Patents

Literature

9422results about "Graphene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

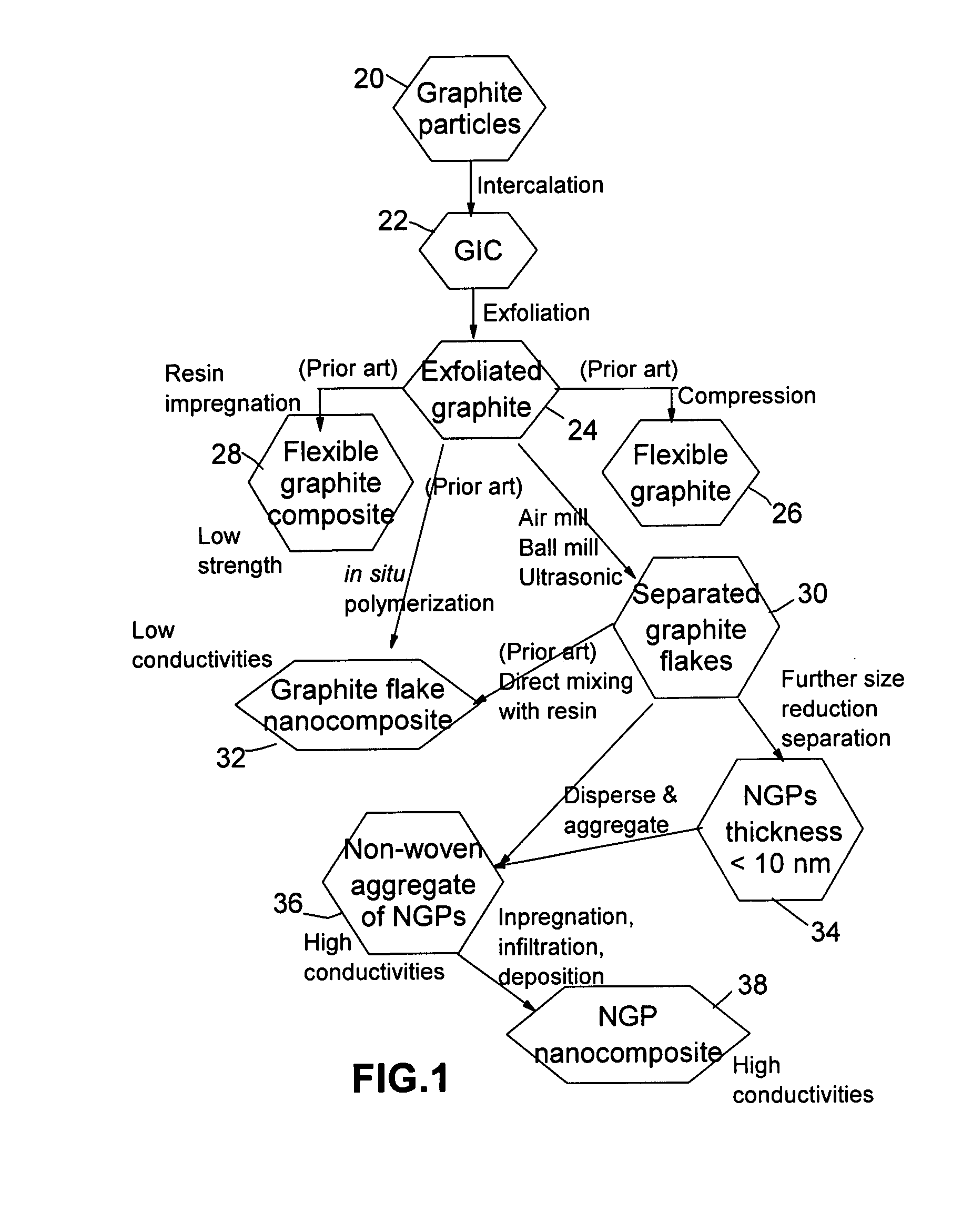

Process for producing nano-scaled graphene plates

InactiveUS20050271574A1Faster and cost-effective processHighly cost-effectiveMaterial nanotechnologyGraphiteGrapheneGraphite particle

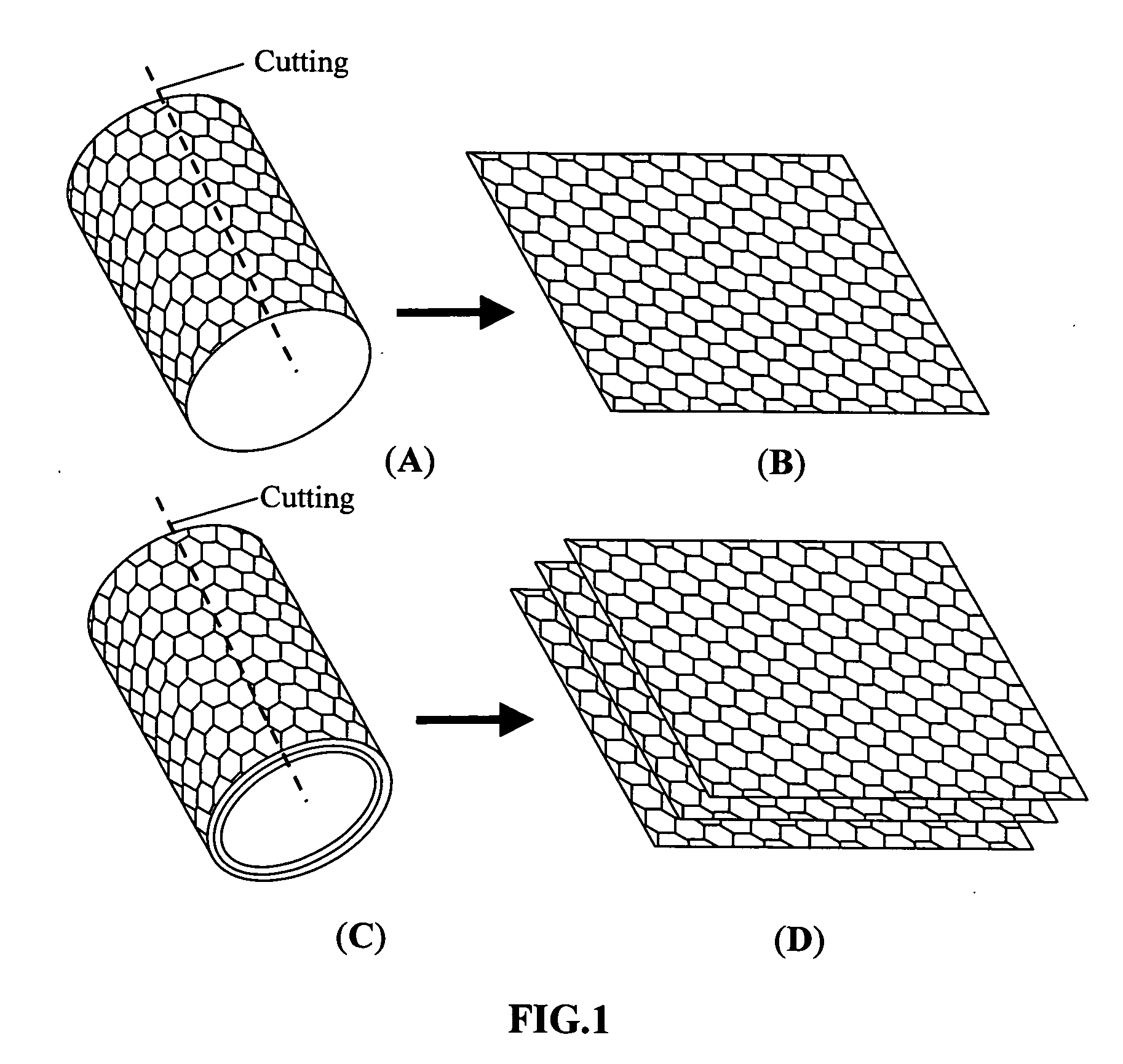

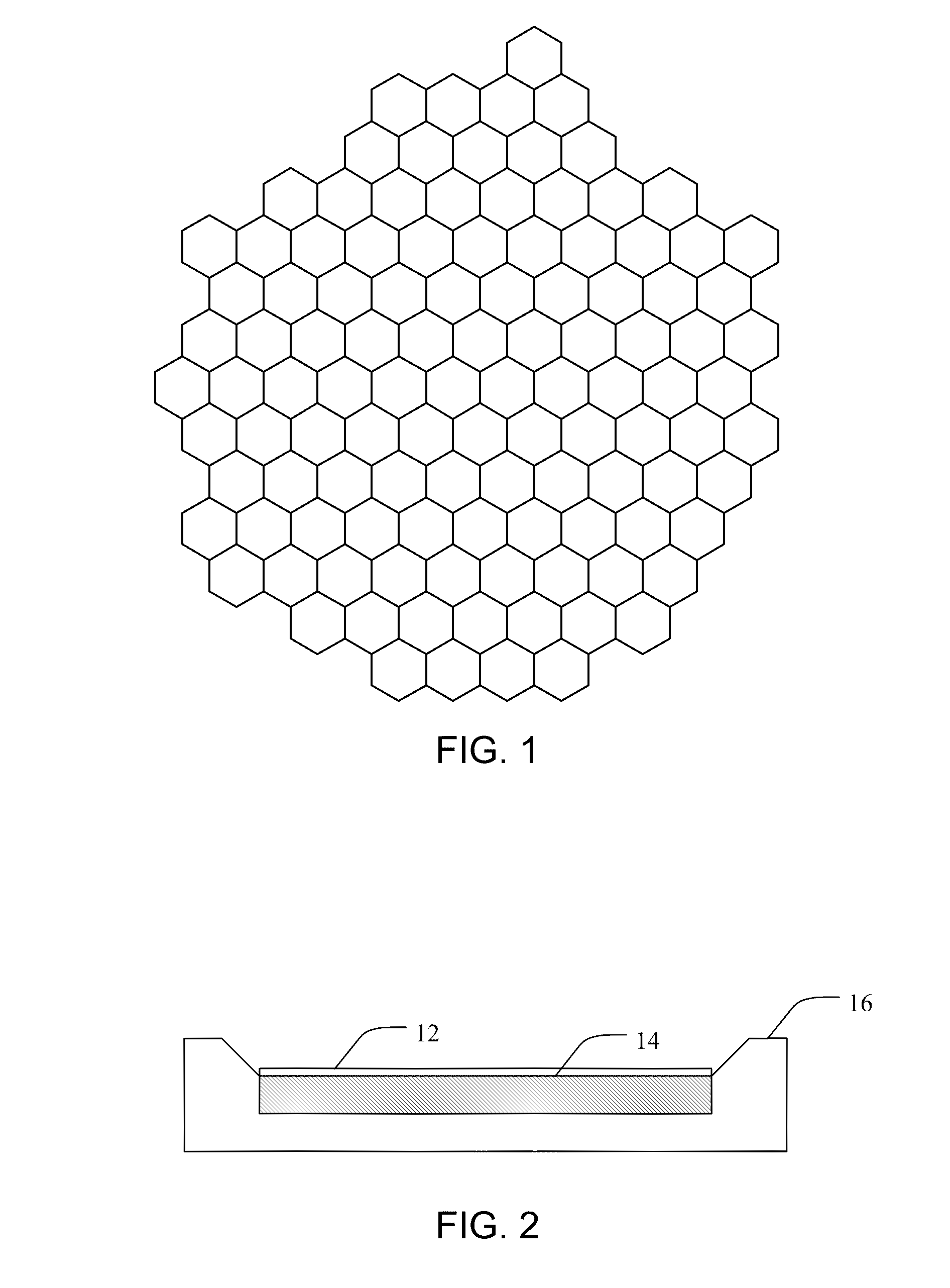

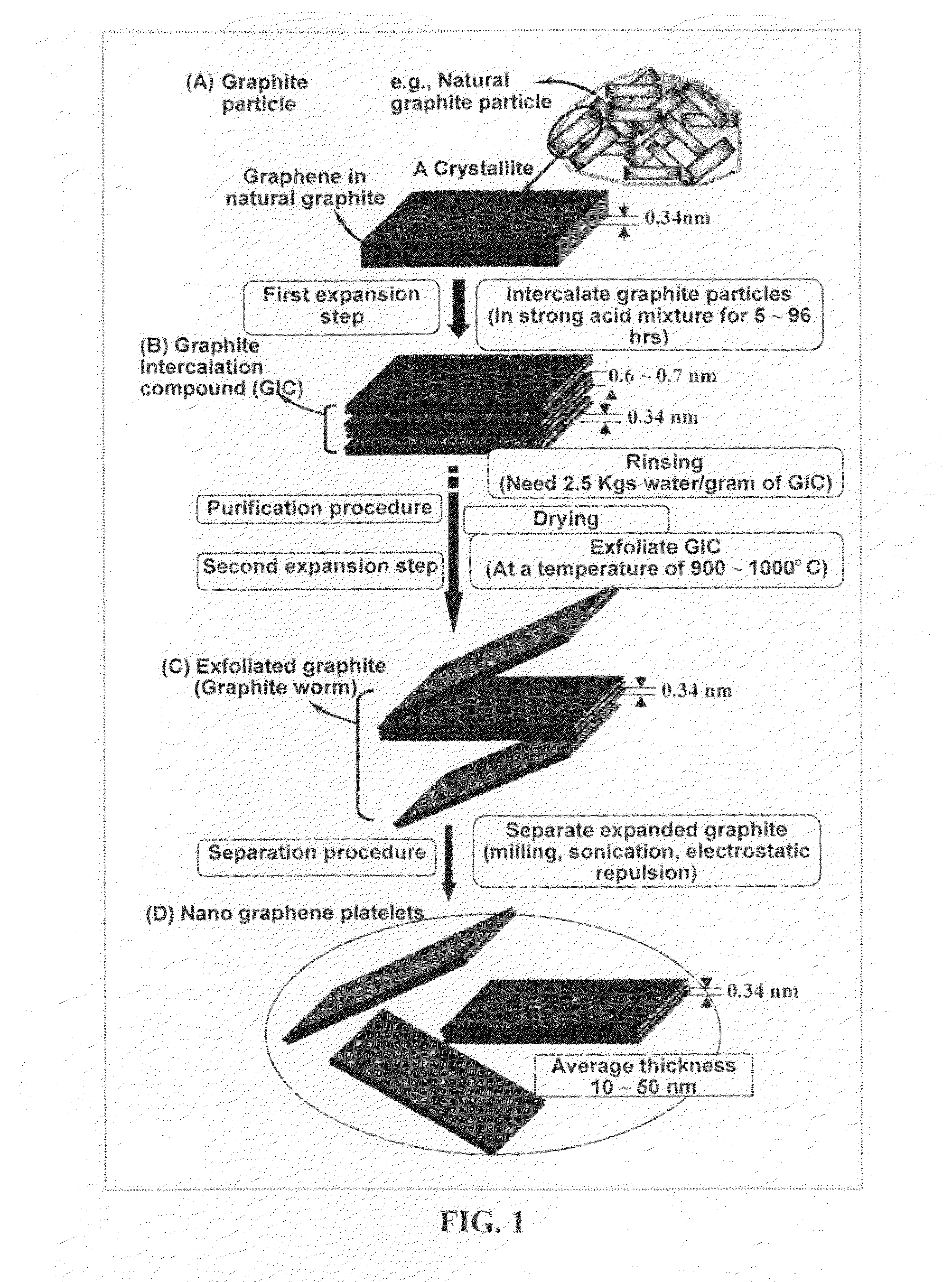

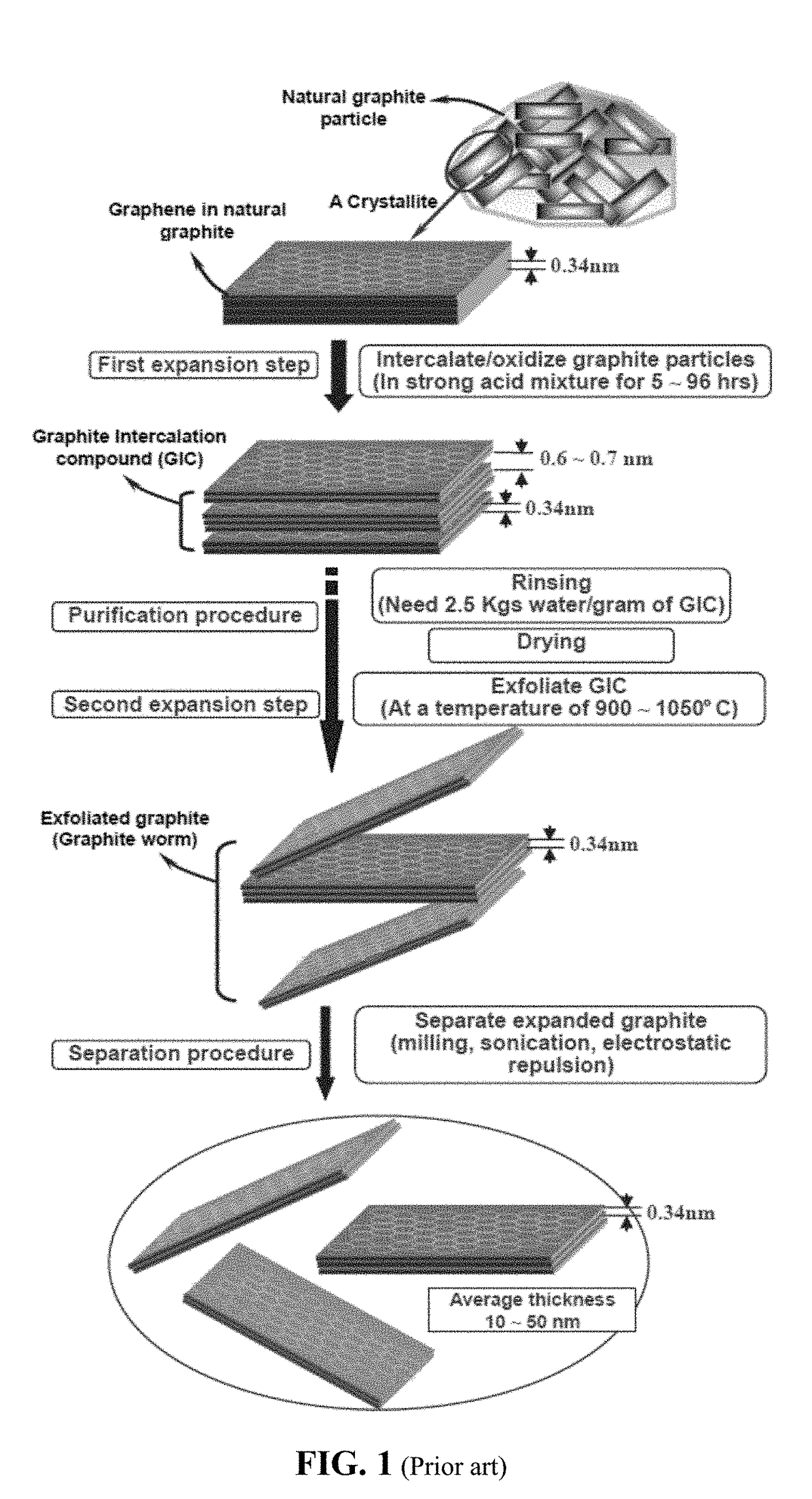

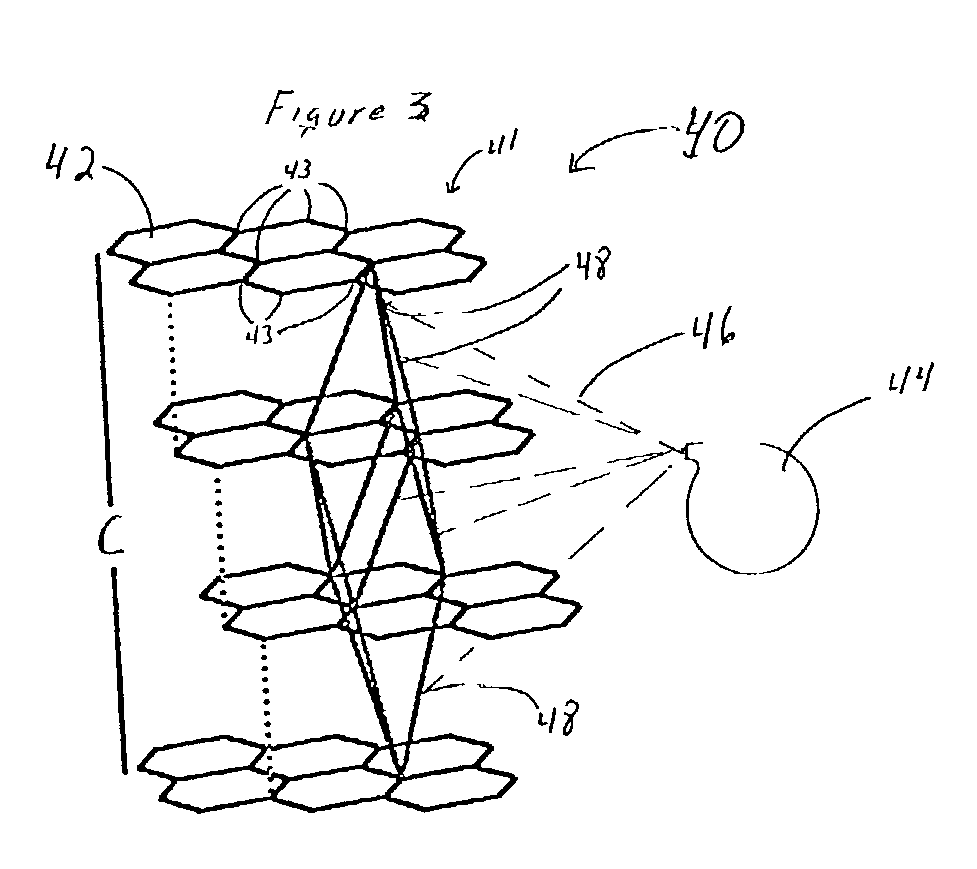

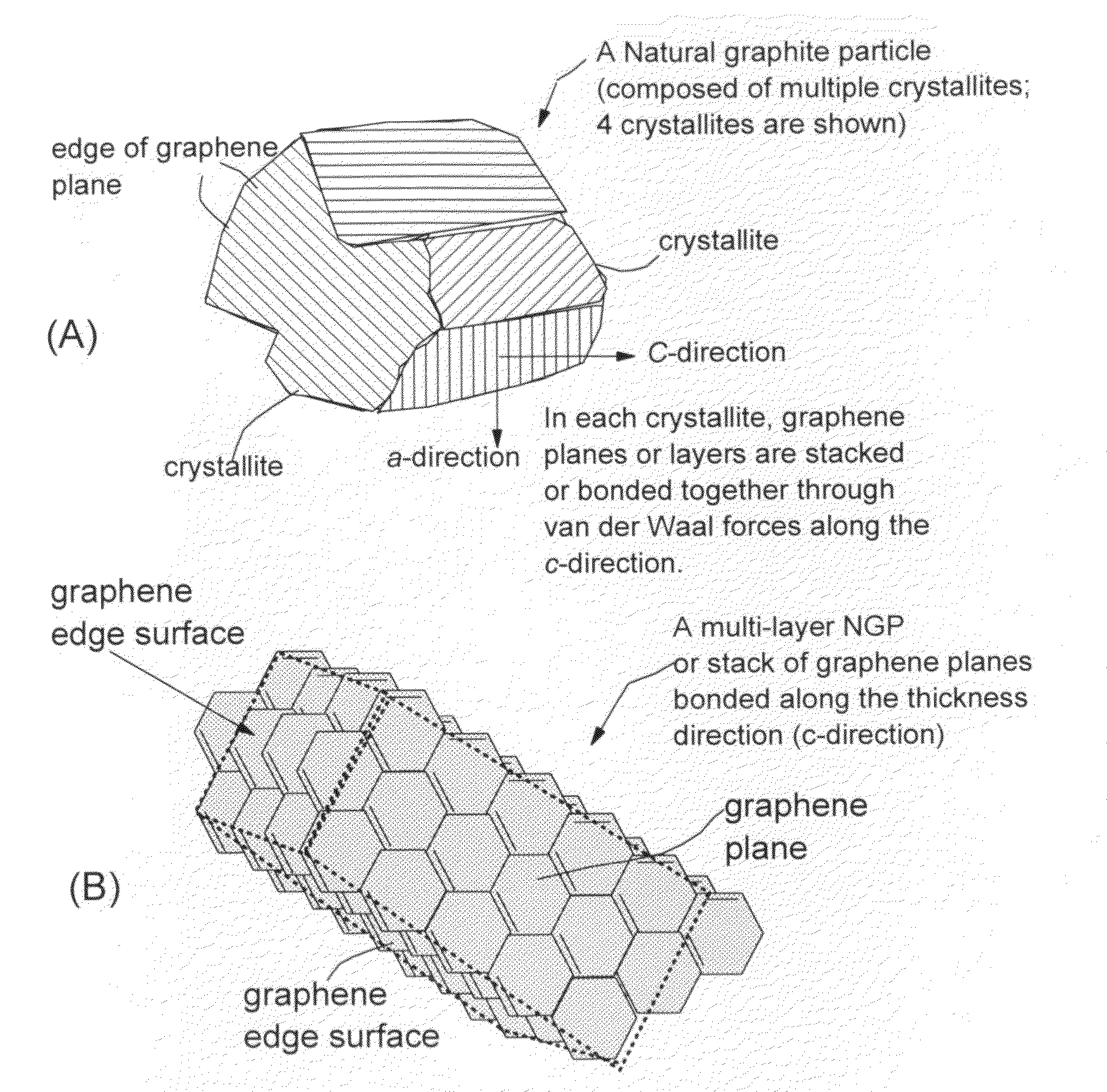

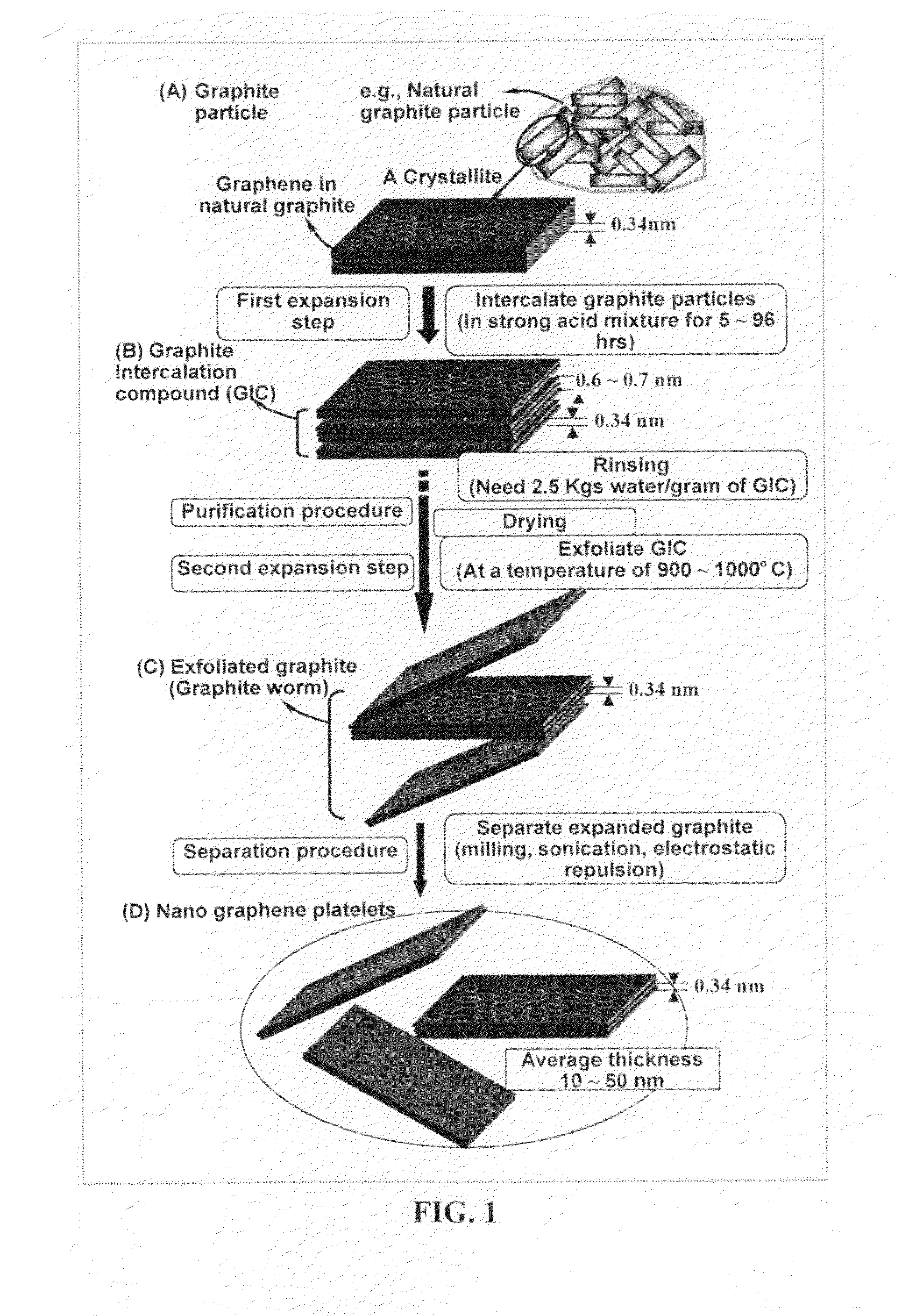

A process for producing nano-scaled graphene plates with each plate comprising a sheet of graphite plane or multiple sheets of graphite plane with the graphite plane comprising a two-dimensional hexagonal structure of carbon atoms. The process includes the primary steps of: (a) providing a powder of fine graphite particles comprising graphite crystallites with each crystallite comprising one sheet or normally a multiplicity of sheets of graphite plane bonded together; (b) exfoliating the graphite crystallites to form exfoliated graphite particles, which are characterized by having at least two graphite planes being either partially or fully separated from each other; and (c) subjecting the exfoliated graphite particles to a mechanical attrition treatment to further reduce at least one dimension of the particles to a nanometer scale, <100 nm, for producing the nano-scaled graphene plates.

Owner:GLOBAL GRAPHENE GRP INC

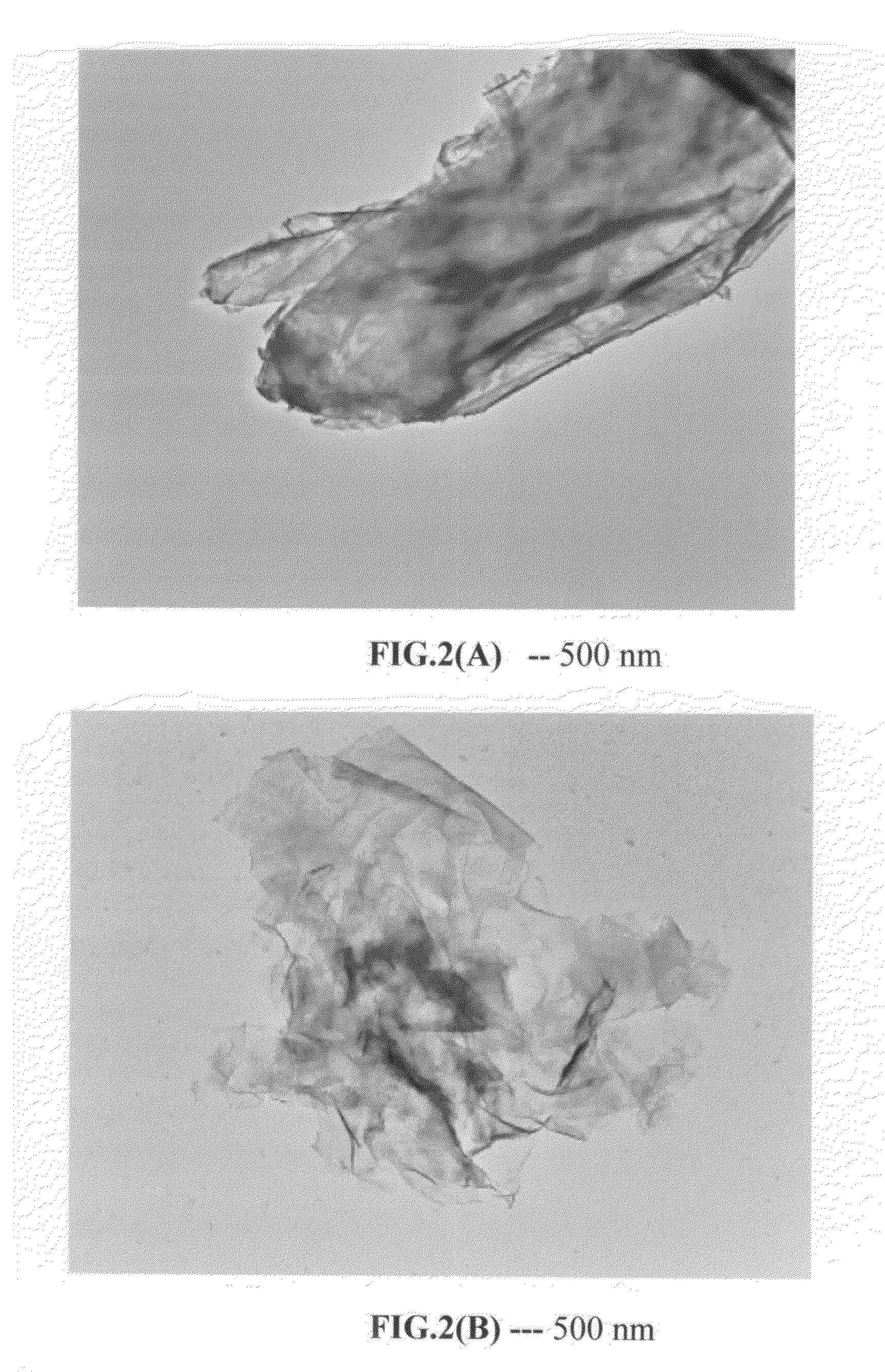

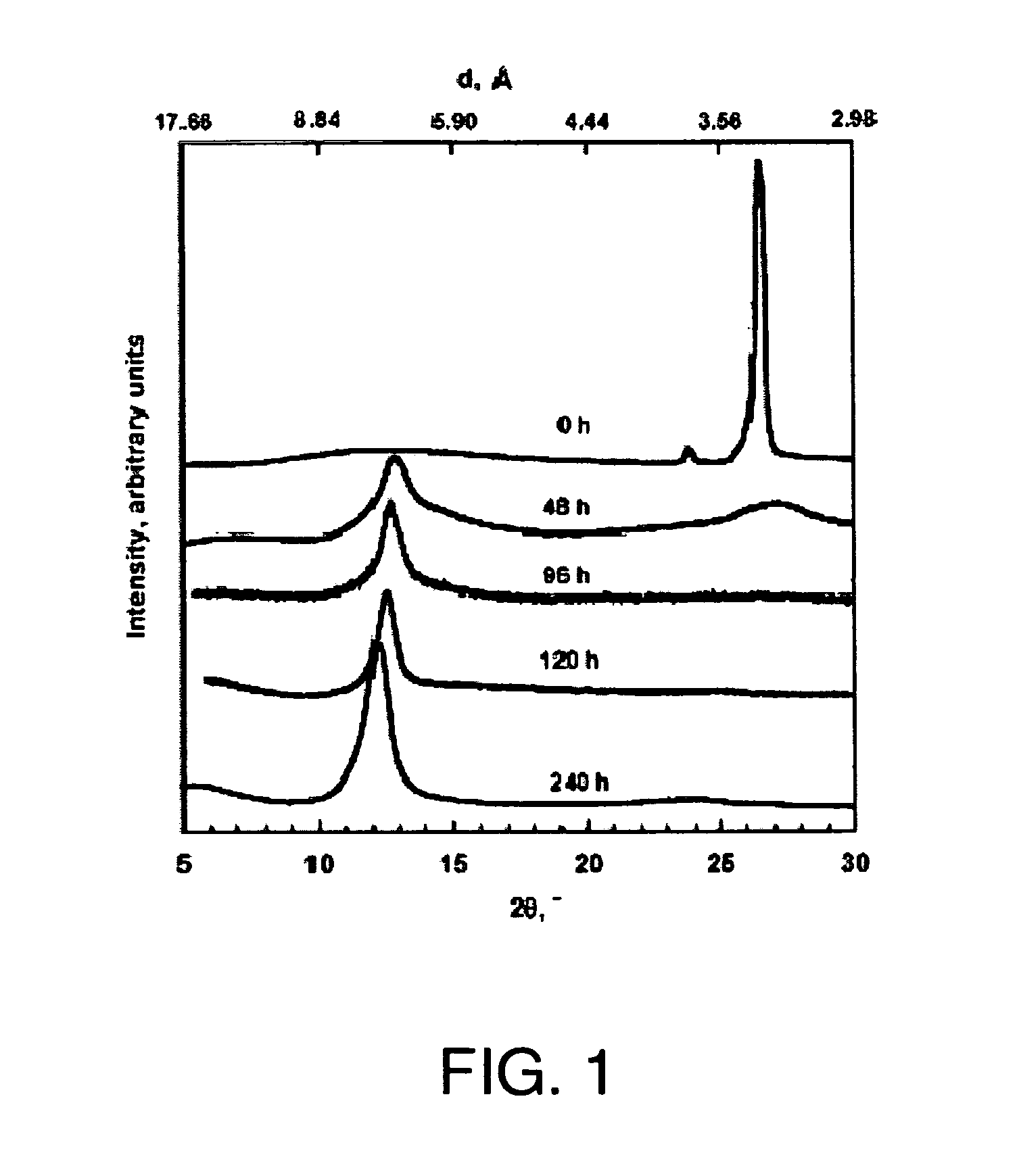

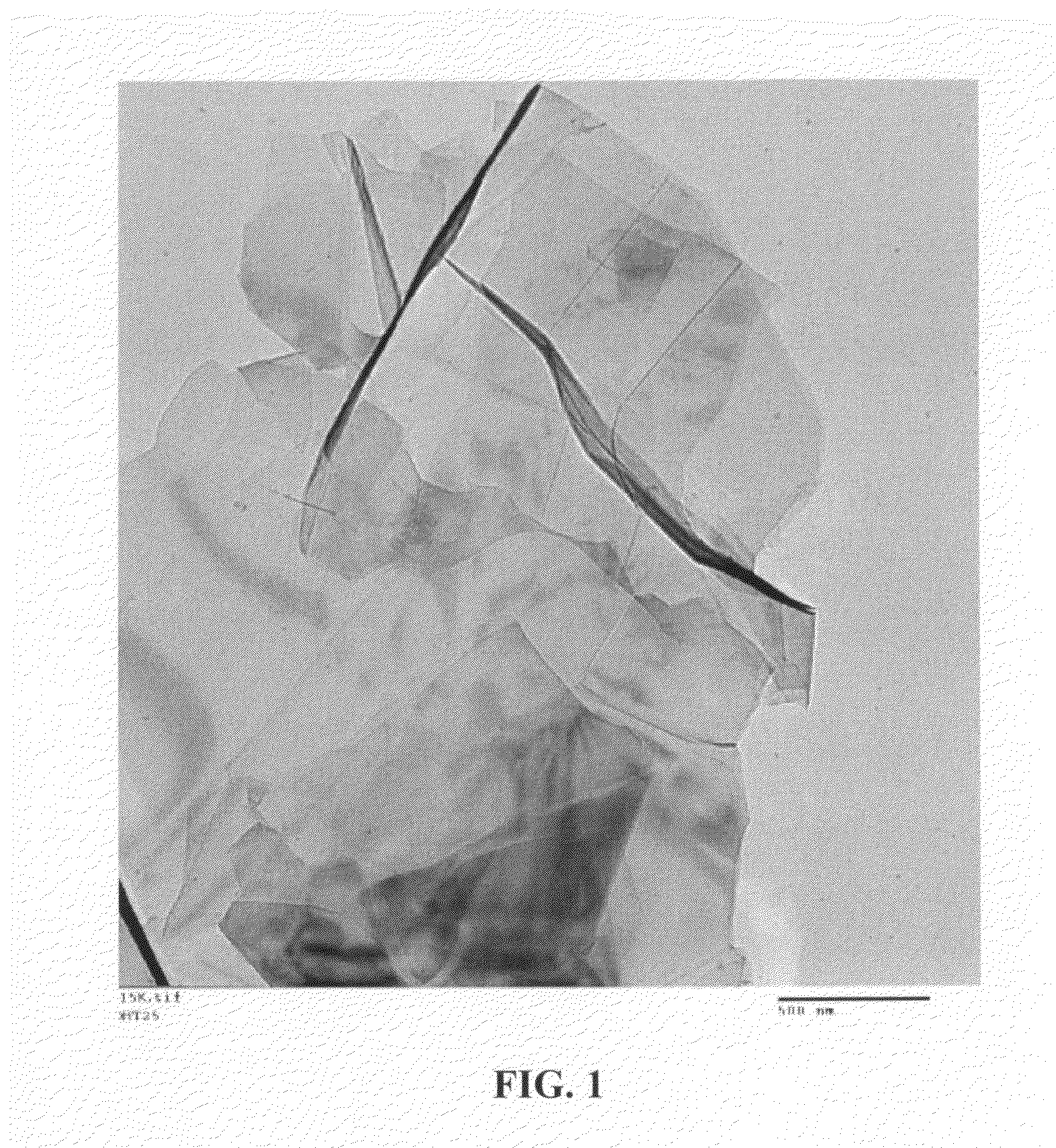

Thermally exfoliated graphite oxide

ActiveUS20070092432A1Improve diffusion barrier propertyHigh aspect ratioMaterial nanotechnologyGraphiteX-rayMaterials science

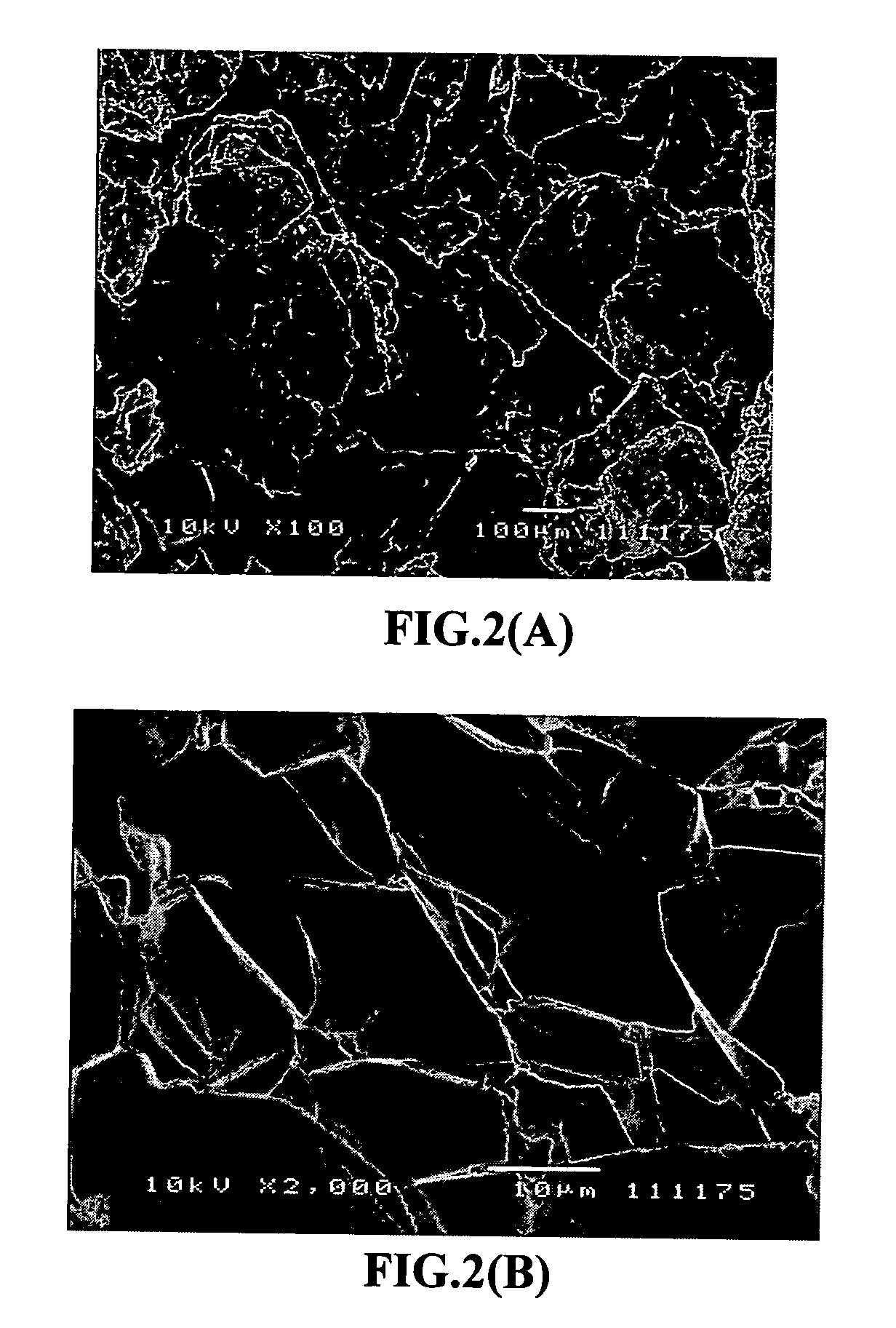

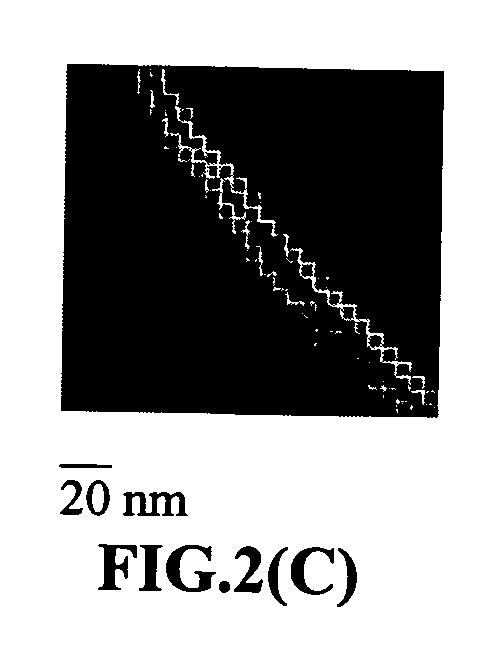

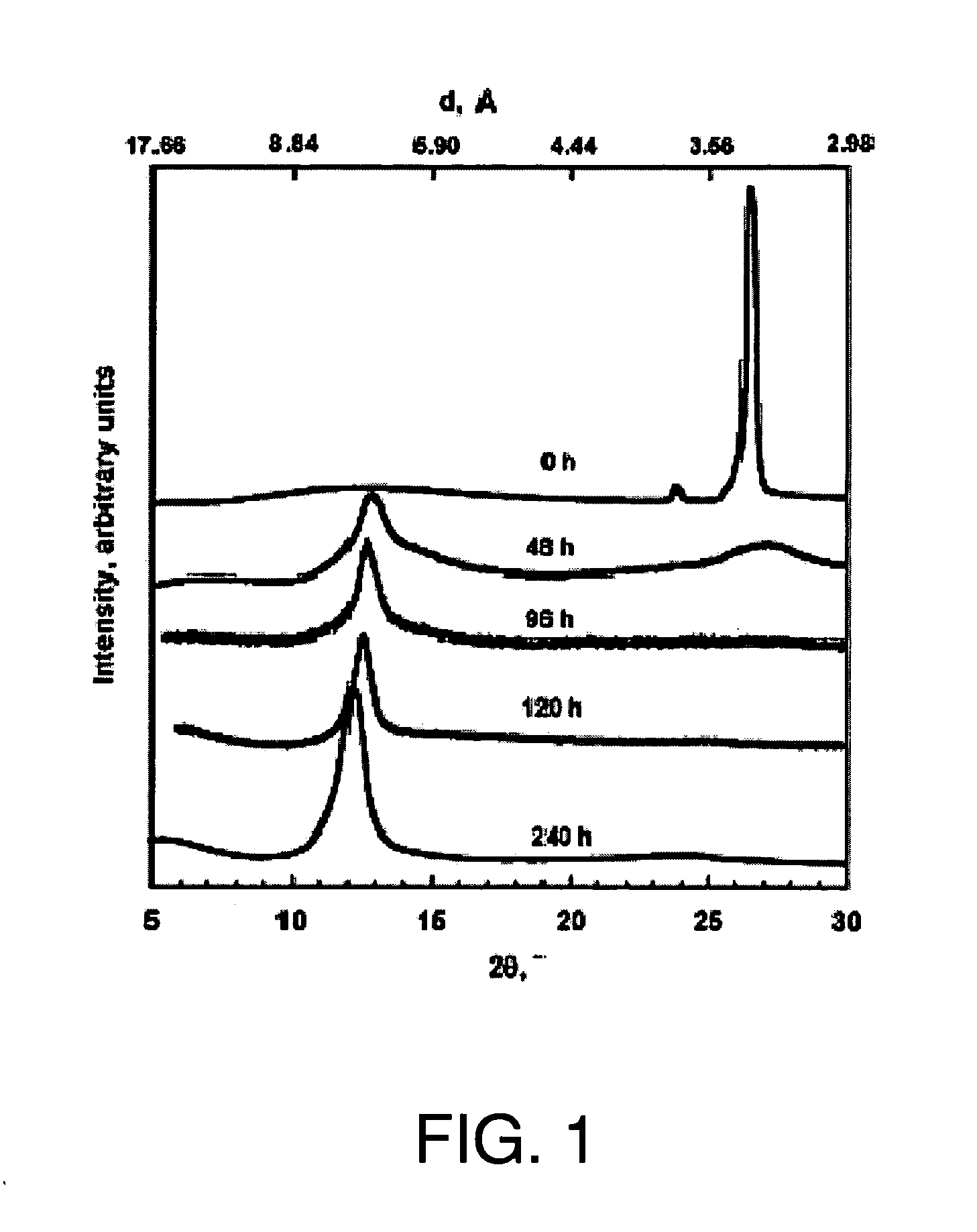

A modified graphite oxide material contains a thermally exfoliated graphite oxide with a surface area of from about 300 m2 / g to 2600 m2 / g, wherein the thermally exfoliated graphite oxide displays no signature of the original graphite and / or graphite oxide, as determined by X-ray diffraction.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Graphene film as transparent and electrically conducting material

ActiveUS20070284557A1Material nanotechnologyConductive materialGraphene flakeTransparent conducting film

A transparent and conductive film comprising at least one network of graphene flakes is described herein. This film may further comprise an interpenetrating network of other nanostructures, a polymer and / or a functionalization agent(s). A method of fabricating the above device is also described, and may comprise depositing graphene flakes in solution and evaporating solvent therefrom.

Owner:SAMSUNG ELECTRONICS CO LTD

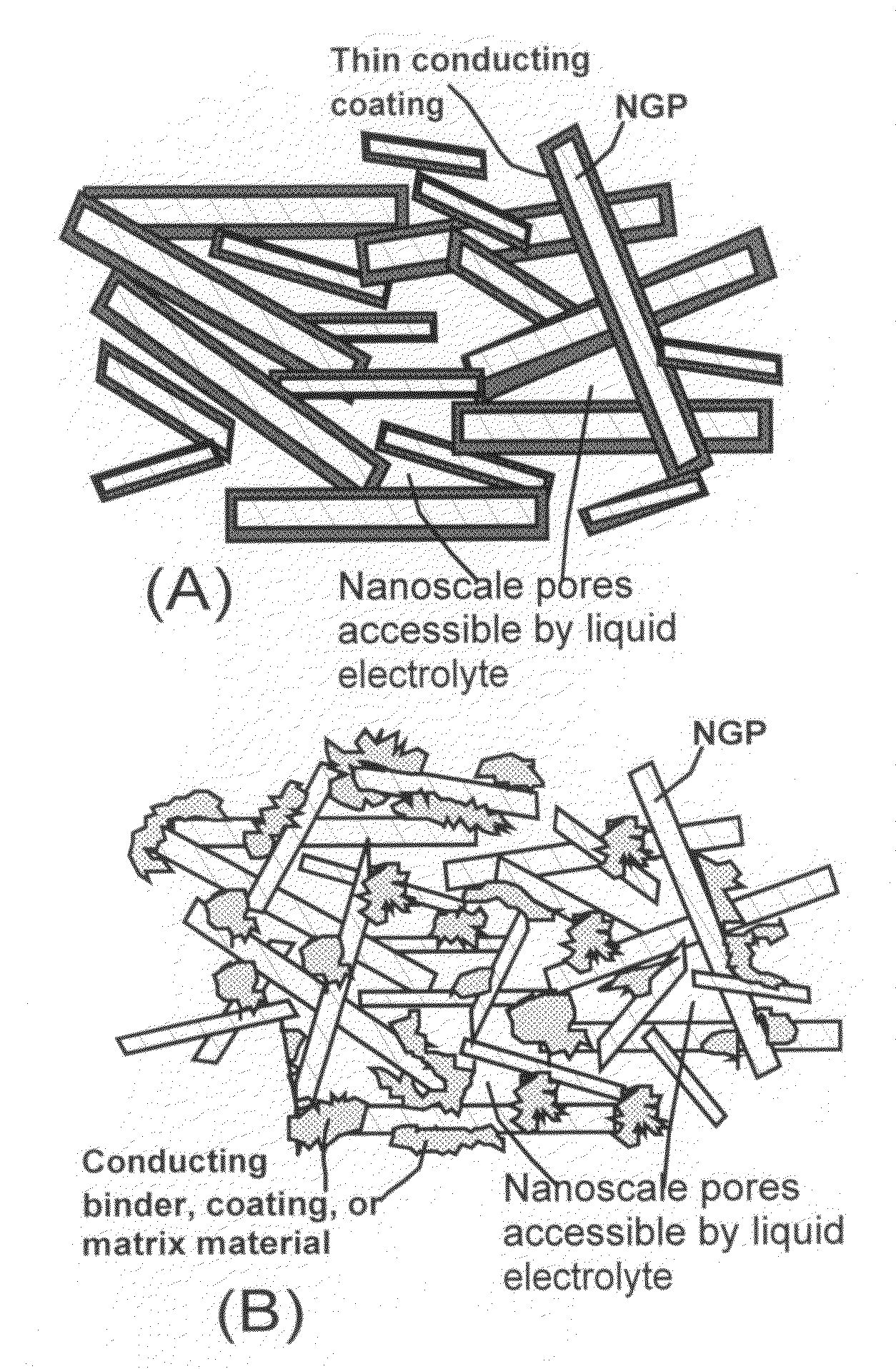

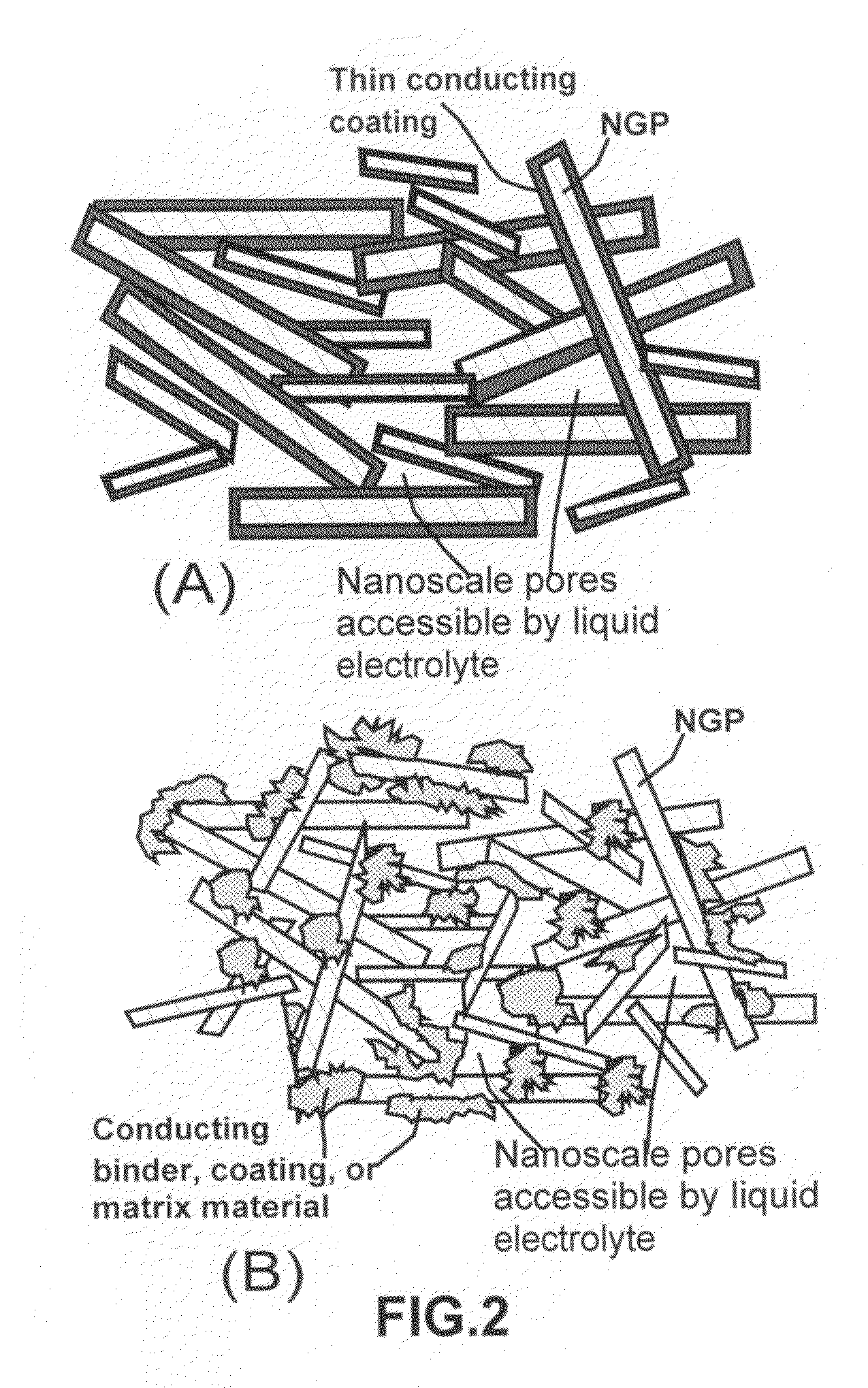

Nano-scaled graphene plate nanocomposites for supercapacitor electrodes

ActiveUS7623340B1Increase specific surface area and electrical conductivityMaterial nanotechnologyElectrolytic capacitorsCapacitancePolymer science

A preferred embodiment of the present invention is a meso-porous nanocomposite material comprising: (A) nano-scaled graphene platelets, wherein each of the platelets comprises a sheet of graphite plane or multiple sheets of graphite plane, and the platelets have a thickness no greater than 100 nm (preferably smaller than 10 nm) and an average length, width, or diameter no greater than 10 μm (preferably smaller than 500 nm); and (B) an electrically conducting binder or matrix material attached or bonded to the platelets to form the nanocomposite material having liquid accessible pores, which provide a surface area greater than about 100 m2 / gm, preferably greater than 500 m2 / gm, and most preferably greater than 1000 m2 / gm. Also disclosed is a capacitor that includes at least an electrode comprising such a meso-porous nanocomposite material. A supercapacitor featuring such a nanocomposite exhibits an exceptionally high capacitance value.

Owner:SAMSUNG ELECTRONICS CO LTD +1

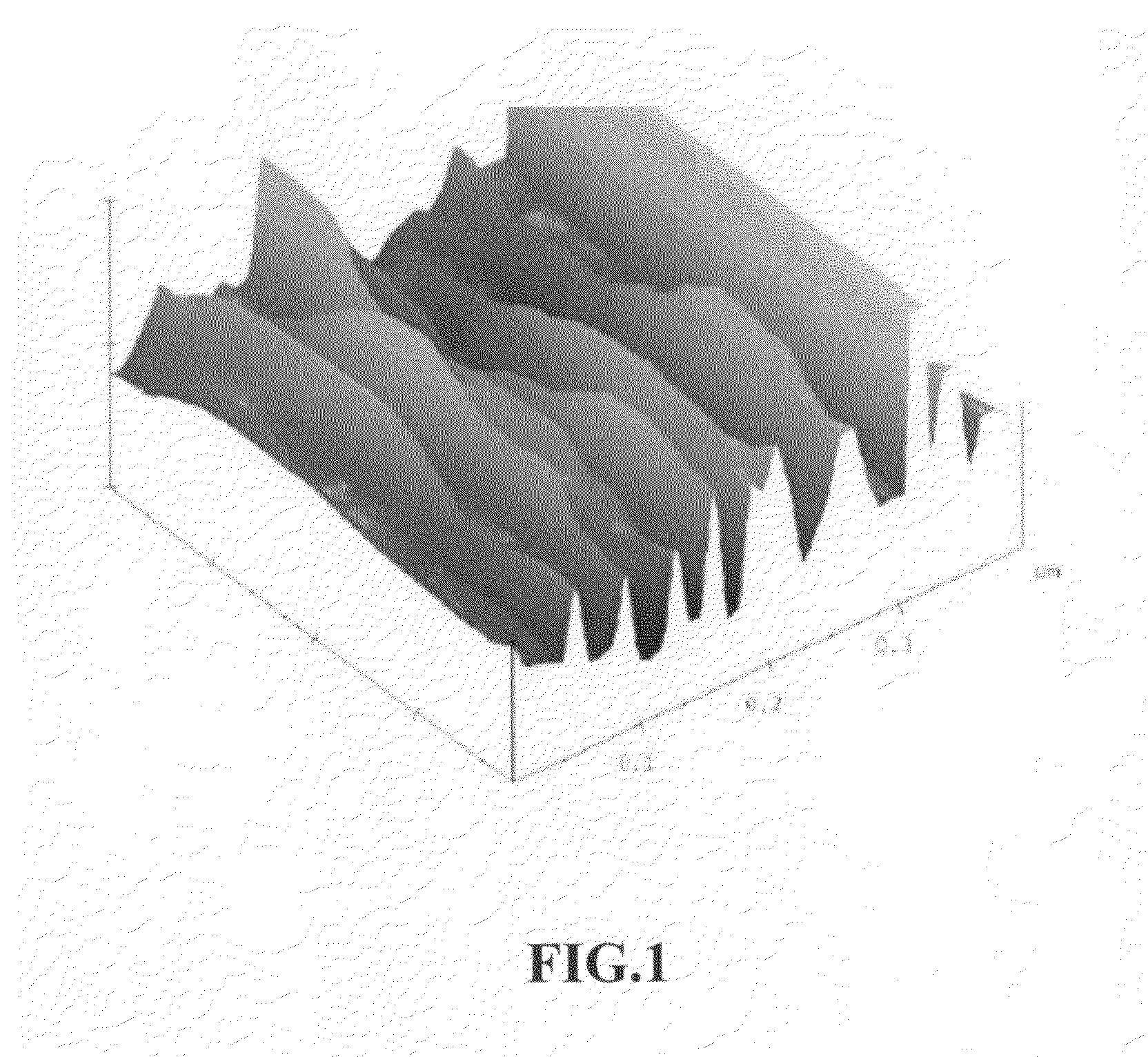

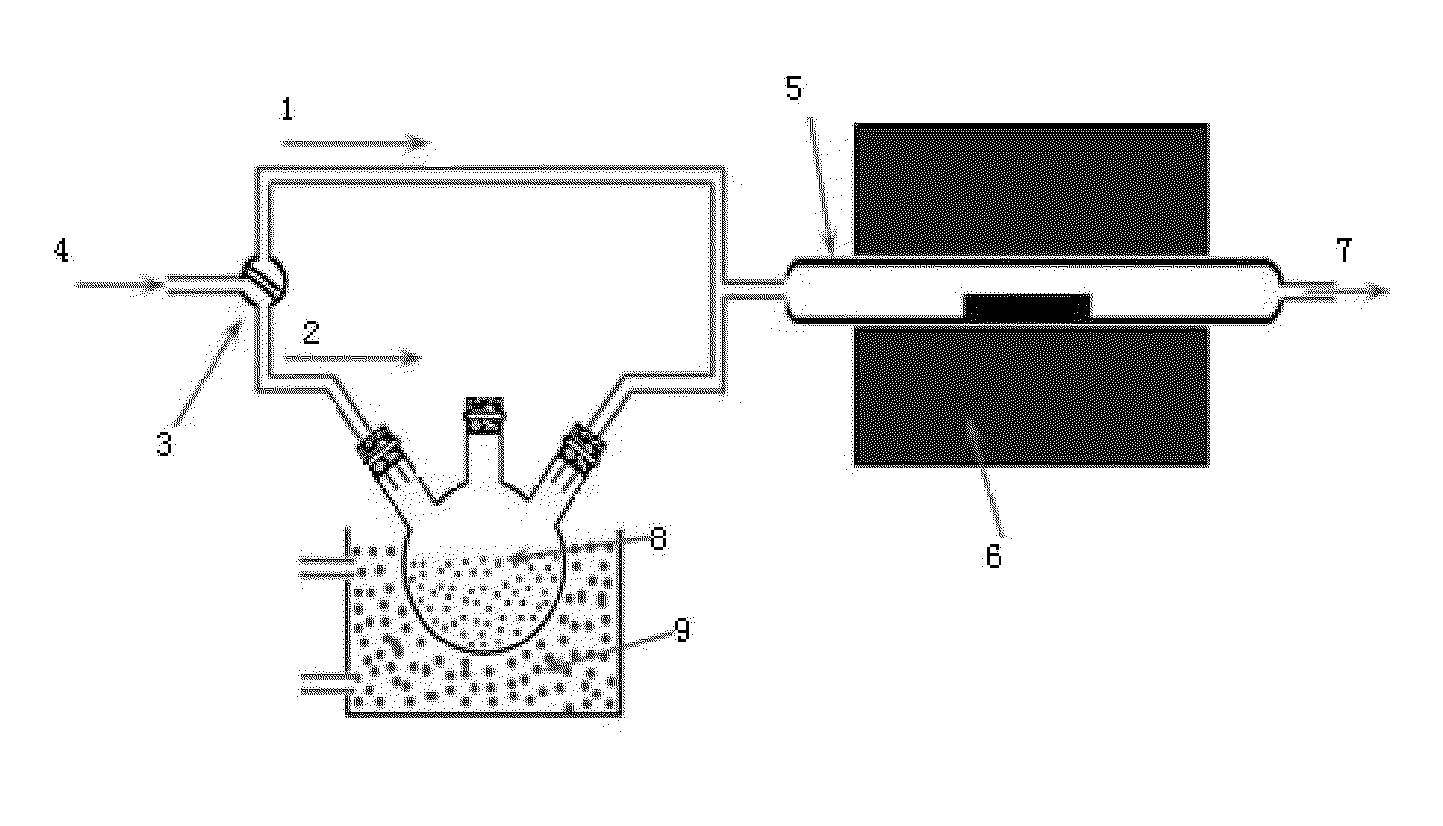

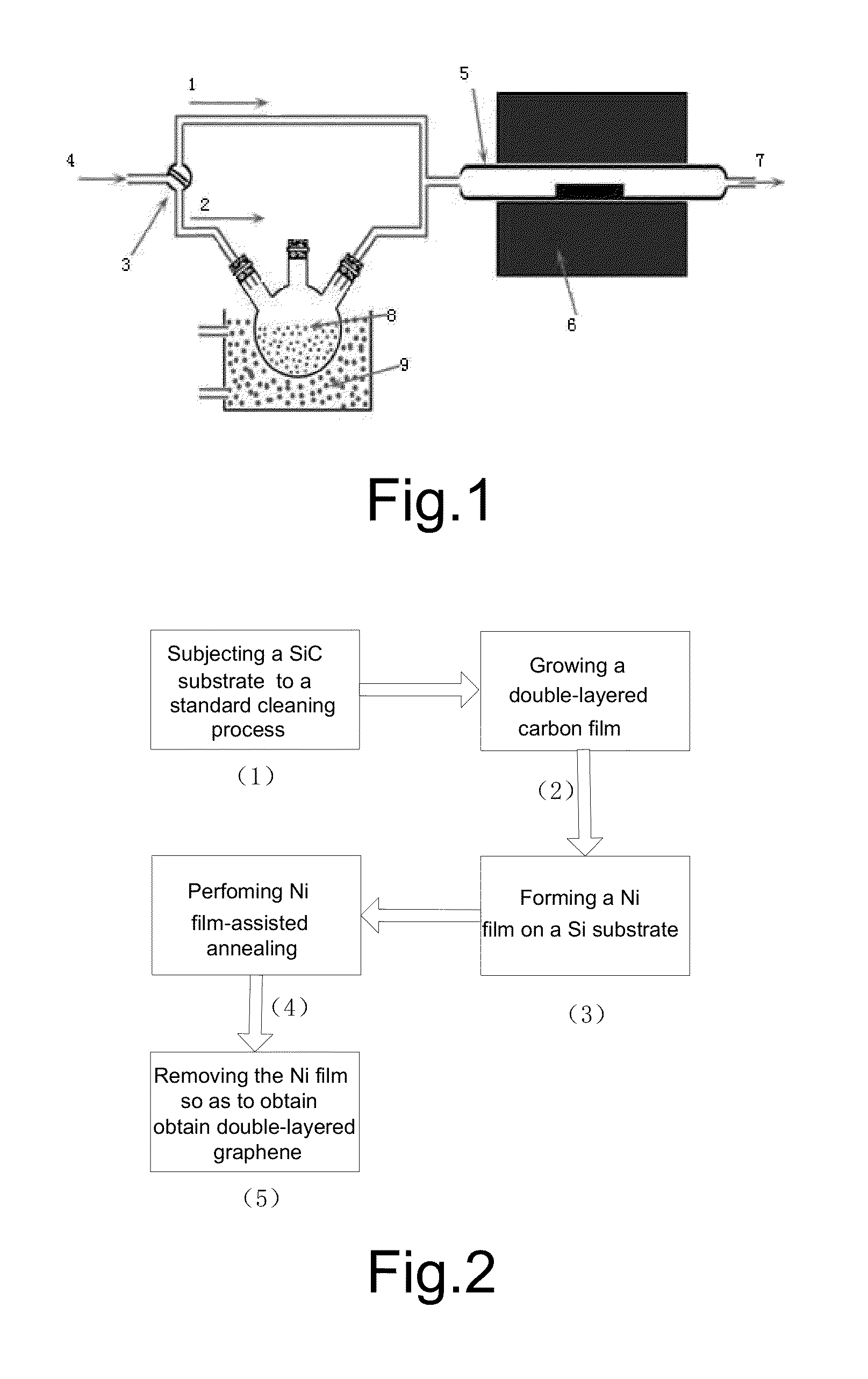

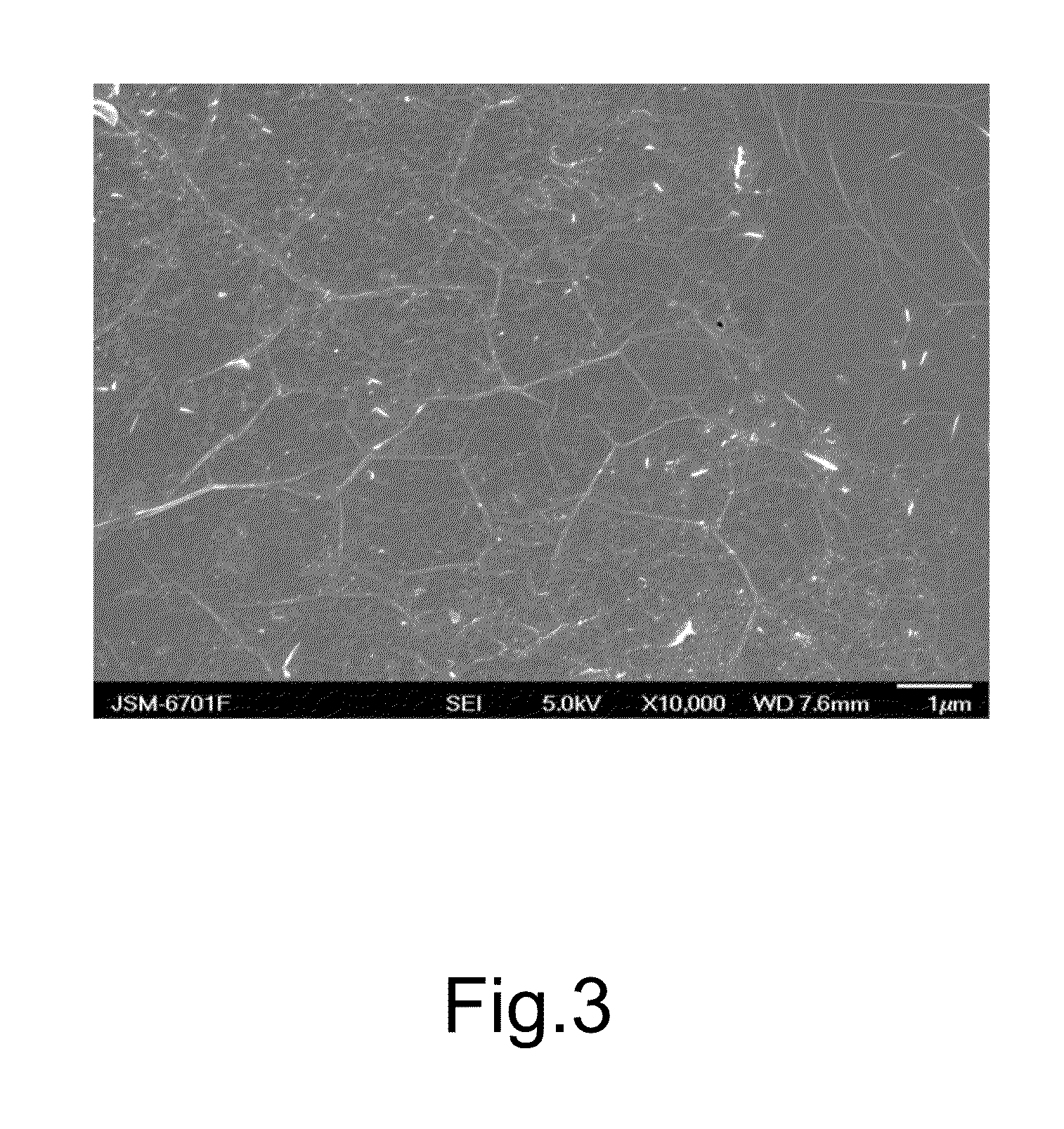

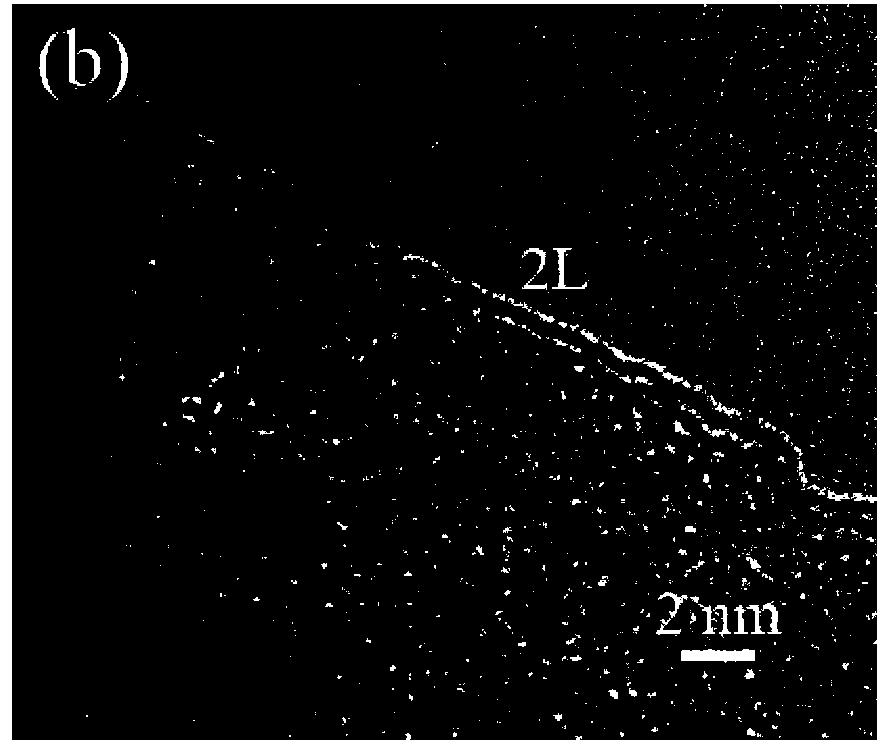

Process for Preparing Graphene on a SiC Substrate Based on Metal Film-Assisted Annealing

ActiveUS20140367642A1Simply and energy-efficientFlat surfaceMaterial nanotechnologyVacuum evaporation coatingCarbon filmElectron beam deposition

Provided is a process for preparing graphene on a SiC substrate, based on metal film-assisted annealing, comprising the following steps: subjecting a SiC substrate to a standard cleaning process; placing the cleaned SiC substrate into a quartz tube and heating the quartz tube up to a temperature of 750 to 1150° C.; introducing CCl4vapor into the quartz tube to react with SiC for a period of 20 to 100 minutes so as to generate a double-layered carbon film, wherein the CCl4 vapor is carried by Ar gas; forming a metal film with a thickness of 350 to 600 nm on a Si substrate by electron beam deposition; placing the obtained double-layered carbon film sample onto the metal film; subsequently annealing them in an Ar atmosphere at a temperature of 900 to 1100° C. for 10-30 minutes so as to reconstitute the double-layered carbon film into double-layered graphene; and removing the metal film from the double-layered graphene, thereby obtaining double-layered graphene. Also provided is double-layered graphene prepared by said process.

Owner:XIDIAN UNIV

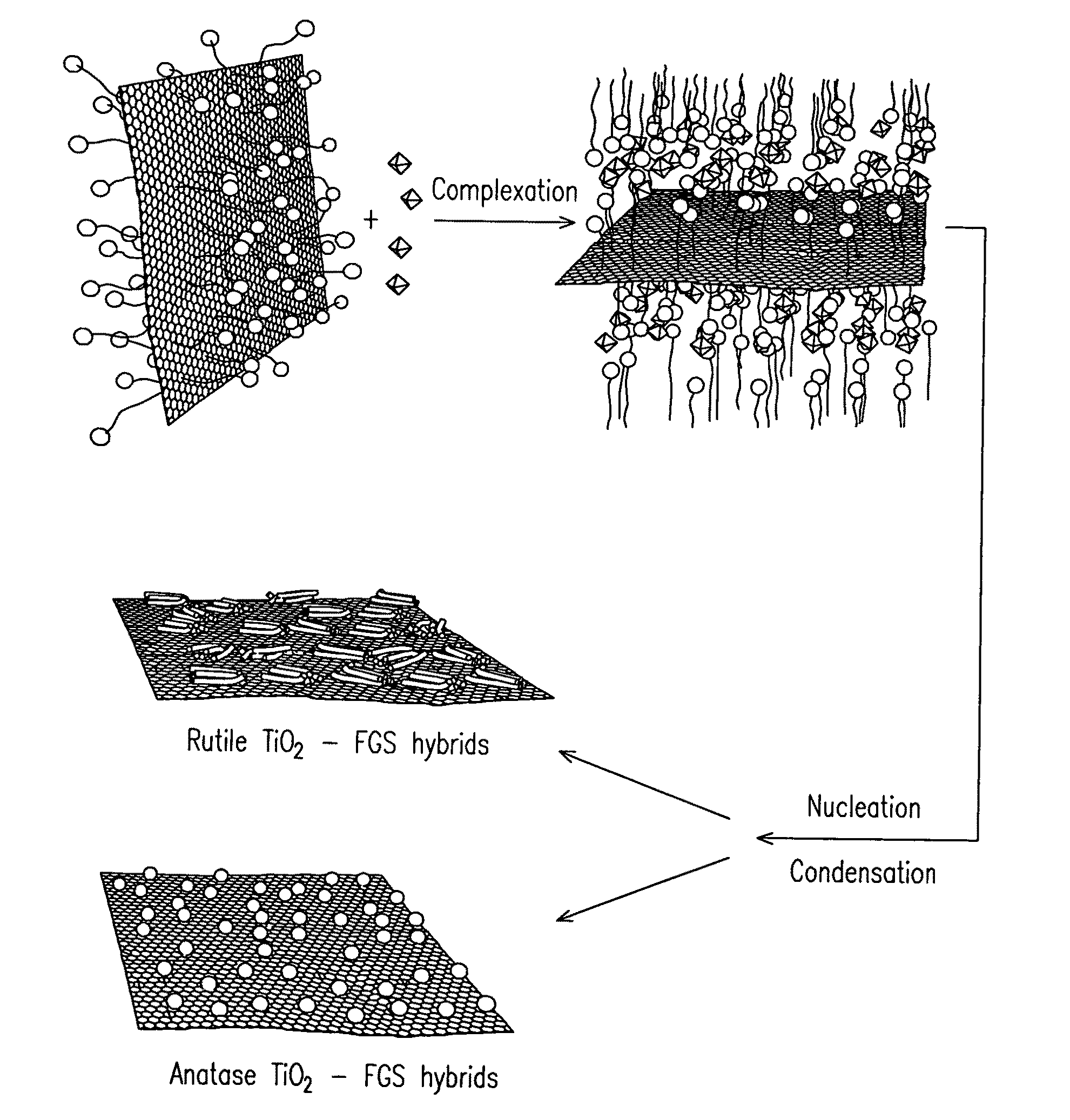

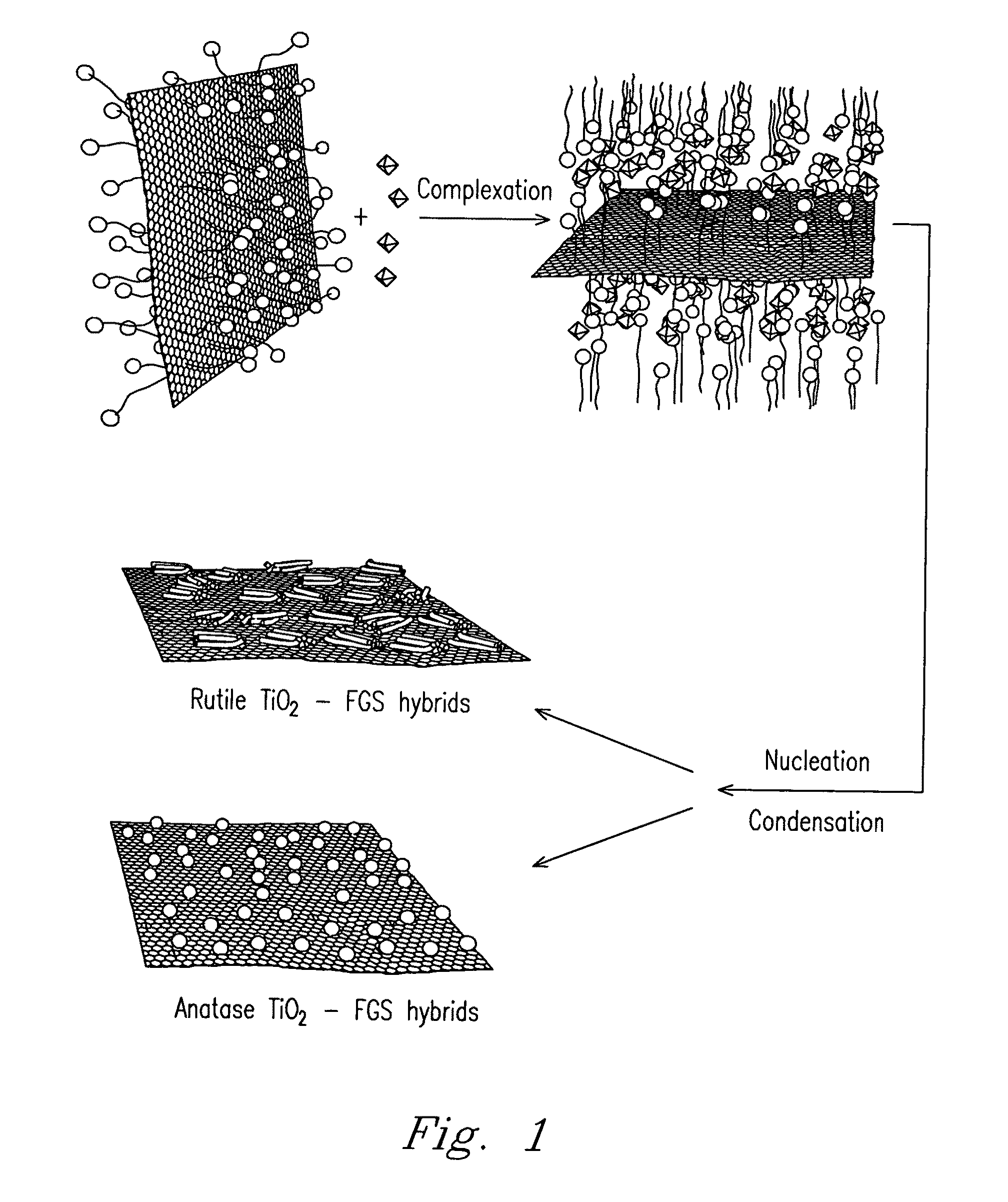

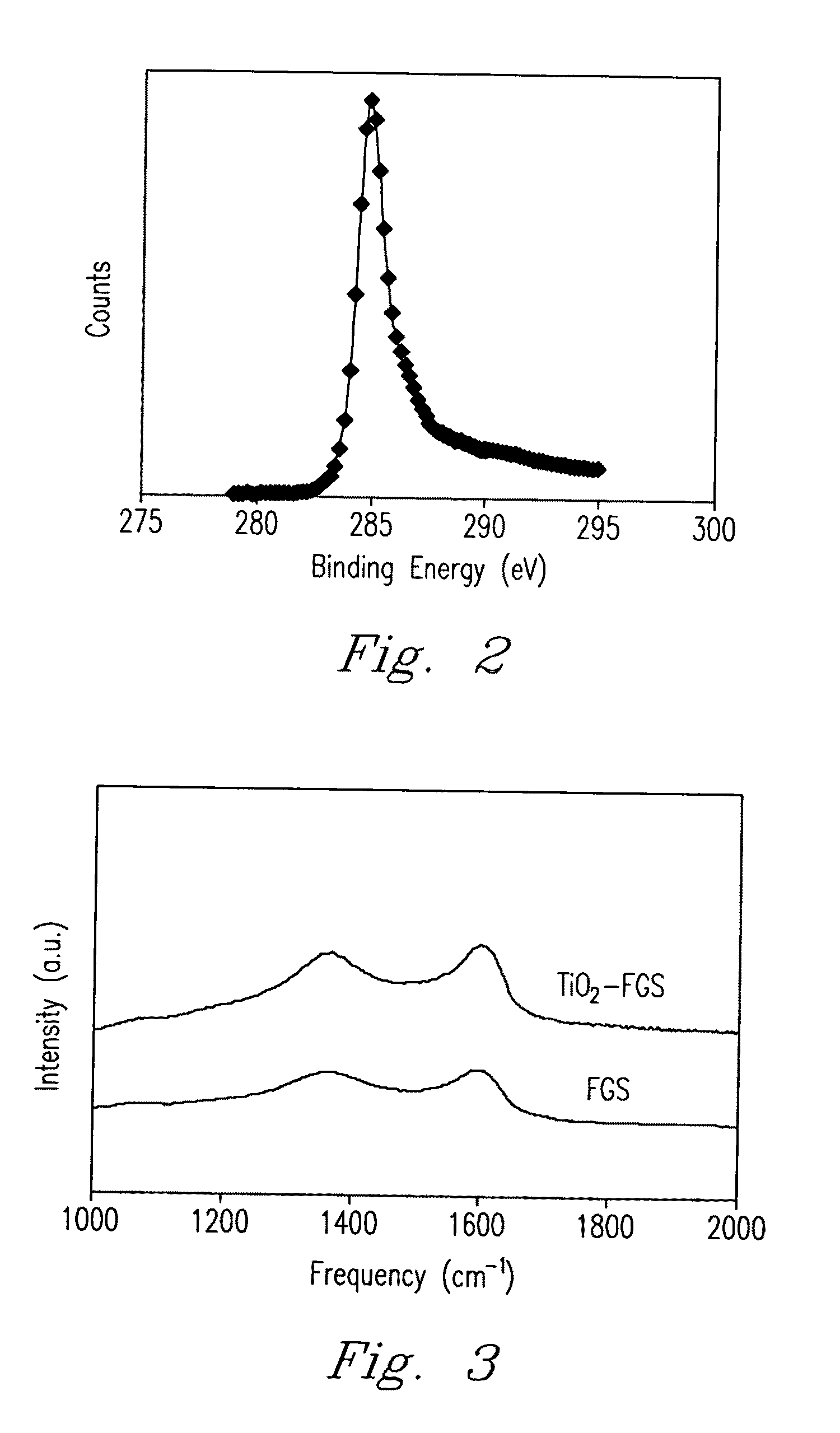

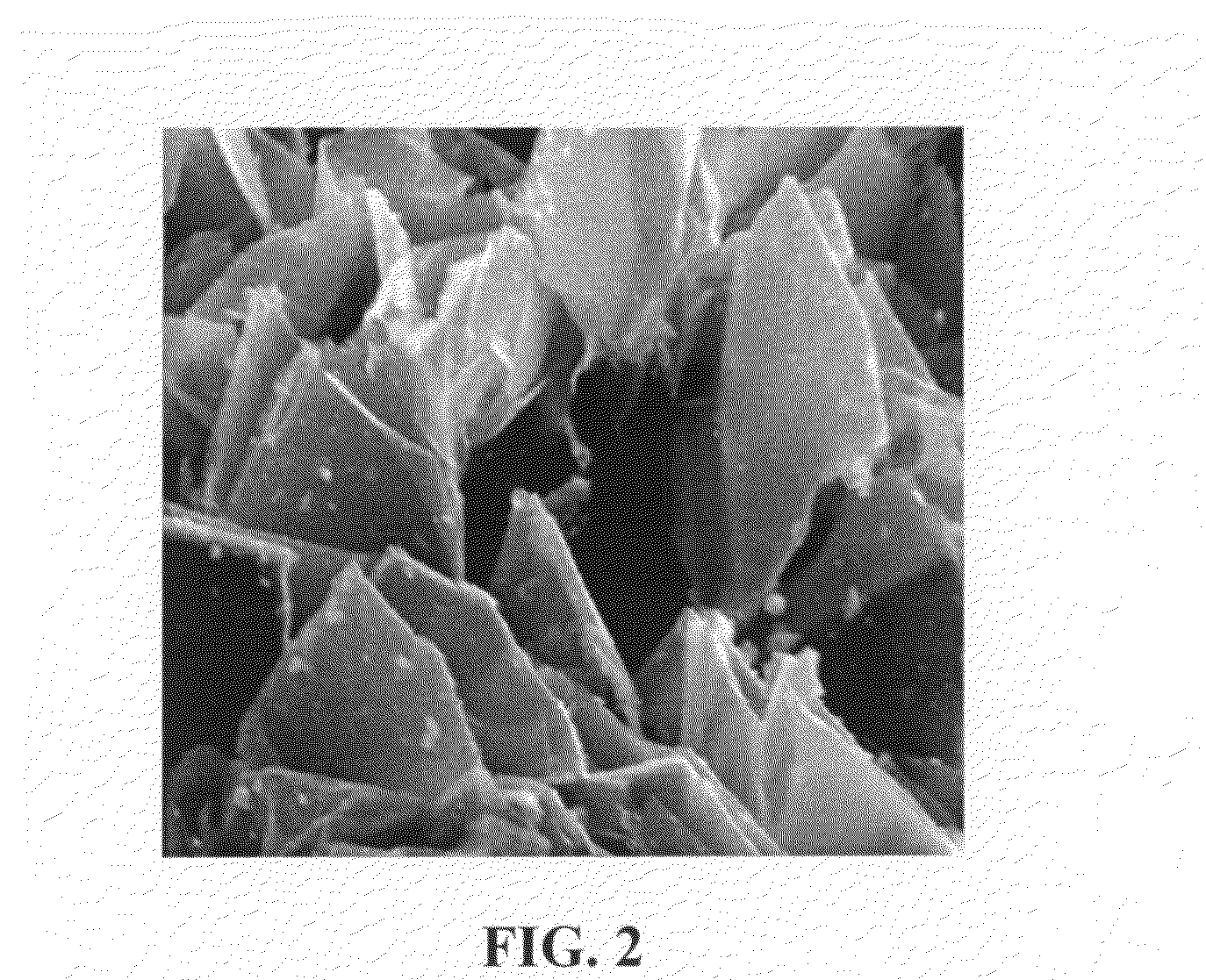

Nanocomposite of graphene and metal oxide materials

ActiveUS20100081057A1Easy to distinguishMaterial nanotechnologyRecord information storageDischarge rateCvd graphene

Nanocomposite materials comprising a metal oxide bonded to at least one graphene material. The nanocomposite materials exhibit a specific capacity of at least twice that of the metal oxide material without the graphene at a charge / discharge rate greater than about 10C.

Owner:THE TRUSTEES FOR PRINCETON UNIV +1

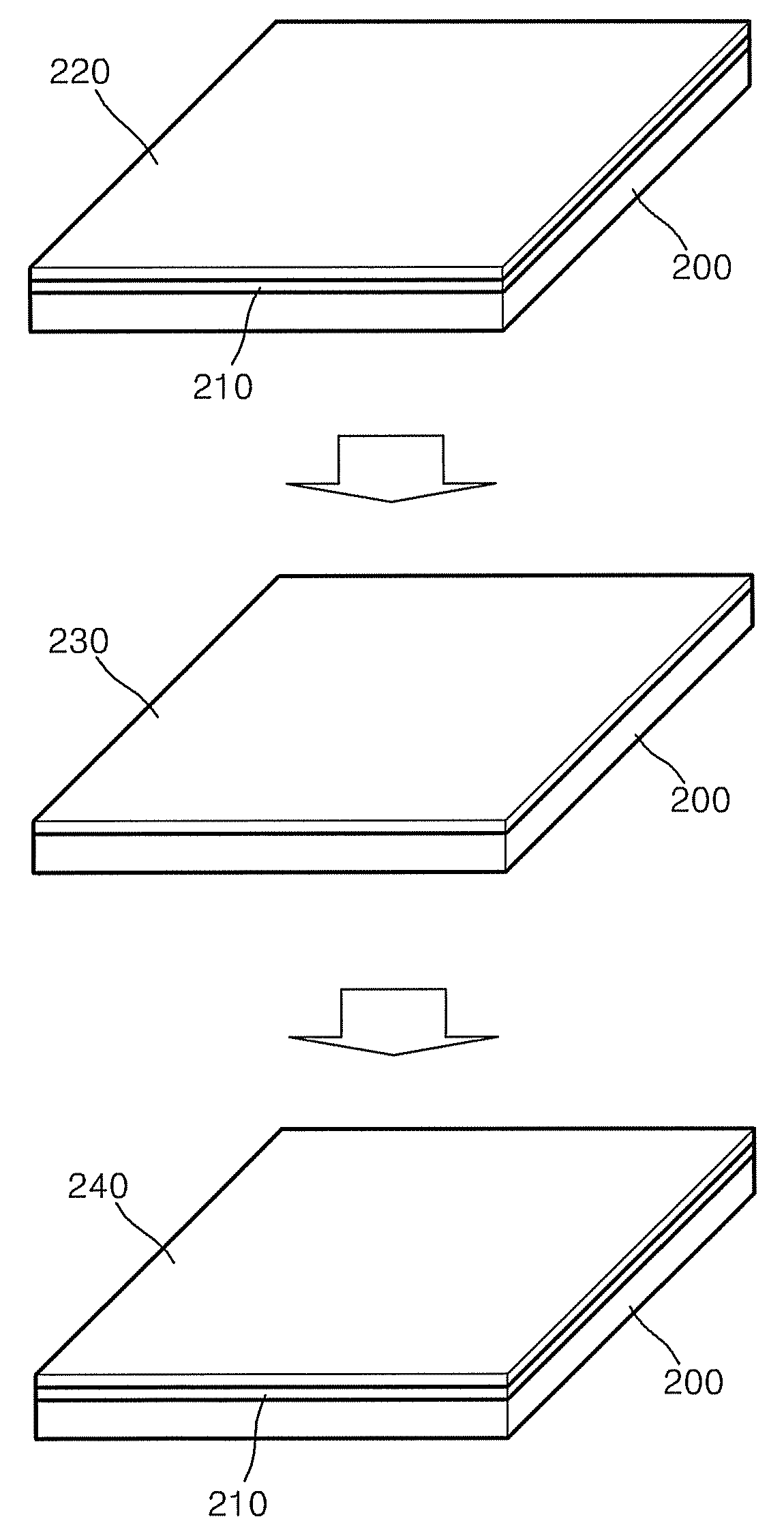

Single crystalline graphene sheet and process of preparing the same

A single-crystal graphene sheet includes a polycyclic aromatic molecule wherein a plurality of carbon atoms are covalently bound to each other, the single-crystal graphene sheet comprising between about 1 layer to about 300 layers; and wherein a peak ratio of a Raman D band intensity to a Raman G band intensity is equal to or less than 0.2. Also described is a method for preparing a single-crystal graphene sheet, the method includes forming a catalyst layer, which includes a single-crystal graphitizing metal catalyst sheet; disposing a carbonaceous material on the catalyst layer; and heat-treating the catalyst layer and the carbonaceous material in at least one of an inert atmosphere and a reducing atmosphere. Also described is a transparent electrode including a single-crystal graphene sheet.

Owner:SAMSUNG ELECTRONICS CO LTD

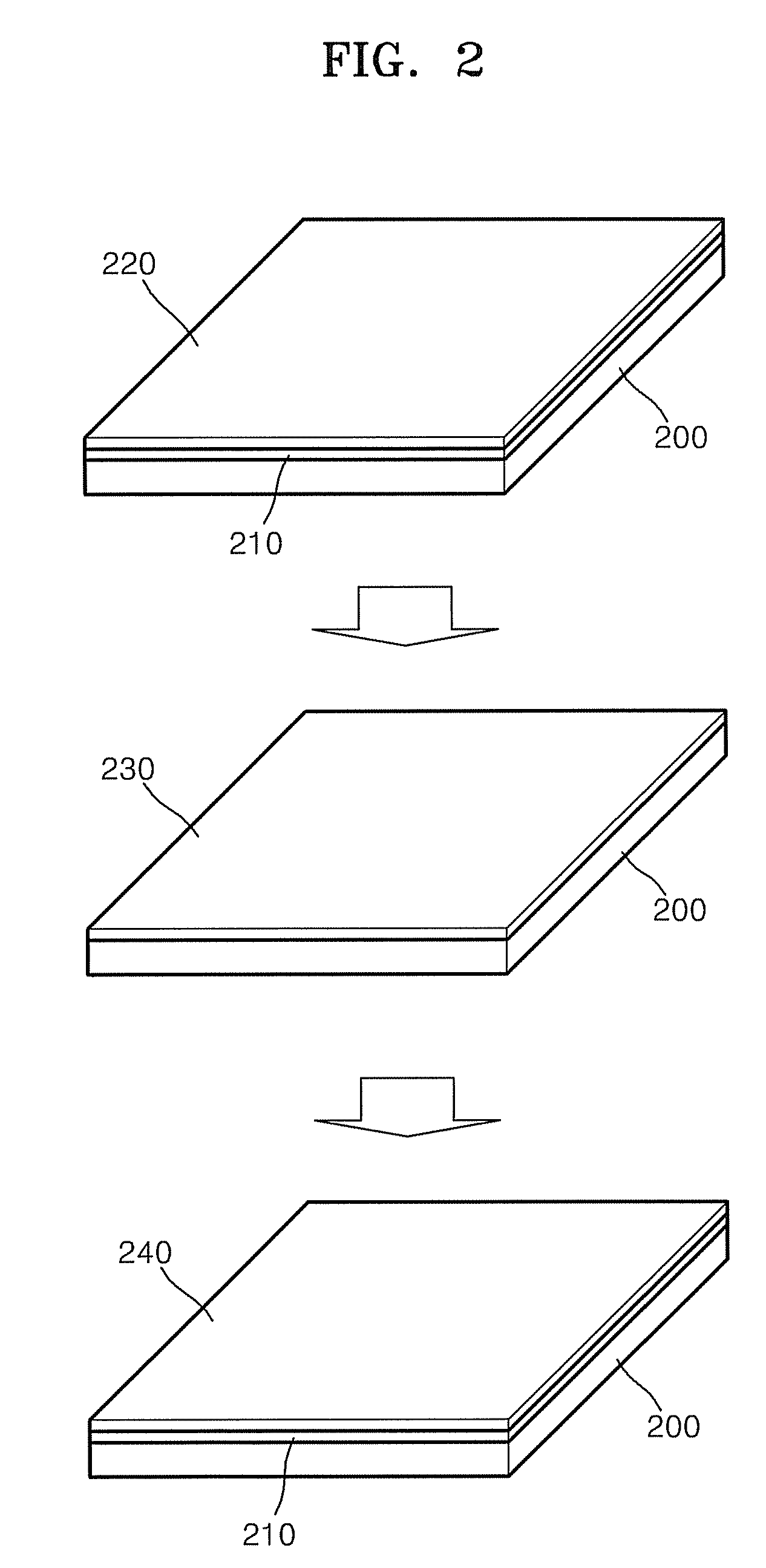

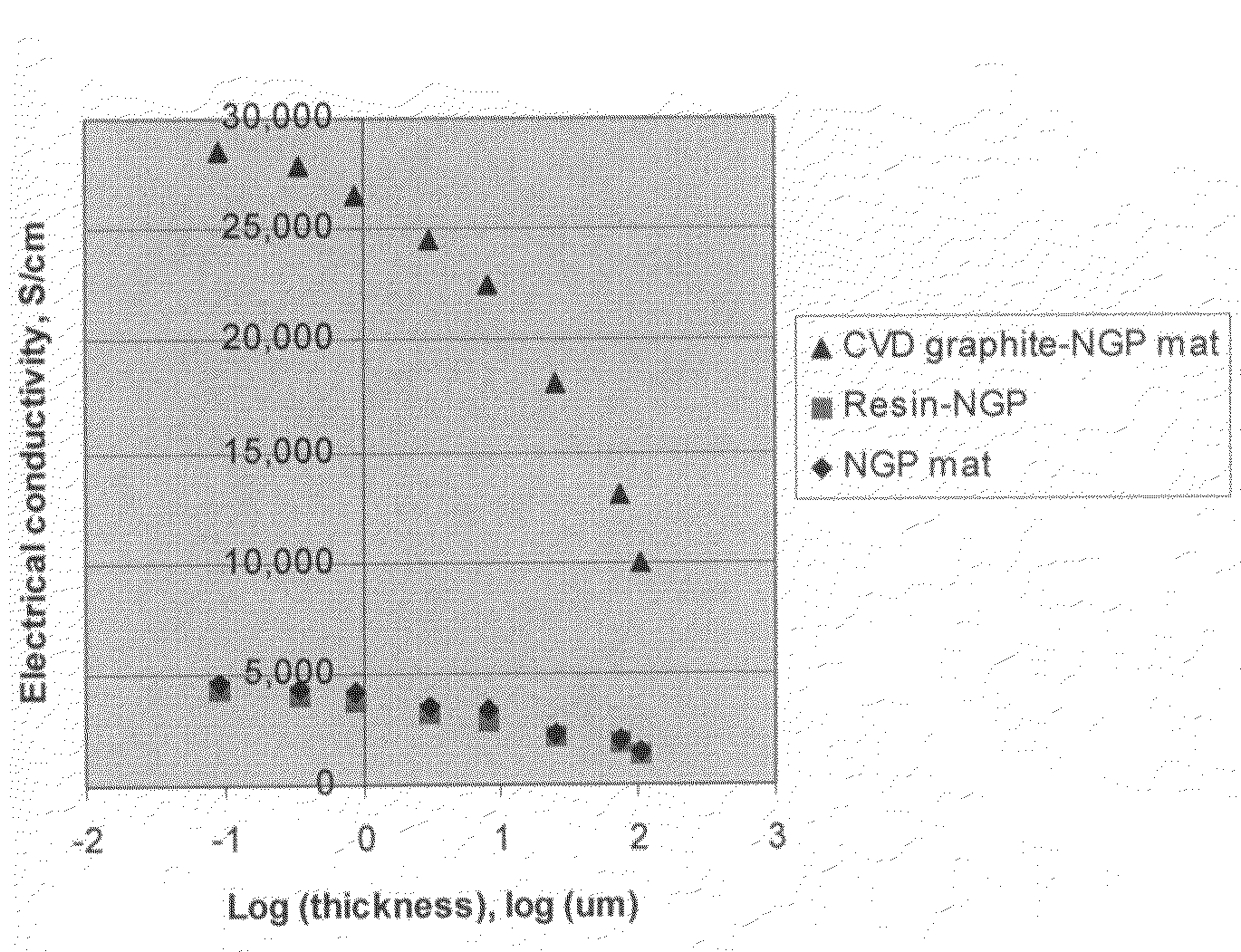

Nano-scaled graphene plate films and articles

ActiveUS20080248275A1Improve thermal conductivityNon-metal conductorsMaterial nanotechnologyLightning strikePlatelet

Disclosed is a nano-scaled graphene article comprising a non-woven aggregate of nano-scaled graphene platelets wherein each of the platelets comprises a graphene sheet or multiple graphene sheets and the platelets have a thickness no greater than 100 nm (preferably smaller than 10 nm) and platelets contact other platelets to define a plurality of conductive pathways along the article. The article has an exceptional thermal conductivity (typically greater than 500 Wm−1K−1) and excellent electrical conductivity (typically greater than 1,000 S / cm). Thin-film articles of the present invention can be used for thermal management in micro-electronic devices and for current-dissipating on an aircraft skin against lightning strikes.

Owner:GLOBAL GRAPHENE GRP INC

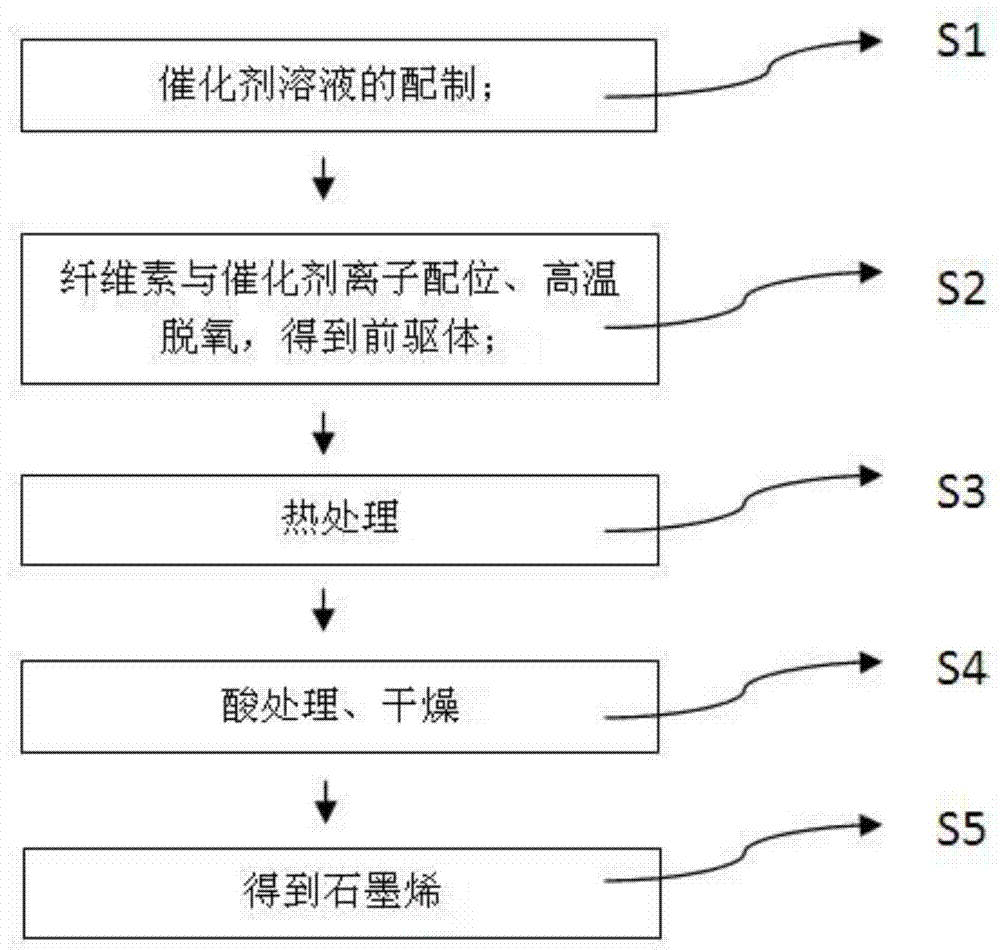

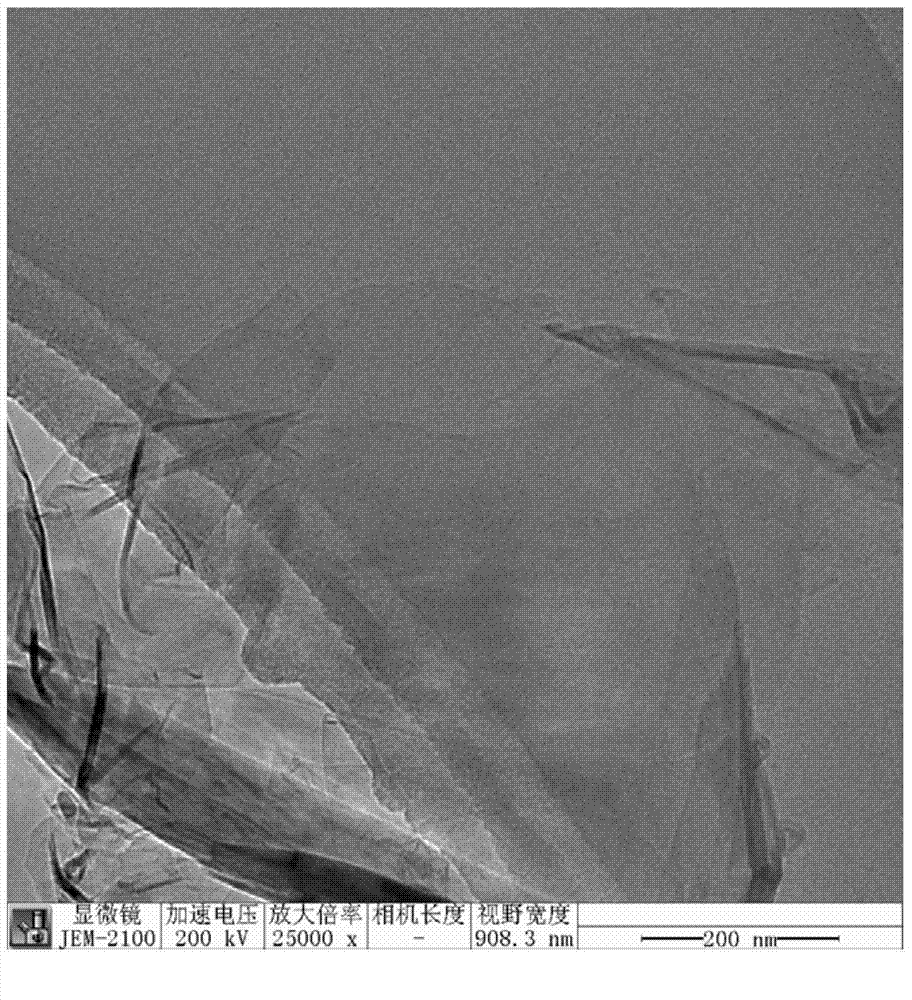

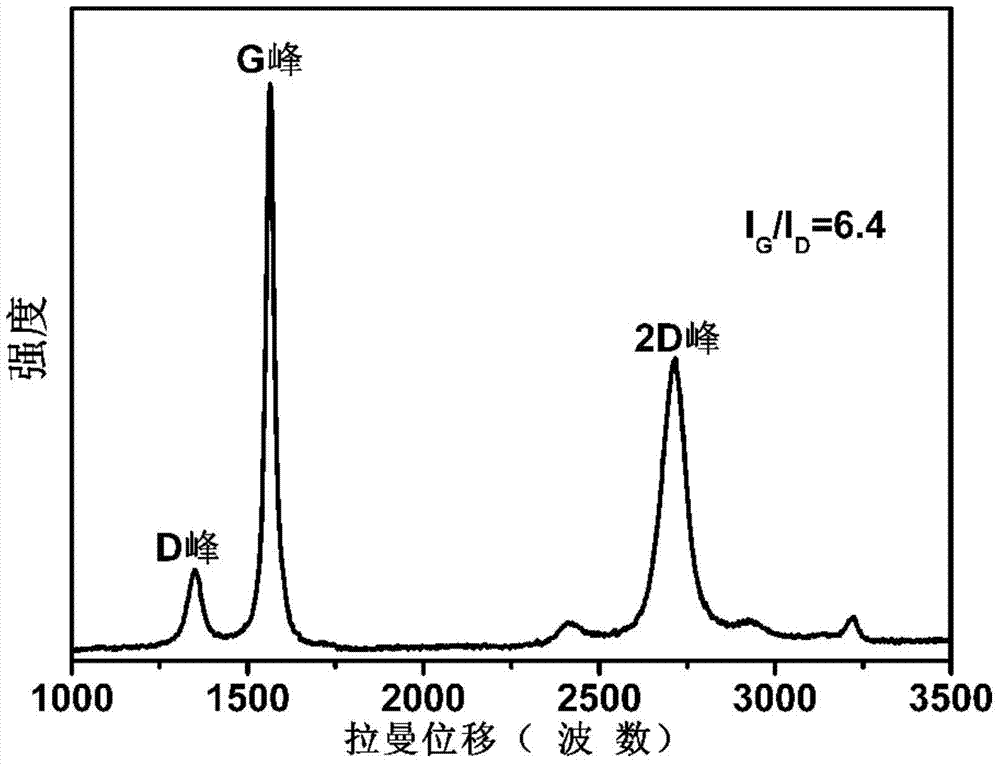

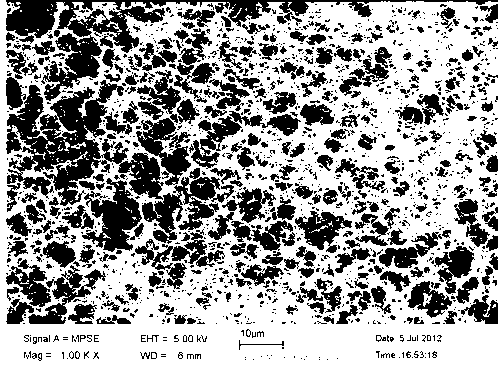

Method for preparing biomass graphene employing cellulose as raw material

ActiveCN104724699AUniform sizeIncrease productionPhysical/chemical process catalystsGrapheneCellulosePolymer science

The invention provides a preparation method of graphene, and particularly relates to a method for preparing biomass graphene employing cellulose as a raw material. The specific preparation method comprises the following steps: 1, preparing a catalyst solution; 2, carrying out ionic coordination and high-temperature deoxidization on cellulose and a catalyst, so as to obtain a precursor; 3, carrying out thermal treatment; 4, carrying out acid treatment, and drying to obtain the graphene, wherein the prepared graphene is uniform in morphology, has a single-layer or multi-layer two-dimensional layered structure; the dimension is 0.5-2 microns; and the electrical conductivity is 25,000-45,000S / m. The preparation method is simple in preparation technology, low in cost, high in yield, high in production safety, and controllable in product dimension and physical property; industrialized production can be realized; the graphene prepared by the method can be applied to electrode materials of super capacitors and lithium ion batteries, and can also be added to resin and rubber as an additive; and the physical property of the material can be improved.

Owner:HEILONGJIANG UNIV +1

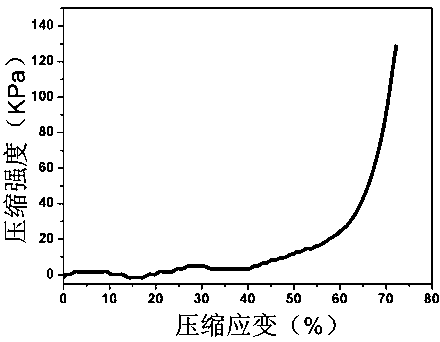

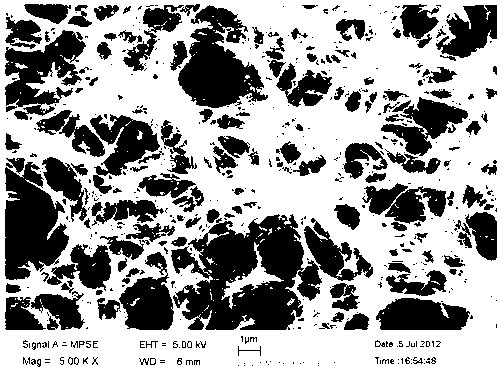

Graphene foam with three dimensional fully connected network and macroscopic quantity preparation method thereof

The invention relates to a graphene-based novel material and a chemical vapor deposition preparation technology thereof, in particular to graphene foam with a three dimensional fully connected network and a macroscopic quantity preparation method thereof. The method is suitable for a mass preparation of the graphene foam with high qualities. Three dimensional connected graphene can grow by catalytic cracking of carbon source gases on the surface of a three dimensional porous metal through the chemical vapor deposition technology, and a porous foam-shaped graphene three dimensional macroscopic body can be obtained after a porous metal base is removed by dissolving subsequently. According to the graphene foam with the three dimensional fully connected network and the macroscopic quantity preparation method thereof, a simple template replication method is used for preparing the three dimensional connected graphene macroscopic body, and the method has the advantages that the operation is simple and convenient, the rate of production is high, and the adjustment and control of the structure are easy. The graphene foam forms the fully connected network in a seamless connection mode, has a low density, a high porosity and specific surface area and excellent capabilities of charge conduction and heat conduction and establishes a foundation for applications of graphene in fields of electric conduction, thermally conductive composite materials, electromagnetic shielding, wave absorbing, catalysis, sensing and energy storage materials and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Reduced graphene oxide doped with dopant, thin layer and transparent electrode

InactiveUS20090146111A1Improve electrical performanceMaterial nanotechnologyNon-metal conductorsDopantDisplay device

Disclosed herein is a reduced graphene oxide doped with a dopant, and a thin layer, a transparent electrode, a display device and a solar cell including the reduced graphene oxide. The reduced graphene oxide doped with a dopant includes an organic dopant and / or an inorganic dopant.

Owner:SAMSUNG ELECTRONICS CO LTD

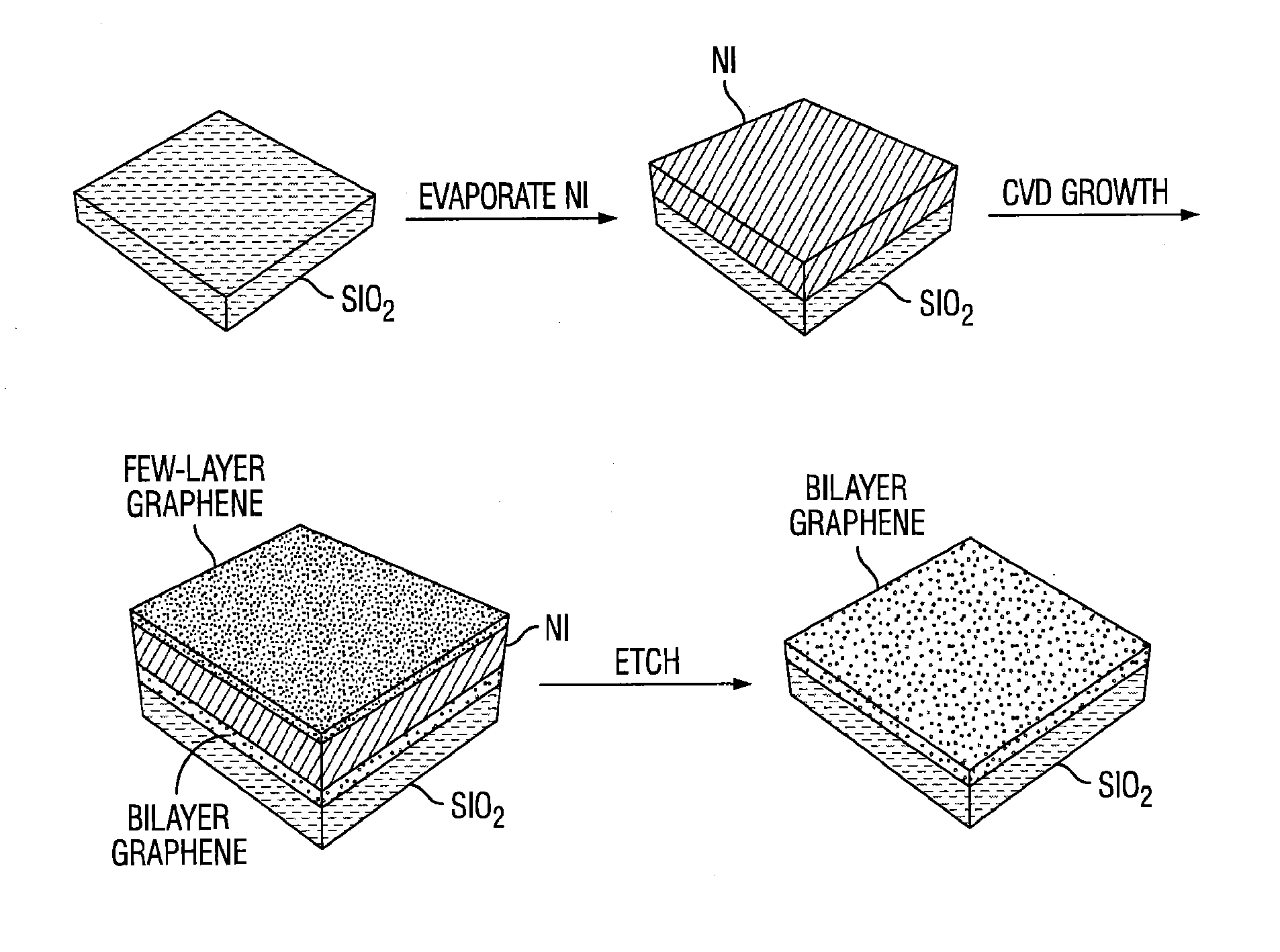

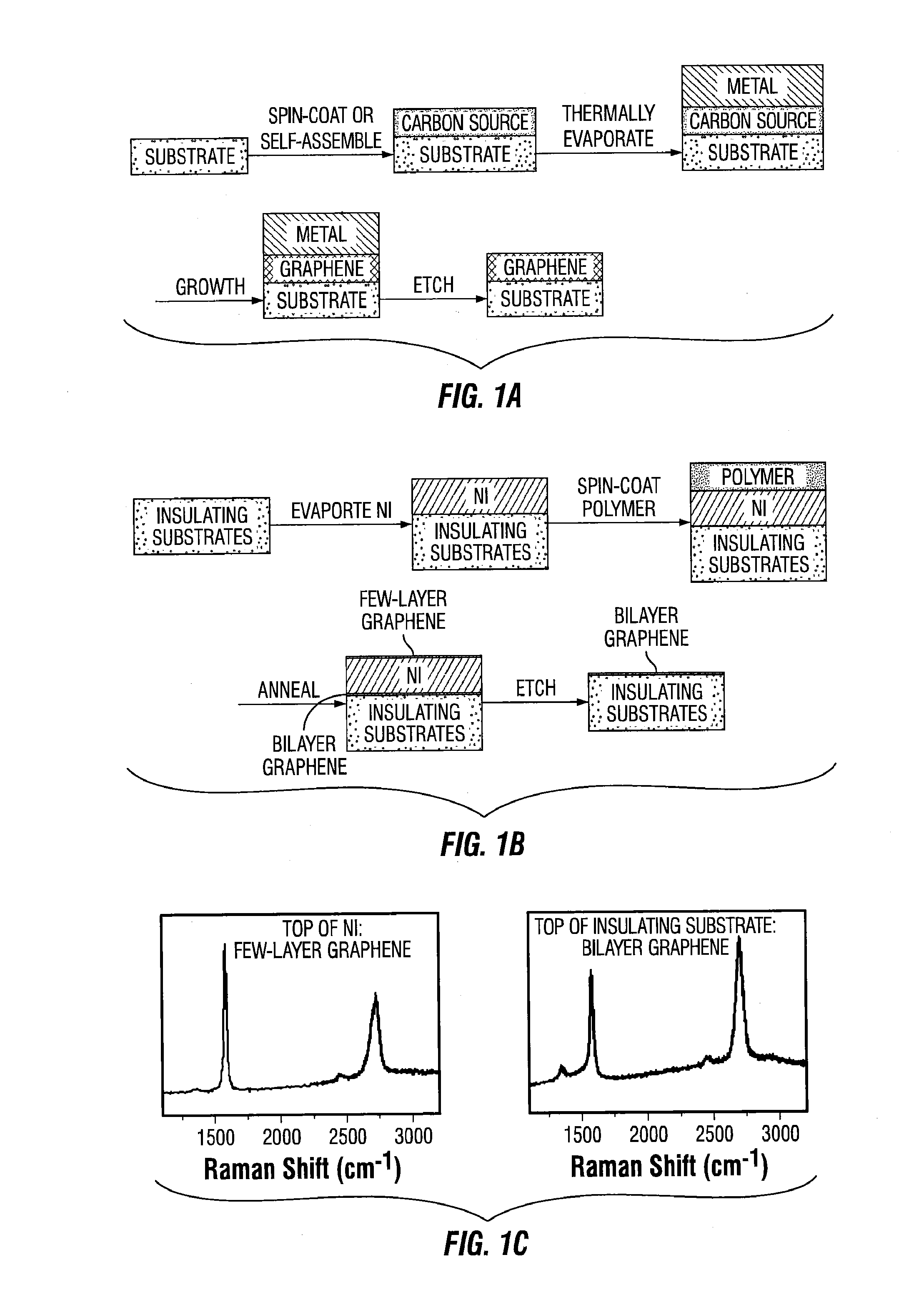

Direct growth of graphene films on non-catalyst surfaces

The present invention provides methods of forming graphene films on various non-catalyst surfaces by applying a carbon source and a catalyst to the surface and initiating graphene film formation. In some embodiments, graphene film formation may be initiated by induction heating. In some embodiments, the carbon source is applied to the non-catalyst surface before the catalyst is applied to the surface. In other embodiments, the catalyst is applied to the non-catalyst surface before the carbon source is applied to the surface. In further embodiments, the catalyst and the carbon source are applied to the non-catalyst surface at the same time. Further embodiments of the present invention may also include a step of separating the catalyst from the formed graphene film, such as by acid etching.

Owner:RICE UNIV

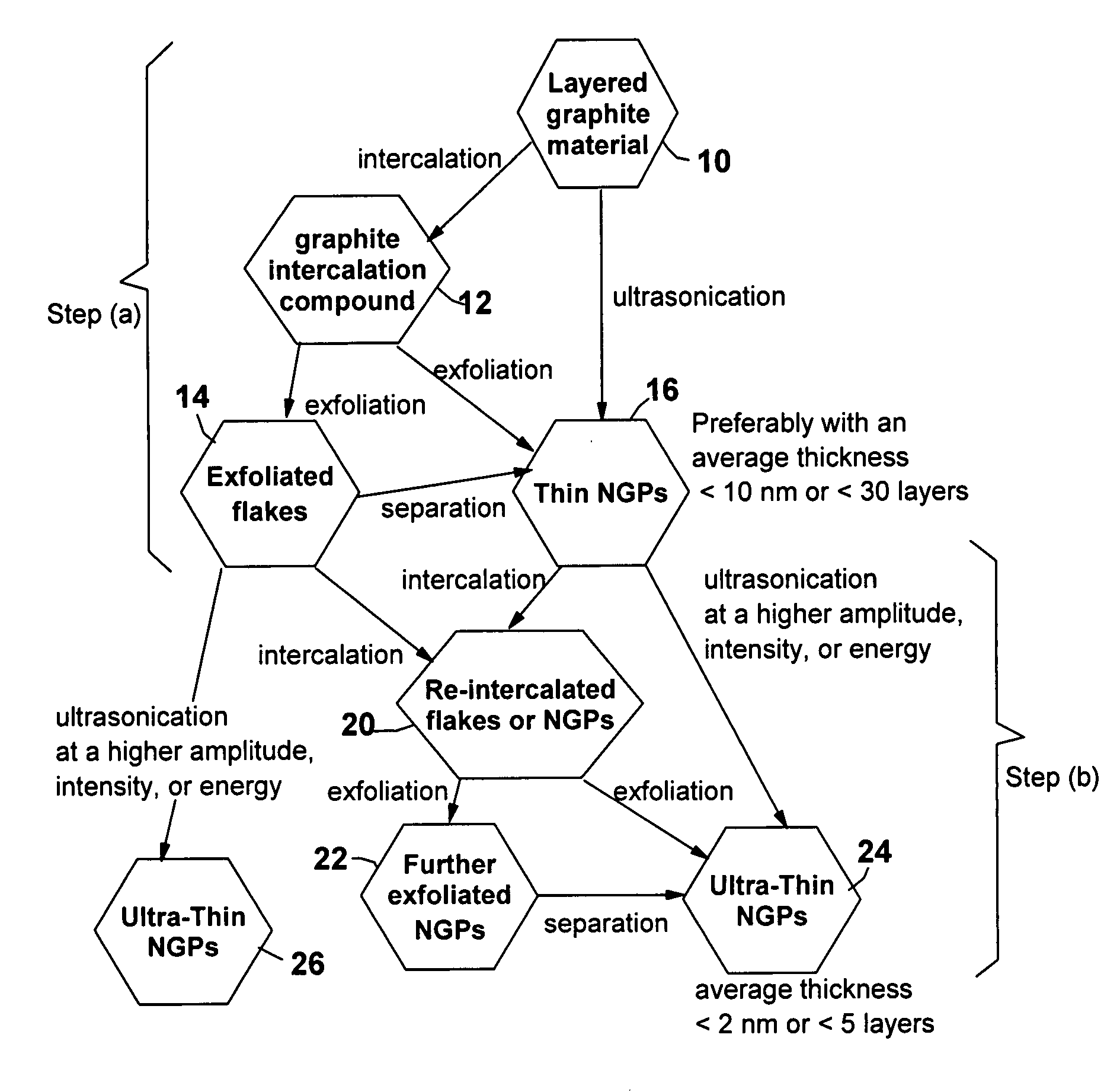

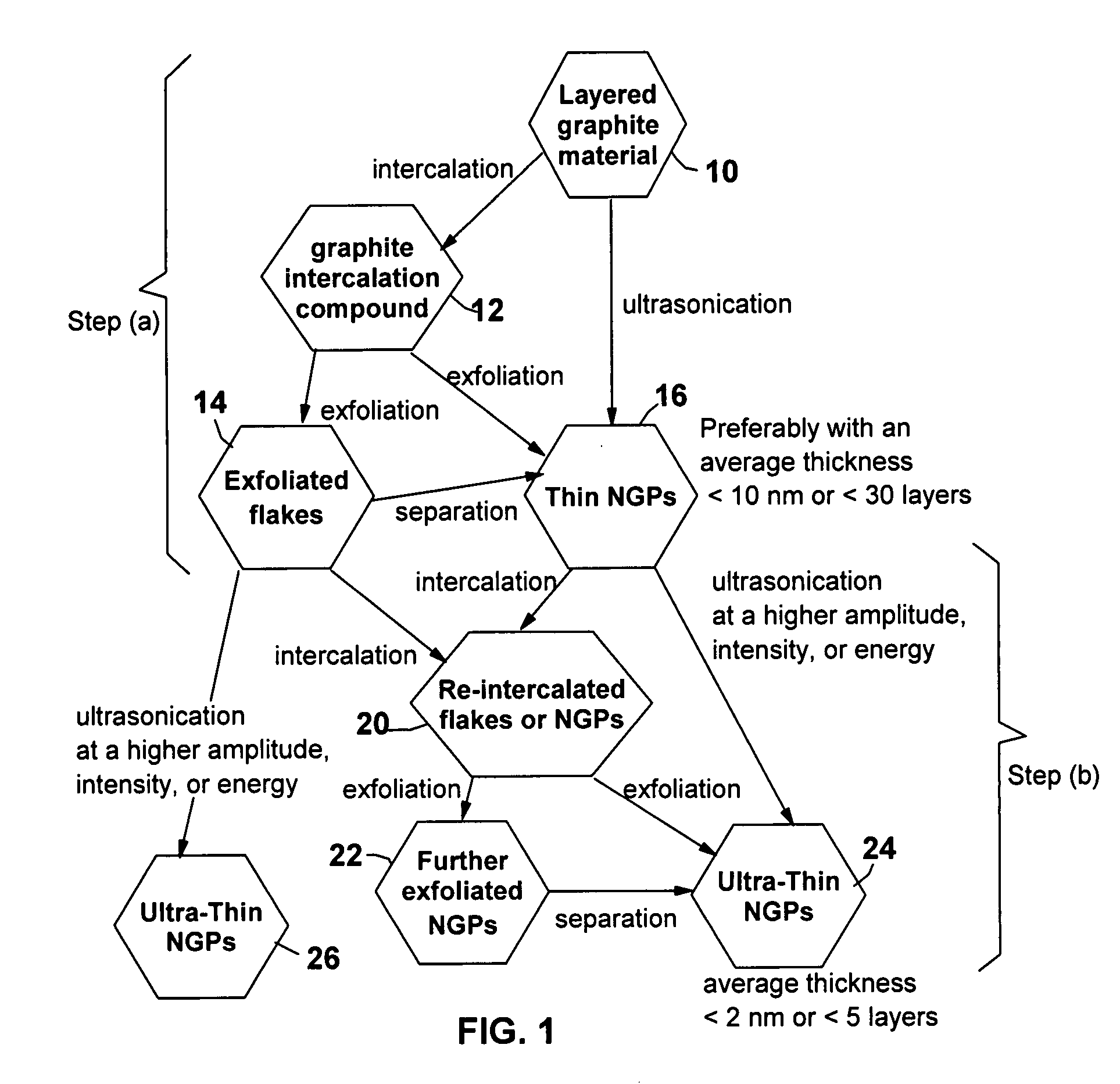

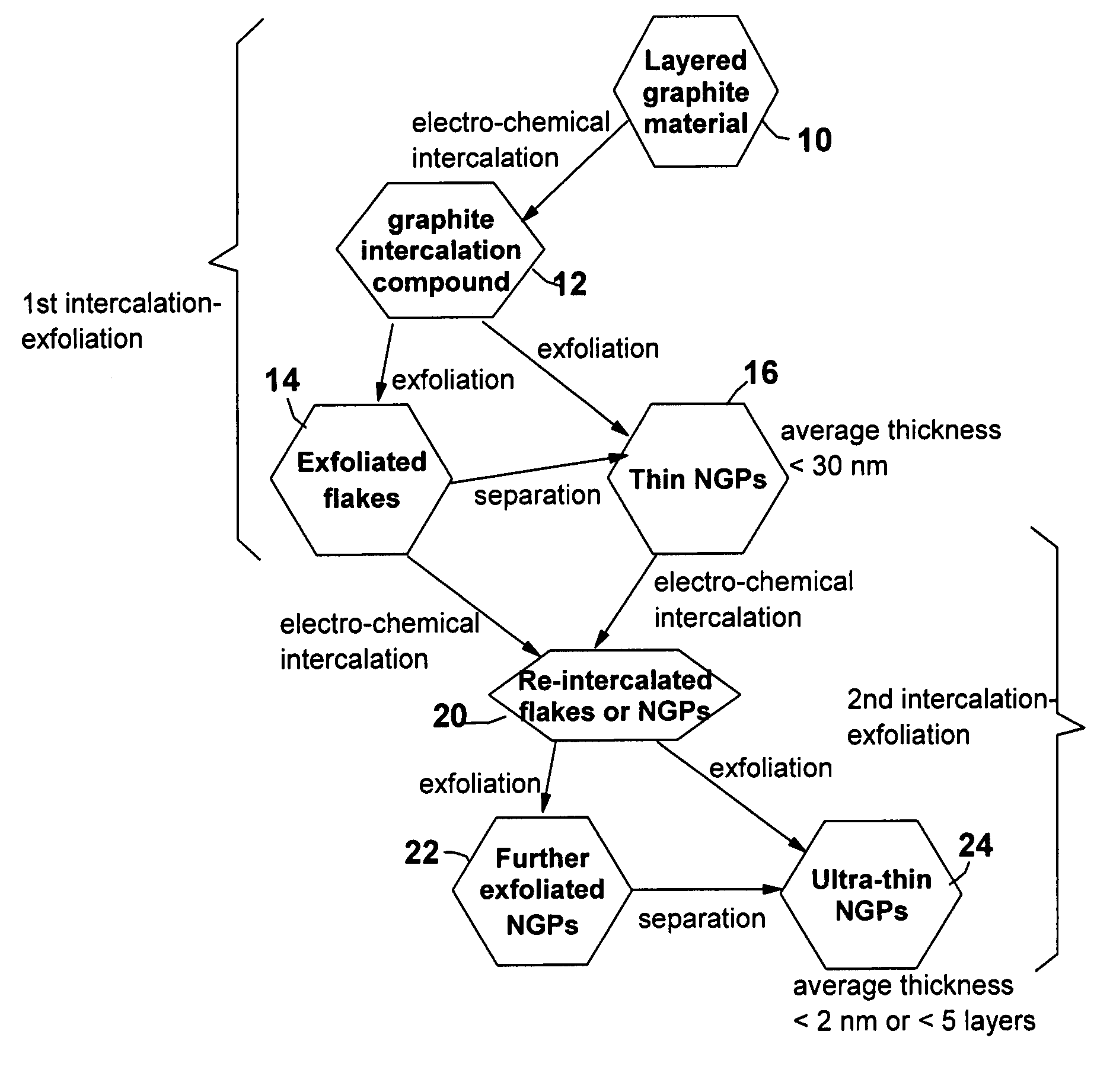

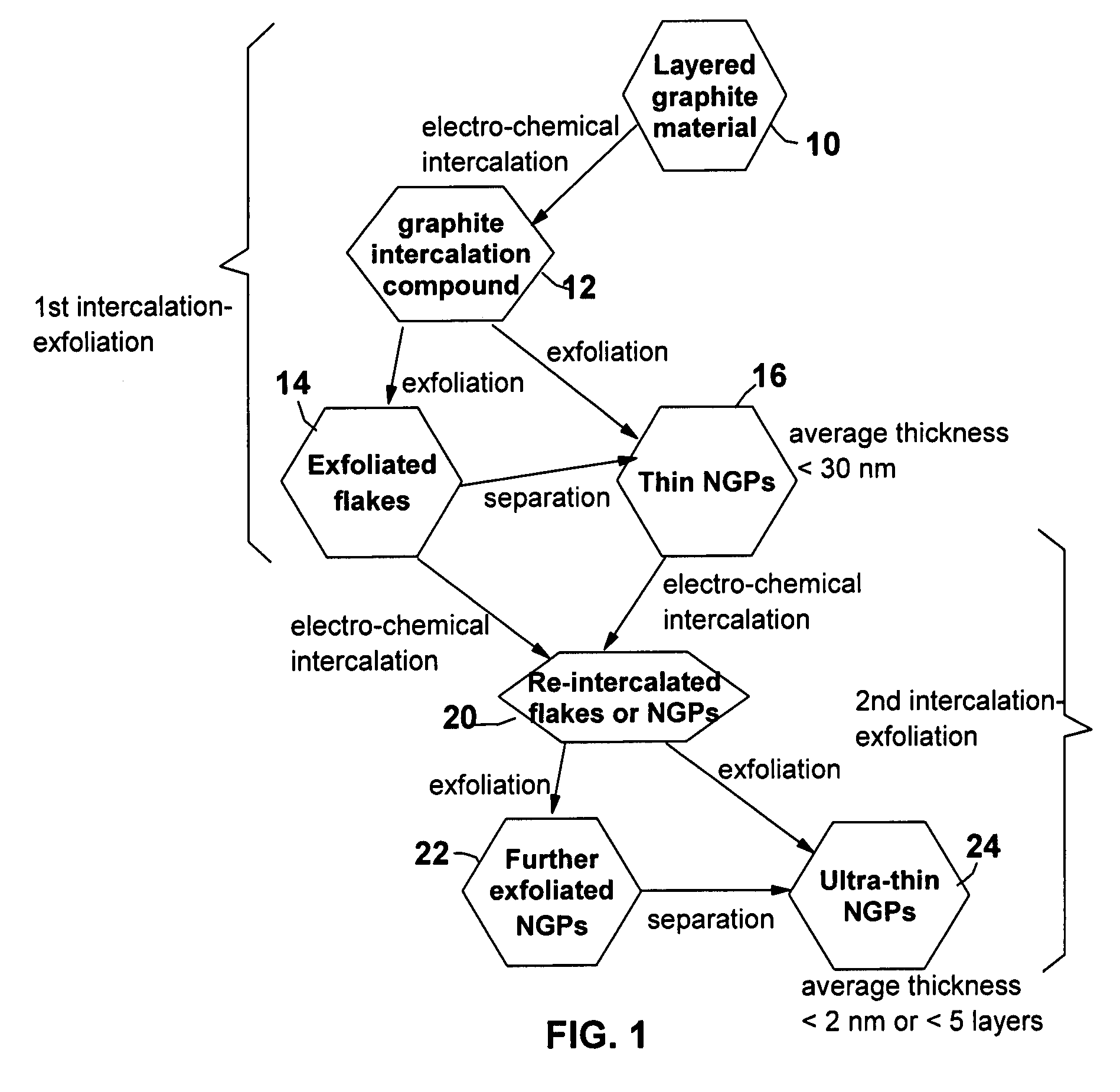

Method for producing ultra-thin nano-scaled graphene platelets

InactiveUS20090022649A1Good dispersionImprove conductivityMaterial nanotechnologyGraphiteFiberCarbon nanotube

A method of producing ultra-thin, separated nano-scaled platelets having an average thickness no greater than 2 nm or comprising, on average, no more than 5 layers per platelet from a layered graphite material. The method comprises: (a) providing a supply of nano-scaled platelets with an average thickness of no more than 10 nm or having, on average, no more than 30 layers per platelet; and (b) intercalating the supply of nano-scaled platelets to produce intercalated nano platelets and exfoliating the intercalated nano platelets at a temperature and a pressure for a sufficient period of time to produce the ultra-thin nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:NANOTEK INSTR

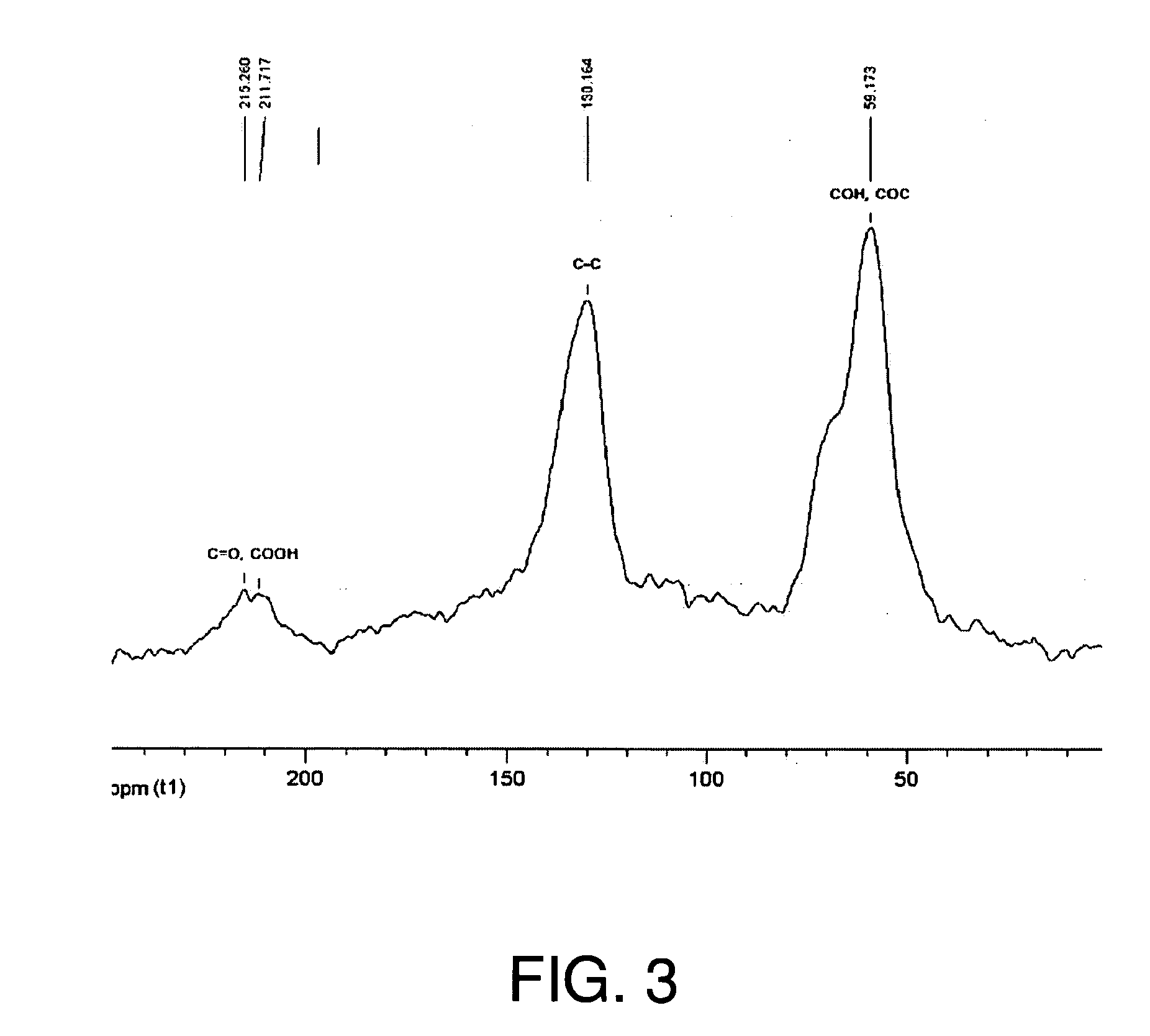

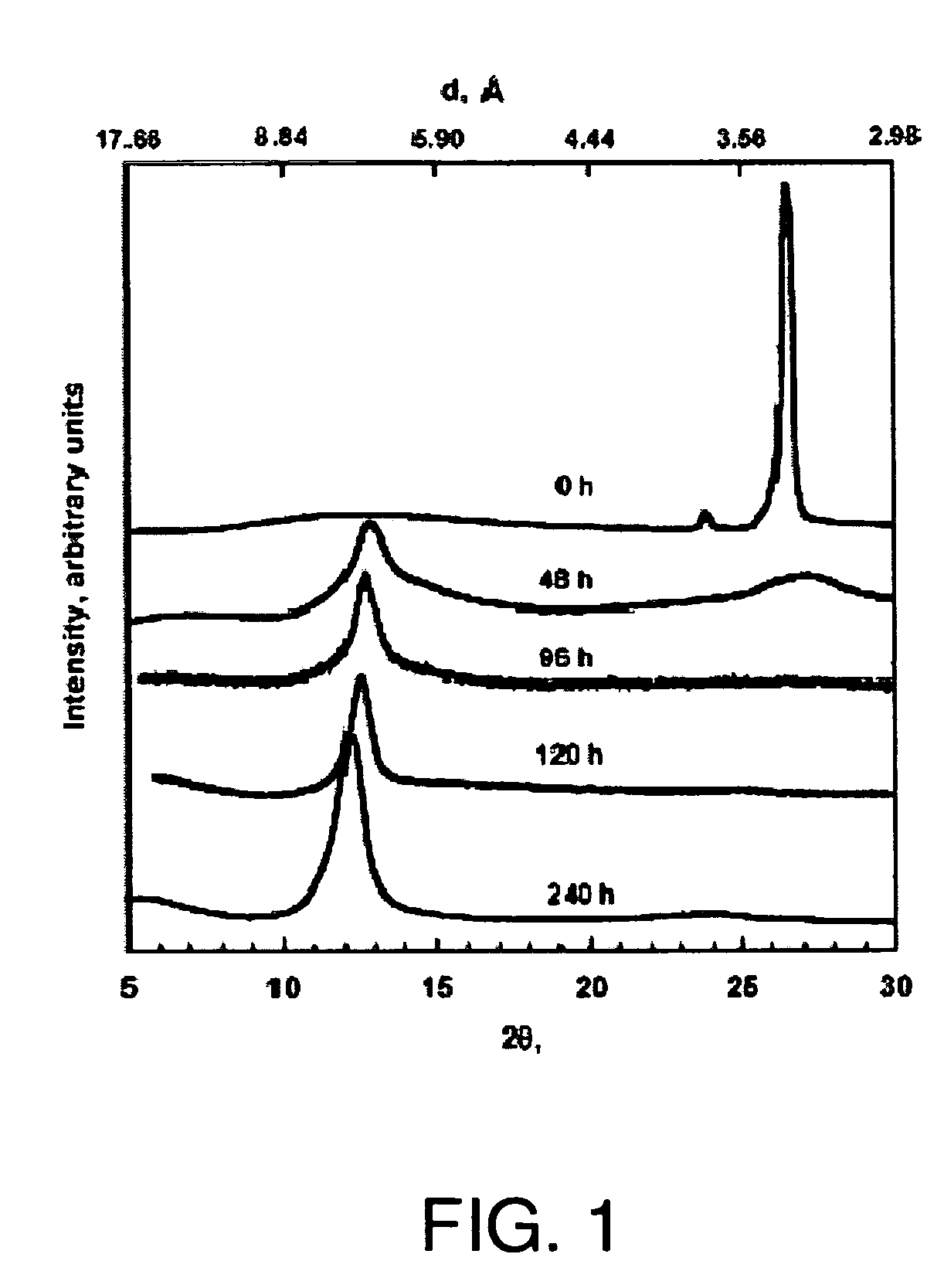

Functional graphene-rubber nanocomposites

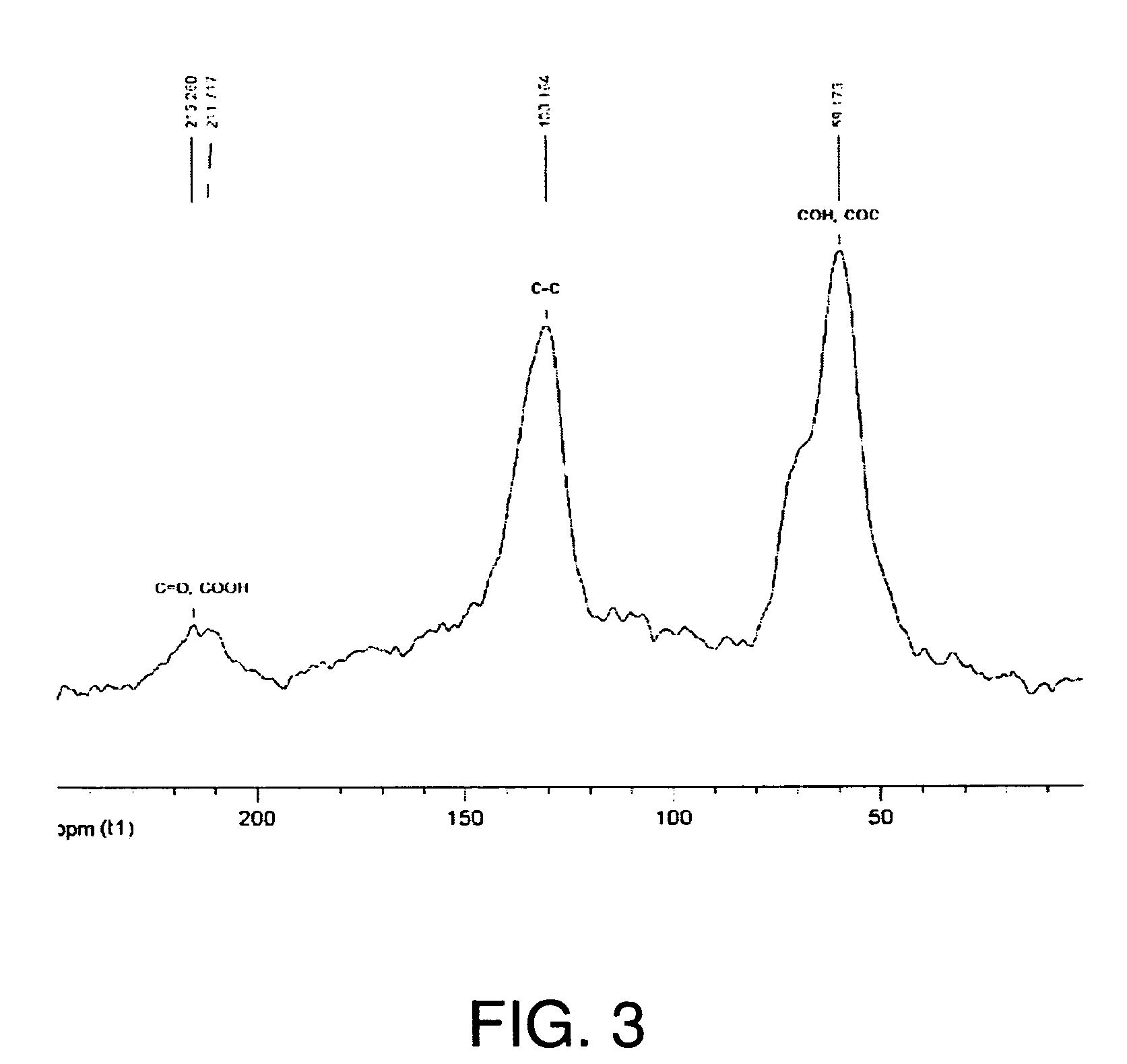

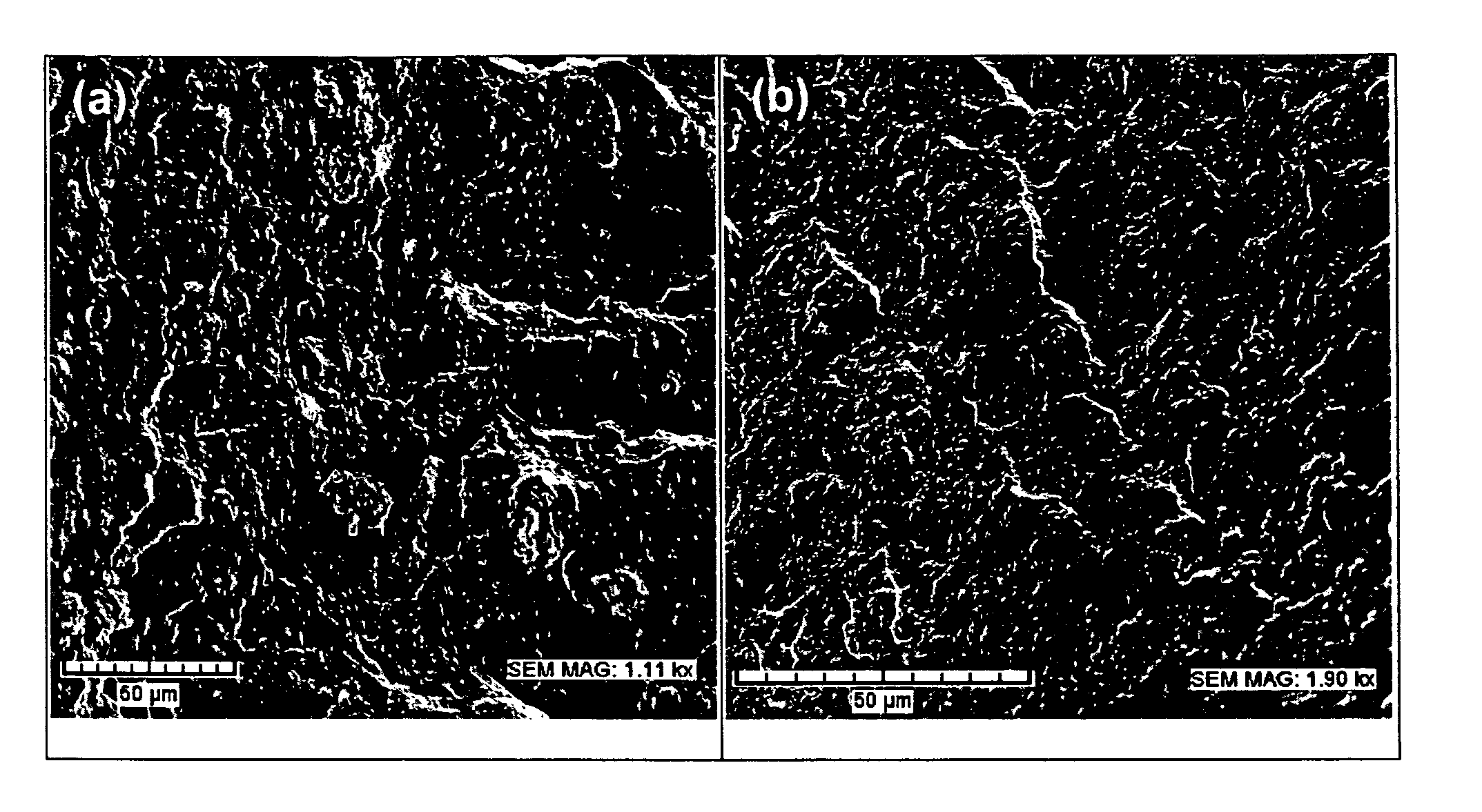

ActiveUS7745528B2Increase modulusImprove toughnessMaterial nanotechnologyPigmenting treatmentElastomerX-ray

A polymer composition, containing a polymer matrix which contains an elastomer; and a functional graphene which displays no signature of graphite and / or graphite oxide, as determined by X-ray diffraction, exhibits excellent strength, toughness, modulus, thermal stability and electrical conductivity.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Functional graphene-rubber nanocomposites

ActiveUS20100096597A1Increase modulusImprove toughnessMaterial nanotechnologyPigmenting treatmentElastomerPolymer science

A polymer composition, containing a polymer matrix which contains an elastomer; and a functional graphene which displays no signature of graphite and / or graphite oxide, as determined by X-ray diffraction, exhibits excellent strength, toughness, modulus, thermal stability and electrical conductivity.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Synthesis of graphene sheets and nanoparticle composites comprising same

A method for producing isolatable and dispersible graphene sheets, wherein the graphene sheets may be tailored to be soluble in aqueous, non-aqueous or semi-aqueous solutions. The water soluble graphene sheets may be used to produce a metal nanoparticle-graphene composite having a specific surface area that is 20 times greater than aggregated graphene sheets. Graphene sheets that are soluble in organic solvents may be used to make graphene-polymer composites.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

Graphene and Hexagonal Boron Nitride Planes and Associated Methods

InactiveUS20100055464A1Material nanotechnologyNitrogen compoundsHexagonal boron nitrideBoron nitride

Graphene layers, hexagonal boron nitride layers, as well as other materials made of primarily sp2 bonded atoms and associated methods are disclosed. In one aspect, for example, a method of forming a graphene layer is provided. Such a method may include mixing a carbon source with a horizontally oriented molten solvent, precipitating the carbon source from the molten solvent to form a graphite layer across the molten solvent, and separating the graphite layer into a plurality of graphene layers.

Owner:SUNG CHIEN MIN

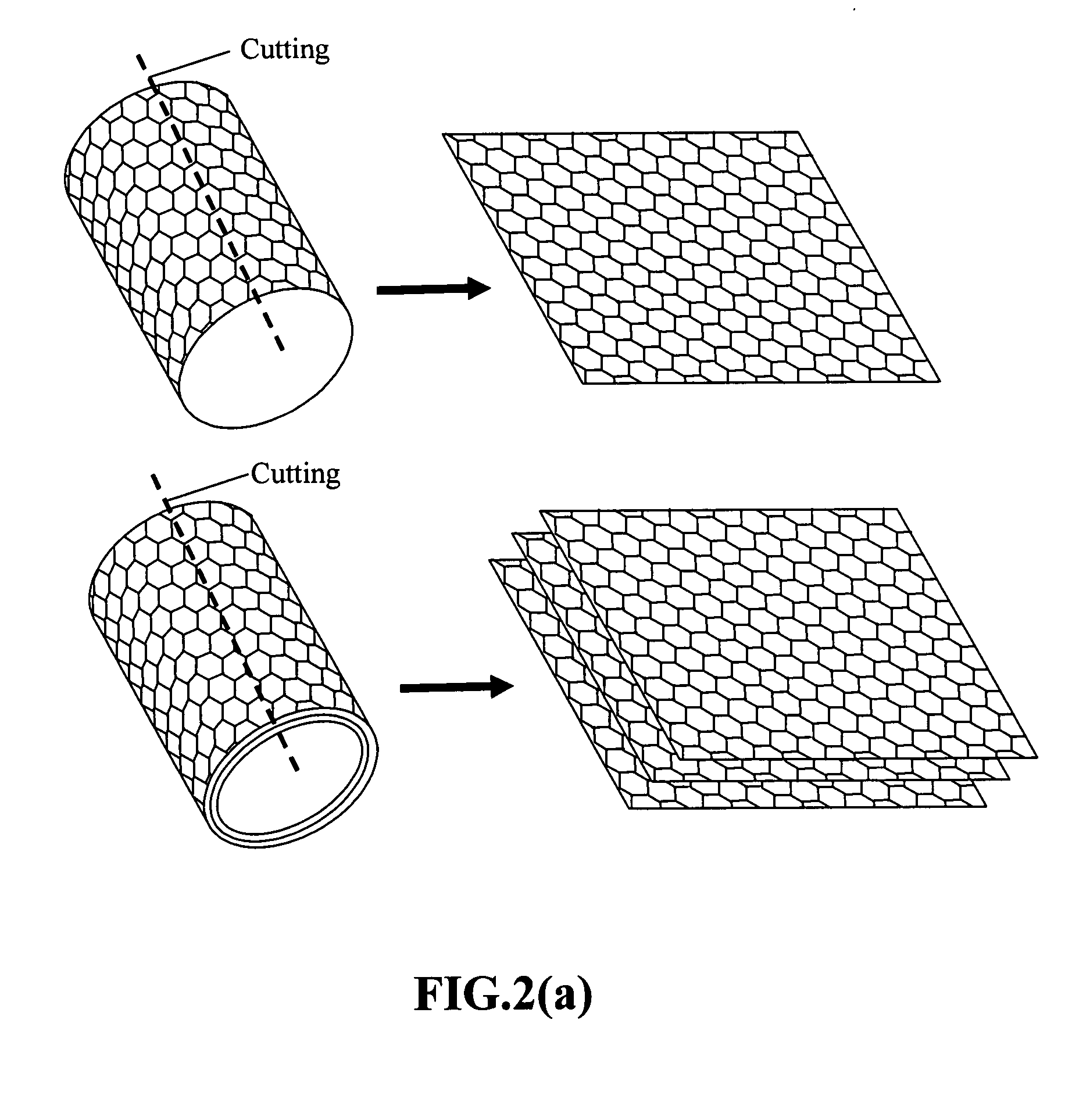

Nano-scaled graphene platelets with a high length-to-width aspect ratio

ActiveUS20090155578A1High aspect ratioHigh stiffnessMaterial nanotechnologyShielding materialsFiberCarbon fibers

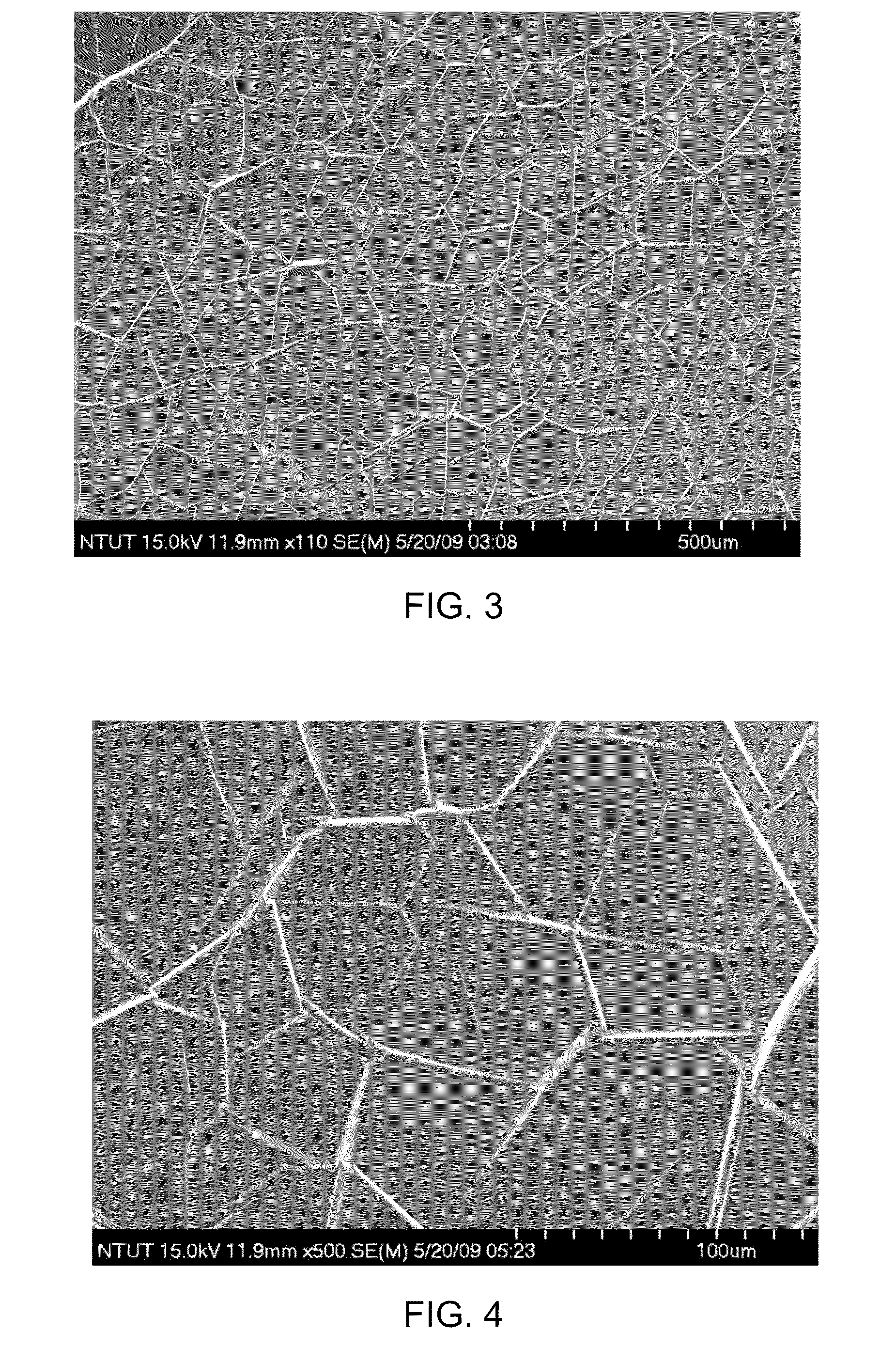

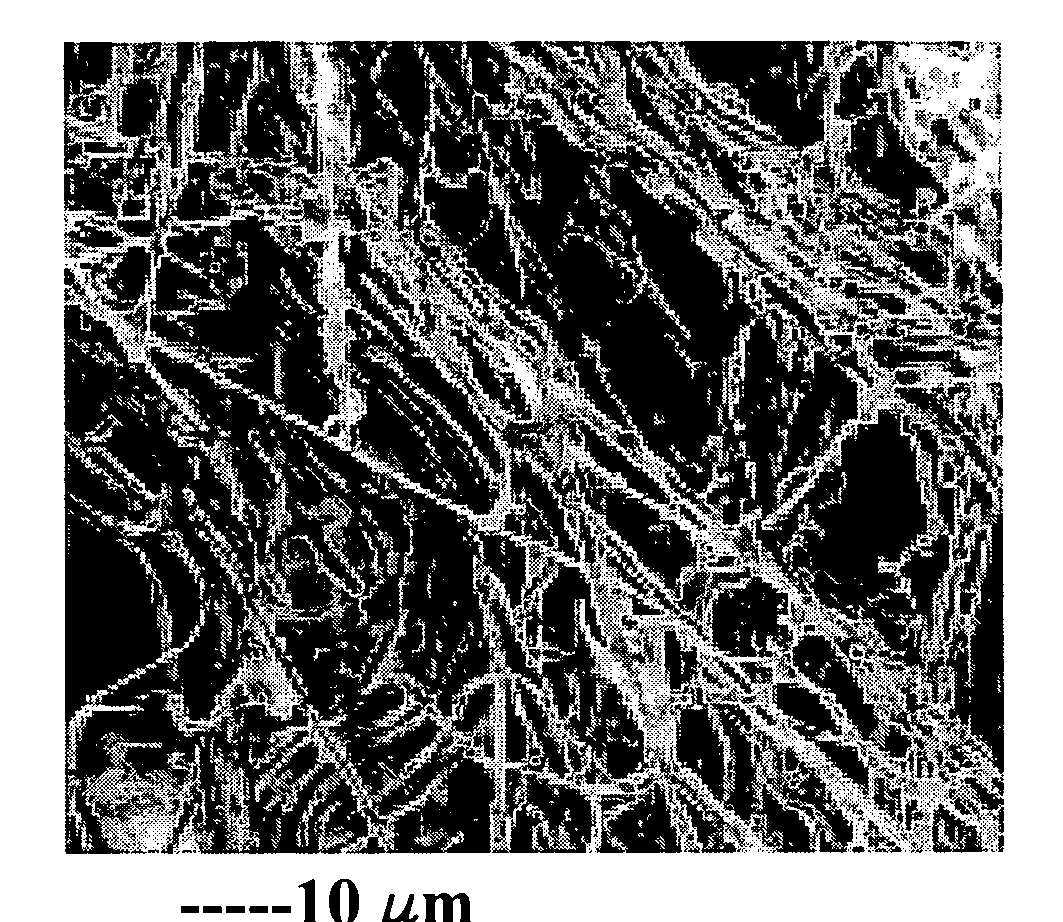

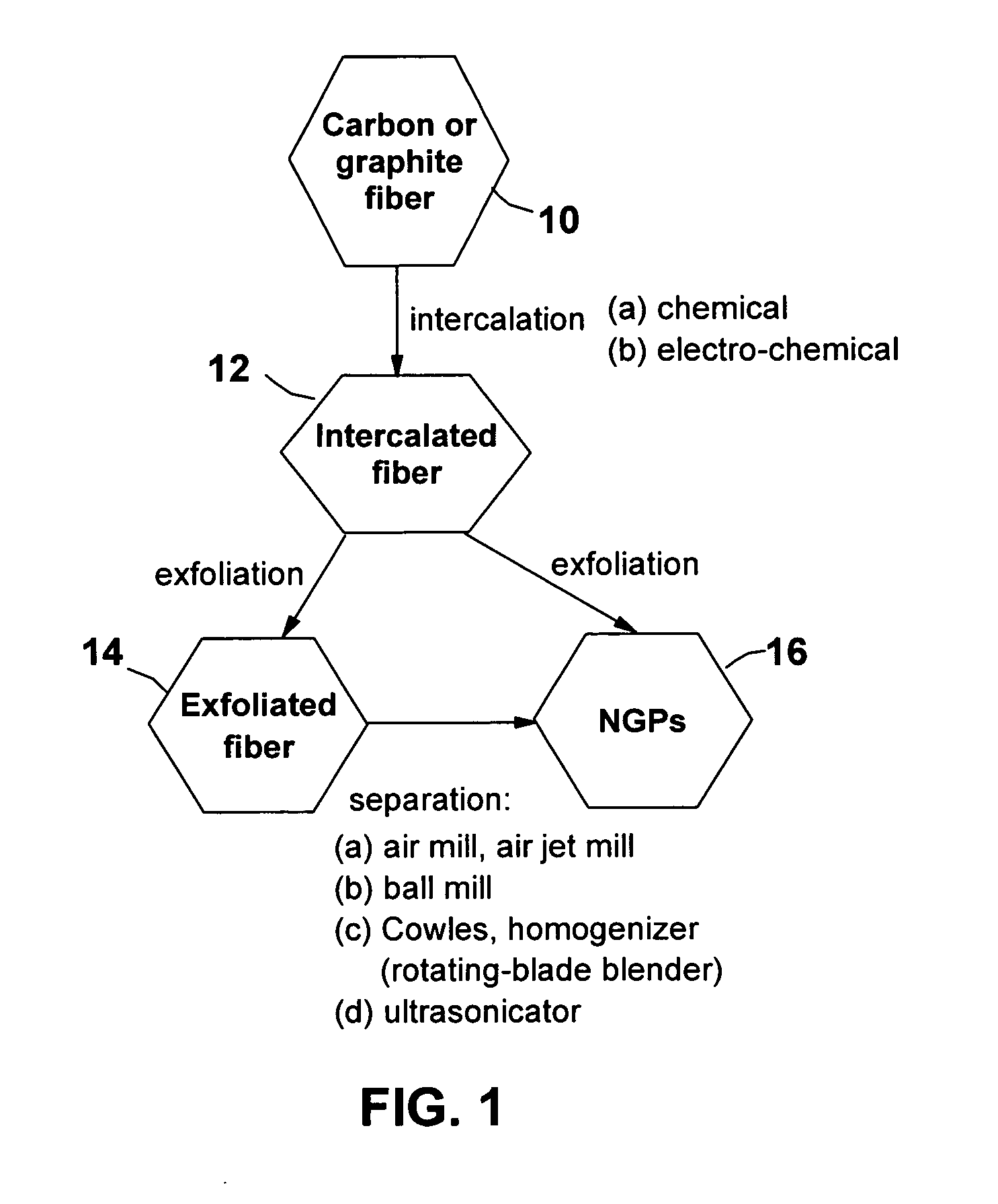

This invention provides a nano-scaled graphene platelet (NGP) having a thickness no greater than 100 nm and a length-to-width ratio no less than 3 (preferably greater than 10). The NGP with a high length-to-width ratio can be prepared by using a method comprising (a) intercalating a carbon fiber or graphite fiber with an intercalate to form an intercalated fiber; (b) exfoliating the intercalated fiber to obtain an exfoliated fiber comprising graphene sheets or flakes; and (c) separating the graphene sheets or flakes to obtain nano-scaled graphene platelets. The invention also provides a nanocomposite material comprising an NGP with a high length-to-width ratio. Such a nanocomposite can become electrically conductive with a small weight fraction of NGPs. Conductive composites are particularly useful for shielding of sensitive electronic equipment against electromagnetic interference (EMI) or radio frequency interference (RFI), and for electrostatic charge dissipation.

Owner:GLOBAL GRAPHENE GRP INC

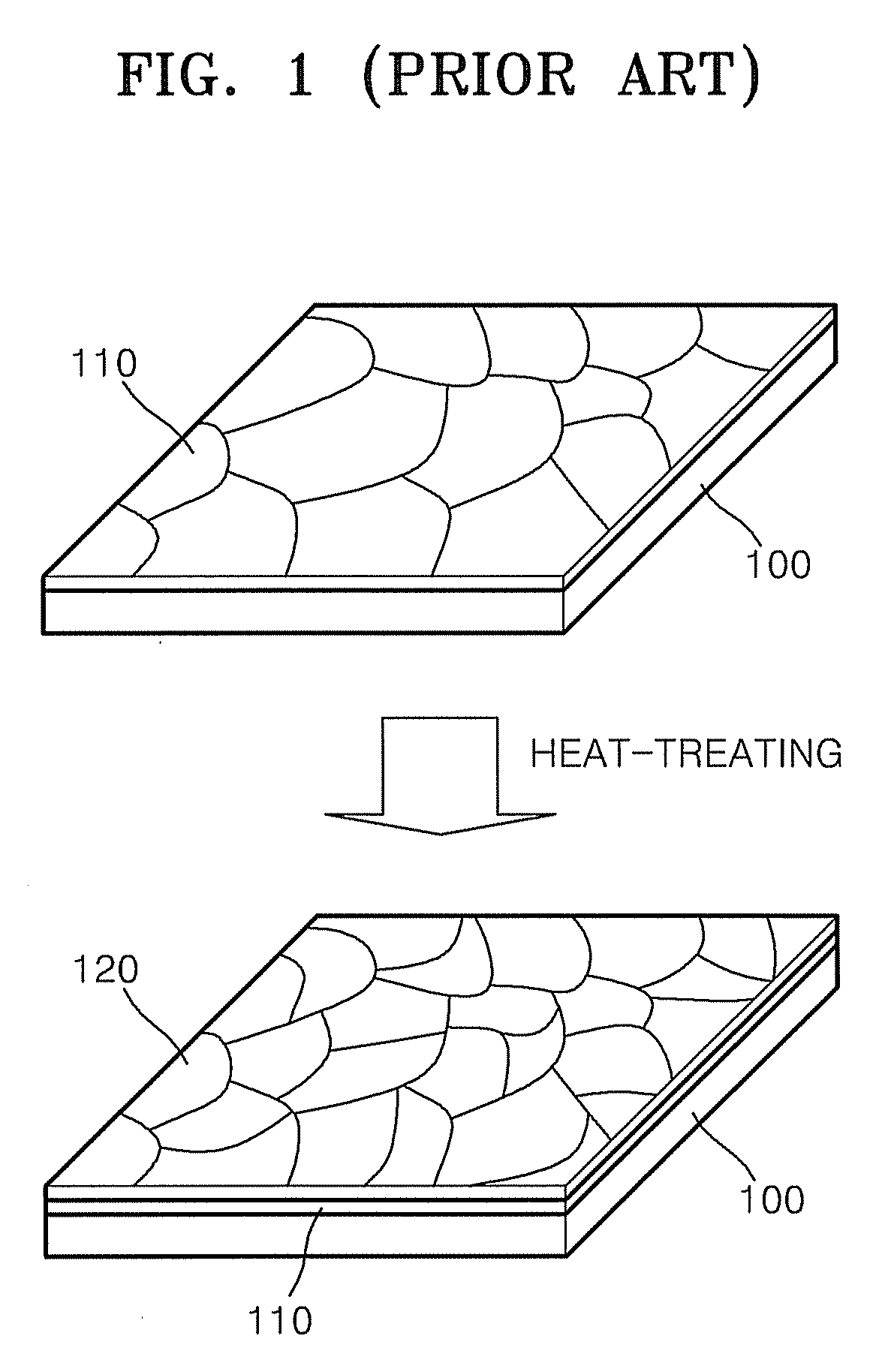

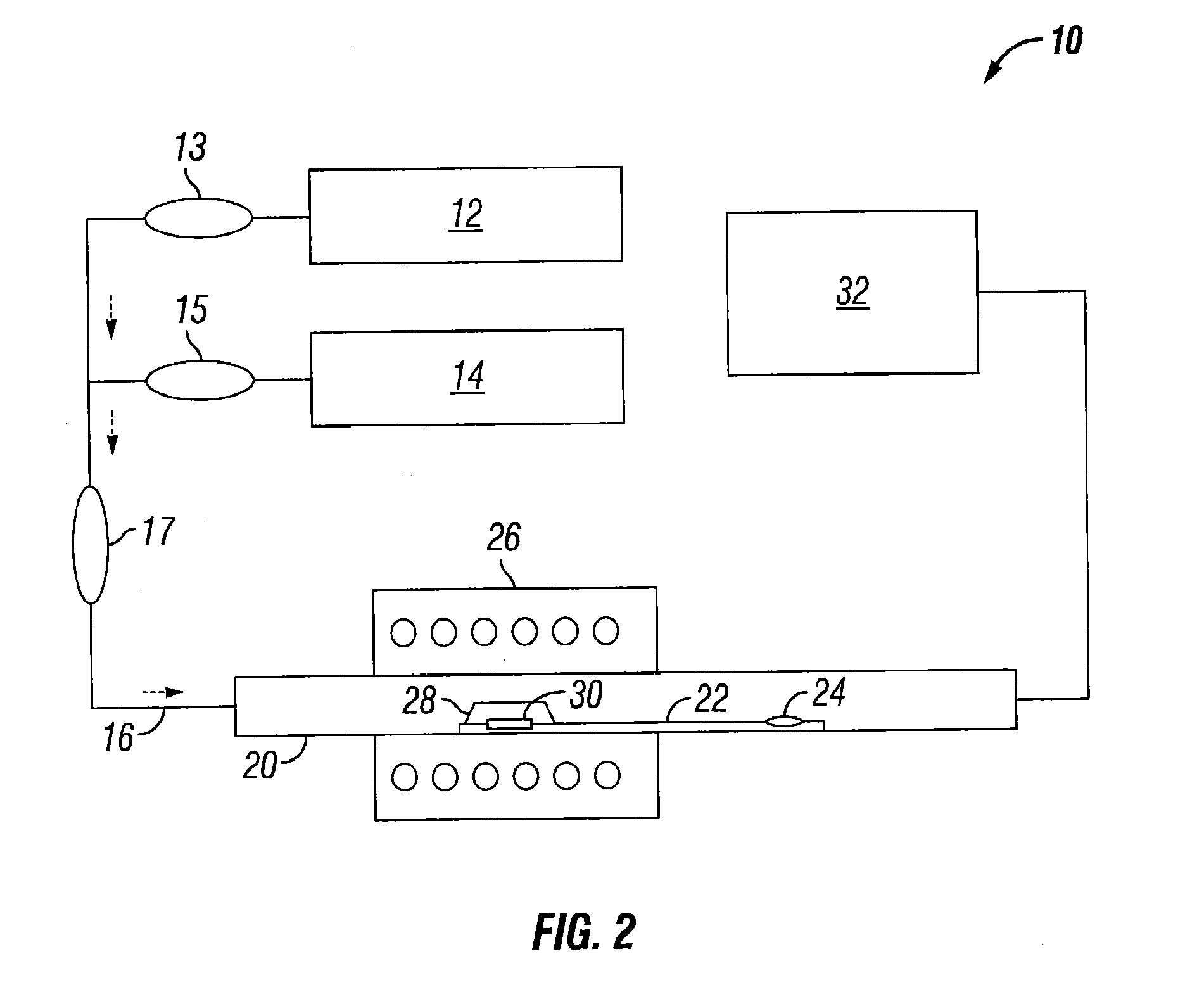

Large area deposition and doping of graphene, and products including the same

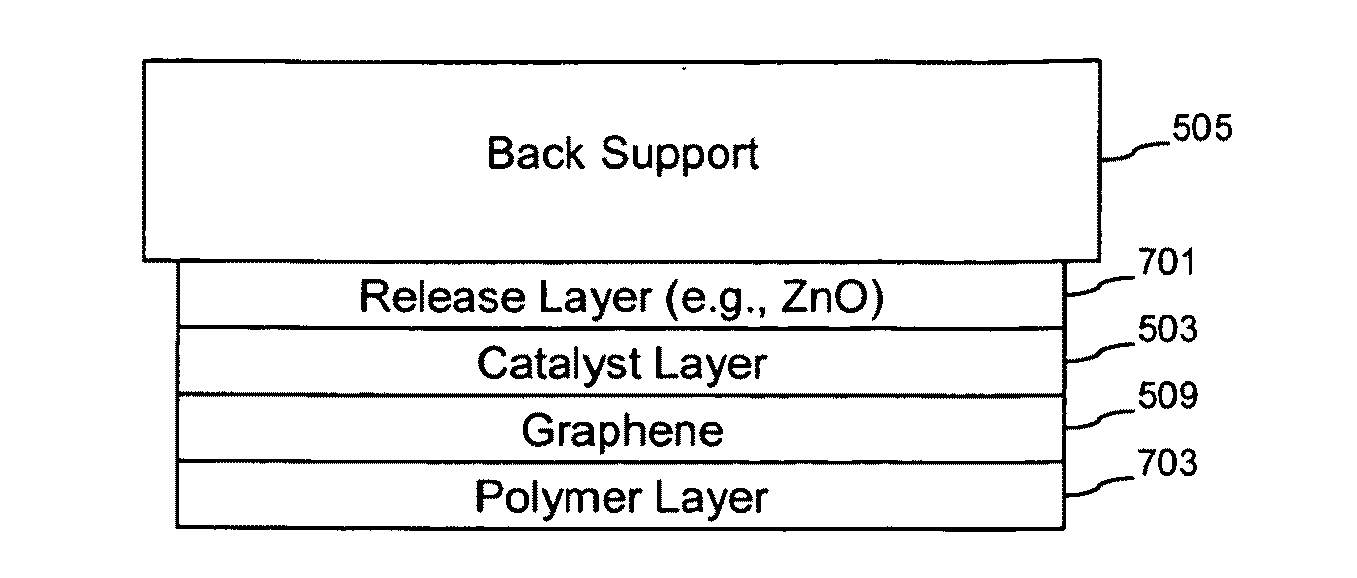

InactiveUS20110030991A1Reduced dimensionGood effectMaterial nanotechnologyNon-insulated conductorsConductive coatingTransmittance

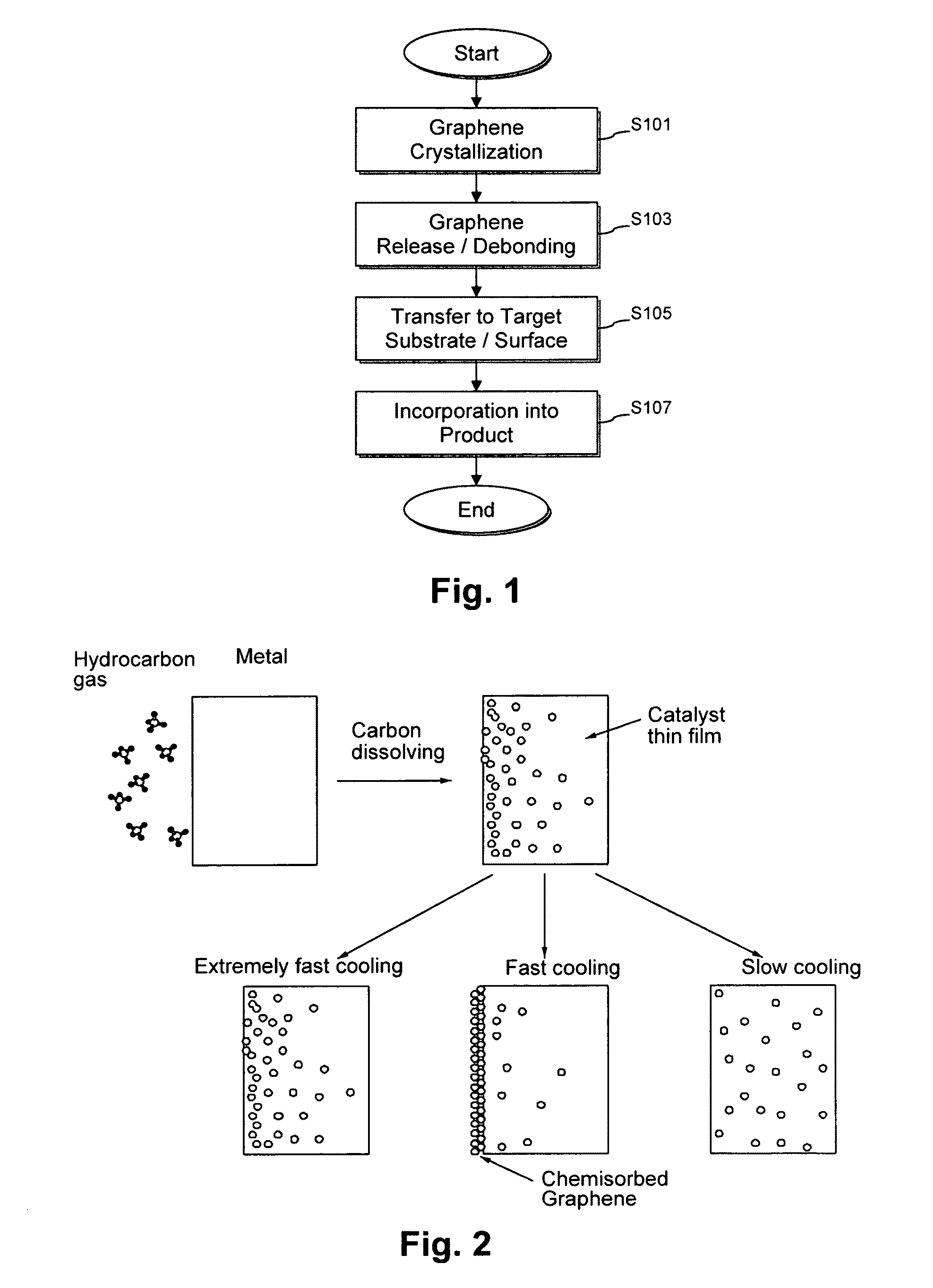

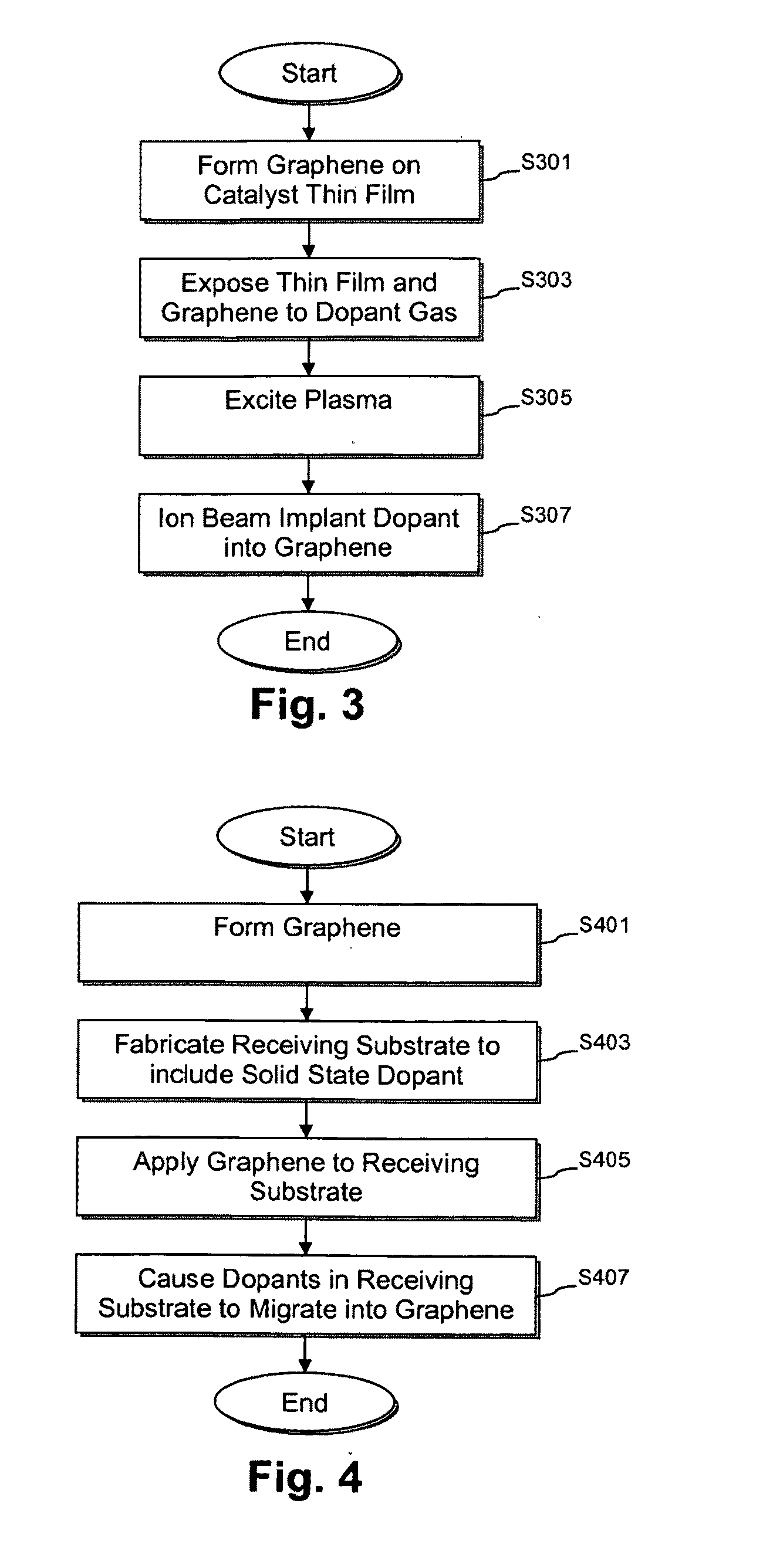

Certain example embodiments of this invention relate to the use of graphene as a transparent conductive coating (TCC). In certain example embodiments, graphene thin films grown on large areas hetero-epitaxially, e.g., on a catalyst thin film, from a hydrocarbon gas (such as, for example, C2H2, CH4, or the like). The graphene thin films of certain example embodiments may be doped or undoped. In certain example embodiments, graphene thin films, once formed, may be lifted off of their carrier substrates and transferred to receiving substrates, e.g., for inclusion in an intermediate or final product. Graphene grown, lifted, and transferred in this way may exhibit low sheet resistances (e.g., less than 150 ohms / square and lower when doped) and high transmission values (e.g., at least in the visible and infrared spectra).

Owner:GUARDIAN GLASS LLC

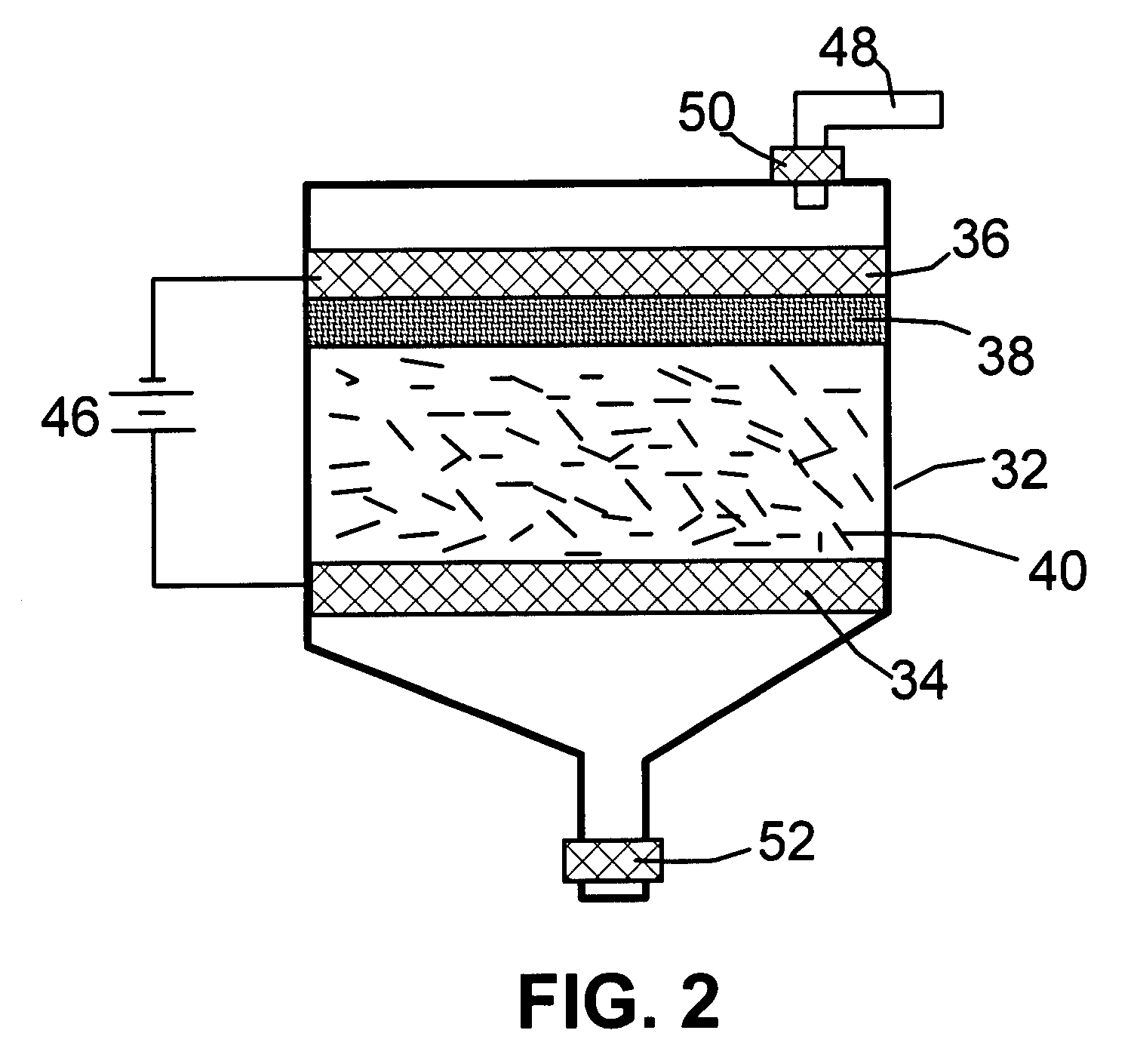

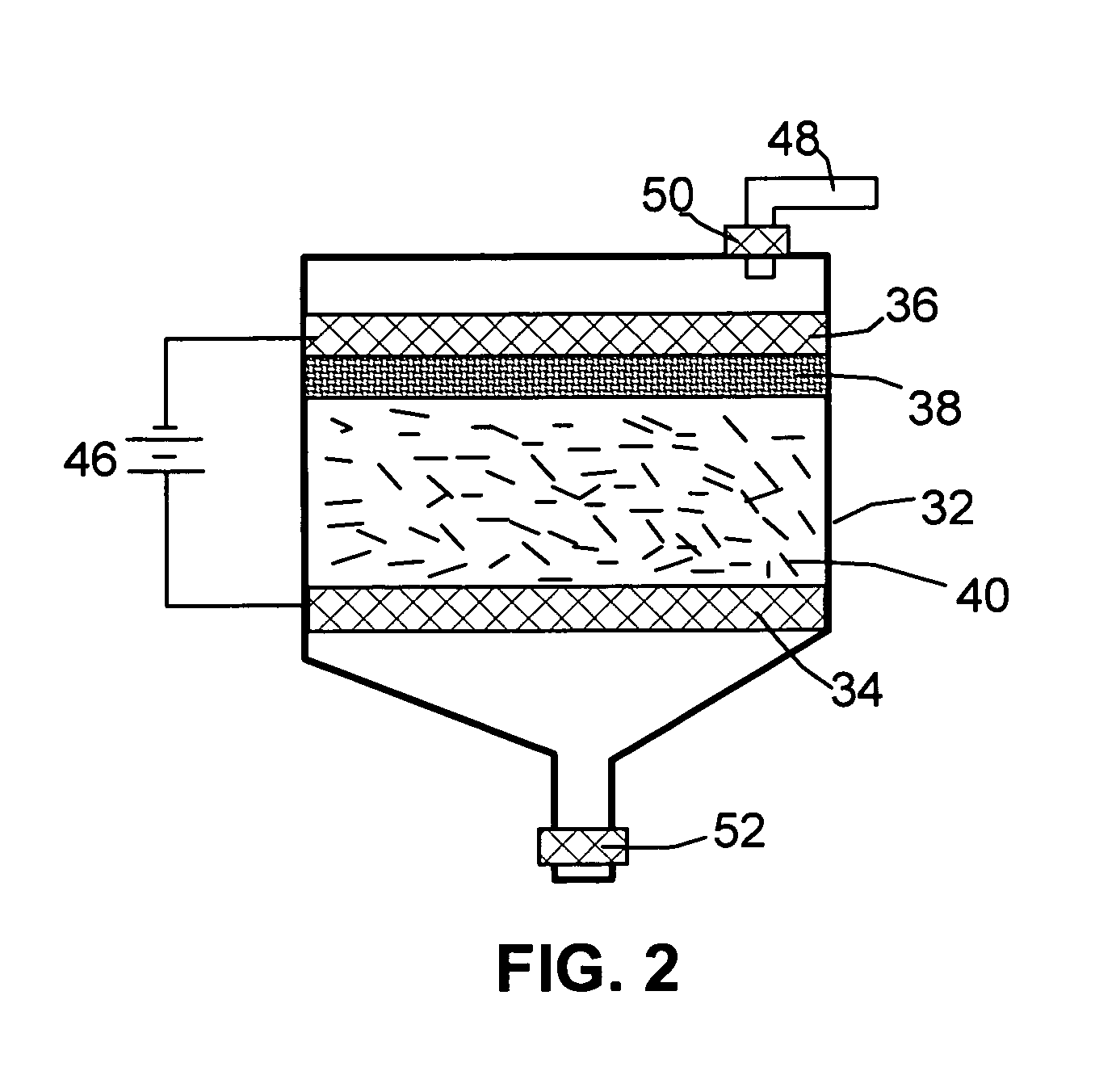

Electrochemical method of producing nano-scaled graphene platelets

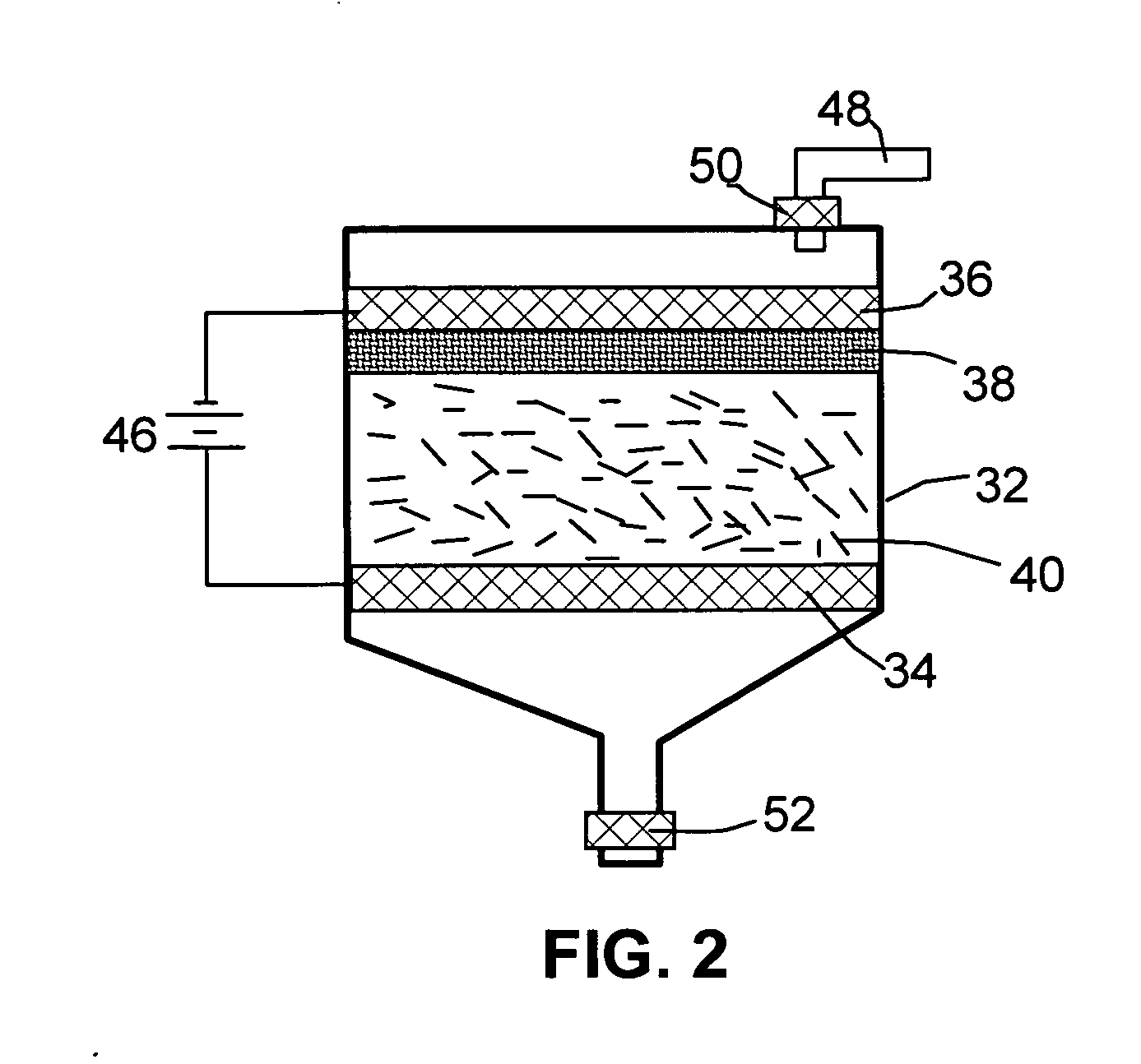

A method of producing nano-scaled graphene platelets with an average thickness smaller than 30 nm from a layered graphite material. The method comprises (a) forming a carboxylic acid-intercalated graphite compound by an electrochemical reaction which uses a carboxylic acid as both an electrolyte and an intercalate source, the layered graphite material as an anode material, and a metal or graphite as a cathode material, and wherein a current is imposed upon the cathode and the anode at a current density for a duration of time sufficient for effecting the electrochemical reaction; (b) exposing the intercalated graphite compound to a thermal shock to produce exfoliated graphite; and (c) subjecting the exfoliated graphite to a mechanical shearing treatment to produce the nano-scaled graphene platelets. Preferred carboxylic acids are formic acid and acetic acid. The exfoliation step in the instant invention does not involve the evolution of undesirable species, such as NOx and SOx, which are common by-products of exfoliating conventional sulfuric or nitric acid-intercalated graphite compounds. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

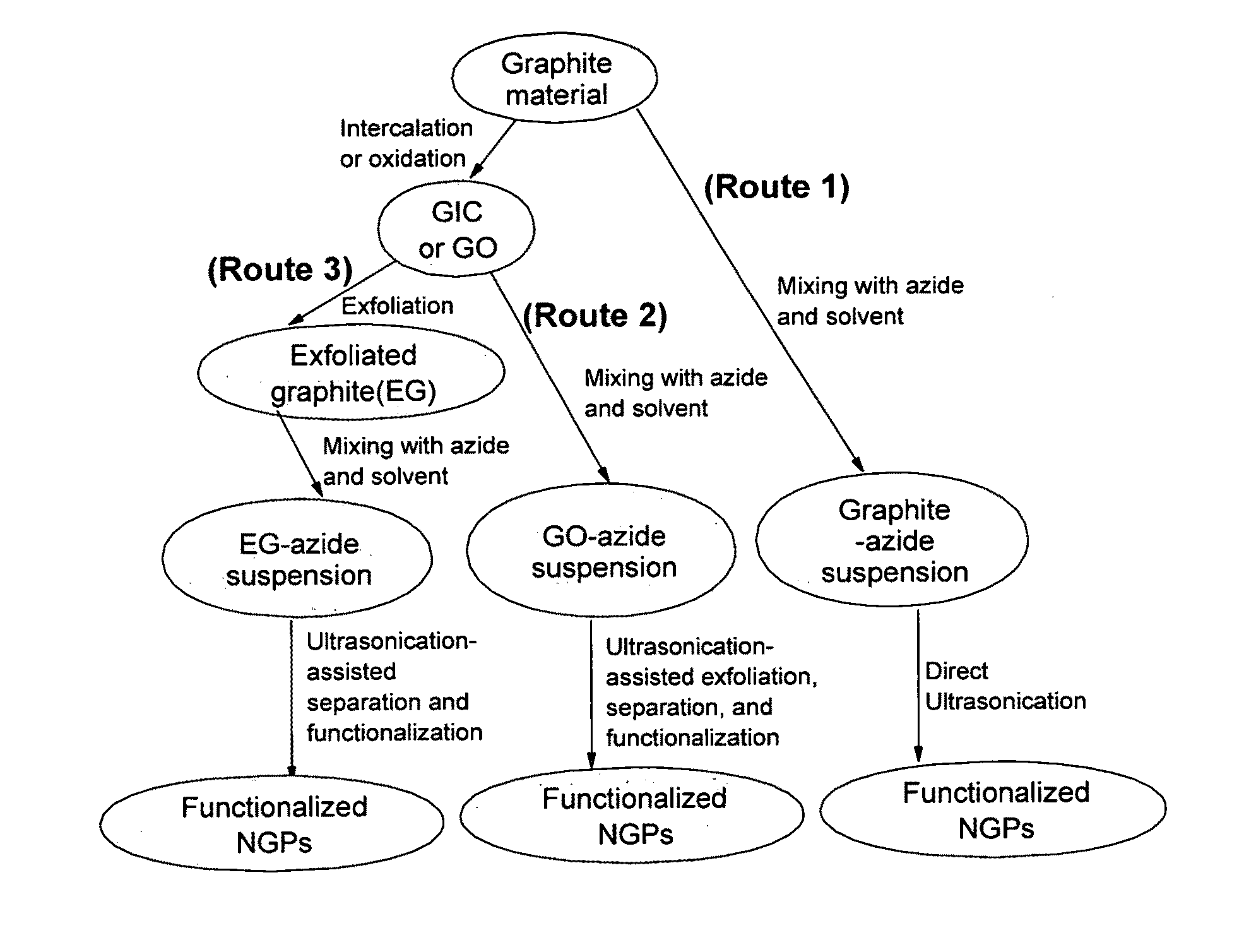

Production of chemically functionalized nano graphene materials

Provided in this invention is a process for producing chemically functionalized nano graphene materials, known as nano graphene platelets (NGPs), graphene nano sheets, or graphene nano ribbons. Subsequently, a polymer can be grafted to a functional group of the resulting functionalized NGPs. In one preferred embodiment, the process comprises (A) dispersing a pristine graphite material and an azide or bi-radical compound in a liquid medium comprising to form a suspension; and (B) subjecting the suspension to direct ultrasonication with to ultrasonic waves of a desired intensity or power level for a length of time sufficient to produce nano graphene platelets and to enable a chemical reaction to occur between the nano graphene platelets and the azide or bi-radical compound to produce the functionalized nano graphene material. Concurrent production and functionalization of NGPs directly from pristine graphitic materials can be achieved in one step and in the same reactor.

Owner:GLOBAL GRAPHENE GRP INC

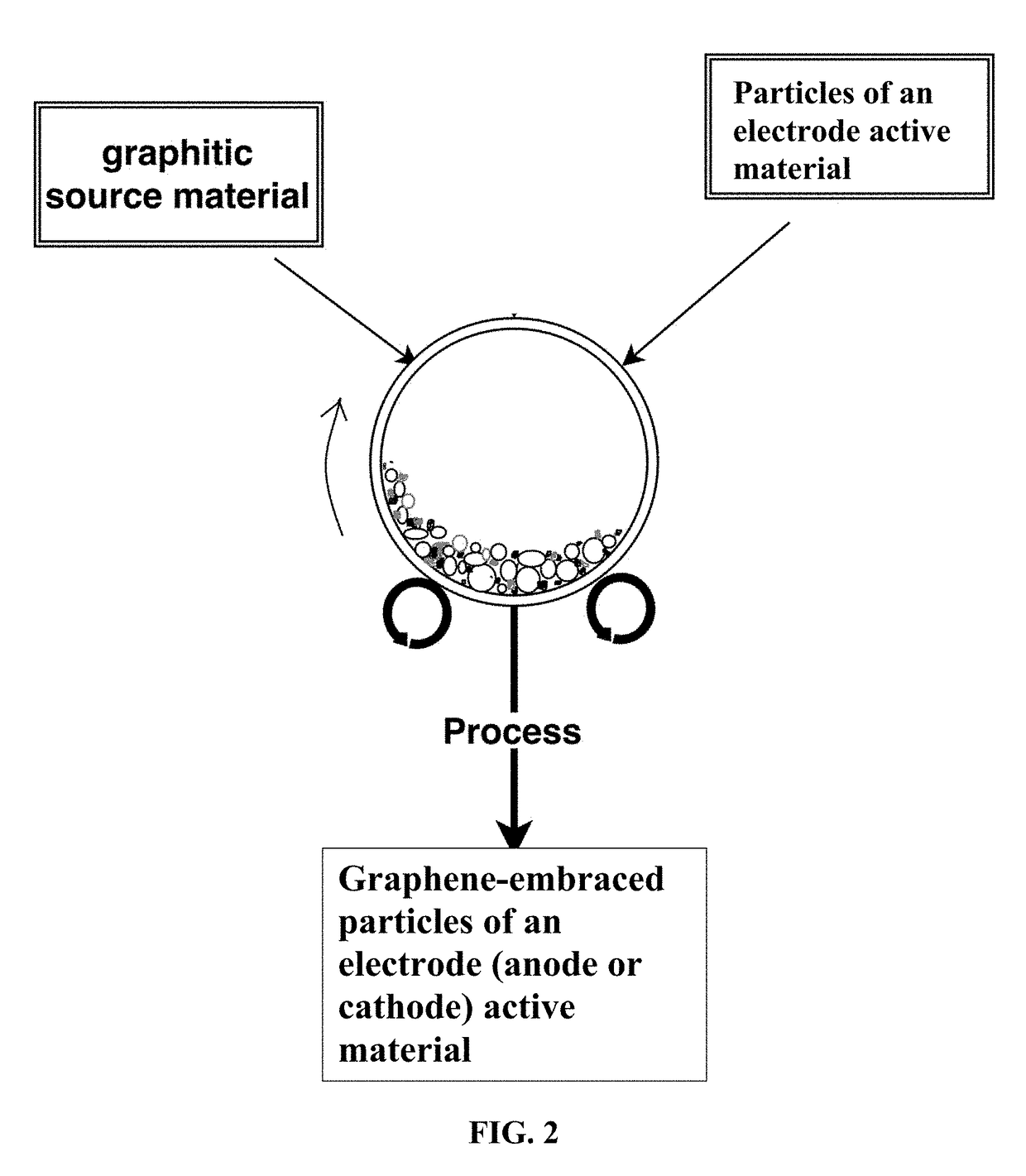

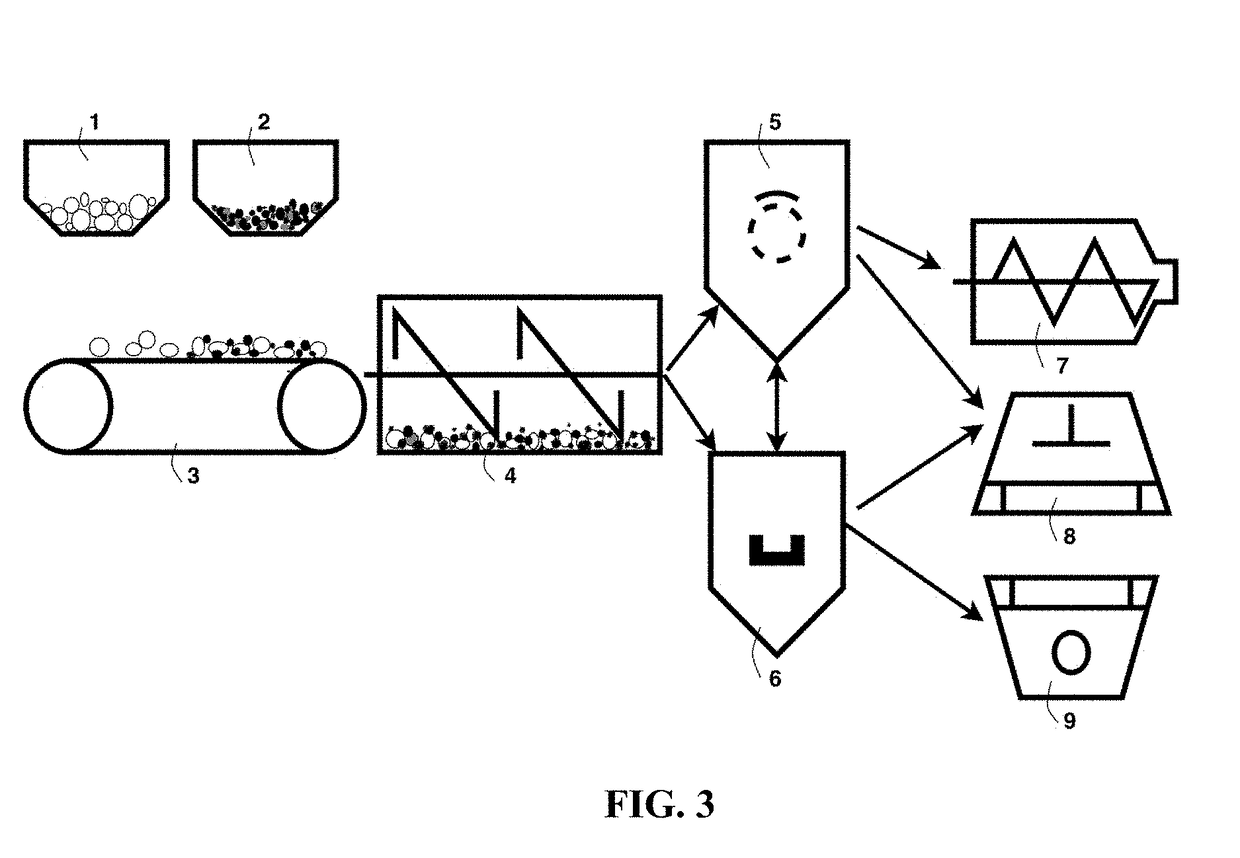

Chemical-Free Production of Graphene-Encapsulated Electrode Active Material Particles for Battery Applications

ActiveUS20170338472A1Improve mechanical propertiesImprove thermal conductivityGrapheneNegative electrodesEnergy impactGraphite

Provided is a simple, fast, scalable, and environmentally benign method of producing graphene-embraced or encapsulated particles of a battery electrode active material directly from a graphitic material, the method comprising: a) mixing graphitic material particles and multiple particles of a solid electrode active material to form a mixture in an impacting chamber of an energy impacting apparatus, wherein the graphitic material has never been intercalated, oxidized, or exfoliated and the chamber contains therein no previously produced graphene sheets and no ball-milling media; b) operating the energy impacting apparatus with a frequency and an intensity for a length of time sufficient for transferring graphene sheets from the graphitic material to surfaces of electrode active material particles to produce graphene-embraced electrode active material particles; and c) recovering the particles from the impacting chamber. Also provided is a mass of the graphene-embraced particles, electrode containing such particles, and battery containing this electrode.

Owner:GLOBAL GRAPHENE GRP INC

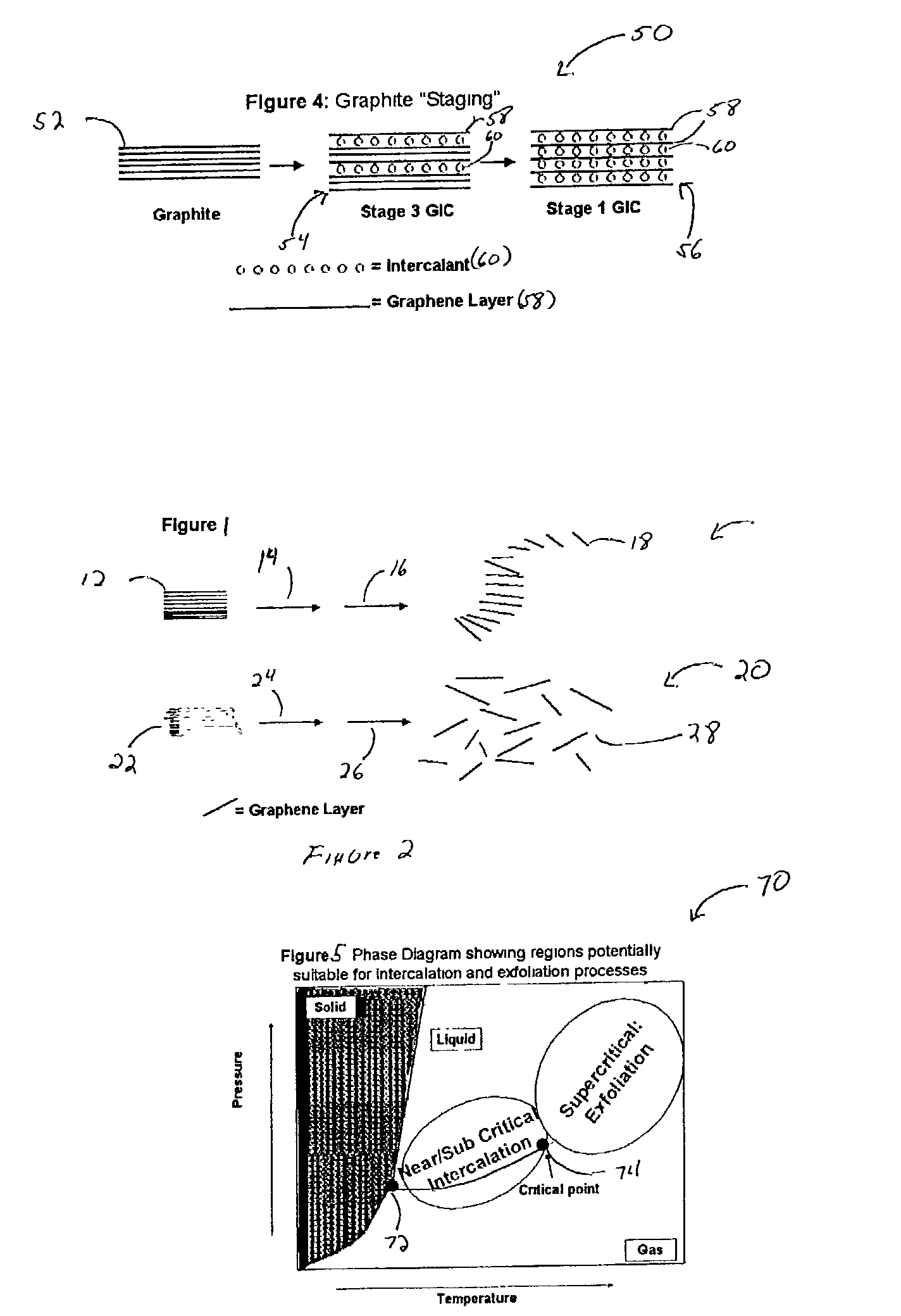

Graphite intercalation and exfoliation process

InactiveUS7105108B2Improve volume expansionReduce needMaterial nanotechnologyGraphiteConductive polymerGraphite particle

The invention relates to expanded graphite and methods of making the graphite and products that can be made from the graphite made from the inventive process. The invention includes the step of introducing a fluid into at least one of a plurality of interstices of graphite flake, wherein the fluid comprises at least one of a sub-critical point fluid, a near critical point fluid, or a supercritical fluid. The graphite flake is also intercalated with an intercalant and optionally an oxidizing agent. The invention may further include novel techniques of exfoliating the graphite. The invention may be practiced to make nano-sized graphite particles and also graphite composites. Preferred composites which may be made in accordance with the invention include conductive polymeric composites (thermally or electrically), paint composites, battery composites, capacitor composites, and pollution abatement catalyst support composites.

Owner:GRAFTECH INT HLDG INC

Graphene heat conducting membrane and preparation method thereof

Owner:CHANGZHOU FUXI TECH CO LTD

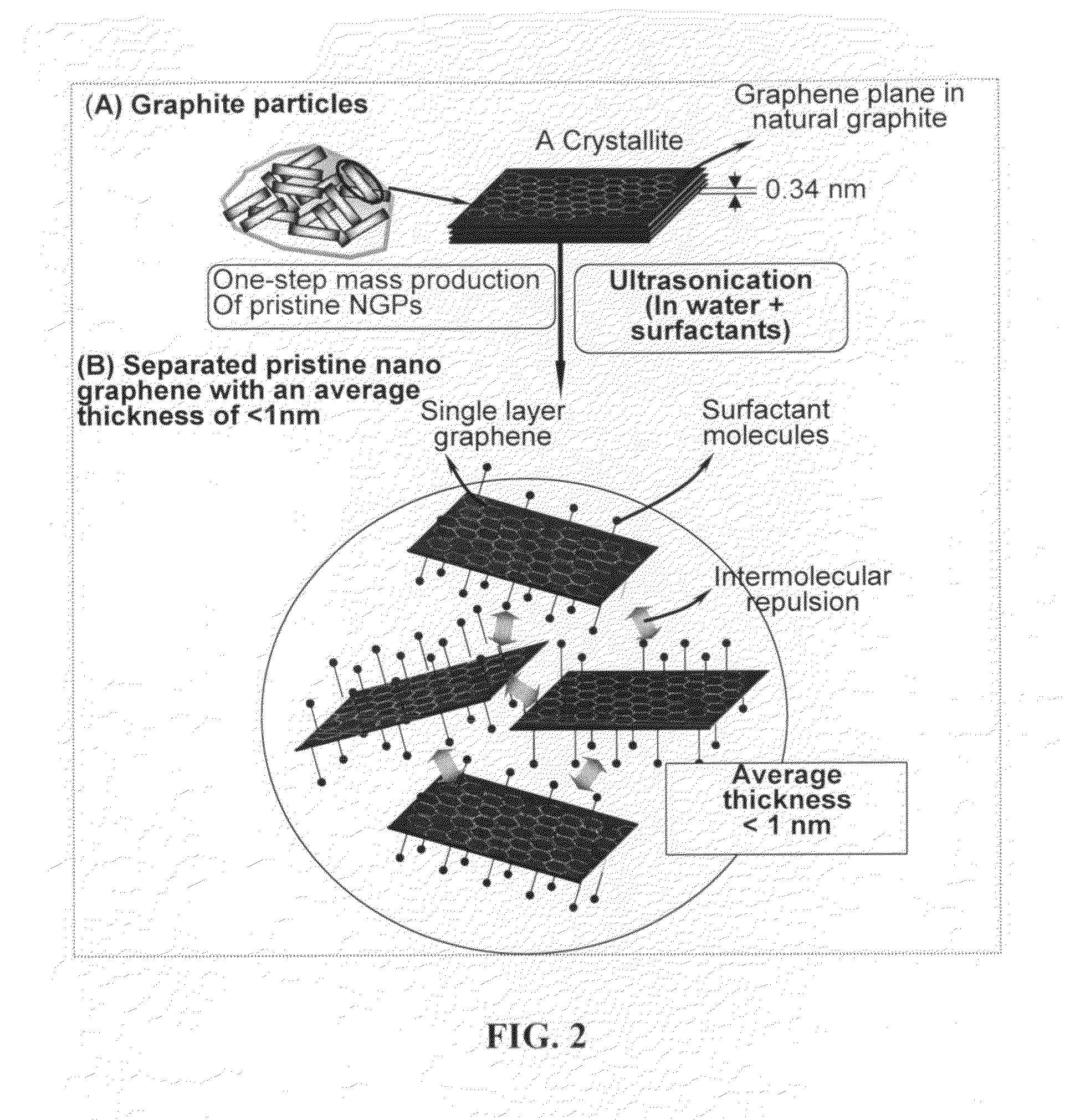

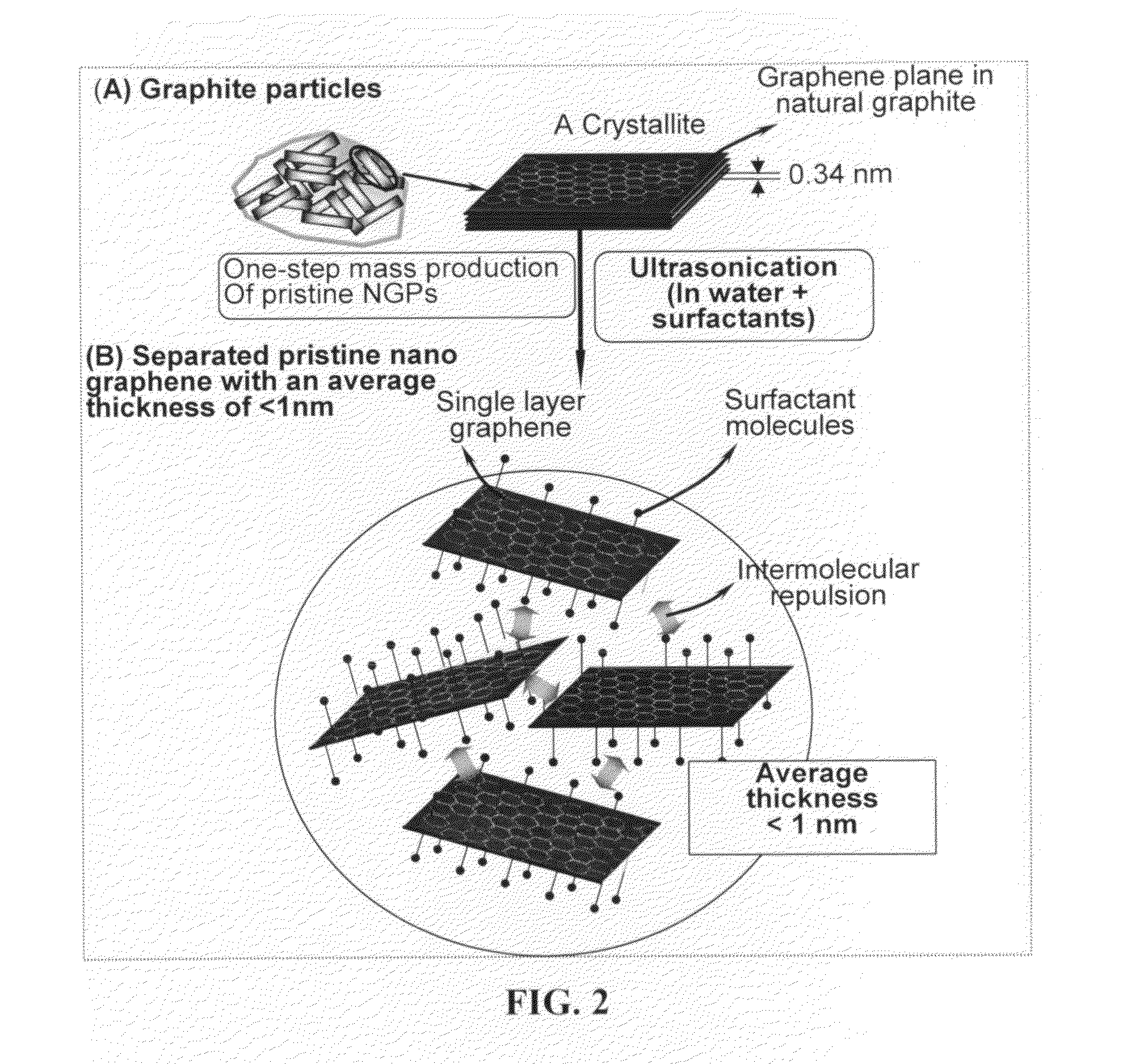

Mass production of pristine nano graphene materials

ActiveUS20110017585A1Reduce surface tensionImprove production yieldMaterial nanotechnologyGrapheneLiquid mediumDisplay device

The present invention provides a method of producing pristine or non-oxidized nano graphene platelets (NGPs) that are highly conductive. The method comprises: (a) providing a pristine graphitic material comprising at least a graphite crystallite having at least a graphene plane and an edge surface; (b) dispersing multiple particles of the pristine graphitic material in a liquid medium containing therein no surfactant to produce a suspension, wherein the multiple particles in the liquid have a concentration greater than 0.1 mg / mL and the liquid medium is characterized by having a surface tension that enables wetting of the liquid on a graphene plane exhibiting a contact angle less than 90 degrees; and (c) exposing the suspension to direct ultrasonication at a sufficient energy or intensity level for a sufficient length of time to produce the NGPs. Pristine NGPs can be used as a conductive additive in transparent electrodes for solar cells or flat panel displays (e.g., to replace expensive indium-tin oxide), battery and supercapacitor electrodes, and nanocomposites for electromagnetic wave interference (EMI) shielding, static charge dissipation, and fuel cell bipolar plate applications.

Owner:GLOBAL GRAPHENE GRP INC

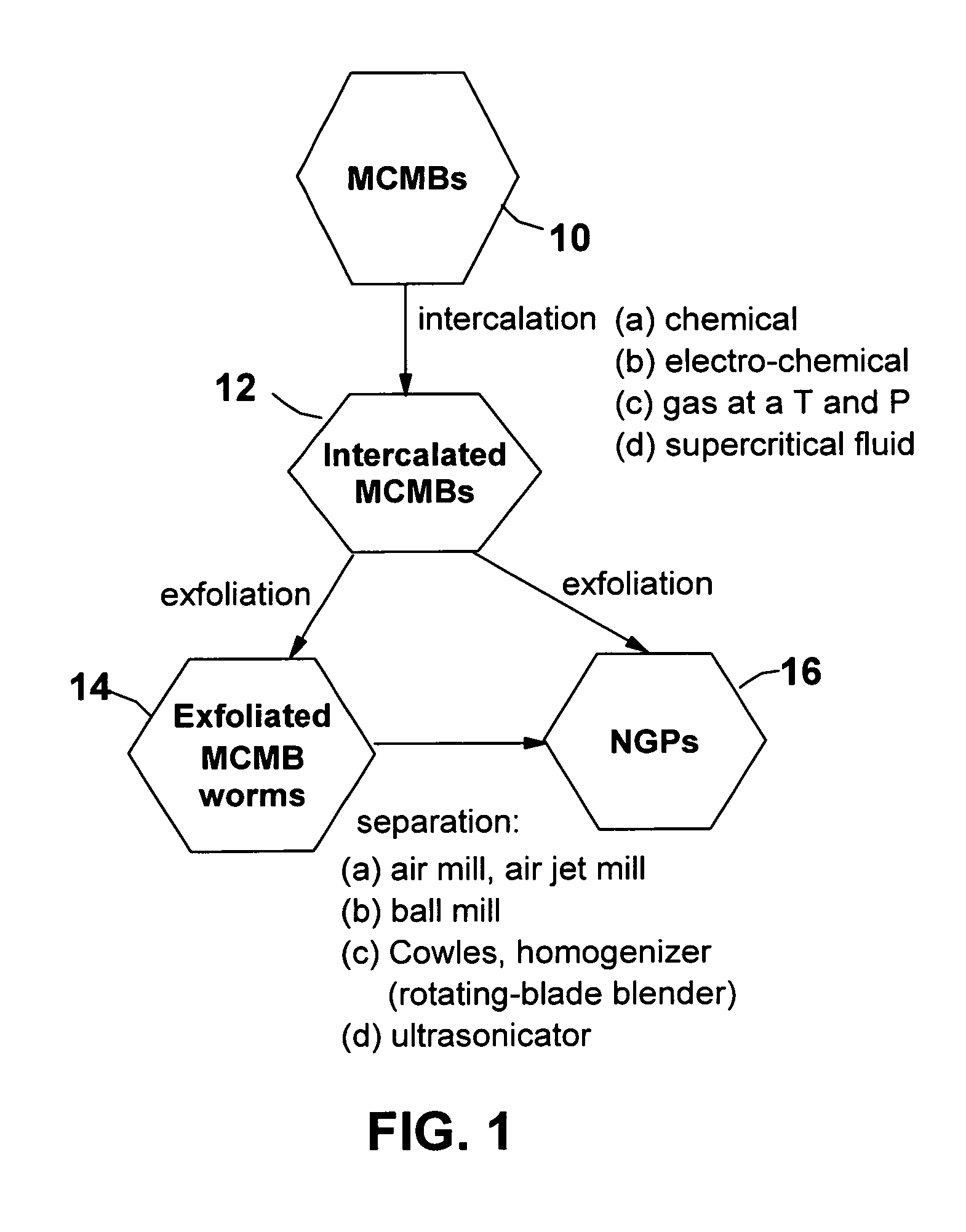

Production of ultra-thin nano-scaled graphene platelets from meso-carbon micro-beads

ActiveUS20090169467A1Improve permeabilityPromote quick completionMaterial nanotechnologyPigmenting treatmentFiberMetallurgy

A method of producing nano-scaled graphene platelets (NGPs) having an average thickness no greater than 50 nm, typically less than 2 nm, and, in many cases, no greater than 1 nm. The method comprises (a) intercalating a supply of meso-carbon microbeads (MCMBs) to produce intercalated MCMBs; and (b) exfoliating the intercalated MCMBs at a temperature and a pressure for a sufficient period of time to produce the desired NGPs. Optionally, the exfoliated product may be subjected to a mechanical shearing treatment, such as air milling, air jet milling, ball milling, pressurized fluid milling, rotating-blade grinding, or ultrasonicating. The NGPs are excellent reinforcement fillers for a range of matrix materials to produce nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

Continuous process for producing spacer-modified nano Graphene electrodes for supercapacitors

ActiveUS20110165321A1Increase surface areaMaterial nanotechnologyElectrolytic capacitorsSupercapacitorSolvent

A specific embodiment of the present invention is a process for continuously producing a porous solid film of spacer-modified nano graphene platelets for supercapacitor electrode applications. This process comprises: (a) dissolving a precursor material in a solvent to form a precursor solution and dispersing multiple nano graphene platelets into the solution to form a suspension; (b) continuously delivering and forming the suspension into a layer of solid film composed of precursor material-coated graphene platelets overlapping one another, and removing the solvent from the solid film (e.g., analogous to a paper-making, mat-making, or web-making procedure); (c) continuously converting the precursor material into nodules bonded to surfaces of graphene platelets to form a porous solid film composed of spacer-modified graphene platelets; and (d) continuously collecting the porous solid film on a collector (e.g., a winding roller). The roll of porous solid film (mat, paper, or web) can then be cut into pieces for used as supercapacitor electrodes.

Owner:NANOTEK INSTR GRP LLC

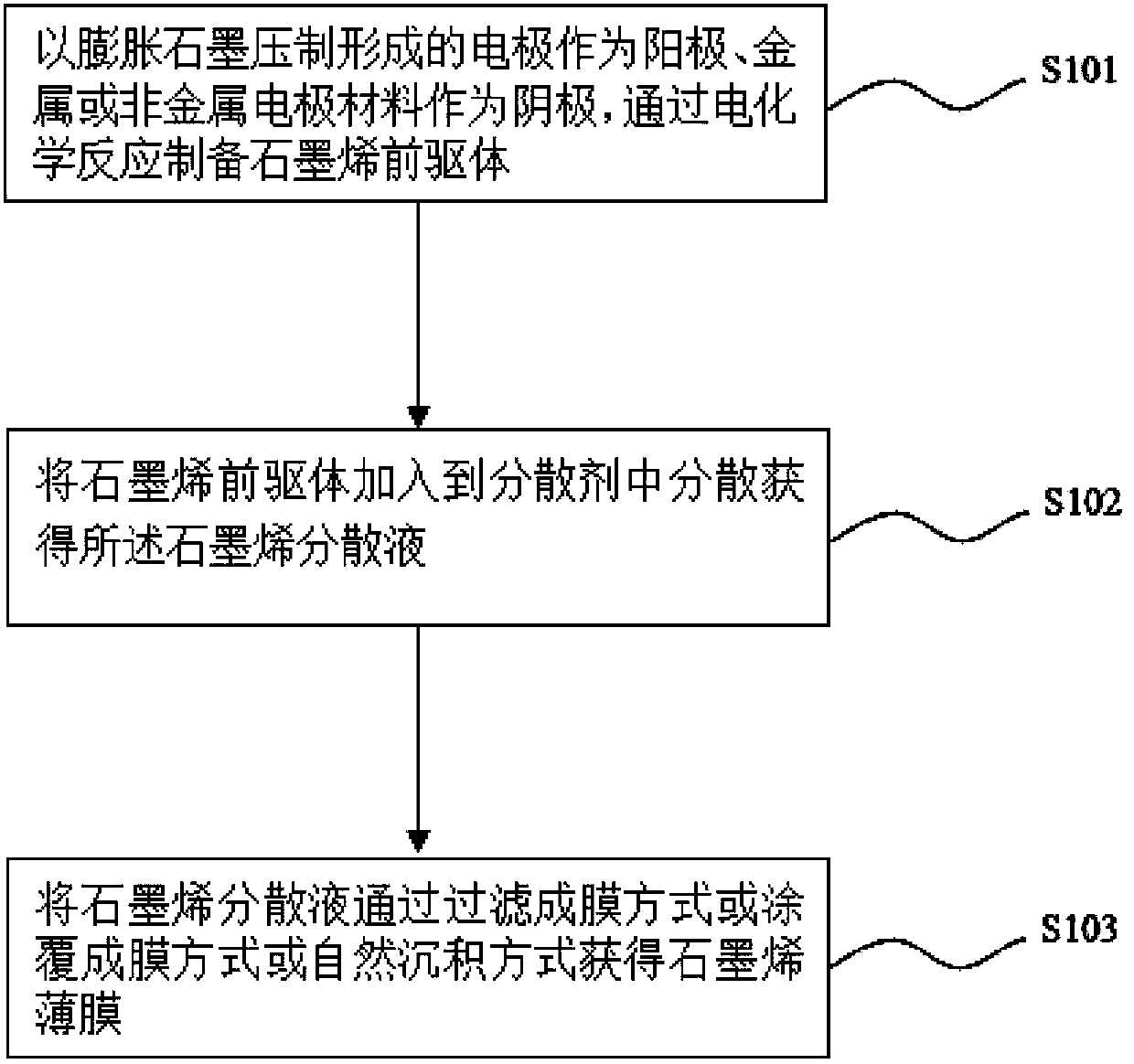

Preparation method of graphene dispersion liquid, and preparation method of graphene film

ActiveCN103466603AIncrease layer spacingIncrease concentrationMaterial nanotechnologyGrapheneElectrochemical responseMetallic electrode

The invention discloses a preparation method of a graphene dispersion liquid. The preparation method of the graphene dispersion liquid comprises the following steps: placing an expanded graphite compacted electrode and a metallic or non-metallic electrode material in an electrolyte solution as an anode and a cathode respectively, and applying a voltage of 1-20V and / or a current having a density of 1-200mA / cm<2> between the anode and the cathode for carrying out an electrochemical reaction for 1-120min; and washing an anode product obtained after the electrochemical reaction, adding to a dispersant, and carrying out ultrasonic or / and mechanical stirring dispersion to obtain the graphene dispersion liquid. The invention also discloses a preparation method of a graphene film. The graphene dispersion liquid forms the graphene film on a substrate in a filter film forming mode or a coating film forming mode or a natural deposition mode. The preparation methods have the advantages of simple process, easy operation, high controllability, low cost and mild reaction condition, and are suitable for the industrialized large-scale production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Nitrogen mixed grapheme hydrogel or aerogel and preparation method thereof

InactiveCN102874796AImprove adsorption capacityGood processing effectGrapheneApparent densityNitrogen

The invention provides nitrogen mixed grapheme hydrogel of which the water content is 90 to 99.5 percent, the electric conductivity is 10-3-100 S / m, and the molar ratio of N and C is 1 to 25 percent. The invention further provides nitrogen mixed aerogel of which the molar ratio of N and C is 2 to 20 percent, the molar ratio of C and O is 15 to 5, nitrogen atoms existing in the form of amidogen nitrogen accounts for 40 to 70 percent, pyridine type nitrogen accounts for 10 to 40 percent, graphite type nitrogen accounts for 10 to 30 percent, the specific area is 300 to 1500 m<2> / g, the apertures which are micropore account for 10 to 20 percent, the apertures which are mesoporous 20 to 50 percent, the apertures which are macropore 30 to 70 percent, the apparent density is 0.01 to 0.2 g / cm<3>, the pore volume is 5 to 20 cm<3> / g, and the electric conductivity is 1 to 1000 S / m. The nitrogen mixed grapheme hydrogel or aerogel and preparation method thereof provided by the invention has the characteristics that the operation is simple, the equipment requirement is low, the production efficiency is high, the scale-up of the technology is easy, the nitrogen mixed content is controllable and the compounding with other functional substances is simple.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com