Patents

Literature

75 results about "Gas foaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biodegradable scaffolds and uses thereof

InactiveUS20060002978A1Strengthen cellsEnhanced tissue growthPowder deliveryPeptide/protein ingredientsBiodegradable scaffoldPolymer chemistry

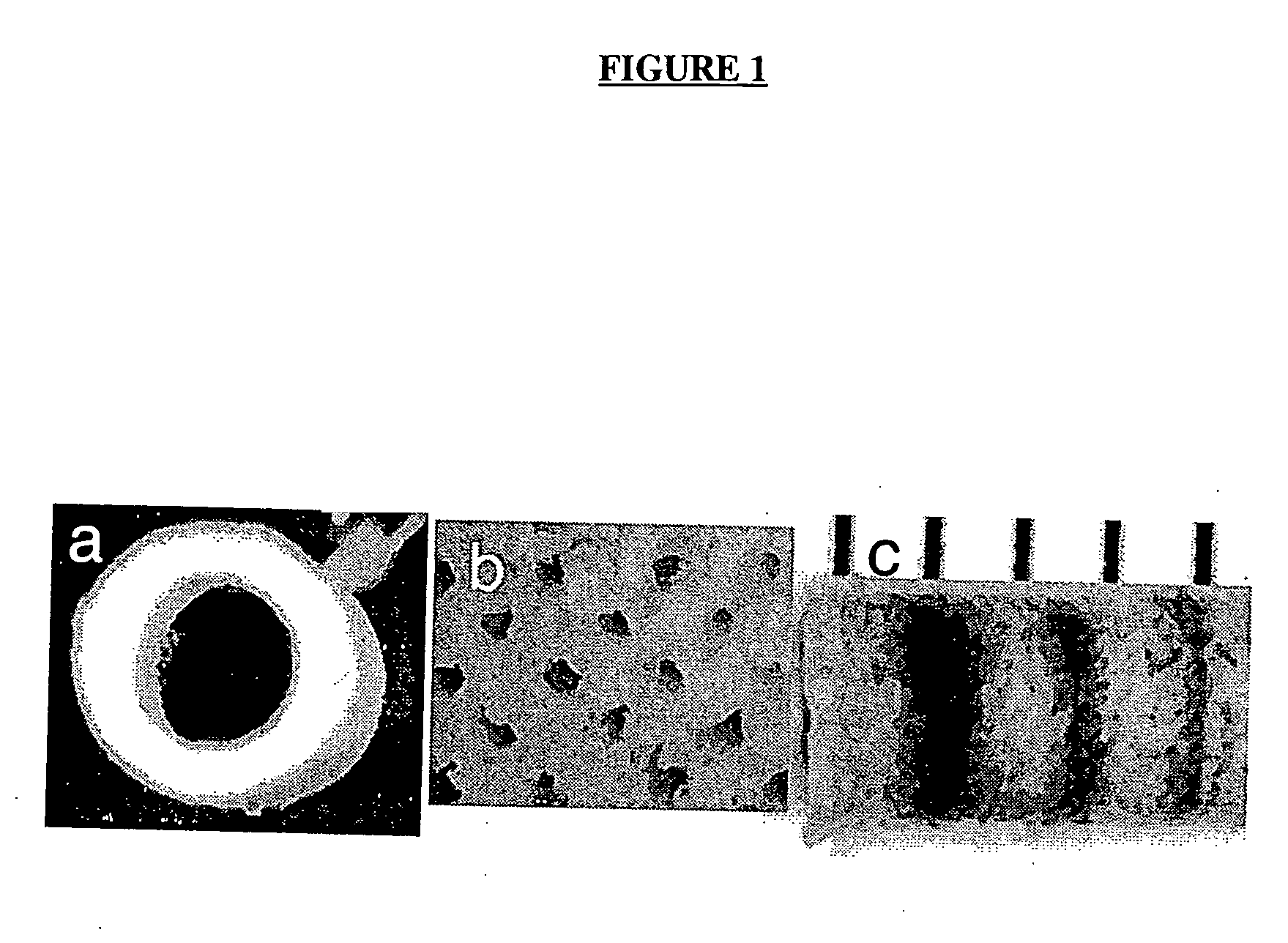

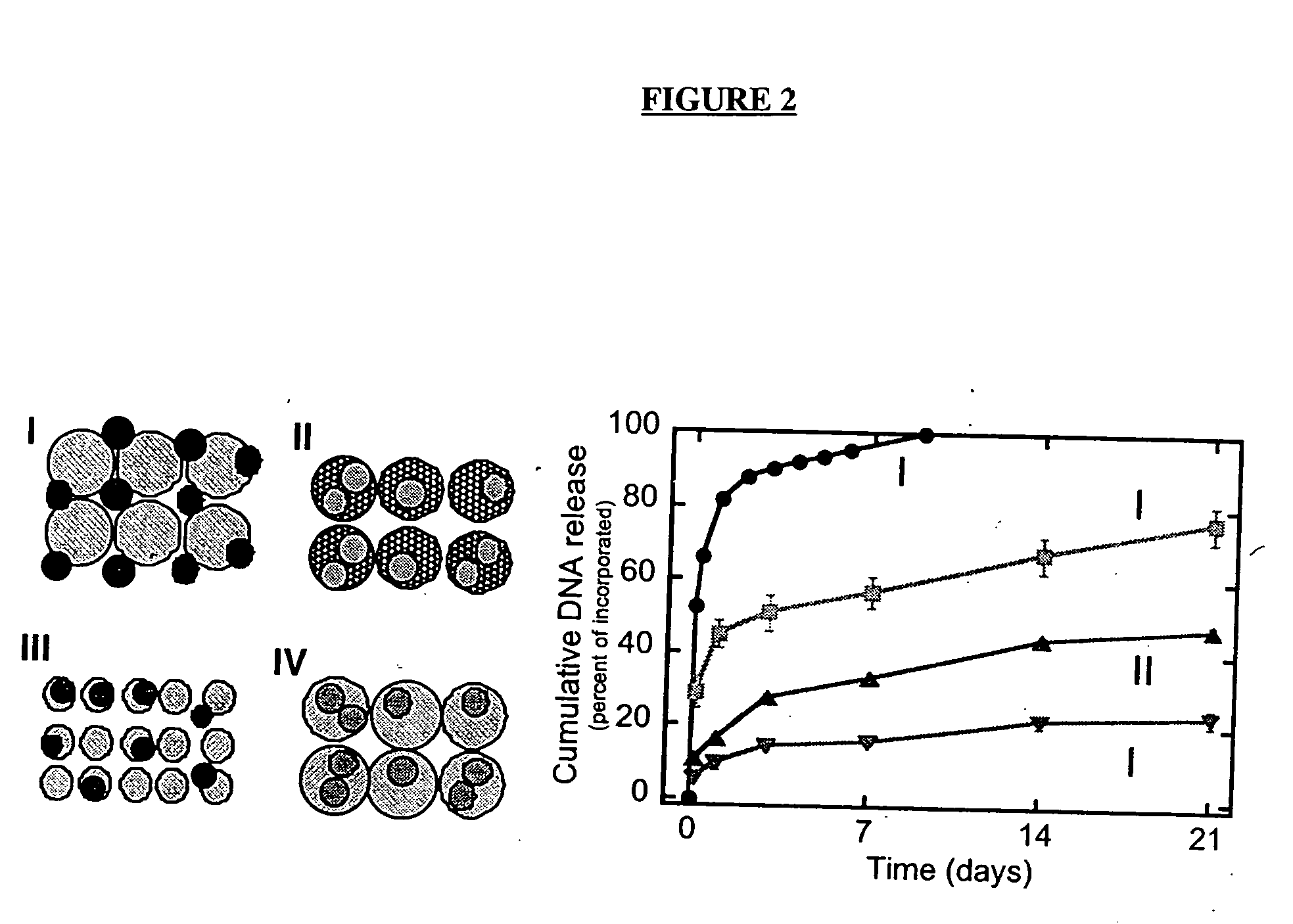

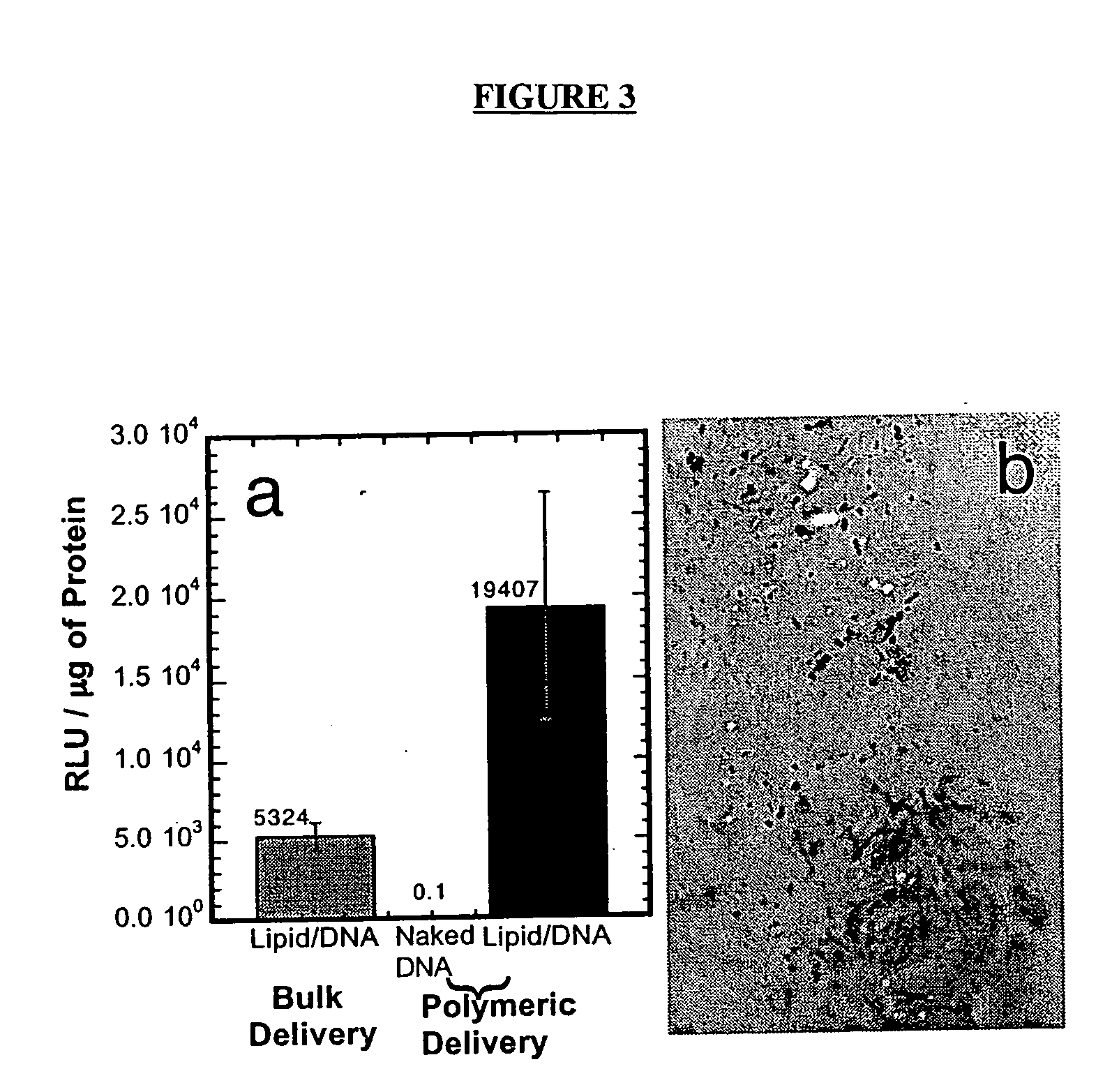

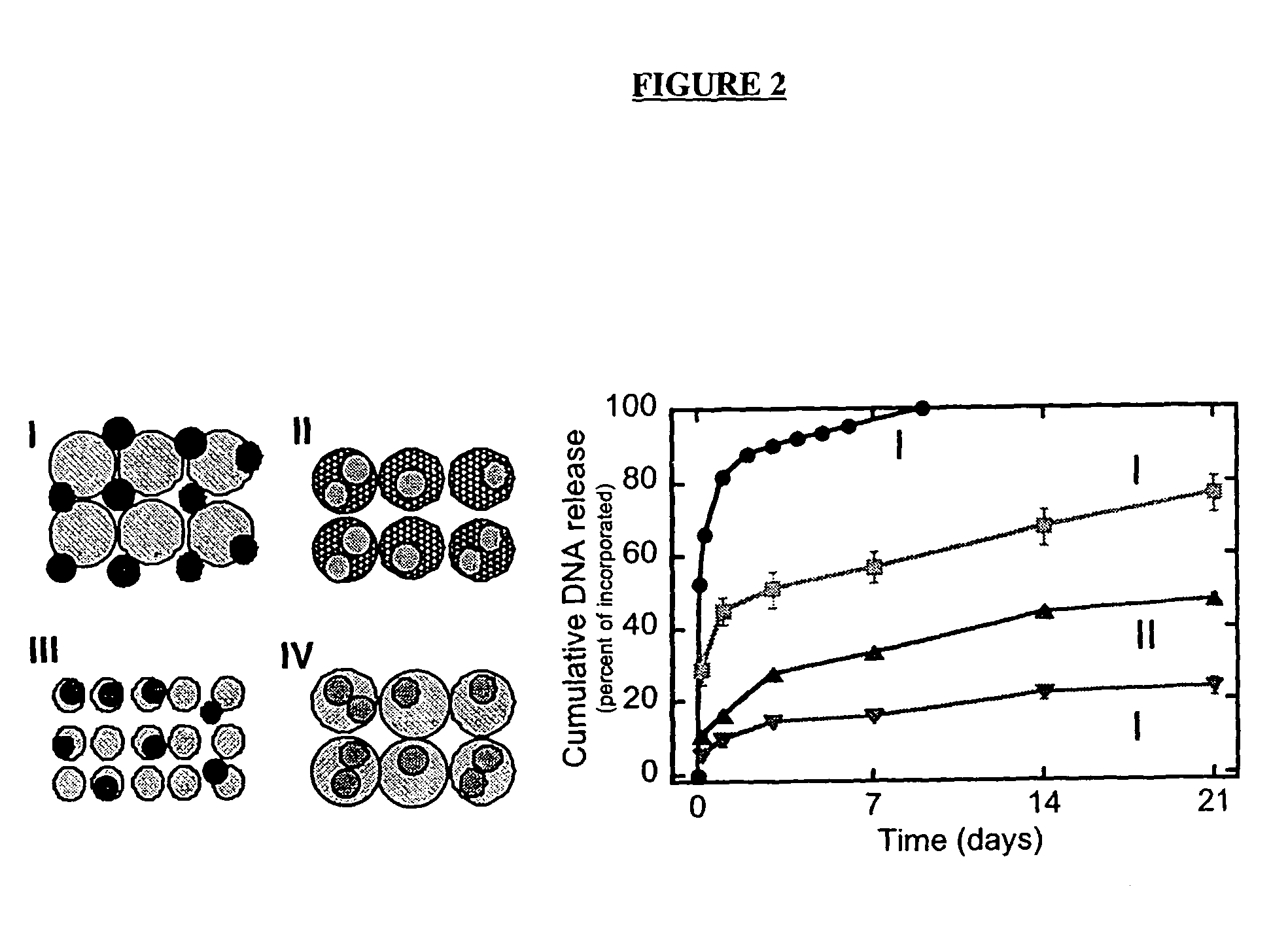

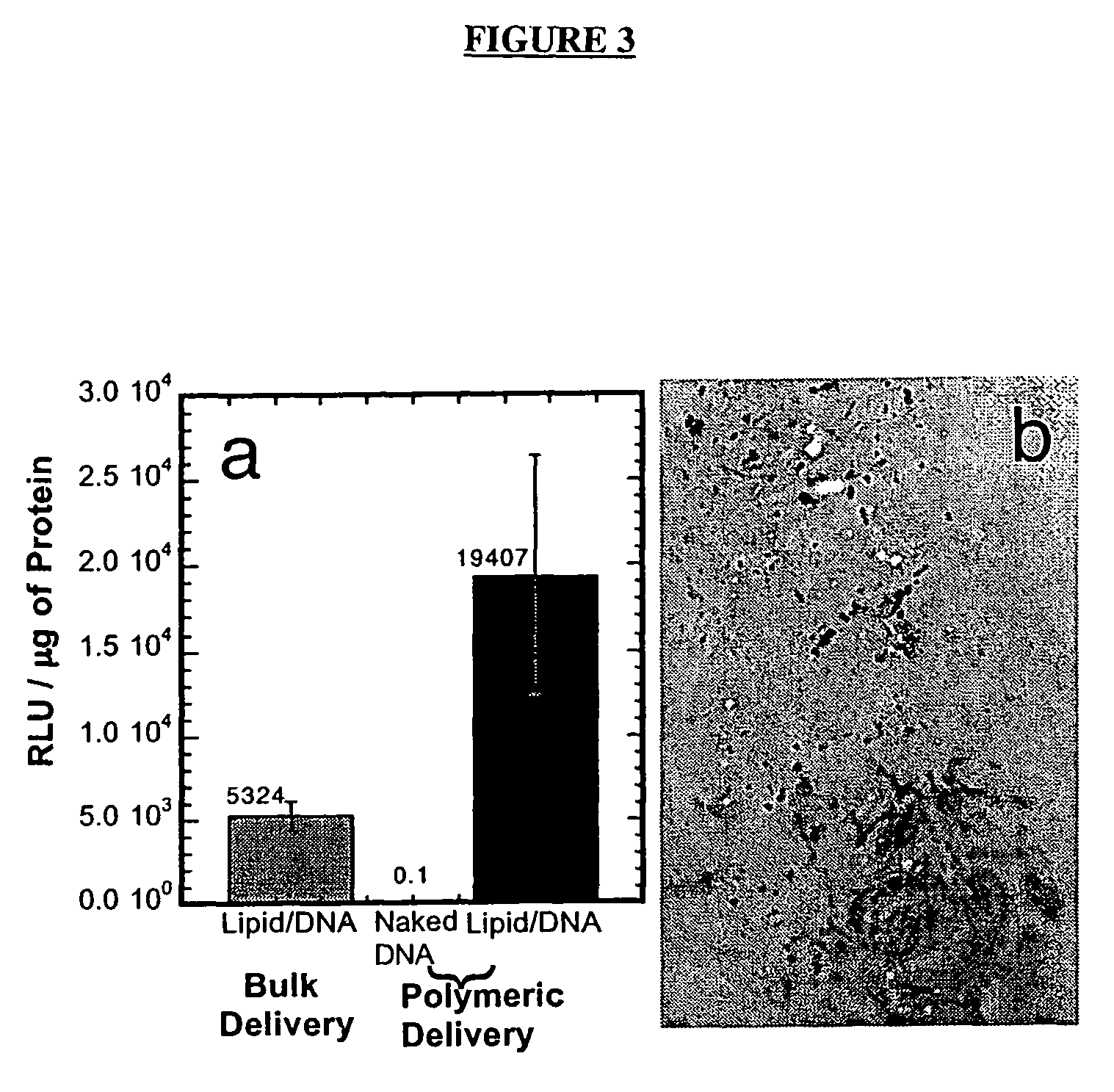

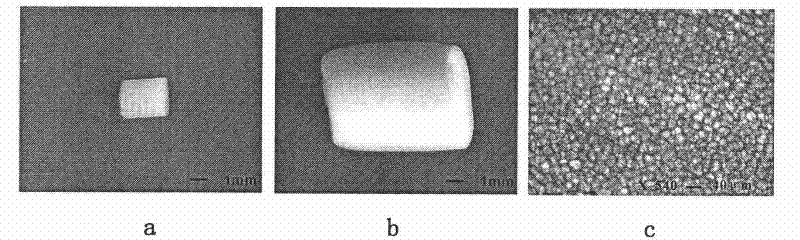

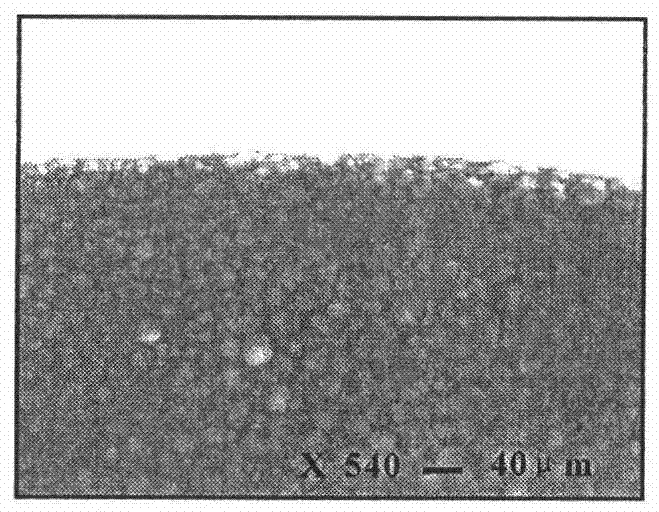

The invention is directed to scaffolds containing porous polymer material prepared by a process of gas foaming / particulate leaching and a wet granulation step prior to gas foaming and particulate leaching, particularly having a characteristic interconnected pore structure, as well as sustained release of protein, DNA or cells, and to methods for using such porous polymer material for preparation of scaffolds, particularly for tissue engineering.

Owner:NORTHWESTERN UNIV

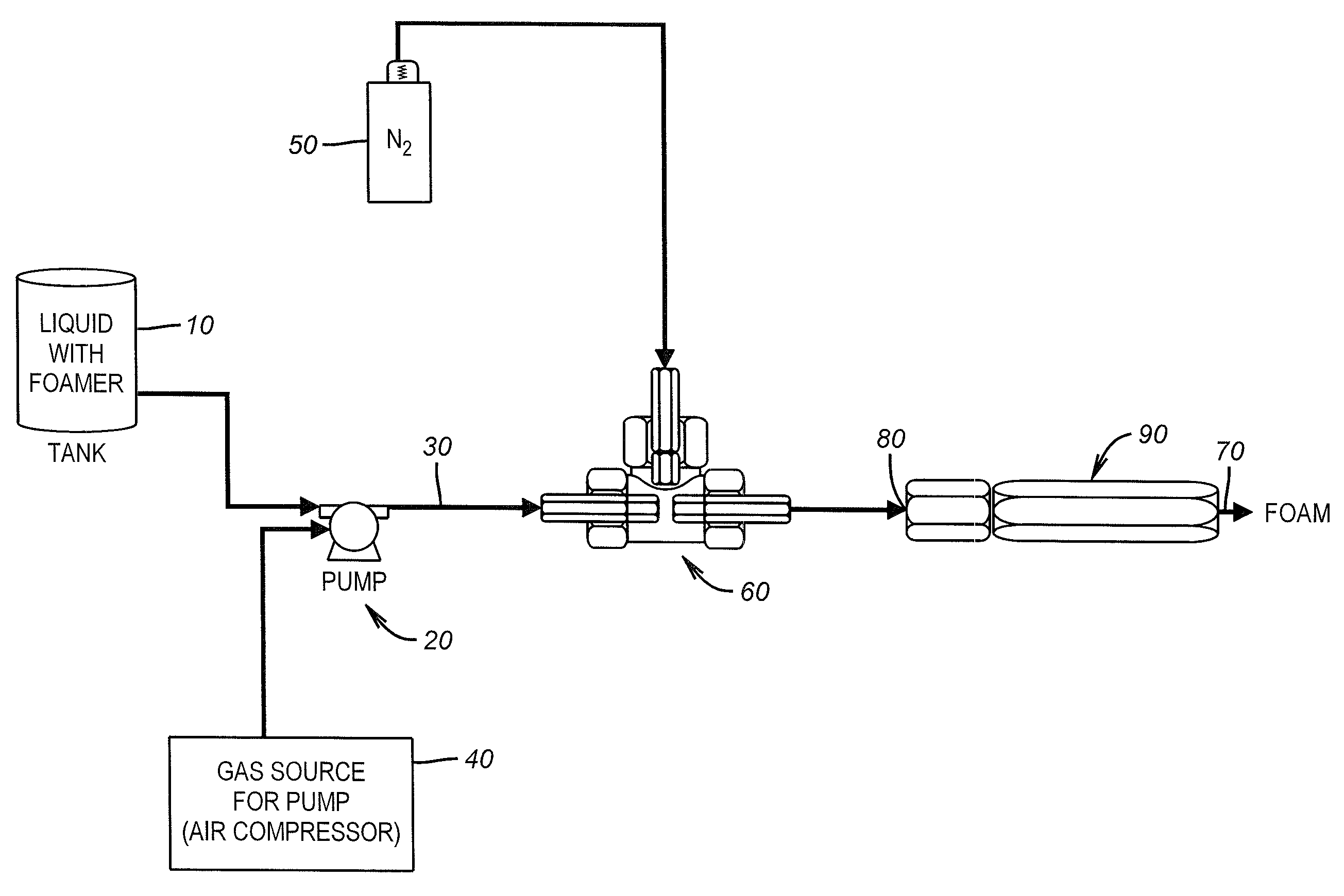

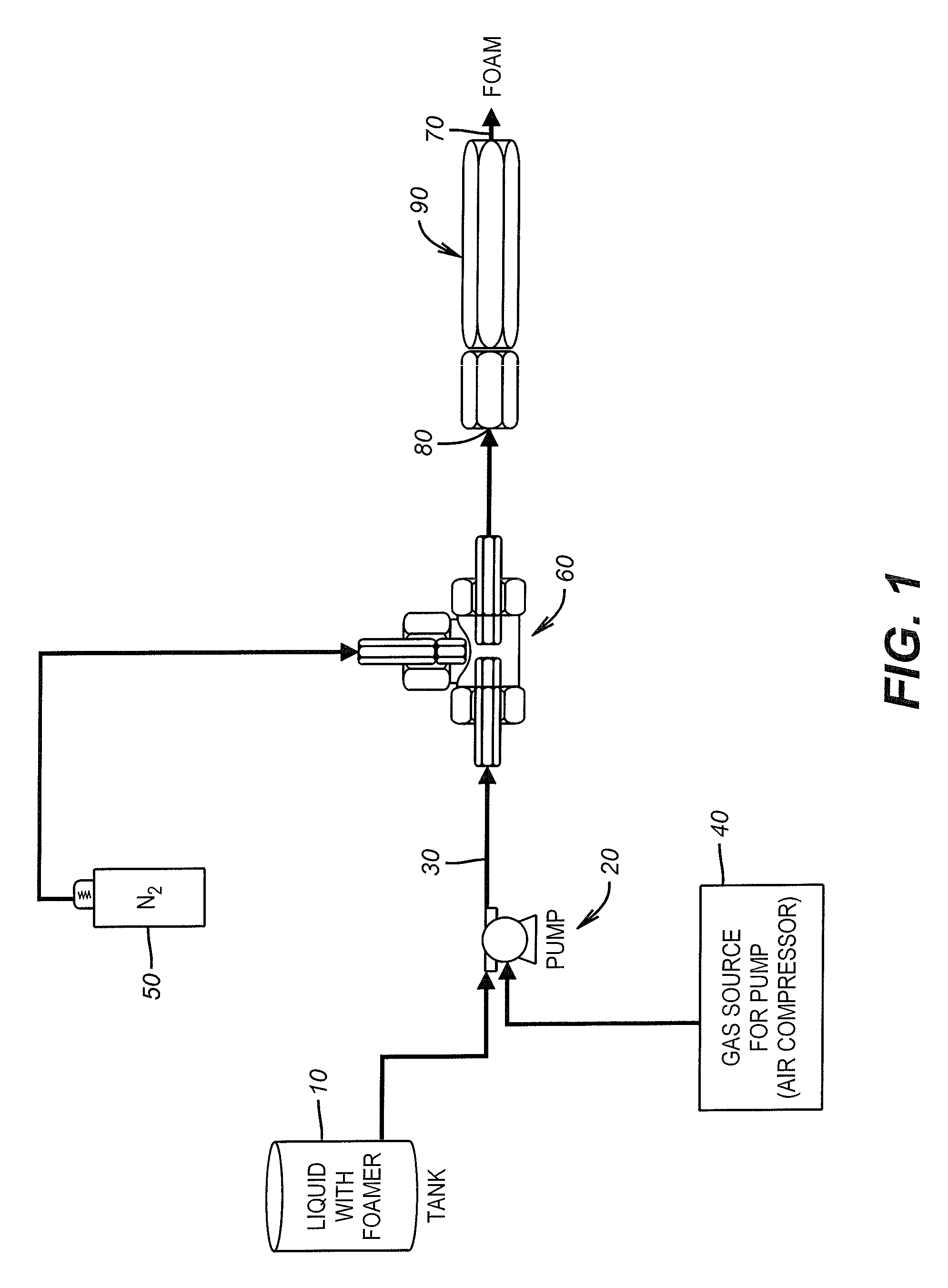

Method of Treating Flow Conduits and Vessels with Foamed Composition

InactiveUS20090114247A1Lower hydrostatic loadingReduce liquid volumeHollow article cleaningCleaning apparatusFoaming agentMedicine

The annular surface between the tubing and casing of an oil or gas well as well as flow conduits and vessels may be contacted with a foamed treatment composition containing a gas, a foaming agent and a treatment agent. The treatment agent may be an inhibitor or removal agent for scales, corrosion, salts, paraffins or asphaltenes. The foam, upon destabilization, renders a thin film of concentrated treatment agent on the external surfaces of the tubing, inside the casing and in the perforations of the oil or gas well or on the flow conduits or vessels.

Owner:BAKER HUGHES INC

Nontoxic, odorless and recoverable environmentally-friendly polyurethane foaming material and preparation method thereof

ActiveCN102229709ANo chemical reactions involvedHuge energy savingCoatingsEnvironmental resistanceHuman health

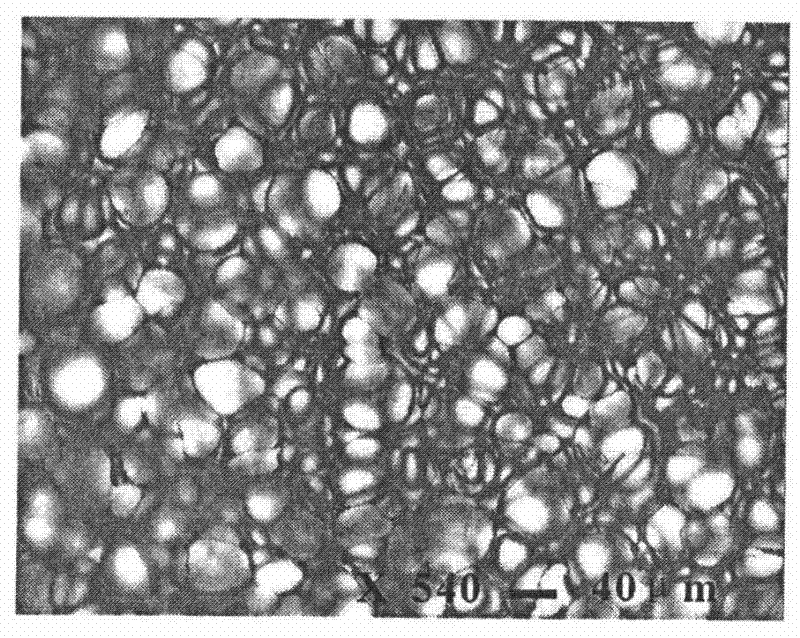

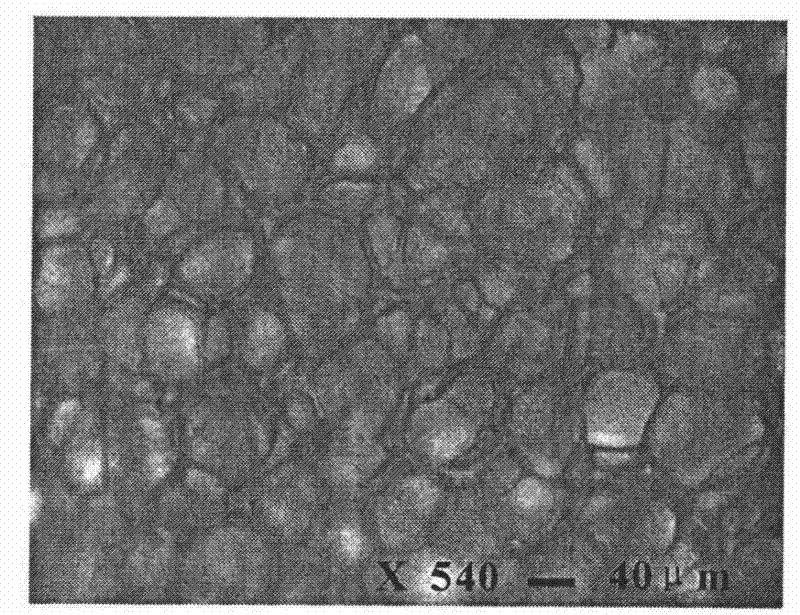

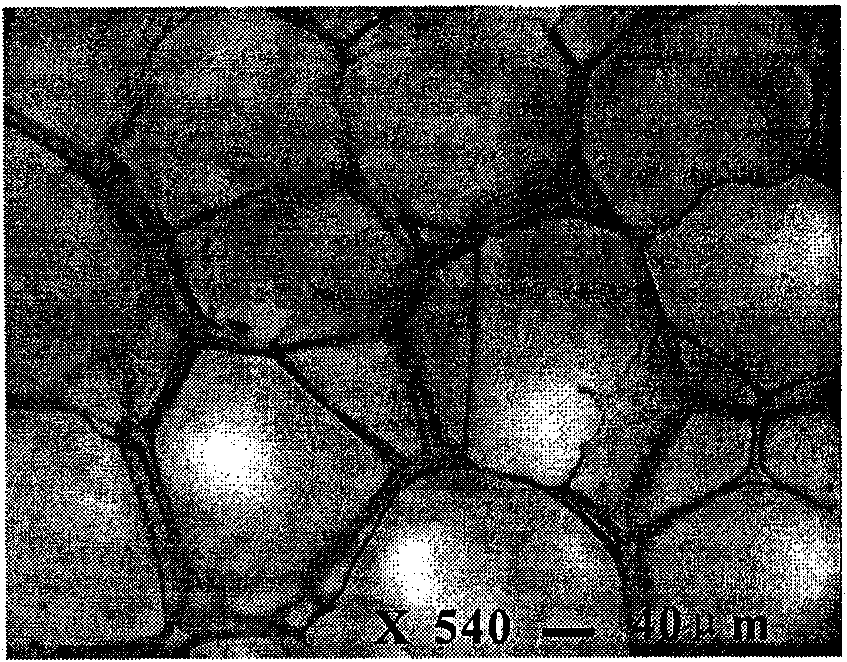

The invention discloses a nontoxic, odorless and recoverable environmentally-friendly polyurethane foaming material and a preparation method thereof. The foaming material is characterized in that a raw material of polyurethane is adopted and is directly subjected to a physical gas foaming in the presence of a physical gas foaming agent to prepare the foaming material. The foaming material has a foaming density of 0.08-0.80 g / cm<3>, a foaming ratio of 1.5-15 times, a average pore diameter of 10-100 [mu]m, uniform distribution of cells, wherein diameter deviations of 95% of the cells do not exceed 10% of the average pore diameter. In addition, the foaming material has no surface structure and can be the foaming material with any shape. The foaming material has an adjustable softness and hardness and excellent performance, and can be widely applicable for the fields of packaging, human protector, shoe product, automobile inner garnish, amortization cushion, building energy conservation, acoustic insulating material and the like. According to the present invention, the following problems that: harmful gas is discharged during the production process of the polyurethane foaming material, and monomer residues are harmful to human health and cause environmental pollution, are thoroughly solved from the source, such that a practicable development approach is provided for green environmental protection, energy saving and emission reduction of the foaming material.

Owner:浙江博发新材料股份有限公司

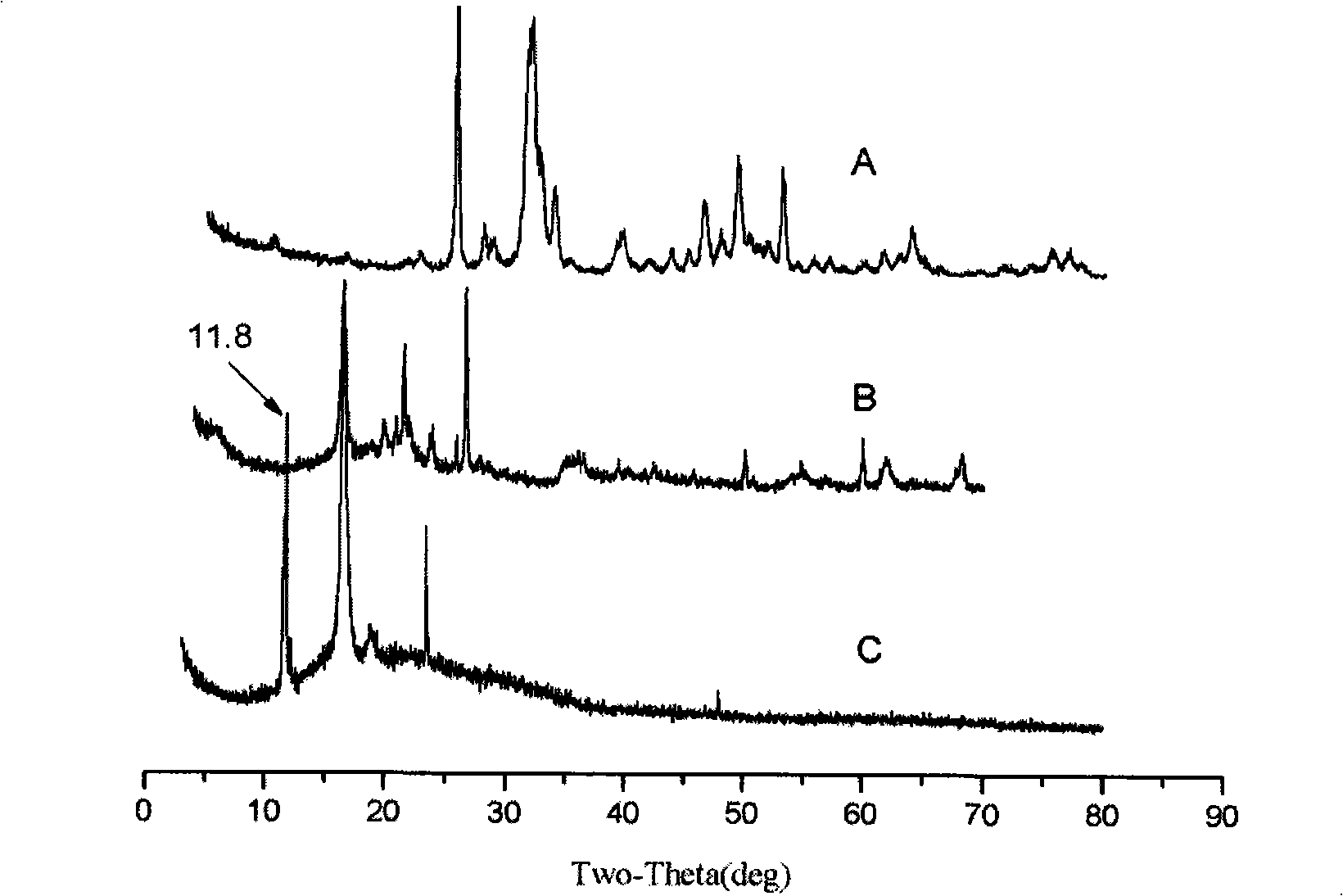

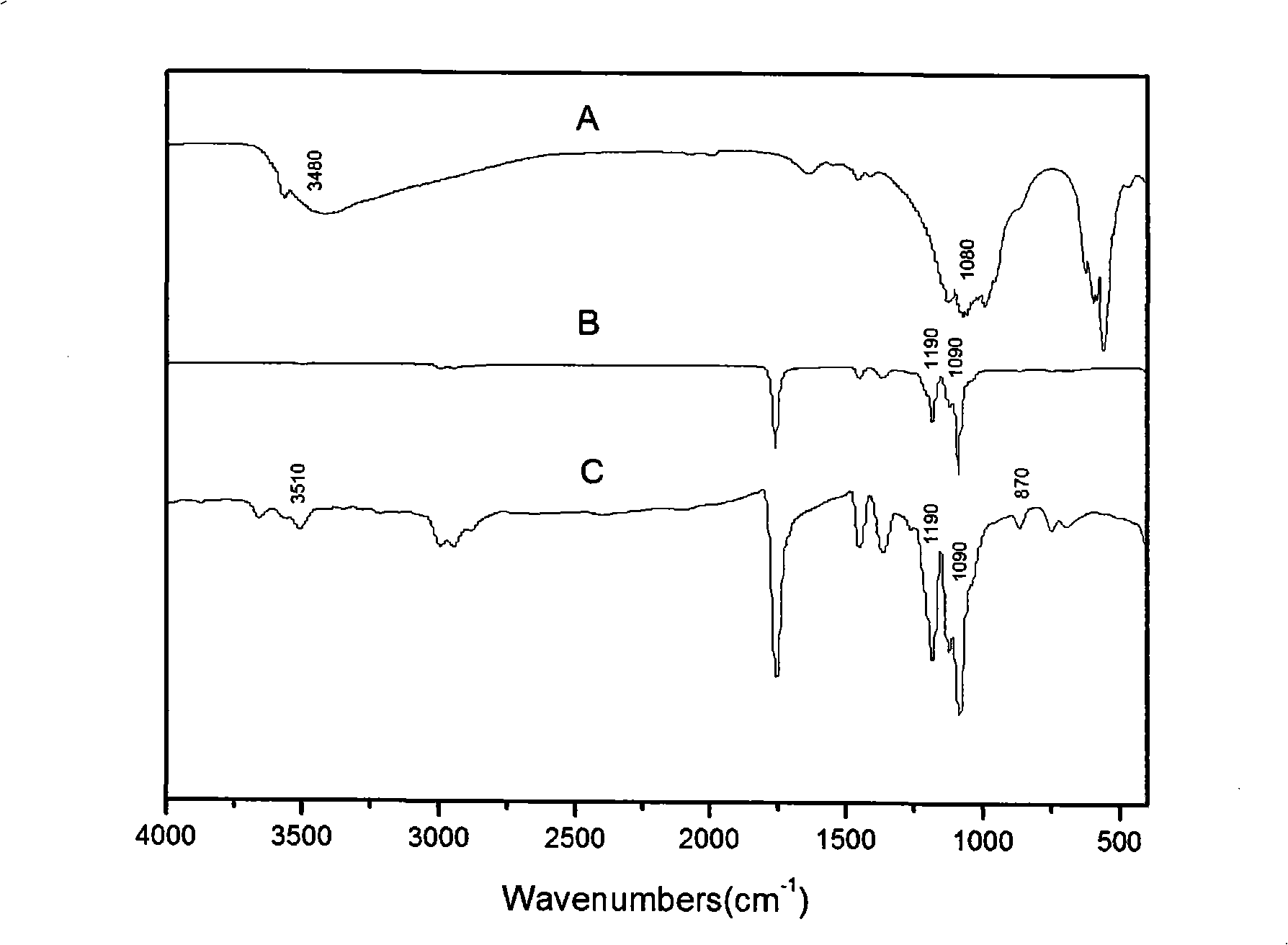

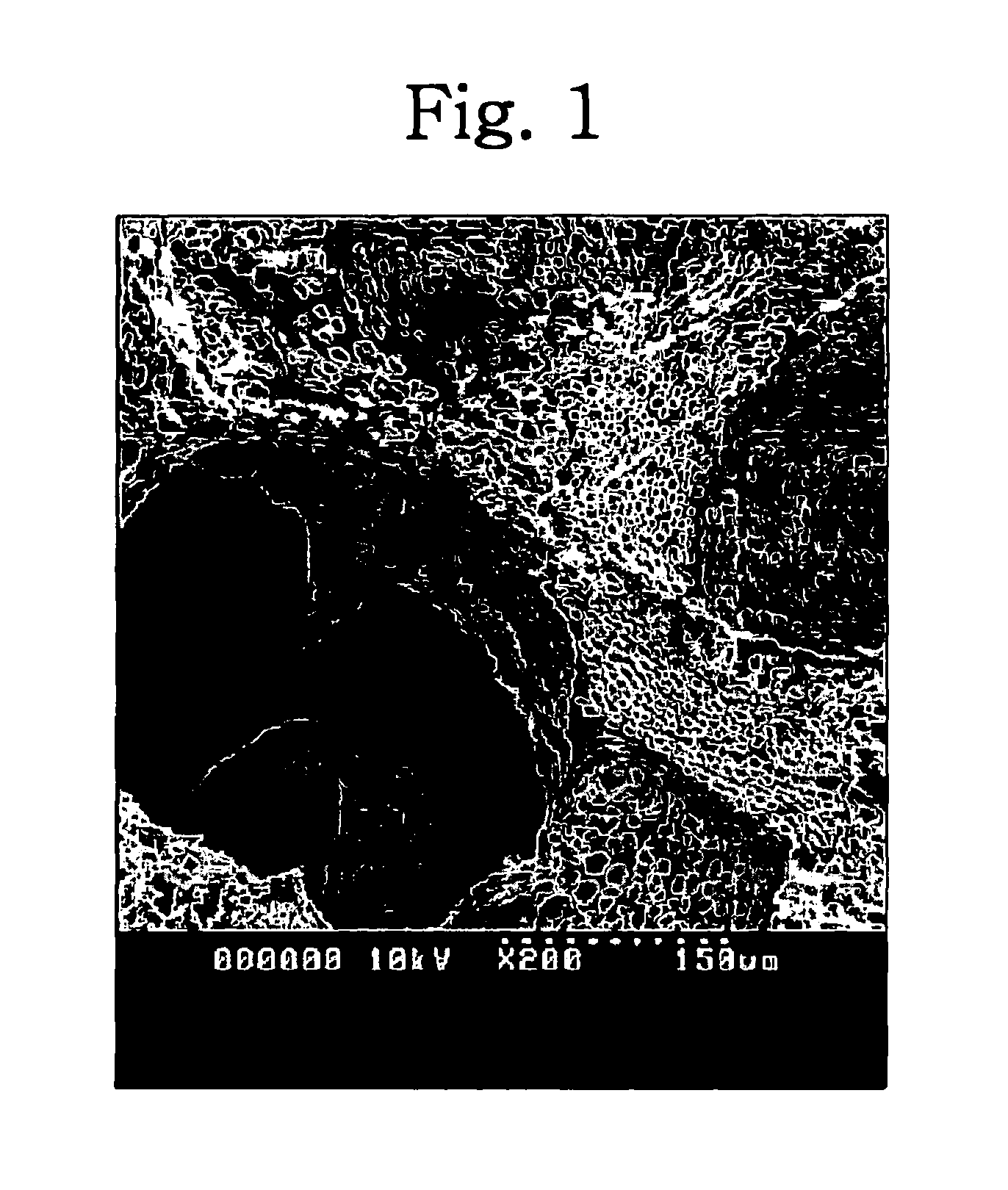

Method for preparing galvanic deposit calcium phosphorus mineralized layer superfine fibre bone material

The invention relates to a method for preparing superfine fiber bone materials of an electrodeposition calcium phosphate mineralized layer, which comprises the following steps: firstly, high-polymer superfine fibers are prepared on the surface of a metal electrode by adoption of electrostatic spinning and taken as an electrochemical deposition template; a layer of bone salt ingredients which are rich in calcium and phosphor is deposited on the surface of the fibers by the constant-voltage or constant-current deposition technology; mineralized superfine fibers are soaked into 0.1 to 1.0 mol per liter of NaOH solution for 1 to 24 hours; mineralized electro spinning fibers are subjected to die stamping into blocks under the pressure of between 10 and 40 MPa; and the porous bone materials with a porosity between 50 and 90 percent and a pore diameter between 50 and 500 micrometers are processed by the salt particle leaching / gas foaming technology, and are used for bone defect restoration after freeze-drying sterilization. The porous bone materials prepared by the method have better biocompatibility; and the electrochemical deposition technology can prepare organic-inorganic composite materials with higher bone salt content within a shorter period; and the preparation time is short and the preparation conditions are mild.

Owner:DONGHUA UNIV

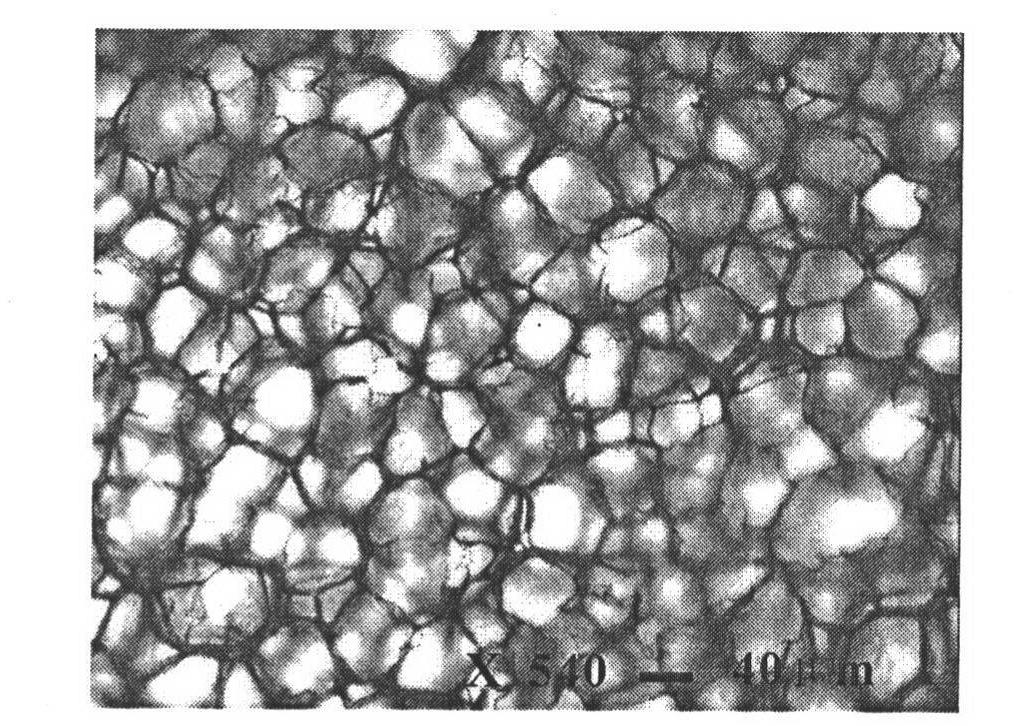

High foaming-ratio and high-density polyethylene microporous foaming section bar and its preparation method

ActiveCN102229708AHigh foaming ratioMeet the needs of different application fieldsCoatingsPolymer scienceFoaming agent

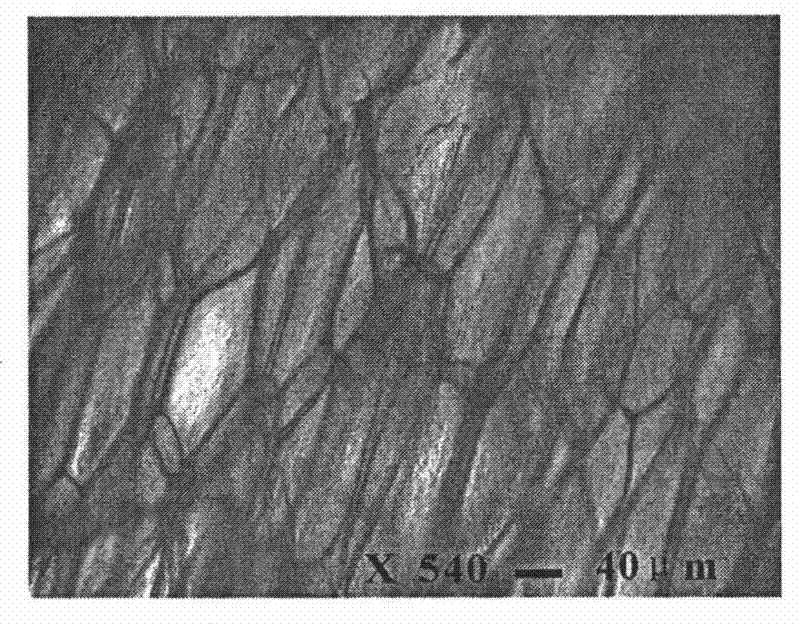

The invention discloses a high foaming-ratio and high-density polyethylene microporous foaming section bar and its preparation method. The invention is characterized in that the foaming section bar is directly prepared by using a high-density polyethylane raw material in the presence of a physical gas foaming agent by the physical gas foaming method. The foaming density is 0.032-0.20g / cm<3>; the foaming ratio is 5-30 times; the average pore diameter of bubbles is 10-120 microns; the bubbles are uniformly distributed; the diameter difference of 95% bubbles is less than 15% the average pore diameter; the foaming section bar has no cortex construction and can be a material of any shape. The high foaming-ratio and high-density polyethylene microporous foaming section bar has advantages of high mechanical strength, good resilience, good hear resistance, good chemical corrosion resistance and recycling and reusing possibility of wastes, and can make up the defects of present foaming materials. The preparation method of the foaming product provided by the invention is easy to operate, has a simple process flow as well as a short production period, and is in favor of industrial production.

Owner:浙江博发新材料股份有限公司

Biodegradable scaffolds and uses thereof

InactiveUS7846466B2Optimal for incorporationPromote tissue growthPowder deliveryPeptide/protein ingredientsBiodegradable scaffoldDNA

The invention is directed to scaffolds containing porous polymer material prepared by a process of gas foaming / particulate leaching and a wet granulation step prior to gas foaming and particulate leaching, particularly having a characteristic interconnected pore structure, as well as sustained release of protein, DNA or cells, and to methods for using such porous polymer material for preparation of scaffolds, particularly for tissue engineering.

Owner:NORTHWESTERN UNIV

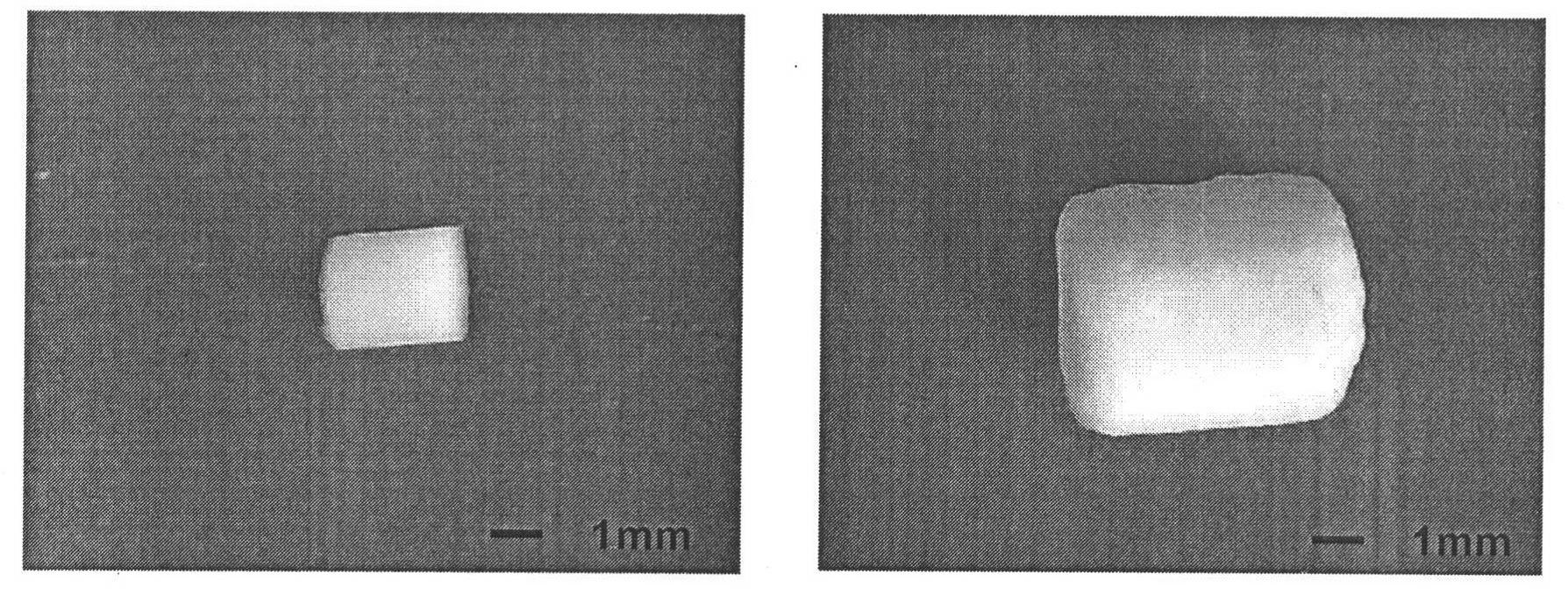

Biodegradable poly (butylene adipate terephthalate) micro-pore foaming particle with high foamability and preparation method thereof

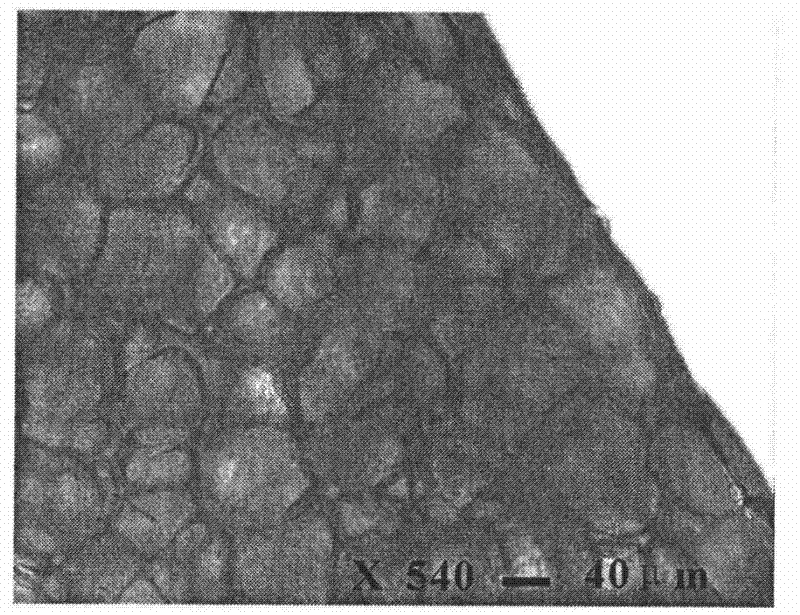

The invention discloses a biodegradable poly (butylene adipate terephthalate) (PBAT) micro-pore foaming particle with high foamability and a preparation method thereof. The preparation method comprises the following steps: placing a chain extension PBAT particle with a melting point of Tm DEG C into a high-pressure mould of a mould-pressing physical gas foaming device; filling 8-20MPa CO2; keeping pressure for 5-20 minutes at a constant temperature within a range of Tm minus 30 DEG C to Tm plus 5 DEG C; releasing pressure at a speed of 5-30MPa / s; and sampling and cooling within 30 seconds, thereby acquiring the micro-pore foaming particle with high foamability. Compared with the raw material, the acquired micro-pore foaming particle with high foamability has the advantages that the volumeis increased by 10-30 times, the diameter of foaming pore is less than 100 microns, the foaming pore distribution is uniform, and the cortex structure does not exist. The preparation method provided by the invention has the advantages that the process flow is simple, the production period is short, the cost is low, the product property is excellent, and the preparation method is beneficial to industrial production, thereby being beneficial to the developing application of the biodegradable material in disposable catering and packaging industries.

Owner:浙江博发新材料股份有限公司

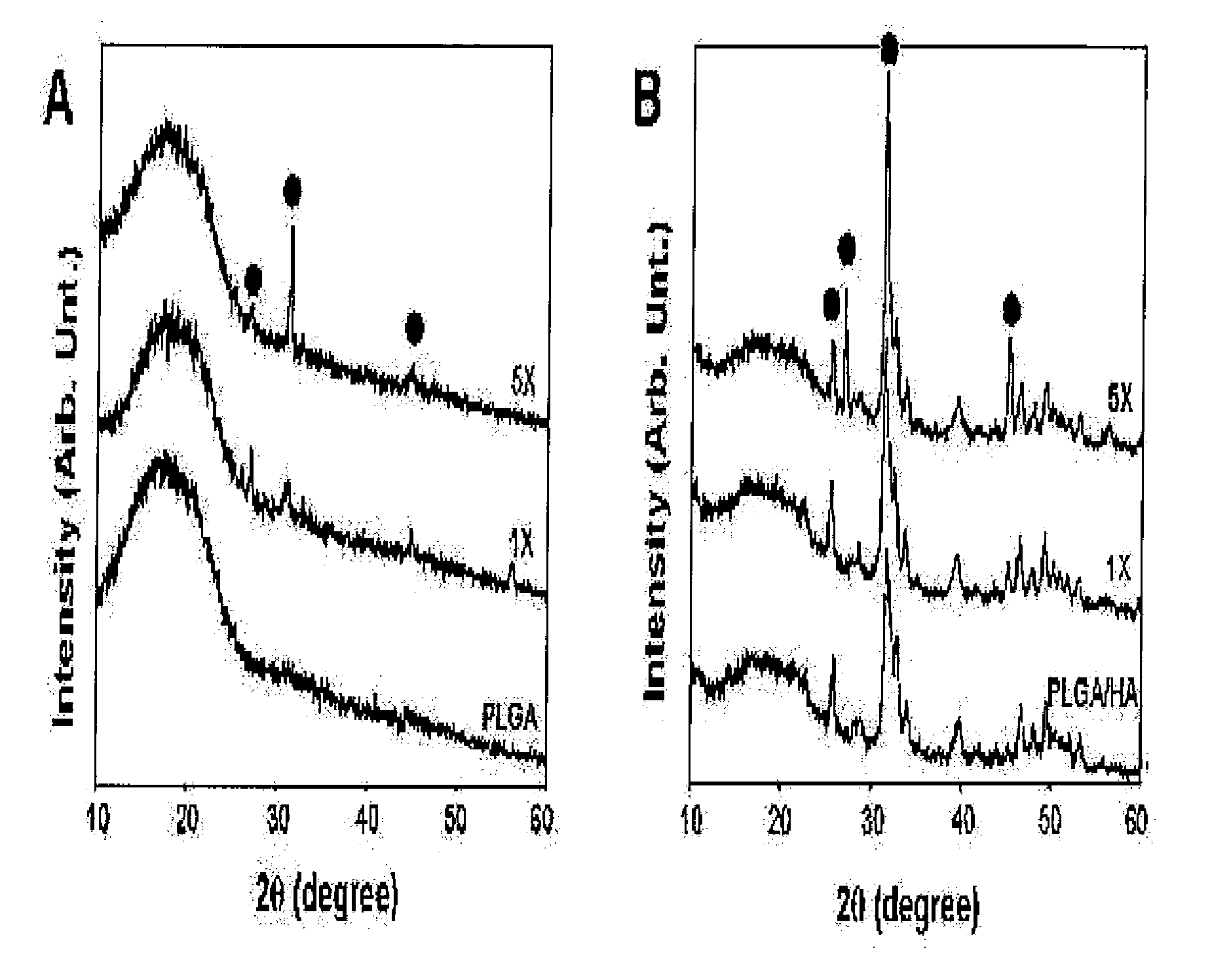

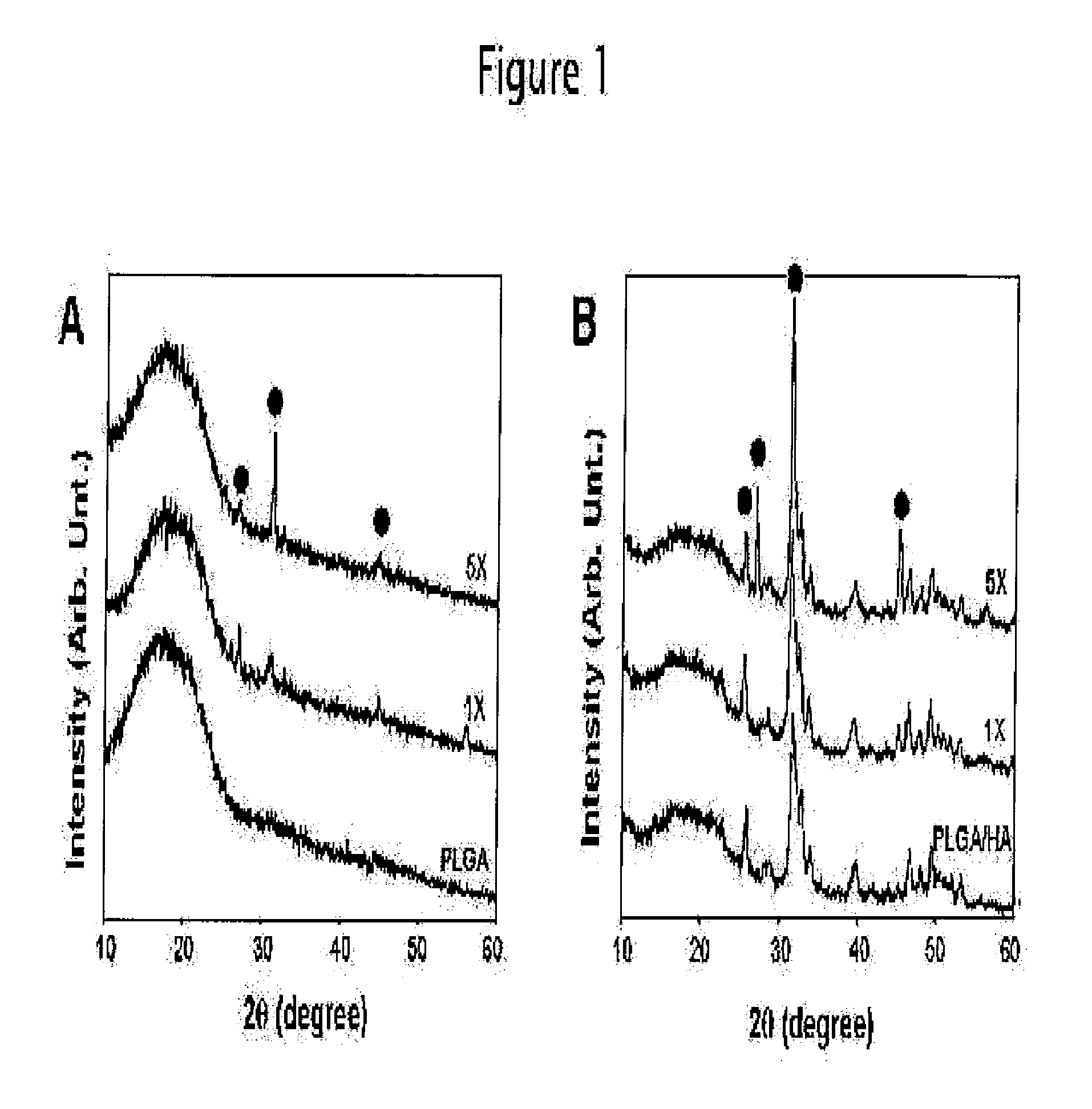

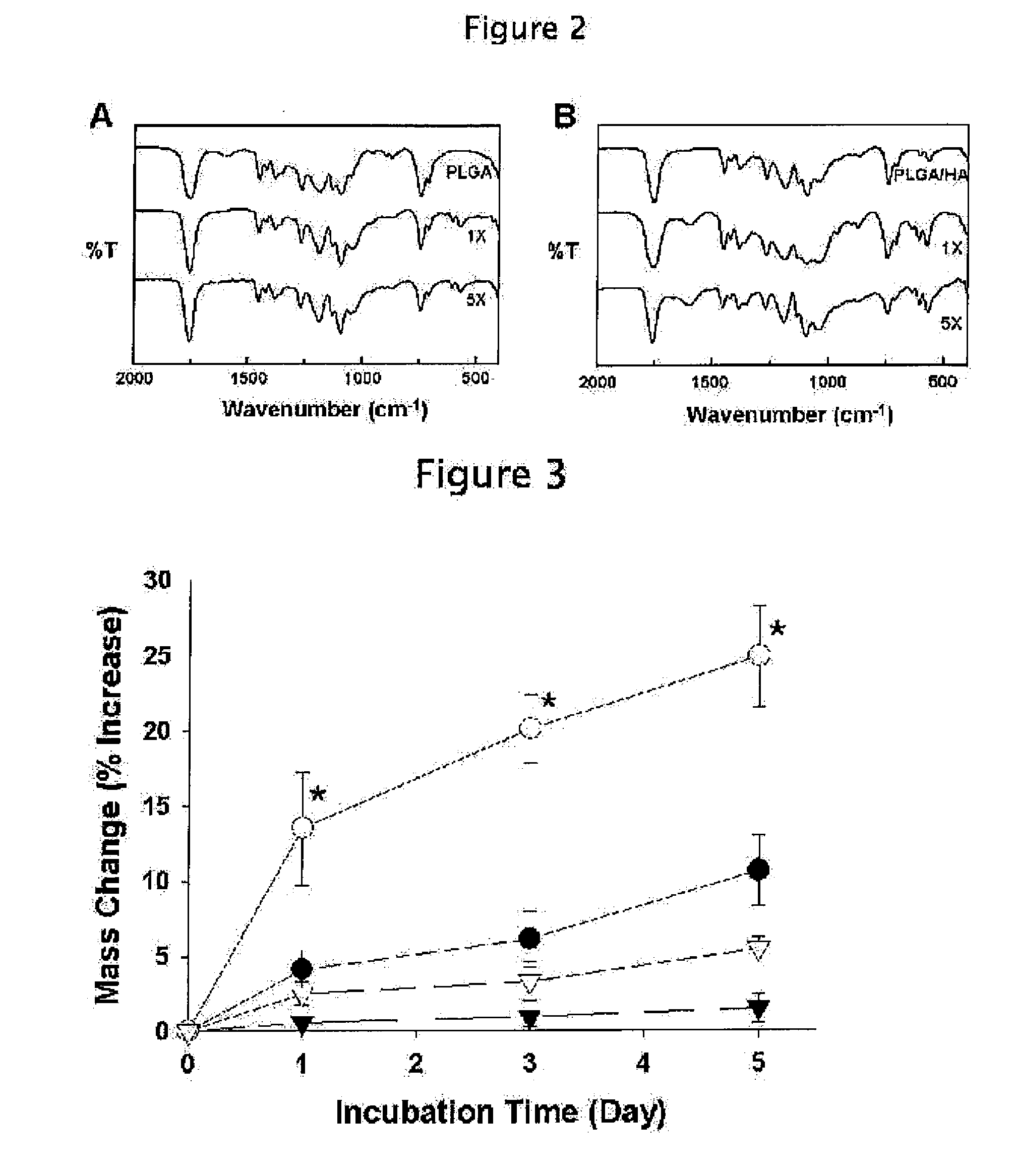

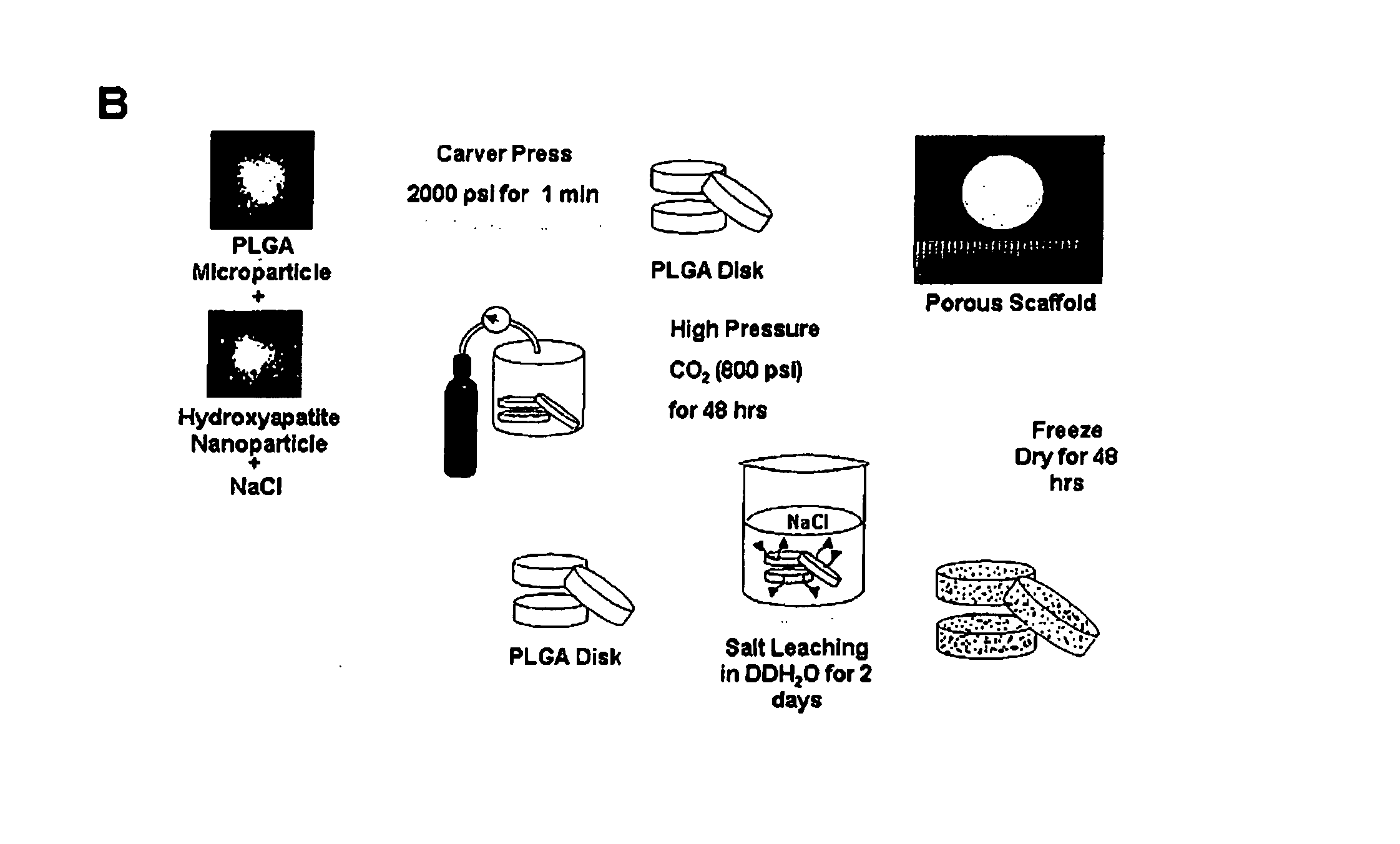

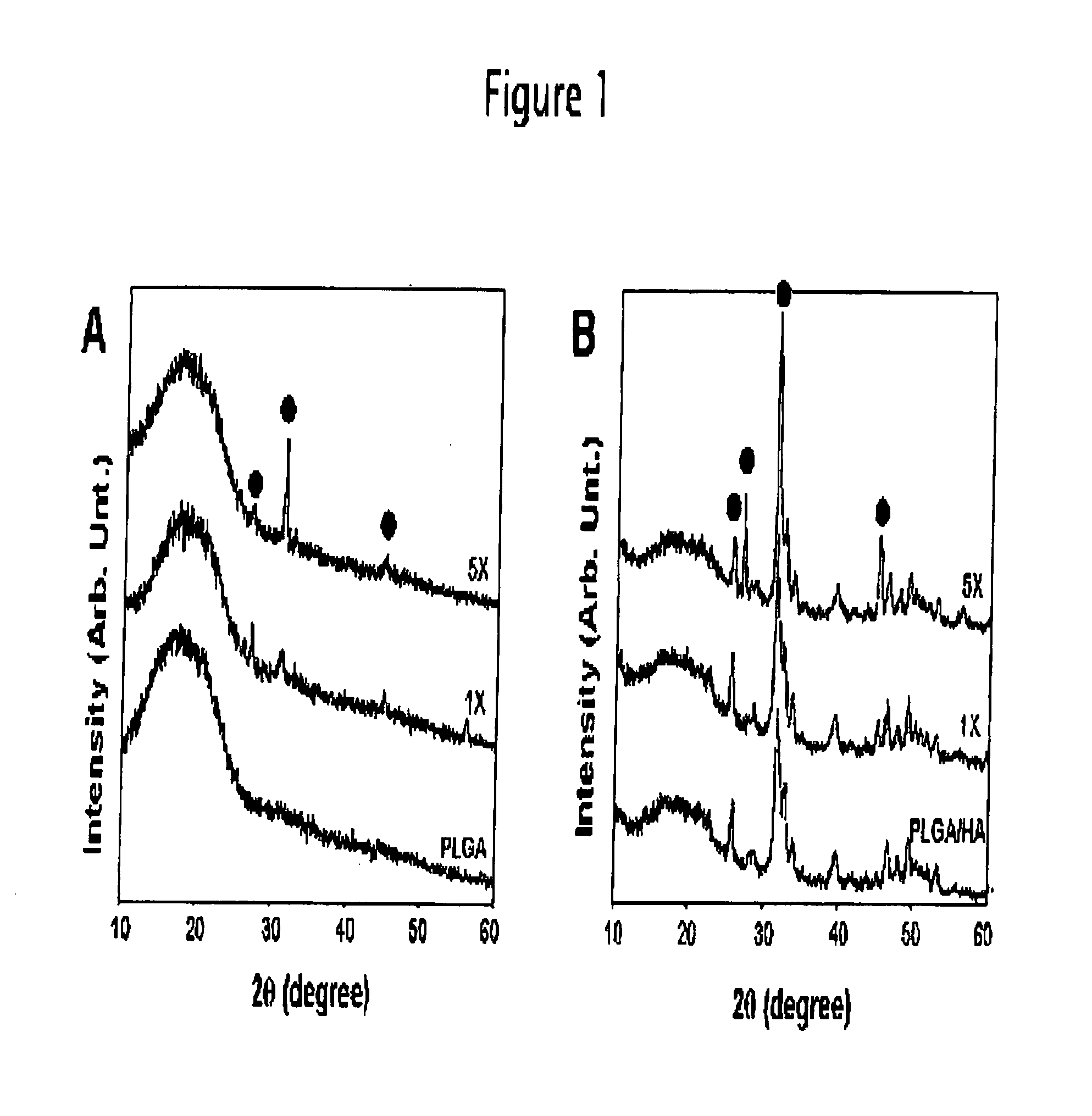

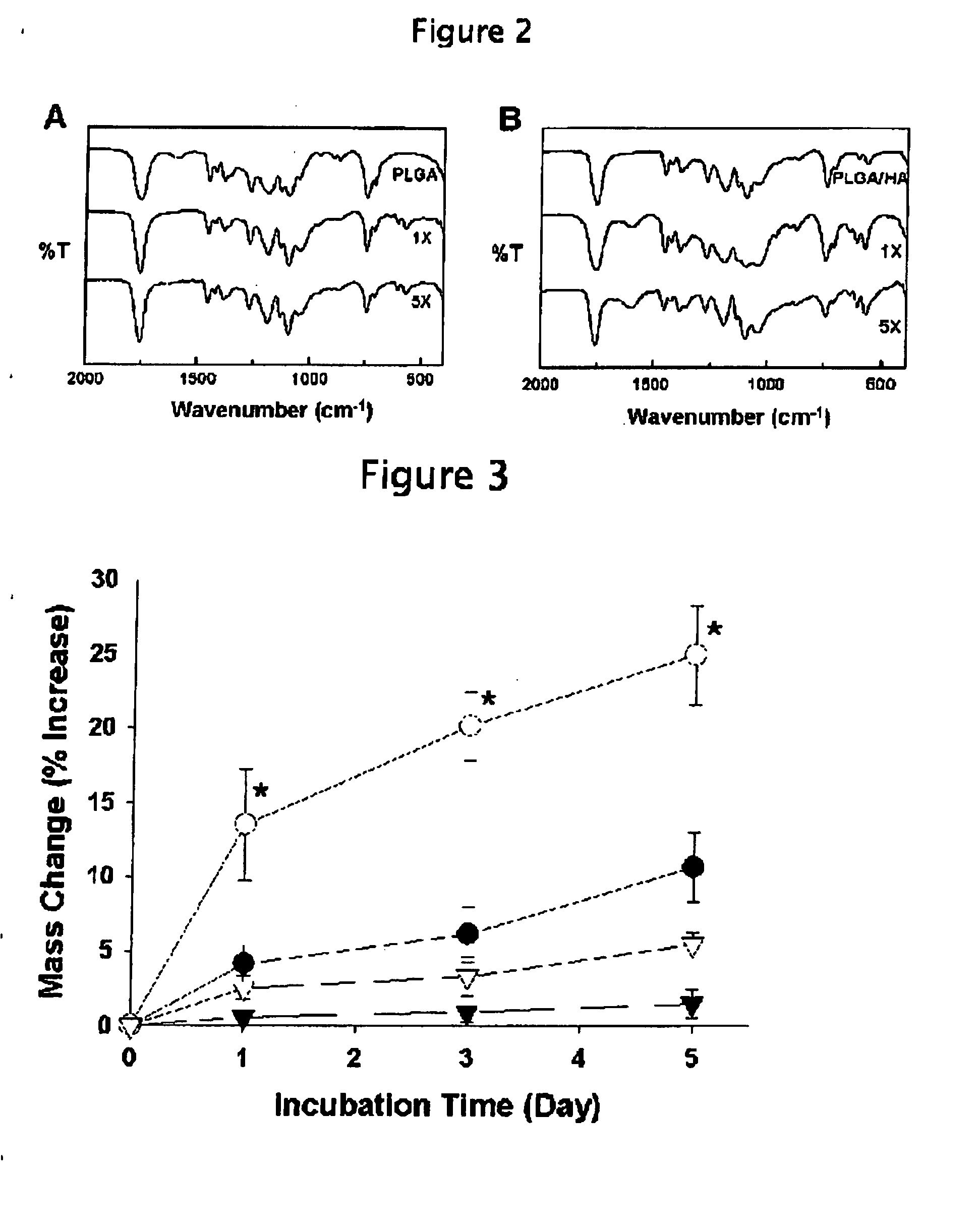

PLGA/Hydroxyapatite Composite Biomaterial and Method of Making the Same

InactiveUS20090048358A1Fastly and highly and uniformly coatedGood at propagatingCosmetic preparationsImpression capsDiseaseApatite

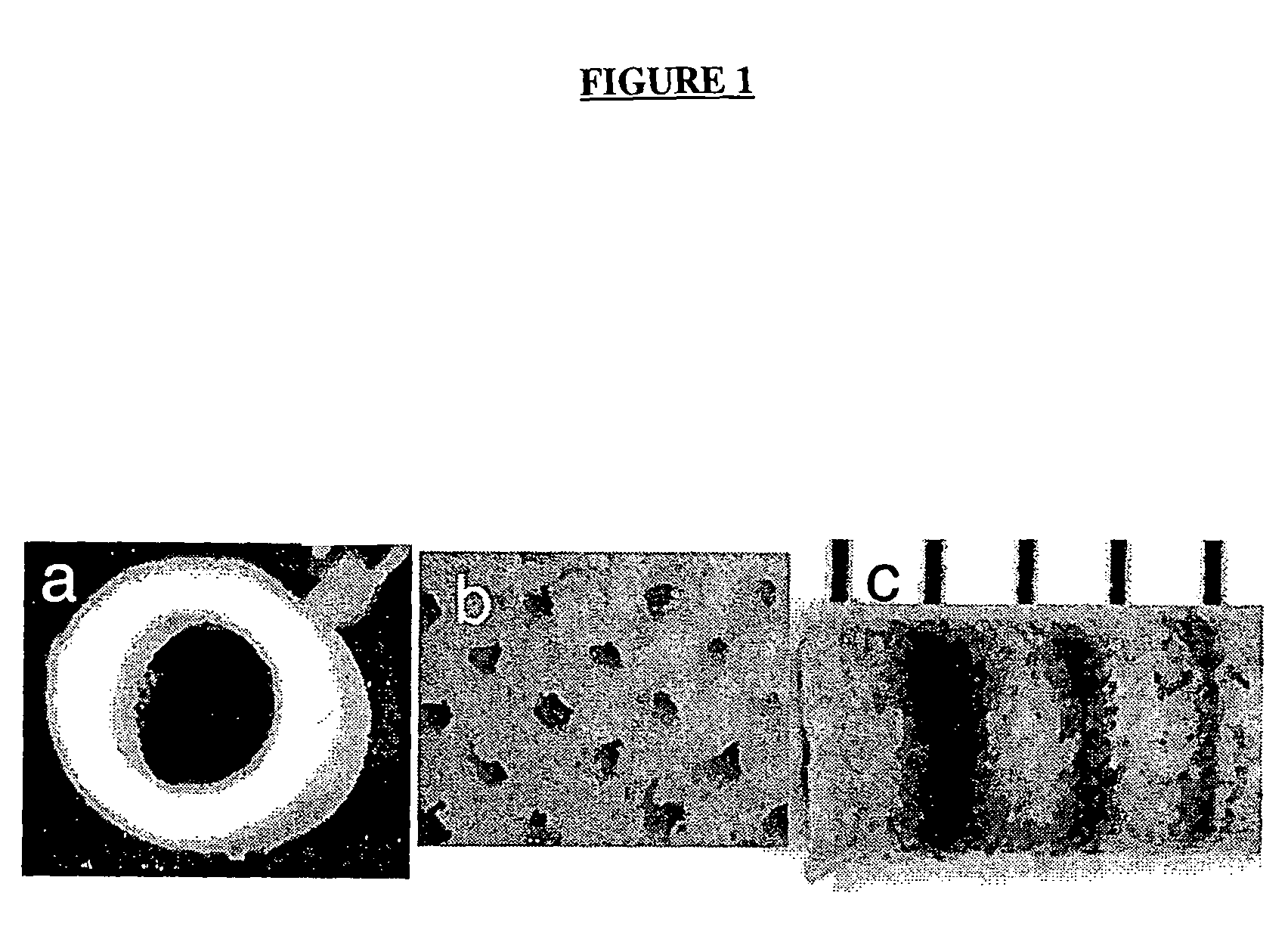

Tissue engineering is a growing field where new materials are being developed for implantation into the body. One important area involves bone graft materials to replace areas of bone lost to trauma or disease. Traditionally, graft material may be harvested from the bone of the individual receiving the graft material. However, this requires an additional surgery and additional recovery. Bone also may be taken from others, or even cadavers, but this introduces biocompatibility problems as well as the risk of disease transfer. Ideally, a biocompatible material is sought that will act as a filler with appropriate mechanical strength, encourage bone healing, and degrade to allow new bone ingrowth without the risk of disease transfer. The present invention is a new composite bone graft material made from biocompatible poly(D,L-lactic-co-glycolic acid) (PLGA) and nano-sized hydroxyapatite particles exposed on its surface using a gas foaming particle leaching (GF / PL) method. A further embodiment of this invention involves coating this PLGA / hydroxyapatite biomaterial with an adherent, fast, uniform coating of a mineral such as apatite. The PLGA polymer portion of the composite provides sufficient mechanical strength to replace bone and is degradable over time to allow new bone tissue ingrowth. The incorporated hydroxyapatite particles increase the composite material's osteogenic properties by providing sites for tissue attachment and propagation. Finally, a uniform coating of mineral apatite on the surface of this novel biomaterial composite further enhances its osteogenic qualities.

Owner:NANO ORTHOPEDICS

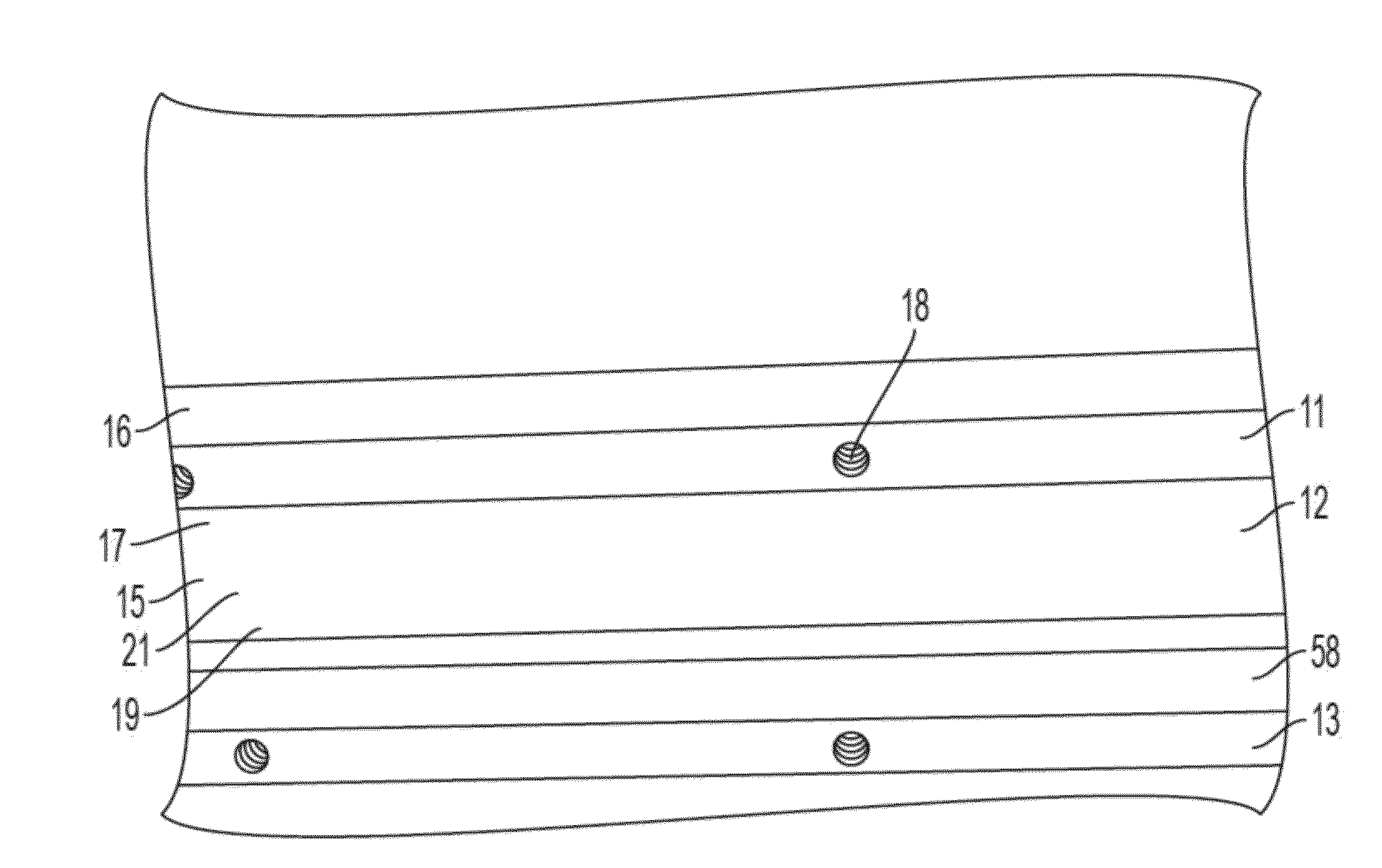

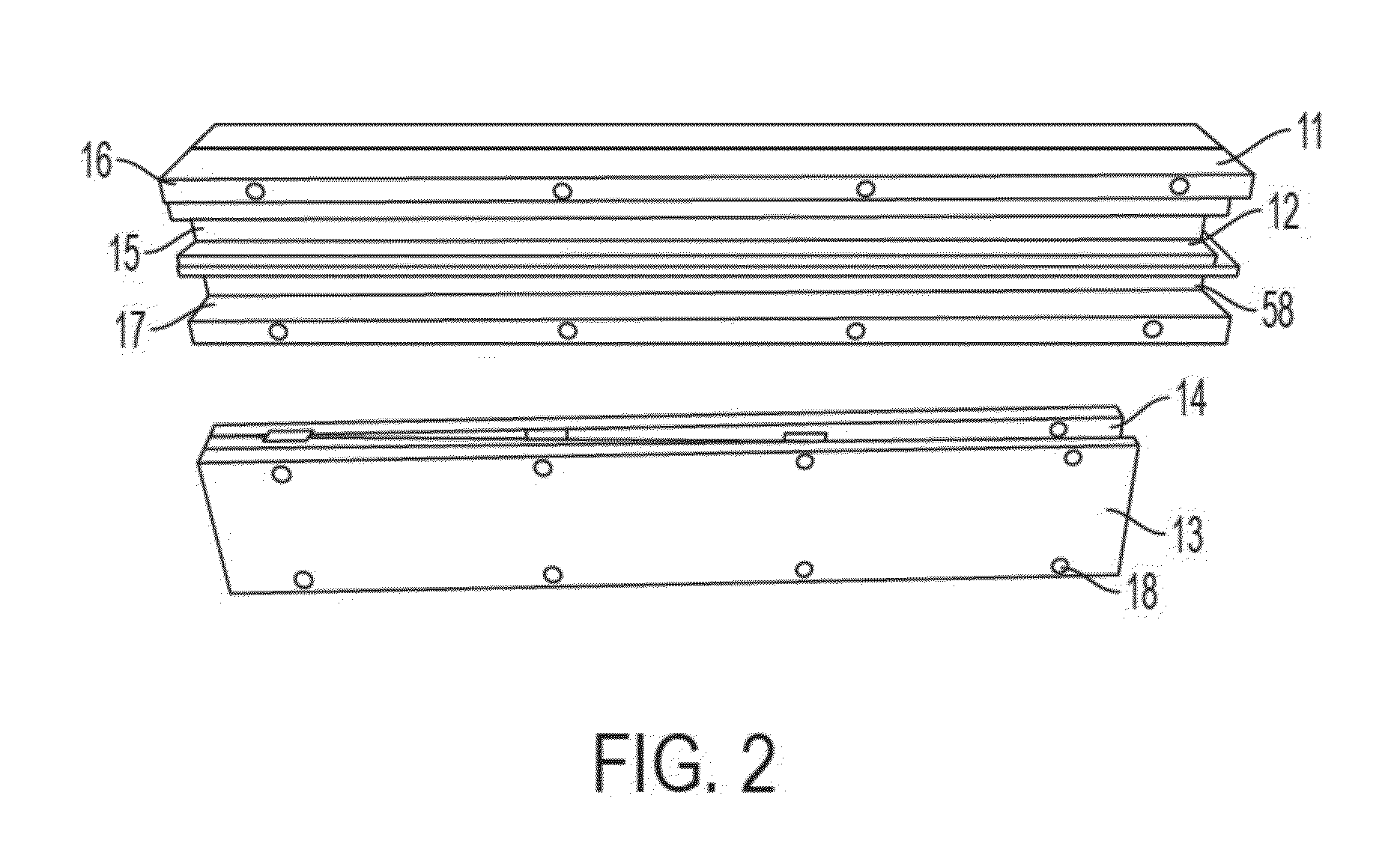

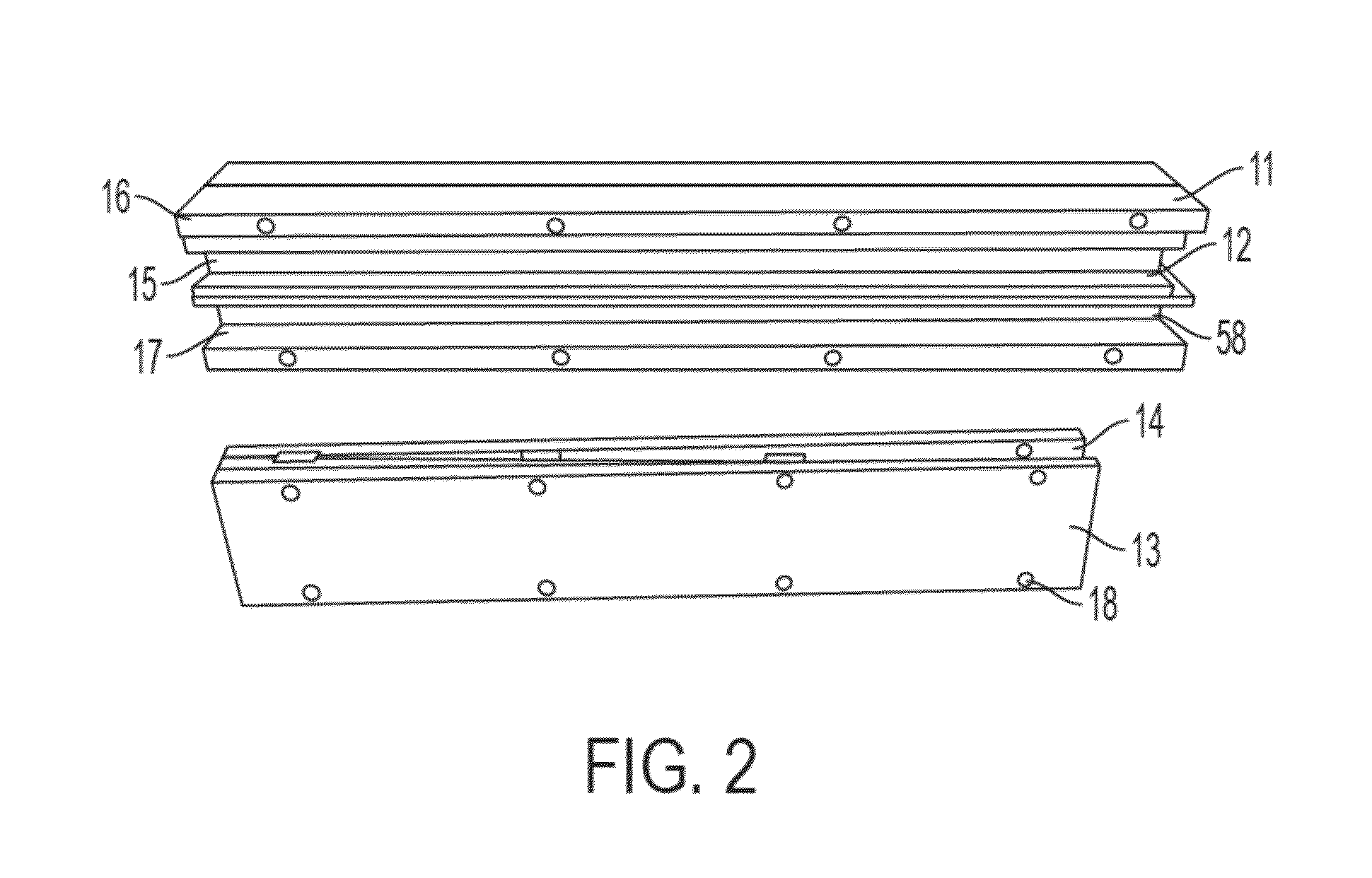

Plga/ha hydroxyapatite composite bone grafts and method of making

InactiveUS20130218291A1Fastly and highly and uniformly coatedGood at propagatingImpression capsBone implantGlycolic acidBioceramic

The present invention involves tissue engineering constructs made from a new composite bone graft material made from biocompatible poly(D,L-lactic-co-glycolic acid) (PLGA) and bioceramic particles exposed on its surface using a gas foaming particle leaching (GF / PL) method and infused with collagen. Methods and apparatus for of forming scaffolds are also disclosed.

Owner:THIERRY GIORNO

PLGA/hydroxyapatite composite biomaterial and method of making the same

InactiveUS20080065228A1Fastly and highly and uniformly coatedGood at propagatingCosmetic preparationsBone implantApatiteBiocompatibility Testing

Tissue engineering is a growing field where new materials are being developed for implantation into the body. One important area involves bone graft materials to replace areas of bone lost to trauma or disease. Traditionally, graft material may be harvested from the bone of the individual receiving the graft material. However, this requires an additional surgery and additional recovery. Bone also may be taken from others, or even cadavers, but this introduces biocompatibility problems as well as the risk of disease transfer. Ideally, a biocompatible material is sought that will act as a filler with appropriate mechanical strength, encourage bone healing, and degrade to allow new bone ingrowth without the risk of disease transfer. The present invention is a new composite bone graft material made from biocompatible poly(D,L-lactic-co-glycolic acid) (PLGA) and nano-sized hydroxyapatite particles exposed on its surface using a gas foaming particle leaching (GF / PL) method. A further embodiment of this invention involves coating this PLGA / hydroxyapatite biomaterial with an adherent, fast, uniform coating of a mineral such as apatite. The PLGA polymer portion of the composite provides sufficient mechanical strength to replace bone and is degradable over time to allow new bone tissue ingrowth. The incorporated hydroxyapatite particles increase the composite material's osteogenic properties by providing sites for tissue attachment and propagation. Finally, a uniform coating of mineral apatite on the surface of this novel biomaterial composite further enhances its osteogenic qualities.

Owner:NANO ORTHOPEDICS

Highly flame-resistant external wall heat preservation material and process for producing same

InactiveCN101748811ALow water absorptionLow smoke densityHeat proofingEngineeringVolumetric Mass Density

The invention discloses a highly flame-resistant external wall heat preservation material and a process for producing the same, which are mainly used for the construction of isolation belts and the heat preservation of high-rise buildings and building bodies with relatively higher requirement on fire-protection rating. According to the process, the highly flame-resistant external wall heat preservation material is produced by taking modified phenol aldehyde resin with low hydroxyl content as a raw material and performing low-acid curing on the modified phenol aldehyde resin. The modified phenol aldehyde resin with the low hydroxyl content is prepared by heating phenol, formaldehyde, a modifier and chopped glass fiber firstly under an acidic condition and then under an alkali condition and then performing copolymerization and condensation on the phenol, the formaldehyde, the modifier and the chopped glass fiber. The modified phenol aldehyde resin with the low hydroxyl content, a surfactant, a gas foaming agent, a modified moisture repel and an organic acid catalytic system are cured and molded on a continuous line. The highly flame-resistant external wall heat preservation material has the following advantages that: a terminal hydroxyl group of the adopted phenol aldehyde resin is closed, so the water absorbing capacity of the material is reduced; the cured molding material has high strength and low acidity; the service life of the material is prolonged and simultaneously convenience is provided for construction; the highly flame-resistant external wall heat preservation material has excellent flame resistance, lower smoke density and a higher oxygen index; and fire protecting safety property in a construction and use process is greatly improved due to the non-smoldering property of the highly flame-resistant external wall heat preservation material.

Owner:滕州市华海新型保温材料有限公司

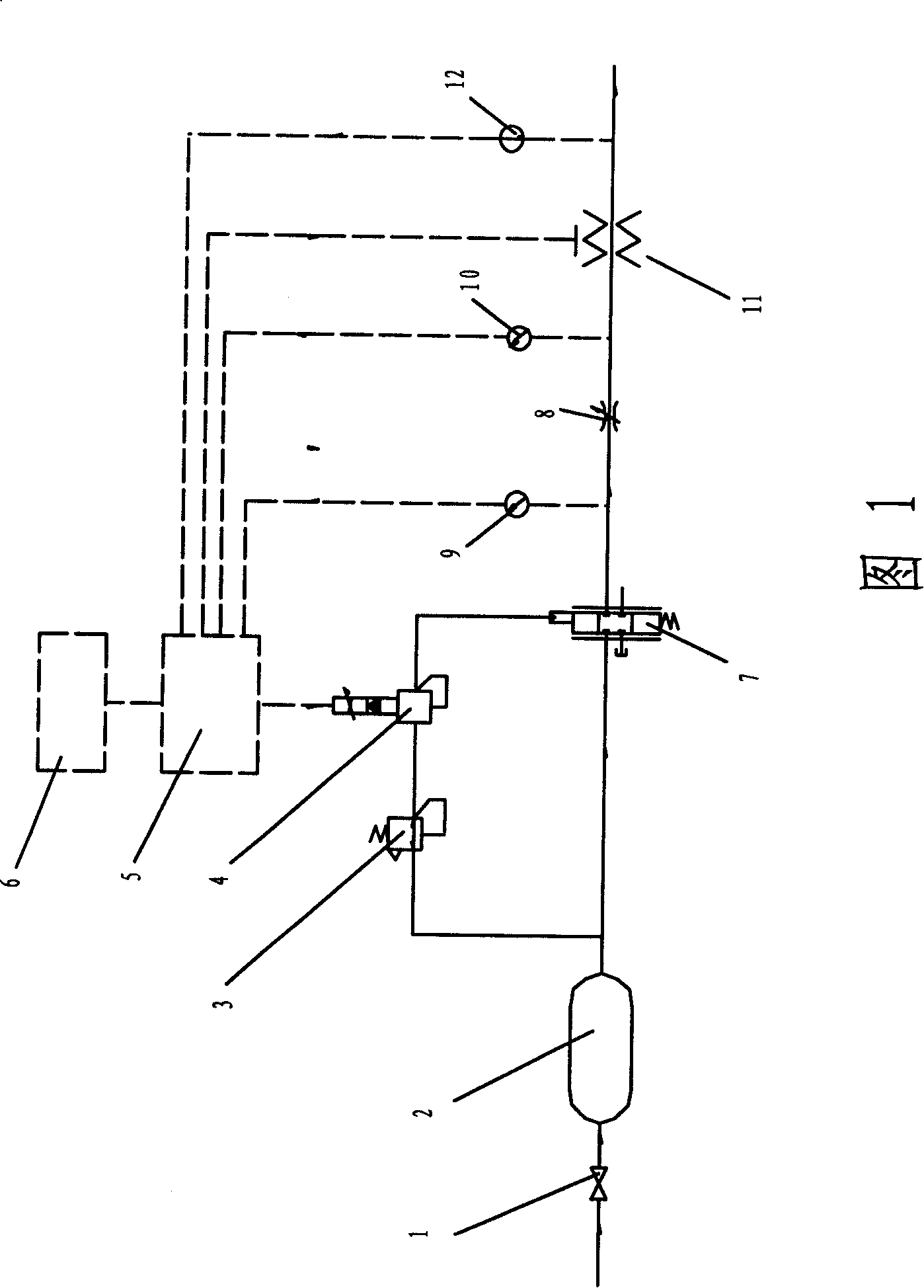

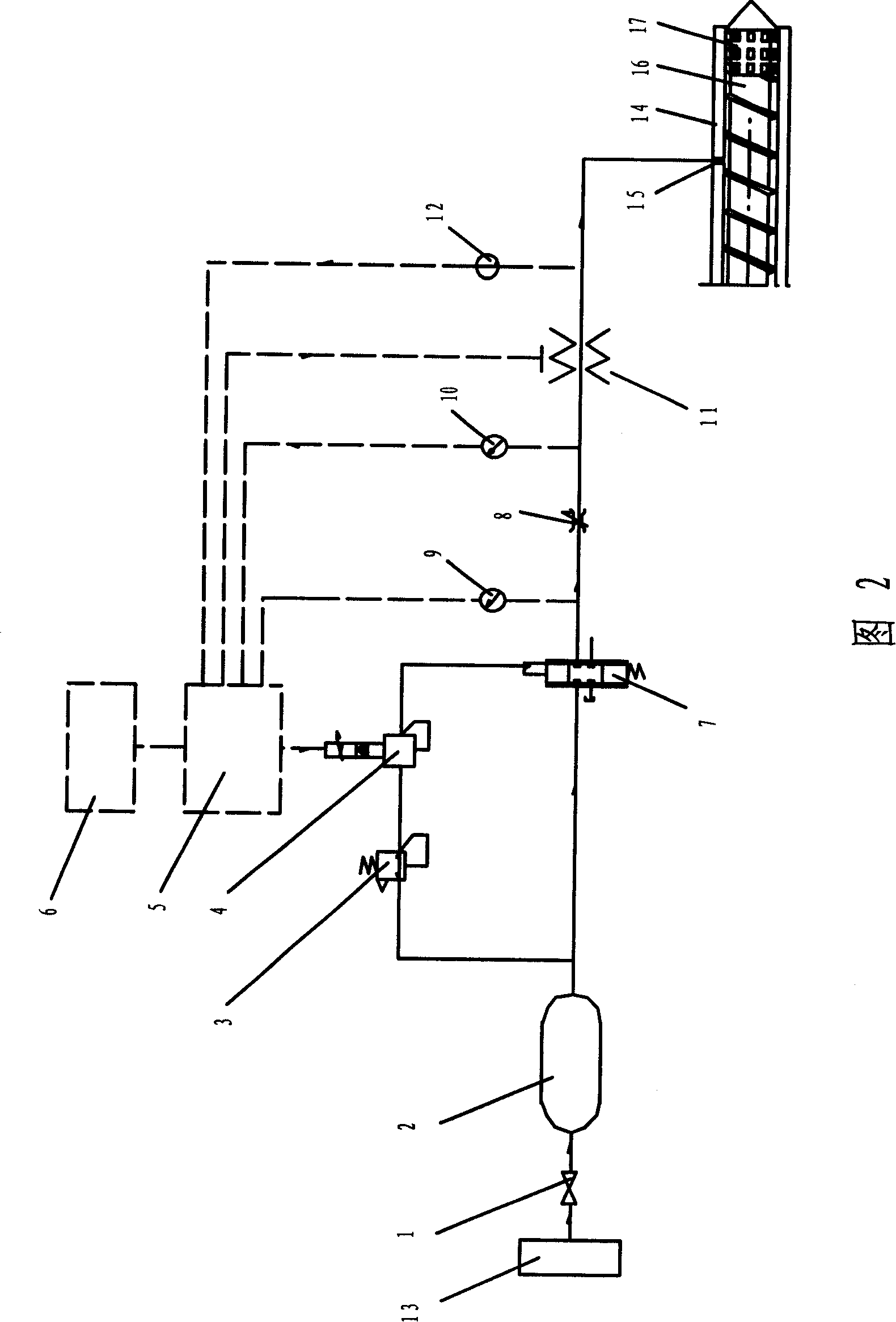

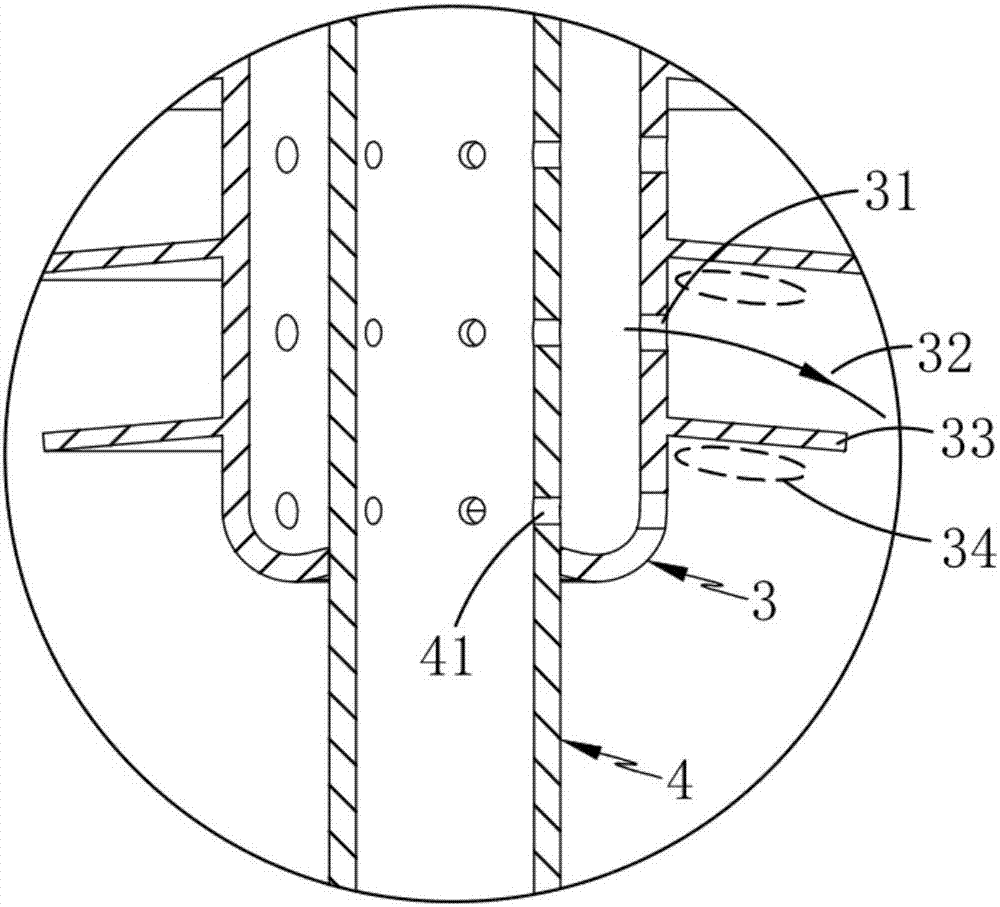

Fluid flow control system of gas foaming agent

The invention relates to a control system and control method for the flow of a gas foaming agent, in particular to a control system for the flow of the foaming agent when a physical gas foaming agent is adopted for the processing of thermoplastic foam. The control system of the flow of gas foaming agent described in the invention comprises a stop valve 1, a high pressure vessel 2, a pressure reducing valve 3, a proportional solenoid valve 4, a high voltage servo valve 7, an adjustable throttle valve 8, pressure sensors 9 and 10, a foaming agent temperature control module 11, a temperature sensor 12, a data processing and control module 5, an operation interface 6, pressure conduits connecting the above components, and communication wires or cables. The invention has the advantages that in accordance with the set flow and temperature value of the foaming agent injected into a processing device, with the system of the invention, a closed loop is adopted to control the flow and temperature of the flow agent. Therefore, the foaming agent flow required in the foaming process can be precisely and uniformly led into a polymer.

Owner:BEIJING CHN TOP MACHINERY

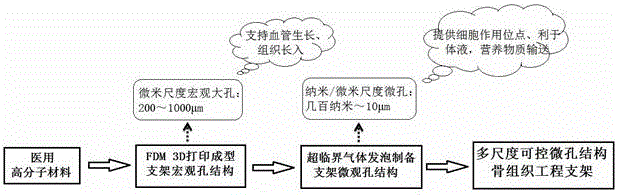

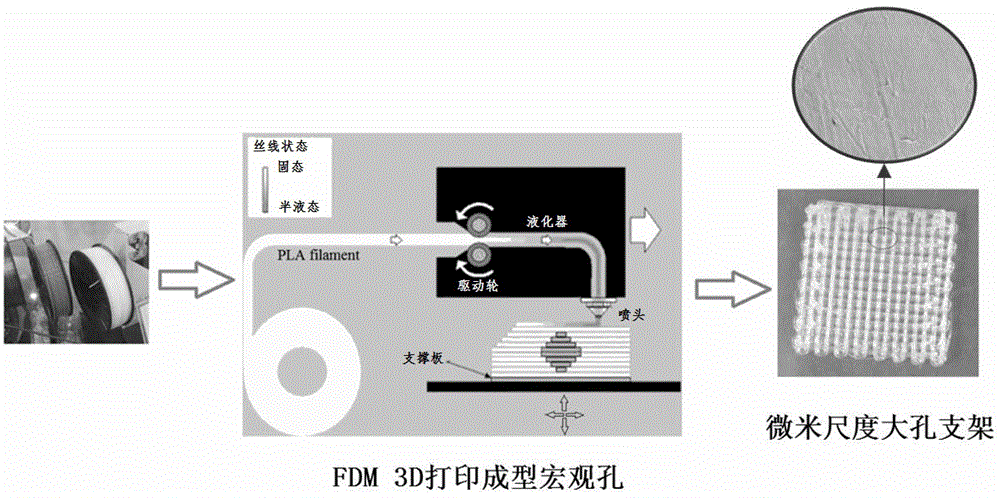

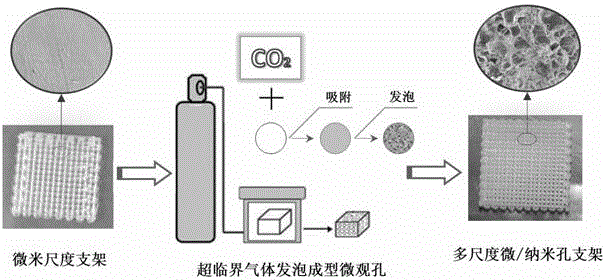

Bone tissue engineering scaffold with multi-scale controllable micropore structure and preparation method thereof

ActiveCN105944147AImprove repair functionEnsure biosecurityTissue regenerationProsthesisMetaboliteNanoscopic scale

The invention provides a bionic bone tissue engineering scaffold material and preparation method thereof, and the scaffold material has multi-level micropore structure similar to the natural bone tissue. The scaffold has multi-level bionic bone three-dimensional pore structure which can be adjusted in the range from 500 nm to 1000 mum. The preparation method of the bone tissue engineering scaffold with multi-scale controllable micropore structure includes performing three-dimensional printing with medical polymer material by using a rapid proto-typing technology, customizing the primary-level micrometer scale three-dimensional pore structure and the shape of the scaffold, and preparing the second-level micrometer and nanometer scale micropore inside of the scaffold by using supercritical gas foaming. The prepared bone tissue engineering scaffold with multi-scale micropore structure can provide the three-dimensional supporting needed by the bone tissue regeneration, can meet the requirements of protein adsorption, nutriment / metabolite transportation, cell migration, and tissue growing in different scales, and has wide application prospect in orthopedic clinic.

Owner:成都百年贝雅医疗科技有限公司

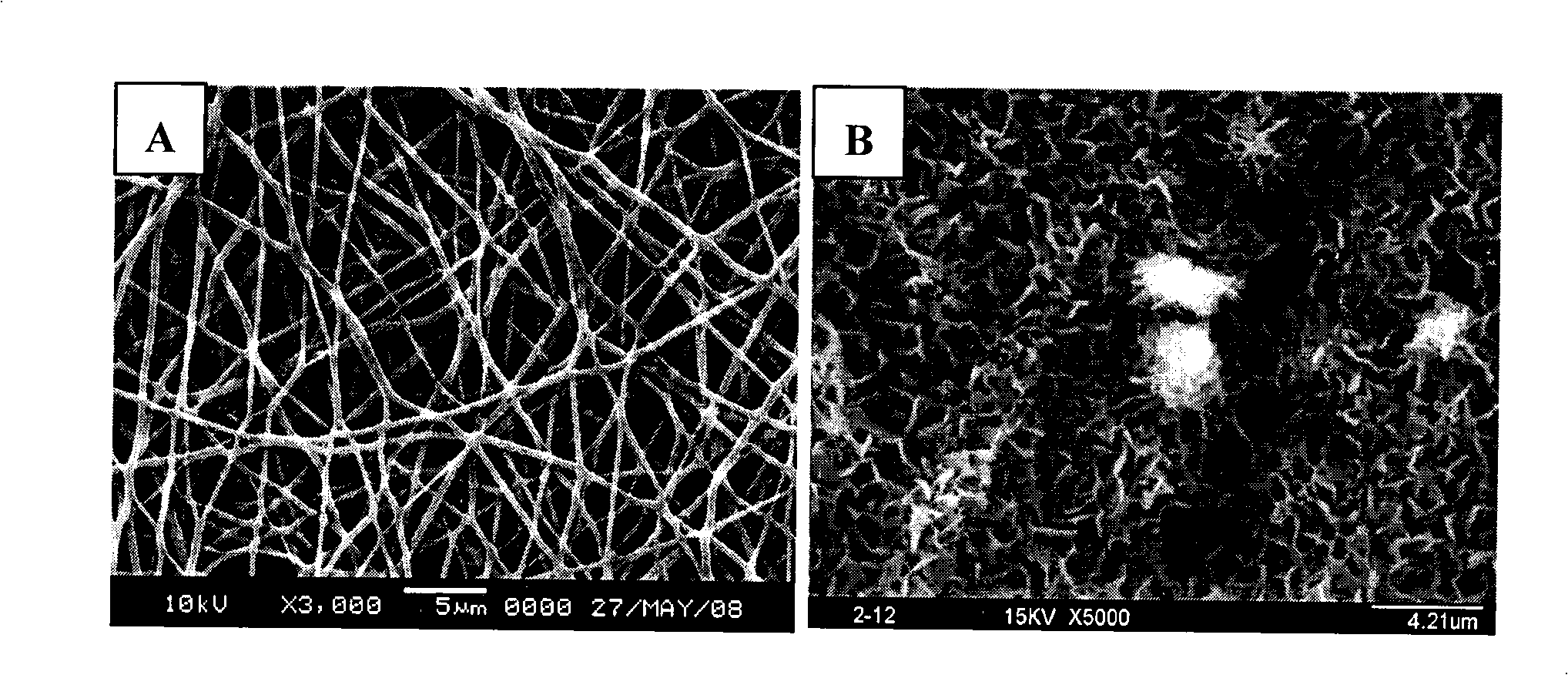

Nerve growth factor loaded silk fibroin nanofiber scaffold and preparation method

InactiveCN104667351AImprove performanceImprove efficiencyNon-woven fabricsProsthesisFiberFreeze-drying

The invention provides highly-oriented silk fibroin based nanofiber which adopts silk fibroin as a base material, adopts a nerve growth factor as a functional material for inducing neuronal cell growth and is obtained by an in-phase spinning controller with special design through an electrospinning fiber technique. Compared with traditional nano preparation technologies such as freeze drying, gas foaming, self-assembling and the like, the nerve growth factor loaded highly-oriented silk fibroin nanofiber scaffold as an artificial nerve graft has the advantages of high efficiency, simple process, low cost and the like, has structural and functional controllability which is not likely to be realized with the traditional nanotechnology, and is better in forming effect. Meanwhile, a composite of a biological material and cells is directly spun into a composite of a bracket material and the cells once with a blended spinning technology, and compared with a tradition process of firstly bracket material preparation and later cell culture on the bracket material, the process is simple.

Owner:YANCHENG INST OF IND TECH

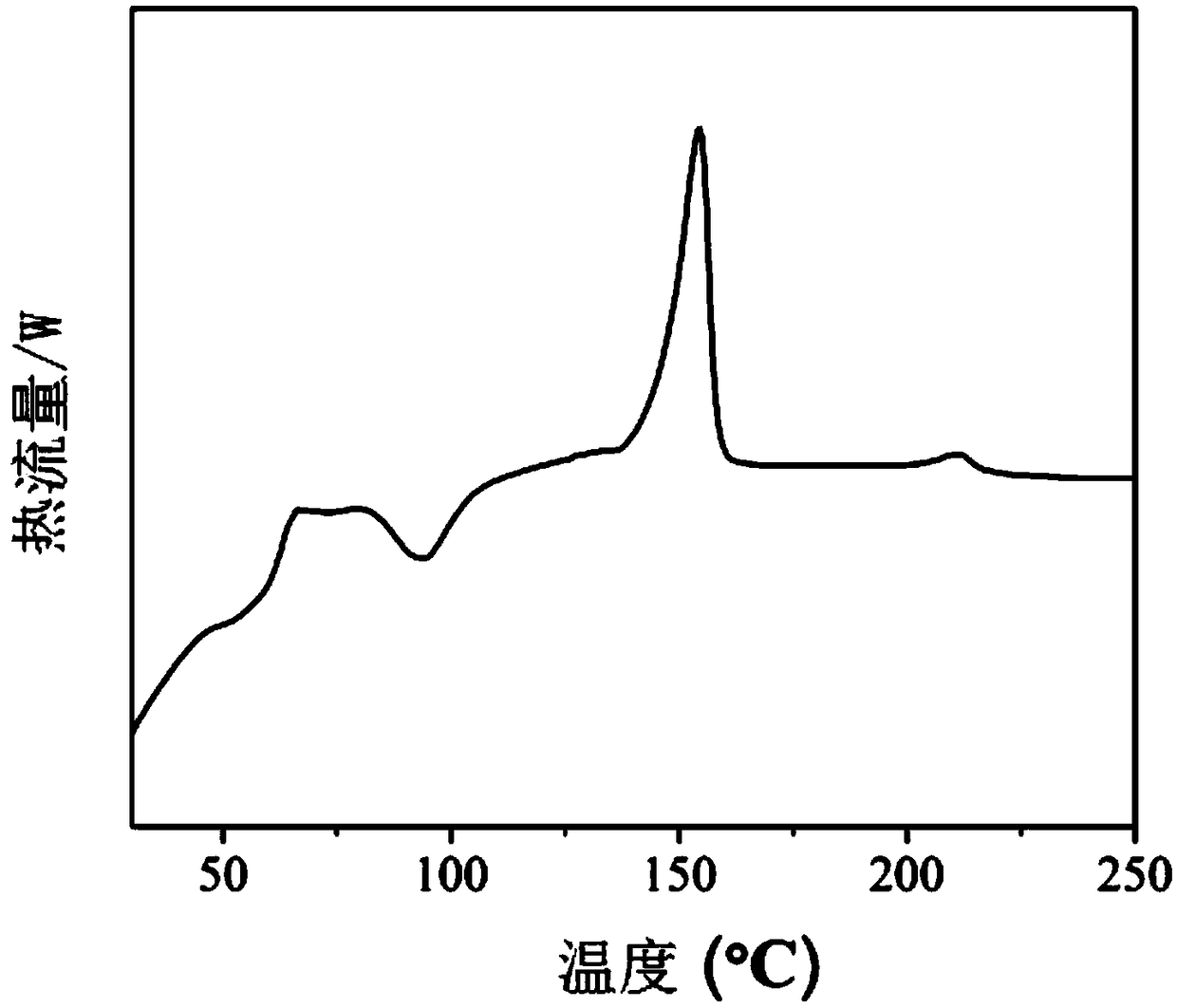

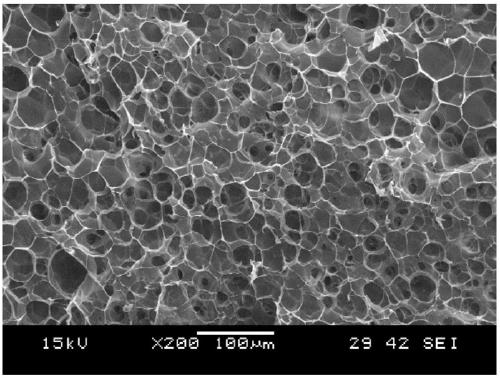

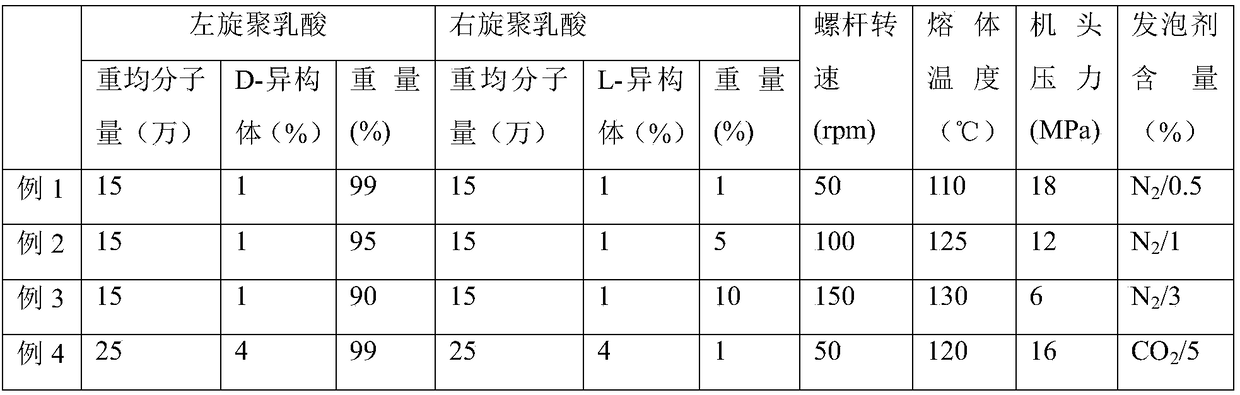

Full bio-based polylactic acid foaming material and preparation method thereof

InactiveCN109294187AImproved melt propertiesIncrease the rate of crystallizationPolymer scienceExpansion ratio

The invention discloses a full bio-based polylactic acid foaming material and a preparation method thereof. The method comprises the following steps: mixing dried L-polylactic acid and D-polylactic acid, and then adding a mixture to a twin-screw extruder and subjected to melt blending to obtain a polylactic acid containing a stereocomplex crystal; placing the material into an extrusion foaming machine to melt the material, then inputting a gas foaming agent into a screw through a gas injection port metering pump on the extrusion foaming machine, and uniformly mixing the material with a polylactic acid melt; reducing the temperature from a gas injection port to the screw at a head so that the temperature of the melt at the head is 110-140 DEG C and the pressure at the head is 6-8MPa, and finally performing extrusion foaming through a die, and performing cooling and fixing to obtain the polylactic acid foaming material. The method adopts L-polylactic acid and D-polylactic acid as raw materials, and forms the polylactic acid containing a stereocomplex crystal in the process of melt blending, which can significantly improve the melt strength and crystallization property of the polylactic acid. Therefore, the obtained polylactic acid foaming material has stable quality, uniform foam size, high foam density, and high foaming expansion ratio.

Owner:合肥华聚微科新材料有限责任公司

Method of preparing biodegradable dual pore polymer scaffolds for tissue engineering

There is provided a method of preparing biodegradable dual pore polymer scaffolds, comprising the steps of: maintaining a polymer solution containing a biodegradable polymer, an effervescent mixture of carbonate and organic acid, and solvent at a temperature range of −196° C. to ambient temperature so as to evaporate the solvent and produce a polymer sample; and foaming the polymer sample in a mixed solution of water and alcohol. According to the present invention, the pore size of the polymer scaffolds can be easily controlled, and biodegradable polymer scaffolds can be more simply prepared compared to conventional methods such as salt leaching technique, phase separation technique or gas foaming technique. Further, since the biodegradable polymer scaffolds prepared according to the present invention have a high surface area and porosity without formation of skin layer, secretion of toxic substances and remnant phenomenon, they can be advantageously used for regenerating almost all living tissues and organs in tissue engineering.

Owner:KOREA INST OF SCI & TECH

Polypropylene and blends particles thereof physical gas foaming preparation method

The invention discloses a polypropylene and blends particles thereof physical gas foaming preparation method and is characterized in that the preparation method comprises the following steps: placing polypropylene and blends particles thereof in a high pressure container of which the volume is 25 times or more than 25 times of the total volume of the particles, injecting 10-20MPa of pressure gas in the container at 135-175 DEG C, keeping the temperature and the pressure for 1-30min and then relieving the pressure in a speed of 5-20MPa / s to the normal pressure to obtain the foaming particles with uniform and controllable cell and controllable foaming density. The preparation method of the invention overcomes the specific requirement that polypropylene with high melt strength is needed to use in the foaming process, and the increase of the machining temperature increases the gas permeability and shortens holding time so as to improve the production efficiency and reduce the production cost.

Owner:SICHUAN UNIV

PLGA/HA hydroxyapatite composite bone grafts and method of making

InactiveUS9005286B2Fastly and highly and uniformly coatedGood at propagatingImpression capsBone implantGlycolic acidBioceramic

The present invention involves tissue engineering constructs made from a new composite bone graft material made from biocompatible poly(D,L-lactic-co-glycolic acid) (PLGA) and bioceramic particles exposed on its surface using a gas foaming particle leaching (GF / PL) method and infused with collagen. Methods and apparatus for of forming scaffolds are also disclosed.

Owner:THIERRY GIORNO

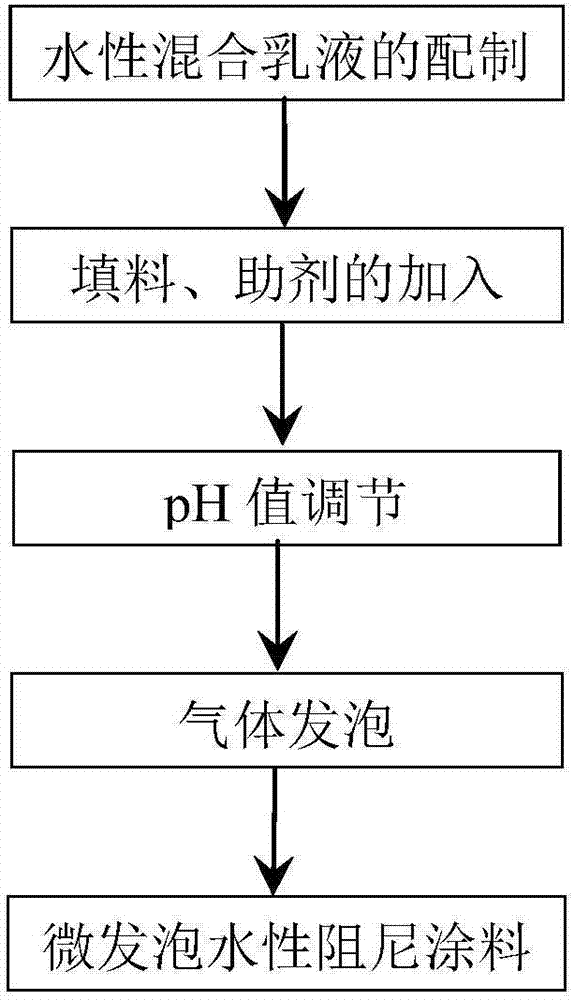

Micro-foamed water-based damping coating and preparation method thereof

ActiveCN107057500AReduce sizeLow densityPolyurea/polyurethane coatingsEpoxy resin coatingsWater basedEmulsion

The invention relates to the technical field of high polymer materials, in particular to micro-foamed water-based damping coating and a preparation method thereof and aims to solve the problem that the size and the density of cells of the damping coating in the prior art are difficult to control. To solve the problem, the micro-foamed water-based damping coating is prepared from a water-based emulsion serving as a main agent, damping filler serving as main filler, organic filler serving as auxiliary filler as well as a proper amount of a crosslinking agent, a catalyst, a gas foaming agent and water; specifically, the micro-foamed water-based damping coating is prepared from raw materials by weight as follows: 10-60 parts of the water-based emulsion, 20-80 parts of the damping filler, 0.5-10 parts of the organic filler, 10-50 parts of the crosslinking agent, 0.01-2 parts of the catalyst and 5-30 parts of water, wherein the temperature of the gas foaming agent ranges from 220 DEG C to 250 DEG C, and the pressure of the gas foaming agent ranges from 8 Mpa to 10 Mpa. Besides, the invention further provides a method for preparing the micro-foamed water-based damping coating. The size and density of cells of the damping coating can be controlled effectively after the coating is foamed through the gas foaming agent.

Owner:段辉

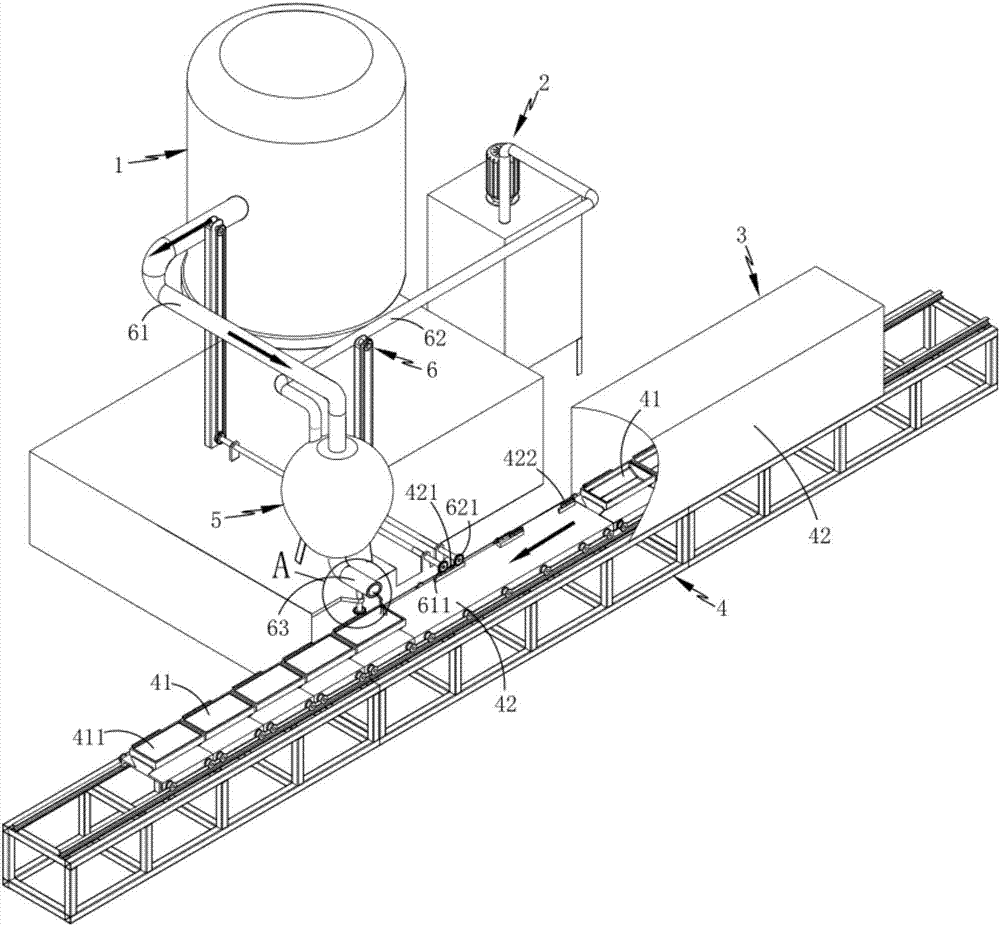

Production system for continuously manufacturing foamed aluminum through gas foaming method

The invention relates to a production system for continuously manufacturing foamed aluminum through a gas foaming method. The production system for continuously manufacturing the foamed aluminum through the gas foaming method comprises a heat preservation bin, a nitrogen supply station and a preheating chamber and further comprises a conveying mechanism, a foaming mechanism and a control mechanism, wherein the conveying mechanism linearly conveys a mold group arranged on the upper side of the conveying mechanism and a connecting assembly used for controlling output of the heat preservation bin and the gas supply station, the foaming mechanism is used for secondary foaming of molten aluminum, and the control mechanism is used for controlling all steps to be operated in order. In the secondary foaming process of the molten aluminum, the staying time of gas in the molten aluminum is prolonged, so that the foaming rate is improved, the loss of nitrogen is reduced, the foaming period is shortened, and therefore the production efficiency is improved; in the operation process of the conveying mechanism, all the steps are controlled to operate in order according to the movement displacement of the conveying mechanism, and the automatic production process of the foamed aluminum ingots is formed. The production system for continuously manufacturing the foamed aluminum through the gas foaming method has the advantages of being simple in structure, high in foaming efficiency, uniform in foaming, controllable in quality, efficient in production and environmentally friendly and saving energy.

Owner:陈明海

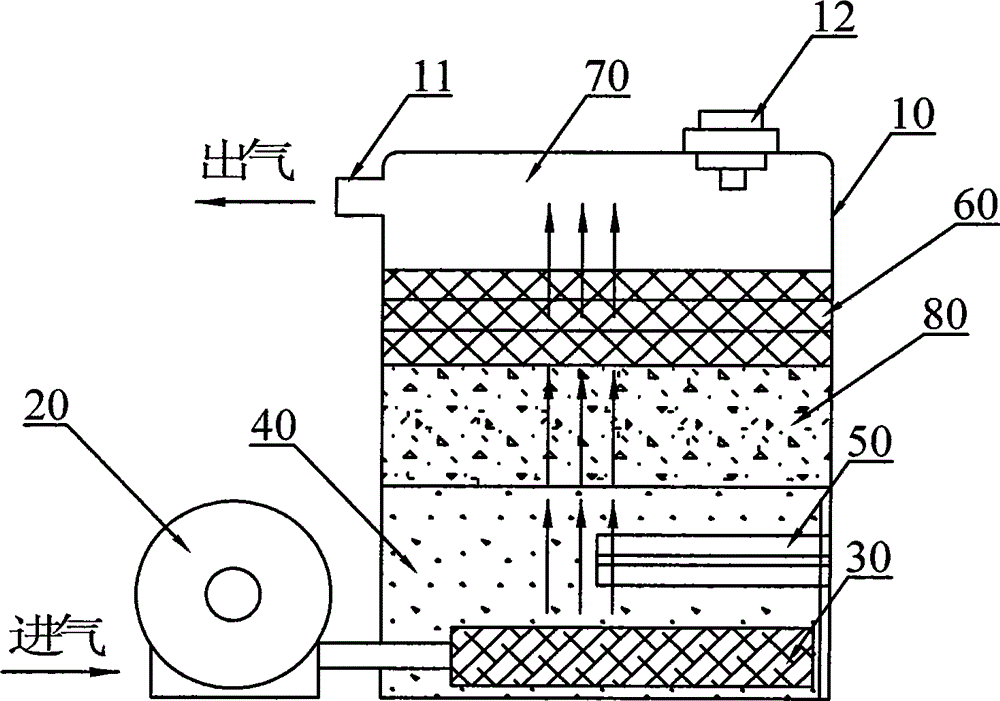

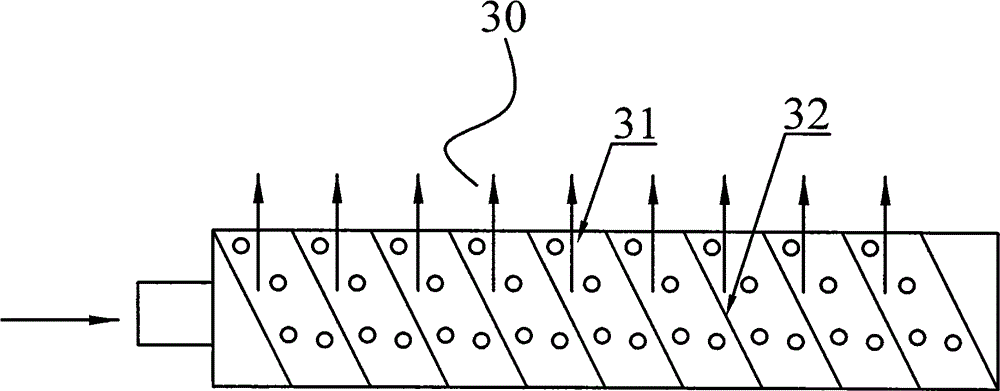

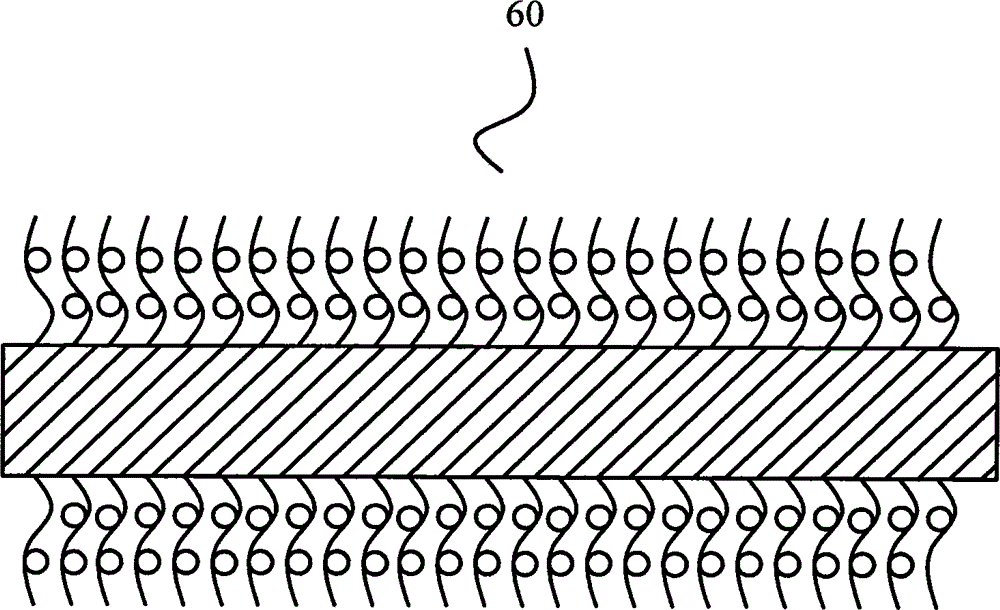

Water bath type atomizing air purifying device

InactiveCN104014211ASimple structureReasonable designUsing liquid separation agentWater bathsAir purification

The invention relates to a water bath type atomizing air purifying device. The device comprises a tank body, a gas collector, a gas foaming and refining device, an atomizing medium cavity, an atomizer, atomizing gas condensers and a gas collecting device, wherein the tank body is in a bucket structure or a closed rectangular hollow body structure, an air exhausting hole is formed in the upper part of the tank body and is communicated with external air, the gas collector is arranged at the outer part of the tank body, the atomizing medium cavity is arranged at the bottom of an inner cavity of the tank body and is filled with an atomizing medium, the gas foaming and refining device and the atomizer are arranged in the atomizing medium cavity, the gas foaming and refining device is communicated with the gas collector, multiple layers of atomizing gas condensers are arranged at the whole section of the middle of the inner cavity of the tank body and are located above the atomizing medium cavity, and the gas collecting device is arranged above the inner cavity of the tank body and is connected with the air exhausting hole. The water bath type atomizing air purifying device is simple in structure, reasonable in design, low in cost, and easy to generalize and can play an air purification role.

Owner:李军

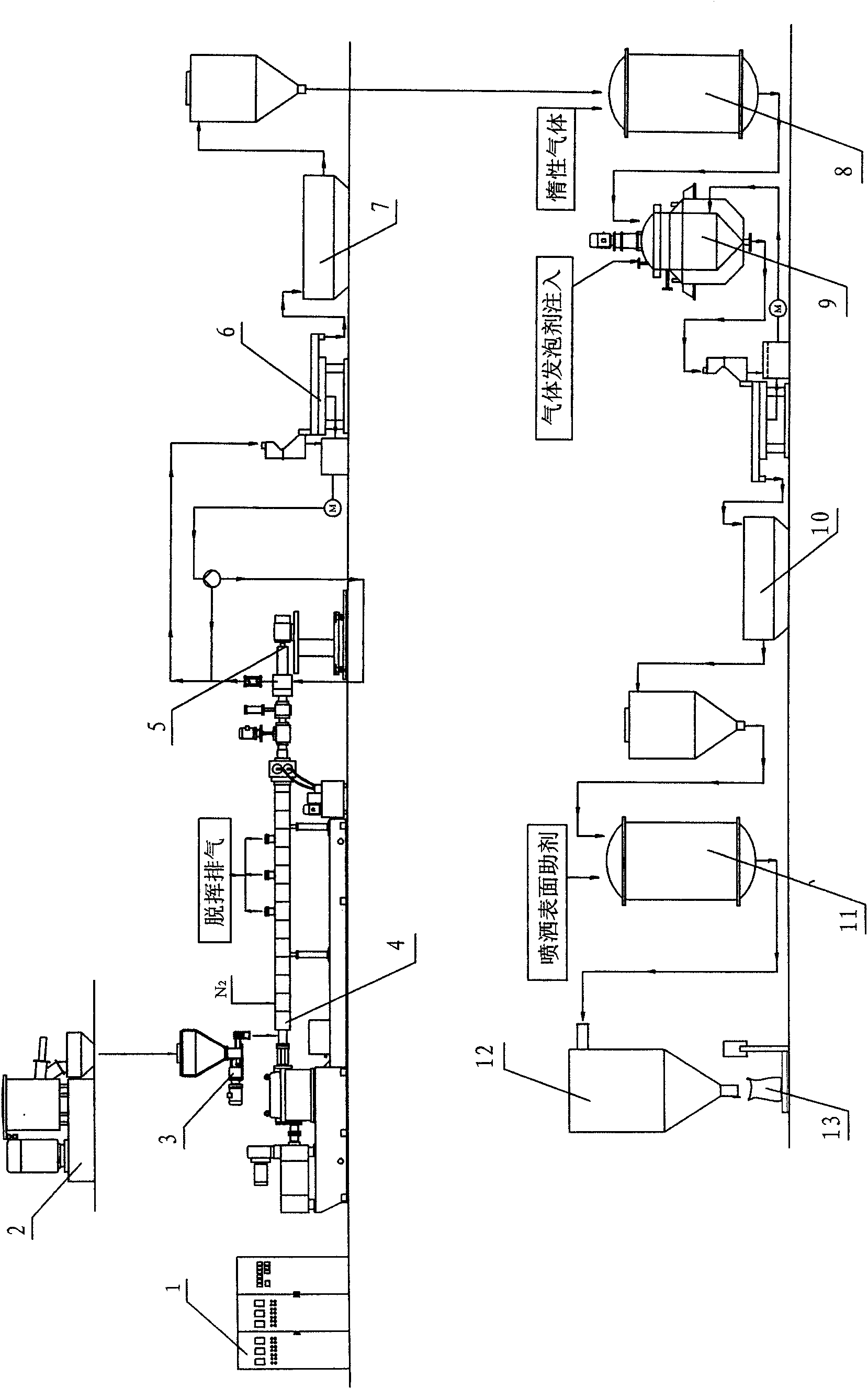

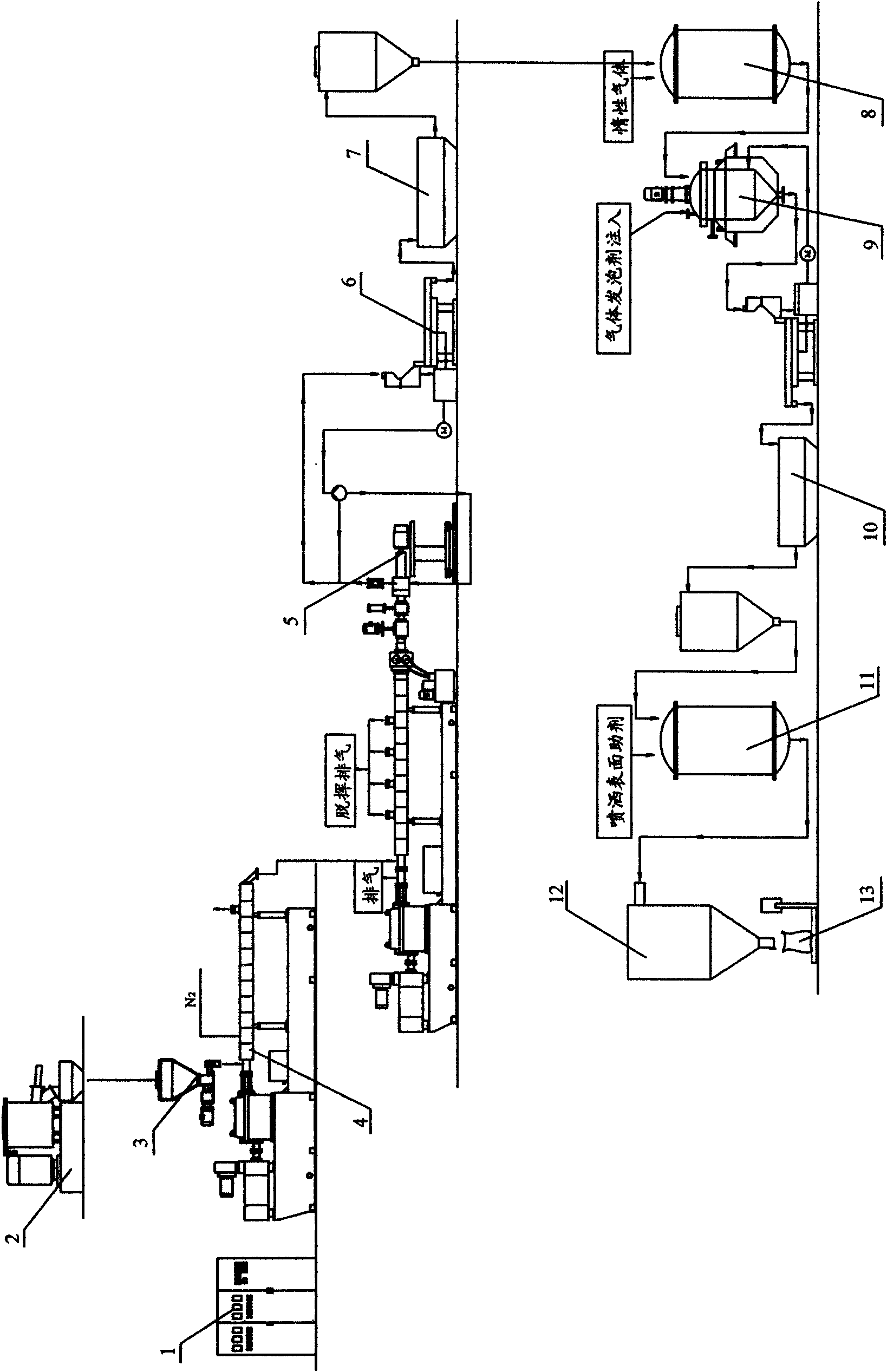

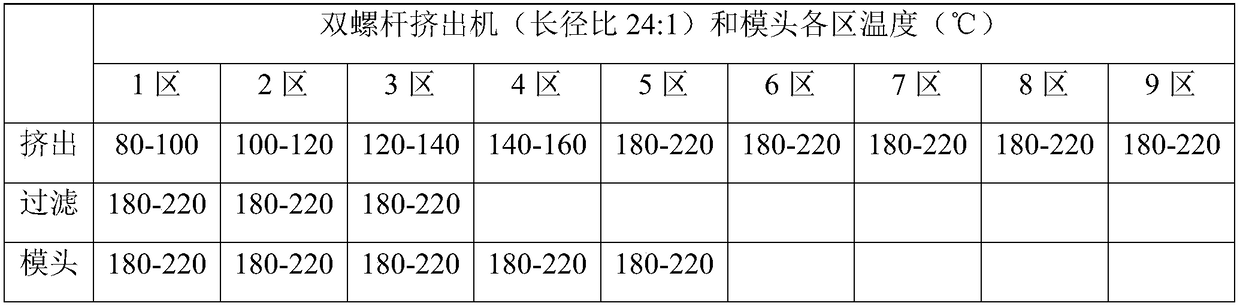

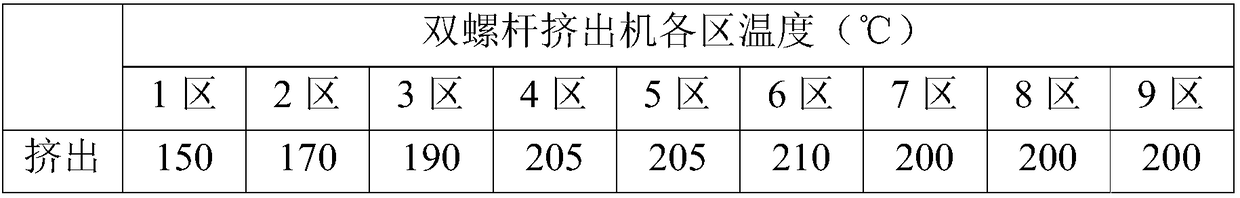

Production line of EPP polypropylene foaming beads

The invention discloses a production line of EPP polypropylene foaming beads, which is characterized in that devices or systems are connected in turn according to the following sequence: a low-temperature mixing system, a sealed leakage-proof feeding machine, a double-screw extruder, an underwater grain cutting system, a first depth drying system, a plasma fluidized bed reactor, a water-soluble reaction system, a second depth drying system, a surface treatment mixing system, a finished product storage hopper and a packing system; the double-screw extruder is provided with a gas foaming agent filling opening; a plasma reaction device and an inert gas filling device are arranged on a plasma fluidized bed of the plasma fluidized bed reactor; and the water-soluble reaction system comprises a water-soluble reaction kettle which is provided with an auxiliary low-temperature liquid medium filling opening and a liquid foaming agent filling opening. The foaming agent content in the EPP polypropylene foaming beads produced by the production line is even, and the product quality is stable.

Owner:江苏诚盟装备股份有限公司

Rich mineral paper preparation method

InactiveCN102615702ALight weightQuality improvementCeramic shaping apparatusFoaming agentFilling materials

The invention discloses a rich mineral paper preparation method, which comprises the following steps of: A) evenly mixing rich mineral paper master batch; B) feeding the evenly mixed rich mineral paper master batch into a charging barrel of a screw extruder, adding an ultramicro gas foaming agent with weight being 0.5-1 percent of the weight of the rich mineral paper master batch into the charging barrel, evenly mixing the rich mineral paper master batch and the ultramicro gas foaming agent and foaming, wherein the ultramicro gas foaming agent is inert gas; and C) feeding the foamed materials into a calender to produce rich mineral paper products. By evenly distributing the ultramicro inert gas with tiny size into the rich mineral paper under conditions of proper temperature and screw mixing reinforcement, the gas becomes a filling material of the rich mineral paper, the specific weight of the rich mineral paper is greatly reduced, the uniformity and the fluidity of the melt of the rich mineral paper are improved at the same time and the overall quality of the rich mineral paper is further improved.

Owner:深圳市石头记环保科技有限公司

Polyolefin composition, polyolefin masterbatch, polyolefin film and surface decorative composite material and preparation method of surface decorative composite material

ActiveCN109422944ALow densityDense surface structureSynthetic resin layered productsFlat articlesMasterbatchCross-link

The invention discloses a polyolefin composition, a polyolefin masterbatch, a polyolefin film and a surface decorative composite material and a preparation method of the surface decorative composite material. The composition comprises, in parts by weight, 100 parts of a polyolefin system, 0.01-3 parts of a crosslinking agent, 0.01-3 parts of a crosslinking assistant and 0.1-10 parts of a microsphere expansion agent when the weight of the polyolefin system is counted as a standard, wherein the crosslinking agent is an organic peroxide crosslinking agent, and the cross-linking assistant is an acrylate crosslinking assistant and / or a polybutadiene-based crosslinking assistant. The microsphere expansion agent is added, and a mode of microsphere expansion is adopted to replace the mode of gas foaming, so that not only can the density of the formed polyolefin film be reduced, but also no formation of pinholes in the surface of the formed polyolefin film can be achieved, and the surface structure of the polyolefin film is dense, soft and comfortable.

Owner:BYD CO LTD

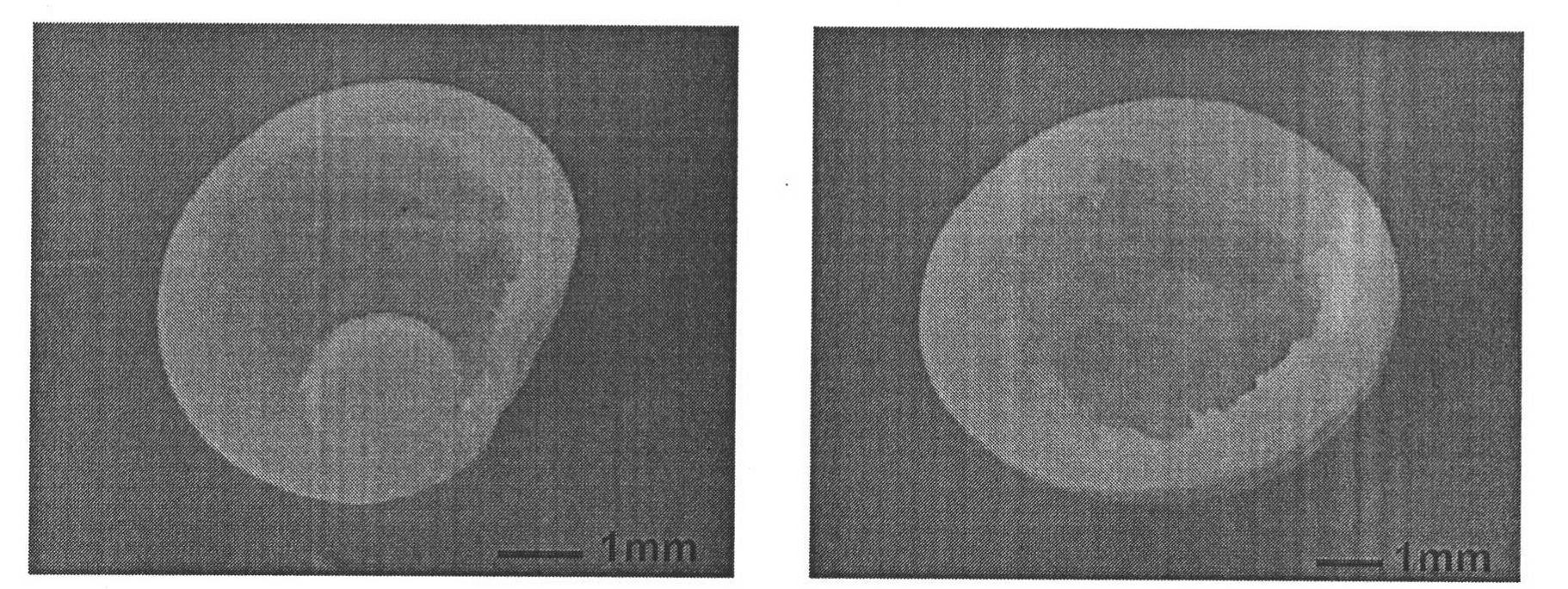

Biodegradable poly(butylene adipate/terephthalate) hollow foamed particle and preparation method thereof

ActiveCN102219986AReduce consumption costReduce manufacturing costPharmaceutical non-active ingredientsMicrocapsulesPolymer scienceSolvent

The invention discloses a biodegradable poly(butylene adipate / terephthalate) hollow foamed particle and a preparation method thereof. The preparation method is characterized by comprising the following steps of: carrying out a mould pressing physical gas foaming method on poly(butylene adipate / terephthalate) granules with a melting point of Tm DEG C in the presence of a physical gas foaming agent at the temperature of (Tm-25 DEG C)-(Tm+15 DEG C) and the pressure of 8-20MPa; performing constant temperature pressure preservation for 5-20 minutes; releasing pressure at the speed of 5-30MPa / s, and sampling and cooling within 30 seconds so as to obtain hollow foamed particles with a foamed shell layer and a hollow inside. Because the foamed layer is more beneficial to drug release and filling as compared with a solid and the hollow foamed particle has the biodegradable characteristic, thus the hollow foamed particle has excellent property, and is hopeful to be widely used in the fields of drug controlled release, agricultural fertilizer controlled release, filling material storage and use and the like. The preparation method is convenient, has simple process flow, wide applicable range, short production period and low cost, is environmentally-friendly and is suitable for industrial product; and the hollow foamed particle disclosed by the invention has no solvent and no impurities, and the size of the particle is controllable and adjustable.

Owner:浙江博发新材料股份有限公司

Anti-compression type autoclaved aerated concrete block

Owner:FOSHAN LINGXIE ENVIRONMENTAL PROTECTION TECH CO LTD

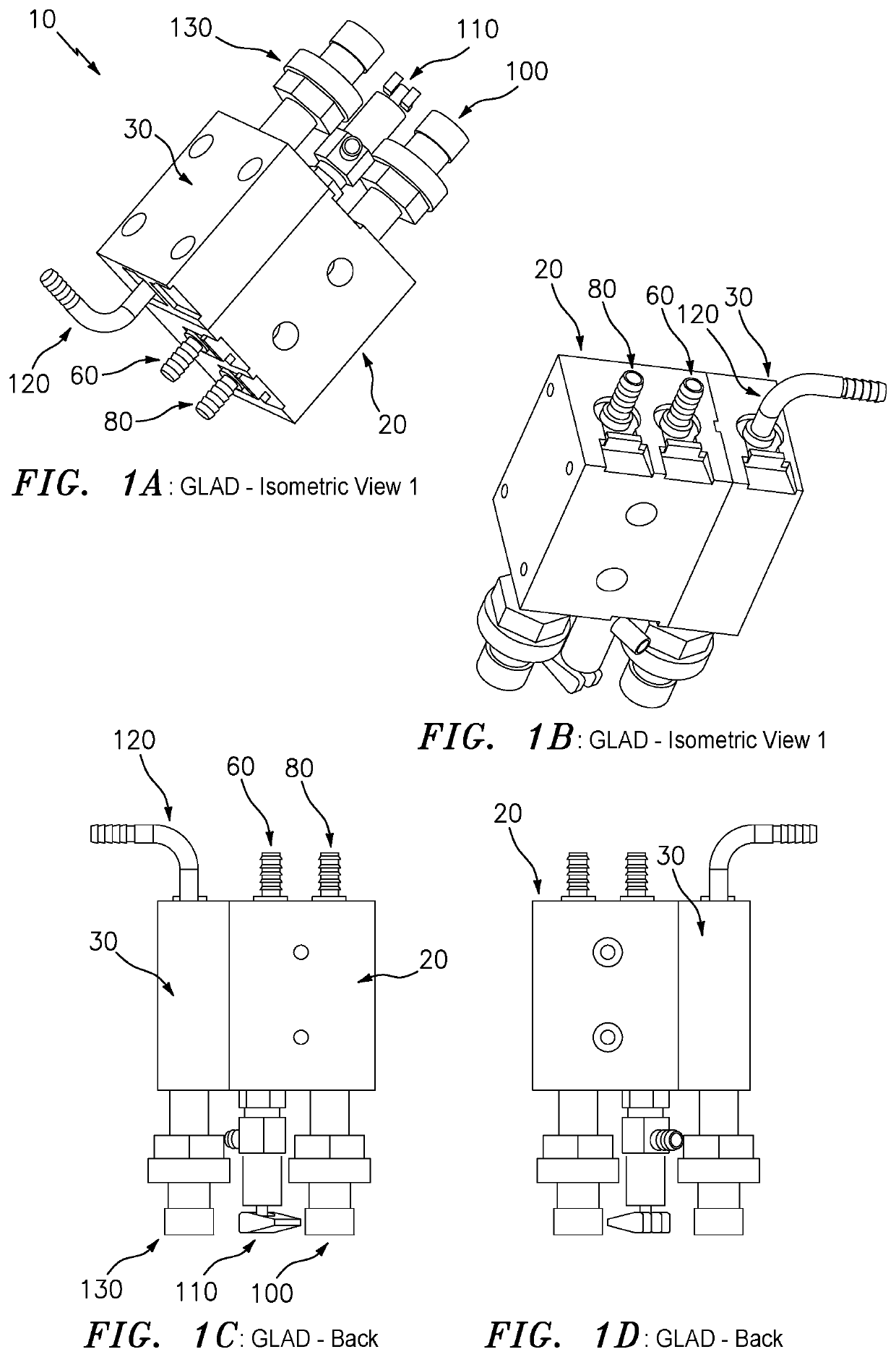

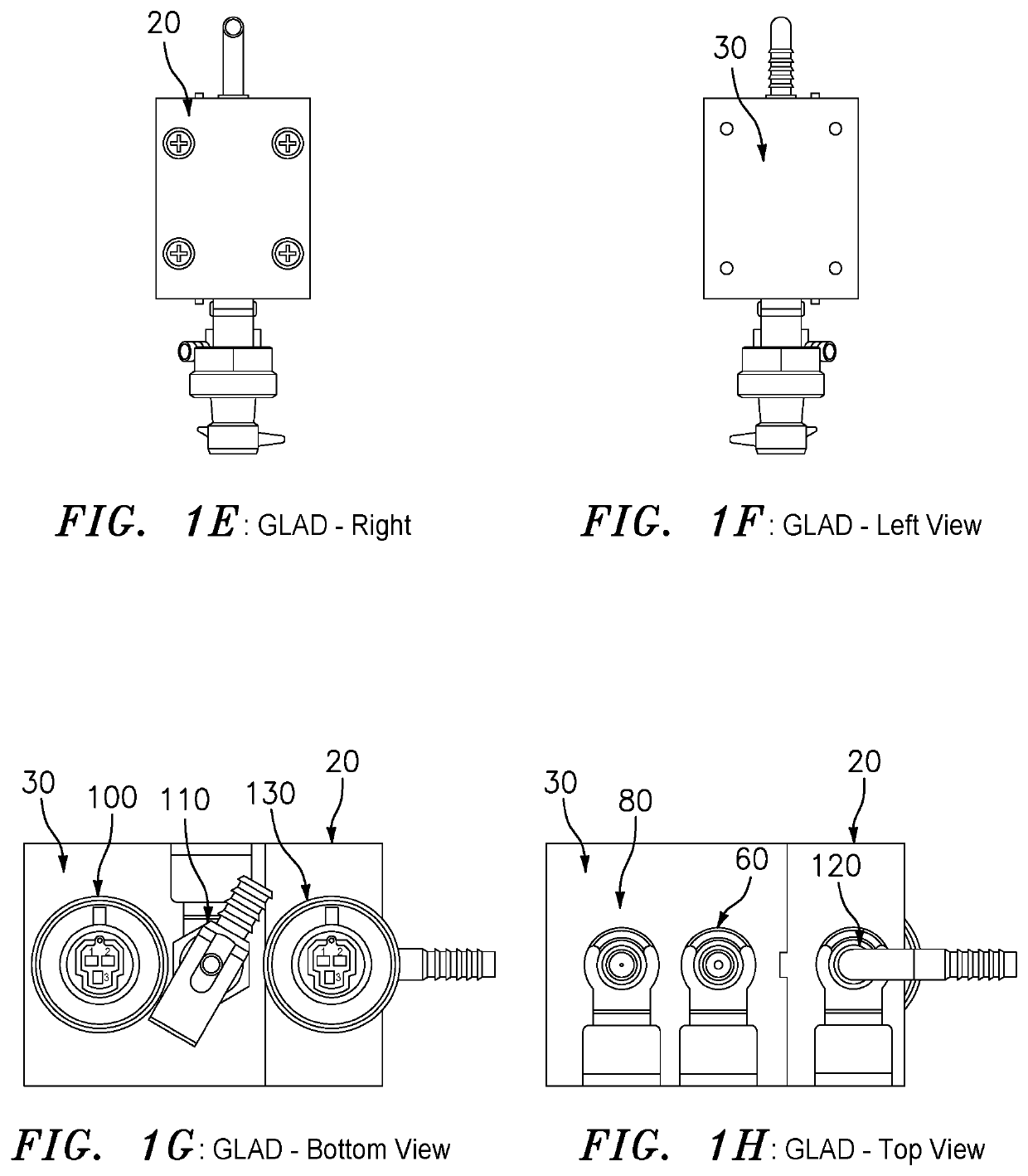

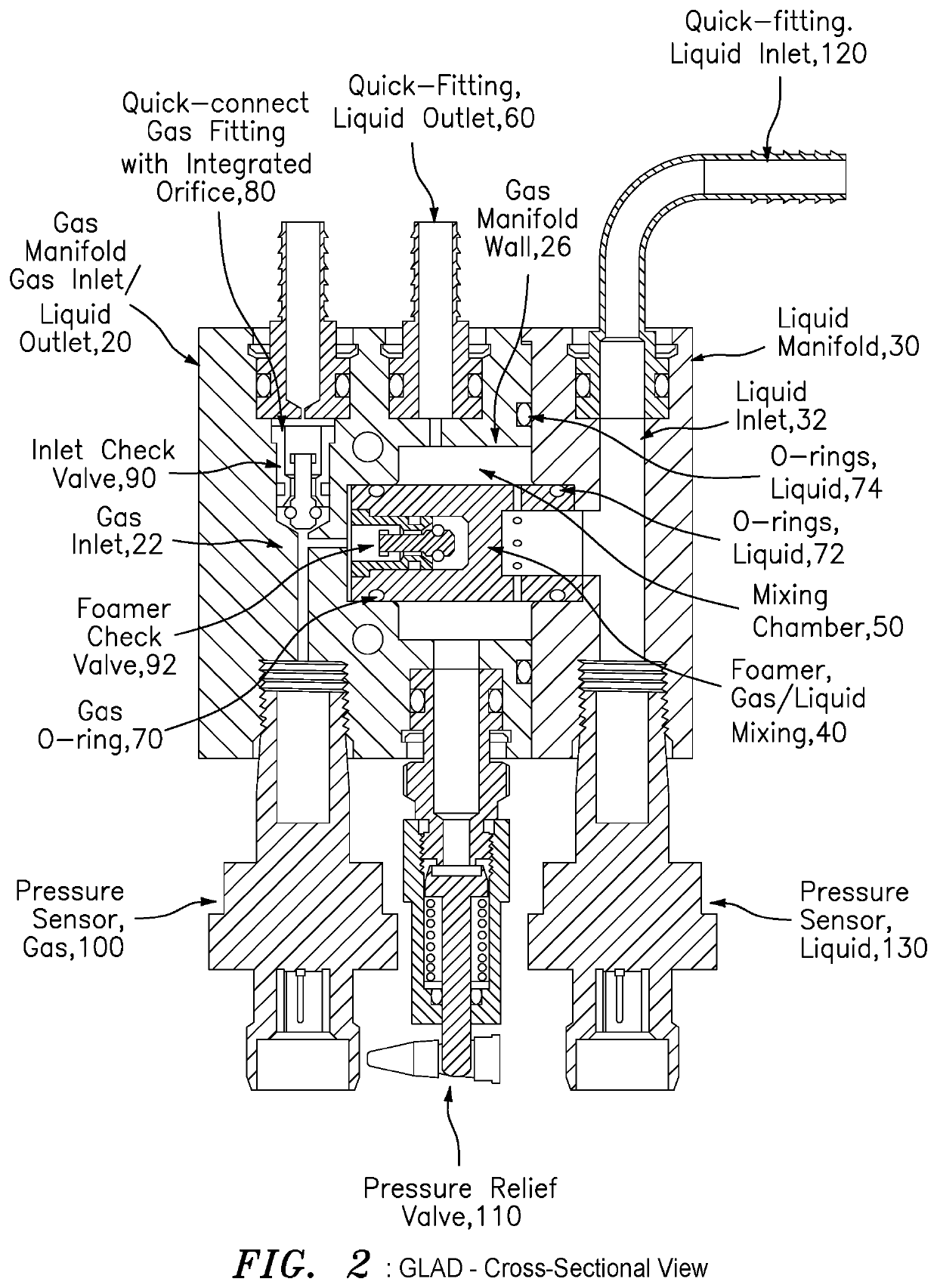

Gas liquid absorption device (GLAD) with replaceable gas orifice fittings and sensors

ActiveUS20200316534A1Great tasteEasy to operateMixing methodsLiquid flow controllersFoaming agentEngineering

A gas liquid absorption device (GLAD), featuring a gas inlet manifold, a liquid inlet manifold and a gas / liquid mixing foamer. The gas inlet manifold has a gas inlet configured to receive and provide an inlet gas, and also has a gas foamer cavity formed therein and coupled fluidically to the gas inlet to receive the inlet gas. The liquid inlet manifold has a liquid inlet configured to receive and provide a non-infused liquid, and also has a liquid foamer cavity formed therein and coupled fluidically to the liquid inlet to receive the non-infused liquid. The gas / liquid mixing foamer is configured between the gas inlet manifold and the liquid inlet manifold and arranged in the gas foamer cavity and the liquid foamer cavity. The gas / liquid mixing foamer has a gas foamer wall configured to form a gas receiving foamer chamber that is fluidically coupled to the gas foamer cavity. The gas foamer wall has gas provisioning holes formed therein to provide dispersed inlet gas from the gas receiving foamer chamber. The gas / liquid mixing foamer has a liquid foamer wall configured to form a liquid receiving foamer chamber that is fluidically coupled to the liquid foamer cavity. The liquid foamer wall having liquid provisioning holes formed therein to provide dispersed non-infused liquid from the liquid receiving foamer chamber. The mixing chamber is configured to receive the dispersed inlet gas and the dispersed non-infused liquid, infuse the dispersed inlet gas and the dispersed non-infused liquid, and provide a foamed gas / liquid mixture from the mixing chamber.

Owner:FLOW CONTROL LLC

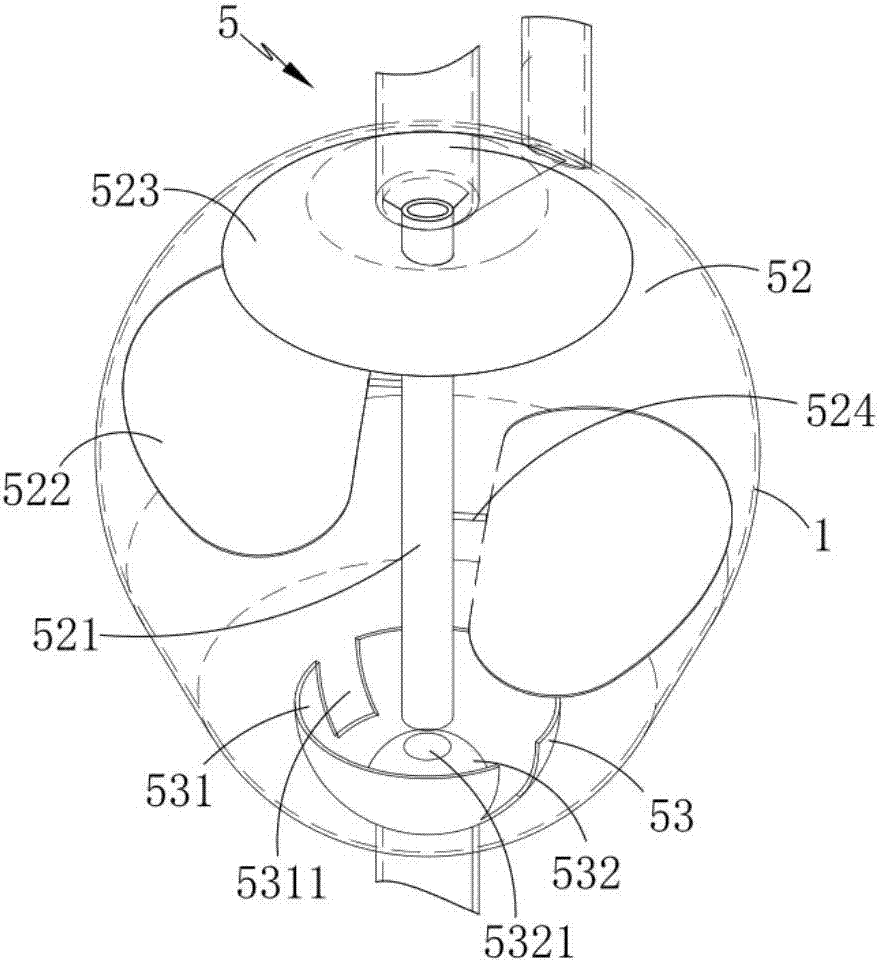

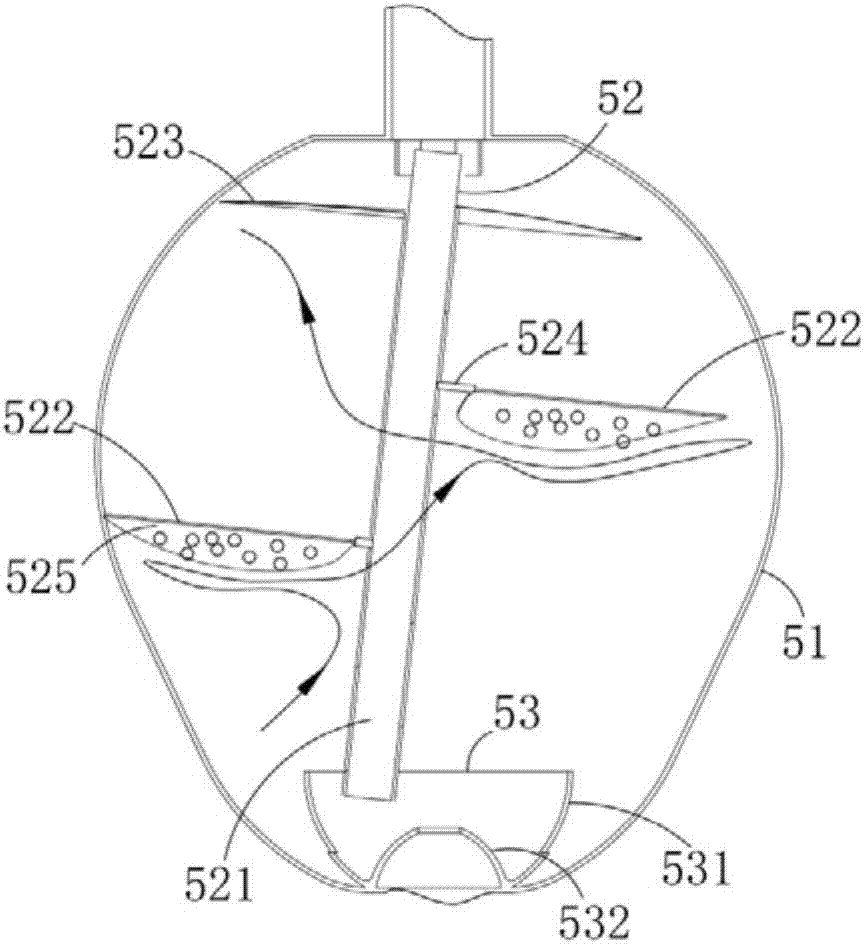

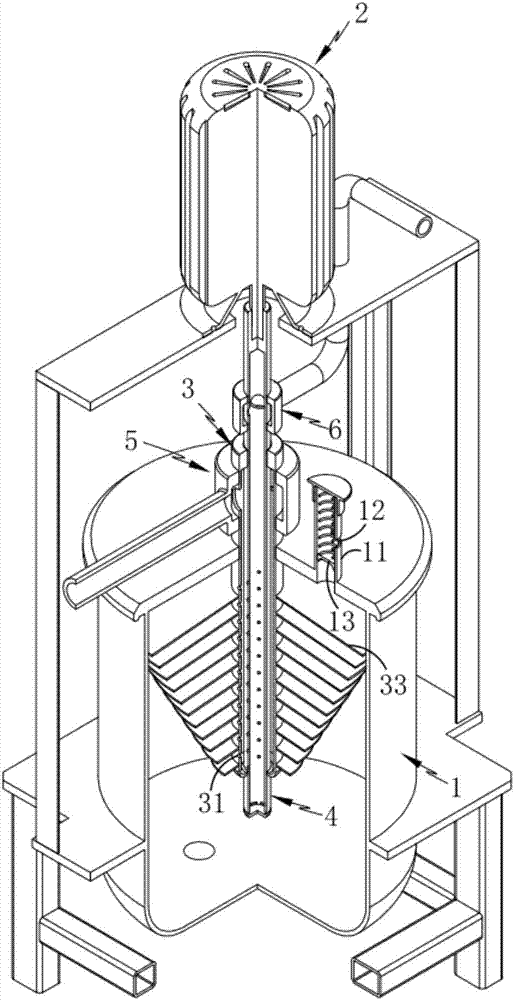

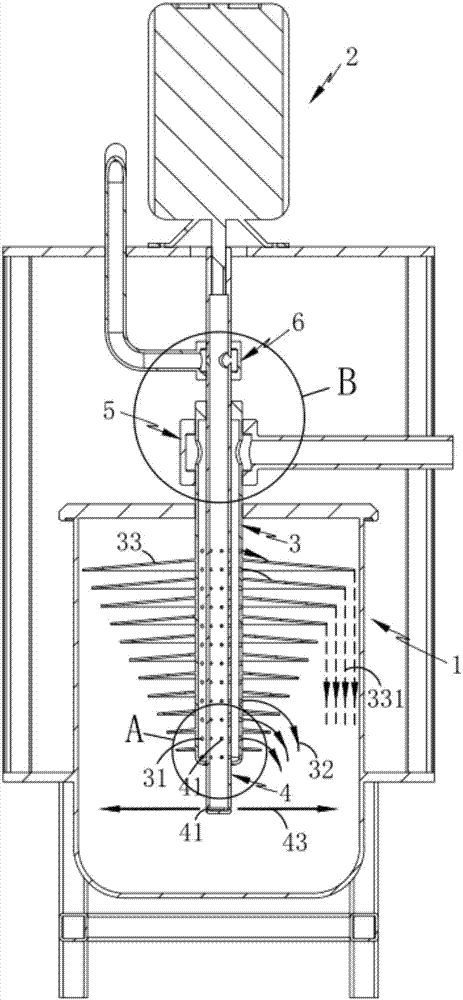

Rotary gas foaming device

The invention relates to a rotary gas foaming device comprising a foaming chamber and a driving assembly fixedly arranged above the foaming chamber and also comprising a molten aluminum output pipe and a gas output pipe; the molten aluminum output pipe is rotatably arranged at the top of the foaming chamber along a vertical direction, the inside of the molten aluminum output pipe is hollow and communicates with the foaming chamber by a plurality of liquid outlet holes formed in the molten aluminum output pipe; the gas output pipe passes through the molten aluminum output pipe and is fixedly connected with two end surfaces in the axial direction of the molten aluminum output pipe in a sealing way; one end of the gas output pipe is fixedly connected with the driving assembly, and the other end of the gas output pipe is set to be closed and is provided with a gas nozzle; and molten aluminum is output by a high-pressure foaming gas at high pressure and is then scattered by a gas curtain, and the molten aluminum is in sufficient contact with the foaming gas for many times, so that gas foaming of the molten aluminum is realized, and the problem of foaming nonuniformity existing in the prior art is solved.

Owner:浙江金汤塑胶科技股份有限公司

Method of preparing biodegradable dual pore polymer scaffolds for tissue engineering

InactiveUS7842305B2High porosityHigh surface areaProsthesisSheet deliveryOrganic acidPolymer scaffold

There is provided a method of preparing biodegradable dual pore polymer scaffolds, comprising the steps of: maintaining a polymer solution containing a biodegradable polymer, an effervescent mixture of carbonate and organic acid, and solvent at a temperature range of −196° C. to ambient temperature so as to evaporate the solvent and produce a polymer sample; and foaming the polymer sample in a mixed solution of water and alcohol.According to the present invention, the pore size of the polymer scaffolds can be easily controlled, and biodegradable polymer scaffolds can be more simply prepared compared to conventional methods such as salt leaching technique, phase separation technique or gas foaming technique. Further, since the biodegradable polymer scaffolds prepared according to the present invention have a high surface area and porosity without formation of skin layer, secretion of toxic substances and remnant phenomenon, they can be advantageously used for regenerating almost all living tissues and organs in tissue engineering.

Owner:KOREA INST OF SCI & TECH

Biomass-doped enhanced concrete

The invention discloses a formula for enhancing concrete strength and relates to the technical field of building materials. The formula comprises 70-72% of phosphorus slag, 18-23% of fly ash and 6-19% of cement; and the water-material weight ratio is 0.33-0.43, an alkaline activator accounts for 3.6-4.3% of the total weight of a cementing material, a gas foaming agent accounts for 0.2-0.3% of the total weight of the cementing material, water glass slurry accounts for 1-3% of the total weight of the cementing material, and the total amount of straw is 0.1-0.5%. The concrete strength is greatly enhanced, the application range of the concrete is expanded, the utilization rate of the concrete is increased, the preparation cost is low, and the concrete is nontoxic and harmless and has high safety coefficient and good groutability.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com