Patents

Literature

699results about How to "Low requirements for production equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and preparing method of Fe-based nanocrystalline soft magnetic alloy

ActiveCN104934179AHigh saturation magnetic inductionLow coercivityMagnetic materialsCopper moldMagnetic alloy

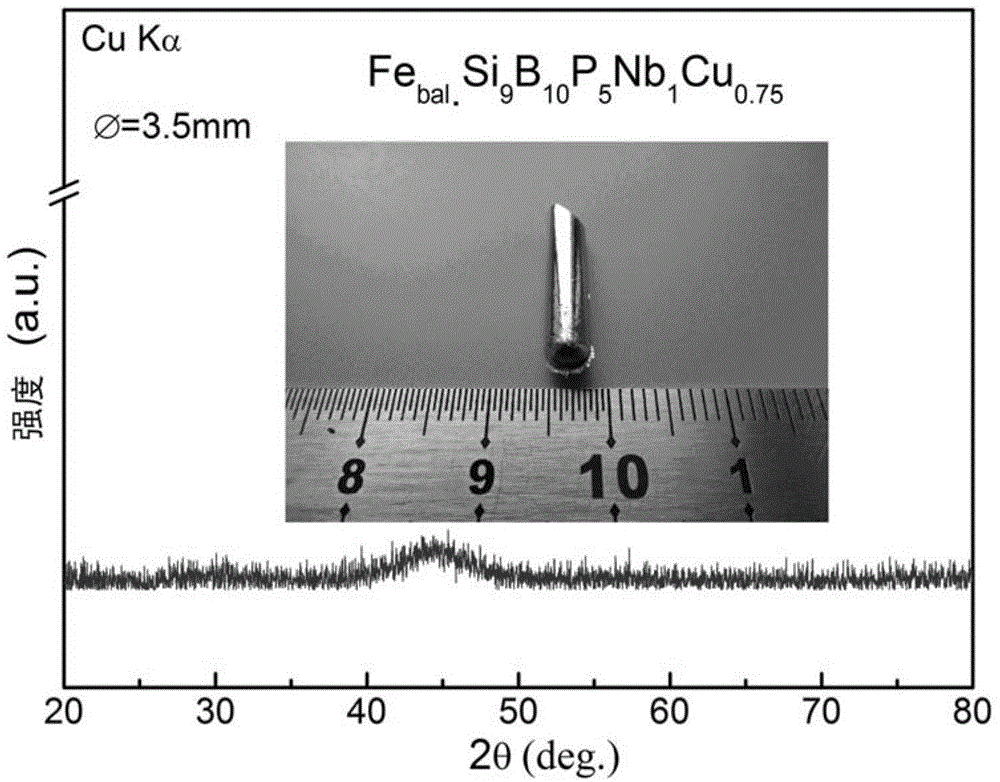

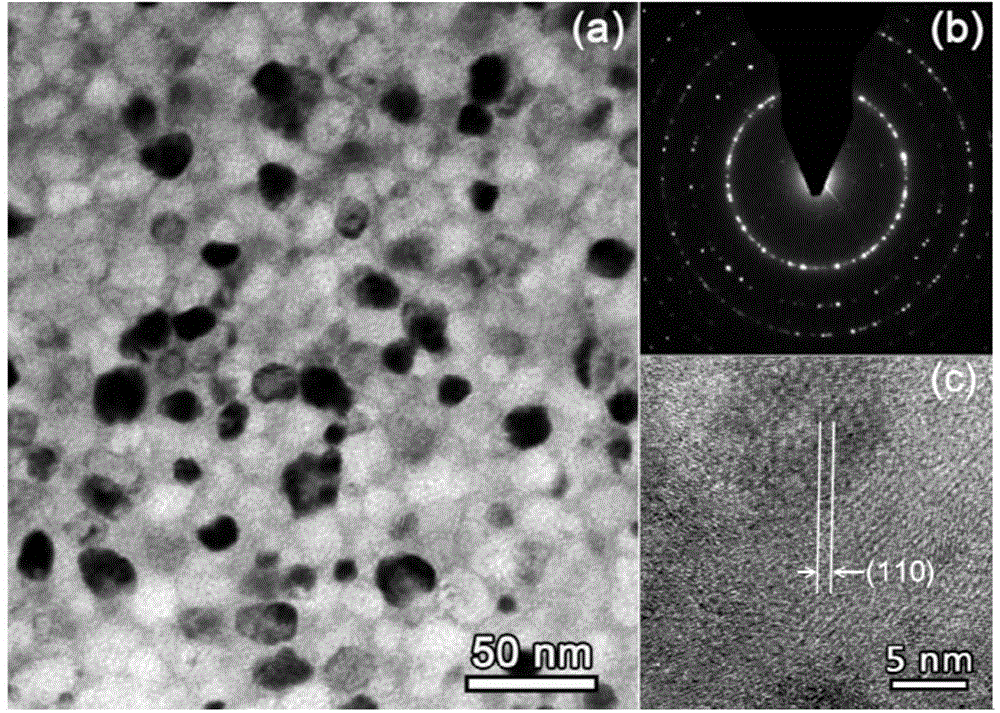

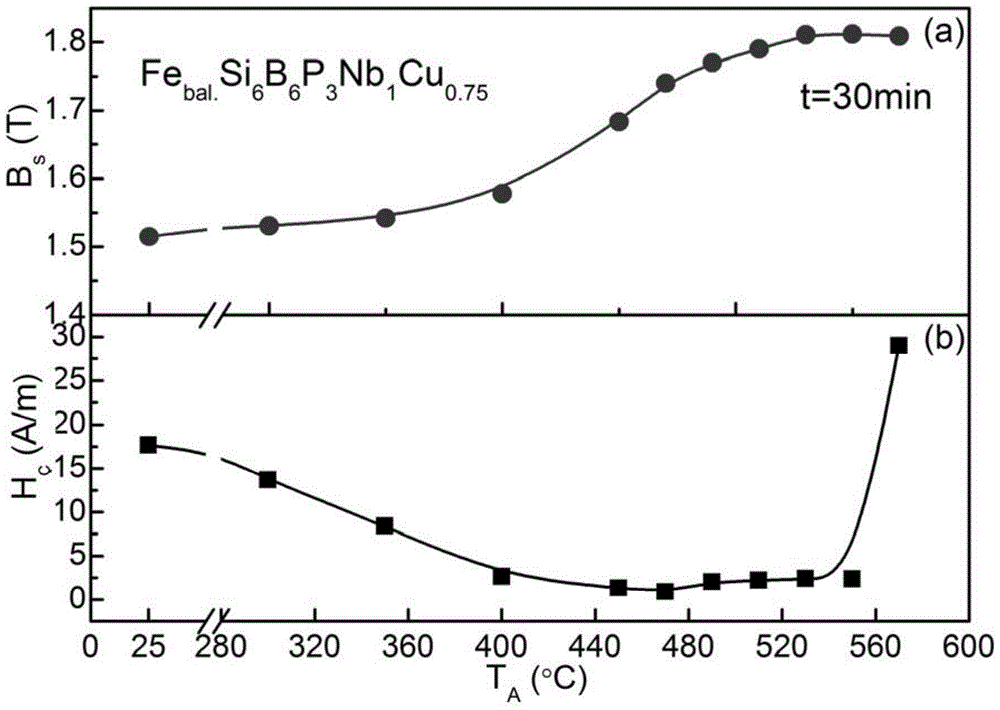

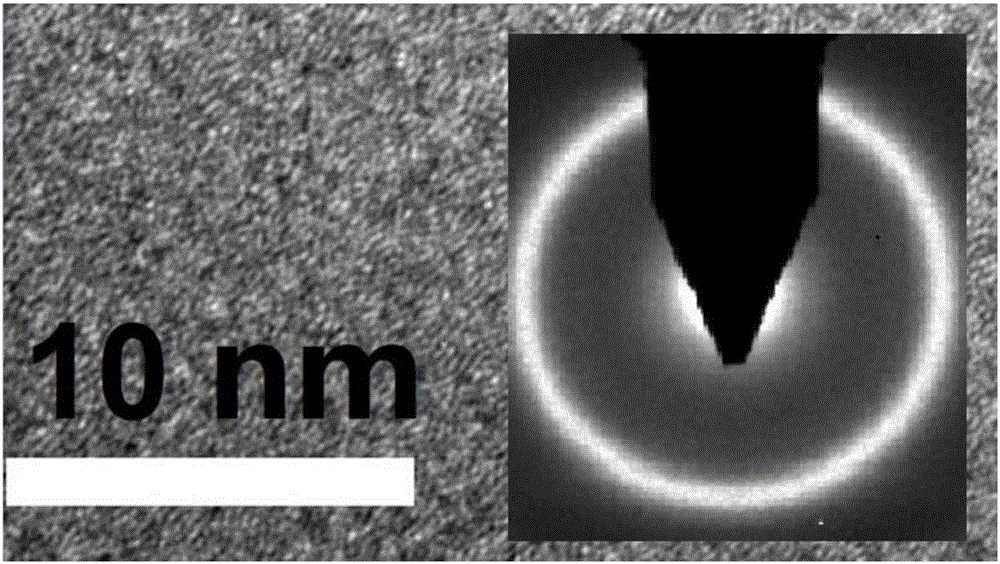

The invention discloses a Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and a preparing method of the Fe-based nanocrystalline soft magnetic alloy. The alloy has an expression of Fe<x>SiBP<c>Nb<d>Cu<e>, wherein in the expression, each of the x, the a, the b, the c, the d and the e shows the atomic percentage content of the corresponding ingredient, and meets the following conditions that the a is greater than or equal to 0.5 but smaller than or equal to 12; the b is greater than or equal to 0.5 but is smaller than or equal to 15; the c is greater than or equal to 0.5 but smaller than or equal to 12; the d is greater than or equal to 0.1 but smaller than or equal to 3; the e is greater than or equal to 0.1 but smaller than or equal to 3; the x is greater than or equal 70 but smaller than or equal to 85; and the sum of the x, the a, the b, the c, the d and the e is 100 percent. The soft magnetic alloy has the advantages that an ordinary copper mold casting method can be used for preparing a Fe-based amorphous alloy with the critical dimension being 3.5mm; after the annealing; the saturation flux density is greater than 1.5T; and the coercive force value is smaller than 1A / m.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Concrete demoulding agent and preparation method thereof

ActiveCN105296122ADry fastGood demoulding qualityCeramic shaping apparatusLubricant compositionMaterials scienceDefoamer

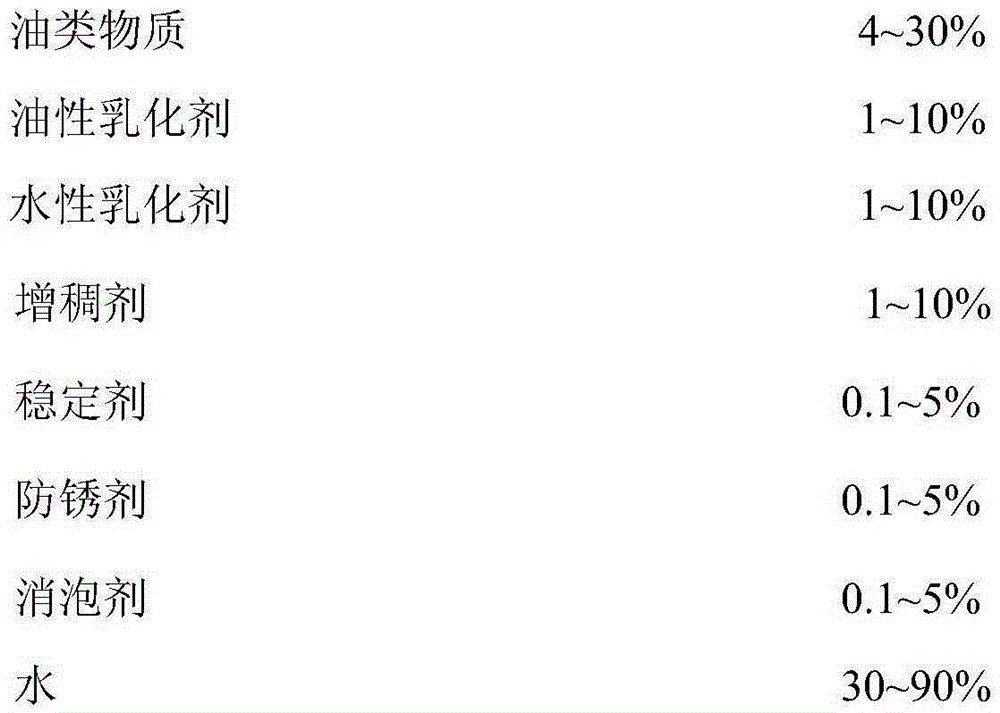

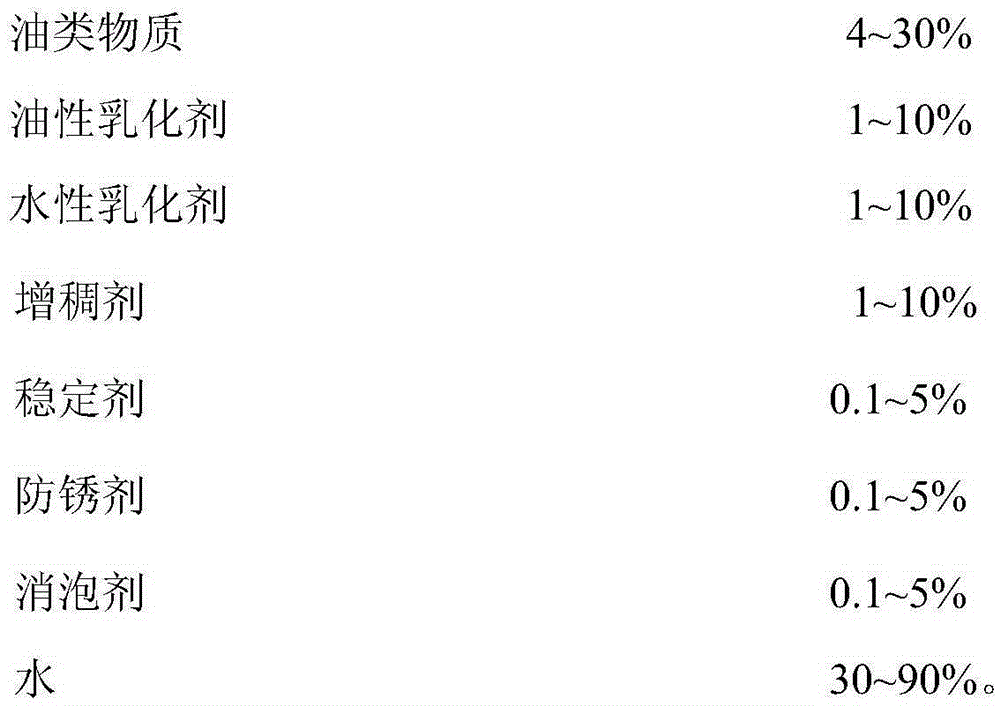

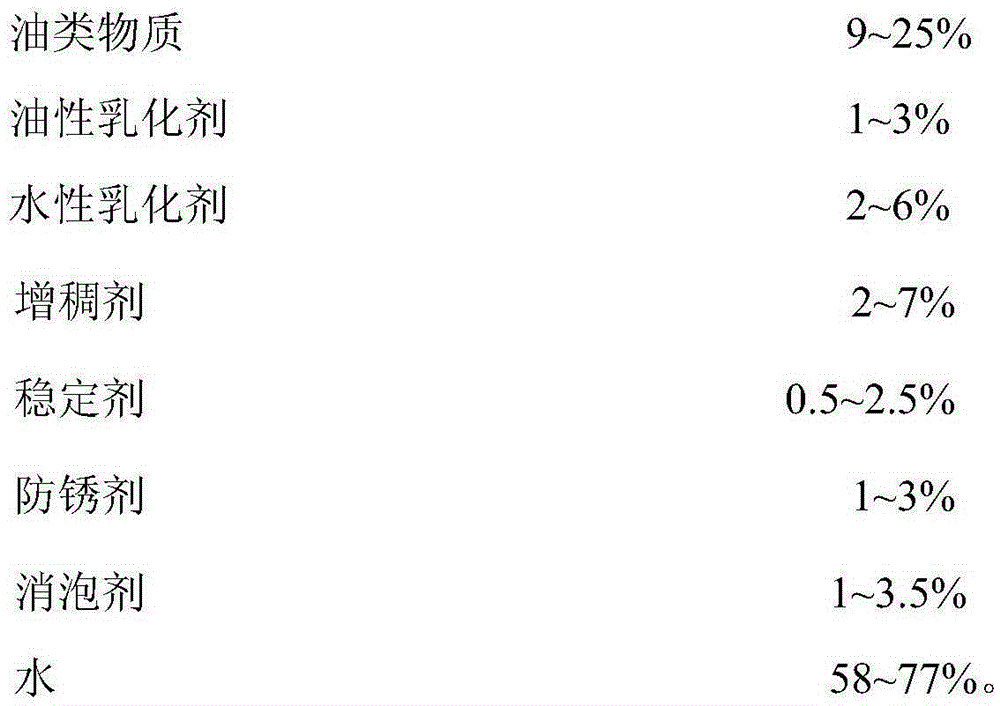

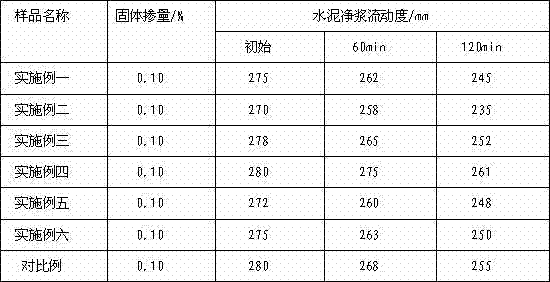

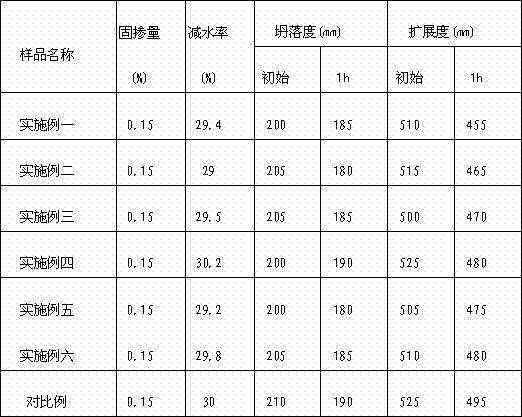

The invention discloses a concrete demoulding agent and a preparation method thereof. The demoulding agent is composed of the following raw materials in percentage by weight: 4 to 30% of oil substance, 1 to 10% of oily emulsifier, 1 to 10% of aqueous emulsifier, 1 to 10% of thickening agent, 0.1 to 5% of stabilizing agent, 0.1 to 5% of antirust agent, 0.1 to 5% of antifoaming agent, and 30 to 90% of water. The concrete demoulding agent has the advantages that the demoulding agent can be rapidly dried after film forming, the surface of moulded members is smooth and does not contain bubbles, the amount of residual ash in the mould is little, and the demoulding quality is good.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Polycarboxylate water reducer and preparation method thereof

InactiveCN102826784AOvercome the defect of high homopolymerization tendency of monomers with high activityGood dispersionCarboxylic acidWater reducer

The invention relates to a water reducer used for concrete and a preparation method thereof, in particular to a polycarboxylate water reducer and a preparation method thereof, belonging to the field of concrete admixture technology. The polycarboxylate water reducer comprises the following components, based on parts by mass: 100 parts of polyoxyethylene methyl alkenyl ether macromer, 4-18 parts of unsaturated carboxylic acid and acid amide or acid anhydride, 1-6 parts of unsaturated sulfonate monomer, 0.5-3 parts of oxidizer, 0.01-0.5 parts of a reducing agent, 3- 15 parts of sodium hydroxide and 100-200 parts of water. According to the method, the characteristics such as excellent ability of water-reducing, low slump loss and good adaptability to different types of cement and concrete admixture are shown in the product at low accretion by means of one time addition; and the cost performance is high. The method has advantages that requirements for production equipment and production conditions in industrial production can be further lowered, energy consumption is reduced, and the method is economical, environment-friendly and beneficial to be generalized.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Vinegar koji and biological edible vinegar, and method of producing the same

The invention relates to a vinegar melody, biological vinegar and the preparing method, which dissolve the problem that glacial acetic acid or the like in the edible vinegar has side effect for the human. The vinegar melody is made by Avena sativa, wheat, black rice, peart barley, soya bean, black soya bean, green bean, red bean, broad bean, pea, tea, traditional Chinese medicine herbal pieces prepared for decoction and vinegar melody bacterial. The preparing method of the vinegar melody comprises the following steps: 1, boiling after disintegrating high starch raw material and infiltrating with the water; 2, adding the other raw material, water and vinegar melody bacterial and fermenting. The biological vinegar is made by vinegar melody, Daqu, Shenqu, bran melody, wine yeast, aspergillus oryzae, Chinese sorghum, corn, millet, glutinous millet, peart barley, glutinous rice, black rice, citrate bacterial, yeast, acetic acid bacteria and fruit normal juice. The preparing method of the biological vinegar comprises the following steps: 1, boiling after disintegrating high starch raw material and infiltrating with the water; 2, adding the other raw material and saccharifying and acetous fermenting zymogeneous bacteria; 3, adding the salt and afterripening; 4, drenching the vinegar; ageing; sterilizing and filtering. The local flavor of the biological vinegar comes from the raw material and the metabolite of the microorganism completely without the glacial acetic acid or the like, and the biological vinegar doesn't have the side effect for the human and has the delicious taste and more than 8. 13g / 100ml high vinegar yield.

Owner:范英祝

Wood lacquer for purifying formaldehyde and preparation method thereof

The invention discloses wood lacquer for purifying formaldehyde and a preparation method thereof. The wood lacquer is prepared by mixing a component A with a component B in a mass ratio of (1:0.25)-(1:0.5), and then stirring the mixture uniformly, wherein the component A is prepared by putting alkyd resin and alcohol solvents into a reaction kettle under the protection of nitrogen, stirring the materials uniformly and heating the materials to 50-75 DEG C, adding first diluents, fillers, driers, wax powder, formaldehyde removal agents and an anti-settling agent in sequence, continuing stirring, maintaining the temperature at 40-70 DEG C and reacting for 15-60 minutes, and discharging the material after returning to the room temperature; the component B is prepared by putting second diluents into the reaction kettle under the protection of nitrogen, stirring and insulating the materials, putting curing agents, a levelling agent and a defoaming agent into the reaction kettle, insulating and stirring the materials, and discharging the material after returning to the room temperature. The wood lacquer has high formaldehyde removal efficiency and good durability, dispenses with recoating films, and is convenient to use.

Owner:SOUTH CHINA UNIV OF TECH

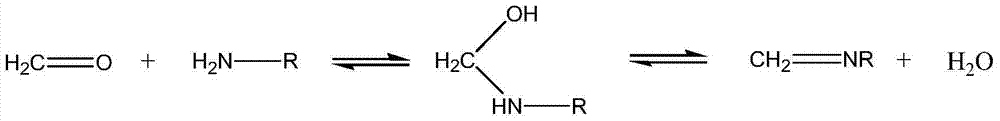

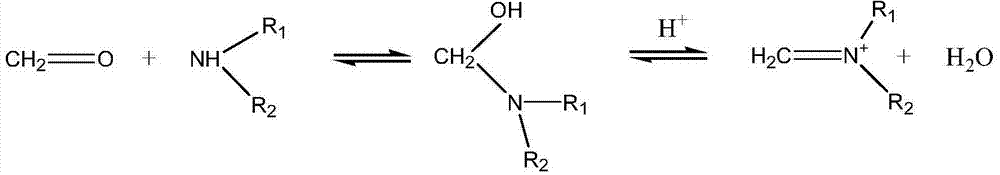

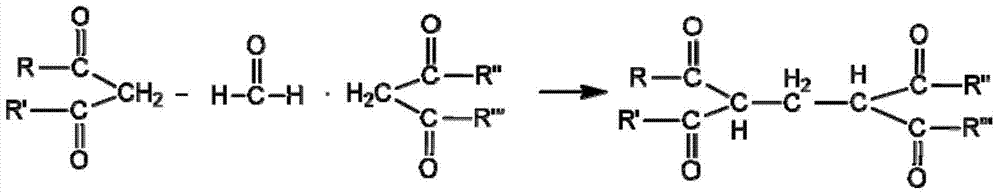

Preparation method of graphene coating polyacrylonitrile fiber composite material

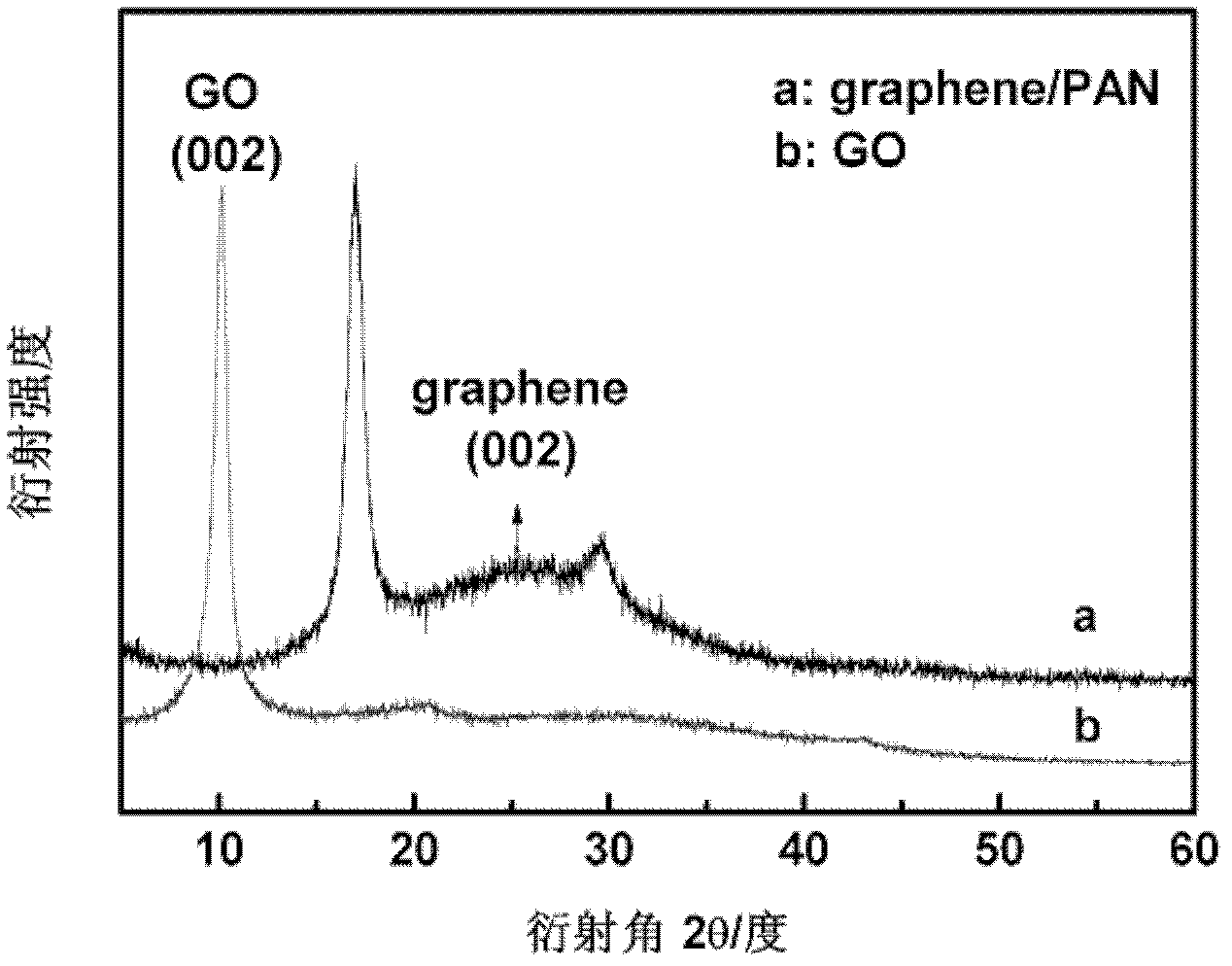

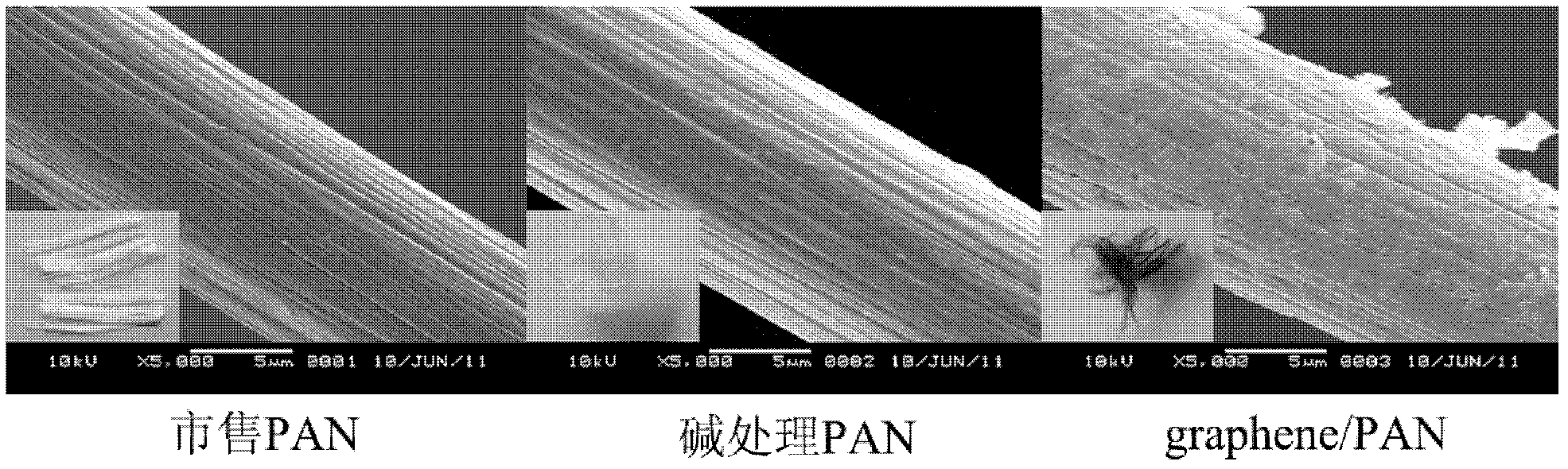

ActiveCN102619080APromote functional designSimple methodFibre typesGrapheneGraphene coatingHydrazine compound

The invention relates to a preparation method of a graphene coating polyacrylonitrile fiber composite material. The preparation method comprises the following steps of: (1) processing polyacrylonitrile by using alkali; (2) preparing a polyacrylonitrile fiber with modified single layer KH550; (3) preparing a polyacrylonitrile fiber with modified single layer graphite oxide; (4) using the polyacrylonitrile fiber with the modified single layer graphite oxide as a raw material, repeating the step (2) and the step (3), and obtaining the polyacrylonitrile fiber with modified multiplayer graphite oxide; and (5) placing the polyacrylonitrile fiber with the modified multiplayer graphite oxide in a graphite oxide dispersion liquid, then dropwise adding a hydrazine hydrate aqueous solution, carrying out heating reaction, finally cooling, washing and drying to obtain the graphene coating polyacrylonitrile fiber composite material. The preparation method provided by the invention is simple; the graphite of the composite material provided by the invention is good in reduction degree and uniformly coats the surface of the polyacrylonitrile; and compared with a commercial finished product, the composite material has the advantages that the resistivity of a single wire is reduced by six order of magnitudes, and the composite material has the application prospect of conductive fiber preparation.

Owner:SHENGQUAN HEALTANG

Synthesis method of imidazoline compound

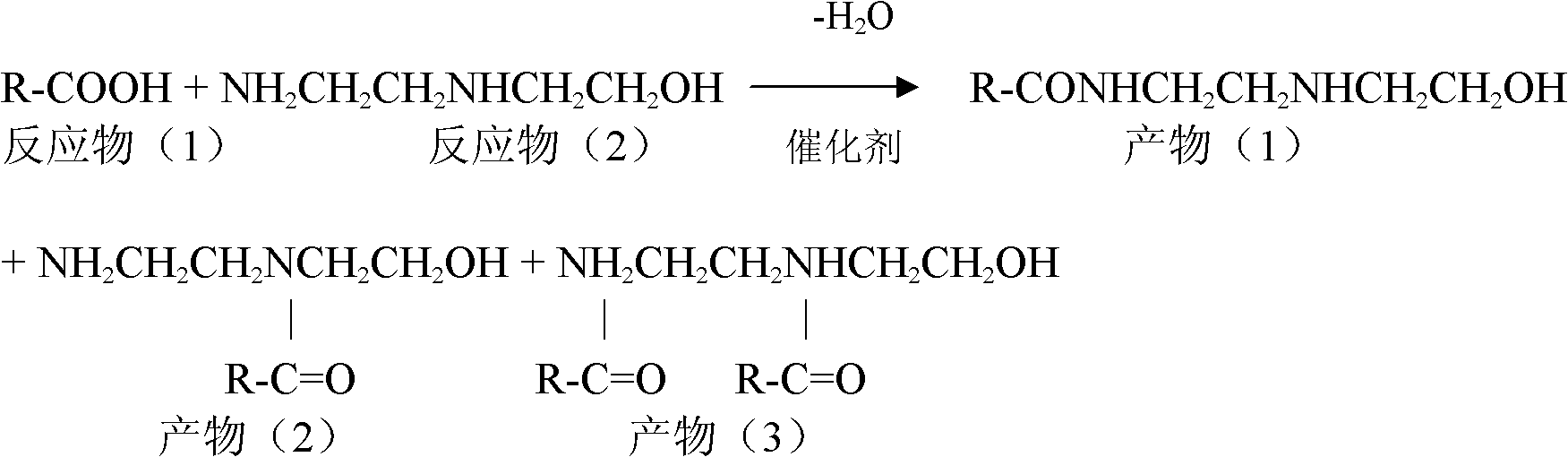

ActiveCN102093296AReasonably determine the ratioReasonably determine the dosageOrganic chemistryTransportation and packagingEthylenediamineSynthesis methods

The invention discloses a synthesis method of an imidazoline compound. The method comprises the following steps of: heating fatty acid and hydroxyethyl ethylenediamine which are used as raw materials to 80-150 DEG C in the presence of a catalyst in a nitrogen atmosphere, and then rising the temperature to 190-220 DEG C in a gradient mode for carrying out a nitrogen acylation reaction to form alkyl amide; and carrying out gradient pressure reduction, dewatering and cyclization on the formed alkyl amide to prepare the imidazoline compound. The synthesis method has simple process and low requirement on production equipment; by adopting the method of the invention, the generation quantity of bi-amide which is a side product can be reduced, and the content of the bi-amide in the prepared imidazoline compound can be reduced to be below 0.5 percent by mass; and meanwhile, the prepared imidazoline compound has stable quality and can be placed for a long time without turbid phenomena.

Owner:广州星业科技股份有限公司

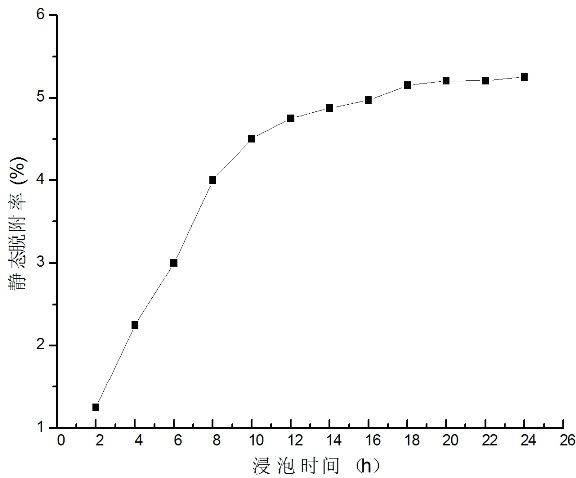

Method for preparing radioisotope tracer

The invention discloses a method for preparing a radioisotope tracer. The method comprises the following steps of: dissolving carbonate which contains a radioisotope by using an acid; immersing a porous carrier into a solution, absorbing an isotope ion, and then stirring at the temperature of 100 to 300 DEG C for a certain time until the porous carrier is dried; after the porous carrier is dried, fixing the isotope ion by using a precipitant, and drying at the temperature of 100 to 300 DEG C; carrying out surface treatment on the dried porous carrier, and adding a resin adhesive, an antistatic agent, temperature-resistant resin and a surfactant sequentially; and carrying out surface treatment on the porous carrier to obtain the radioisotope tracer for injection profile logging. The method is simple and convenient to operate; the prepared injection profile logging tracer is low and uniform in density and good in suspension property, avoids agglomeration in a water suction solution and cannot sink or float upwards; and the radioisotope tracer is low in isotope desorption rate, stable in radiation strength and low in isotope contamination, and resists high temperature of 120 DEG C and pressure of 60 MPa.

Owner:河南省同新科技有限责任公司

Biological preparation method for natural safe starch nano particles

The invention discloses a biological preparation method for natural safe starch nano particles. The natural safe starch nano particles are prepared by gelatinization and recrystallization by using natural starch as a raw material, and the method belongs to the technical field of nano structure materials. The method comprises the following steps of: mixing the natural starch with water in a certain proportion to form starch milk; and performing gelatinization, debranching, low-speed centrifugation, recrystallization, differential speed centrifugation and vacuum freezing and drying to prepare the nanoscale starch crystalline. Toxic and harmful organic solvents and inorganic metal ions are not added during the preparation of the starch nano particles, and the starch nano particles are wide in sources of raw materials, biodegradable, good in biocompatibility, low in cost, and simple in production process, and industrial scale production of starch nano particles can be realized easily. The method has a special function in the fields of biological membrane preparation, medicine carriers, high-molecular polymer and the like.

Owner:QINGDAO AGRI UNIV

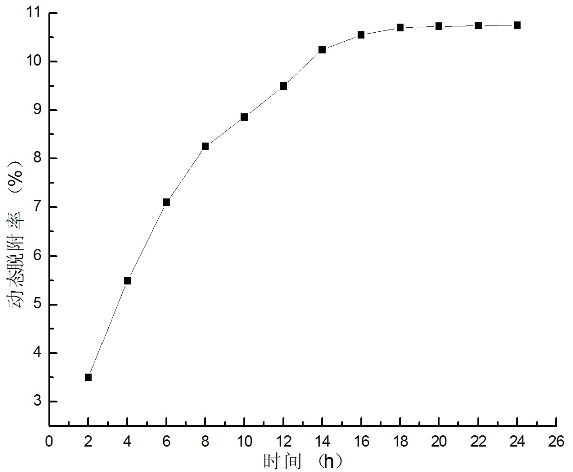

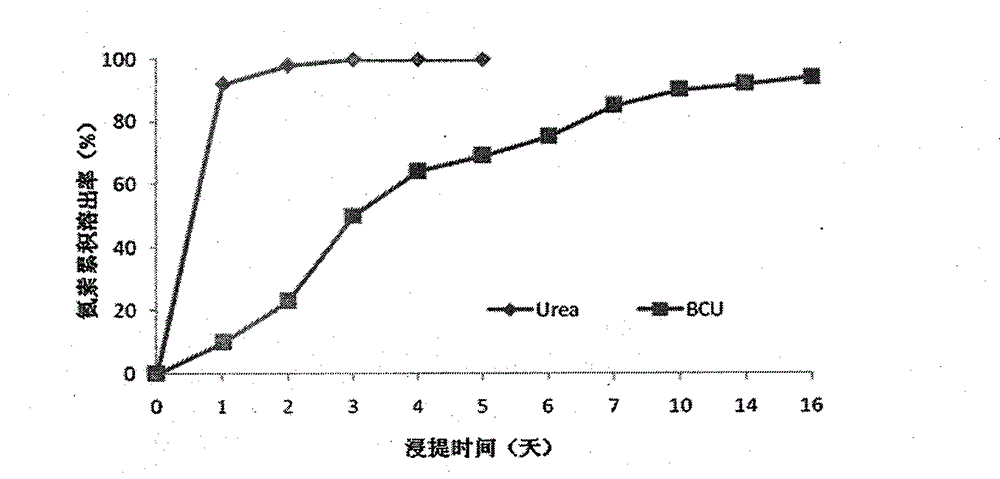

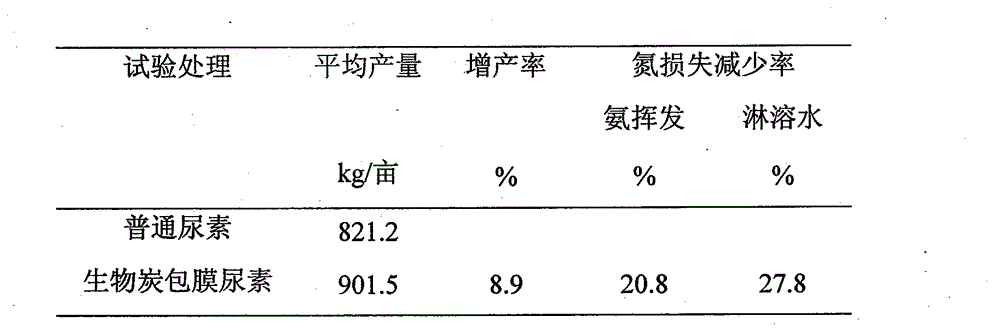

Formula and film-coating preparation method for biological carbon coated urea

InactiveCN105294363ALow costRich varietyClimate change adaptationEnergy inputCoated ureaLow nitrogen

The invention relates to a formula and a film-coating preparation method for biological carbon coated urea. The biological carbon coated urea is characterized in that the outside of a fertilizer core is coated with solid-powder-shaped biological carbon, sulfur, dicyandiamide and bentonite by using granular urea with a size of 3 to 4 mm as the fertilizer core and oxidized corn starch as bonding liquid, wherein the above-mentioned components have weight proportions as follows: 50 to 80 parts of the urea, 10 to 30 parts of the biological carbon, 2 to 10 parts of the sulfur, 2 to 3 parts of the dicyandiamide, 2 to 3 parts of the bentonite and 3 to 5 parts of the corn starch. The film-coating preparation method for the biological carbon coated urea comprises the following steps: placing the urea into a disc granulator, carrying out preheating with hot air for 5 min, spraying the bonding liquid on the surface of the urea with a high-pressure spray gun, blowing the hot air for 3 to 5 min, adding a mixed film-coating material into the disc granulator in batches and carrying out rotating for 10 min, then spraying the bonding liquid again, and carrying out drying in the air so as to obtain the biological carbon coated urea. According to the invention, the biological carbon can improve physical and chemical properties of soil and adsorb ammonium-nitrogen and nitrate-nitrogen ions; the dicyandiamide reduces nitrification; and S4O62- generated by decomposition of the sulfur can delay decomposition of the dicyandiamide, and H+ and S2O32- generated by decomposition of the sulfur can inhibit nitrification. The biological carbon coated urea provided by the invention has the advantages of low ammonia volatilization, slow generation of nitrate nitrogen, low nitrogen loss and high nitrogen effectiveness.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

Granular saline-alkali soil conditioner and production method thereof

ActiveCN103756685AEnhance salt-alkali resistanceImprove lodging resistanceOther chemical processesOrganic fertilisersGypsumNutrient

The invention relates to a granular saline-alkali soil conditioner. The conditioner is prepared from the following raw materials in parts by weight: 70-90 parts of phosphogypsum, 5-15 parts of humic acid and 5-15 parts of filler. The invention also relates to a production method of the saline-alkali soil conditioner. The production method comprises the following steps: preparing the filler, preparing a spray, palletizing, baking, sieving and the like. The granular saline-alkali soil conditioner disclosed by the invention plays a good saline-alkali soil improvement role by combined action of adjusting a plurality of aspects such as the soil pH level and ion components, enhancing the salt resistance ability of crops, activating nutrient elements in soil and the like. The product disclosed by the invention is granular, convenient to use, and convenient for mechanical fertilization. The production method of the product disclosed by the invention has the characteristics that production equipment is low in demands, and just conventional equipment needs to be adopted, special equipment does not need to be added, and the method is wide in raw material source, low in production cost, convenient to transport and fertilize, and the like.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

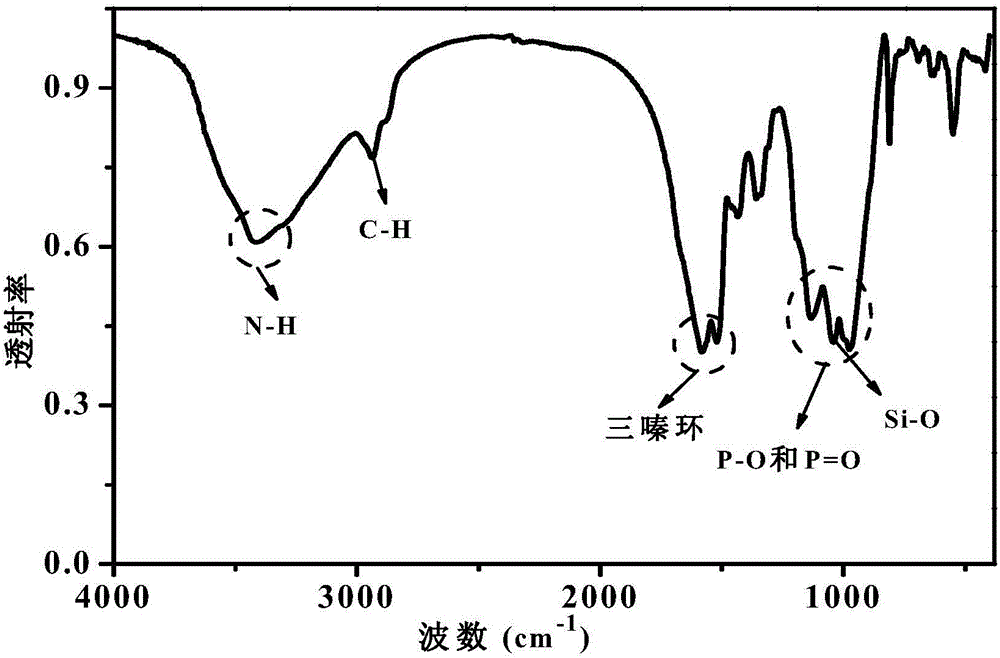

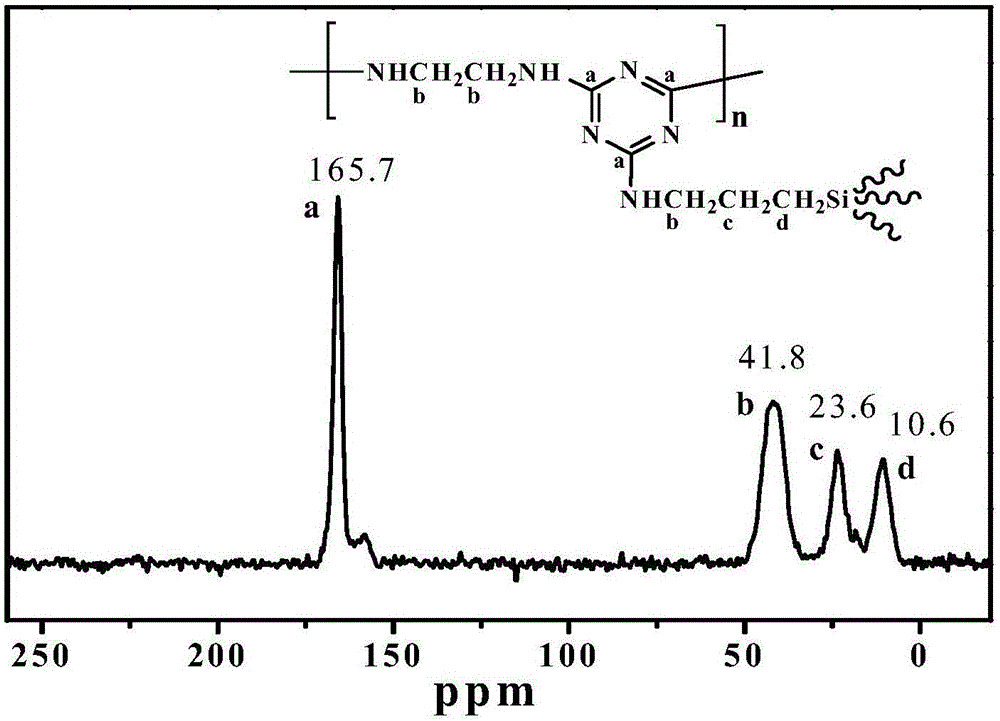

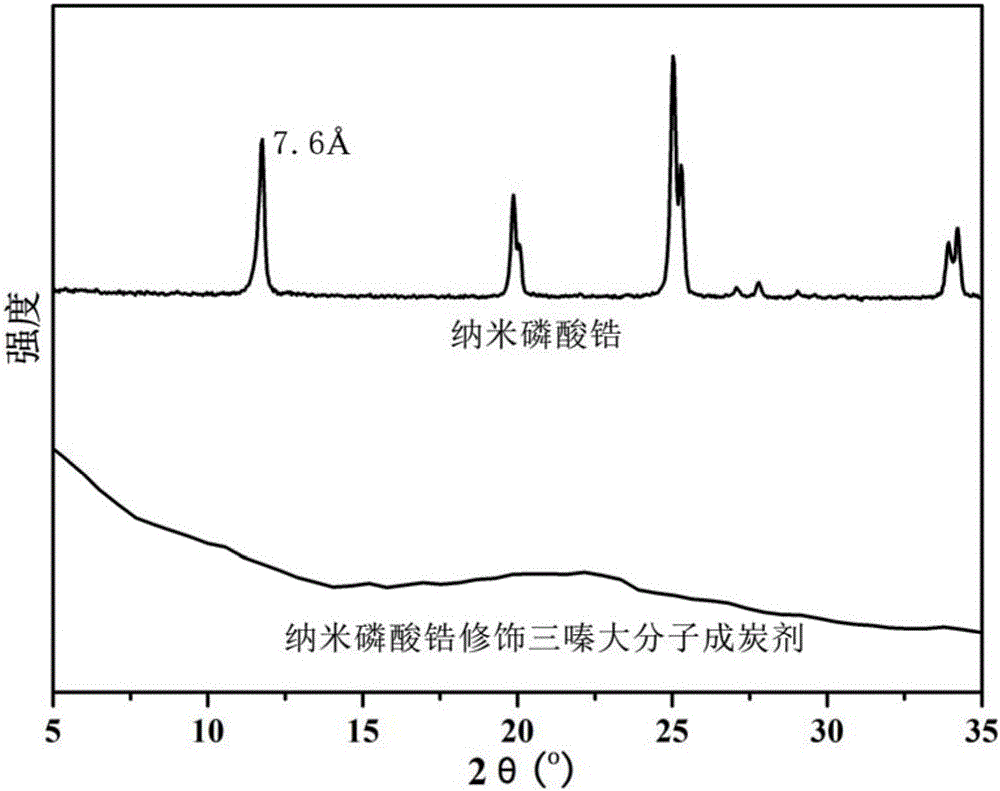

Nano zirconium phosphate-modified triazine macromolecular charring agent, and preparation method and application thereof

The invention discloses a nano zirconium phosphate-modified triazine macromolecular charring agent, and a preparation method and application thereof. The preparation method comprises the following steps: using a silane coupling agent to modify nano zirconium phosphate in an intercalation manner, and preparing an intermediate product through an organic solvent, cyanuric chloride, the silane coupling agent-modified nano zirconium phosphate through intercalation, a diamine monomer and an acid-binding agent; performing in-situ polymerization reaction on the organic solvent, the intermediate product, the diamine monomer and the acid-binding agent to prepare the nano zirconium phosphate-modified triazine macromolecular charring agent. Compared with the prior art, the macromolecular charring agent prepared by the invention is excellent in thermal stability and charring property, has a good synergistic flame-retardant effect with ammonium polyphosphate, and can effectively improve the thermal stability and the compactness of an expandable carbon layer under the high temperature condition, so that the flame-retardant efficiency of an intumescent flame retardant is remarkably improved. A prepared flame-retardant polypropylene material can be widely used in fields of automotive exteriors, furniture, appliances, wires, cables, construction materials and the like.

Owner:SOUTH CHINA UNIV OF TECH

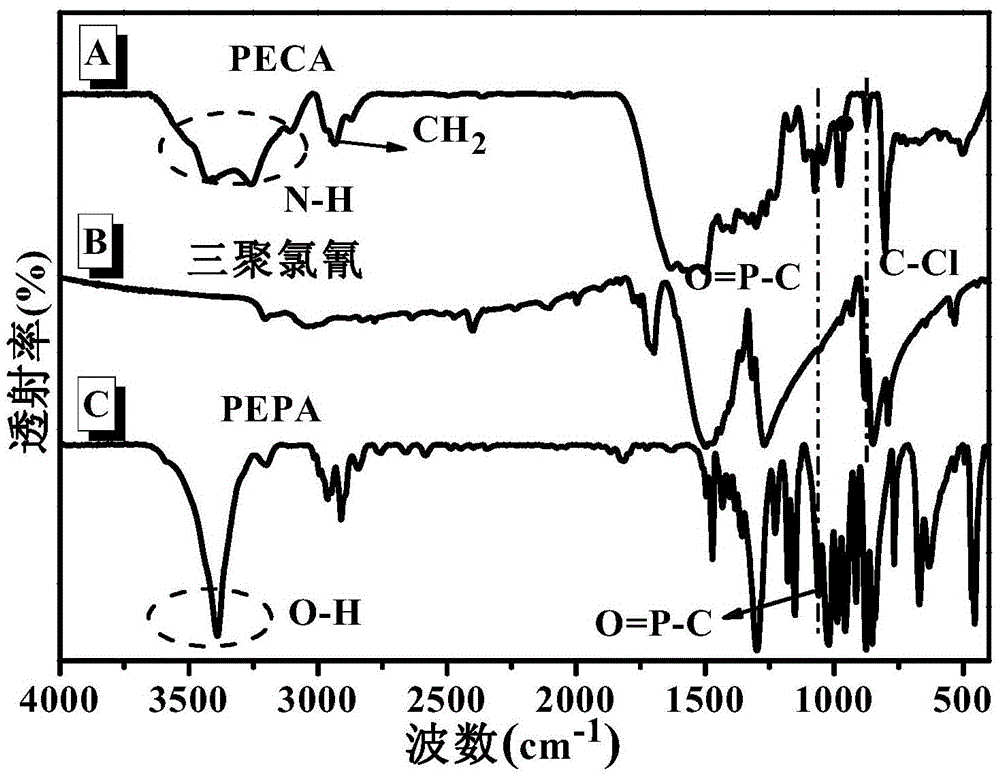

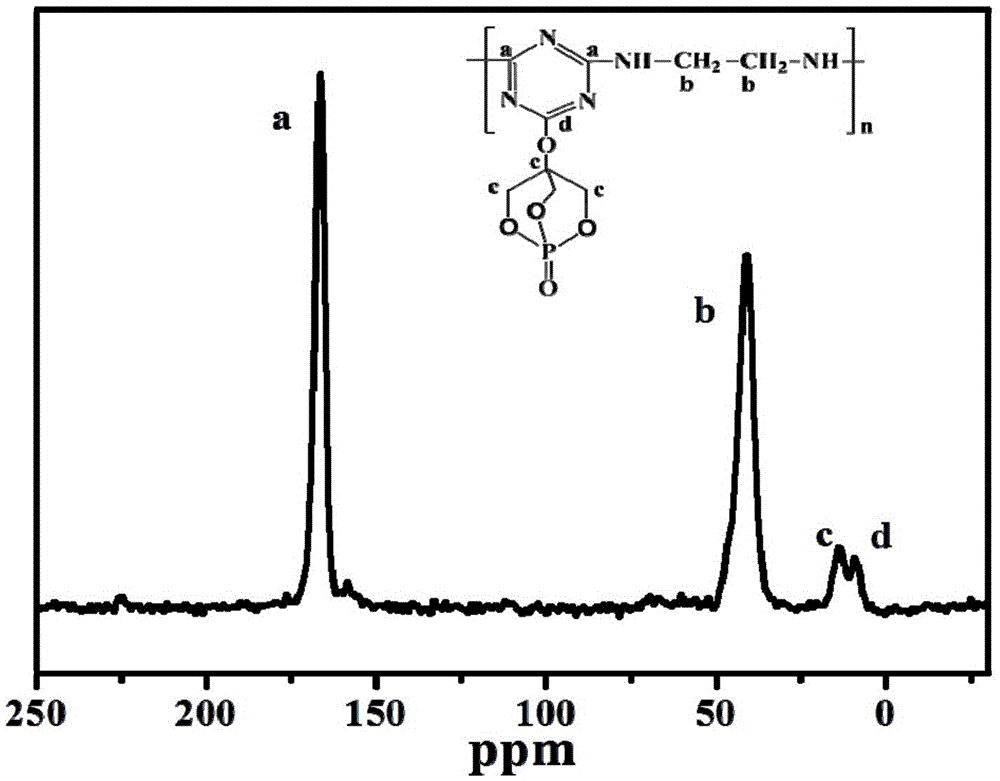

Single-component phosphor-nitrogen double-ring cage-shaped macromolecular intumescent flame retardant as well as preparation method and application thereof

The invention discloses a single-component phosphor-nitrogen double-ring cage-shaped macromolecular intumescent flame retardant as well as a preparation method and an application thereof. the preparation method comprises the following steps: at 90-110 DEG C, a nucleophilic substitution reaction is carried out between pentaerythritol and phosphorous oxychloride, and PEPA is obtained; a reaction between PEPA and cyanuric chloride is carried out at -5-10 DEG C for 3-6 hours, a reaction between a product and a diamine compound is carried out at 50-60 DEG C for 5-10 hours, and then a reaction between the product and the diamine compound is carried out at 90-110 DEG C for 5-10 hours; finally the single-component phosphor-nitrogen double-ring cage-shaped macromolecular intumescent flame retardant is obtained for flame retardant modification of polymers. Compared with the prior art, the prepared single-component macromolecular intumescent flame retardant has the advantages of high flame retardation efficiency, good compatibility with polymers, etc.; the intumescent flame retardant whose weight is 20-25 wt% of polypropylene can be added into the polypropylene for endowing the polypropylene with good flame retardation performance, and the intumescent flame retardant can be widely applied to the fields of internal and external decorative parts of automobiles, furniture and electric appliances, wires and cables, building material, etc.

Owner:SOUTH CHINA UNIV OF TECH

Bitumen recycling agent for improving high temperature stability of waste and old bitumen mixture

InactiveCN101177535AImprove high temperature stabilityLow costBuilding insulationsAntioxidantBituminous materials

The invention discloses an asphalt regenerator for improving the high temperature stability for mixing material of waste asphalt. According to the parts by weight, the components are as below: 70 to 95 of refinery waste rich in aromatic fraction and colloid; 5 to 25 of resin; 0.1 to 1 of antioxidant; 0.1 to 1 of anti-ultraviolet addition agent; 2 to 5 of stabilizing agent for high temperature. The invention also discloses the preparation method for the asphalt regenerator. Aiming at aged asphalt property in waste asphalt mixing material, the invention adds the resin, the antioxidant and the anti-ultraviolet addition agent in refinery waste rich in aromatic fraction and colloid and makes rational selection and matching for material of each material. The invention has the advantages of easy availability for raw material, low requirement for equipments, simple preparing art and convenient use. The invention obviously improves stability of high temperature for regenerated asphalt mixing material and other active results, lowers construction cost and is suitable for green ecological and sustainable development.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

Granular acidic or acidified soil conditioner and preparation method thereof

ActiveCN103787796AImprove convenienceImprove applicabilityFertilizer mixturesSoil conditionerHumic acid

The invention relates to a granular acidic or acidified soil conditioner and a preparation method thereof. The granular acidic or acidified soil conditioner comprises the following components in parts by weight: 70-90 parts by weight of calcium magnesium phosphate fertilizer, 5-15 parts by weight of humic acid salt and 5-15 parts by weight of filler. The invention further relates to the preparation method of the granular acidic or acidified soil conditioner. The preparation method comprises the steps: preparing the filler, preparing a spray, pelletizing, drying and screening. The granular acidic or acidified soil conditioner is granular, and is convenient to use, and convenient to mechanically apply. The preparation method of the granular acidic or acidified soil conditioner has the advantages of low requirement of production equipment, simple production process, high yield, low cost and environmental friendliness; conventional equipment is adopted without adding special equipment.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

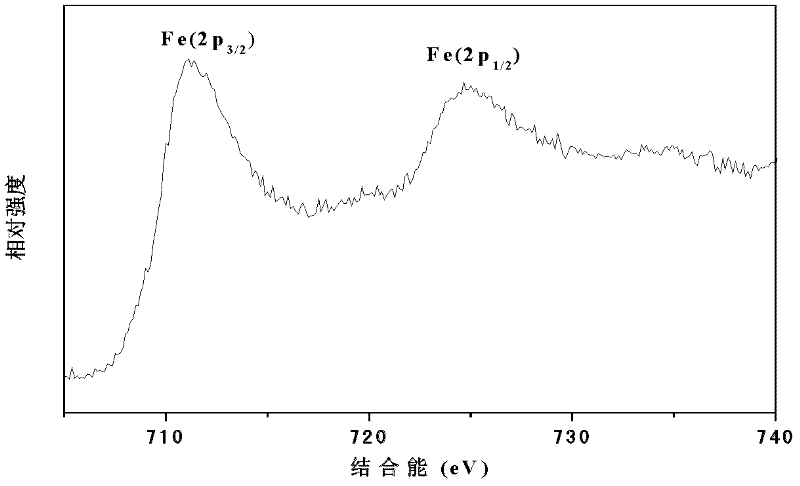

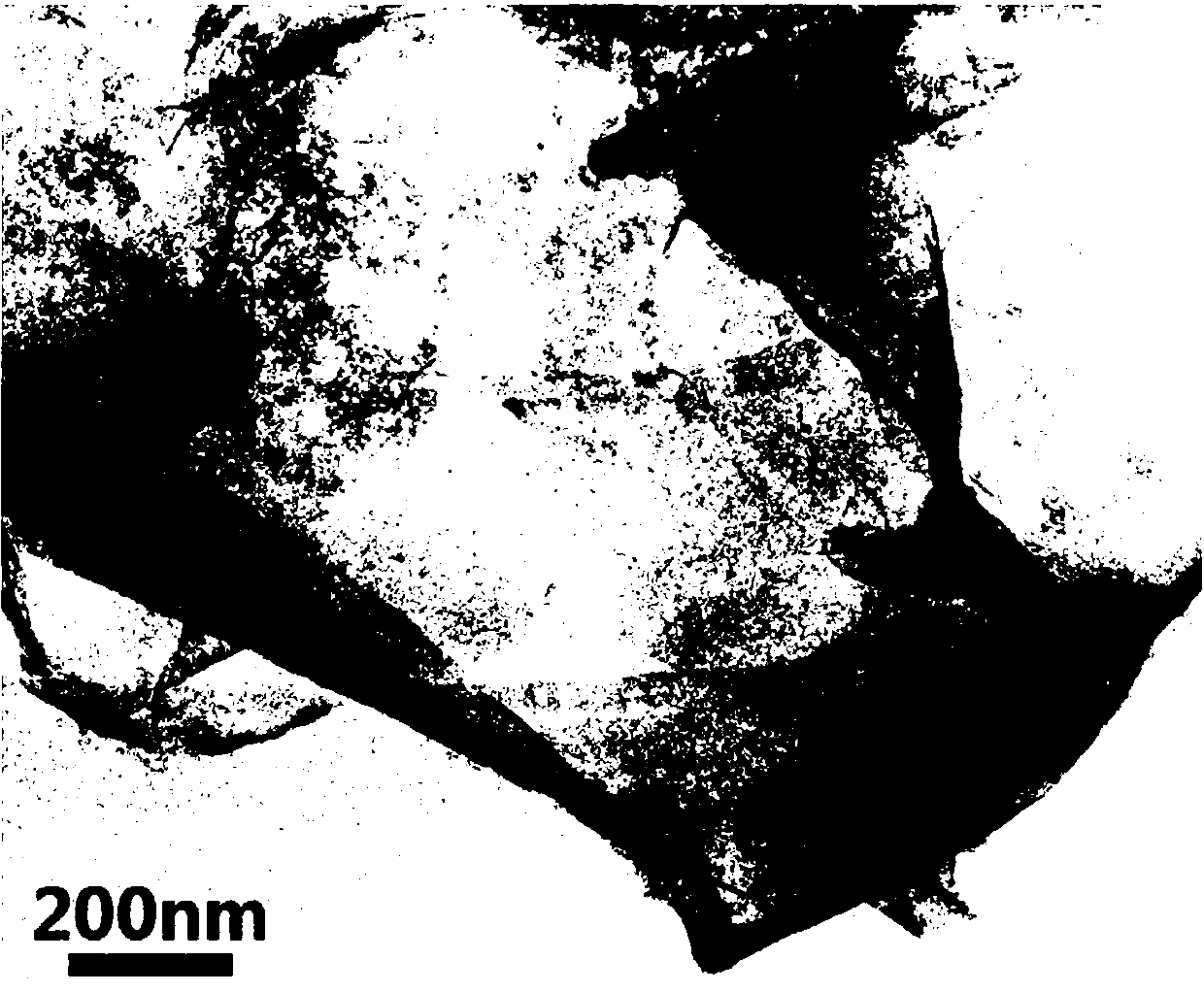

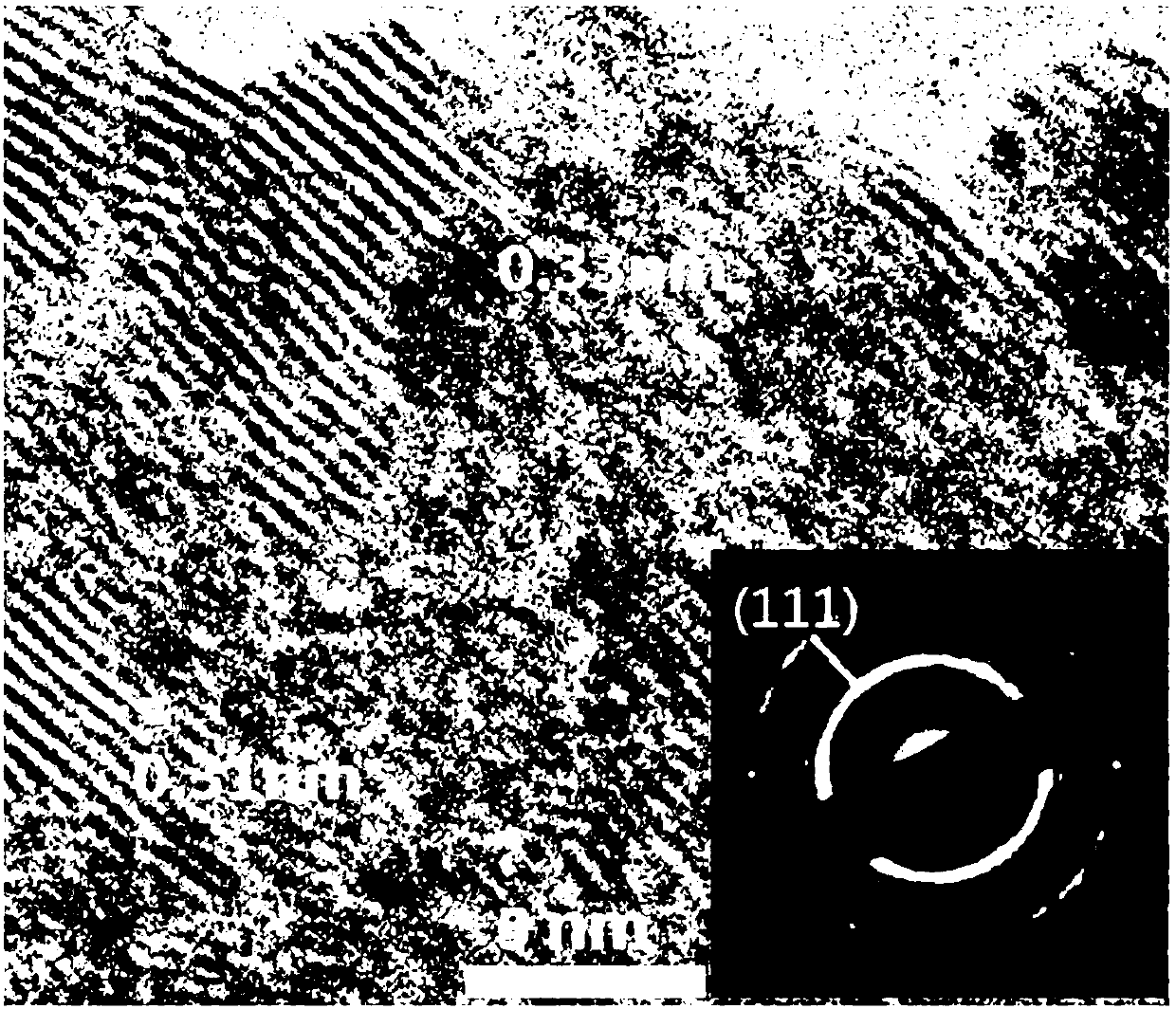

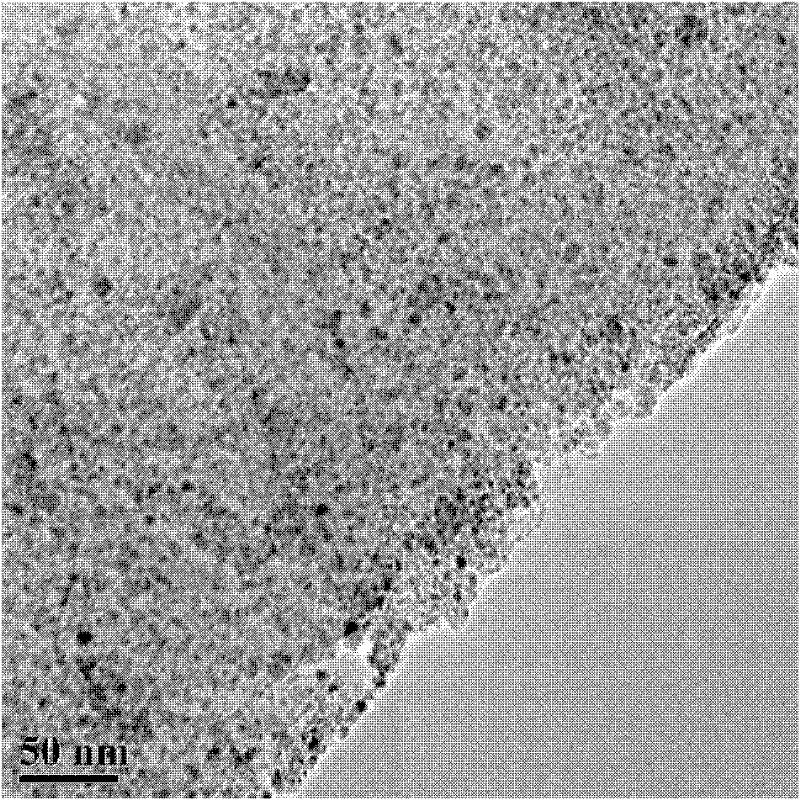

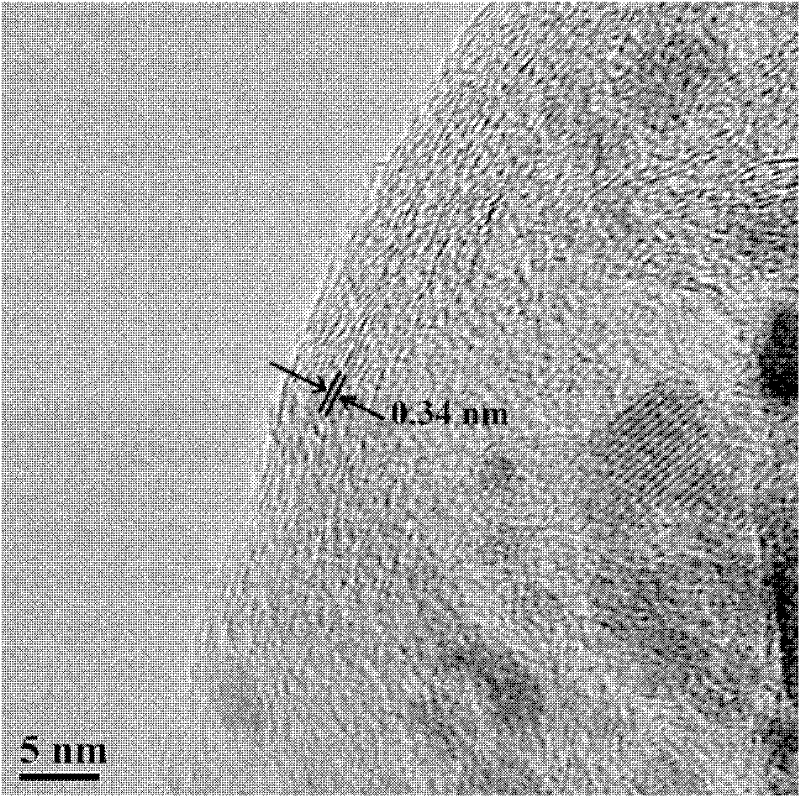

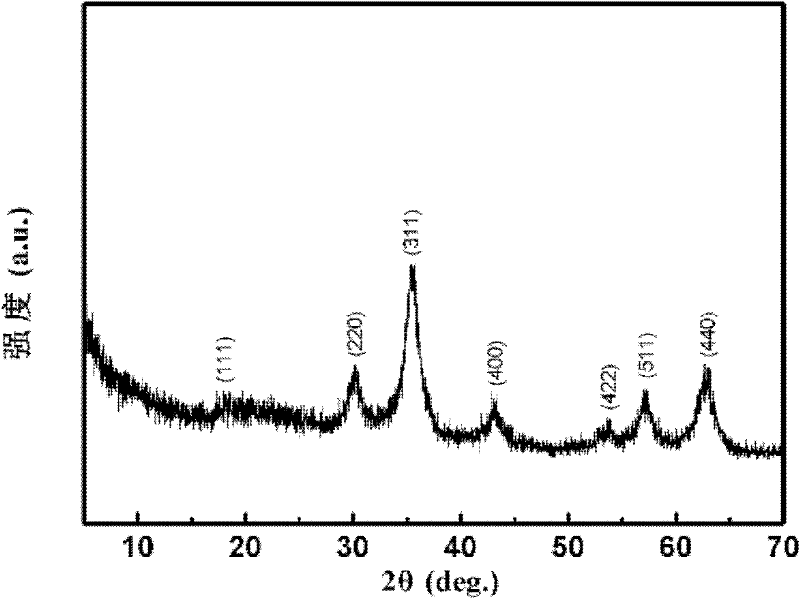

Preparation method of magnetic-functionalized graphene composite material

InactiveCN102583336AHas superparamagnetic propertiesImprove conductivityCarbon compoundsInorganic material magnetismEthylenediamineMagnetization

The invention provides a preparation method of a magnetic-functionalized graphene composite material, and relates to preparation of a graphene composite material. According to the invention, the preparation method is simple, the raw material is easily obtained, and the industrial production is easy; the prepared magnetic-functionalized graphene composite material has superparamagnetic property and is higher in saturated magnetization; and the graphene carrier is good in conductivity, and loaded ferroferric oxide nano particles are uniformly distributed, are small and are good in crystallizability. The preparation method comprises the following steps of: matching ethanediamine and water into a mixed solvent, then ultrasonically dispersing graphite oxide and iron acetylacetonate in the mixed solvent, and obtaining ethanediamine / dispersion of the graphite oxide and the iron acetylacetonate; transferring the ethanediamine / dispersion of the graphite oxide and the iron acetylacetonate into a reactor lined with polytetrafluoroethylene for reaction and obtaining solid products; and cleaning the solid products, collecting the products with a magnet, drying and obtaining the magnetic-functionalized graphene composite material.

Owner:XIAMEN FUNANO NEW MATERIAL TECH COMPANY

Method for removing sulfur from waste lead-acid storage battery gypsum mud by using magnesium chloride

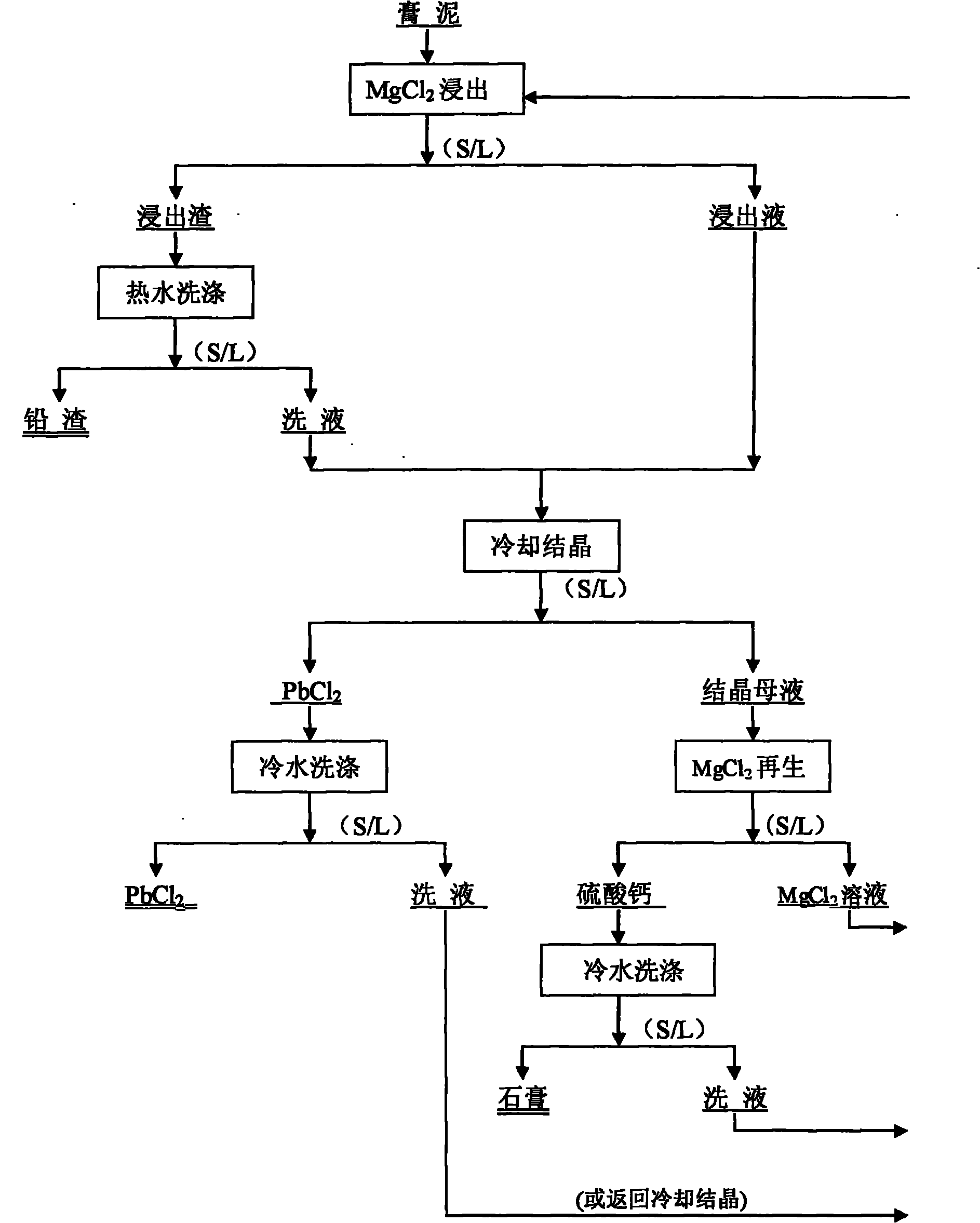

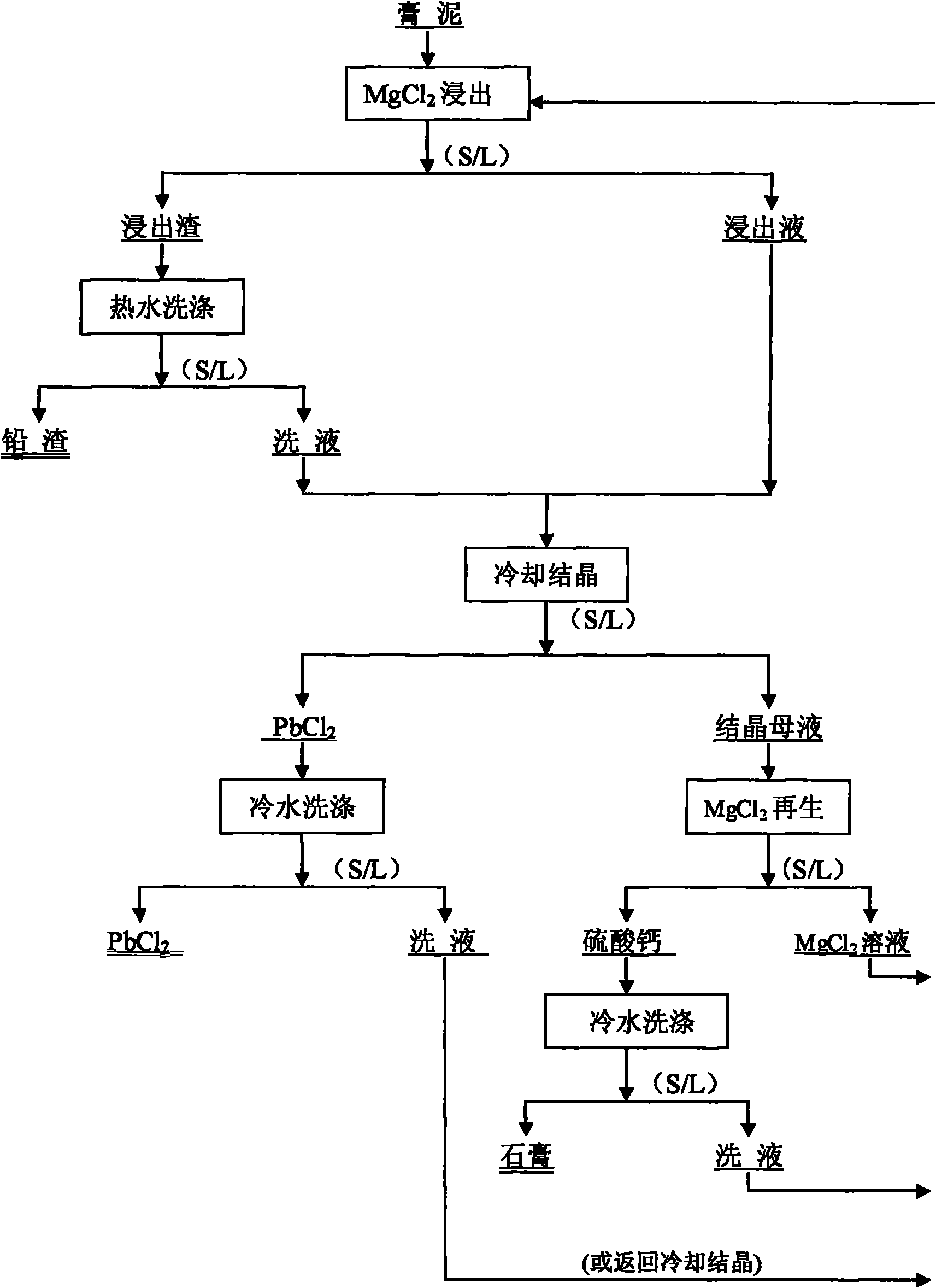

The invention relates to a method for removing sulfur from waste lead-acid storage battery gypsum mud by using magnesium chloride, which is characterized by comprising the following steps of: firstly, decomposing a waste lead storage battery subjected to acid pouring to obtain the gypsum mud, and entering the next process for later treatment; then leaching the gypsum mud by using a magnesium chloride solution, converting lead sulfate in the gypsum mud into lead chloride entering into the solution, leaving other oxides of lead in leached slag, carrying out liquid-solid separation after leaching is ended, and smelting the leached slag at the low temperature to produce wet lead; cooling to crystallize a leachate to obtain solid lead chloride and crystallized mother liquor, smelting the solid lead chloride at low temperature to produce the wet lead, carrying out regeneration treatment on the crystallized mother liquor by using the crystallized mother liquor and then returning to the step of desulfurizing and leaching the gypsum mud; and finally, adding calcium chloride to the crystallized mother liquor to regenerate the magnesium chloride as a desulfurizing agent and simultaneously produce calcium sulfate as a byproduct. The invention has good desulfurizing effect, and the magnesium chloride as the desulfurizing agent has low price, is easy to regenerate and can be recycled. The invention does not have high requirement on production equipment, greatly reduces the production cost and has obvious advantages.

Owner:SHENYANG RES INST OF NONFERROUS METALS

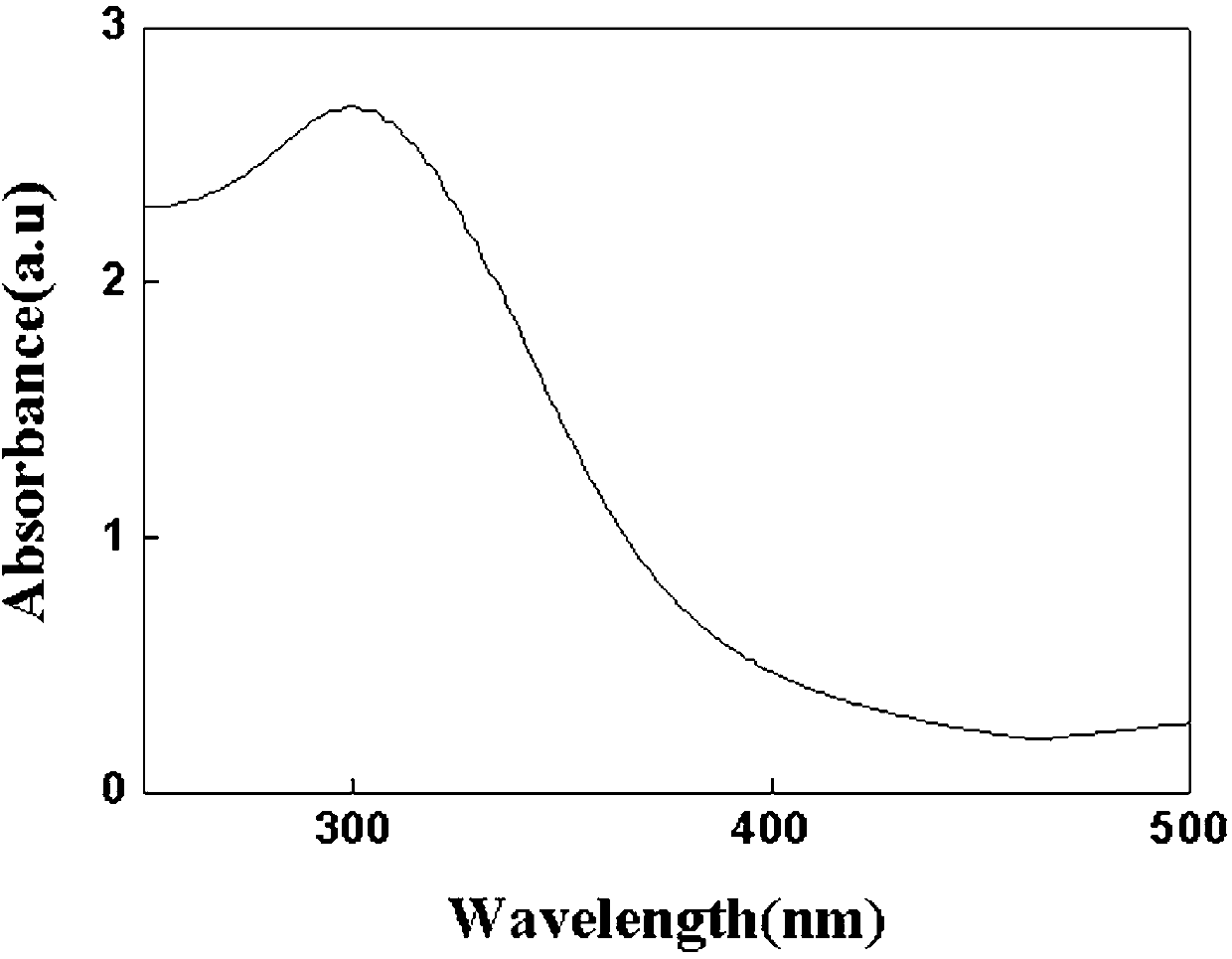

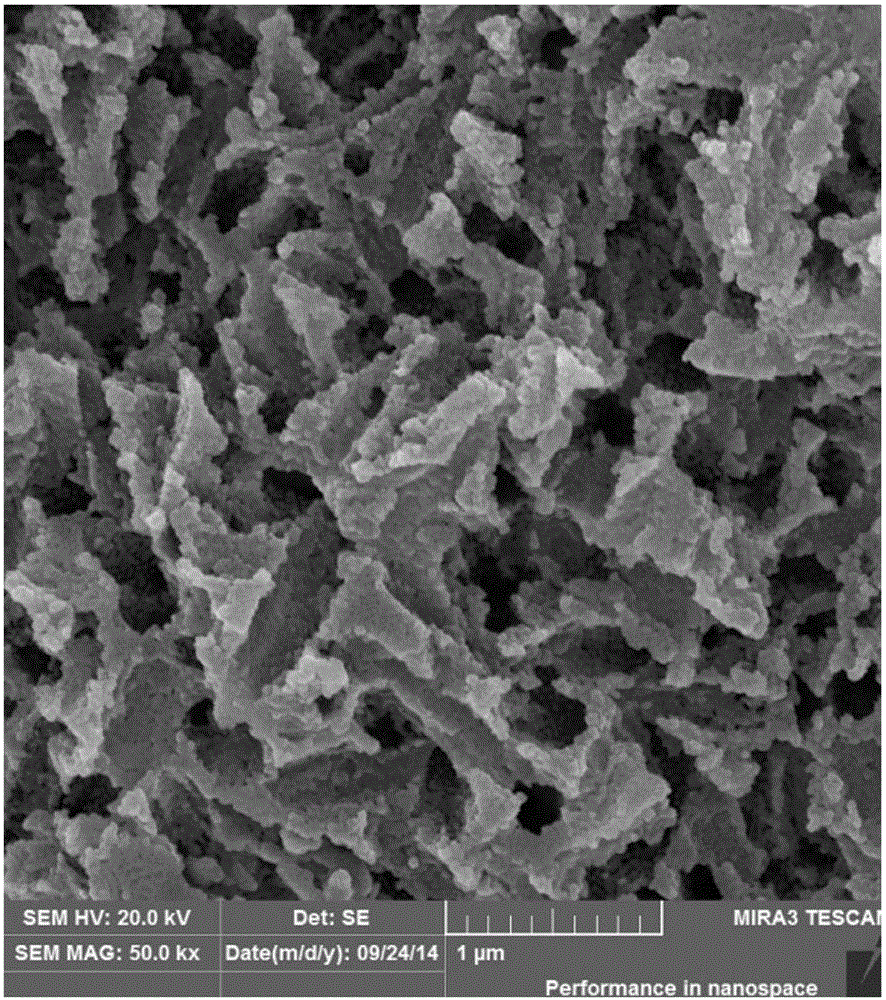

Method for preparing nanoscale sheet cerium oxide by hydrothermal method

InactiveCN103274441ASimple preparation processLow requirements for production equipmentMaterial nanotechnologyRare earth metal compoundsOrganic solventRoom temperature

The invention discloses a method for preparing nanoscale sheet cerium oxide by a hydrothermal method. The method comprises the following steps of: 1) preparing a 0.01-0.05mol / L Ce<3+> ion aqueous liquor at room temperature; preparing an ammonia water liquor at room temperature, wherein pH value of the ammonia water liquor is greater than 11; 2) placing the ammonia water liquor in a reaction kettle in a temperature range from -10 DEG C to 20 DEG C, taking the Ce<3+> ion aqueous liquor, and slowly dropping to excessive ammonia water liquor while stirring; and 3) stirring the mixed liquor obtained in the step (2) at constant temperature for reacting for 2-24 hours, centrifugalizing after reaction, removing the supernatant liquid, washing the powder obtained by centrifugalization and drying to obtain the solid sheet cerium oxide. According to the method disclosed by the invention, the nanoscale sheet cerium oxide is synthesized by one step by the hydrothermal method. The method is simple in preparation process, and low in demand on production and process conditions. No template materials are required and no organic solvents are added. The method is basically free from pollution and very environmental-friendly.

Owner:ZHEJIANG SCI-TECH UNIV

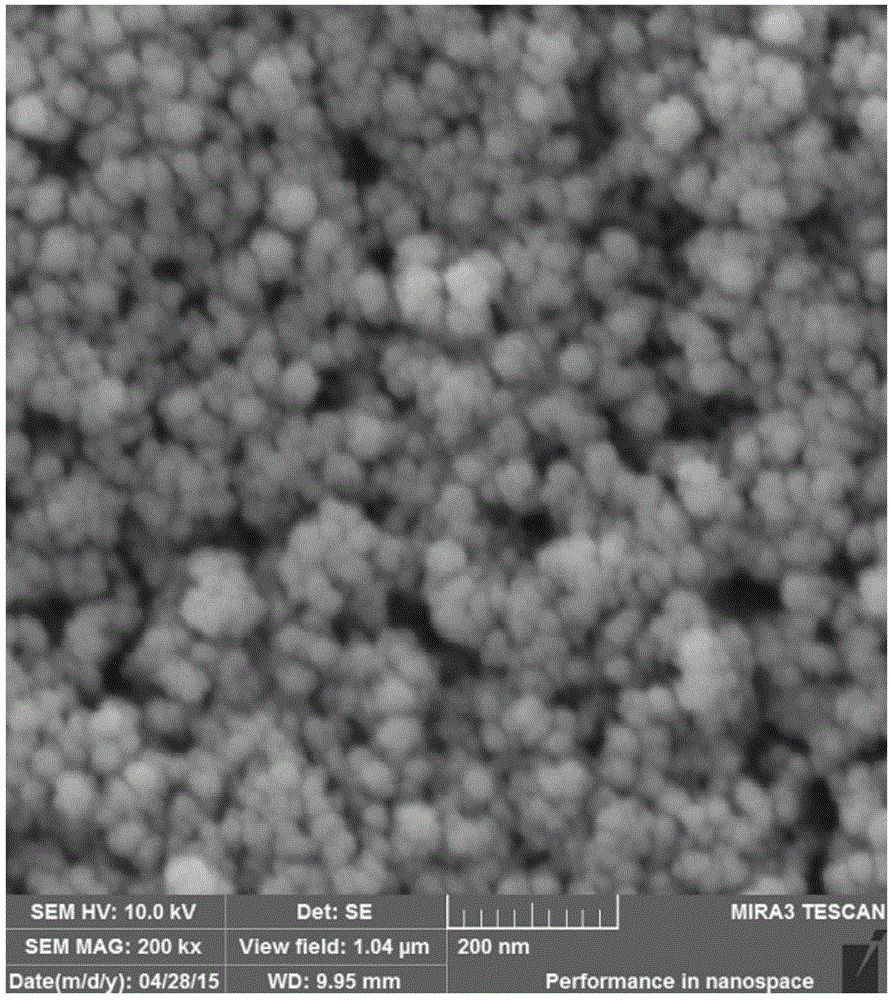

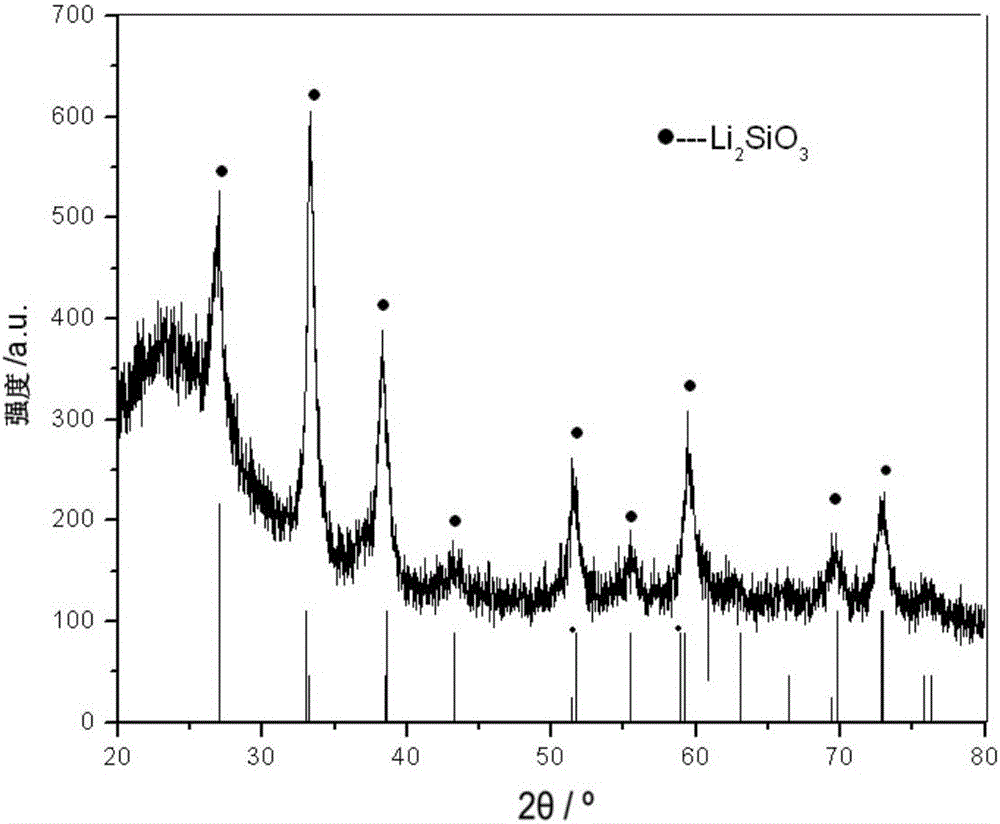

Lithium metasilicate glass ceramic and preparation method thereof

ActiveCN106277798ASimple production processLow requirements for production equipmentCrystal morphologyThermal insulation

Owner:SHENZHEN UPCERA DENTAL TECH

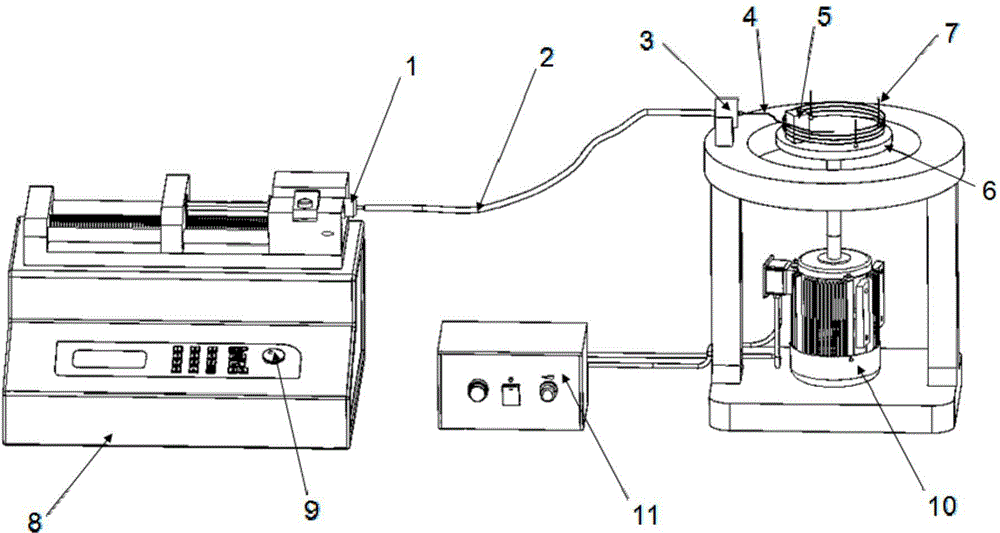

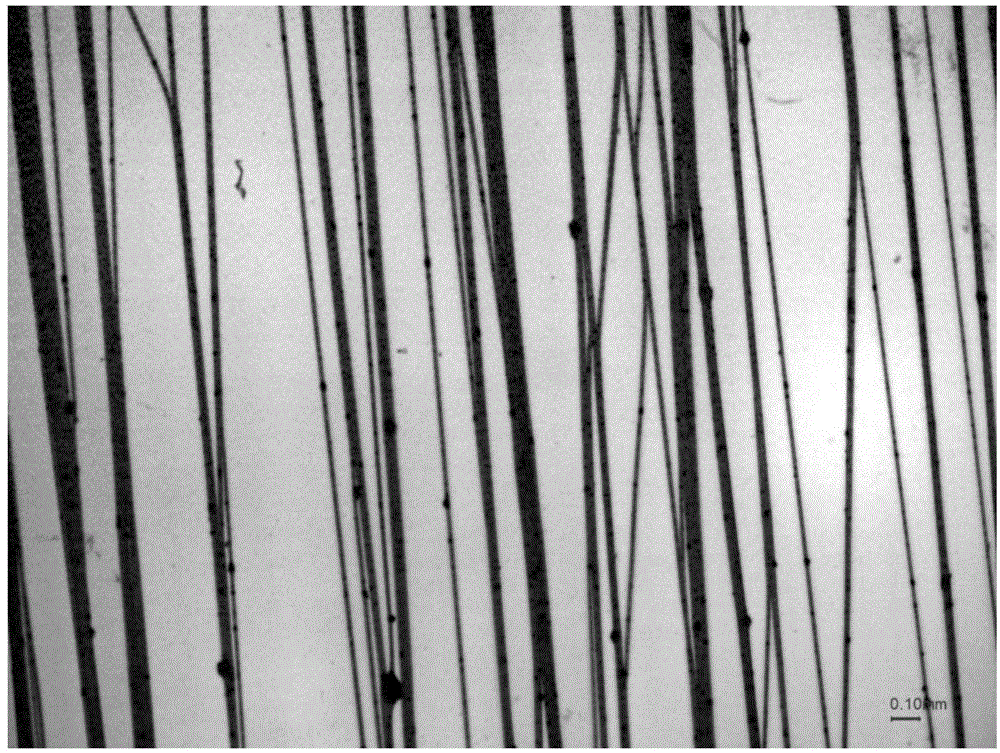

Method for preparing conducting polymer micro-nanofibers in magnetic spinning mode

ActiveCN104911719AArranged in an orderly mannerIncrease productionElectroconductive/antistatic filament manufactureFilament/thread formingMicro nanoFiber

The invention discloses a method for preparing conducting polymer micro-nanofibers in a magnetic spinning mode. The method comprises the steps that 1, a magnetic spinning device is built, wherein the magnetic spinning device comprises a rotary collection disc with a permanent magnet; 2, a spinning precursor solution is prepared, wherein magnetic nano particles, high-molecular polymer and conducting polymer are mixed and dissolved in an organic solvent solution; 3, the magnetic spinning device is utilized for preparing conducting polymer micro-nano complex fibers, wherein the spinning precursor solution is injected into a feeding device, the feeding device is started, liquid drops on an opening of a spinning nozzle forms a jet flow under the effect of magnetic field force to be connected with the permanent magnet to be a bridge, a brushless direct-current motor is started to drive the collection disc to rotate, the ferrofluid jet flow is continuously pulled out under the effect of magnetic field force, and conducting polymer micro-nanofibers are wound and formed among vertical supporting columns of the collection disc. The method does not need the high voltage effect, reduces the production cost and potential safety hazards, is suitable for large-scale production and has the good application prospect, and the fibers are distributed in order.

Owner:QINGDAO UNIV

Method for effectively extracting anthocyanidin and anthocyanin

ActiveCN104961783AWide variety of sourcesHigh puritySugar derivativesNatural dyesAlcohol freePurified water

The invention discloses a method for effectively extracting anthocyanidin and anthocyanin, and the method comprises the following steps: (1) extracting fresh anthocyanidin and anthocyanin raw materials, performing rapid stirring and extracting with 70-90% ethanol solution for 2-3 times, mixing and filtering obtained an extraction solution, performing vacuum concentration of the extraction solution to alcohol-free state, and obtaining the a concentrate; (2) centrifuging the concentrate obtained from the step (1), preserving a supernatant, refining the supernatant with CAD-40 macroporous adsorption resin, performing cleaning with purified water, performing washing out with 65-75% ethanol and collecting the eluate; (3) performing vacuum concentration of the eluate to the non-alcohol state so as to obtain a concentrate, and carrying out spray drying of the concentrate and obtaining the extract product containing anthocyanidin and anthocyanin. According to the invention, the method for effectively extracting anthocyanidin and anthocyanin is provided, and the method has the advantages of simple production equipment, short production period and low cost, and substantially increased purities of the effective components in the extract product.

Owner:ZHEJIANG HUISONG PHARMA

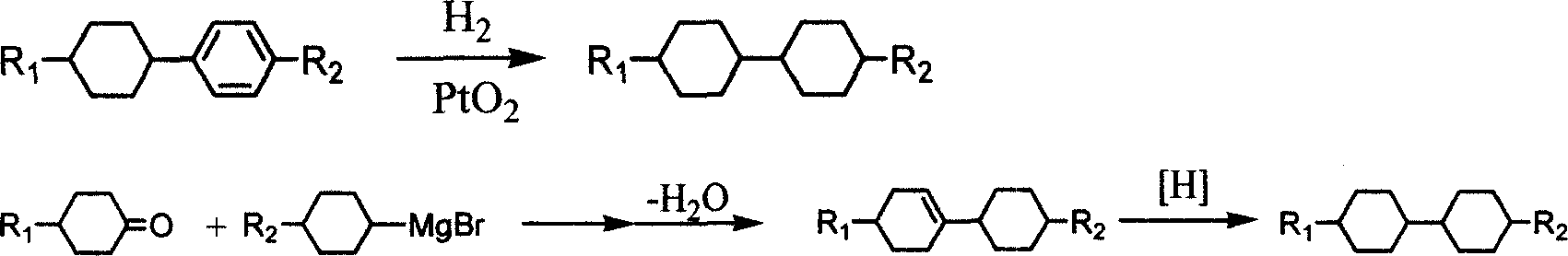

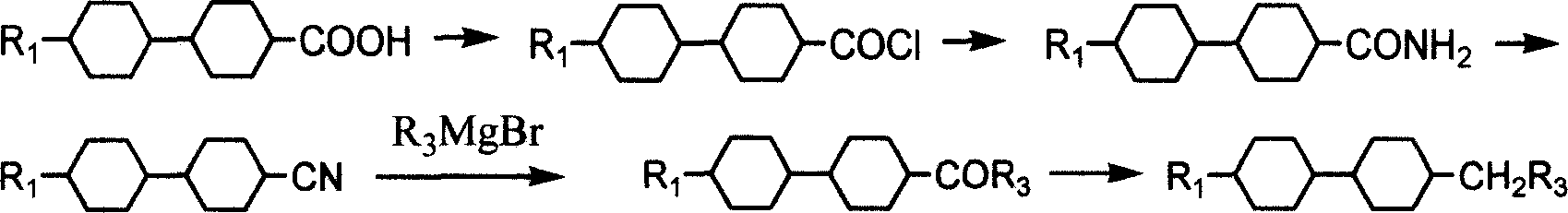

Method for preparing bis cyclohexane monomer liquid crystal using grignard reaction

InactiveCN1962580AAvoid drop in yieldLow costLiquid crystal compositionsHydrocarbon from oxygen organic compoundsGrignard reactionStructural formula

The invention discloses a preparing method of bicyclohexane monomer LCD in the monomer LCD preparing technical domain, which utilizes Grignard reaction to prepare the product with structural formula as graph I and synthetic feature route as graph II, wherein R1 and R2 is C2-C10; R3 is C1-C9 straight-chain alkyl; X is Cl or Br or I; A is C2H4 or cyclohexane; n is 0 or 1.

Owner:VALIANT CO LTD

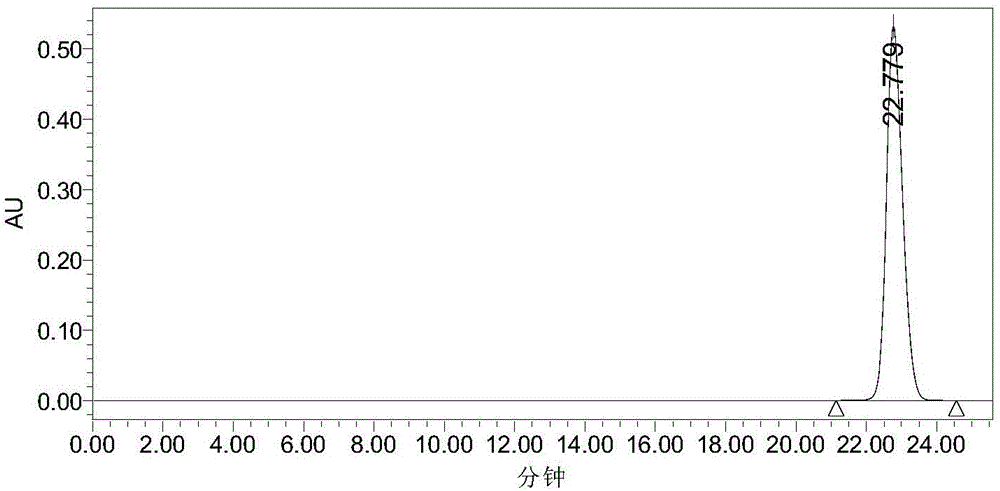

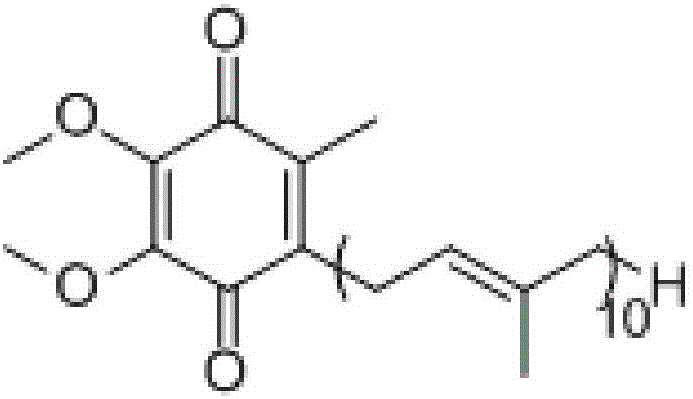

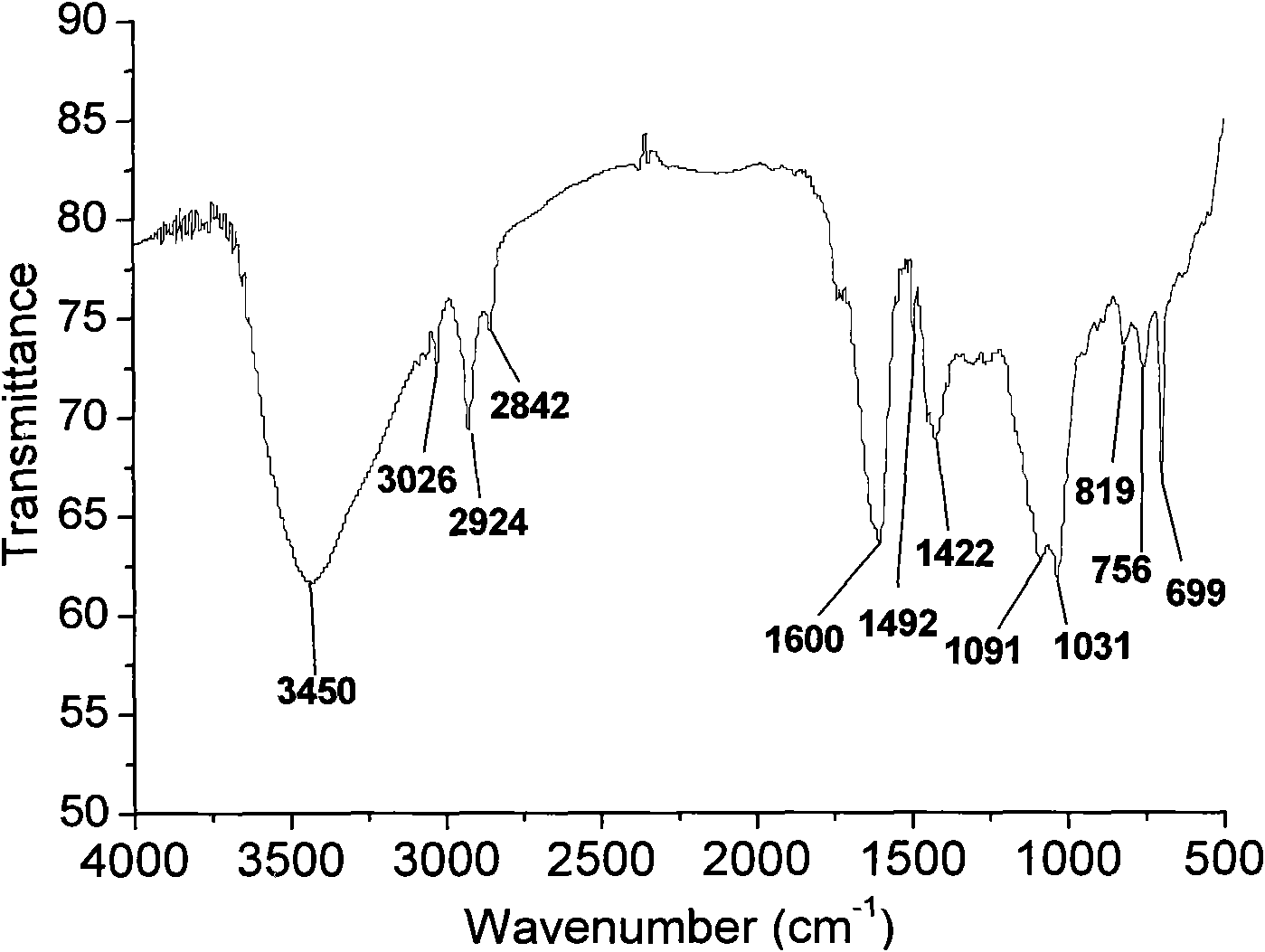

Process for extracting and separating coenzyme Q10 from mushroom dregs

The invention discloses a process for extracting and preparing high-purity coenzyme Q10 from mushroom dregs. The mushroom dregs serve as raw materials to be subjected to percolation extraction, and a coenzyme Q10 percolation extracting solution is obtained; the coenzyme Q10 percolation extracting solution is subjected to multilevel extraction for purification, and raffinate is obtained; the raffinate is subjected to crystallization treatment, finally, the high-purity coenzyme Q10 with the purity reaching 98% or above is obtained, and the yield is 95% or above. The whole process is simple, reliable and easy to operate and achieve, and parameters are convenient to control.

Owner:ZHEJIANG UNIV

Polystyrene/calcium alginate composite gel microsphere in nuclear shell structure and preparation method thereof

InactiveCN101857698AAchieve adsorptionSynthetic conditions are mildPharmaceutical non-active ingredientsOn/in organic carrierUltrasonic emulsificationFiltration

The invention provides a polystyrene / calcium alginate composite gel microsphere in a nuclear shell structure and a preparation method thereof, relating to biopolymer materials. The polystyrene / calcium alginate composite gel microsphere in the nuclear shell structure takes a polystyrene microsphere as a core and calcium alginate gel as a shell, wherein the grain size of the core is 1-100 microns, and the thickness of the shell layer is 50-800 nm. The preparation method comprises the following steps of: mixing polystyrene microsphere with aqueous solution containing a surface active agent I, and carrying out ultrasonic emulsification to obtain mixed solution A; adding sodium alga acid solution in the mixed solution A, and stirring to obtain mixed solution B; adding organic solution containing a surface active agent II into the mixed solution B, and stirring to obtain mixed solution C; adding calcium chloride solution which has the same volume with the sodium alga acid solution into the mixed solution C under stirring to react, and carrying out vacuum filtration, washing the solution until no calcium ion residue exists on the surface and drying to obtain a product D; and dispersing the product D into water, centrifuging the mixture, pouring out supernate and taking out precipitate to obtain the product.

Owner:XIAMEN UNIV

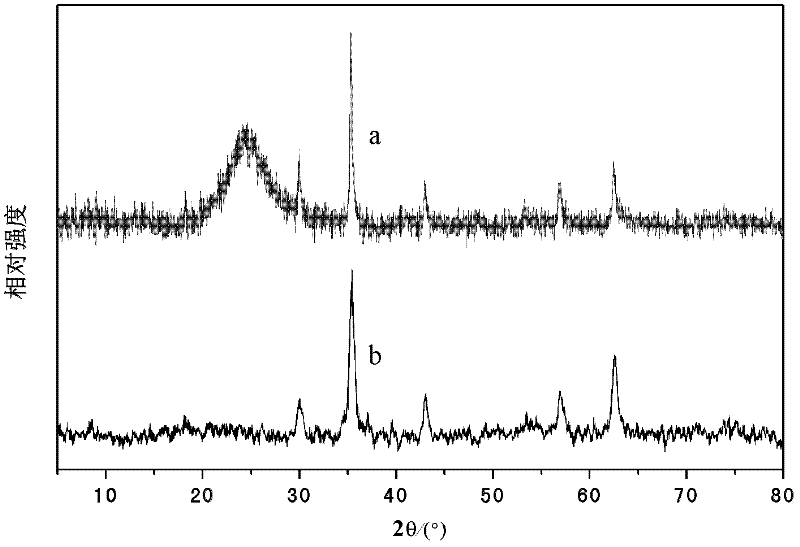

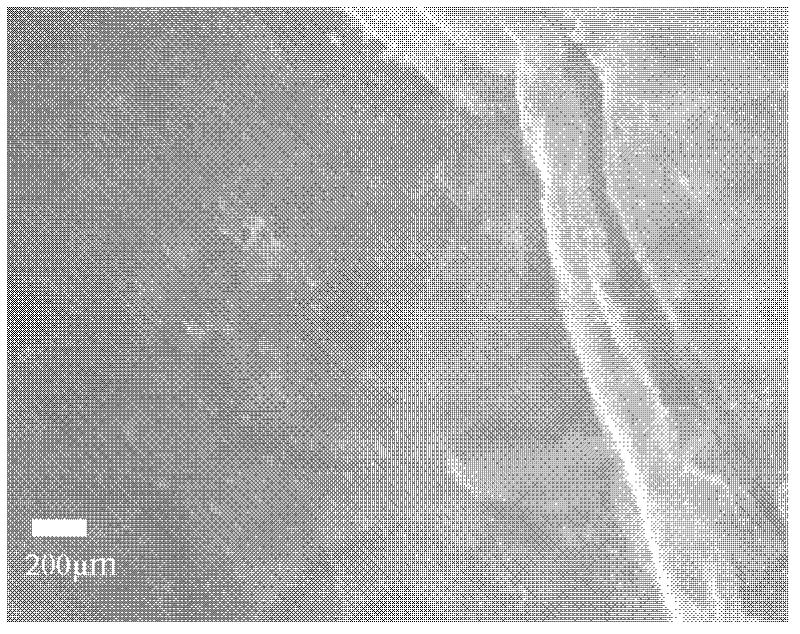

Preparation method of water-dispersible graphene/ferroferric oxide (Fe3O4) composite powder

InactiveCN102173411AEasy to prepareLow requirements for production equipmentFerroso-ferric oxidesWater dispersibleFerrous salts

The invention relates to a preparation method of water-dispersible graphene / ferroferric oxide (Fe3O4) composite powder. The method comprises the following steps of: (1) ultrasonically dispersing graphite oxide and sodium polystyrene sulfonate into water at room temperature to form reaction liquid, raising a temperature to 90 to 110 DEG C, and reacting for 8 to 16 hours; (2) adding ferric salt and ferrous salt into the reaction liquid under the protection of nitrogen atmosphere at room temperature, adding ammonia water, reducing the temperature to 70 to 90 DEG C, reacting for 20 to 40 minutes, and then adding an oleic acid for continuous reaction; and (3) cooling to room temperature, collecting the graphene / Fe3O4 composite powder by using a magnet, washing and drying to obtain the finished product. The method is simple and easy for industrial production; Fe3O4 in the prepared composite powder has pure crystalline phase; the Fe3O4 is well combined with the graphene; the Fe3O4 has good dispersibility on a surface of the graphene and in a layer of the graphene; the composite powder is low in resistivity, high in magnetic intensity and good in underwater dispersibility and has a good application prospect.

Owner:DONGHUA UNIV

Novel wood-plastic composite material

The invention discloses a novel wood-plastic composite material, which is prepared from a wood meal raw material, waste fiber textiles, solid wastes and thermoplastics by the processes of crushing, blending, granulation, extrusion molding and the like. According to the novel wood-plastic composite material, waste mushroom stems, the waste fiber textiles, the solid wastes and the like can be comprehensively utilized, and the wood-plastic composite material prepared from the waste mushroom stems, the waste fiber textiles and the solid wastes is low in cost and high in mechanical performance and service performance, and has the characteristics of low cost and strong strength; in addition, a production method is easy to operate, has lower requirements on a process condition and production equipment, and has broad market application prospect, and large-scale production can be implemented.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

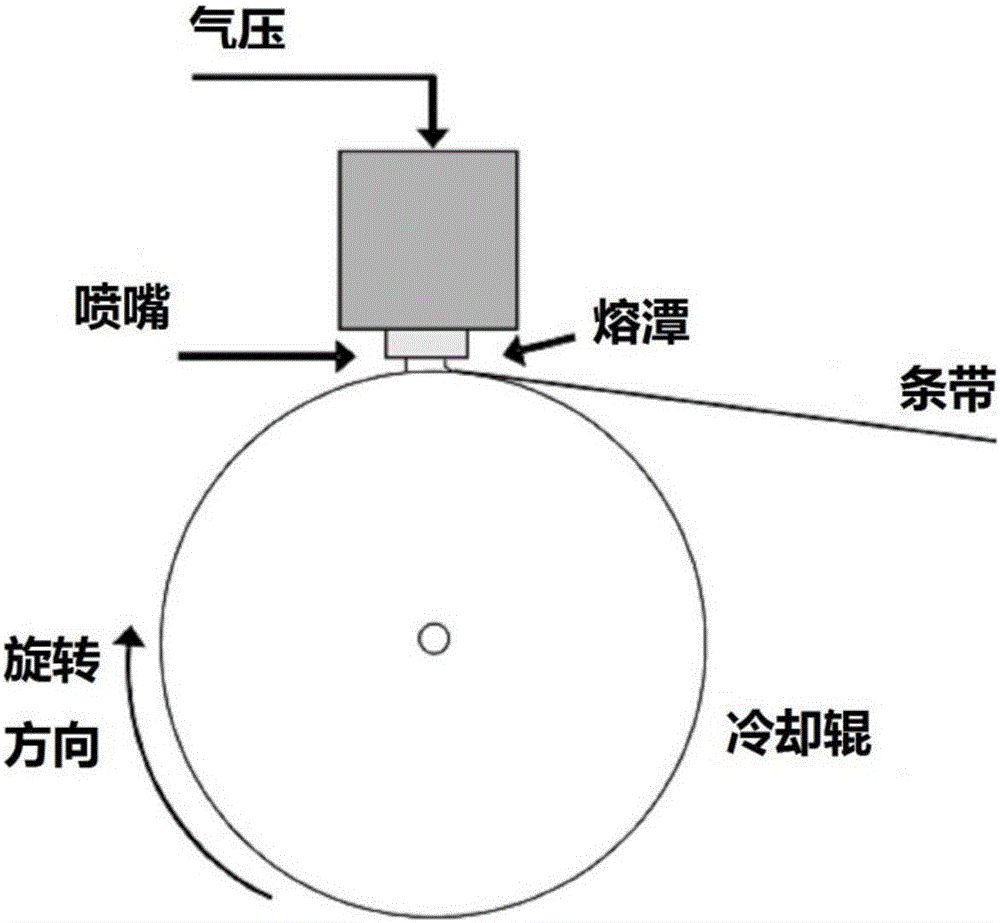

Rare-earth-doped iron-based amorphous thick strip and preparing method thereof

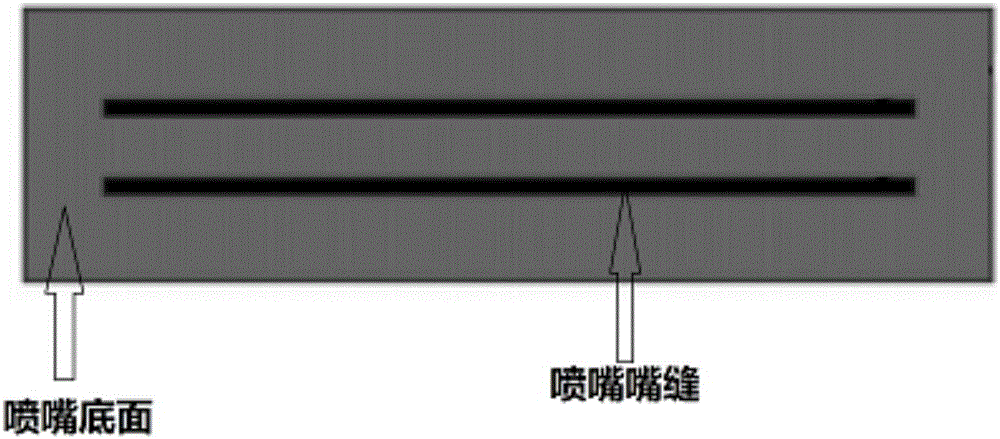

The invention relates to a rare-earth-doped iron-based amorphous thick strip and a preparing method thereof. The component expression of the iron-based amorphous thick strip is FexSiaBbPcYd, wherein x, a, b, c and d are atomic percents of corresponding elements, wherein a is larger than or equal to 0.5 and smaller than or equal to 10, b is larger than or equal to 0.5 and smaller than or equal to 12, c is larger than or equal to 0.5 and smaller than or equal to 8, d is larger than or equal to 0.001 and smaller than or equal to 0.5, and x+a+b+c+d is equal to 100. A plane flow casting method is adopted for manufacturing the strip, during strip manufacturing, a double-line nozzle is adopted, the thickness of the prepared amorphous thick strip ranges from 50 micrometers to 100 micrometers, the lamination coefficient is larger than 0.92, the saturated magnetic induction density is larger than 1.67T. Micro rare earth yttrium is contained in an alloy, the content of impurities of oxygen, sulphur and the like is greatly reduced, and the molten steel mobility is improved; meanwhile the rare earth yttrium improves the amorphous forming capacity of an alloy system, and the amorphous alloy strip with the thickness ranging from 50 micrometers to 100 micrometers can be prepared through the technology method.

Owner:南京腾元软磁有限公司 +3

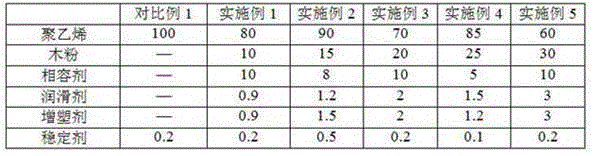

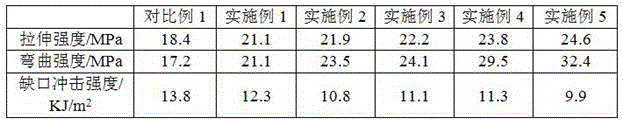

Polyethylene/wood powder composite wire for fused deposition modeling, and preparation method thereof

InactiveCN105295175APrevent crystallizationSmall shrinkage deformationAdditive manufacturing apparatusPlasticizerProcess conditions

The invention discloses a polyethylene / wood powder composite wire for fused deposition modeling, and a preparation method thereof. Raw materials and assistants used by the polyethylene / wood powder composite wire for fused deposition modeling comprise 70-90 parts of polyethylene, 10-30 parts of wood powder, 5-10 parts of a compatilizer, 0.9-3 parts of a lubricant, 0.9-3 parts of a plasticizer and 0.1-0.5 parts of a stabilizer. Addition of the wood powder to the polyethylene / wood powder composite wire inhibits crystallization of polyethylene, reduces shrinkage deformation of a fused deposition modeled product, and improves the modeling precision of the product. The fused deposition modeled product has the advantages of good toughness, improved mechanical performances and strong practicality. The invention also provides the making method of the polyethylene / wood powder composite wire. The method has the advantages of easy operation, low technological conditions and production device requirements, realization of large-scale popularization and production, wide market prospect and extremely good market benefits.

Owner:HENAN INST OF ENG

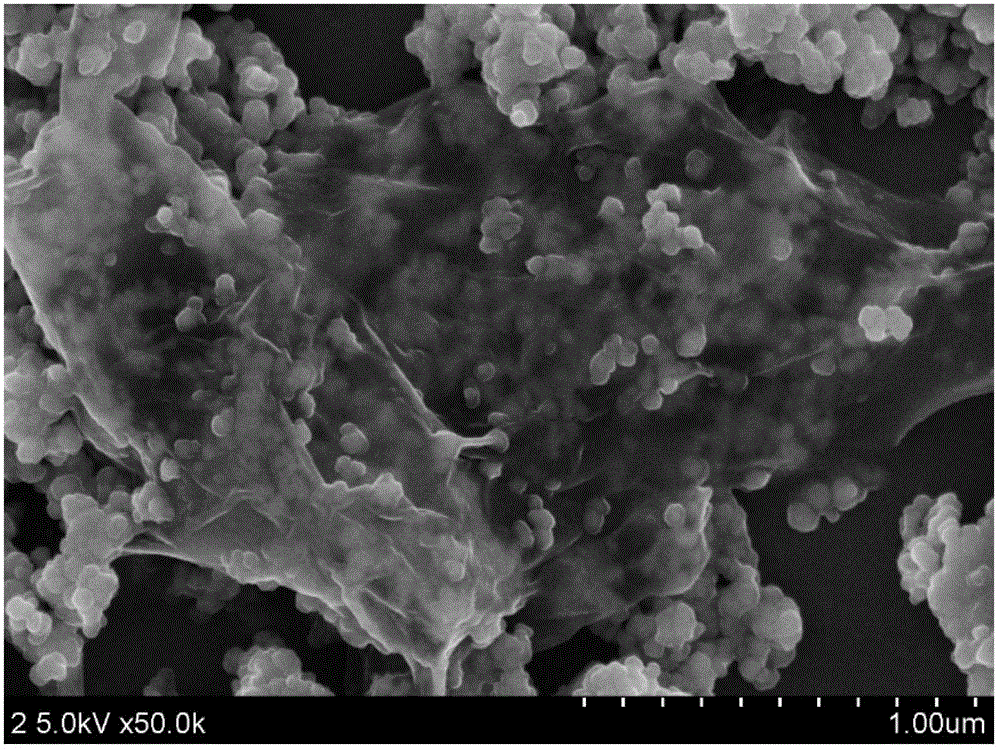

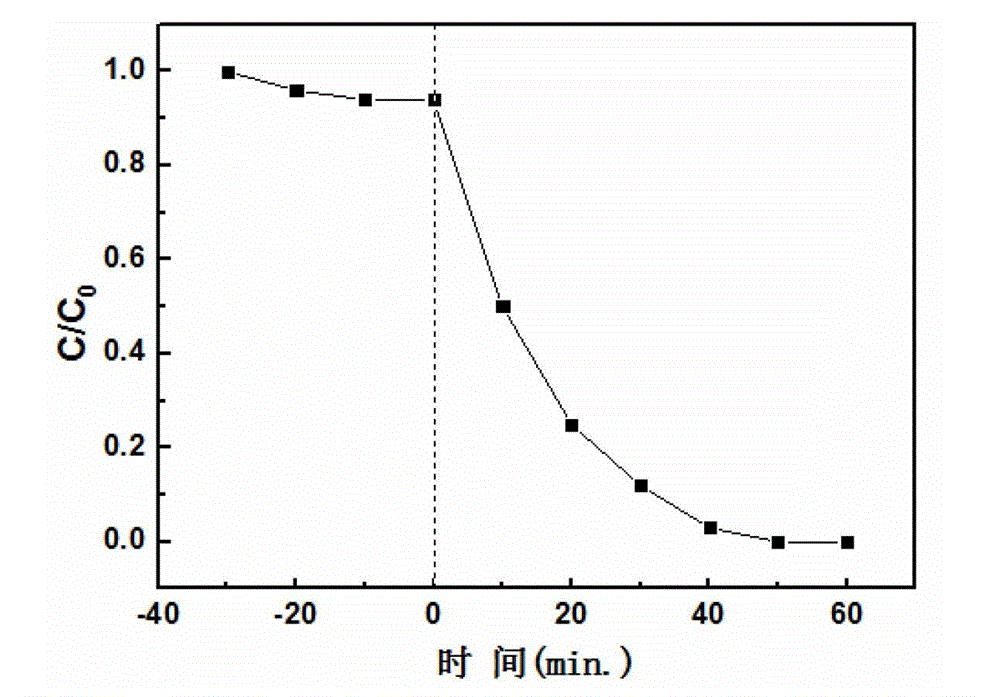

Method for preparing aqueous dispersion nano-cuprous oxide/graphene composite powder

InactiveCN102716743AEasy to prepareLow requirements for production equipmentWater/sewage treatment by irradiationEnergy modified materialsHydrazine compoundRoom temperature

The invention relates to a method for preparing aqueous dispersion nano-cuprous oxide / graphene composite powder. The method includes (1) ultrasonically dispersing graphite oxide, surfactant and copper salt in water at room temperature to form reaction liquid; and (2) dripping hydrated hydrazine liquor of a reducing agent into the reaction liquid at the room temperature, heating so that the temperature of the mixed liquid ranges from 90 DEG C to 110 DEG C, carrying out reaction for 8 to 12 hours, cooling the mixed liquid to the room temperature, leaching and collecting a product, and washing and drying the product to obtain the Cu2O / graphene composite powder. The method is simple, requirements on equipment are low, and industrial production is realized easily. The prepared composite powder is good in dispersibility in water, is excellent in photocatalytic dye degradation ability in visible light with the wavelength of 500nm, and is good in photocatalytic tumor cell killing ability, and has a wide application prospect in the field of environmental protection and tumor therapy.

Owner:DONGHUA UNIV

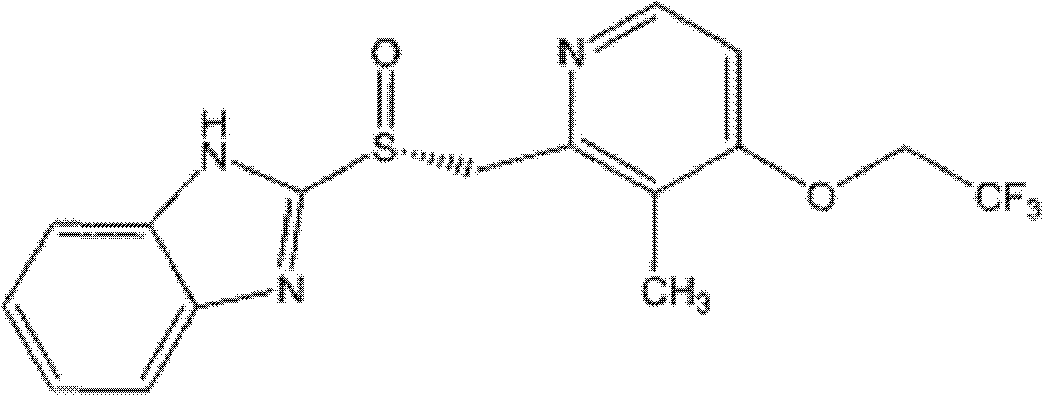

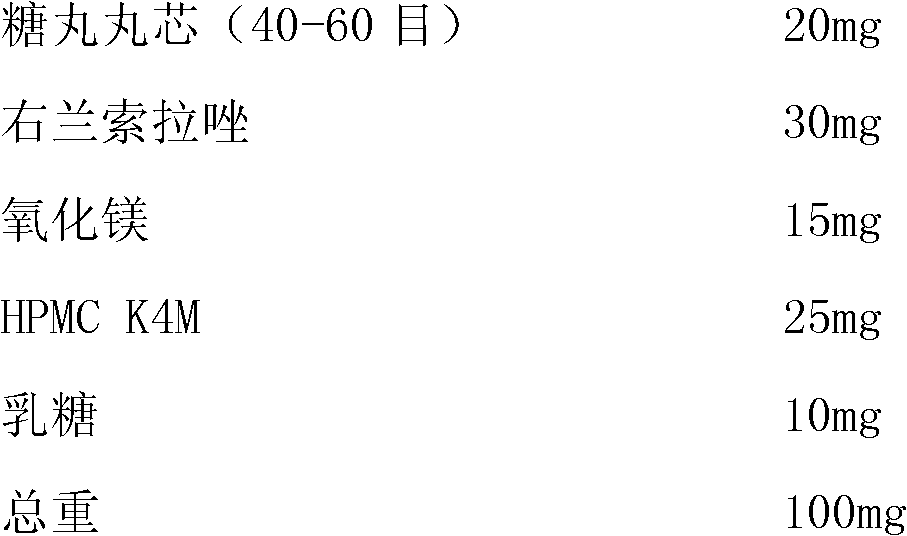

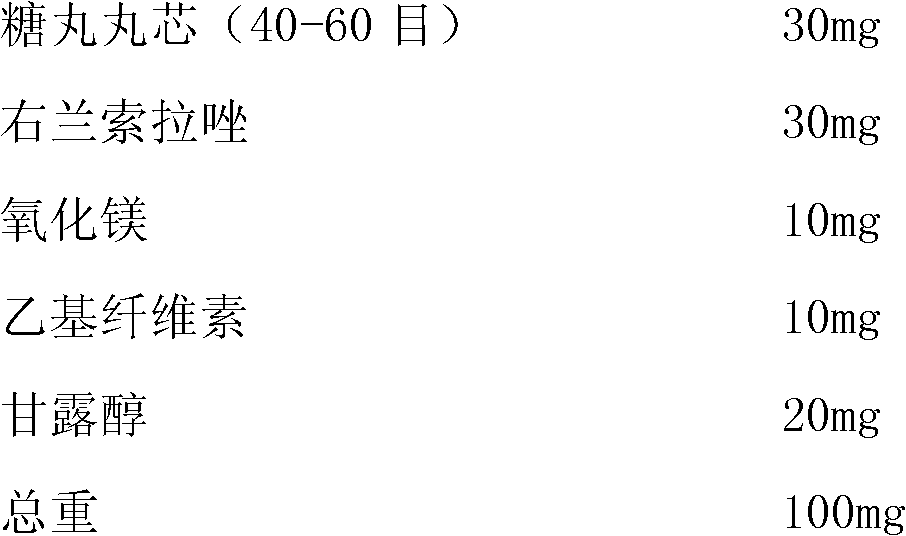

Dexlansoprazole enteric-coated slow controlled-release pellet tablets

InactiveCN103565770AEasy product industrializationTrouble swallowingAntibacterial agentsOrganic active ingredientsDexlansoprazoleBULK ACTIVE INGREDIENT

The invention discloses dexlansoprazole enteric-coated slow controlled-release pellet tablets belonging to the field of slow controlled-release preparations, and in particular relates to a preparation method of acid-sensitive proton pump inhibitor (PPI) slow controlled-release pellet tablets. The pellet tablets are prepared by tabletting and coating two types of pellets with different release speeds as well as a filler, a disintegrating agent and a lubricant, and release active ingredients at different release speeds, wherein one type of the pellets are enteric-coated quick-release pellets, and the other type of the pellets are enteric-coated slow-release pellets.

Owner:FUKANGREN BIO PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com