Biodegradable poly(butylene adipate/terephthalate) hollow foamed particle and preparation method thereof

A technology of terephthalic acid and polyadipic acid, which is applied in the direction of medical preparations, pharmaceutical formulas, and capsule delivery of non-active ingredients, and can solve problems such as difficult large-scale industrial production, a large amount of organic solvents, and low production efficiency , to achieve the effects of universality, low requirements for production equipment, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

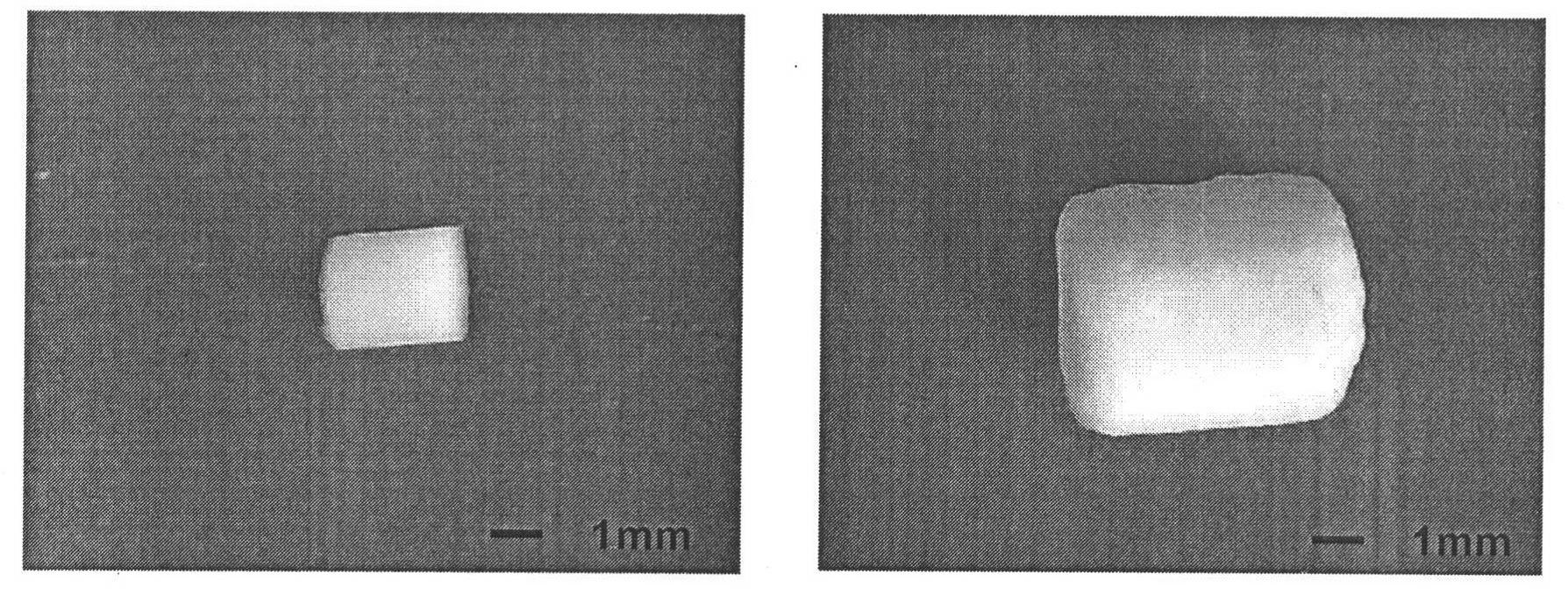

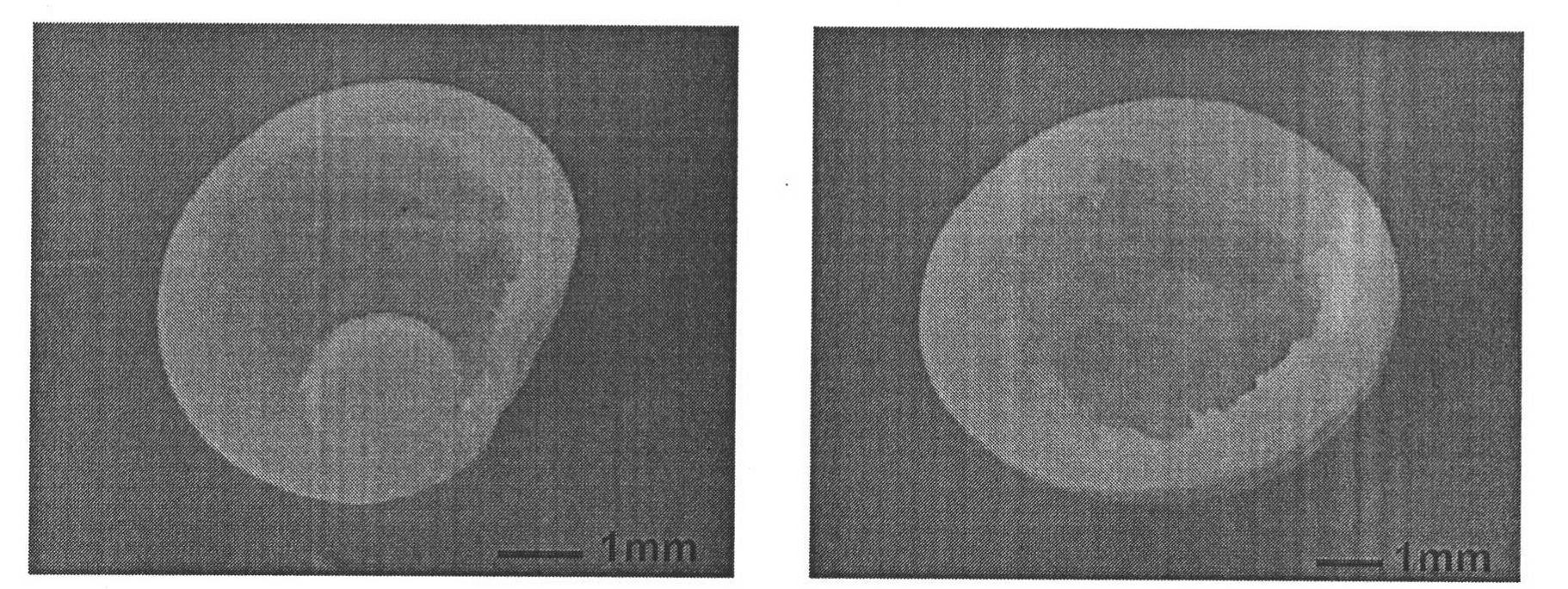

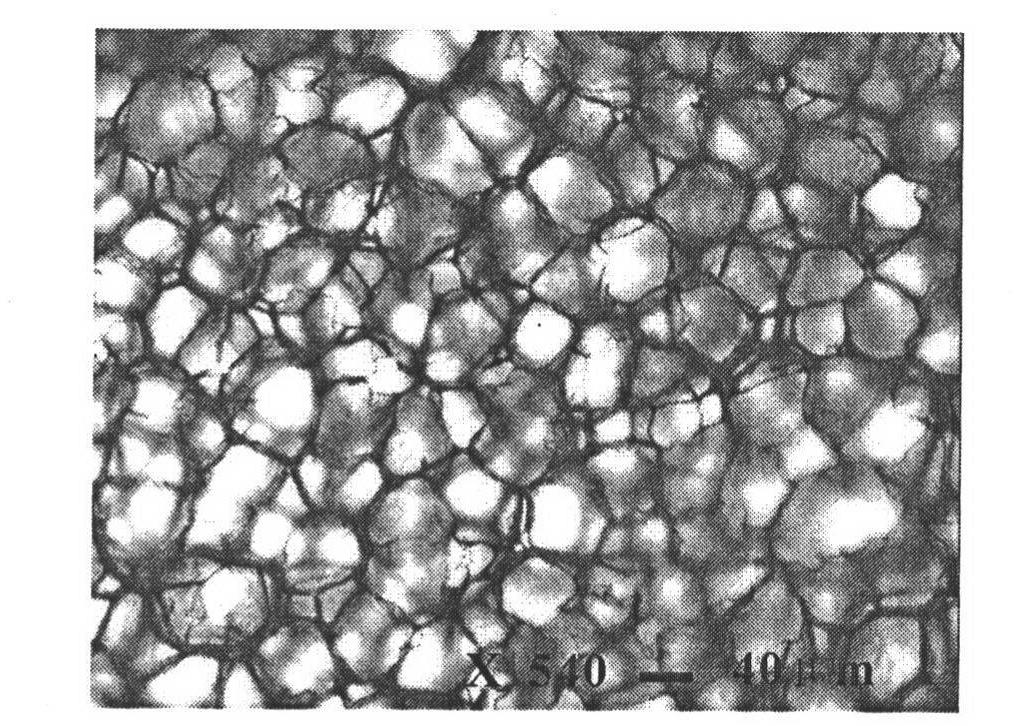

[0039] PBAT particles are placed in a high-pressure mold in a molded physical gas foaming device to ensure that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. When the mold reaches the set temperature of 110°C, fill it with 16MPa of CO 2 , kept at constant temperature and pressure for 5-15 minutes, and then released to normal pressure at a speed of 23MPa / s. The foamed material was taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 1.

[0040] Table 1 Comparison of structural properties of PBAT hollow expanded particles prepared by different holding times

[0041]

Embodiment 2

[0043] PBAT particles are placed in a high-pressure mold in a molded physical gas foaming device to ensure that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. When the mold reaches the set temperature of 100-120°C, fill it with 16MPa of CO 2 , kept at constant temperature and pressure for 15 minutes, and then released to normal pressure at a speed of 23MPa / s. The foamed material was taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 2.

[0044] Table 2 Comparison of structural properties of PBAT hollow expanded particles prepared at different foaming temperatures

[0045]

Embodiment 3

[0047] PBAT particles are placed in a high-pressure mold in a molded physical gas foaming device to ensure that the total volume of the particles does not exceed 1 / 25 of the mold volume, so that the particles have enough space for foaming. When the mold reaches the set temperature of 120°C, fill it with CO at the set pressure. 2 , kept at constant temperature and pressure for 15 minutes, and then released to normal pressure at a certain speed. The foamed material was taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 3.

[0048] Table 3 Comparison of structural properties of PBAT hollow expanded particles prepared by different foaming pressures

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com