet, the forming temperature is within Tg-Tg+40 DEG C for an amorphous polymer, and Tg is a glass-transition temperature of the amorphous polymer; for a crystallized polymer, the foaming temperature is within Tm-20 DEG C and Tm, and Tm is a melting point of the crystallized polymer.

Owner:HANGZHOU BOSTE NEW MATERIALS TECH CO LTD

Sound absorption and thermal insulation polyolefin foamed sheet and preparation method thereof

ActiveCN106046483AHigh densityImprove uniformitySynthetic resin layered productsThermal insulationPolyolefin

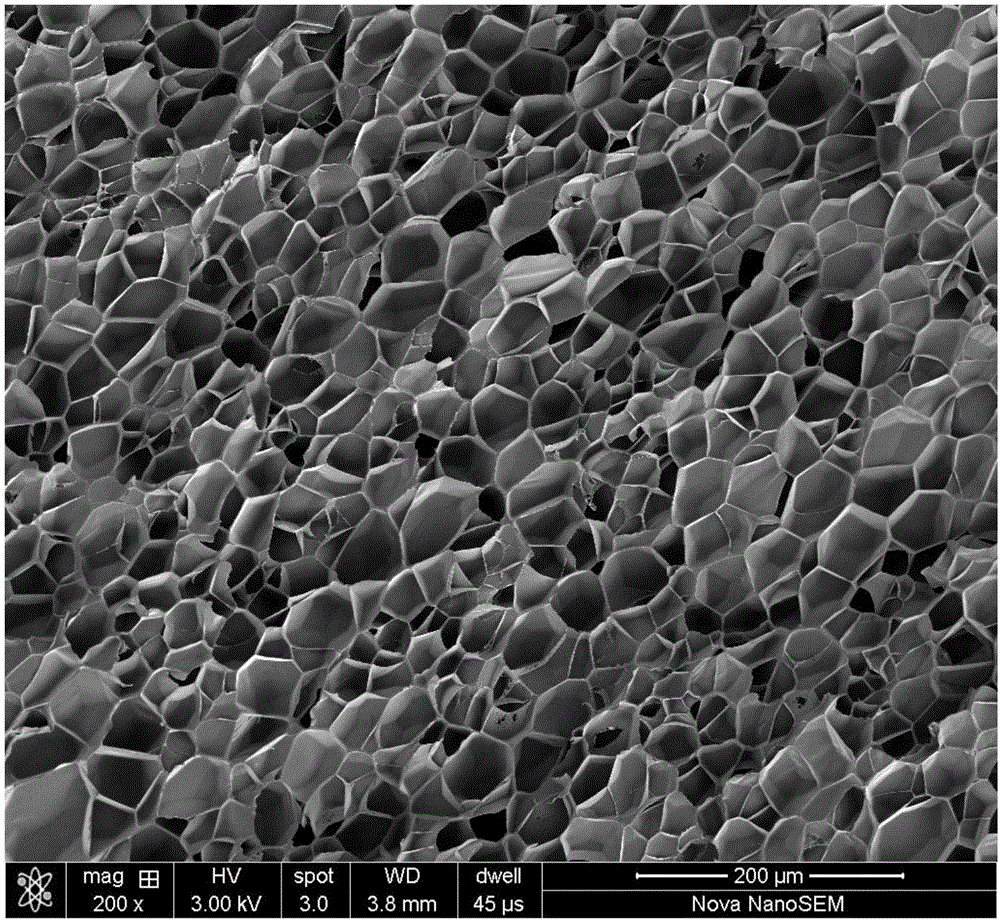

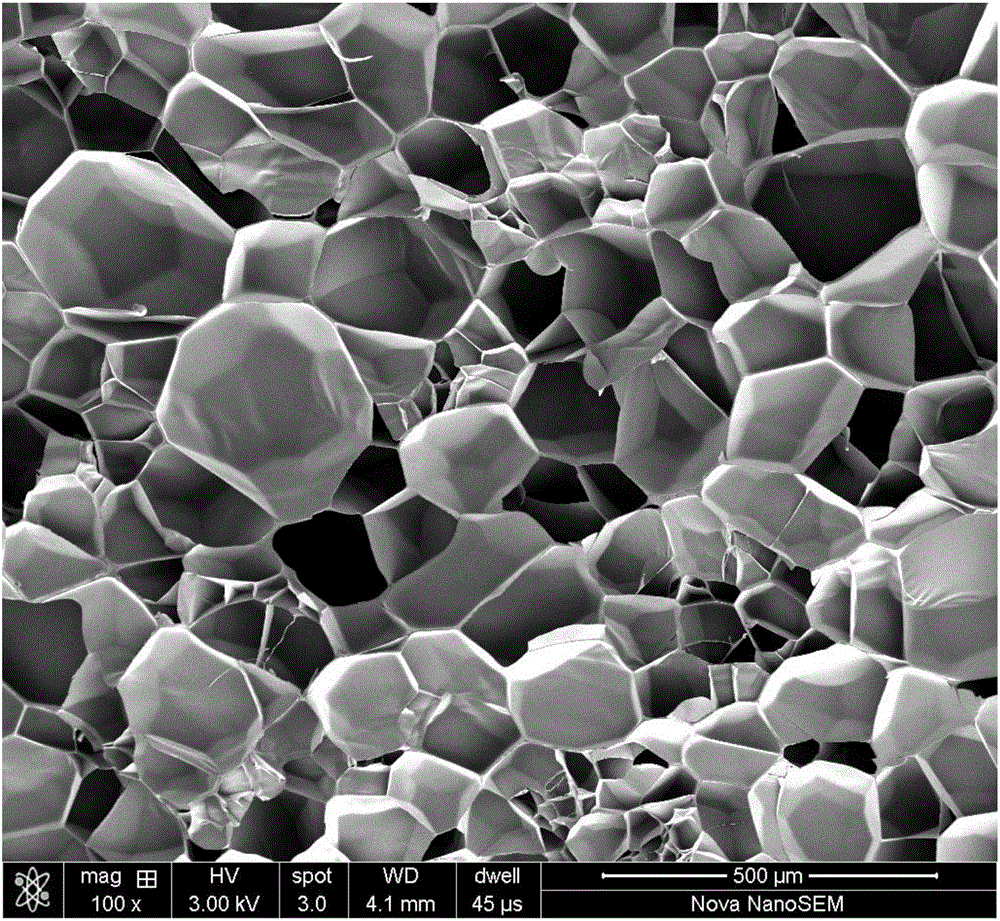

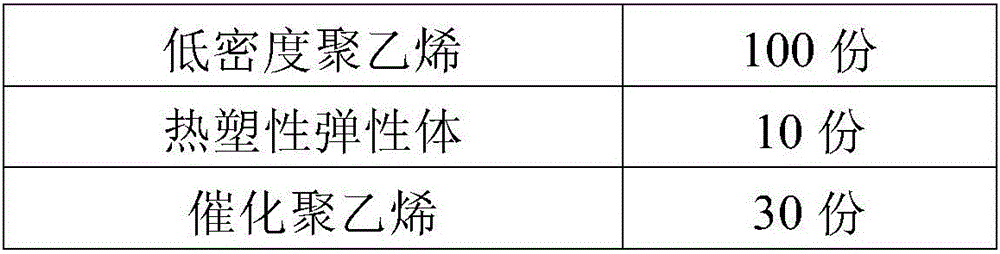

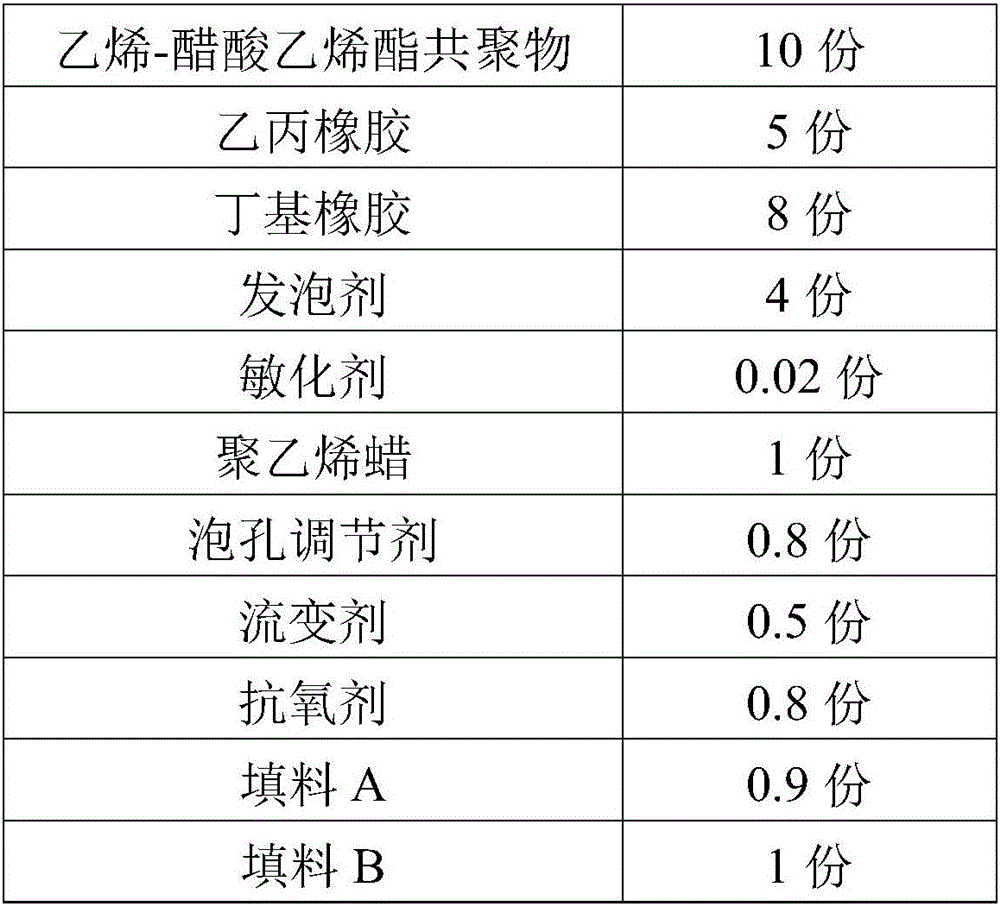

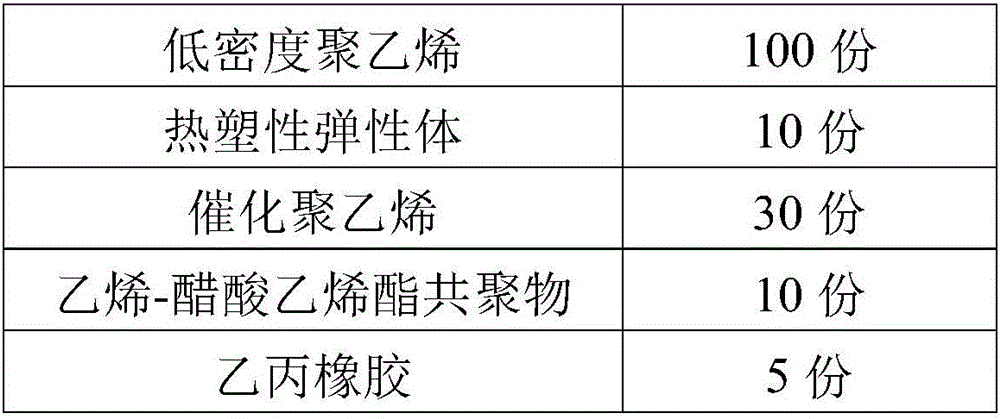

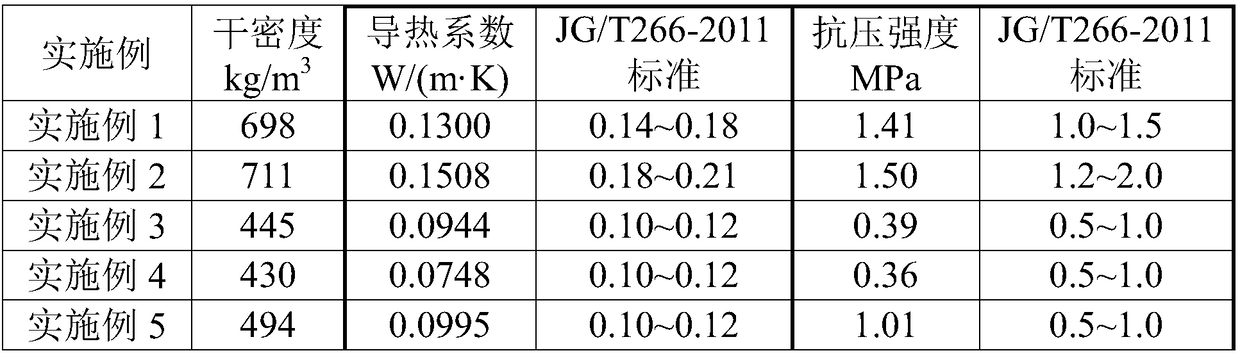

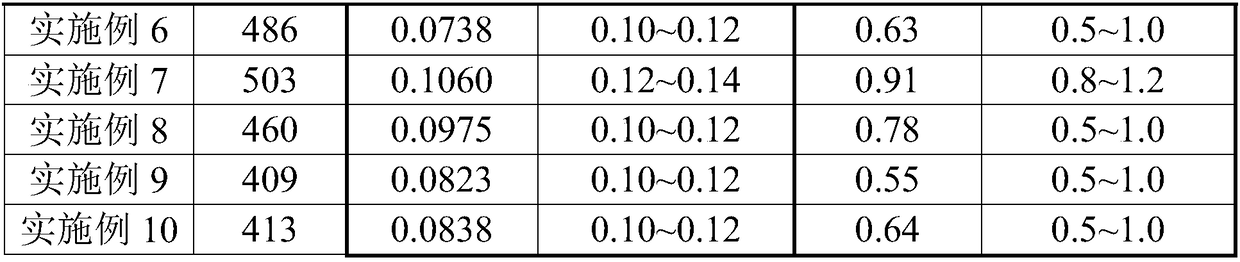

The invention discloses a sound absorption and thermal insulation polyolefin foamed sheet and a preparation method thereof. The foamed sheet comprises the following raw materials in parts by weight: 110-140 parts of component A, 20-170 parts of component B, 1-20 parts of foaming agent, 0.01-8 parts of cell regulator and 0.1-20 parts of filler, wherein the component A consists of 100 parts of polyethylene and 10-40 parts of polyethylene copolymer; and the component B consists of 10-30 parts of thermoplastic elastomer, 10-80 parts of polyolefin resin and 0-60 parts of rubber. The method comprises the following steps: weighing the polyethylene resin, the thermoplastic elastomer, the polyolefin resin, the rubber, the foaming agent, the cell regulator and the filler according to the weight parts; and performing mixing granulation, sheet extrusion, irradiation crosslinking and free foaming to obtain the foamed sheet. In the invention, the prepared foamed material integrates the sound absorption and thermal insulation functions, the opening rate reaches 5-70%, the sound absorption coefficient reaches 0.2-0.5, and the heat conductivity coefficient reaches 0.026-0.035.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

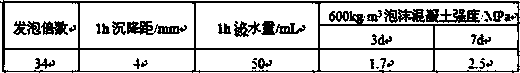

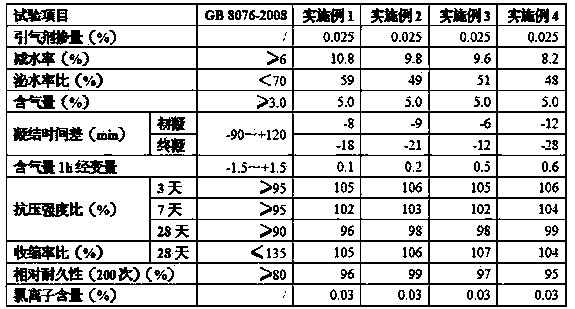

Method for preparing foam concrete

The invention discloses foam concrete and a method for preparing the same. The foam concrete comprises, by weight, 80 parts of cement, 20 parts of fly ash, 1.25 parts of coagulants, 0.35 part of waterreducing agents, 0.4 part of fibers, 3.5 parts of admixtures, 0.025 part of foam stabilizers, 10 parts of foaming agent solution and 50 parts of water. SDS (sodium dodecyl sulfate), APFA (animal protein foaming agents) and water with certain proportions are mixed with one another to obtain the foaming agent solution, foam is prefabricated by the aid of air compressors, then the foam and cement slurry are mixed with one another, and the foam concrete can be prepared under the conditions of the stirring water temperature of 22.5-45 DEG C, the secondary stirring time of 10-75 s and the foam mixing amount of 2250-2875 ml. The foam concrete and the method have the advantages that the foaming agents of the novel foam concrete are easy to manufacture and operate and low in manufacturing cost, and accordingly the foam concrete is low in input and energy consumption and reliable in quality and can be applied to energy-saving buildings and prefabricated buildings.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for preparing extruding physical foaming polypropylene bead granule

The invention discloses a preparation method of an extrusion physical foaming polypropylene bead; the method is as follows: an injector port is arranged at the middle of a machine barrel of a screw extruder, a machine head is provided with a bushing type neck ring mold and a die surface chip cutter, polypropylene foaming material and addition agents are added into the screw extruder, alkane foaming agent is injected into the machine barrel from the injector port, the proportion by weight between the polypropylene foaming material and the alkane foaming agent is 10-25%, the pressure of the neck ring mold is controlled to be 5-30MPa, and the temperature of the neck ring mold is 110-150 DEG C, thus leading the cut material to generate foams when the material enters the atmosphere, and then the product is obtained after cooling and drying. The method of the invention has the advantages of continuous extrusion of the polypropylene foaming beads, low energy consumption, little environmental pollution due to the adoption of the alkane foaming agent, low residue of foaming agent in the foaming bead and high foaming rate.

Owner:浙江华江科技股份有限公司

High foaming-ratio and high-density polyethylene microporous foaming section bar and its preparation method

ActiveCN102229708AHigh foaming ratioMeet the needs of different application fieldsCoatingsPolymer scienceFoaming agent

The invention discloses a high foaming-ratio and high-density polyethylene microporous foaming section bar and its preparation method. The invention is characterized in that the foaming section bar is directly prepared by using a high-density polyethylane raw material in the presence of a physical gas foaming agent by the physical gas foaming method. The foaming density is 0.032-0.20g / cm<3>; the foaming ratio is 5-30 times; the average pore diameter of bubbles is 10-120 microns; the bubbles are uniformly distributed; the diameter difference of 95% bubbles is less than 15% the average pore diameter; the foaming section bar has no cortex construction and can be a material of any shape. The high foaming-ratio and high-density polyethylene microporous foaming section bar has advantages of high mechanical strength, good resilience, good hear resistance, good chemical corrosion resistance and recycling and reusing possibility of wastes, and can make up the defects of present foaming materials. The preparation method of the foaming product provided by the invention is easy to operate, has a simple process flow as well as a short production period, and is in favor of industrial production.

Owner:浙江博发新材料股份有限公司

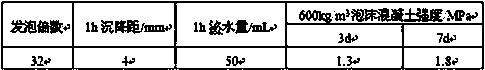

Compound foaming agent for foam concrete and preparation method thereof

The invention belongs to the technical field of building materials, and specifically relates to a compound foaming agent for a foam concrete and the preparation method of the compound foaming agent. The compound foaming agent is composed of a surfactant, a protein foaming agent, a foam stabilizing agent, a coagulation accelerator and a water reducing agent. The compound foaming agent provided by the invention is doped with few protein foaming agent and foam stabilizing agent in a surfactant solution to remarkably improve the foaming capability and the foam stabilizing time of the surfactant solution and create favorable conditions for preparing the foam concrete at a low-density grade (not more than 500 Kg / m<3>). In addition, the coagulation accelerator is doped to accelerate the condensation of cement slurry and effectively prevent collapsing; the water reducing agent is doped to improve the working property of a freshly mixed concrete, and reduce the water dosage and improve the strength of the foam concrete at the same time. The product provided by the invention has various functions, and is not limited to only prepare the foam; at the same time, the product provided by the invention has the actions of accelerating coagulation and reducing water, and the product provided by the invention is suitable for preparing the low-density foam concrete.

Owner:TONGJI UNIV

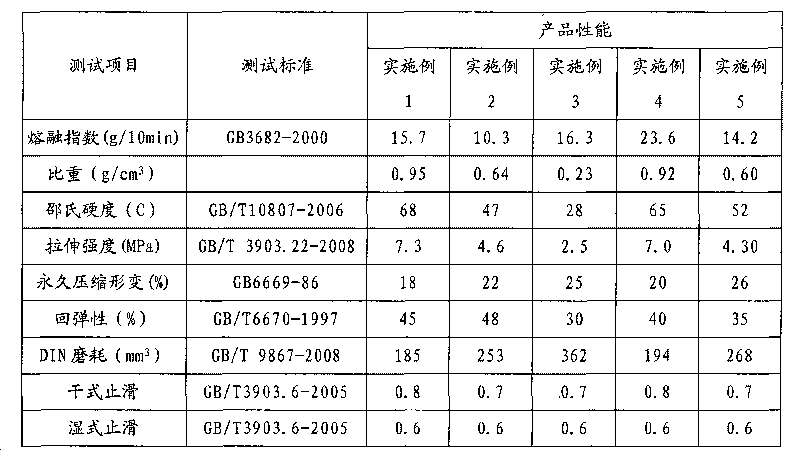

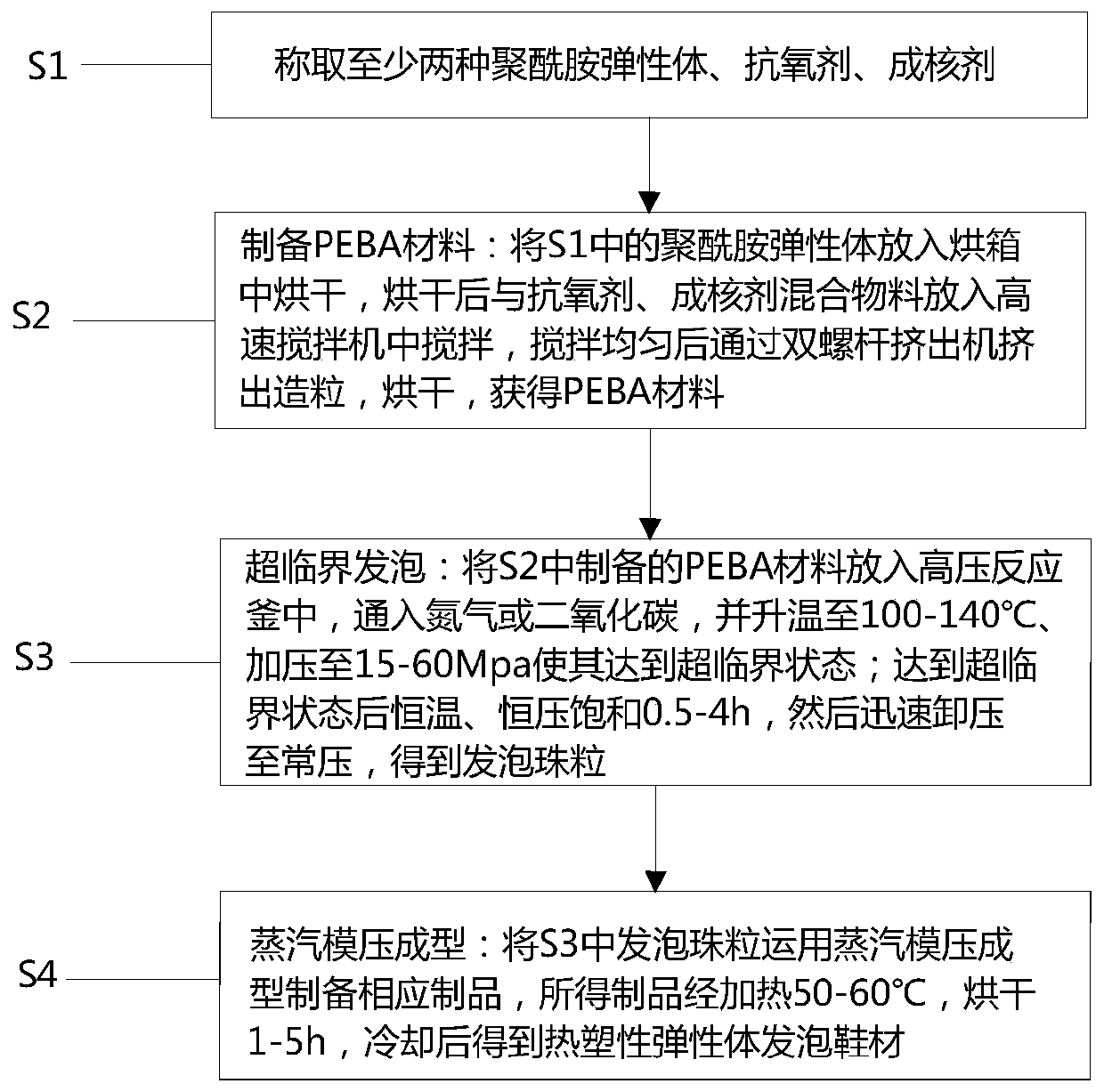

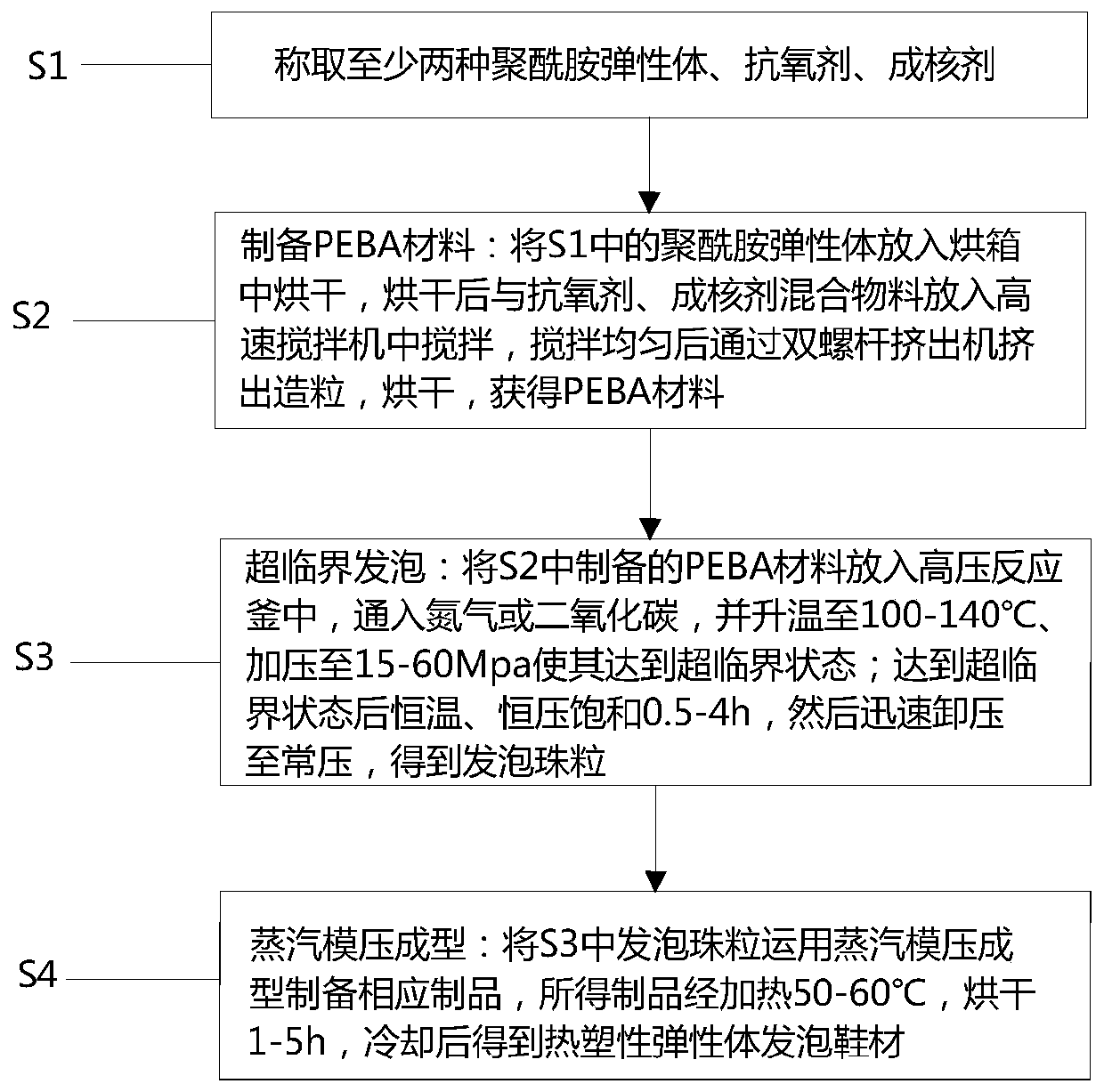

Thermoplastic elastomer foamed shoe material and preparation method thereof

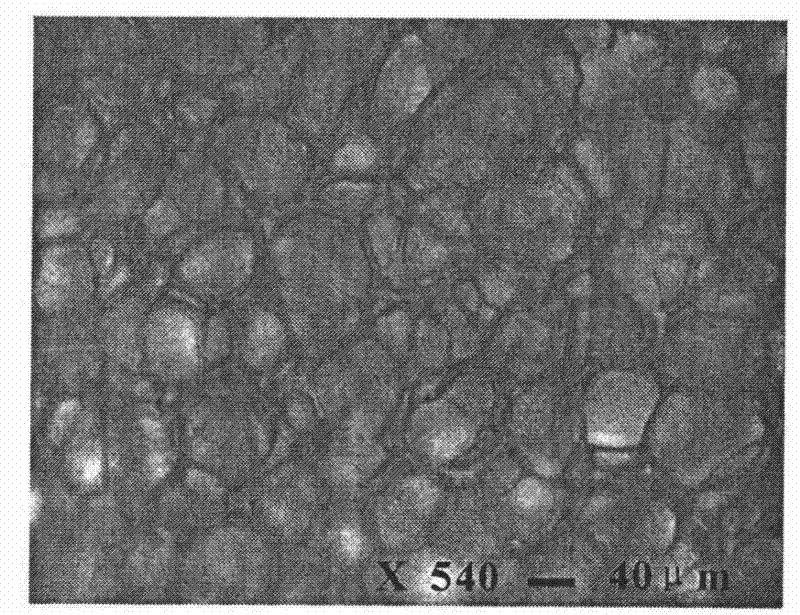

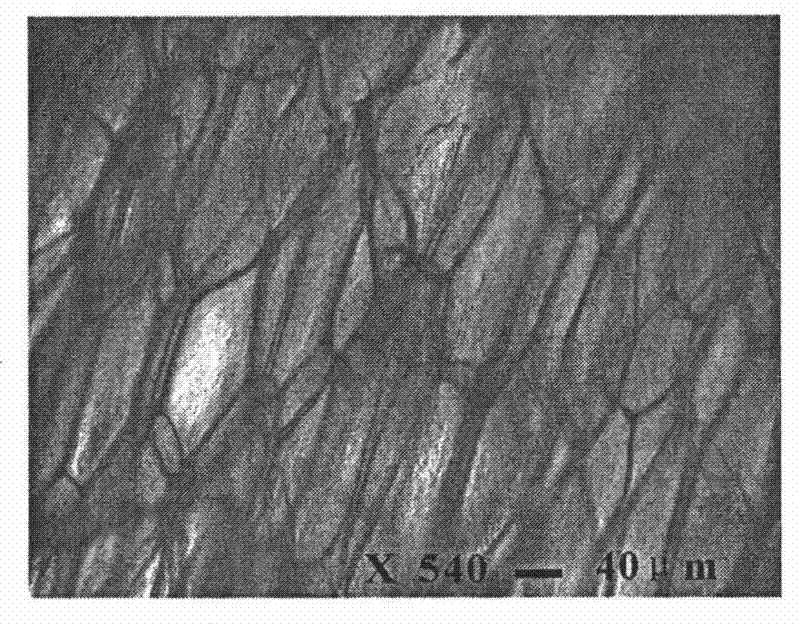

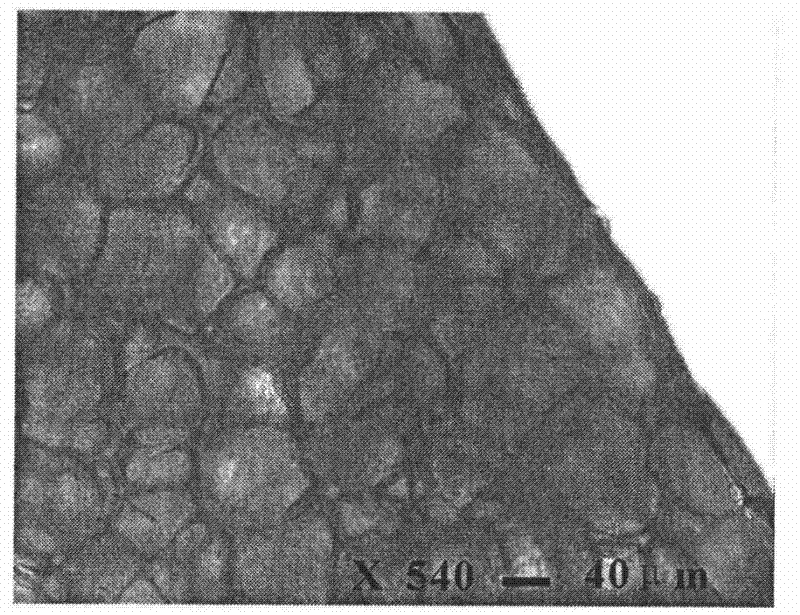

The invention belongs to the technical field of shoe material manufacturing, and particularly relates to a thermoplastic elastomer foaming shoe material and a preparation method thereof. The thermoplastic elastomer foaming shoe material is prepared from the following raw materials in parts by mass: 100 parts of a modified polyamide elastomer, 0.1 to 0.5 part of an antioxidant and 0 to 10 parts ofa nucleating agent, the modified polyamide elastomer at least comprises two polyamide elastomers so that the regulated and controlled melt strength is more excellent, a series of shoe foaming materials with higher foaming ratios and better elasticity are prepared through a supercritical fluid foaming technology, the foaming material has the advantages of low density, excellent resilience, excellent deformation resistance and the like, meanwhile, the material is applied to the field of sneakers, a force feedback mechanism is started for the whole running process, energy in each step of a weareris recycled and then released again, the light and efficient resilience property is guaranteed, and power can be provided for the wearer.

Owner:LI NING CHINA SPORTS GOODS

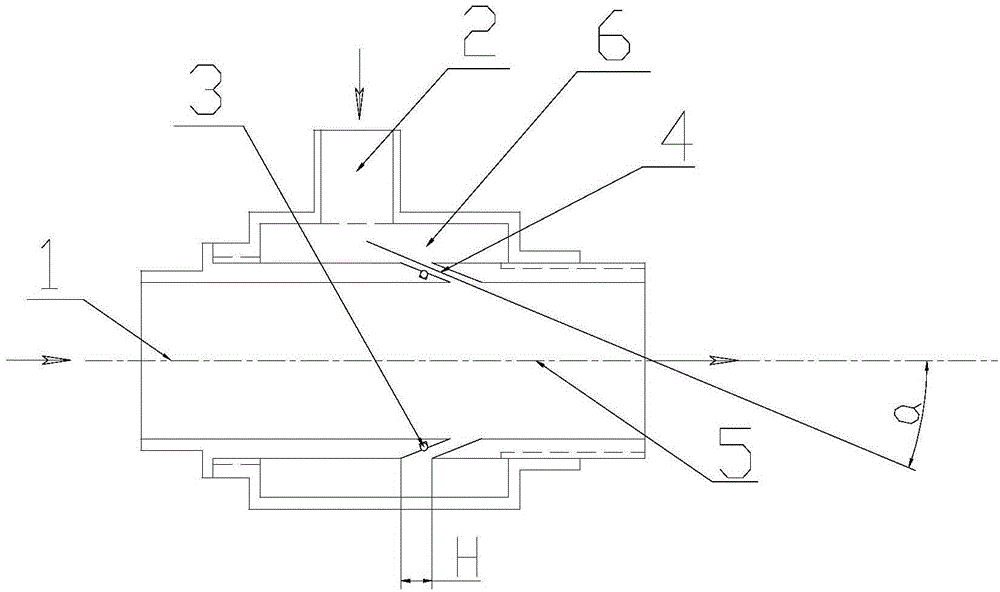

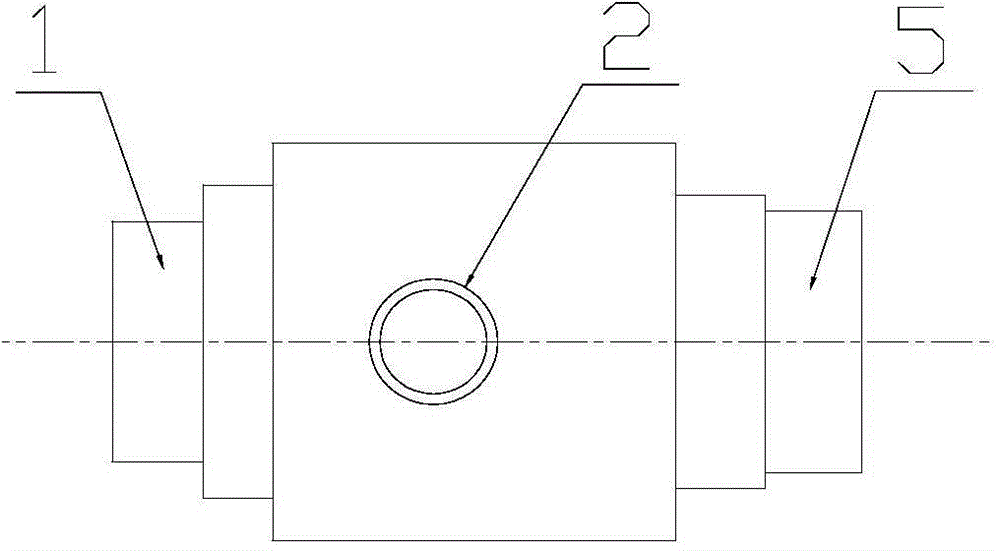

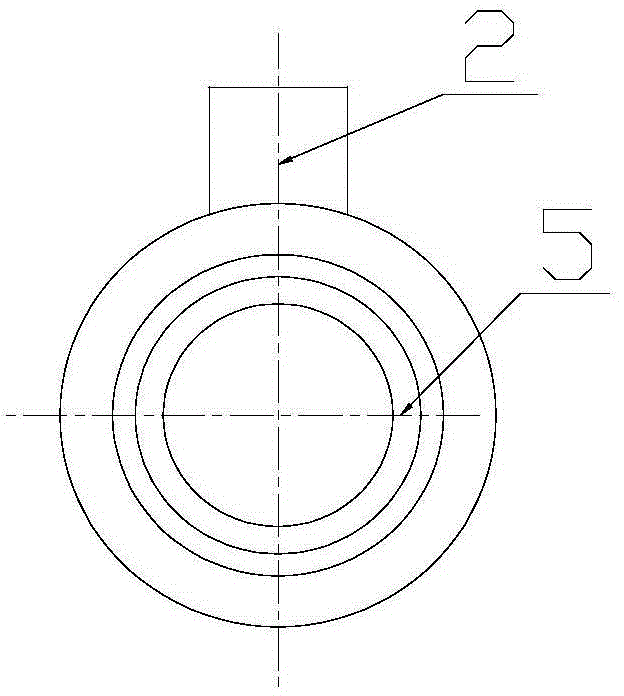

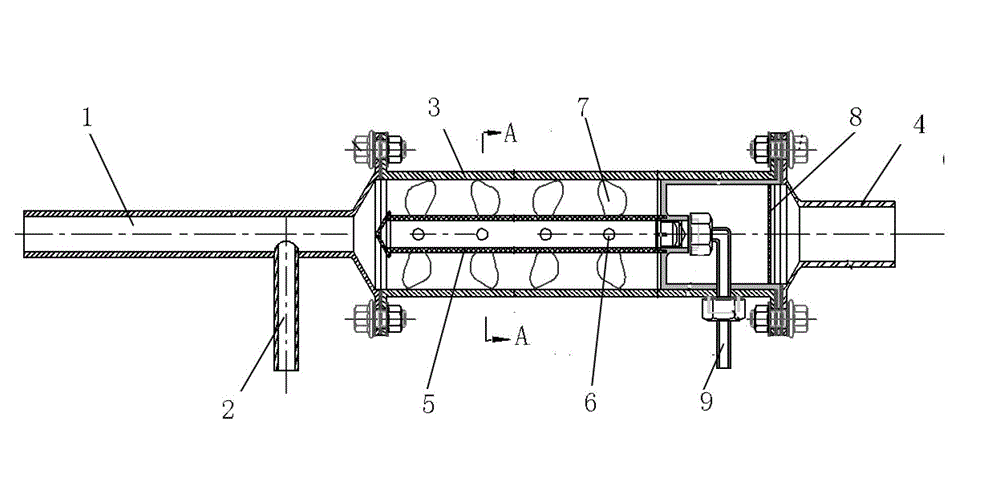

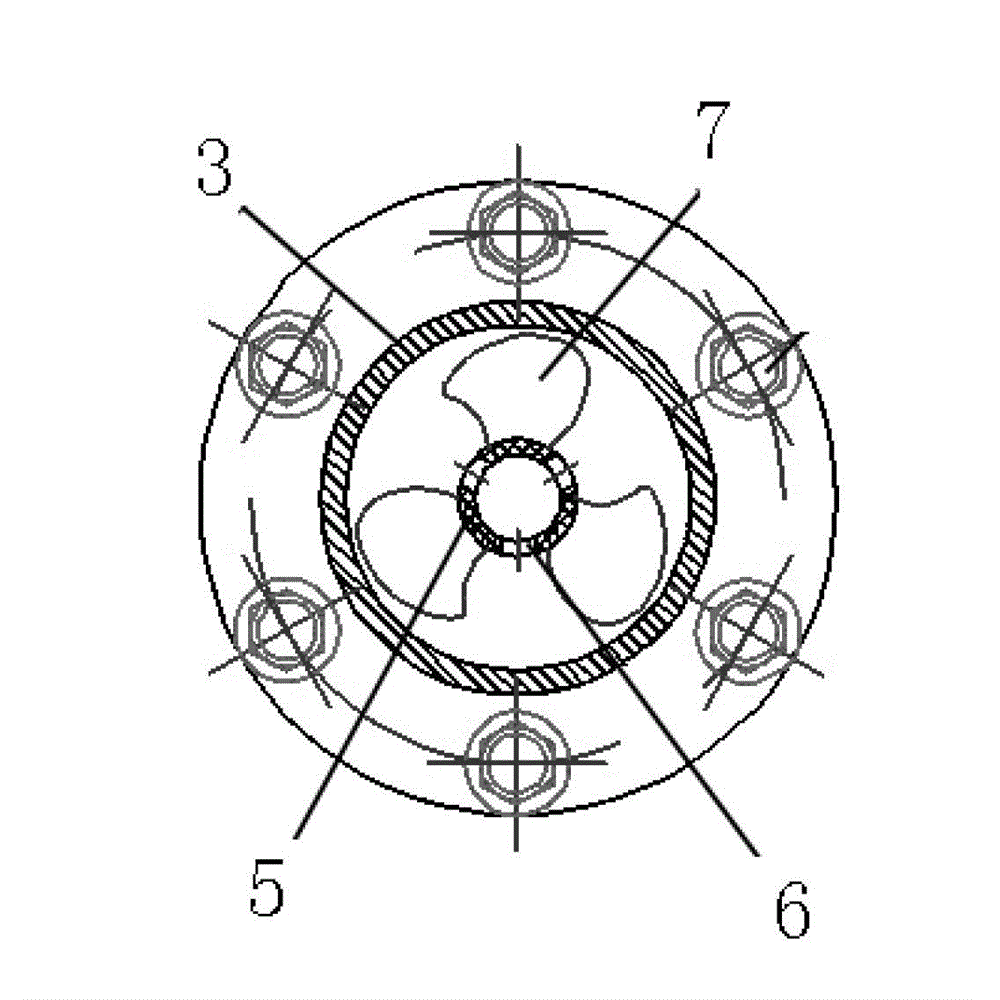

Gas-liquid mixing device

InactiveCN104147733ASimple structureLong spray distanceMixing methodsFire rescueProduct gasEngineering

The invention discloses a gas-liquid mixing device. The gas -liquid mixing device comprises a gas inlet, a liquid inlet and a mixed solution outlet, wherein the gas inlet and the mixed solution outlet are formed in the same axial line, a combining part of the gas inlet and the mixed solution outlet is an annular nozzle, an included angle alpha formed by the annular nozzle is 45-80 degrees, an annular liquid cavity is arranged at the inlet end of the annular nozzle in a surrounding manner and is connected with the liquid inlet; the annular nozzle can be opened or closed, the width of the annular nozzle can be adjusted; the liquid inlet is formed along a radial direction or a tangent direction of the annular liquid cavity. The gas-liquid mixing device has the advantages that a conventional mixing structure is changed, the spraying is performed by adopting the annular nozzle with a certain slope as a liquid outlet, a negative pressure higher than that of a conventional nozzle can be generated, more gas is sucked, relatively high foam expansion ratio is generated, fluid flows without resistance, the device has no recoiling force, and is relatively long in spraying distance; the mixed solution outlet can be adjusted, and even closed, so that the liquid flow is adjusted; the gas-liquid mixing device is simple in structure, convenient to operate; the cost of system equipment is lowered.

Owner:CHENGDU ZINENG FIRE EQUIP

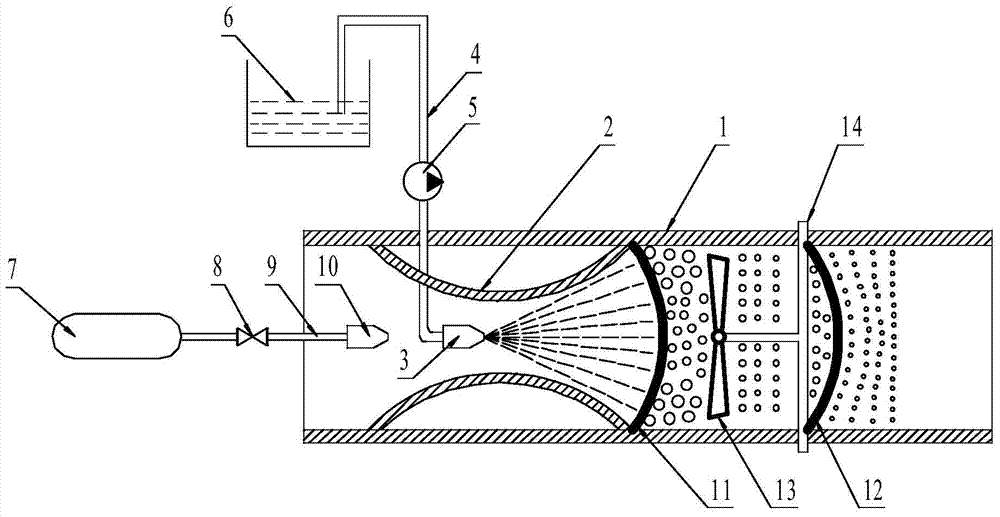

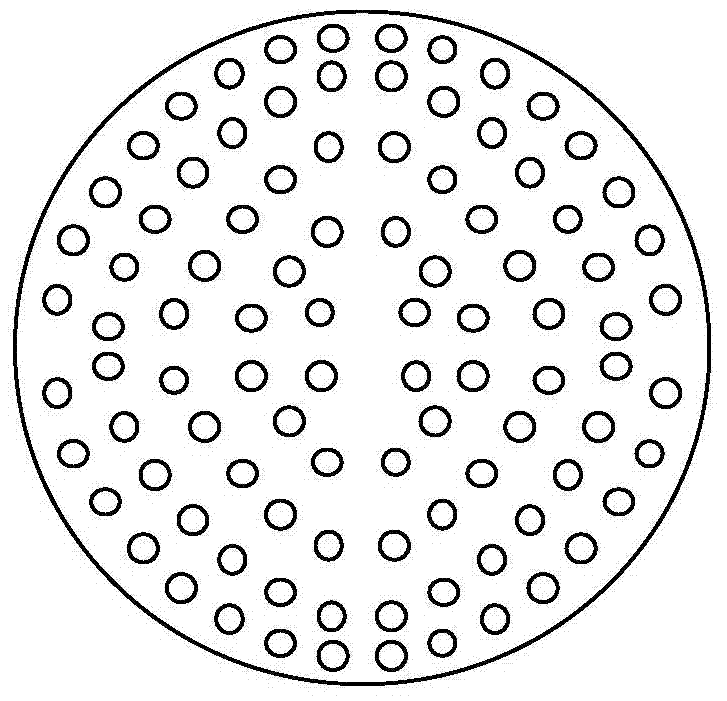

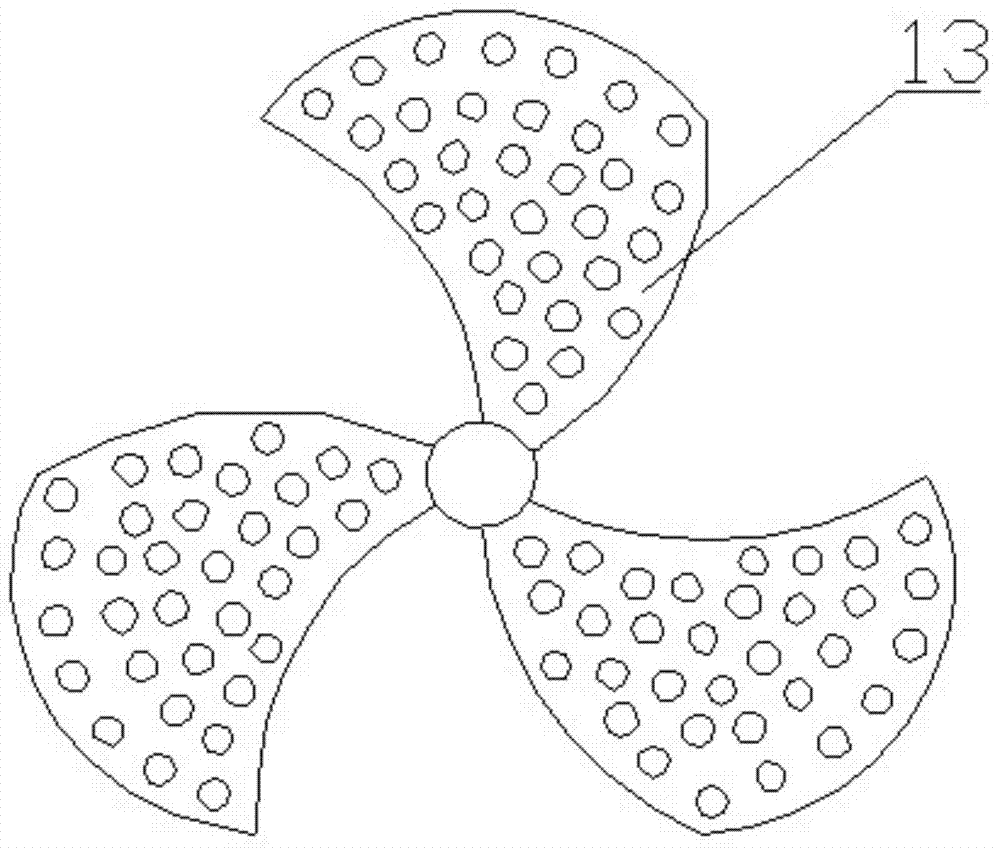

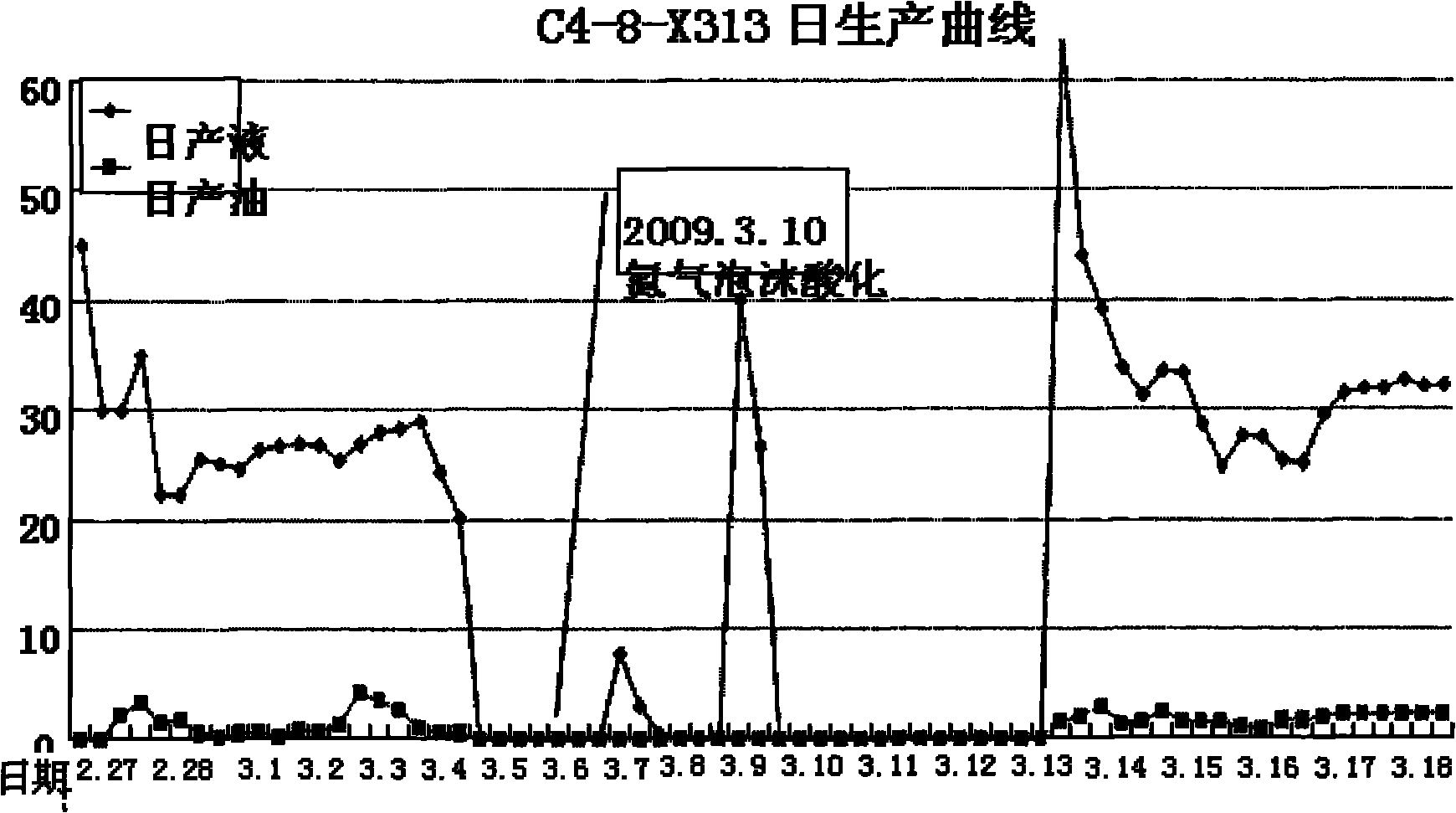

Mining foam generator for preventing and extinguishing fire

The invention discloses a mining foam generator for preventing and extinguishing fire. The foam generator is characterized in that a Venturi tube is (2) is arranged in a foaming cylinder (1), a liquid pipeline (4) penetrates the wall of the foaming cylinder to extend into the Venturi tube, an atomizing nozzle (3) is arranged at the throat of the Venturi tube and connected to the extending end of the liquid pipeline, the other end of the liquid pipeline is connected with a foaming agent container (6), a pump (5) is mounted on the liquid pipeline, a gas nozzle (10) is arranged at the rear of the atomizing nozzle and connected with an air compressor (7) through a gas inlet pipeline (9), a first foaming screen (11) is disposed at the front end of the Venturi tube, an impeller (13) is disposed in front of the first foaming screen and rotationally connected with an impeller support (14) which is fixedly connected with the wall of the foaming cylinder, and a second foaming screen (12) is fixed at the front end of the impeller support. The mining foam generator is small in size, simple in structure and high in foaming efficiency, the generated foam is fine, even and high in stability, and fire extinguishing effect is increased.

Owner:CHINA UNIV OF MINING & TECH

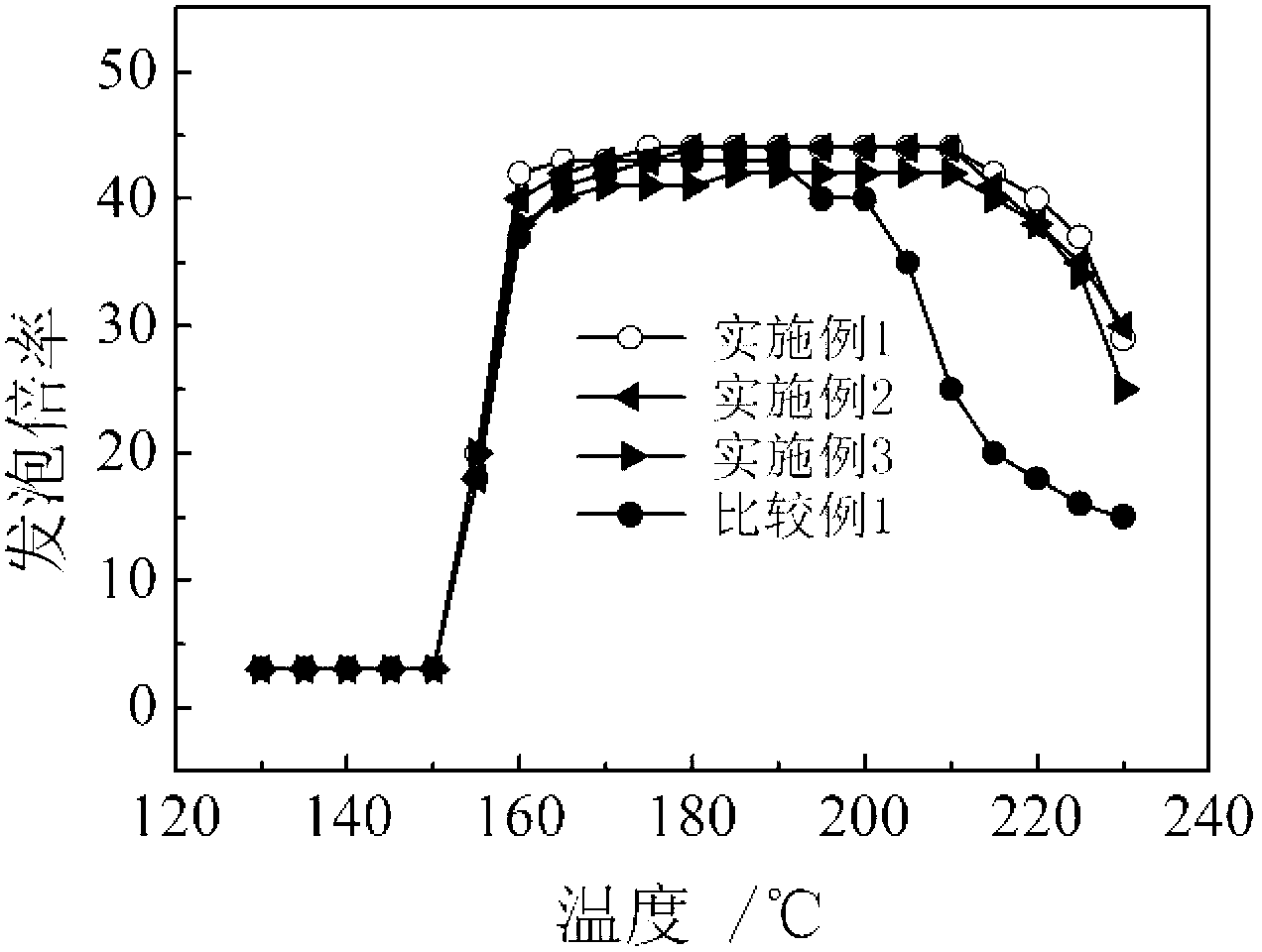

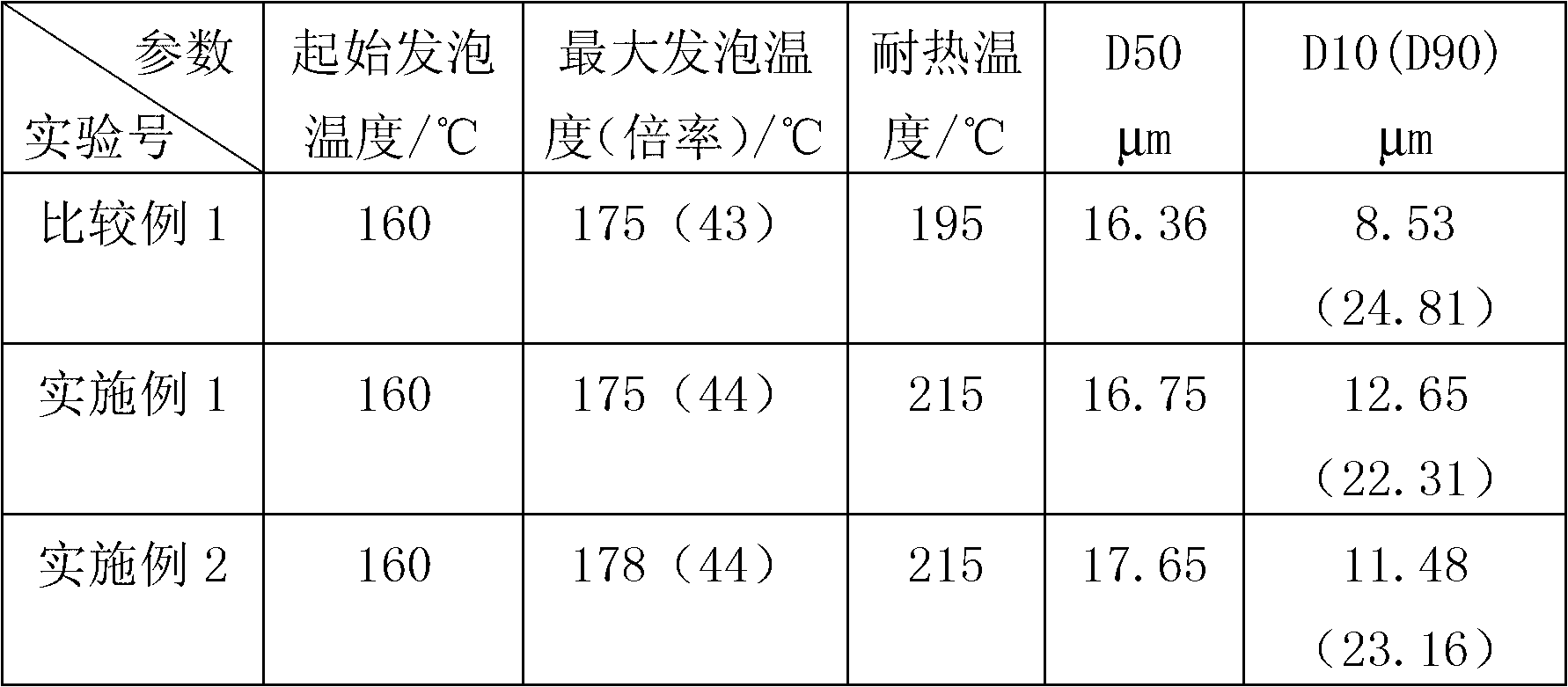

Preparation method of heat-resistant foamed microcapsule

The invention provides a preparation method of a heat-resistant foamed microcapsule. The heat-resistant foamed microcapsule is prepared through suspension polymerization by taking an acrylonitrile monomer polymer as a cyst wall and taking a low-boiling-point alkane foaming agent as a core material. The method comprises the following steps of: (1) generating a main dispersing agent: adding silica sol into a reflowing and stirrinreaction kettle, and dripping an organic silicon coupling agent at a constant temperature for reacting to obtain a main dispersing agent; (2) generating a suspension emulsion: dispersing an aqueous mixed liquid and an oil-phase mixed liquid into small liquid drops under the action of a high-speed homogenizer to obtain a suspension emulsion; and (3) preparing a foamed microcapsule: transferring the suspension emulsion into a stirring reaction kettle, performing suspension polymerization at a constant temperature, reacting, naturally cooling to the room temperature, filtering, cleaning, drying and sieving to obtain a foamed microcapsule product. A product obtained with the preparation method implemented in the invention has the characteristics of high foaming rate, high heat resistance and uniform particle diameters, and can be applied in the fields of spinning, papermaking, ink, plastic, rubber and the like.

Owner:三明市锦浪新材料科技有限公司

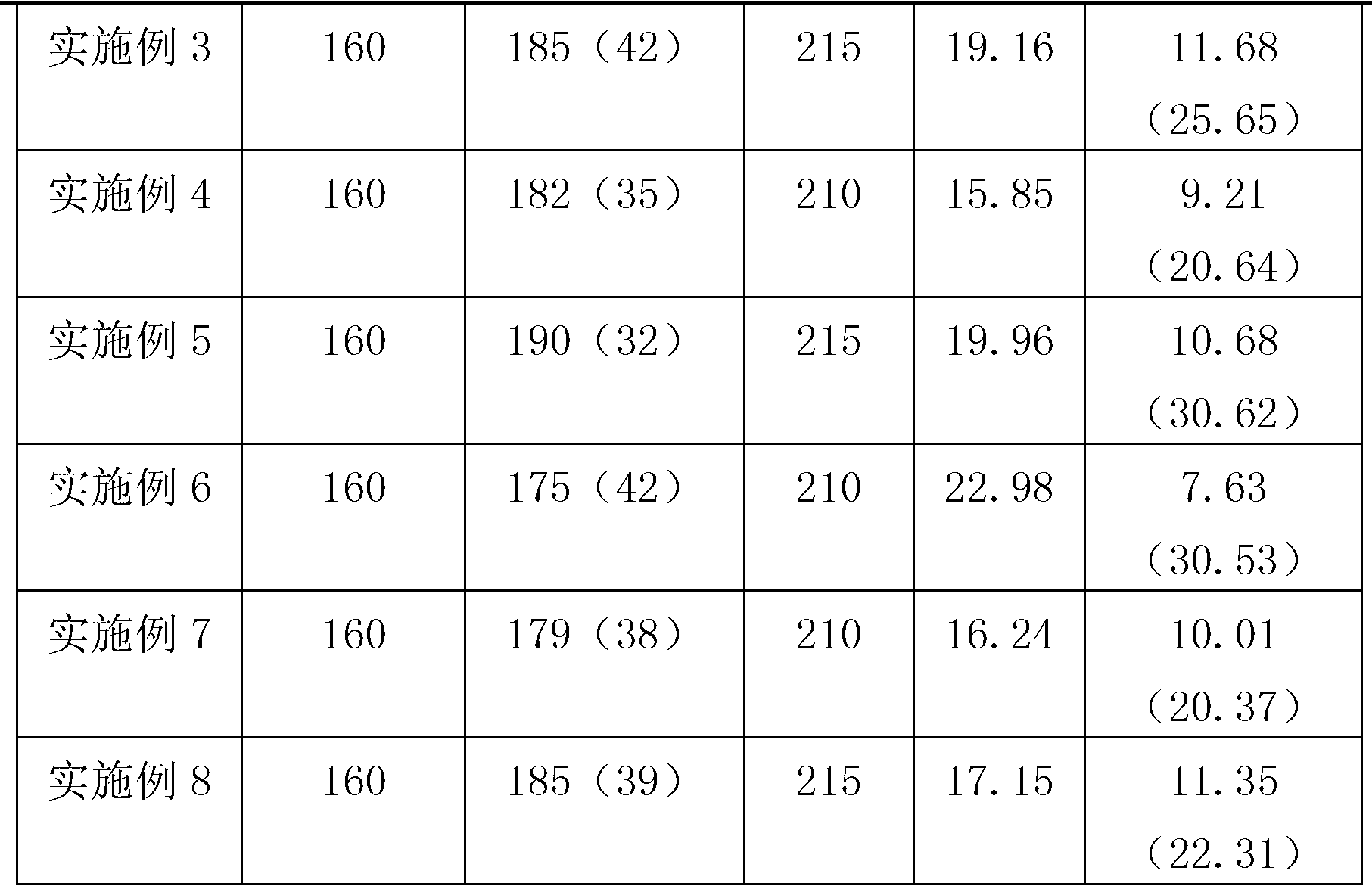

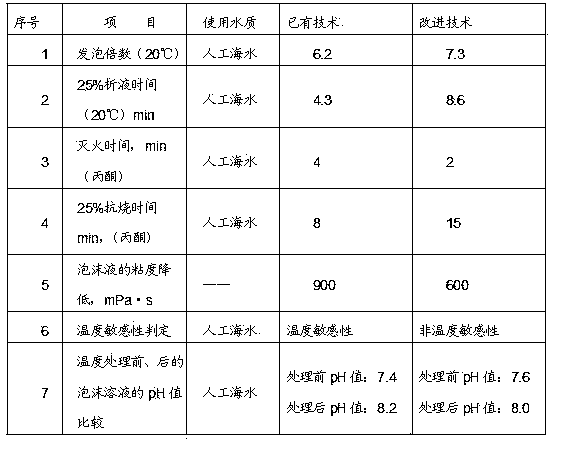

Preparation method of cold-resistant and seawater-resistant aqueous film-forming foam fire extinguishing agent

ActiveCN102284171AComprehensive performance is smallHigh foaming ratioFire extinguisherActive agentSurface-active agents

The invention discloses a novel method for preparing a cold-resistant and seawater-resistant aqueous filmforming foam extinguishing agent. According to the formula, the cold-resistant and seawater-resistant aqueous filmforming foam extinguishing agent consists of the following raw materials in part by weight: 300 to 400 parts of composite burn resistance agent, 6 to 10 parts of sodium benzoate, 50 to 100 parts of urea, 5 to 9 parts of xanthan gum, 200 to 400 parts of amphoteric hydrocarbon surfactant, 20 to 40 parts of alkyl polyglucoside (APG), 80 to 200 parts of glycol, 30 to 60 parts of butyl cellosolve, 10 to 30 parts of FC115710, 20 to 60 parts of FC120320, 20 to 40 parts of low-molecular-weight fluorinated surfactant, and 20 to 60 parts of buffering agent. The product prepared by the method is low in cost, and suitable for fresh water and seawater; and after the agent and the seawater or the fresh water are mixed in a use mixing ratio, the foam property and the extinguishment performance of the agent change slightly, the expansion rate of foam is high, 25 percent liquid drainage time is long, the foams are stable, the extinguishment speed is high and the burn resistance performance is good.

Owner:江苏江亚消防科技股份有限公司

Formula and preparation method for non-toxic and environment-friendly polyvinyl chloride high-foaming glue for bottle cap

The invention discloses a formula and a preparation method for non-toxic and environment-friendly polyvinyl chloride high-foaming glue for bottle caps. In the formula, the foaming glue comprises the following components in part by weight: 90 to 100 parts of polyvinyl chloride resin, 60 to 70 parts of acetyl tributyl citrate, 1.8 to 2.4 parts of foaming agent, 0.6 to 1 part of dimethyl silicon oiland 10 to 30 parts of heavy calcium carbonate. In the formula, by regulating and controlling the plasticizing action of polyvinyl chloride (PVC) sealant strictly, the plasticizing action of the PVC sealant is matched with the decomposition temperature of the foaming agent, so the prepared PVC high foaming glue is high in foaming magnification, uniform in foaming density, appropriate in softness and hardness and good in a sealing effect, and basically reaches the performance of conventional sealing gaskets in which azodicarbonamide is taken as the foaming agent. The high-foaming glue is non-toxic, low in production cost, easy to produce and good in a using effect.

Owner:国家复合改性聚合物材料工程技术研究中心

Method for preparing thermoplastic elastomer foamed beads

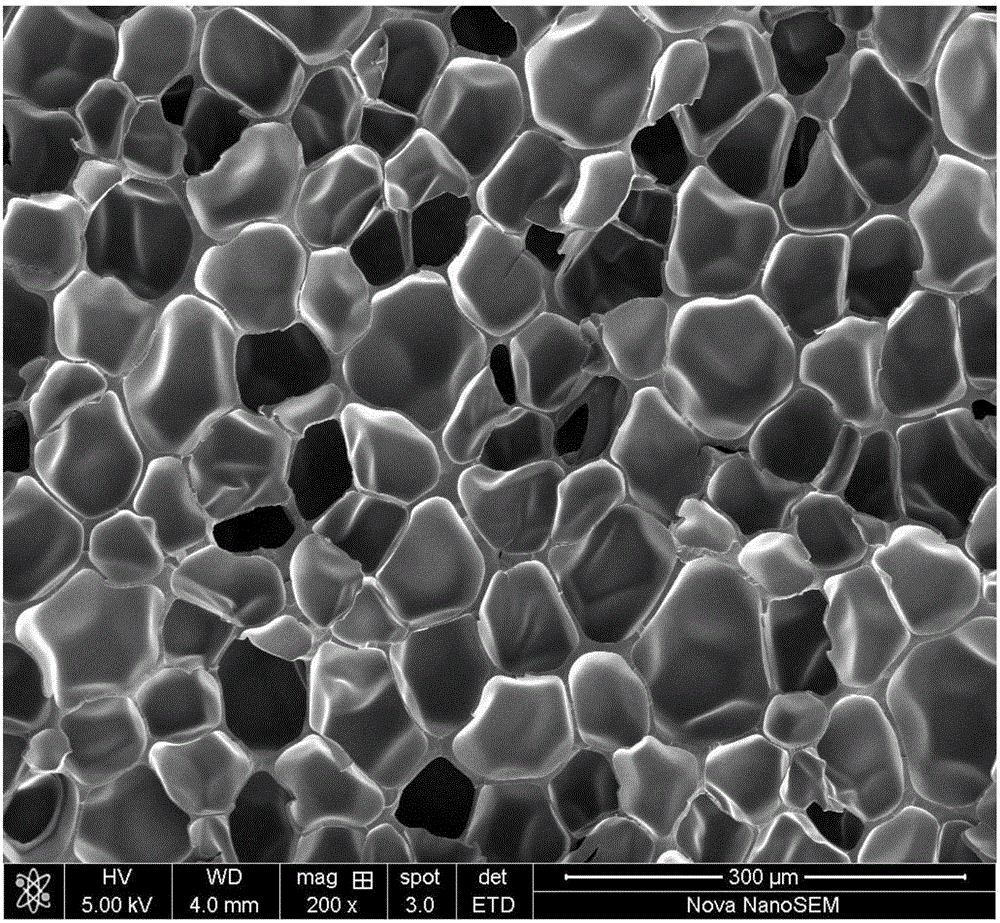

The invention discloses a method for preparing thermoplastic elastomer foamed beads. According to the method, carbon dioxide and nitrogen mixed gas can be retained inside foamed bead bubbles, so that volume shrinkage of the foamed bead bubbles in the air exchange process is inhibited, and large expansion ratio is maintained. The method includes the steps: dipping thermoplastic elastomer beads in high-pressure nitrogen atmosphere at normal temperature; placing the thermoplastic elastomer beads sufficiently absorbing nitrogen in carbon dioxide in a super-critical state, performing swelling diffusion and inducing the thermoplastic elastomer beads dissolving the nitrogen and the carbon dioxide to expand in a foaming manner to prepare the thermoplastic elastomer foamed beads. The nitrogen and carbon dioxide mixed gas is retained inside the thermoplastic elastomer foamed beads, a bubble structure is supported by nitrogen molecules in the bubbles in the process of gas exchange with external air in a natural environment, and high product foaming ratio is maintained.

Owner:HANGZHOU BOSTE NEW MATERIALS TECH CO LTD

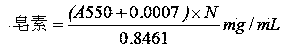

Sasanqua saponin concrete air entraining agent and preparation method thereof

The invention provides a sasanqua saponin concrete air entraining agent and a preparation method thereof. The air entraining agent is characterized by containing sasanqua saponin therein. The preparation method is characterized by extracting sasanqua as a raw material at normal temperature by hydrophilic solvent water solution, and filtering; removing large-molecule impurities from the filtrate by membrane separation under pressure, removing small-molecule impurities by membrane separation, concentrating to be concentrate with Baume degree of not lower than 10Be (60 DEG C), and spray-drying to form solid formulation; or adding a modifying agent to prepare the air entraining agent in liquid formulation. The idea is novel, the raw materials are abundant, the production efficiency is high, the energy consumption in the production is low, the production cost is low, the preparation method is simple in process, green and environment-friendly and is convenient to implement; when the air entraining agent is used in concrete engineering, the dosage of the air entraining agent is low, the air production rate is high, the aperture of the entrained air bubbles is small and the distance among the entrained air bubbles is small, and the air holes of the concrete are more even, more compact and non-communicated, therefore, the sasanqua saponin concrete air entraining agent is valuable for popularizing.

Owner:FUZHOU UNIV

Foam concrete containing recycled inorganic lightweight aggregate and preparation method thereof

InactiveCN105777018AHigh strengthSmall shrinkageSolid waste managementCeramicwareBuilding materialWater reducer

The invention discloses foam concrete containing recycled inorganic lightweight aggregate. The foam concrete is prepared from 20-60 parts of cement, 20-60 parts of slag, 0-50 parts of sand, 0.5-3 parts of a water reducer, 0.1-3 parts of fibers, 25-60 parts of water, foam with the addition amount accounting for 1-80% of the total volume of the foam concrete and the recycled inorganic lightweight aggregate with the addition amount accounting for 1-80% of the total volume of the foam concrete, wherein the recycled inorganic lightweight aggregate is obtained by smashing, screening and grading one or more inorganic heat insulation building materials including but not limited to aerated concrete, foam concrete, foamed ceramic and foamed glass. The invention further discloses a preparation method of the foam concrete. The foam concrete containing the recycled inorganic lightweight aggregate has the advantages of being high in strength, small in shrink, free of formwork collapse, good in fluidity, homogeneous, low in cost and the like and is especially suitable for cast-in-situ lightweight walls, roofs, lightweight cement product elements and the like.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD +1

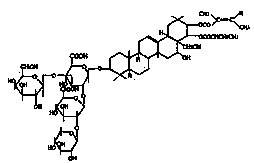

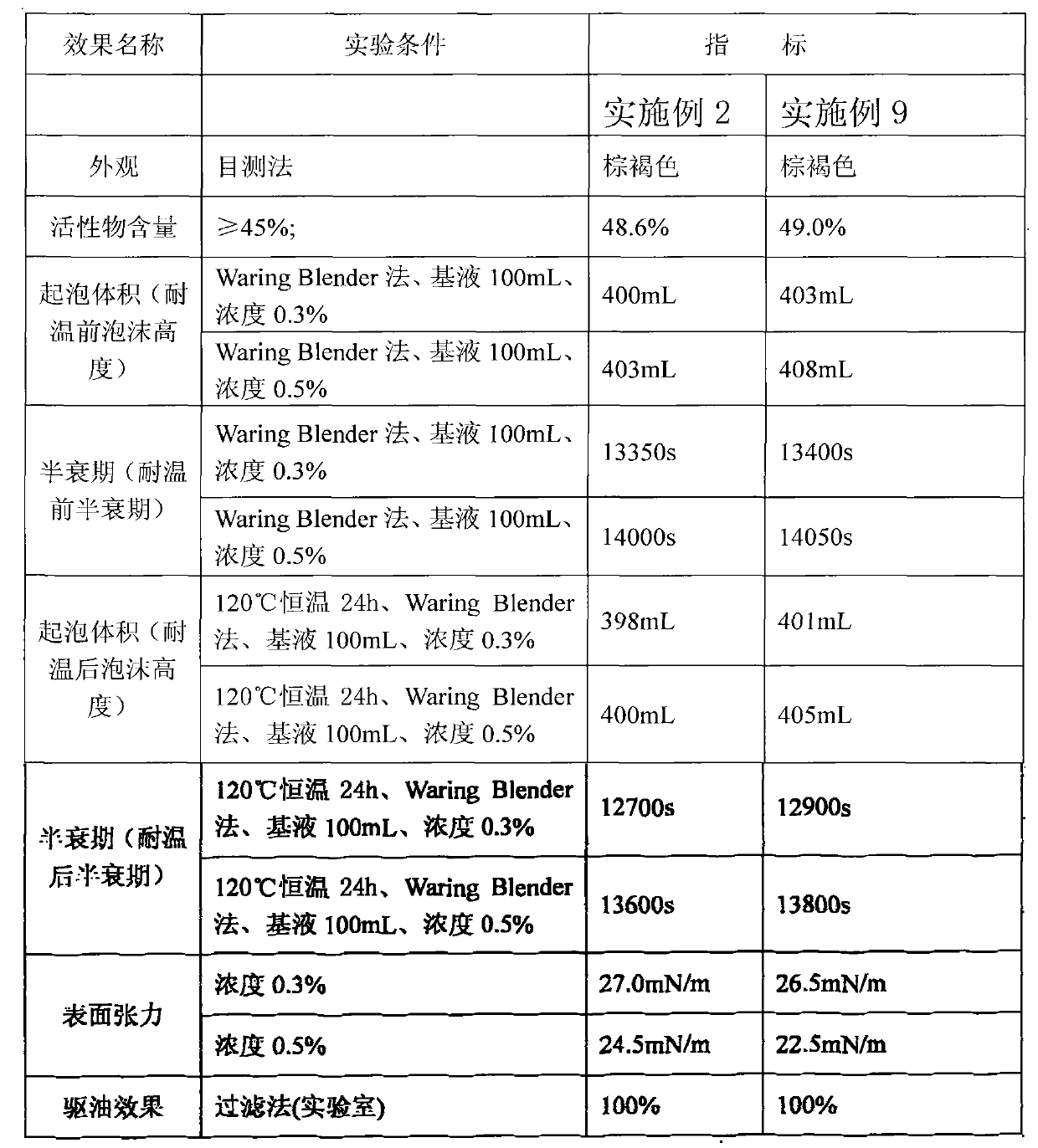

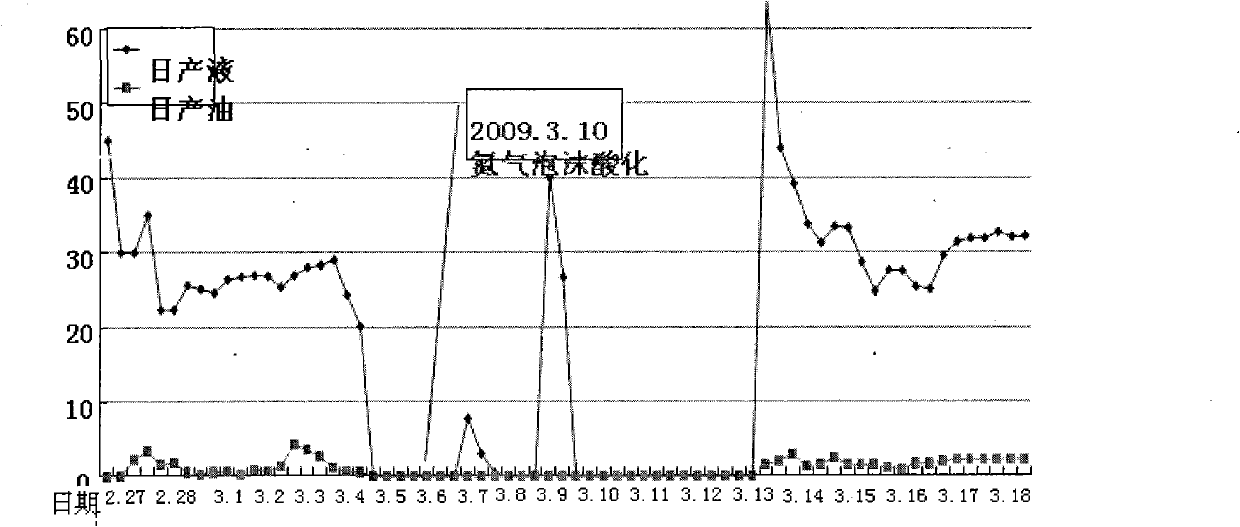

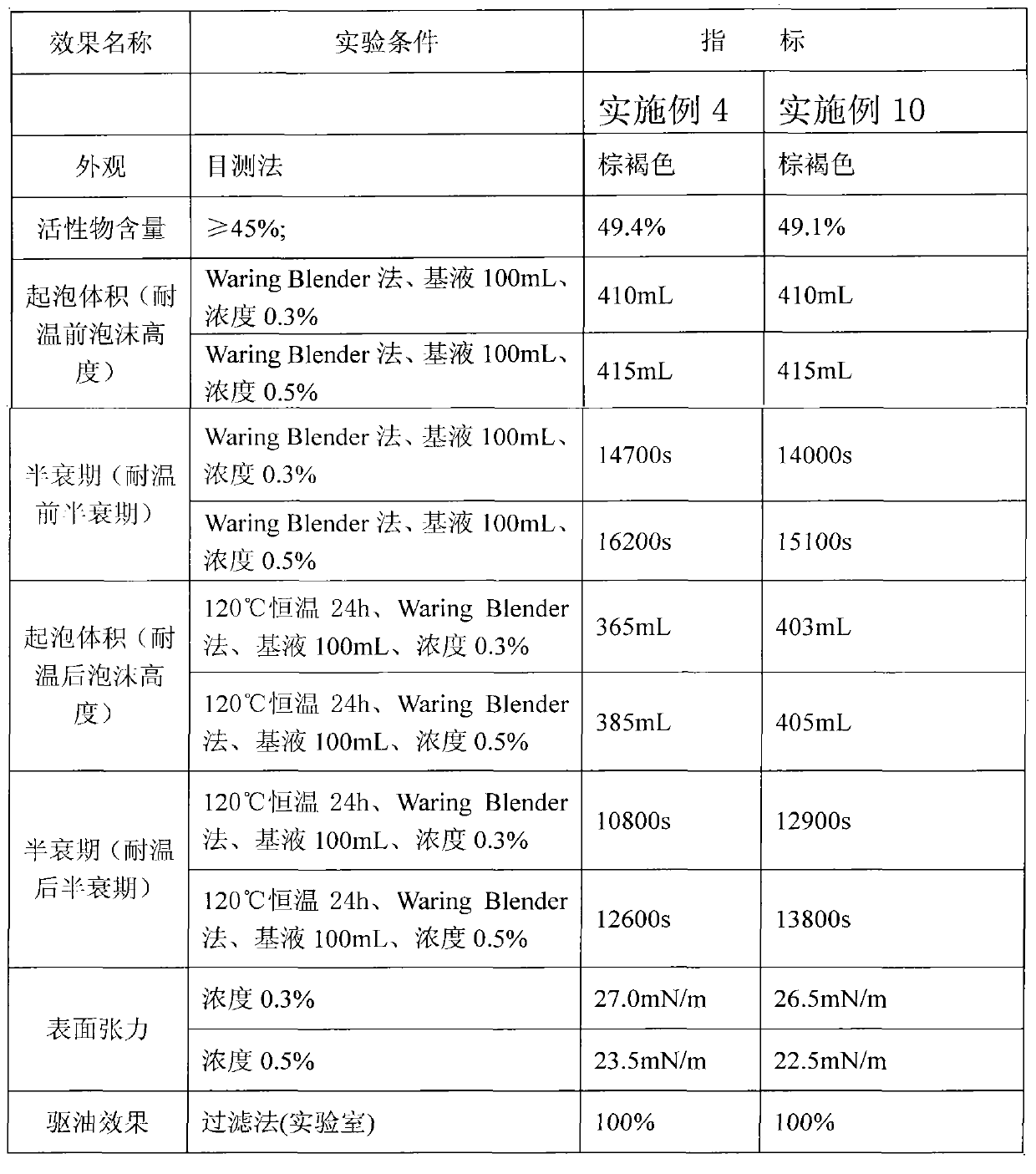

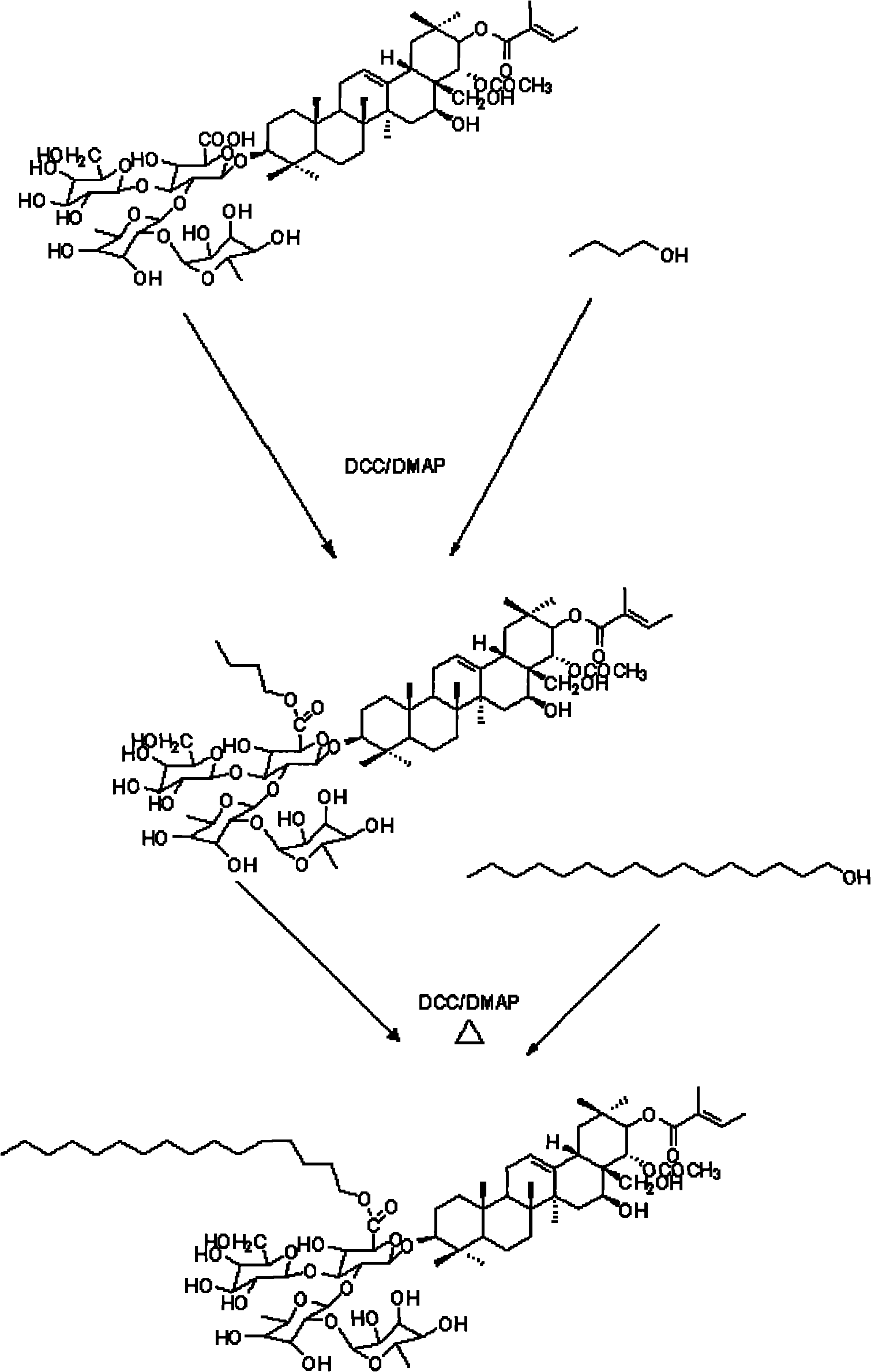

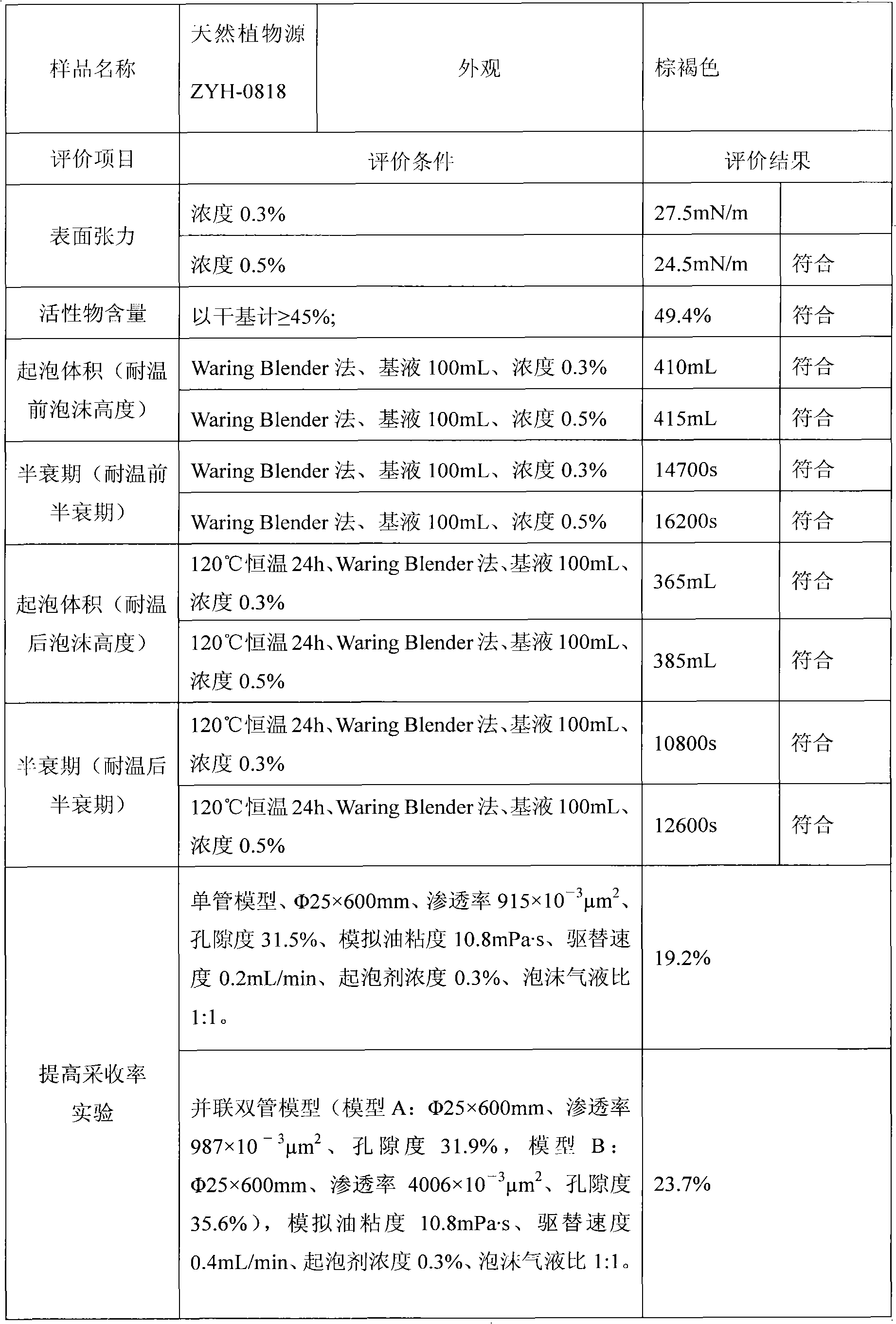

Camellia saponin type oilfield foaming agent and preparation method and application thereof

ActiveCN101906296AHigh foaming ratioLong bubble timeDrilling compositionChemical recyclingChemistryChemical synthesis

The invention relates to a camellia saponin type oilfield foaming agent and a preparation method and application thereof. The oilfield foaming agent comprises the following components in part by mass: 100 parts of camellia saponin based on the solid content, 1 to 10 parts of cocoanut oil diethanol amide, 1 to 10 parts of amine ether alkyl glucoside, 1 to 10 parts of dodecyl betaine, and 0.5 to 2 parts of lauryl dimethy amine oxide, wherein the camellia saponin is natural plant source camellia saponin or structure-modified camellia saponin. The camellia saponin type oilfield foaming agent is used as an oilfield foaming agent in oil recovery, has the characteristics of acid, alkali and salt resistance, temperature resistance, high foam expansion ratio, long stable foam time and the like, can meet oil extraction requirements under different geological and weather conditions, cannot pollute an oilfield soil layer employing the foaming agent, can prevent a chemically synthesized foaming agent from harming the oilfield stratum, and has remarkable environmental protection characteristic.

Owner:青田中野天然植物科技有限公司

Device for preventing coal from burning spontaneously and rapidly extinguishing under coal mine and working method thereof

InactiveCN102979552APrevent spontaneous combustionAchieve fire extinguishingMixing methodsDust removalSpiral bladeEngineering

The invention discloses a device for preventing coal from burning spontaneously and rapidly extinguishing under a coal mine and a working method thereof. The device comprises a cylindrical foamed shell of which the two ends contract, wherein one end of the foamed shell is connected with a compressed air line; one side of the compressed air line is provided with a foam stock solution inlet; the other end of the foamed shell is connected with a foam output pipeline; 6-8 groups of spiral blades are arranged on a hollow shaft of an axis in the foamed shell at certain intervals; air outlet holes are formed among the spiral blades; included angles between the turning directions of the spiral blades and the axial direction of the hollow shaft are 45-60 degrees; each group of spiral blades has the same turning direction; and two adjacent groups of spiral blades have opposite turning directions. A mixture is foamed twice, so that the foaming times are raised to 50-150 times rapidly within a short period of time, and the aims of preventing and controlling spontaneous turning of coal and rapidly extinguishing are fulfilled.

Owner:SHANDONG UNIV OF SCI & TECH

Structural modification type cameclia oleifera saponin and preparation method and application thereof

The invention discloses structural modification type cameclia oleifera saponin, which is prepared by the following method: stirring cameclia oleifera saponin and normal butanol at room temperature and carrying out an esterification reaction under the action of 4-dmethylamino pyridine as a catalyst and N-dicyclohexylcarbodiimide as a dehydrating agent; tracking and detecting to complete reaction; adding fatty alcohol and stirring at room temperature and reacting for 2-5 hours; heating to 70-100DEG C; controlling the reaction pressure to be 0.005-0.015MPa; stirring and carrying out an ester exchange reaction, tracking and detecting to complete reaction; filtering reaction liquid; washing filtrate B; drying and then filtering an organic layer to obtain filtrate C; carrying out reduced pressure distillation to recover the normal butanol; and obtaining a remainder which is the structural modification type cameclia oleifera saponin. The structural modification type cameclia oleifera saponinhas the characteristics of high foaming multiplying power, long foam stabilizing time and the like and can be used as a matrix raw material of an oil filed foaming agent; and the oil filed foaming agent synthesized by matching and optimizing has the performances of resisting acid, alkali, temperature and salt and capability of meeting the oil extracting requirements under different conditions.

Owner:江西新中野茶业科技有限公司

Environment protection type efficient aerating powder for shield construction

ActiveCN101462844AHigh foaming ratioEasy to operateTransportation and packagingMixingFoaming agentSlag

The invention discloses an environmental protection high efficiency foaming agent for shield construction. The foaming agent comprises the following components in percentage by weight: 5 to 20 percent of aliphatic alcohol polyethenoxy ether sulfate, 1 to 8 percent of alcohol amide, 0.5 to 8 percent of alcohol ether, and 64 to 93.5 percent of water. The foaming agent for shield construction has a high foaming ratio and produces abundant and fine foams with even diameter distribution. The produced bubbles have small pores, good lubricity and stability, simple production operation, and lower cost. The foaming agent can better meet the requirements of the slag soil improvement during the process of earth pressure balanced shield.

Owner:GUANGZHOU AORUN SYNTHETIC MATERIAL

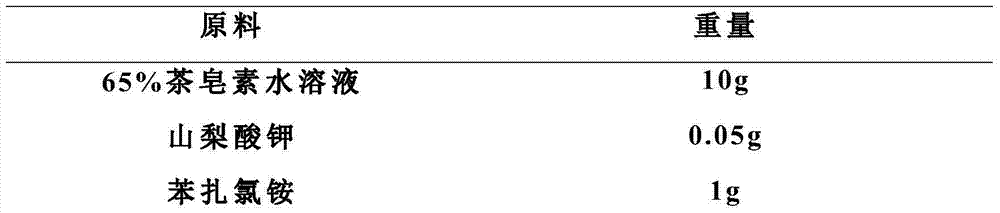

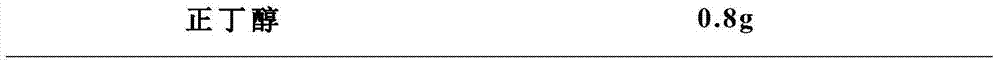

Natural tea saponin foaming agent and preparation method thereof

The invention discloses a natural tea saponin foaming agent, which is characterized by comprising the following components in percentage by mass: 50-70% of tea saponin, 0.01-2% of a preservative, 1-20% of a surfactant, 5-20% of a foam stabilizer, and the balance of water. The foaming agent is non-perishable, and stable and reliable in foaming performance, and has good economic and social benefits.

Owner:LUMIGENEX (SUZHOU) CO LTD

Inorganic cured foam material for surface leaking stoppage of shallow buried coal seam mining area and preparation method of inorganic cured foam material

InactiveCN103396154APromotes hydrationImprove foam production efficiencySolid waste managementCeramicwareFiberCopper oxide

The invention discloses an inorganic cured foam material for surface leaking stoppage of a shallow buried coal seam mining area and a preparation method of the inorganic cured foam material, which belong to the inorganic cured foam material and the preparation method thereof. The leaking-stoppage cured foam comprises water, coal ash, slaked lime, cement, ox horn powder, aluminum powder, copper oxide, polyphosphoric acid, aluminum hydroxide, hydroxypropyl methyl cellulose and steel fiber. The preparation method of the inorganic cured foam material comprises the following steps of: firstly, adding the coal ash, the cement, the hydroxypropyl methyl cellulose, the steel fiber and the slaked lime in water to form a coal ash substrate serous fluid; secondly, adding the ox horn powder into a little water for stirring to form prefabricated mucus, and sufficiently stirring the coal ash substrate serious fluid and the prefabricated mucus to form a mixed solution; thirdly, adding an inorganic adhesive system into the mixed solution and sufficiently stirring to form a mixed adhesive solution; and finally, adding the aluminum powder for sufficiently stirring uniformly, foaming the serious fluid by utilizing an organic self-foaming system, and preparing the inorganic cured foam material for surface leaking stoppage of the shallow buried coal seam mining area. According to the invention, the seam infiltration capacity is strong, the compressive strength is large, the high temperature resistance and the heat insulation performance are good, and the substrate is purely inorganic and pollution-free.

Owner:CHINA UNIV OF MINING & TECH +1

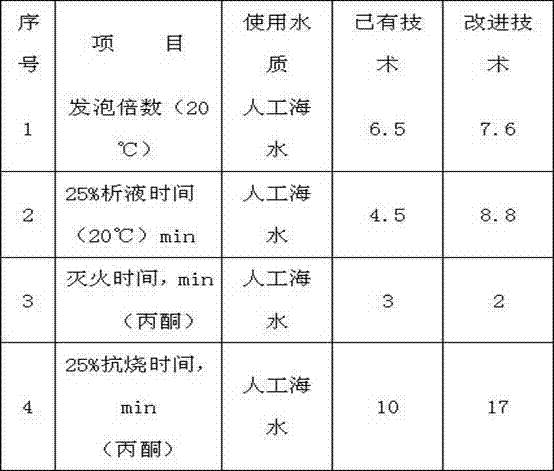

Seawater-resistant insoluble aqueous film-forming foam extinguishing agent and preparation method thereof

InactiveCN103463790AFire extinguishing speedShorten fire fighting timeFire extinguisherCocamidopropyl betaineChemistry

The invention discloses a seawater-resistant insoluble aqueous film-forming foam extinguishing agent and a preparation method thereof. The extinguishing agent comprises the following components in parts by weight: 300-400 parts of deionized water, 6-10 parts of sodium benzoate, 20-80 parts of urea, 5-9 parts of xanthan gum, 100-400 parts of Cocamidopropyl betaine, 20-60 parts of APG, 80-200 parts of ethylene glycol, 20-60 parts of ethylene glycol monobutyl ether, 10-50 parts of F1157, 10-50 parts of F1203, 10-60 parts of F1460 and 20-60 parts of a buffer agent. The seawater-resistant insoluble aqueous film-forming foam extinguishing agent is used for being mixed with seawater for fire extinguishing and has the advantages of low viscosity, high fire-extinguishing speed, high expansion rate, stable property, long storage time and the like.

Owner:江苏江亚消防科技股份有限公司

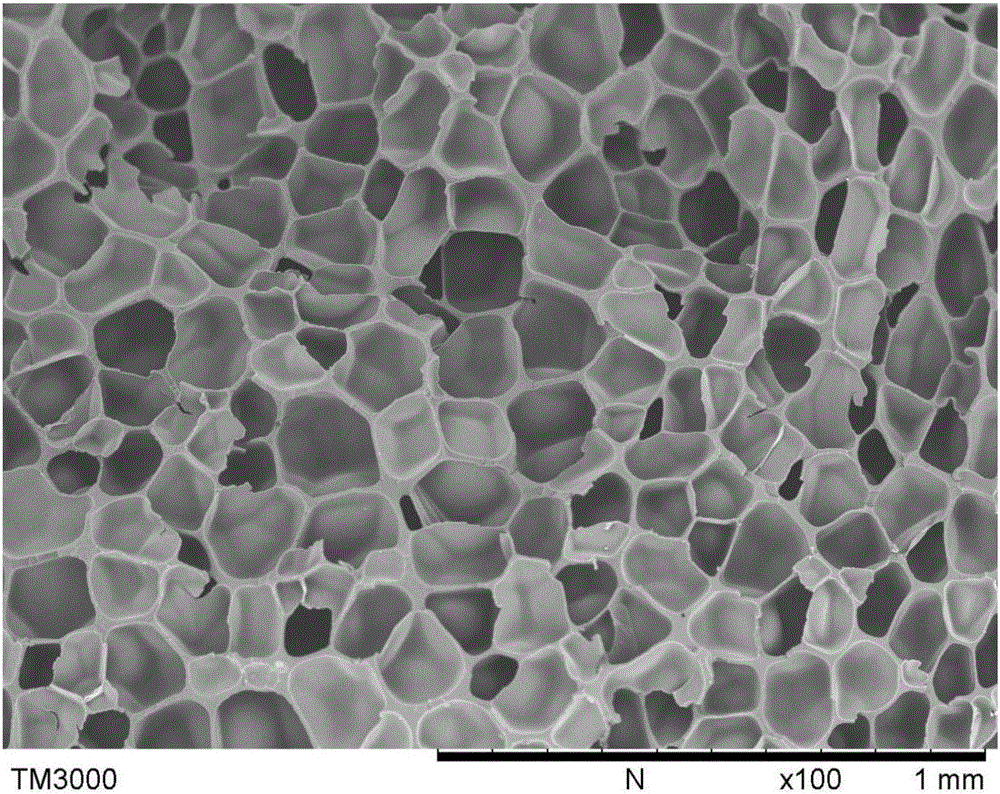

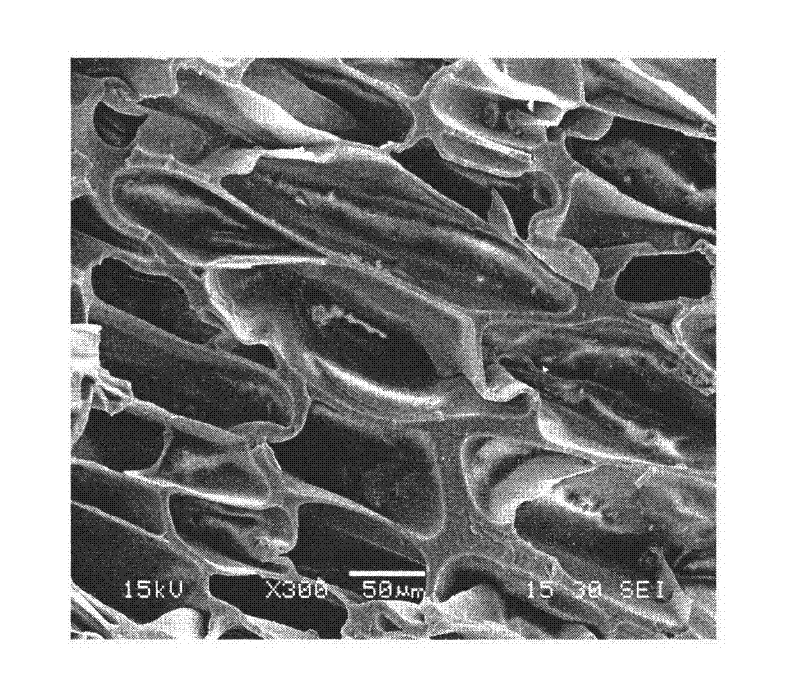

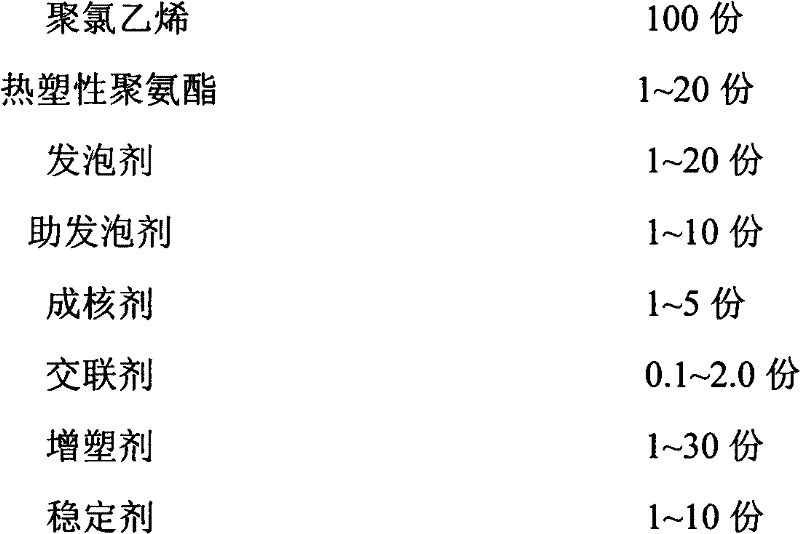

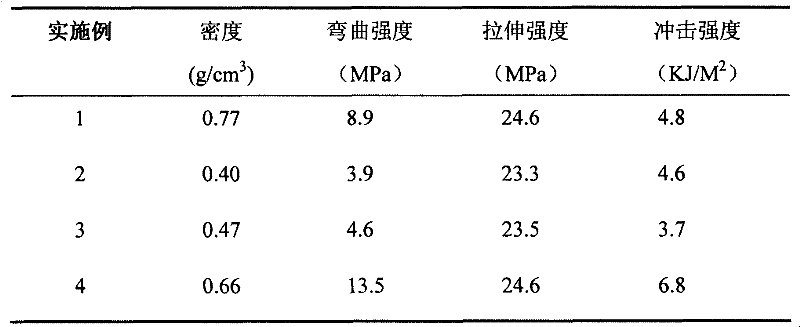

Crosslinking type polyvinyl chloride/thermoplastic polyurethane light foaming material and preparation method thereof

The invention provides a crosslinking type polyvinyl chloride light foaming material and a preparation method of the crosslinking type polyvinyl chloride light foaming material. The foaming material consists of 100 by weight of polyvinyl chloride, 1 to 20 by weight of thermoplastic polyurethane, 1 to 20 by weight of foaming agents, 1 to 10 by weight of auxiliary foaming agents, 1 to 5 by weight of nucleating agents, 0.1 to 2.0 by weight of crosslinking agents, 1 to 30 by weight of plasticizing agents and 1 to 10 by weight of stabilizing agents, and in addition, the foaming material is prepared through preplastification, melting plastication, chemical crosslinking and chemical foaming. The foaming material has the apparent density being 25 to 100 kg / m<3>, the material thickness being 1 to 8mm, the bending strength being 5 to 20 MPa, the tensile strength being 15 to 25 MPa and the impact strength being 5 to 10 KJ / M<2>. The micro-crosslinking foam plastic provided by the invention has the advantages that the foam hole is uniform and controllable, the foaming ratio is high, the size stability is good, the physical performance and the mechanical strength are excellent, and the micro-crosslinking foam plastic is suitable for being made into large-scale foaming products.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method of isocyanate-based polyimide foam

ActiveCN104829835AImprove heat resistanceImprove thermal stabilityMaterials preparationHeat resistance

The invention provides a preparation method of isocyanate-based polyimide foam. The preparation method comprises that 1, polybasic aromatic anhydride is heated and dissolved in a polar solvent and undergoes a reaction with fatty alcohol to produce a polybasic aromatic anhydride derivative solution, 2, the polybasic aromatic anhydride derivative solution and a foam stabilizer are blended to form a white material, 3, polybasic aromatic anhydride and isocyanate undergo a reaction to produce a black material, 4, the foaming white material is immediately poured into the foaming black material at a room temperature under normal pressure, and the mixture is uniformly stirred, then is fast poured into a mold and is subjected to free foaming molding to form a foam intermediate and 5, the foam intermediate is heated and cured to form the isocyanate-based polyimide foam. The preparation method inhibits production of an amino group and an isocyanate group in foam material preparation, reduces a polyurea generation amount and improves isocyanate-based polyimide foam heat resistance, heat stability and flame resistance. The preparation method has the advantages of simple processes, excellent product comprehensive properties, and industrial production and wide application feasibility.

Owner:HARBIN ENG UNIV

Expandable polystyrene product and production method thereof

The invention discloses an expandable polystyrene product and a production method thereof. The expandable polystyrene product is made by processing the following ingredients in parts by weight: 100 parts of styrene, 110 to 150 parts of water, 0.25 to 0.5 part of evocating agent A: BPO, 0.04 to 0.1 part of evocating agent B: CP-02, 7 to 10 parts of vesicant: pentane, 0.05 to 0.15 part of dispersant: TCP, 0.05 to 0.2 part of suspending agent: polyethylene wax and 0 to 0.01 part of emulsifier: GMS, and the ingredients react and are evocated as per certain sequence at rated temperature by stages. Compared with the prior art, the product has uniform particle size distribution, high foaming multiplying factor (no less than 90), favorable elasticity, stable quality, high yield rate and favorable comprehensive economic and technical norms, and the production method of the product has little pollution on environment.

Owner:新疆蓝山屯河新材料有限公司

PVC foaming coating, PVC foaming wallpaper and preparation method thereof

InactiveCN105062246AIdeal pore structureEnsure decompositionCovering/liningsFibre treatmentFoaming agentMicrosphere

The invention discloses a PVC foaming coating. The PVC foaming coating comprises, by weight, 330-350 parts of environmentally-friendly plasticizer, 360-390 parts of PVC paste resin, 15-18 parts of liquid stabilizer, 20-22 parts of AC foaming agent, 20-22 parts of microsphere foaming agent, 75-80 parts of titanium dioxide, 250-275 parts of ground calcium carbonate and 30-33 parts of matting agent. By means of the potassium / zinc liquid stabilizer, the AC foaming agent and the microsphere foaming agent, the foaming function of the PVC foaming coating can be effectively improved, the foaming ratio of PVC foaming wallpaper can be improved, and satisfactory foaming quality can be obtained.

Owner:NINGHAI CHANGHE ENVIRONMENTAL COATINGS

Super-light plastic formula for sports shoe soles

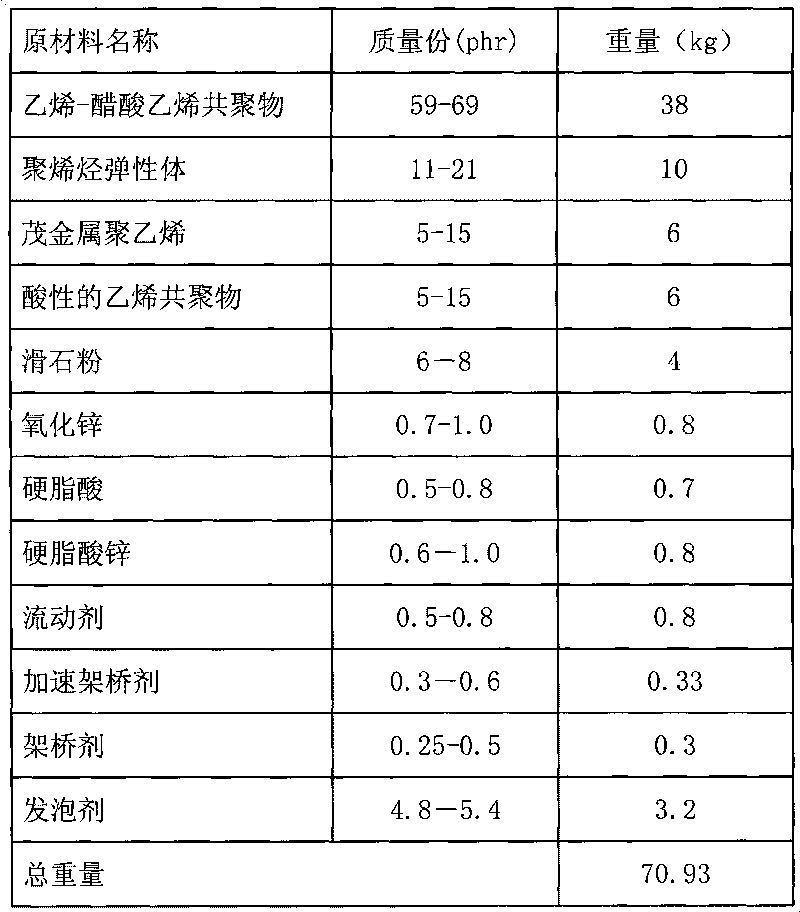

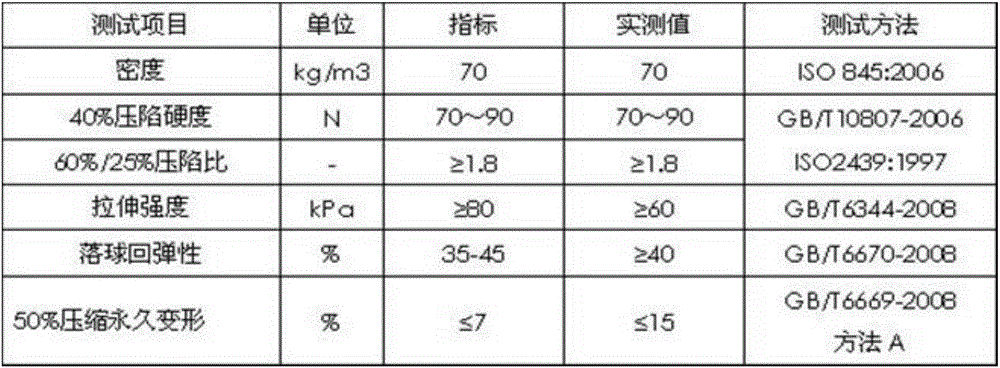

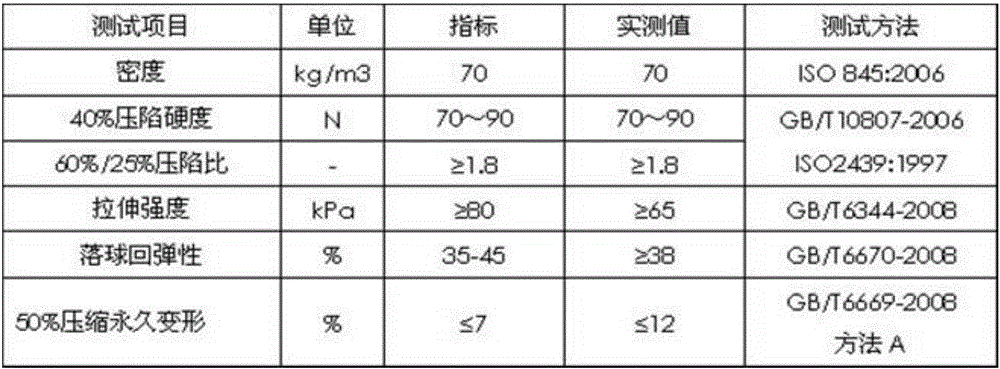

The invention discloses a super-light plastic formula for sports shoe soles, and the formula comprises the following components in parts by weight: 59-69 parts by weight of ethylene-vinyl acetate copolymer, 11-21 parts by weight of polyolefin elastomer, 5-15 parts by weight of metallocene polyethylene, 5-15 parts by weight of acidic ethylene copolymer, 6-8 parts by weight of talc powder, 0.7-1.0 part by weight of zinc oxide, 0.5-0.8 part by weight of stearic acid, 0.6-1.0 part by weight of zinc stearate, 0.5-0.8 part by weight of flowable agent A, 0.3-0.6 part by weight of accelerated bridging agent, 0.25-0.5 part by weight of bridging agent and 4.8-5.4 parts by weight of foaming agent. Plastic soles of sports shoes produced by the technical scheme have super-light performance and the comfort which are unmatched by the ordinary plastic formula, have durable comfort, durable damping performance and other performances and can greatly reduce the consumption of physical strength of athletes.

Owner:ANTA CHINA

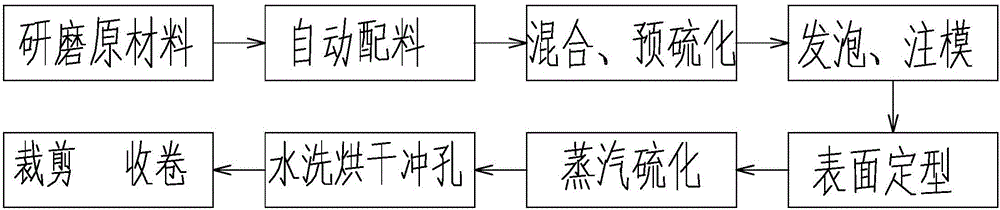

Intermittent vulcanized latex sponge mattress production technology

ActiveCN106478997AIncrease elasticityImprove carrying capacityStuffed mattressesSpring mattressesPunchingAccelerant

The invention provides an intermittent vulcanized latex sponge mattress production technology which is capable of improving bearing performance and comfort by vulcanizing and ripening latex and auxiliaries before foaming. The intermittent vulcanized latex sponge mattress production technology includes the steps of 1), grinding and refining raw materials; 2), using a compounding system for automatically compounding according to a formula, wherein the raw materials comprise, by weight, 80-100 parts of natural rubber, 0-20 parts of rubber polymer, 3-10 parts of vulcanizing agent, 1-8 parts of activator, 0.5-6 parts of emulsifying agent, 1-5 parts of accelerant and 0.5-5 parts of gels; 3), mixing and prevulcanization; 4), adding a hardening agent, foaming by a foaming machine, conducting injection molding and surface setting; 5), using a vulcanizing device for vulcanizing, washing with water after vulcanizing, cooling, drying and punching; 6), cutting and winding so as to obtain a sponge mattress. The sponge mattress produced according to the technology has the advantages of high elasticity, shock absorption, good bearing performance and excellent comfort and durability.

Owner:江苏金世缘乳胶制品股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com