High foaming-ratio and high-density polyethylene microporous foaming section bar and its preparation method

A high-density polyethylene and microcellular foaming technology, applied in the coating and other directions, can solve the problems of only 1.1-2.0 times the foaming ratio, inevitable core layer and skin layer structure, uneven product foaming, etc. Achieve the effect of easy operation, favorable industrial production and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

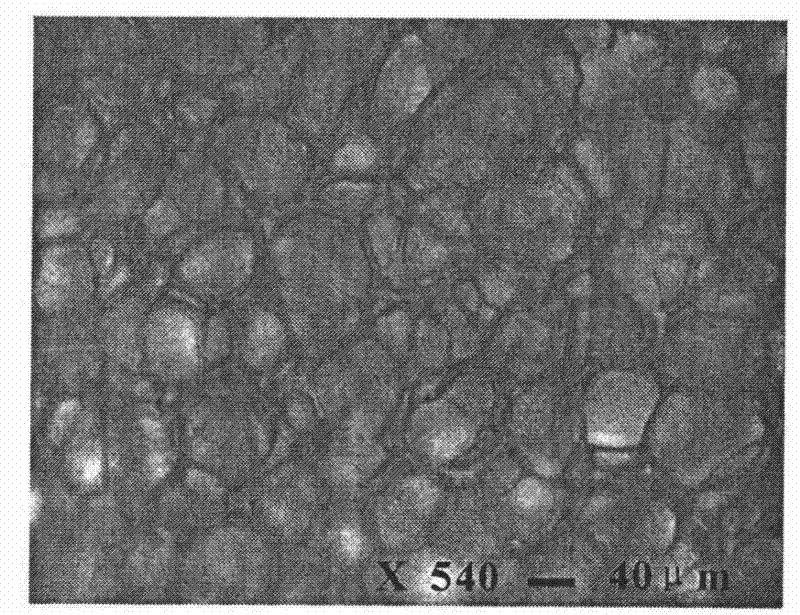

[0039] Put the 6 kinds of HDPE raw material particles with a melt index in the range of 0.7-20g / 10min into the high-pressure mold of the physical gas foaming device to ensure that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space Foaming is performed. When the mold reaches the set temperature of 132°C, fill it with 20MPa of N2, keep the pressure at a constant temperature for 10 minutes, and then release the pressure to normal pressure at a speed of 28MPa / s. The foamed material was taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 1.

[0040] Table 1 Comparison of structural properties of foamed materials with different melt index HDPE raw materials

[0041]

Embodiment 2

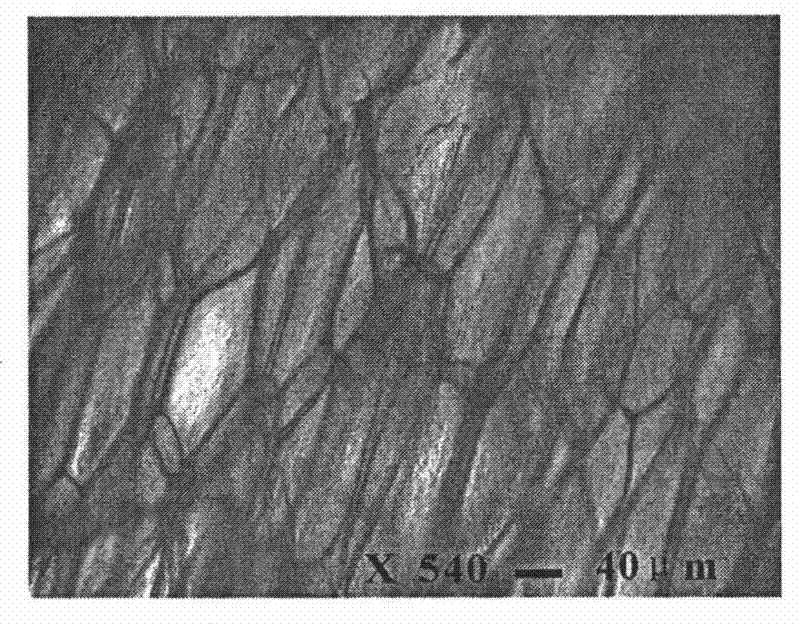

[0043] The HDPE 6 particles are placed in a high-pressure mold in a physical gas foaming device to ensure that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. When the mold reaches the set temperature, fill it with 20MPa N 2 , kept at constant temperature and pressure for 10 minutes, and then released to normal pressure at a speed of 28MPa / s. The foamed material was taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 2.

[0044] Table 2 Comparison of structural properties of HDPE foamed materials prepared at different foaming temperatures

[0045]

Embodiment 3

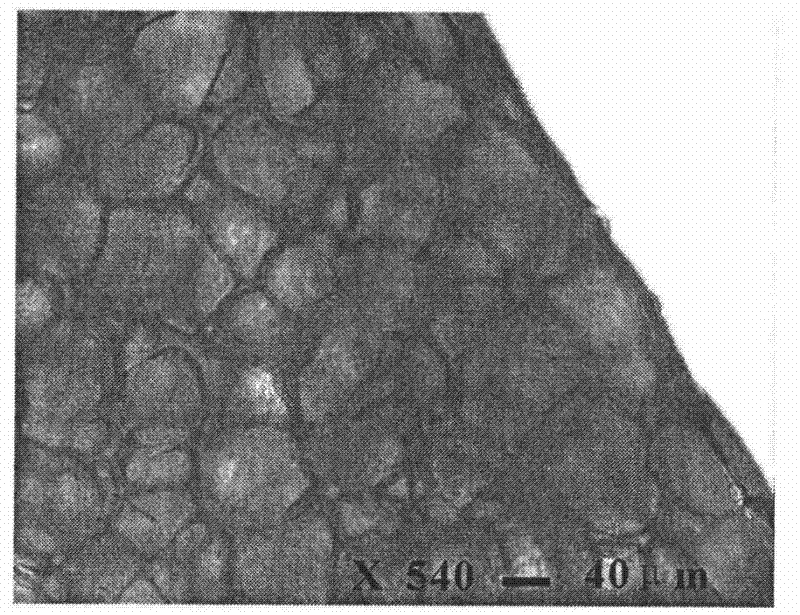

[0047] Put the HDPE 1 particles in the high-pressure mold of the molding physical gas foaming device to ensure that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. When the mold reaches the set temperature of 130°C, fill it with different pressures of N 2 , constant temperature and pressure for 5-20 minutes, and then release the pressure to normal pressure at a certain speed. The foamed material was taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 3.

[0048] Table 3 Comparison of structural properties of HDPE foamed materials prepared by different foaming pressures

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com