Preparation method of graphene coating polyacrylonitrile fiber composite material

A technology of ene-coated polyacrylonitrile fibers and polyacrylonitrile fibers, which is applied in the field of preparation of graphene-based composite materials, to achieve the effects of reducing catalyst loss, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

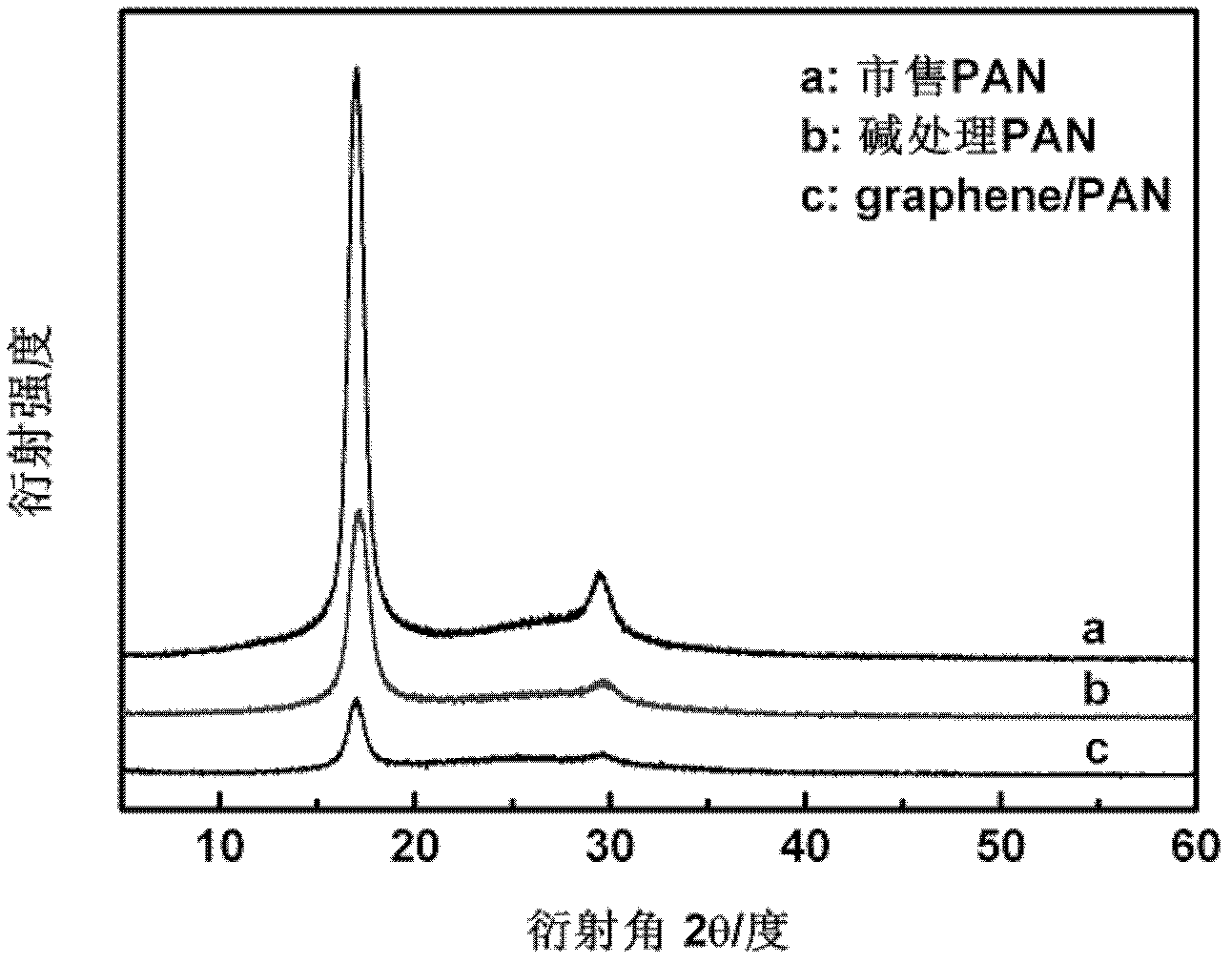

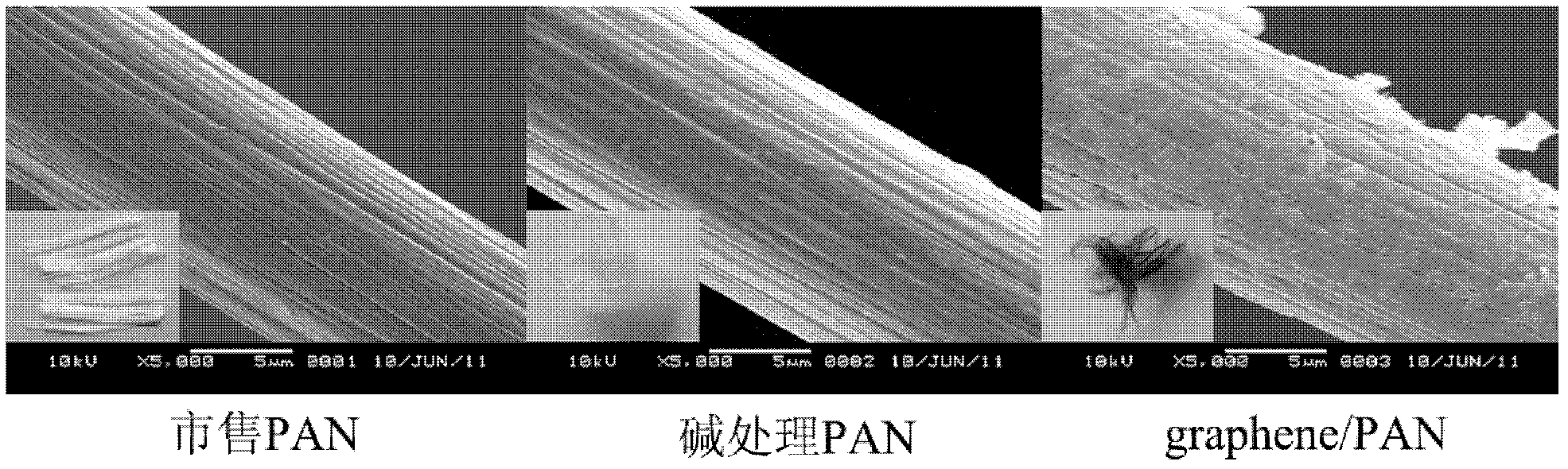

[0033] (1) Prepare 14wt% NaOH aqueous solution at room temperature, weigh 200mg of commercially available PAN, place it in 60ml NaOH aqueous solution, keep it warm at 110°C for 30min, wash PAN with deionized water until neutral, and dry at 70°C for 12h to obtain Alkali treatment of PAN.

[0034] (2) Prepare 100 mL of 1 mg / mL KH550 solution at room temperature, in which the solvent is a mixture of water and absolute ethanol with a volume ratio of 1:2, soak the alkali-treated PAN in KH550 solution for 12 hours, and dry at 70 ° C for 12 hours to obtain a single layer KH550 modified PAN;

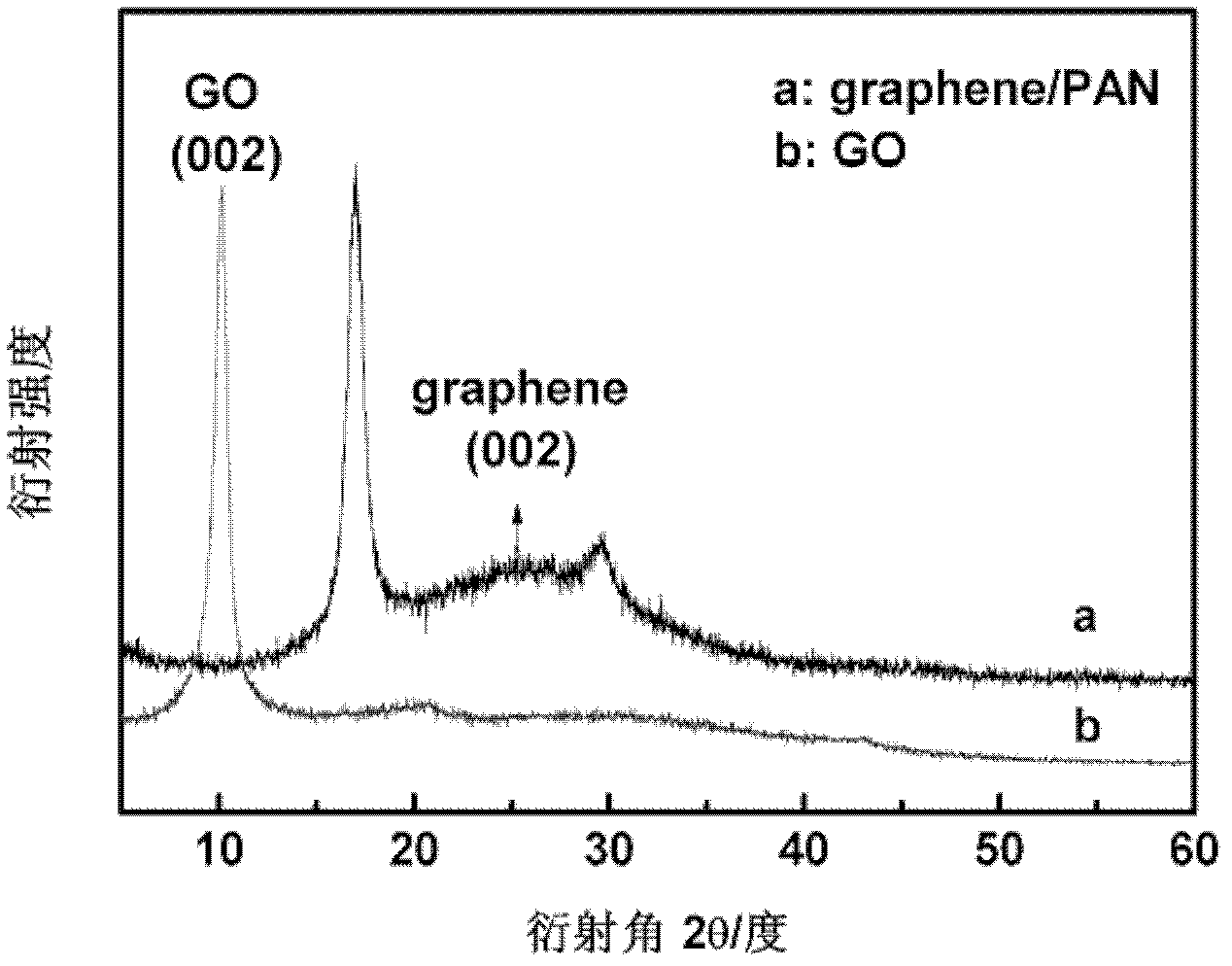

[0035] (3) Prepare a 1 mg / mL GO dispersion at room temperature, place KH550 modified PAN in the GO dispersion, keep warm at 70°C for 3h, and dry at 60°C for 10h to obtain a single-layer GO-modified PAN;

[0036] (4) Repeat steps (2), (3) 3 times to obtain 4 layers of GO modified PAN;

[0037] (5) Put 4 layers of GO modified PAN in a single-necked flask, add 60 mL of 1 mg / mL GO dispersion, and ...

Embodiment 2

[0043] (1) Prepare 10wt% NaOH aqueous solution at room temperature, weigh 60mg of commercially available PAN, place it in 60mL NaOH aqueous solution, keep it at 120°C for 15min, wash PAN with deionized water until neutral, and dry at 40°C for 24h, Alkaline treatment of PAN was obtained.

[0044] (2) Prepare 50 mL of 0.5 mg / mL KH550 solution at room temperature, wherein the solvent is a mixture of water and absolute ethanol with a volume ratio of 1:1, soak the alkali-treated PAN in KH550 solution for 16 h, and dry at 80 ° C for 10 h to obtain a single Layer KH550 modified PAN;

[0045] (3) Prepare a 0.5mg / mL GO dispersion at room temperature, place KH550 modified PAN in the GO dispersion, keep warm at 65°C for 5h, and dry at 45°C for 12h to obtain a single-layer GO-modified PAN;

[0046] (4) Repeat steps (2), (3) twice to obtain 3 layers of GO modified PAN;

[0047] (5) Put the 3-layer GO modified PAN in a single-necked flask, add 0.5mg / mL GO dispersion 60mL, and add 0.6mL hy...

Embodiment 3

[0050] (1) Prepare 15wt% NaOH aqueous solution at room temperature, weigh 1200mg of commercially available PAN, place it in 60mL NaOH aqueous solution, keep it at 90°C for 60min, wash PAN with deionized water until neutral, and dry at 80°C for 8h to obtain Alkali treatment of PAN.

[0051] (2) Prepare 200mL of 2mg / mL KH550 solution at room temperature, in which the solvent is a mixture of water and absolute ethanol with a volume ratio of 1:3, soak the alkali-treated PAN in KH550 solution for 16h, and dry at 65°C for 16h to obtain a single layer KH550 modified PAN;

[0052] (3) Prepare a 2 mg / mL GO dispersion at room temperature, place KH550 modified PAN in the GO dispersion, keep warm at 85°C for 1.5h, and dry at 70°C for 5h to obtain a single-layer GO-modified PAN;

[0053] (4) Repeat steps (2), (3) twice to obtain 3 layers of GO modified PAN;

[0054] (5) Put 3 layers of GO modified PAN in a single-necked flask, add 60 mL of 2 mg / mL GO dispersion, and 1.2 mL of hydrazine h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com