Preparation method of Pd elementary substance coated ZnO nanorod array

A nanorod array and elemental technology, which is applied in the field of preparation of ZnO nanorod arrays, can solve the problems of many by-products, low catalytic efficiency, difficult separation and recovery of catalysts, etc., and achieves the effects of simple process, increased specific surface area, and avoidance of agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

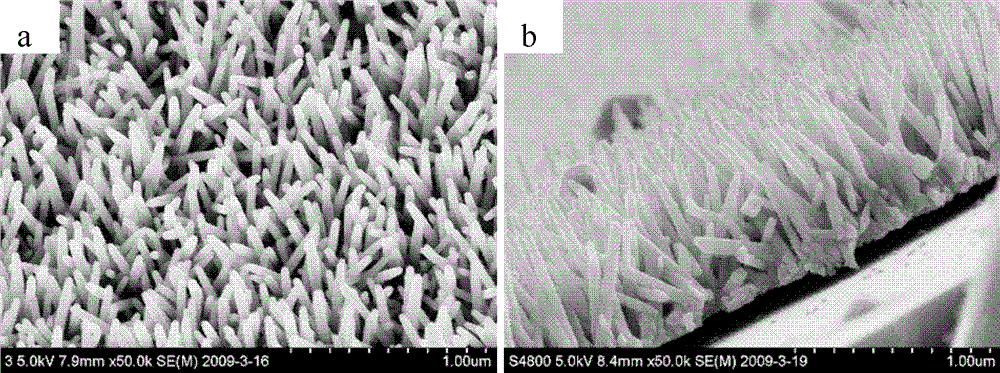

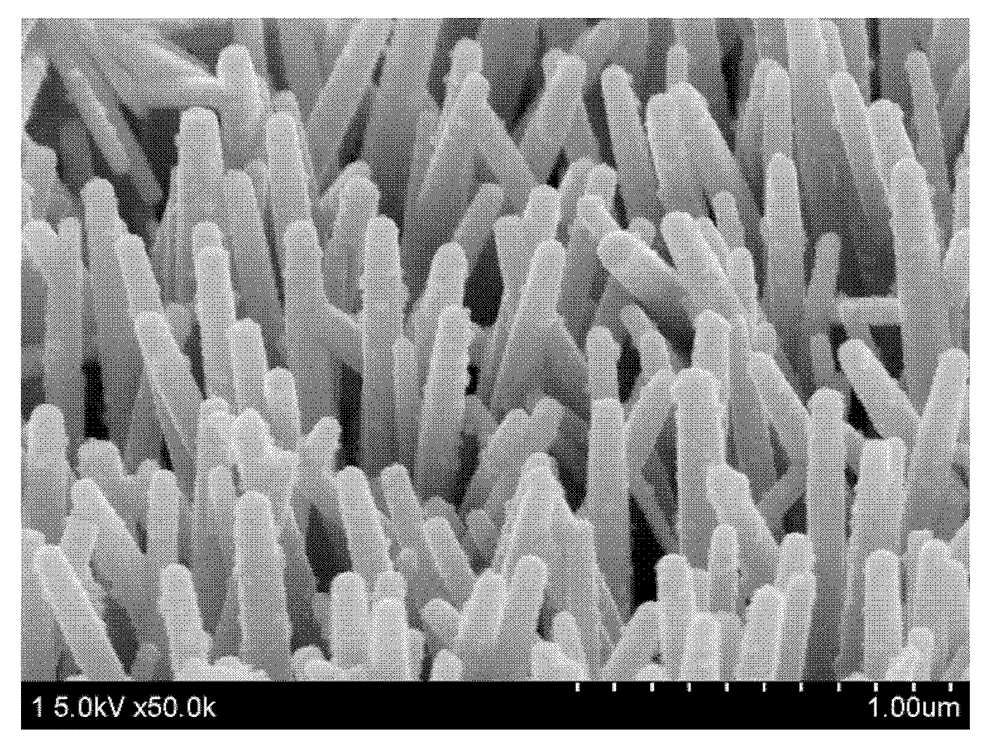

[0034] Prepare lotion I (the volume ratio of concentrated sulfuric acid, hydrogen peroxide and distilled water is 4:1:20) and lotion II (the volume ratio of ammonia, hydrogen peroxide and distilled water is 1:4:20). At room temperature, soak the microchannel in lotion I for 30 minutes, rinse with deionized water, then soak the microchannel in lotion II for 30 minutes, rinse with deionized water, and dry for later use. Simultaneously transport zinc acetate dihydrate ethanol solution (0.01M) and sodium hydroxide ethanol solution (0.04M) at a speed of 25 μL / min into the microchannel pre-placed in a 60°C oven, and stop the delivery after the microchannel is filled. , after reacting for 2 hours, the temperature was raised to 70°C, reacted for another 2h, and then heated to 150°C for 2h annealing, the microchannel was cleaned with deionized water, and dried at 150°C to obtain a ZnO seed layer film on the inner surface of the microchannel. At 90°C, the zinc nitrate hexahydrate soluti...

Embodiment 2

[0039]Prepare lotion I (the volume ratio of concentrated sulfuric acid, hydrogen peroxide and distilled water is 4:1:20) and lotion II (the volume ratio of ammonia, hydrogen peroxide and distilled water is 1:4:20). At room temperature, soak the microchannel in lotion I for 20 minutes, rinse with deionized water, then soak the microchannel in lotion II for 20 minutes, rinse with deionized water, and dry for later use; dihydrate zinc acetate ethanol The solution (0.01M) and the sodium hydroxide ethanol solution (0.04M) were delivered to the microchannel pre-placed in a 60°C oven at the same time at a speed of 25μL / min. After the microchannel was filled, the delivery was stopped, and the temperature was raised to 70°C, react for another 2h, heat up to 150°C and anneal for 2h, wash the microchannel with deionized water, and dry at 150°C to obtain a ZnO seed layer film on the inner surface of the microchannel; Zinc solution (0.05M) and hexamethylenetetramine solution (0.05M) were s...

Embodiment 3

[0044] Prepare lotion I (the volume ratio of concentrated sulfuric acid, hydrogen peroxide and distilled water is 4:1:20) and lotion II (the volume ratio of ammonia, hydrogen peroxide and distilled water is 1:4:20). At room temperature, soak the microchannel in lotion I for 40 minutes, rinse with deionized water, then soak the microchannel in lotion II for 40 minutes, rinse with deionized water, and dry for later use. Simultaneously transport zinc acetate dihydrate ethanol solution (0.01M) and sodium hydroxide ethanol solution (0.04M) at a speed of 25 μL / min into the microchannel pre-placed in a 60°C oven, and stop the delivery after the microchannel is filled. , After reacting for 2 hours, the temperature was raised to 70°C, and then reacted for 2 hours, and then the temperature was raised to 150°C for 2 hours of annealing. The microchannel was cleaned with deionized water and dried at 150° C. to obtain a ZnO seed layer film on the inner surface of the microchannel. At 90°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com